Patents

Literature

9077results about How to "Flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

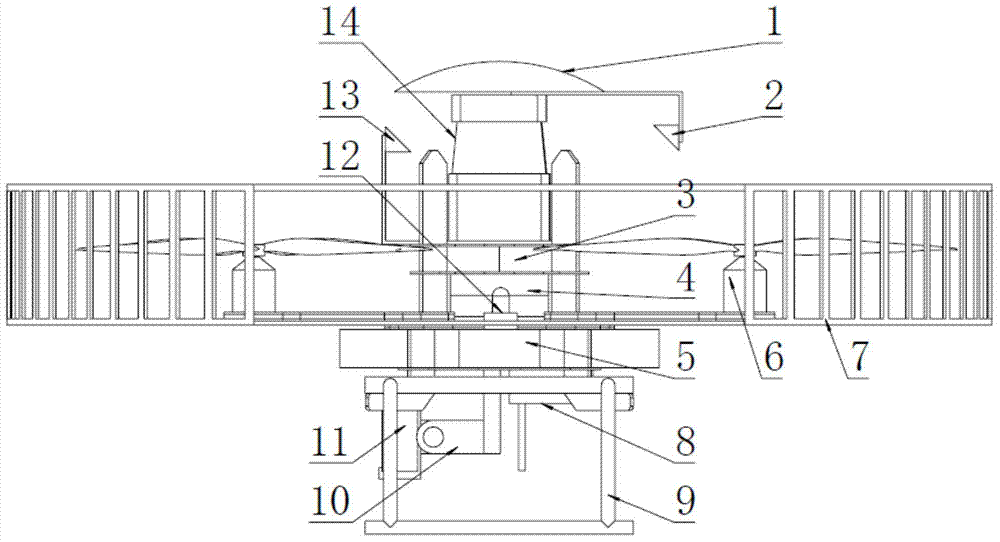

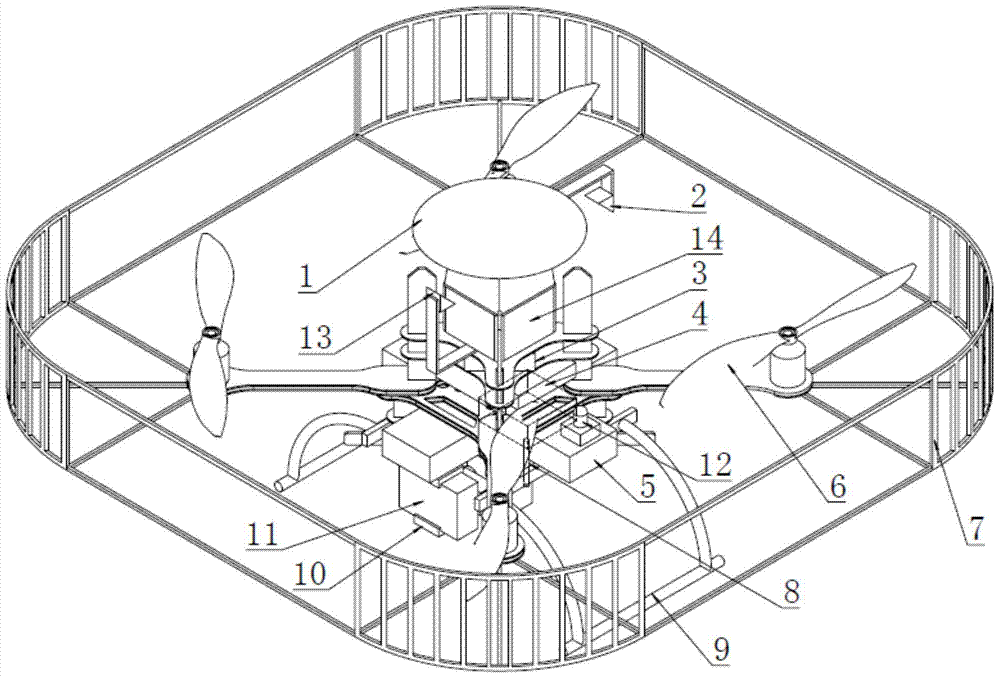

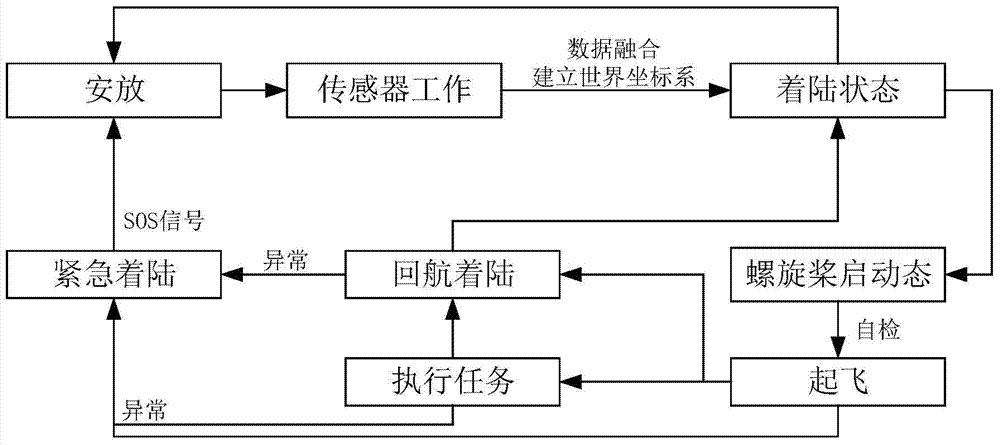

Unmanned-gyroplane system used for automatic-inspection of bridges and tunnels and navigation method

ActiveCN104843176AFlexibleEffective dodgeNavigation by speed/acceleration measurementsSatellite radio beaconingUncrewed vehicleNavigation system

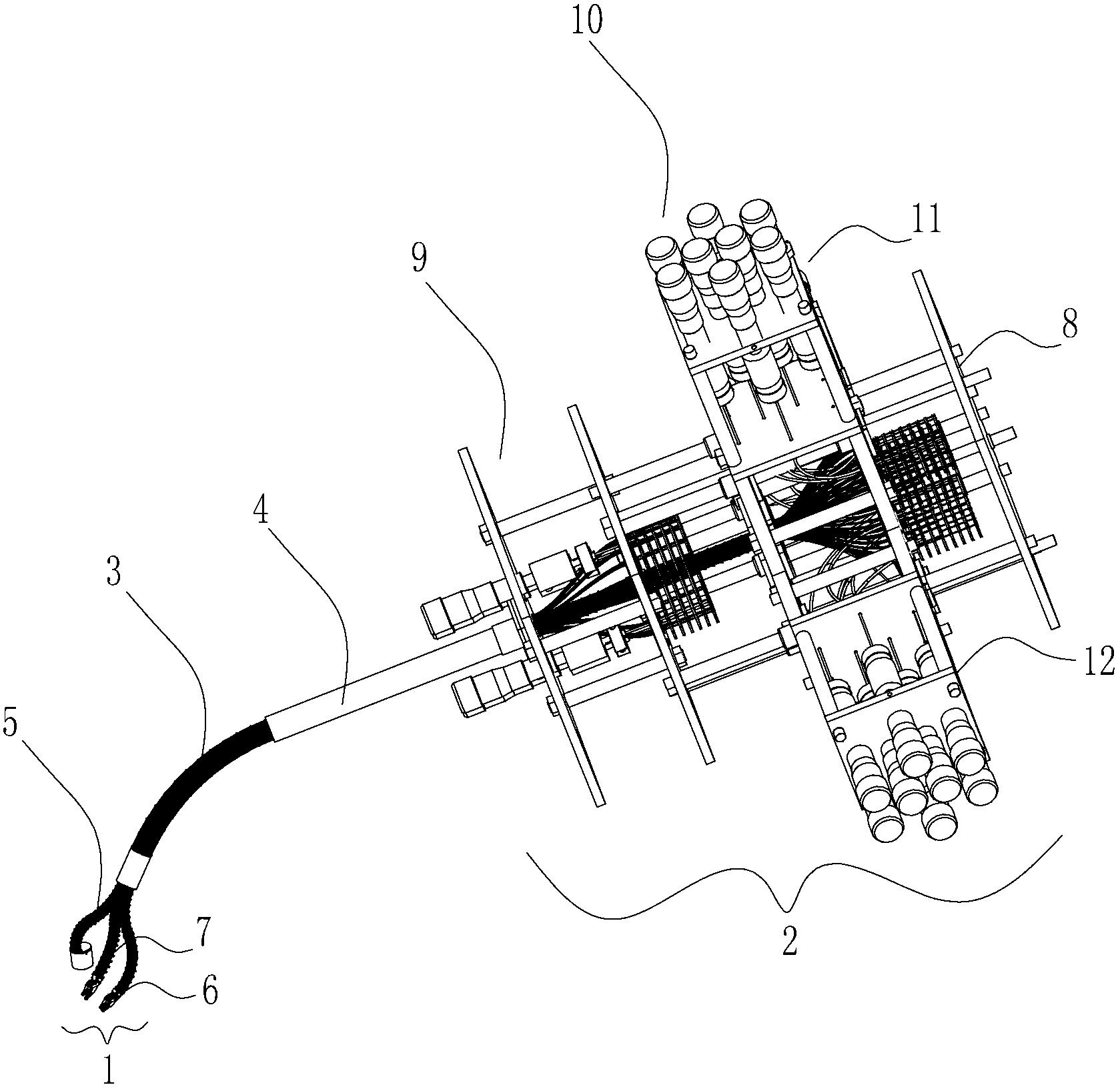

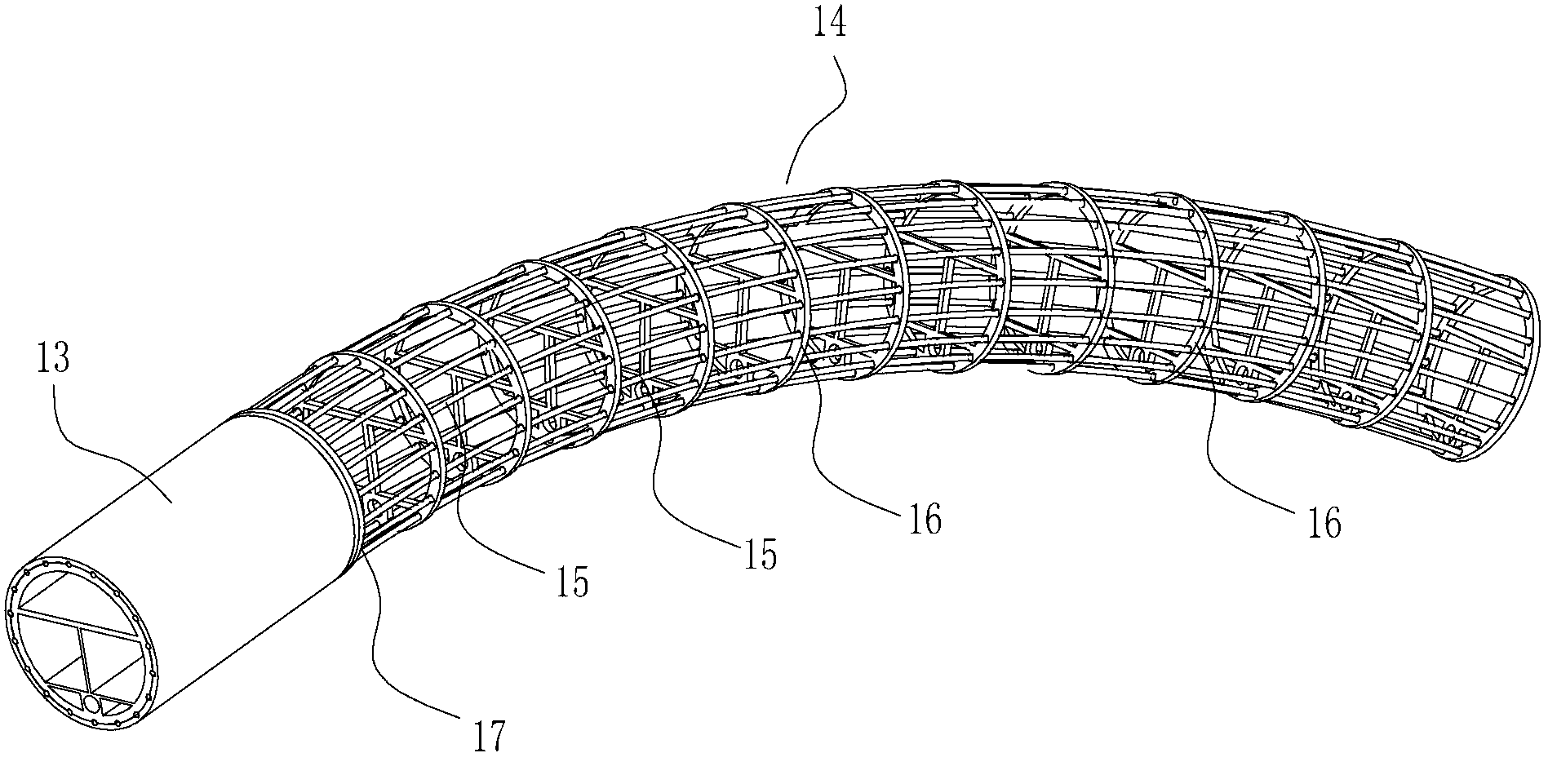

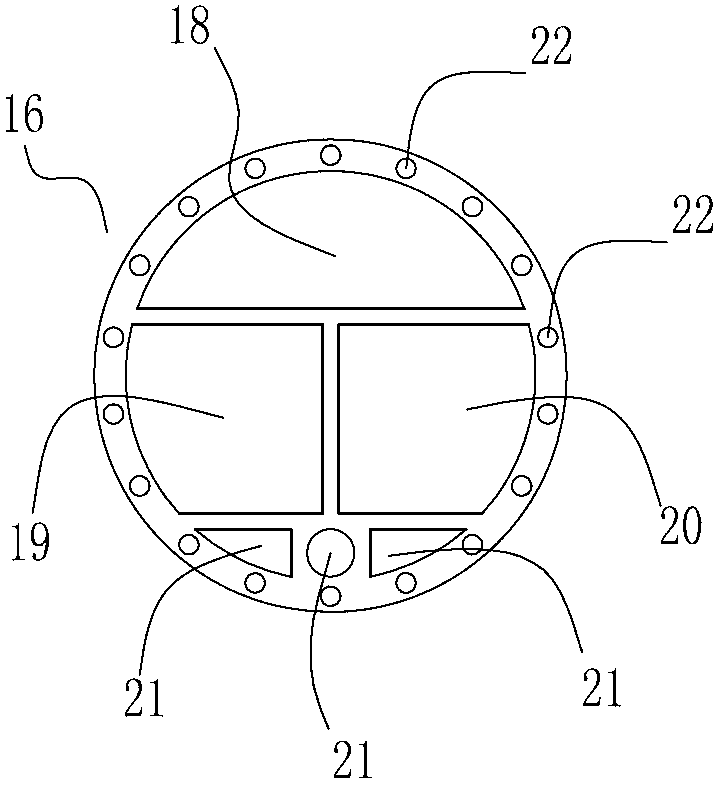

The invention provides an unmanned-gyroplane system used for automatic inspection of bridges and tunnels and a navigation method, belonging to the field of automatic detection of bridge and tunnel diseases. According to the invention, aimed at the characteristics of bridge and tunnel areas, the unmanned gyroplane inspection system which realizes autonomous navigation in virtue of GPS, laser radar and IMU is designed; and the system realizes autonomous inspection of an open bridge area by using a GPS navigation system and autonomous inspection of a closed tunnel area by using a laser radar navigation system, dodging of bridges, tunnels and motor vehicles via an automatic evadible system, and shooting of images of key areas, wherein the images are sent back to a ground station, and thematic pictures of diseases of bridge and tunnels are generated by the ground station and provided to related personnel for use. The unmanned-gyroplane system provided by the invention has the characteristics of mobility and flexibility in the process of inspection and has the advantages of a wide inspection coverage area, unblocking of traffic, real-time returning of live shots, etc.

Owner:恒华数元科技(天津)有限公司

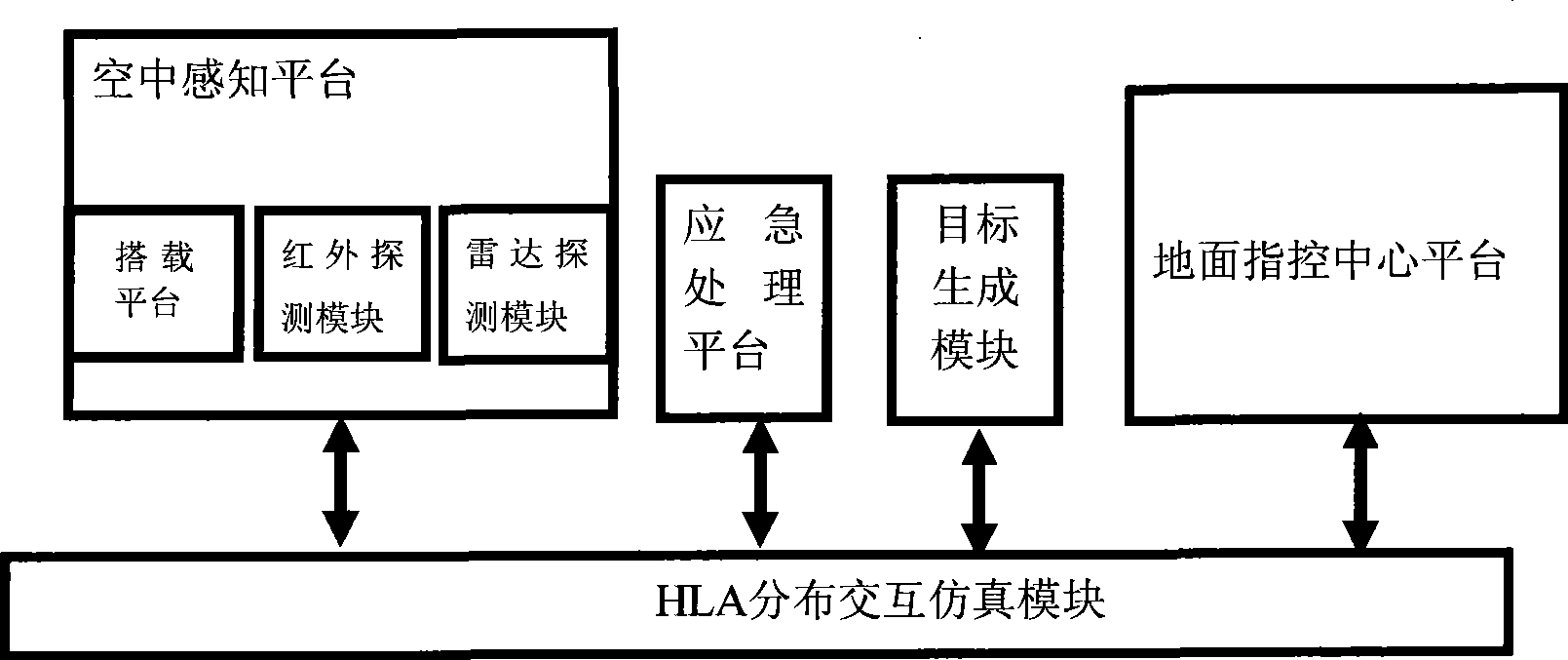

Multi-platform target tracking and distribution interactive simulation system

InactiveCN101465071ARealize transmissionGuaranteed reliabilityCosmonautic condition simulationsSpecial data processing applicationsExtensibilityVisibility

The invention relates to a multi-platform target tracking and distributed interactive simulation system in the technical field of simulation. The system comprises a target generation module, an aerial sensing platform, an emergency processing platform, a ground control center platform and an HLA distributed interactive simulation module, wherein, the target generation module generates a system tracking object at random; the aerial sensing platform comprises various detecting devices for performing fusion to the detected information and then transmitting the information to the ground control center platform; the ground control center platform integrates all the field information, evaluates the entire field situation and promptly makes an emergency decision; the emergency processing platform receives the information and the commands and realizes target tracking by using airborne equipment; and the HLA distributed interactive simulation module enables the modules to establish an HLA distributed system structure through a distributed network and realizes the multi-information network interconnection. The invention has the advantages of flexibility and extendability, can improve the tracking effect, enhance the visibility of scene demonstration and be widely applied to the fields such as public safety, disaster relief assistance and the like.

Owner:SHANGHAI JIAO TONG UNIV

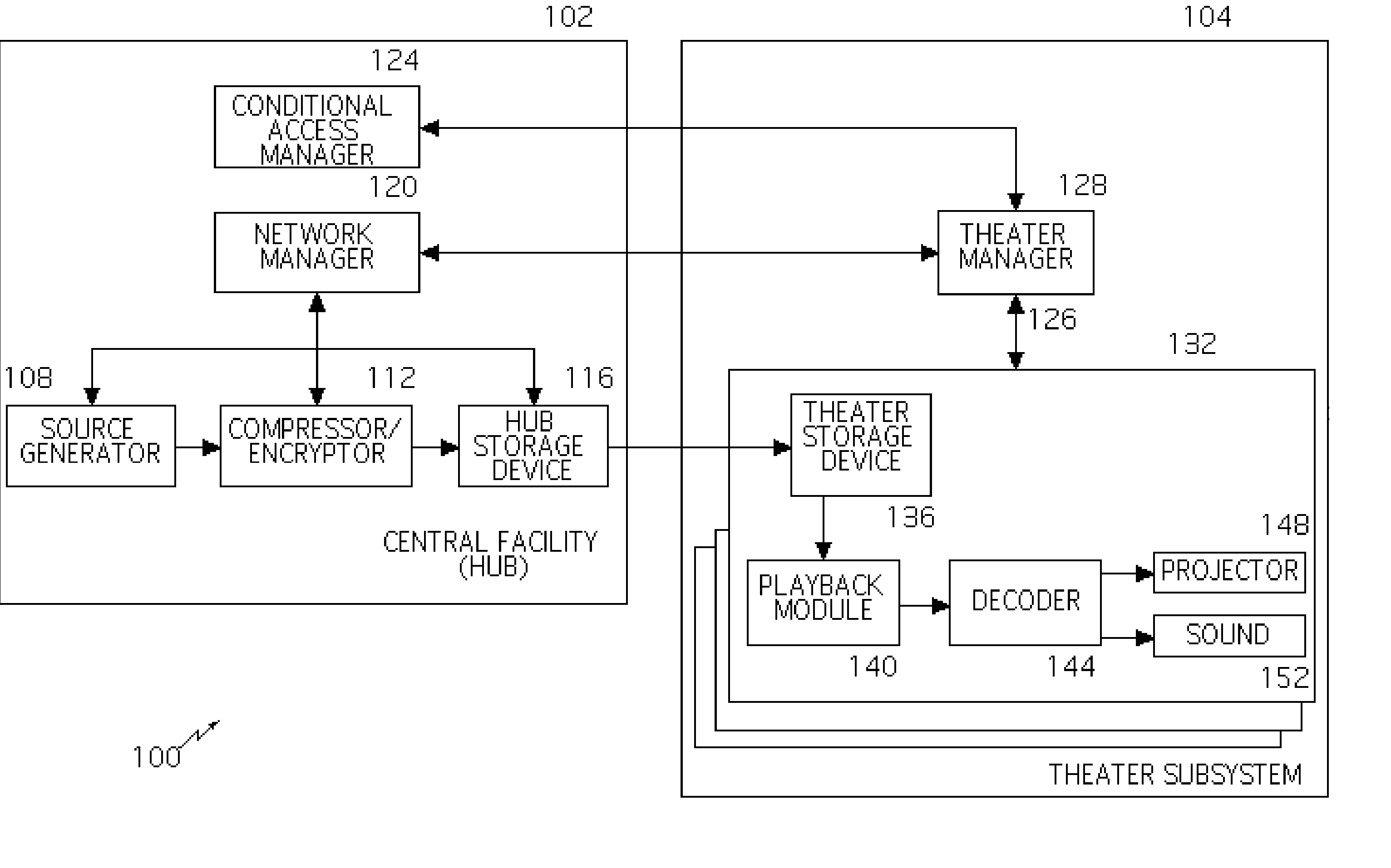

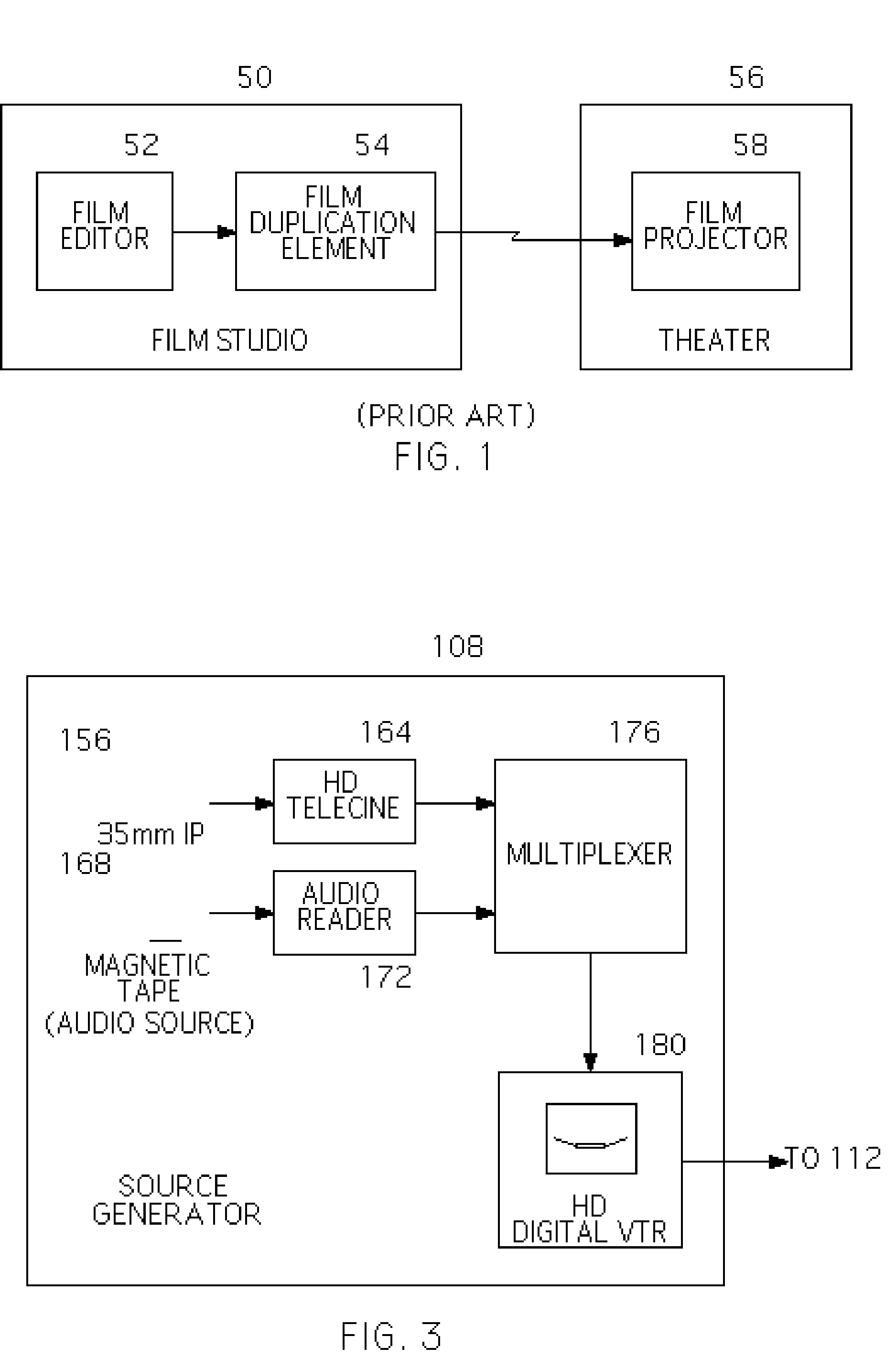

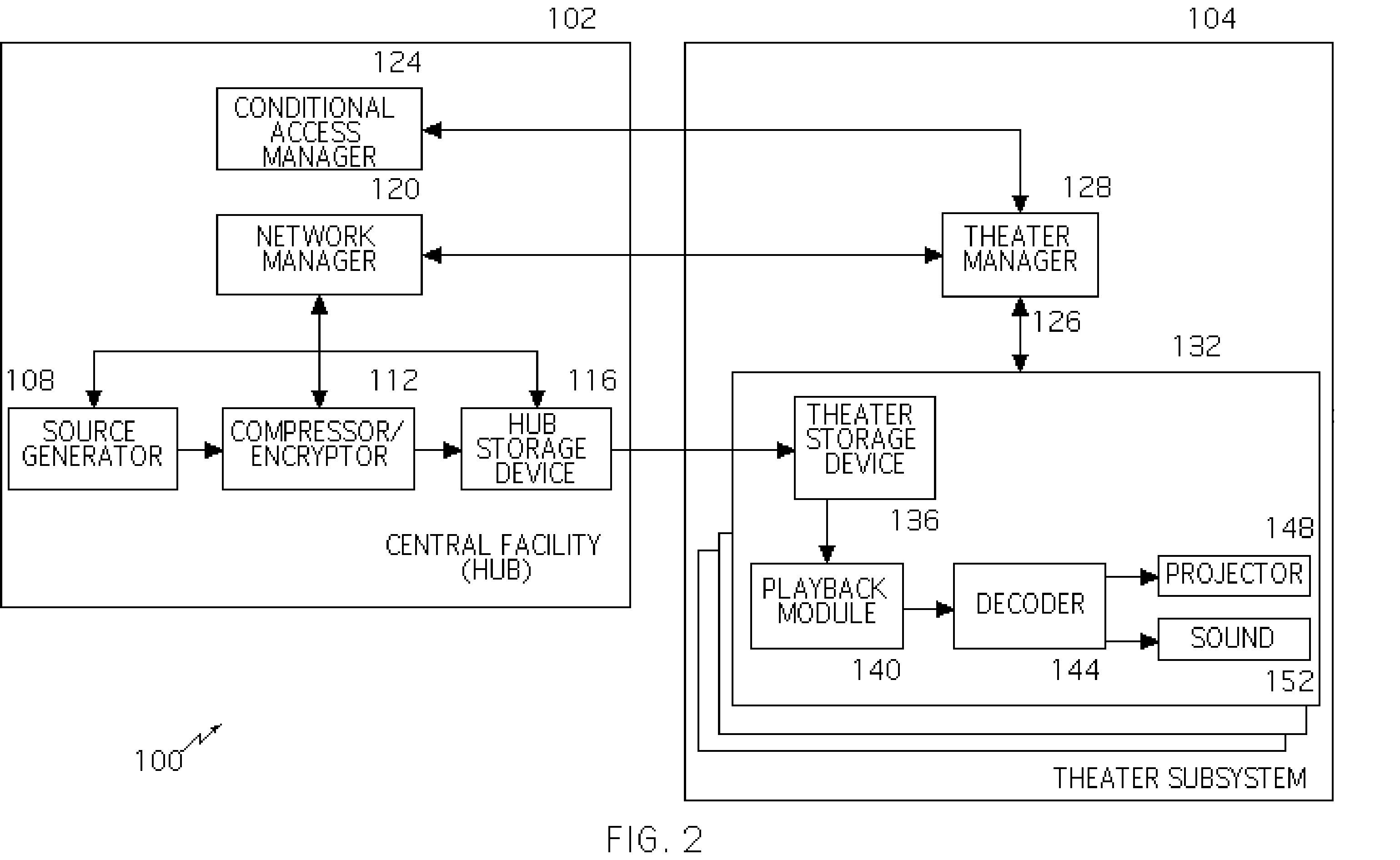

Apparatus and method for encoding and storage of digital image and audio signals

InactiveUS20030206635A1FlexibleAdditional protectionTelevision system detailsKey distribution for secure communicationAudio signalInformation storage

