Patents

Literature

1334 results about "Amorphous metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

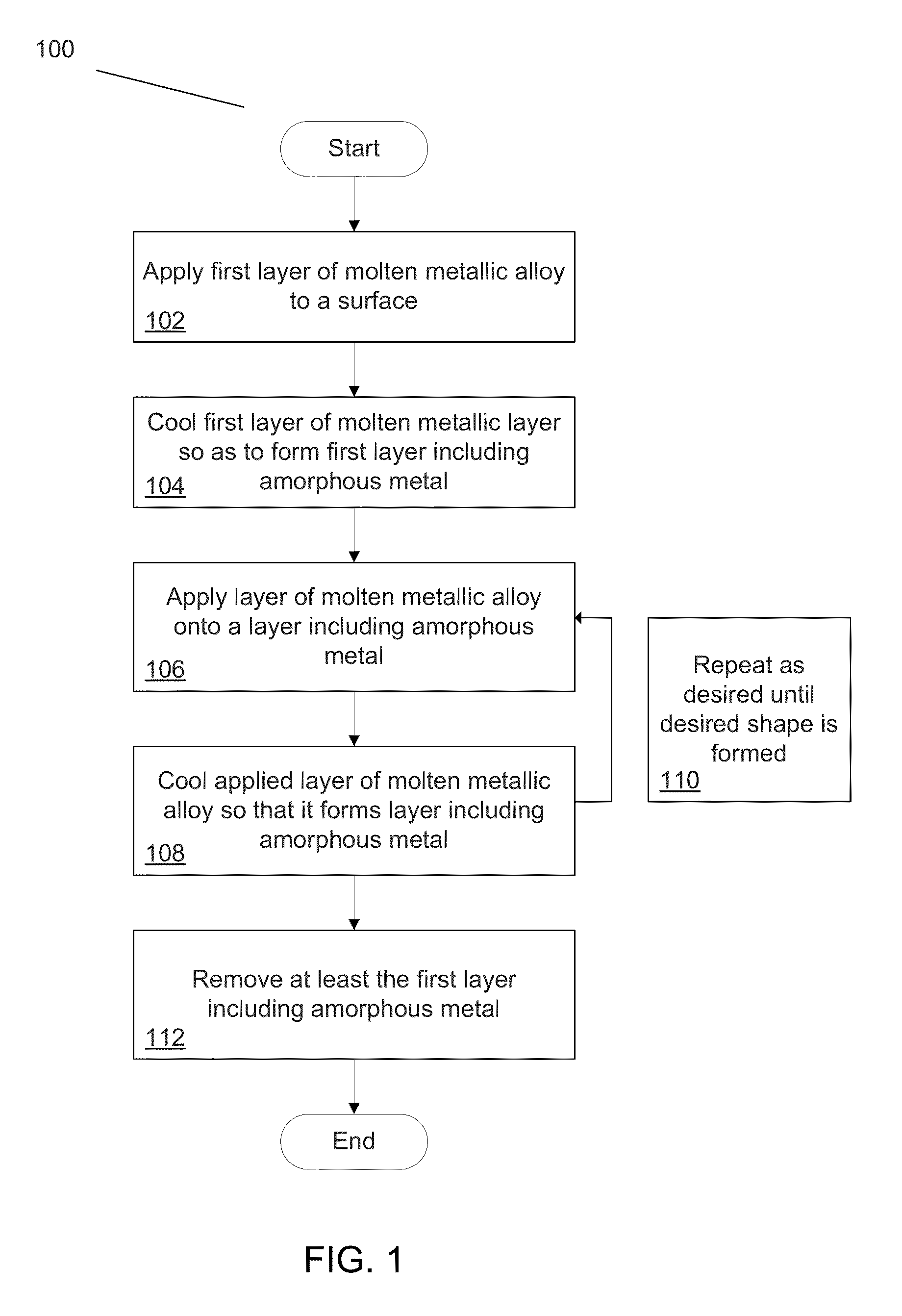

An amorphous metal (also known as metallic glass or glassy metal) is a solid metallic material, usually an alloy, with disordered atomic-scale structure. Most metals are crystalline in their solid state, which means they have a highly ordered arrangement of atoms. Amorphous metals are non-crystalline, and have a glass-like structure. But unlike common glasses, such as window glass, which are typically electrical insulators, amorphous metals have good electrical conductivity. There are several ways in which amorphous metals can be produced, including extremely rapid cooling, physical vapor deposition, solid-state reaction, ion irradiation, and mechanical alloying.Previously, small batches of amorphous metals had been produced through a variety of quick-cooling method, such as amorphous metal ribbons which had been produced by sputtering molten metal onto a spinning metal disk (melt spinning). The rapid cooling (on the order of millions of degrees Celsius a second) is too fast for crystals to form and the material is "locked" in a glassy state. Currently, a number of alloys with critical cooling rates low enough to allow formation of amorphous structure in thick layers (over 1 millimeter) have been produced; these are known as bulk metallic glasses (BMG). More recently, batches of amorphous steel with three times the strength of conventional steel alloys have been produced .

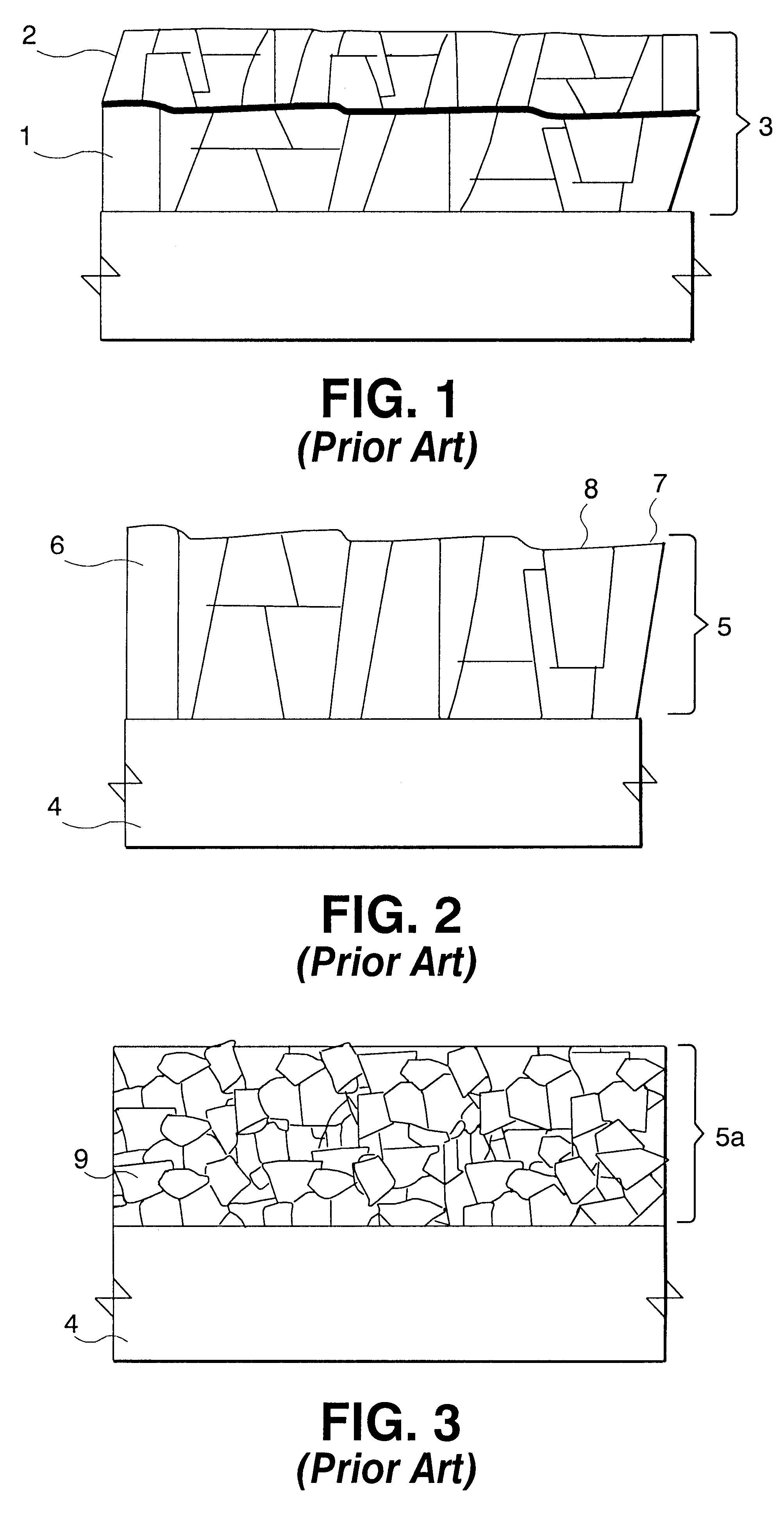

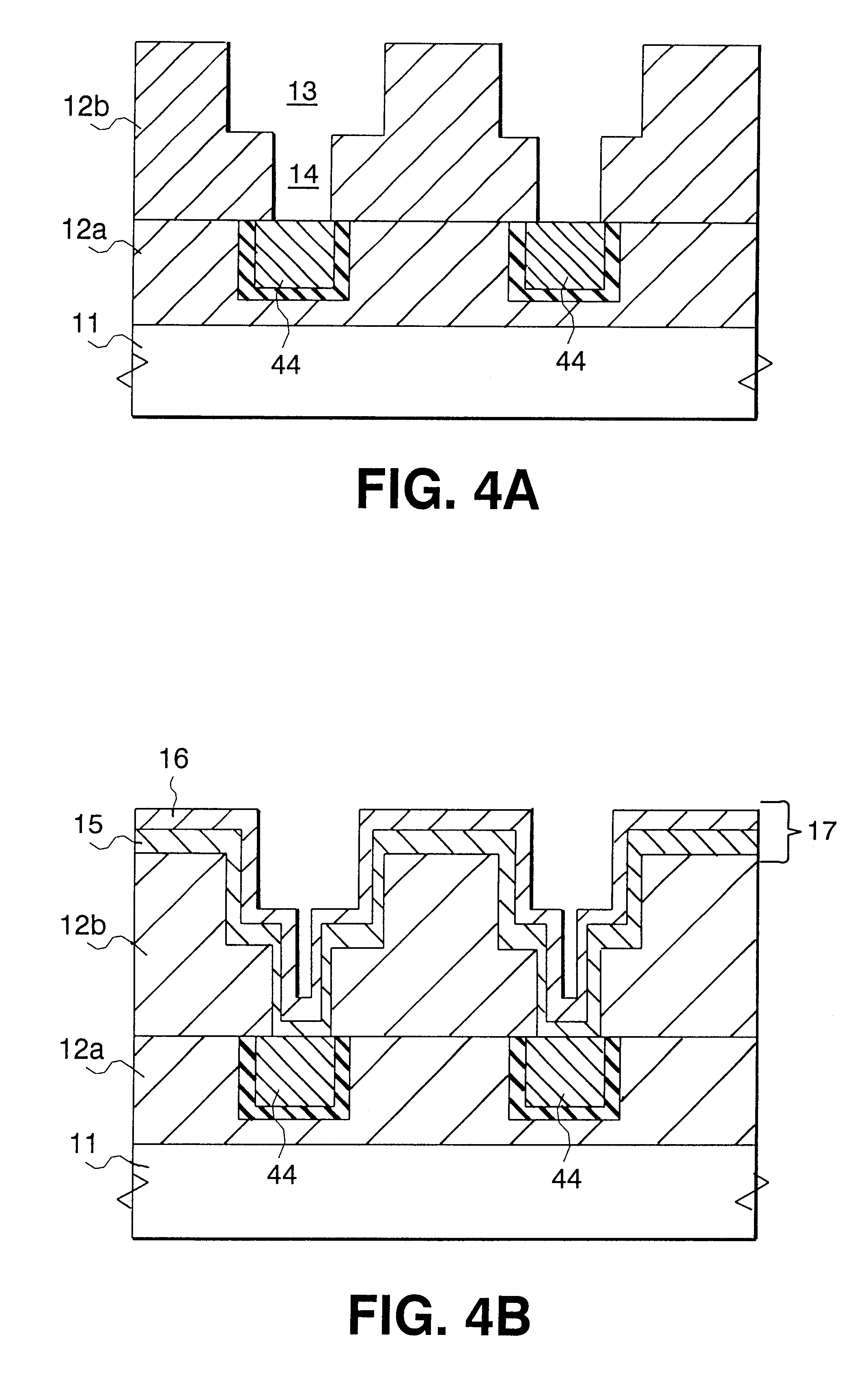

Selective epitaxial formation of semiconductor films

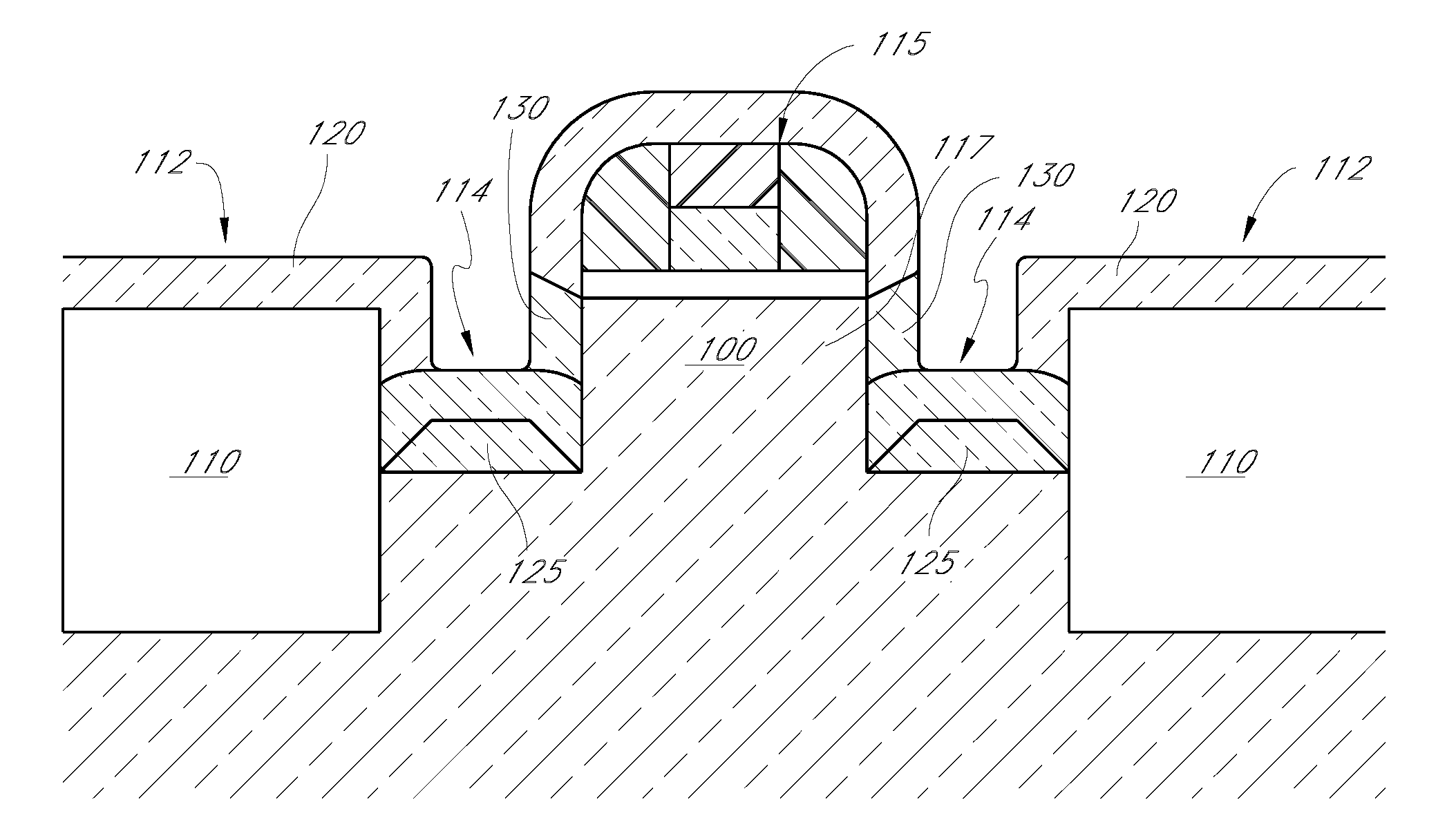

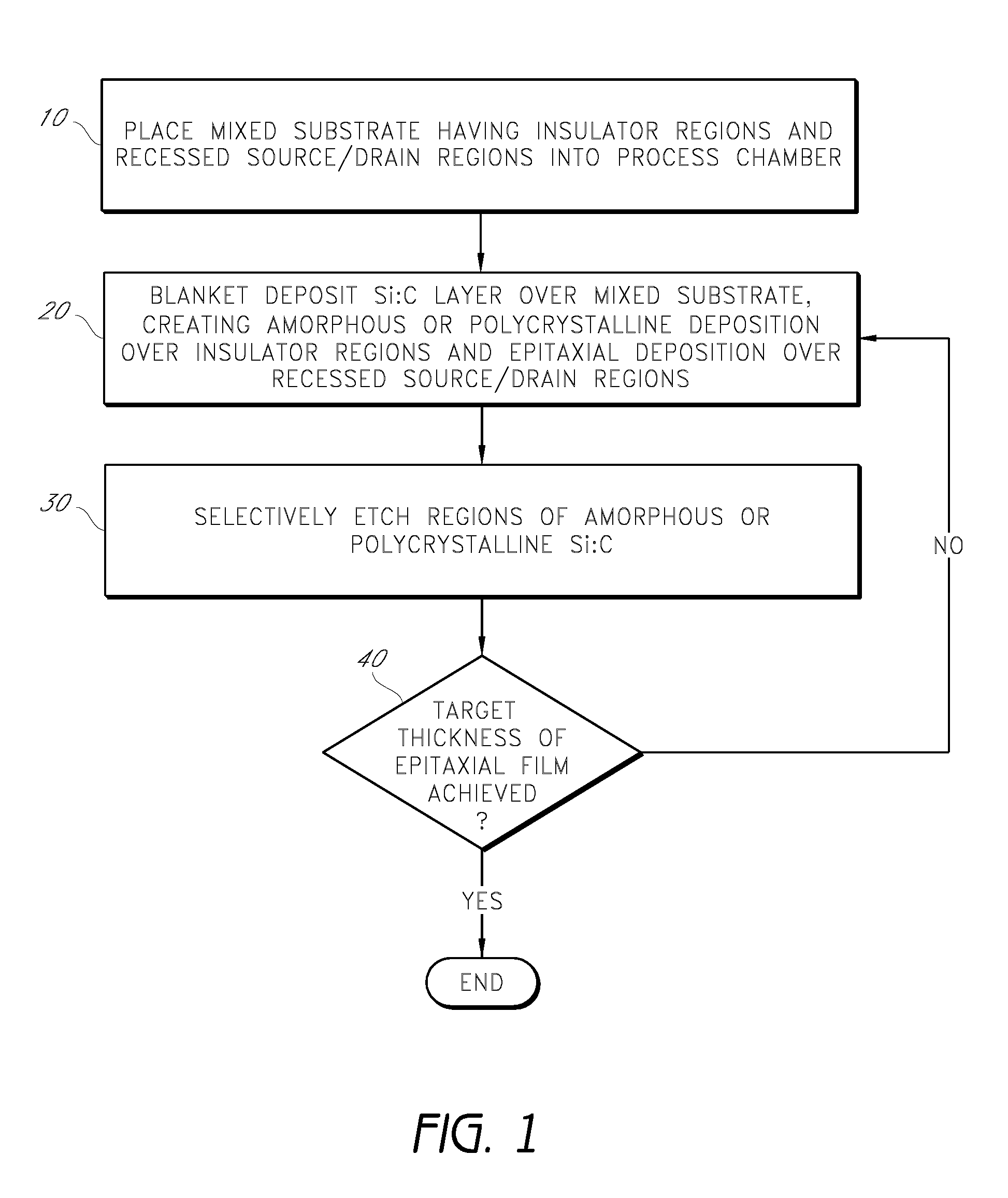

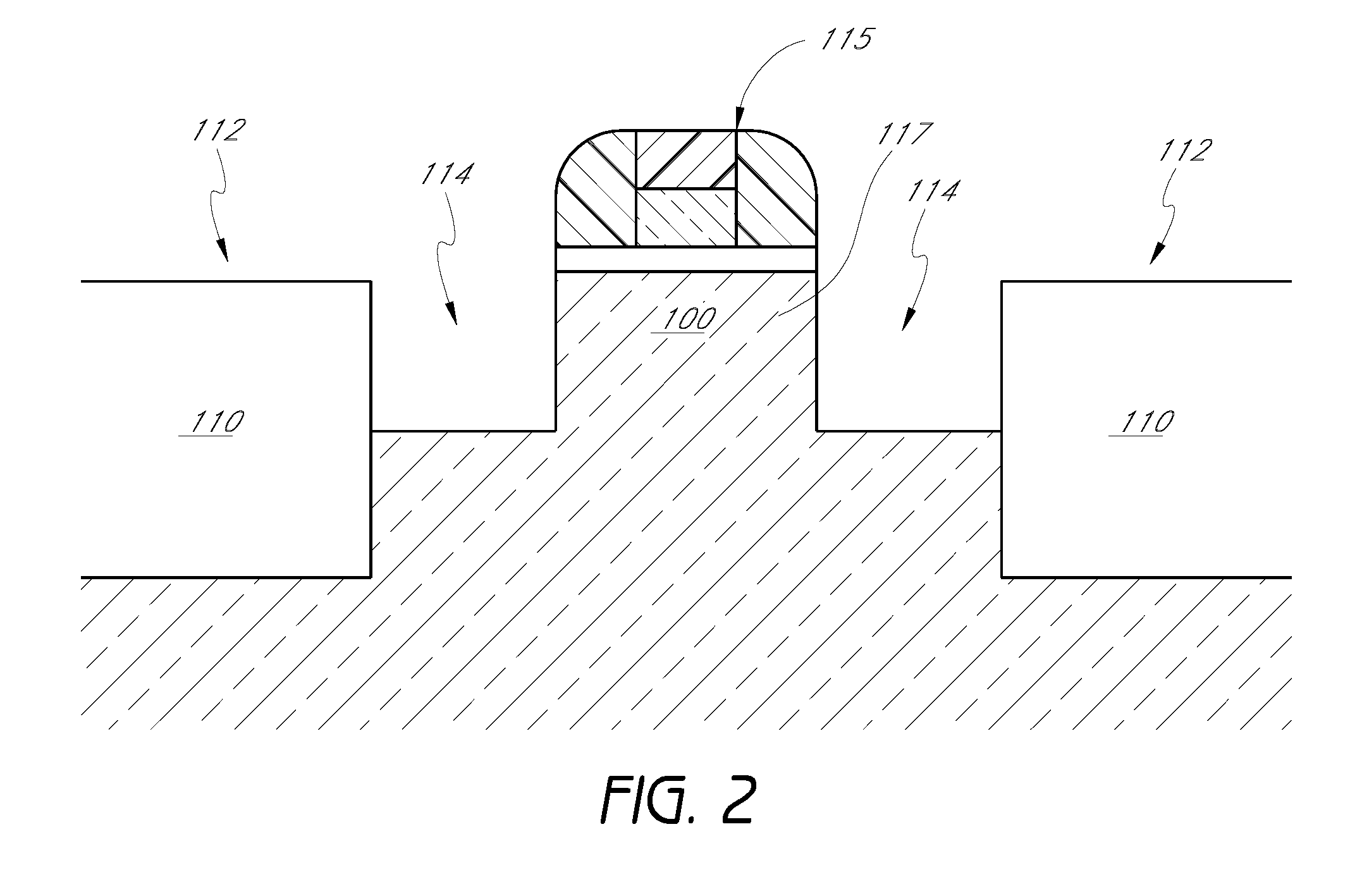

ActiveUS8278176B2Semiconductor/solid-state device manufacturingSemiconductor devicesCyclic processMetallurgy

Epitaxial layers are selectively formed in semiconductor windows by a cyclical process of repeated blanket deposition and selective etching. The blanket deposition phases leave non-epitaxial material over insulating regions, such as field oxide, and the selective etch phases preferentially remove non-epitaxial material while deposited epitaxial material builds up cycle-by-cycle. Quality of the epitaxial material improves relative to selective processes where no deposition occurs on insulators. Use of a germanium catalyst during the etch phases of the process aid etch rates and facilitate economical maintenance of isothermal and / or isobaric conditions throughout the cycles. Throughput and quality are improved by use of trisilane, formation of amorphous material over the insulating regions and minimizing the thickness ratio of amorphous:epitaxial material in each deposition phase.

Owner:ASM IP HLDG BV

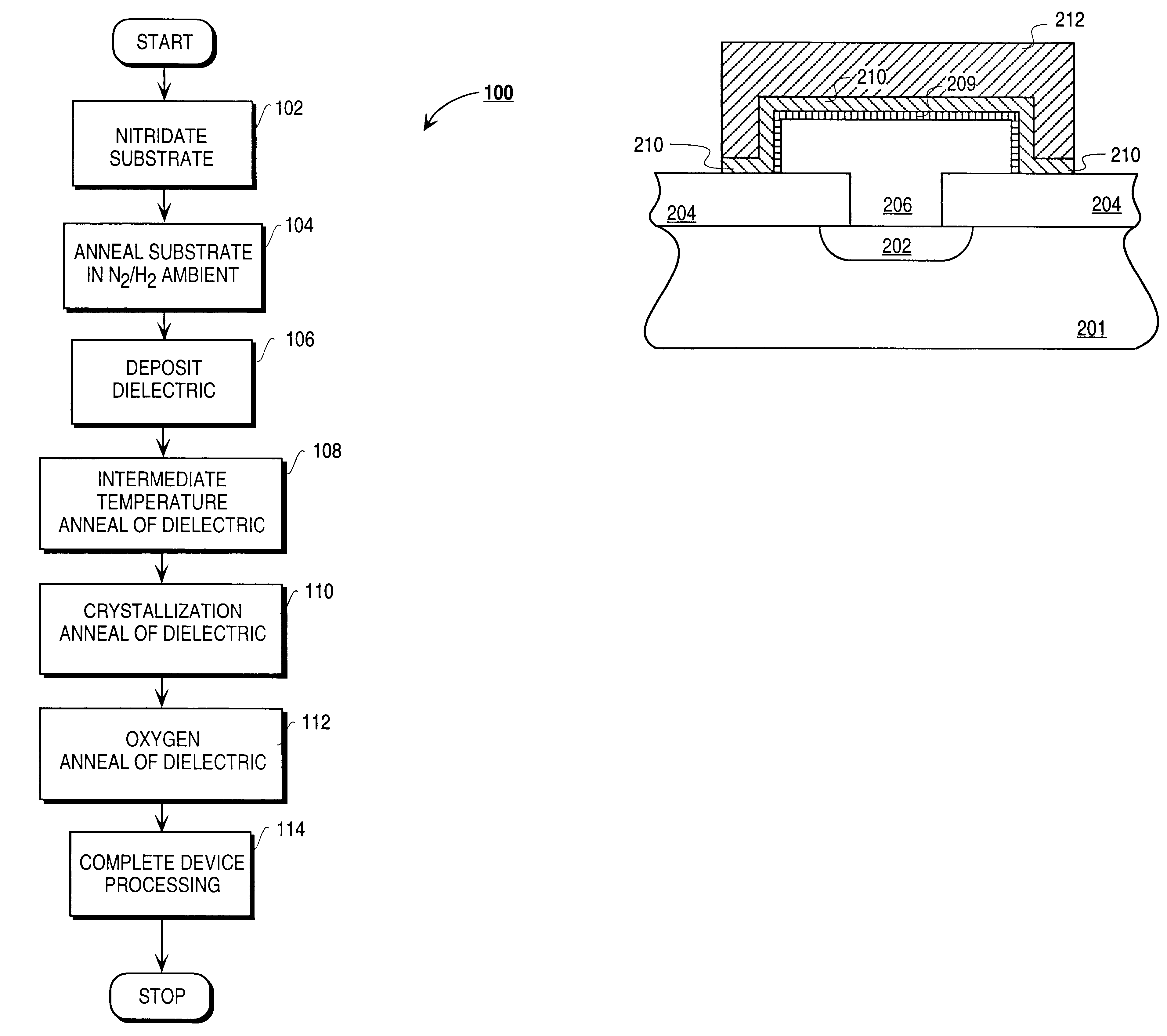

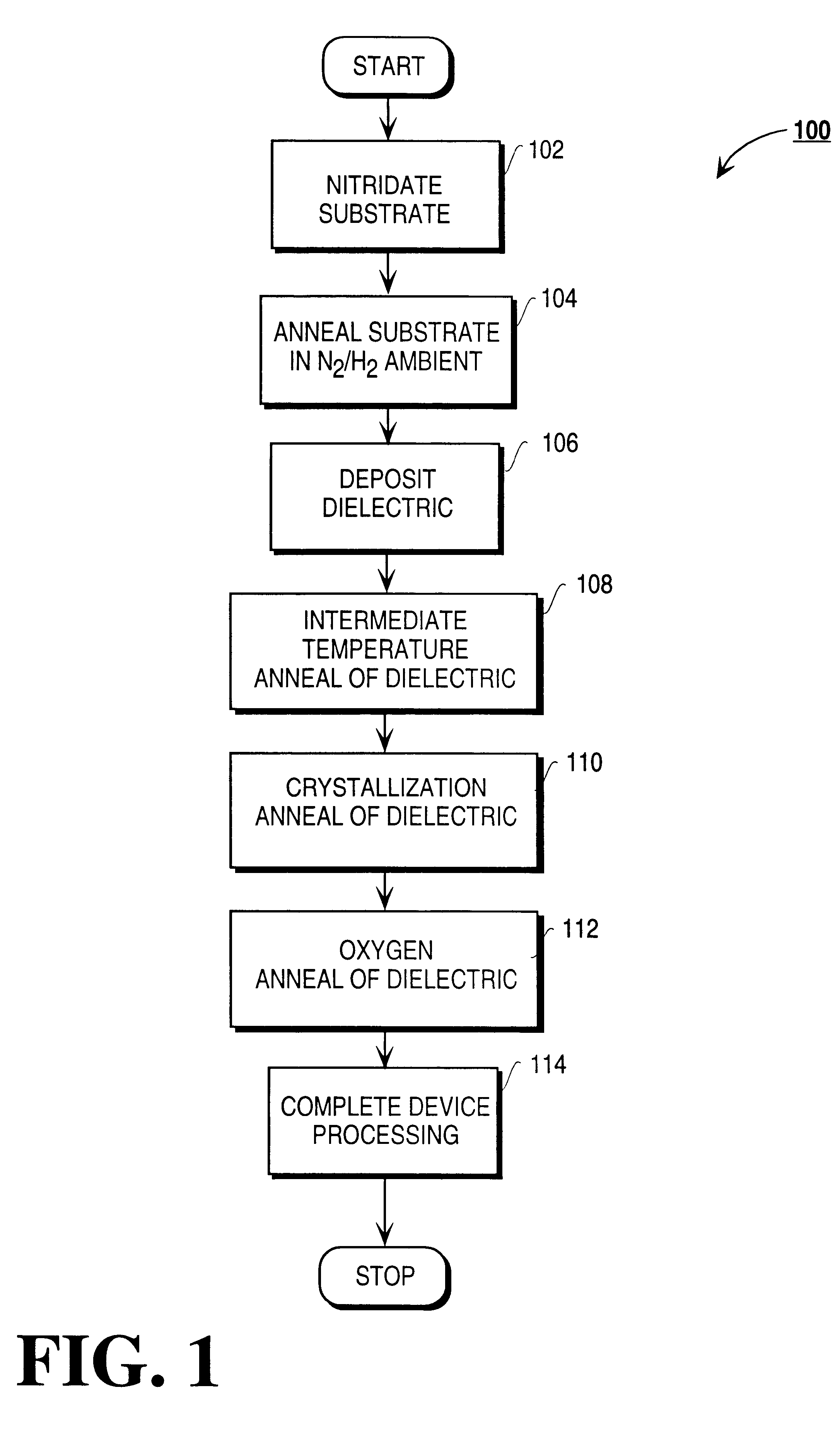

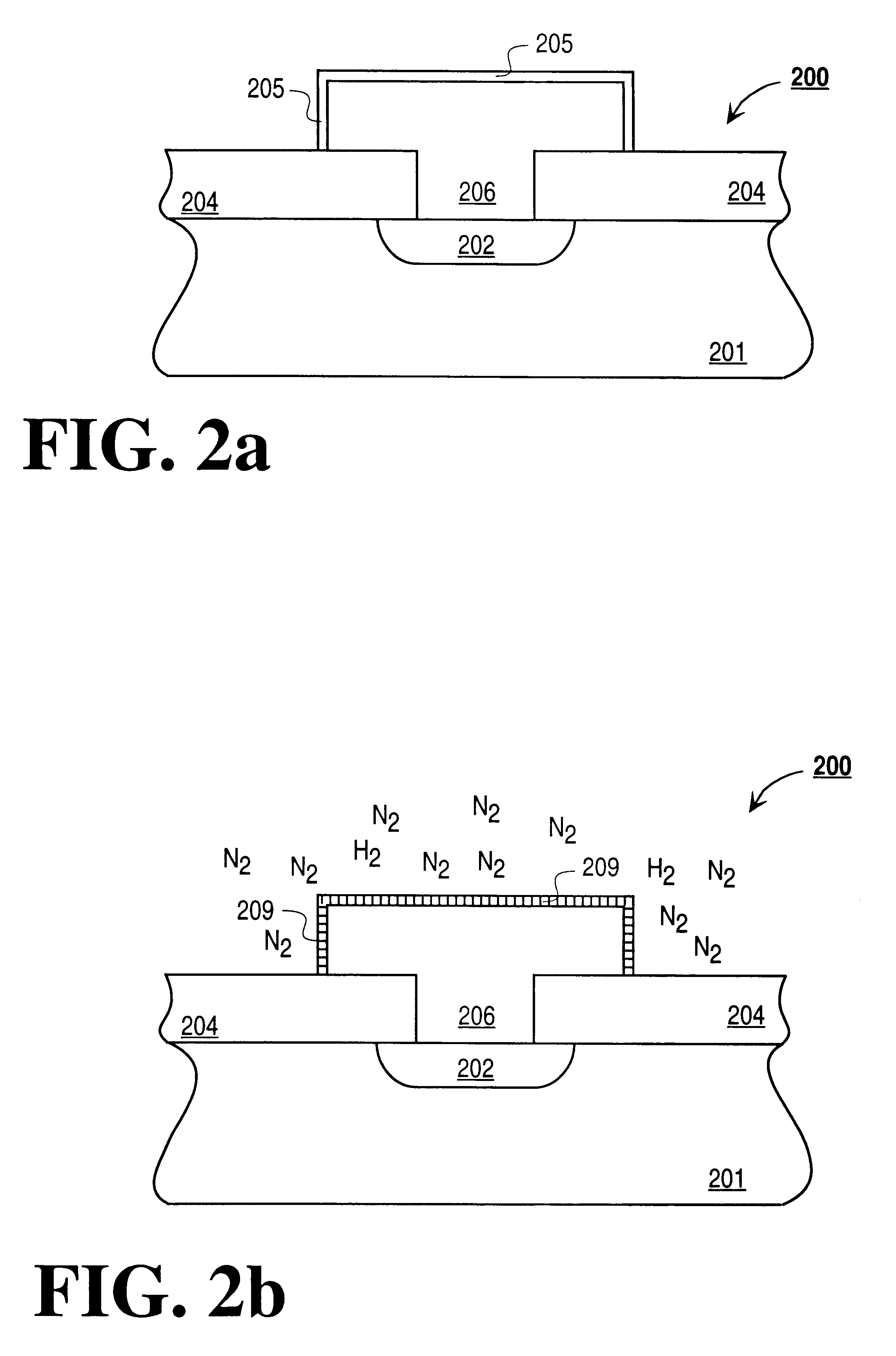

Post deposition treatment of dielectric films for interface control

A method of forming a metal oxide dielectric film. According to the present invention an amorphous metal oxide dielectric film is deposited over a substrate utilizing a metal organic precursor. The substrate is then heated in an inert ambient to convert the amorphous metal oxide dielectric to a polycrystalline metal oxide dielectric. The polycrystalline metal dielectric is then heated in a oxygen containing ambients.

