Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

295results about "Power plant fuel supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

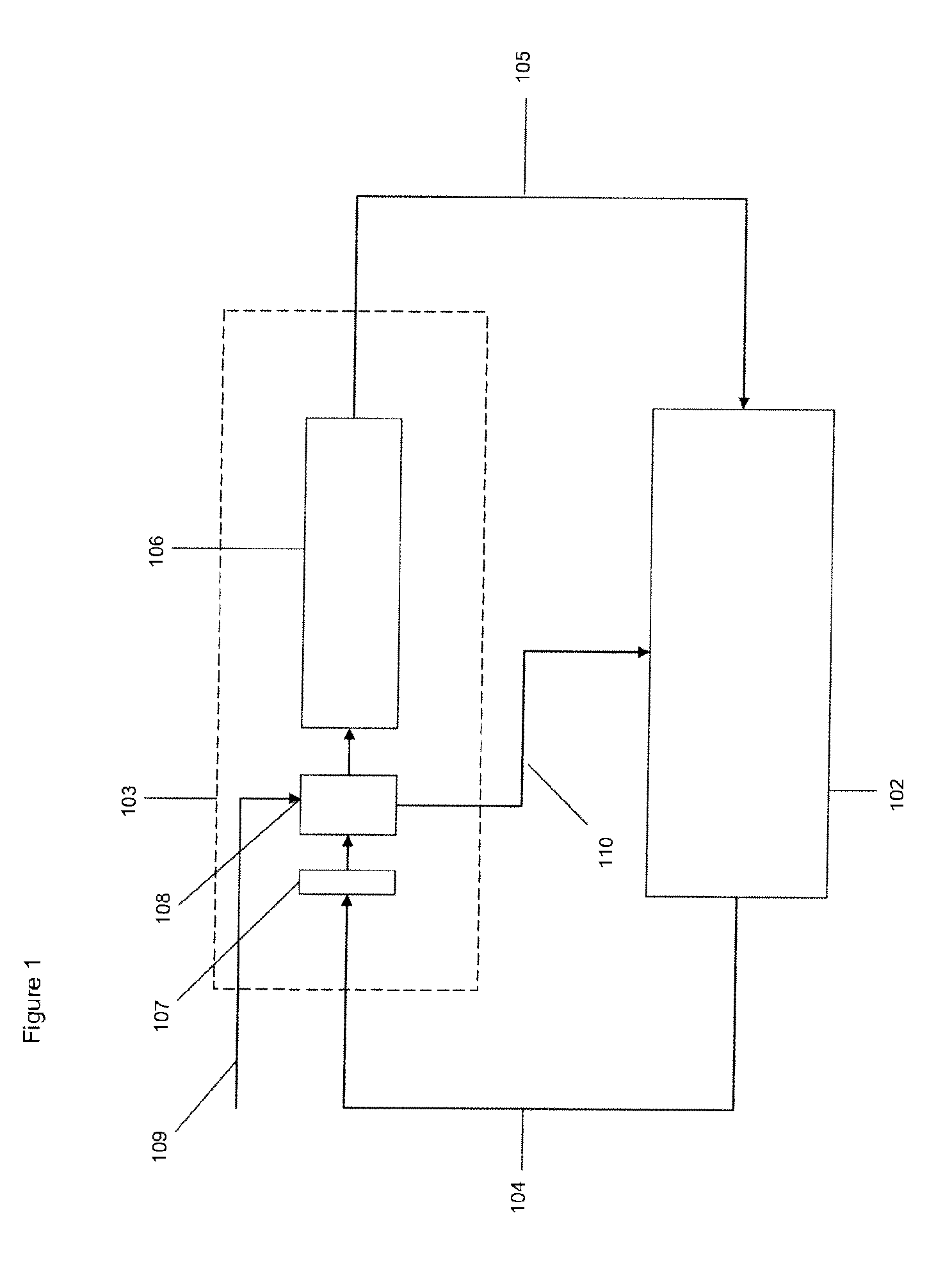

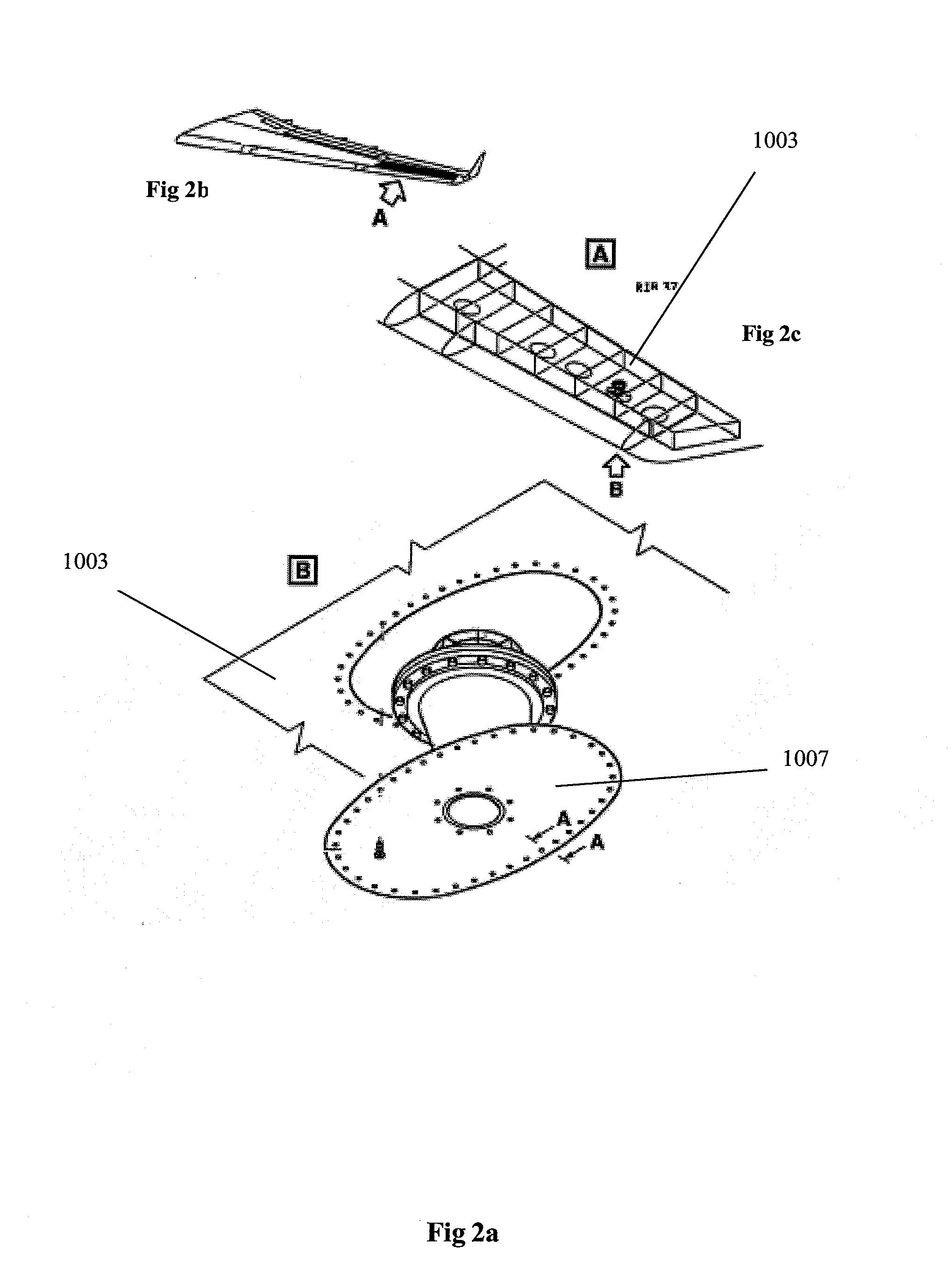

Unmanned aerial vehicle and method for collecting video using the same

InactiveUS20110264311A1Analogue computers for vehiclesUnmanned aerial vehiclesVideo storageUncrewed vehicle

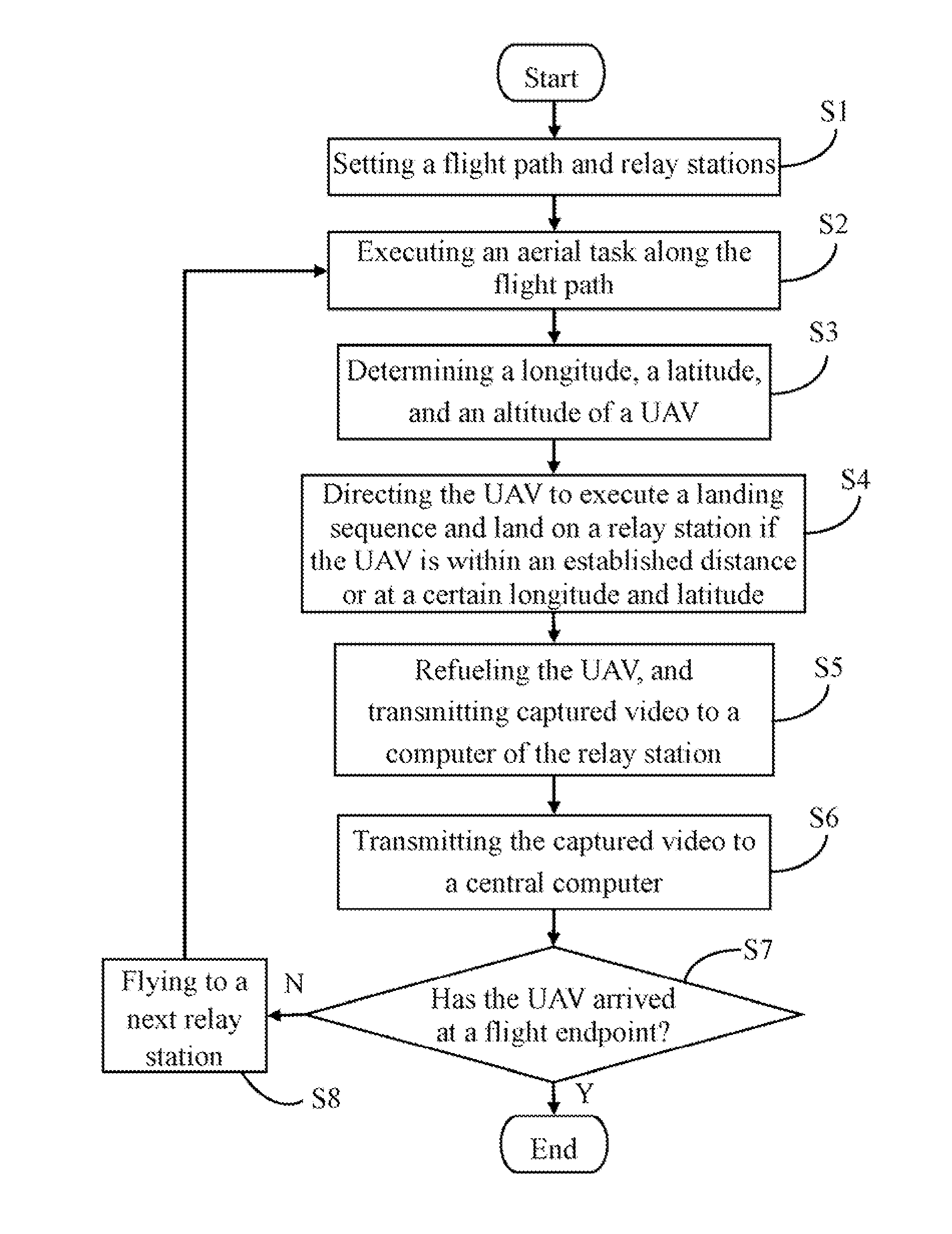

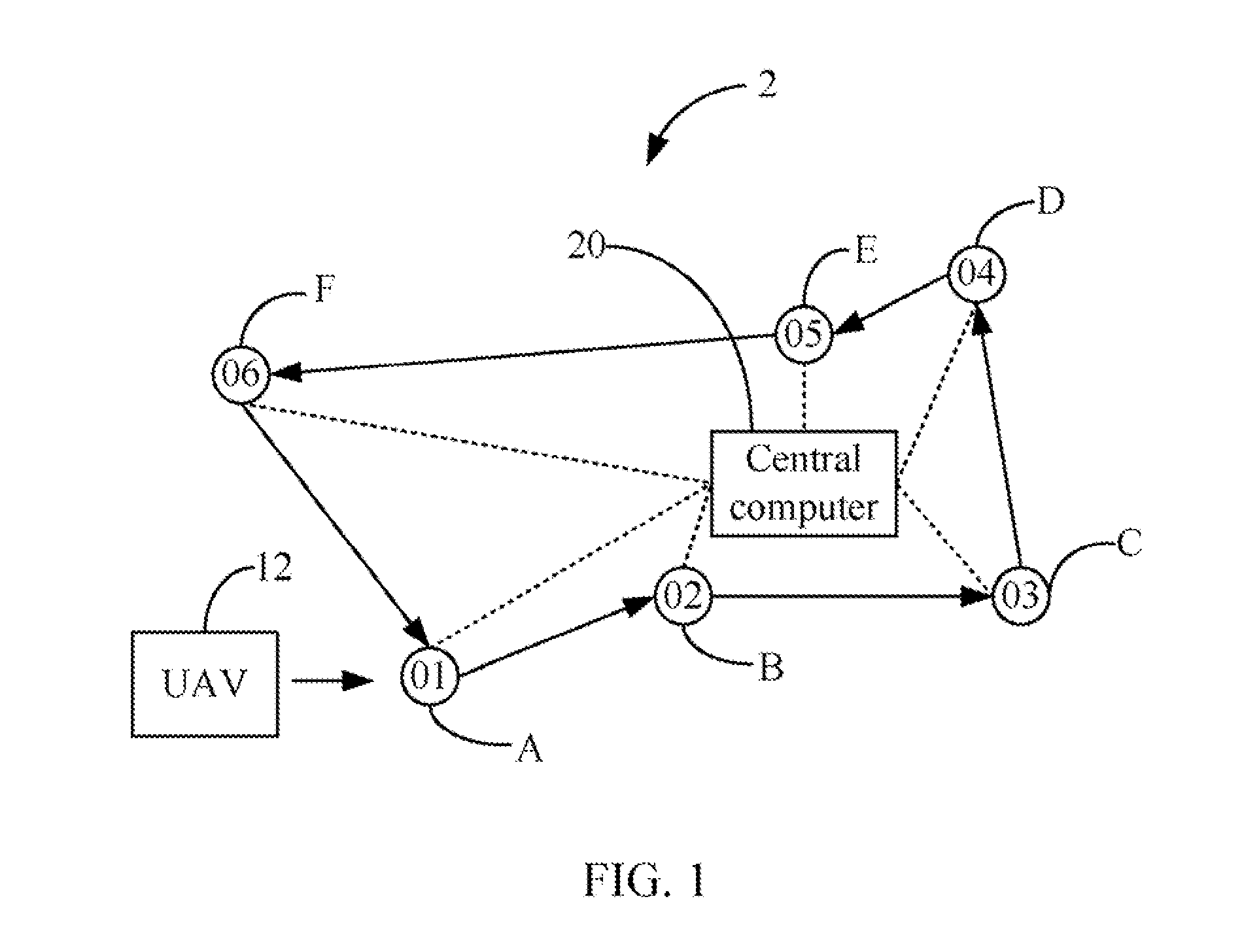

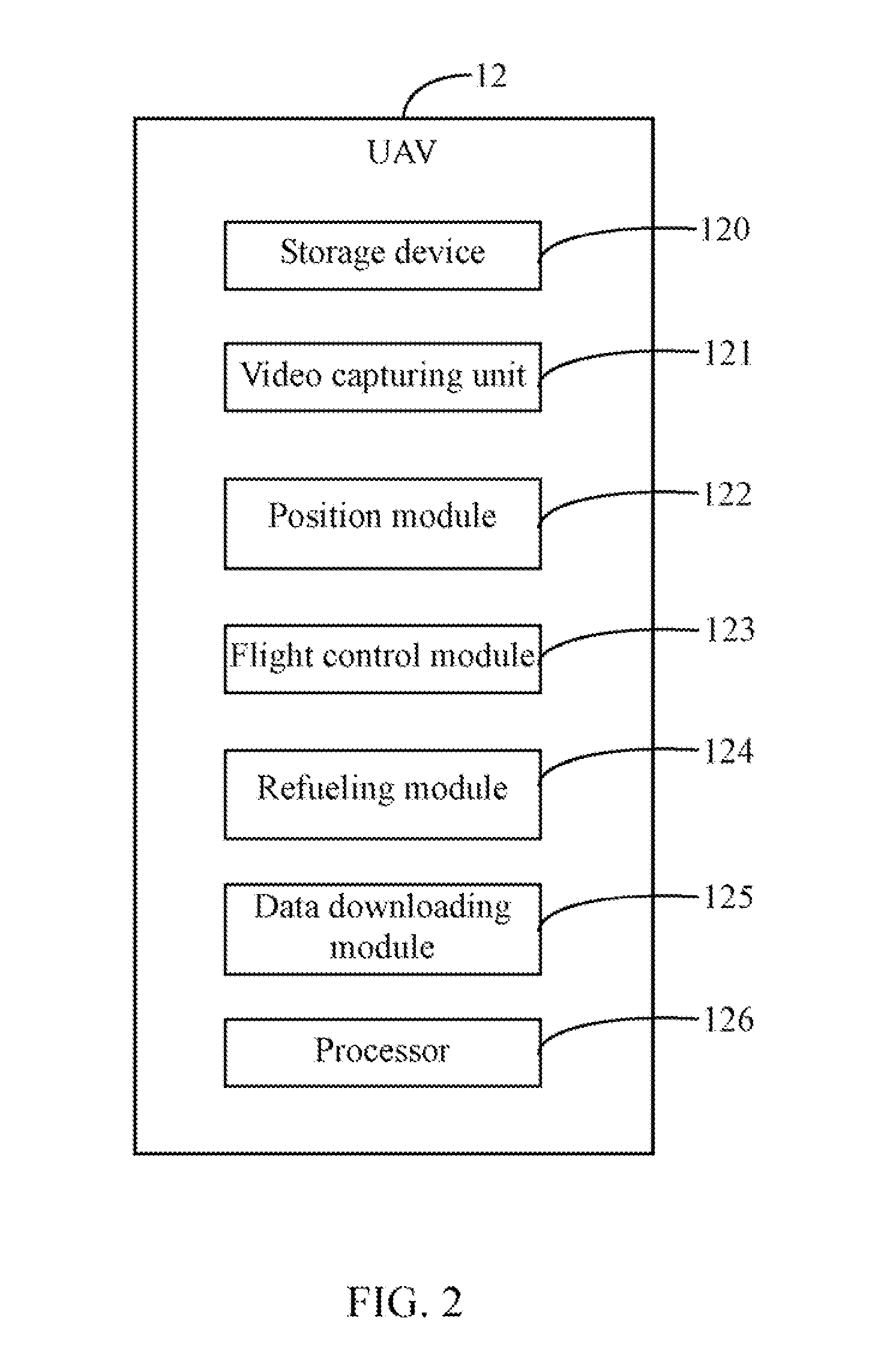

A method for collecting video using an unmanned aerial vehicle (UAV) captures video upon the condition that the UAV flies along a preset flight path, stores the captured video in a storage device of the UAV, and directs the UAV to land on a relay station upon the condition that the UAV is at a certain longitude and latitude relative to the relay station. The method further refuels the UAV at the relay station, transmits the captured video stored in the storage device to a computer of the relay station, and directs the UAV to fly to a next relay station along the flight path.

Owner:HON HAI PRECISION IND CO LTD

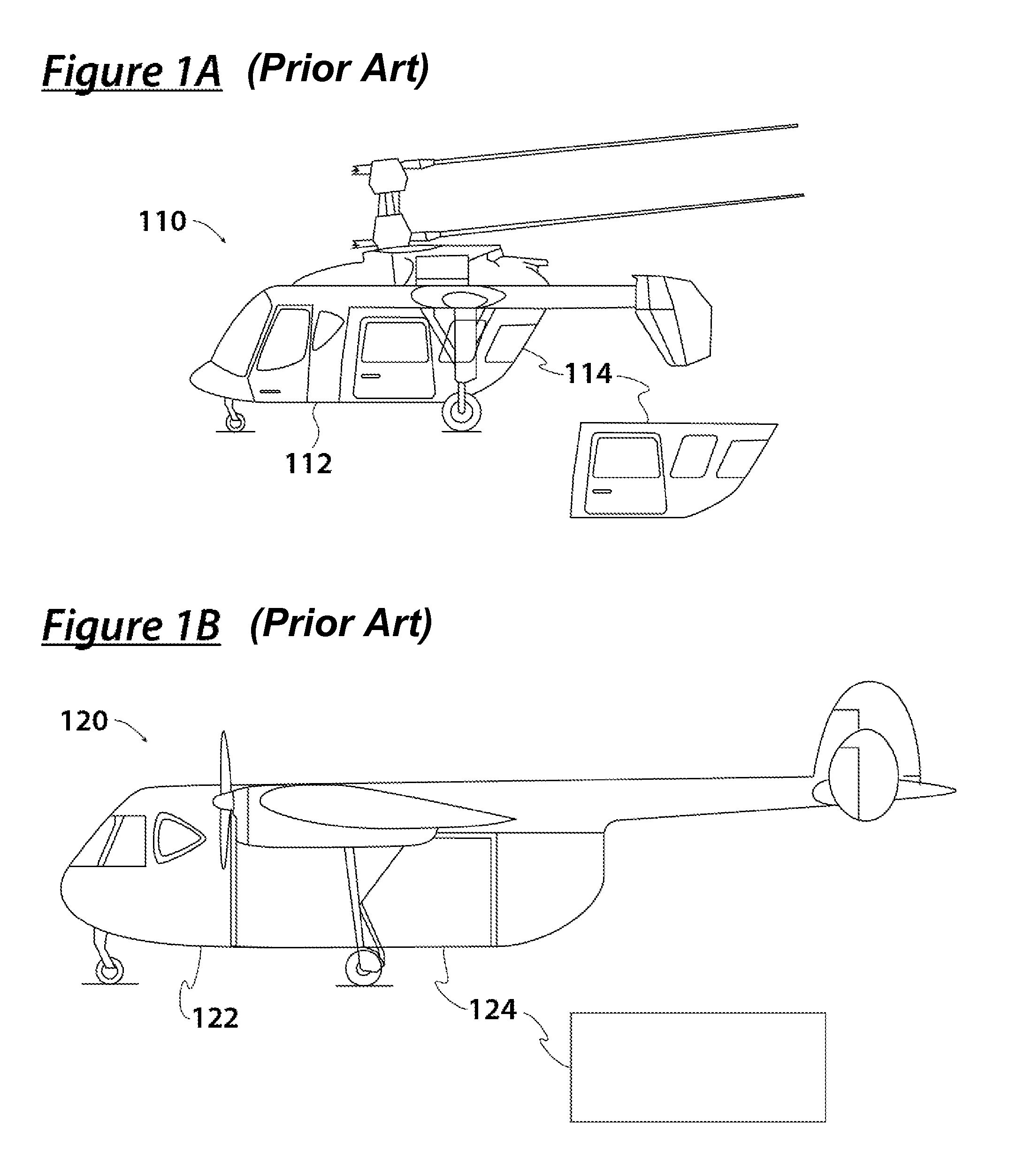

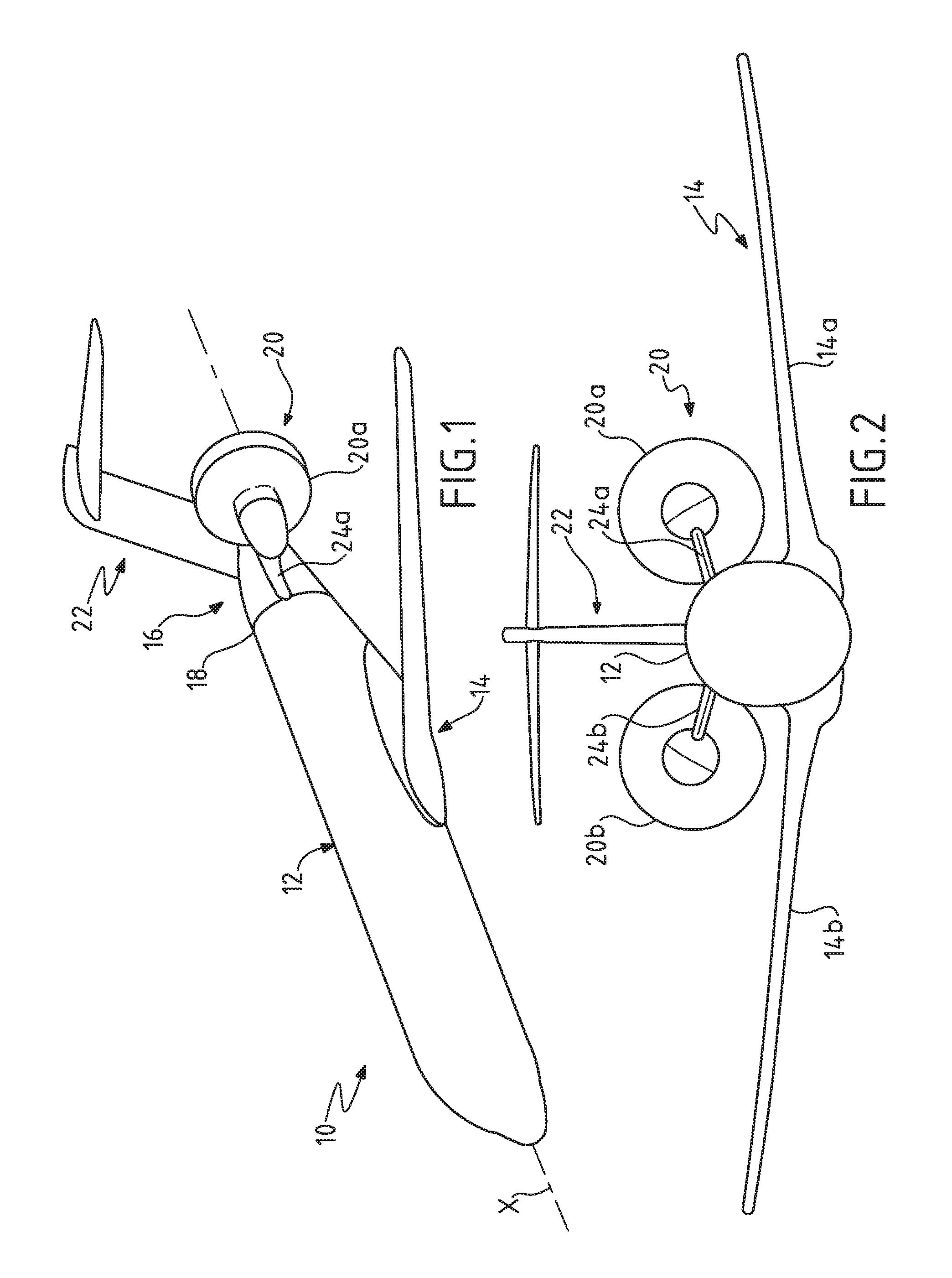

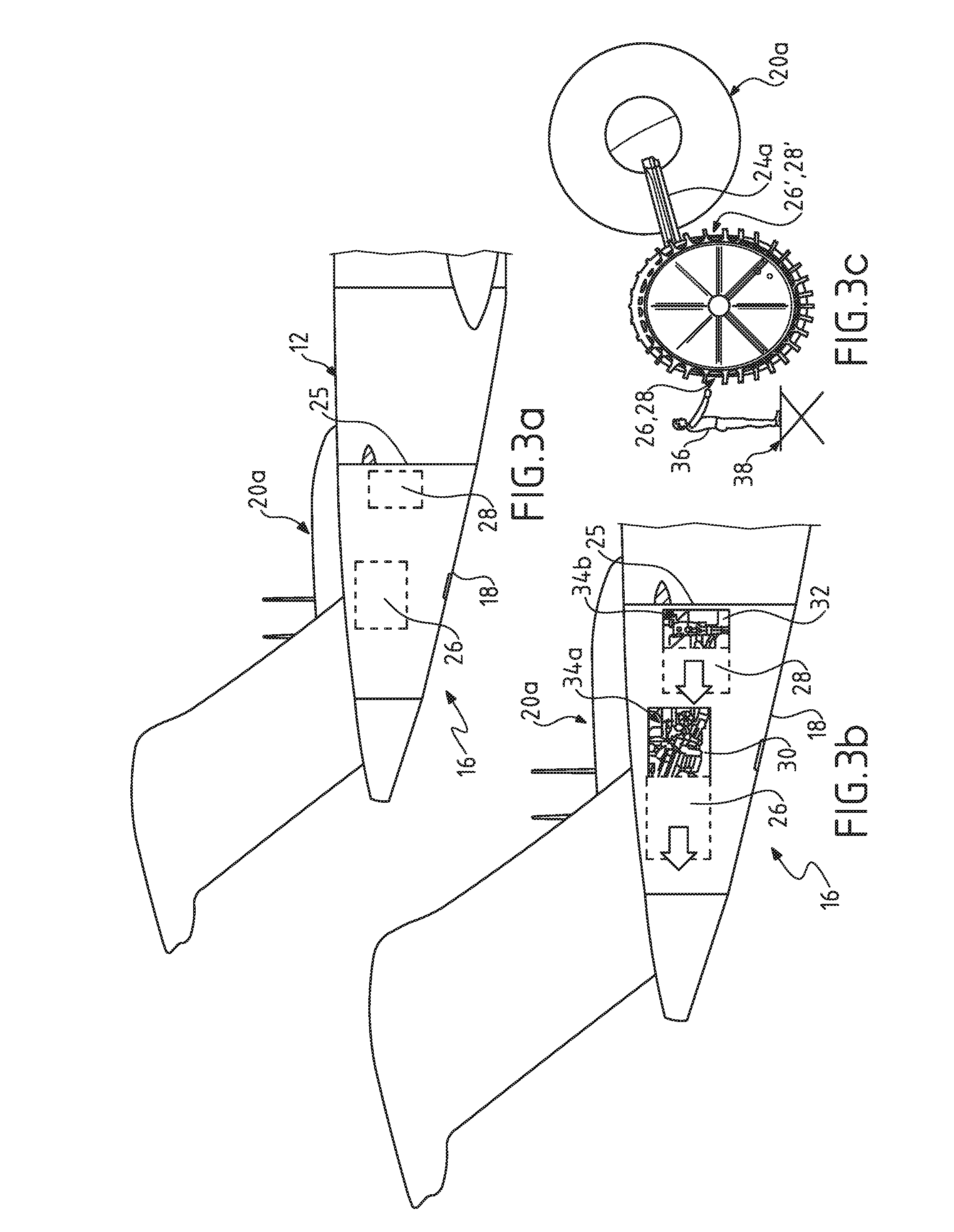

Unmanned air vehicle

InactiveUS20100051741A1Easy to moveEasy to startArrester hooksArresting gearLeading edgeTrailing edge

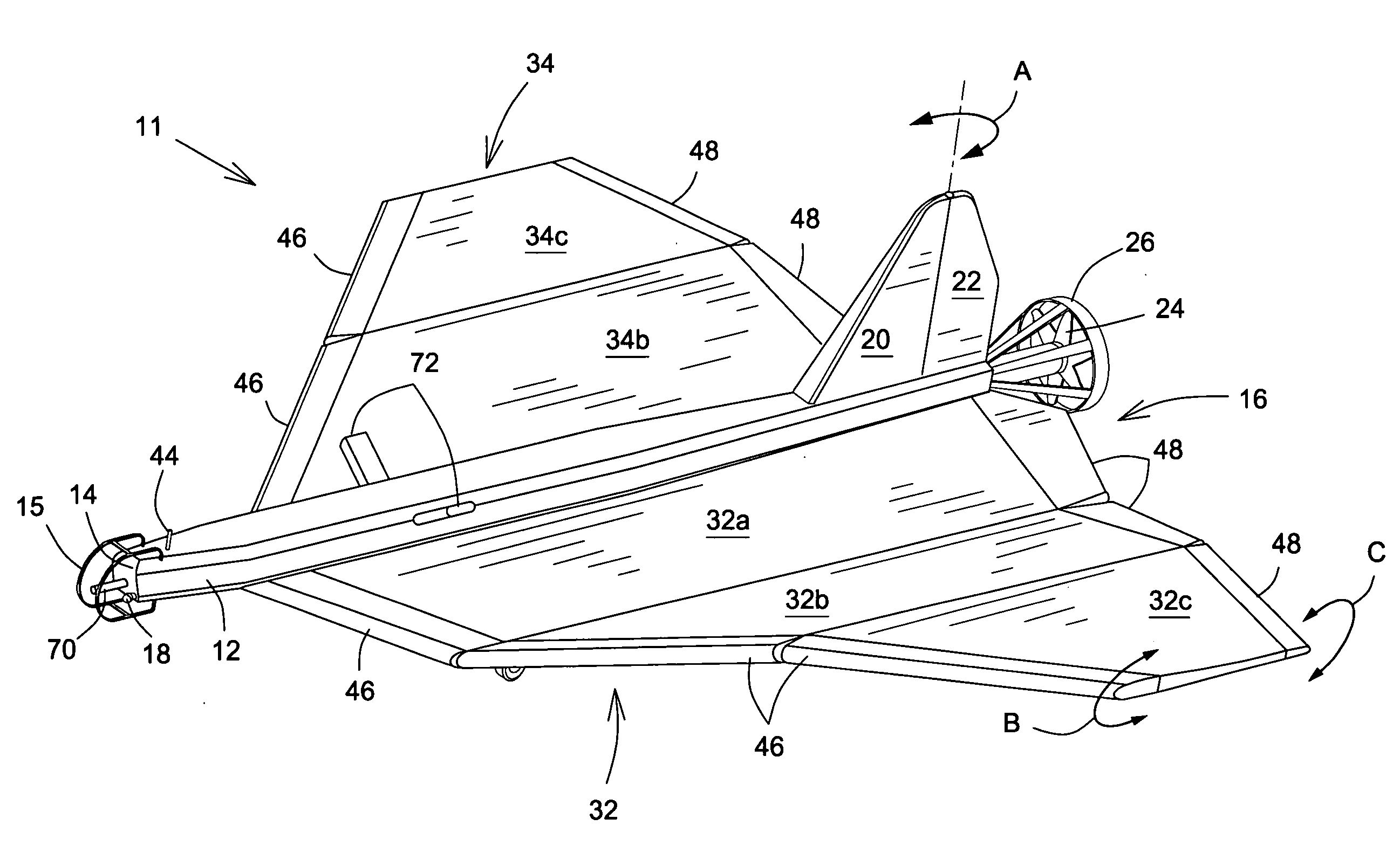

An unmanned air vehicle for military, land security and the like operations includes a fuselage provided with foldable wings having leading edge flaps and trailing edge ailerons which are operable during ascent from launch to control the flight pattern with the wings folded, the wings being deployed into an open unfolded position when appropriate. The vehicle is contained within a pod from which it is launched and a landing deck is provided to decelerate and arrest the vehicle upon its return to land.

Owner:ISMAILOV ANVAR +1

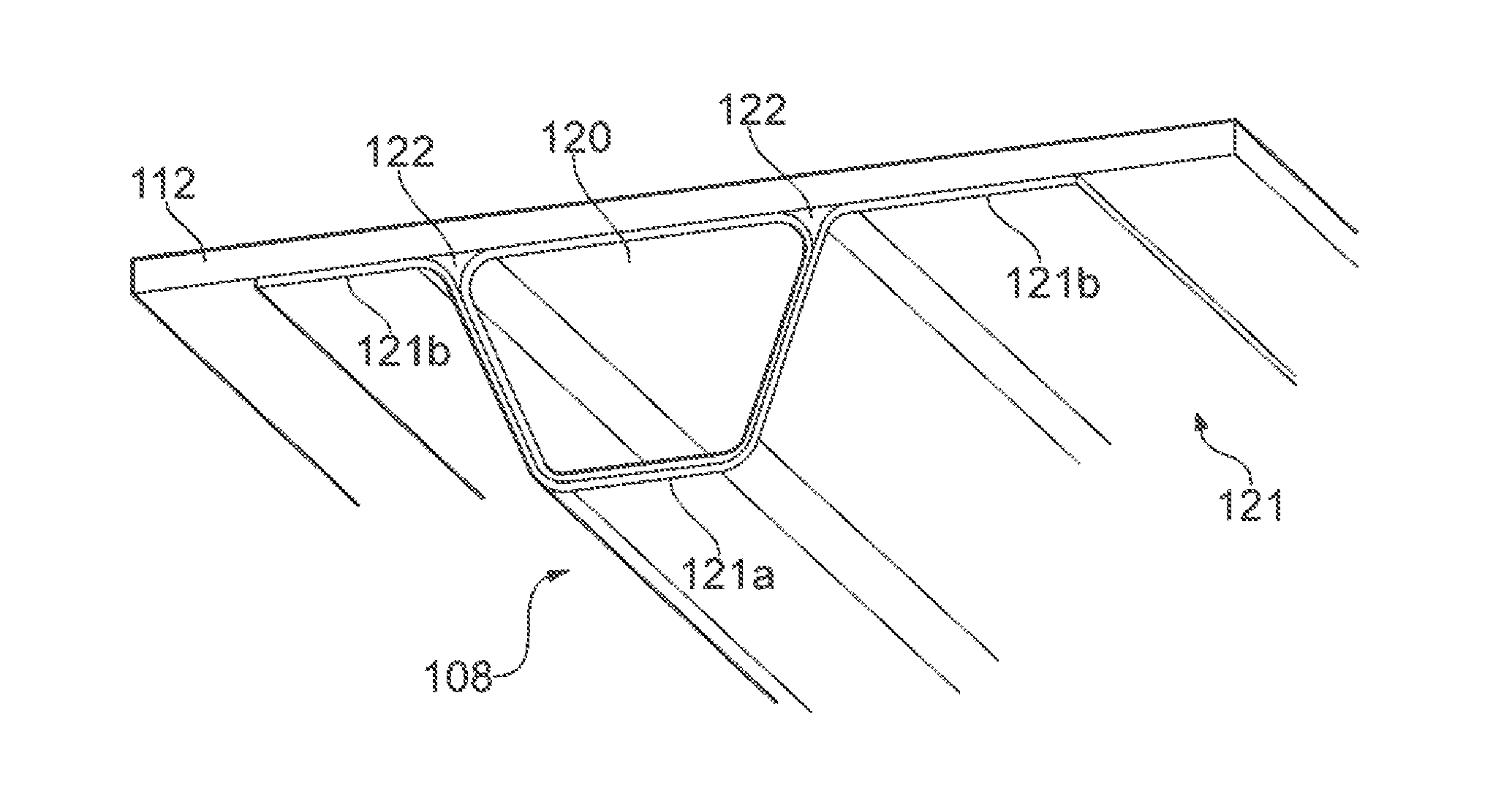

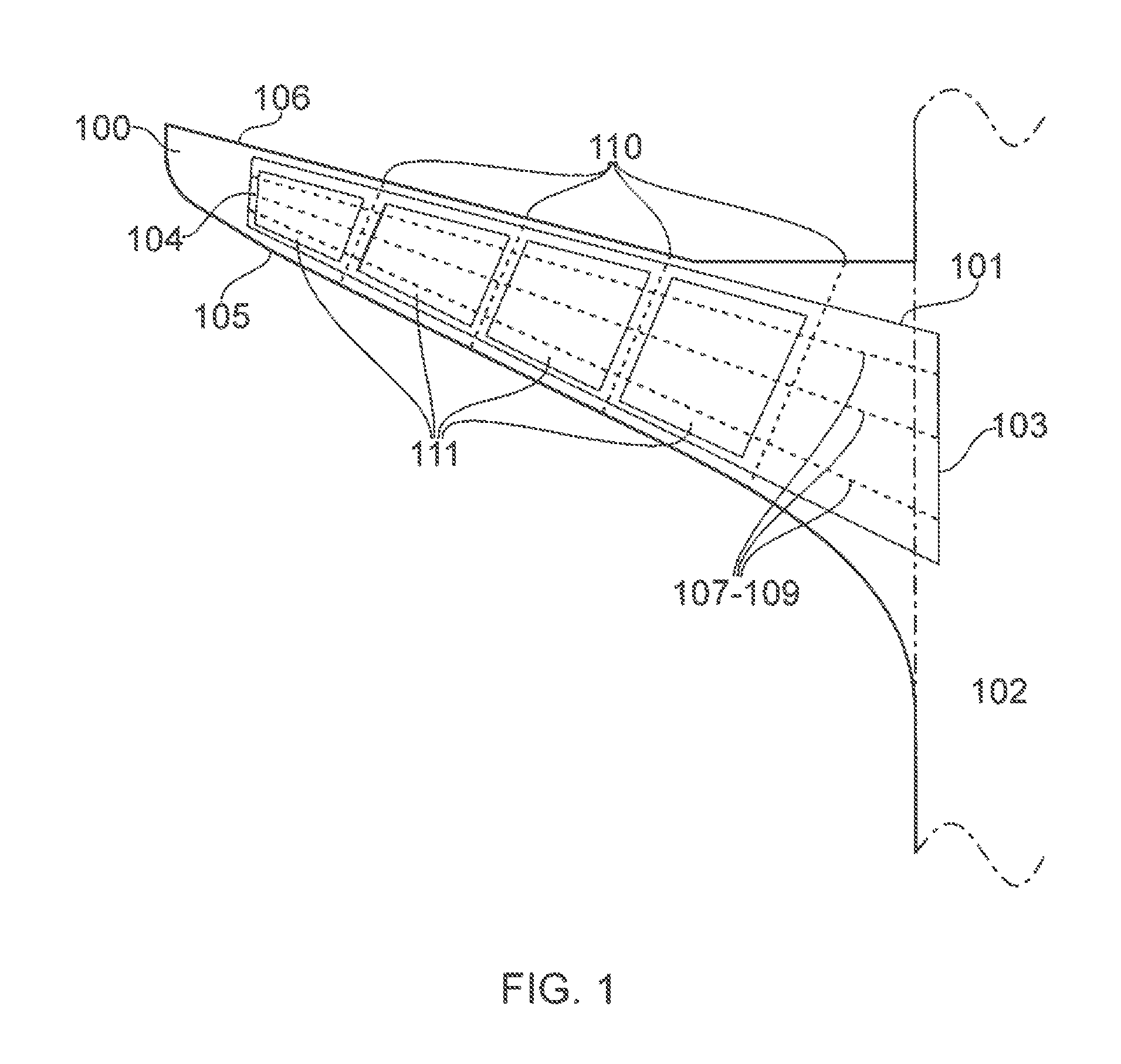

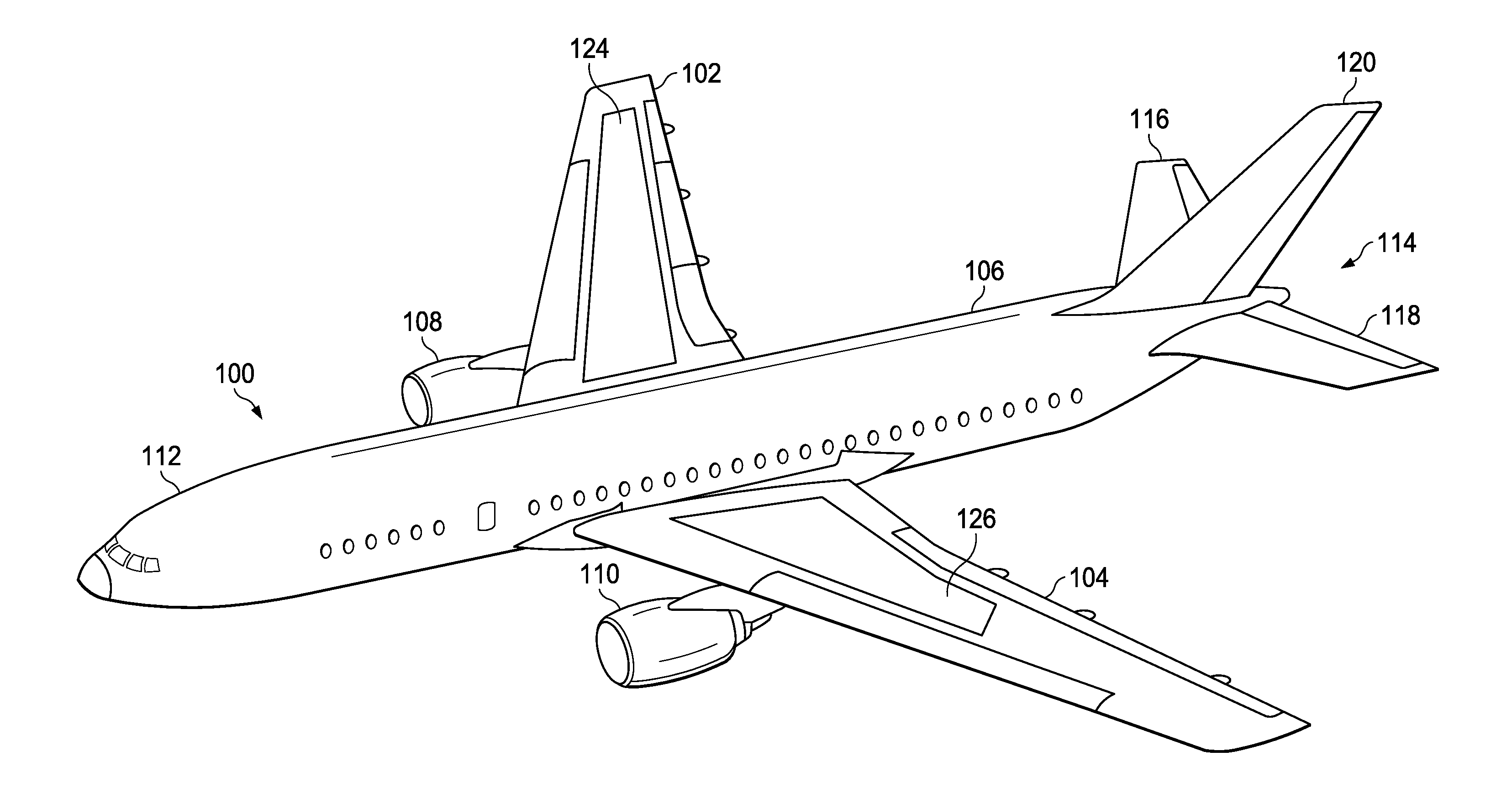

Stringer, aircraft wing panel assembly, and method of forming thereof

Embodiments of the invention relate to a stringer (108) adapted to transport fluid in an aircraft wing (100). For example, the stringer may be adapted to provide venting to one or more fuel tanks (111) in the aircraft wing, or may be adapted to provide fuel to the one or more fuel tanks. To perform this function, the stringer comprises a duct member (120) providing a duct and a structural member (121) providing an attachment surface for attachment of the stringer to a wing panel (112). Typically, the stringer is formed from a composite material such as carbon fibre reinforced plastic. A method of manufacturing the stringer is also disclosed.

