Patents

Literature

206 results about "Aircraft fuel system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aircraft fuel system allows the crew to pump, manage, and deliver aviation fuel (also called jet fuel) to the propulsion system and auxiliary power unit (APU) of an aircraft. Fuel systems differ greatly due to different performance of the aircraft in which they are installed. A single-engine piston aircraft has a simple fuel system; a tanker (such as the KC-135), in addition to managing its own fuel, can also provide fuel to other aircraft.

Aircraft fuel systems

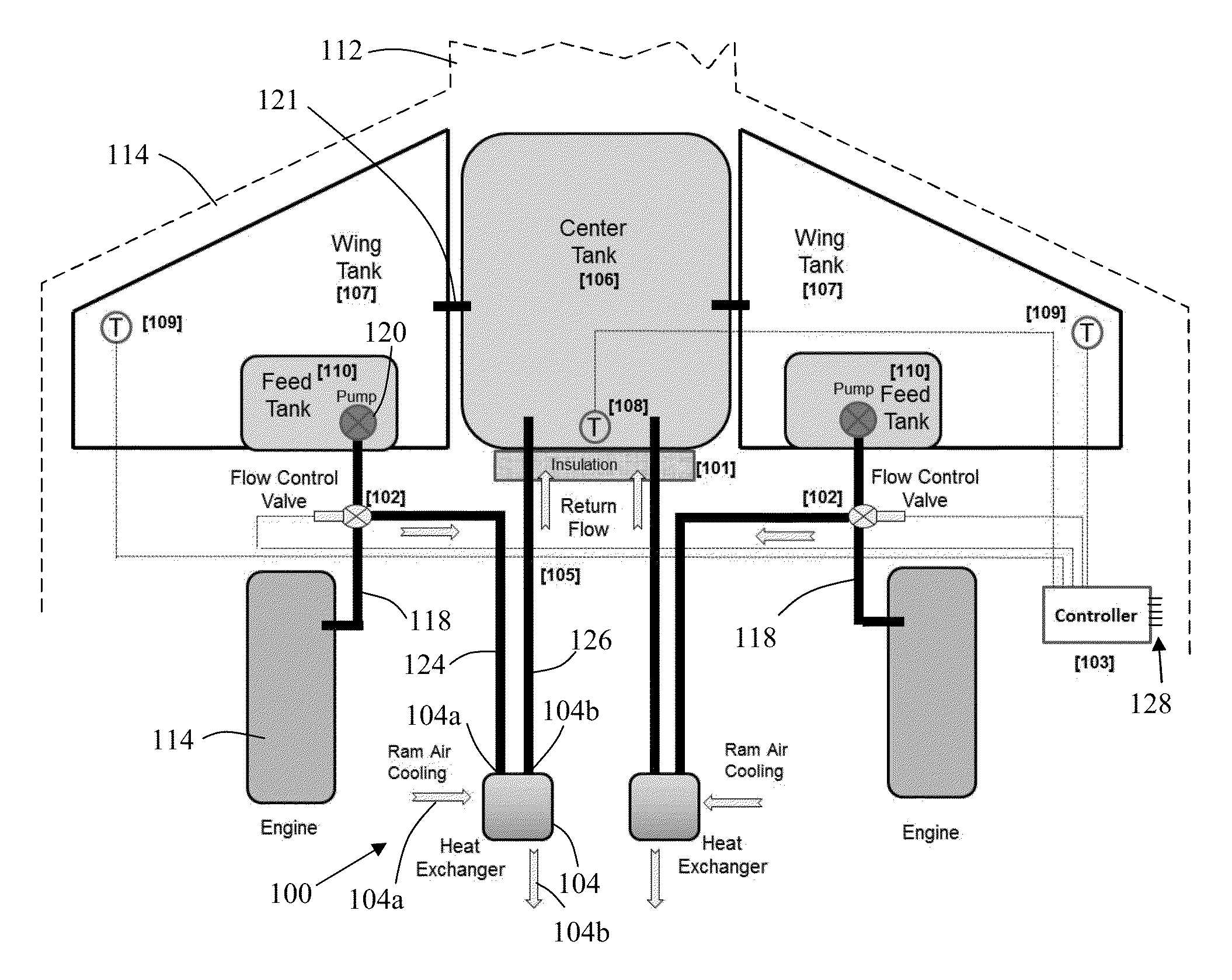

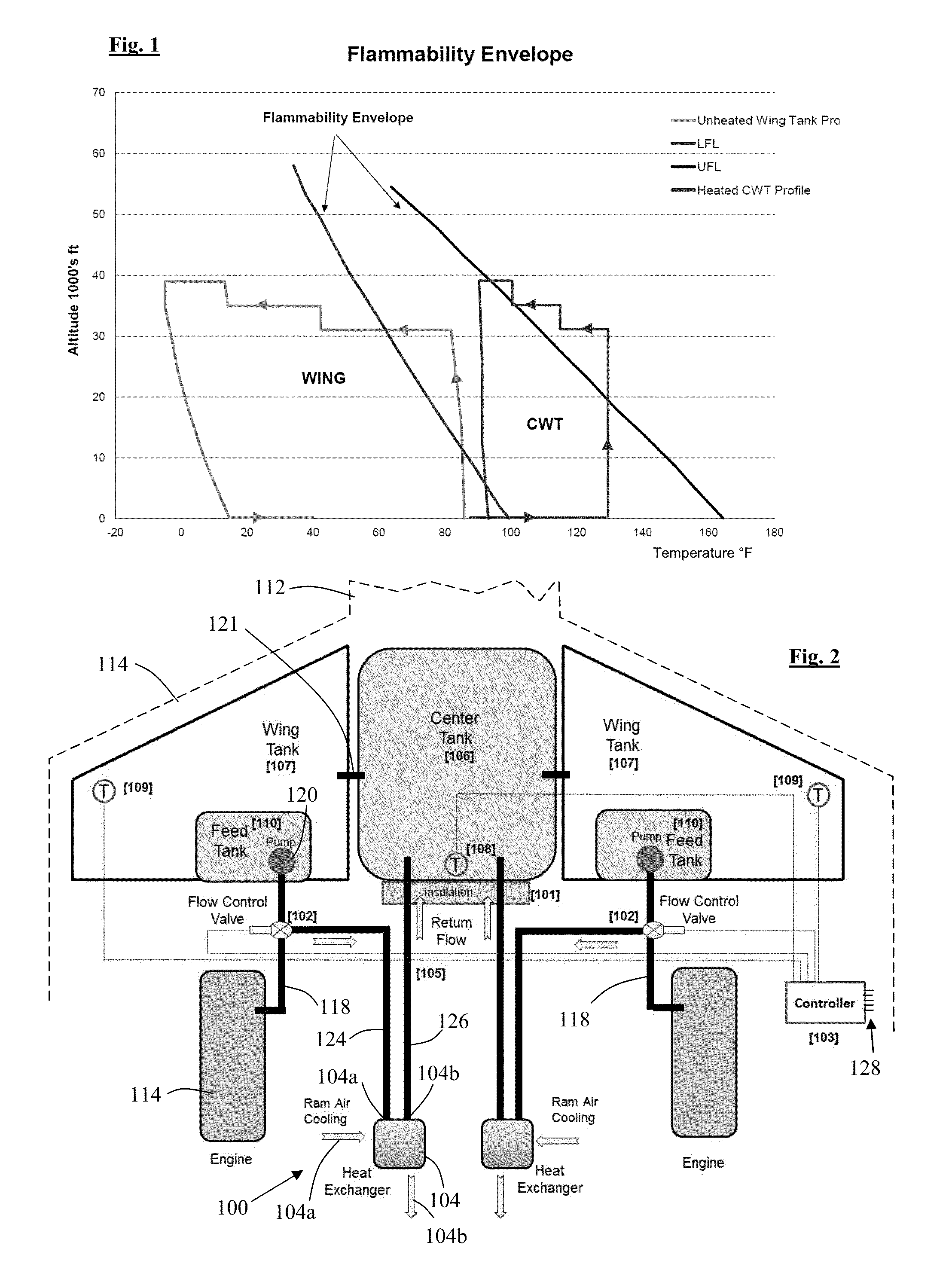

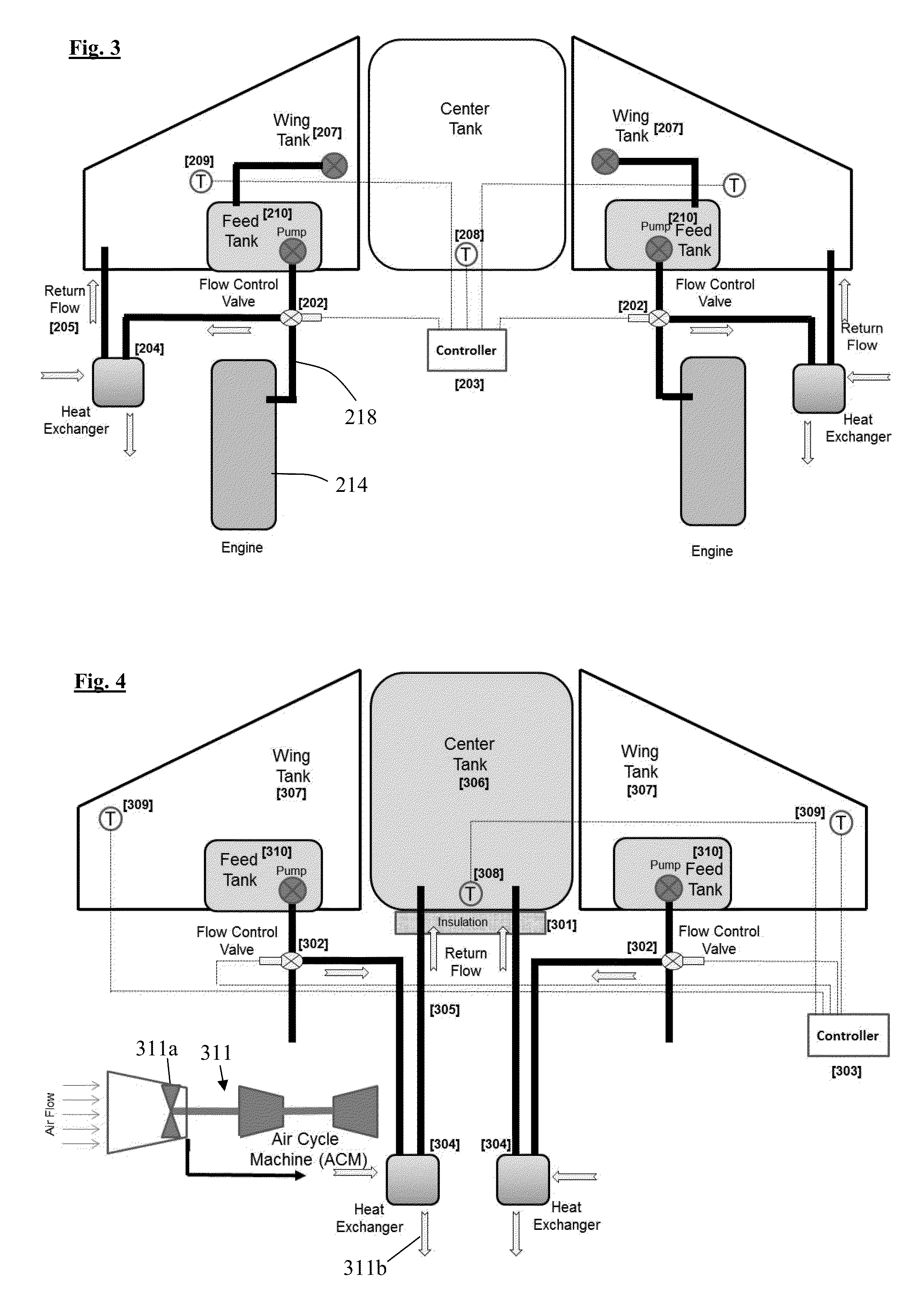

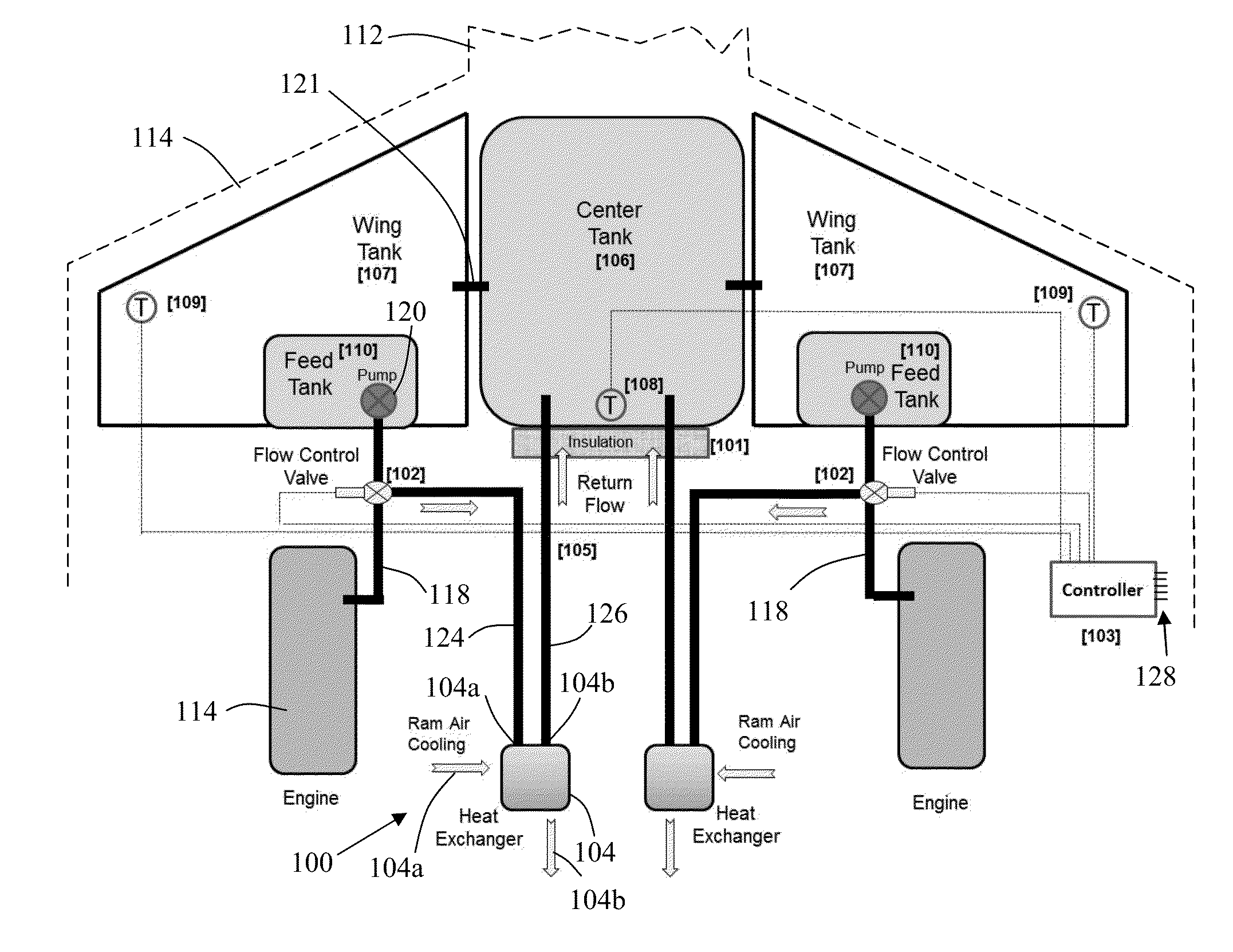

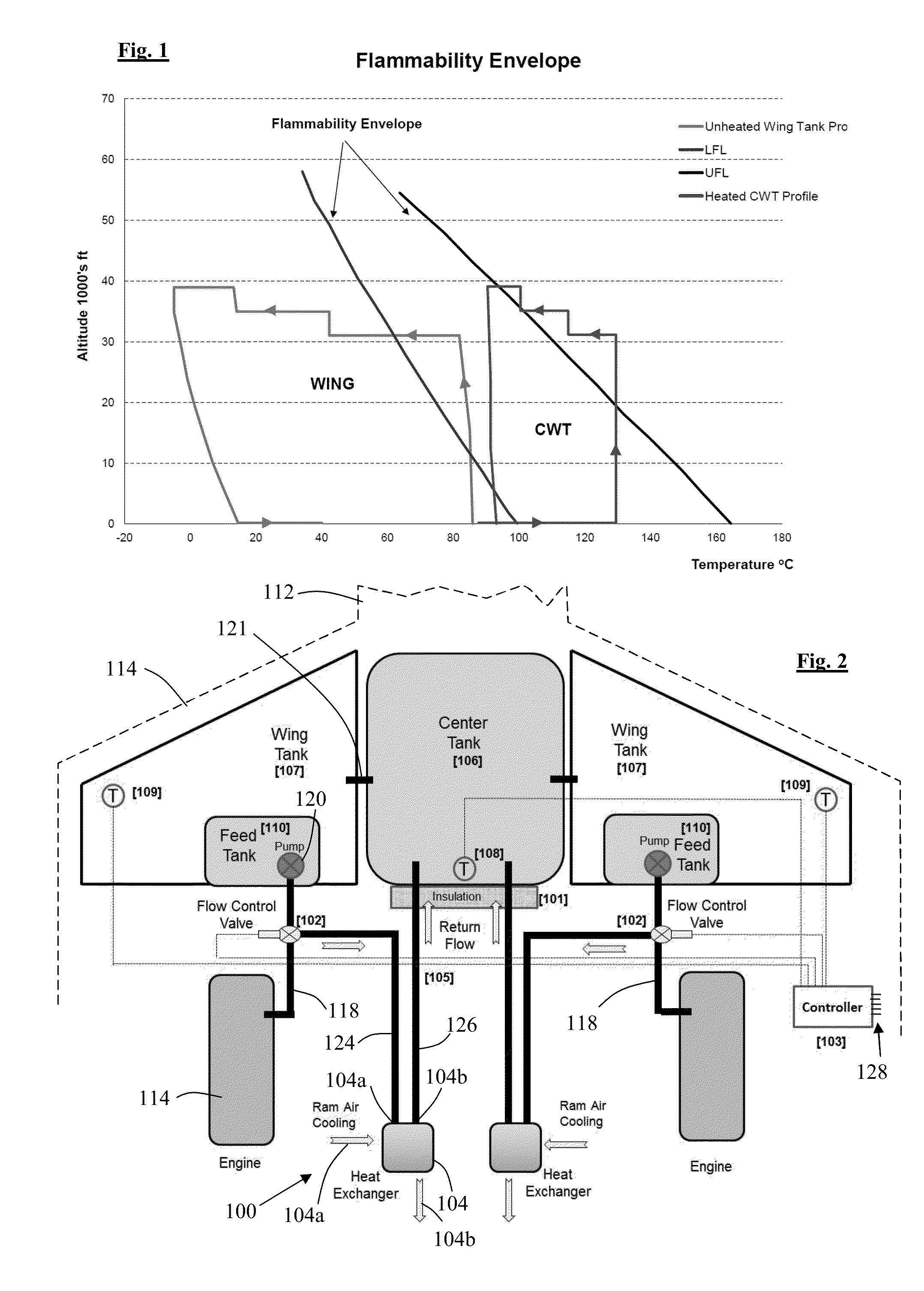

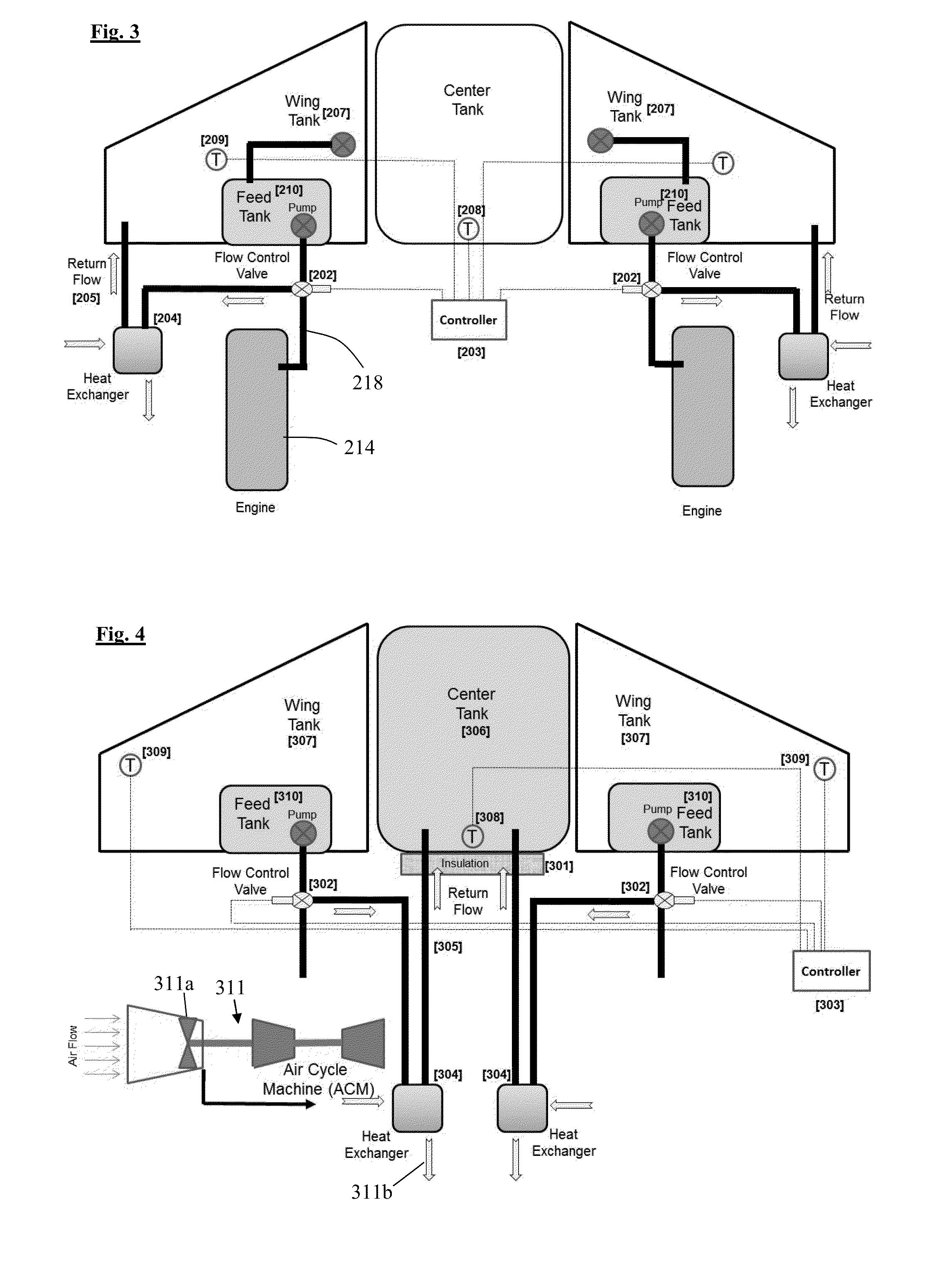

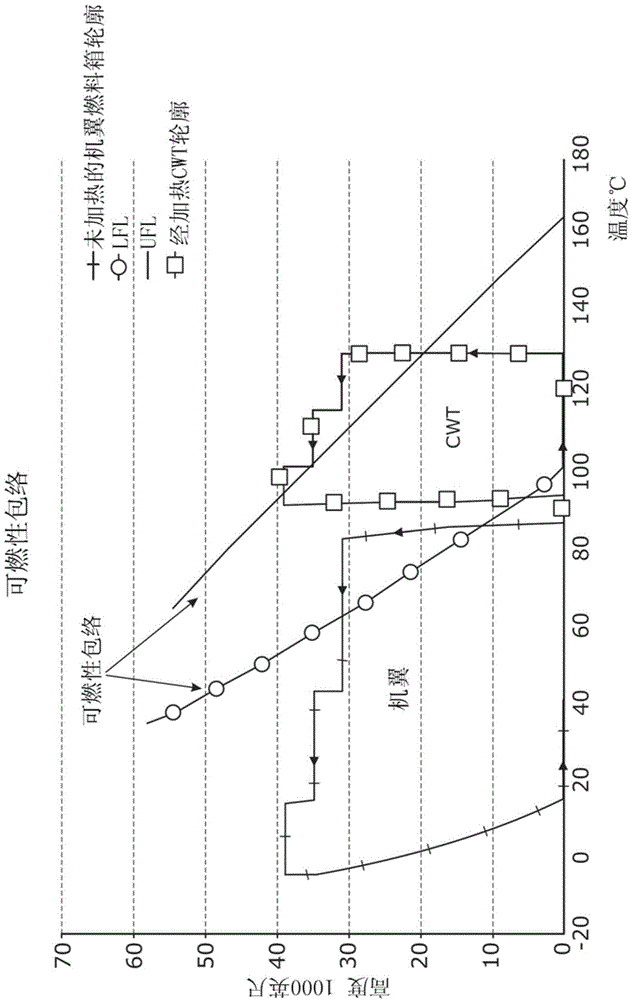

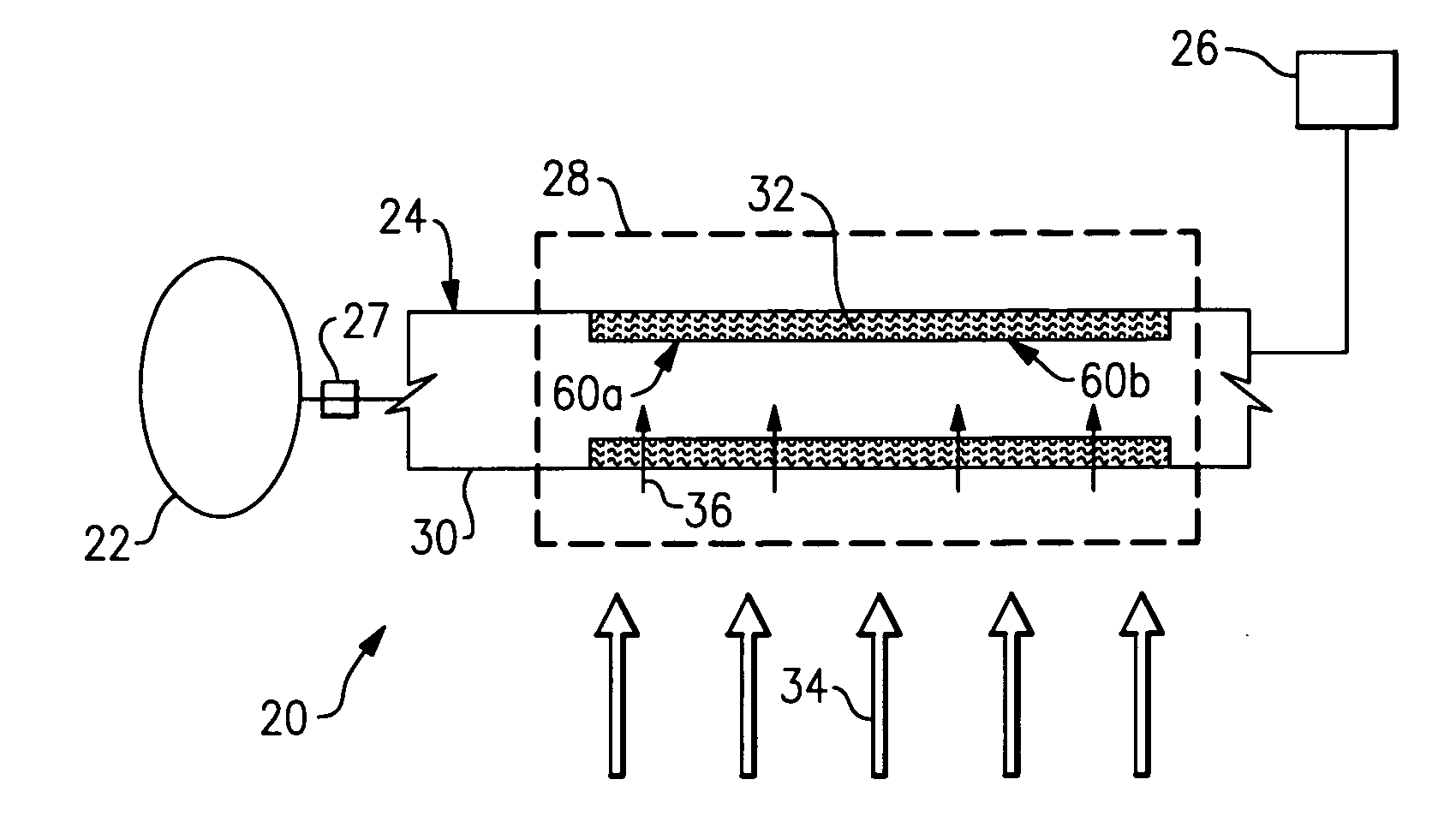

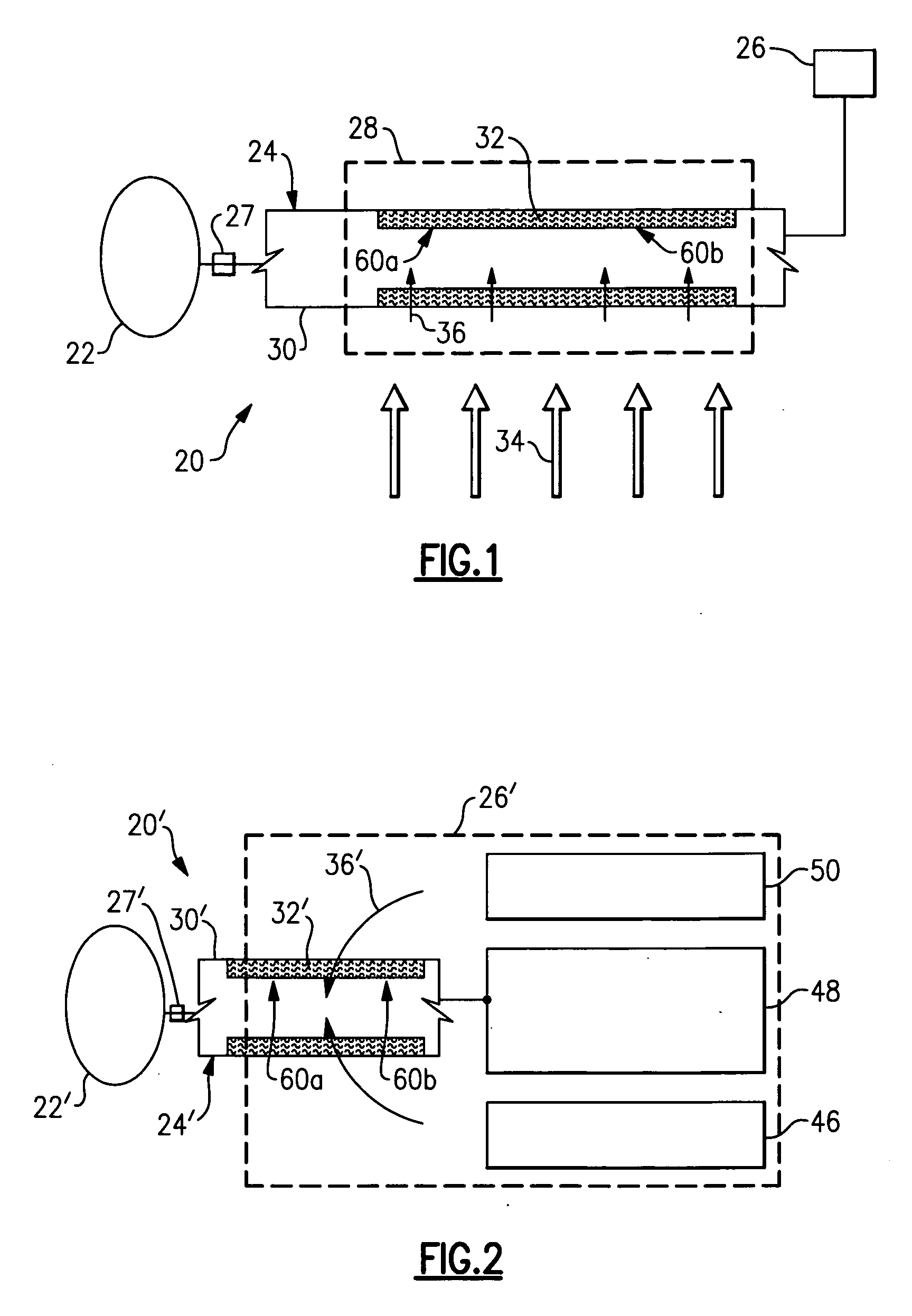

ActiveUS20150217153A1Reduce flammabilityPower plant fuel tanksAir-treatment apparatus arrangementsAircraft fuel systemHeat flow