Owner:APPLIED MATERIALS INC

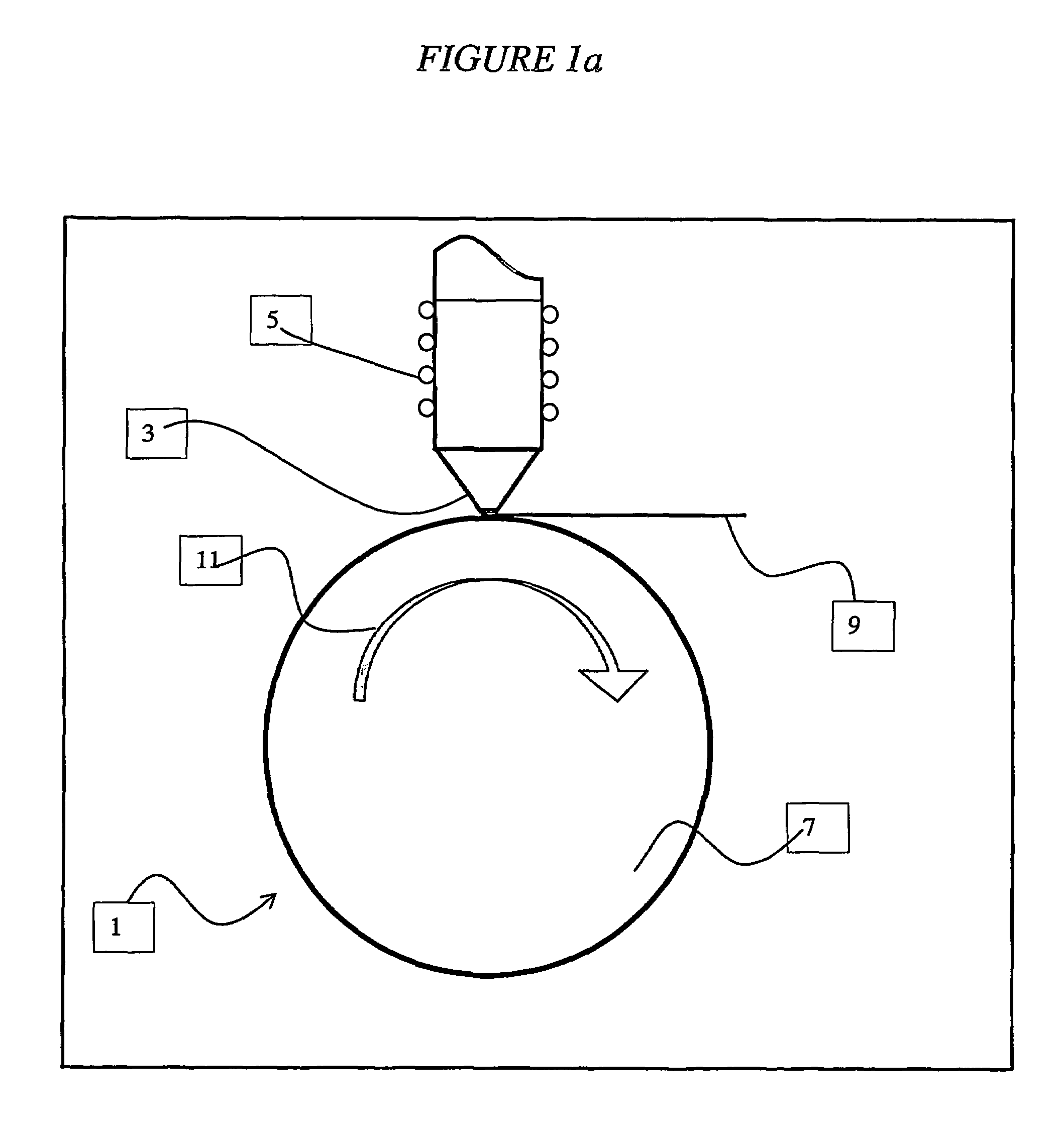

Continuous casting of bulk solidifying amorphous alloys

Owner:CRUCIBLE INTPROP LLC

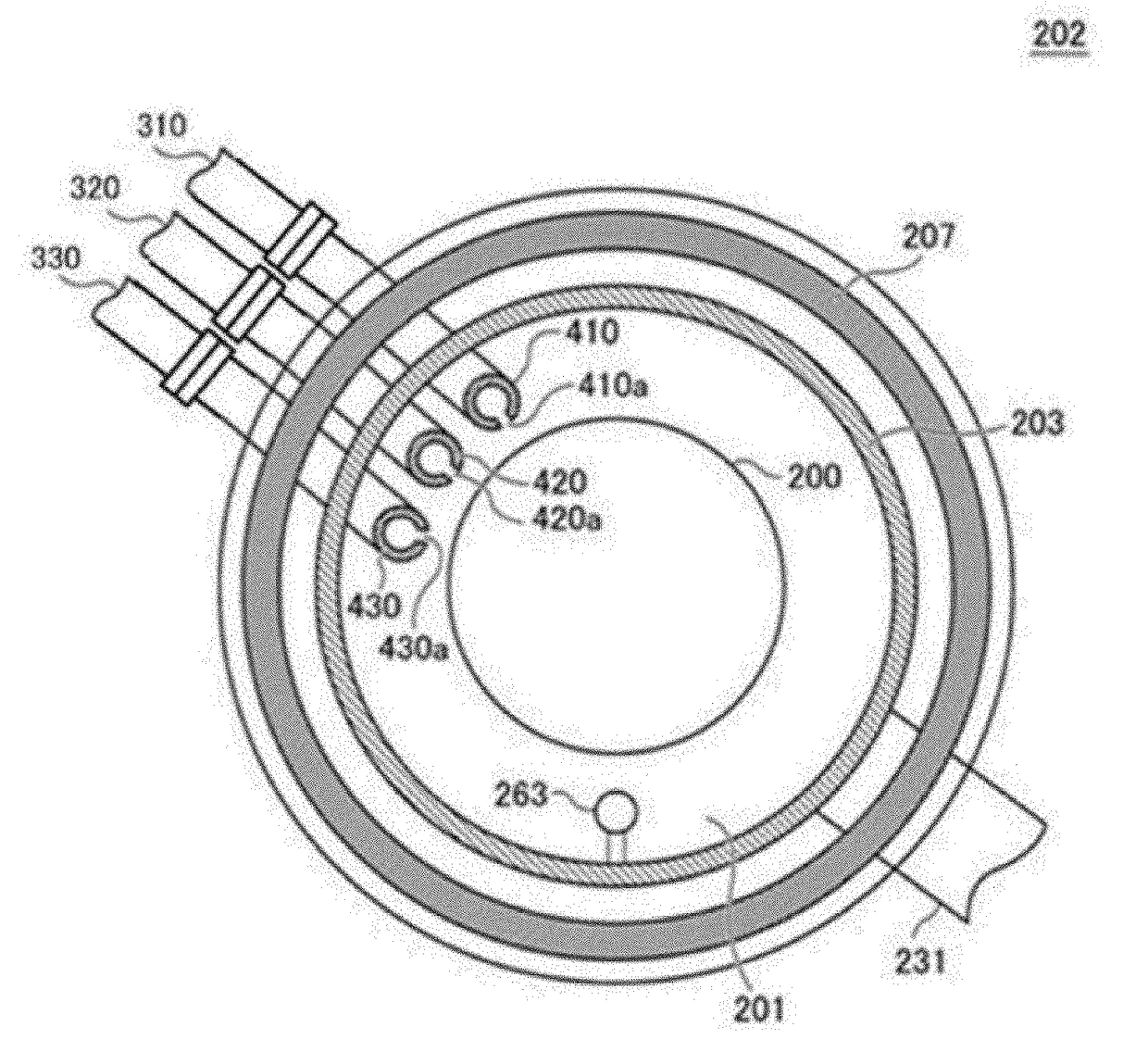

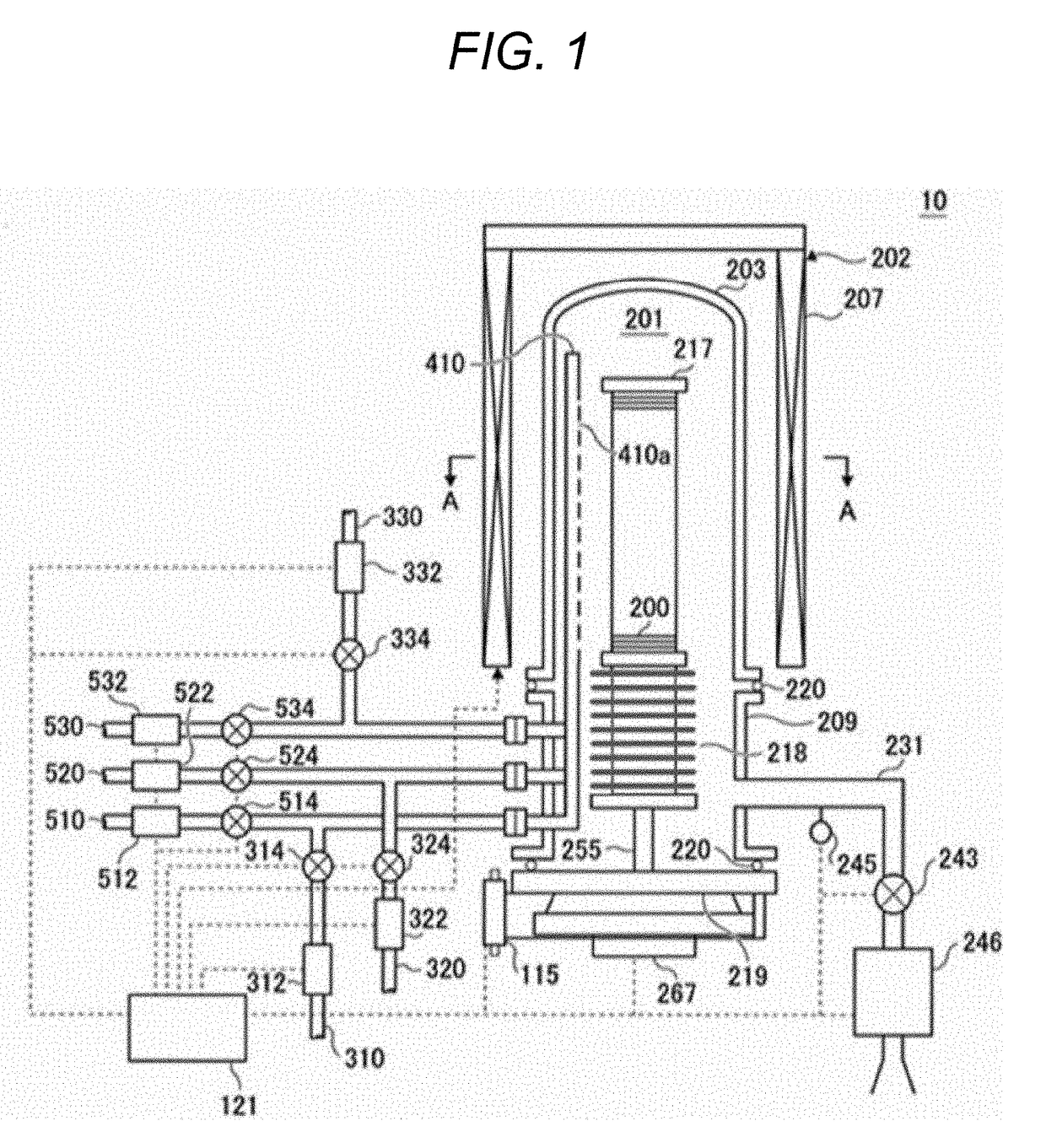

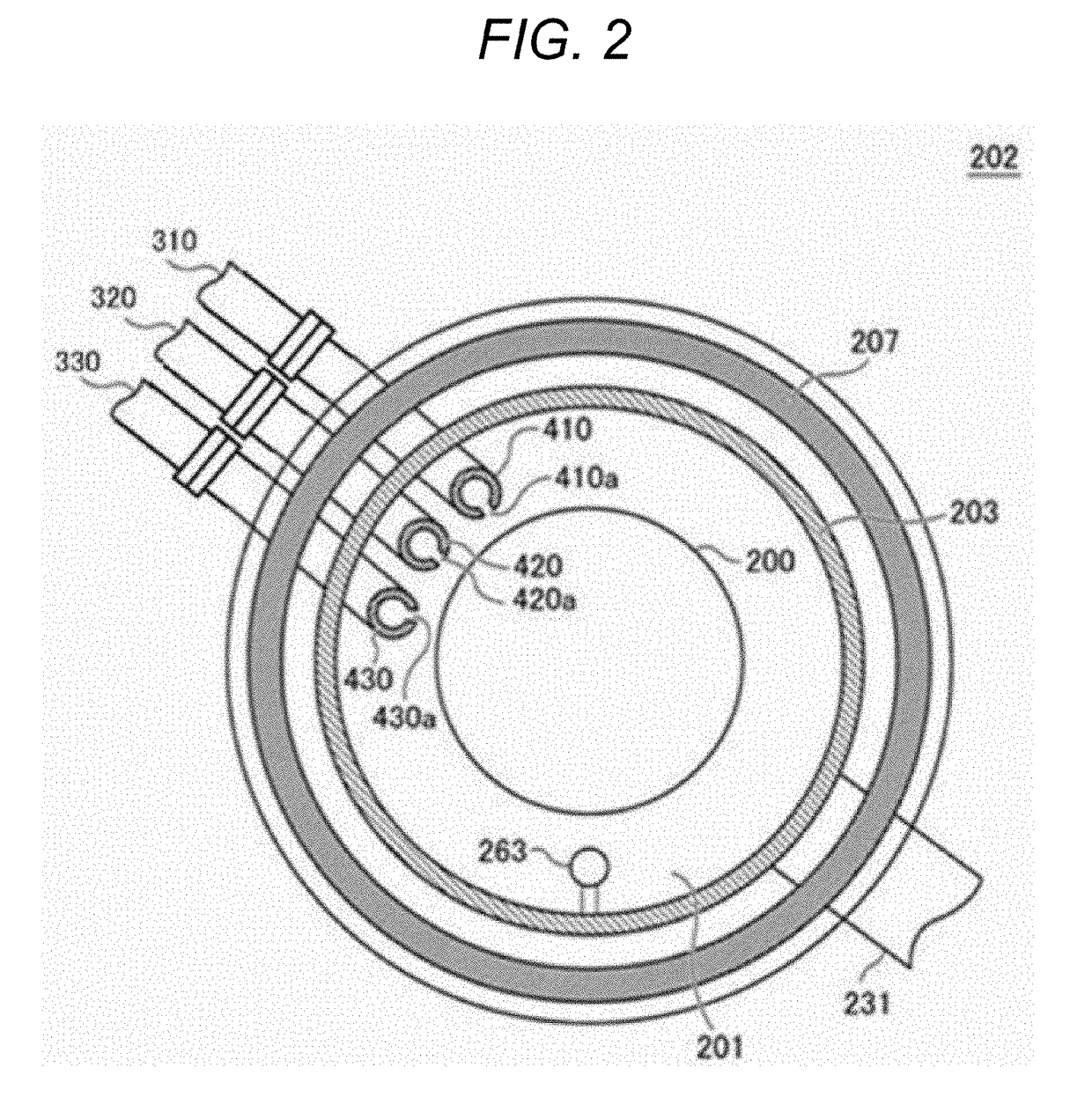

Method of manufacturing semiconductor device

PendingUS20170309490A1Reduce roughnessLow resistivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductorAmorphous metal

A method of manufacturing a semiconductor device includes: forming an amorphous metal film on a substrate by time-divisionally conducting a cycle a predetermined number of times, the cycle including: (a) simultaneously supplying a metal-containing gas and a first reducing gas to the substrate to form a first amorphous metal layer on the substrate, and (b) forming a second amorphous metal layer on the first amorphous metal layer by time-divisionally supplying, a predetermined number of times, the metal-containing gas and a second reducing gas to the substrate on which the first amorphous metal layer is formed; and forming a crystallized metal layer on the substrate by simultaneously supplying the metal-containing gas and the first reducing gas to the substrate on which the amorphous metal film is formed.

Owner:KOKUSA ELECTRIC CO LTD

Electrochromic counter electrode

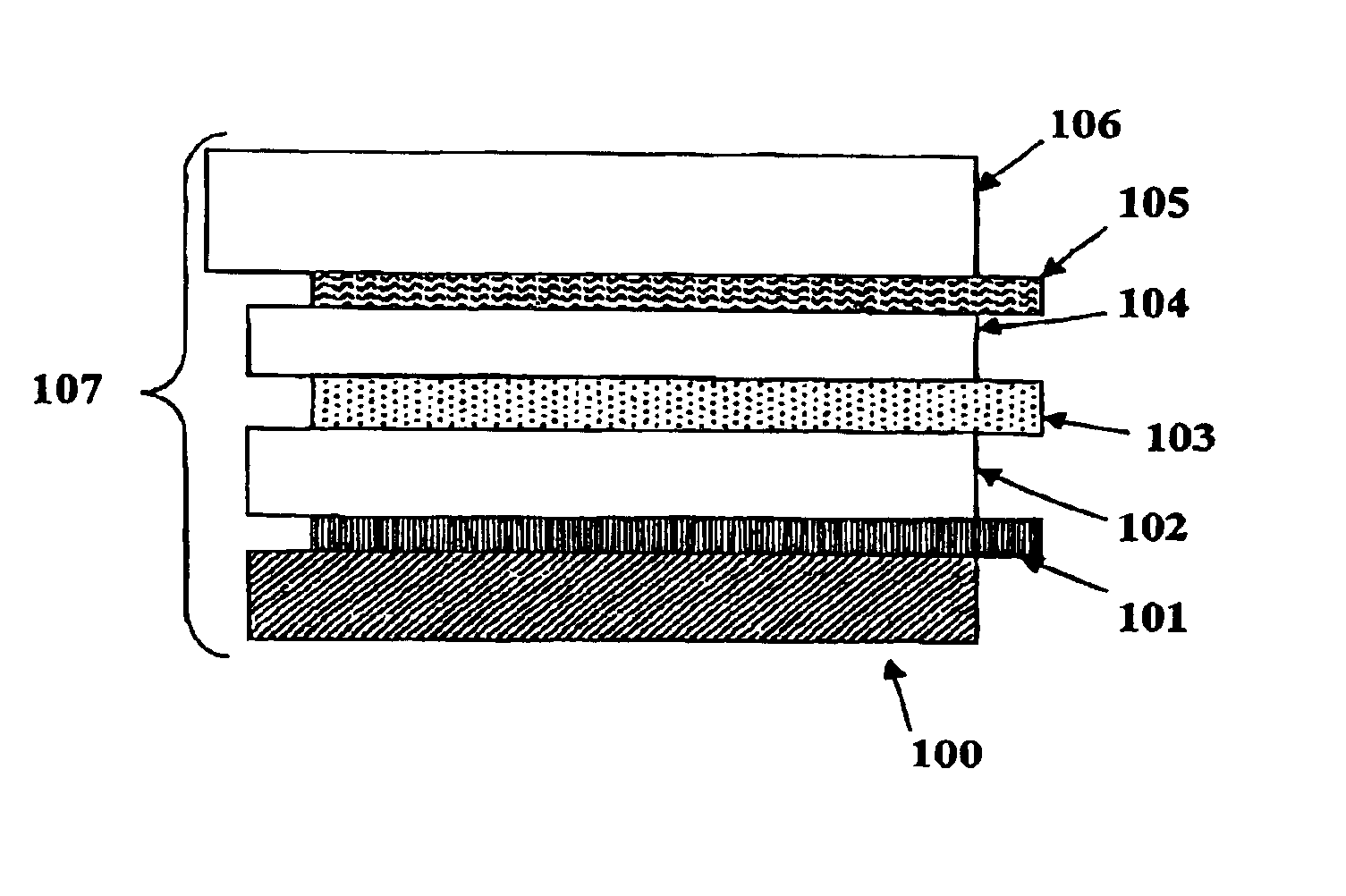

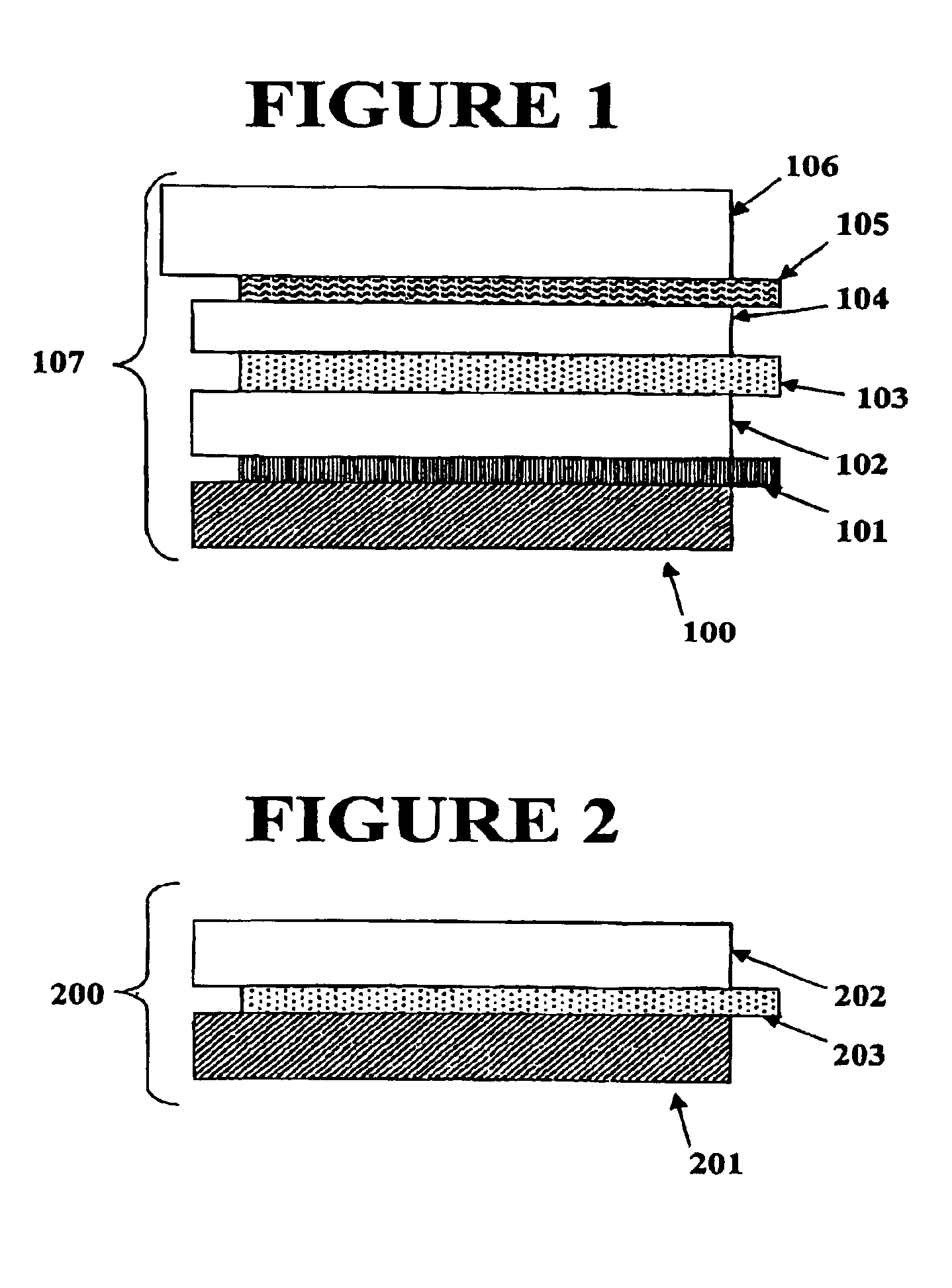

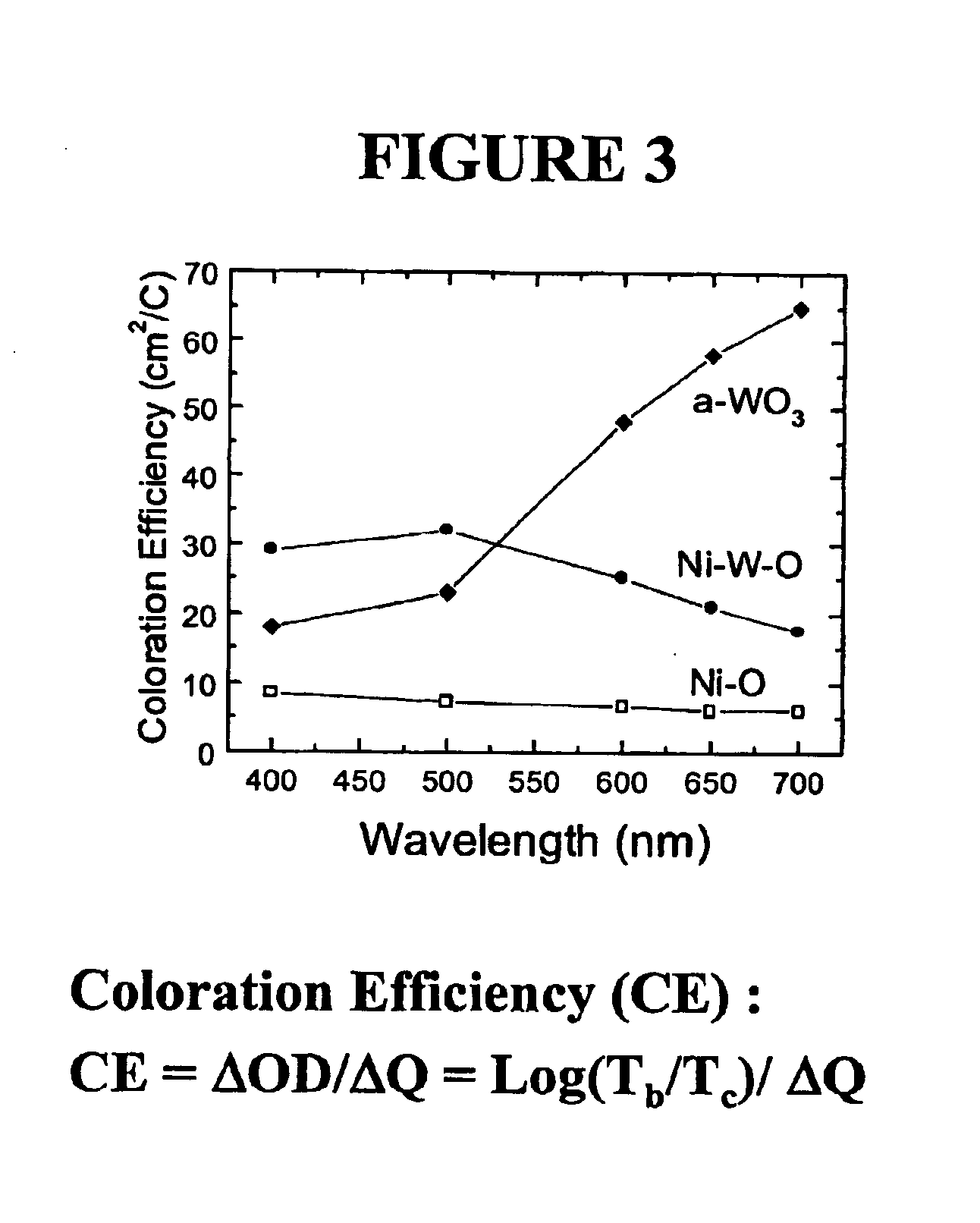

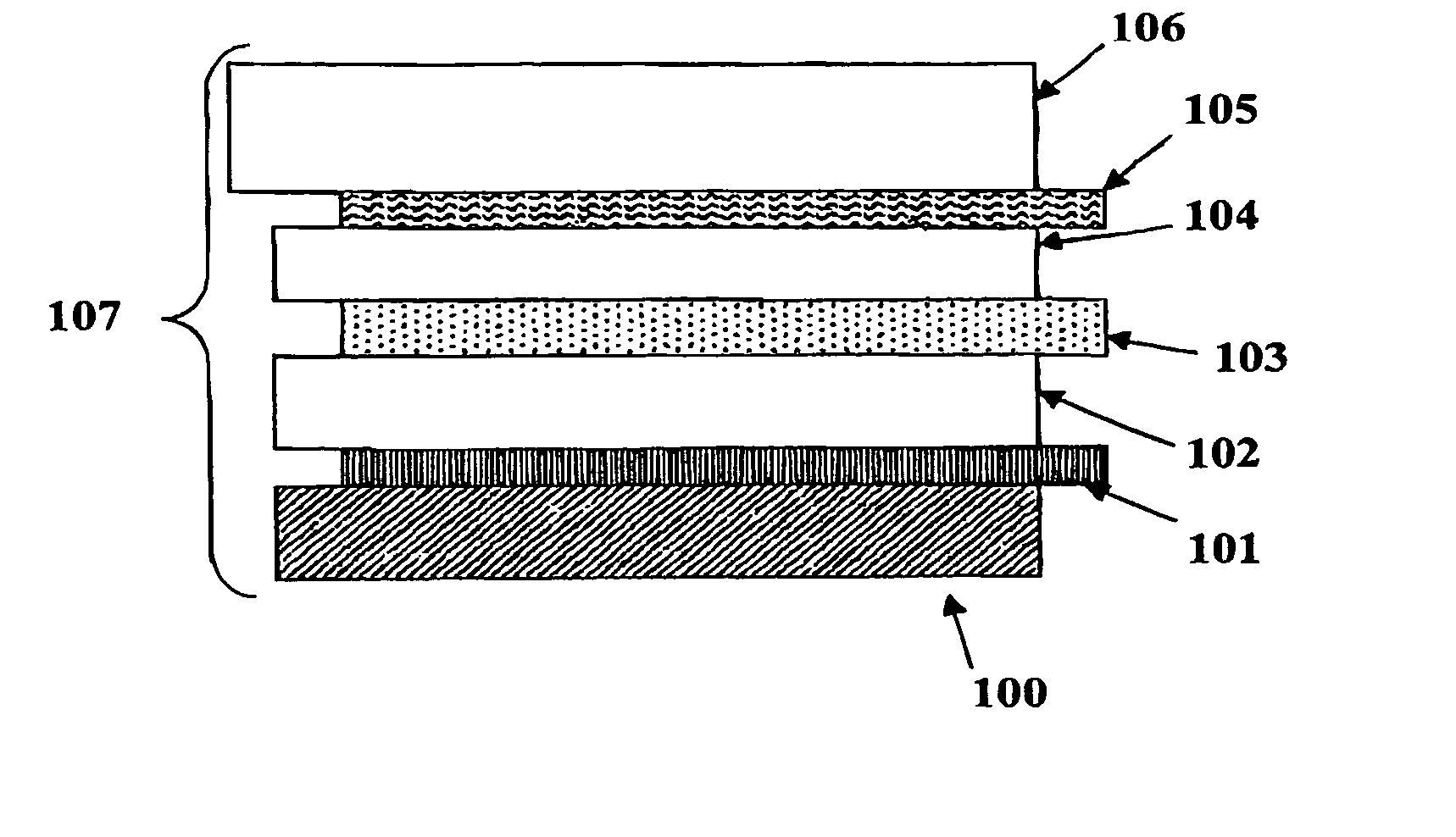

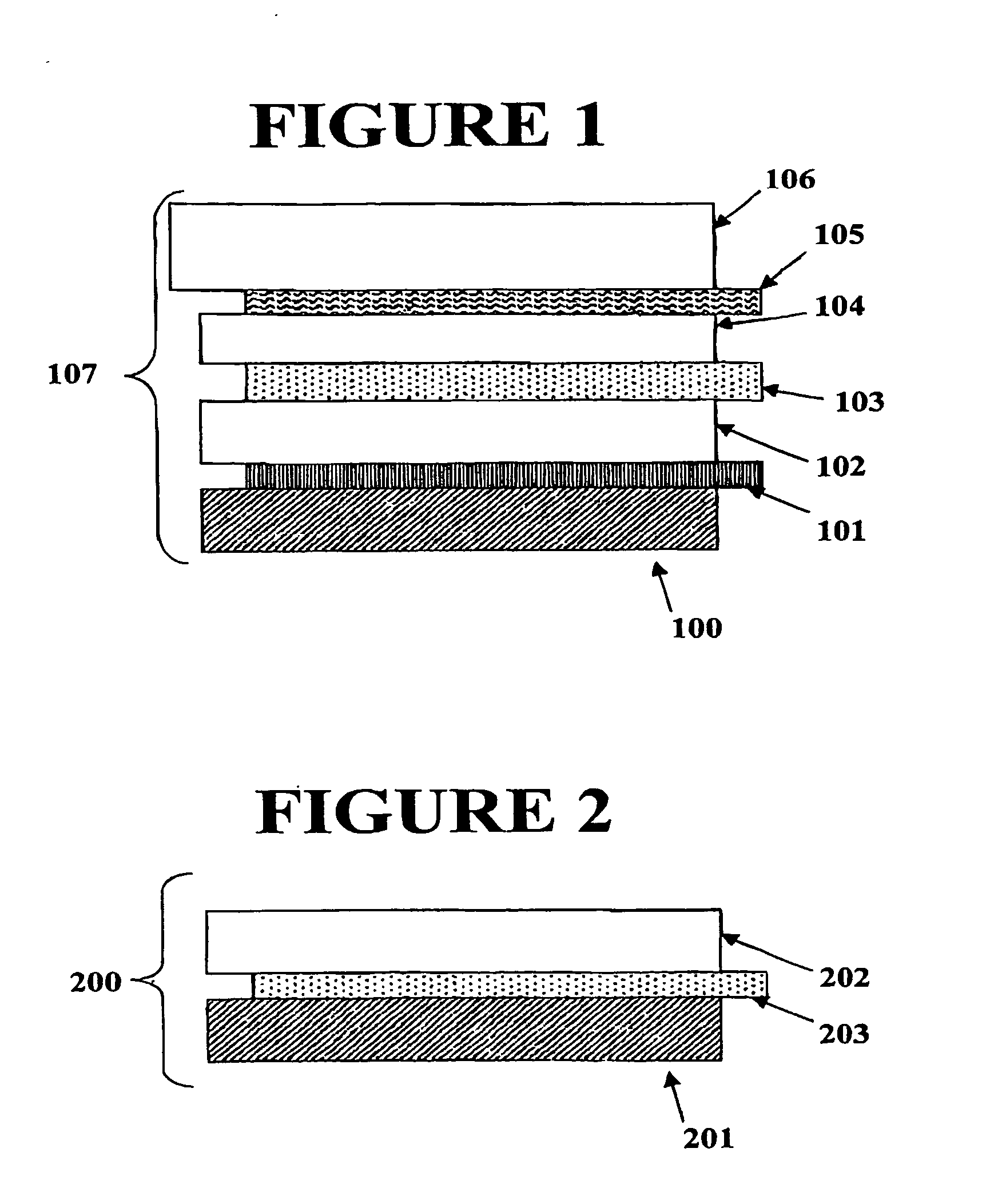

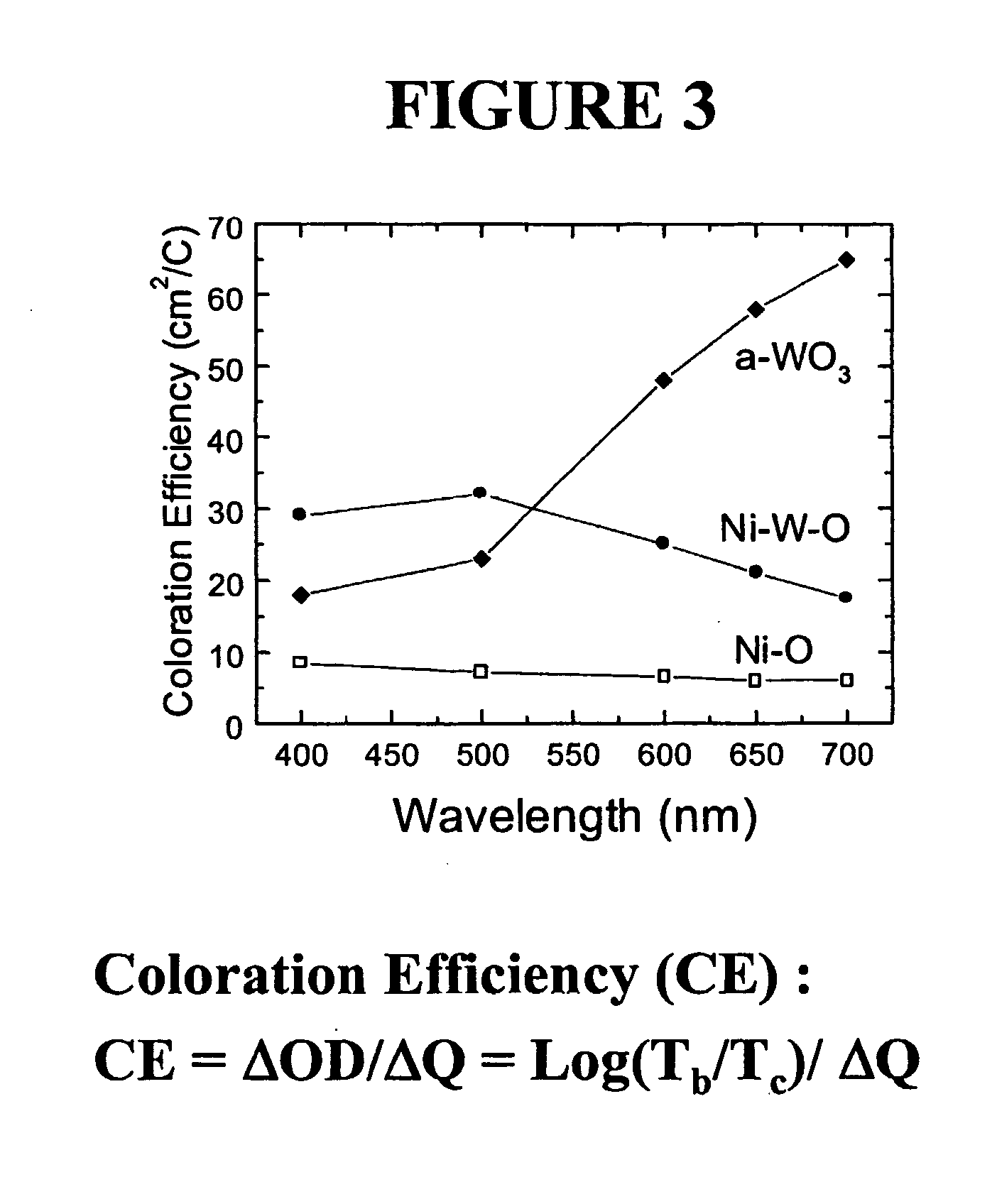

The present invention discloses an amorphous material comprising nickel oxide doped with tantalum that is an anodically coloring electrochromic material. The material of the present invention is prepared in the form of an electrode (200) having a thin film (202) of an electrochromic material of the present invention residing on a transparent conductive film (203). The material of the present invention is also incorporated into an electrochromic device (100) as a thin film (102) in conjunction with a cathodically coloring prior art electrochromic material layer (104) such that the devices contain both anodically coloring (102) and cathodically coloring (104) layers. The materials of the electrochromic layers in these devices exhibit broadband optical complimentary behavior, ionic species complimentary behavior, and coloration efficiency complimentary behavior in their operation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

Electrochromic counter electrode

InactiveUS20040150867A1Easy to calculateSpeed of coloring/bleaching can be alteredNon-linear opticsElectricityElectrochromism

The present invention discloses an amorphous material comprising nickel oxide doped with tantalum that is an anodically coloring electrochromic material. The material of the present invention is prepared in the form of an electrode (200) having a thin film (202) of an electrochromic material of the present invention residing on a transparent conductive film (203). The material of the present invention is also incorporated into an electrochromic device (100) as a thin film (102) in conjunction with a cathodically coloring prior art electrochromic material layer (104) such that the devices contain both anodically coloring (102) and cathodically coloring (104) layers. The materials of the electrochromic layers in these devices exhibit broadband optical complimentary behavior, ionic species complimentary behavior, and coloration efficiency complimentary behavior in their operation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

Efficient high-speed electric device using low-loss materials

InactiveUS7230361B2Reduce lossHigh frequencyMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringHigh torque

The invention relates generally to an electric device, such as an electric motor, a generator, or a regenerative motor, having a wound stator core made from advanced low-loss material. In preferred embodiments, the electric device is an axial airgap-type configuration. The invention provides an electric device having a high pole count that operates at high commutating frequencies, with high efficiency and high torque and power densities. Advanced low-loss materials exploited by the present invention include amorphous metals, nanocrystalline metals, and optimized Fe-based alloys.

