Patents

Literature

556results about How to "Avoid sparking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

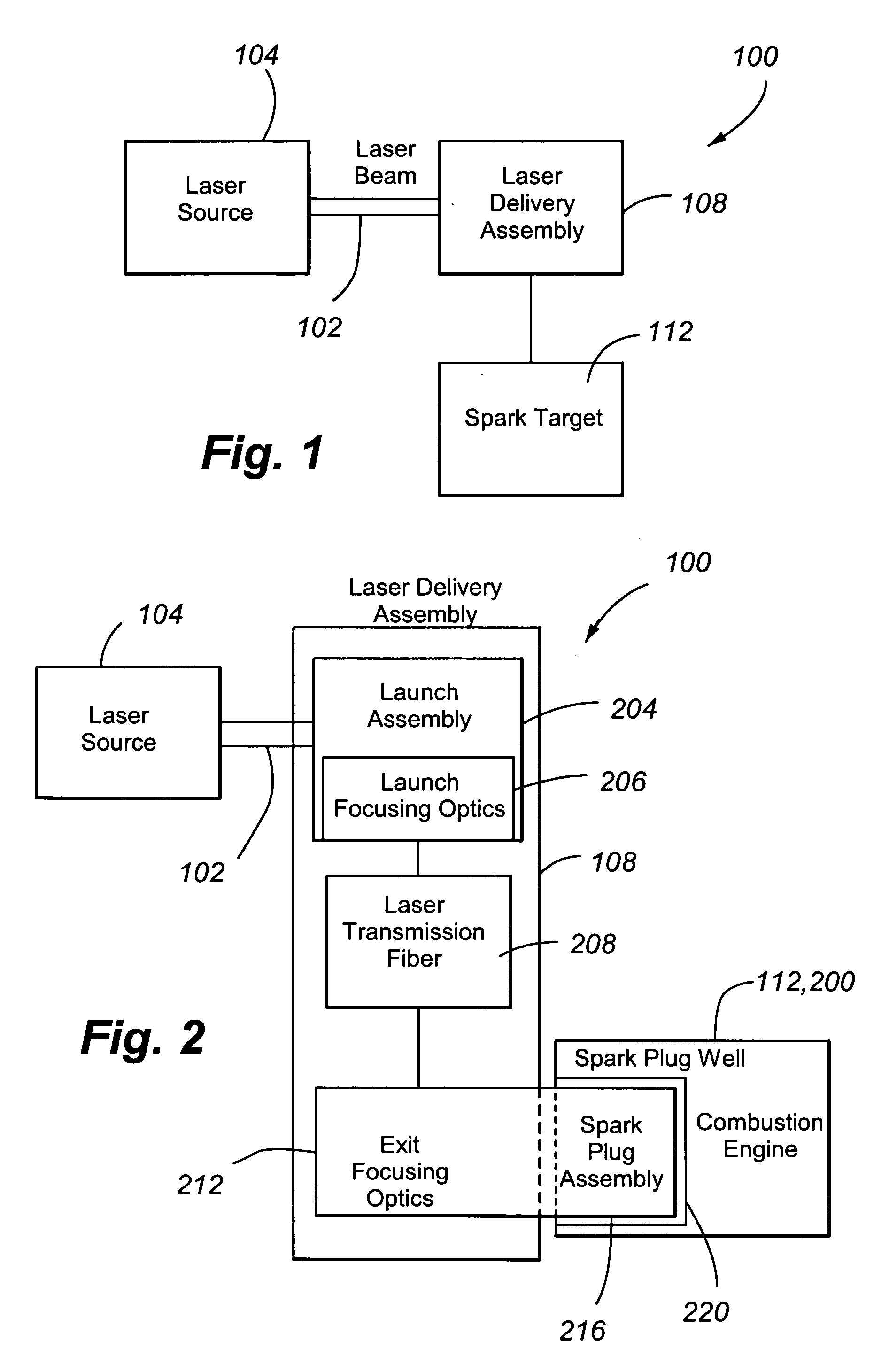

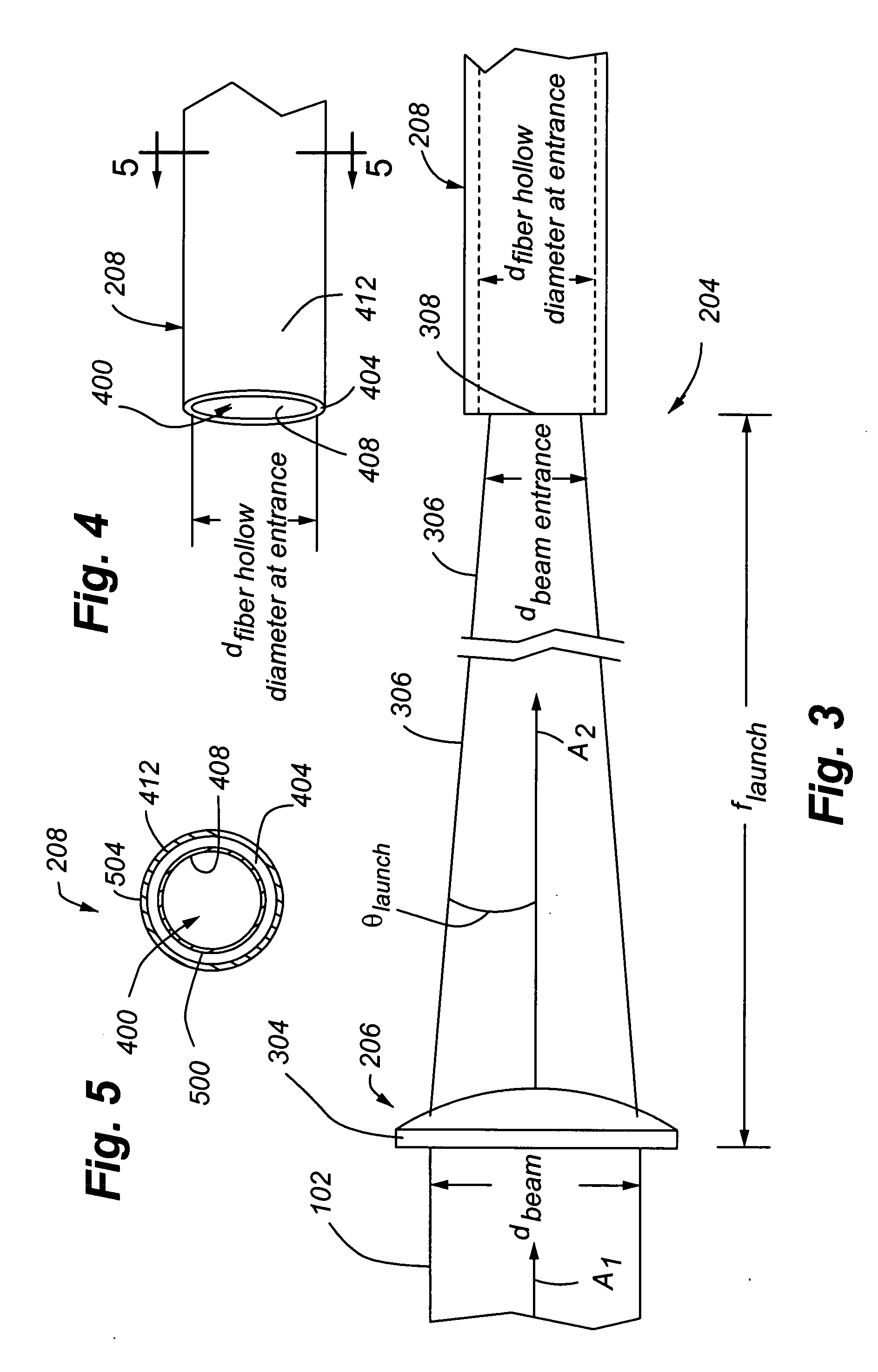

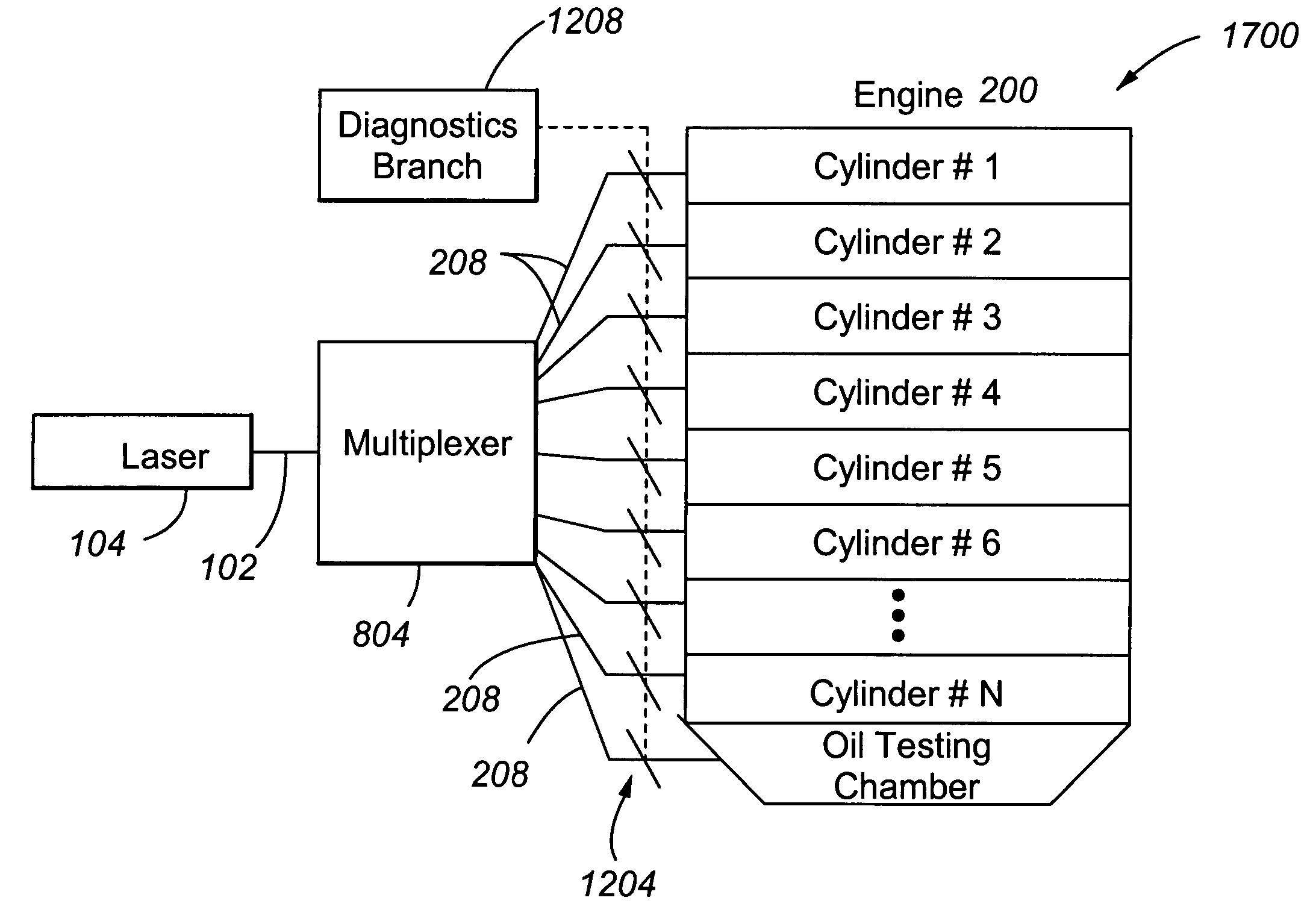

Optical diagnostics integrated with laser spark delivery system

ActiveUS20060037572A1Promote growthEasy to createRadiation pyrometrySpectrum investigationTransfer systemLight beam

