Open circuit protective circuit for secondary side output circuit of current transformer

A technology of current transformer and output circuit, which is applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems of easy breakdown, slow movement of mechanical mechanism, sparking, etc., and achieve large continuous current carrying capacity and large instantaneous overload capacity , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

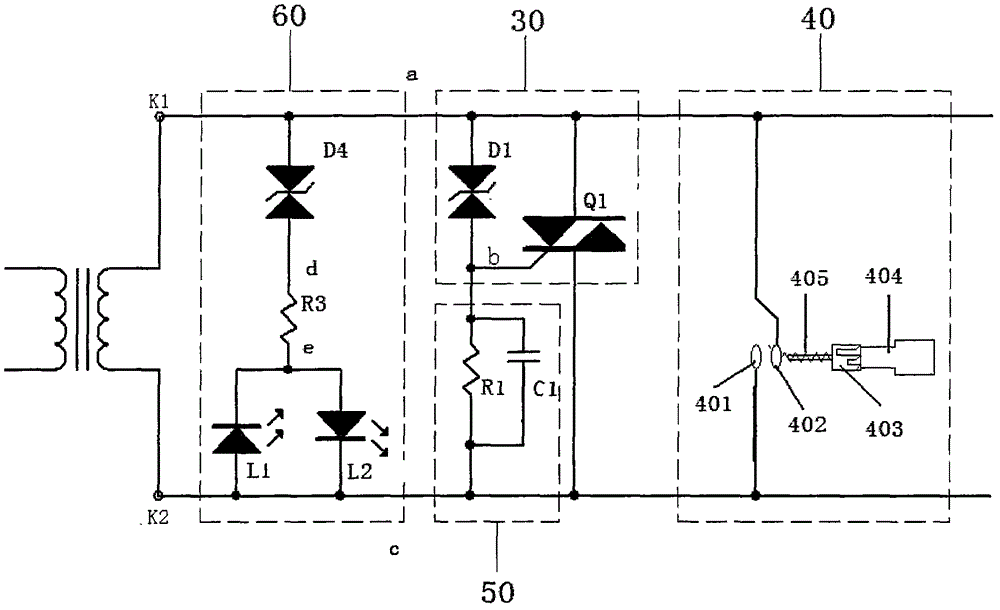

[0042] This embodiment includes an automatic protection circuit 30 and a manual protection mechanism 40 connected in parallel with the secondary side output end of the current transformer for secondary side output circuit open circuit protection. The automatic protection circuit 30 includes a group of basic circuits, which include a two-way voltage regulator diode D1 and a two-way thyristor Q1; the lower end of the two-way voltage regulator diode D1 is connected to the gate G of the two-way thyristor Q1; The MT2 pole of the bidirectional thyristor Q1 is connected to the first terminal K1 of the output terminals, and the MT1 pole of the bidirectional thyristor Q1 is connected to the second terminal K2 of the output terminal.

[0043] A first auxiliary protection circuit 50 is drawn from the connection line b between the bidirectional Zener diode D1 and the gate G of the bidirectional thyristor Q1. The first auxiliary protection circuit 50 includes a resistor R1 and a capacitor C...

Embodiment 2

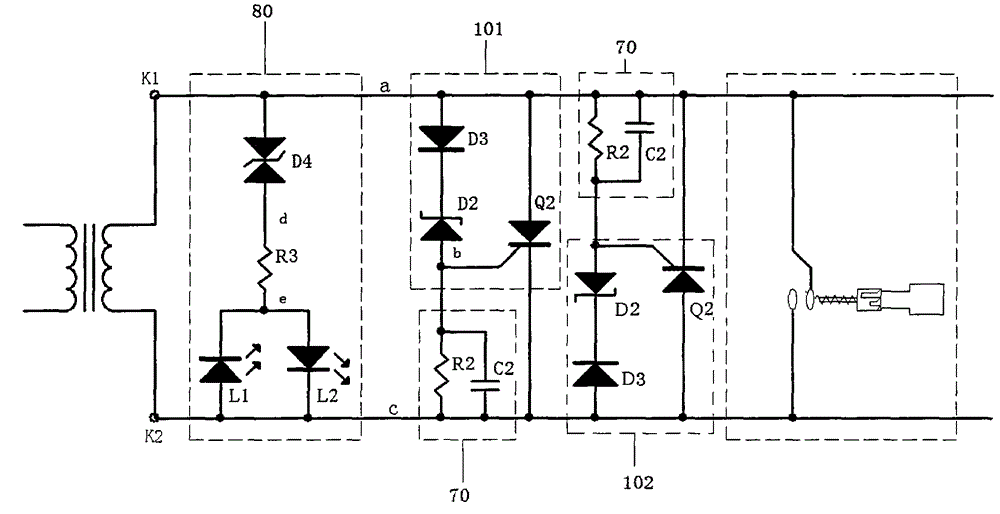

[0050] The only difference between this embodiment and Embodiment 2 is that the automatic protection circuit includes a first basic circuit 101 and a second basic circuit 102 which have the same circuit structure and are reversely connected to the output terminal of the secondary side. Since the circuit structures of the first basic circuit and the second basic circuit are the same, only the first basic circuit is used here as an example for illustration, which includes a zener diode D2 and a rectifier diode D3 connected in series, and the zener diode D2 A silicon-controlled thyristor Q2 connected in parallel with the rectifier diode D3, the silicon-controlled thyristor Q2 is a unidirectional conduction thyristor; wherein the A pole of the Zener diode D2 is connected to the G pole of Q2, and the K pole of the Zener diode D2 is connected to the G pole of the Zener diode D2. The K pole of the rectifier diode D3 is connected, and the A pole of the rectifier diode D3 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com