Patents

Literature

561 results about "Drag reducing agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drag-reducing agents (DRA), or drag-reducing polymers (DRP's), are additives in pipelines that reduce turbulence in a pipe. Usually used in petroleum pipelines, they increase the pipeline capacity by reducing turbulency and therefore allowing the oil to flow more efficiently.

Shale gas acid fracturing drag reducer and reparation method thereof

InactiveCN103694984AImprove acid resistanceImprove stabilityDrilling compositionEthylenediamineOil phase

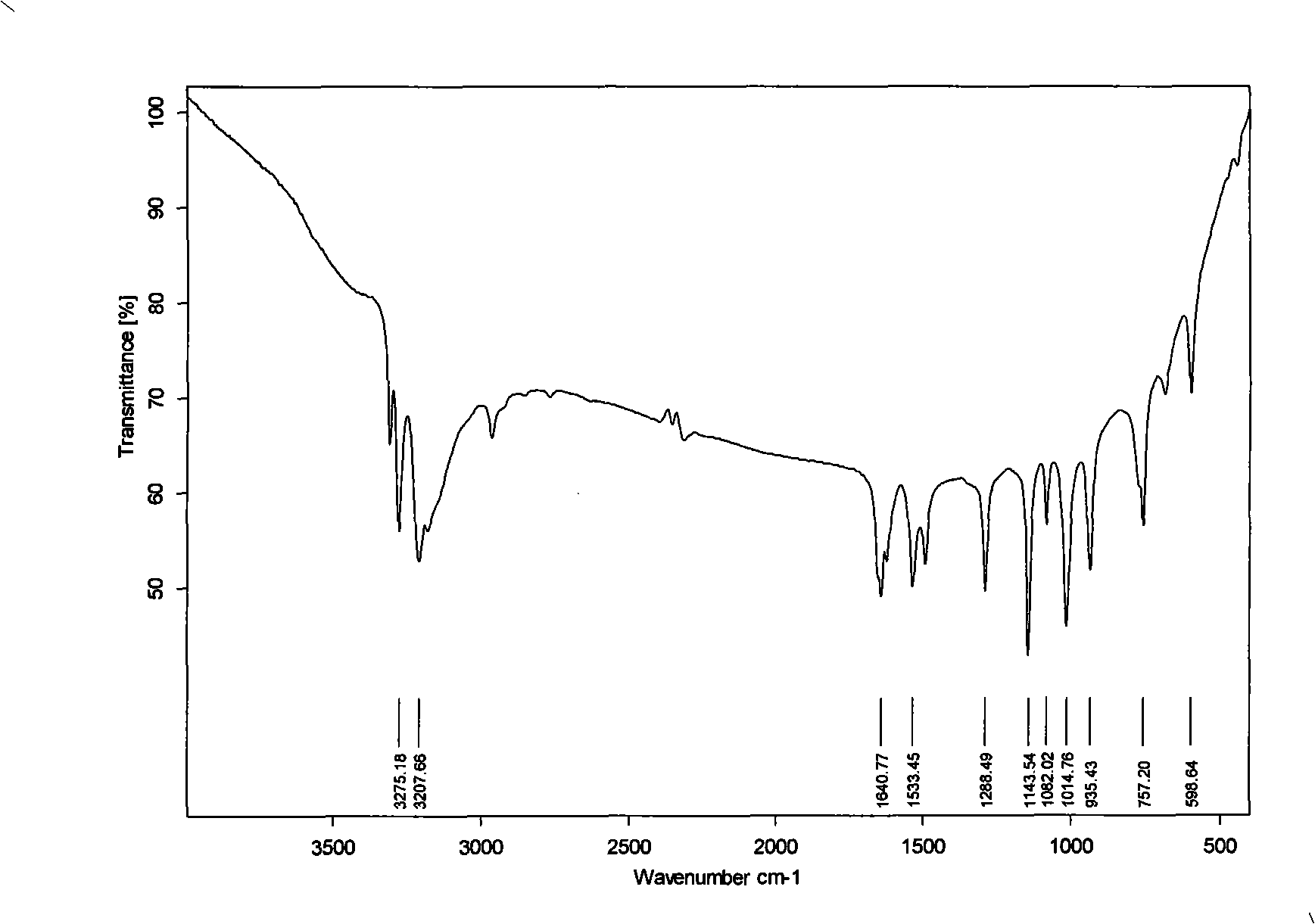

The invention discloses a shale gas acid fracturing drag reducer and a reparation method of the shale gas acid fracturing drag reducer. The preparation method comprises the following steps: mixing monomer acrylic acid and 2-acrylamide-2 methyl propane sulfonic acid, dissolving in water, subsequently adding acrylamide, and finally adding ethylenediamine tetraacetic acid disodium to prepare into a water phase; mixing and dissolving a compounded surfactant with base oil to form an oil phase; performing inverse emulsion polymerization on the oil phase and the water phase to prepare the shale gas acid fracturing drag reducer. As a great amount of acid resistance monomers are introduced into the drag reducer, the acid resistance of the dreg reducer is greatly improved; the dreg reducer is milk white emulsion in appearance, is high in stability, non-ignitable, non-explosive, safe to transport and store, rapid to dissolve in water and free of fisheye; the requirements of continuous blending in shale gas acid fracturing can be met; the resistance reduction rate of a dreg reducer solution with the mass percentage of 0.2% can be greater than 70%.

Owner:SOUTHWEST PETROLEUM UNIV

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

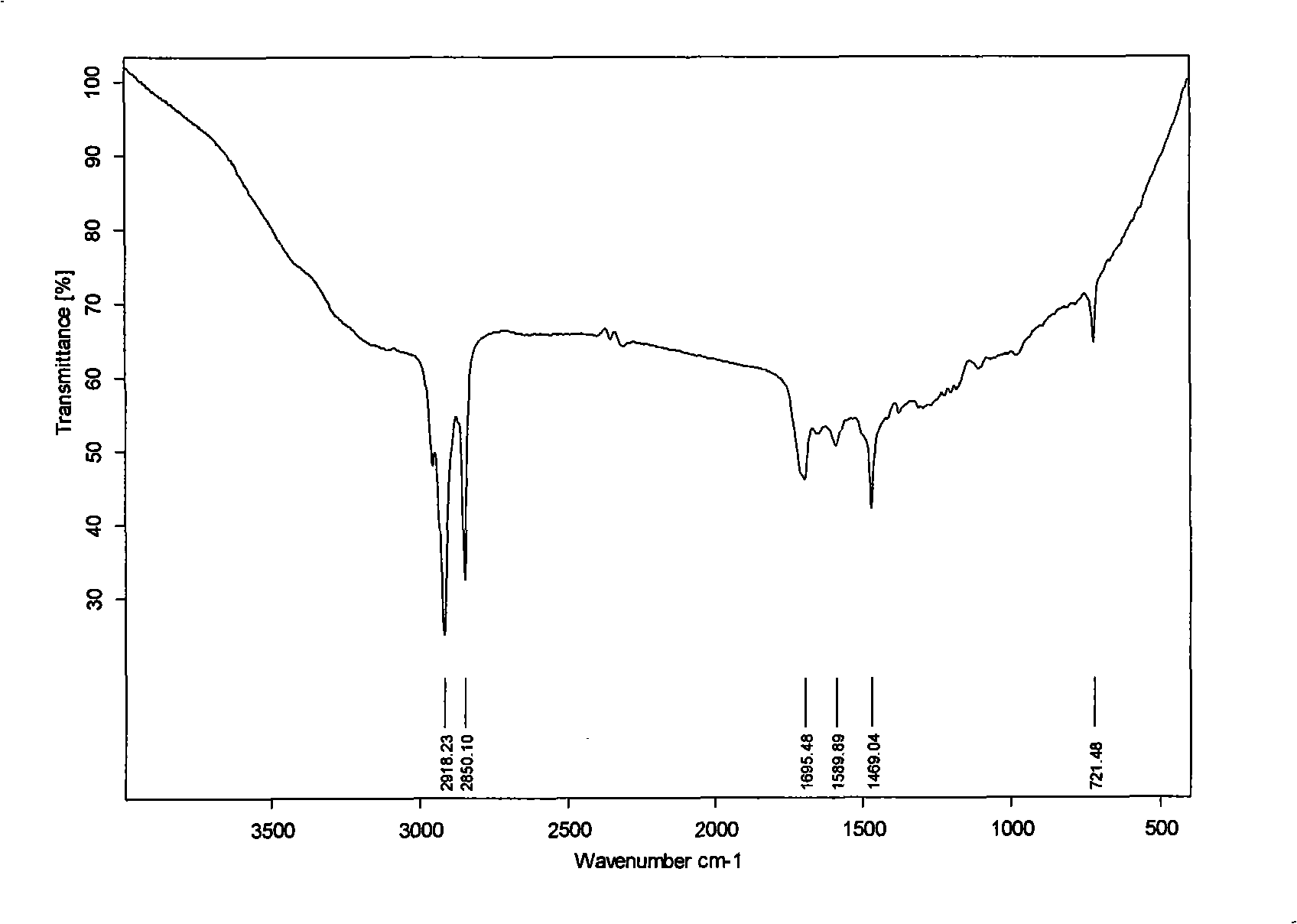

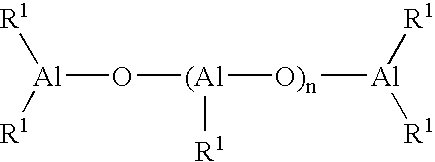

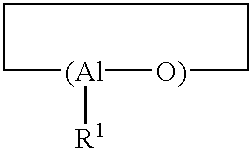

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

Process for homogenizing polyolefin drag reducing agents

ActiveUS6894088B2Accelerated dissipationImprove solubilityOther chemical processesRefining by heating/coolingPolyolefinKetone

A process for producing polymer drag reducing agent (DRA) slurries without cryogenic temperatures or conventional grinding is described. The homogenizing or size reduction of polymer, such as poly(alpha-olefins), may be achieved by the use of granulated polymer and at least one liquid, non-solvent for the polymer DRA. In one non-limiting embodiment of the invention, the homogenizing is conducted at ambient temperature. Examples of suitable non-solvents include water and non-aqueous non-solvents including, but not necessarily limited to, alcohols, glycols, glycol ethers, ketones, and esters; having from 2-6 carbon atoms, and combinations thereof. The polymeric DRA may be homogenized to an average particle size of about 600 microns or less.

Owner:BAKER HUGHES INC

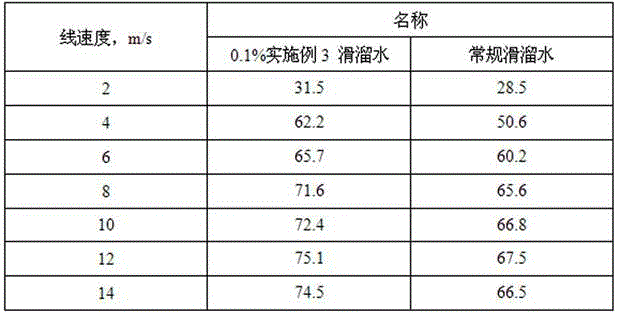

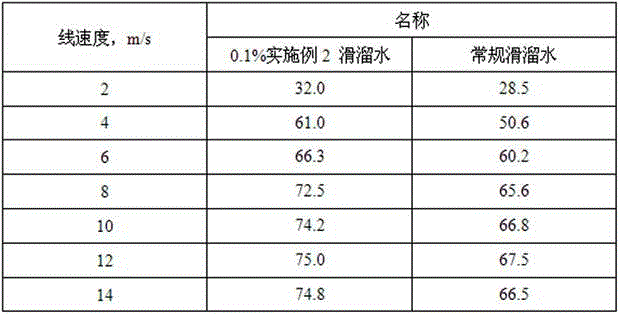

Slickwater fracturing fluid drag reducer and preparation method thereof

ActiveCN103013488AImprove stabilityReduce system complexity indexDrilling compositionFunctional monomerFracturing fluid

The invention discloses drag reducer which can be applied to slickwater fracturing fluid and a method for preparing drag reducer. The method includes: adding organic salt into acrylamide and functional monomer aqueous solution to prepare an aqueous phase, adding the aqueous phase into an oil phase system consisting of surfactant and base oil under the condition of high-speed stirring to form a stable W / O (water in oil) type microemulsion system, feeding nitrogen for dispersing oxygen, and adding initiator for polymerization to form a branchless long chain structure. The polymer microemulsion is a transparent or semitransparent thermodynamic stable system, can be quickly swelled into water and is directly usable. Adding a small quantity of the drag reducer during fluid transport can improve flow quantity and reduce energy consumption to some extent, and the drag reduction effect can reach 30%-65% when the drag reducer is compared with clear water. The drag reducer has the advantages of high stability, dissolving speed and dissolving performance, convenience in use, remarkable drag reduction effects and the like and is applicable to the slickwater fracturing technology, and excellent yield increasing effects are obtained after the drag reducer is applied to field fracturing operations.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

Preparation method of multifunctional resistance-reducing polymer suspension

The invention discloses a method of preparing multifunctional drag reduction polymer suspension, which includes steps: mixing alpha-olefin polymer with molecular weight of 4-5 millions, pour-point depressant, viscosity modifier and scale inhibitor, and comminuting the mixture to solid powder under temperature of minus 60 to minus 160 DEG C, mixing the solid powder, surfactant, foam resistant agent, thickening agent and residual alcohol-water mixture to prepare drag reduction polymer suspension. The prepared drag reduction polymer suspension has function of pour point depression, viscosity reduction, scale inhibition and drag reduction, can be widely used for multiple type crude oil transportation pipe, and can greatly increase drag reduction effect of different drag reducing agent in different crude oil.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Non-cryogenic process for grinding polyolefin drag reducing agents

ActiveUS6946500B2Accelerated dissipationImprove solubilityOther chemical processesInksParaffin waxDrag reducing agent

A process for producing fine particulate polymer drag reducing agent (DRA) without cryogenic temperatures, is described. The grinding or pulverizing of polymer, such as poly(alpha-olefin) may be achieved by the use of at least one solid organic grinding aid and at least one liquid grinding aid. In one non-limiting embodiment of the invention, the grinding is conducted at ambient temperature. Examples of a solid organic grinding aid include ethene / butene copolymer particles, paraffin waxes and solid alcohols. An example of a suitable liquid grinding aid includes a blend of glycol, water and isopropyl alcohol. Particulate DRA may be produced at a size of about 500 microns or less. Use of an attrition mill is preferred.