Owner:AIRBUS OPERATIONS LTD

Apparatus having an energy generating skin as an outer covering

The invention relates to an outer covering of an apparatus made of an energy generating skin. The energy generating skin encloses a fuel that is capable of reacting with oxygen in an electrochemical reaction to form electricity and gaseous products. In preferred embodiments, the energy generating skin is a hydrogen oxygen fuel cell which serves as the outer covering of an aircraft such as a lighter than air ship or an airplane.

Owner:LOCKHEED MARTIN CORP

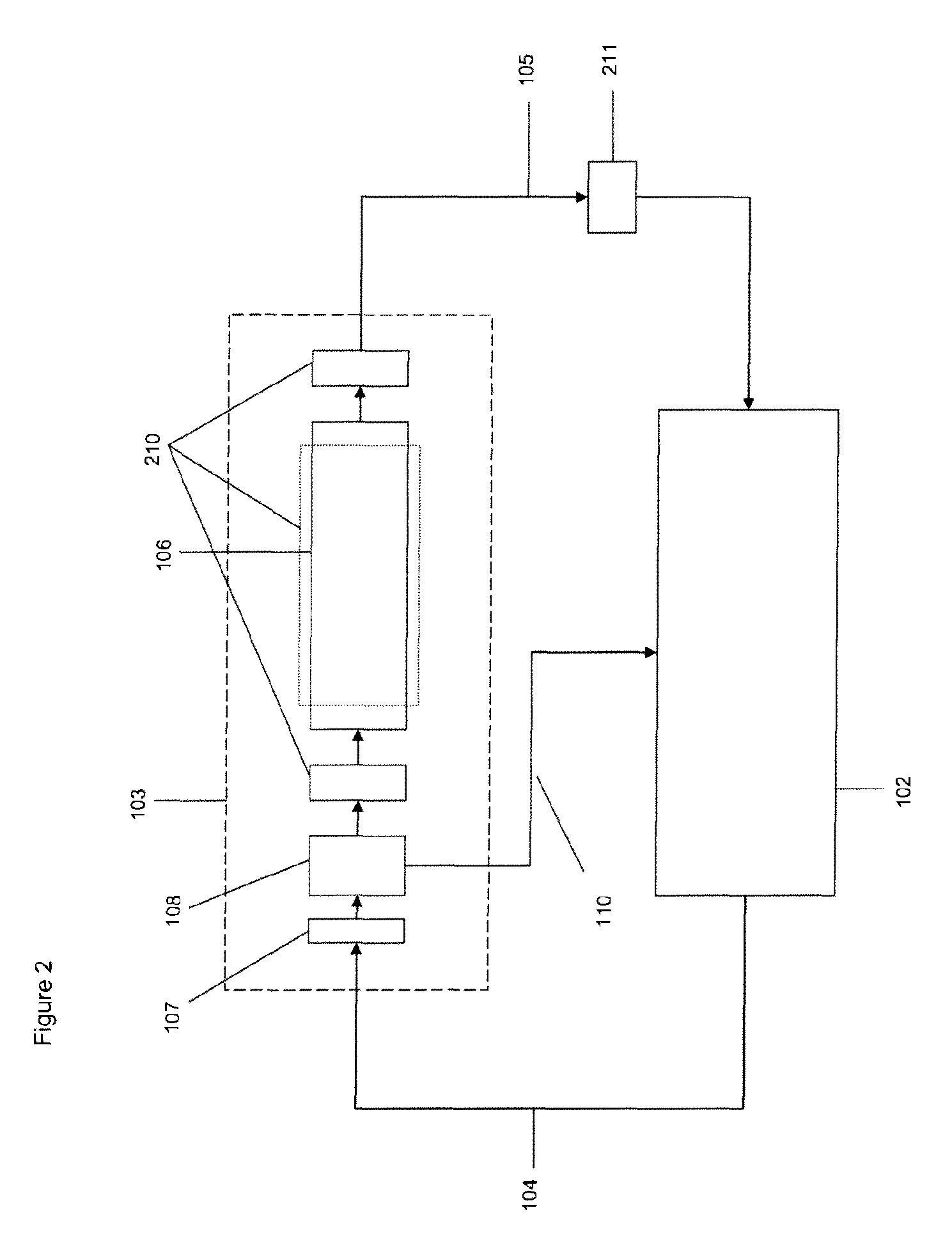

Reactive component reduction system and methods for the use thereof

ActiveUS7896292B2Reduce riskMinimizes ventingUsing liquid separation agentIndirect heat exchangersGas phaseEngineering

In accordance with the present invention, there are provided simplified systems and methods for catalytically deactivating, removing, or reducing the levels of reactive component(s) from the vapor phase of fuel storage tanks. The simple apparatus described herein can be utilized to replace complex systems on the market. Simply stated, in one embodiment of the invention, the vapor phase from the fuel tank is passed over a catalytic bed operated at appropriate temperatures to allow the reaction between free oxygen and the fuel vapor by oxidation of the fuel vapor, thus deactivating reactive component(s) in the gas phase.

