Arm lifting type high voltage transmission line automatic polling robot

An automatic inspection and transmission line technology, applied in the field of robots, can solve the problems of difficulty in inspection of transmission lines, high cost and danger, and high labor intensity, and achieves improved quality and scientific management technology level, easy obstacle crossing, and operation. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

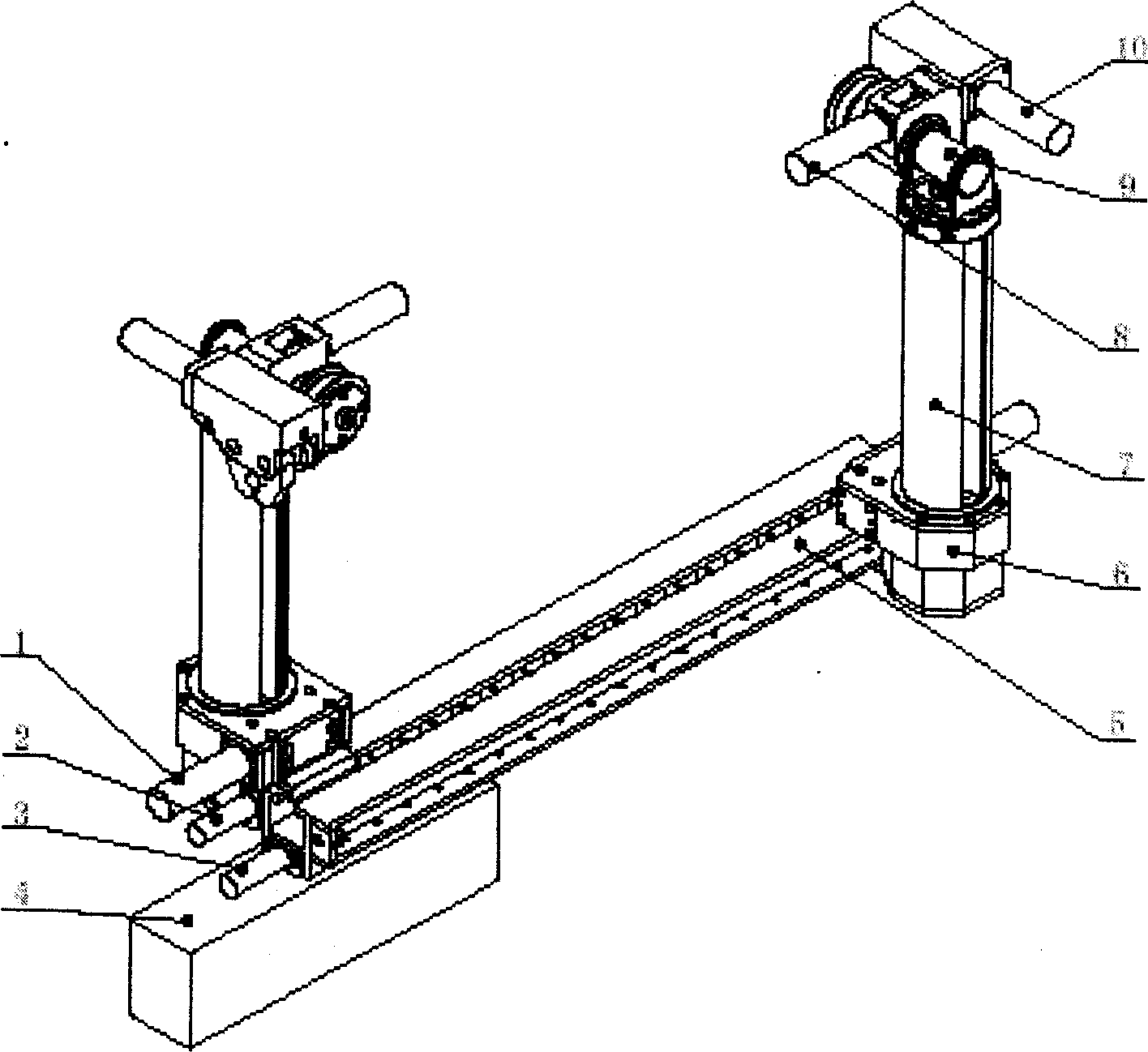

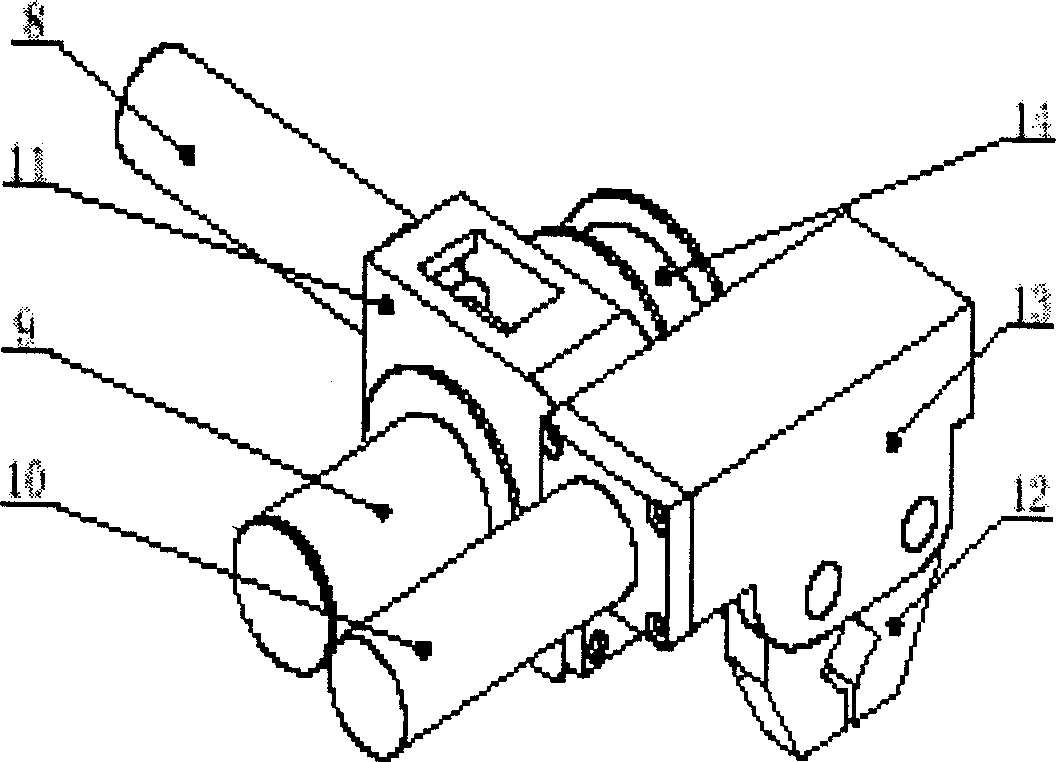

