Patents

Literature

326 results about "Composite wing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

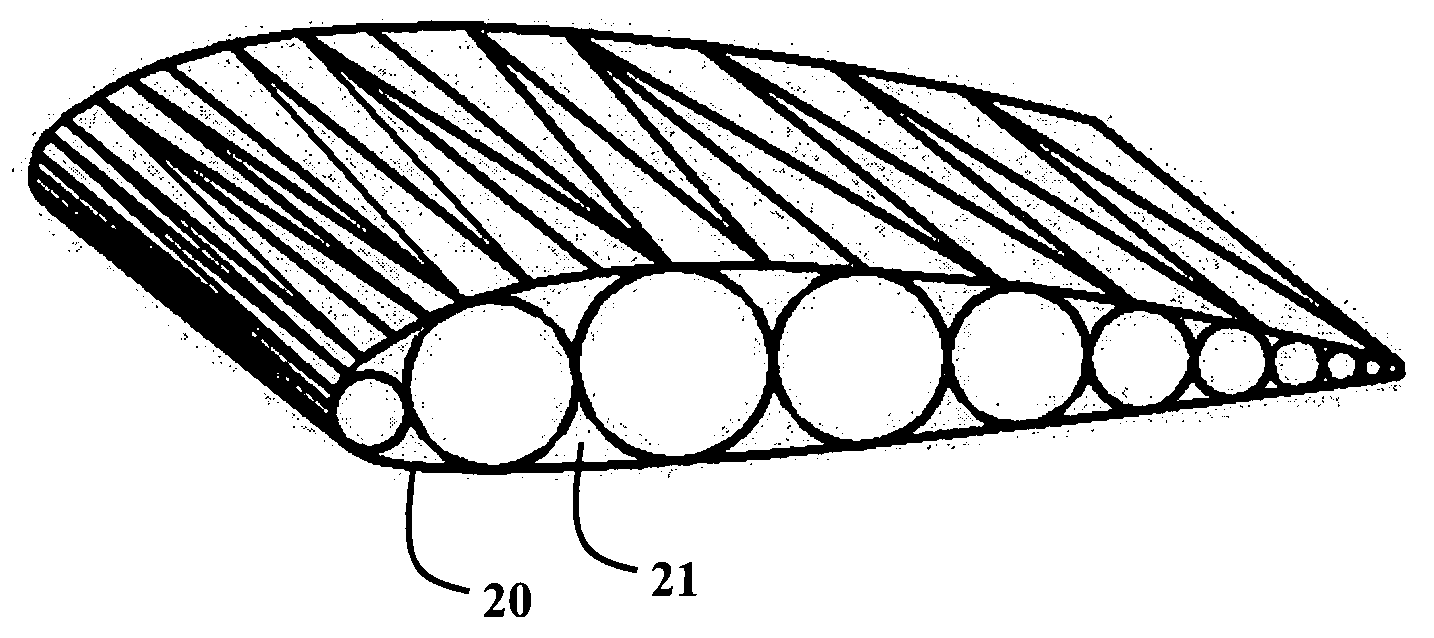

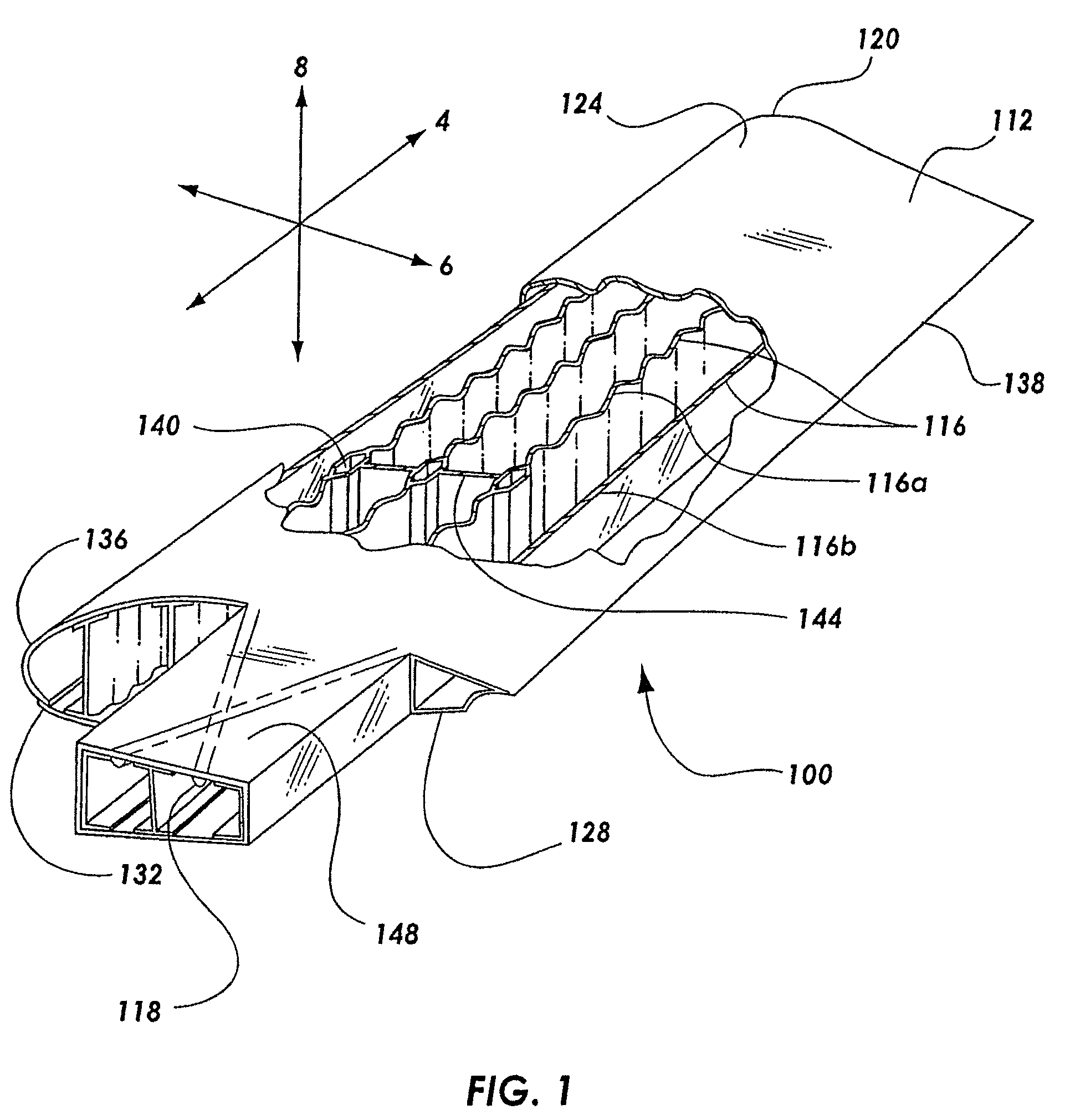

Monolithic composite wing manufacturing process

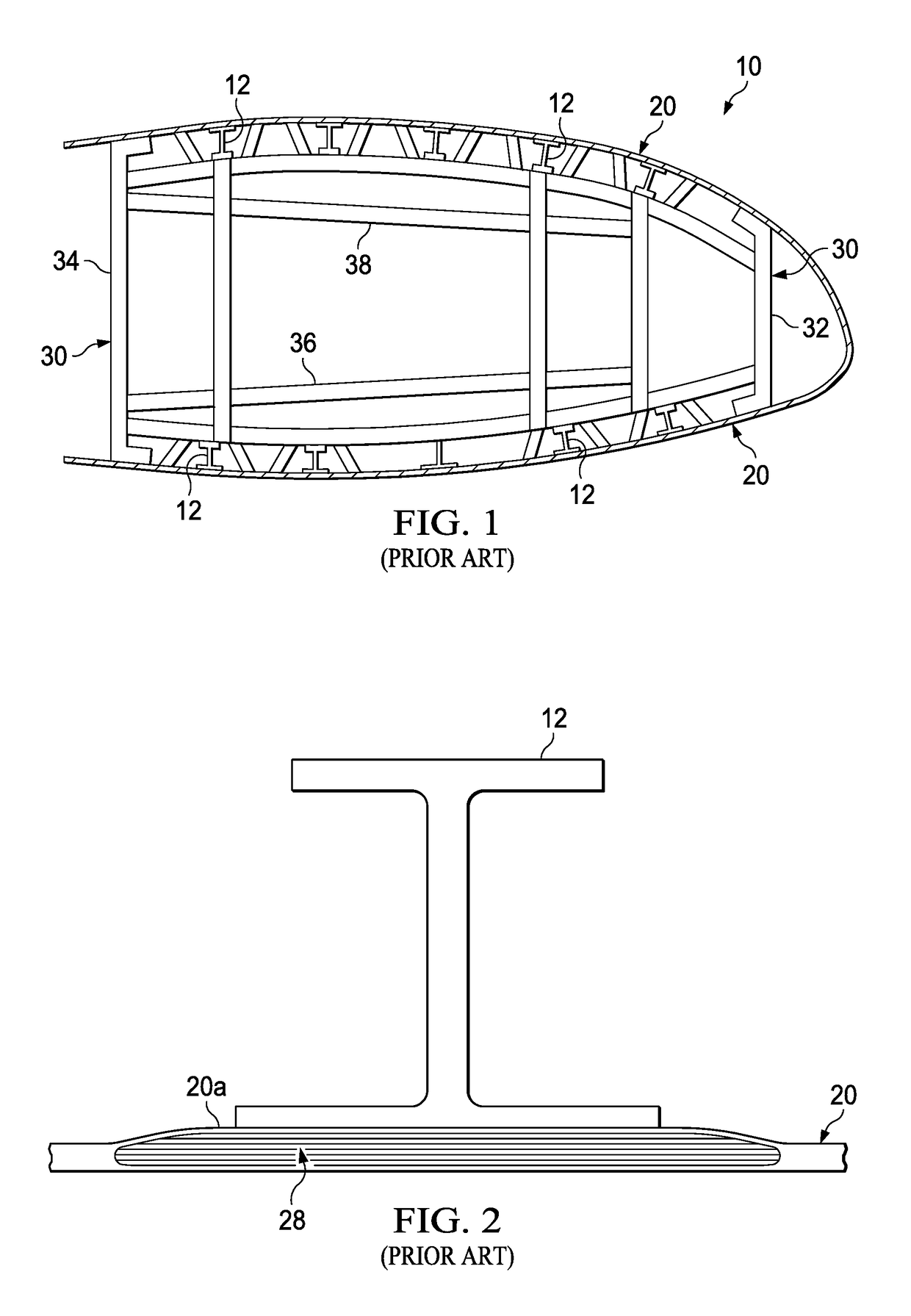

InactiveUS6190484B1Aircraft stabilisationPaper/cardboard wound articlesLeading edgeIncreased torsion

A method of manufacturing a monolithic composite wing without using mechanical fasteners is described. The process begins with the formation of a center wing box in combination with a pair of spars, riblets and a pair of skin-molds including the wrapping and binding of the box by means of resin impregnated composite tapes. Next, additional cells are adjoined contiguously on either side of the current framework and an overlap wrapping and bonding process is continued around the current framework. The overlap wrapping and binding procedure provides increased torsion stiffness and reduced structural weight. All cells up to the leading and trailing edges will be included in the assembly process. Conduits to convey fuel, hydraulic fluid and electrical wiring will also be installed in designated cells. Finally, the completed wing will be cured in an autoclave under uniform pressure and temperature.