Owner:BAKER HUGHES INC

Drag reducing agents for multiphase flow

InactiveUS20050049327A1Easy to manufactureReduce resistanceOther chemical processesLiquid carbonaceous fuelsOil and greaseHydrophilic polymers

A process for using high molecular weight, anionic, hydrophilic polymers without formation of deleterious emulsions to facilitate flow in multiphase pipelines containing both oil and water (e.g., oil / water, oil / water / gas, oil / water / solids, and oil / water / gas / solids) such as are used for oil or gas production, gathering, and transmission; hydrotransport of oilsand or heavy oil slurries is described. Specific examples of suitable drag reducing polymers include anionic, hydrophilic polyacrylamides having a molecular weight of greater than 1 megadalton.

Owner:BAKER HUGHES INC

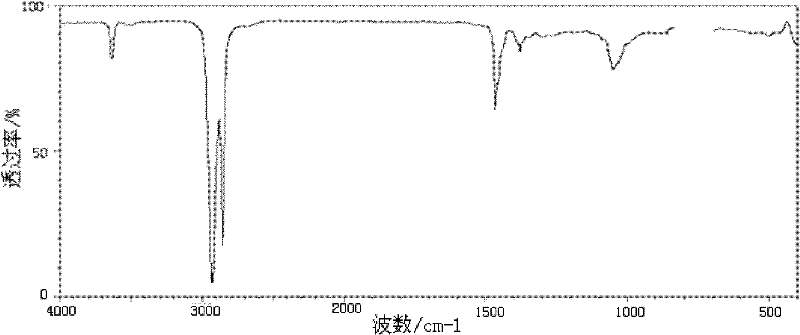

Gas pipeline drag reduction agent and preparing method thereof

The invention relates to a gas line drag reduction agent and a preparation method thereof, relating to the technical field of the composite of high-molecular compound and piping systems. The drag reduction agent consists of carbon bisulfide, hydrazine hydrate and long chain acid, the mol ratio of which is 1.8:1:1 to 2.2:1:1. The preparation method comprises the following steps: step one, CS2 is taken according to proportional quantity, dripped into the mixed liquor of the hydrazine hydrate and water with proportional quantity under agitation, reflowed for certain time in the temperature range of 90 to 95 DEG C, then cooled for 30 to 60 minutes in ice water bath and pumped and filtered, the mother liquor continues to react for two times, products of the third time are merged, washed by using ethanol and ether sequentially, and recrystallized by using boiling water so as to obtain symmetrical diaminothiourea clear crystal; and step two, symmetrical diaminothiourea with proportional quantity and the long chain acid with proportional quantity are dissolved in a pyridine solvent with nitrogen protection, reflowed at the temperature of 140 to 220 DEG C by adopting a temperature programming method, and react for 3 to 4 hours, then the mixture is cooled to the room temperature and recrystallizated by using the ethanol of 95 percent to obtain the brown product.

Owner:PIPECHINA SOUTH CHINA CO

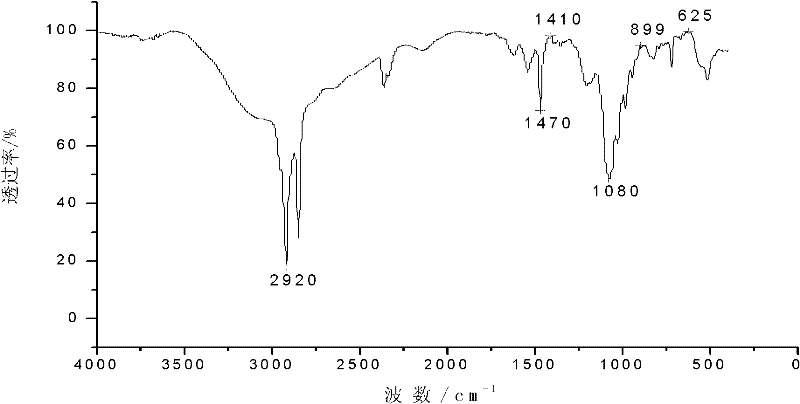

Sulfuric acid ester gas pipeline drag reduction agents and preparation method thereof

ActiveCN101575497AGood drag reduction effectRaw material source directlyOther chemical processesPipeline systemsGas pipelineSulfuric Acid Esters

The invention discloses sulfuric acid ester gas pipeline drag reduction agents for drag reduction of long-distance pipelines of gas, particularly natural gas and a preparation method thereof. The drag reduction agents are formed by sulfuric acid esters, aromatic compounds and heterocyclic compounds according to the molar ratio of 1:5:1-1.5:10:1. The preparation method comprises the steps of: 1) adding a heterocyclic compound and an aromatic compound with certain proportion into a reactor, adding nitrogen for protection, and stirring for fixed time period at low temperature, and then adding sulfuric acid ester; 2) reacting for certain time to ensure that a formed liquid is changed into opacity and layering from initial lucidity and transparency; 3) using extraction layering to separate a residual liquid and a generated sulfuric acid ester drag reduction agent; and 4) distilling a residual liquid of an organic solvent under reduced pressure to obtain a product in vacuum. The drag reduction agents have obvious effect on the drag reduction of gas pipelines, have the advantages of direct raw material sources, simple operation, mild reaction conditions, relatively simple process and low requirement on equipment, and are easy to realize mass industrialized production.

Owner:PIPECHINA SOUTH CHINA CO

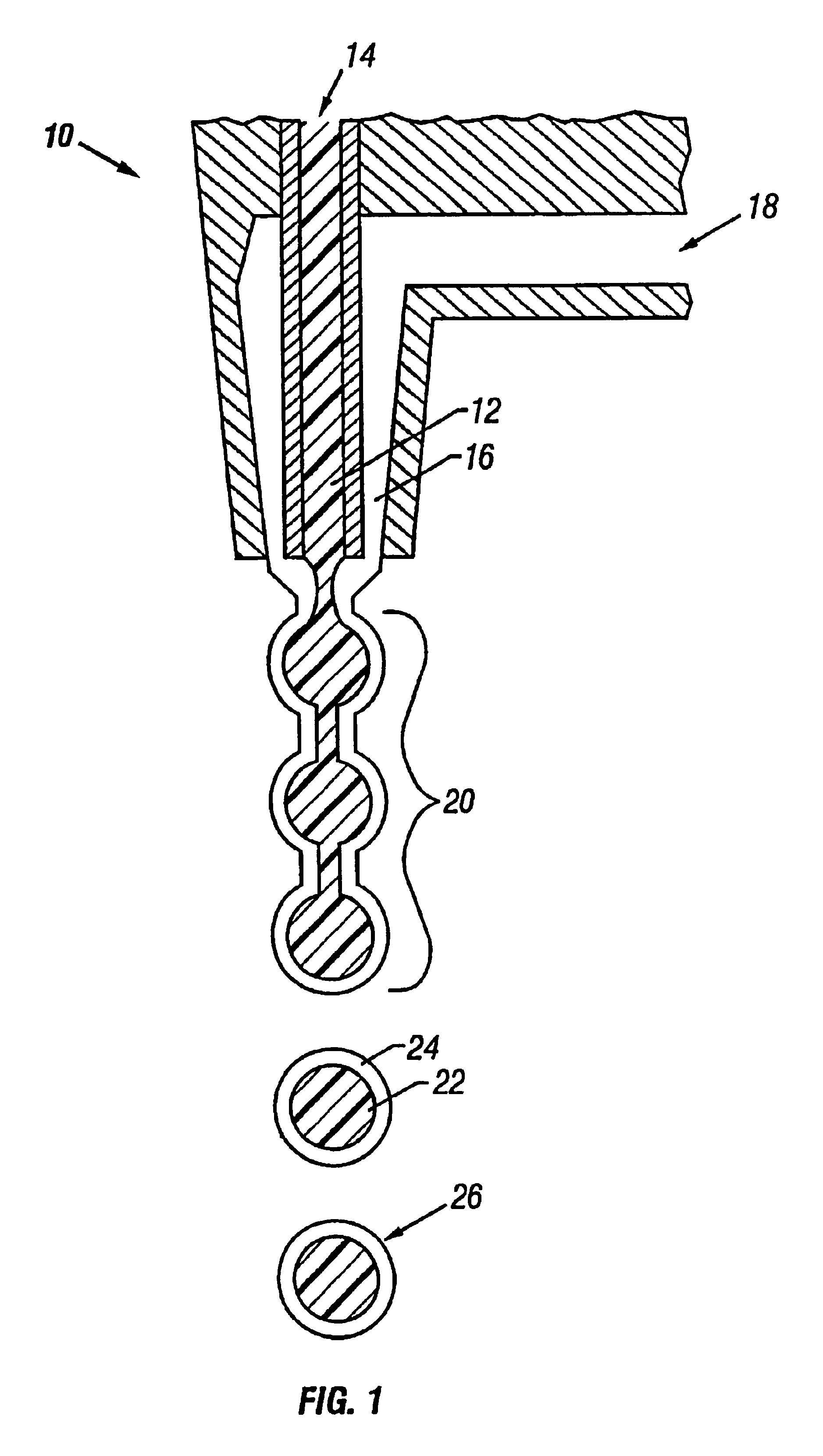

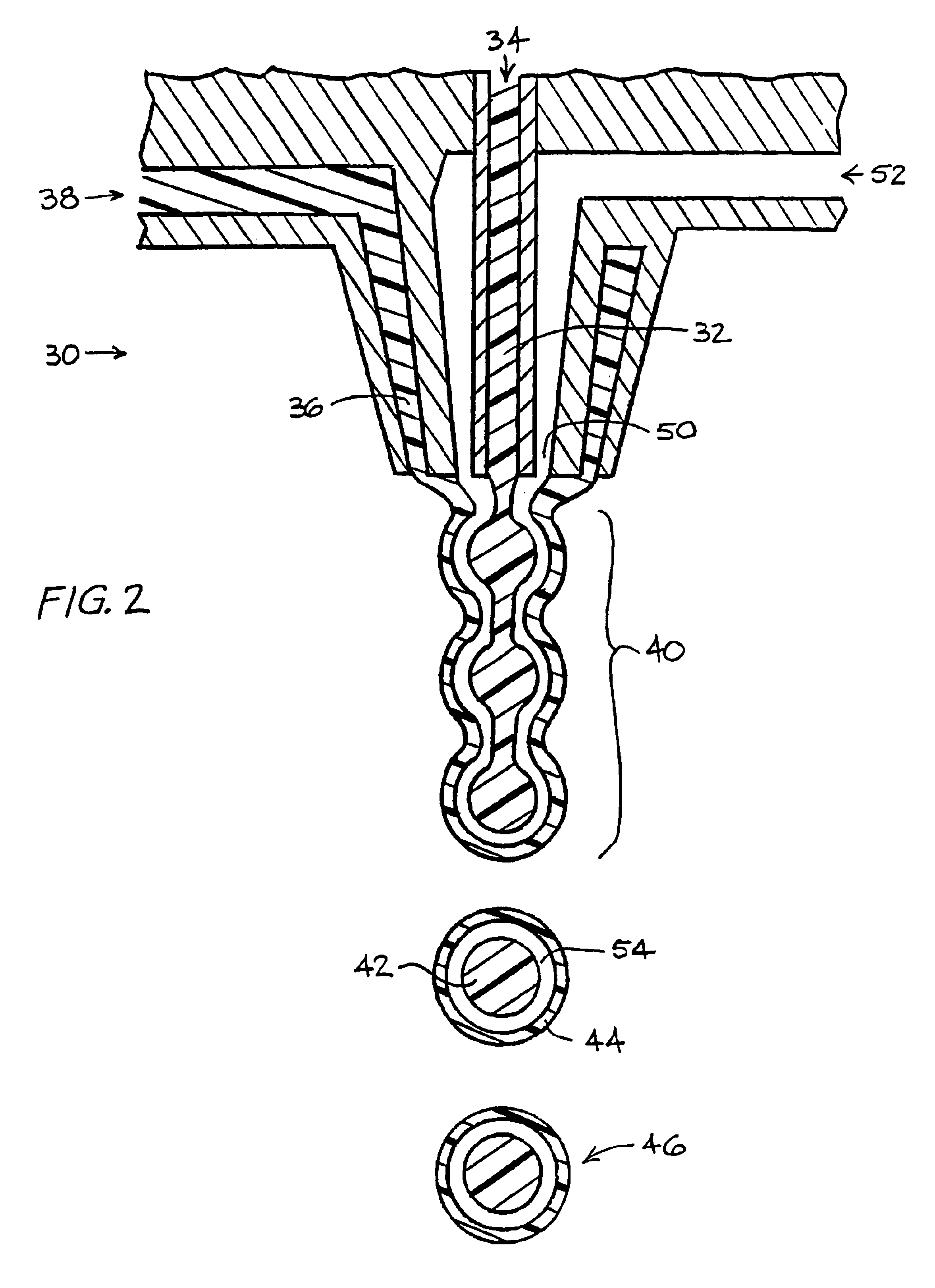

Microencapsulated and macroencapsulated drag reducing agents

InactiveUS6841593B2Easy to manufacturePipeline systemsGlass/slag layered productsHigh concentrationBulk polymerization

High concentration drag reducing agents may be prepared by microencapsulating and / or macroencapsulating polymer drag reducing agent. The encapsulation may be performed prior to, during, or after the polymerization of monomer into effective drag reducing polymer. If encapsulation is done before or during polymerization, a catalyst may be present, but little or no solvent is required. The result is very small scale bulk polymerization within the capsule. The inert capsule or shell may be removed before, during or after introduction of the encapsulated drag reducer into a flowing liquid. No injection probes or other special equipment is expected to be required to introduce the drag reducing slurry into the liquid stream, nor is grinding (cryogenic or otherwise) of the polymer necessary to form a suitable drag reducing agent.