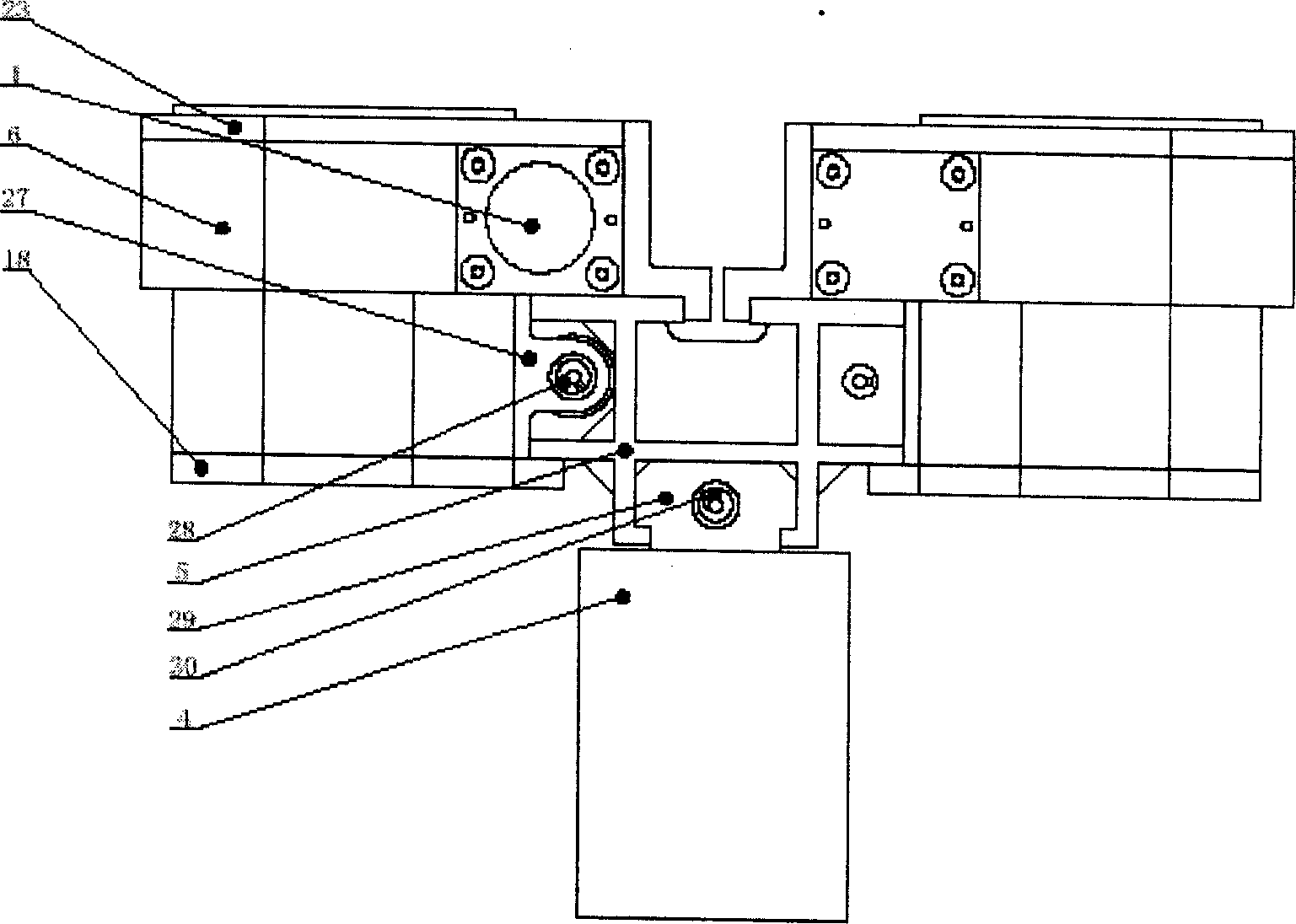

[0013] With reference to accompanying drawing 1-5, the embodiment that illustrates the structure of automatic inspection robot of arm lifting type high-voltage transmission line is as follows:

[0014] An arm lifting type automatic inspection robot for high-altitude power transmission lines includes two sets of claw mechanisms (FIG. 2), two sets of arm mechanisms 7, a machine base 5 and an electrical box 4. The claw mechanism can realize the sliding of the robot along the transmission line, and can not only clamp the wire but also clamp the angle steel of the iron tower when crossing obstacles. The arm mechanism 7 is connected with the claw mechanism and the machine base, which can realize the lifting of the claw mechanism relative to the machine base, and can drive the claw to rotate around the vertical axis. The screw mandrel 28 nut 27 on the support 5 can make the arm move in parallel along the length direction of the guide rail of the support. The image acquisition, contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com