Patents

Literature

988 results about "Molecular oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular oxygen Molecular oxygen (O 2) is a diatomic molecule that is composed of two oxygen atoms held together by a covalent bond. ... Combustion is the reaction of a compound (the fuel) with an oxidant (which is usually molecular oxygen) to produce oxides. The third component of combustion is a "boost" of energy needed in order to start the reaction - the activation energy.

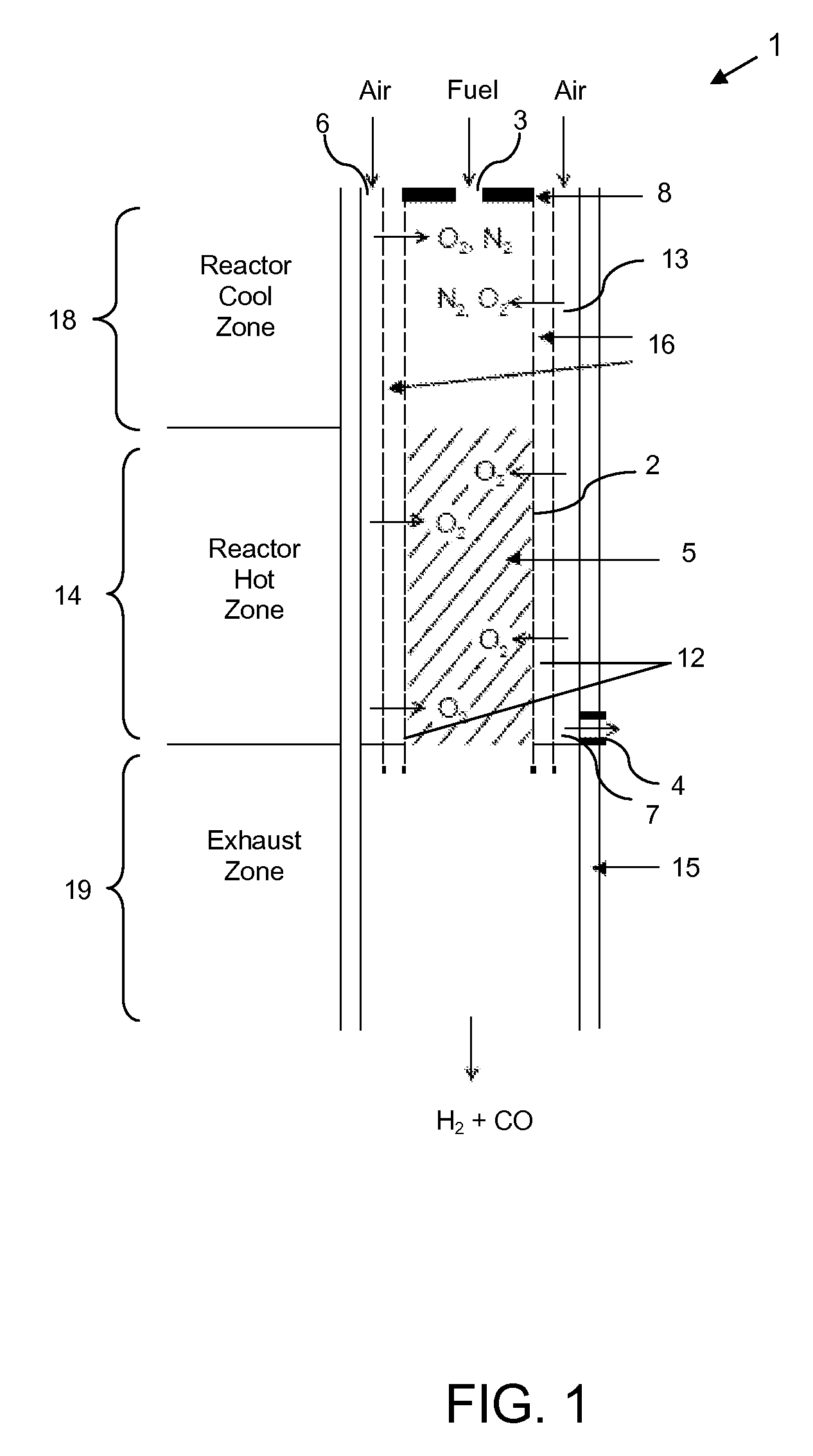

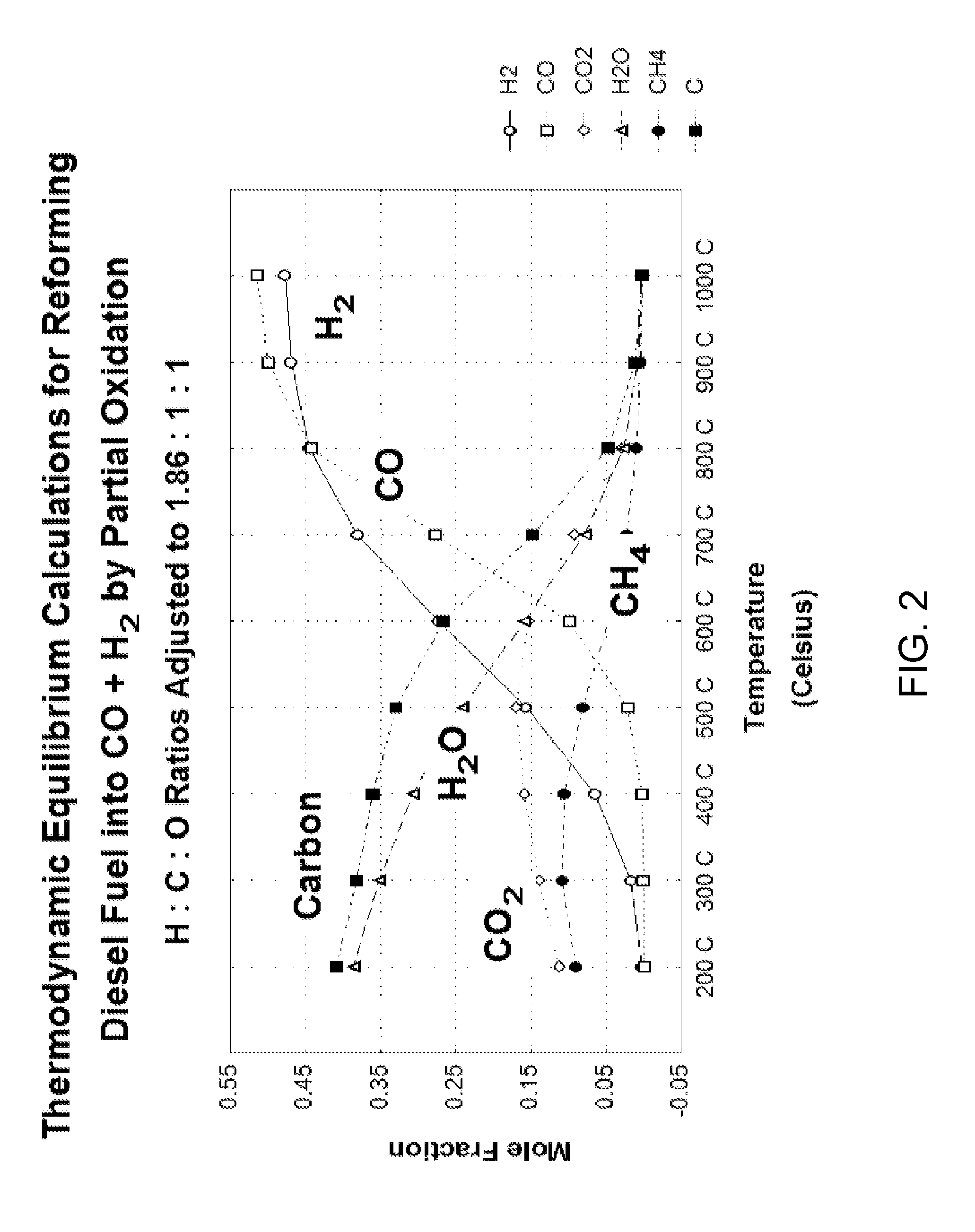

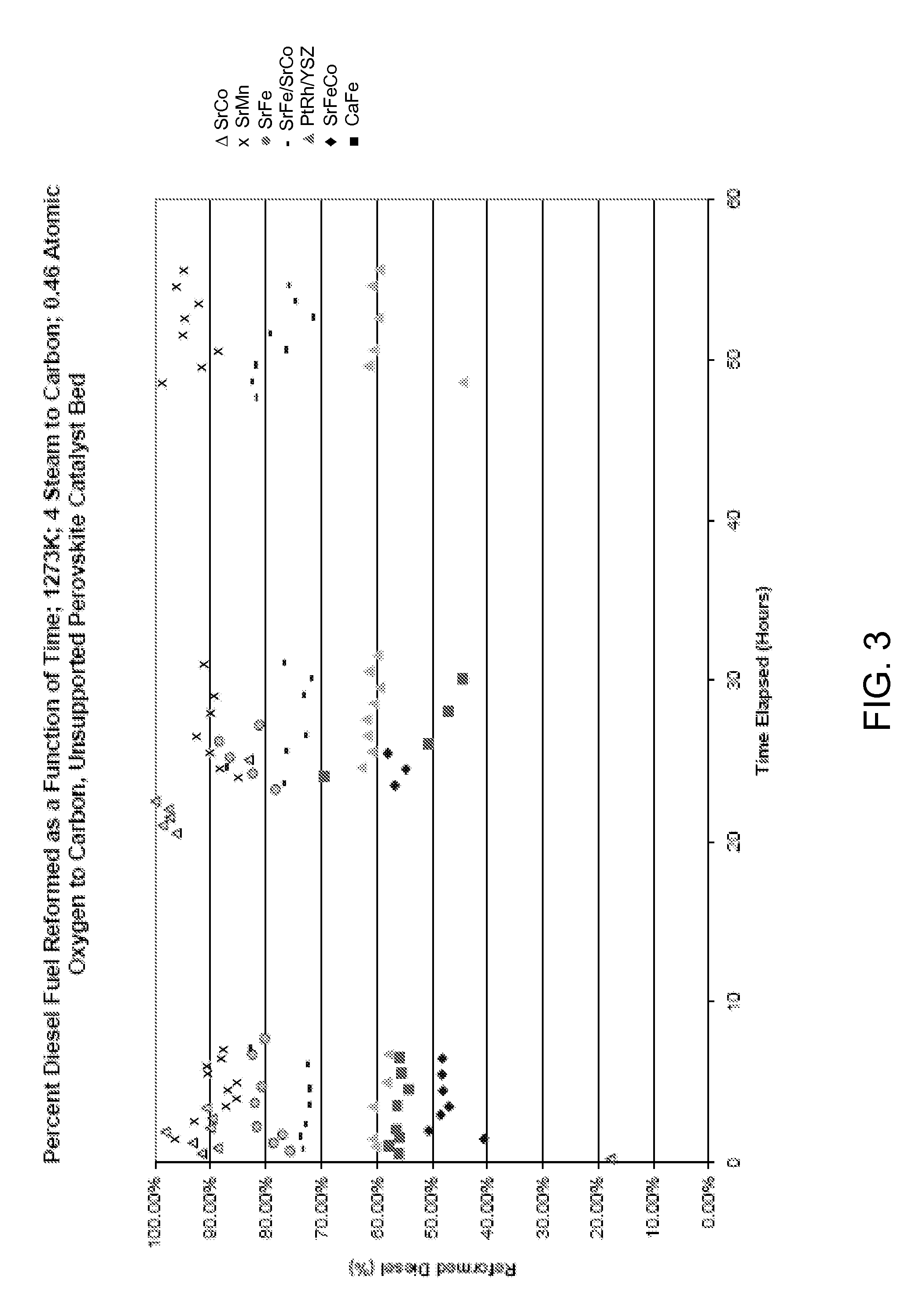

Catalytic membrane reactor and method for production of synthesis gas

InactiveUS20080169449A1High oxygen fluxHydrogenSemi-permeable membranesSulfur containingPhotochemistry

A solid state membrane for a reforming reactor is disclosed which comprises at least one oxygen anion-conducting oxide selected from the group consisting of hexaaluminates, cerates, perovskites, and other mixed metal oxides that are able to adsorb and dissociate molecular oxygen. The membrane adsorbs and dissociates molecular oxygen into highly active atomic oxygen and allows oxygen anions to diffuse through the membrane, to provide high local concentration of oxygen to deter formation and deposition of carbon on reformer walls. Embodiments of the membrane also have catalytic activity for reforming a hydrocarbon fuel to synthesis gas. Also disclosed are a reformer having an inner wall containing the new membrane, and a process of reforming a hydrocarbon feed, such as a high sulfur-containing diesel fuel, to produce synthesis gas, suitable for use in fuel cells.

Owner:ELTRON RES

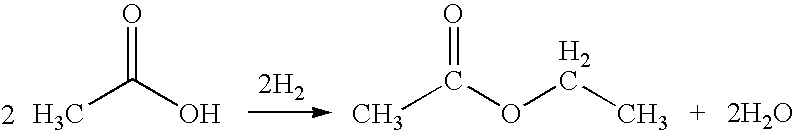

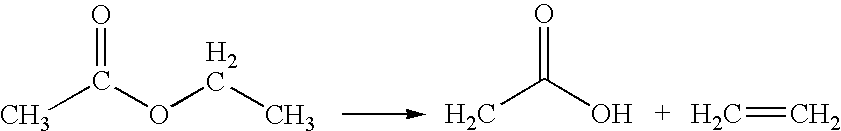

Integrated process for the production of viny acetate from acetic acid via ethy acetate

This invention provides an integrated three step economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form ethyl acetate which is cracked to form ethylene and acetic acid in the second step and in a subsequent step so formed ethylene and acetic acid is reacted with molecular oxygen over a suitable catalyst to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and copper supported on silica selectively produces ethyl acetate in a vapor phase at a temperature of about 250° C., which is cracked over a NAFION catalyst to form ethylene and acetic acid at a temperature of about 185° C., which is mixed with molecular oxygen and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

