Patents

Literature

491 results about "Carbon bisulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon disulfide (CS2), also called Carbon Bisulfide, a colourless, toxic, highly volatile and flammable liquid chemical compound, large amounts of which are used in the manufacture of viscose rayon, cellophane, and carbon tetrachloride; smaller quantities are employed in solvent extraction processes or converted into other chemical products, ...

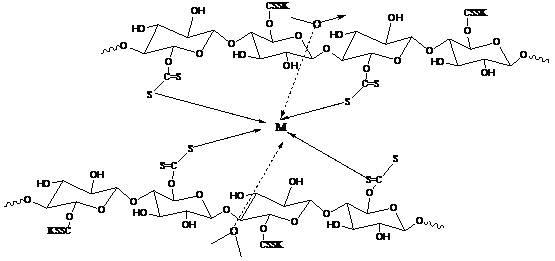

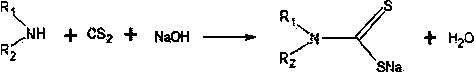

Chelating agent capable of simultaneously processing multiple heavy metallic ions

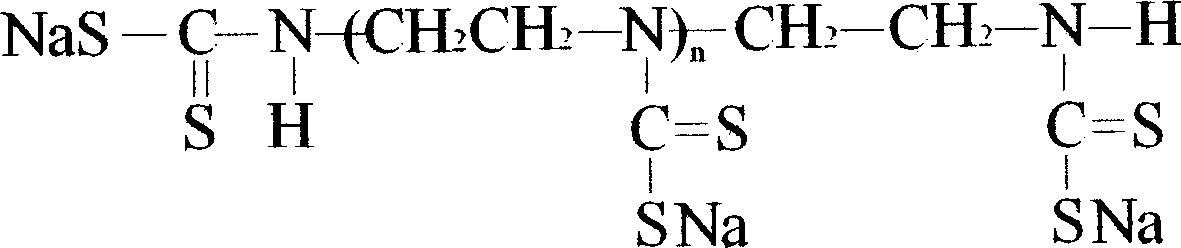

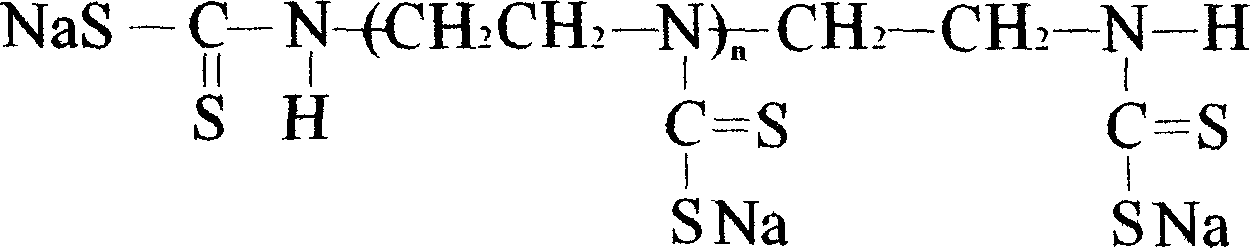

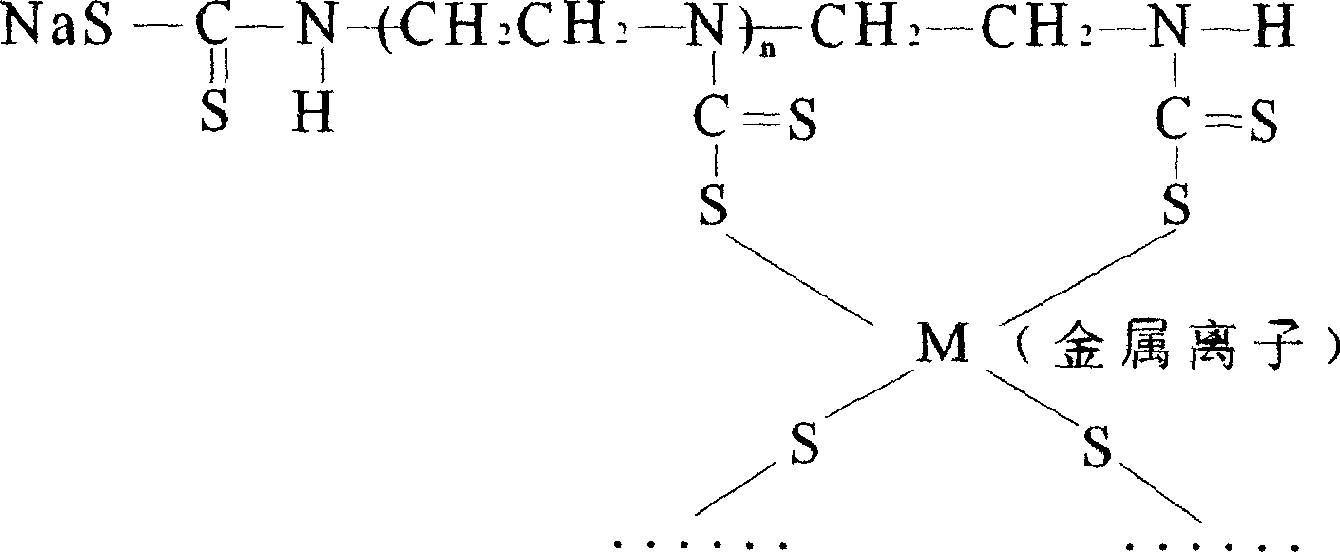

InactiveCN101081827AMeet the use requirementsReduce contentOrganic chemistryWater/sewage treatmentPrinted circuit boardPolyamine

The present invention discloses one kind of chelating agent capable of treating several kinds of metal ion simultaneously. The chelating agent is synthesized with polyamine or polyethylene imine as basic skeleton and carbon disulfide in alkaline condition, where, polyamine or polyethylene imine and carbon disulfide have weight ratio of 1 to 0.6-2.0. The chelating agent of the present invention can form chelate precipitate simultaneously with several kinds of metal ion, and is especially suitable for use in purifying waste water, chemical intermediate and chemicals for printed circuit board containing metal ions.