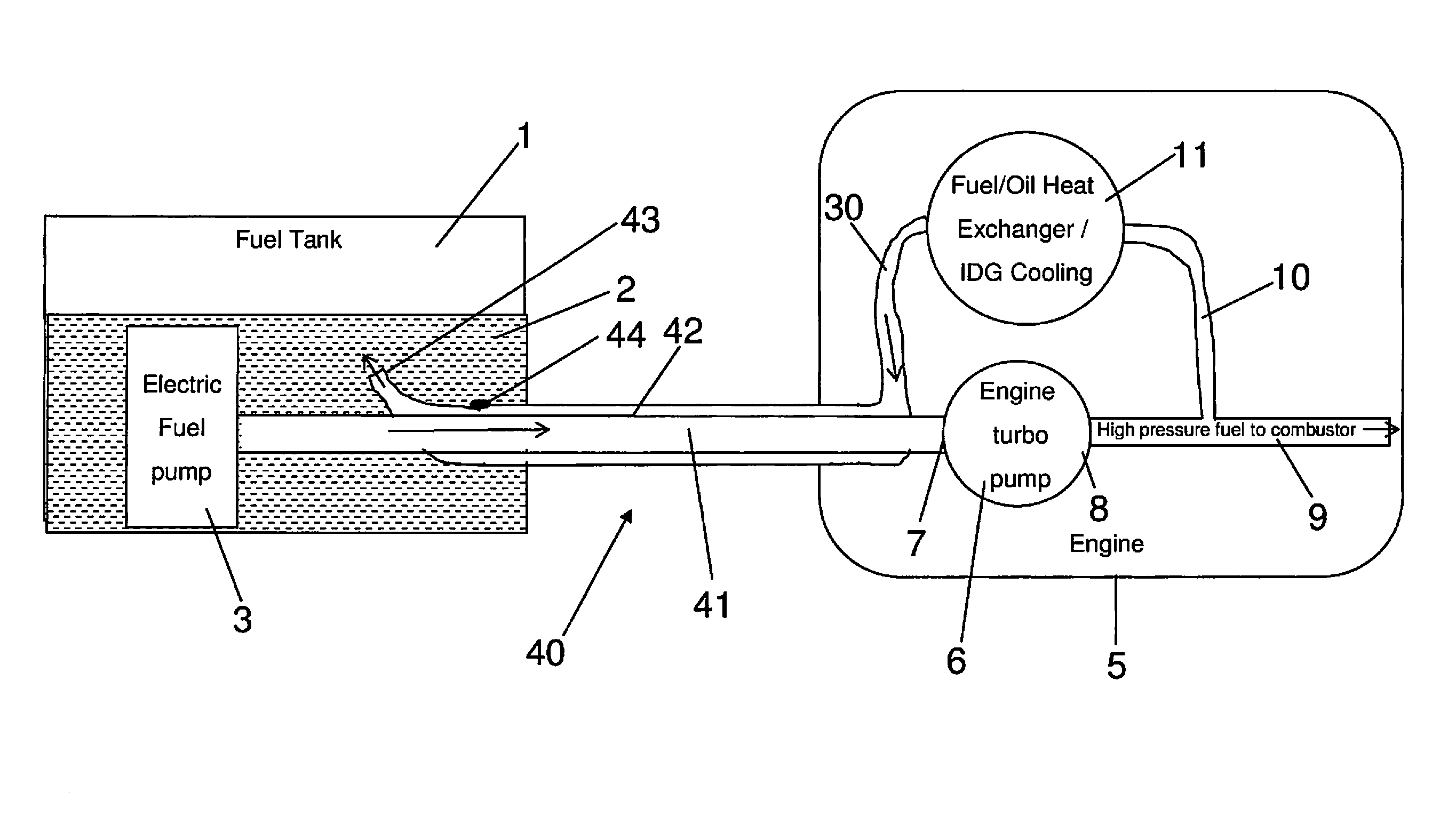

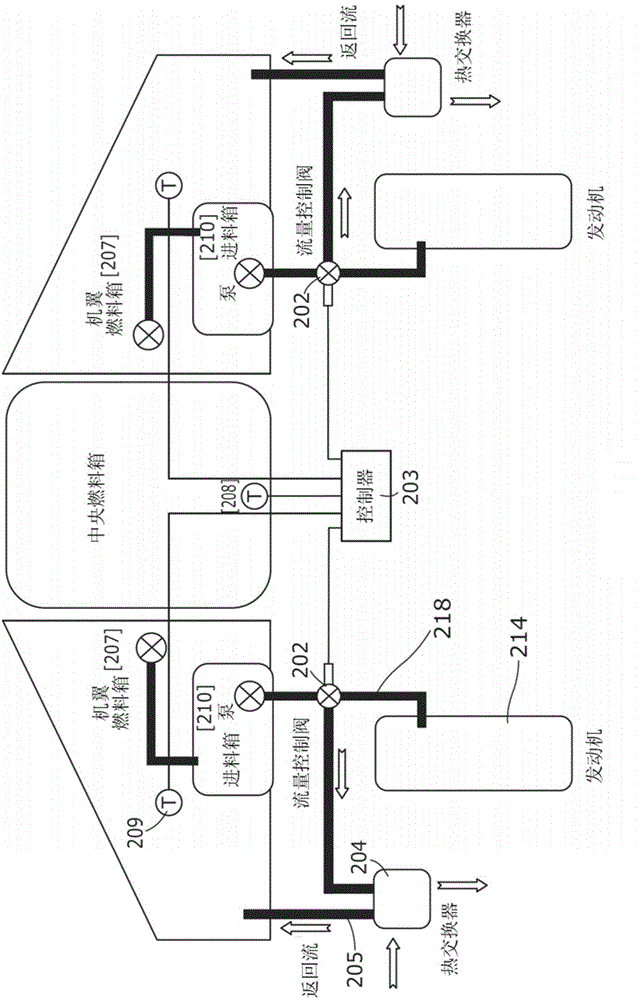

An aircraft fuel system architecture which reduces the fleet-wide flammability exposure of the fuel tanks. In one embodiment, the aircraft center fuel tank fuel is cooled at certain times in a flight to reduce its flammability exposure to be similar to that of an unheated conventional metal wing fuel tank. Aircraft fuel tanks that have adjacent heat sources are also insulated to minimize heat flow into the fuel. Fuel tanks that have lower cooling properties, such as composite wing tanks are cooled at certain times during flight such that their temperatures are reduced to be similar to metal wing tanks when the fuel is flammable. A fuel tank that is pressurized relative to outside pressure at altitude having a lower flammability exposure than unpressurized tanks is combined with the cooling of fuel in the tank to reduce the fleet-wide flammability exposure of the fuel tank to be similar to that of an unpressurized metal wing tank. Fuel is cooled by recirculating flow from a tank, passing through a heat exchanger and returning to the tank to be cooled. The heat exchanger is optionally cooled by flow of air from the outside of the aircraft, or by conditioned air from the aircraft environmental control system. The system is controlled by start and stop of fuel flow to the various tanks by means of a system controller. The controller uses sensors in the fuel tanks to command flow only when required to reduce the flammability exposure of the fuel tanks.

Owner:AERO SYST CONSULTANTS

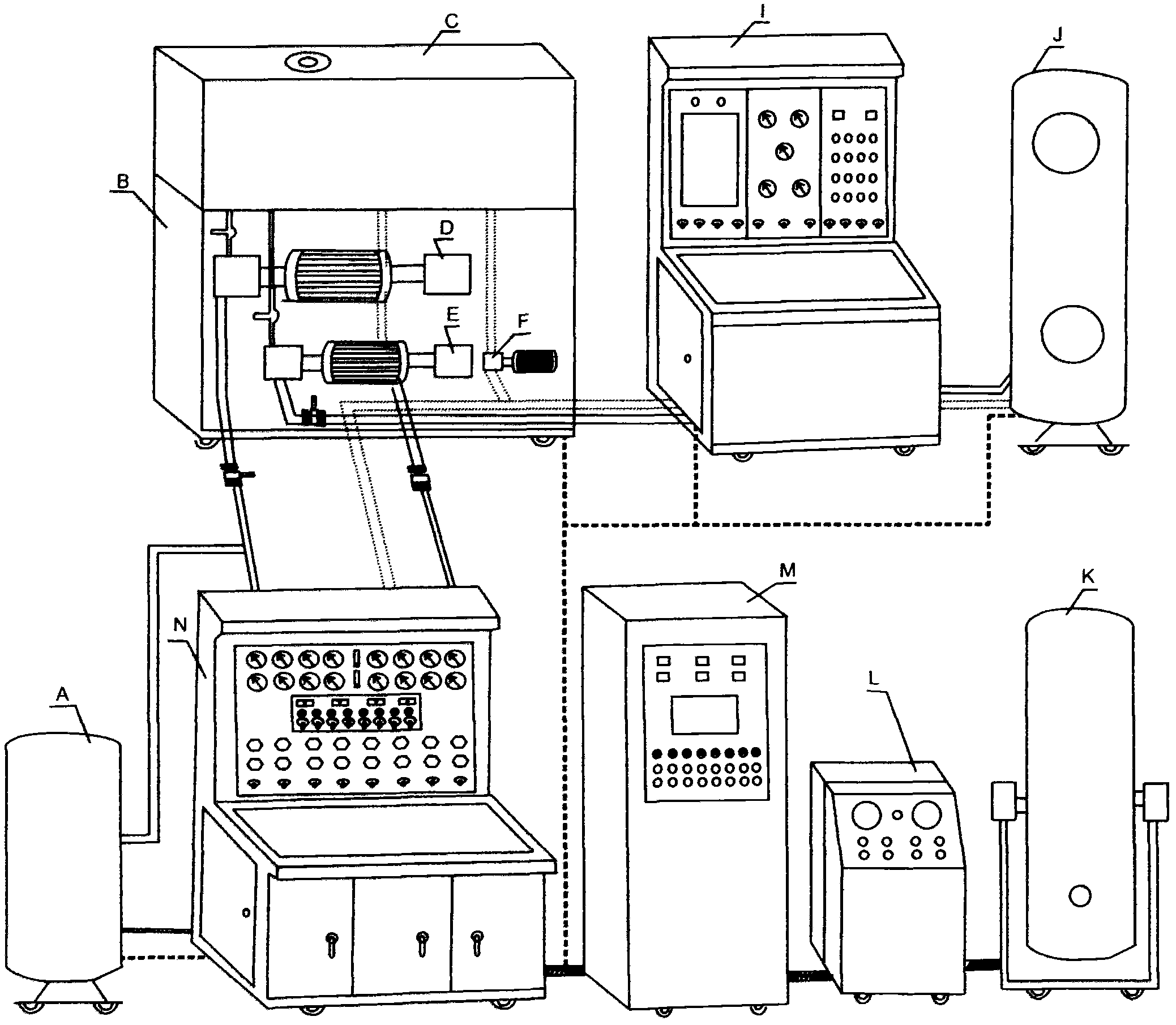

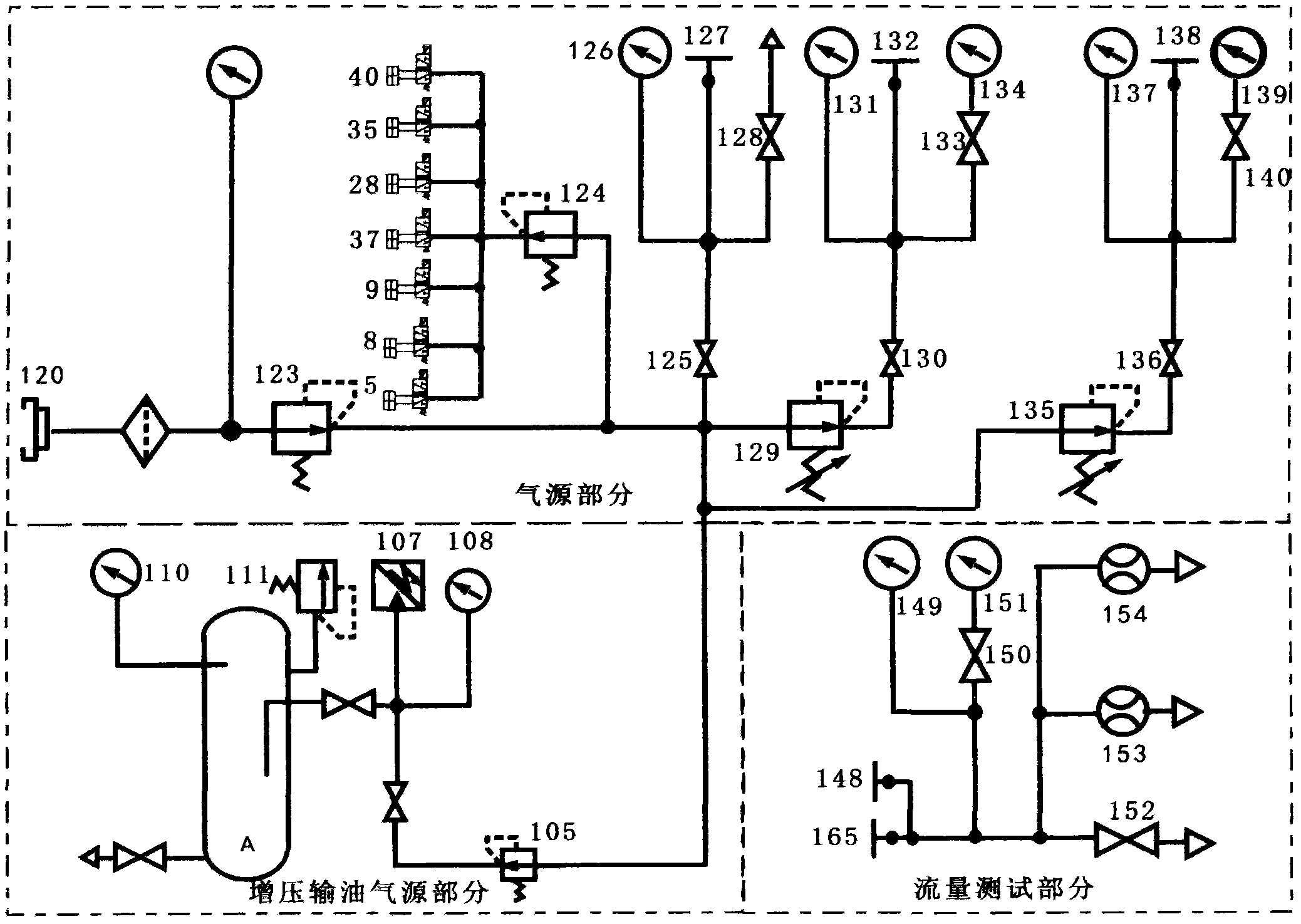

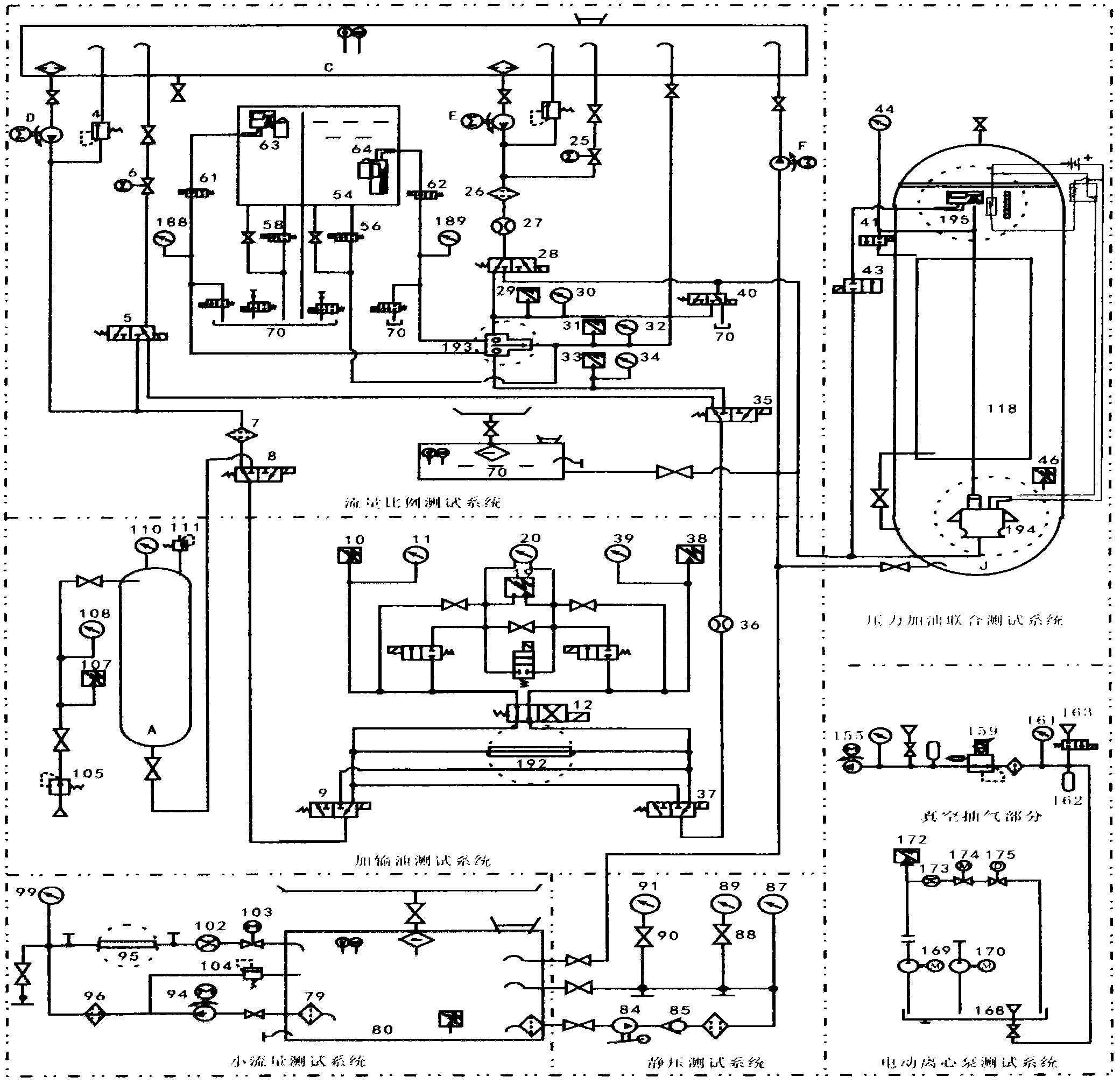

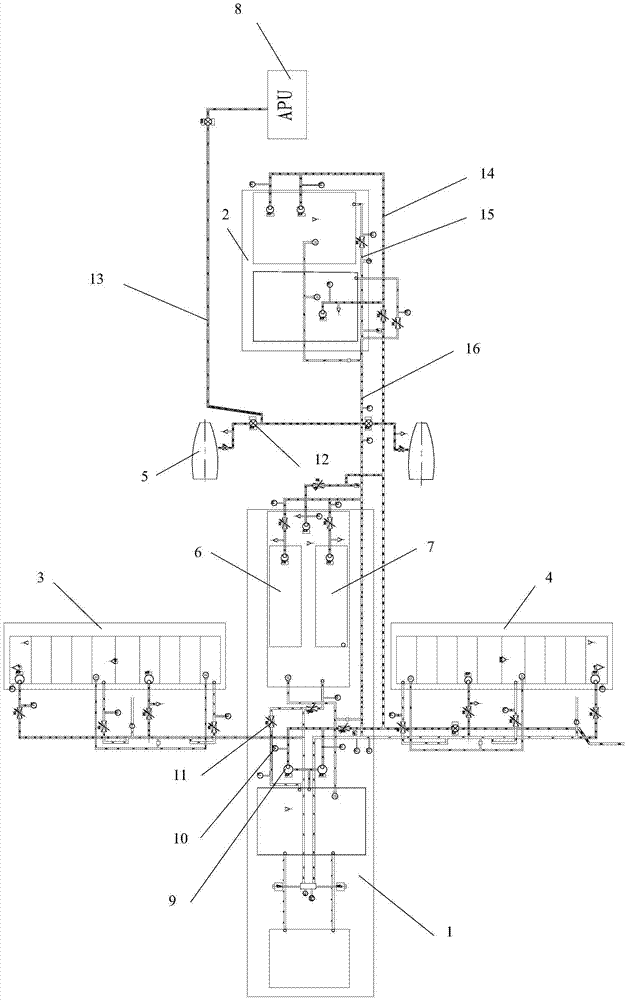

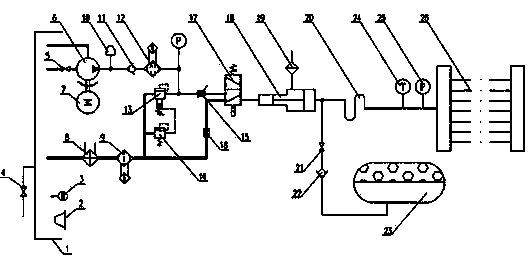

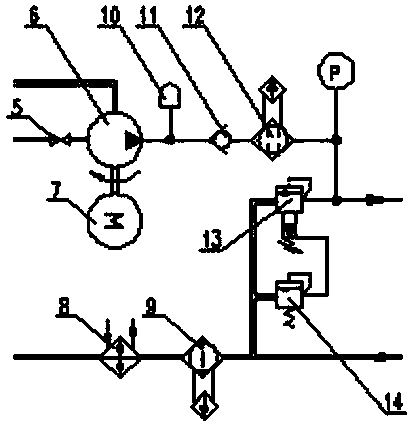

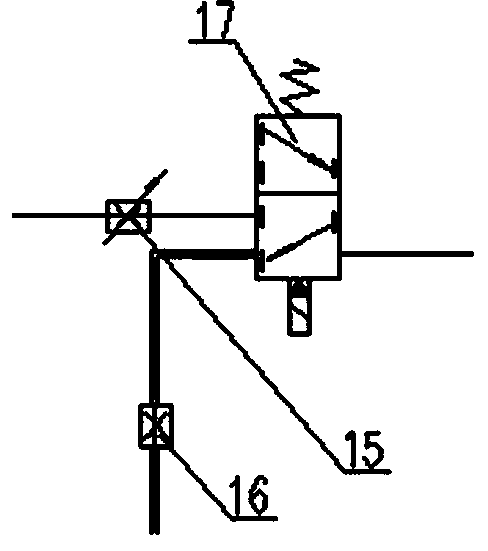

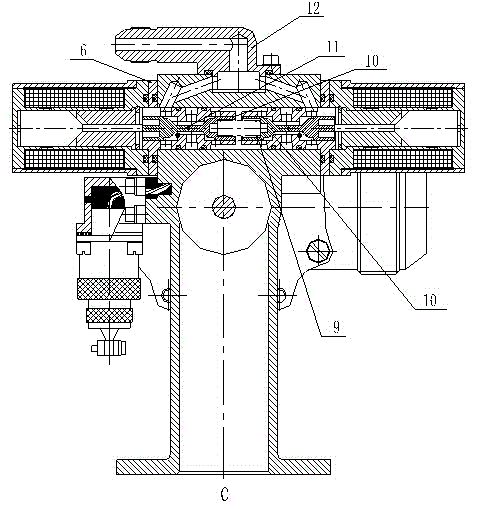

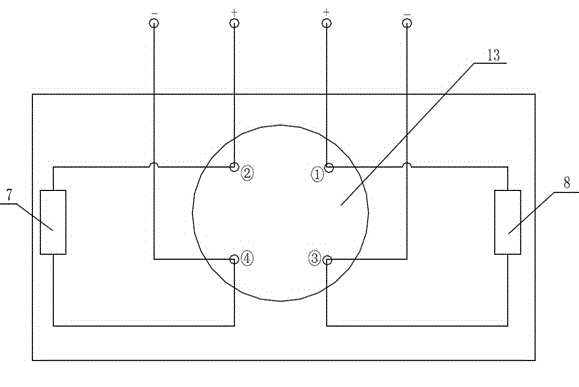

Integrated testing system for aviation fuel accessories

InactiveCN102589860AReduce purchasing costsLower requirementMachine part testingPump testingAviationAircraft fuel system

The invention relates to an integrated testing system for aviation fuel accessories. The integrated testing system comprises an electric control cabinet, a mechanical operating platform, an integrated pump station, a flow proportion testing platform, a pneumatic testing system and a fuel testing system, wherein the mechanical operating platform is connected with a pressurizing oil delivery gas storage tank through the pneumatic testing system; the integrated pump station is connected with the fuel testing system through an oil delivery pipeline; the pneumatic testing system is connected with the fuel testing system through a pneumatic pipeline; the flow proportion testing platform is connected with a pressure refueling joint testing oil tank; and the electric control cabinet is electrically connected with the mechanical operating platform, the integrated pump station, the flow proportion testing platform, the pneumatic testing system, the fuel testing system, the pressurizing oil delivery gas storage tank and the pressure refueling joint testing oil tank. The integrated testing system can perform performance test on all accessories of an aircraft fuel system, is high in integrity,convenient to maintain, compact in structure, small in occupation area and low in cost and expenditure, and is in accordance with specific using environment and support conditions under the field condition of an aviation equipment support army.

Owner:QINGDAO CAMPUS AVIATION ENG COLLEGE OF THE PEOPLES LIBERATION ARMY NAVY

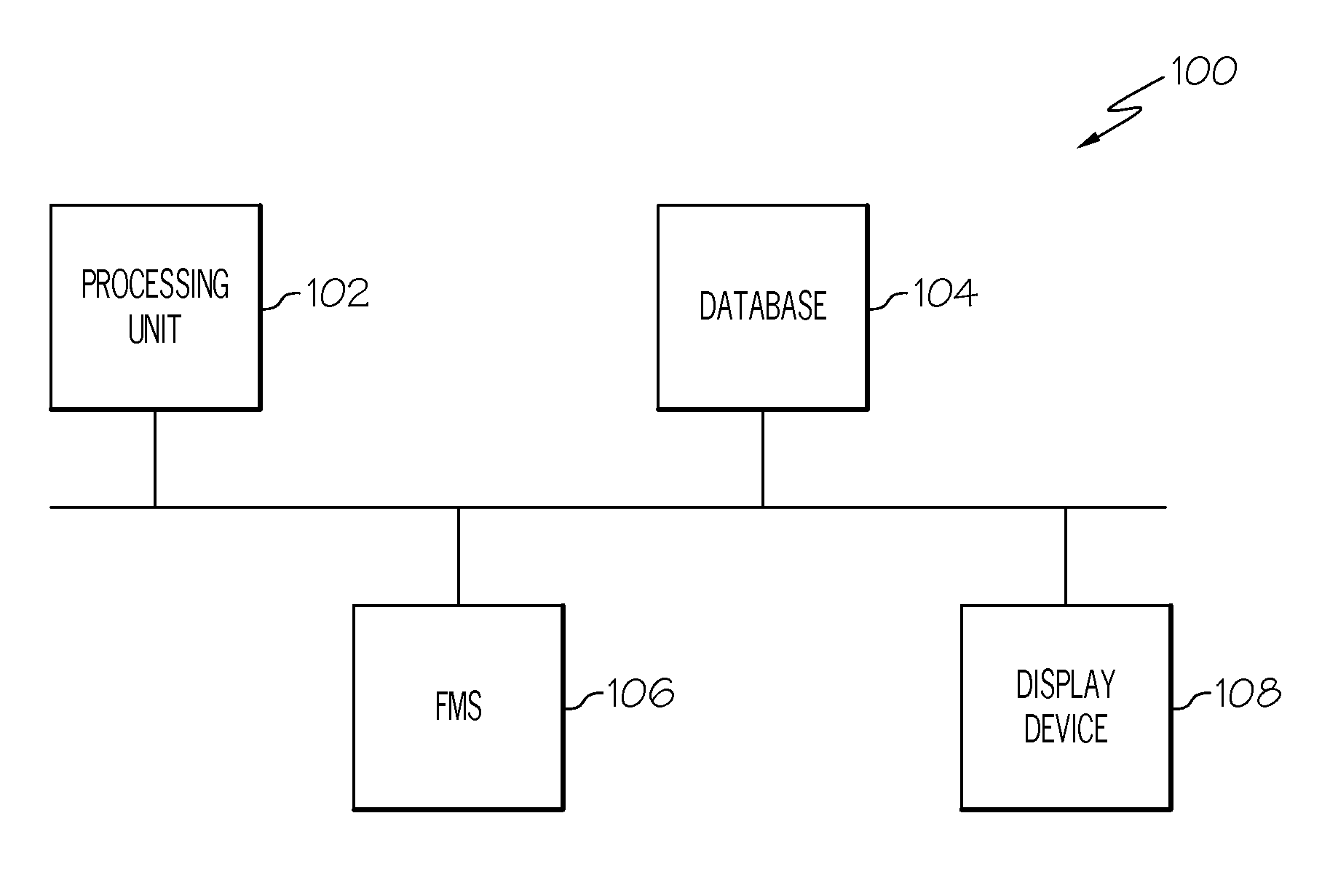

Aircraft systems and methods for displaying visual segment information

ActiveUS20120215388A1Analogue computers for trafficNavigation instrumentsAircraft fuel systemSymbolic Systems

A display system and method are provided for an aircraft. The system includes a processing unit configured to determine a visual segment for the aircraft and to generate display commands based on the visual segment; and a display device coupled the processing unit and configured to receive the display commands and to display symbology representing the visual segment as a visual segment marker.

Owner:HONEYWELL INT INC

Aircraft fuel systems

InactiveUS20150151845A1Reduce heat loadReduced and zero heat inputPower plant fuel tanksFuel tank safety measuresAircraft fuel systemHeat flow

Aircraft fuel system reduces flammability exposure of fuel tanks. In one embodiment, aircraft center fuel tank fuel is cooled in flight to reduce flammability exposure to be similar to that of an unheated metal wing tank. Fuel tanks having adjacent heat sources are insulated to minimize heat flow into the fuel. Fuel tanks having lower cooling properties, e.g., composite wing tanks, are cooled during flight so temperatures are reduced to be similar to metal wing tanks. A fuel tank, pressurized relative to outside pressure at altitude, having lower flammability exposure than unpressurized tanks and cooling fuel in the tank reduces flammability exposure of the fuel tank to be similar to that of an unpressurized metal wing tank. Recirculating flow from a tank, passing through heat exchanger, and returning to the tank cools fuel. A controller starts / stops fuel flow to tanks and uses sensors to command flow to reduce flammability.