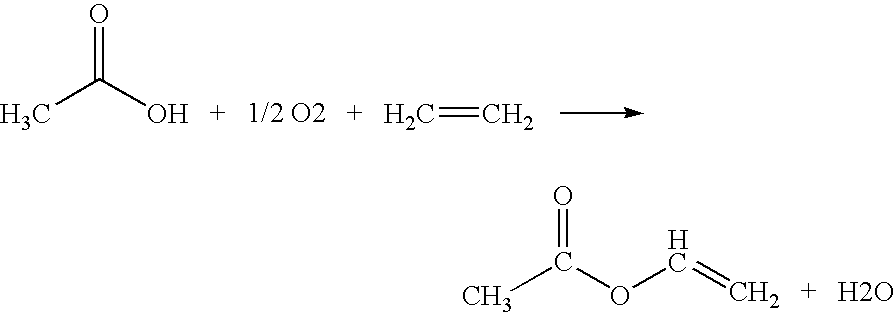

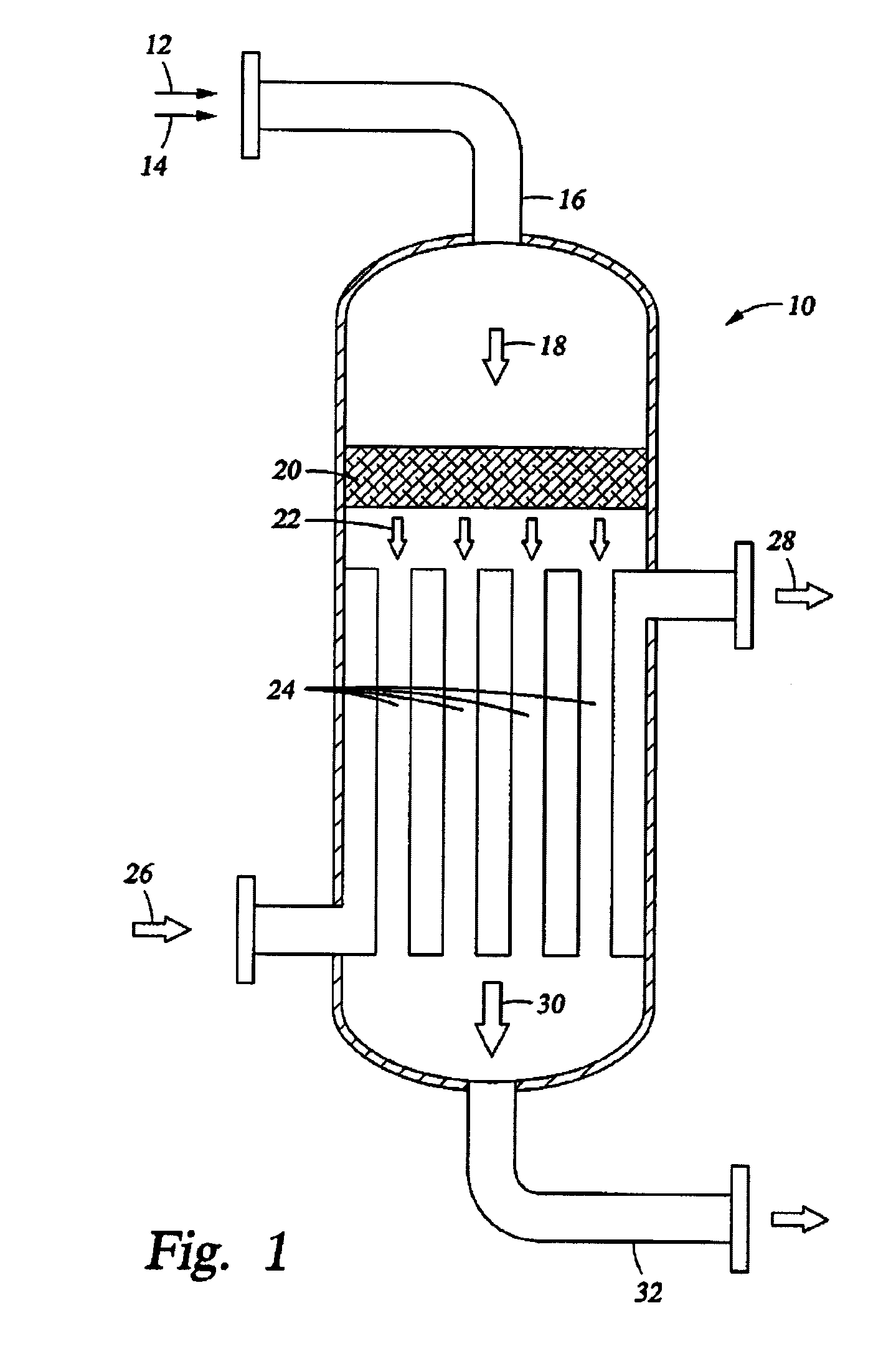

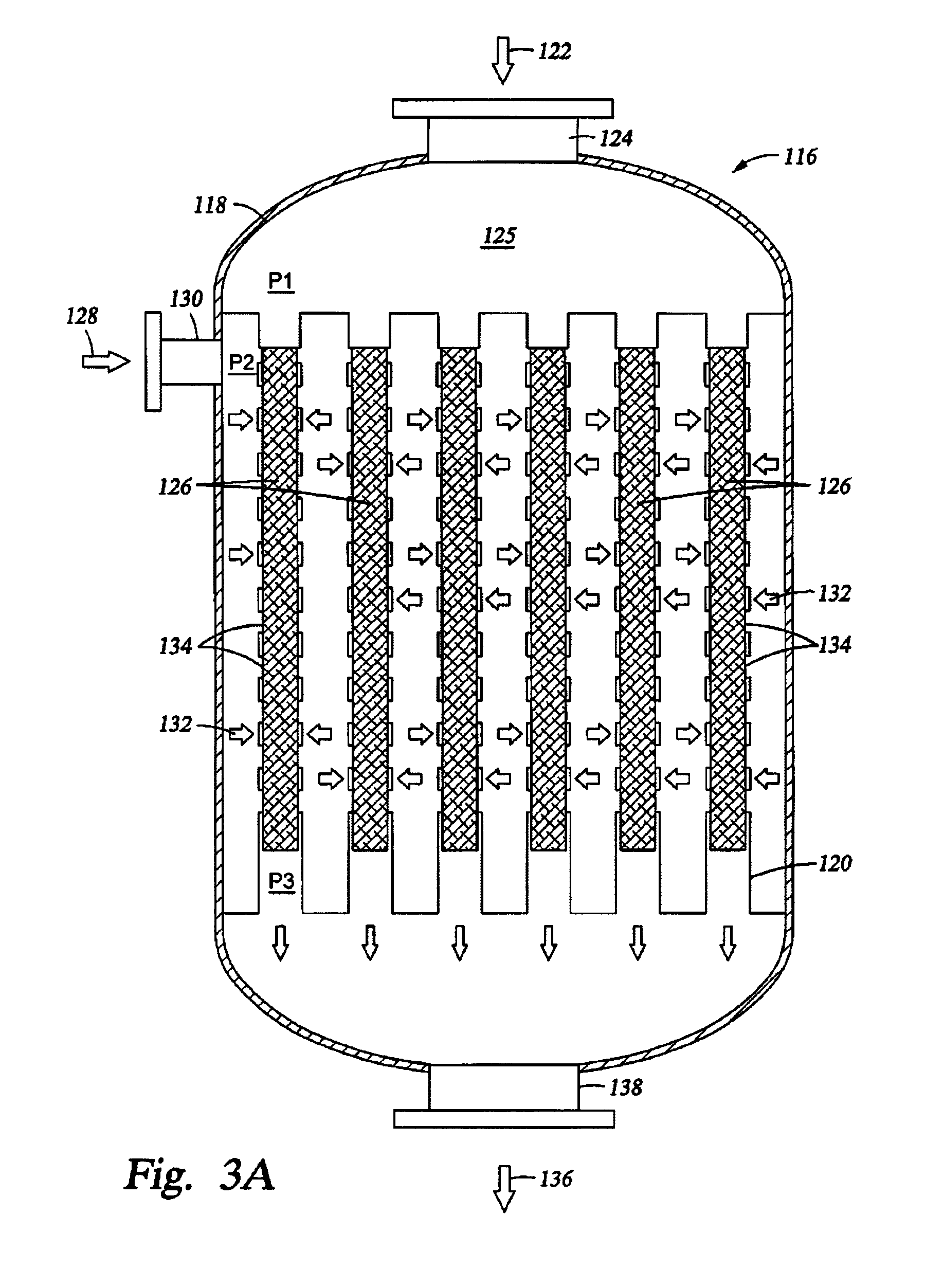

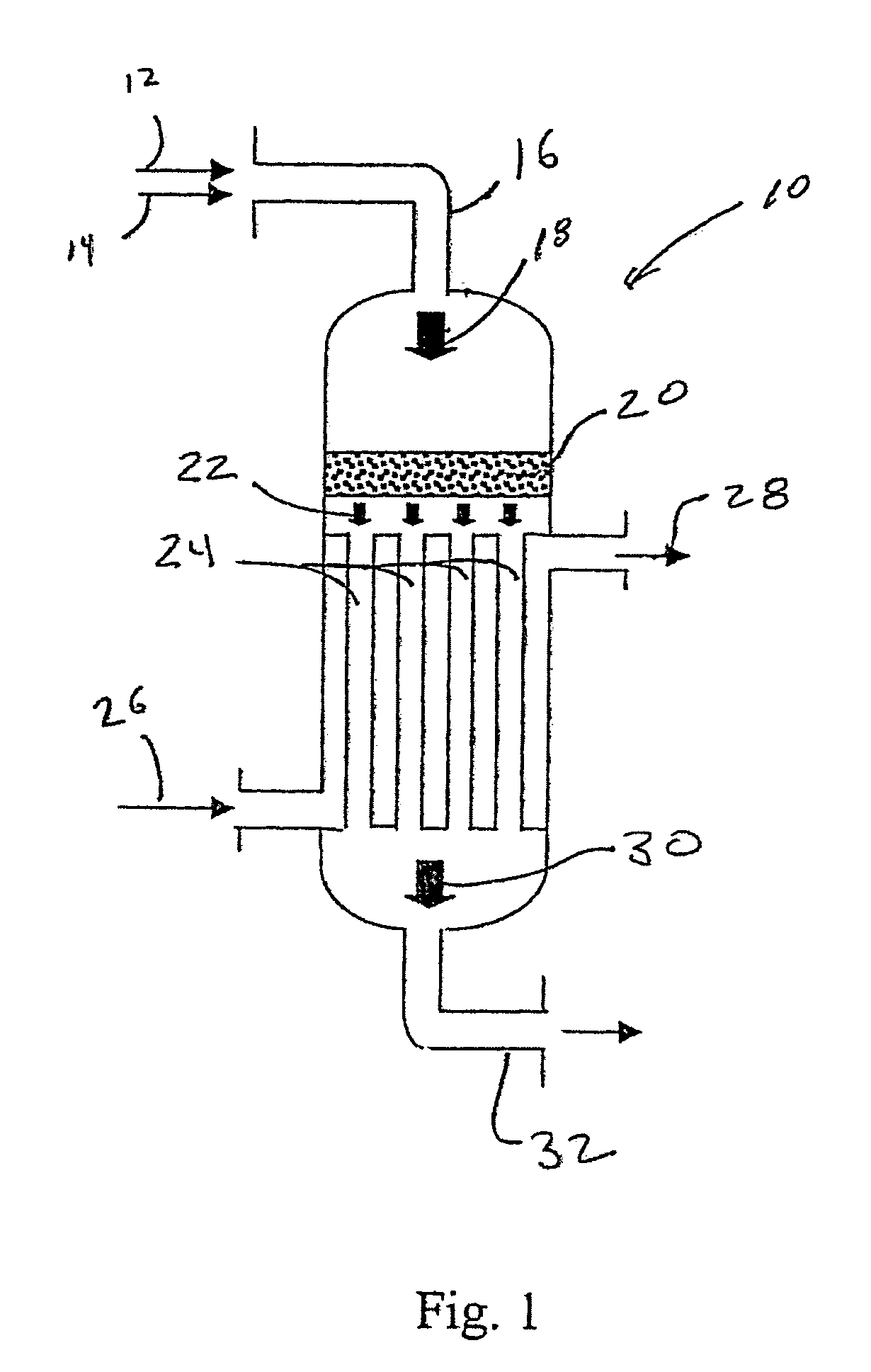

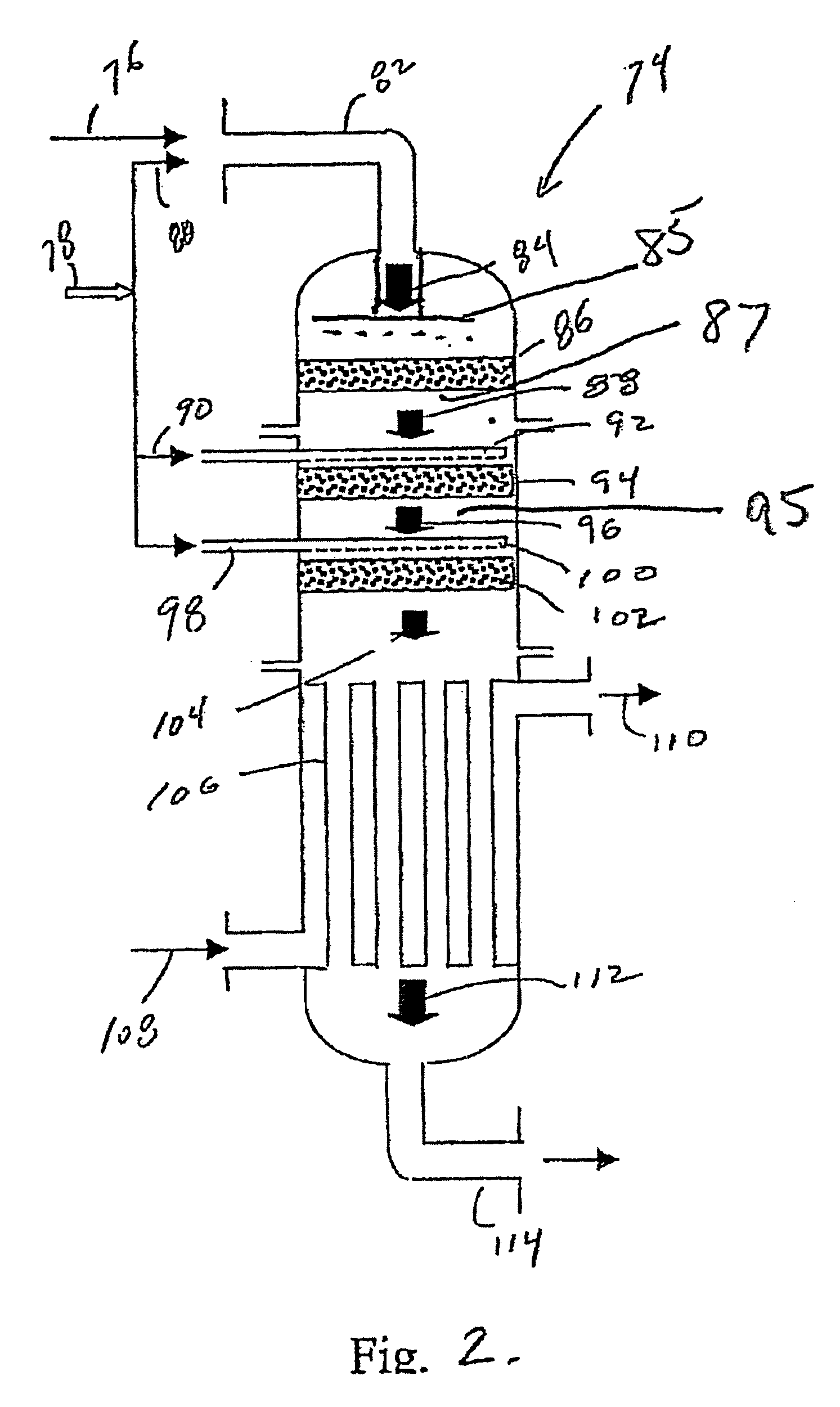

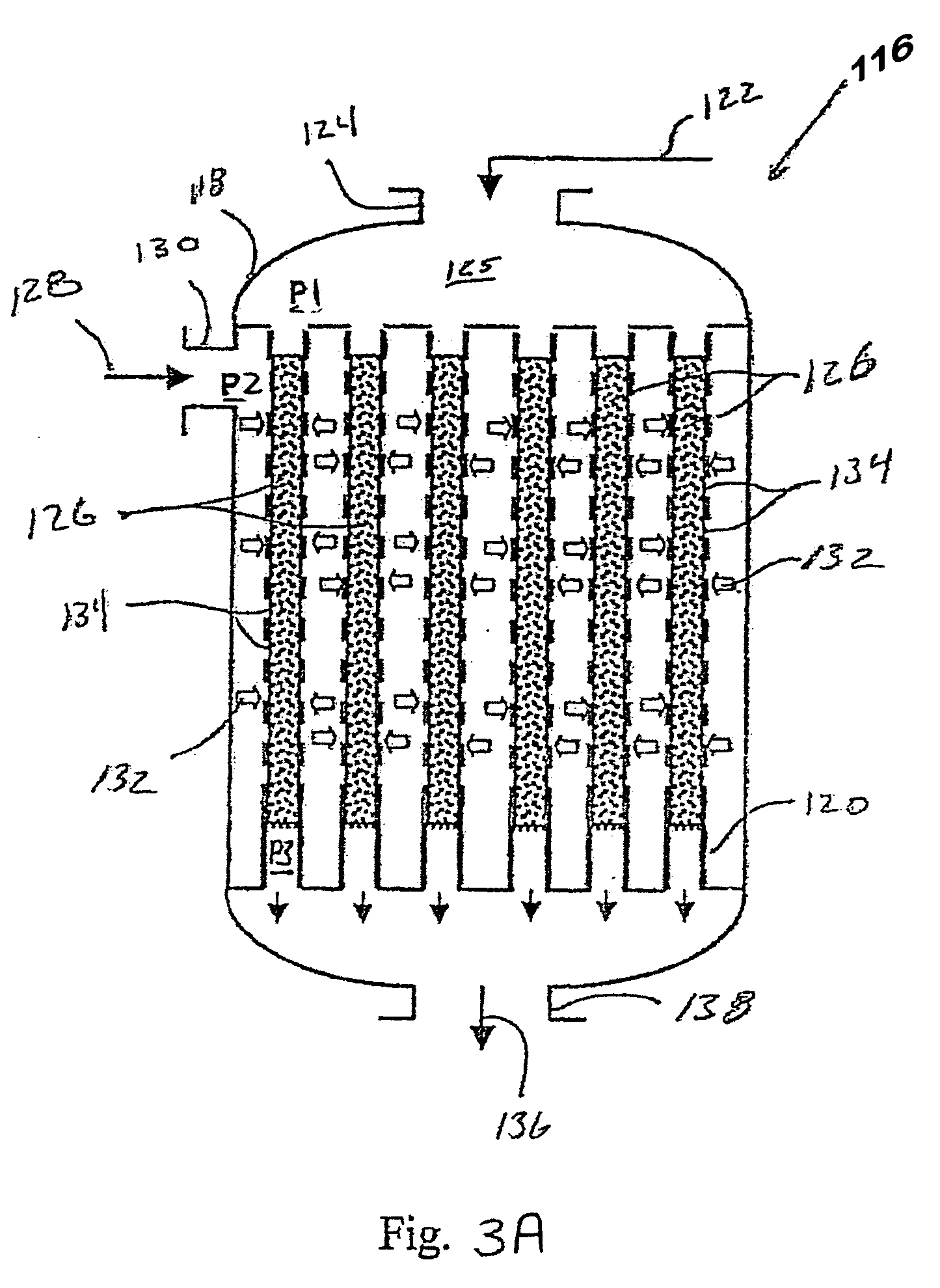

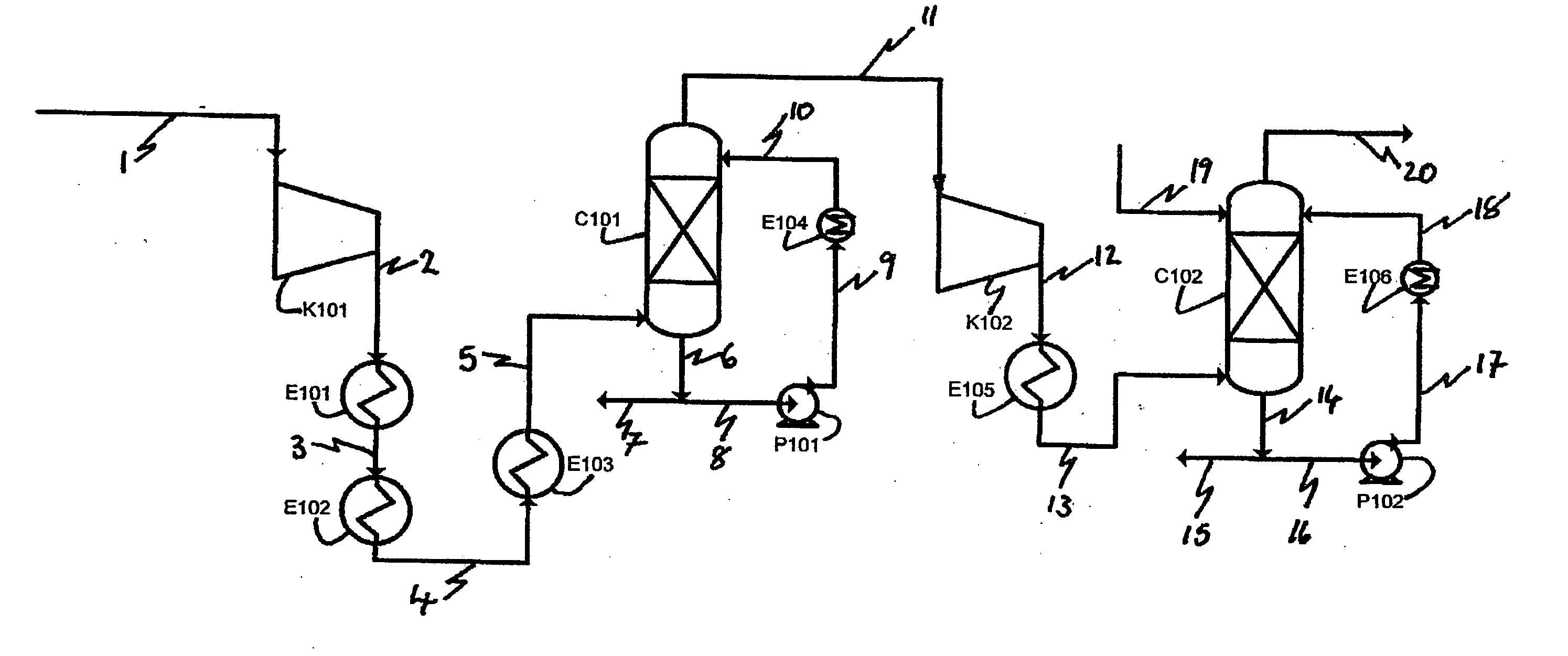

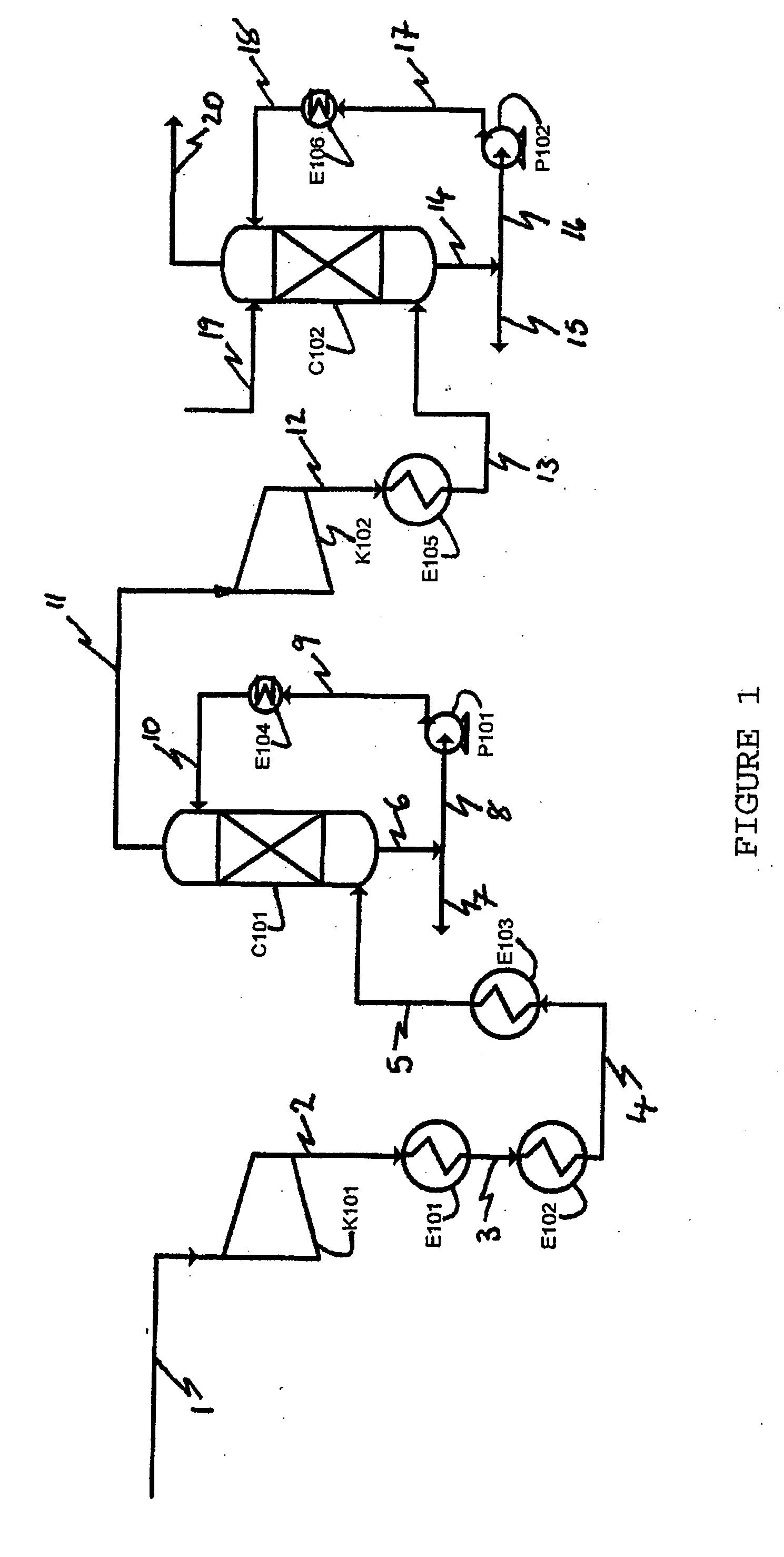

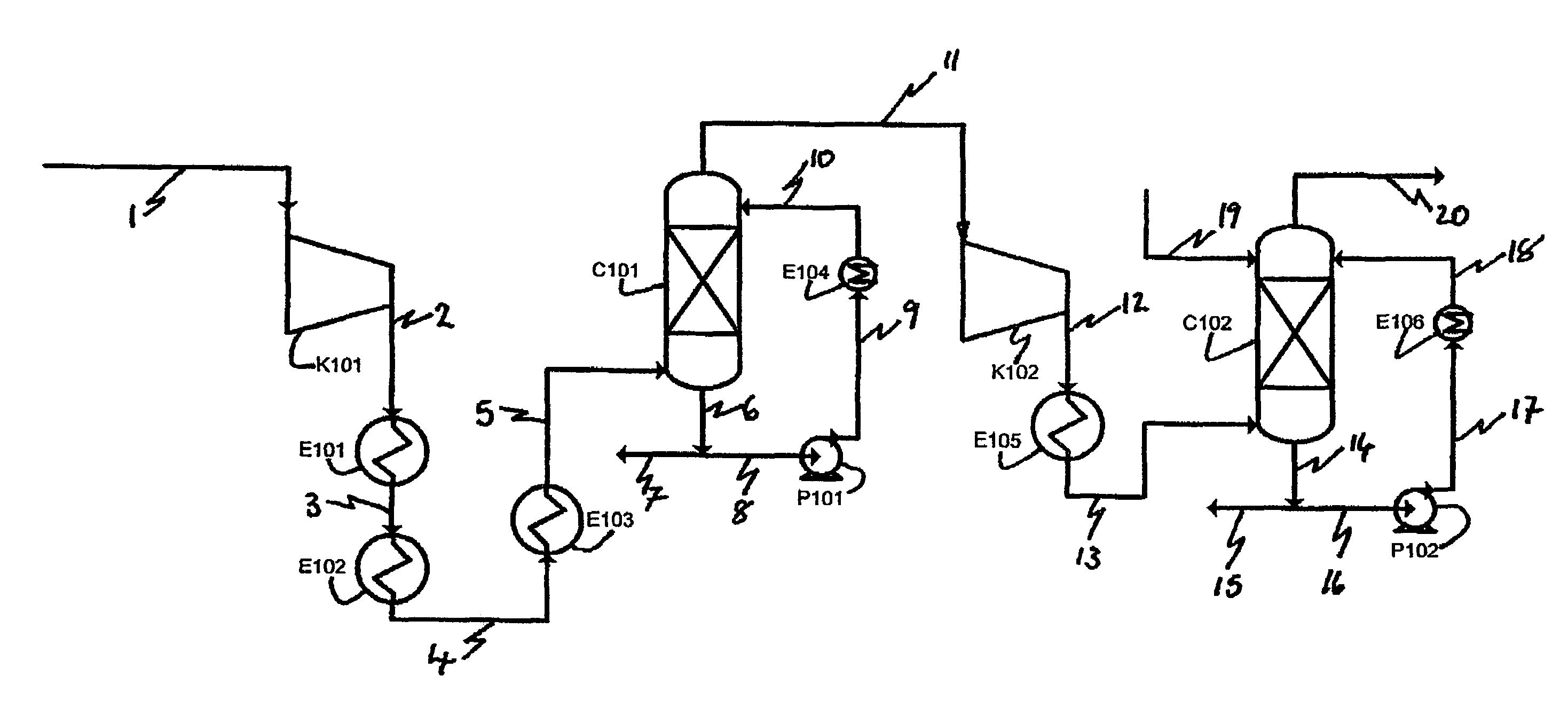

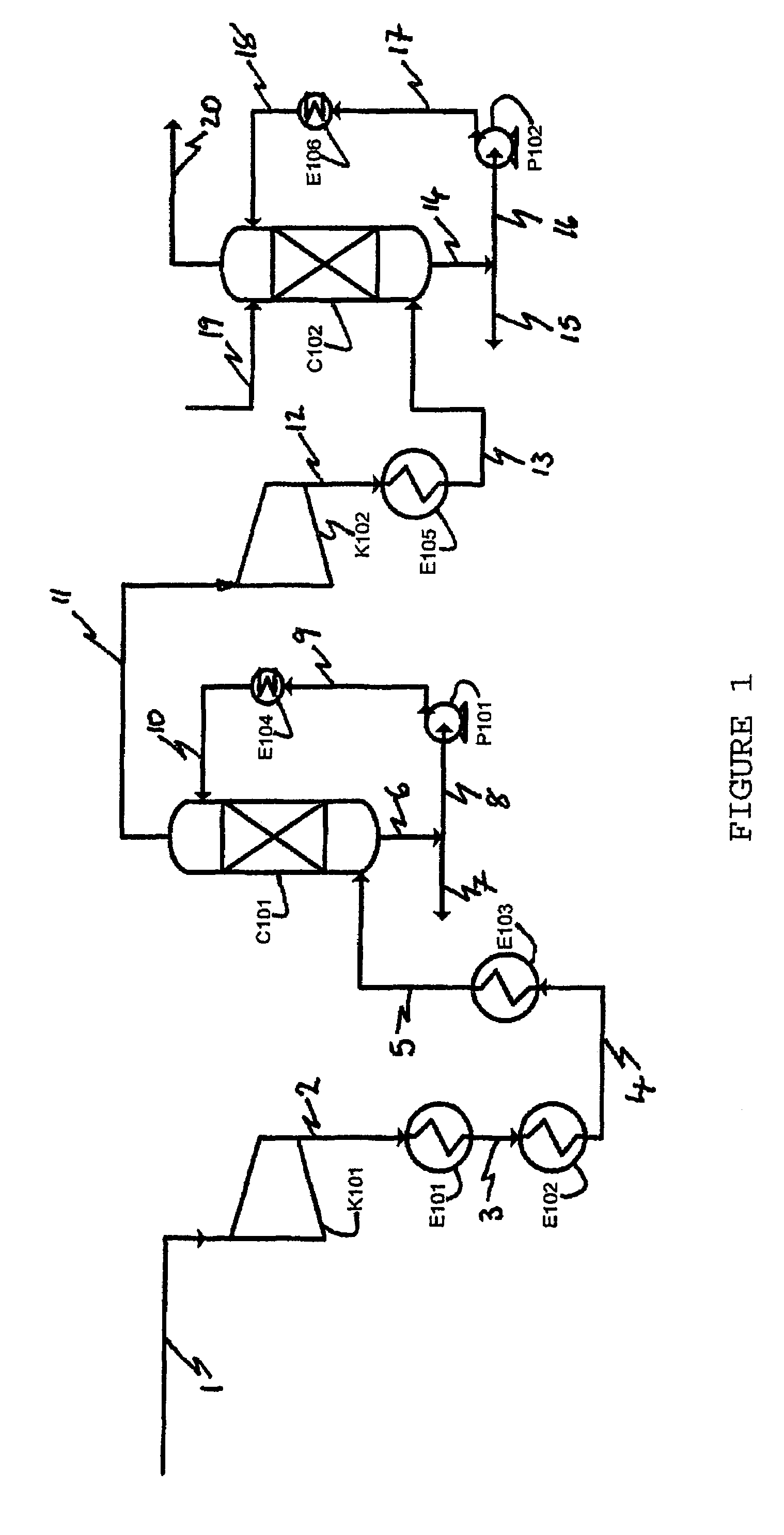

Synthesis gas process comprising partial oxidation using controlled and optimized temperature profile

ActiveUS7261751B2Low selectivityRisk of explosion can be minimizedHydrocarbon from carbon oxidesCarburetting by solid carbonaceous material pyrolysisPartial oxidationFixed bed

Owner:PHILLIPS 66 CO

Synthesis gas process comprising partial oxidation using controlled and optimized temperature profile

ActiveUS20060029539A1Risk of explosion can be minimizedIncrease the molar ratioHydrocarbon from carbon oxidesCarburetting by solid carbonaceous material pyrolysisForming gasPartial oxidation

This invention relates to methods for reacting a hydrocarbon, molecular oxygen, and optionally water and / or carbon dioxide, to form synthesis gas. The preferred embodiments are characterized by delivering a substochiometric amount of oxygen to each of a multitude of reaction zones, which allows for optimum design of the catalytic packed bed and the gas distribution system, and for the optimization and control of the temperature profile of the reaction zones. The multitude of reaction zones may include a series of successive fixed beds, or a continuous zone housed within an internal structure having porous, or perforated, walls, through which an oxygen-containing stream can permeate. By controlling the oxygen supply, the temperatures, conversion, and product selectivity of the reaction can be in turn controlled and optimized. Furthermore the potential risks of explosion associated with mixing hydrocarbon and molecular oxygen is minimized with increased feed carbon-to-oxygen molar ratios.