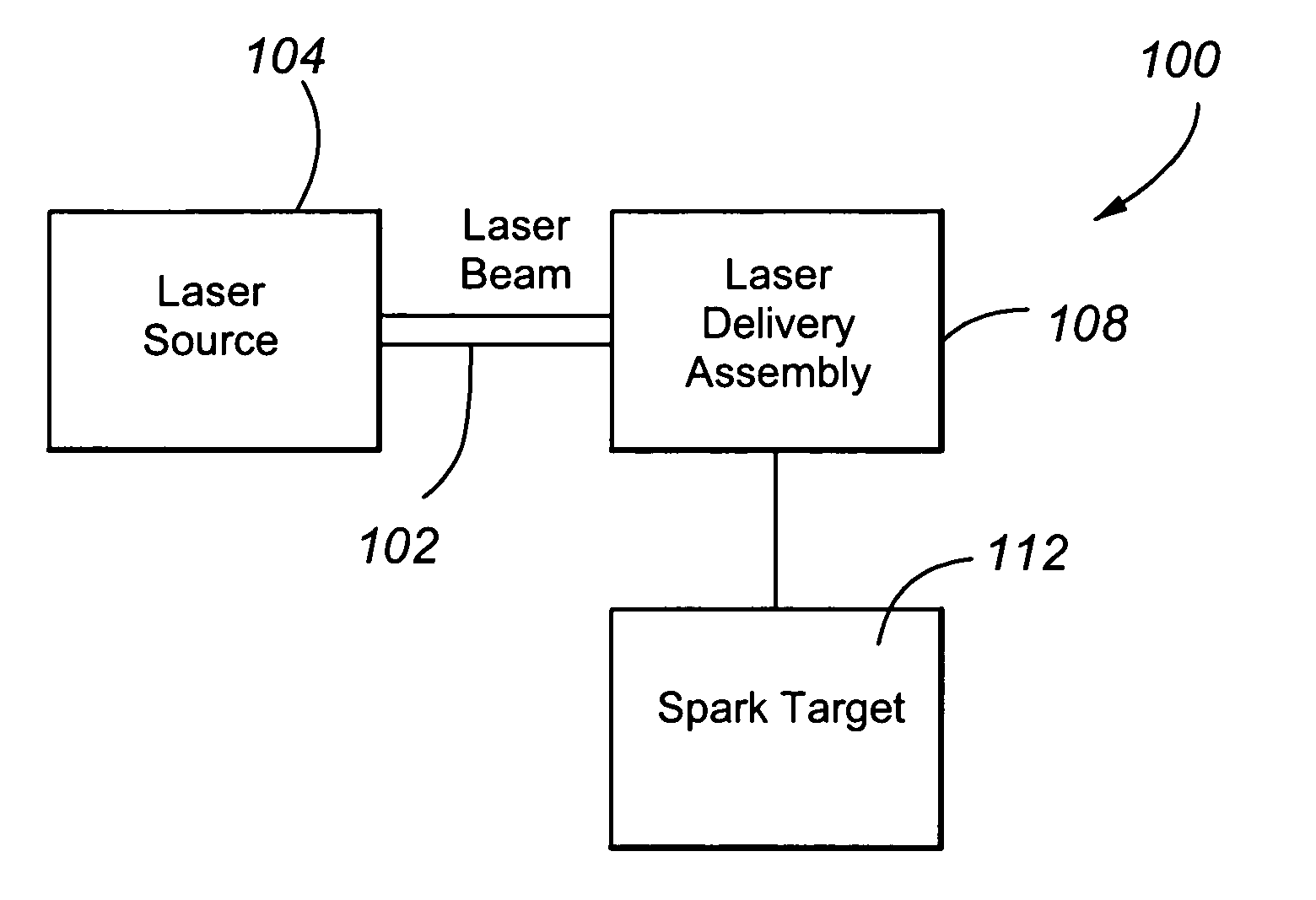

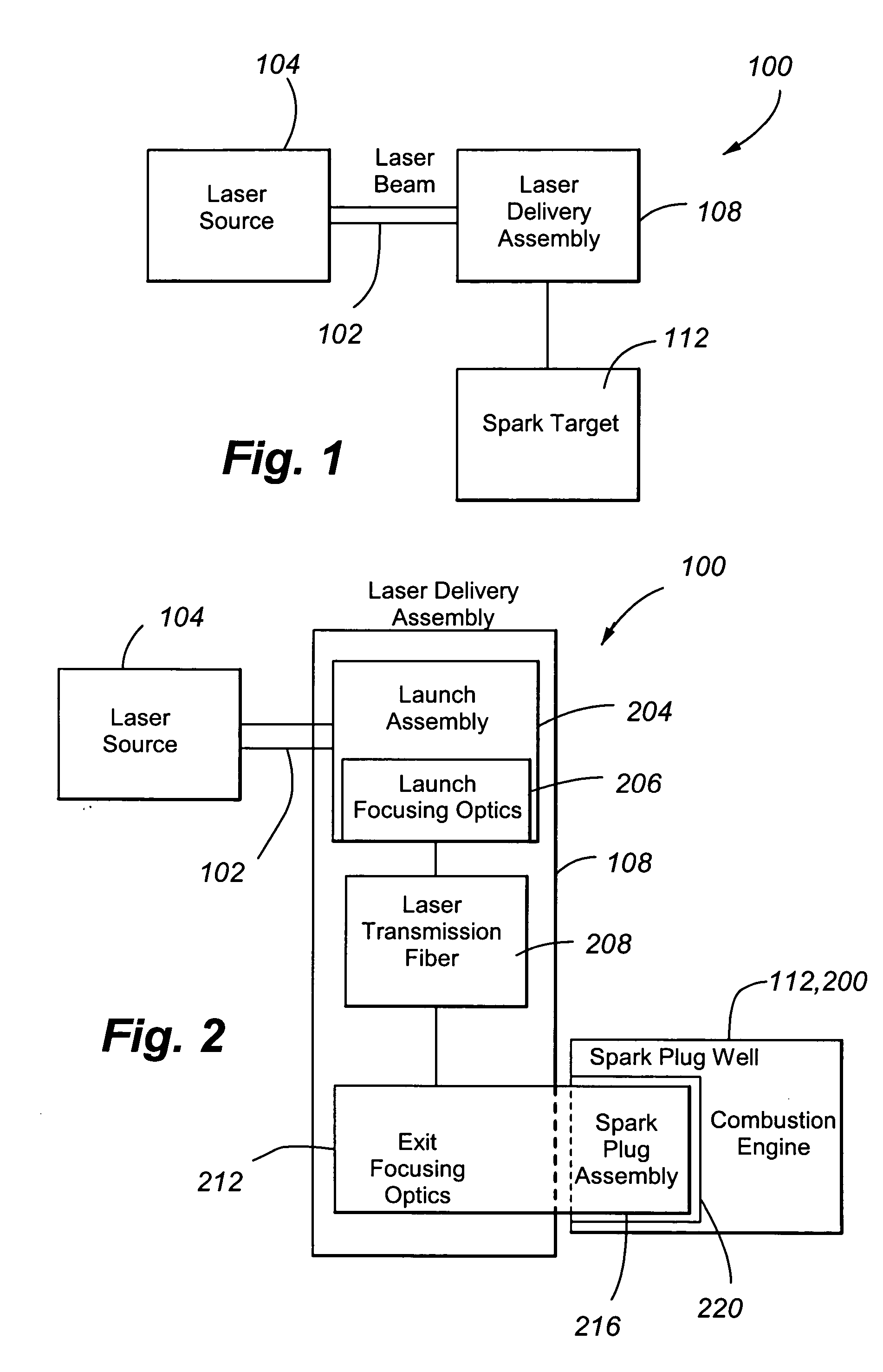

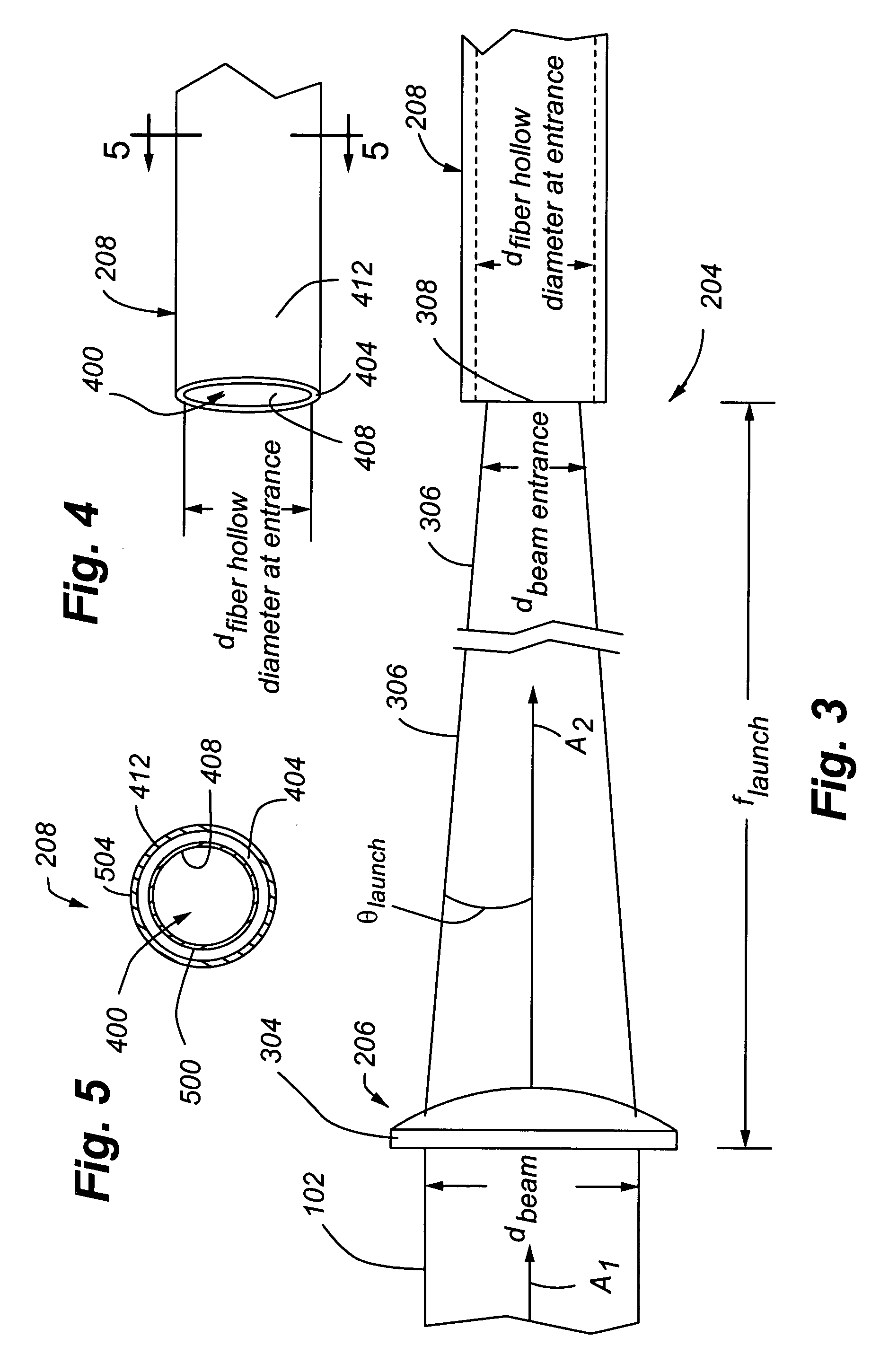

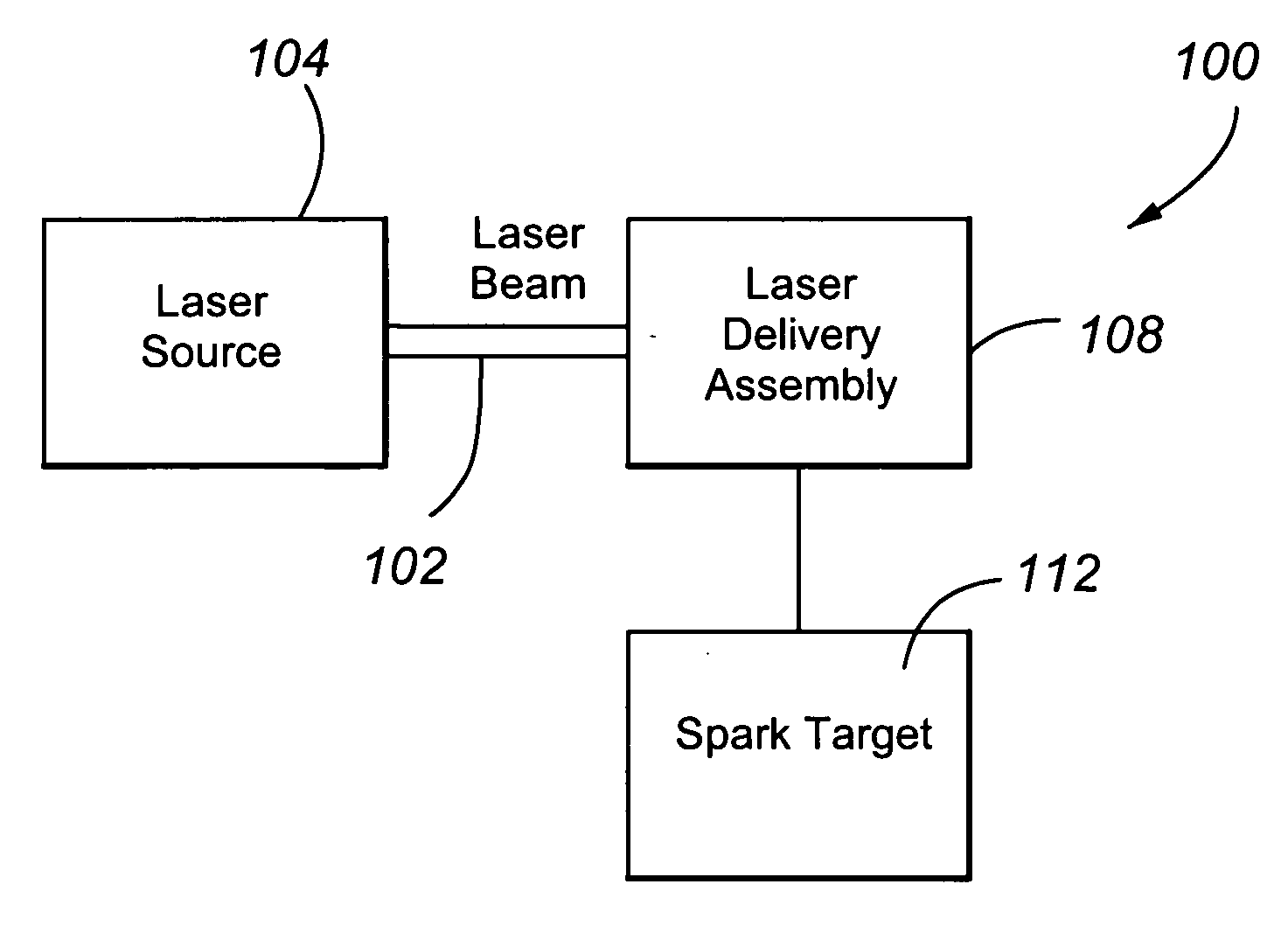

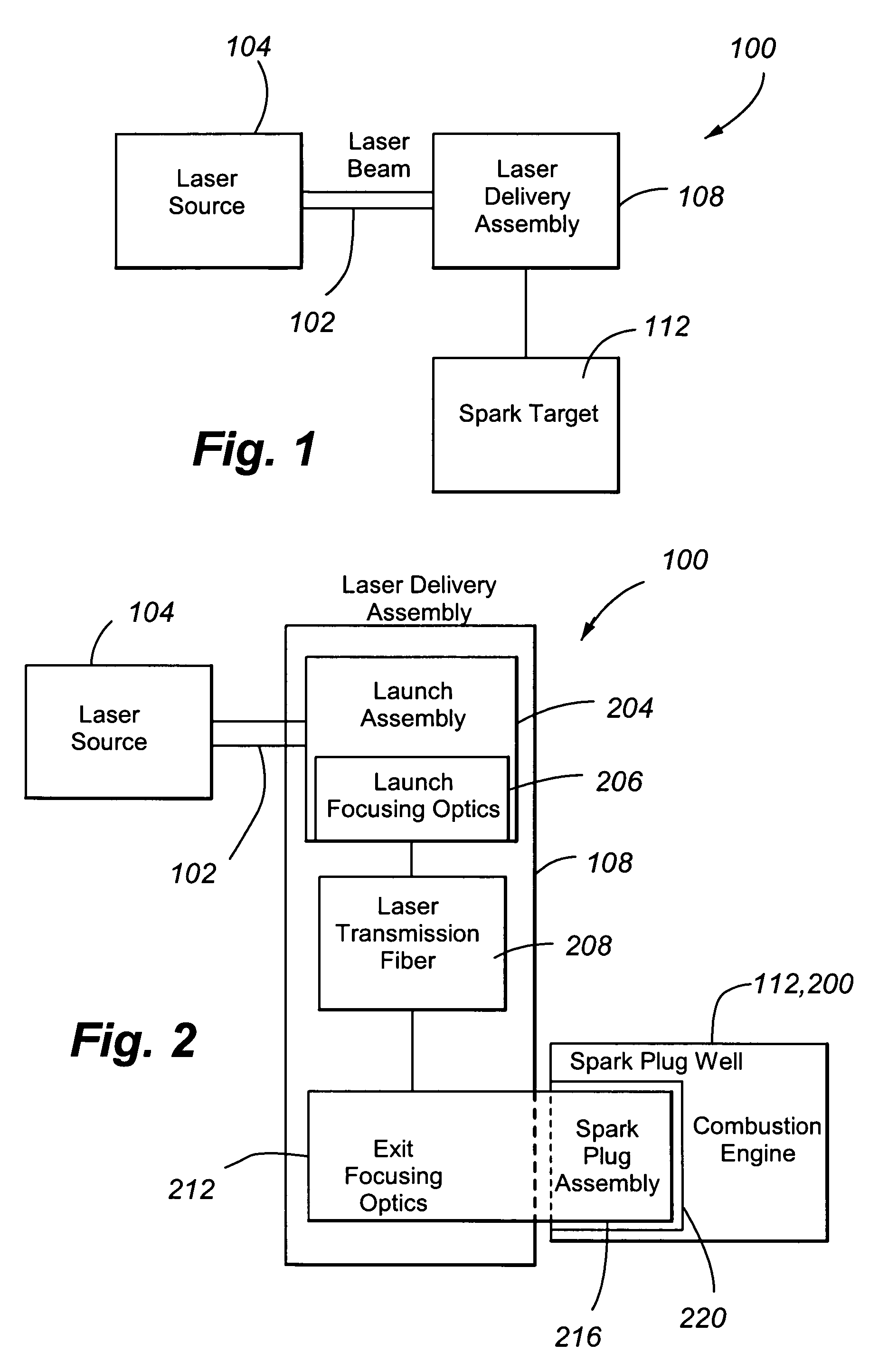

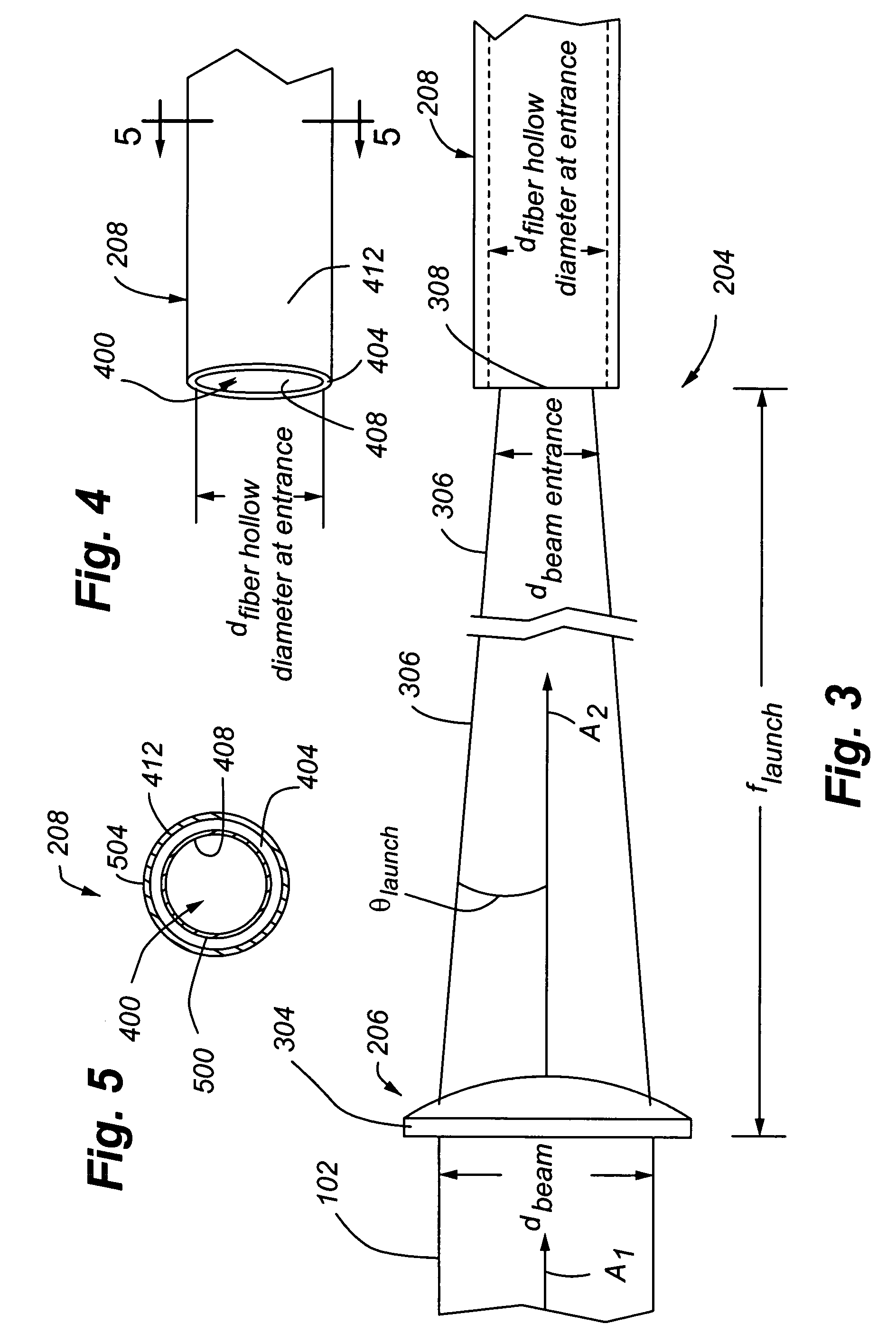

A spark delivery system for generating a spark using a laser beam is provided, and includes a laser light source and a laser delivery assembly. The laser delivery assembly includes a hollow fiber and a launch assembly comprising launch focusing optics to input the laser beam in the hollow fiber. The laser delivery assembly further includes exit focusing optics that demagnify an exit beam of laser light from the hollow fiber, thereby increasing the intensity of the laser beam and creating a spark. Other embodiments use a fiber laser to generate a spark. Embodiments of the present invention may be used to create a spark in an engine. Yet other embodiments include collecting light from the spark or a flame resulting from the spark and conveying the light for diagnostics. Methods of using the spark delivery systems and diagnostic systems are provided.

Owner:COLORADO STATE UNIVERSITY

Fiber laser coupled optical spark delivery system

ActiveUS20060032471A1Promote growthEasy to createCombustion enginesEngine ignitionTransfer systemLight beam

A spark delivery system for generating a spark using a laser beam is provided, and includes a laser light source and a laser delivery assembly. The laser delivery assembly includes a hollow fiber and a launch assembly comprising launch focusing optics to input the laser beam in the hollow fiber. The laser delivery assembly further includes exit focusing optics that demagnify an exit beam of laser light from the hollow fiber, thereby increasing the intensity of the laser beam and creating a spark. Other embodiments use a fiber laser to generate a spark. Embodiments of the present invention may be used to create a spark in an engine. Yet other embodiments include collecting light from the spark or a flame resulting from the spark and conveying the light for diagnostics. Methods of using the spark delivery systems and diagnostic systems are provided.

Owner:COLORADO STATE UNIVERSITY

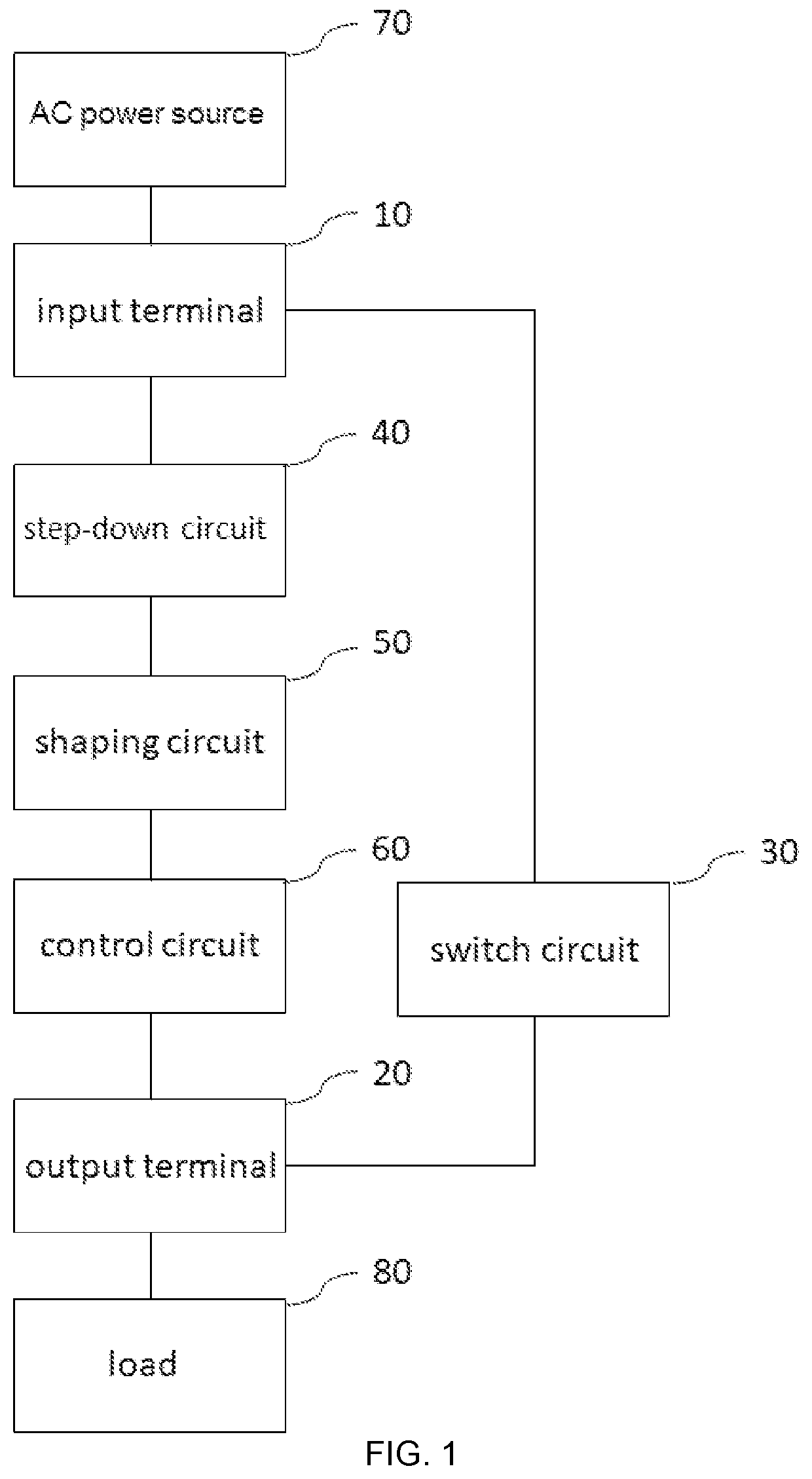

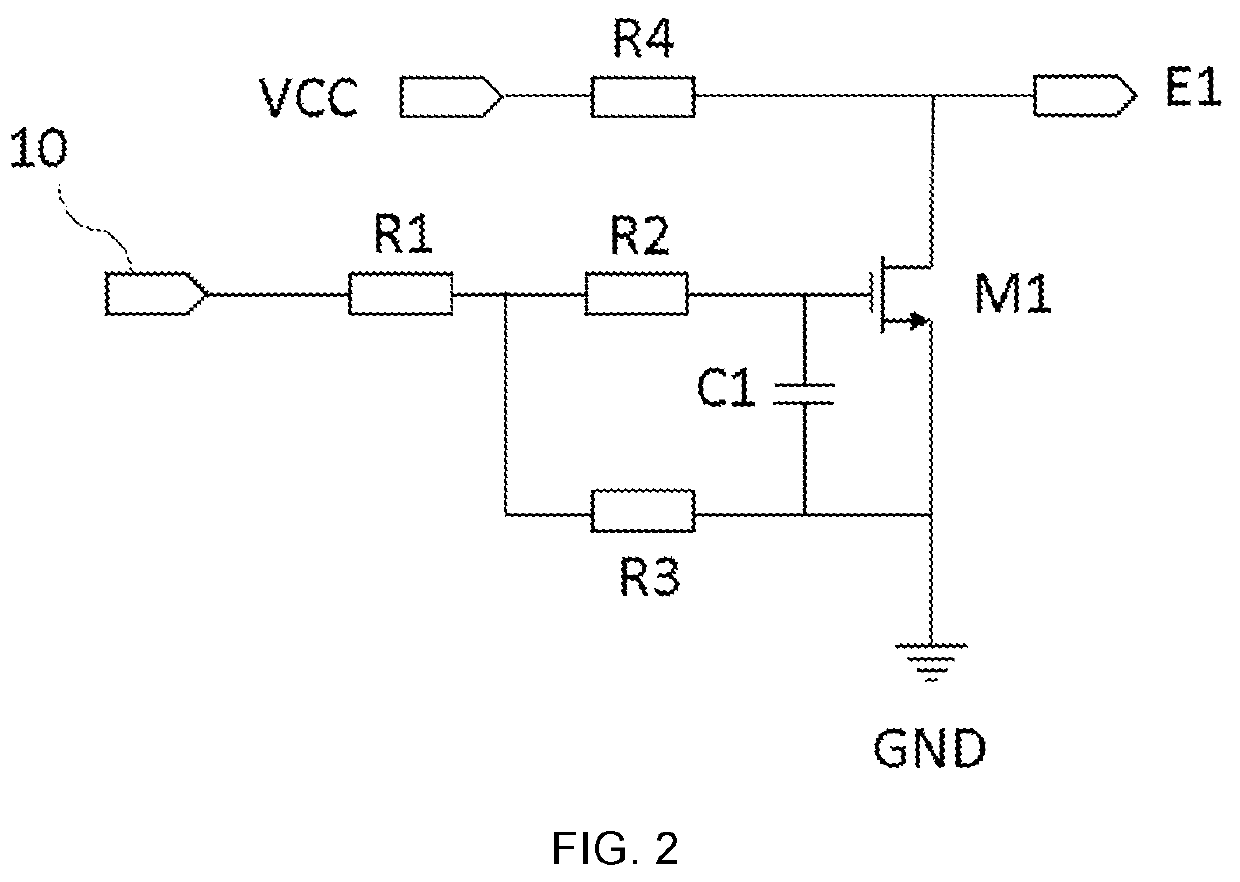

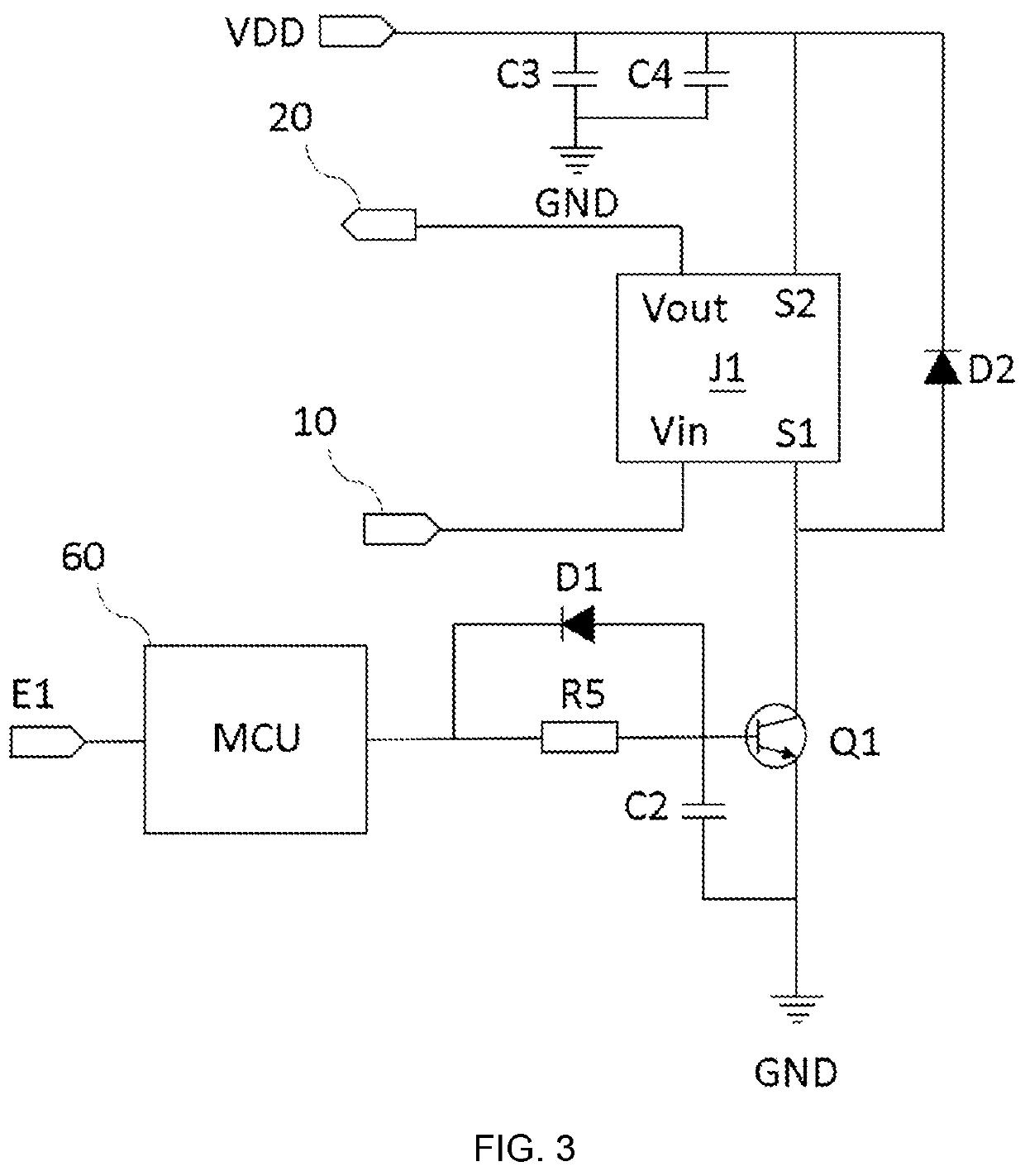

Socket and door with same

ActiveUS11205880B1Avoid sparkingReduce the amplitudeCoupling device detailsNon-mechanical controlsSoftware engineeringElectrical connection

A socket includes: an input terminal configured to be electrically connected to an AC power source; an output terminal configured to output an AC signal of the AC power supply; a switch circuit electrically connected between the input terminal and the output terminal; a step-down circuit electrically connected to the input terminal and configured to reduce the amplitude of the AC signal; a shaping circuit electrically connected to the step-down circuit and configured to convert the AC signal with reduced amplitude into a shaped signal; and a control circuit electrically connected to the shaping circuit and the switch circuit and configured to control the switch circuit based on the shaping signal to enable the switch circuit performs switching operation only when the AC signal is at zero potential. A door includes the socket.