Owner:AERO SYST CONSULTANTS

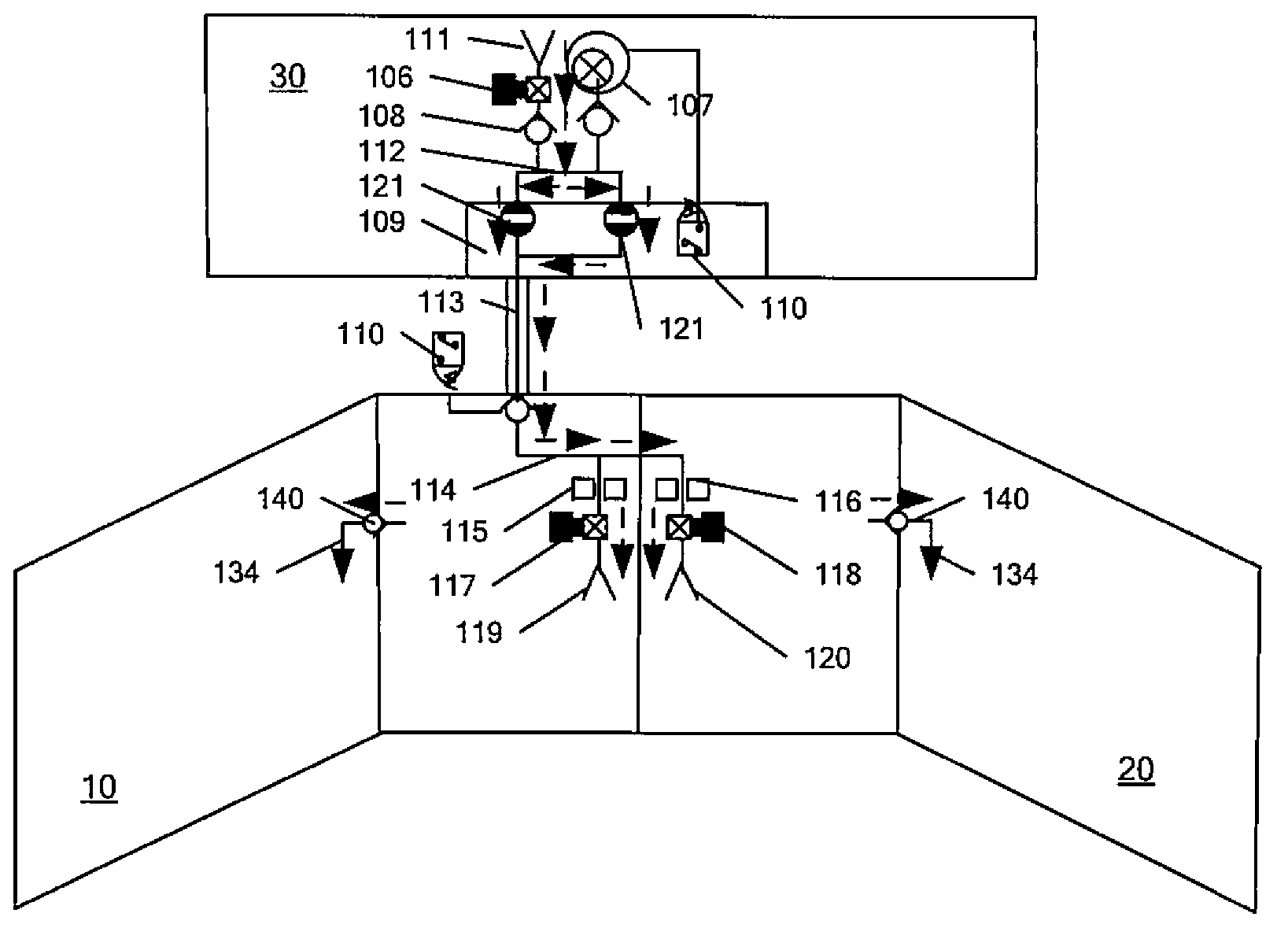

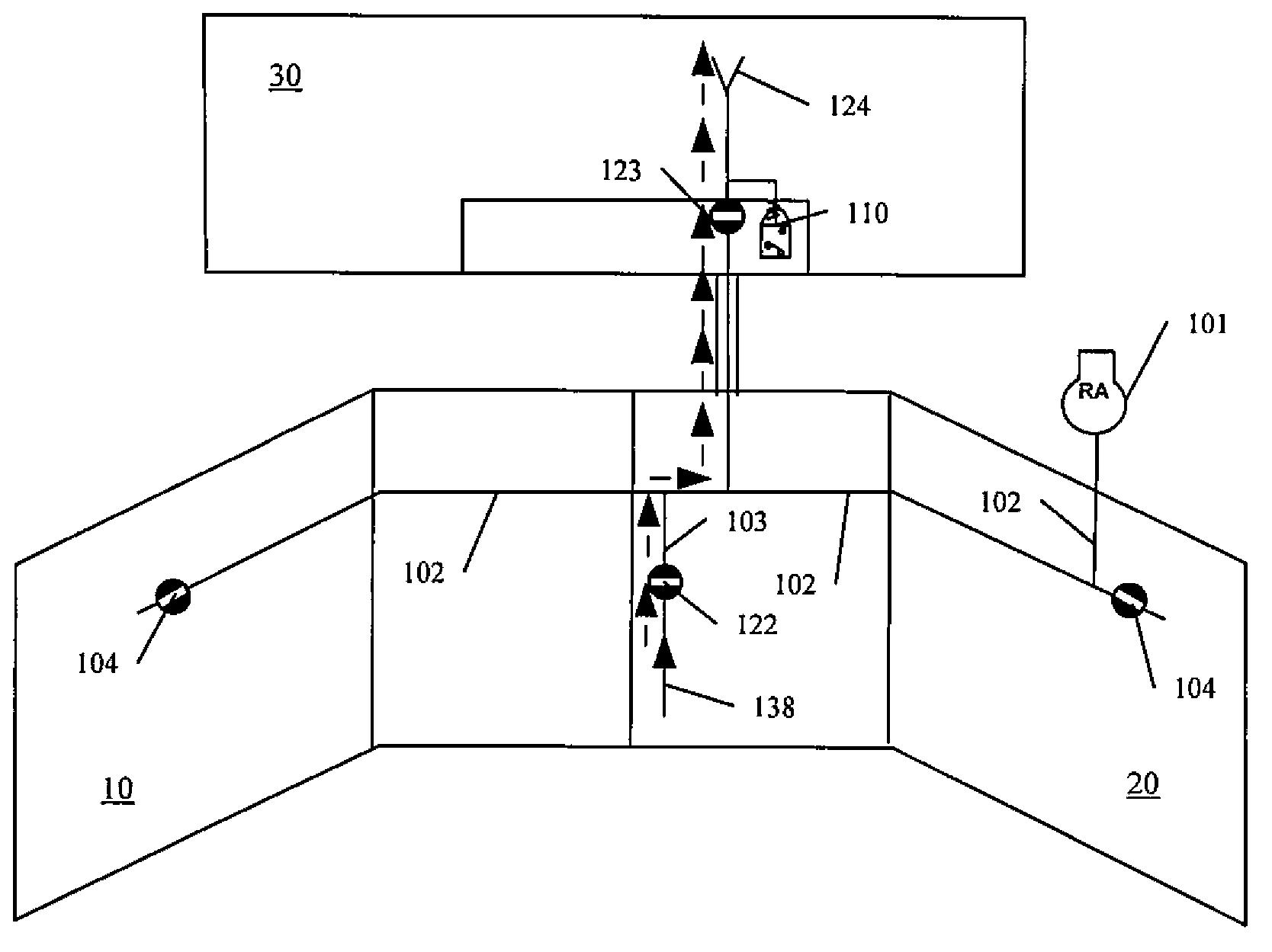

Auxiliary fuel system

The invention provides an auxiliary fuel system which comprises a fuel feed subsystem, a ventilating subsystem and a delivering subsystem. The fuel feed subsystem is used for feeding fuel in an auxiliary oil tank. The ventilating subsystem is used for guaranteeing pressure in the auxiliary oil tank. The delivering subsystem is used for simultaneously delivering fuel in the auxiliary oil tank to a left main oil tank and a right main oil tank of a plane fuel system. The auxiliary fuel system can simultaneously deliver fuel to the two main oil tanks, automatically control fuel delivering of the auxiliary tank during flight of a plane, and effectively maintains gravity center of the plane fuel system.

Owner:COMAC +1

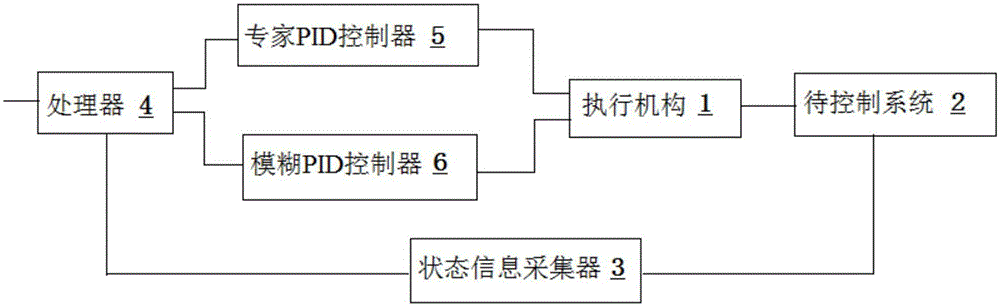

Adaptive PID control method and control system of executing mechanism

InactiveCN105045137AImprove control qualityQuick responseSimulator controlAircraft fuel systemControl system

The invention belongs to the aircraft fuel system full-mold test field and relates to an adaptive PID control method and control system of an executing mechanism. The objective of the invention is to solve the problems of poor effects and low precision of an existing PID control method. The adaptive PID control system includes an expert PID controller and a fuzzy PID controller which are respectively connected with the executing mechanism, a state information acquisition device used for monitoring the current status information of a system to be controlled in real time, and a processor used for selecting the expert PID controller or the fuzzy PID controller according to the current status information and expected status information to control the executing mechanism. According to the adaptive PID control system of the invention, the expert PID controller or the fuzzy PID controller is selected to perform control, and therefore, the adaptive PID control system has the advantages of high adjustment speed, short rise time, low overshoot and high control precision. With the control system adopted, requirements for high speed of a servo system can be satisfied, and the control quality of the servo system can be improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

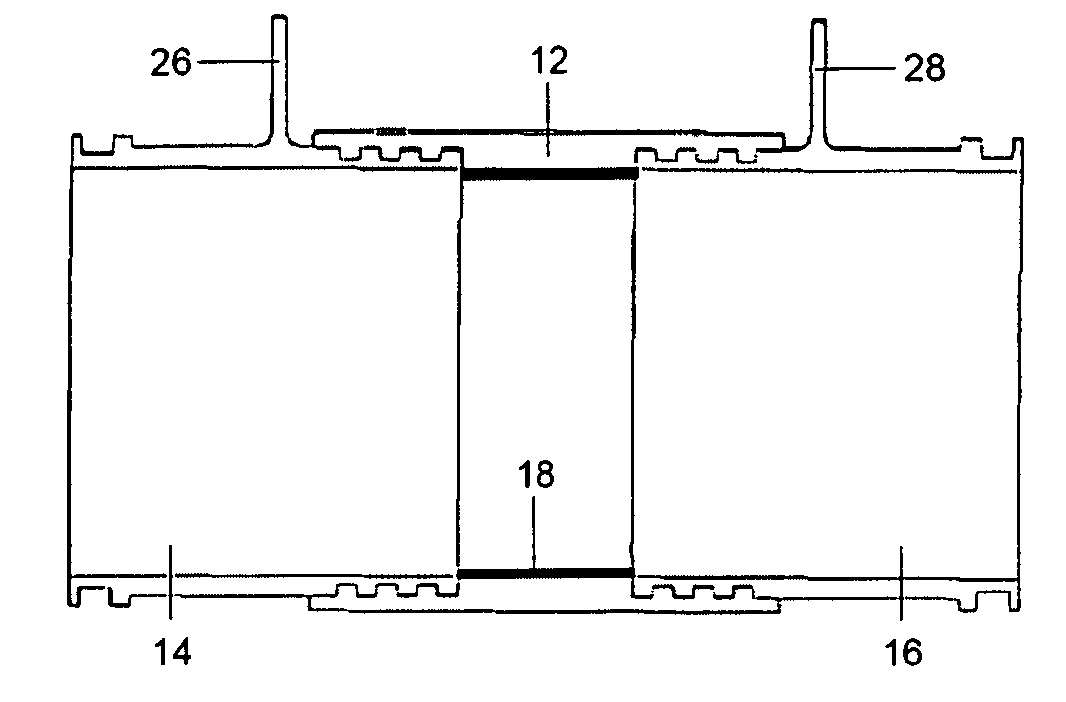

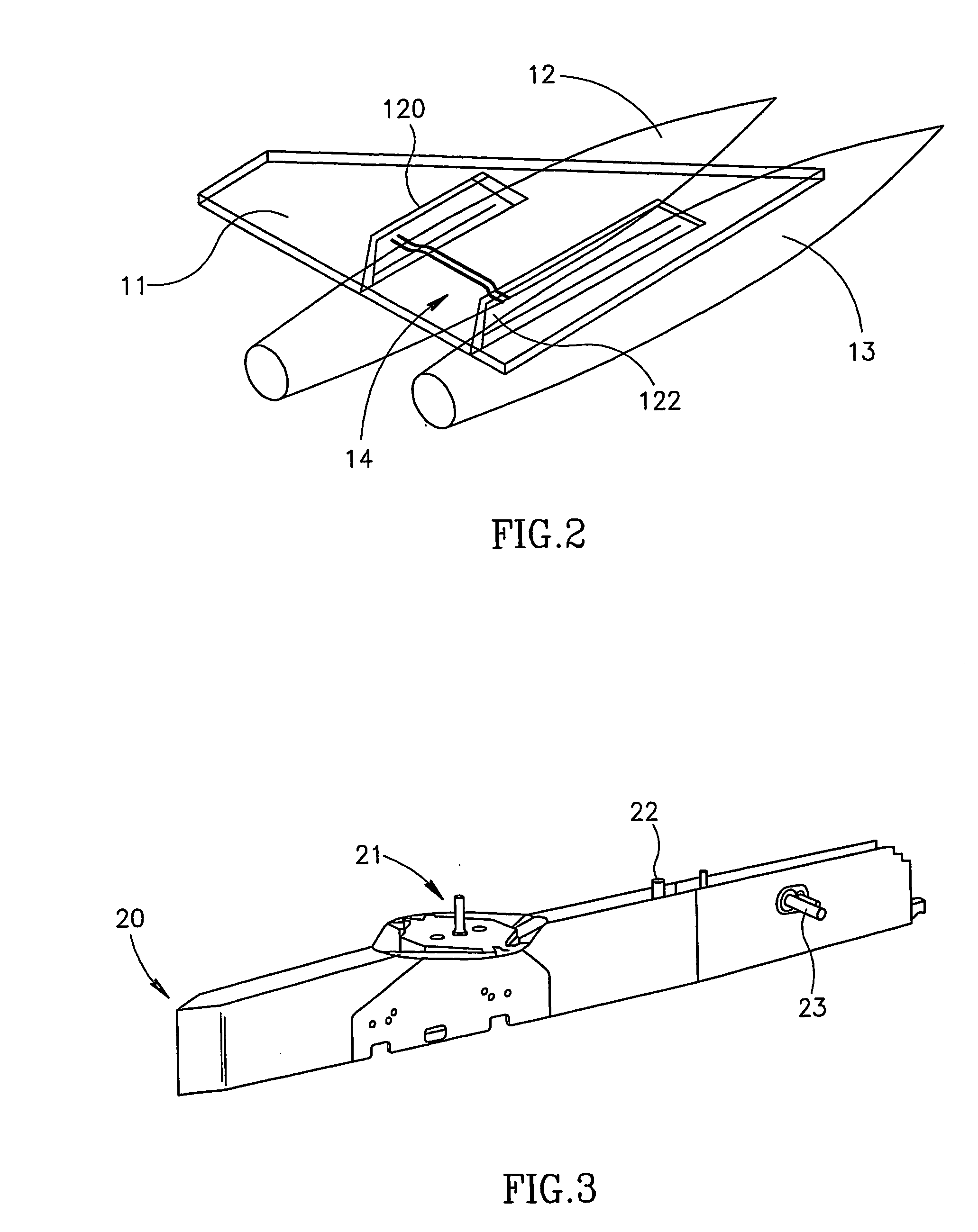

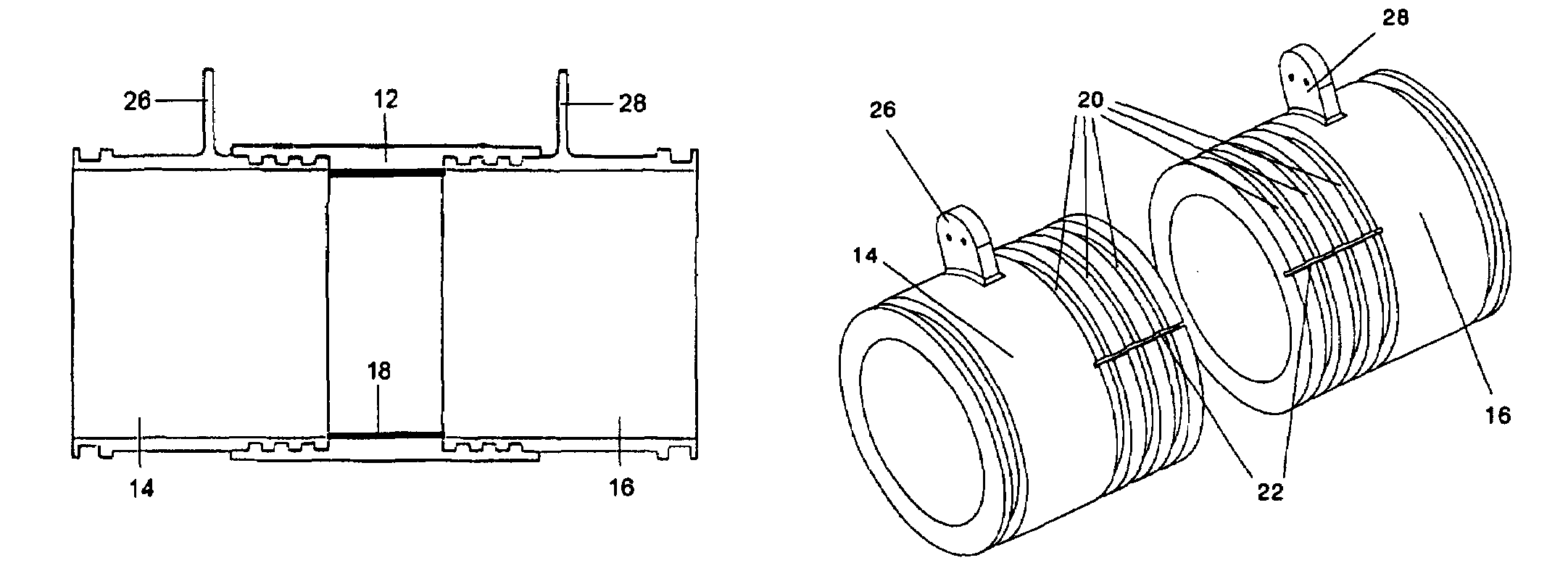

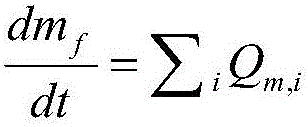

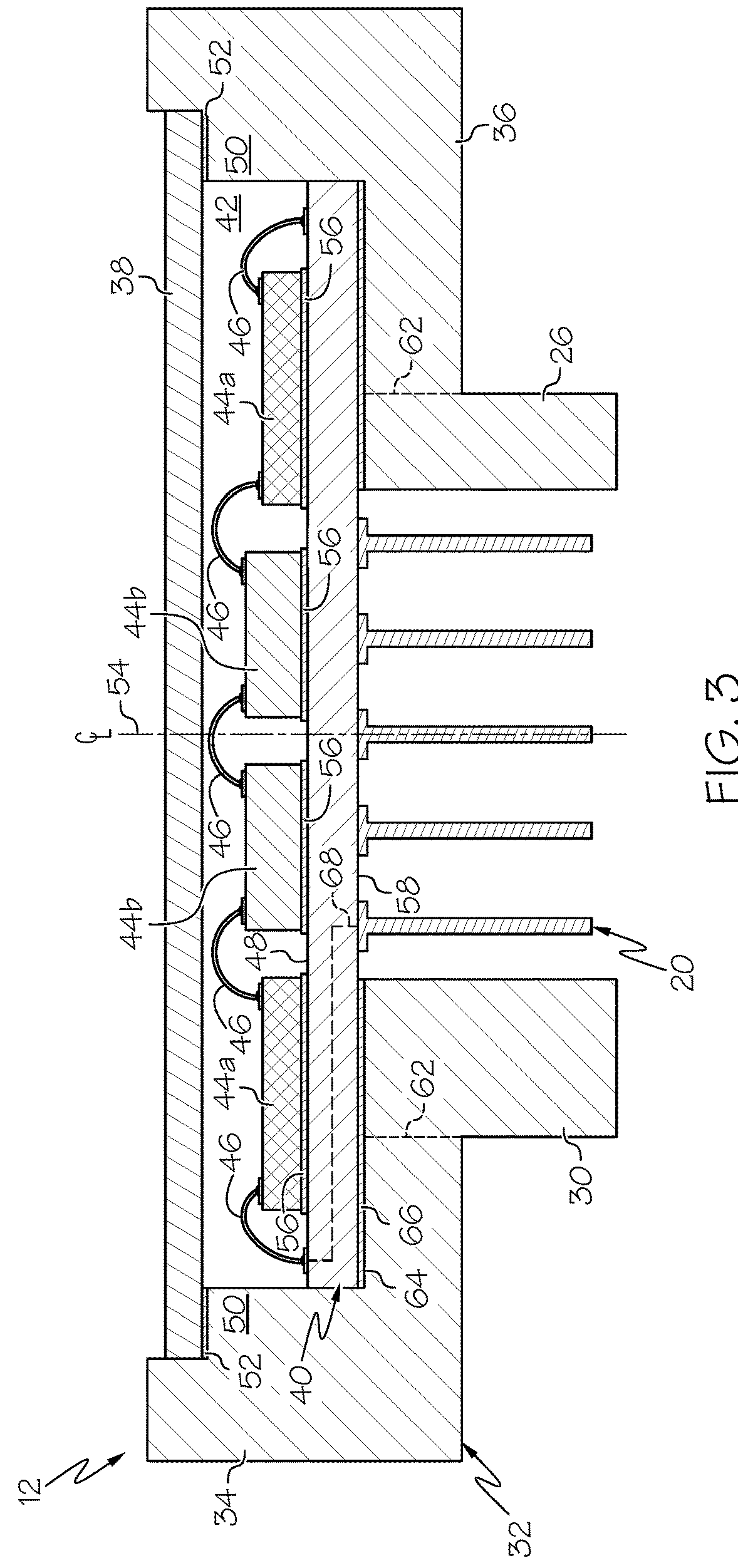

Current insulation system for fluid systems

InactiveUS20090071676A1Reduce maintenance costsLower manufacturing requirementsPipe elementsPipe protection by thermal insulationAircraft fuel systemLinear element

An electrical insulation system for a linear element forming part of a fluid system subjected to risks of possible external electrical discharges, such as an aircraft fuel system, using an insulating insert (12) between two parts (14, 16) of said linear element, consisting of providing said parts (14, 16) with grooved edges and in forming the insulating insert (12) between them preferably by an injection technique, such that the insulating insert (12) provides an inner duct for the passage of fluid between said parts (14, 16) and covers said grooved edges, assuring the leak-tight joint of the insulating insert (12) with said parts (14, 16).