Owner:PHILLIPS 66 CO

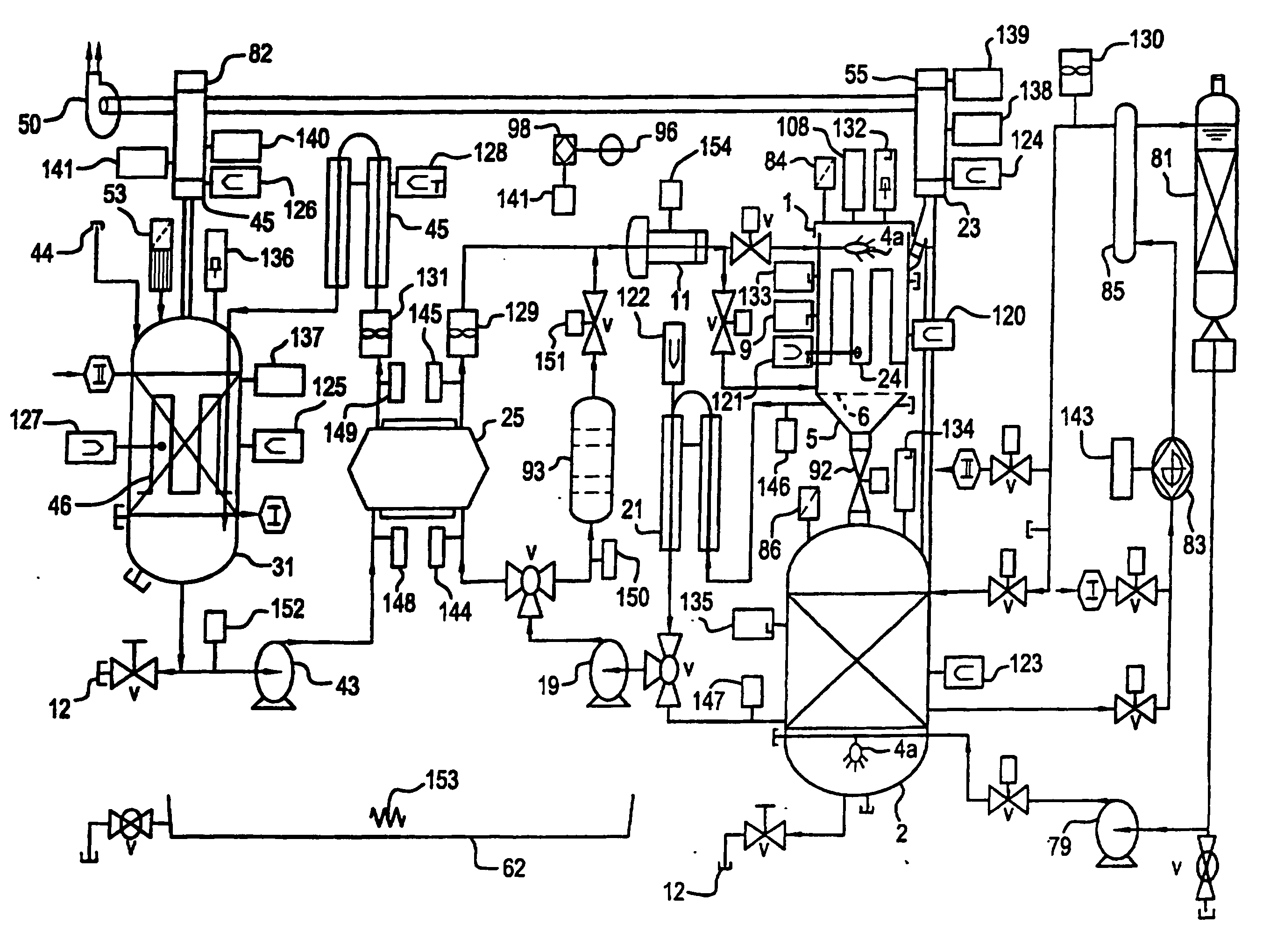

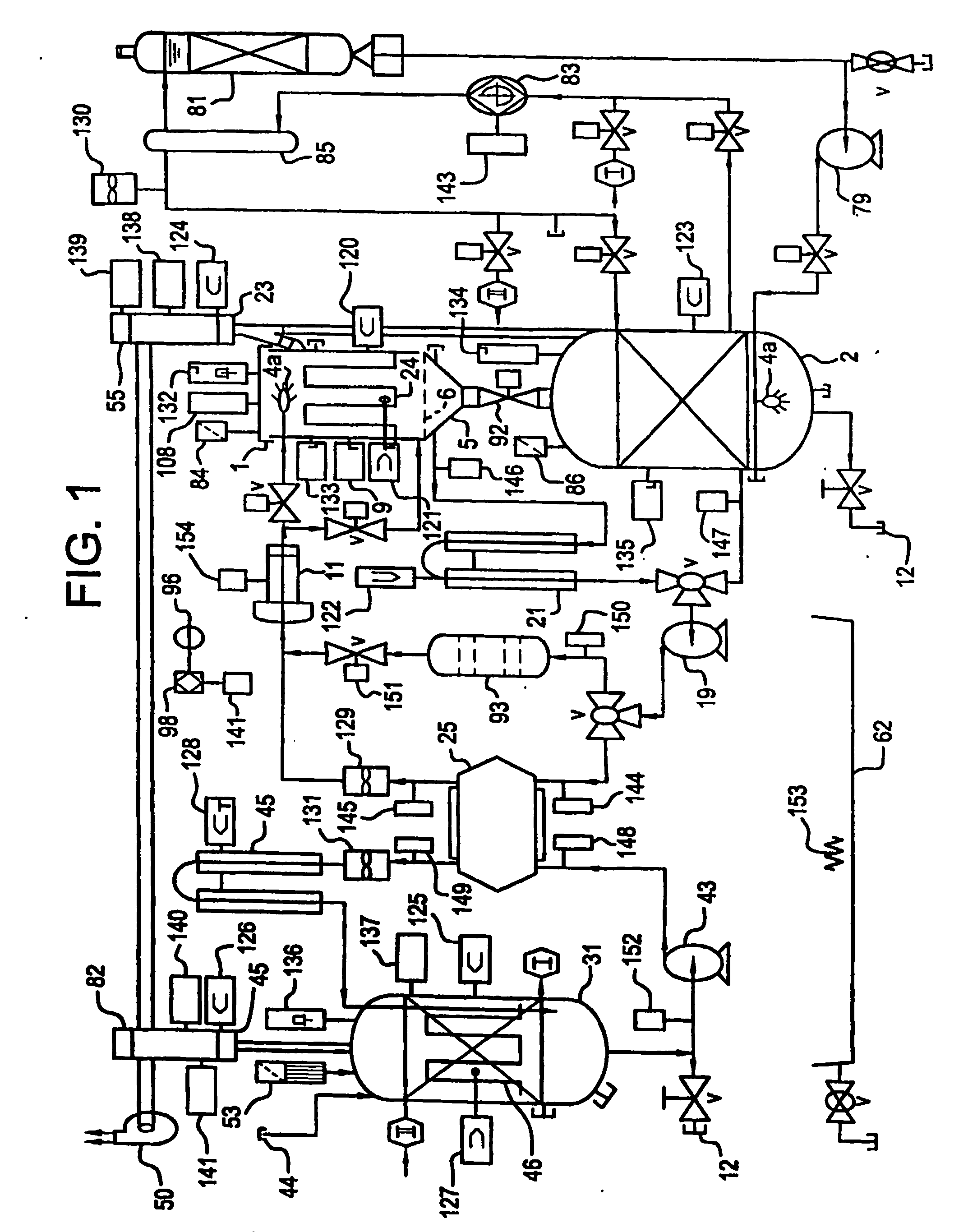

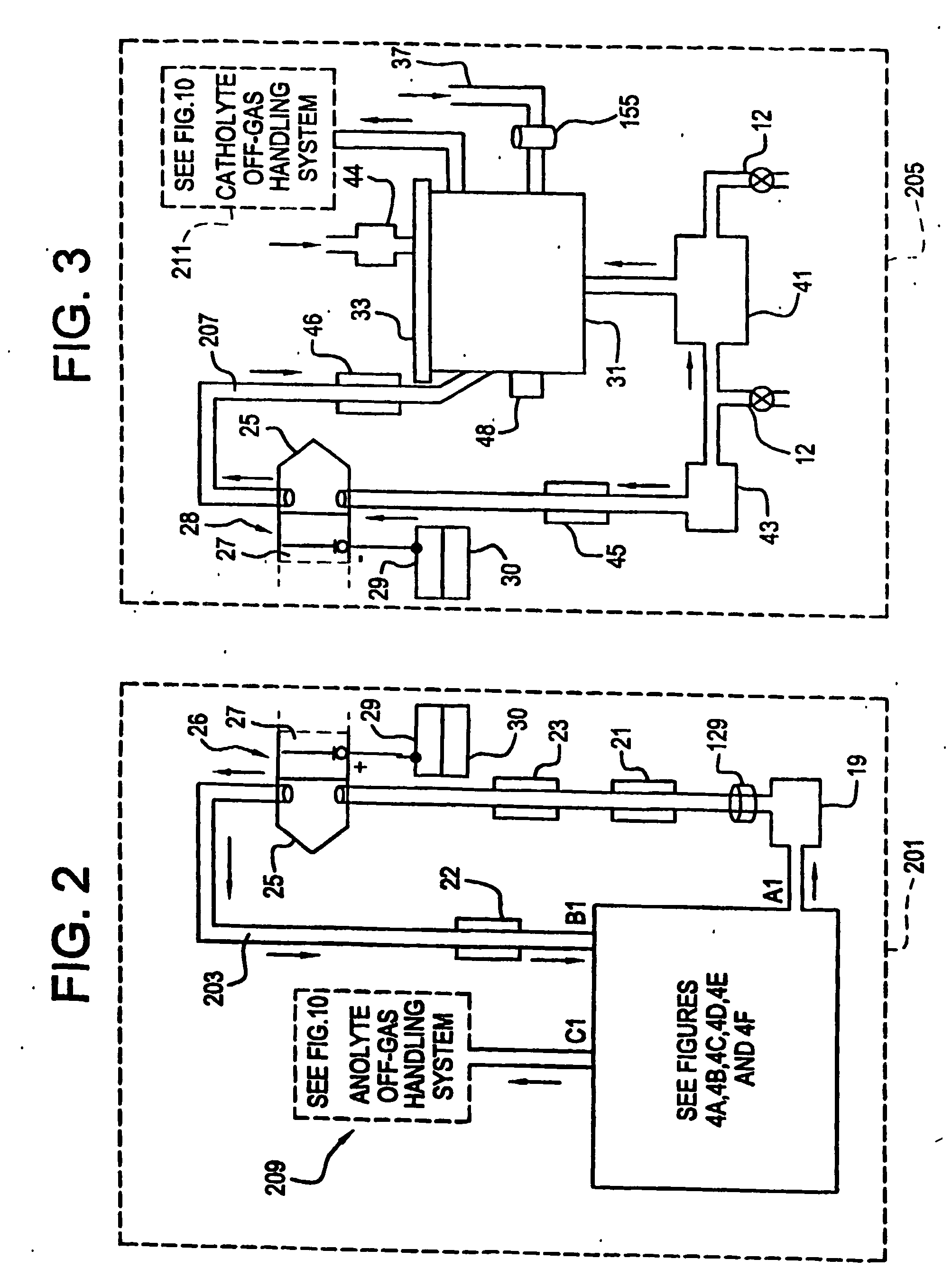

Apparatus and process for mediated electrochemical oxidation of materials

A unique apparatus unique apparatus and process that uses mediated electrochemical oxidation (MEO) for: (1) Destruction of: a) nearly all organic solid, liquid, and gases materials, except fluorinated hydrocarbons; b) all biological solid, liquid, and gases materials; c) and / or dissolution and decontamination (such as cleaning equipment and containers, etc.) of nearly all inorganic solid, liquid, or gas where higher oxidation states exist which includes, but is not limited to, halogenated inorganic compounds (except fluorinated), inorganic pesticides and herbicides, inorganic fertilizers, carbon residues, inorganic carbon compounds, mineral formations, mining tailings, inorganic salts, metals and metal compounds, etc.); and d) combined materials (e.g. a mixture of any of the foregoing with each other); henceforth collectively referred to as materials. (2) Sterilization / disinfection of equipment, glassware, etc., by destroying all existing infectious materials. (3) Dissolution of transuranic / actinide materials and / or destruction of the oxidizable components in the hazardous waste portion of mixed waste. (4) Generation of hydrogen and oxygen from MEO of materials. (5) Alteration of organic, biological, and inorganic materials by MEO to produce other compounds from these materials. The materials are introduced into an apparatus for contacting the materials with an electrolyte containing the oxidized form of one or more reversible redox couples, at least one of which is produced electrochemically by anodic oxidation at the anode of an electrochemical cell. The oxidized forms of any other redox couples present are produced either by similar anodic oxidation or reaction with the oxidized form of other redox couples present and capable of affecting the required redox reaction. The oxidized species of the redox couples oxidize the materials molecules and are themselves converted to their reduced form, whereupon they are reoxidized by either of the aforementioned mechanisms and the redox cycle continues until all oxidizable material species, including intermediate reaction products, have undergone the desired degree of oxidation. The entire process takes place at temperatures between ambient and approximately 100° C. The oxidation process may be enhanced by the addition of reaction enhancements, such as: ultrasonic energy and / or ultraviolet radiation.

