Unmanned automatic gear shifting device and method for crawler running equipment

An automatic shifting and unmanned driving technology, which is applied in the direction of transmission control, mechanical equipment, and components with teeth, can solve the problems of large motion torque, uncompact clutch structure, and error-prone, so as to improve efficiency and accuracy rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

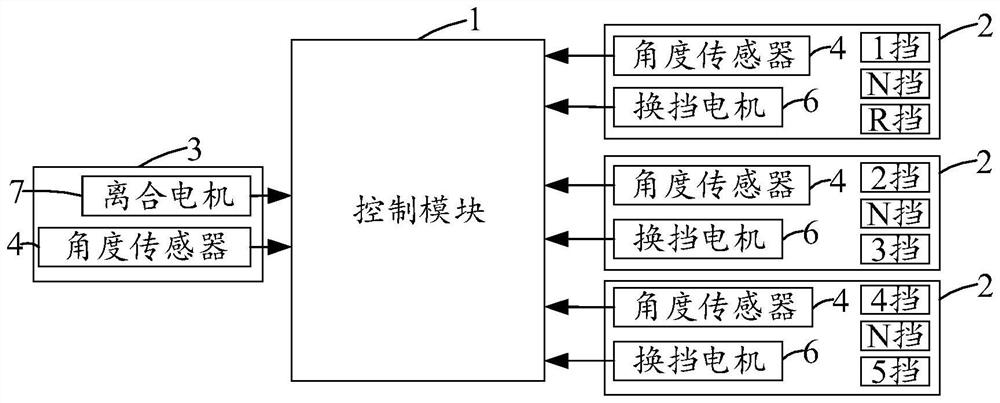

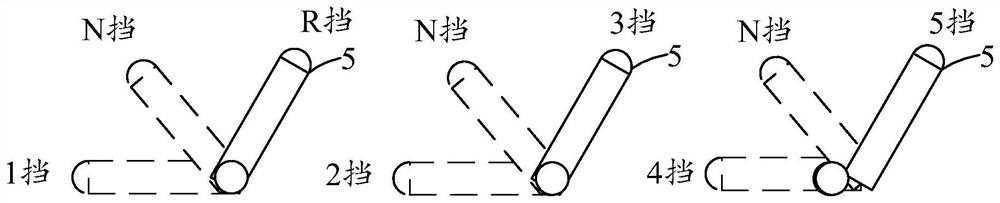

[0065] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is:

[0066] An unmanned automatic shifting device for crawler driving equipment, such as figure 1 As shown, it includes a control module 1 , an angle sensor 4 , an automatic clutch actuator 3 and at least two automatic shift devices 2 . Wherein, each automatic shifting device 2 is used for correspondingly controlling different gears of the crawler-tracked traveling equipment except the neutral gear. All automatic shifting devices 2 are provided with a neutral gear and are used to control the crawler traveling equipment to be in a neutral gear when all automatic shifting devices 2 are in neutral gear. Each automatic shifting device 2 includes a shifting motor 6 and a shifting swing arm 5 . The control module 1 is connected with the shift motor 6 and the angle sensor 4 respectively, the movable end of the shift motor 6 is connected with the shift arm 5 and is used to drive the shift arm 5 ...

Embodiment 2

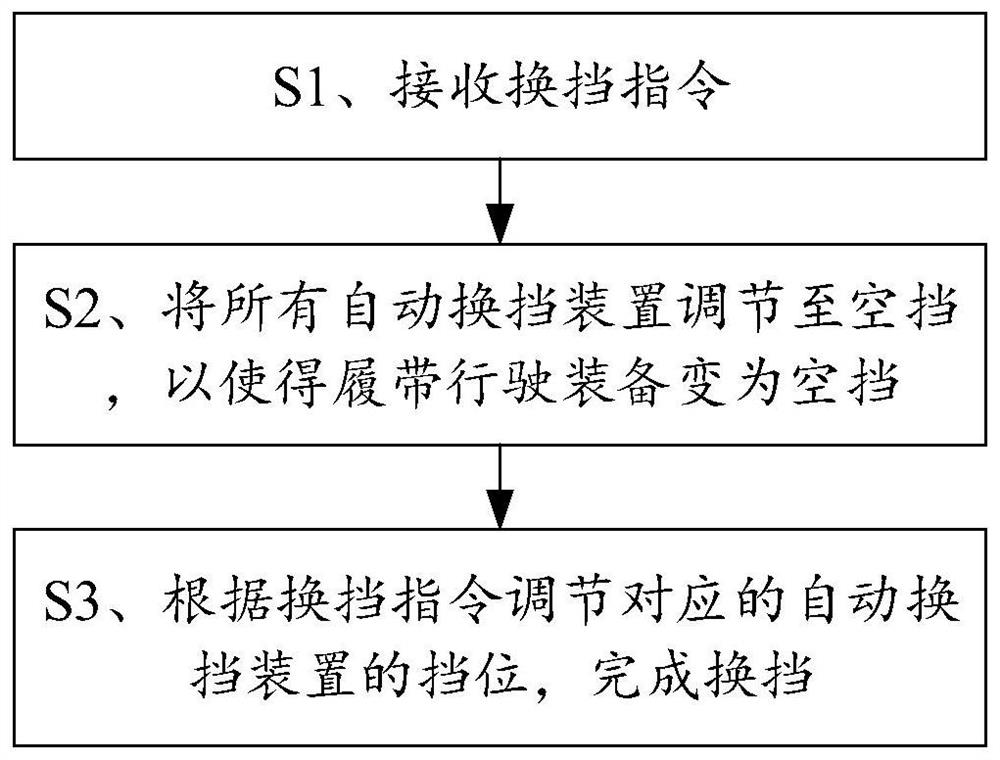

[0069] Please refer to image 3 , the second embodiment of the present invention is:

[0070] An unmanned automatic shifting method for crawler driving equipment, on the basis of the first embodiment above, such as image 3 shown, including the following steps:

[0071] S0, judging whether the self-learning instruction is received, if so, recording the measurement values of the corresponding angle sensors 4 when the shift arm 5 on each automatic shifting device 2 is in different gear positions, as a preset shift value group; Record the measurement values of the corresponding angle sensor 4 when the clutch motor 7 is at the clutch separation position, the clutch separation critical position and the clutch connection position, respectively record as the clutch separation value, the clutch separation critical value and the clutch connection value; otherwise judge again. In this embodiment, the device needs to carry out a self-learning process when it is enabled, manually pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com