Owner:QUALCOMM INC

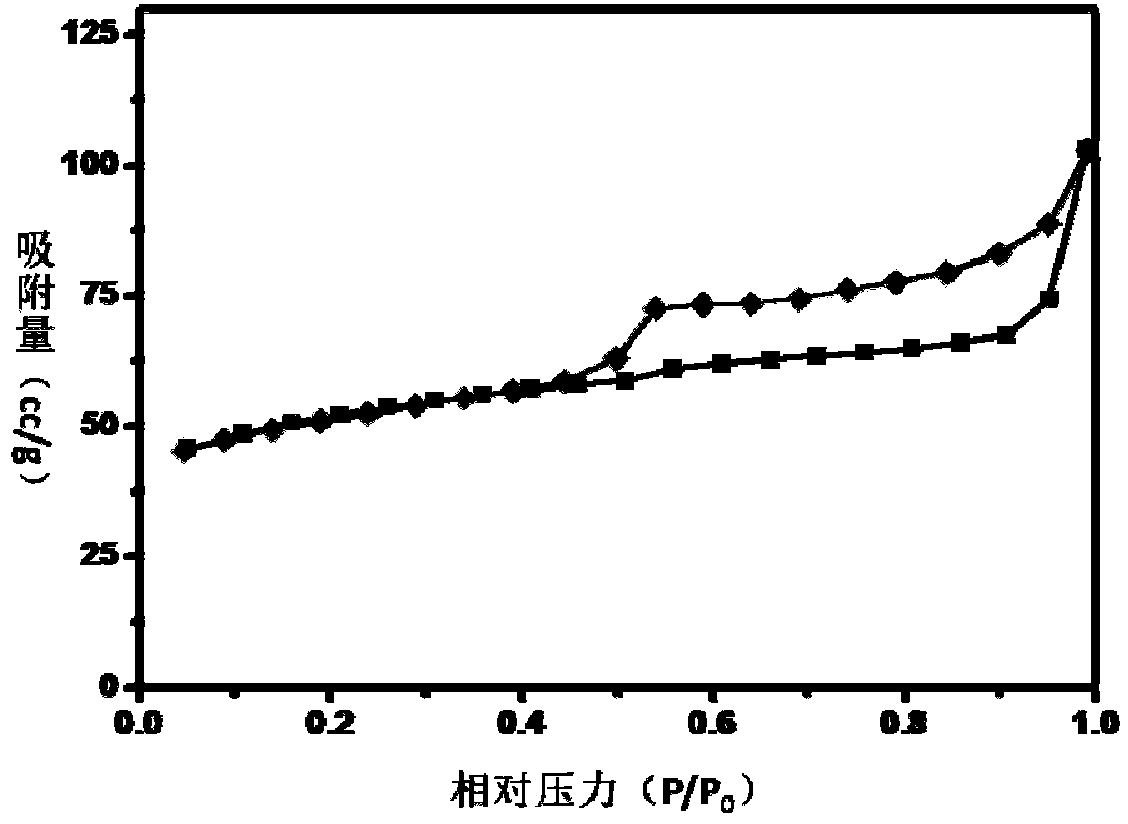

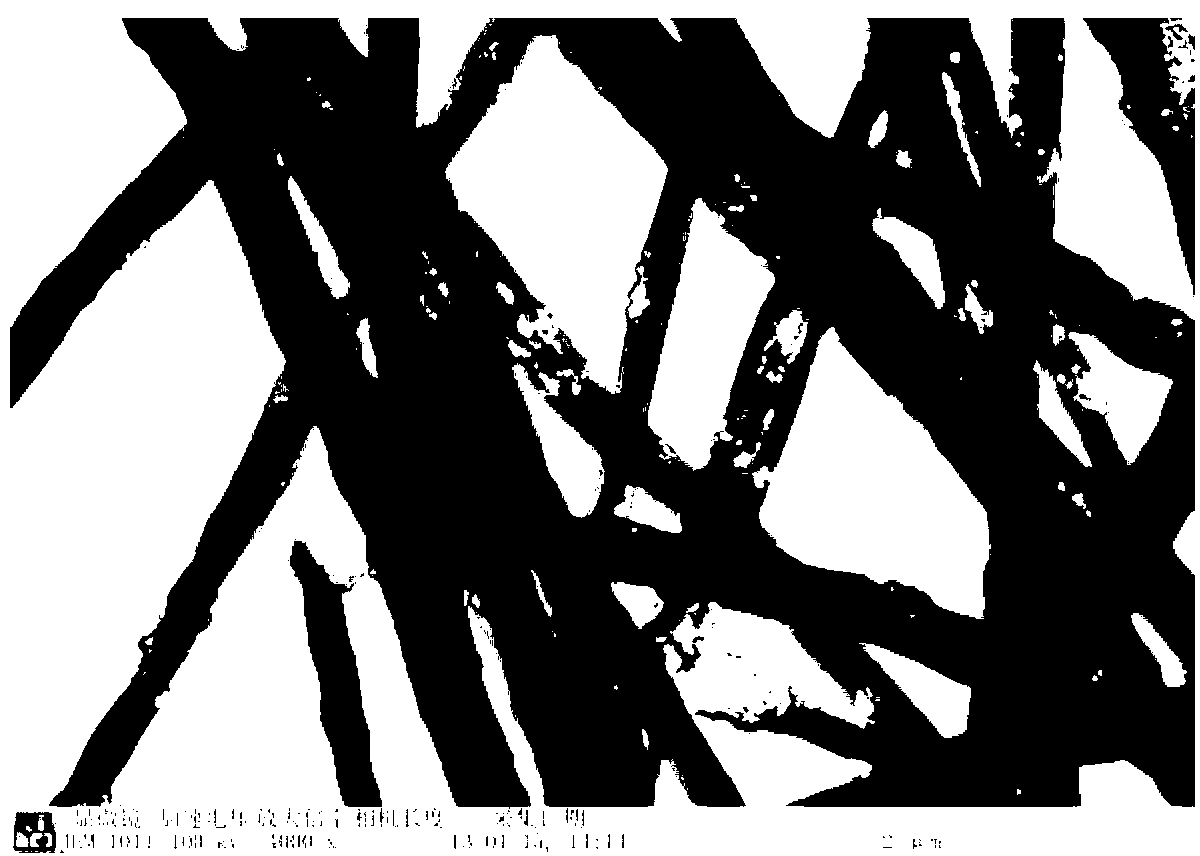

Porous carbon fiber, and preparation method and application thereof

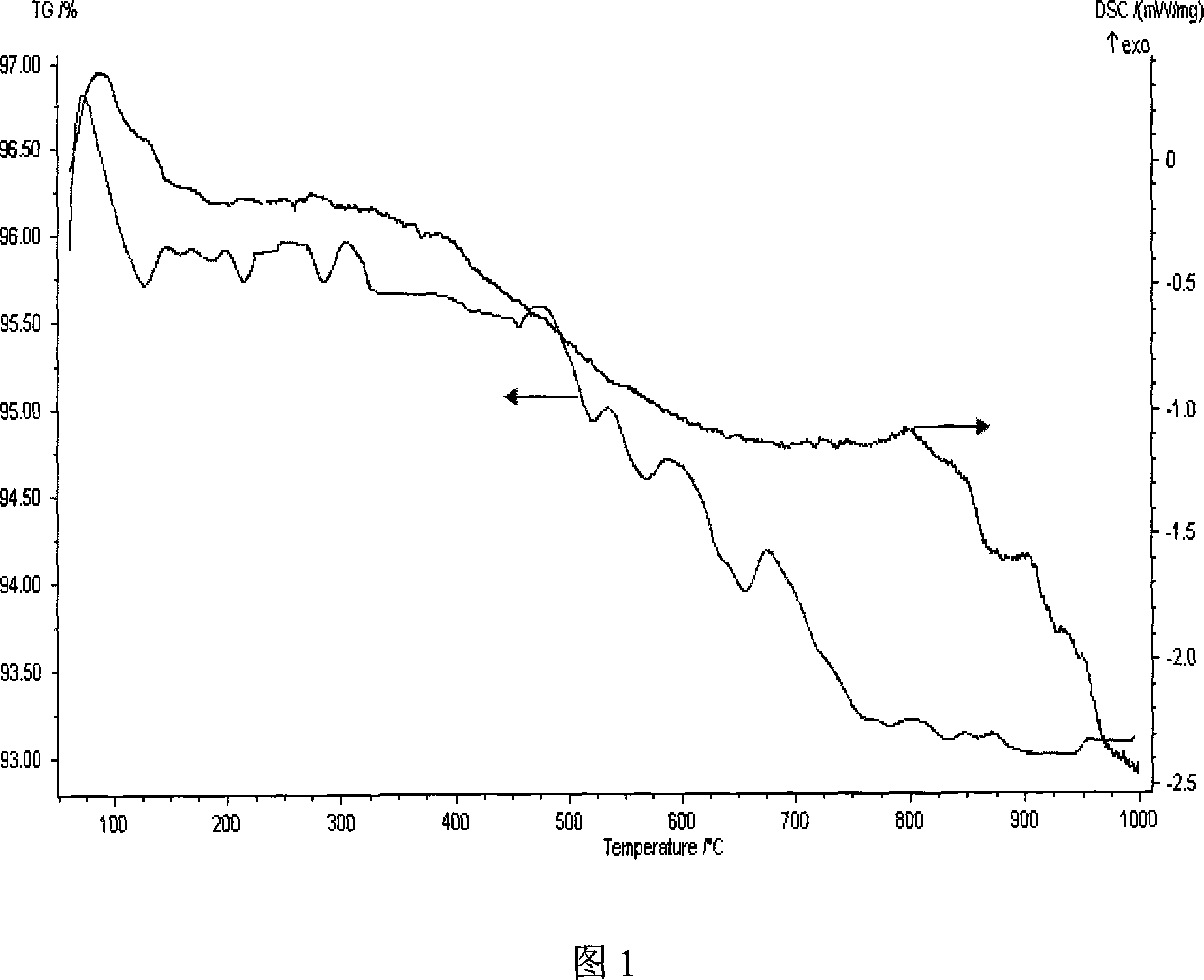

ActiveCN103225135AEasy to makeLow costFilament/thread formingArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a porous carbon fiber and a preparation method thereof. The method comprises the following steps: spinning a spinning liquid composed of a pore forming agent, a high polymer and an organic solvent, carbonizing, and pickling to obtain the porous carbon fiber. The method has the advantages of simple preparation, high output and low cost, and allows the porous carbon fiber simultaneously having micro-pores, meso-pores and macro-pores to be prepared; and the carbon fiber prepared in the invention is more flexible than that of carbon fibers prepared through other methods.

Owner:INST OF CHEM CHINESE ACAD OF SCI

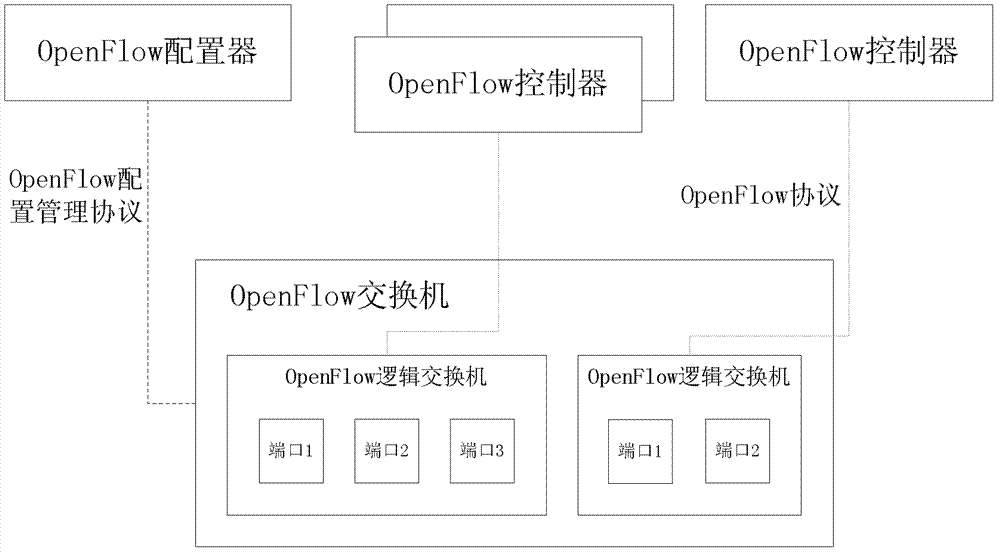

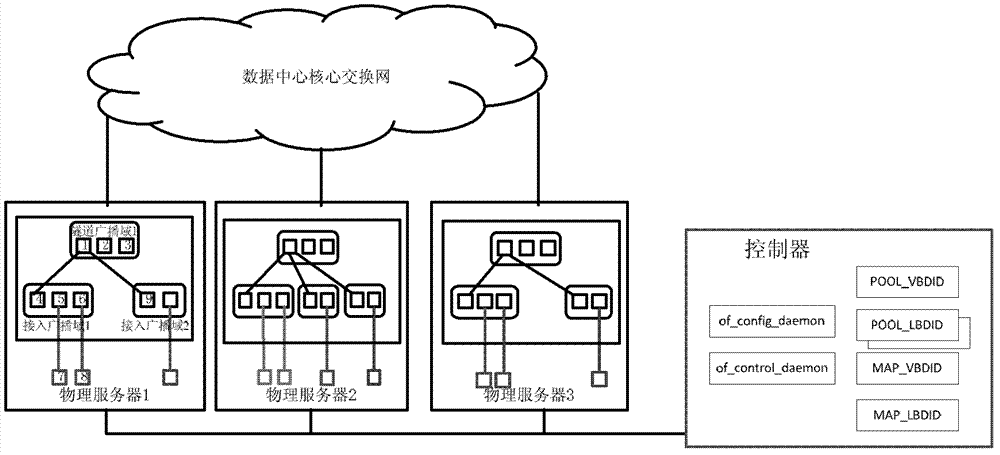

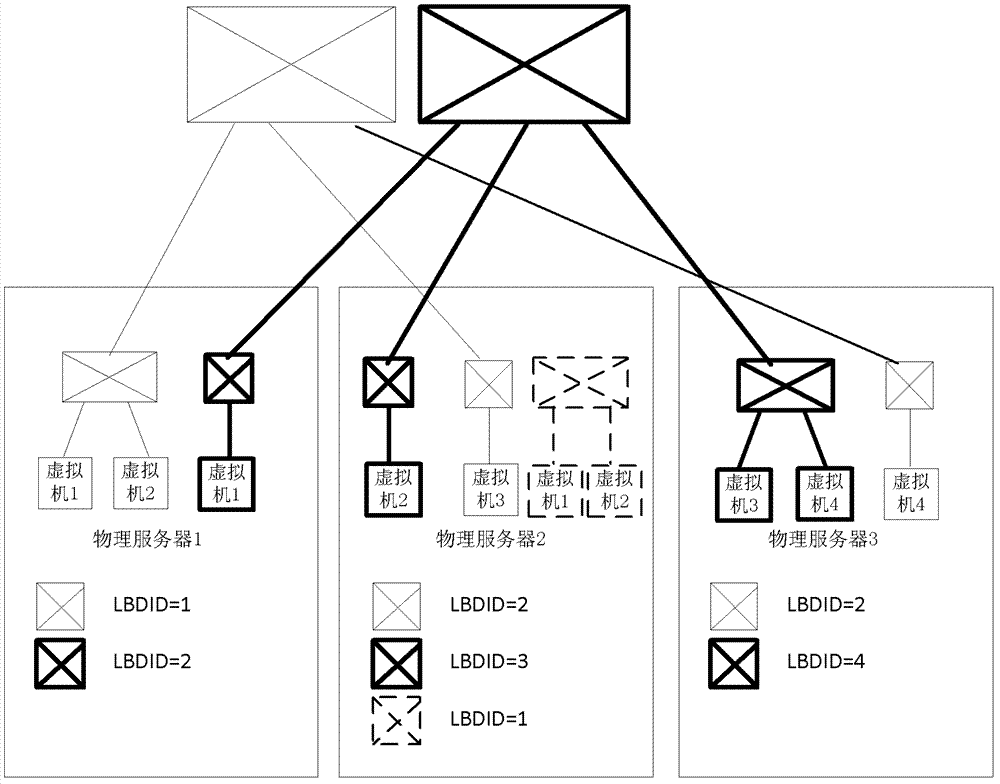

System and method for managing virtual network in cloud computation data center

ActiveCN102710432AEffective isolationRelieve pressureNetworks interconnectionTraffic capacityBroadcast domain

The invention discloses a system and a method for managing a virtual network in a cloud computation data center, and relates to the technical field of network system structures and network communication protocols. The system comprises physical servers and a controller, the physical servers are connected with a core switching network of the data center, each physical server is provided with at least one switch supporting OpenFlow related protocols and is connected with the controller, and the controller builds the virtual network, maintains configuration of the virtual network and a mapping relation among the virtual network, a virtual broadcast domain and a local broadcast domain, and configures and controls the switches of the physical servers. By the aid of the system and the method, pressure on broadcasting and double-layer address tables and forwarding tables of the core switching network of the data center can be effectively reduced, large-scale management is facilitated, flows of different users can be effectively isolated, security is strengthened, and configuration of the virtual network of the data center can be quickly and flexibly changed along with dynamic distribution of virtual resources.

Owner:北京云杉世纪网络科技有限公司

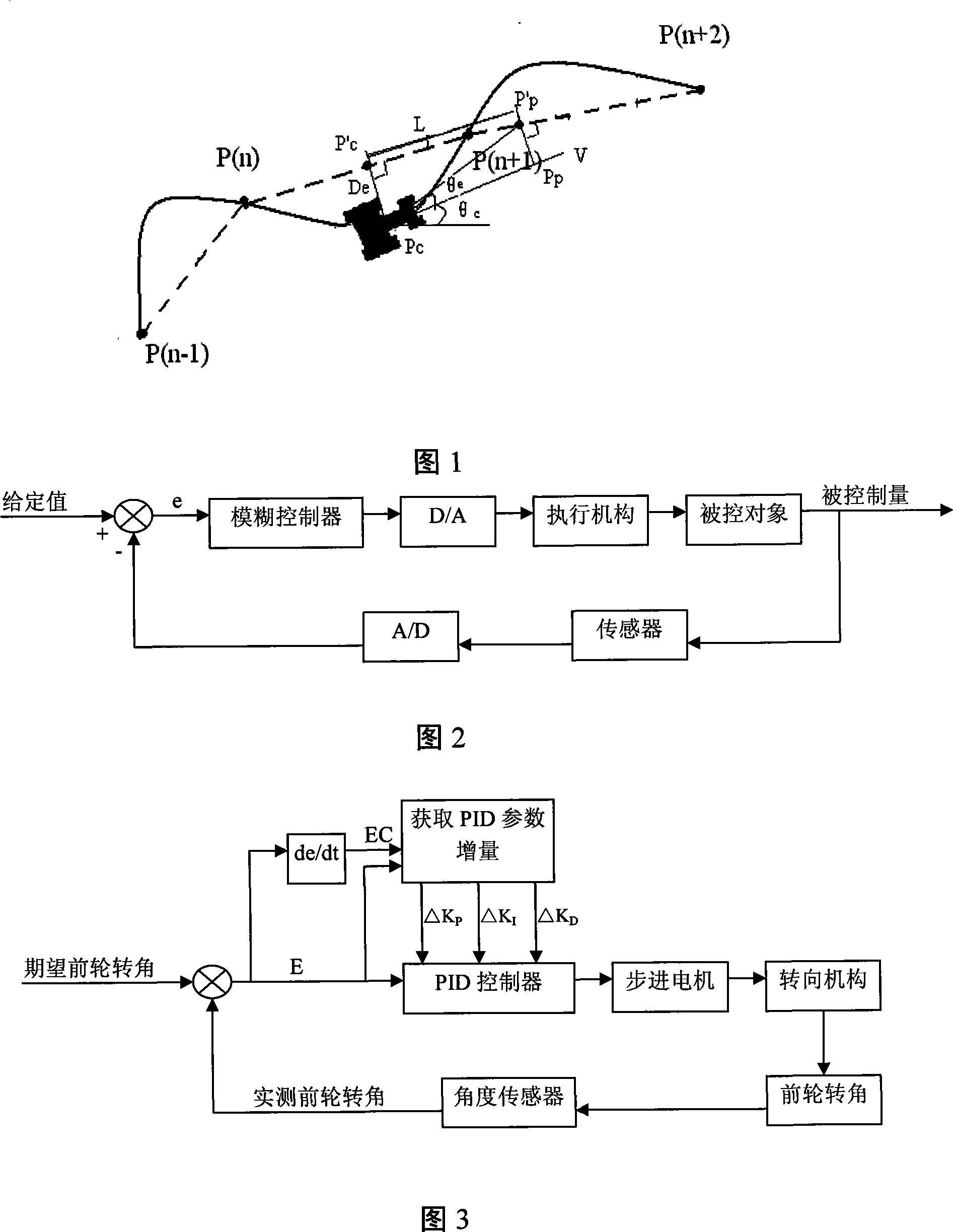

Mechanical automatic steering control method

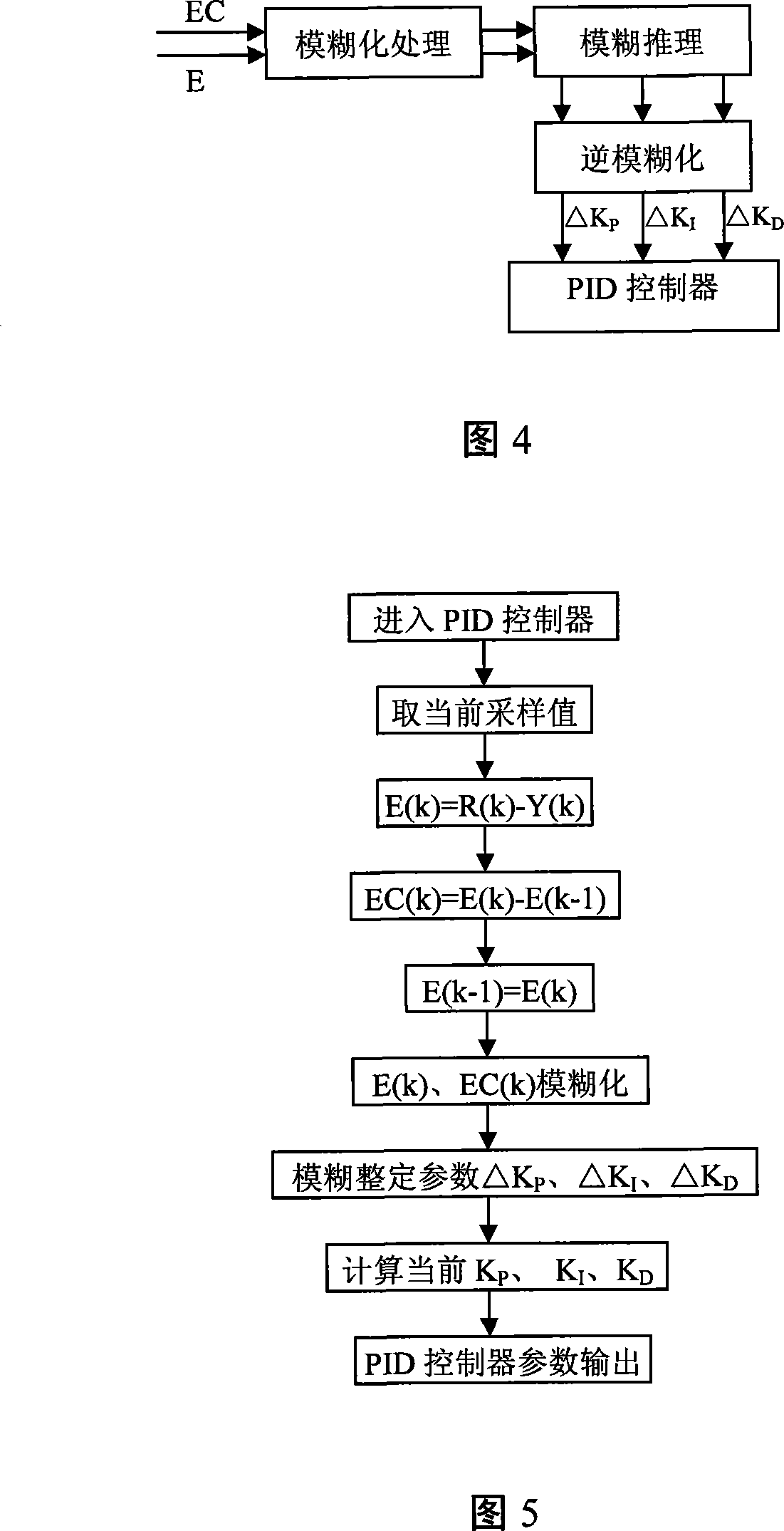

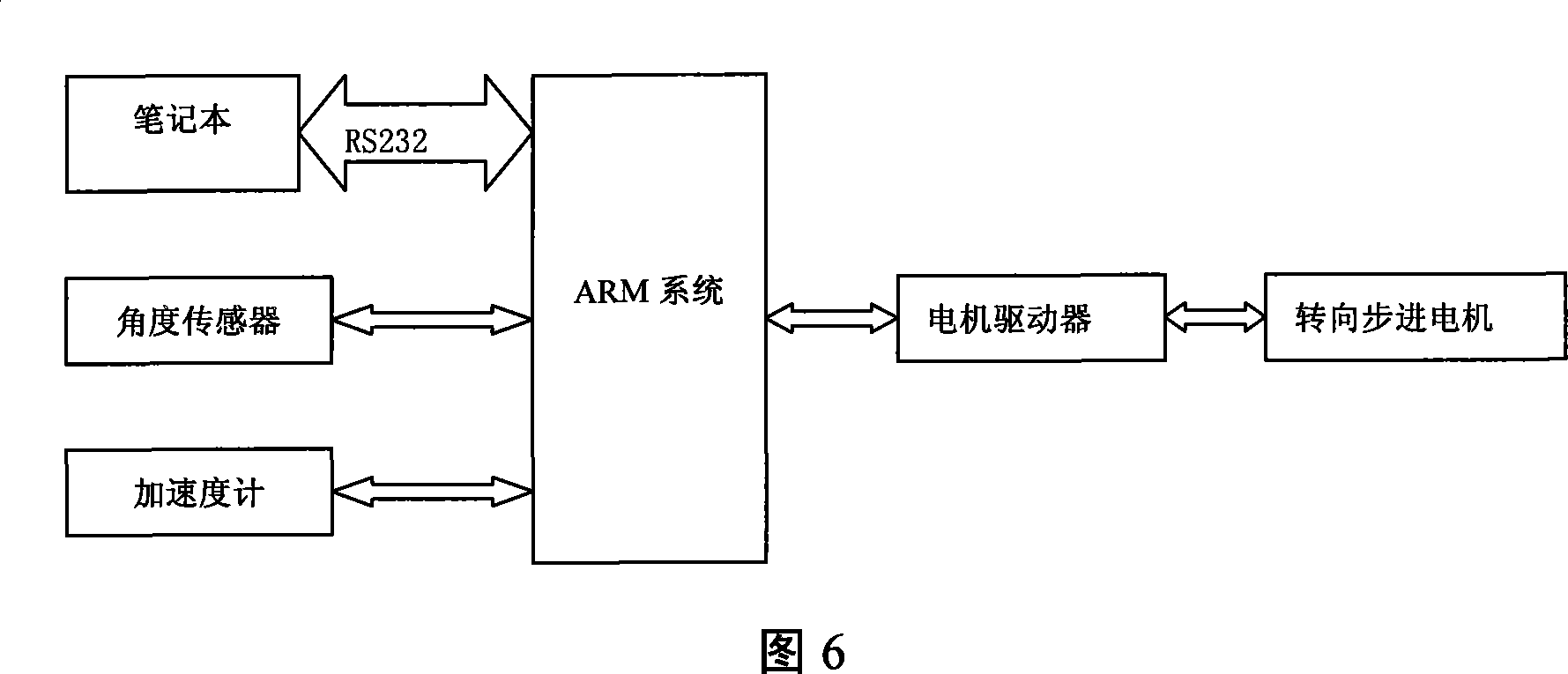

InactiveCN101221447AHigh control precisionFlexibleGuiding agricultural machinesTarget-seeking controlAutomatic steeringPid control algorithm