Owner:TIANJIN RUIJI CHEM

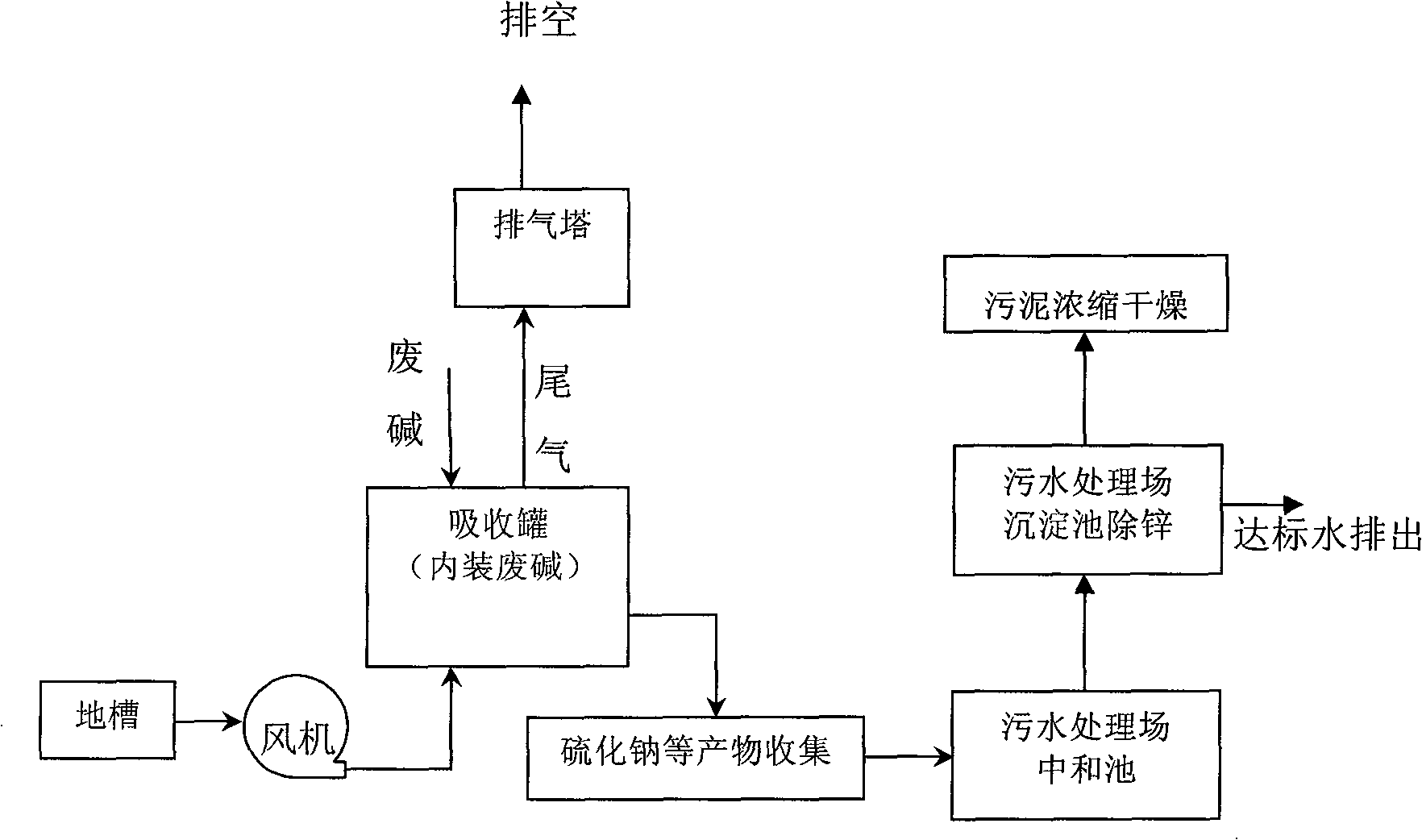

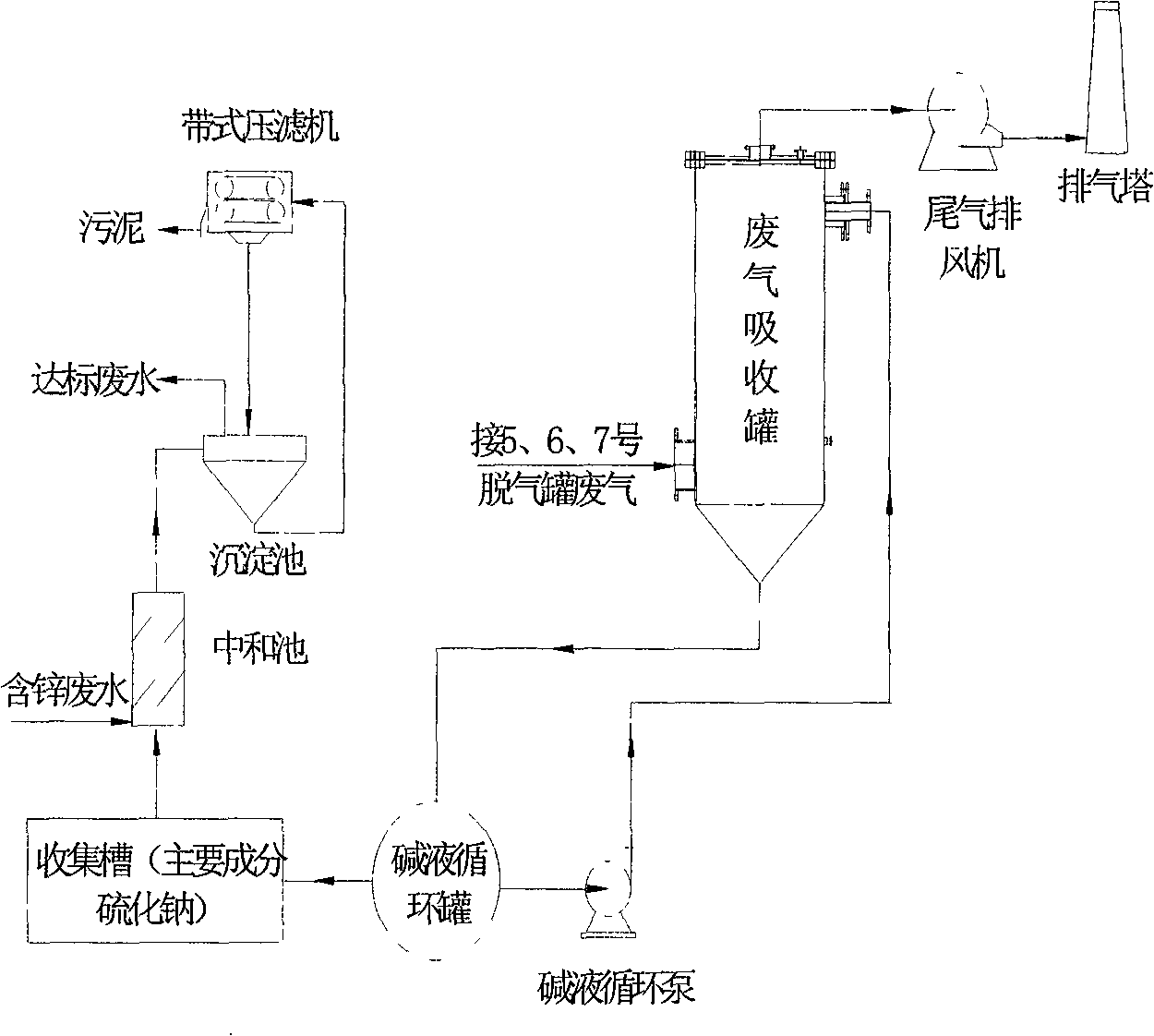

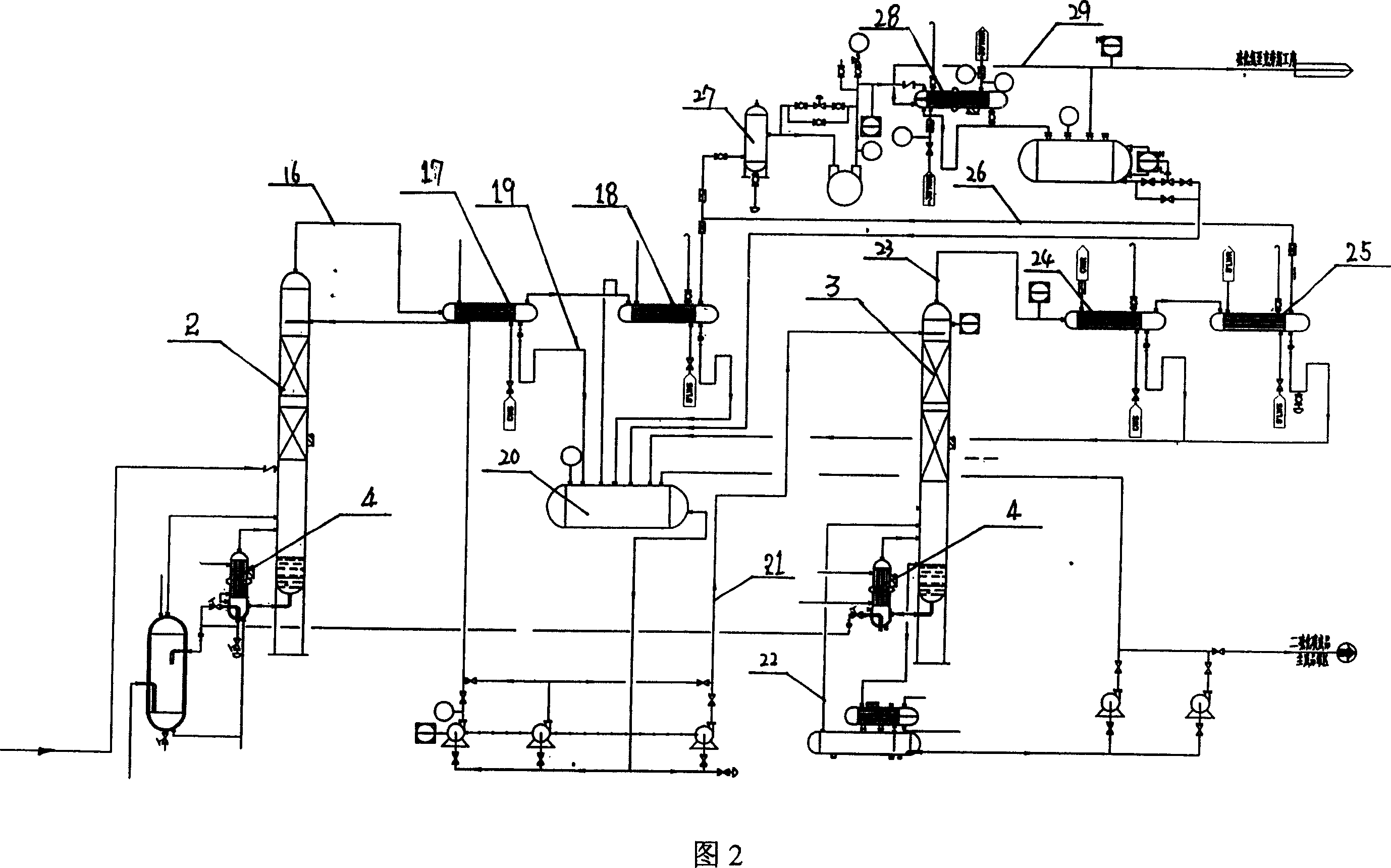

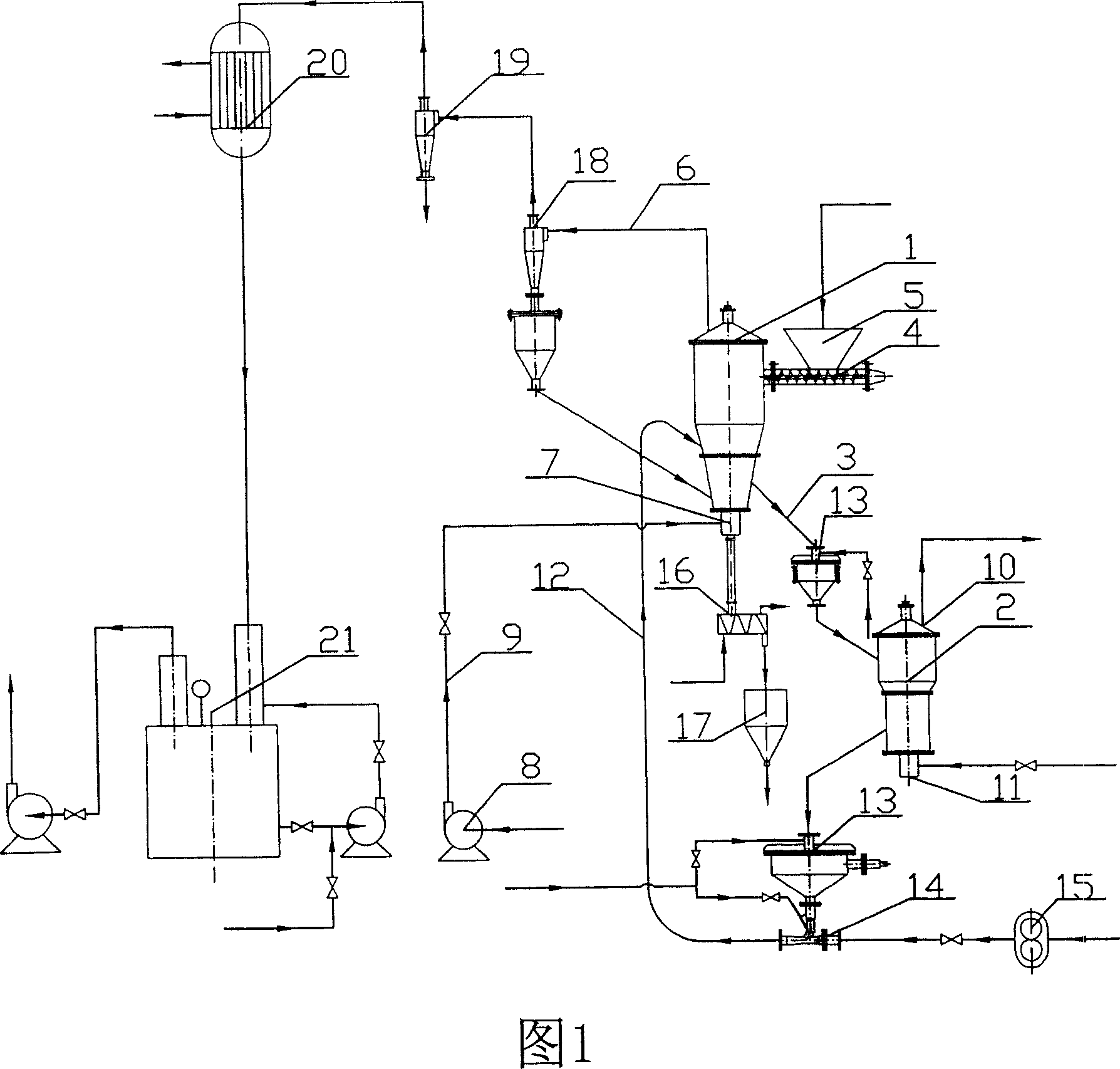

Method and equipment for comprehensive treatment of waste water and waste gas in viscose fiber preparation

InactiveCN101343124ASolve the environmental protection problems that have restricted the development of the industry for a long timeSolve processing problemsDispersed particle separationMultistage water/sewage treatmentHydrogenWastewater

The invention discloses a method for comprehensively treating wastewater and waste gas in the viscose fiber production as well as a device thereof, aiming at solving the difficult problem of waste gas and wastewater treatment in the viscose fiber production. The method comprises the steps of: putting the waste lye collected in the viscose fiber production into an absorption tank; inputting the process waste gas containing sulfureted hydrogen and carbon bisulfide into the absorption tank, and colleting the absorbed neutralizer for standby; and putting the neutralizer into the wastewater containing zinc ions for having the reaction with the zinc ions, and removing the precipitate after reaction products are deposited. The device comprises the absorption tank, a collecting tank, a neutralization pond and a sedimentation tank. The method and device comprehensively consider the problems of spent soda, waste gas and zinc-containing wastewater treatment in the viscose fiber production, thereby reaching the comprehensive utilization of resources, also reducing the waste discharge, and solving the environmental protection problem that restricts the industry development over a long period of time in the viscose production process.

Owner:YIBIN HIEST FIBER

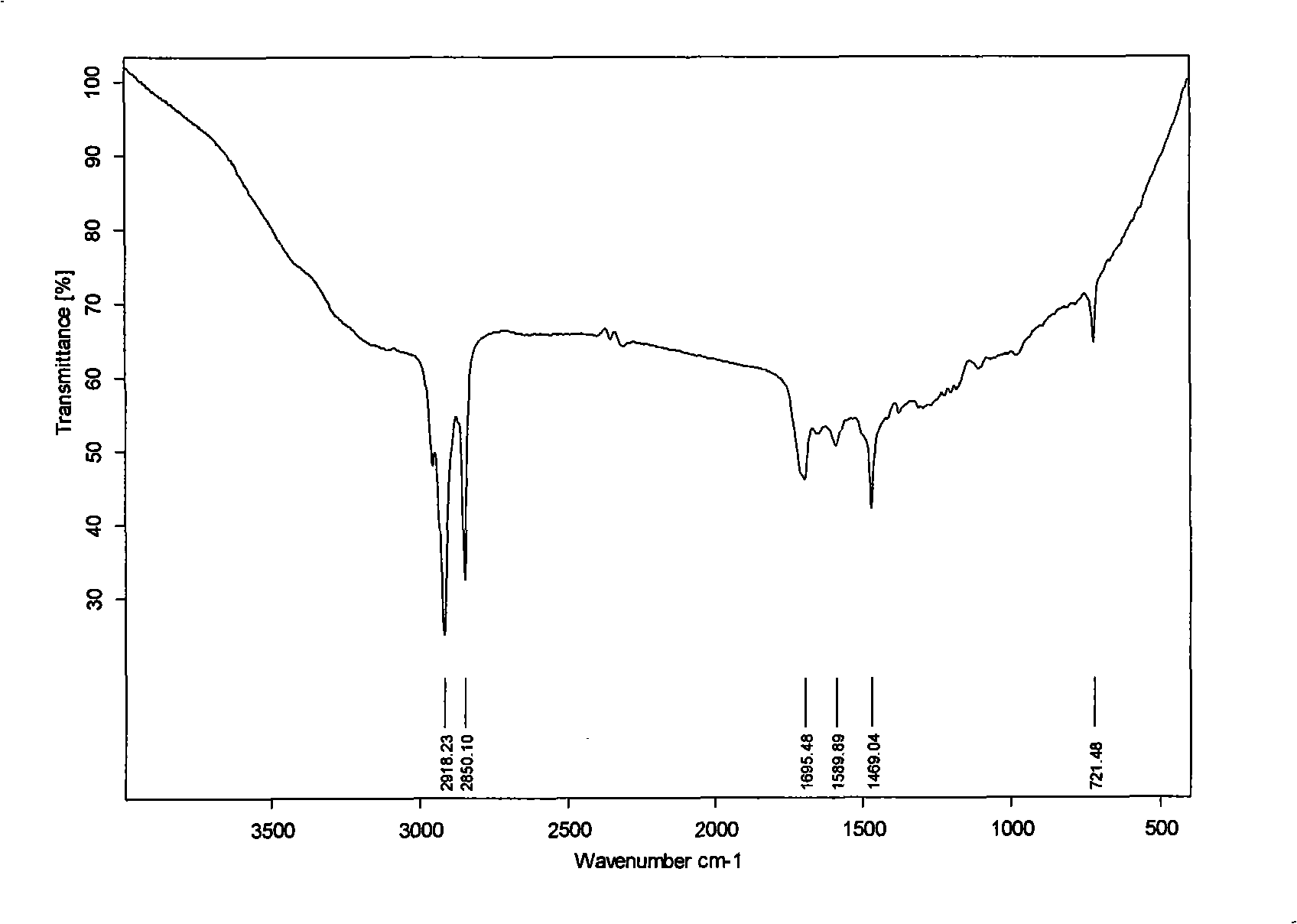

Gas pipeline drag reduction agent and preparing method thereof

The invention relates to a gas line drag reduction agent and a preparation method thereof, relating to the technical field of the composite of high-molecular compound and piping systems. The drag reduction agent consists of carbon bisulfide, hydrazine hydrate and long chain acid, the mol ratio of which is 1.8:1:1 to 2.2:1:1. The preparation method comprises the following steps: step one, CS2 is taken according to proportional quantity, dripped into the mixed liquor of the hydrazine hydrate and water with proportional quantity under agitation, reflowed for certain time in the temperature range of 90 to 95 DEG C, then cooled for 30 to 60 minutes in ice water bath and pumped and filtered, the mother liquor continues to react for two times, products of the third time are merged, washed by using ethanol and ether sequentially, and recrystallized by using boiling water so as to obtain symmetrical diaminothiourea clear crystal; and step two, symmetrical diaminothiourea with proportional quantity and the long chain acid with proportional quantity are dissolved in a pyridine solvent with nitrogen protection, reflowed at the temperature of 140 to 220 DEG C by adopting a temperature programming method, and react for 3 to 4 hours, then the mixture is cooled to the room temperature and recrystallizated by using the ethanol of 95 percent to obtain the brown product.

Owner:PIPECHINA SOUTH CHINA CO

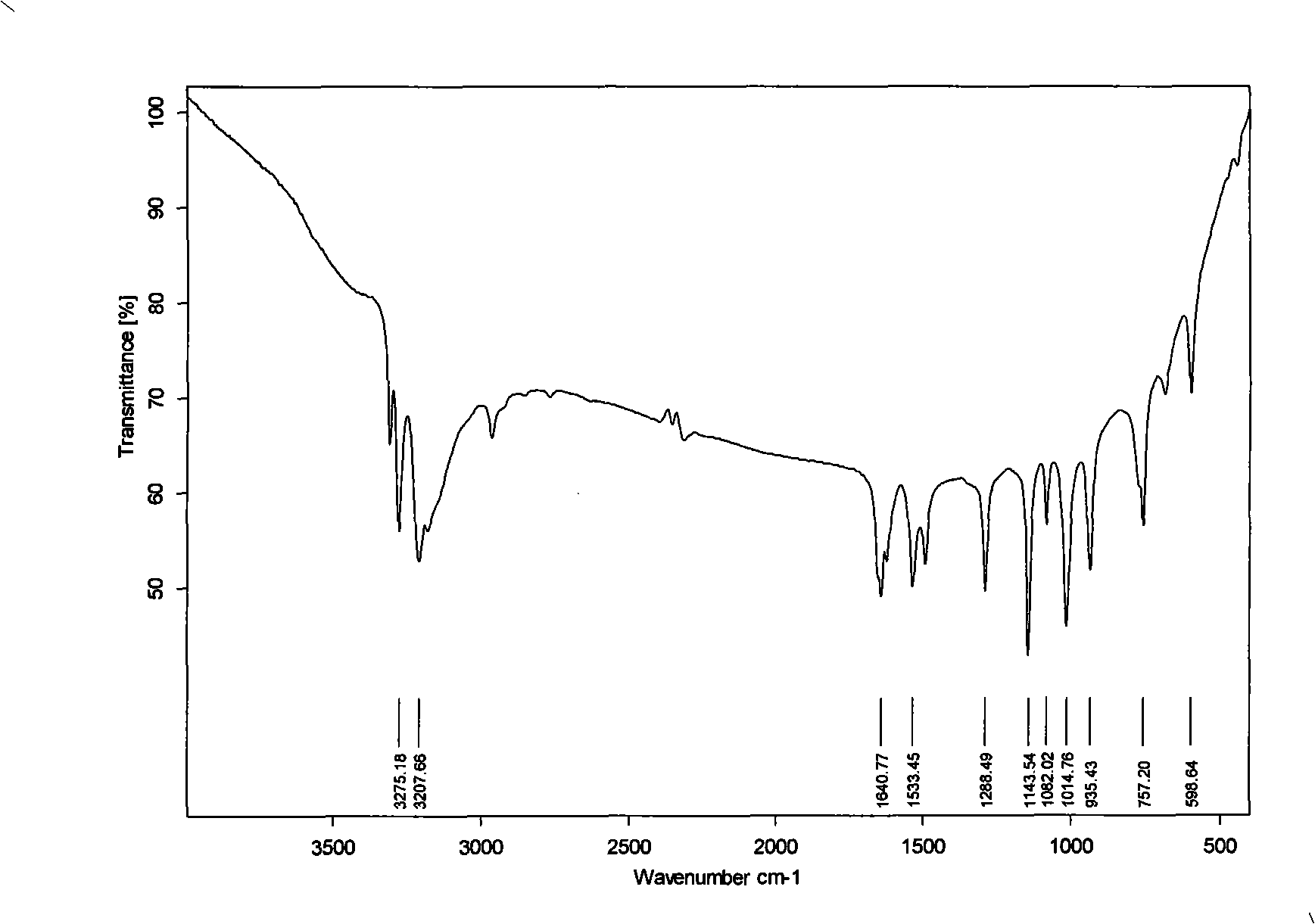

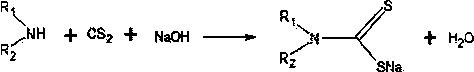

Method for synthesizing dithioamino formic acid and diivinyl triamineethyl polymers

The invention disclosed a synthetic method of the dithiocarbamic acid diethylene ethyl polymer and deals with the composing method of the dithiocarbamic acid polymer. The invention is the single stage process; the water, the sodium hydroxide, the diethylene tren, the carbon bisulfide and 1,2-dichloethane is mixed in turn to the polyreaction, so the adsorbent having the good ability of adsorbing the metallic ion. The invention has some merits of the easy means, the easy operation, the operator saving and the time saving, the water and organic solvent economy, the low cost of the producing, the wild acting condition, the safe produce, the energy saving, easy industrial production, the benefit of extending and applying. The production of the invention can be used for fathering the sullage containing the heavy-metal ion, so it can be applied to some trades such as the plate, the electron, the metallurgy, the petroleum processing and the pulp producing and is favourable to the environmental protection.