Owner:BERG & BERG ENTERPRISES

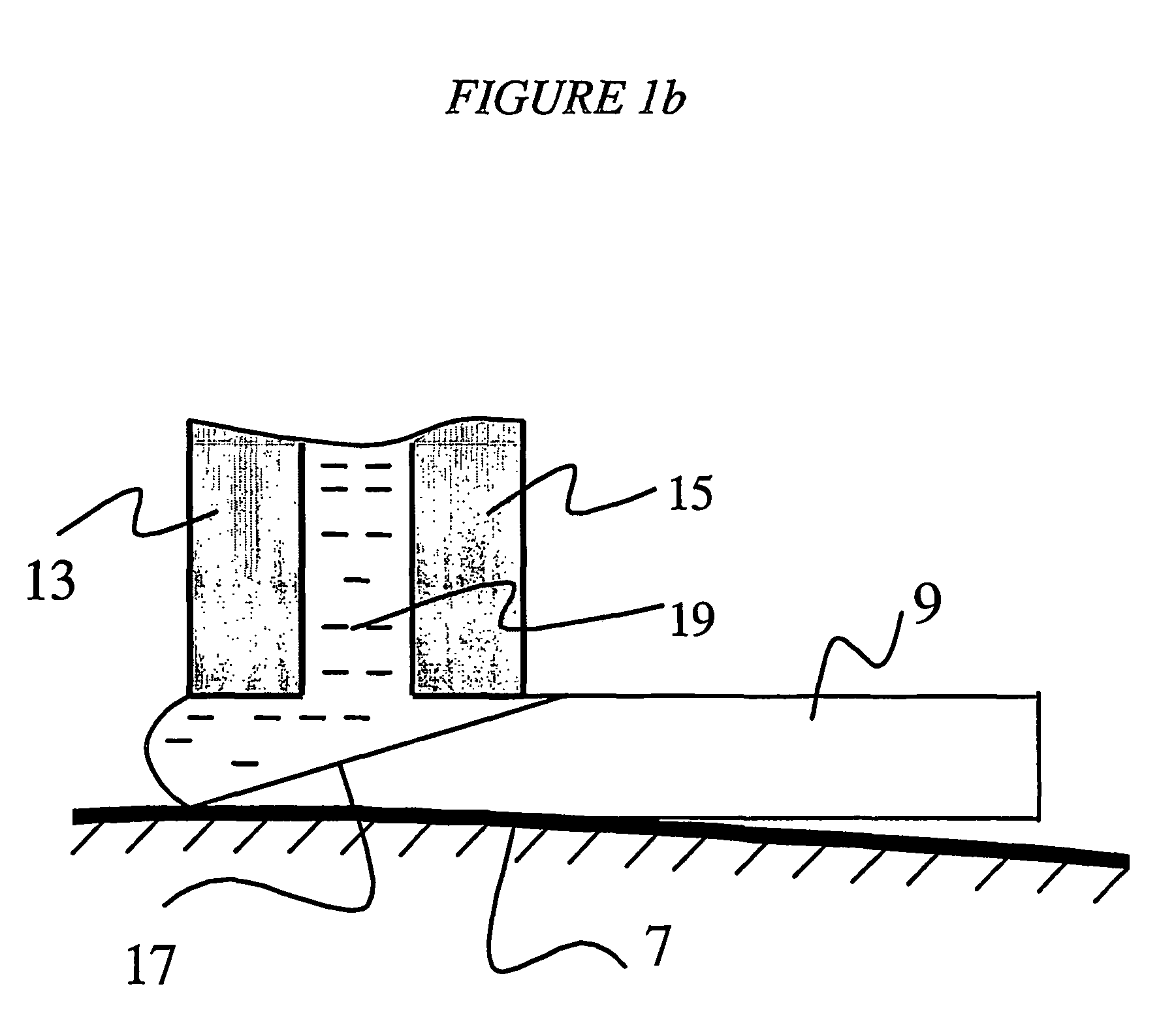

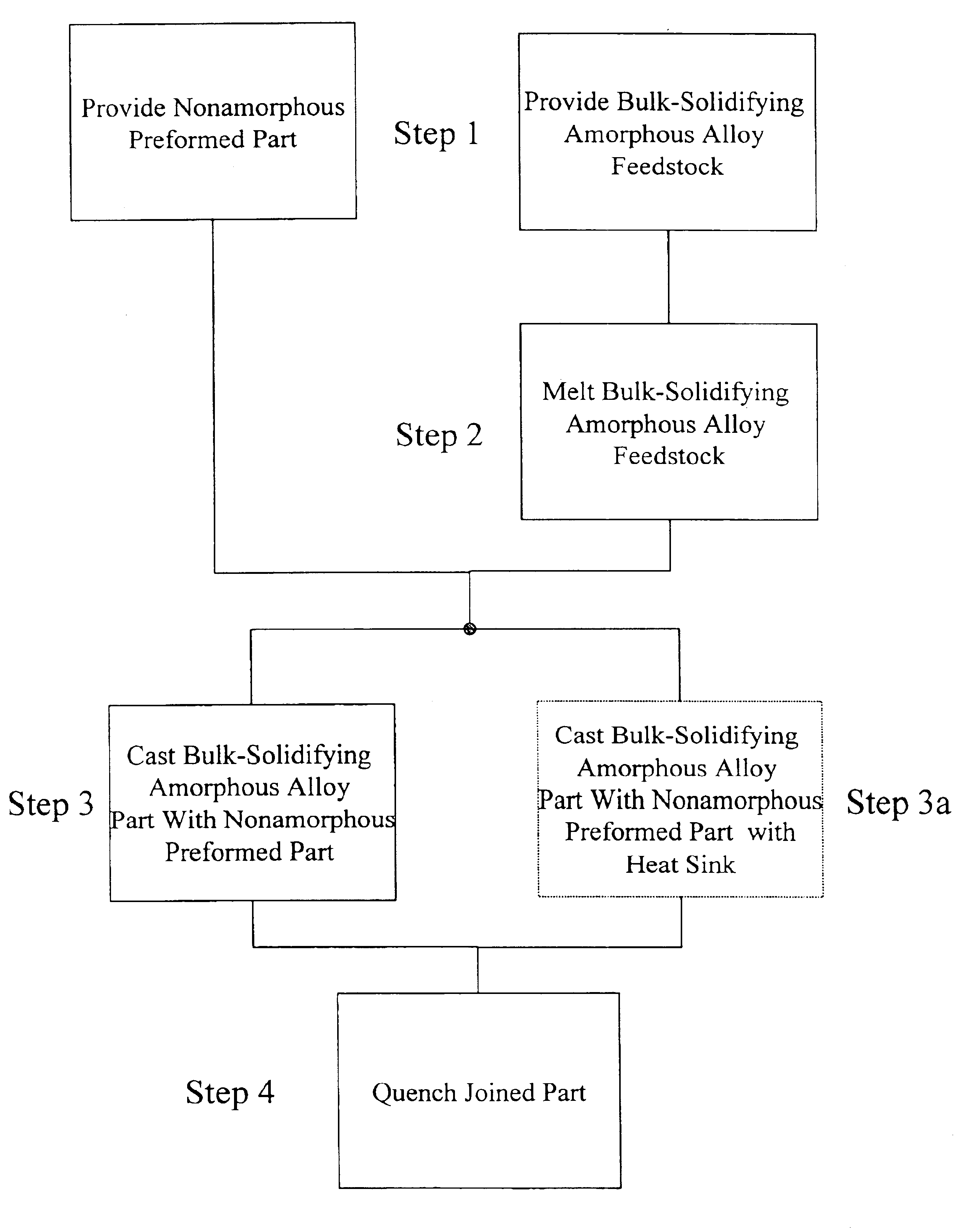

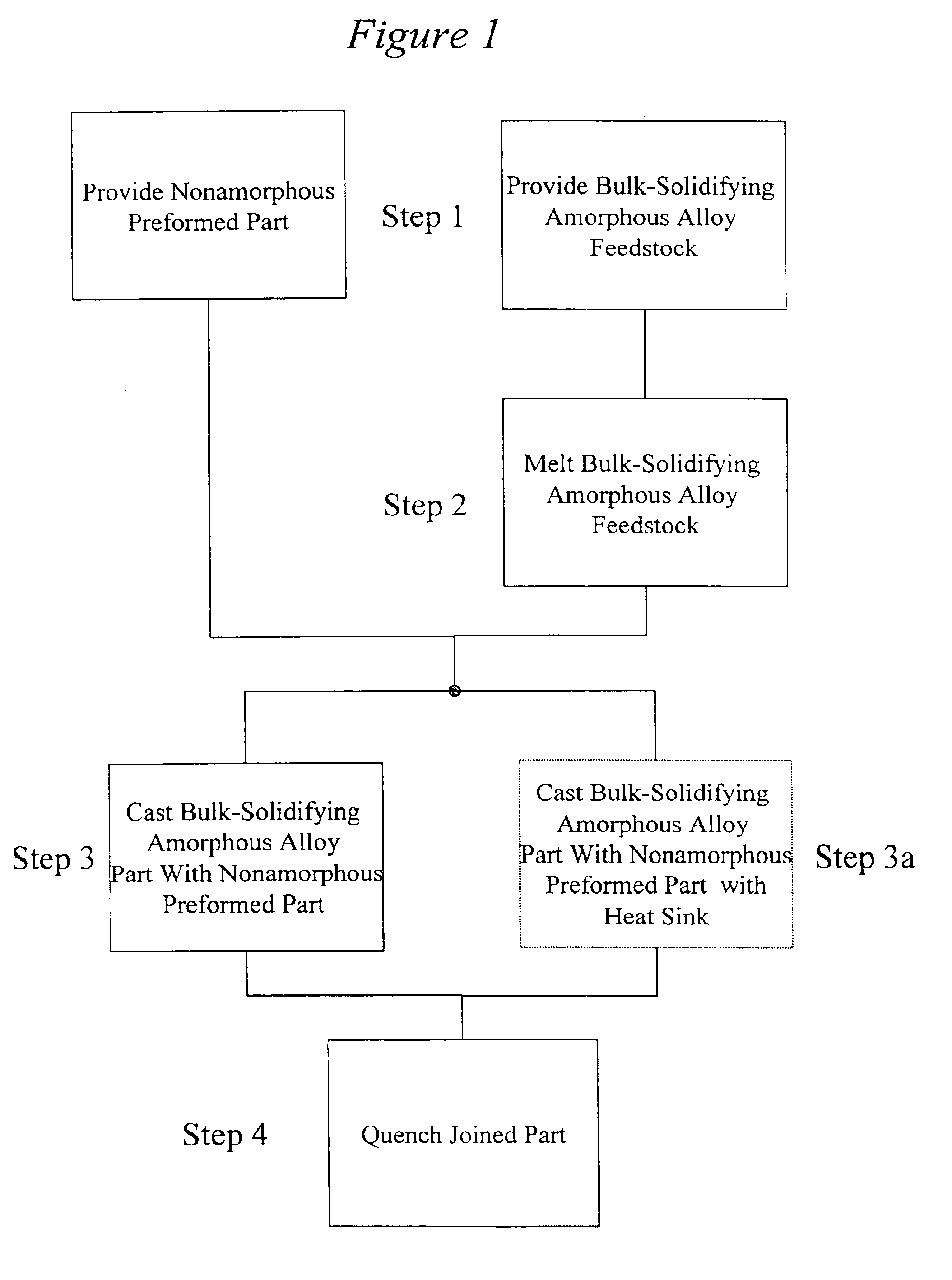

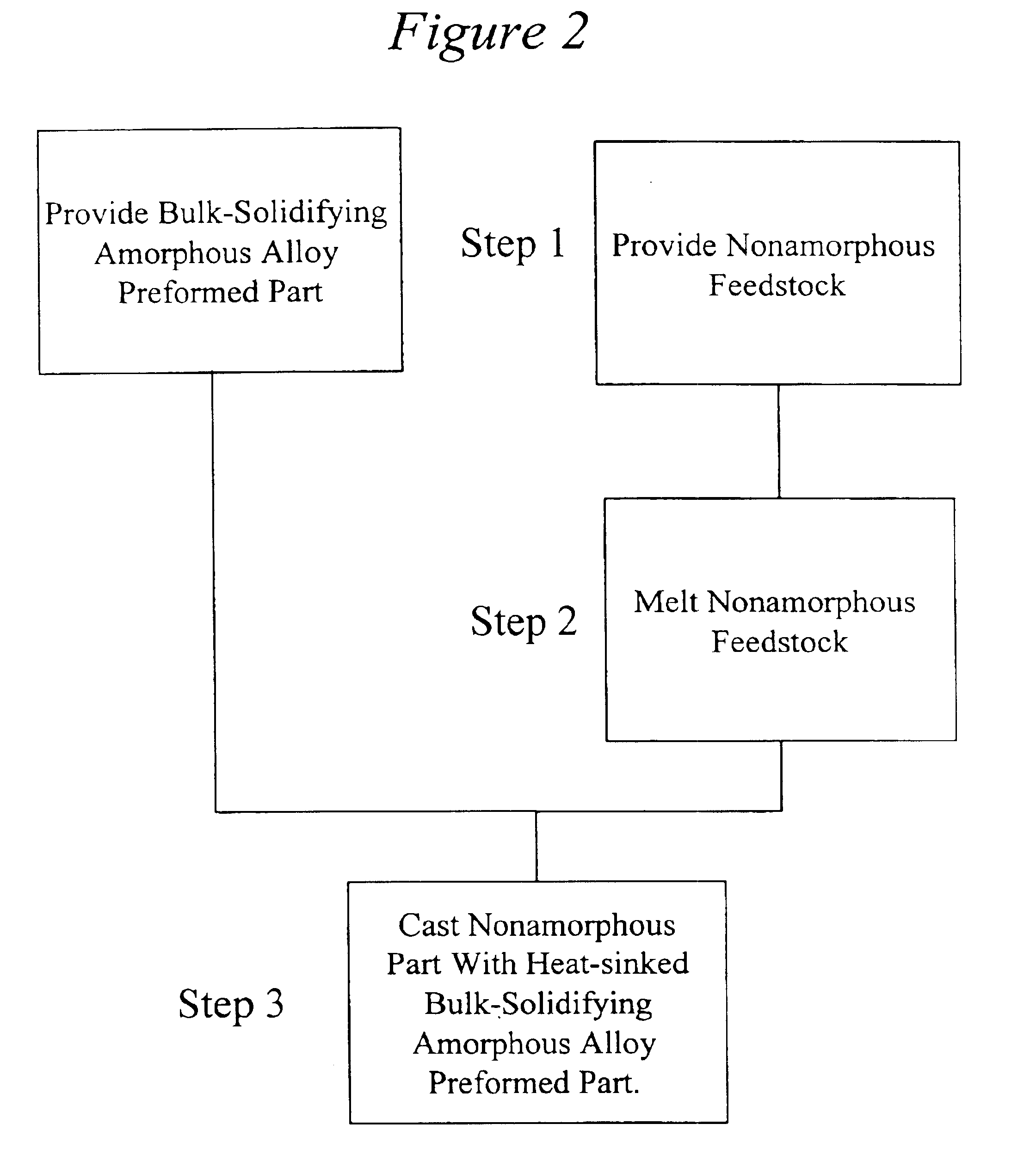

Joining of amorphous metals to other metals utilzing a cast mechanical joint

The present invention is directed to a method of joining an amorphous material to a non-amorphous material including, forming a cast mechanical joint between the bulk solidifying amorphous alloy and the non-amorphous material.

Owner:CRUCIBLE INTPROP LLC

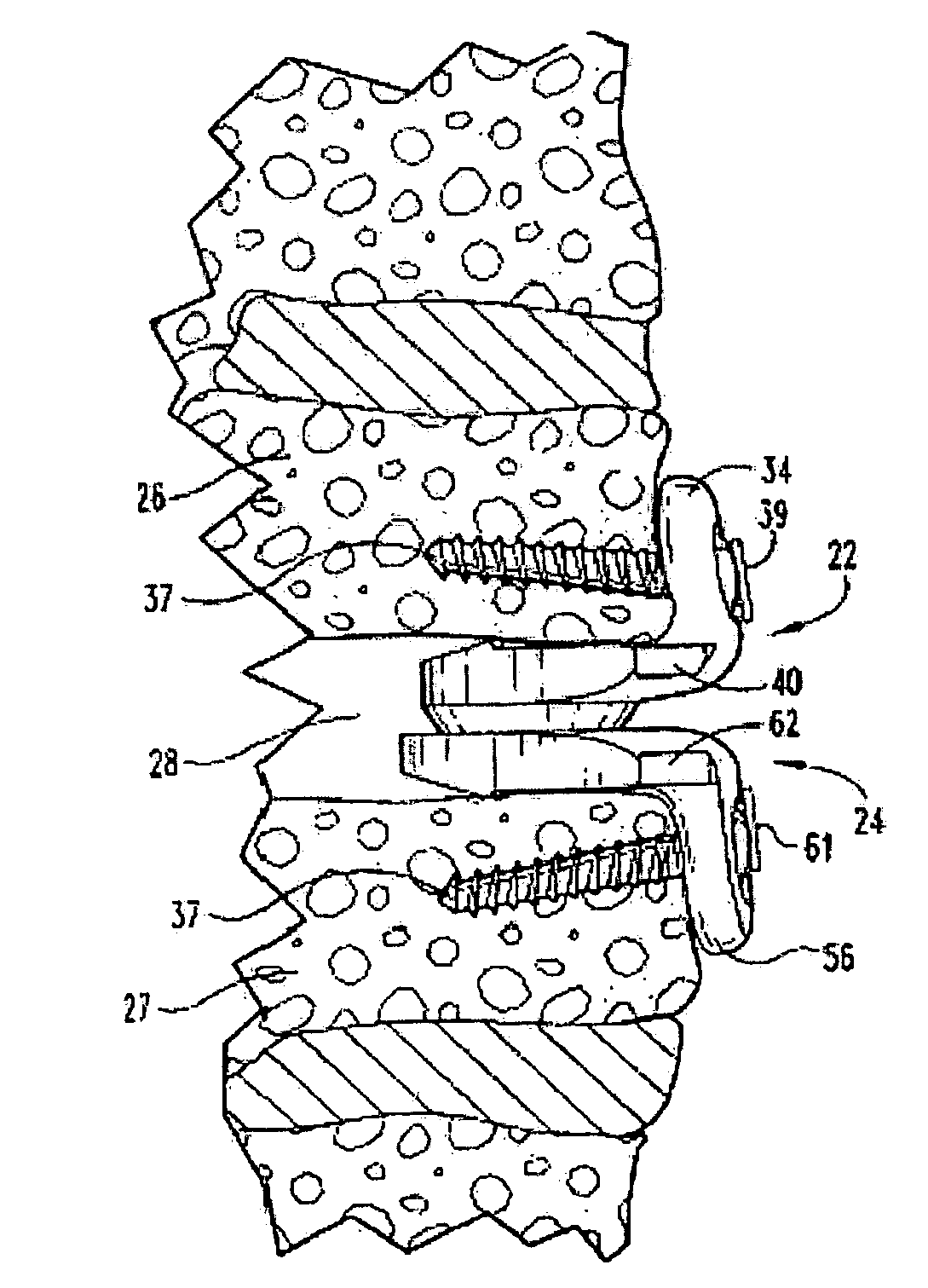

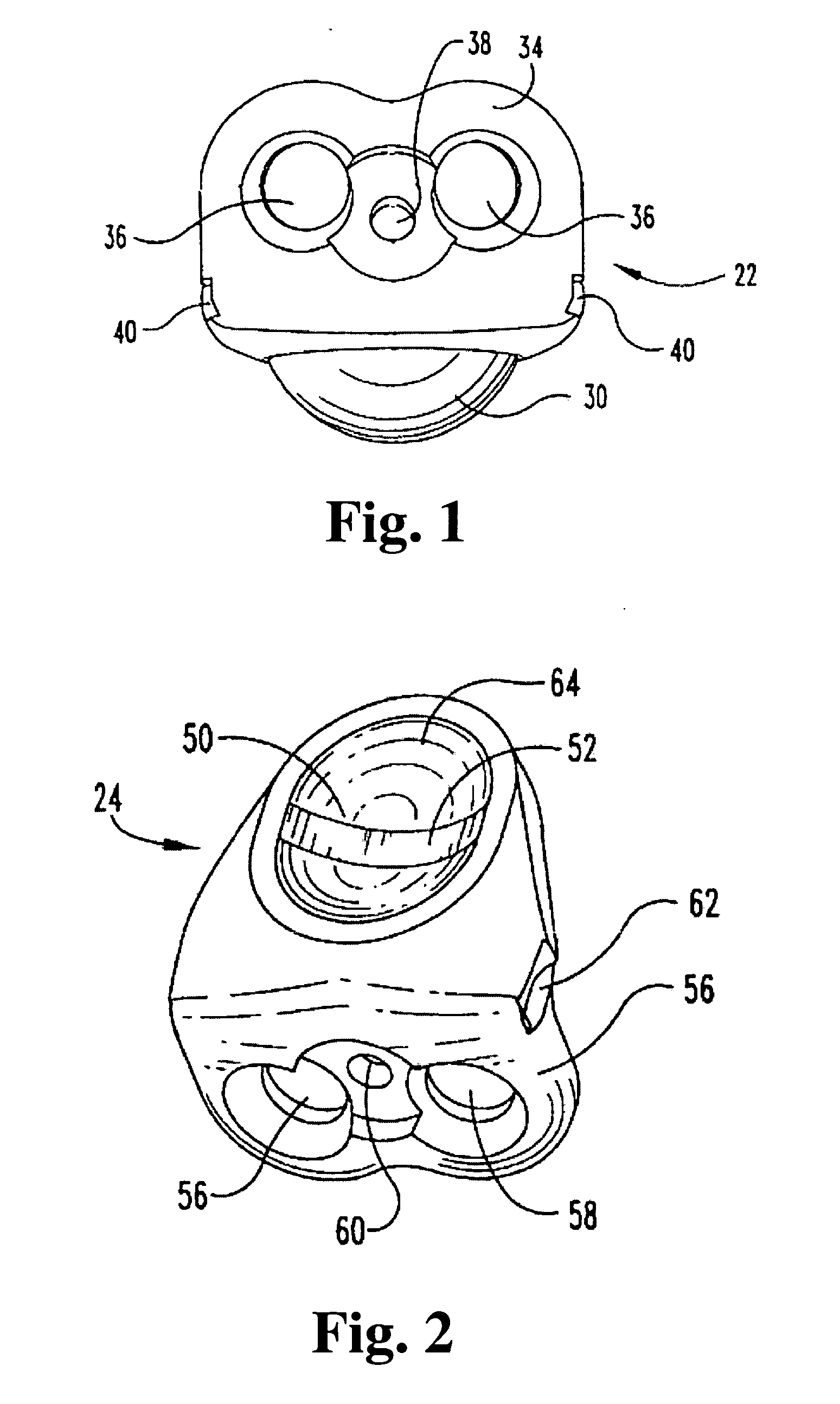

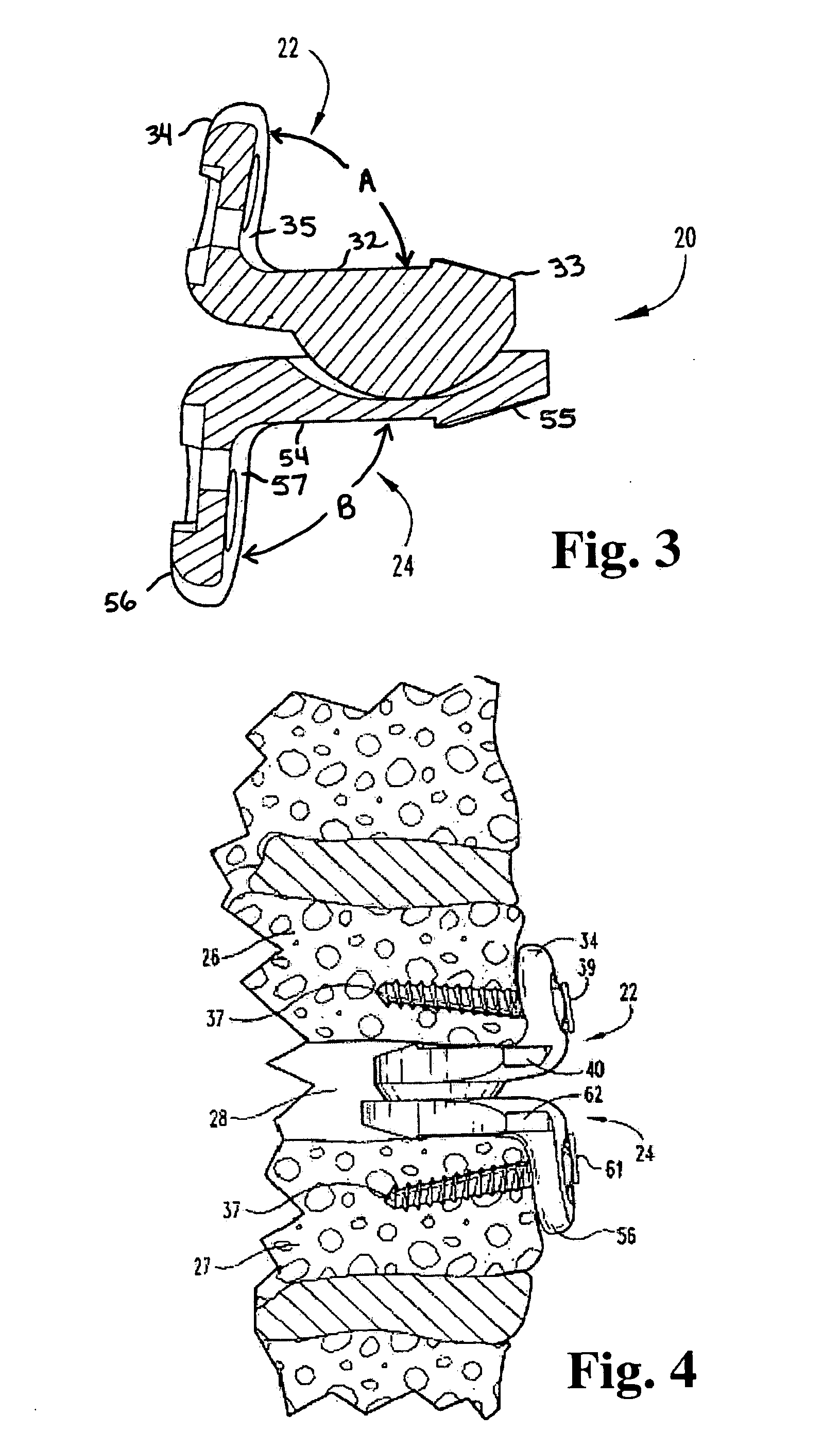

Articulating spinal disc implants with amorphous metal elements

Described are artificial disc implants for insertion between first and second adjacent vertebrae in a patient. The implants have a first member and a second member in articulating relationship. At least one member of the implant includes an amorphous metal element. Also described are related methods of making and using artificial disc implants.

Owner:WARSAW ORTHOPEDIC INC

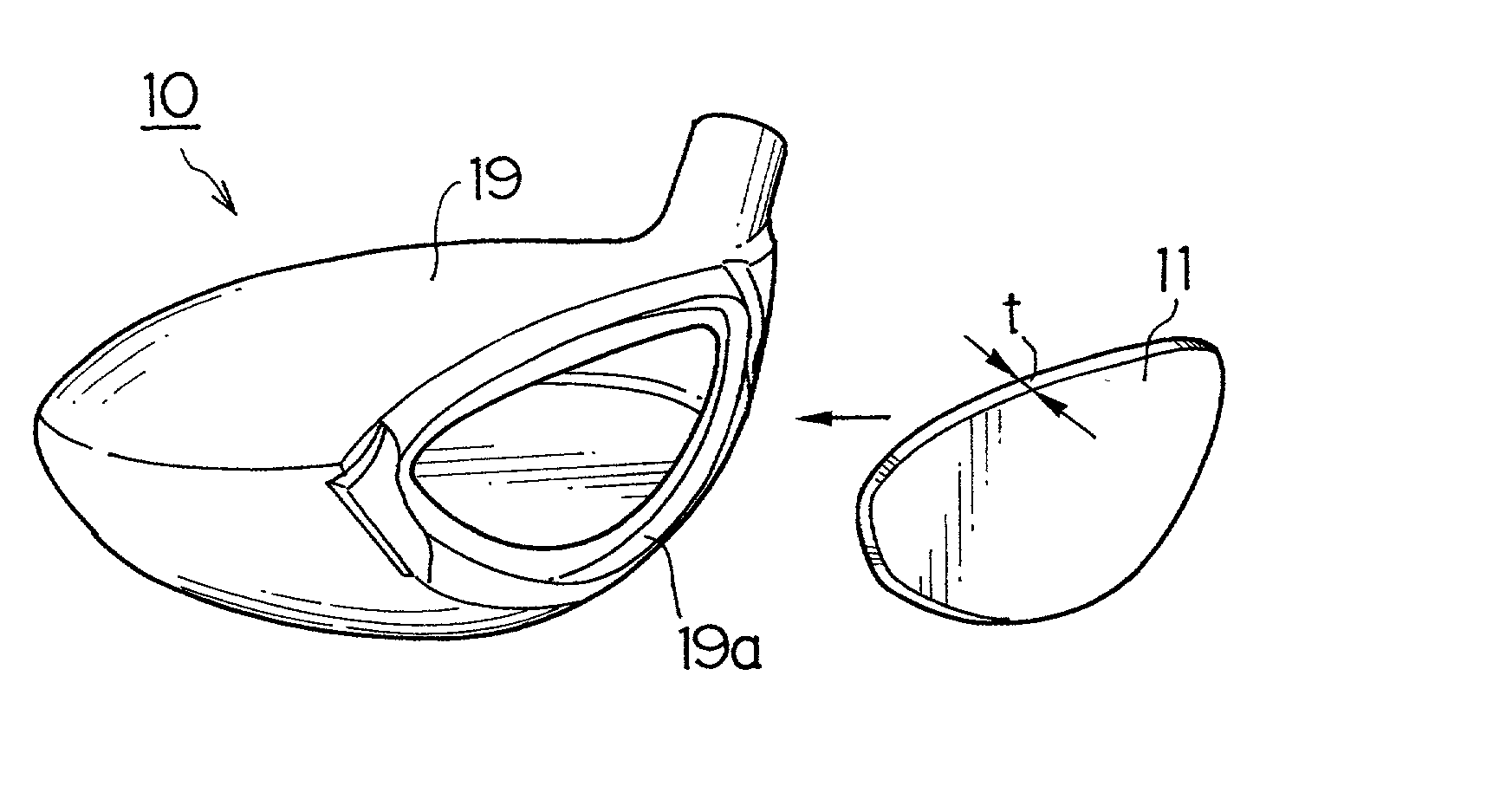

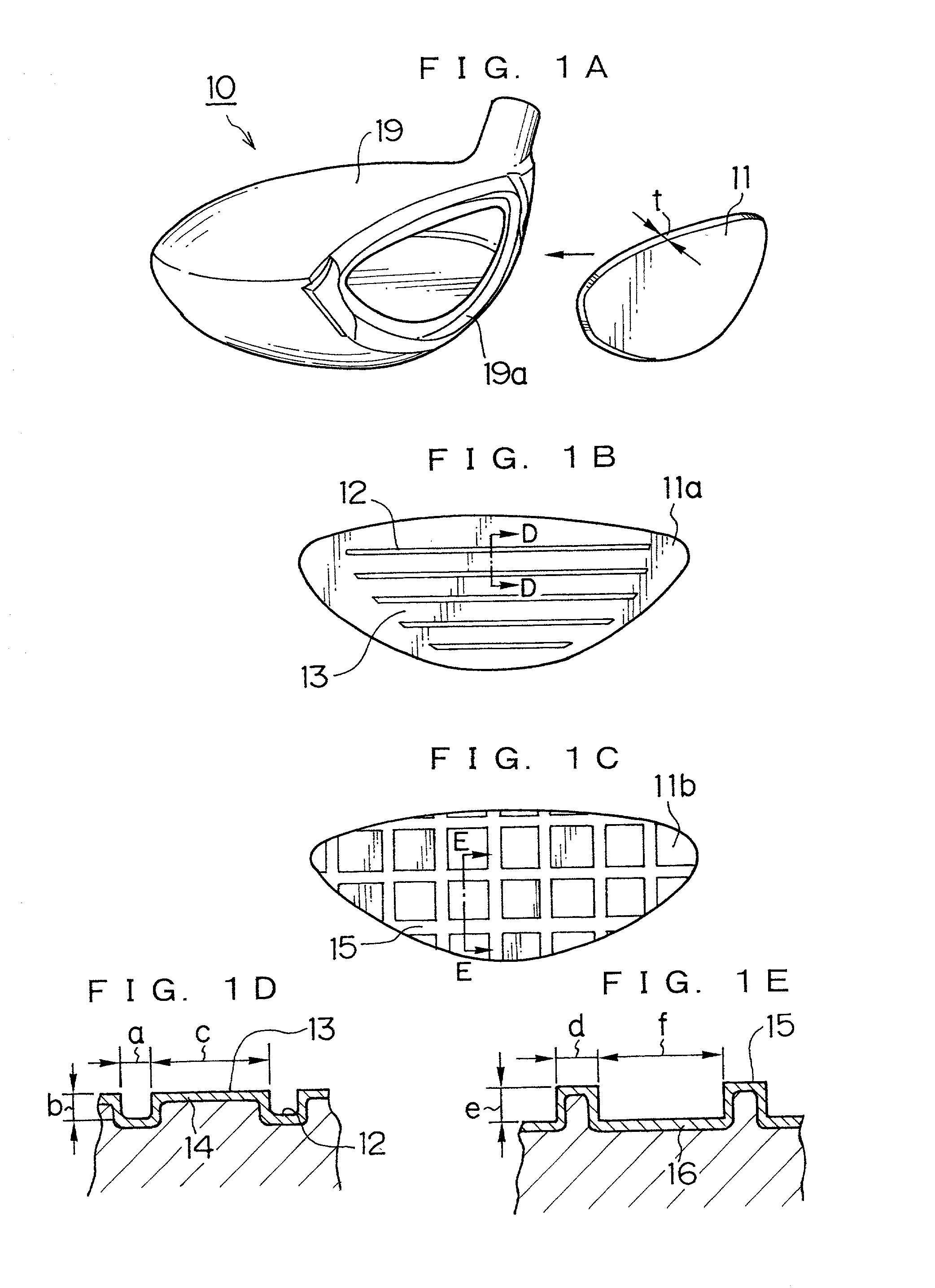

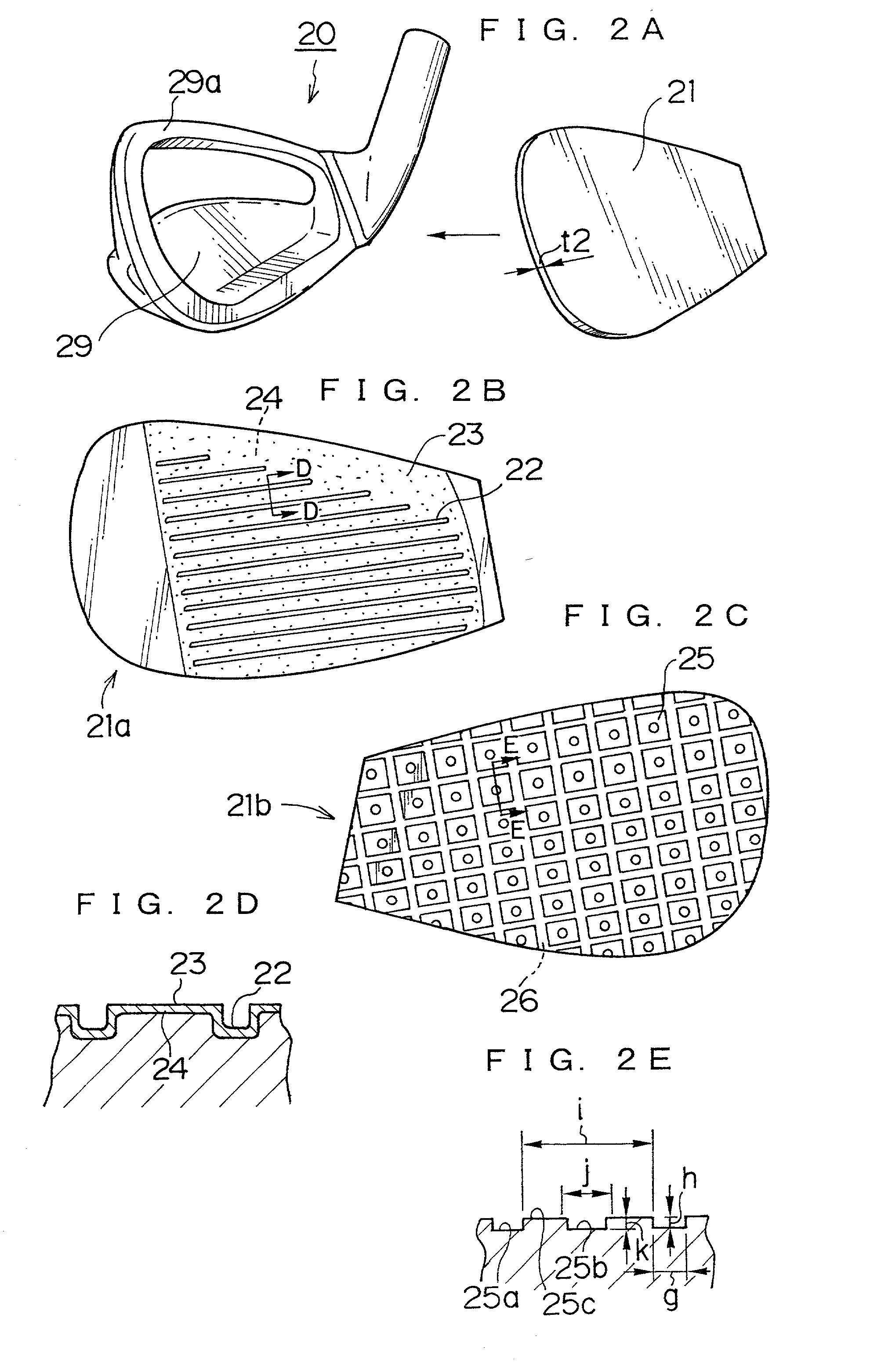

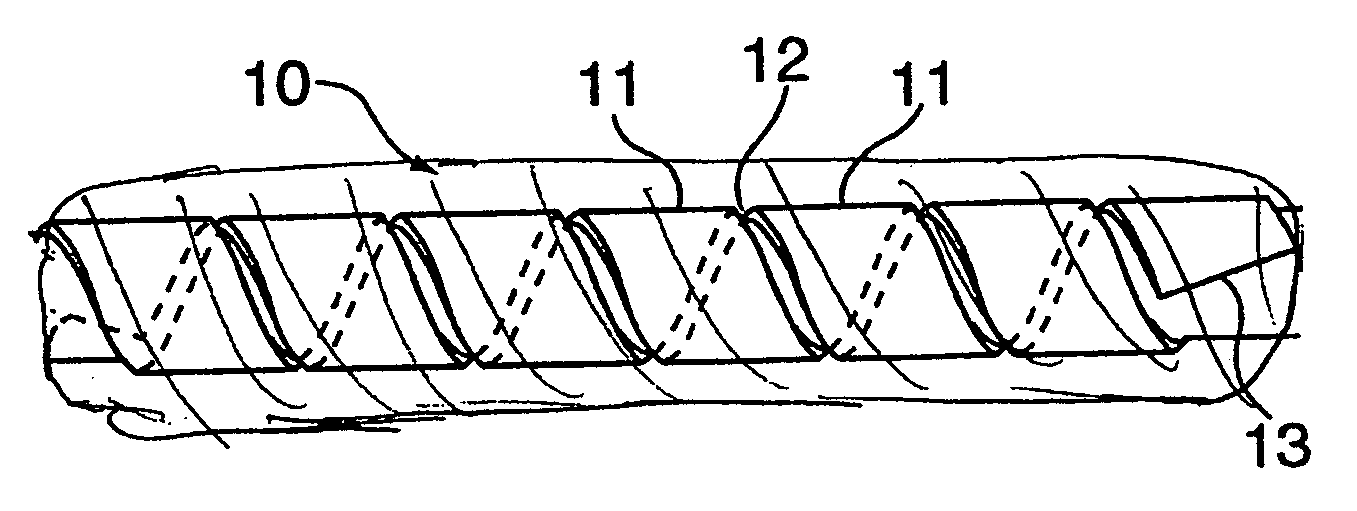

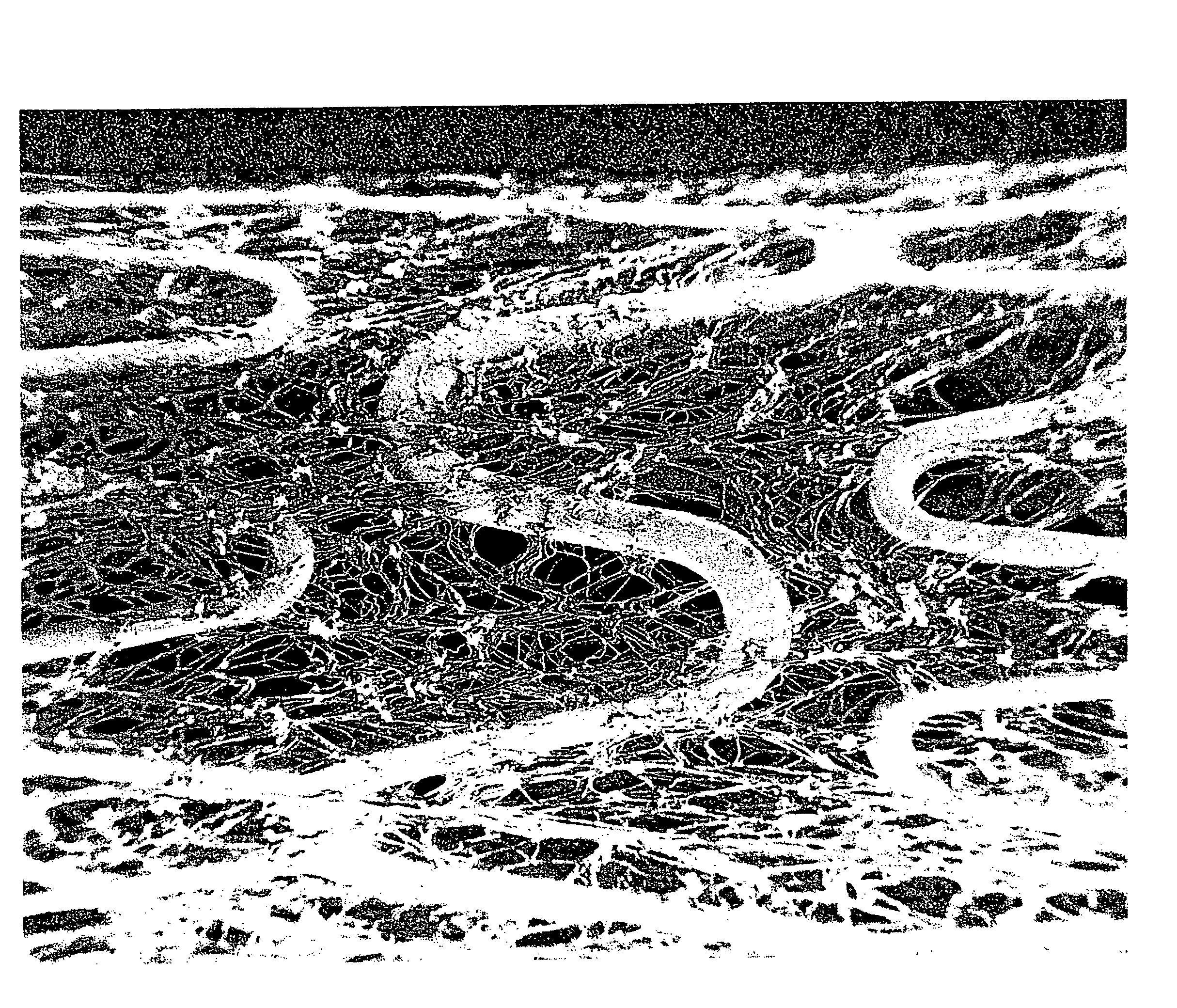

Golf club head and method of manufacturing the same

A face portion 11 of a golf club head 10 is obtained press-forming a metal plate into a predetermined shape. On the front surface 11a of the face portion 11, score lines 12 are formed by means of die sinking of electrical discharge machining, and a mirror finished surface portion 13 is formed by means of finish processing of electrical discharge machining. On the rear surface 11b of the face portion 11, a rib structure 15, and a high hardness layer 16 of an amorphous metal layer are formed. The electrical discharge machining is numerically controlled.