The invention relates to a machinery automatic steering control method which comprises the following steps that: positional deviation and course deviation are determined; according to the variance in the practical front wheel rotating angle of an agricultural machine, online setting of PID parameter is completed by means of parameter self-setting PID control algorithm; moreover, the expected front wheel rotating angle of the next moment is calculated, thereby realizing automatic steering control of the agricultural machine. Based on conventional PID navigation control method, the invention makes full use of the fuzzy control method; according to the variance in the practical front wheel rotating angle of an agricultural machine, the invention meets the different requirements of the machine on PID control parameter under different errors and error change rate, thereby realizing online setting of PID parameter. The invention not only has the advantages of fuzzy control such as flexibility and adaptability, but also has the characteristics of higher precision of PID control; therefore, the invention can increase the stability and precision of agricultural machine automatic steering control and the robustness of a control system.

Owner:CHINA AGRI UNIV

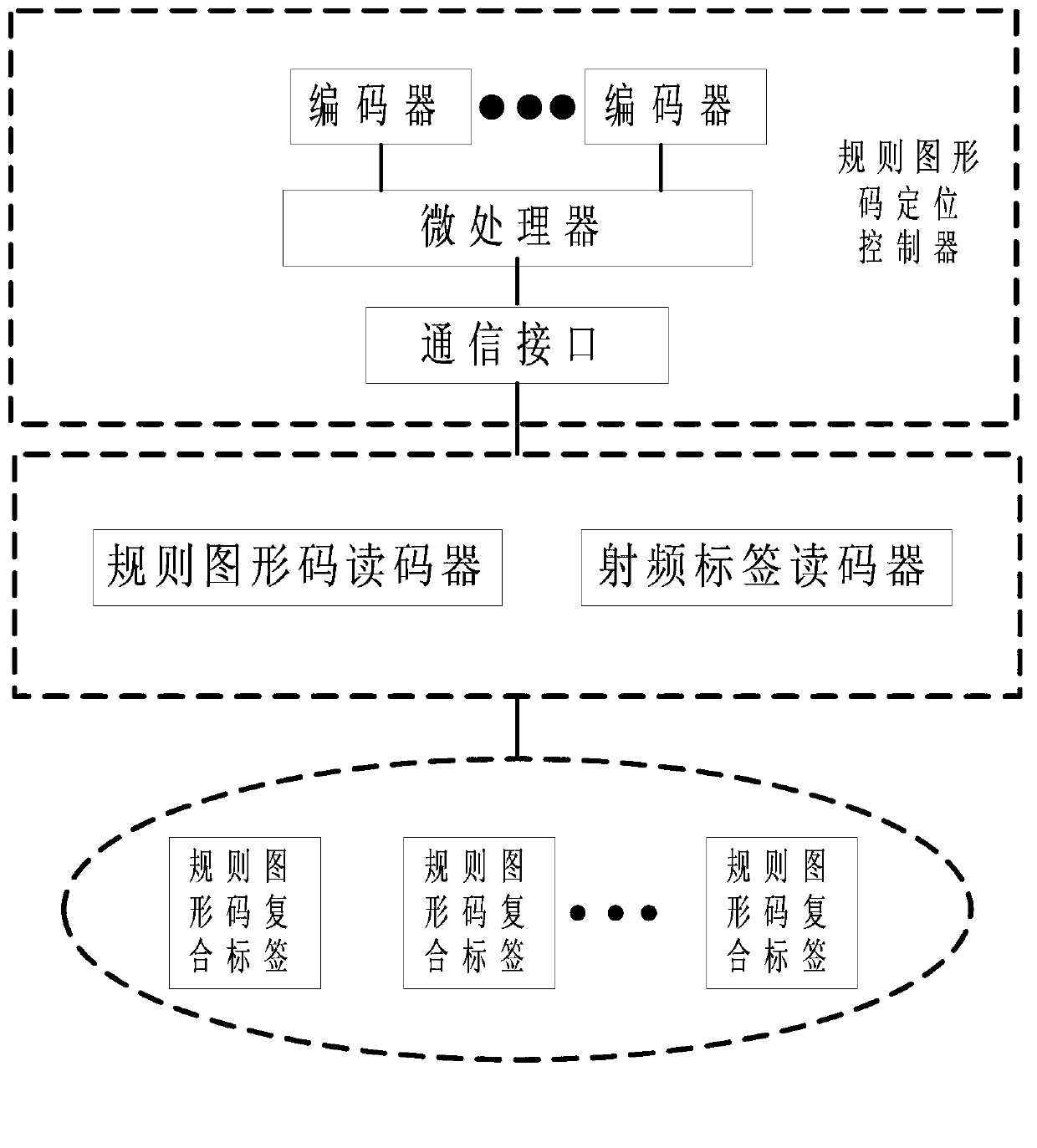

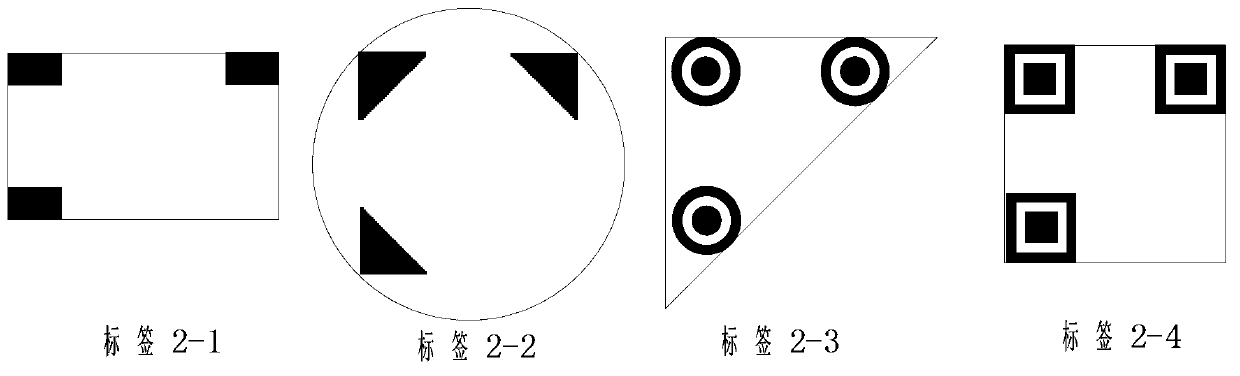

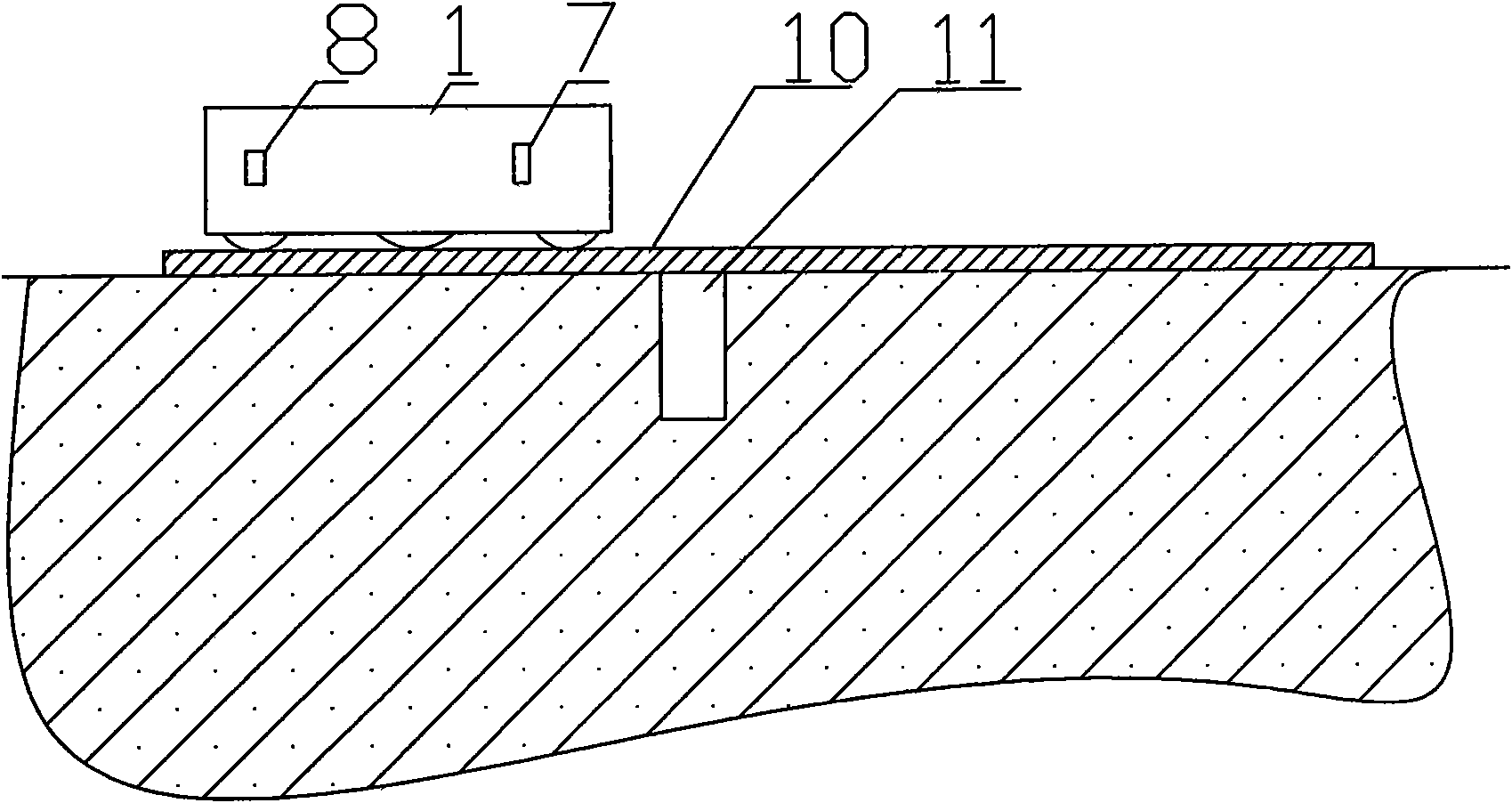

System and method for positioning mobile robot based on regular graphic code composite tags

InactiveCN103123682ARealize precise positioning functionReasonable designNavigation instrumentsRecord carriers used with machinesGraphicsPosition angle

The invention relates to a system and a method for positioning a mobile robot based on regular graphic code composite tags. The system comprises a regular graphic code positioning controller, a regular graphic code reader, a radio frequency identification (RFID) tag code reader, and the regular graphic code composite tags which are distributed on the ground, wherein each regular graphic code composite tag is formed by compositing a regular graphic code tag and an RFID tag. The method comprises the following steps of: (1) establishing an image coordinate system, a trolley coordinate system and a world coordinate system; (2) calculating the deviation position and position angle of a mobile robot trolley relative to each composite tag in the trolley coordinate system; (3) calculating the deviation position and angle of each composite tag relative to the world coordinate system; and (4) calculating the deviation position and angle of the mobile robot trolley relative to the world coordinate system. The invention is reasonable in design, the characteristics of the regular graphic code tag and the RFID tag are effectively combined, a function of accurately positioning the mobile robot trolley is realized, and positioning efficiency is improved.

Owner:SHENZHEN PUZHILIANKE ROBOT TECH CO LTD

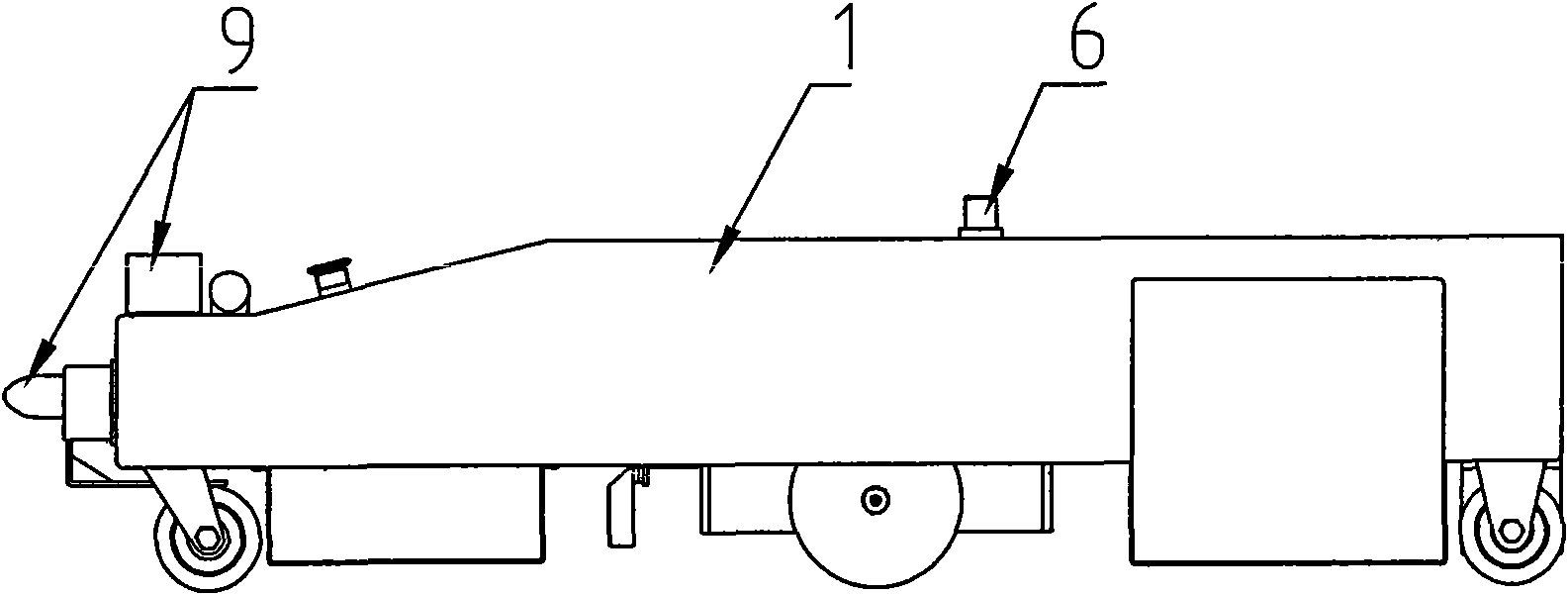

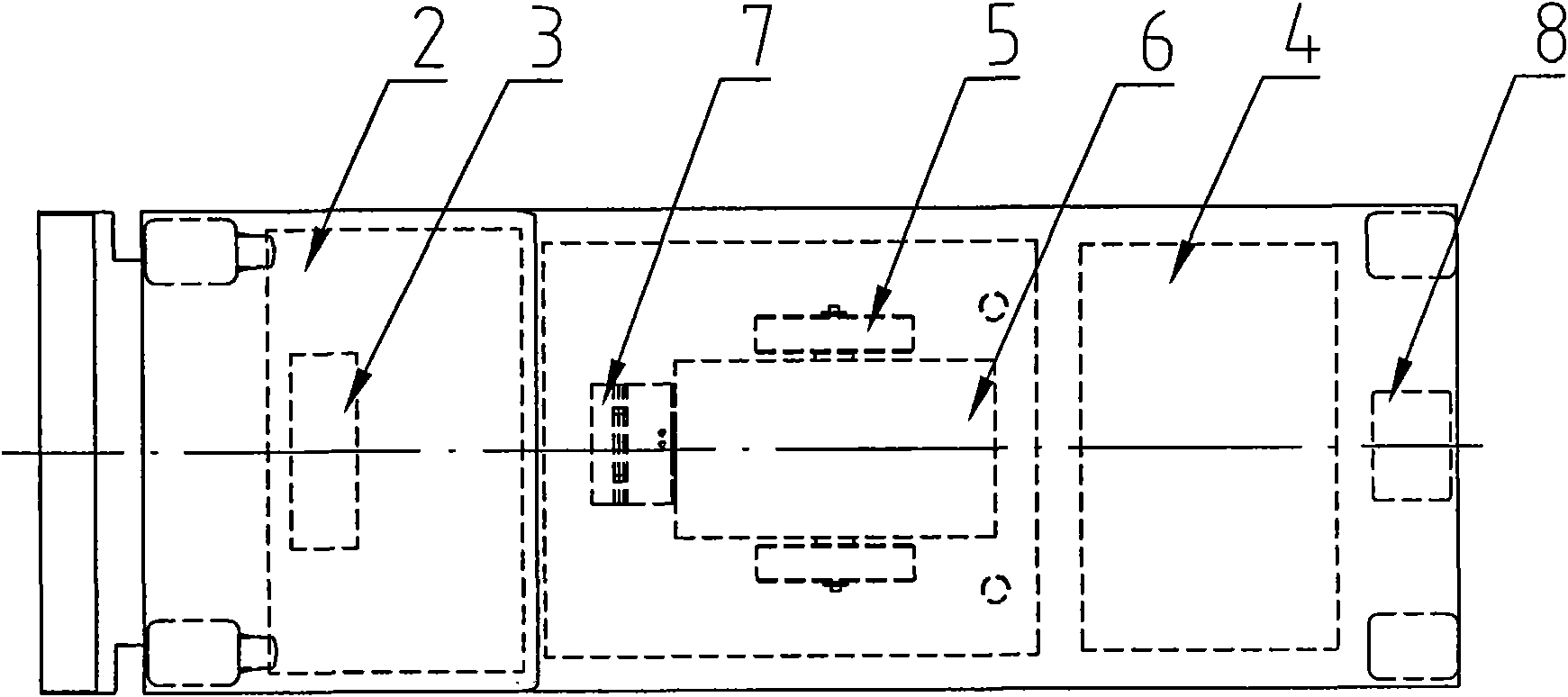

Automatic navigation vehicle system and multiple task control method

InactiveCN101603830AImprove reliabilityImprove stabilityNavigation instrumentsSensing record carriersFlexible manufacturing systemComputer module

The invention discloses an automatic guild system and a multiple task control method and belongs to the transport vehicles field. The automatic guild vehicle system comprises a vehicle part and a guild part; wherein, the vehicle part comprises a vehicle body, an electronic control tank, a central control device, a battery group, a driving mechanism, a suspending mechanism, a road magnetic strip signal sensor, a road RFID radio frequency identification card reader, an anti-knocking mechanism and the like. The guild part comprises a magnetic strip paved on the road and an RFID radio frequency identification card; the vehicle body is provided with a road magnetic strip signal sensor and a road RFID radio frequency identification card reader; the road magnetic strip signal sensor is directly connected with an AD module of the central controller for processing the analog signal transmitted by the road magnetic strip signal sensor. In the invention, the magnetic strip paved on the road and the RIFD radio frequency identification card are used for guiding so as to change lines flexibly and be applicable to flexible manufacturing system.

