Patents

Literature

58results about How to "Both strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

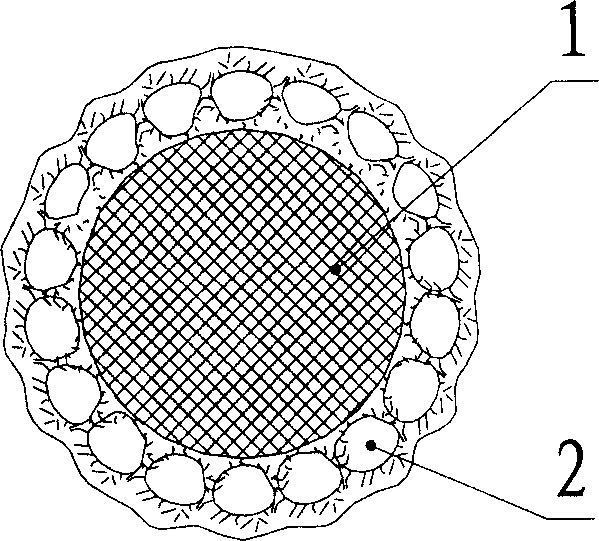

Fiber wall with strong rib material of plastic

The present invention provides a fibre reinforced plastics rib material. It includes fibre reinforced plastics (FRP) core layer and matrix resin impregnating fibre reinforced plastics (FRP), the peripheral surface of said core layer is axially covered with glass fibre bulk yarn reinforced plastics covering layer. Said glass fibre bulk yarn reinforced plastics covering layer can effectively increase roughness of exterior surface of the fibre reinforced plastics rib material core layer, so that the bond stress of said rib material core layer and concrete also can be raised, and the service lift of concrete member also can be raised.

Owner:SINOMA SCI & TECH

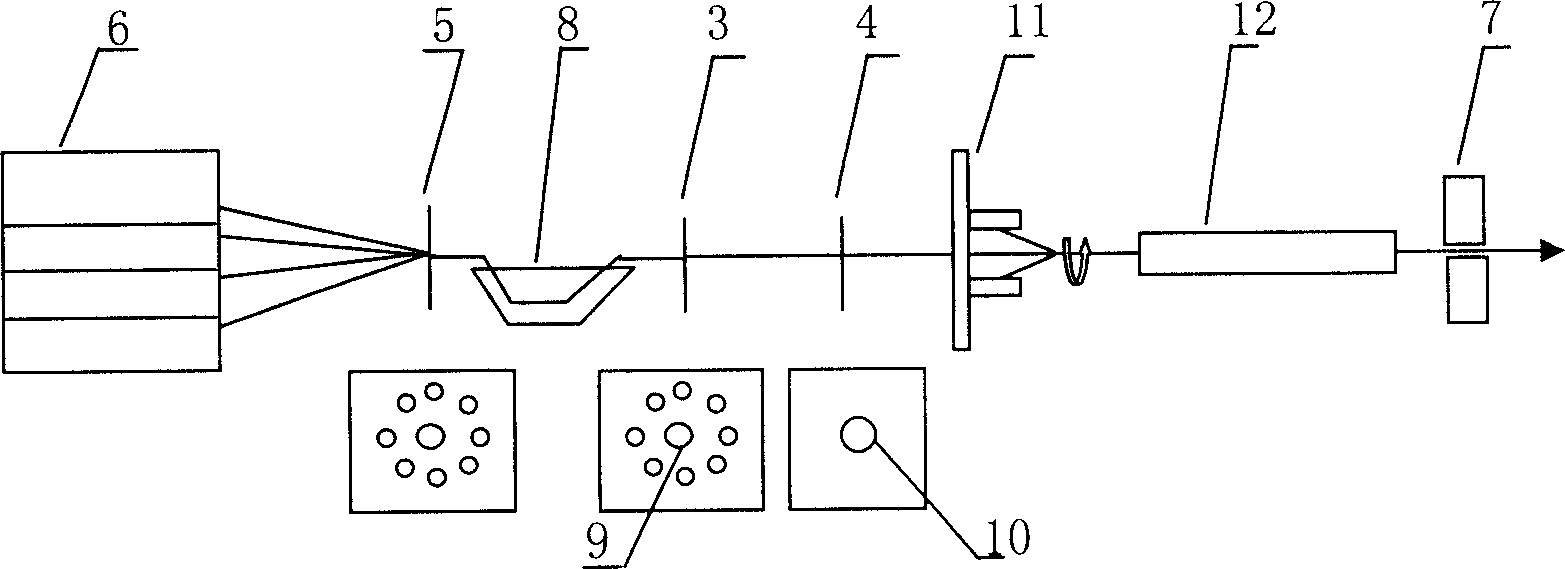

Titanium alloy used for aviation fastener and manufacturing method

InactiveCN102011026AIncreased heterogeneous nucleation coreGrain refinementNiobiumElement composition

The invention discloses a titanium alloy used for an aviation fastener and a manufacturing method, and relates to a titanium base alloy. The titanium alloy comprises the following elements in percentage by mass: 5 to 9 percent of aluminum (Al), 1 to 6 percent of vanadium (V), 8 percent of molybdenum (Mo), 11 to 15 percent of niobium (Nb), 1 percent of zirconium (Zr), 0.1 to 2 percent of chromium (Cr) and the balance of Ti, wherein an amorphous titanium alloy inoculant is added in a melting process of the titanium alloy. The titanium alloy used for the aviation fastener has more reasonable new element compositions; the amorphous titanium alloy inoculant is added into the melting process; a heterogeneous nucleation core when the titanium alloy is solidified is added; the crystal size of an as-cast titanium alloy is refined; the tensile strength of a titanium alloy product used for the aviation fastener manufactured by the manufacturing method for the titanium alloy used for the aviation fastener can reach 1,370 MPa; the elongation rate can reach 11.6 percent; and the titanium alloy has both strength and flexibility and can be widely used for fasteners for manufacturing a civil aviation aircraft.

Owner:HEBEI UNIV OF TECH

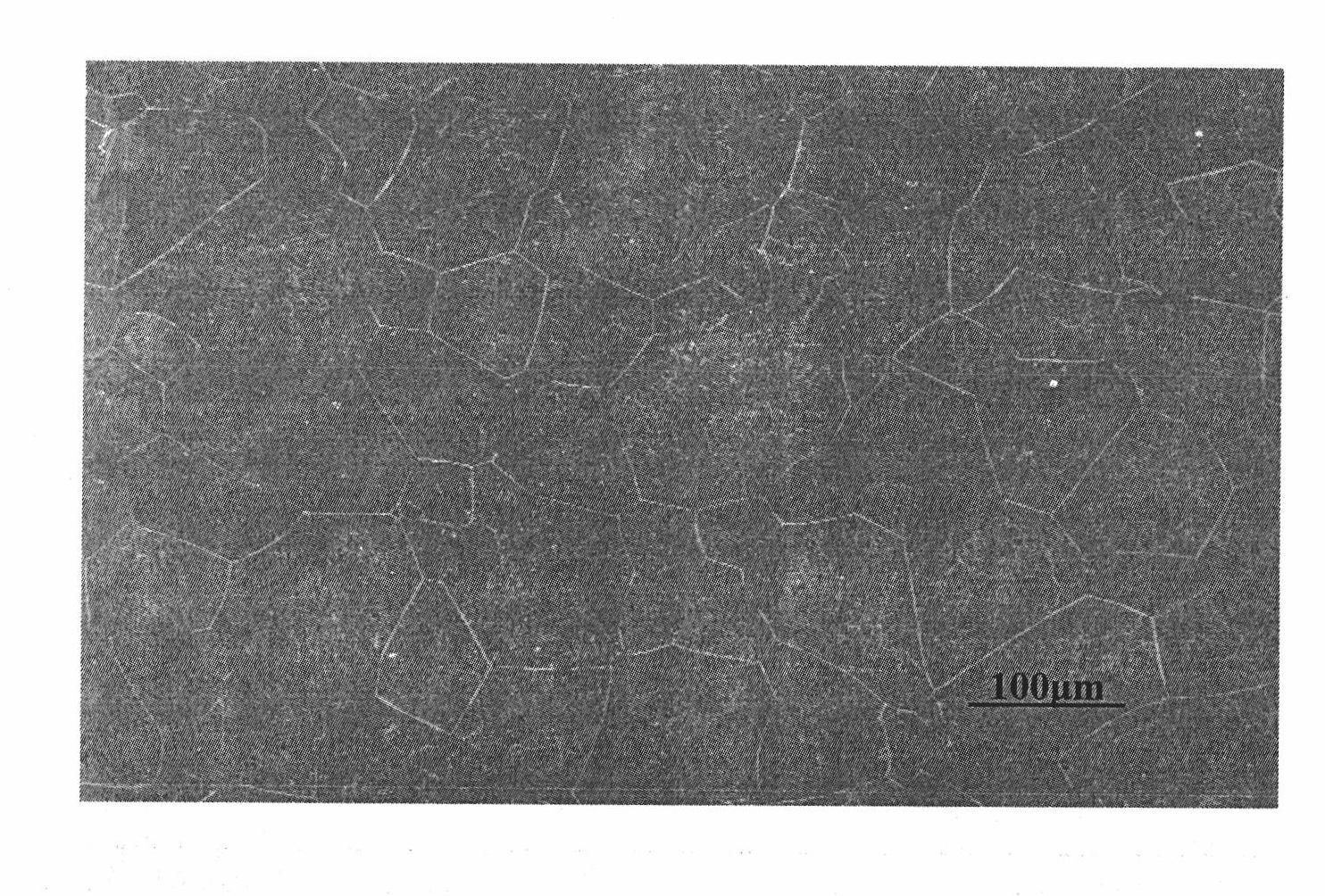

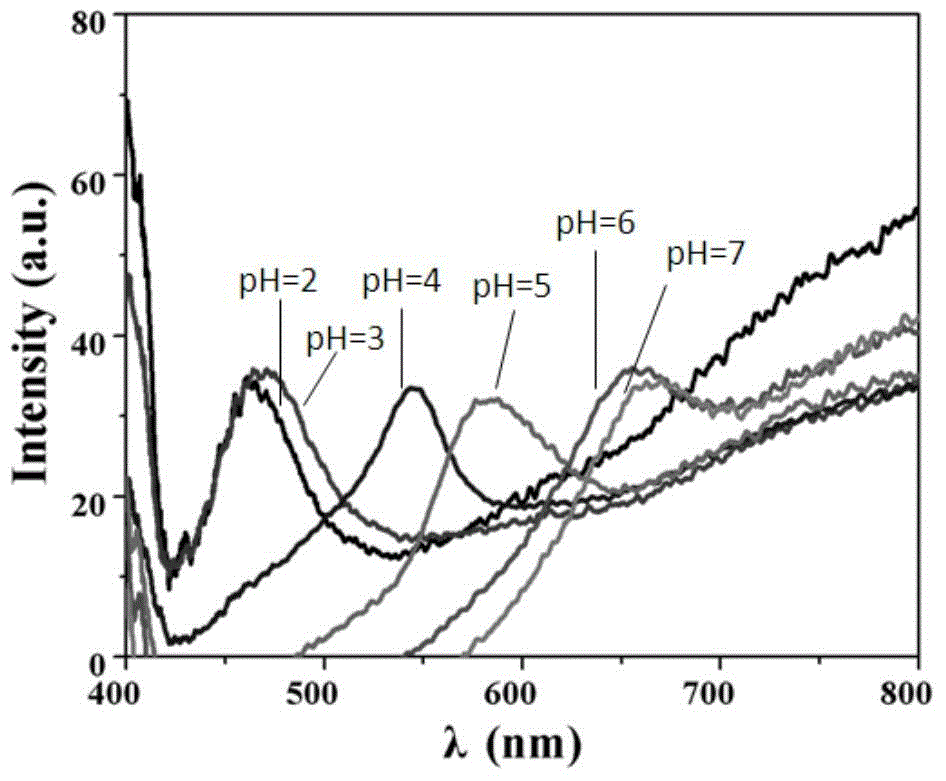

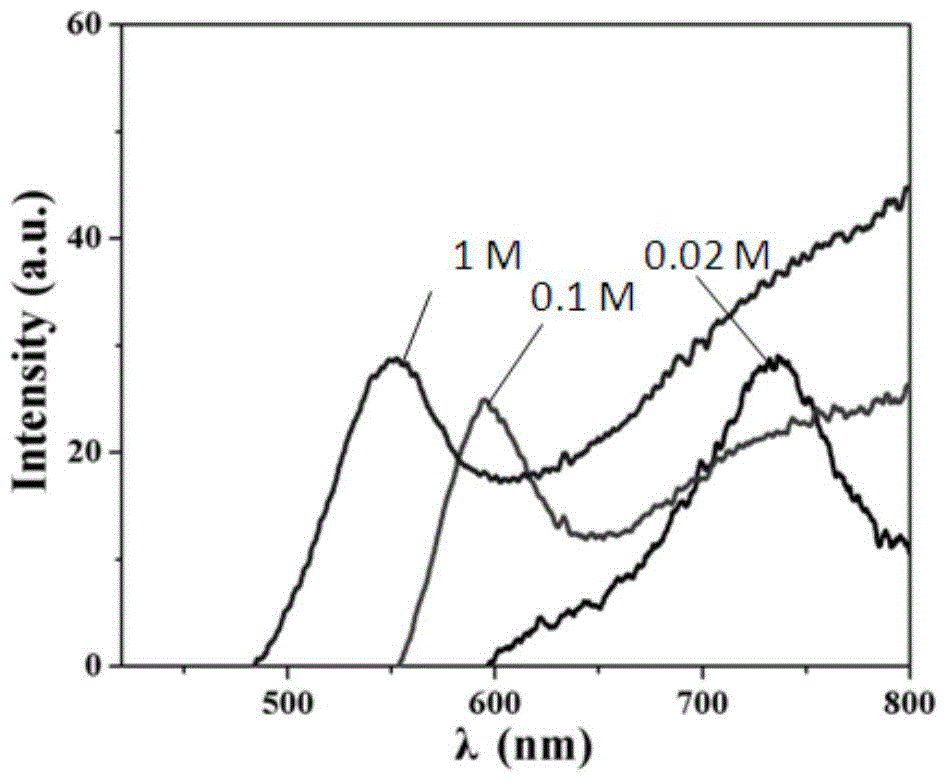

Photonic crystal hydrogel membrane with pH value and ionic strength response, preparation method and application thereof

ActiveCN104961906ABoth pHBoth strengthMaterial analysis by observing effect on chemical indicatorFerroso-ferric oxidesUltraviolet lightsColor changes

The invention discloses a photonic crystal hydrogel membrane with pH value and ionic strength response, a preparation method and an application thereof. The photonic crystal hydrogel membrane comprises Fe3O4 nano particles and polyacrylamide-methacrylate acetic acid hydrogel, wherein the Fe3O4 nano particles are uniformly dispersed in the hydrogel and are arranged in a one-dimensional chain shape, and the concentration of the nano particles in the membrane is 1 to 50 mg / mL. The preparation method of the photonic crystal hydrogel membrane comprises the steps of uniformly mixing the Fe3O4 nano particles and hydrogel monomers, so as to generate curing reaction through ultraviolet light, and soaking in a soluble carbonate aqueous solution at last, so as to obtain the required membrane. The preparation method has the advantages of simplicity in operation, strong repeatability and convenience in large-scale preparation, the carboxyl quantity of the obtained membrane is controllable, the membrane is monochromatic, obvious color change occurs under the stimulation of pH value or ionic strength, and naked-eye detection is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