Owner:PHYRE TECH

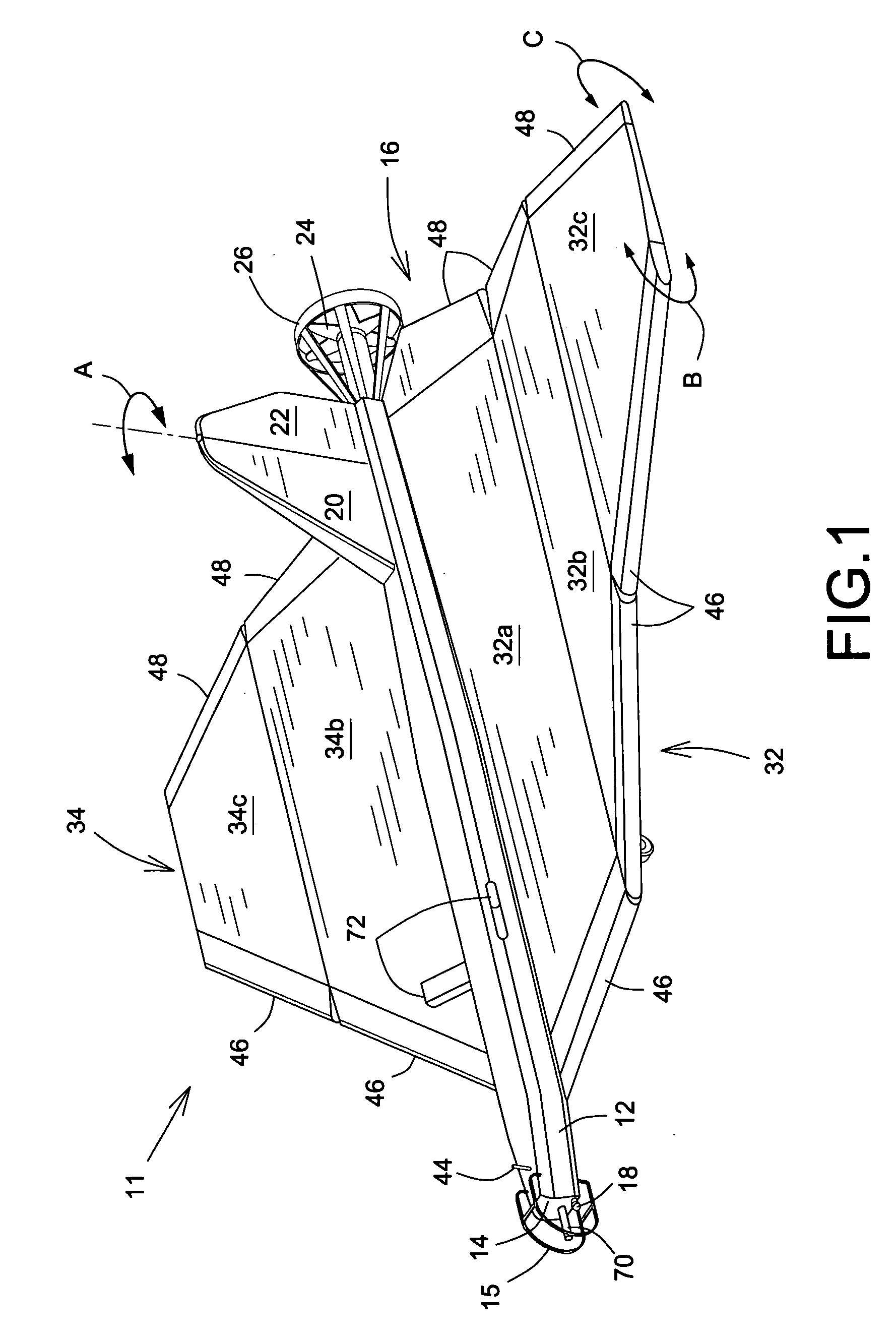

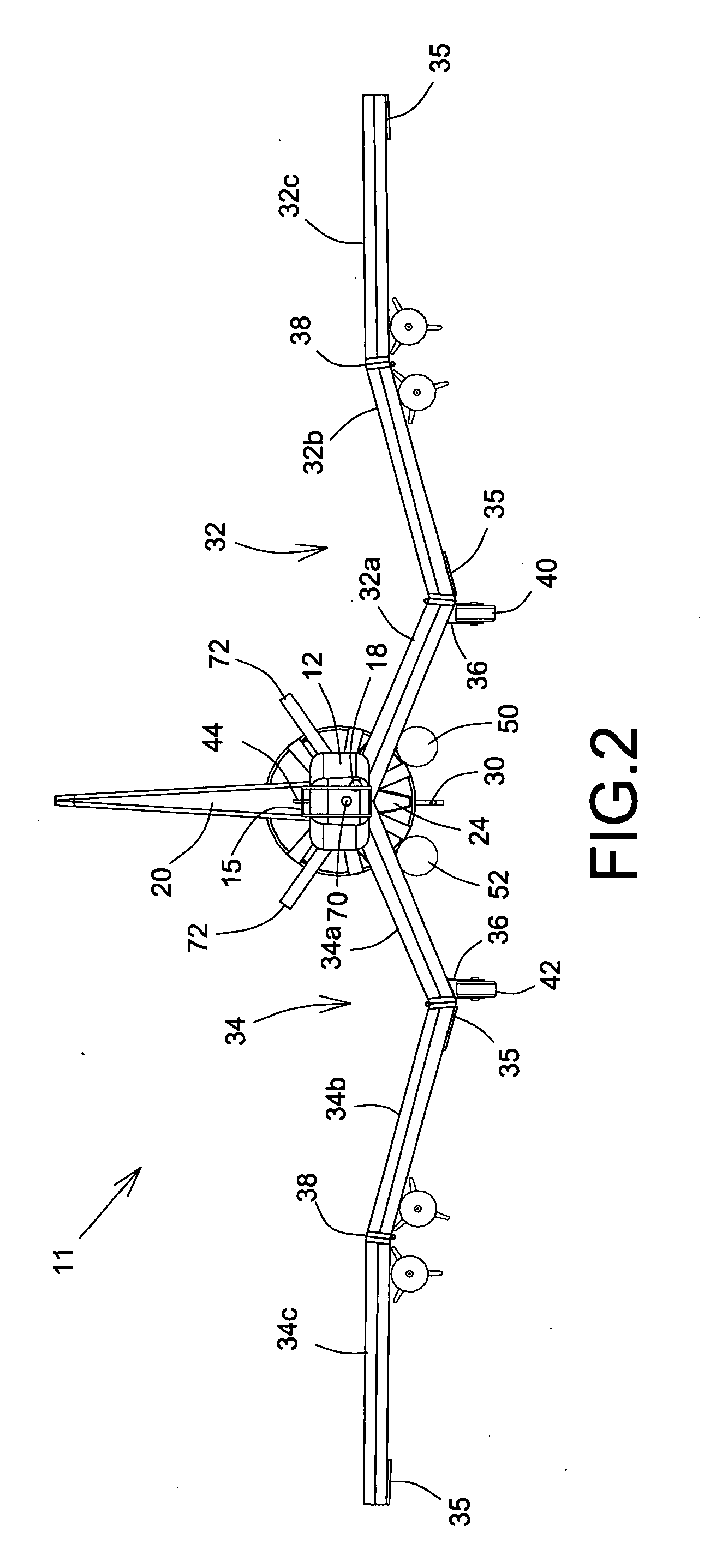

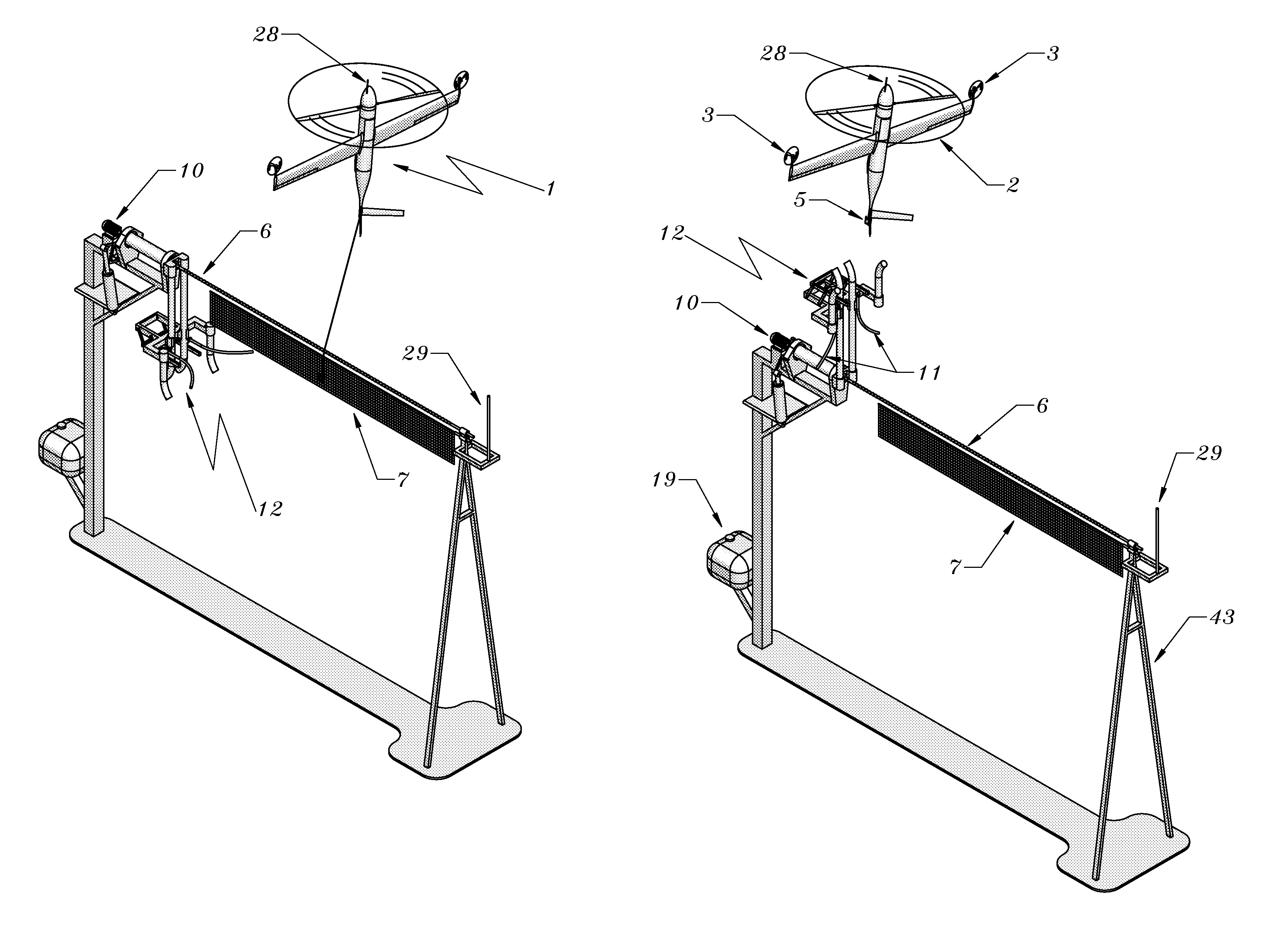

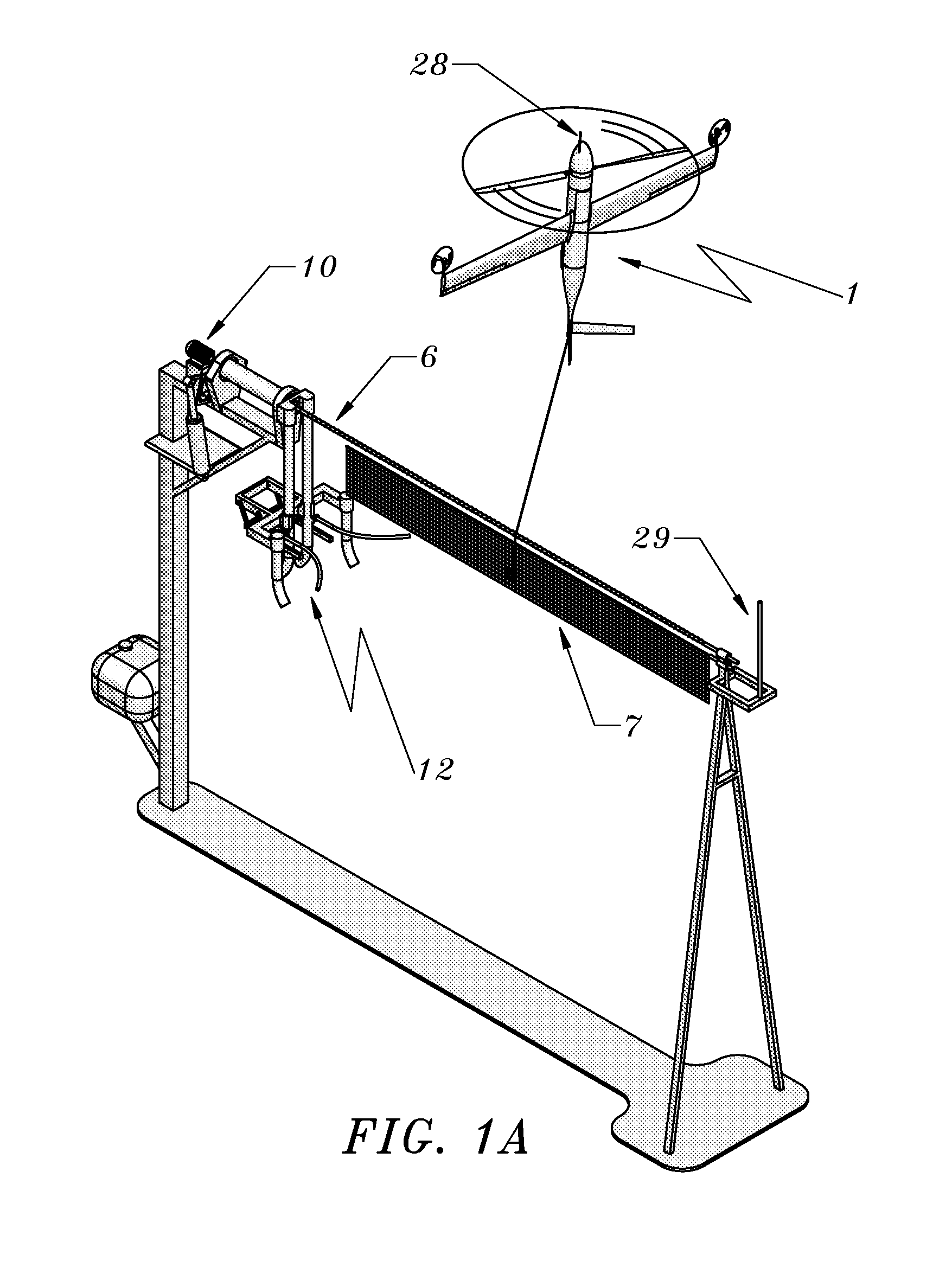

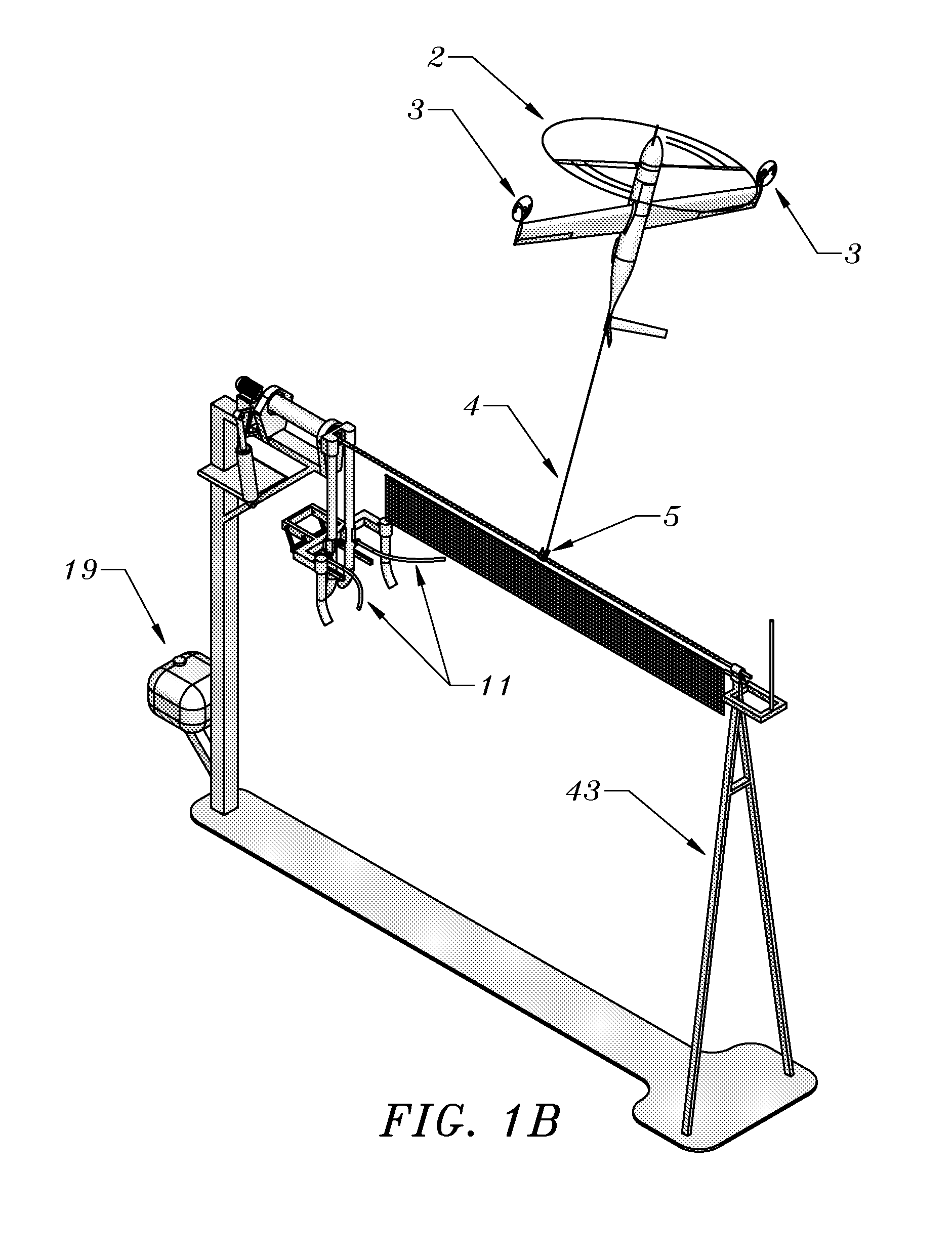

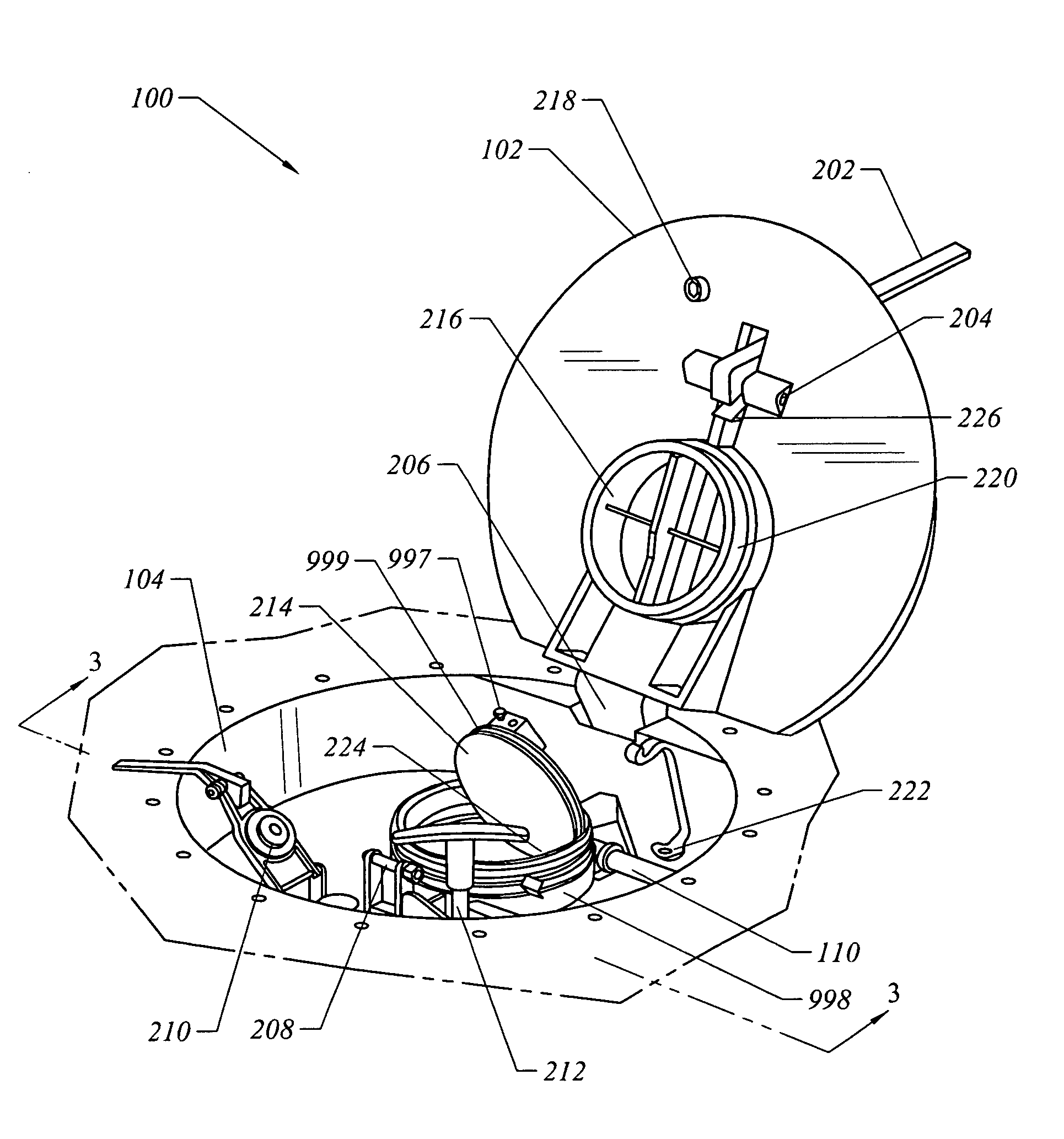

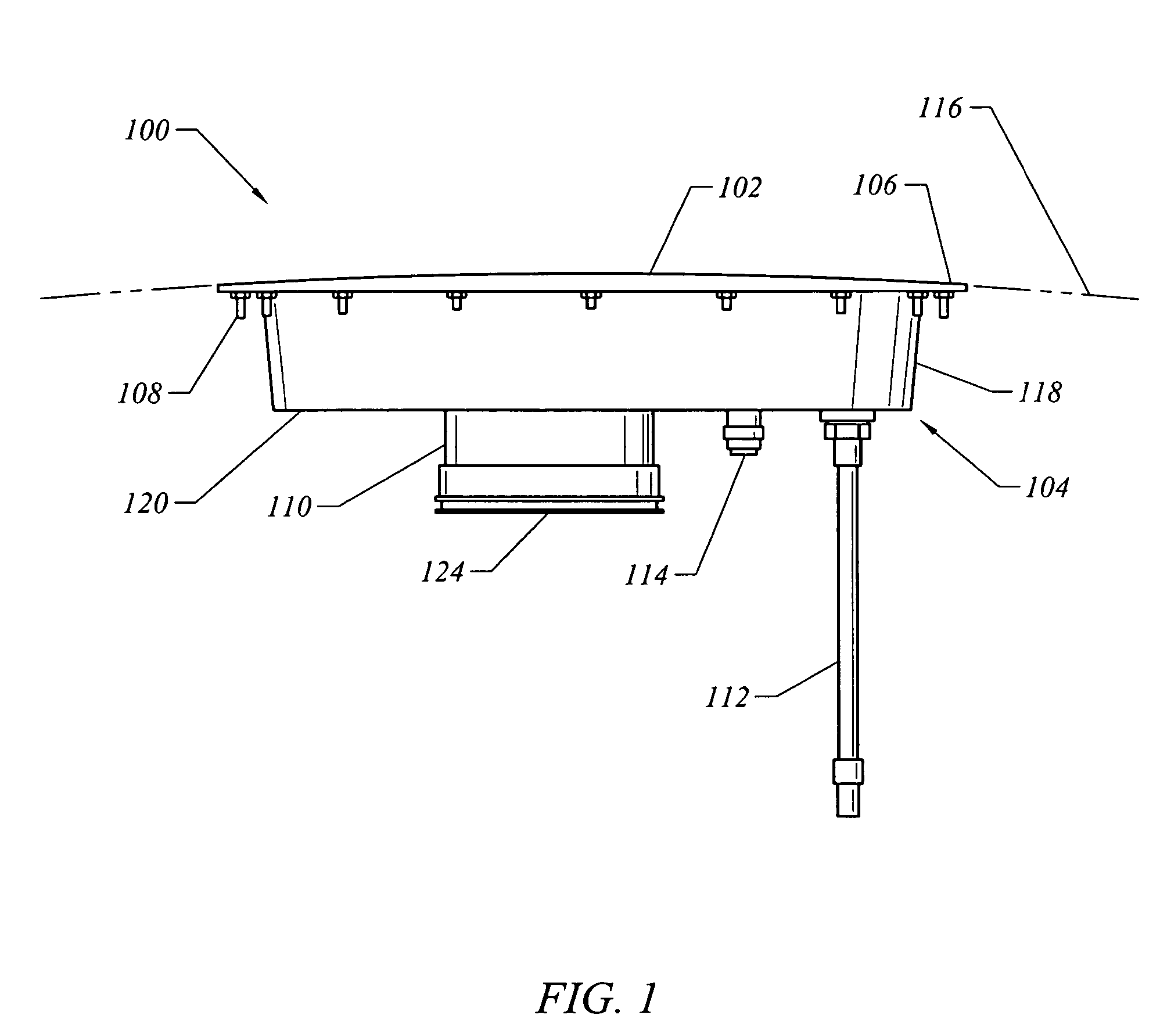

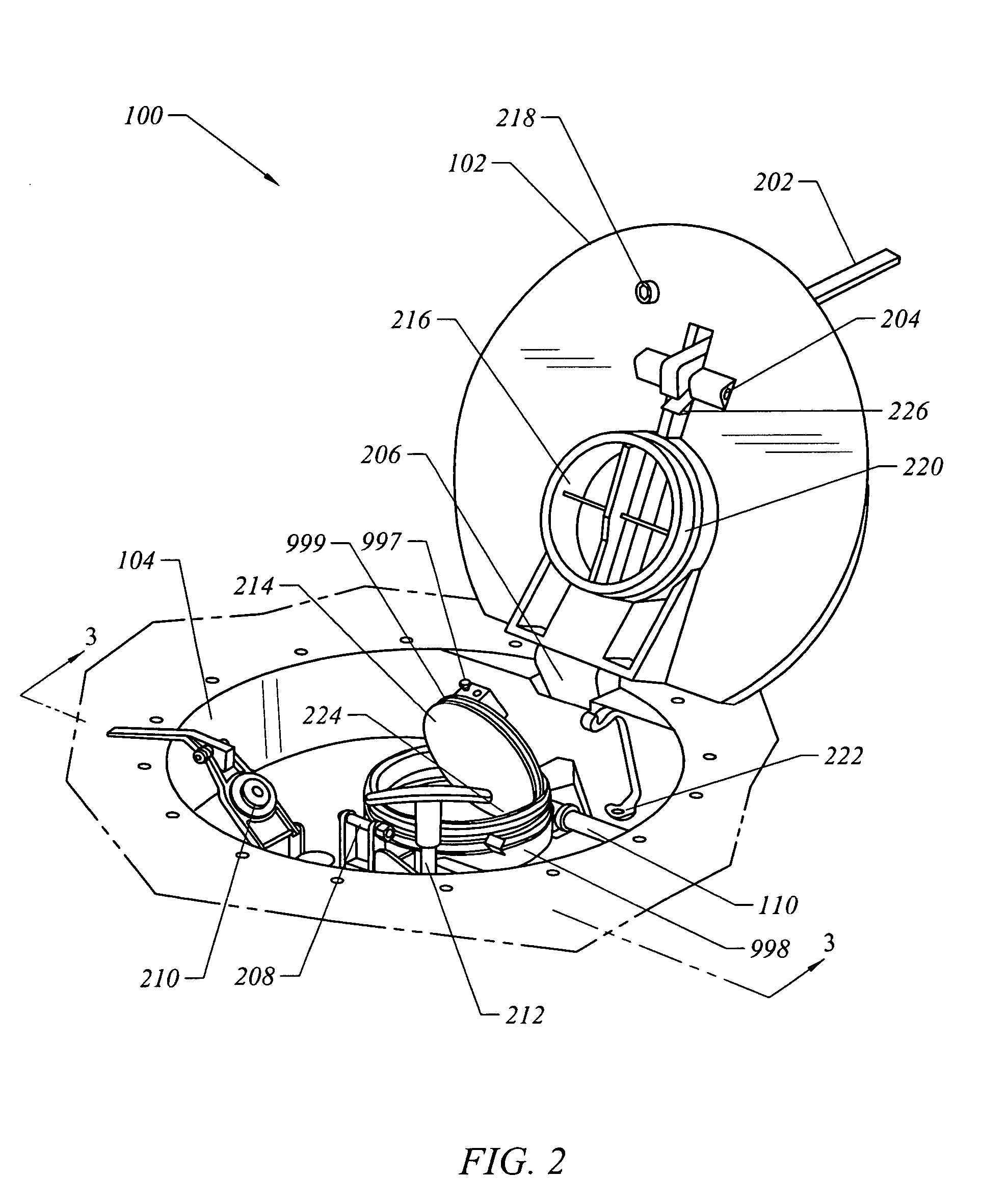

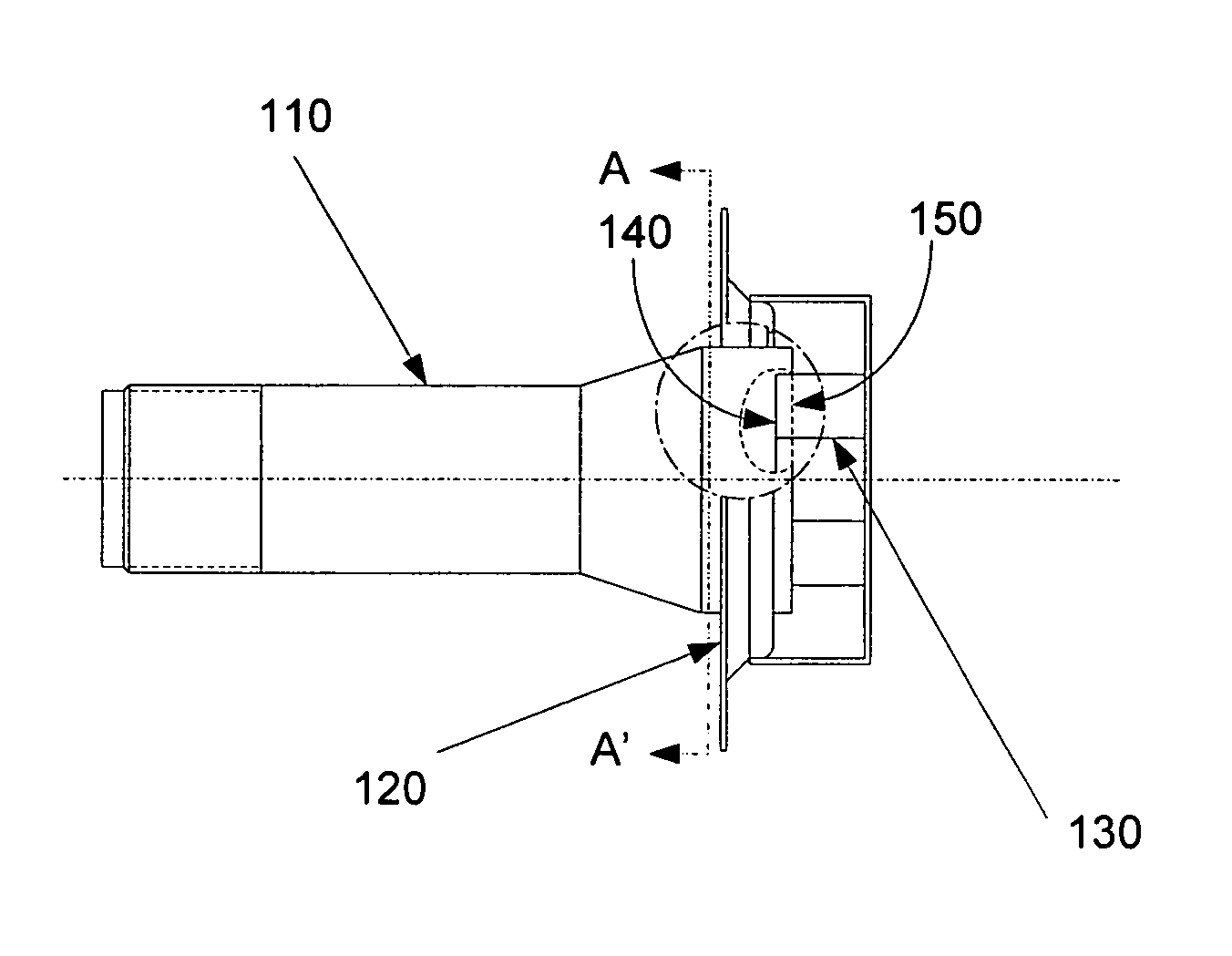

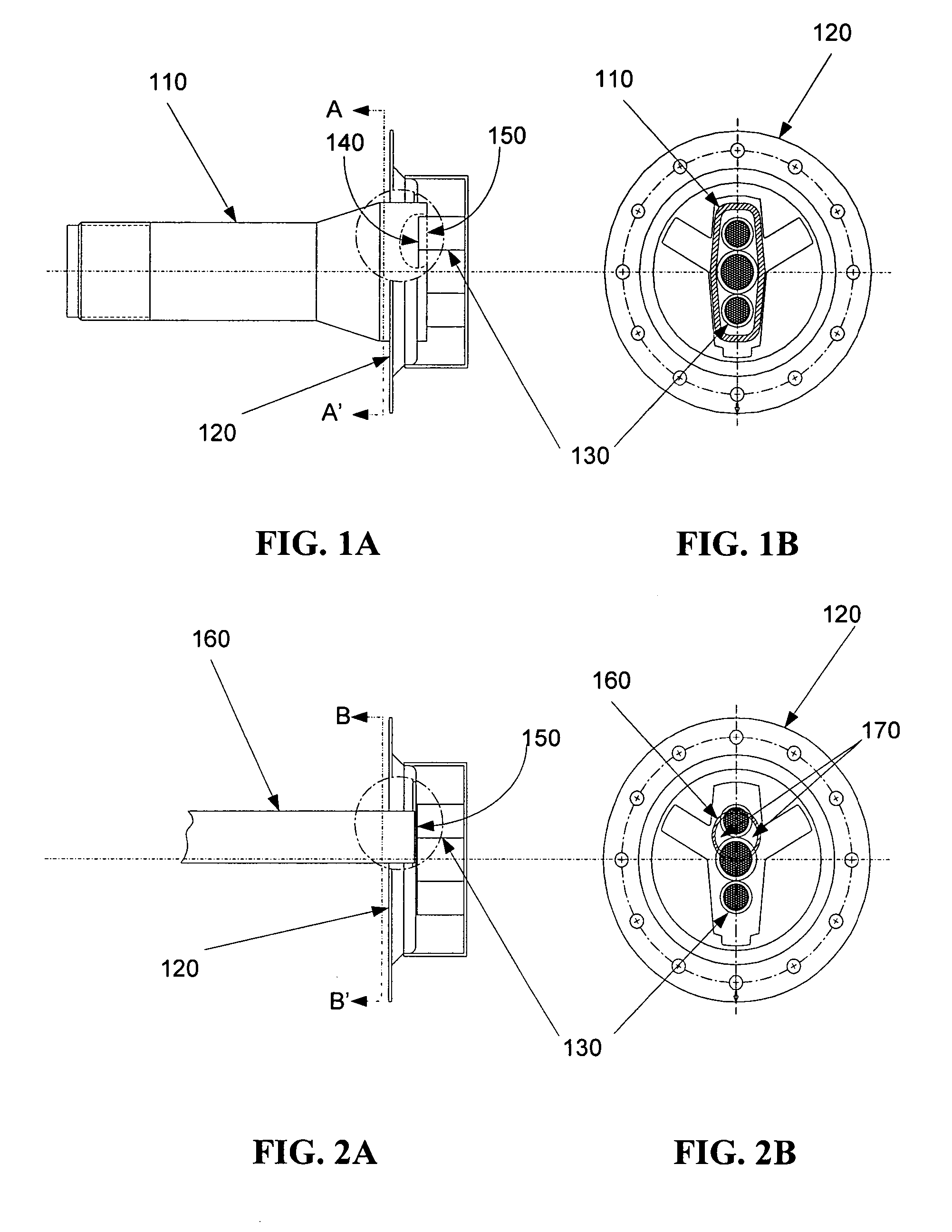

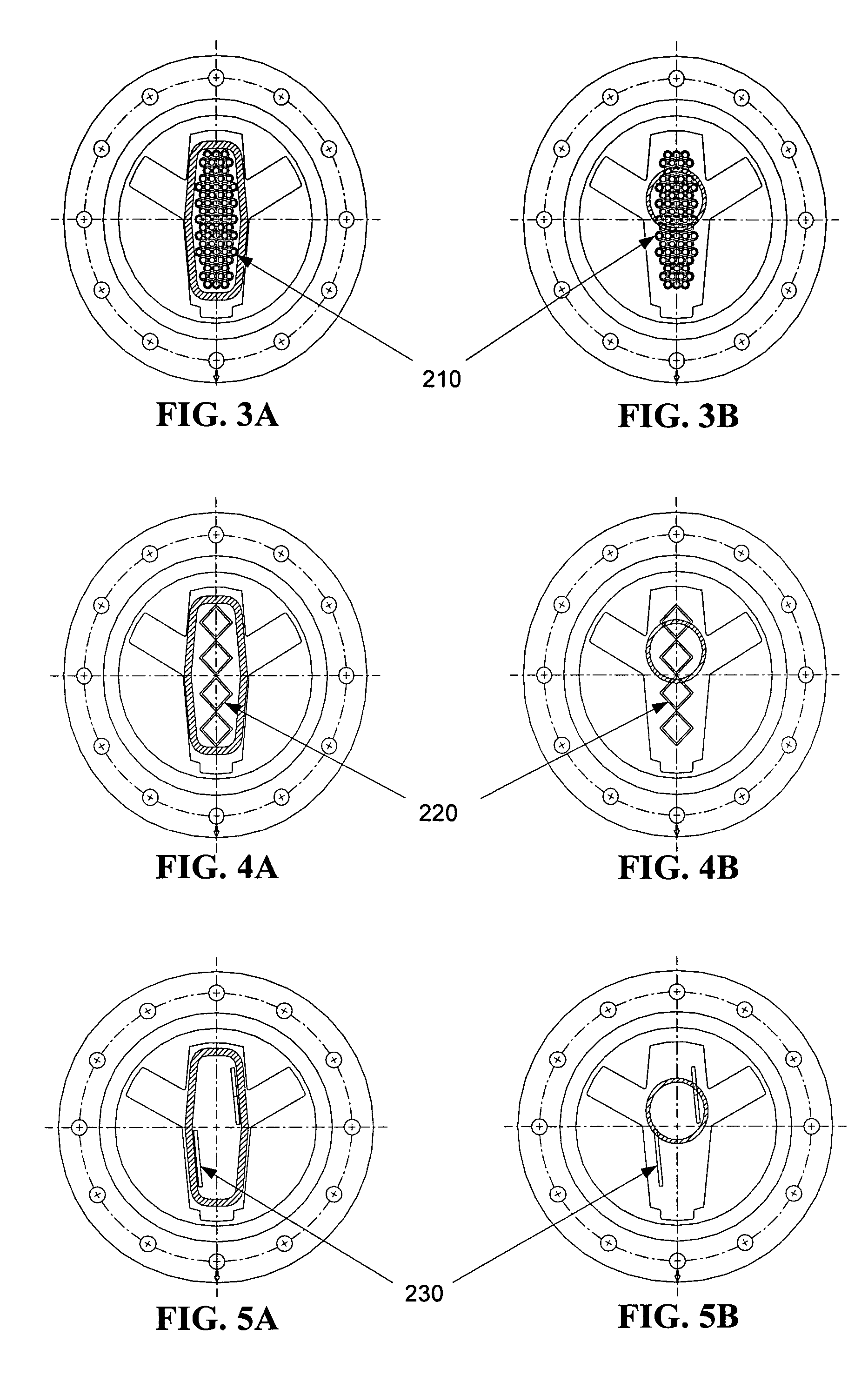

Method and apparatus for automated launch, retrieval, and servicing of a hovering aircraft

An aircraft capable of thrust-borne flight can be automatically retrieved, serviced, and launched using equipment suitable for use on a small vessel, or at a base with similarly limited space or irregular motion. For retrieval, the aircraft drops a tether, and pulls the tether at low relative speed into contact with a horizontal guide. The tether is pulled across the guide until the guide is captured by a hook or other end effector. The tether length is then adjusted as necessary, and the aircraft swings on the guide to hang in an inverted position. Translation of the tether along the guide then brings the aircraft to a docking carriage, in which the aircraft parks for servicing. For launch the carriage is swung upright, the end effector is released from the guide, and the aircraft thrusts into free flight. A full ground-handling cycle can thus be accomplished automatically with simple and economical apparatus. It can be used with low risk of damage, and requires only moderate accuracy in manual or automatic flight control.

Owner:AEROVEL CORP

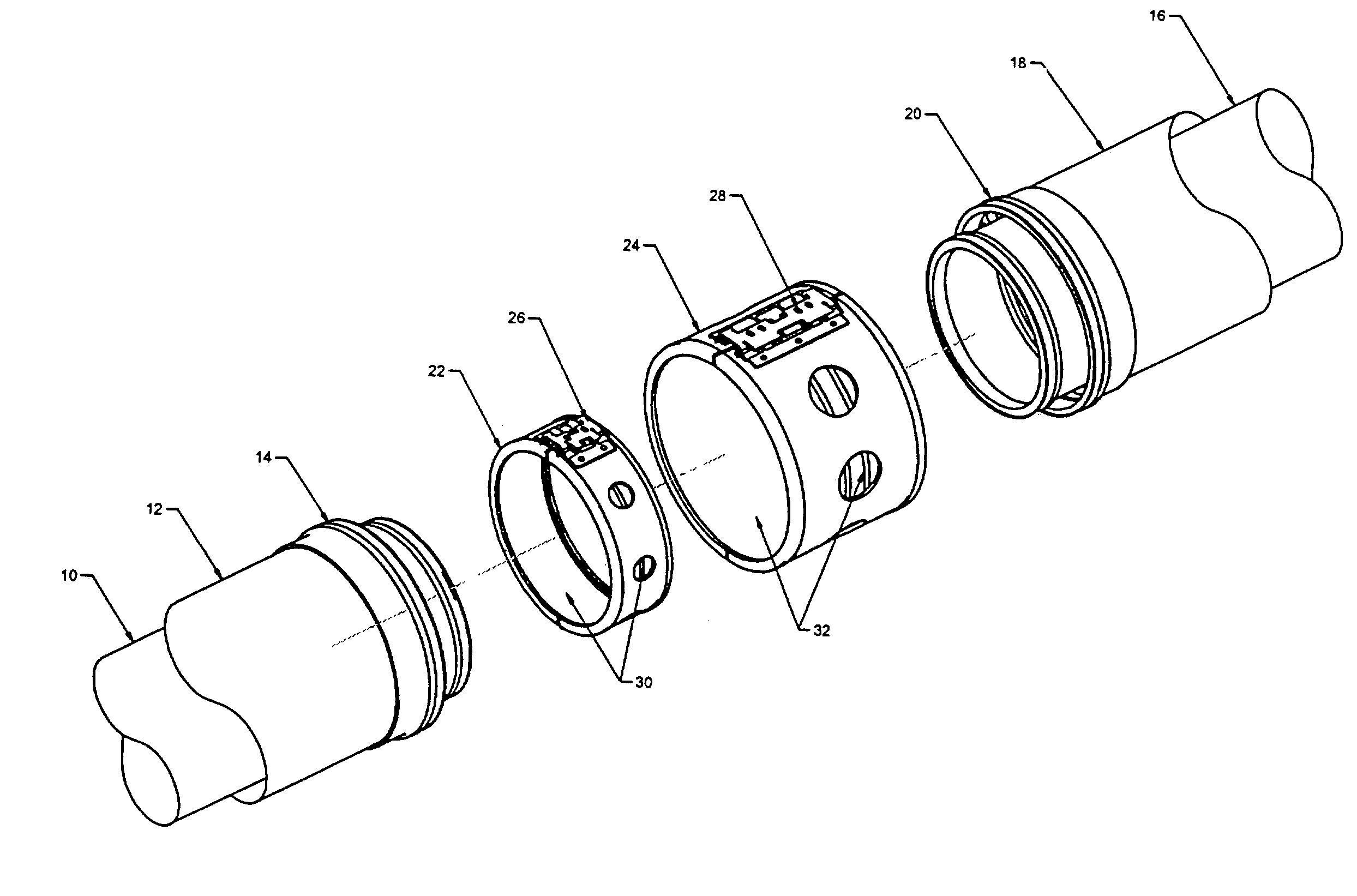

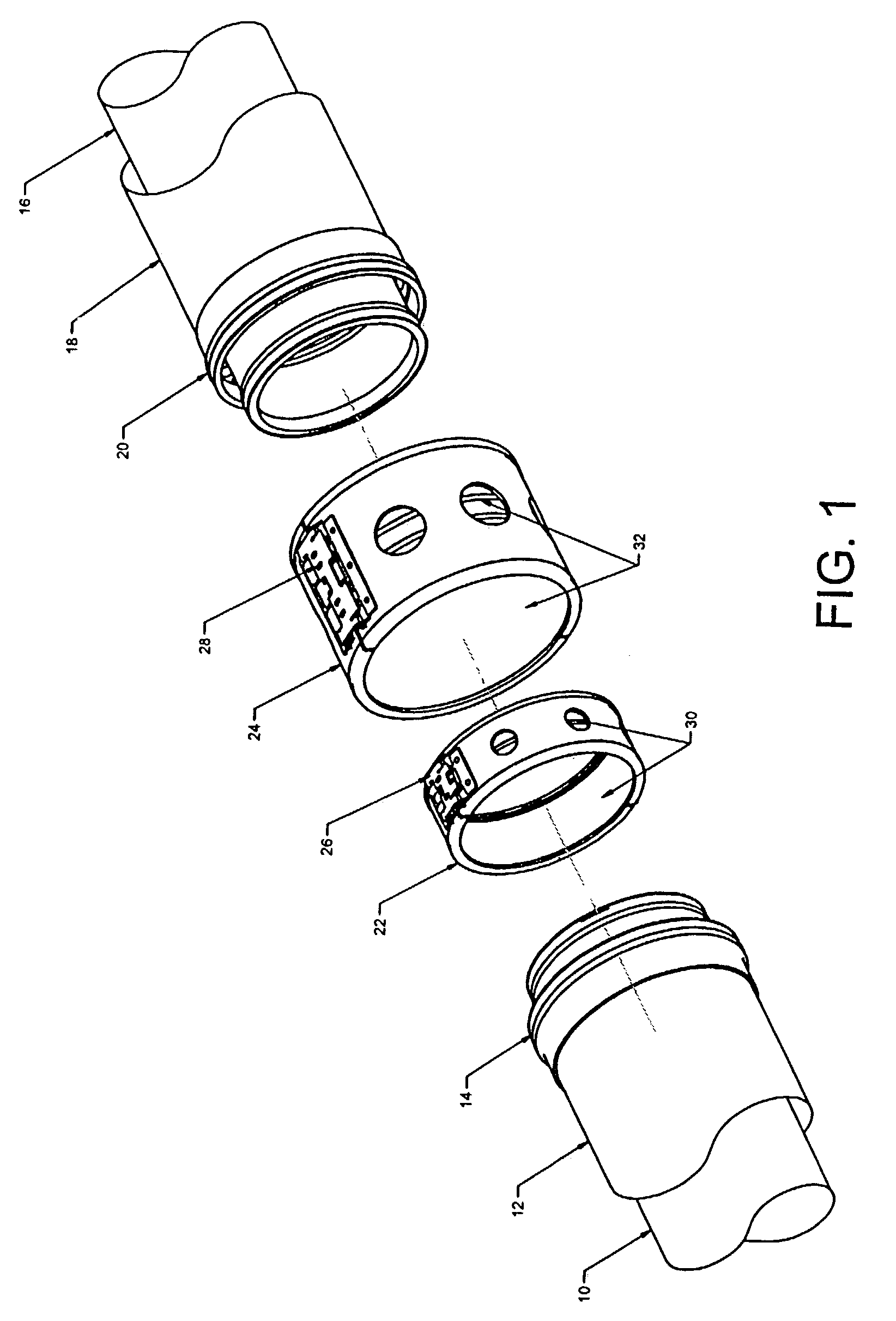

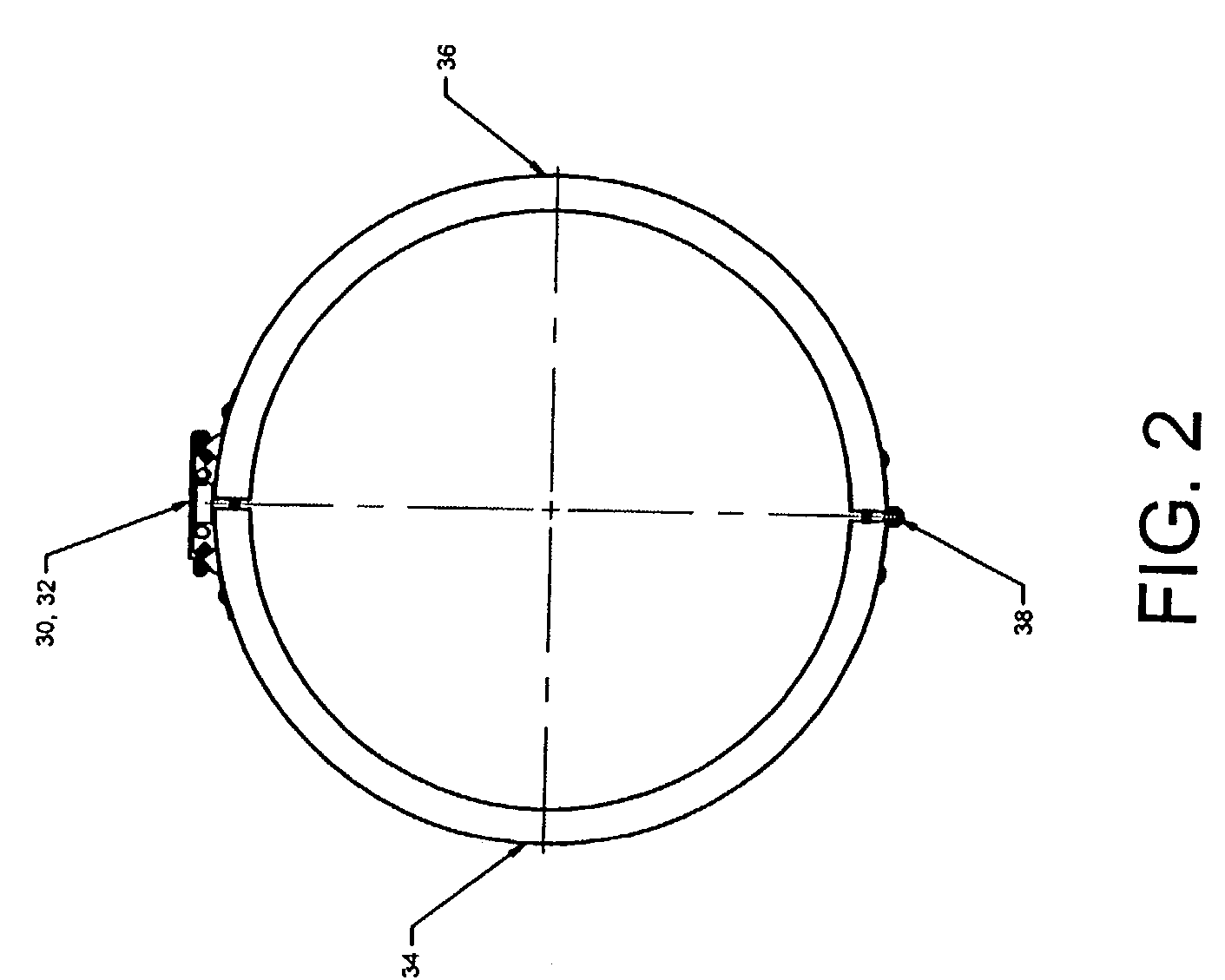

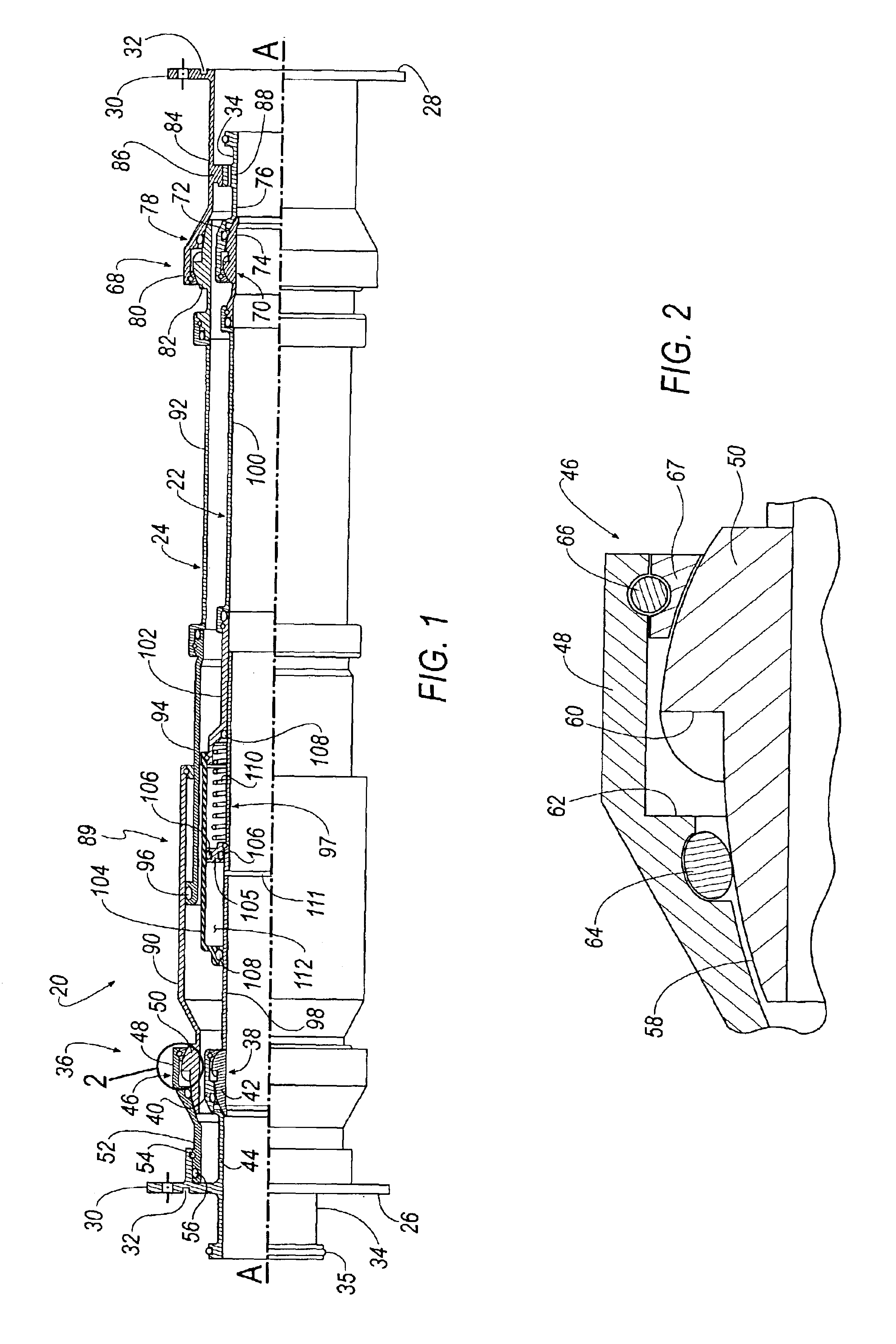

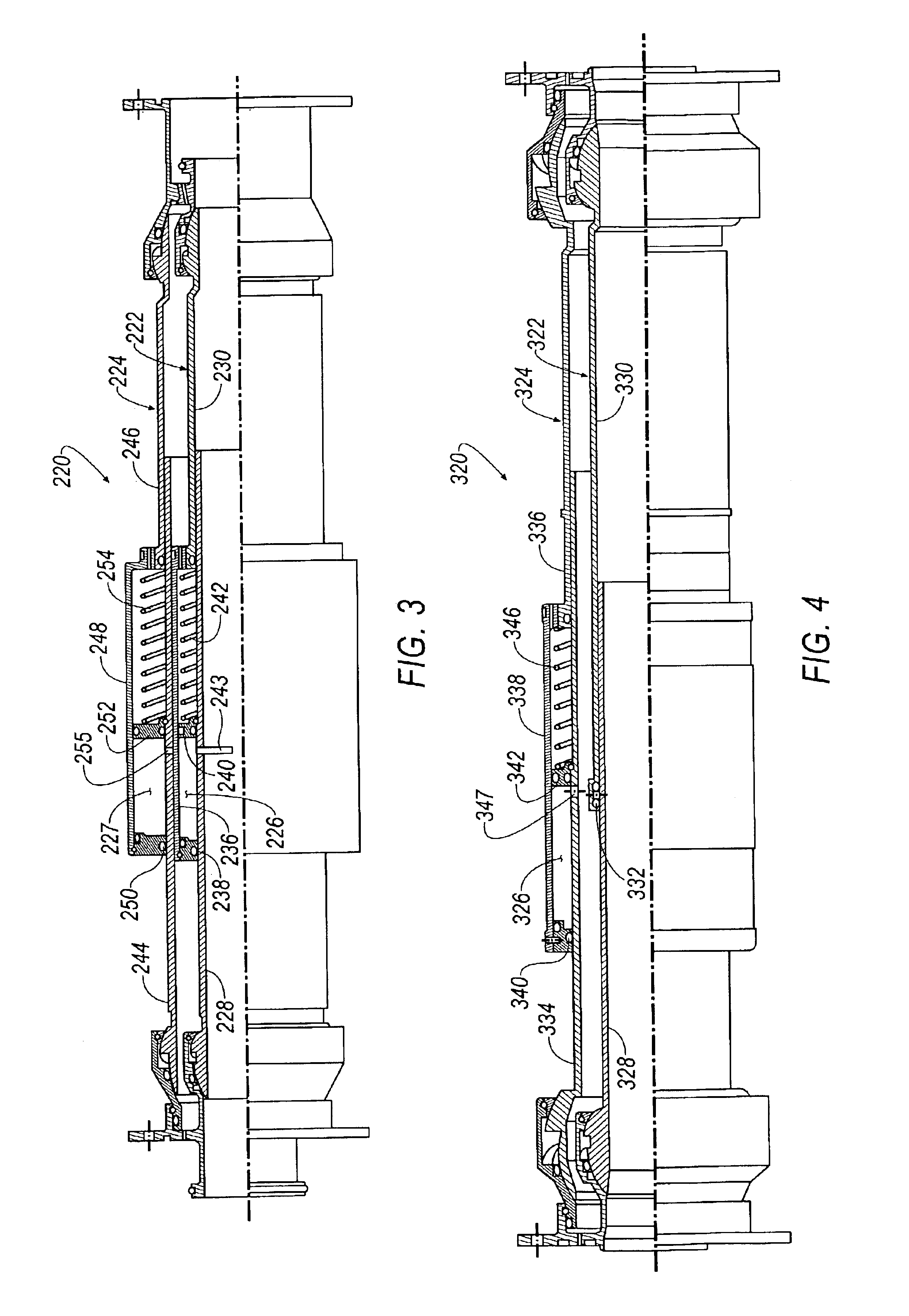

Coupling assembly

A coupling assembly for fuel transfer includes a first inner conduit attached to a first ferrule adapter and a second inner conduit attached to a second ferrule adapter. An inner conduit coupling engages the first inner conduit sealing mechanism and the second inner conduit sealing mechanism, thereby connecting the first inner conduit to the second inner conduit. A first outer conduit surrounds the first inner conduit. The first outer conduit is attached to the first ferrule adapter and the second outer conduit is attached to the second ferrule adapter. An outer conduit coupling engages the first and second outer conduit sealing mechanism thereby connecting the first outer conduit to the second outer conduit.

Owner:ADEL WIGGINS GRP TRANSDIGM INC

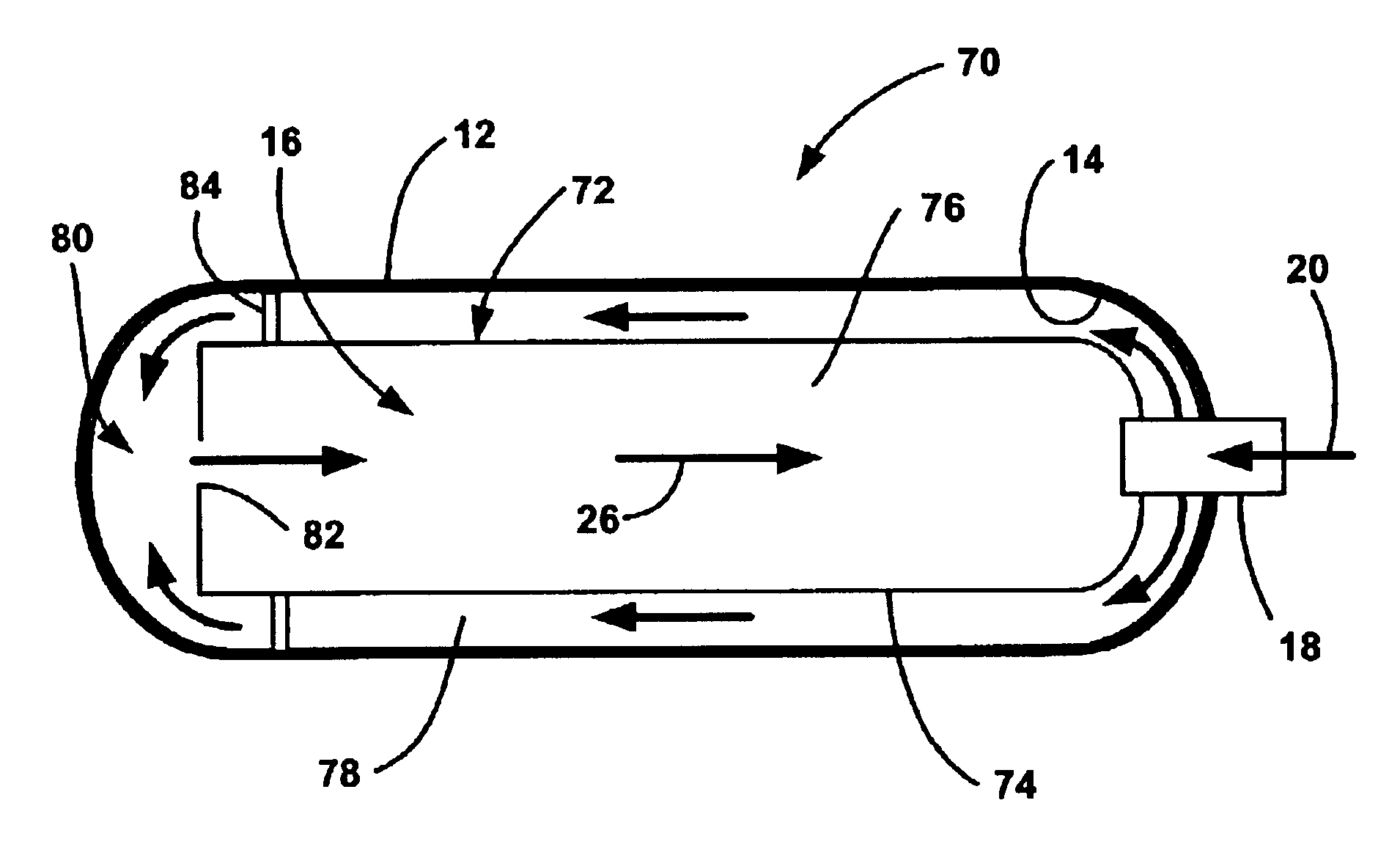

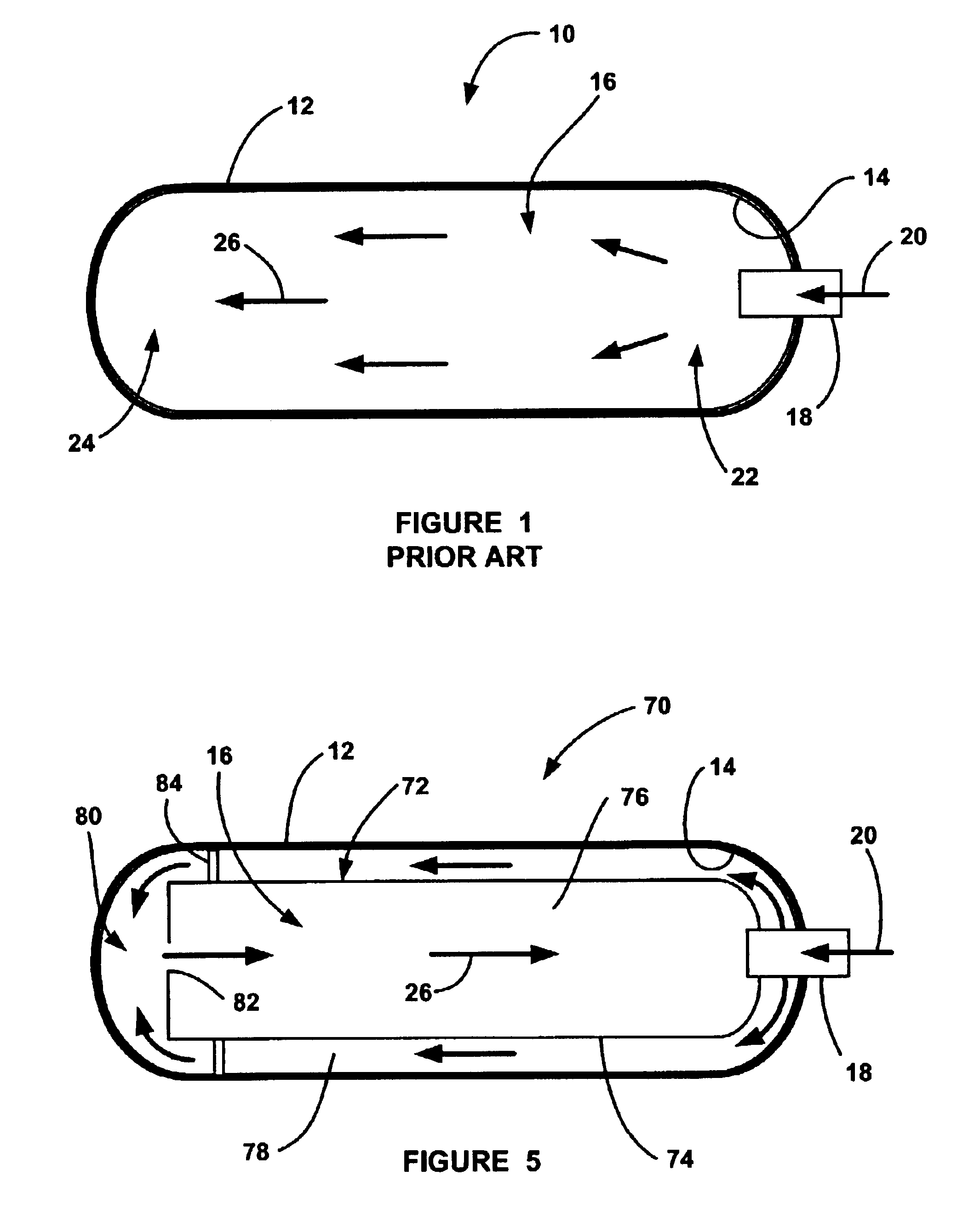

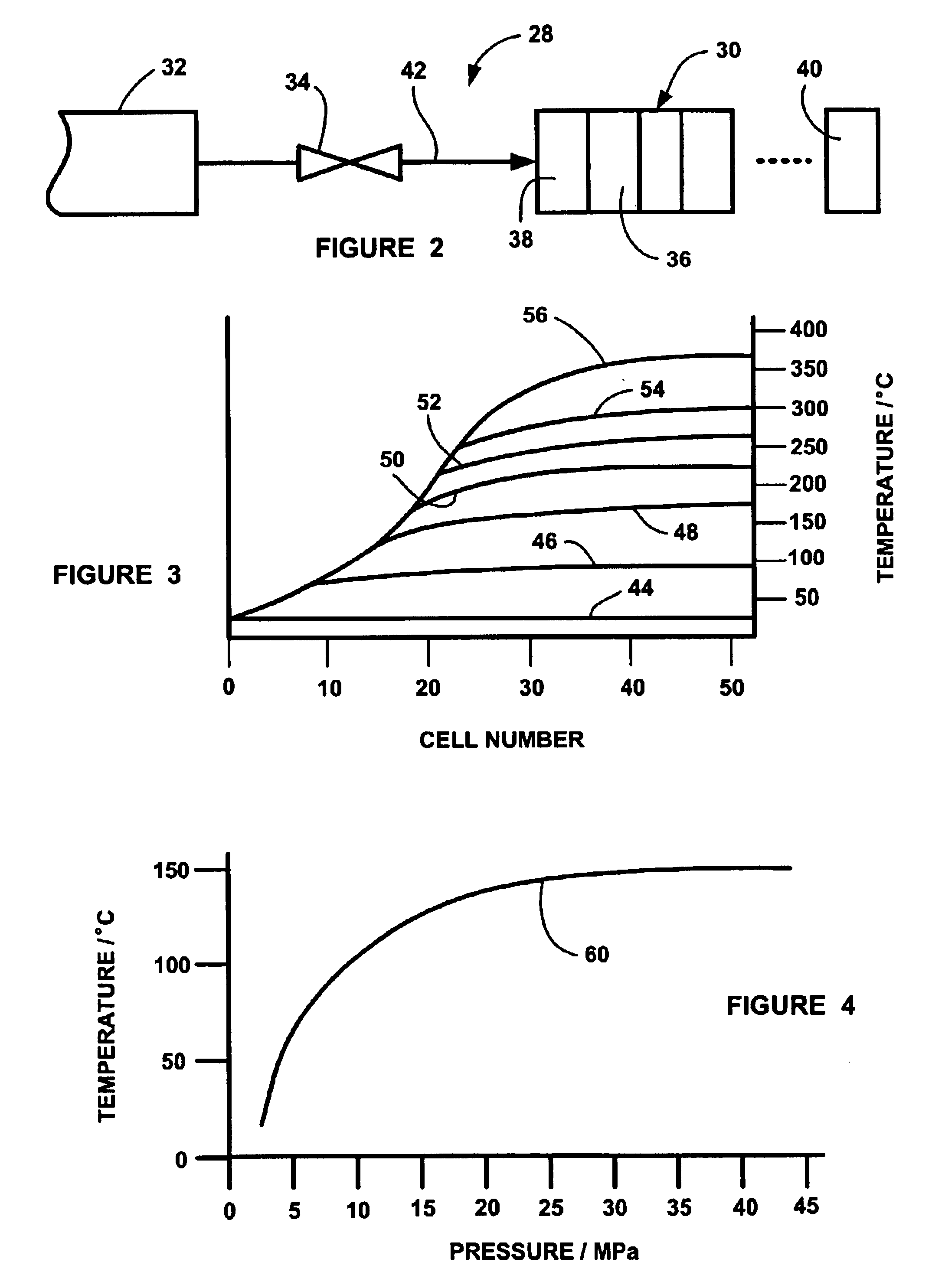

Device for overheat protection for a type 4 compressed gas container

A pressure container (70) for storing hydrogen gas (26) under pressure for a fuel cell engine. The container (70) includes an outer support layer (12) and a thermoplastic liner (14). An adapter (18) is provided in the outer layer (12) and the liner (14) to allow fill gas (20) to fill the container (70) under pressure. A fill vessel (72) is provided within the liner (14) and is sealed and thermally coupled to the adapter (18). The fill gas (20) is confined within a gap (78) between an outer surface of the fill vessel (72) and the liner (14) so that the temperature of the liner (14) is not significantly increased during the fill process. An opening (82) is provided in the fill vessel (72) so that the fill gas (20) forces the contained gas (26) within the container (70) into the fill vessel (72) through the opening (82).

