Method for continuously purifying vulcanization accelerator 2-mercaptobenzothiazole

A technology of mercaptobenzothiazole and vulcanization accelerator, applied in organic chemistry and other directions, can solve the problems of large solvent consumption, complex process, low yield and the like, and achieve the effects of high yield, simple process operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

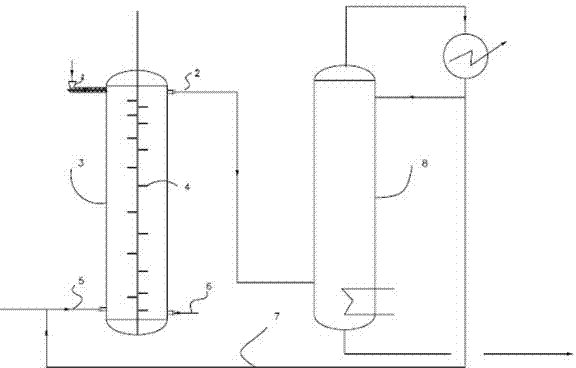

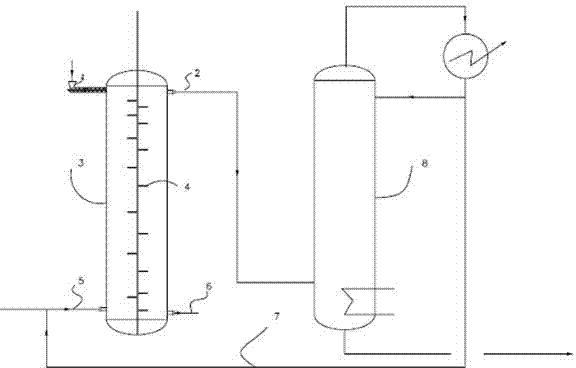

[0020] as attached figure 1 As shown, through the closed screw feeding device 1, the vulcanization accelerator with a content of about 90% is continuously added from the top of the continuous extraction tower 3 at a rate of 50-100 kg / hour, and at the same time from the extraction agent feeding port 5 at the bottom of the extraction tower 3 Continuously add the extraction agent toluene with a pump at a speed of 80-170kg / hour, the toluene is heated to 50-160°C by the preheater, the extraction pressure is 0.5MPa, and the continuous stirring device 4 of the extraction tower 3 is started to carry out countercurrent extraction operation. The final vulcanization accelerator M relies on gravity to pass through the outlet 6 at the bottom of the extraction tower 3 and enter the centrifuge through the outlet pipe for centrifugal separation and drying. The extraction solvent is continuously added to the solvent from the extraction agent overflow port 2 at the top of the extraction tower 3...

Embodiment 2

[0022] as attached figure 1 As shown, through the closed screw feeding device 1, the vulcanization accelerator M with a content of about 90% is continuously added from the top of the continuous extraction tower 3 at a rate of 50-100 kg / hour, and at the same time, it is fed from the extraction agent feeding port at the bottom of the extraction tower 3 5. Continuously add the extractant xylene with a pump at a rate of 80-170kg / hour. The xylene is heated to 20-180°C by the preheater, and the extraction pressure is 0.55MPa. Start the continuous stirring device 4 of the extraction tower 3 for countercurrent extraction. Operation, the vulcanization accelerator M after extraction relies on gravity to enter the centrifuge through the discharge port 6 at the bottom of the extraction tower 3 through the outlet pipe for centrifugal separation and drying, and the extraction solvent passes through the overflow pipe from the extraction agent overflow port 2 at the top of the extraction towe...

Embodiment 3

[0024] as attached figure 1 As shown, through the closed screw feeding device 1, the vulcanization accelerator M with a content of about 90% is continuously added from the top of the continuous extraction tower 3 at a rate of 50-100 kg / hour, and at the same time, it is fed from the extraction agent feeding port at the bottom of the extraction tower 3 5 Continuously add the extractant ethanol with a pump at a speed of 80-170kg / hour, the ethanol is heated to 20-180°C through the preheater, the extraction pressure is 0.6MPa, and the continuous stirring device 4 of the extraction tower 3 is started to carry out countercurrent extraction operation, The extracted vulcanization accelerator M relies on gravity to pass through the discharge port 6 at the bottom of the extraction tower 3 and enters the centrifuge through the outlet pipe for centrifugal separation and drying. The extraction solvent is continuously added from the extraction agent overflow port 2 at the top of the extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com