Patents

Literature

344 results about "Sulfenamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfenamides (also spelled sulphenamides) are a class of organosulfur compounds characterized by the general formula RSNR'₂, where R and R' are H, alkyl, or aryl. Sulfenamides have been used extensively in the vulcanization of rubber using sulfur. They are related to the oxidized compounds sulfinamides (RS(O)NR'₂) and sulfonamides (RS(O)₂NR'₂).

Diene rubber composition

PCT No. PCT / JP96 / 02509 Sec. 371 Date Mar. 5, 1998 Sec. 102(e) Date Mar. 5, 1998 PCT Filed Sep. 5, 1996 PCT Pub. No. WO97 / 09378 PCT Pub. Date Mar. 13, 1997A rubber composition comprising 100 parts by weight of a diene rubber ingredient containing an amino group-containing diene rubber, 10 to 120 parts by weight of silica, 0.1 to 15 parts by weight a vulcanizer and 0.1 to 15 parts by weight of a sulfenamide vulcanization accelerator. This rubber composition exhibits excellent heat build-up, tensile property and abrasion resistance, and is suitable for tires and others.

Owner:ZEON CORP

Tire tread-use rubber composition

A tire tread-use rubber composition includes from 10 to 50 parts by weight of a tackifying resin having a softening point of from 100° C. to 150° C.; from 70 to 130 parts by weight of a carbon black having a nitrogen specific surface area of from 250 to 400 m2 / g; from 1 to 3 parts by weight of sulfur; from 0.5 to 4.0 parts by weight of a sulfenamide vulcanization accelerator; and from 1.5 to 5.0 parts by weight of a thiuram vulcanization accelerator per 100 parts by weight of a rubber component; wherein when A is a compounded amount in parts by weight of the sulfenamide vulcanization accelerator, T is a compounded amount in parts by weight of the thiuram vulcanization accelerator, and S is a compounded amount in parts by weight of the sulfur, a weight ratio (A+T) / S is from 2 to 4.

Owner:YOKOHAMA RUBBER CO LTD

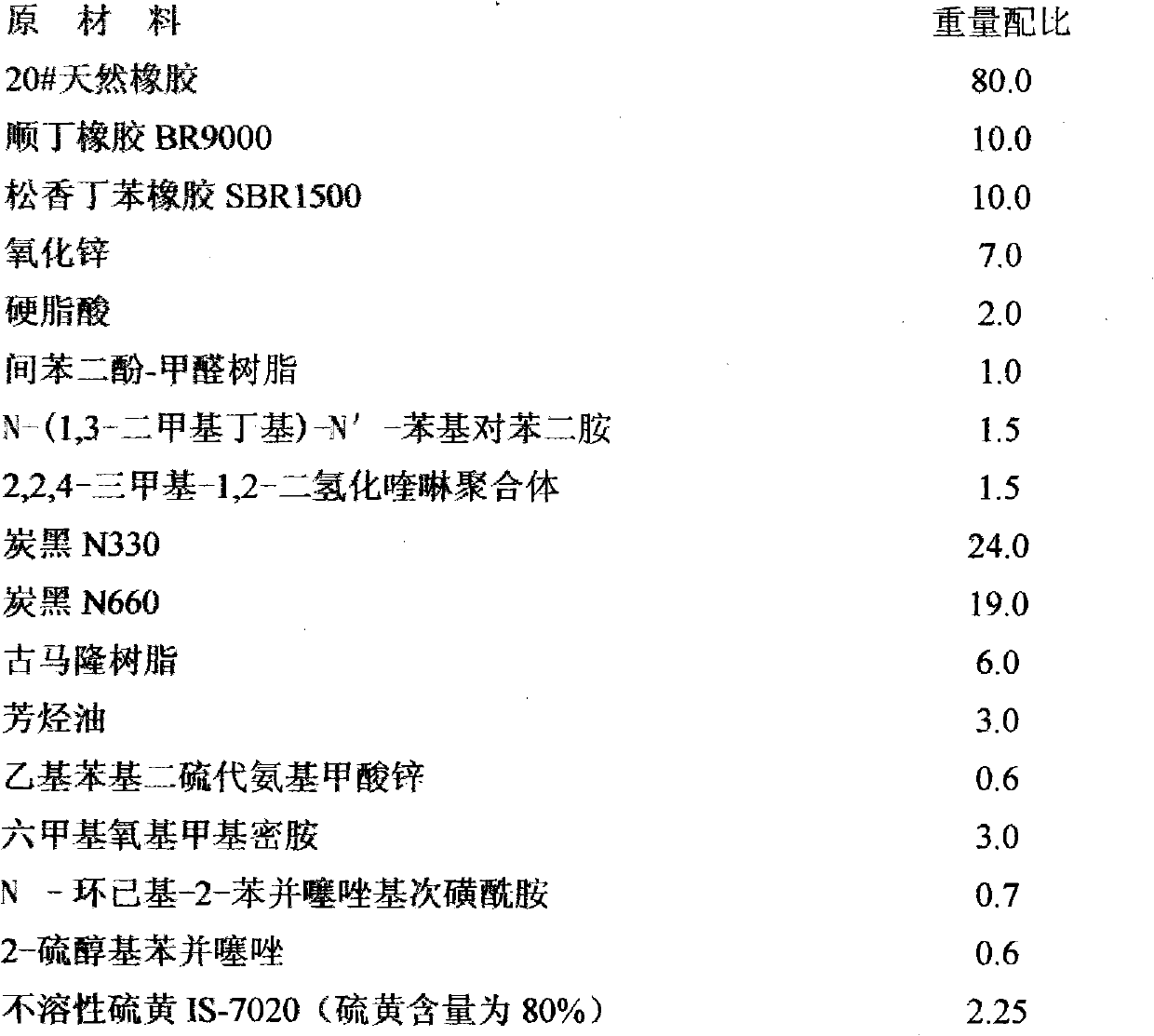

Formula of adhesive agent for aircraft tire renewing

ActiveCN101200625AHigh adhesion retentionMeet performance requirementsNatural rubber adhesivesSulfurGasoline

The present invention discloses a prescription of an adhesive used for an aircraft tire retreading. The adhesive considers caoutchouc as the main material and also contains the main auxiliary materials of styrene butadiene rubber, adhesion promoter, adhesive, high abrasion furnace black, high dispersion white carbon black, ketoamine age inhibitor, indiscerptible sulfur and sulfenamide accelerant. The main material and the main auxiliary materials are made into gross rubber according to certain weight portion ratio, and the gross rubber is mixed with gasoline by certain proportion to be made into the adhesive. The adhesive of the prescription has the advantage that the adhesive solves the problem of sticking an old tire body with a retreading component when the aircraft tire is retreaded, which ensures that the aircraft tire does not have the problem of the delamination of the glue material between the old tire body and the retreading component, bulging and other quality problems during the use course, and the tire is safe for using.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

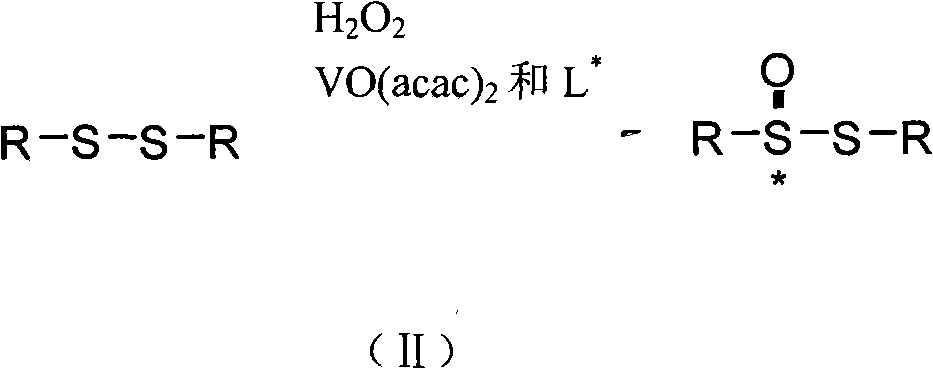

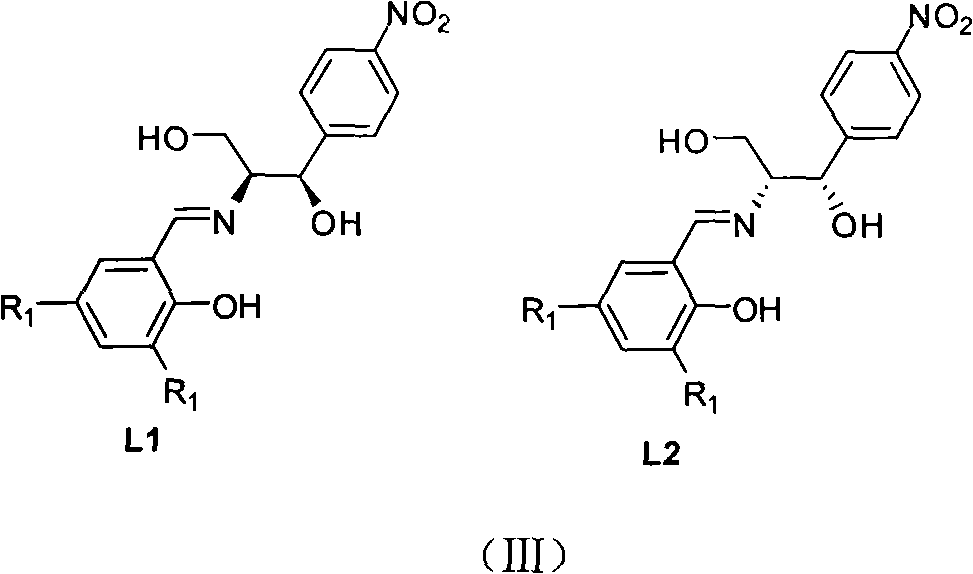

Chiral sulfinylamine monophosphine, and full-configuration preparation method and application thereof