Owner:SHANGHAI IMILAB TECHNOLOGY CO LTD

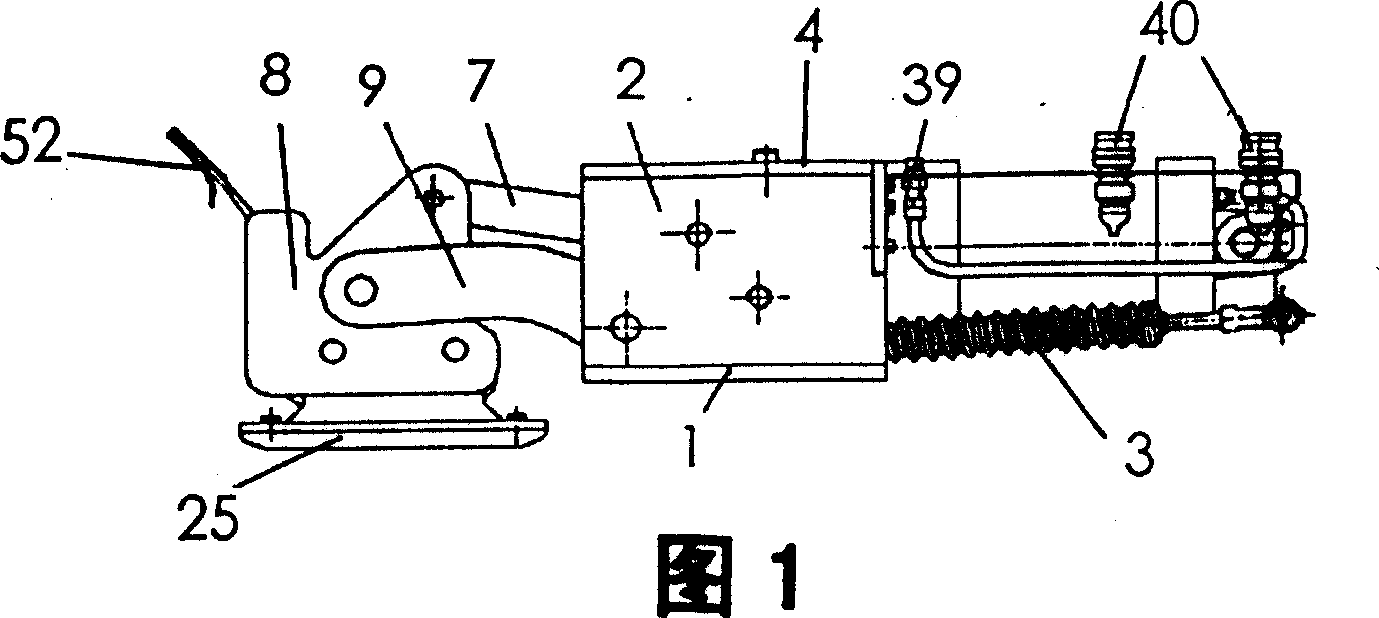

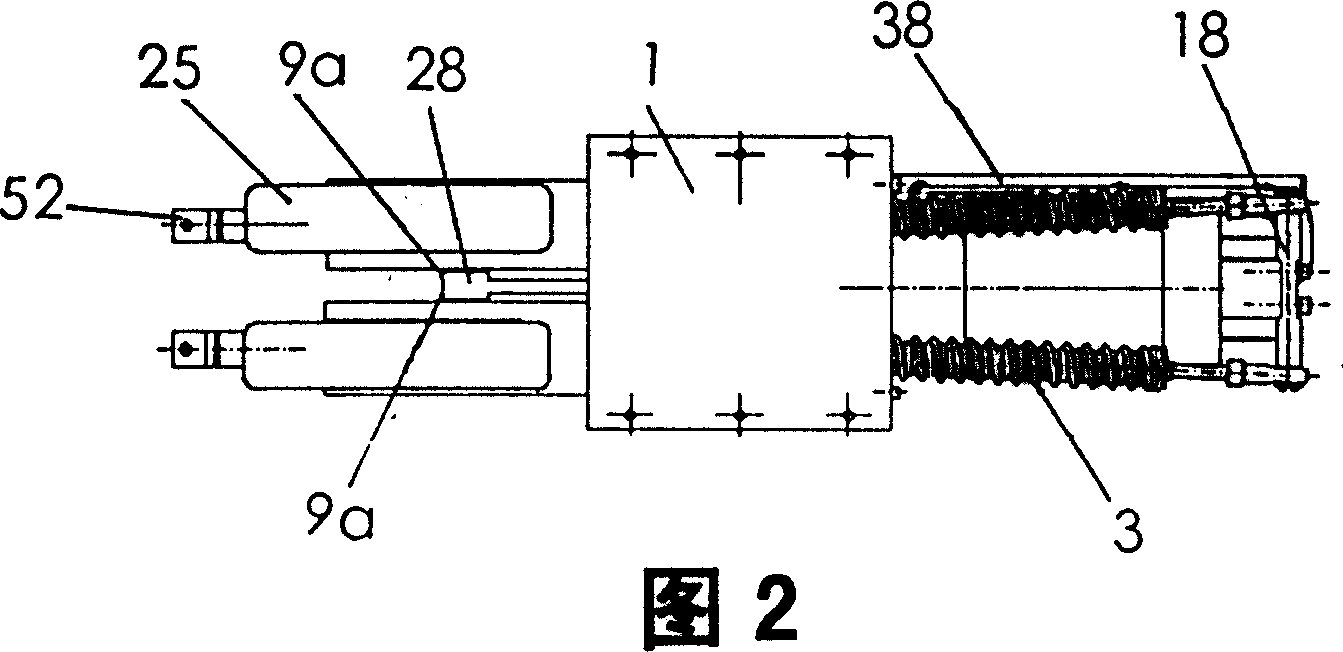

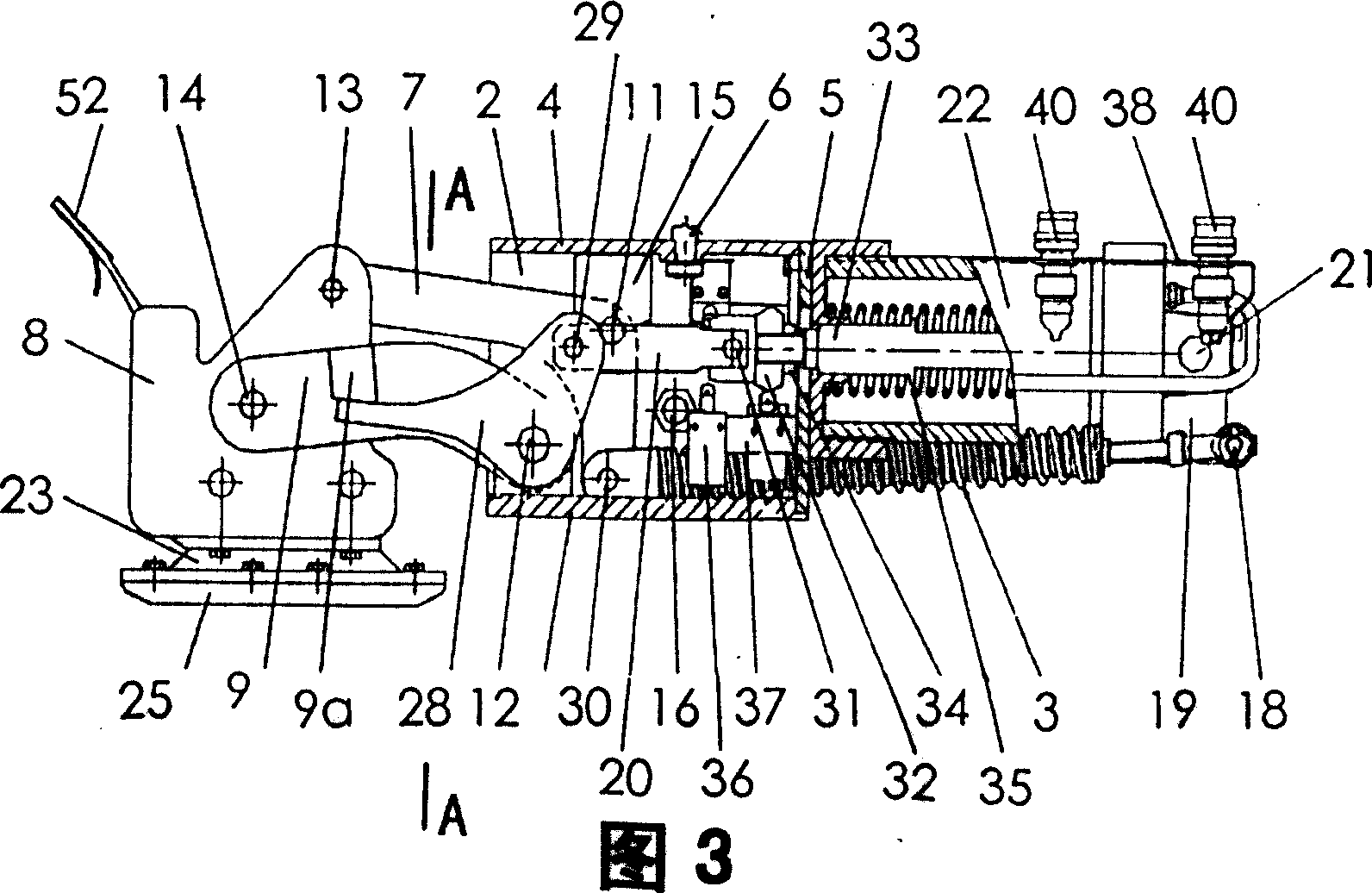

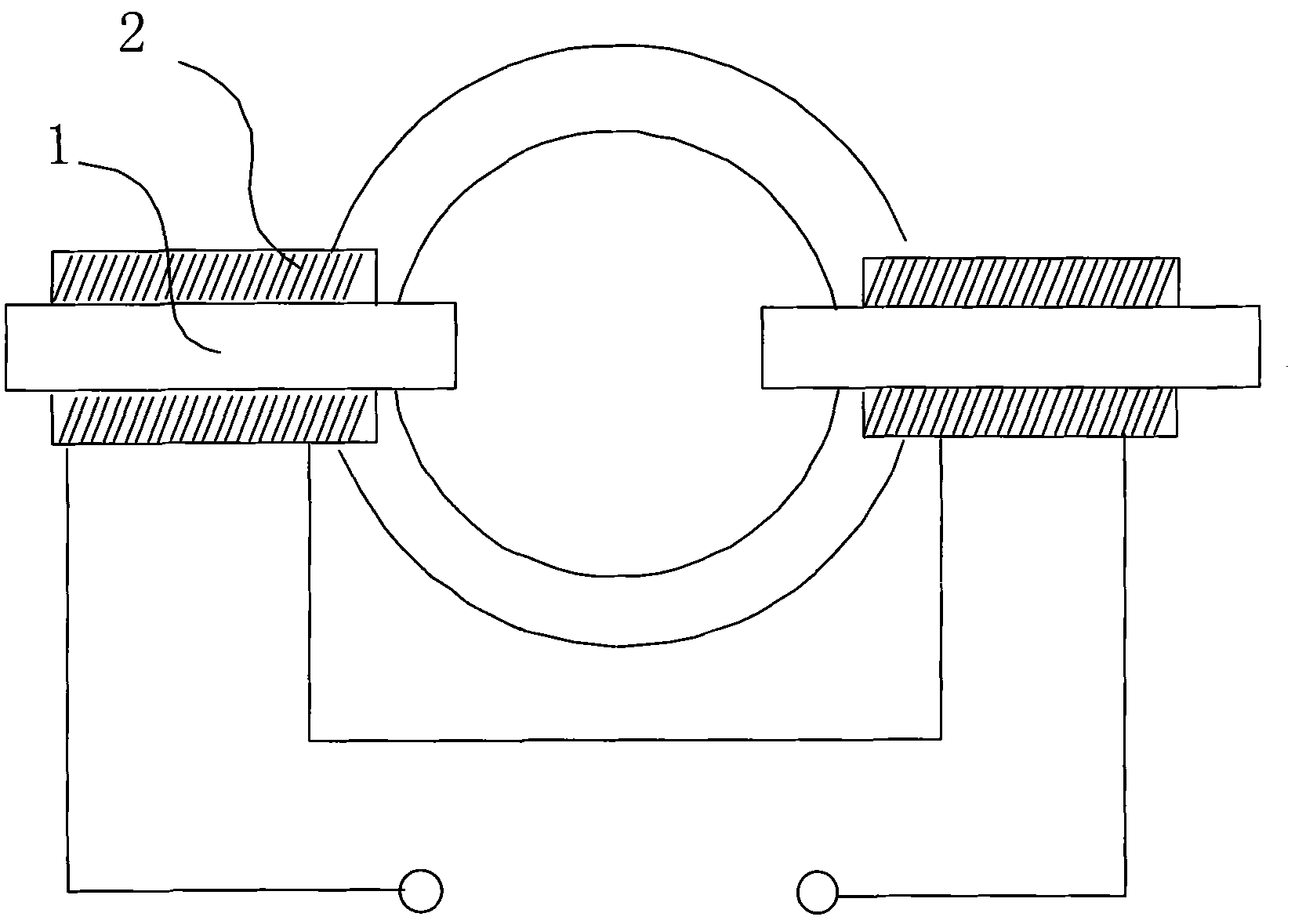

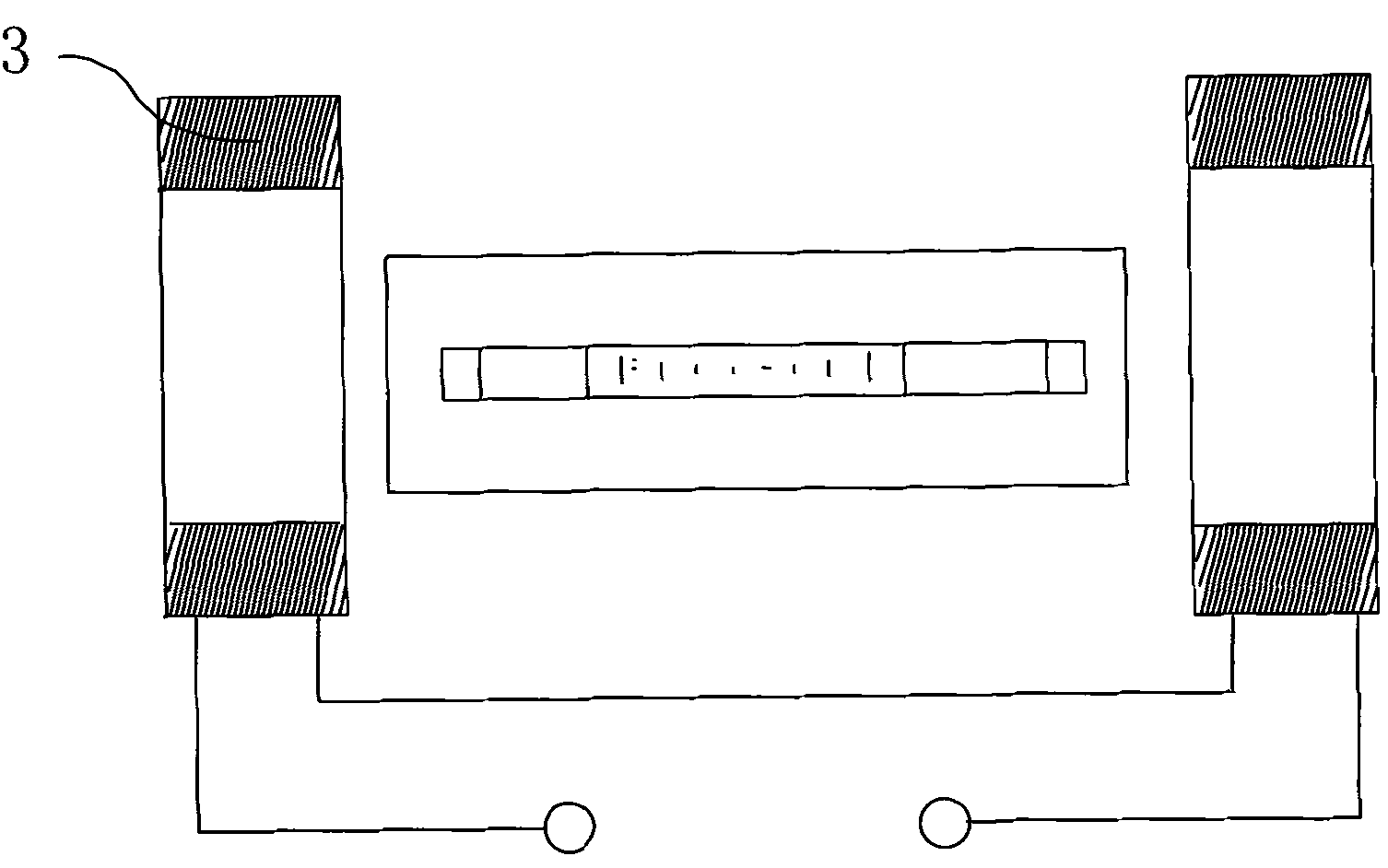

Current for acceptor current enter and reflux

InactiveCN101062660AAchieve insulationSimple mechanical structurePower current collectorsElectricityEngineering

The invention relates to the electric receiving device of the electric vehicle. The current receiver for current in and return comprises the electric boots and the spring device, with two parallel parallelogram four linking bar structure and a separation structure, each four link structure made by the top and down lining bars hinged to the corresponding side plate and isolation plate, the separation structure composed of the air cylinder, air cylinder linking pole hinged to the cylinder piston end, lower linking brake bar with two rocker arms with the lower linking brake bar hinged to the lower linking bar pin shaft fixed to two side walls, one of the rocker arm hinged to the air cylinder linking bar, the other being the stop leaning against the low linking bar, each isolation plate bottom installed with an electric receiving boot, each four link bar structure having its top link bar connected to the said spring device. It solves the technical issues of current receiver contact or separation with the electric supply track smoothly, and the grounding issue of it.

Owner:SHANGHAI MAGNETIC SUSPENSION COMM ENG TECH RES CENTE +1

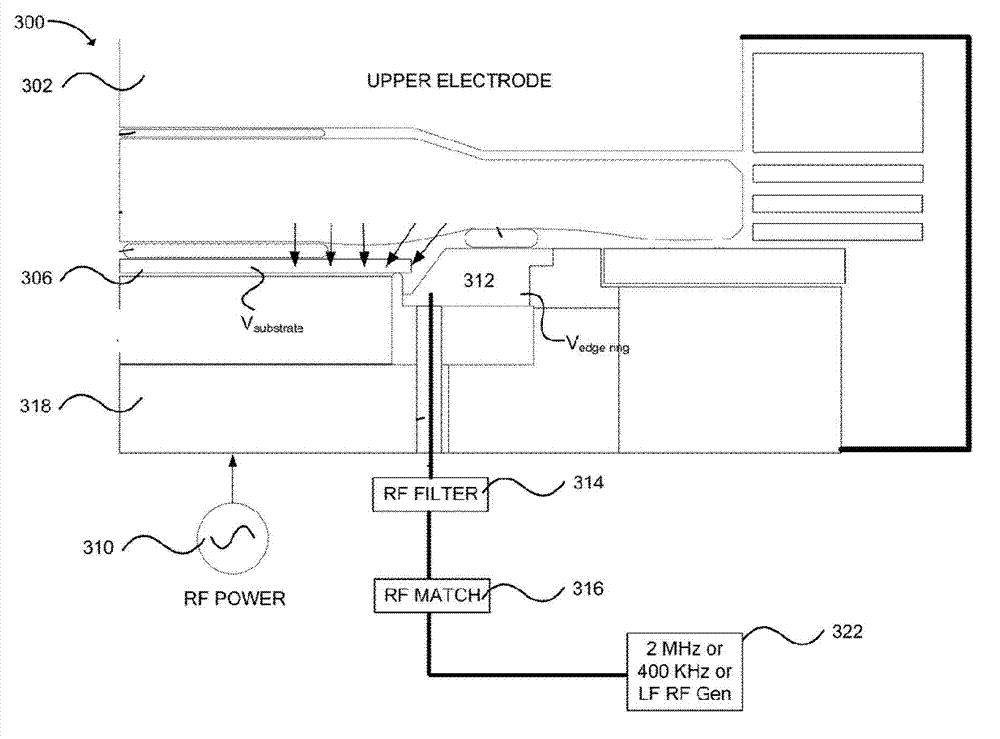

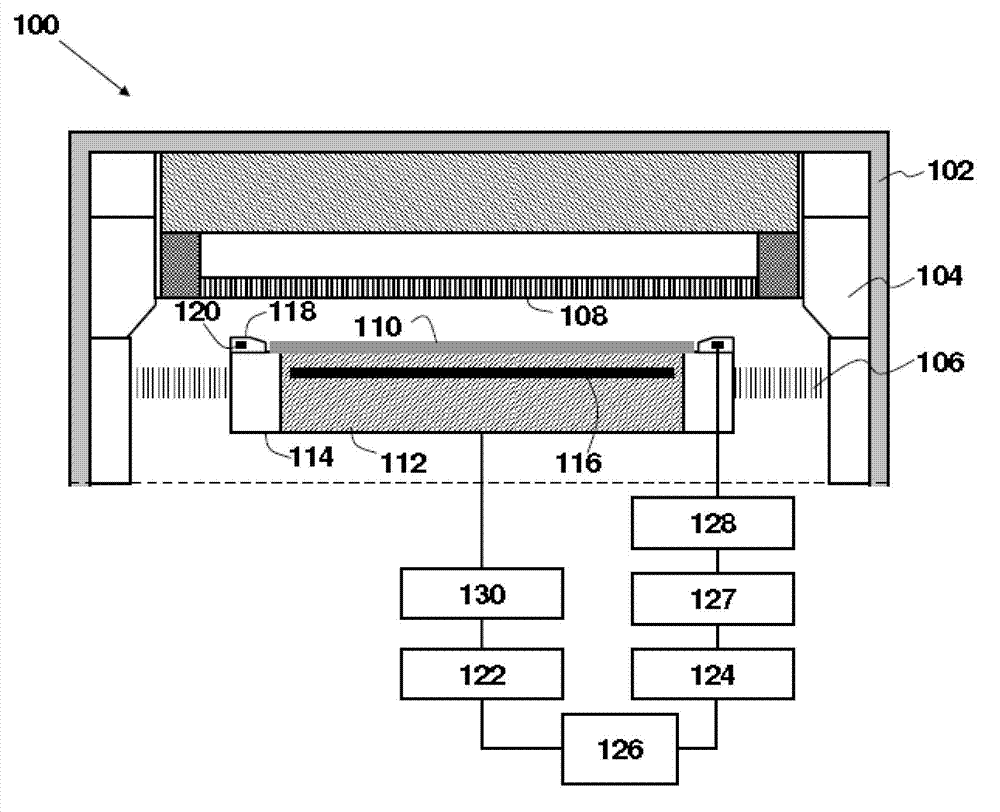

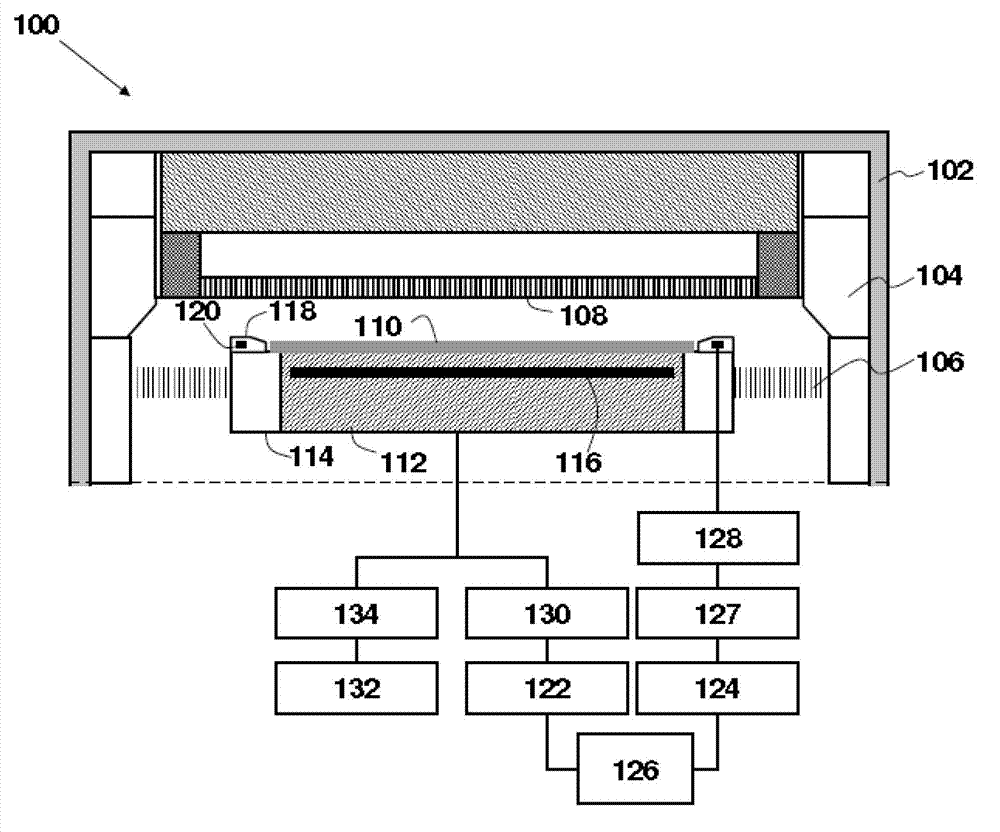

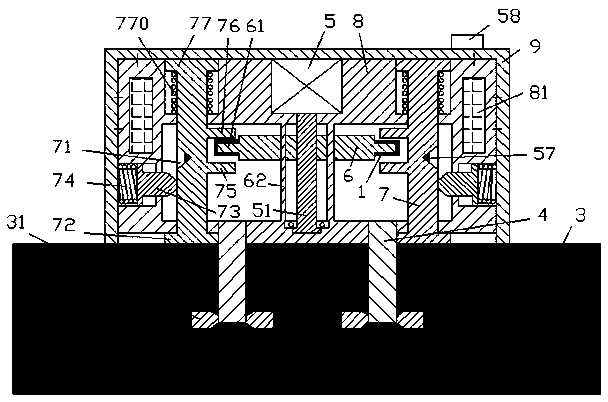

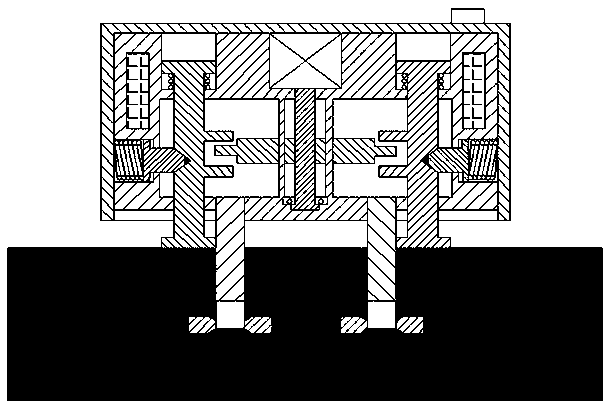

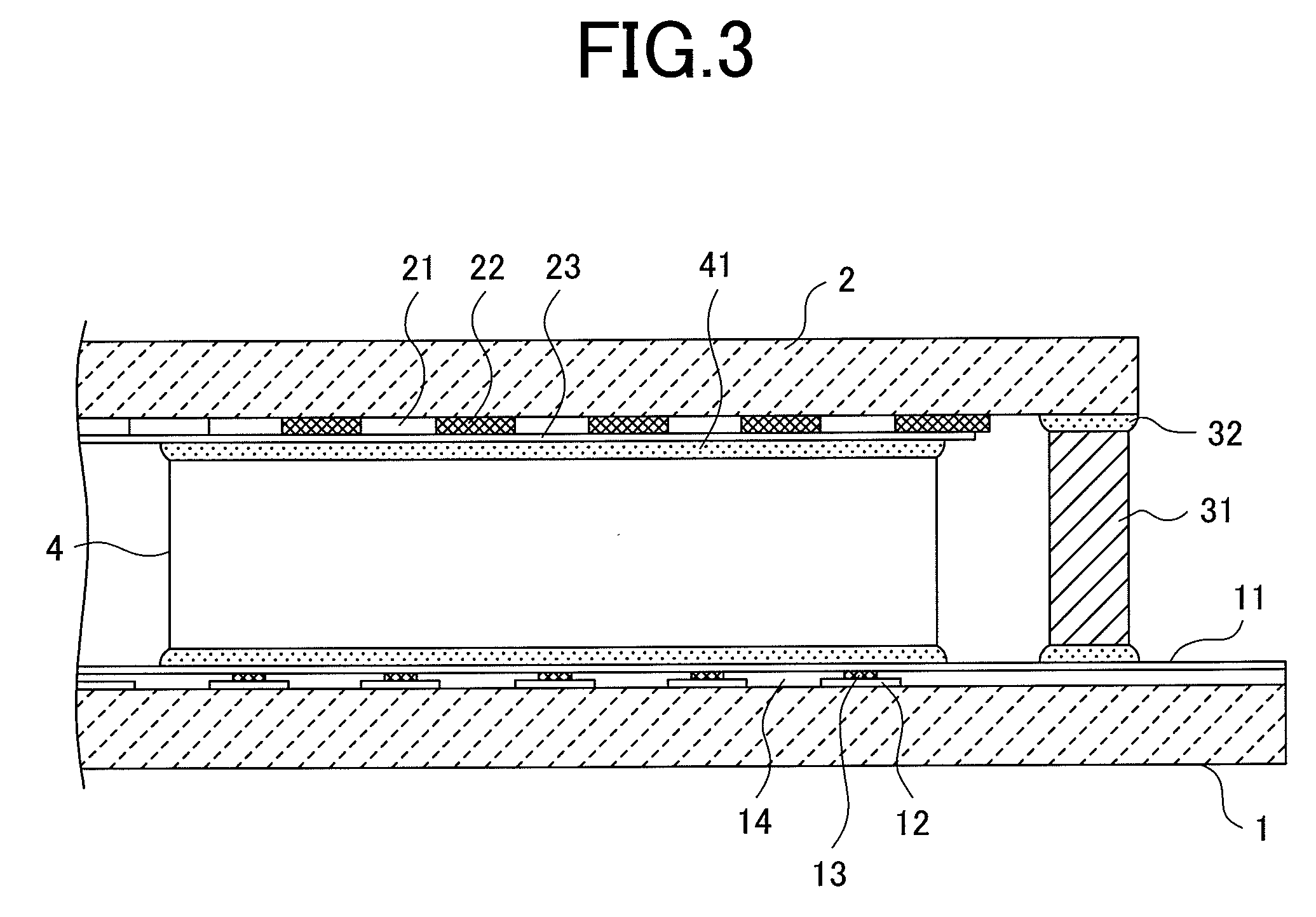

Plasma processing apparatus and method for adjusting process rate of marginal area of substrate

ActiveCN103715049ACompensate for edge effectsAvoid arcingElectric discharge tubesEdge effectsShortest distance

The invention relates to a plasma processing apparatus and a method for adjusting a process rate of a marginal area of a substrate. The plasma processing apparatus comprises a cavity, a pedestal arranged in the cavity, a gas spay header arranged at the top of the cavity, a lower electrode arranged in the pedestal, a focusing ring arranged around the substrate, an edge electrode, and a phase shifter. To be specific, an electrostatic chuck is arranged above the pedestal; and a substrate is arranged above the electrostatic chuck. The gas spay header is used as an upper electrode; and process gas enters the cavity through the gas spay header. The lower electrode is connected with a first radio frequency power supply. The edge electrode approaches the edge area of the substrate and is connected with a second radio frequency power supply. And the phase shifter is connected with the first radio frequency power supply and the second radio frequency power supply. According to the invention, the edge effect can be effectively compensated; and phenomena of arc discharging and sparking due to the short distance between voltages applied to the central zone and the edge zone of the substrate can be avoided.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Glass grinding fluid and preparation method thereof

InactiveCN103275803AGood cleaning penetration performanceGood self-sharpeningLubricant compositionCamera lensCleansing Agents

The invention discloses a glass grinding fluid and a preparation method thereof. A technical scheme in the invention is characterized in that the glass grinding fluid comprises 5-20wt% of a grinding dust settling agent, 2-8wt% of a cleaning agent, 1-20wt% of a pH stabilizing agent, 1-20wt% of a lubricant, 0.3-2wt% of an organosilicon antifoaming agent, and the balance water. The invention also discloses the preparation method of the glass grinding fluid. The glass grinding fluid has good cleaning and penetrating performances, can effectively prevent grinding tools from passivating, has a good self-sharpening effect on the grinding tools, increases the cutting force of diamond tools, and is suitable for grinding common glass, resin glass, optical glass, flat glass, camera lens, spectacle lens, handset cover plates, sapphire glass, optical products of quartz, high-grade marble or superfine granite.

Owner:HENAN NORMAL UNIV

Fiber laser coupled optical spark delivery system

ActiveUS7340129B2Promote growthEasy to createEngine ignitionMachines/enginesTransport systemLight beam

A spark delivery system for generating a spark using a laser beam is provided, and includes a laser light source and a laser delivery assembly. The laser delivery assembly includes a hollow fiber and a launch assembly comprising launch focusing optics to input the laser beam in the hollow fiber. The laser delivery assembly further includes exit focusing optics that demagnify an exit beam of laser light from the hollow fiber, thereby increasing the intensity of the laser beam and creating a spark. Other embodiments use a fiber laser to generate a spark. Embodiments of the present invention may be used to create a spark in an engine. Yet other embodiments include collecting light from the spark or a flame resulting from the spark and conveying the light for diagnostics. Methods of using the spark delivery systems and diagnostic systems are provided.

Owner:COLORADO STATE UNIVERSITY

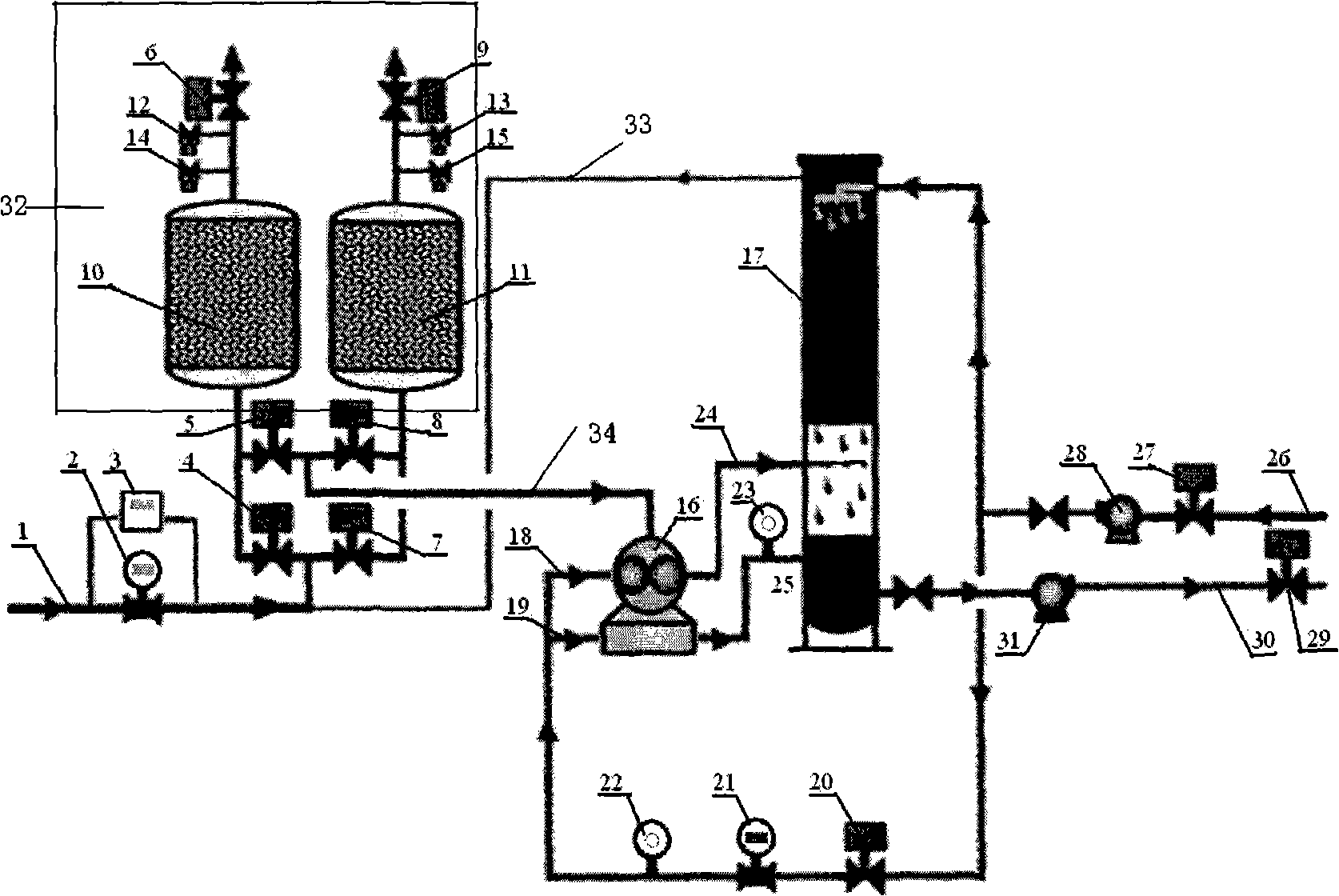

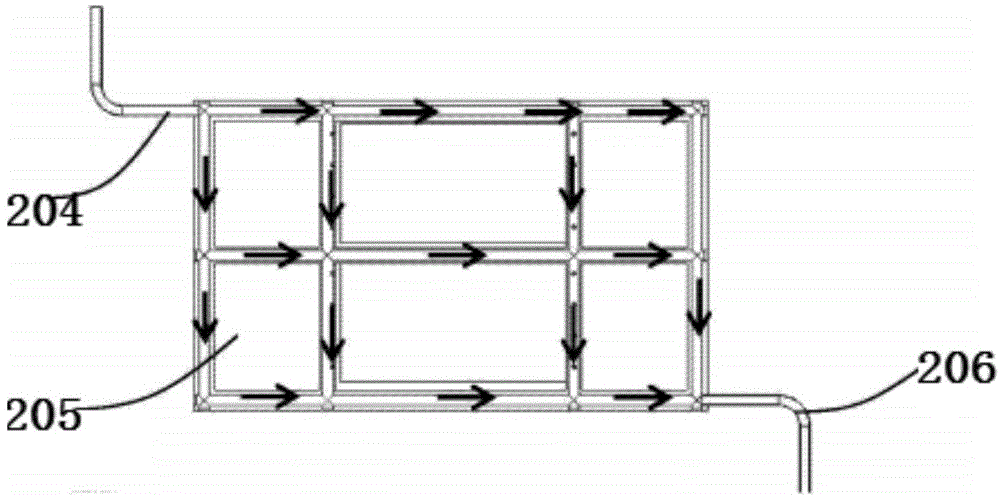

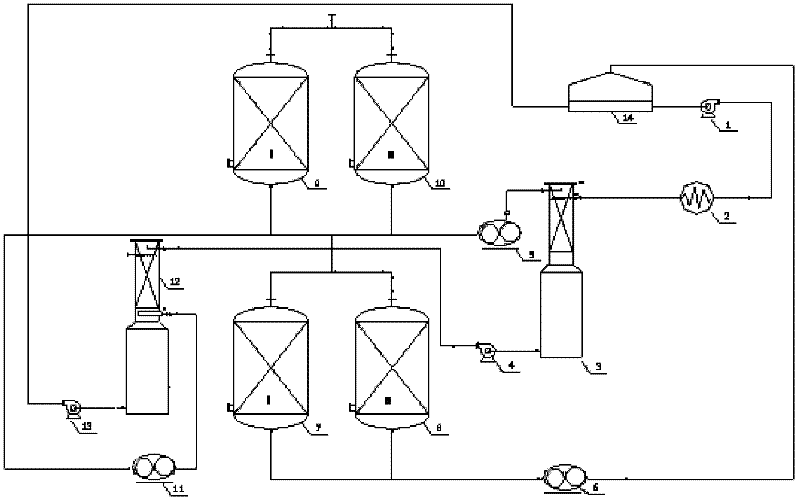

Continuous circulating type oil-gas adsorption recovery method

InactiveCN101259358AEasy to realize fully automatic controlEasy to realize remote monitoringDispersed particle separationHigh concentrationRecovery method

The invention discloses a sustained circulating type method for adsorbing and recycling oil gas , which consists of the following steps: (1) adsorbing and recycling the oil gas by means of an active carbon bed in an adsorption tower; (2) the desorption and regeneration of the adsorption tower saturated is carried out; (3) the oil gas desorbed with high concentration enters a recovery tower to be absorbed by the body of liquid meager gasoline; (4) the tail gas in the recovery tower reenters the adsorption tower to be cycled in a sustaining way, wherein, at least two adsorption tanks in the adsorption tower alternately carry out adsorption and desorption generation, thus leading the oil gas adsorption to be carried out in a sustained circulating way, at the same time, the remote monitoring can be realized by using an automatic control program. The sustained circulating type method for adsorbing and recycling oil gas of the invention is characterized by high efficiency, low energy consumption, convenient operation and safe and reliable running.