Owner:AIRBUS OPERATIONS SL

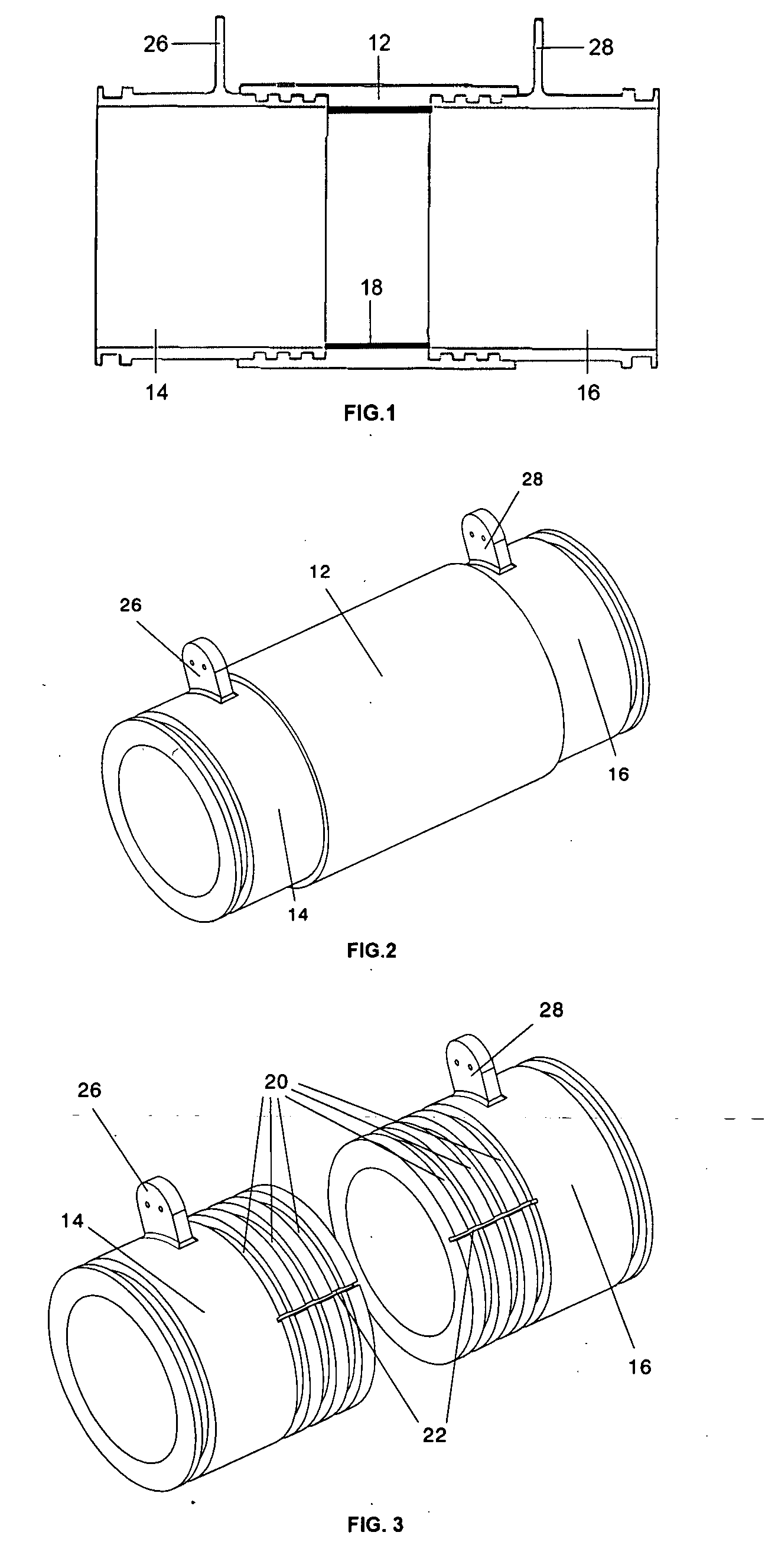

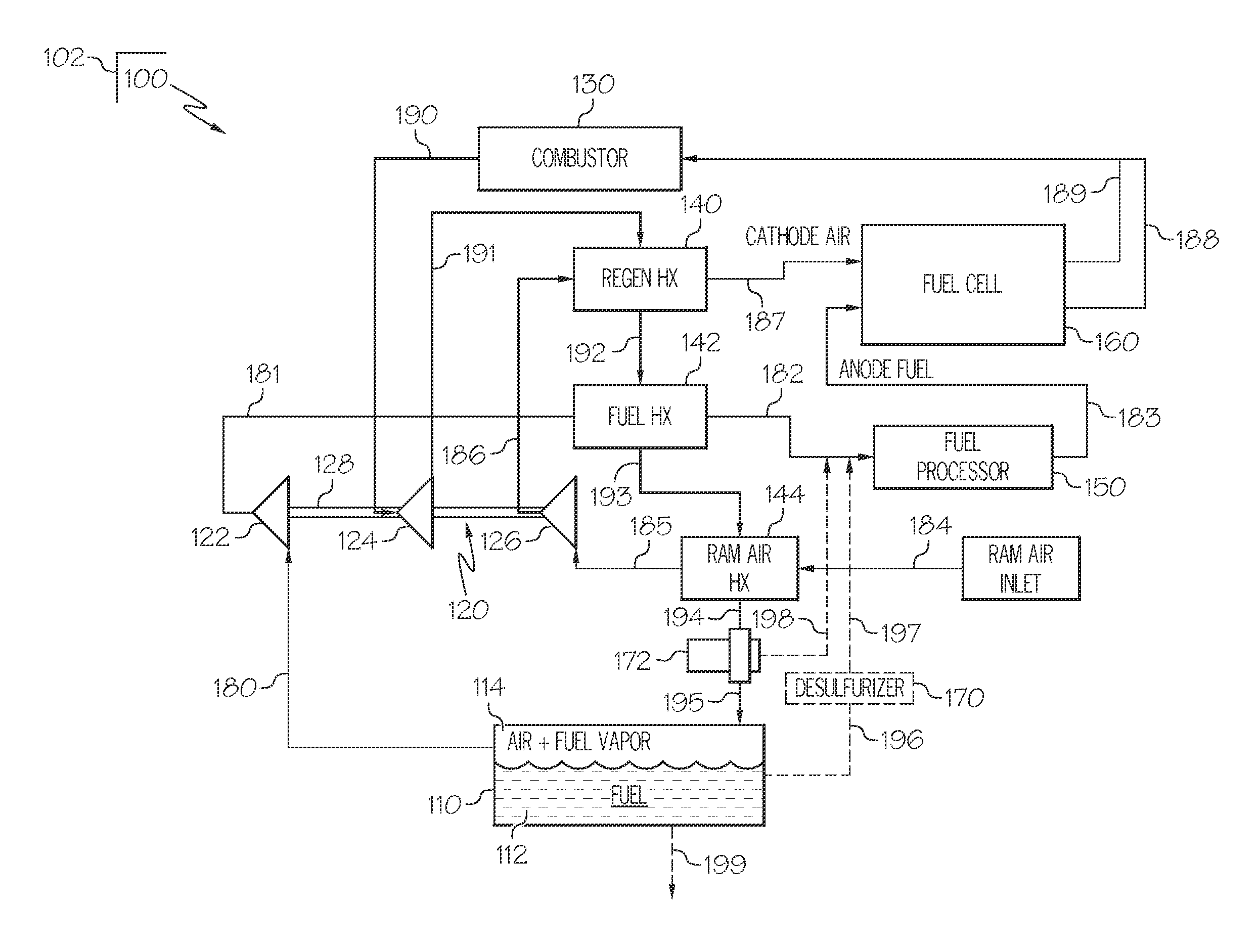

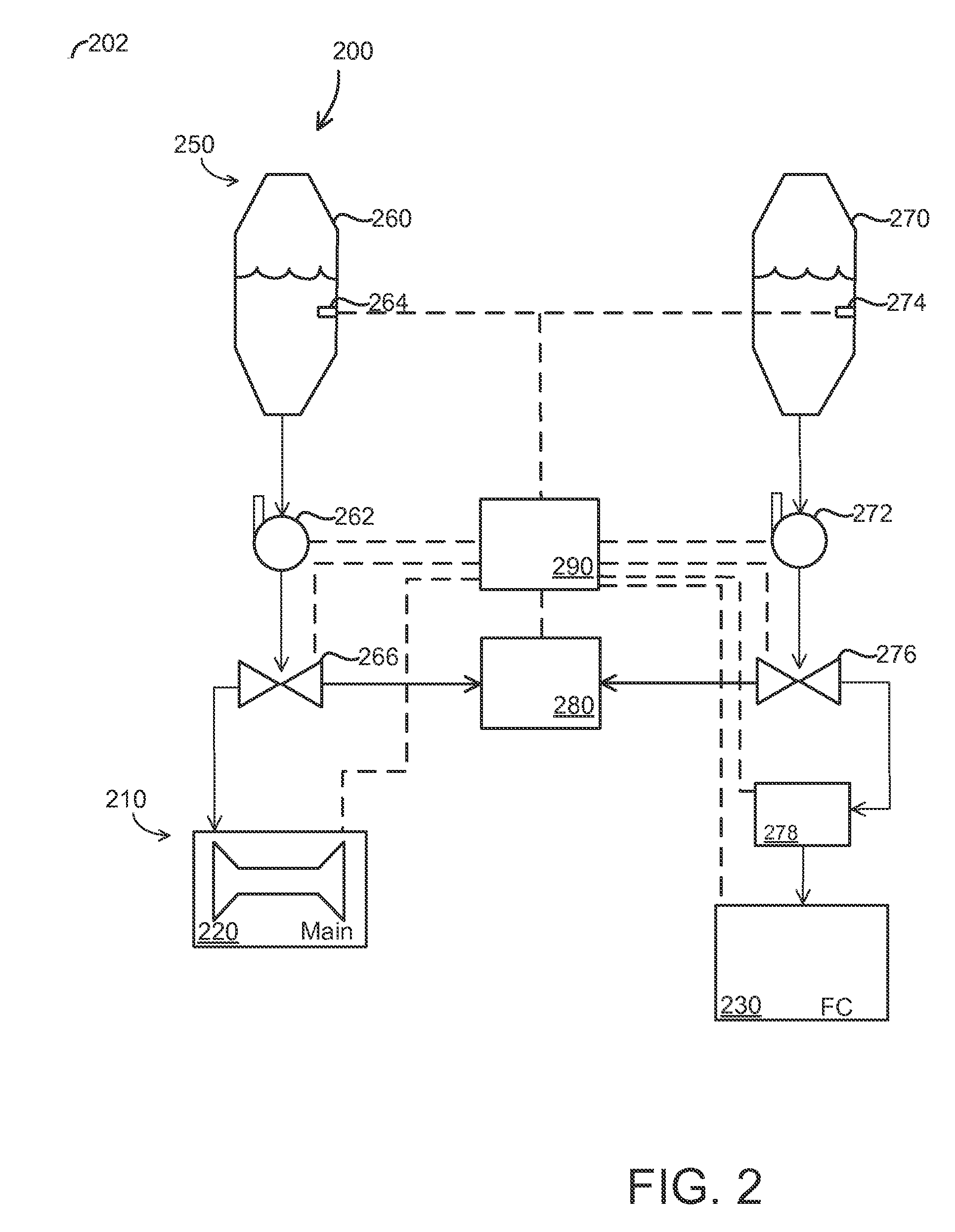

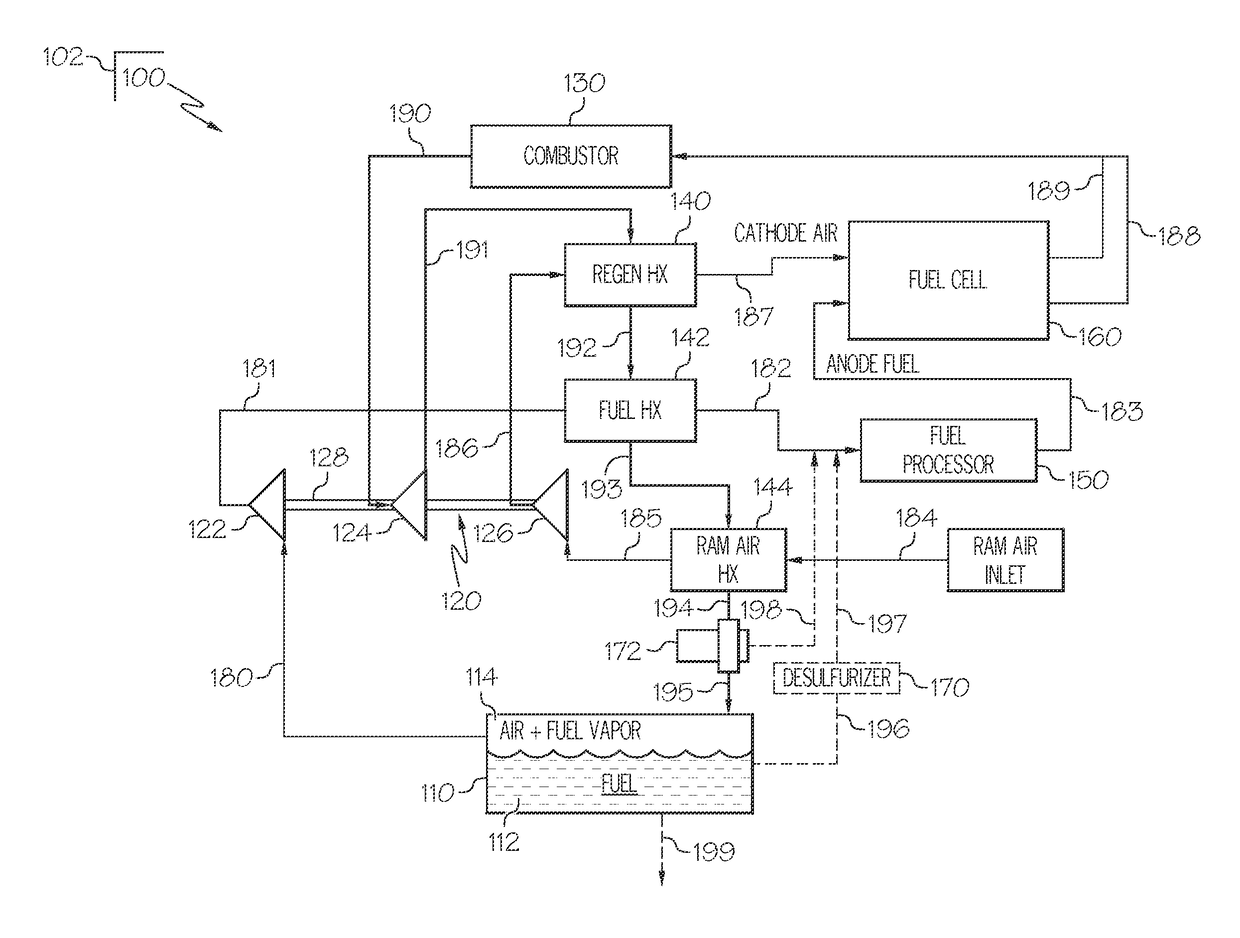

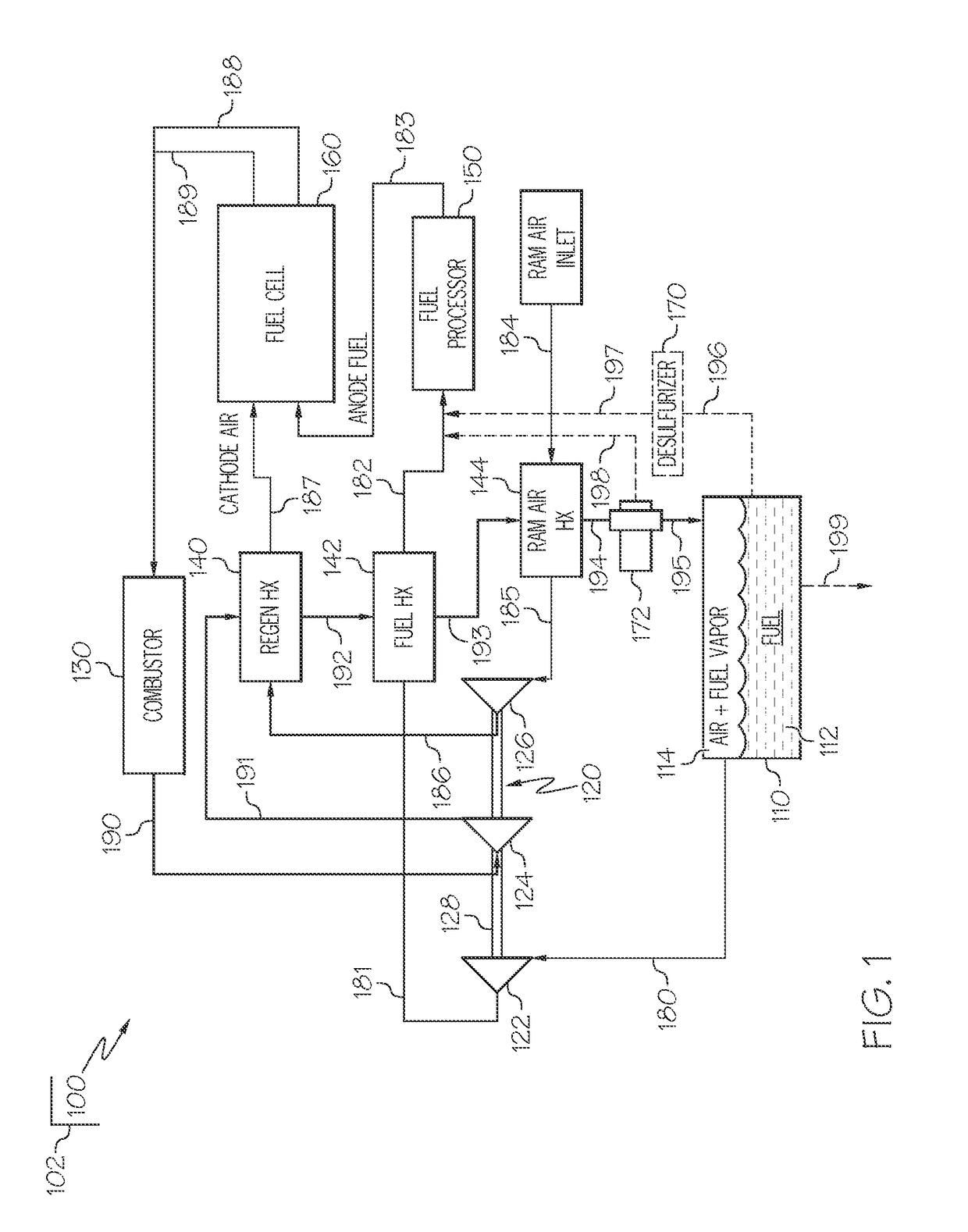

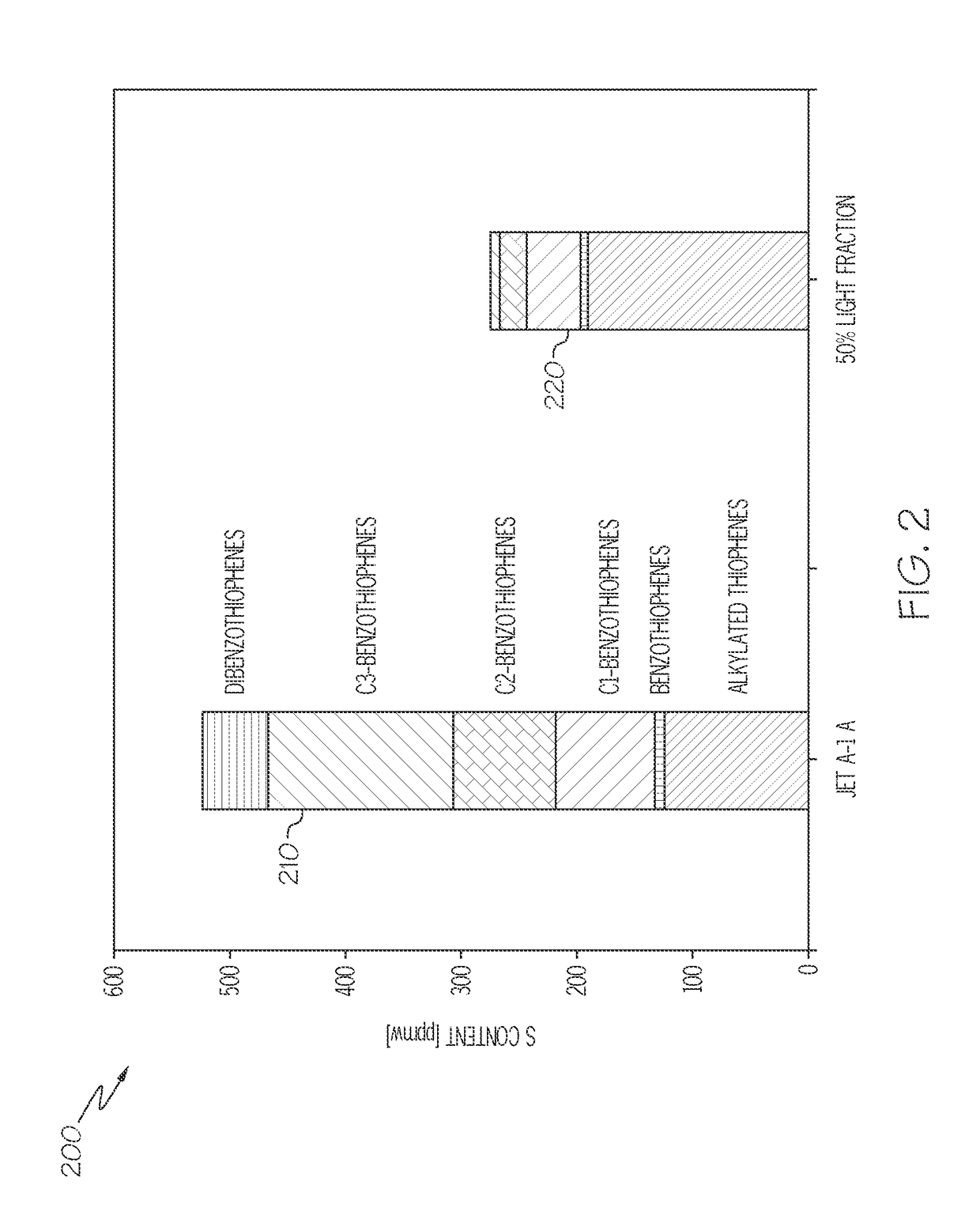

Aircraft systems and methods with integrated tank inerting and power generation

InactiveUS20150353201A1Easy to operateReduce thrustTurbine/propulsion fuel supply systemsPower installationsAircraft fuel systemElectricity

A system is provided for inerting a fuel tank of an aircraft. The system includes a first compressor fluidly coupled to the fuel tank for removing an air and fuel vapor mixture from an ullage of the fuel tank. The system further includes a fuel processor fluidly coupled to the first compressor and configured to receive the air and fuel vapor mixture and to generate hydrogen from the air and fuel vapor mixture. The system further includes a fuel cell fluidly coupled to the fuel processor and configured to receive the hydrogen as anode fuel to produce electricity. The system further includes a combustor fluidly coupled to the fuel cell and configured to combust the exhaust product to produce combustion gas, and a first heat exchanger fluidly coupled to the combustor and configured to cool the combustion gas into inerting gas for the fuel tank.

Owner:HONEYWELL INT INC

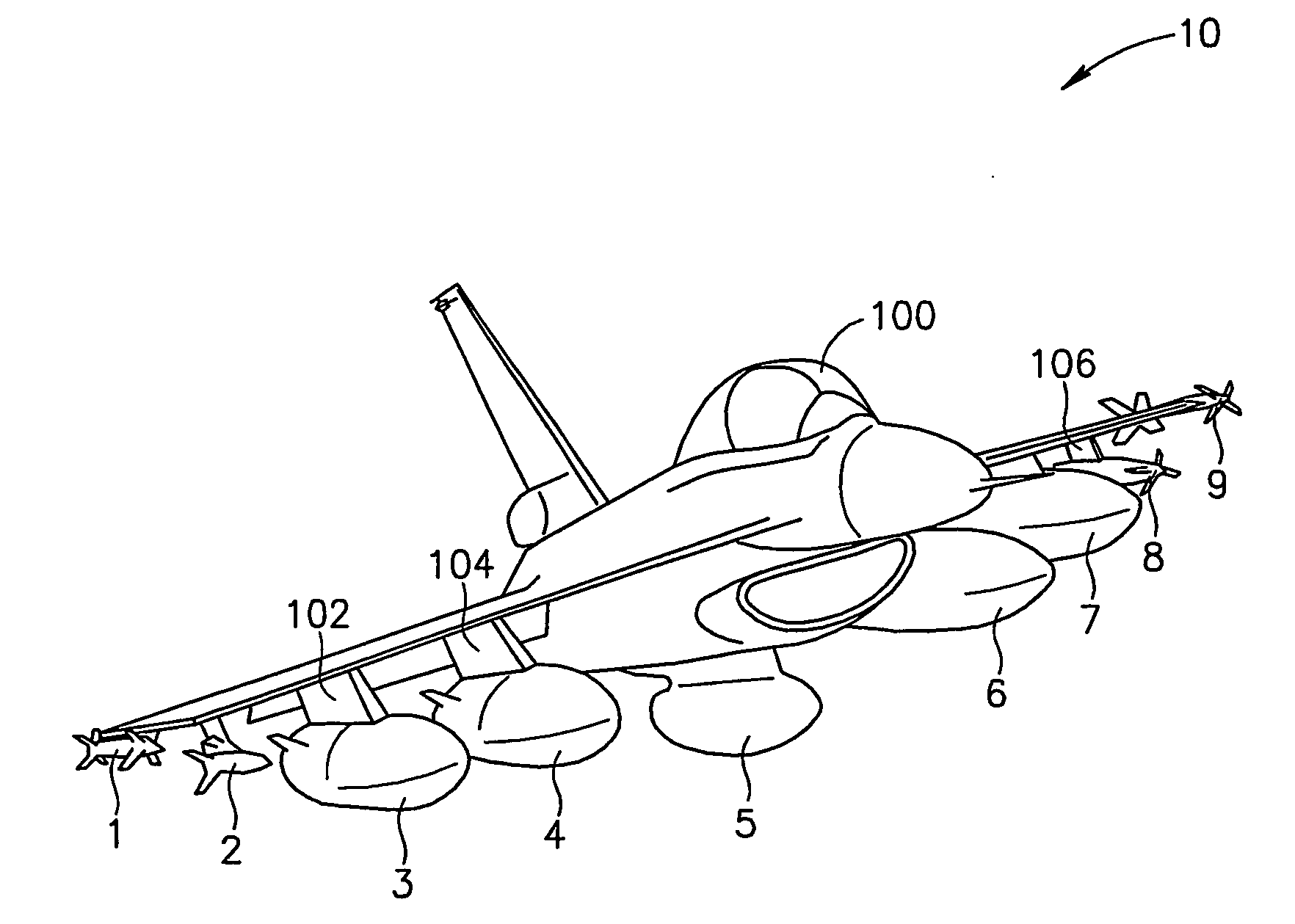

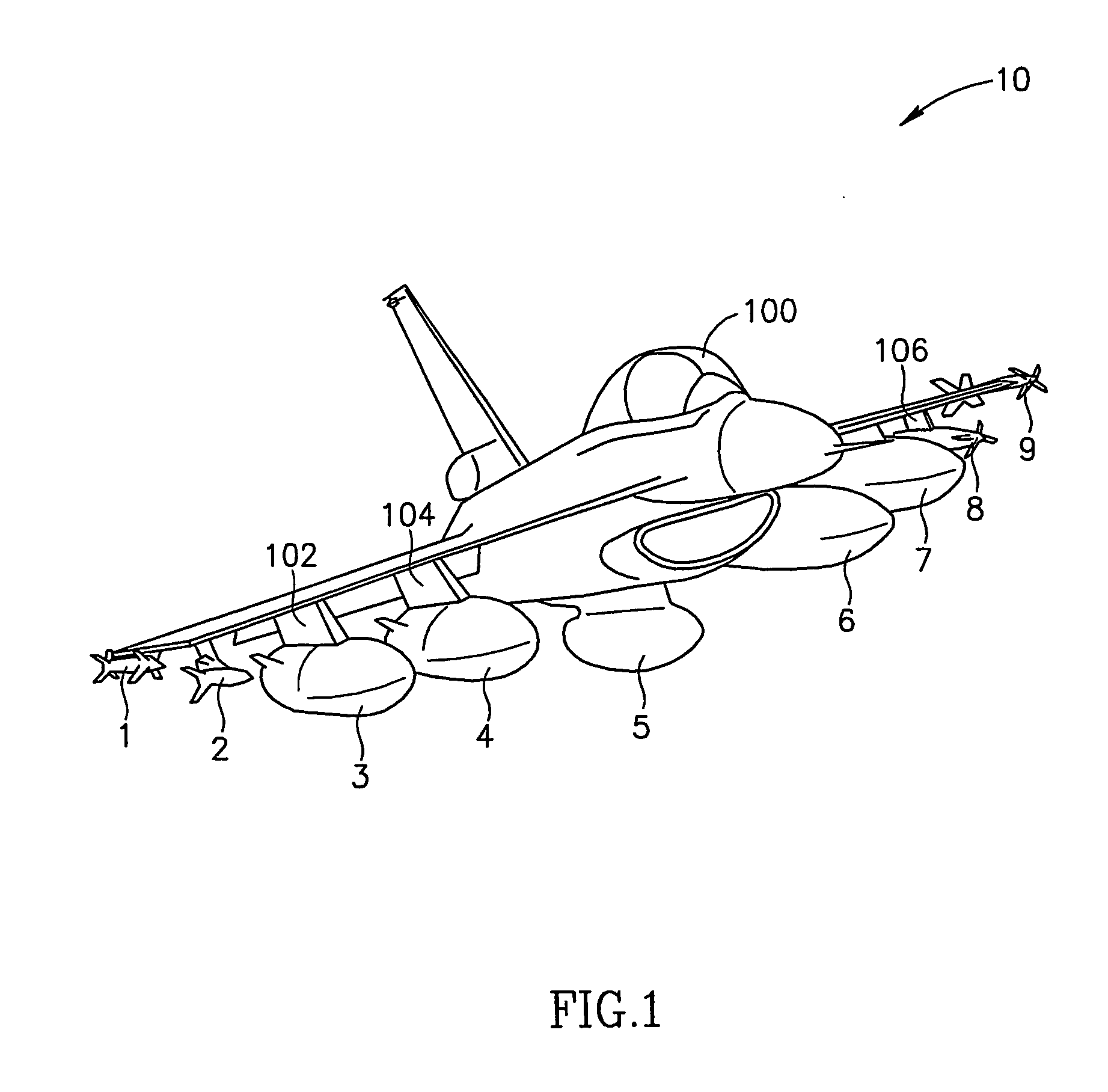

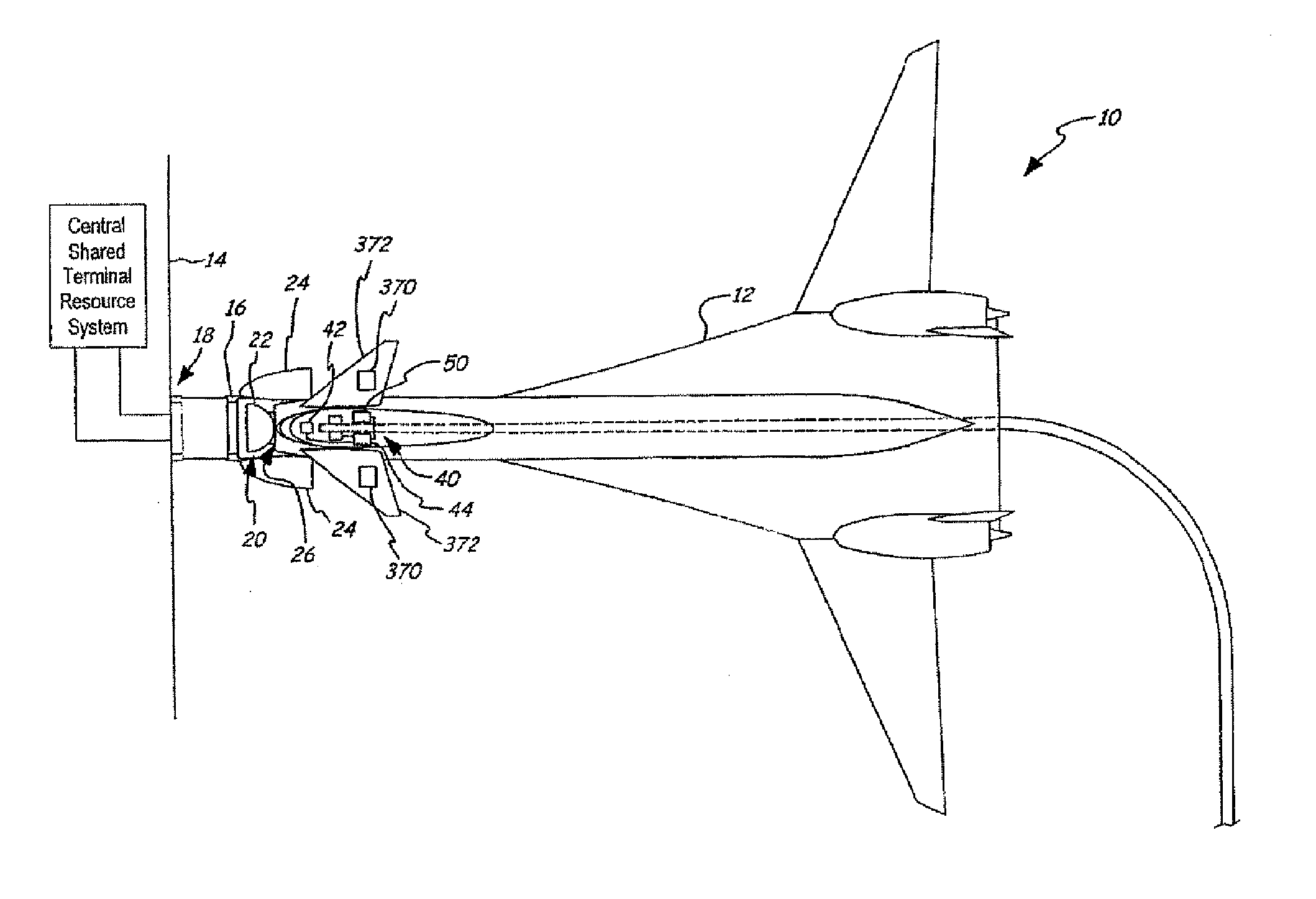

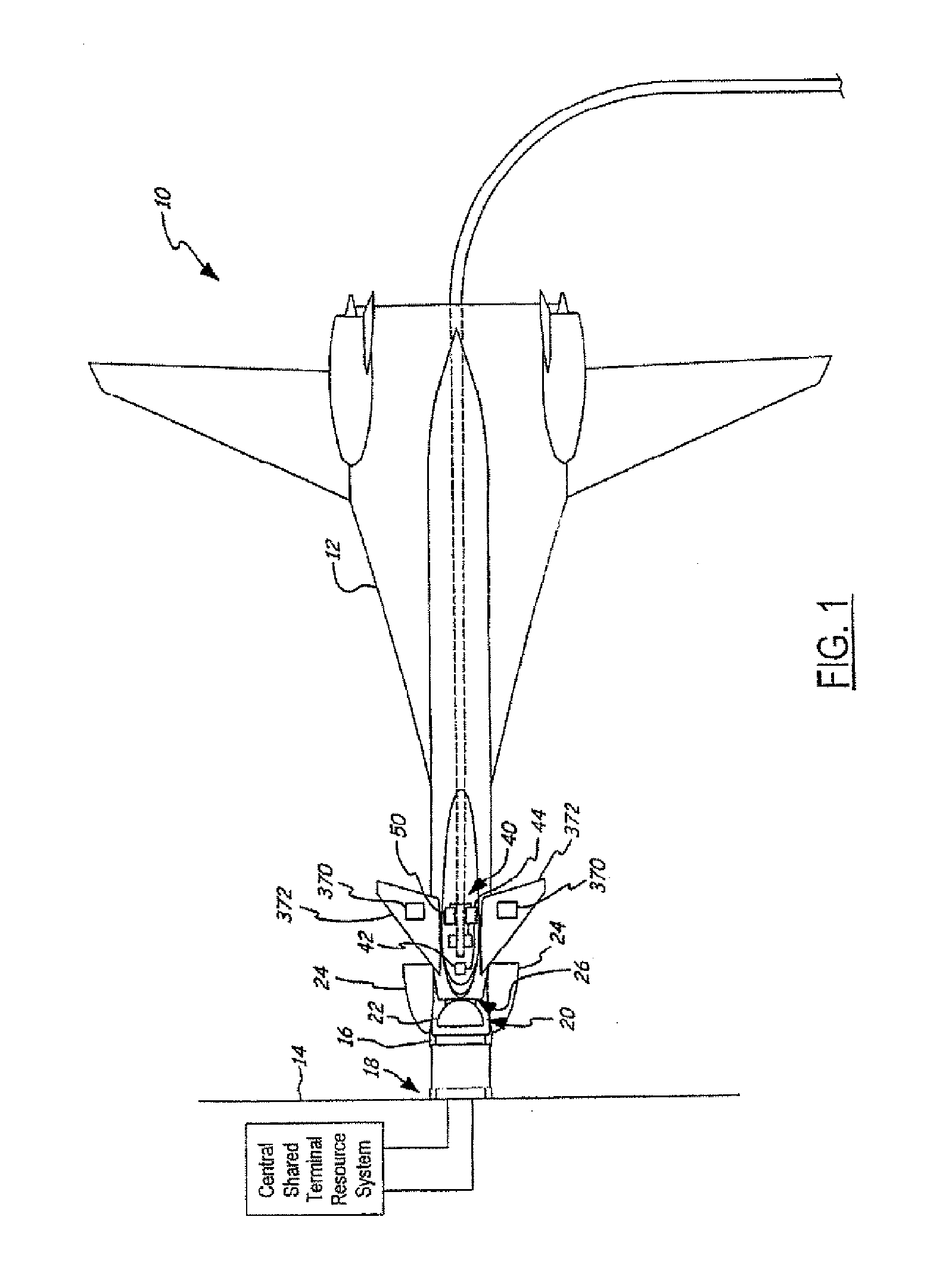

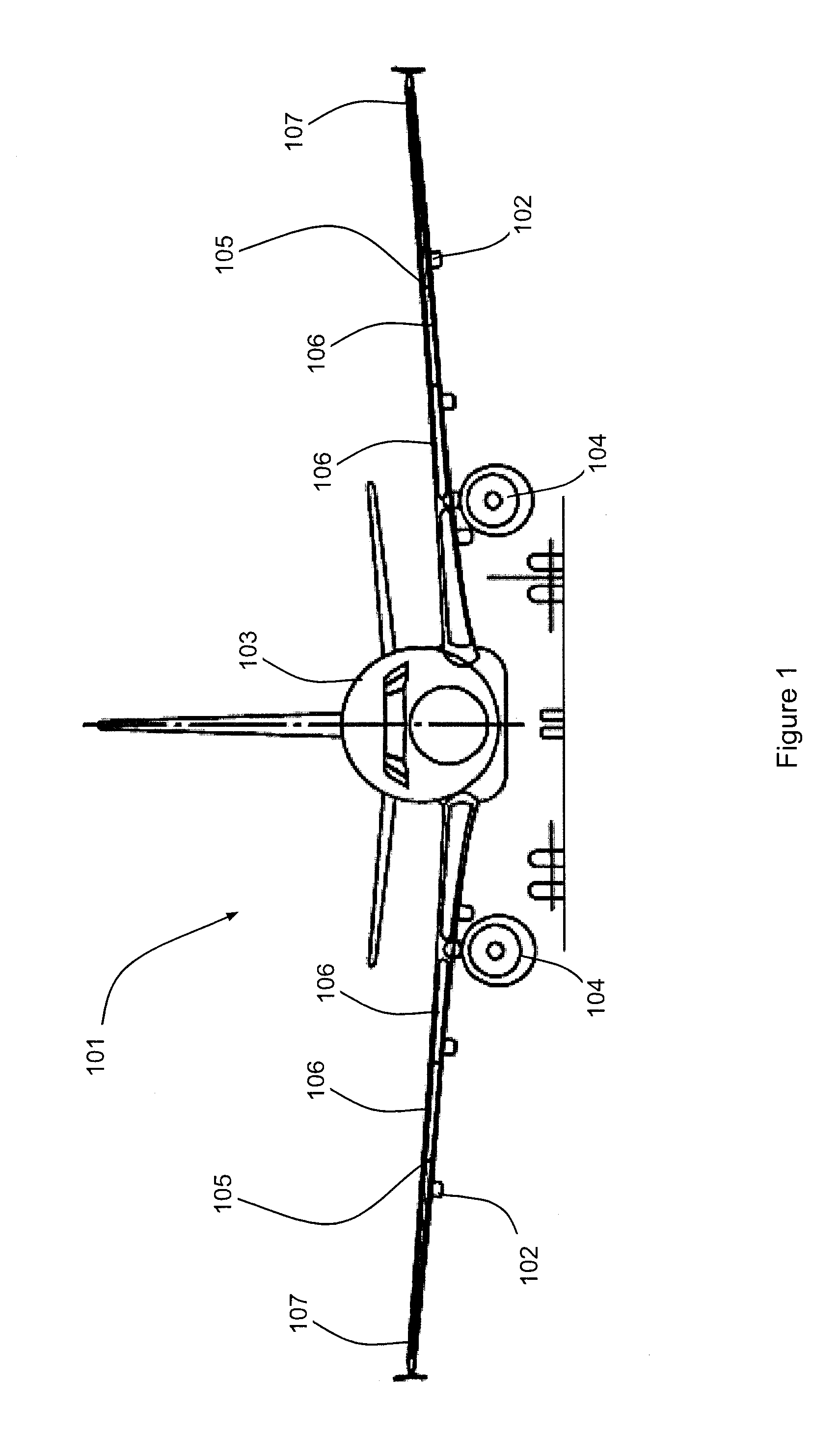

System and method for enhancing the fuel storage volume and the fuel carriage capacity of external fuel stores carried by an aerial vehicle

InactiveUS20060108476A1Increase fuel capacityIncrease volume capacityPower plant fuel tanksLaunching weaponsAircraft fuel systemFlight vehicle

A system and method for enhancing the fuel stores volume of an aerial vehicle is disclosed. An extended external fuel stores configuration utilizes an alternative fuel transfer path. An external fuel tank is suspended on a external fuel tank carrier pylon uploaded on a outboard wing “pseudo-wet” stores station. The pylon is linked to a dual functionality external fuel tank carrier pylon uploaded on an inboard wing “wet” station. The pylon is capable of transferring fuel from an external fuel container to the aircraft fuel system and capable of transmitting, and controlling the fuel store in the auxiliary fuel container attached to the pylon uploaded on a outboard wing “pseudo-wet” station. An externally mounted stores transfer kit links the inboard pylon and the outboard pylon.

Owner:PADAN NIR

Current insulation system for fluid systems

InactiveUS7686344B2Reduce maintenance costsPipe elementsPipe protection by thermal insulationAircraft fuel systemElectricity

An electrical insulation system for a linear element forming part of a fluid system subjected to risks of possible external electrical discharges, such as an aircraft fuel system, using an insulating insert (12) between two parts (14, 16) of said linear element, consisting of providing said parts (14, 16) with grooved edges and in forming the insulating insert (12) between them preferably by an injection technique, such that the insulating insert (12) provides an inner duct for the passage of fluid between said parts (14, 16) and covers said grooved edges, assuring the leak-tight joint of the insulating insert (12) with said parts (14, 16).