Owner:GM GLOBAL TECH OPERATIONS LLC

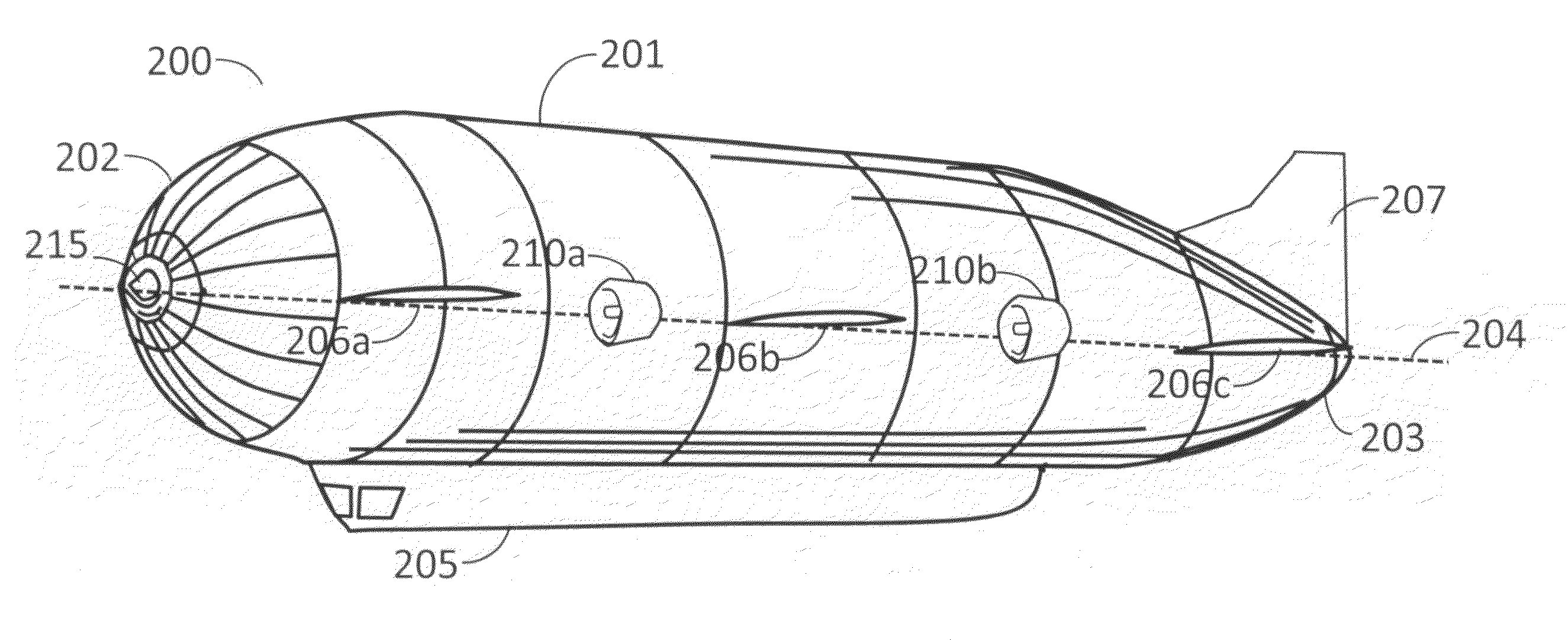

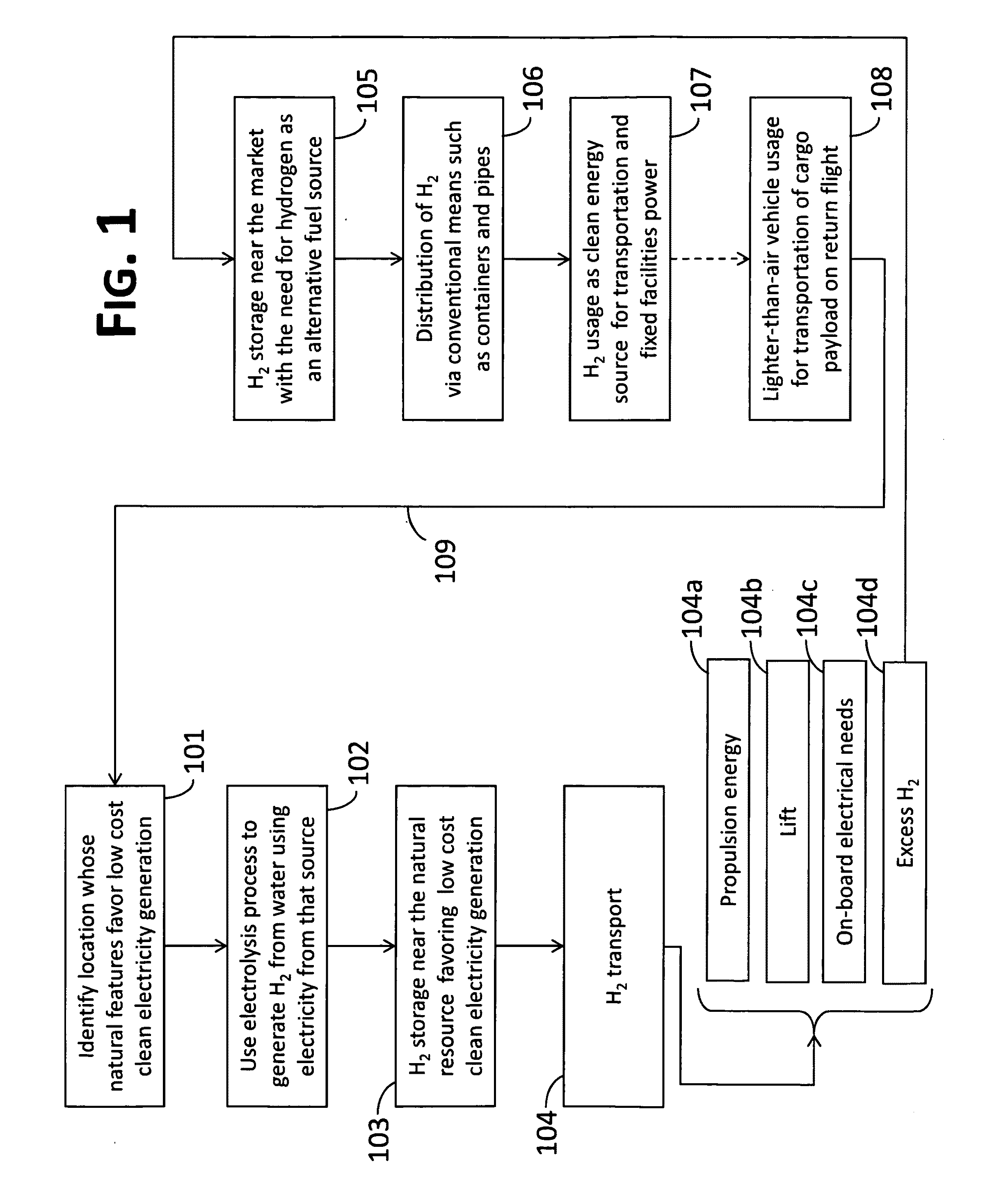

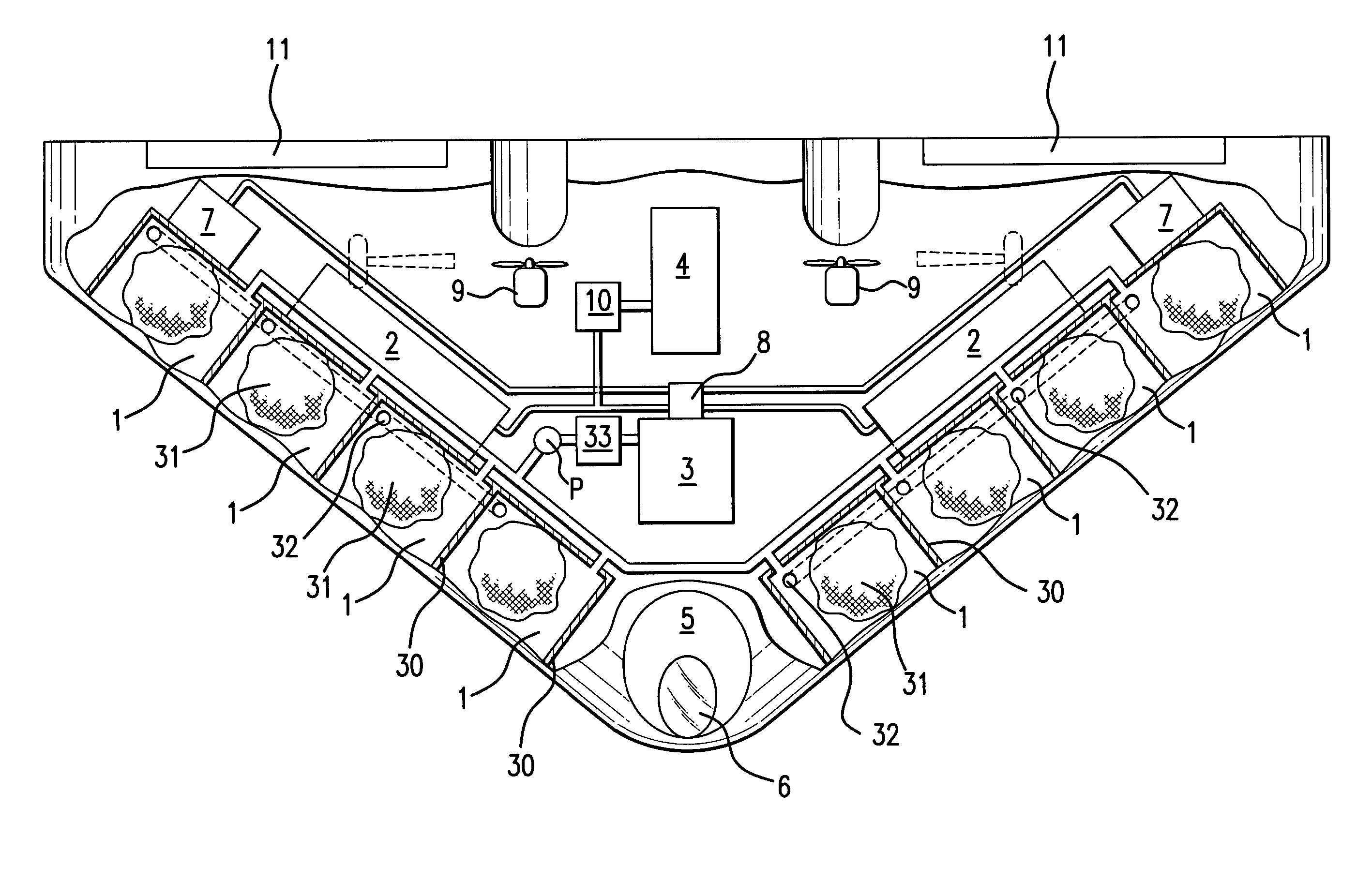

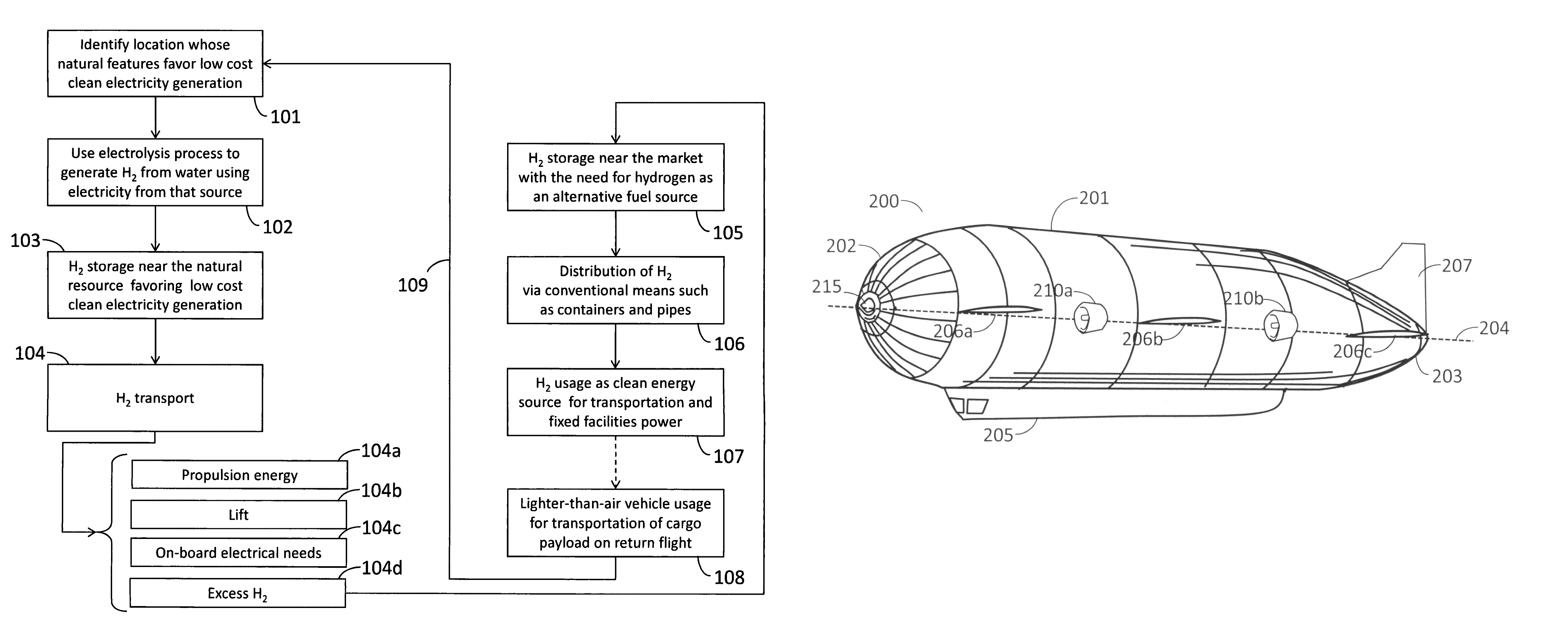

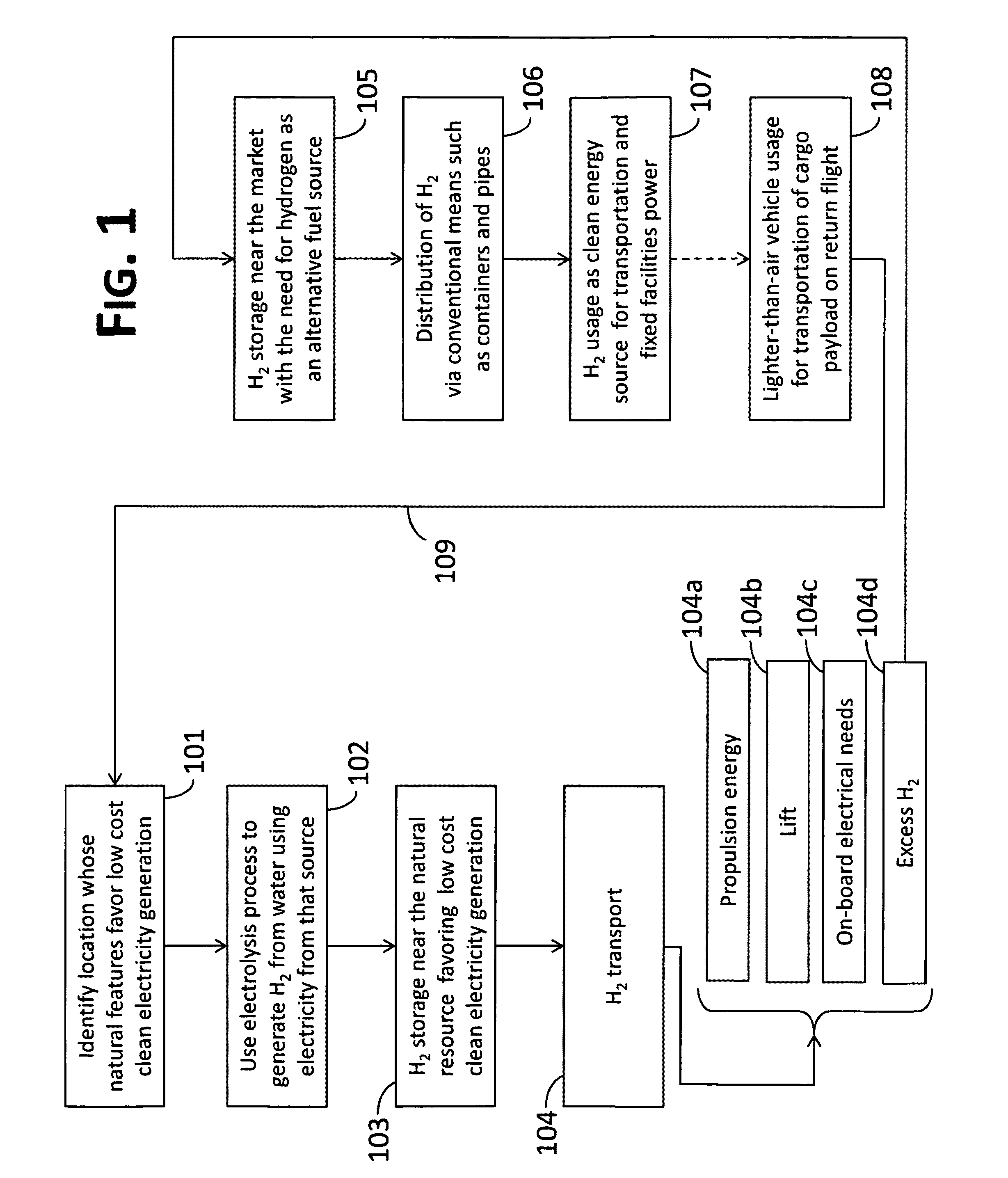

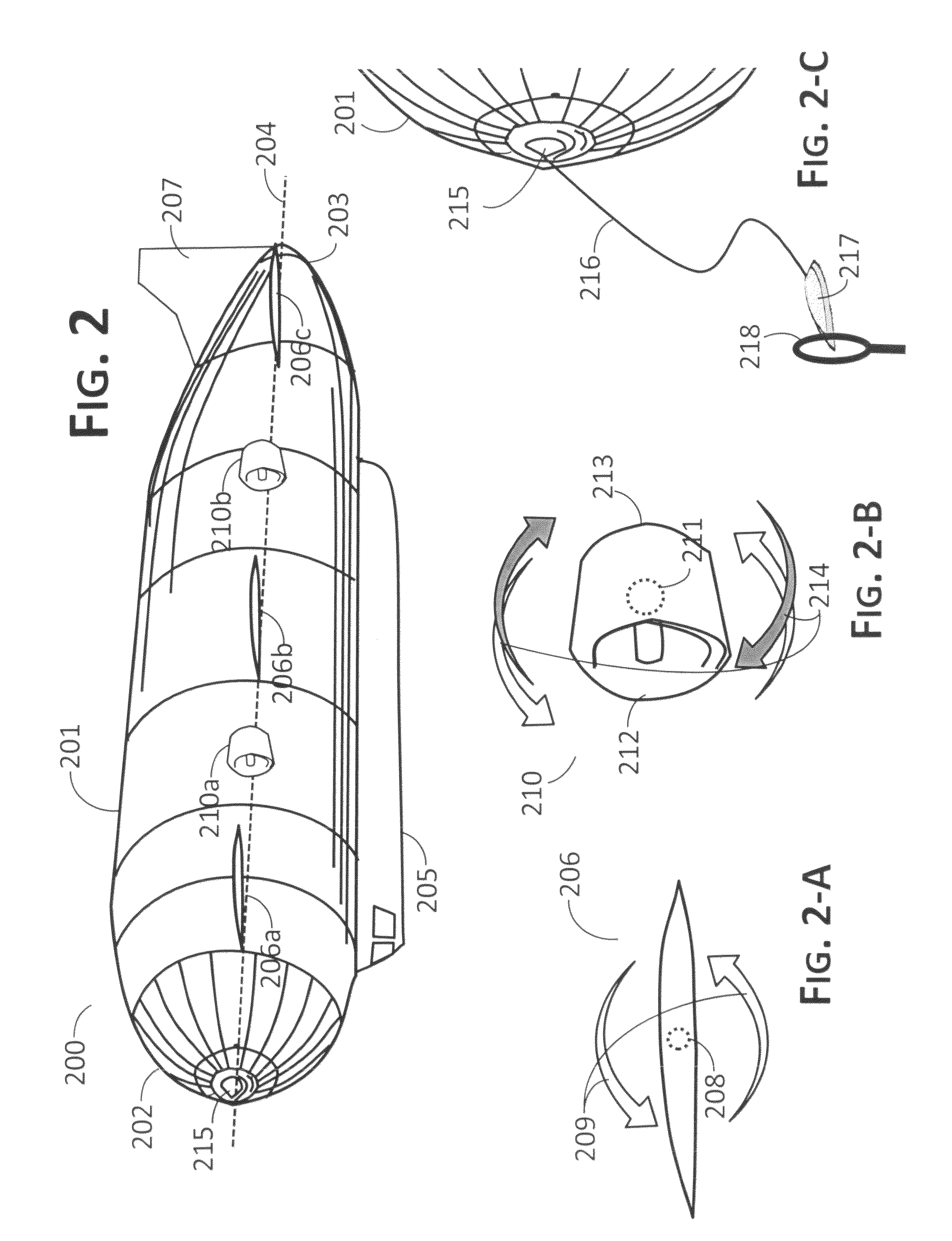

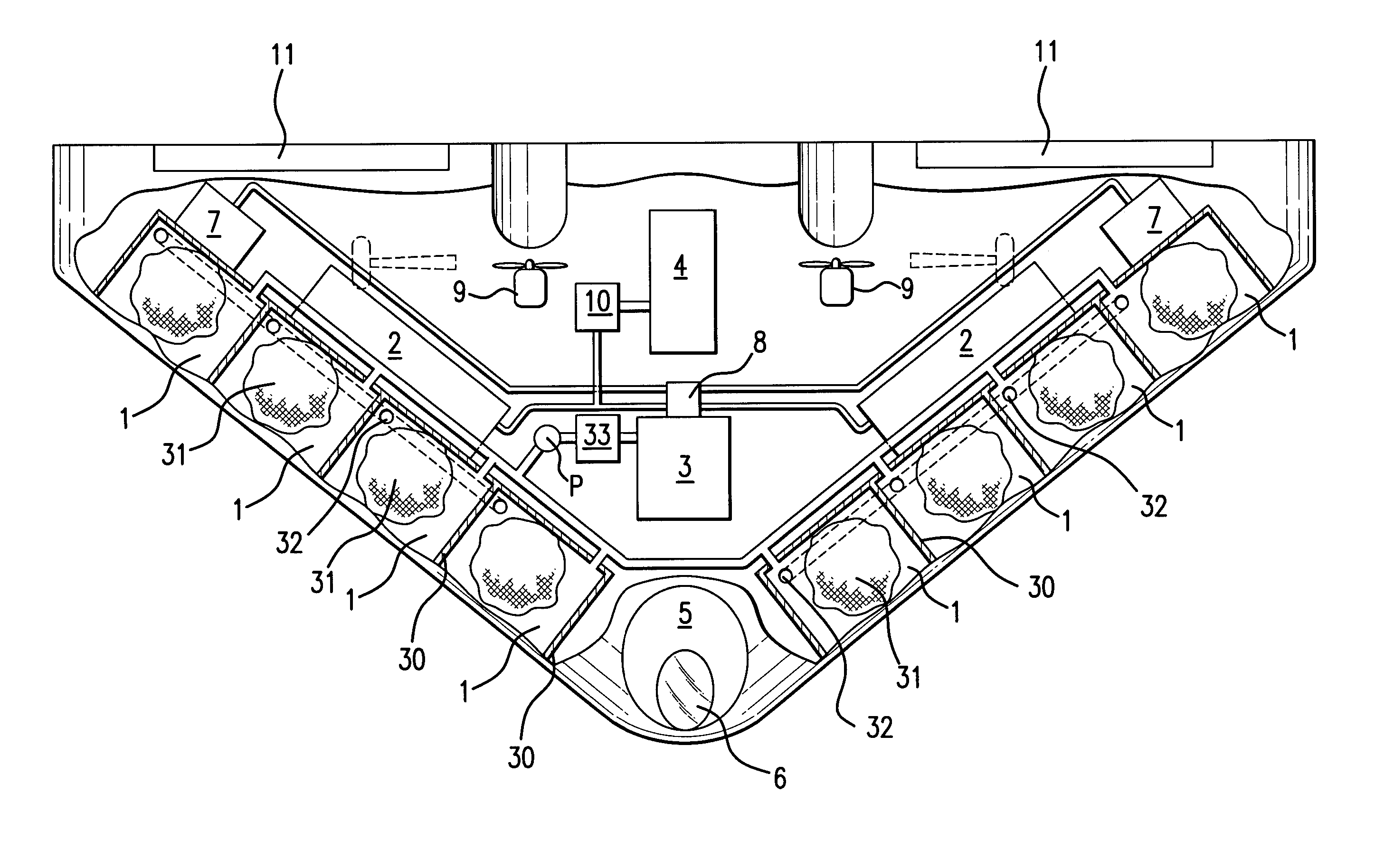

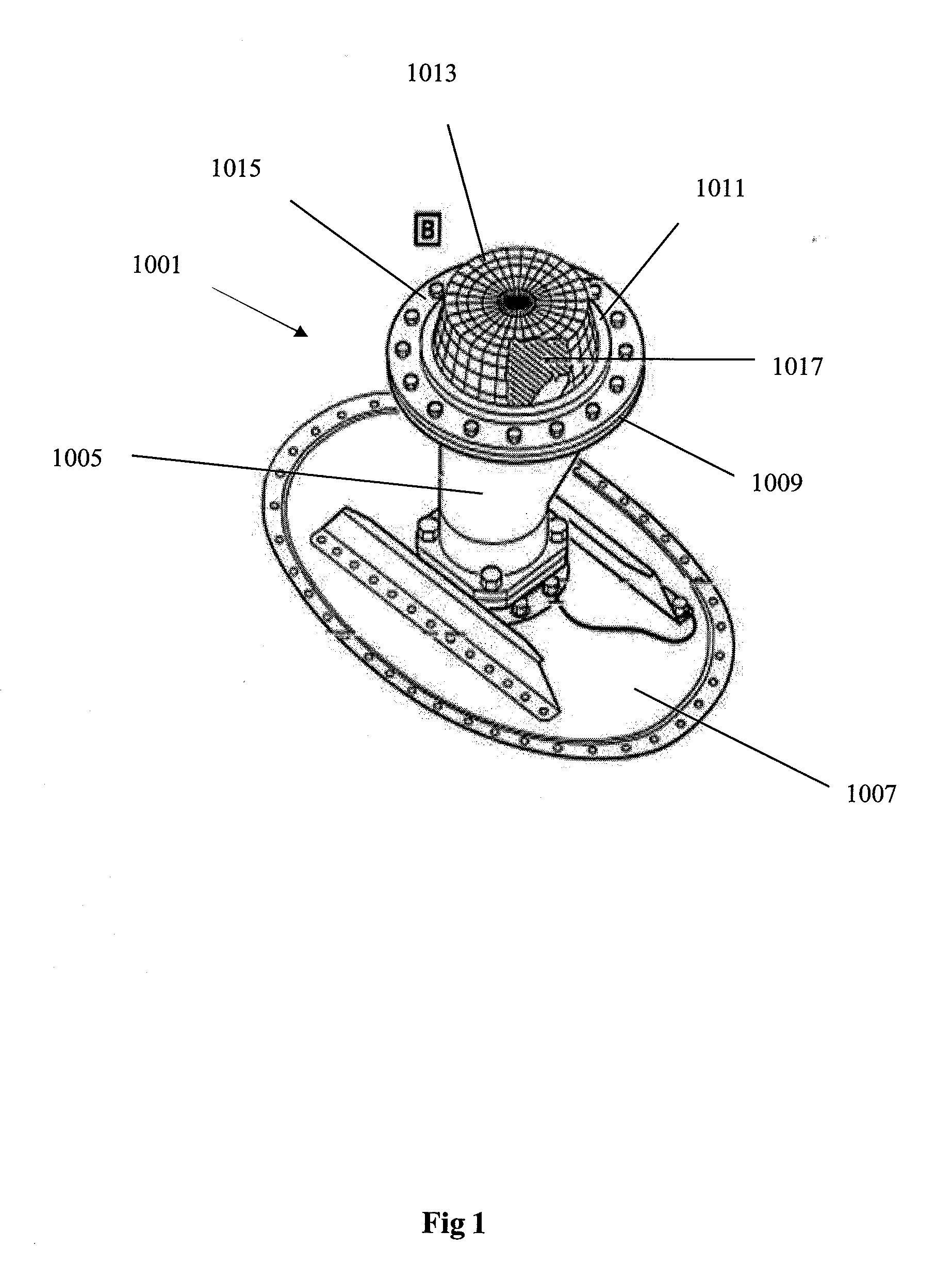

System, method and apparatus for widespread commercialization of hydrogen as a carbon-free alternative fuel source

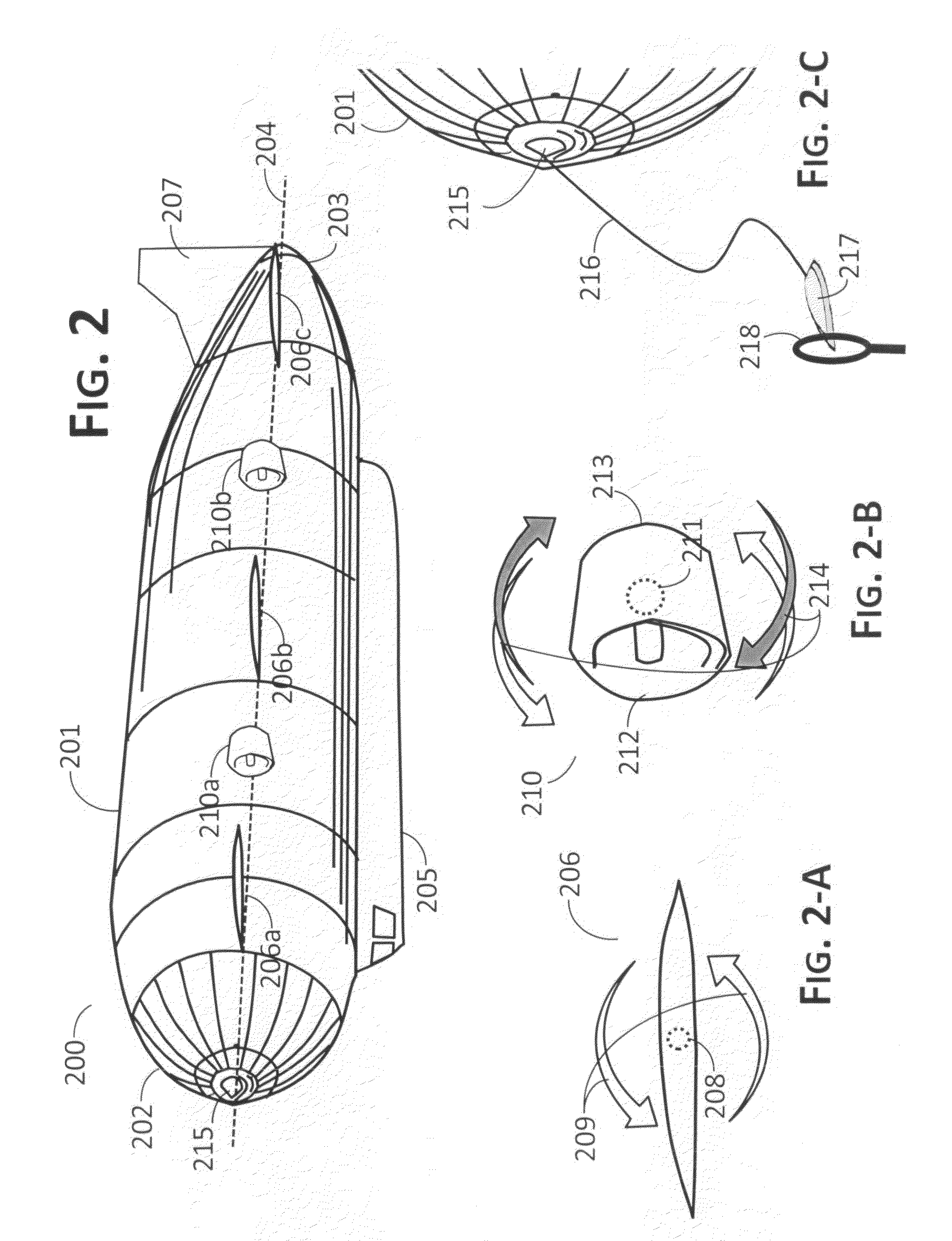

ActiveUS20100102164A1Reduce shipping costsSave extra spaceArresting gearPower plant arrangements/mountingElectricityHydrogen

A system for efficiently transporting hydrogen from where it can be economically made to where it is most needed using specially designed airships. Technologies such as geothermal, wind, solar, wave tidal or hydropower can be used to generate electricity in-situ or very near to the primary energy sources. This electricity can then be used to produce hydrogen directly from water through various methods known in the art. Hydrogen can be delivered from the place where it is produced to the place where it is needed using an airship in which the hydrogen gas can also be used for generating lift, providing propulsion energy and serving ancillary needs. In other embodiments of the invention, the airship of the present invention can be used to dramatically reduce the cost of transportation of freight, the cost of passenger transportation, and to save on the area required for landing at the points of loading / unloading and embarkation / debarkation. And in another embodiment, the airship of the present invention can be used for transporting water and food to areas where needed. A unique docking system can use a remotely piloted unmanned aircraft flown from the mother craft to carry a guide line into a receiving attachment point.