Owner:APPA KARI

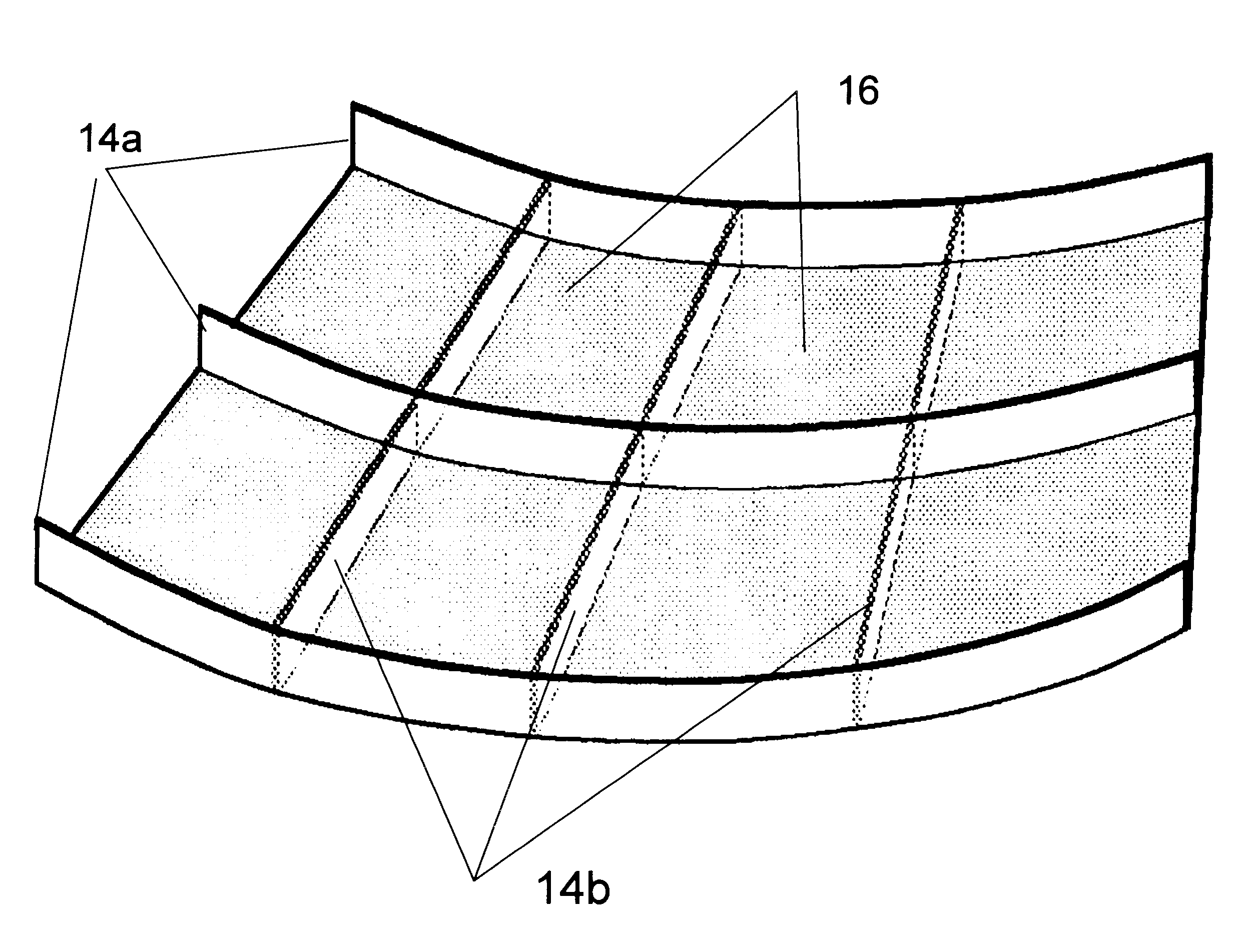

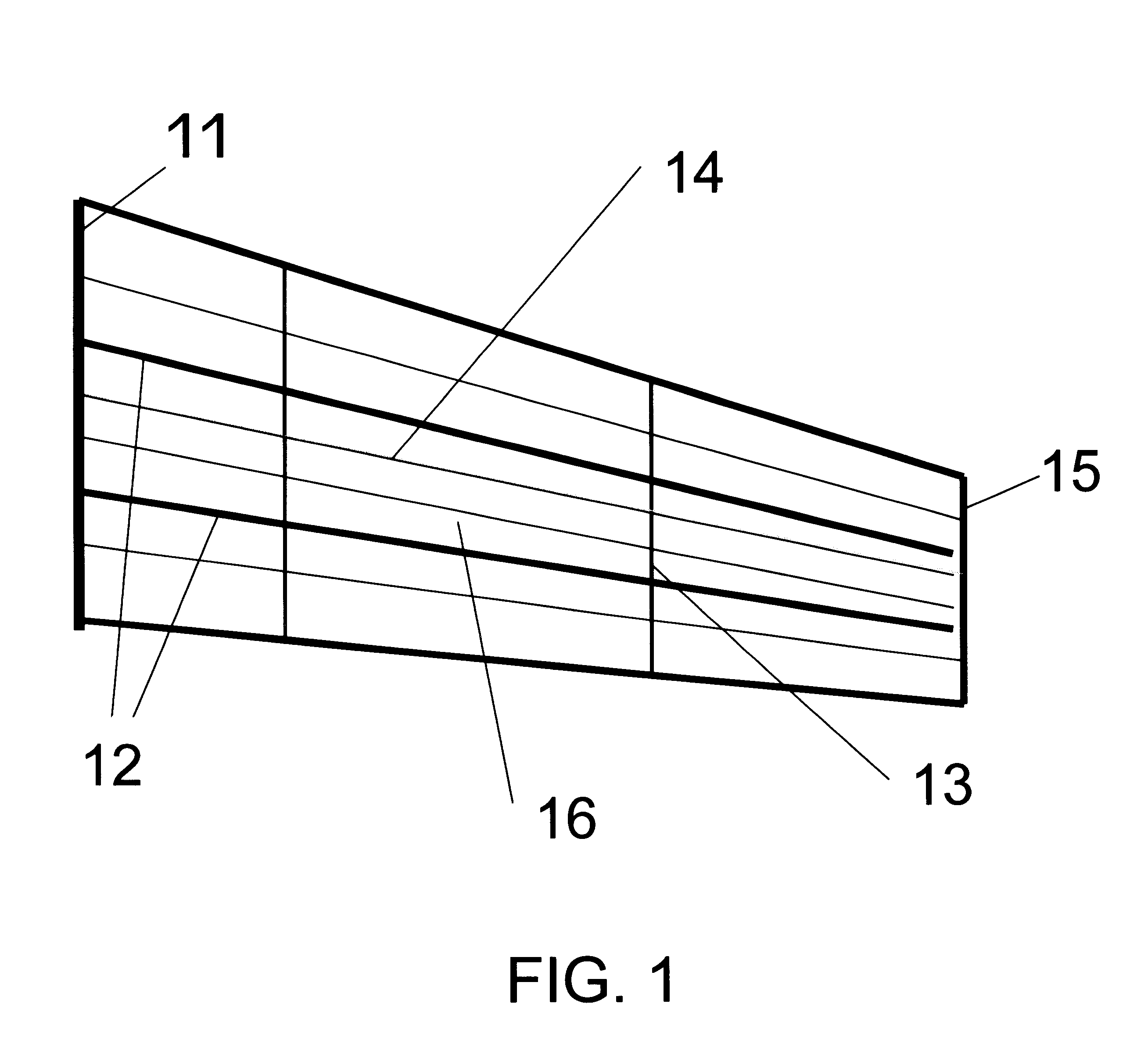

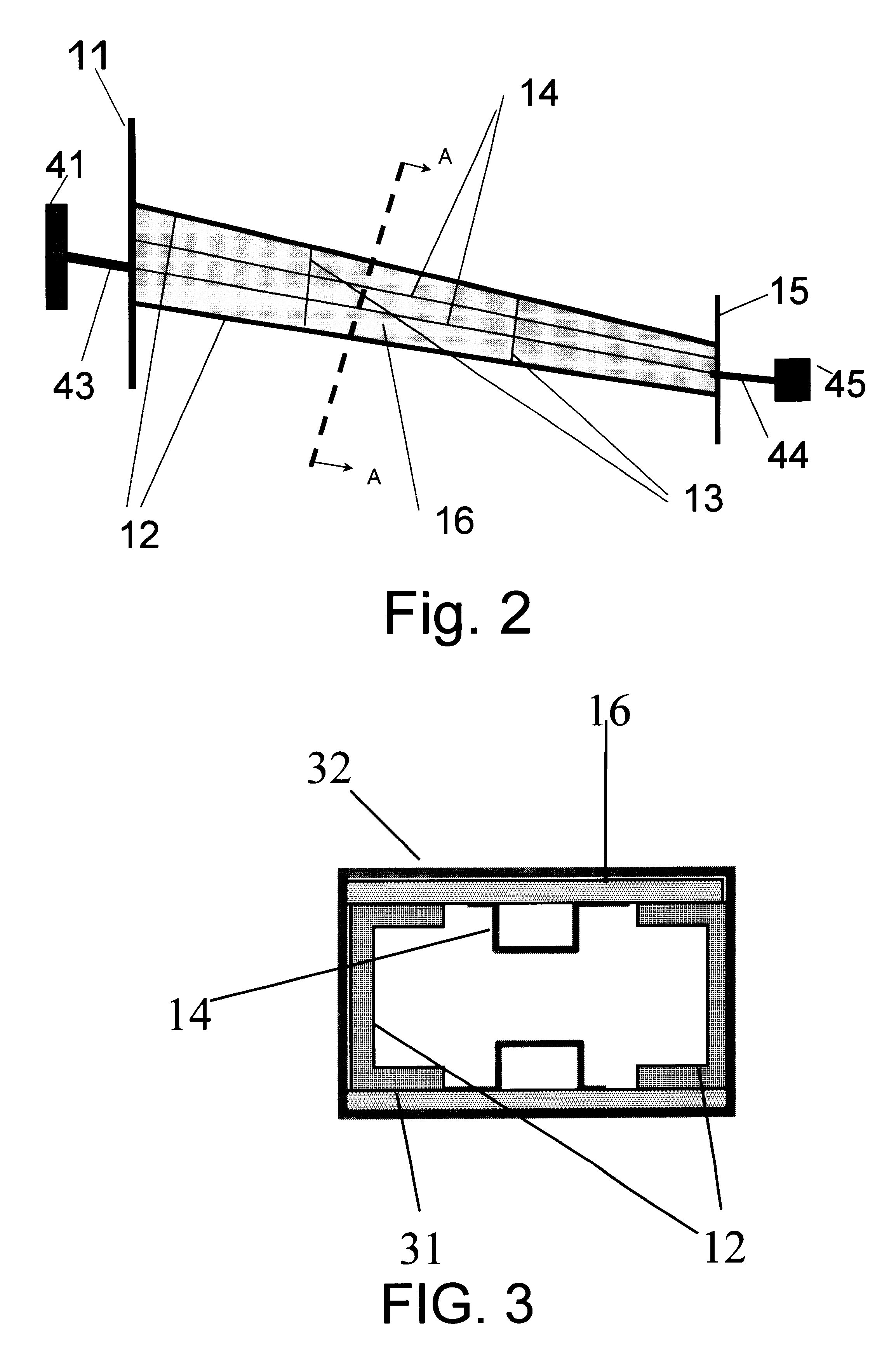

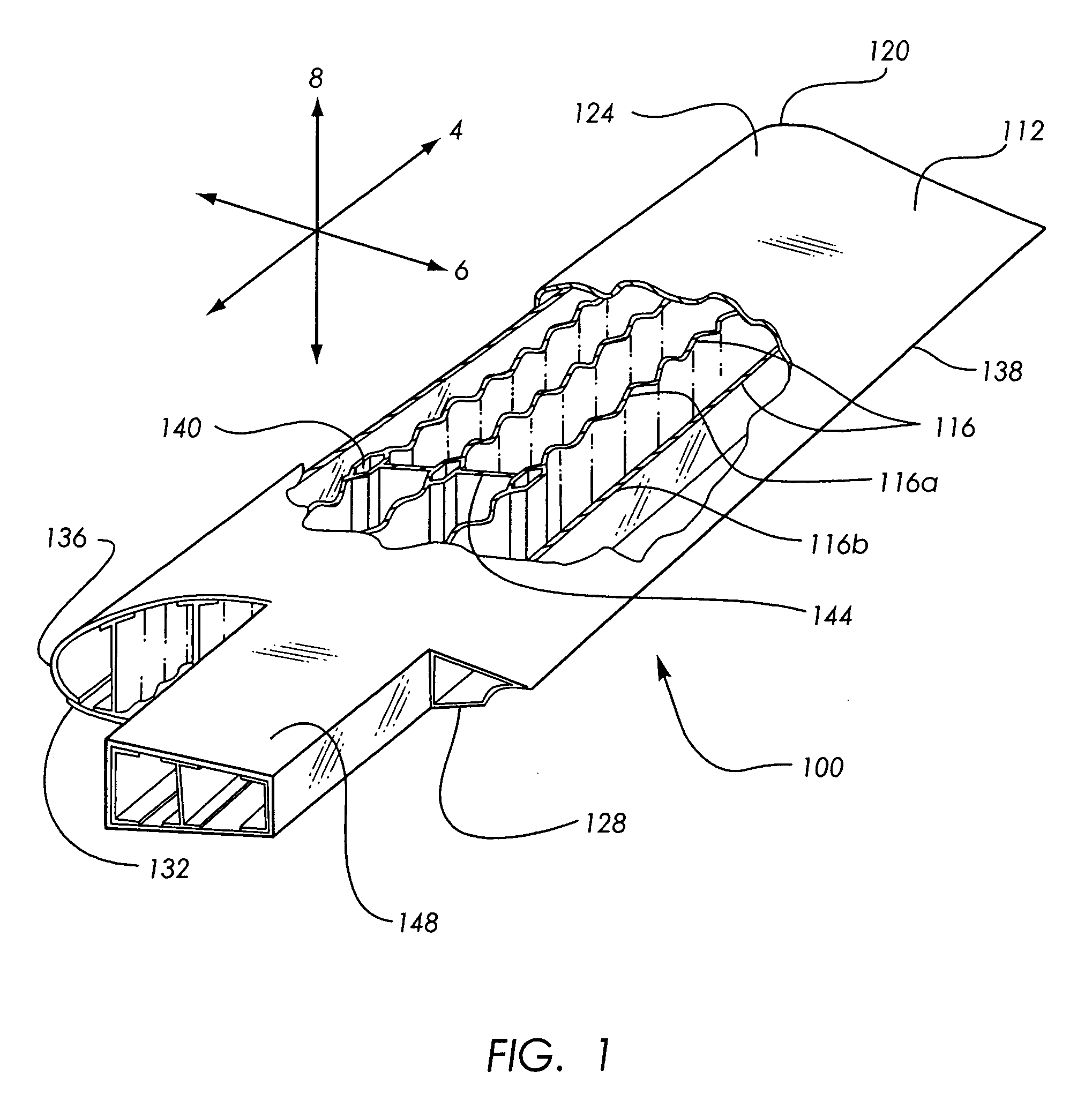

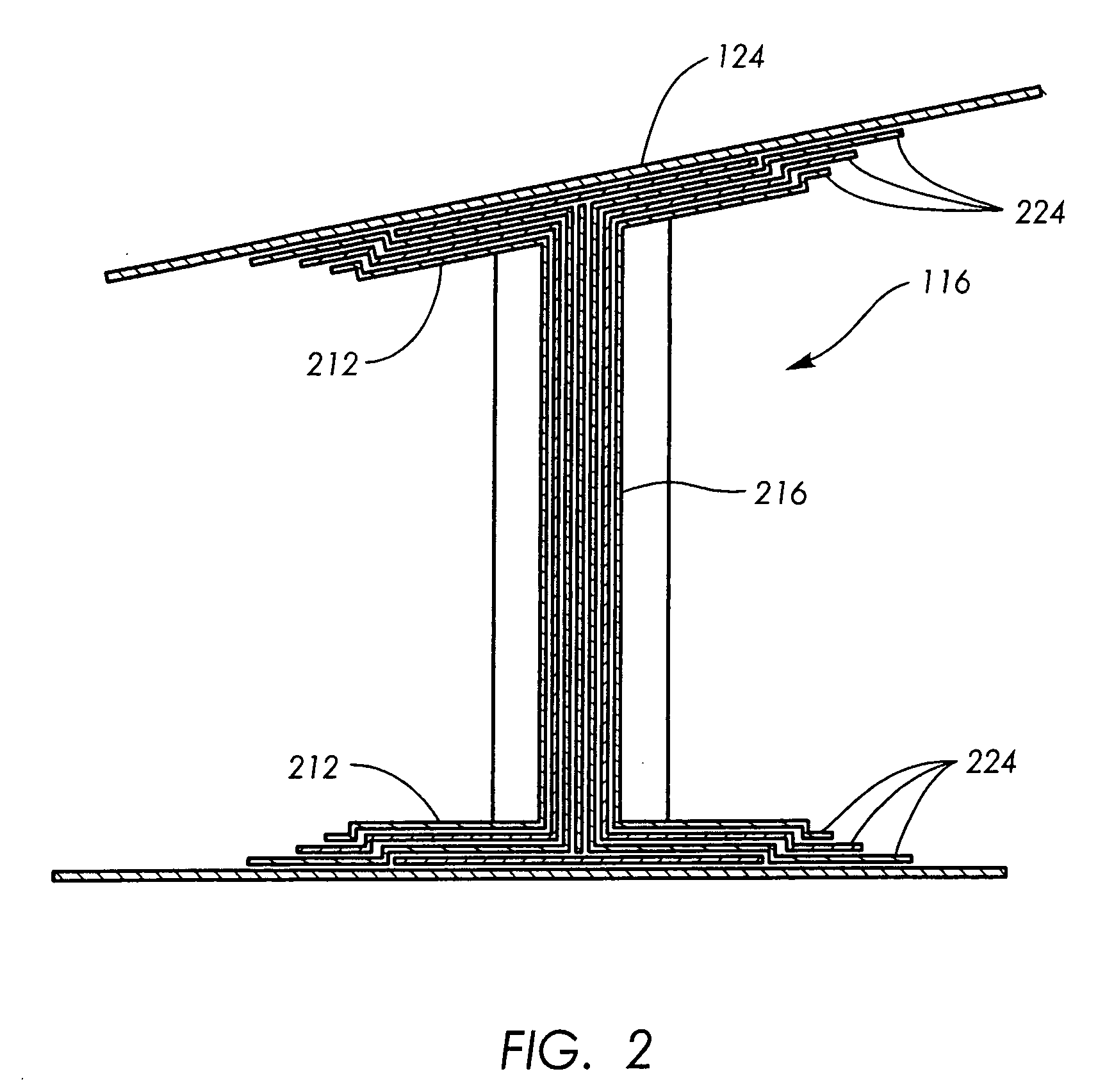

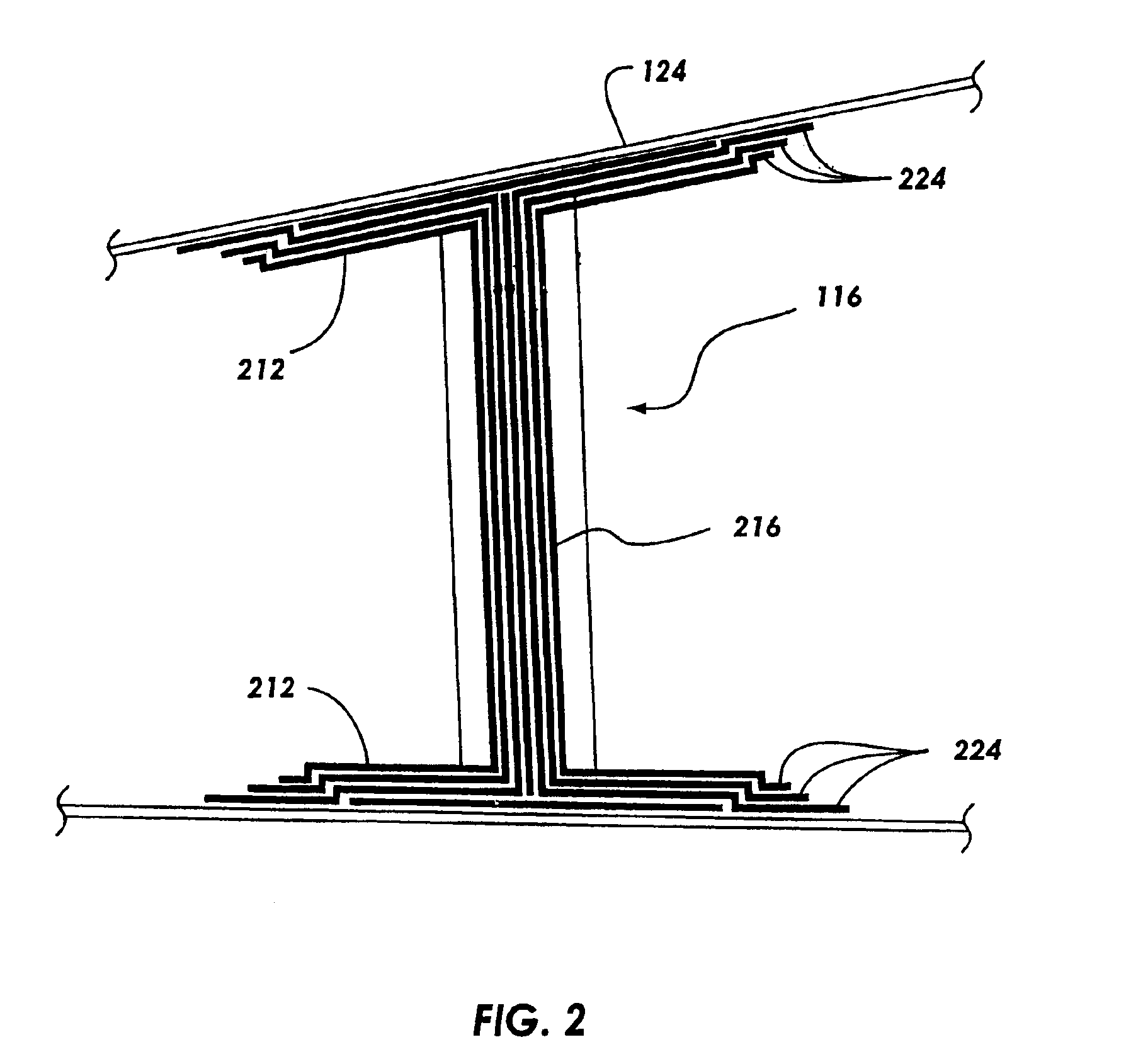

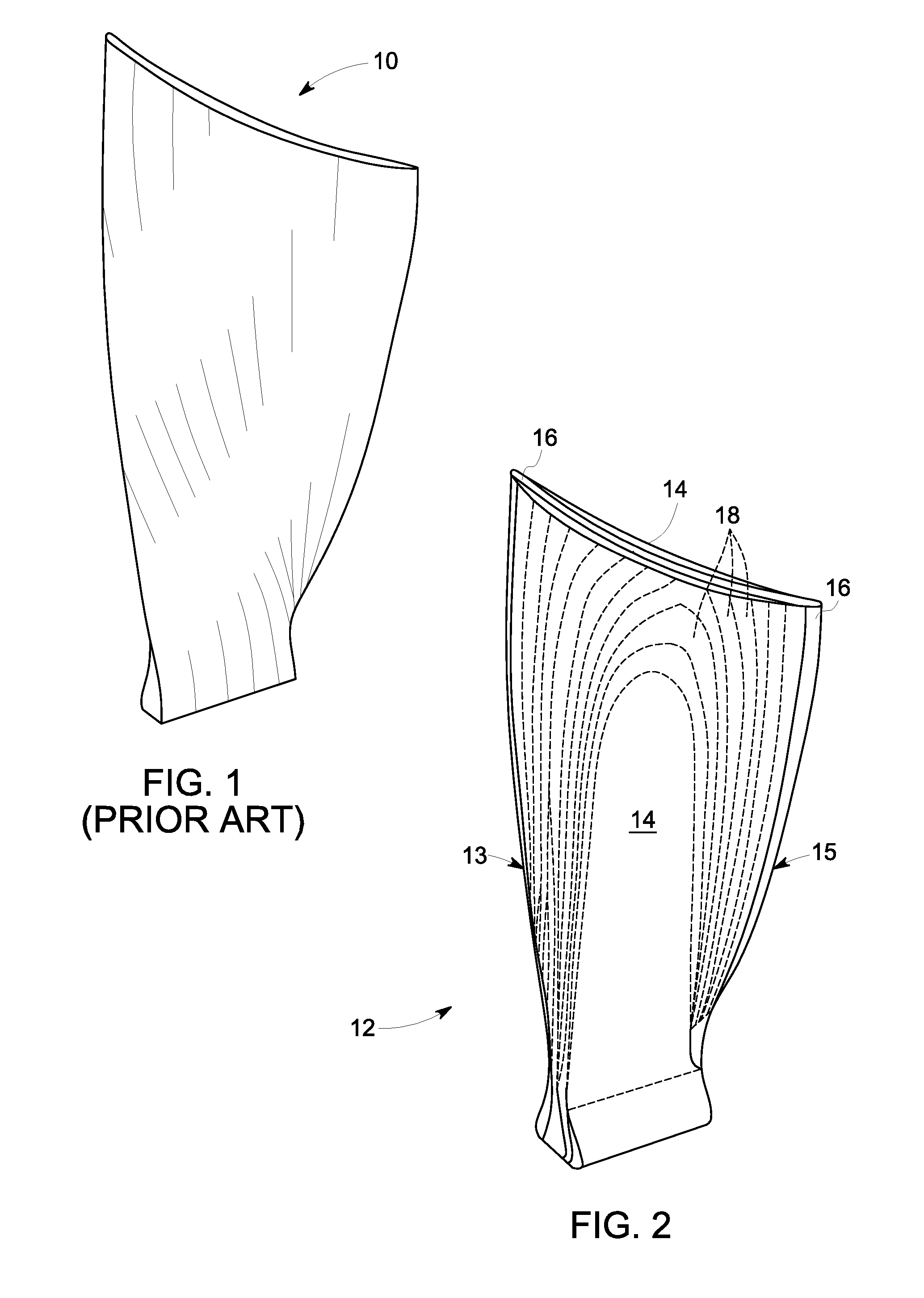

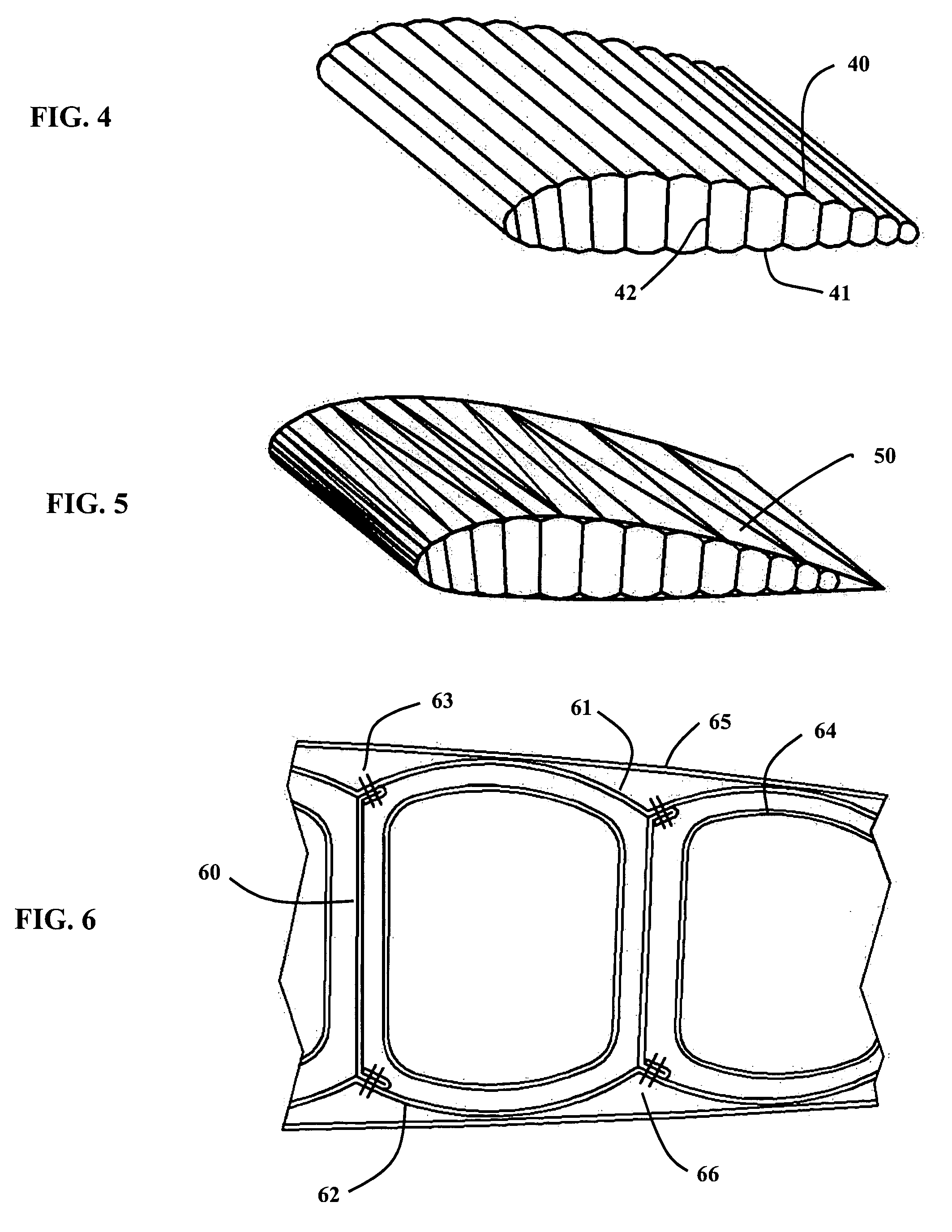

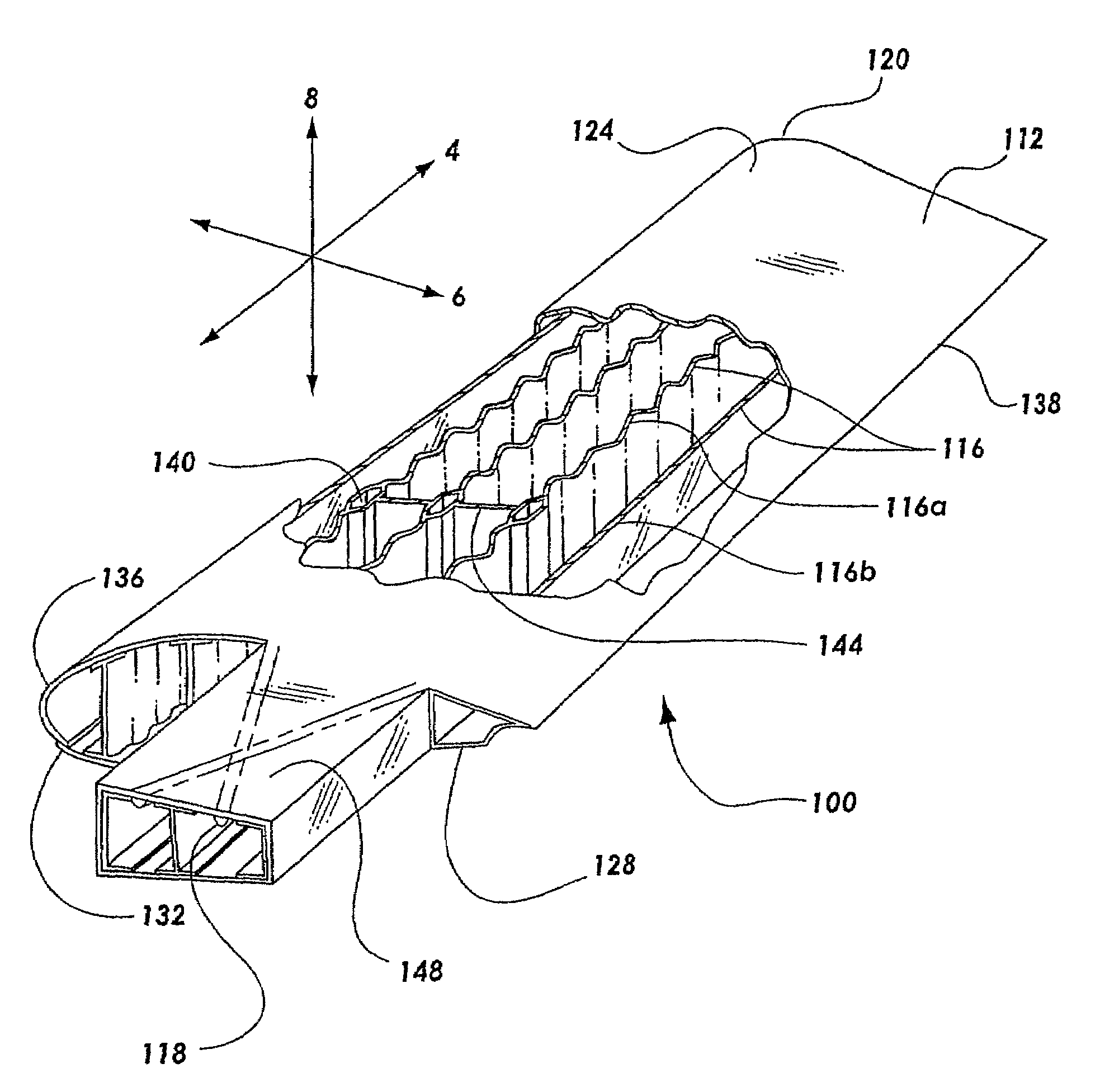

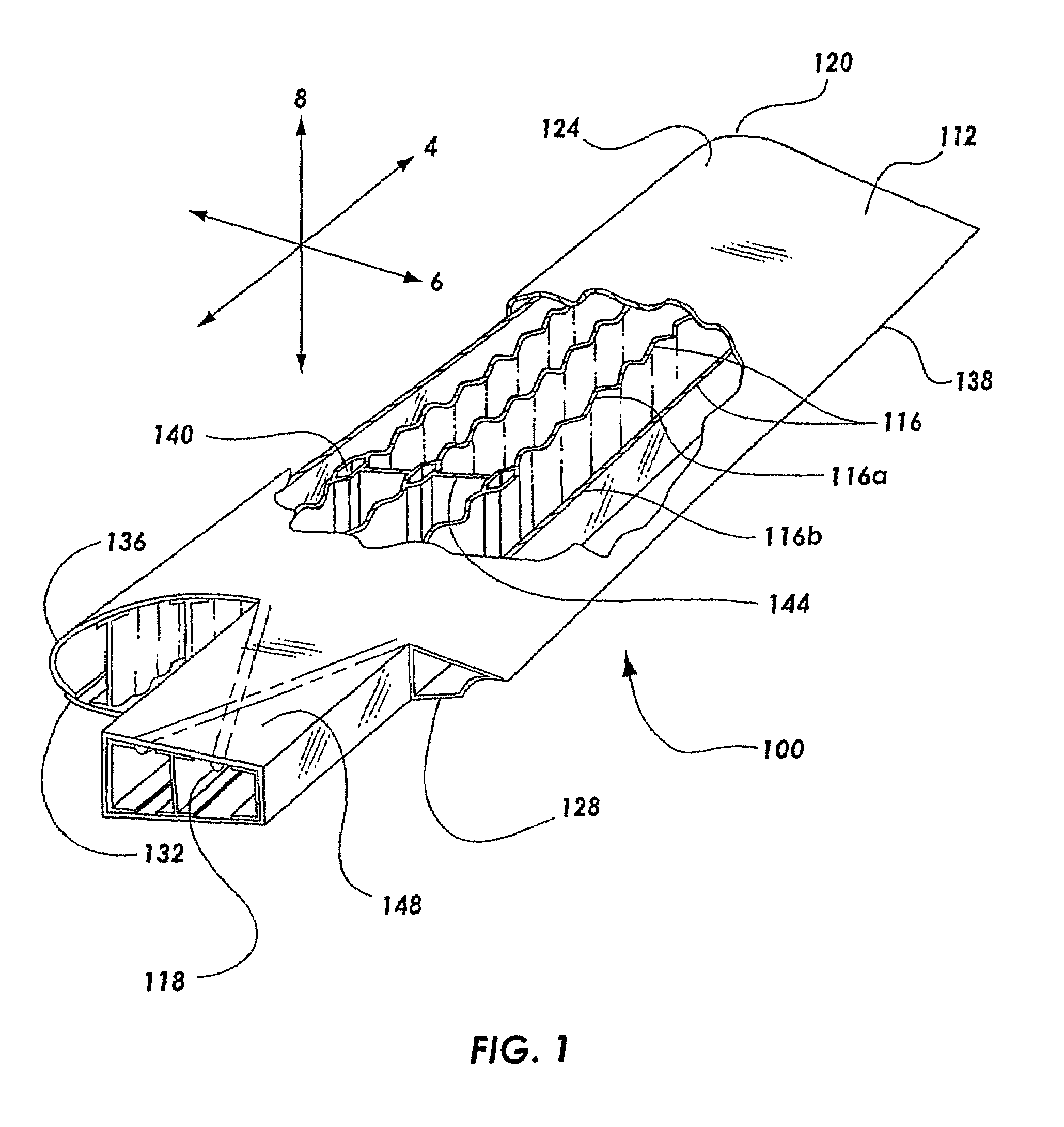

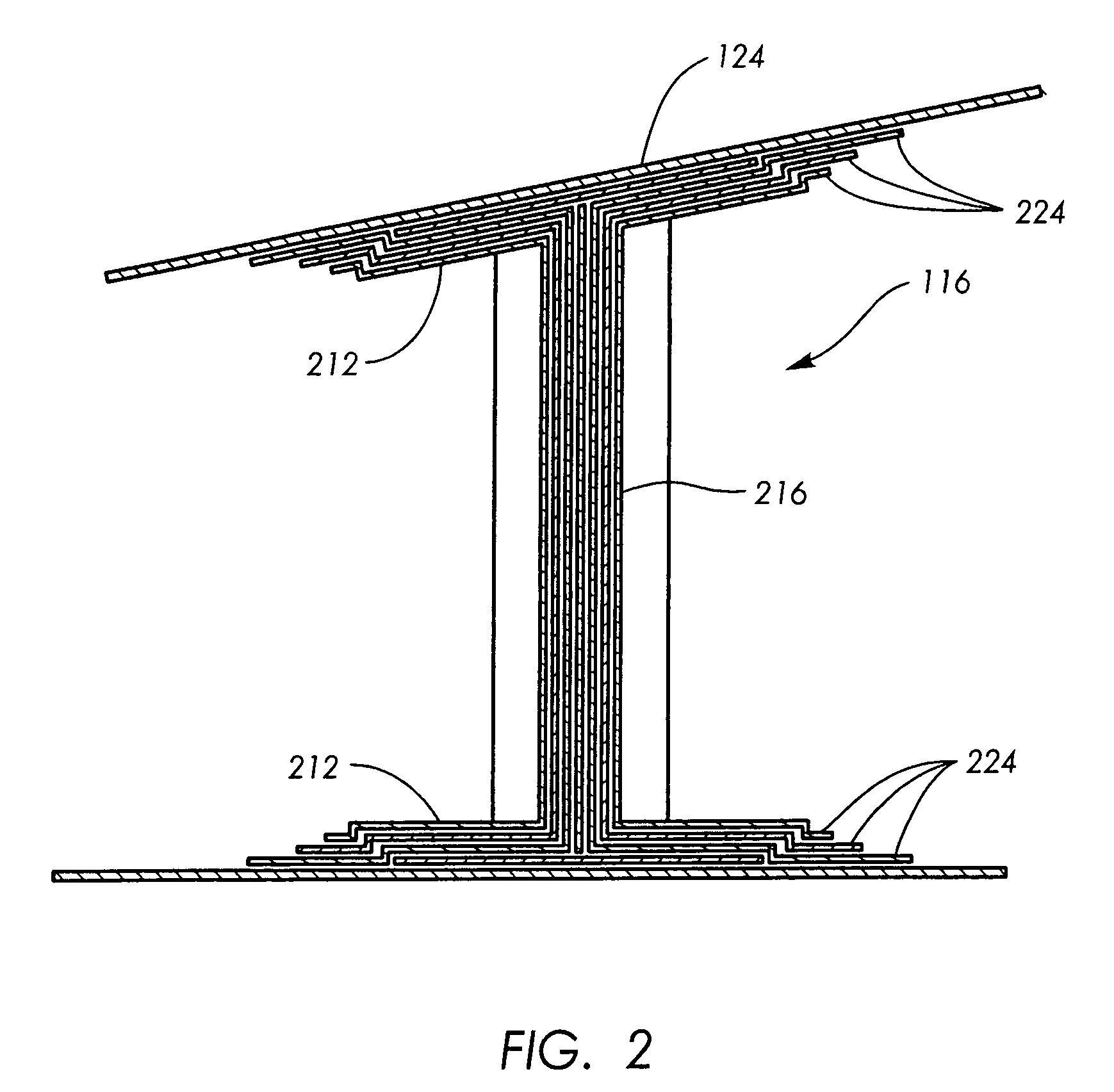

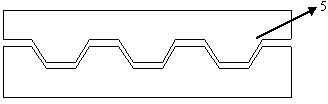

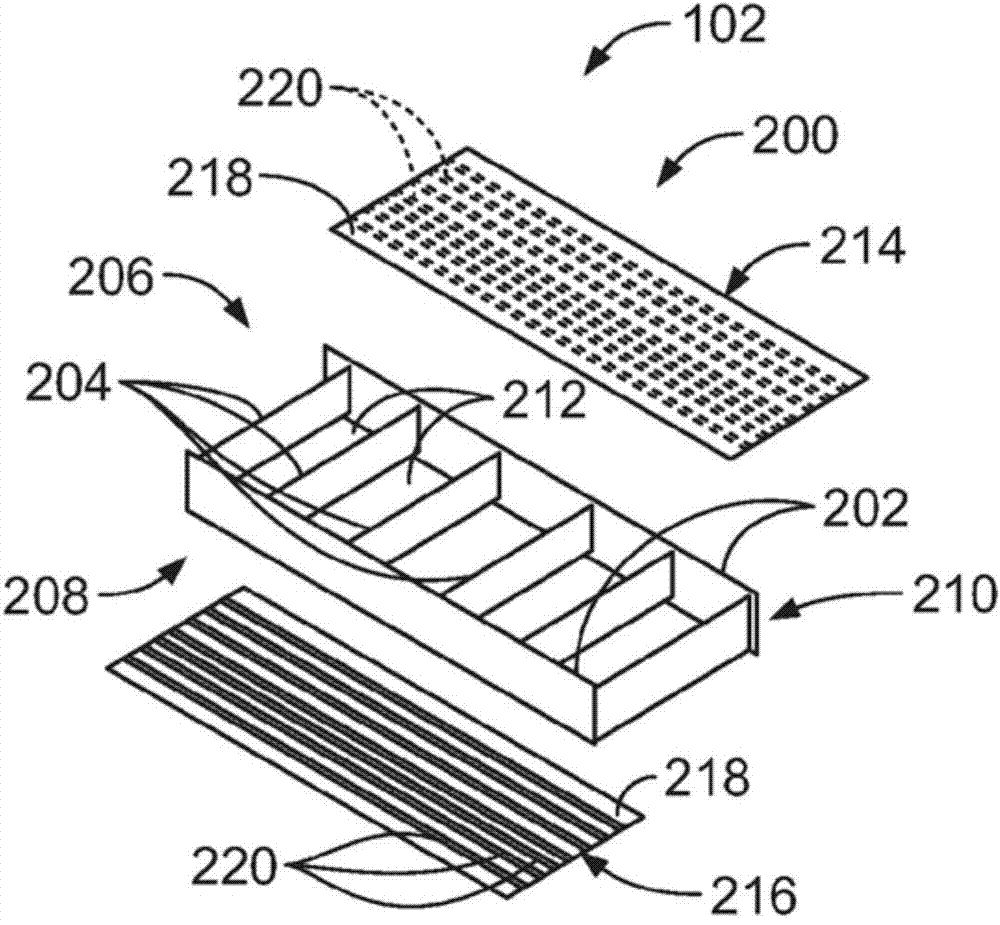

Single piece co-cure composite wing

InactiveUS20060249626A1Improve performanceImprove protectionAircraft stabilisationLayered productsWave shapeComposite wing

Owner:SPECTRUM AERONAUTICAL

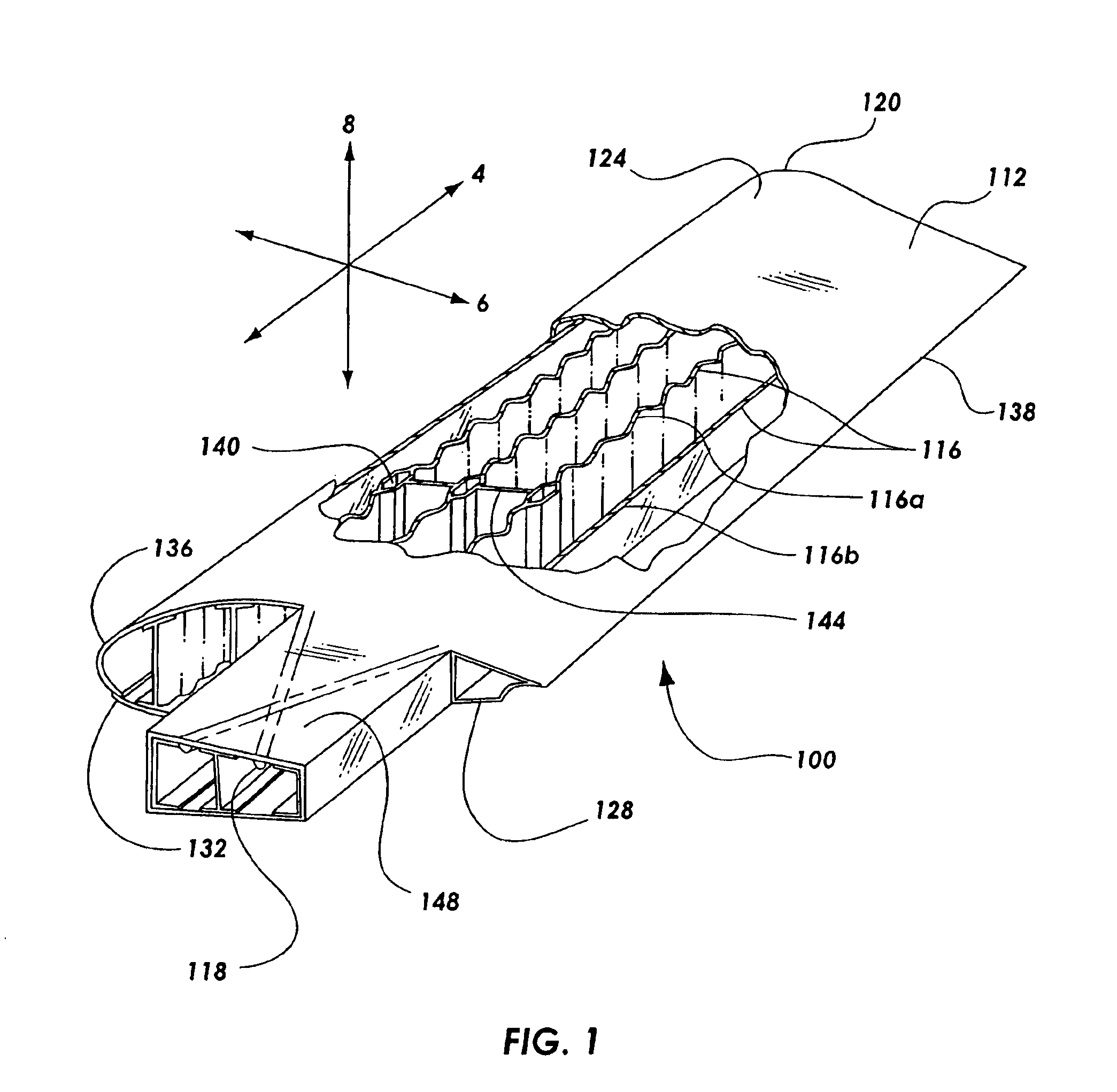

Single piece co-cure composite wing

InactiveUS6889937B2Easy to disassembleAircraft stabilisationOther chemical processesWave shapeComposite wing

A single piece co-cured composite wing is disclosed. The wing has a flying surface and structural members. In one embodiment the structural members may be a plurality of spars. The spars may have various shapes to increase the buckling strength. The spars may be wave shaped, such as a sinusoidal shape. The flying surface and the structural members are co-cured in order to form a single piece, integral wing structure. A process for manufacturing a single piece co-cured wing is also disclosed. The process may include laying out composite sheets for the flying surface of the wing. Then, the composite material of the spars is arranged around a plurality of pressurizable forms. Finally, the composite material is cured in a clamshell frame.