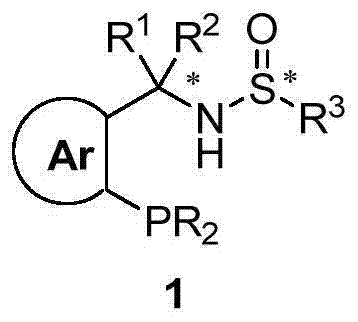

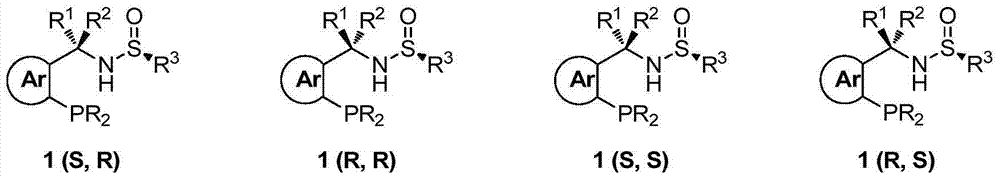

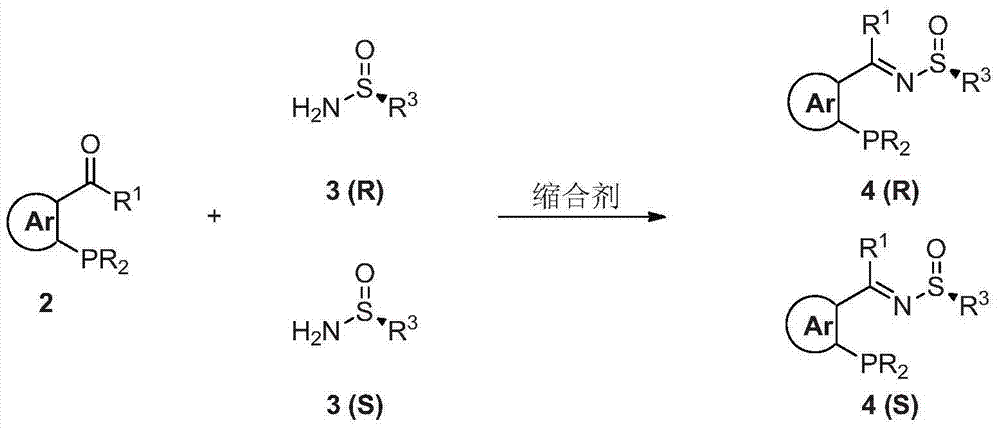

The invention provides a chiral sulfinylamine monophosphine and a preparation method thereof. The preparation method comprises the following steps: carrying out a condensation reaction of 2-disubstituted phosphinoaryl(heteroaryl)formaldehyde (ketone) 2 and chiral sulfonamide 3 to obtain a compound 4, and reacting the compound 4 with a nucleophilic reagent to prepare a compound 1; or carrying out a condensation reaction of aldehyde (ketone) 5 and the chiral sulfonamide 3 to obtain imine 6, and reacting the imine 6 with a 2-disubstituted phosphinoaryl(heteroaryl) metal reagent to obtain the compound 1; or reacting the imine 6 with the 2-disubstituted phosphinoaryl(heteroaryl) metal reagent to obtain a compound, and reducing the compound to obtain the compound 1; or carrying out a condensation reaction of 2-substituted phosphinoaryl(heteroaryl)formaldehyde (ketone) 8 and the chiral sulfonamide 3 to obtain an imine compound 9, reacting the imine compound 9 with the nucleophilic reagent to obtain a compound 7, and reducing the compound 7 to obtain the compound 1. Different chiral sulfenamides and different metal reagents are used to conveniently obtain the optically pure compound of four configurations comprising (R,R), (R,S), (S,S) and (S,R). The above ligand has the advantages of simple skeleton, synthesis convenience and easy reconstruction, can be applied in various metal-catalyzed asymmetric reactions, and has a very high reaction activity and stereoselectivity.

Owner:苏州凯若利新材料科技有限公司

Heavy vehicle treads/undertread

Heavy vehicle tire treads and / or undertread constituted at least in part from a rubber composition comprising between 80 and 100 phr of a natural rubber and between 0 and 20 phr of a synthetic polyisoprene rubber, a reinforcement filler comprising a) between 30 and 50 phr of a highly dispersible silica and b) a carbon black in an amount of between (0.75)C phr and (1.25)C phr as determined by the equation C=−0.8Si+44.3, wherein Si is the amount of the highly dispersible silica, a silane coupling agent and a sulfur curing system comprising between 1.5 and 3 phr of free sulfur and between (0.9)A phr and (L 1)A phr of a sulfenamide accelerator, wherein A is determined by a formula that is a function of the sulfur quantity and the silica weight fraction of the total reinforcement filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Rubber composition for coating tire cord

ActiveUS20080300368A1Improve adhesionMaintaining initial vulcanization rateGroup 4/14 element organic compoundsConductive materialSulfurMedicine

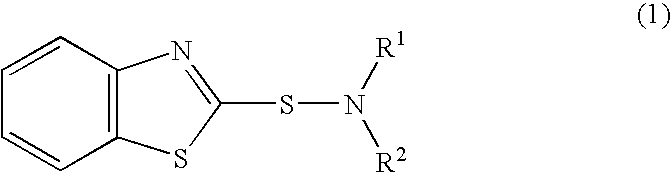

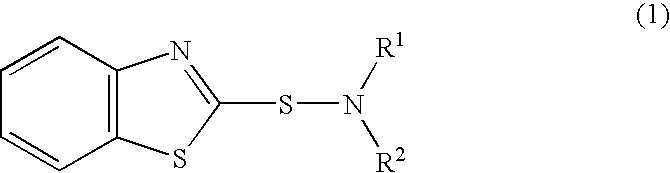

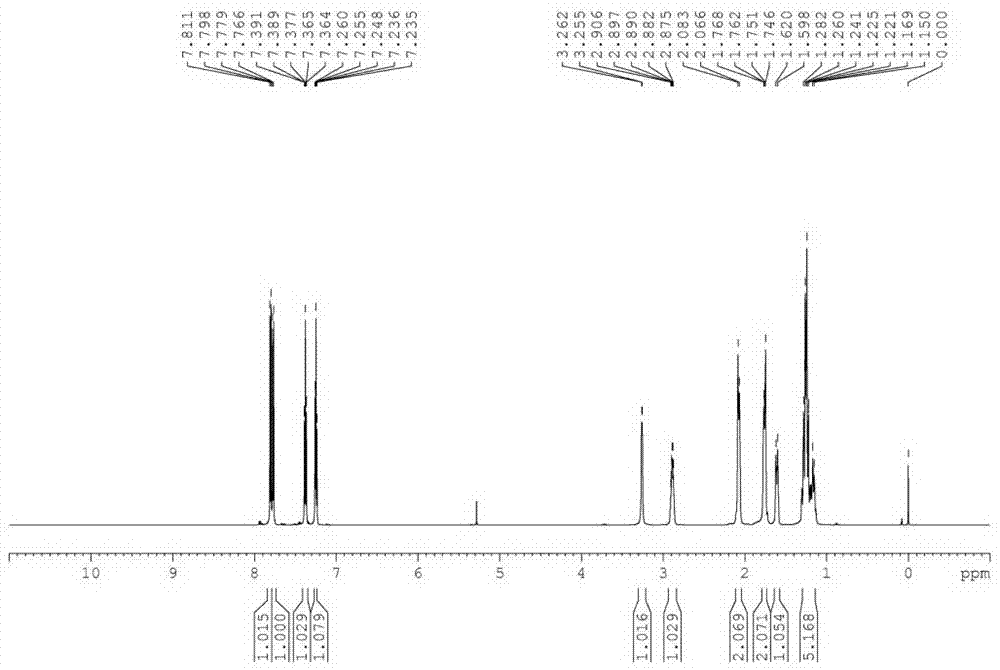

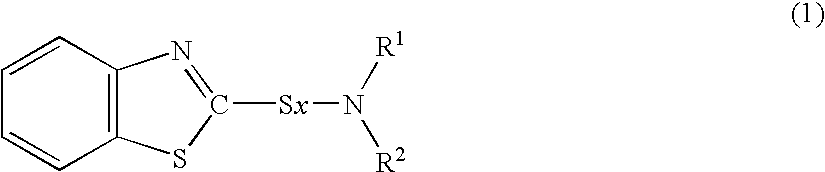

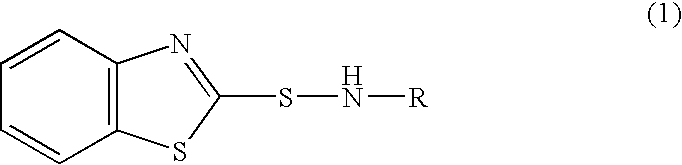

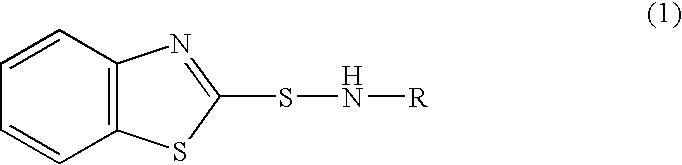

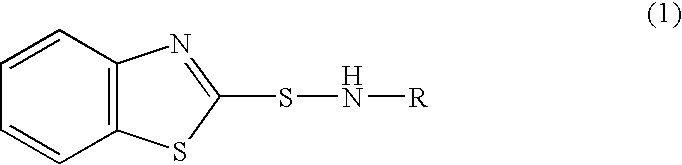

The object of the present invention is provide a rubber composition for coating a tire cord, which improves adhesion with a tire cord and has an effect of recovering adhesion with a tire cord at hygrothermal aging with maintaining the initial vulcanization rate. The present invention relates to a rubber composition for coating a tire cord comprising 0.7 to 3 parts by weight of benzothiazolyl sulfenamide or benzothiazolyl sulfenimide represented by the chemical formula (1):(wherein R1 is a linear alkyl group having a branched structure of 3 to 16 carbon atoms, and R2 is a linear alkyl group having a branched structure of 3 to 16 carbon atoms or a benzothiazolyl sulfide group) and 3 to 7 parts by weight of sulfur based on 100 parts by weight of a rubber component containing at least 60% by weight of a natural rubber and / or an isoprene rubber.

