Heavy-load resistance and corrosion-resistance waterborne polyurethane floor coating and preparation method thereof

A technology of water-based polyurethane and floor coatings, applied in the field of coatings, can solve problems such as "bulging" of epoxy floors, easy bursting of paint films, fire safety threats, etc., to improve safety and environmental sanitation, coating The effect of strong environmental adaptability and simplified coating varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

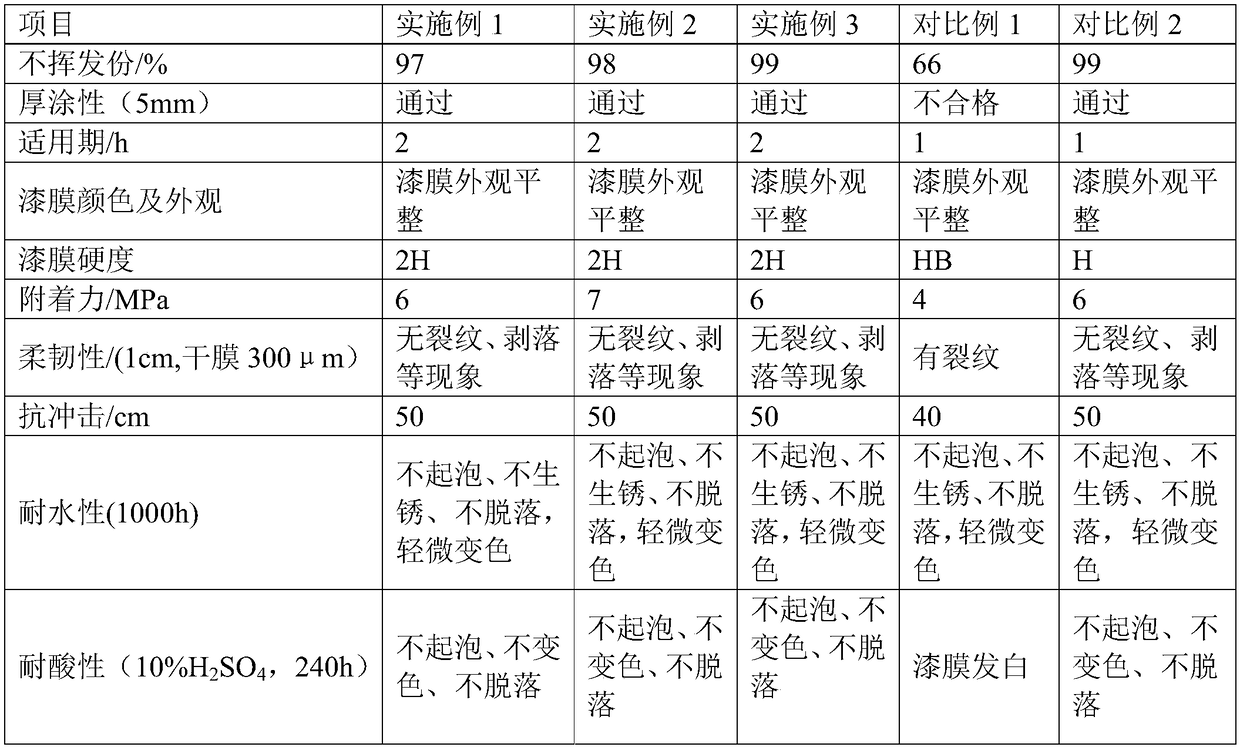

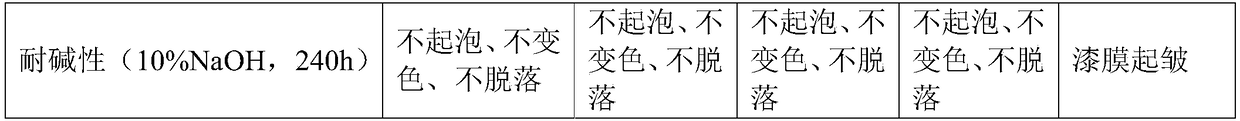

Examples

Embodiment 1

[0034] The preparation method of the waterborne polyurethane floor coating of embodiment 1 is as follows:

[0035] The preparation method of component A is: add the polyol into the emulsification kettle and heat it to 60°C, add the emulsifier into the emulsifier under stirring, keep warm until it dissolves, then add the emulsifier and defoamer, stop heating, and increase the stirring speed to 5000rpm, and add water while stirring, after the water is added, it can be ground by a colloid mill to obtain component A.

[0036] The preparation method of component B is: keep the indoor humidity less than 50%, pour polyisocyanate into the product packaging;

[0037] The preparation method of component C is as follows: put white cement, toner, sodium metasilicate, water reducing agent and quartz sand specified in the formula into a dry powder mixer, mix them evenly, sieve and pack to obtain component C. When in use, weigh and mix components A, B, and C according to the mass ratio, and...

Embodiment 2

[0038] The preparation method of the waterborne polyurethane floor paint of embodiment 2 is as follows:

[0039] The preparation method of component A is: add the polyol into the emulsification kettle and heat it to 80°C, add the emulsifier into the emulsifier under stirring, keep warm until it dissolves, then add the emulsifier and defoamer, stop heating, and increase the stirring speed to 10000rpm, and add water while stirring, after the water is added, it can be ground by a colloid mill to obtain component A.

[0040] The preparation method of component B is: keep the indoor humidity less than 50%, pour polyisocyanate into the product packaging;

[0041] The preparation method of component C is as follows: put white cement, toner, sodium metasilicate, water reducing agent and quartz sand specified in the formula into a dry powder mixer, mix them evenly, sieve and pack to obtain component C. When in use, weigh and mix components A, B, and C according to the mass ratio, and ...

Embodiment 3

[0042] The preparation method of the waterborne polyurethane floor paint of embodiment 3 is as follows:

[0043] The preparation method of component A is: add the polyol into the emulsification kettle and heat it to 90°C, add the emulsifier into the emulsifier under stirring, keep warm until it dissolves, then add the emulsifier and defoamer, stop heating, and increase the stirring speed to 1000rpm, and add water while stirring, after the water is added, it can be ground by a colloid mill to obtain component A.

[0044] The preparation method of component B is: keep the indoor humidity less than 50%, pour polyisocyanate into the product packaging;

[0045] The preparation method of component C is as follows: put white cement, toner, sodium metasilicate, water reducing agent and quartz sand specified in the formula into a dry powder mixer, mix them evenly, sieve and pack to obtain component C. When in use, weigh and mix components A, B, and C according to the mass ratio, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com