Patents

Literature

12994 results about "Electrical wiring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical wiring is an electrical installation of cabling and associated devices such as switches, distribution boards, sockets, and light fittings in a structure. Wiring is subject to safety standards for design and installation. Allowable wire and cable types and sizes are specified according to the circuit operating voltage and electric current capability, with further restrictions on the environmental conditions, such as ambient temperature range, moisture levels, and exposure to sunlight and chemicals.

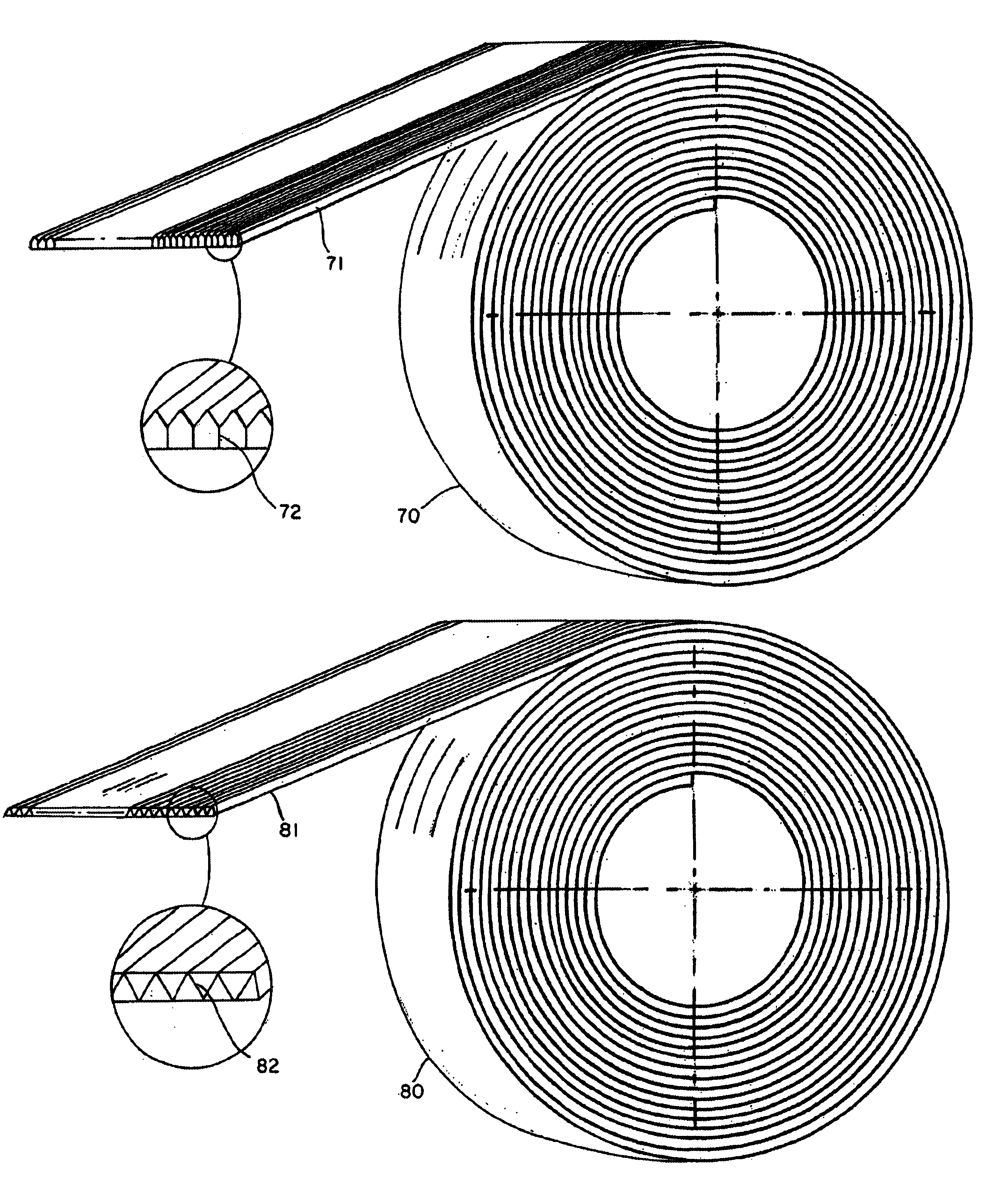

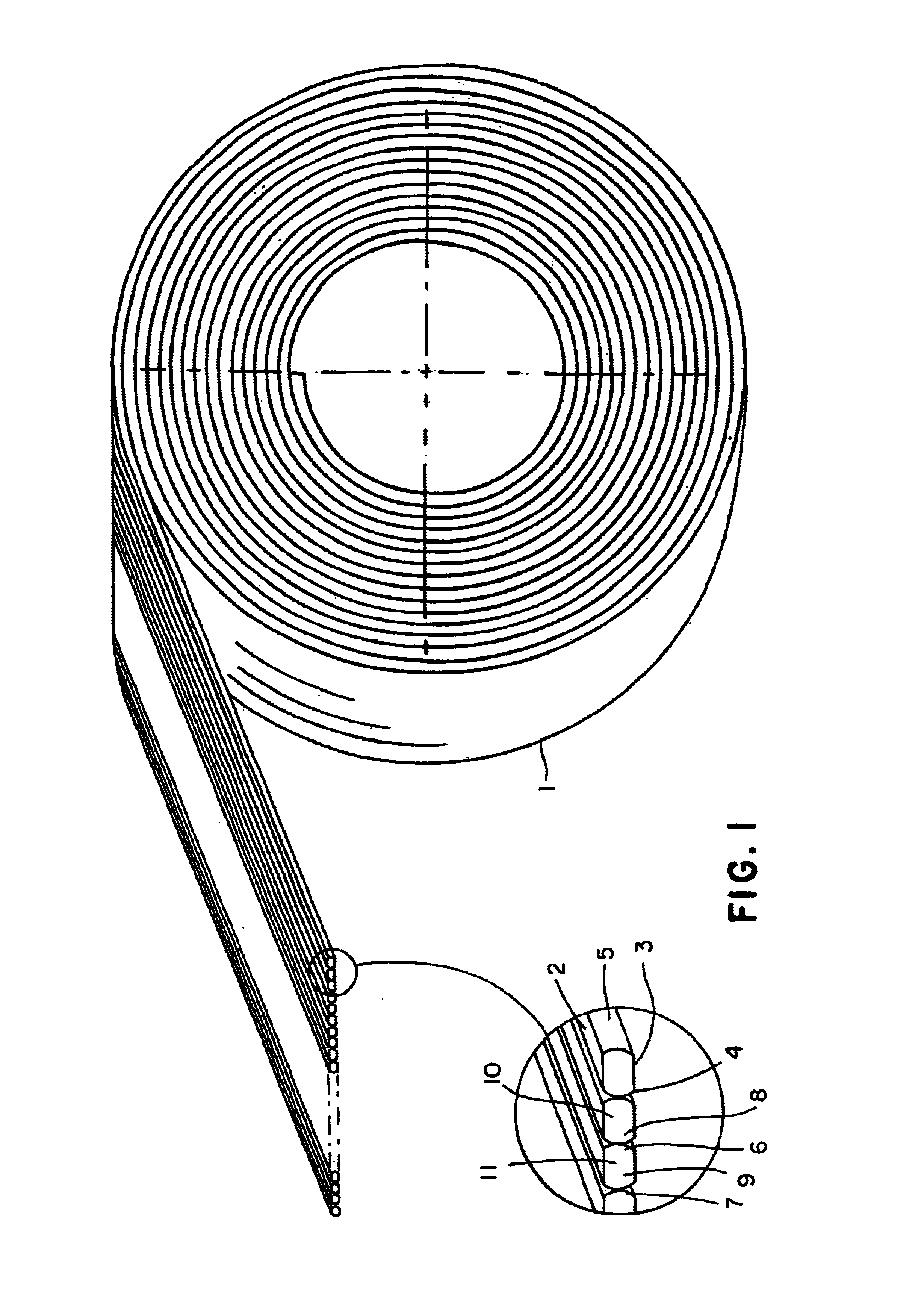

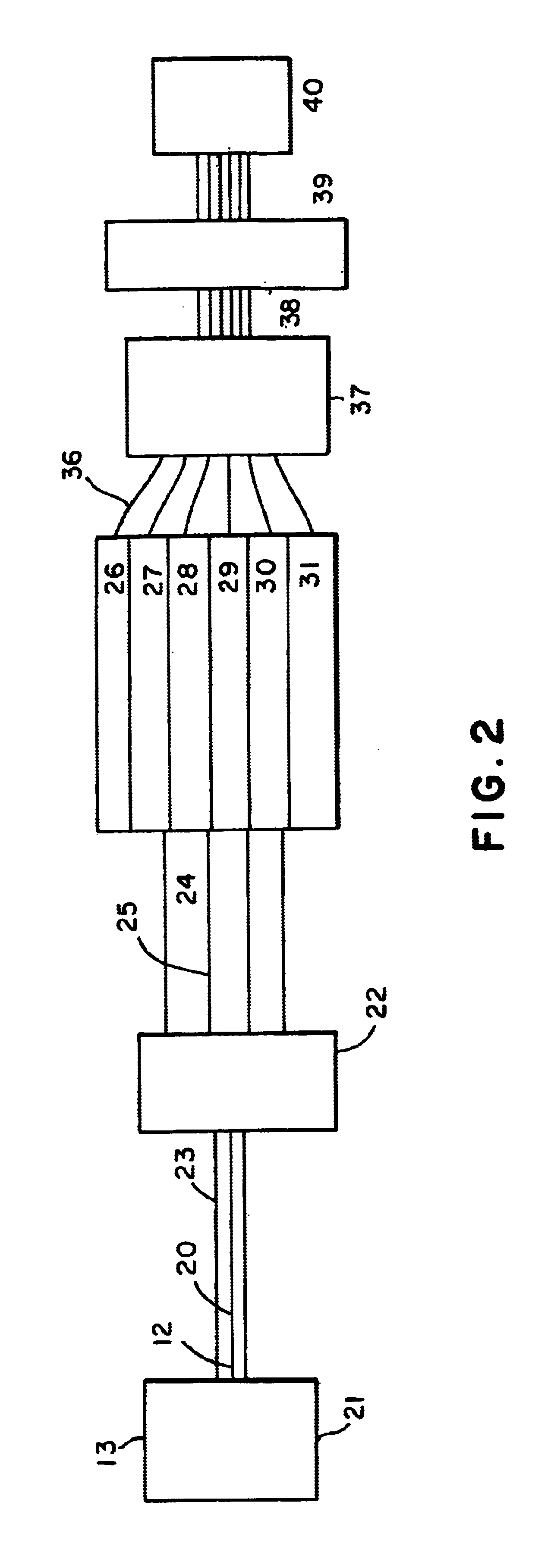

Method of forming a wire package

A method for making a wire package for use as staples or brads is recited as forming a plurality of round wires, forming a plurality of flattened bonding sides on each wire to prepare even bonding surfaces on each wire and bonding each wire to an adjacent wire by adhering the surfaces of each wire. Each staple includes two or more flat surfaces to improve the bonding strength of each staple. A package of diverging staples or brads are formed using the flat bonding surfaces

Owner:LIAO CHASE

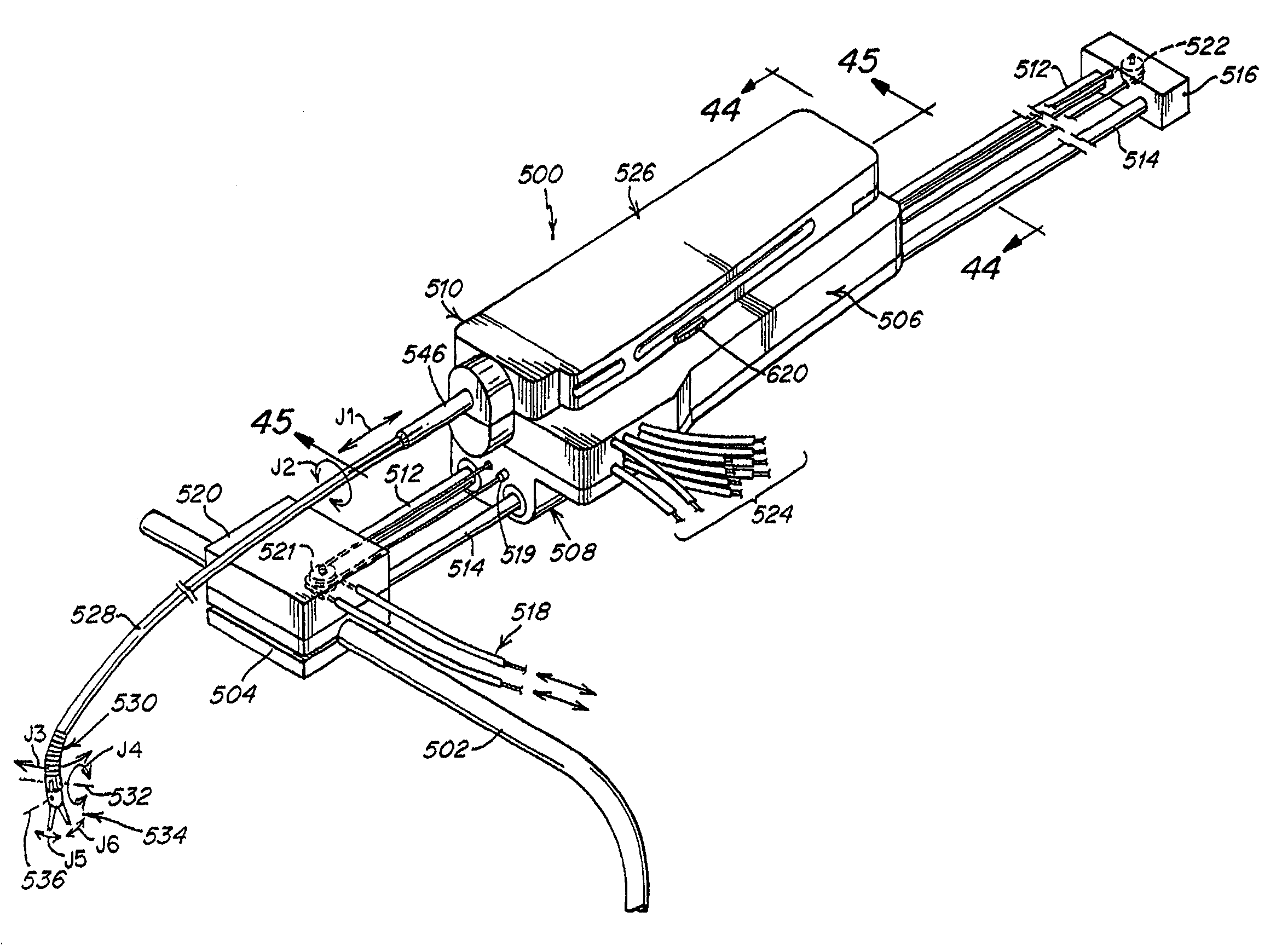

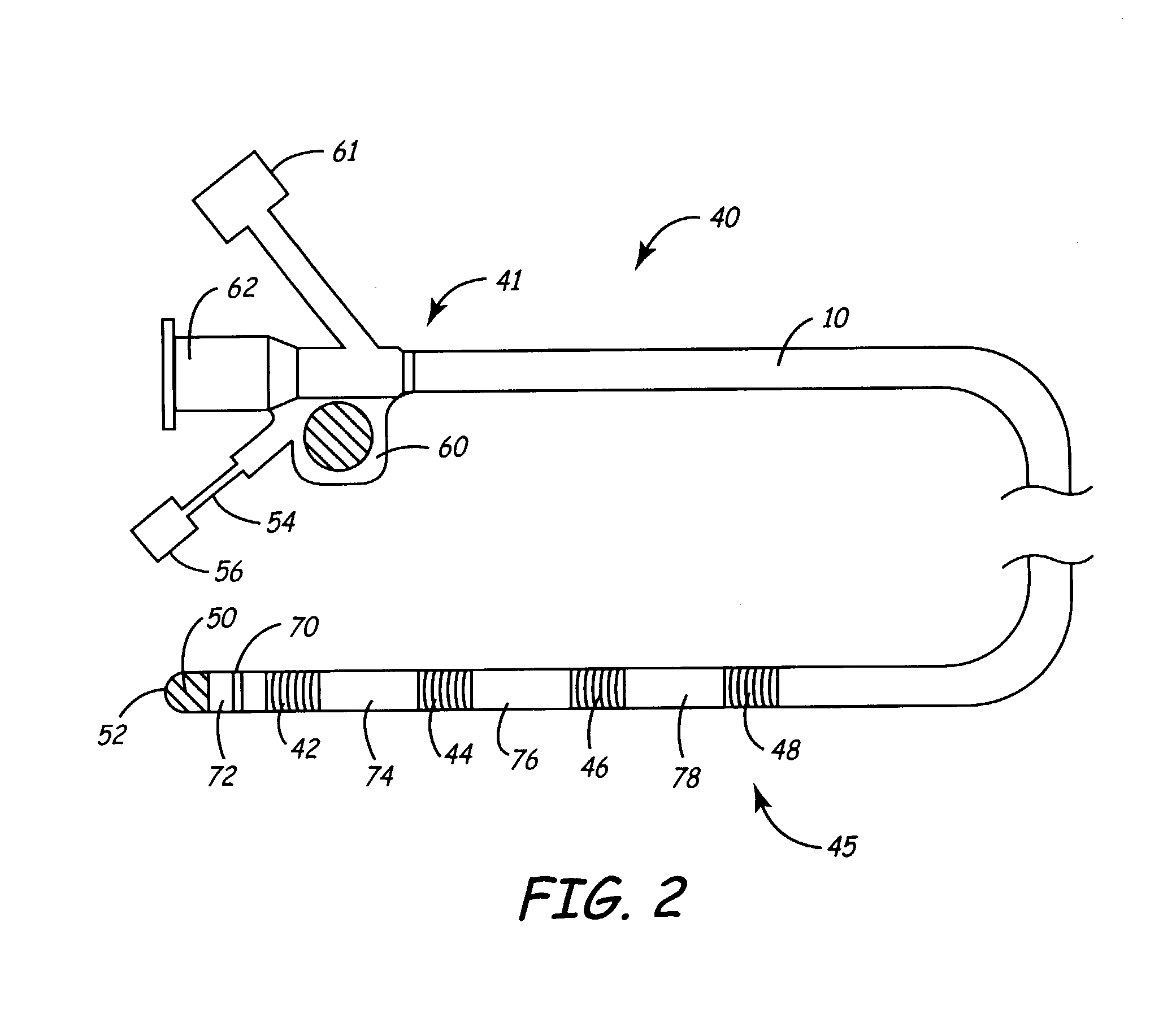

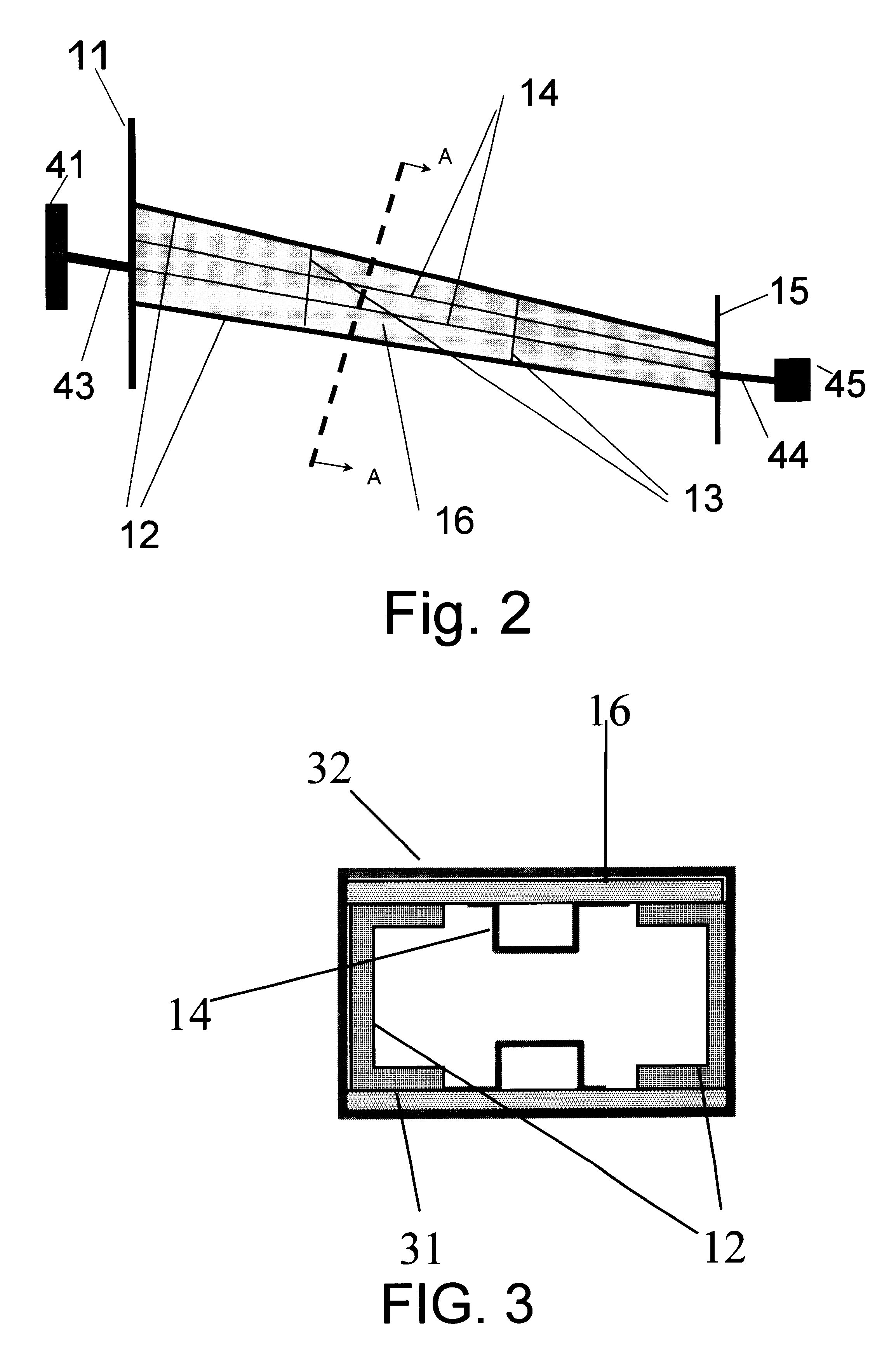

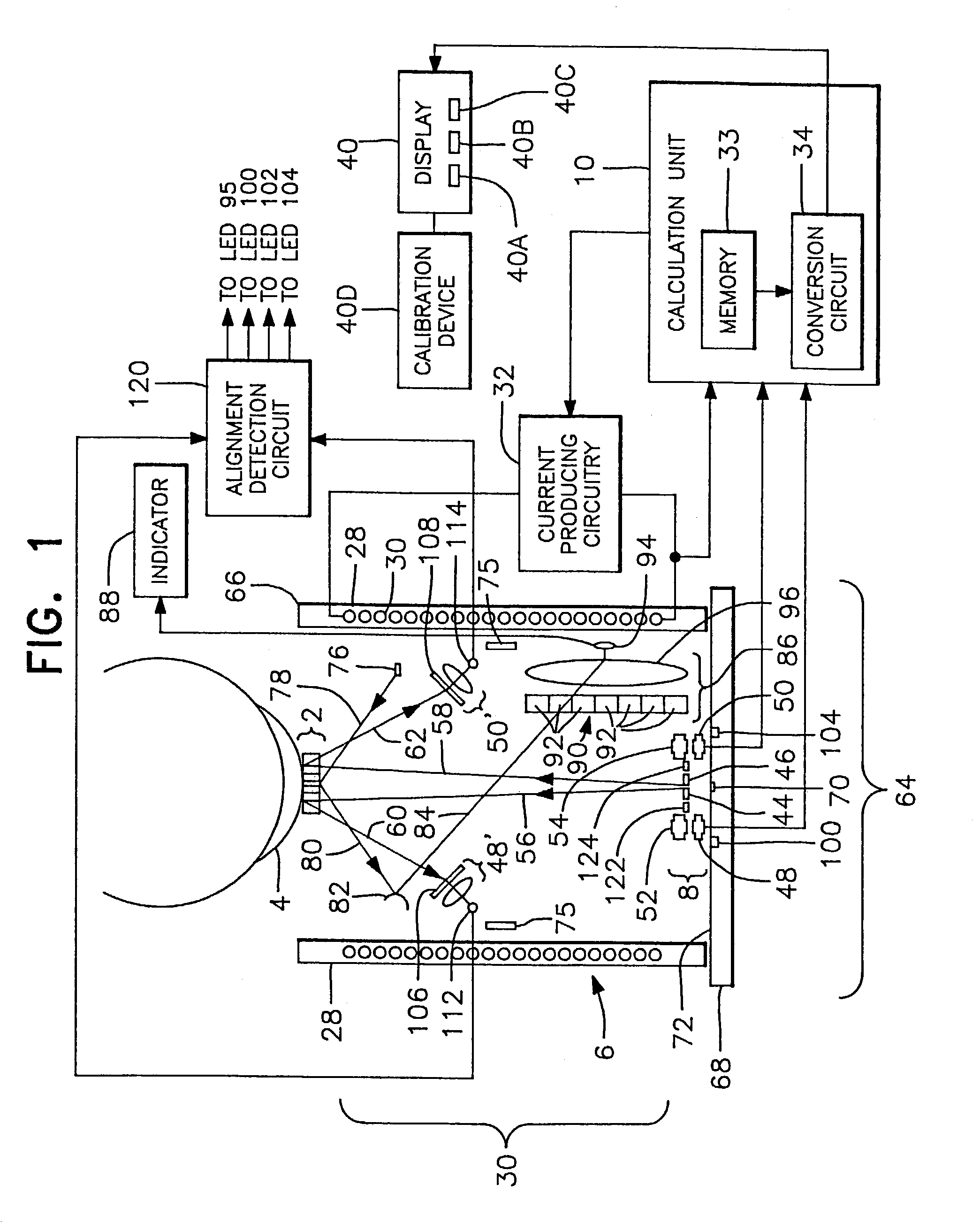

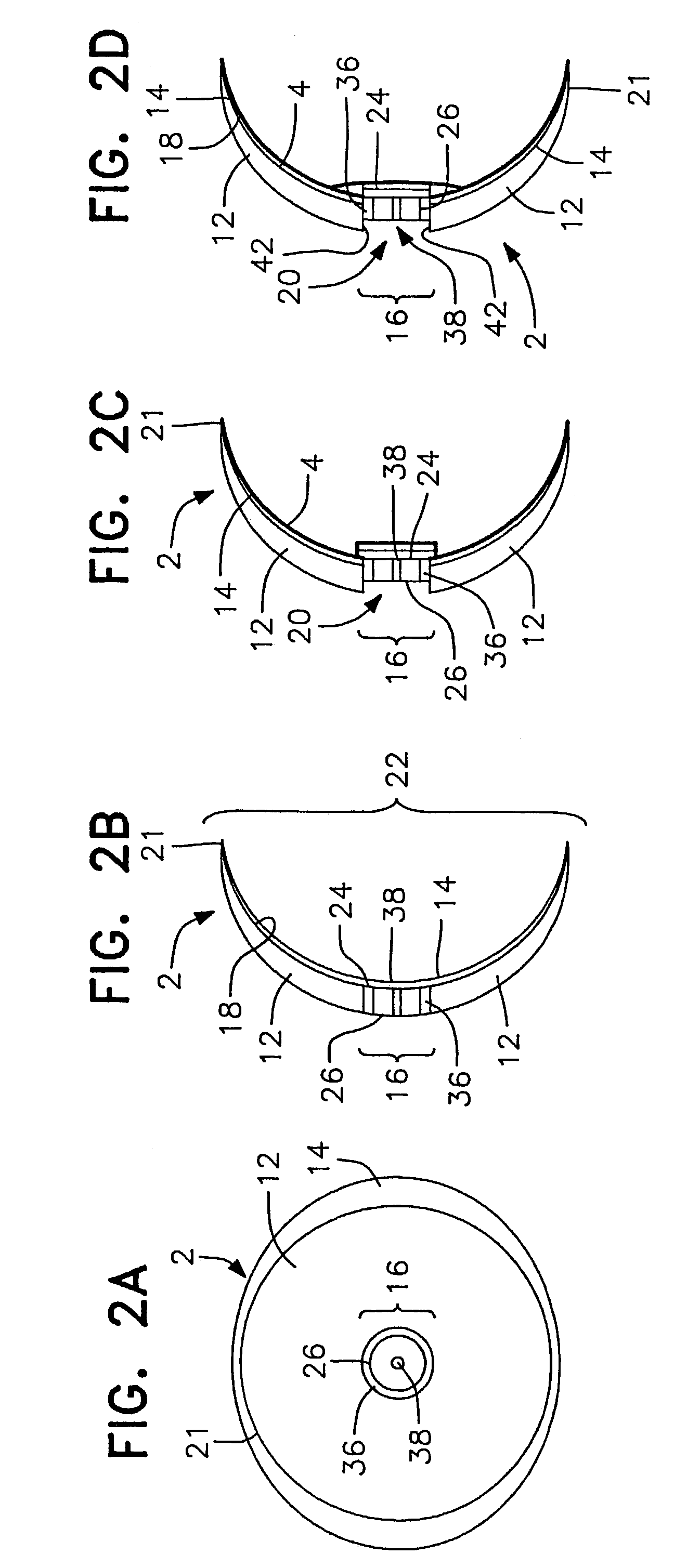

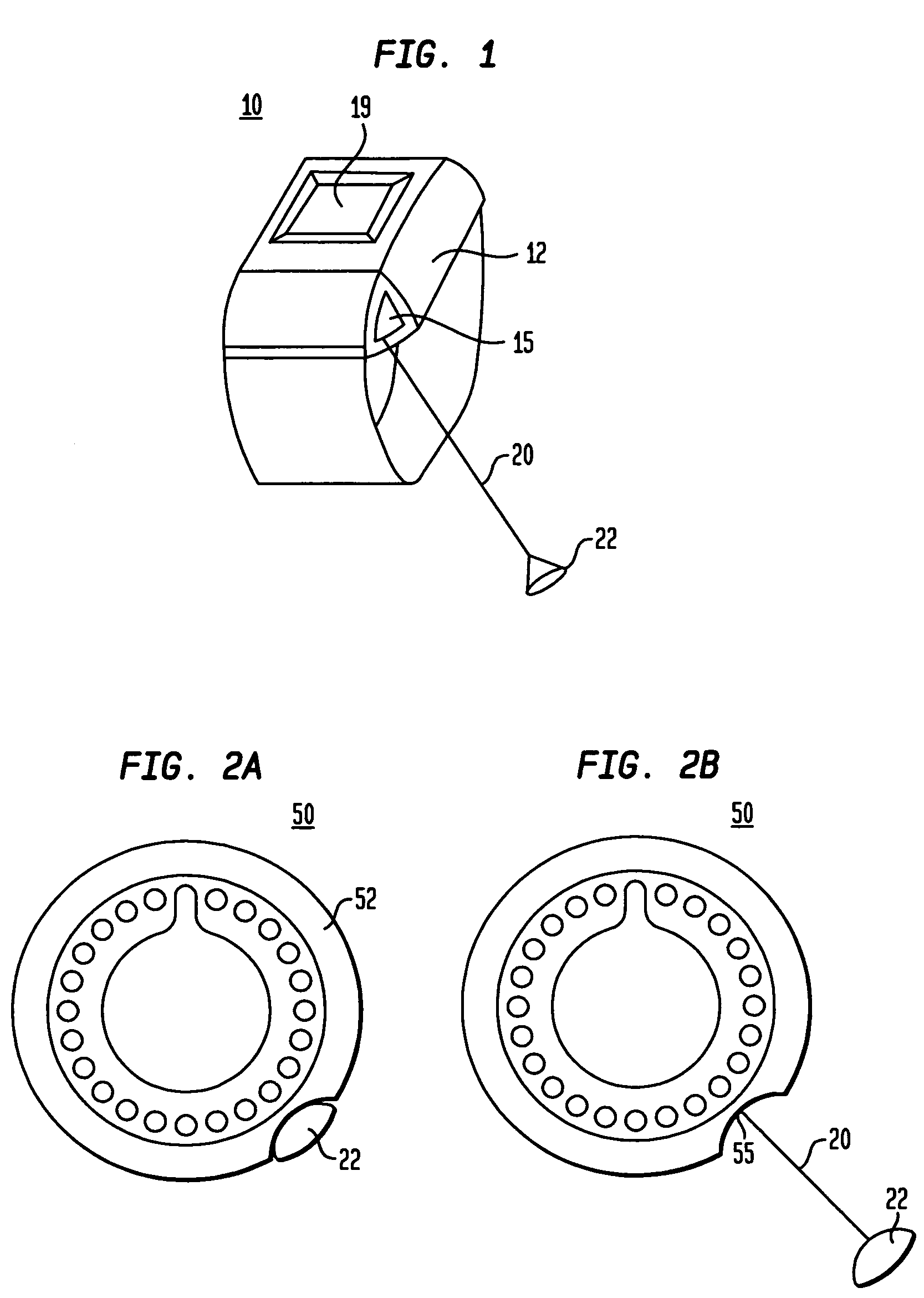

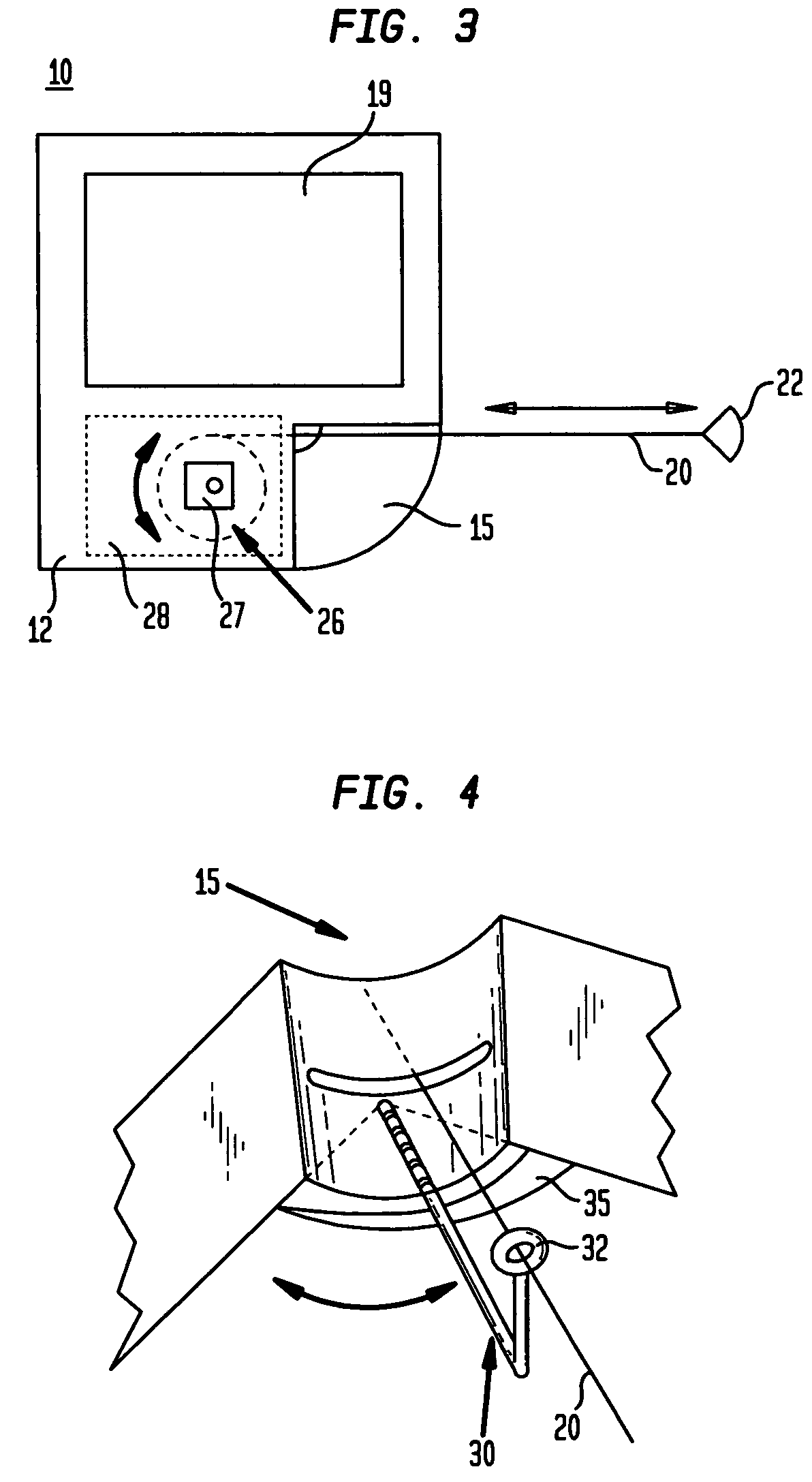

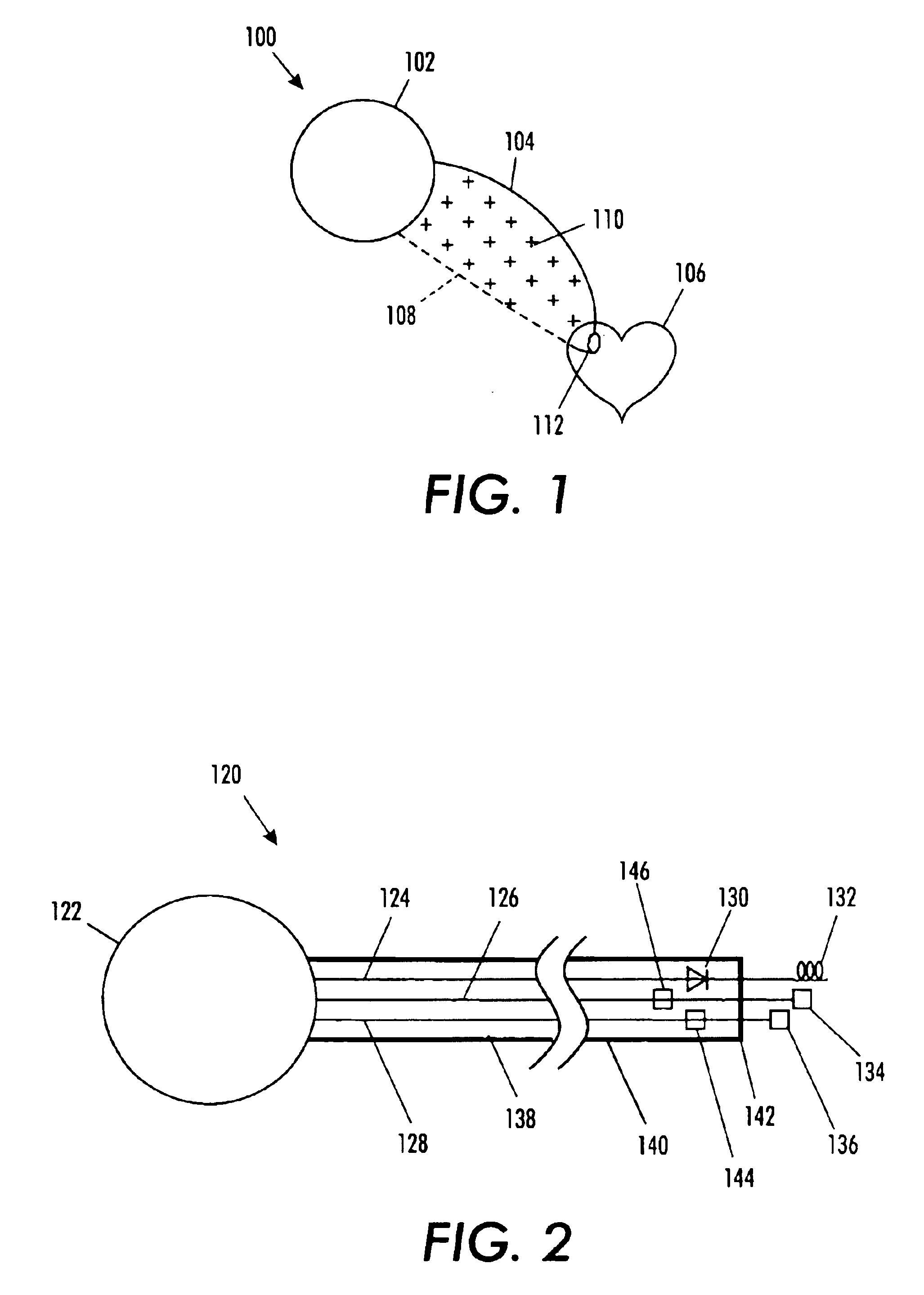

Flexible instrument

InactiveUS7775972B2Suture equipmentsProgramme-controlled manipulatorElement spaceBiomedical engineering