Owner:AIRBUS OPERATIONS SL

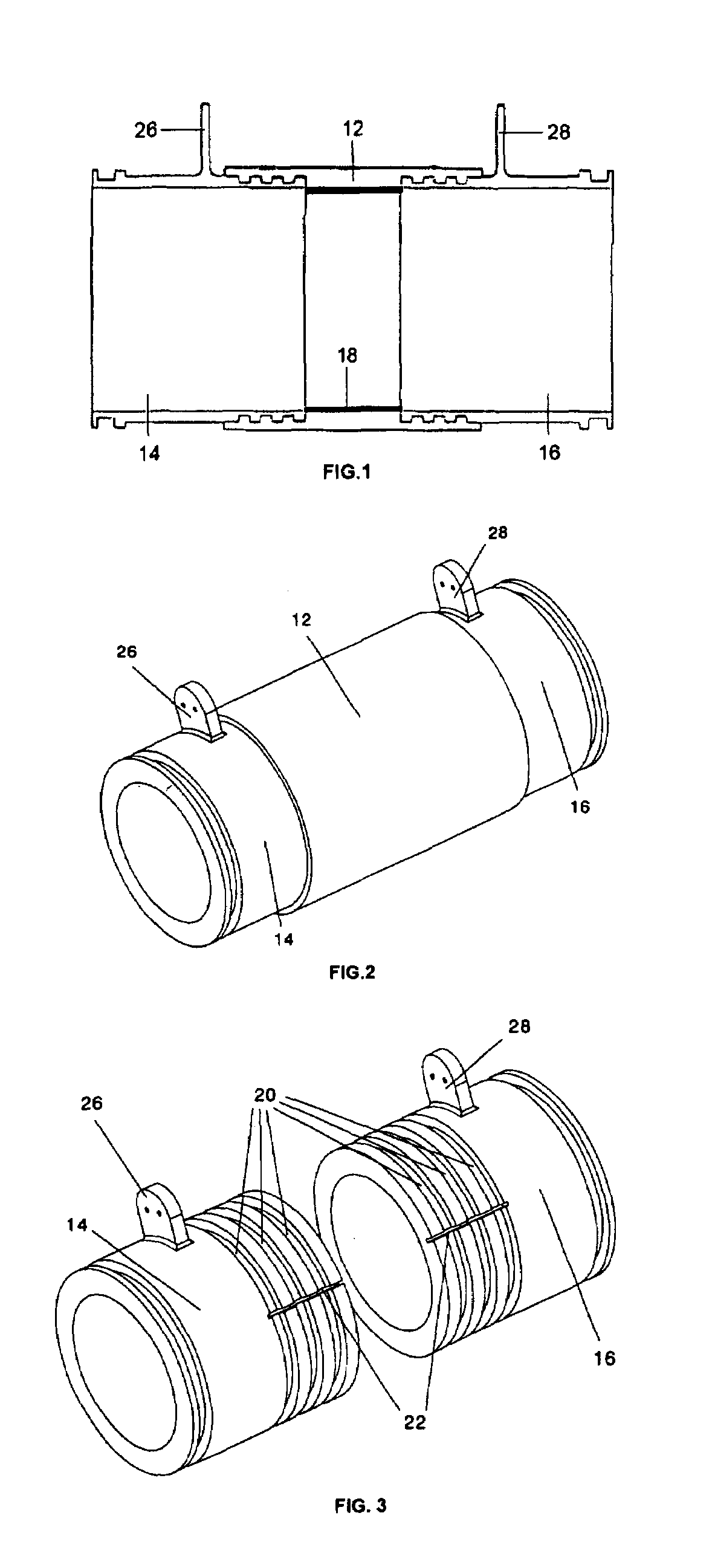

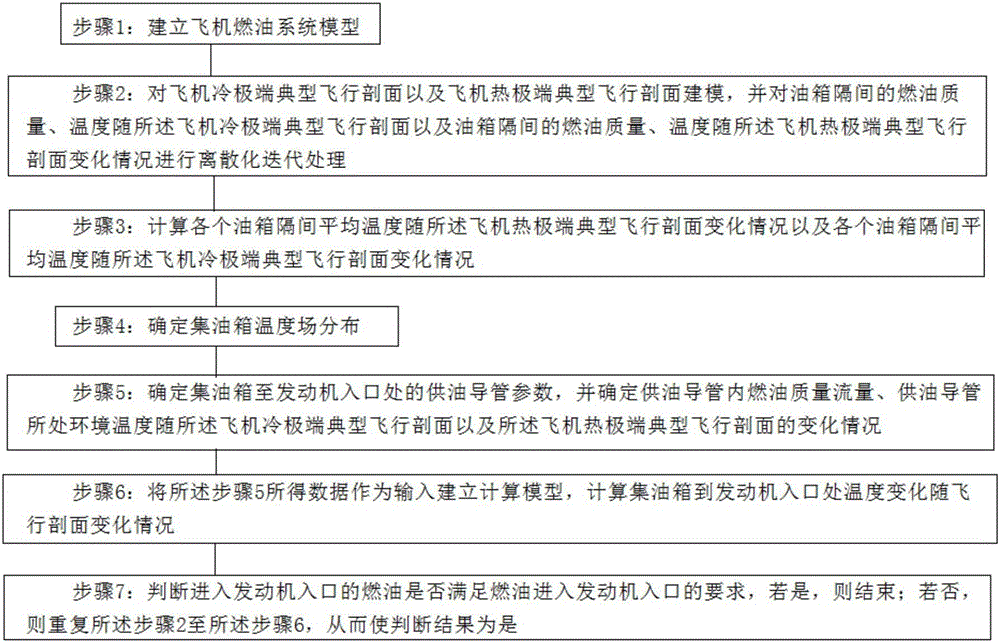

Design method for airplane fuel system

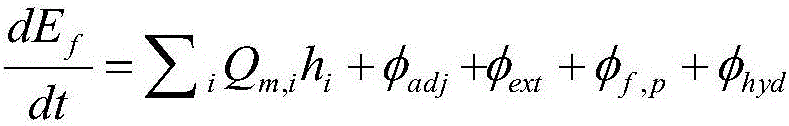

ActiveCN106446325ASolve the accuracy problemSolve environmental problemsGeometric CADDesign optimisation/simulationAircraft fuel systemFuel quality

The invention discloses a design method for an airplane fuel system. The design method for the airplane fuel system comprises the following steps of 1: building fuel flow models of fuel tanks of an airplane; 2: performing discretized iterative processing on fuel quality of fuel tank compartments and change of temperature along with typical flight profiles of cold and hot extremes of the airplane; 3: calculating change of average temperature of the fuel tank compartments along with the typical flight profiles of the cold and hot extremes of the airplane; 4: determining temperature field distribution of a fuel collection tank; 5: determining fuel mass flow in a fuel supply guide pipe and change of temperature of an environment, in which the fuel supply guide pipe is located, along with the typical flight profiles of the cold and hot extremes of the airplane; 6: calculating change of temperature from the fuel collection tank to an engine inlet along with the flight profiles; and 7: judging whether fuel entering the engine inlet meets a requirement of entering the engine inlet by the fuel or not. According to the design method for the airplane fuel system, the problem of low calculation precision in a conventional method is solved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

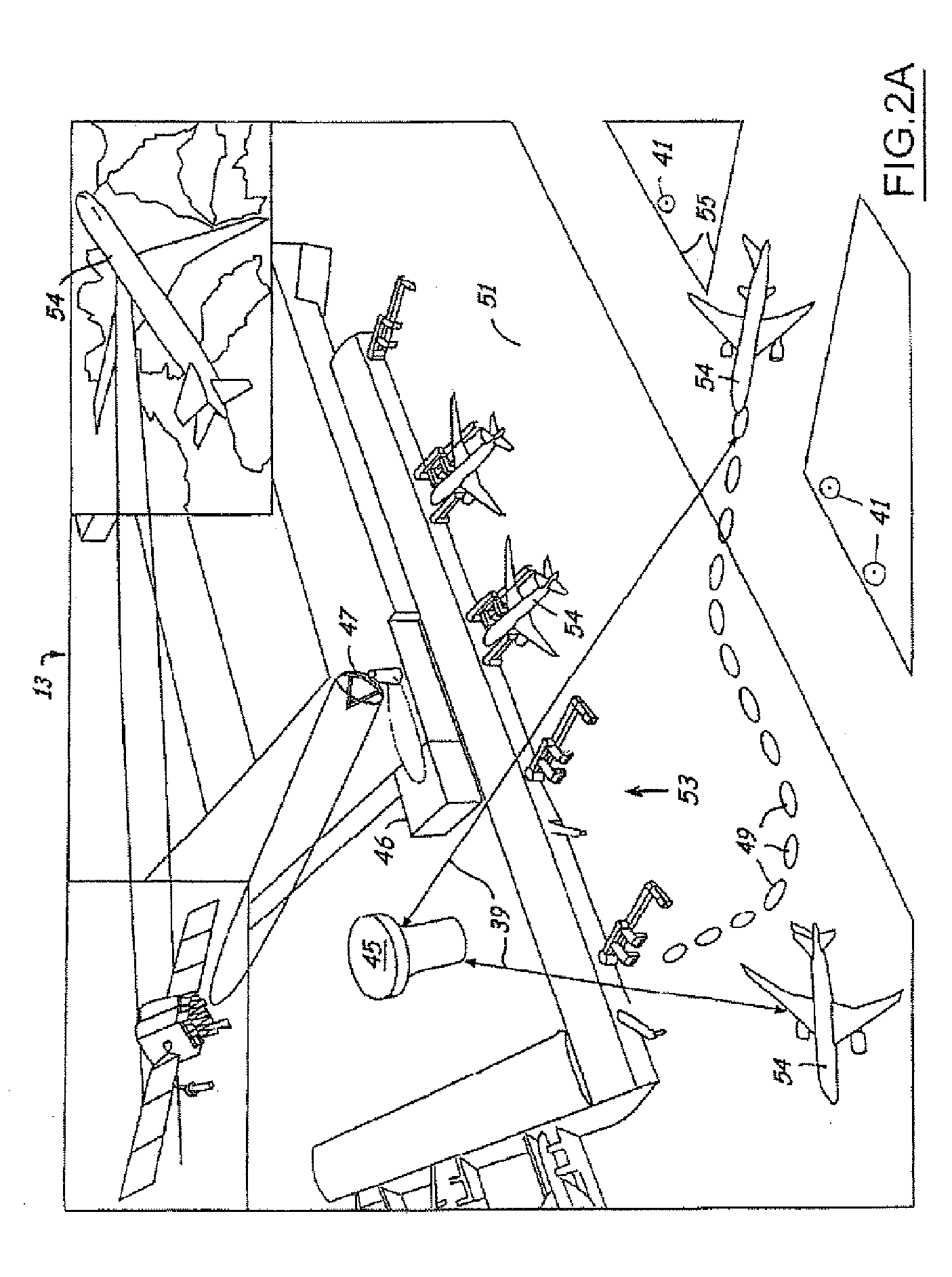

Operational ground support system having automated fueling

InactiveUS20060237591A1Minimal human interventionDecrease tarmac congestionLiquid handling installationsEnergy efficient operational measuresAircraft fuel systemFuel supply

An aircraft fueling system (890) includes an underground fuel supply (904). A fuel pump (906) is coupled to the underground fuel supply 904 and is used to supply fuel to an aircraft (902). A fuel probe (908) is coupled to the fuel pump (906) and is extendible to an aircraft fueling port (926). A fuel probe connection sensor (938) generates a connection signal. A controller (924) is coupled to the fuel pump (906) and the fuel probe connection sensor (938) and adjusts the supply of the fuel (904) to the aircraft (902) in response to the connection signal.

Owner:THE BOEING CO

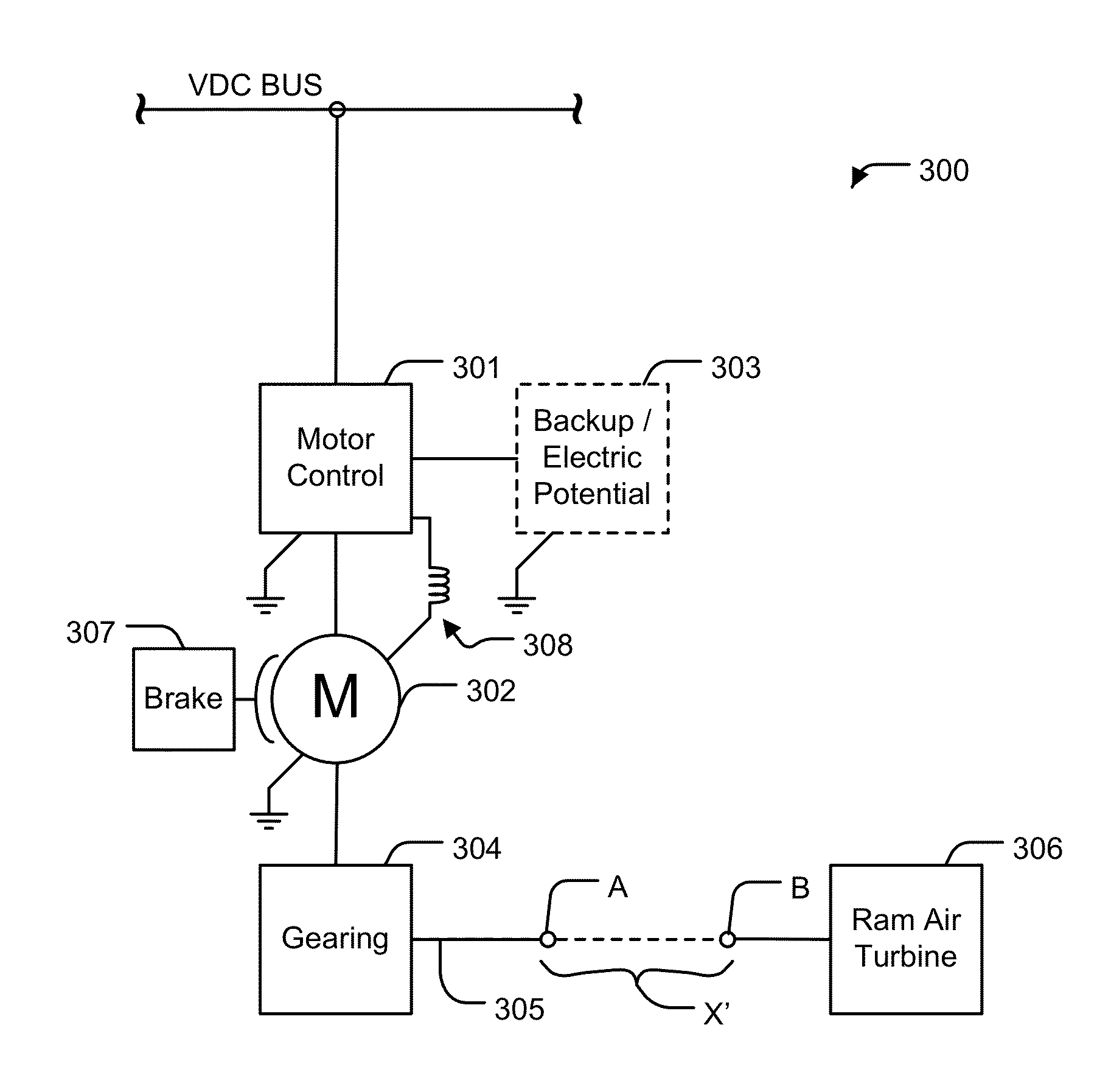

Electric actuators in aircraft systems

An electric actuation system for an emergency power system of an aircraft includes a motor control portion, a motor brake, a motor in electrical communication with the motor control portion, mechanical gearing in mechanical communication with the motor, the mechanical gearing configured to translate rotational motion of the motor into linear motion across at least one axis, and an extension member in mechanical communication with the mechanical gearing, the extension member configured to linearly travel across the at least one axis.

Owner:HAMILTON SUNDSTRAND CORP

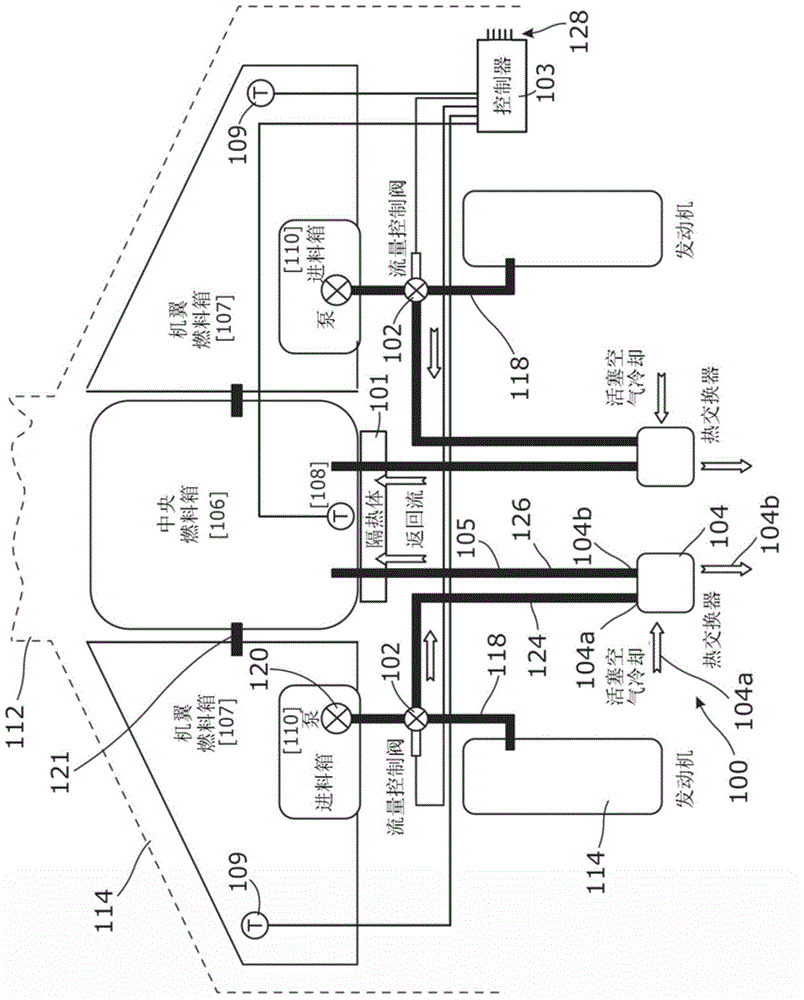

Aircraft fuel system with fuel return from engine

ActiveUS20160167801A1Avoid icingEasy to useInternal combustion piston enginesPower plant fuel tanksAircraft fuel systemLine tubing

An aircraft fuel system, comprising: a fuel tank; a fuel line; and an engine; wherein the fuel line includes a first conduit configured to carry fuel from the tank towards the engine, and a second conduit configured to carry fuel from the engine towards the tank, wherein one of the first conduit or the second conduit is disposed annularly around the other of the first conduit or the second conduit. Also, a method of operating the system. The system may be used to suppress ice formation in the first conduit and / or provide leakage detection.

Owner:AIRBUS OPERATIONS LTD

High temperature avionic line replaceable units and aircraft systems containing the same

ActiveUS10044175B1Improve temperature resistanceEasy to storeAircraft componentsIncorrect coupling preventionAircraft fuel systemAviation

Owner:HONEYWELL INT INC

Aircraft fuel system

InactiveCN105438484AGuaranteed changeBalance weightPower plant fuel tanksAircraft fuel systemFuel tank

The invention provides a new fuel system which comprises a fuel tank, an engine fuel supply pipeline, a pressure refueling pipeline, a fuel tank delivery pipeline and a fuel supply and delivery main pipe, wherein the pressure refueling pipeline and the fuel tank delivery pipeline are provided with adjustable throttle valves and pressure sensors. When fuel is supplied to an engine of an aircraft, the fuel flows of a left fuel tank unit of wings and a right fuel tank unit of the wings or a fuel tank unit of a front fuselage and a fuel tank unit of a rear fuselage can be simultaneously adjusted so as to ensure that the position of the center of gravity of the aircraft is not changed. The fuel system provided by the invention not only can meet the operating requirements of the aircraft but also can increase the refueling speed according to the existing control means so as to balance fuel supply of the engine and effectively improve the efficiency of the fuel system.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

Aircraft fuel system

InactiveCN104670507AImprove insulation performanceMinimize complexityPower plant fuel tanksFuel tank safety measuresAircraft fuel systemHeat flow

Aircraft fuel system reduces flammability exposure of fuel tanks. In one embodiment, aircraft center fuel tank fuel is cooled in flight to reduce flammability exposure to be similar to that of an unheated metal wing tank. Fuel tanks having adjacent heat sources are insulated to minimize heat flow into the fuel. Fuel tanks having lower cooling properties, e.g., composite wing tanks, are cooled during flight so temperatures are reduced to be similar to metal wing tanks. A fuel tank, pressurized relative to outside pressure at altitude, having lower flammability exposure than unpressurized tanks and cooling fuel in the tank reduces flammability exposure of the fuel tank to be similar to that of an unpressurized metal wing tank. Recirculating flow from a tank, passing through heat exchanger, and returning to the tank cools fuel. A controller starts / stops fuel flow to tanks and uses sensors to command flow to reduce flammability.

Owner:AERO SYST CONSULTANTS

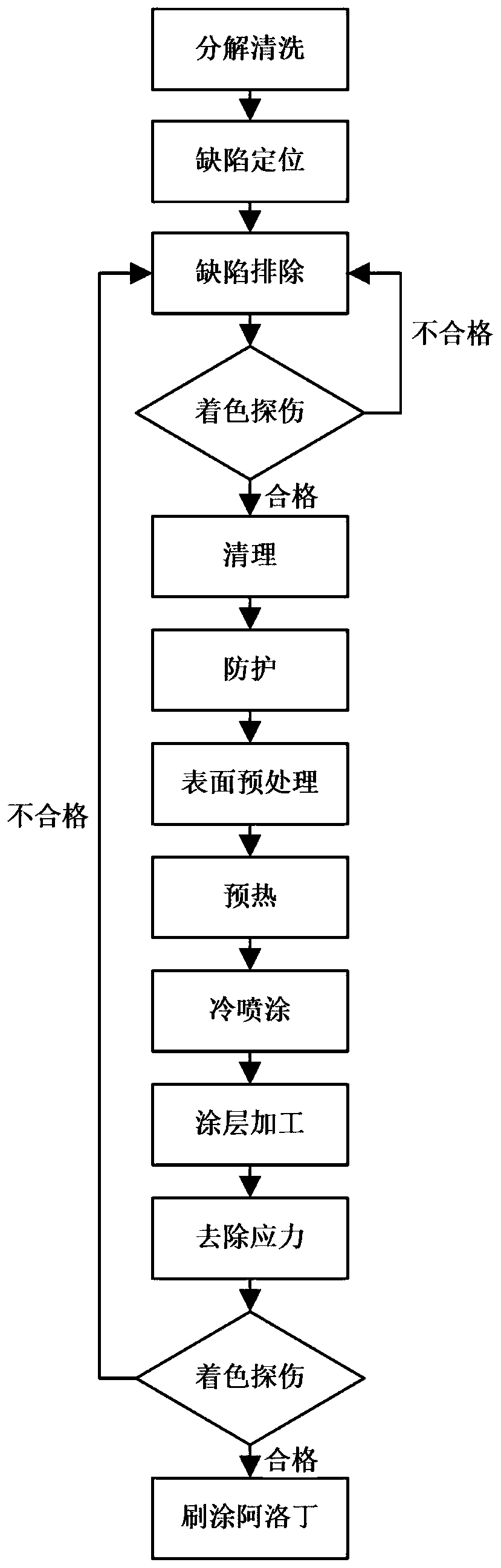

Method for repairing aircraft fuel system aluminum silicon alloy shell casting defects

ActiveCN110480254AAvoid heat cracksAvoids the problem of substrate annealing softeningAircraft componentsAircraft fuel systemDecomposition

The invention relates to the technical field of aircraft fuel system mechanical part accessory repairing, in particular to a method for repairing aircraft fuel system aluminum silicon alloy shell casting defects. The method includes the following steps of S1, decomposition cleaning; S2, defect positioning and removal; S3, dye penetration; S4, cleaning; S5, protection; S6, surface pretreatment; S7,preheating before spraying; S8, cold spraying; S9, coating processing; S10, stress relief treatment; S11, dye penetrant inspection; and S12, anti-corrosion treatment. According to the method for repairing the aircraft fuel system aluminum silicon alloy shell casting defects, the problems of a heat crack of a shell and base material annealing softening caused by large heat input of a traditional surfacing process are effectively avoided, the repairing problem of the aircraft fuel system aluminum silicon alloy shell casting defects is solved, at the same time, casting defect repairing of the shell can be realized under the operation temperature of less than 120 DEG C, the problem of scrapping of a whole part of accessories due to shell damage or secondary damage caused by repairing is avoided, and economic benefits are significant.