Owner:BAY ENVIRONMENTAL TECH BEIJING

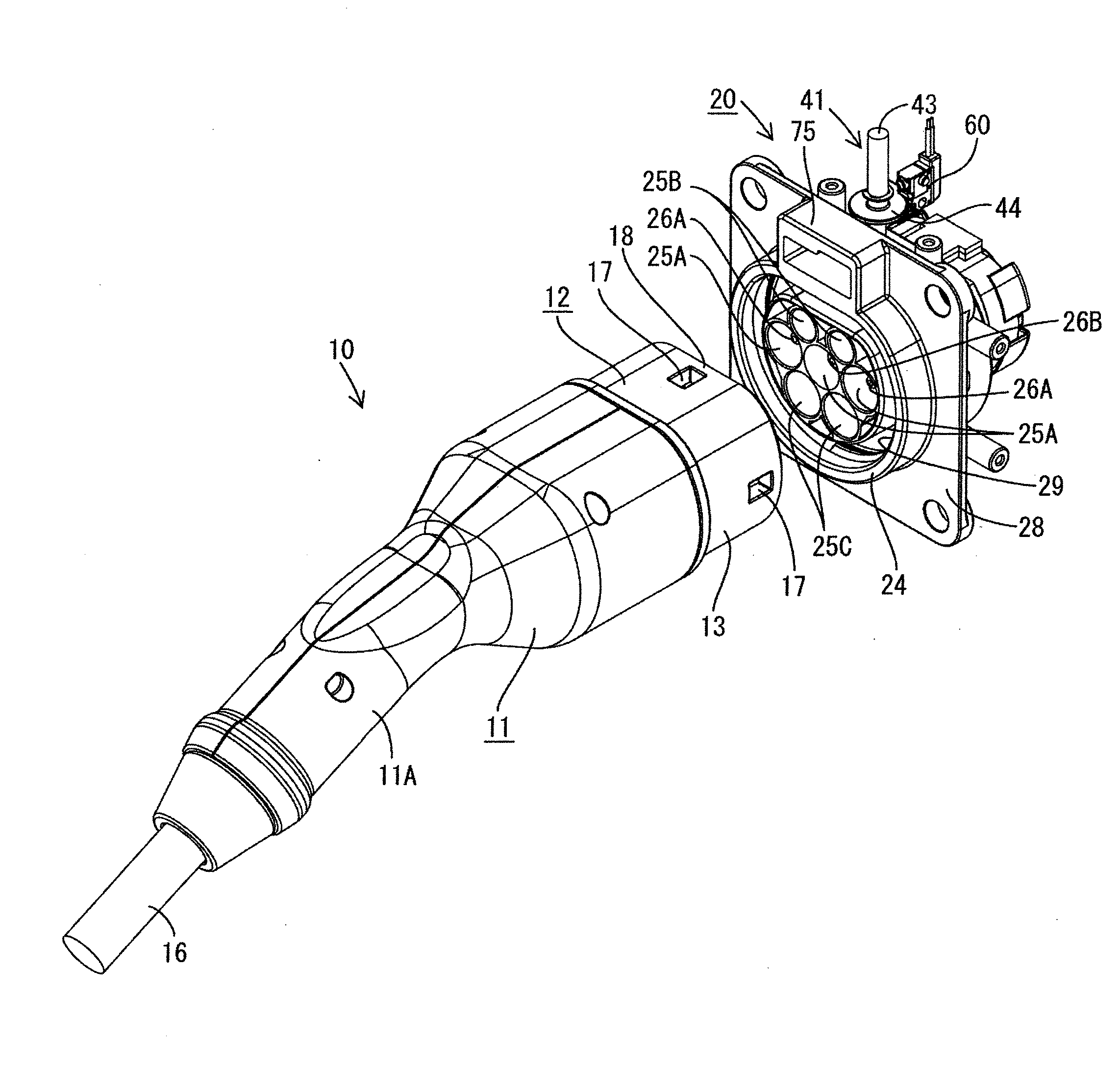

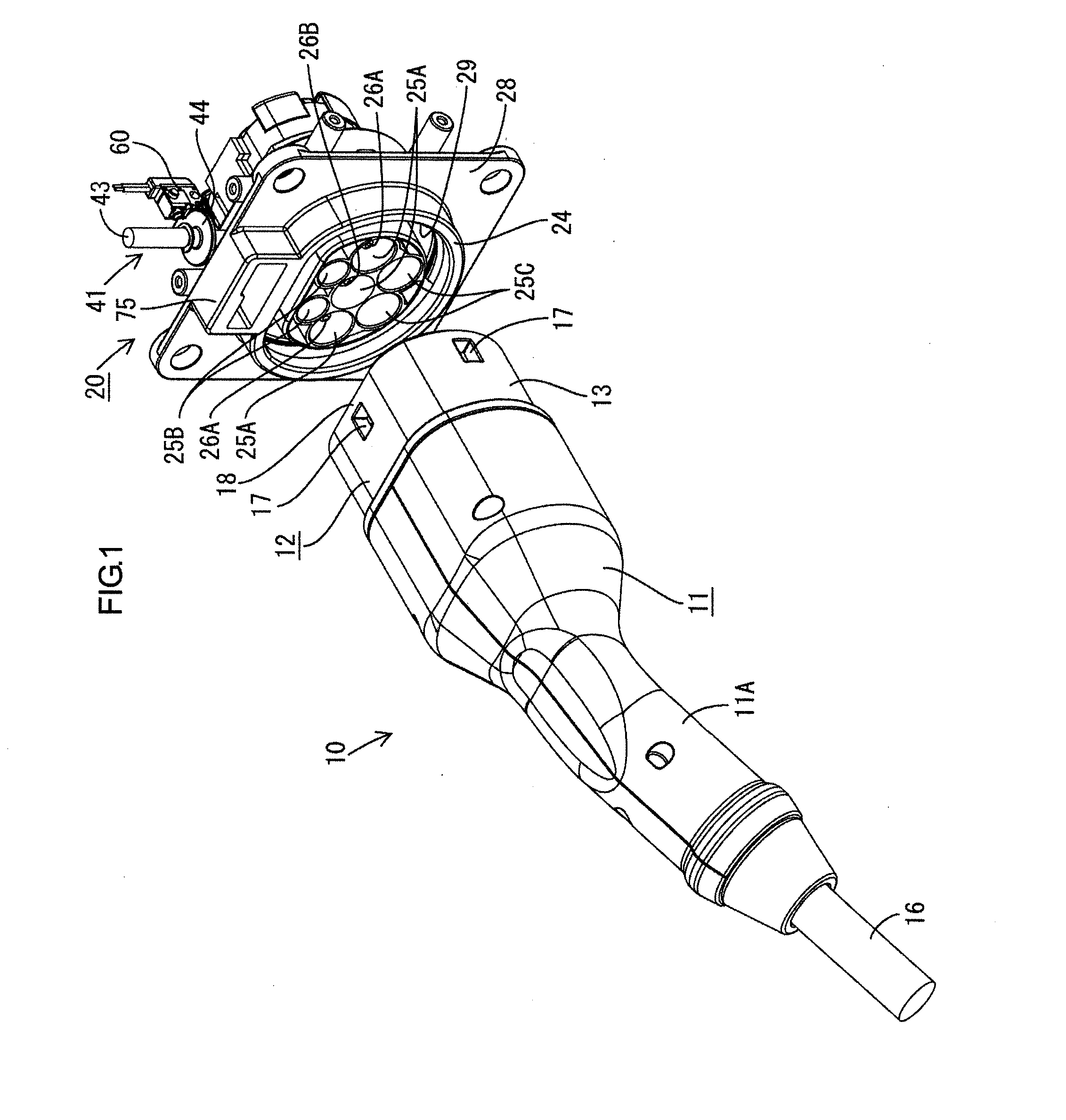

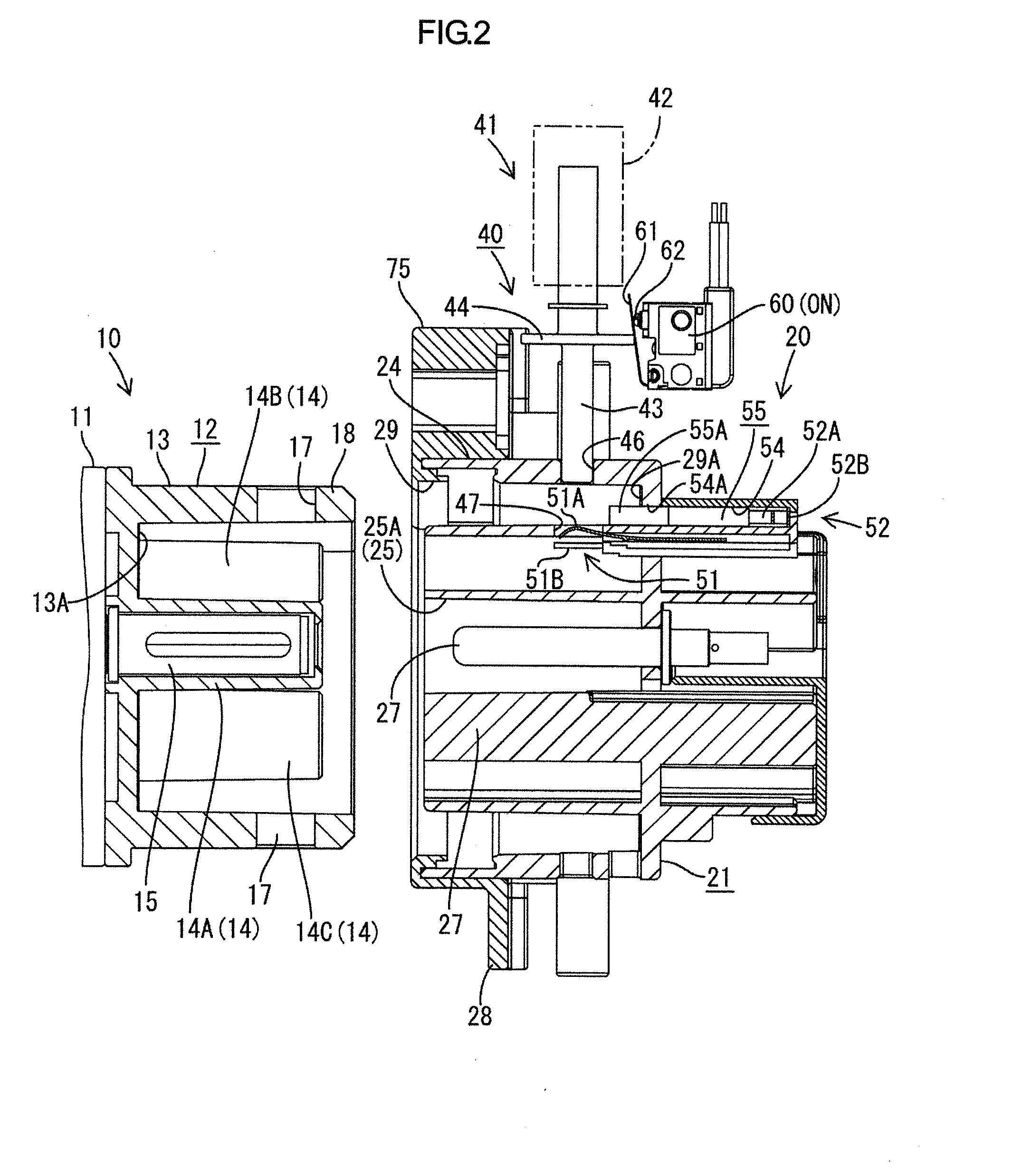

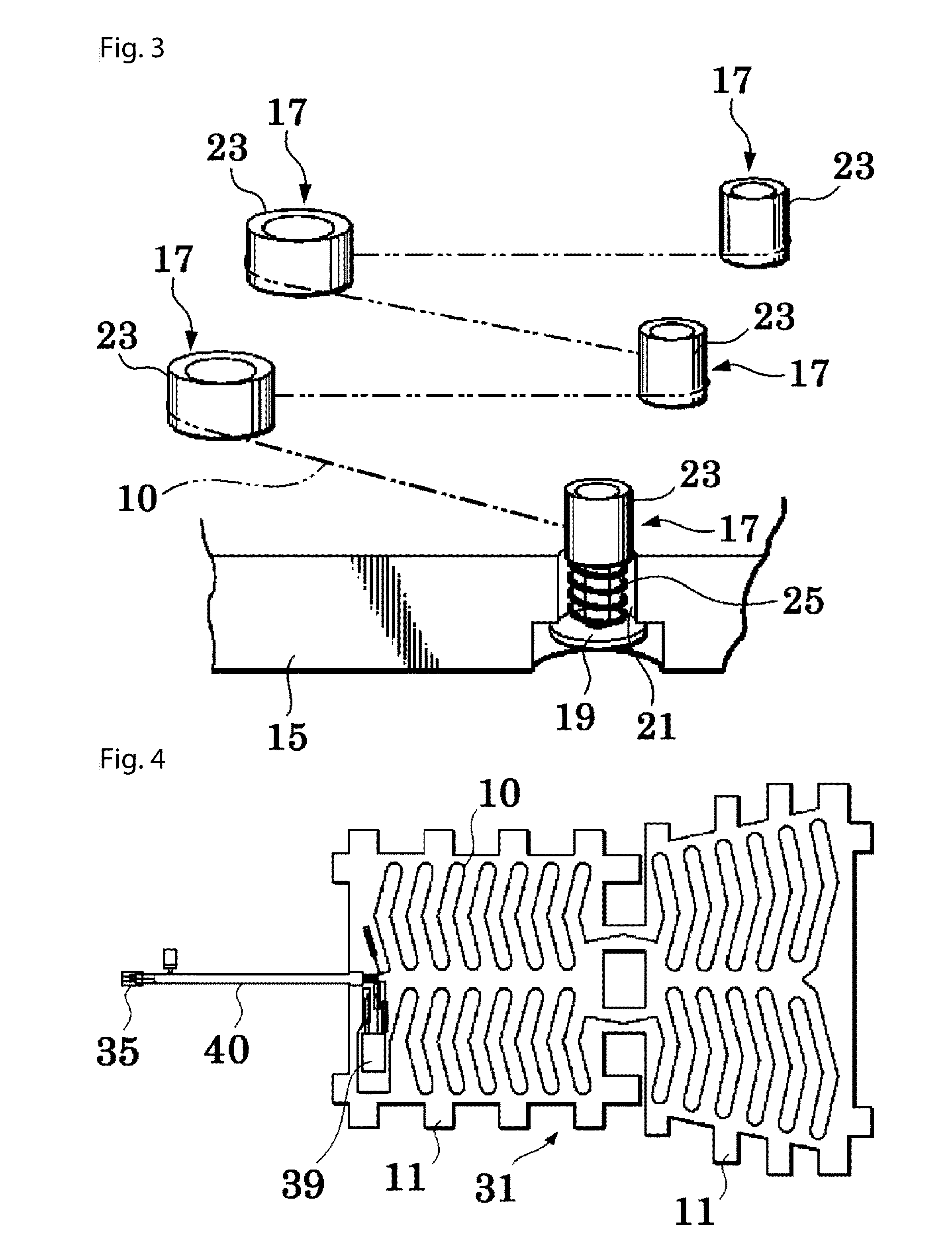

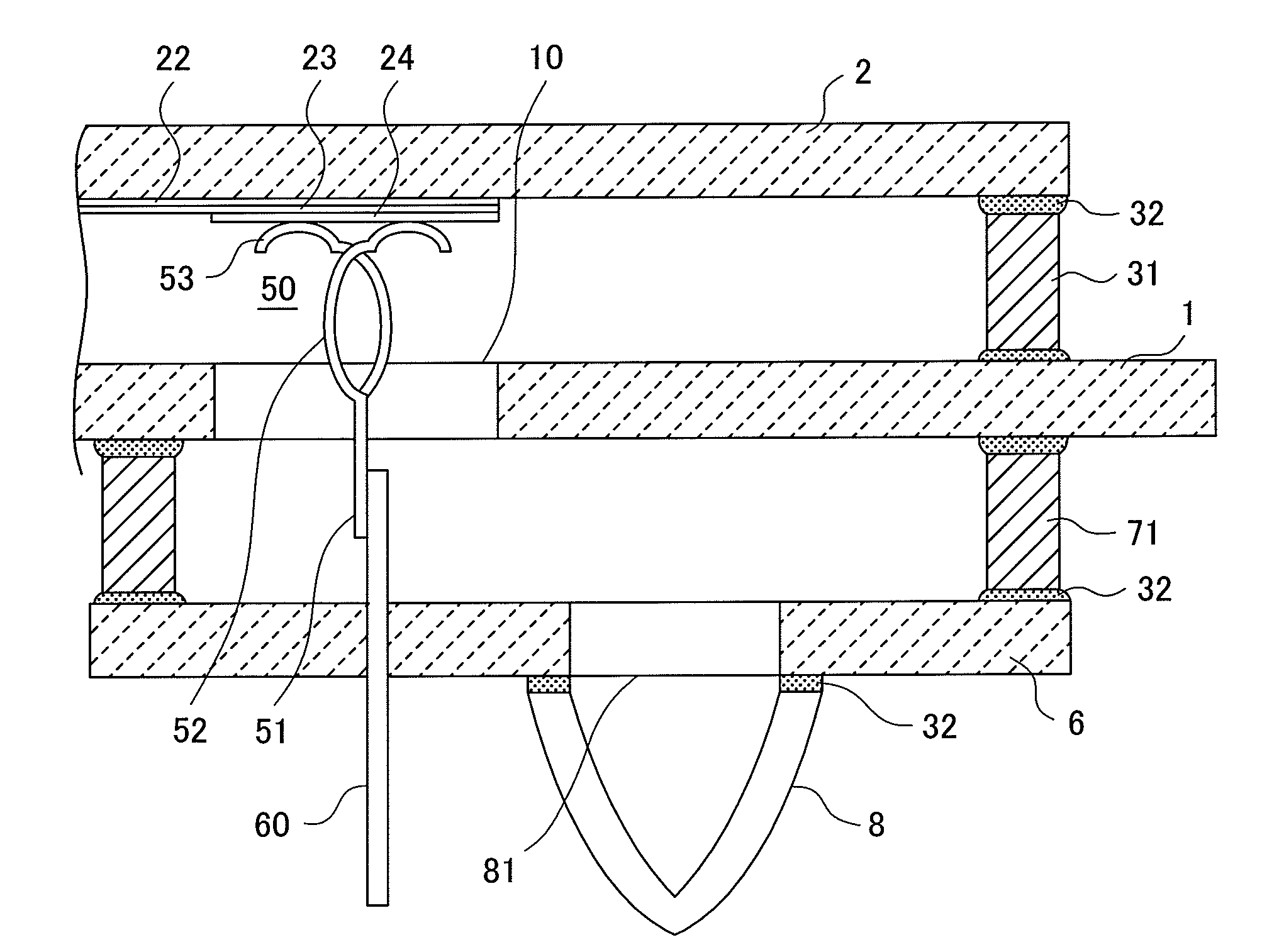

Vehicle charging device

InactiveUS20140285148A1Prevented from being inadvertentlyAvoid sparkingBatteries circuit arrangementsCharging stationsElectrically conductiveActuator

A vehicle charging device configured such that both connectors 10, 20 are locked in a connected state by an advancing movement of a locking portion 43 of an actuator 41 to be locked to a locked portion 18 when the connection of the both connectors 10, 20 is detected by a connection detector 31 includes a locking portion detector 51 for detecting whether or not the locking portion 43 of the actuator 41 has advanced to a predetermined locking position, and a power supply controller 71 for setting a power supply path to an electrically conductive state on a condition that an advancing movement of the locking portion 43 to the predetermined locking position is detected by the locking portion detector 51.

Owner:SUMITOMO WIRING SYST LTD

Power plug

InactiveCN105514690ASolve the problem of not easy to pull outAvoid sparkingCoupling device detailsMechanical engineeringElectric power

Owner:XIAOGAN CITY KAPULONG DAILY NECESSITIES CO LTD

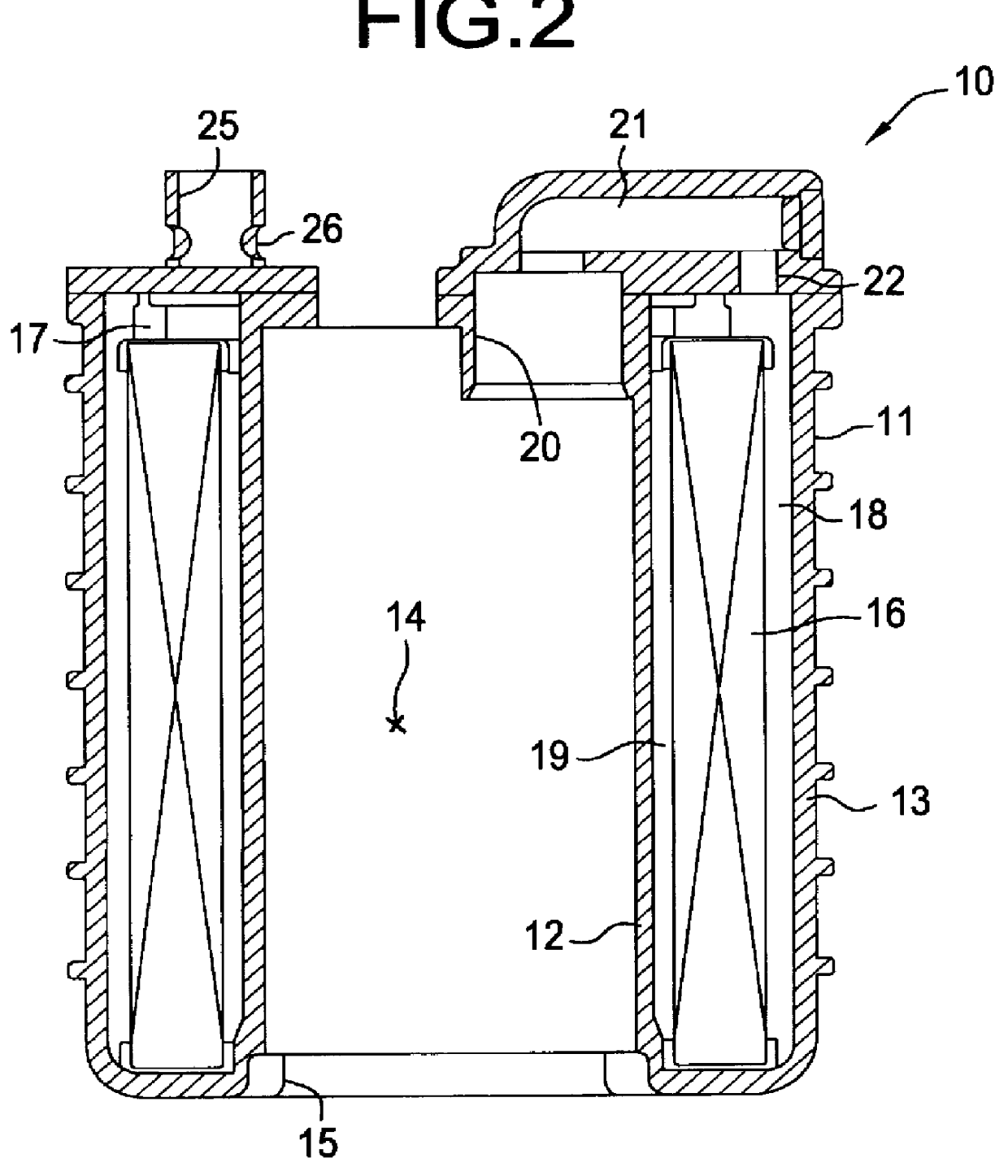

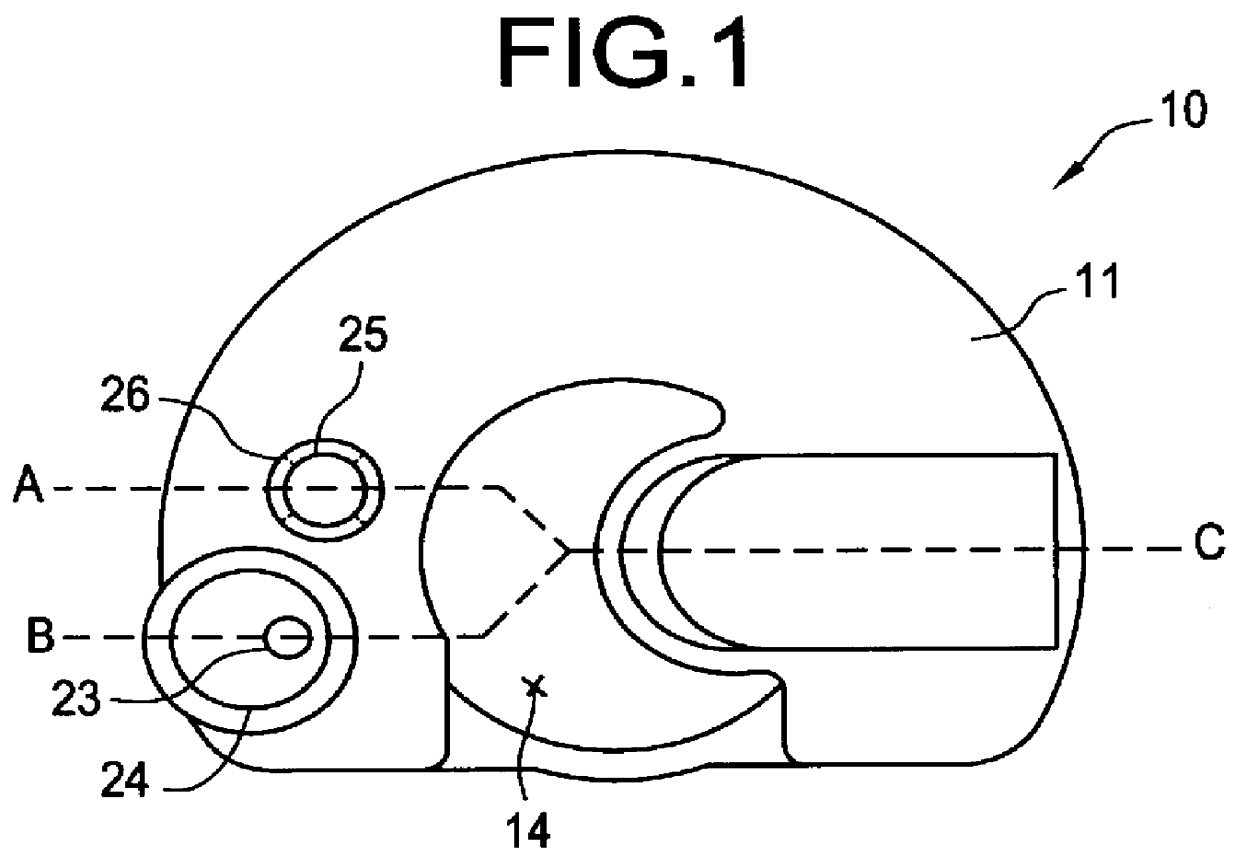

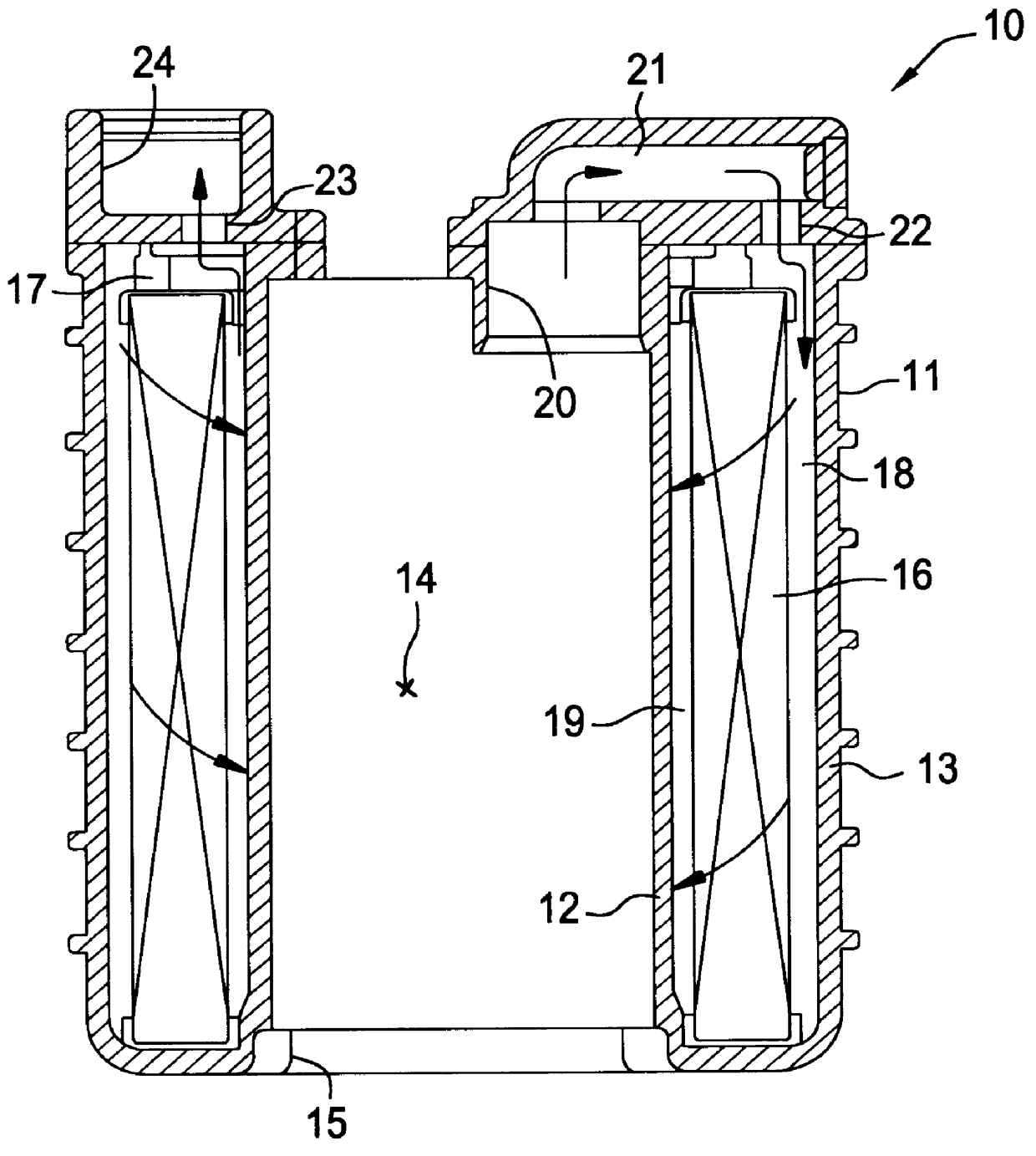

Fuel filter with return path for reducing electrical charge buildup

InactiveUS6156201AAvoid chargingReduce chargePositive displacement pump componentsSettling tanks feed/dischargeNuclear engineeringAcoustic wave

PCT No. PCT / JP97 / 02517 Sec. 371 Date Jul. 25, 1998 Sec. 102(e) Date Feb. 25, 1998 PCT Filed Jul. 22, 1997 PCT Pub. No. WO98 / 03787 PCT Pub. Date Jan. 29, 1998A fuel filter (10) has a filter case (11), and a return path (25) is provided on the upper surface of the filter case (11). Return fuel discharged from a pressure regulator is supplied to the return path (25). The return path (25) having a closed lower end is provided with branch paths (26). The return fuel supplied to the return path (25) passes through the branch paths (26) and flows down into fuel reservoir along the outside peripheral surface of the filter case (11). Electrical charge on the surface of the filter case (11) is reduced when the return fuel flows along the outside peripheral surface of the filter case (11). Kinetic energy of the return fuel is reduced by the energy absorbing effect of the return path (25), the energy distributing effect of the branch paths (26), and the energy absorbing effect when the return fuel flows down along the outside peripheral surface of the filter case. Thus, fuel return sound waves from the returning fuel dropping into the fuel reservoir are reduced.