Owner:BAKER HUGHES INC +1

Natural gas pipeline drag-reducing agent and preparation method thereof

InactiveCN102443022ASource directlyEasy to operateGroup 5/15 element organic compoundsPipeline systemsEsterification reactionFatty alcohol

Owner:CHINA NAT OFFSHORE OIL CORP +2

Anti-blowby cement slurry

InactiveCN102492404ABlocking channelingSmall brittleness coefficientDrilling compositionPolymer adhesiveWell cementing

The invention relates to anti-blowby cement slurry, and relates to the technical field of cement slurry. The anti-blowby cement slurry consists of the following components in percentage by mass: 90 to 95 percent of cement matrix, 1 to 8 percent of polymer rubber latex powder, 0.1 to 0.7 percent of drag reducer, 0.3 to 3.5 percent of filtration-reducing agent, 0.1 to 1.5 percent of cement defoaming agent and 0.05 to 3.5 percent of thickening time control agent. The anti-blowby cement slurry is a single-component system; and due to the adoption of the rubber latex powder, the brittleness coefficients and elastic modulus of cement are reduced, the well cementation quality can be improved effectively, the fluid channeling can be prevented, and the problem generated when liquid polymer rubber latex is used is solved; and the anti-blowby cement slurry is stirred only by adding water at a construction site, and is convenient to prepare, store, transport and use, so the construction process is simplified, the cost is reduced, and the anti-blowby cement slurry has a bright application prospect.

Owner:JIAHUA SPECIAL CEMENT

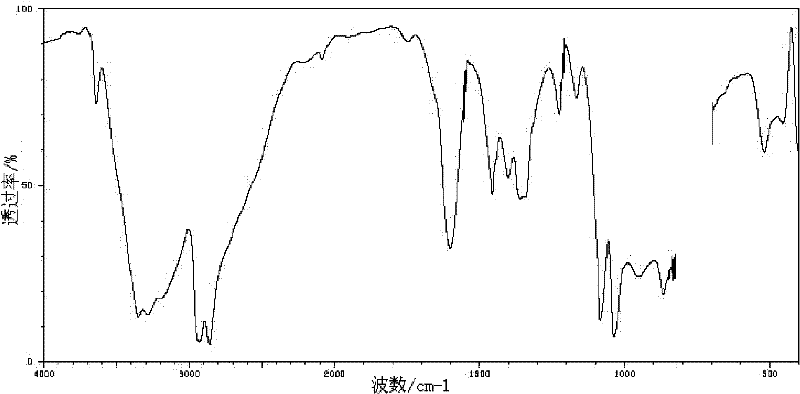

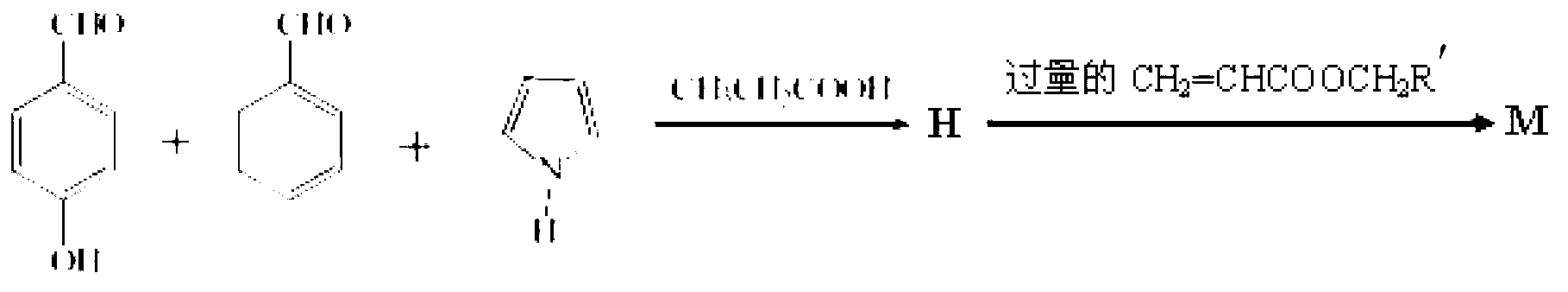

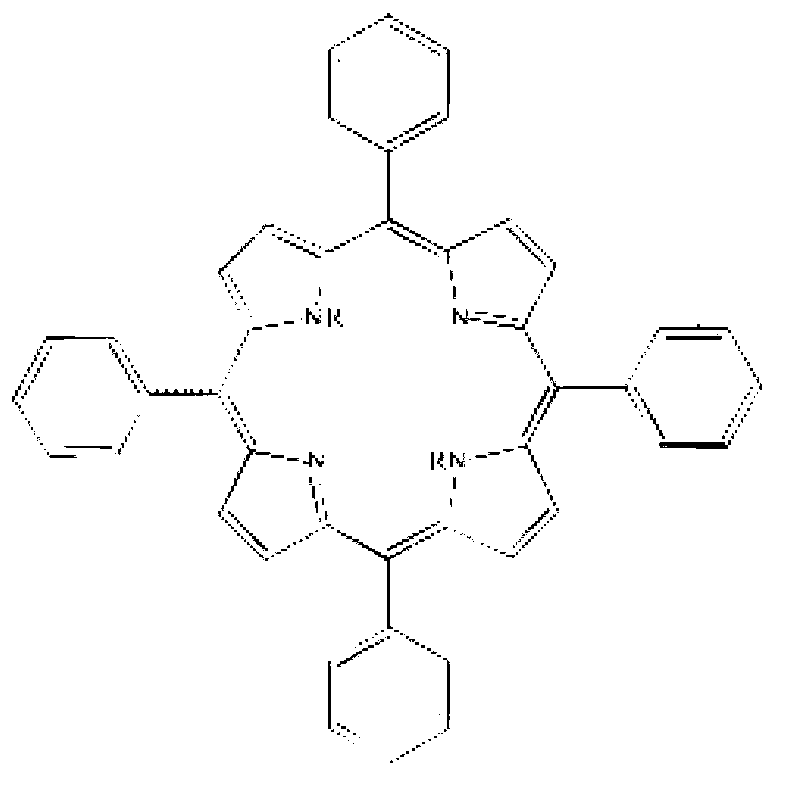

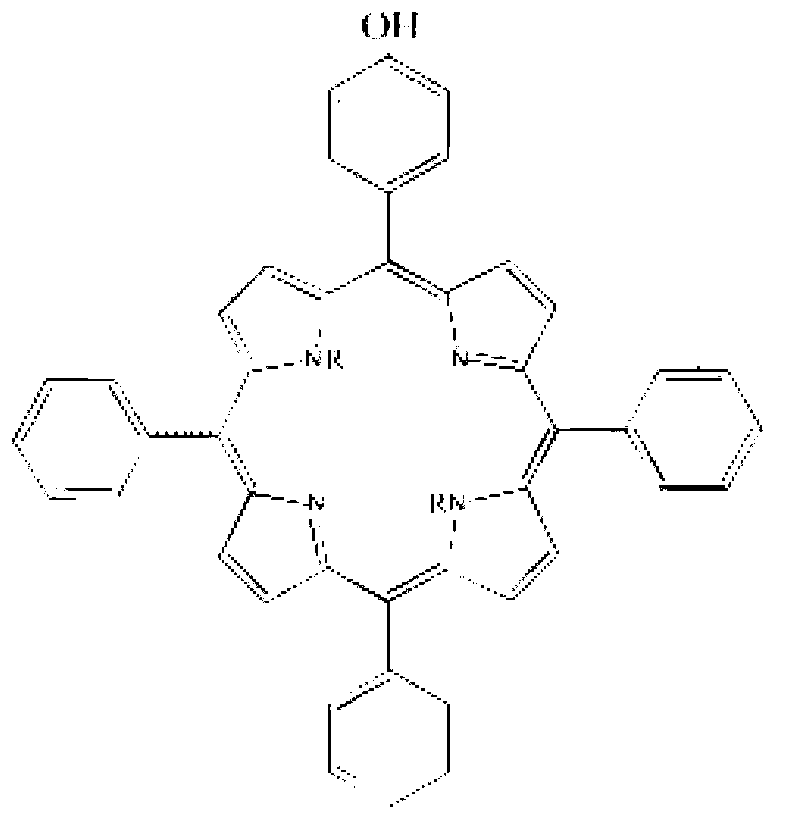

Corrosion-inhibition drag reducer for alkyl porphyrin compound natural gas pipelines and preparation method of corrosion-inhibition drag reducer

ActiveCN102838606AImprove anti-corrosion performanceOrganic chemistryPipeline systemsBenzaldehydePorphyrin

The invention relates to a corrosion-inhibition drag reducer for alkyl porphyrin compound natural gas pipelines of and a preparation method of the corrosion-inhibition drag reducer. The preparation method comprises the steps as follows: firstly, benzaldehyde, 4-hydroxyl benzaldehyde and pyrrole are used as raw materials to be reacted so as to prepare the mixture of six kinds of porphyrin compounds (H); then, the mixture H of the porphyrin compounds is reacted with acrylic acid long-chain alkyl esters to prepare six kinds of alkyl orphyrin compounds, wherein each kind of the compounds is 15 to 20wt%; and the prepared compounds are dissolved in 30 to 50wt% of solvent prepared with p-dioxane so as to form the corrosion-inhibition type drag reducer for the alkyl porphyrin compound natural gas pipelines. The proportion is that the mole ratio of methanal to the 4-hydroxyl benzaldehyde is (0.8:1) to (1.2:1); the mole ratio of the benzaldehyde to the pyrrole is (0.8:2) to (1.2:2); and the mole ratio of the acrylic acid long-chain alkyl esters to the pyrrole synthetizing H is (1:1) to (2:1). The drag reducer provided by the invention has the advantages of good drag reduction and anticorrosion property.

Owner:PIPECHINA SOUTH CHINA CO

Novel active water fracturing fluid for fracturing of coal bed gas well

InactiveCN101948684AWith anti-expansion effectHas the effect of reducing resistanceDrilling compositionPotassiumFracturing fluid

The invention relates to a fracturing fluid for the fracturing construction of coal bed gas well. In general, a coal bed gas well cannot be put into operation before the fracturing construction. Owing to the characteristics of small harm, low cost, convenient preparation and the like, the active water is extensively applied to the fracturing construction of coal bed gas well. The typical active water fracturing fluid is generally prepared from clear water, anti-swelling agent (typically potassium chloride) and cleanup additive (typically complex of surfactants, typical cleanup additive for oil field is D-60 and HP-8, etc.) based on certain proportions. The active water fracturing fluid shows, when being used for the fracturing construction, the defects of high frictional resistance and no dispersion effect on coal dusts generated in the process of the fracturing construction. The active water fracturing fluid according to the invention is prepared in a manner of adding the typical active water fracturing fluid with drag-reducing agent (anionic or nonionic polyacrylamide) and coal dust dispersing agent (lignosulfonate, such as sodium lignin sulfonate) based on the mass percents as below: 1%-2% of potassium chloride, 0.02% to 0.06% of drag-reducing agent and 0.01% to 0.03% of dispersing agent. The fracturing fluid according to the invention has the characteristics of simple formula, the effect of reducing frictional resistance of construction tubular columns and uniformly dispersing coal dusts, small harm to coal bed and easy flowback.