Owner:SUMITOMO RUBBER IND LTD

Method for preparing sulfenamide thiofide by catalyzing oxidization of molecular oxygen in water phase

ActiveCN106866577AHigh catalytic activityImprove reaction efficiencyOrganic chemistryChemical recyclingPhthalocyanineBy-product

The invention relates to a method for preparing sulfenamide thiofide by catalyzing oxidation of molecular oxygen in a water phase. According to the method, a water-soluble transition metal phthalocyanine compound is utilized as a catalyst, and 2-mercaptobenzothiazole generates oxidation cross coupling reaction with amine (tert-butylamine or cyclohexane) for 1 to 30 hours to generate sulfenamide thiofide in the water phase under the conditions that oxygen (or air) pressure is 0,01 to 1MPa, and temperature is 40 to 100 DEG C. Reaction of the preparation method disclosed by the invention is performed in the water phase, other organic solvents are prevented from being added, catalyst activity is high, reaction efficiency is high, the catalyst can be used repeatedly, a synthesizing technology is concise, product selectivity is high, by products are few, waste is little, environmental friendliness is achieved, and the preparation method has stronger industrial application prospect.

Owner:WILLING NEW MATERIALS TECH CO LTD

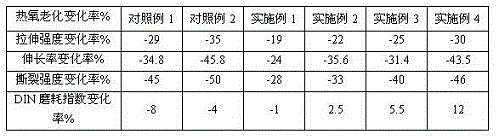

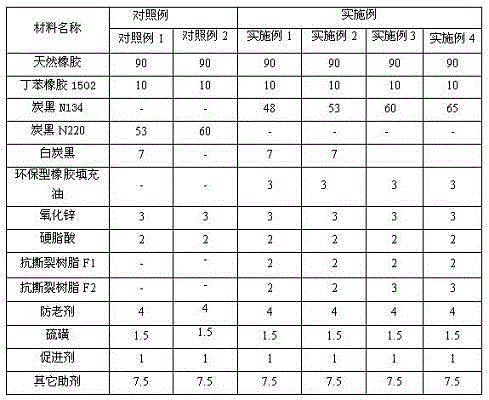

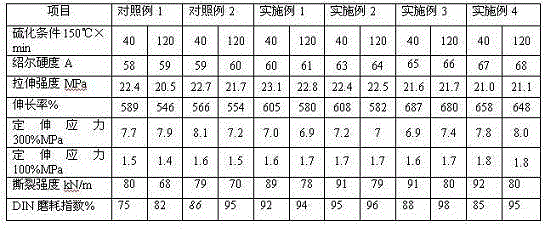

Articulated truck tire tread rubber composition and preparation method thereof

InactiveCN104356442AImprove wear resistanceImprove cut resistanceSpecial tyresSulfenamideStearic acid

The invention relates to an articulated truck tire tread rubber composition and a preparation method thereof, belonging to the field of tire production. The articulated truck tire tread rubber composition is composed of the following components in parts by weight: 75-100 parts of natural rubber, 0-25 parts of styrene-butadiene rubber, 50-70 parts of small-particle-size highly-structure-reinforced carbon black, 0-15 parts of silica white, 0-10 parts of tear-resistant resin, 0-3 parts of protective wax, 0-4 parts of N-(1,3-dimethyl butyl)-N'-phenyl-p-phenylenediamine, 0-1 part of acetone-diphenylamine high-temperature condensate, 0-3 parts of stearic acid, 0-10 parts of environment-friendly oil, 0-5 parts of phenol formaldehyde resin tackifier, 0-5 parts of zinc oxide, 0-1 part of anti-reversion agent WK-901, 0-5 parts of dispersing agent, 0-2.5 parts of sulfur and 0.5-2.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide. The articulated truck tire tread rubber composition has the advantages of excellent wear resistance, excellent cutting resistance and excellent thermo-oxidative aging resistance, and can adapt to the operating requirements of high wear resistance, high cutting resistance and excellent thermo-oxidative aging resistance for the articulated truck tire tread rubber.

Owner:TRIANGLE TIRE

Intermediate adhesive material for retreaded tires

InactiveCN102086353AImprove adhesionImprove driving safetyNatural rubber adhesivesQuinolineHigh doses

The invention discloses an intermediate adhesive material for retreaded tires. The adhesive material disclosed by the invention contains resorcinol-formaldehyde resin, hexamethoxy methyl melamine, zinc oxide (in high dose ratio), and N-ethyl-N-phenyldithiocarbamic acid zinc salt serving as a low-temperature promoter. The key points of the intermediate adhesive material include: the intermediate adhesive material is prepared from various raw materials including No.20 natural rubber, cis-1,3-butadiene rubber (BR)9000, abietic styrene butadiene rubber (SBR)1500, resorcinol-formaldehyde resin, zinc oxide (in high dose ratio), stearic acid, N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine,poly(1,2-dihydro-2,2,4-trimethyl-quinoline), poly(2-dihydroquinoline), carbon black N330, carbon black N660, coumarone-indene resin, aromatic oil, zinc ethylphenyl dithiocarbamate, hexamethoxy methyl melamine, N-cyclohexylbenzolthiazole-2-sulfenamide, 2-mercaptobenzothiazole, and insoluble sulphur (IS)-7020( the sulfur content is 80 percent). The adhesive material disclosed by the invention is mainly used in the intermediate adhesive layers of retreated diagonal tires and retreaded steel-belted radial tires and when the adhesive material disclosed by the invention is used, the tire tread and tire body adhering strength of the intermediate adhesive material is improved obviously; the H drawing force of the adhesive material with all-steel cords and nylon cords is improved to reduce the tire tread and tire body separation phenomenon of the finished retreaded diagonal tires and retreaded steel-belted radial tires; and thus, the driving safety and service life of the diagonal tires and the retreaded steel-belted radial tires are improved.

Owner:SICHUAN TYRE & RUBBER CO LTD

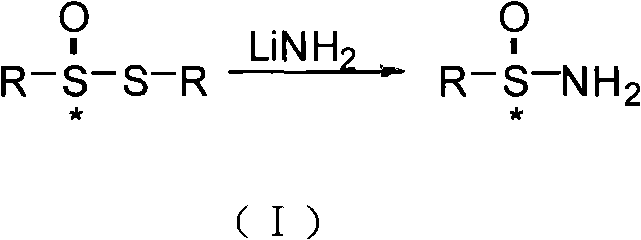

Method for synthesizing chiral sulfenamide

InactiveCN101525308AReduce dosageLower synthesis costOrganic-compounds/hydrides/coordination-complexes catalystsAsymmetric synthesesThiosulfinateSalicylaldehyde

The invention discloses a method for synthesizing chiral sulfonamide. In the method, chiral thiosulfinate is taken as a raw material and reduced with liquid ammonia containing lithium amide to obtain the chiral sulfonamide, and a reaction formula is as above, wherein, R is one of C1-C10 alkyl, phenyl, p-cresyl, o-cresyl, metal-cresyl, p-ethyl benzyl, p-tertiary-butyl phenyl, p-acetyl phenyl, o-acetyl phenyl and naphthyl. The method sequentially comprises the following steps: preparing the lithium amide; dropwise adding the lithium amide to chiral thiosulfinate solution and stirring for reaction; and adding ice to obtained mixture after the reaction, extracting, combining organic phases and eliminating solvents, and crystallizing to obtain the chiral sulfonamide. The method has the advantages that synthesis cost is reduced by an oxidation method in the presence of a chiral catalyst; a ligand is a condensation product of cheap and available chloromycetin derivative and salicylaldehyde derivative; and reaction steps are less, the reaction conditions are mild and post-treatment is simple.

Owner:上海立科化学科技有限公司

Formula of multi-functional rubber soles

InactiveCN102660057ATo achieve the purpose of multi-functionLow costSolesPolymer scienceStearic acid

The invention relates to a formula of a pair of multi-functional rubber soles, which comprises 50 to 70 parts of butadiene rubber, 8 to 12 parts of natural rubber SCR No.10, 18 to 22 parts of regenerated rubber, 5 to 5.5 parts of zinc oxide, 24 to 28 parts of N774 carbon black, 24 to 28 parts of N550 carbon black, 5 to 8.5 parts of polyisoprene, 1 to 1.5 parts of jianlumizuoxin, 1.5 to 2.5 parts of stearic acid, 1.5 to 2.5 parts of dibenzothiazyl disulfide, 2.5 to 3.5 parts of N-tertiary butyl-(2-benzothiazole) sulfenamide, 0.8 to 1.2 parts of dithiodimorpholine, 3.5 to 4.5 parts of barium sulfate, 5.5 to 8 parts of organic silicon rubber, 10 to 15 parts of nitrile rubber and 5 to 8 parts of polyurethane anti-static agent. According to the soles, the aim of a plurality of functions is achieved; and moreover, the cost is also very low, and the economic benefit is very considerable.