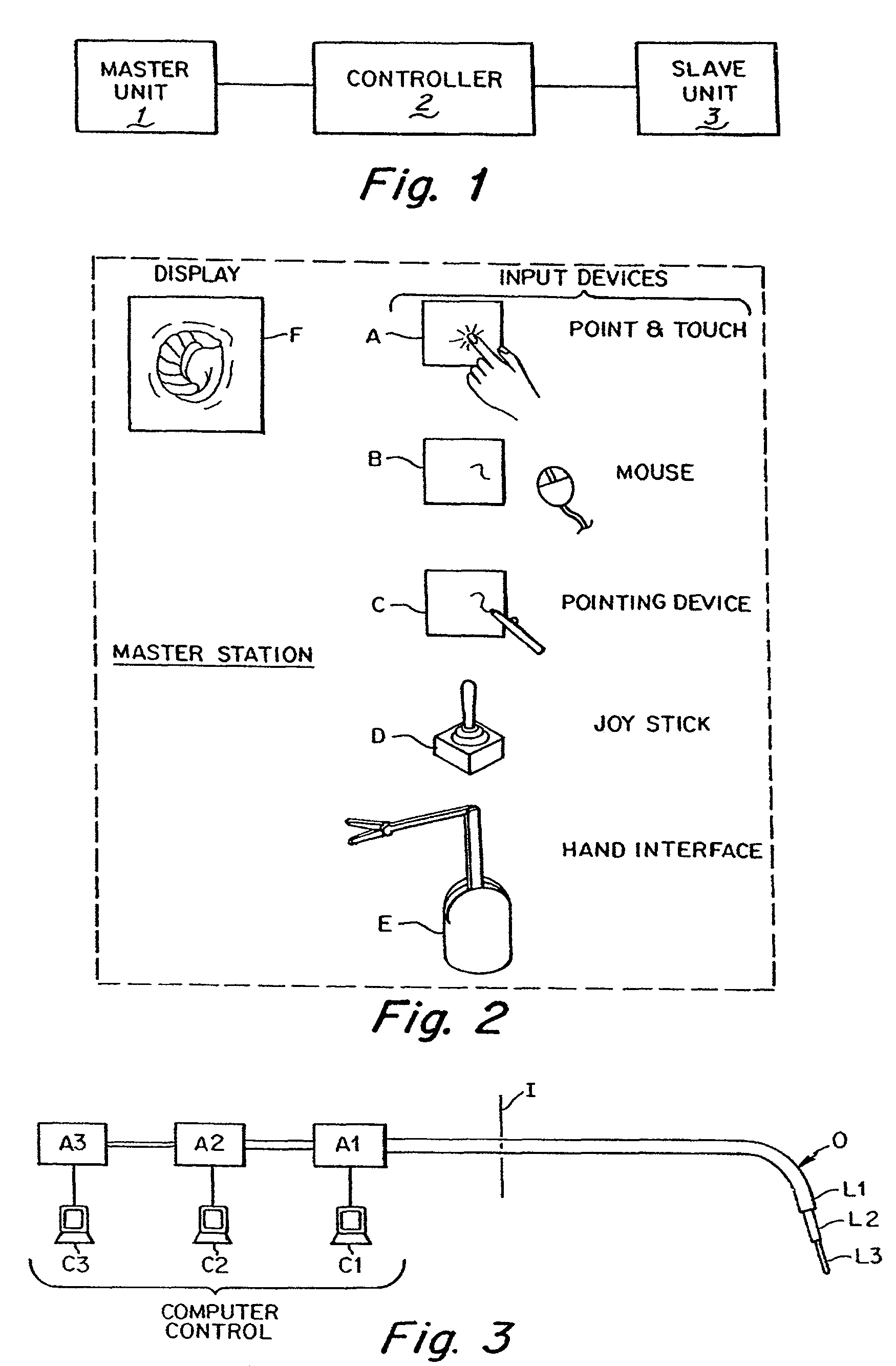

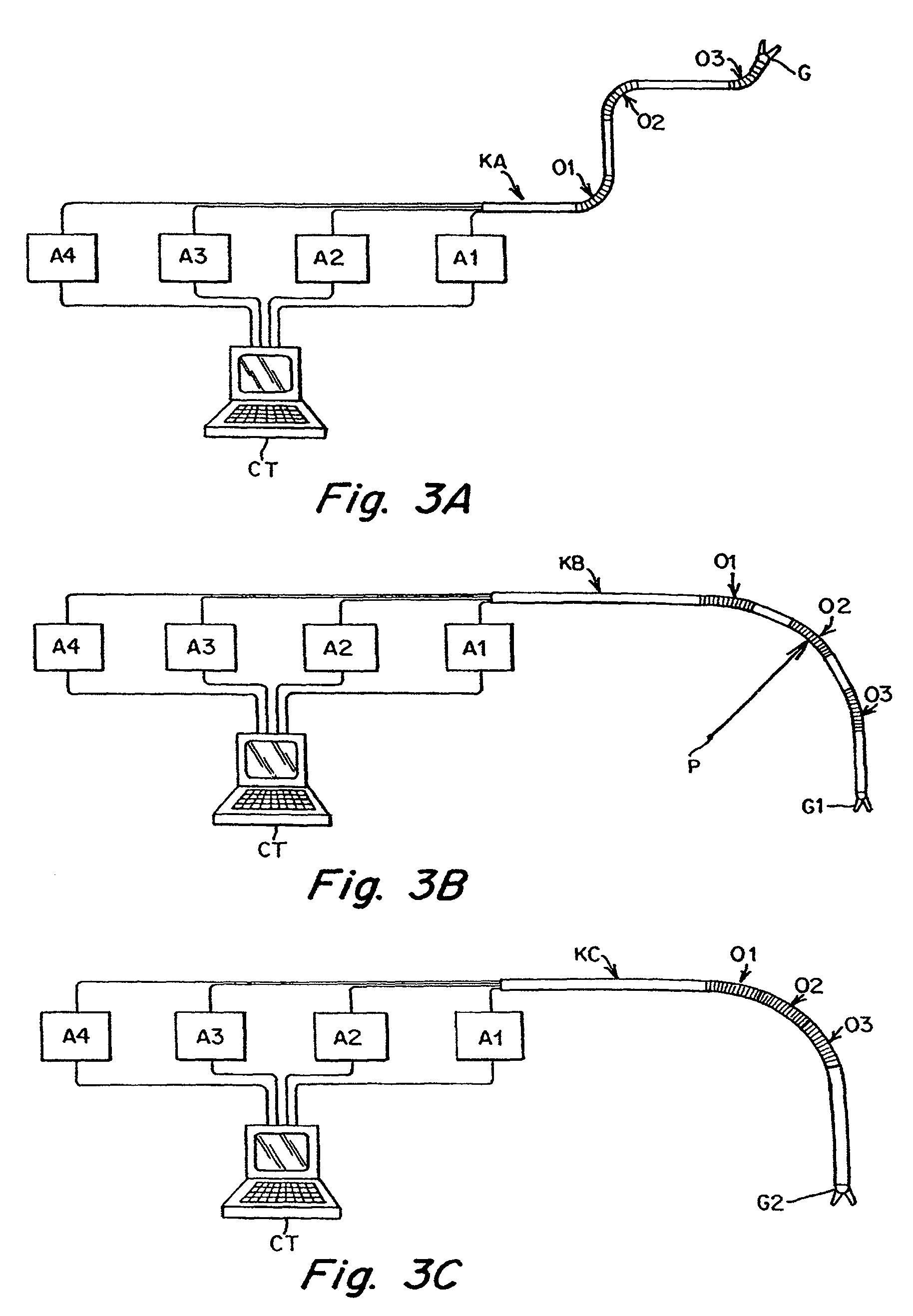

A medical probe and medical system are provided. The medical probe comprises an elongated shaft, a plurality of electromagnetic elements spaced along the elongated shaft, and a plurality of wires extending through the elongated shaft and configured for energizing the electromagnetic elements that actuate a controlled bending of the elongated shaft. The medical system may comprise the medical probe and a controller configured for energizing the electromagnetic elements via the wires to actuate the controlled bending of the elongated shaft. The medical system may optionally comprise a user interface configured for conveying commands to the controller, in which case, the controller will be configured for energizing the electromagnetic elements via the wires to actuate a controlled bending of the elongated shaft in response to the commands.

Owner:HANSEN MEDICAL INC

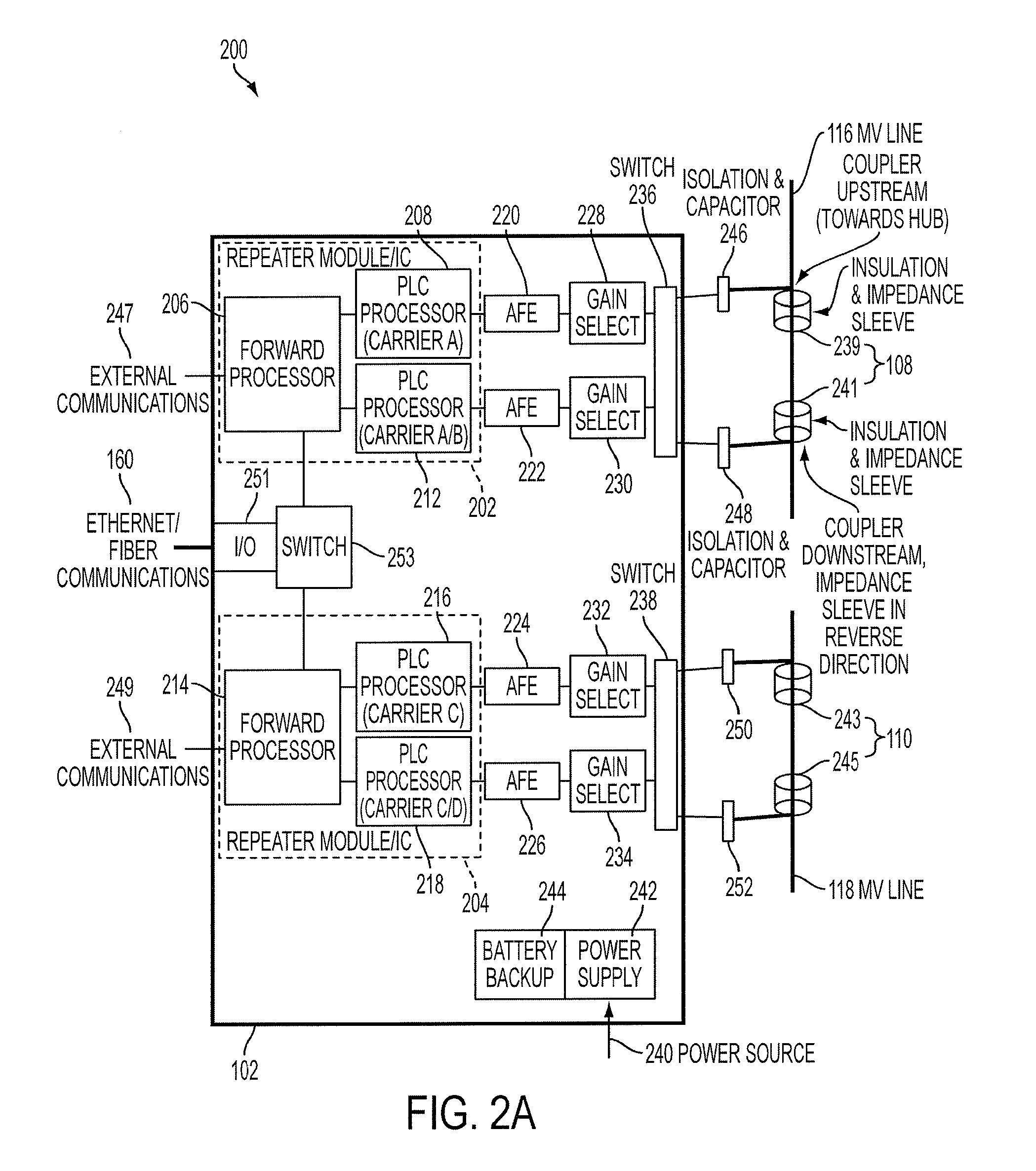

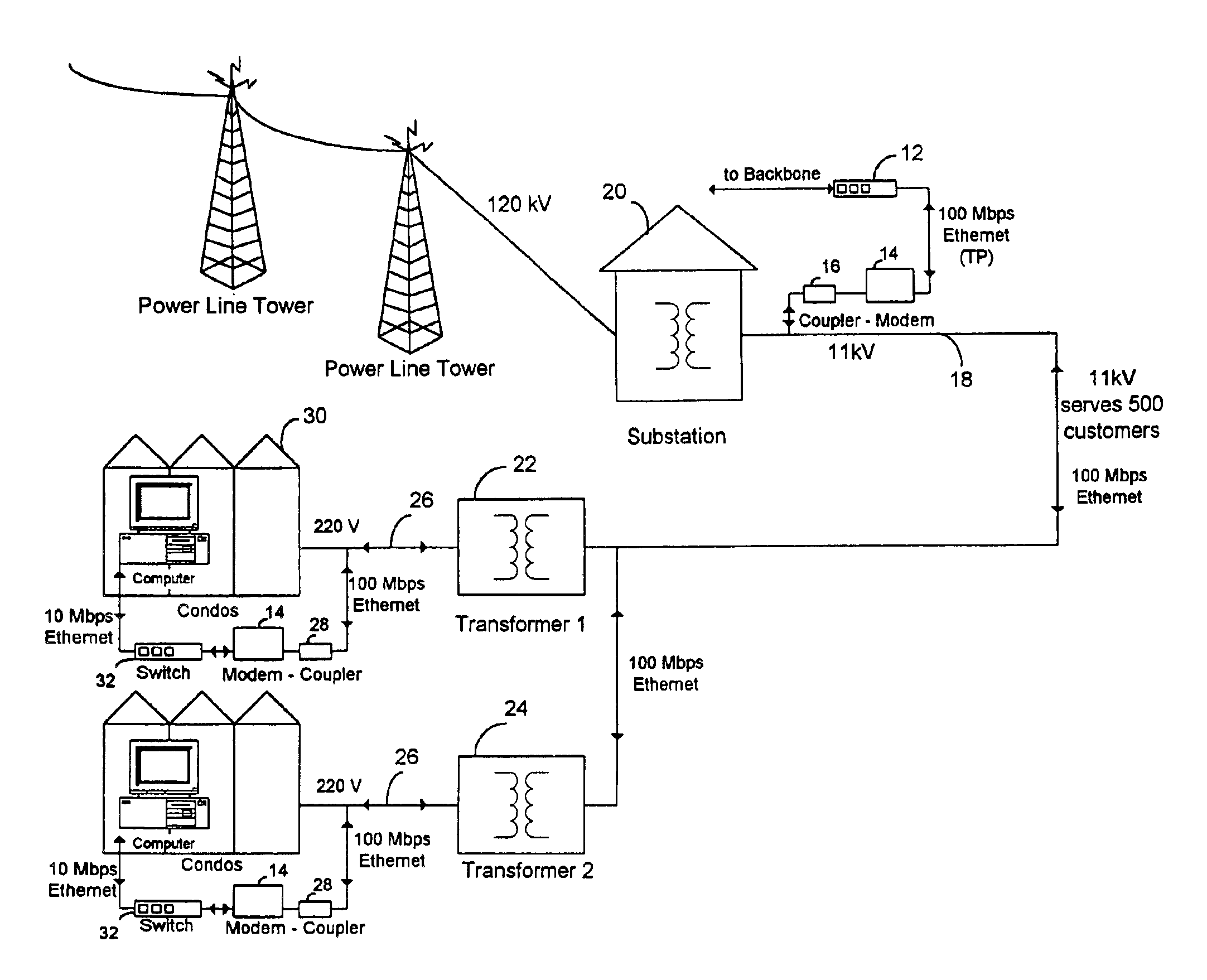

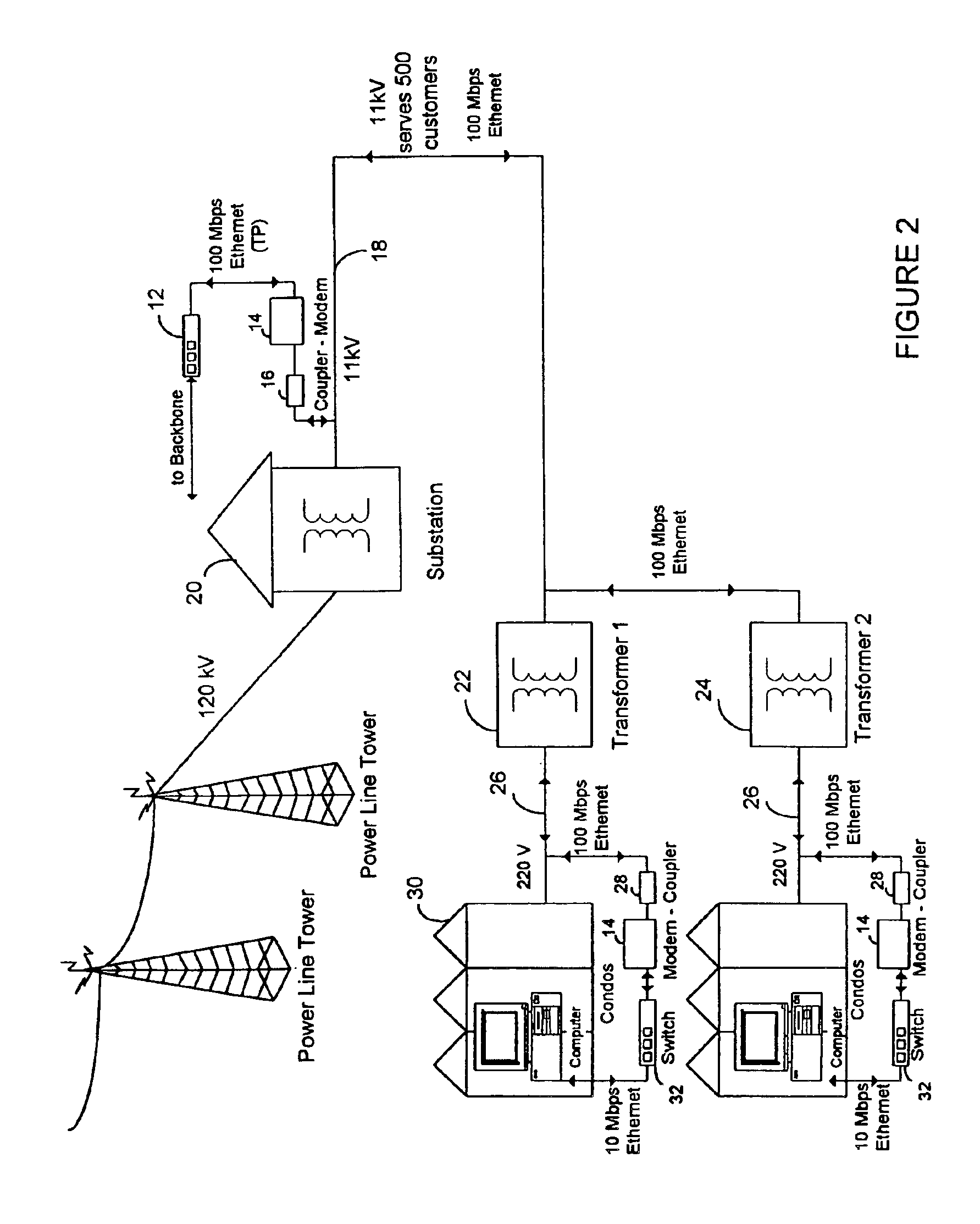

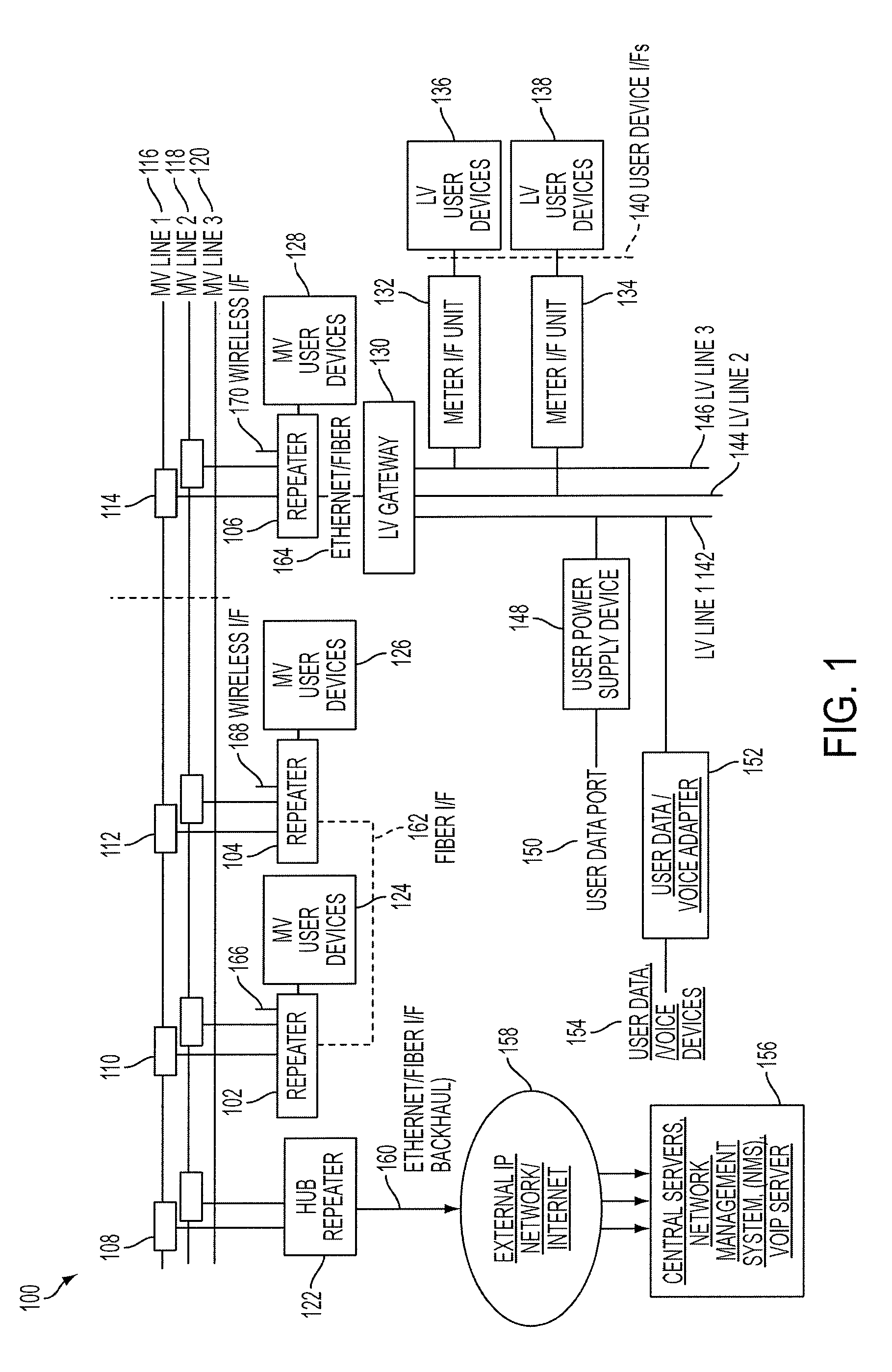

Reliable, long-haul data communications over power lines for meter reading and other communications services

InactiveUS20110140911A1Highly long-haulImprove reliabilityElectric signal transmission systemsPower distribution line transmissionPower qualitySignal quality

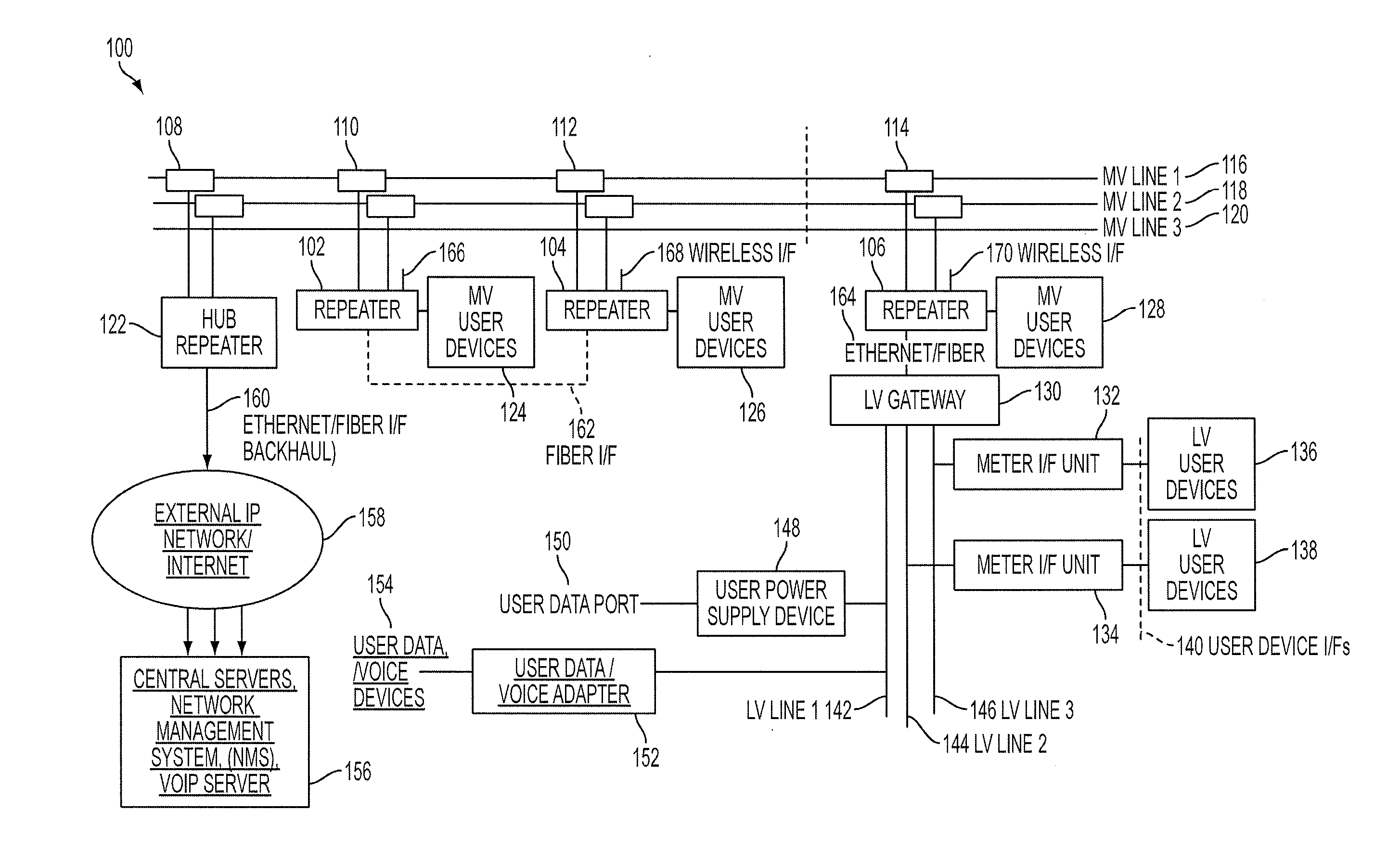

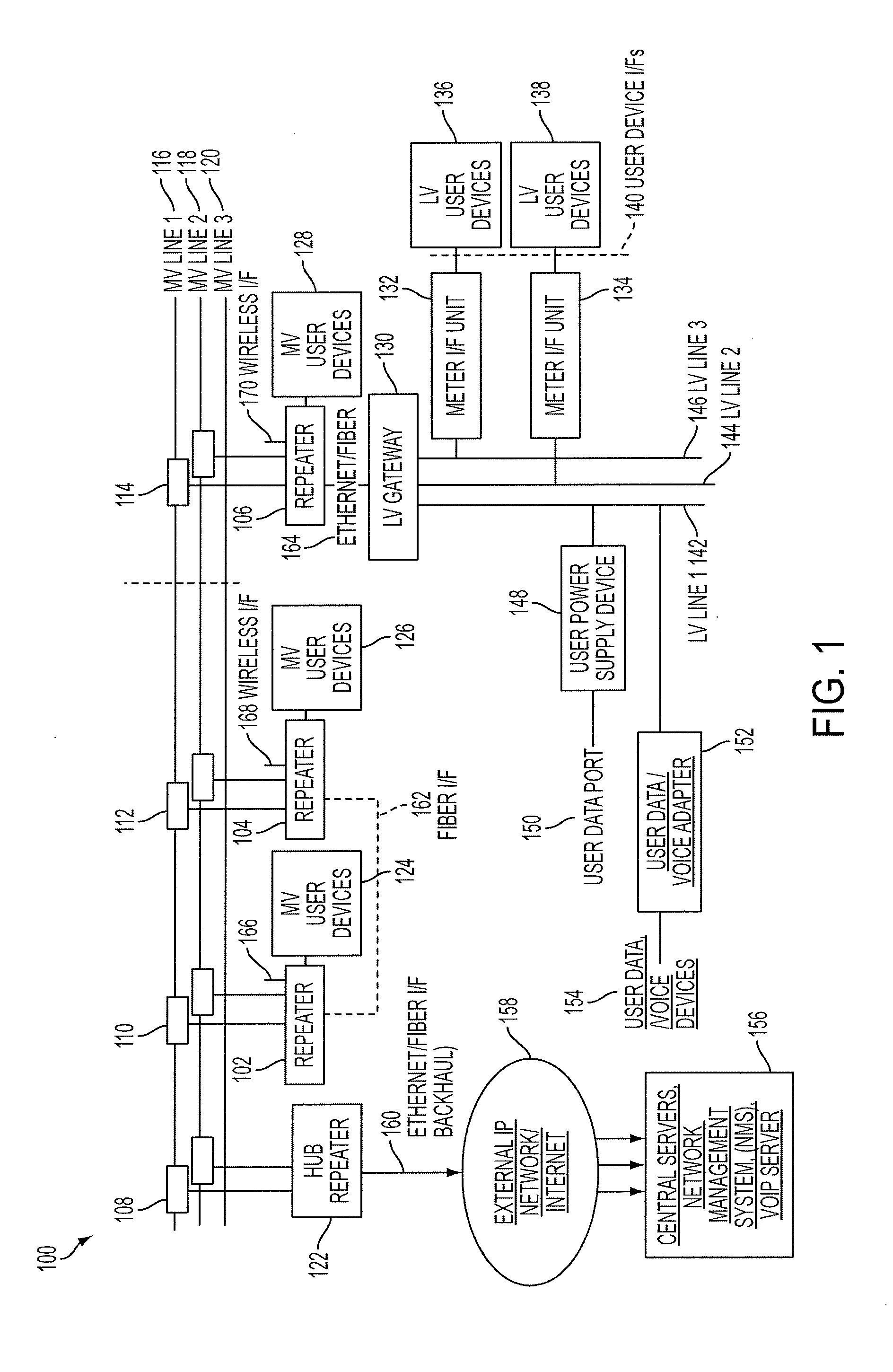

A system, method and computer program product provides for power line communications (PLC) over electric power lines includes a device mountable near an electrical distribution transformer (DT) to provide a high speed interface and communicates with one or multiple access devices, which provide low speed interfaces for analog signals or digital signals over RS 232, RS 485, optical, wireless and Ethernet. The device transmits data to / from these access devices over the electric lines to other repeaters over one or more wires of an electrical line or over multiple lines, and serves to strengthen and improve signal quality. Upon detecting a wire or line is having problems carrying data, the data is sent over other wires, and upon power line failures, wireless backup to mobile / GSM and WiMax networks is utilized. The device permits utilities and others to read electric meters, monitor the power quality of the distribution grid and detect power losses / failures / outages, and permits telecom service providers and others to provide a communications link to cell phone towers, WiFi Access Points and enable broadband Internet and telephony in rural, remote or sparely populated areas.