Owner:AISAN IND CO LTD

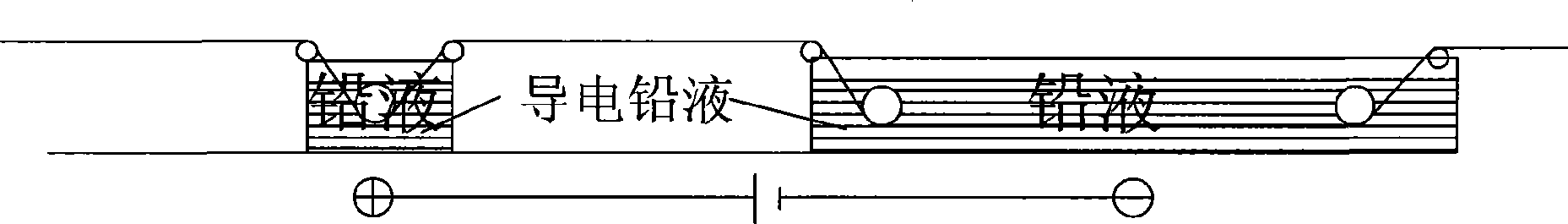

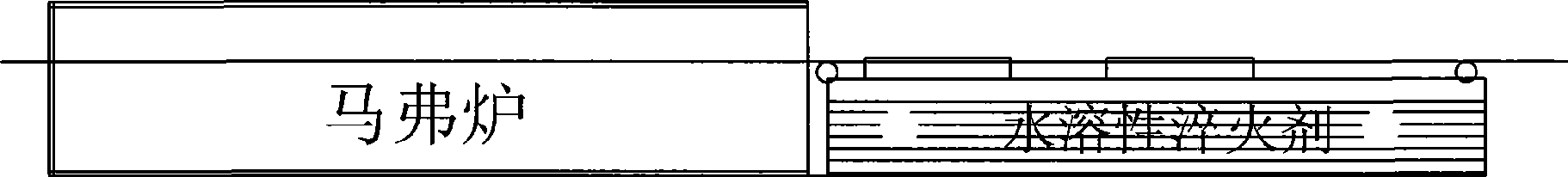

Power-on water-bath steel wire quenching heat treatment method

InactiveCN101503751AQuenching achievedHigh cost of heat treatmentFurnace typesQuenching agentsWater bathsSocial benefits

The invention relates to a method for quenching heat treatment of a steel wire in a power-on water bath, which can effectively solve the problems of high cost of heat treatment of the steel wire, fire striking phenomenon between the steel wire and conductive rollers, generation of martensite when the steel wire passes through a water bath tank at low speed, and poor insulativity of equipment and a pipeline. The invention adopts a technical proposal that the steel wire is tensioned by a tensioning device, passes through an insulation protection sleeve after tensioning, is compacted by an insulated tension roller, passes through a first conductive roller, horizontally passes through a refractory heat-insulated sleeve, passes through a parallel insulated carrier roller which is on the same plane with the first conductive roller, is compacted by a second conductive roller and sprayed by a cold water pipe, enters two upper tanks which are arranged on the water bath tank and communicated with the water bath tank, passes through the two upper tanks, and is quickly cooled, and quenching of the steel wire is realized. The invention has simple equipment, scientific and advanced method, low cost and non environmental pollution, effectively solves the problems of the fire striking phenomenon between the steel wire and the conductive rollers, generation of the martensite when the steel wire passes through the water bath tank at low speed, and poor insulativity of the equipment and the pipeline, and has significant economic benefit and social benefit.

Owner:张国宝

Immersion-liquid-type battery compartment temperature control system

ActiveCN105762437ATemperature controlUniform temperatureSecondary cellsTemperature controlControl system

The present invention relates to an immersion-liquid-type battery compartment temperature control system comprising an immersion-liquid-type battery compartment; a first cooling pipe; a second cooling pipe; a third cooling pipe; a temperature sensor which is disposed on the battery pack side of the immersion-liquid-type battery compartment and is used for detecting battery pack temperature; and a temperature control unit which receives battery pack temperature signals sent by the temperature sensor to control startup and shutdown of a first cooling loop, a second cooling loop, a third cooling loop or a heating device. The immersion-liquid-type battery compartment temperature control system has excellent temperature control and temperature balancing capability.

Owner:CH AUTO TECH CORP CO LTD

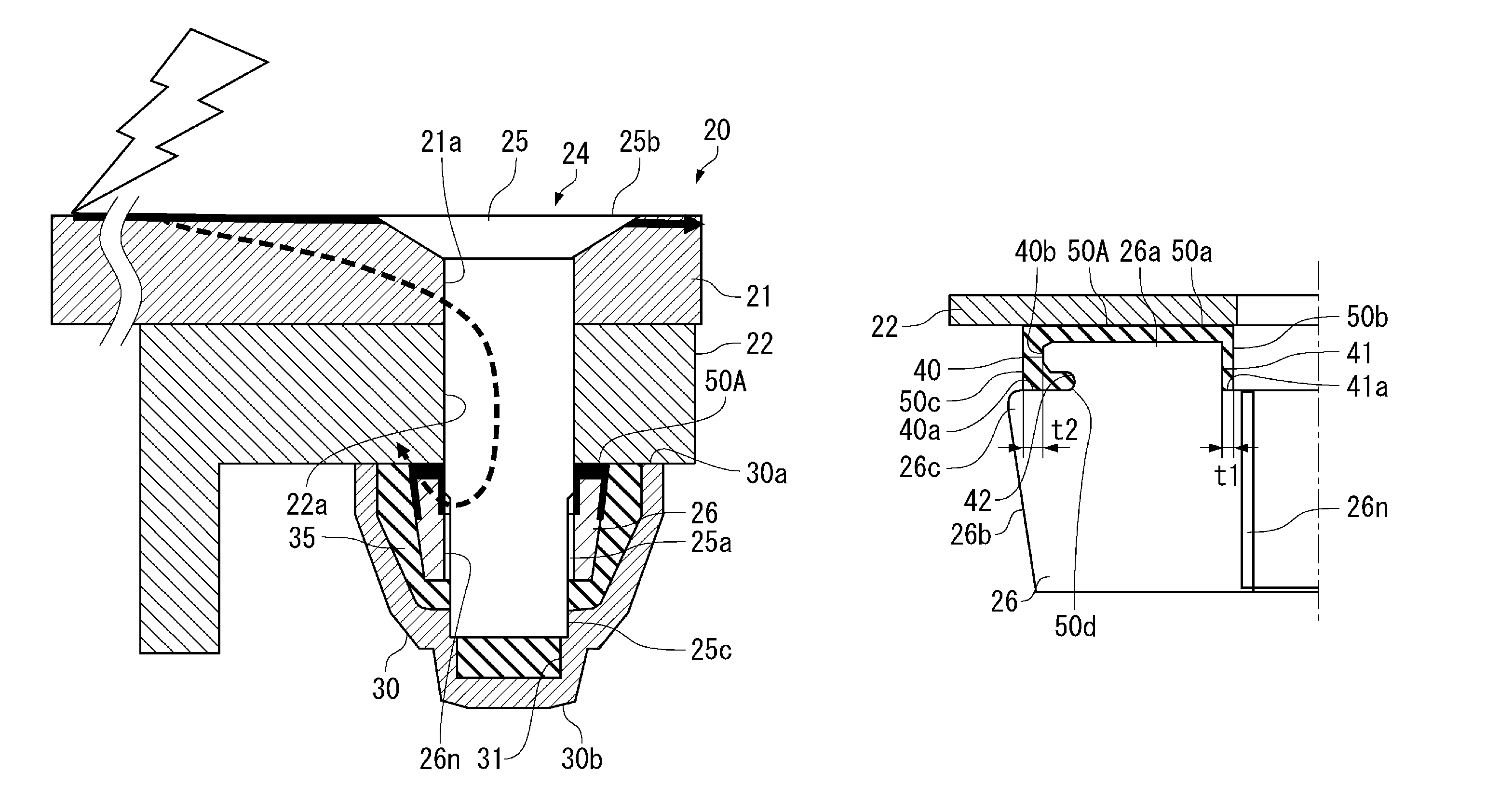

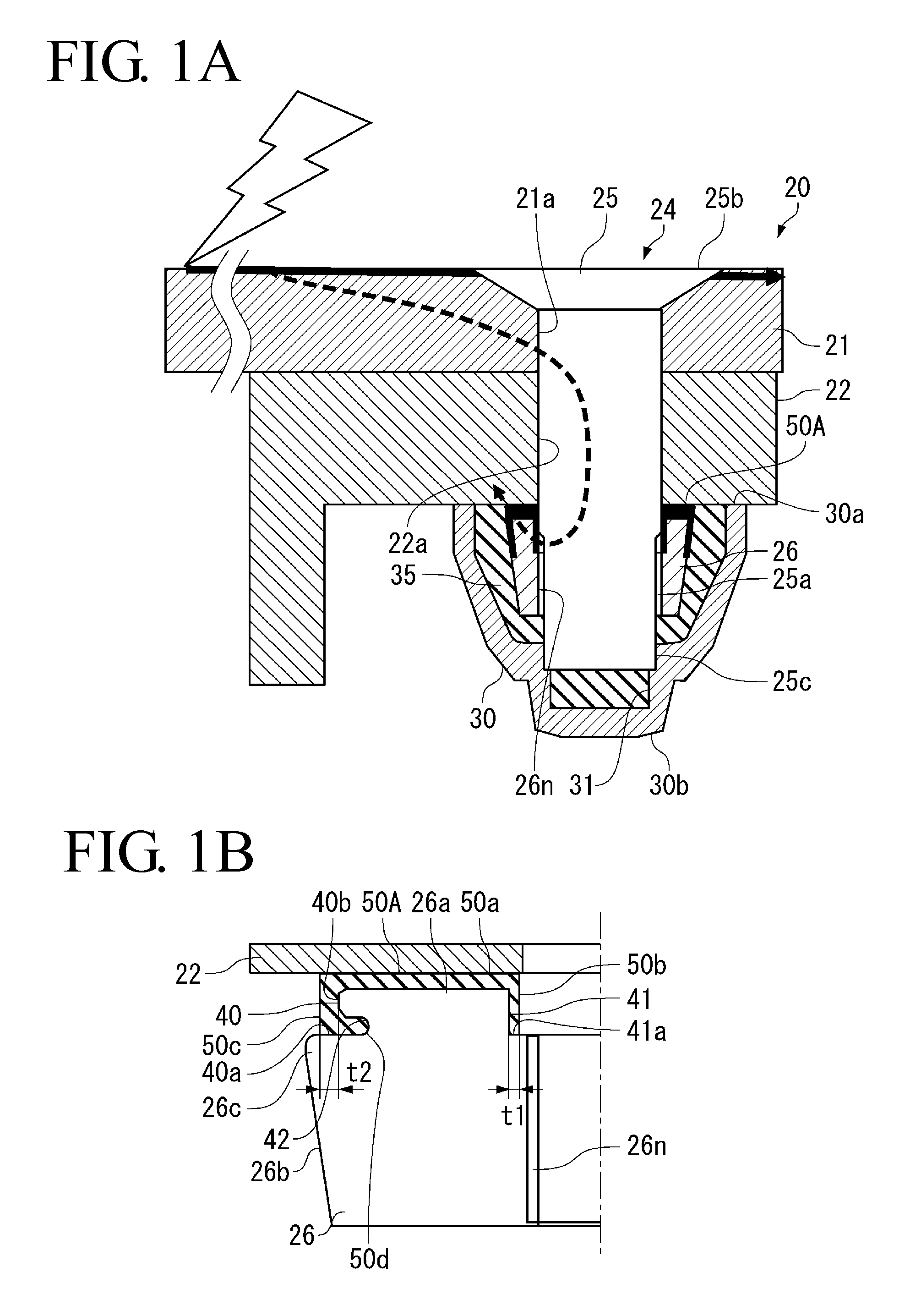

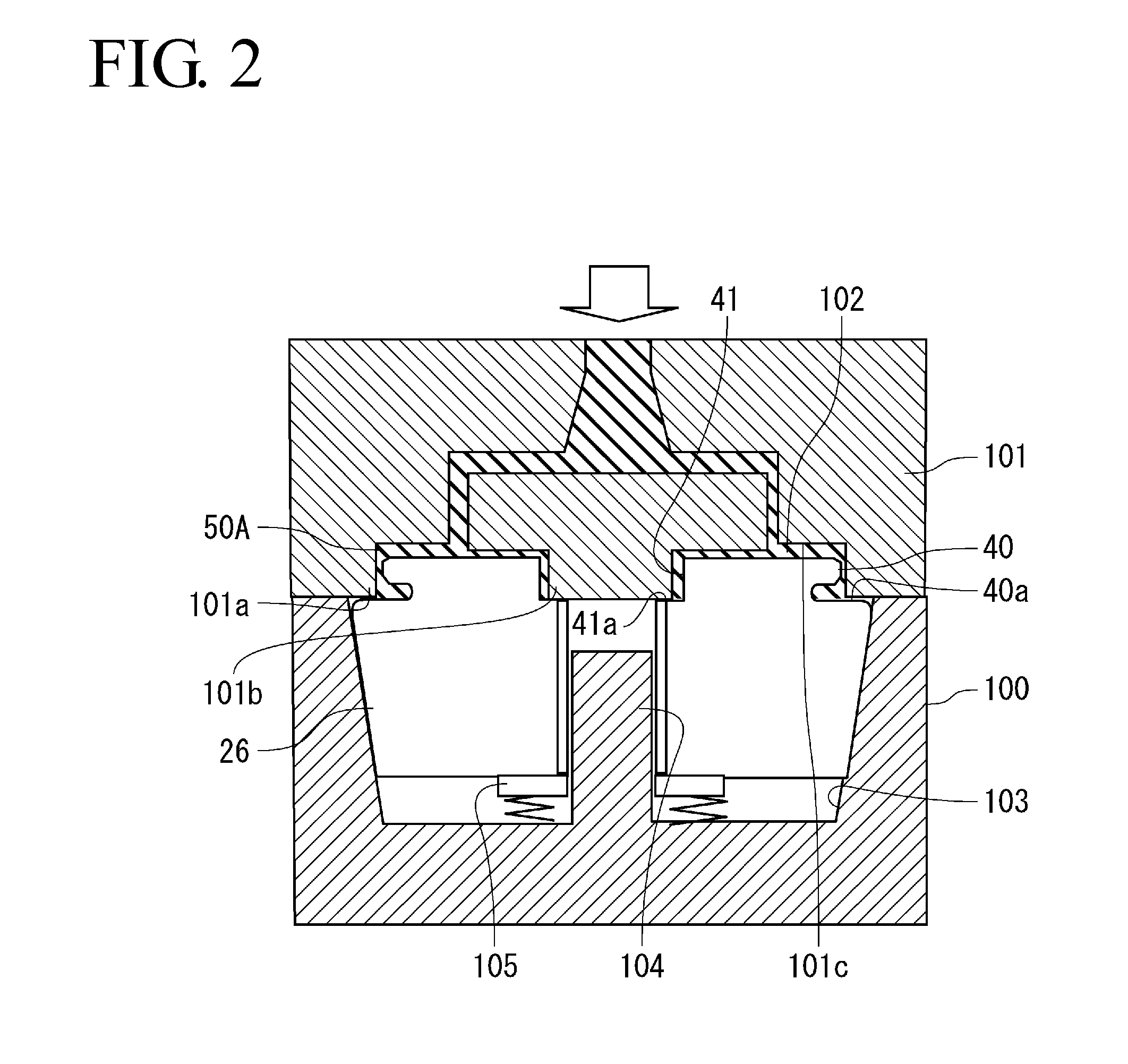

Lightning-protective explosion-preventive fastener

ActiveUS8711541B2Sufficient effectImprove job stabilityAircraft lighting protectorsAircraft static dischargersBiomedical engineeringFastener

In an insulating cover 50A according to the present invention, a dimension of each of an outer-circumferential-side cylindrical part 50c and an inner-circumferential-side cylindrical part 50b fitting in step parts 40 and 41 in an axial direction of a fastener body 25 is set large with respect to a tip covering part 50a covering a tip surface 26a of a fastening member 26. As a result, on an outer circumferential side and an inner circumferential side of the fastening member 26, a distance from a member 22 is sufficiently ensured by the cylindrical part 50b and 50c. The tip covering part 50a is thinner than the cylindrical part 50B and 50c. Therefore, when the fastener body 25 and the fastening member 26 are fastened together, the amount of deformation of the tip covering part 50a in a thickness direction can be made small.

Owner:MITSUBISHI AIRCRAFT

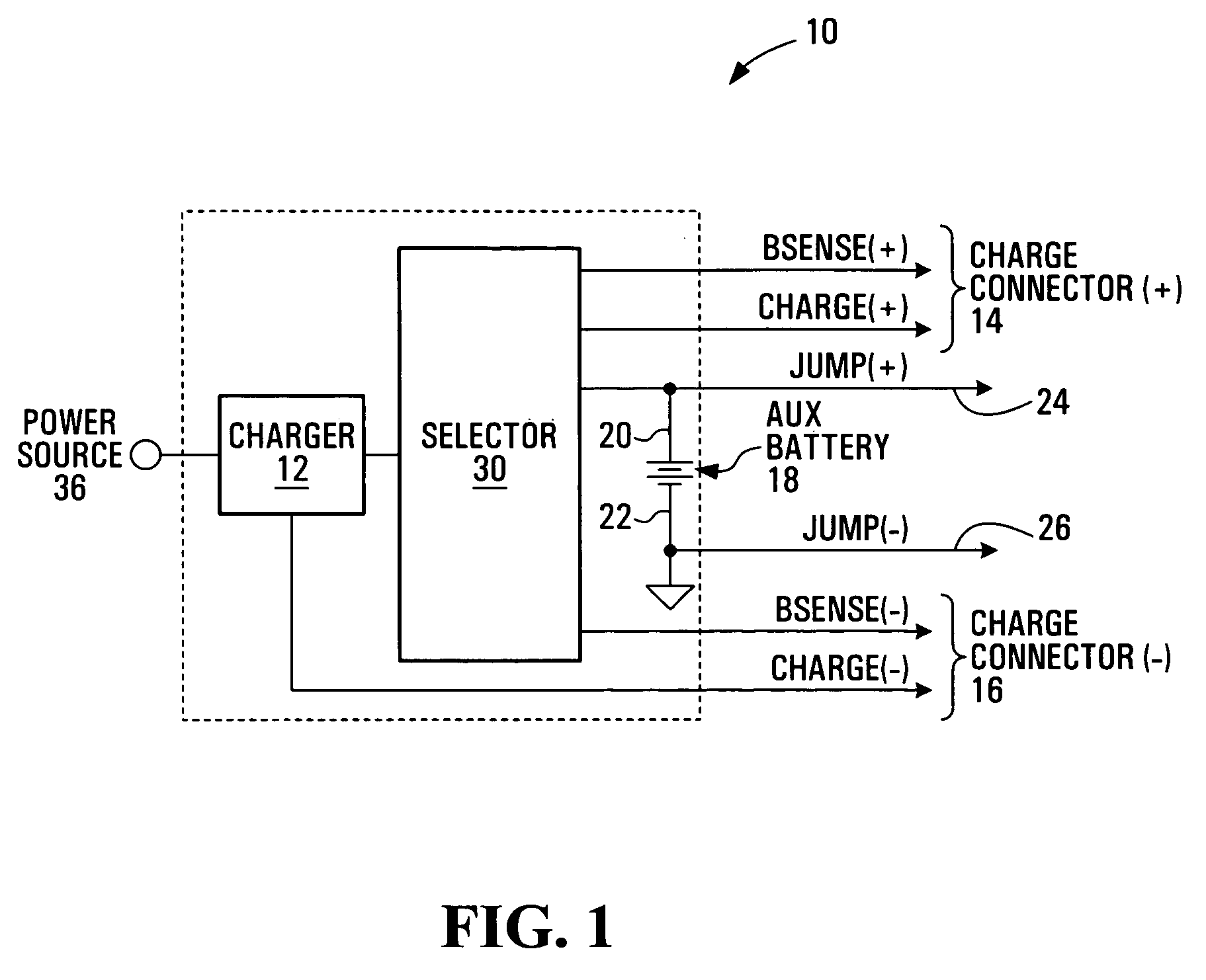

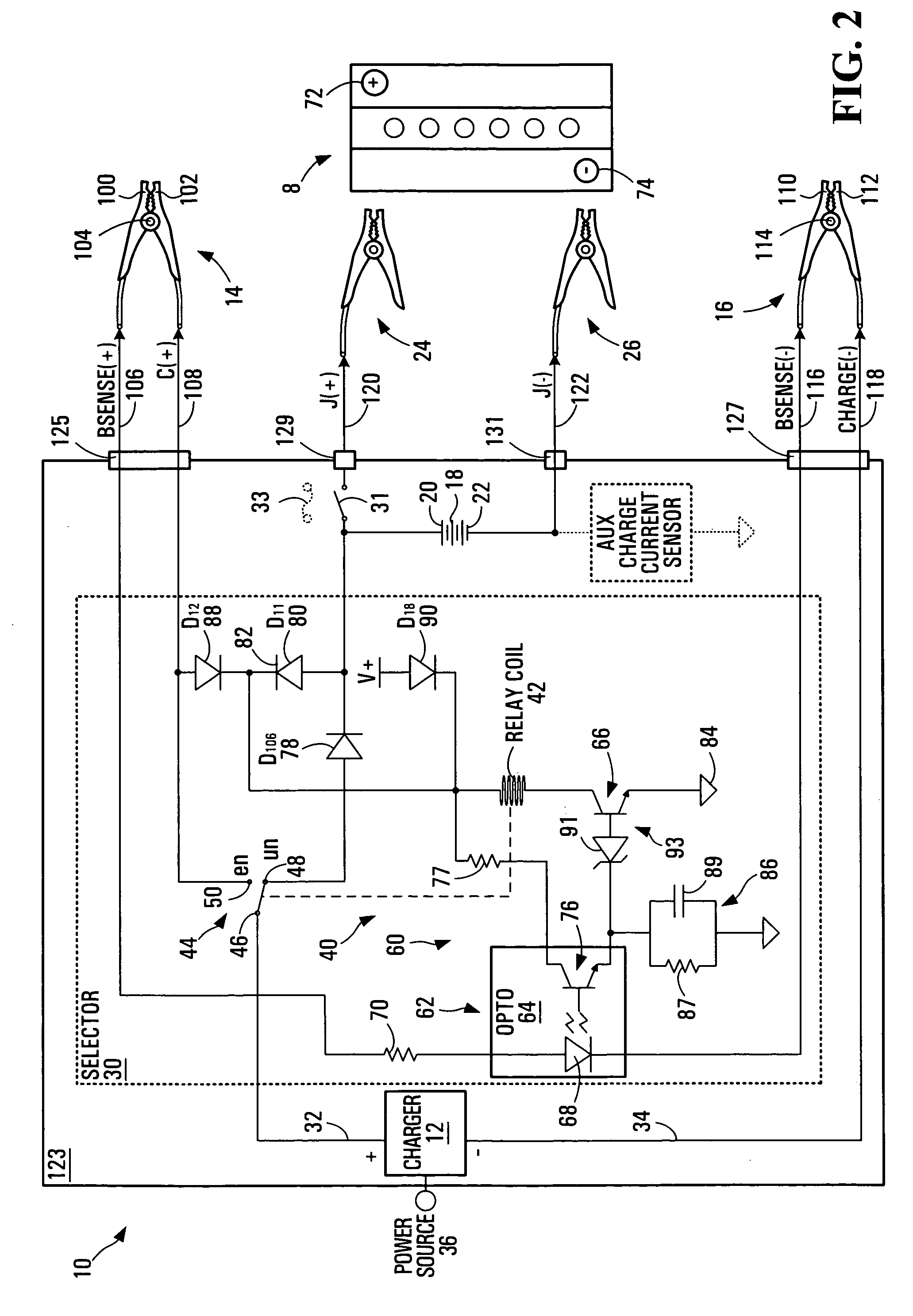

Charger/jumper method and apparatus

ActiveUS20060071631A1Avoid sparkingExtra delayDc network circuit arrangementsElectric powerEngineeringElectrical and Electronics engineering

An apparatus for jumping and charging a remote battery. The apparatus includes a charger, positive and negative charge connectors operable to be connected to the remote battery, an auxiliary battery having positive and negative terminals, and positive and negative jumper connectors separate from the positive and negative charge connectors. The positive and negative jumper connectors are connected to the positive and negative terminals of the auxiliary battery and are operable to be connected to the remote battery. The apparatus further includes a selector responsive to connecting the positive and negative charge connectors to the remote battery and operable to connect the charger to the auxiliary battery when the charge connectors are not connected to the remote battery and to connect the charger to the positive and negative charge connectors to charge the remote battery when the positive and negative charge connectors are connected to the remote battery.