Owner:CHINA UNITED COALBED METHANE +1

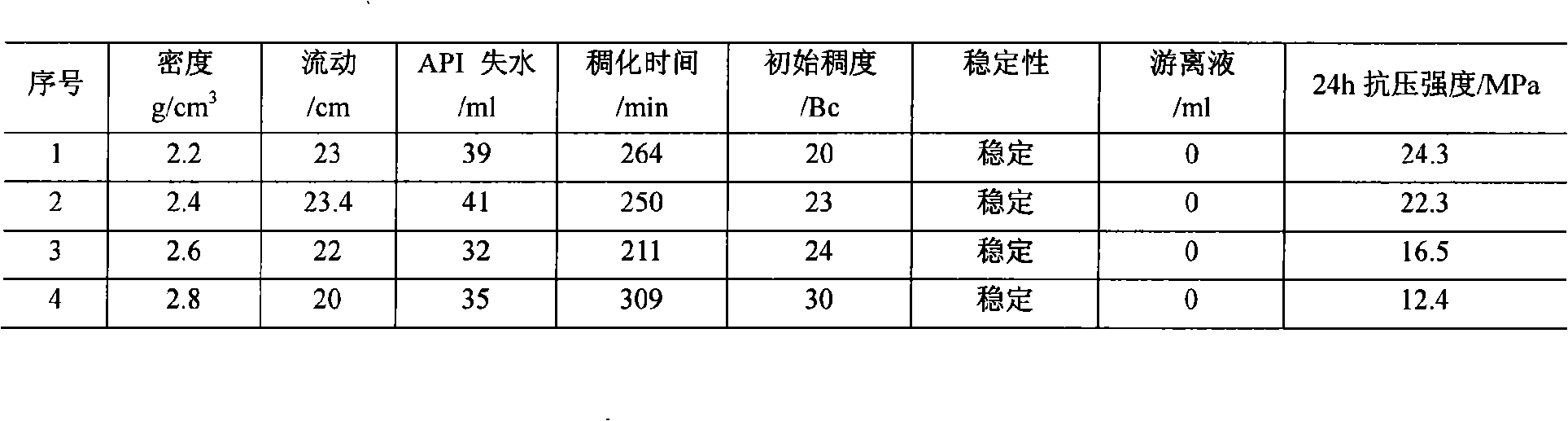

Anti-salt high-density cement mortar

InactiveCN101338183APacked tightlyGuaranteed solid phaseDrilling compositionHigh densityWell cementing

The invention relates to a cement slurry system used for solidifying a well in a petroleum drilling engineering: 50-300 percent of well cement aggravating agent A, 10-100 percent of well cement aggravating agent B, 0.5-4 percent of drag reducing agent, 2.5-8 percent of fluid loss additive, 0.1-5 percent of retarder and 0.15-1.2 percent of defoaming agent. The mixture of wet mixed additive occupies 50-100 percent of the cement quality. According to a salt layer, NaCl can be added during the solidifying of the well. 30-40 percent of high temperature resisting declining agent is added at high temperature. The cement slurry, the density of which reaches to 2.8g / cm3, can be prepared.

Owner:CNPC RES INST OF ENG TECH +1

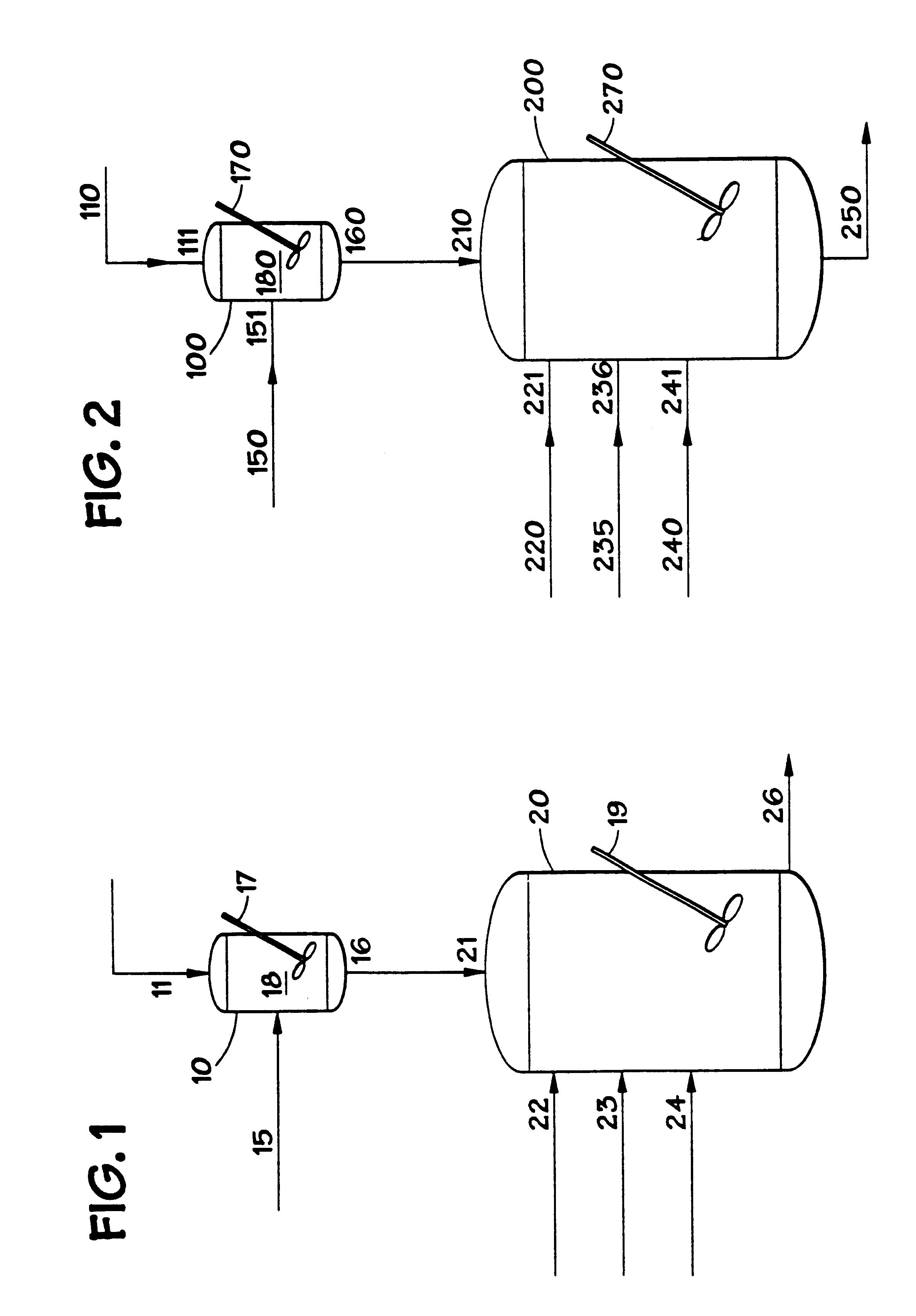

Continuous neat polymerization and ambient grinding methods of polyolefin drag reducing agents

ActiveUS7119132B2Speed up the conversion processHigh molecular weightOther chemical processesPipeline systemsParticulatesPolyolefin

A process for continuously producing a polymer drag reducing agent (DRA) is described. The process concerns mixing a monomer and a catalyst in at least one continuously stirred tank reactor (CSTR) to form a mixture. The mixture is continuously injected into a volume continuously formed by a thermoplastic material, such as polyethylene. The thermoplastic material is periodically sealed off to form a temporary container or bag. The monomer is permitted to polymerize in the temporary container to form polymer. In one non-limiting embodiment, the polymerization in the bag takes place within an inert, circulating fluid that accelerates heat transfer. The polymer and the temporary container are then ground together, preferably at non-cryogenic temperatures, to produce a particulate polymer drag reducing agent. In one preferred, non-limiting embodiment, the grinding or pulverizing occurs in the presence of at least one solid organic grinding aid. Finally, the particulate polymer drag reducing agent may be combined with a dispersing fluid.

Owner:BAKER HUGHES INC

Methods for forming amorphous ultra-high molecular weight polyolefins for use as drag reducing agents

InactiveUS6730750B2Low costReduce polymerizationHydrocarbon by isomerisationCatalystsPolyolefinLiquid hydrocarbons

The present invention is directed to improved drag reducing agents and methods of forming improved drag reducing agents comprising the steps of isomerizing olefin monomers to form isomerized olefin monomers, polymerizing the isomerized olefin monomers in the presence of at least one catalyst to form a polyolefin drag reducing agent having unexpectedly superior drag reduction properties when combined with liquid hydrocarbons, such as viscous crude oil. Therefore, the drag reducing agents of the present invention may be introduced into conduits, such as pipelines, to increase the flow of the hydrocarbons through the conduit.