Owner:GUANGZHOU JINGYUAN MECHANO ELECTRIC EQUIP

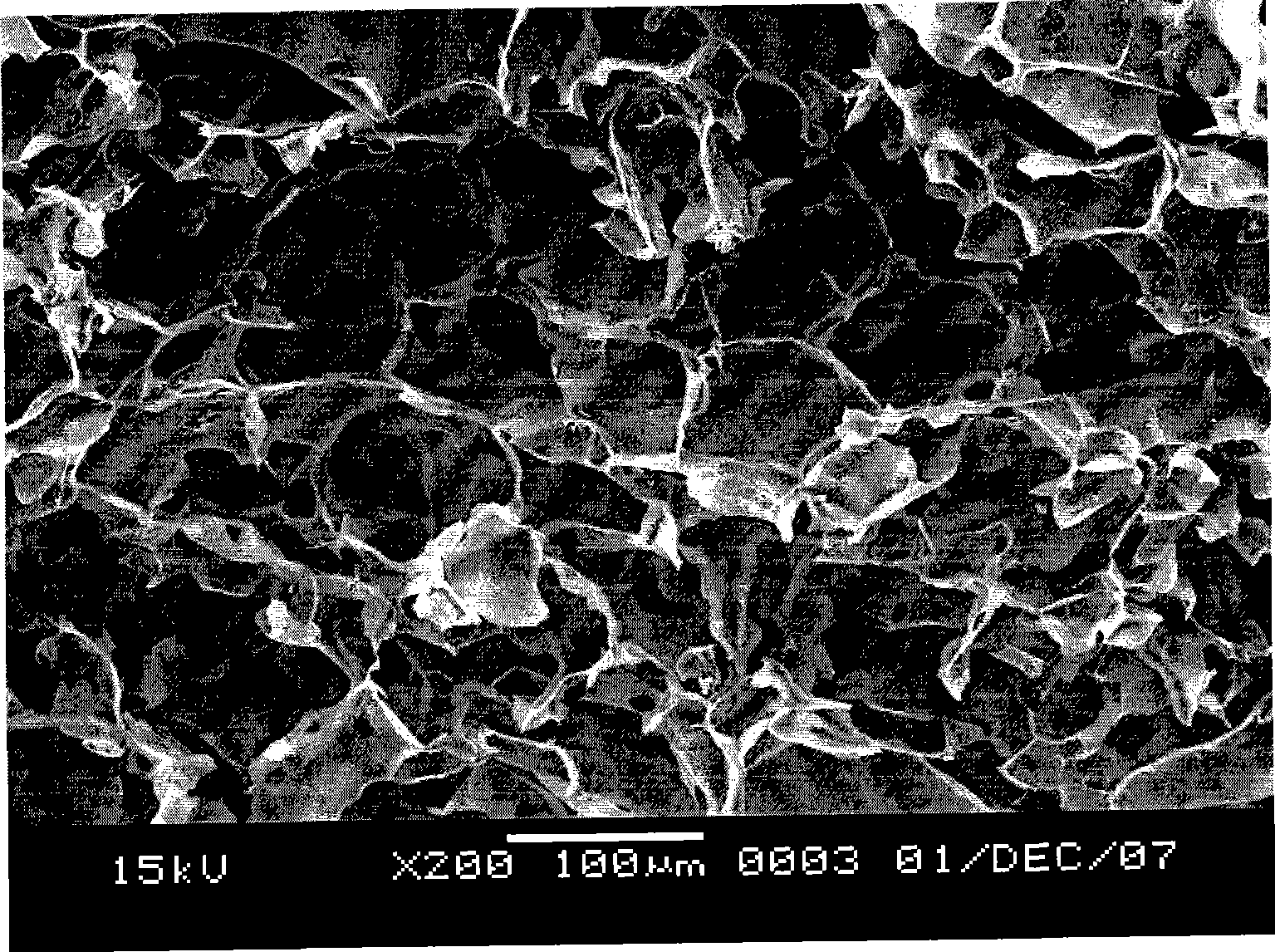

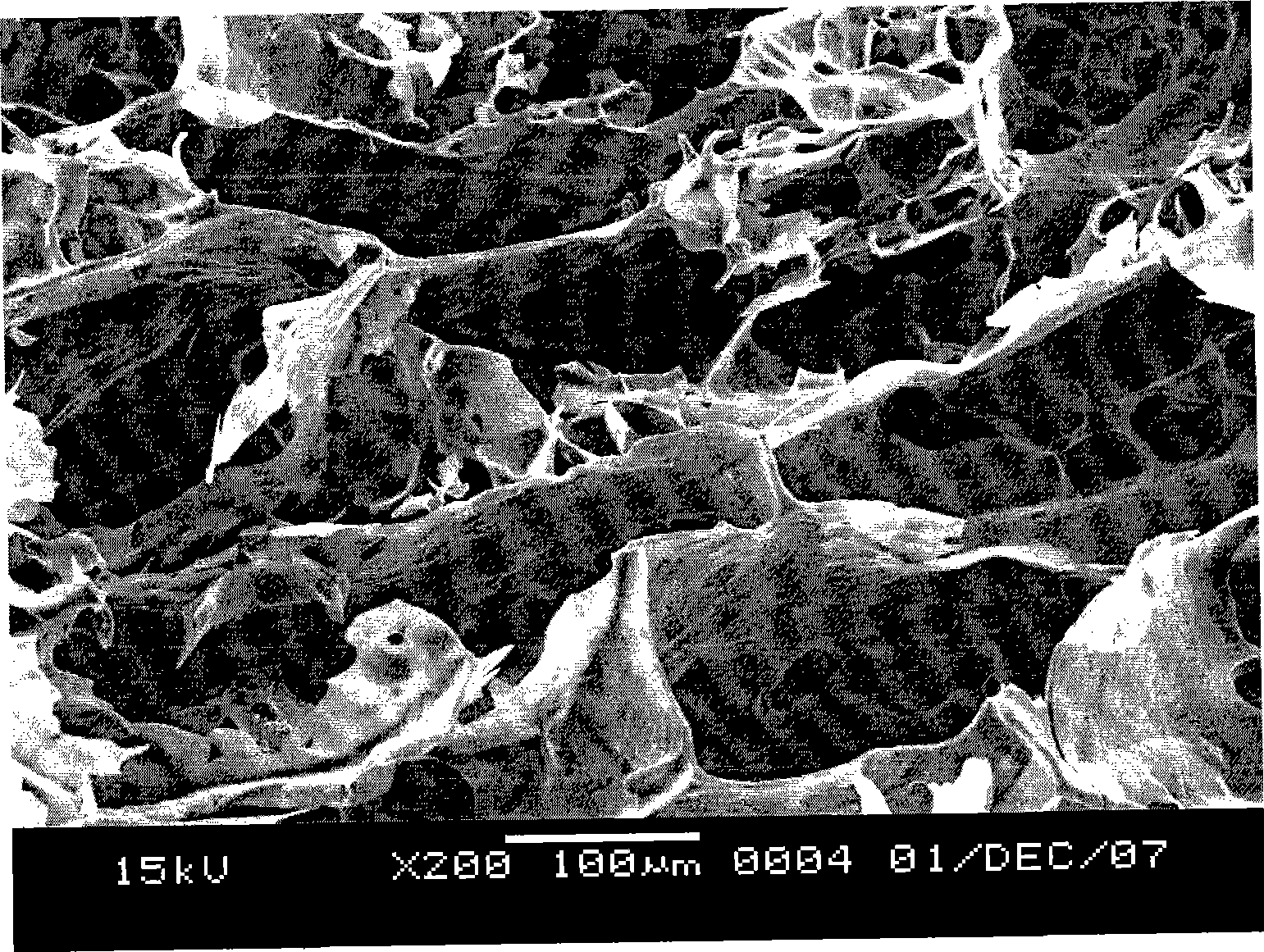

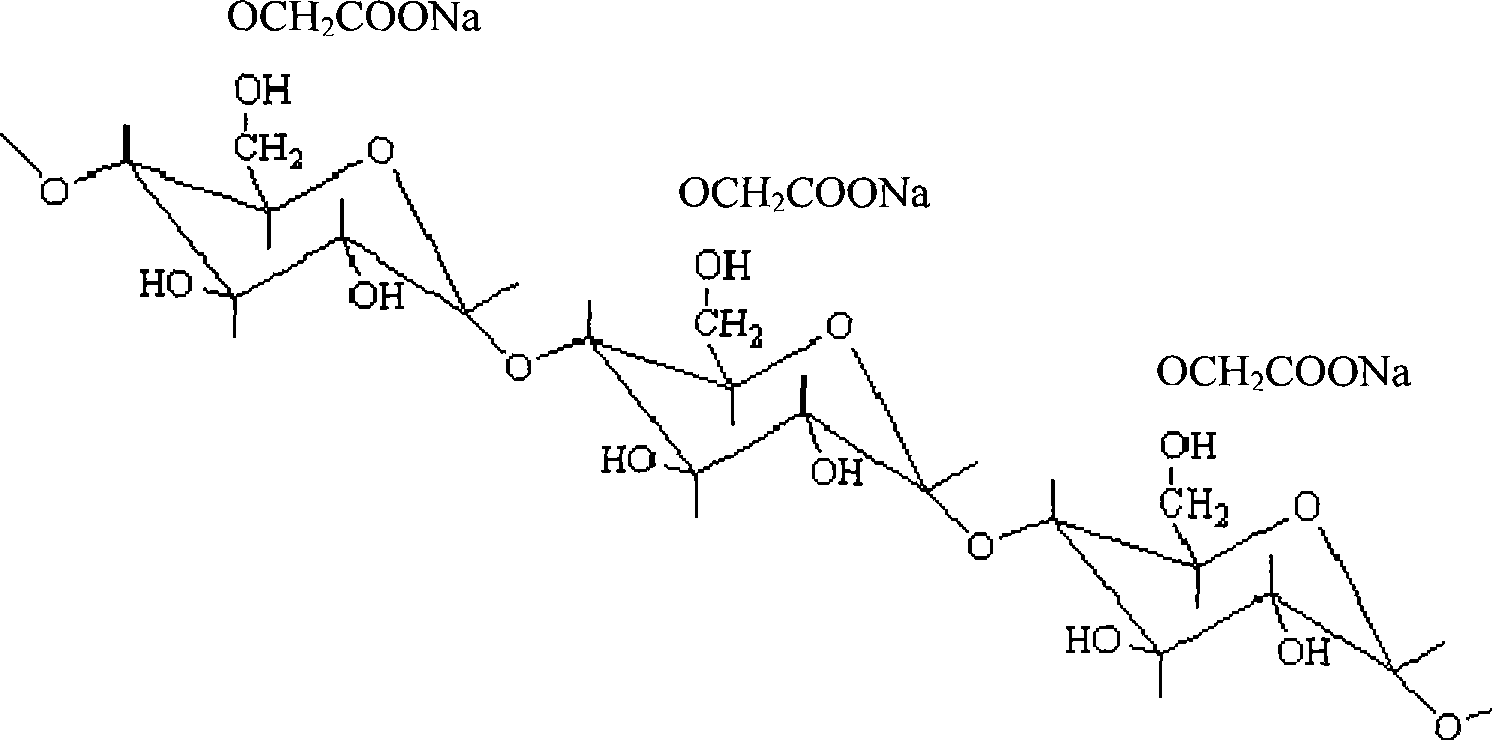

Biocompatibility modified starch sponges

ActiveCN101455857AFlexibleActive bleeding is easily controlledAbsorbent padsBandagesFreeze-dryingBiocompatibility Testing

The invention relates to biocompatible modified starch sponge and use of the biocompatible modified starch sponge as a hemostatic material, an anti-adhesion material, a material for promoting tissue healing, a surgical sealant or a wound tissue adhesive. Modified starch is one or a combination of more than one among pre-gelatinized starch, acid modified starch, dextrin, oxidized starch, esterified starch, etherified starch, crosslinked starch, grafted starch and composite modified starch. The sponge is prepared by vacuum freeze drying of the modified starch and other biocompatible hemostatic material, coagulant, plasticizer and so on. The biocompatible modified starch sponge has the advantages that the biocompatible modified starch sponge has flexible form and good biocompatibility, can be directly acted on bloody wound surfaces, avoids the conditions of hypersusceptibility, infection and difficult healing of wounds caused by adoption of hemostatic materials such as animal source / human source collagens, obviously improves the water absorption speed, has larger viscosity, forms a zymoplastic mixture which has good adhesion, calks broken tissues and blood vessels, and is used for hemostasis of active hemorrhage.

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

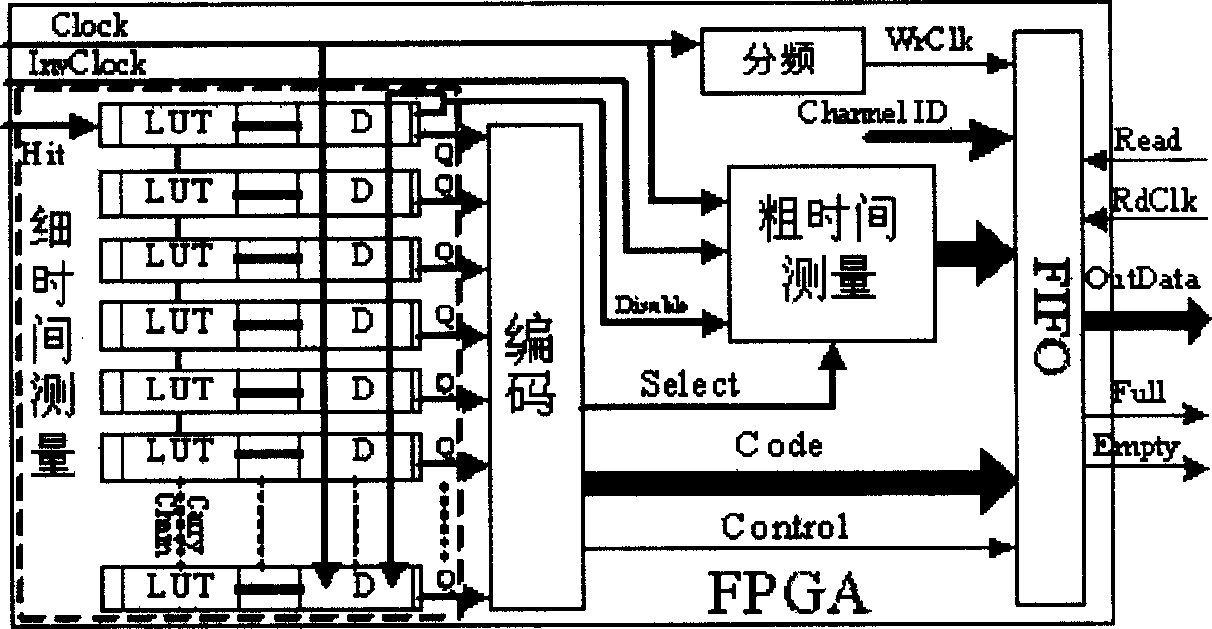

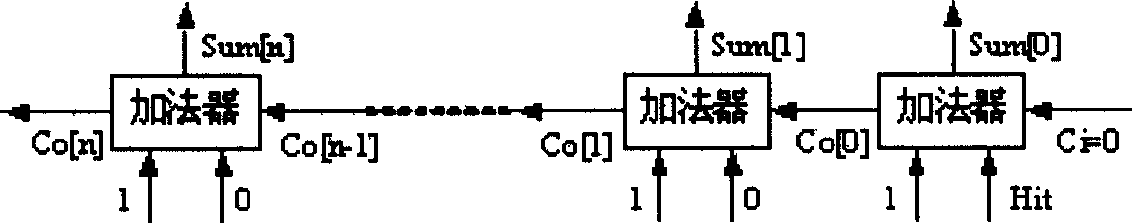

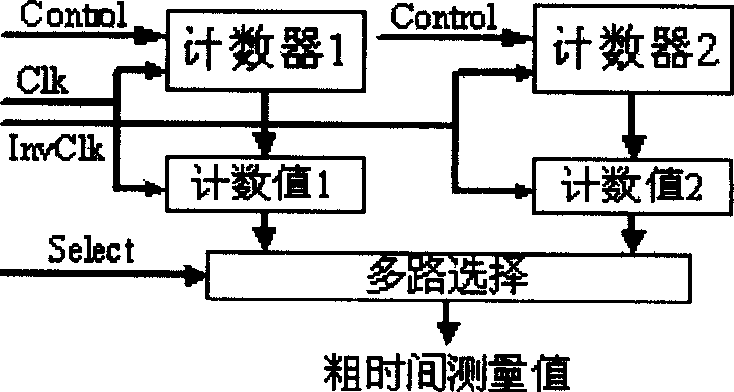

Time digital converter based on RPGA and its conversion method

InactiveCN1719353AFlexible useSimple designElectric unknown time interval measurementProgramme control in sequence/logic controllersDigital converterComputer science

The present invention relates to a time / digital converter based on FPGA and its conversion method, belonging to the field of time measurement technology. Said converter includes the following components: fine time measurement unit, coding unit, coarse time measurement unit and data buffer storage unit. The main application of said invention is to make high accuracy time measurement, it can be used in the fields of basis research and various application researches.

Owner:UNIV OF SCI & TECH OF CHINA

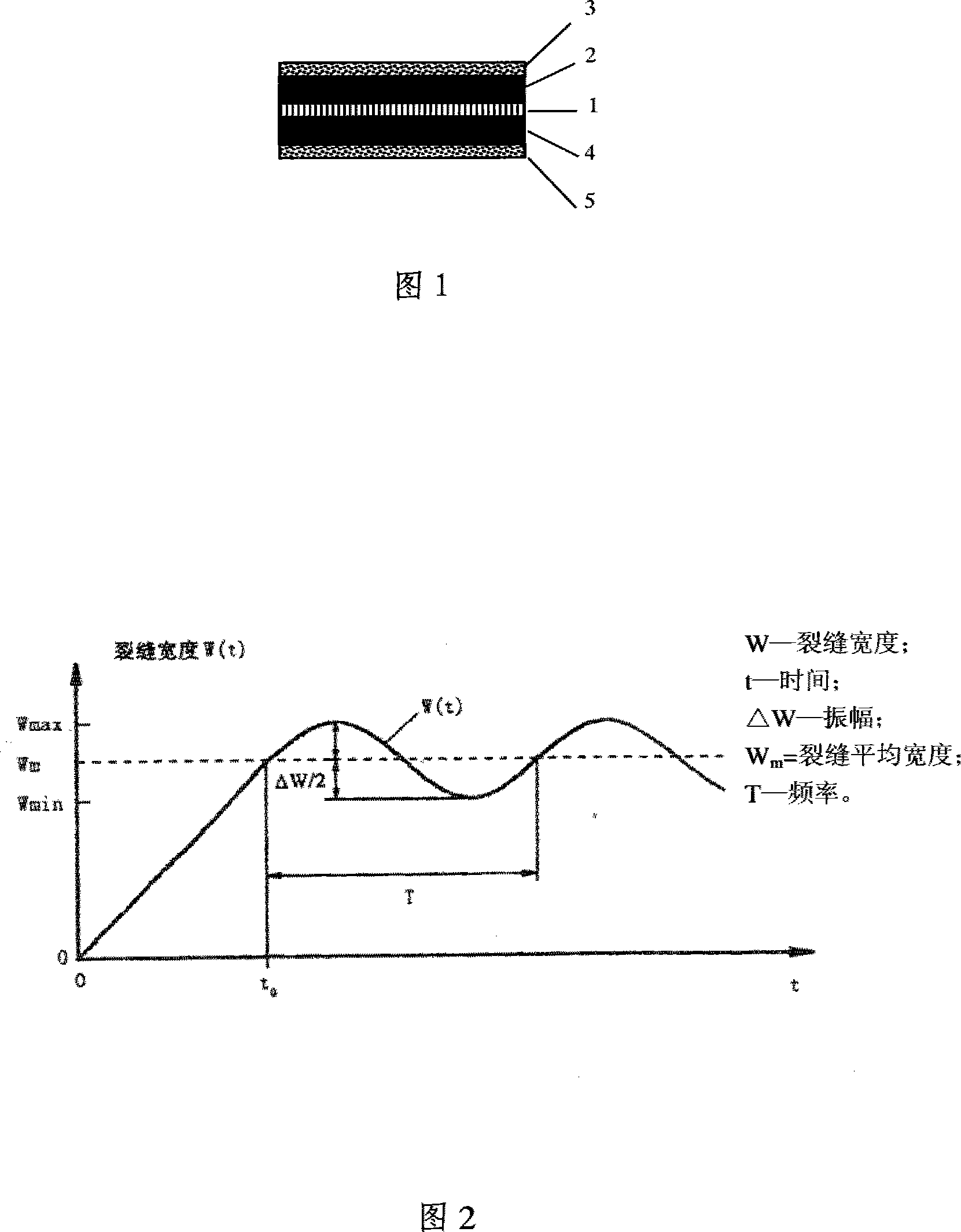

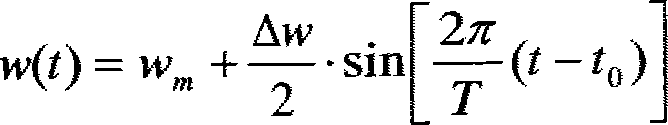

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

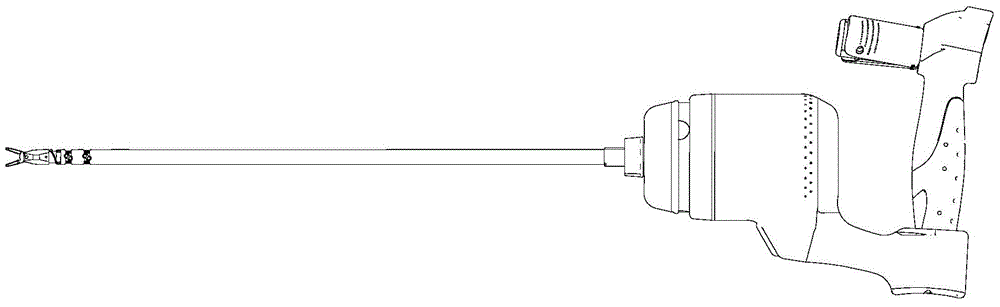

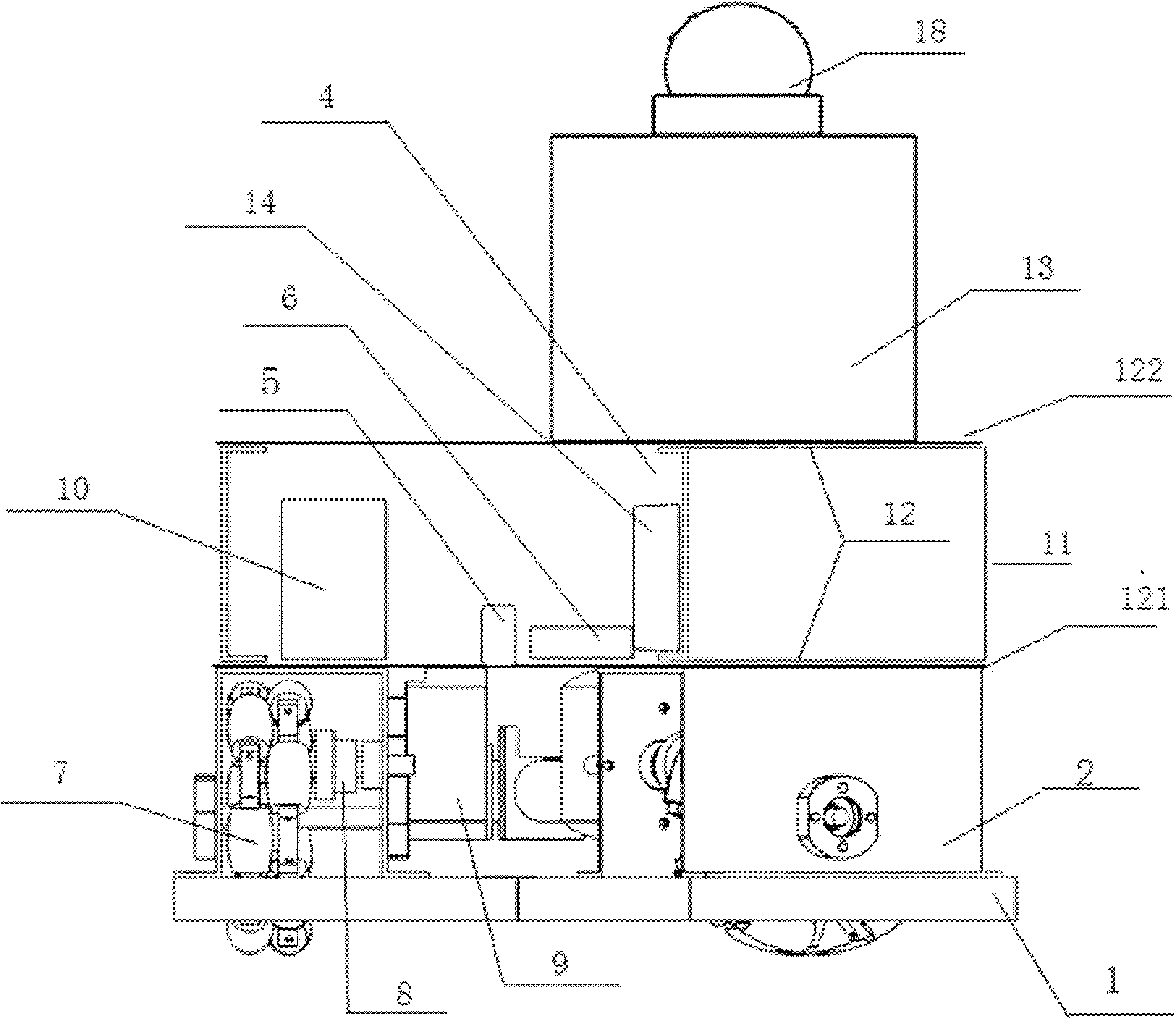

Endoscope noninvasive surgery system

The invention discloses an endoscope noninvasive surgery system. The system comprises a function end and a control end. The function end comprises an endoscope body, a flexible sleeve pipe, a camera shooting illumination module and a function mechanical arm. A rigid pipe body section is arranged at the front end of the endoscope body. The control end comprises a control end base, an endoscope body control module, a camera shooting illumination module control module and a function mechanical arm control module, wherein the endoscope body control module, the camera shooting illumination module control module and the function mechanical arm control module respectively control stretching and / or bending of the endoscope body, the camera shooting illumination module and the function mechanical arm, so that a surgical instrument carried by the function mechanical arm can enter a surgical site under the posture that the surgical instrument is retracted into a rigid pipe body, and the endoscope body, the camera shooting illumination module and the function mechanical arm can stretch and / or bend after the surgical instrument reaches the surgical site. The endoscope noninvasive surgery system has the advantages of being small in size, convenient to use and the like.

Owner:BEIJING SURGERII TECH CO LTD

Nubby low-density gel heat-insulation composite material

The invention discloses a low-density aerogel composite material and block-shaped low-density gel insulating composite material through packing the low-density aerogel composite material, which comprises the following steps: utilizing high-polymerization degree polyacrylic acid as porous nanometer silica reinforced frame to make the silica gel and composite material with certain elasticity and contractility; inhibiting crack during gel preparing course and hyper-critical drying course effectively; adopting packing slurry with alumina, titania, carborundum, hollow glass microball or ferroferric oxide and soluble silicate, organosilicon resin or silica gel to pack the surface of large block of silica aerogel; sintering the packed aerogel composite material at 650-700 deg. c; using the material under 1000 deg. c at most.

Owner:NANJING UNIV OF TECH

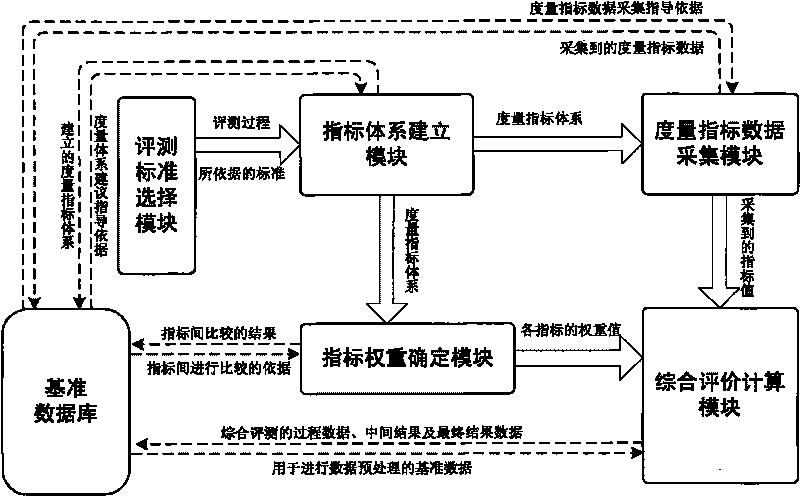

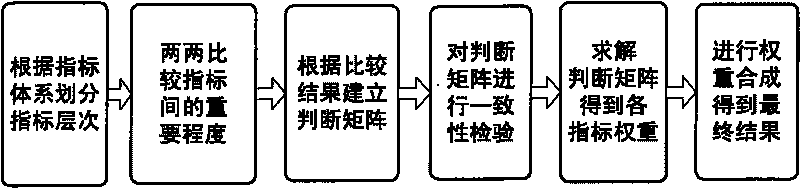

Method for evaluating implementation quality of software process

InactiveCN101710304AFlexible indicator organizationCovering the whole life cycleSoftware testing/debuggingImplementation qualityComputer Software Engineering

The invention discloses a method for evaluating the implementation quality of a software process, which belongs to the field of computer software engineering. The method comprises the following steps that: 1) a user selects an evaluation model or a standard of the software process from an evaluation standard library by using an evaluation standard selection module; 2) an index system establishment module establishes an measurement index system by adopting a target-problem-measurement method or a utility software measurement method; 3) an index measurement data acquisition module performs data acquisition on the software process to be evaluated according to the established measurement index system, and simultaneously, an index weight determination module determines the weight of each measurement index according to the established measurement index system; 4) a comprehensive evaluation computing module performs numerical value standardization and form unitization on the acquired data; and 5) the comprehensive evaluation computing module evaluates the processed data by adopting a fuzzy comprehensive evaluation method and outputs the evaluation result. The method not only ensures flexibility and the strictness of the result, but also ensures the accuracy of the evaluation process and the validity of the evaluation result.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