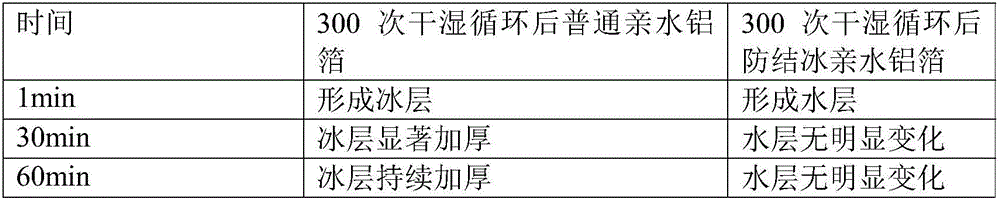

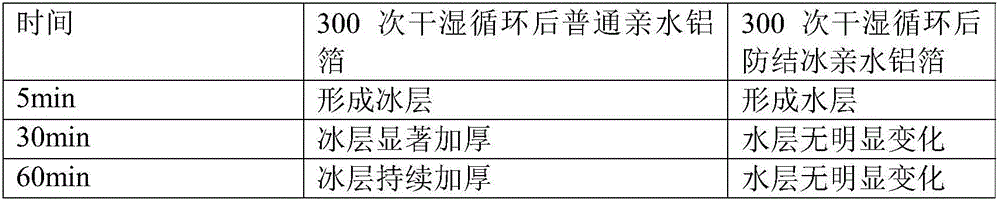

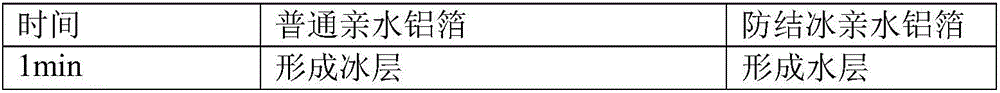

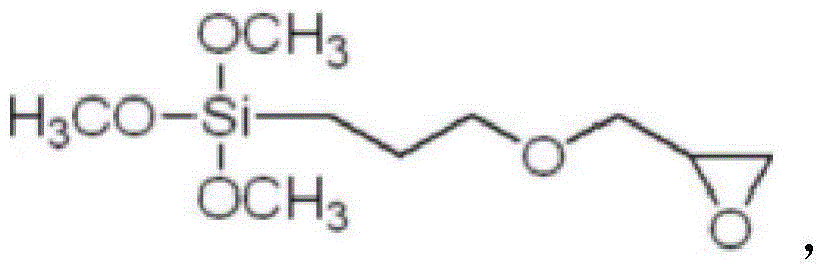

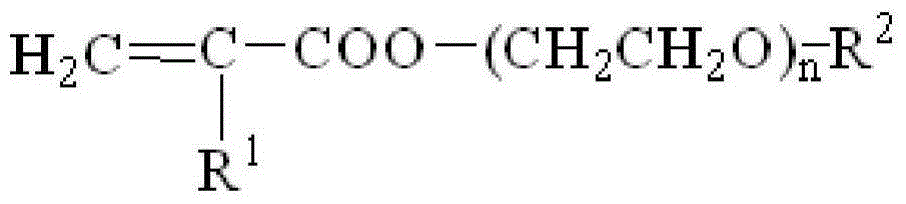

Water-based organic-inorganic hybrid anti-freezing coating

InactiveCN106366822ADelay and resist icing/frostSolve the icing/frost problemOther chemical processesAnti-corrosive paintsCross-linkWater based

The invention relates to the technical field of anti-freezing coatings, in particular to a water-based organic-inorganic hybrid anti-freezing coating, which is prepared from the following components in parts by weight: 1 to 50 parts of water-base resin, 1 to 20 parts of water-soluble curing agent, 0 to 30 parts of functional filler, 0.01 to 1.00 part of accessory ingredient, 1 to 20 parts of solvent, and the balance of deionized water for complementing 100 parts by weight. The water-soluble curing agent is a nitrogen-containing derivative and / or polyhydroxy-alcohol and water-soluble amino resin cross-linked with active groups such as hydroxide radical, carboxyl, amino, epoxy group and (sealed) isocyanate in the water-base resin. The water-based organic-inorganic hybrid anti-freezing coating provided by the invention is prepared by blending the water-base resin, the curing agent, the filler, a surface active agent and the solvent, and is particularly suitable for heat exchange surface treatment of an air conditioner coating aluminum foil, a refrigerator / cabinet inner container and the like.

Owner:合肥普庆新材料科技有限公司

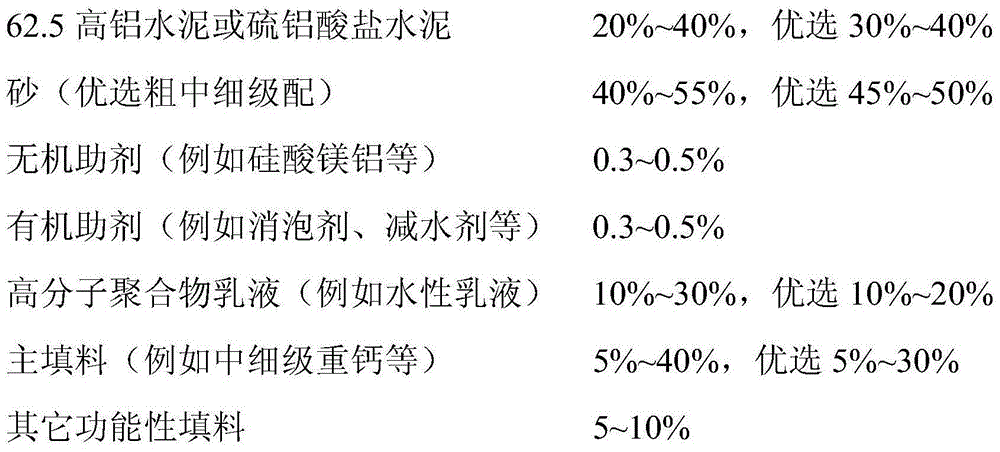

Flexible finishing soft stone or tile

The invention discloses a flexible finishing soft stone or tile which is made by the materials including following components in weight ratio of total weight of materials :20-40% of 62.5 aluminous cement or aluminate cement, 40-55% of graded sand of large, intermediate and fine size, 5-40% of intermediate fine fillers, 10-30% of high-molecular polymer emulsion, 5-40% of main fillers, and 5-10% of other functional fillers. The invention also discloses a manufacture method and a construction method of the flexible finishing soft stone or tile which has good flexibility and intensity.

Owner:北京翰高兄弟科技发展有限公司

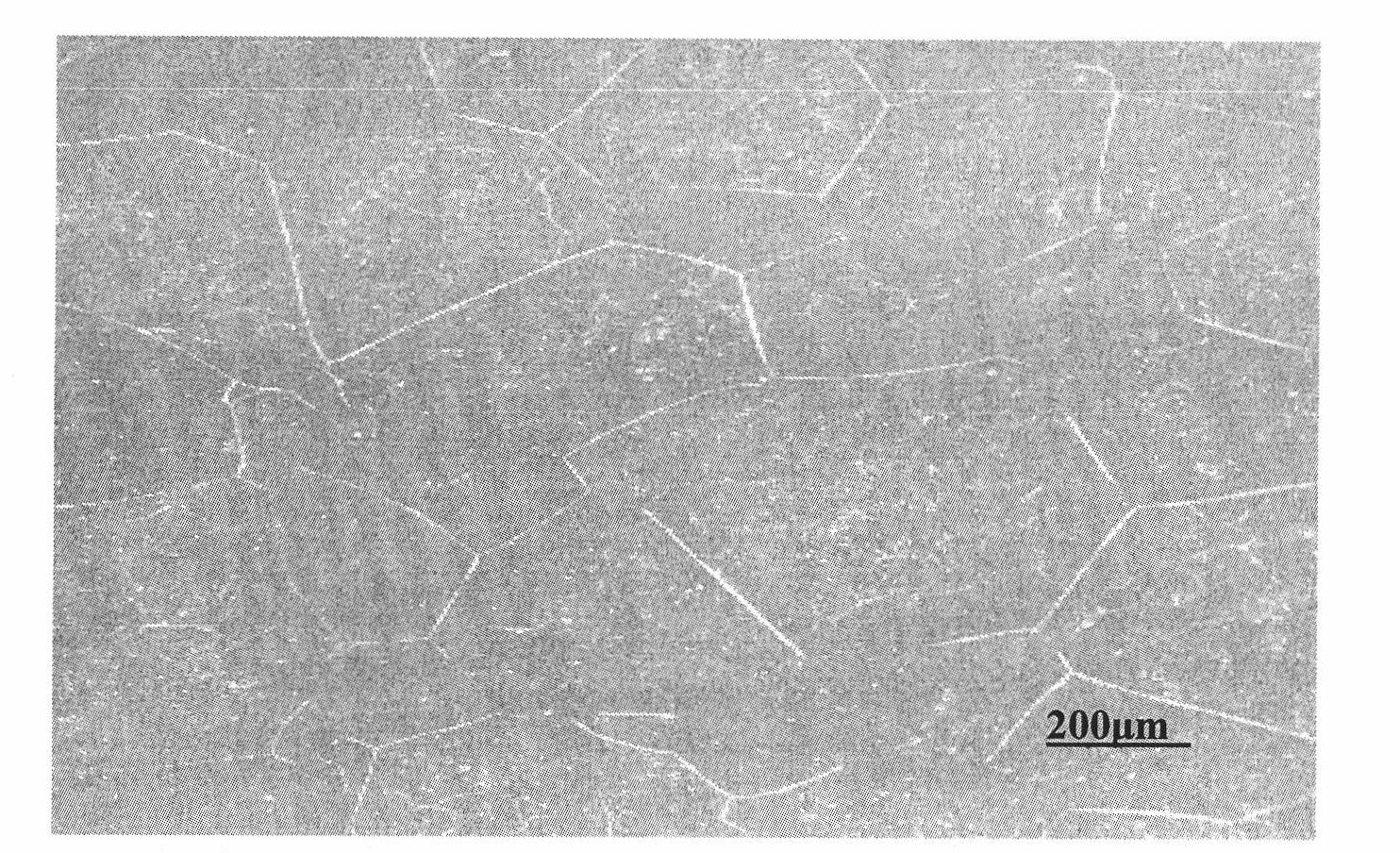

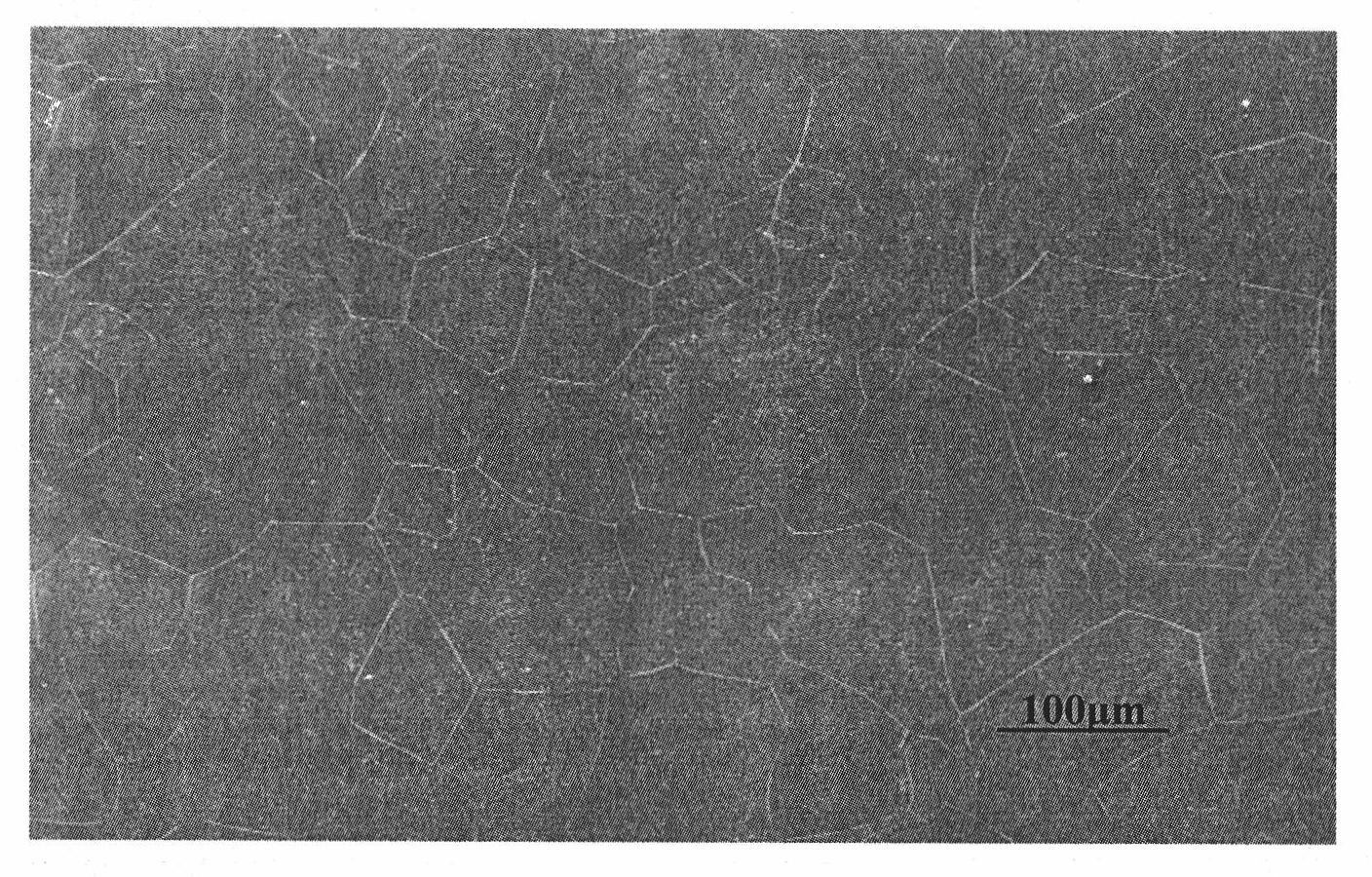

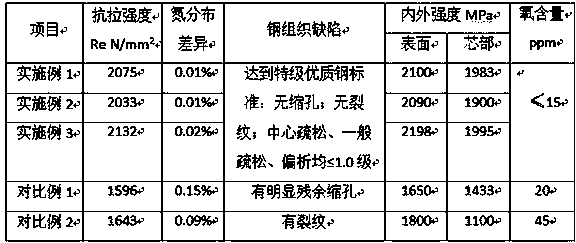

Preparation method of high-strength high-nitrogen rare earth stainless bearing steel

InactiveCN111334702AHigh nitrogen contentHigh strengthProcess efficiency improvementRare-earth elementMolten steel

The invention discloses a preparation method of high-strength high-nitrogen rare earth stainless bearing steel. The preparation method comprises the processes of primary smelting, refining, vacuum degassing, casting, pressurized electroslag remelting and heat treatment. Nitride is added in the pressurized electroslag remelting process, meanwhile, the nitrogen pressure is controlled, the nitrogen content in steel is increased to 0.3%-0.5%, the nitrogen increasing process is stable, and nitrogen distribution is uniform; rare earth elements are added before nitrogen dissolving to purify molten steel, so that the stability and uniformity of the nitrogen dissolving process are further improved, and the strength of the bearing steel is effectively improved; 80-90% of rare earth elements are usedfor purifying molten steel, the rest of rare earth elements are dissolved in the molten steel for microalloying, and the toughness of the bearing steel is remarkably improved through the two parts ofrare earth elements which are matched in a labor-division mode; and in addition, the mode of combining diffusion deoxidation, vacuum deoxidation and rare earth deep deoxidation is adopted, the deoxidation effect is guaranteed, meanwhile, use of aluminum is reduced, harm of the aluminum is reduced, and the anti-fatigue performance of the steel is improved.

Owner:DEQING TIANMA BEARING CO LTD

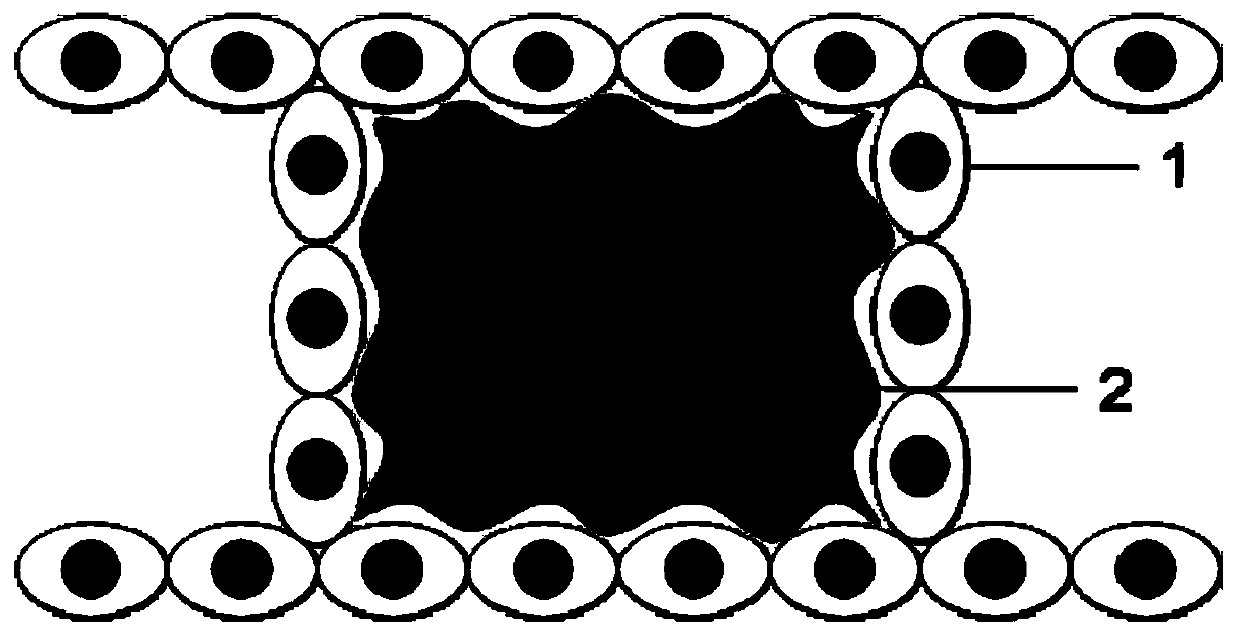

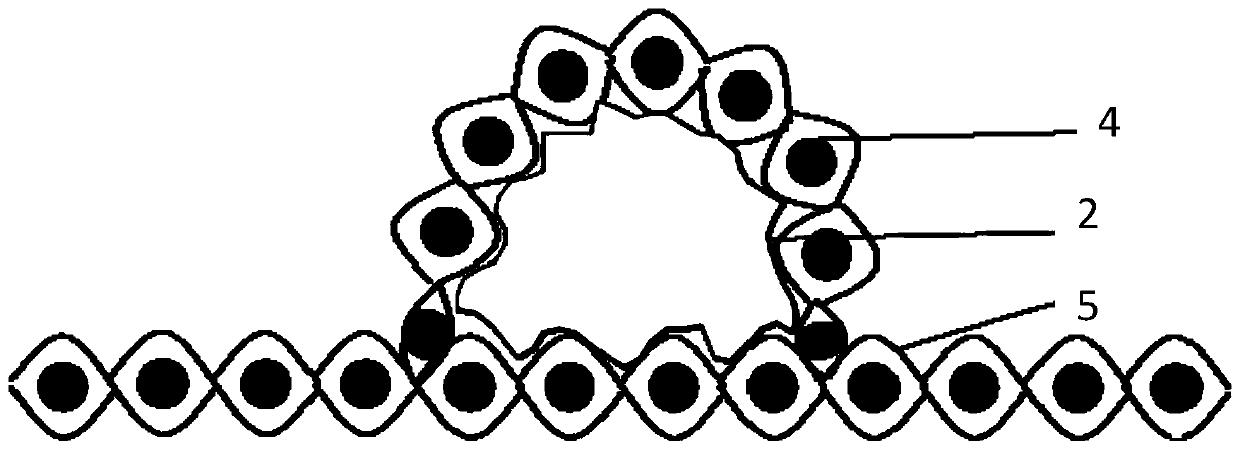

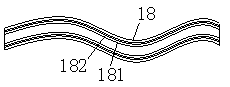

Anti-stab fabric with shear thickening fluid and rheid

ActiveCN109944074AComfortable to wearImprove wearing comfortFibre treatmentFluid viscosityHigh intensity