Owner:XANTREX LLC

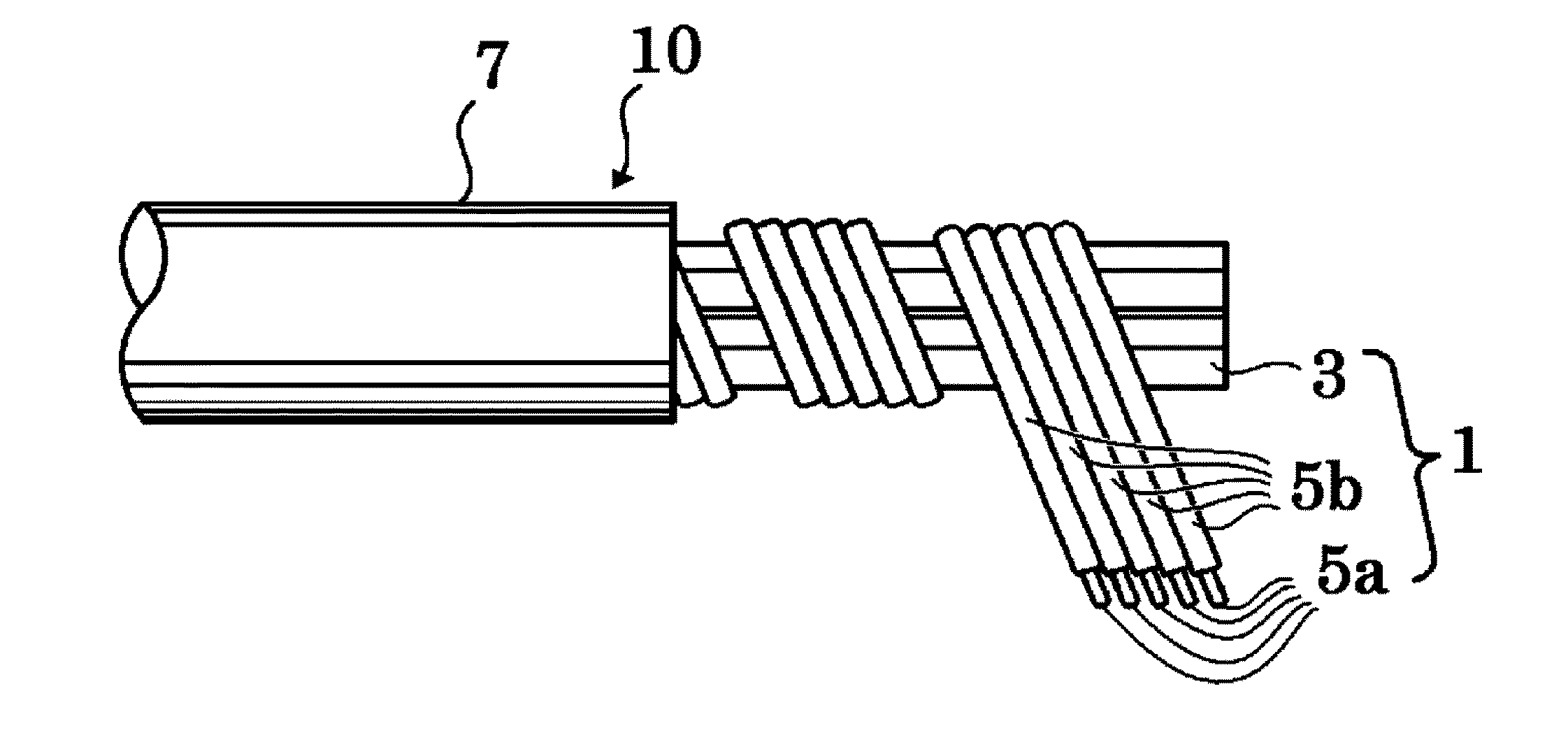

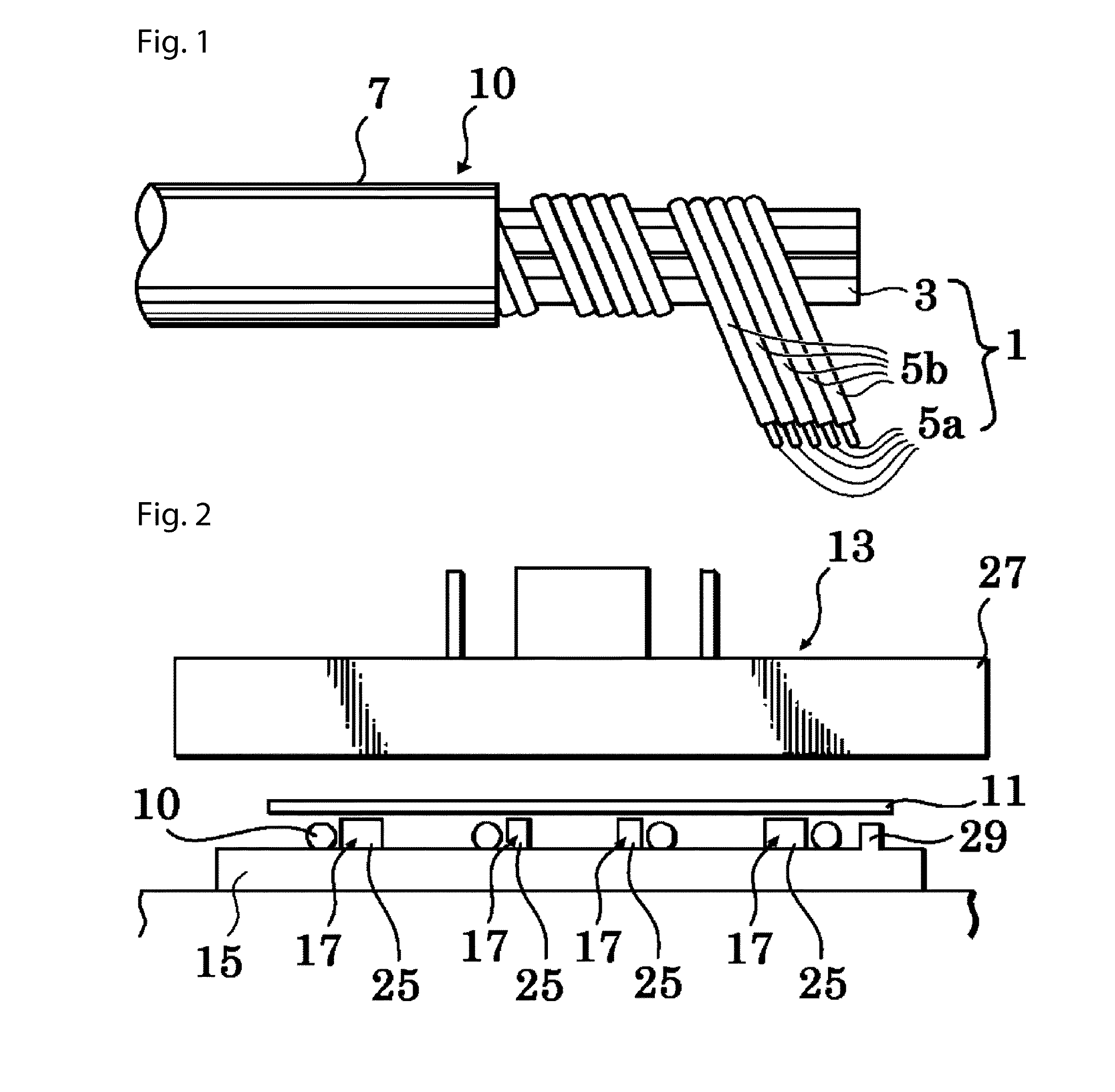

Cord-shaped heater and sheet-shaped heater

ActiveUS20150257205A1Improve heat resistanceExcellent incombustibilityOhmic-resistance heating detailsHeating element shapesEngineeringElectrical and Electronics engineering

A cord-shaped heater 10 has a plurality of conductive wires 5a that are covered with an insulating film 5b. The insulating film 5b includes a silicone resin. A quantity of the silicone resin included in the insulating film 5b is 40 to 80% by a weight ratio. The conductive wires 5a are wound around a core material 3 in a state of being paralleled together. An insulation body layer 7 is formed on an outer periphery of the conductive wires. A part or all of the insulation body layer 7 is formed of a heat-fusing material. A sheet-shaped heater 31 is wherein the cord-shaped heater 10 is arranged on a substrate 11.

Owner:KURABE IND CO LTD

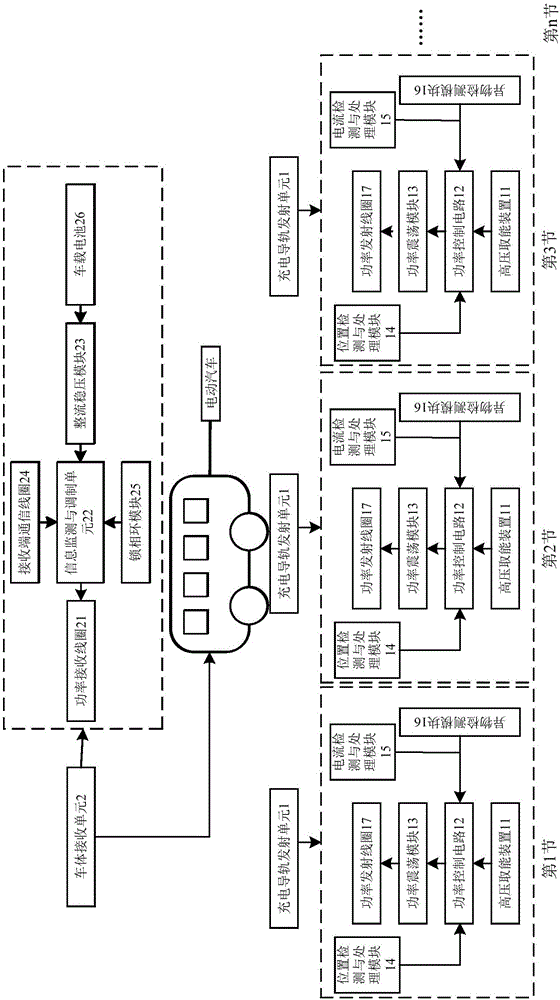

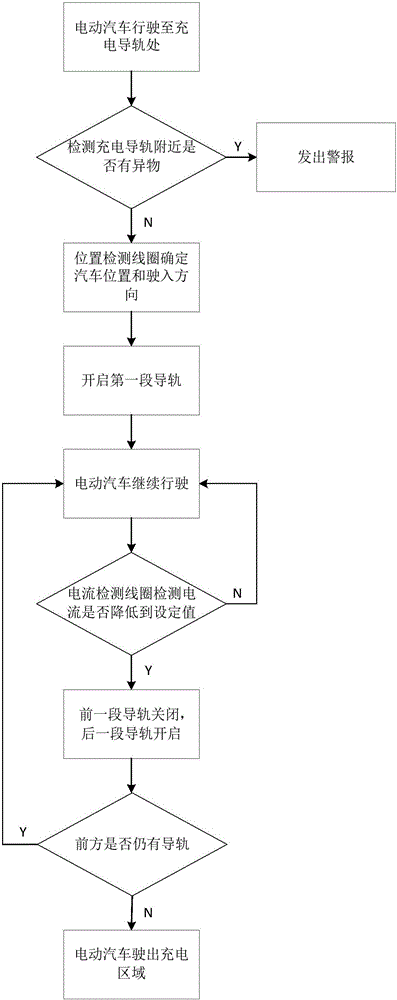

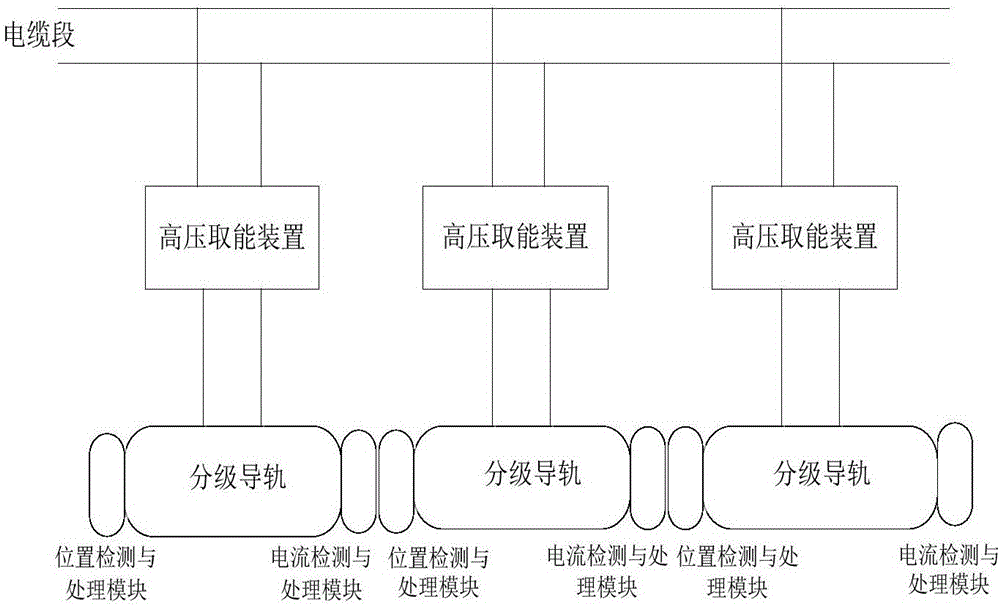

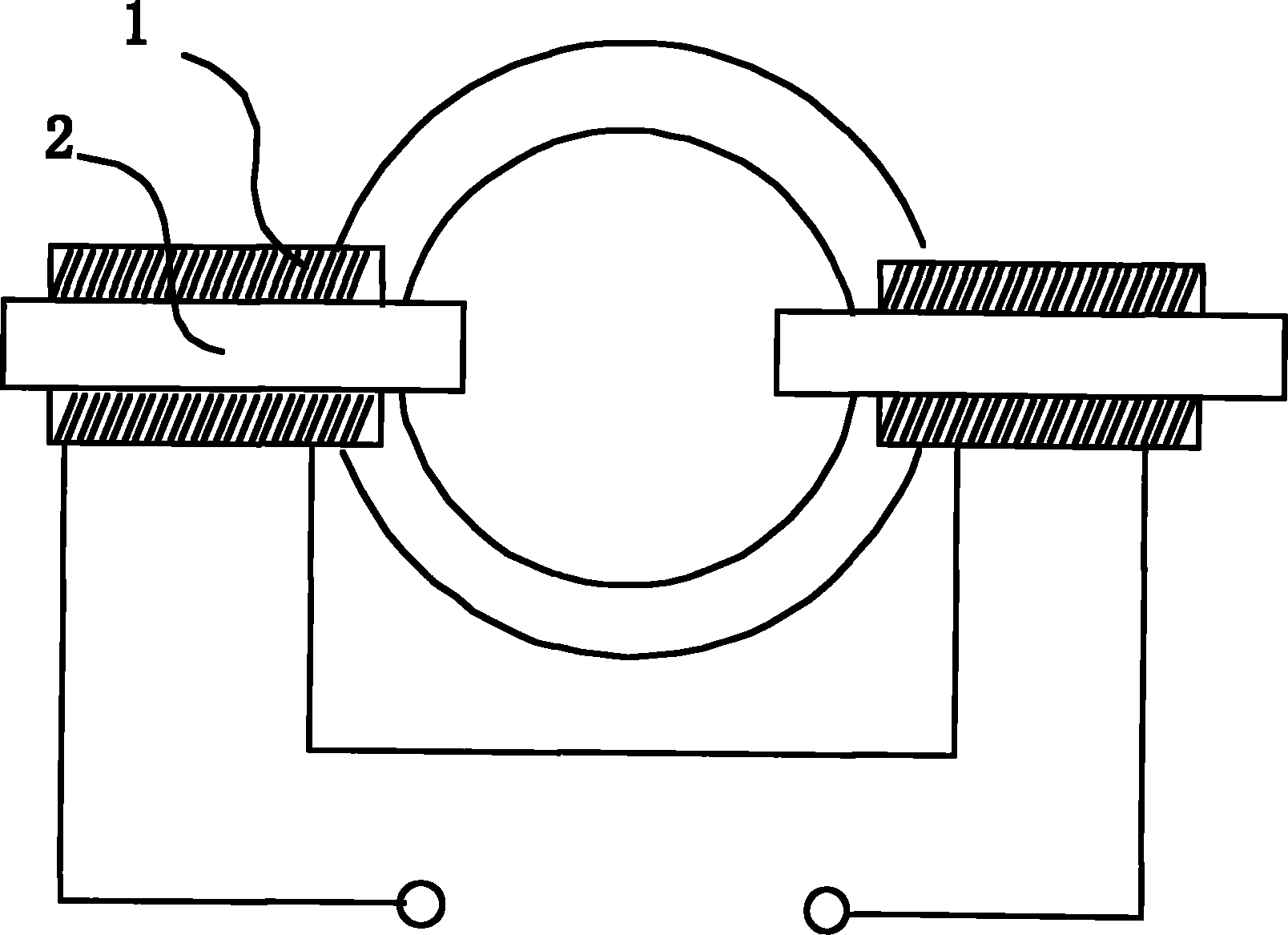

Electric vehicle dynamic multistage wireless charging system

ActiveCN106787249AReduce contact lossReduce mechanical wearBatteries circuit arrangementsCharging stationsEngineeringRoad surface

The invention relates to electric vehicle wireless charging technique, in particular to an electric vehicle dynamic multistage wireless charging system, comprising: an electric vehicle and cable segment including graded guide rails 1 to n connected in sequence, with n being a positive integer; charging guide rail transmitting units and a vehicle body receiving unit. One charging guide rail transmitting unit is built in each graded guide rail; the vehicle body receiving unit is mounted on an electric vehicle. The electric vehicle dynamic multistage wireless charging system is convenient to use, runs reliably, is low in maintenance cost and is good in safety and high in efficiency; through a power supply guide rail buried underground and a high voltage energy-acquiring device that acquires energy from an underground cable, an electric vehicle can be charged conveniently and efficiently with no need for parking and using road surface; working frequency of an LC (inductor-capacitor) oscillating circuit is designed to correspond to a maximum working point of transmitted powder; the guide rail is in graded design, so that the graded guide rails supply power in different periods of time, and power supply efficiency is improved; through frequency self-tracing, a transmitter and a receiver operate constantly in resonant state, and working efficiency is high.

Owner:武汉珞森源科技有限公司

A circulating crude oil storage tank oil gas vacuum adsorption recovery system

ActiveCN102295118AEasy to monitor remotelyIncrease contact areaDispersed particle separationLarge containersExhaust gasProcess engineering

The invention provides a circulating type oil-gas vacuum adsorption and recovery system comprising a crude-oil storage tank, comprising the crude-oil storage tank, a vacuum desulfurization device, an adsorption tank, a vacuum pump, an absorbent treating device and an absorption tower, wherein the absorbent treating device treats crude oil pumped from the crude-oil storage tank into lean gasoline;volatile oil gas of the crude-oil storage tank enters the vacuum desulfurization device and then enters the adsorption tank for adsorption and recovery after desorption and desulfurization; standard air is exhausted into atmosphere from the upper end of the adsorption tank, and nonstandard tail gas reenters the adsorption tank for circulating adsorption and recovery; the vacuum pump is used for carrying out vacuum desorption and regeneration on the adsorption tank with saturated adsorption; and desorbed high-concentration oil gas enters the absorption tower, and is absorbed by the lean gasoline body from the absorbent treating device, and the rich gasoline after absorption returns to the crude-oil storage tank. The circulating type oil-gas vacuum adsorption and recovery system is convenient and simple, volatile oil gas is absorbed and recovered by fully utilizing the self characteristic of the crude oil, additional equipment and resources do not need to be added, and the secondary pollution is not caused as well.

Owner:BAY ENVIRONMENTAL TECH BEIJING

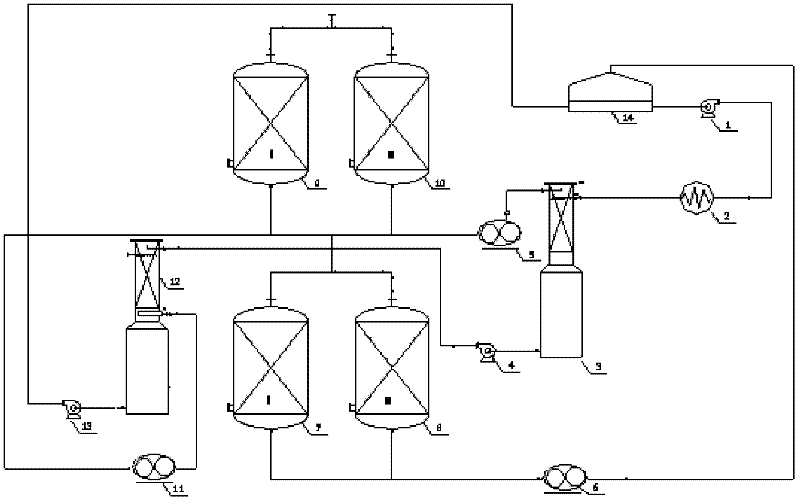

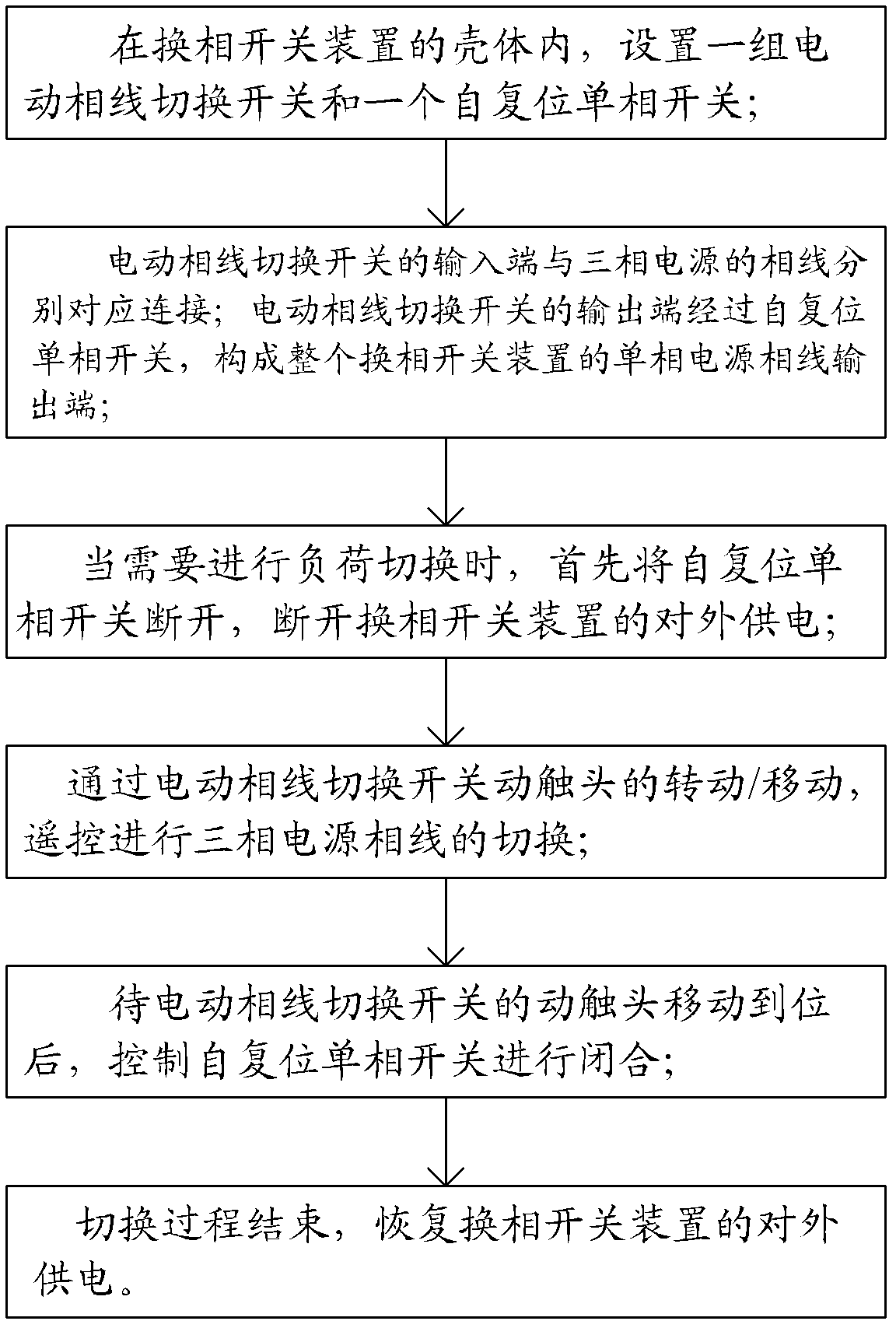

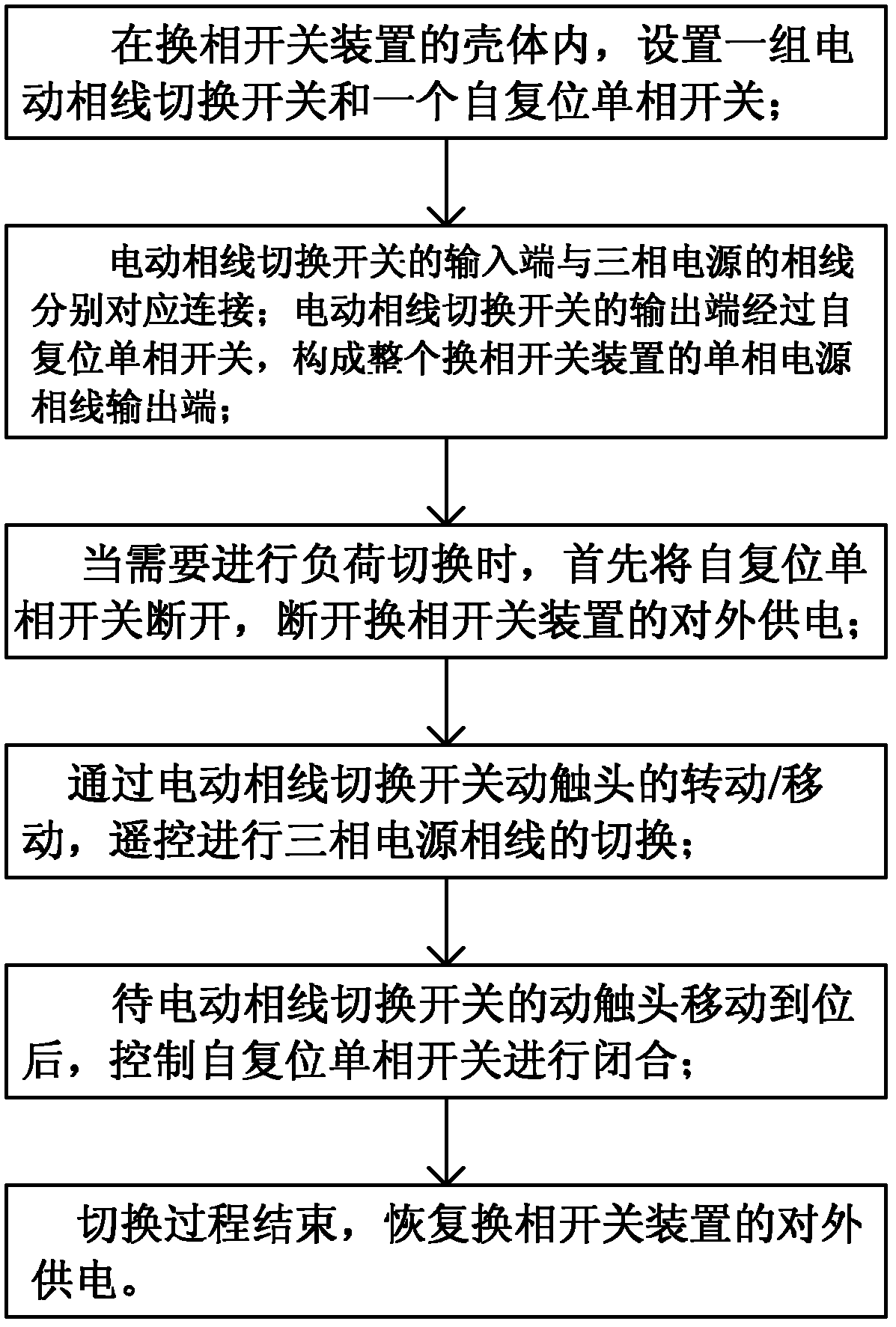

Method for switching phase lines of three-phase circuit and capable of preventing inter-phase short-circuit and phase change switch device

InactiveCN102522760AAvoid short circuit conditionsAvoid sparkingPolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionLow voltagePower grid

The invention relates to a method for switching the phase lines of a three-phase circuit and capable of preventing inter-phase short-circuit and a phase change switch device, which belong to the field of transformation and distribution devices. A phase line switch and a self-resetting single-phase switch are arranged in the shell body of the phase change switch; when load switching needs to be carried out, first the self-resetting single-phase switch is controlled to be off, and the external power supply of the phase change switch device is cut off; then the moving contact of an electric rotation switch is rotated and a 'one-from-three' rotation switch method is adopted, so that the phase sequence of the phase line input end of a single-phase power supply is switched to specified phase lines; and finally the self-resetting single-phase switch to be on, and the external power supply of the phase change switch device is recovered. Because the 'one-from-more' rotation switch method is adopted, the connection with a load end is cut off when in switching, the phenomenon that two phase lines are short-circuited when the phase change switch fails to work is thoroughly overcome, the whole switching process is safe and reliable, and the safety of power supply is improved. The invention can be widely applied to the field of low-voltage power supply and the operation of power grids.