Owner:SCIMIST LNC

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

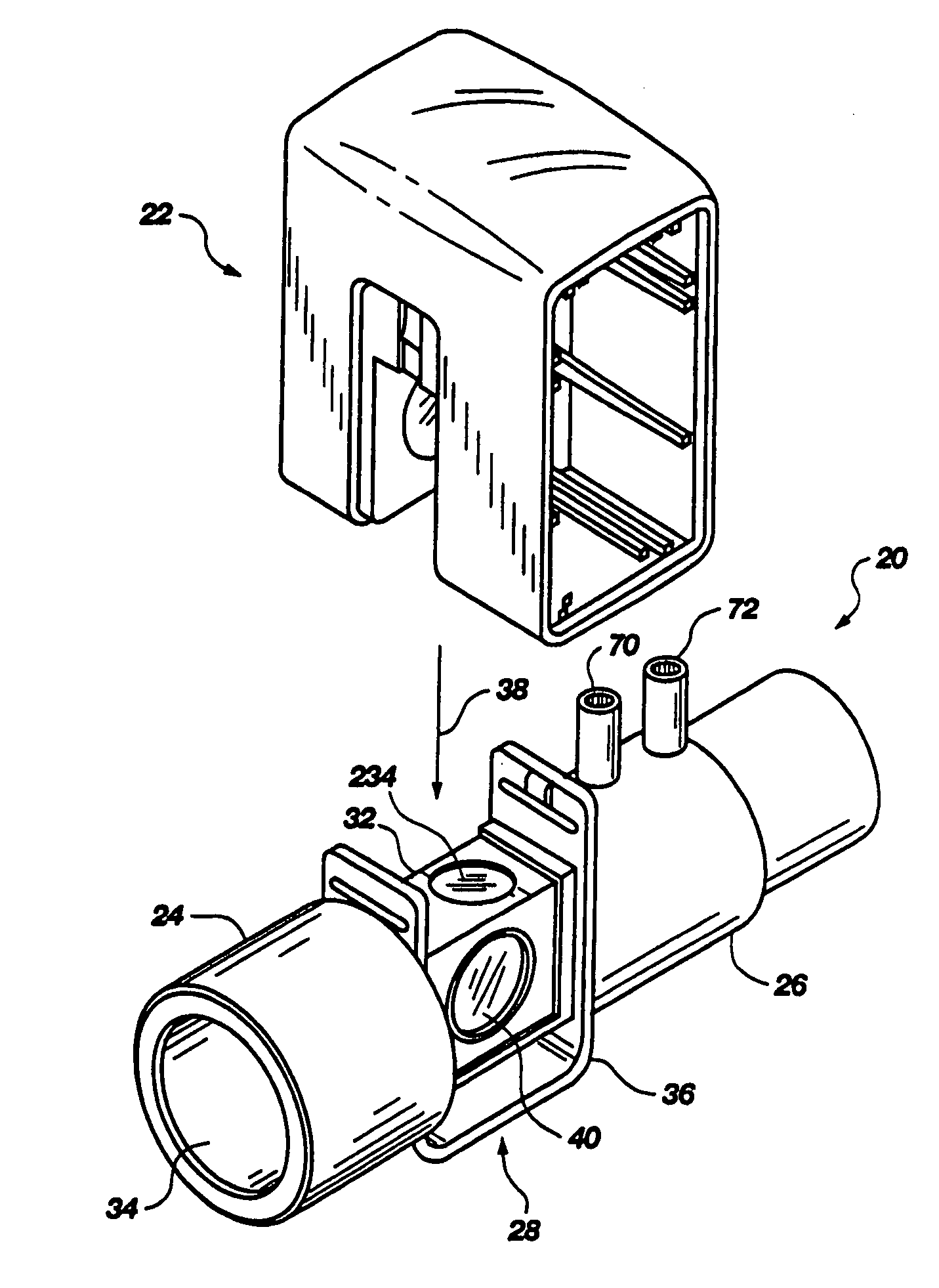

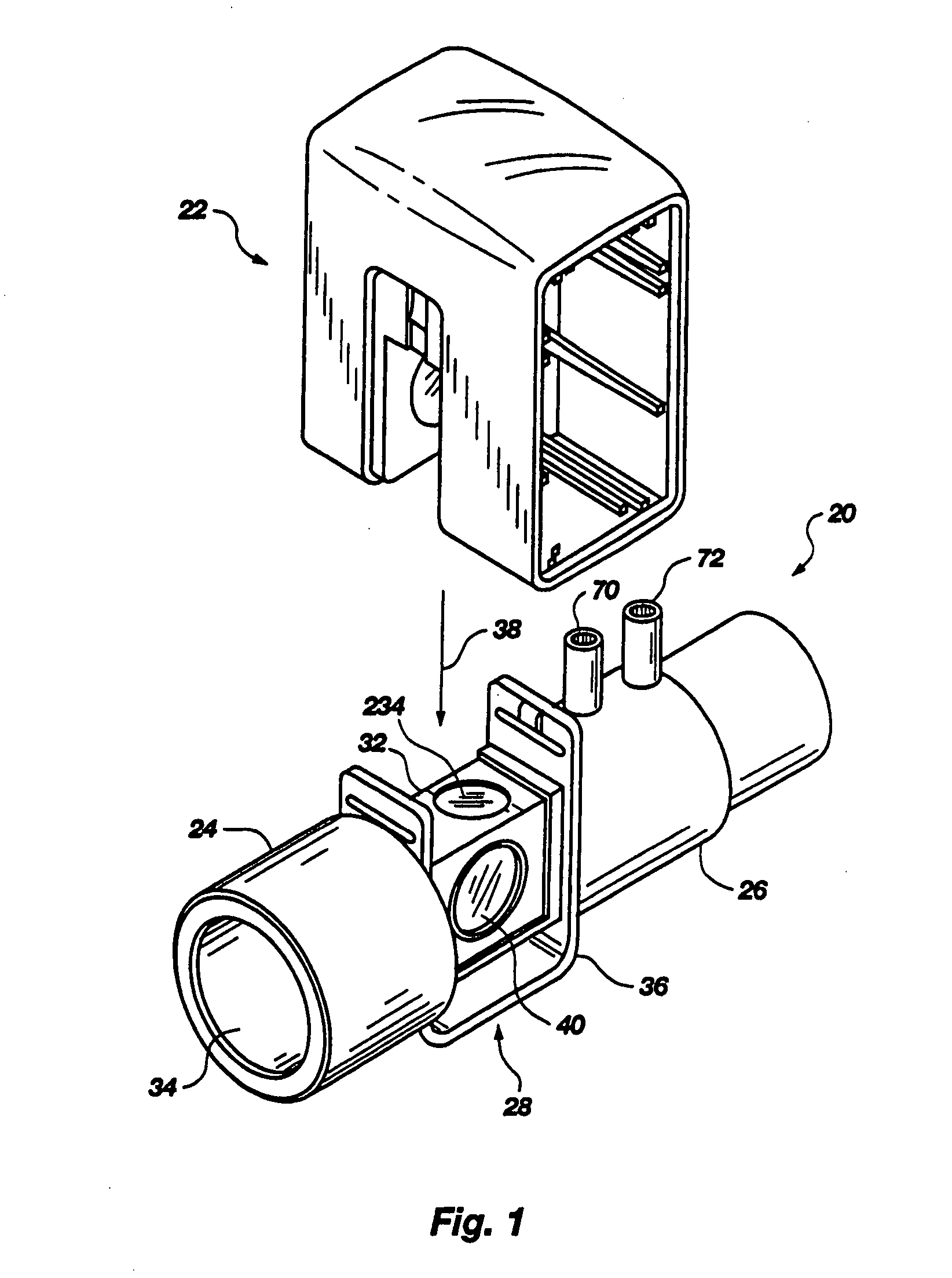

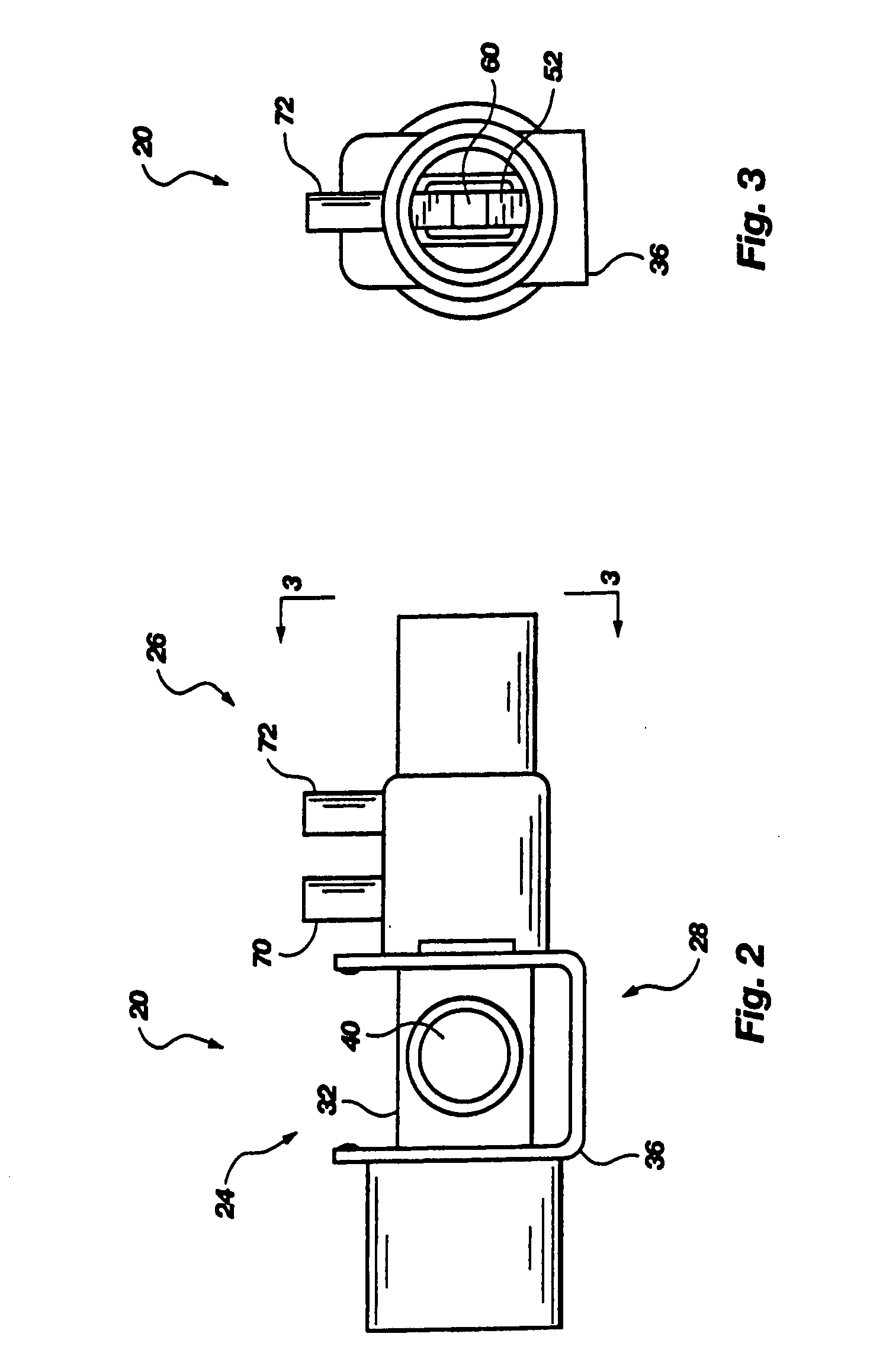

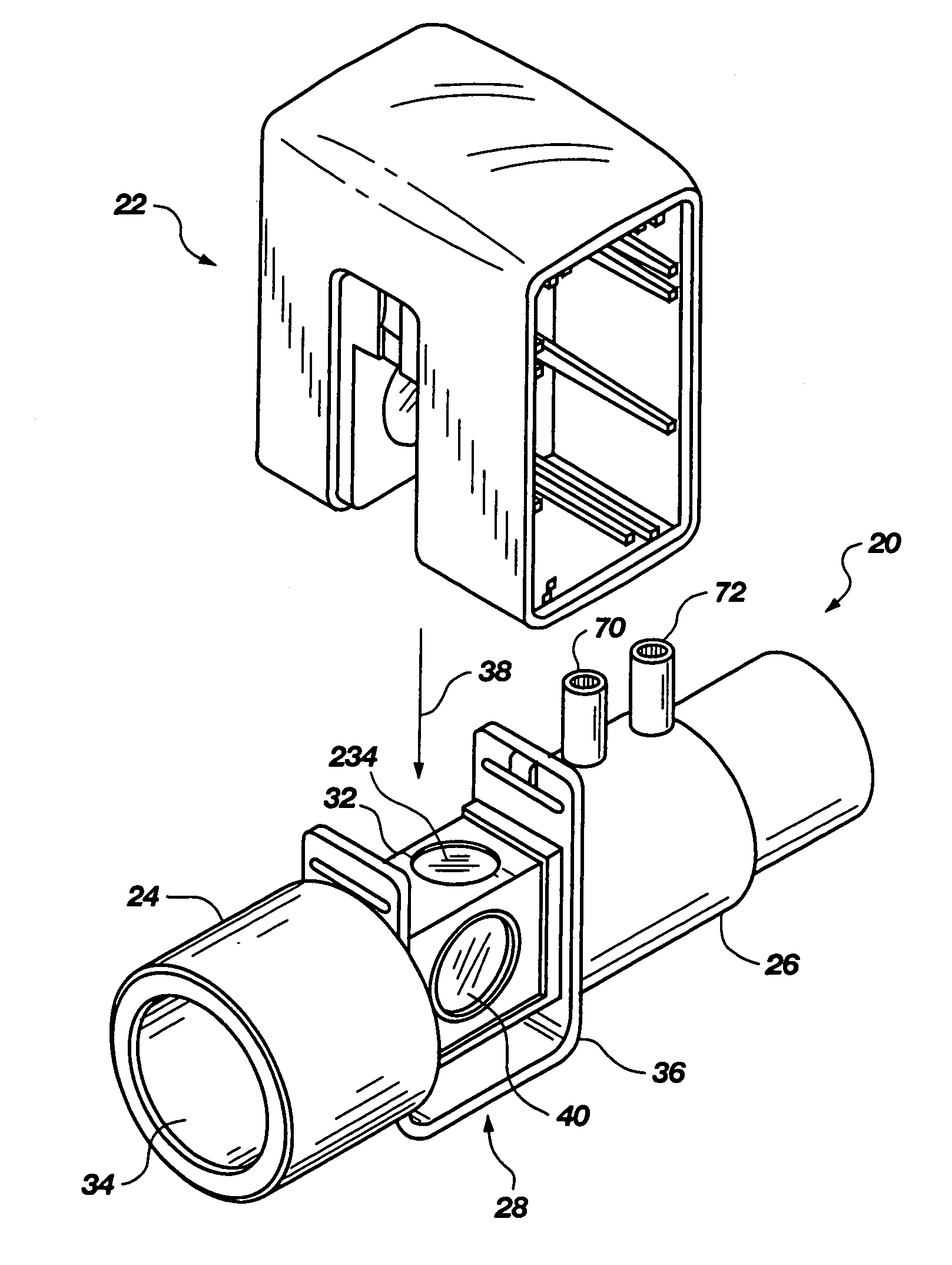

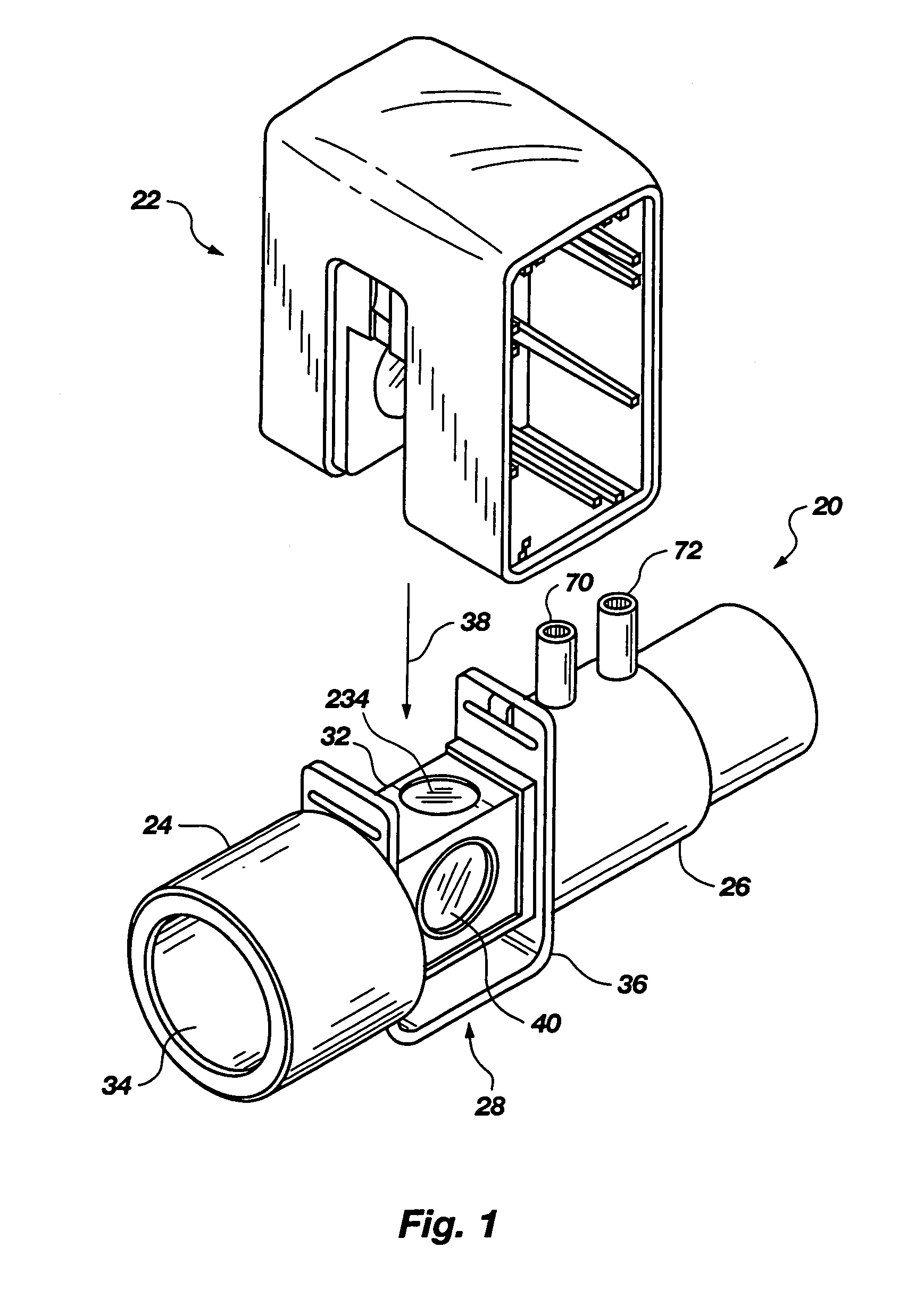

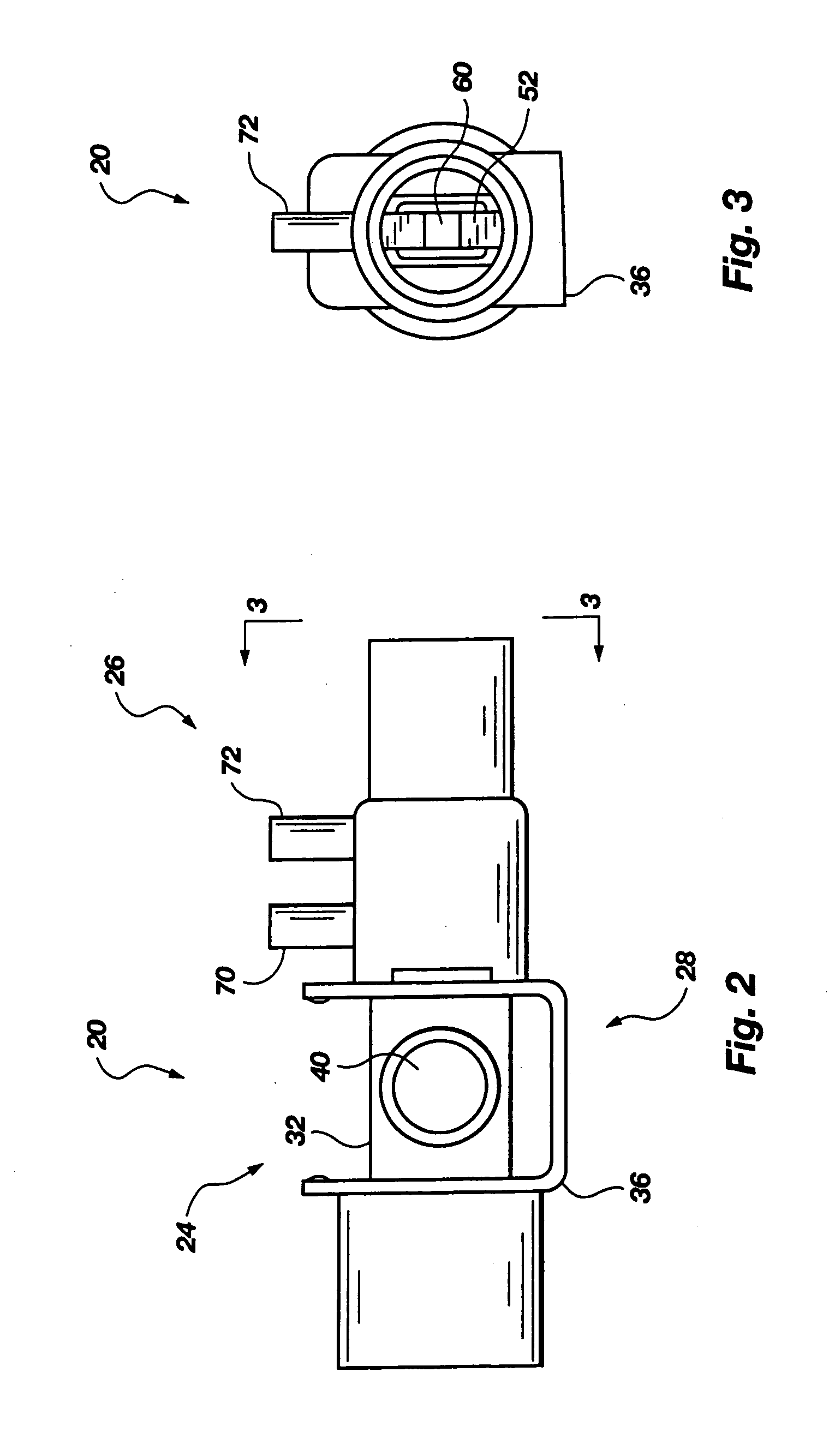

Metabolic measurements system including a multiple function airway adapter

InactiveUS20070225612A1Easy to reusePromote generationRespiratory organ evaluationSensorsAnesthetic AgentRespiratory flow

A system for measuring a metabolic parameter. The system includes an integrated airway adapter capable of monitoring any combination of respiratory flow, O2 concentration, and concentrations of one or more of CO2, N2O, and an anesthetic agent in real time, breath by breath. Respiratory flow may be monitored with differential pressure flow meters under diverse inlet conditions through improved sensor configurations which minimize phase lag and dead space within the airway. Molecular oxygen concentration may be monitored by way of luminescence quenching techniques. Infrared absorption techniques may be used to monitor one or more of CO2, N2O, and anesthetic agents.

Owner:RIC INVESTMENTS LLC

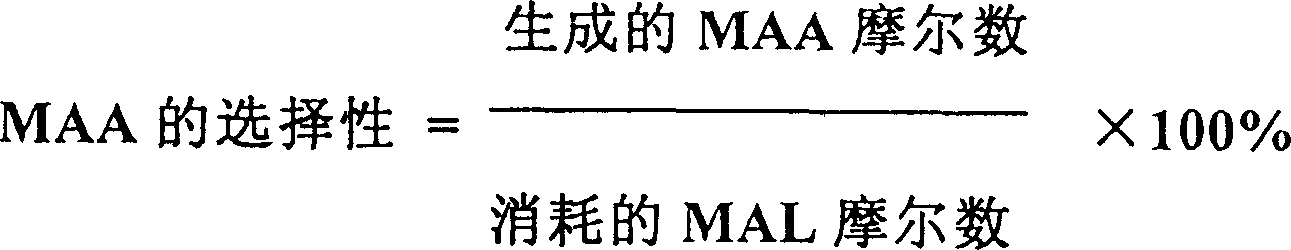

Catalyst for selectively oxidizing methyl acrylic aldehyde to synthesize methyl propenoic acid and its use

ActiveCN1647854AHigh reactivityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationHeteropoly acidGas phase

The present invention provides catalyst for selectively oxidizing methyl acrolein to synthesize methylpropenoic acid and its usage in catalyzing gas phase oxidation of methyl acrolein to synthesize methylpropenoic acid. The catalyst is one heteropoly acid salt containing Mo, P, K, Sb, Cu, As, etc., and has high catalytic activity and stability, long service life, methyl acrolein converting rate higher than 85 % and methylpropenoic acid selectivity over 87 % in the presence of molecular oxygen and diluting gas.