The invention provides an anti-stab fabric with shear thickening fluid and rheid. The fabric is characterized by comprising a three-dimensional-structure fabric as a framework structure, the three-dimensional-structure fabric is provided with a cavity, and the cavity of the three-dimensional-structure fabric is filled with the shear thickening fluid. According to the anti-stab fabric, since the viscosity of the shear thickening fluid is rapidly increased at high shear speed, and the shear thickening fluid has an energy consumption characteristic of liquid and high strength performance of a solid, the novel anti-stab fabric for the rheid, particularly the anti-stab fabric for the shear thickening fluid and rheid is provided. The shear thickening fluid is injected into the three-dimensional-structure fabric, if the fabric is subjected to any impact or shearing force, the viscosity of the shear thickening fluid is quickly increased, the shear thickening fluid is in a solid state, and accordingly the anti-stab function is achieved.

Owner:DONGHUA UNIV

Sintered water permeable brick with smooth and mildew-proofing surface

The invention discloses a sintered water permeable brick with a smooth and mildew-proofing surface. The water permeable brick is prepared from the following raw materials in parts by weight: 40-43 parts of sludge of a sewage plant, 6-7 parts of rice husks, 4-5 parts of potassium feldspar powder, 5-6 parts of pulverized fuel ash, 3-4 parts of bamboo powder, 8-10 parts of activated pozzolana, 19-21 parts of fluorite tailings, 4-5 parts of noan-silicon carbide, 2-3 parts of sodium carboxymethyl cellulose and 3-4 parts of light magnesium oxide. According to the sintered water permeable brick, the fluorite tailings, palm fibers, nano-silicon carbide and other ingredients are added to serve as aggregate ingredients of a brick blank, so that the tensile strength and crack resistance of a brick body can be enhanced, and the porosity of the brick body is further improved; the bamboo powder added into the brick is turned into a bamboo charcoal ingredient by means of sintering, so that the water permeable brick has excellent antibacterial and mildew-proofing effect. The manufactured water permeable brick has an attractive appearance and smooth surface, and integrates strength, water permeability and corrosion resistance into a whole.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

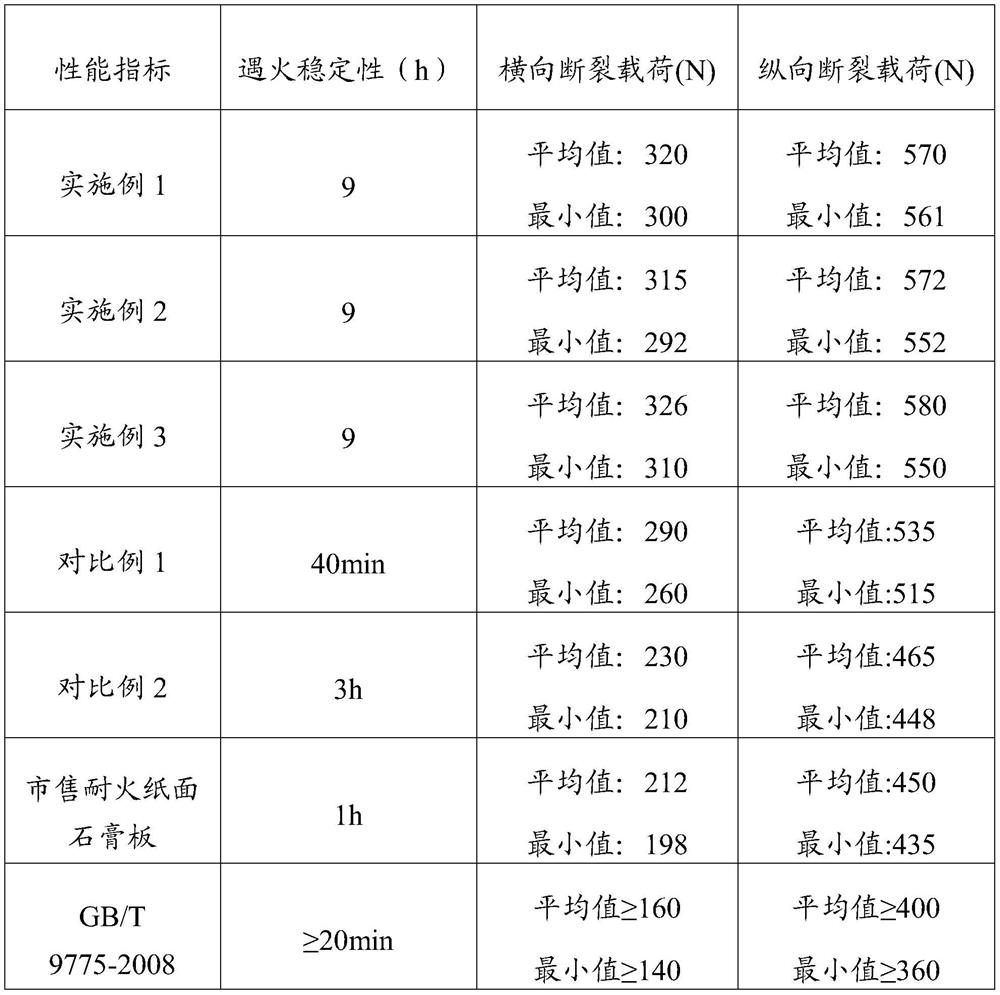

High-strength fire-resistant paper surface gypsum board and preparation method thereof

ActiveCN111605263ASingle weight increaseHigh strengthLamination ancillary operationsLaminationFoaming agentGrog

The invention provides a high-strength fire-resistant paper surface gypsum board and a preparation method thereof. The paper surface gypsum board is prepared from the following raw materials in partsby mass: 100 parts of gypsum clinker; 0.1 to 0.3 part of a water reducing agent; 0.2 to 0.8 part of modified starch; 0.03 to 0.05 part of a foaming agent; 1.5 to 3.5 parts of a fire-resistant material; and 70 to 80 parts of water. The preparation method comprises the following steps that: raw materials are weighed, the raw materials are mixed with water, the mixture is added into a stirrer, and uniform mixing is performed to obtain gypsum slurry; the uniformly stirred gypsum slurry is made to be in lap joint with and firmly adhered to surface protection paper so as to be subjected to molding,so that a wet board can be obtained ; and after the wet board is solidified, the wet board enters a drying machine, and the dried wet board is a gypsum plaster board. According to the gypsum plaster board, the performance of the board core of the gypsum plaster board is improved, so that the gypsum board with higher strength and good fire resistance is obtained.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Automotive toughened polypropylene corrugated pipe and preparation method thereof

The invention relates to an automotive toughened polypropylene corrugated pipe and a preparation method thereof. The automotive toughened polypropylene corrugated pipe is prepared from the following raw materials in parts by weight: 100-120 parts of polypropylene, 6-12 parts of polyethylene octylene co-elastomer, 3-6 parts of tetrabromobisphenol A-di(2, 3-dibromopropyl ether), 1.5-3 parts of antimonous oxide, 0.5-2 parts of color master and 2-5 parts of antioxidant. The corrugated pipe provided by the invention is a corrugated pipe for the automobile; in order to solve the existed toughness problem of the automotive polypropylene corrugated pipe, the special requirements of the flame retardance, the ageing resistance and the temperature resistance of the corrugated pipe are considered, the formula is integrally adjusted to integrally increase the toughness of the automotive polypropylene corrugated pipe; after toughening modification is performed on the corrugated pipe prepared by the formula provided by the invention, the intensity and the toughness are obtained, the strength requirements such as processing and installation can be met, and the bend property, the abrasive resistance, the temperature resistance, the flame retardant property and the moulding processability are excellent.

Owner:LUOYANG NORMAL UNIV

Layered wear-erosion resistant rubber lining plate and preparation method thereof

InactiveCN104441852AHigh strengthImprove erosion resistanceLaminationLamination apparatusRubber materialPolymer science

The invention relate to a layered wear-erosion resistant rubber lining plate and a preparation method thereof, belonging to rubber materials in the field of polymer materials. The rubber lining plate is formed by splicing a rubber substrate with a surface wear resistant rubber through heat curing. The rubber lining plate is prepared from a surface wear resistant rubber, a special anticorrosion rubber and additives, wherein the surface wear resistant rubber serves as a framework and comprises aramid glass fiber and polyamide fiber, the special anticorrosion rubber servers as a substrate, and the additives comprise silicon carbide micropowder or zirconium carbide micropowder, aluminium oxide micropowder, silicon oxide micropowder and elemental silicon micropowder. The rubber lining plate can be used as a lining material, has a certain strength, abrasion resistance, erosion resistance and puncture resistance and also has a certain resilience and flexibility. Compared with the conventional metal linings or inorganic nonmetallic material poured linings, the rubber lining plate provided by the invention has the characteristics of light weight and easiness for installation and replacement.

Owner:平顶山华瑞锦橡耐磨材料有限公司

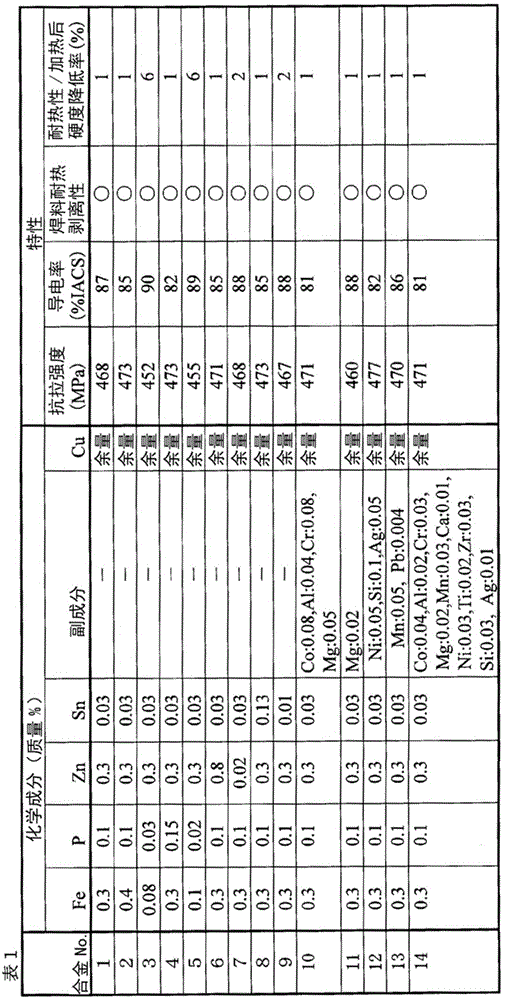

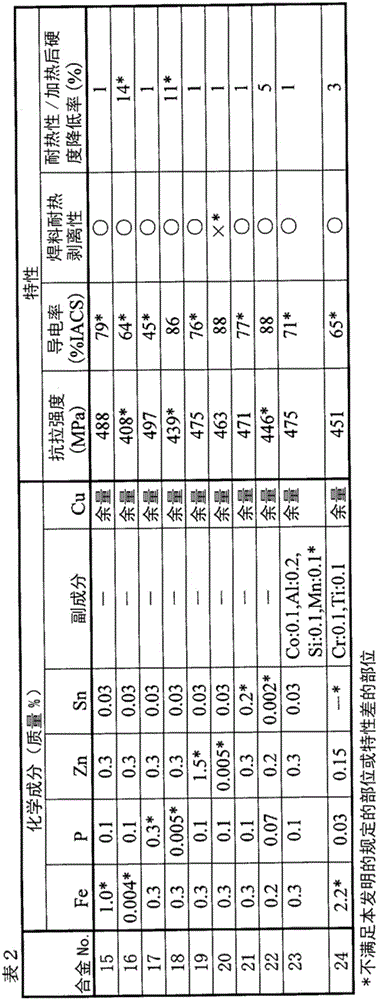

Copper alloy plate strip for use in led lead frame

InactiveCN106574325AIncrease heat releaseReduce hardnessSingle bars/rods/wires/strips conductorsSemiconductor/solid-state device detailsSurface roughnessLead frame

Owner:KOBE STEEL LTD

Preparation method of composite ceramic coating

The invention discloses a preparation method of a composite ceramic coating. The preparation method comprises the following steps: a, grinding and mixing: uniformly grinding and mixing 100 parts of silicon carbide micro-powder, 3 to 7 parts of nano tungsten powder, 3 to 7 parts of ultrafine graphite powder and 5 to 10 parts of a binding agent to prepare a mixture; b, carrying out wet-process ballmilling: adding de-ionized water which accounts for 80 to 120 percent of the mass of the mixture in step a and a dispersant which accounts for 1 to 3 percent of the mass of the mixture in step a intoa planetary ball mill; carrying out the wet-process ball milling for 18 to 20h according to a rotary speed of 1500 to 1800r / min to obtain a uniform suspension solution. According to the preparation method disclosed by the invention, the silicon carbide micro-powder, the nano tungsten powder, the ultrafine graphite powder and the binding agent are subjected to the wet-process ball milling and dispersion according to a certain ratio to obtain the uniform suspension solution. Then a nano hot spray-coating technology is adopted to obtain the composite ceramic coating. The preparation method disclosed by the invention has the advantages of green and environment-friendly materials and simple spray-coating technology; the obtained composite ceramic coating has the advantages of high temperature resistance, wear resistance, corrosion resistance and the like of a ceramic material, but also has the strength and toughness of a metal material; the composite ceramic coating is a novel composite ceramic coating material.