Owner:CMC MATERIALS INC

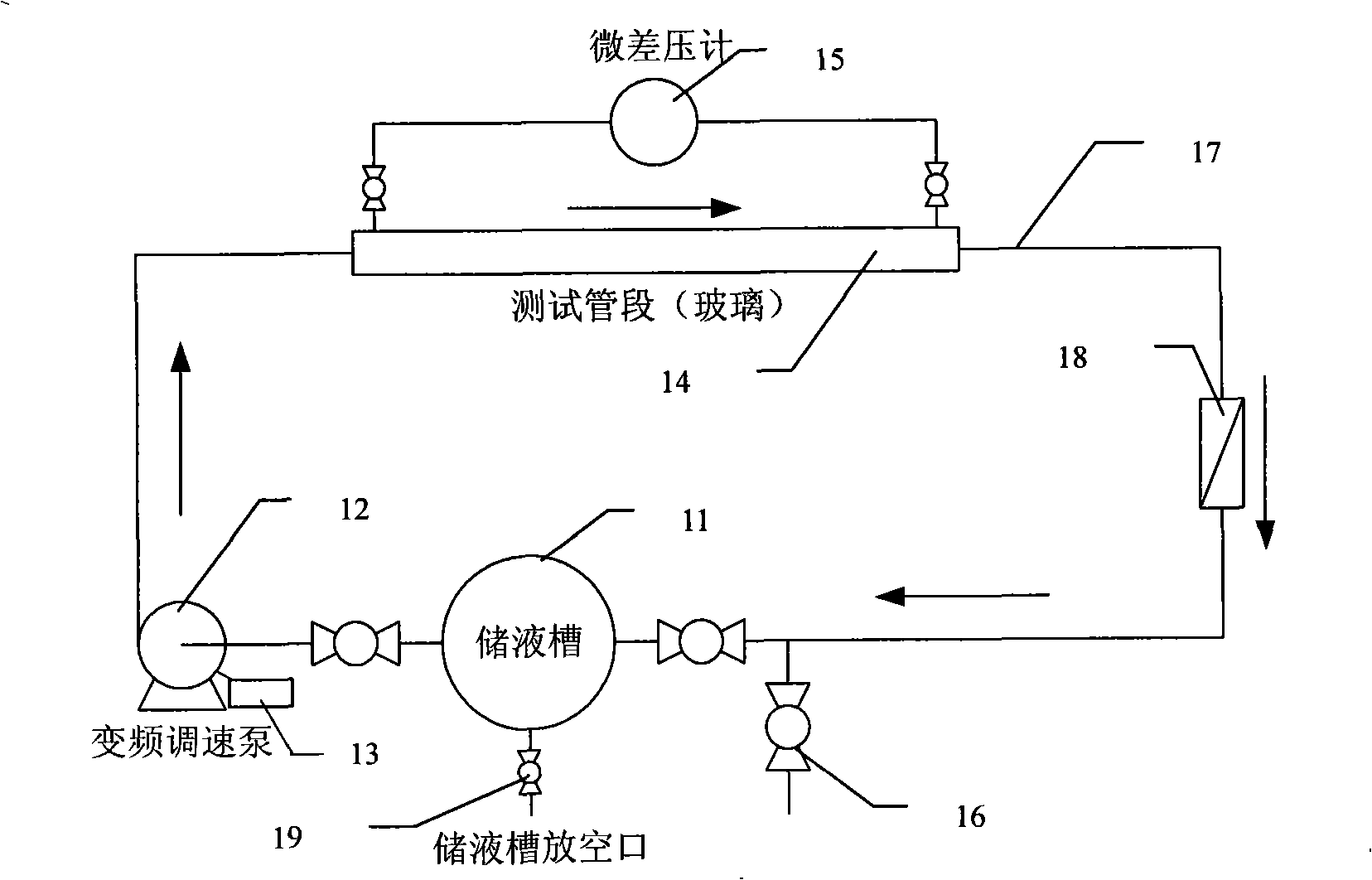

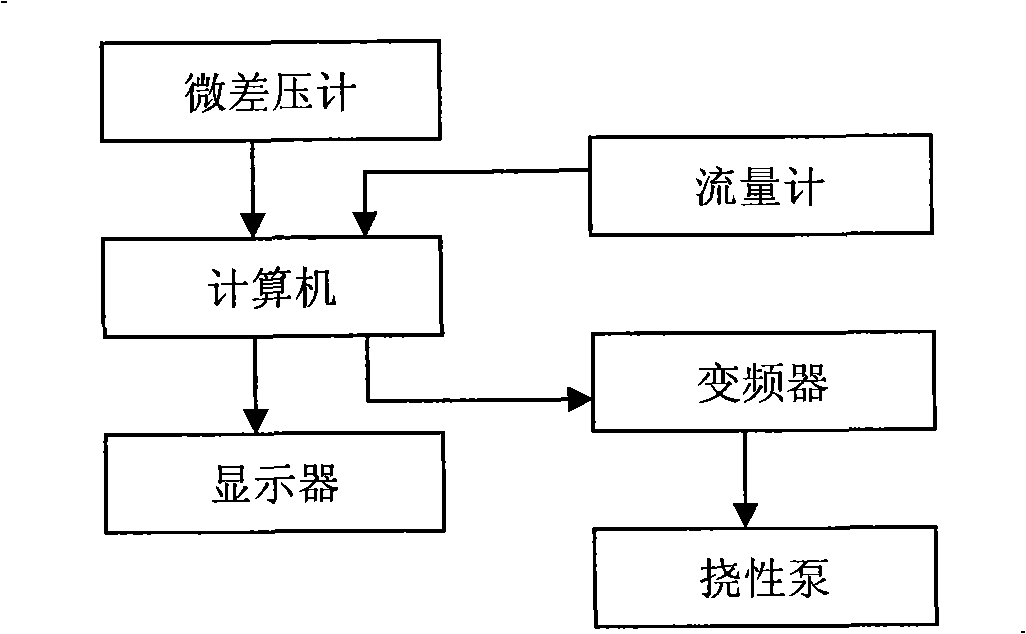

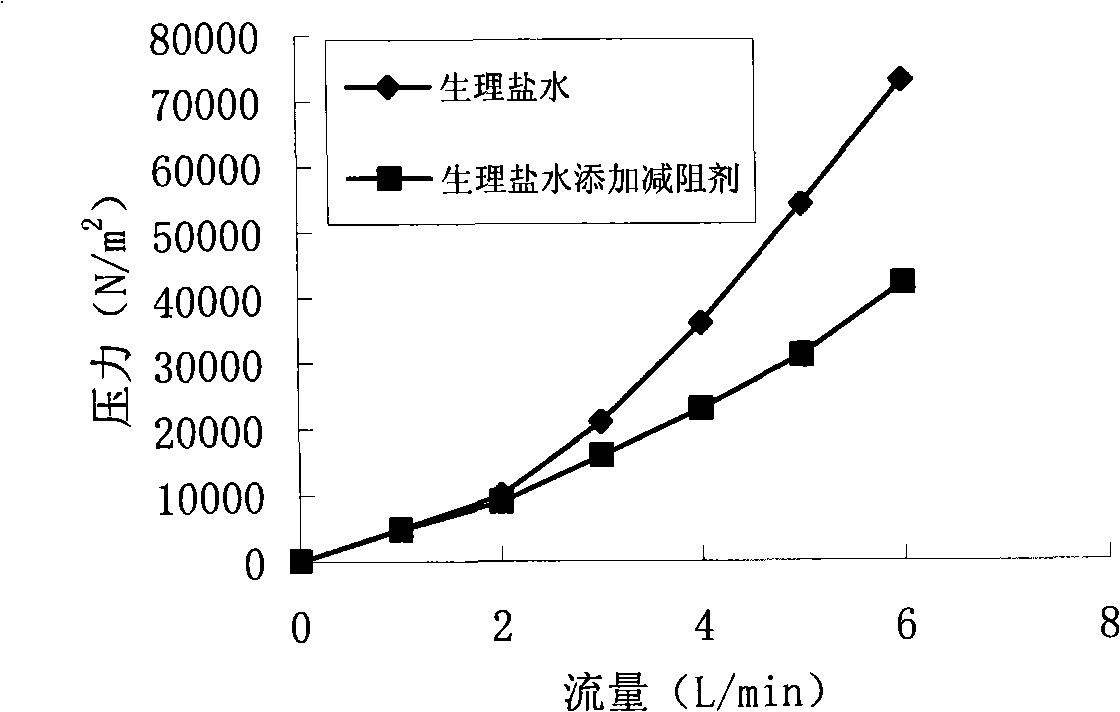

Liquid line flow resistance force detection device and method for detecting drag reduction effect of drag reducer

InactiveCN101329245AIncrease credibilityLow shear strengthVolume/mass flow by differential pressureDirect flow property measurementFrequency changerLiquid storage tank

