Inorganic modified high-temperature-resistant high-emissivity graphene coating and preparation method thereof

A high-emissivity, inorganic modification technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of low heat transfer efficiency, reduce the curing time of inorganic adhesives, low emissivity, etc., and achieve extended base The effect of material life, adhesion improvement, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the second technical scheme, the present invention proposes a kind of preparation method of inorganic modification high temperature resistant high emissivity graphene coating, comprises the following steps successively:

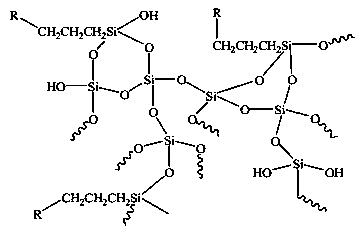

[0047] Step 1. Mix the graphene powder, surface treatment agent and deionized water, and use an ultrasonic emulsification disperser to ultrasonically emulsify for more than 30 minutes to prepare a graphene dispersion;

[0048] Step 2. Slowly add deionized water, sodium silicate, potassium silicate, silica sol, and zirconium sol in order and stir evenly at a low speed to prepare an inorganic high-temperature adhesive;

[0049] Step 3. Add deionized water and thickener to the dispersing tank and stir evenly at a low speed. After adding all of them, continue to stir slowly for at least 30 minutes to fully expand the thickener;

[0050] Step 4. Add the graphene dispersion liquid, silicone resin emulsion, functional filler, dispersant, and defoamer into ...

Embodiment 1

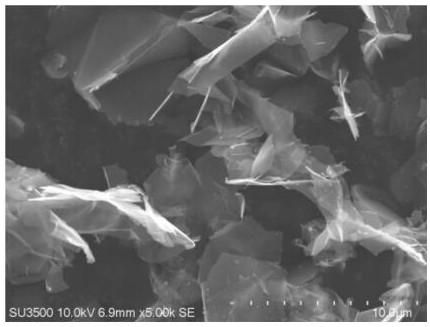

[0053] A modified inorganic high-temperature-resistant, high-emissivity graphene coating is prepared by the following method:

[0054] (1) Preliminarily mix 0.1 parts of graphene powder, 0.2 parts of KH560, and 7.7 parts of deionized water, and use an ultrasonic emulsification disperser to ultrasonically emulsify for 1 hour to obtain a graphene dispersion;

[0055] (2) Take 10 parts of deionized water, 20 parts of sodium silicate with a modulus of 4.7, 2 parts of potassium silicate with a modulus of 4.7 and 15 parts of silica sol with a solid content of 25% and slowly add them to the dispersion tank in order and stir evenly at high speed to obtain an inorganic high-temperature adhesive agent;

[0056] (3) Add 15 parts of deionized water and 2 parts of rectorite to the dispersion tank and stir evenly at a low speed. After adding all of them, continue stirring for at least 30 minutes to fully expand the rectorite;

[0057] ⑷With the graphene dispersion obtained in step ⑴, 6.5 p...

Embodiment 2

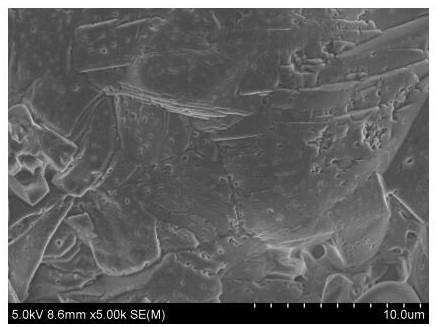

[0061] A modified inorganic high-temperature-resistant, high-emissivity coating is prepared by the following method:

[0062] (1) Preliminarily mix 0.5 parts of graphene powder, 1.5 parts of CTAB, and 8 parts of deionized water, and use an ultrasonic emulsification disperser to ultrasonically emulsify for 1 hour to obtain a graphene dispersion;

[0063] (2) Take 10 parts of deionized water, 5 parts of sodium silicate with a modulus of 4.7, 22 parts of potassium silicate with a modulus of 2.7 and 17 parts of zirconium sol with a solid content of 20% and slowly add them to the dispersion tank in order and stir evenly at high speed to obtain an inorganic high-temperature adhesive agent;

[0064] (3) Add 10 parts of deionized water and 1 part of bentonite to the dispersion tank and stir evenly at a low speed. After adding all of them, continue stirring for at least 30 minutes to fully expand the bentonite;

[0065] ⑷With the graphene dispersion obtained in step ⑴, 3.4 parts of Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com