Owner:SHANGHAI HUAYI NEW MATERIAL

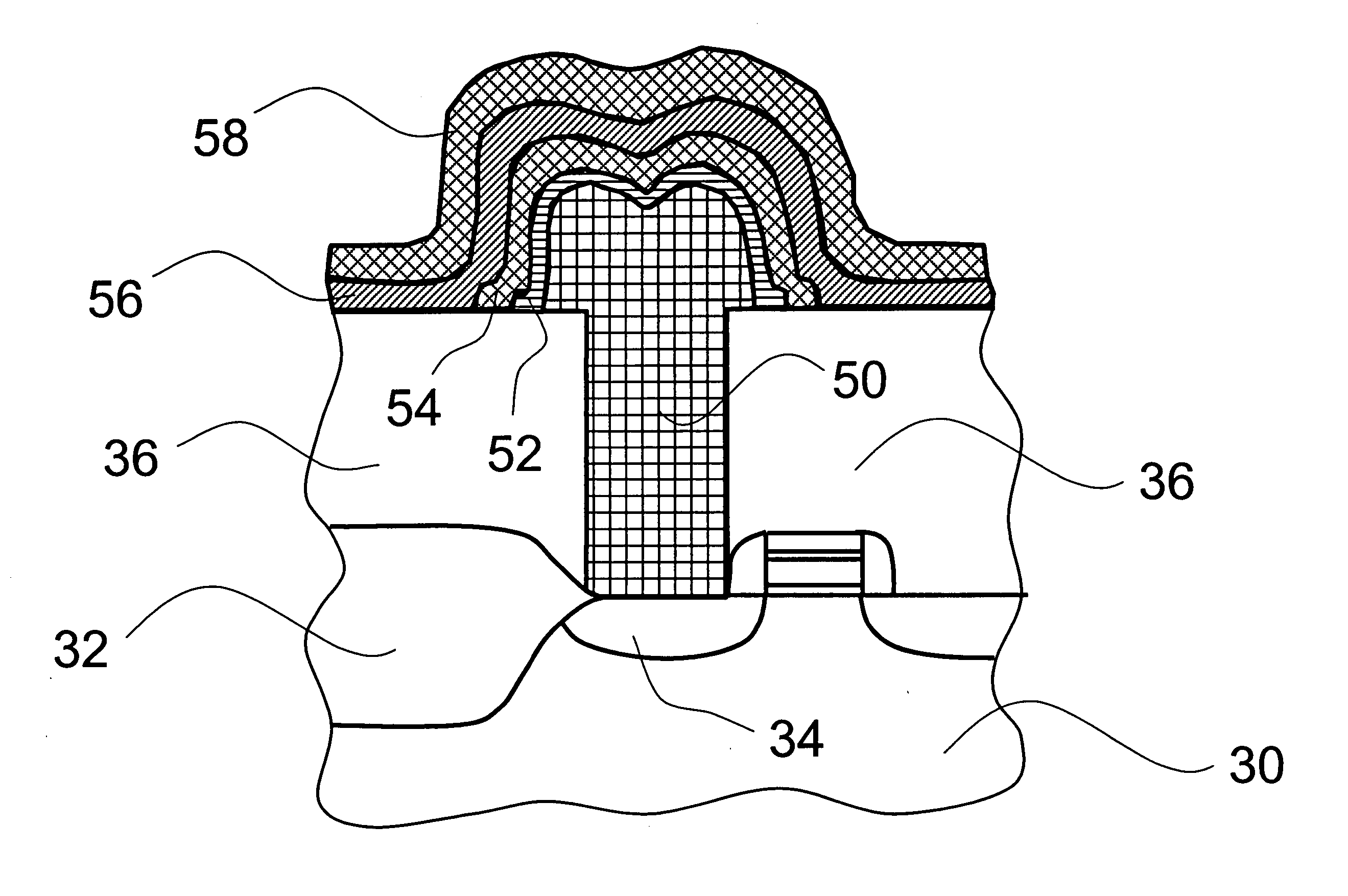

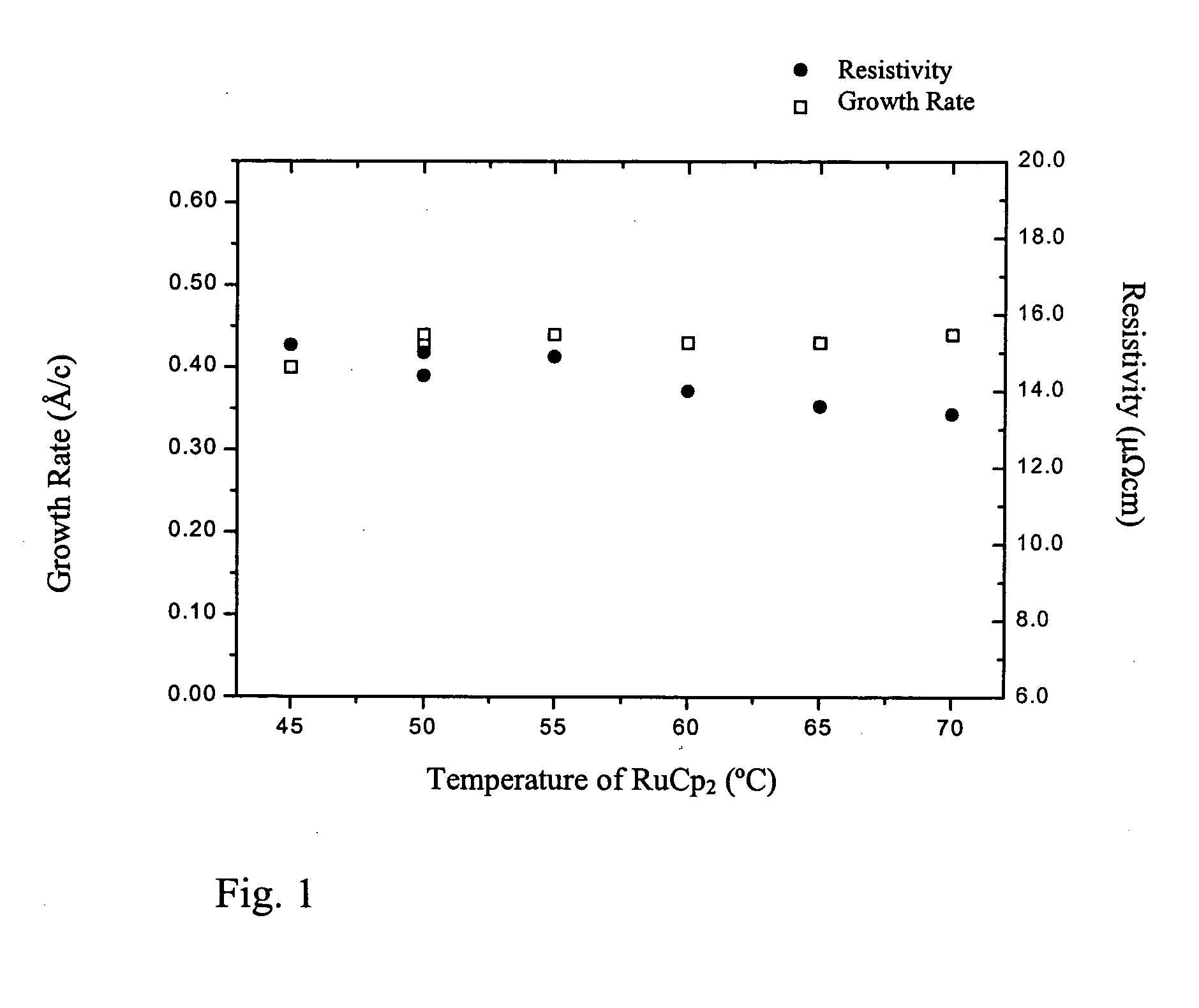

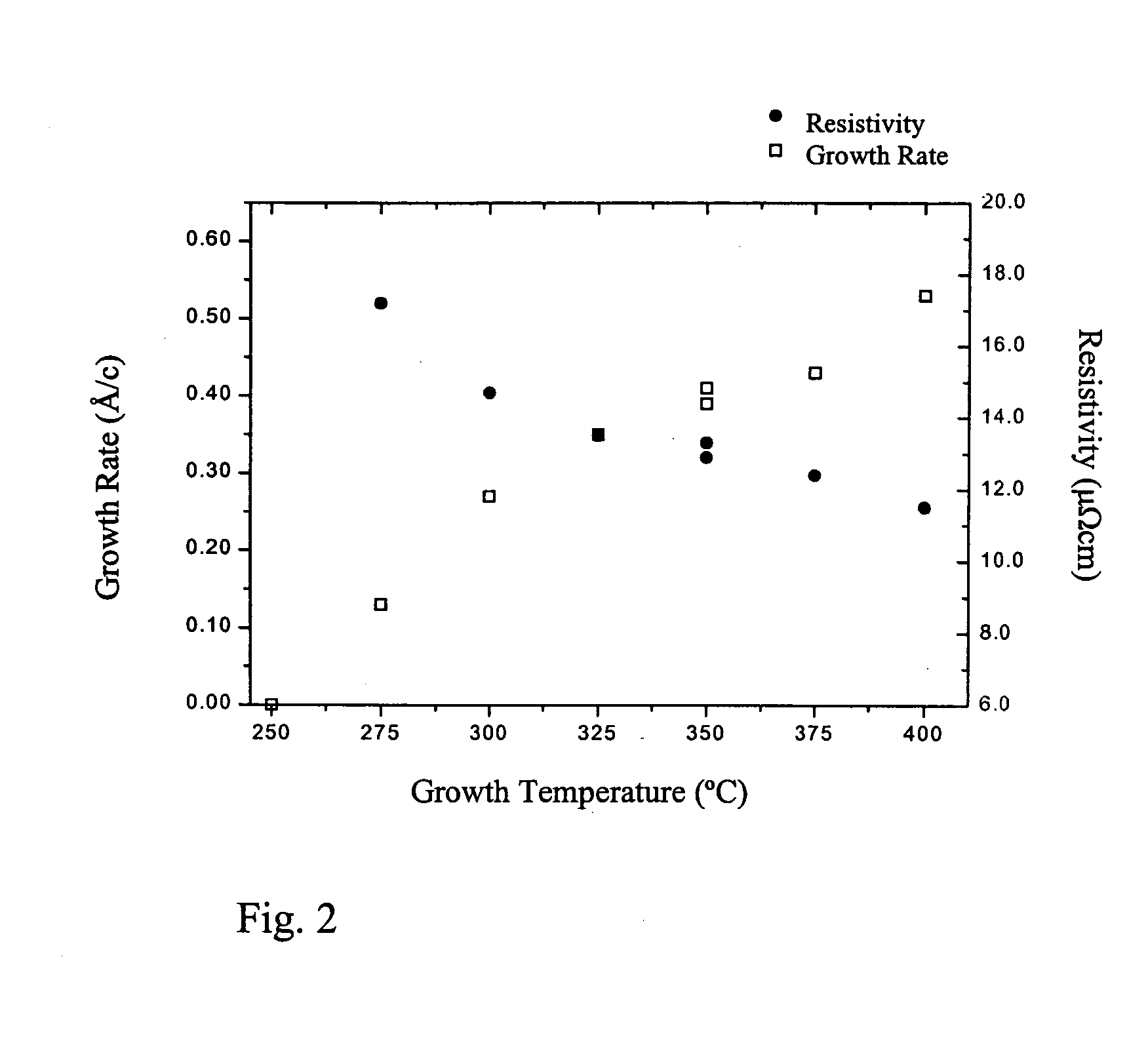

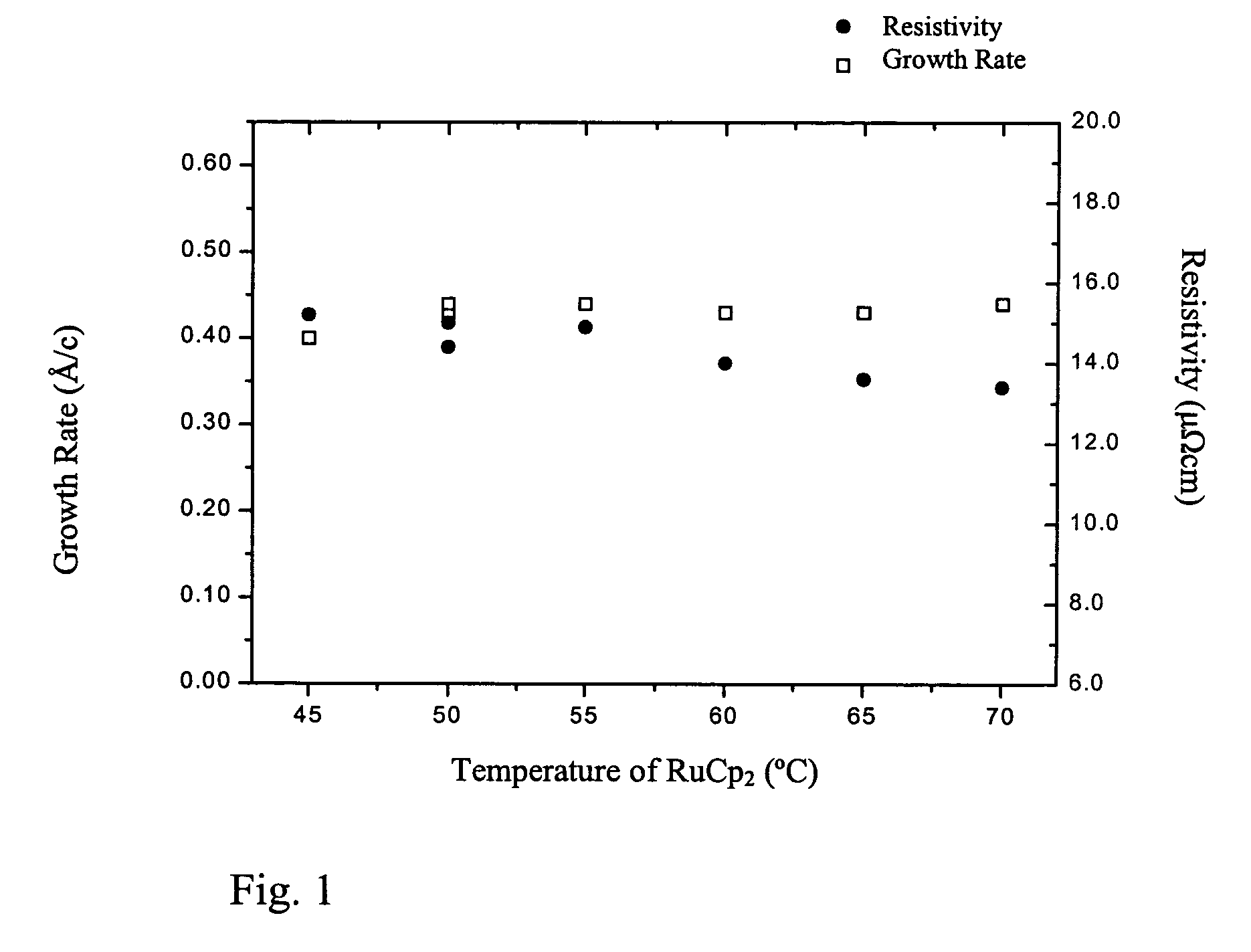

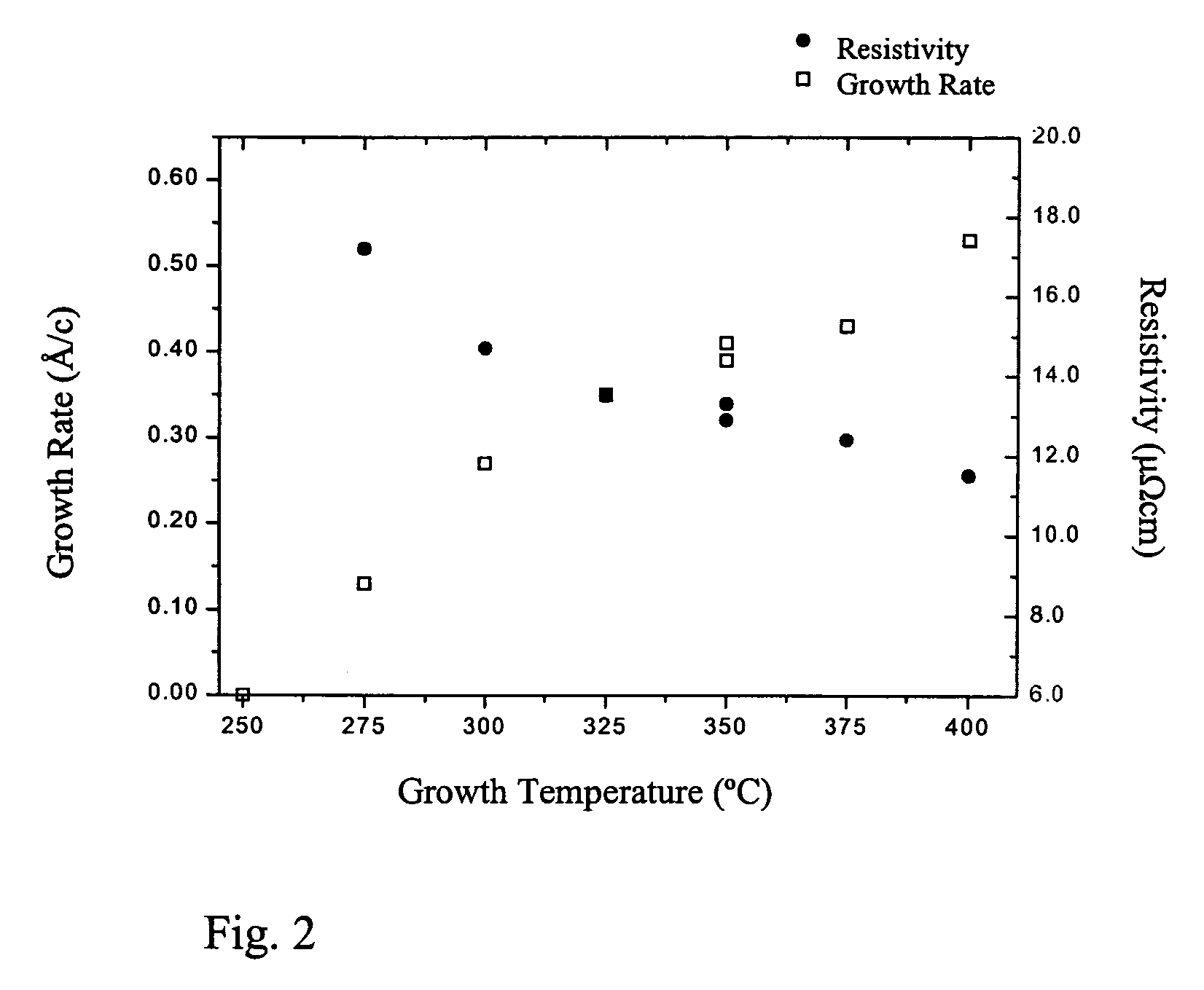

Process for producing metal thin films by ALD

InactiveUS20050020060A1Promote nucleationGood film uniformityNanomagnetismSolid-state devicesHigh elevationSurface structure

The invention relates generally to processes for producing electrically conductive noble metal thin films on a substrate by atomic layer deposition. According to one embodiment of the invention a substrate with a surface is provided in a reaction chamber and a vaporised precursor of a noble metal is pulsed into the reaction chamber. By contacting the vaporised precursor with the surface of the substrate, no more than about a molecular layer of the metal precursor is formed on the substrate. In a next step, a pulse of molecular oxygen-containing gas is provided in the reaction chamber, where the oxygen reacts with the precursor on the substrate. Thus, high-quality metal thin films can be deposited by utilising reactions between the metal precursor and oxygen. In one embodiment, electrically conductive layers are deposited in structures that have high aspect ratio vias and trenches, local high elevation areas or other similar surface structures that make the surface rough.

Owner:ASM INTERNATIONAL

Multiple function airway adapter

InactiveUS7335164B2Promote generationEasy to measureAnalysis using chemical indicatorsChemiluminescene/bioluminescenceRespiratory flowAirway adaptor

An integrated airway adapter capable of monitoring any combination of respiratory flow, O2 concentration, and concentrations of one or more of CO2, N2O, and an anesthetic agent in real time, breath by breath. Respiratory flow may be monitored with differential pressure flow meters under diverse inlet conditions through improved sensor configurations which minimize phase lag and dead space within the airway. Molecular oxygen concentration may be monitored by way of luminescence quenching techniques. Infrared absorption techniques may be used to monitor one or more of CO2, N2O, and anesthetic agents.

Owner:NTC TECH

Process for dehydrating glycerol to acrolein

The present invention relates to a process for manufacturing acrolein by dehydration of glycerol in the presence of molecular oxygen. The reaction is performed in the liquid phase or in the gas phase in the presence of a solid catalyst. The addition of oxygen makes it possible to obtain good glycerol conversion by inhibiting the deactivation of the catalyst and the formation of by-products.

Owner:ARKEMA FRANCE SA

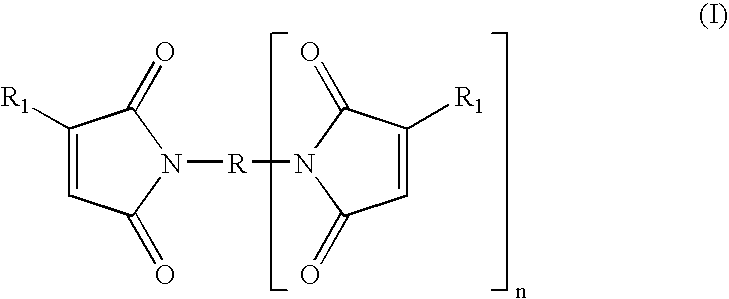

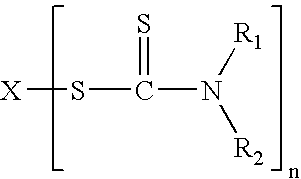

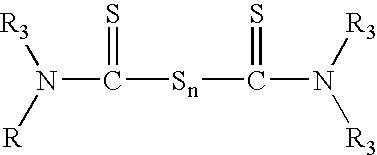

Tack free surface cures of polymers by organic peroxides in the presence of air

Compositions are disclosed which comprise mixtures of at least one compound selected from silicone elastomers, bis-, tri- or higher polymaleimides and / or bis-, tri- or higher polycitraconimides, and at least one compound selected from p-phenylene-diamine based antiozonants, sulfur compounds capable of accelerating sulfur vulcanization of polymers capable of being crosslinked by sulfur and polysulfide polymers which when compounded into polymers curable by free radical initiators in the presence of free radical initiators permit substantially tack free surface cure of the polymers by decomposition of the free radical initiator in the presence of molecular oxygen. Compositions containing the above ingredients and at least one free radical initiator, curable compositions containing the combination and processes for making and using the compositions are also disclosed.

Owner:ARKEMA INC

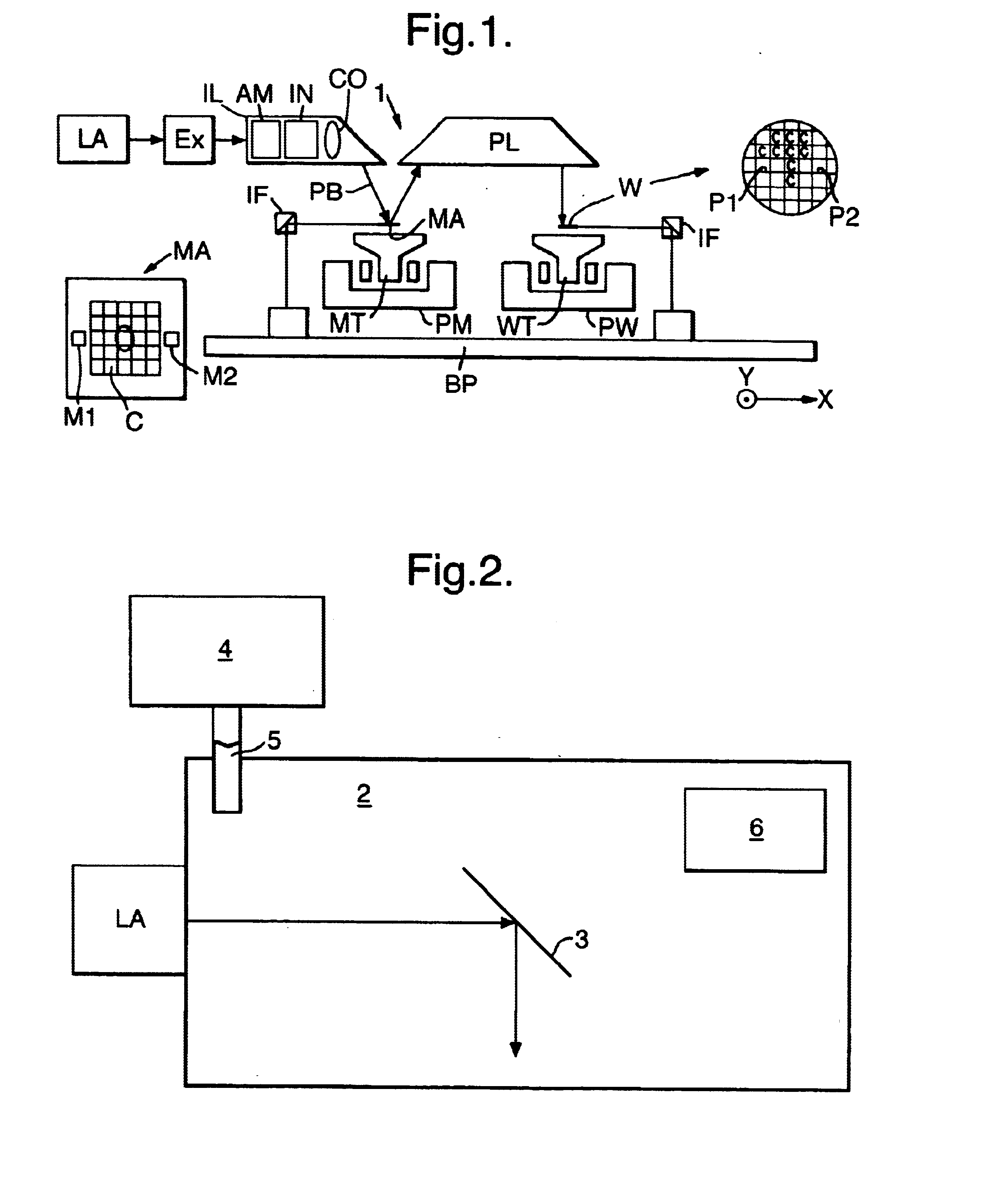

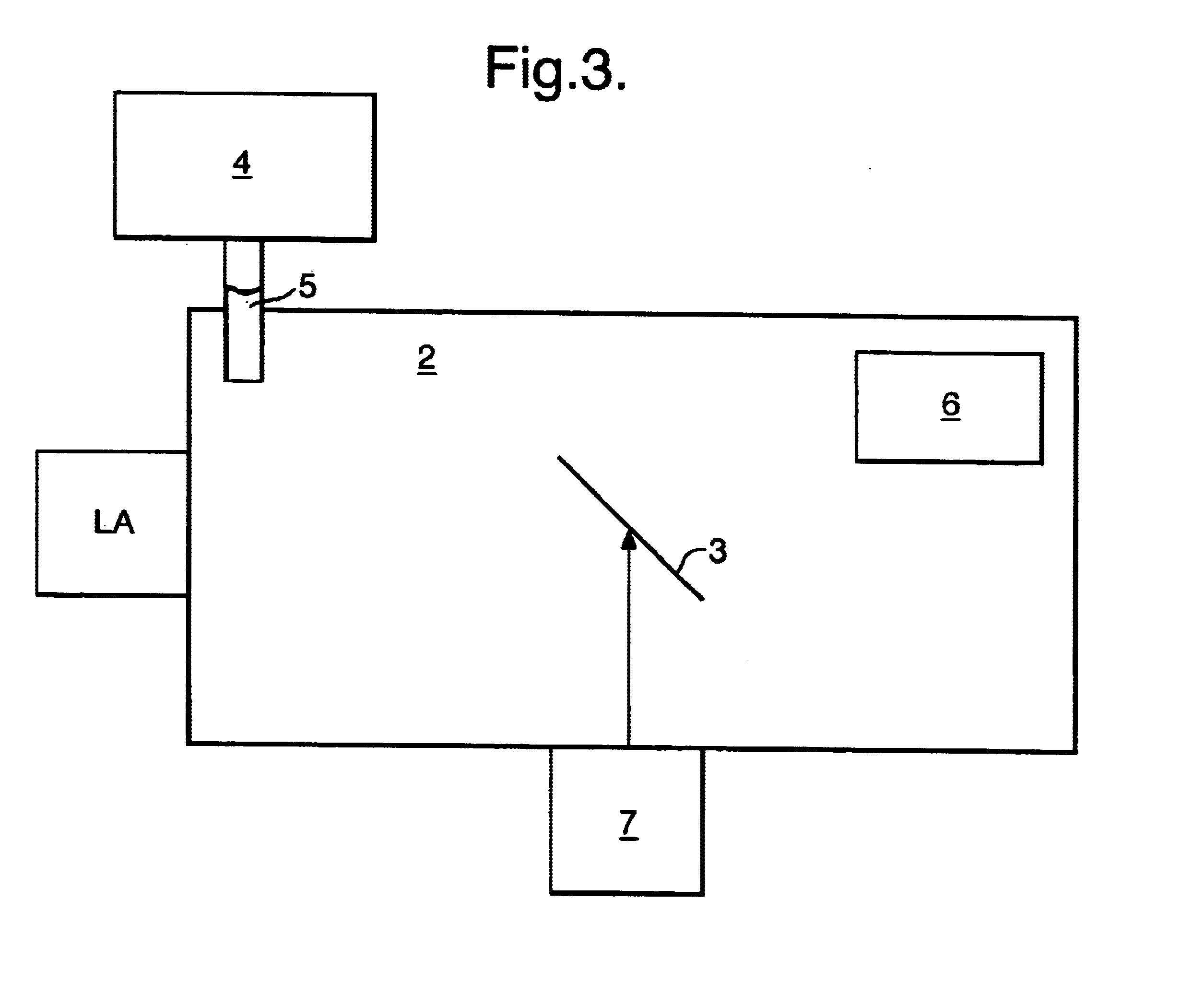

Lithographic projection apparatus, device manufacturing method, device manufactured thereby, cleaning unit and method of cleaning contaminated objects

InactiveUS6724460B2Stable cleaning materialSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGas compositionLength wave

In-situ cleaning of optical components for use in a lithographic projection apparatus can be carried out by irradiating a space within the apparatus containing the optical component with UV or EUV radiation having a wavelength of less than 250 nm, in the presence of molecular oxygen. Generally, the space will be purged with an ozoneless purge gas which contains a small amount of molecular oxygen in addition to the usual purge gas composition. The technique can also be used in an evacuated space by introducing a low pressure of molecular oxygen into the space.