Owner:POWERMAX GLOBAL

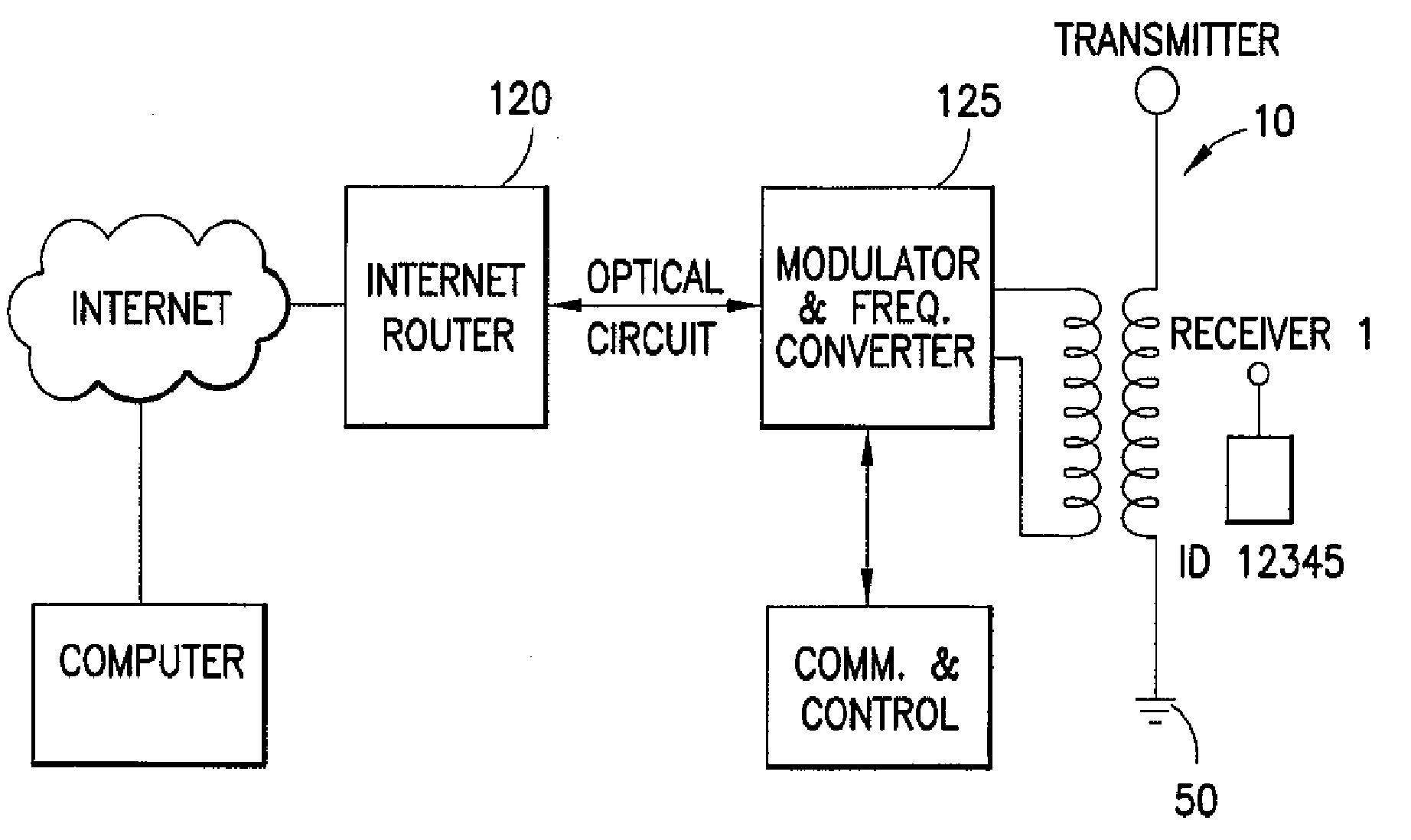

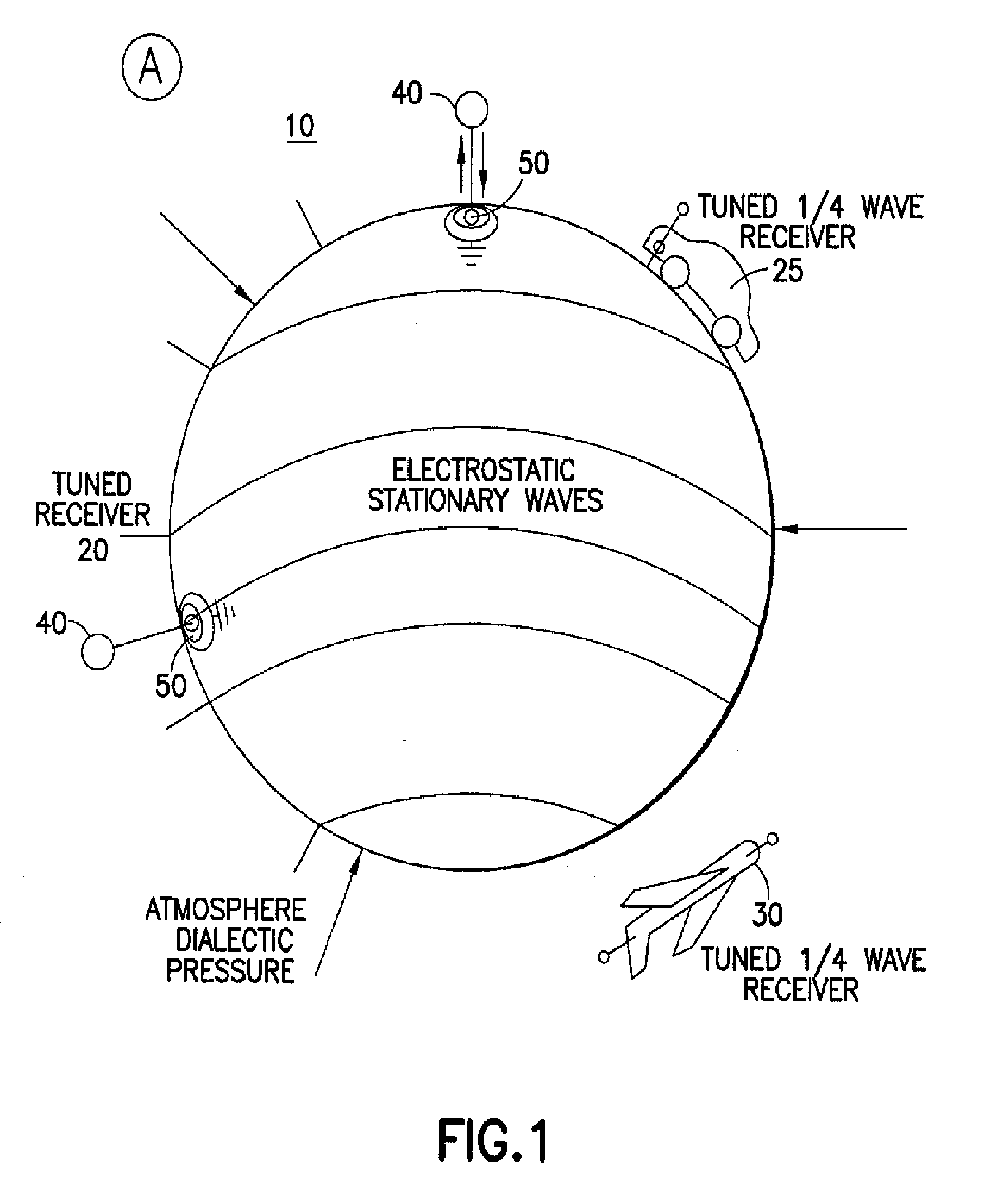

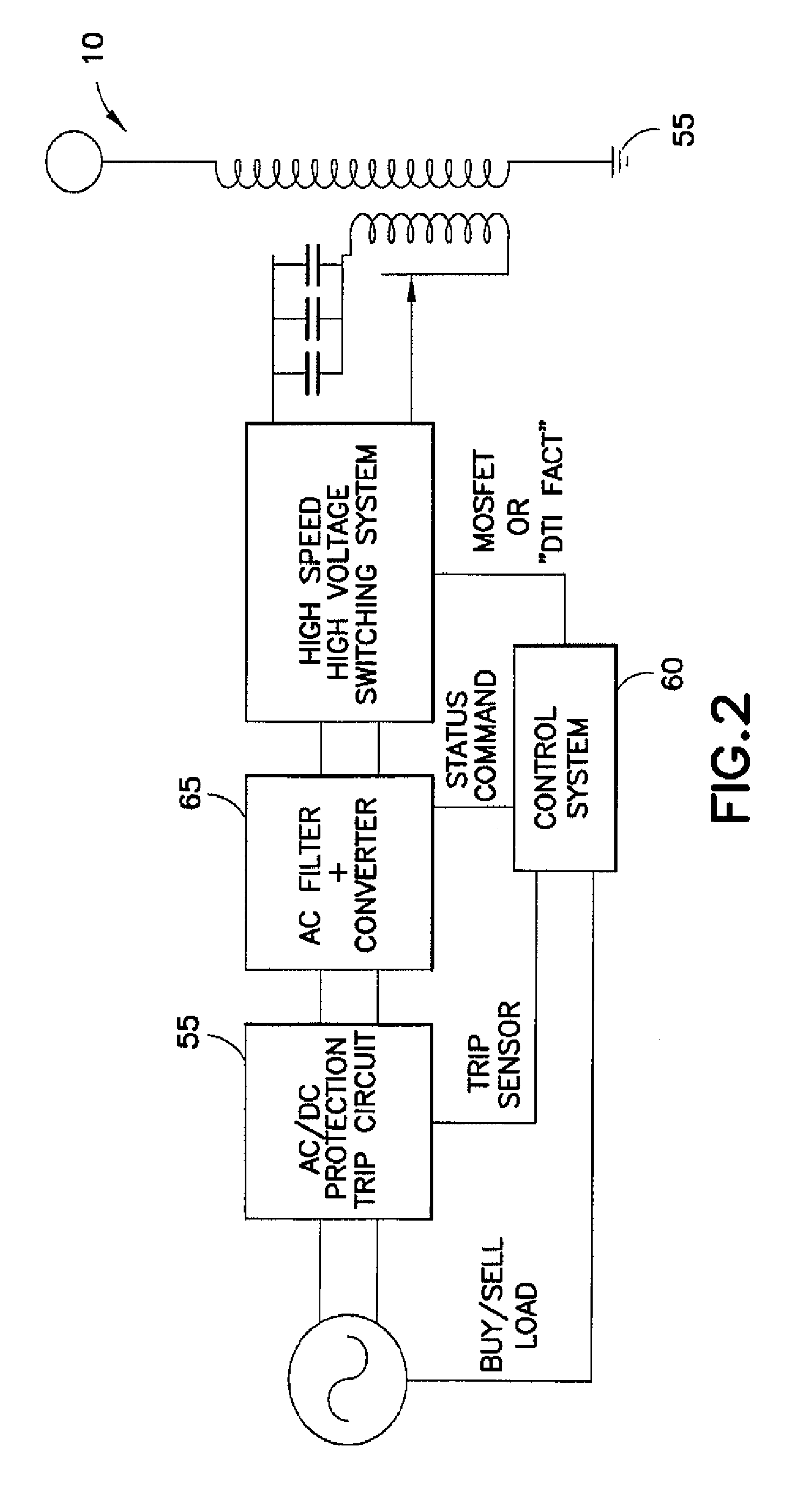

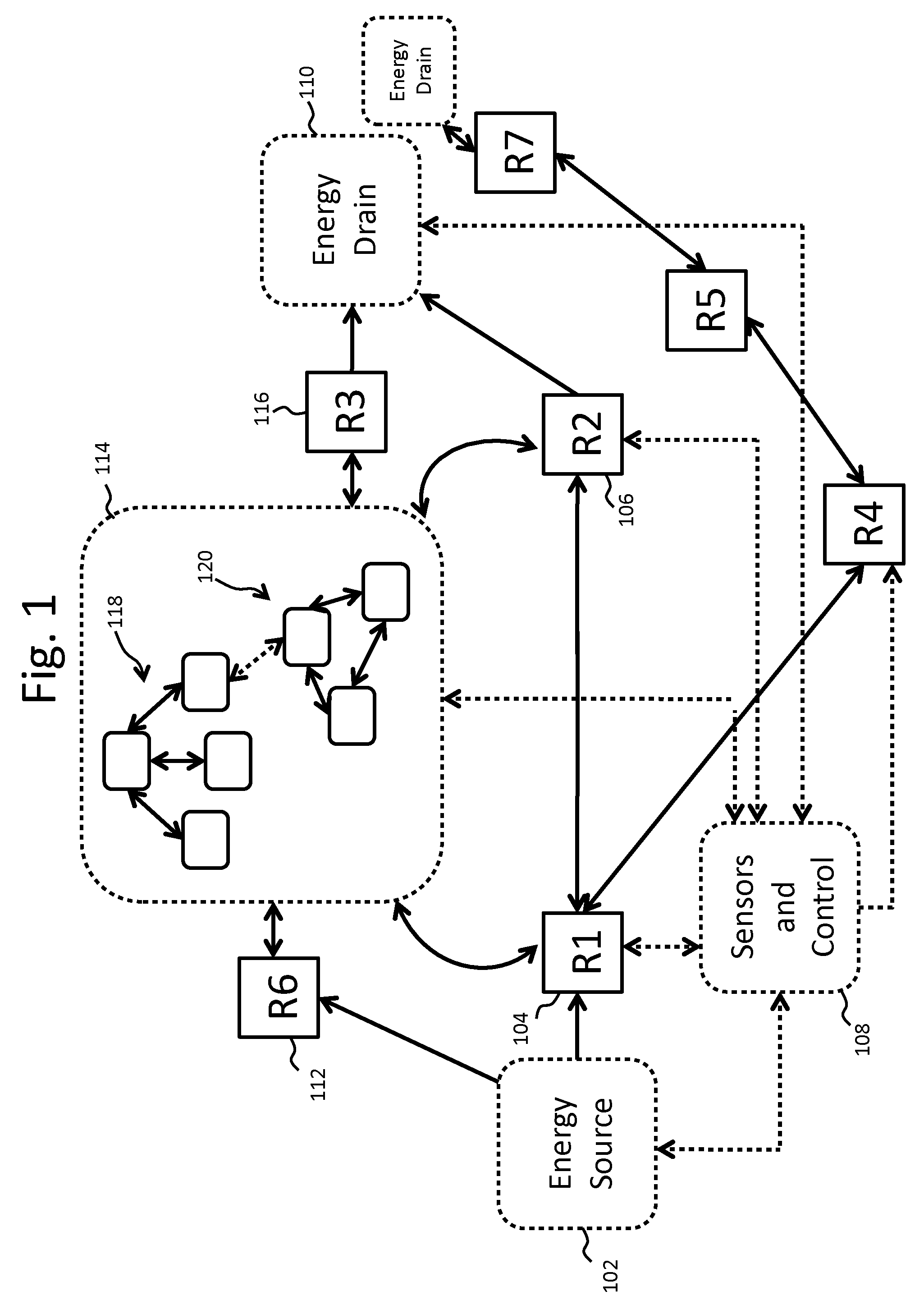

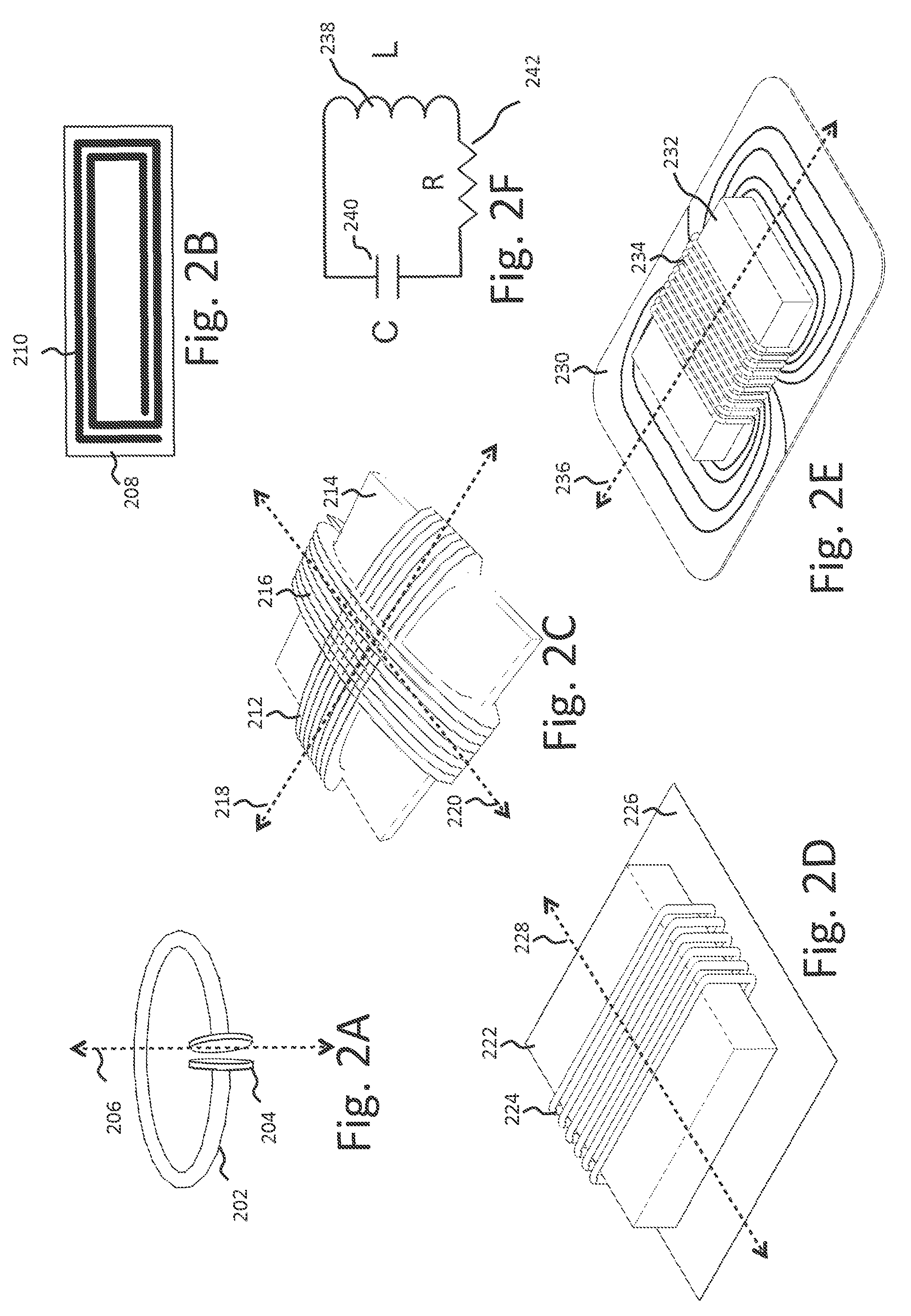

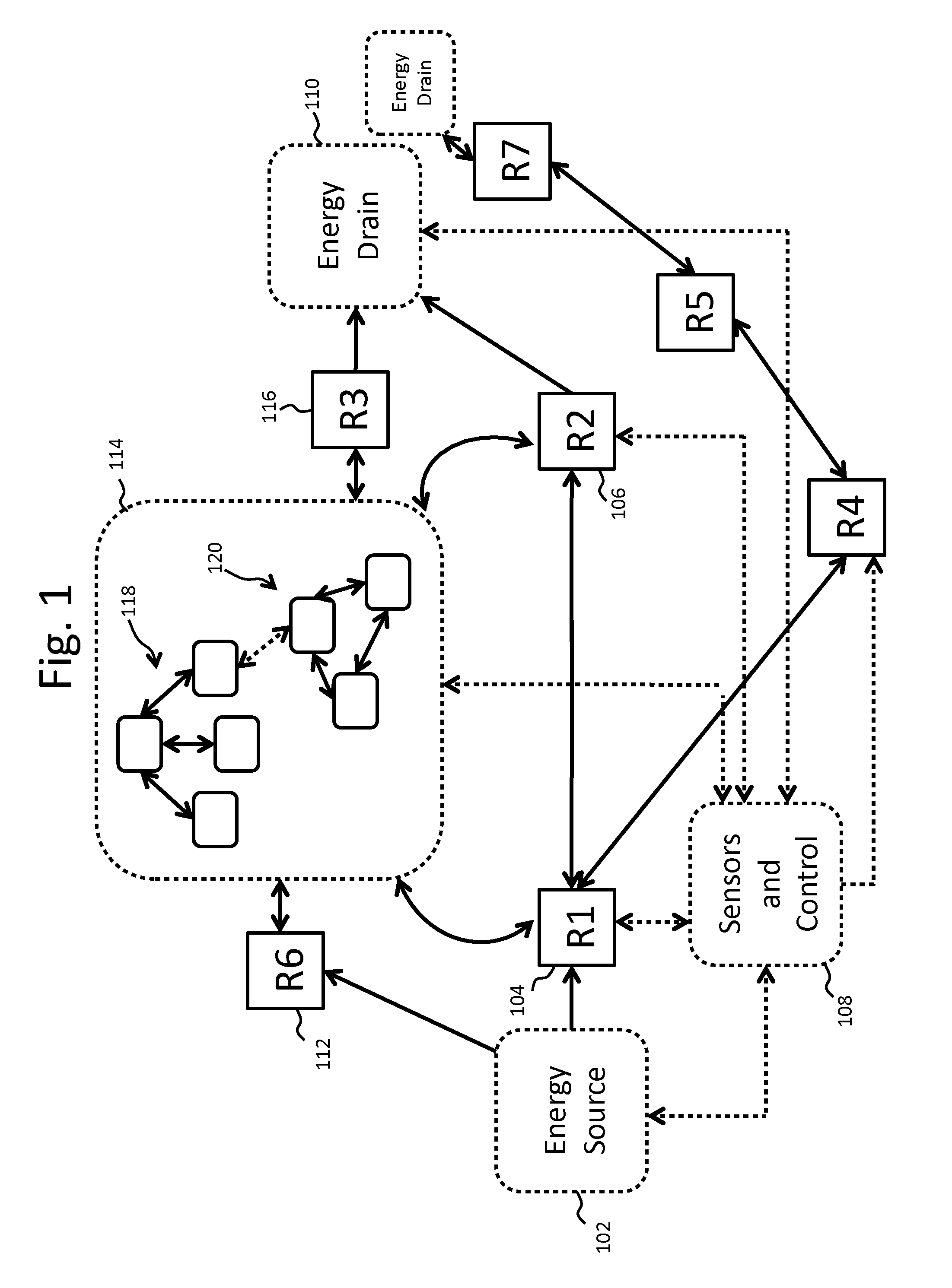

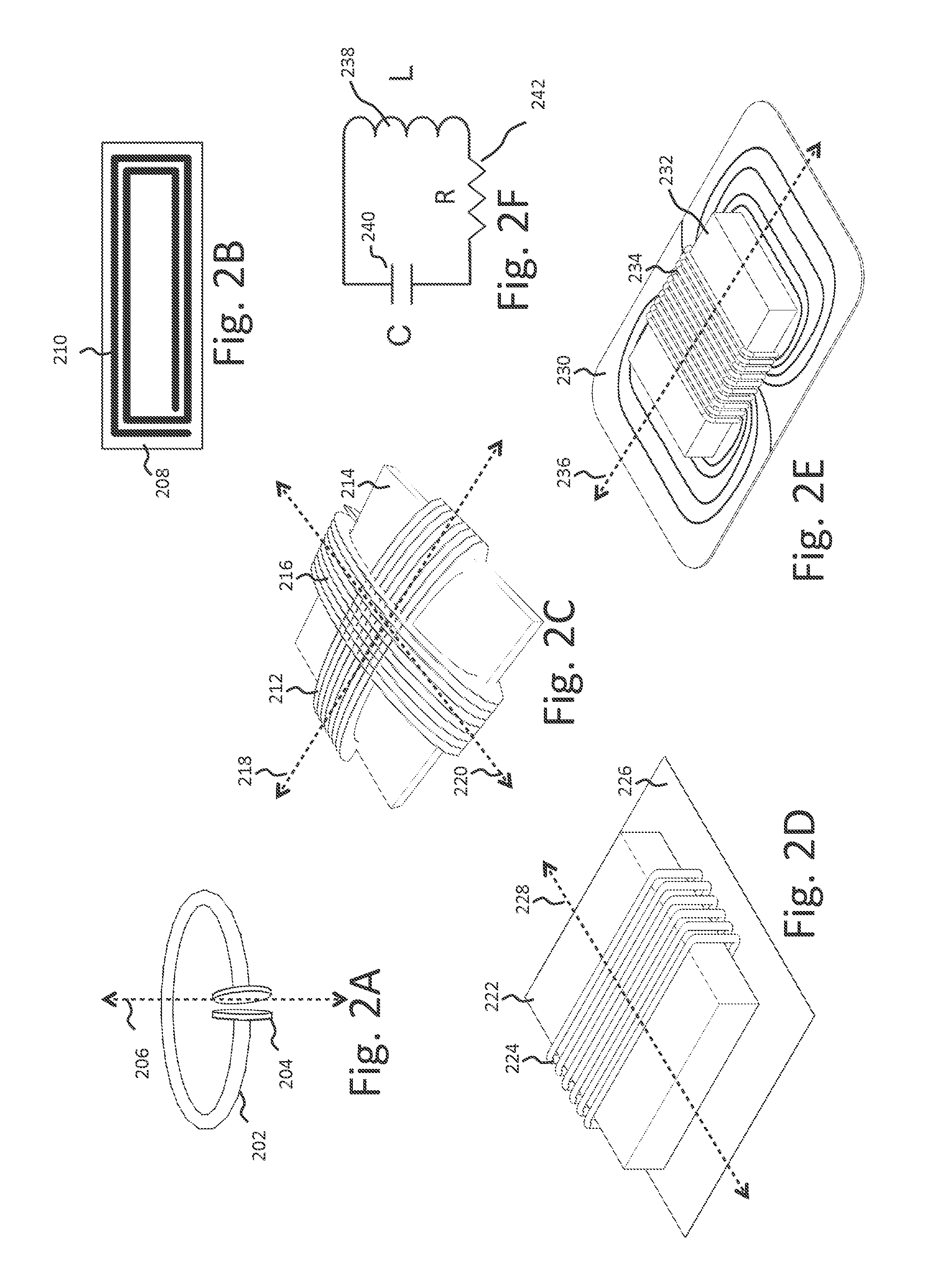

Wireless Energy Transfer System

InactiveUS20110156494A1Increase positive chargeHigh energyElectromagnetic wave systemTransformersEnergy transferTransmitted power

A system for transmitting power without wires or with no more than one connection, wherein communication is provided between an unlimited number of electronic devices, or to connect these devices to an unlimited number networks that are located externally to the system to thereby enable high speed voice and data communications over a single resonant connection At least one transmitter and one receiver are utilized, which may have the same or different configurations, such that an induced oscillating electπc current, which occurs at the resonant frequency of a transmitter, induces a standing wave The standing wave is tuned and “tapped” by a receiver having a coil or set of plates and receivers that are tuned to oscillate at the same frequency or one of its harmonics and, thus, absorb an electrical current and / or signals at the receiver

Owner:GOVERNING DYNAMICS LLC

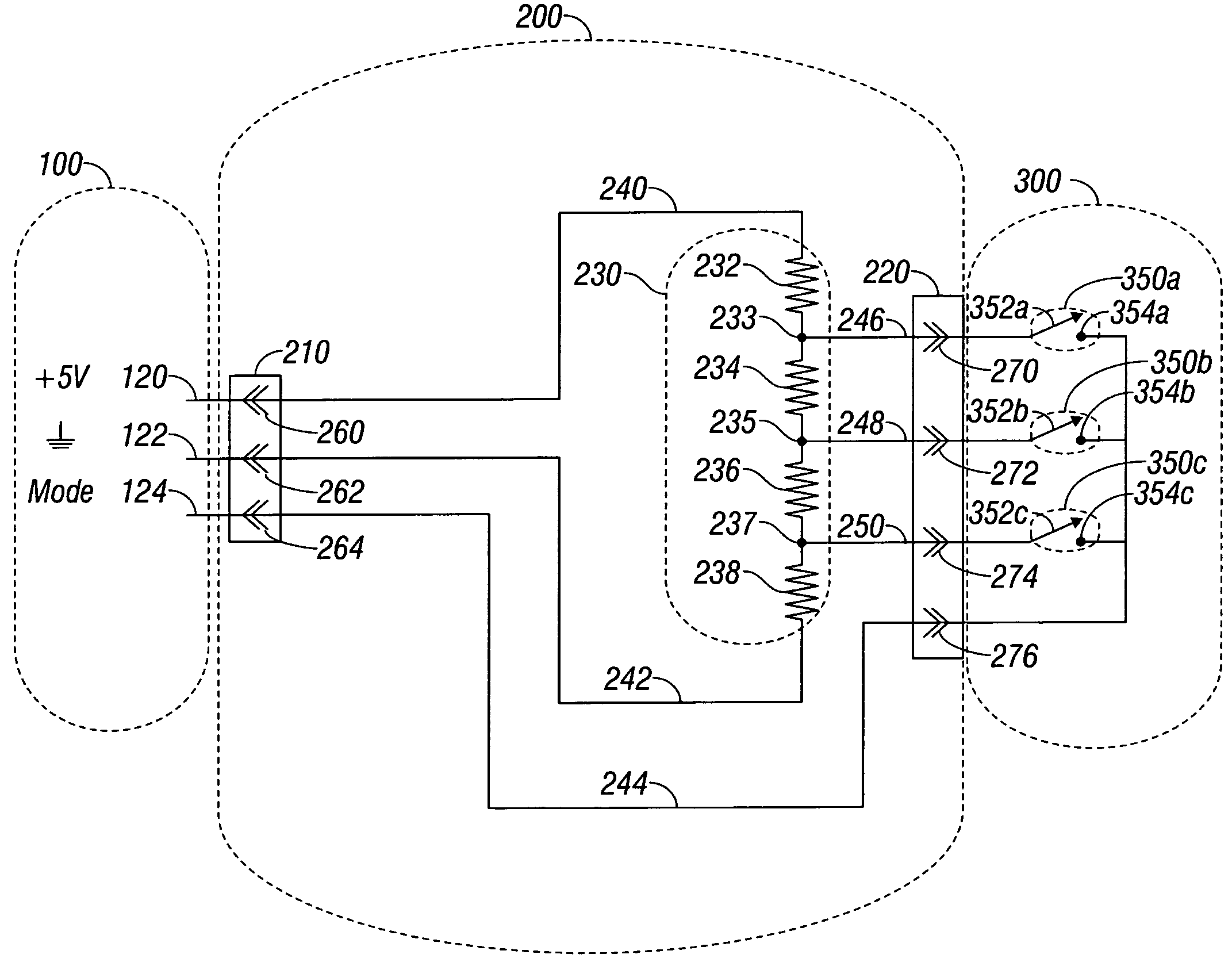

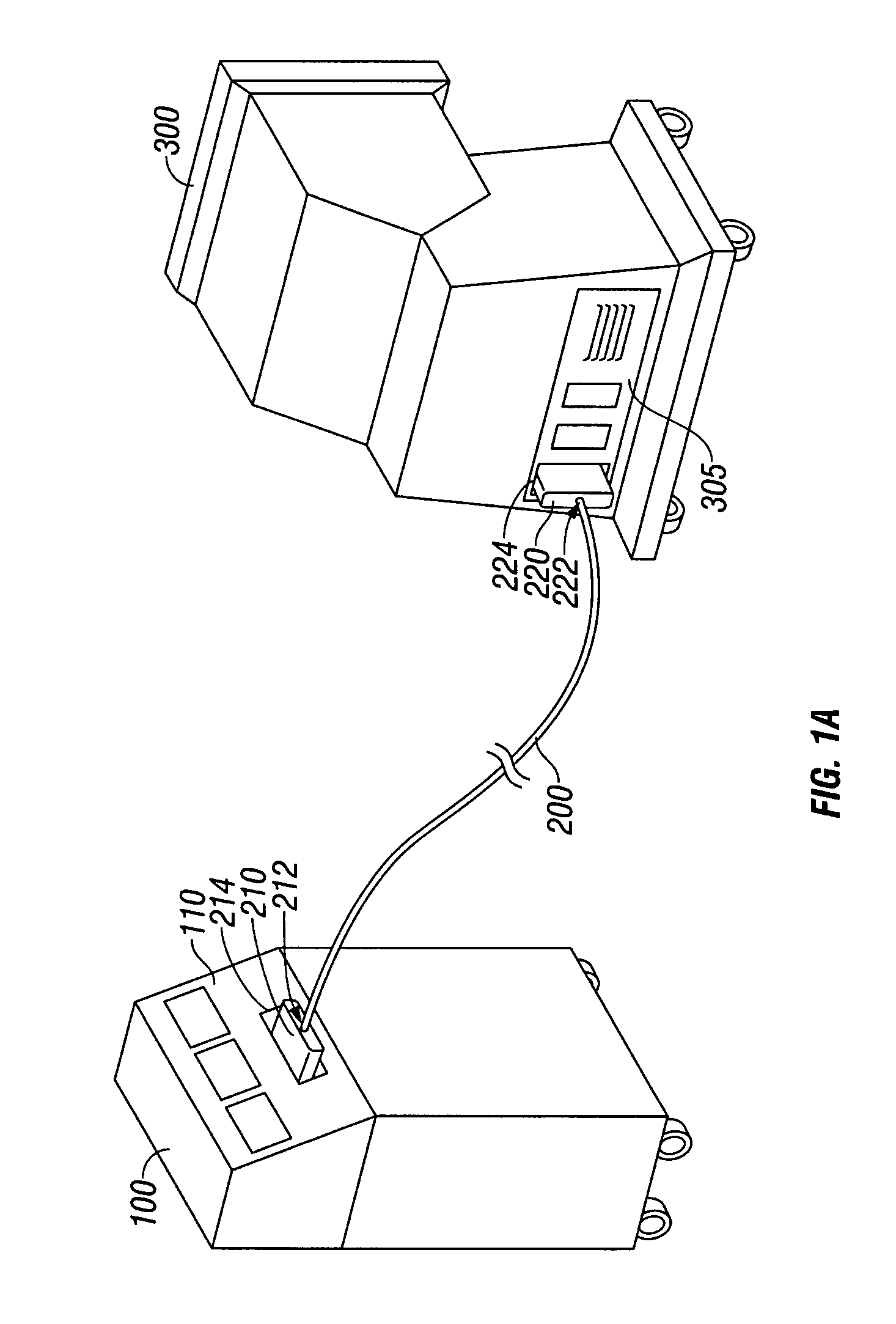

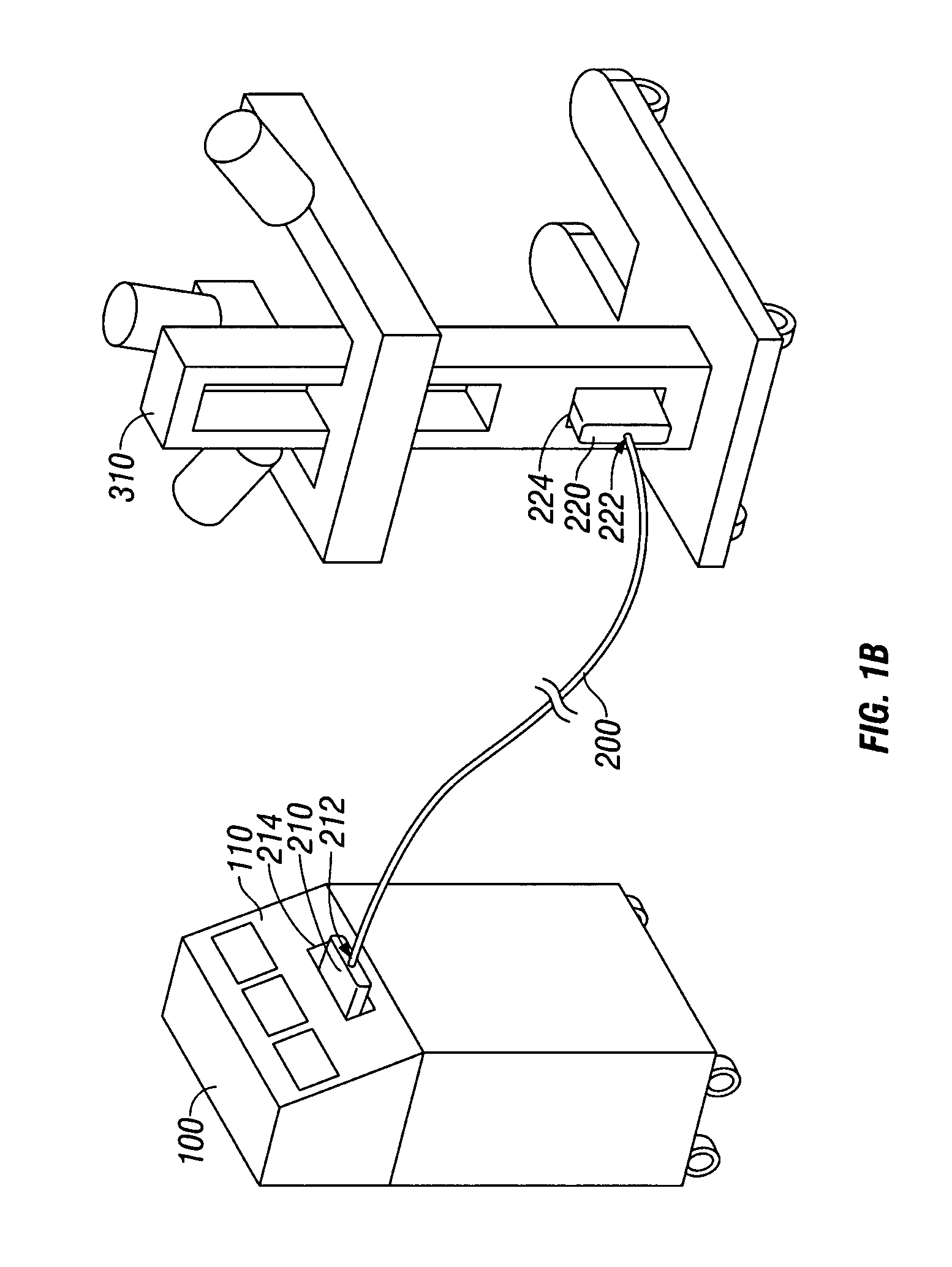

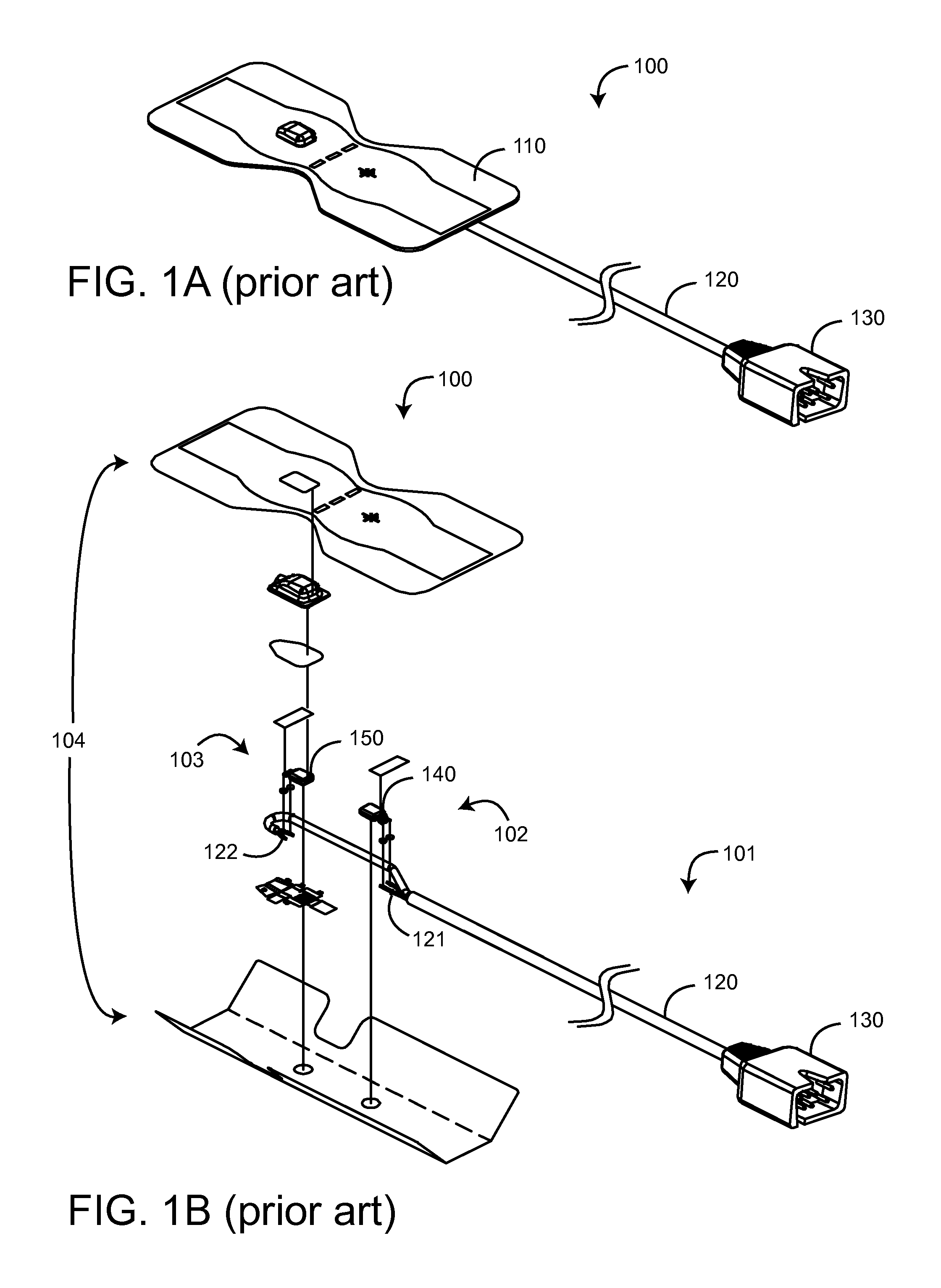

Connection cable and method for activating a voltage-controlled generator

ActiveUS7834484B2Batteries circuit arrangementsIncorrect coupling preventionSurgical operationElectrosurgery

A connection cable is disclosed for controlling a voltage-controlled generator such as an electrosurgery generator from a controlling device such as a robotic surgery system. The cable includes a first connector adapted to connect to a voltage-controlled generator and a second connector adapted to connect to a controlling device. Within the cable is a voltage divider interdisposed between the first connector and the second connector. The voltage divider is configured to divide a reference voltage provided by the voltage-controlled generator into at least one control voltage which is selectable by the controlling device. The cable additionally includes a plurality of electrical wires which operatively connect the first connector, the second connector and the voltage divider. During robotic electrosurgery, said operating parameters can be actuated by a surgeon operating at the robotic surgical system console, which causes a corresponding control voltage to be switched to a control voltage input on an electrosurgery generator, which, in turn, generates a corresponding electrosurgical signal in response thereto.