Owner:曹志欢

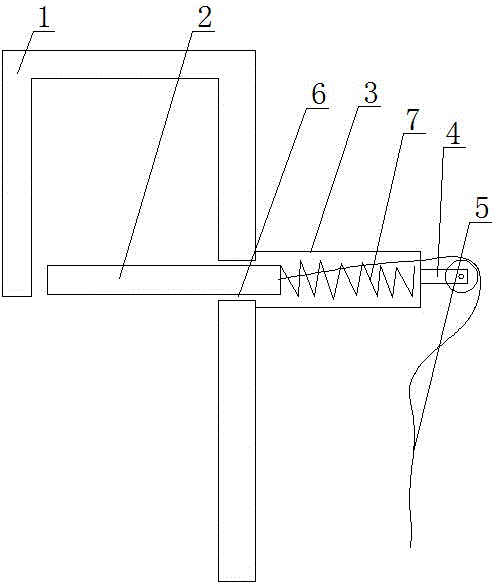

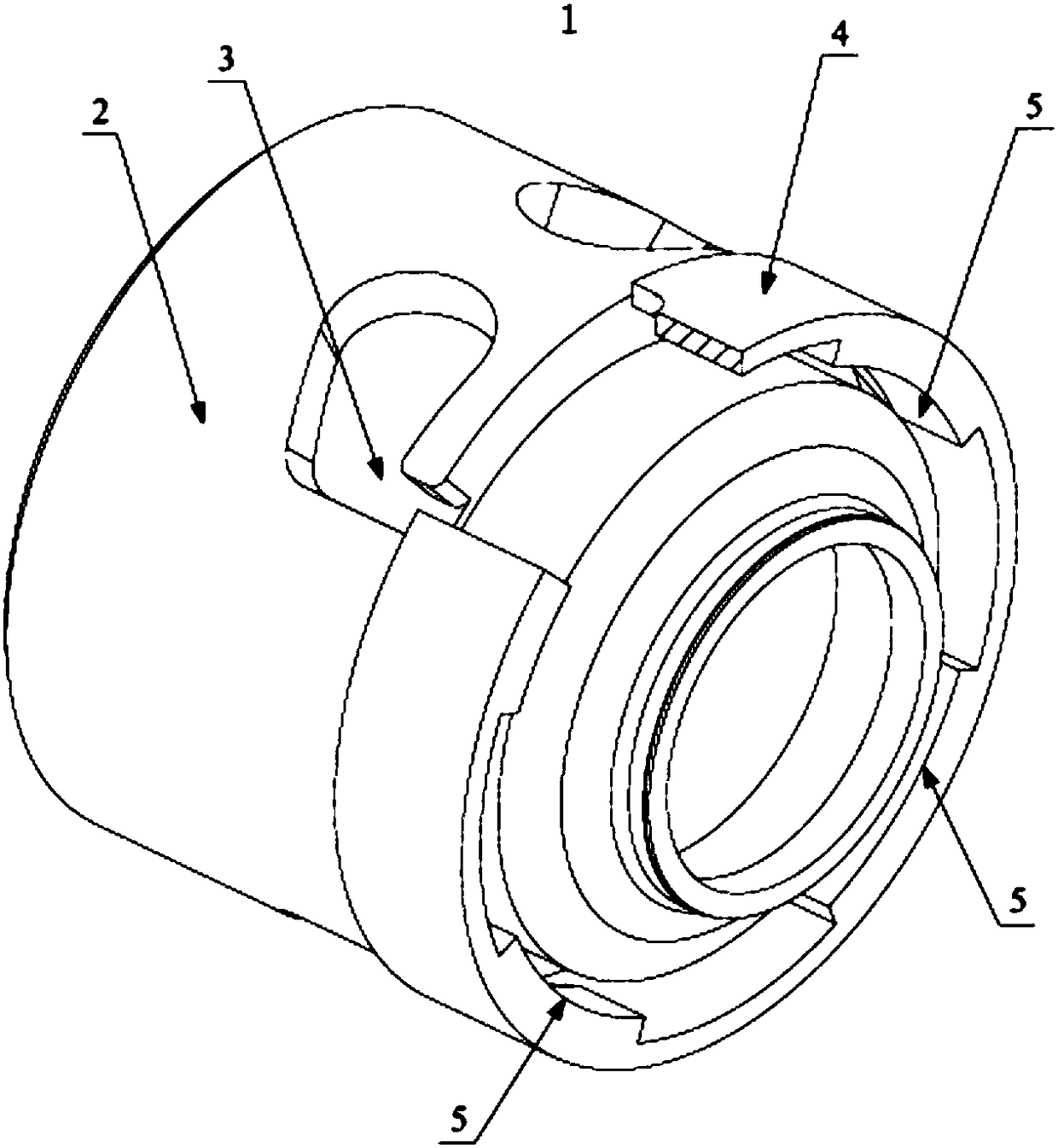

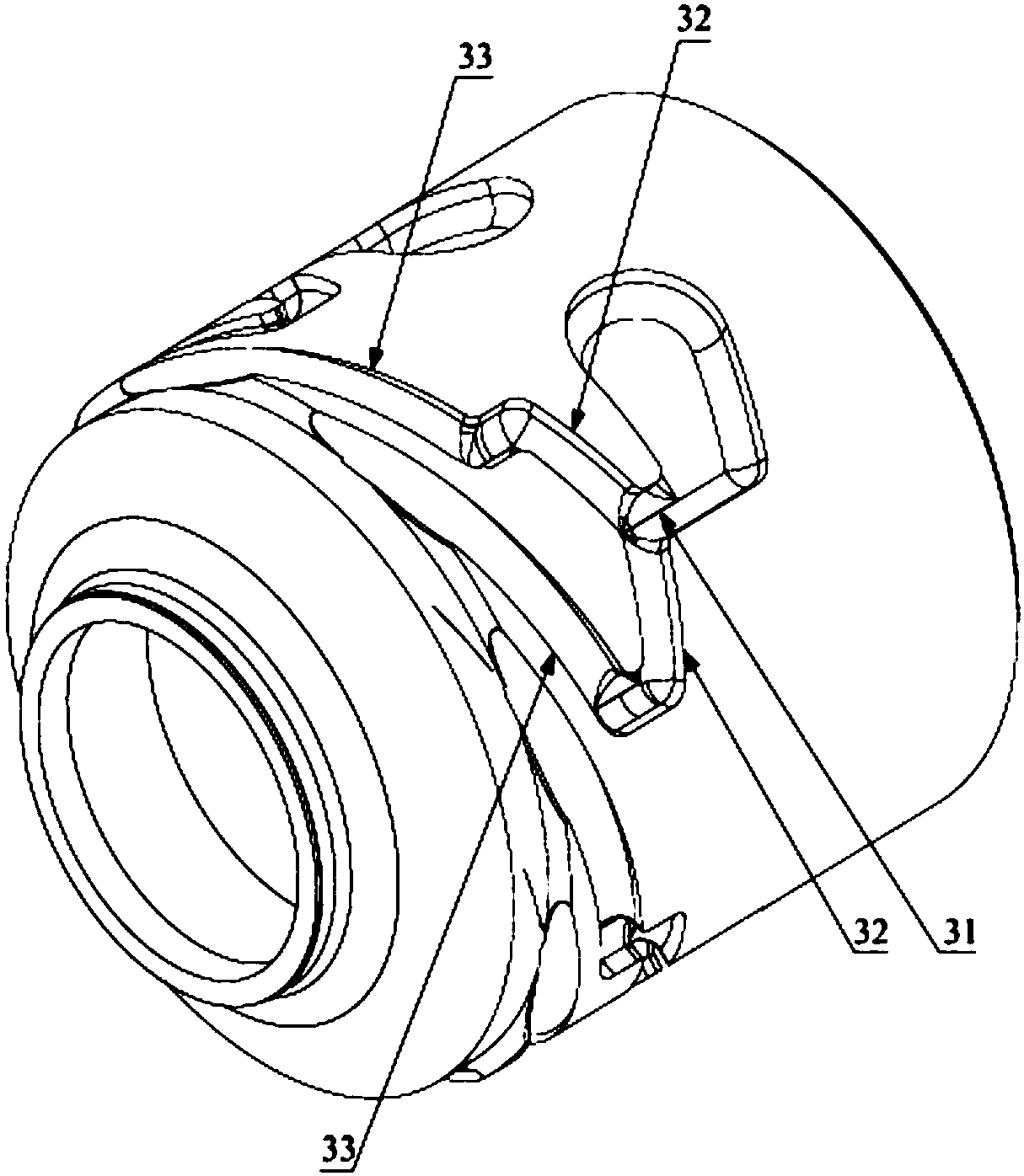

Combined type special hanger insulation tool for safety belt

InactiveCN104998360AHigh bonding strengthGood chemical resistanceSafety beltsLocking mechanismSelf locking

The invention discloses a combined type special hanger insulation tool for a safety belt. The combined type special hanger insulation tool for the safety belt comprises a hook body. A self-locking mechanism is arranged at the opening of the hook body. The self-locking mechanism comprises a barrel arranged on the hook body. The hook body is provided with a through hole, wherein a sliding rod in the barrel stretches out through the through hole. The sliding rod is connected with the bottom of the barrel through a spring. A round hole allowing a rope to penetrate through is formed in the end of the barrel. A pulley is arranged on the barrel.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

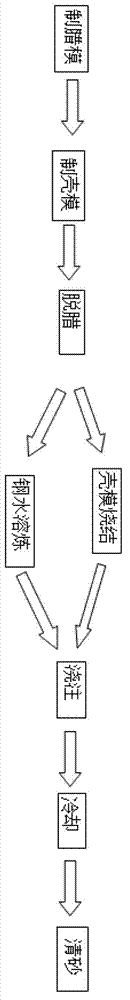

Preparation method of graphene composite

InactiveCN108330311ABoth conductivityBoth strengthTransportation and packagingMetal-working apparatusHigh volume manufacturingAlloy

The invention provides a preparation method of a graphene composite. The method comprises the steps of powder mixing, vacuum degassing and continuous extrusion. A device for the continuous extrusion comprises an extrusion module and a powder degassing module. A graphene composite conductor prepared by the method has strength of an alloy and conductivity of pure aluminum; the structural homogenityand performance stability are good; a material utilization rate is high and can reach 95% generally; heat generated by friction is used for raising the temperature; heating is not required; an energysource is saved; the device has few procedures, is high in production efficiency, can achieve continuous production of a product without time intervals and is suitable for large-scale production and small-scale multi-variety production; and the product is high in finished product rate, good in performance, and high in dimensional precision and smoothness.

Owner:新疆烯金石墨烯科技有限公司

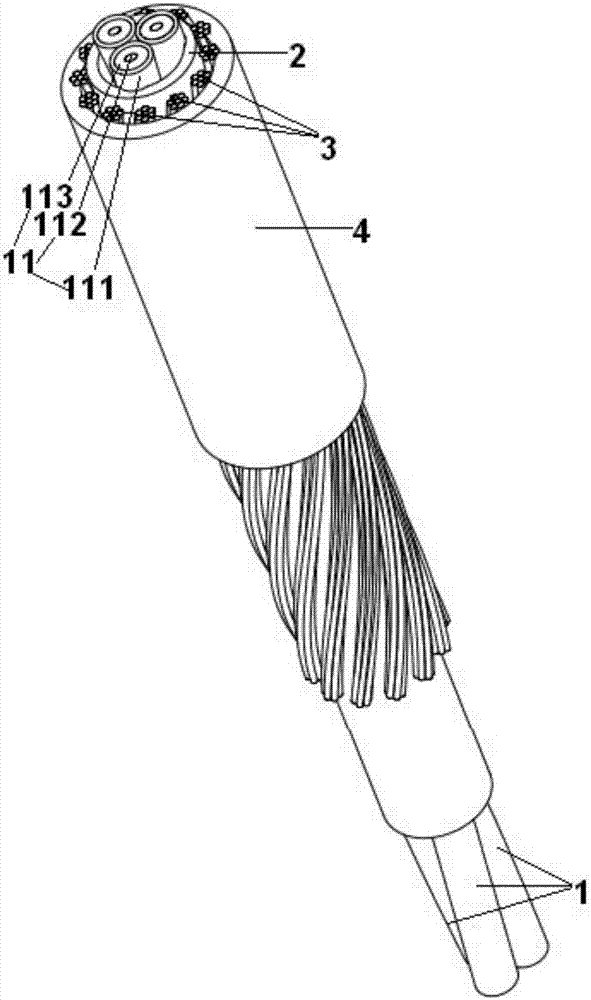

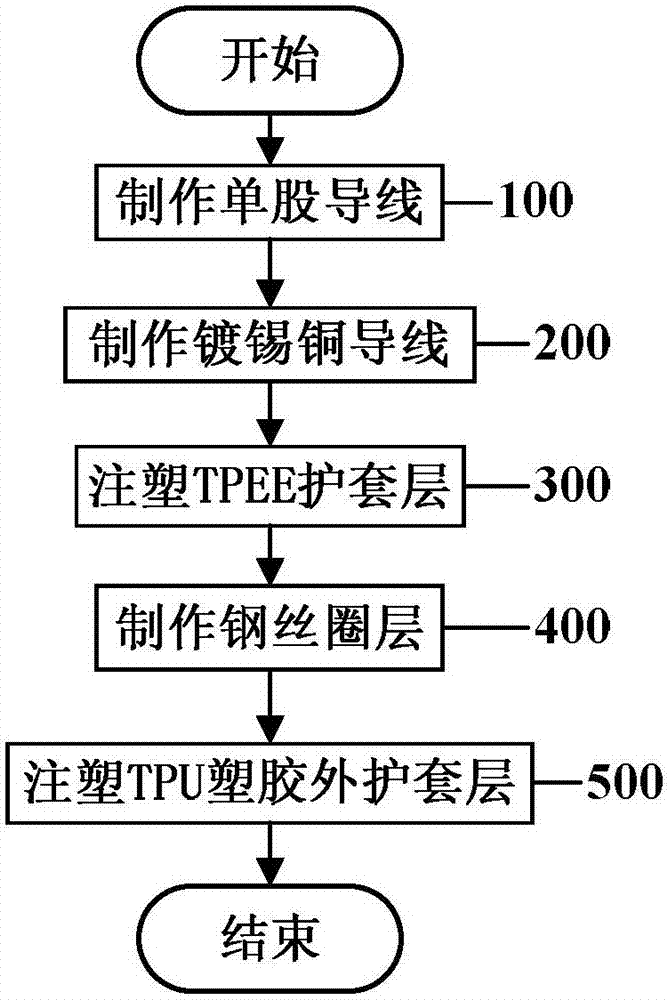

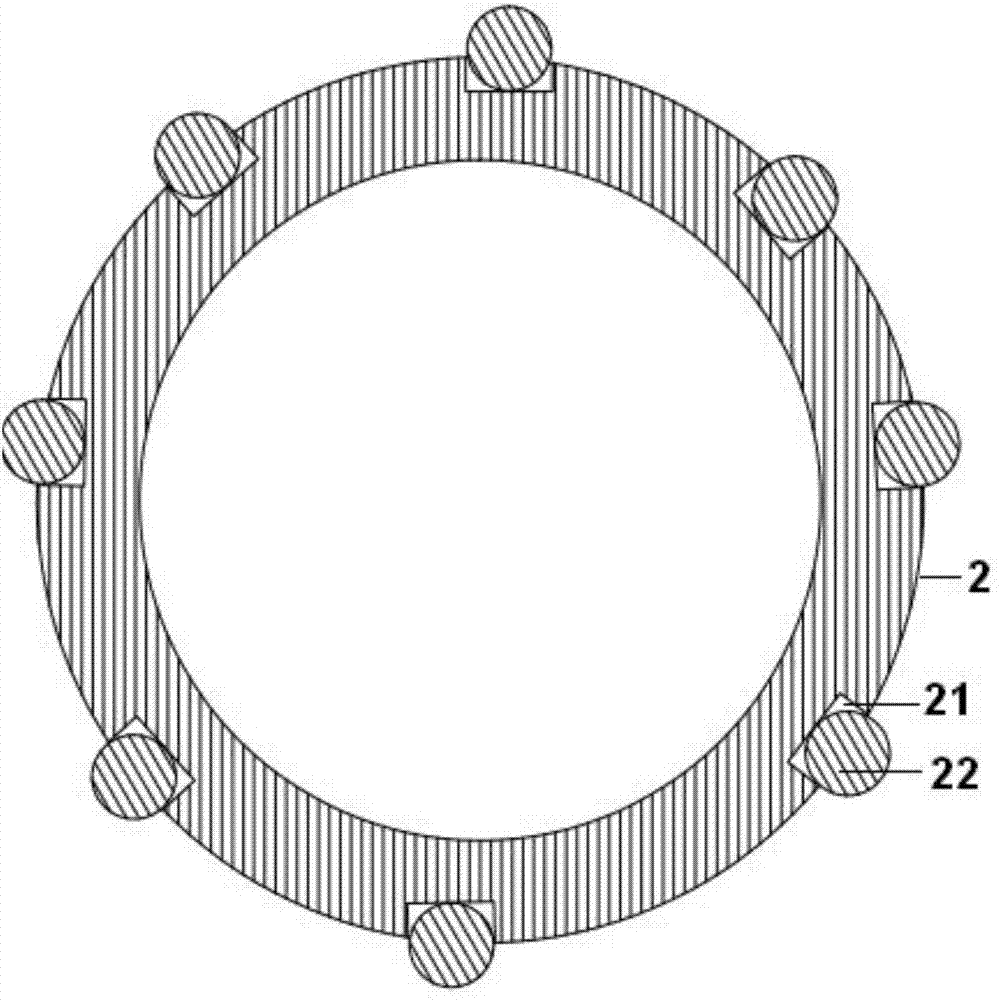

Digital product charging anti-theft cable

ActiveCN106057317BHigh strengthImprove conductivityInsulated cablesInsulated conductorsFiberCopper wire

The invention discloses an anti-theft charging cable for a digital product. The anti-theft charging cable comprises a twisted wire layer, a TPU sheath layer, a steel wire ring layer and a TPU plastic outer sheath layer which are arranged in sequence from inside to outside, wherein the twisted wire layer comprises a plurality of tinned copper leads twisted together; each tinned copper lead comprises a TPEE sheath, a plurality of DuPont fibers distributed along an axis of the TPEE sheath, and a plurality of tinned copper wires encircling the DuPont fibers; and a lubricant is arranged between the adjacent layers of the twisted wire layer, the TPU sheath layer, the steel wire ring layer and the TPU plastic outer sheath layer. The anti-theft charging cable has the characteristics of shearing resistance, tension resistance, bending resistance, difficult heating during strong charging, good impact resistance, easy stretching, tearing prevention, high temperature resistance and oxidation resistance.