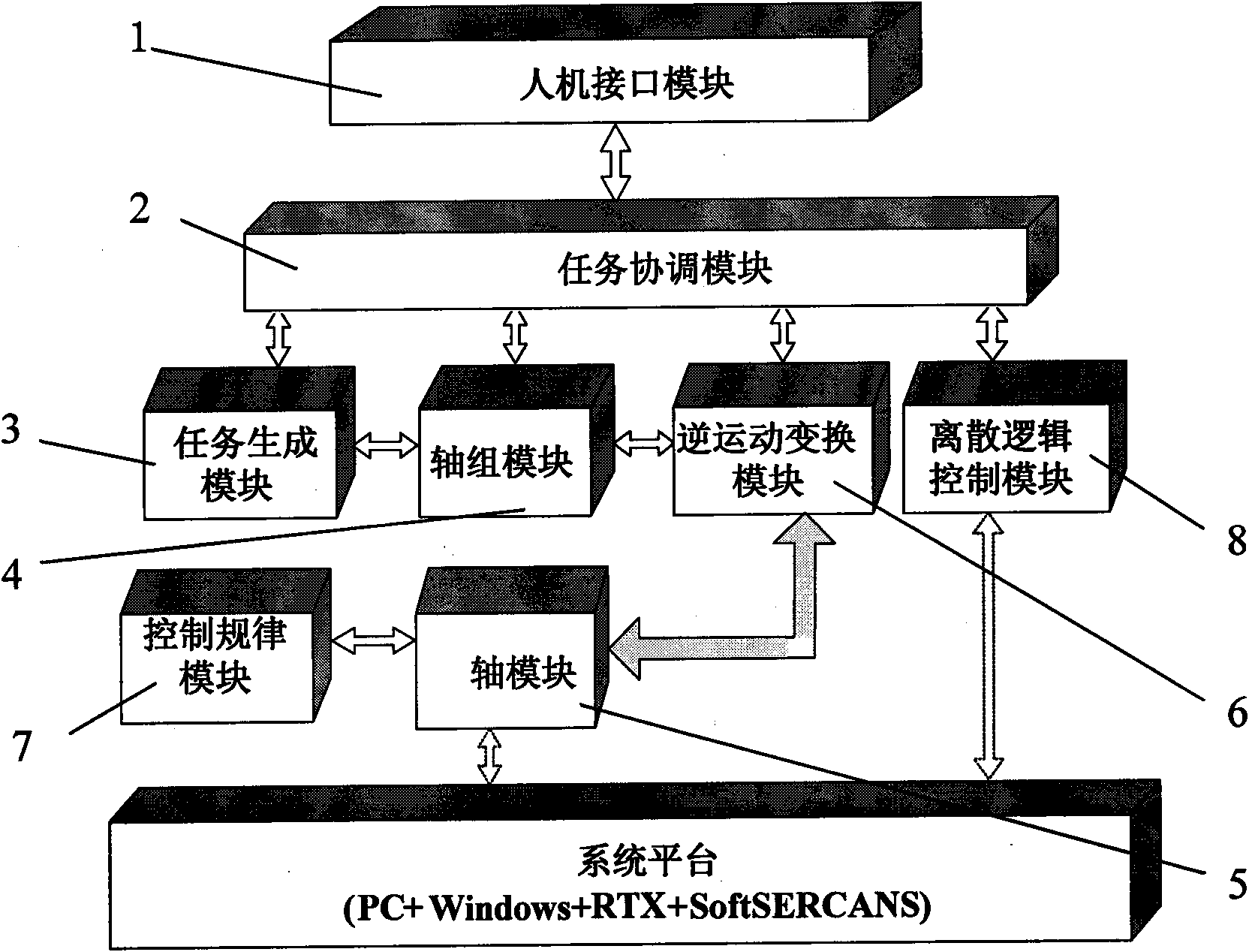

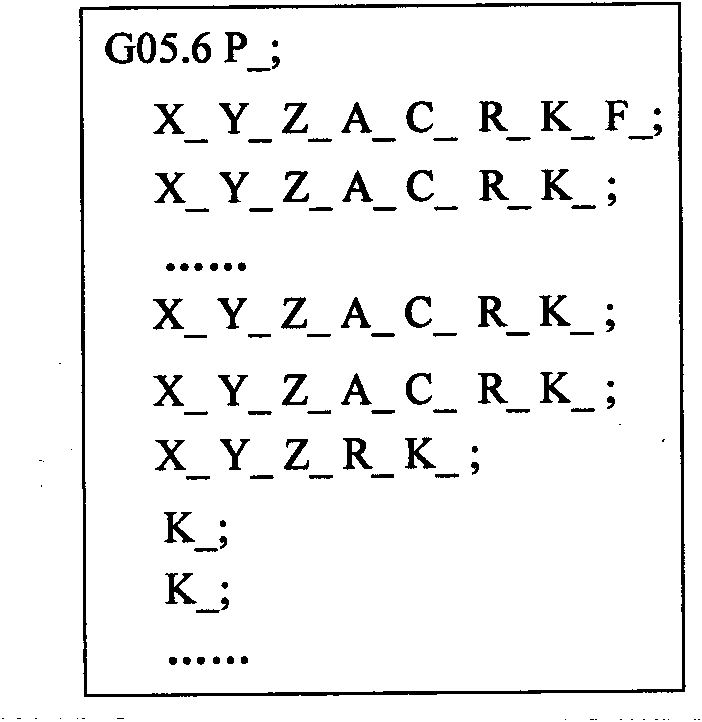

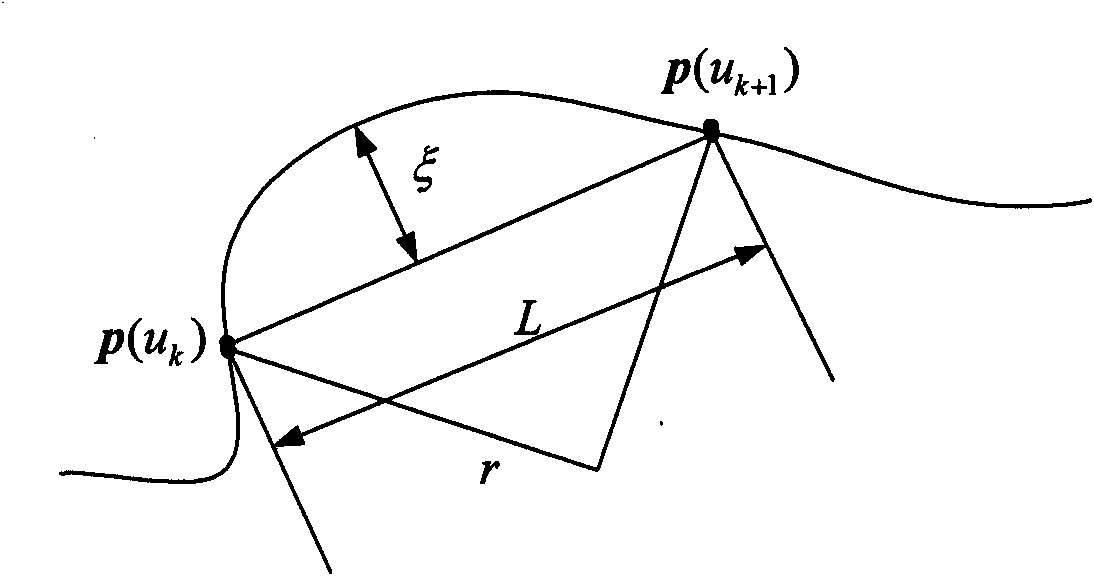

Five-coordination numerical control machine tool motion controller with NURBS interpolation function

The invention discloses a five-coordination numerical control machine tool motion controller with an interpolation function, and relates to a numerical control machine tool motion controller. The purpose of the invention is to solve the problems that the functions of the controller can not be easy to be expanded and modified, which is caused by the poor openness and flexibility of the existing numerical control machine tool motion controller, and the requirements of a configurable motion controller can not be met, and NC program size is seriously limited, which is caused by the multiplication of information amount in the controller by adopting a type value point direct interpolation method. The motion controller comprises a man-machine interface module, a task coordination module, a task generation module, an axis group module, an axis module, a reverse motion transformation module, a control rule module and a discrete logic control module. When the NURBS interpolation method of the invention is adopted to carry out NC machining, the NC program is reduced substantially; meanwhile, the machining error is more greatly reduced than the linear interpolation error. By adopting a modularized systematic structure, the requirements of the configurable motion controller can be met, the openness of the numerical control system can be enhanced, and the function expansion and modification of the controller can be carried out on the specific modules.

Owner:HARBIN INST OF TECH

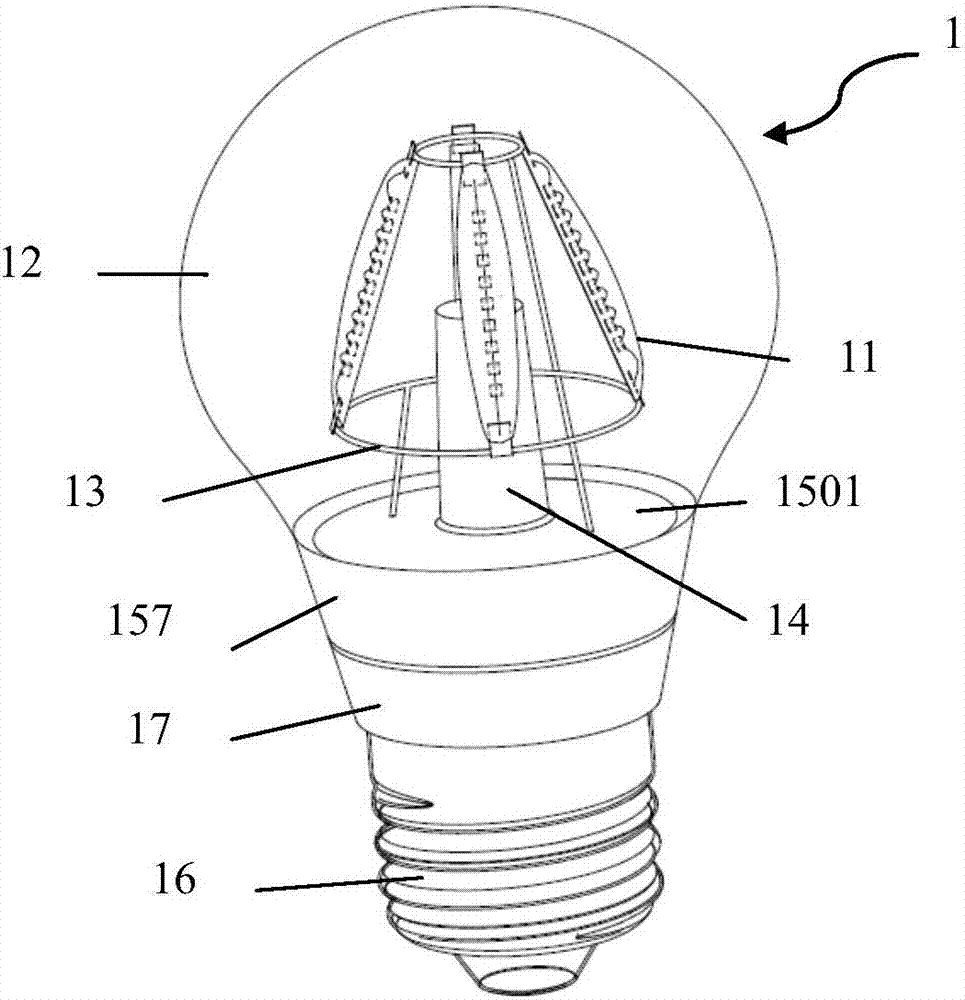

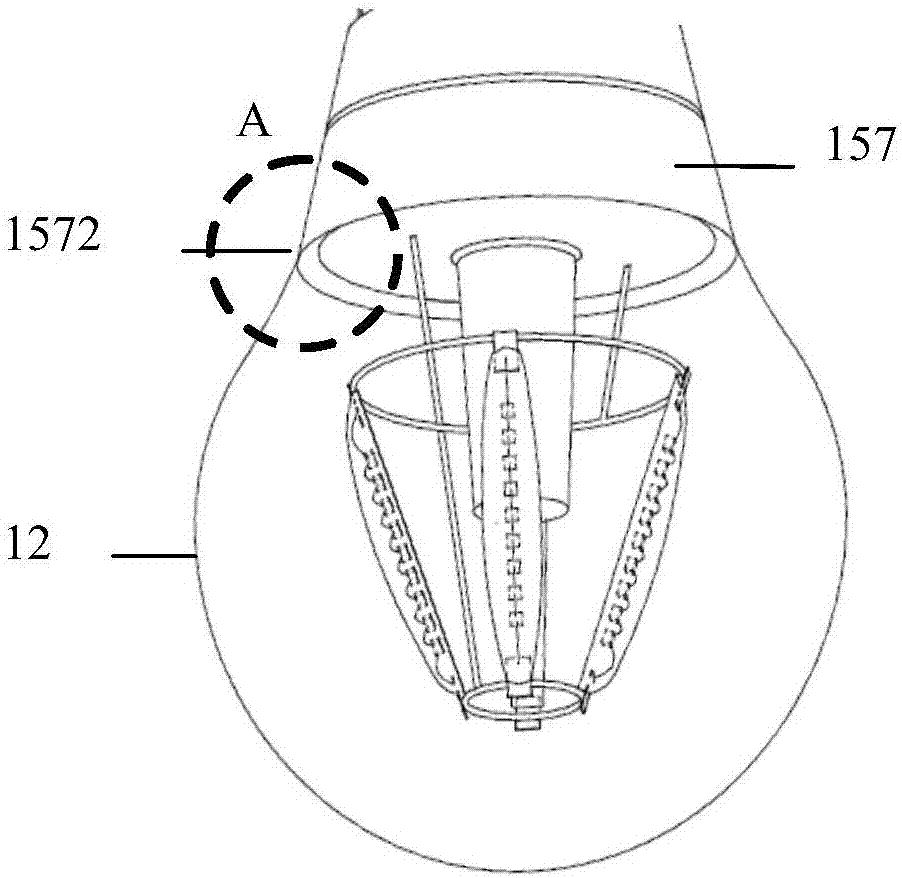

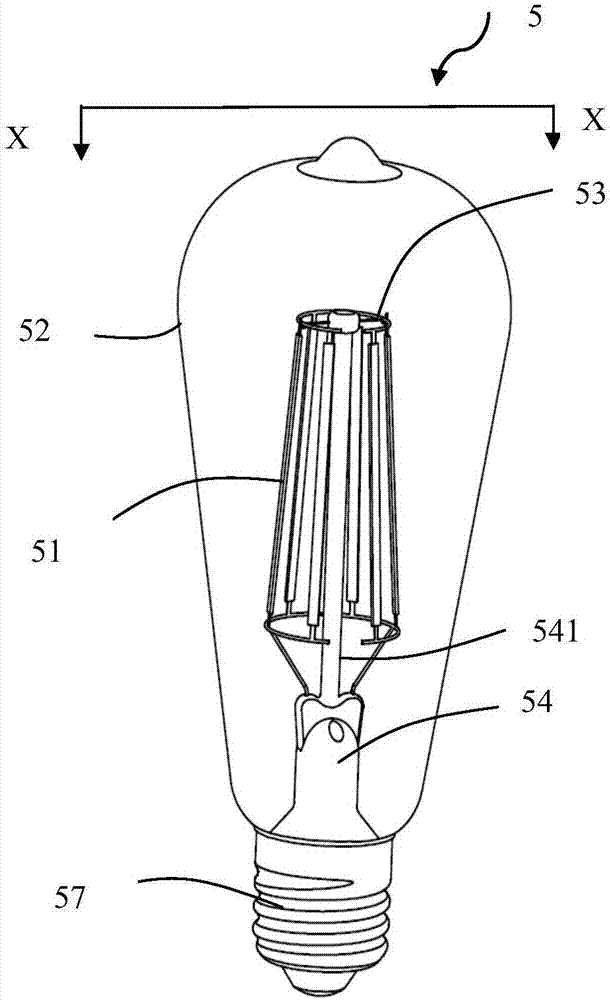

LED bulb lamp and LED filament thereof

ActiveCN107123641AAdjust the refractive indexLayered adjustment of light extraction efficiencyElongate light sourcesSolid-state devicesRefractive indexTransmittance

The invention discloses an LED filament. The LED filament comprises multiple LED chips, at least two electrodes and a light conversion layer, wherein the multiple LED chips are electrically connected with the at least two electrodes, the light conversion layer has a top layer and a base layer, the top layer and the base layer are respectively arranged at at least two sides of the multiple LED chips and the at least two electrodes, and parts of the two electrodes are exposed by the light conversion layer. The LED filament is advantaged in that the light conversion layer has a multi-layer layered structure, layered adjustment on hardness, light transmittance and a refractive index can be realized, so hardness, light transmittance and the refractive index of the LED filament can be adjusted to an optimum state, and the LED filament can be made to satisfy different demands of LED bulb lamps.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

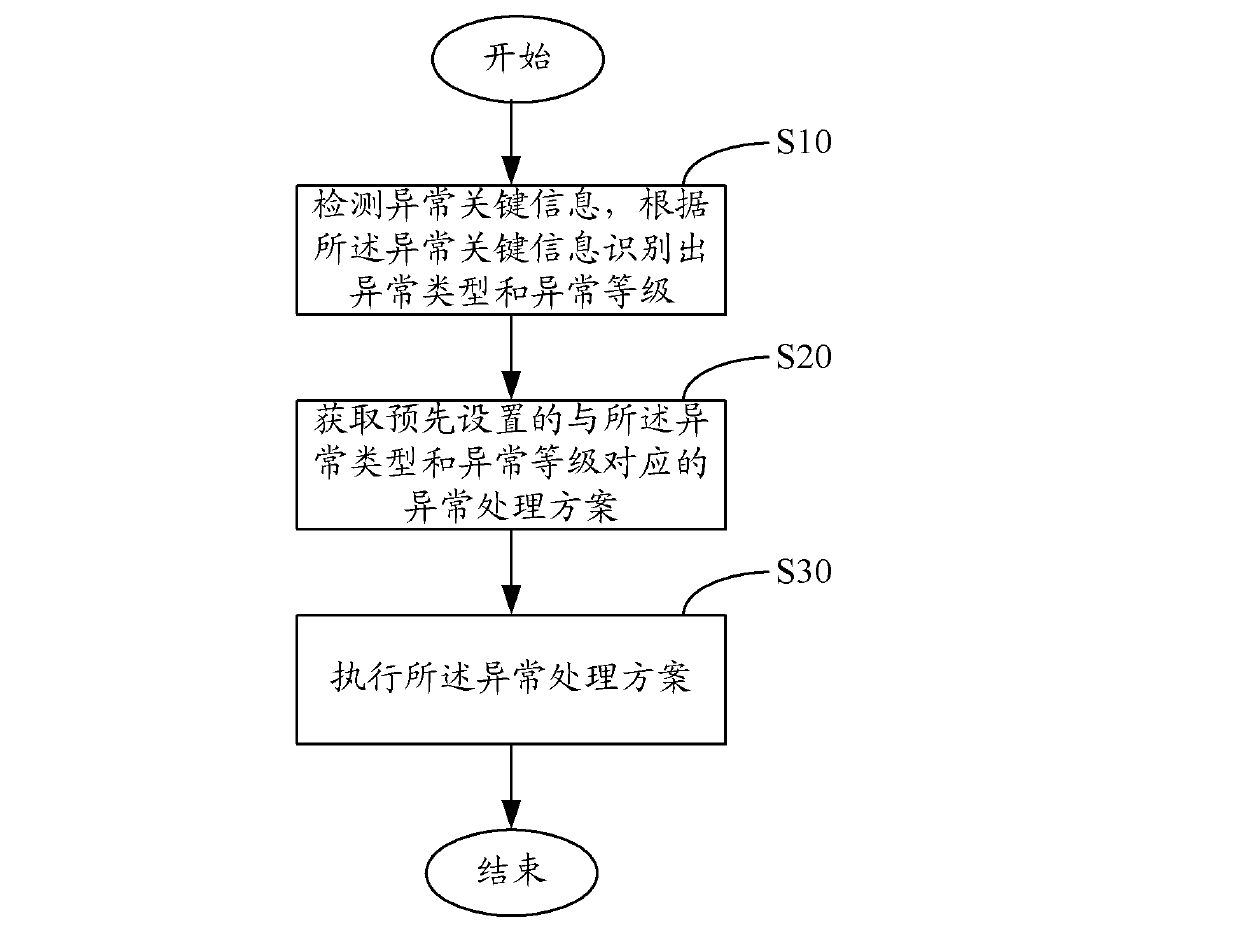

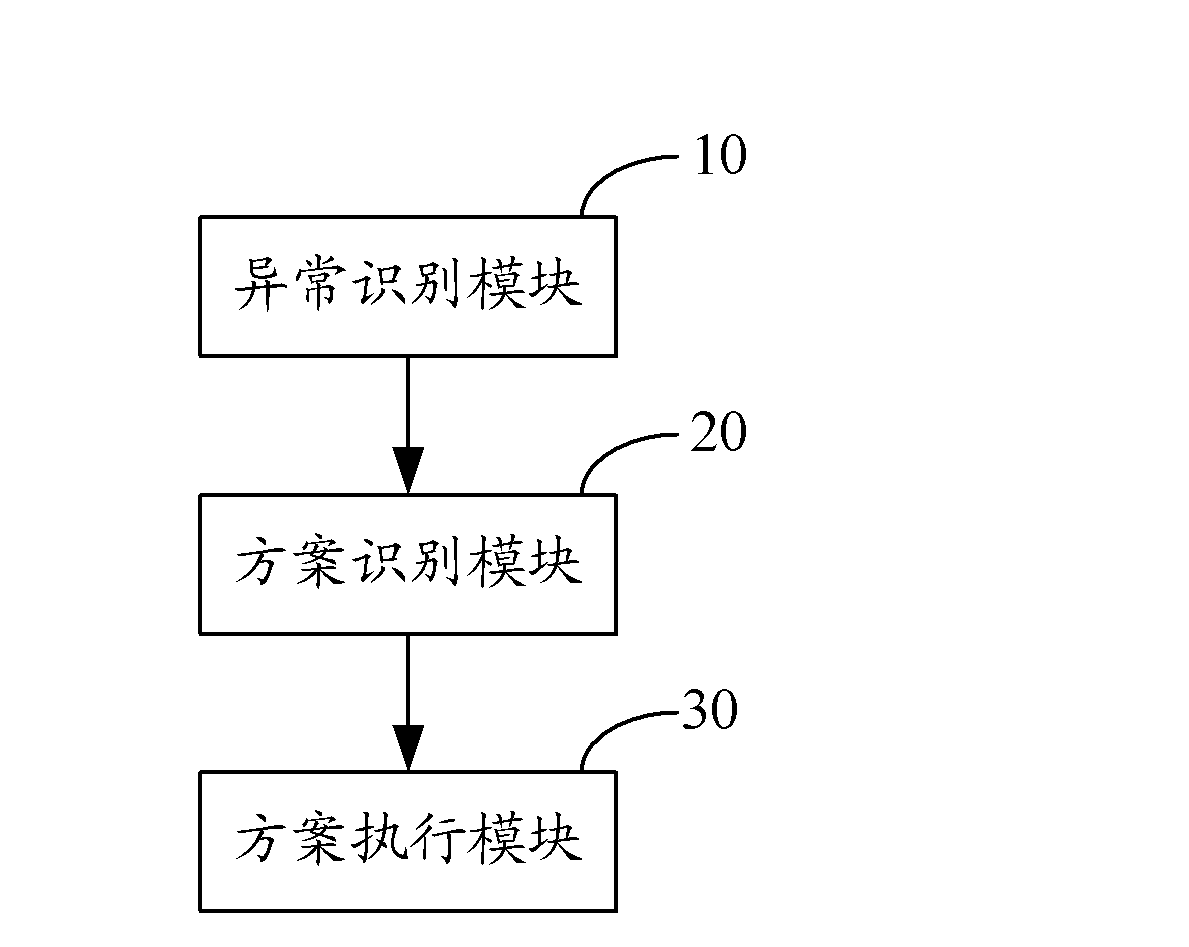

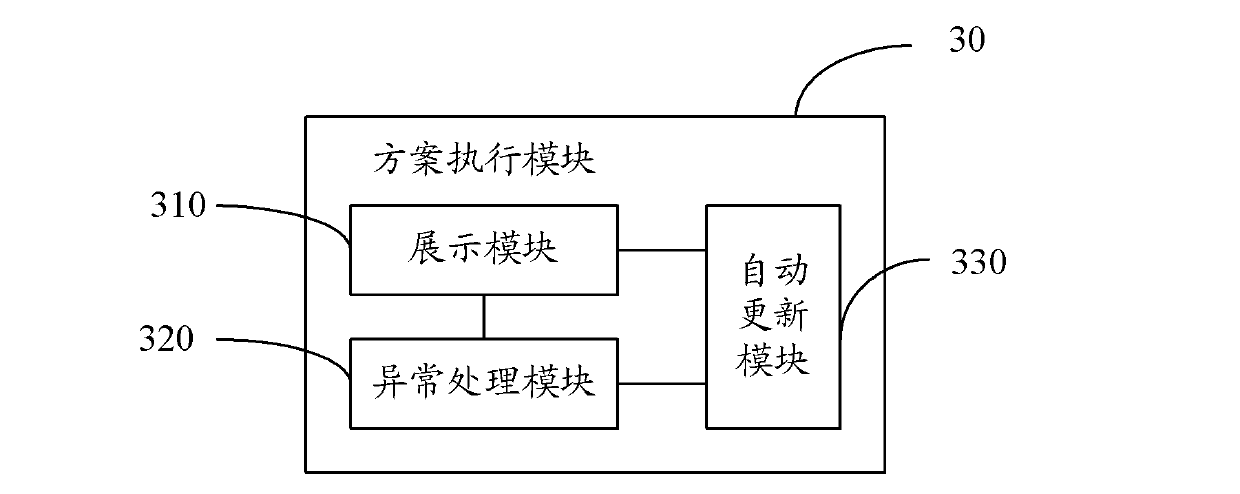

Abnormity monitoring method and abnormity monitoring device

The invention discloses an abnormity monitoring method. The method includes the following steps: monitoring abnormal key information, and recognizing an abnormality type and an abnormality grade of the abnormal key information; acquiring a preset abnormity processing scheme corresponding to the abnormity type and the abnormity grade; executing the abnormality processing scheme. By the method, abnormities can be monitored in real time, and different abnormity processing schemes can be adopted according to different types and grades for abnormity repairing, so that more flexibility is provided. In addition, the invention further provides an abnormity monitoring device.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

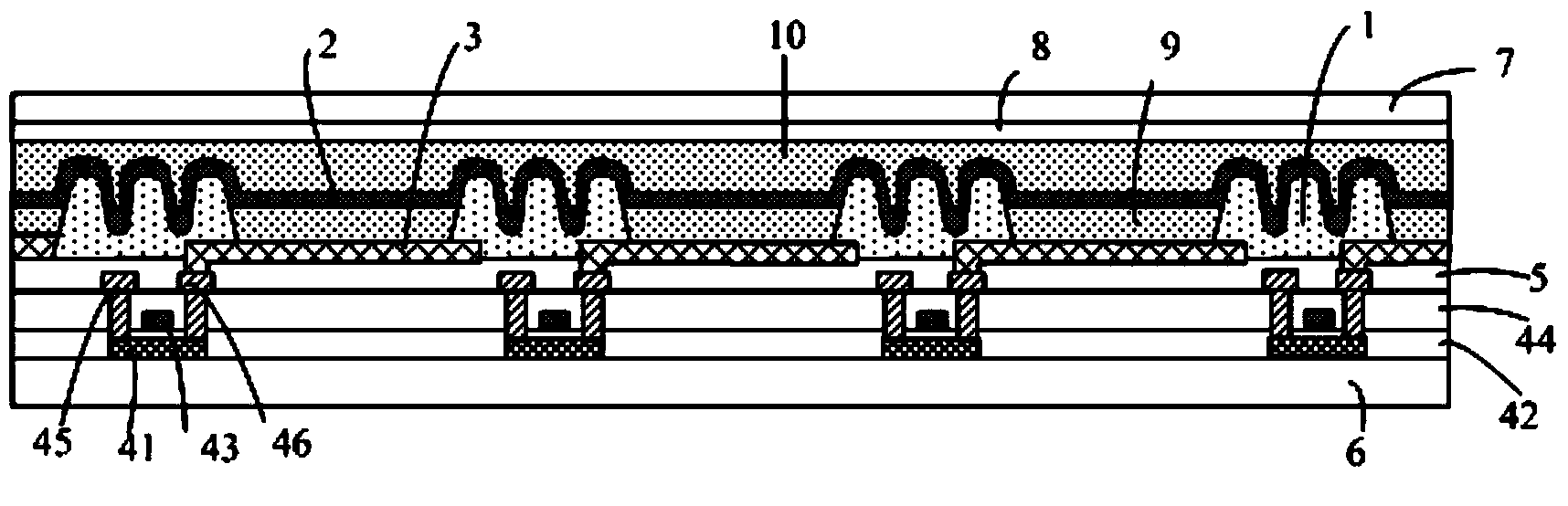

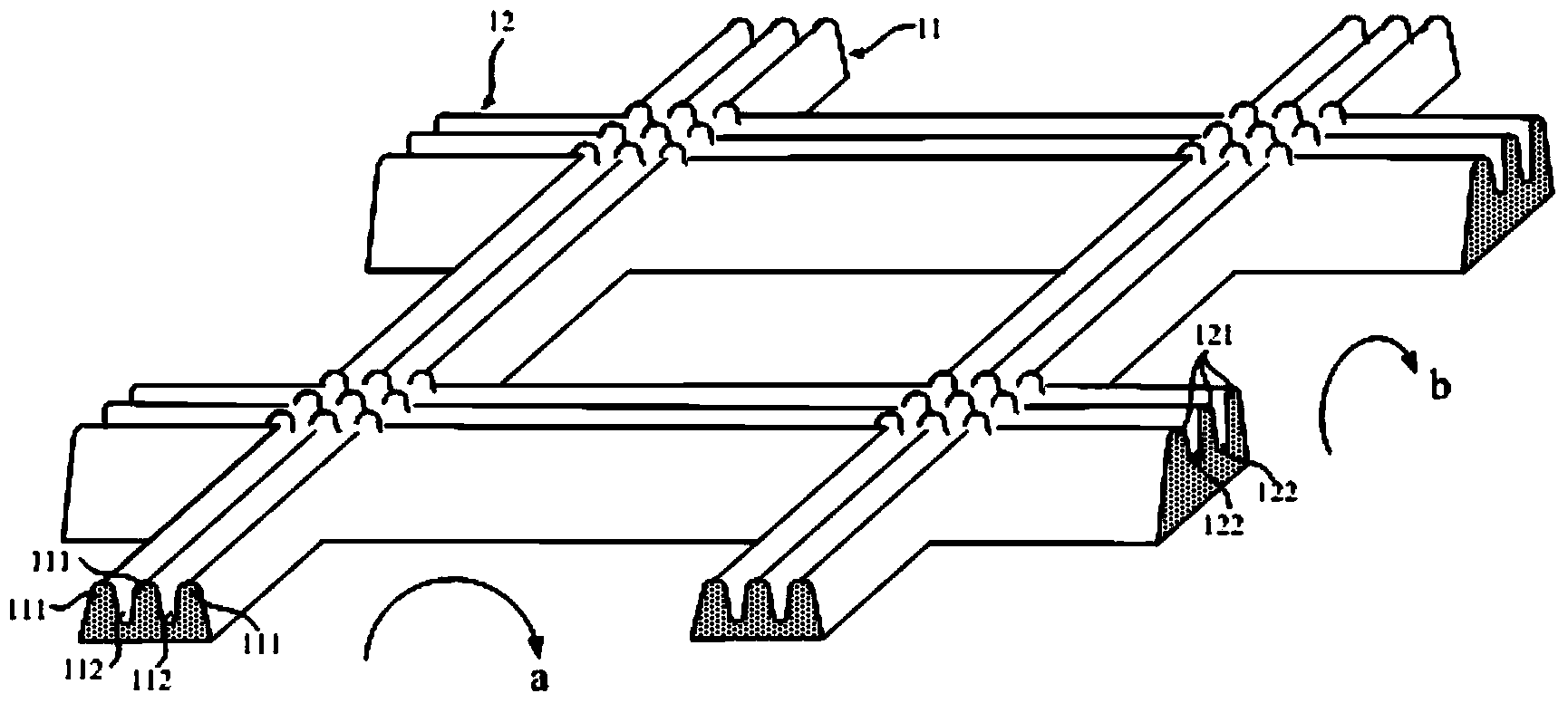

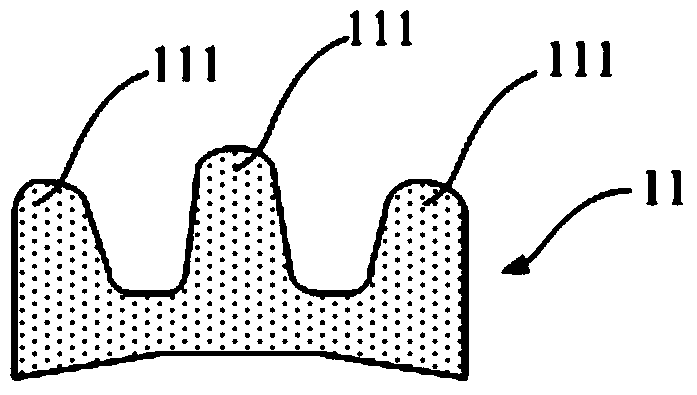

Flexible displayer and manufacturing method thereof

ActiveCN103887261AFlexibleFinal product manufactureSemiconductor/solid-state device detailsDisplay deviceEngineering

The invention relates to the technical field of flexible display, and discloses a flexible displayer and a manufacturing method thereof. The flexible displayer comprises a first flexible substrate, a pixel defining layer and a cathode. The pixel defining layer is made of resin materials. First division walls are provided with protruding structures, and first channels provided with openings deviating from the first flexible substrate and extending along the length direction of the first division wall are formed by the protruding structures. Second division walls are provided with protruding structures, and second channels provided with openings deviating from the first flexible substrate and extending in the length direction of the second division walls are formed by the protruding structures. The parts, directly facing the first division walls, of the cathode are provided with bends corresponding to the first channels, and the parts, directly facing the second division walls, of the cathode are provided with bends corresponding to the second channels. When the flexible displayer is bent along the first division walls or the second division walls, the cathode can release stress borne by the cathode, and the quality of the flexible displayer is improved.