Owner:COVIDIEN LP

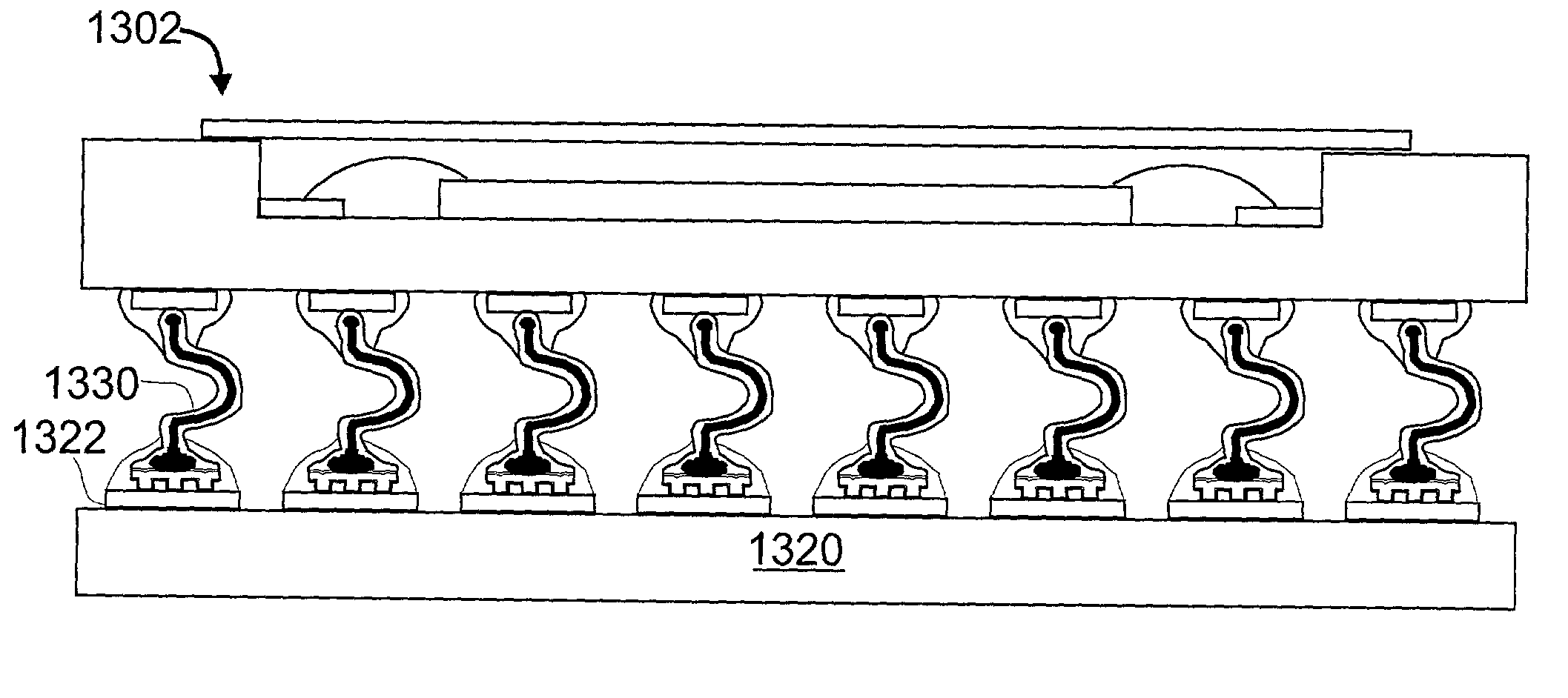

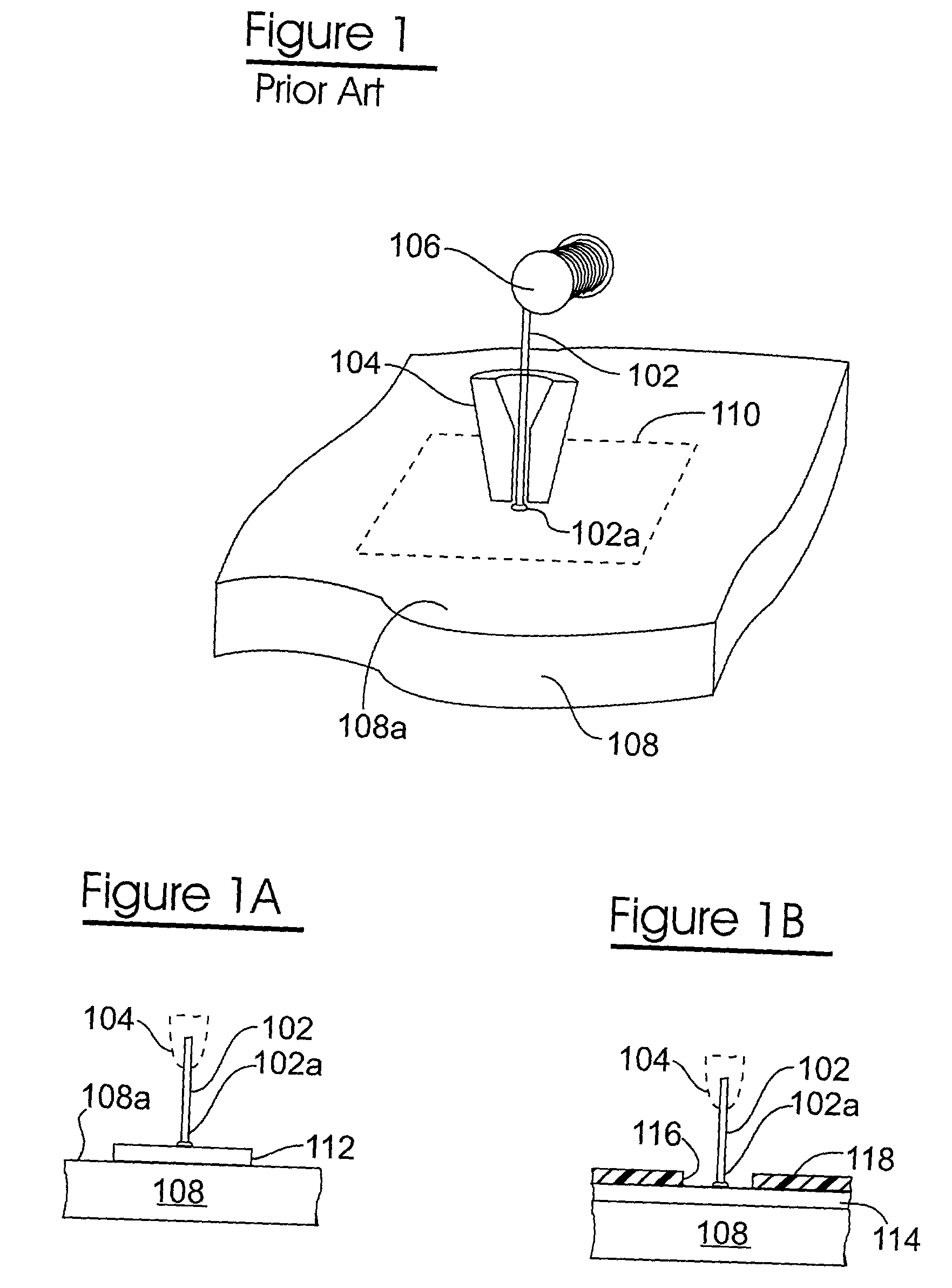

Resilient contact structures formed and then attached to a substrate

InactiveUS20020117330A1Simple technologyCoupling device connectionsSemiconductor/solid-state device testing/measurementEngineeringTopography

Owner:FORMFACTOR INC

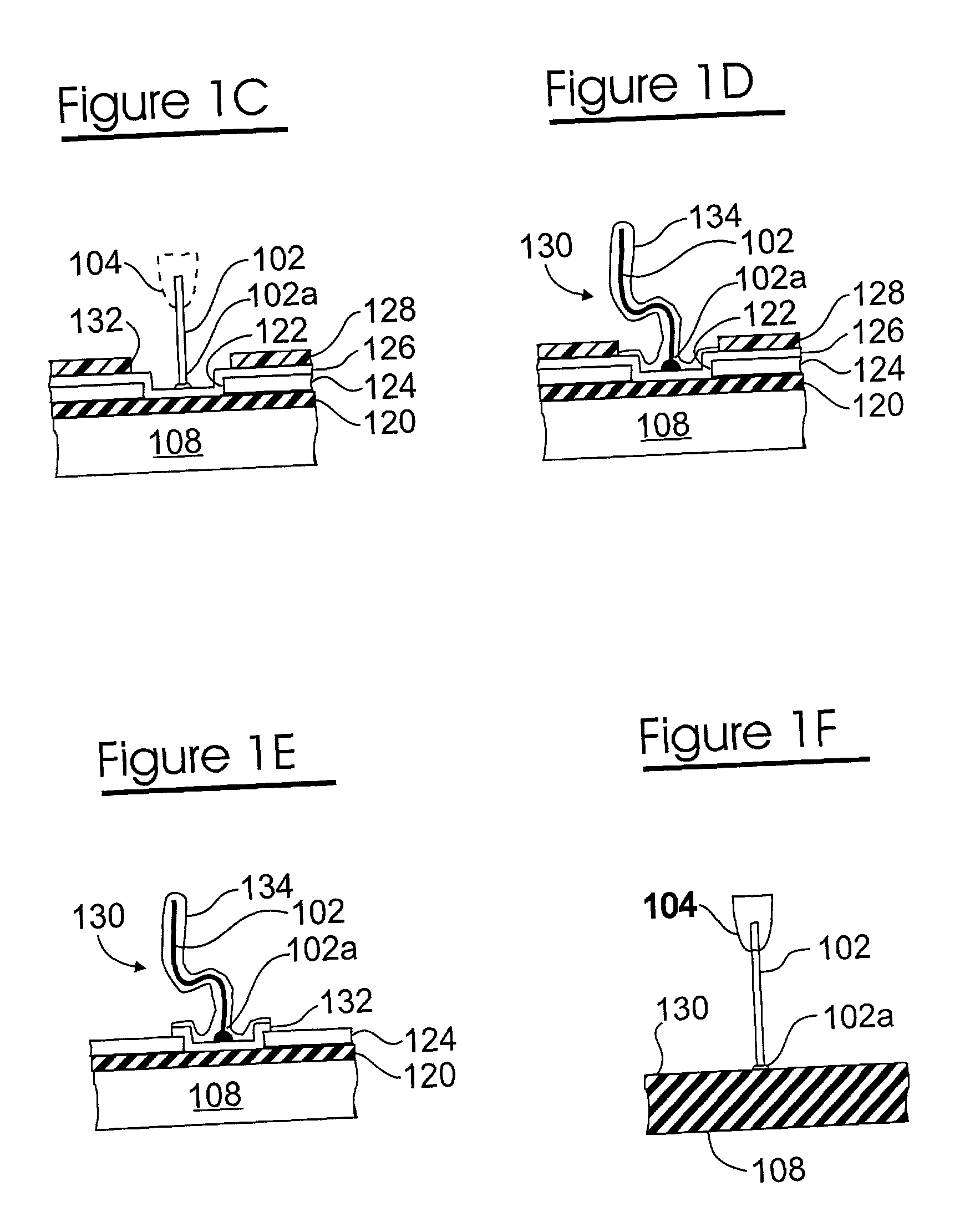

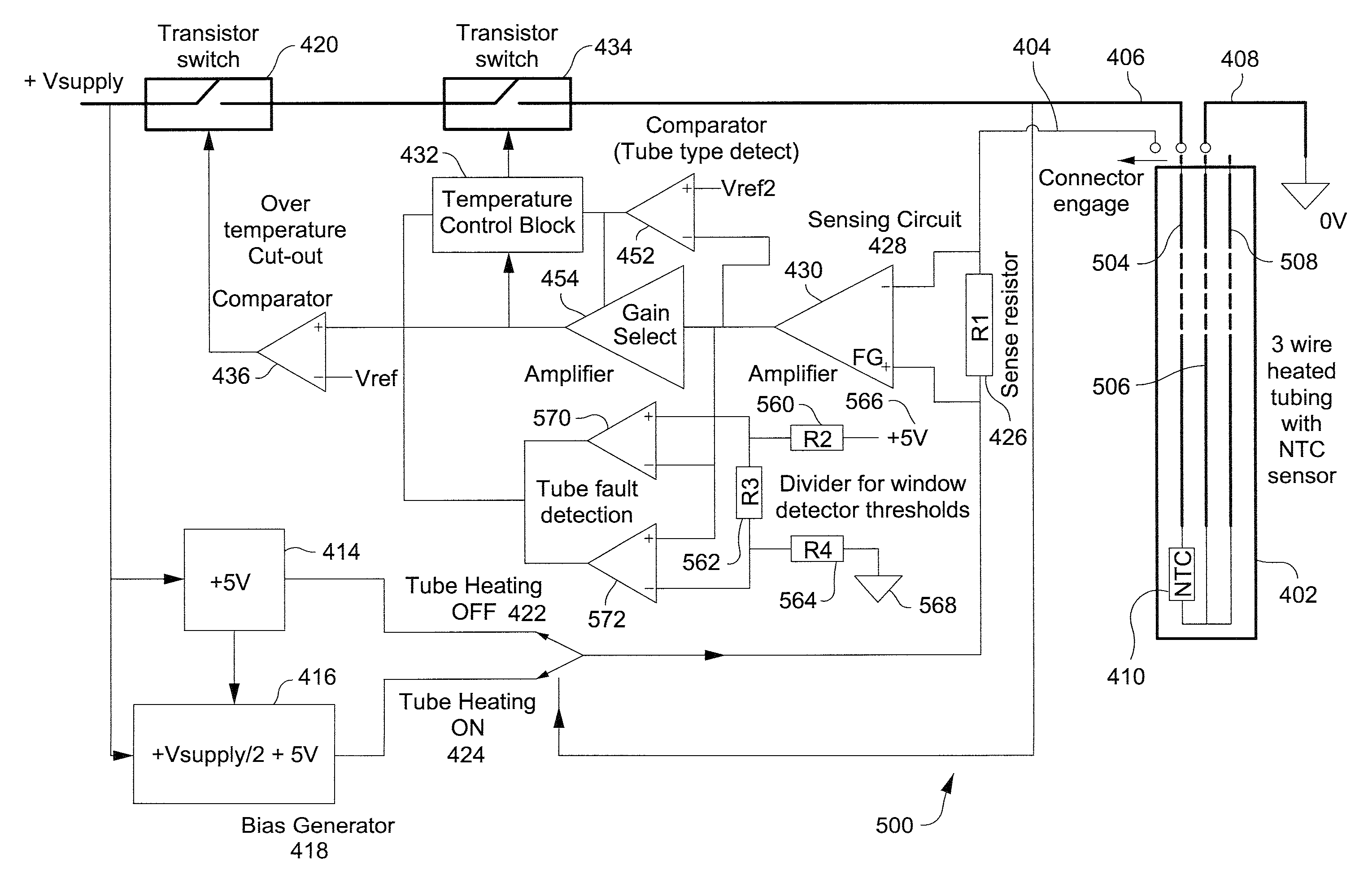

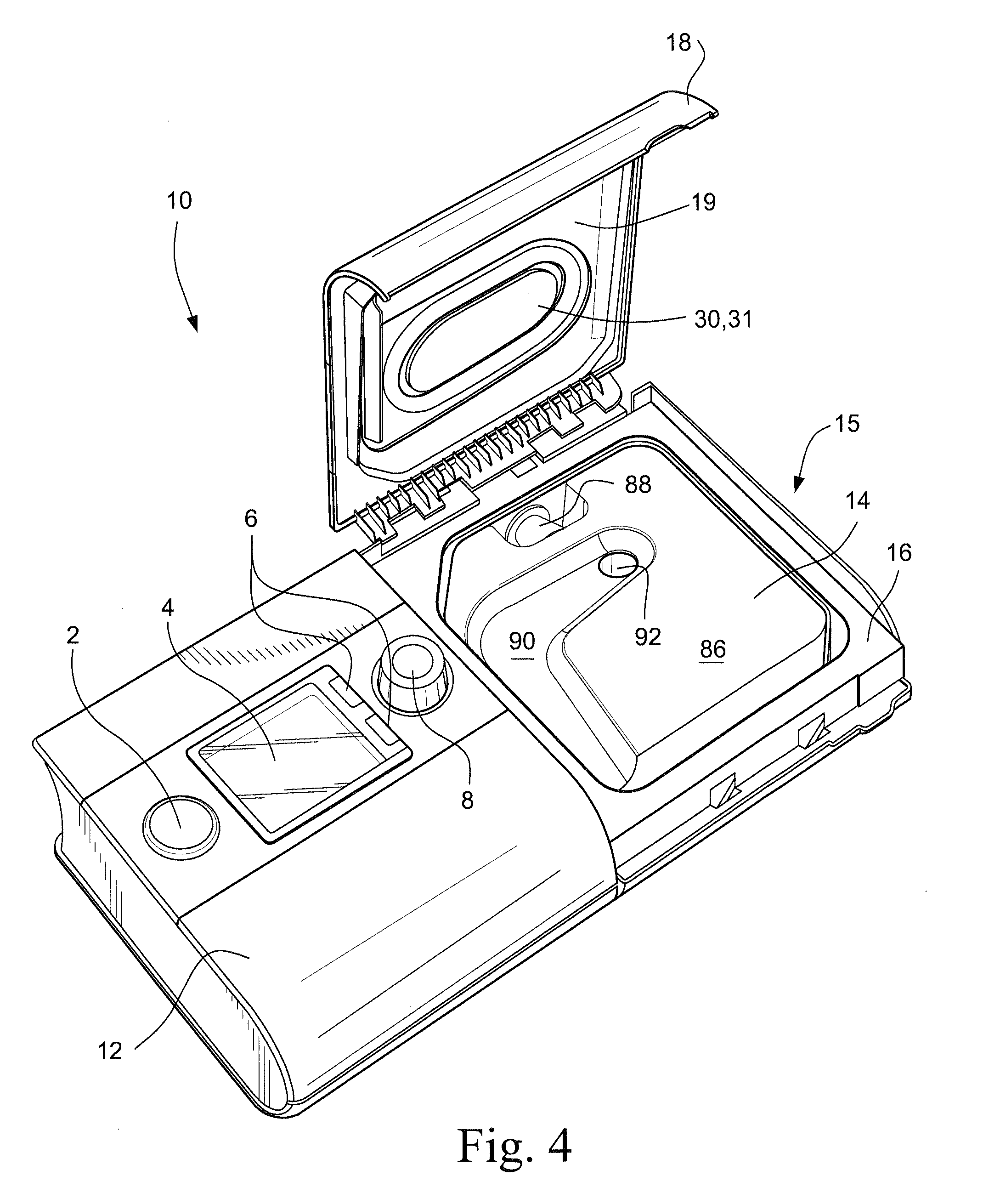

Wire heated tube with temperature control system, tube type detection, and active over temperature protection for humidifier for respiratory apparatus

ActiveUS8733349B2Reduce condensationAvoid overall overheatingOther heat production devicesRespiratory masksTemperature controlWater vapor

A PAP system for delivering breathable gas to a patient includes a flow generator to generate a supply of breathable gas to be delivered to the patient; a humidifier including a heating plate to vaporize water and deliver water vapor to humidify the supply of breathable gas; a heated tube configured to heat and deliver the humidified supply of breathable gas to the patient; a power supply configured to supply power to the heating plate and the heated tube; and a controller configured to control the power supply to prevent overheating of the heating plate and the heated tube.

Owner:RESMED LTD

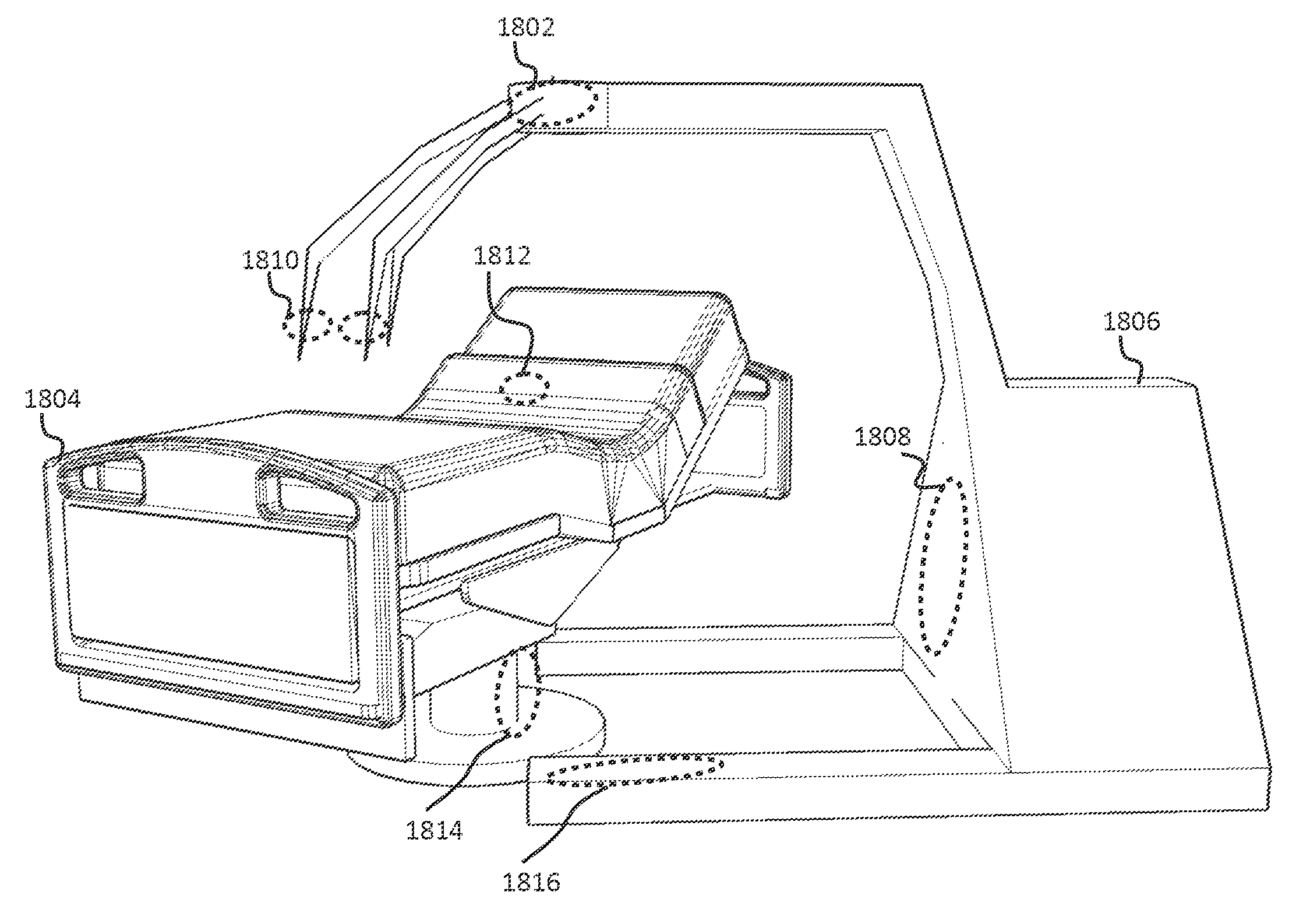

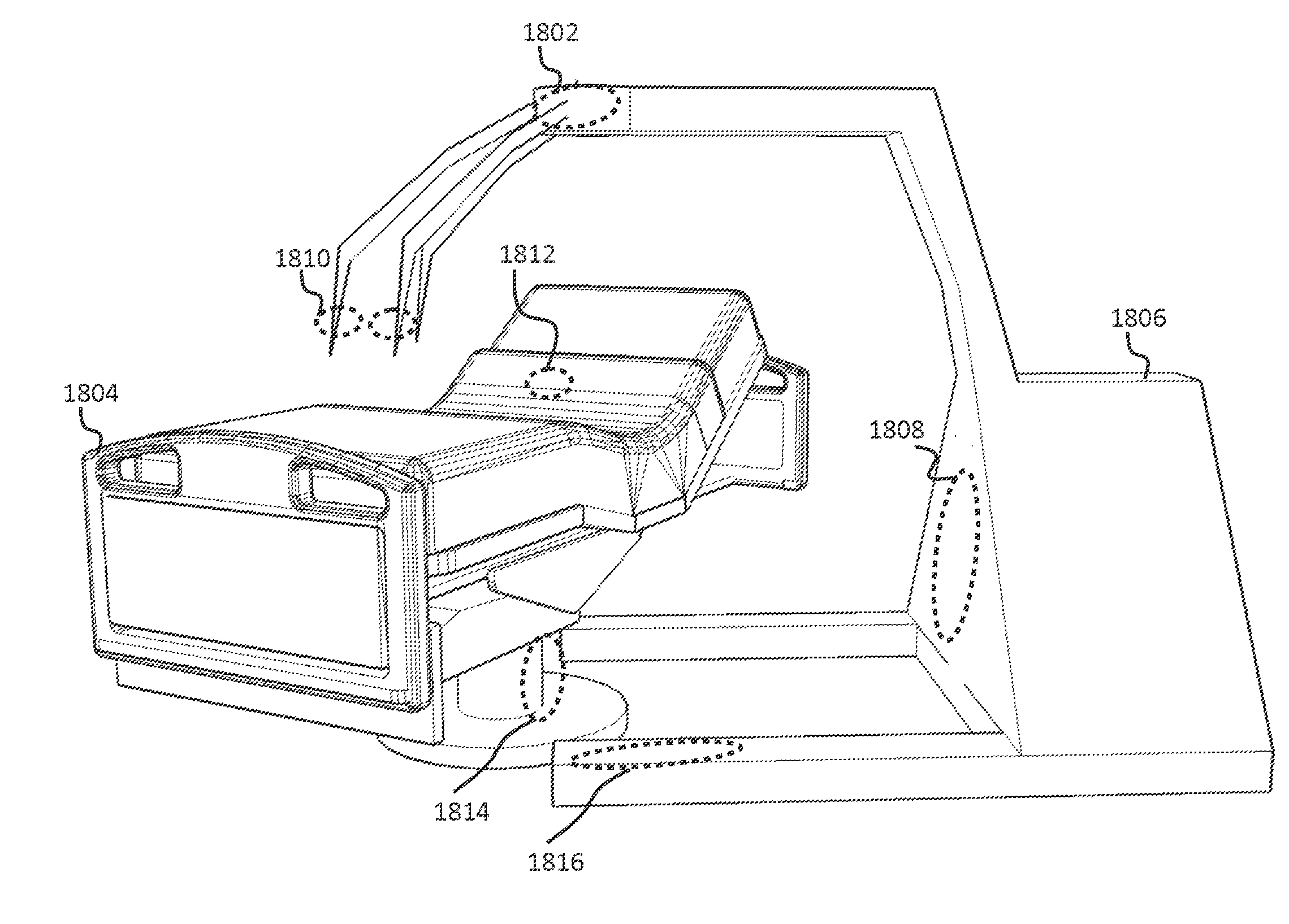

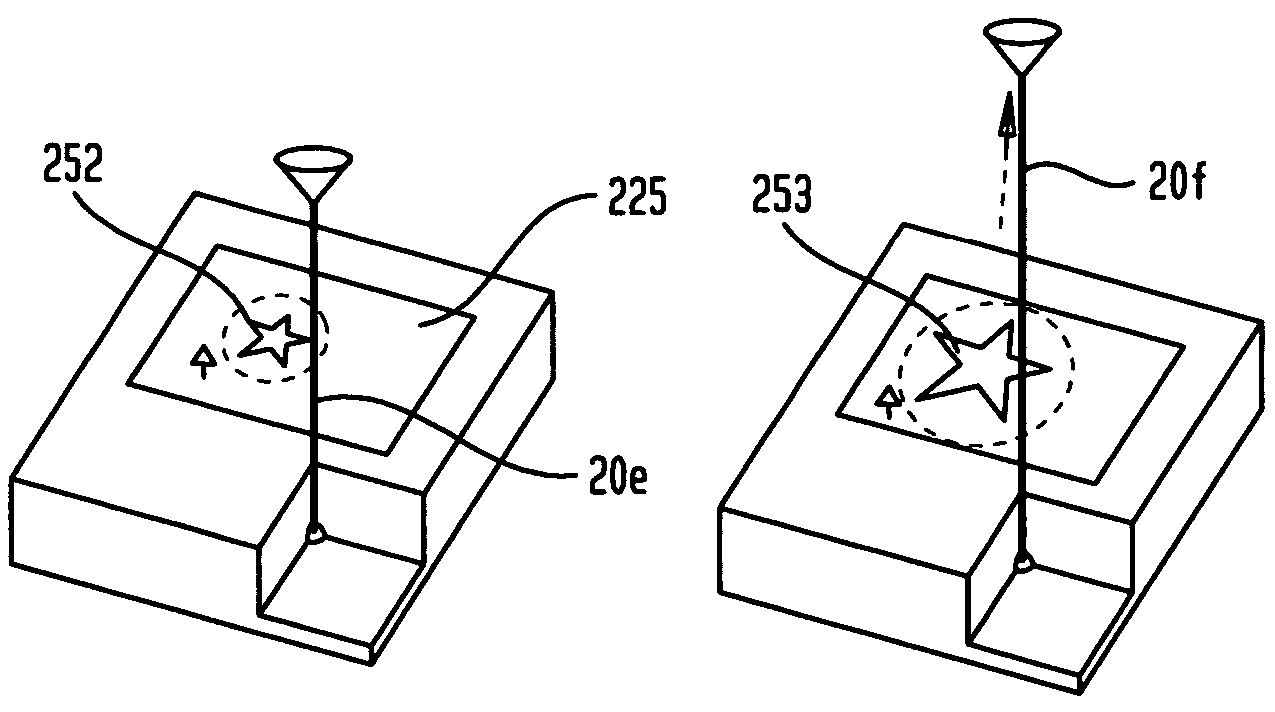

Wireless energy transfer for medical applications

Described herein are improved configurations for a wireless power transfer. Described are methods and designs for medical environments and devices. Wireless energy transfer is utilized to eliminate cords and power cables from operating instruments and electronic equipment requiring mobility.

Owner:WITRICITY CORP

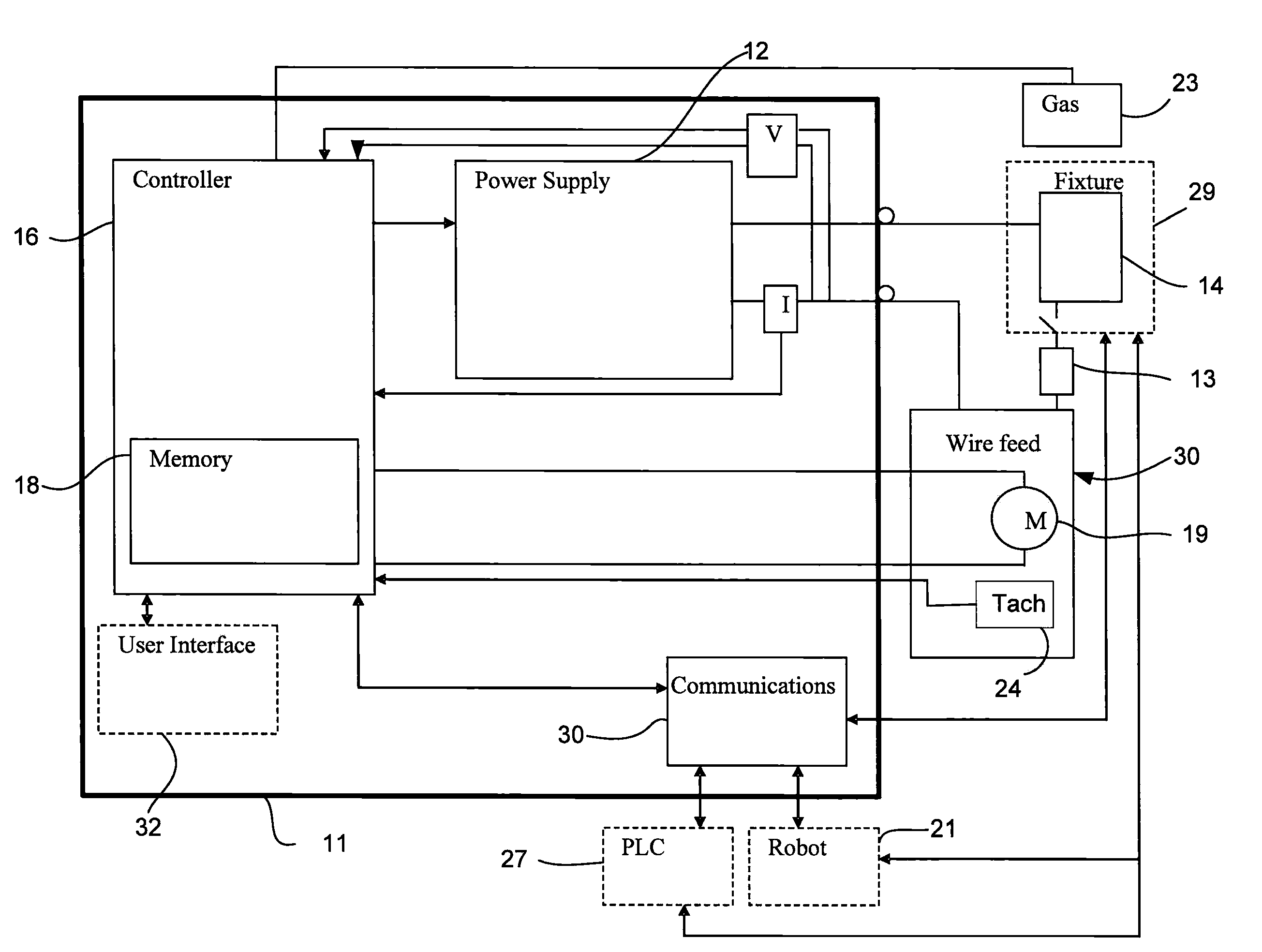

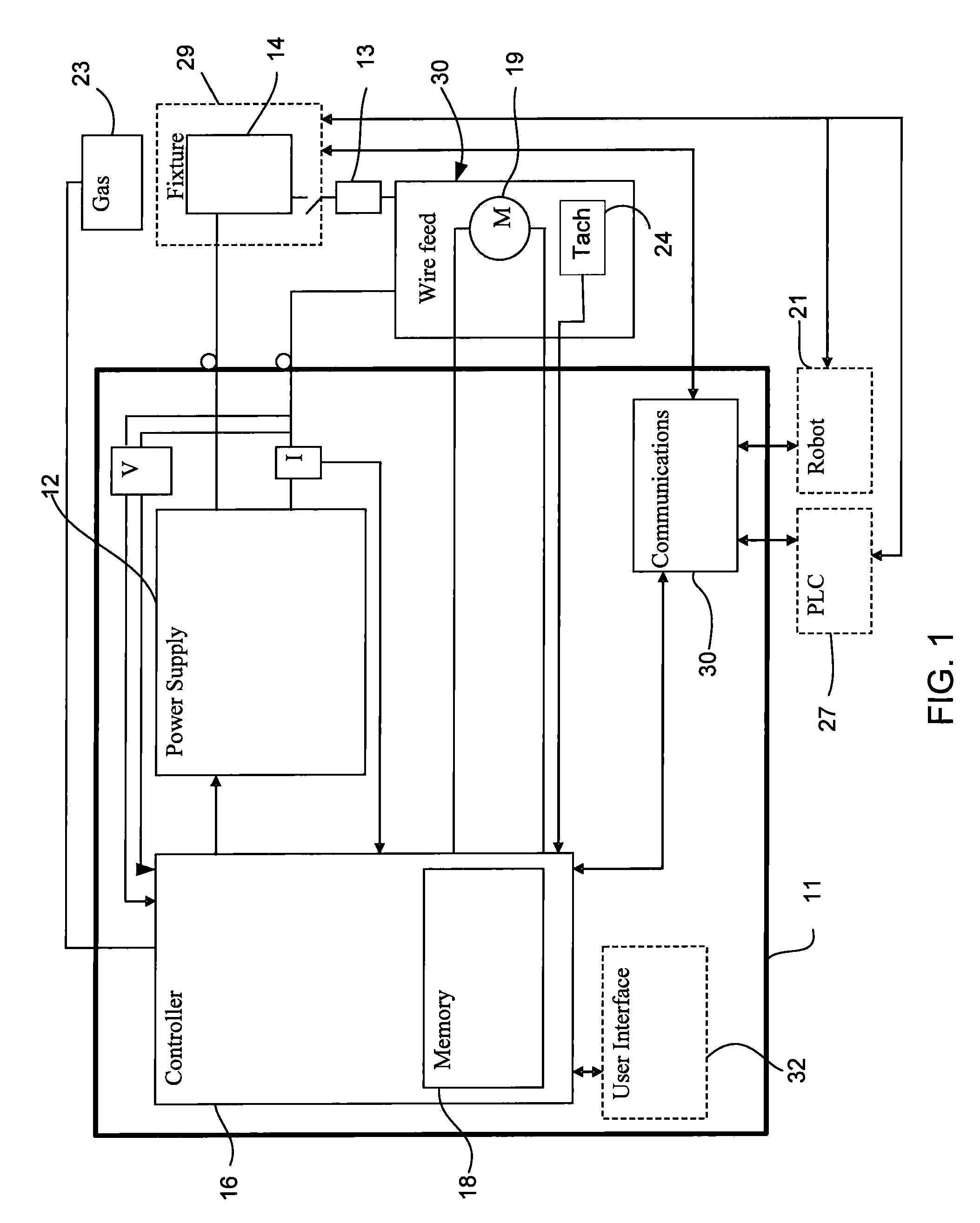

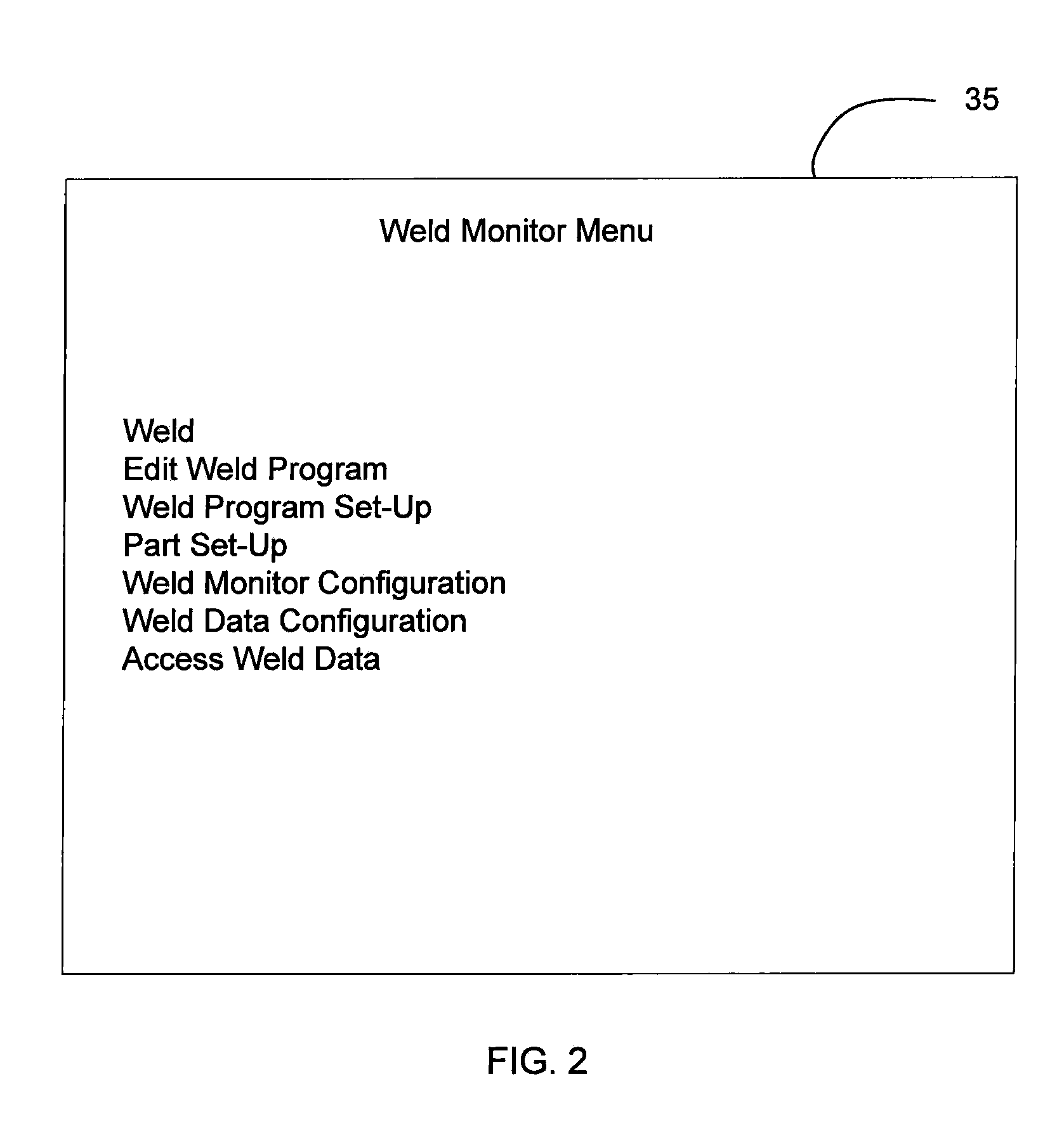

Automatic Weld Arc Monitoring System

A welding system including an arc monitoring, training, and control system is disclosed. The welding system includes a power supply, controller, and associated memory. When a weld is performed, the weld command and weld feedback parameters can be stored in the memory, along with associated alarm limit values. During subsequent welds, the input weld commands and actual feedback values can be compared to the established limits, and a fault signal provided to an operator or supervisor when the value exceeds the established limits. The fault signals can be used for training operators, as well as providing monitoring signals, and can be stored with weld data in a database for later analysis. In addition, collected weld data can be used to determine when to clean, repair, or replace consumables, including, for example, contact tips, wire drive liners, and drive rolls, and to monitor usage of wire and gas.