Owner:HANGZHOU LANGHONG TECH

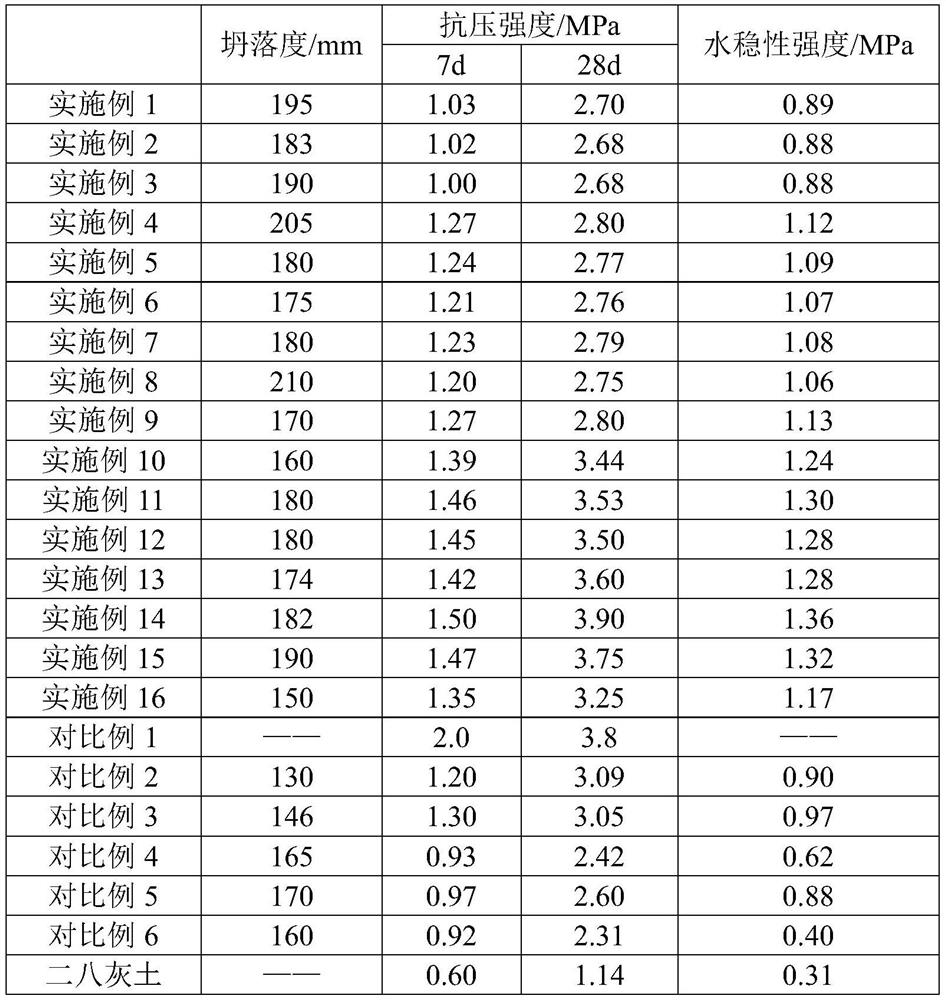

Fluid-state cured recycled mixture, preparation method and application thereof in pit slot backfilling

The invention relates to the technical field of civil construction materials, in particular to a fluid-state cured recycled mixture, a preparation method and application of the fluid-state cured recycled mixture in pit slot backfilling. The fluid-state cured recycled mixture is prepared from the following raw materials in percentage by weight: 60-70% of a recycled material, 10-20% of a cementing material and 15-25% of an additive and water. The additive is added in an external mixing manner, and the mixing amount of the additive is 0-0.5% of the total weight of the cementing material. The recycled material comprises recycled fine aggregate and redundant soil in a weight ratio of (3-5): (5-7), has good fluidity, is especially suitable for filling deep concave narrow space, has the characteristics of no vibration and convenience in construction, and has moderate 28d strength and good secondary excavability. Construction waste is adopted to replace natural materials such as soil and riversand, cyclic utilization of waste resources is achieved, and saving and environmental protection are achieved.

Owner:北京城建华晟交通建设有限公司

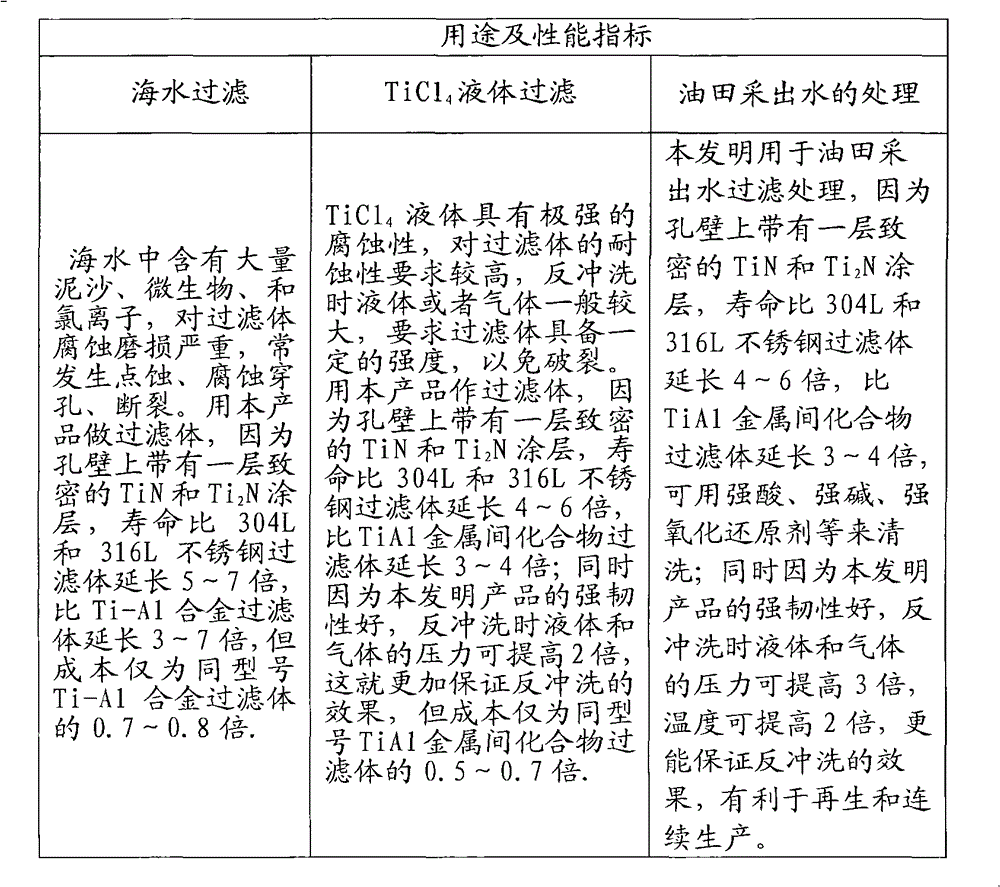

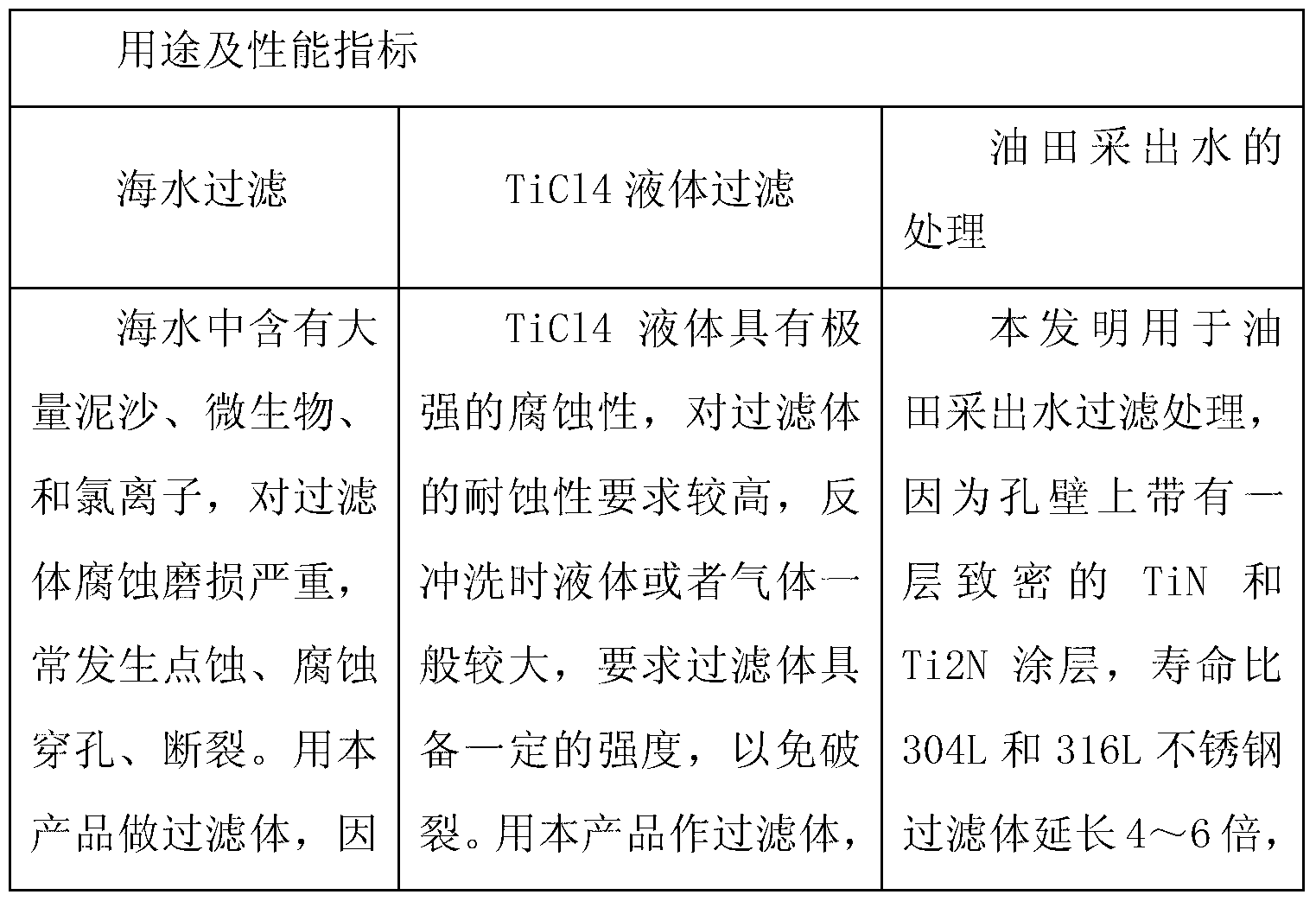

Porous membrane with TiN coating and preparation method thereof

ActiveCN102719691ABoth strengthBoth corrosion resistanceSolid state diffusion coatingFiltration separationNitrogen plasmaPorous membrane

A porous membrane with a TiN coating. A nitrogen plasma beam is utilized to carry out scanning heating azotizing treatment on a lamellar compact prepared from Ti and TiH2, so as to form a pore-like structure and obtain compact and continuous TiN coating and Ti2N coating surrounding a Ti skeleton matrix on the Ti skeleton among the pores. The method of the invention completes acquisition of the porous material and formation of the coating in one step, and has advantages of large porosity range of the film, short preparation process, high efficiency and high yield. The porous Ti membrane with TiN coatings on surfaces of the pores has uniform and dense tissue, is in good metallurgical combination with the matrix, and has micro hardness of 1270-1430 HV. The porous membrane has similar shape and size as a blank and good similarity. Besides, the membrane with good abrasion resistance and corrosion resistance can be used as a catalyst carrier and a filtering body in the industries of catalysis, environment purification and medicine, and has wide application prospects.

Owner:SHANDONG UNIV OF SCI & TECH

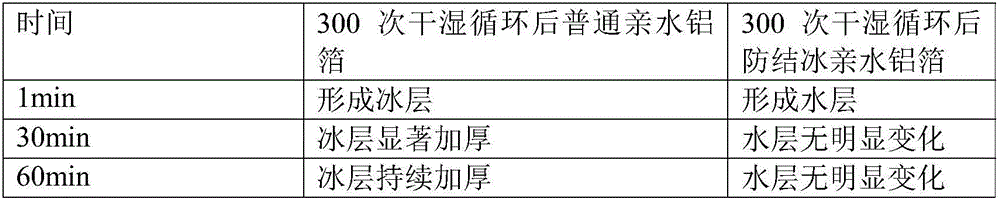

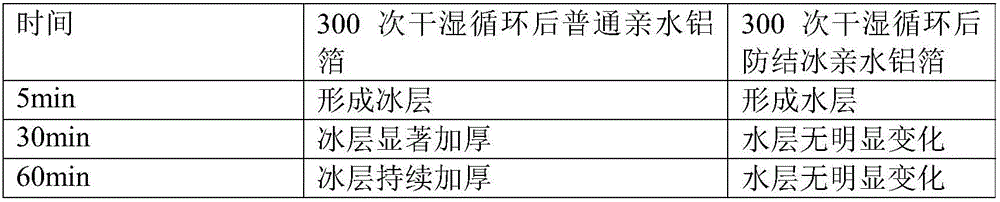

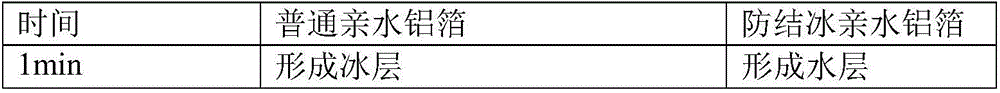

Method for preparing anti-freezing coating aluminum foil

InactiveCN106179916ADelay and resist icing/frostSolve the icing/frost problemAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedPolyethylene glycol

The invention relates to the technical field of anti-freezing coatings, in particular to a method for preparing anti-freezing coating aluminum foil. An aluminum foil surface subjected to degreasant cleaning and deionized water cleaning is coated with a corrosion-resistant first coat, curing is carried out, then the cured first coat is coated with a water-based organic and inorganic hybrid anti-freezing coating, then curing is carried out, and the hydrophilic aluminum foil with an anti-freezing function can be obtained. A quite thick non-frozen water layer is provided through an ultra-water absorption resin tail end penetrating into the water layer, and the combined action of the surface water film thickness is reduced through the super-hydrophilic surface, so that the treated hydrophilic surface is only provided with the non-frozen water layer almost; and therefore, anti-freezing performance is obtained. Sodium silicate, polyethylene glycol and ultru-water absorption resin are adopted in topcoat, and a super-hydrophilic freezing preventing coating is obtained in a mutual restraining manner. When water exists, the water absorption resin expands and stretches into the water layer, but cannot be taken away along with water flow due to restraint of a silicon dioxide network. Therefore, continuous freezing preventing performance is achieved.

Owner:合肥普庆新材料科技有限公司

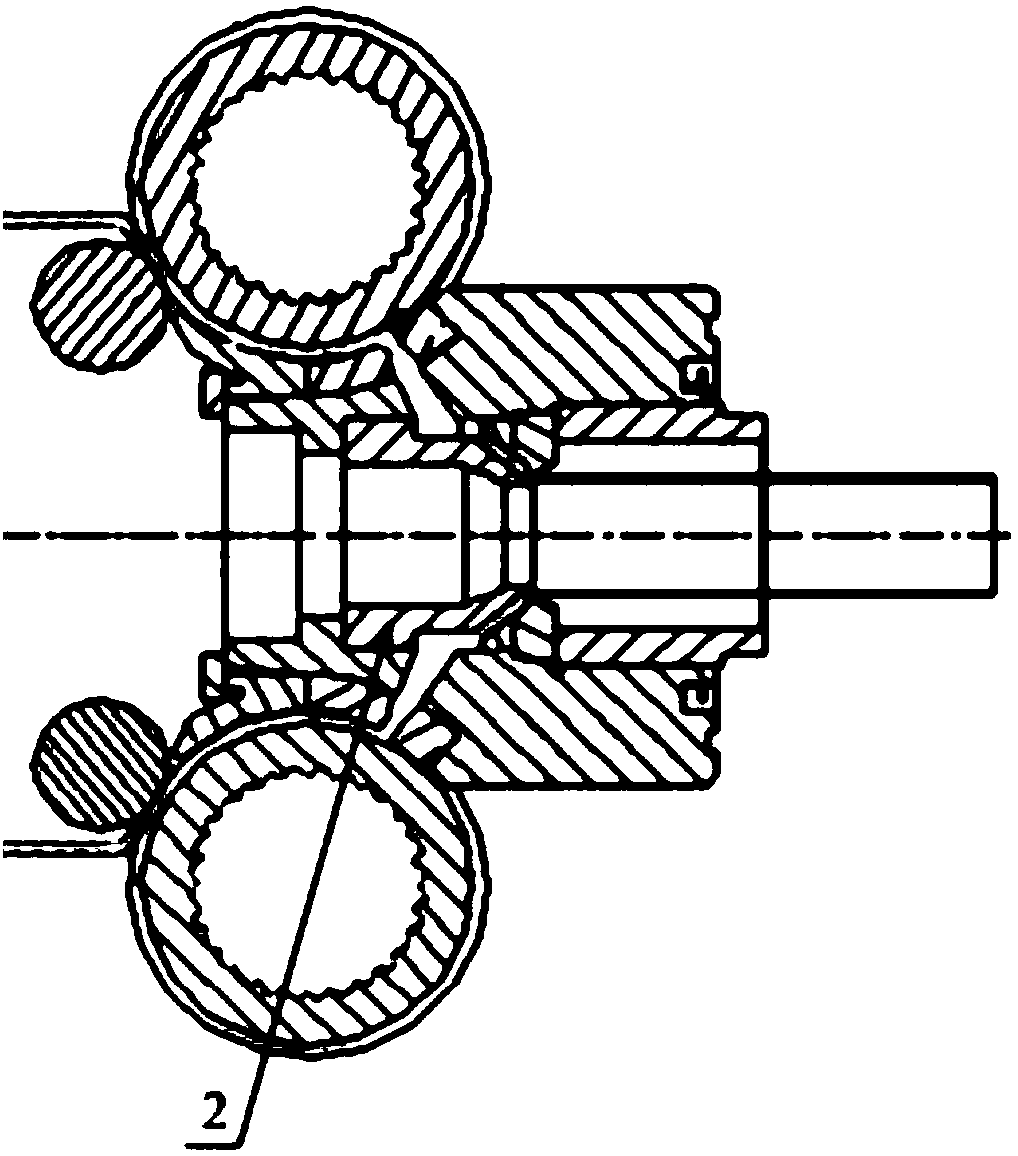

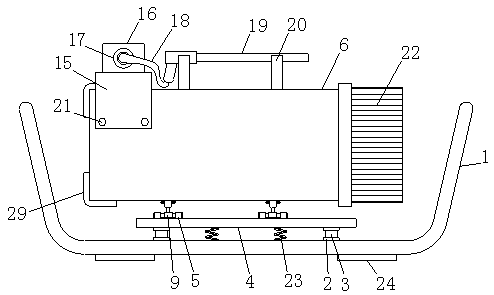

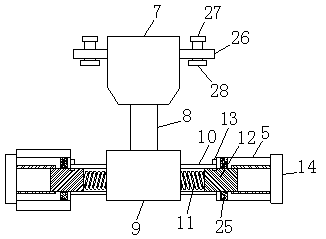

Oil field oil well pump capable of being installed conveniently and preventing leakage

