ITo coated plate and its preparing method

A substrate and alloy film technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of not meeting the requirements of ITO substrate surface flatness, increasing process difficulty, and low yield , to achieve high visible light transmittance, excellent realization effect, and low square resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

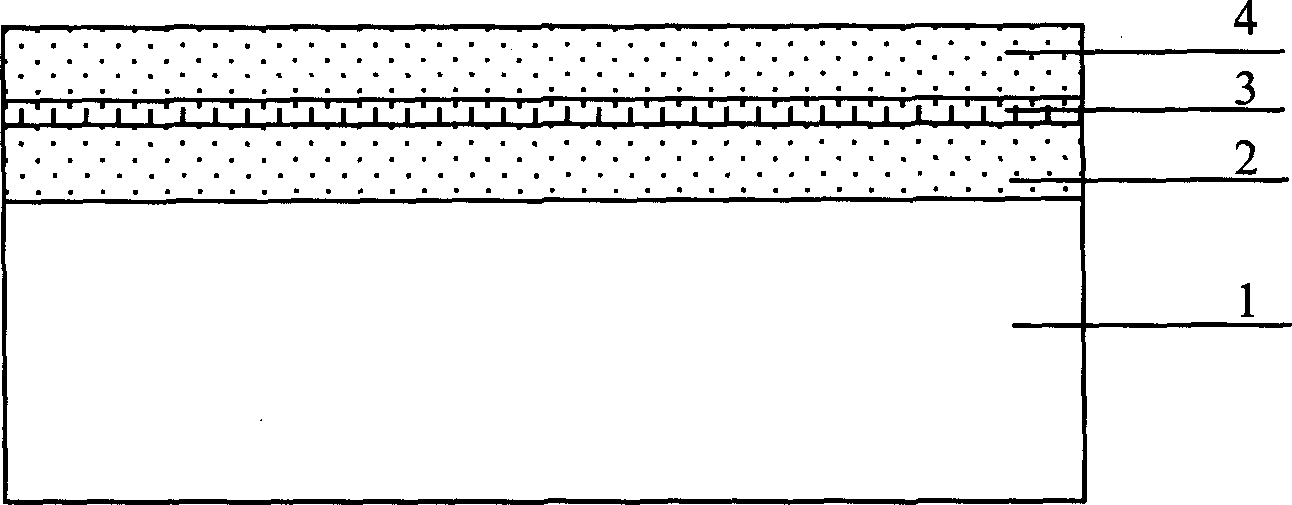

[0020] Embodiment 1. An ITO coated board includes a glass substrate 1 , a first layer of ITO film 2 , a silver-gold alloy film 3 and a second layer of ITO film 4 . The first layer of ITO film 2 is deposited on the surface of the substrate, the silver-gold alloy film is deposited on the first layer of ITO film, and the second layer of ITO film is deposited on the silver-gold alloy film. The weight ratio of silver and gold in the silver-gold alloy film is 97:3. The thickness of the first and second layers of ITO film is 45nm, and the thickness of the silver-gold alloy film is 15nm.

[0021] The square resistance of the above-mentioned ITO coated plate is less than 15Ω / □, the transmittance of visible light is 80%, and it can be used as an excellent flat panel display substrate.

Embodiment 2

[0022] Embodiment two, the preparation method of a kind of ITO coating plate, is to adopt the dc magnetron sputtering process to deposit the first layer of ITO film on the substrate, then deposit the alloy film on the first layer of ITO film, then deposit the second layer on the alloy film Two layers of ITO film. The DC magnetron sputtering process is used in the coating process. In this process, the working gas is fed into the background vacuum environment, and the power source is used to generate plasma to bombard the target material, so as to obtain a deposited film on the substrate. Its power supply is composed of a pulse power supply in series with a DC power supply, the pulse frequency is 20-100kHz, and the background vacuum should be better than 1×10 -3 Pa.

[0023] When depositing the ITO film, indium tin oxide ceramics are used as the target, where In 2 o 3 with SnO 2 The weight ratio is 90:10; argon-oxygen mixed gas is used as the working gas, wherein oxygen acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com