Owner:ILLINOIS TOOL WORKS INC

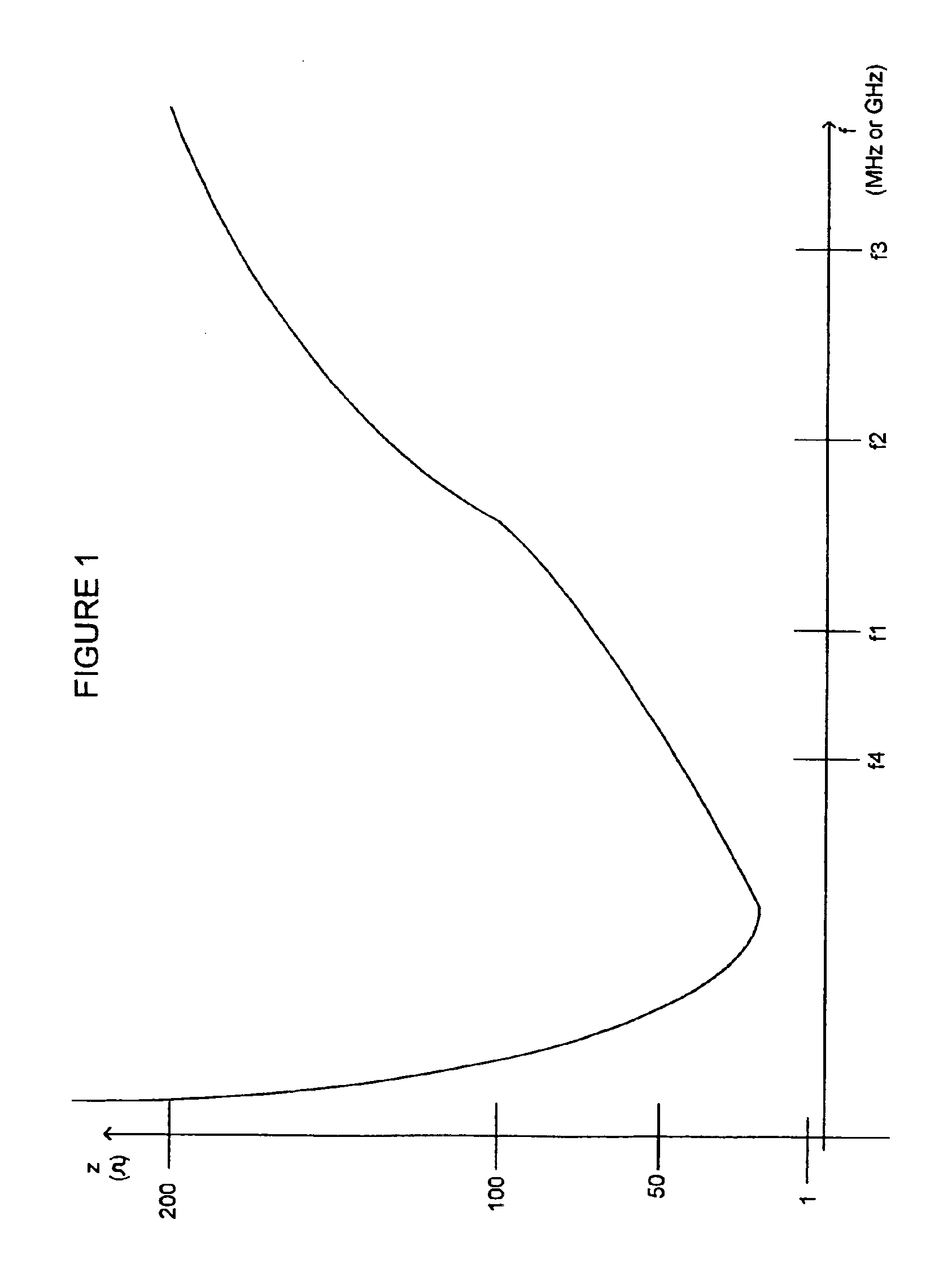

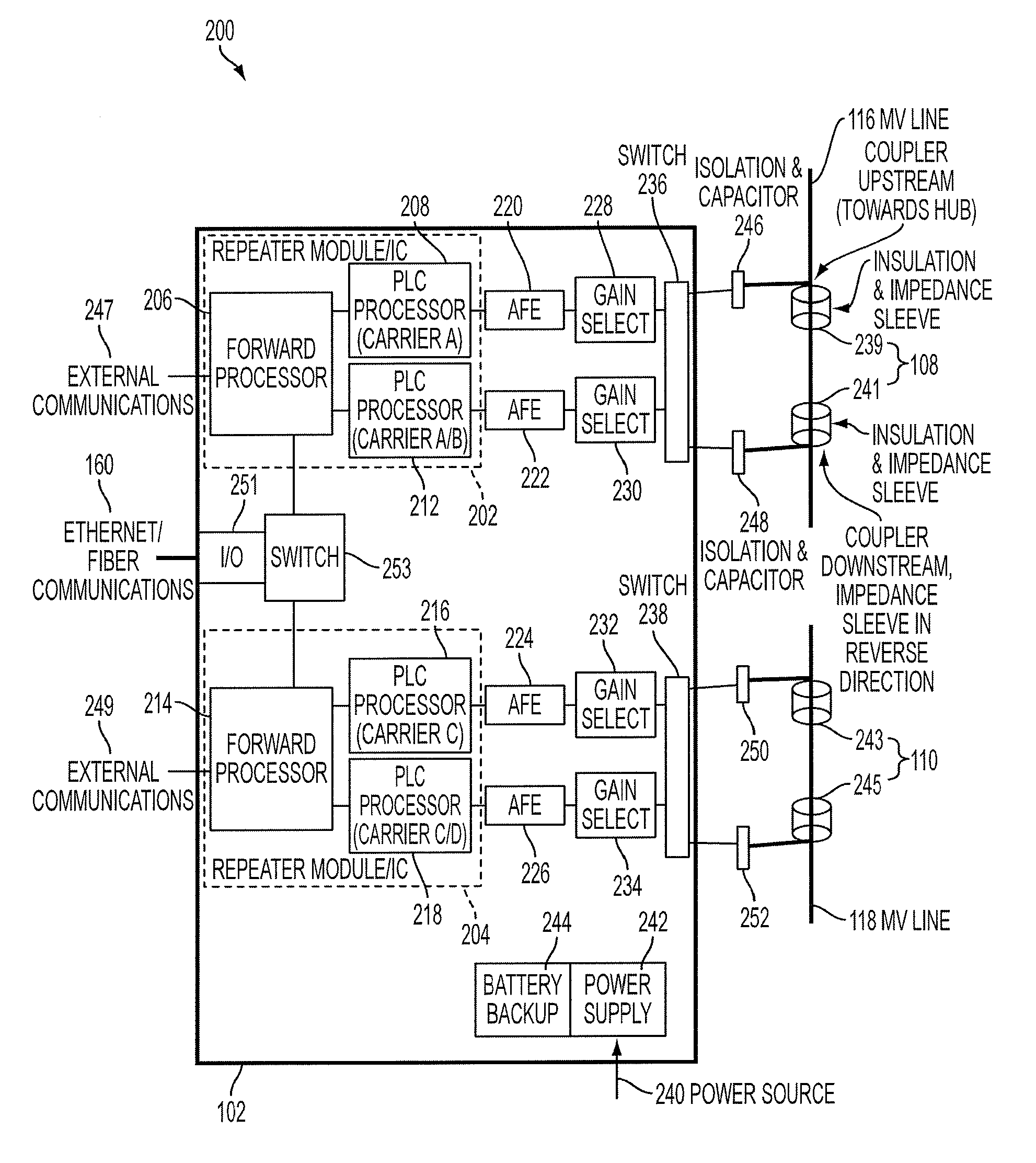

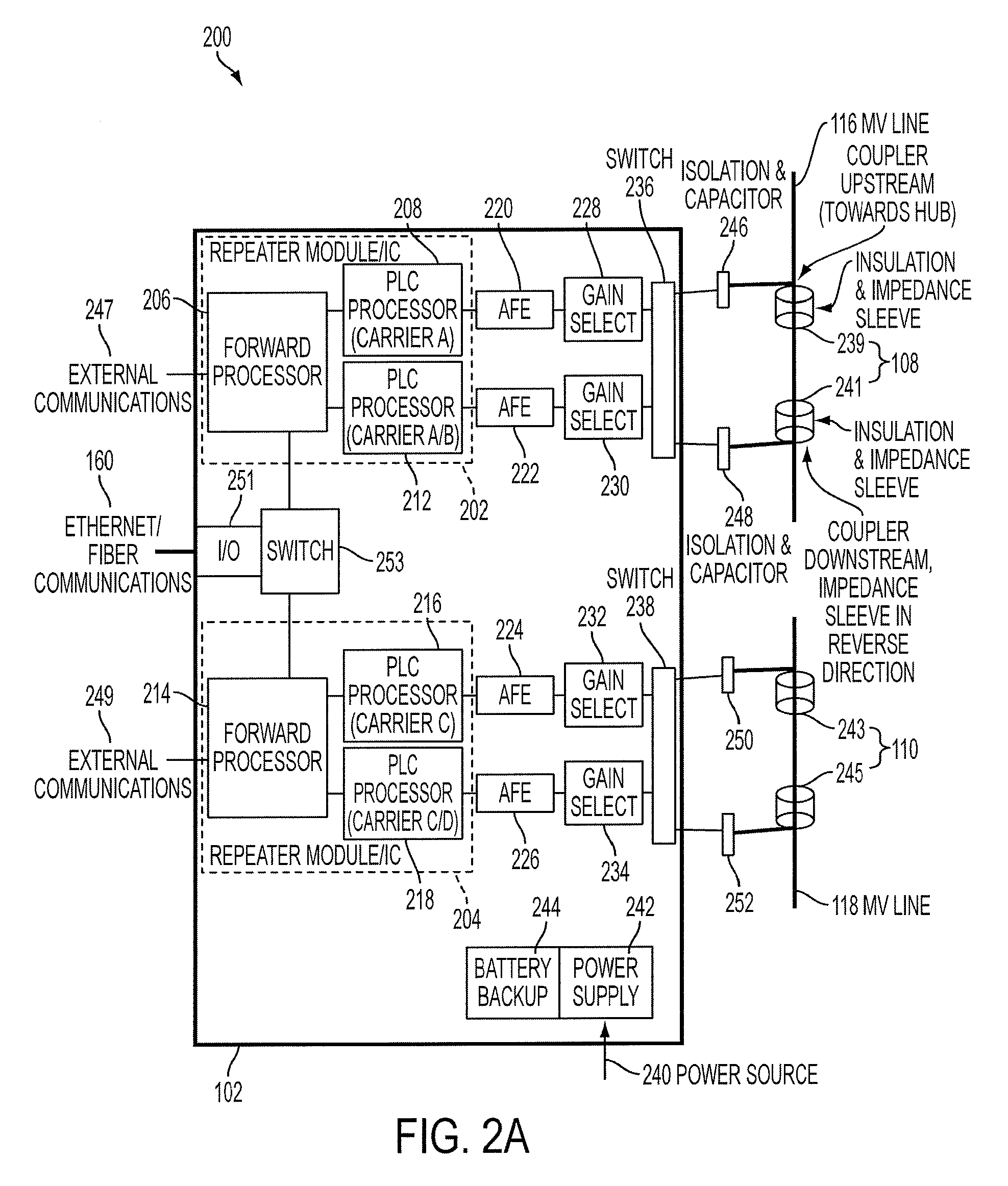

High frequency network multiplexed communications over various lines using multiple modulated carrier frequencies

InactiveUS6922135B2Substantial phase distortionMultiple-port networksPowerline communication systemsCapacitanceModem device

An apparatus is provided for high frequency multiplexed electrical line communication for cable TV, telephone, internet, security and other control applications over the mid and low voltage power lines and directly through the transformers. The apparatus includes a transmitter, a receiver, a modem, a multiplexer and multiple couplers at each of two or more locations along an electrical line. The couplers have capacitive circuits serially connected with an air-core or dielectric-core transformer. The capacitive circuits resonate with the transformer at a preselected frequency. The coupler eliminates noise and is matched to the characteristic impedance of the line at the preselected frequency, which linearizes communication on the line and allows high speed data and voice communication over long distances. Multiple modulators and demodulators are used to produce multiple modulated carrier frequencies.

Owner:SATIUS

System and method for high speed communication of video, voice and error-free data over in-wall wiring

InactiveUS6014386AElectric signal transmission systemsInterconnection arrangementsDielectricSignal lines

A communication network and method, including an information signal line which carries a plurality of selectable information signals. Electrical lines run throughout a building, with electrical outlets connected to the electrical line. An electrical line distribution panel connects the information signal line and the electrical line for distributing the selectable information signals over the electrical line to the location of a given electrical outlet. Dielectric-core couplers which are impedance-matched with the electrical line are connected to the electrical outlets. At least one communication station is connected to a dielectric-core coupler for receiving the selectable information signals.

Owner:SATIUS

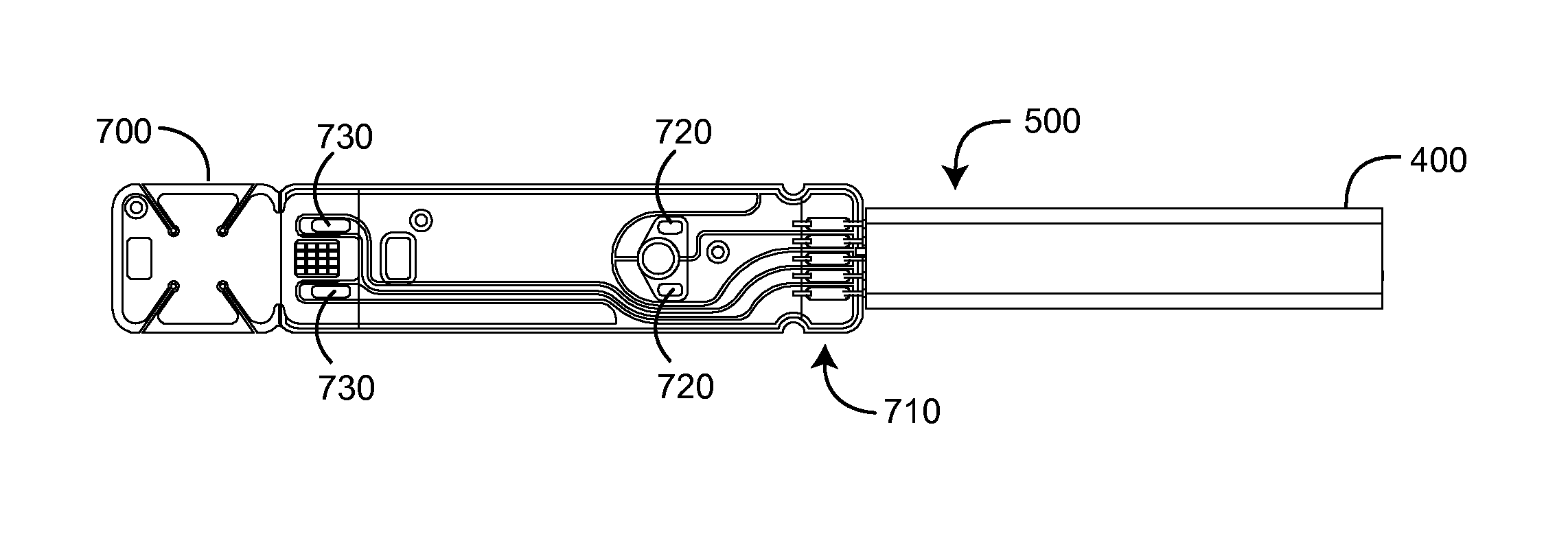

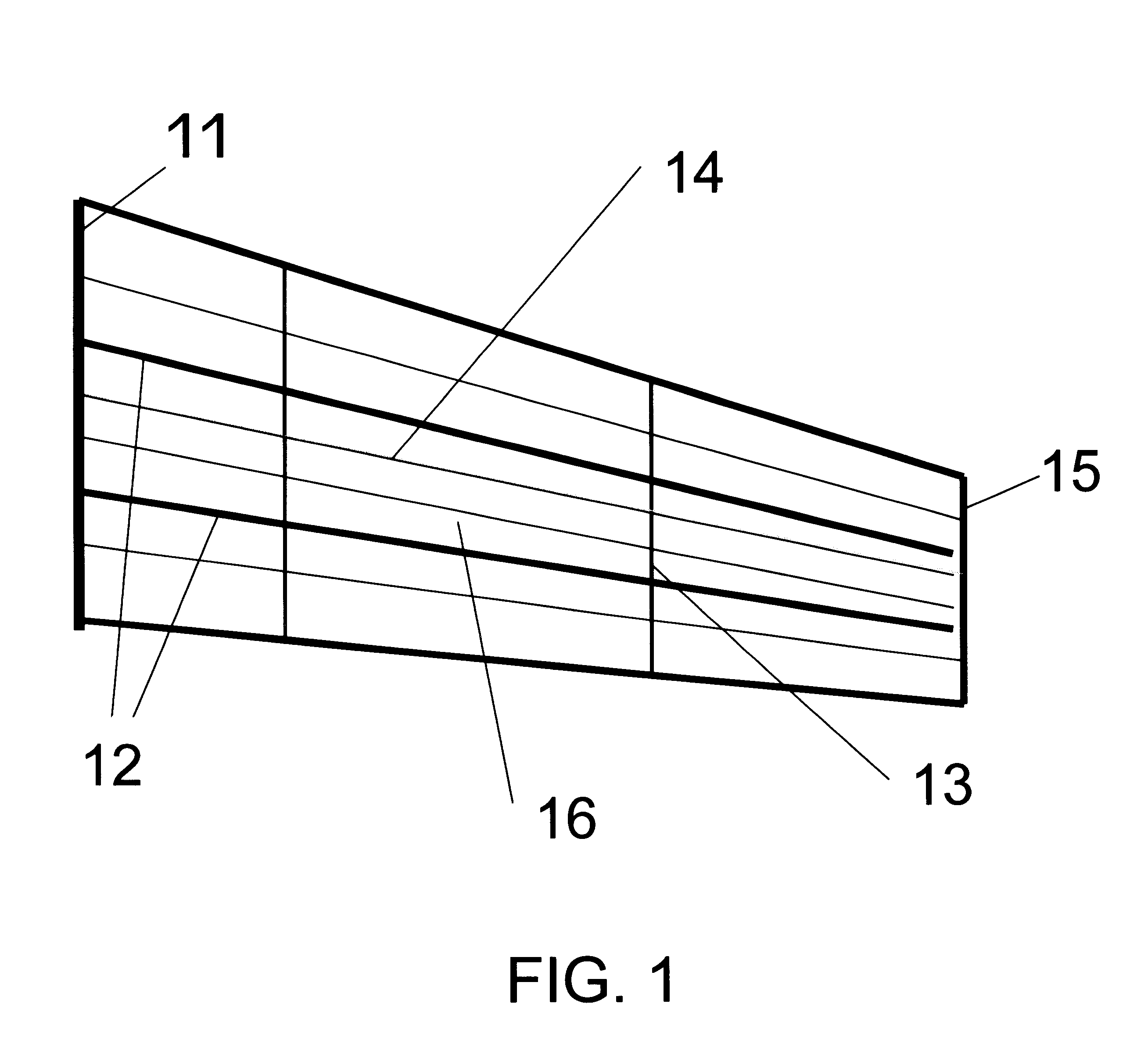

Automated assembly sensor cable

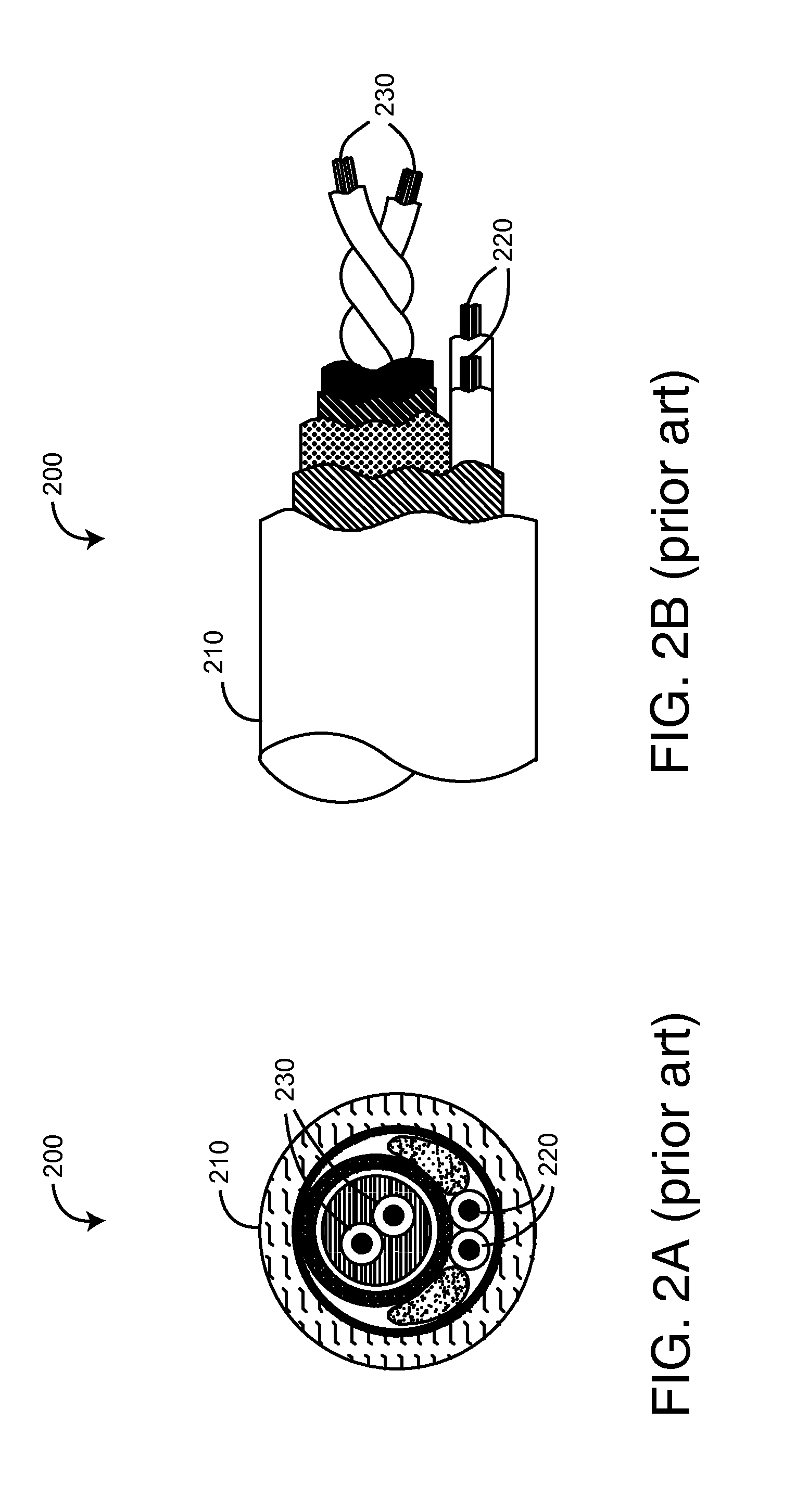

ActiveUS20140034353A1High strengthLine/current collector detailsElectrically conductive connectionsElectrical conductorBiomedical engineering

An automated assembly sensor cable has a generally wide and flat elongated body and a registration feature generally traversing the length of the body so as to identify the relative locations of conductors within the body. This cable configuration facilitates the automated attachment of the cable to an optical sensor circuit and corresponding connector. In various embodiments, the automated assembly sensor cable has a conductor set of insulated wires, a conductive inner jacket generally surrounding the conductor set, an outer jacket generally surrounding the inner jacket and a registration feature disposed along the surface of the outer jacket and a conductive drain line is embedded within the inner jacket. A strength member may be embedded within the inner jacket.

Owner:JPMORGAN CHASE BANK NA

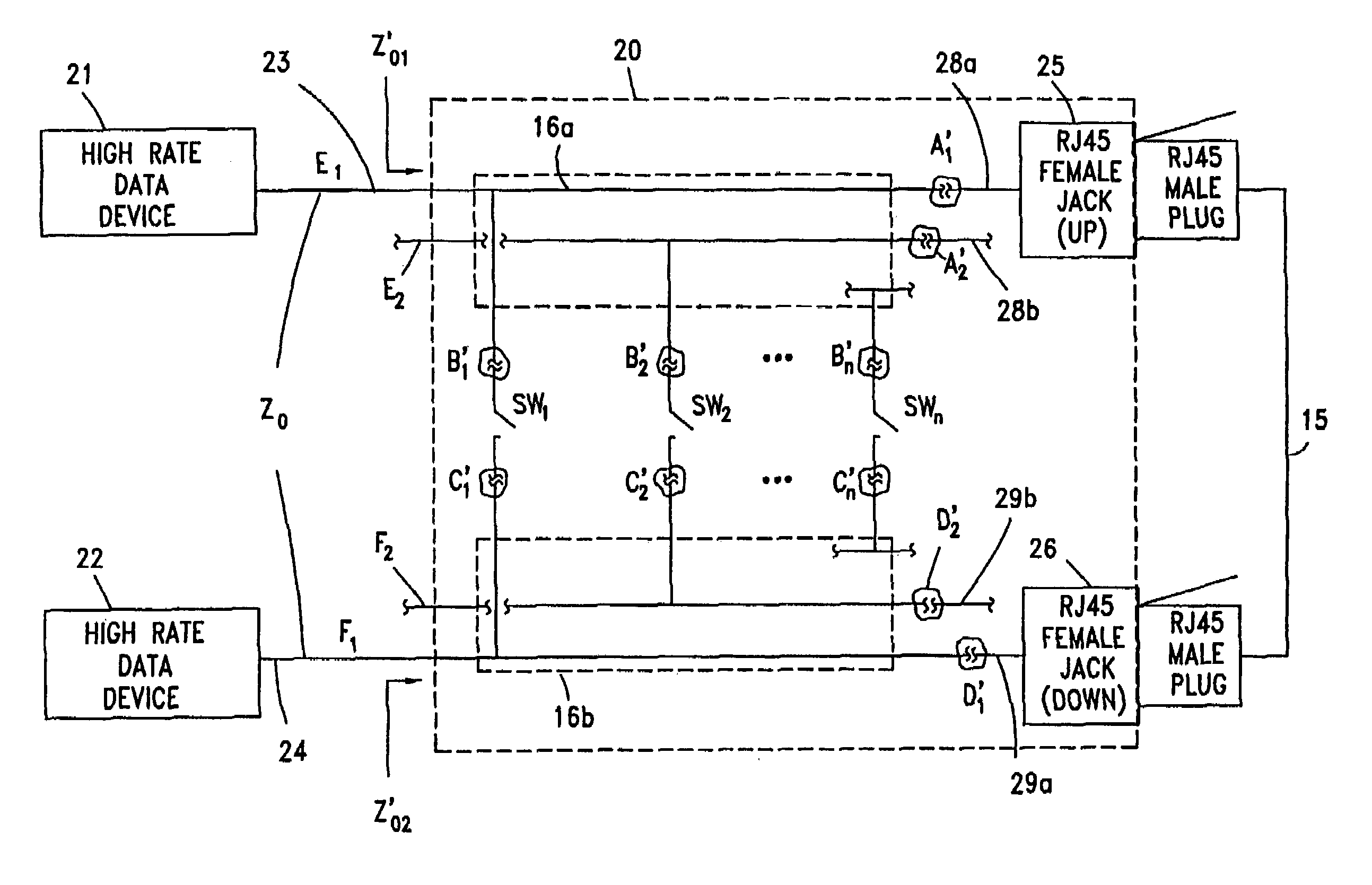

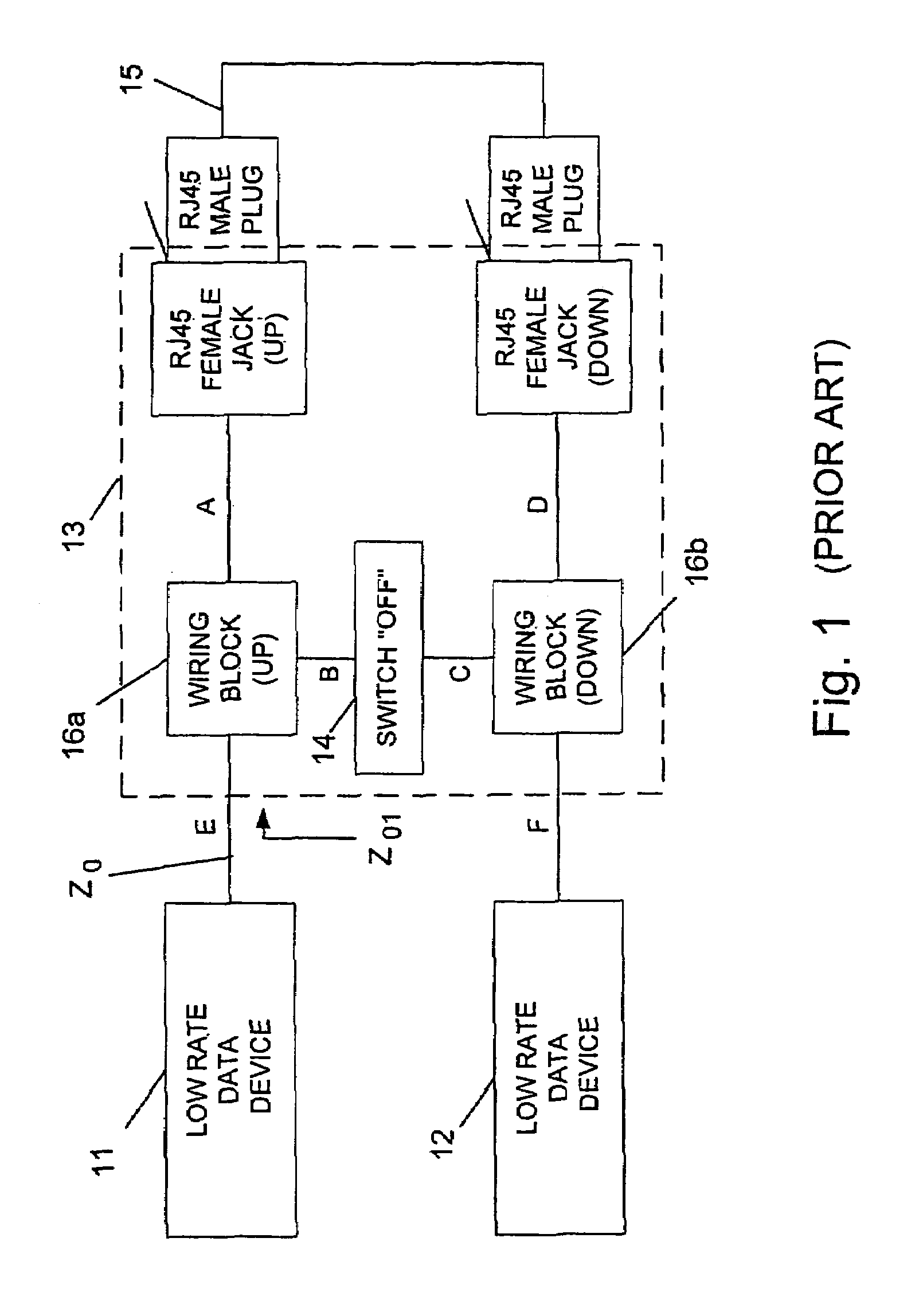

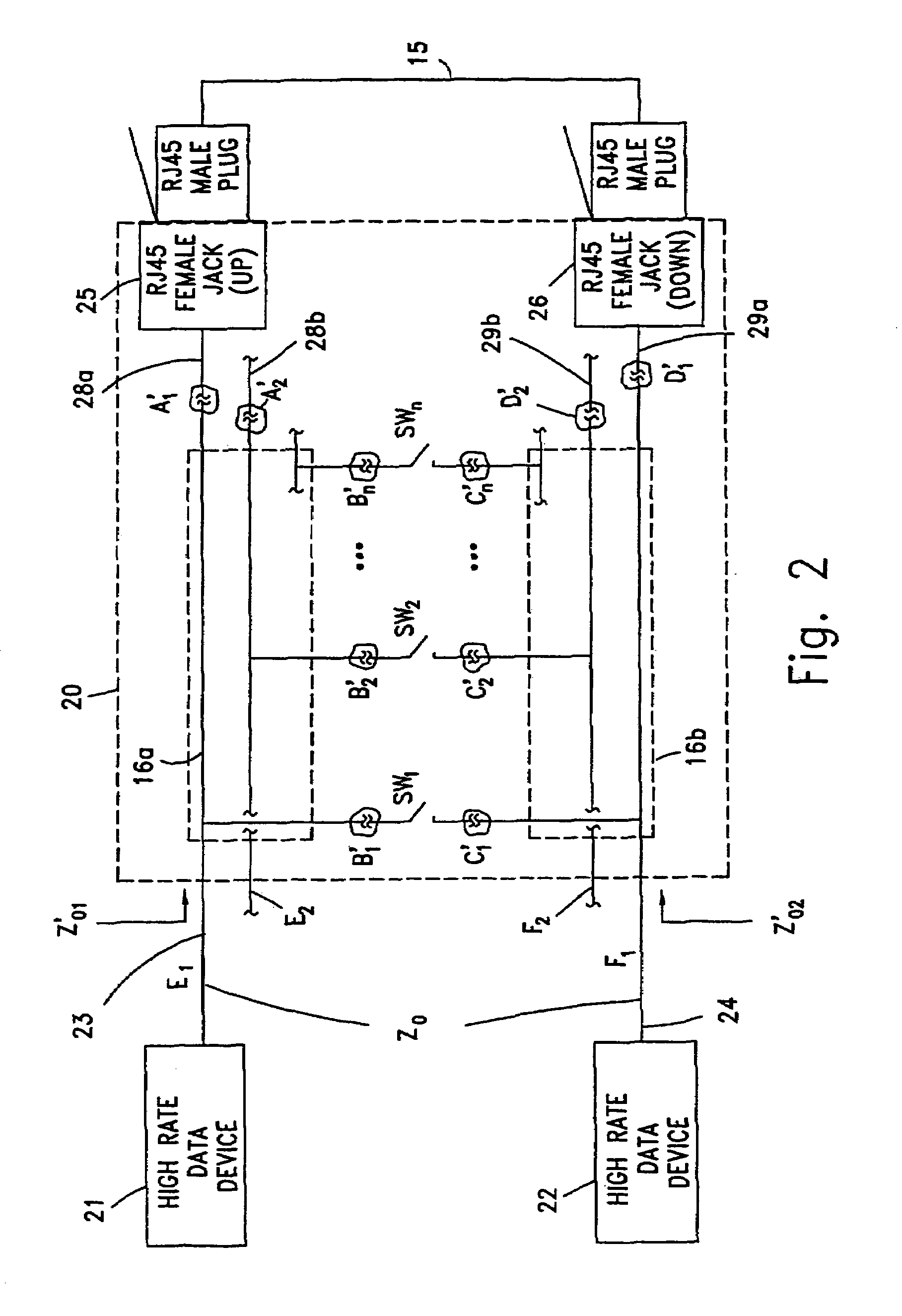

High data rate interconnecting device

InactiveUS7315224B2Minimize impedance mismatchConsiderable immunity to external interferenceCoupling for high frequencyPrinted circuit detailsData signalEngineering

An interconnect apparatus for providing a communication path for data signals in a predetermined frequency band, that includes a first and a second sections of a transmission line, connected at one end to first and second data transceiving devices, respectively. A switch, such as a mechanical, electro-mechanical, electronic, electro-magnetic and electro-optical switch, having conductive / non-conductive states, is provided for connecting / disconnecting between the other ends of the first and the second sections, for providing a data communication path between the data transceiving devices while being in its conductive state a third and a fourth sections of a transmission line, each of which connected at one end to a contact of the switch and at the other end to a first and a second connector, respectively. A compensation circuitry is provided for compensating, within the frequency band, parasitic effects caused by the switch and / or cord, while the switch is in its conductive state or, while the switch is in its non-conductive state and while a connection between the first and the second connectors is provided by a cord having predetermined characteristics, such that the compensation circuitry compensates the influence of parasitic effects introduced along the communication path by the switch while being in its non-conductive state and while the cord is a part of the communication path or, by the combination of the third and a fourth sections and the connectors while the switch is in its conductive state.