Owner:CHONGQING UNIV

Method for preparing novel remover for heavy metal ion and application thereof

The invention provides a method for preparing a novel heavy metal ion remover and an application thereof, and relates to a method for preparing a raw material of the heavy metal ion remover, a process for synthesizing the heavy metal ion remover and an application thereof. The invention is characterized in that the method comprises the following steps that: methenamine and epoxy chloropropane react with carbon bisulfide after the methenamine and the epoxy chloropropane are subject to the cross linking reaction, thereby obtaining a quaternary ammonium salt xanthate chelating agent-the novel heavy metal ion remover. The prepared novel heavy metal ion remover can be used for treating wastewater containing heavy metal ions, and the dosage and the adding process of the novel heavy metal ion remover can be controlled through detecting changes of an oxidation-reduction reaction electrode potential (ORP), thereby achieving the aim of automatically treating the wastewater containing the heavy metal ions with high efficiency.

Owner:陈德琪

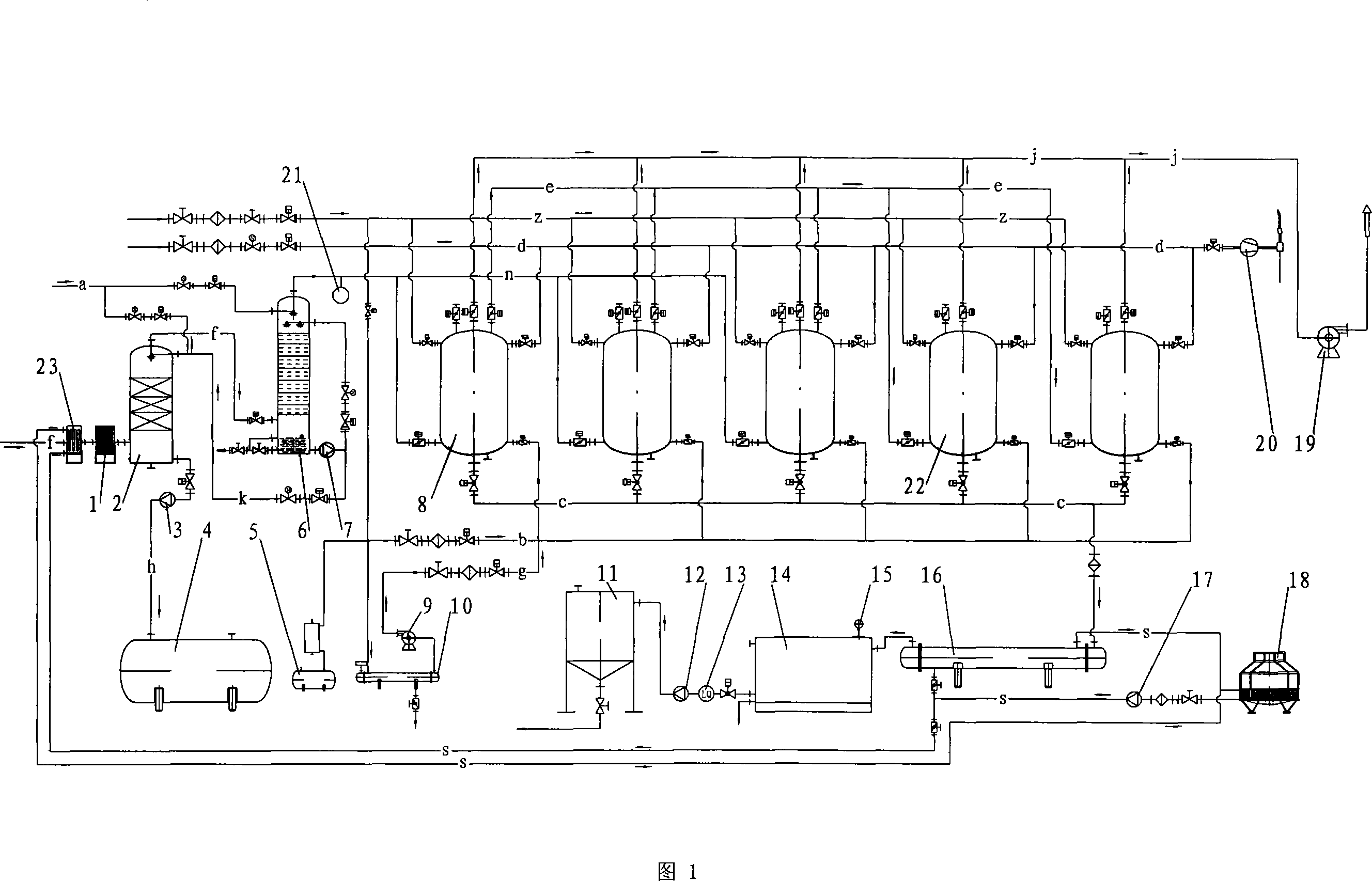

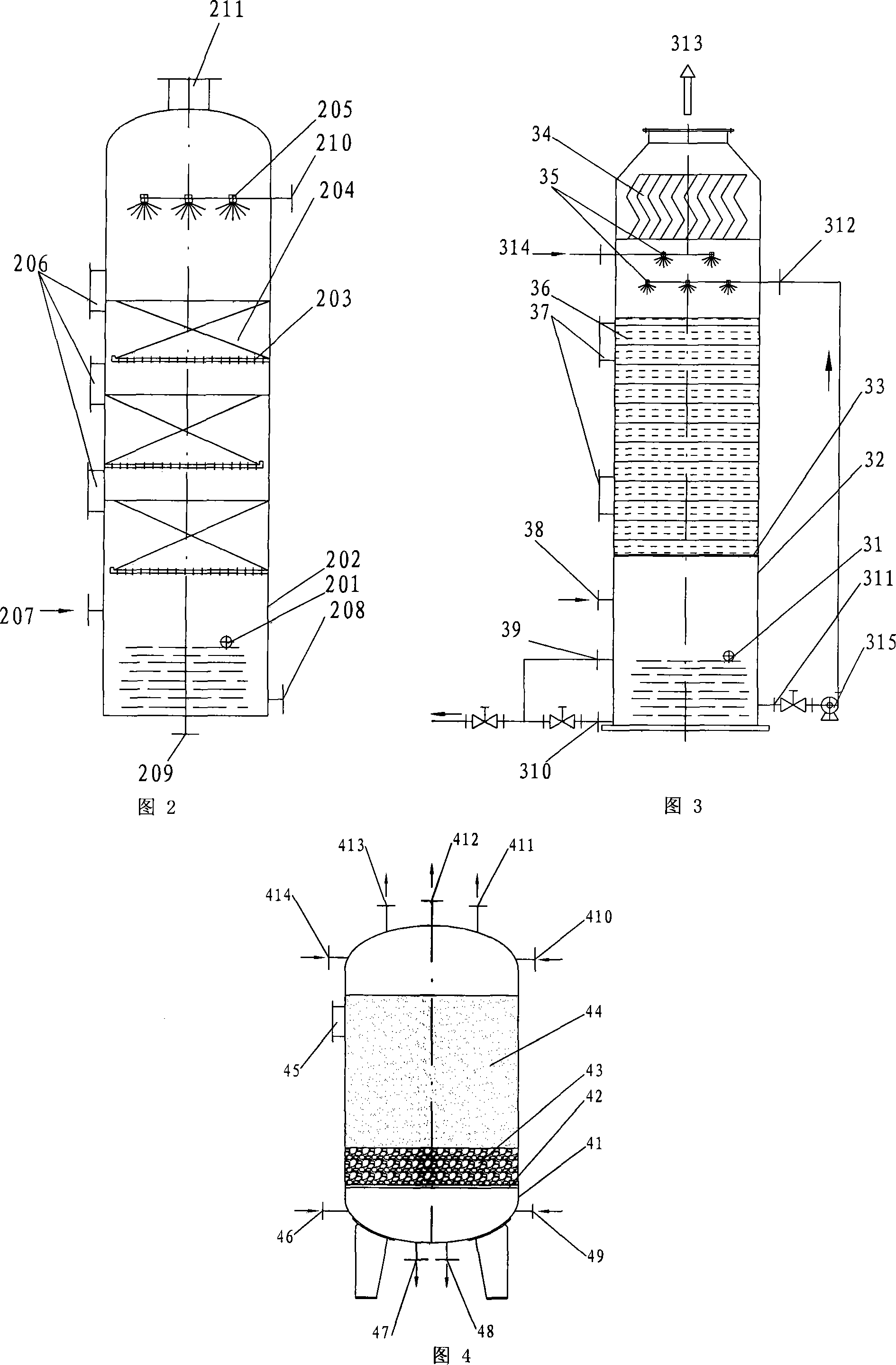

Device for recovering viscose fiber production exhaust-gas with soda washing-adsorption condensing method

The invention relates to a device for recycling waste gas generated by viscose through an alkali cleaning-absorbing condensation method, which relates to the equipment for recycling waste gas generated by industries. The device for recycling waste gas generated by viscose through an alkali cleaning-absorbing condensation method has relatively good processing effects and can recycle useful resources in the waste gas with high efficiency. The device is equipped with a waste gas filter, an alkaline tower, a solution transfer pump, a storing tank of sodium hydrosulfide, an air compressor, a washer, a recycle pump, an adsorption tank, an air heater, a heater, a storing tank of carbon bisulfide, a gear transfer pump, a flowmeter, a solution separator, a magnetic levitation ball liquid level switch, a condenser, a water pump, a cooling tower, a draft fan, a vacuum pump, a concentration analyzer of H2S and CS2, an adsorption tank, a cooler and a pneumatic ball valve. Sulfureted hydrogen gas in the waste gas is transformed into sodium hydrosulfide liquid and carbon bisulfide gas in the waste gas is transformed into carbon bisulfide liquid through washing, absorbing, condensing and separating. The carbon bisulfide liquid is employed as raw materials and is directly sent back to the production of the viscose.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

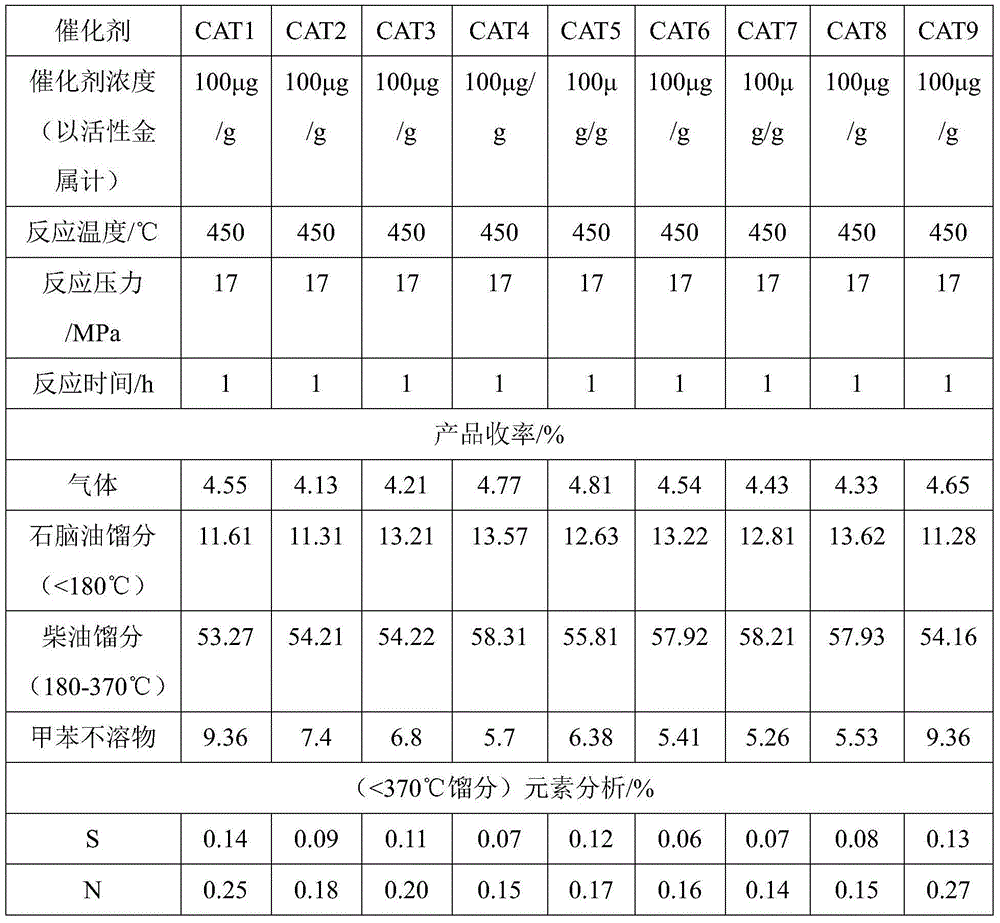

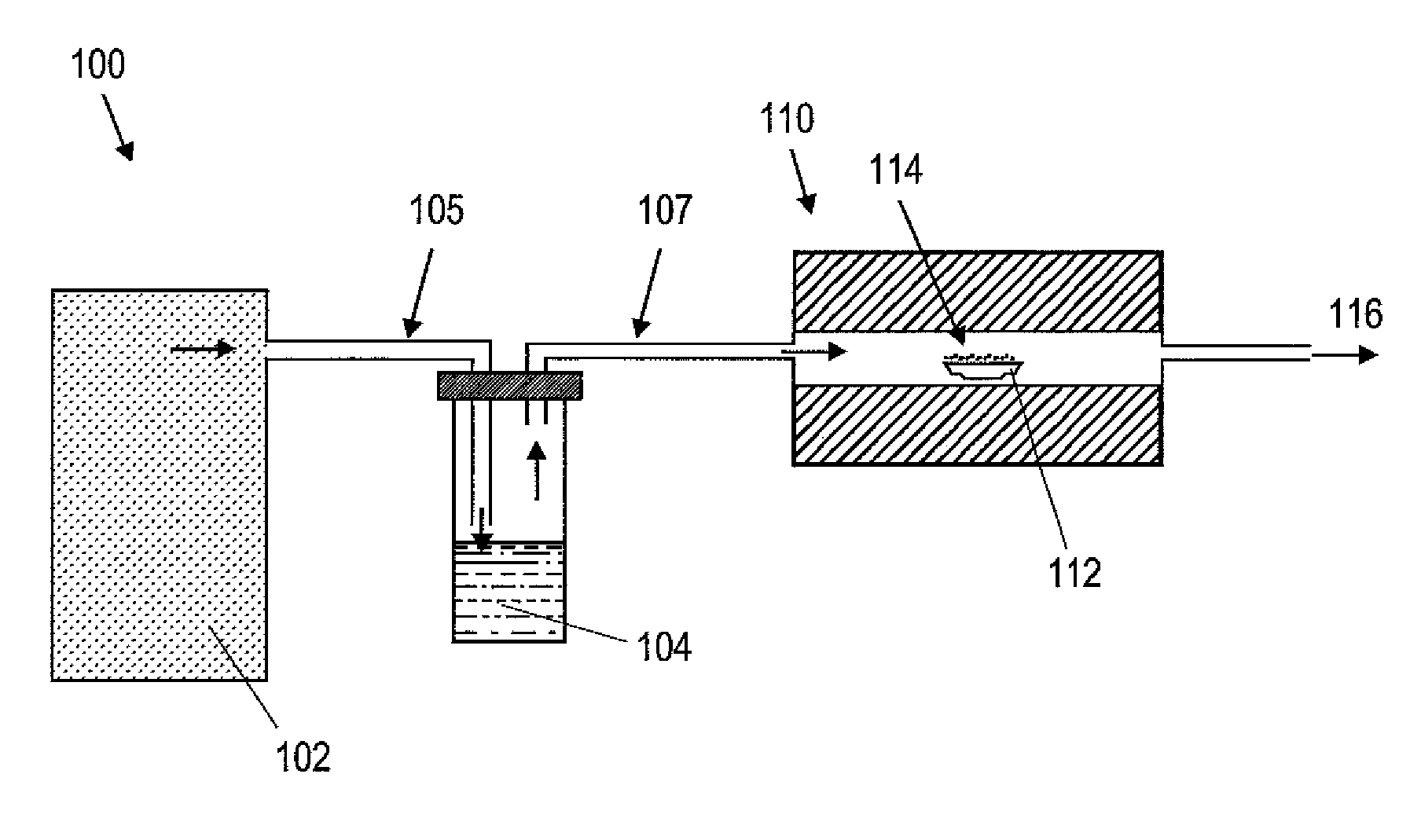

Oil solubility compound-type suspended bed hydrocracking catalyst as well as preparation method thereof

ActiveCN103977822AImprove catalytic performanceReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSolubilityReaction temperature

The invention discloses an oil solubility compound-type suspended bed hydrocracking catalyst, wherein the catalyst is prepared by the following steps: 1) enabling compounds of metal elements in the VIB family, the VIIB family or the VIII family in a periodic table of elements as metal sources with alkali metal sulfide or alkali metal hydrosulfide according to the mole ratio of (0.5 to 1)-(2 to 1), thereby obtaining a metal element compound at a reduction state; 2) adding the metal element compound at the reduction state and amine substances into a reaction medium according to the mole ratio of (1:0.6)-(1 to 2), and meanwhile dropwise adding carbon disulfide with the corresponding quantity into the reaction medium according to the mole ratio of (1 to 1)-(2 to1) with the metal element compound at the reduction state, warming to react at the reaction temperature of 30-110 DEG C for 2-10 hours; 3) filtering and washing the product obtained by the step 2) so as to obtain the oil solubility compound-type suspended bed hydrocracking catalyst. The catalyst prepared by the invention can inhibit the coke yield, and improve the light oil yield.