Owner:SPECTRUM AERONAUTICAL

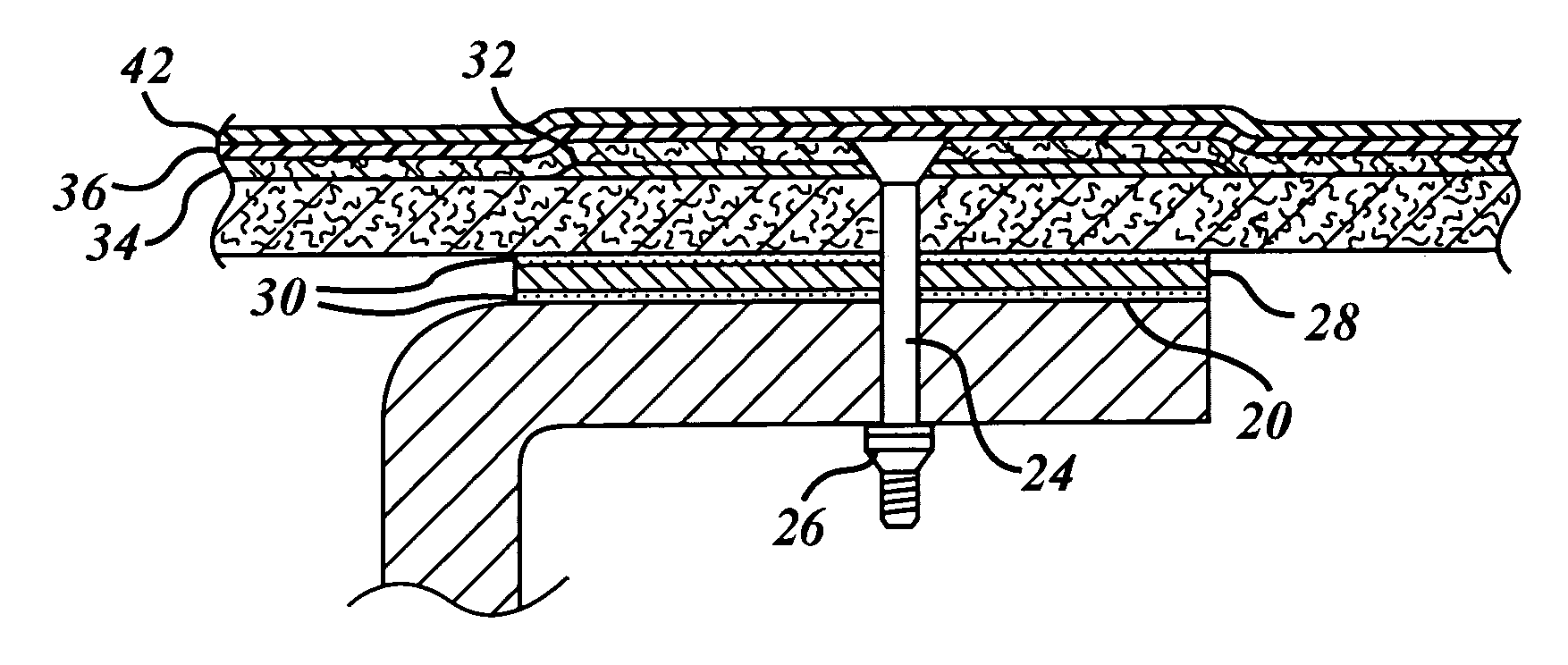

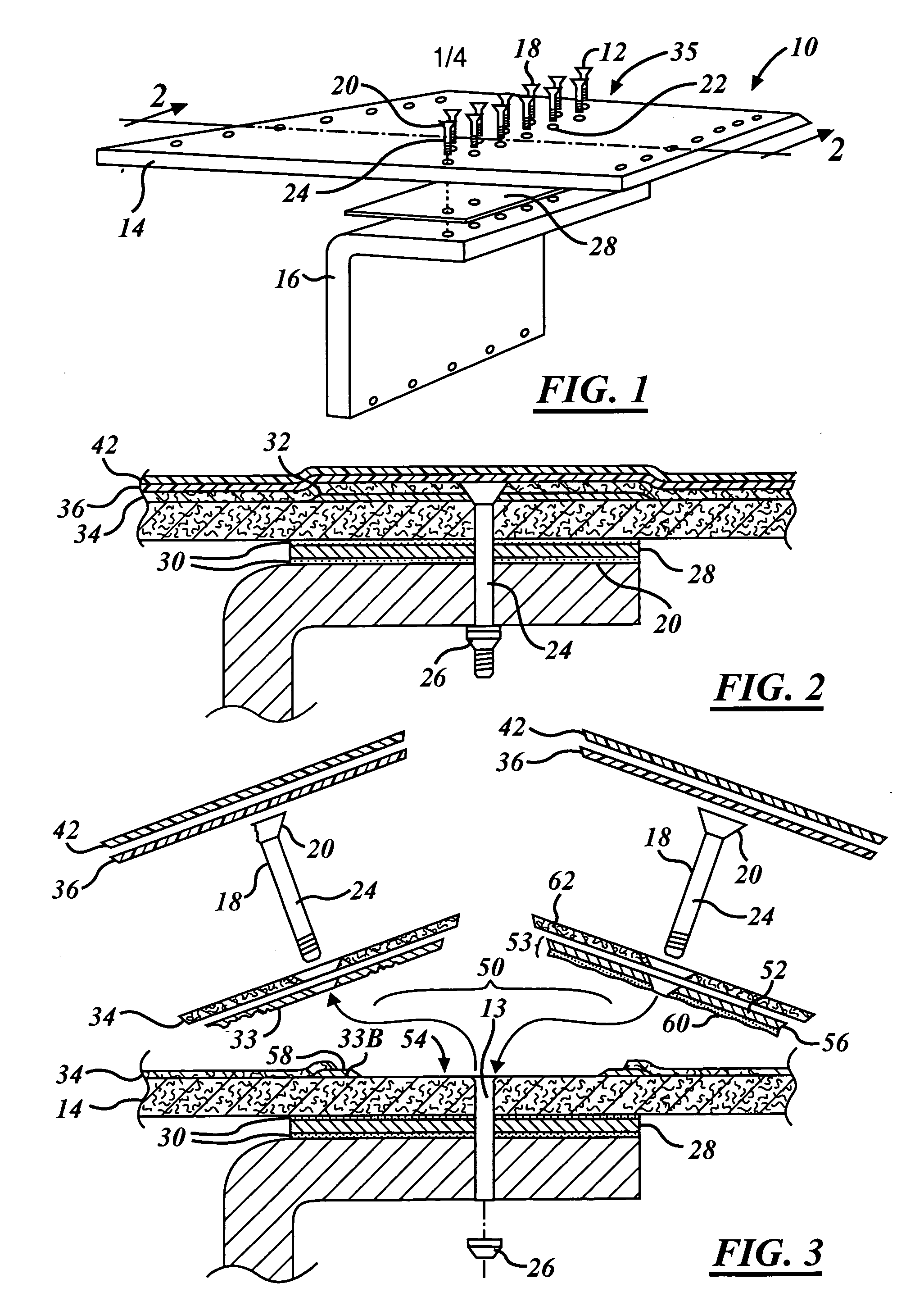

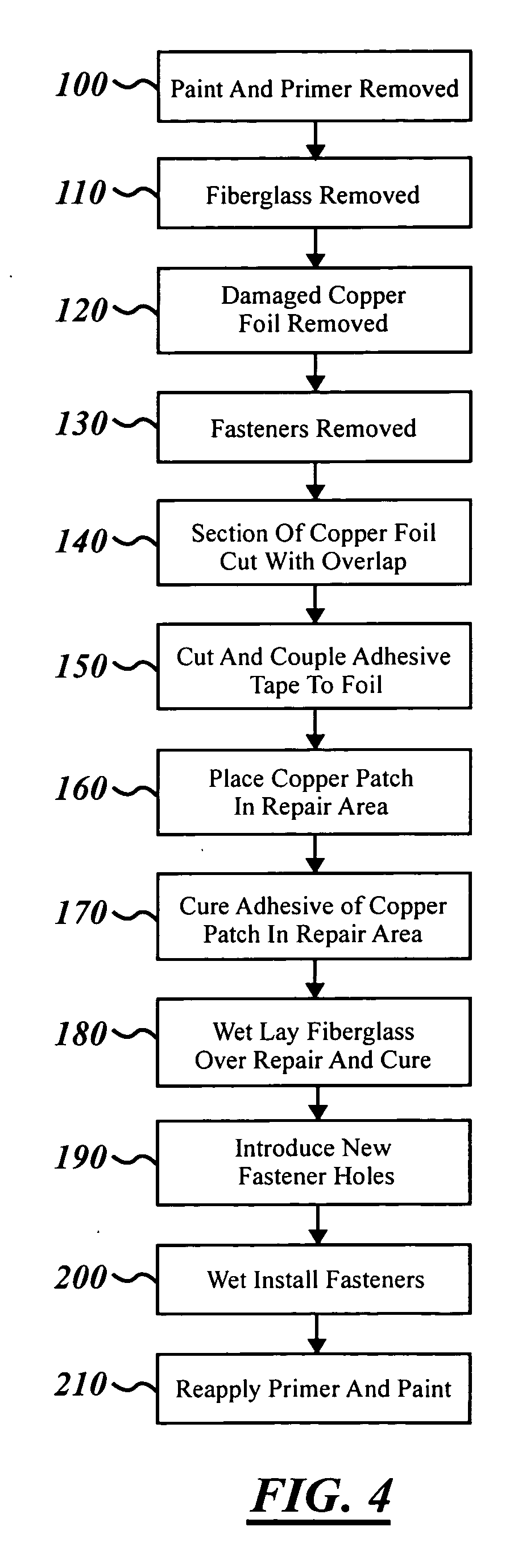

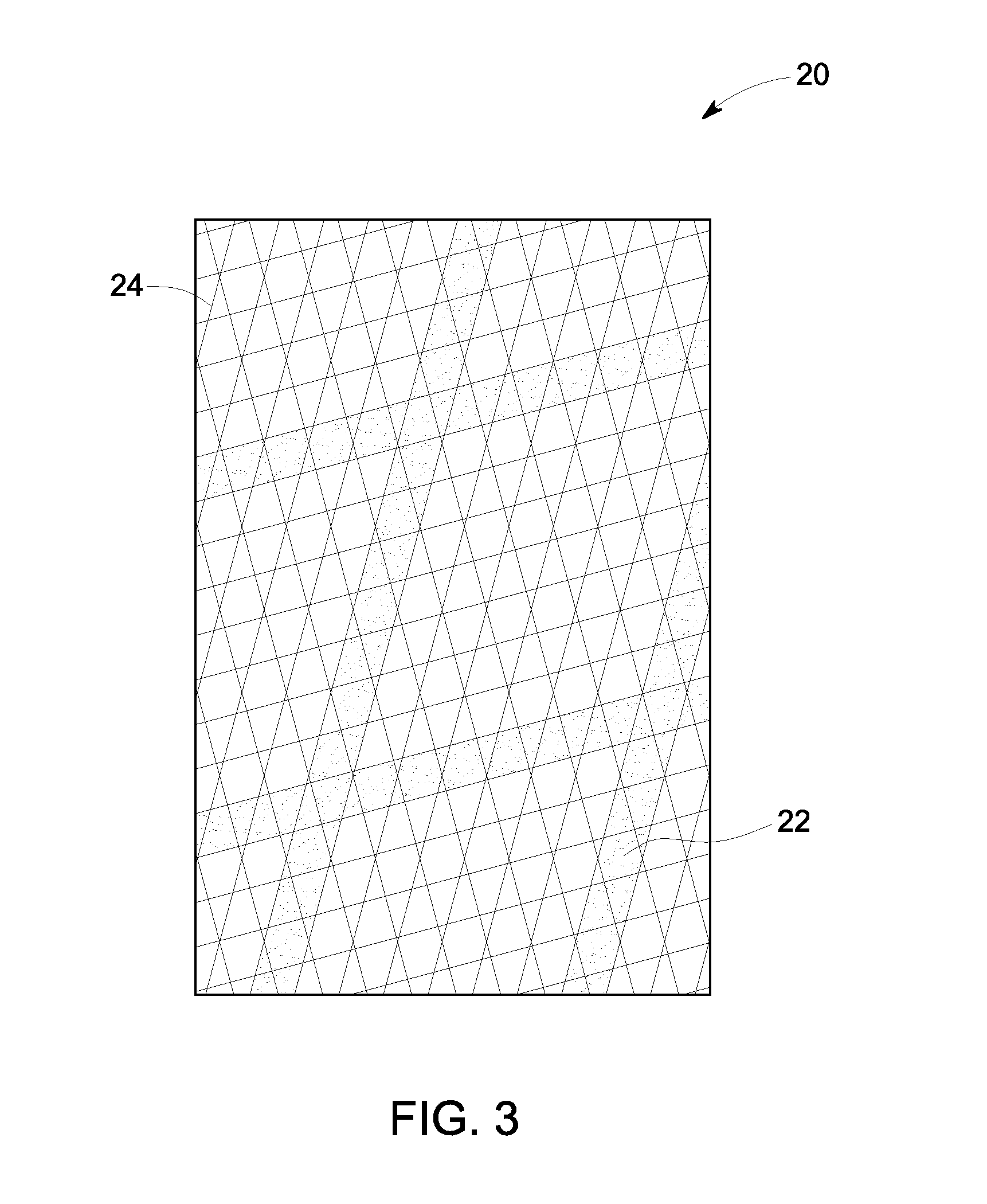

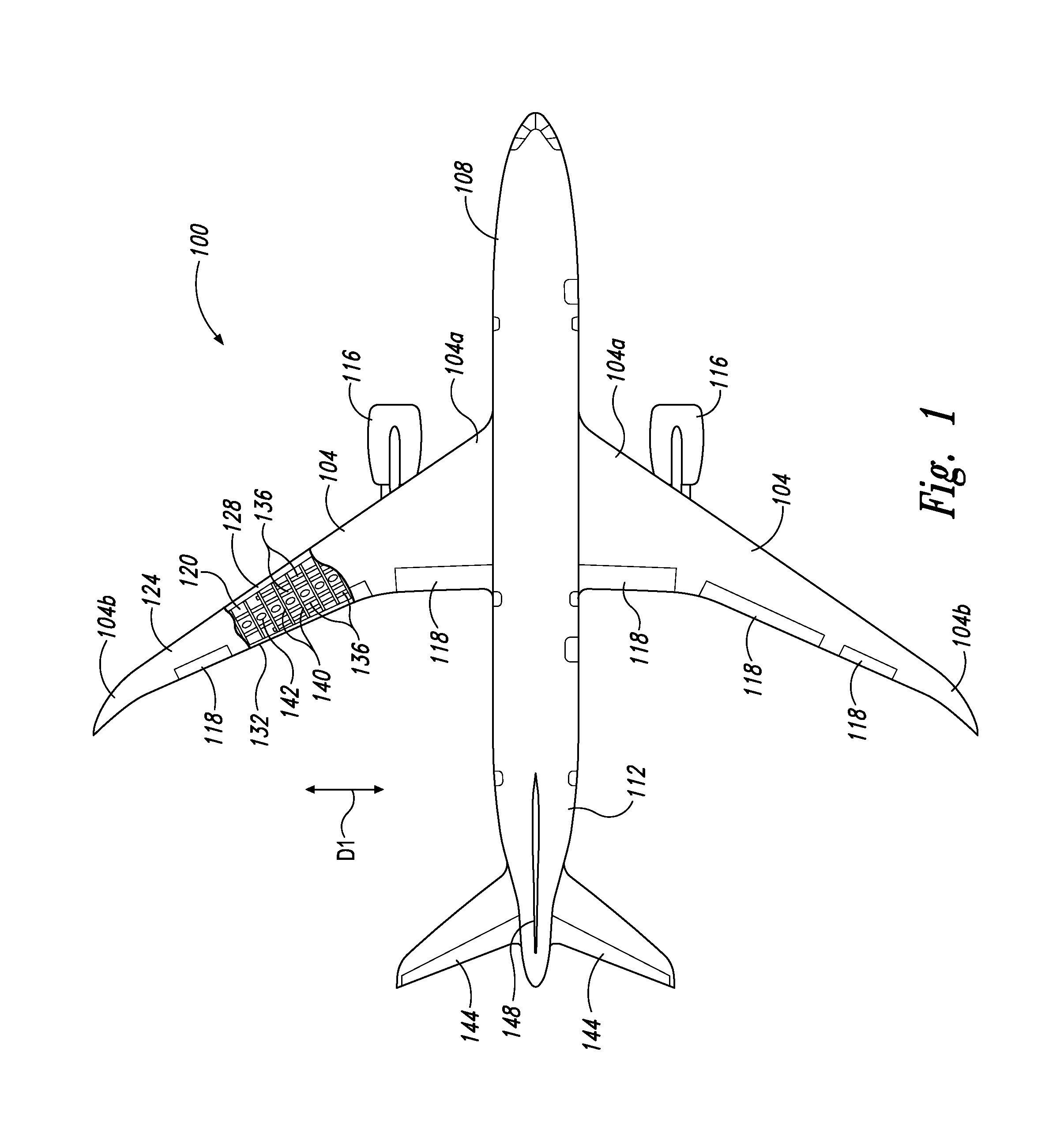

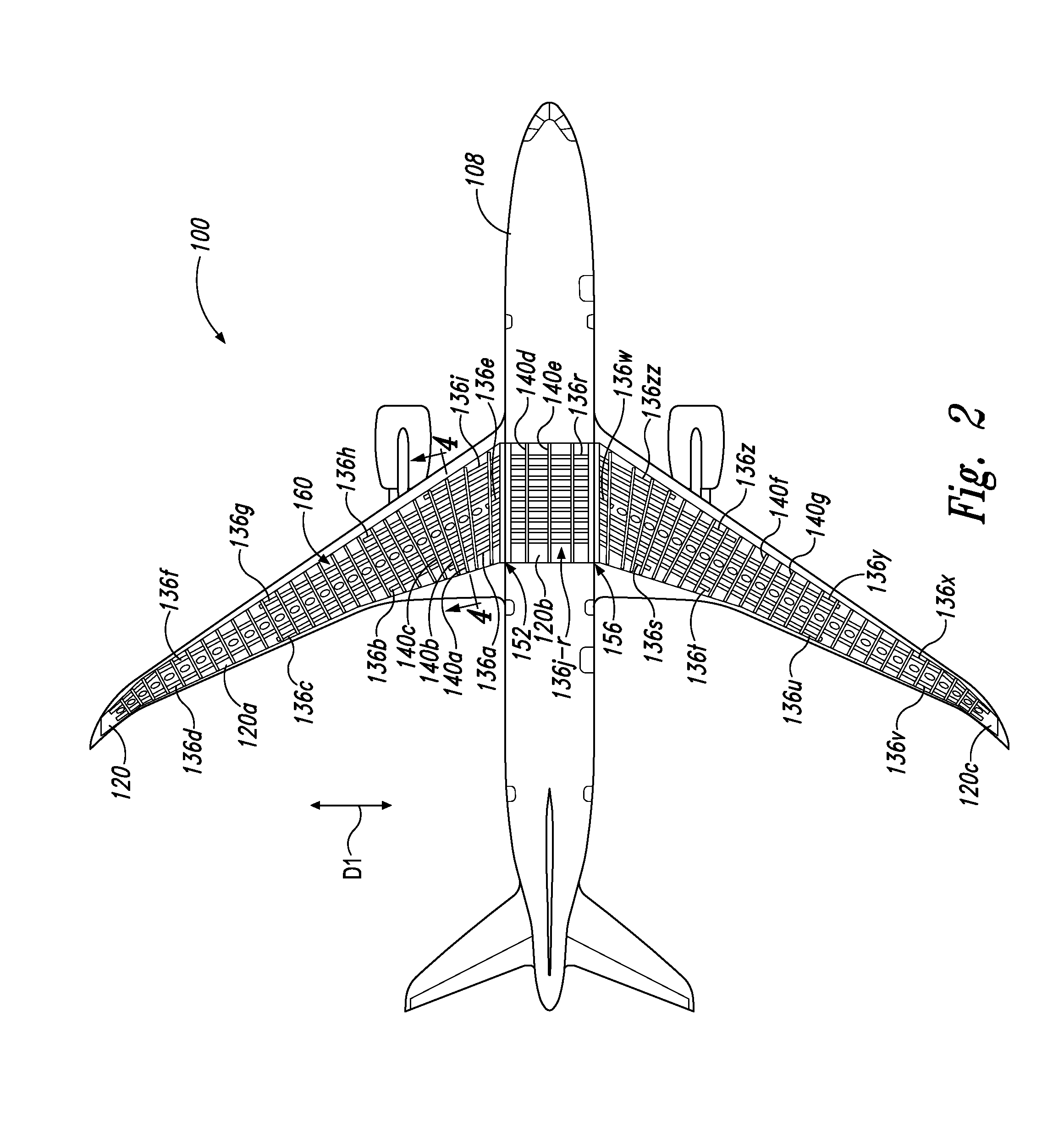

Copper grid repair technique for lightning strike protection

ActiveUS20070177330A1Quick and cost-effective repairMaintain integrityFuselage framesAircraft lighting protectorsGlass fiberLightning strike

A method for reestablishing the electrical continuity of an electrically conductive layer of a composite aircraft wing damaged by a lightning strike or other mechanical event is disclosed in which a copper patch replaced the damaged section of the electrically conductive layer contained. The repair is performed by first removing any surfacers, fasteners, and damaged electrically conductive layer to expose a portion of the underlying composite skin. A copper patch having a copper foil section coupled to an unsupported film adhesive is then introduced onto an underlying composite skin opening contained within an undamaged section of a copper foil grid and covered with resin-impregnated fiberglass material. The film adhesive and resin-impregnated fiberglass material are then cured and fasteners are then reinserted within the fiberglass material, copper patch and underlying composite skin. The surface of the composite wing is then reprimed and repainted to complete the repair.

Owner:THE BOEING CO

Aircraft fuel systems

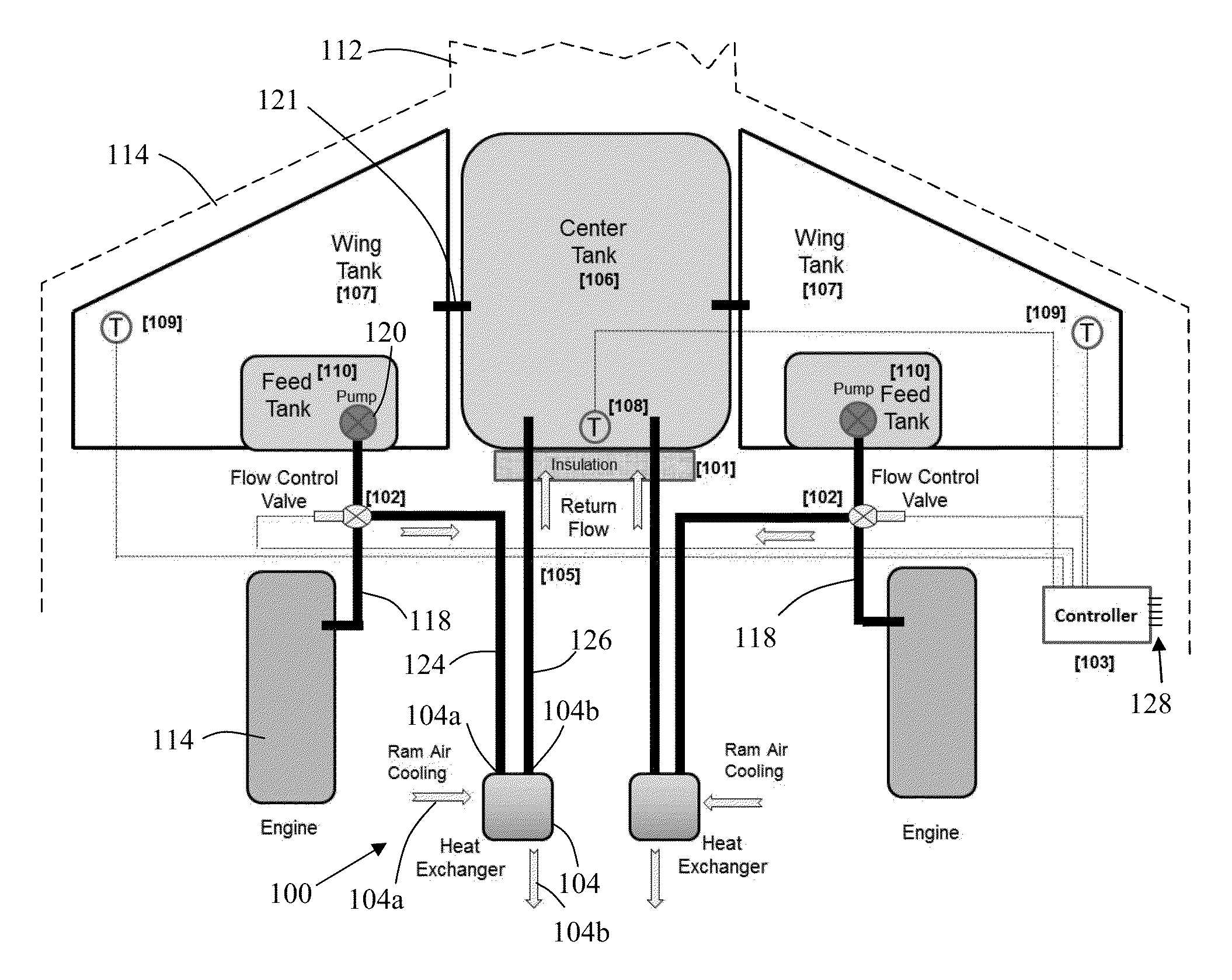

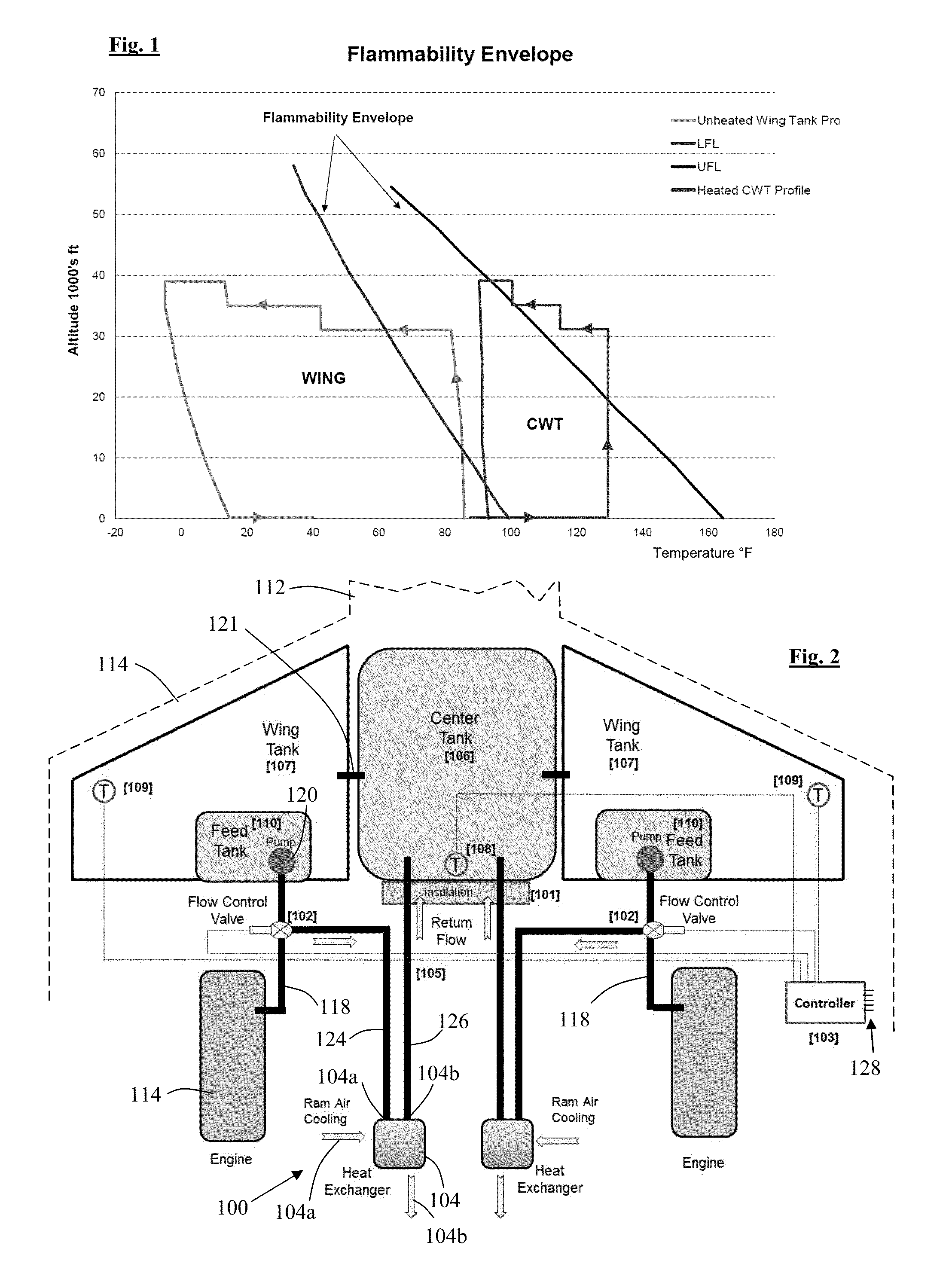

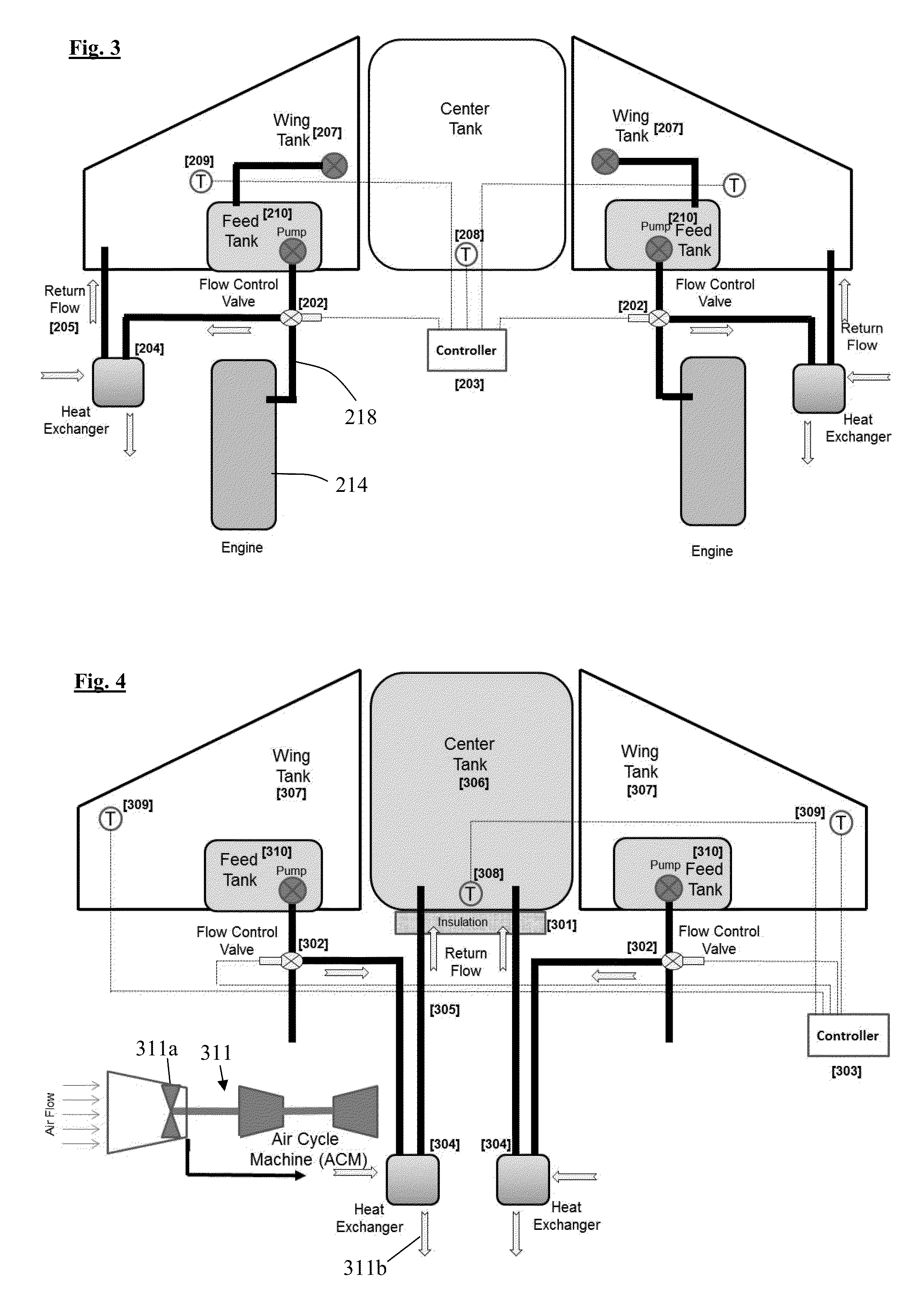

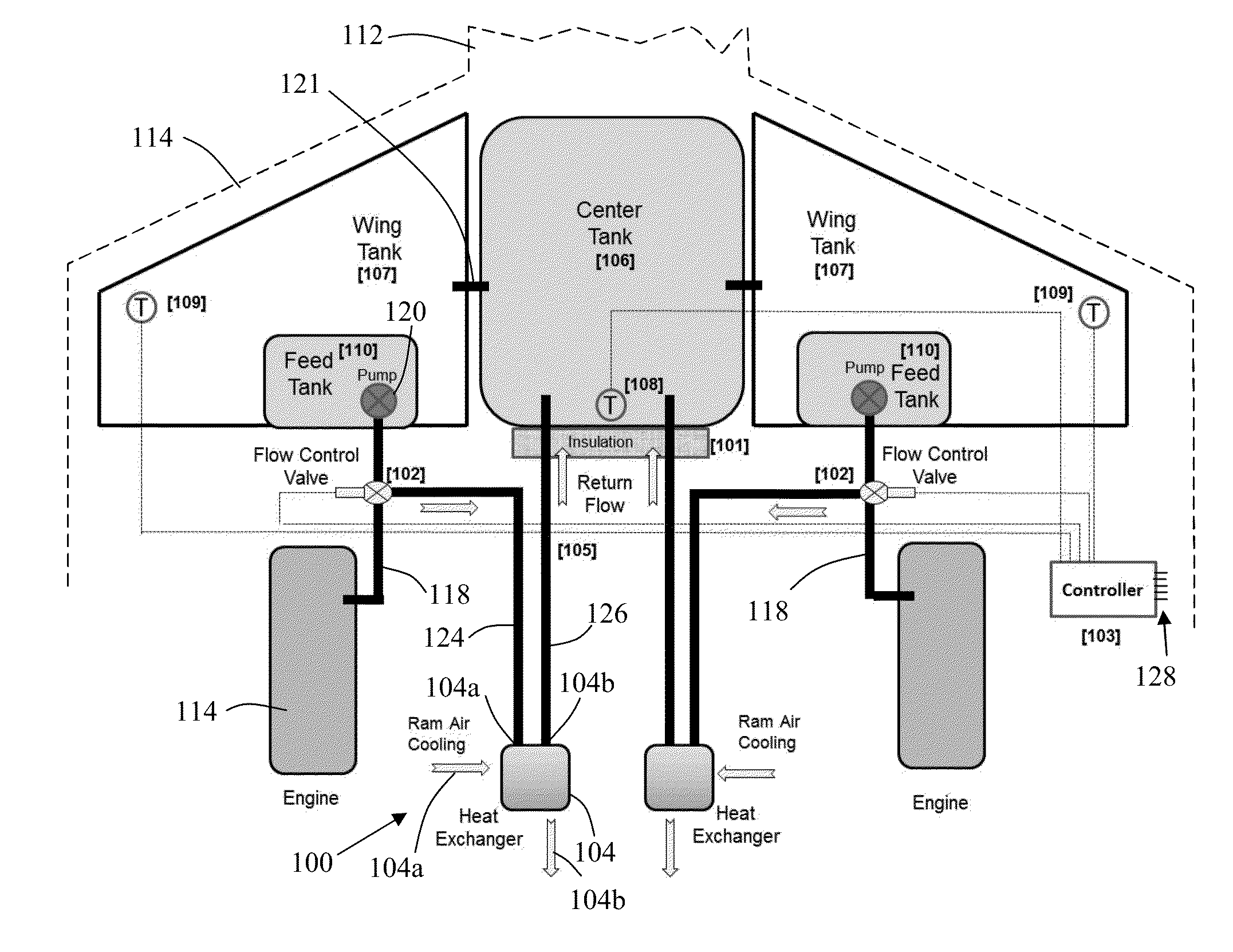

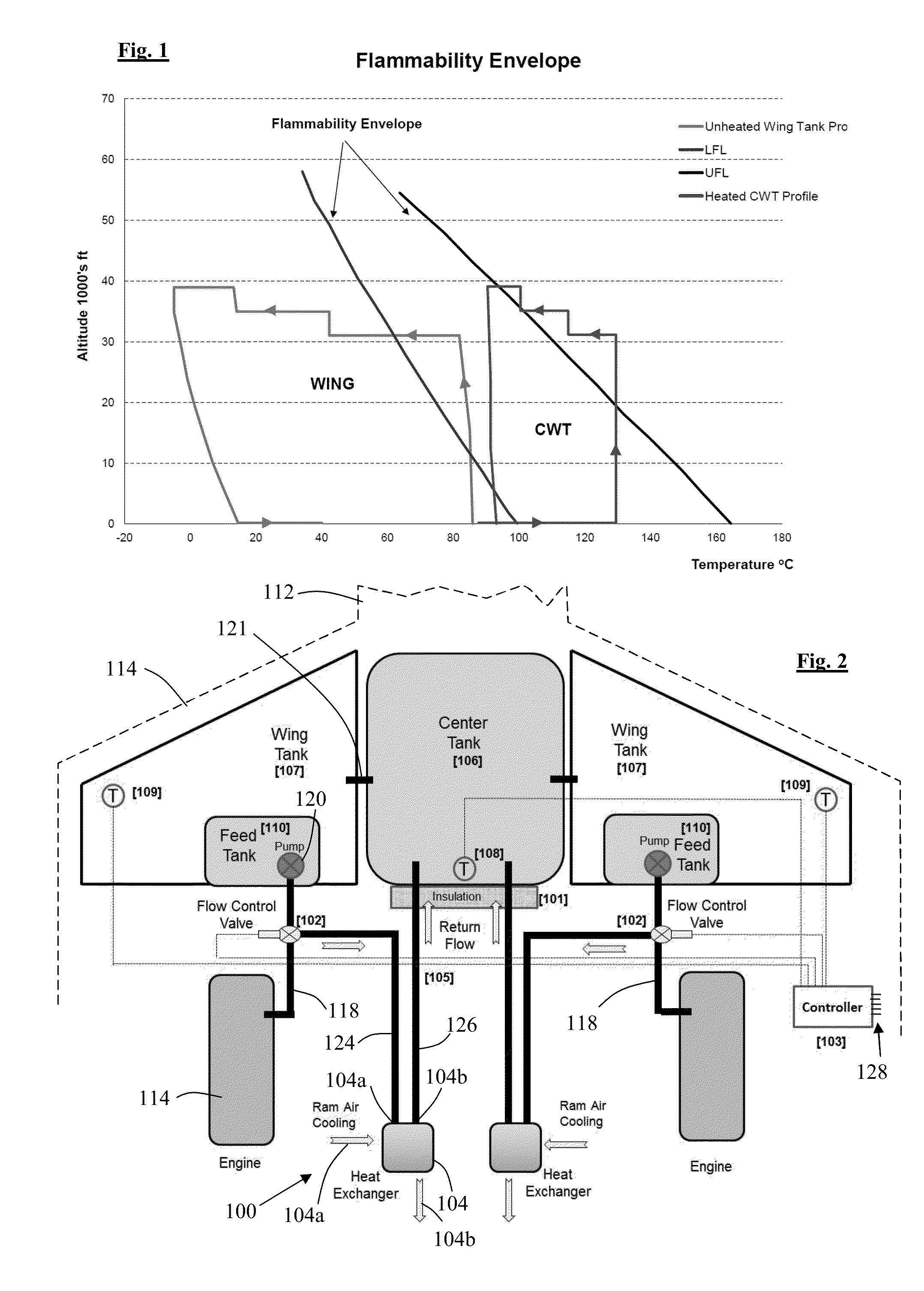

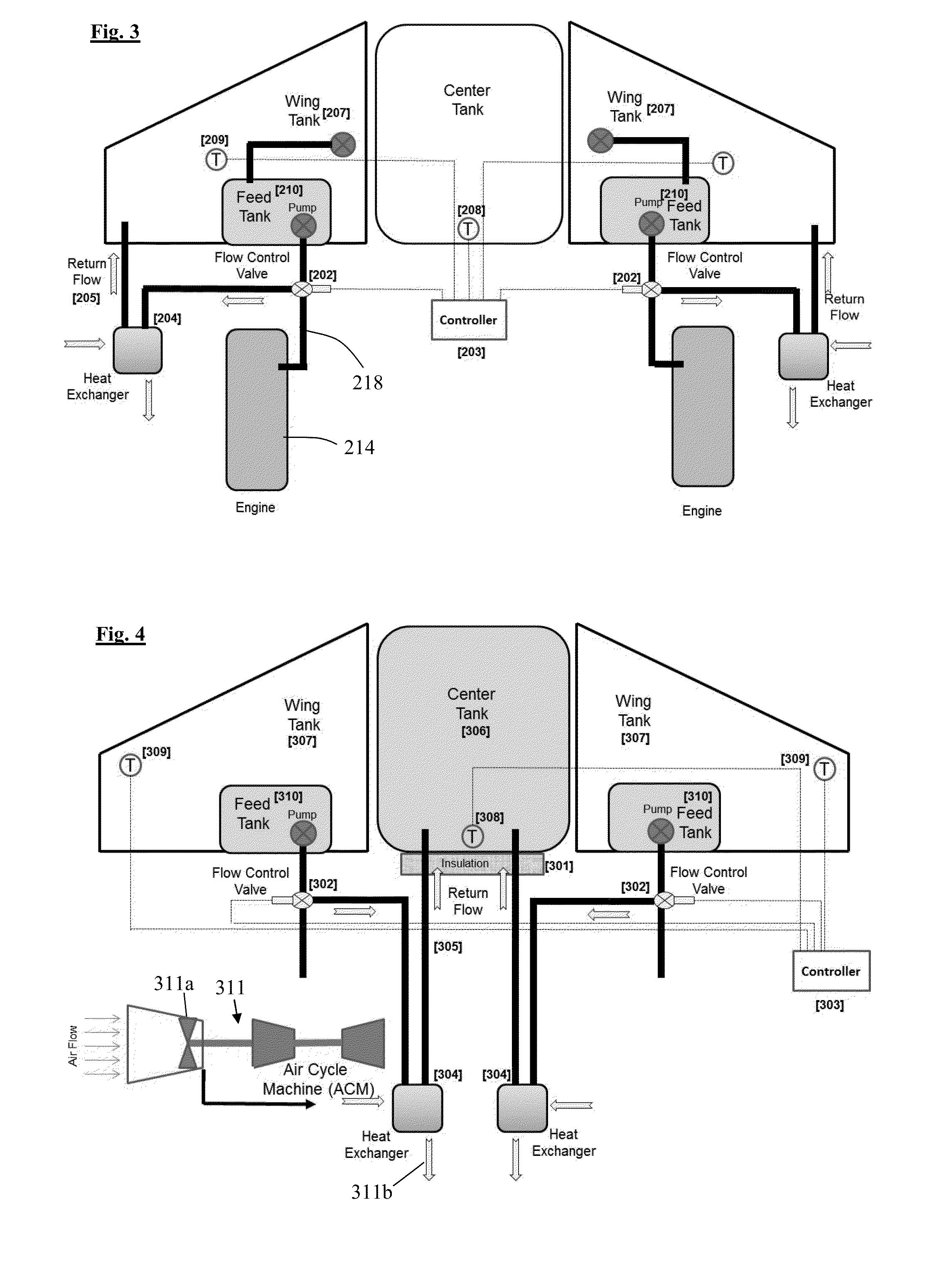

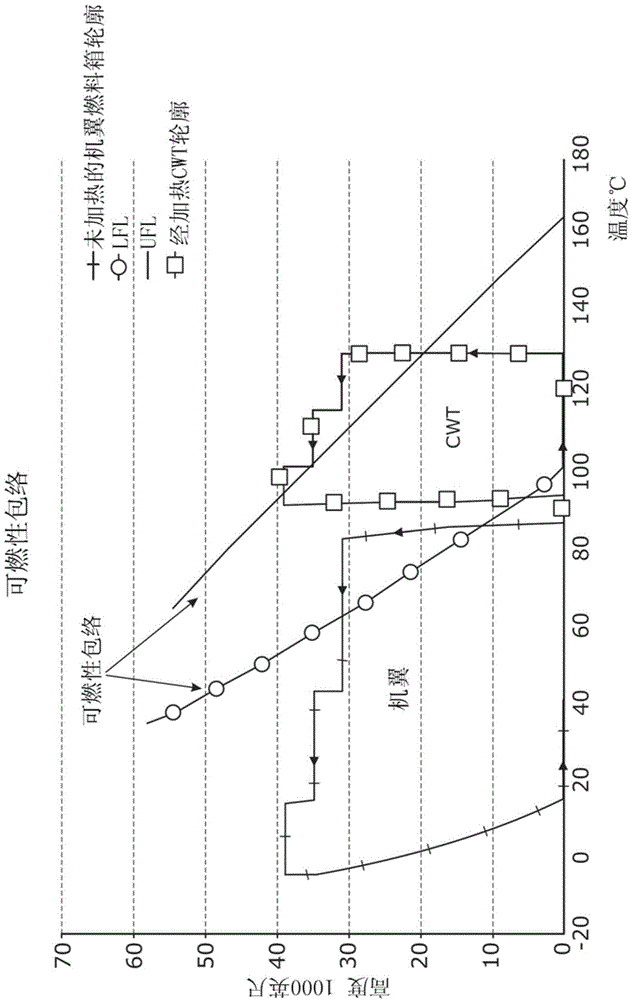

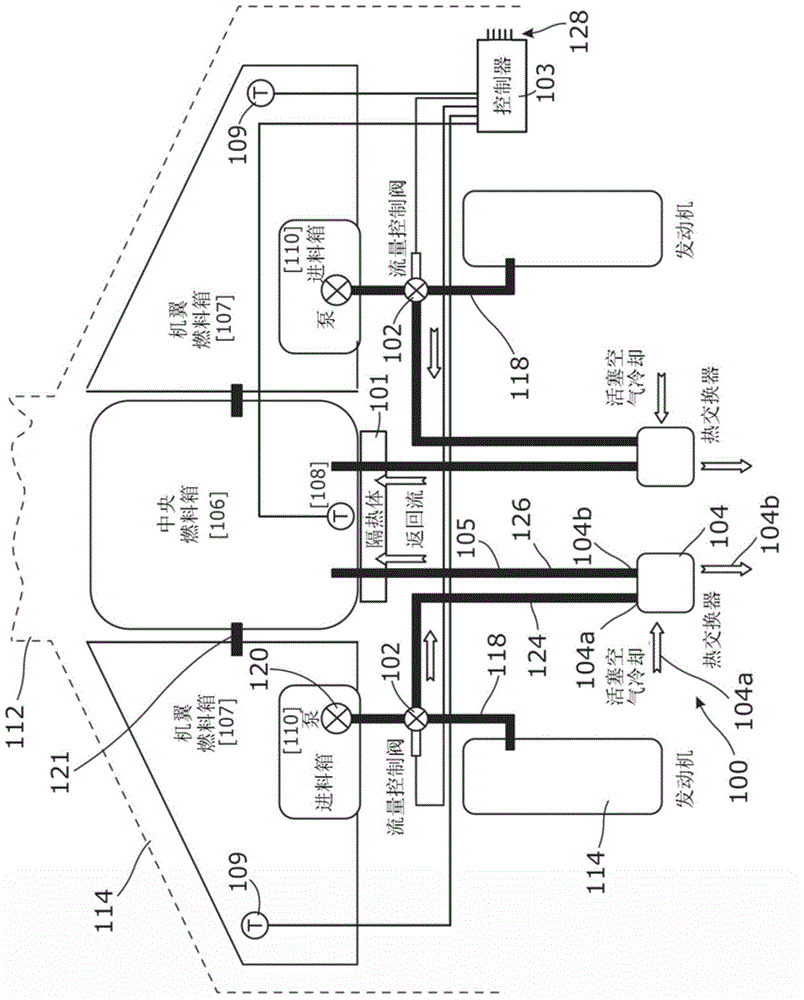

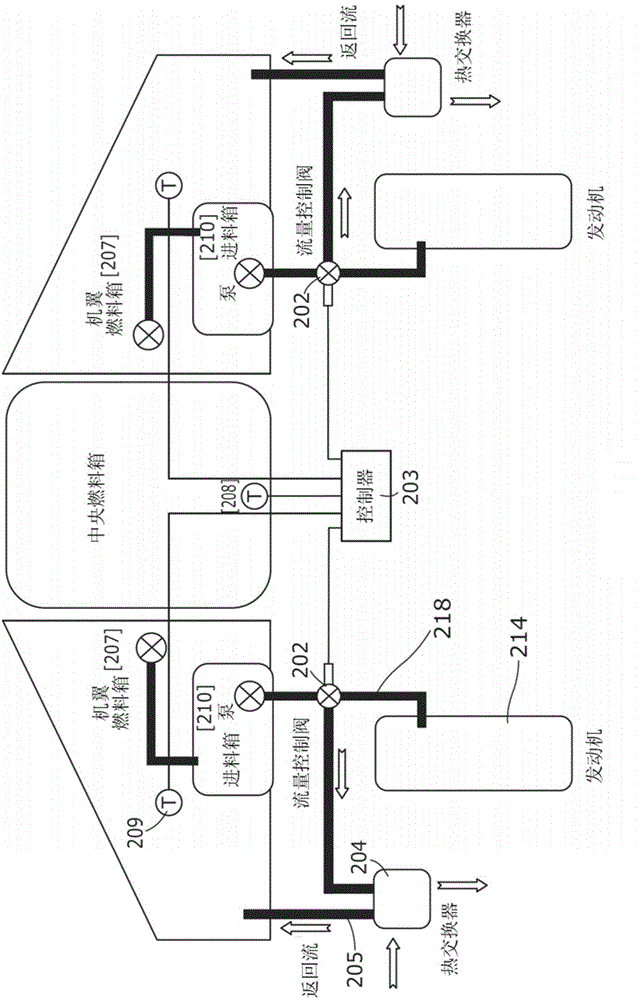

ActiveUS20150217153A1Reduce flammabilityPower plant fuel tanksAir-treatment apparatus arrangementsAircraft fuel systemHeat flow

An aircraft fuel system architecture which reduces the fleet-wide flammability exposure of the fuel tanks. In one embodiment, the aircraft center fuel tank fuel is cooled at certain times in a flight to reduce its flammability exposure to be similar to that of an unheated conventional metal wing fuel tank. Aircraft fuel tanks that have adjacent heat sources are also insulated to minimize heat flow into the fuel. Fuel tanks that have lower cooling properties, such as composite wing tanks are cooled at certain times during flight such that their temperatures are reduced to be similar to metal wing tanks when the fuel is flammable. A fuel tank that is pressurized relative to outside pressure at altitude having a lower flammability exposure than unpressurized tanks is combined with the cooling of fuel in the tank to reduce the fleet-wide flammability exposure of the fuel tank to be similar to that of an unpressurized metal wing tank. Fuel is cooled by recirculating flow from a tank, passing through a heat exchanger and returning to the tank to be cooled. The heat exchanger is optionally cooled by flow of air from the outside of the aircraft, or by conditioned air from the aircraft environmental control system. The system is controlled by start and stop of fuel flow to the various tanks by means of a system controller. The controller uses sensors in the fuel tanks to command flow only when required to reduce the flammability exposure of the fuel tanks.