Owner:新疆泰安鞋业有限公司

Ink-jet recording apparatus

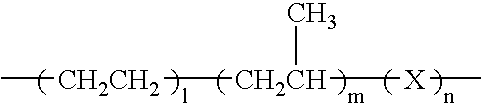

InactiveUS20070103527A1CompatibilityPrevent precipitationMeasurement apparatus componentsDuplicating/marking methodsWater basedSulfenamide

The ink-jet recording apparatus has an-ink passage into which a water-based ink or a preservation solution is filled. The ink passage employs a rubber member formed from an ethylene propylene diene rubber in which a sulfenamide-based vulcanization accelerator or a thiazole-based vulcanization accelerator is employed. The water-based ink has a dynamic surface tension at a lifetime of 100 ms of about 35 mN / m to about 45 mN / m as measured by means of a maximum bubble pressure method at a measurement temperature of 25° C. Furthermore, the preservation solution has a dynamic surface tension at a lifetime of 100 ms of about 30 mN / m to about 35 mN / m as measured by means of the maximum bubble pressure method at a measurement temperature of 25° C.

Owner:BROTHER KOGYO KK

Adhesive for brake block of oil field drilling machine

InactiveCN1421504AStable coefficient of frictionReduce wearAldehyde/ketone condensation polymer adhesivesFriction liningAdhesiveAcrylonitrile

The adhesive for brake block of oil field drilling machine consists of adhesive, curing agent, promoter, friction performance regulator, activator, assistant and solvent. The adhesive is linear phenolic resin and acrylonitrile-butadiene rubber, the curing agent is sulfur and hexamethine tetramine, the promoter is cyclohexyl-benzothiazole sulfenamide, the friction performance regulator is carbon black and stannous chloride, the assistant is barium sulfate and the solvent is mixed solvent. The adhesive is suitable for brake block of oil field drilling machine and may be also used in brake blockfor train, automobile, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