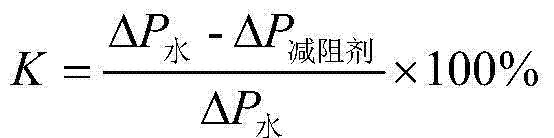

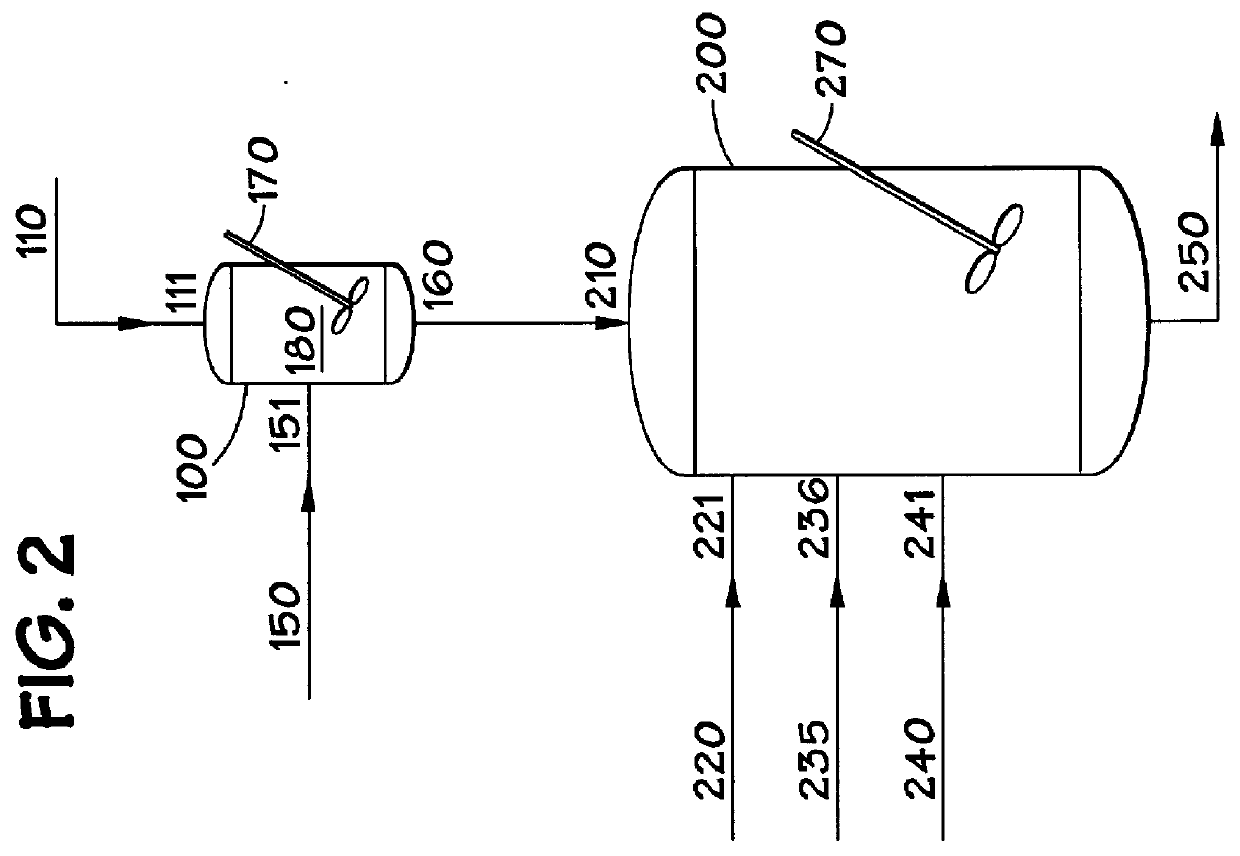

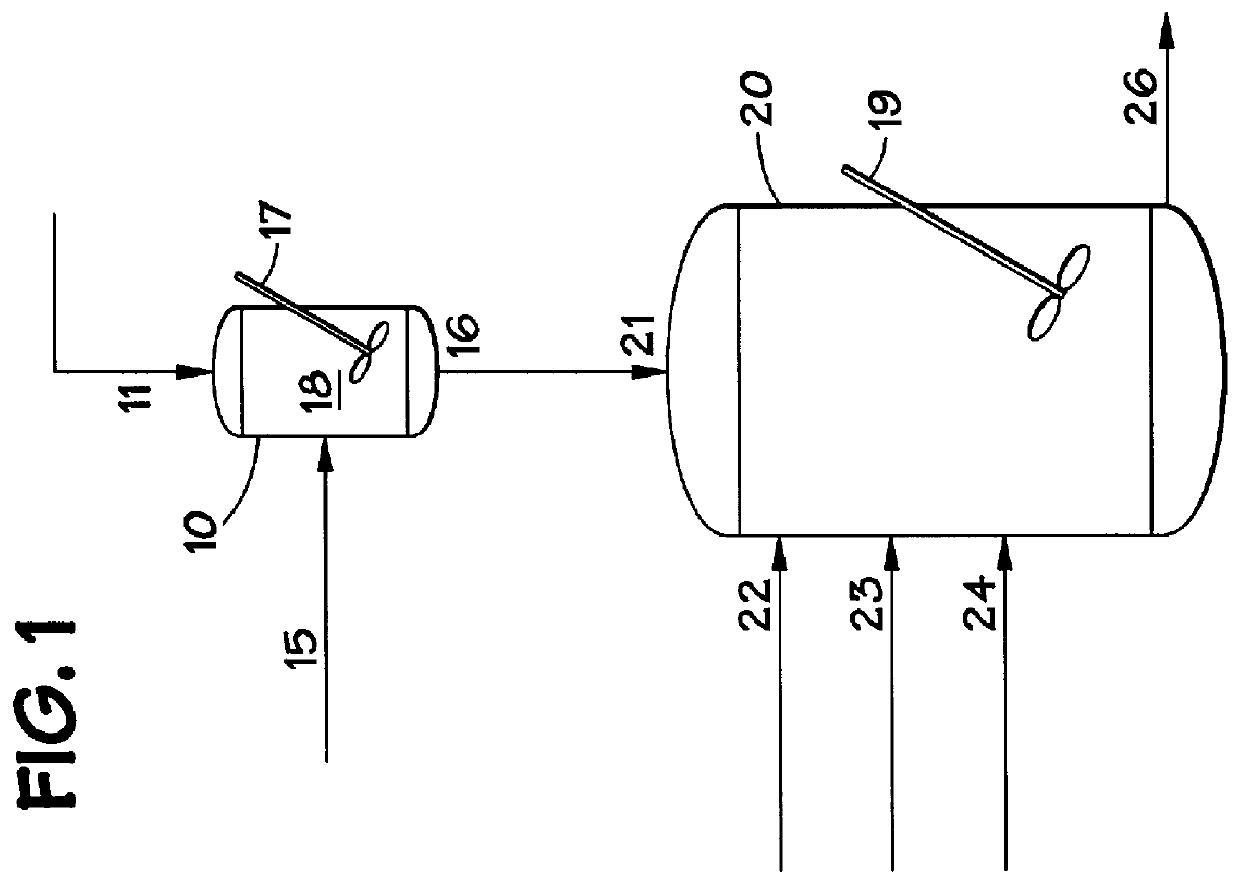

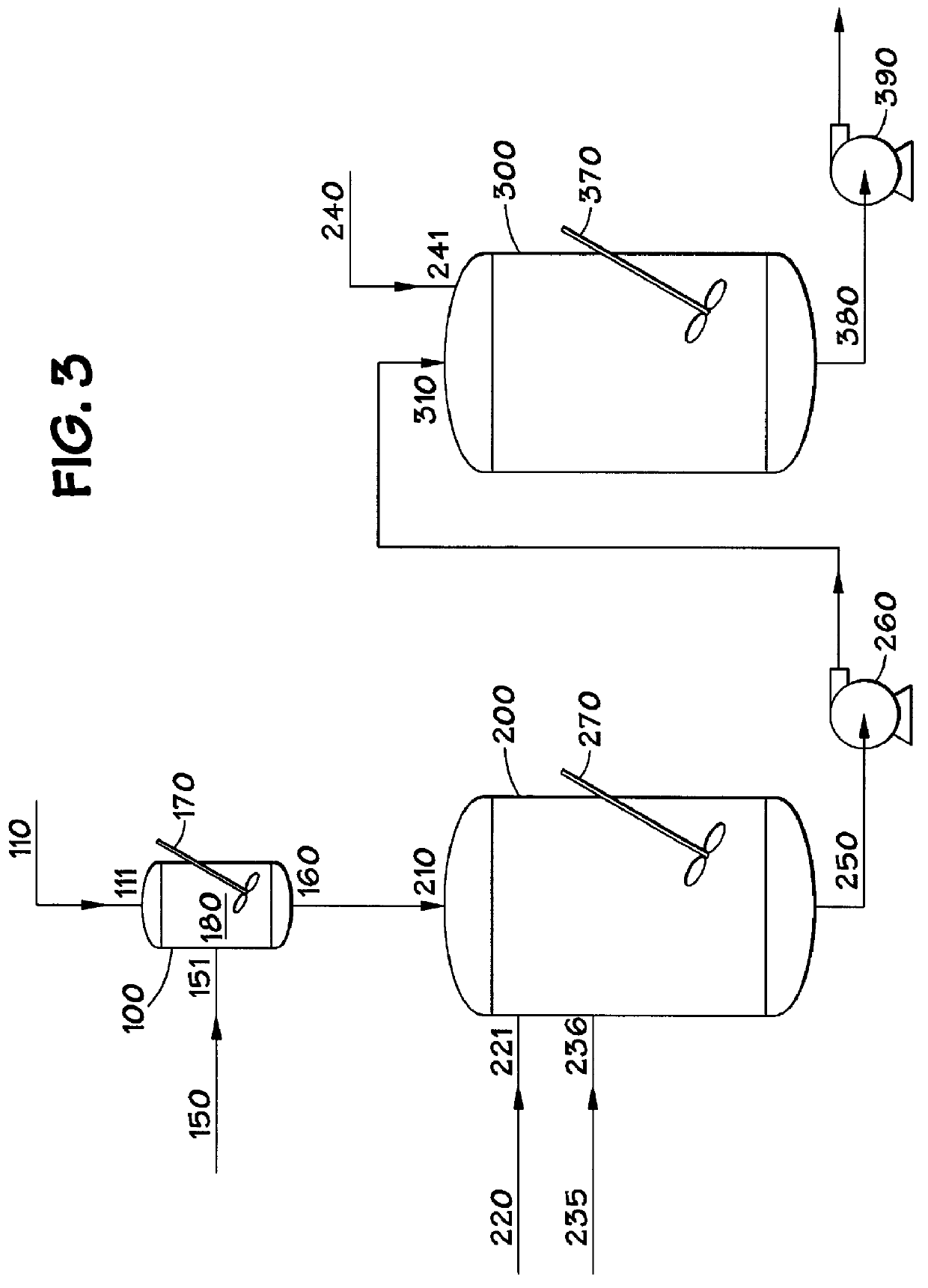

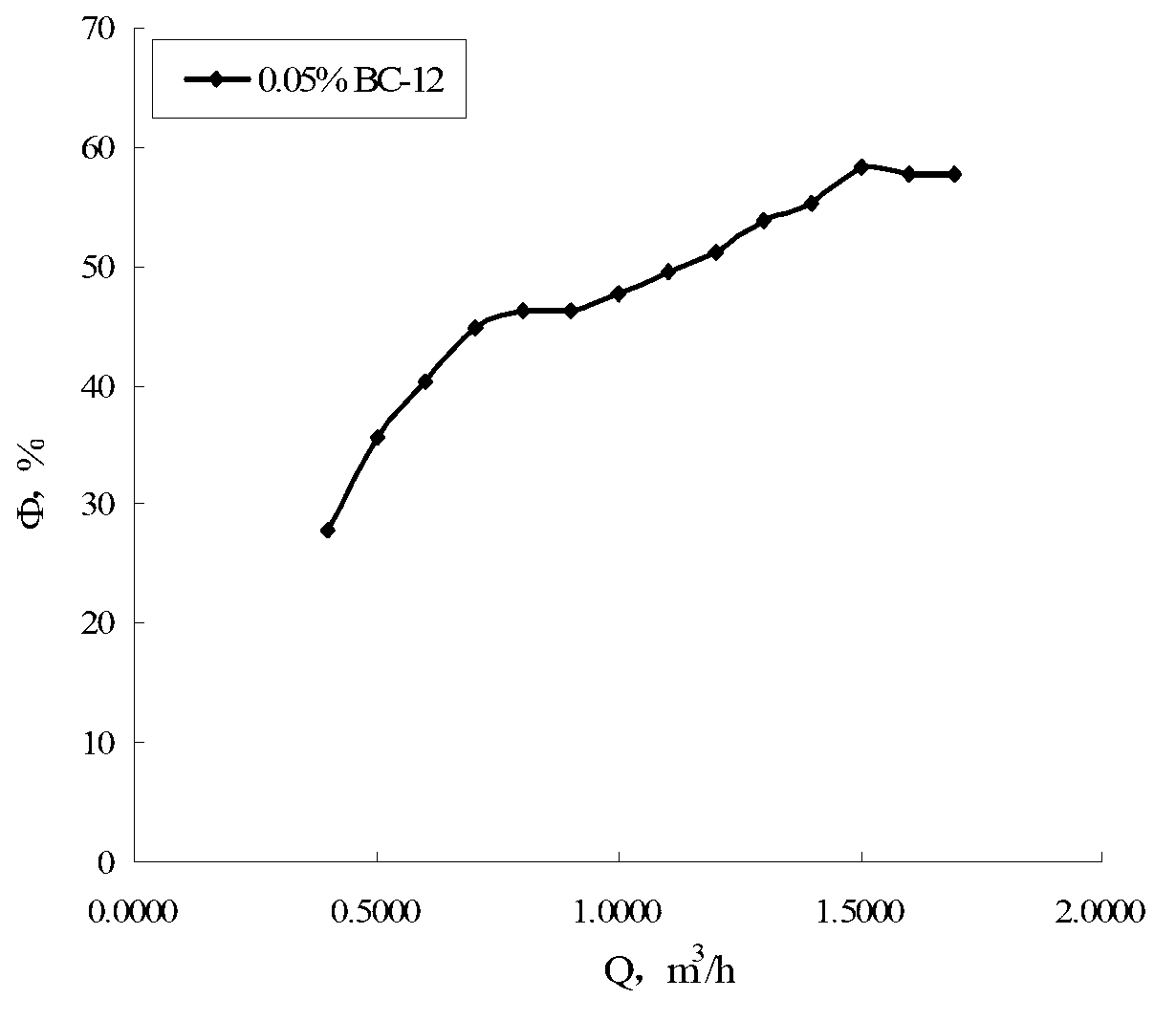

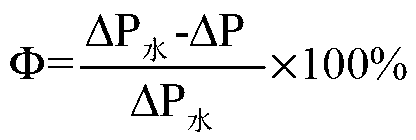

The invention discloses a liquid pipe resistance detection device which is used for evaluating the drag reduction effect of drag reduction agent. The detection device comprises a set of liquid circulation units and a detection unit; the liquid circulation unit is provided with a liquid storage tank and a circulation pipeline which is formed by a plurality of connecting pipelines and ball valves; the circulation pipeline is provided with a flexible pump and a transducer; furthermore, two ends of a measurement pipe section are respectively provided with a micro-difference pressure meter; the detection unit is electrically connected with the transducer and the micro-difference pressure meter. The liquid pipe resistance detection device adopts the flexible pump which has lower shearing strength than that of a centrifugal pump used in the prior art and is more suitable for evaluating the drag reduction effect; the liquid pipe resistance detection device uses the transducer to control the displacement of the pump, and measures the difference pressure only to simplify the detection device and the operation step, to reduce the measurement links and possible errors and to improve the reliability of results.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

Friction-reducing agent for natural-gas transfer pipeline and its production

ActiveCN101074344AReduce conveying resistanceLow viscosityWax coatingsCorrosion preventionSolventEnergy loss

A friction reducing agent for natural-gas transfer pipeline and its production are disclosed. The process is carried out by dissolving oleate amide by dimethyl benzene solvent, adding into castor, mixing, decompress distilling to remove dimethyl benzene solvent, adding into liquefied paraffin and mixing. It forms into smooth friction-reducing liquefied film layer of transfer pipeline internal wall in natural transfer pipeline and decreases friction resistance and transfer pressure drop, has less energy loss and increases gas output.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

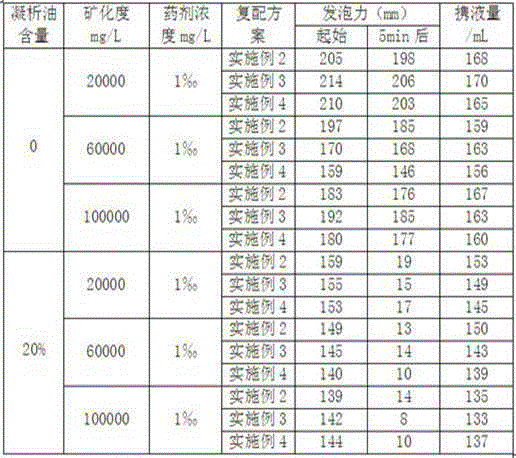

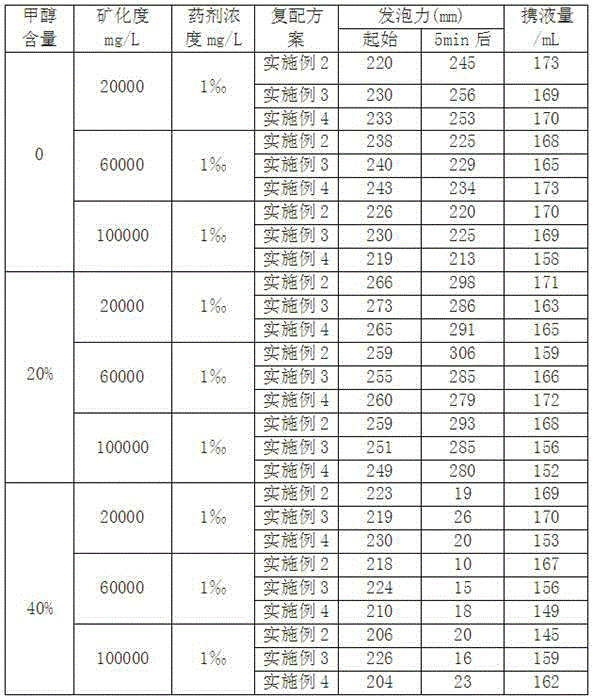

Foaming drainage agent resisting methanol, condensate oil and high salinity

ActiveCN104531121APromote degradationGood compatibilityDrilling compositionBetainePolyethylene glycol

The invention belongs to the technical field of oil-gas field chemical accessories, and in particular relates to a foaming drainage agent resisting methanol, condensate oil and high salinity. The foaming drainage agent is compounded from various nonionic surfactants, an anionic surfactant, an amphoteric surfactant, a drag reducer and pure water, wherein the various nonionic surfactants comprise polyether type surfactants including fatty alcohol-polyoxyethylene ether and alkyl alcohol ether carboxylate, the anionic surfactant comprises sodium lauryl alcohol sulfate and a Gemini cationic surfactant, the amphoteric surfactant is dodecyl dimethyl betaine, and the drag reducer is polyethylene glycol. The foaming drainage agent has relatively good biodegradability, and cannot be deposited and layered when in use. The foaming drainage agent provided by the invention is strong in foaming power, has rich and stable foams, is moderate in salt resistance, can be used in an oil-water-gas three-phase coproduction well containing condensate oil, has excellent foaming performance, is good in compatibility with various corrosion inhibitors, and also has good corrosion inhibiting ability.

Owner:PETROCHINA CO LTD

Slick-water fracturing fluid with high imbibition efficiency and preparation method

InactiveCN108641699AImprove and increase the imbibition efficiencyIncrease productionDrilling compositionNanoparticleFracturing fluid

The invention provides a slick-water fracturing fluid with high imbibition efficiency. The slick-water fracturing fluid comprises the following components in percentages by weight: 0.08 to 0.1% of a slick-water drag-reducing agent, 0.3 to 0.5% of a surfactant, 0.1 to 0.3% of hydrophilic nanoparticles and 0.3 to 0.5% of a clay stabilizer, with the balance being water. According to the invention, the surfactant and the hydrophilic nanoparticles are utilized to change wetting performance of a reservoir, so the slick-water fracturing fluid entering a well can enter fine pore channels of matrix rock through spontaneous imbibition after breaking of a gel under the driving of capillary force; and crude oil is gradually collected into large pore channels and main fractured fractures through oil-water displacement, so the dual purposes of supplementing stratum energy and improving the yield of an oil well are realized. The slick-water fracturing fluid provided by the invention can increase theimbibition efficiency of a gel breaking fluid of the slick-water fracturing fluid, thereby finally improving recovery efficiency.

Owner:PETROCHINA CO LTD

Stabilized polymer drag reducing agent slurries

A method for producing a stabilized polymer drag reducing agent slurry comprising combining a fatty acid wax and a liquid carrier to form a dispersion; pre-treating the dispersion by heating to partially dissolve the fatty acid wax in the liquid carrier; and adding the polymer drag reducing agent thereto, to form a stabilized polymer drag reducing agent slurry. The resulting slurry is relatively stable against settling, separation and agglomeration.

Owner:BAKER HUGHES INC

Preparation method of multifunctional emulsion type drag reducer for shale gas fracturing

InactiveCN105669895AExcellent anti-expansion abilityIncrease connection forceDrilling compositionReaction temperatureOil phase

The invention provides a preparation method of a multifunctional emulsion type drag reducer for shale gas fracturing. The preparation method comprises steps as follows: (1) firstly, an aqueous phase is prepared from water, anionic monomers, nonionic monomers and cationic monomers, the anionic monomers are added to the water, the mixture is neutralized to have the pH of 7 by the aid of a functional base, and then the nonionic monomers, the cationic monomers and an aid are added; (2) an oil phase is prepared from a solvent and an emulsifier which accounts for 5%-20% of the solvent in mass; (3) the aqueous phase and the oil phase are mixed, the water accounts for 10%-60% of the mixture in mass in the aqueous phase and oil phase mixture, high-speed shearing emulsification is performed, and then an initiator is slowly added at the reaction temperature of 20-80 DEG C under protection of nitrogen so as to initiate an emulsion polymerization reaction; (4) after the reaction is ended, a product is cooled to the room temperature, a low-surface-tension reverse phase agent is added, and the multifunctional drag reducer is obtained. The preparation method has the benefits as follows: the anti-swelling ability is outstanding, the discharge aiding effect is good, the drag reducer is multifunctional, and construction is convenient.

Owner:SHENGLI OILFIELD SHENGLI CHEM

Drag reducing composition

The invention relates to a concentrated, non-agglomerating, soluble and compatible drag reducing agent composition. It contains (a) from 1 to 60% of a polymer, e.g. non-crystalline and ultrahigh molecular weight poly-alpha-olefin, capable of reducing drag, and (b) from 40 to 99% of a natural fat or oil, e.g. linseed or rapeseed oil, based on the comined weight of (a) and (b). Preferably, it also contains (c) from 0.1 to 50% of a dispersion stabilising agent, e.g. a fatty acid soap, based on the combined weight of (a), (b) and (c).