Owner:AERO SYST CONSULTANTS

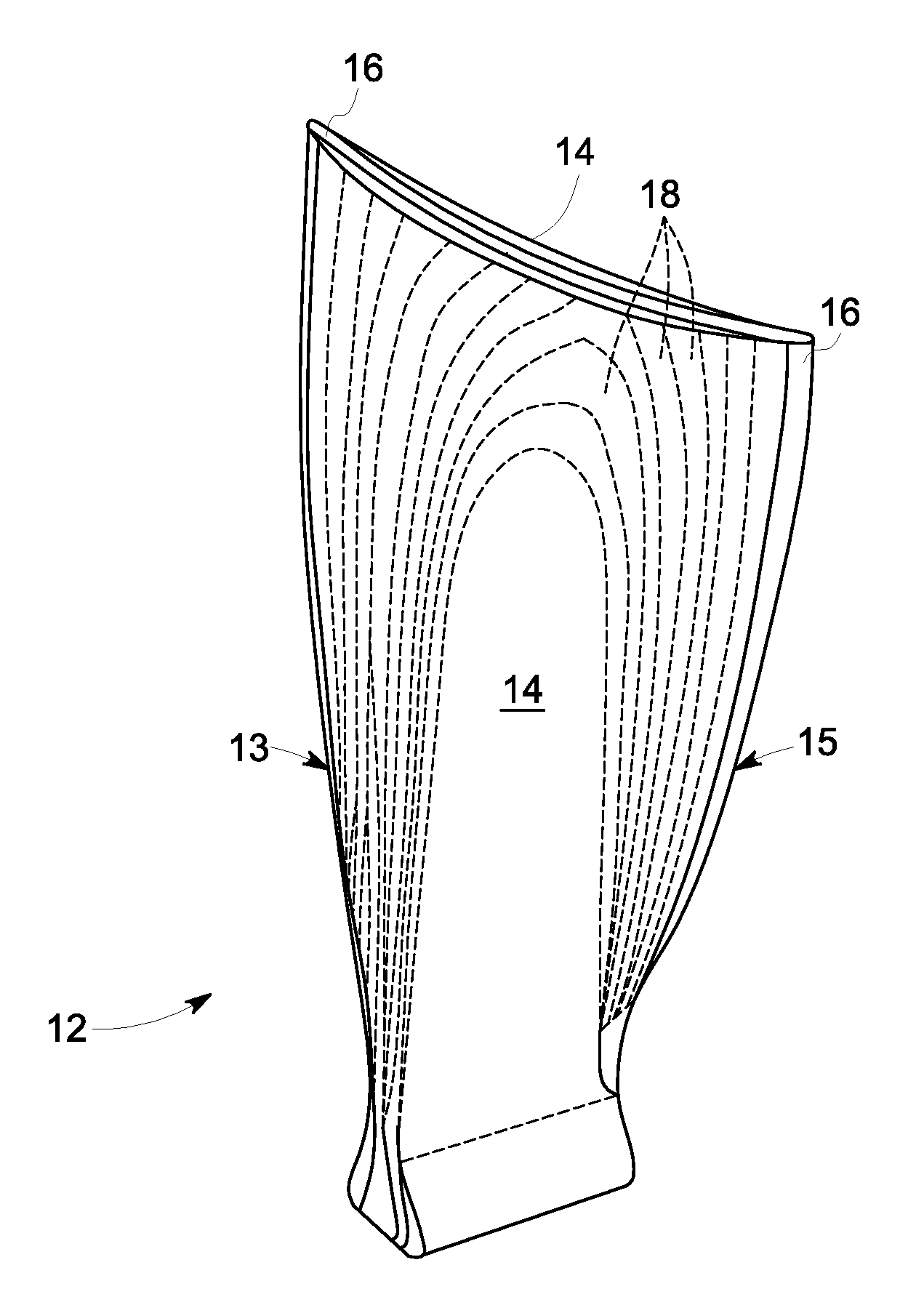

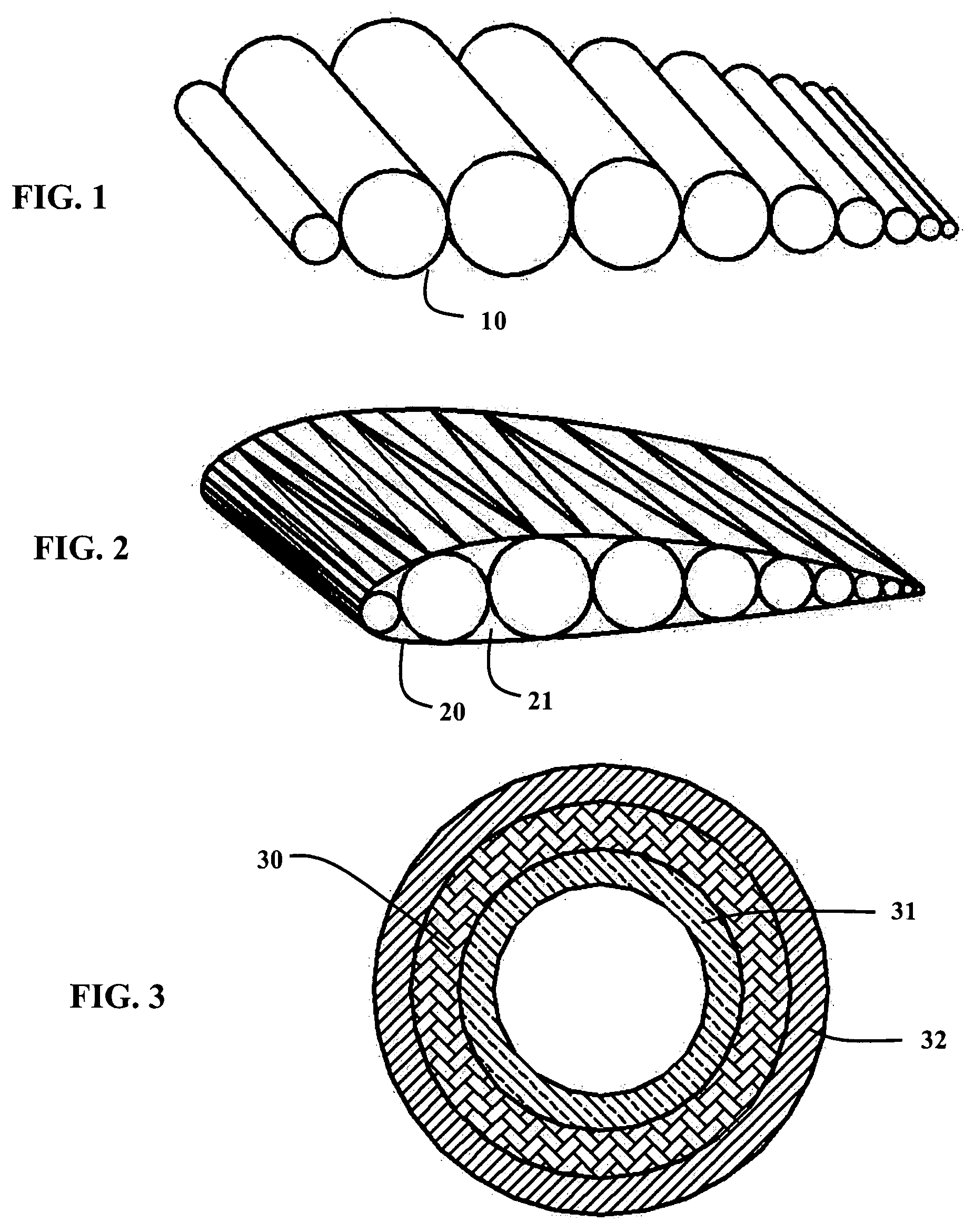

Composite airfoil structures

An airfoil structure is presented. The airfoil structure includes an outer casing substantially surrounding a composite core. The composite core includes a plurality of fiber bands, each of the plurality of fiber bands is placed at a predetermined position and orientation at a time, wherein the plurality of fiber bands are interwoven in an in-plane and out-of-plane orientation by interleaving each of the plurality of fiber bands placed in a plane with one or more of the plurality of fiber bands of an adjacent plane to define an interleaved structure. A method for manufacturing an airfoil structure including the composite core is also presented.

Owner:GENERAL ELECTRIC CO

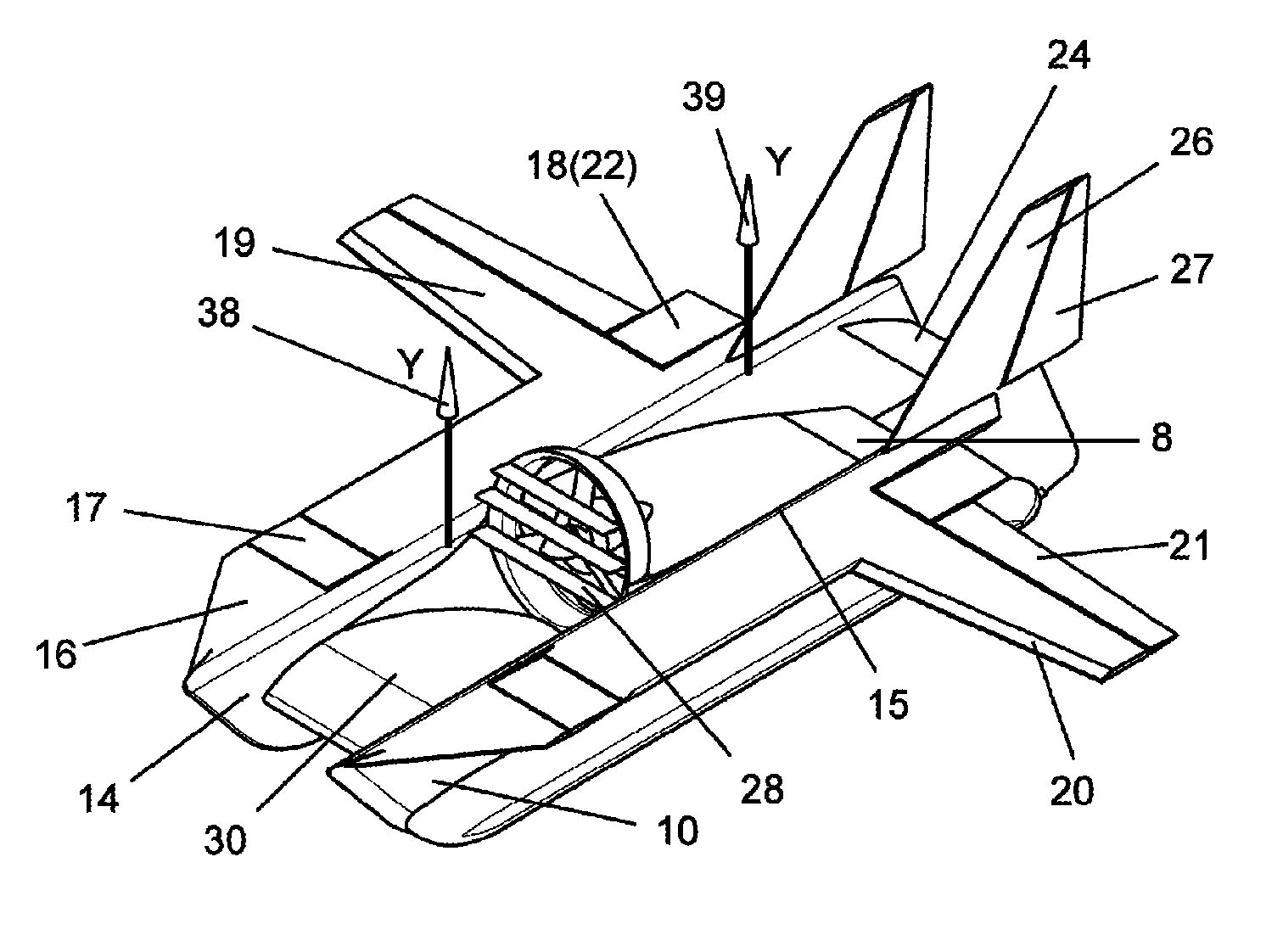

Deployable, rigidizable wing

InactiveUS20050151007A1Increase stiffnessImprove aerodynamic characteristicsUnmanned aerial vehiclesWing shapesChemical compositionPolymer resin

A novel design and construction method for an inflatable, rigidizable wing for a terrestrial or planetary flying vehicle. The wing is caused to deploy from an initially packed condition and to assume its functional shape by means of an inflation gas. After inflation, the wing is rigidized by any of several means, such that the inflation gas is no longer required. The composite wing is fabricated from a base reinforcement material, often a fabric, which is coated with a polymer resin that hardens when exposed to a curing mechanism. Several activation mechanisms exist by which to initiate rigidization of such a structure, including elevated temperature, ultraviolet light, and chemical constituents of the inflation gas. The resultant wing has fundamental advantages compared to existing inflatable wings, including improved stiffness, and reduced susceptibility to structural failure in response to puncture.

Owner:ILC DOVER LP

Single piece co-cure composite wing

InactiveUS7681835B2Light weightSuperior strength and durabilityAircraft stabilisationLayered productsWave shapeComposite wing

A single piece co-cured composite wing is disclosed. The wing has a flying surface and structural members. In one embodiment the structural members may be a plurality of spars. The spars may have various shapes to increase the buckling strength. The spars may be wave shaped, such as a sinusoidal shape. The flying surface and the structural members are co-cured in order to form a single piece, integral wing structure. A process for manufacturing a single piece co-cured wing is also disclosed. The process may include laying out composite sheets for the flying surface of the wing. Then, the composite material of the spars is arranged around a plurality of pressurizable forms. Finally, the composite material is cured in a clamshell frame. A single piece co-cured composite structure is also disclosed that includes an outer skin, and inner skin, a frame, and a stringer.

Owner:SPECTRUM AERONAUTICAL

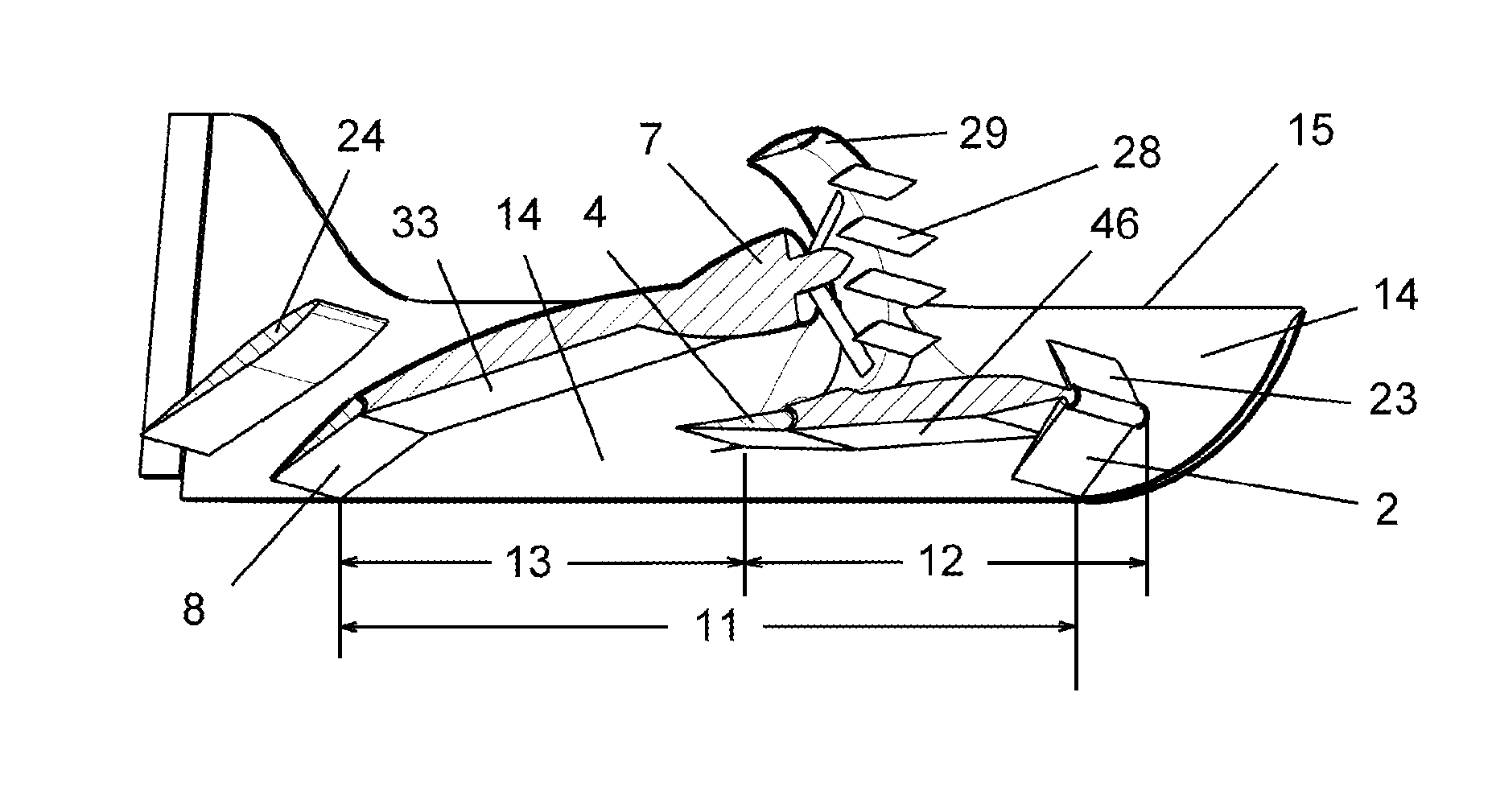

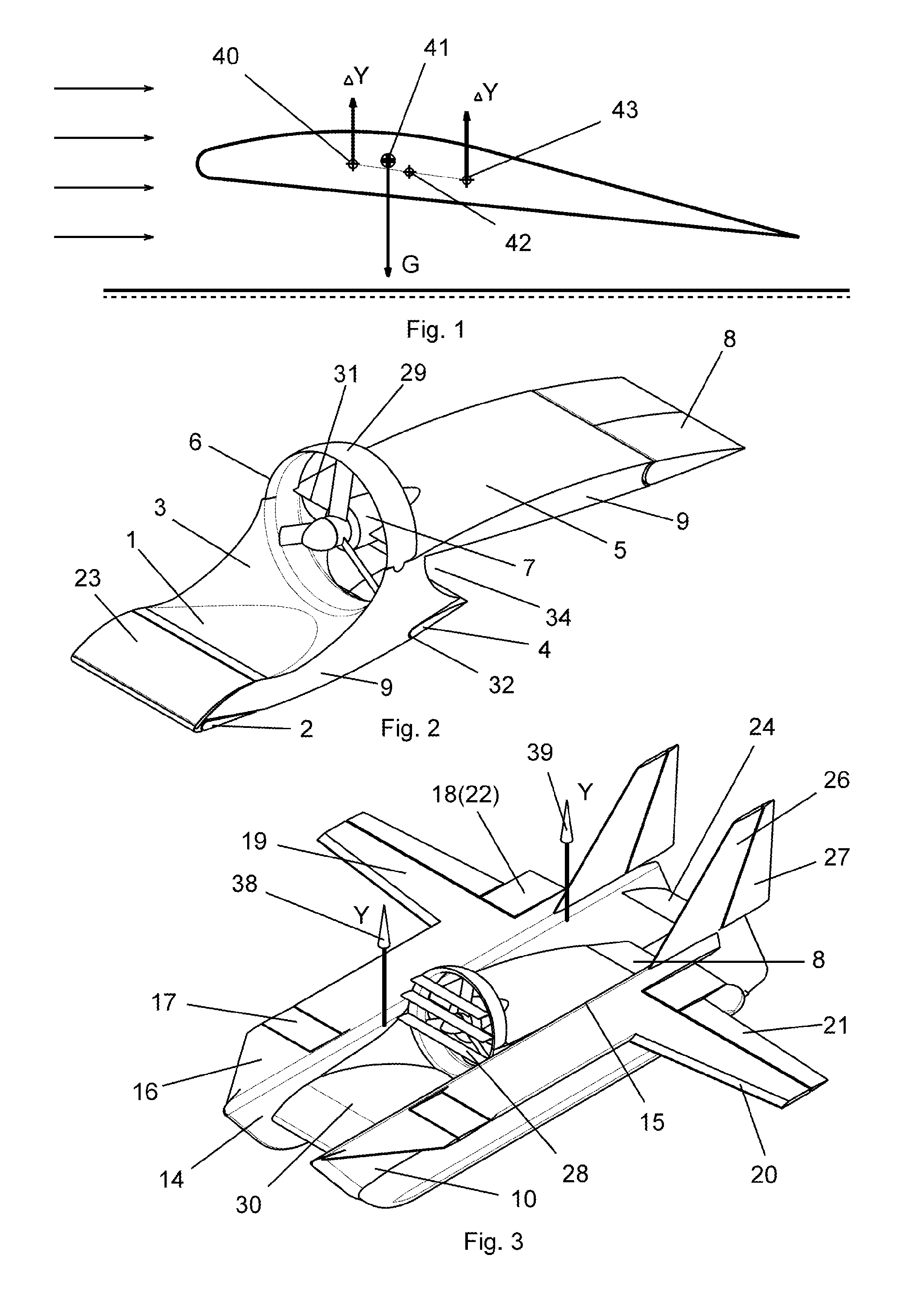

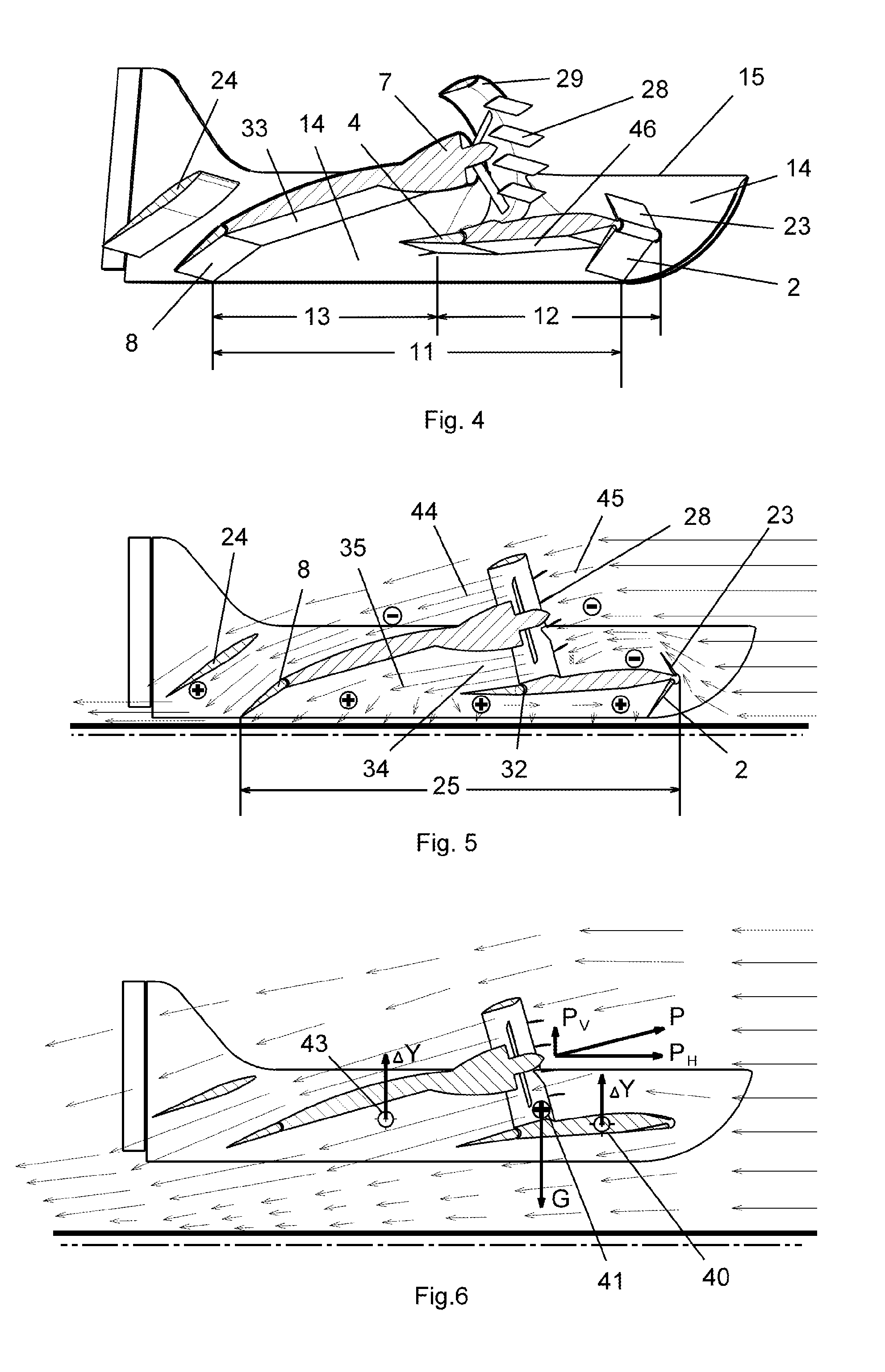

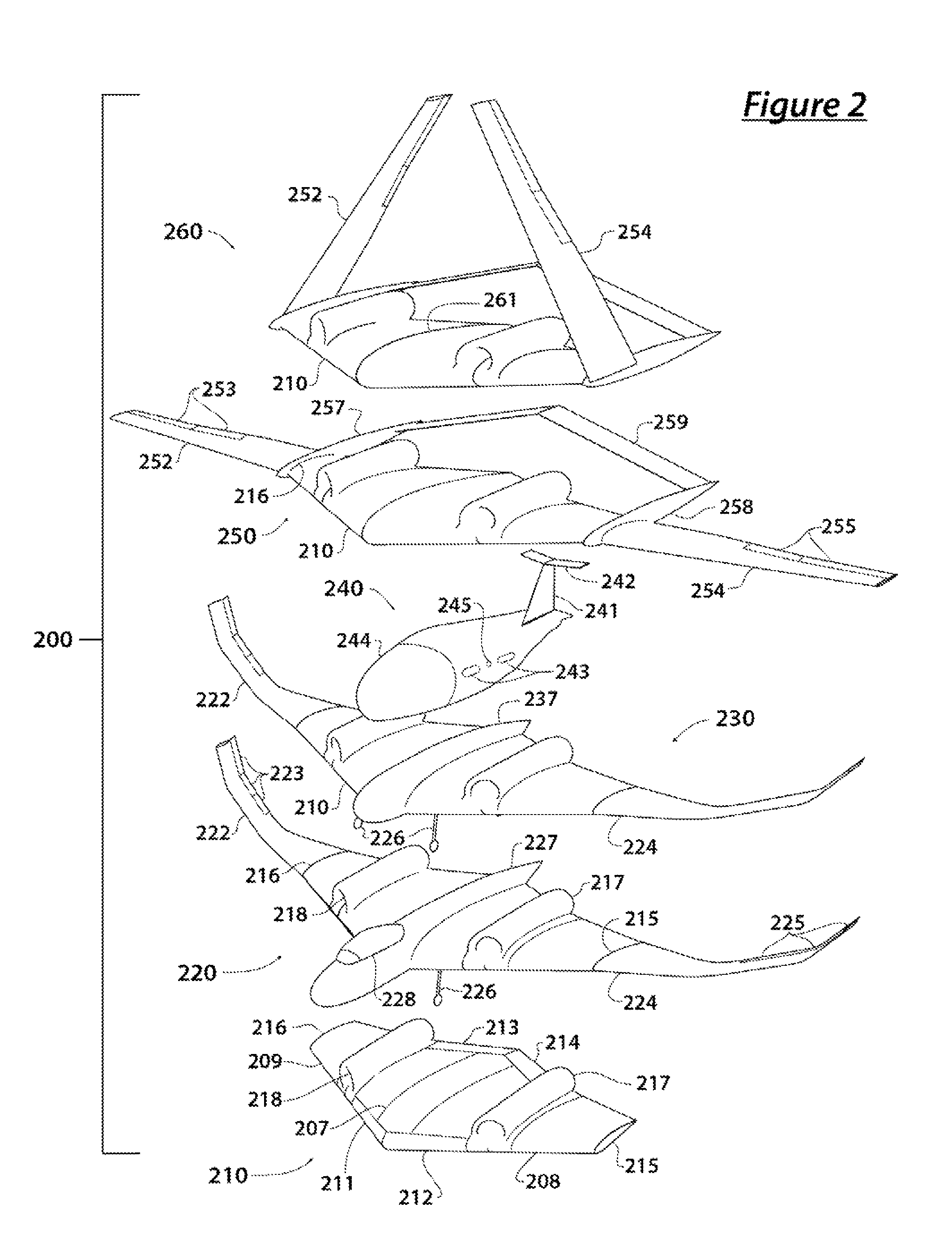

Method for comprehensively increasing aerodynamic and transport characteristics, a wing-in-ground-effect craft for carrying out said method (variants) and a method for realizing flight

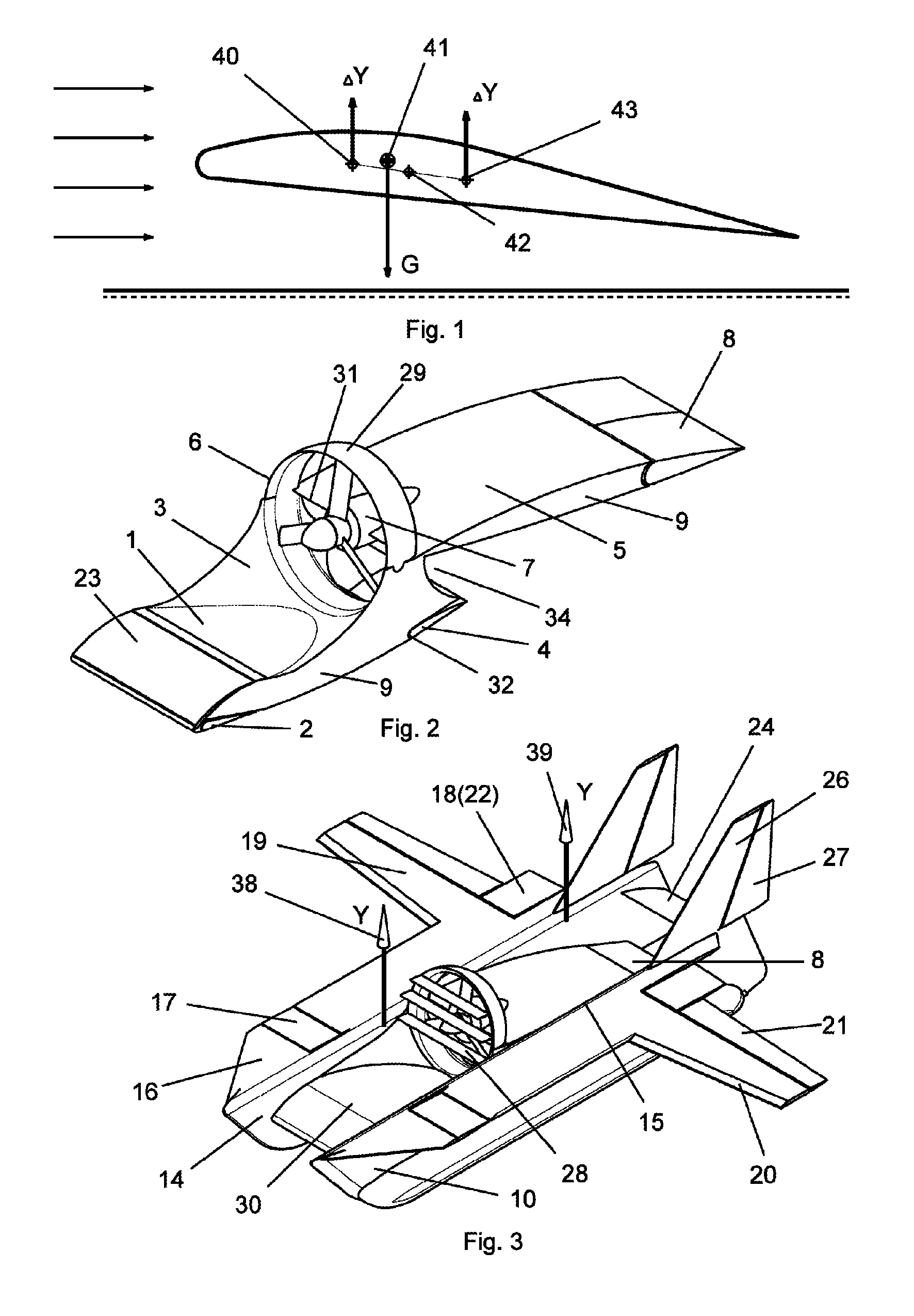

InactiveUS20110266081A1Improve securityImprove carrying capacityAmphibious vehiclesConvertible vehiclesAviationFlight height

The group of inventions relates to aviation and to transport means having (static and dynamic) air discharge, in particular to self-stabilizing wing-in-ground-effect craft of types A, B and C. The following technical results are achieved: increased flight safety and maneuvering safety, increased load-bearing capacity and flight height in ground effect mode, reduced dimensions, improved take-off and landing characteristics, as well as amphibian characteristics and economic efficiency, increased functionality and a wider range of operational alignments, and greater ease of use and maintenance. This result is achieved by simultaneously applying the methods for generating a system of aerodynamic forces, the structural solutions and the piloting methods conceptually linked therewith which are proposed in the present group of inventions to “flying wing” or “composite wing” design layouts.