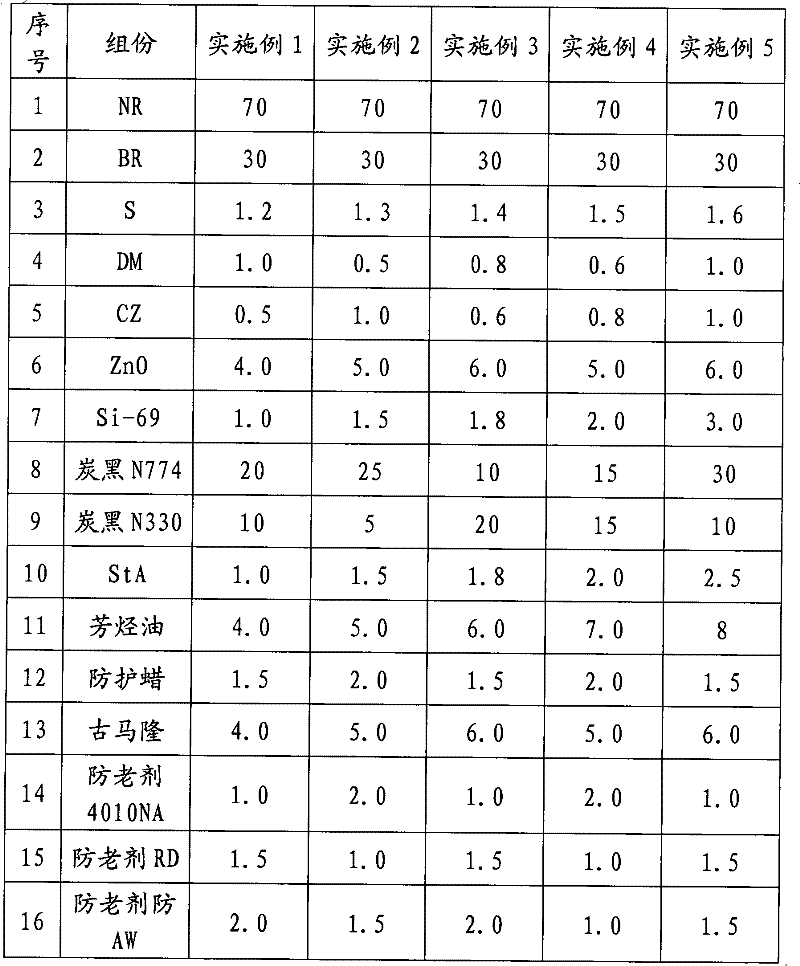

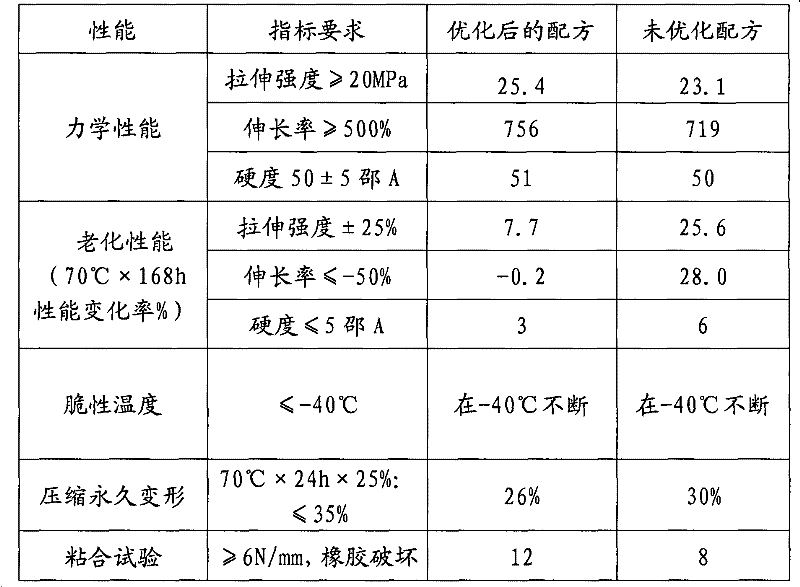

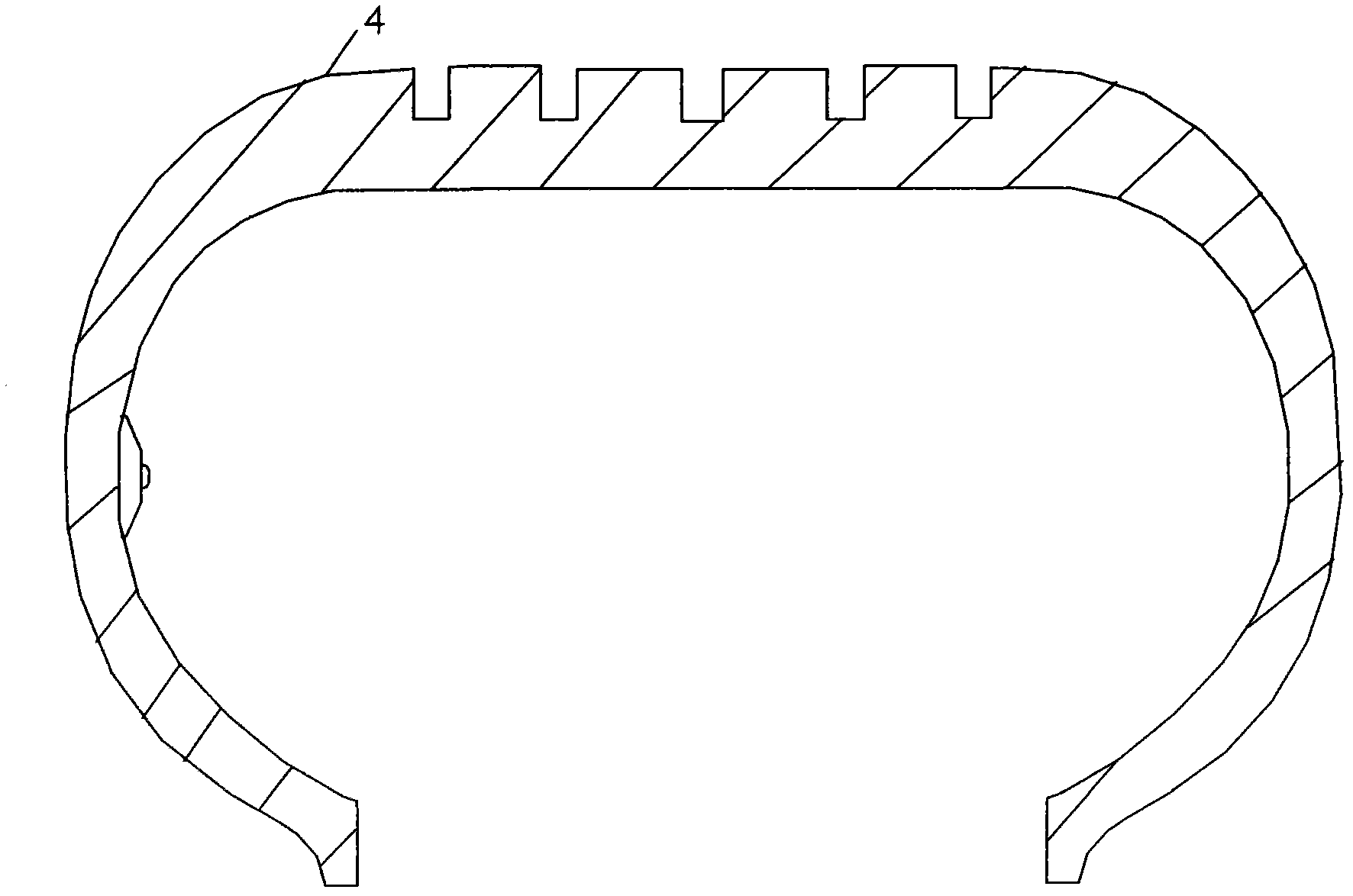

Rubber used for building shock-isolation support and manufacture method thereof

The invention relates to a manufacture method of rubber used for a building shock-isolation support, which is performed by carrying out internal mixing, open mixing, sheet adding and sheet vulcanizing processes on natural rubber (NR), butadiene rubber (BR), S, an accelerator DM (2,2'-dibenzothiazole disulfide), an accelerator CZ (N-cyclohexyl-2-benzothiazole sulfenamide), ZnO, a coupling agent Si-69, carbon black N774 and N330, stearic acid (StA), an aromatic oil, protective wax, coumarone, an antiageing agent 4010NA (N-isopropyl-N'-phenyl-p-phenylenediamine), an antiageing agent RD (poly(1,2-dihydro-2,2,4-trimethyl-quinoline)) and an antiageing agent AW (6-ethoxyl-2,2,4-trimethyl-1,2-dihydroquinoline). According to the manufacture method, the use of a semi-efficient vulcanization system can well balance the performance of the rubber support during the low-temperature long-time vulcanization process; the combined use of the accelerators DM and CZ can well balance the relationship between the vulcanization characteristics and physical properties; and the appropriate combined use of natural rubber and butadiene rubber can improve anti-reversion properties and heat aging performance of the rubber.

Owner:TIANJIN RUBBER IND RES INST

Method of manufacturing thermoplastic olefine polymer modified asphalt having good stability

InactiveCN1429880AMeet layingFulfil requirementsVertical chamber coke ovensBuilding insulationsPolymer sciencePolymer modified

A process for preparing high-stability modified asphalt features that the asphalt is modified by thermoplastic olefine polymer (SBS) or unsulfurized rubber (SBR) while a composite stabilizer is added, which is prepared from arylhydrocarbon concentration regulator, zinc oxide, S,N-substituted 2-benzothiazole sulfenamide, zinc dithioaminoformate, and p-phenyldiamine.

Owner:重庆美仑道路沥青工程有限公司

Rubber cement for static balance patching of aircraft tire

ActiveCN103289596AHigh tensile strengthHigh tear strengthNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesiveMechanical engineering

The invention discloses a rubber cement for the static balance patching of an aircraft tire. The rubber cement comprises a main material natural rubber, and main auxiliary materials comprising styrene butadiene rubber, an adhesive SL-3090, an adhesive A, a high-dispersivity white carbon black, a silane coupling agent, high-wear-resistance carbon black, an antioxidant BLE, a tackifying resin TKM-M, insoluble sulfur, a sulfonamide promoter and a thiuram promoter. The rubber cement is prepared through mixing by an open mixing machine or a closed mixing machine to prepare a gross rubber, and mixing the gross rubber with a solution gasoline according to a weight ratio of 1:2-5. The adhesive strength between a static balance patch using the rubber cement and the tire liner of the tire is high, so the shedding of the static balance patch is difficult during the use of the tire. The rubber cement has the advantages of high tensile strength and tear tensile, good thermal ageing resistance, fast vulcanization speed, no use of toxic materials comprising polyisocyanate or toluene, and protection of the health of operators.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Method for synthesizing TBBS (Tertiarybutyl Benzothiazole Sulfenamide) by mechanically applying mother solution

The invention discloses a method for synthesizing TBBS (Tertiarybutyl Benzothiazole Sulfenamide) by mechanically applying a mother solution, comprising the following steps of: adding water or mother solution and a rubber accelerator according to the mass ratio of 1:2-6 in a kettle for pulping, wherein the mechanical apply ratio of the mother solution is 20-100 percent; adding tert-butylamine, wherein the mol ratio of the tert-butylamine to the rubber accelerator is 1:1.05-5; dropping an NaCLO oxidant solution in the material at the temperature of 20-70DEG C, detecting the ending point with copper acetate and starch potassium iodide and stopping dropping the oxidant at the ending point; and carrying out the filtering, the washing and the drying to obtain the accelerator TBBS product. The invention has the advantages that: the mother solution is directly recycled, thereby not only reducing the discharge of high-salinity sewage, the pressure of distilling and recovering the tert-butylamine and energy consumption, but also according with the environment-friendly policy of the state. The accelerator TBBS has over 98 percent of yield, 98 percent of purity and over 105DEG C of melting point. The invention also has the advantages that the method has simple process and is easy to industrialize and the mother solution is directly recycled, thereby reducing the discharge of high-salinity sewage, the pressure of distilling and recovering the tert-butylamine and energy consumption; in addition, the yield of the product is improved and the consumption of the tert-butylamine is reduced, so that the invention reduces the production cost and accords with the environment-friendly policy of the state.

Owner:KEMAI CHEM

Steel wire protective layer repair adhesive for retreading radial aircraft tire and application of steel wire protective layer repair adhesive

ActiveCN104262699AHigh tensile strengthHigh tear strengthNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesive cementKetone

The invention discloses a steel wire protective layer repair adhesive for retreading a radial aircraft tire and application of the steel wire protective layer repair adhesive. The steel wire protective layer repair adhesive is prepared by taking natural rubber as a main material, taking styrene-butadiene rubber, an adhesive, cobalt boroacylate, phenolic resin, high-dispersion white carbon black, a silane coupling agent, carbon black with high wear resistance, a ketone amine type anti-aging agent, insoluble sulfur and a sulfonamide type accelerator as main auxiliary materials, and mixing by an open mill or an internal mixer. The application is that a rubber compound is mixed with a solvent, namely gasoline according to the mixture ratio of 1: (3-6) to prepare adhesive cement of the repair adhesive, and the rubber compound is additionally pressed into a slice on a tabletting machine and cut into a certain size to form a rubber piece which is used as the rubber piece of the repair adhesive. The adhesive has the advantages of relatively high tensile strength, tear strength and stress at definite elongation, good resistance to thermal aging and low dynamic heat production; furthermore, the adhesive has good adhesion performance with a steel wire, and the adhesion performance of the adhesive after thermal aging with the steel wire is not reduced significantly.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

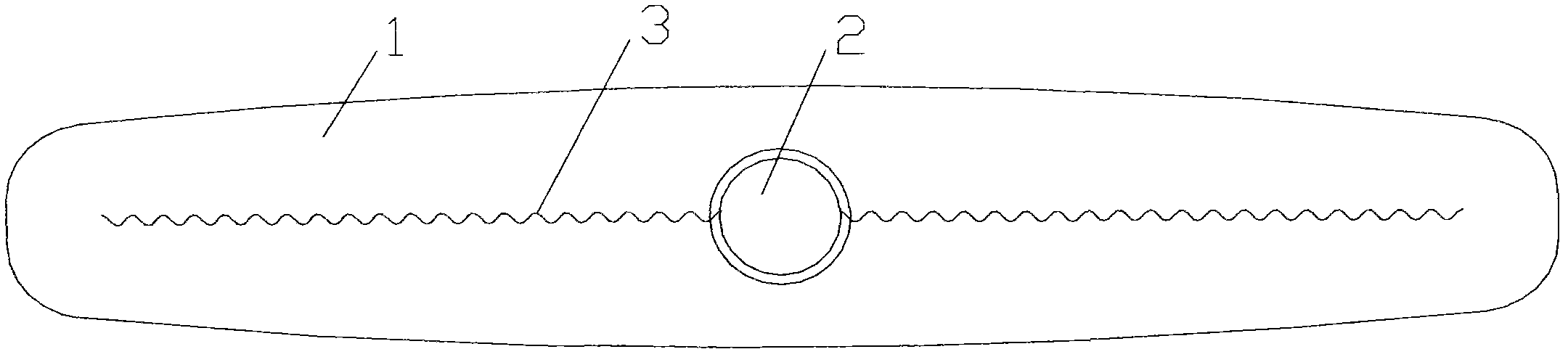

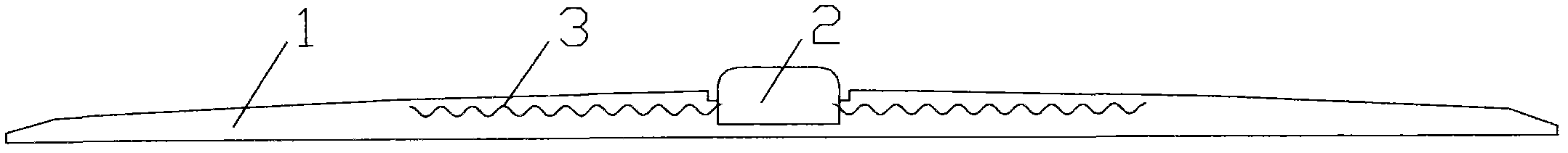

Dielectric rubber body for packaging sensor and radio-communication system taking dielectric rubber body as carrier

ActiveCN103183876AIncrease elasticityImprove mechanical propertiesOther chemical processesTyre measurementsDielectricPolymer science

The invention relates to a dielectric rubber body for packaging a sensor. The dielectric rubber body is characterized in that the formula thereof comprises 60-70 parts of chlorinated butyl rubber, 10-20 parts of butadiene styrene rubber, 20-30 parts of natural rubber, 20-30 parts of light calcium carbonate, 30-40 parts of carbon black, 5-10 parts of conductive carbon black, 1-3 parts of stearic acid, 2-5 parts of magnesium oxide, 1-5 parts of octyl phenol-phenolic resin, 3-6 parts of zinc oxide, 1-3 parts of N-tertiary butyl-2-benzothiazole sulfenamide, 0.5-2 parts of tetramethyl thiuram disulfide, and 0.5-2 parts of insoluble sulphur. The dielectric rubber body disclosed by the invention is used for a conductive radiofrequency device in tire; the device comprises a radio assembly and an antenna, and can be used for tracking and recording data during manufacturing, sales and use; and the measurement range covers temperature, pressure or other physical parameters in tire. During the loading process of a sensor, the conductive material with a certain dielectric constant and a certain adhesive force disclosed by the invention is chosen, so that the device can be firmly connected with a tire and can be used for transmitting data more stably; simultaneously, via high elasticity and good mechanical property of rubber, the device can withstand the stress brought by cyclic deformation of the tire excellently.