Owner:G P S CO LTD

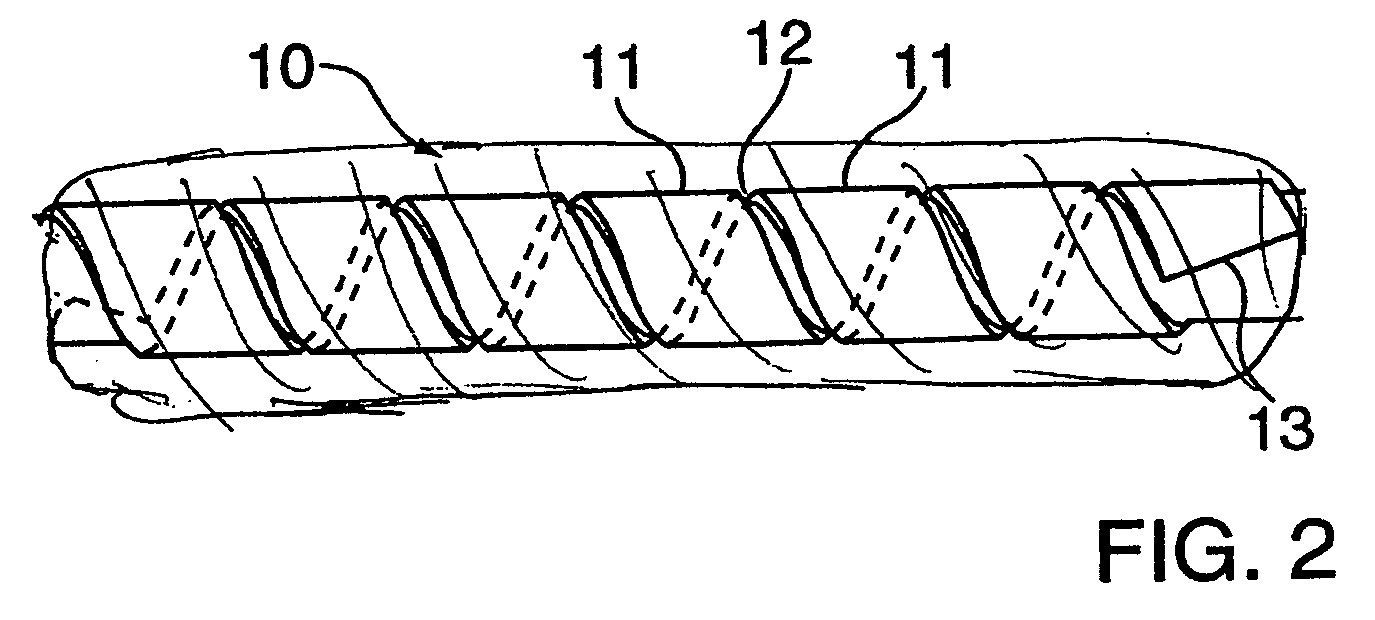

Hybrid amorphous metal alloy stent

InactiveUS20060178727A1Inhibit and decrease cell proliferationReduce restenosisStentsSurgeryMetal alloyBalloon dilatation

An expandable stent is provided, wherein the stent is advantageously formed of at least one amorphous metal alloy and a biocompatible material. The stent is formed from flat metal in a helical strip which is wound to form a tubular structure. The tubular structure is not welded but rather is wrapped or coated with a biocompatible material in order to maintain the amorphous metal in its tubular configuration. Said stent can be balloon expanded or self expanding.

Owner:MEDINOL LTD

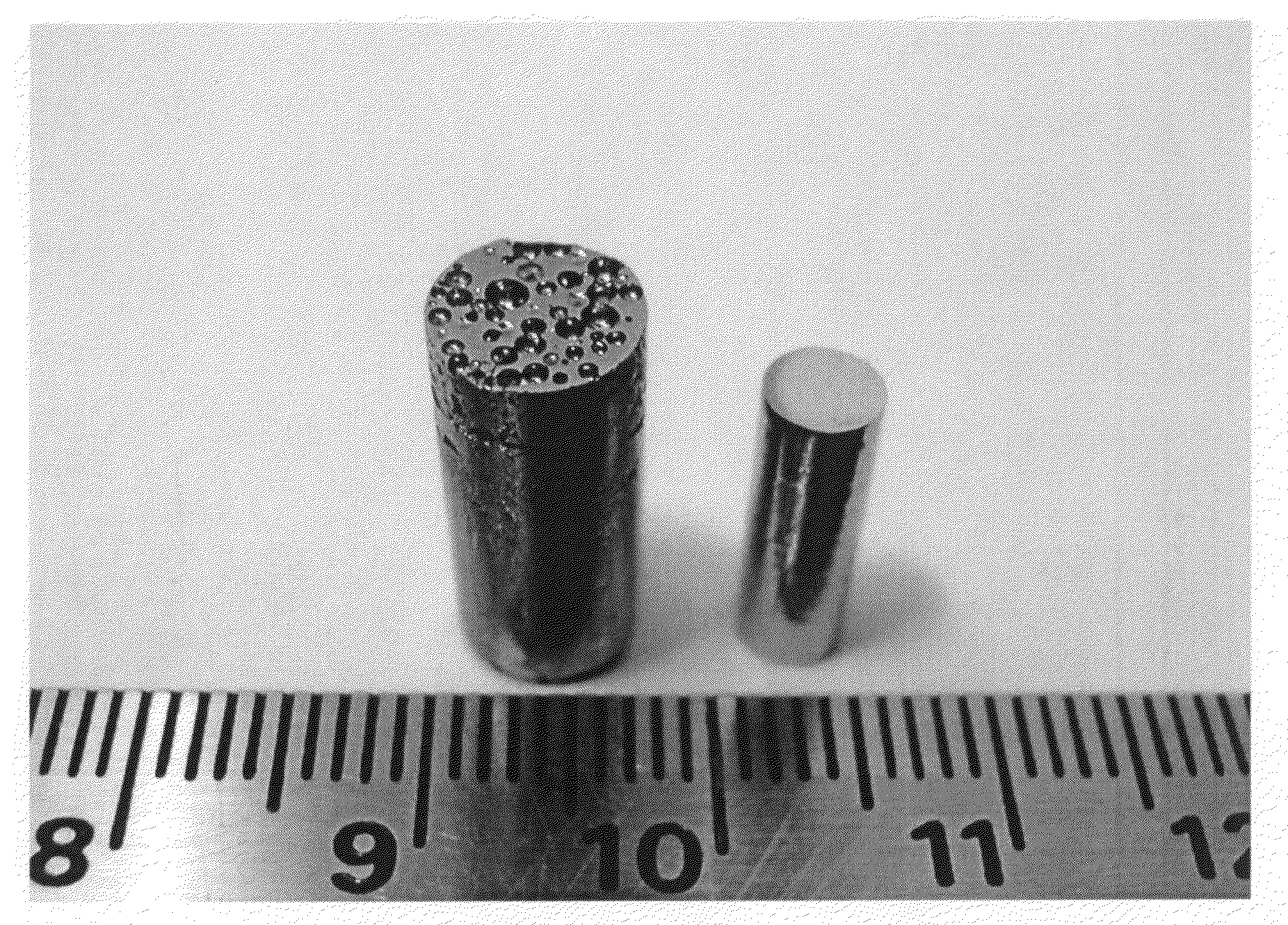

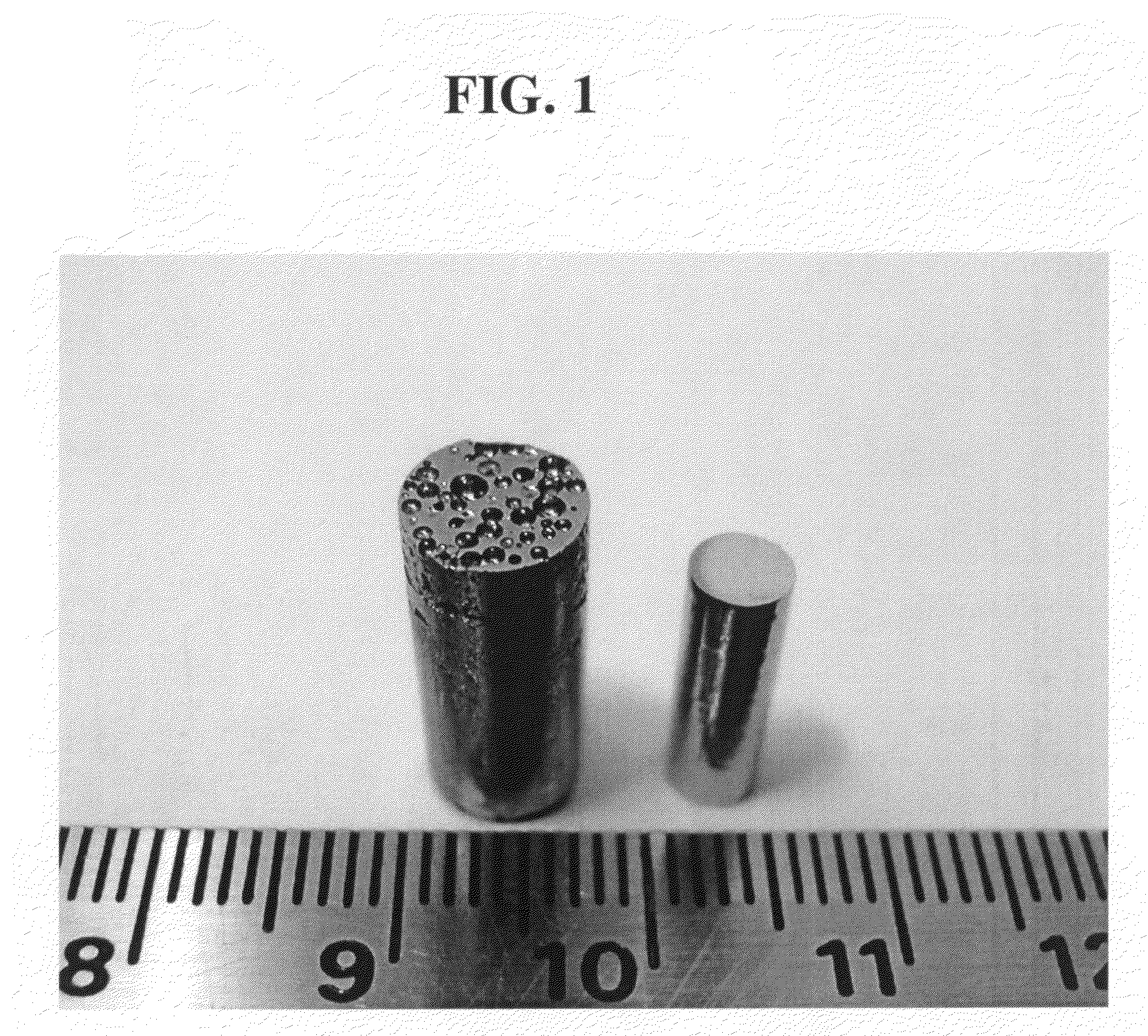

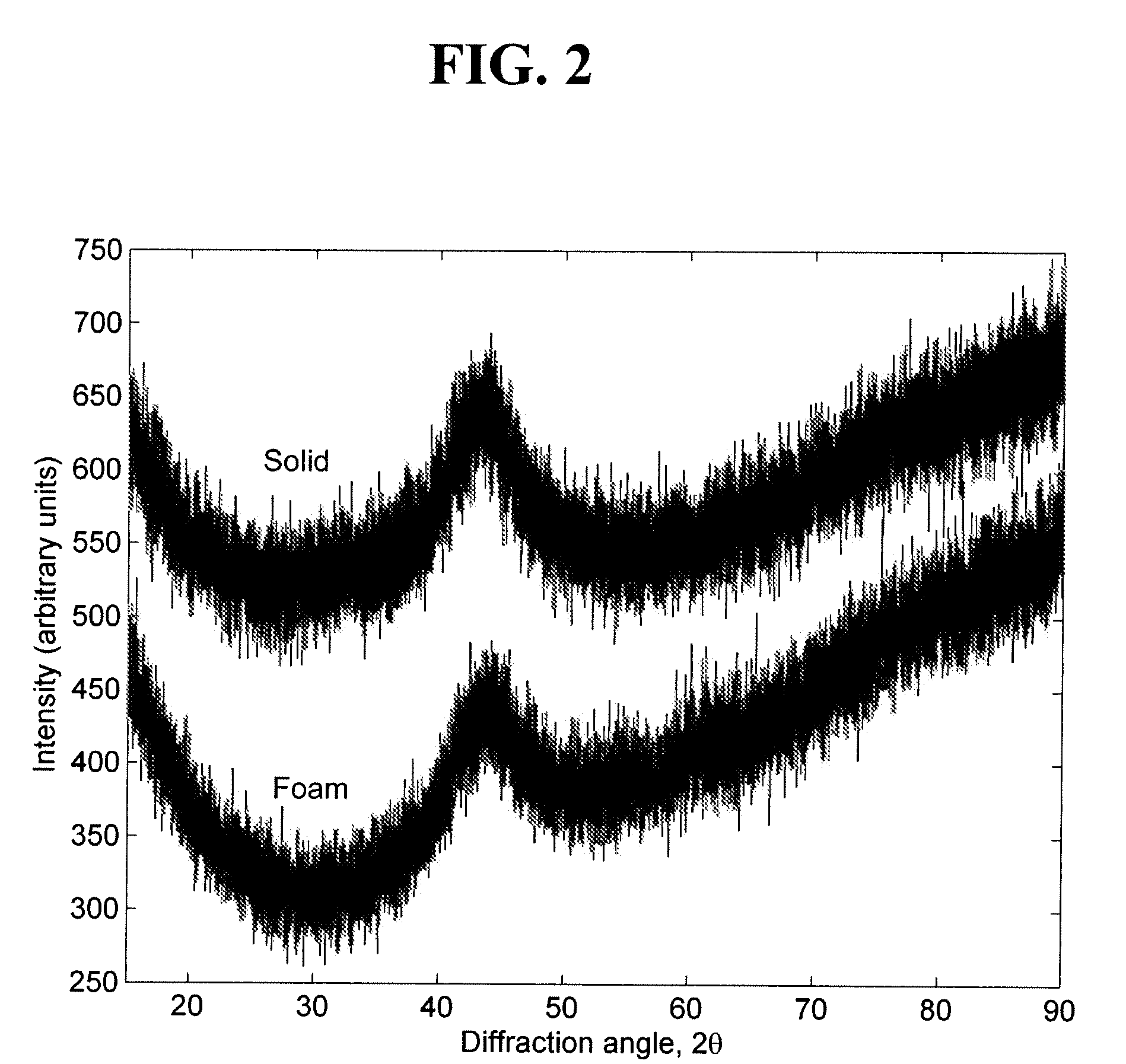

Amorphous fe and co based metallic foams and methods of producing the same

Amorphous Fe- and Co-based metal foams and methods of preparing the same are provided. The Fe- and Co-based foams are prepared from Fe- and Co-based metal alloys of low hydrogen solubility having an atomic fraction of Fe or Co greater than or equal to the atomic fraction of each other alloying element. A method for producing the Fe- and Co-based foams includes the in situ decomposition of a hydride in a molten Fe- or Co-based alloy.

Owner:CALIFORNIA INST OF TECH

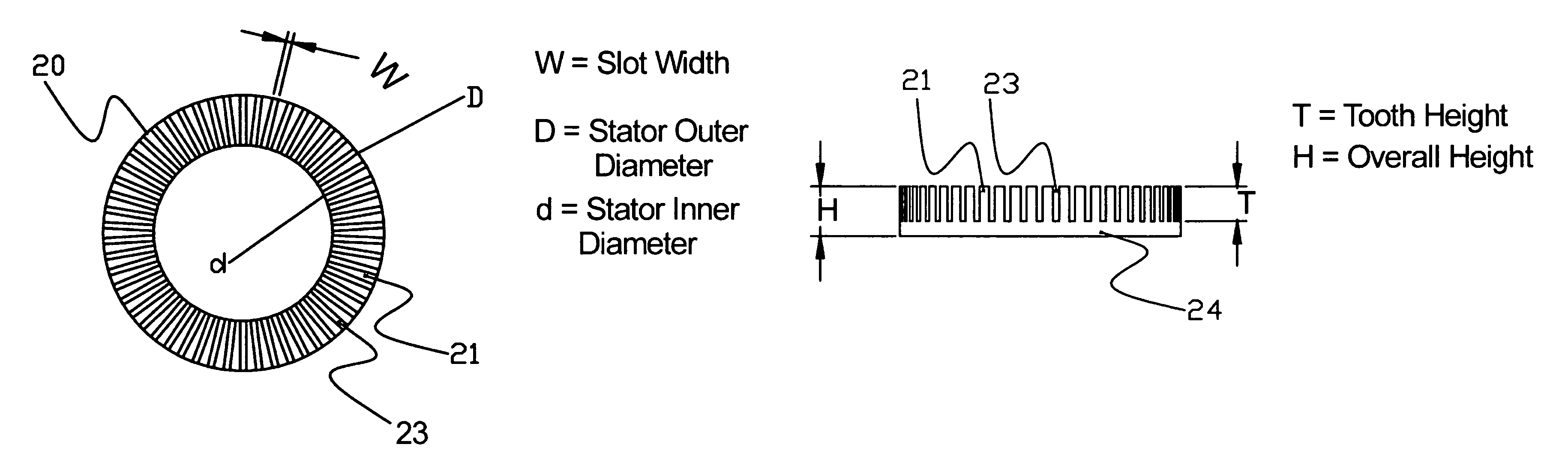

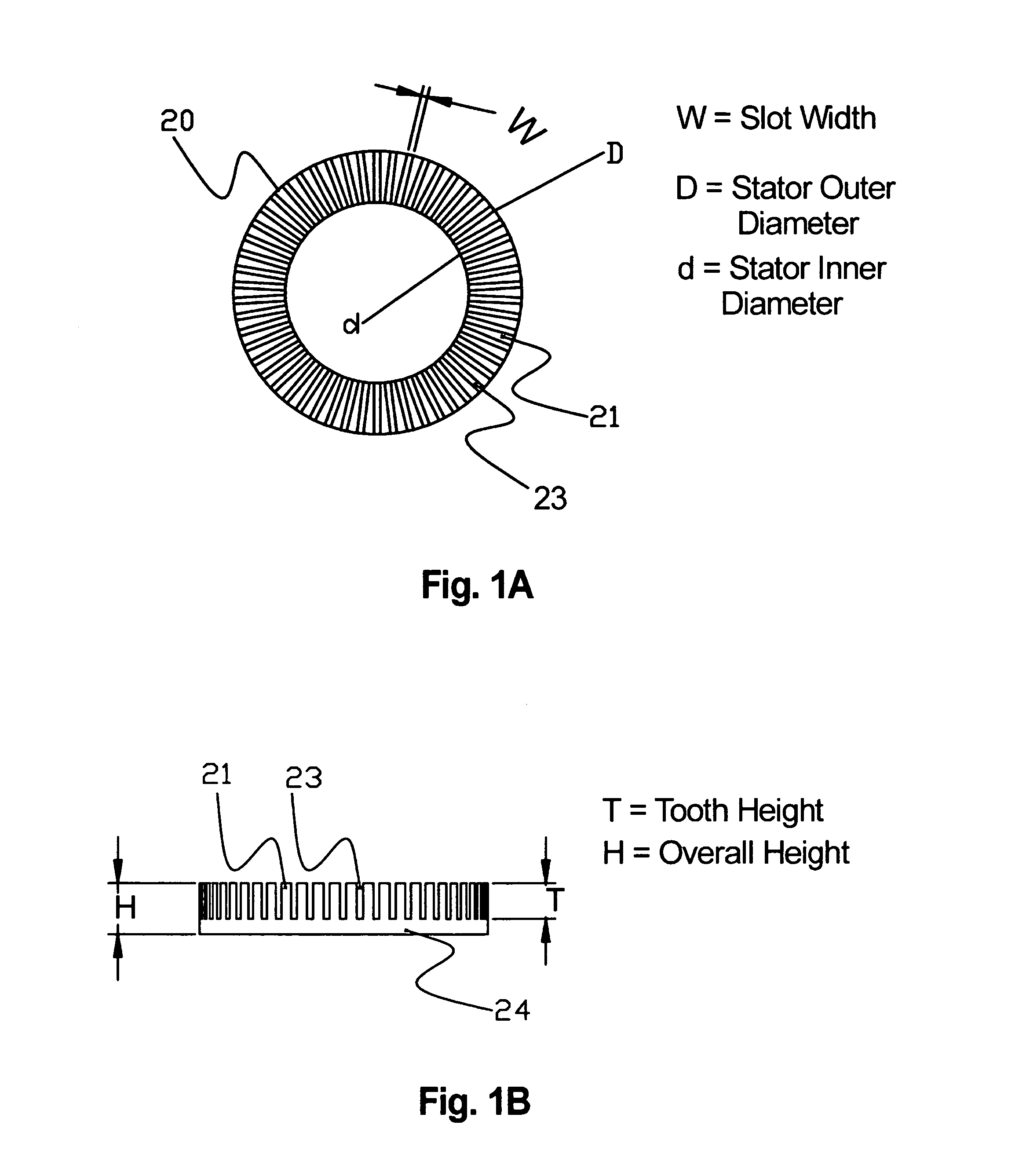

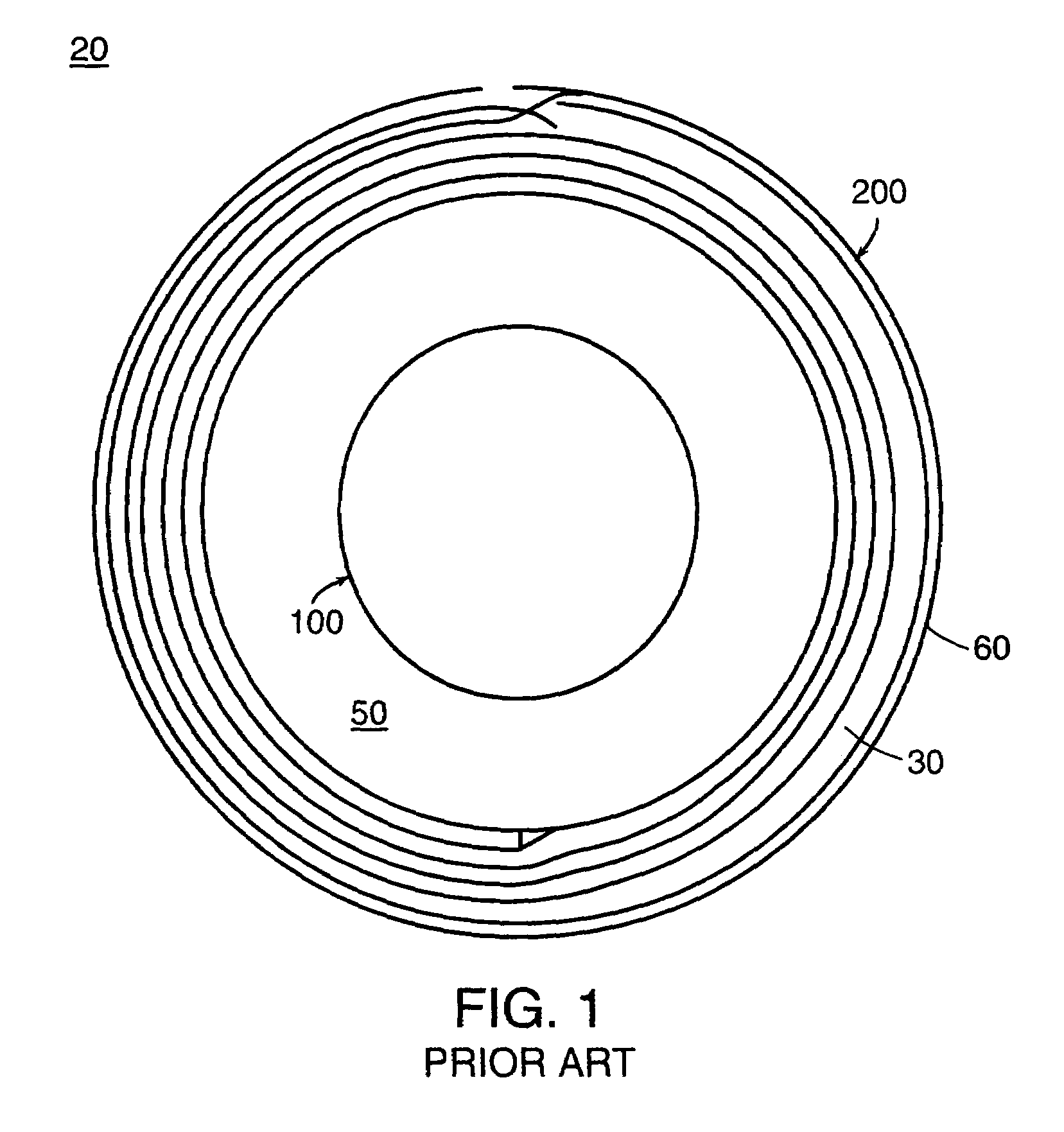

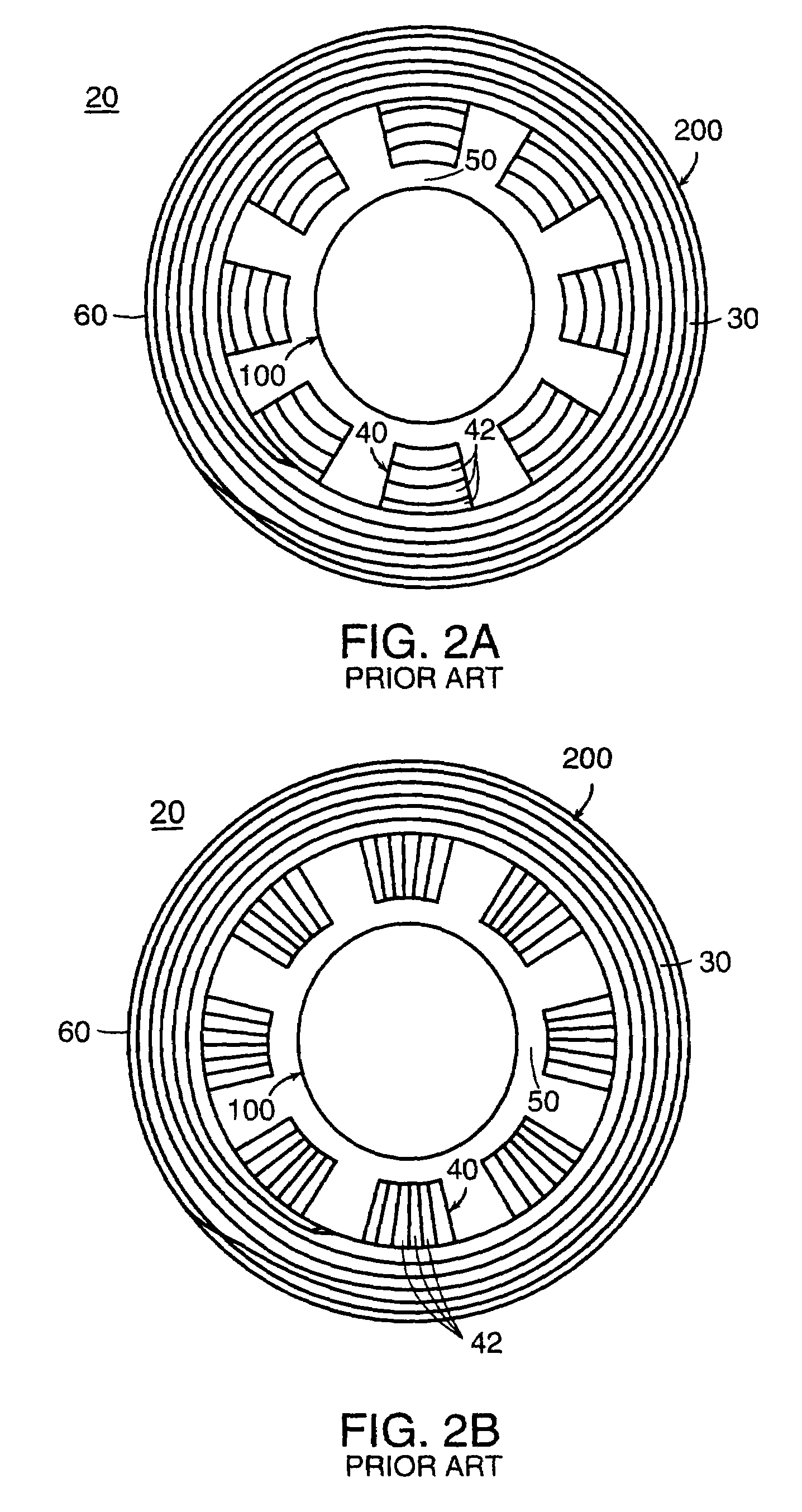

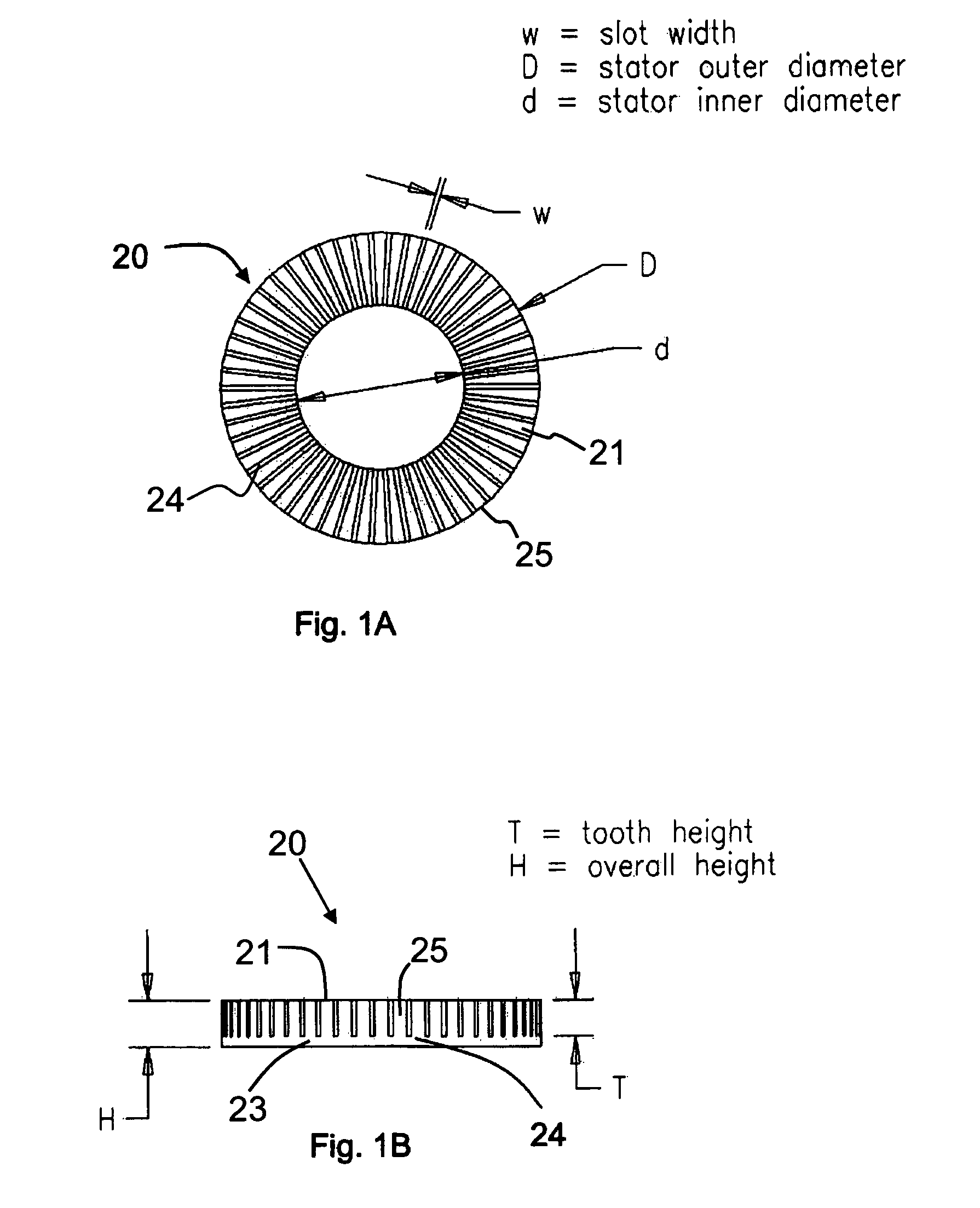

Amorphous metal stator for a radial-flux electric motor

InactiveUS6960860B1Improve motor efficiencyLow core lossMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesEngineering

An amorphous metal stator for a high efficiency radial-flux electric motor has a plurality of segments, each of which includes a plurality of layers of amorphous metal strips. The plural segments are arranged to form a generally cylindrical stator having a plurality of teeth sections or poles protruding radially inward from the inner surface of the stator. In a first embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator crosses just one air gap when traversing each segment of the stator. In a second embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator traverses each segment without crossing an air gap.

Owner:METGLAS INC

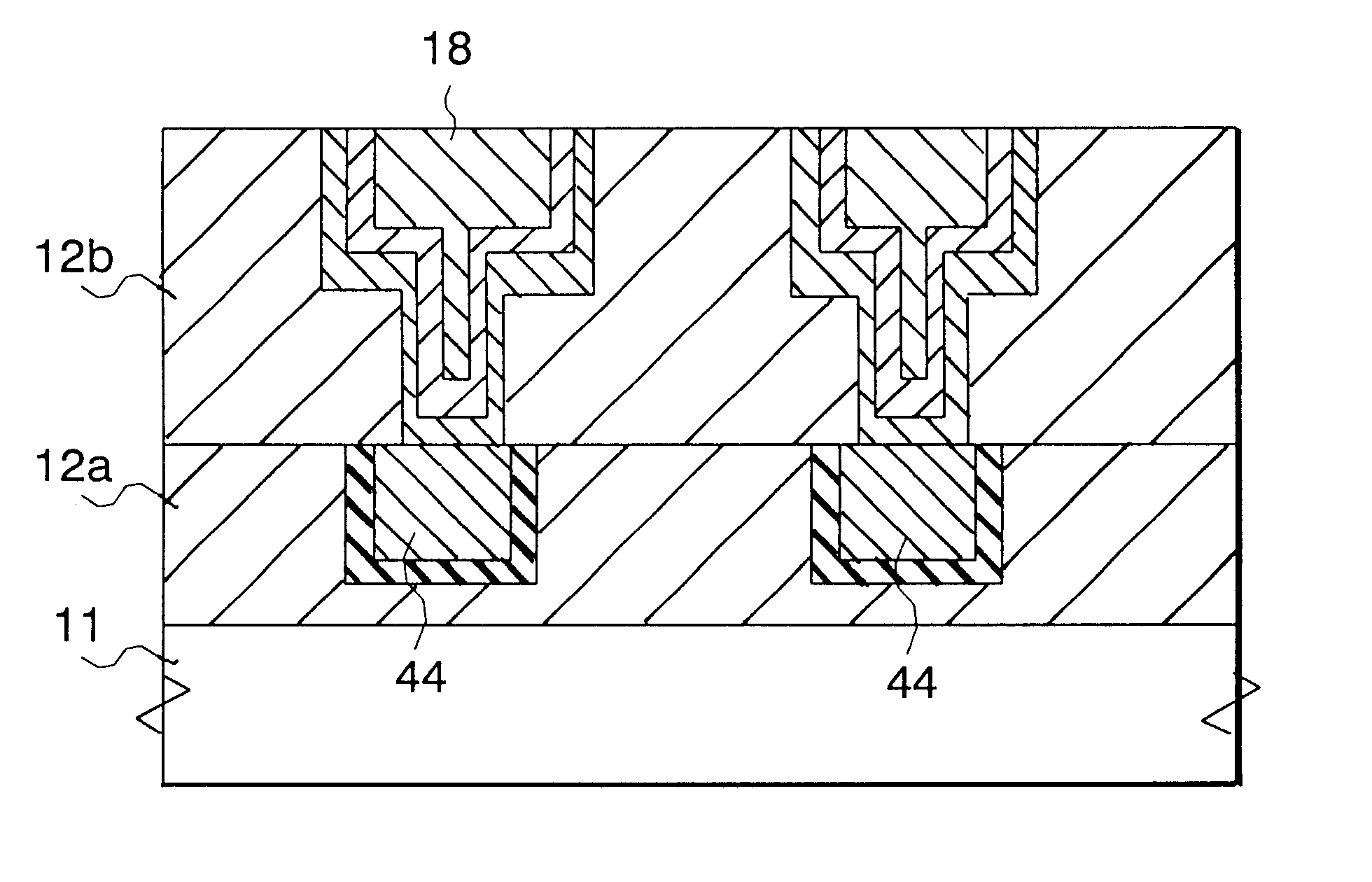

Multi-layered wiring layer and method of fabricating the same

InactiveUS6538324B1Semiconductor/solid-state device detailsSolid-state devicesDevice materialNitrogen

There is provided a barrier film preventing diffusion of copper from a copper wiring layer formed on a semiconductor substrate. The barrier film has a multi-layered structure of first and second films wherein the first film is composed of crystalline metal containing nitrogen therein, and the second film is composed of amorphous metal nitride. The barrier film is constituted of common metal atomic species. The barrier film prevents copper diffusion from a copper wiring layer into a semiconductor device, and has sufficient adhesion characteristic to both a copper film and an interlayer insulating film.