Owner:NOVIKOV KOPP IVAN

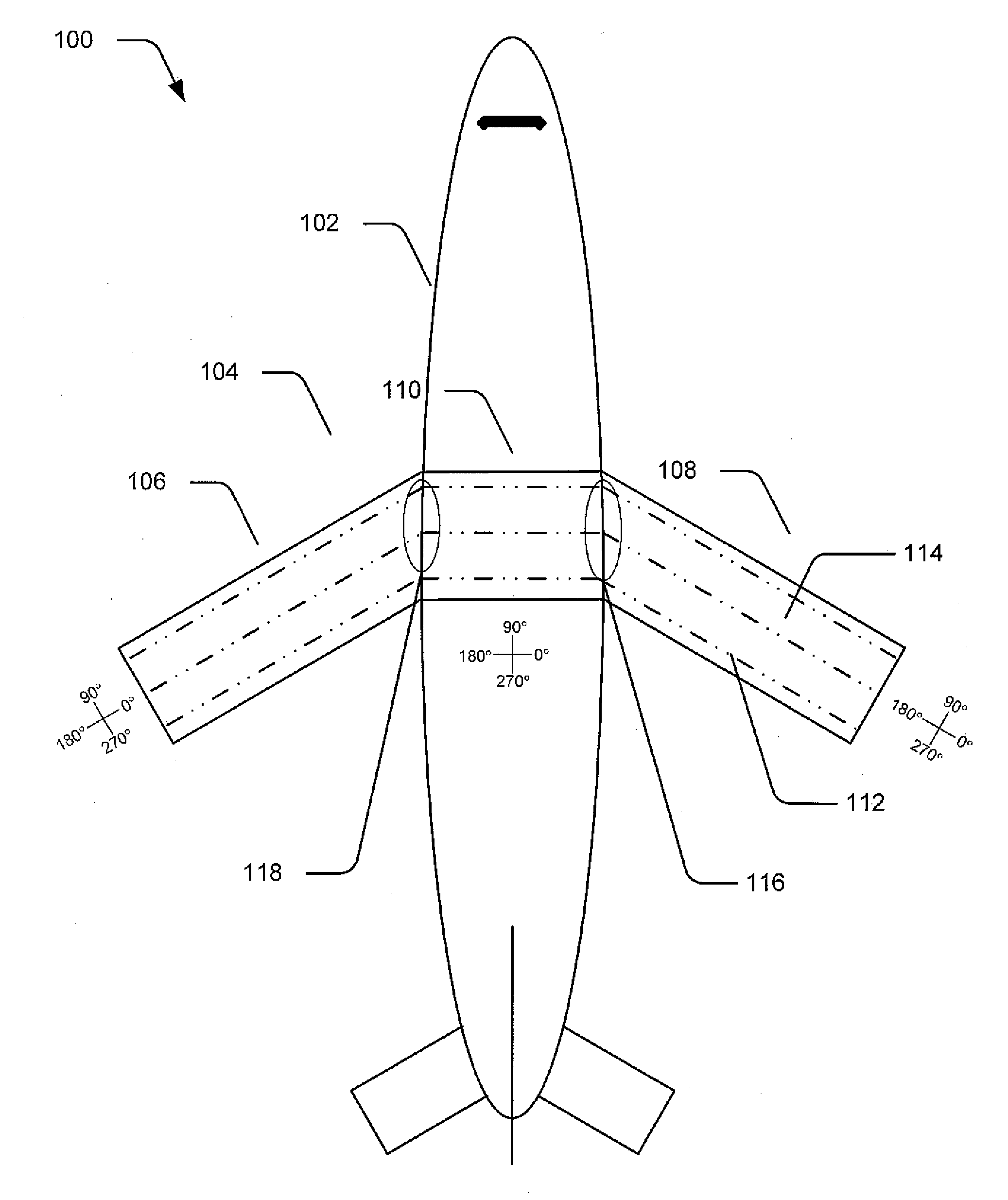

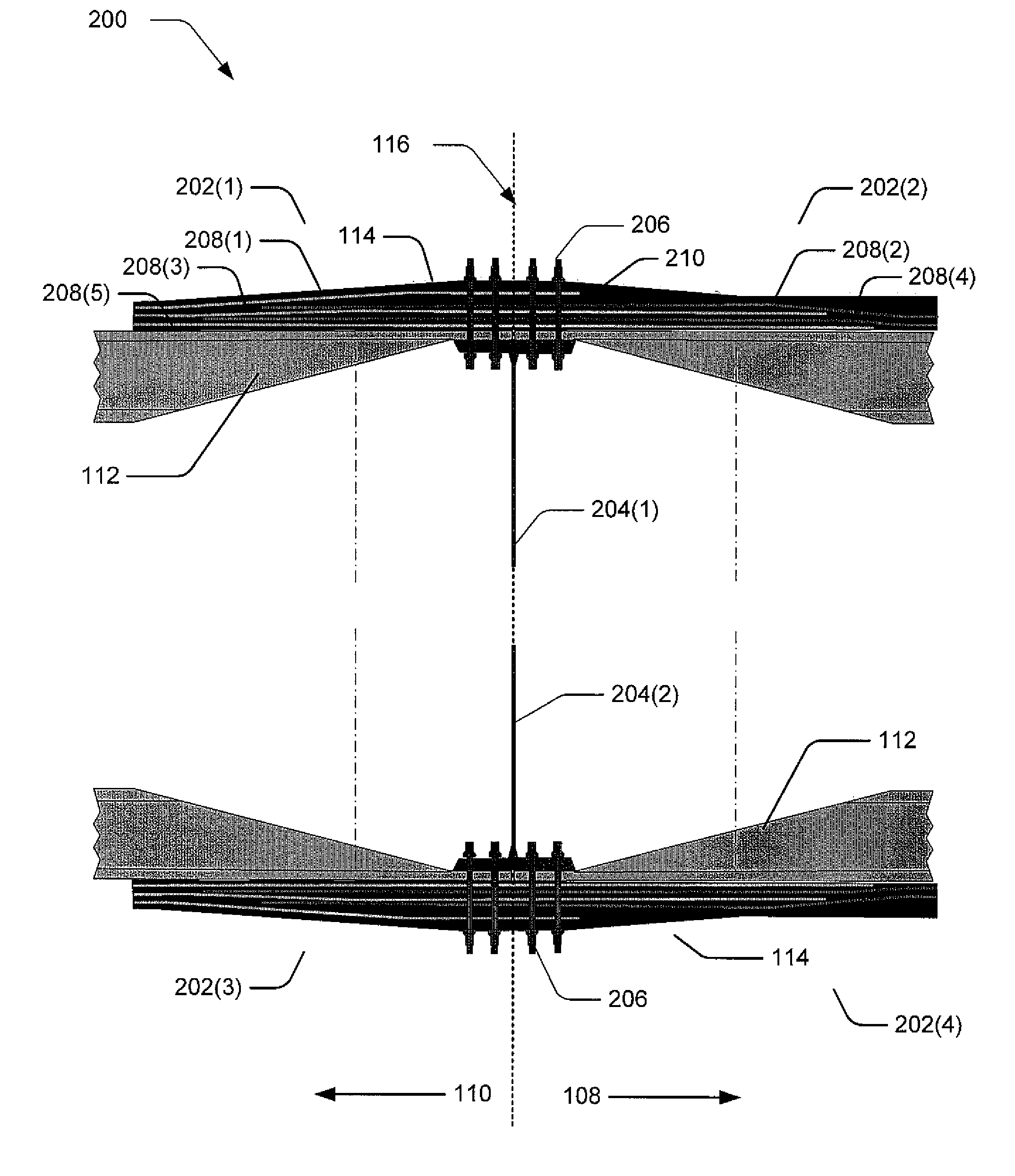

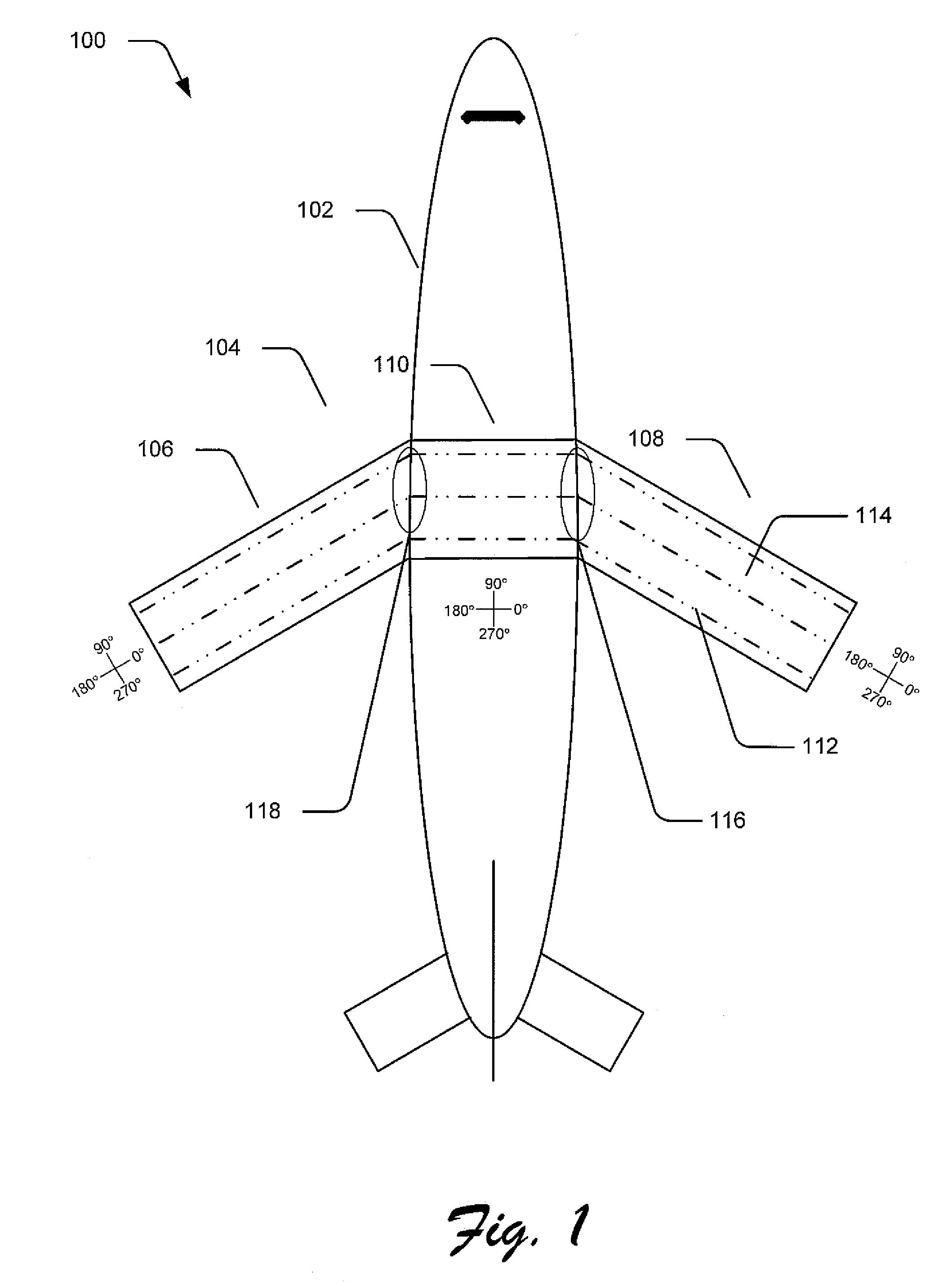

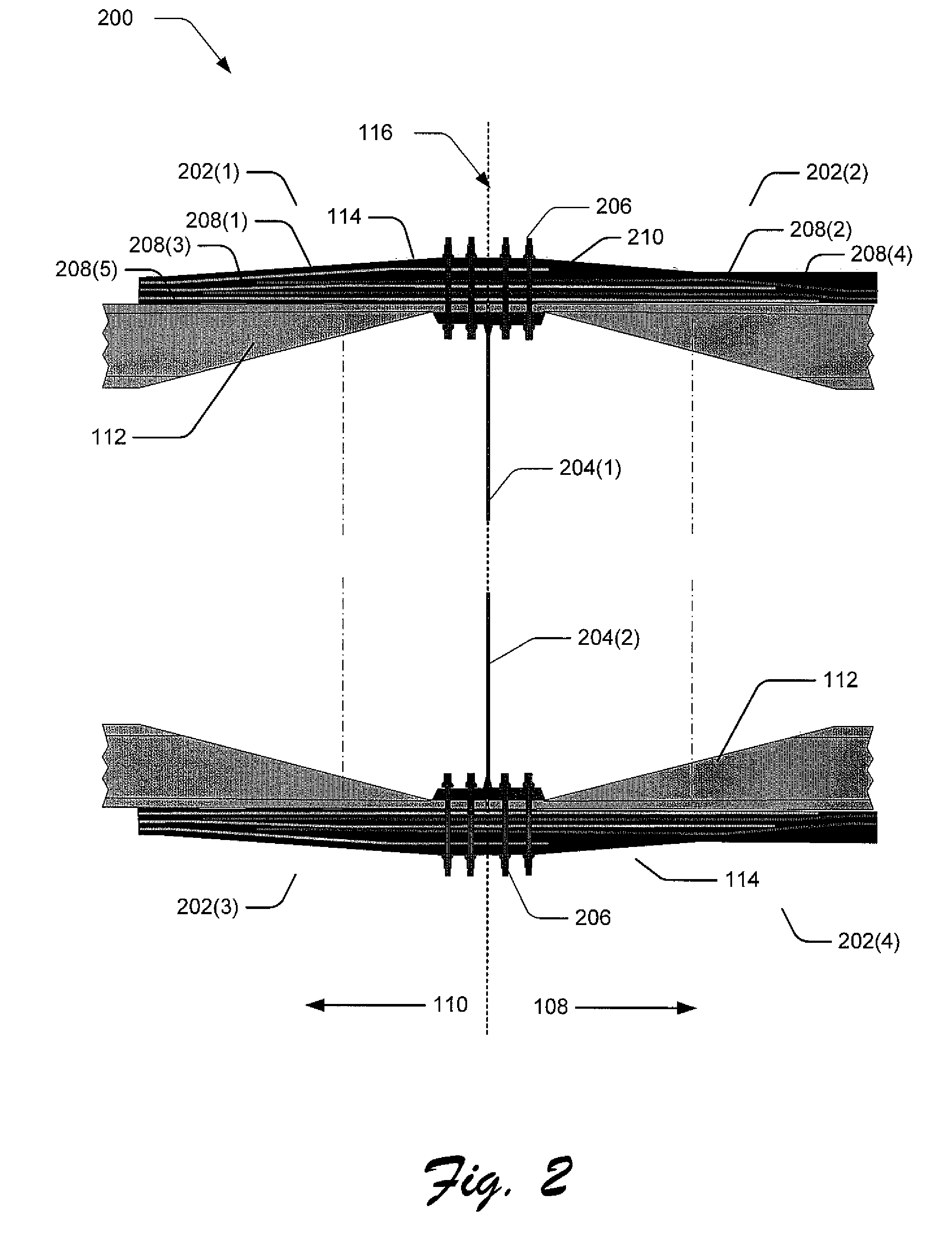

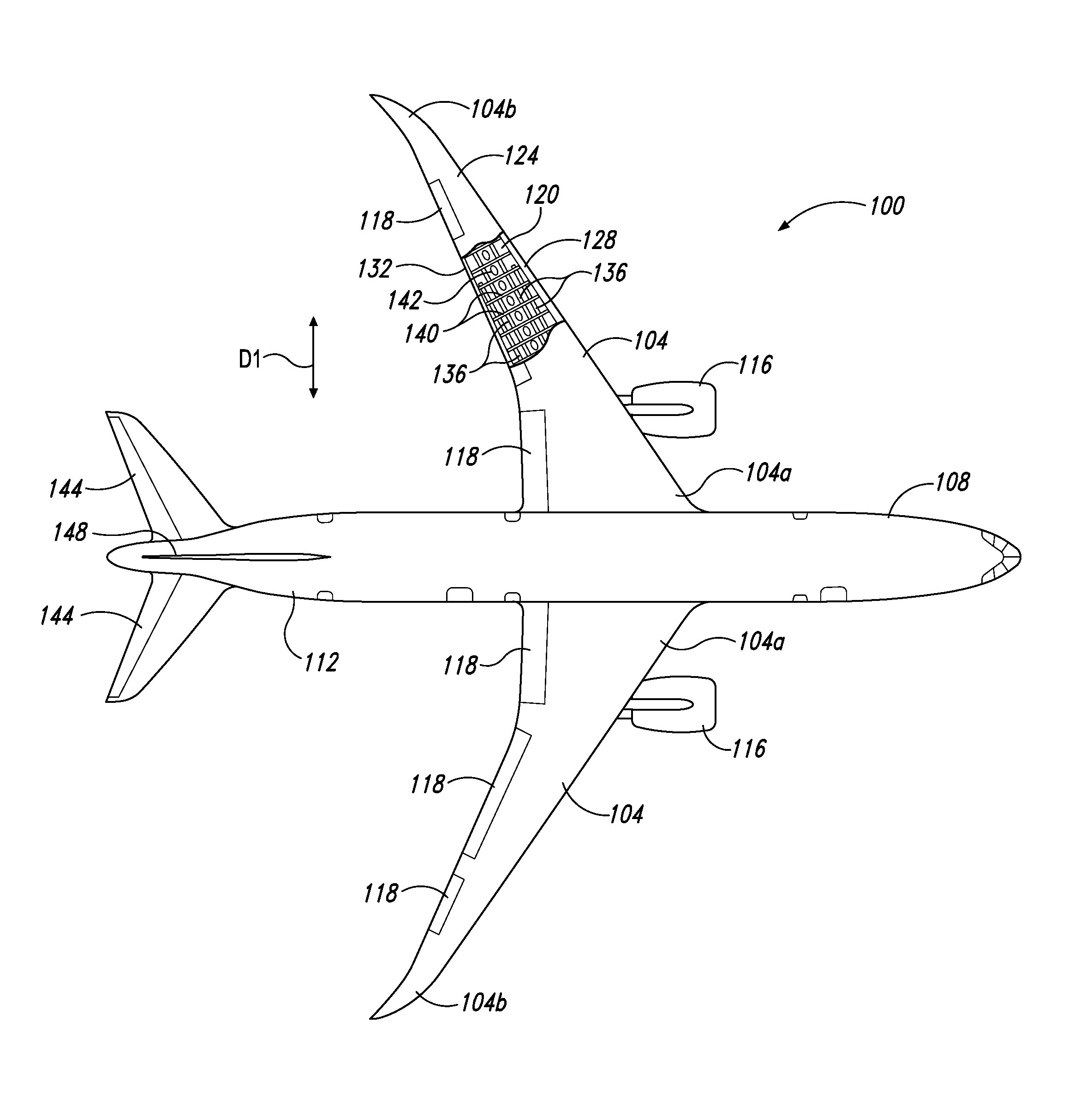

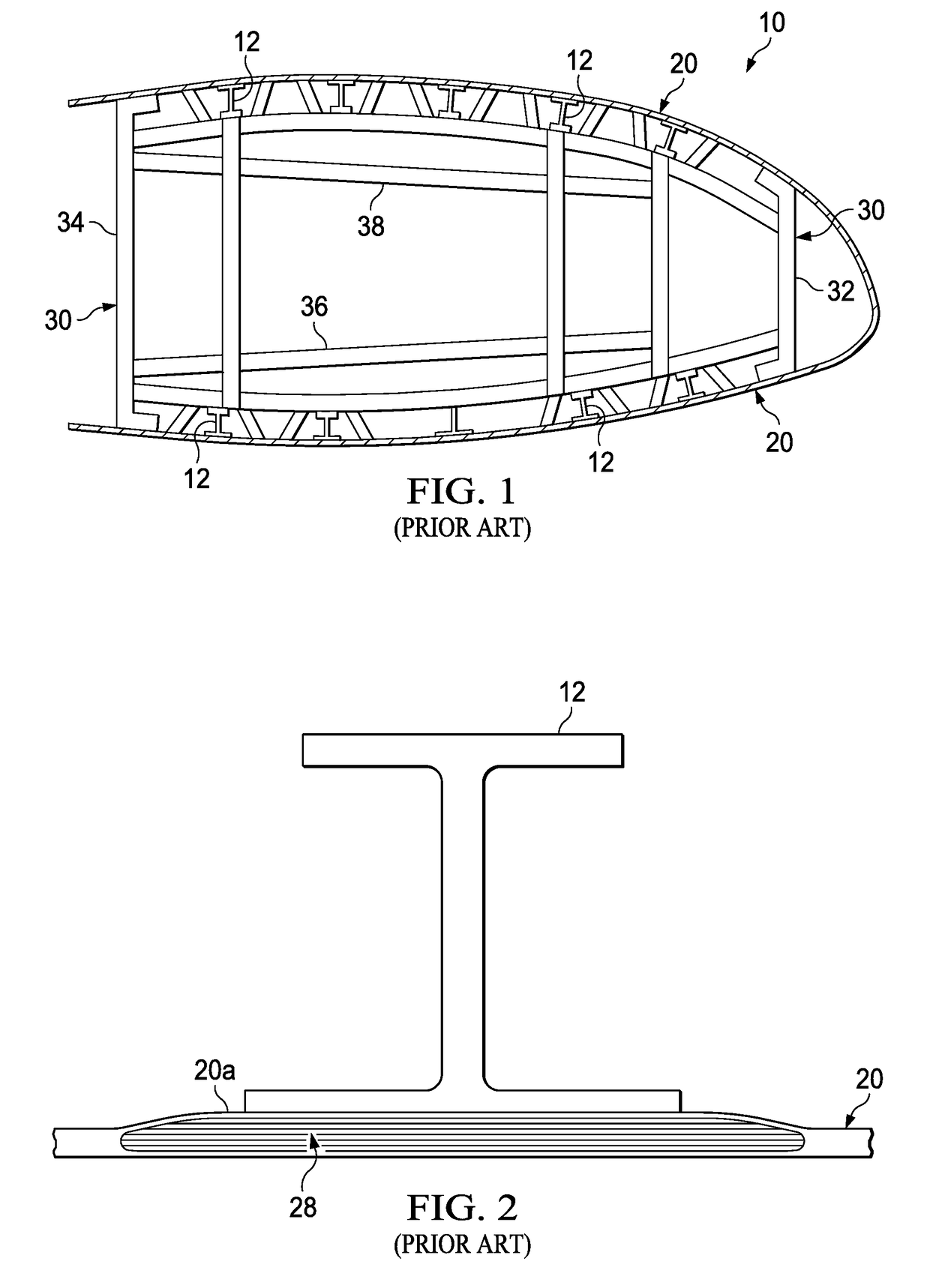

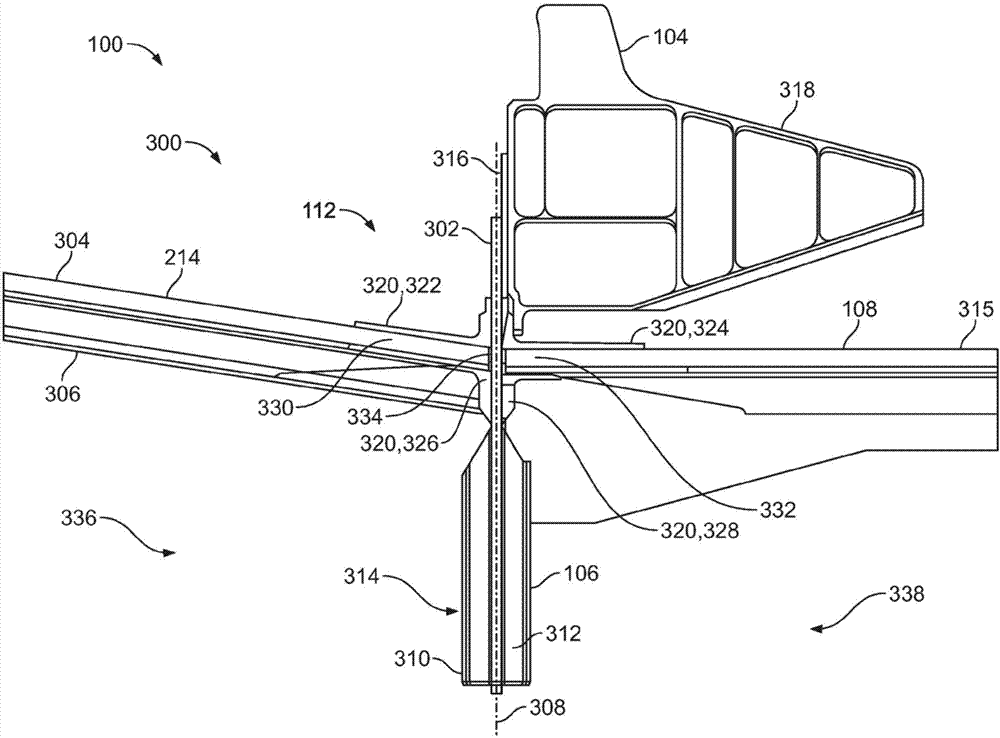

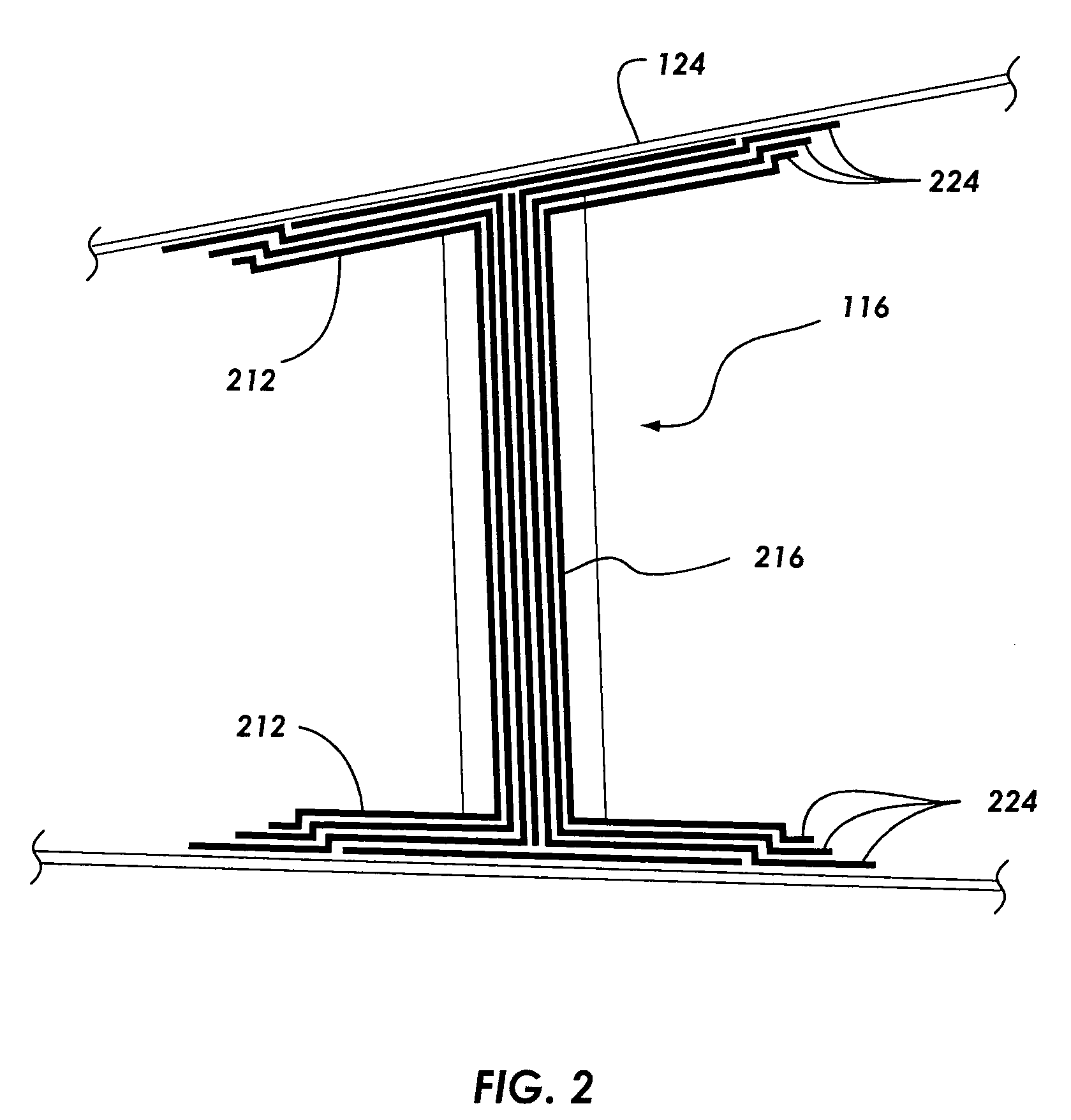

Composite wing-body joint

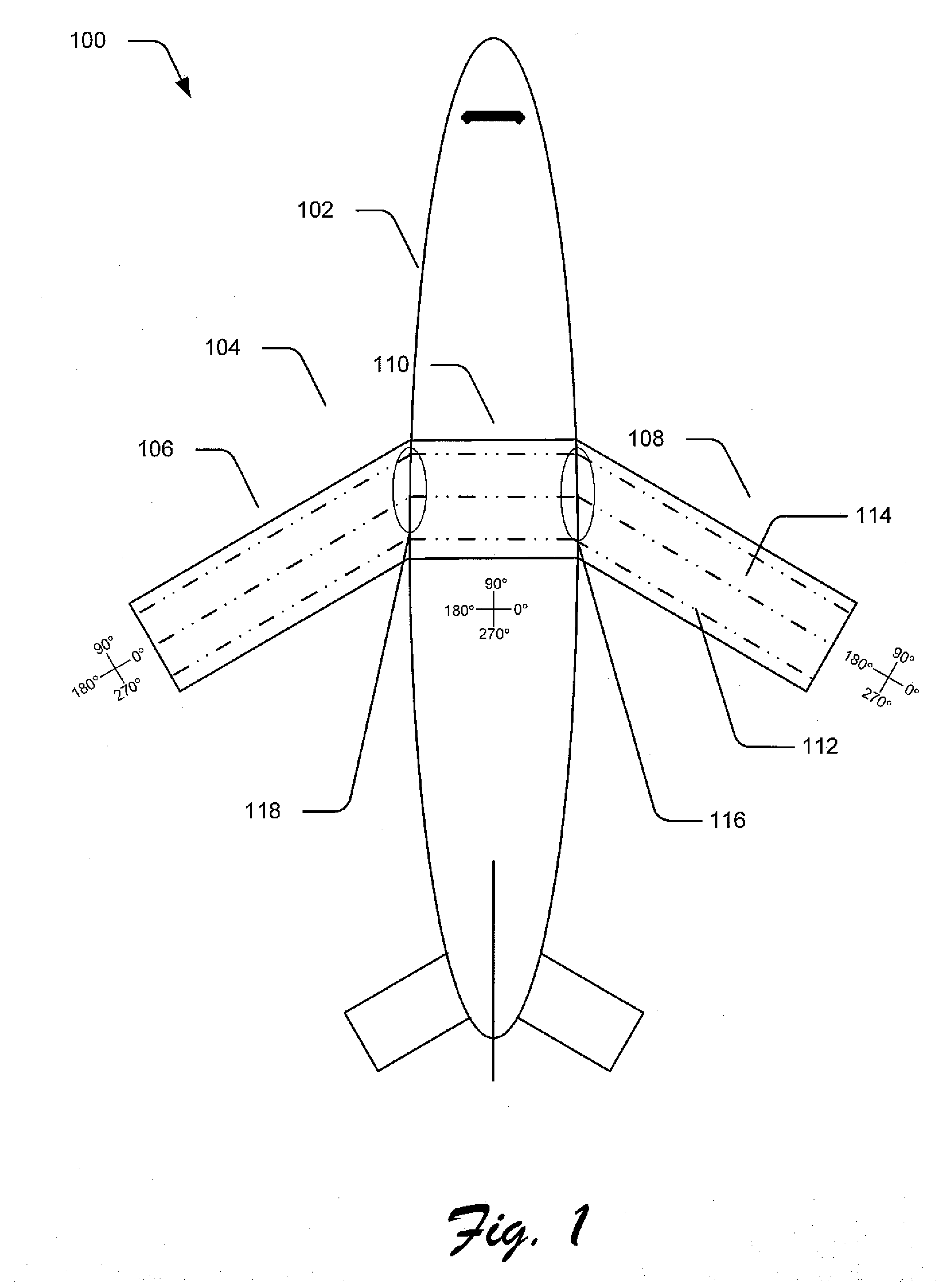

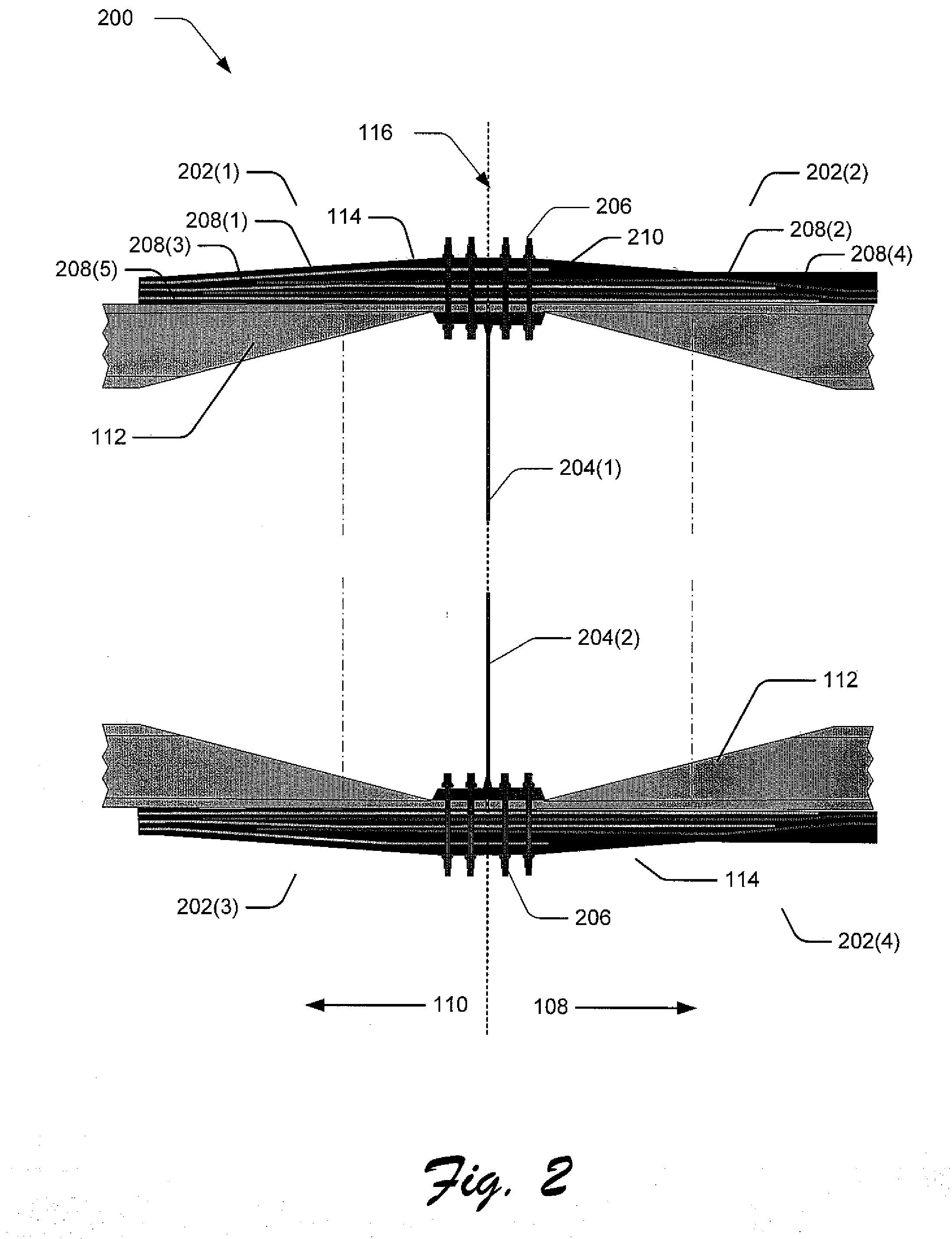

ActiveUS20090084899A1The overall structure is light in weightLight structureFuselage framesAircraft stabilisationBody jointsWingspan

Embodiments of integral composite panels and joints for composite structures are described In one implementation, an integrated panel spanning substantially the entire wingspan of an aircraft, includes at least a center portion and a pair of outwardly projecting wing portions. The portions may include a skin formed from successive layers or plies of composite material which overlap and offset at the joint between respective sections creating a pad-up area to carry loads between the portions. In a particular implementation, the skin is laid over one or more structural stringers which are transitioned into the joints between sections such as by tapering of the thickness and / or stiffness of the stringer.