Owner:H2 CLIPPER INC

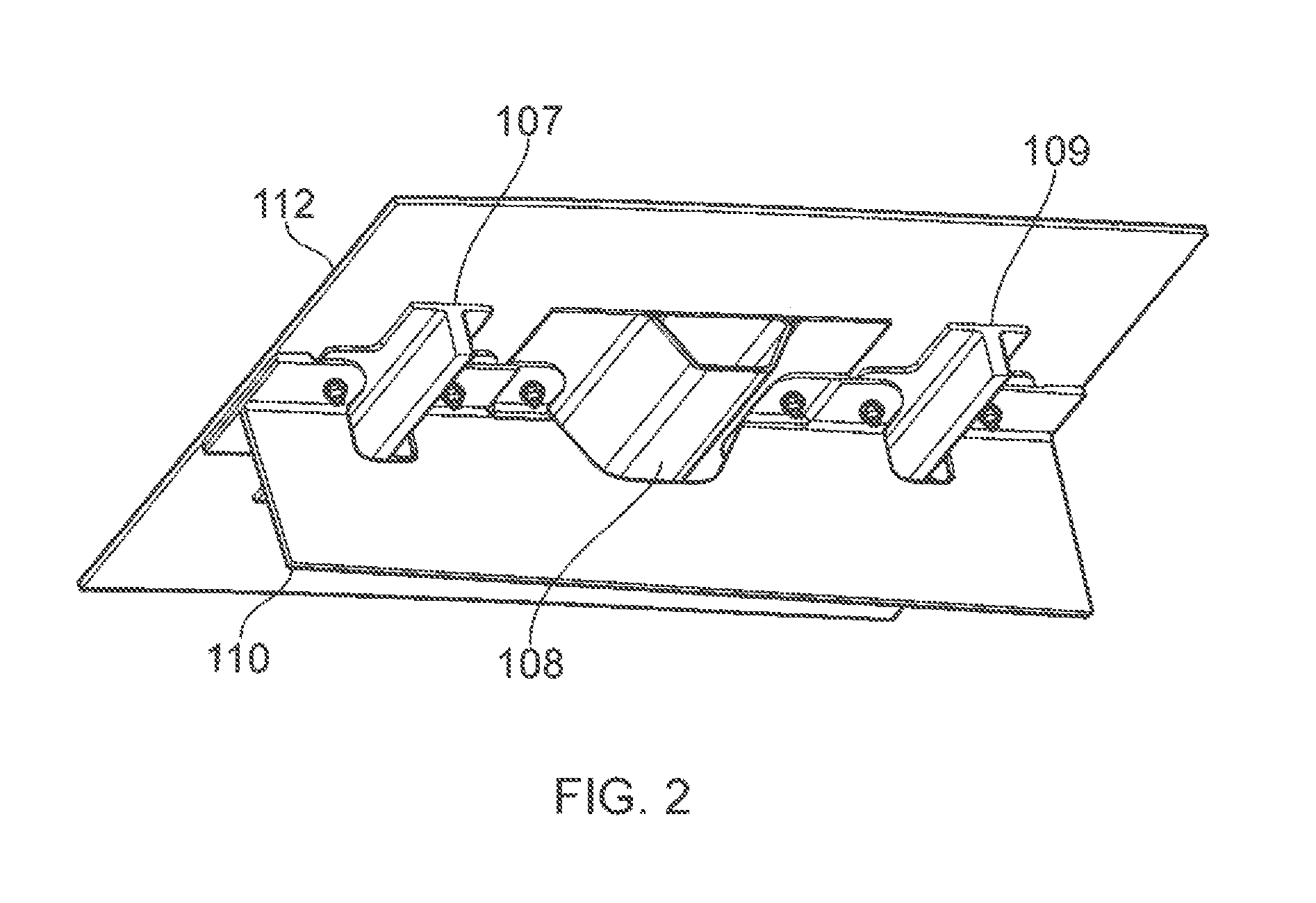

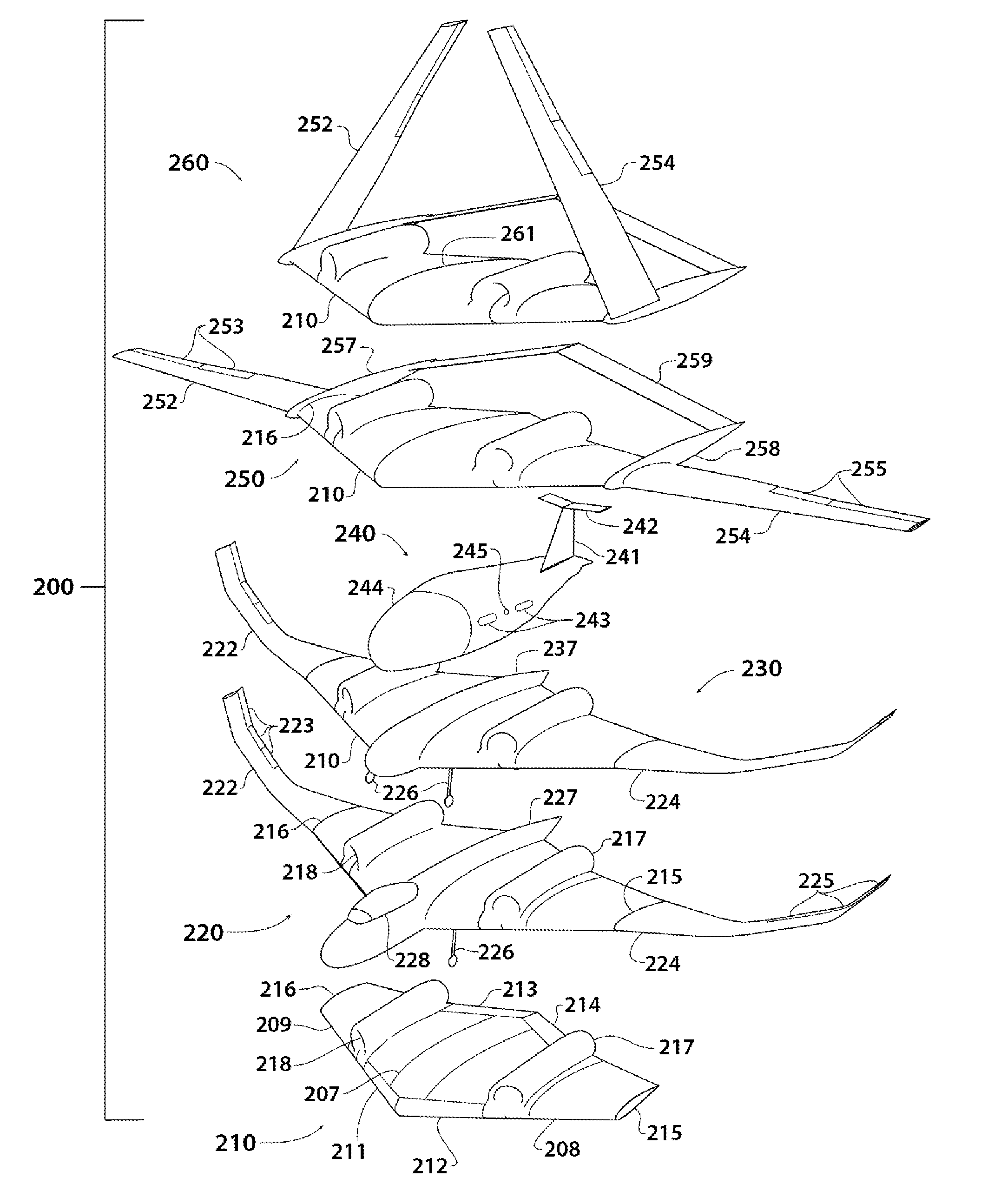

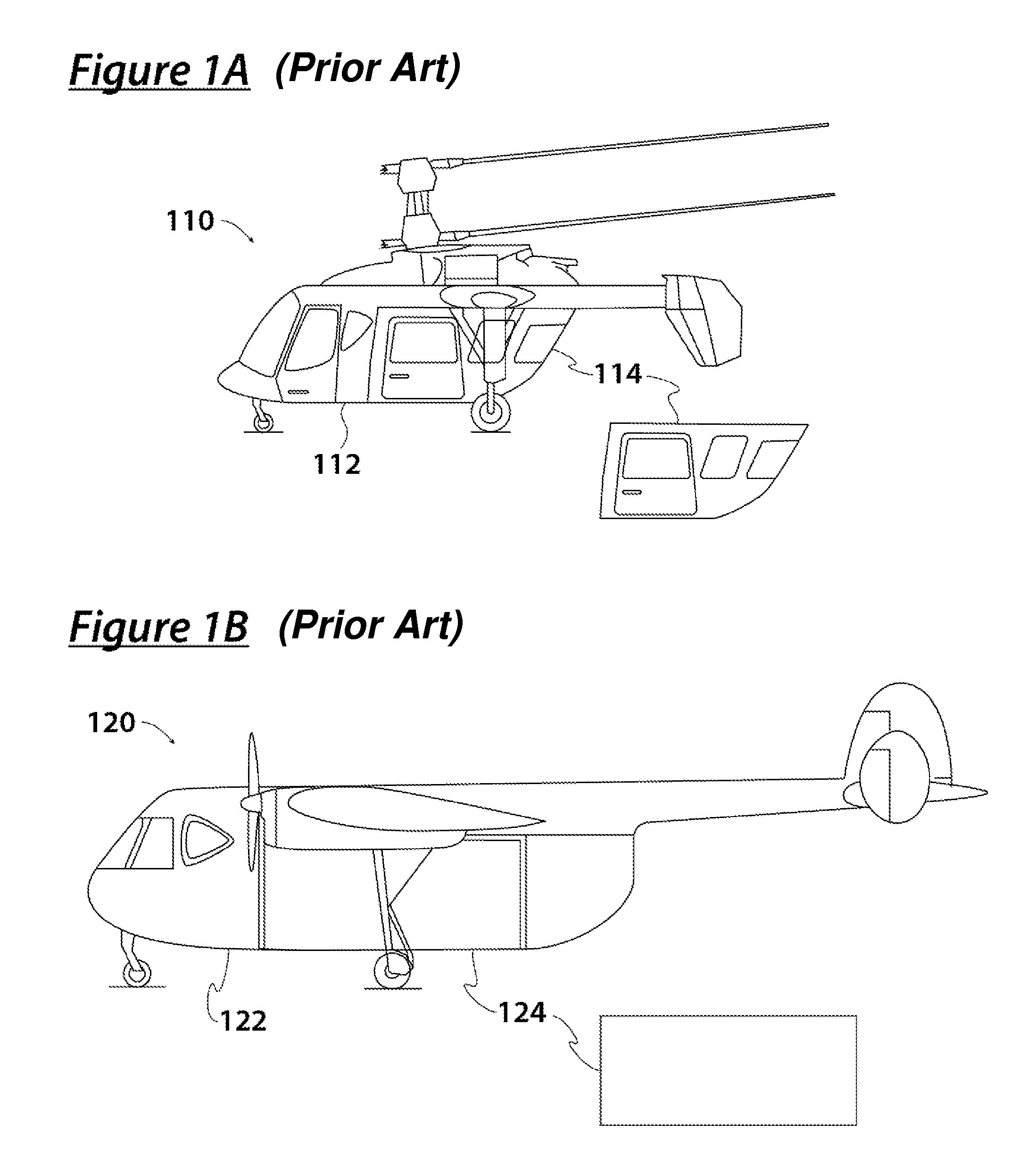

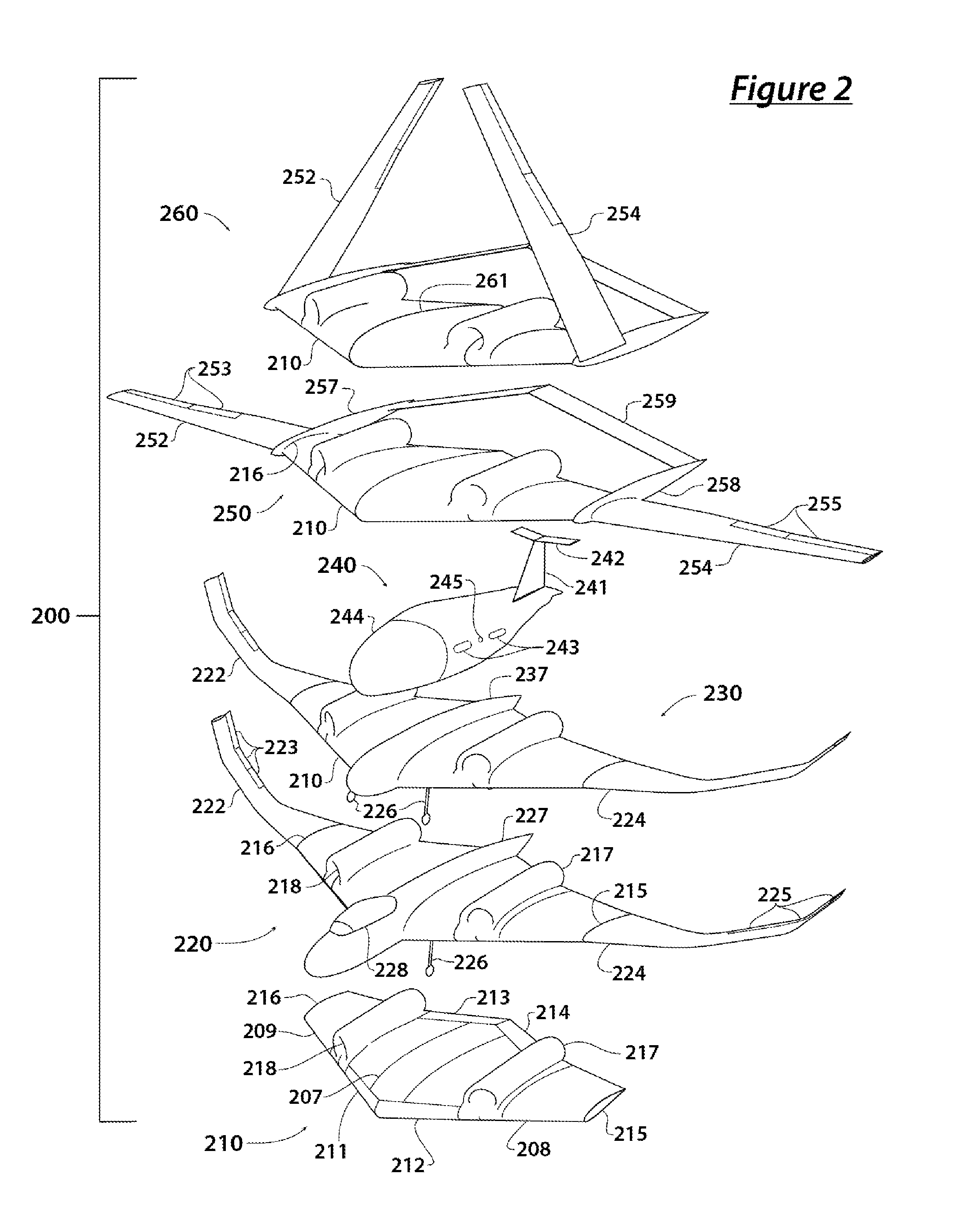

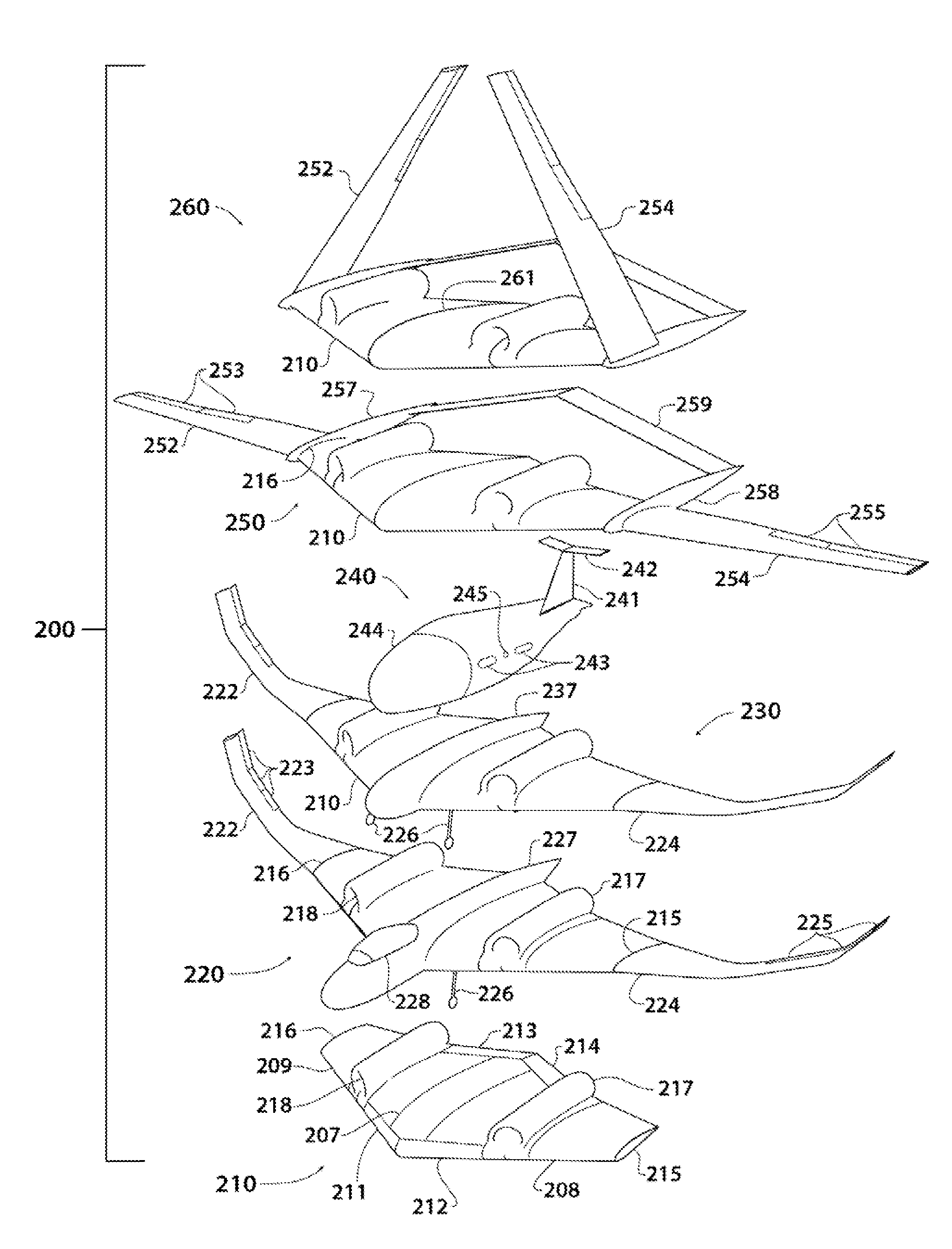

Modular aircraft system

ActiveUS9505484B1Easy constructionImprove aerodynamic performanceActuated automaticallyDe-icing equipmentsCarrying capacityFlight vehicle

The modular aircraft system includes a single fuselage having a permanently installed empennage and plural sets of wing modules and engine modules, with each wing and engine module optimized for different flight conditions and missions. The fuselage and each of the modules are configured for rapid removal and installation of the modules to minimize downtime for the aircraft. Short wings having relatively low aspect ratio are provided for relatively high speed flight when great endurance and / or weight carrying capacity are not of great concern. Long wings having high aspect ratio are provided for longer range and endurance flights where speed is not absolutely vital. A medium span wing module is also provided. Turboprop, single turbojet, and dual turbojet engine modules are provided for installation depending upon mission requirements for any given flight. The aircraft is primarily adapted for use as an autonomously operated or remotely operated unmanned aerial vehicle.

Owner:AL SABAH NASSER M

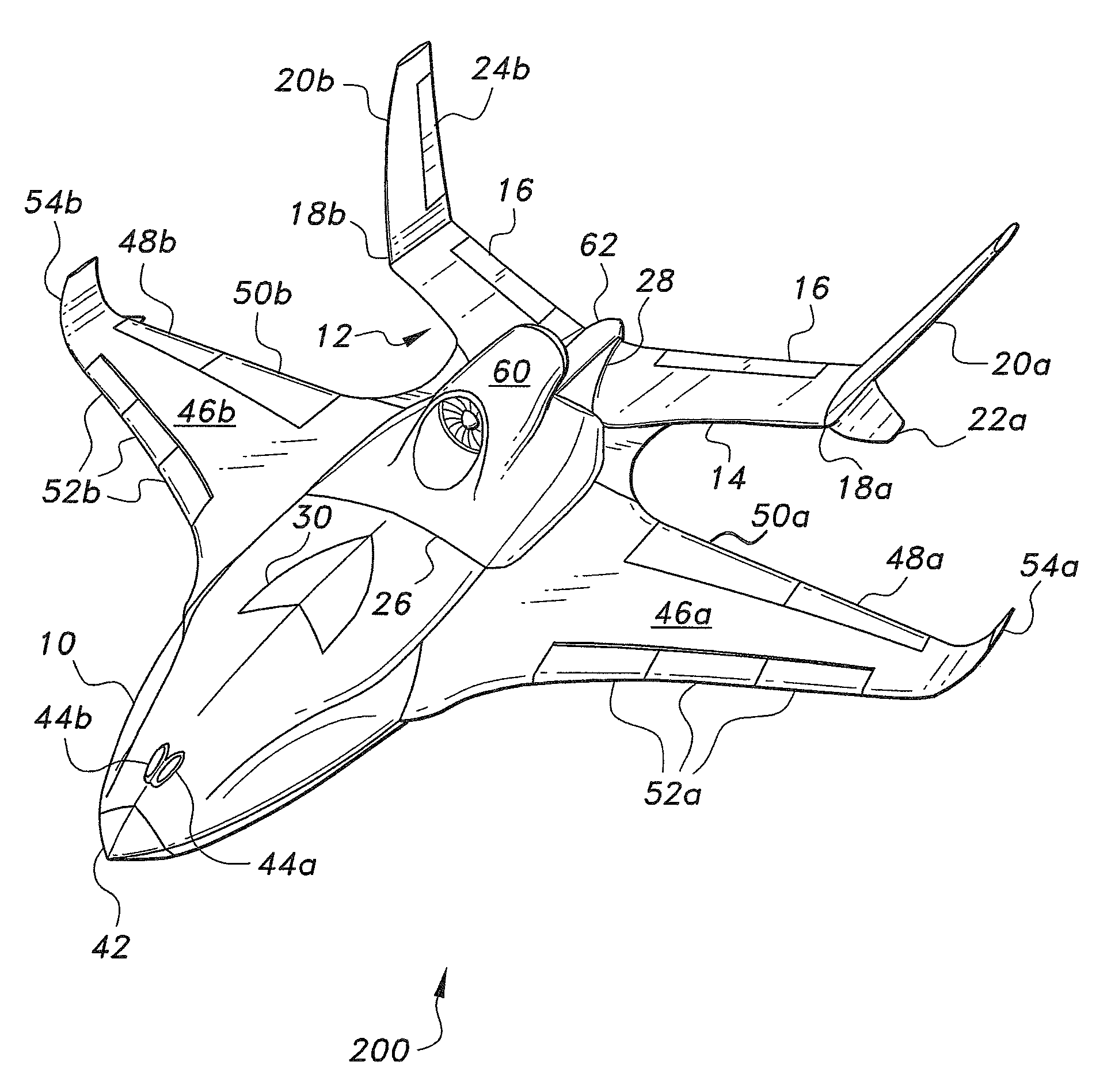

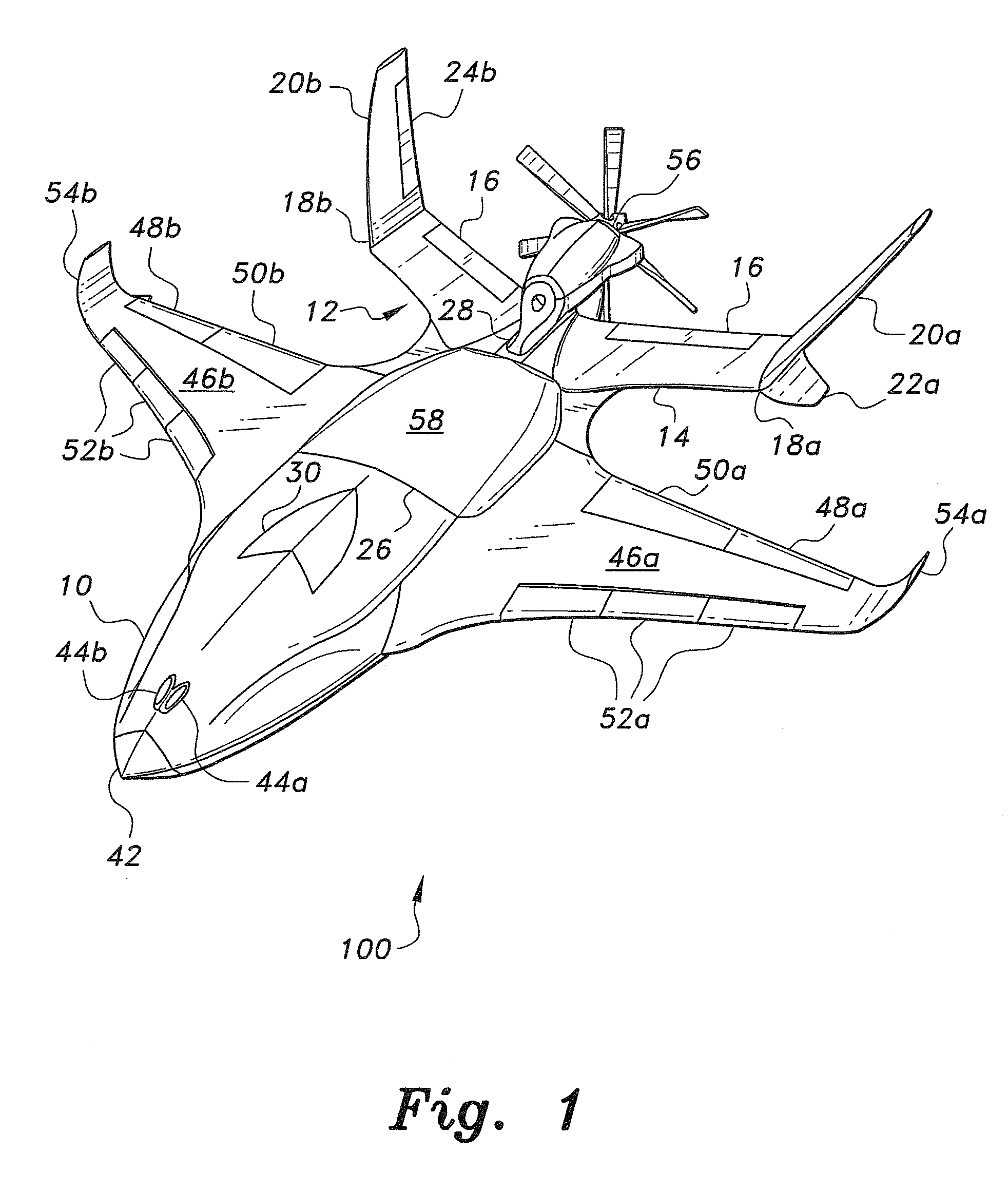

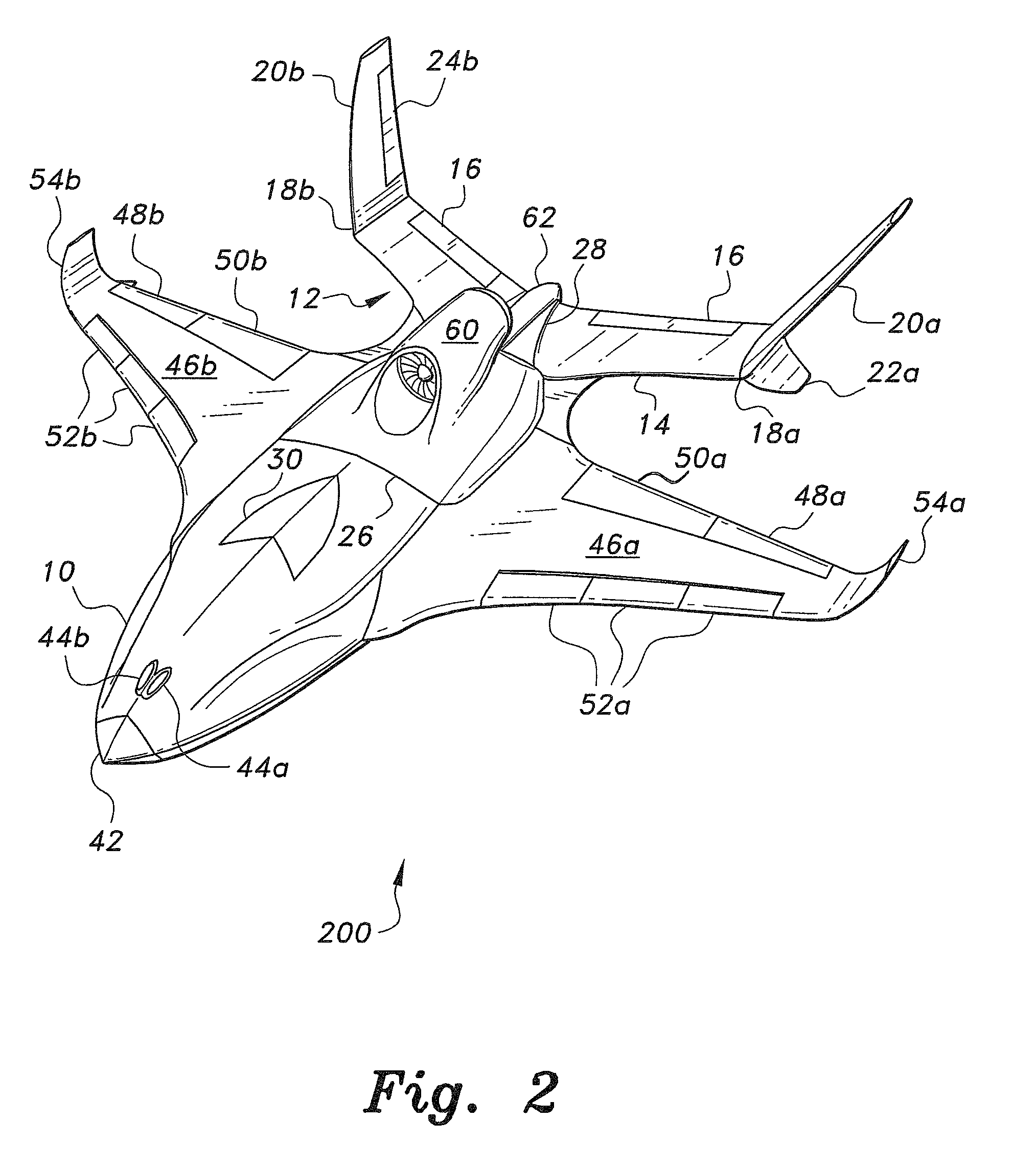

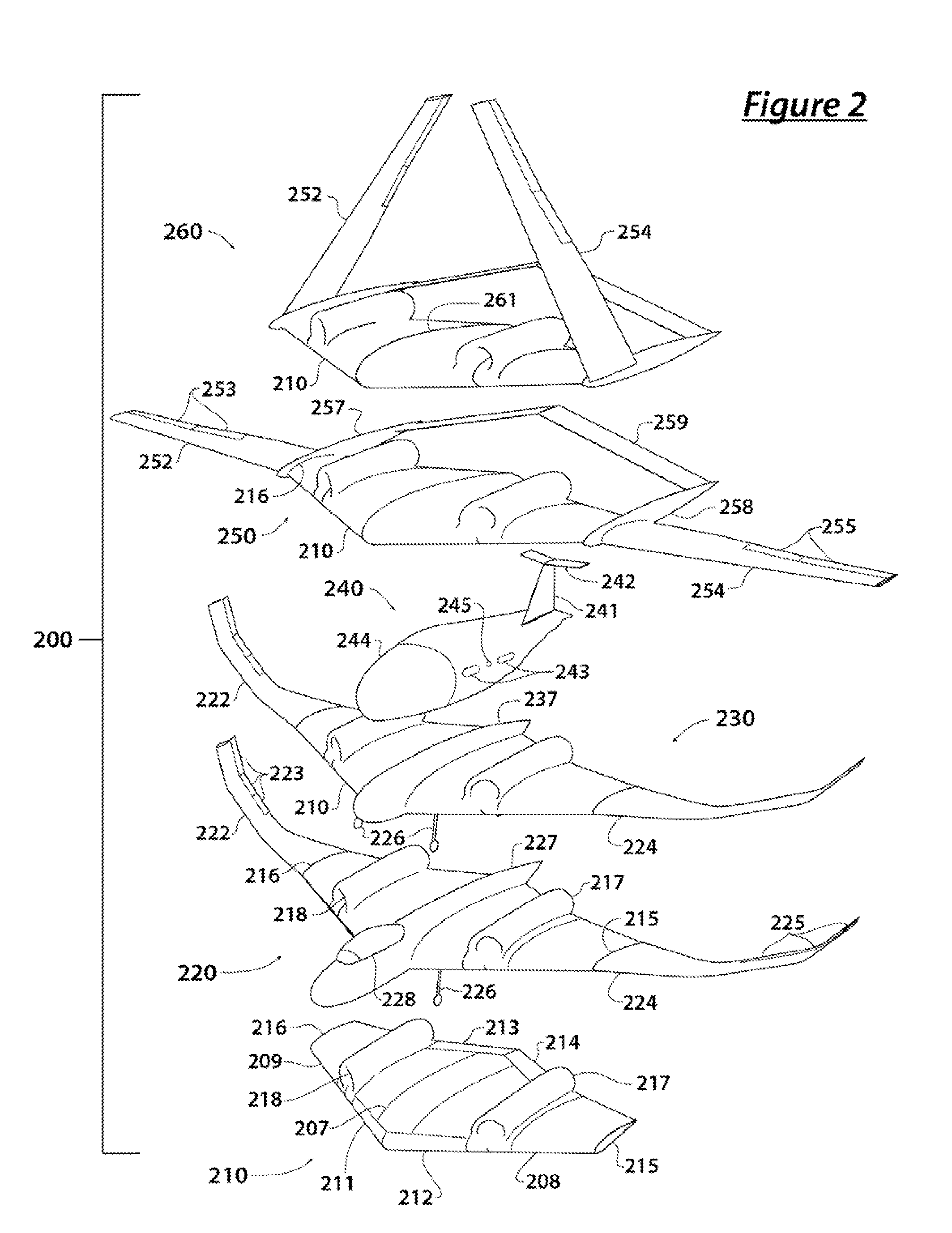

Multi-Role Aircraft With Interchangeable Mission Modules

ActiveUS20140231593A1Without adding undue weightFuselage framesAll-wing aircraftAviationTrailing edge

A flight-operable, truly modular aircraft has an aircraft core to which one or more of outer wings members, fuselage, cockpit, leading and trailing edge couplings, and empennage and tail sections can be removably coupled and / or replaced during the operating life span of the aircraft. In preferred embodiments the aircraft core houses the propulsive engines, avionics, at least 80% of the fuel, and all of the landing gear. The aircraft core is preferably constructed with curved forward and aft composite spars, that transfer loads across the center section, while accommodating a mid-wing configuration. The aircraft core preferably has a large central cavity dimensioned to interchangeably carry an ordnance launcher, a surveillance payload, electronic countermeasures, and other types of cargo. Contemplated aircraft can be quite large, for example having a wing span of at least 80 ft.

Owner:KAREM ABE

Multi-Role Aircraft with Interchangeable Mission Modules

A flight-operable, truly modular aircraft has an aircraft core to which one or more of outer wings members, fuselage, cockpit, leading and trailing edge couplings, and empennage and tail sections can be removably coupled and / or replaced during the operating life span of the aircraft. In preferred embodiments the aircraft core houses the propulsive engines, avionics, at least 80% of the fuel, and all of the landing gear. The aircraft core is preferably constructed with curved forward and aft composite spars, that couple to outer wing sections and possibly other sections using hardpoints. The aircraft core preferably has a large central cavity dimensioned to interchangeably carry an ordnance launcher, a surveillance payload, electronic countermeasures, and other types of cargo. Contemplated aircraft can be quite large, for example having a wing span of at least 80 ft.

Owner:KAREM ABE

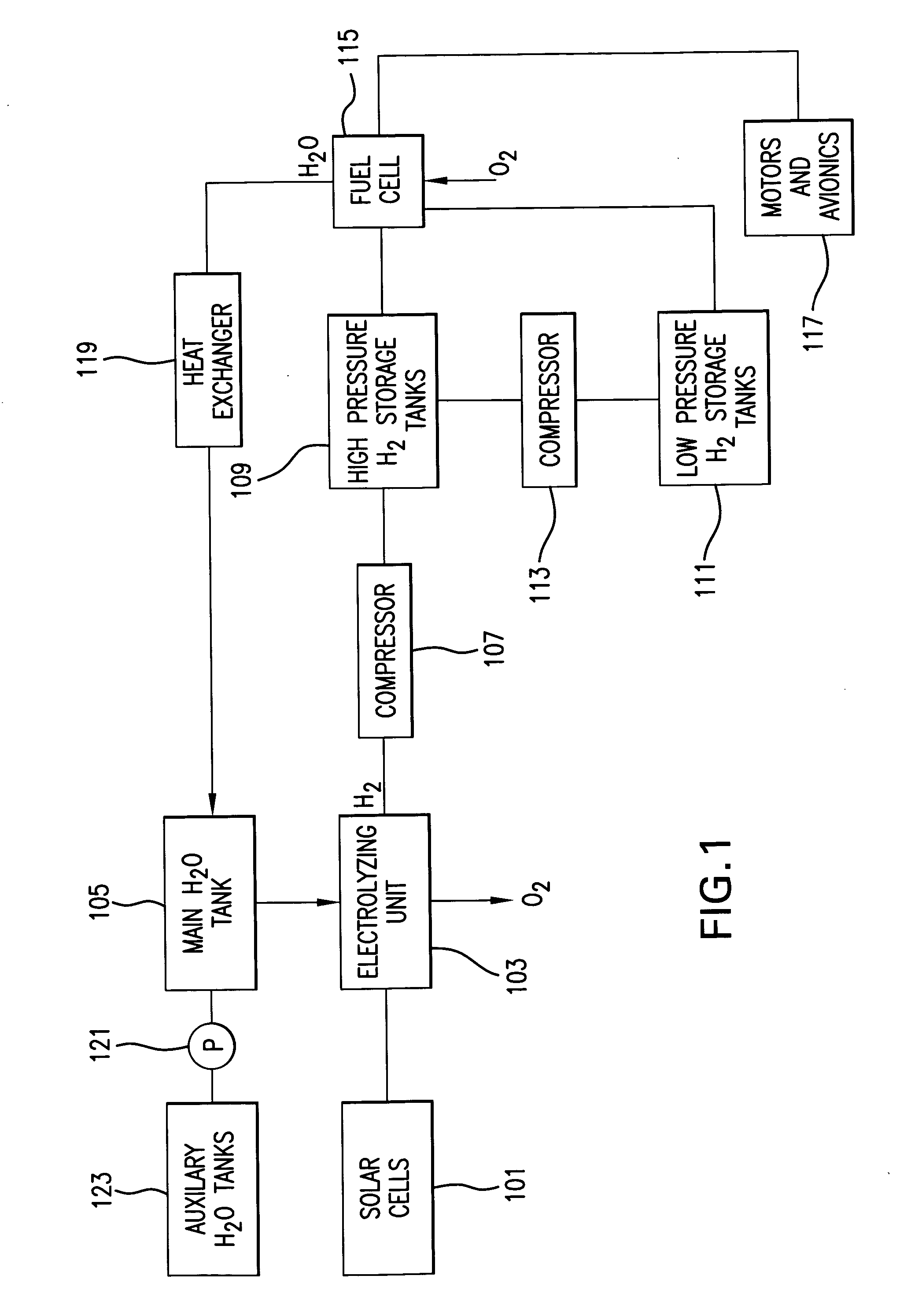

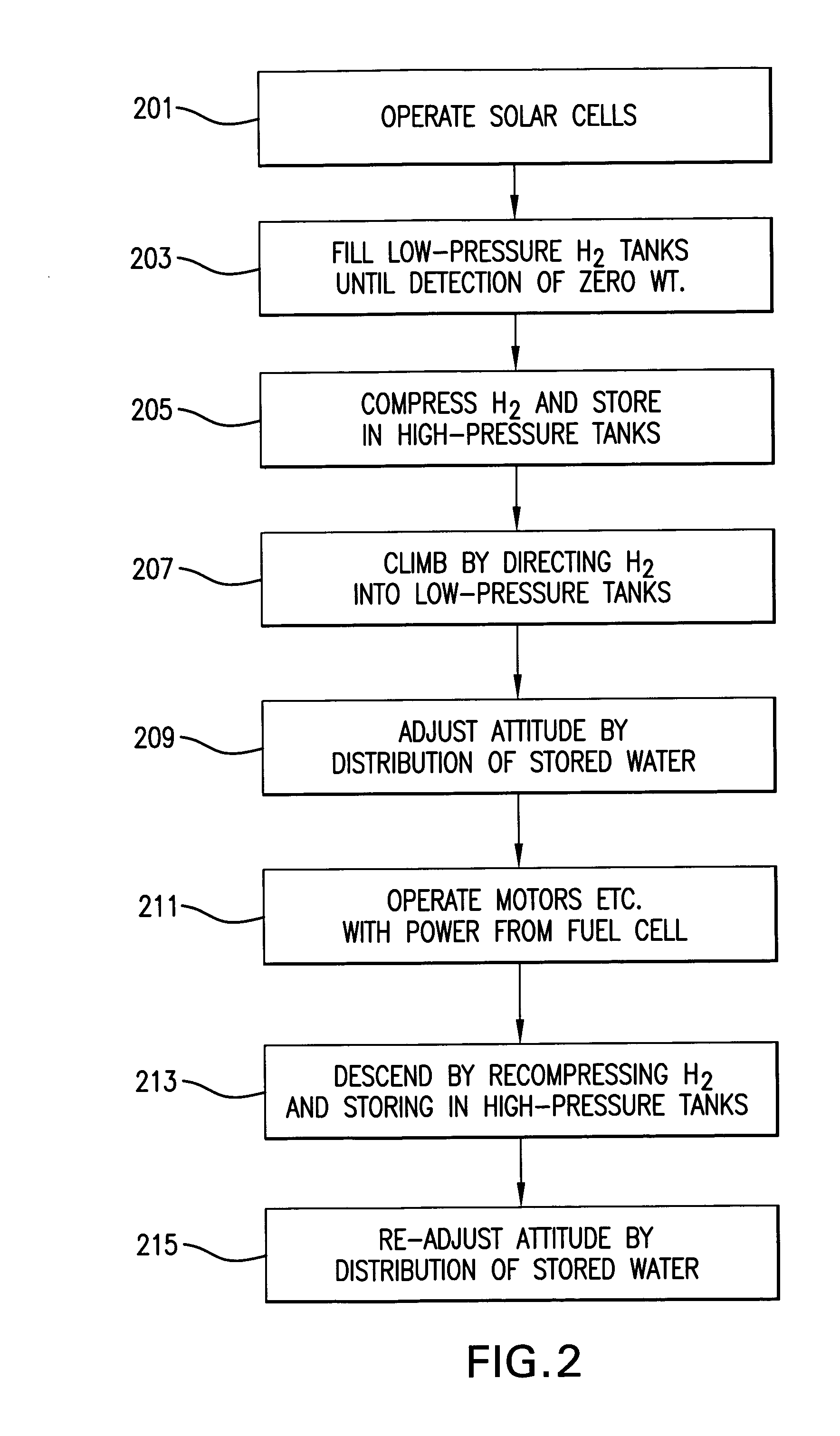

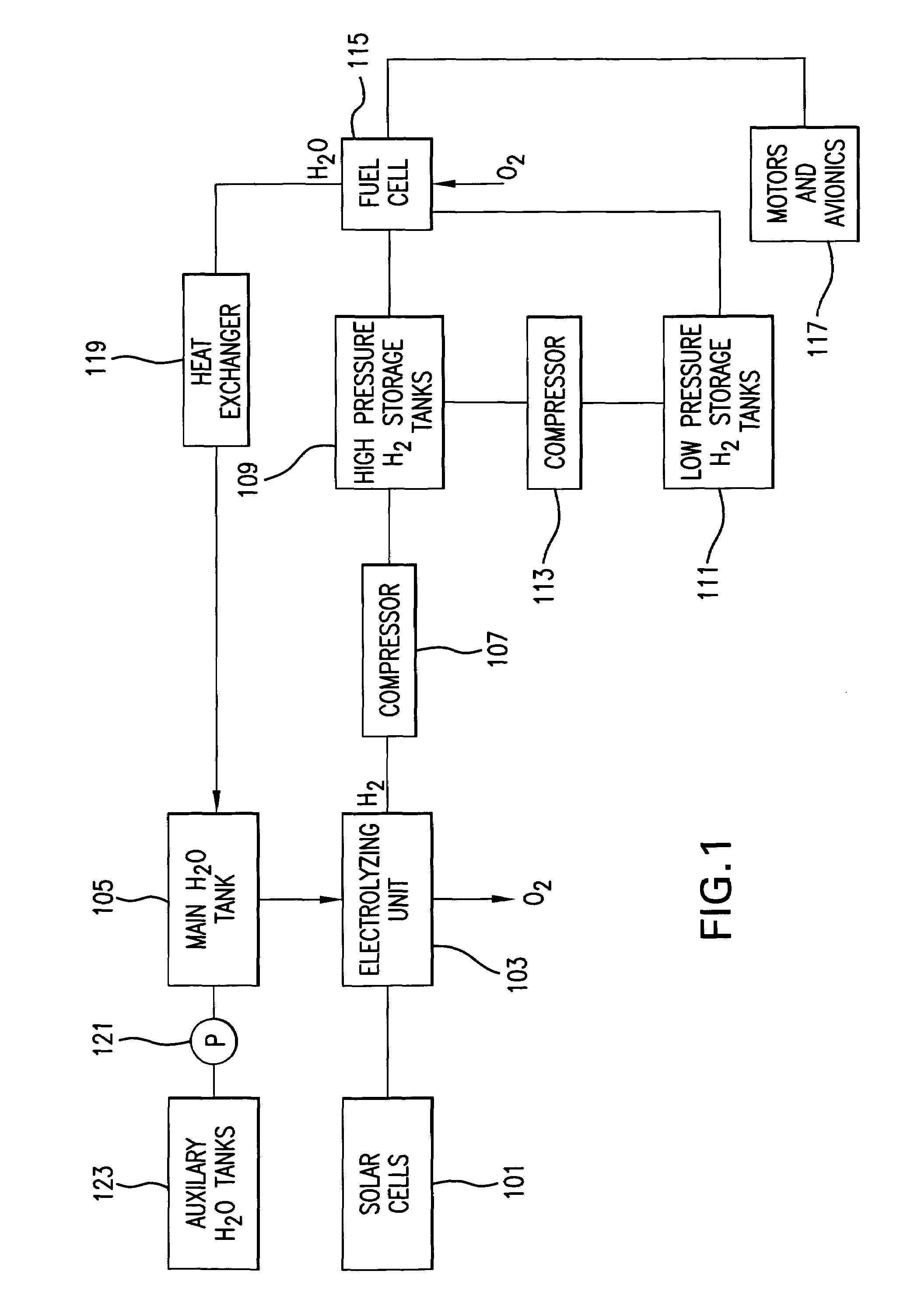

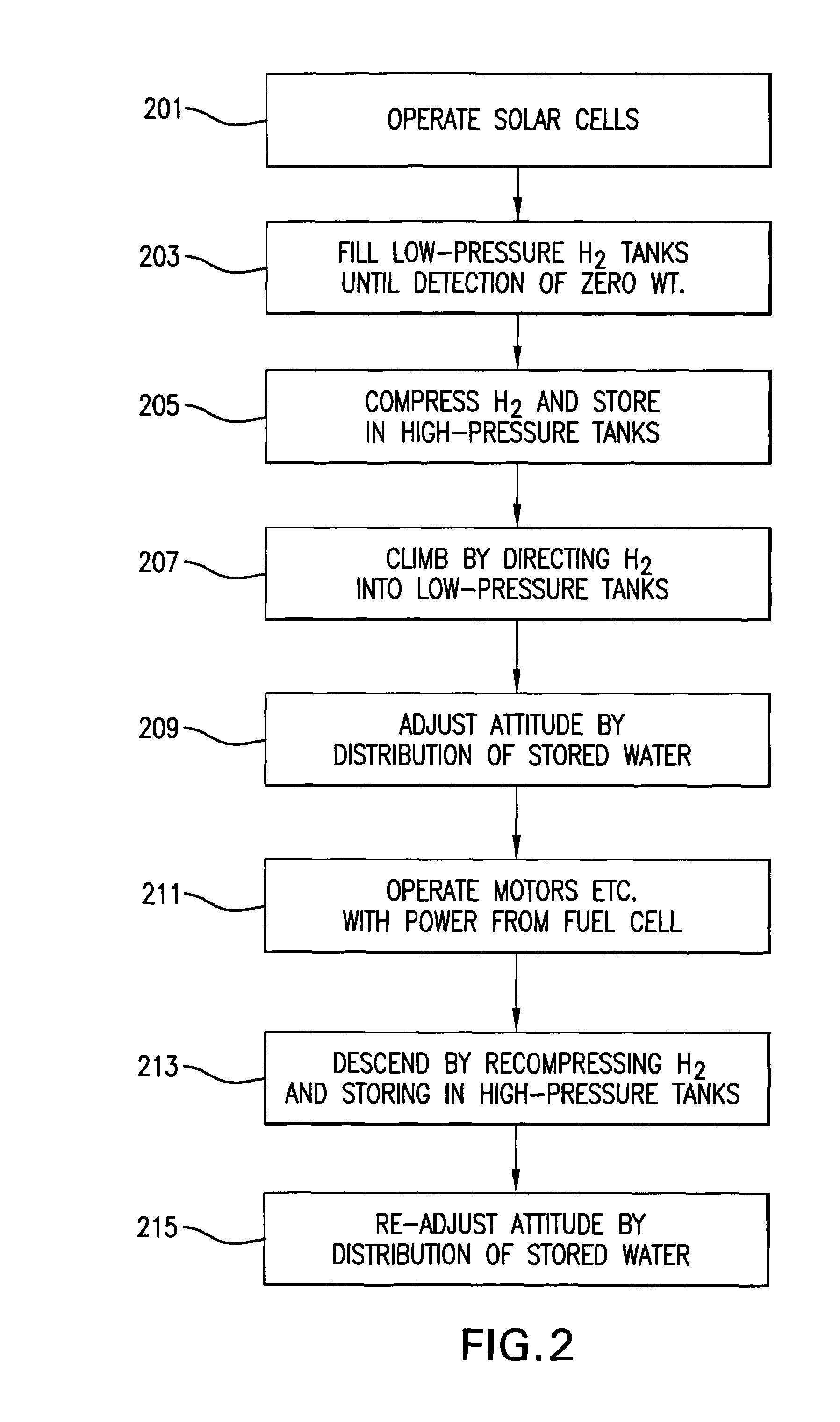

Solar-powered aircraft

InactiveUS20070034741A1Weight of to shiftPower installationsEnergy efficient board measuresHydrogenFuel cells

A solar-powered aircraft uses solar energy to electrolyze on-board water to produce hydrogen. The hydrogen fills various on-board tanks, causing the aircraft to become lighter than air. The hydrogen is also used to operate a fuel cell which provides power for electrical equipment, including a motor for turning a propeller. Water produced as waste by the fuel cell is recycled for use in the production of hydrogen. When hydrogen is removed from the tanks, either because it is consumed by the fuel cell or because it is compressed and pumped out of the tanks, air returns to the tanks, and the aircraft becomes heavier than air. The aircraft can thus be made to climb and descend by making it lighter than air, or heavier than air. The aircraft emits no harmful substances into the environment. The aircraft can remain aloft indefinitely, limited only by an insignificant amount of leakage of hydrogen and water.