Owner:RIT TECHNOLOGIES

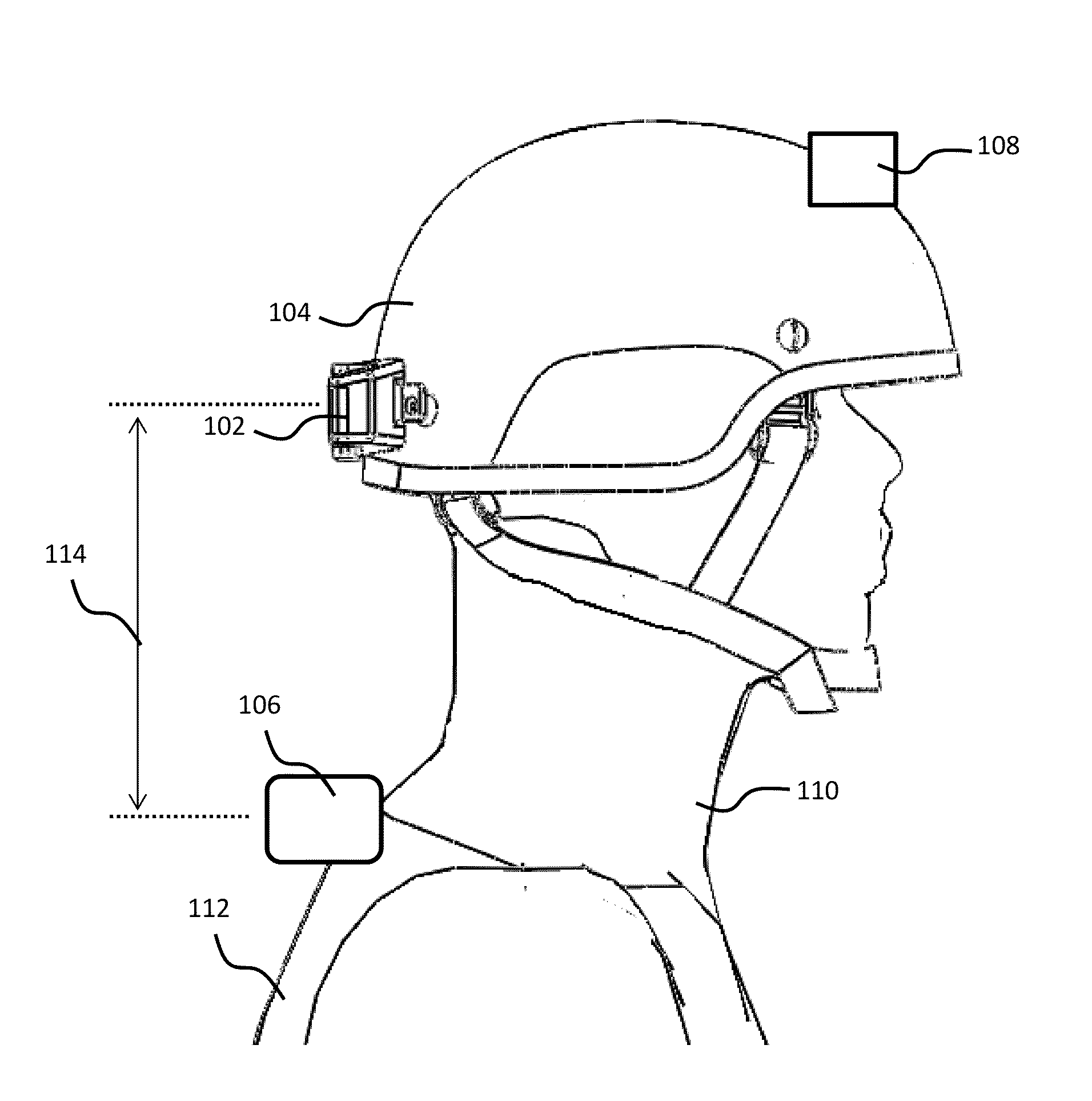

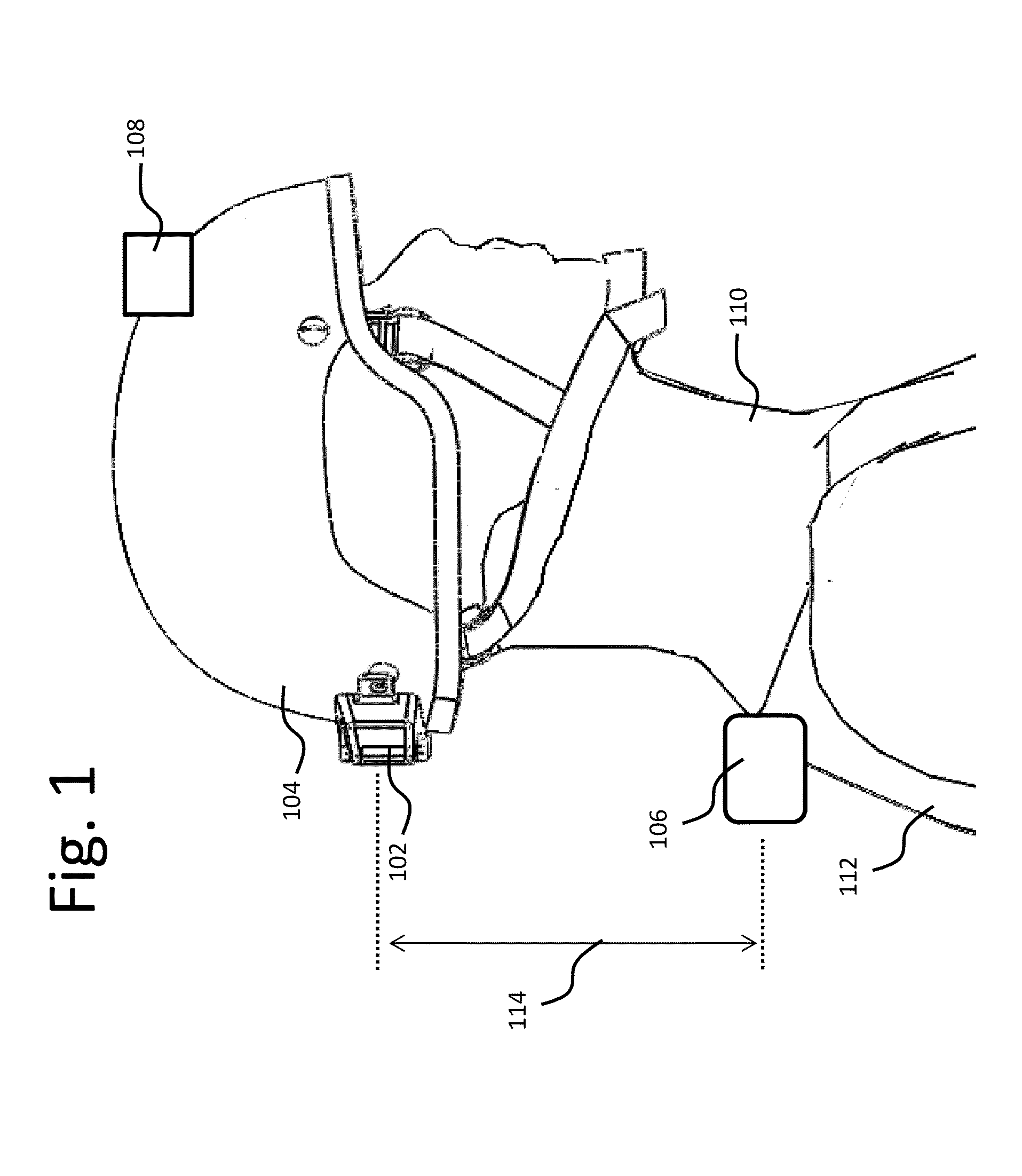

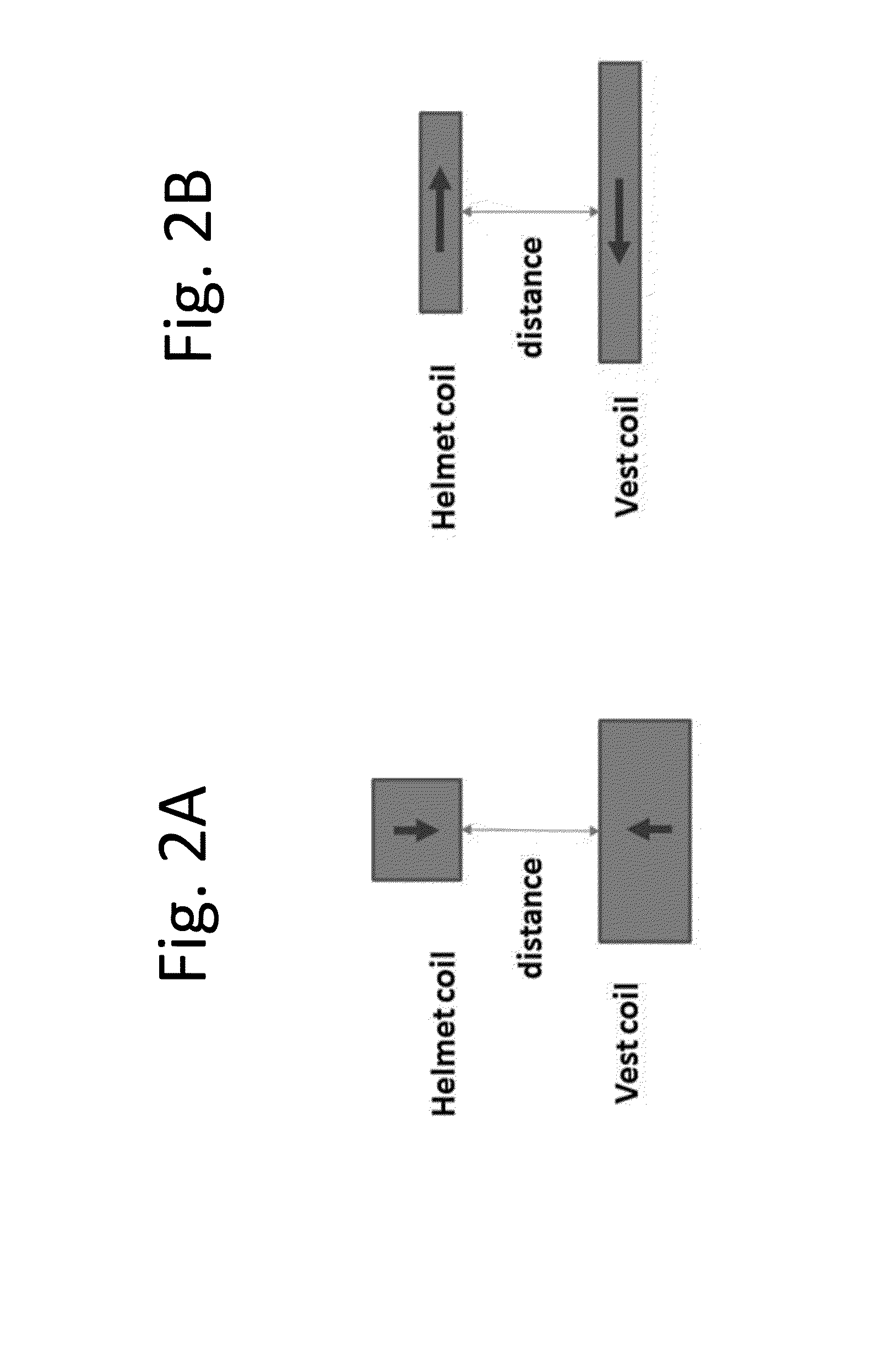

Wireless energy transfer for person worn peripherals

InactiveUS20130007949A1Reduce interactionBatteries circuit arrangementsElectromagnetic wave systemHand heldEngineering

Described is a system for wireless energy transfer for person worn peripherals. The system makes use of a technique referred to as strongly-coupled magnetic resonance to transfer energy across a distance without wires and enables efficient transfer of energy over distances of 10 to 18 cm or more. The system comprises a resonant power source, which could be embedded in a person's equipment vest or backpack receiving power from a central battery pack or micro fuel cell, and a resonant power capture unit which could be integrated with the helmet or hand held weapon, electronic device, and the like that may be carried or handled by a person.

Owner:WITRICITY CORP

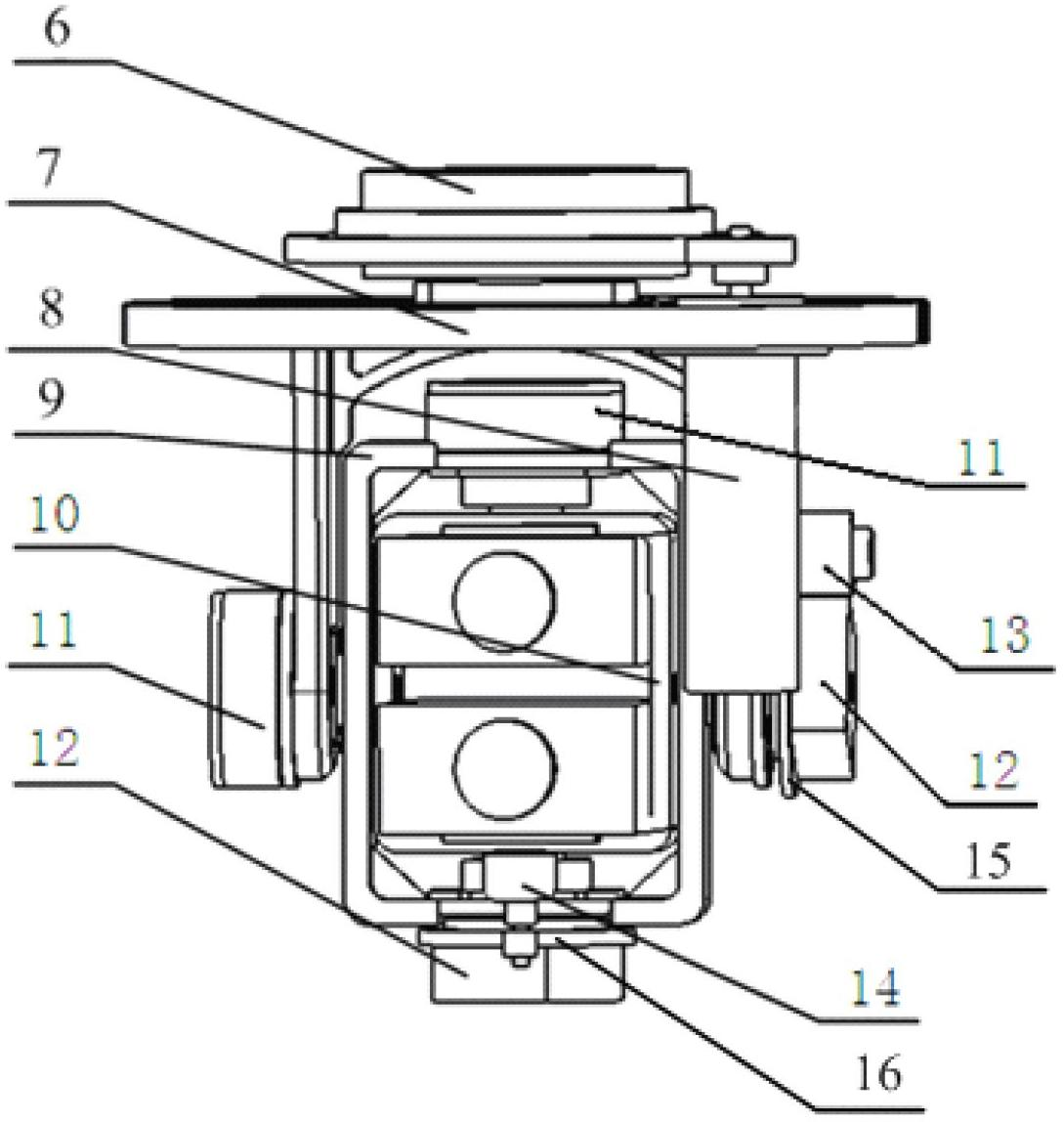

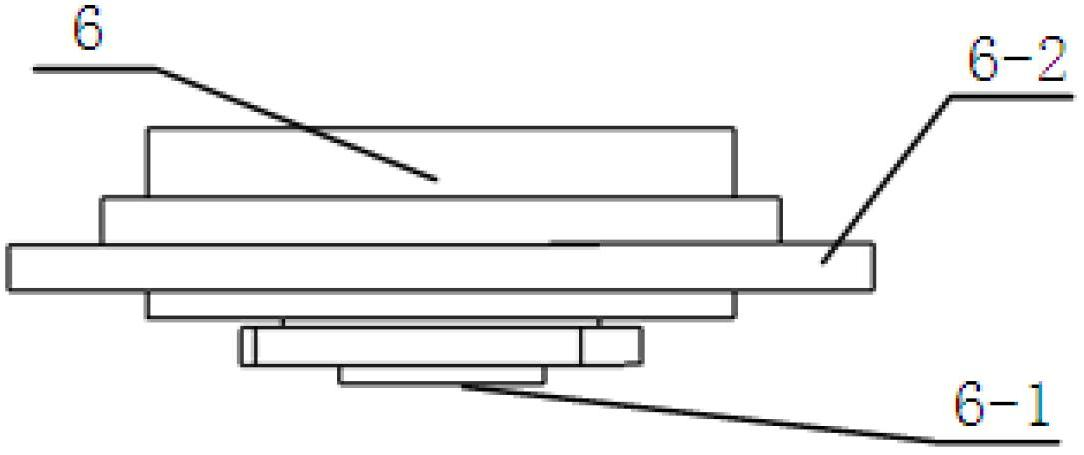

High voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device

ActiveCN102694351AAchieve rotationPrecise Line Tracking TasksCable installation apparatusAircraftsNacelleEngineering

The invention relates to a high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device belonging to the technical field of power line inspection. The invention aims at solving the problem of single technology of the existing overhead transmission line line-inspection. The high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device mainly comprises an unmanned aerial vehicle, a GPS (global position system) inertial integrated attitude azimuth detection device, a damping device, a rotation detection nacelle, a ground data receiving processor and a controller. The high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device is characterized in that the GPS inertial integrated attitude azimuth detection device is arranged at the inner part of the unmanned aerial vehicle; the rotation detection nacelle is hung below the unmanned aerial vehicle by the damping device; a photoelectric stabilized platform is installed in the rotation detection nacelle; flexible combination of any two or more of a visible light camera, an ultraviolet ray imager and a full-digital dynamic thermal infrared imager and a laser ranging device are borne on the photoelectric stabilized platform; and the rotation detection nacelle is provided with a visible window. With the adoption of the high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device, a high voltage transmission line can be monitored, and a comprehensive and precise high voltage overhead transmission line line-inspection task is realized by combining interchange among a plurality of sensors.

Owner:CHANGCHUN UNIV OF SCI & TECH +1

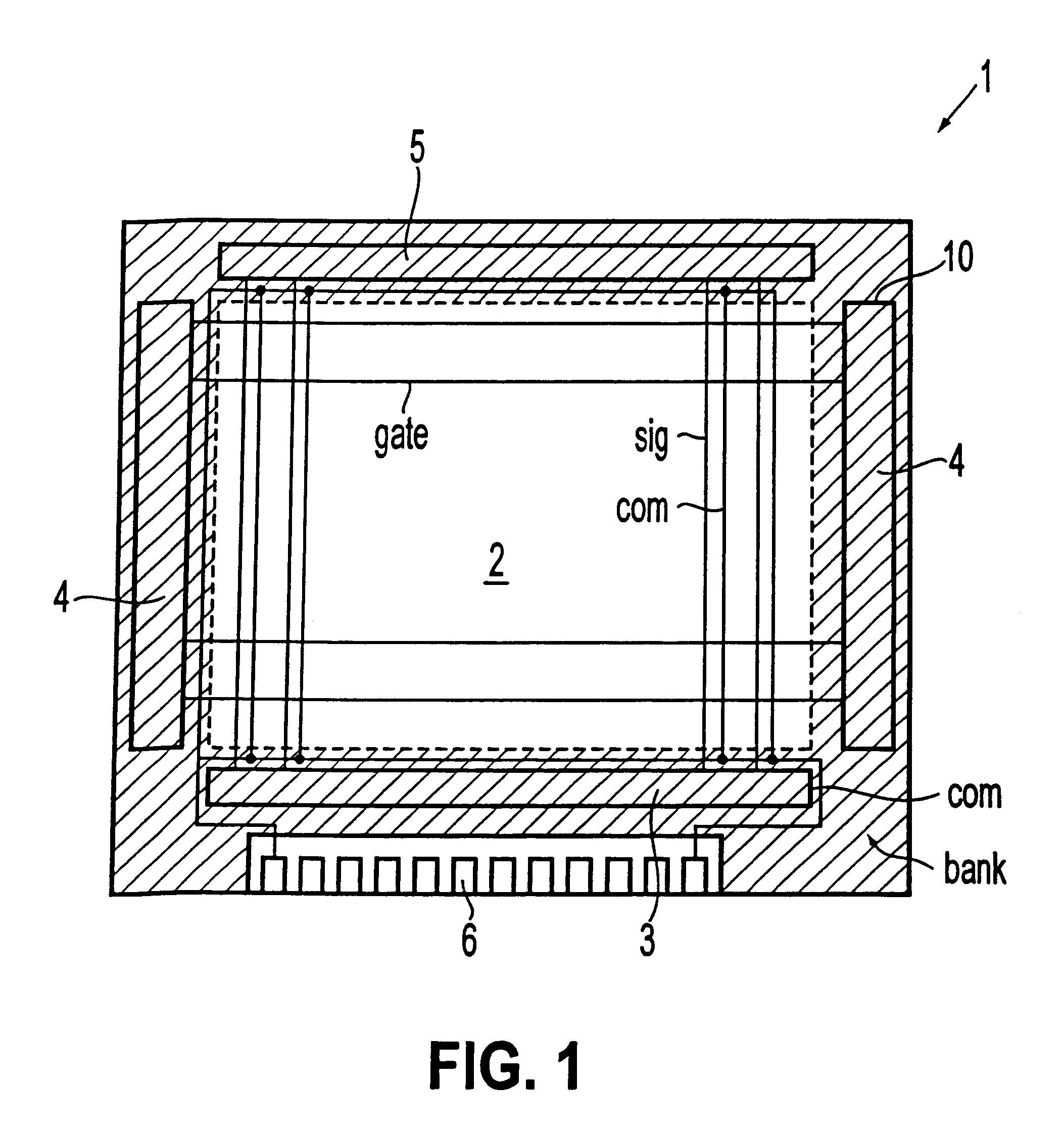

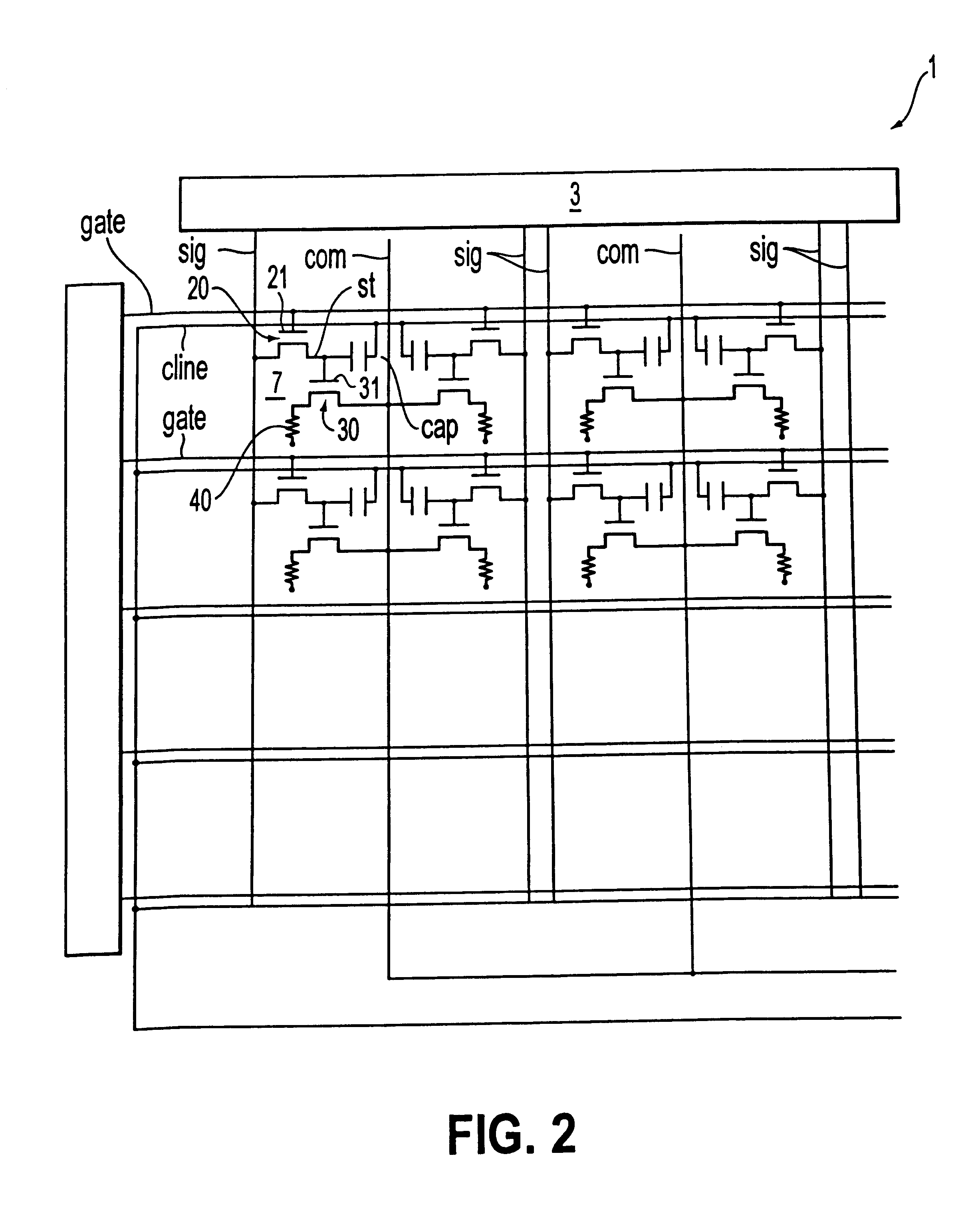

Display apparatus

InactiveUS6618029B1Discharge tube luminescnet screensStatic indicating devicesElectricityDriving current

A display apparatus is provided which is capable of improving display quality by expanding the light-emission area of pixels by improving the layout of pixels and common power-feed lines formed on a substrate. Pixels including a light-emission element, such as an electroluminescence element or an LED element, are arranged on both sides of common power-feed lines so that the number of common power-feed lines is reduced. Further, the polarity of a driving current flowing between the pixels and the light-emission element is inverted so that the amount of current flowing through the common power-supply lines is reduced.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Wireless energy transfer for medical applications

ActiveUS20120139355A1Wide rangeMultiple-port networksBatteries circuit arrangementsEnergy transferPower cable

Described herein are improved configurations for a wireless power transfer. Described are methods and designs for medical environments and devices. Wireless energy transfer is utilized to eliminate cords and power cables from operating instruments and electronic equipment requiring mobility.

Owner:WITRICITY CORP

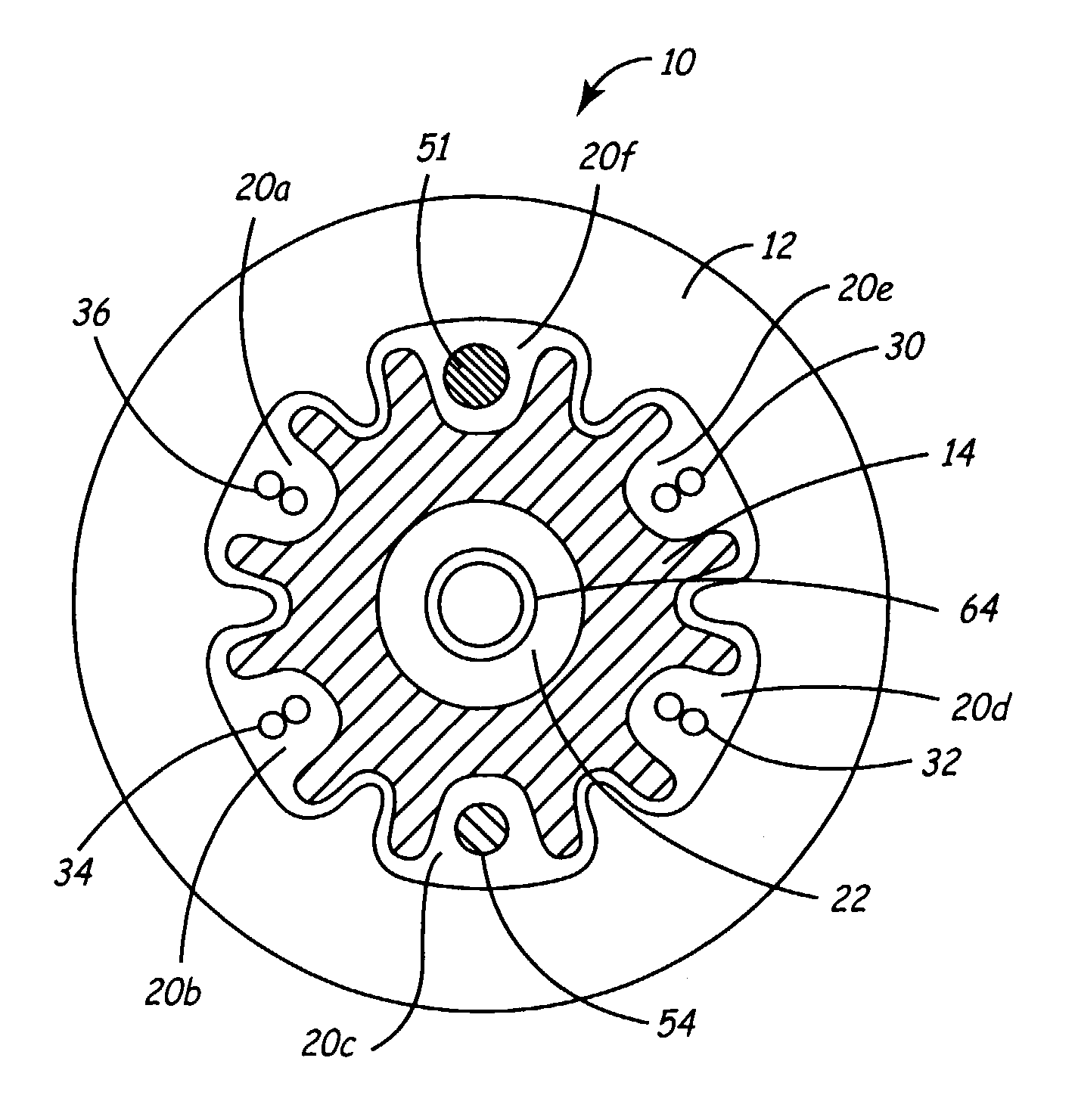

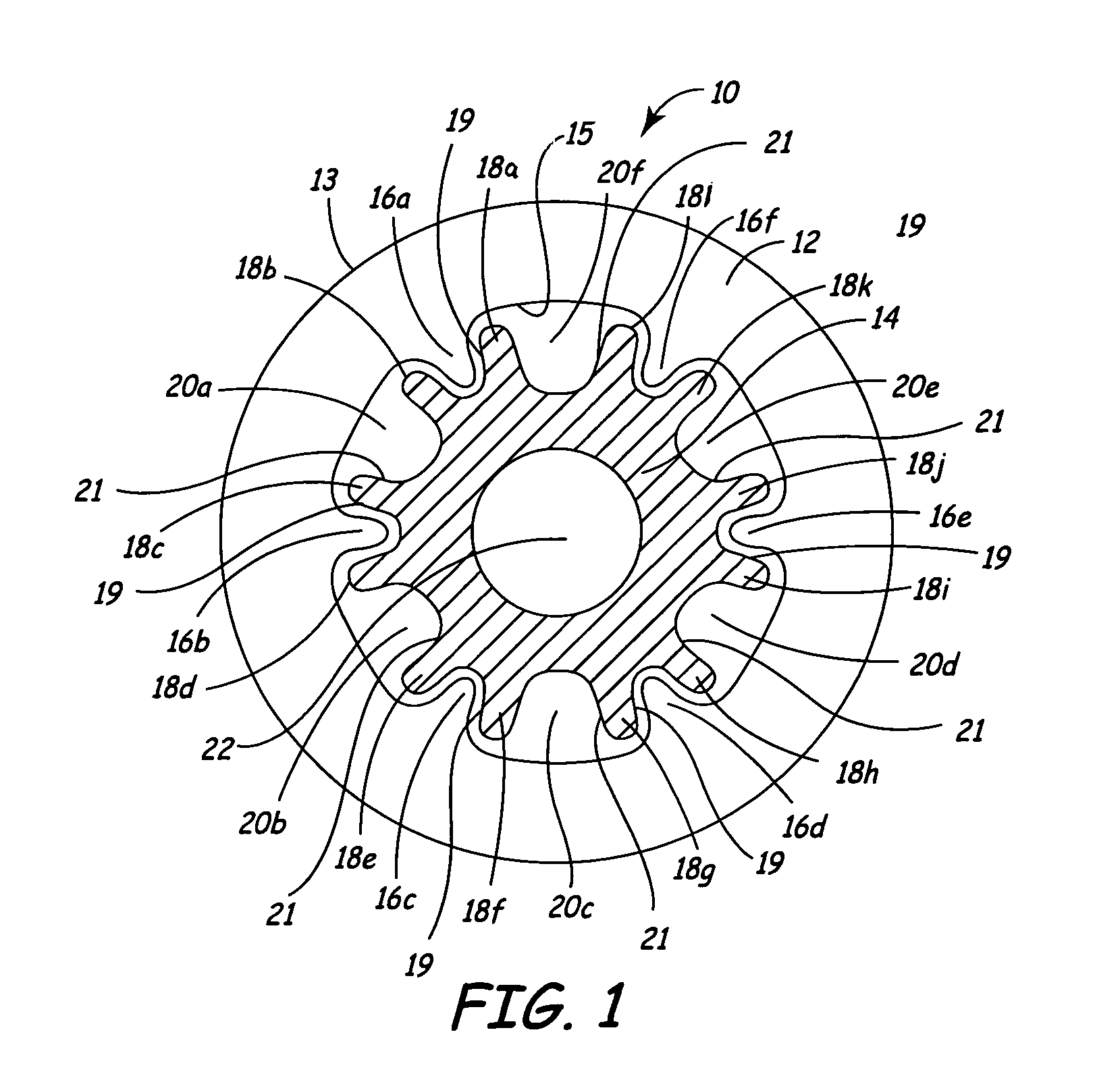

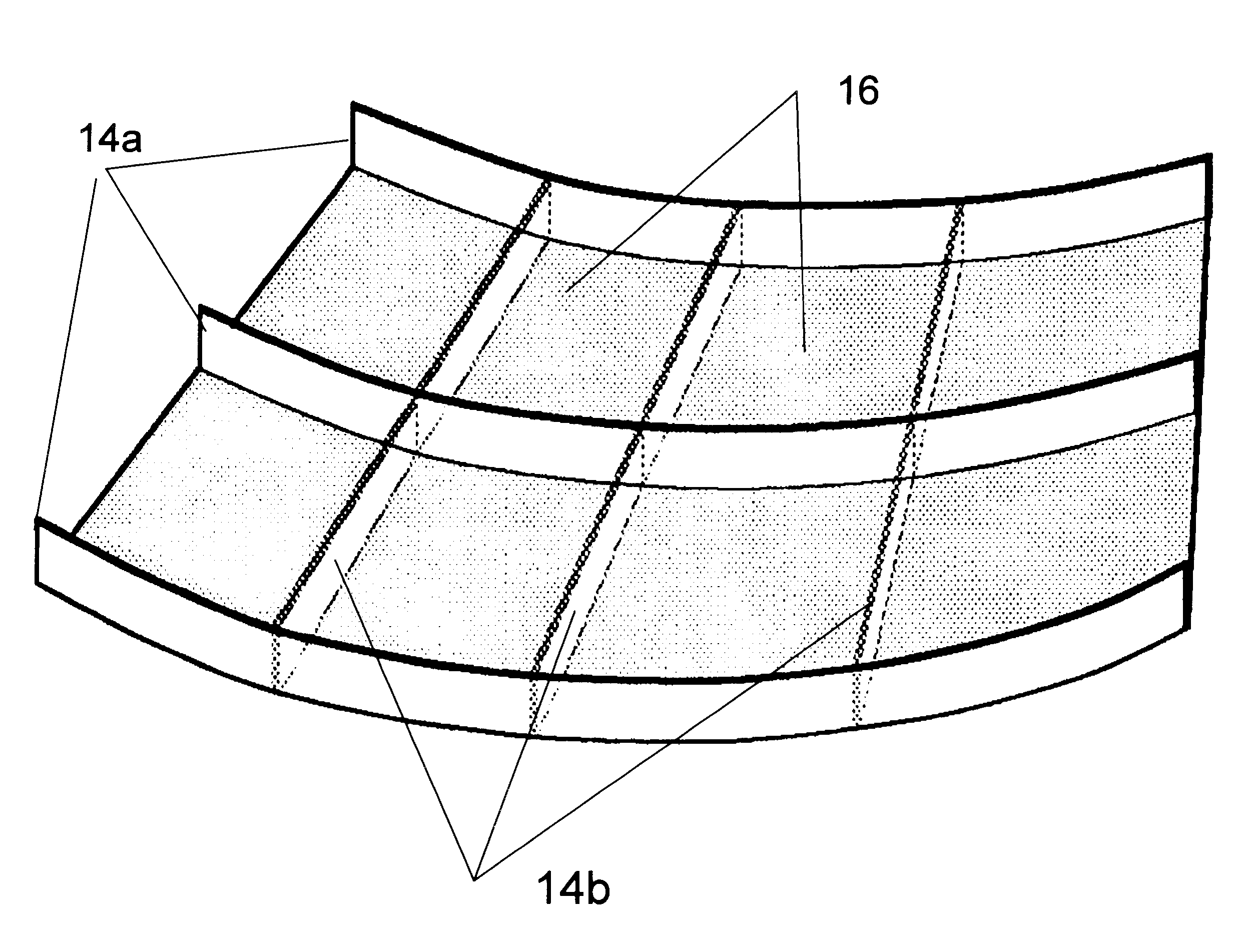

Multilumen body for an implantable medical device

A splined multilumen body for use in elongated medical devices is provided for carrying multiple conductors, wires or cables to multiple device components along the device body. Open lumens may be provided through which medical devices or therapies may be delivered. The multilumen body is constructed from a generally tubular outer member having inward-radiating splines that mate with outward-radiating splines on a generally tubular inner member. Lumens formed between sets of mated splines isolate conductors carried therein. Interaction of mated splines provides good torque transfer between outer and inner members. Materials for fabricating outer and inner members may be selected to achieve desired torque transfer properties, flexibility, and surface friction.

Owner:MEDTRONIC INC

Monolithic composite wing manufacturing process

InactiveUS6190484B1Aircraft stabilisationPaper/cardboard wound articlesLeading edgeIncreased torsion

A method of manufacturing a monolithic composite wing without using mechanical fasteners is described. The process begins with the formation of a center wing box in combination with a pair of spars, riblets and a pair of skin-molds including the wrapping and binding of the box by means of resin impregnated composite tapes. Next, additional cells are adjoined contiguously on either side of the current framework and an overlap wrapping and bonding process is continued around the current framework. The overlap wrapping and binding procedure provides increased torsion stiffness and reduced structural weight. All cells up to the leading and trailing edges will be included in the assembly process. Conduits to convey fuel, hydraulic fluid and electrical wiring will also be installed in designated cells. Finally, the completed wing will be cured in an autoclave under uniform pressure and temperature.

Owner:APPA KARI

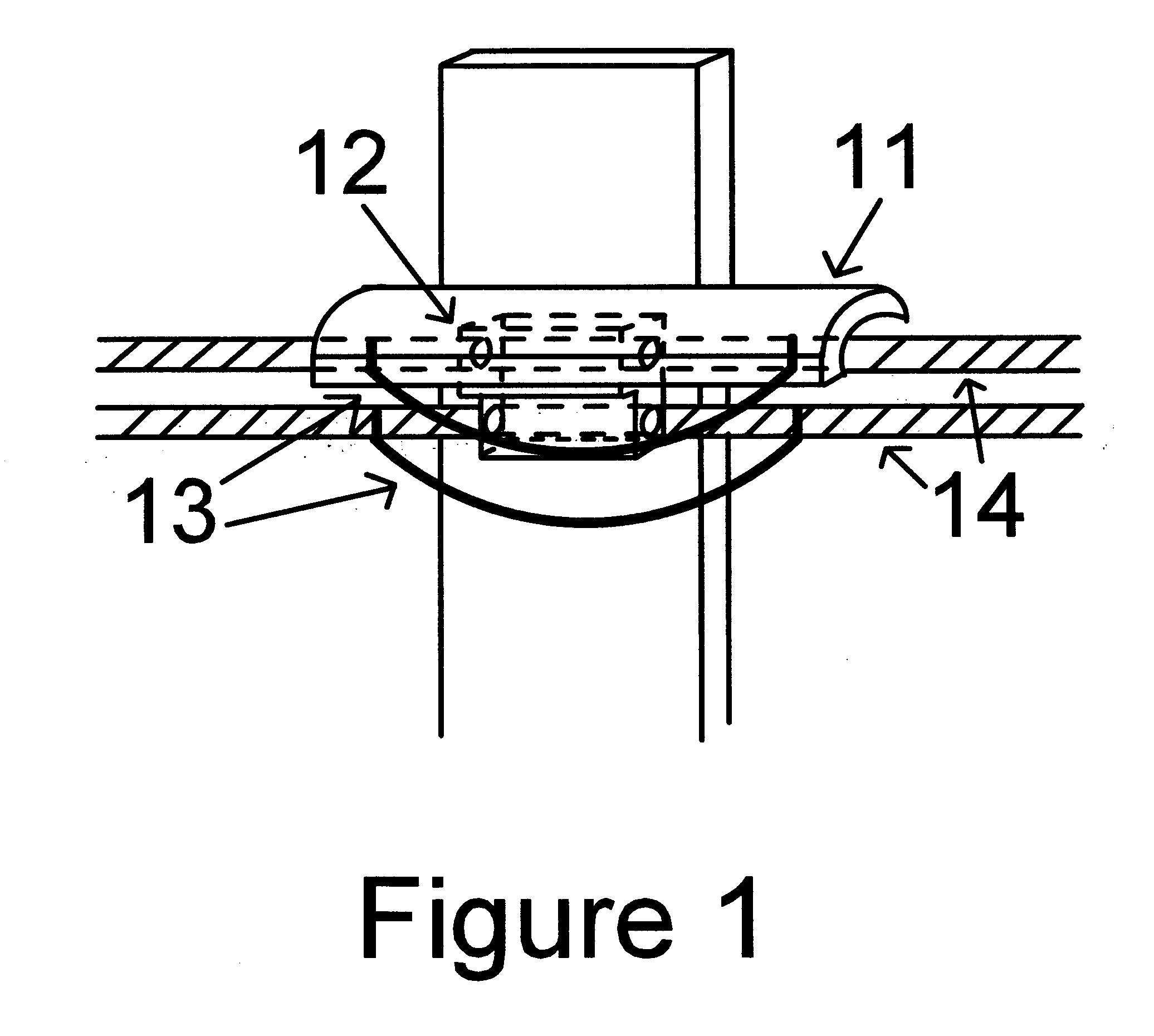

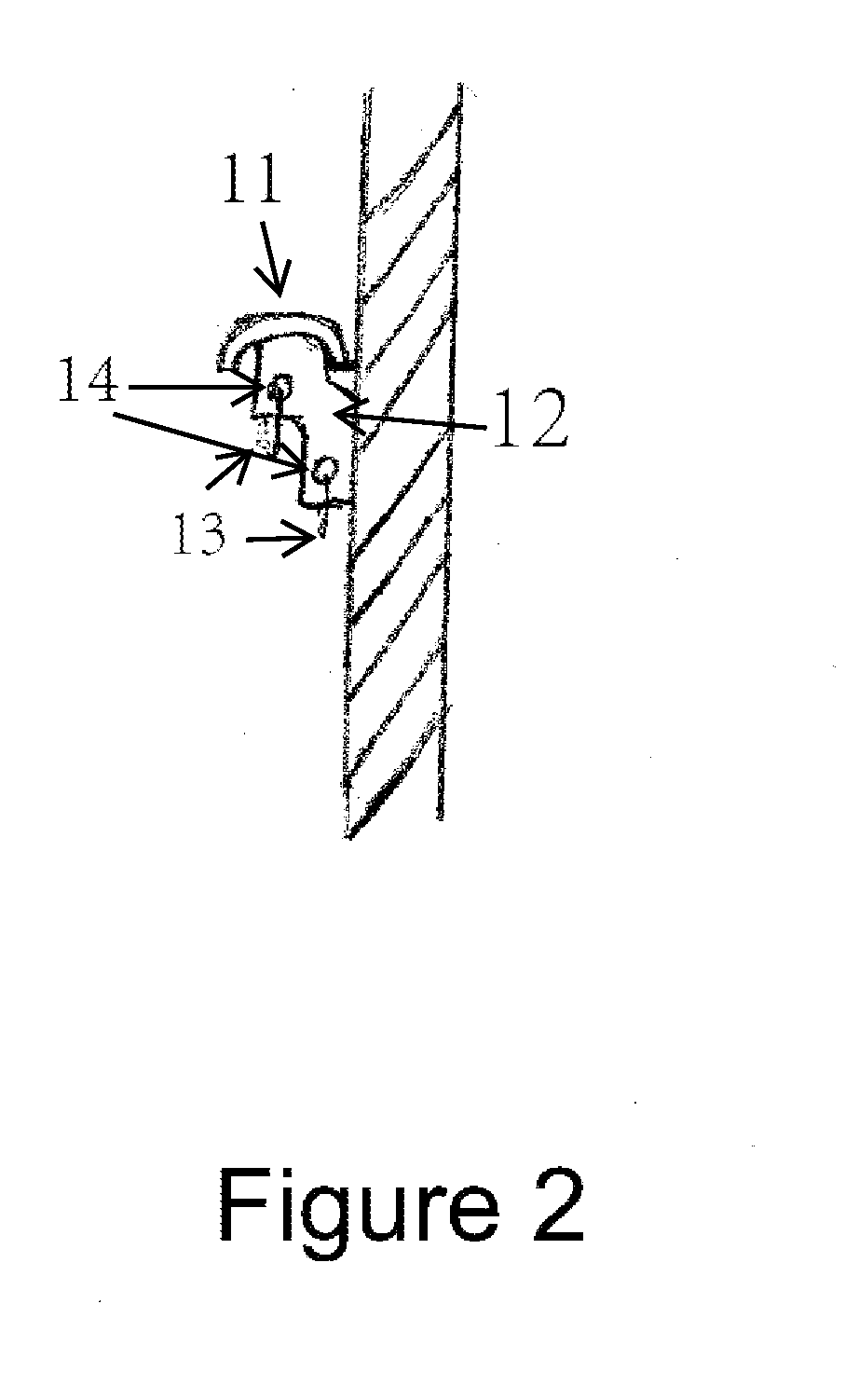

Apparatus and methods for transmission line based electric fence insulation

InactiveUS20120181258A1Avoid flowPrevent short-circuitingOhmic-resistance heatingSupporting insulatorsElectricityEngineering

Apparatus and methods for wire insulation in transmission line based electric fence are described in this invention. An insulator holds a wire pair that form the transmission line in its wire clamps. The insulator has a rain shed that sheds the wire clamps from getting wet by rain water. The insulator also has a pair of rain water divert guides that guide rain water accumulated on the wire to flow to the guide instead of to the wire clamps. This invention also describes a wire heating method that uses electric current to heat the fence wires such that the wire / wire clamp contact point will be kept dry and ice, snow accumulated on fence wires will be melted. Performance of the transmission line based electric fence can thus be greatly improved in advert weather conditions.