Owner:THE BOEING CO

Aircraft fuel systems

InactiveUS20150151845A1Reduce heat loadReduced and zero heat inputPower plant fuel tanksFuel tank safety measuresAircraft fuel systemHeat flow

Aircraft fuel system reduces flammability exposure of fuel tanks. In one embodiment, aircraft center fuel tank fuel is cooled in flight to reduce flammability exposure to be similar to that of an unheated metal wing tank. Fuel tanks having adjacent heat sources are insulated to minimize heat flow into the fuel. Fuel tanks having lower cooling properties, e.g., composite wing tanks, are cooled during flight so temperatures are reduced to be similar to metal wing tanks. A fuel tank, pressurized relative to outside pressure at altitude, having lower flammability exposure than unpressurized tanks and cooling fuel in the tank reduces flammability exposure of the fuel tank to be similar to that of an unpressurized metal wing tank. Recirculating flow from a tank, passing through heat exchanger, and returning to the tank cools fuel. A controller starts / stops fuel flow to tanks and uses sensors to command flow to reduce flammability.

Owner:AERO SYST CONSULTANTS

Composite wing-body joint

Embodiments of integral composite panels and joints for composite structures are described In one implementation, an integrated panel spanning substantially the entire wingspan of an aircraft, includes at least a center portion and a pair of outwardly projecting wing portions. The portions may include a skin formed from successive layers or plies of composite material which overlap and offset at the joint between respective sections creating a pad-up area to carry loads between the portions. In a particular implementation, the skin is laid over one or more structural stringers which are transitioned into the joints between sections such as by tapering of the thickness and / or stiffness of the stringer.

Owner:THE BOEING CO

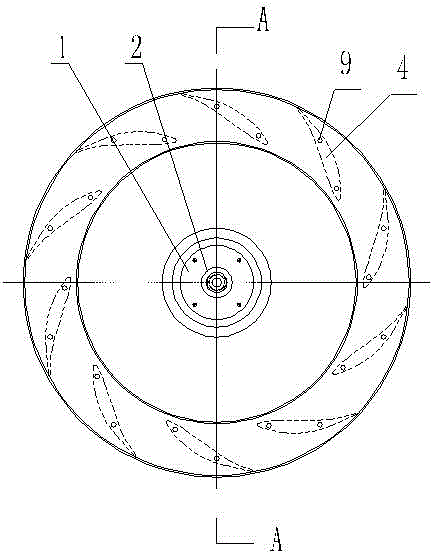

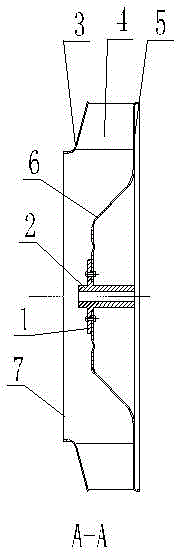

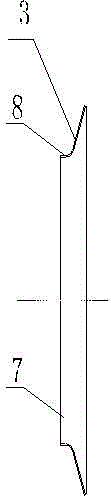

Wing sectional material combination type turbine centrifugal impeller

The invention provides a wing sectional material combination type turbine centrifugal impeller and belongs to the field of turbine mechanical vane machining. Aviation aerodynamic force standard wing type structure sectional materials and composite wing type structure sectional materials generated on the basis of a standard wing type are used, the structure sectional materials are used as vane blank materials, and a centrifugal impeller vane is manufactured. A wing type structure vane with the uniform section or the non-uniform section is used, according to the difference of calculating flow patterns and using places (media), the space warping structure of the vane is determined, and the front edge and the back edge of the vane can be decorated according to situations. The front disc space curve face and the back disc space curve face are matched through the methods of cutting, stamping and forming milling, and the vane, a front disc and a back disc are integrally connected to form the impeller. The method is suitable for large-batch, large-scale and module production of centrifugal impellers, universality is high, the centrifugal impeller is especially suitable for centrifugal fan and centrifugal water pump industries, and great promotional value is achieved.

Owner:张凤荣

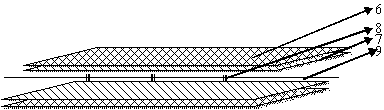

Laminate composite wing structures

ActiveUS20160207607A1Stiffening wingAircraft stabilisationMetal-working apparatusLaminated compositesFlange

A wing may include a wing skin, a laminate composite first stringer, a rib, and at least one fastener. A majority of the first stringer may be characterized by a stacked plurality of generally planar plies of reinforcement material structurally joined as a stack to an interior surface of the wing skin and extending generally parallel to the interior surface and a span-wise direction of the wing along a substantial portion of the interior surface. The first stringer may have a generally solid trapezoidal cross section when viewed in a plane that is generally perpendicular to the span-wise direction. The rib may be positioned adjacent the interior surface, and may extend generally perpendicular to the span-wise direction. The trapezoidal cross section may be interfaced with the rib flange. The fastener may extend through the wing skin, the trapezoidal cross section, and the rib flange.

Owner:THE BOEING CO

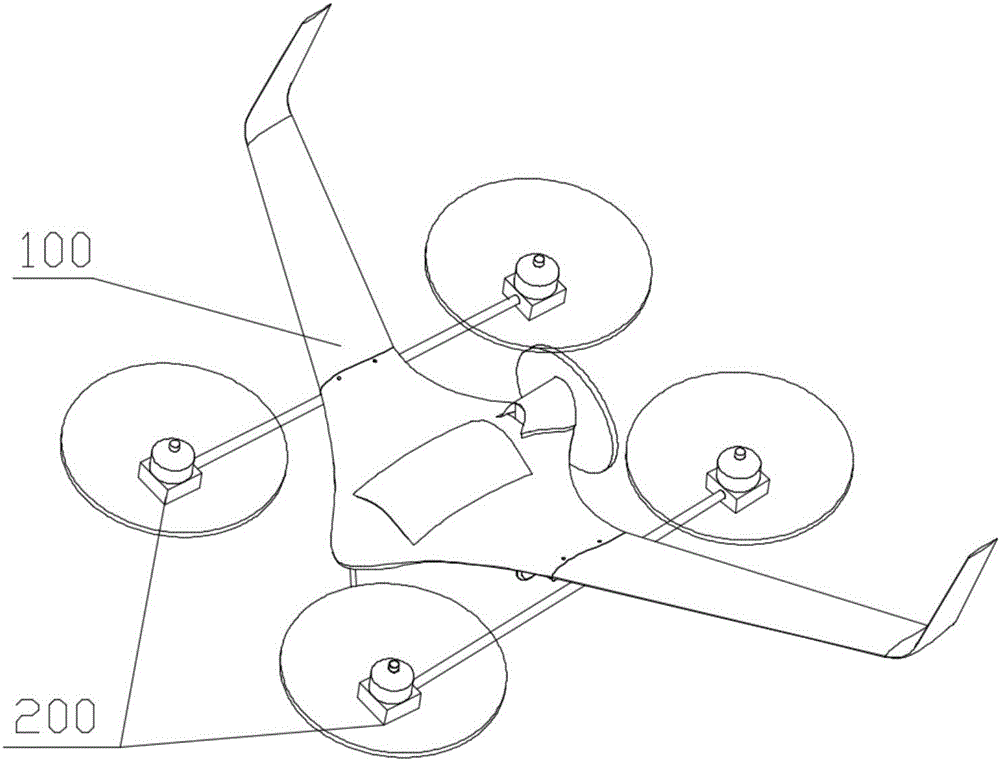

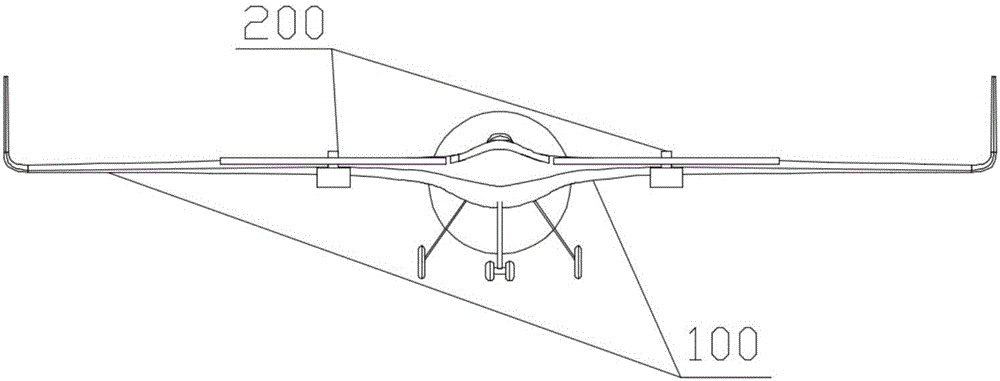

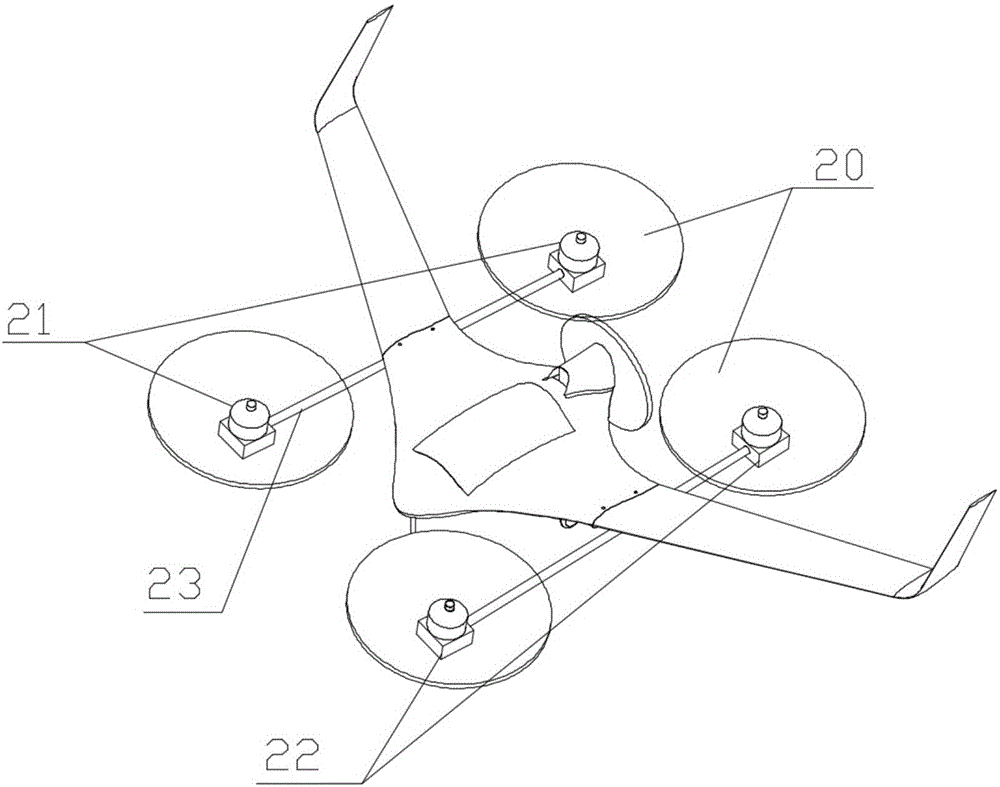

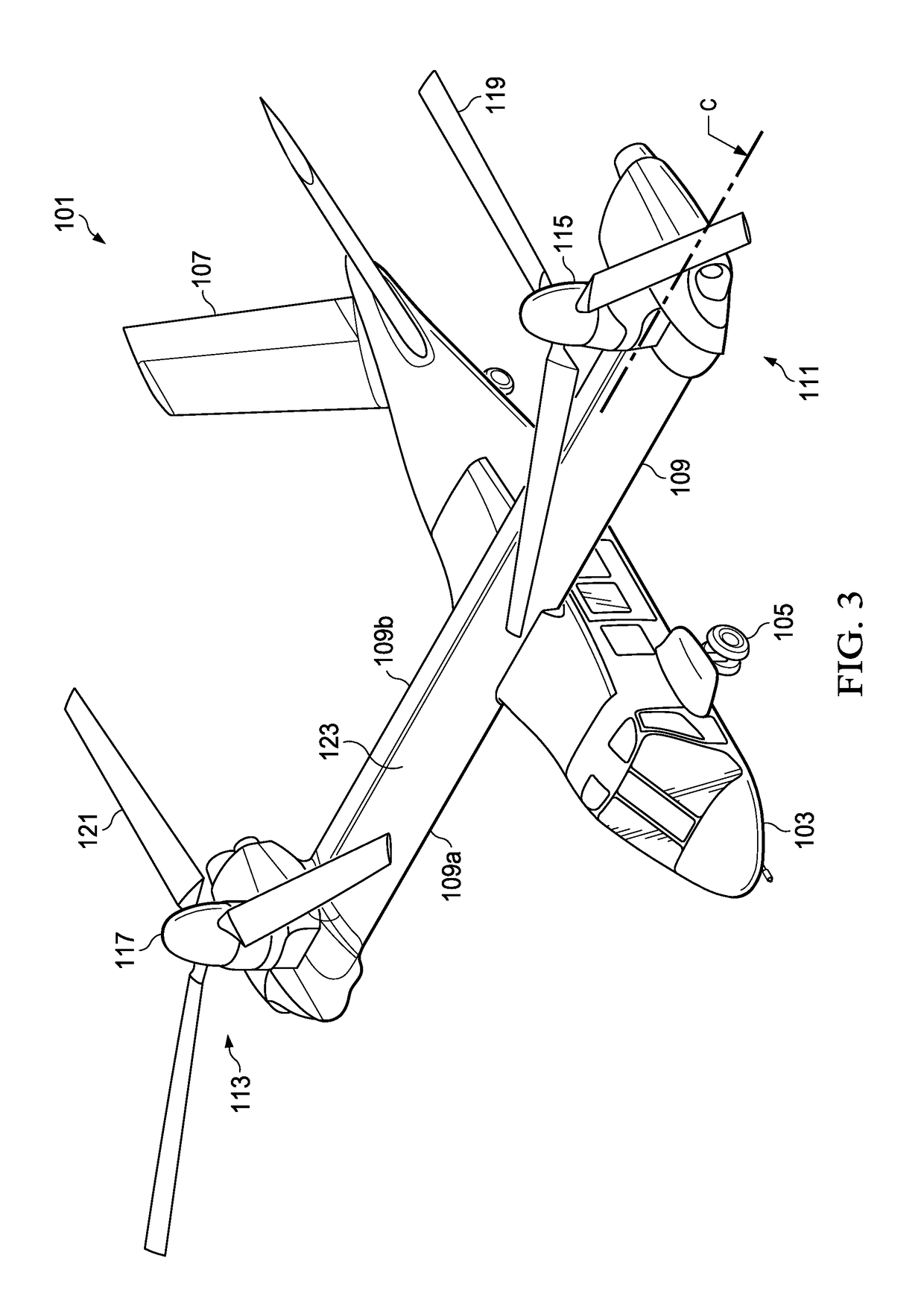

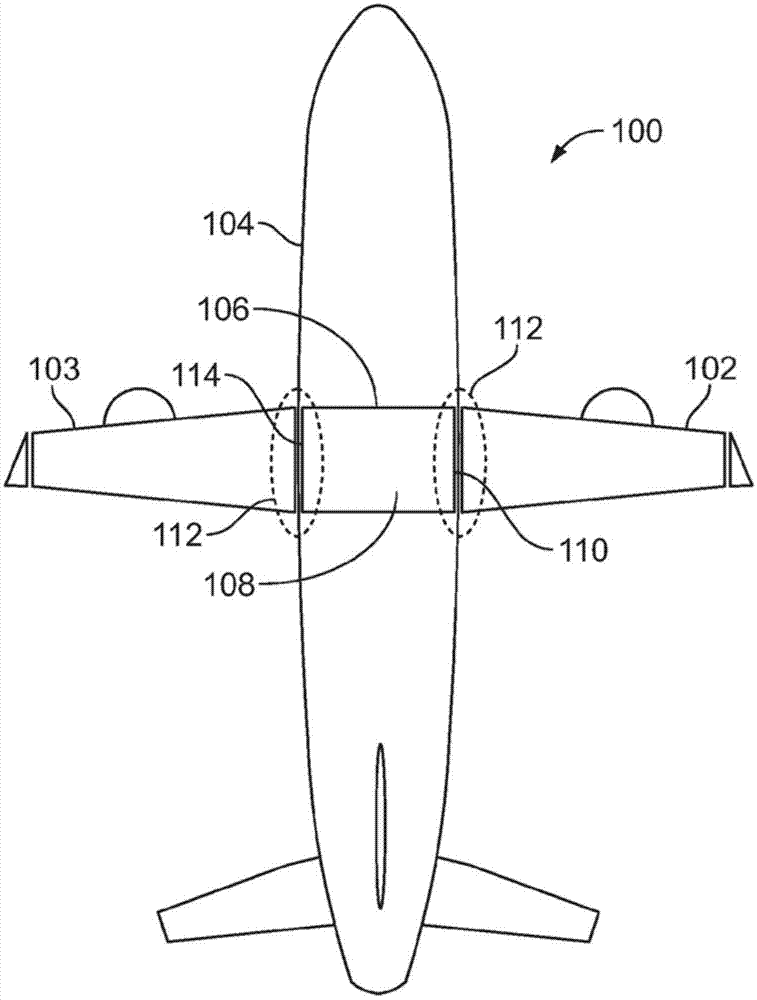

Composite wing unmanned aerial vehicle

ActiveCN106394856AGuaranteed to pass throughTo achieve a fixed connectionAll-wing aircraftFuselagesFlight vehiclePropeller

The invention relates to the technical field of aircrafts, in particular to a composite wing unmanned aerial vehicle. The composite wing unmanned aerial vehicle comprises a wing and body combination body, a fixed wing part, a multi-rotor part, an undercarriage, a propeller and a power mechanism. The fixed wing part comprises two fixed wings arranged on the two sides of the wing and body combination body. The multi-rotor part comprises multiple rotor mechanisms symmetrically arranged on the two sides of the wing and body combination body, each rotor mechanism comprises a connecting rod and a rotor, each connecting rod is connected with the corresponding fixed wing, each rotor is horizontally arranged on the corresponding connecting rod, each connecting rod is provided with an installation shaft arranged perpendicular to the axial direction of the connecting rod, and the end portion of each installation shaft is provided with a first slope; and each fixed wing is provided with a connecting hole matched with the corresponding installation shaft, clamping grooves are formed in the hole wall of each connecting hole, telescopic buckles are arranged in the clamping grooves, and each installation shaft is provided with grooves matched with the telescopic buckles. By the adoption of the composite wing unmanned aerial vehicle, the fixed wing part and the multi-rotor part of the unmanned aerial vehicle can be quickly installed and detached without a tool.

Owner:北京尖翼科技有限公司

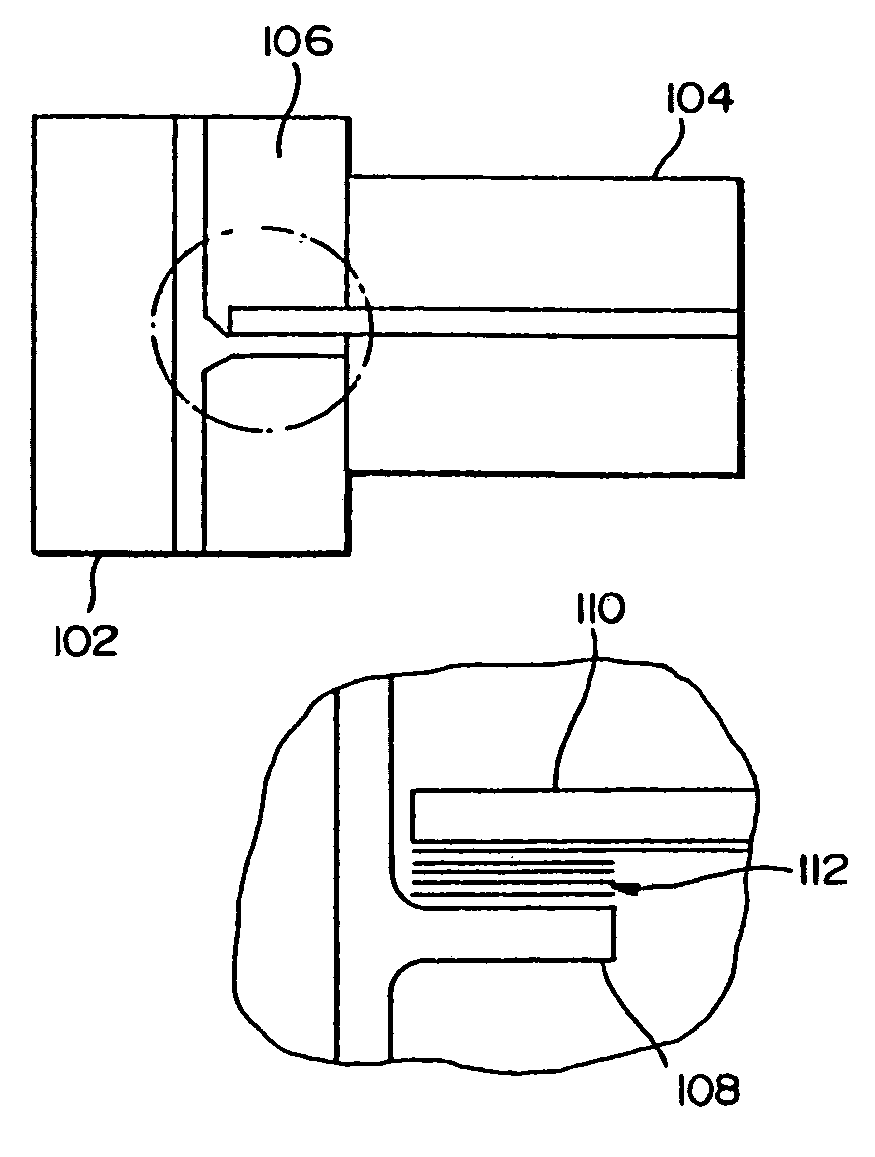

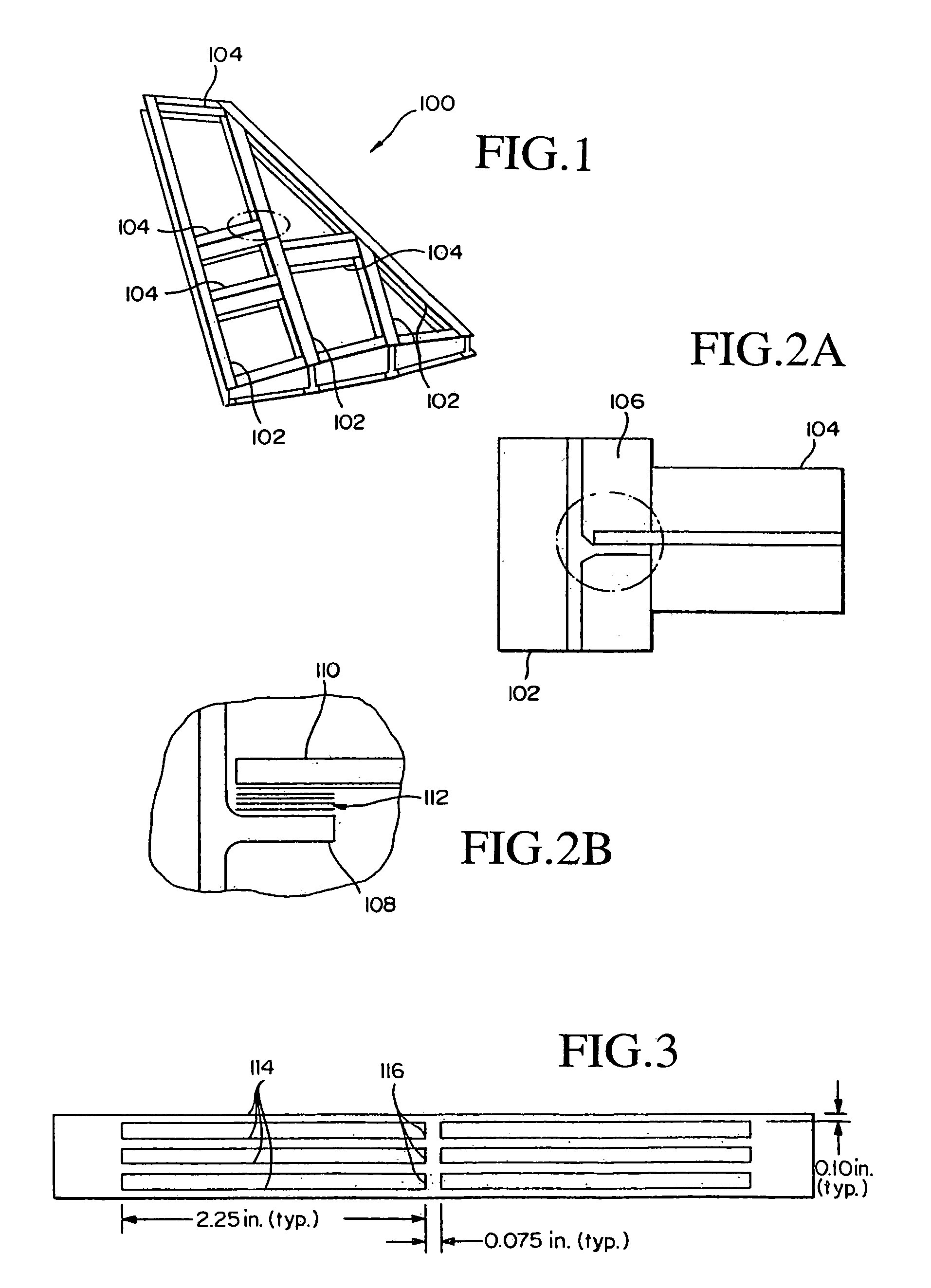

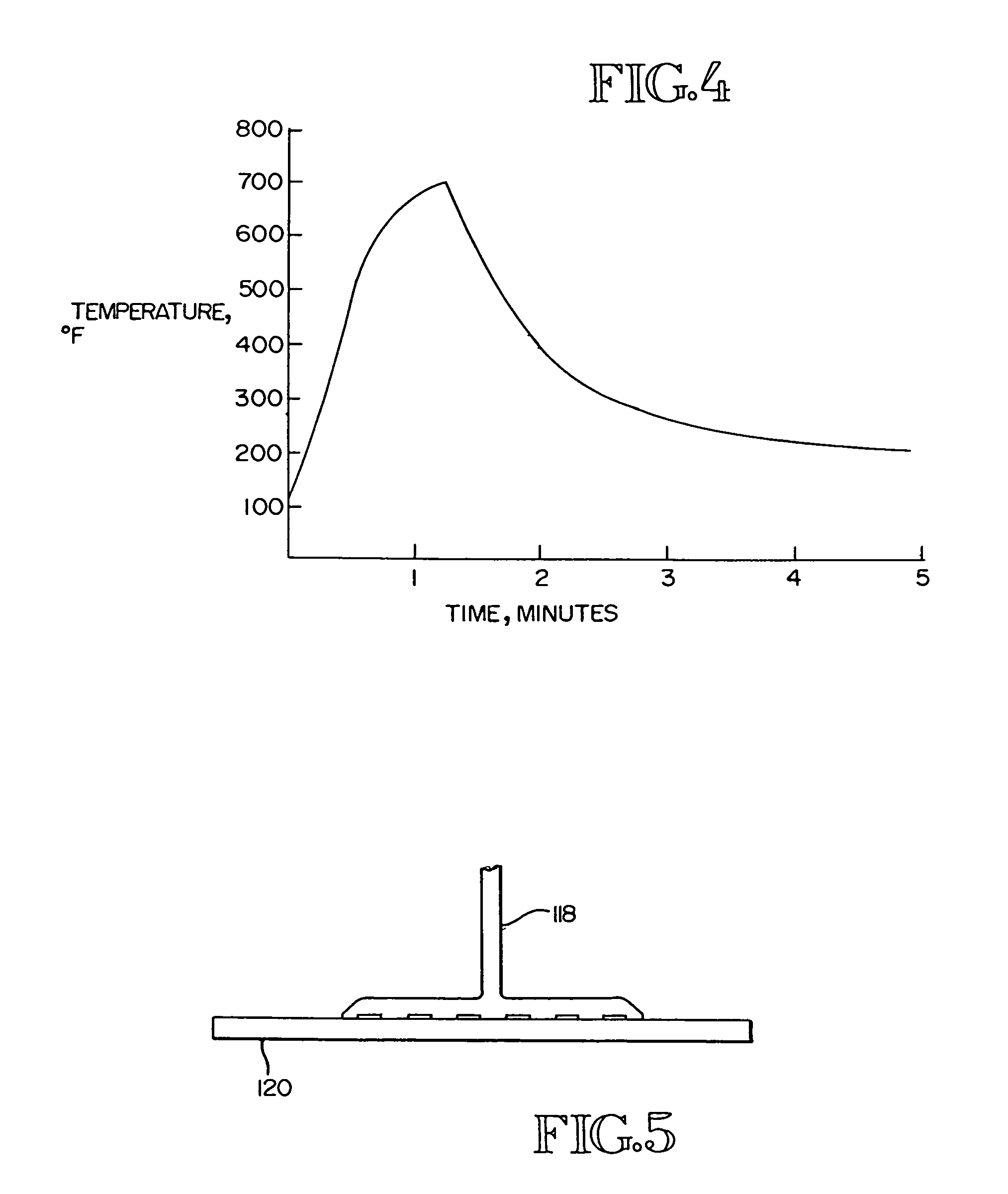

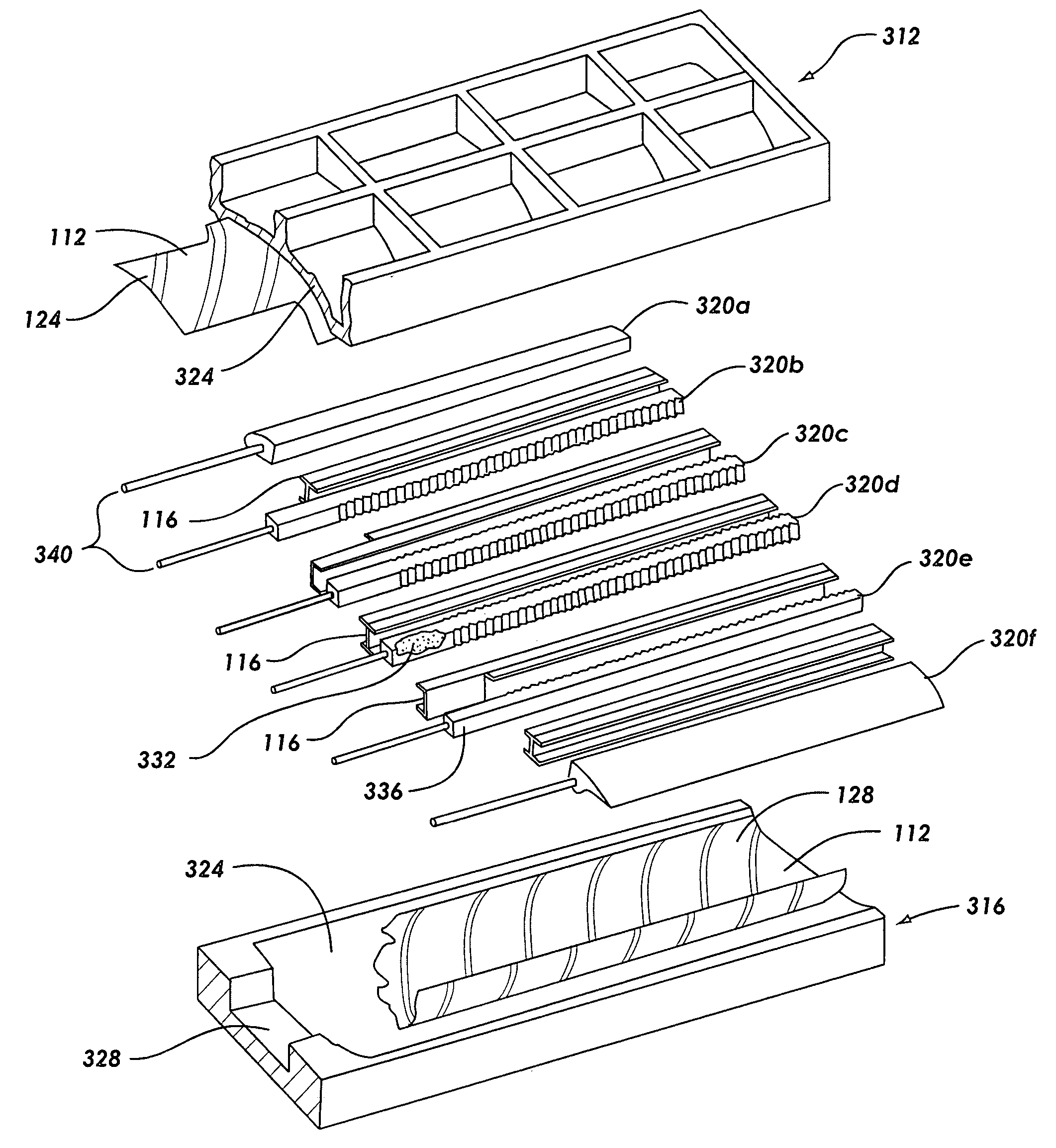

Resistance welding of thermoplastics in aerospace structure

InactiveUS7126096B1Layered product treatmentCoil arrangementsThermoplasticElectrical resistance and conductance

Rib and spar webs are joined in a composite wingbox to eliminate fasteners by welding the webs along bondlines defined by overlapping sections of the webs. Heat to produce the weld is generally achieved resistively by connecting a multistrip susceptor positioned along the bond line to a current source, since the geometry makes it difficult to heat these web joints inductively. The wingbox is completed without fasteners by welding skins to the rib-spar wingbox.