Owner:QINGDAO TONGSHENGTONG RUBBER & PLASTIC

Isophthalic dihydrazide-contained tread rubber composition for radial tire and preparation method thereof

The invention relates to the technical field of tire rubber, and particularly discloses an isophthalic dihydrazide-contained tread rubber composition for a radial tire and a preparation method thereof. The isophthalic dihydrazide-contained tread rubber composition is prepared from the following raw materials in parts by weight: 100 parts of polyisoprene, 30 to 50 parts of carbon black, 2 to 10 parts of a petroleum plasticizer, 5 to 20 parts of silicon dioxide, 1 to 3 parts of stearic acid, 2 to 5 parts of zinc oxide, 1 to 4 parts of protective wax, 1 to 3 parts of a silane coupling agent, 0.2to 1 part of isophthalic dihydrazide, 0 to 3 parts of N-tert-butyl-2-benzothiazolyl sulfenamide, 1 to 3 parts of N,N'-dimethyl-p-phenylenediamine, 1 to 4 parts of sulfur powder and 0.1 to 1 part of ascorch retarder, and is prepared through mixing.

Owner:TRIANGLE TIRE

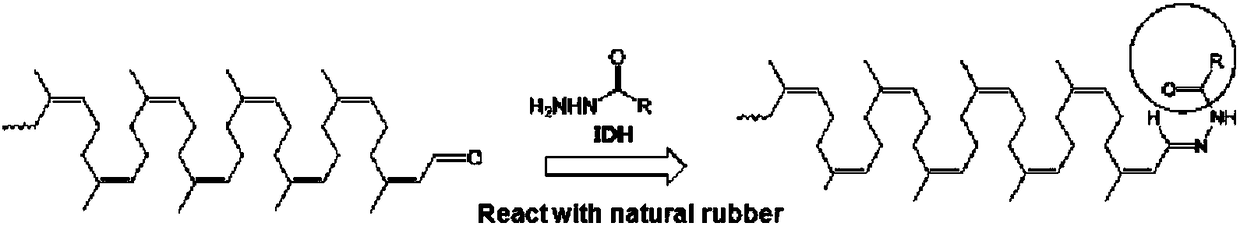

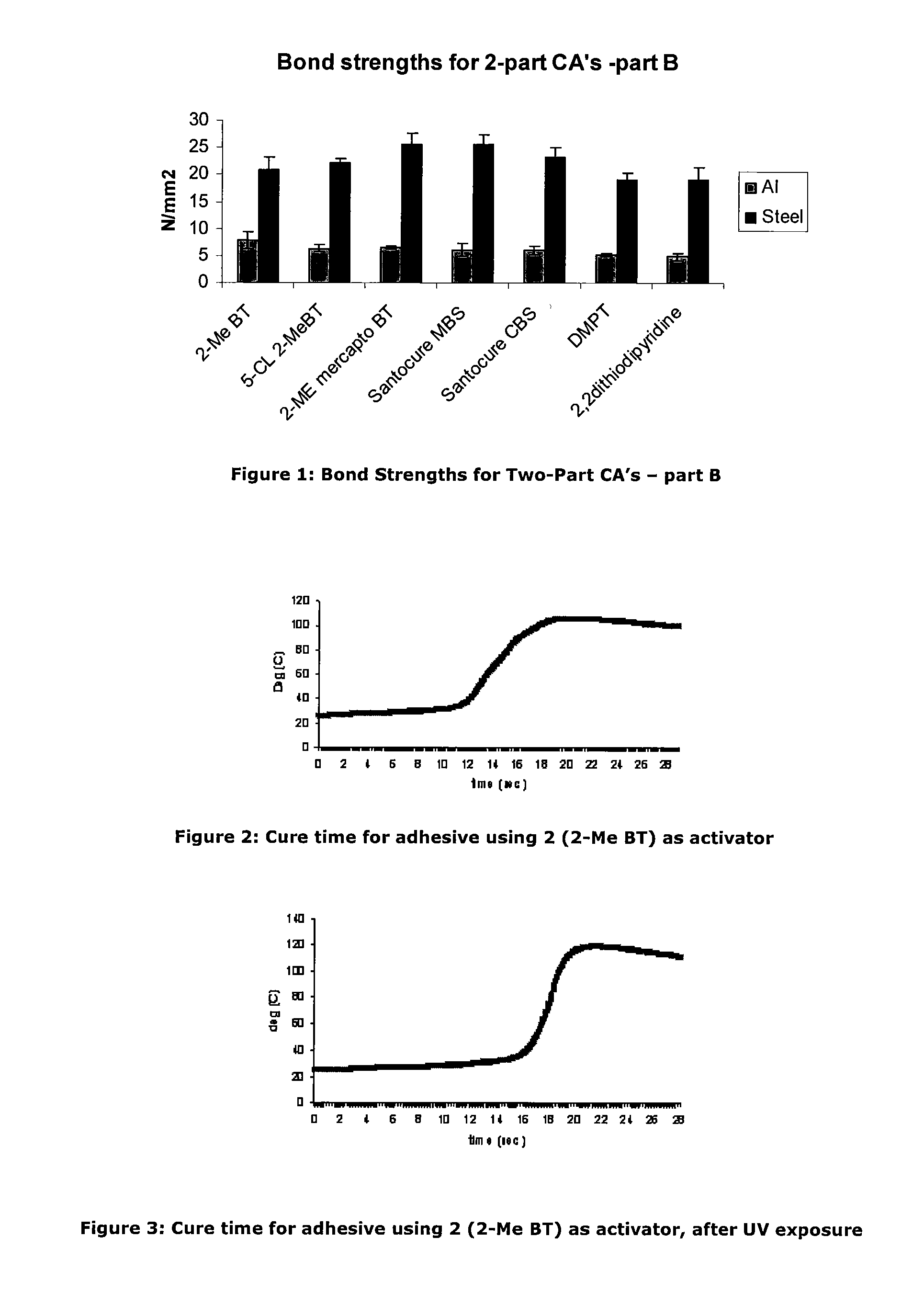

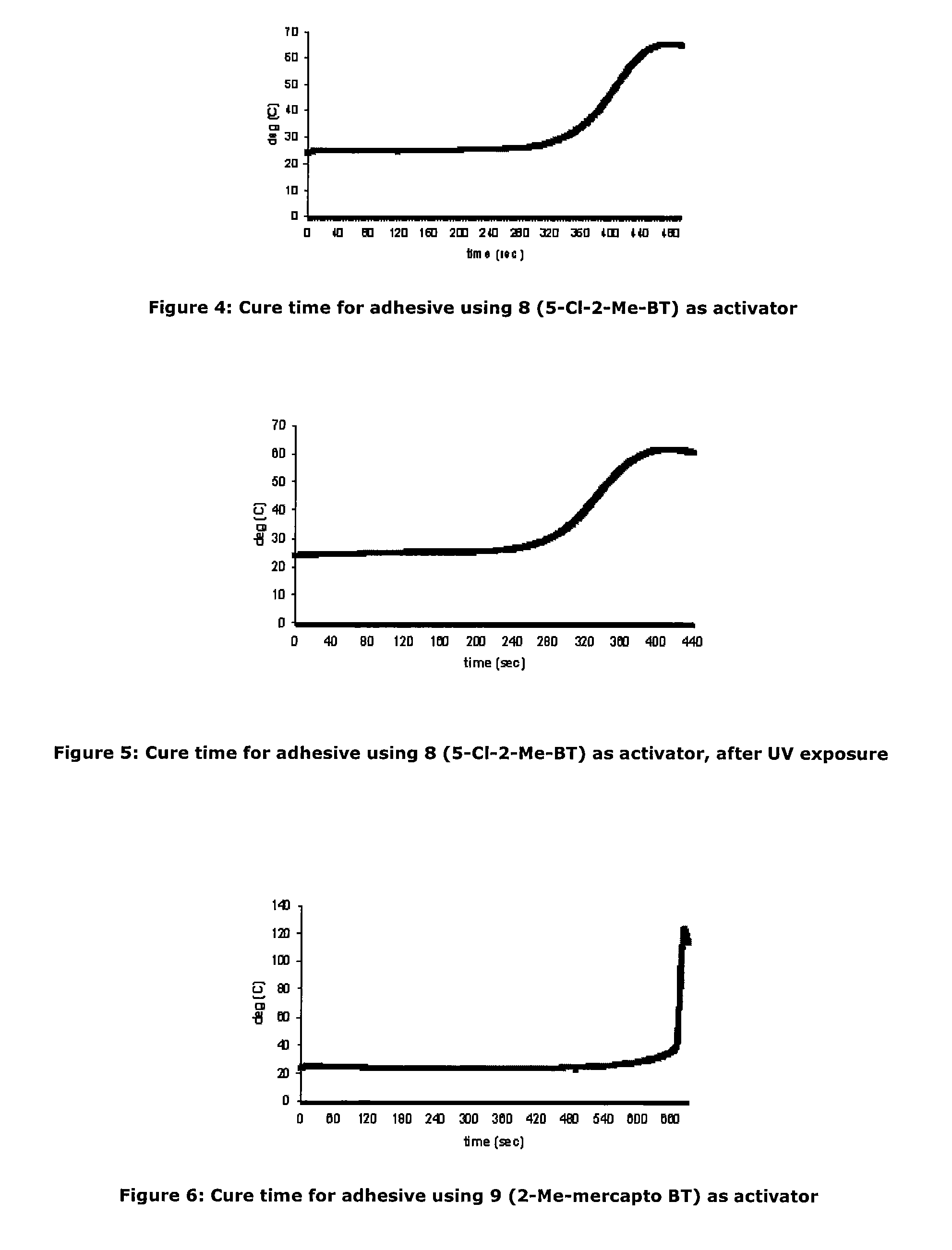

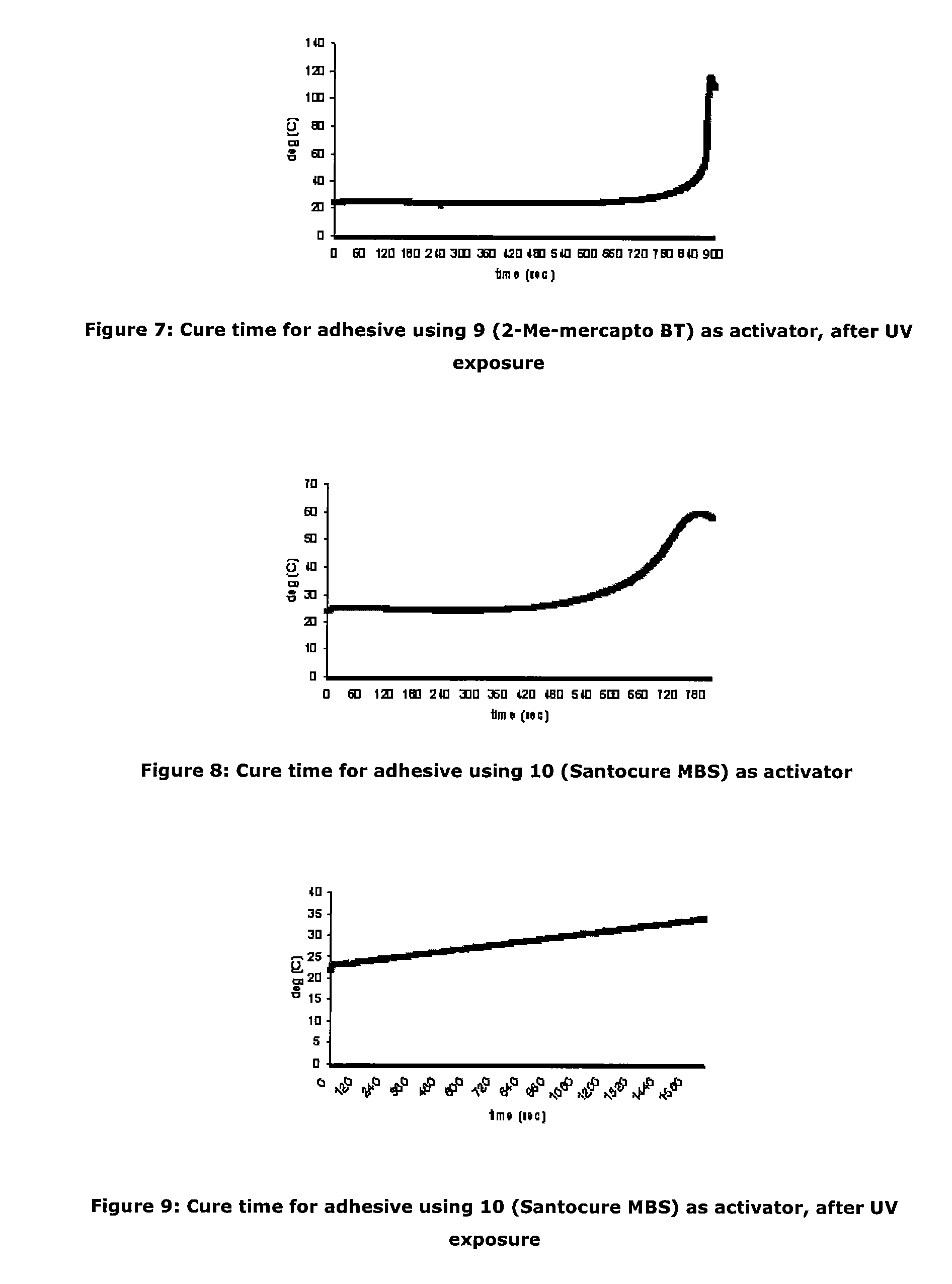

Activators for two part cyanoacrylate adhesives

ActiveUS20110196092A1Rapid adhesive bond formationLess-prone to moisture sensitivityNon-macromolecular adhesive additivesMixingMorpholineSulfenamide

There is provided a cyanoacrylate composition comprising:a cyanoacrylate; anda 2-substituted benzothiazole or a derivative thereofwherein the 2-substituent is an alkyl, an alkene, an alkylbenzyl, an alkylamino, an alkoxy, an alkylhydroxy, an ether, a sulfenamide, a thioalkyl or a thioalkoxy group, with the proviso that an amide portion of the sulfenamide does not have a tert butylamino or a morpholine group.

Owner:HENKEL KGAA

Formula for belt coating rubber of all-steel engineering radial tire

The invention relates to a formula for belt coating rubber of an all-steel engineering radial tire. The formula is characterized in that a rubber material contains the ingredients: natural rubber, styrene-butadiene rubber, zinc oxide, stearic acid, carbon black, a post vulcanization stabilizer HTS, an anti-aging agent 4020, an anti-aging agent RD, resorcinol, hexamethoxy methylmelamine, cobalt neodecanoate, N-tert-butyl-2-benzothiazole sulfenamide, insoluble sulfur, a vulcanizing agent DTDM, Koresin resin, aromatic hydrocarbon oil and the like. The milled rubber material is high in adhesion with steel wires, low in heat generation and excellent in puncture resistance, and thus the service life of the tire is prolonged.

Owner:天津国际联合轮胎橡胶股份有限公司

EPDM composition and automotive brake sytem rubber component