Owner:CCTEG CHINA COAL RES INST

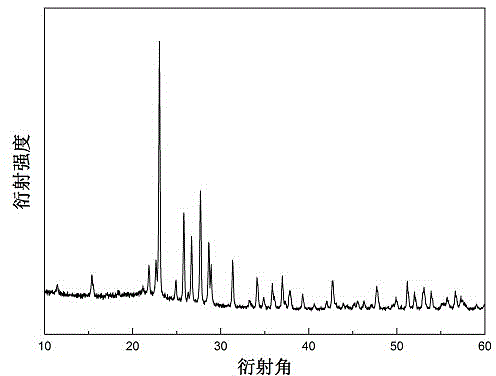

Synthetic methods for generating WS2 nanostructured materials

InactiveUS8303926B1Cell electrodesSulfide/polysulfide preparationSynthesis methodsNanostructured materials

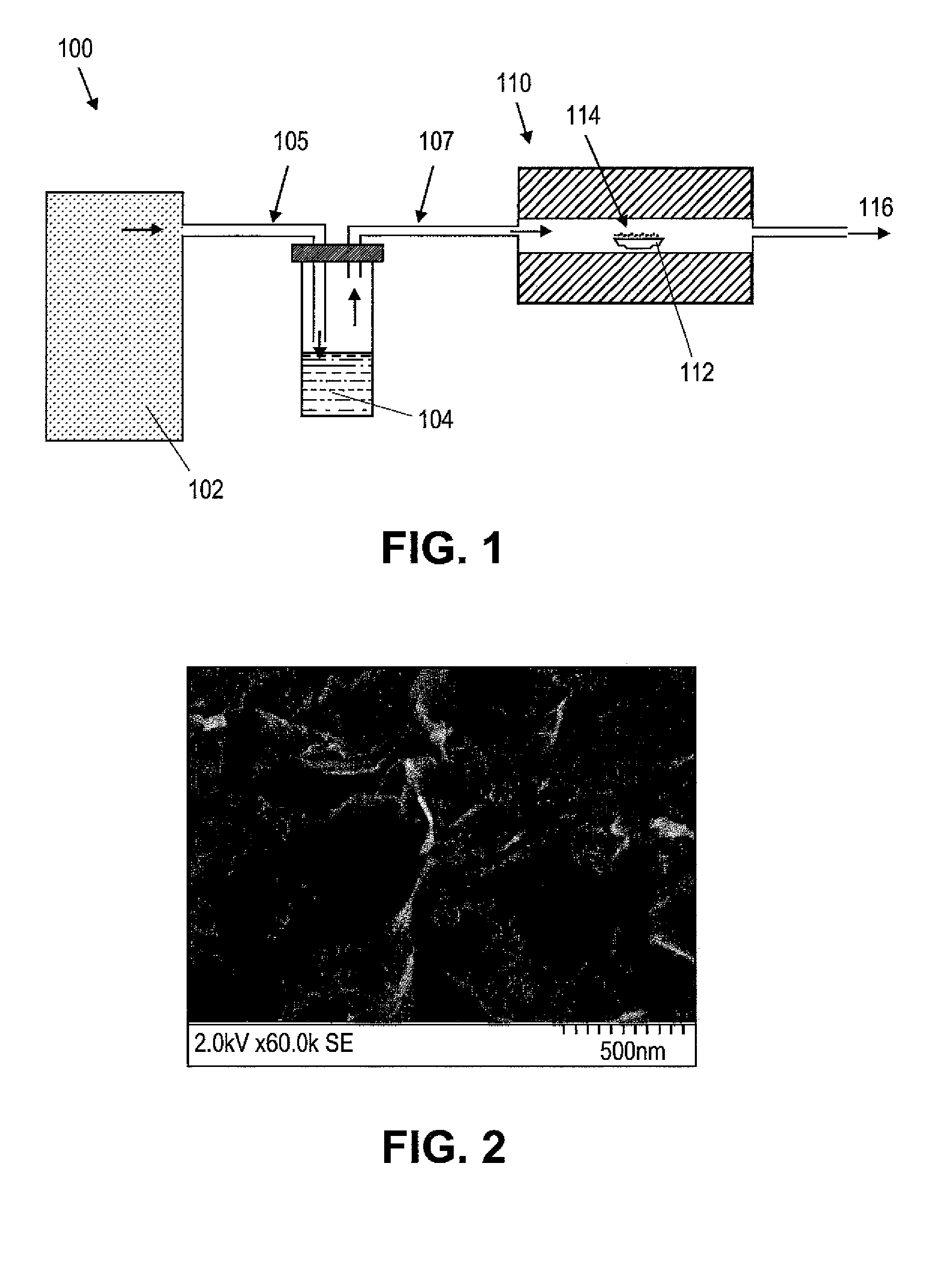

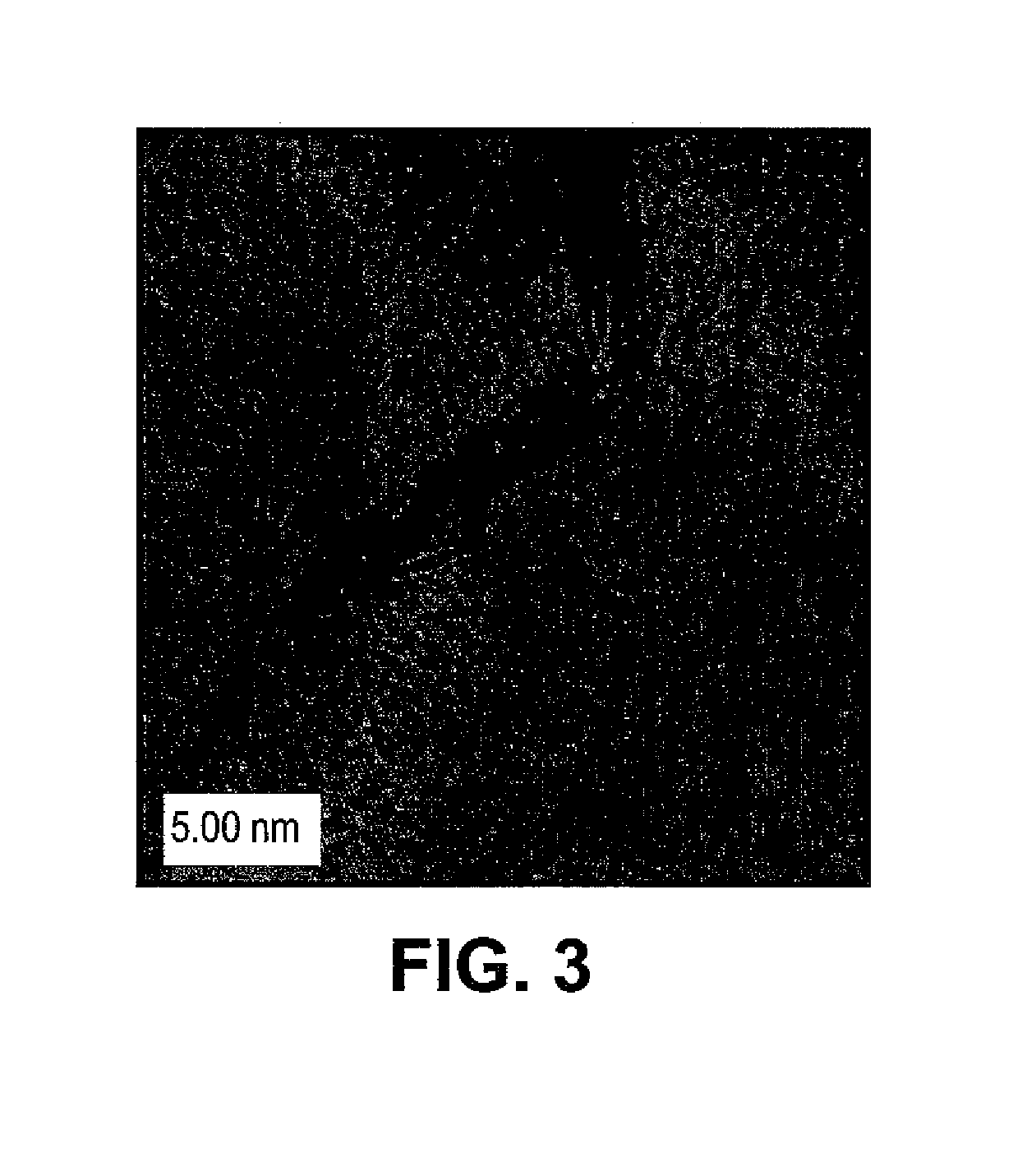

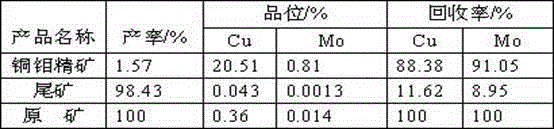

In accordance with various embodiments, there are nanostructured materials including WS2 nanostructures and composites of WS2 nanostructures and other materials and methods for synthesizing nanostructured materials. The method can include providing a plurality of precursor materials, wherein each of the plurality of precursor materials can include a tungsten reactant. The method can also include flowing, for a reaction time, a substantially continuous stream of carbon disulfide (CS2) vapor in a carrier gas over the plurality of precursor materials at a temperature in the range of about 700° C. to about 1000 C, wherein the reaction time is sufficient to permit the tungsten reactant to react with carbon disulfide to form a plurality of tungsten disulfide (WS2) nanostructures.

Owner:STC UNM

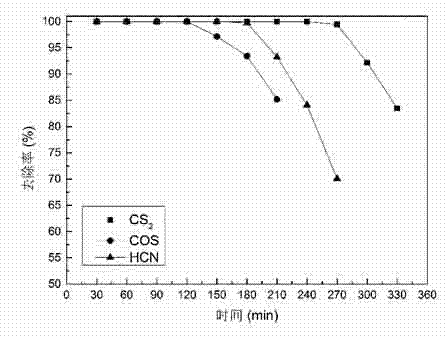

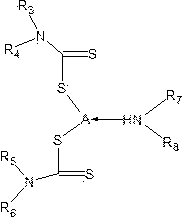

Copper sulfide flotation collector as well as preparation method and application thereof

InactiveCN104475266ASimple manufacturing methodReduce net negative chargeFlotationChloroformateCarbon chain

The invention discloses a copper sulfide ore flotation collector as well as a preparation method and application thereof. The collector is alkoxy carbonyl alkyl dithiocarbamate and has a structural formula as shown in the specification, wherein R1 is carbon chain 1-4 alkyl and R2 is carbon chain 2-4 alkyl. The preparation method comprises the following steps: performing nucleophilic substitution reaction on alkylamine, sodium hydroxide and carbon bisulfide to obtain sodium dithiocarbamate; reacting the sodium dithiocarbamate and alkyl chloroformate to obtain a target collector alkoxy carbonyl alkyl dithiocarbamate. The application refers to application of the copper sulfide ore flotation collector in performing flotation on copper sulfide ore and recycling valuable metal minerals in the copper sulfide ore. The collector is capable of realizing effective separation of the copper sulfide ore and pyrite under an ore pulp environment with the pH value of 6-10, reducing the lime consumption, and further effectively recycling useful metals such as gold, silver and molybdenum. Compared with the existing collector, the collector has the advantages of good selectivity and high useful metal recovery rate.

Owner:KUNMING METALLURGY INST

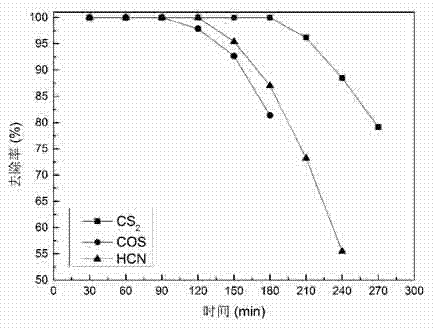

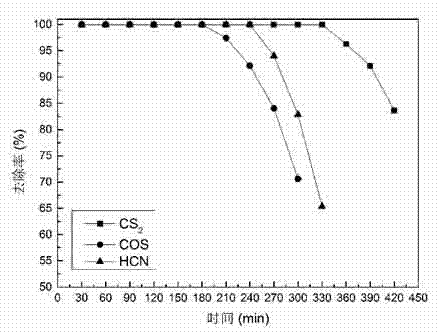

Preparation method of modified bio-charcoal based catalyst

InactiveCN104772146AImprove removal effectFully removedDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCarbonyl sulfide

Owner:KUNMING UNIV OF SCI & TECH

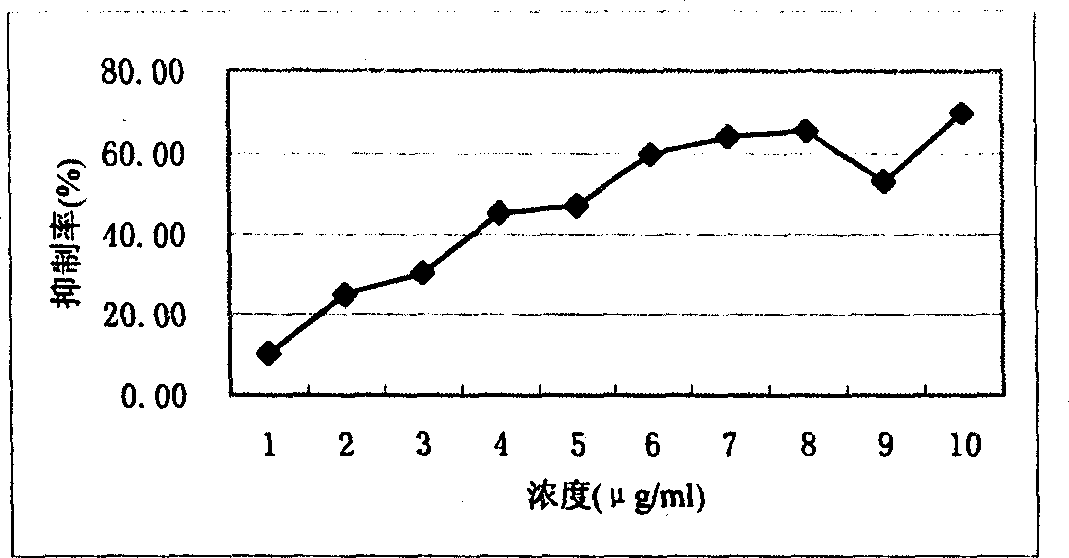

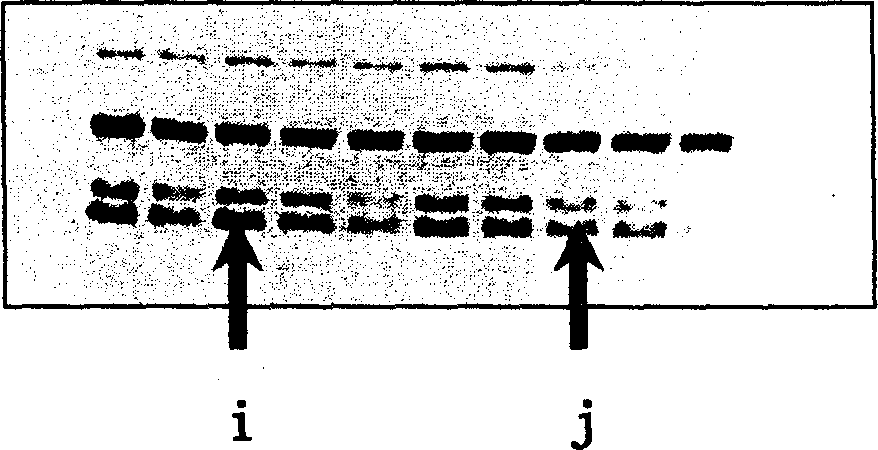

Cyanoacrylate derivatives and their preparation method and biological activity

This invention discloses a medicine of anti-tumor and anti-plant virus effect---- cyanoacrylate category derivative and its preparing method and biological activity. The following general formula denotes the compound and its preparing method. The definition of R1, R2, R3 in the formula is in instruction book. Materials are carbon bisulfide, cyan acetic ester, dimethyl sulfate, aromatic amine, and sodium cyanide is catalyst, cyanoacrylate category derivative is synthesized by three steps. There is proliferation inhibitory effect of compound b, k to PC3 prostate cancer cell gene stock, and proliferation inhibitory effect of compound i, j to NIN3T3 cell ERK albumen phosphorylation, and good anti-cancer activity is revealed. There is inhibitory activity of compound b, n to tobacco mosaic, and certain anti-plant virus activity is revealed.

