Hydraulic low-pressure pulse experiment method of aircraft

A technology of low-pressure pulse, experimental method, applied in the field of hydraulic pulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

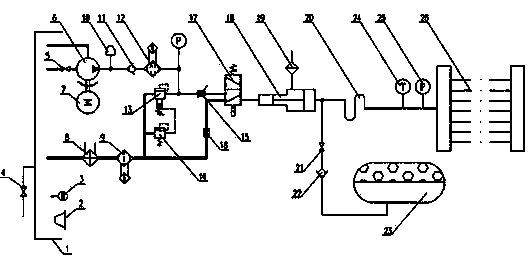

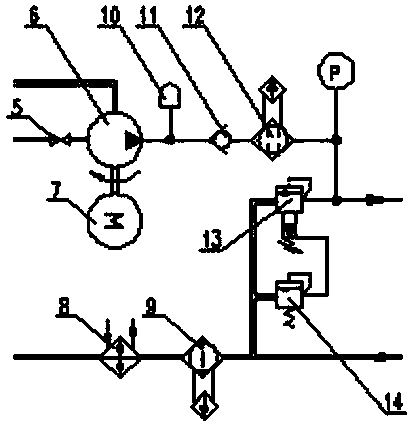

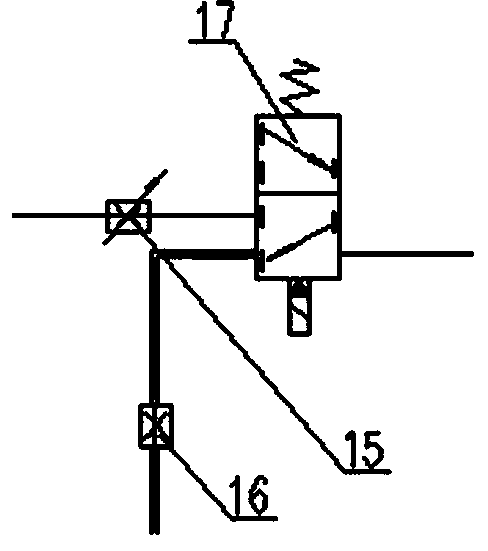

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025] An experimental method of aircraft hydraulic low pressure pulse, the experimental method is realized in the low pressure pulse test system, the test method is characterized in that:

[0026] A) When performing the pulse test, firstly fill the pressurized oil tank 25 with the initial pressure required by the test piece 26, close the stop valve 21, start the oil source, and boost the pressure to the working pressure specified in the test; at this stage, the electromagnetic reversing valve 17 is in the closed position, the output flow of the oil pump 6 stops at the oil supply port of the electromagnetic reversing valve 17, and the pressure level at the front end of the electromagnetic reversing valve 17 is the system pressure; while the pipeline from the electromagnetic reversing valve 17 to the end of the test piece The flow rate is zero, and the pressure is the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com