Owner:FORTUM OY

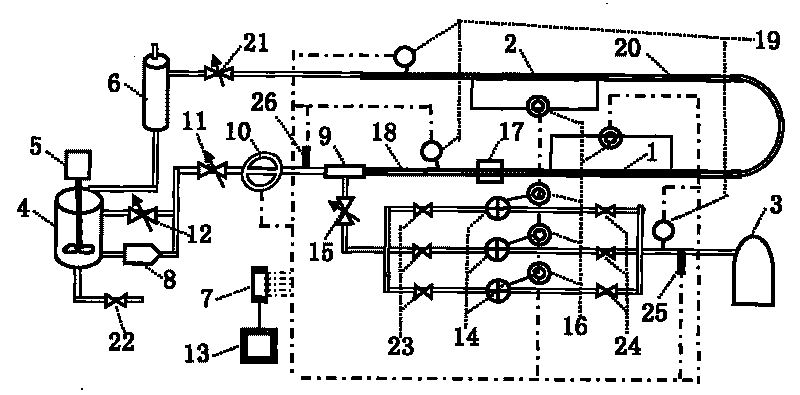

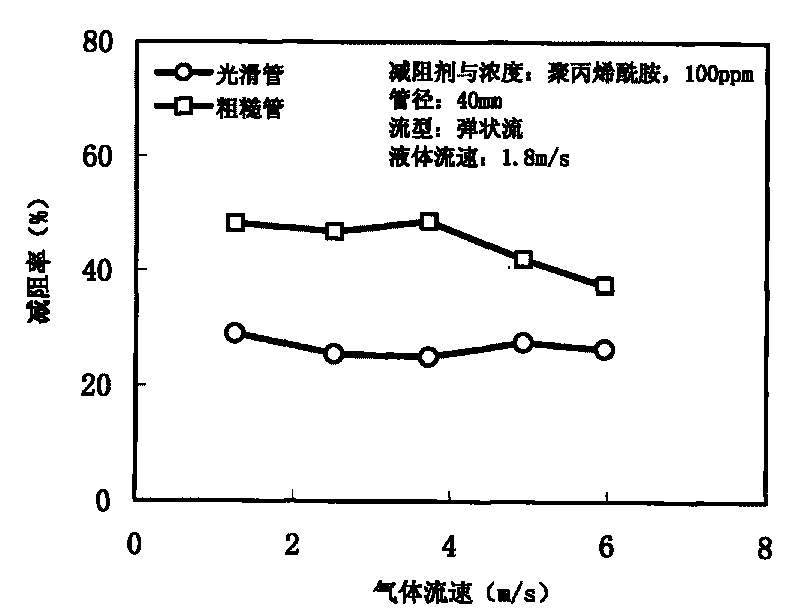

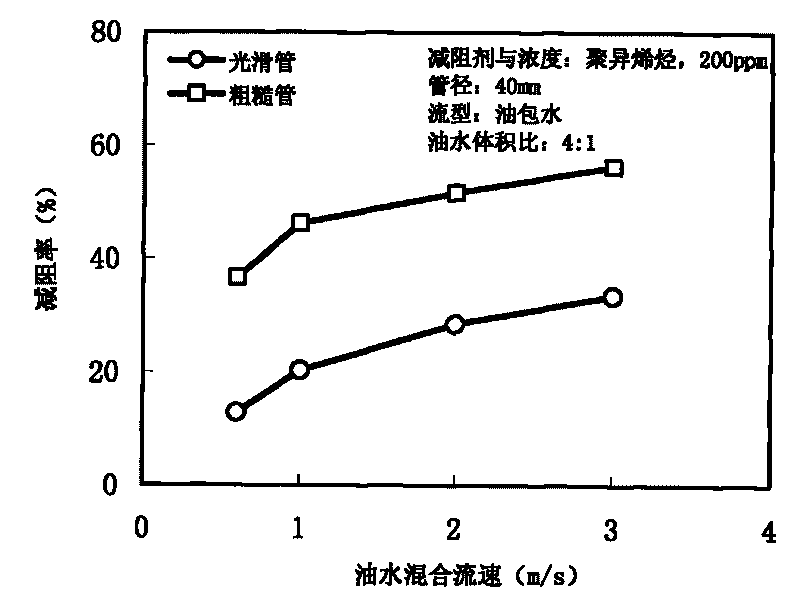

Device and method for testing performance of two-phase flow drag reducer

The invention discloses a device and a method for testing the performance of a two-phase flow drag reducer, which are used for testing the drag reduction performance of the drag reducer for reducing the two-phase flow frictional resistance of a horizontal pipe under the condition of different gas speeds, liquid speeds, drag reducer concentrations and the like. A smooth pipe horizontal test section and a rough pipe horizontal test section with the same pipe diameter are adopted to form a loop test device, and the method for testing the performance of the two-phase flow drag reducer comprises the following basic steps: testing the drag reduction performance of the drag reducer when a solvent phase and a non-solvent phase of the drag reducer are in mixed flow in a horizontal smooth pipe; testing the drag reduction performance of the drag reducer when the solvent phase and the non-solvent phase of the drag reducer are in mixed flow in a horizontal rough pipe under the condition of the same fluid flow rate, two-phase flow pattern, drag reducer concentration and the like as that in the horizontal smooth pipe; and representing the test result of the performance of two-phase flow drag reducer by taking the drag reduction rate of the drag reducer to the two-phase flow in the smooth pipe as a lower boundary and taking the drag reduction rate of the drag reducer to the two-phase flow in the rough pipe as an upper boundary.

Owner:XI AN JIAOTONG UNIV

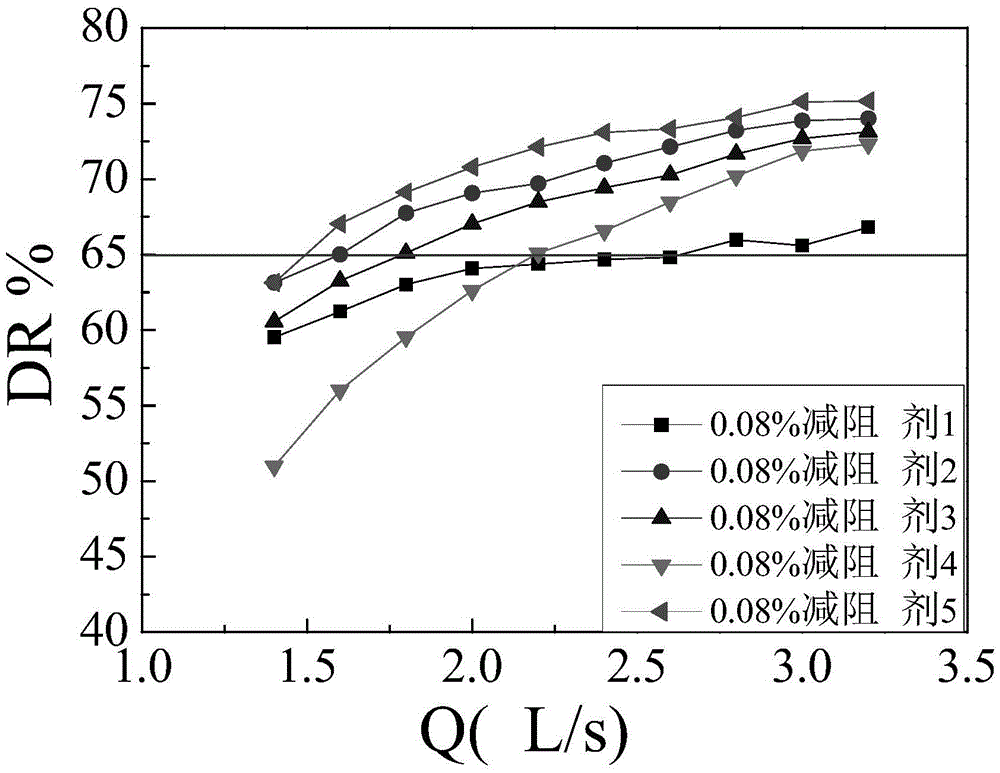

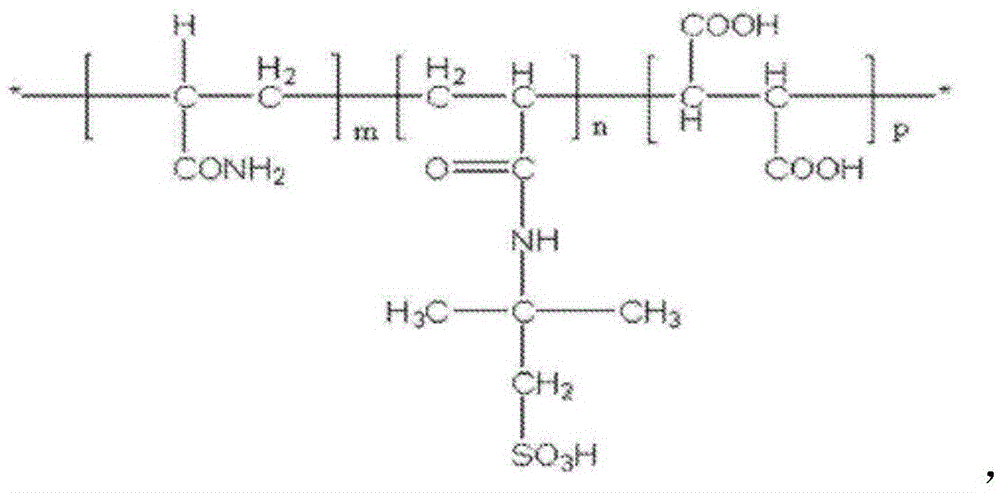

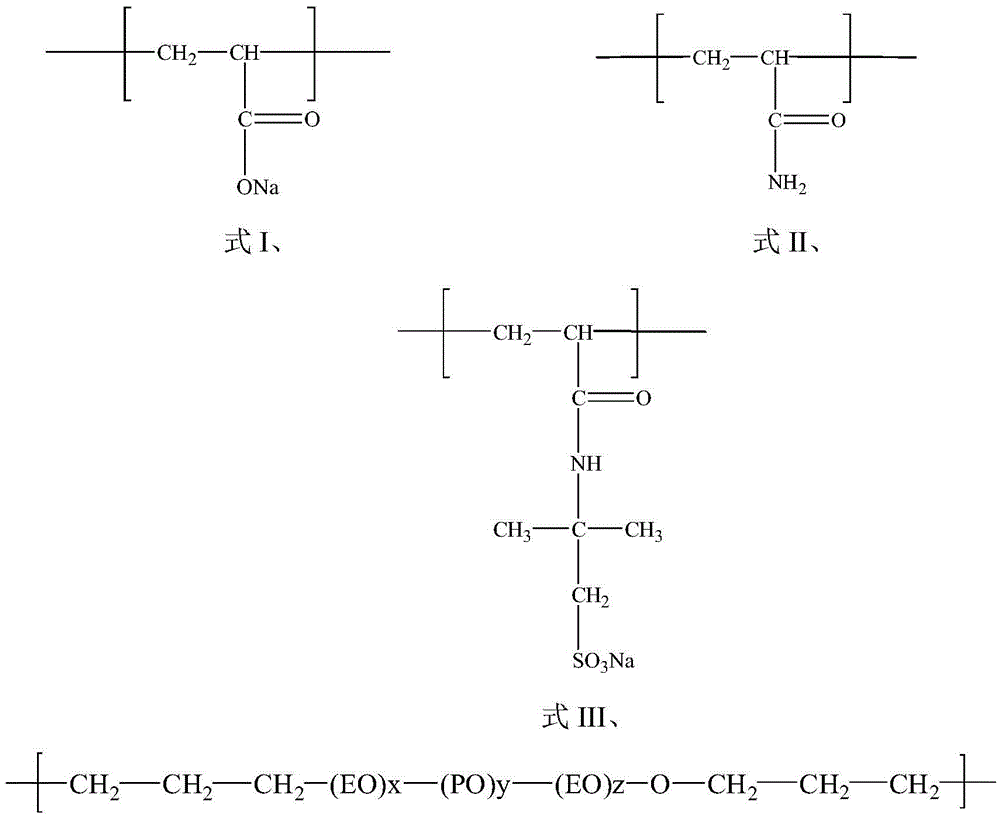

Acrylamide/sodium acrylate multi-component copolymer, method for preparing same and emulsion water-based fracturing fluid drag reducer

ActiveCN105601840AReduce consumptionReduce friction lossDrilling compositionWater basedFracturing fluid

The invention discloses an acrylamide / sodium acrylate multi-component copolymer, a method for preparing the same and an emulsion water-based fracturing fluid drag reducer. The acrylamide / sodium acrylate multi-component copolymer contains four structural units as shown in formulas I-IV. The method includes 1), mixing organic solvents and emulsifiers with one another to obtain oil phases; adding reactive monomers into water to obtain aqueous solution and regulating pH (potential of hydrogen) of the aqueous solution by the aid of sodium hydroxide until the pH is 7.0-7.5 so as to obtain water phases; 2), adding the water phases into the oil phases to obtain mixtures, stirring the mixtures to emulsify the mixtures, adding initiators into the mixtures and polymerizing the mixtures to obtain the acrylamide / sodium acrylate multi-component copolymer. The reactive monomers are acrylamide, acrylic acid, 2- acrylamide-2-methyl propane sulfonic acid and diallyl polyether. The acrylamide / sodium acrylate multi-component copolymer, the method and the emulsion water-based fracturing fluid drag reducer have the advantages that when the acrylamide / sodium acrylate multi-component copolymer is used as a drag reducer, the mass concentration is 0.06%-0.15%, the apparent viscosity is 6-21 mPa.s, the drag reduction rate is higher than or equal to 65%, and the acrylamide / sodium acrylate multi-component copolymer is excellent in drag reduction performance; the acrylamide / sodium acrylate multi-component copolymer is high in initial apparent viscosity, accordingly, the gel breaking speed can be increased, and the acrylamide / sodium acrylate multi-component copolymer and the emulsion water-based fracturing fluid drag reducer are excellent in gel breaking performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biocidal aldehyde composition for oil and gas extraction

ActiveUS20120087993A1Good killing effectReduce surface tensionBiocidePhosphorous compound active ingredientsCellulosePolyethylene oxide

A combination biocide (Glutaraldehyde or OPA), quaternary phosphonium biocide (preferably TTPC), alcohol (preferably isopropyl alcohol), and functional excipients for the oil and gas recovery industry. The functional excipients for the oil and gas recovery industry are a cellulose type proppant, a poloxamer wetting agent, a friction-reducing pluronic block copolymer, a drag reducing agent such as polyethylene oxide, and a flocculating agent. The OPA may be of the dialdehyde C6H4(CHO)2 form, and the Glutaraldehyde of formula C5H8O2. Both will produce an inherent bacteriostatic effect and lower surface tension and thus aids in the spread of the TTPC on the biofilm covered surface where it is readily absorbed by the negative surfaces of proteins and bacteria. It thus serves as a binding agent between the TTPC and the application surface. The foregoing constituents are combined in preferred concentrations within acceptable ranges to provide a synergistic biological chemical complementarity system.