Owner:GUIZHOU UNIV

Method for recovering silicon powder from cut mortar waste

The invention discloses a method for recovering silicon powder from cut mortar waste. According to the adopted technical scheme, the method comprises the following steps of: carrying out solid-liquid separation on the cut mortar waste to obtain a solid mixture, and adding an ethanol solution of carbon bisulfide to wash away suspended impurities to obtain mixed sand powder; carrying out magnetic separation on the obtained mixed sand powder to remove iron, iron oxides and metal impurities; carrying out acid cleaning; carrying out solution floatation and gravity separation to recover suspended matters, then washing the suspended matters by using ethanol, and drying to obtain high-purity silicon powder. The method disclosed by the invention effectively integrates the silicon powder recovery process through the steps of a solid-liquid separation procedure, a magnetic separation procedure, an acid cleaning procedure, a solution floatation procedure and the like, thus achieving the advantages of simple process, operation controllability, excellent economical performance and no secondary pollution. According to the method for recovering the silicon powder from the cut mortar waste, the recovery rate of silicon powder is higher than 80%, the content of silicon powder monomers is higher than 99%, and the silicon powder can be used as a raw material of a solar silicon wafer and is suitable for industrial popularization and application.

Owner:佳明新材料科技有限公司

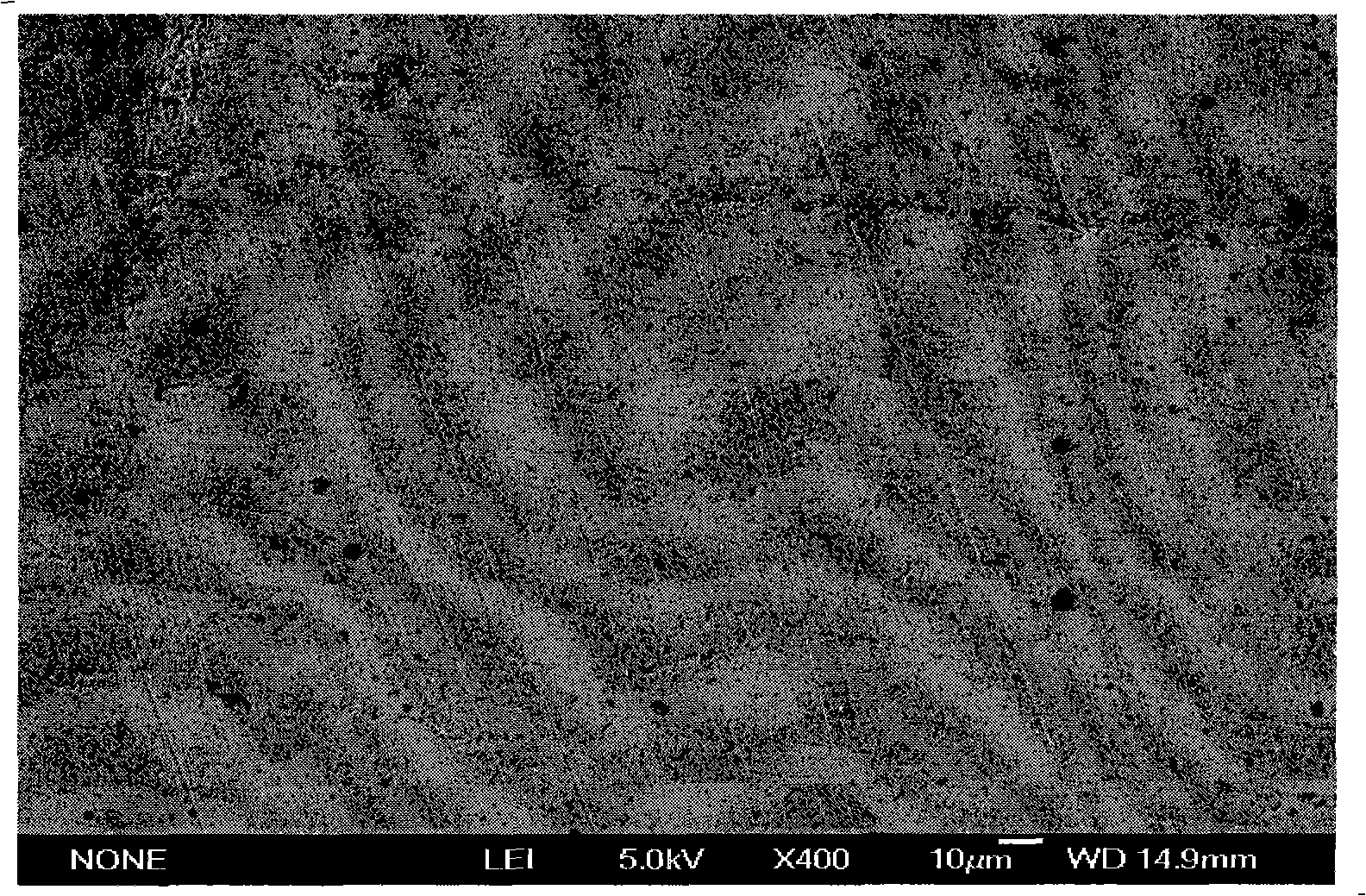

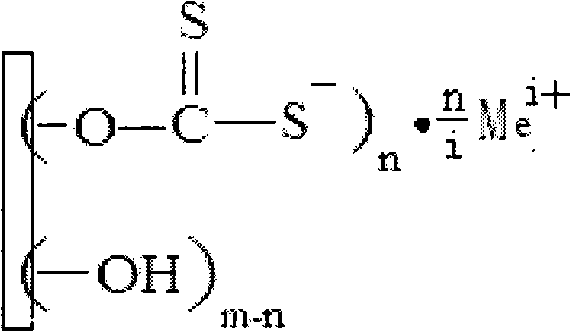

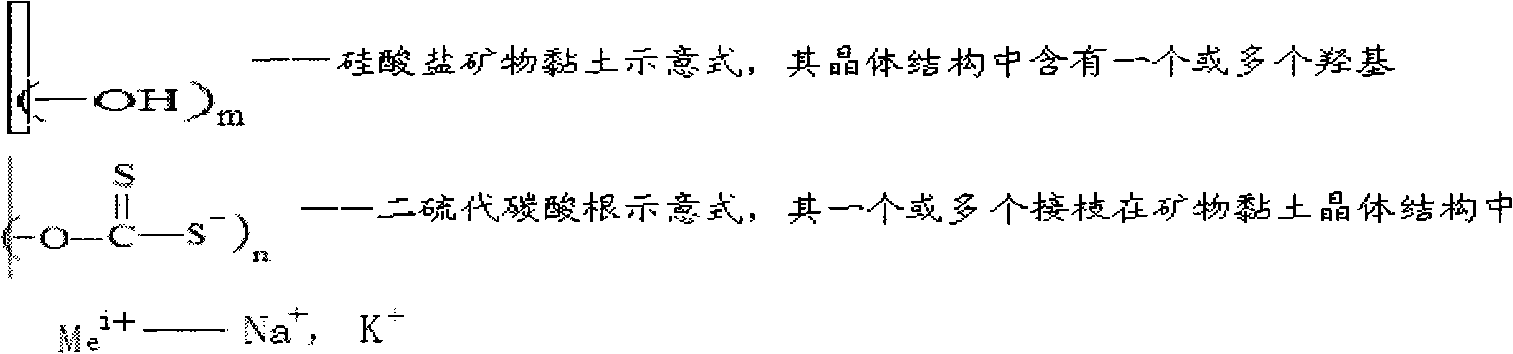

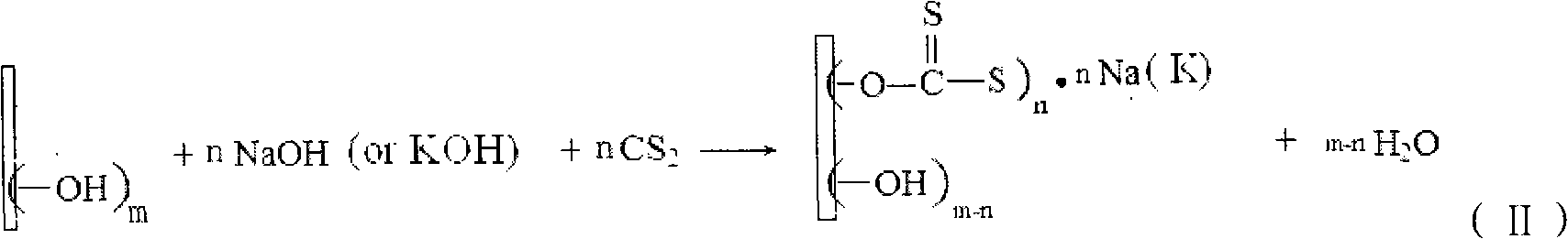

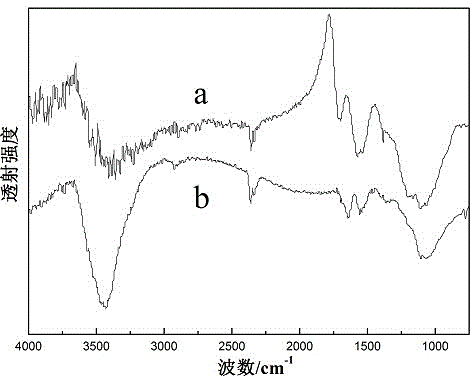

Clay-based xanthogenate, and preparation method and application thereof

InactiveCN102463104ARich reservesSimple processing technologyOther chemical processesWater/sewage treatment by flocculation/precipitationSoil remediationGraft reaction

The invention belongs to chemical materials and mainly relates to clay-based xanthogenate, and a preparation method and application thereof. The invention provides a clay-based xanthogenate compound. The other purpose of the invention is to provide the preparation method and the application of the clay-based xanthogenate. The clay-based xanthogenate compound and the preparation method thereof are characterized in that the compound is formed by alkalifying various mineral clays and then carrying out modifying or grafting reaction by adding carbon disulfide; and the method is simple, strong in operability, low in cost and easy for large-scale production, popularization and application. More particularly, the clay-based xanthogenate compound provided by the invention can be used as novel high-efficient heavy metal ion coagulant and can be applied in the fields, such as waste water treatment, soil remediation, wet-process metallurgy, environmental protection, ecological construction and the like, thus, the clay-based xanthogenate compound has the characteristics of simple and easy operation, rapidness, convenience, high metallic ion removing rate, easy solid-liquid separation and the like. The clay-based xanthogenate compound is an environment-friendly functional material and also has a wide application prospect in other fields.

Owner:王永斌

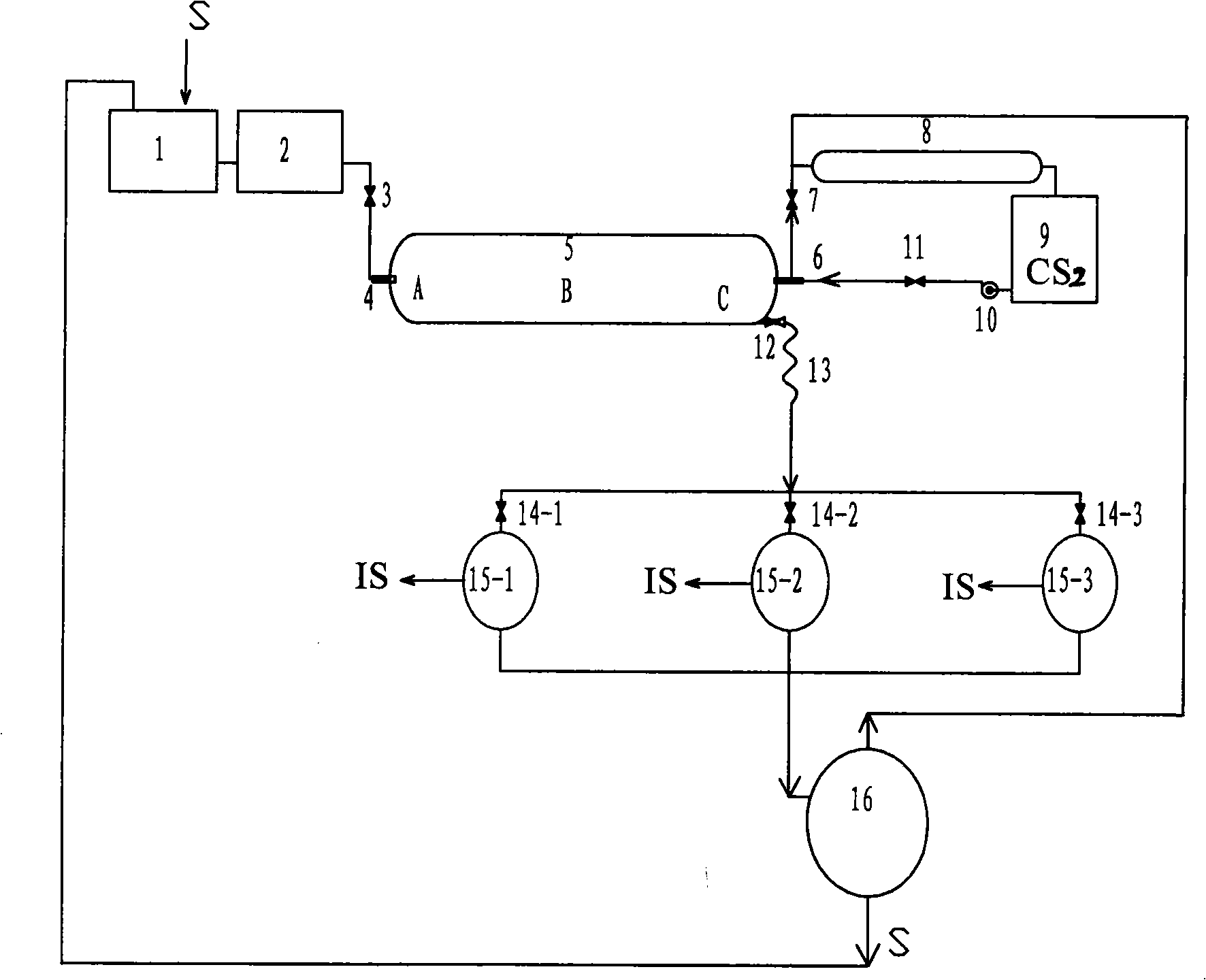

Method for producing insoluble sulfur

InactiveCN101337660AProduction safety and environmental protectionAvoid pollutionSulfur preparation/purificationSulfurNitrogen

The invention discloses a method for producing insoluble sulfur, which comprises the steps of melting sulfur, extracting, drying and pulverizing. By using the method, the insoluble sulfur is continuously produced under the totally-enclosed condition of normal pressure, nitrogen of normal pressure is used for sealing a heating groove, and the extracting step and the pulverizing step are completed in the same reactor. The specific operation steps are as follows in sequence: (1) melting the sulfur and heating up; (2) extracting and pulverizing; and (3) drying to obtain products produced through the method. The method has the advantages that: (1) the insoluble sulfur is continuously produced under the totally-enclosed condition of the normal pressure, and nitrogen is used for sealing the upper space of the sulfur heating groove, thereby resulting in no oxide leakage of carbon bisulfide and sulfur, and achieving safe and environmental-friendly production; (2) the pulverizing and quenching processes are finished in the same multifunctional rotary reactor, thus saving pulverizing devices, avoiding dust pollution when pulverizing, and protecting production environment.