Owner:FULLER HOWARD J

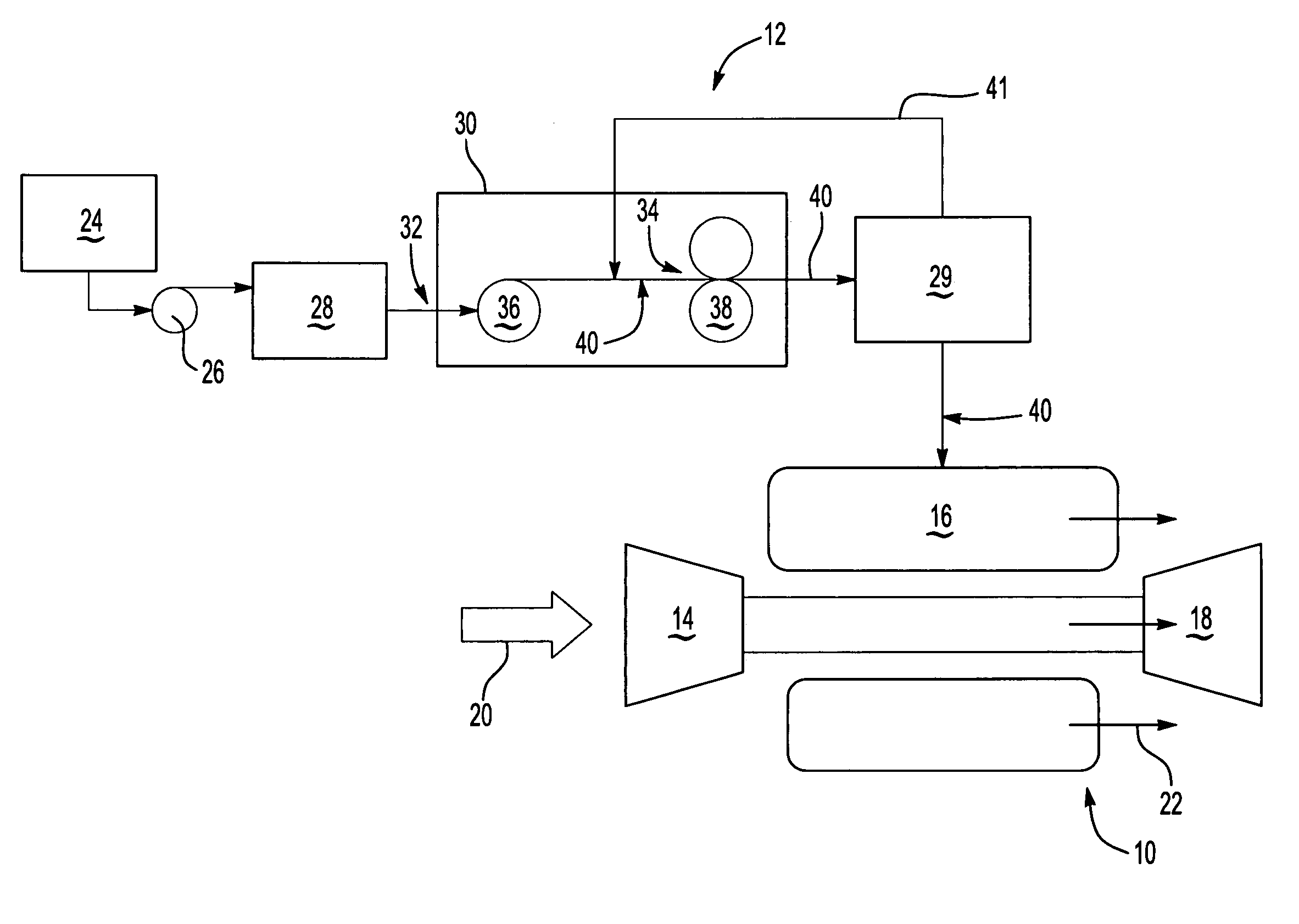

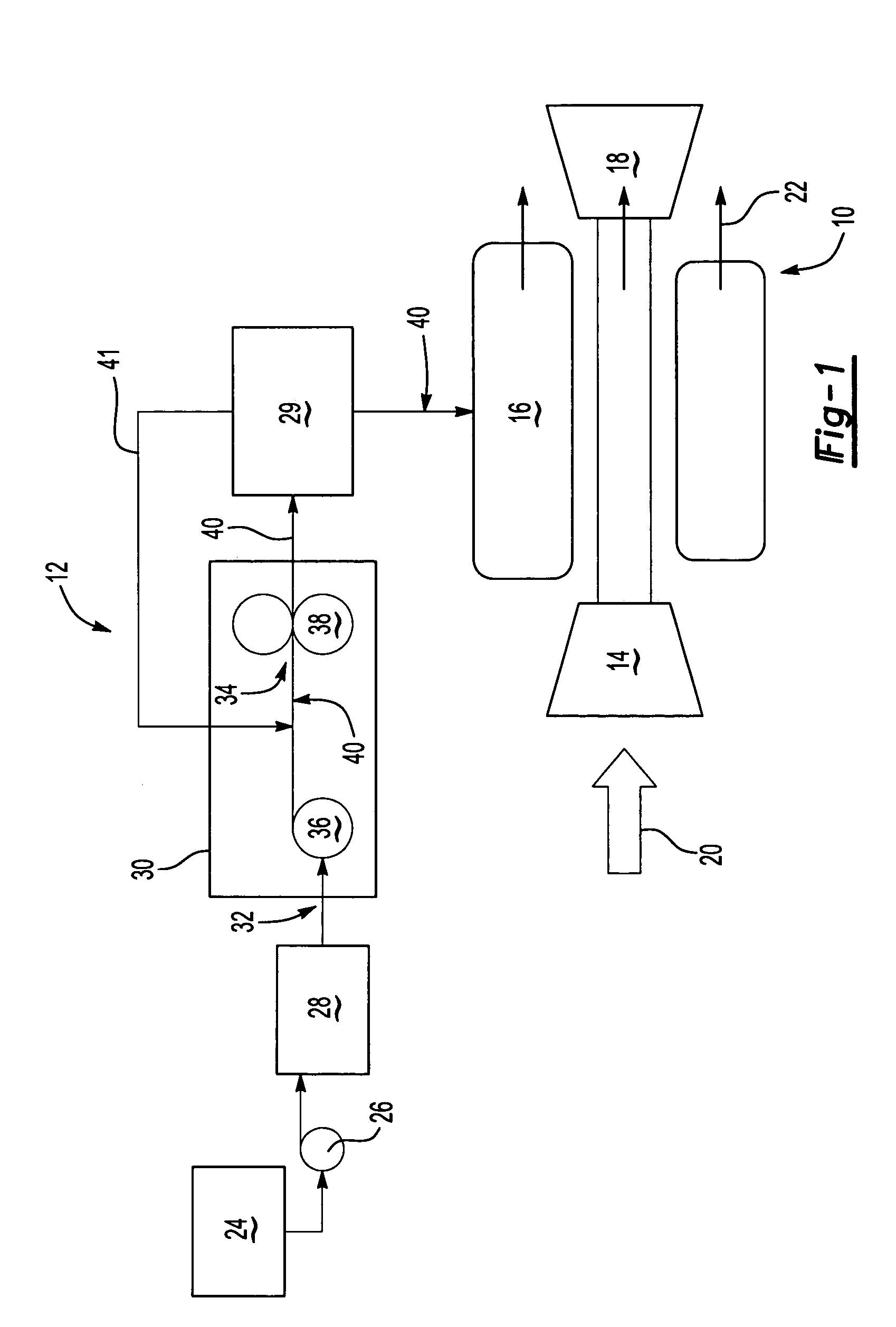

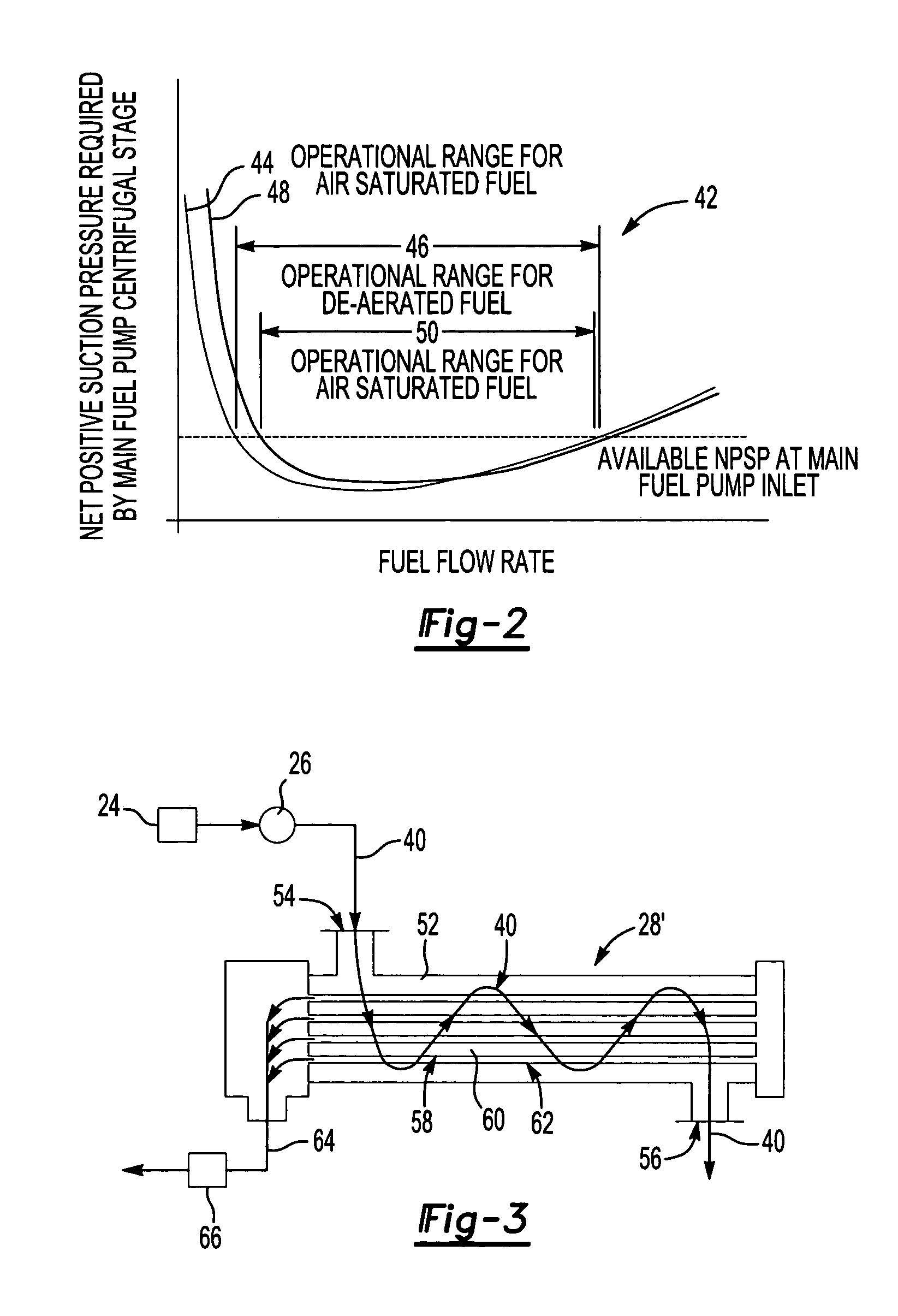

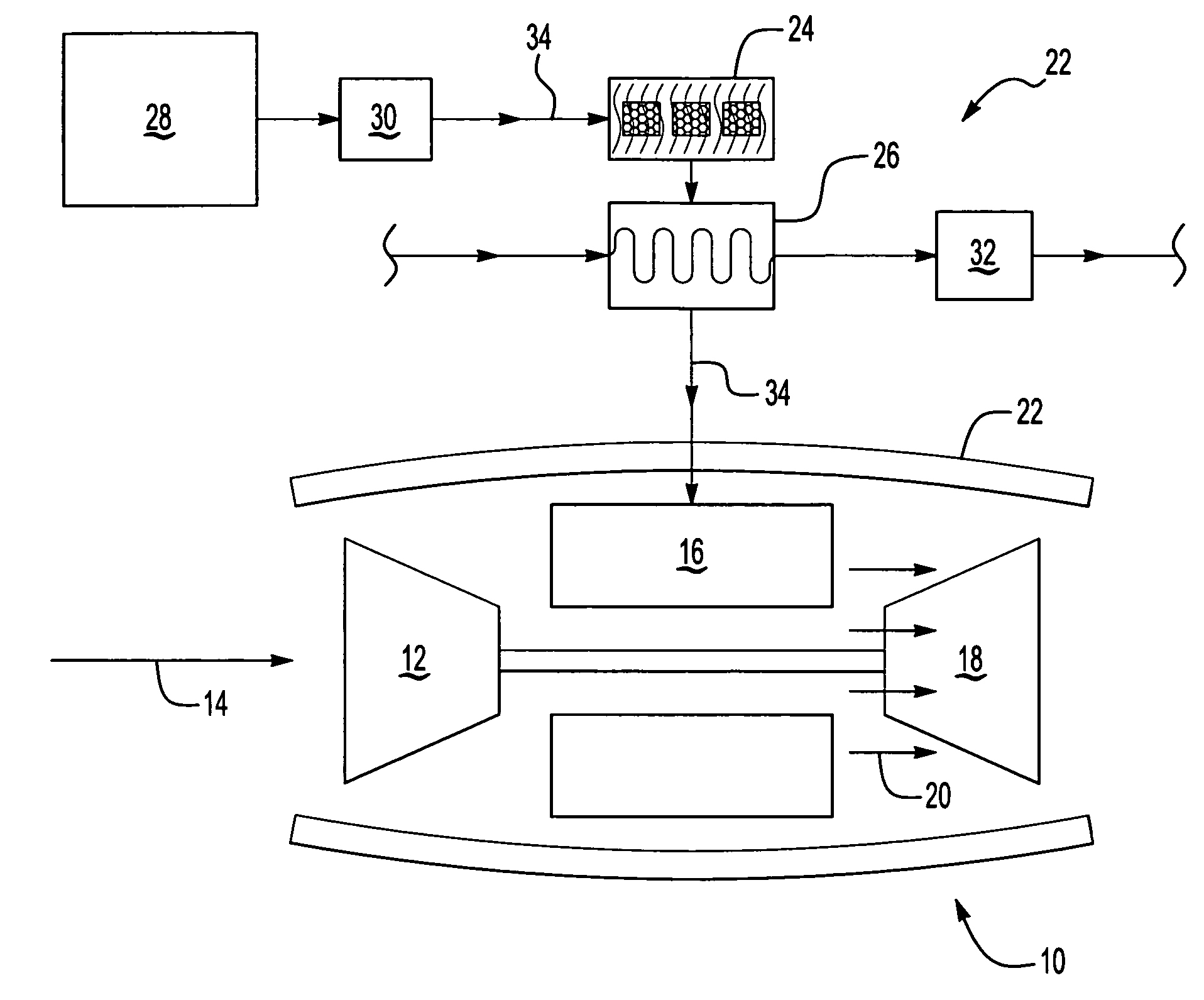

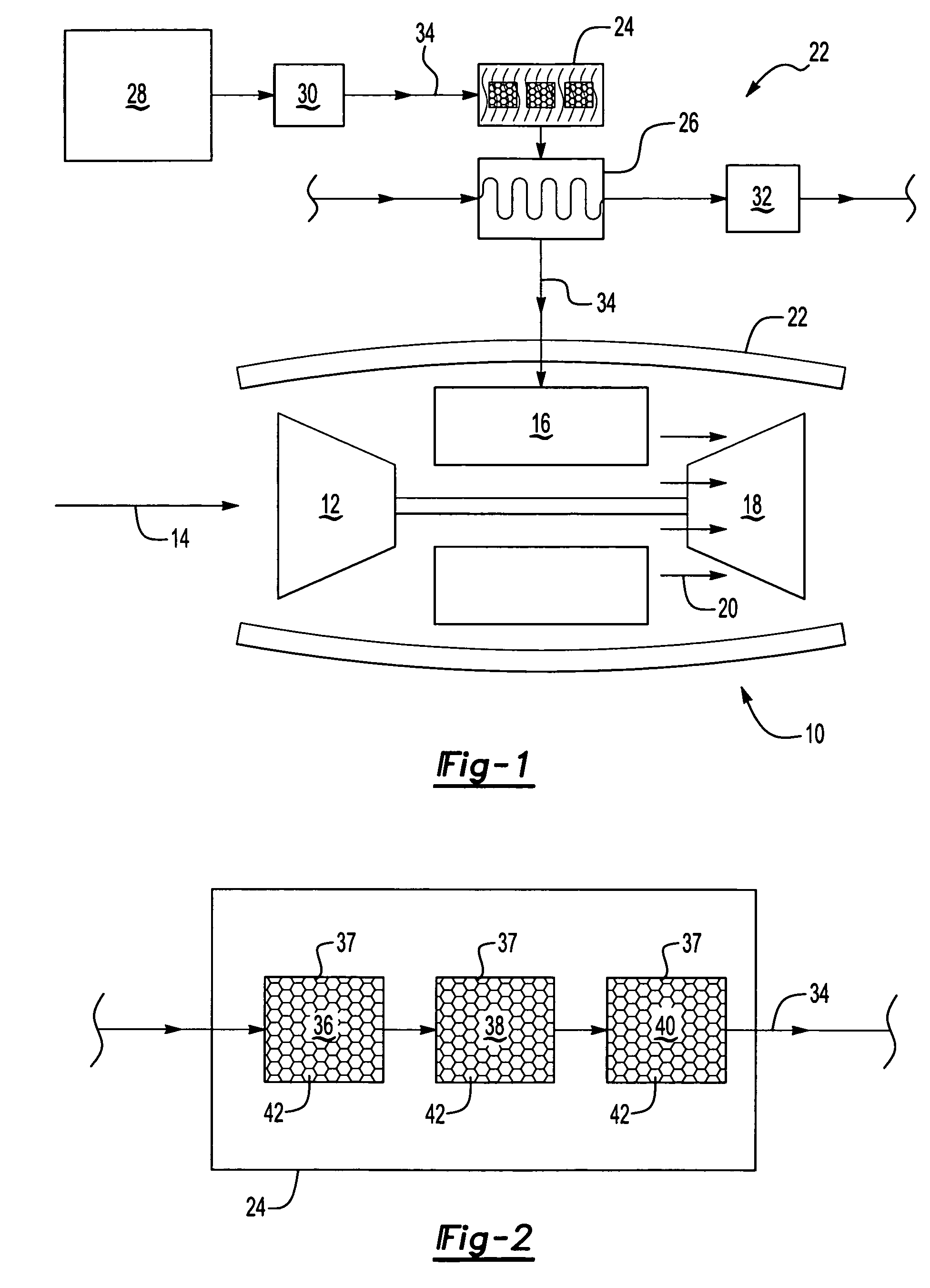

Extended operability aircraft fuel delivery system

InactiveUS7093437B2Reduce amountExpand the scope of operationEngine fuctionsTurbine/propulsion engine ignitionCavitationOperability

Owner:RTX CORP

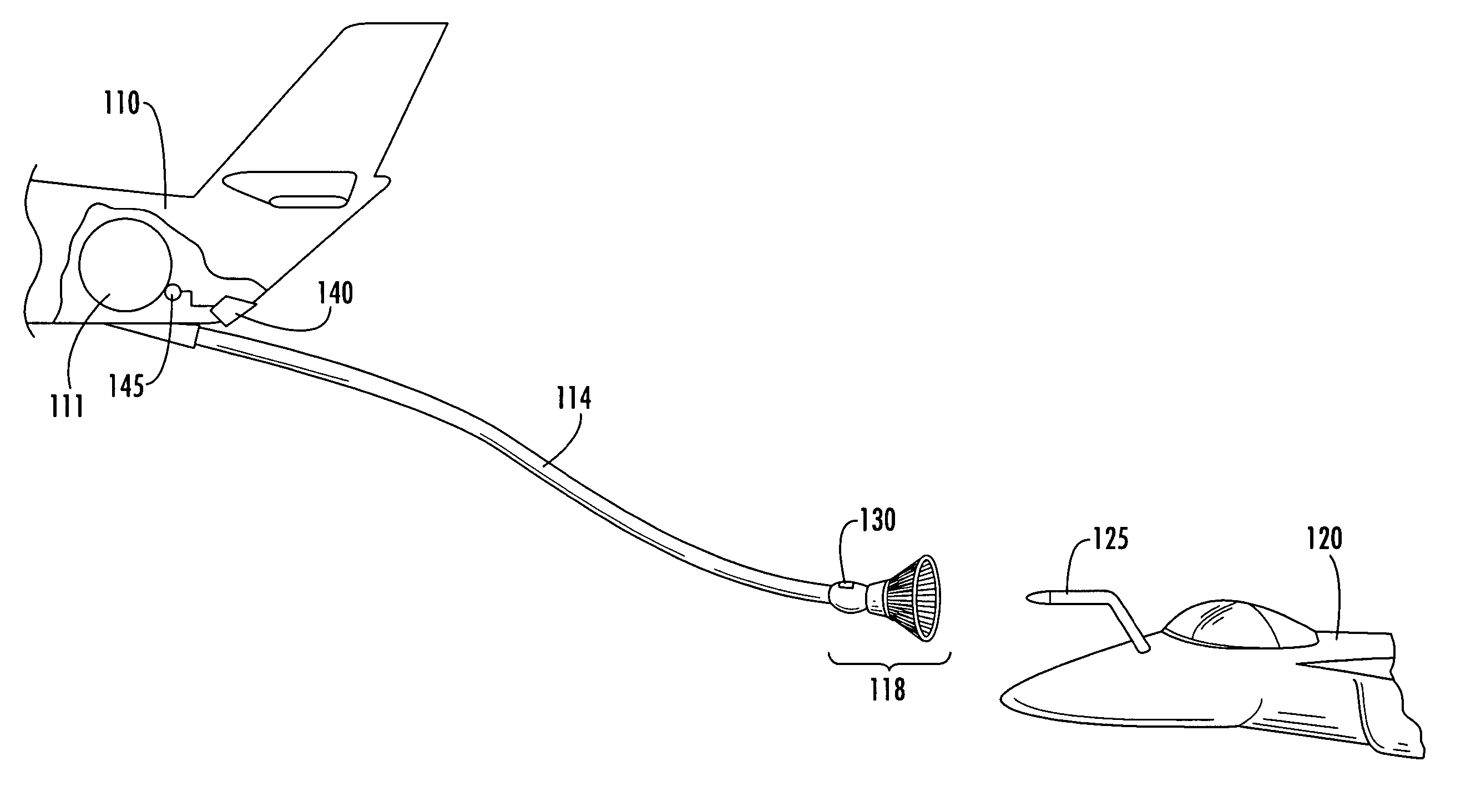

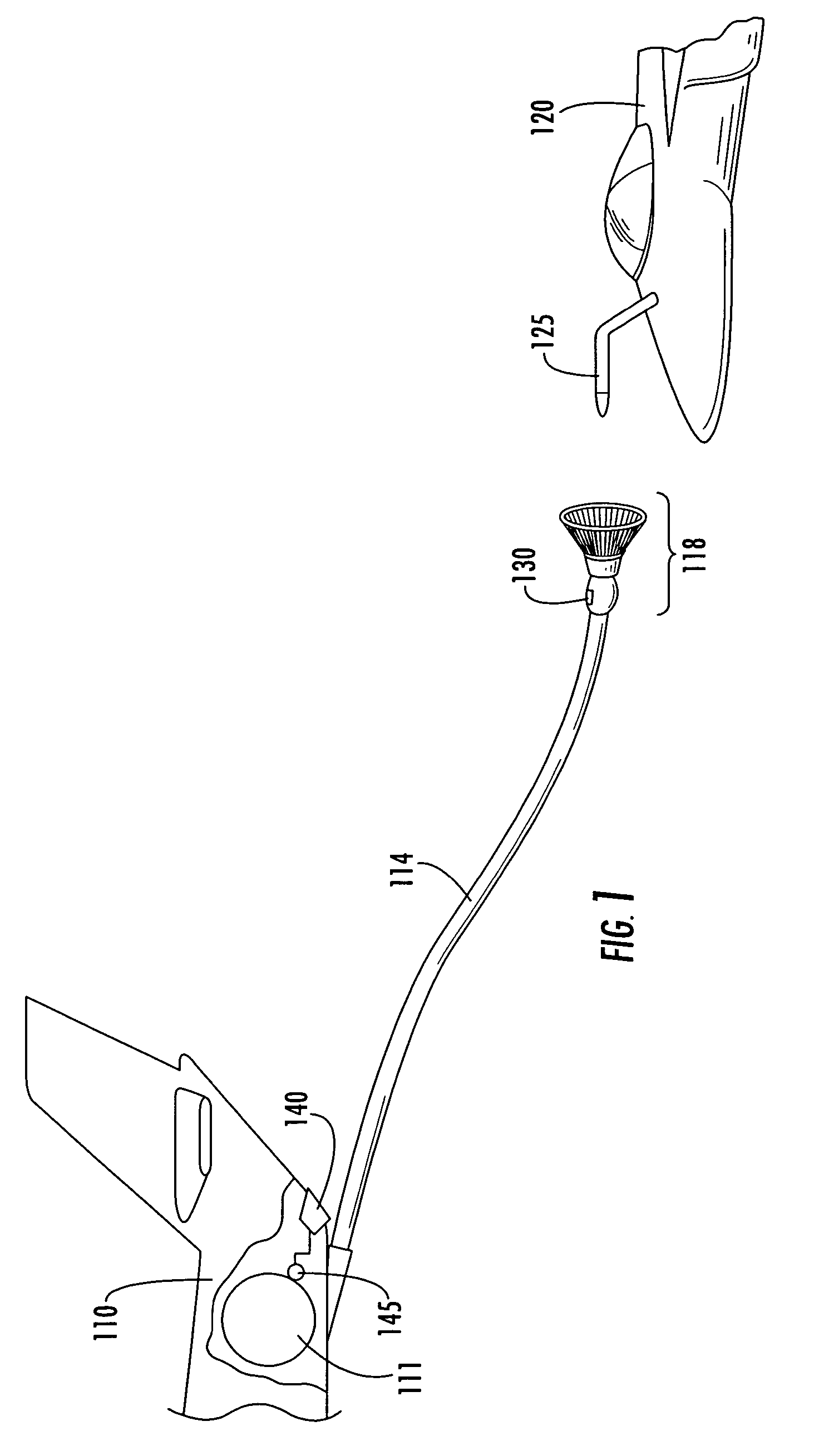

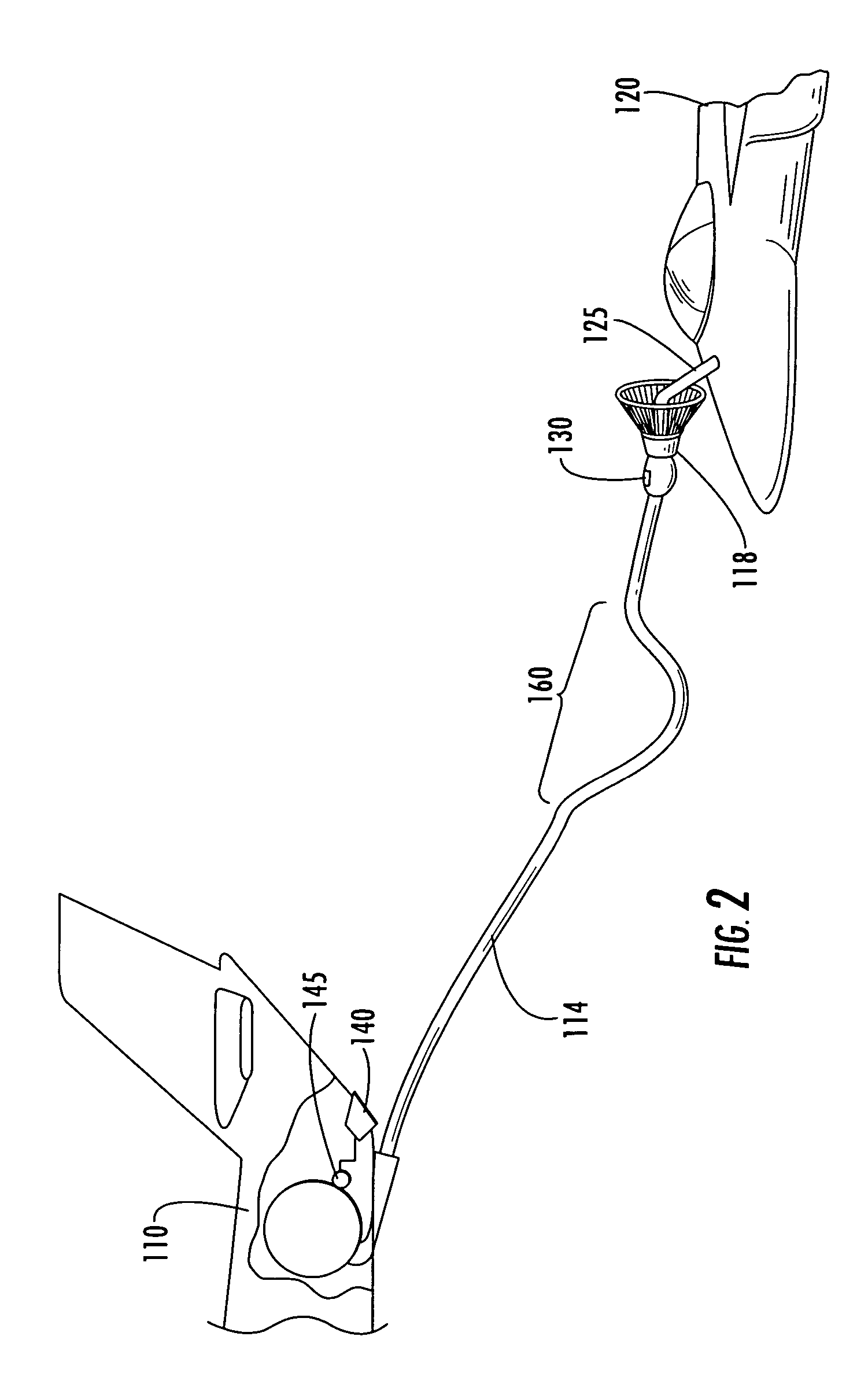

In-flight refueling system, sensor system and method for damping oscillations in in-flight refueling system components

InactiveUS7137598B2Improve stabilityCause resistanceOptical rangefindersPower plant fuel supplyFlight vehicleEngineering

An in-flight refueling system, sensor system and method are provided for detecting and damping changes in the disposition of an elongate hose extending from a tanker aircraft during an in-flight refueling operation. The various embodiments provide a compact, lightweight, and low-profile sensor device that may be fitted to the elongate hose so as to detect oscillations in the elongate hose and transmit a signal to a hose retracting device carried by the tanker aircraft such that the hose retracting device retracts the elongate hose in response to the signal so as to counteract the occurrence of oscillations within the elongate hose. Thus, these embodiments may minimize the effect of oscillations in the elongate hose by selectively retracting the elongate hose in response to oscillations detected therein as it extends from the tanker aircraft during an in-flight refueling operation.

Owner:THE BOEING CO

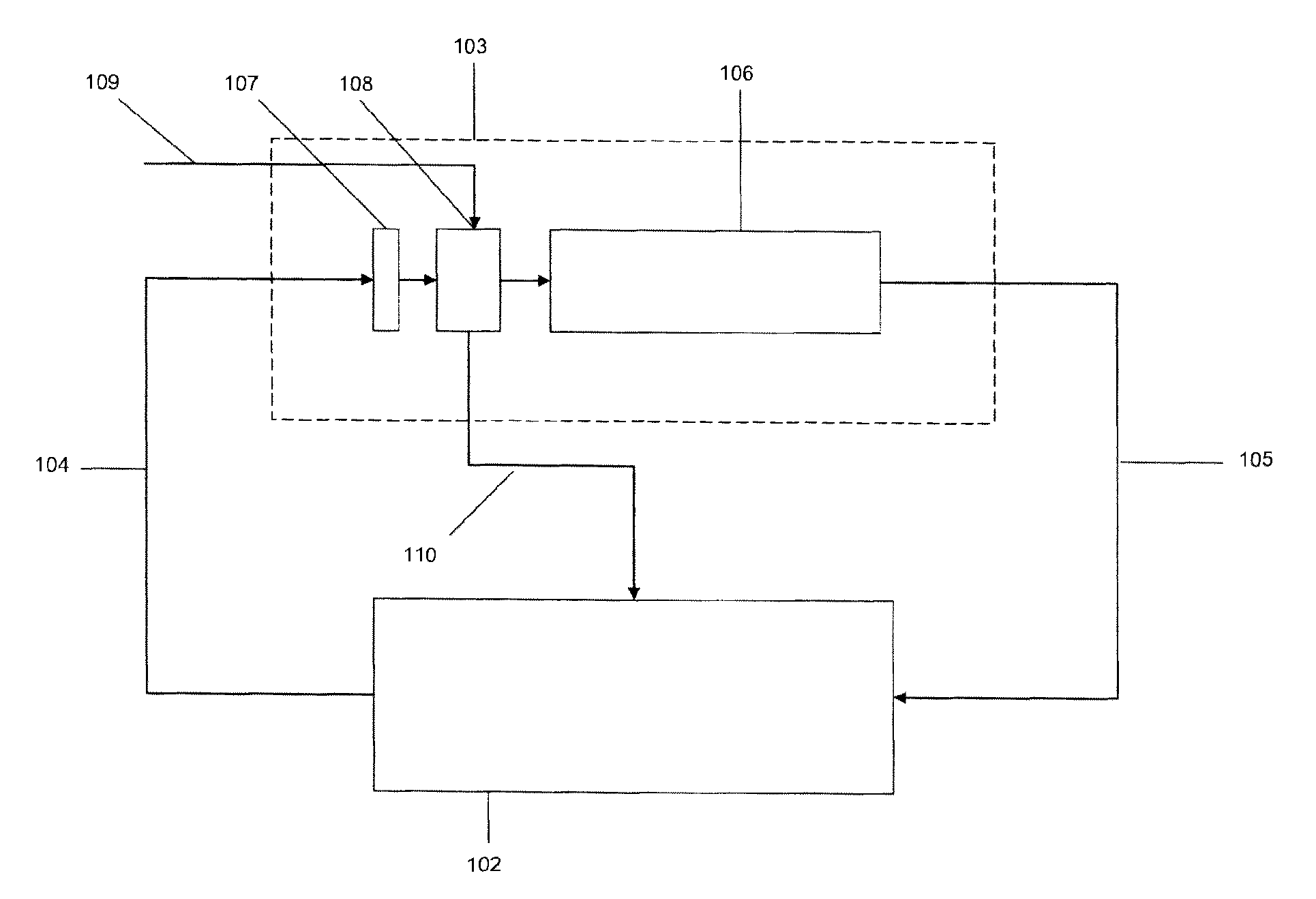

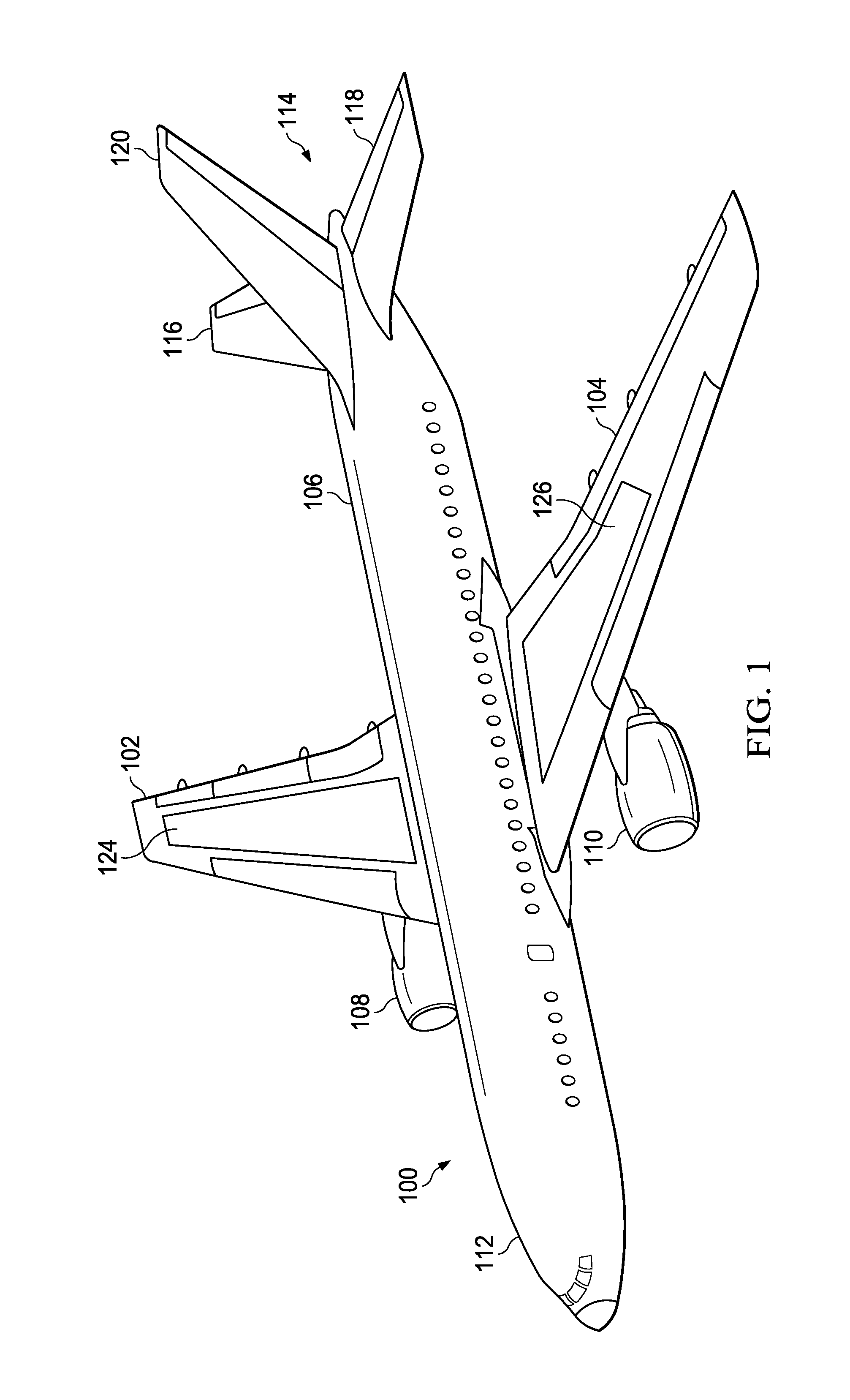

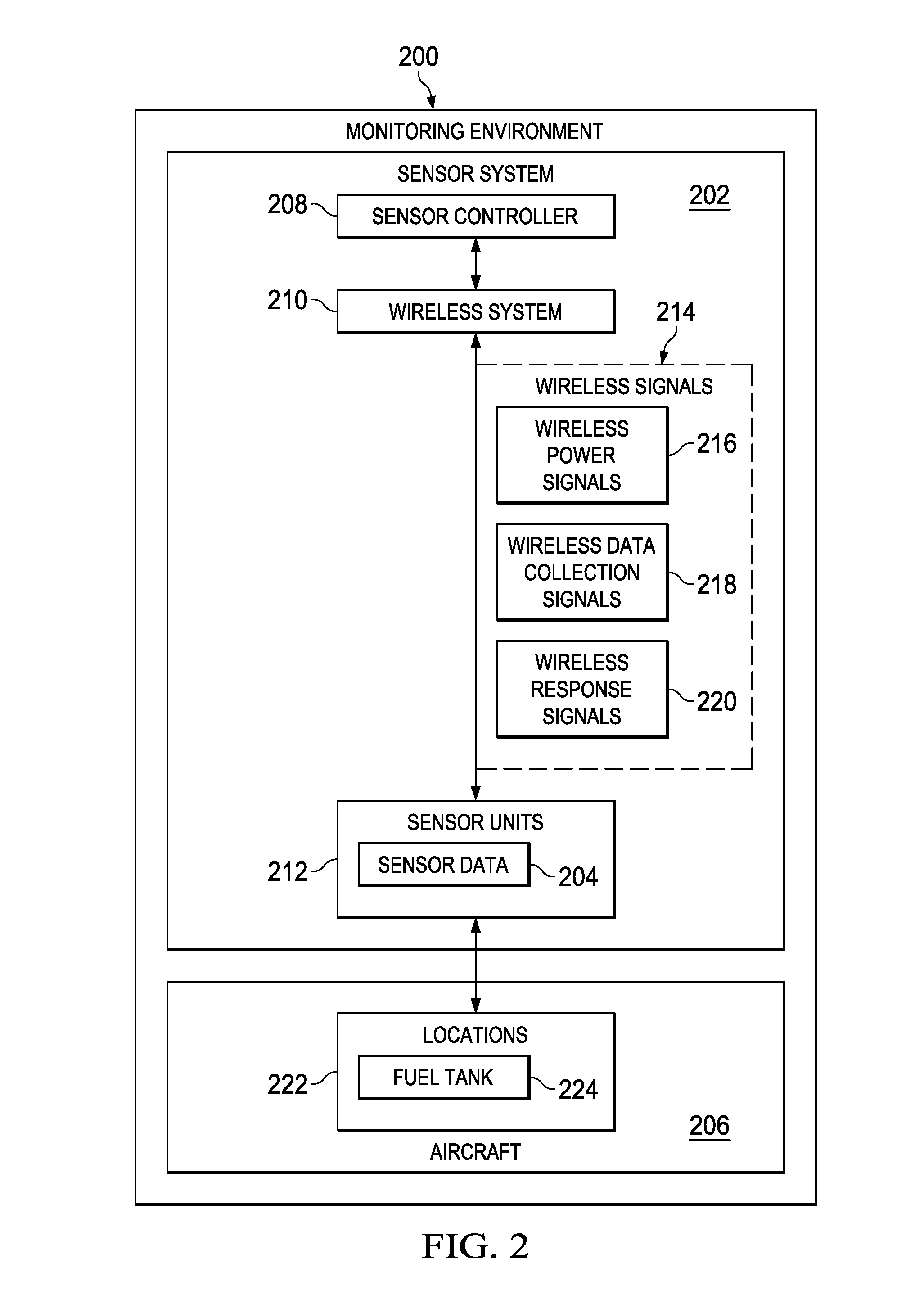

Wireless Fuel Sensor System

ActiveUS20150022373A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsWireless dataEngineering

A method for generating sensor data is presented. A number of wireless power signals is sent to a group of sensor units. A number of wireless data collection signals is sent to the group of sensor units after the number of wireless power signals have been sent to the group of sensor units. Sensor data in a number of wireless response signals is received from the group of sensor units.