A sulfur curing system EPDM composition in which one or more types of vulcanization accelerators selected from thiazole type and sulfenamide type accelerators and one or more types of vulcanization accelerators selected from dithiocarbamate type and thiuram type accelerators are combined together so as to be compounded into the EPDM composition as a vulcanization accelerator, and an automotive brake system rubber component made of the EPDM composition.

Owner:TOYODA GOSEI CO LTD

Nitrile-butadiene rubber sealing material and preparation method thereof

InactiveCN105061840AGood high and low temperature resistanceExcellent medium resistanceMicrocrystalline waxStearic acid

The invention discloses a nitrile-butadiene rubber sealing material which is prepared from the following raw materials in parts by weight: 40-60 parts of nitrile-butadiene rubber N241, 20-40 parts of nitrile-butadiene rubber N240S, 1-4 parts of zinc oxide, 1-3 parts of sulfur S-80, 1-2 parts of tetramethyl-thiuram disulfide, 1-2 parts of accelerator TMTD, 0.5-0.9 part of N-cyclohexyl-2-benzothiazole sulfenamide, 20-35 parts of carbon black N-774, 20-30 parts of calcined argil, 1-2 parts of stearic acid, 1-2 parts of coumarone, 1-2 parts of microcrystalline wax OK1987, 1-3 parts of anti-aging agent RD, 1-3 parts of anti-aging agent H, 1-3 parts of anti-aging agent A and 2-6 parts of plasticizer TP-90B. The invention also discloses a preparation method of the nitrile-butadiene rubber sealing material.

Owner:宋晓梅

Wear-resistant and aging-resistant cable sheath material

InactiveCN105623112AHigh mechanical strengthImprove wear resistanceRubber insulatorsPolymer scienceWear resistant

The invention discloses a wear-resistant and aging-resistant cable sheath material. The material is prepared from, by weight, 40-60 parts of ethylene propylene diene monomer rubber, 15-30 parts of polyamide 66, 10-20 parts of modified white mica powder, 2-5 parts of a wear-resisting auxiliary agent, 10-20 parts of semi-reinforced carbon black, 1-4 parts of a flame-retardant auxiliary agent, 1-2 parts of N-tertiary butyl-2-benzothiazole sulfenamide, 2-4 parts of N, N'-m-phenylene dimaleimide, 3-8 parts of stearic acid, 0.5-1 part of zinc dibutyl dithiocarbamate, 0.5-1 part of an anti-aging agent DPPD, 2-5 parts of white oil and 2-3 parts of fortifier DH-3. The wear-resistant and aging-resistant cable sheath material is good in mechanical strength, wear resistance, aging resistance, weatherability, impact elasticity, chemical corrosion resistance and excellent in electrical insulation property, and meanwhile the modified white mica powder is adopted, so that the processing property of the ethylene propylene diene monomer rubber is improved, and the obtained cable sheath material can be used in environments with various climatic conditions.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Environment-friendly modified natural rubber material applied to cable insulation layer

InactiveCN104356447AReduce pollutionImprove mechanical propertiesRubber insulatorsInsulated cablesPolymer scienceInsulation layer