Owner:GK BRIDGE 1

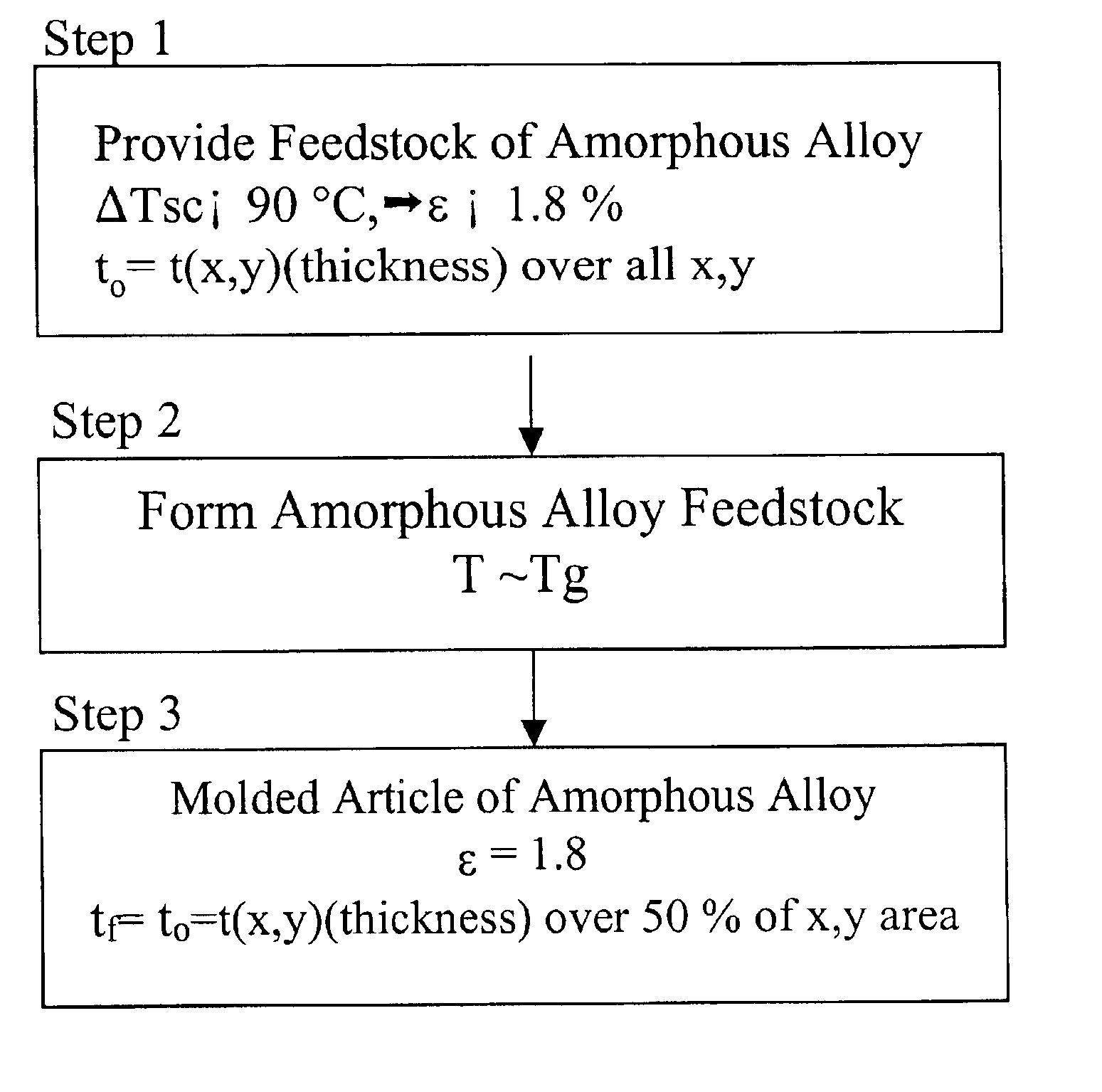

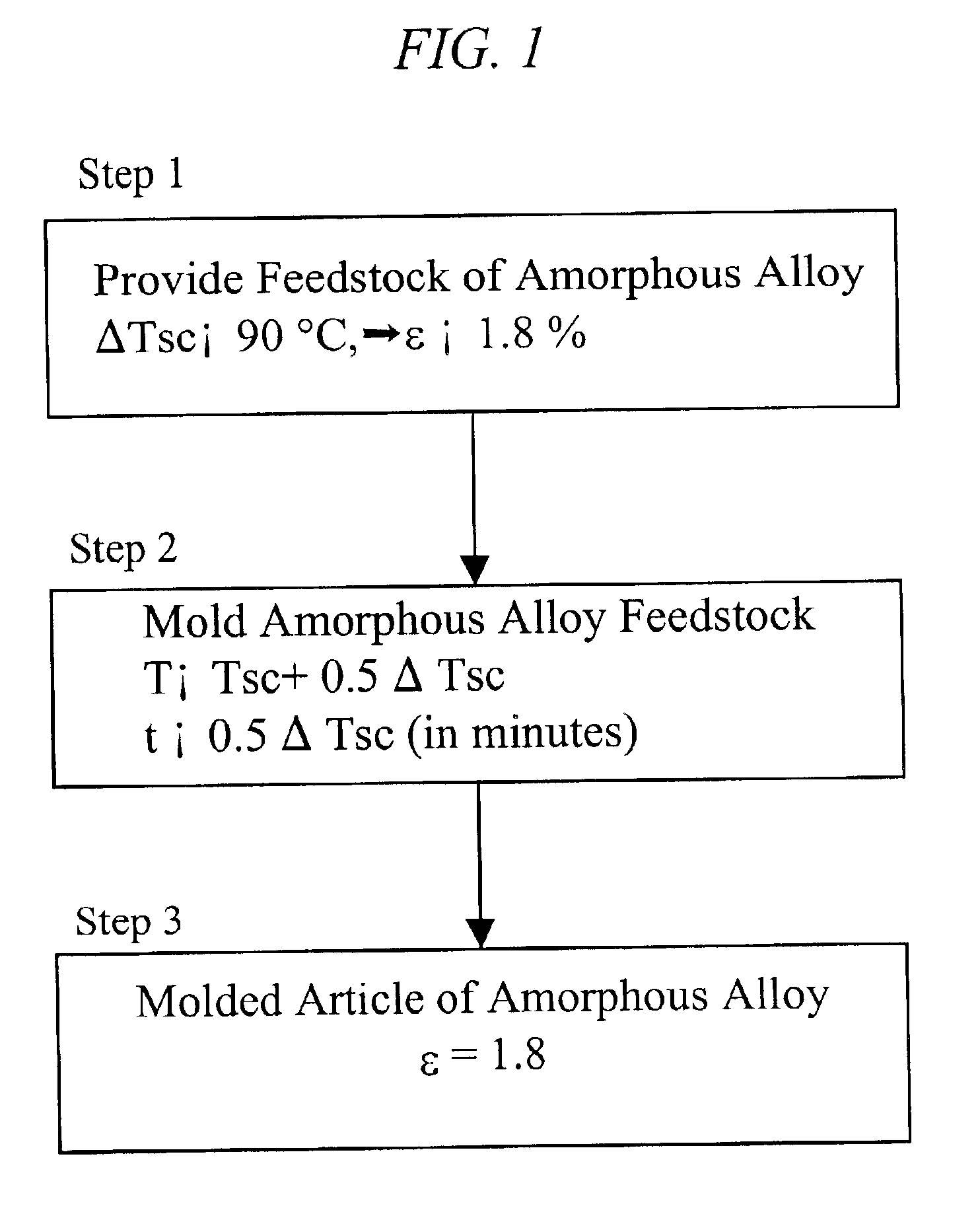

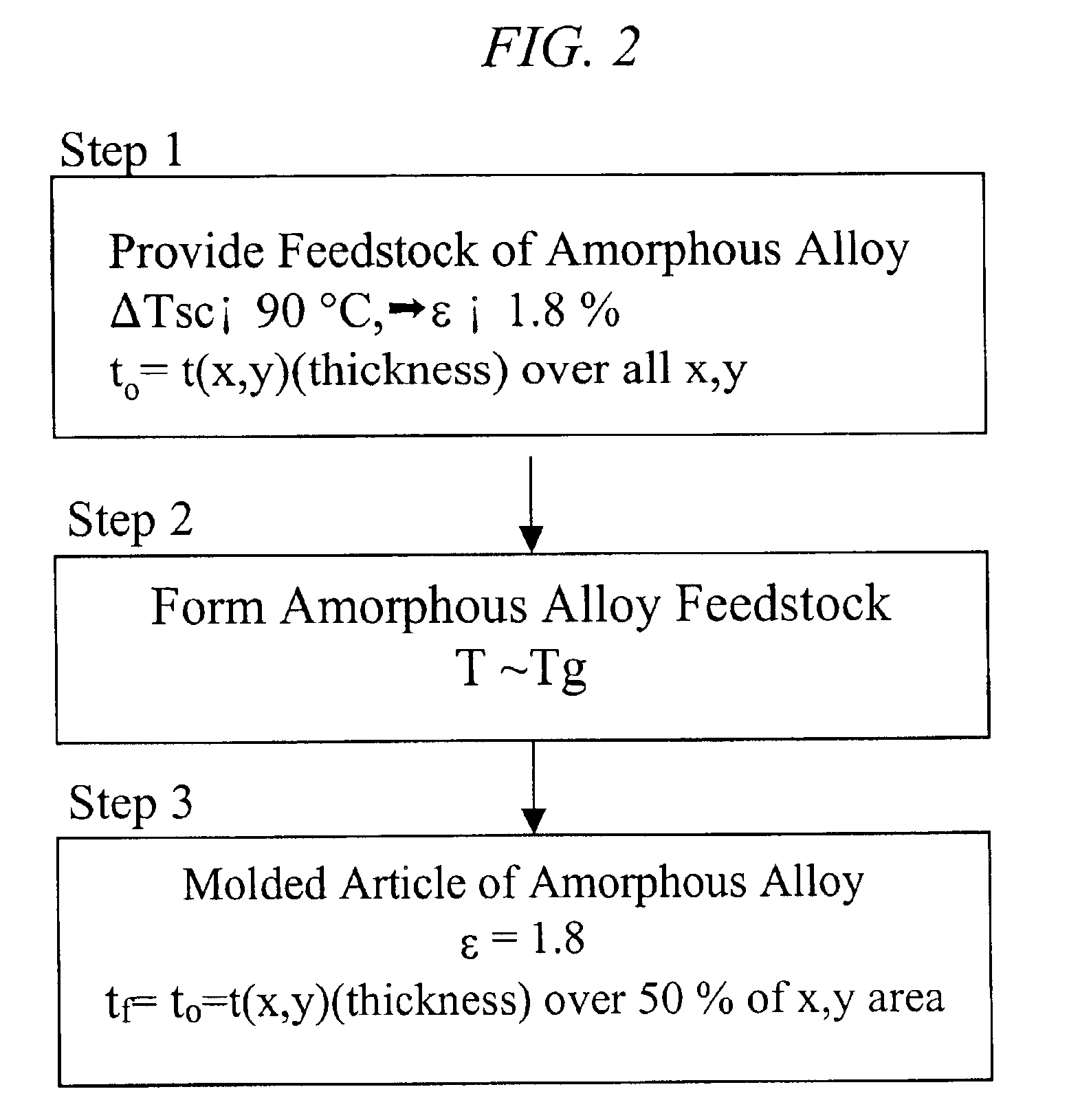

Method of forming molded articles of amorphous alloy with high elastic limit

Owner:CRUCIBLE INTPROP LLC

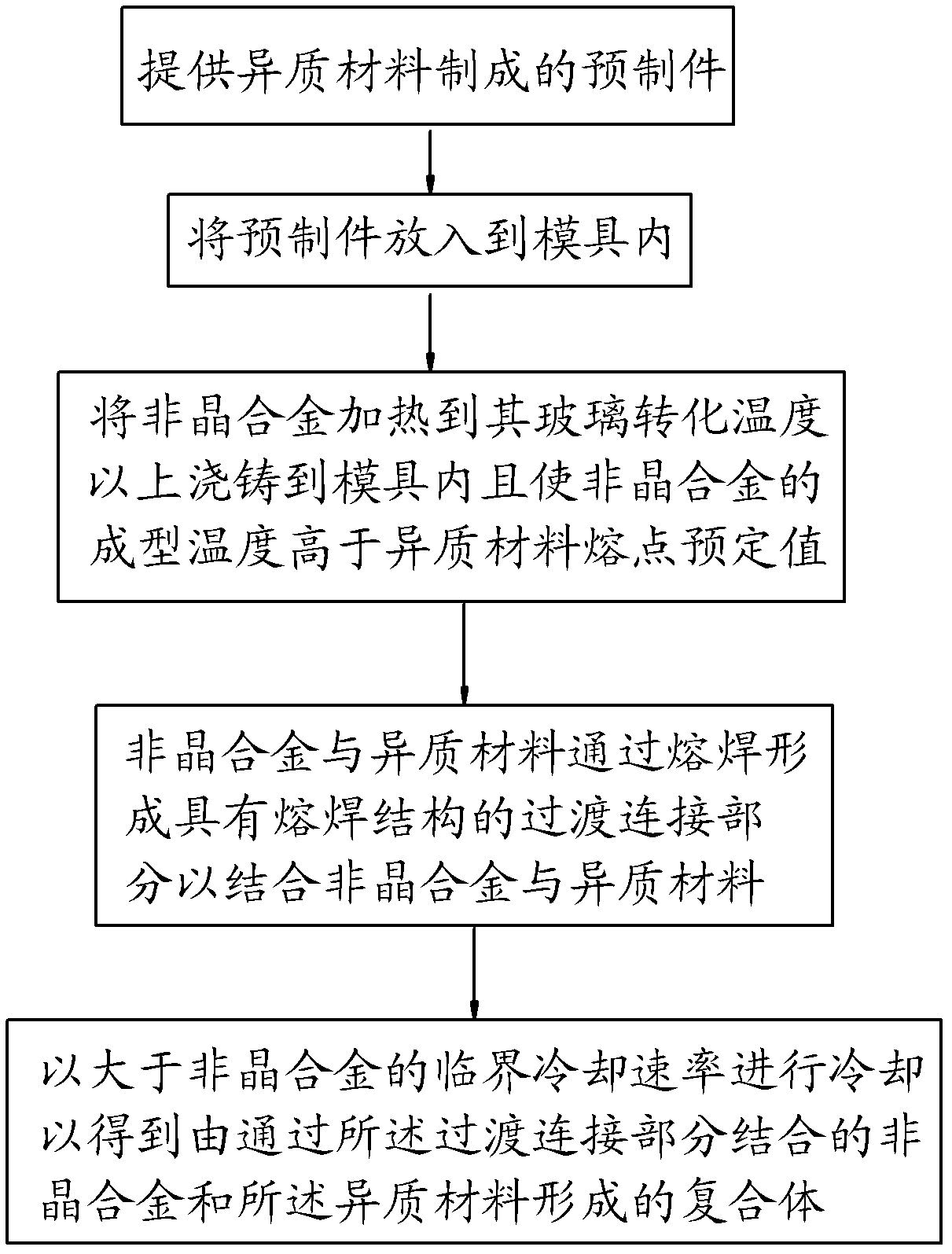

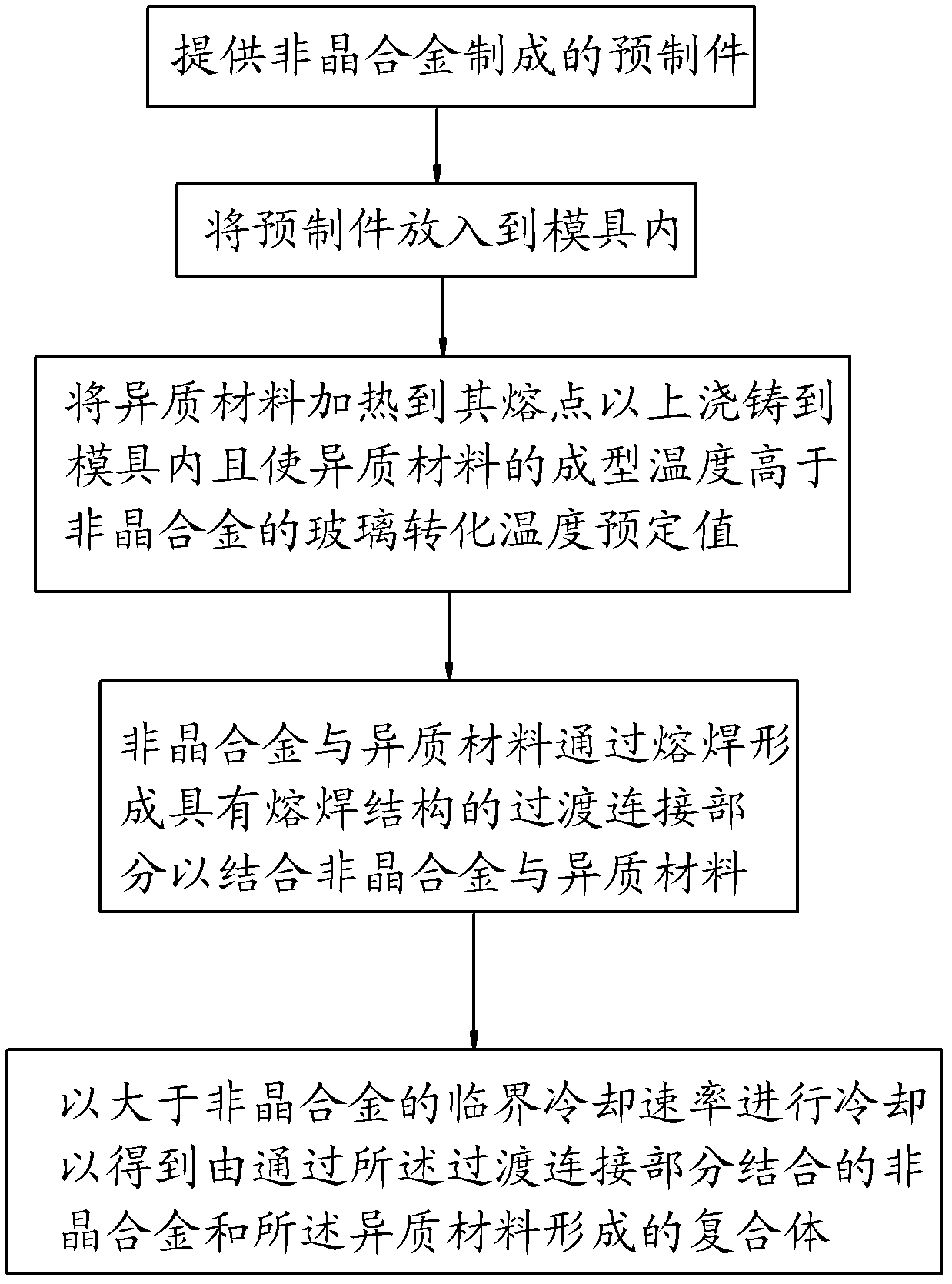

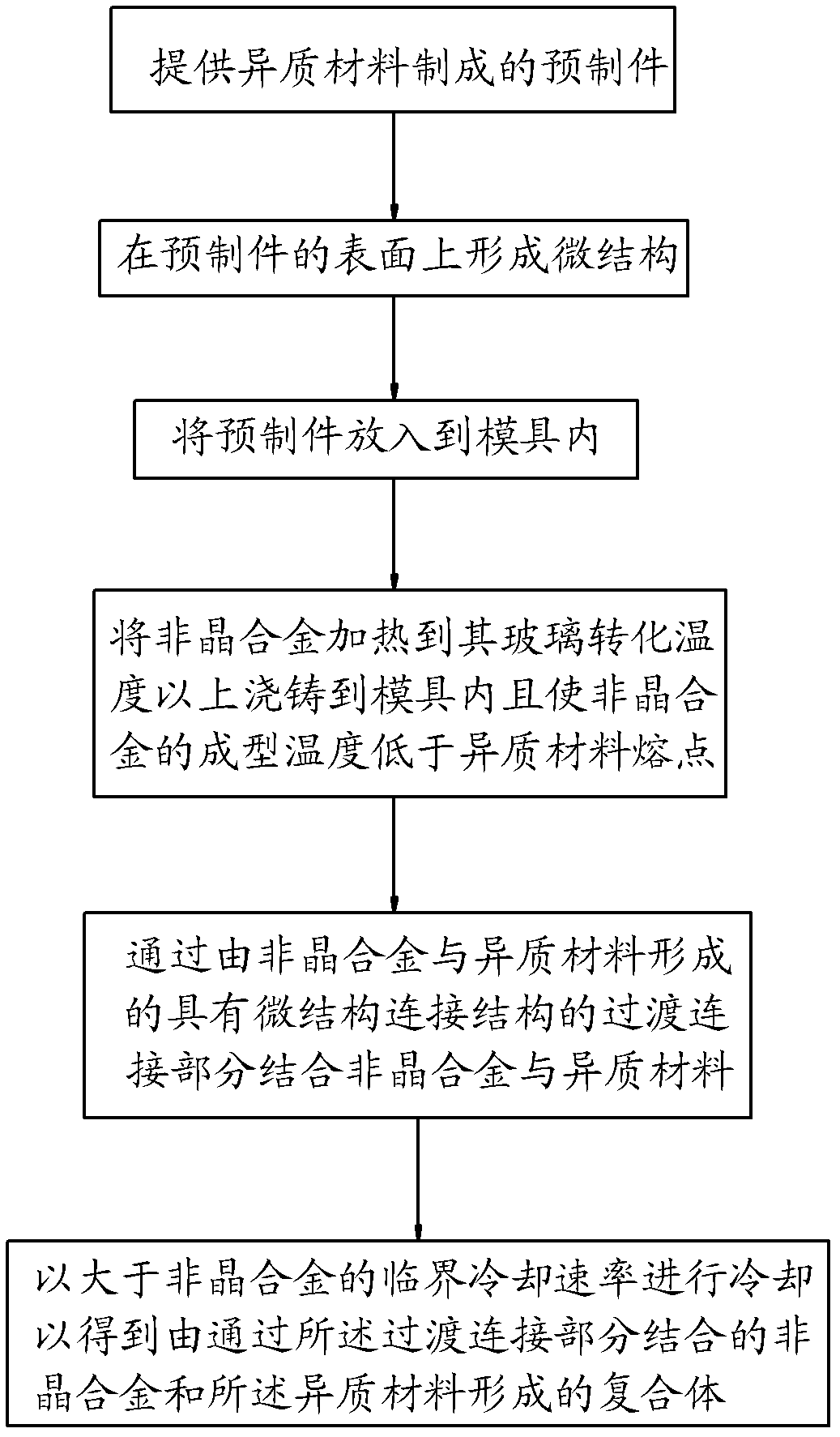

Method for combining amorphous alloy and heterogeneous material and complex

ActiveCN102430745AReduced molding capacityLower requirementThin material handlingMetal layered productsUltimate tensile strengthFusion welding

The invention discloses a method for combining an amorphous alloy and a heterogeneous material and a complex formed thereby. The method comprises the following steps of: putting a prefabricated part made from one of the heterogeneous material and the amorphous alloy into a mould; heating the other one of the heterogeneous material and the amorphous alloy to a predetermined temperature and casting into the mould to form a transitional connection part combining the heterogeneous material and the amorphous alloy, wherein the transitional connection part has a fusion welding structure, a micro structural reinforcing connection structure or a mixed connection structure; and cooling at a speed greater than the critical cooling rate of the amorphous alloy to obtain the complex formed by the amorphous alloy and heterogeneous material. According to the method disclosed by the invention, the combination strength of the amorphous alloy and the heterogeneous material is enhanced, requirements on the forming capability and performance of the amorphous alloy are reduced, requirements on the elastic deformation of the amorphous alloy are reduced, and the applicability of the amorphous alloy is improved.

Owner:BYD CO LTD

Systems and methods for fabricating objects including amorphous metal using techniques akin to additive manufacturing

ActiveUS20140202595A1Additive manufacturing apparatusMolten spray coatingLaser additive manufacturingAmorphous metal

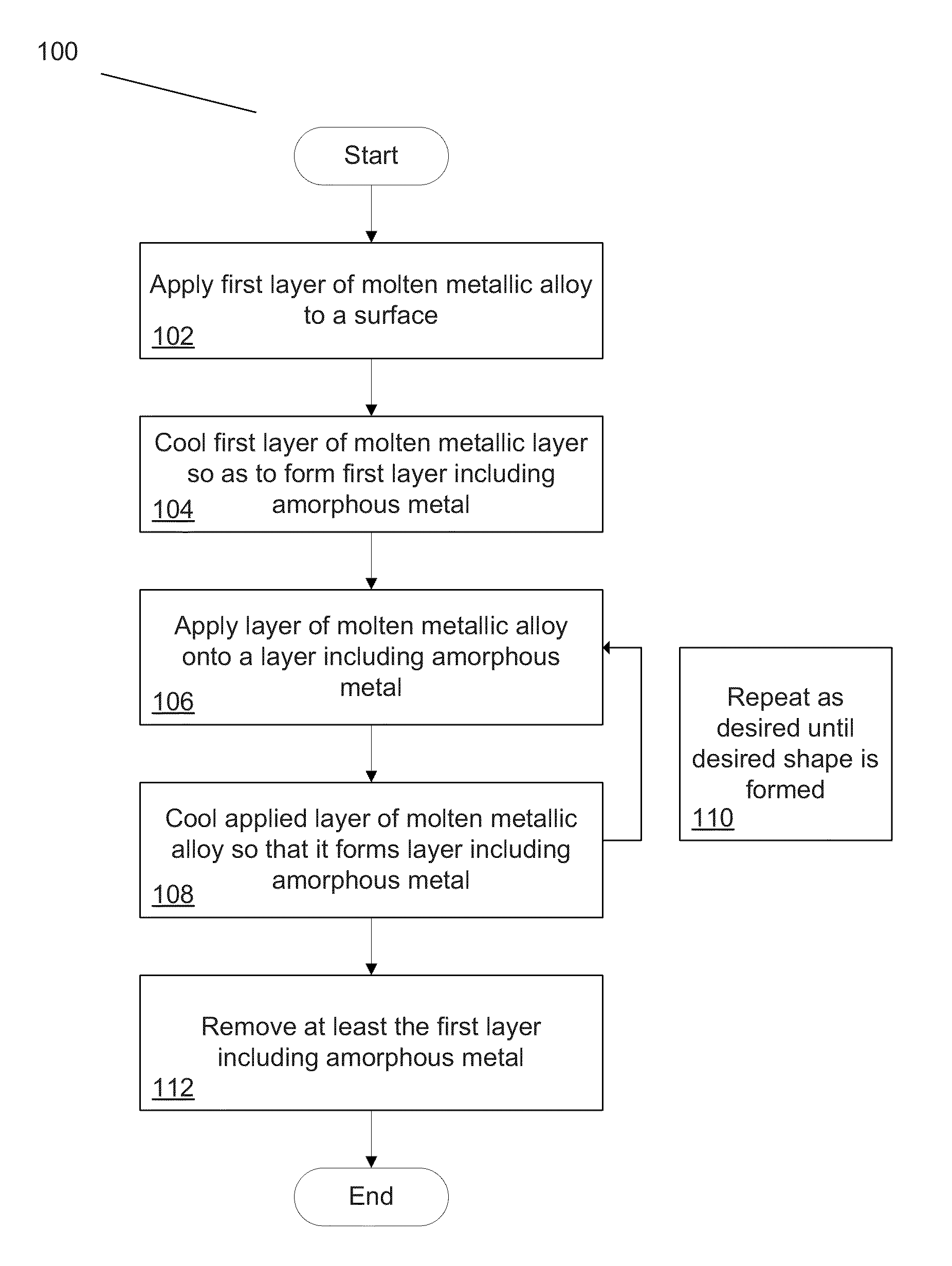

Systems and methods in accordance with embodiments of the invention fabricate objects including amorphous metals using techniques akin to additive manufacturing. In one embodiment, a method of fabricating an object that includes an amorphous metal includes: applying a first layer of molten metallic alloy to a surface; cooling the first layer of molten metallic alloy such that it solidifies and thereby forms a first layer including amorphous metal; subsequently applying at least one layer of molten metallic alloy onto a layer including amorphous metal; cooling each subsequently applied layer of molten metallic alloy such that it solidifies and thereby forms a layer including amorphous metal prior to the application of any adjacent layer of molten metallic alloy; where the aggregate of the solidified layers including amorphous metal forms a desired shape in the object to be fabricated; and removing at least the first layer including amorphous metal from the surface.

Owner:CALIFORNIA INST OF TECH

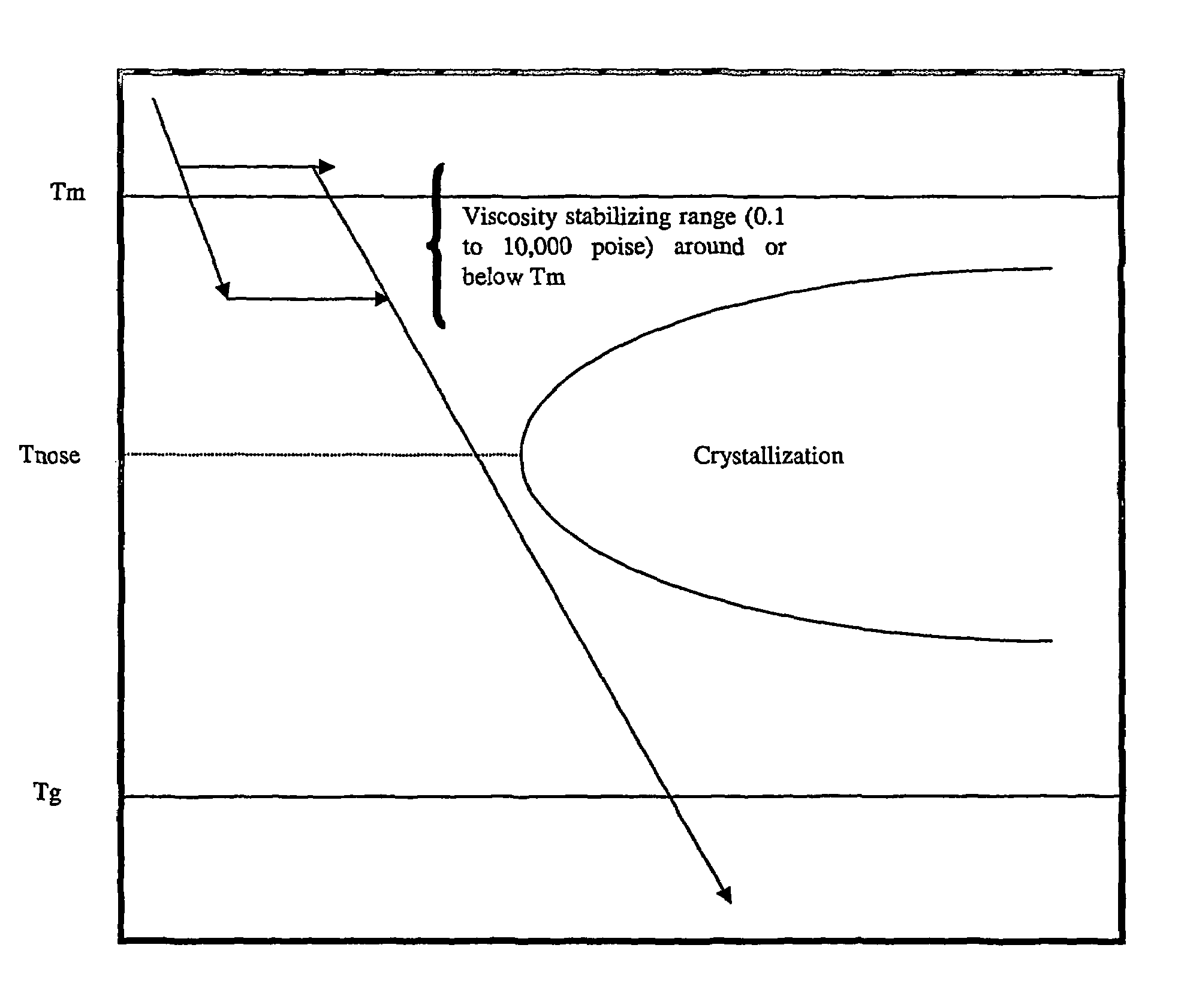

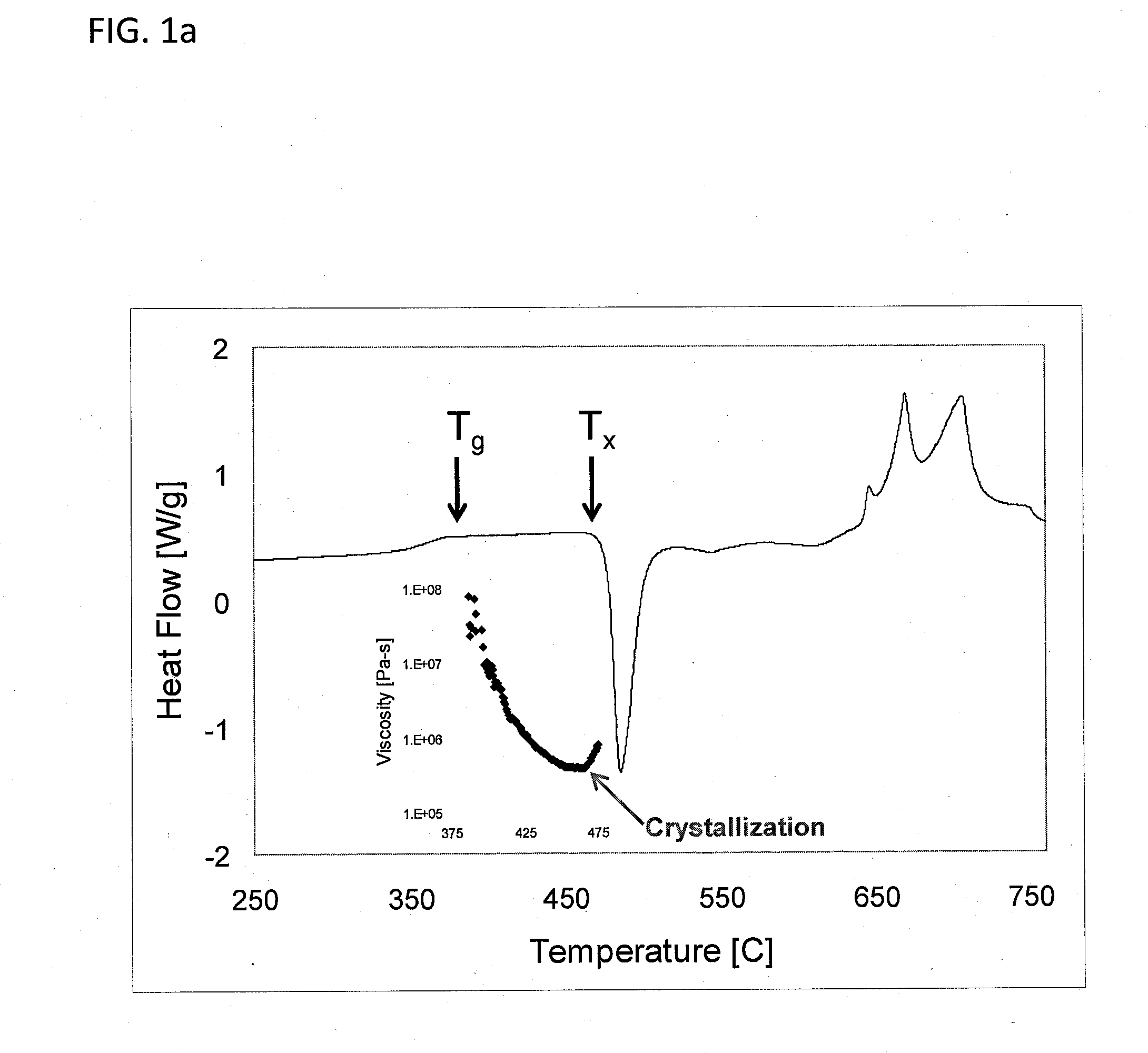

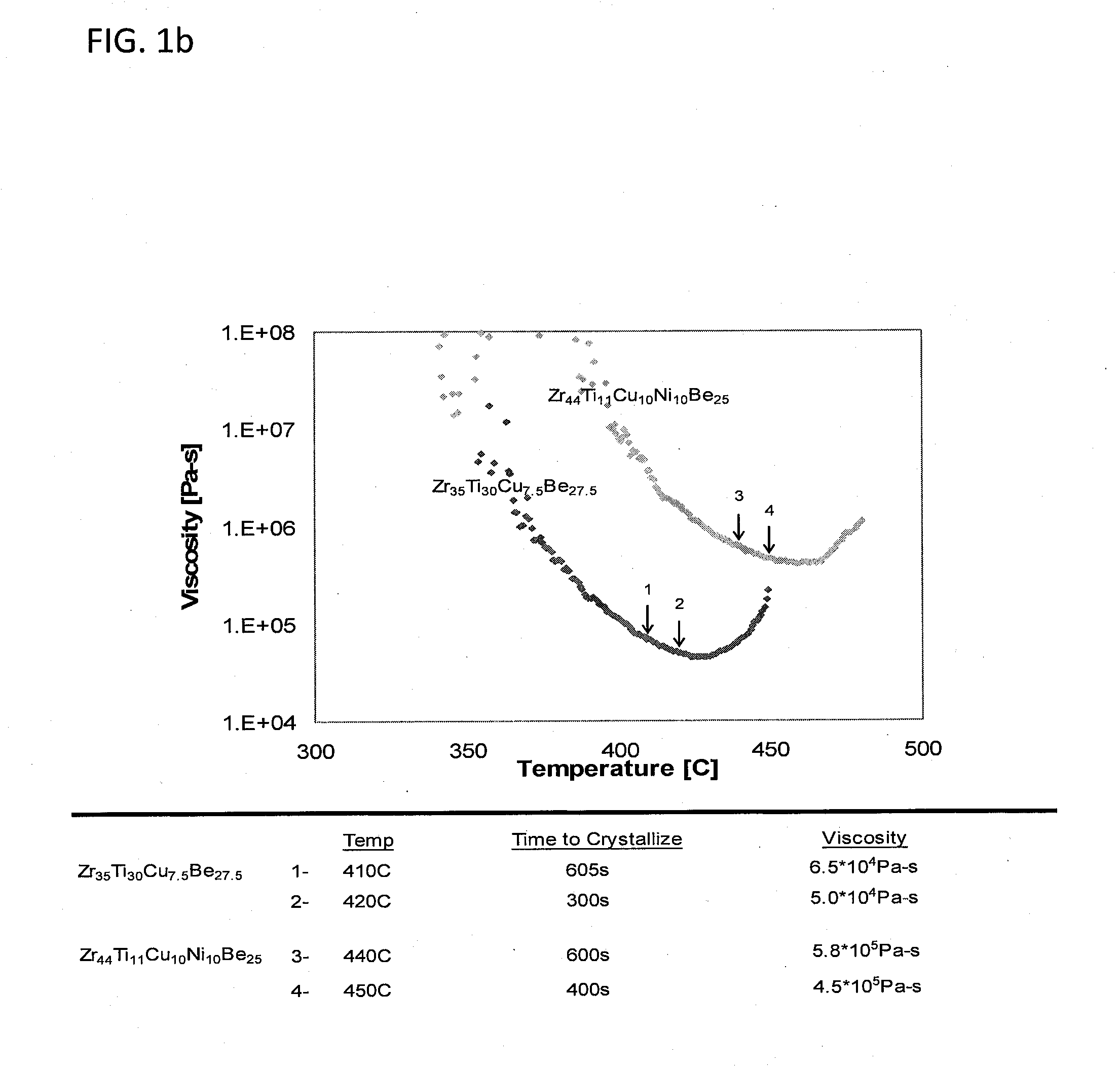

Thermoplastically processable amorphous metals and methods for processing same

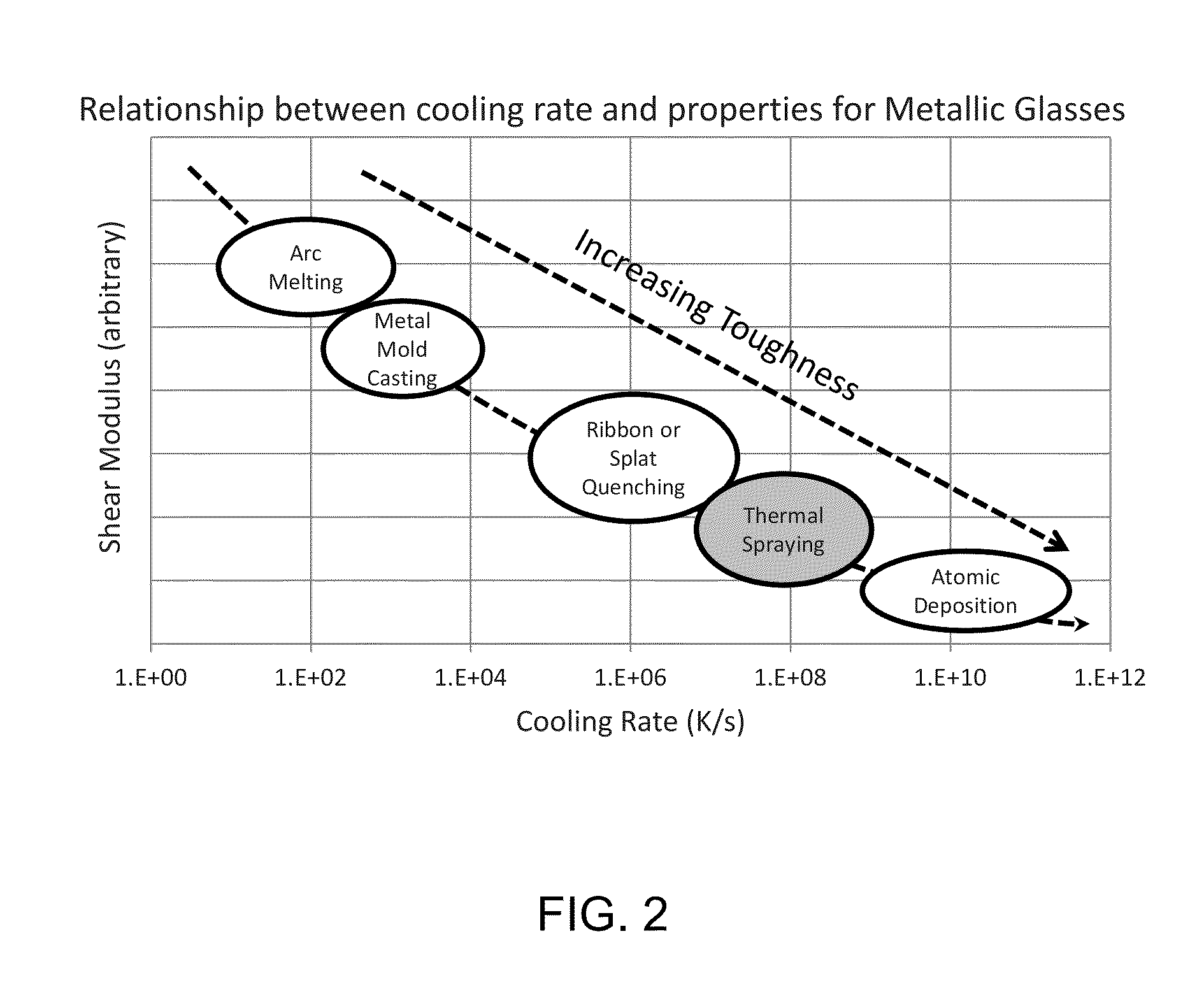

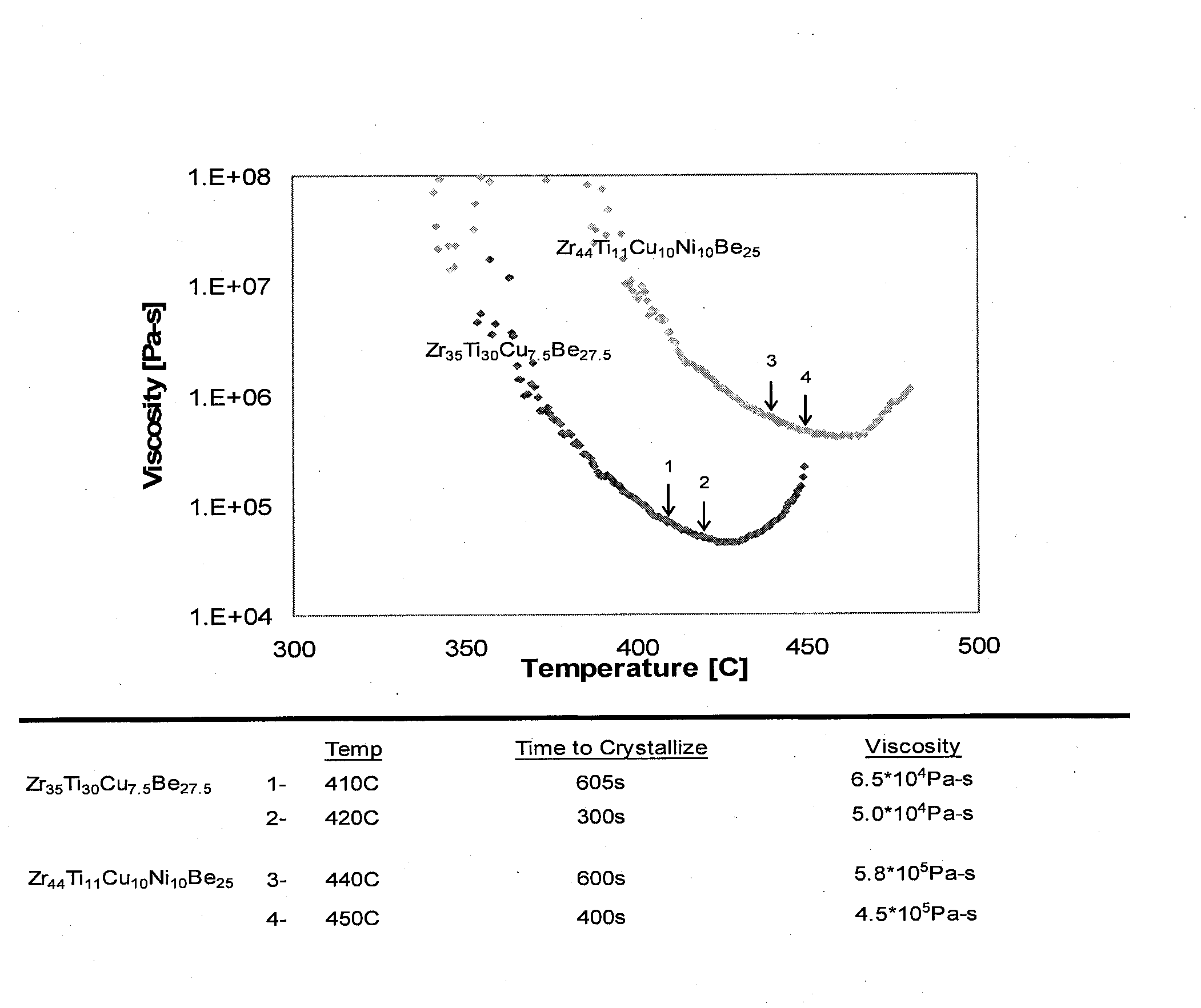

High strength, thermoplastically processable (TPF) amorphous alloys composed of Beryllium and at least one ETM and at least one LTM, as well as methods of processing such alloys are provided. The TPF alloys of the invention demonstrate good glass forming ability, low viscosity in the supercooled liquid region (SCLR), a low processing temperature, and a long processing time at that temperature before crystallization.