Owner:THE BOEING CO

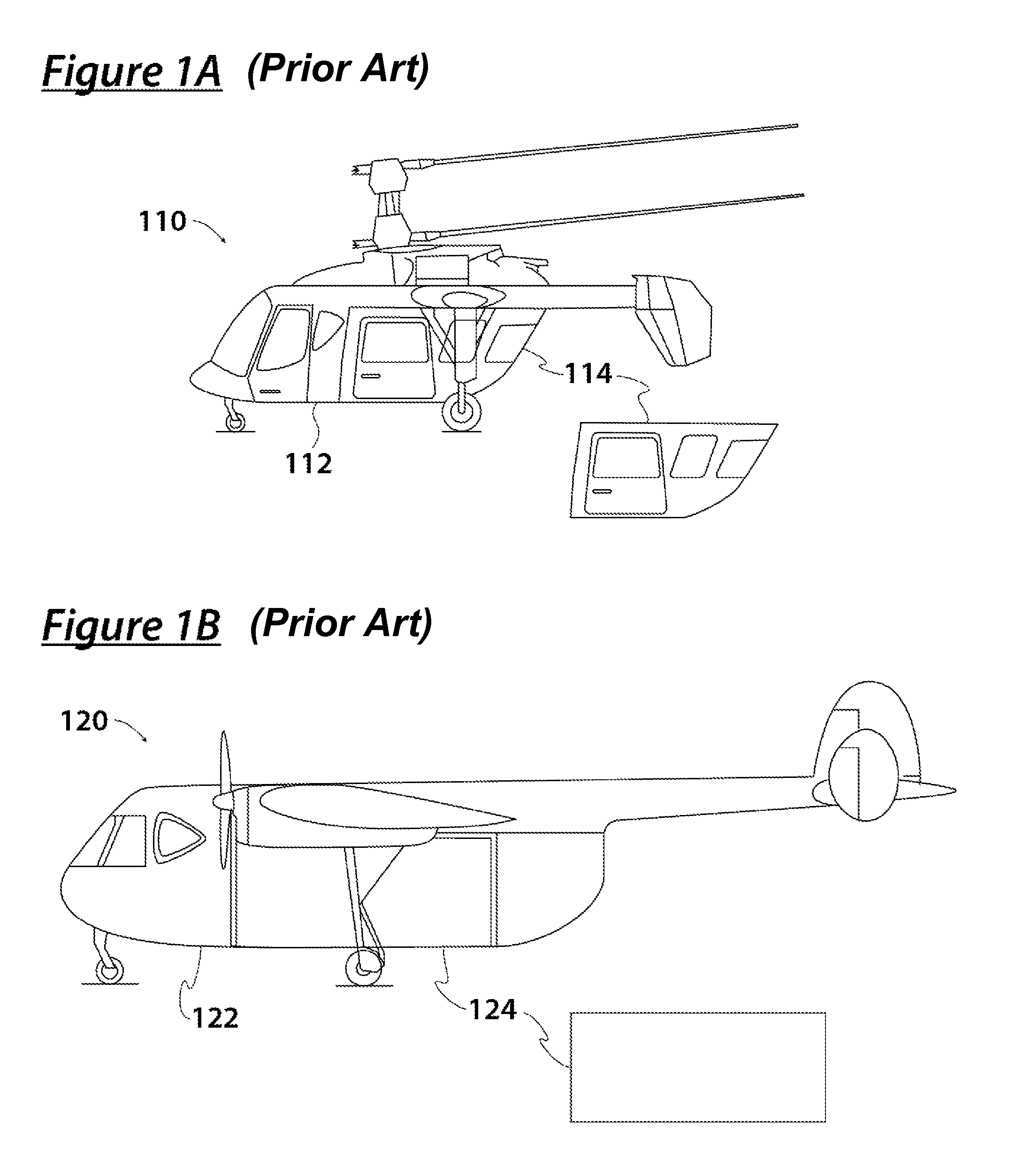

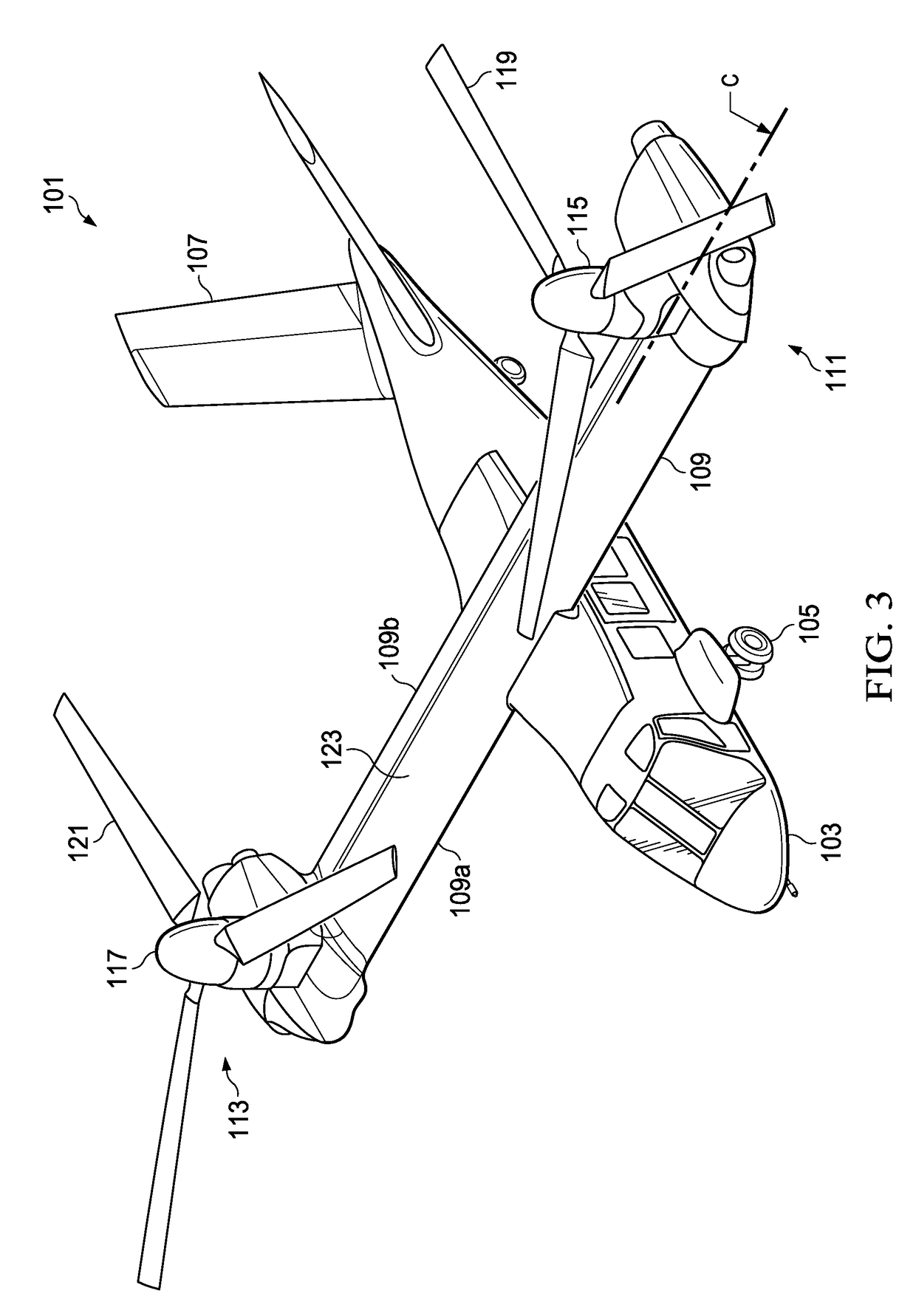

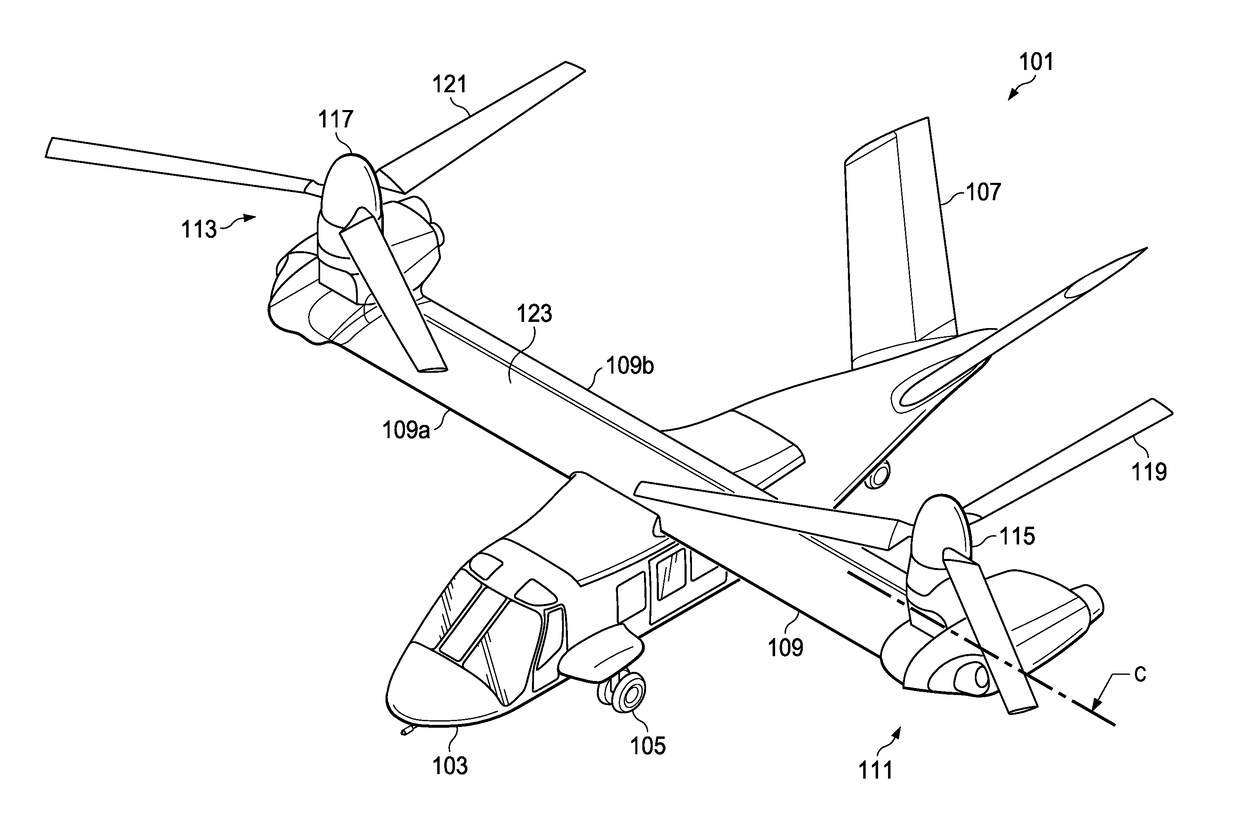

Multi-role aircraft with interchangeable mission modules

Owner:KAREM ABE

Method for comprehensively increasing aerodynamic and transport characteristics, a wing-in-ground-effect craft for carrying out said method (variants) and a method for realizing flight

InactiveUS8657053B2Improve maintainabilityAmphibious vehiclesConvertible vehiclesFlight heightAviation

The group of inventions relates to aviation and to transport means having (static and dynamic) air discharge, in particular to self-stabilizing wing-in-ground-effect craft of types A, B and C. The following technical results are achieved: increased flight safety and maneuvering safety, increased load-bearing capacity and flight height in ground effect mode, reduced dimensions, improved take-off and landing characteristics, as well as amphibian characteristics and economic efficiency, increased functionality and a wider range of operational alignments, and greater ease of use and maintenance. This result is achieved by simultaneously applying the methods for generating a system of aerodynamic forces, the structural solutions and the piloting methods conceptually linked therewith which are proposed in the present group of inventions to “flying wing” or “composite wing” design layouts.

Owner:NOVIKOV KOPP IVAN

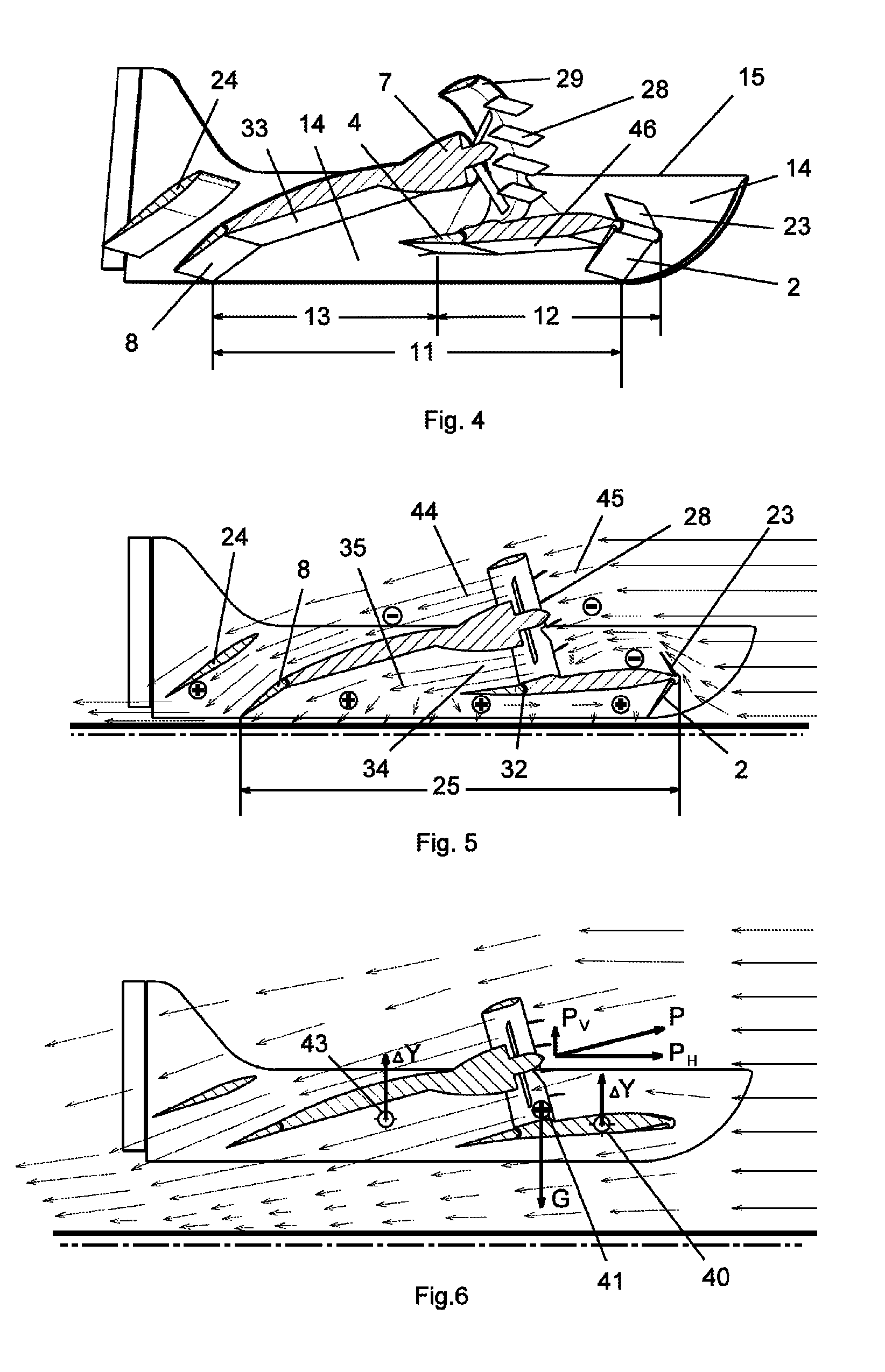

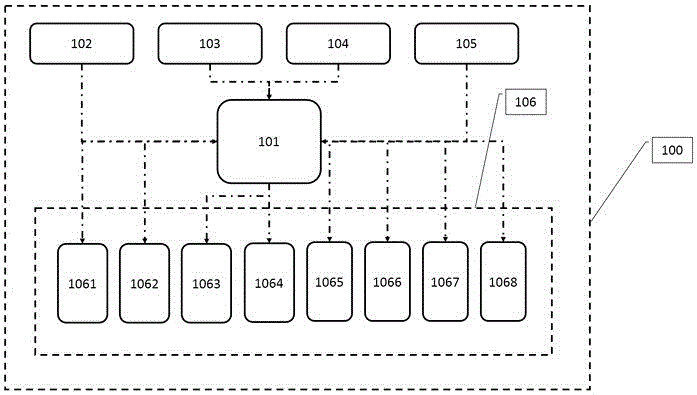

Composite wing unmanned plane automatic pilot and control method employed by composite wing unmanned plane automatic pilot

ActiveCN105912015AAvoid time delaySmall aerodynamic angle of attackAttitude controlPosition/course control in three dimensionsFixed wingAutopilot

The invention discloses a composite wing unmanned plane automatic pilot and a control method employed by the composite wing unmanned plane automatic pilot. Through the automatic pilot and the control guidance algorithm, a multi-shaft and fixed wing coordination control problem is solved, and full-state full-autonomous course flight of a composite wing unmanned plane is realized.

Owner:CHENGDU JOUAV AUTOMATION TECH

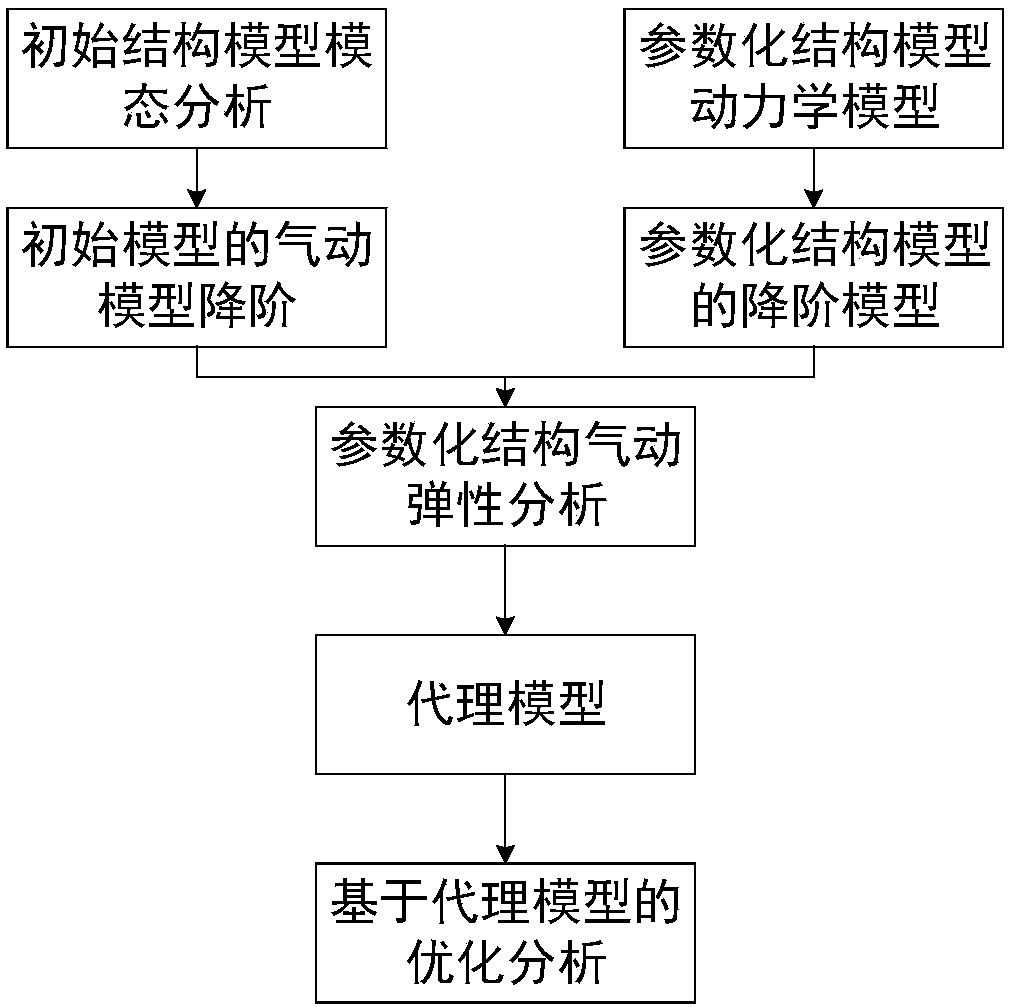

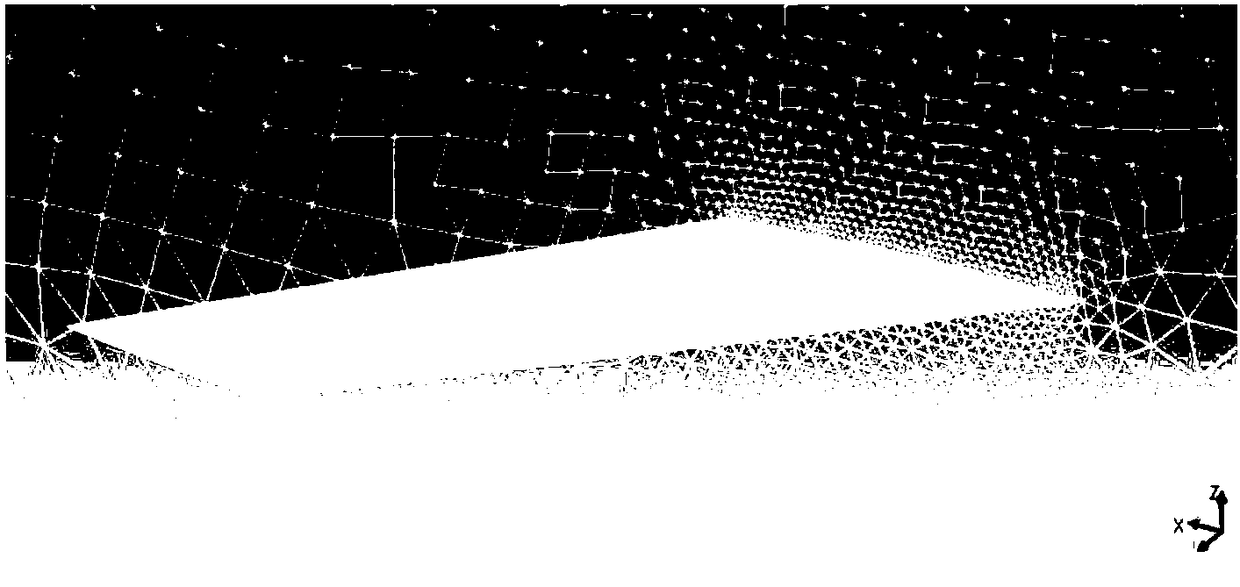

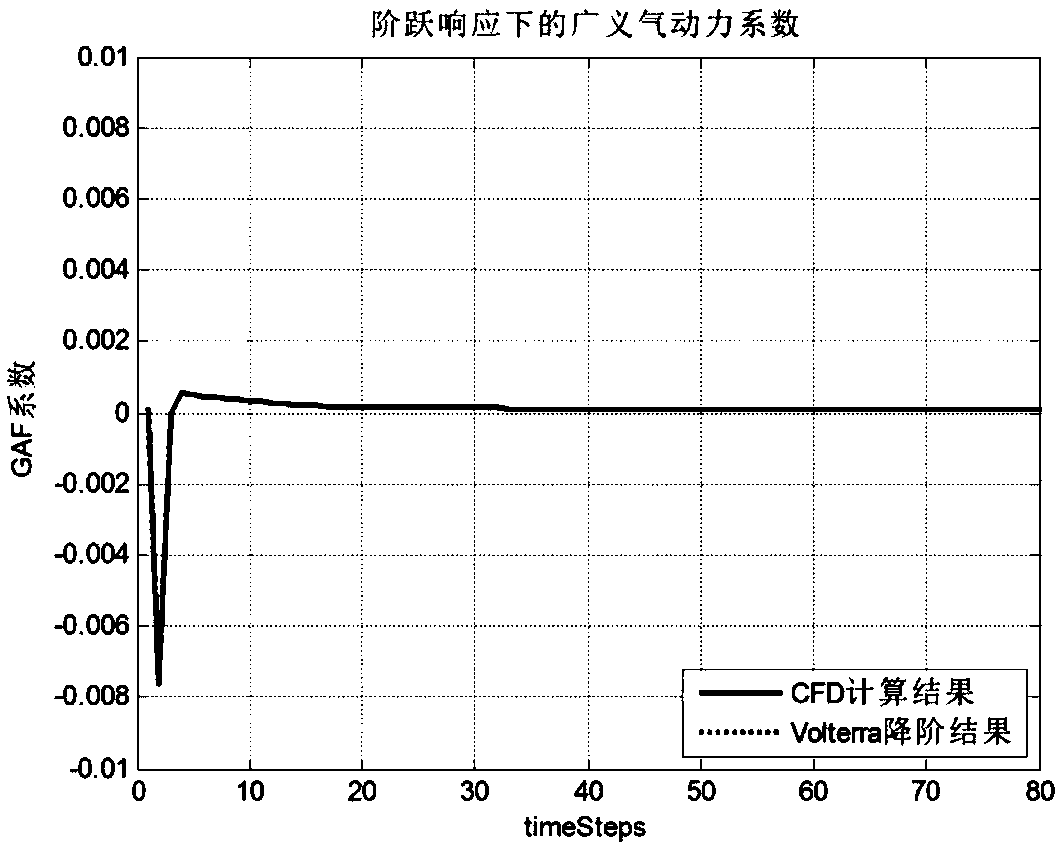

Composite wing optimization design method based on aerodynamic reduced-order model

ActiveCN108446445AImprove accuracyImprove performanceGeometric CADSustainable transportationReference modelElement model

Owner:BEIHANG UNIV

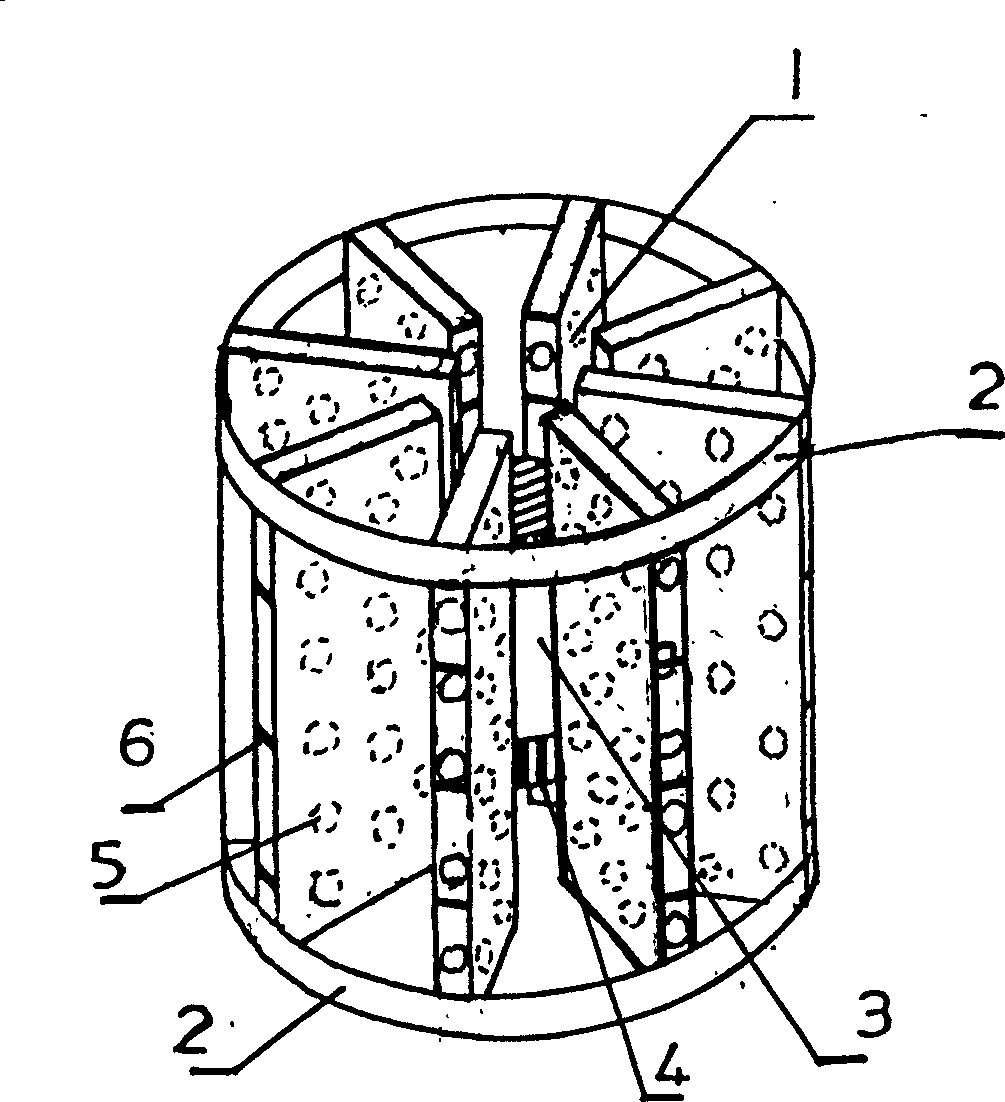

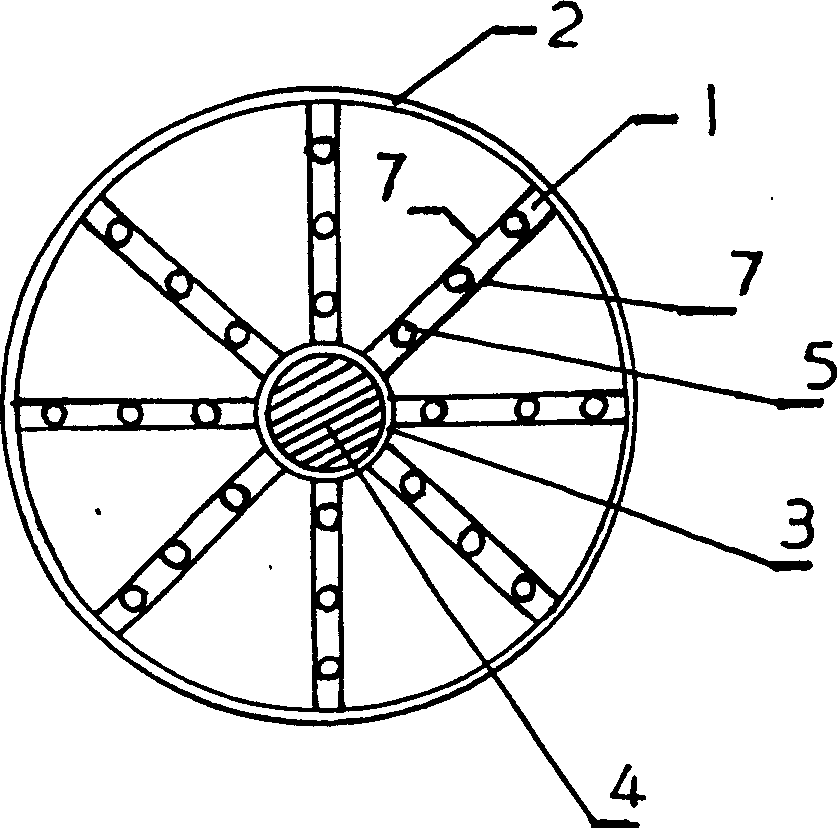

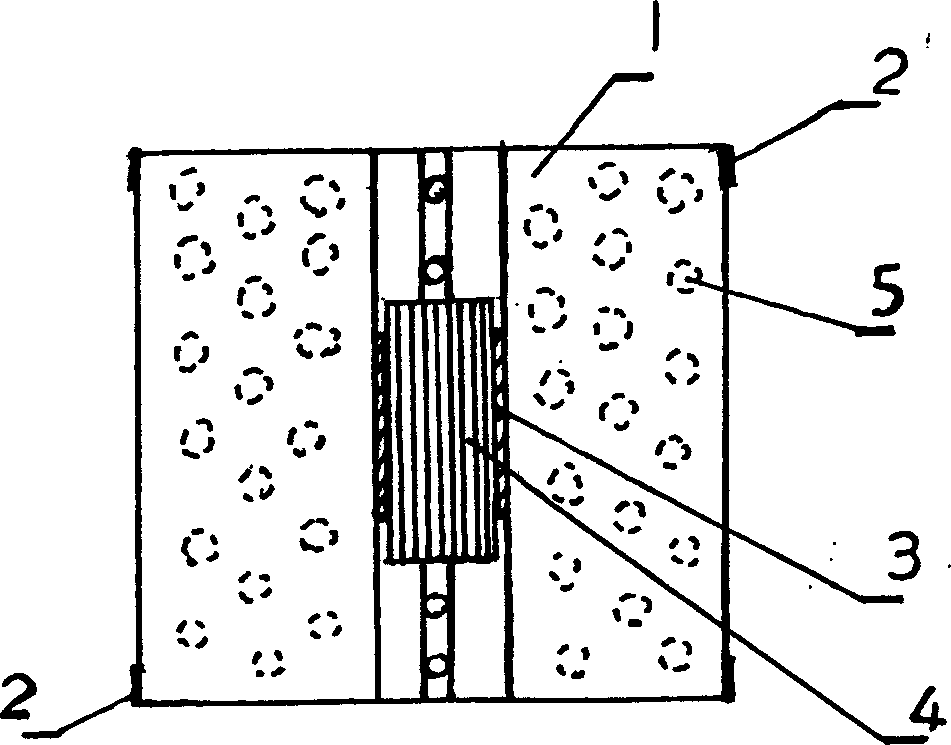

Novel functional suspension filler

InactiveCN1532152APlay a role in biological regenerationPromote sheddingSustainable biological treatmentBiological water/sewage treatmentWastewaterSewage

The novel functional suspension filler is used in processing various organic sewage. The functional water processing material grains or blocks are sandwiched in plastic plates to form composite winged plate and are used as the main carrier for microbe to attach and propagate on them to form biomembrane with flourishing growing microbes. The functional suspension filler contains water repellent foamed plastic to regulate water specific weight, so that the functional suspension filler may be fluidized together with water and gas and the mass transferring of microbe, organic matter in waste water and oxygen in the air is reinforced. The functional water processing material can adsorb and enrich pollutant in waste water to raise the elimination of pollutant effectively, and the microbe can regenerate the functional material biologically. The present invention has high organic sewage processing effect.