Owner:国营芜湖机械厂

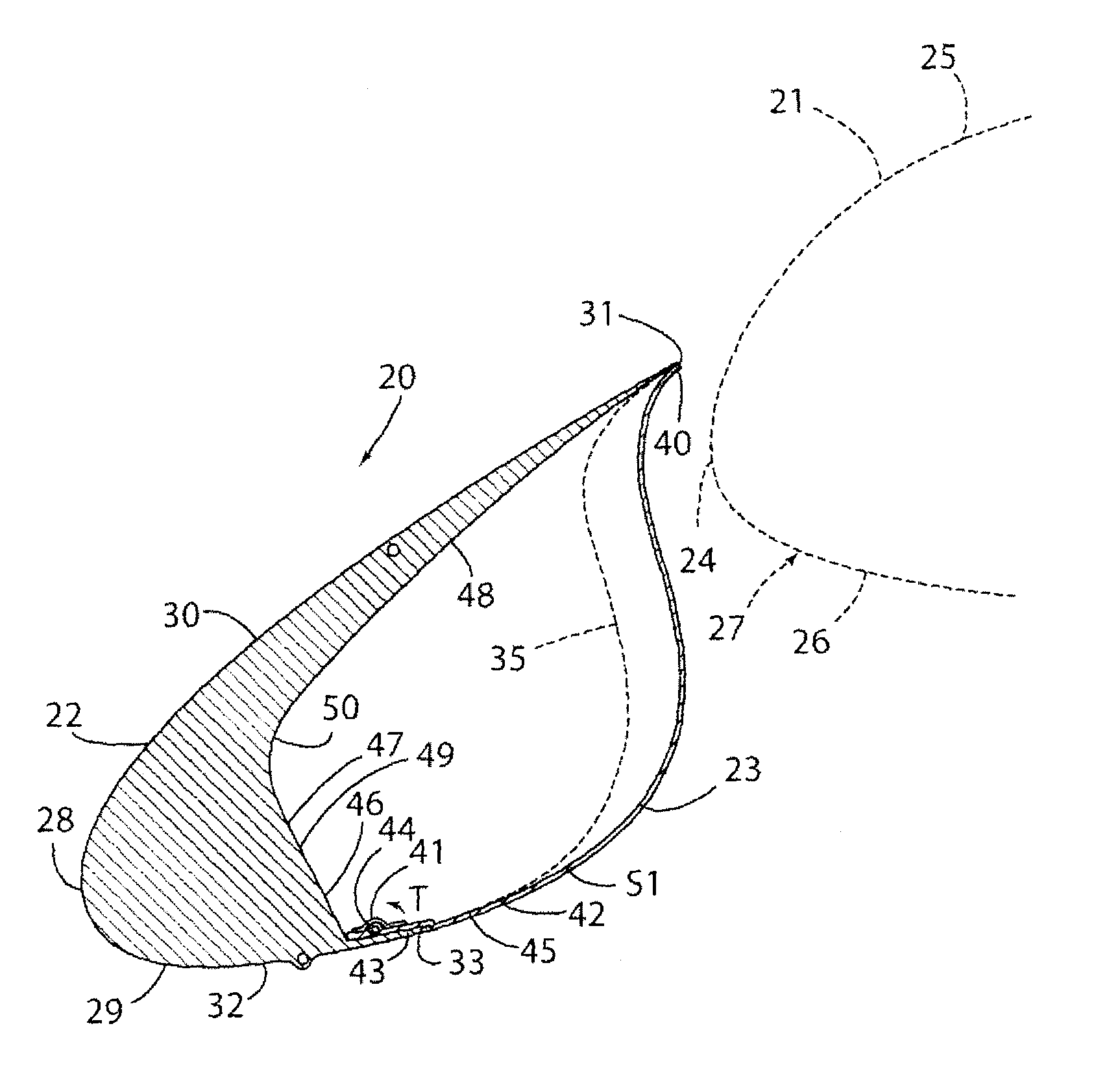

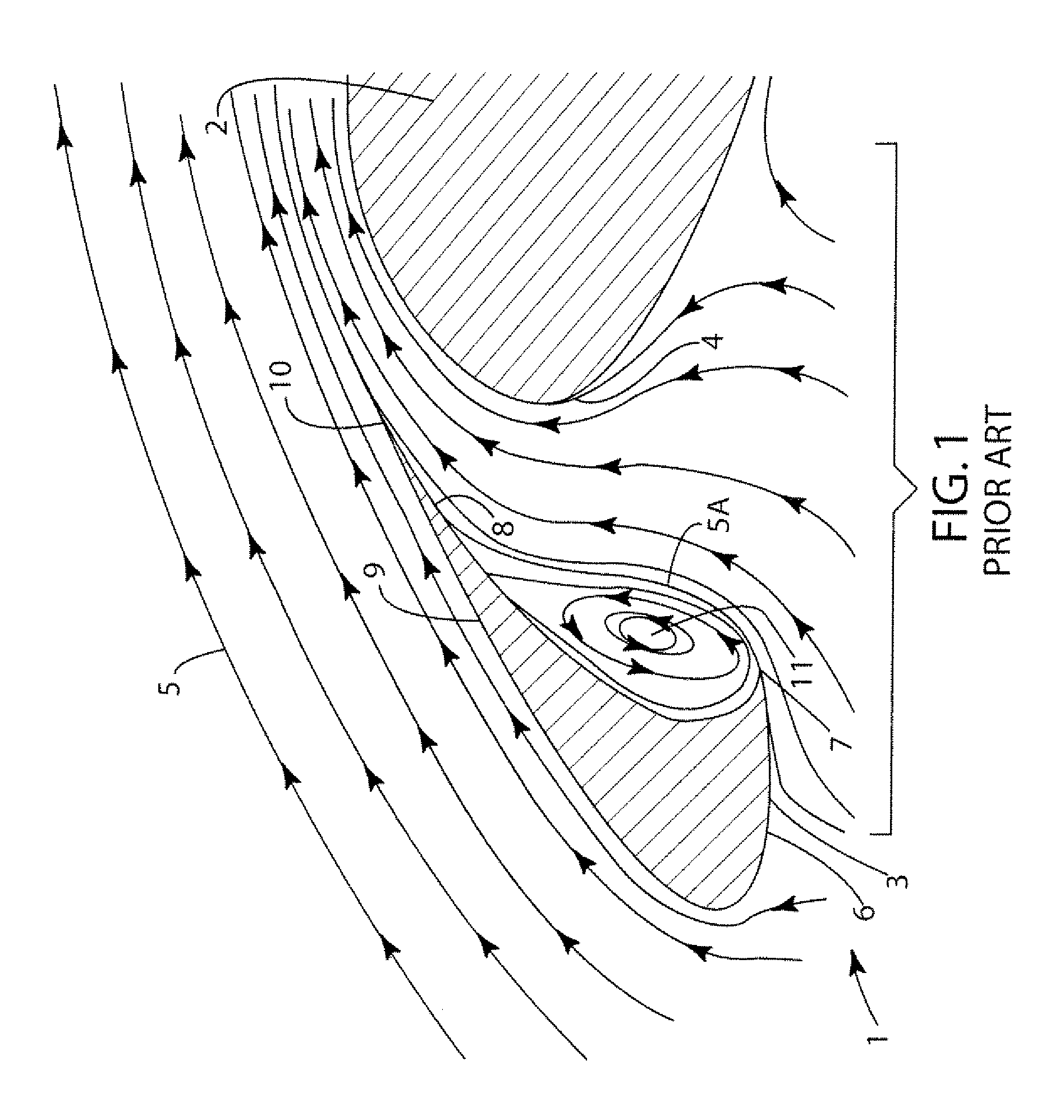

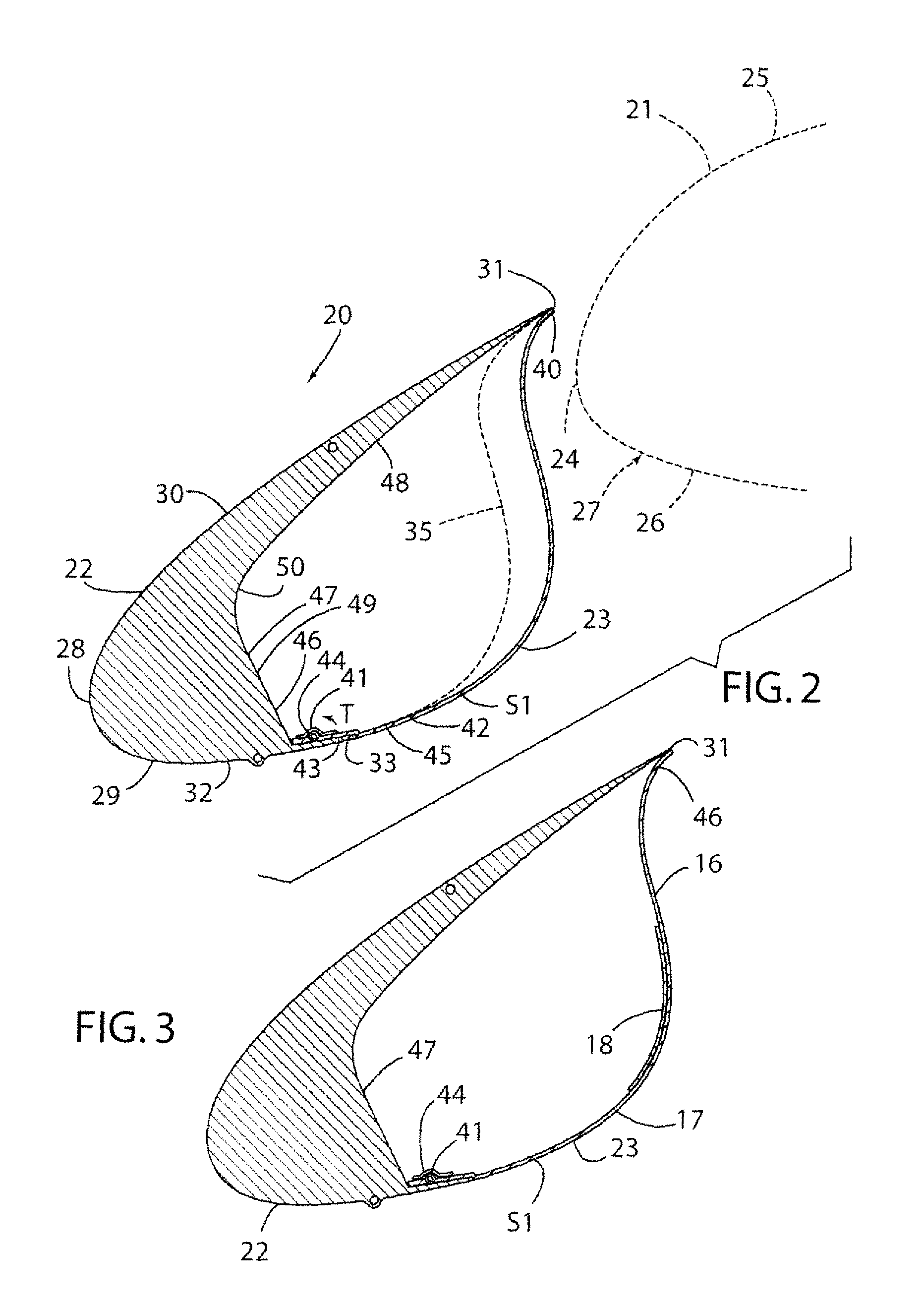

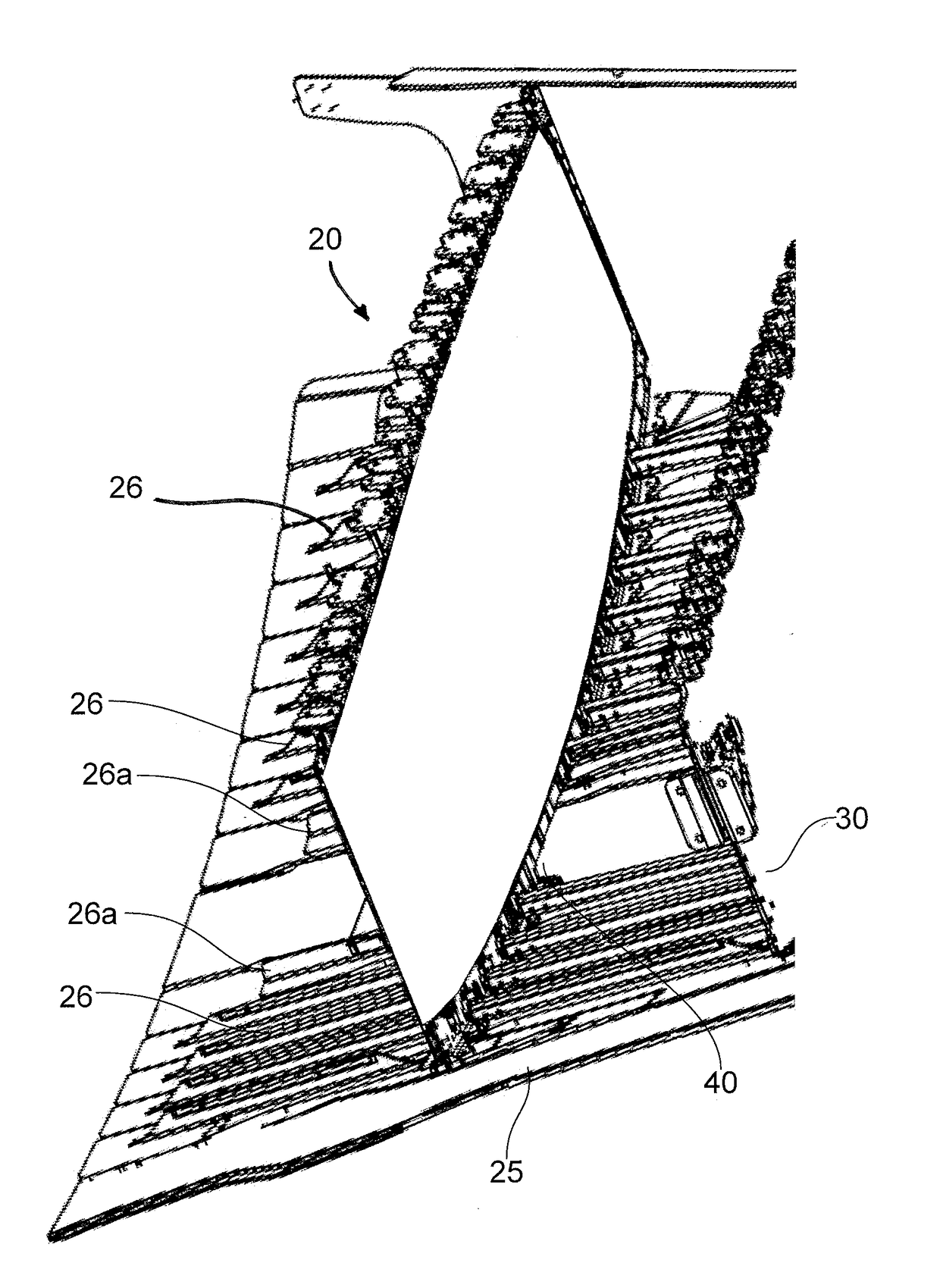

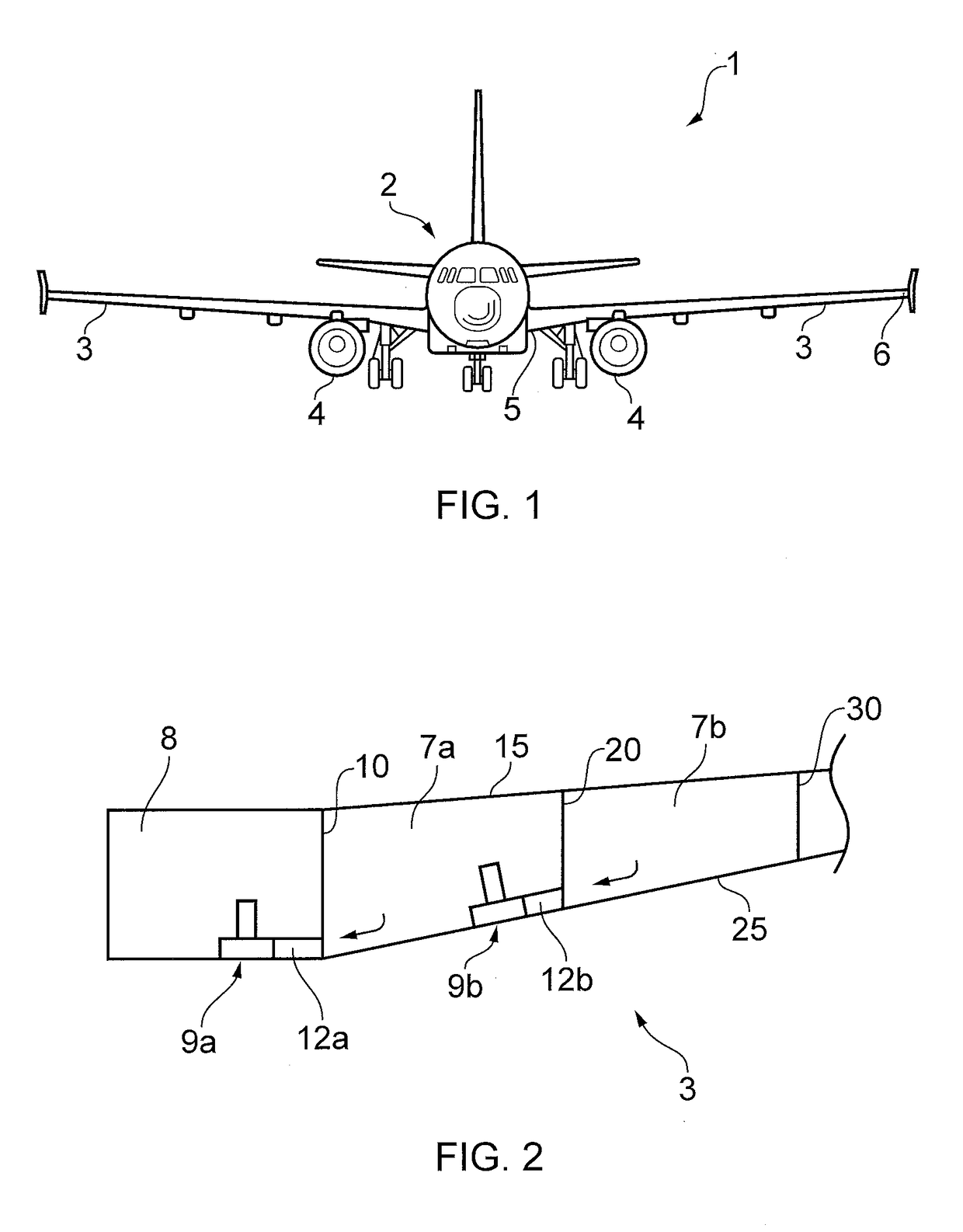

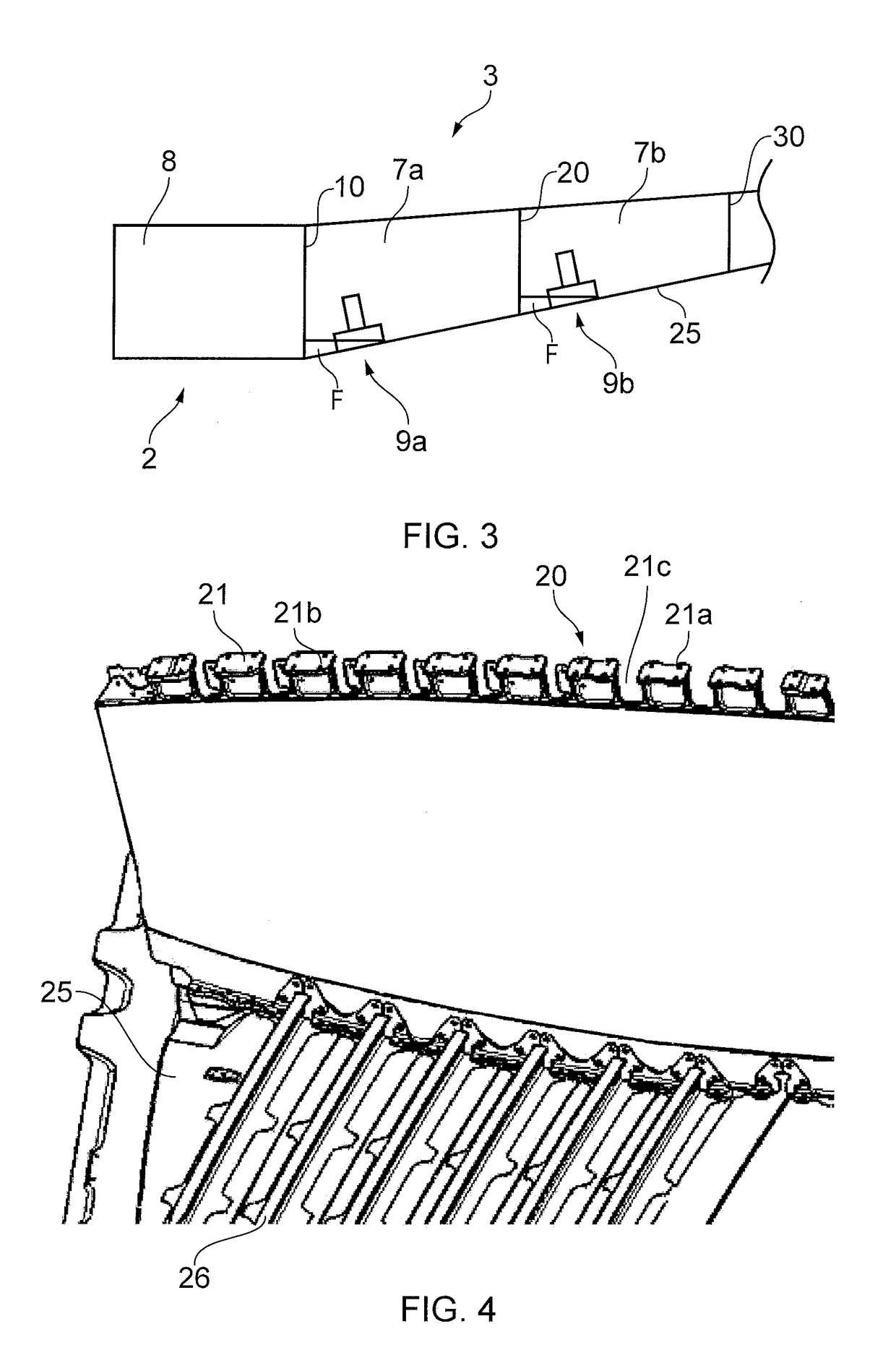

Autonomous slat-cove-filler device for reduction of aeroacoustic noise associated with aircraft systems

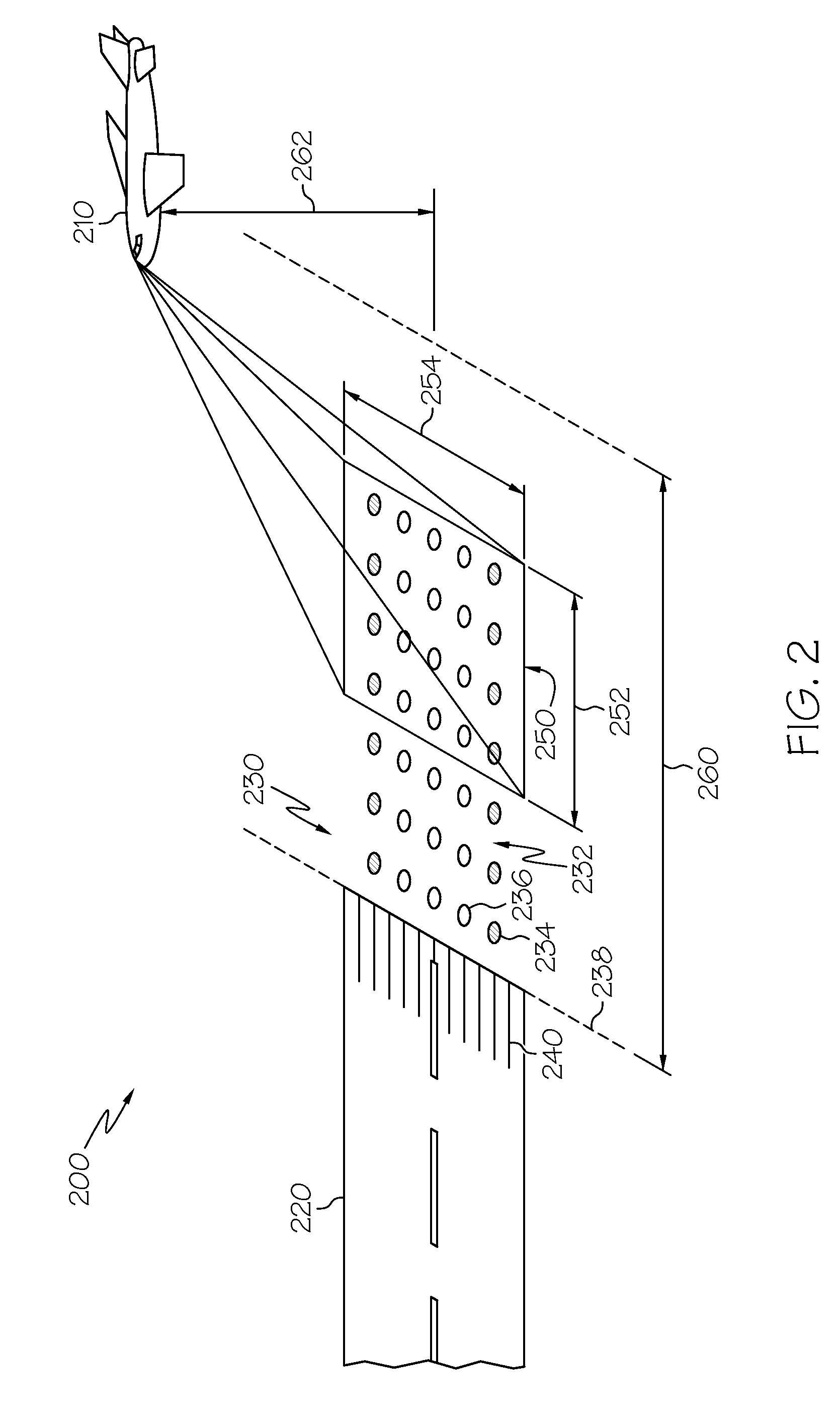

ActiveUS9242720B2Reduced airframe noiseBoundary layer controlsEfficient propulsion technologiesAircraft fuel systemLeading edge

A slat cove filler is utilized to reduce airframe noise resulting from deployment of a leading edge slat of an aircraft wing. The slat cove filler is preferably made of a super elastic shape memory alloy, and the slat cove filler shifts between stowed and deployed shapes as the slat is deployed. The slat cove filler may be configured such that a separate powered actuator is not required to change the shape of the slat cove filler from its deployed shape to its stowed shape and vice-versa. The outer contour of the slat cove filler preferably follows a profile designed to maintain accelerating flow in the gap between the slat cove filler and wing leading edge to provide for noise reduction.

Owner:NASA

Hydraulic low-pressure pulse experiment method of aircraft

ActiveCN103644170AOutput flow can be adjustedSolve the pulse testFluid-pressure actuator testingAircraft components testingAircraft fuel systemEngineering

The invention relates to a hydraulic low-pressure pulse experiment method of an aircraft and belongs to a hydraulic pulse technology. The hydraulic low-pressure pulse experiment method comprises the steps of firstly providing initial pressure required by a test piece for a supercharged oil tank during a pulse experiment, driving a magnetic exchange valve by utilizing a signal generated by a control system when hydraulic pulse pressure begins to produce, and stilling keeping certain pressure after pulse waves attenuate, wherein the pressure is identical to rated pressure of the tested piece; adjusting a precise throttle valve, controlling flows entering a pressure reducing cylinder and achieving the purpose of accurately controlling pulse waveform parameters at an ascent stage. By adopting the hydraulic low-pressure pulse experiment method, the pulse experiment in a flexible connecting assembly qualification test of an aircraft fuel system is achieved, and conditions are provided for localization of flexible connecting assemblies of aircraft fuel systems in outer country.

Owner:JIANGXI HONGDU AVIATION IND GRP

Endothermic cracking aircraft fuel system

ActiveUS20090166001A1Improve cooling effectTurbine/propulsion fuel supply systemsCatalytic crackingAircraft fuel systemEngineering

An aircraft system includes a heat source and a passage near the heat source for carrying fluid having a cooling capacity to cool the heat source. The passage includes a catalyst that endothermically cracks the fluid to increase the cooling capacity.

Owner:RAYTHEON TECH CORP

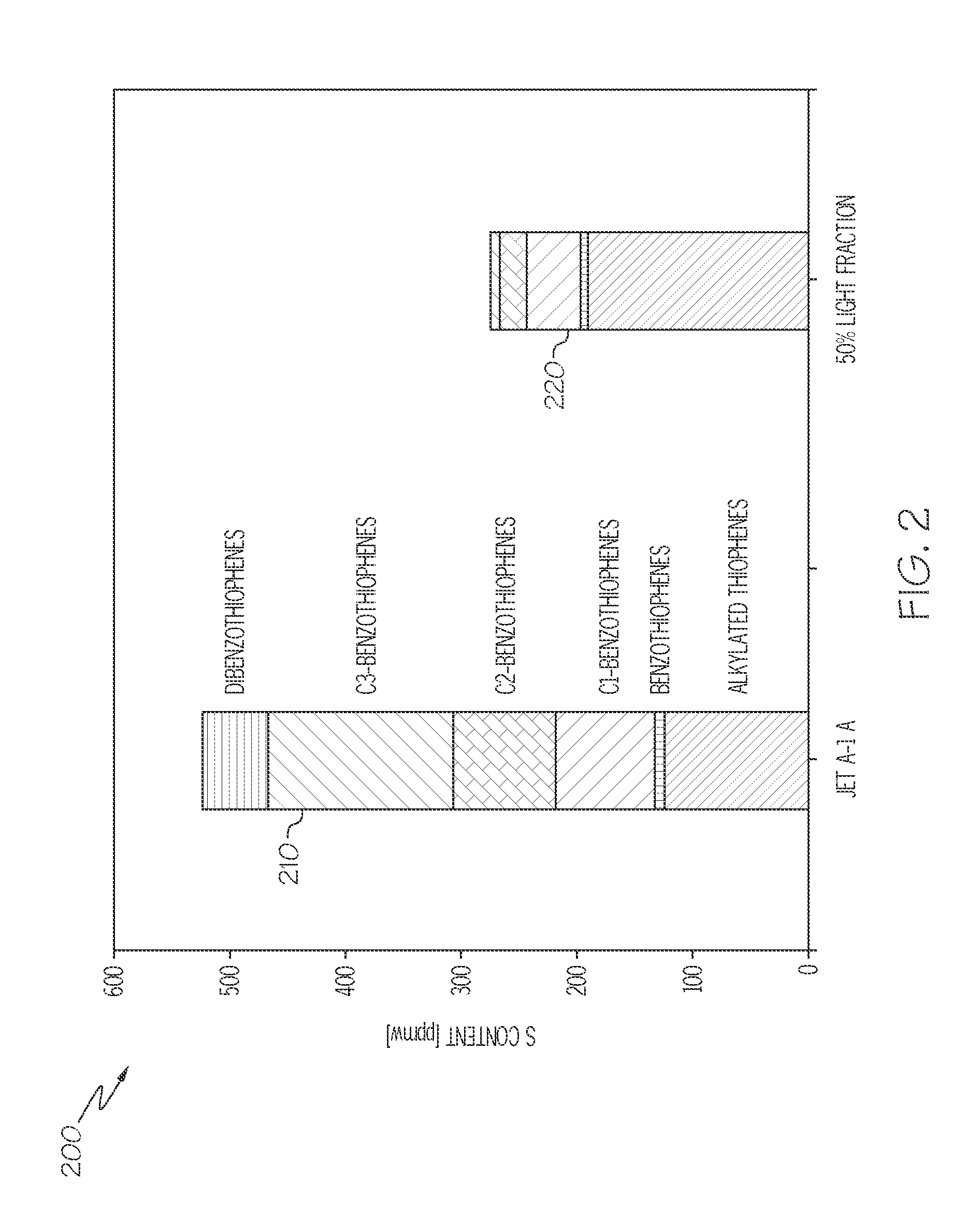

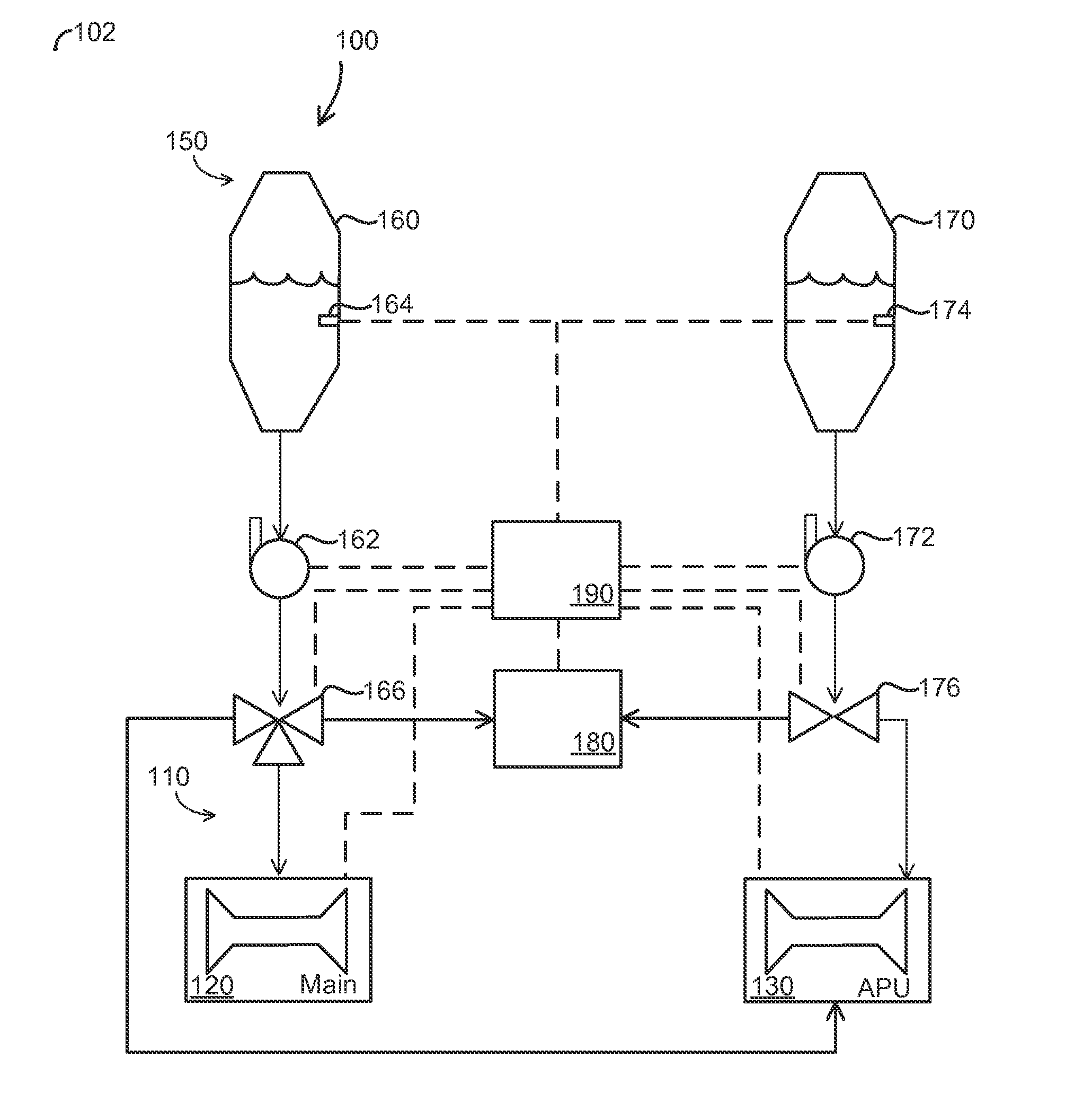

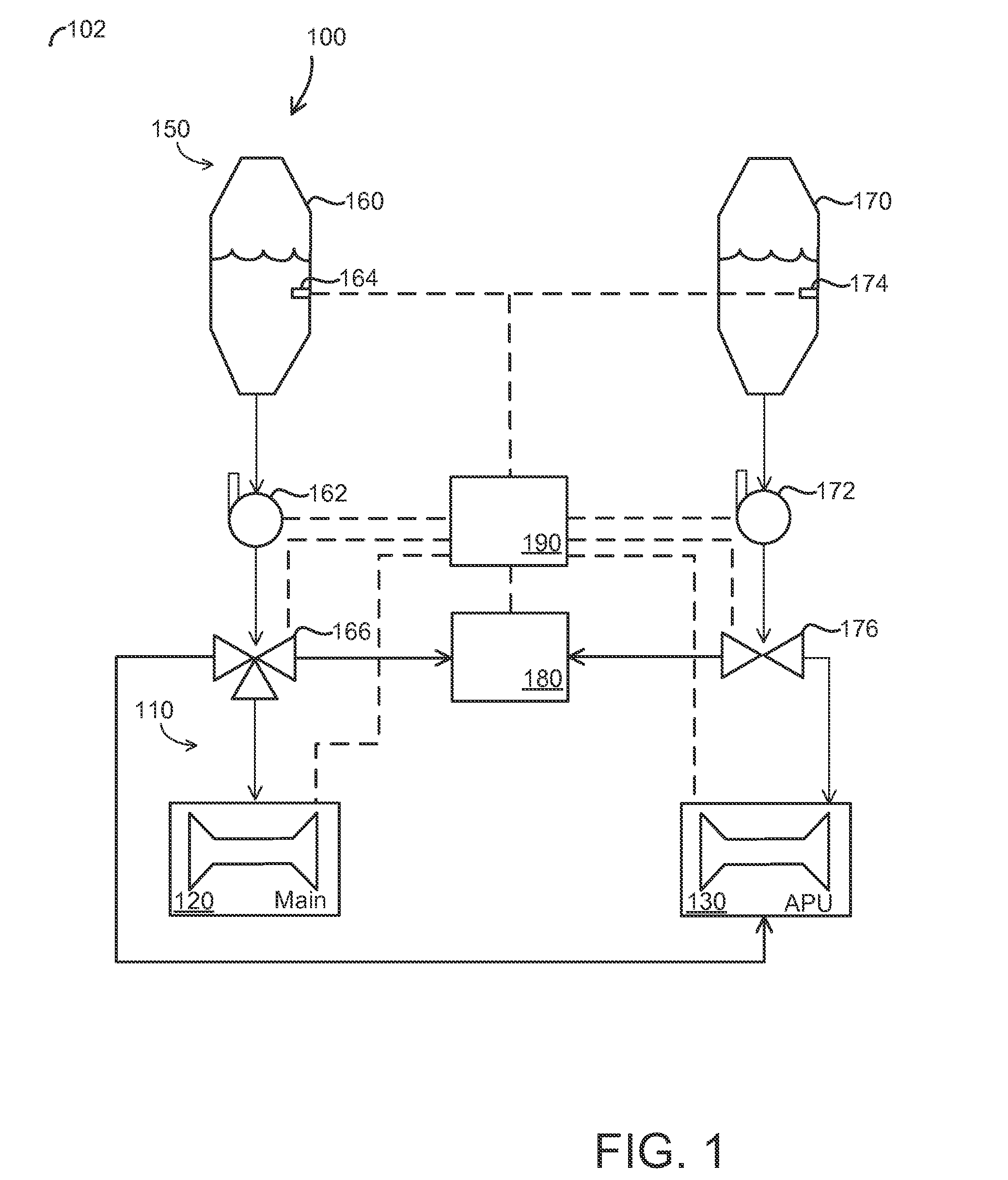

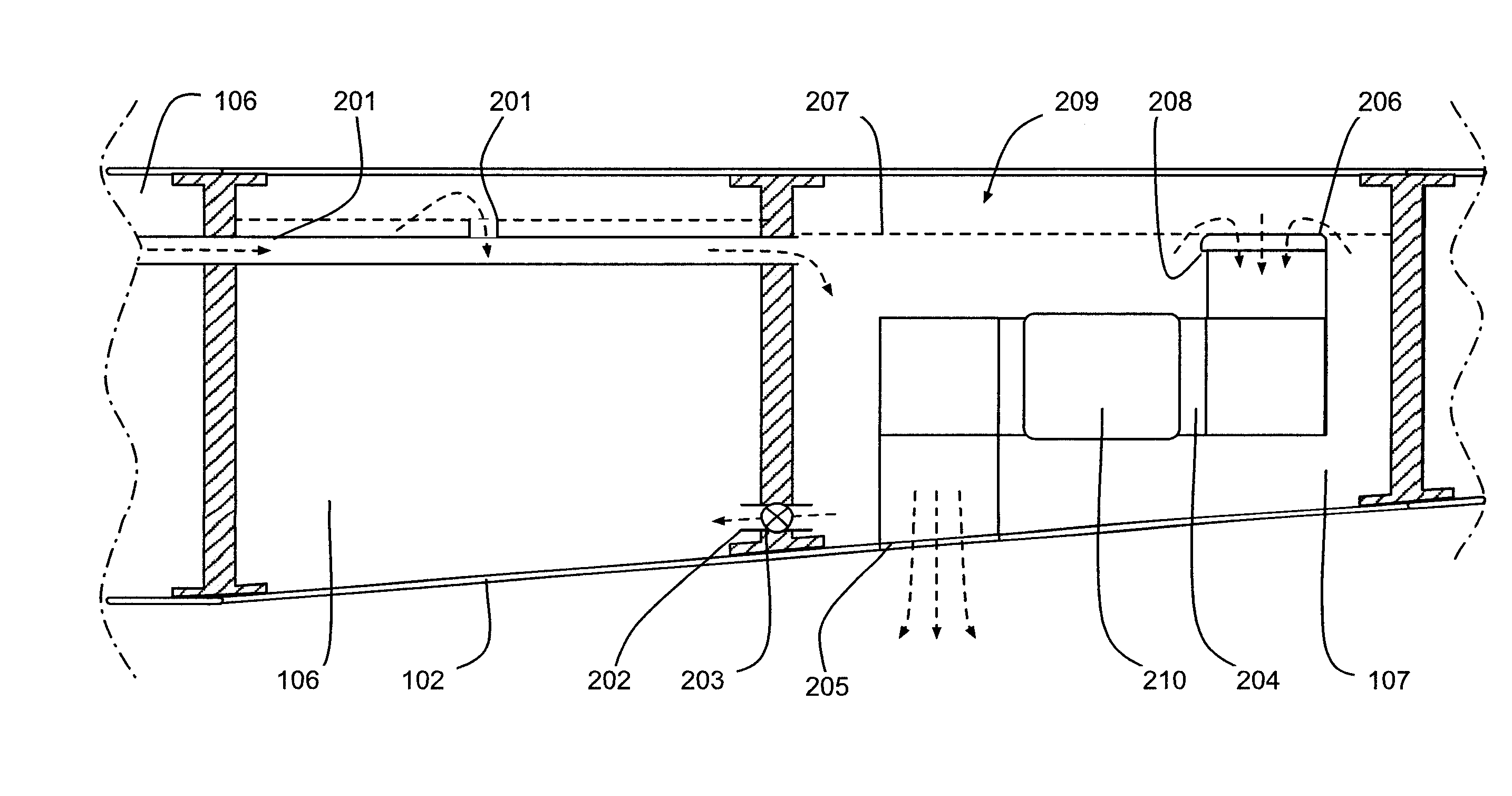

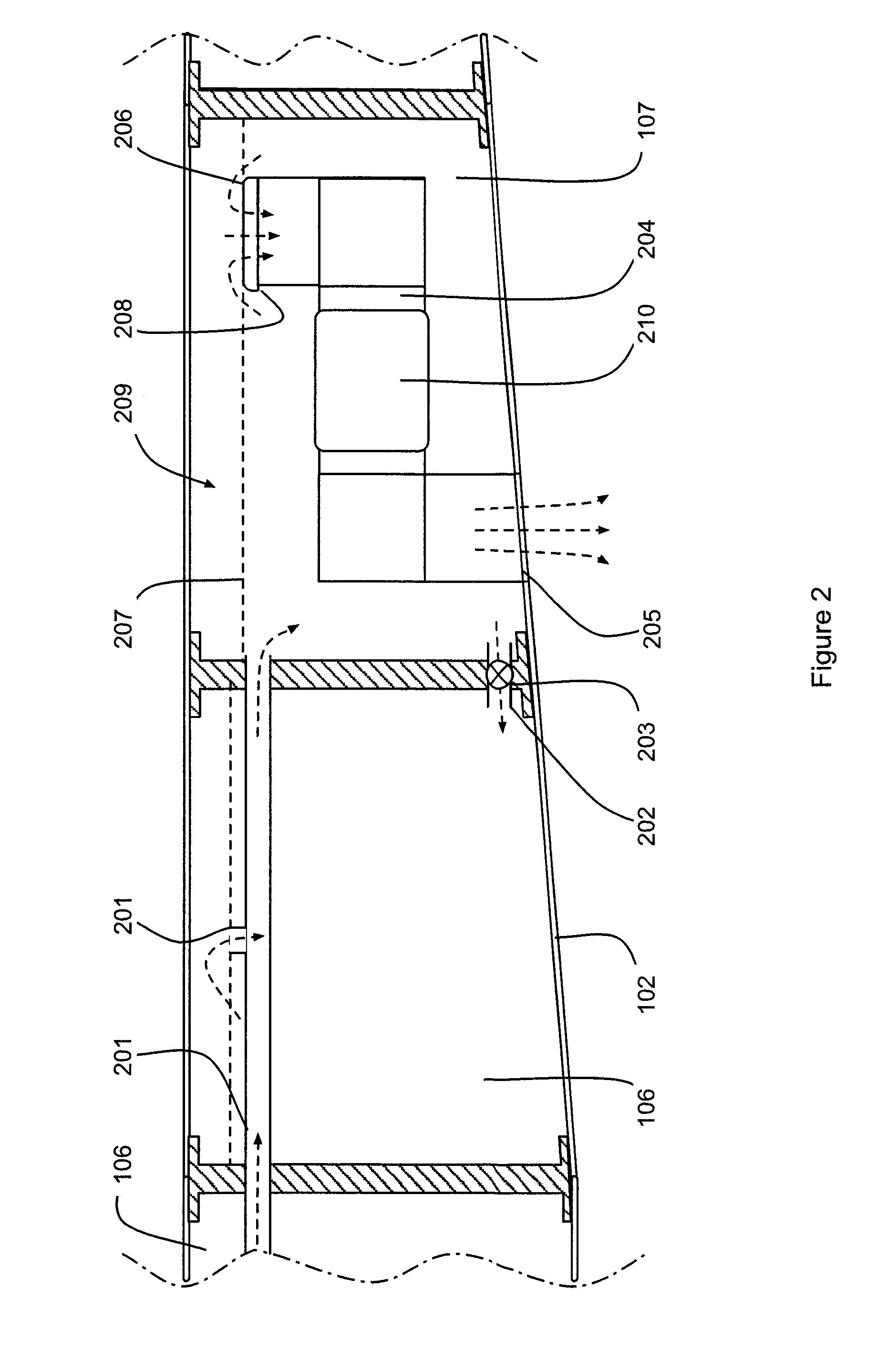

Aircraft systems and methods with green fuel tanks

An aircraft system includes a main fuel tank configured to house primary fuel and a green fuel tank configured to house green fuel. The mixing apparatus is configured to mix the primary fuel and the green fuel to result in a predetermined ratio of mixed fuel. A controller selectively commands a first amount of primary fuel and a second amount of green fuel to result in the predetermined ratio of mixed fuel. The main aircraft engine is configured to operate, in a first main engine mode, with the primary fuel from the main fuel tank and to operate, in a second main engine mode, with the mixed fuel from the mixing apparatus based on commands from the controller. The auxiliary power source is configured to operate with at least a portion of the green fuel from the green fuel tank based on commands from the controller.