Owner:CALIFORNIA INST OF TECH

Amorphous metals and composites as mirrors and mirror assemblies

ActiveUS20130139964A1Reduce mirror costRobust scratch resistanceMolten spray coatingMirrorsGlass compositesOptical surface

Owner:CALIFORNIA INST OF TECH

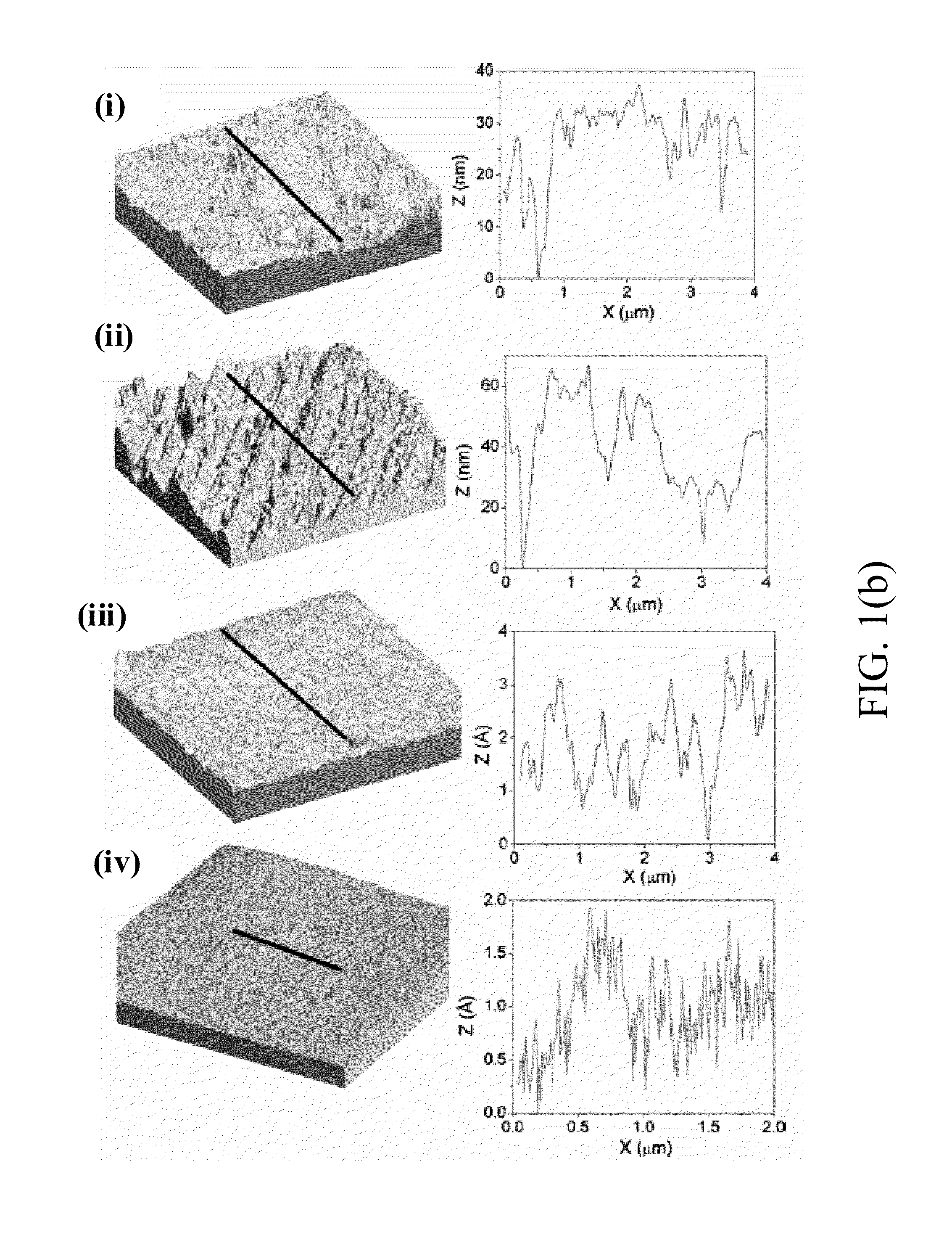

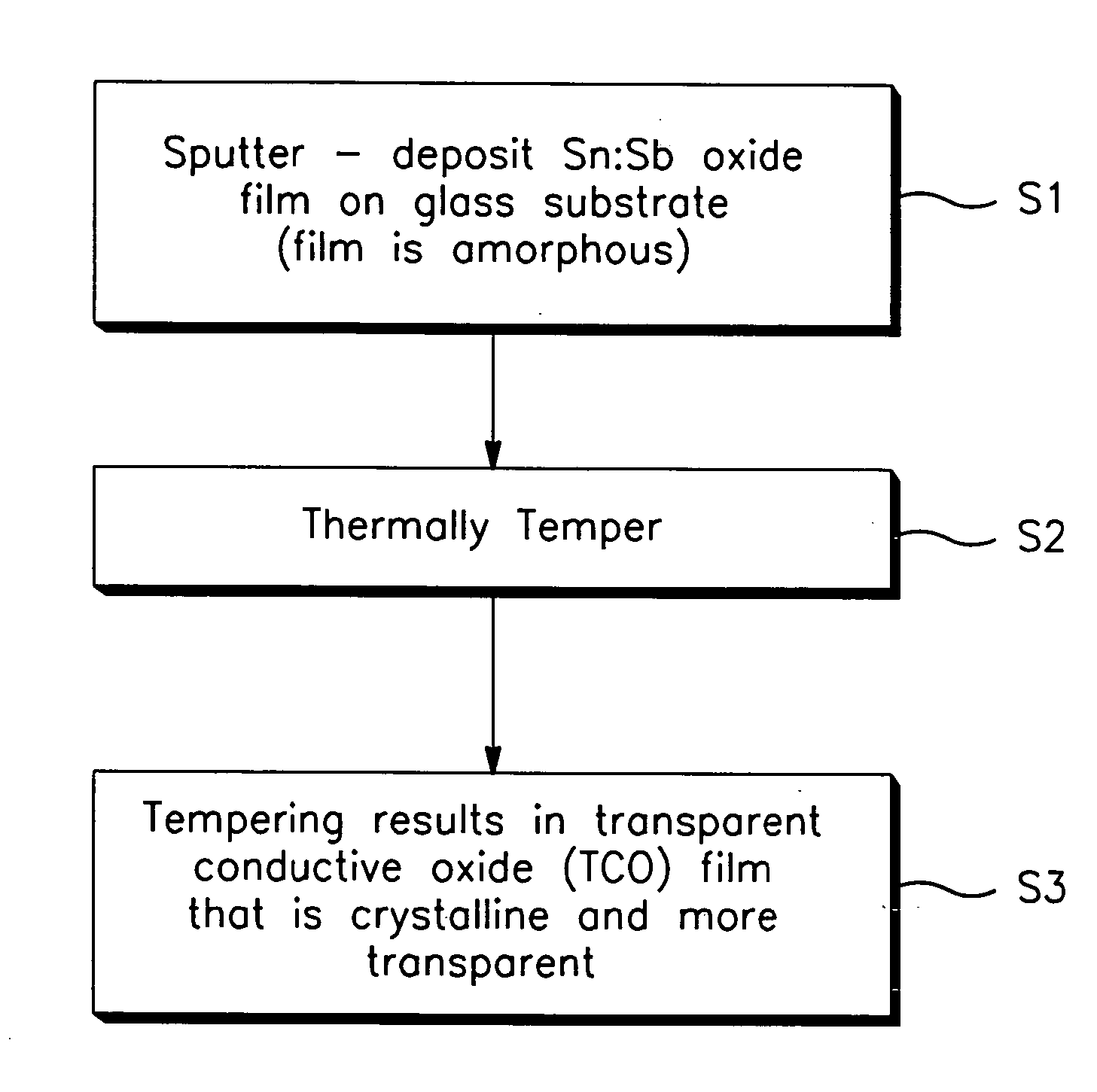

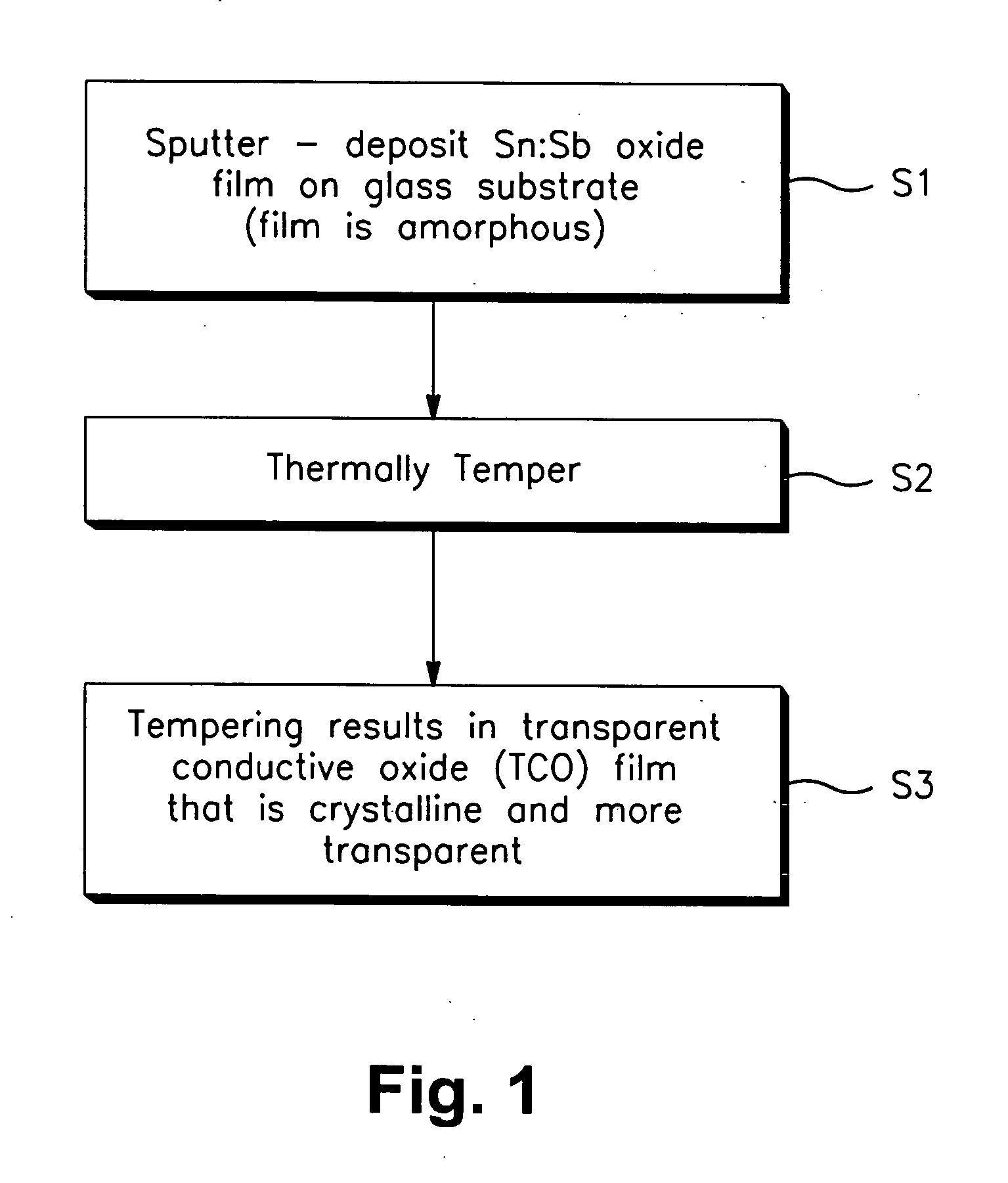

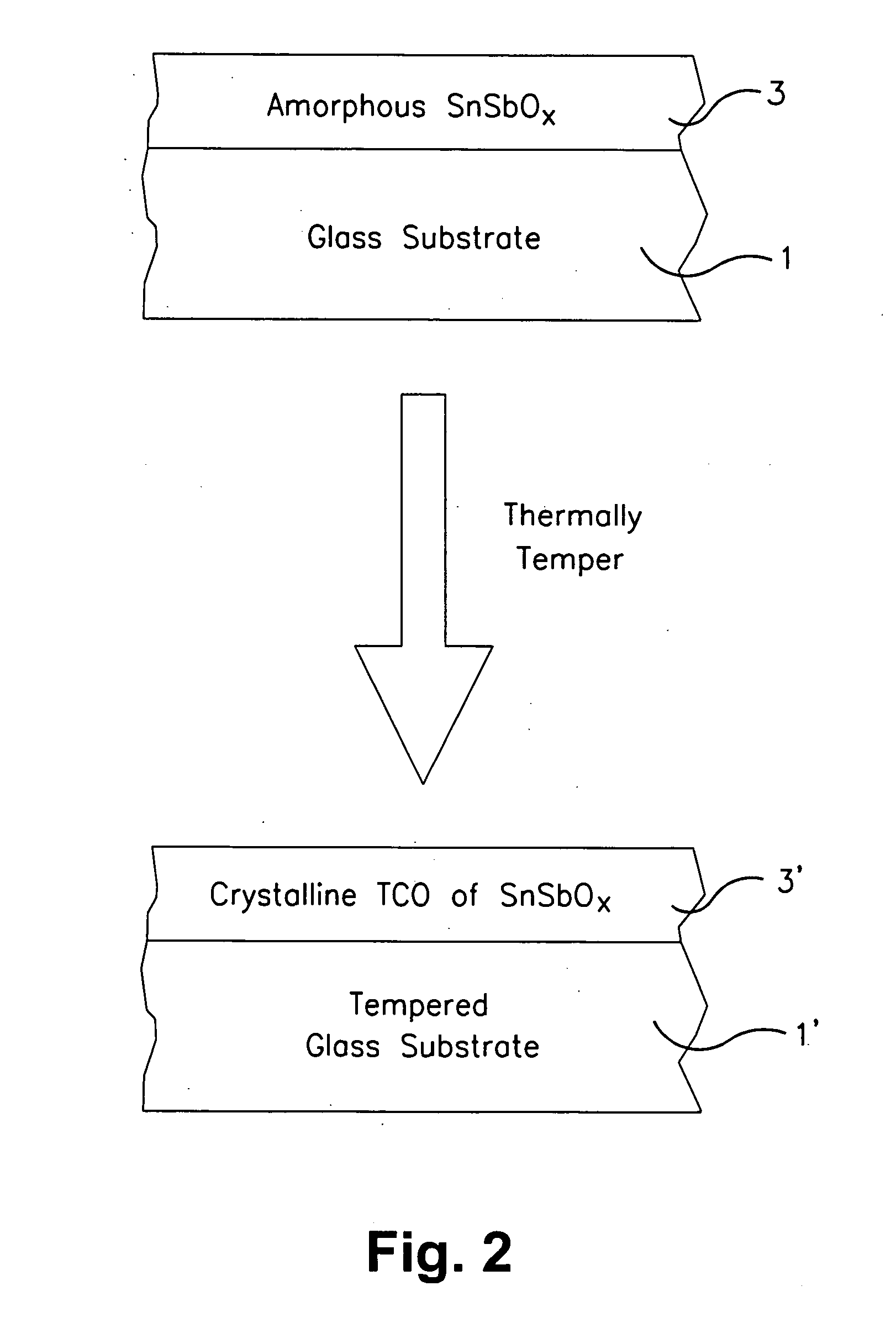

Method of making thermally tempered coated article with transparent conductive oxide (TCO) coating and product made using same

InactiveUS20070029187A1Efficient and effectiveVacuum evaporation coatingSputtering coatingOptoelectronicsToughened glass

A method of making a coated article including a transparent conductive oxide (TCO) film supported by a tempered glass substrate is provided. Initially, an amorphous metal oxide film is sputter-deposited onto a non-tempered glass substrate, either directly or indirectly. The glass substrate with the amorphous film thereon is then thermally tempered using high temperatures. The thermal tempering causes the amorphous film to be transformed into a crystalline transparent conductive oxide (TCO) film. The heat used in the thermal tempering of the glass substrate causes the amorphous film to turn into a crystalline film, causes the visible transmission of the film to increase, and / or causes the film to become electrically conductive.

Owner:GUARDIAN GLASS LLC

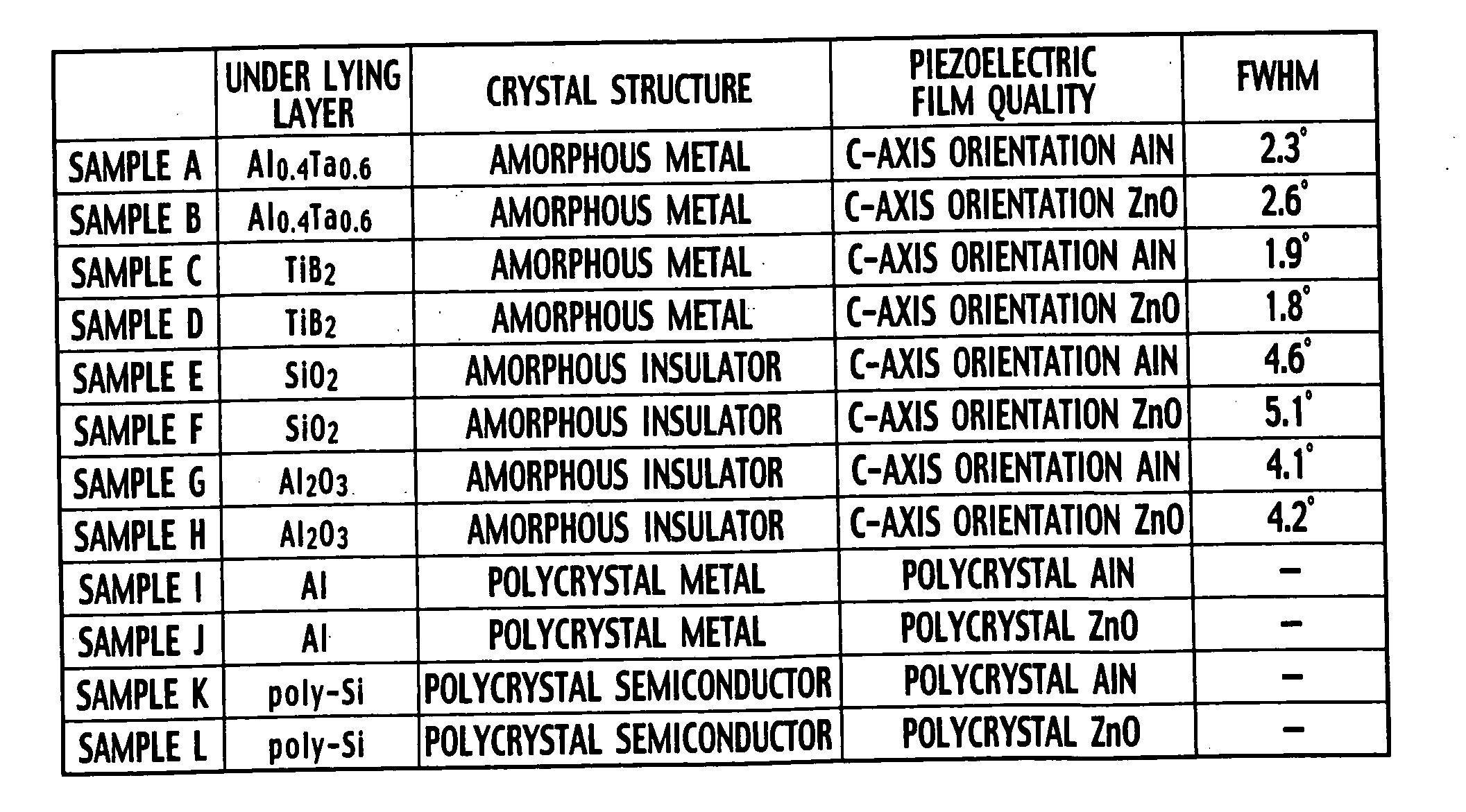

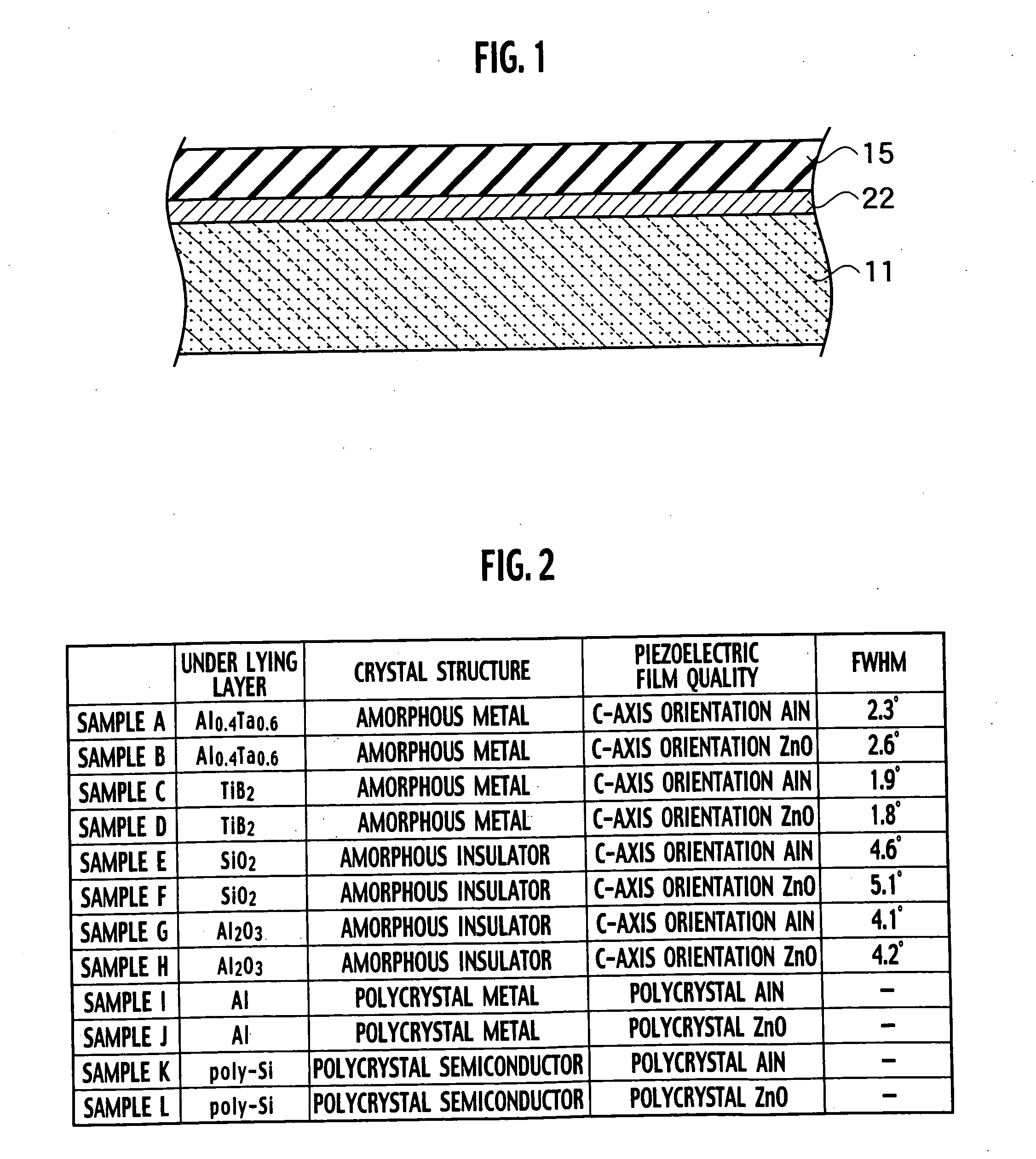

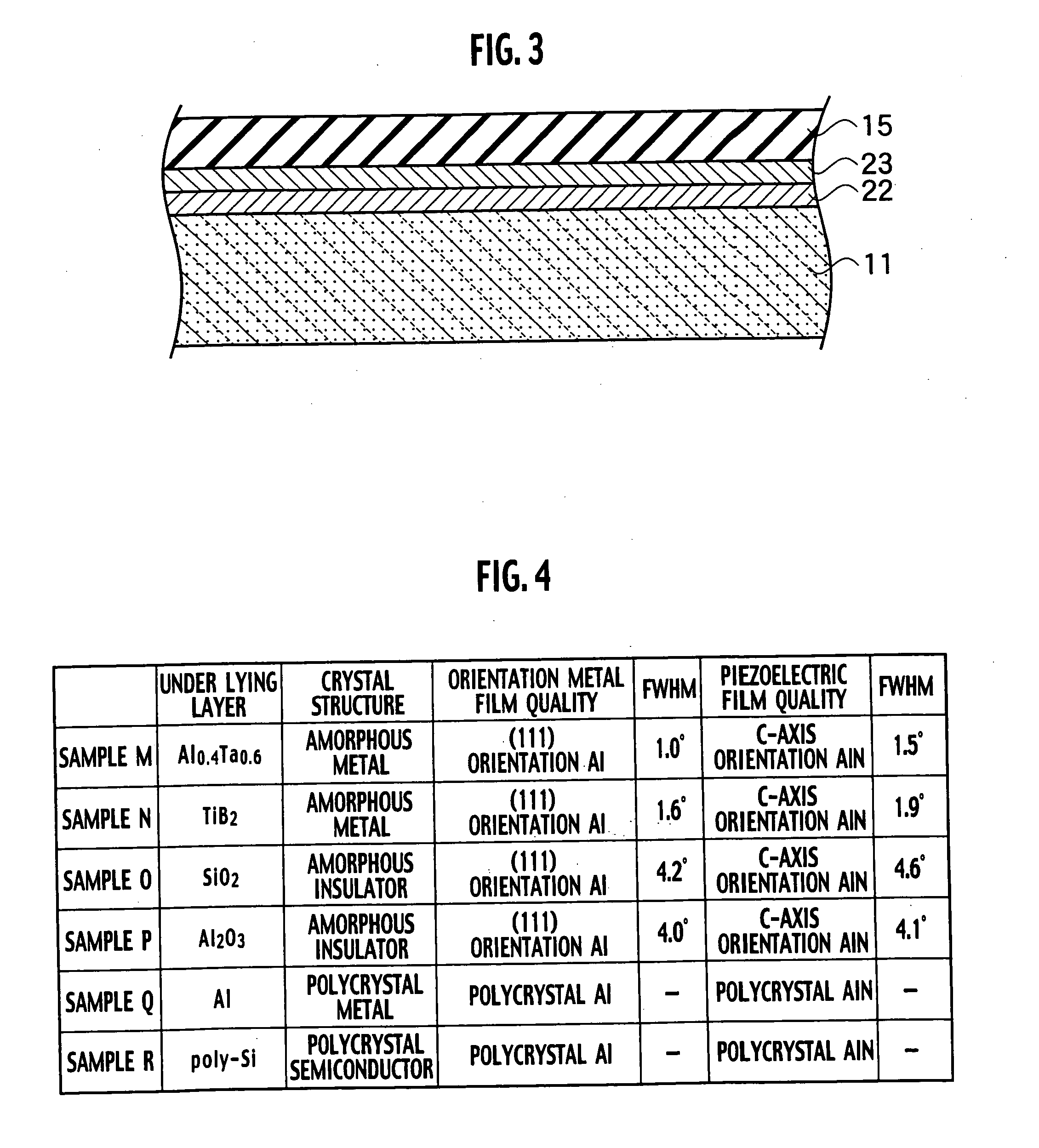

Piezoelectric thin film device and method for manufacturing the same

InactiveUS20050184627A1Constant gainPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsAmorphous metal

A piezoelectric thin film device includes an amorphous metal film disposed on a substrate and a piezoelectric film disposed on the amorphous metal. One of crystal axis of the piezoelectric film is aligned in a direction perpendicular to a surface of the amorphous metal.