Owner:TONGJI UNIV

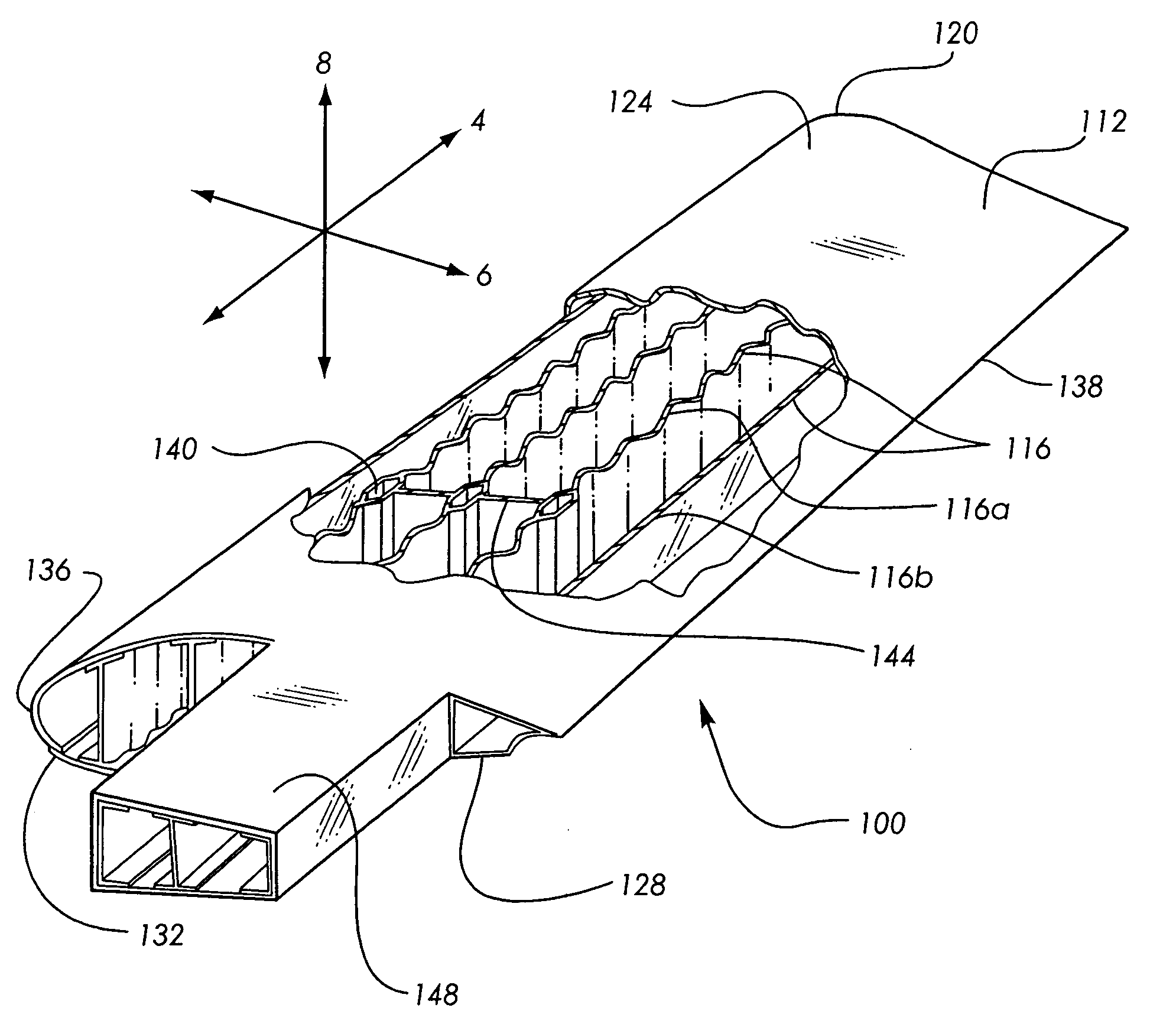

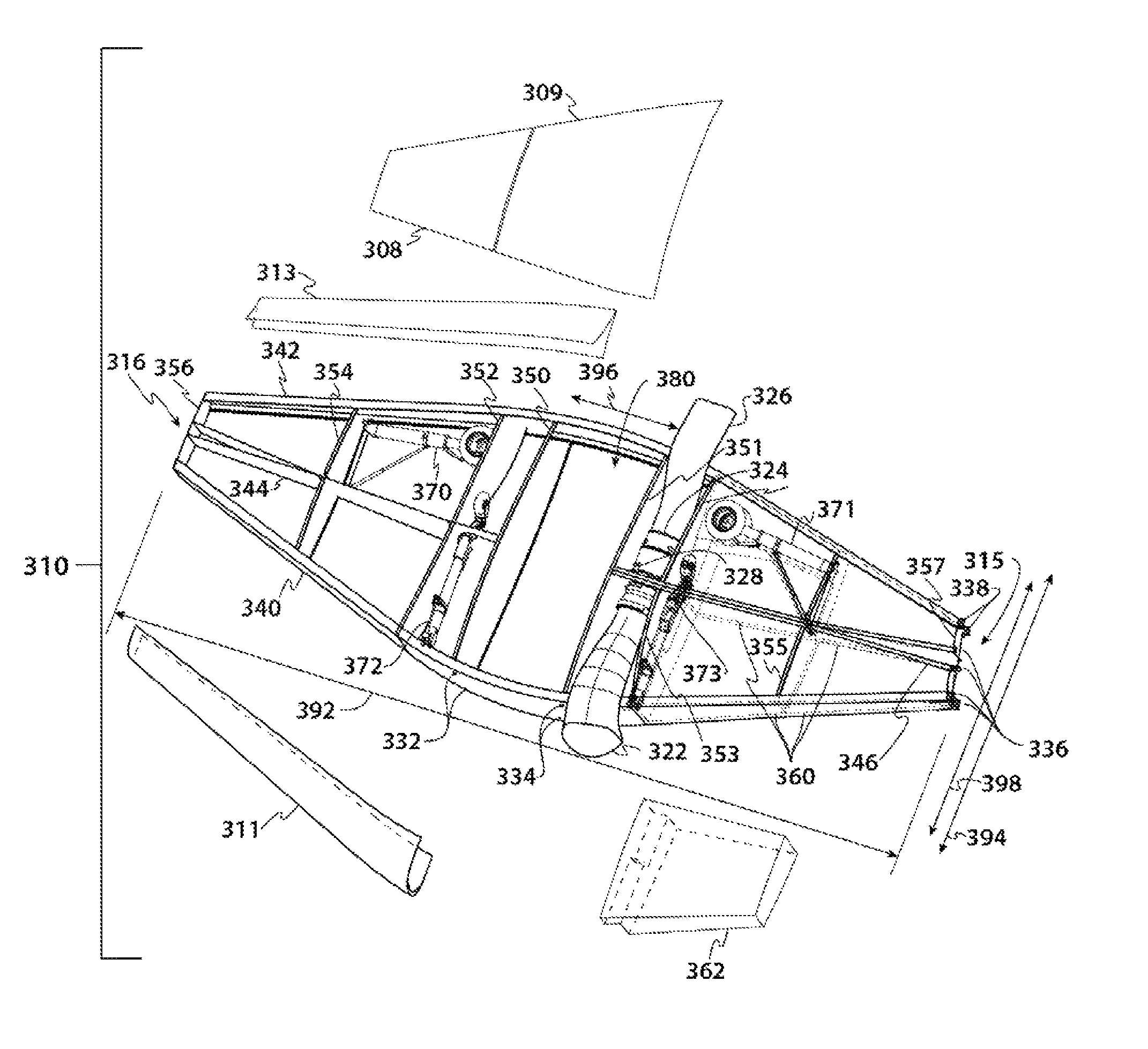

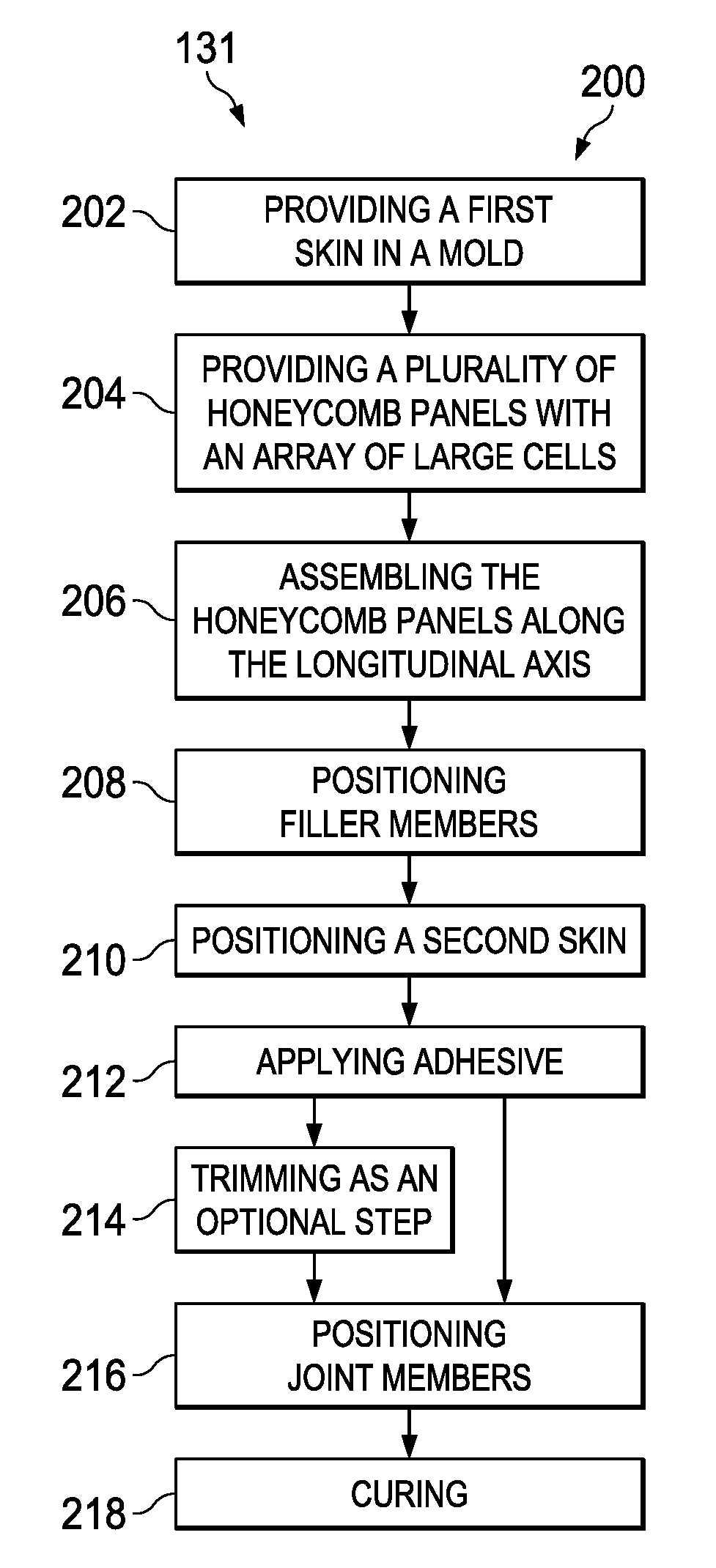

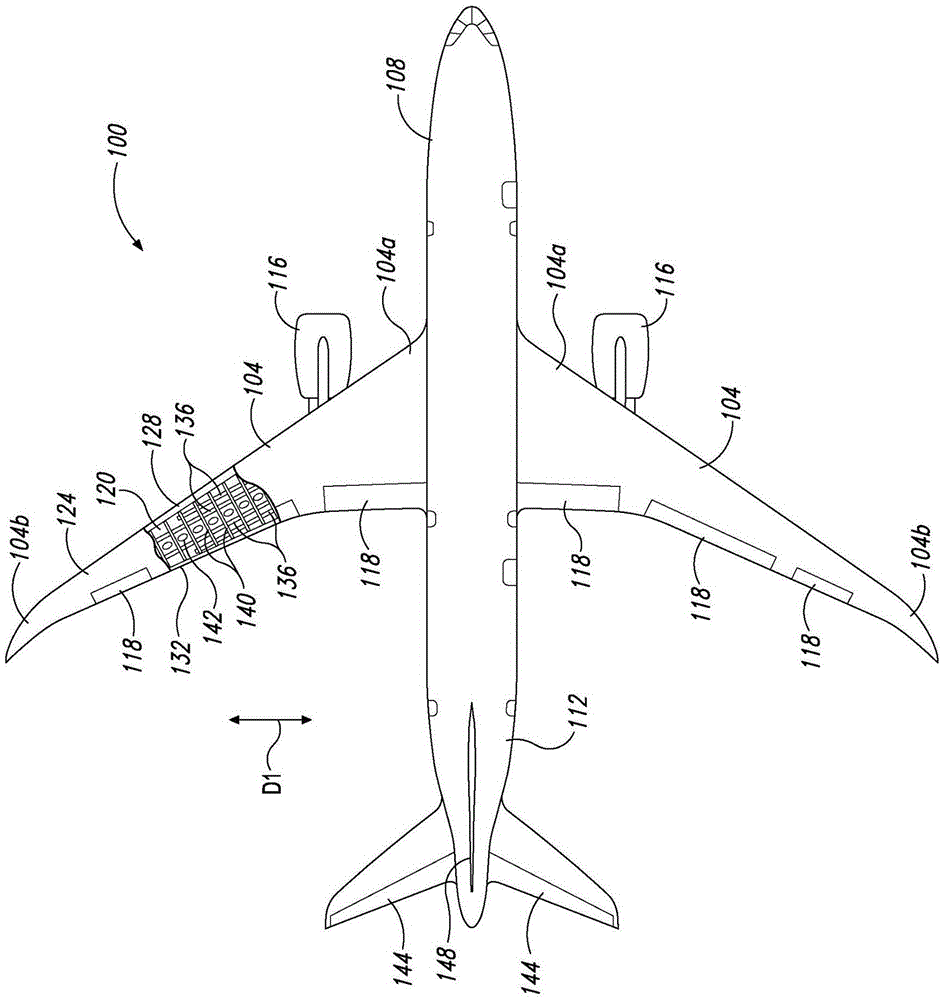

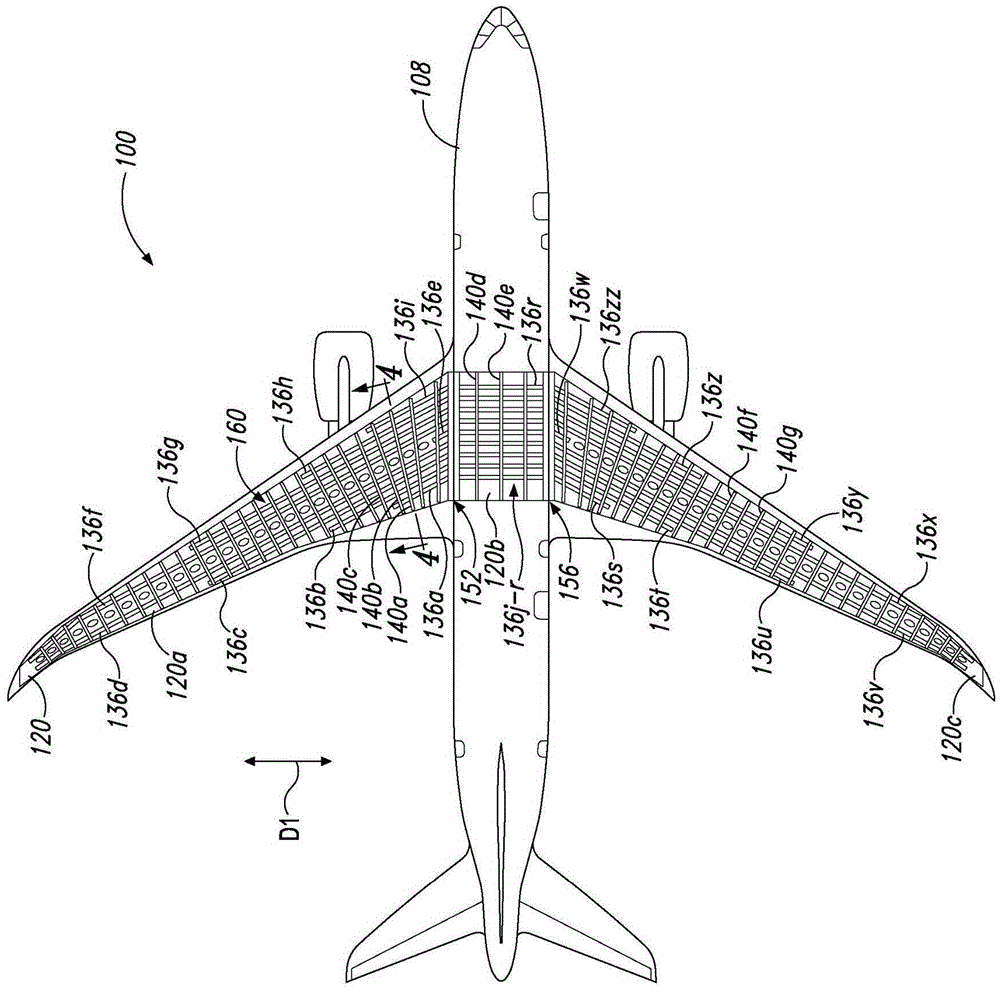

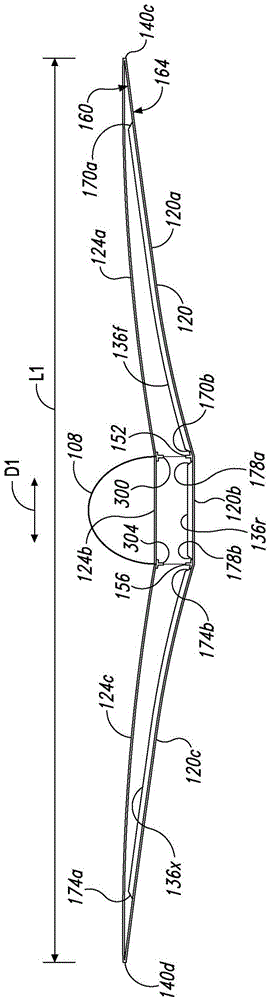

Composite wing structure and methods of manufacture

Owner:BELL HELICOPTER TEXTRON INC

Laminate composite wing structures

The application discloses laminate composite wing structures. A wing may include a wing skin, a laminate composite first stringer, a rib, and at least one fastener. A majority of the first stringer may be characterized by a stacked plurality of generally planar plies of reinforcement material structurally joined as a stack to an interior surface of the wing skin and extending generally parallel to the interior surface and a span-wise direction of the wing along a substantial portion of the interior surface. The first stringer may have a generally solid trapezoidal cross section when viewed in a plane that is generally perpendicular to the span-wise direction. The rib may be positioned adjacent the interior surface, and may extend generally perpendicular to the span-wise direction. The trapezoidal cross section may be interfaced with the rib flange. The fastener may extend through the wing skin, the trapezoidal cross section, and the rib flange.

Owner:THE BOEING CO

Aircraft fuel system

InactiveCN104670507AImprove insulation performanceMinimize complexityPower plant fuel tanksFuel tank safety measuresAircraft fuel systemHeat flow

Aircraft fuel system reduces flammability exposure of fuel tanks. In one embodiment, aircraft center fuel tank fuel is cooled in flight to reduce flammability exposure to be similar to that of an unheated metal wing tank. Fuel tanks having adjacent heat sources are insulated to minimize heat flow into the fuel. Fuel tanks having lower cooling properties, e.g., composite wing tanks, are cooled during flight so temperatures are reduced to be similar to metal wing tanks. A fuel tank, pressurized relative to outside pressure at altitude, having lower flammability exposure than unpressurized tanks and cooling fuel in the tank reduces flammability exposure of the fuel tank to be similar to that of an unpressurized metal wing tank. Recirculating flow from a tank, passing through heat exchanger, and returning to the tank cools fuel. A controller starts / stops fuel flow to tanks and uses sensors to command flow to reduce flammability.

Owner:AERO SYST CONSULTANTS

Composite wing structure and methods of manufacture

ActiveUS20170225769A1Precise drillingLayered productsSpars/stringersMechanical engineeringHelicopter rotor

Owner:BELL HELICOPTER TEXTRON INC

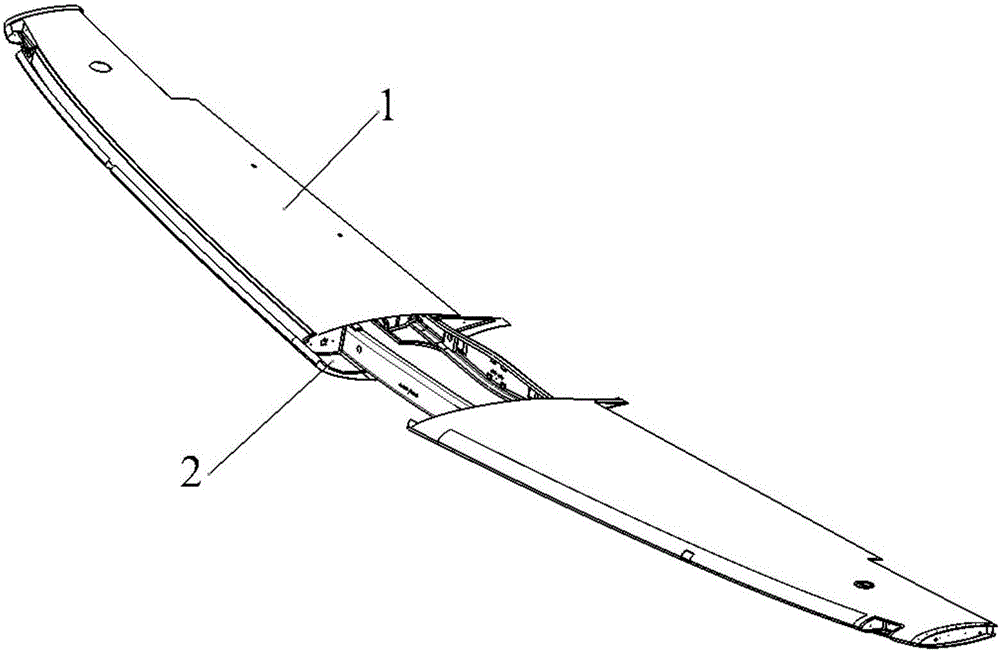

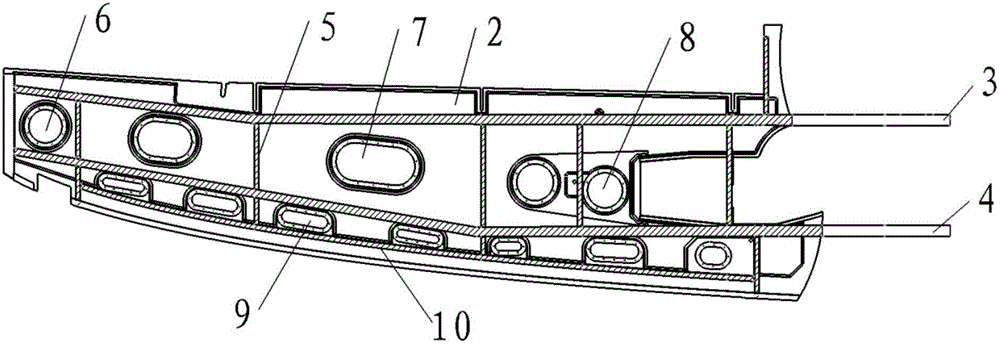

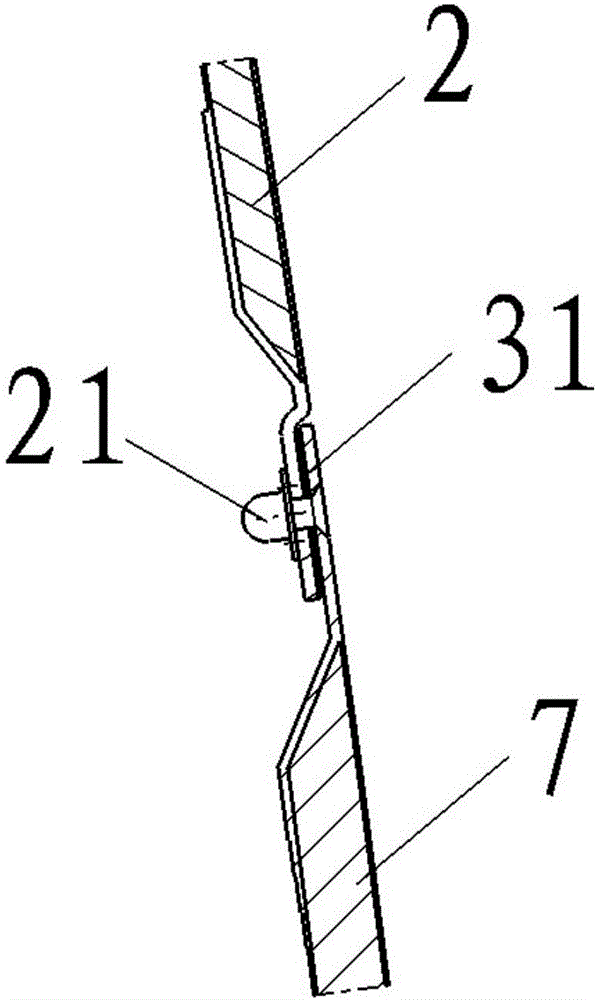

Composite wing integral oil tank and manufacturing method thereof

ActiveCN106585957AReduce manufacturing costRealize large-scale productionWingsWeight reductionFuel tankEngineering

The invention relates to a composite wing integral oil tank. The composite wing integral oil tank comprises upper coverings 1, lower coverings 2, crossbeams and wing ribs 5, wherein each of the crossbeams is arranged between the corresponding upper covering 1 and the corresponding lower covering 2, the crossbeams are a front crossbeam 3 and a rear crossbeam 4, and each of the front crossbeams 3 and the corresponding rear crossbeam 4 are arranged in the spanwise direction; the wing ribs 5 are arranged between the corresponding front crossbeam 3 and the corresponding rear crossbeam 4 in the navigation direction; a front edge oil tank access cover 9 is arranged between each wing oil tank front wall 10 and the corresponding front crossbeam 3; a wing oil tank box section is formed between the corresponding front crossbeam and the corresponding rear crossbeam; each oil tank access cover 7 and a corresponding maintenance access cover are arranged on one side close to the corresponding lower covering 2, of the corresponding box section; and each of the oil tank access covers 7 is connected with the corresponding lower covering 2 through a corresponding sealing support plate nut 21, and a fuel oil sealing ring 31 is arranged between each of the oil tank access covers 7 and the corresponding lower covering 2. According to the composite wing integral oil tank disclosed by the invention, the manufacturing cost of composite airplanes is greatly reduced, the structural utilization efficiency is improved, the assembling tooling is saved, the assembling time is shortened, the workload is reduced, and the large-scale production of full-composite wing integral oil tanks is realized.

Owner:R&D INST OF CHINA AVIATION IND GENERAL AIRCRAFT

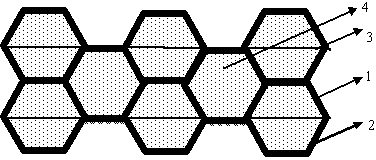

Sensing and driving integrated composite wing cover, and test system and application thereof

InactiveCN103434639AImprove flexibilityLarge amount of deformationWingsUsing optical meansGratingShape-memory alloy

The invention relates to a sensing and driving integrated composite wing cover, and a test system and application thereof, and belongs to the field of pneumatic design and structure design of airplanes. The cover is formed by splicing N-layer semi-honeycomb structure composite material sensing layers in sequence from the top down, and the longitudinal cross section of the cover is of a honeycomb structure after the sensing layers are spliced; a shape memory alloy drive sandwich layer (3) is arranged between the adjacent semi-honeycomb composite sensing layers; each semi-honeycomb composite sensing layer comprises upper and lower fiber-enhanced composite material layers (1) and an optical fiber sensing sandwich layer (2) arranged between the upper and the lower fiber-enhanced composite layers; the hollow part of the honeycomb structure is filled with silicon rubber (4); an optical fiber grating sensor (8) is arranged in each optical fiber sensing sandwich layer (2); each shape memory alloy drive sandwich layer (3) is provided with a shape memory alloy wire (10). According to the wing cover, the self-sensing and efficient active control requirements of a deformation state of a morphing wing can be met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

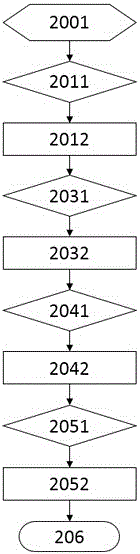

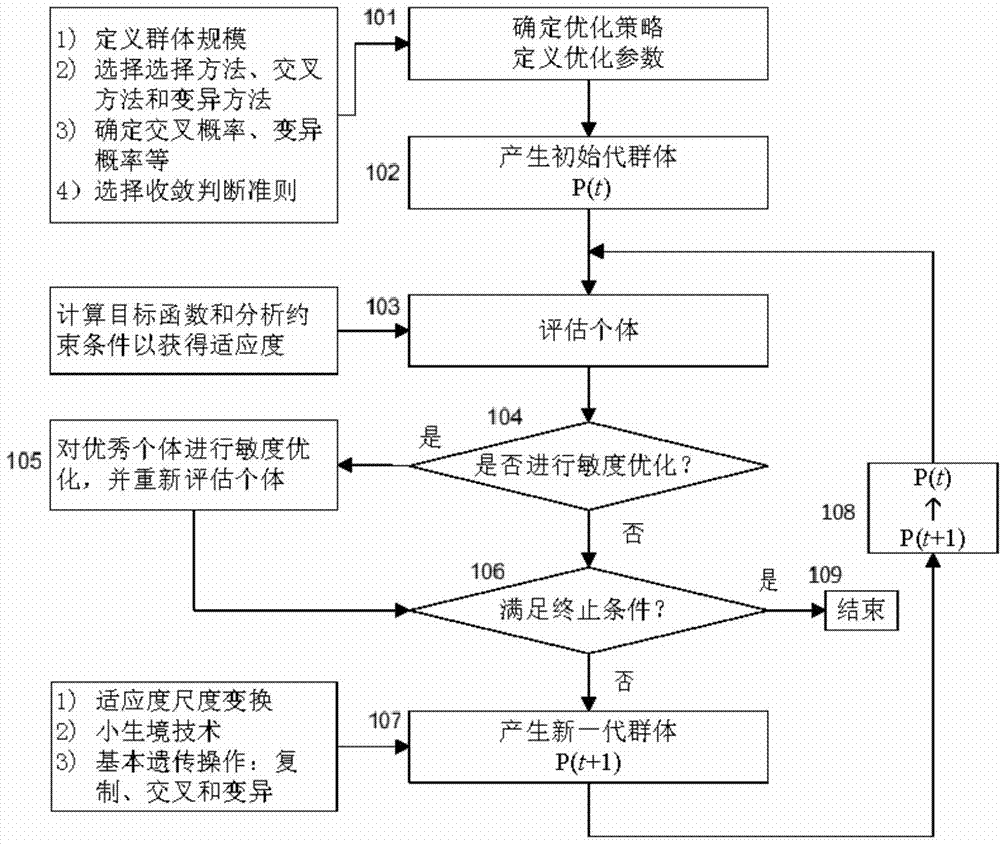

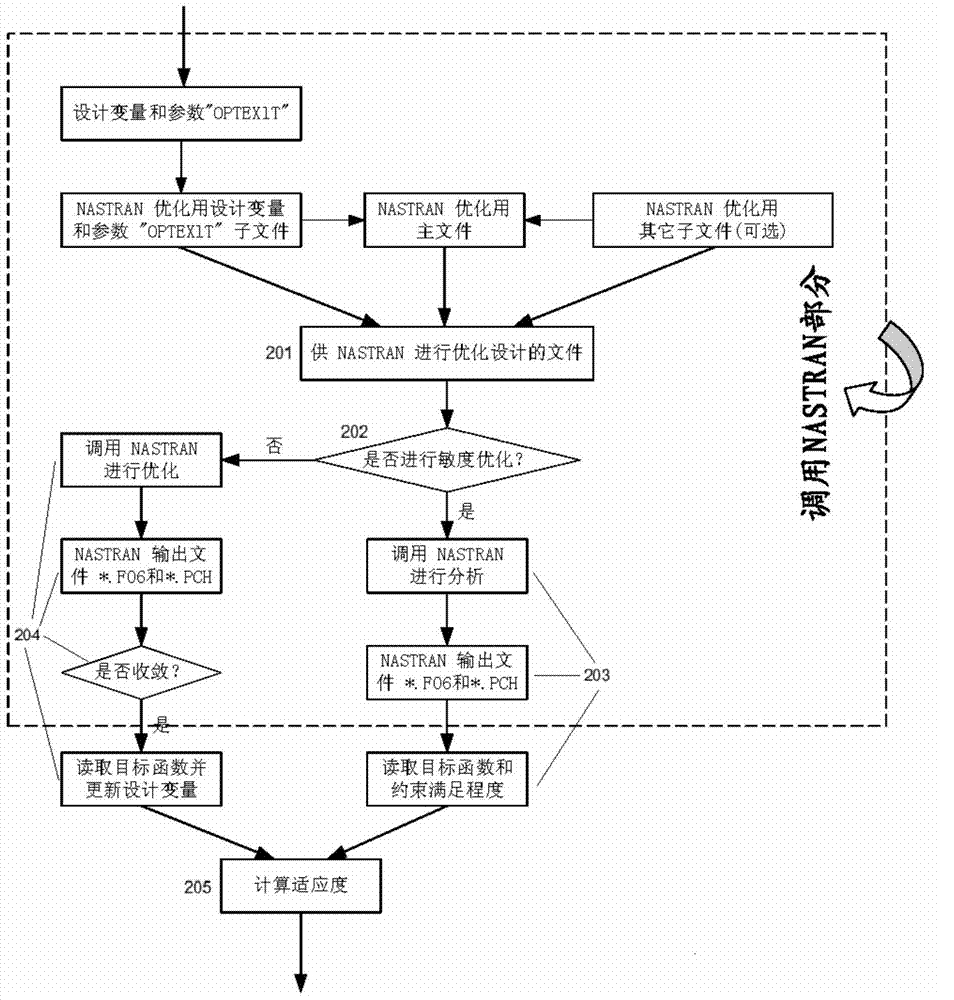

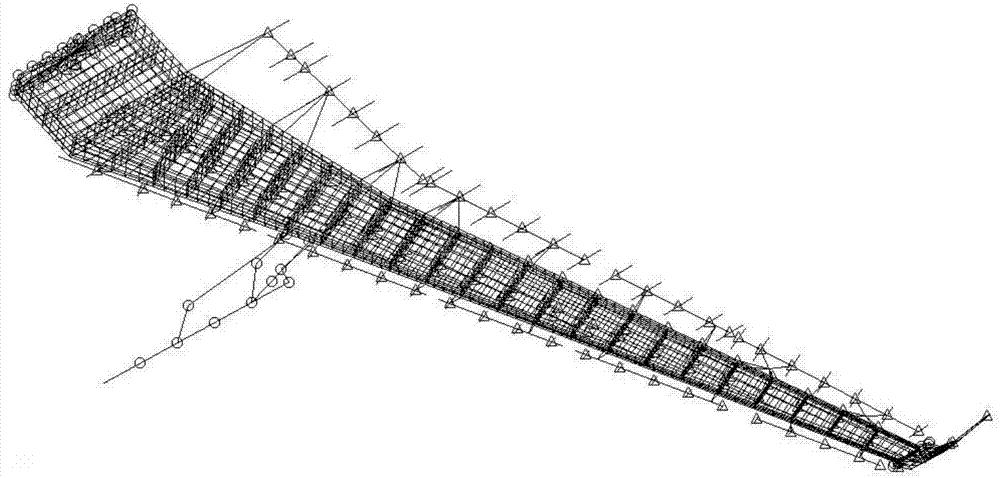

Method for aeroelastic tailoring of composite wing and genetic/sensitivity-based hybrid optimization method of composite wing

The invention provides a method for aeroelastic tailoring of a composite wing. The method for aeroelastic tailoring of the composite wing comprises the steps that aeroelastic tailoring of the composite wing is achieved by means of aeroelasticity optimization, and solution of aeroelasticity optimization is conducted according to a genetic / sensitivity-based hybrid optimization method. The genetic / sensitivity-based hybrid optimization method comprises the steps that (A) a group of individuals are generated randomly according to a genetic algorithm; (B) performance evaluation is conducted on the individuals in the group one by one; (C) according to a user definition, whether sensitivity-based optimization is applied or not is judged; (D) whether the end condition is met or not is judged; (E) if the end condition is not met, a new generation of excellent individuals are generated; if the end condition is met, operation is ended. By the adoption of the method for aeroelastic tailoring of the composite wing and the genetic / sensitivity-based hybrid optimization method, under the condition that multiple requirements for flutter, diffusion, inherent frequency, deformation, aileron efficiency, strength, the flight load, weight and the like are met, tailoring design of the structure is achieved and optimized.

Owner:BEIHANG UNIV +1

Apparatus and methods for joining composite structures of aircrafts

Apparatus and method for joining composite structures of aircrafts are disclosed. An example apparatus disclosed herein includes an inboard composite wing panel having a first end portion configured to be coupled to upper and lower inboard fittings composed of a metallic material and an outboard composite wing panel having a first end portion configured to be coupled to upper and lower outboard fittings composed of a metallic material. A side of body rib has a plate shaped first end portion composed of a metallic material. A fuselage frame is configured to be joined at one end of the upper inboard fitting, and the upper and lower inboard fittings and the upper and lower outboard fittings are coupled to the side of body rib at the plate shaped first end portion.

Owner:THE BOEING CO

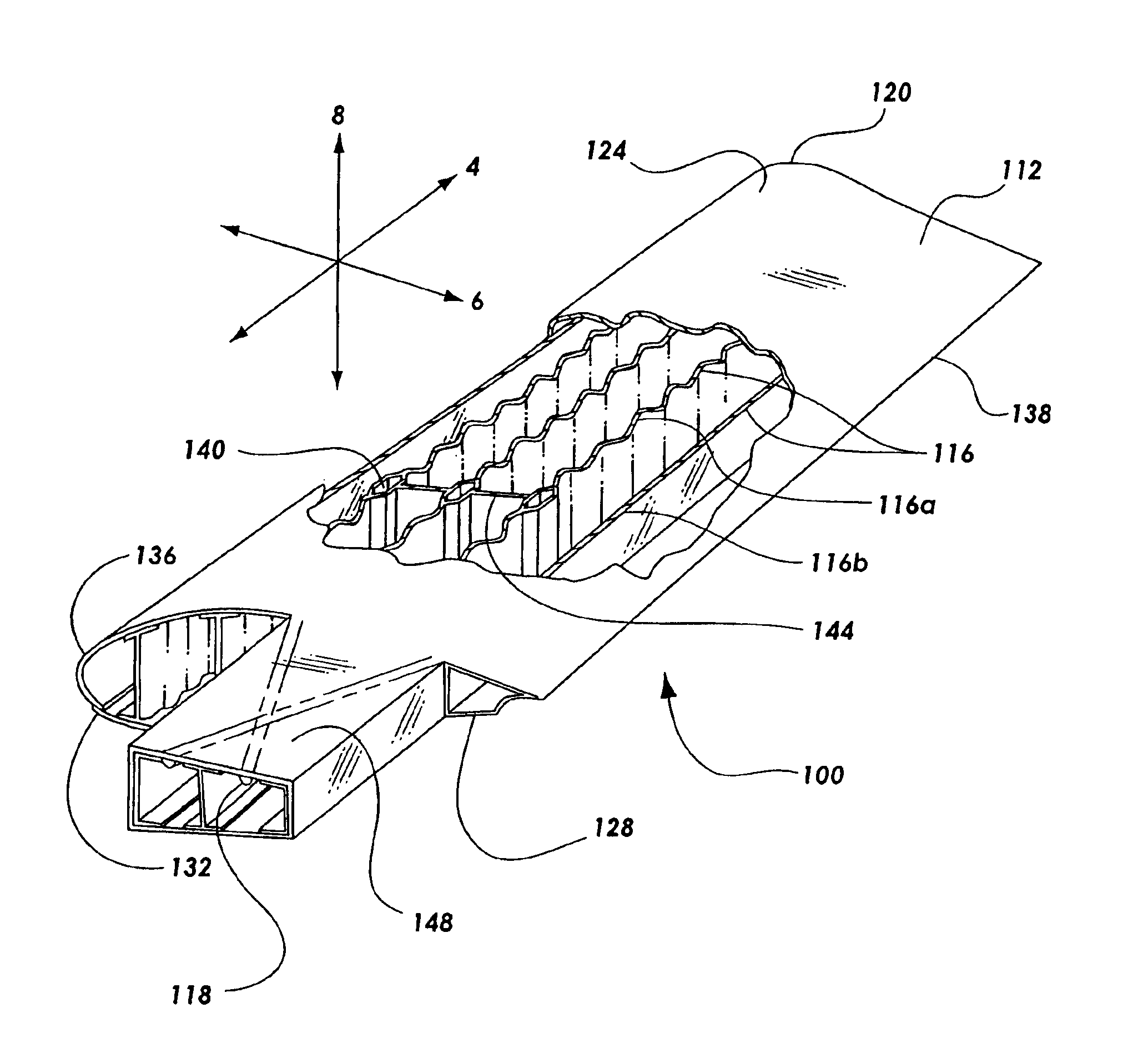

Process for forming a single piece co-cure composite wing

InactiveUS7445744B2Easy to disassembleOther chemical processesEfficient propulsion technologiesWave shapeComposite wing

A single piece co-cured composite wing is disclosed. The wing has a flying surface and structural members. In one embodiment the structural members may be a plurality of spars. The spars may have various shapes to increase the buckling strength. The spars may be wave shaped, such as a sinusoidal shape. The flying surface and the structural members are co-cured in order to form a single piece, integral wing structure. A process for manufacturing a single piece co-cured wing is also disclosed. The process may include laying out composite sheets for the flying surface of the wing. Then, the composite material of the spars is arranged around a plurality of pressurizable forms. Finally, the composite material is cured in a clamshell frame.

Owner:GENERAL ATOMICS AERONAUTICAL SYSTEMS INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com