Owner:广州市烨荣贸易有限公司

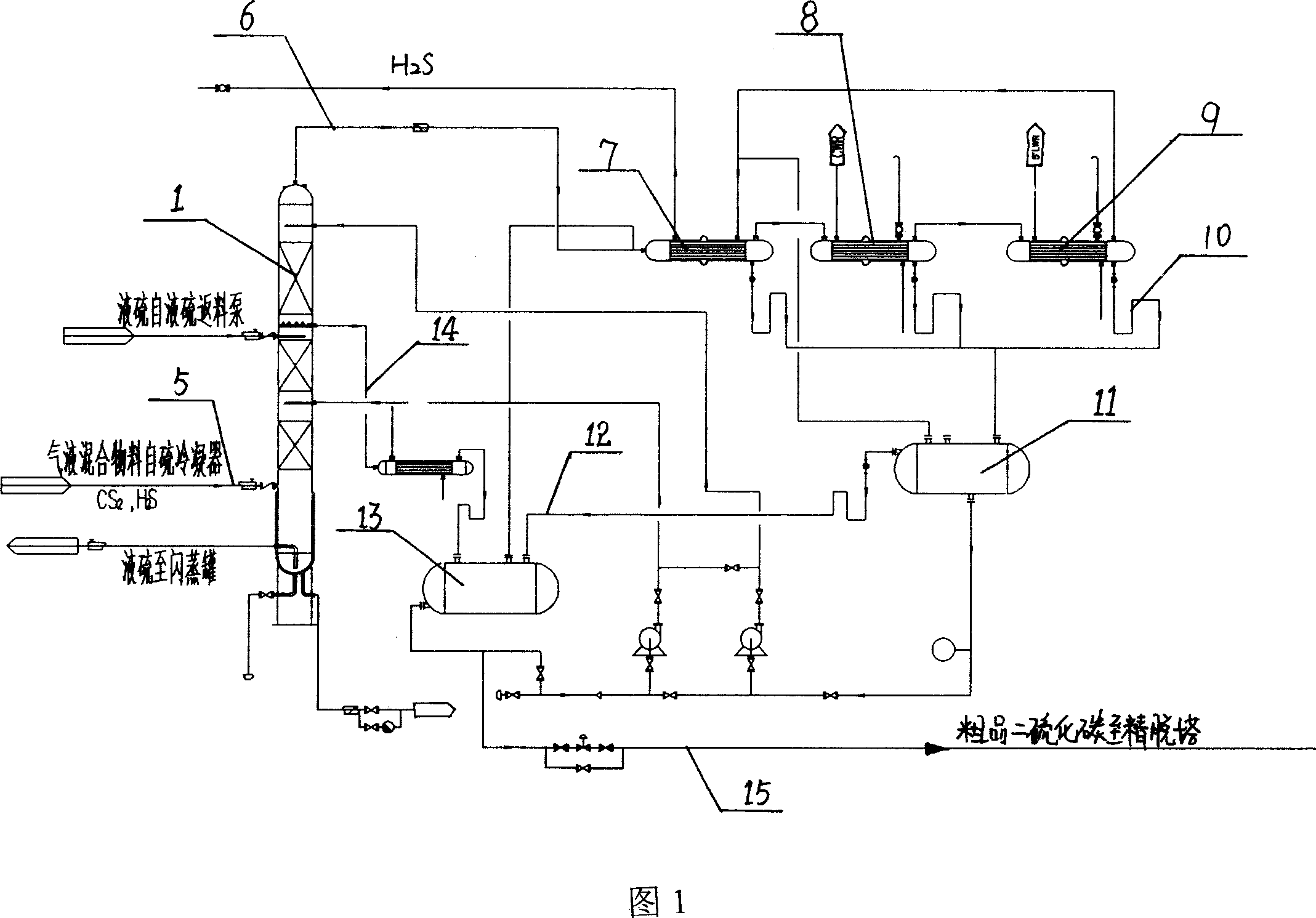

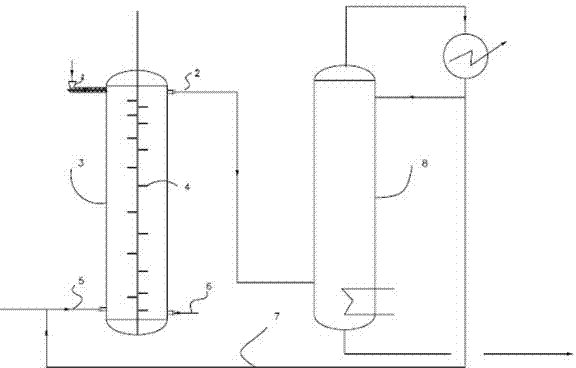

Coarse carbon bisulfide rectifying equipment and method

The invention relates to the rectifying technical field, concretely a coarse CS2 rectifying device and method, where the gas-liquid mixture of S, methane, sulfureted hydrogen and CS2 coming from a reactor and condensed by S condenser are rectified by rough removing tower, fine removing tower and finished product tower, i.e. three-tower continuous rectification. And it adopts a three-tower continuous rectifying mode, making the sulfureted hydrogen concentration reach 99.0-99.95%; after rectification, it pressurizes the uncondensed gas to continue condensation to recover CS2, and then feeds the recoverd CS2 into a Claus tail gas recovering system, avoiding environmental pollution and product waste caused by high-altitude exhaust of the uncondensed gas (or exhaust after burnt).

Owner:SHANGHAI BAIJIN CHEM GROUP

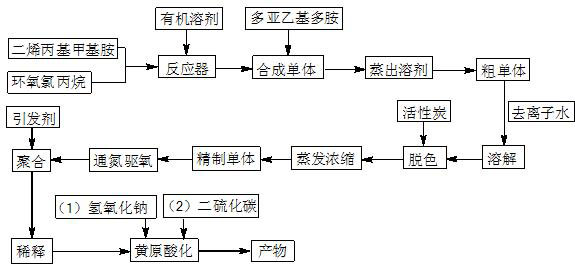

High molecular heavy metal chelating flocculant and preparation method thereof

InactiveCN102491473AEvenly distributedPromote formationWater/sewage treatment by flocculation/precipitationStructural unitSodium hydroxide

The invention discloses a high molecular heavy metal chelating flocculant and a preparation method thereof. The high molecular heavy metal chelating flocculant is prepared by the following steps of: quaternizing diallyl methylamine and epoxy chloropropane in an organic solvent, and grafting polyethylene polyamine onto molecules by performing epoxy group ring opening with polyethylene polyamine; decolorizing with active carbon, and evaporating and concentrating to obtain a diallyl quaternary ammonium salt monomer solution; polymerizing through a free radical aqueous solution to synthesize a diallyl quaternary ammonium salt polymer; and reacting with carbon bisulfide and sodium hydroxide. The high molecular heavy metal chelating flocculant is characterized in that: each structural unit of ahigh molecular chain is provided with a positive charge and a plurality of strong chelation groups -CSS- with negative charges, so that the defect of non-uniform positive charge distribution of the conventional ampholytic chelating flocculant is avoided, neutralization of negative charges produced in a floc forming process is facilitated, a floc structure is improved, the formation and growth of floc are promoted, the heavy metal ion chelating capability and flocculating settling performance are enhanced, and the size of sediments is reduced.

Owner:HUNAN UNIV OF SCI & TECH

Method for preparing water-retention fertilizer from aquatic plants

ActiveCN101962308ASimple structurePrevent compaction degradationFertilizer mixturesCellulosePotamogeton crispus

The invention relates to a method for preparing water-retention fertilizer from aquatic plants, comprising the followings steps: using aquatic plants of water hyacinth, Potamogeton crispus L, and alternanthera philoxeroides as raw materials, using haloacetic acid and potassium salt thereof or carbon disulfide in alkaline solution containing potassium ion as chemical modifier, and using FeCl3 or AlCl3 as cross-linking agent so as to obtain aquatic plant fiber with water absorption and water retention property. In the invention, a large amount of aquatic plant fiber generated by ecosystem restoration of water and pollution prevention engineering is used so as to ensure long time operation of ecosystem restoration engineering. The water-retention fertilizer prepared by the invention can regulate water in soil, supply potassium fertilizer and nitrogen fertilizer in soil after applying since containing the potassium ion, ammonia water, and urea. The natural aquatic plant fiber is used as basis material to prepare water-retention fertilizer which can be completely biodegraded, can improve soil structure and can prevent hardening of tilled land.

Owner:溧阳常大技术转移中心有限公司

Carbon bisulfide production process and equipment

Owner:SHANGHAI BAIJIN CHEM GROUP

Novel synthetic heavy metal chelating agent

The invention belongs to the technical field of harmless treatment of municipal solid waste incineration fly ash, and solves the solidification problem of heavy metal ions in fly ash. A method for preparing a novel synthetic heavy metal chelating agent comprises the following steps: mixing a polyethyleneimine water solution with a sodium hydroxide water solution, and dropwise adding carbon disulfide to obtain an orange red jelly-like solid, namely the heavy metal chelating agent. The method is simple in process, low in cost, easy and convenient to operate, wide in application range, low in environmental pollution and suitable for industrialized production.

Owner:SICHUAN UNIV

Environment-friendly preparation method of high-dispersity insoluble sulfur

InactiveCN105694096AGood dispersionImprove wear resistanceSulfur preparation/purificationDispersitySulfur

The invention discloses an environment-friendly preparation method of high-dispersity insoluble sulfur, belonging to the technical field of sulfur preparation. The preparation method comprises the following steps: preparing chlorinated polystyrene as an initiator, compounding the chlorinated polystyrene with sulfur, melting at high temperature, cooling by a cooling agent, extracting by a composite extractant, carrying out surface spray modification on stearic acid and polyethyleneglycol, and finally, extending oil, thereby obtaining the high-dispersity insoluble sulfur. The example proves that the method is simple to operate and lowers the production cost; the mixed solvent is used instead of carbon bisulfide as the extractant, so that the method has the advantages of low operation risks, low toxicity and recoverable solvent and is not corrosive for carbon steel equipment; and the dispersity of the insoluble sulfur in rubber is obviously enhanced, and the wear resistance of the rubber product is enhanced.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

Manufacturing method for protein short staples

ActiveCN1584146AEasy to weaveGood effectMonocomponent protein artificial filamentWet spinning methodsCelluloseFiber

The invention relates to a method to produce filature-industry material. It provides a process that use chrysalides albumen filature liquid and fibrin xanthate ester to spin excellent albumen soy fiber by the mode of injection before spinning and the principle of static admixture. It contains plasm, chrysalides albumen, vitriol, NaOH, carbon bisulfide, formaldehyde glutaraldehyde and propylene acyl-amine. The production is soft and its color is golden. In short, it remains favorable weaving ability.

Owner:YIBIN GRACE

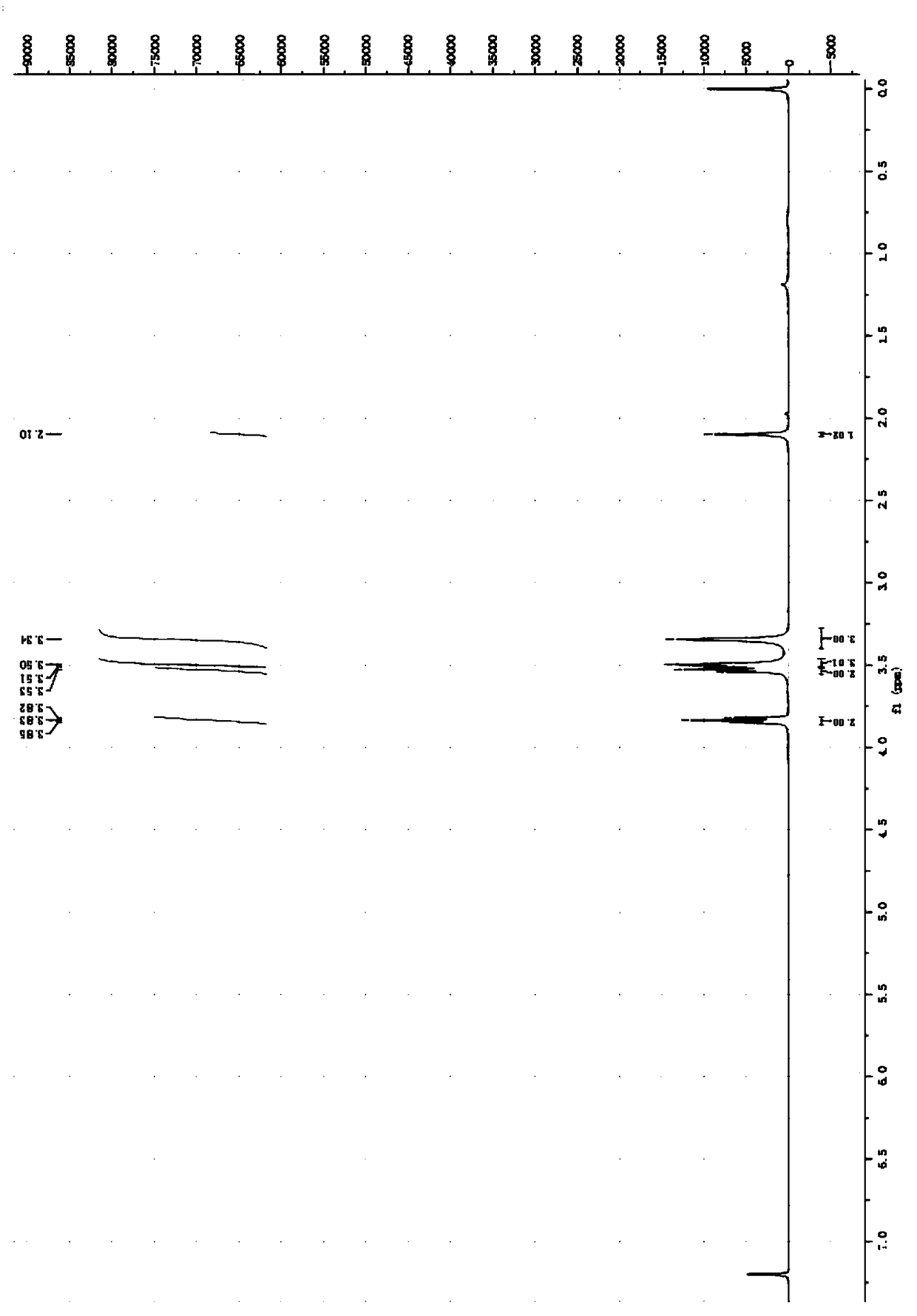

Preparation method of nanopore cellular membrane

Owner:ZHEJIANG UNIV

N,N-dialkyl-S-hydroxyalkyl-dithiocarbamate collecting agent and preparation method and application thereof

The invention discloses a N,N-dialkyl-S-hydroxyalkyl-dithiocarbamate collecting agent and a preparation method and an application thereof. The collecting agent is N,N-dialkyl-S-hydroxyalkyl-dithiocarbamate which is synthesized by a one-pot process by taking carbon disulfide and water as a solvent, and diamine, carbon disulfide, sodium hydroxide and haloalkyl alcohol as raw materials. The preparation method is simple to operate and mild in reaction condition. The floating collecting agent has a good collecting property, and the action of the collecting agent with metal ions on the surfaces of minerals can be improved well. The prepared collecting agent has a relatively good collecting ability and selectivity to sulphide ores such as copper sulphide ores, copper-molybdenum cores and lead zinc ores, and shows a relatively good floating index.