Owner:KK TOSHIBA

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

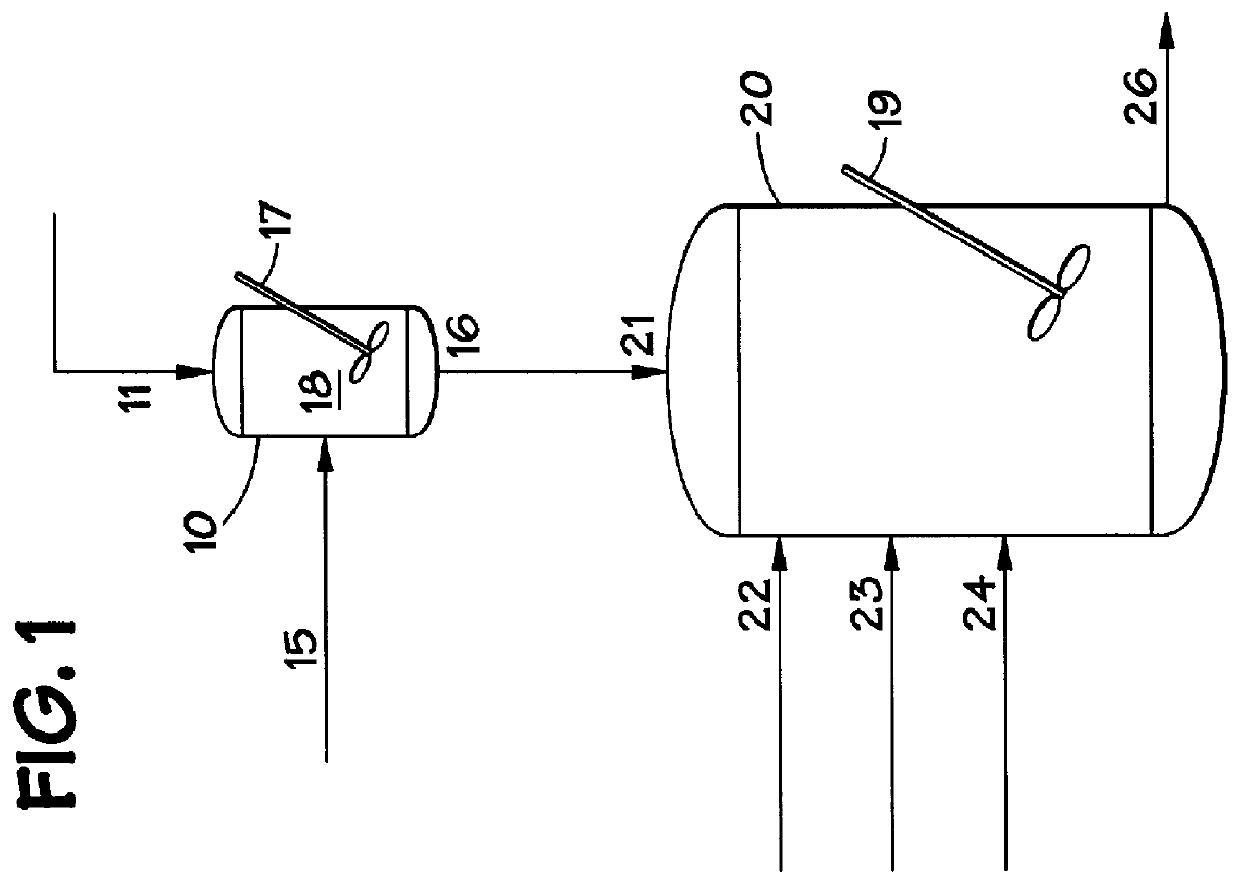

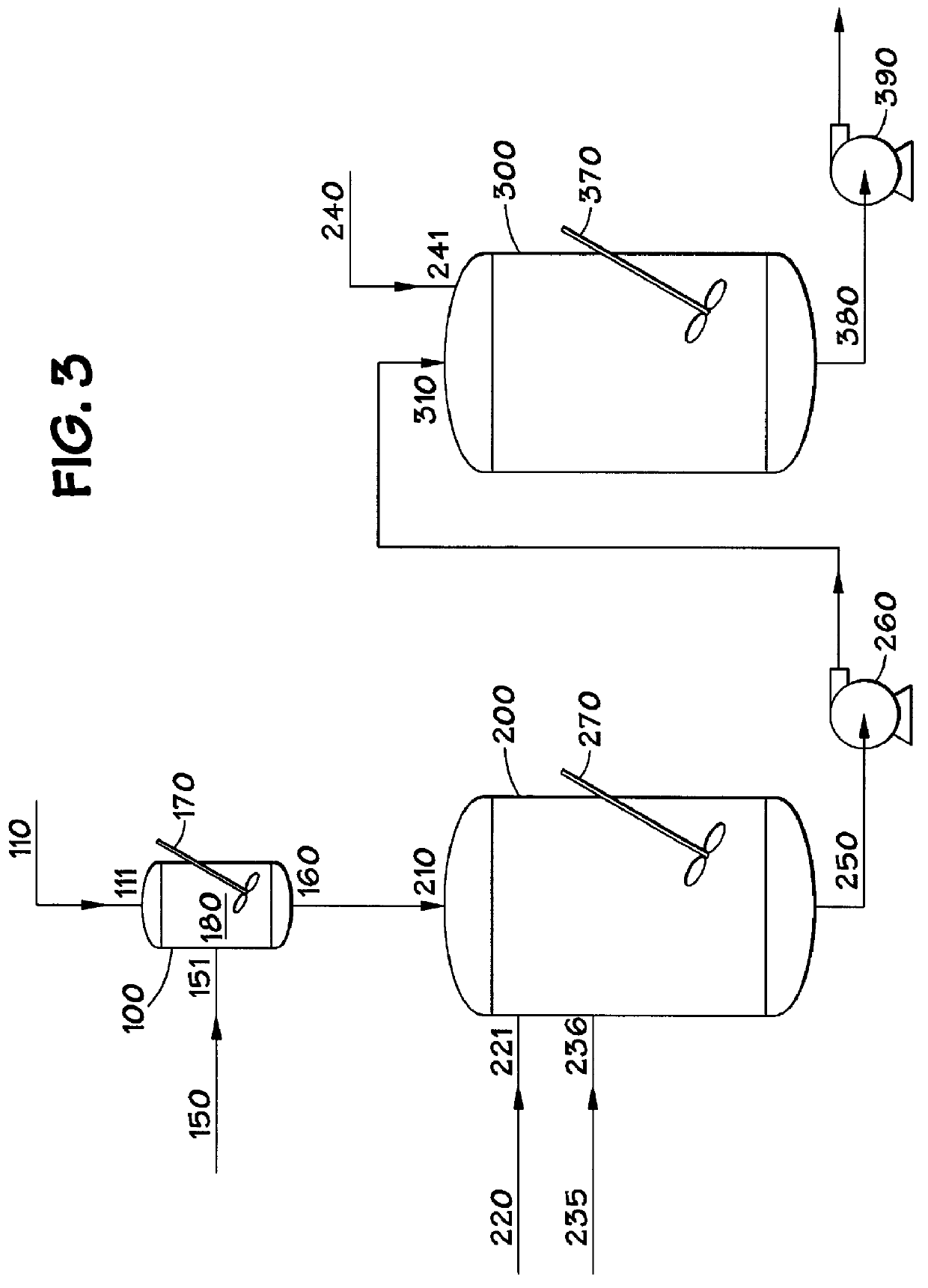

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

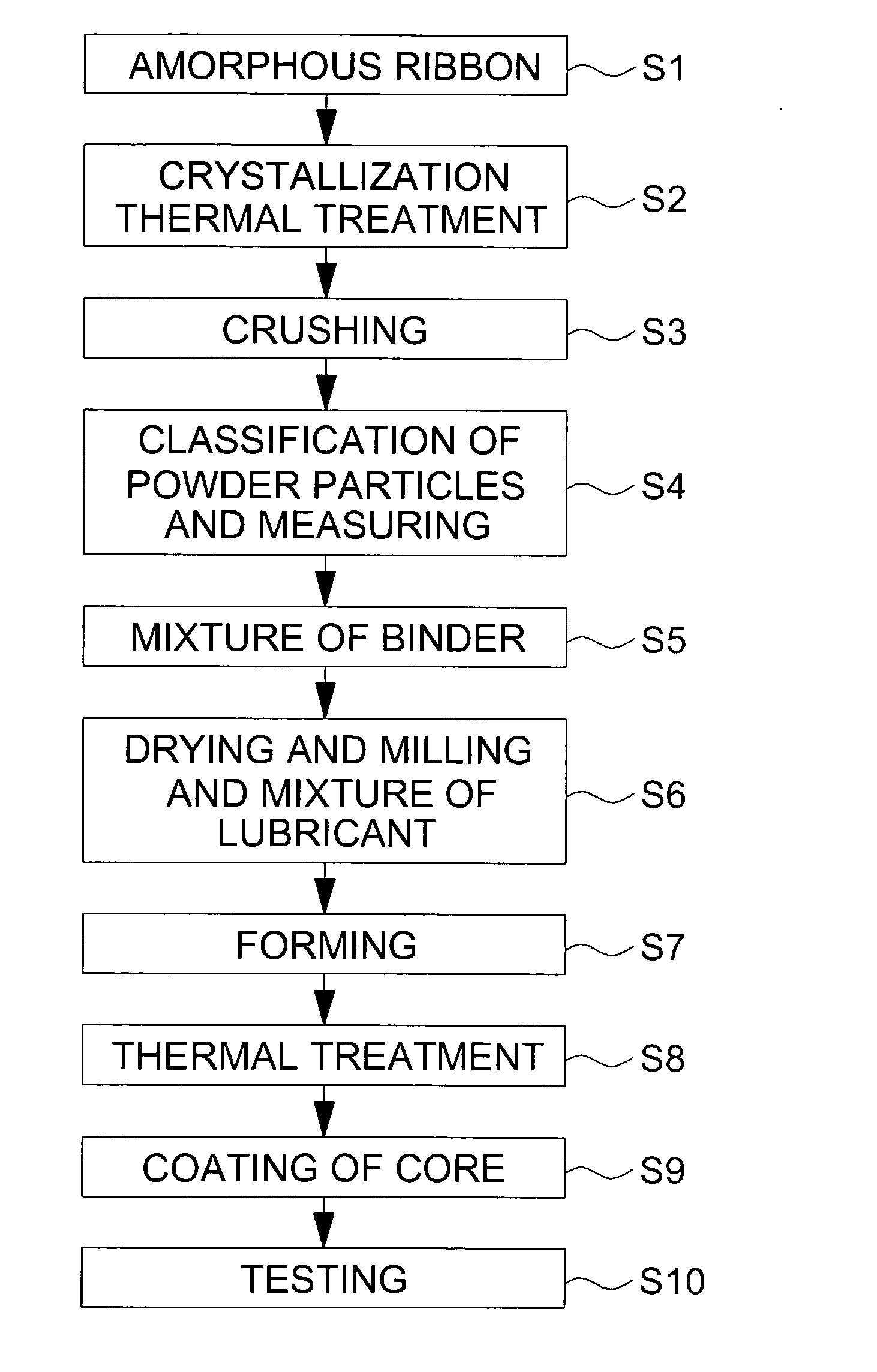

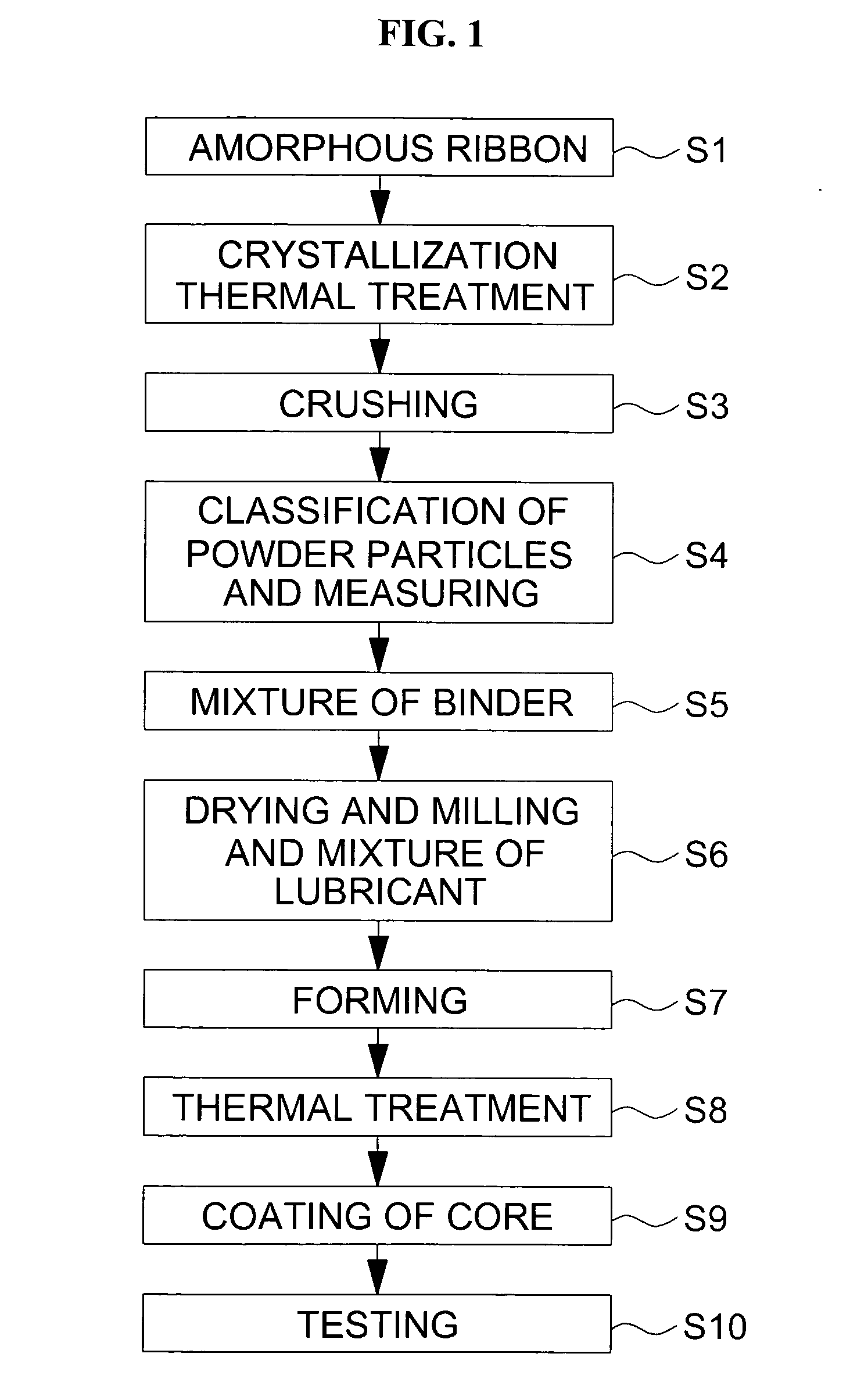

Method for making nano-scale grain metal powders having excellent high-frequency characteristic and method for making high-frequency soft magnetic core using the same

ActiveUS20050034787A1Improve thermal stabilityReduce processing costsNanostructure manufactureTransportation and packagingThermal treatmentMetal powder

A method for making a nano-scale amorphous soft magnetic powders obtained by thermally processing and crystallizing amorphous ribbons produced using a rapid solidification process (RSP) and crushing the same. The amorphous soft magnetic core having an excellent high-frequency characteristic is obtained by performing a preliminary thermal treatment of Fe-based amorphous metal ribbons produced by using RSP to then be converted into nano-scale grain metal ribbons, crushing the metal ribbons to thereby obtain nano-scale grain metal powders, classifying the nano-scale grain metal powders to then be mixed into a distribution of powder particles having an optimal uniform composition, mixing the mixed powder with a binder, and then forming a core, and annealing the formed core to then coat the core with an insulating resin.

Owner:AMOSENSE

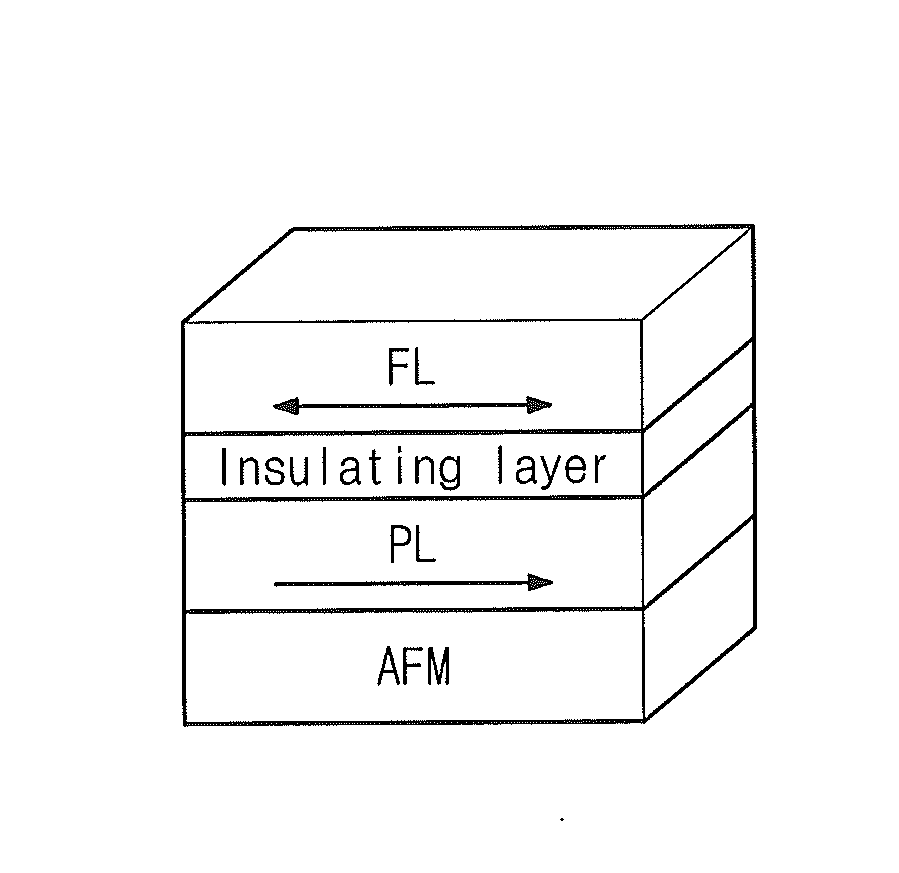

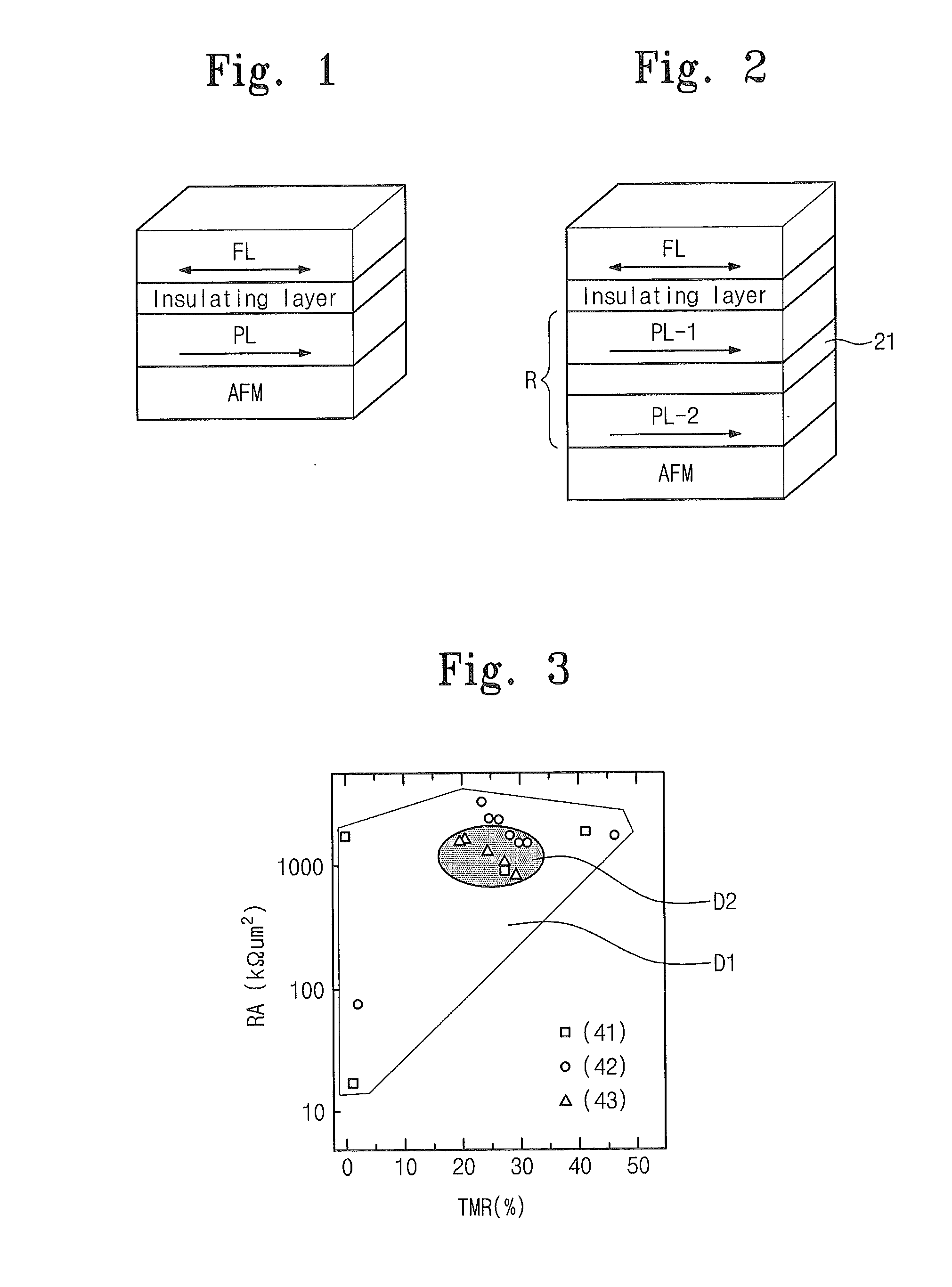

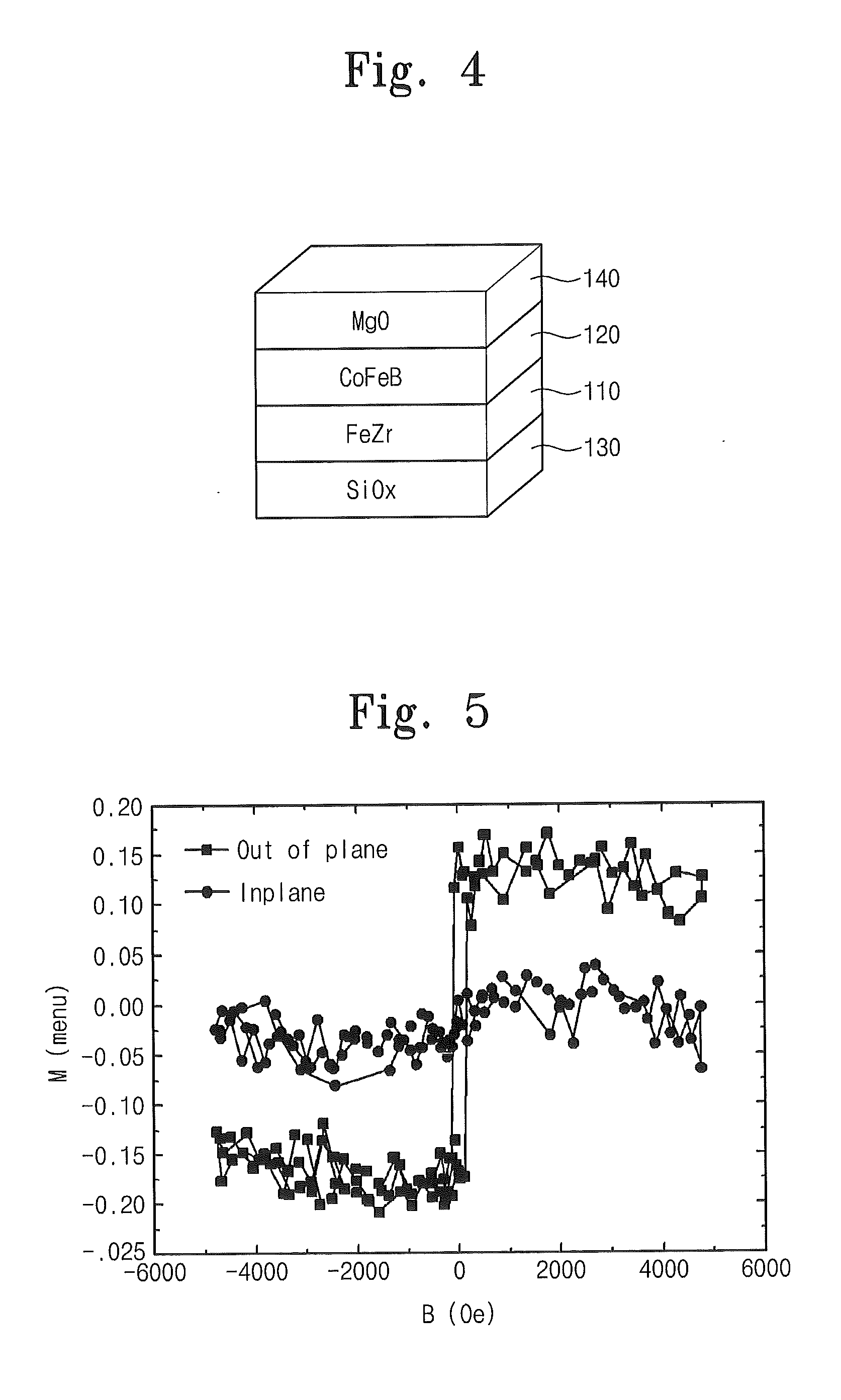

Magnetic Tunnel Junction Device Having Amorphous Buffer Layers That Are Magnetically Connected Together And That Have Perpendicular Magnetic Anisotropy

ActiveUS20130313665A1Improve uniformityIncreased junctionNanomagnetismGalvano-magnetic material selectionMagnetizationNanometre

According to a first embodiment of the present invention, a magnetic tunnel junction device comprises: a free layer having a magnetization in a variable direction; a pinned layer having a magnetization in a pinned direction; and a tunnel insulation film formed between the free layer and the pinned layer, wherein the pinned layer includes a ferromagnetic film and an amorphous metal film. In addition, a magnetic device according to a second embodiment of the present invention comprises: an amorphous or nanocrystal material layer; and a perpendicular magnetic anisotropic material layer formed on the amorphous or nanocrystal material layer. The amorphous or nanocrystal material layer is a predefined amorphous material or nanocrystal material layer serving as a lower layer, and the perpendicular magnetic anisotropic material layer is formed on the amorphous or nanocrystal material layer.

Owner:SAMSUNG ELECTRONICS CO LTD

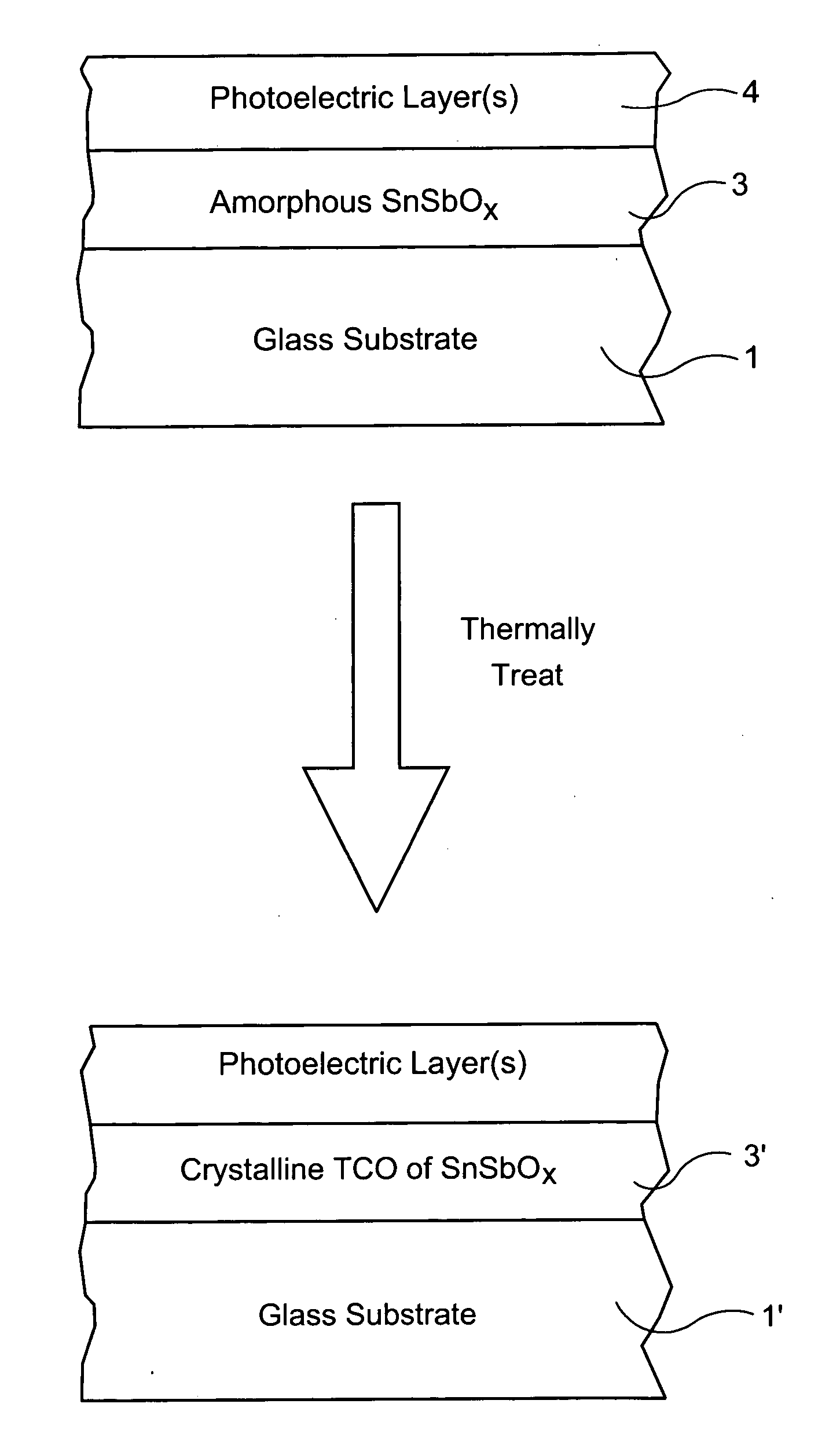

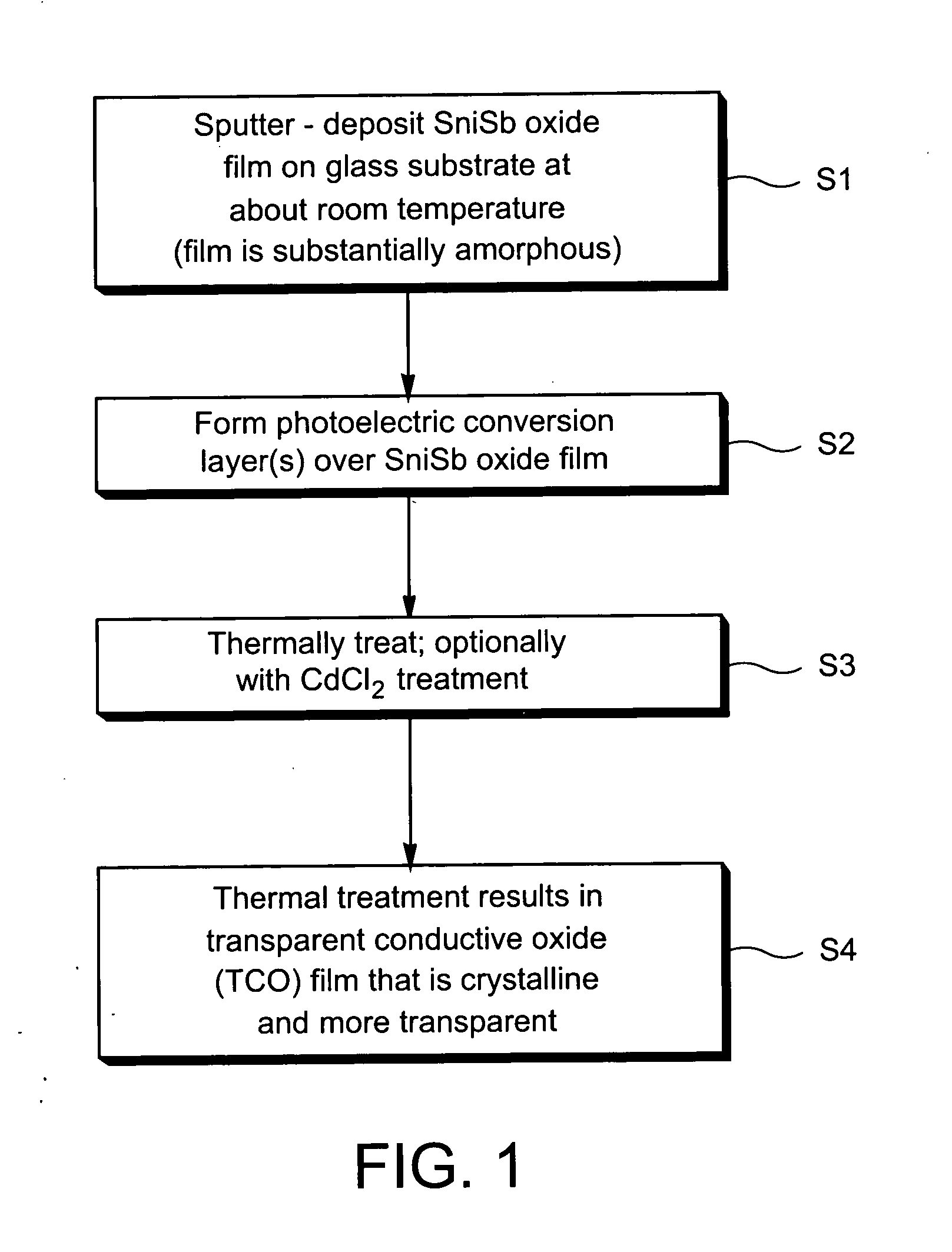

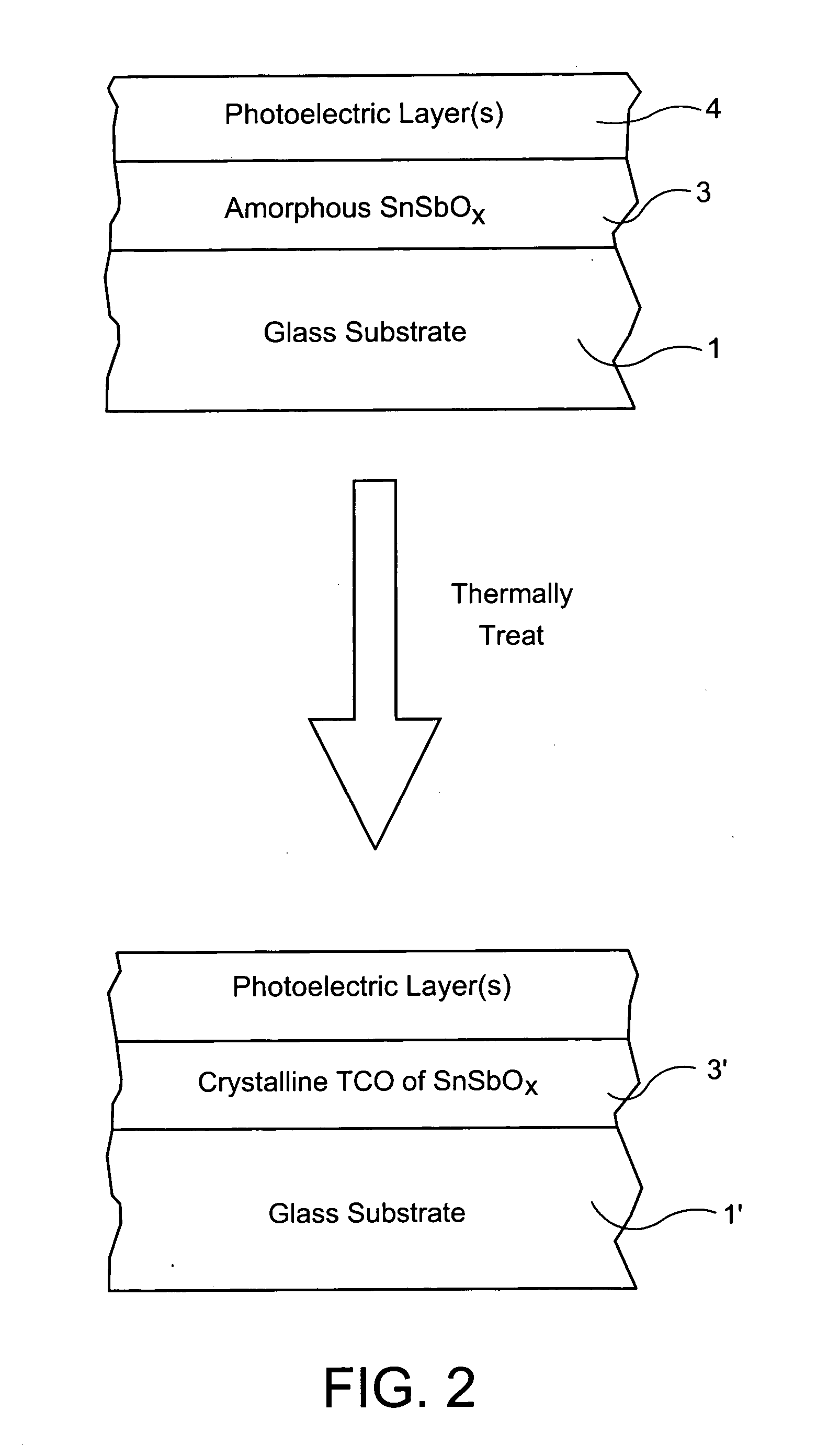

Method of making a thermally treated coated article with transparent conductive oxide (TCO) coating for use in a semiconductor device

InactiveUS20070184573A1Easy to groupFree up spaceVacuum evaporation coatingSputtering coatingSputteringDevice material

A method of making a coated article including a transparent conductive oxide (TCO) film supported by a glass substrate is provided. Initially, an amorphous metal oxide film is sputter-deposited onto a glass substrate, either directly or indirectly. The glass substrate with the amorphous film and a semiconductor film thereon is then thermally treated at high temperature(s). The thermal treating causes the amorphous film to be transformed into a crystalline transparent conductive oxide (TCO) film. The heat used in the thermal treating causes the amorphous film to turn into a crystalline film, causes the visible transmission of the film to increase, and / or causes the film to become electrically conductive.

Owner:GUARDIAN GLASS LLC

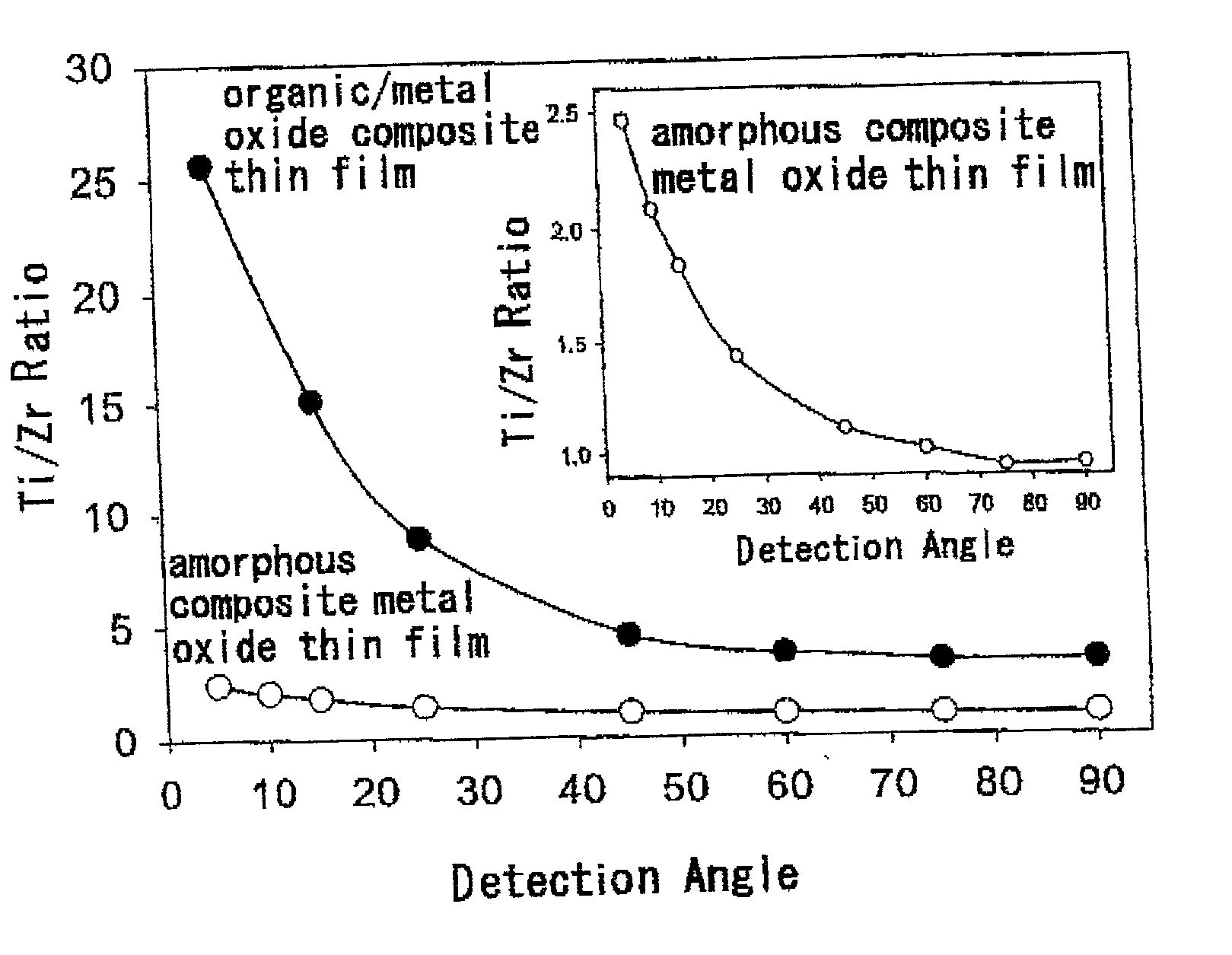

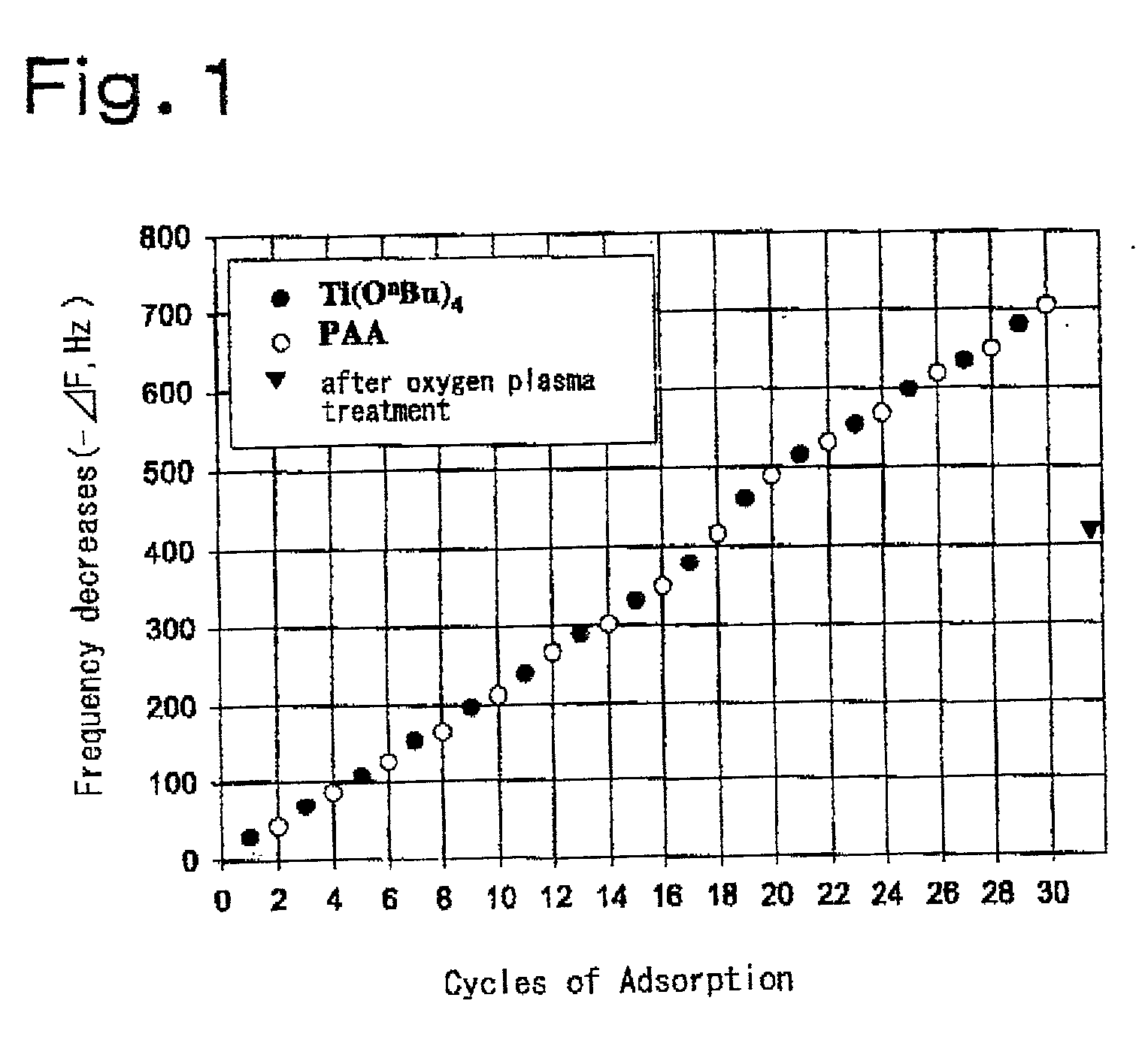

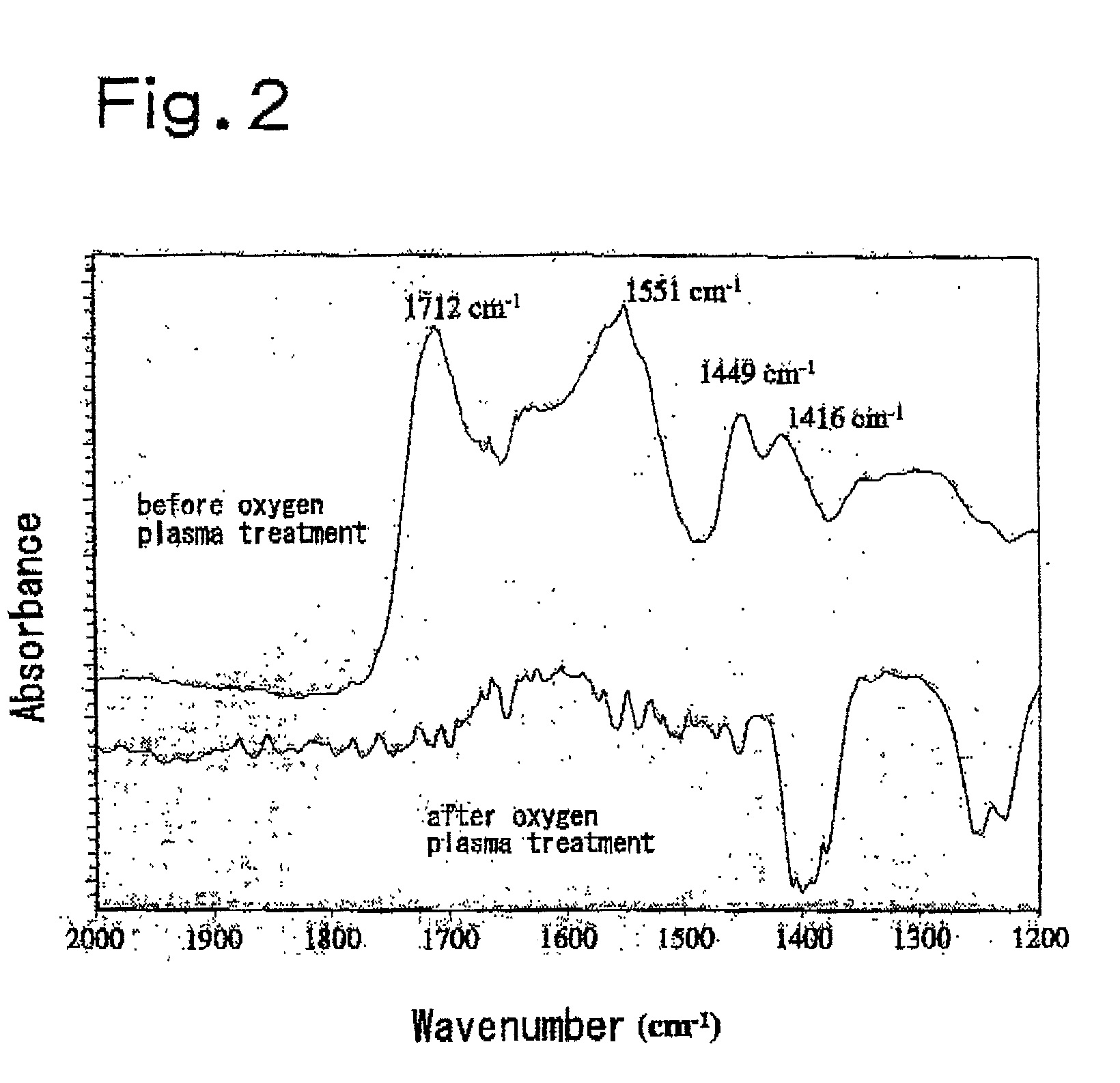

Thin film materials of amorphous metal oxides

InactiveUS20020190251A1Oxide/hydroxide preparationSemiconductor/solid-state device manufacturingOxygen plasmaOxide composite

Amorphous metal oxide thin film is produced by removing through oxygen plasma treatment the organic component from an organics / metal oxide composite thin film having thoroughly dispersed therein such organic component at molecular scale. This ensures production of amorphous metal oxide thin film with low density and excellent thickness precision.