InactiveCN108999771AEasy to installAvoid shakingPositive displacement pump componentsFlexible member pumpsPumpjackOil well

The invention discloses an oil field oil well pump capable of being installed conveniently and preventing leakage. The oil field oil well pump includes a seat frame. Rubber cushions are arranged at the top of the seat frame, and the tops and the bottoms of the rubber cushions are fixedly connected with connection pads. The connection pads at the bottoms of the rubber cushions are fixedly connectedto the top of the seat frame, and the connection pads at the tops of the rubber cushions are fixedly connected with a seat plate. Fixing sleeves are welded at the top of the seat plate, and a pump machine body is arranged at the top of the seat plate. The oil field oil well pump capable of being installed conveniently and preventing leakage can not only greatly shorten the installation time, butalso ensures that the pump machine body is not prone to falling off by arranging a fixing mechanism capable of locking fast and being installed firmly; and secondly, the oil well pump is provided witha stronger shock absorbing mechanism in a matched mode, good buffering and shock absorbing effects can be achieved, the own vibration of the pump machine body is reduced, adverse effects on the wholeoil field oil well pump are prevented, and thus the working efficiency of the oil well pump is improved.

Owner:东营亦润信息技术有限公司

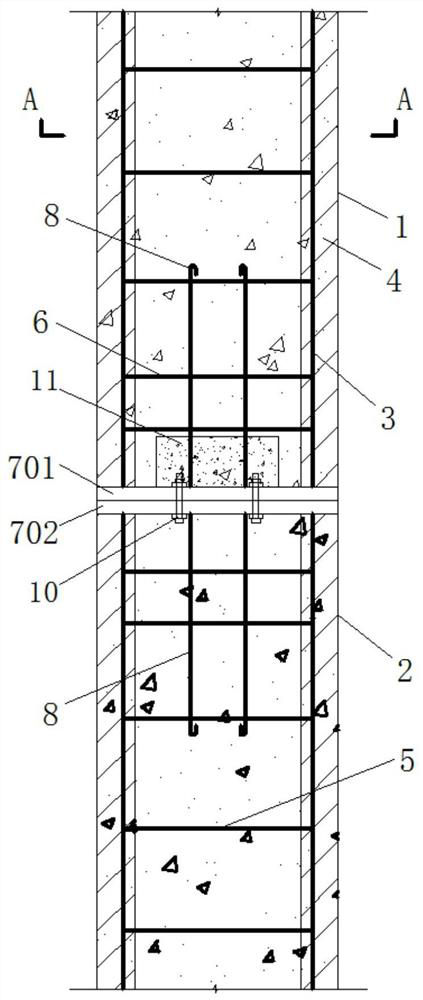

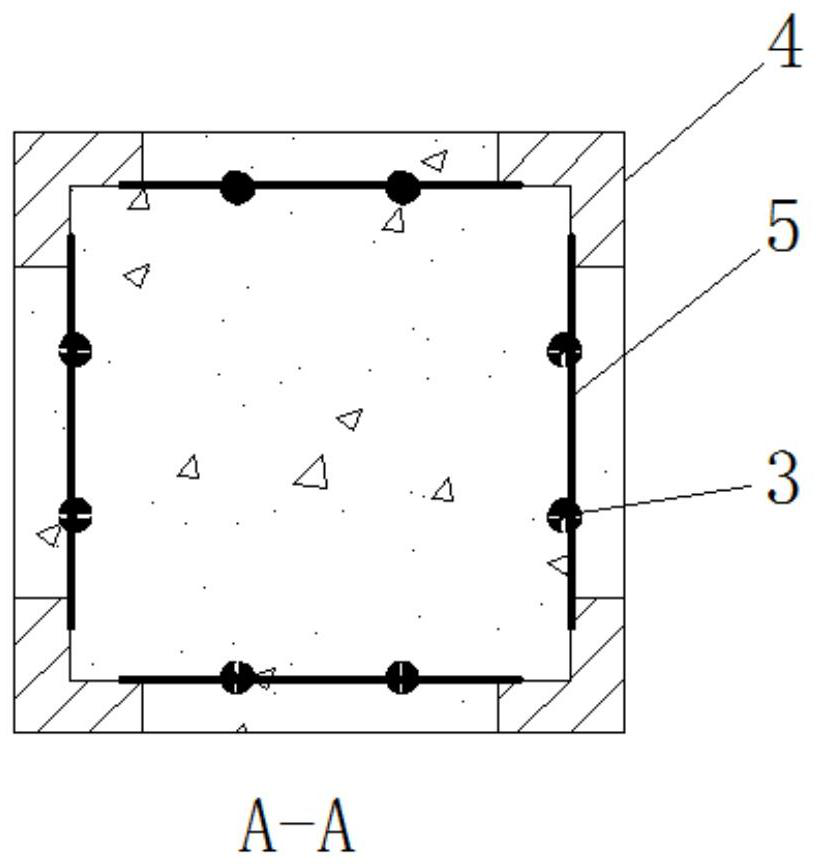

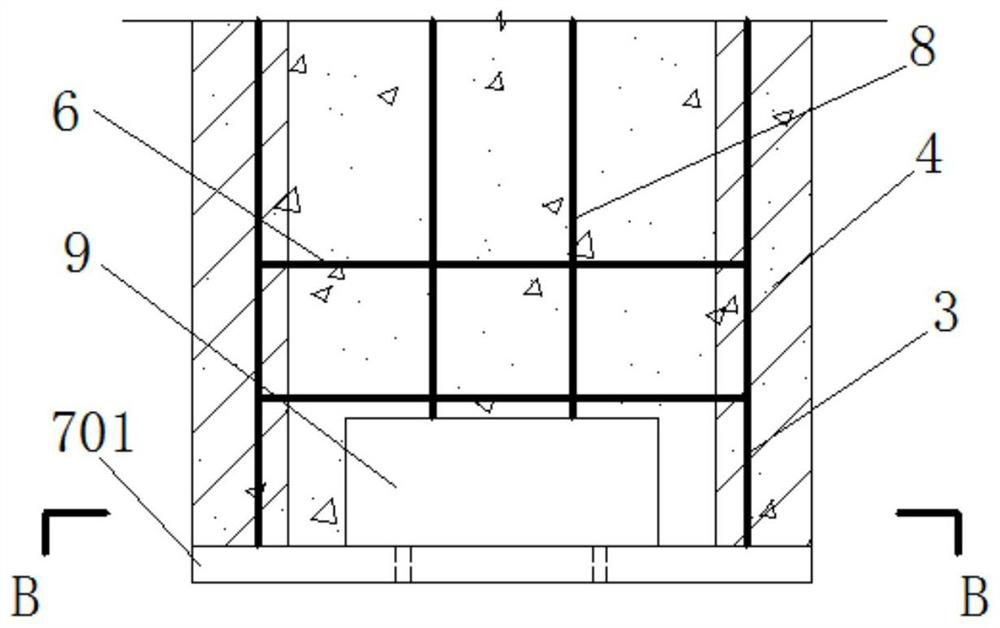

Prefabricated steel-encased concrete spliced column and construction process

The invention discloses a prefabricated steel-encased concrete spliced column and construction process. The prefabricated steel-encased concrete spliced column is divided into three connection forms.The first connection form is end plate connection, the prefabricated steel-encased concrete spliced column comprises an upper column section and a lower column section, the lower column section and the upper column section are both prefabricated steel-encased concrete columns, or the lower column section is a prefabricated steel-encased concrete column, and the upper column section is a prefabricated reinforced concrete column; the second connection form is bolting splicing, the prefabricated steel-encased concrete spliced column comprises an upper column section and a lower column section, the lower column section and the upper column section are the same in structure and are both prefabricated steel-encased concrete columns, or the lower column section is a prefabricated steel-encased concrete column, and the upper column section is a prefabricated reinforced concrete column; the third connection form is grouting sleeve connection, the prefabricated steel-encased concrete spliced column comprises an upper column section and a lower column section, the lower column section and the upper column section are both prefabricated steel-encased concrete columns, or the lower column section is a prefabricated steel-encased concrete column, and the upper column section is a prefabricated reinforced concrete column. Due to the splicing joint form of the prefabricated steel-encased concrete spliced column, the prefabricated spliced column has strength, rigidity and good anti-seismic property.

Owner:吉林建筑科技学院

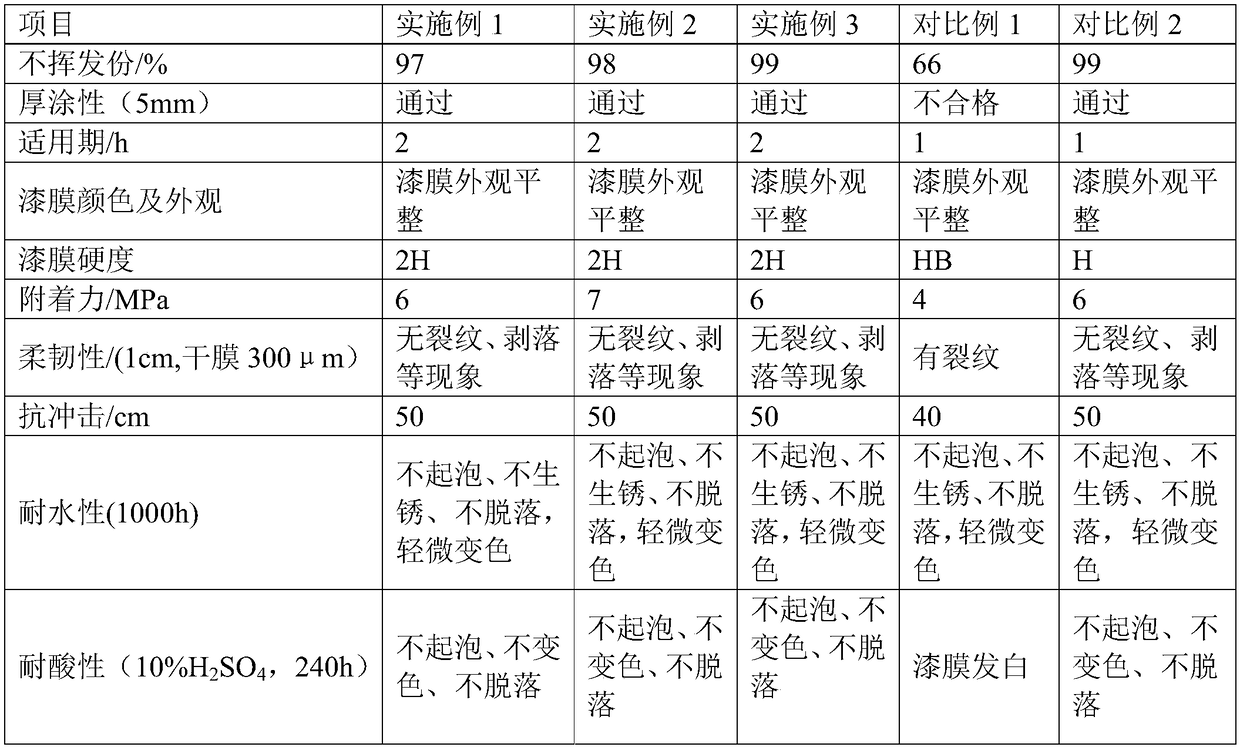

Heavy-load resistance and corrosion-resistance waterborne polyurethane floor coating and preparation method thereof

InactiveCN109401600AHigh tensile strengthHigh compressive strengthAnti-corrosive paintsPolyurea/polyurethane coatingsSodium metasilicatePolyol

The invention discloses a heavy-load resistance and corrosion-resistance waterborne polyurethane floor coating and a preparation method thereof. The waterborne polyurethane floor coating comprises acomponent A, a component B and a component C, wherein the component A comprises polyol, an emulsifier, a defoaming agent, a flatting agent and water; the component B comprises polyisocyanate; and thecomponent C comprises white cement, toner, sodium metasilicate, a water reducing agent and quartz sand. The preparation method comprises the following steps that firstly, the component A and the component C are separately prepared, and then the three components A, B and C are mixed during use. The coating has low viscosity, high solid content, no solvent volatilization, rapid drying and long recoating time, can realize thick-film formation, and has high adaptability to coating environment, so that the requirements of various factories on rapid and environment-friendly coating are met.

Owner:JIANGSU HUAXIA PAINT MAKING

Mixed filler added filter paper for hydraulic filter

InactiveCN105986520AWell dispersedGood dispersionNon-fibrous pulp additionPaper/cardboardAlkali freePolyvinyl chloride

The invention discloses a hydraulic filter filter paper with mixed fillers, which is prepared from the following raw materials in parts by weight: 50-55 mm of alkali-free ultrafine glass fiber of 3-5 mm, 55-60 mm of bleached coniferous wood pulp, appropriate amount of distilled water, Anionic polyacrylamide 0.8-1, an appropriate amount of concentrated sulfuric acid with a concentration of 98wt%, nano-titanium dioxide 10-12, a solid content of 30% iron ferric oxide colloid solution 20-25, an appropriate amount of absolute ethanol, and a solid content of 40wt% fluorine Silicon emulsion 60-65, PAE wet strength agent 0.8-1, white carbon black 7-8, mica powder 3-4, nano bamboo carbon powder 2-3, PVC resin powder 2-3, stearic acid emulsion 2-3. The surface of the filter paper made by the invention is fine and porous, has good gas permeability, has both strength and toughness, and has good effects of high temperature resistance and corrosion resistance.

Owner:ANHUI PHOENIX INT CO LTD

Stainless steel alloy for golf ball head

The invention discloses a stainless steel alloy for a golf ball head. The stainless steel alloy for the golf ball head is characterized by comprising the following components in weight percentages: 1-2% of manganese, 1-2% of silicon, less than 0.08% of carbon, 6-8% of nickel, 16-18% of chromium, 2-4% of copper, more than 0.2% of nitrogen, and the balance of iron. Hardness HRB (Rockwell hardness B-grade scale) value of the stainless steel alloy consisting of the components is 70-80. The stainless steel alloy is one type of stainless steel, is good in abrasive resistance, and has a better shocking-proof performance when being struck than stainless steel #304 or low carbon steel #8620, and the harness is HRB70-80. When struck at the same time, a golf ball and the ball head face have long contact time, the ball control performance is good, and the stainless steel alloy is applicable to a pull rod, an iron rod and a wedge. The stainless steel alloy has good hardness and abrasive resistance, the ball head is not easily deformed, and a groove of the ball face is difficult to abrade, so that the stainless steel alloy is an excellent golf ball head material.