Owner:HONEYWELL INT INC

Vent pipe for an aircraft fuel system vent tank

A vent pipe is disclosed for use in the vent tank of an aircraft fuel system. The vent pipe is arranged with guide vanes or corner cascades for assisting the flow of fluid around the corners.

Owner:AIRBUS OPERATIONS LTD

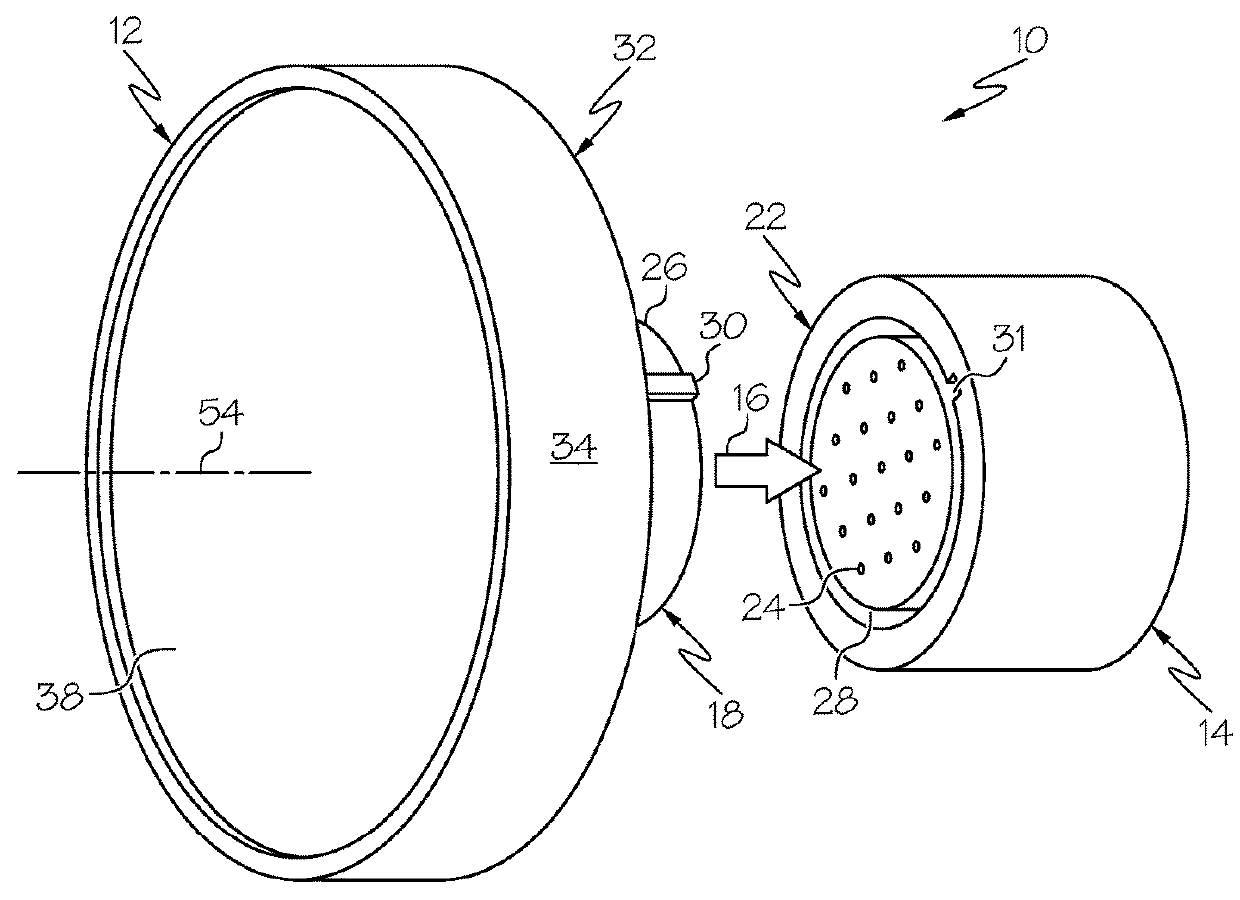

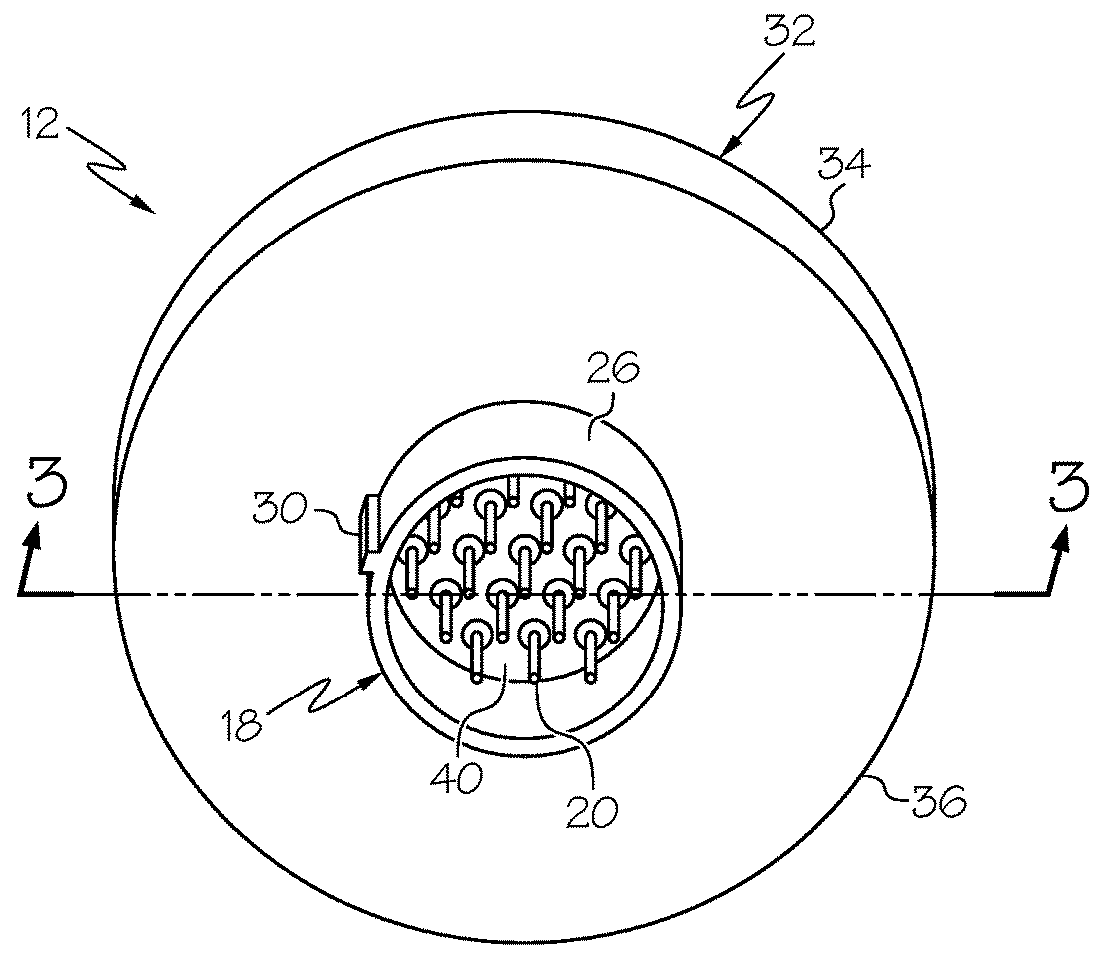

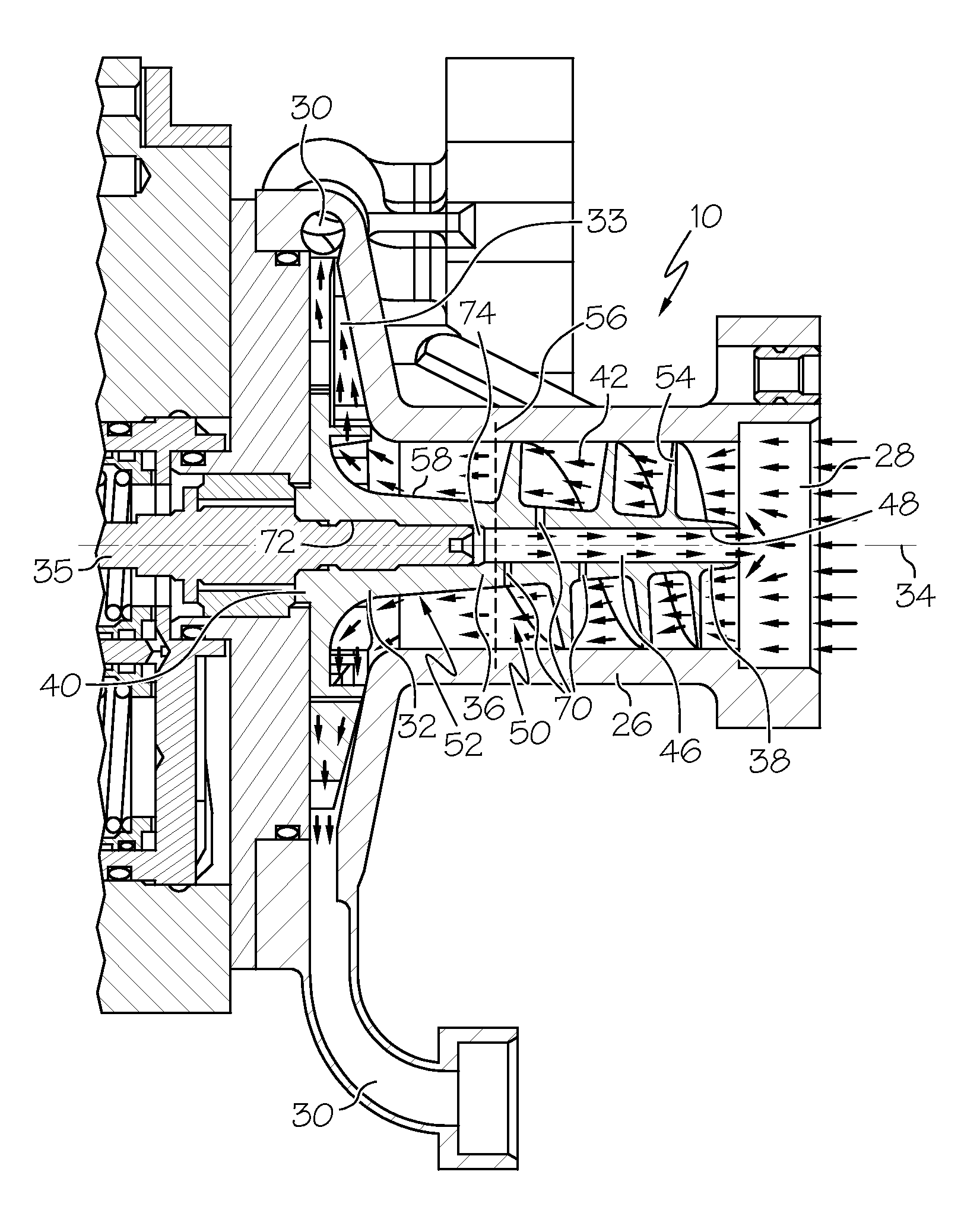

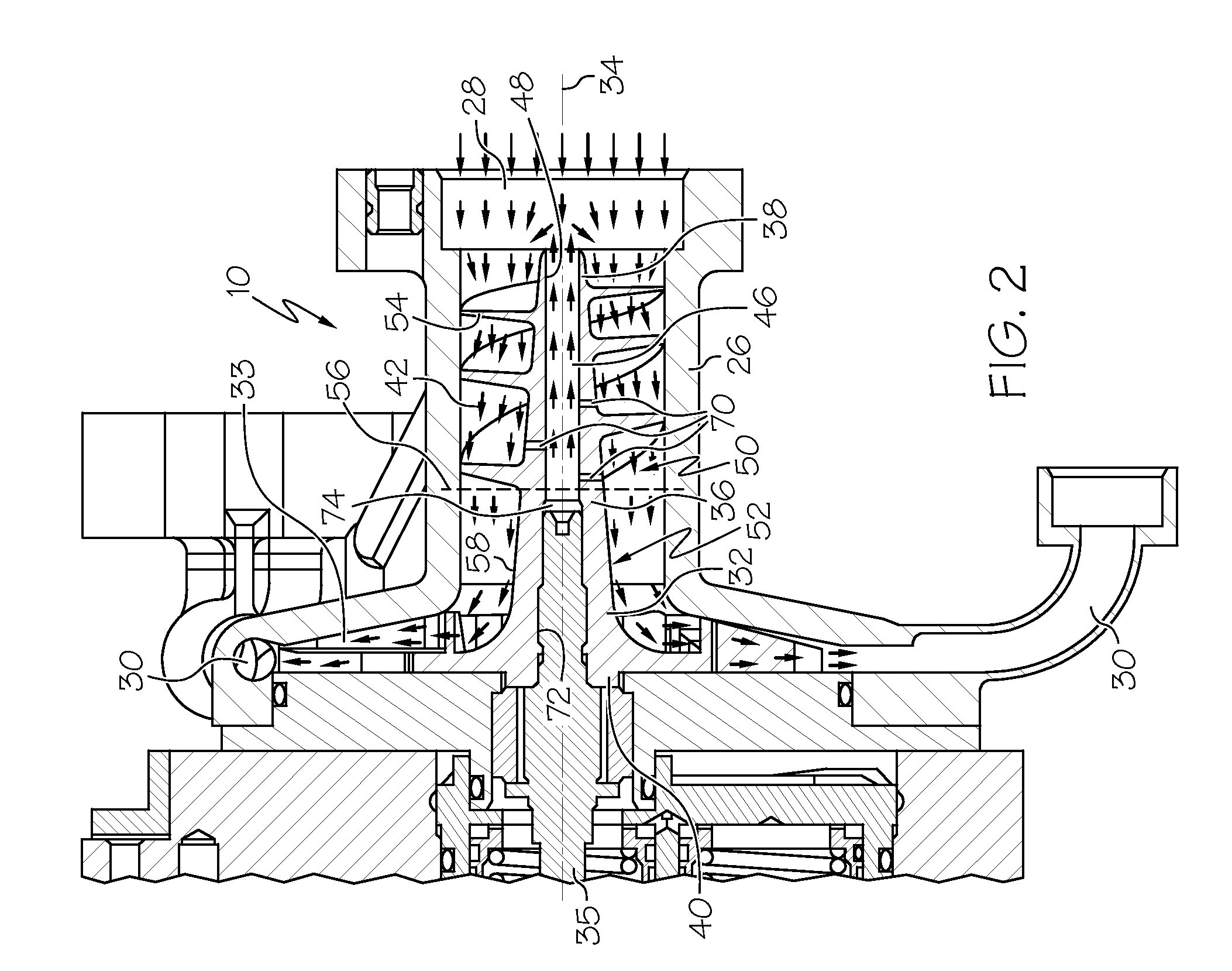

Impeller, centrifugal pump including the same, and aircraft fuel system including the centrifugal pump

InactiveUS20130320148A1Improve fluid flowPower plant fuel tanksPump componentsAircraft fuel systemRotational axis

An impeller, a centrifugal pump, and an aircraft fuel system are provided. The impeller includes a central hub disposed along a rotational axis of the impeller and that defines an axial bore extending through at least a portion of the central hub along the rotational axis. The central hub further defines an opening to the axial bore at a leading end of the central hub. The impeller further includes an impeller section spaced from the leading end and that includes at least one impeller vane fixed to the central hub. The impeller further includes an inducer section that is disposed between the leading end of the central hub and the impeller section and that includes at least one inducer vane extending along an outer surface of the central hub. The central hub defines at least one radial aperture in the inducer section in fluid communication with the axial bore.

Owner:HONEYWELL INT INC

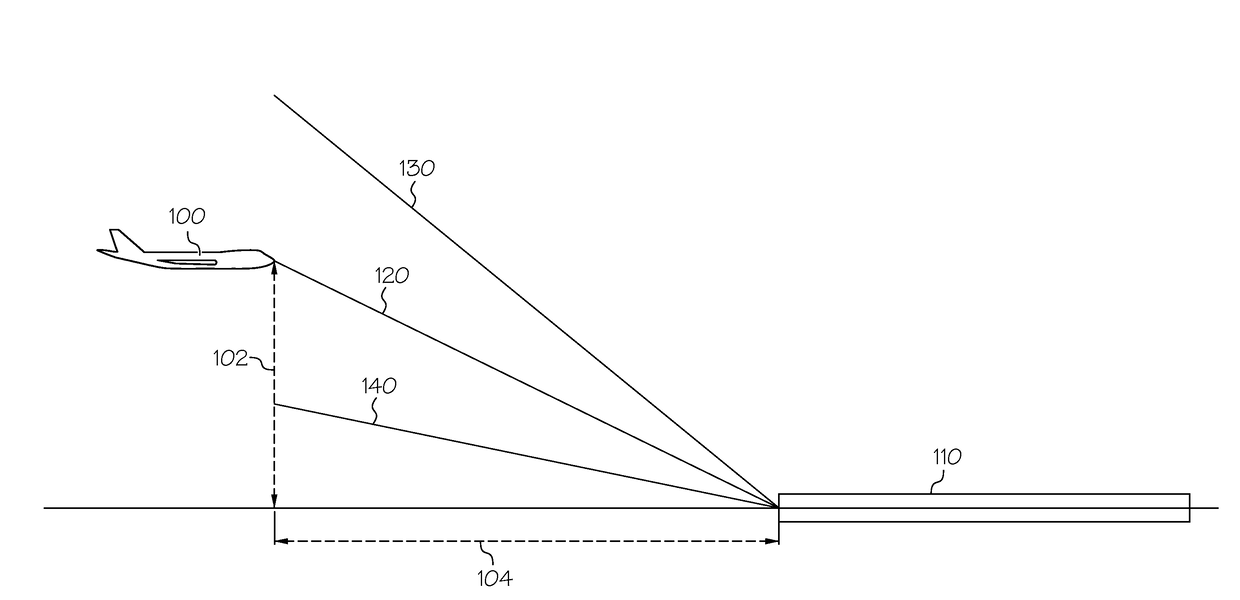

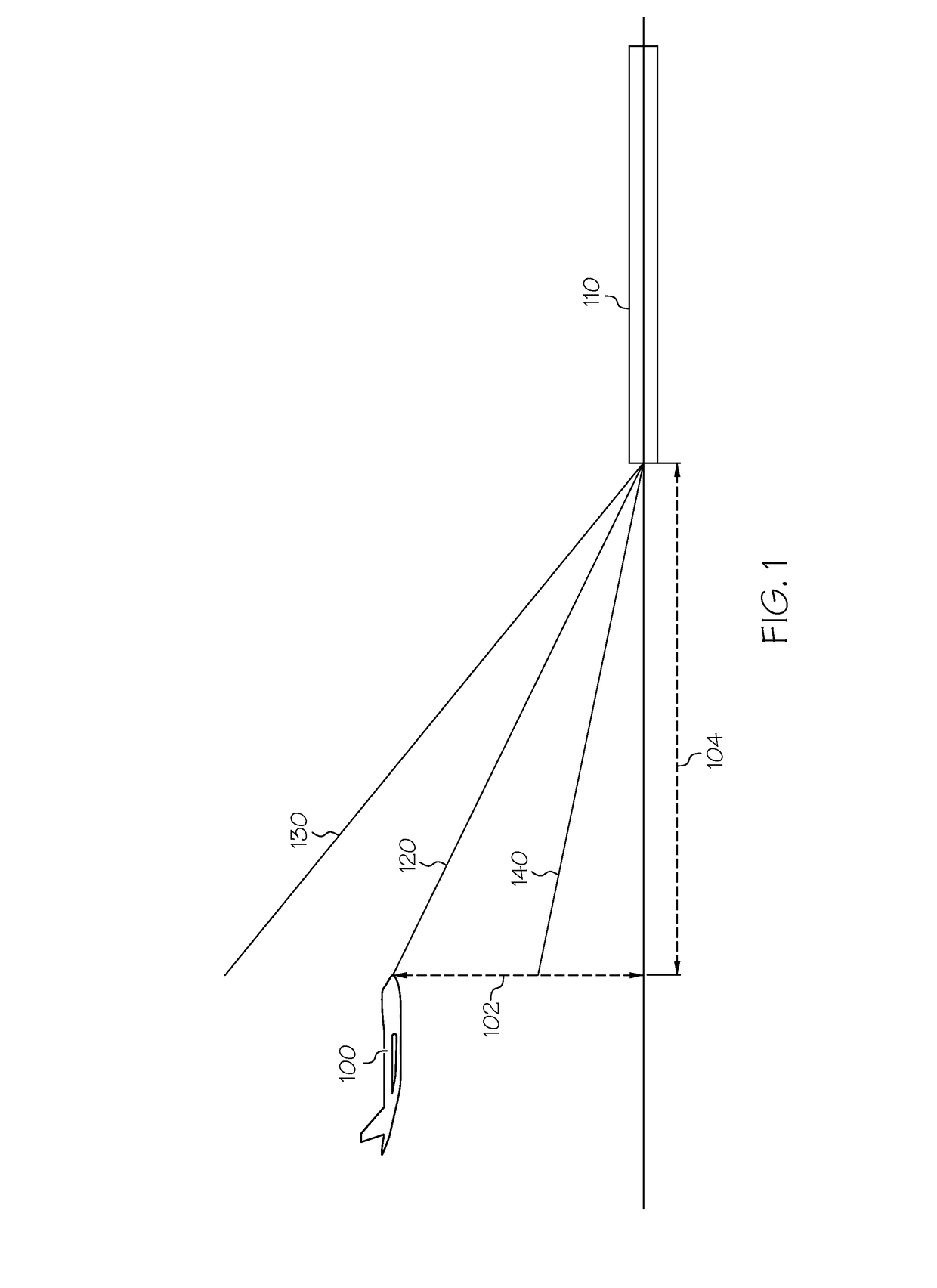

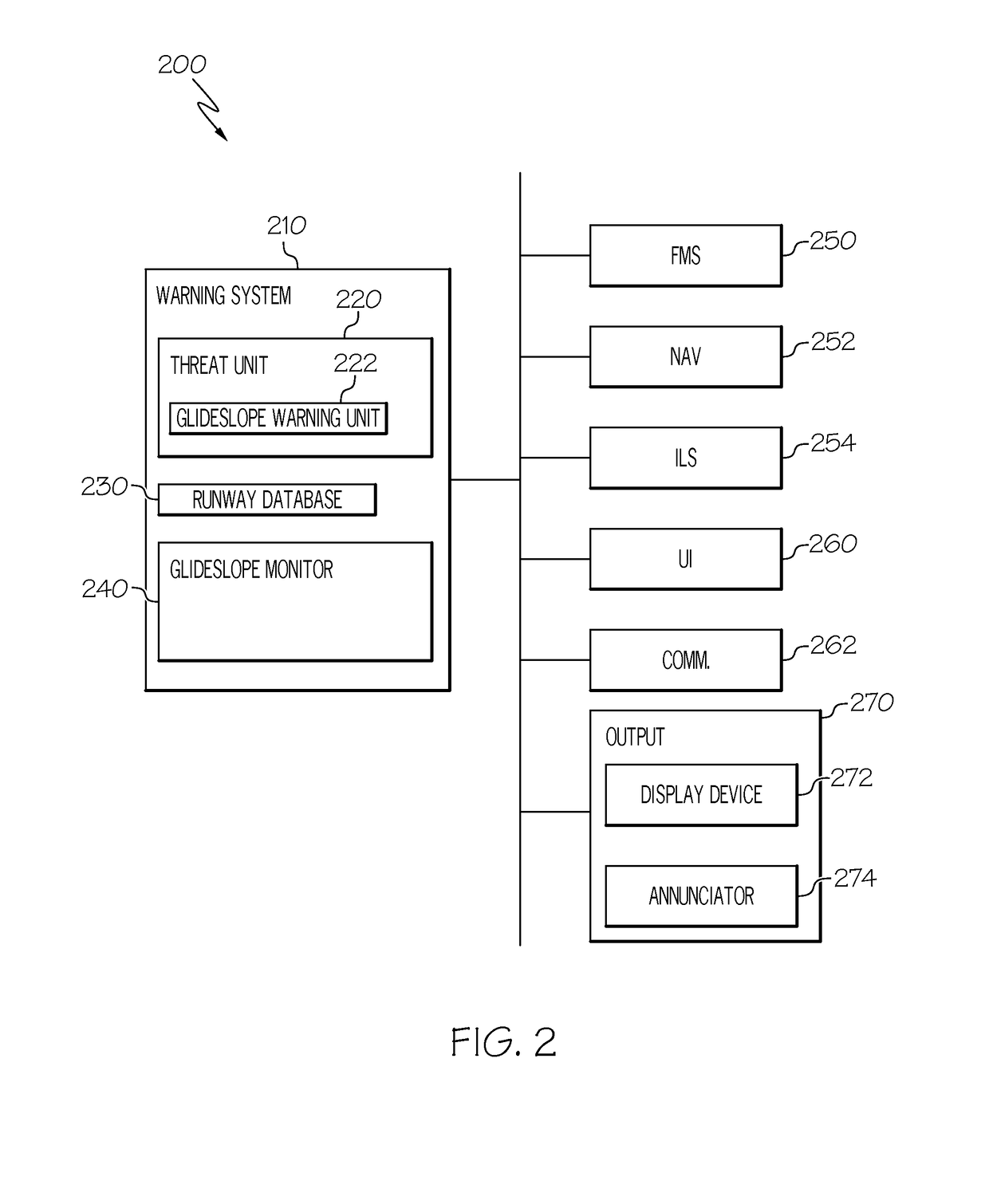

Aircraft systems and methods for providing landing approach alerts

ActiveUS20170124886A1Beacon systems using radio wavesAutomatic aircraft landing aidsAircraft fuel systemInstrument landing system

A method is provided for monitoring a landing approach of an aircraft. The method includes receiving instrument landing system (ILS) signals; determining a glideslope deviation from the ILS signals; disabling, when the glideslope deviation is less than a first predetermined threshold, at least one glideslope alert function; evaluating a current glideslope condition by comparing a designated glideslope angle to a glideslope check value; and re-enabling the at least one glideslope alert function when the glideslope check value differs from the designated glideslope angle by more than a second predetermined threshold.