Owner:CENT SOUTH UNIV

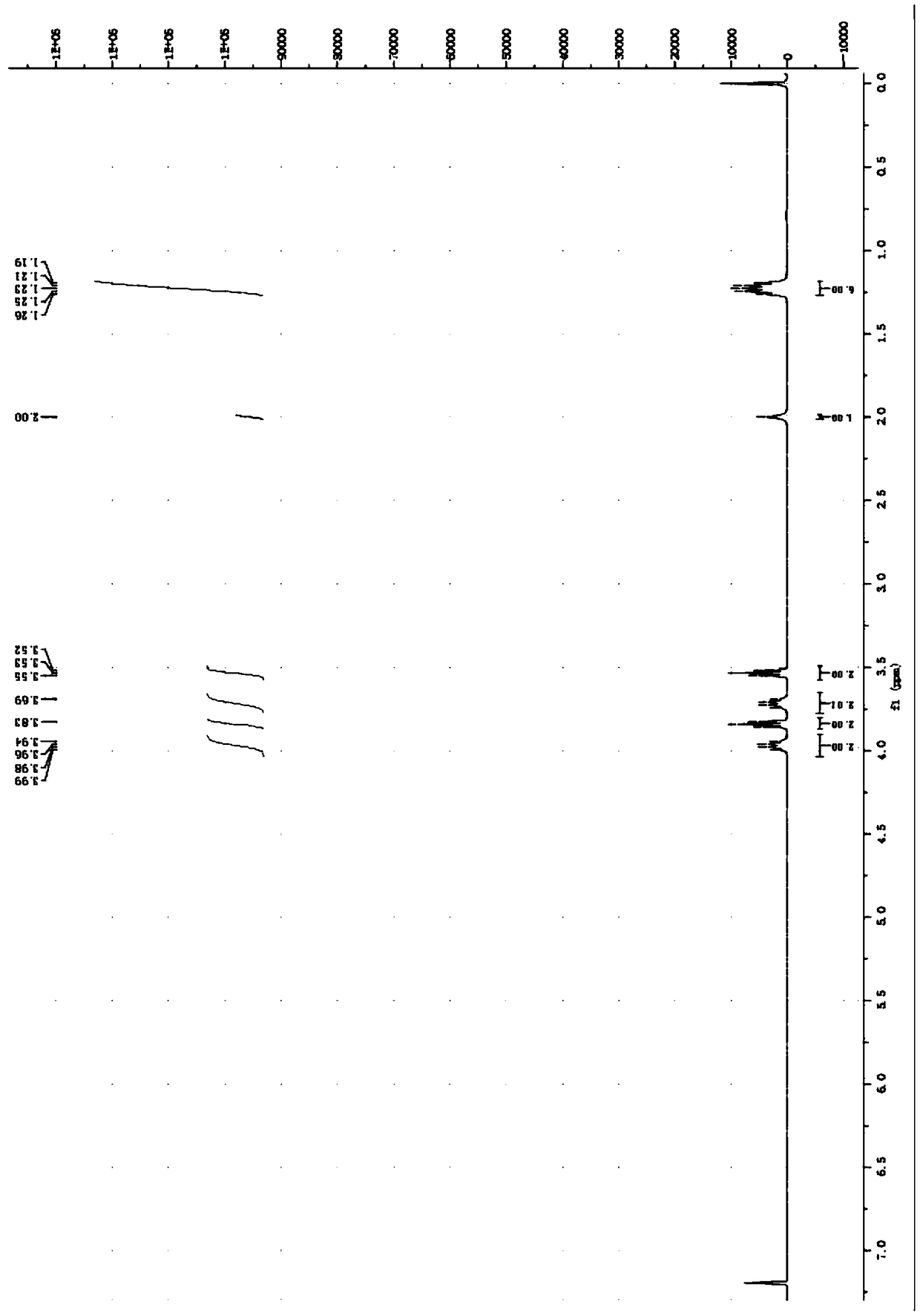

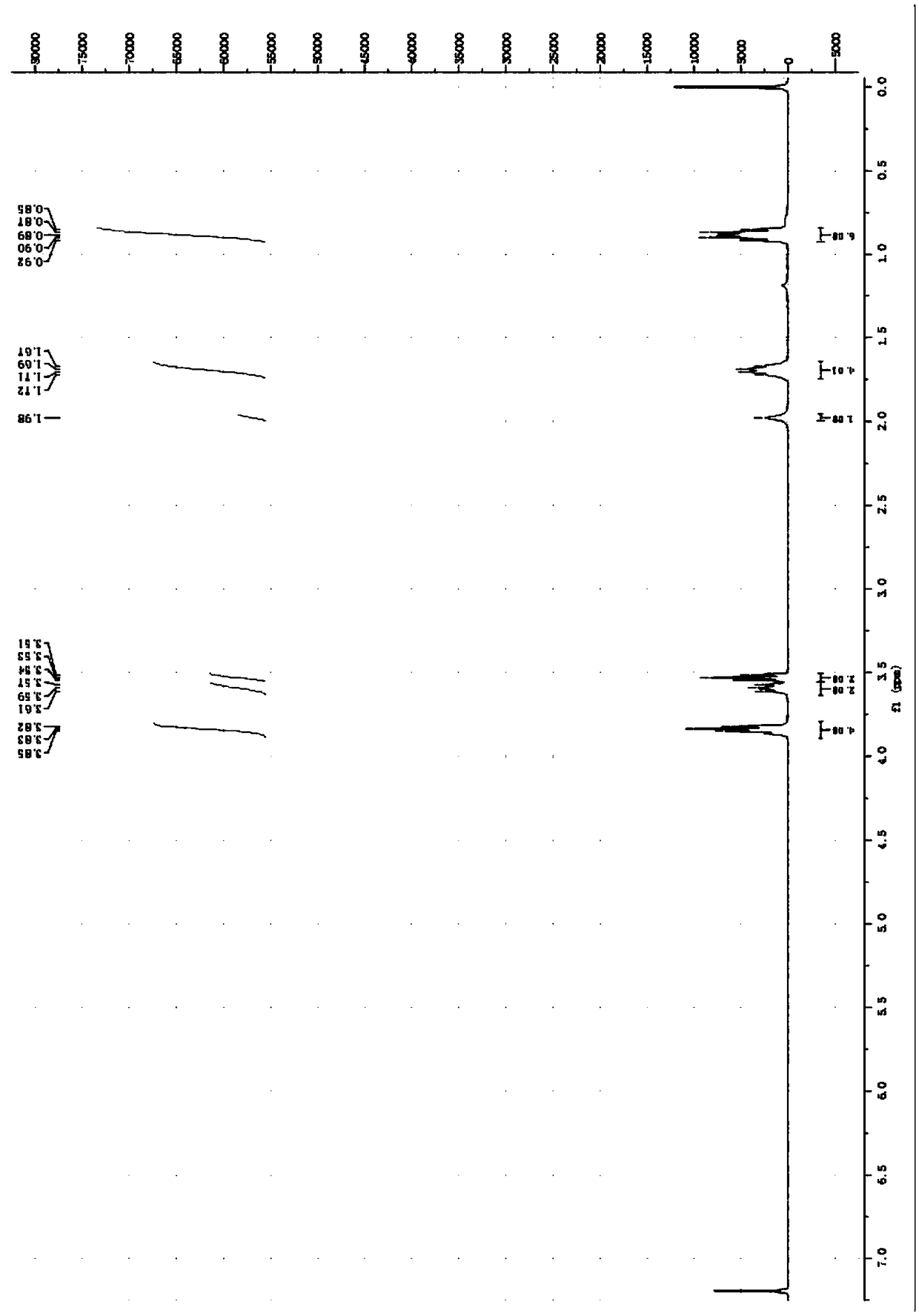

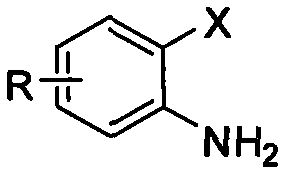

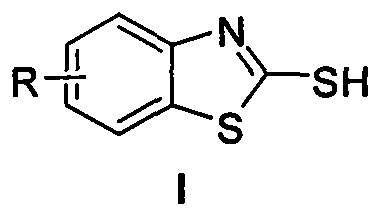

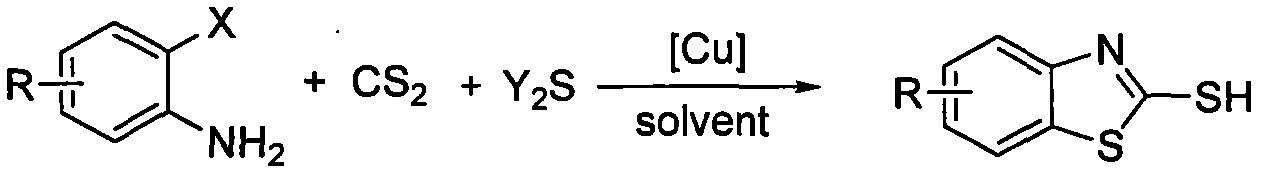

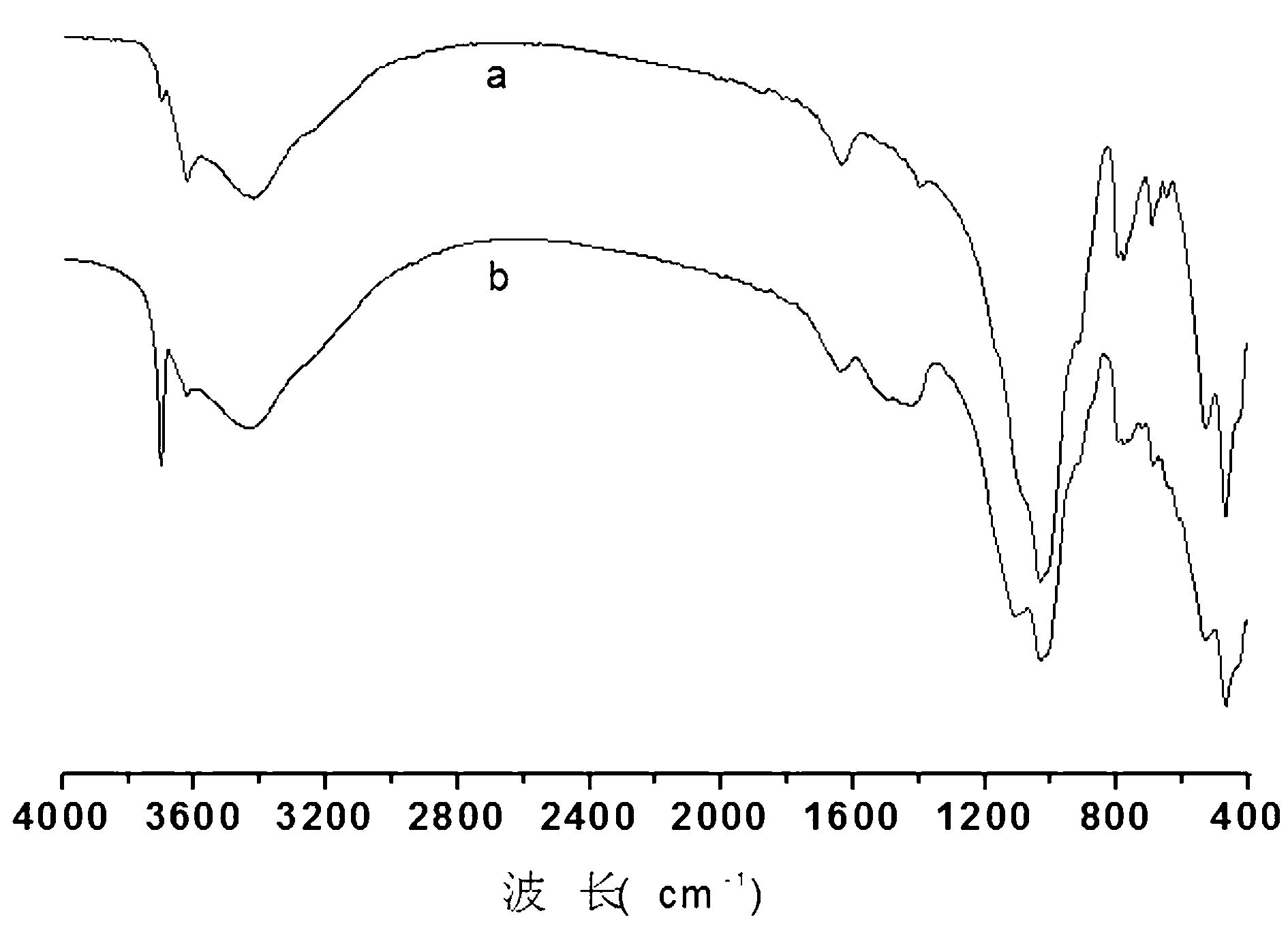

2-mercapto benzothiazole derivative synthetic method with copper-catalyzed carbon disulfide

InactiveCN104098528ANo pollution in the processSave raw materialsOrganic chemistryRecreationMetallic sulfide

The invention relates to the technical field of agriculture, industry and pharmacy and provides a 2-mercapto benzothiazole derivative synthetic method. According to the 2-mercapto benzothiazole derivative synthetic method, 2-mercapto benzothiazole derivatives are synthesized by take 2-halogen phenylamine, carbon disulfide and inorganic metal sulfide as the raw materials and through catalysis of copper salt. The method comprises dissolving the 2-halogen phenylamine, the inorganic metal sulfide and copper salt catalyst inside an appropriate solvent, adding the carbon disulfide inside the mixture for recreation under 50-110 DEG C for a certain time and performing purification treatment to obtain the 2-mercapto benzothiazole derivatives. The 2-mercapto benzothiazole derivative synthetic method with the copper-catalyzed carbon disulfide is rapid and efficiency, by taking the nontoxic, cheap and easily-obtained copper salt as the catalyst, omits ligand for recreations, and has the advantages of being high in yield rate, mild in conditions, low in the amount of by-products and the like.

Owner:INNER MONGOLIA UNIV OF TECH

Wide-range spectral absorption perovskite photovoltaic material and preparation method thereof

ActiveCN105514277AIncrease contact areaImprove separation efficiencySolid-state devicesSemiconductor/solid-state device manufacturingCarbon disulfideSpectral absorption

The invention discloses a wide-range spectral absorption perovskite photovoltaic material and a preparation method thereof. The method comprises the following steps: adding additives to a perovskite reactant to form an inorganic particle hybrid perovskite precursor solution; and then, spin-coating a substrate covered with an electron transport material with the precursor solution, and forming a composite perovskite light absorption layer film after heat treatment at 150 DEG C, wherein the additives include halide, carbon disulfide, zirconium oxide nanoparticles and hexyl amine. In the scheme, the light absorption layer of the perovskite solar cell is a perovskite light absorption layer doped with a nanometer cuprous sulfide or stannous sulfide material generated by chemical reaction and the zirconium oxide nanoparticles, and therefore, the light absorption range of the perovskite layer is expanded, and the battery efficiency is increased from 6% to more than 10%. The method is simple, effective and cost-saving. Therefore, the method for improving the performance of the light absorption layer of the perovskite solar cell is of very high industrial application value.

Owner:ANHUI HUASUN ENERGY CO LTD

Method for continuously purifying vulcanization accelerator 2-mercaptobenzothiazole

The invention belongs to the technical field of fine chemistry, and relates to a method for purifying a vulcanization accelerator 2-mercaptobenzothiazole (M). In the method, organic arenes, alcohols, carbon disulfide or phenylamine is used as a solvent; and a continuous solvent extraction and solvent distillation recycling device is adopted at an extraction temperature of 20-180 DEG C and an extraction pressure of 0-0.8 MPa to remove tar and byproducts in accelerant M, and the solvent is continuously recycled at the same time. By adopting the method provided by the invention, the consumption of the solvent is reduced, the purifying yield of the accelerant M is improved, and the production of technical waste water is avoided.