Owner:颜重乐

Porous membrane with TiN coating and preparation method thereof

ActiveCN102719691BBoth strengthBoth corrosion resistanceSolid state diffusion coatingFiltration separationNitrogen plasmaPorous membrane

Owner:SHANDONG UNIV OF SCI & TECH

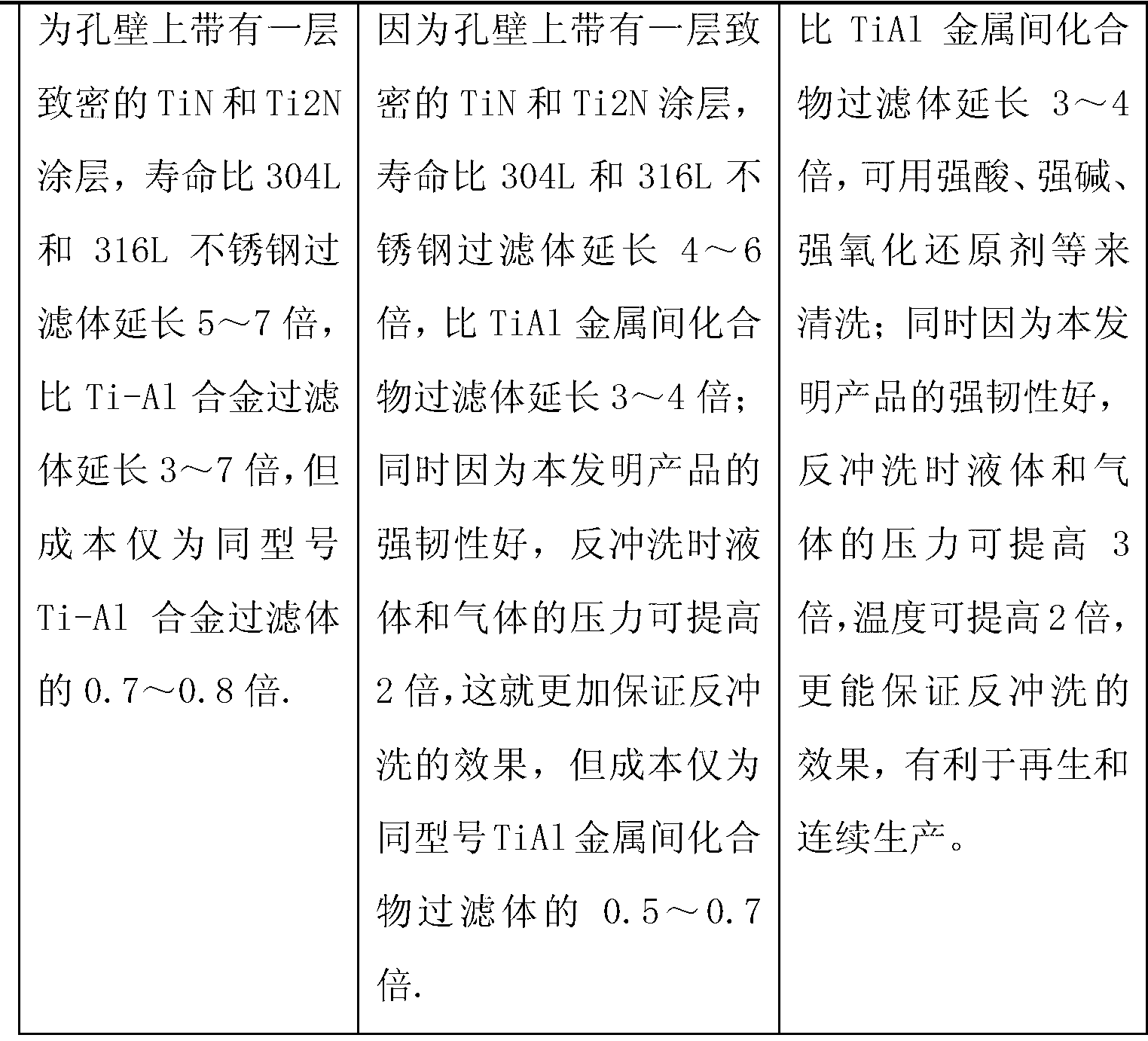

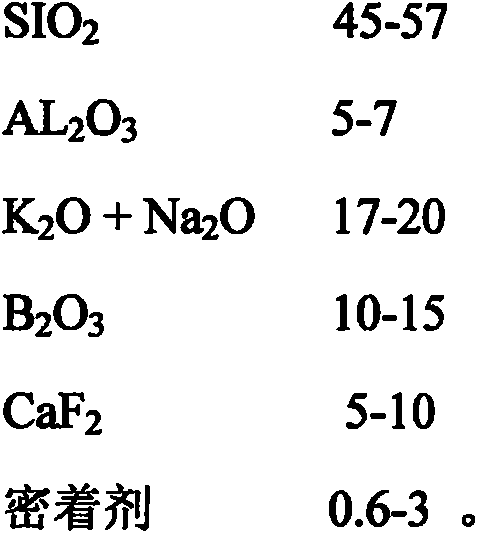

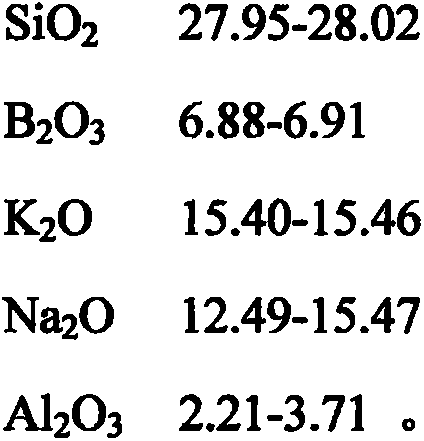

Manufacturing process of enamel for lamp

The invention relates to a manufacturing process of enamel for a lamp. The manufacturing process of the enamel for the lamp comprises the step a of processing of metal materials of the lamp, the step b of the manufacturing process of an enamel material, and the step c of the manufacturing process of the lamp. The step b of the manufacturing process of the enamel material specifically comprises the sub-step b1 of adoption of enamel frit made of SiO2 or potash feldspar and the like; the sub-step b2 of ball milling, specifically added materials are ground through a ball mill; the sub-step b3 of adoption of a wet process or dry powder; and the sub-step b4 of preparation of glaze slip, specifically the corresponding formula is prepared according to different metal surface requirements or different color requirements. The enamel manufactured through the process has the advantages of being better in corrosion resistance, heat resistance and abrasion resistance, good in heat conductivity, easy to clean, insulating, colorful, environmentally friendly, sanitary, and the like.

Owner:施鹏程

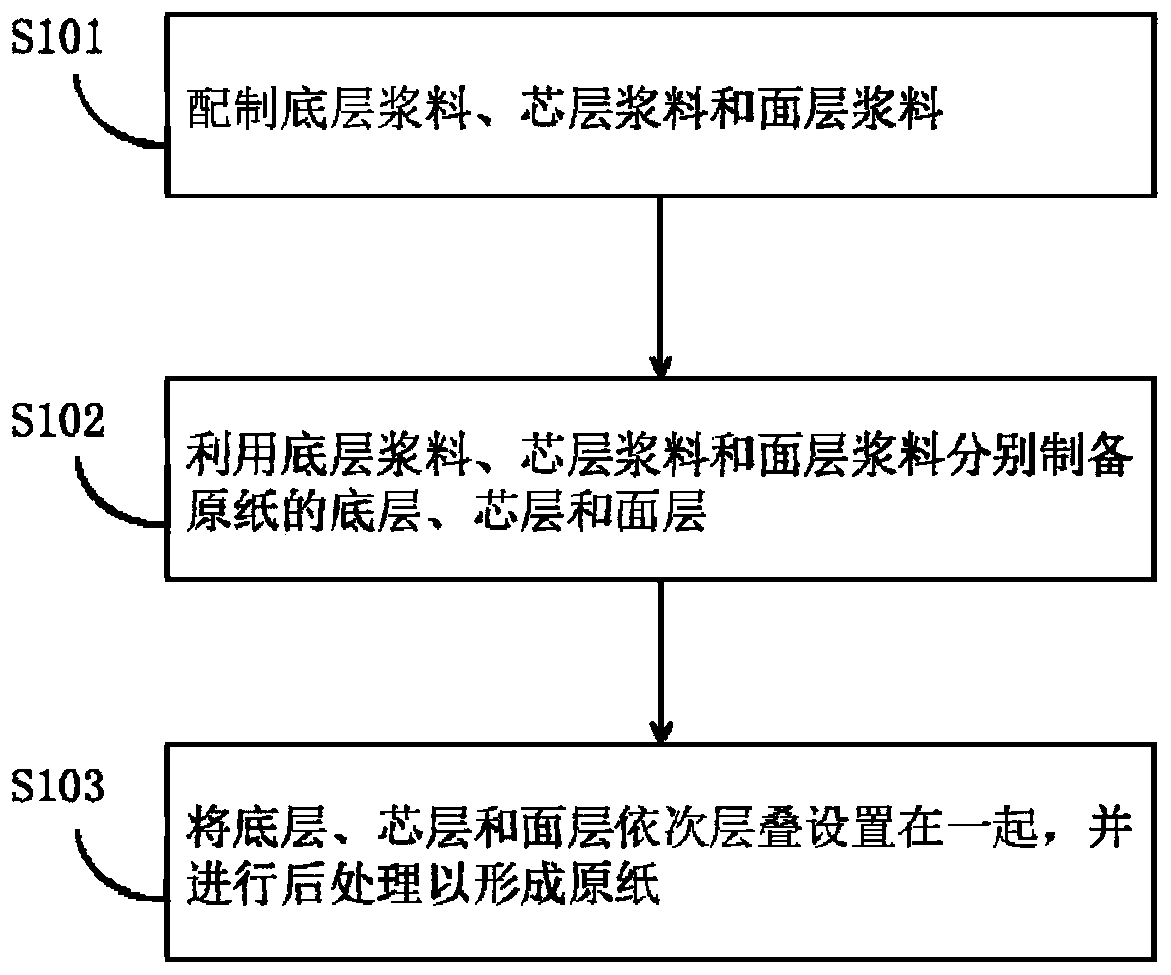

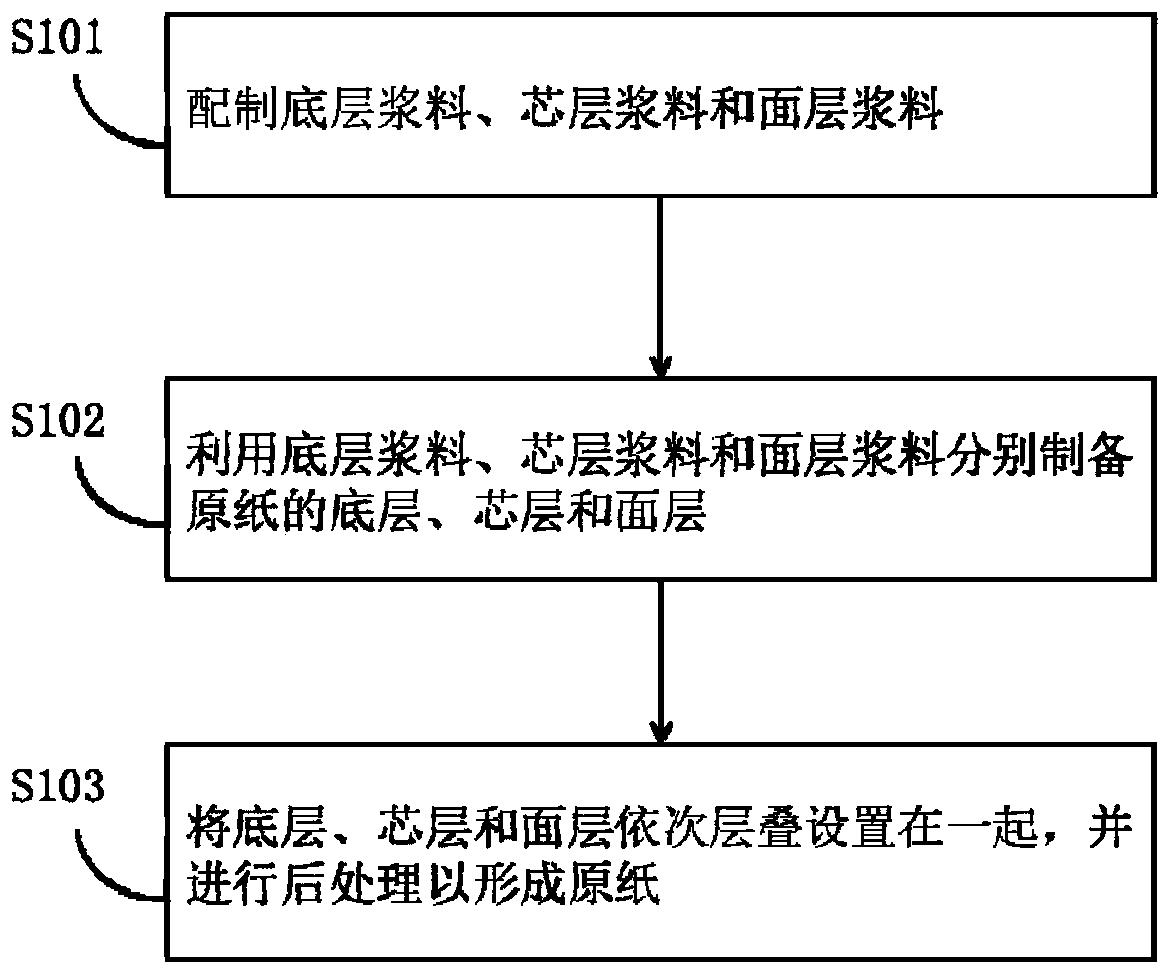

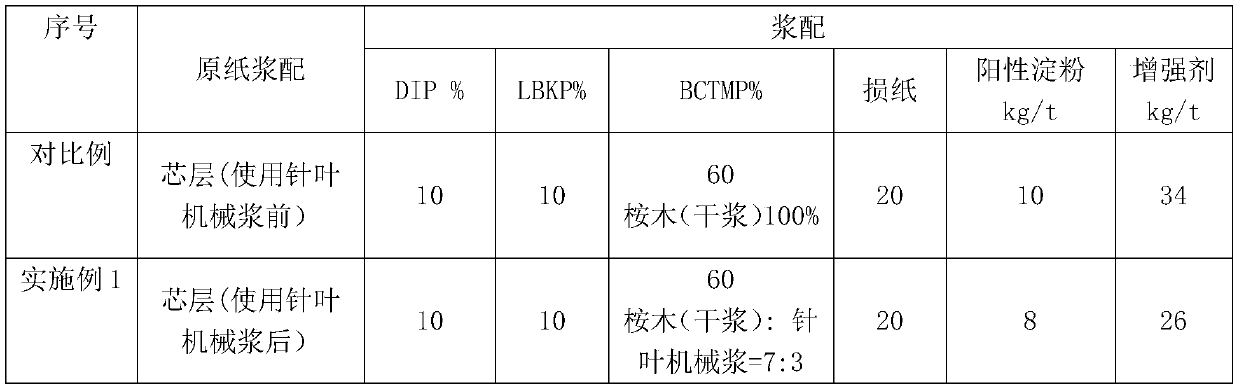

Core layer pulp for packaging paperboard, and packaging paperboard

InactiveCN111139690AGood tensile strengthIncrease bulkFlexible coversWrappersPulp (paper)Food packaging

The invention discloses a core layer pulp for a packaging paperboard. The core layer pulp comprises a bleached chemical thermo-mechanical pulp which comprises a needle leaf mechanical pulp with an absolute dry mass accounting for 25%-30% of the absolute dry mass of the bleached chemical thermo-mechanical pulp. The core layer pump provided by the invention has the following advantages: through addition of the needle leaf mechanical pulp which has long fiber length and good tensile strength, the needle leaf mechanical pulp has the characteristics of high bulk and high stiffness; the bleached chemical thermo-mechanical pulp added with 25%-30% of the needle leaf mechanical pulp has high bulk and strength; meanwhile, the core layer pulp containing the bleached chemical thermo-mechanical pulp improves the interweaving capability of core layer fibers and increases the Z-direction (thickness direction) strength of a core layer; a paperboard prepared from the core layer pump has the characteristics of high bulk, high strength and stiffness; and thus, the core layer pulp provided by the invention can be used for manufacturing core layers of packaging paperboards like ivory boards and food paperboards, and is specifically applicable to the field of middle-grade and high-grade food packaging paperboards.

Owner:NINGBO ASIA PULP & PAPER

Manufacturing method of diamond compacts

The invention relates to a manufacturing method of diamond compacts. Specifically, metal powder needed for preparing a hard alloy matrix is mixed and formed in a cold pressing mode to obtain alloy powder, the alloy powder and diamond single crystals are assembled and sintered at the pressure of 80-100 MPa and the temperature of 650-1150 DEG C, and finally the diamond compacts can be obtained. According to the manufacturing method, the production cost can be saved by 10-20%, the energy consumption can be lowered, the manufacturing steps are simplified, and the rate of finished products is increased; the diamond compacts with the high impact strength and the good wear resistance are obtained; the prepared diamond compacts can serves as boring tools of the fields of petroleum, natural gas, shale gas, the geological engineering and the like.