Owner:BOE TECH GRP CO LTD

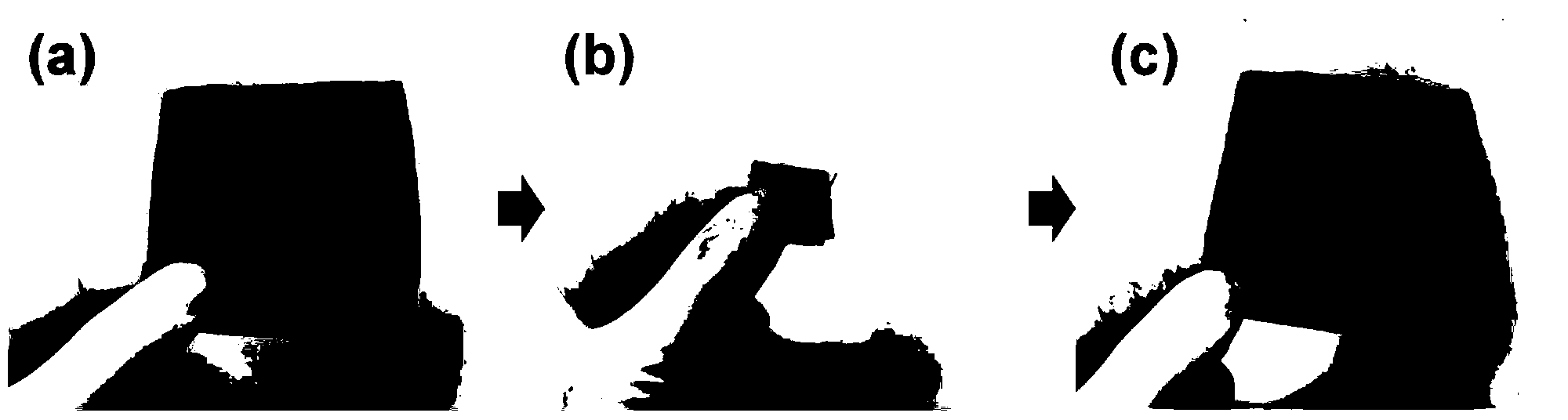

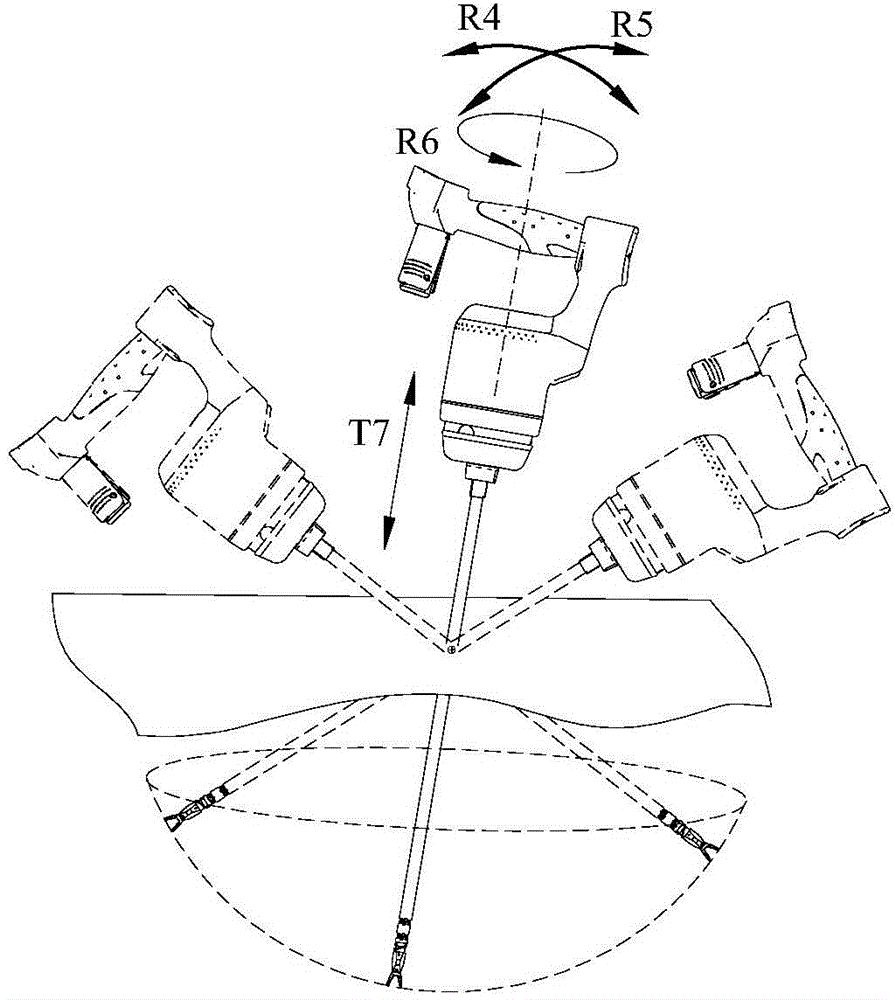

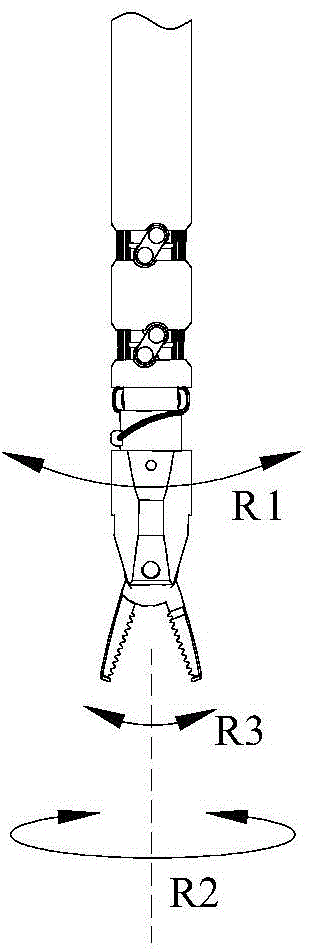

Surgery operational method by adopting intelligentized minimally invasive surgery instrument

InactiveCN104783846AFlexibleLow technical requirementsDiagnosticsSurgeryLess invasive surgeryControl signal

The invention discloses a surgery operational method by adopting an intelligentized minimally invasive surgery instrument. The method comprises the following steps that 1, the intelligentized minimally invasive surgery instrument is held in hand, and a tail-end motion joint of the instrument is made to enter into a human body for conducting the surgery operation, wherein the hand-holding operation process comprises the steps of operating a handle driving device of the instrument by hand, and then outputting a detected space multi-freedom-degree motion control signal of the hand-operated handle driving device to a driving motor; 2, according to the space multi-freedom-degree motion control signal, the driving motor drives a transmission device to move to transmit the hand operation motion to the tail-end motion joint, and the tail-end motion joint outputs space multi-freedom-degree motion. By the adoption of the intuition operation in the method, the equipment cost is low, the maintenance cost and use cost are high, the operation technical requirements for a doctor are low, and the method conforms to operational habits of the doctor.

Owner:TIANJIN SHOUZHI MEDICAL TECH CO LTD

Multi-sensor information collection analyzing system and autism children monitoring auxiliary system

InactiveCN102176222AImprove environmental adaptabilityFlexiblePsychotechnic devicesSpecial data processing applicationsArea networkPhysical medicine and rehabilitation

The invention belongs to the field of robots, and relates to a multi-sensor information collection analyzing system, a robot device which performs real-time monitor and adjuvant treatment for autism children by using the system and a control technology of the robot device. In the multi-sensor information collection analyzing system, a plurality of sensors, collectors and information output equipment transmit communication information by adopting a controller area network (CAN) fieldbus, and the distribution type information fusion technology ensures that mounting and clipping of the equipmentto be more convenient and efficient. By adopting the multi-information fusion technology, the ways for the robot to collect interactive object emotions are increased, and the affinity and interactivesuccessful rate of human-machine interaction are improved.

Owner:UNIV OF SCI & TECH BEIJING

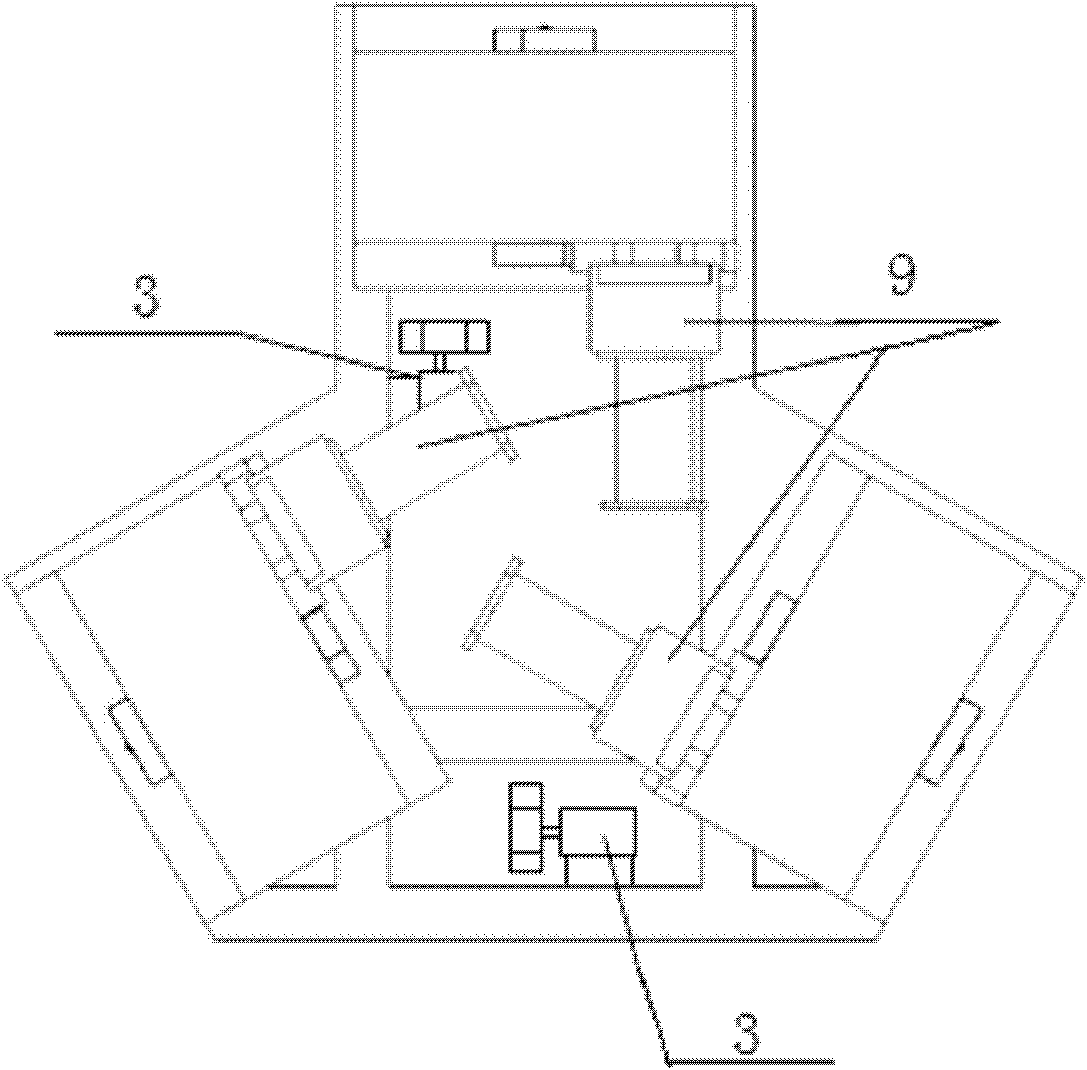

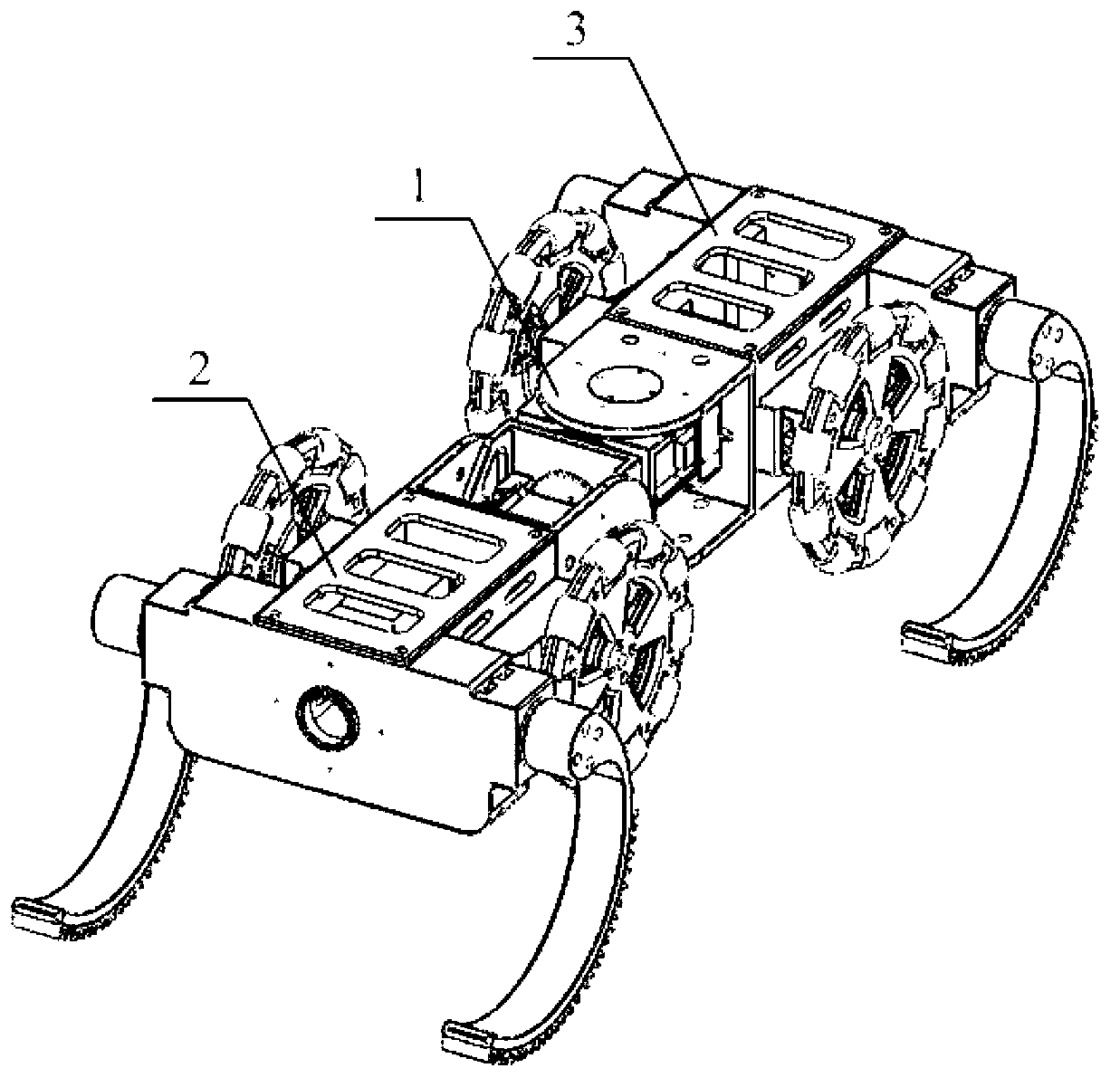

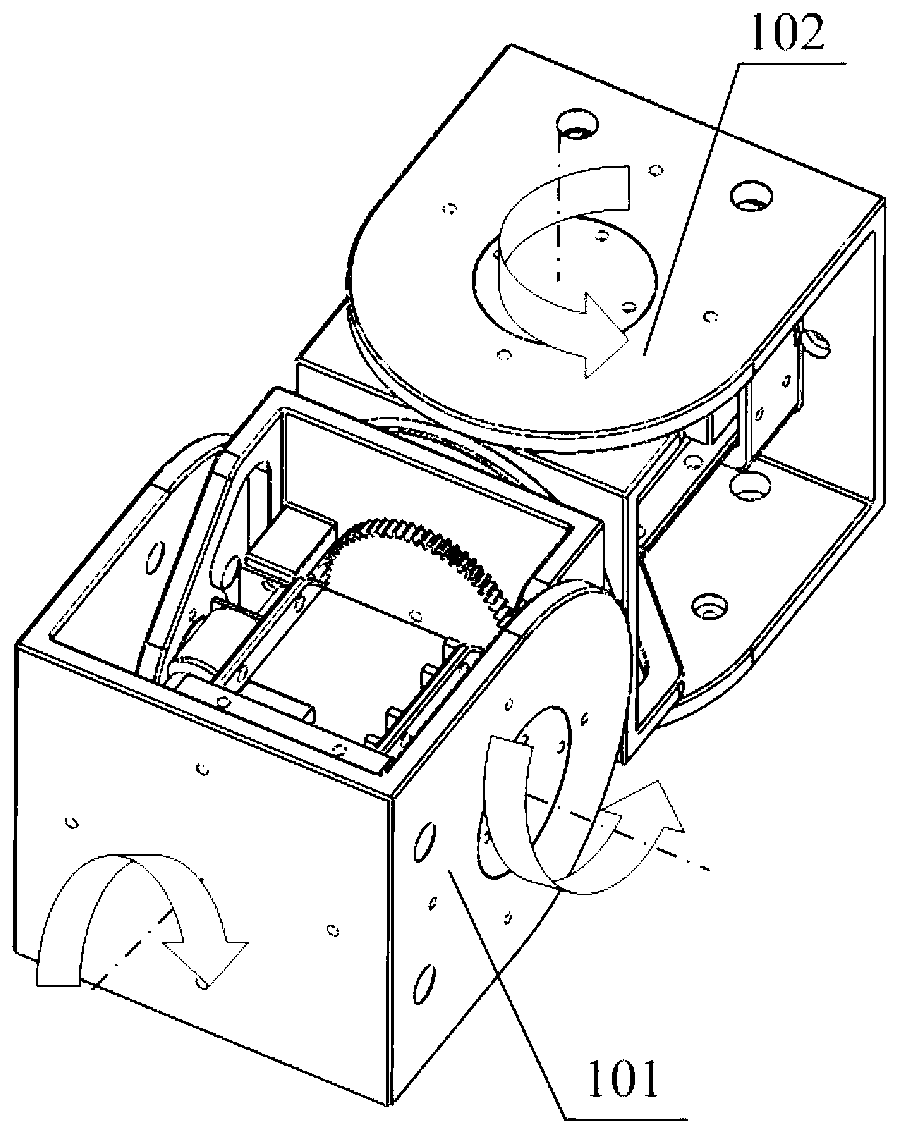

Wheel leg type mobile robot with flexible trunk

InactiveCN103241303AAvoid overall overturningFlexibleProgramme-controlled manipulatorVehiclesLeg typeGear wheel

A wheel leg type mobile robot with a flexible trunk is composed of the robot trunk, a front wheel leg device and a rear wheel leg device. The robot trunk is formed by connecting two isomorphic joint modules. Each joint module is composed an outer U-shaped frame, an inner U-shaped frame, an overturning steering gear, rotating shafts, a steering gear output disc, a direct-current motor, a direct-current motor output gear, a rotating gear, a bearing and a rotating disc. The overturning steering gear is fixed in the outer U-shaped frame and drives the inner U-shaped frame to be overturned up and down, and the direct-current motor output gear is meshed with the rotating gear to drive the rotating disc. The front wheel leg device comprises a steering gear box, steering gears, steering gear output discs, universal wheels and legs. The rear wheel leg device and the front wheel leg device are basically identical and only different in leg orientations, four steering gears and the steering gear box are fixedly connected through screws, and the universal wheels and the legs are respectively fixedly connected with steering gear rotating shafts. The wheel leg type mobile robot with the flexible trunk is simple in structure, can continuously move when overturned, and has high environment adapting capability.