Owner:CHINA PETROCHEMICAL CORP +1

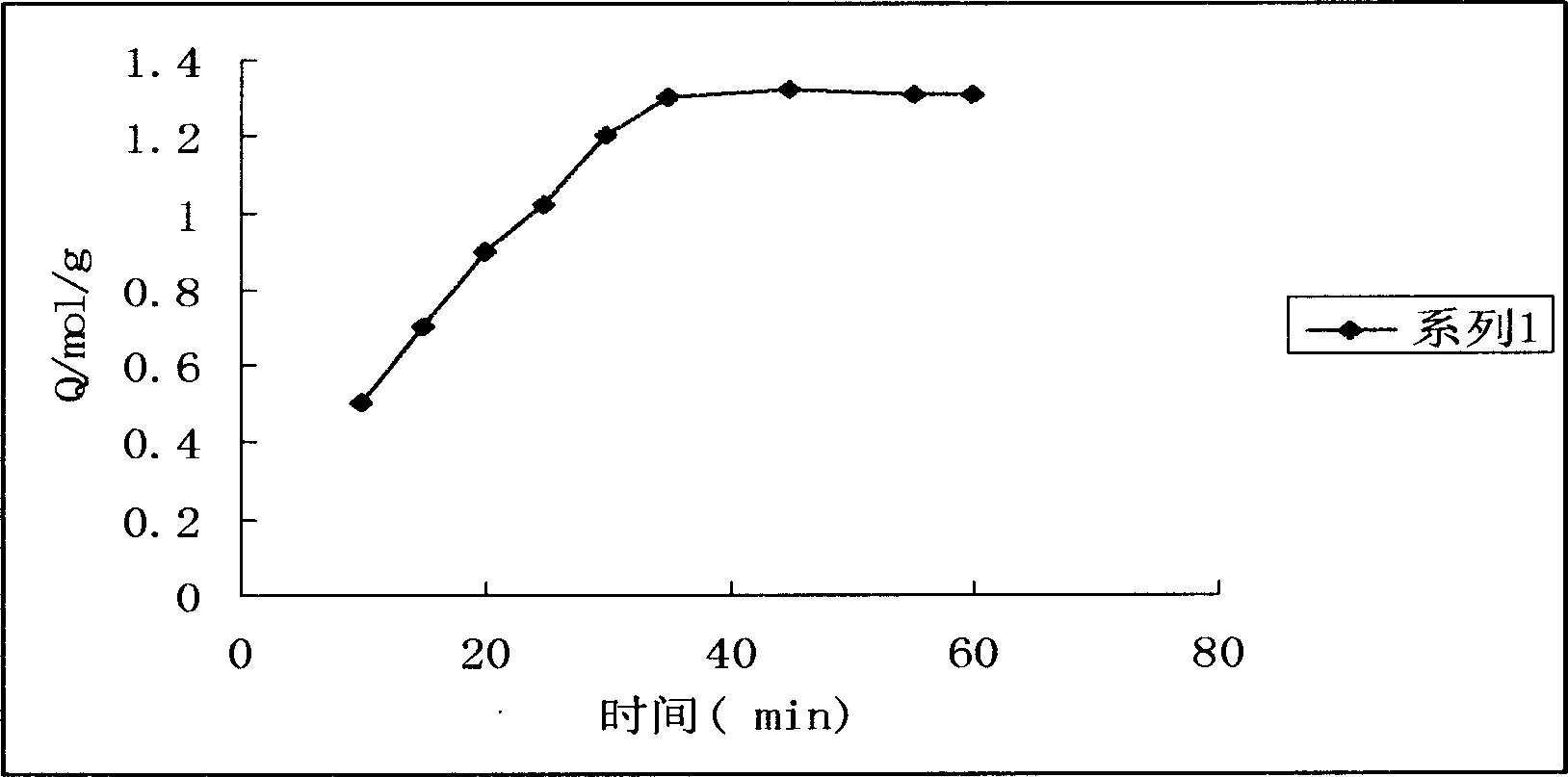

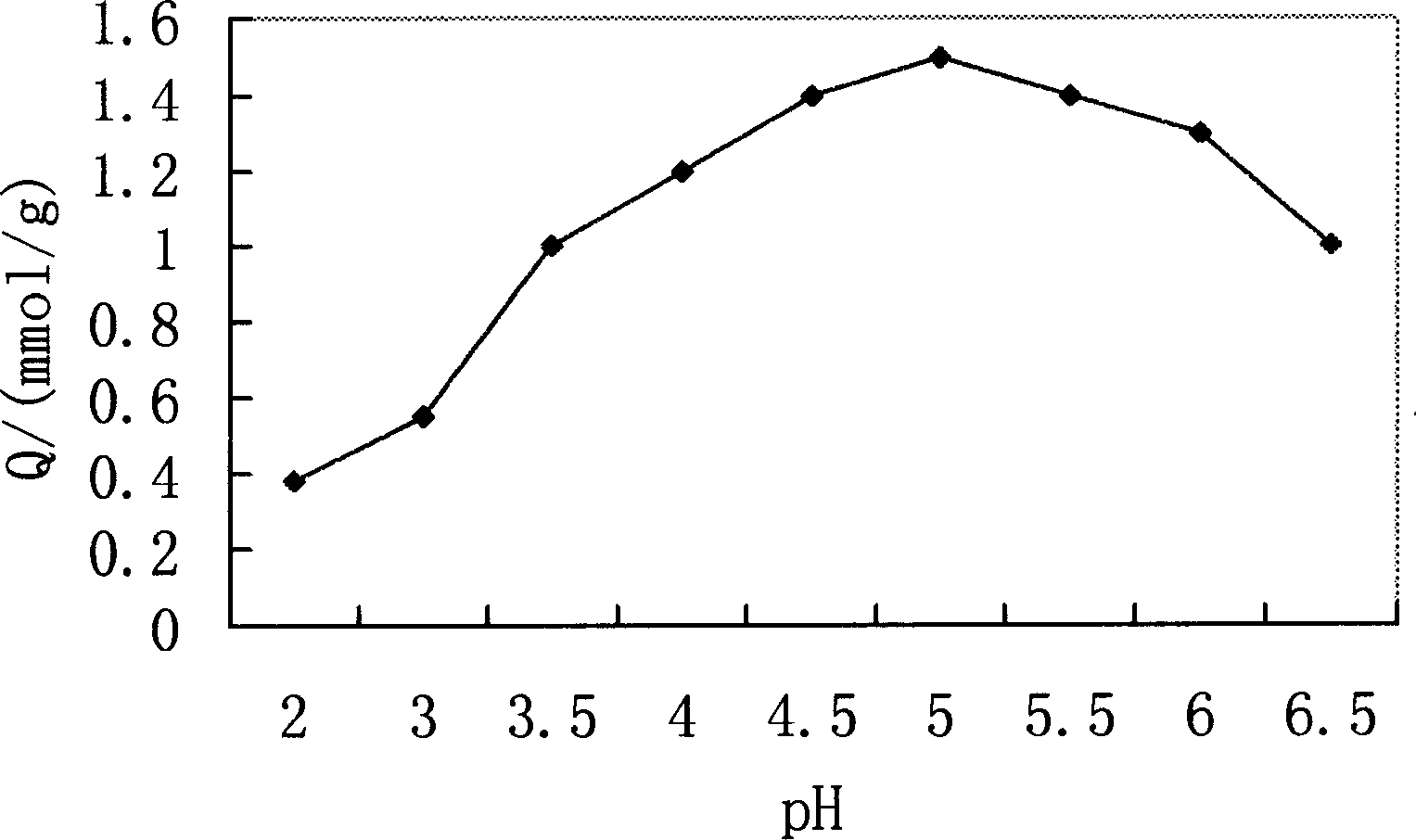

Preparation of xanthated loess adsorbent and application of xanthated loess adsorbent to waste water treatment

InactiveCN103071461ALoose surface structureLarge specific surface areaOther chemical processesWater contaminantsMalachite greenMalachite green stain

The invention provides a preparation method of a xanthated loess adsorbent. The method comprises the following steps of: dispersing loess into a sodium hydrate solution to form a suspension; dropwise adding carbon bisulfide into a system, and stirring for reacting to generate a xanthated loess sodium salt; adding a soluble sodium salt into the system, and stirring for reacting to generate a xanthated loess magnesium salt; and washing, drying in vacuum, and grinding into powder to obtain the xanthated loess adsorbent. As proved by a large quantity of experiments, the xanthated loess adsorbent disclosed by the invention has a looser surface structure than that of natural loess, has a large specific surface area, has very high adsorption performance on heavy metal copper ions and malachite green in waste water, has a high adsorption capability and a large adsorption volume when applied to treatment of waste water containing heavy metal copper ions and a malachite green dye, and can be used for treating waste water containing the heavy metal copper ions and the malachite green dye.

Owner:NORTHWEST NORMAL UNIVERSITY

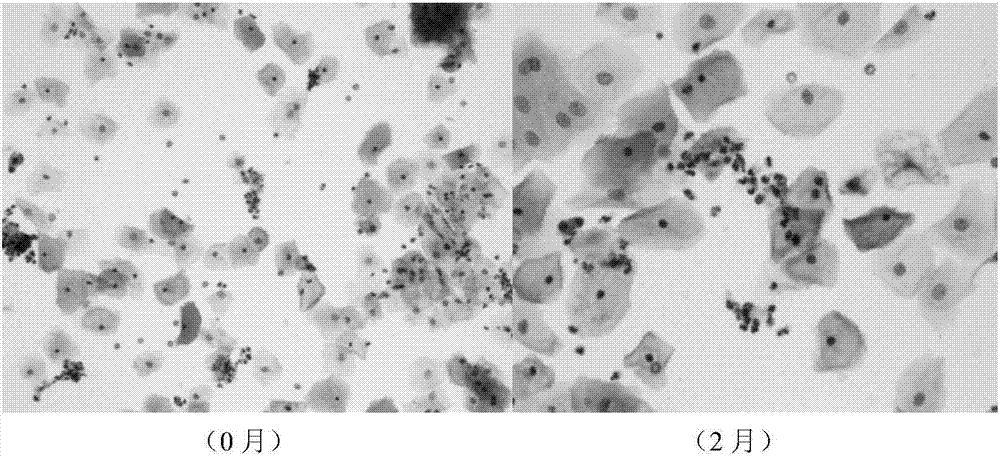

Cell preservation solution and application thereof

PendingCN107410287AEasily brokenAvoid destructionDead animal preservationTreatment effectAnticoagulant

The invention provides a cell preservation solution and application thereof. The cell preservation solution is prepared from the following components in parts by weight: 60 to 1000 parts of pH buffer, 10 to 150 parts of osmotic pressure maintenance agent, 4 to 55 parts of anticoagulant, 1 to 30 parts of mucolytic agent, 800 to 5000 parts of fixing agent, 1 to 150 parts of component A, 10 to 30 parts of component B and 10000 to 20000 parts of water, wherein the component A is prepared from sodium azide and lauryl sodium sulfate according to a weight ratio of (1 to 10) to (2 to 110); the component B is carbon disulfide. The cell preservation solution of the invention has a better impurity treatment effect, and reduces the interference factors in cell samples; at the same time, target cells therein can retain the characteristics of structural morphology for a long time, thereby facilitating the medical detection and analysis of the target cells, and the cost is low.

Owner:GUANGZHOU HONGQI OPTICAL INSTR TECH

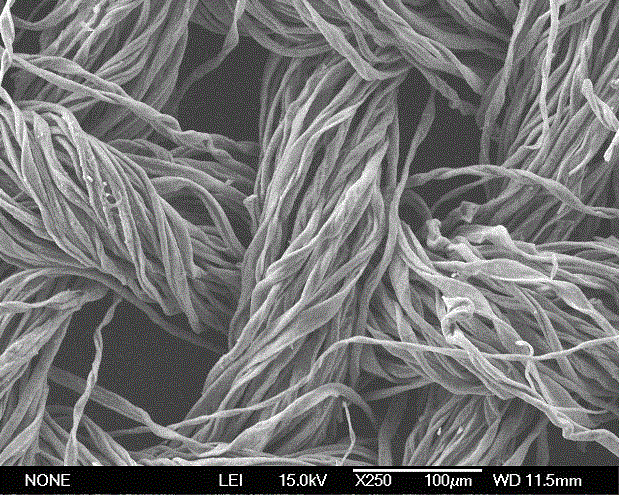

Method for preparing carbon fibre cloth loaded sulphur composite material

ActiveCN104600266AProminent structureOutstanding performanceMaterial nanotechnologyCell electrodesFiberCarbon fibers

The invention relates to a method for preparing a carbon fibre cloth loaded sulphur composite material, belonging to the technical field of electrode materials for ion batteries. The method disclosed by the invention comprises the following main steps of thermally treating by using cotton woven fibre cloth as the raw material so as to obtain functionalized conductive fibre cloth, and carrying out hydrothermal reaction by taking deionized water / alcohol solvent / sulphur / carbon disulfide as a reaction system so as to obtain a carbon fibre cloth loaded nano sulphur particle composite material. According to a composite positive electrode of carbon fibre cloth loaded sulphur, carbon fibre cloths are connected in a staggered manner so as to form a three-dimensional orderly conductive network; more sulphur can be adsorbed through the supramaximal specific surface area; the carbon fibre cloth loaded sulphur composite material prepared through the simple method can be directly used as a pole piece; the fussy processes of pulping, coating and the like in traditional electrode preparation can be omitted; and a beneficial way is provided for application of the sulphur positive electrode.

Owner:SHANGHAI UNIV

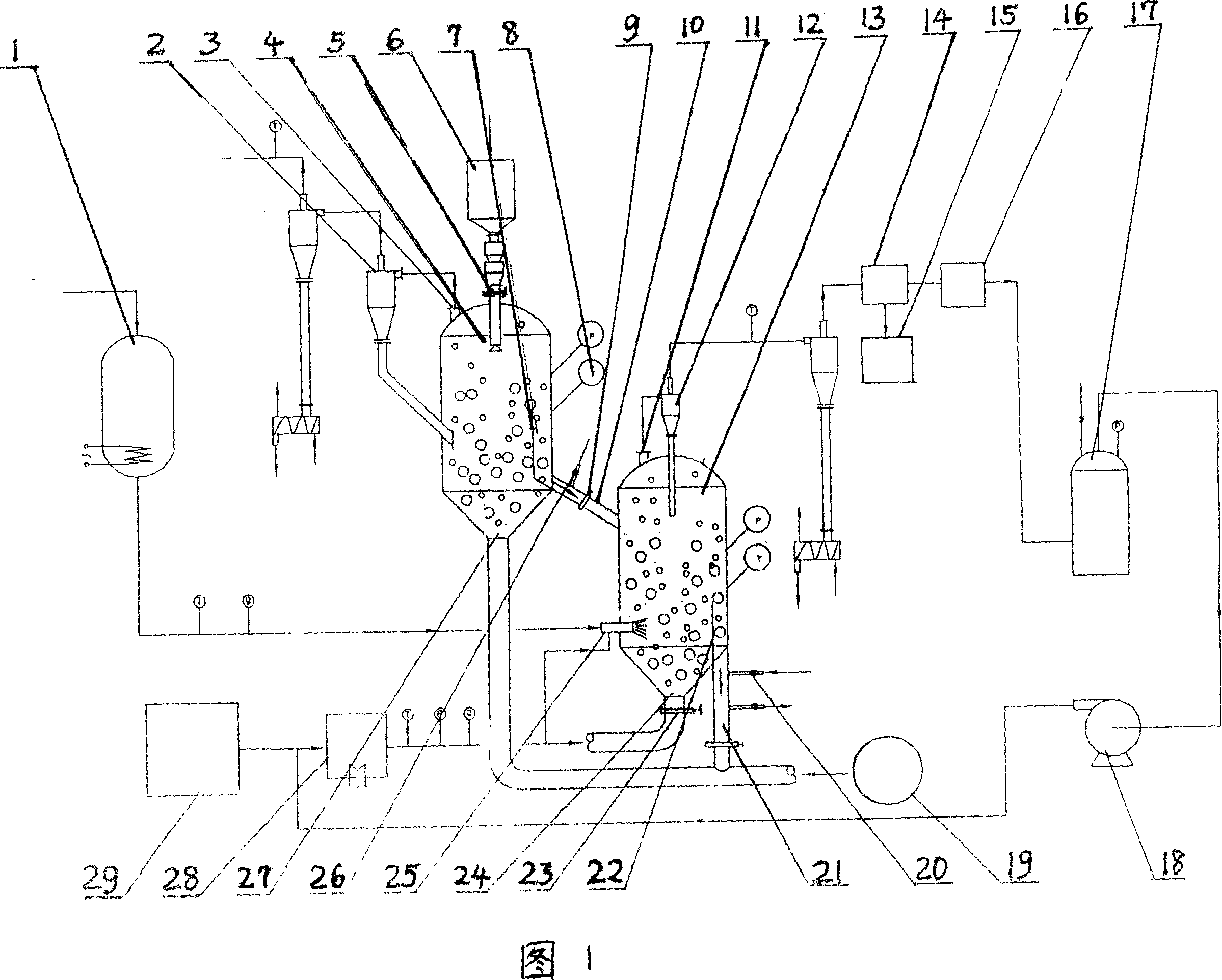

Method for producing carbon bisulfide by fluidization process and its special equipment

The invention relates to a method of producing carbon bisulfide by fluidizing process, adding powdered raw materials into a heating furnace to heat to 750-1100 deg.C, leading them into a reaction furnace and charging inert gas to fluidize them, simultaneously adding in sulfur to react and producing carbon bisulfide. And it has advantages of wide raw material sources, low price, high reacting efficiency, etc.

Owner:SHANGHAI BAIJIN CHEM GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com