Owner:ASML NETHERLANDS BV

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

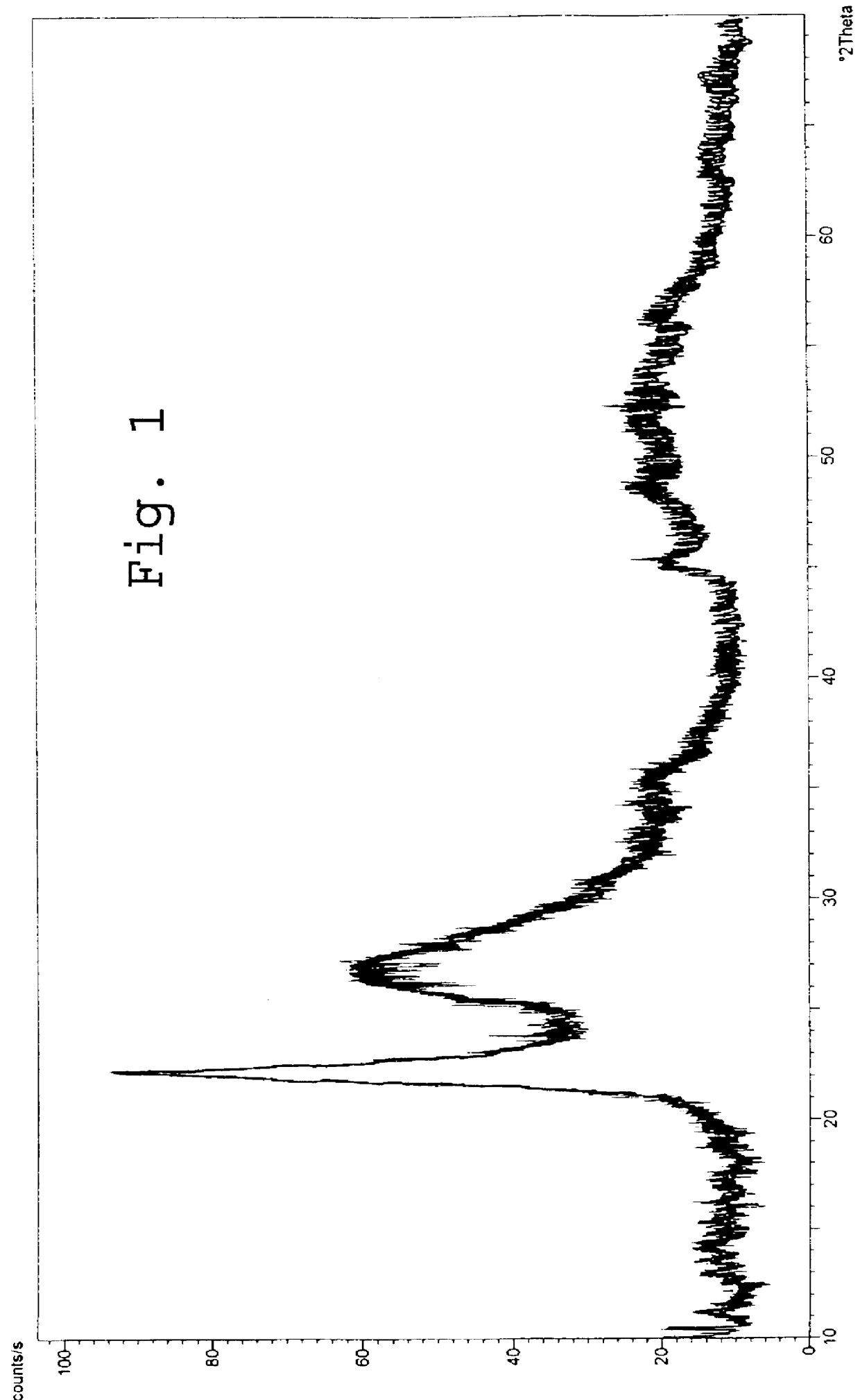

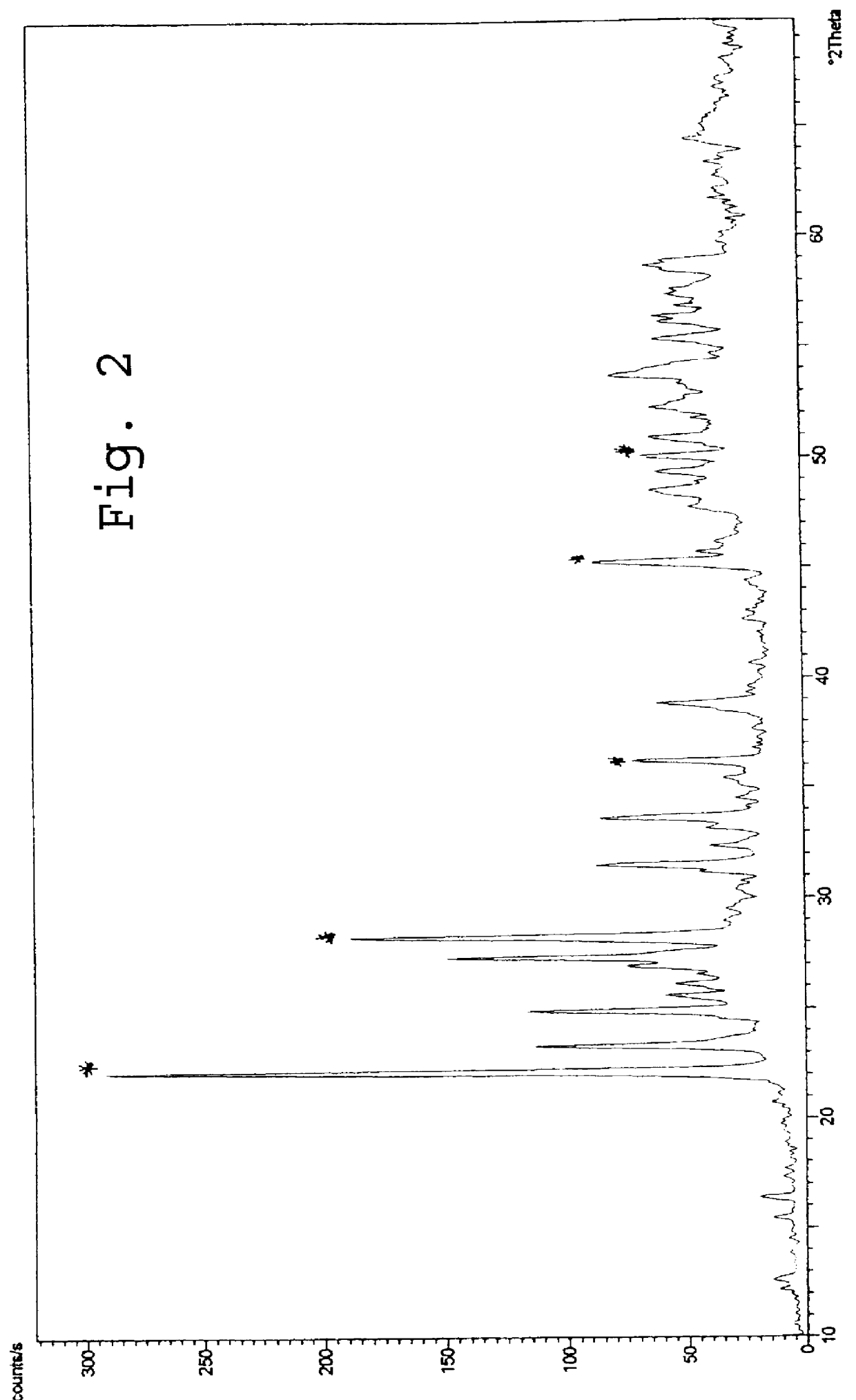

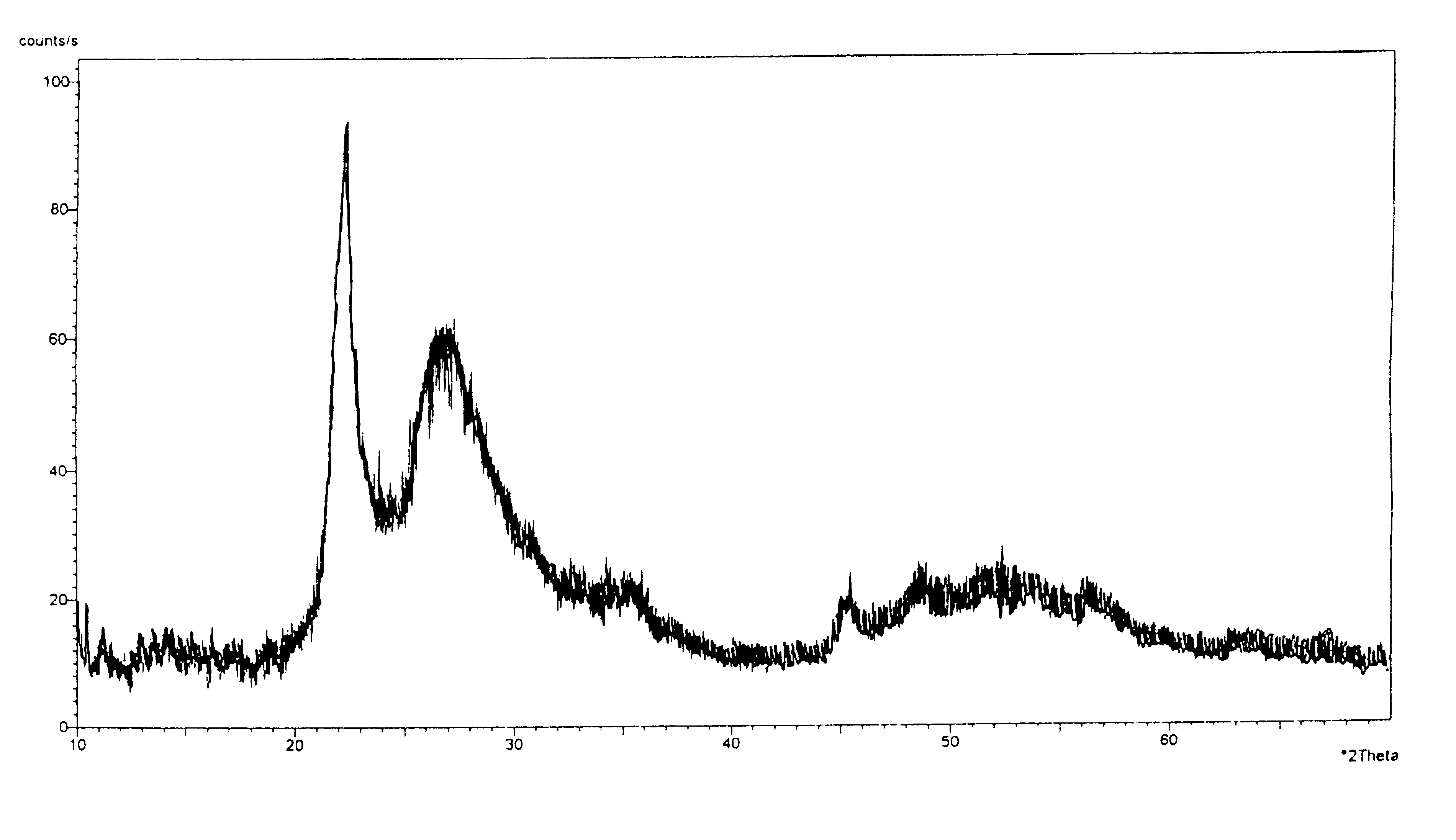

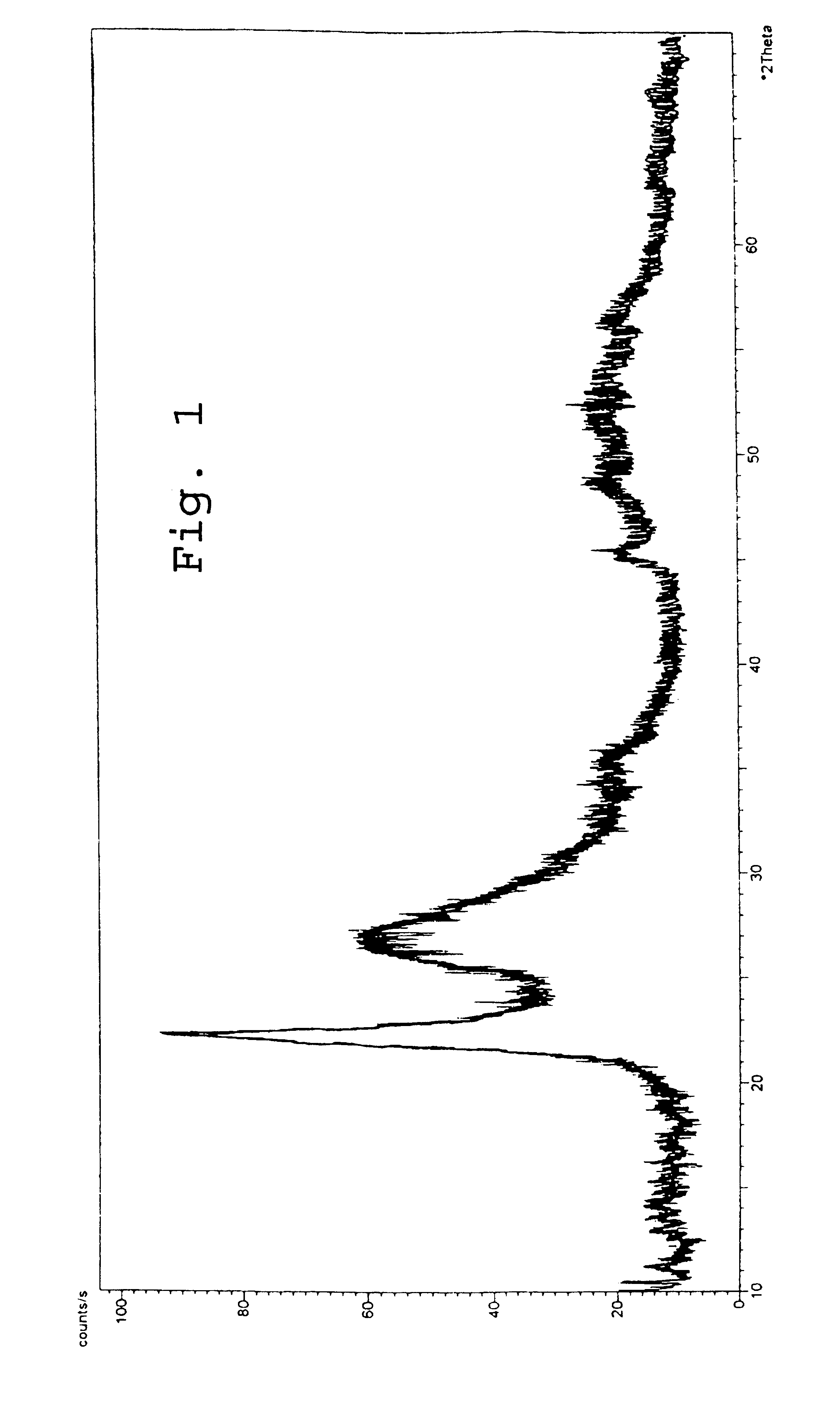

Process for producing composite oxide catalyst

InactiveCN1697701AImprove conversion rateGood choiceOrganic compound preparationOrganic chemistry methodsAdditive ingredientSolvent

A catalyst for producing from an olefin the corresponding unsaturated aldehyde and unsaturated carboxylic acid in high yield; and a process for producing the catalyst. The process is for producing a composite oxide catalyst which is for use in catalytically oxidizing an olefin in a vapor phase with a gas containing molecular oxygen to produce the corresponding unsaturated aldehyde and corresponding unsaturated carboxylic acid, and which comprises (A) molybdenum, (B) bismuth, (C) cobalt and / or nickel, and (D) iron. It is characterized in that catalyst precursor particles produced through a preceding step in which an aqueous dispersion containing a raw material for the ingredient (A), raw material for the ingredient (C), and raw material for the ingredient (D) which have been united with one another and having a nitric acid radical content satisfying the relationship 1.2<=NO3 / (3xFe+2x(Co+Ni)) is dried and then heated are united with a raw material for the ingredient (B) in a water-miscible solvent and the resultant united matter is dried and burned. In the relationship, NO3, Fe, Co, and Ni indicate the molar contents of nitric acid radicals, iron, cobalt, and nickel, respectively.

Owner:MITSUBISHI CHEM CORP

Catalysts for catalytic oxidation of propane to acrylic acid, methods of making and using the same

InactiveUS6114278AIncrease productivityHigh yieldOrganic compound preparationOrganic chemistry methodsPartial oxidationCatalytic oxidation

A mixed metal oxide Mo-V-Ga-Pd-Nb-X (where X=La, Te, Ge, Zn, Si, In or W) catalytic system providing a higher selectivity to acrylic acid in the low temperature partial oxidation of propane with a molecular oxygen-containing gas.

