Flexible finishing soft stone or tile

A flexible veneer and stone technology, applied in the field of flexible veneer soft stone or brick "), can solve the problems of difficulty in taking into account flexibility and strength, poor flexibility of veneer materials, insufficient combustion resistance, etc. Variety of colors and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

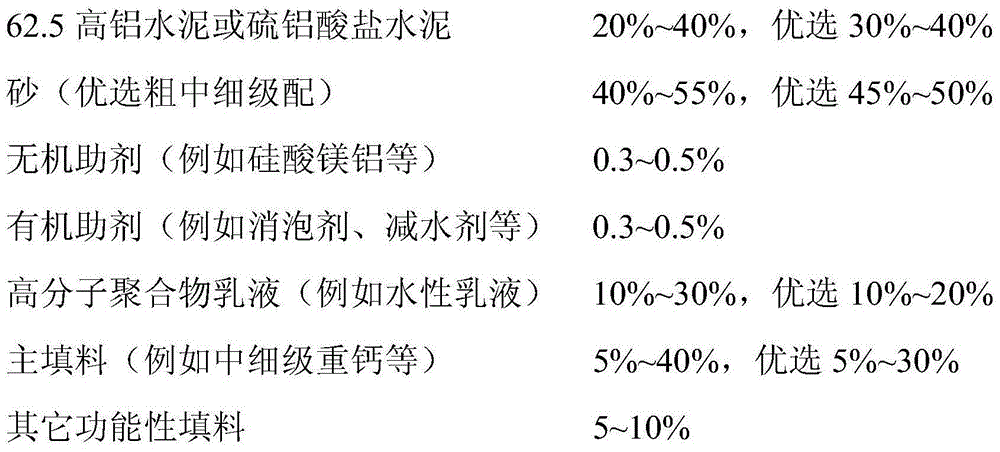

[0069] 30% of cement, 50% of sand, 5% of gypsum, 2% of additives, and 13% (by weight) of high molecular polymers are used as raw materials to prepare flexible facing bricks, wherein the additives are composed of 30% by weight MgO, 40% by weight Fly ash, 5% by weight MgCl 2 , 20% by weight of bentonite, and 5% by weight of coal gangue powder are mixed and ground.

[0070] Described polymer is obtained by following method:

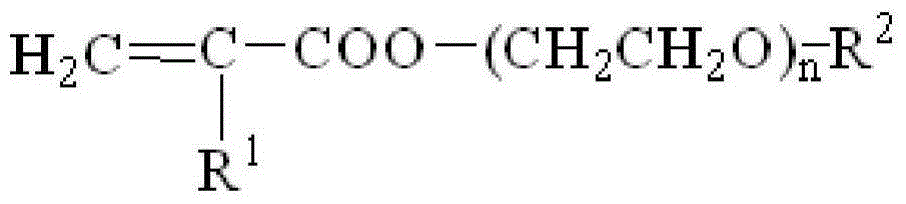

[0071] The chemical structural formula of monomer (I) is:

[0072]

[0073] where R 1 is ethyl, R 2 Isopropyl, n is 6, this monomer is prepared by esterifying polyethylene glycol and ethacrylic acid according to a conventional esterification method, and then reacting the esterified product with ethoxychloride according to a conventional elimination reaction, or it can be directly commercialized Purchased from Fluka-RdH company;

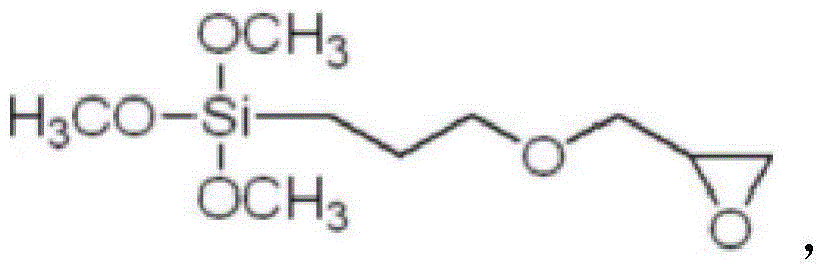

[0074] The chemical structural formula of monomer (II) is:

[0075] The monomer is commercially available from China Ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com