Owner:THE BOEING CO

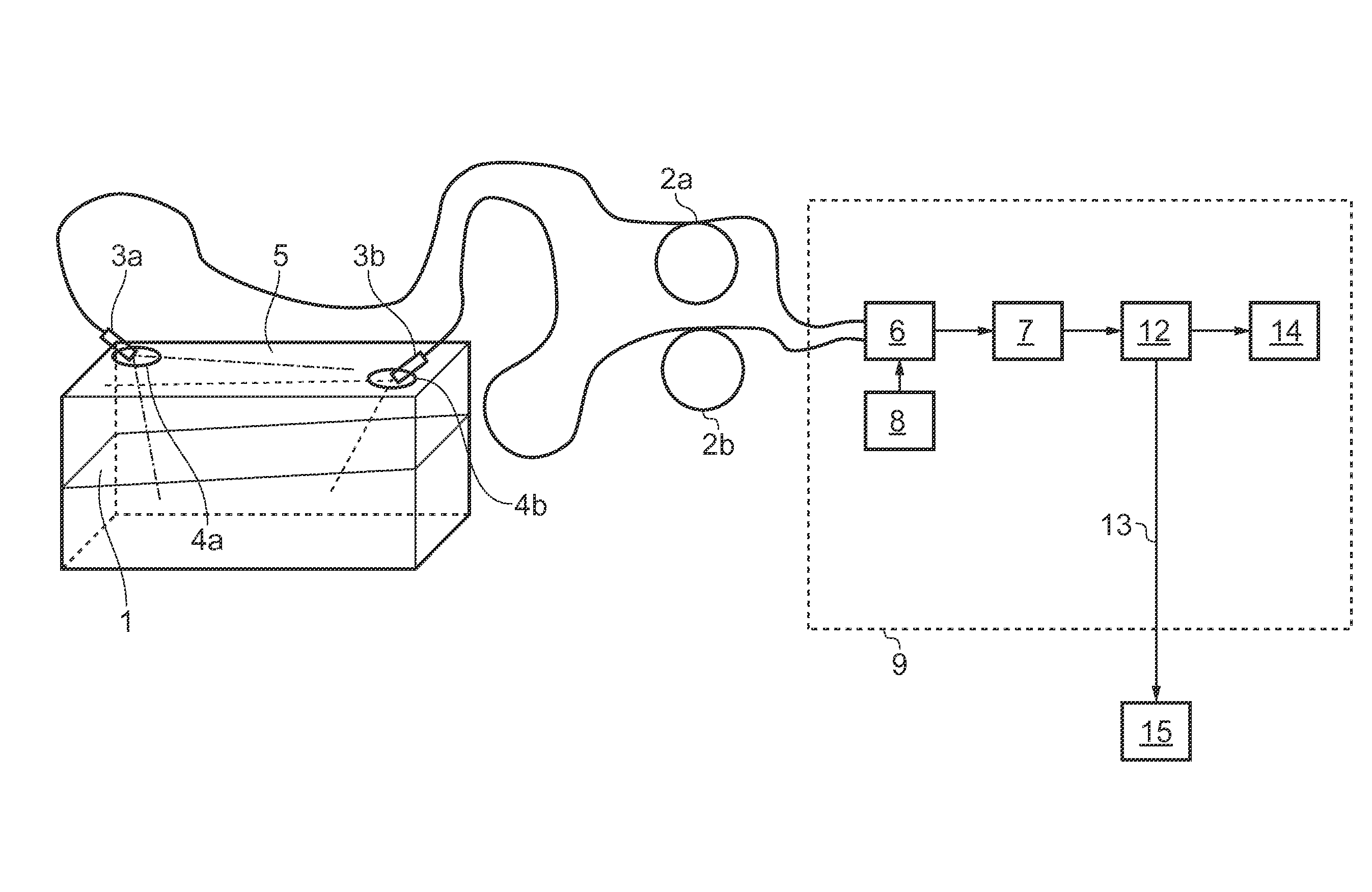

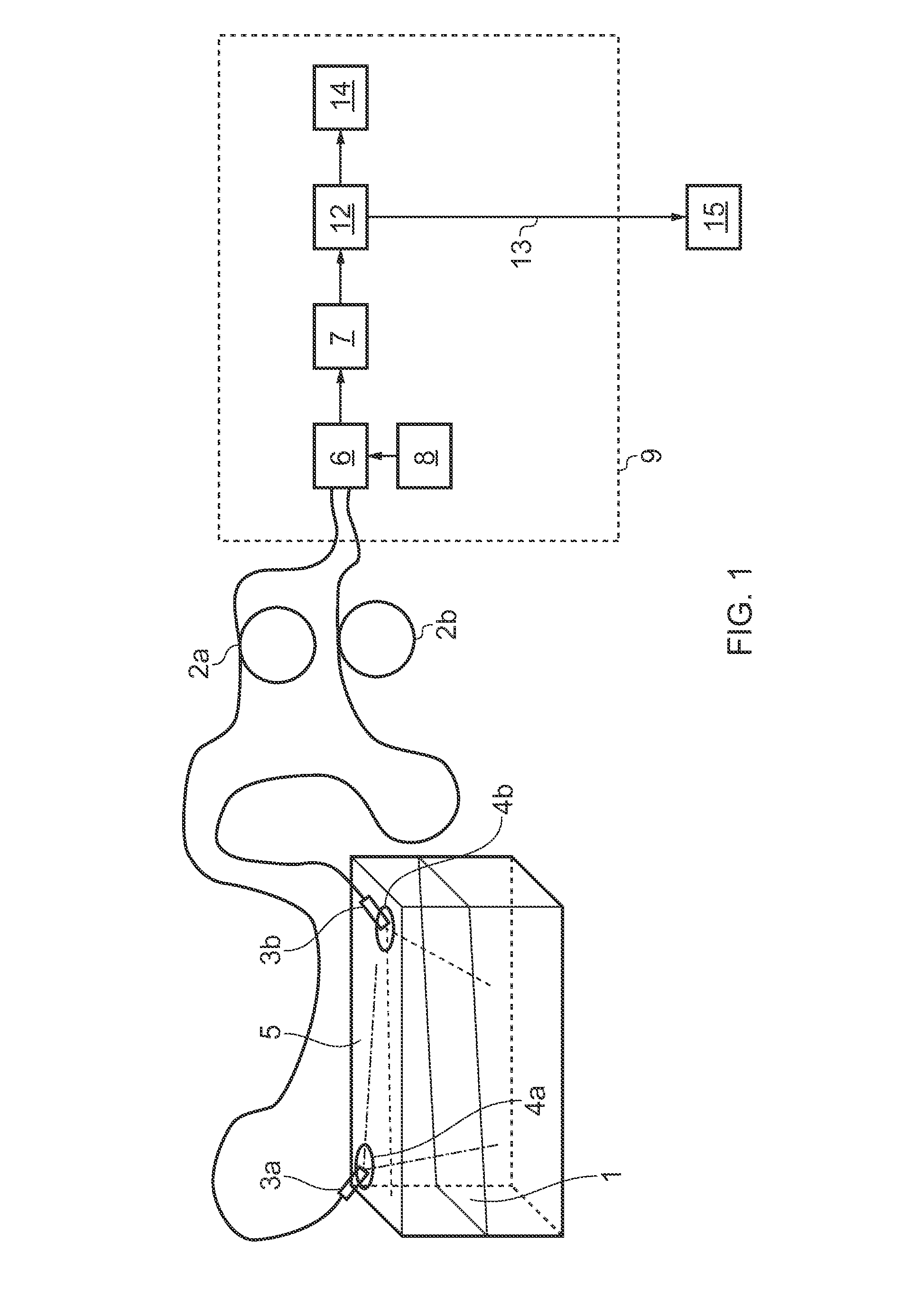

Fuel surface height measurement

InactiveUS20150153212A1Character and pattern recognitionPower plant fuel supplyFuel tankSurface level

A method of measuring a height of a fuel surface of fuel in an aircraft fuel tank. One or more images of the fuel surface are captured, each image including a fuel surface line where the fuel surface meets a structure. Each image is analysed in order to determine a height of the fuel surface line at three or more points in the image. If the fuel surface line is not a straight line, then an average angle of the fuel surface line can be determined from the points in the image by spatial averaging. Preferably a series of images of the fuel surface are captured over a time period, and an average height of the fuel surface is determined from the series of images by time averaging. The height of the fuel surface line(s) at three or more points is used to determine a volume of the fuel, a mass of the fuel, and / or an attitude of the fuel surface.

Owner:AIRBUS OPERATIONS LTD

Catalytic treatment of fuel to impart coking resistance

ActiveUS7744827B2Increase fuel capacityImprove rendering capabilitiesTurbine/propulsion fuel supply systemsCosmonautic vehiclesDecompositionEngineering

A fuel delivery system for a gas turbine engine includes a catalytic device for treating fuel to increase the usable cooling capability of an endothermic fuel. The catalytic device operates to treat and decompose components within in the fuel to render the fuel non-coking beyond 250° F. The catalytic device includes material that initiates reactions, and decomposition of coke forming components within the fuel to non-coke forming components within the fuel.

Owner:RTX CORP

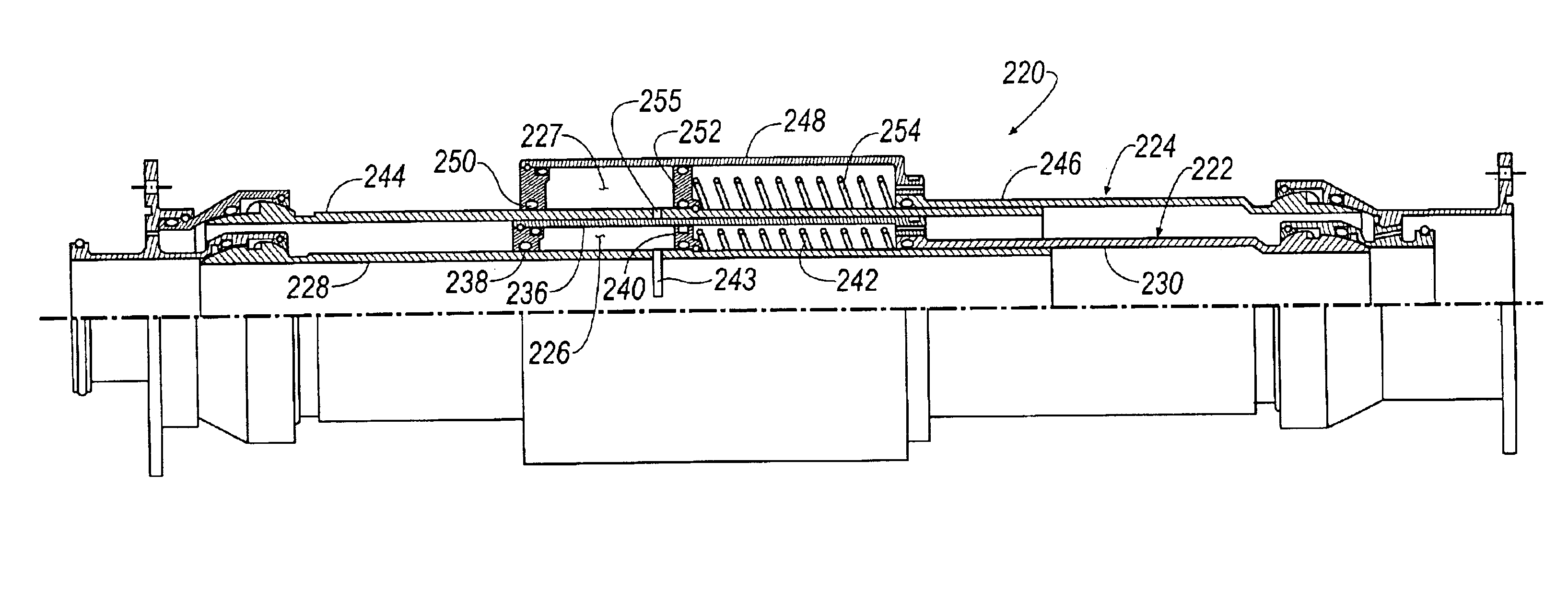

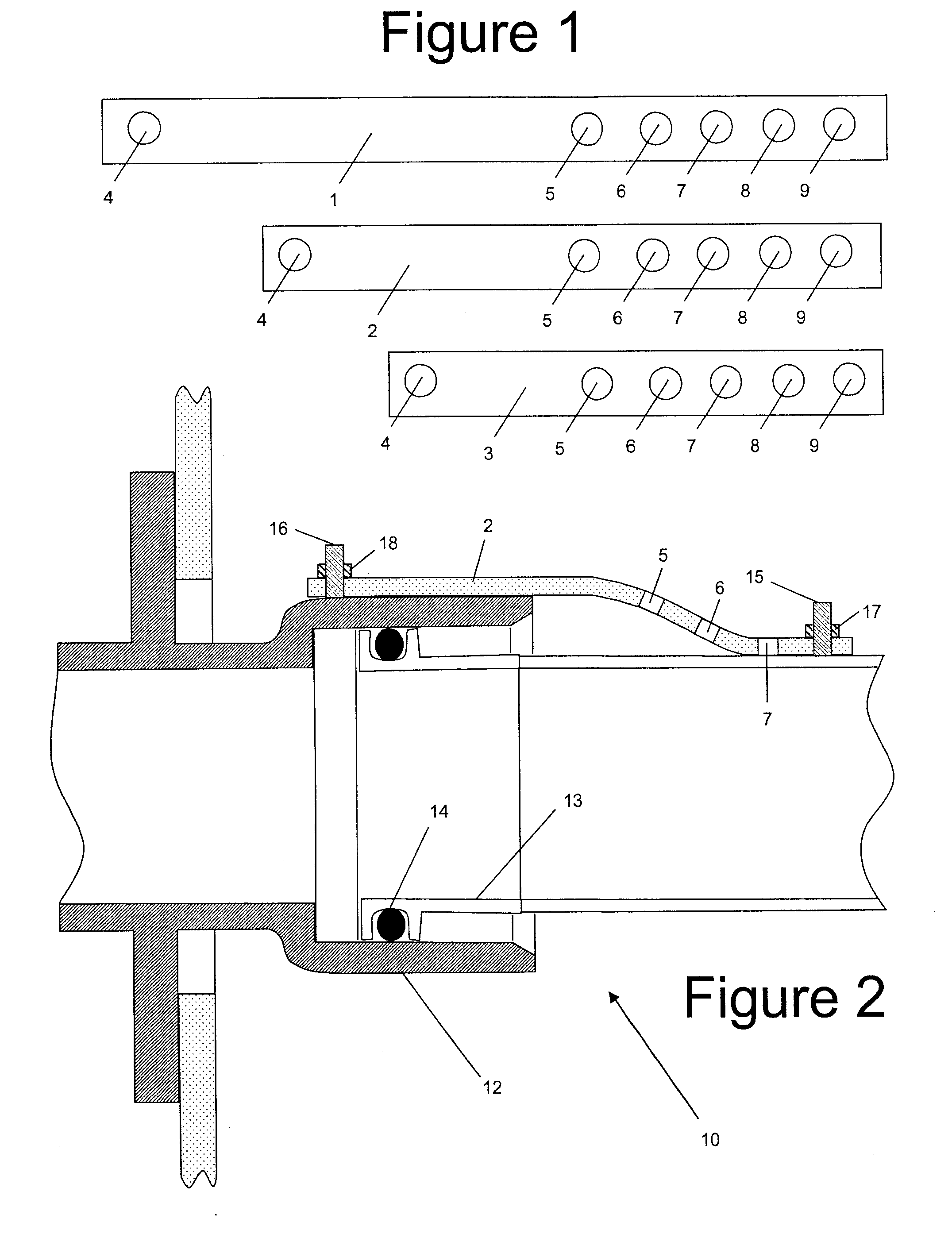

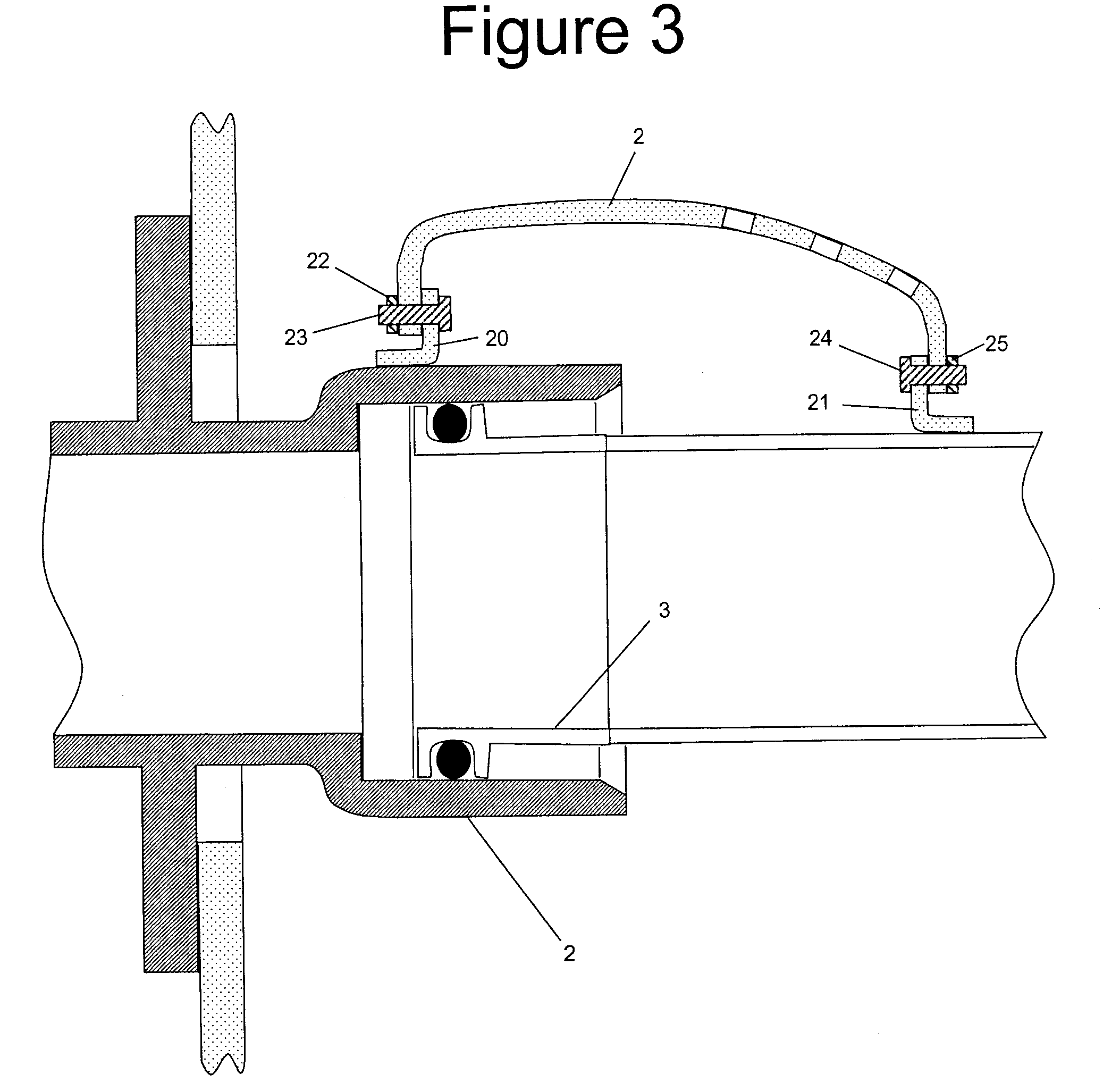

Fluid line assembly

A fluid line assembly is disclosed that includes an outer fluid line and an inner fluid line disposed substantially within the outer fluid line. The inner and outer fluid lines each include a slip joint. In an embodiment of the invention, at least one of the slip joints includes a reservoir in communication with the interior of the corresponding fluid line. Among other things, the reservoir is suitable for receiving fluid from the corresponding fluid line as the fluid line assembly is contracted and expelling fluid into the corresponding fluid line as the fluid line assembly is extended. In another embodiment of the invention, the inner and outer fluid lines include a ball joint assembly.

Owner:EATON CORP

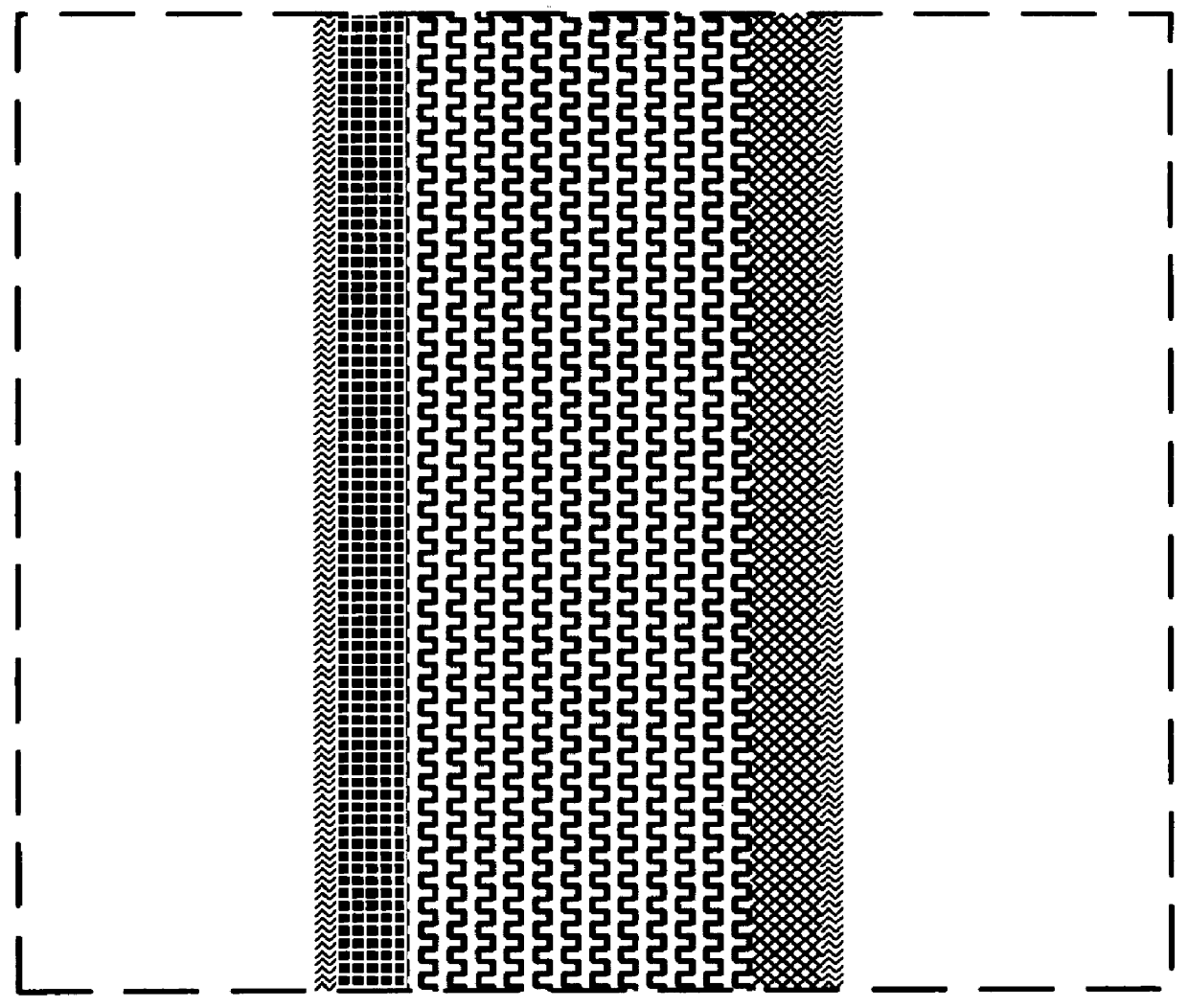

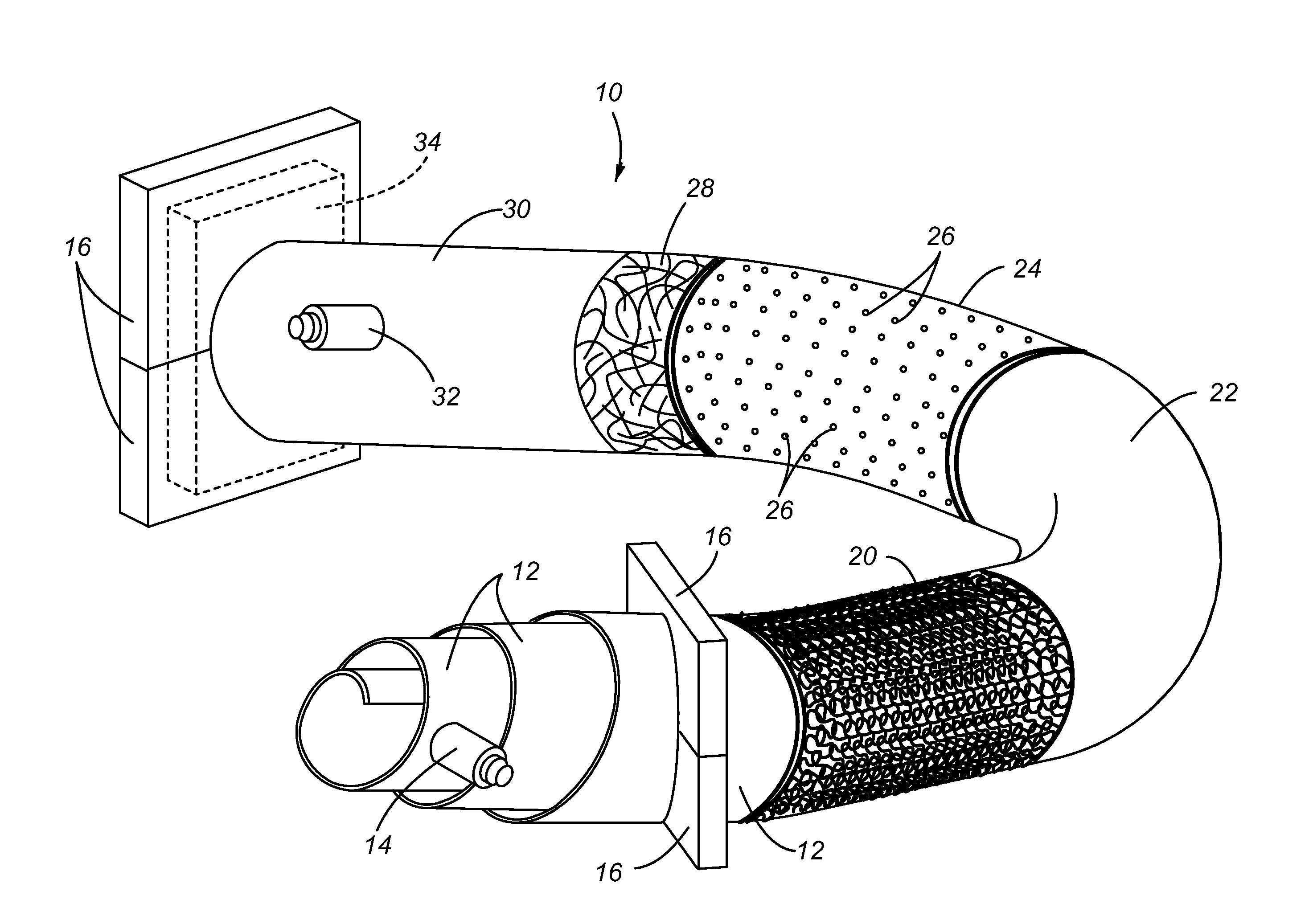

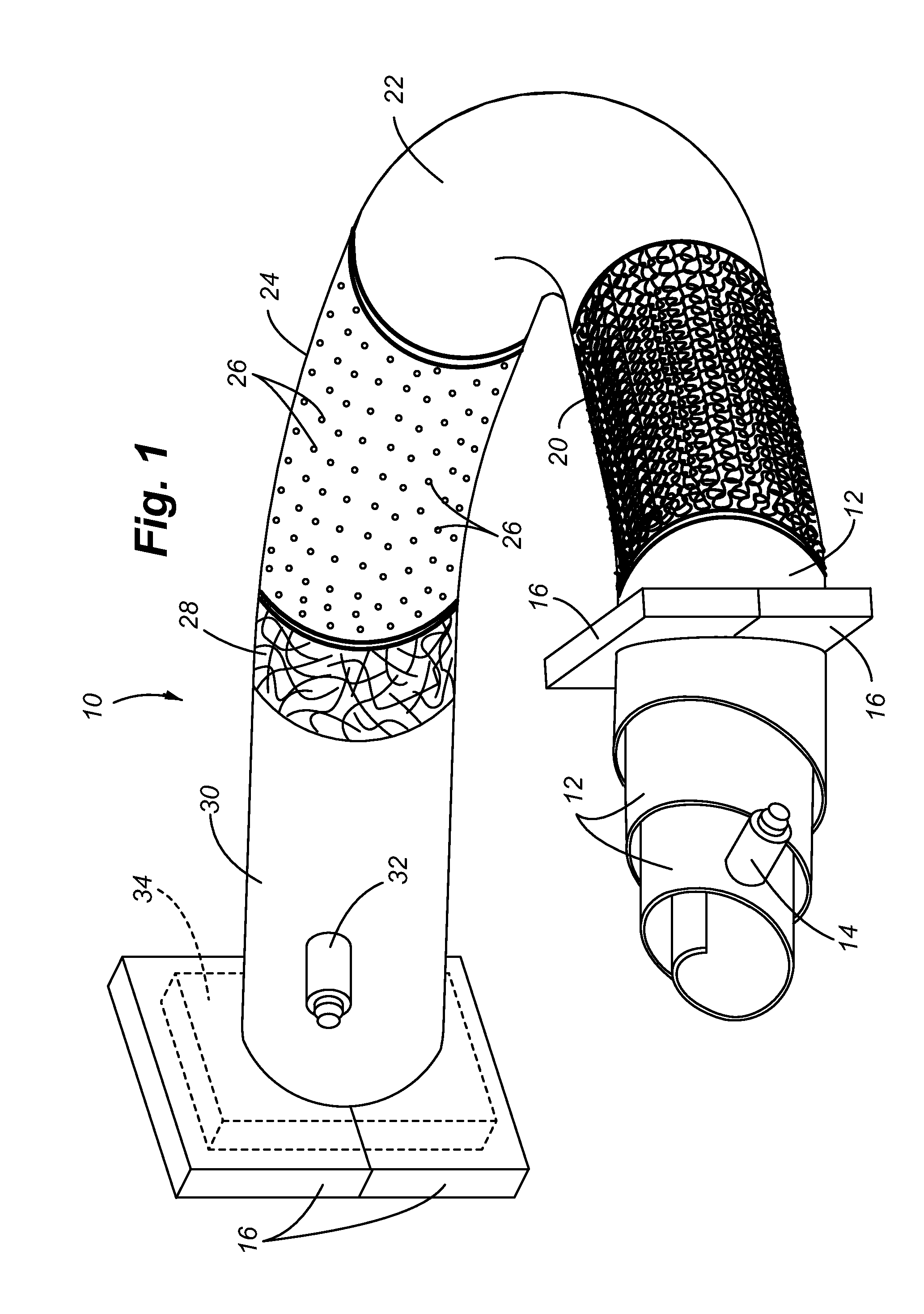

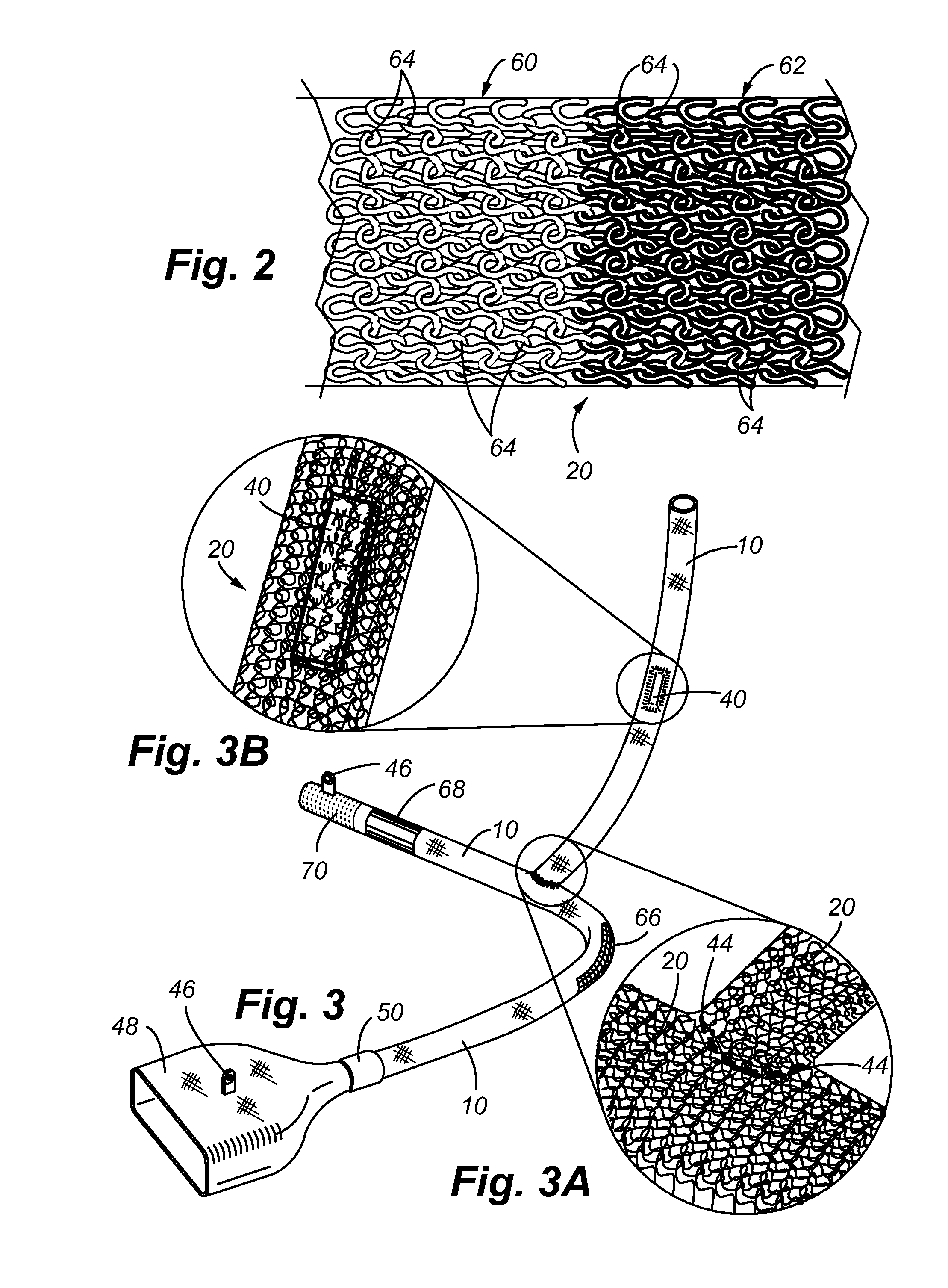

Composite tube for fluid delivery system

ActiveUS20120168012A1Avoids laminated seamAvoid layeringLabelling non-rigid containersPipe elementsFiberCarbon fibers

The composite tube comprises a tubular arrangement of knitted fiber characterized by a plurality of interlocking loops. Selected knitted patterns provide desired density or spacing between fibers. Selected fibers may include materials such as Kevlar®, carbon fiber, and combinations thereof. The tubular knitted pattern allows for variable electrical, mechanical and geometrical options. A matrix material is applied over the knitted fiber pattern and is allowed to cure. The matrix material may include a combination of resin and epoxy constituents. The matrix material may be applied by a vacuum bag molding process. Electrical and mechanical properties can also be controlled by selecting desired resin and epoxy constituents. The flexible knitted reinforcing layer allows use of an inflatable bladder to hold the reinforcing layer in the desired shape, thereby facilitating tube constructions of varying shapes and diameters. Continuous application of the matrix material avoids overlapping seams that are prone to delamination.