Owner:SAUDI BASIC IND CORP SA

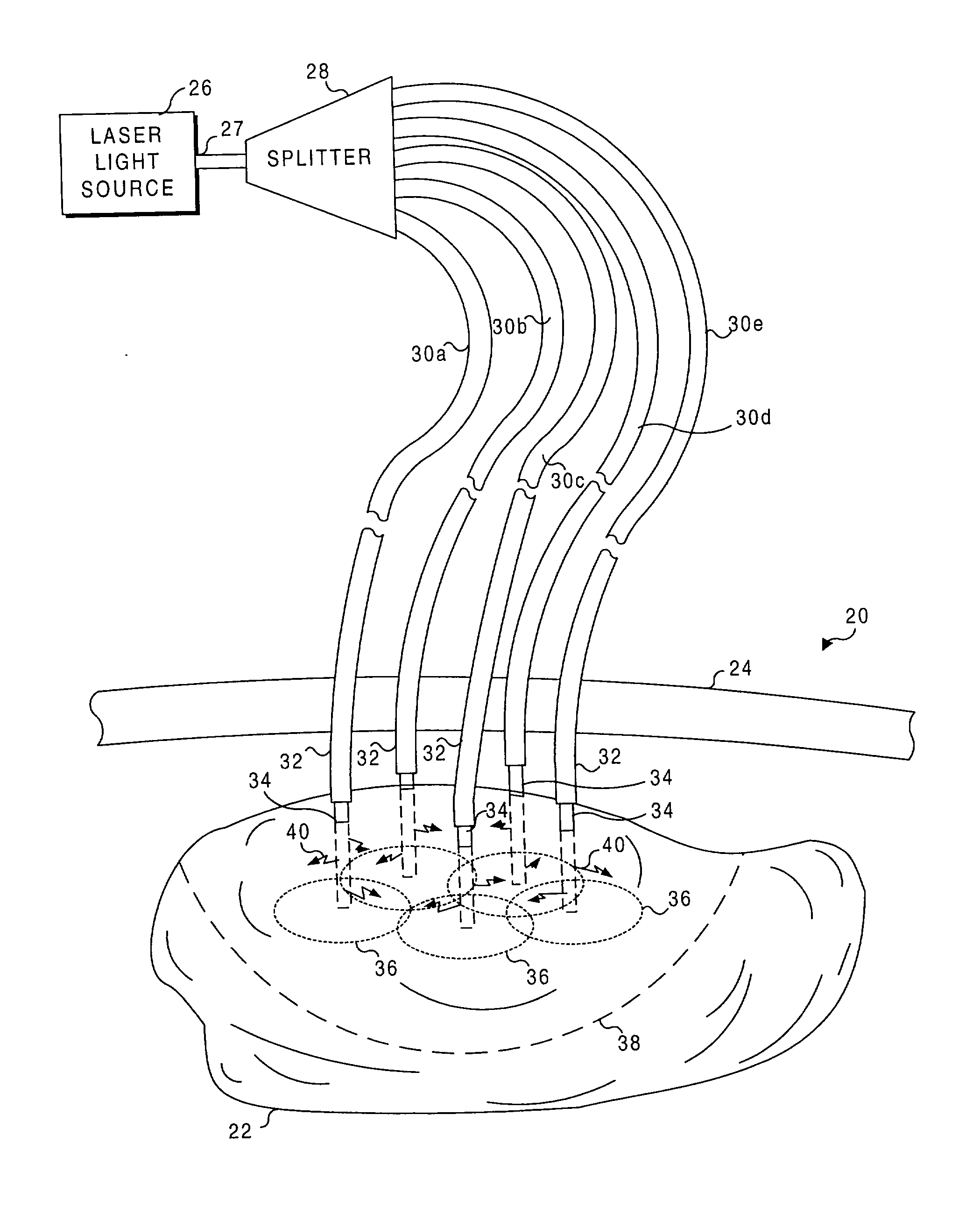

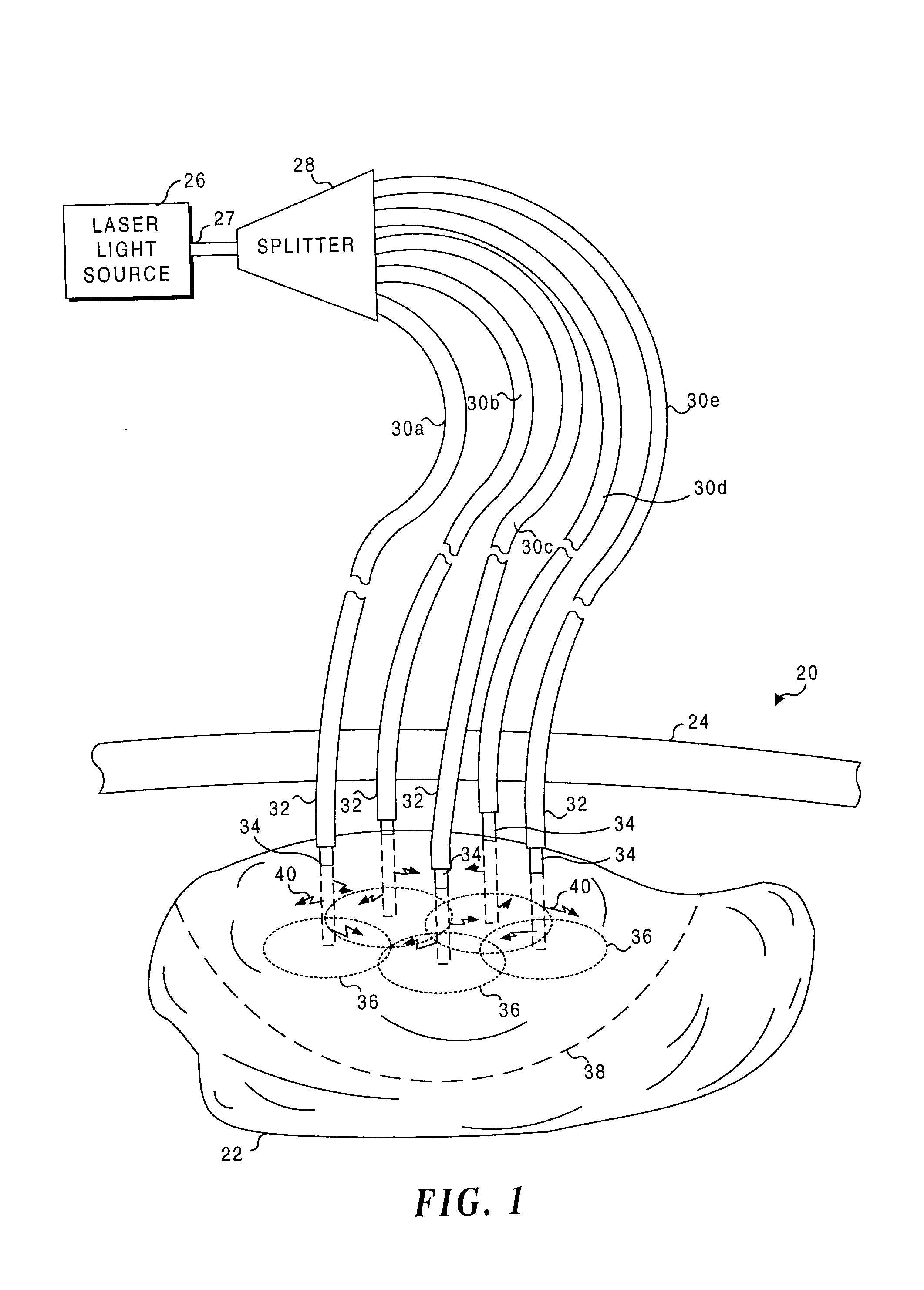

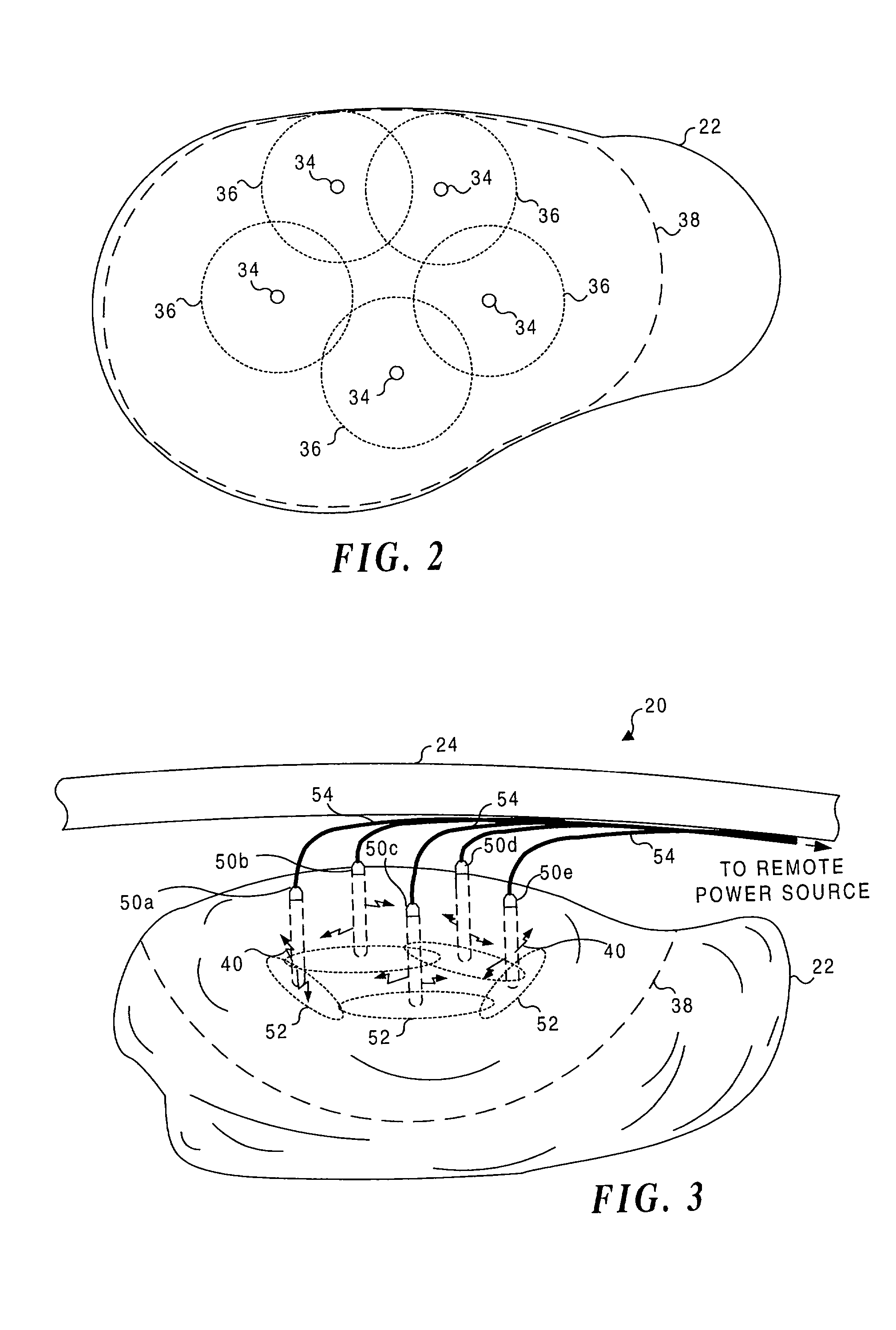

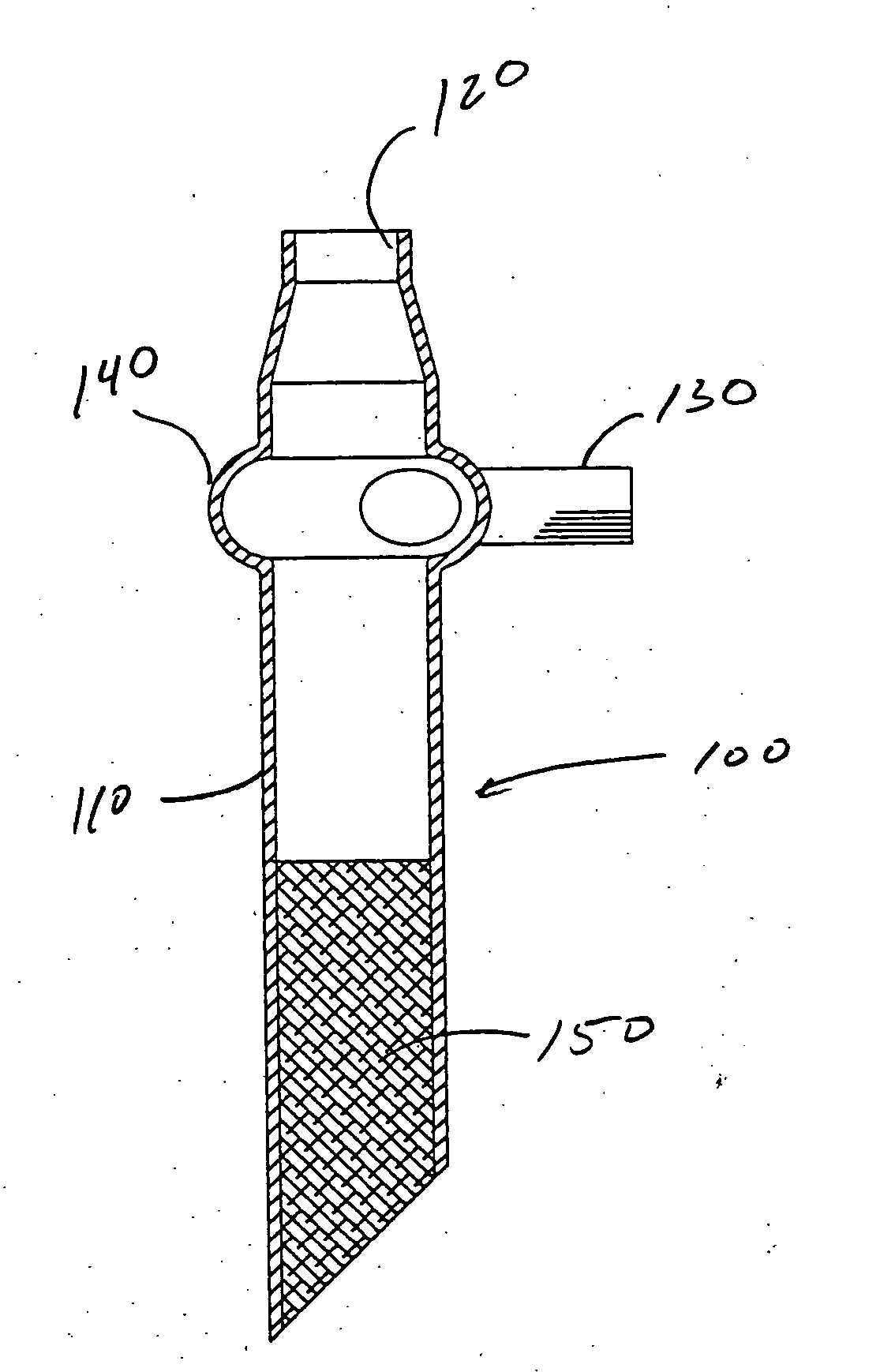

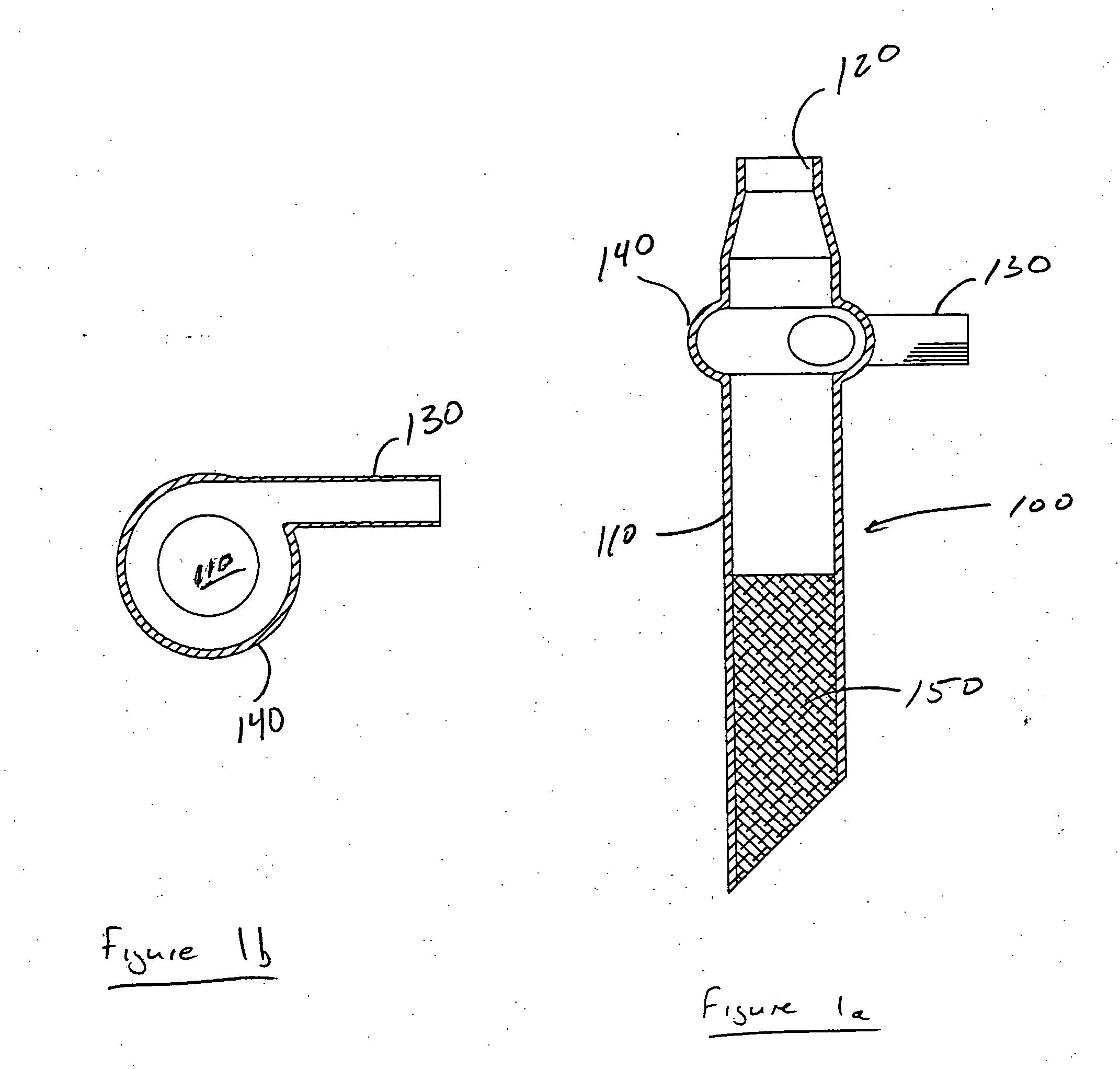

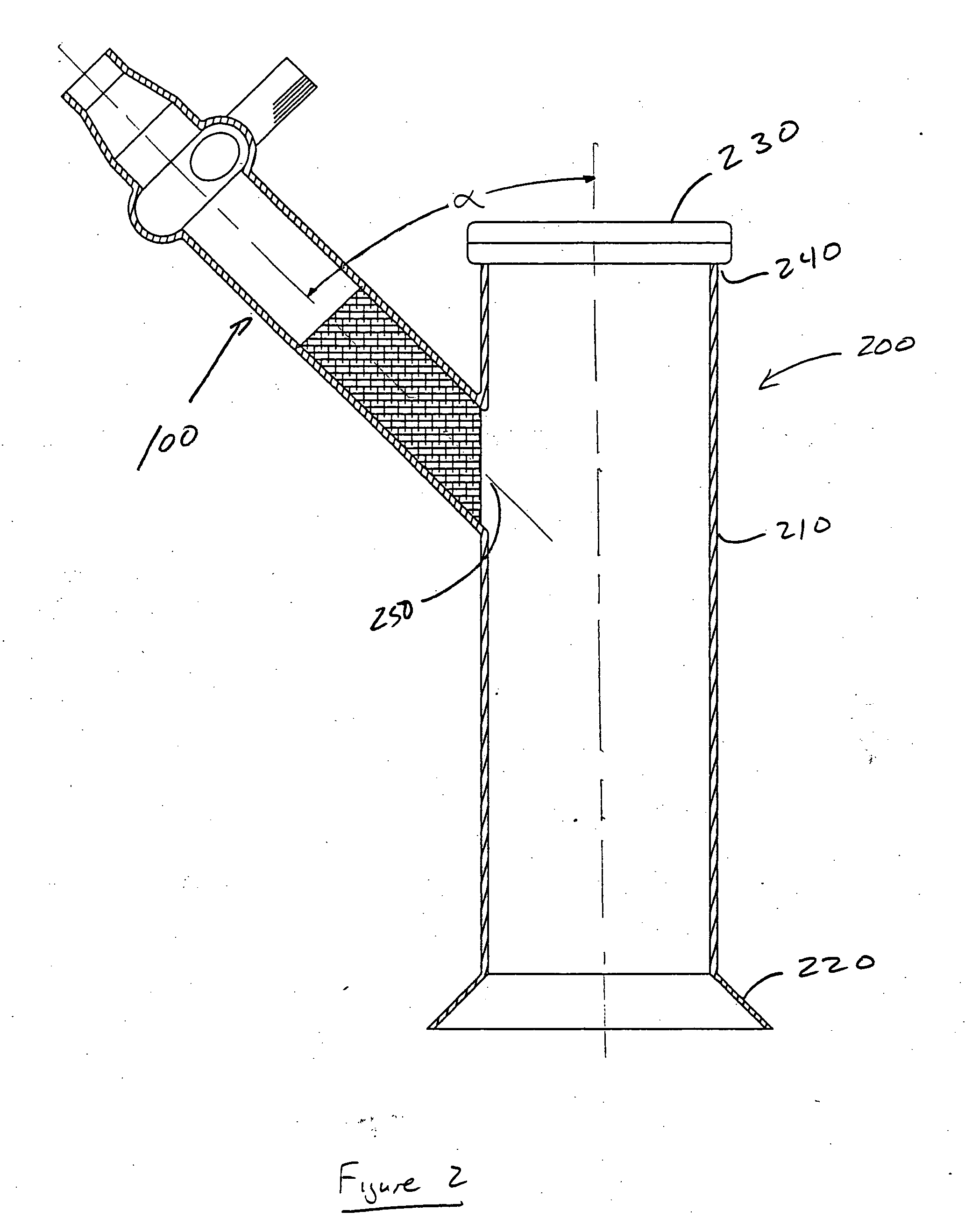

Application of light at plural treatment sites within a tumor to increase the efficacy of light therapy

Light is administered during photodynamic therapy (PDT) for an extended period of time at a plurality of sites distributed within the abnormal tissue of a tumor. A clinical study has shown that a substantially greater volume of abnormal tissue in a tumor is destroyed by the extended administration of light therapy from a plurality of probes than would have been expected based upon the teaching of the prior art. In this process, a plurality of light emitting optical fibers or probes are deployed in a spaced-apart array. After a photoreactive agent is absorbed by the abnormal tissue, the light therapy is administered for at least three hours. The greater volume of necrosis in the tumor is achieved due to one or more concomitant effects, including: the inflammation of damaged abnormal tissue and resultant immunological response of the patient's body; the diffusion and circulation of activated photoreactive agent outside the expected fluence zone, which is believed to destroy the abnormal tissue; a retrograde thrombosis or vascular occlusion outside of the expected fluence zone; and, the collapse of the vascular system that provides oxygenated blood to portions of the tumor outside the expected fluence zone. In addition, is possible that molecular oxygen diffusing and circulating into the expected fluence zone is converted to singlet oxygen during the extended light therapy, causing a gradient of hypoxia and anoxia that destroys the abnormal tissue outside the expected fluence zone.

Owner:LIGHT SCI ONCOLOGY

Multi-layer non-carbon metal-based anodes for aluminum production cells and method

InactiveUS6077415AImprove electrochemical activitySolution to short lifeMachining electrodesIsotope separationElectrical batteryOxygen ions

A composite, high-temperature resistant, non-carbon metal-based anode of a cell for the electrowinning of aluminium comprises a metal-based core structure of low electrical resistance, for connecting the anode to a positive current supply, coated with a series of superimposed, adherent, electrically conductive layers. These layers consist of at least one layer on the core structure constituting a barrier substantially impervious to monoatomic oxygen and molecular oxygen; one or more intermediate, protective layers on the oxygen barrier layer which remain inactive in the reactions for the evolution of oxygen gas; and an electrochemically active layer for the oxidation reaction of oxygen ions present at the anode / electrolyte interface into nascent monoatomic oxygen, as well as for subsequent reaction for the formation of gaseous biatomic oxygen. The active layer on the outermost intermediate layer is slowly consumable during electrolysis and protects the intermediate protective layer by inhibiting its dissolution into the electrolyte.