Owner:RIKEN

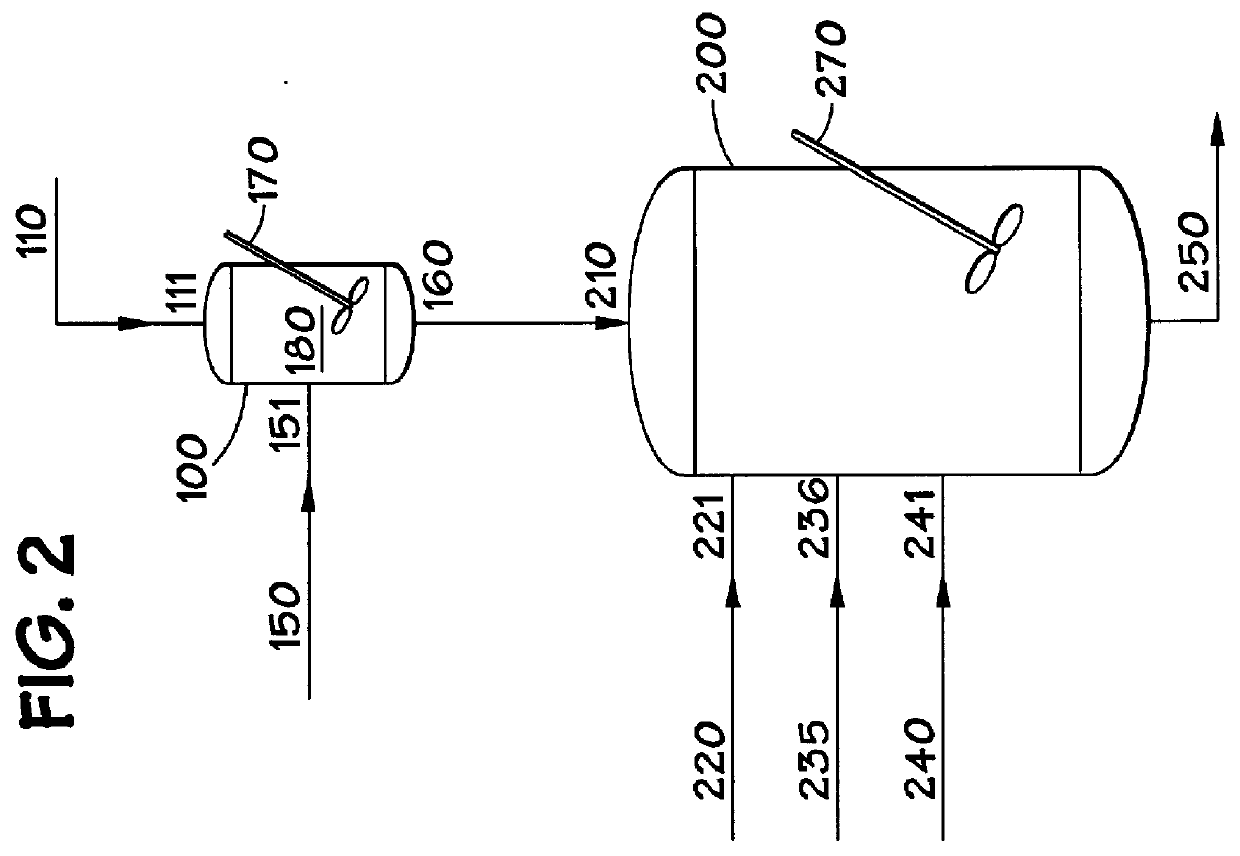

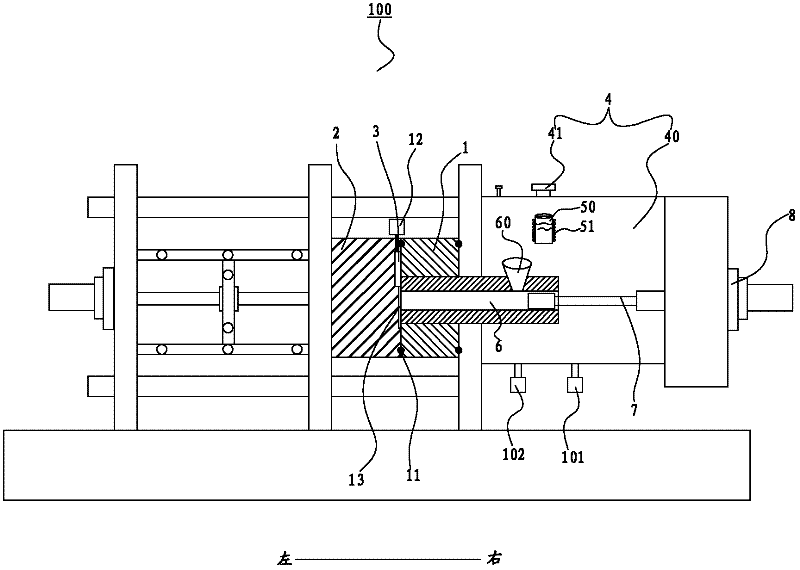

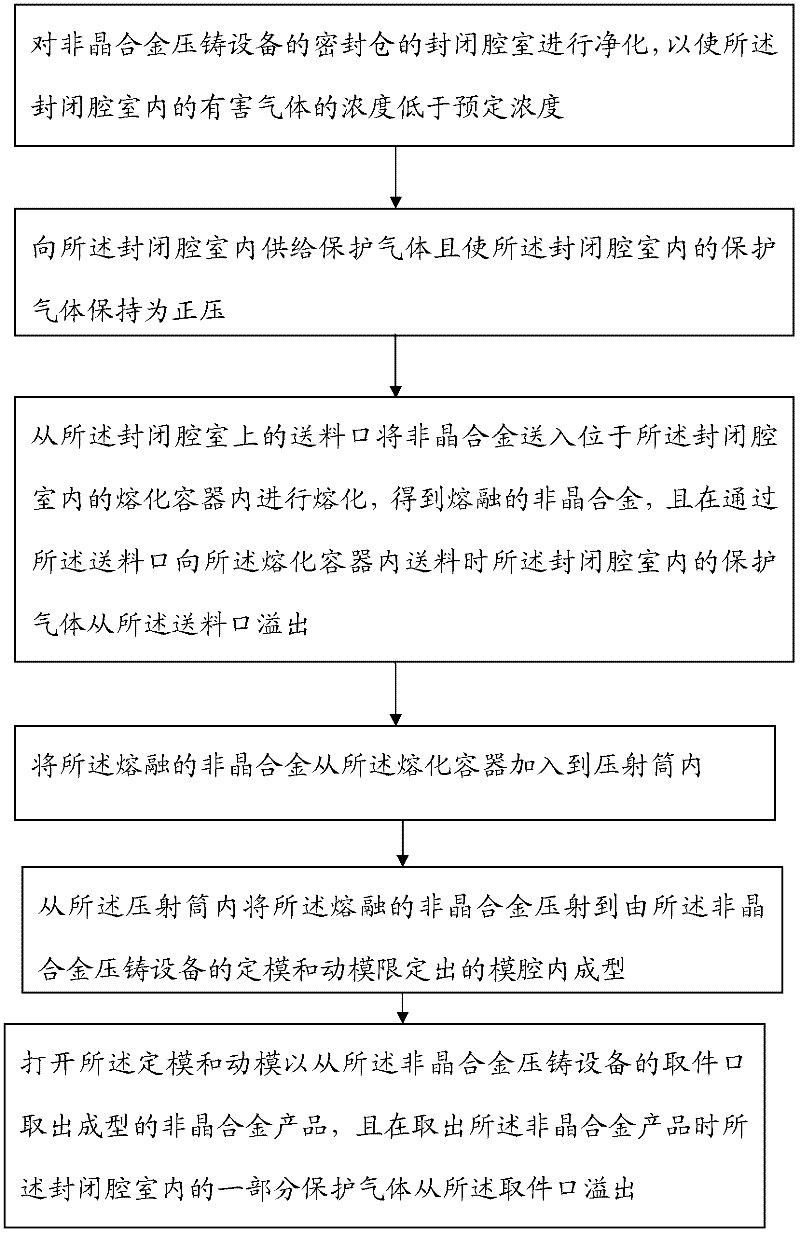

Amorphous alloy diecasting equipment and amorphous alloy diecasting process

ActiveCN102527982ACritical dimension reductionSimple structureMelt-holding vesselsMolten metal conveying equipmentsPositive pressureShielding gas

The invention discloses an amorphous alloy diecasting equipment and an amorphous alloy diecasting process. The amorphous alloy diecasting equipment comprises a fixed die, a movable die, a sealed bin, a protection-gas supplying device, a melting container, a pressing and ejecting cylinder, a driving device and a harmful-gas purifying device; the fixed die and the movable die can be opened and closed, and a die cavity is formed between the fixed die and the movable die in a defining way when the fixed die and the movable die are closed; a sealed chamber is formed in the sealed bin in a defining way, and the sealed bin is provided with a feeding opening; the protection-gas supplying device is connected with the sealed chamber and used for supplying a protection gas to the sealed chamber, wherein the protection gas in the sealed chamber is at positive pressure; the melting container is arranged in the sealed bin; the pressing and ejecting cylinder is communicated with the die cavity and provided with a melt inlet; the pressing and ejecting cylinder is internally provided with a pressing and ejecting piston used for ejecting the melted amorphous alloy into the die cavity; and the harmful-gas purifying device is connected with the sealed chamber and used for purifying the harmful gas in the sealed chamber. The amorphous alloy diecasting equipment disclosed by the embodiment of the invention has a simple structure, adopts the protective gas at positive pressure, does not need to establish a high vacuum degree and has low manufacturing and maintaining cost.

Owner:BYD CO LTD

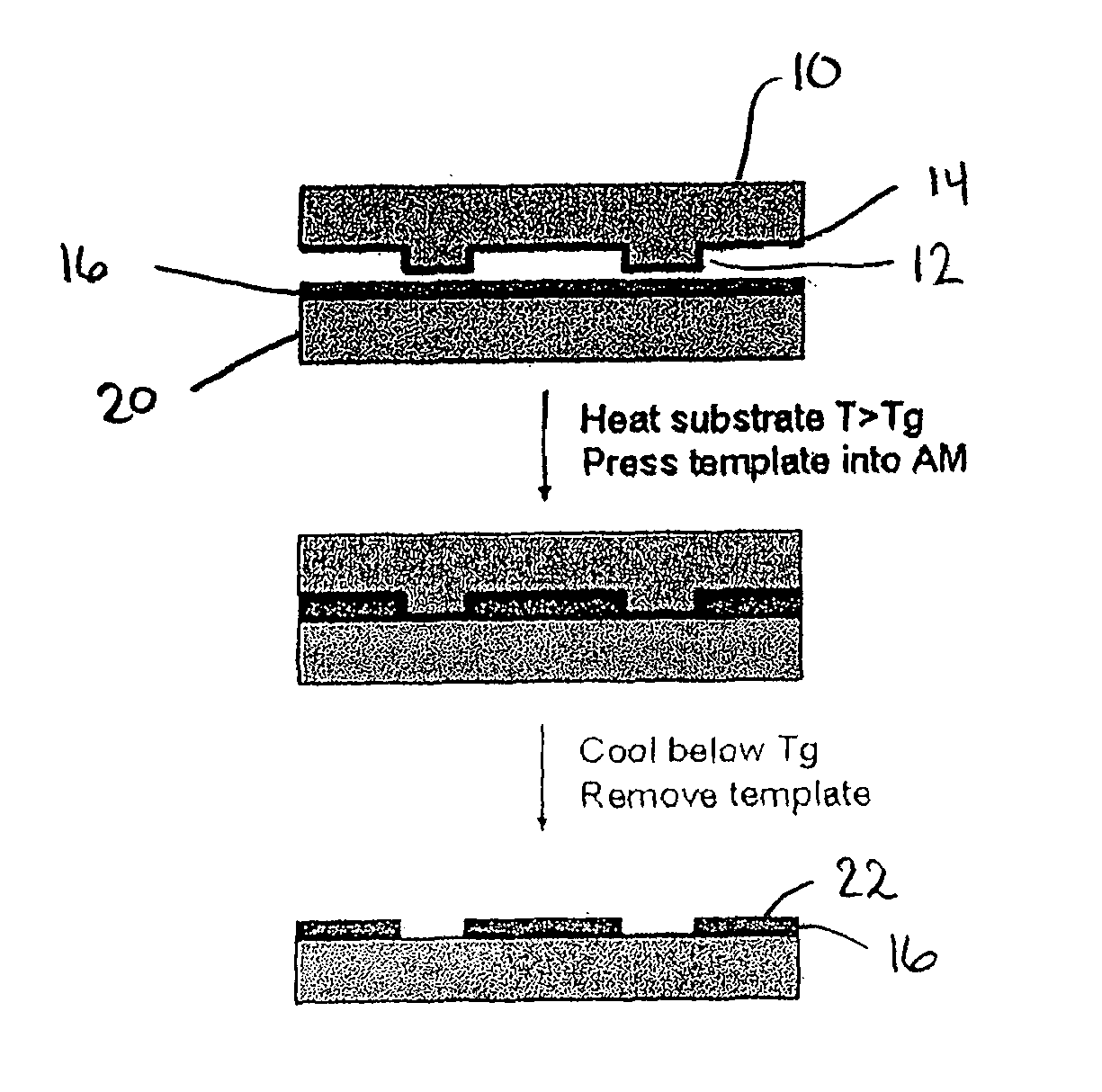

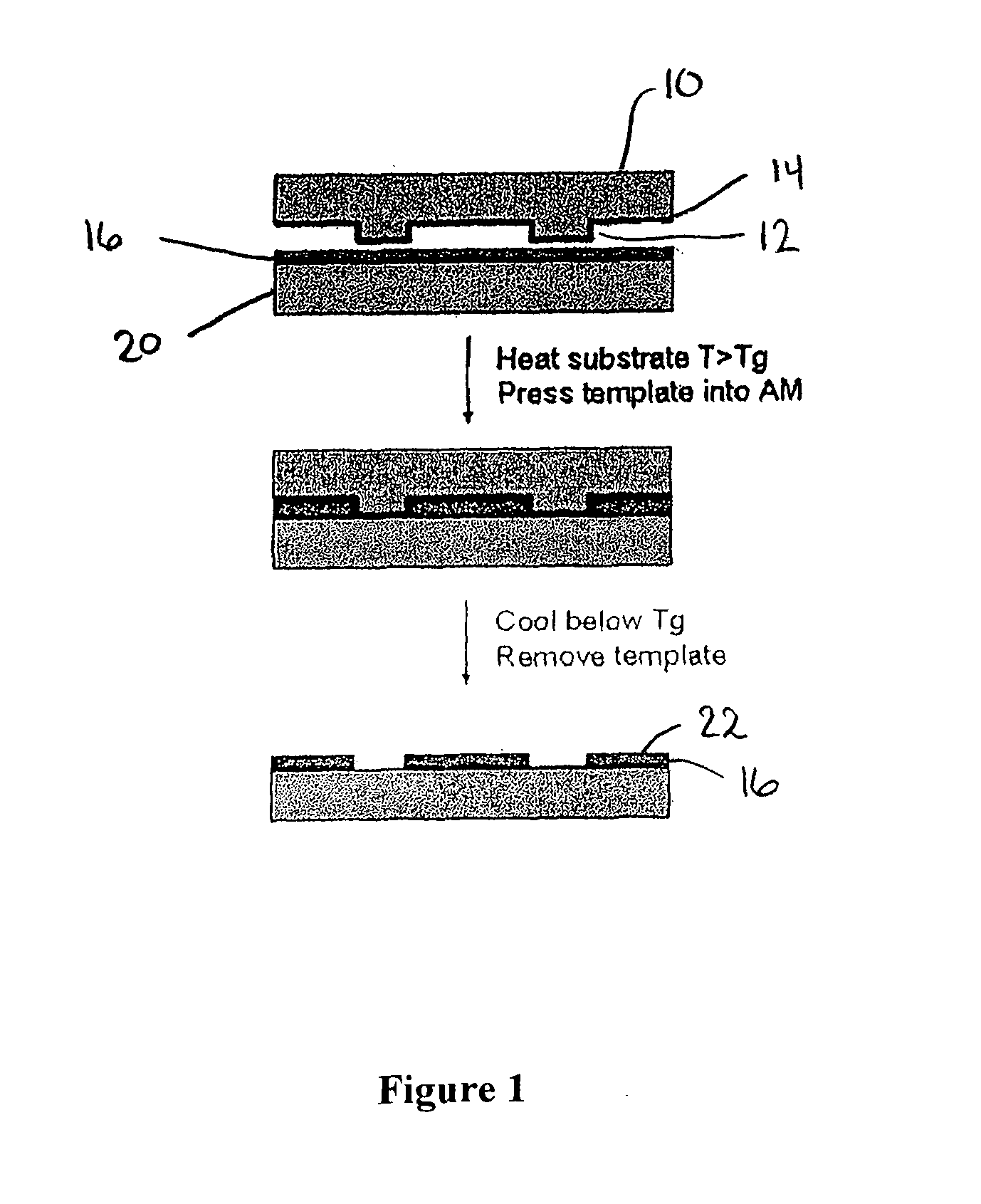

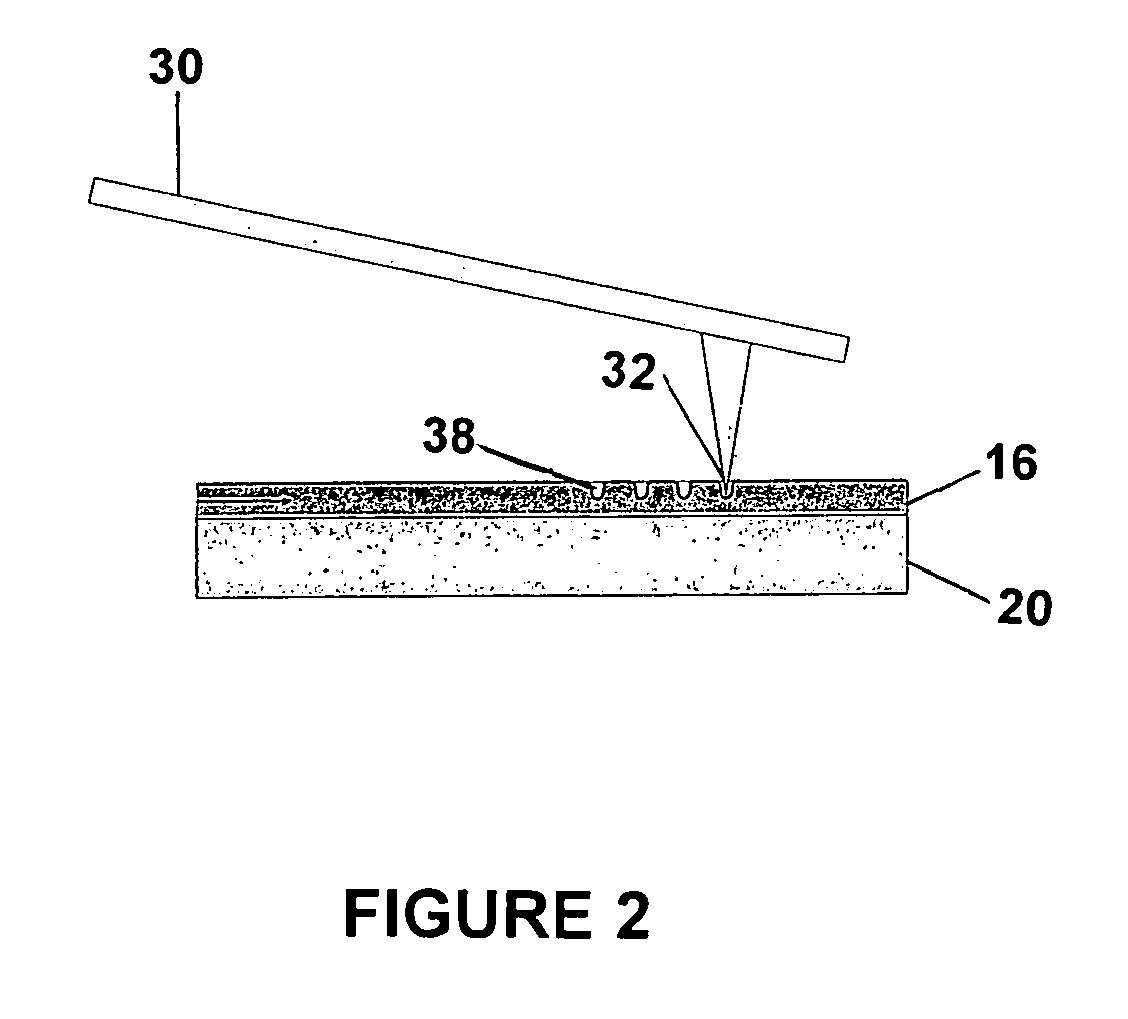

Method for Imprinting and Erasing Amorphous Metal Alloys

ActiveUS20100098967A1Surface roughnessLayered productsMechanical recordingMicron scaleNano manufacturing

The present invention relates to materials, methods and apparatuses for performing imprint lithography using amorphous metallic materials. The amorphous metallic materials can be employed as imprint media and thermoplastic forming processes are applied during the pattern transfer procedure to produce micron scale and nanoscale patterns in the amorphous metallic layer. The pattern transfer is in the form of direct mask embossing or through a serial nano-indentation process. A rewriting process is also disclosed, which involves an erasing mechanism that is accomplished by means of a second thermoplastic forming process. The amorphous metallic materials may also be used directly as an embossing mold in imprint lithography to allow high volume imprint nano-manufacturing. This invention also comprises of a method of smoothening surfaces under the action of the surface tension alone.

Owner:YALE UNIV

Metallic mirrors formed from amorphous alloys

Owner:CRUCIBLE INTPROP LLC

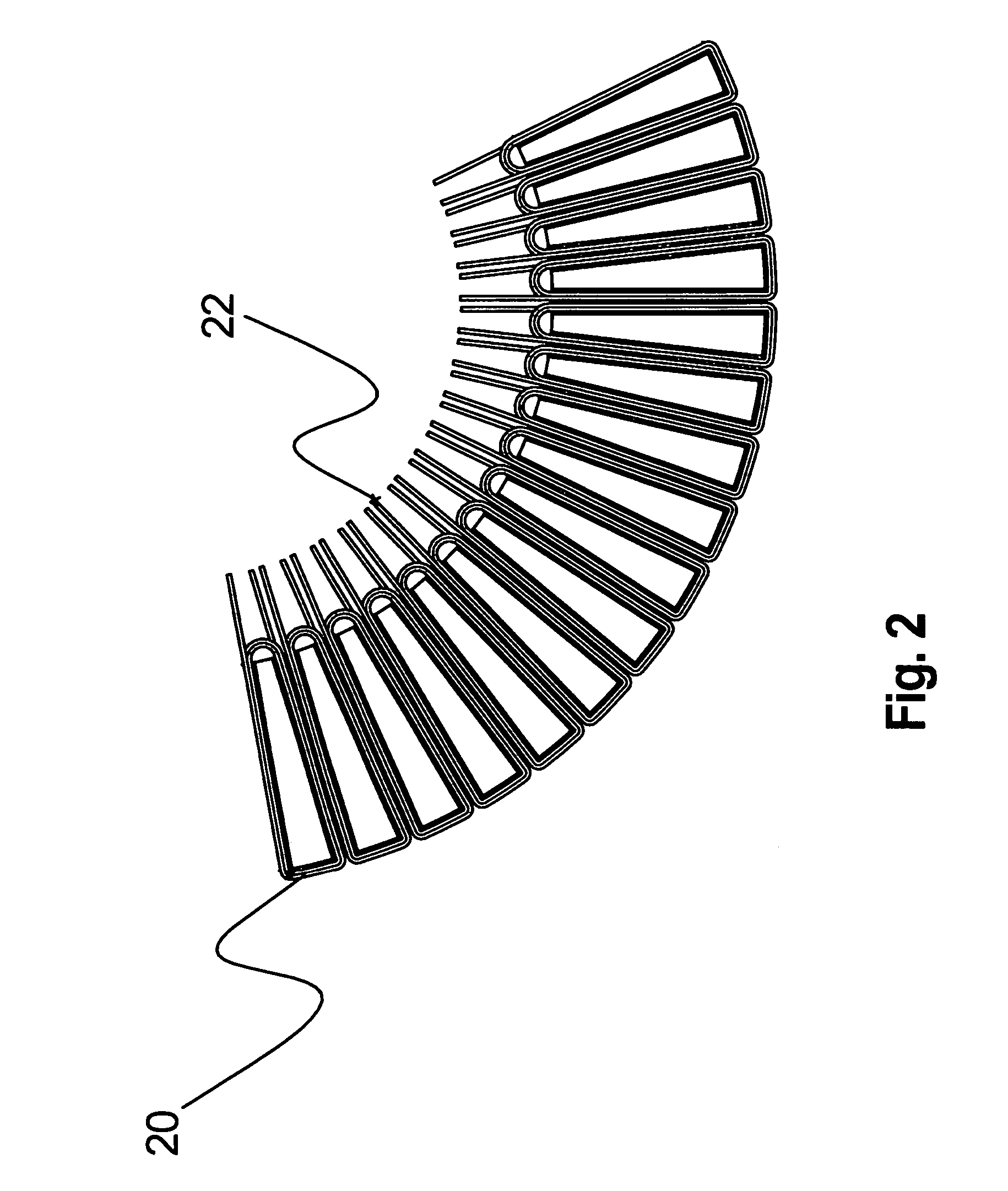

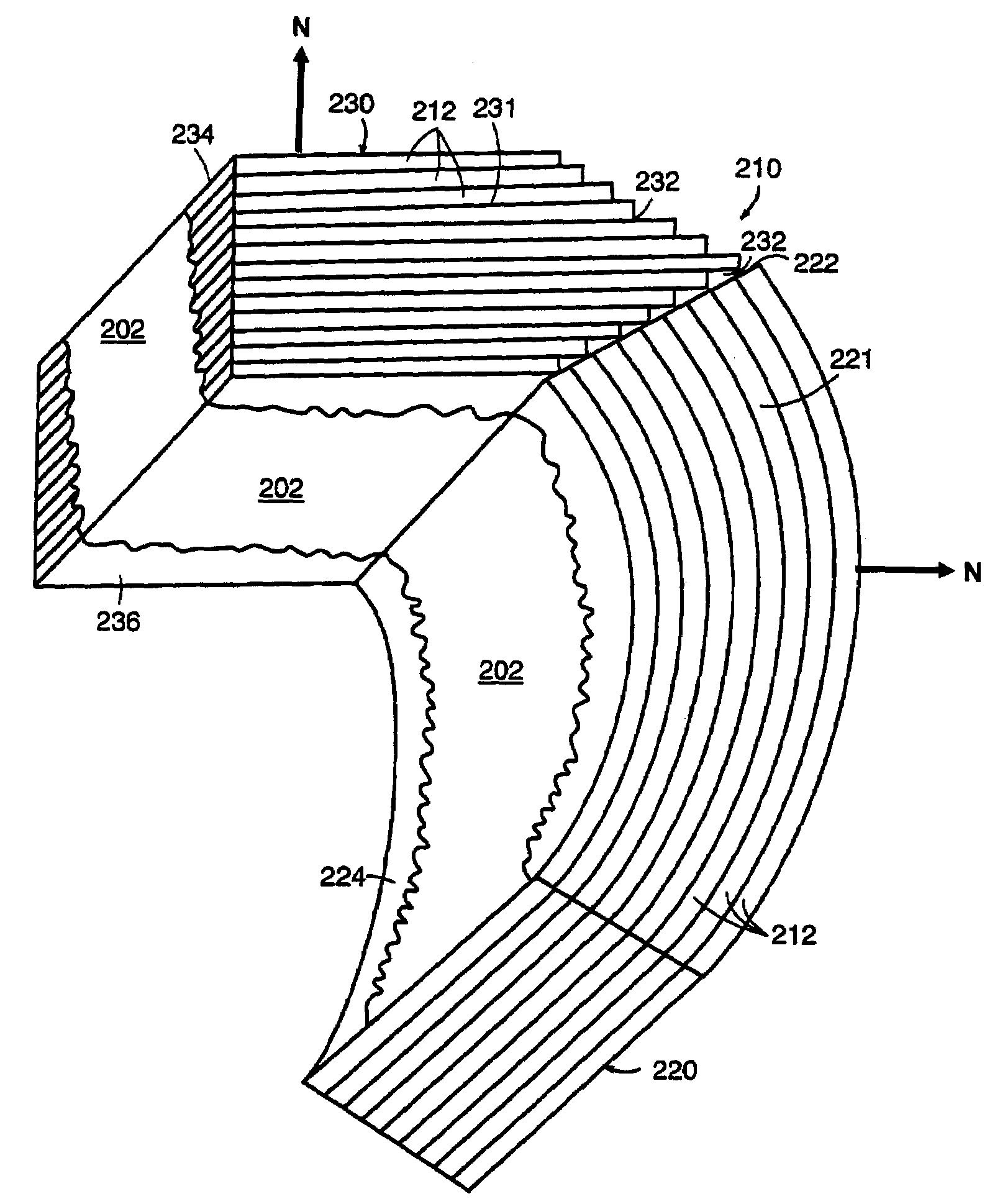

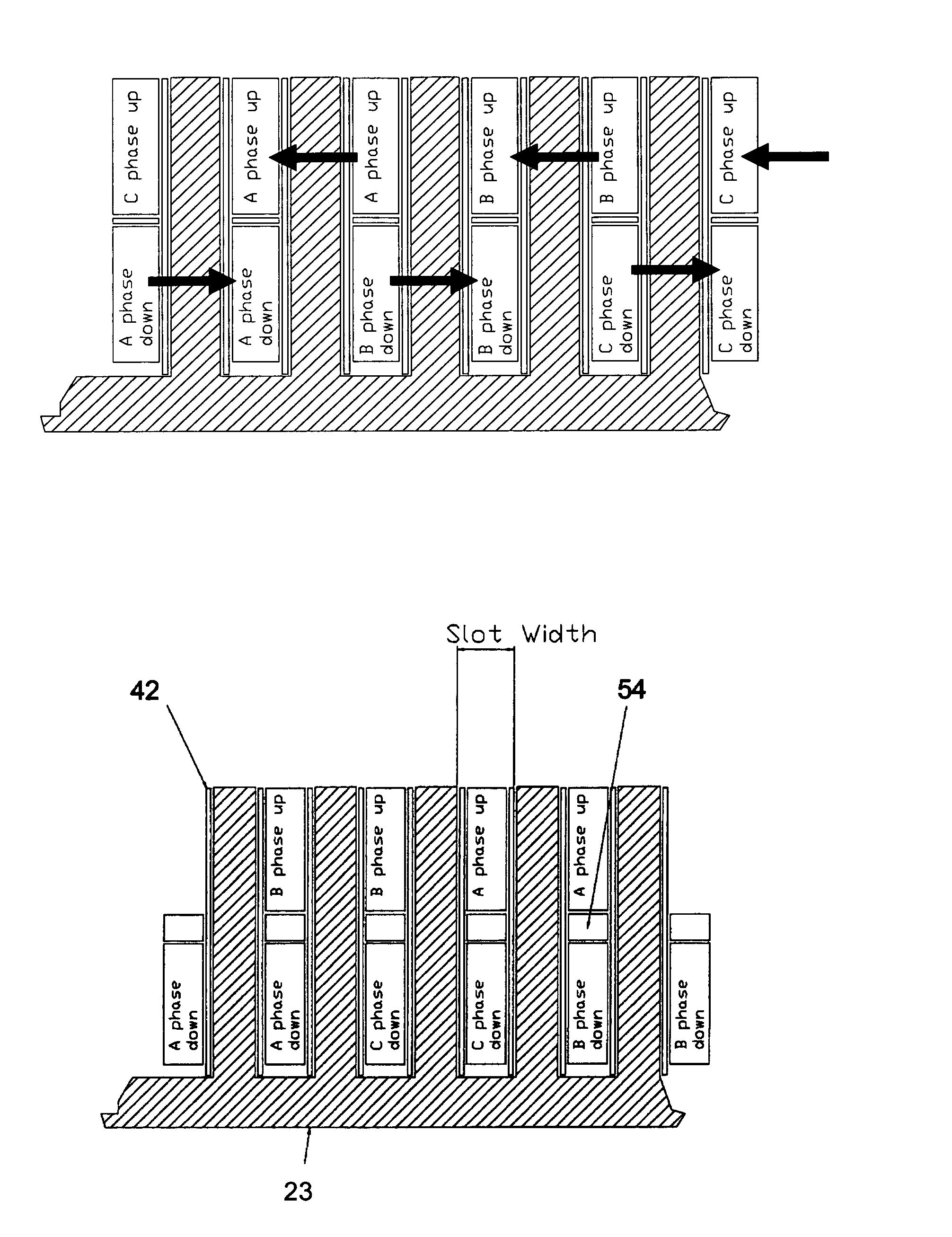

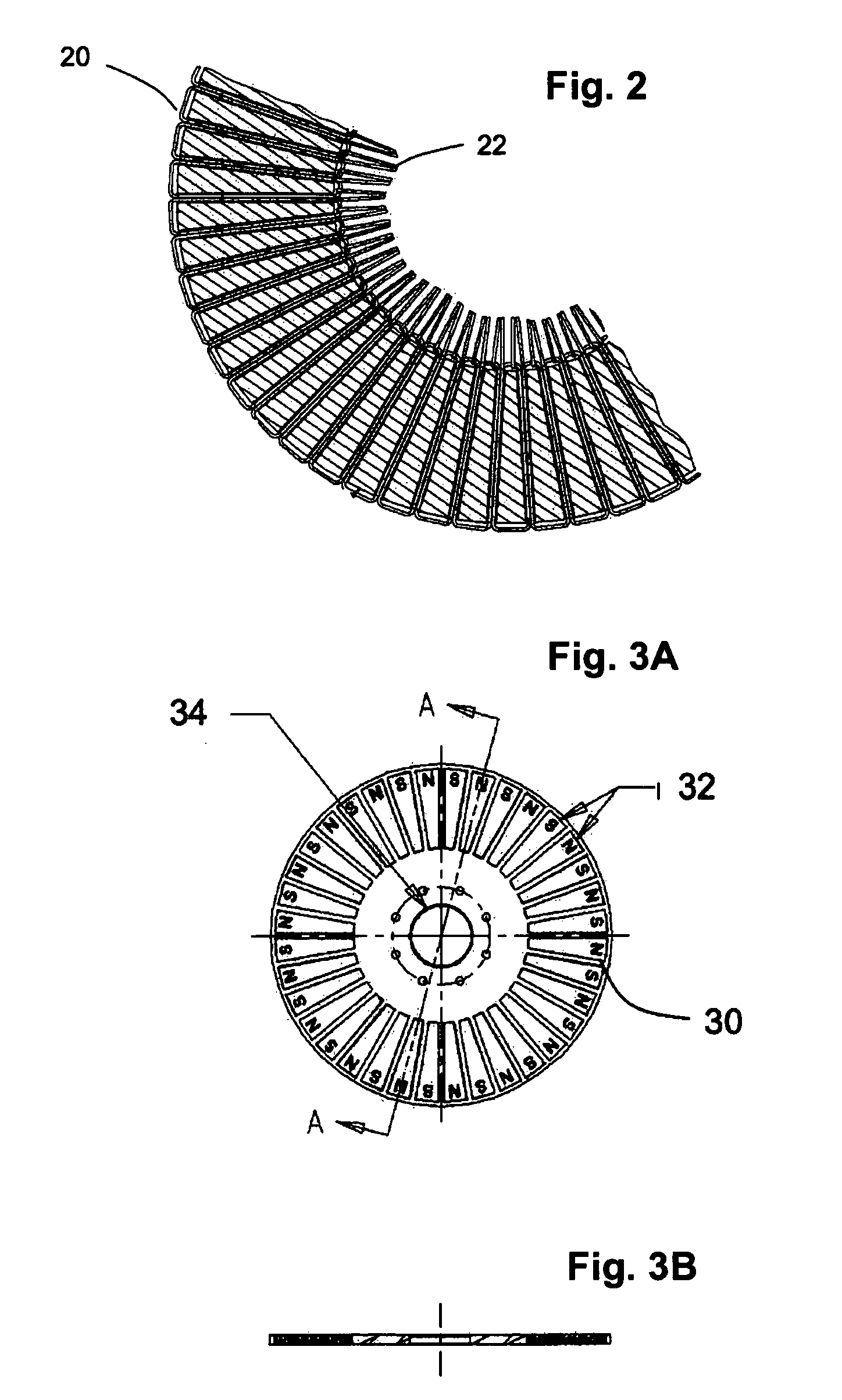

Stator coil arrangement for an axial airgap electric device including low-loss materials

InactiveUS7190101B2Bulky designHigh operating requirementsSynchronous generatorsMagnetic circuit rotating partsElectric machineStator coil

A dynamoelectric, rotating electric machine includes a stator assembly that includes stacked stator coil windings. The machine is preferably a polyphase, axial airgap device. Improved slot filling results from the stacked stator coil configuration. Device performance capability is thereby increased. The stator assembly of the electric device has a magnetic core made from low loss, high frequency material. A high pole count permits the electrical device to operate at high commutating frequencies, with high efficiency, high power density and improved performance characteristics. Low-loss materials incorporated by the device include amorphous metals, nanocrystalline metals, optimized Si—Fe alloys, grain-oriented Fe-based materials or non-grain-oriented Fe-based materials.

Owner:LIGHT ENGINEERING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com