Owner:山东卓尔电气有限公司

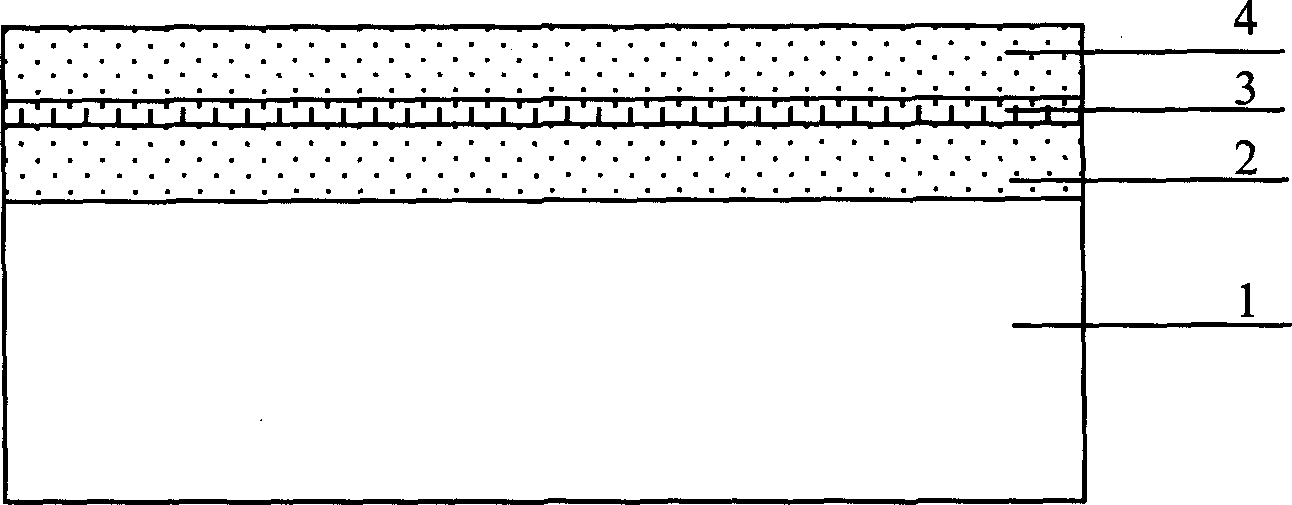

ITo coated plate and its preparing method

InactiveCN1709689APrevent crystallizationEliminate accumulationGlass/slag layered productsAlloyGrain growth

The invention discloses s one kind of ITO board with film-plate, it not only includes base board and the first deposited ITO film on it, also includes alloy film and the secondary ITO film, the alloy film is on the primacy film, and the secondary ITO film is on the surface of alloy film. This invention also unfurls the preparation method of this kind of ITO board with film-plate. The beneficial effect of this invention is that if this ITO / alloy / ITO layers is used, we can get low electric resistance using the electrical conductivity. Because the ITO film include two films when it deposit, it can avoid the growth of the crystal or pole fabric, and pledge to receive low degree of roughness.

Owner:深圳豪威显示科技有限公司

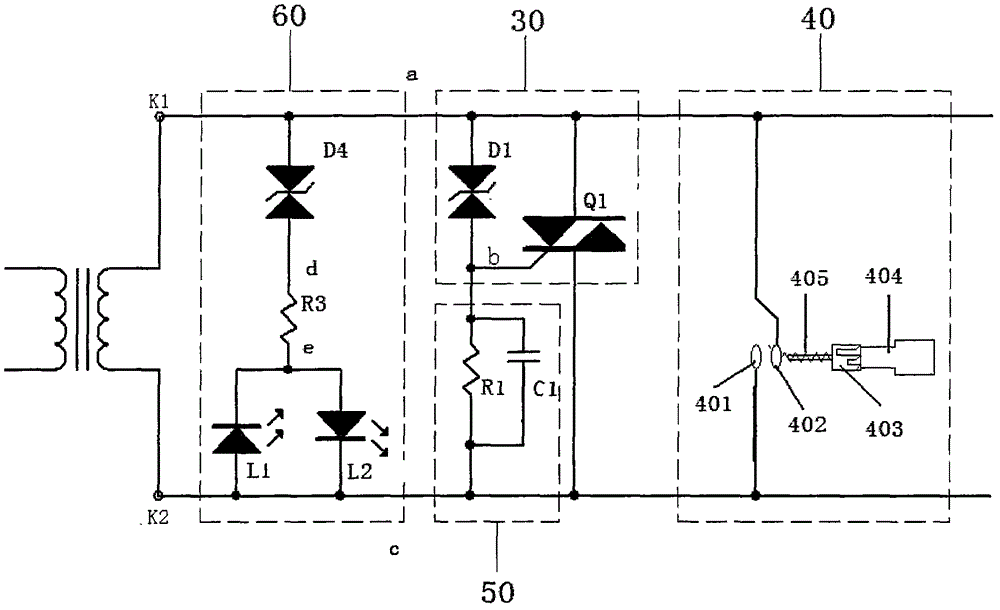

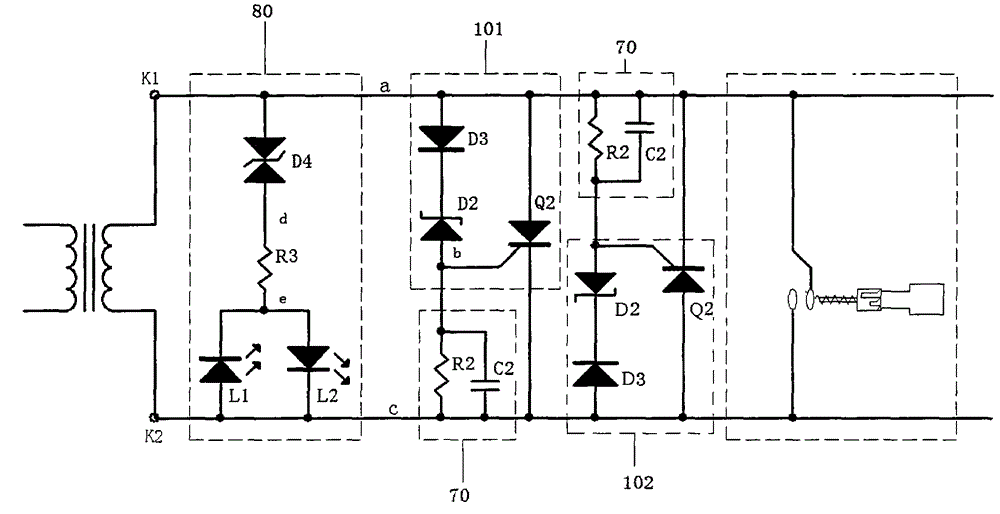

Open circuit protective circuit for secondary side output circuit of current transformer

ActiveCN104577982AEnsure safetyElectric shock preventionEmergency protective circuit arrangementsOvervoltageThyratron

The invention discloses an open circuit protective circuit for a secondary side output circuit of a current transformer, and belongs to the technical field of overvoltage protection circuits. The open circuit protective circuit for the secondary side output circuit of the current transformer comprises an automatic protective circuit and a manual protective mechanism, wherein the automatic protective circuit and the manual protective mechanism are connected with a secondary side output end of the current transformer in parallel and are used for open circuit protection of the secondary side output circuit. The automatic protective circuit comprises at least one basic circuit, and each basic circuit comprises a thyristor and a voltage stabilizer used for sensing voltages of the two ends of the secondary side output end of the current transformer and controlling the connecting and disconnecting of the thyristor. By the adoption of the open circuit protective circuit for the secondary side output circuit of the current transformer, the situation that high voltage is formed at the open circuit when primary side current of the current transformer is not equal to zero and the open circuit is formed at the output end is avoided, the accidents of arc striking at the open circuit, burning up of contacts, destroyed equipment and the like are further avoided, and production safety and equipment debugging and maintenance convenience are guaranteed. In addition, the manual protective mechanism is arranged, so that two output ends of the current transformer can be in reliable short splice through the manual protective mechanism in the process of equipment debugging and maintenance, and therefore operation safety is guaranteed.

Owner:SHENZHEN PUYUAN ELECTRIC TECH

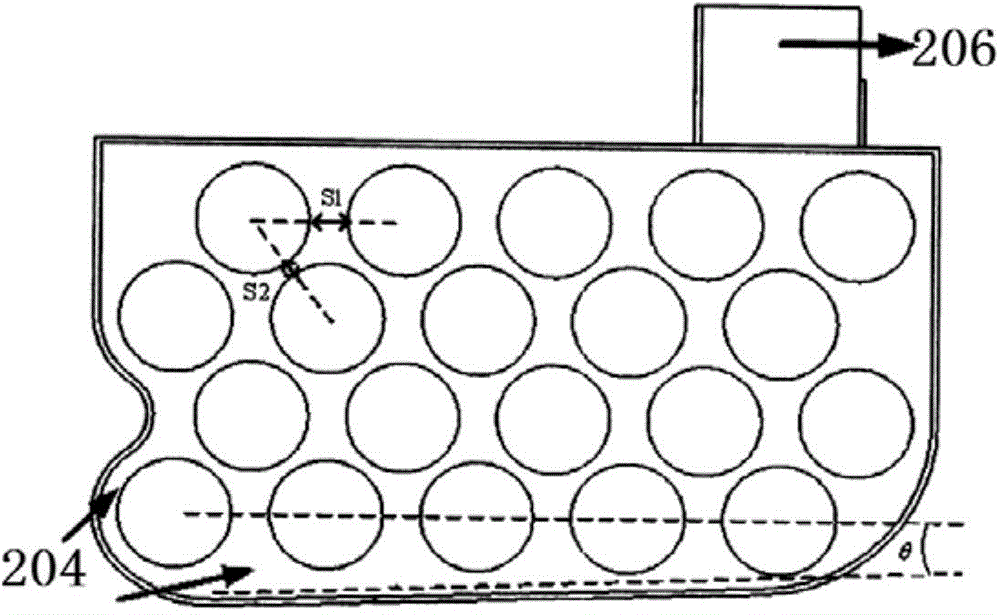

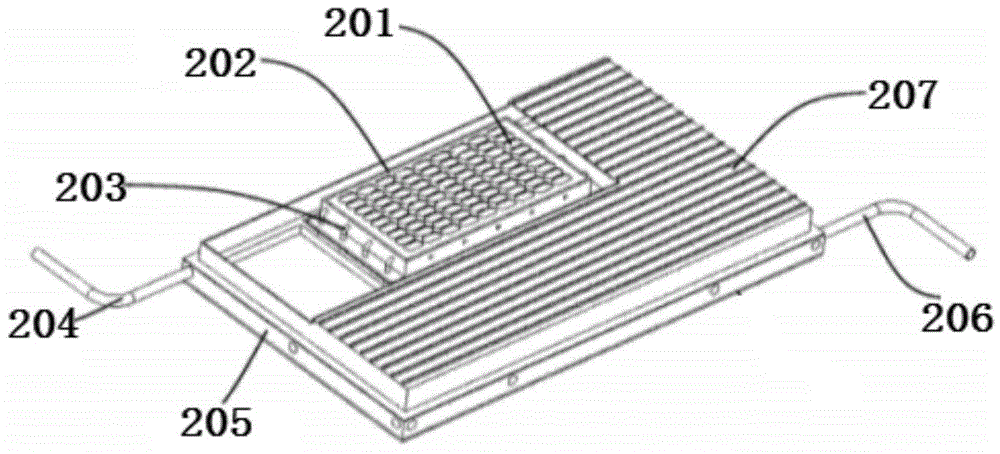

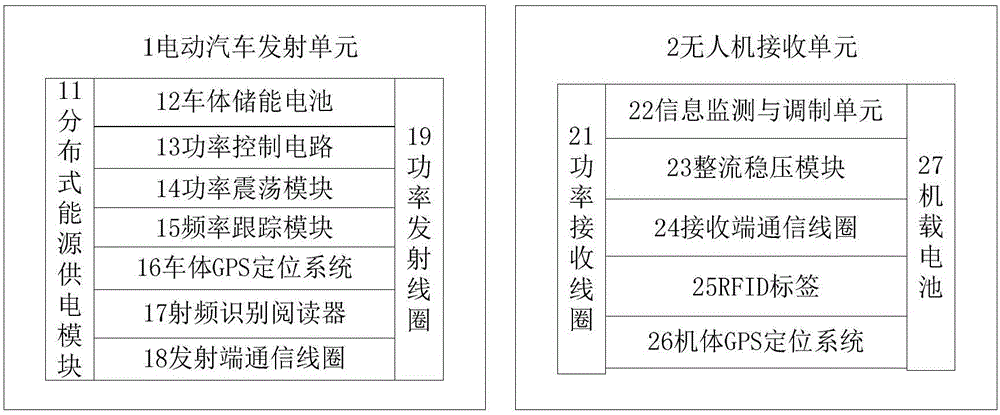

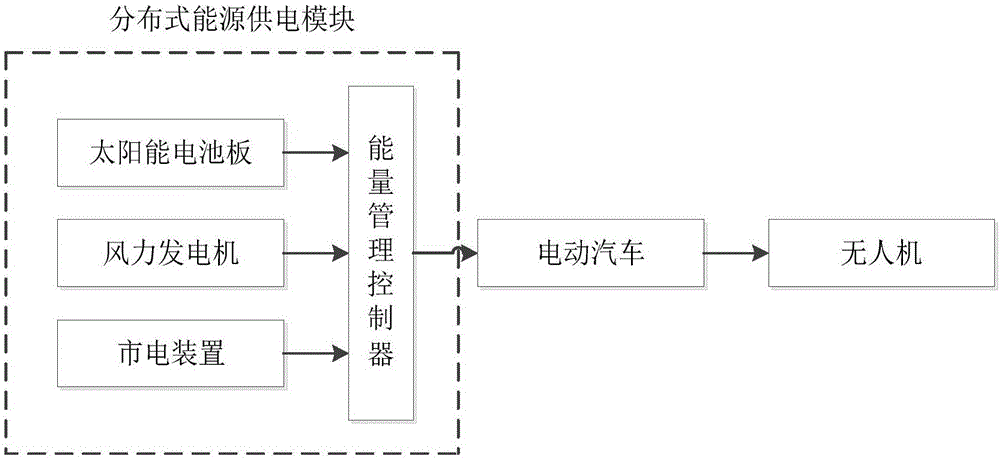

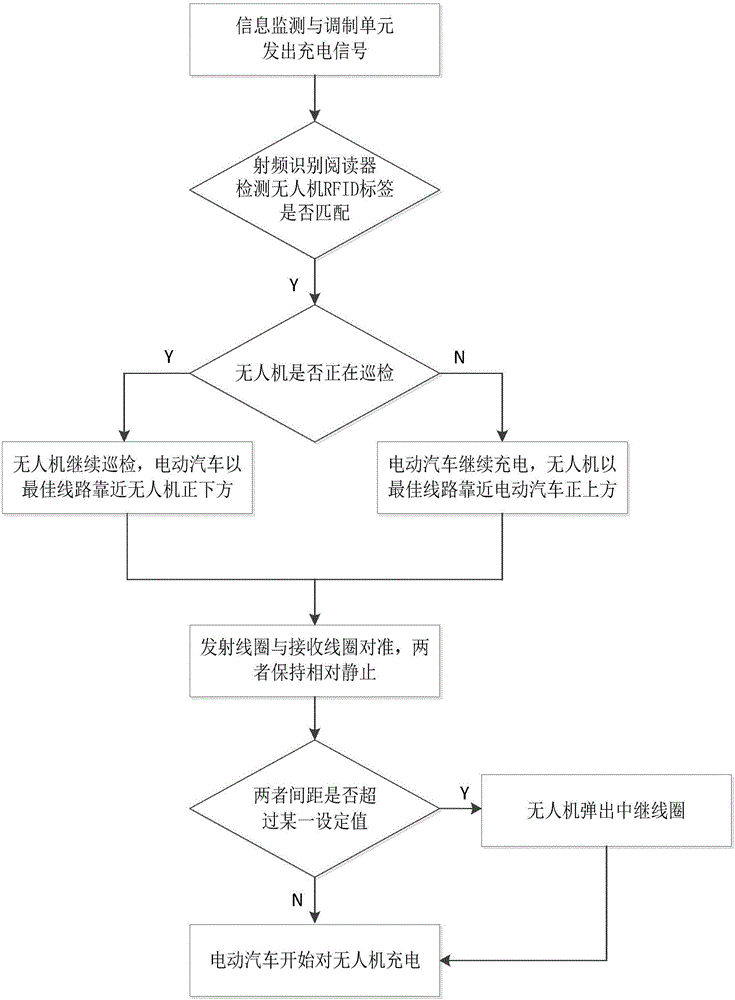

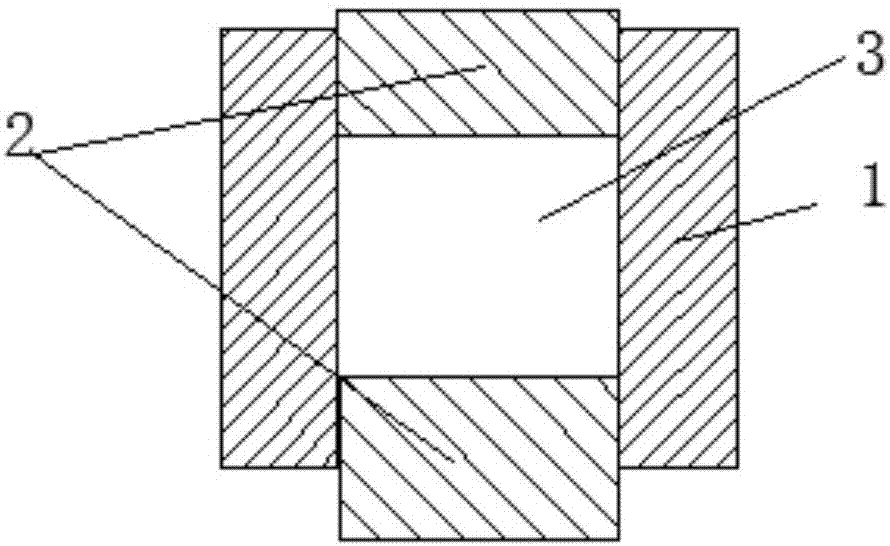

Resonant coupling system for unmanned aerial vehicle dynamic wireless charging and dynamic charging method

ActiveCN106816967AEasy to chargeThe system is stable and reliableCircuit authenticationElectric powerBad weatherSystem usage

The invention relates to the technical field of unmanned aerial vehicle wireless charging and particularly relates to a resonant coupling system for unmanned aerial vehicle dynamic wireless charging and a dynamic charging method. The system comprises an electric car and an unmanned aerial vehicle. The electric vehicle is provided with an electric car emission unit, and the unmanned aerial vehicle is provided with an unmanned aerial vehicle receiving unit. An electric car radio frequency identification reader is wirelessly connected with an RFID tag on the unmanned aerial vehicle, a transmission end communication coil and a reception end communication coil are wirelessly connected, and energy transmission is performed between a power transmission coil and a power reception coil. The power transmission coil adopts a combined coil matrix, and each coil in the combined coil matrix adopts a DD type structure. The power reception coil adopts a coil matrix. The resonant coupling system is easy to use, reliable in operation, low in maintenance cost, safe and efficient for dynamic and stable charging of the unmanned aerial vehicle, has strong adaptability to bad weather and environments, and has a high energy utilization rate.

Owner:南京中科聚能科技有限公司

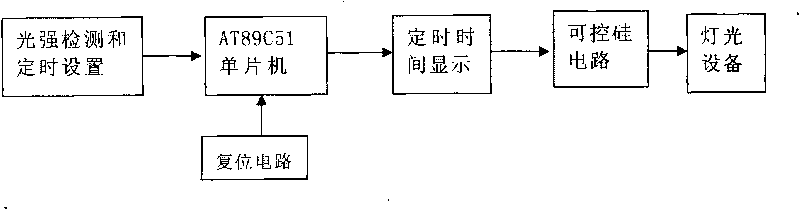

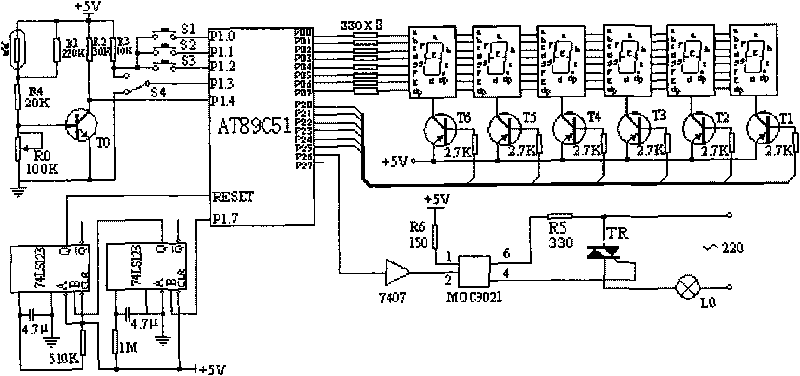

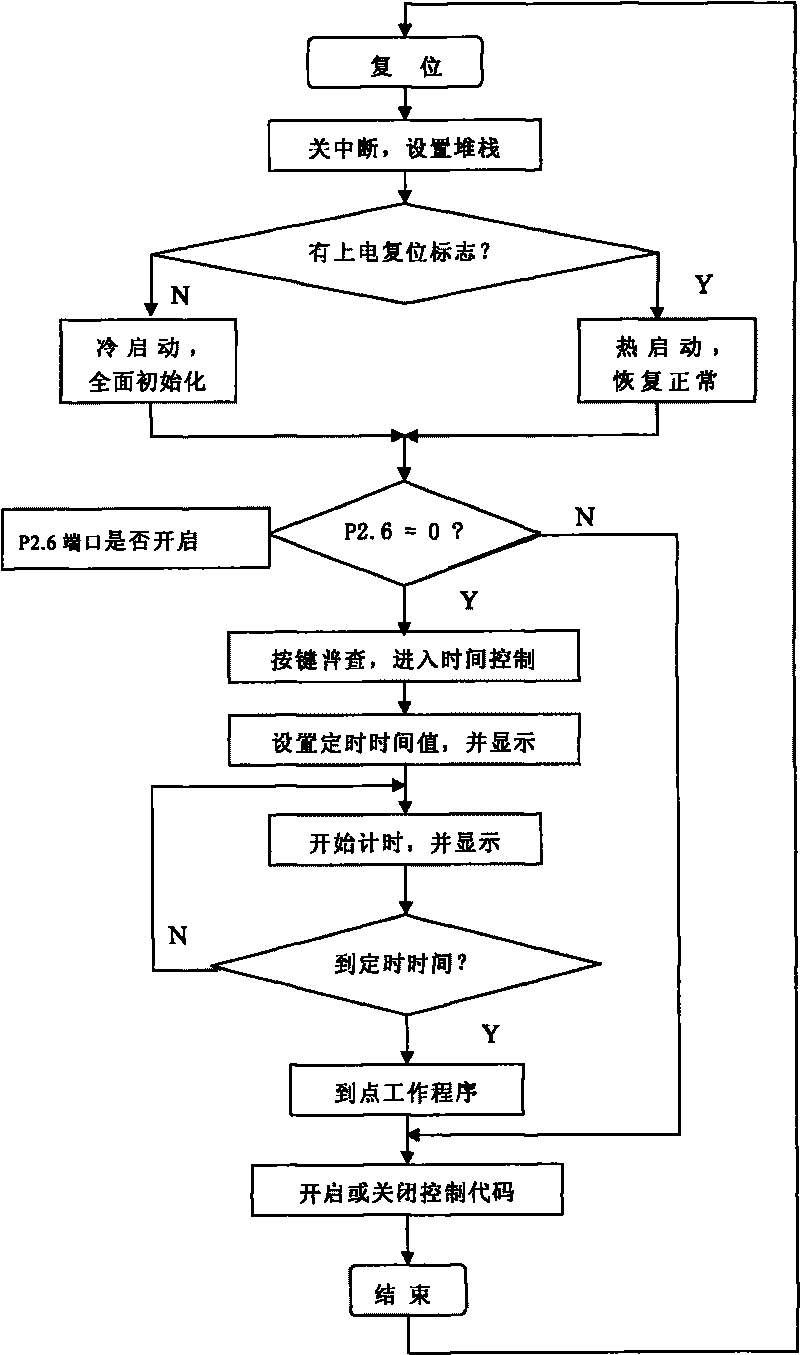

Intelligent street lamp control system

InactiveCN101742754AImprove the level of intelligent controlAutomatically adjust switch timeElectric light circuit arrangementEnergy saving control techniquesMicrocontrollerEffect light

The invention relates to an intelligent street lamp control system, which comprises a lighting device, a light intensity detecting and timing circuit, a single-chip for storing software programs, a reset circuit, a timing time display circuit and a controlled silicon circuit, wherein the light intensity detecting and timing circuit is connected with the single-chip, the timing time display circuit, the controlled silicon circuit and the lighting device in turn, and the reset circuit is connected with the single-chip. The intelligent street lamp control system has the advantages of simple structure design, low cost and energy conservation. The system can be widely used for controlling street lamp light, lighting systems, neon lamps and advertising lamps, can prolong the service life of bulbs and prevent a contact switch from generating sparks, and is suitable for use on inflammable and explosive special occasions.

Owner:TIANJIN SAMSUNG ELECTRONICS CO LTD

Method for compound magnetic powder flaw detection

InactiveCN101806774AAdapt to the requirements of magnetic particle testingAvoid sparkingMaterial magnetic variablesUltimate tensile strengthMagnetic particle inspection

The invention discloses a method for compound magnetic powder flaw detection, comprising the following steps: (1) pretreating; (2) magnetizing; (3) applying magnetic powder or magnetic suspension; (4) observing and recording a magnetic trace; (5) rating the flaw; (6) demagnetizing; and (7) post-treating. The magnetizing mode in the step (2) is circumferential closed magnet yoke magnetization and coil magnetization full sensing. The magnetic powder flaw detection method designed by the technical scheme of the invention has the advantage of high work efficiency, lightens the labor intensity of workers, avoids fire striking phenomenon, does not burn workpieces and has even magnetic field distribution.