Owner:SHAN XUEKANG +1

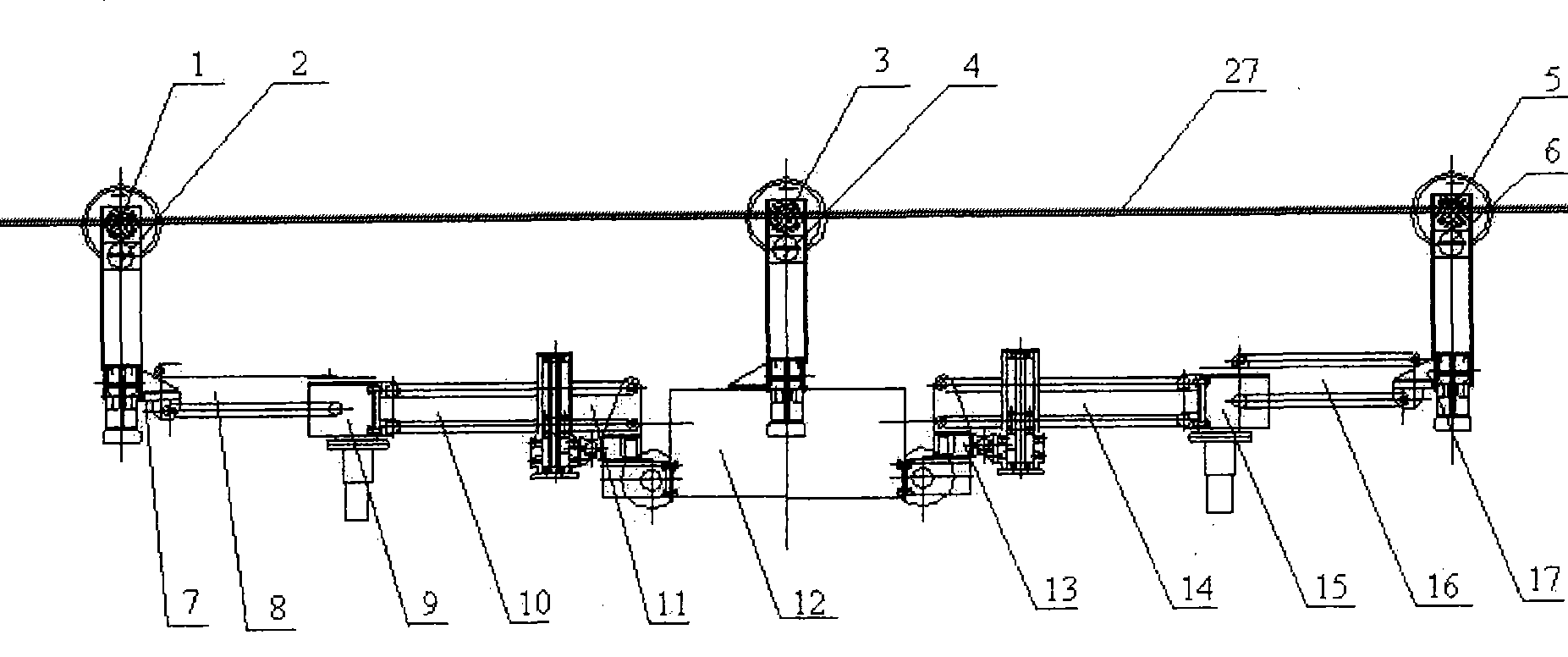

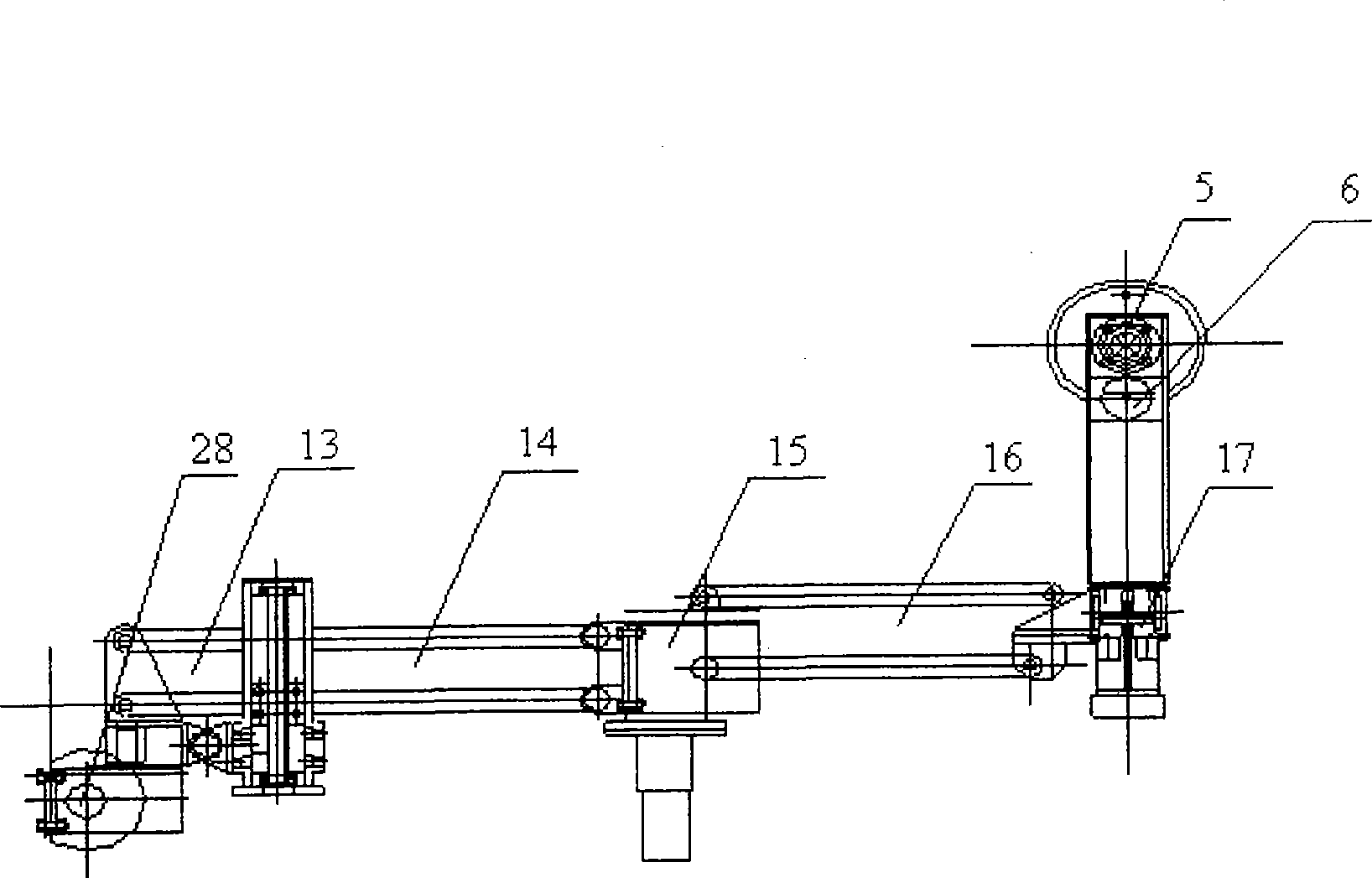

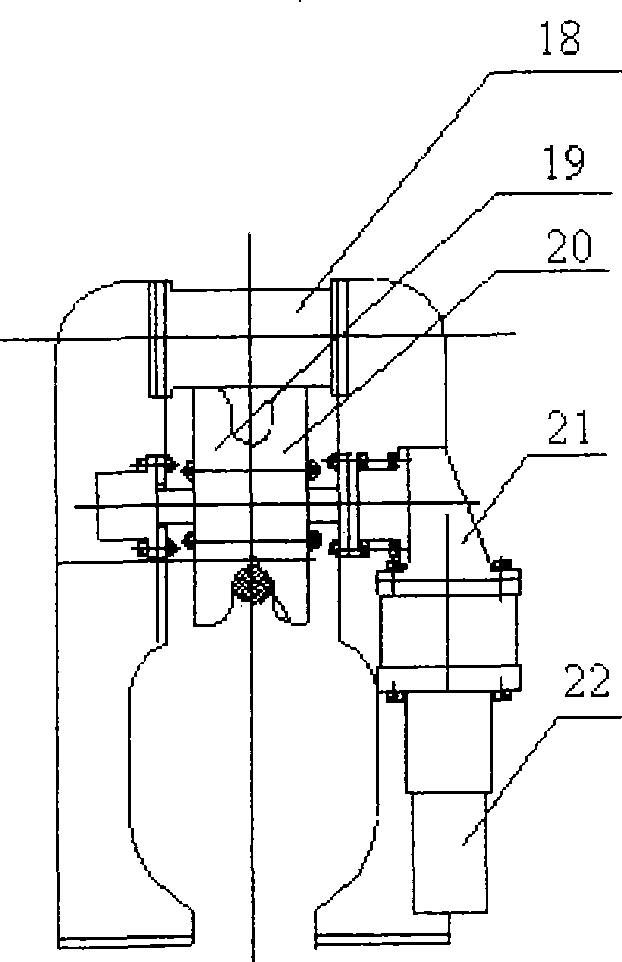

Robot of autonomous moving along 110KV transmission line and its working method

InactiveCN100502181CReduce workloadGuaranteed safe operationManipulatorApparatus for overhead lines/cablesWireless image transmissionSimulation

This invention is a robot walking automatically along 110kV transmitting wire and its operational method. It is composed of the robot reality, the control device, the sensor, the detecting device and wireless image transmitting device; the control device and the wireless image transmitting device are set in the control box in the middle of the robot reality, the position sensors are equipped at the terminals of every joint, the visual sensor CCD measuring the distance of sensors and obstacle is equipped in the front of every hand, the detecting device includes high speed vidicon and the hot imaging device connected to the robot reality through the platform. It can walk stably on the 110kV transmitting wire and automatically span all kinds of obstacles on the wire, and it replaces the human to patrol the transmitting wire and reduces the working amount of patrolling, and improves the working efficiency and detecting precision to assure the safe operation of the electric wire.

Owner:SHANDONG UNIV

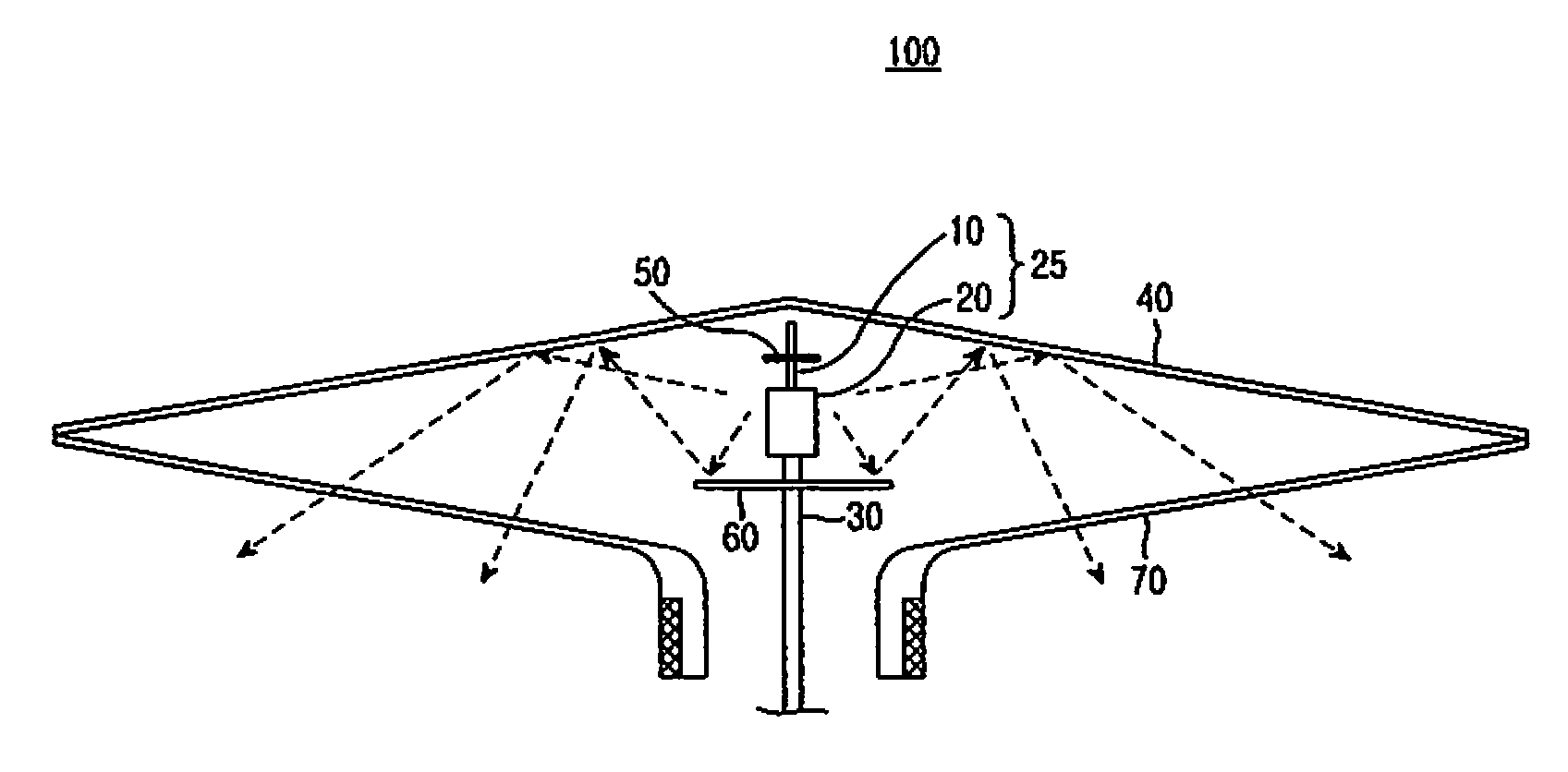

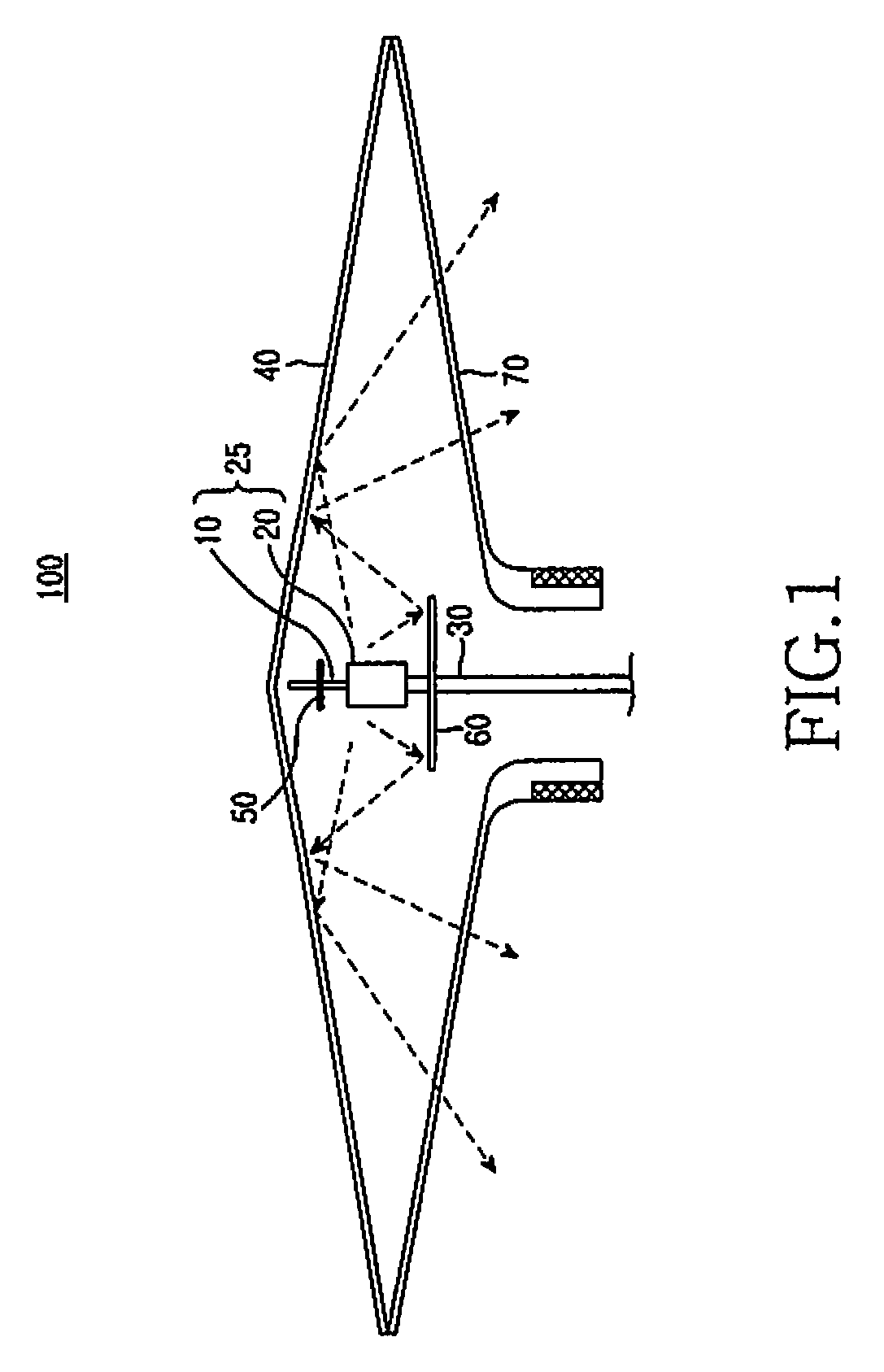

Antenna apparatus

InactiveUS7812778B2Easy to changeRaise the ratioRadiating element housingsElongated active element feedElectrical conductorCoaxial cable

An antenna apparatus is provided, which removes dead directions, and at the same time, has a suppression means for easily suppressing the change of an antenna directivity pattern caused by the effect of a feed line or a radome and an improvement means for simply improving the VSWR deterioration caused by the effect of a reflector or the radome. The antenna apparatus includes a sleeve antenna connected to a coaxial cable and a reflector in the shape of a cone, the sleeve antenna including a central conductor and a sleeve, in which the sleeve antenna is arranged in a concave portion of the cone so that the central conductor is aligned with a central axis of the cone, and a top end of the central conductor is separate from a vertex portion of the cone.

Owner:SAMSUNG ELECTRONICS CO LTD

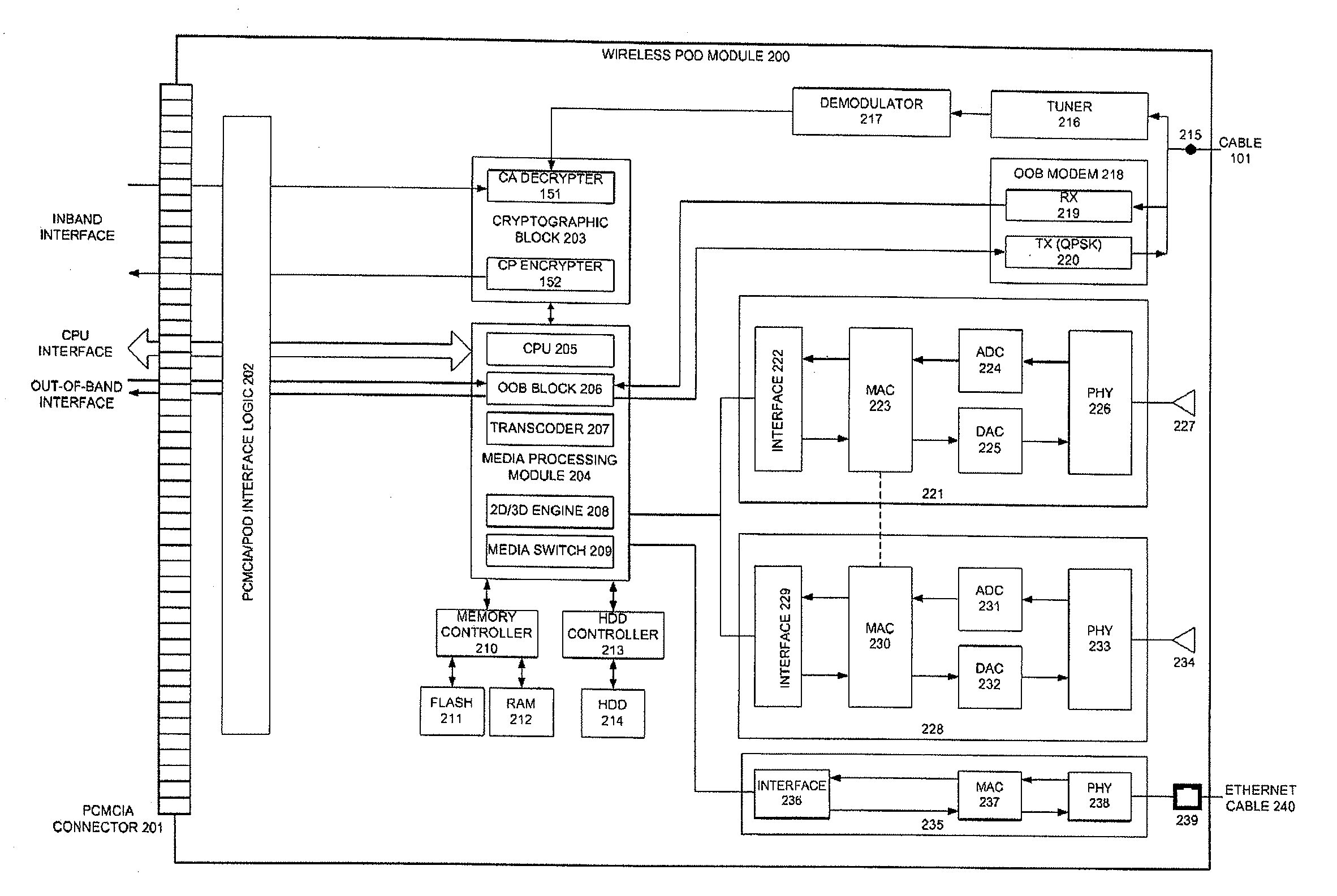

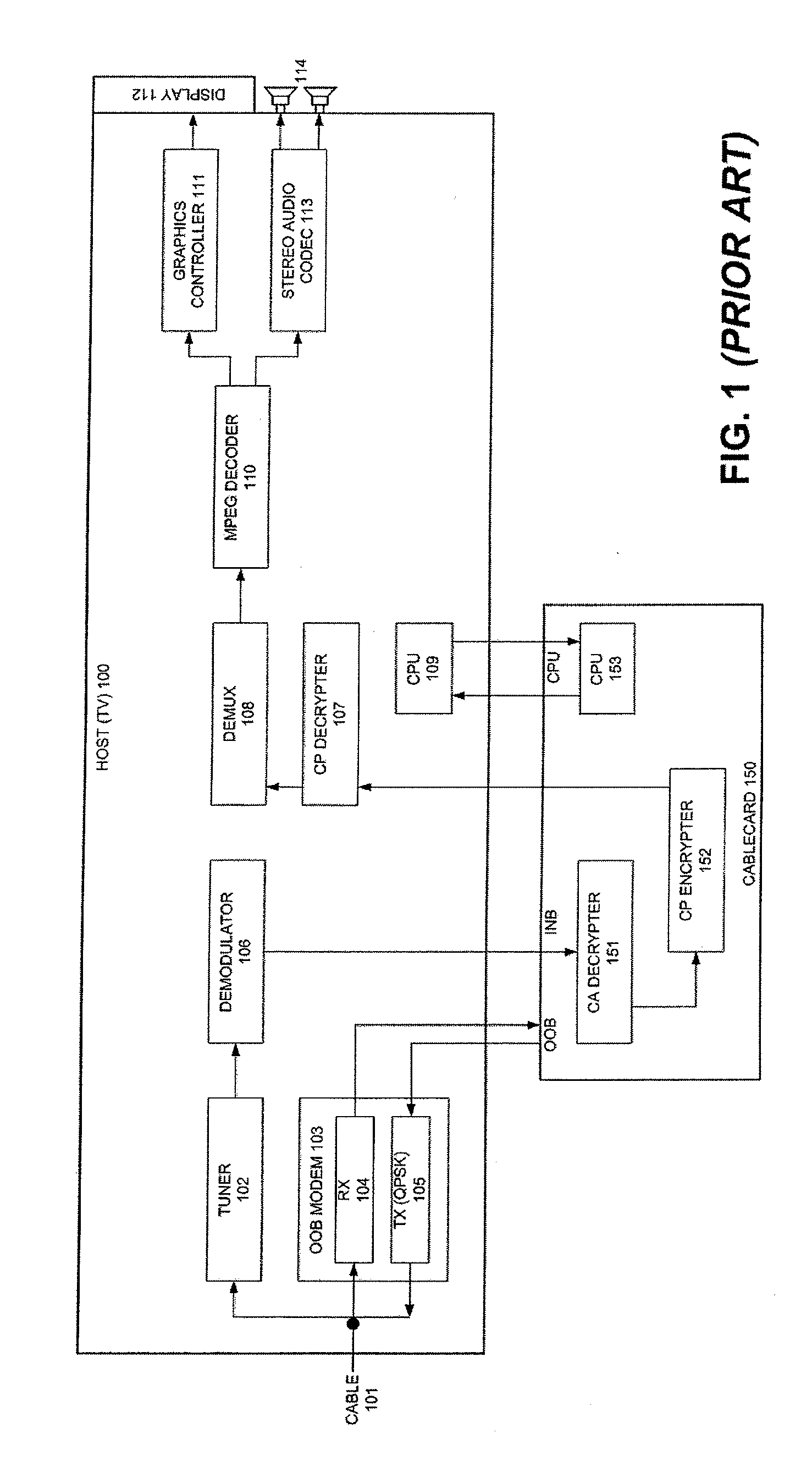

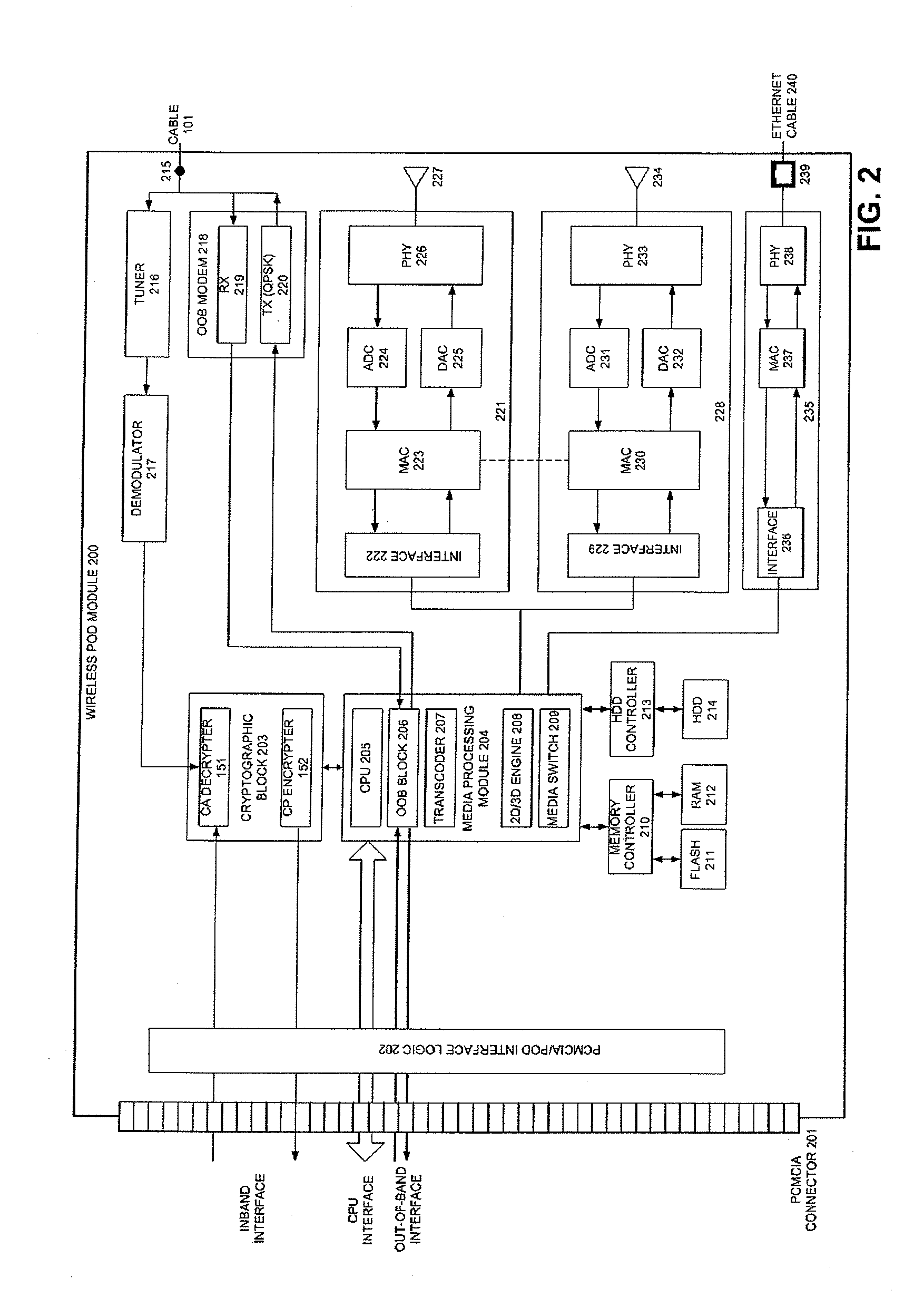

Pod module and method thereof

ActiveUS20070250872A1Secure transmissionEasy to useAssess restrictionGHz frequency transmissionCoaxial cableEngineering

A POD module system includes a housing, a coaxial cable connector formed on the housing and connectable to a first device to receive a cable signal, a port formed on the housing to receive a wire or wireless signal from a second device, a module unit to process at least one of the cable signal and the at least one of the wireless signal to generate at least one of a copy protection signal and one of video and audio signals, respectively, and a connector formed on the housing and connectable to a third device to transmit the at least one of the copy protection signal and the one of video and audio signals to the third device such that the third device generates at least one of an image and a sound to correspond to the at least one of the copy protection signal and the one of video and audio signals.

Owner:SYNDEFENSE

Reliable, long-haul data communications over power lines for meter reading and other communications services

InactiveUS8947258B2Highly long-haulImprove reliabilityElectric signal transmission systemsPower distribution line transmissionPower qualityLow speed

Owner:POWERMAX GLOBAL

Noninvasive measurement of chemical substances

InactiveUS7041063B2High densityEarly diagnosisOrganic active ingredientsHeart defibrillatorsConjunctivaInfrared

Utilization of a contact device placed on the eye in order to detect physical and chemical parameters of the body as well as the non-invasive delivery of compounds according to these physical and chemical parameters, with signals being transmitted continuously as electromagnetic waves, radio waves, infrared and the like. One of the parameters to be detected includes non-invasive blood analysis utilizing chemical changes and chemical products that are found in the conjunctiva and in the tear film. A transensor mounted in the contact device laying on the cornea or the surface of the eye is capable of evaluating and measuring physical and chemical parameters in the eye including non-invasive blood analysis. The system utilizes eye lid motion and / or closure of the eye lid to activate a microminiature radio frequency sensitive transensor mounted in the contact device. The signal can be communicated by wires or radio telemetered to an externally placed receiver. The signal can then be processed, analyzed and stored. Several parameters can be detected including a complete non-invasive analysis of blood components, measurement of systemic and ocular blood flow, measurement of heart rate and respiratory rate, tracking operations, detection of ovulation, detection of radiation and drug effects, diagnosis of ocular and systemic disorders and the like.