Owner:湖南泰鼎新材料有限责任公司

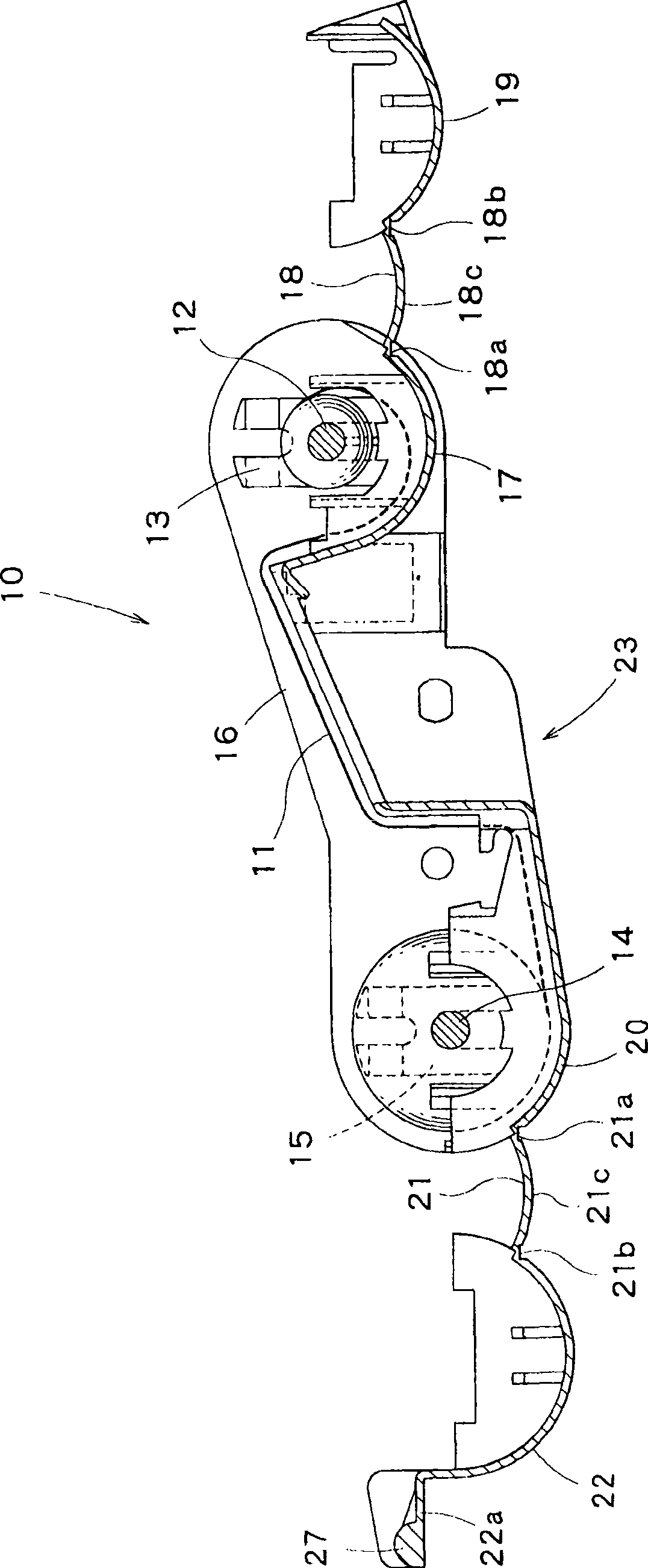

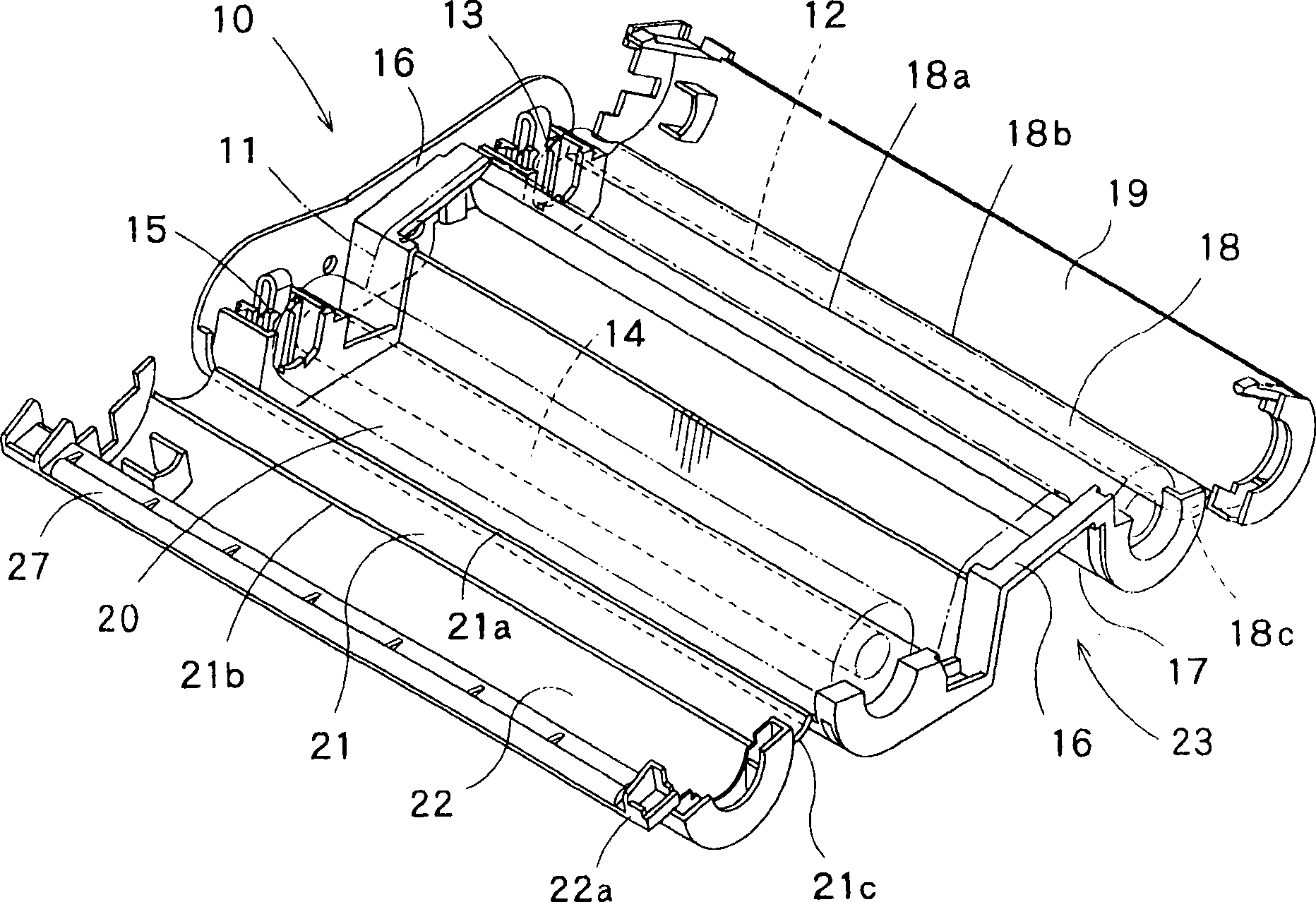

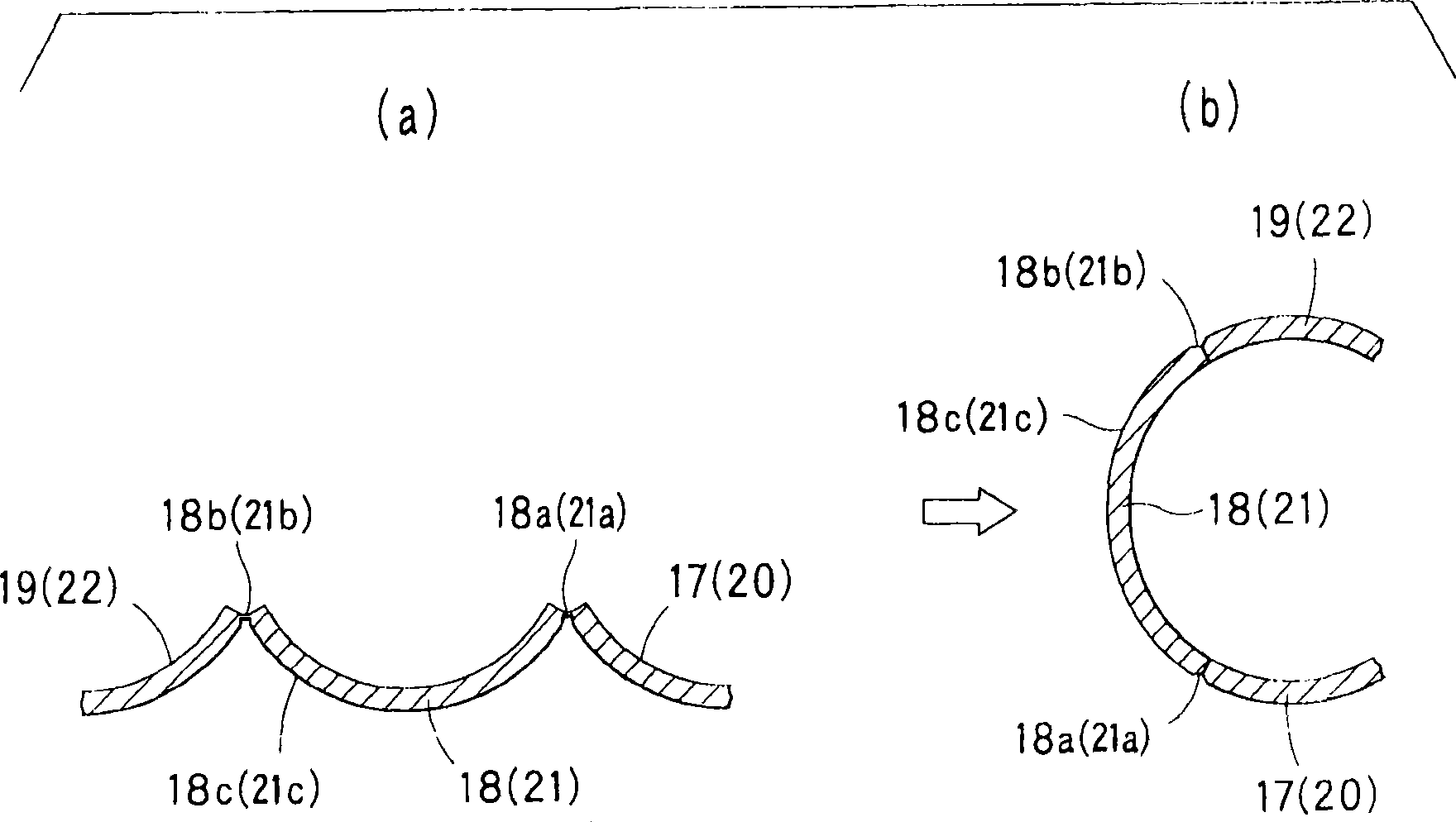

Ink ribbon cassette

InactiveCN101489796AReduce chimeraHingeInk ribbon cartridgesPrinting mechanismsMechanical engineeringHinge angle

Owner:DAI NIPPON PRINTING CO LTD

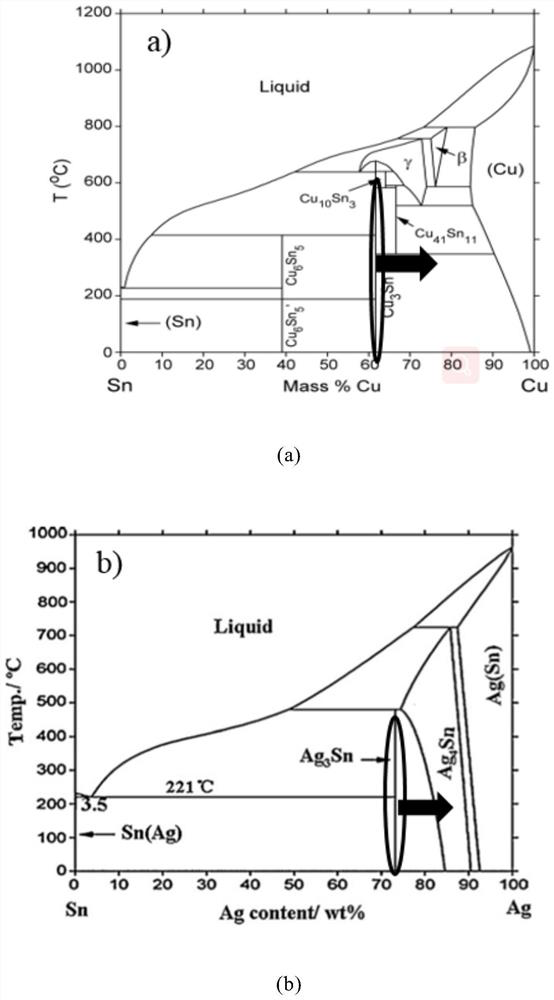

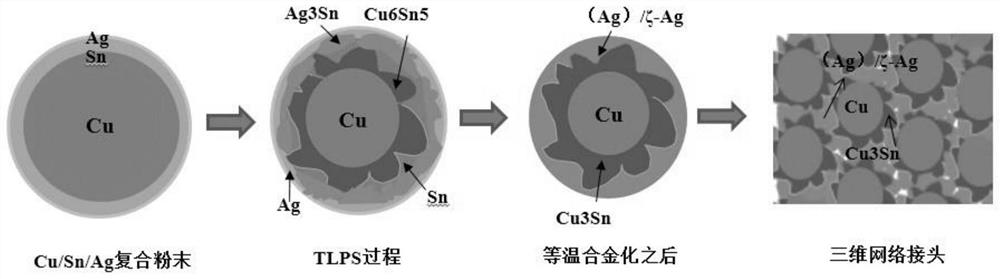

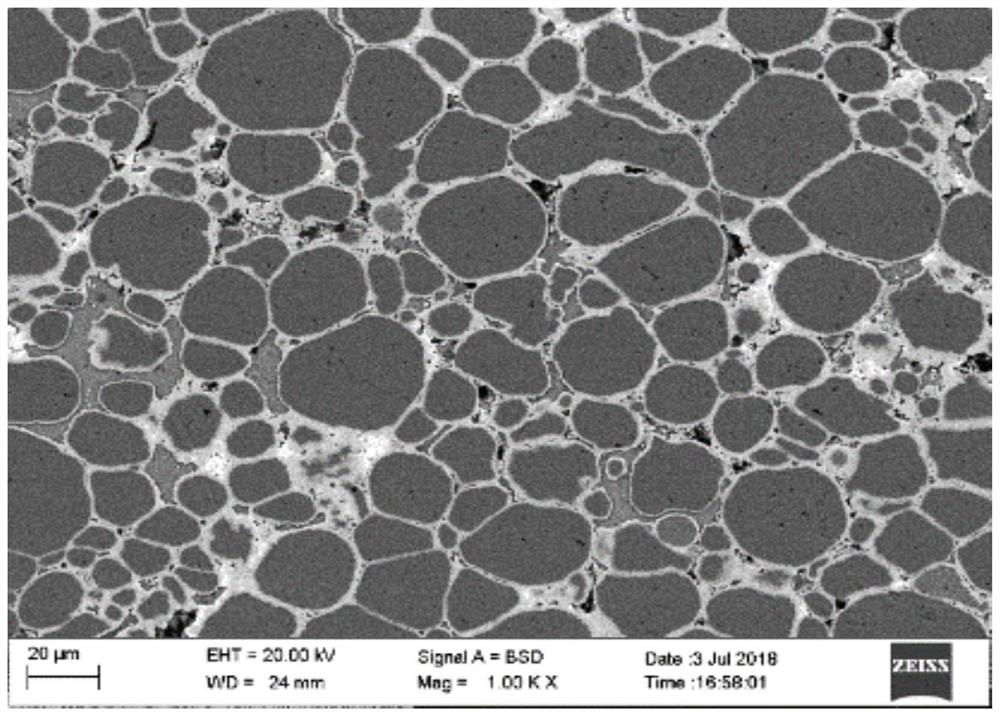

In-situ toughening method for tough integrated Cu/Sn/Ag welding material

ActiveCN112157257AGuaranteed temperature resistanceWill not melt downTransportation and packagingVacuum evaporation coatingElectroplatingMetal

The invention relates to an in-situ toughening method for a tough integrated Cu / Sn / Ag welding material. The method comprises the steps of step (1), uniformly electroplating a 2-3 [mu]m Sn plating layer on copper particles with different particle sizes, then, physically and uniformly depositing a 1 [mu]m Ag layer on the surface of Cu / Sn powder to obtain Cu / Sn / Ag powder; step (2), proportioning theCu / Sn / Ag powder prepared in the step (1), placing the Cu / Sn / Ag powder in a mixer, and performing mechanical mixing for 1 to 2 hours at the speed of 100 to 300 r / min to obtain powder with uniformly mixed particle sizes; step (3), performing pressure forming on the powder prepared in the step (2) on a high-pressure tablet press with the pressure range of 10 MPa to 30 MPa to obtain a Cu / Sn / Ag composite preformed welding chip with the thickness of 100 [mu]m to 400 [mu]m; and step (4), performing low-temperature transient liquid-phase diffusion welding on the composite preformed welding chip, and enabling Sn with a low melting point to be completely converted into a high-temperature-resistant Cu3Sn and Ag3Sn interface intermetallic compound through simultaneous diffusion reaction of Sn and Cu and simultaneous diffusion reaction of Sn and Ag at a point below the melting point of Sn, so as to prepare a Cu3Sn / Ag3Sn-clad Cu particle three-dimensional network structure joint.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com