Owner:HONEYWELL INT INC

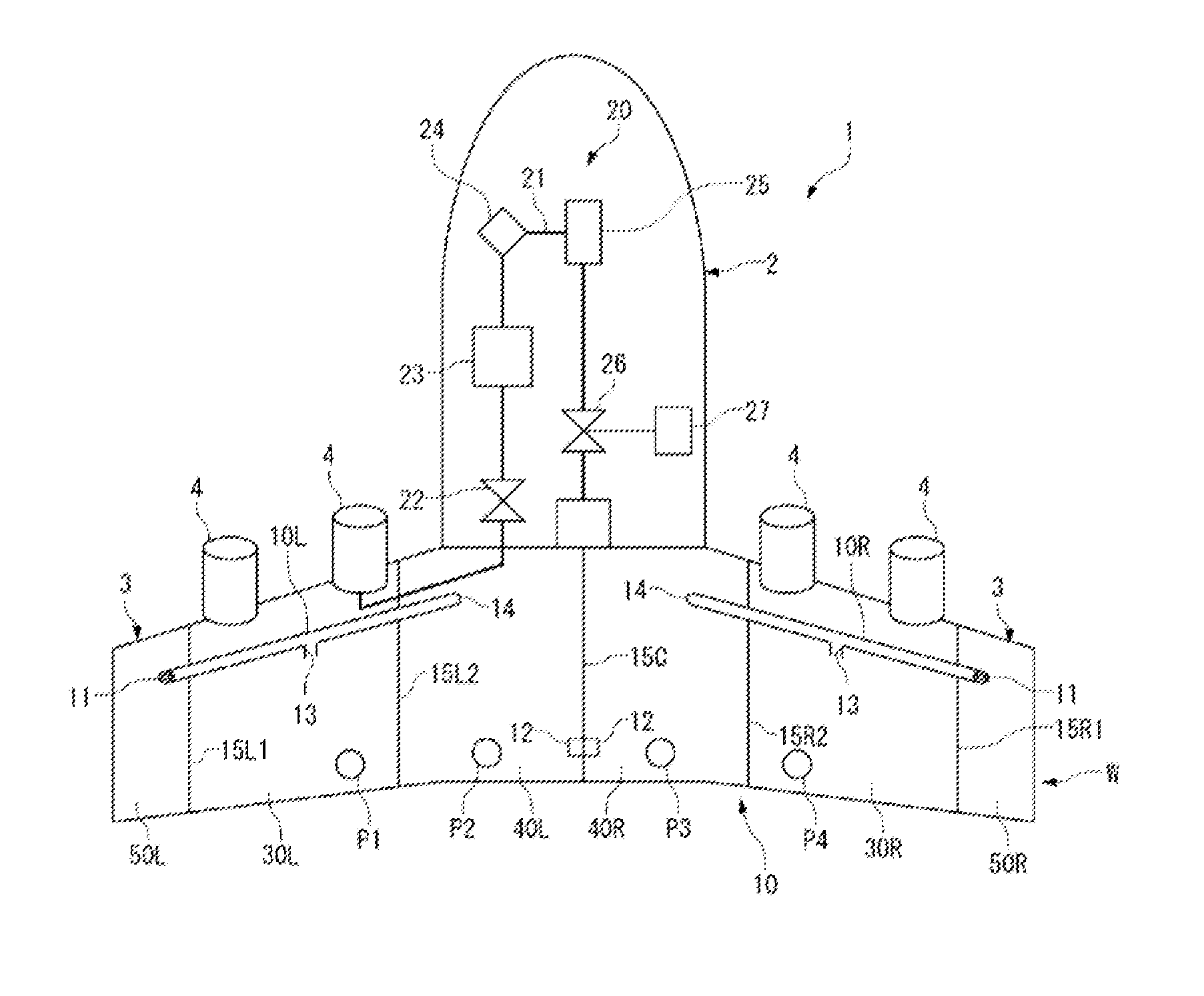

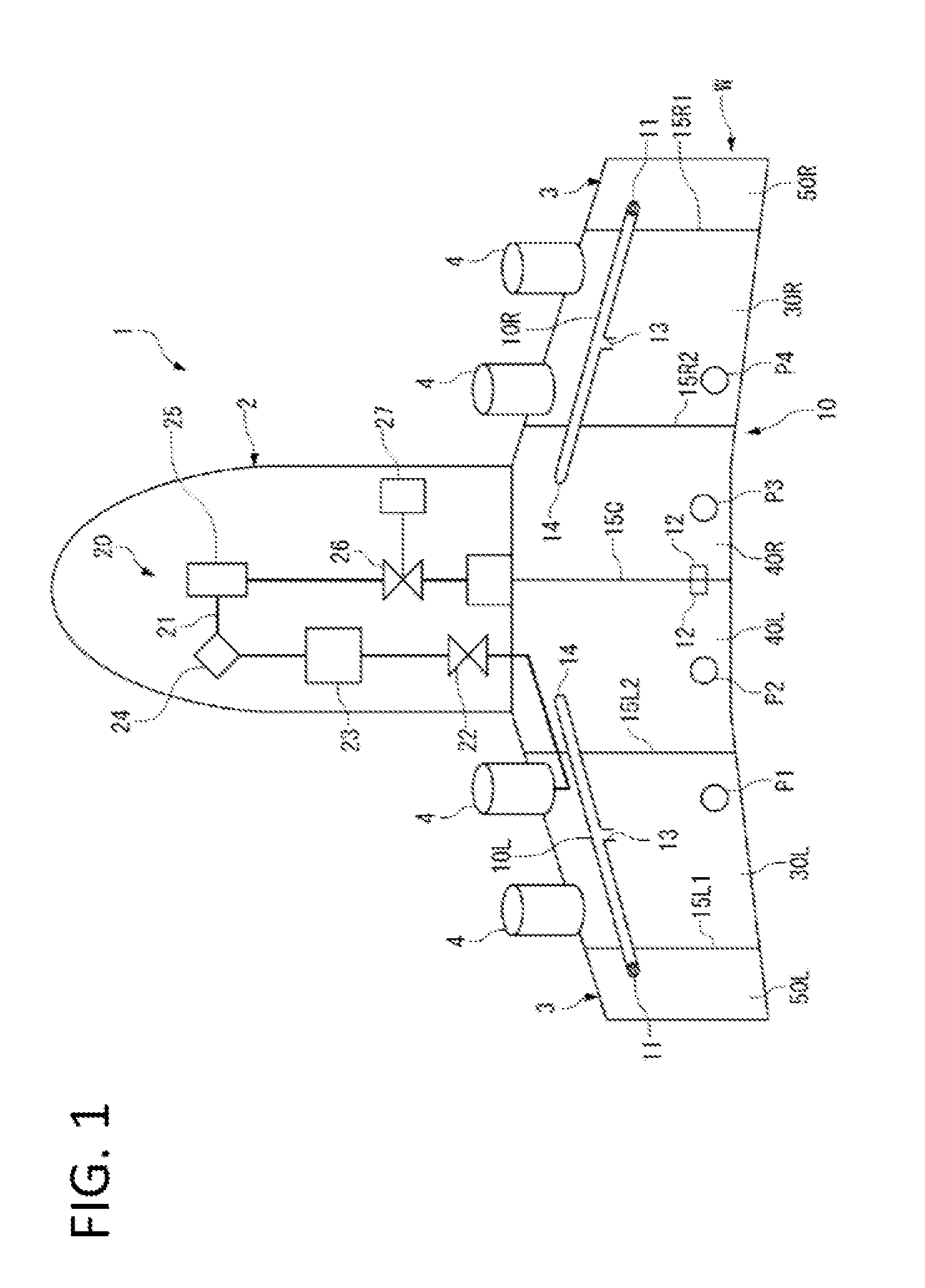

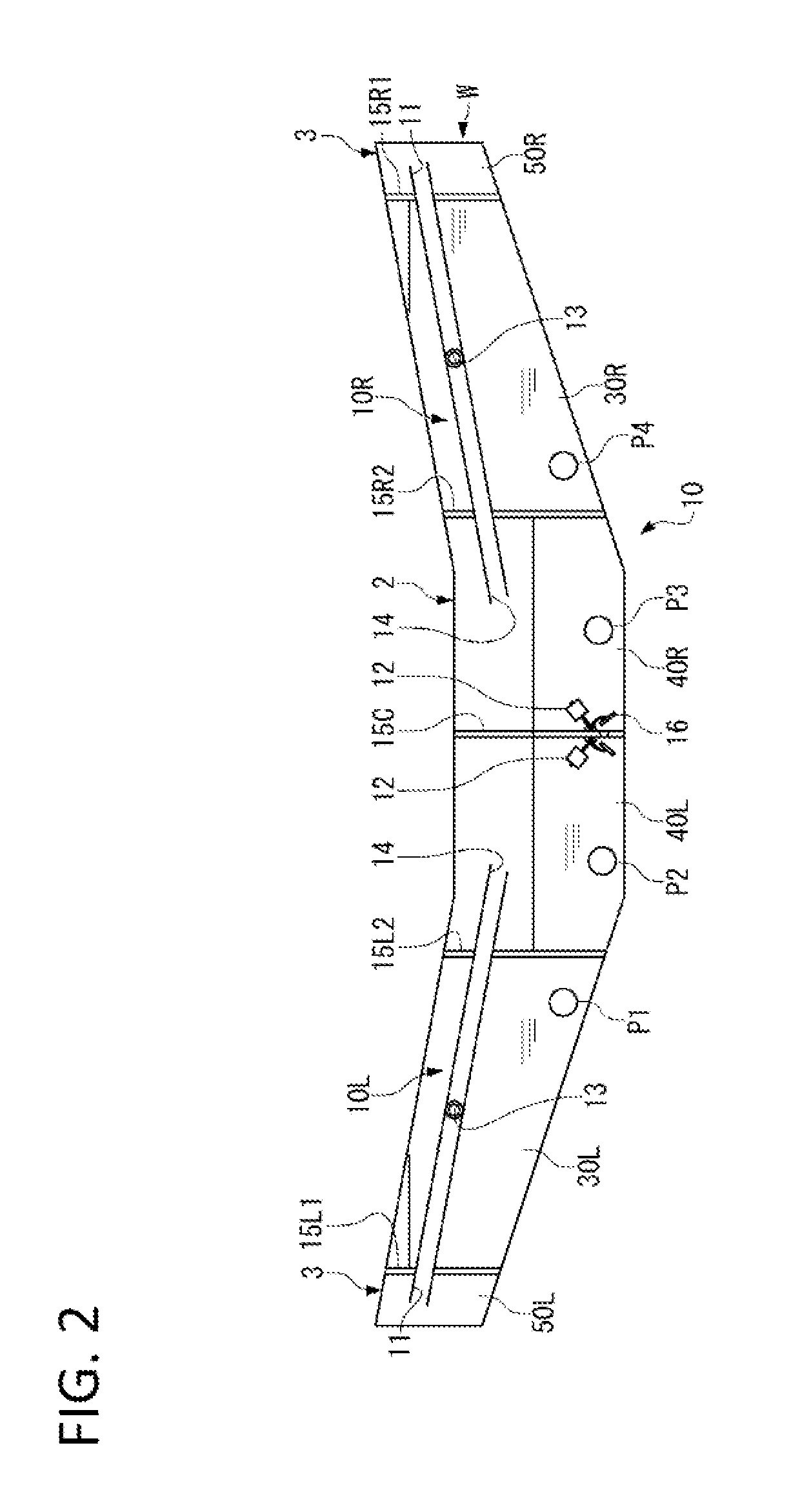

Aircraft fuel system and aircraft

ActiveUS20150034768A1Reduce concentrationAdequate levelPower plant fuel tanksFuel tank safety measuresAircraft fuel systemFuel tank

The present invention ensures explosion-proof performance without increasing the capacity for supplying nitrogen-enriched air in an aircraft fuel system having a ventilation function. An aircraft fuel system includes: fuel tanks; an NEA supply system; a left ventilation channel extending from a ventilation duct to a fuselage and leading into the tanks; and a right ventilation channel extending from a ventilation duct to the fuselage and leading into the tanks. The tank leading to the channel and the tank leading to the channel are separated by a central wall. The tanks communicate with each other through a fuel path, which allows, of fuel and gas, only the fuel to pass through, and float valves.

Owner:MITSUBISHI AIRCRAFT

Aircraft systems and methods with integrated tank inerting and power generation

InactiveUS9604730B2Turbine/propulsion fuel supply systemsFuel cell heat exchangeAircraft fuel systemElectricity

A system is provided for inerting a fuel tank of an aircraft. The system includes a first compressor fluidly coupled to the fuel tank for removing an air and fuel vapor mixture from an ullage of the fuel tank. The system further includes a fuel processor fluidly coupled to the first compressor and configured to receive the air and fuel vapor mixture and to generate hydrogen from the air and fuel vapor mixture. The system further includes a fuel cell fluidly coupled to the fuel processor and configured to receive the hydrogen as anode fuel to produce electricity. The system further includes a combustor fluidly coupled to the fuel cell and configured to combust the exhaust product to produce combustion gas, and a first heat exchanger fluidly coupled to the combustor and configured to cool the combustion gas into inerting gas for the fuel tank.

Owner:HONEYWELL INT INC

Aircraft fuel system

ActiveUS20170210482A1Avoid flowPower plant fuel tanksWingsAircraft fuel systemMechanical engineering

An aircraft fuel system has a bottom wall, and a rib with a bottom edge joined to the bottom wall. The rib provides a boundary between first and second compartments. At least the first compartment is arranged to carry fuel. An open recess is in the bottom edge of the rib and a rib sealing arrangement between the bottom edge of the rib and the bottom wall prevents fuel from flowing across the bottom edge of the rib except at the open recess. The system has a pump and a conduit coupled at one end to the open recess and at another end to the pump. The open recess and the conduit provide a fuel flow path across the bottom edge of the rib from the first compartment into the pump. The flow path is sealed to prevent fuel flowing out of the flow path into the second compartment.

Owner:AIRBUS OPERATIONS LTD

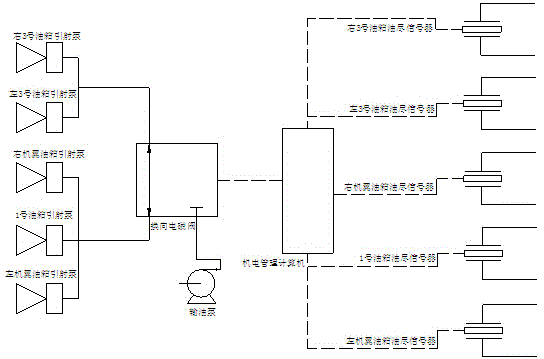

Aircraft fuel oil conveying sequence control system

ActiveCN104627376ARealize automatic oil deliveryReduce weightWeight reductionPower plant fuel supplyAircraft fuel systemSequence control

An aircraft fuel oil conveying sequence control system comprises an oil use-up annunciator, an oil conveying tank, a reversing solenoid valve, a mechanical and electric management computer, an oil conveying pump and a jet pump. The oil use-up annunciator is mounted at the bottom of the oil conveying tank, and the oil use-up annunciator and the reversing solenoid valve are connected with the mechanical and electric management computer. The reversing solenoid valve is mounted at an outlet of the oil conveying pump, meanwhile, a channel A of the reversing solenoid valve is connected with the outlet of the oil conveying pump, and an output channel of the reversing solenoid valve is connected with the jet pump. According to the aircraft fuel oil conveying sequence control system, the oil use-up annunciator which is arranged in the aircraft oil conveying tank is used, and the reversing solenoid valve is arranged so that the oil use-up annunciator and the reversing solenoid valve are made to work in a combined mode to achieve the control over oil conveying sequences. The aircraft fuel oil conveying sequence control system is small in number of accessories, simple in control logic, and capable of effectively lowering the weight of an aircraft fuel oil system; meanwhile, the reversing solenoid valve is electrically controlled through the electric reversing solenoid valve, and the reliability of the aircraft fuel oil system is effectively enhanced.

Owner:JIANGXI HONGDU AVIATION IND GRP

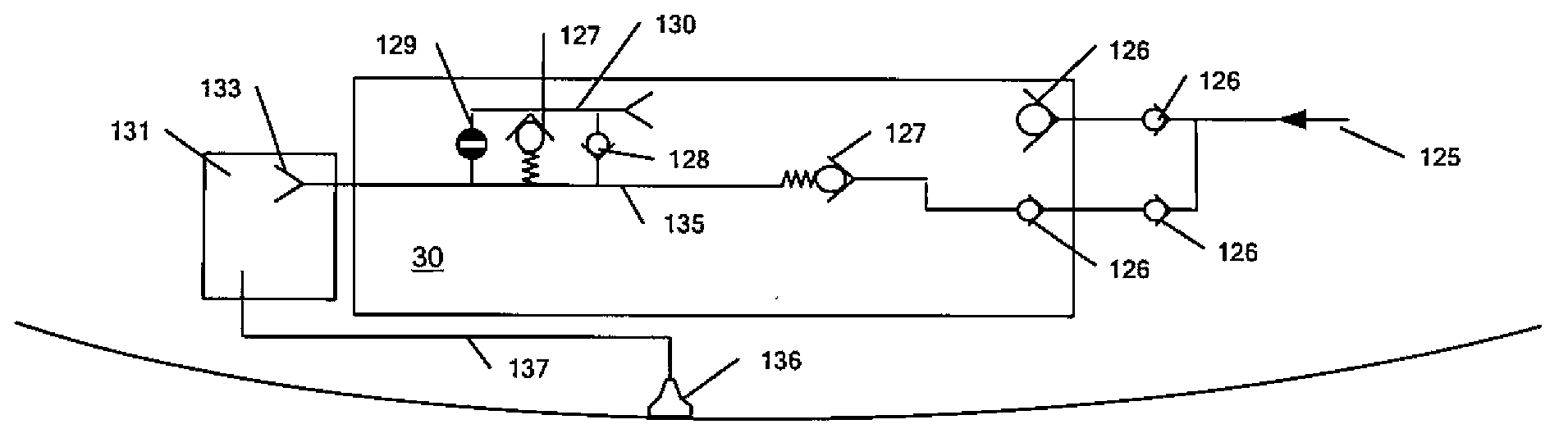

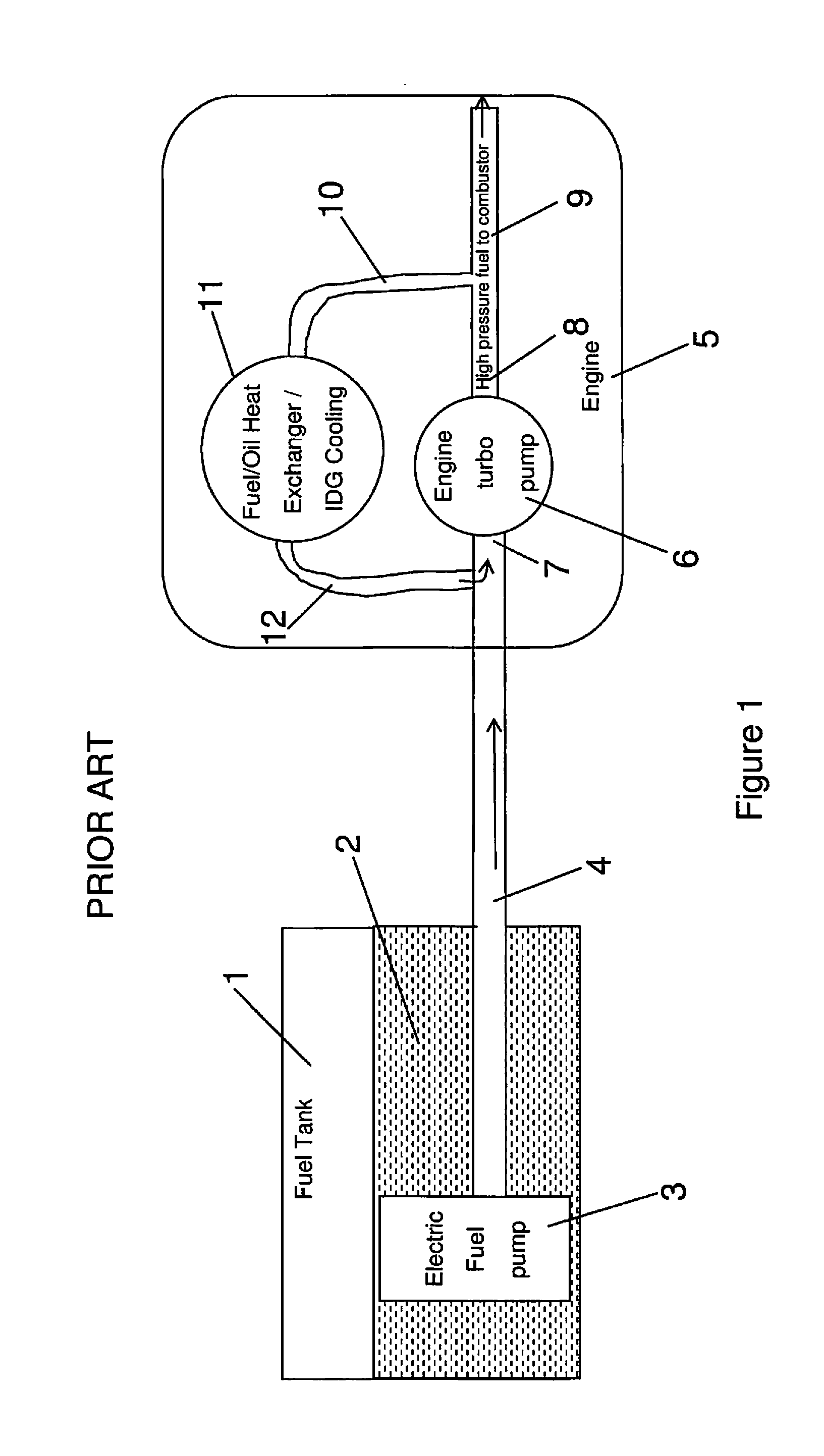

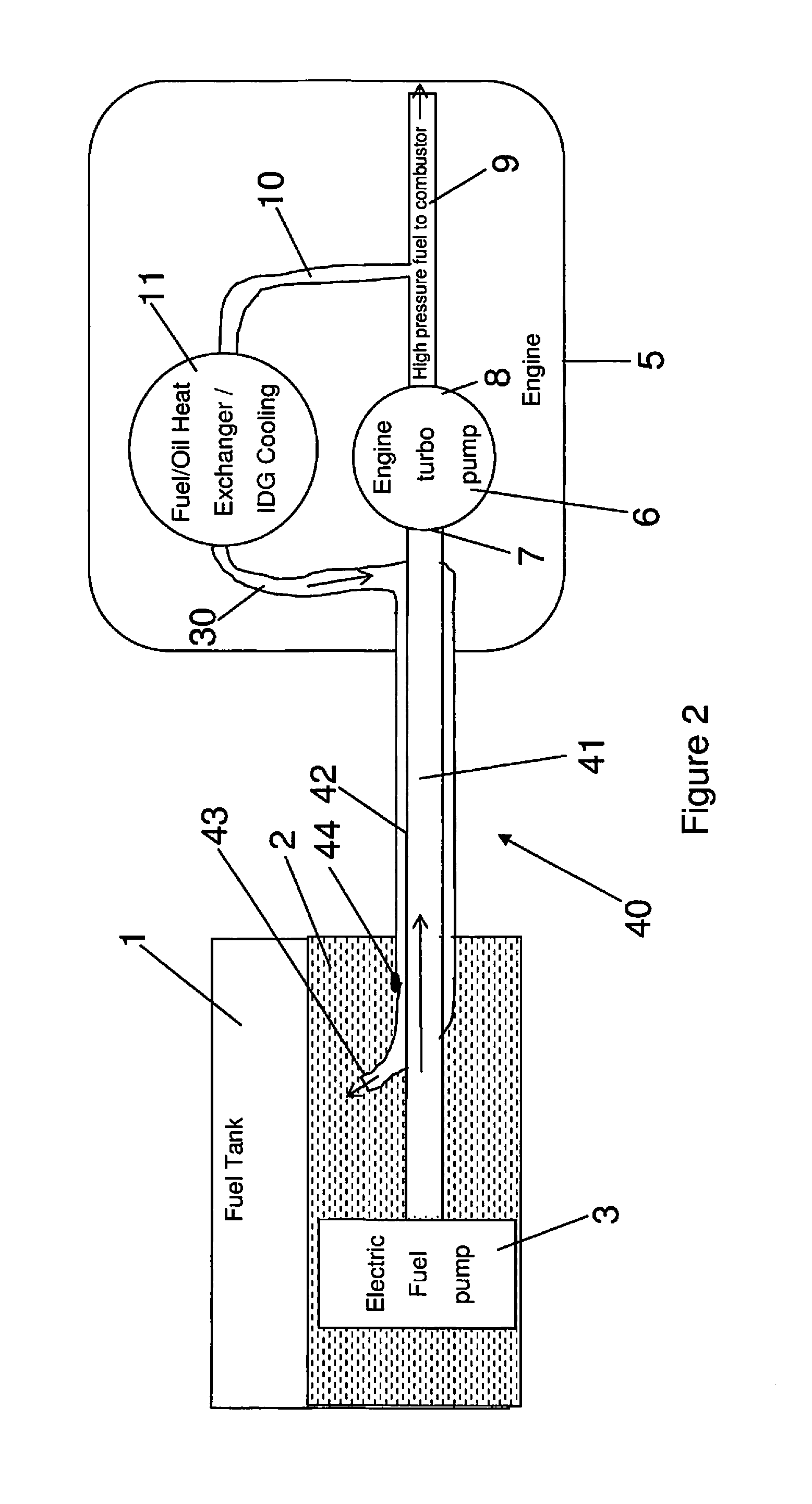

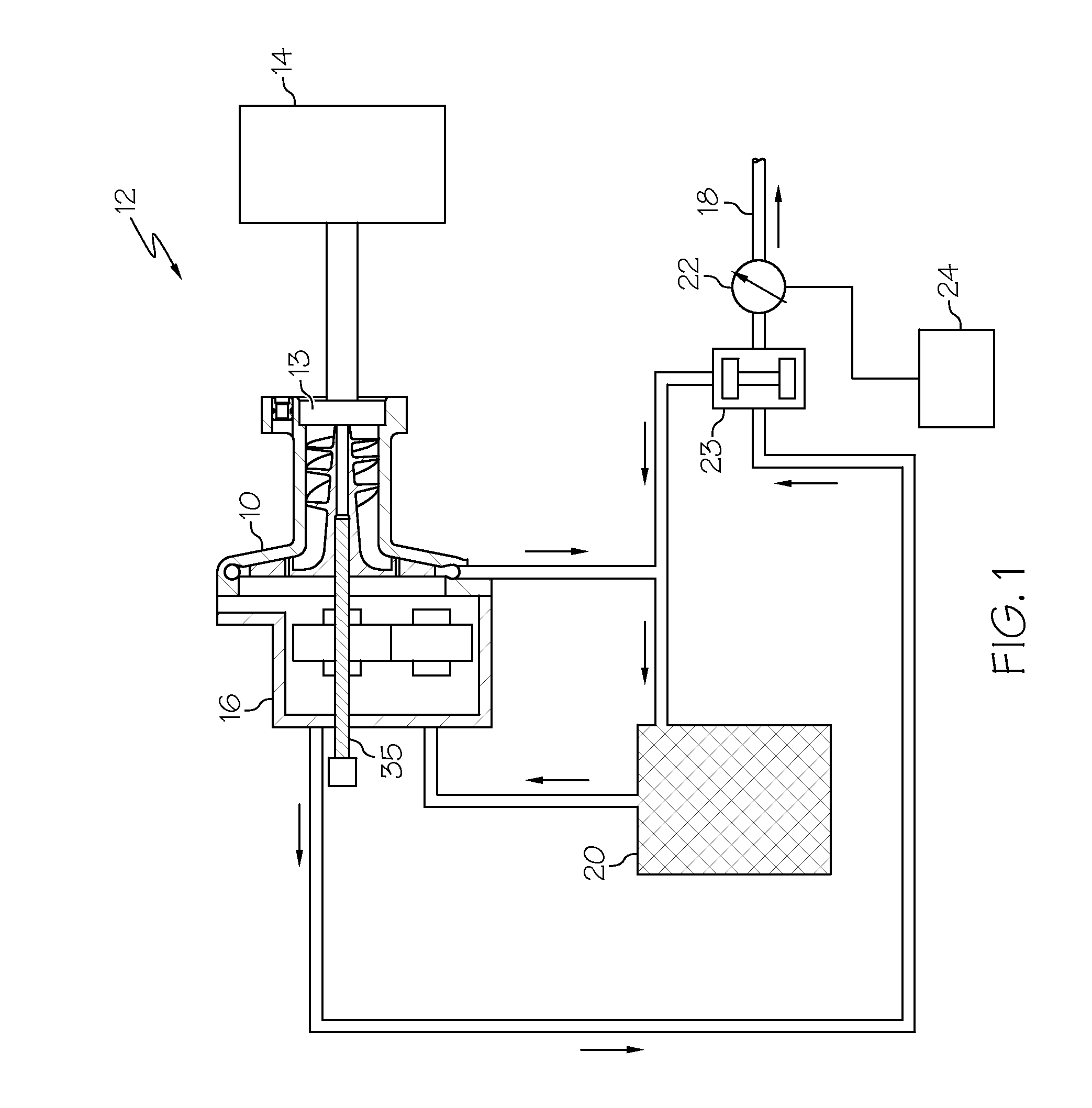

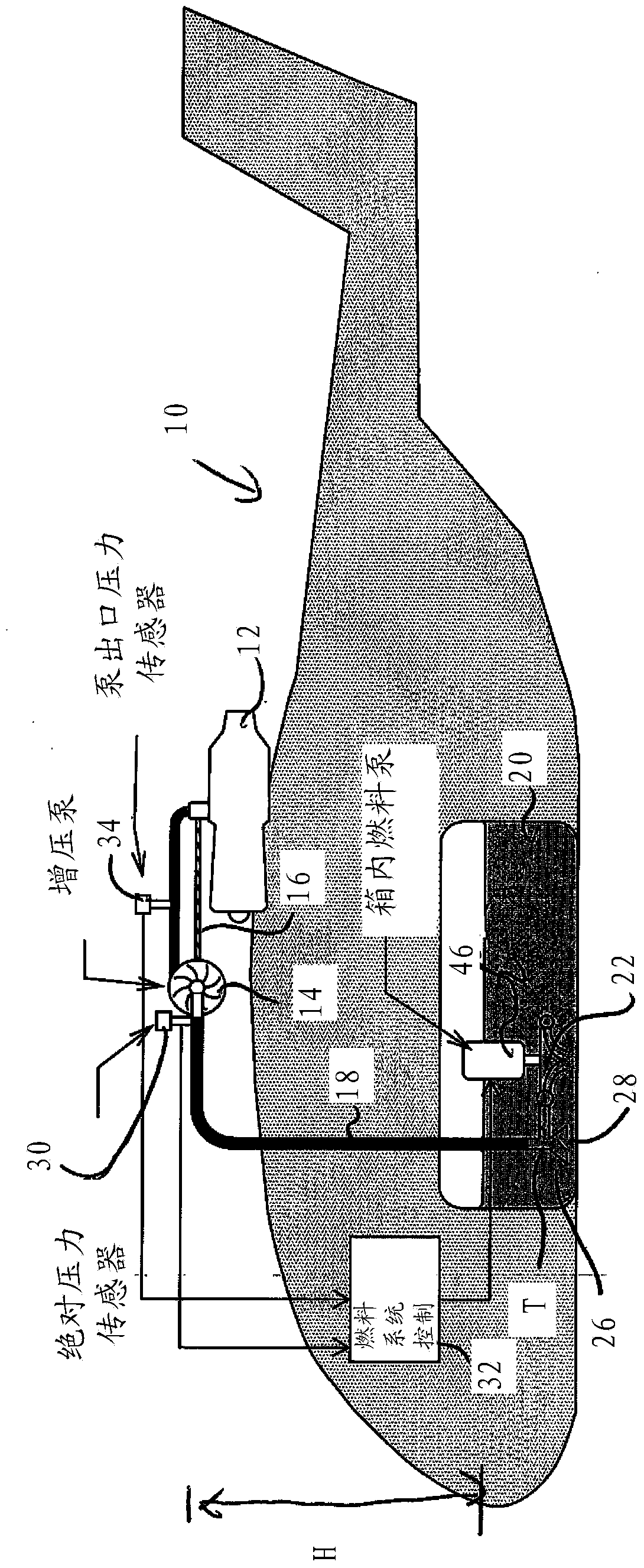

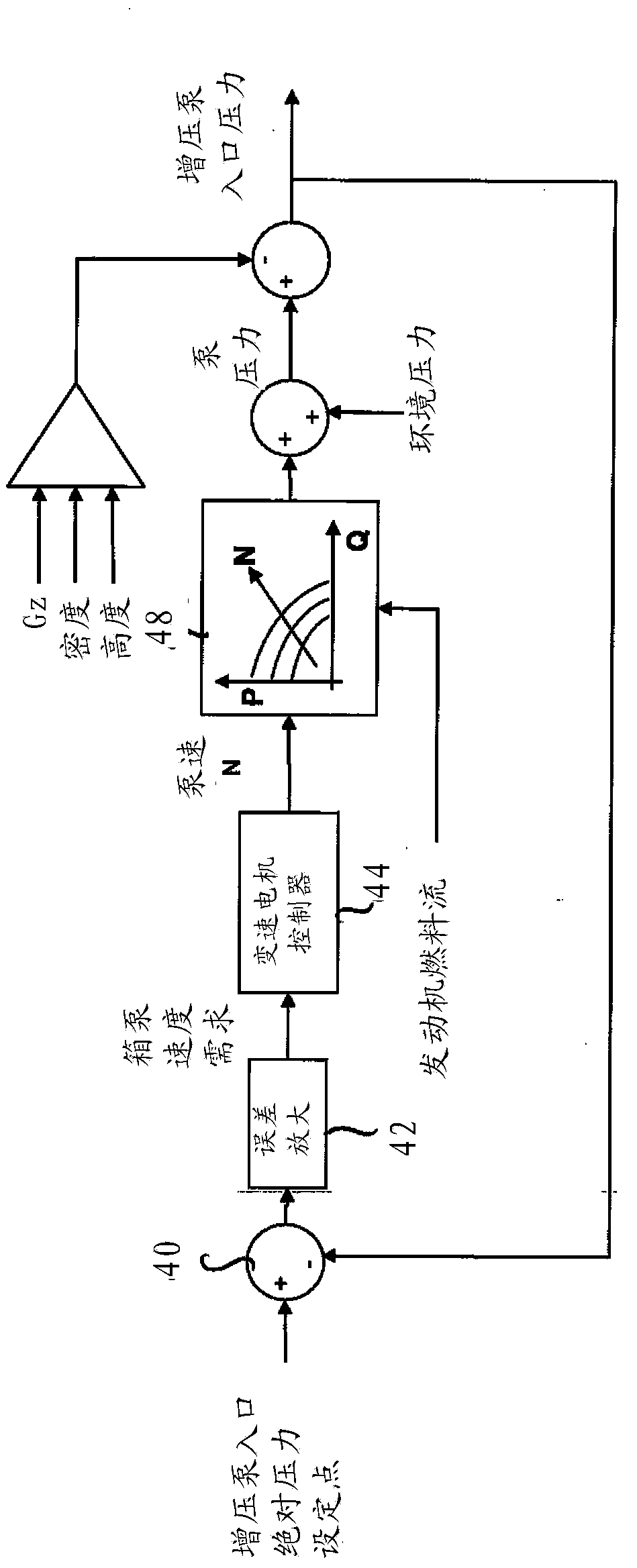

Aircraft fuel supply systems

A fuel supply system for an aircraft 10 for delivering fuel from a fuel tank 20 to an aircraft power plant 12. The fuel supply system comprises a fuel flow passage 18 along which fuel flows from the tank to the power plant. The fuel flow passage has a downstream end adjacent the power plant and an upstream end adjacent the fuel tank. A downstream pump 14 is associated with the power plant for drawing fluid along the passage to supply it to the power plant. An upstream pump 22 is associated with the fuel tank and is operable to pump fluid along the passage. A pressure sensor 30 for monitoring the inlet pressure to the downstream pump, and a fuel system controller 32 are provided; the fuel system controller is responsive to the pressure sensor and controls the upstream pump to maintain the pressure at the inlet to the downstream pump at a predetermined threshold pressure.

Owner:伊顿智能电源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com