Owner:SOUTHEAST UNIV

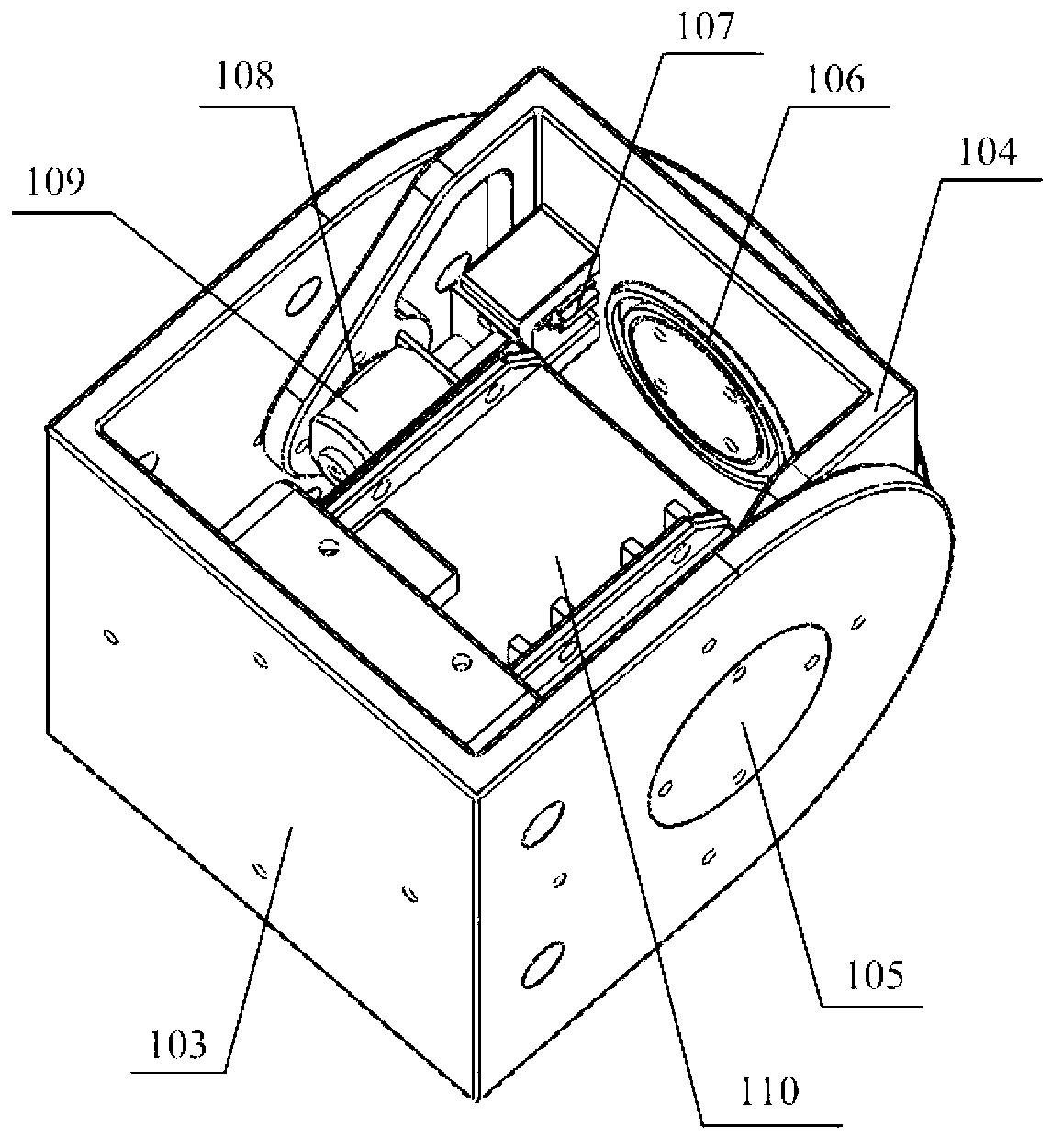

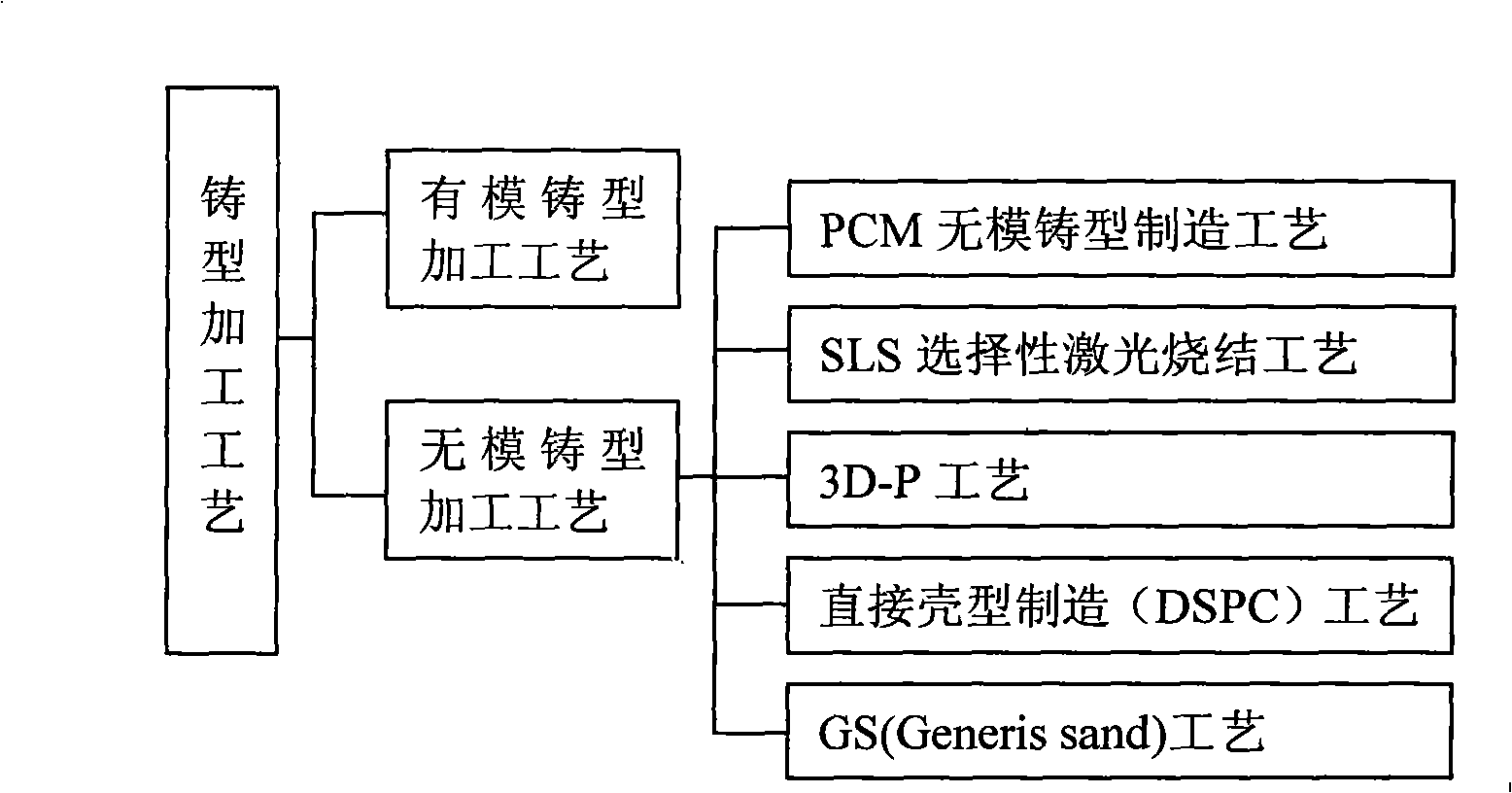

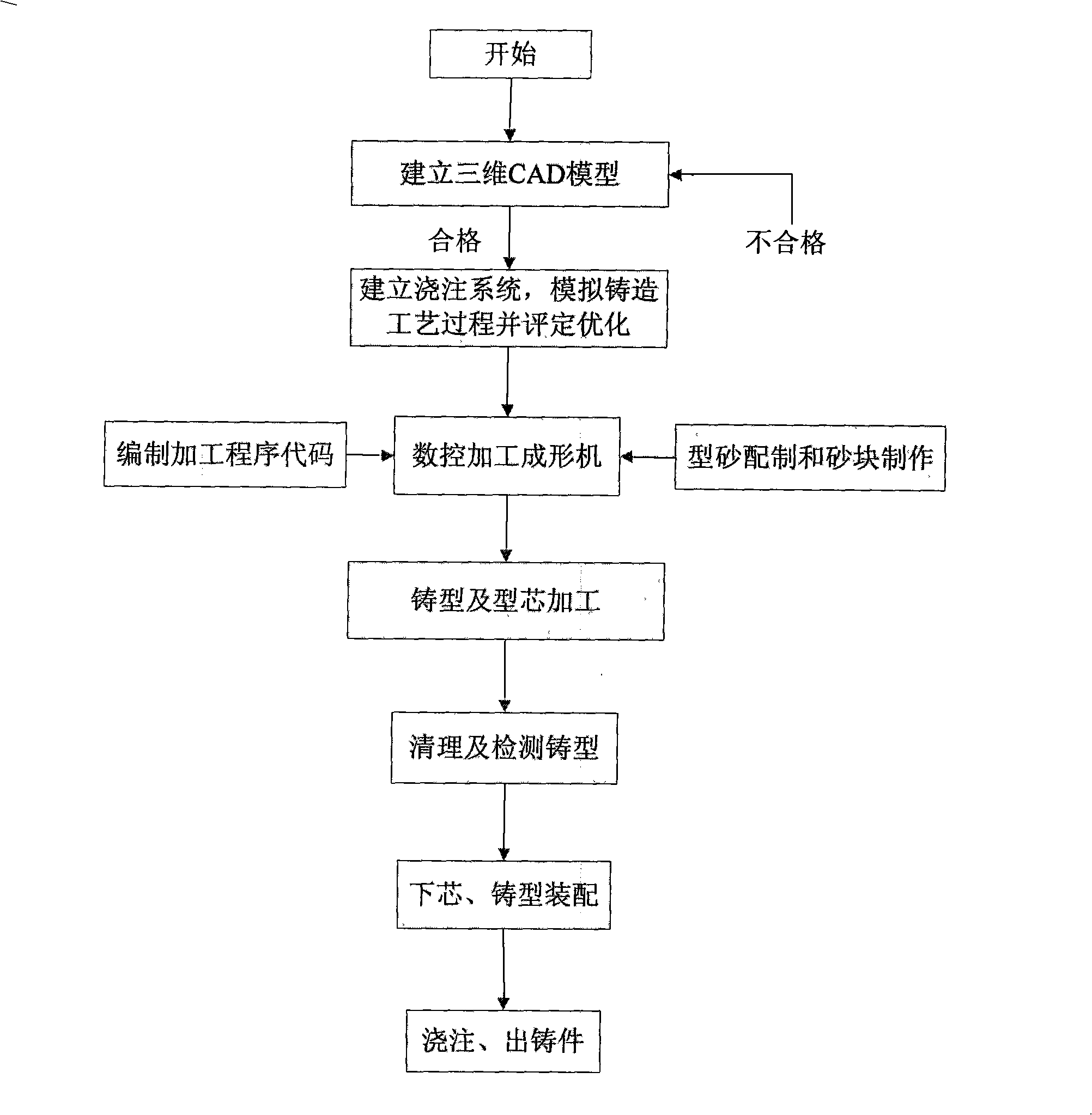

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

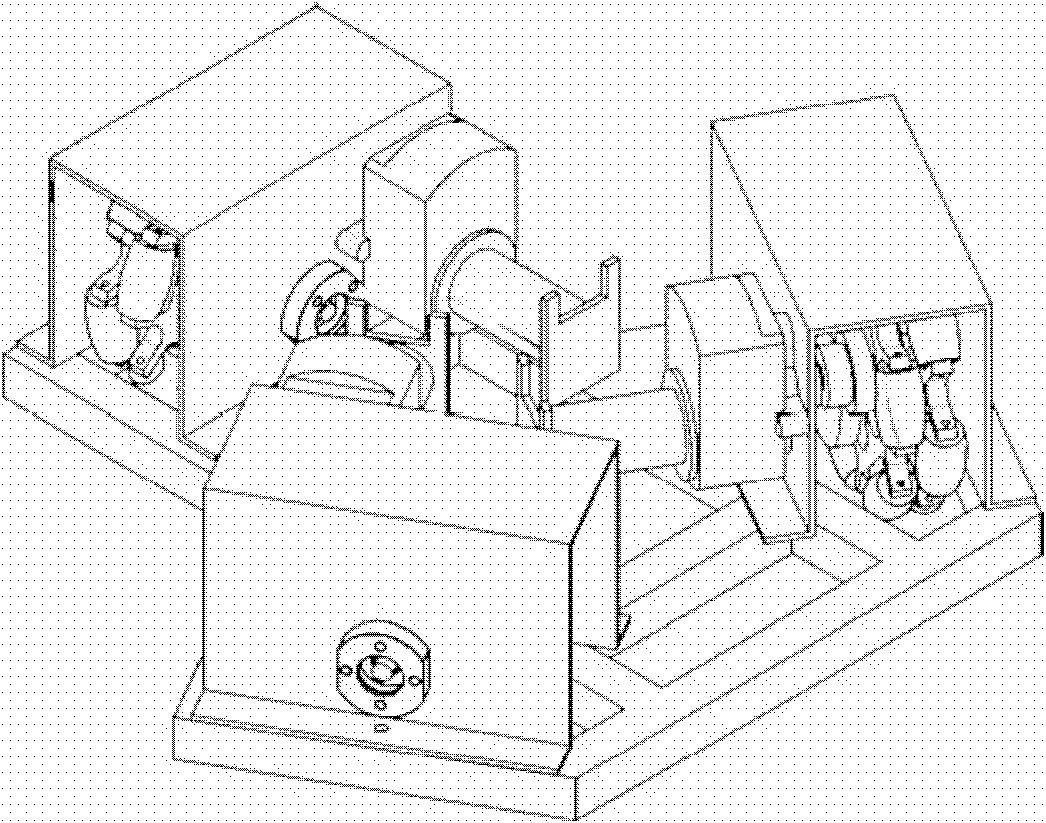

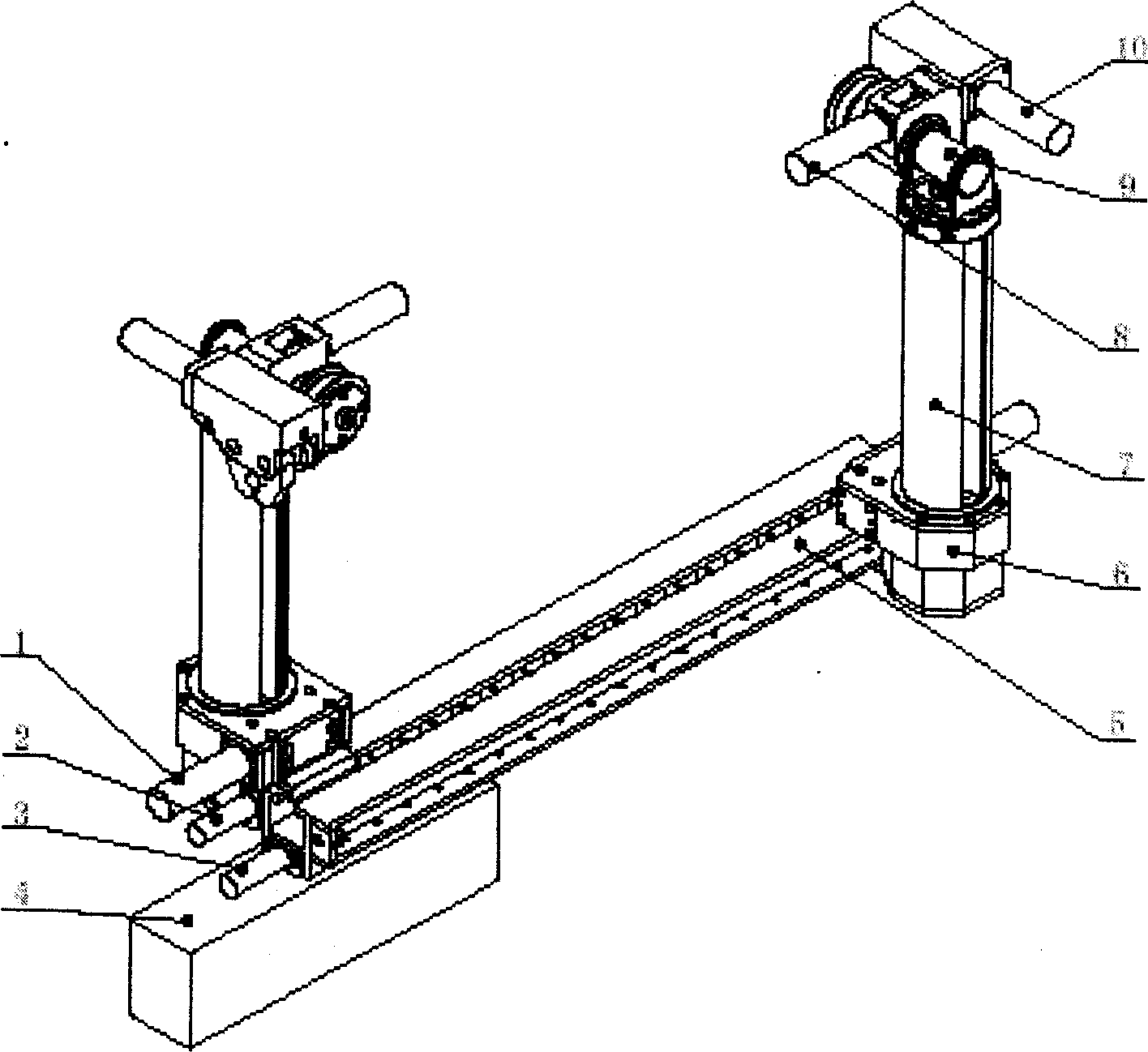

Arm lifting type high voltage transmission line automatic polling robot

InactiveCN101168252AReduce motion torqueOvercoming full automationProgramme-controlled manipulatorGripping headsGravity centerHigh pressure

Provided is an automatic robot for inspection of high air transmission lines, comprising two pairs of hand-paw mechanisms, two pairs of arm mechanisms and an engine base. The hand-paw mechanisms are composed of roller mechanisms, clamping mechanisms and wrist mechanisms and are capable of realizing that the robot slides along electric lines. In the process of obstacle navigation, the hand-paw mechanisms not only can clamp the electric lines but also can clamp a steel tower angle-bar. The arm mechanisms are connected with the hand-paw mechanisms and the engine base, being capable of realizing that the hand-paw mechanisms moves up and down relative to the engine, and driving hand-paws to rotate around a vertical shaft. Feed screw nuts arranged on the engine are capable of enabling the arms to parallel move along the length direction of an engine base guide rail. Elements of image collecting, controlling and driving are installed inside an electric equipment box and are hung under the guide rail, and the regulation of the integral center-of-gravity position of the robot can be realized through the parallel moving of the electric equipment box along the length direction of the guide rail. The invention is powerful, is convenient to realize moving, is capable of easily cross over all forms of tower frames, is adaptable with a wide range, and can actually realize the automatic inspection on a whole line.

Owner:上海求是机器人有限公司 +1

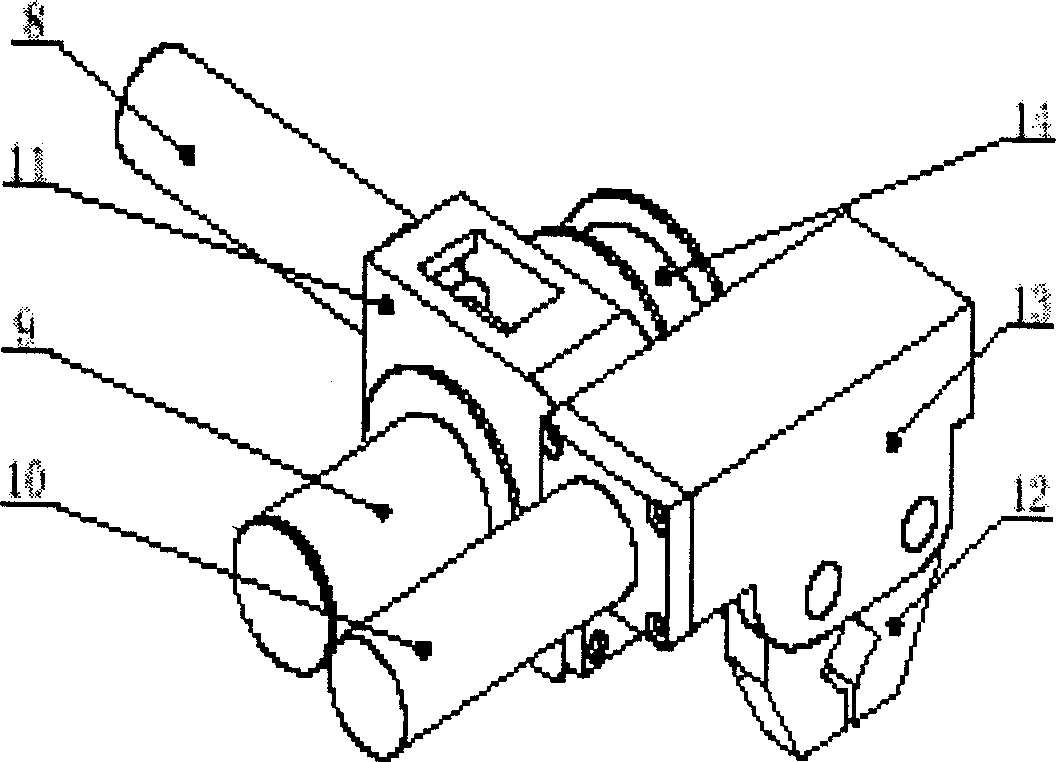

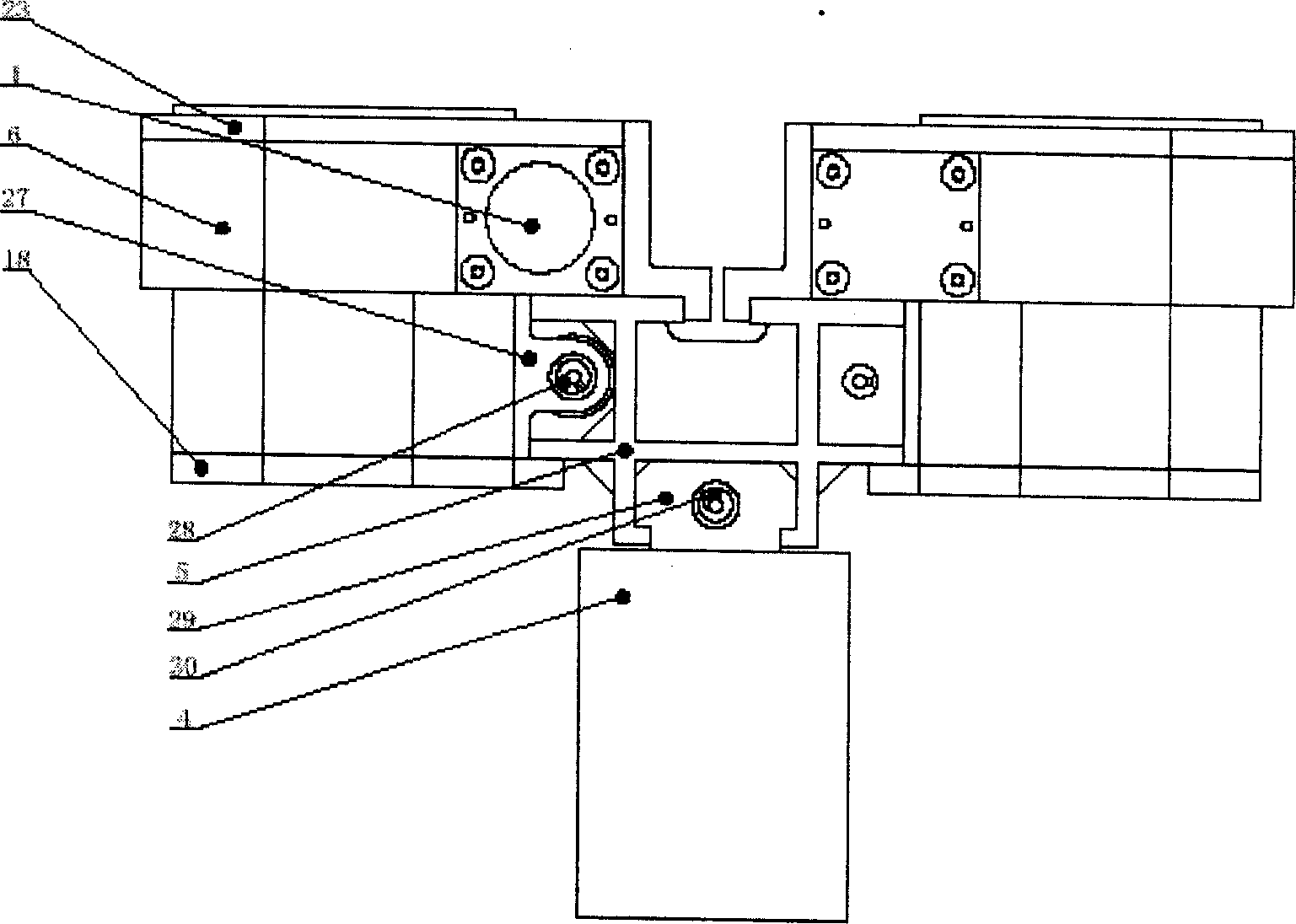

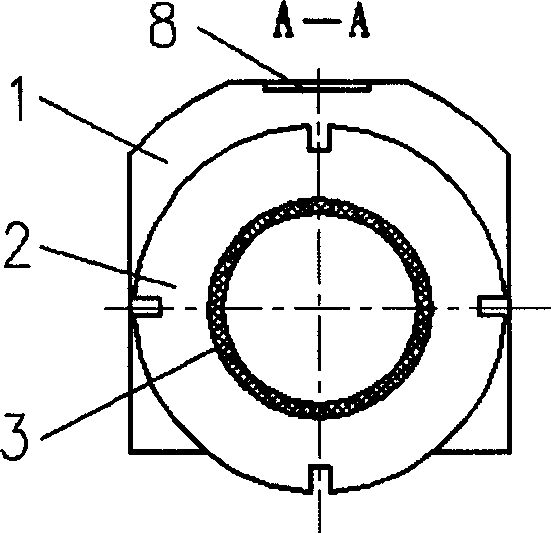

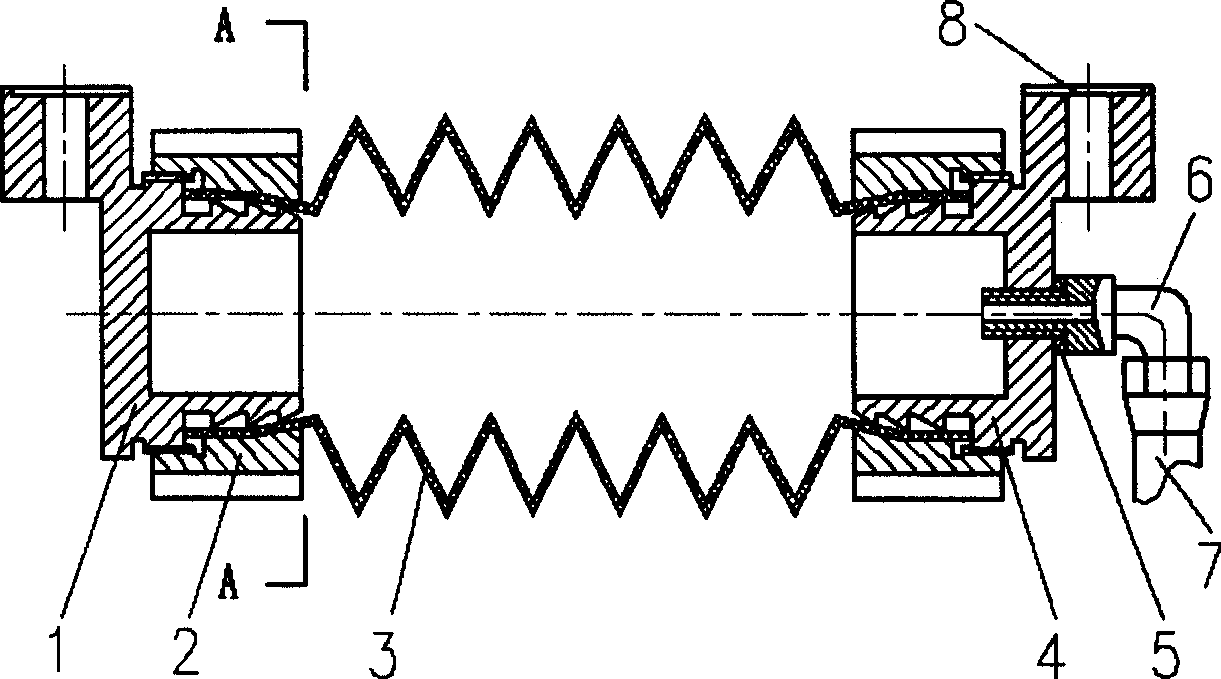

Combined muscular multi-directional bending flexible joint

The present invention relates to a combinatory muscle type flexible joint capable of bending toward several directions. It can be used as various joints of robot and artificial limb. Said flexible joint adopts the axial expasion of elastic corrugated pipe after which is forced by fluid pressure as muscle power, several artificial muscle components are formed into said flexible joint. It adopts plate spring or plate hinge as flexible joint skeleton capable of bending toward two directions, and adopts bar spring and ball universal joint or cross universal joint as flexible joint sekelton capable of bending toward several directions.

Owner:JIANGNAN UNIV

Plate spring skeleton hydrulic pneumatic flexible bending joint

A pneumatic flexible joint for robot or manipulator features that the leaf spring is used as its flexible skeleton and the corrugated shell is pneumatically expanded for providing the muscle power. Under the action of leaf spring, it can be bent but not axially extended. Its advantages are high flexibility and control accuracy, and low energy consumption.

