Aircraft fuel supply systems

A fuel supply system, fuel system technology, applied in the direction of charging system, turbine/propulsion fuel delivery system, power plant fuel supply, etc., can solve problems such as fuel interruption or significant restriction, engine power loss, engine failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

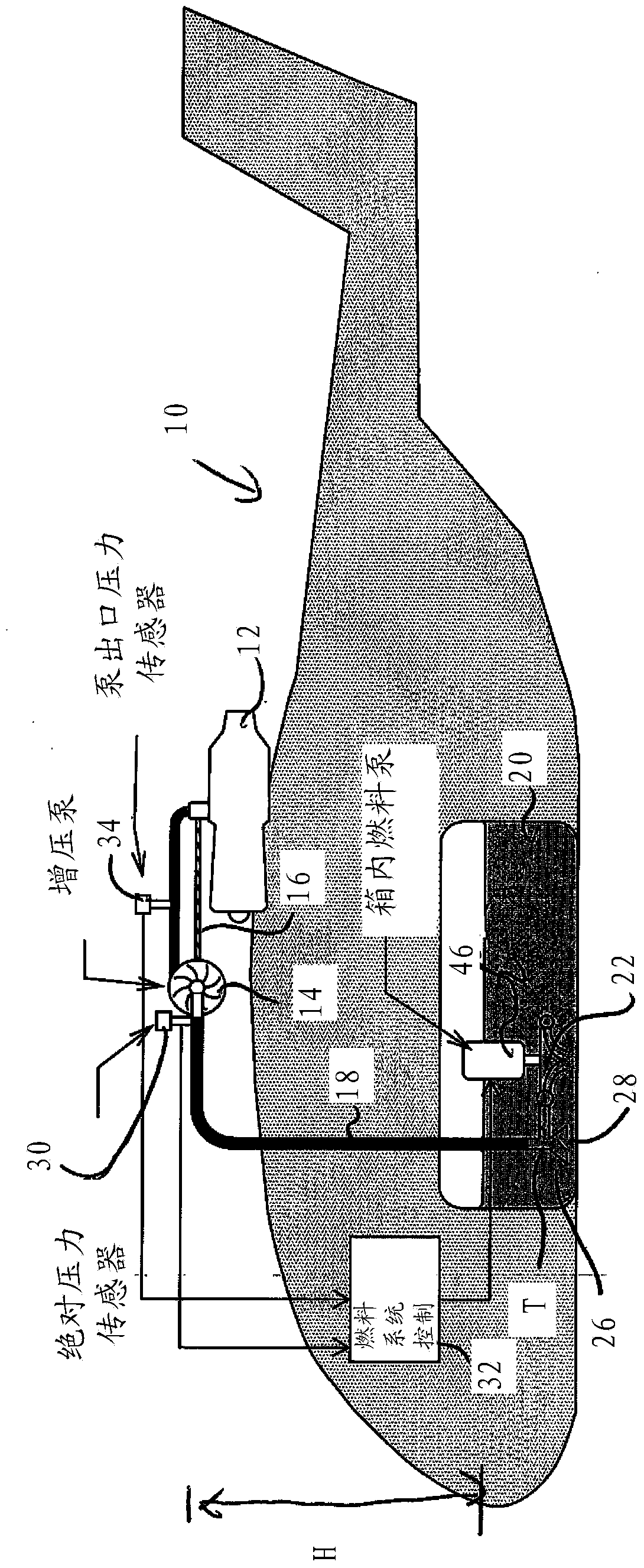

[0037] First refer to figure 1 , the illustrated helicopter 10 includes a power plant 12 to drive a rotor (not shown). The powerplant 12 is mounted on the upper portion of the helicopter fuselage and receives fuel from a main (downstream) fuel pump 14 which in this embodiment is driven by a power take-off shaft 16 from the powerplant 12 . Fuel is supplied to the main fuel pump 14 through a fuel line 18 extending from a fuel tank 20 located in the lower fuselage of the helicopter. It should be noted that there is a distinct oil level "H" between the pump and the fuel tank. As the size of the helicopter increases, so does this oil level, which means that the suction force required to overcome this oil level to get the fuel to the engine also increases. An upstream (supply) pump 22 is arranged in the fuel tank and is connected to the fuel supply line with a T-joint 24 . The other branch of the T-joint goes to the suction inlet 26 which includes a check valve 28 through which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com