Owner:EATON INTELLIGENT POWER LIMITED

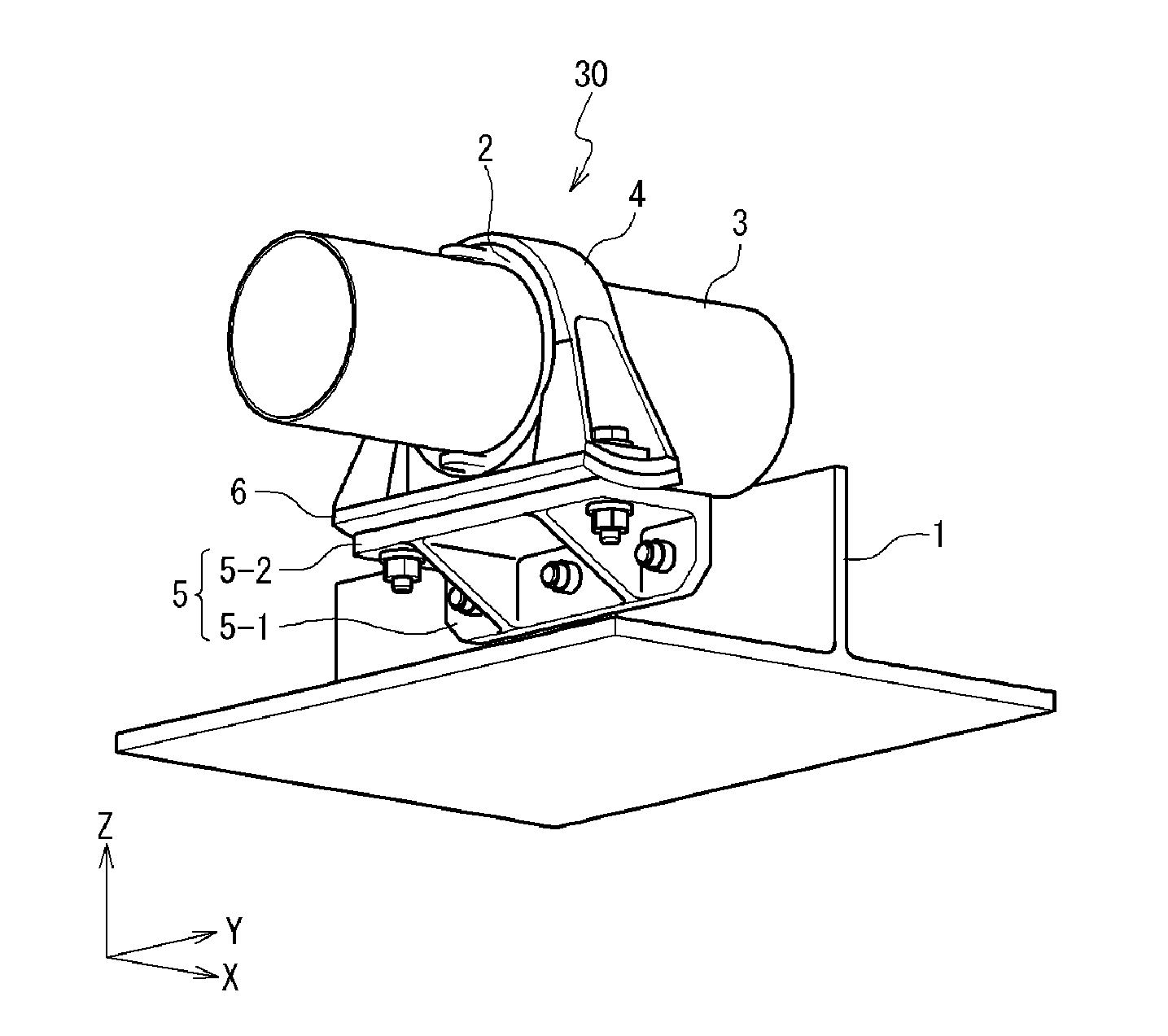

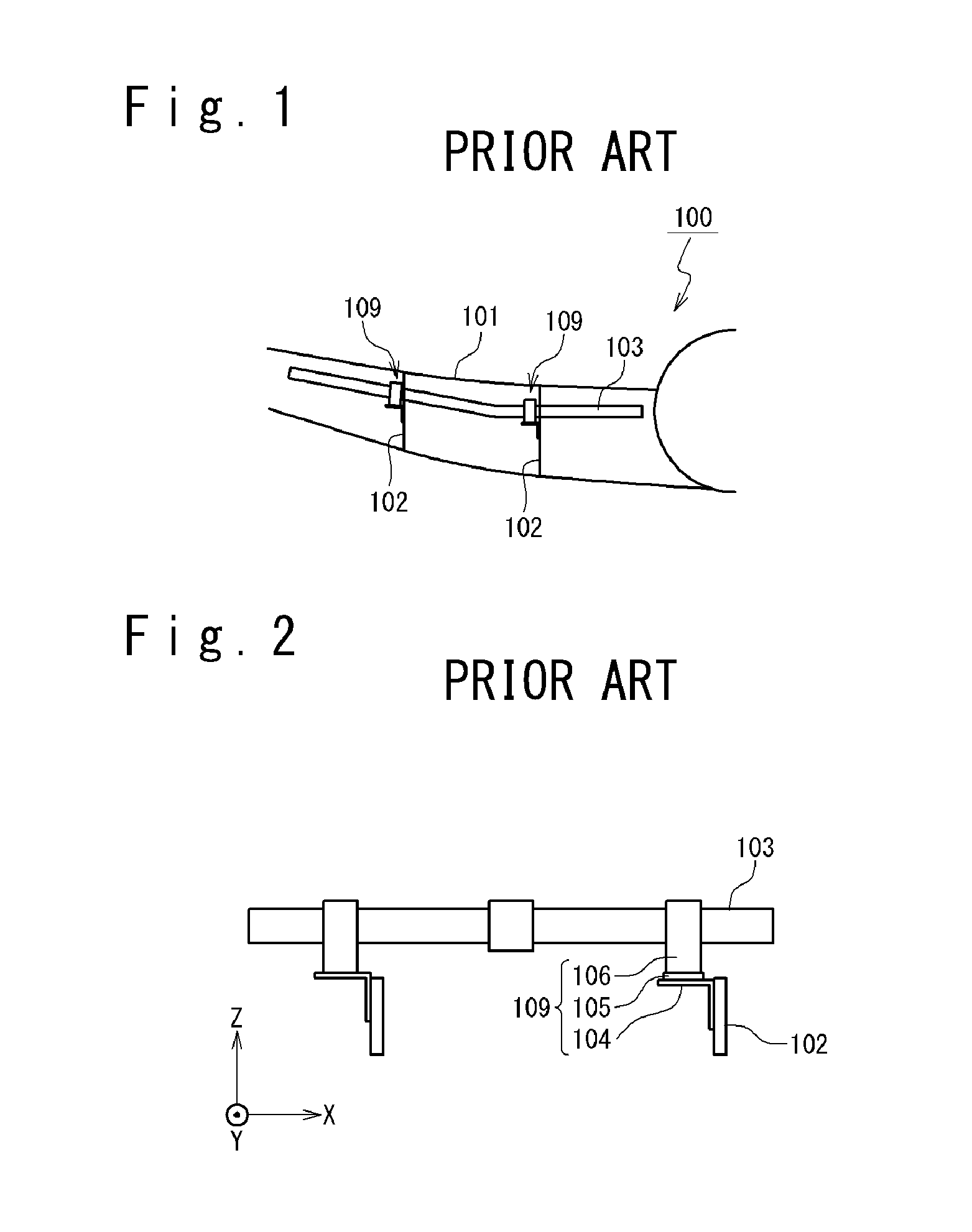

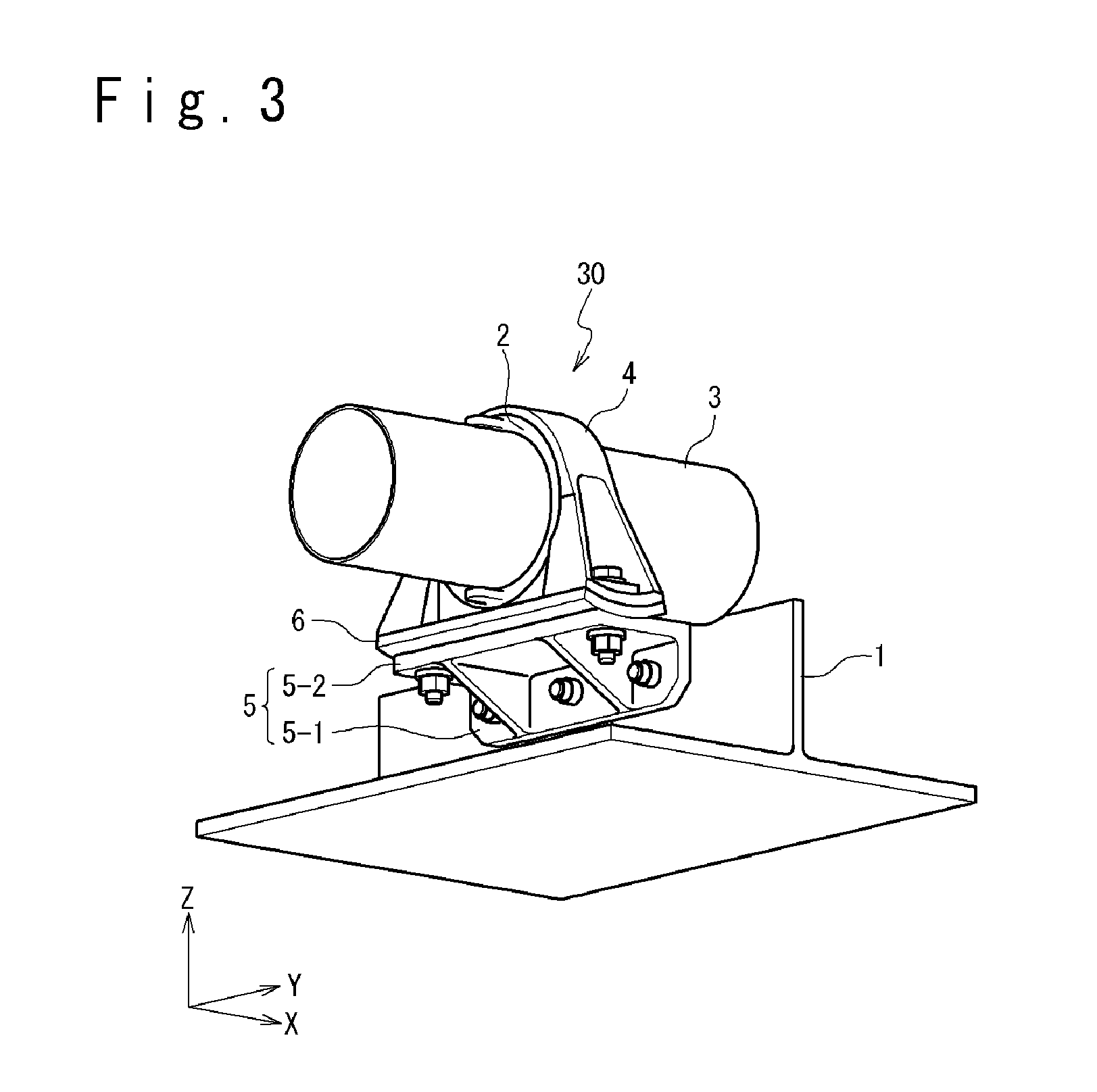

Tube support structure for aircraft

Owner:MITSUBISHI HEAVY IND LTD

System, method and apparatus for widespread commercialization of hydrogen as a carbon-free alternative fuel source

ActiveUS8336810B2Reduce shipping costsSave extra spaceArresting gearPower plant arrangements/mountingElectricityHydrogen

A system for efficiently transporting hydrogen from where it can be economically made to where it is most needed using specially designed airships. Technologies such as geothermal, wind, solar, wave tidal or hydropower can be used to generate electricity in-situ or very near to the primary energy sources. This electricity can then be used to produce hydrogen directly from water through various methods known in the art. Hydrogen can be delivered from the place where it is produced to the place where it is needed using an airship in which the hydrogen gas can also be used for generating lift, providing propulsion energy and serving ancillary needs. In other embodiments of the invention, the airship of the present invention can be used to dramatically reduce the cost of transportation of freight, the cost of passenger transportation, and to save on the area required for landing at the points of loading / unloading and embarkation / debarkation. And in another embodiment, the airship of the present invention can be used for transporting water and food to areas where needed. A unique docking system can use a remotely piloted unmanned aircraft flown from the mother craft to carry a guide line into a receiving attachment point.

Owner:H2 CLIPPER INC

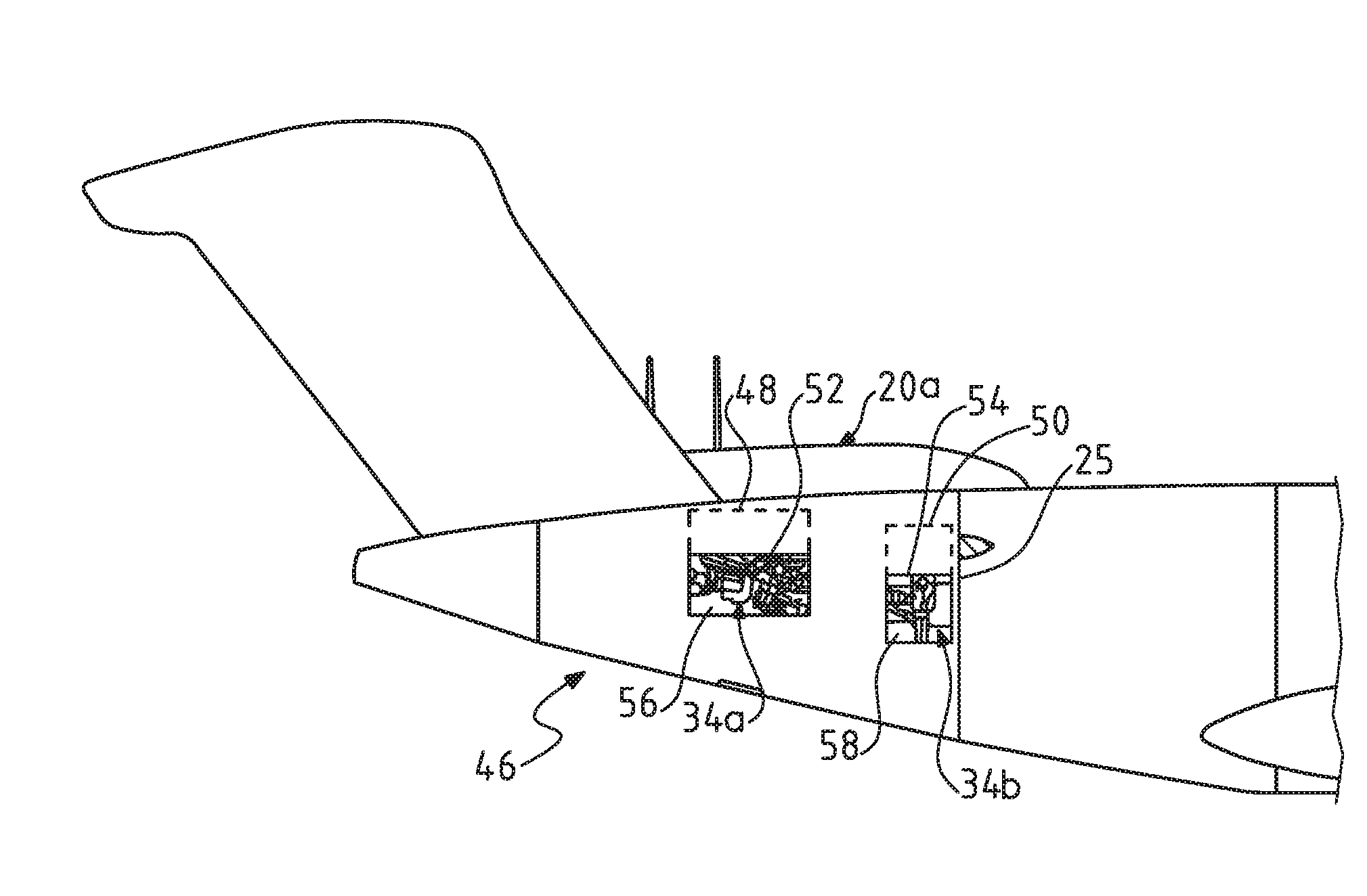

Aircraft tail cone

An aircraft tail cone comprising a fuselage in which avionic equipment is housed. The tail cone comprises two lateral hatches formed in the fuselage, at least one hatch being formed on each of the two opposite sides of the fuselage. Each hatch is mounted removably with respect to the fuselage so as to take up a closed first position in which the hatch closes a lateral opening in the fuselage, and an open second position in which the open hatch allows access to the inside of the tail cone through the corresponding opening The avionic equipment that requires regular inspection and / or maintenance operations is housed in a part of the tail cone which is accessible through the two lateral openings in the fuselage to a person who remains on the outside of the fuselage.

Owner:AIRBUS OPERATIONS (SAS) +2

Solar-powered aircraft

InactiveUS7278607B2Weight of to shiftPower installationsEnergy efficient board measuresFuel cellsHydrogen

Owner:FULLER HOWARD J

Flush mounted waste disposal service panel assembly

InactiveUS20050166983A1Avoid dischargePrevent leakageTank vehiclesWatering devicesWaste collectionVALVE PORT

The waste disposal service panel assembly includes a housing, waste drain valve, rinse / fill valve, handle assembly and service panel door. The housing has a tubular side wall and a base near one end of the side wall. The waste drain valve is at least partially mounted within the housing through the base. The waste drain valve includes an outlet positioned within the housing and an inlet configured to couple to a waste collection tank within a aircraft. The service panel door is pivotally coupled to the housing near an end of the side wall remote from the base. The service panel door has an outer surface configured to substantially match an outer contour of the aircraft's skin, and an outer cap coupled to an inner surface of the service panel door. The outer cap is configured and dimensioned to mate with the outlet to seal the outlet when the service panel door is closed.

Owner:SHAW AERO DEVICES

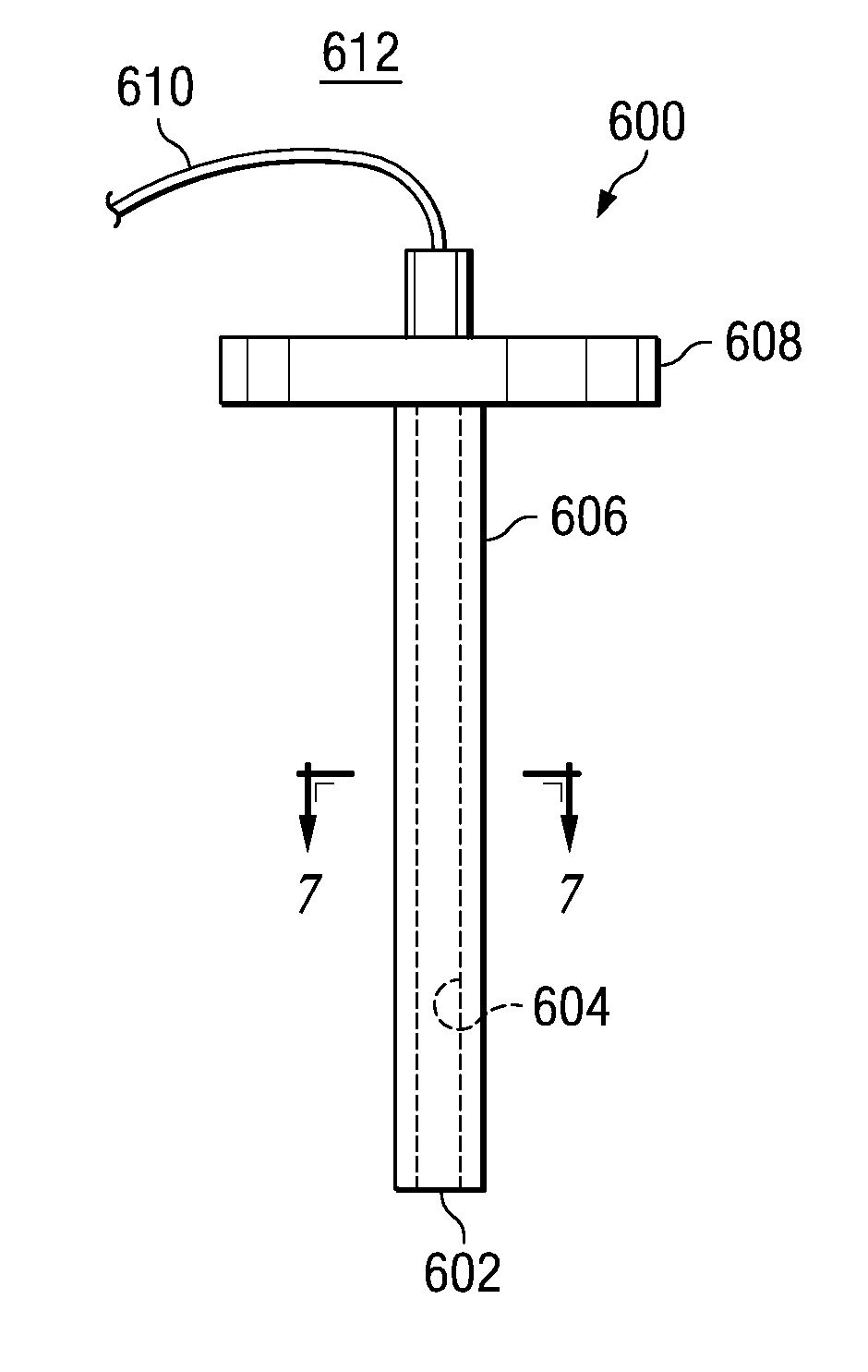

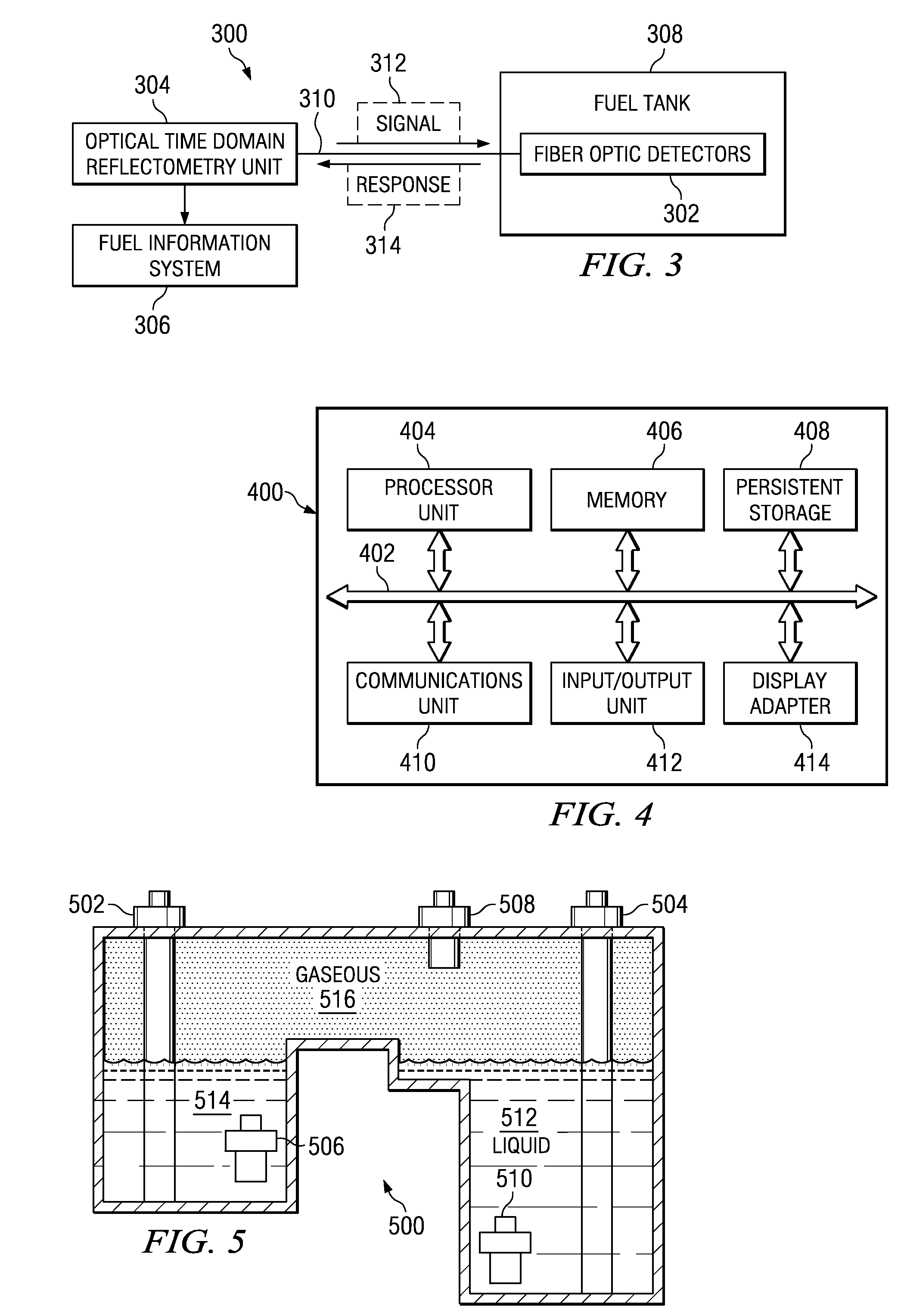

Fiber optic fuel detection system

A method and apparatus for an optical fuel detection system. The optical fuel detection system comprises an outer tube, and inner tube, and a set of optical fibers. The outer tube has a reflective inner surface capable of reflecting light and is configured to allow a liquid fuel to enter an interior of the outer tube on which the reflective inner surface is located. The inner tube is located within the outer tube in which an area is present between the reflective inner surface. The set of optical fibers are mounted to an outer surface of the inner tube. Each optical fiber has a core that is exposed on each part of an optical fiber opposite to the reflective inner surface and the optical fiber has a refractive index that is lower that the liquid fuel but higher than a gaseous form of any gas that may enter the area.

Owner:THE BOEING CO

Aircraft joint and bonding lead

ActiveUS20100226063A1Avoid sparkingIncrease resistanceElectrically conductive connectionsEmergency protective arrangement detailsElectricityHigh resistance

A joint on an aircraft, the joint comprising: a first component; a second component joined to the first component; and a bonding lead which forms an electrical connection between the components with a resistance between 100 kΩ and 10 MΩ. Surprisingly, it has been found that a bonding lead with a relatively high resistance can be used without seriously compromising the static discharge performance of the bonding lead, and that the resulting comparatively low flow of current reduces the risk of sparking in the event of an lightning strike. Bonding leads may be provided as a kit of parts in which at least two of the bonding leads have different lengths and the longer lead is formed from a material having a higher bulk conductivity than the shorter lead. Thus the bonding leads can be made with approximately similar resistances regardless of their lengths.

Owner:AIRBUS OPERATIONS LTD

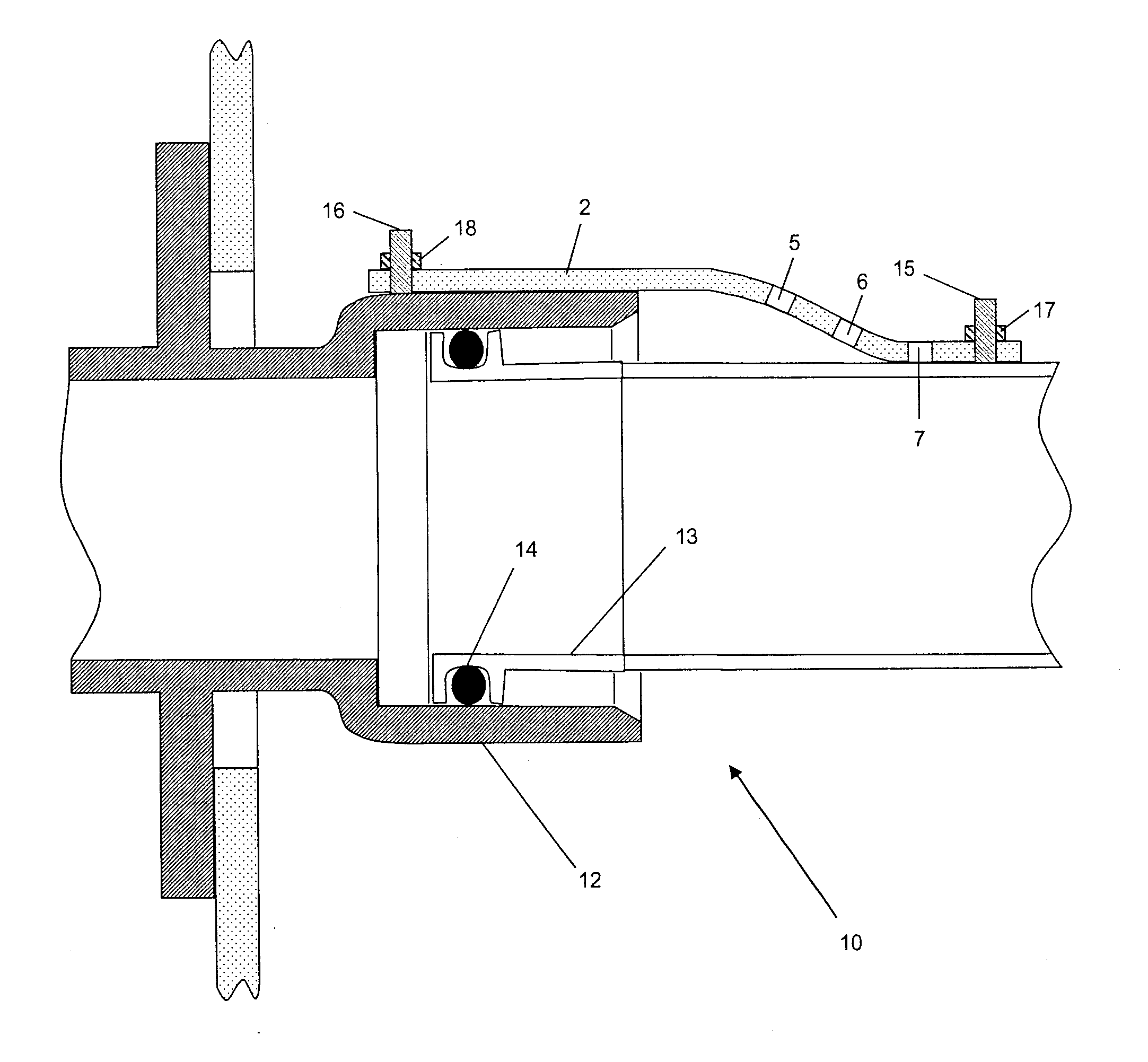

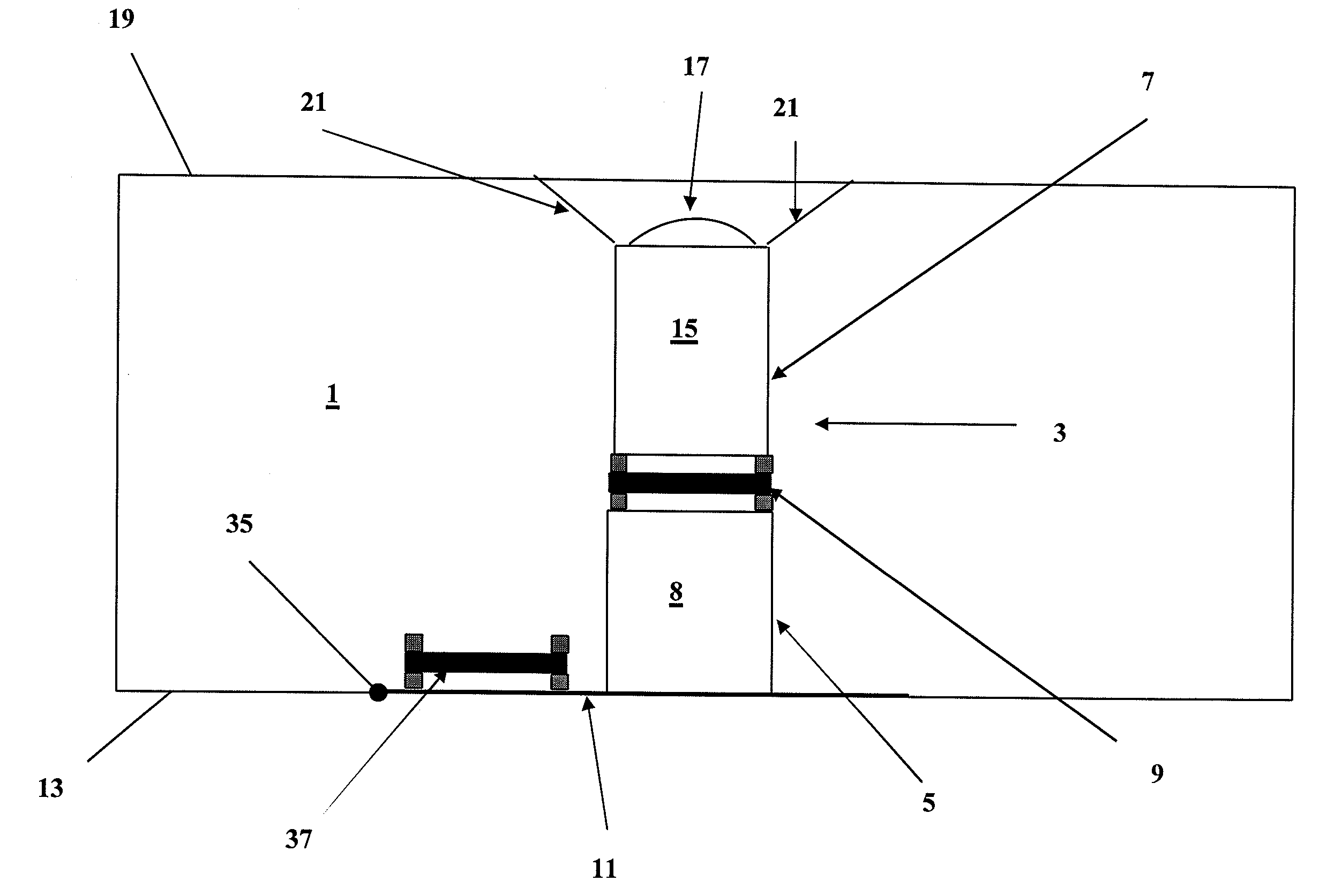

Overpressure protection for an aircraft fuel tank system

ActiveUS20080295905A1Replaced relatively quickly and cheaplyEliminate needPlug valvesEqualizing valvesSurge tankFuel tank

An aircraft venting tank (for example a surge tank) has a stack pipe unit. The stack pipe unit comprises first and second portions and houses a frangible overpressure protector element (for example a frangible disc). The stack pipe unit may be arranged to have a fitted configuration in which the first portion of the stack pipe unit is attached to a part of the venting tank structure, the first portion is coupled to the second portion, and the second portion is coupled to another part of the venting tank structure. The first portion may be held in a relationship with the second portion so as to form a seal between the frangible element, and the first and second portions. In a frangible element-replacement configuration the second portion may be coupled to the venting tank structure, such that the frangible overpressure protector element can be replaced without removal of the second portion from the venting tank structure. The venting tank may include a frangible element holder for holding a spare frangible element for use in an overpressure protector unit.

Owner:AIRBUS OPERATIONS LTD

System and method for preventing incorrect aircraft fuel usage

ActiveUS7464736B2Prevent incorrect refuelingPrevent misfuelingPower plant fuel supplyLiquid transferring devicesJet fuelAirplane

Owner:PARKER INTANGIBLES LLC

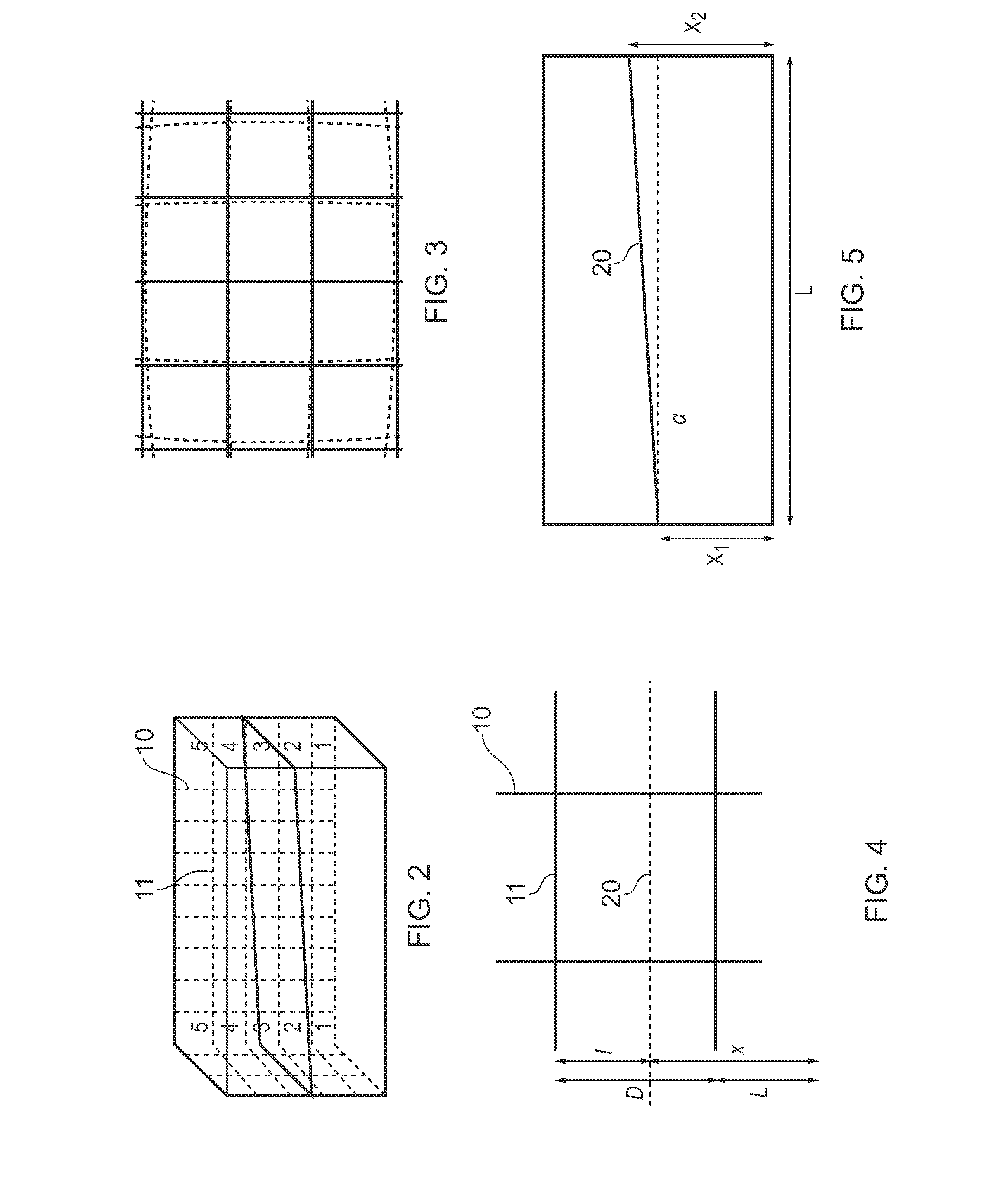

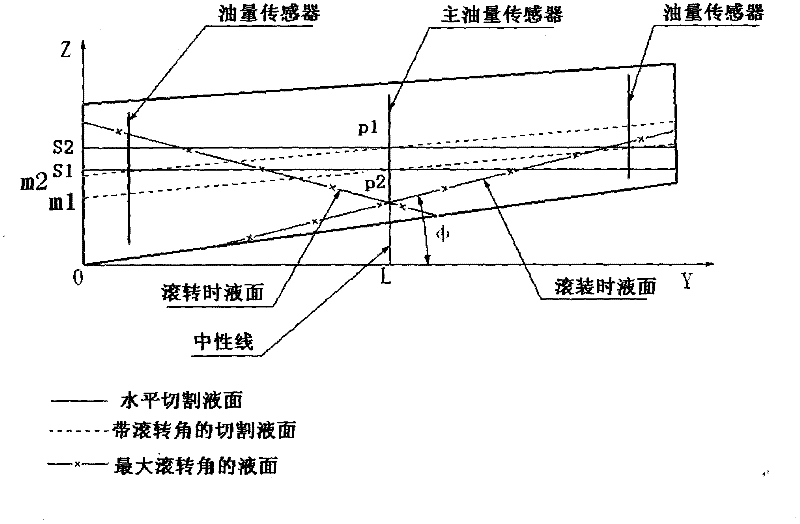

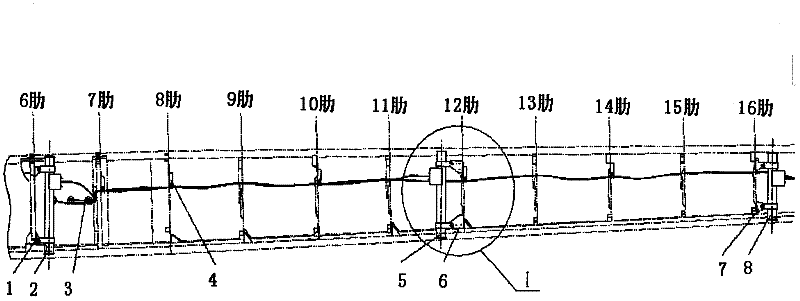

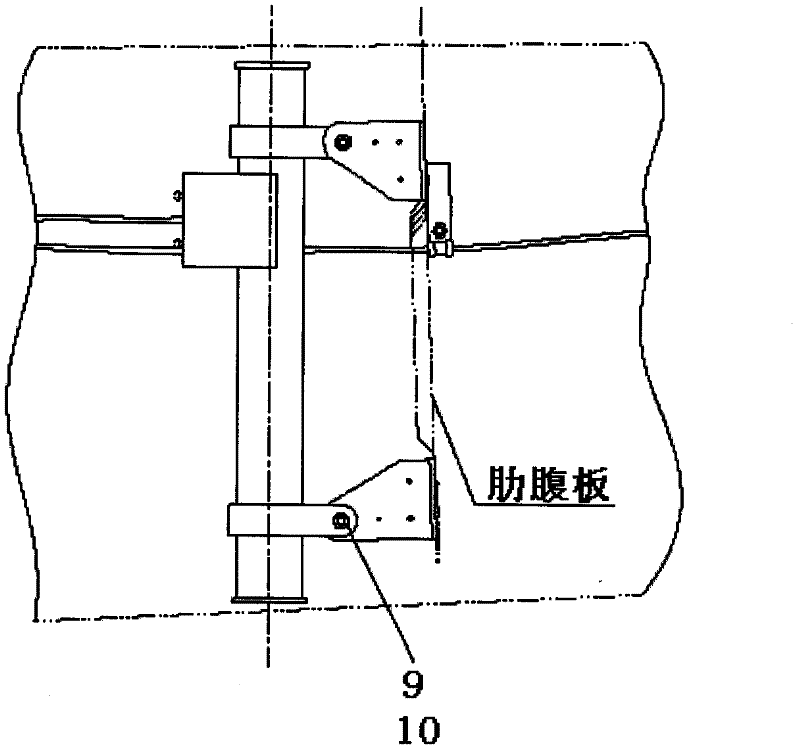

Arrangement method for fuel oil quantity sensors of airplanes

InactiveCN102506956AAccurate measurementShorten the design cyclePower plant fuel supplyMachines/enginesJet aeroplaneDesign cycle

The invention belongs to the field of arrangement for fuel oil quantity measuring systems of airplanes, and particularly relates to an arrangement method for the fuel oil quantity sensors of airplanes. Any oil tank is provided with a neutral surface, and the liquid level height of fuel oil with equal volume is equal at the neutral position when the oil tank is in rolling and pitching attitudes. The method comprises the following steps of: determining a straight line by the intersection point of the fuel oil levels of two airplanes in a parking state and a rolling-angle state as a neutral line, and arranging the fuel oil quantity sensors of the airplanes on the neutral line. Utilizing the method, design cycle can be greatly shortened, and accurate measurement for oil quantity in each state of oil tank based on achieving high-accuracy demand can be satisfied.

Owner:哈尔滨安博威飞机工业有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com