Owner:GEELUX HLDG LTD

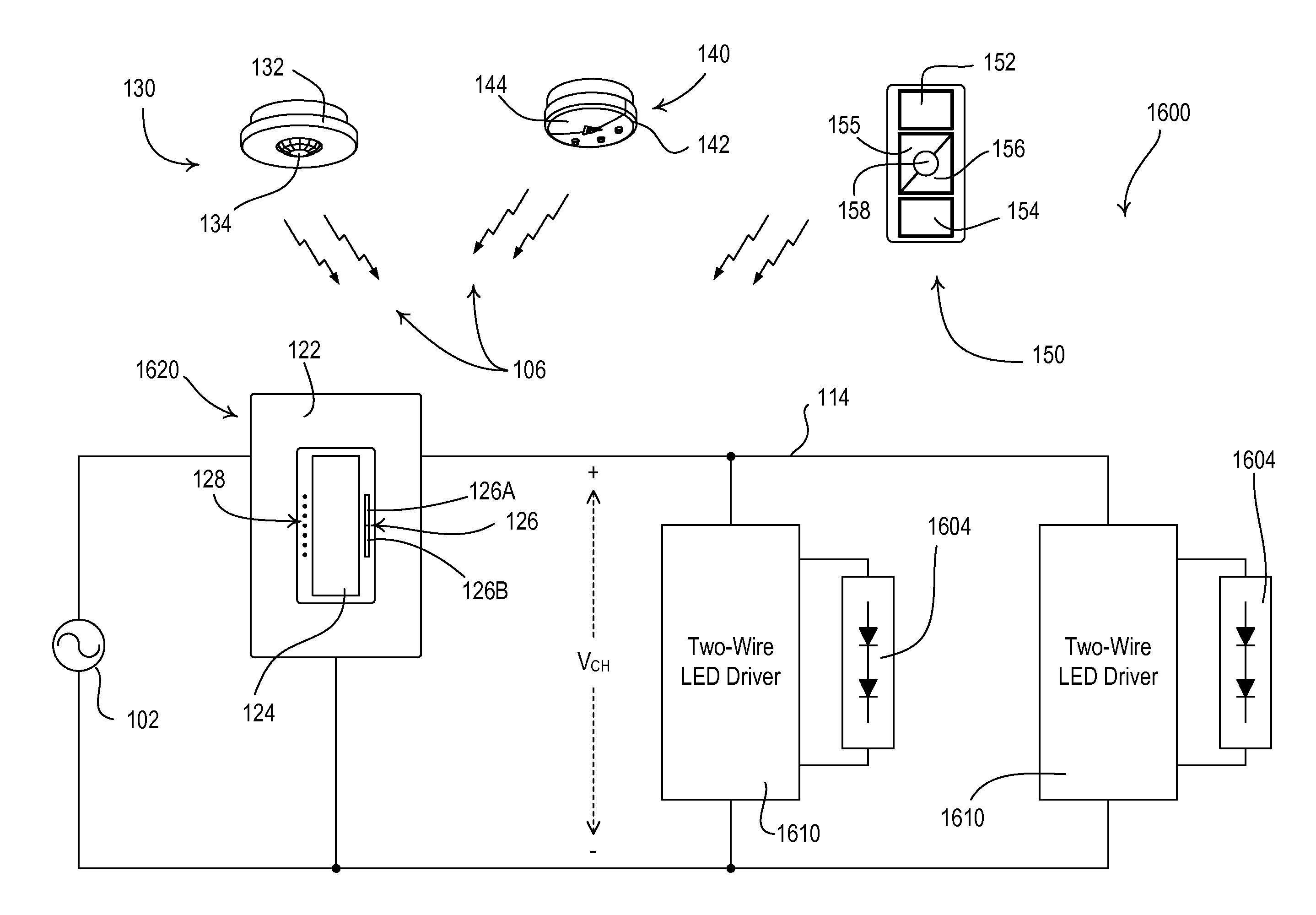

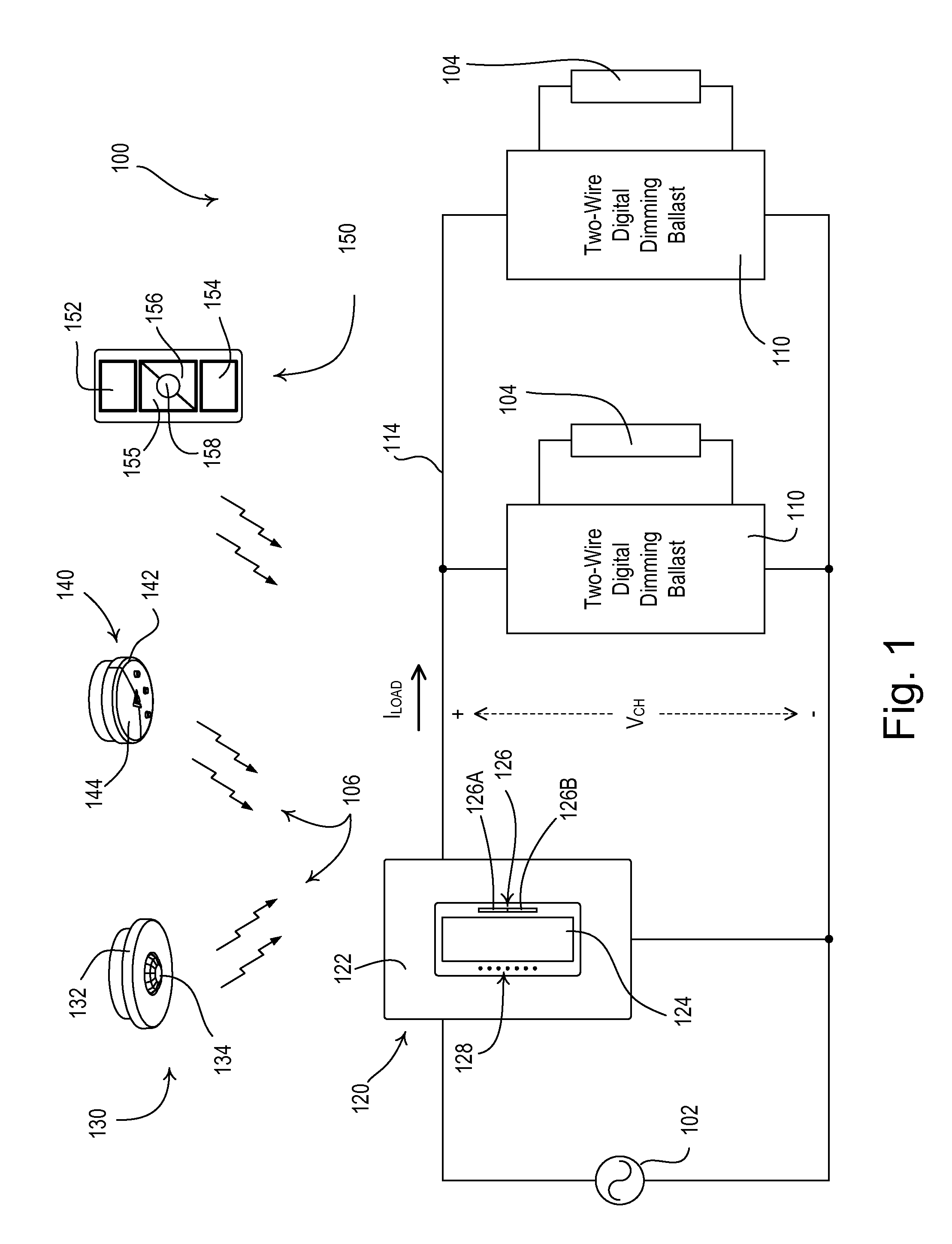

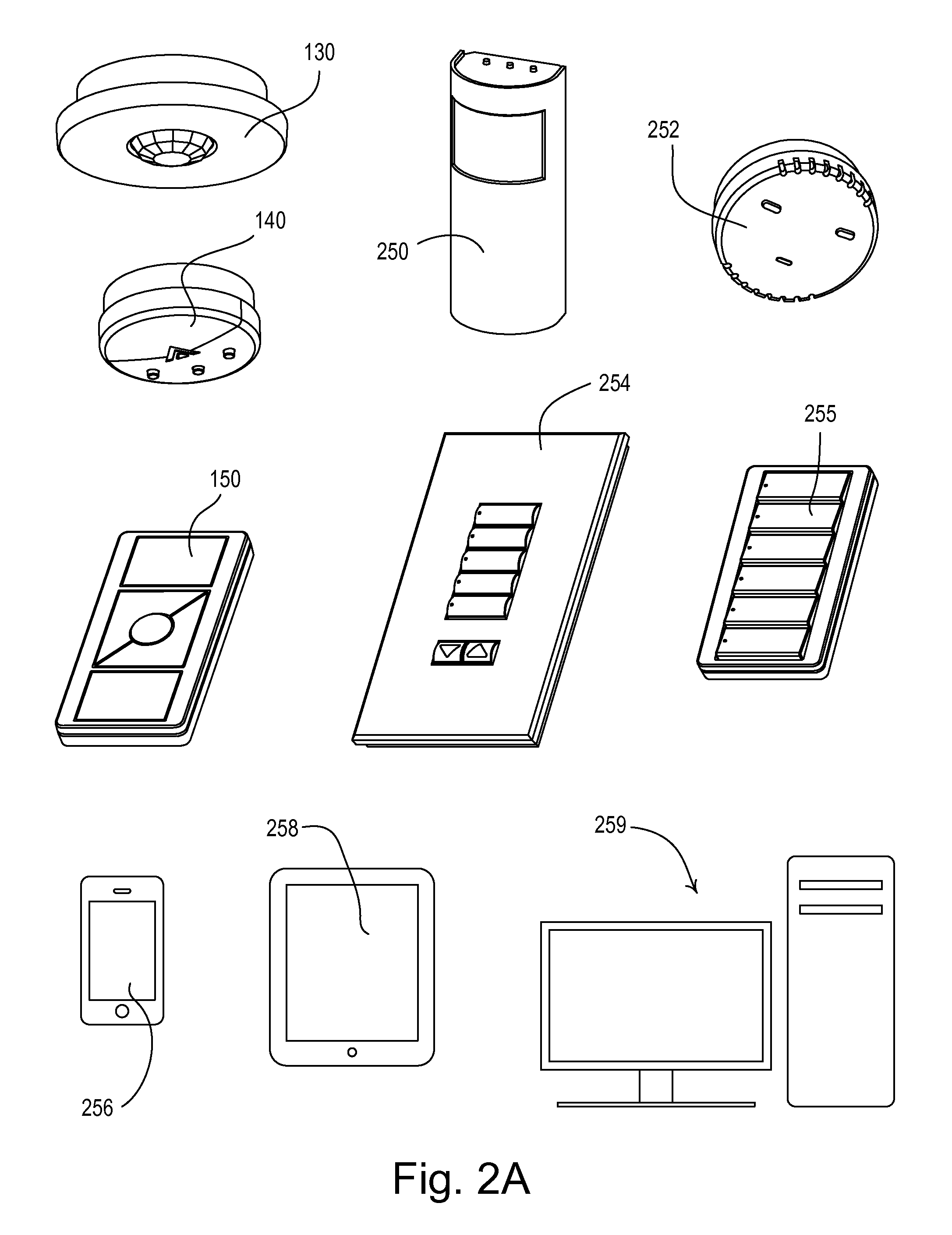

Digital load control system providing power and communication via existing power wiring

ActiveUS20130181630A1Reliable detectionPower distribution line transmissionElectroluminescent light sourcesControl systemPhase control

A load control system comprises a load control device for controlling an electrical load receiving power from an AC power source, and a controller adapted to be coupled in series between the source and the load control device. The load control system may be installed without requiring any additional wires to be run, and is easily configured without the need for a computer or an advanced commissioning procedure. The load control device receives both power and communication over two wires, and the controller generates a phase-control voltage that has at least one timing edge in each half-cycle, and transmits digital messages by modulating a timing edge of the phase-control voltage relative to a reference edge. The controller may be operable to receive inputs from a plurality of different input devices, and the load control device may be operable to control a plurality of different loads.

Owner:LUTRON TECH CO LLC

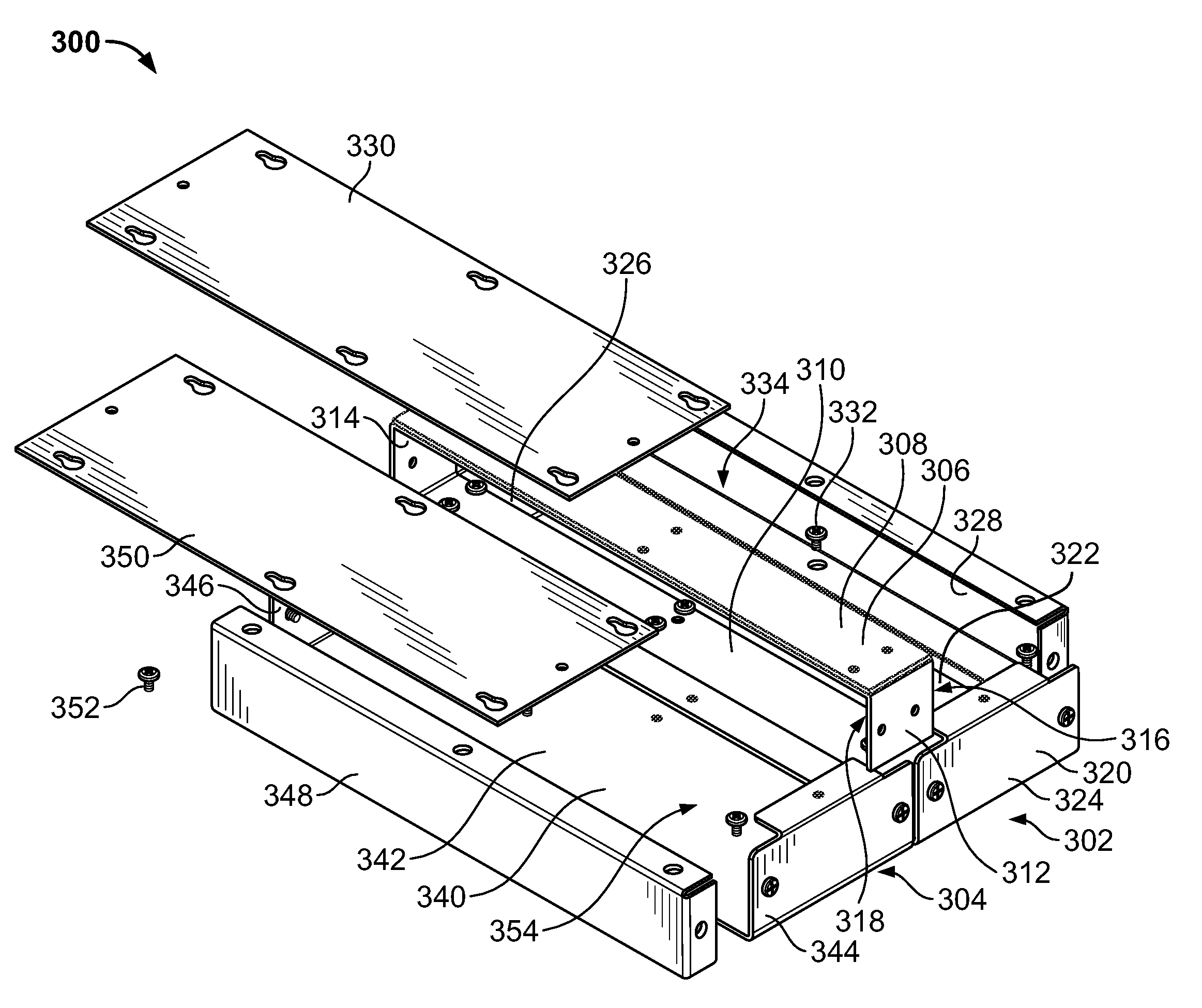

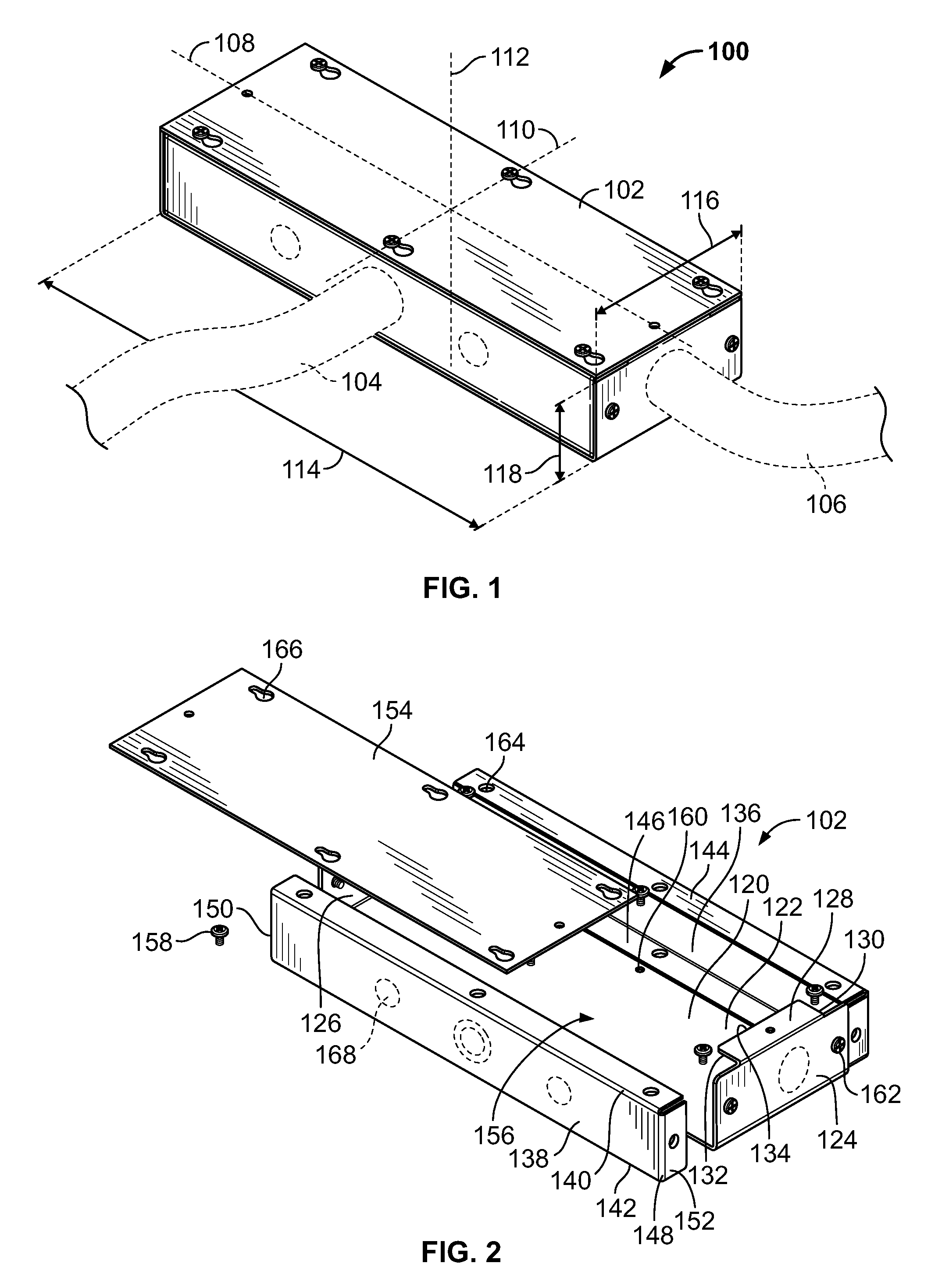

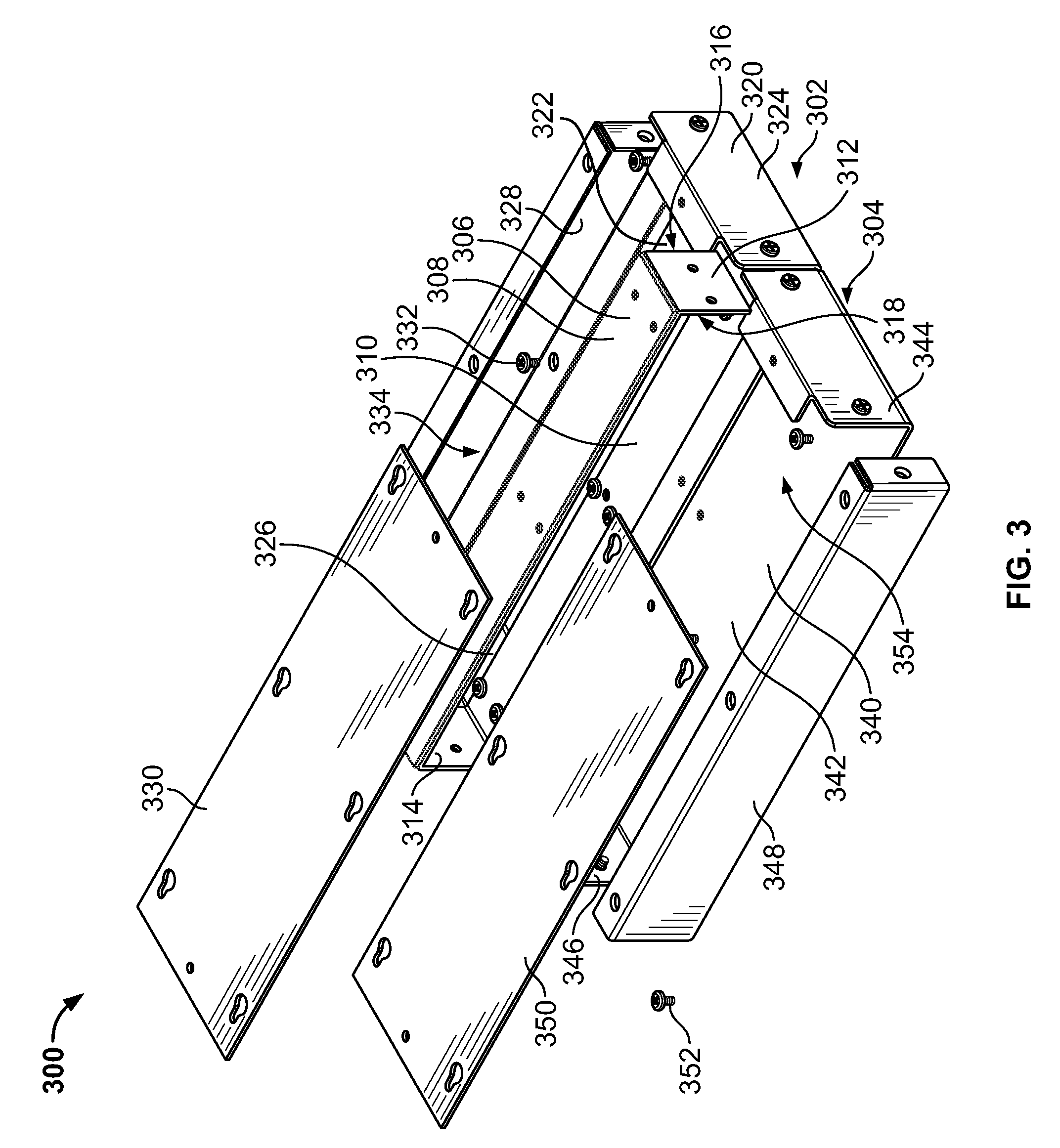

Expandable power distribution unit

A power distribution unit includes a first power box including a first chamber having a first termination zone, wherein a first wire set from a supply conduit is configured to be terminated at the first termination zone. The power distribution unit also includes a second power box ganged together with the first power box. The second power box has a second chamber open to the first chamber, and the second chamber has a second termination zone. A second wire set from at least one of the supply conduit and the first termination zone is configured to be terminated at the second termination zone.

Owner:COMMSCOPE TECH LLC

Retractable string interface for stationary and portable devices

An interface for a small form factor electronic device by enabling explicit measurement of extension or retraction of a retractable cord by monitoring the amount of string that passes by sensors, as the string exits the enclosure of the device. Input to such small form factor devices may be provided by sensors that measure the length of a string or wire that has been pulled out of an enclosure, in addition to an angle or direction (e.g., in 1-, 2- or 3-dimensions) at which the string was pulled out. Additionally, the rate of acceleration for the pulling and retracting motion may also be used as additional forms of input. In a further embodiment, a string interface is provided for a small form factor device that communicates information in the form of a pixel display provided integral with the string in response to string manipulation.

Owner:IBM CORP

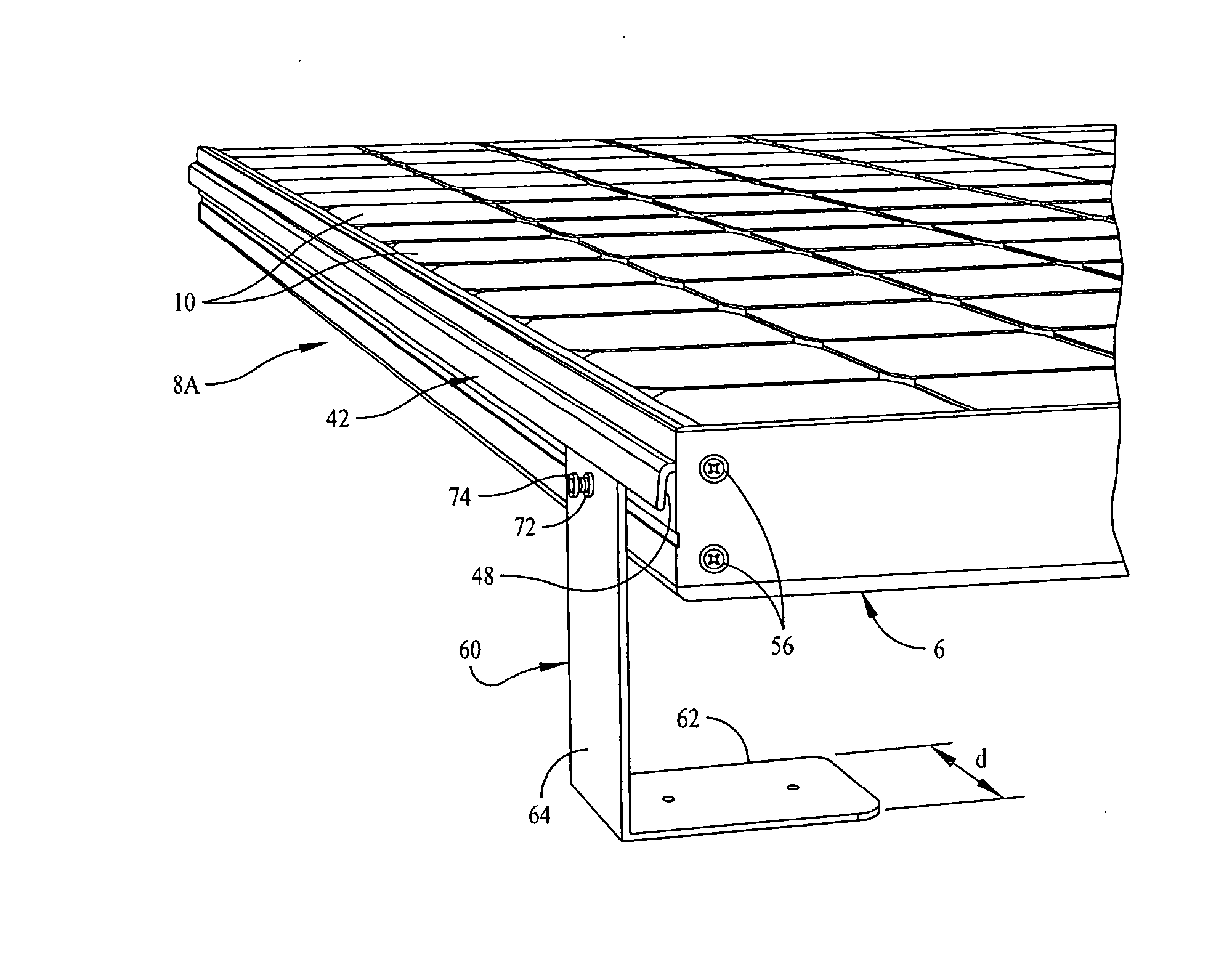

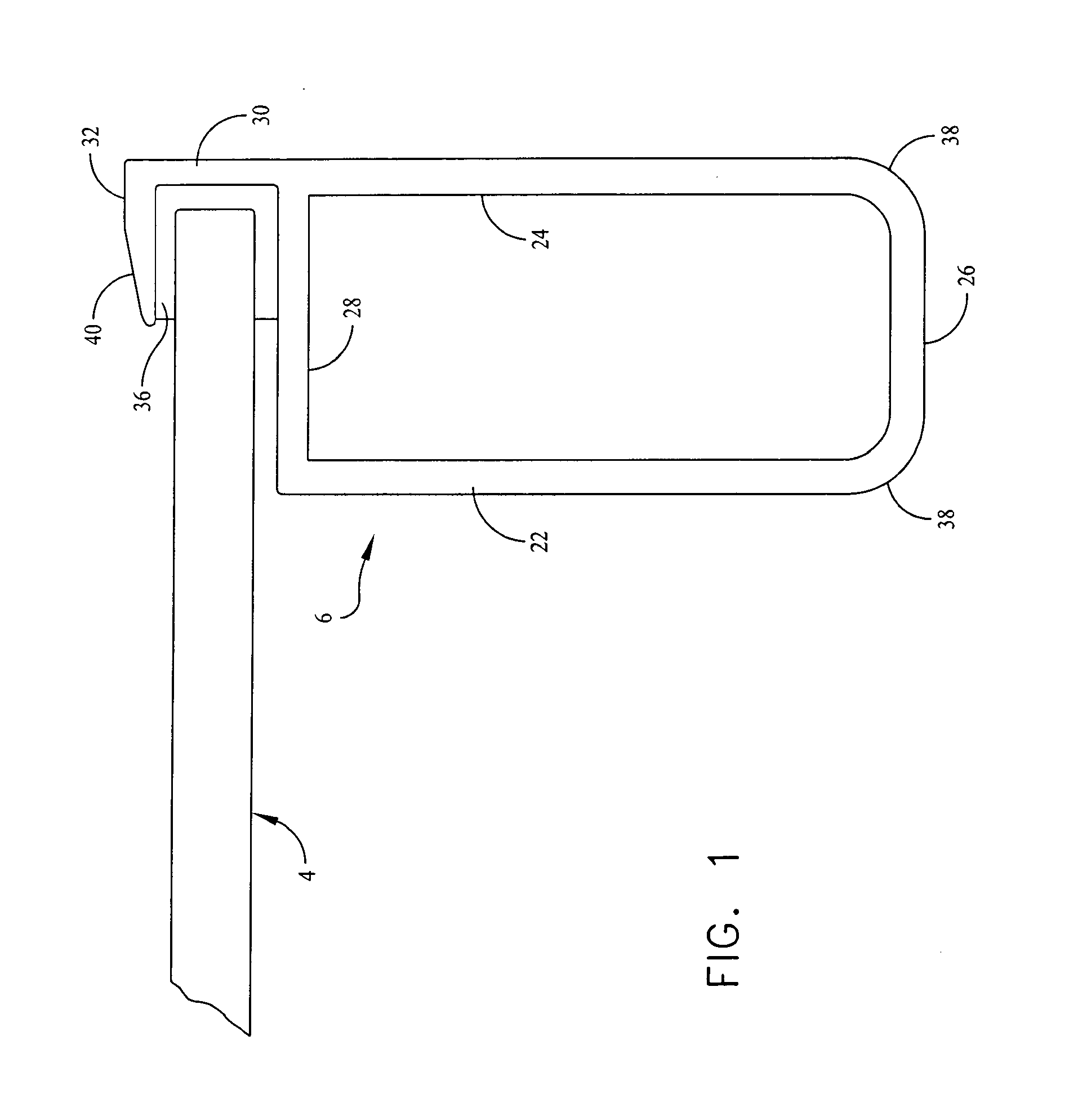

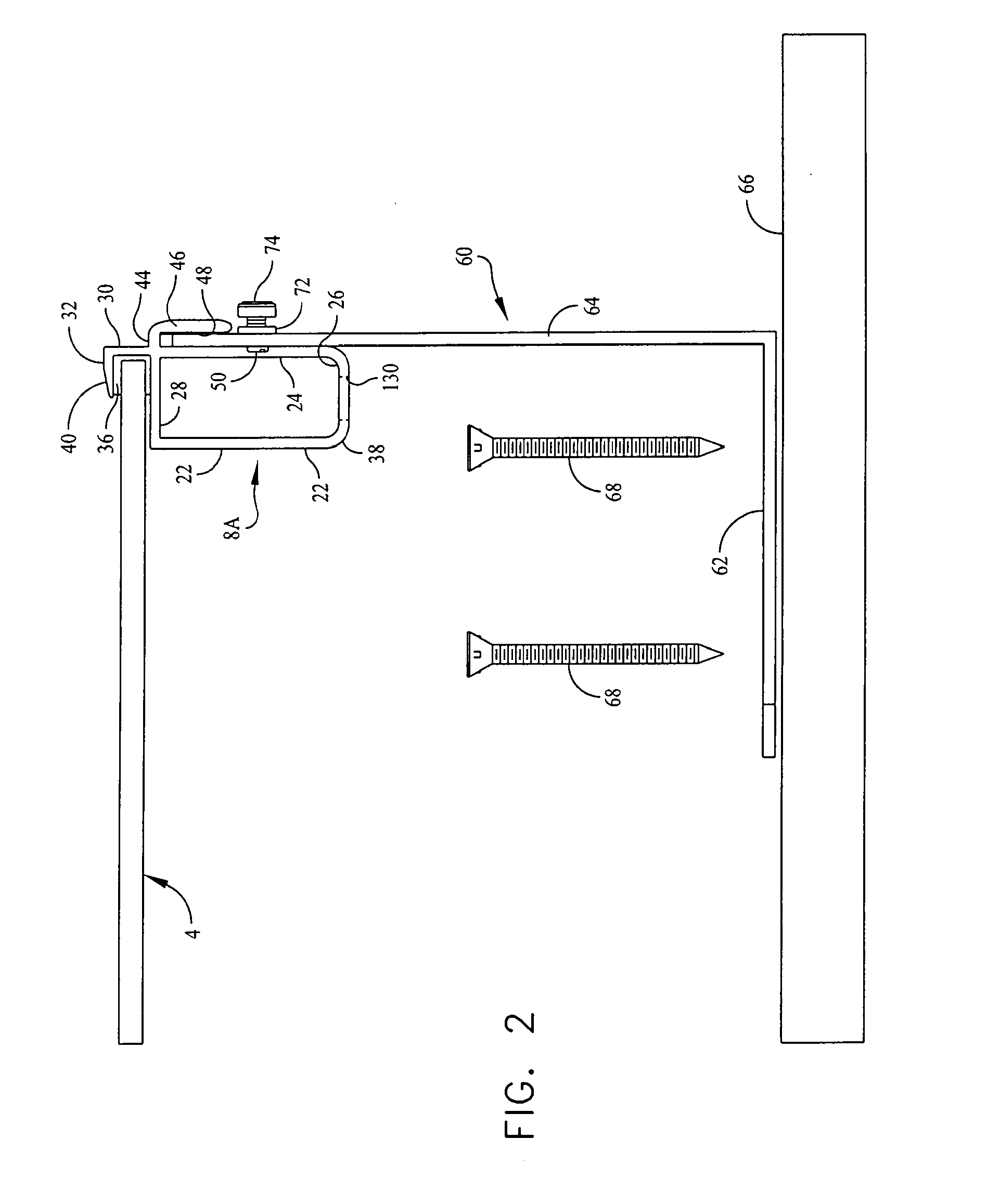

Multi-function frame and integrated mounting system for photovoltaic power generating laminates

InactiveUS20100147362A1Low costShorten the timePhotovoltaic supportsSolar heating energyEngineeringAC power

PV modules are provided that have a frame construction which permits the photovoltaic power-generating cells, DC / AC power conversion means, electrical wiring and other installation aspects to be merged into the module. The modules also are provided with means for coupling them to mounting stands whereby they can be mounted to a roof and also the frame construction is adapted to facilitate mechanically securing adjacent modules to one another.

Owner:GREENRAY

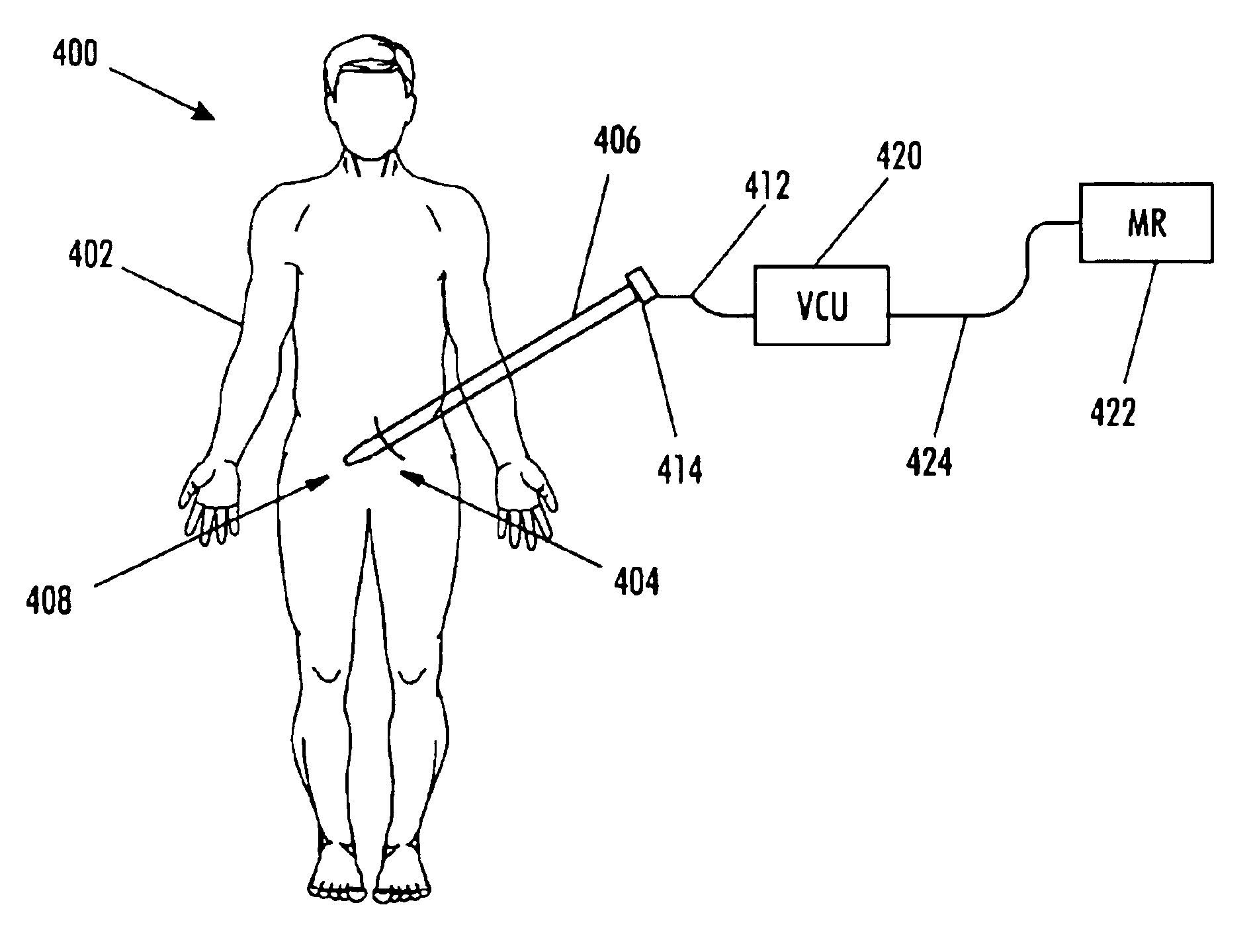

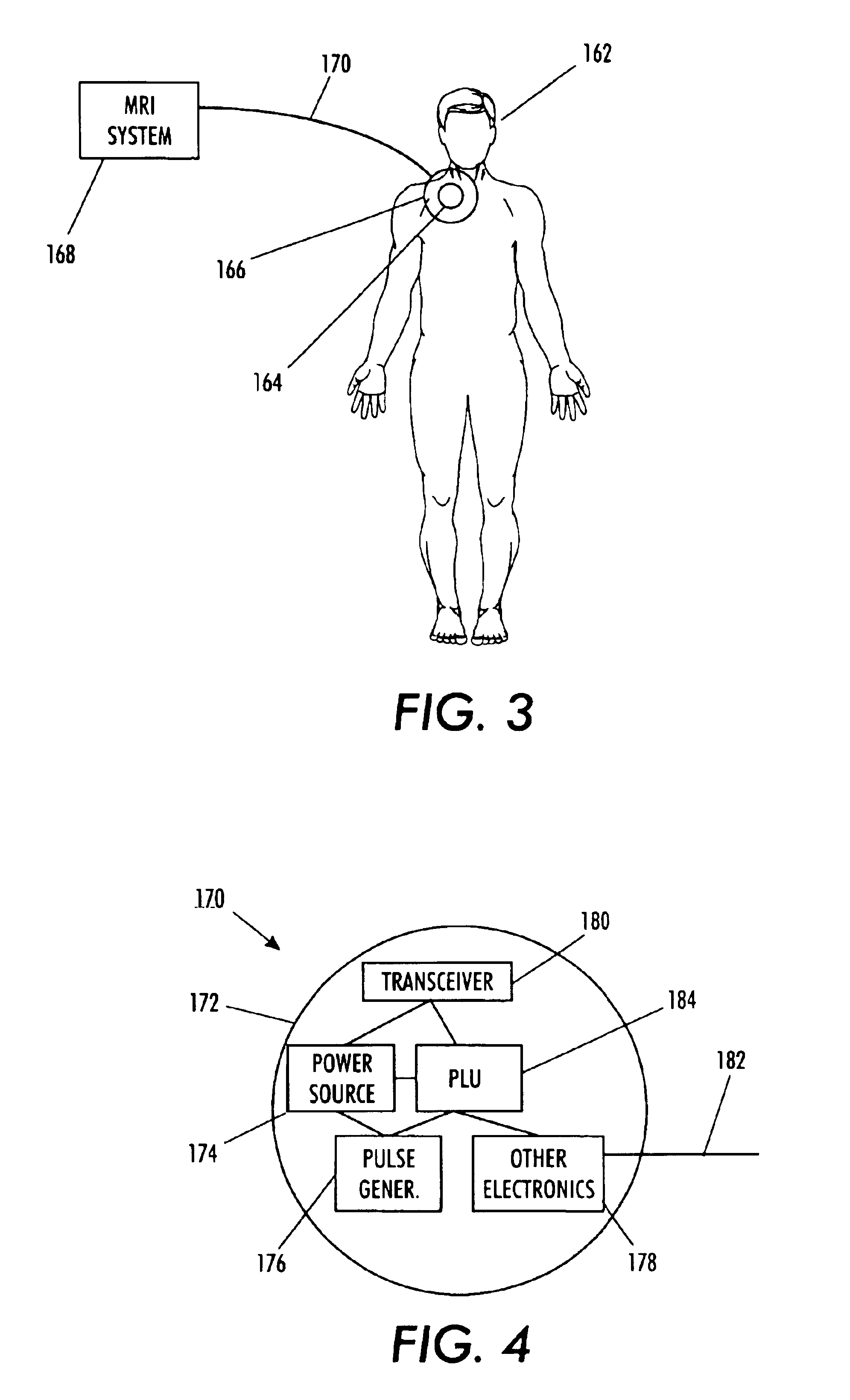

Magnetic resonance imaging interference immune device

InactiveUS6949929B2Reduce impactMultiple-port networksInternal electrodesEngineeringCharacteristic impedance

A voltage compensation unit reduces the effects of induced voltages upon a device having a single wire line. The single wire line has balanced characteristic impedance. The voltage compensation unit includes a tunable compensation circuit connected to the wire line. The tunable compensation circuit applies supplemental impedance to the wire line. The supplemental impedance causes the characteristic impedance of the wire line to become unbalanced, thereby reducing the effects of induced voltages caused by changing magnetic fields.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com