The invention discloses an environment-friendly modified natural rubber material applied to a cable insulation layer. The environment-friendly modified natural rubber material comprises the following raw materials in parts by weight: 60-80 parts of rare earth cis-polybutadiene rubber, 30-40 parts of modified natural rubber, 3-4 parts of a vulcanization system, 5-10 parts of mica powder, 20-30 parts of a lignin reinforcing agent, 30-40 parts of white carbon black, 20-30 parts of silane modified sepiolite, 2-3 parts of nano calcium carbonate, 1.5-1.8 parts of silicone oil, 1-2 parts of naphthenic oil, 40-50 parts of carbon black N330 and 5-6 parts of N-methylene carboxyl-2-benzothiazolyl sulfenamide, wherein the vulcanization system comprises the following components in parts by weight: 0.5-1 part of N-N'-meta-phenylene bismaleimide, 2-3 parts of sulphur, 0.5-1 part of a vulcanization accelerator DPTT, 0.5-1 part of a vulcanization accelerator TMTM and 1-2 parts of a vulcanization accelerator TMTD. The environment-friendly modified natural rubber material is environment-friendly, small in pollution, high in mechanical performance and high in ageing-resistant performance.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

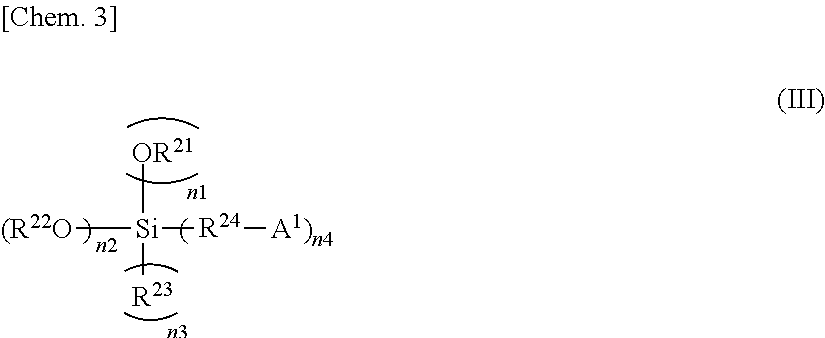

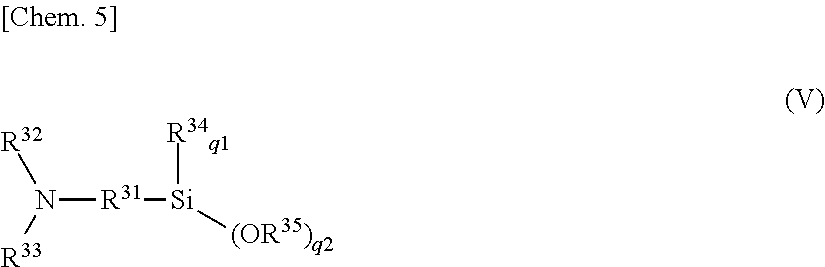

Method for producing rubber composition

ActiveUS20140187693A1Excellent in low-heat-generation propertyHigh activityLayered productsPolymer scienceThiazole

The present invention provides a method for producing a rubber composition containing a rubber component (A) that contains a modified conjugated diene-based polymer obtained by using a modifying agent that has a functional group compatible with silica, a filler containing an inorganic filler (B), a silane coupling agent (C), and at least one promoter (D) selected from guanidines, sulfenamides, thiazoles, thiurams, thioureas, dithiocarbamic acid compounds and xanthogenic acid compounds, wherein the rubber composition is kneaded in plural stages, and in the first stage (X) of kneading, the rubber component (A), all or a part of the inorganic filler (B), all or a part of the silane coupling agent (C) and the promoter (D) are added and kneaded.

Owner:BRIDGESTONE CORP

Rubber composition for tread

ActiveUS20060276583A1Improve vulcanization speedImprove heat aging resistanceSpecial tyresPolymer scienceSulfenamide

A rubber composition for a tread optimizing a vulcanization speed in a vulcanization step and, further, improving heat aging resistance is provided. A rubber composition for a tread comprising 20 to 90 parts by weight of silica, 0.5 to 2 parts by weight of (A) a guanidine vulcanization accelerator, 0.1 to 0.5 part by weight of (B) a thiuram vulcanization accelerator, and 0.5 to 2 parts by weight of (C) a sulfenamide vulcanization accelerator represented by the general formula (1): (wherein R is a linear alkyl group or a branched alkyl group having 1 to 18 carbons), based on 100 parts by weight of a rubber component.

Owner:SUMITOMO RUBBER IND LTD

Fireproof rubber and preparation method therefor

The invention discloses fireproof rubber and a preparation method therefor. The fireproof rubber contains neoprene, zinc sulfate, calcium carbonate, mica powder, stearic acid, N-tert butyl-ethyl benzothiazole sulfenamide, 2-thiol imidazoline, hydroxy silicone oil and an additive, wherein the additive is prepared through mixing lotus leaves and vermiculite and then calcining the mixture. The fireproof rubber can be used for a long time in environment above 200 DEG C; and the preparation method has the advantages that the steps are simple and the raw materials are easily obtained.

Owner:WUHU FENGXUE RUBBER

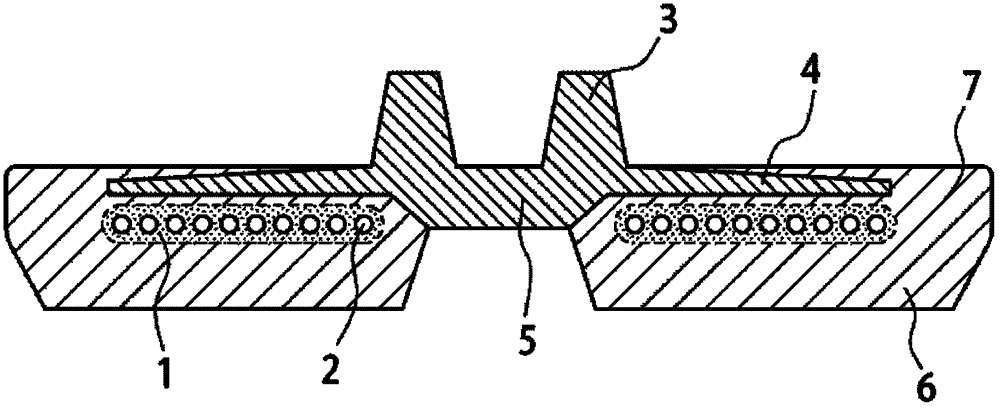

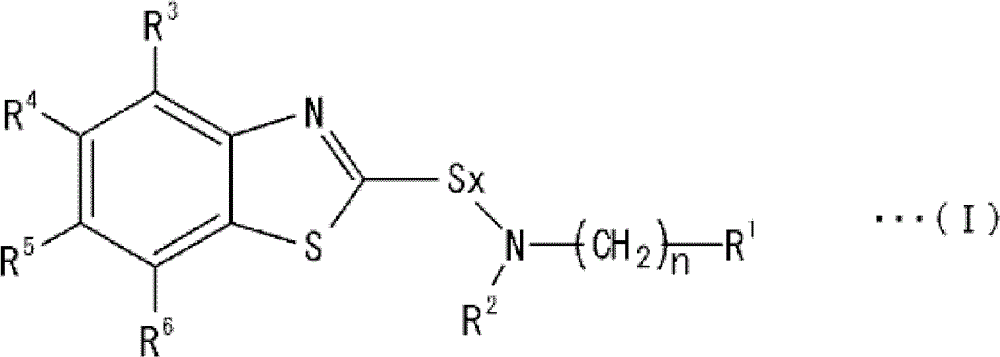

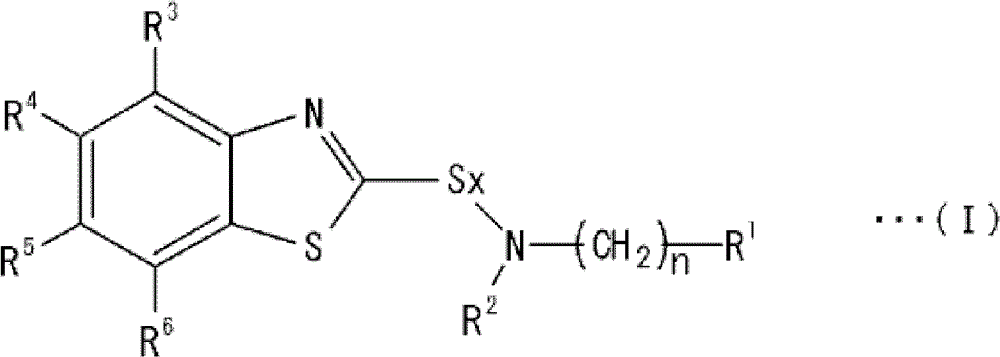

Rubber crawler

InactiveCN102803371AStay scorchedKeep scorch timeOrganic chemistryEndless track vehiclesPolymer scienceHigh humidity

Provided is a highly durable rubber crawler using a rubber composition which contains a vulcanization accelerator having a moderate vulcanization-retarding effect and which does not contain any vulcanization retarder (such as CTP) causative of deterioration of physical properties of vulcanized rubber, blooming, or other problems. The rubber composition ensures good workability with the scorch of rubber minimized, and can achieve an improvement in the adhesiveness between rubber and a metal reinforcement such as steel cord, particularly in the adhesiveness therebetween after thermal aging or under high-humidity conditions. The rubber crawler is characterized by using, as the treat rubber, a rubber composition which contains, per 100 parts by weight of a rubber component, 0.1 to 10 parts by weight of a vulcanization accelerator based on a sulfenamide represented by general formula (I), 0.03 to 3 parts by weight (in terms of cobalt) of a cobalt-containing compound, and 0.3 to 10 parts by weight of sulfur.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com