Owner:MARTIN HOWARD

Shale gas well slickwater fracturing fluid system high-efficiency emulsion quick water-soluble drag reducer

ActiveCN103937484AEasy to useGood drag reduction effectDrilling compositionFracturing fluidDouble bond

The invention relates to a shale gas well slickwater fracturing fluid system high-efficiency emulsion quick water-soluble drag reducer, belonging to the technical field of oilfield drag reducers. The drag reducer is prepared by initiating polymerization of a component A, a component B and a component C by a free-radical initiator in water, wherein the component A is composed of a plurality of nonionic water-soluble monomers with carbon-carbon double bond; the component B is a water-soluble polymer stabilizer of univalent cationic monomers; and the component C is a univalent cationic inorganic salt. The drag reducer is simple to use, quick to hydrate and convenient to add, is green and environment-friendly, and has the advantages of high dissolution rate, no bubbling, salt resistance, calcium resistance, pollution resistance, high temperature resistance, favorable compatibility, no need of adding defoaming agent and the like; and the drag reduction efficiency can reach 70% when the drag reducer is used in fracturing. The drag reducer solves the problems of high tendency to granulation and low tendency to hydration in the use process of the existing drag reducer using dry powder, and the problem that the poor compatibility among various different ions and chemical assistants in the fracturing fluid can directly influence the feasibility and effectiveness of the slickwater fracturing.

Owner:荆州市现代菲氏化工科技有限公司

Non-cryogenic process for granulating polymer drag reducing agents

ActiveUS7271205B2Improve solubilityEasy to manufactureOther chemical processesInksParticulatesAlcohol

A method for producing a particulate polymer drag reducing agent, comprising granulating a bulk polymer DRA having an average size of greater than about 100 mm in the presence of a liquid wetting agent to form a granulated polymer DRA having an average size of from about 1 to about 100 mm. The granulated polymer DRA may then be ground to form a particulate polymer DRA having an average particle size of less than about 1 mm. The “wet” granulation process may advantageously enable one-step granulation and therefore simplified production of polymer DRAs. Examples of the liquid wetting agent include blends of glycols with water and / or an alcohol. Preferred production apparatus includes use of multiple rotary jaws for the granulation.

Owner:BAKER HUGHES INC

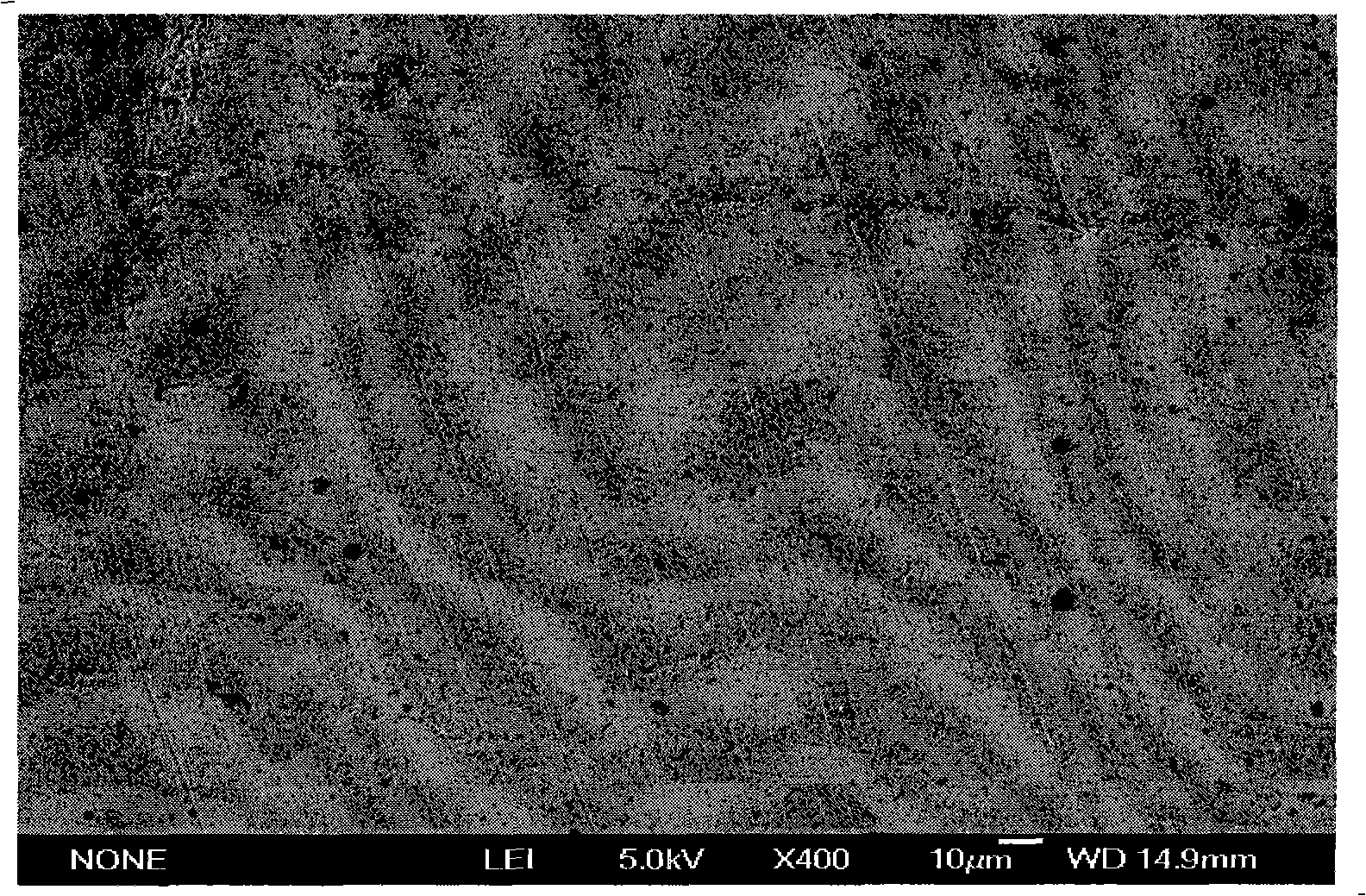

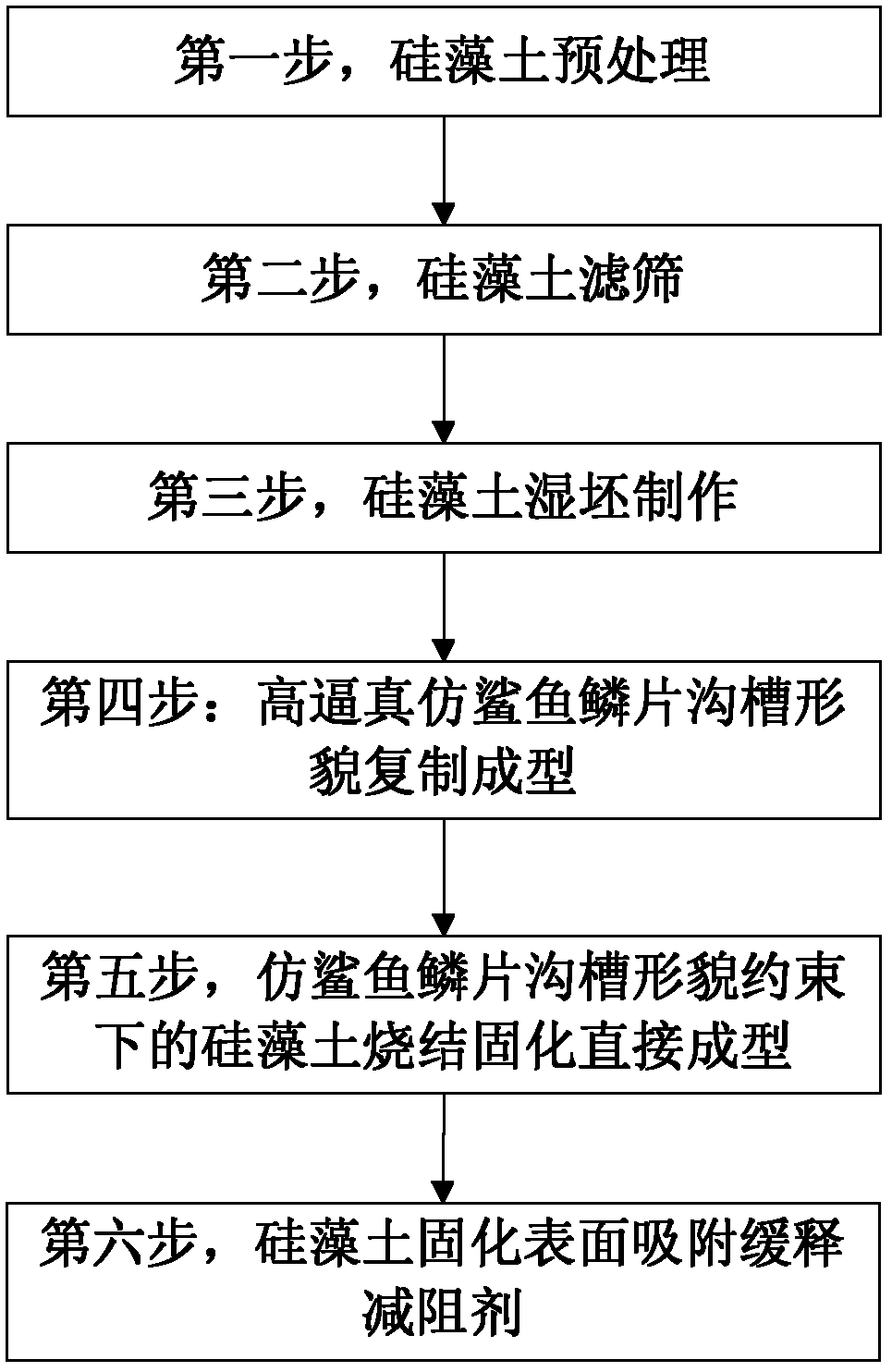

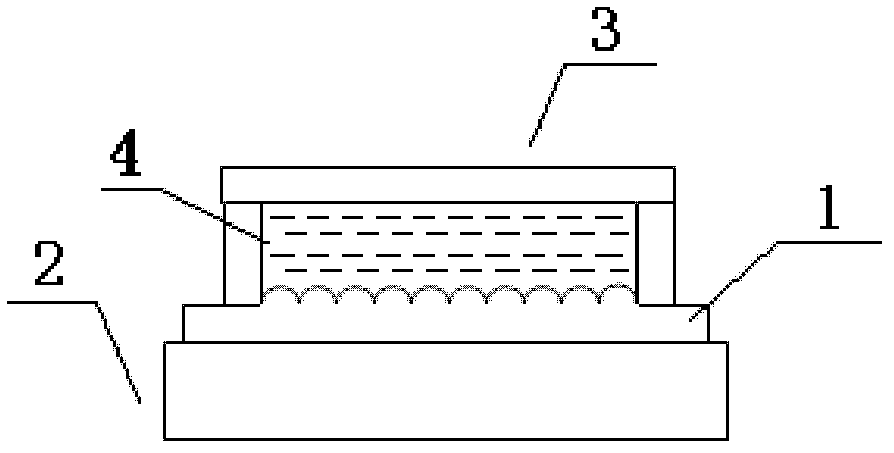

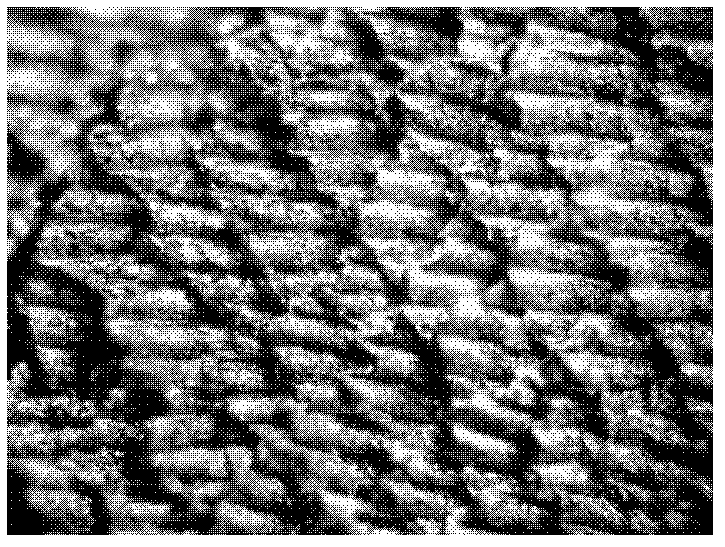

Manufacture method for diatomite composite drag reduction surface absorbed with drag reducer

InactiveCN102424602AGood drag reduction effectImprove adhesionWatercraft hull designCeramicwareReduction functionDrag reducing agent

The present invention relates to the technical field of bionics, specifically to a manufacture method for a drag reduction surface. The manufacture method for the diatomite composite drag reduction surface absorbed with a drag reducer comprises: 1) carrying out a diatomite pretreatment process; 2) carrying out a diatomite filtering and screening process; 3) carrying out a diatomite wet blank manufacture process; 4) duplicating and forming a groove morphology of the high-fidelity artificial shark scales; 5) carrying out sintering, curing and direct forming for the diatomite under the artificial shark scale groove morphology constraint; 6) absorbing a sustained release drag reducer on the cured diatomite surface to prepare the diatomite composite drag reduction surface absorbed with the drag reducer. According to the present invention, the drag reducer is absorbed to the artificial shark diatomite composite drag reduction surface, such that the drag reduction function of the artificial shark scale grooves is provided, and the drag reduction function due to sustained release of the self-lubricating mucus by the artificial shark is further provided.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com