Owner:JIANGNAN UNIV

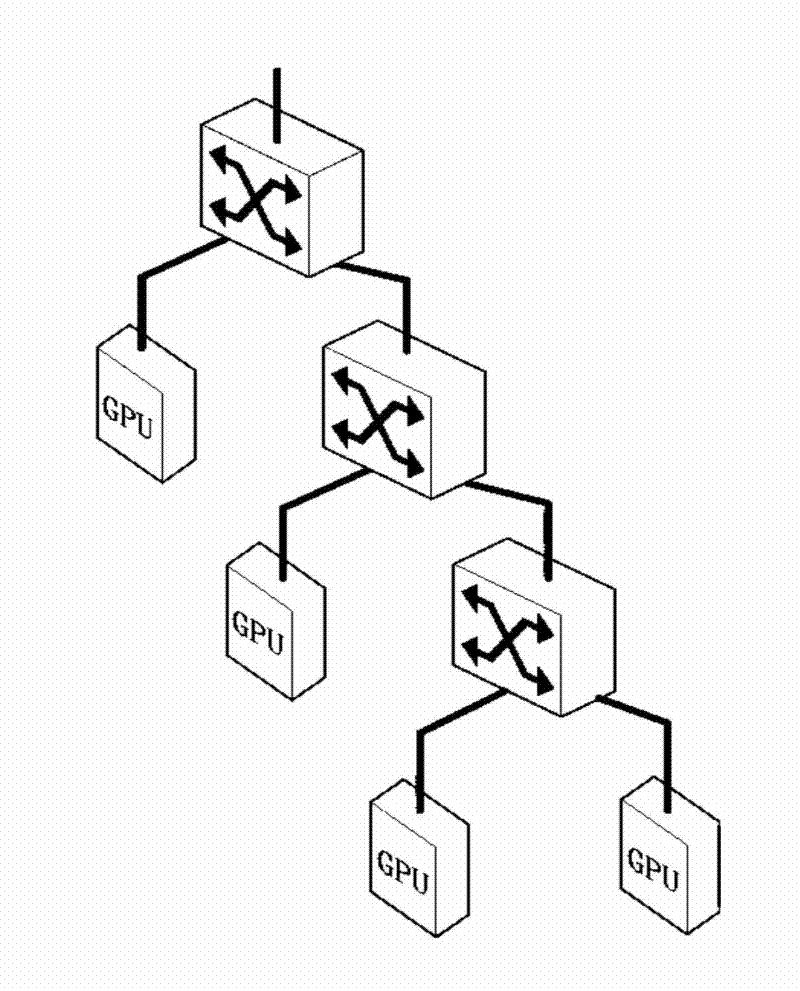

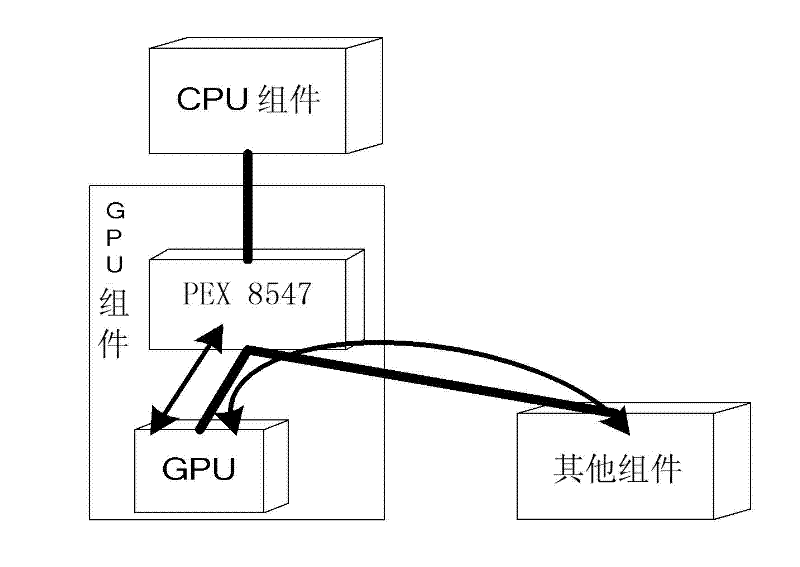

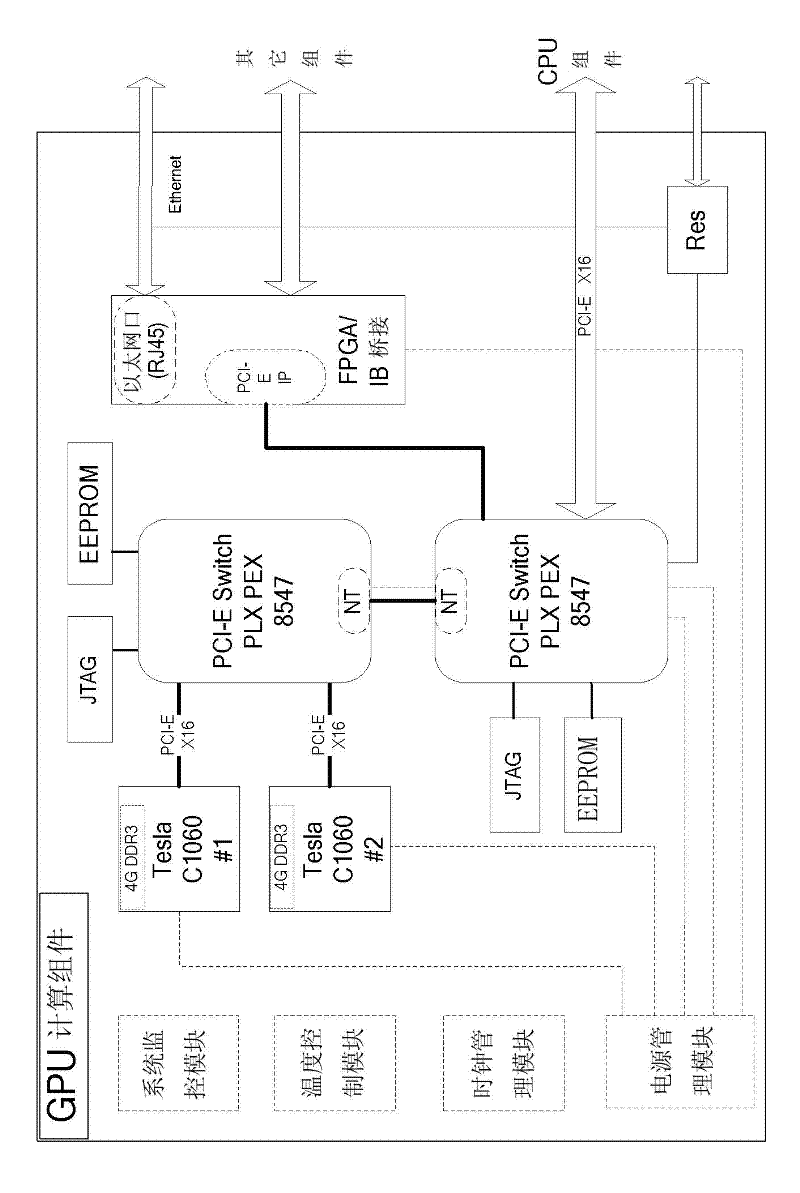

Multi-GPU (graphic processing unit) interconnection system structure in heterogeneous system

ActiveCN102541804ASolving High-Speed Interconnect ProblemsFlexibleDigital computer detailsImage data processing detailsComputer architectureMulti gpu

The invention relates to a GPU (graphic processing unit) hardware configuration management problem in a heterogeneous system in the technical field of computer communication, and in particular relates to a multi-GPU interconnection system structure in the heterogeneous system. In the multi-GPU interconnection system structure in the heterogeneous system, based on a mixed, heterogeneous and high-performance computer system which is combined by multi-core accelerators and a multi-core universal processor, multiple multi-core accelerators, as well as between multiple multi-core accelerators and the multi-core universal processor are subjected to multistage interconnection by adopting multi-port exchange chips based on PCI-E (peripheral component interconnect-express) buses, and a multistage exchange structure which is reconfigurable to an external interface is formed. The multi-GPU interconnection system structure in the heterogeneous system provided by the invention solves the high-speed interconnection problem between the multiple GPUs and between the multiple GPUs and the CPU in the traditional heterogeneous system, is a hardware system structure with flexibility and expandability, supports the expandability and interface flexibility and realizes transparent transmission and memory sharing.

Owner:THE PLA INFORMATION ENG UNIV +1

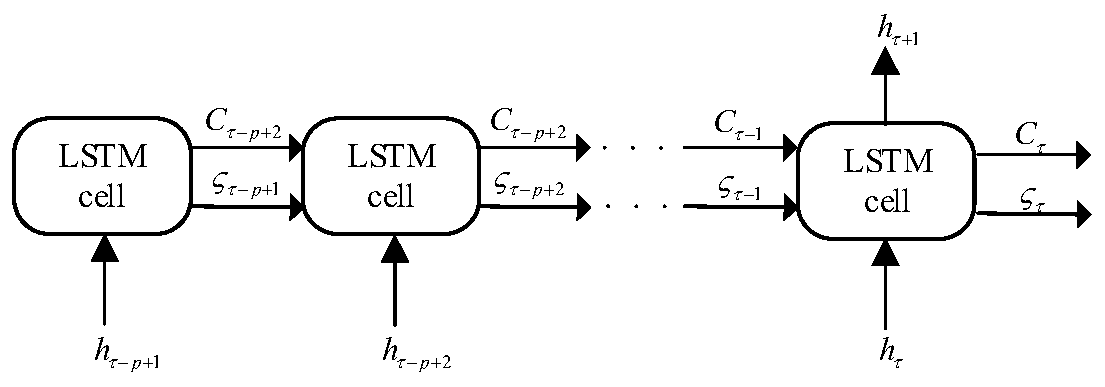

Edge computing task allocation method based on deep Monte Carlo tree search

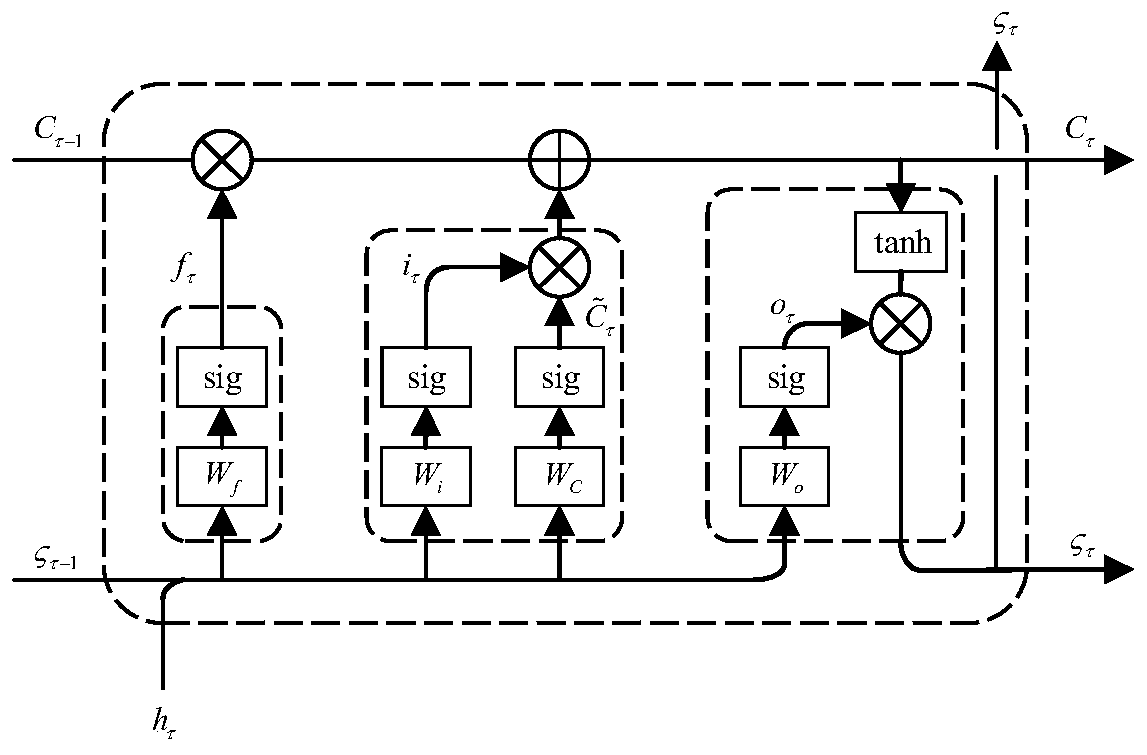

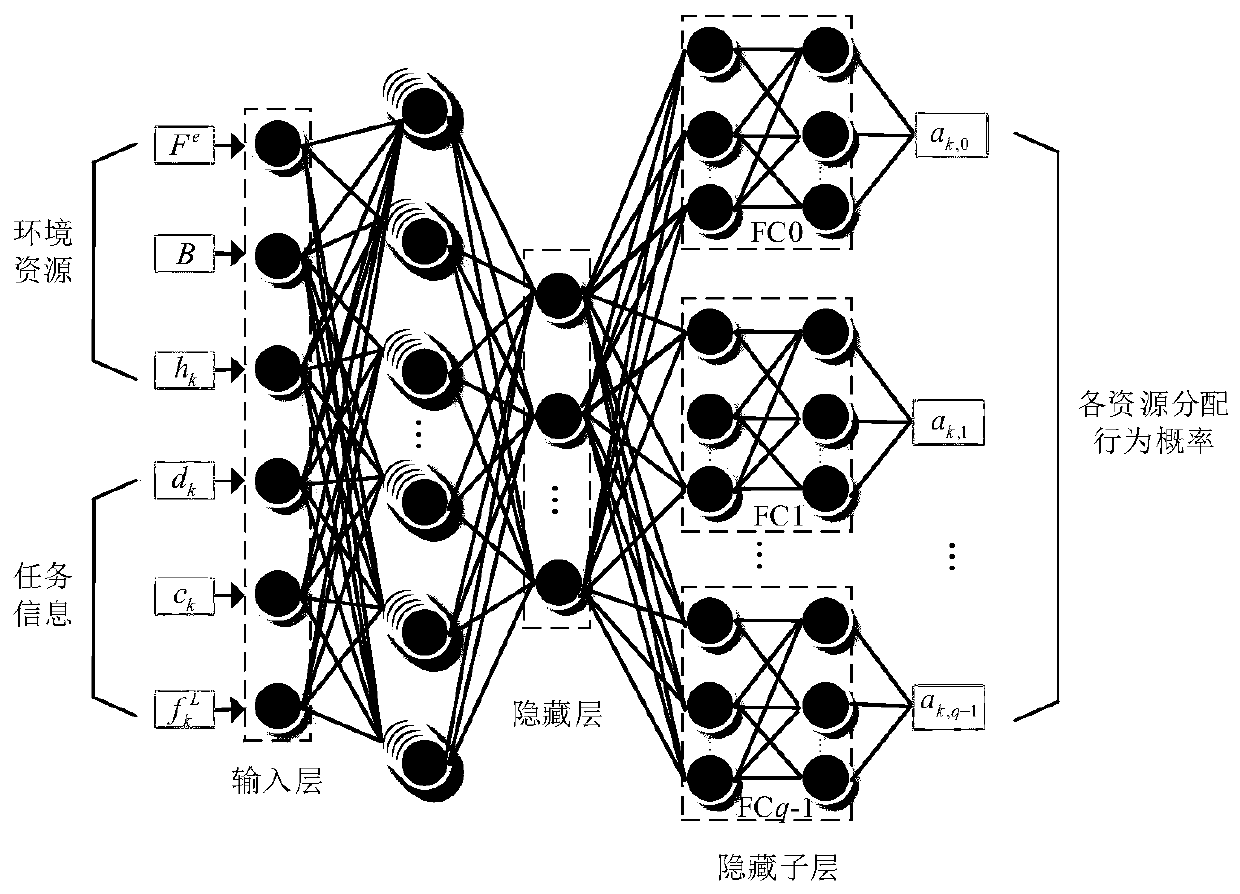

InactiveCN110427261AFewer searchesLess search performanceProgram initiation/switchingResource allocationEdge serverEdge computing

The invention discloses an edge computing task allocation method based on deep Monte Carlo tree search, and aims to support optimization of resource allocation by an edge server. And the edge server takes the state of a mobile edge computing system as input, the edge server resource scheduling module outputs an optimal resource allocation scheme through a deep reinforcement learning algorithm, andthe mobile equipment terminal unloads the task according to the optimal resource allocation scheme and executes the task together with the edge server. The deep reinforcement learning algorithm is completed by mutual cooperation of DNN, MCTS and LSTM, and compared with greedy search and DQN algorithms, the algorithm provided by the invention is greatly improved in the aspects of optimizing service time delay and optimizing service energy consumption of the mobile terminal.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

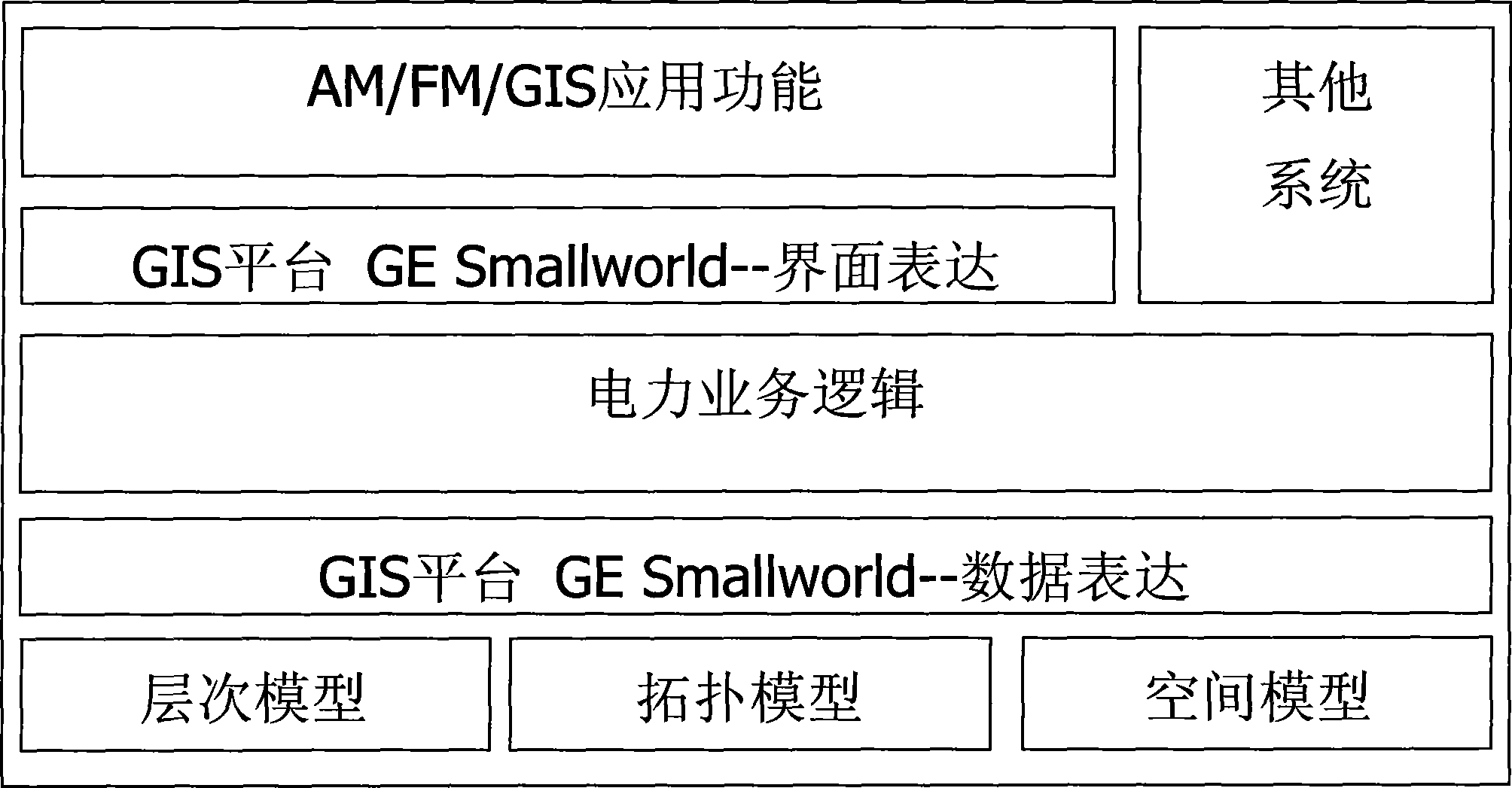

Geographical information system used for electric system

InactiveCN101483342AIncrease opennessNormativeData processing applicationsSpecial data processing applicationsHuman–machine interfaceElectric power system

The present invention relates to a geographical information system used for electrical power system, wherein the system comprises a human-computer interface module, a basic geography data module, a elementary graph operation module, a view display module, a electric network device management module, a power distribution network equipment input module, a power distribution network equipment attribute maintenance module, a electric power network topology maintenance module, a line maintenance module, a underground pipe network management module, a search statistical form module, a pole tower detailed statement management module, a network topology maintenance module, a electric network topology analysis function module, a single line figure management module, a scheduling system drawing management module, a graph input-output function module and a system administration module, wherein the human-computer interface module connects with every other module mutually. Compared with prior art, the present invention is provided with definite openness, normality, flexibility, expandability, high security and economy, and the like.

Owner:SHANGHAI TONGSHENG ENG CONSTR MANAGEMENT

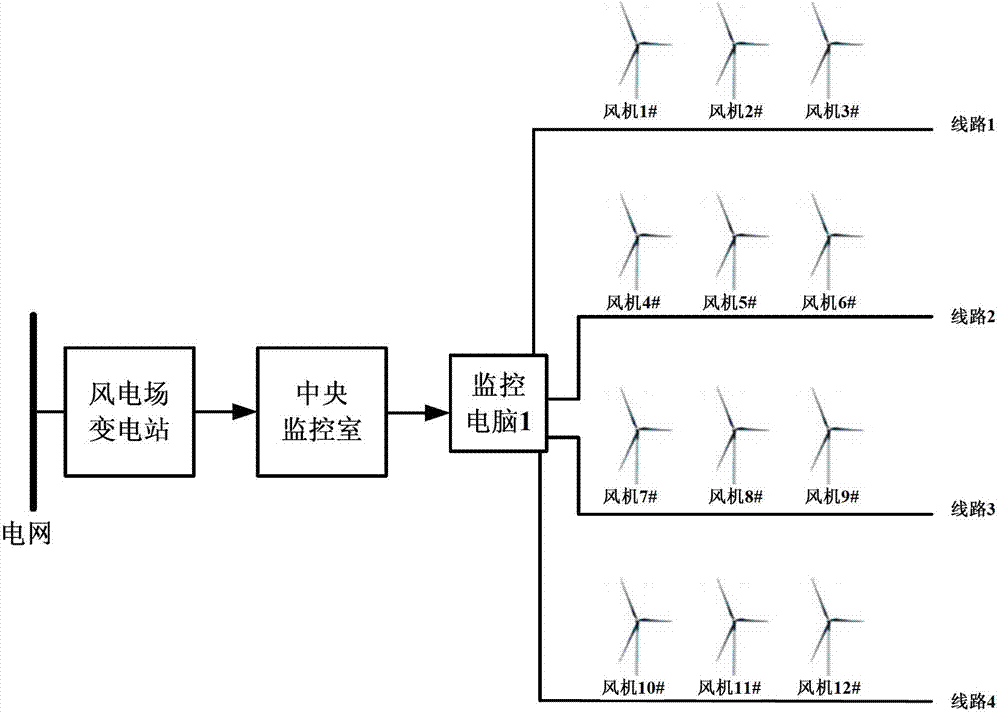

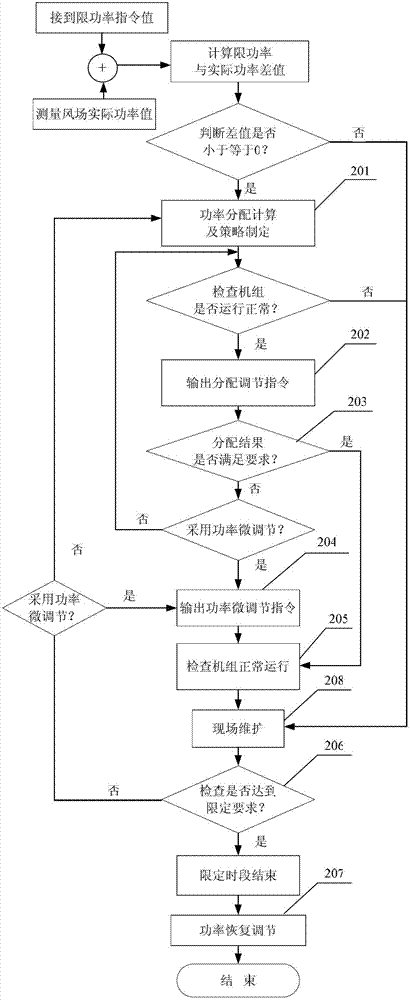

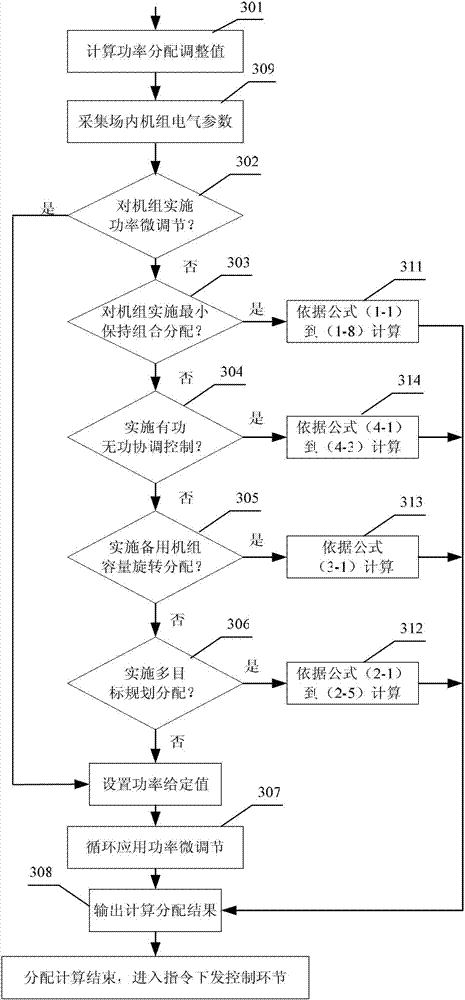

Comprehensive power distribution method for wind power plant

InactiveCN102856925ASafe and stable coordinated operationSafe and stable operationSingle network parallel feeding arrangementsWind energy generationPeaking power plantElectricity

A comprehensive power distribution method for a wind power plant includes steps of real-time data acquisition of the wind power plant, power distribution calculation, distribution adjustment instruction output and power fine adjustment implementation. Wind generation set power distribution values are calculated by means of minimum maintain set combination, multiple objective programming distribution, standby set capacity rotation and active and reactive power coordination control. Power fine adjustment refers to adjustment when a wind power plant monitoring system detects that wind generation sets fail to meet the limiting value index PLim(t) or are in over-adjustment after one-time power distribution is completed. The distribution adjustment instruction output refers to that aiming at power adjustment values obtained by calculating distribution values and the set power value in power fine adjustment, three modes including equal-proportion output, output instruction verification and power fine adjustment are adopted to send power control and adjustment instructions to a wind generation set control system. Real-time power monitoring and adjustment of each set are realized by the aid of the wind power plant monitoring system by judging the current practical operating states of the wind generation sets.

Owner:CORONA WIND EQUIP BEIJING CO LTD

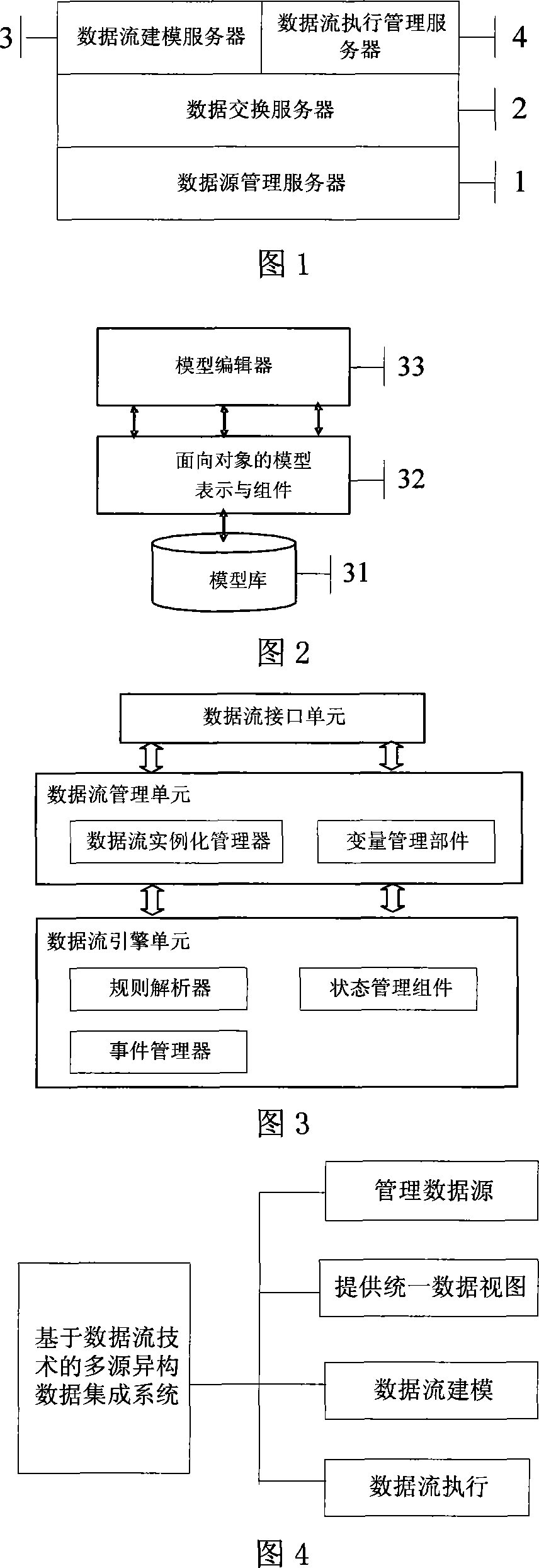

Data stream technique based multi-source heterogeneous data integrated system

InactiveCN101083656AAccurate and efficient dynamic exchange integrationFlexibleData switching networksIntegrated systemsData shipping

The system includes data source management server (DSMS1), data interchange server (DIS), data stream modeling server (DSMS2), and data stream execution and management server (DSEMS). DSMS1 provides interface for outer isomeric data source to realize registration of data source, and transfer the collected data to DIS. DIS manages local mode and global mode as well as stores mapping rules between them, and realizes mapping from local mode to global mode for inputted data. Based on application types ground on global unified view provided by DIS, DSMS2 defines procedure of data stream, generates model of data stream. Connecting outer application system, DSEMS takes charge of starting up execution of data stream, and returns result of flow of data stream to outer application system. Advantages of the invention are: legible modules, as well as dynamic, universal, and flexible features.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com