Owner:SHEYANG SAIFU NDT EQUIP MFG

Method for improving crystallizing rate of reused monocrystal silicon and material block for feeding barium carbonate

ActiveCN107460538AAvoid harmPut an end to ignitionPolycrystalline material growthBy pulling from meltCorrosionMonocrystalline silicon

The invention provides a method for improving a crystallizing rate of reused monocrystal silicon. Silicon material is fed into a crucible via a refeeding cylinder, when a liquid level of the silicon material in the crucible is a certain distance higher than a round corner of the bottom of the crucible, a few grams of barium carbonate are put into the crucible via the refeeding cylinder, and then the silicon material is continuously put into the crucible via the refeeding cylinder. In the method, silicon dioxide is exposed after the crucible is corroded, after barium carbonate powder is fed, barium oxide is generated after heating, the barium oxide reacts with silicon dioxide to generate BaSiO3; due to existence of barium metasilicate, a layer of compact and tiny cristobalite crystals is formed on the wall of the quartz crucible, and thus a corrosion degree of the quartz crucible corroded by solution is relieved; meanwhile, the cristobalite crystals are formed in needle holes, so that foreign gases entering silicon solution are reduced, and the purpose of directly improving the crystallizing rate of the monocrystal silicon after reusing is achieved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Cooling liquid for optical processing and preparation method of cooling liquid

The invention relates to cooling liquid for optical processing. The cooling liquid consists of the following ingredients in percentage by weight: 10 percent to 20 percent of surfactants, 5 percent to 20 percent of lubricants, 0.5 percent to 3 percent of anti-rusting agents, 3 percent to 8 percent of pH value conditioning agents, 0.05 percent to 0.5 percent of sterilizing agents, 0.05 to 0.5 percent of defoaming agents and the balance distilled water. The cooling liquid for optical processing has the advantages that glass chip separation performance and settleability are excellent, the environmental adaptation is wider, the stability is batter, the foaming is low, the rinsing is easy, the wettability is good, no damage is generated on the glass surface, no phosphorus element is contained, no peculiar smell, no poison or no corrosivity is generated, safety and reliability are realized, combustion and explosion are avoided, the environment is not polluted, the use cost is low, and the transportation and the storage are convenient.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

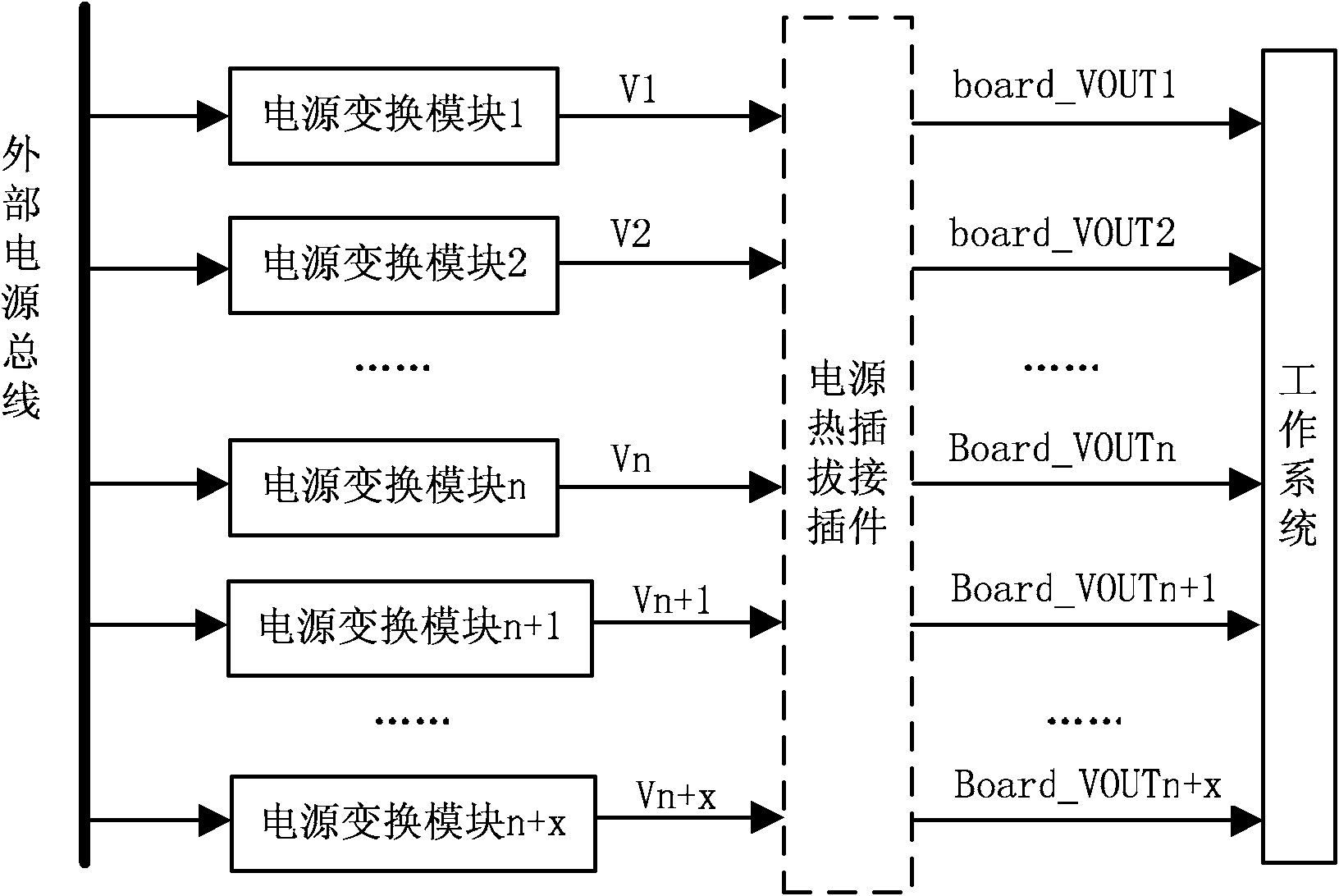

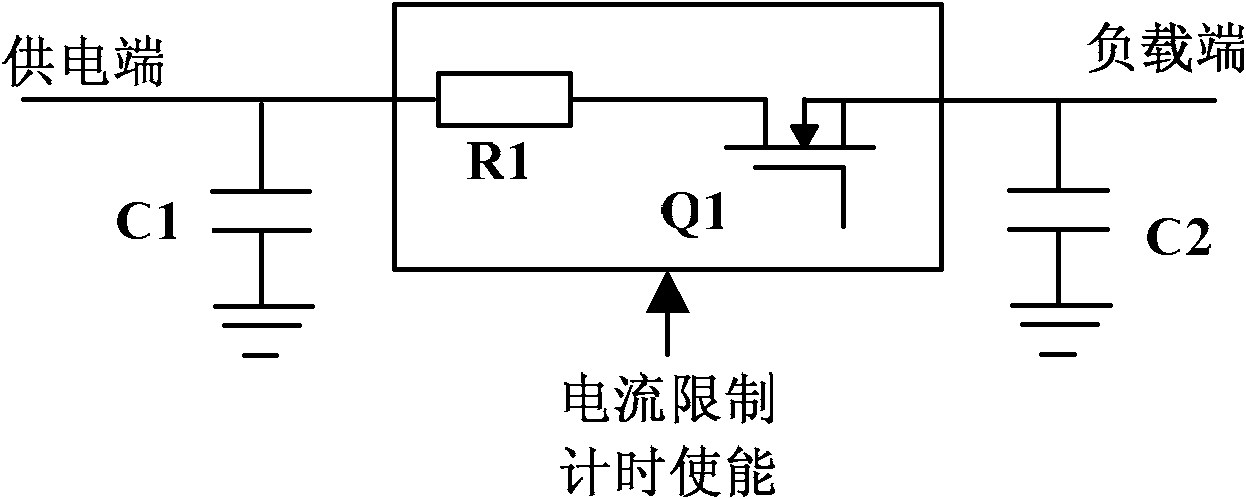

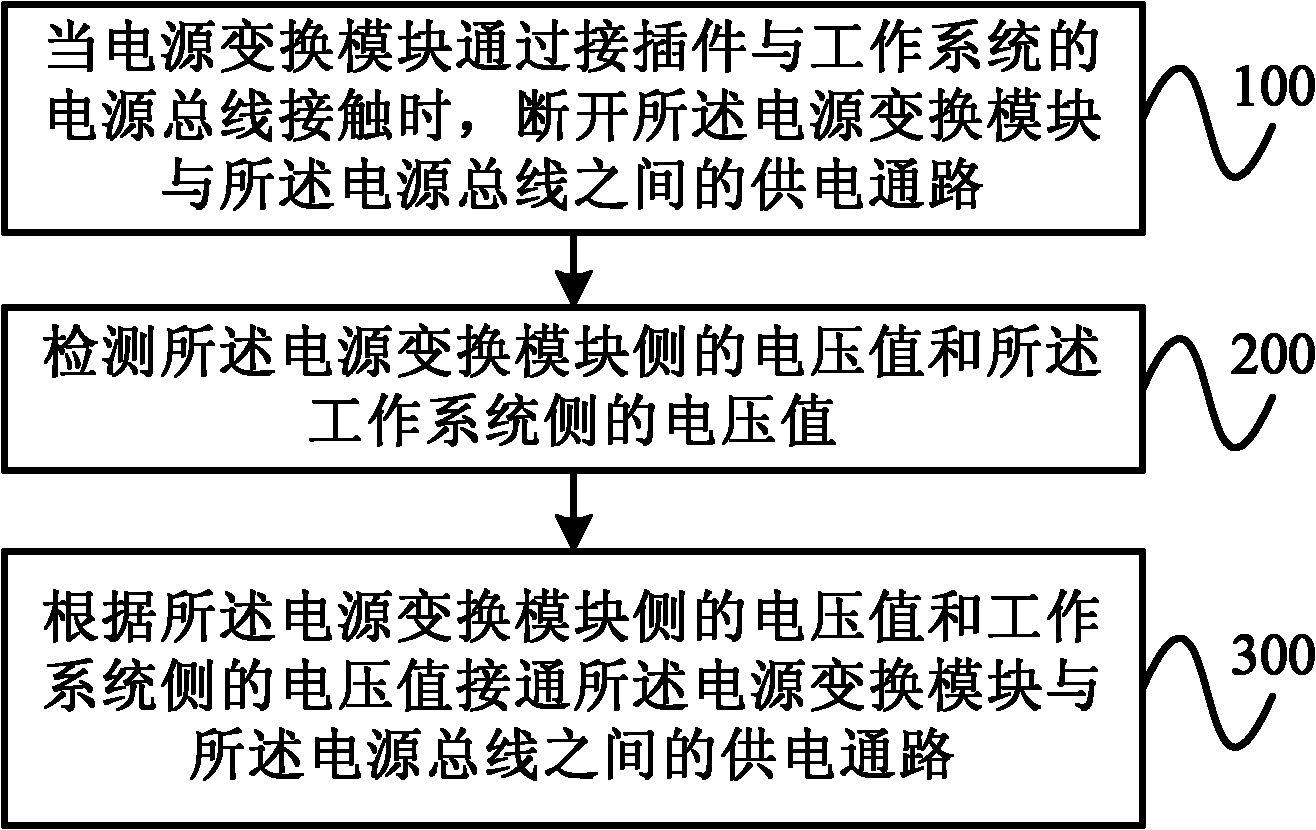

Method, circuit and device for controlling hot plug of power supply

ActiveCN102156525AImprove reliabilityAvoid sparkingPower supply for data processingComputer moduleEngineering

The invention provides a method, a circuit and a device for controlling hot plug of a power supply, wherein the method comprises the flowing steps of: cutting off a current supply path between a power supply conversion module and a power supply bus when the power supply conversion module is contacted with the power supply bus of a work system through a connector; detecting a voltage value at the power supply conversion module side and a voltage value at the work system side; and switching on the current supply path between the power supply conversion module and the power supply bus according to the voltage value at the power supply conversion module side and the voltage value at the work system side. The method, the circuit and the device provided by the invention can effectively solve the problem of the sparking phenomenon generated at the moment of hot plug of the power supply, so that the reliability of the work system is improved.

Owner:RUIJIE NETWORKS CO LTD

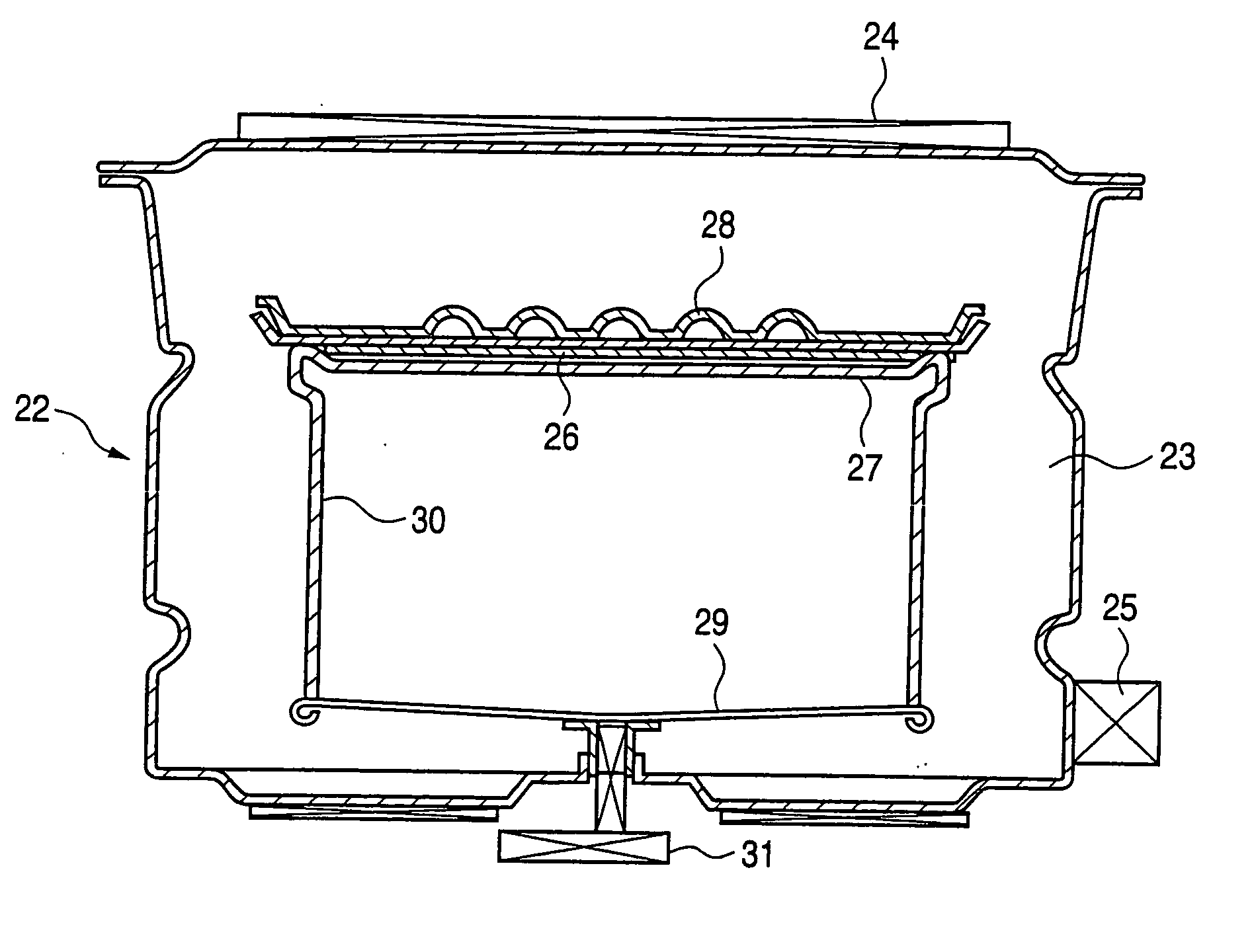

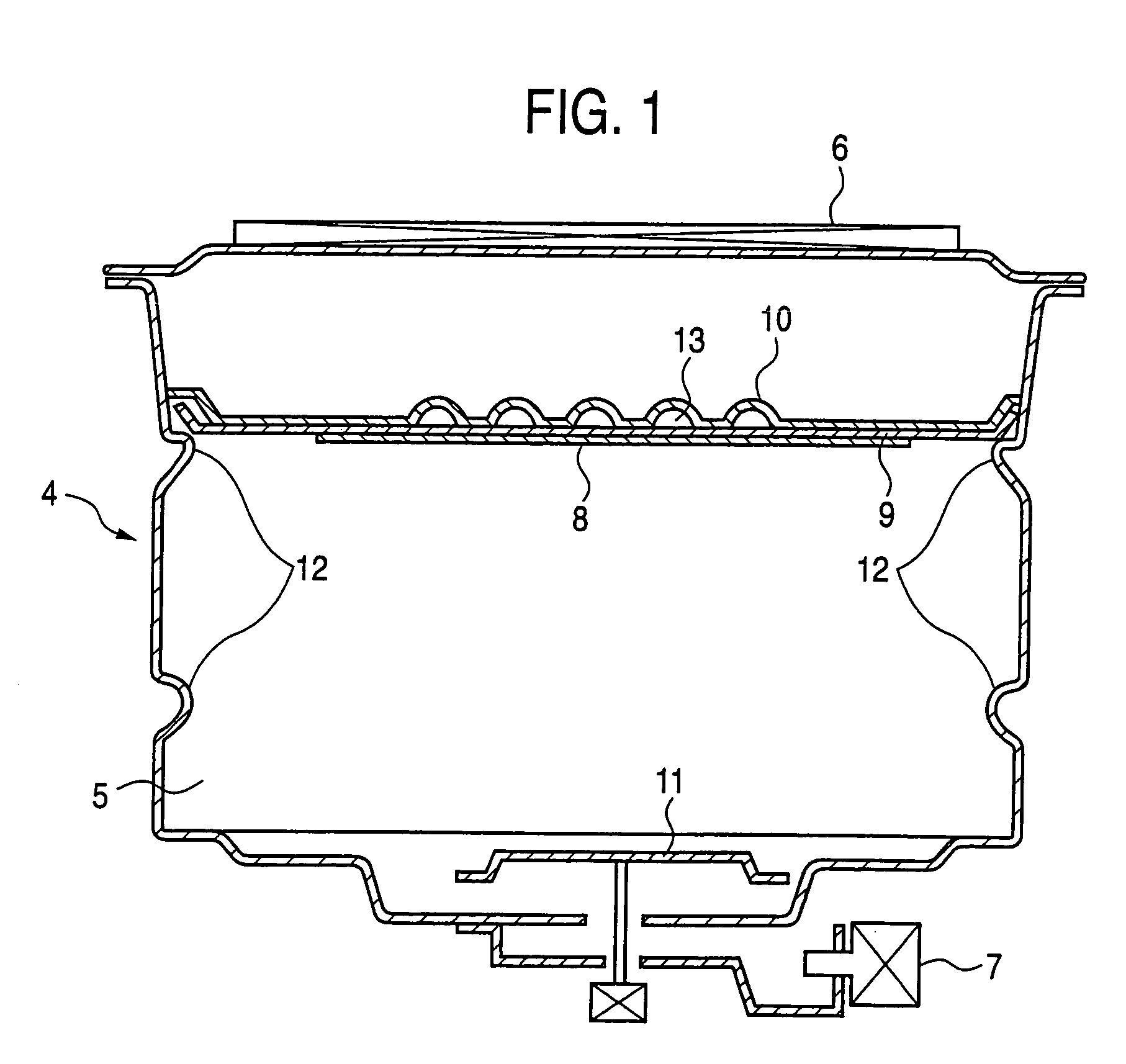

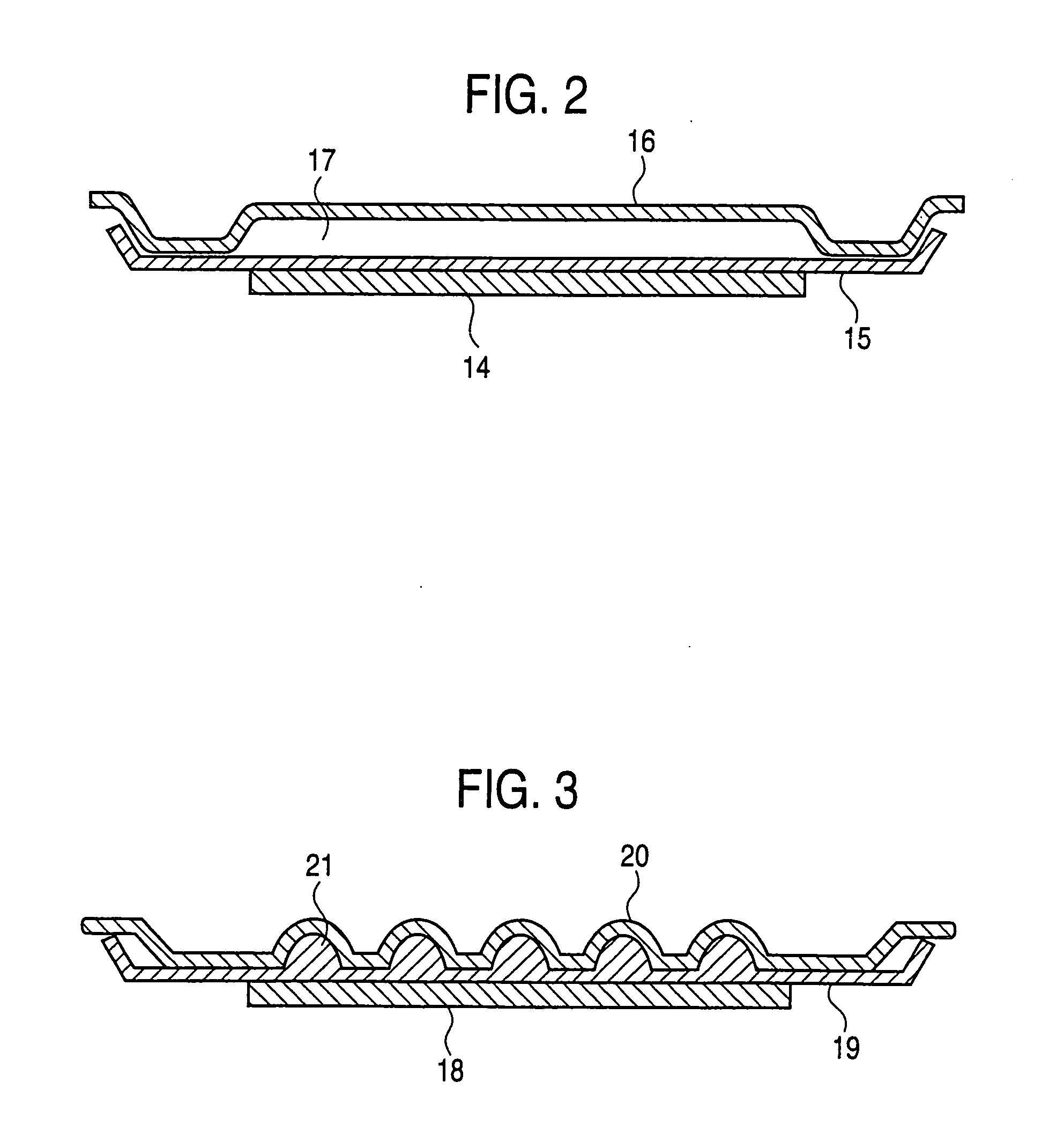

High-frequency heating apparatus

InactiveUS20050051543A1Reduce in quantitySimple constitutionMilk preparationCooking-vessel materialsEngineeringGenerating unit

The present invention provides a high-frequency heating apparatus which can heat the inside of the subject to be heated by high-frequency heating, and can apply scorch onto the surface of the subject to be heated. The high-frequency heating apparatus comprises a heating room for storing therein a subject to be heated, a heating unit that is provided at the upper portion of the heating room and performs heater heating, a high-frequency generating unit that is provided at the bottom of the heating room and generates a high-frequency wave to perform high-frequency heating, a high-frequency heating element having a high-frequency heat generating film on its rear surface, and a saucer for placing thereon the subject to be heated, in which a gap is provided between the high-frequency heating element and the saucer. Hereby, scorch can be applied onto a surface of the subject to be heated.

Owner:PANASONIC CORP

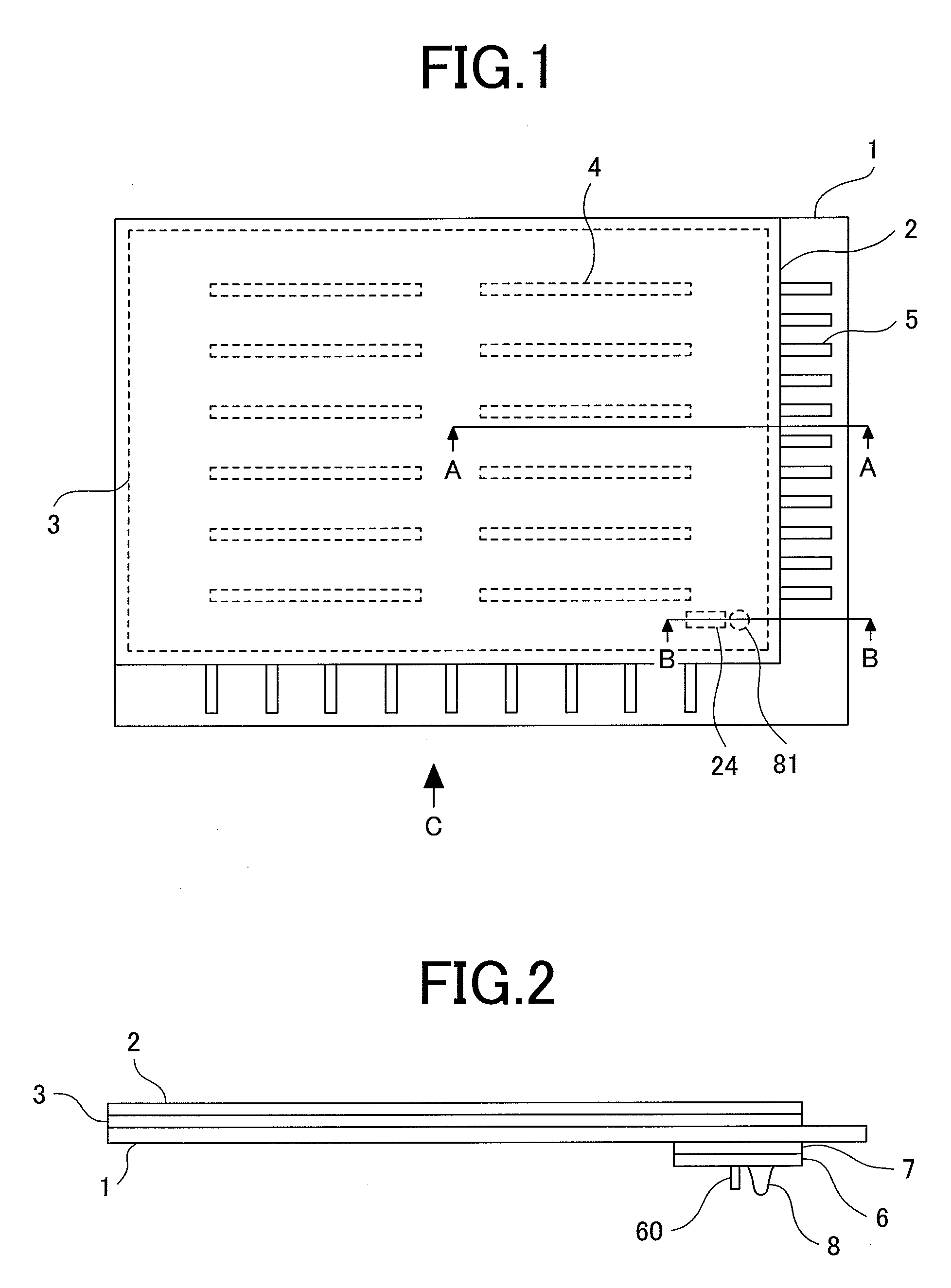

Display Device

InactiveUS20080315748A1High voltageImprove reliabilityCathode-ray/electron-beam tube electrical connectionGas filling substance selectionContact pressureAnode voltage

There is disclosed an FED (field emission display) capable of supplying an anode voltage, which is a high voltage, to an anode substrate with high reliability. A high voltage introduction button is sealed to a sealing plate, in which a contact spring is attached to the high voltage introduction button by spot welding. The high voltage introduction button has a flat portion connected to the contact spring, a sealing portion sealed to the glass substrate, and an external terminal to be connected to an external power source. The contact spring contacts an anode terminal of an anode substrate with an appropriate contact pressure, by a spring force from an arm portion of the contact spring. The anode terminal is formed of a conductive film containing metal particles.

Owner:HITACHI LTD

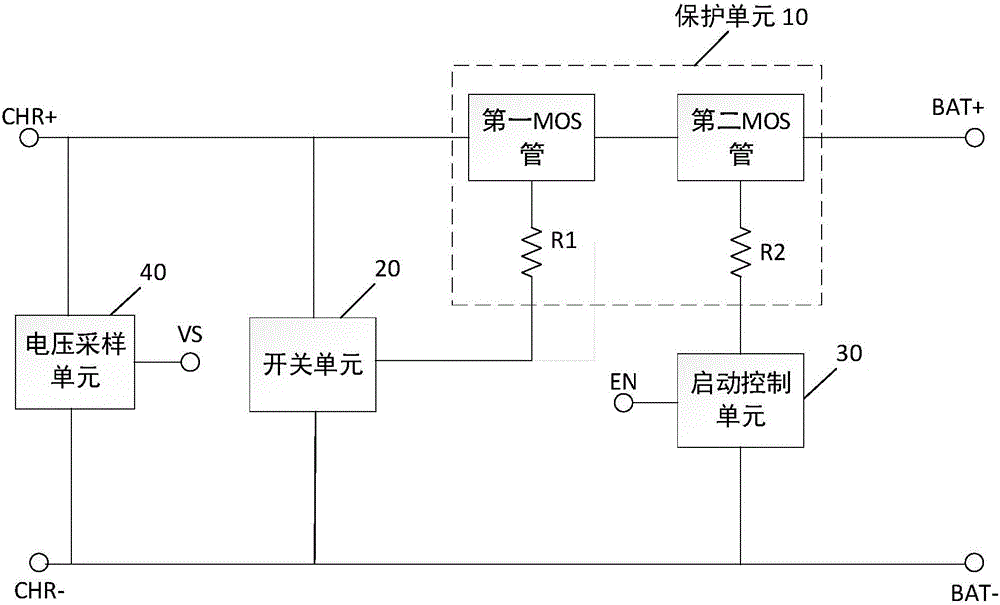

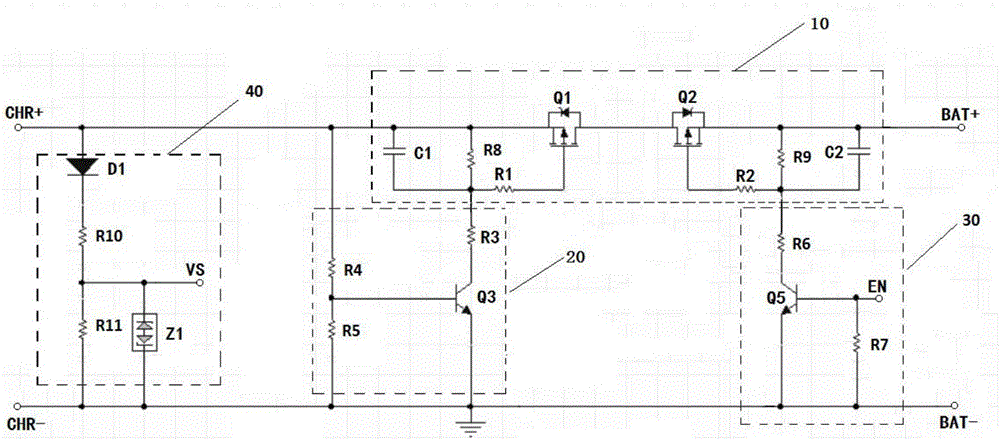

Controllable battery charging circuit and charger

InactiveCN106026277ANo short-circuit discharge will occurReduce power consumptionElectric powerReverse polarity correctionBattery chargeElectrical battery

The invention discloses a controllable battery charging circuit and a charger. The circuit comprises a protection unit, a switch unit, a start-up control unit and a voltage sampling unit. The protection unit comprises a first MOS transistor, a second MOS transistor, a resistor R1 and a resistor R2. The first MOS transistor and the second MOS transistor are in reverse connection and are connected in series between the input positive pole and the output positive pole of a circuit. One end of the resistor R1 is connected with the grid electrode of the first MOS transistor, and the other end of the resistor R1 serves as the first control end of the protection unit. One end of the resistor R2 is connected with the grid electrode of the second MOS transistor, and the other end of the resistor R2 serves as the second control end of the protection unit. The switch unit controls the on / off state of the first MOS transistor. The start-up control unit controls the on / off state of the second MOS transistor. The voltage sampling unit samples the voltage of the charger. The two MOS transistors of the circuit are in reverse connection, so that the forward voltage drop generated by the circuit during the charging process is reduced. Therefore, the battery charging volume is improved and the system power consumption is reduced.

Owner:北京云迹科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com