Owner:MOLTECH INVENT

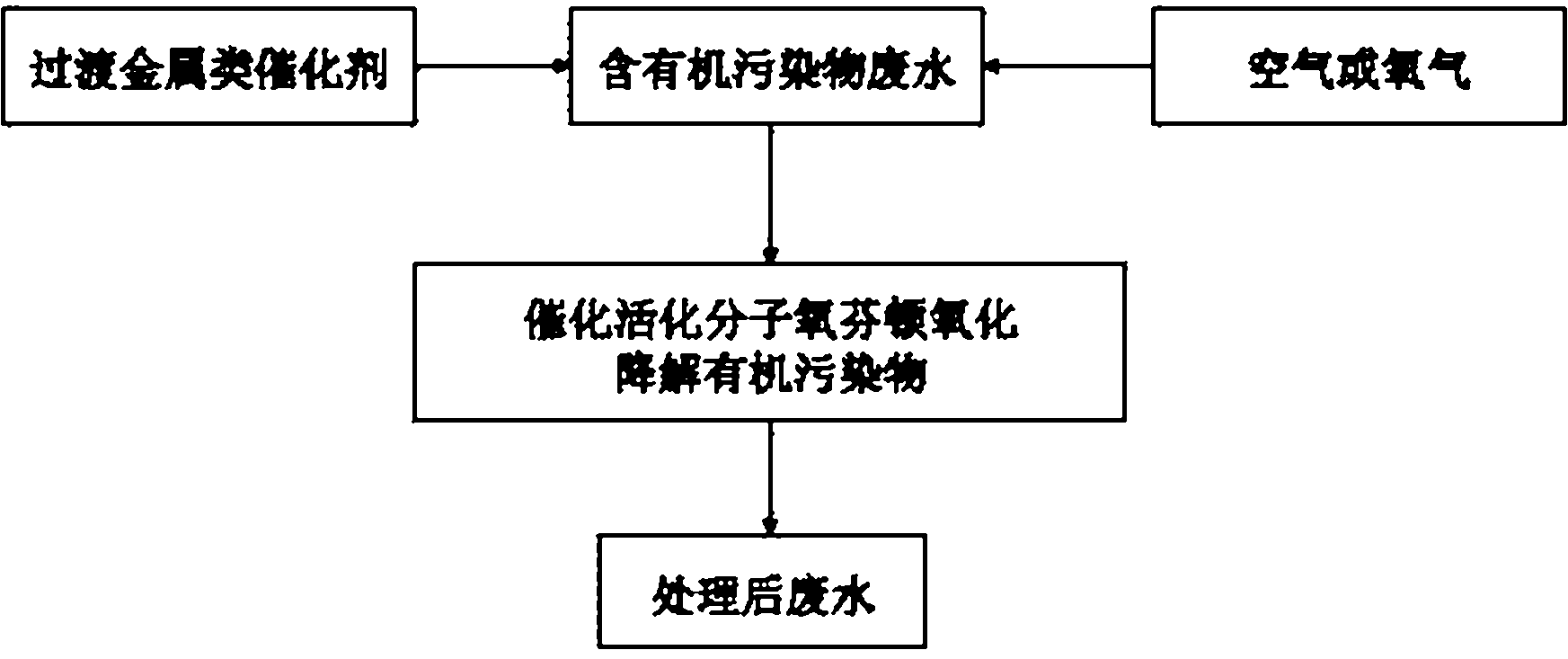

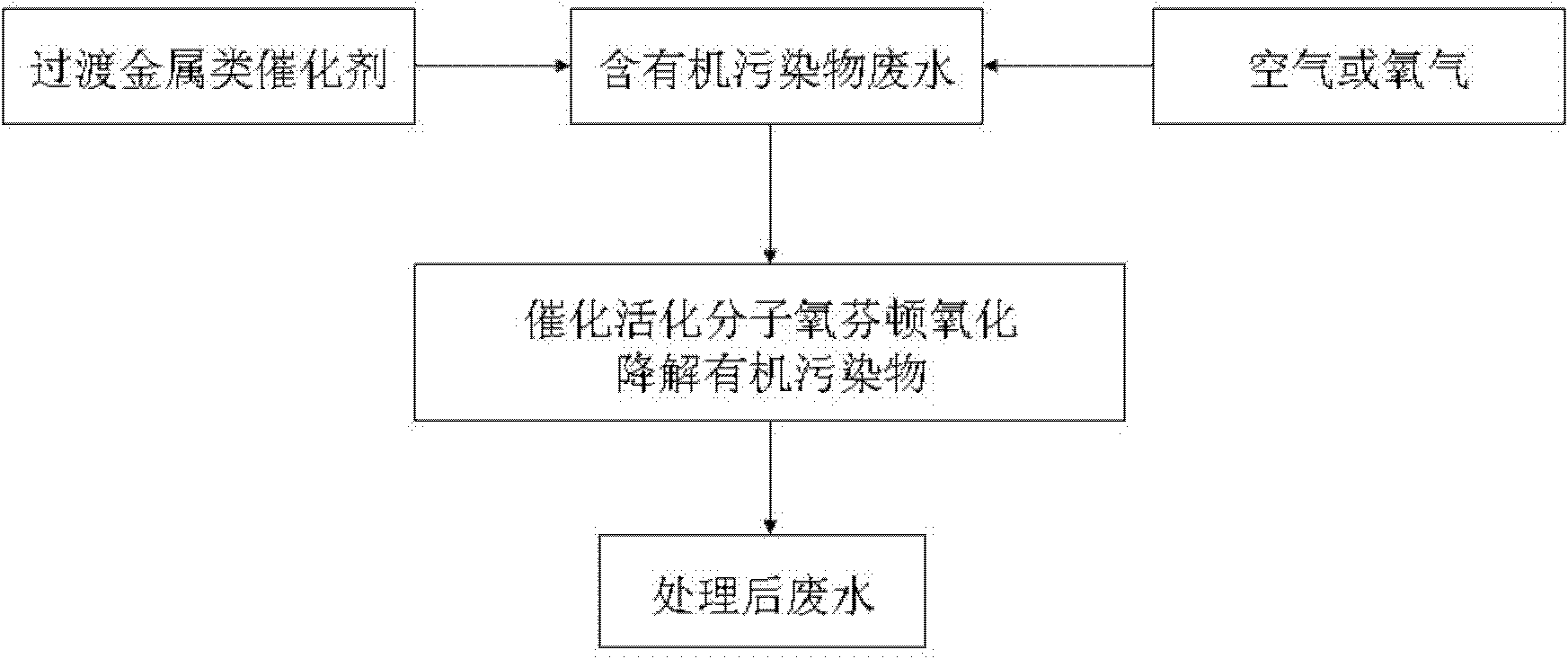

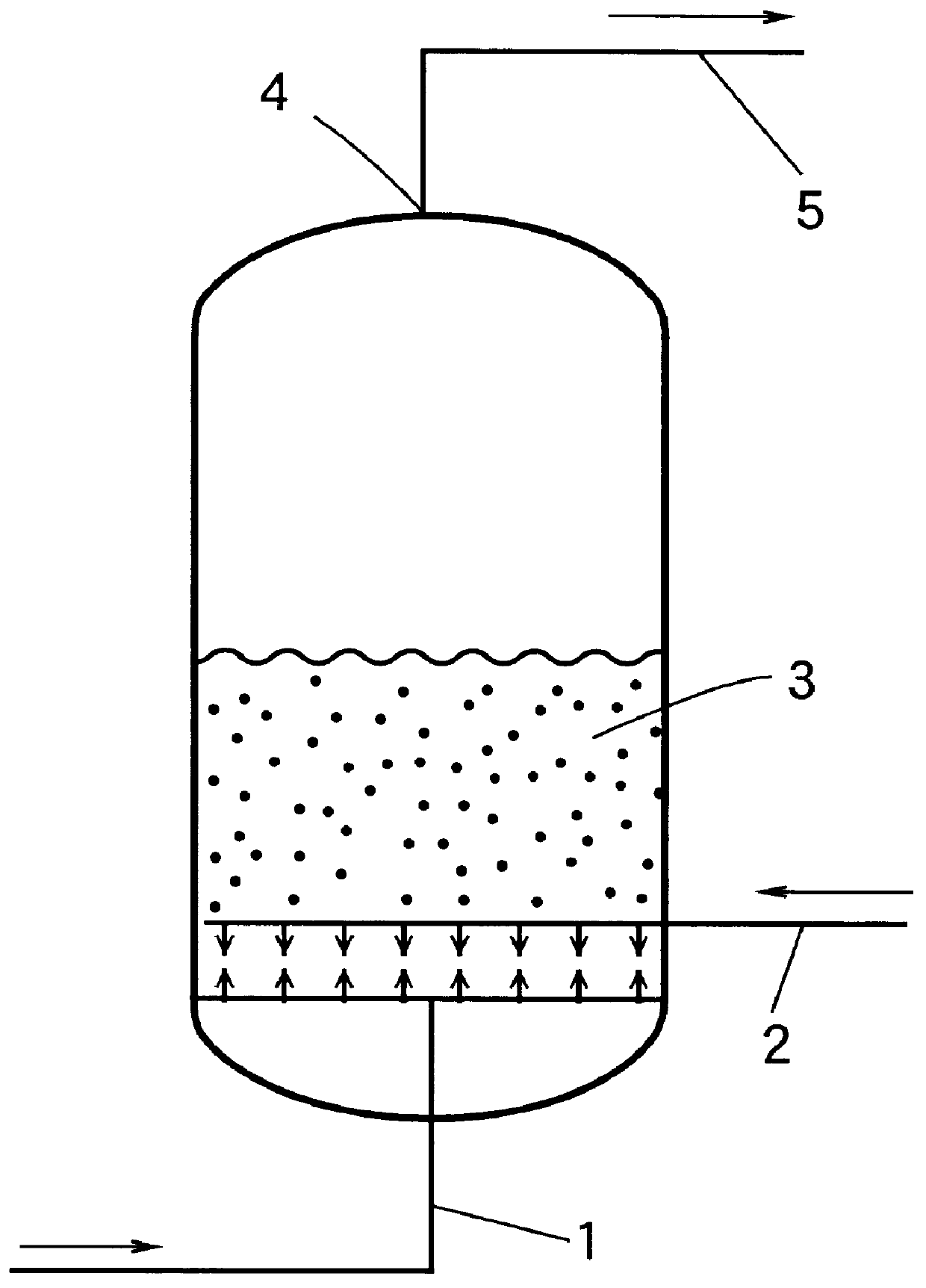

Method for treating water by Fenton oxidization of activated molecular oxygen

InactiveCN102173500AWide variety of sourcesLow costWater/sewage treatment by oxidationCatalytic oxidationPollution

The invention provides a method for treating water by the Fenton oxidization of activated molecular oxygen. In the method, transition metal ions, transition metal and transition metal oxides are used as activated molecular oxygen catalysts to generate hydroxyl radicals, so that organic matters in wastewater are removed by oxidization. Compared with a Fenton water treatment technology in which hydrogen peroxide is used as an oxygen source, the method has the advantages that: in a Fenton reaction of the activated molecular oxygen, molecular oxygen in air and oxygen are used as the oxygen sourcedirectly, so the oxygen source is wide, convenient and low in cost, and the water treatment cost is reduced greatly. The method for treating the water by the Fenton oxidization of the activated molecular oxygen is suitable for the treatment of various kinds of organic wastewater, high in durability and efficiency, is environment-friendly and easy to operate, does not have secondary pollution, meets the requirement of actual water treatment units, and has large application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

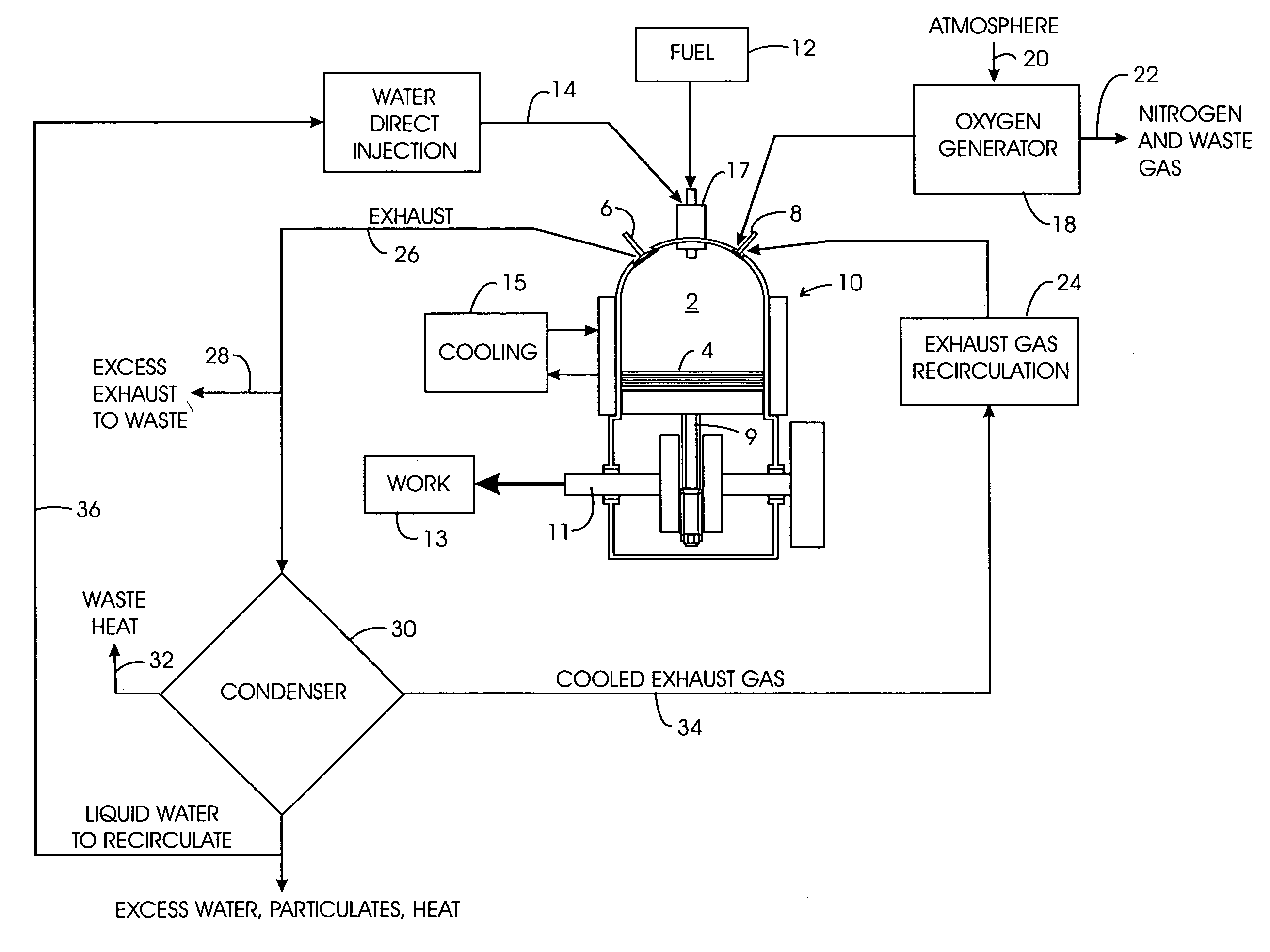

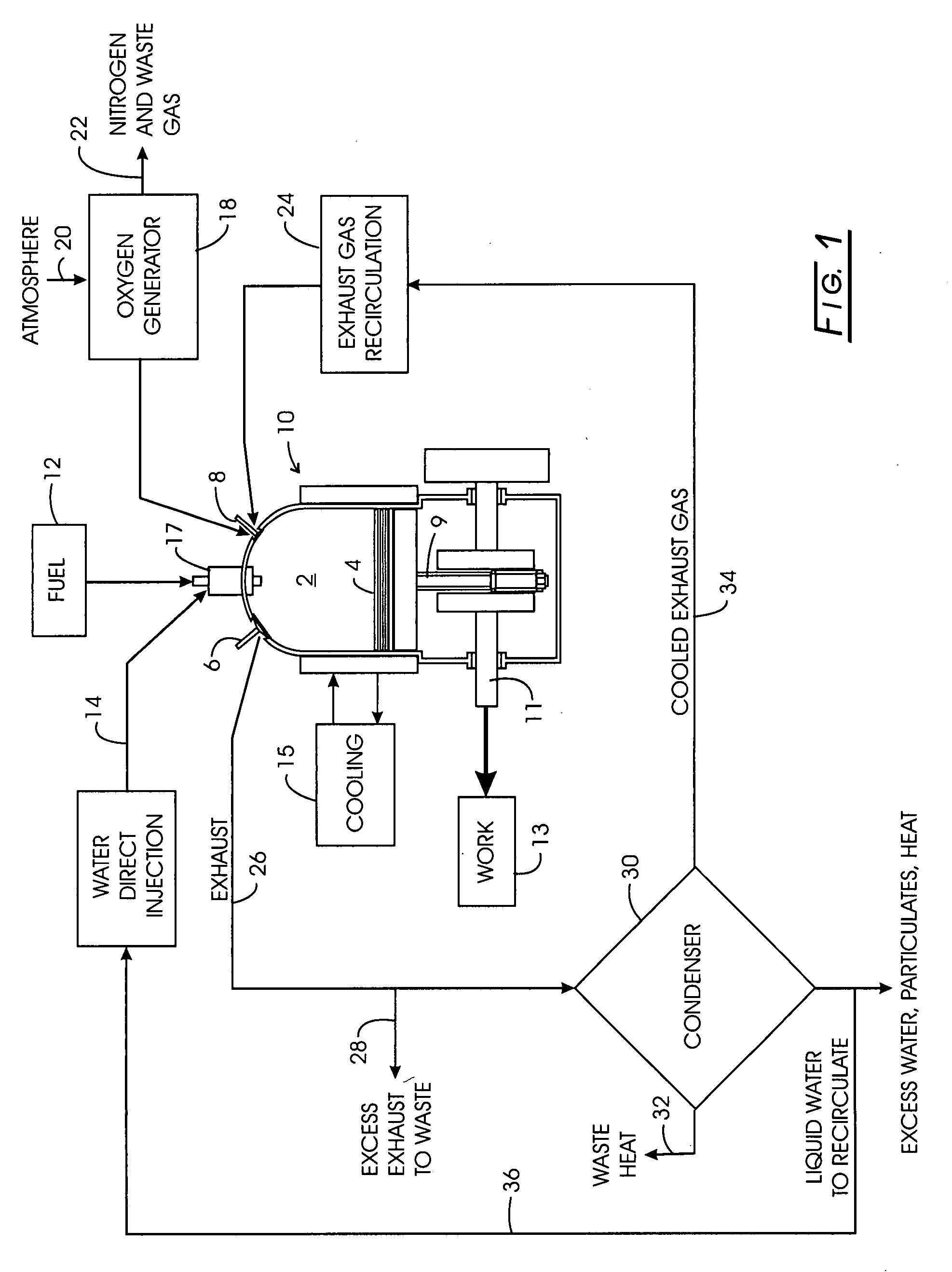

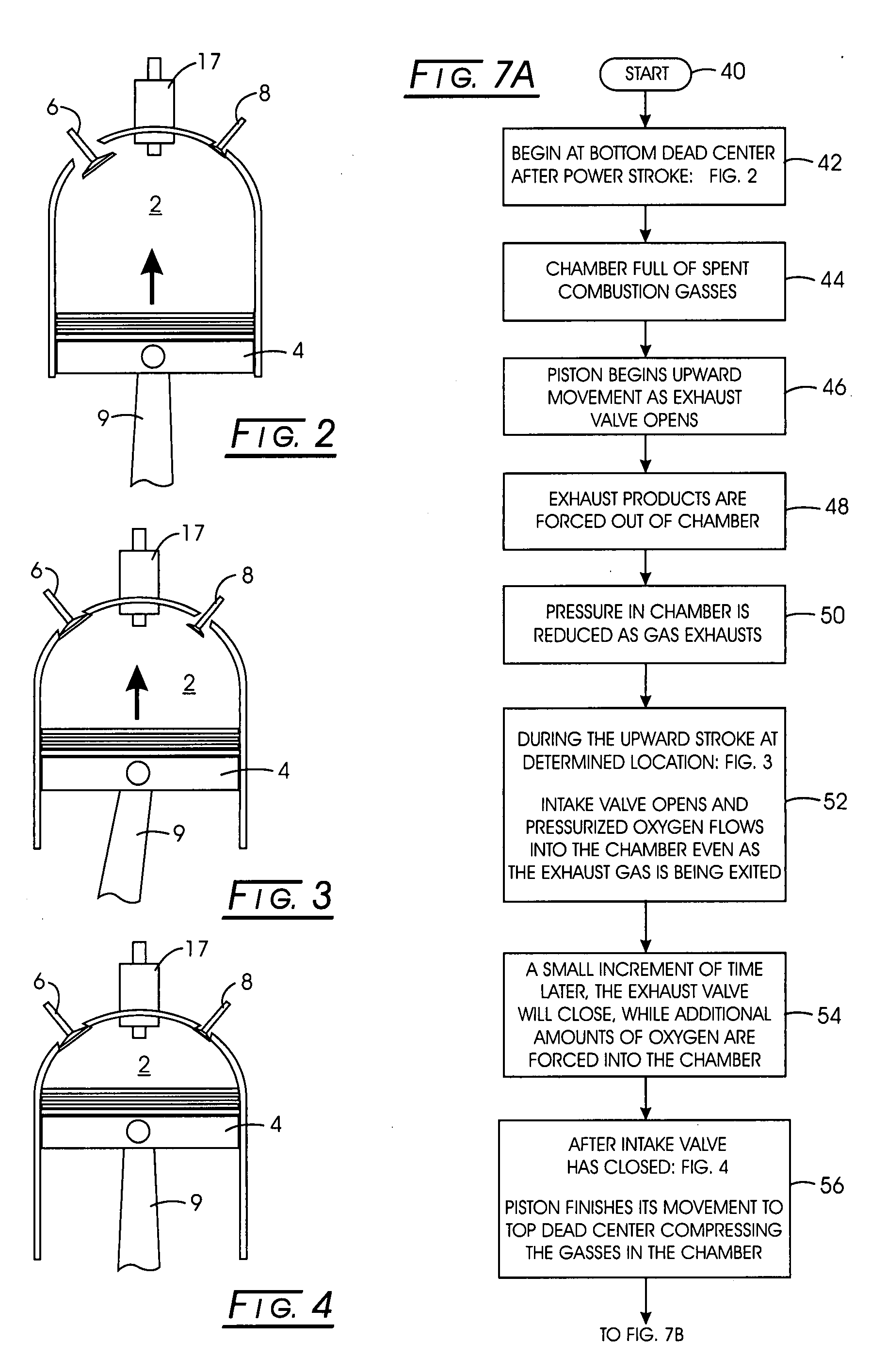

Advanced internal combustion engine

ActiveUS20080223332A1Non-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberAtmospheric air

An internal combustion engine power cycle wherein a combustion chamber is fitted with an inlet valve, an outlet valve, and movable piston coupled to perform work, includes an generator to form a stream of greater than about 95% molecular oxygen from atmospheric air and a nitrogen waste gas stream; a source of fuel; and a source of liquid water. The power cycle includes admission of the molecular oxygen into the chamber, injection of the fuel into the chamber with combustion, and injection of atomized water into the chamber for generation of steam.

Owner:MARO PERFORMANCE GROUP

Process for producing metal thin films by ALD

InactiveUS7220451B2Good step coverageEasy to controlNanomagnetismSolid-state devicesHigh elevationSurface structure

Electrically conductive noble metal thin films can be deposited on a substrate by atomic layer deposition. According to one embodiment of the invention a substrate with a surface is provided in a reaction chamber and a vaporised precursor of a noble metal is pulsed into the reaction chamber. By contacting the vaporised precursor with the surface of the substrate, no more than about a molecular layer of the metal precursor is formed on the substrate. In a next step, a pulse of molecular oxygen-containing gas is provided in the reaction chamber, where the oxygen reacts with the precursor on the substrate. Thus, high-quality metal thin films can be deposited by utilising reactions between the metal precursor and oxygen. In one embodiment, electrically conductive layers are deposited in structures that have high aspect ratio vias and trenches, local high elevation areas or other similar surface structures that make the surface rough.

Owner:ASM INTERNATIONAL

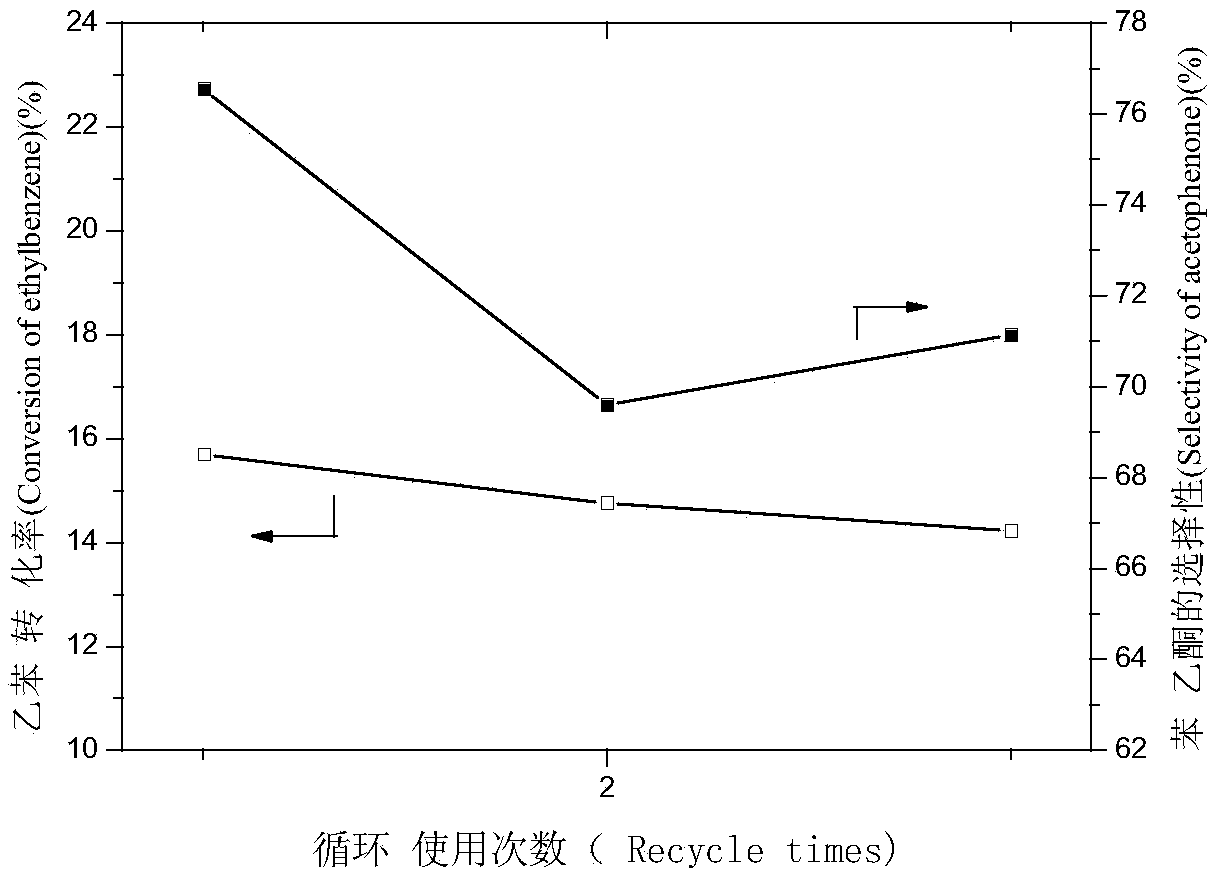

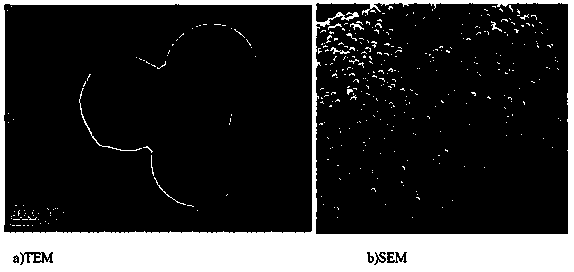

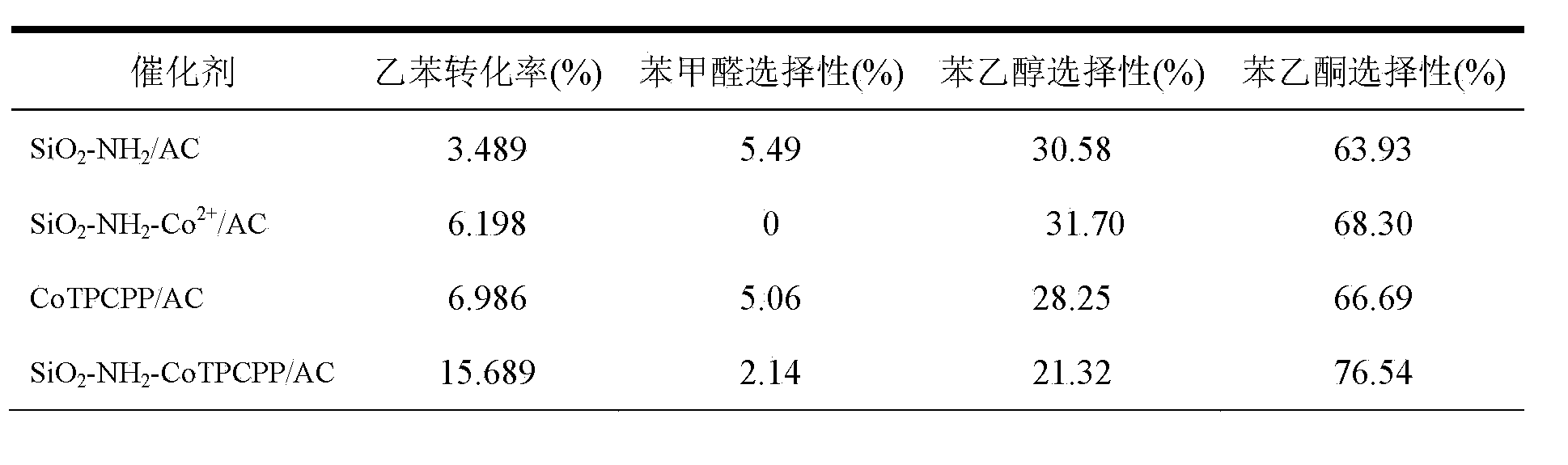

Preparation method of monatomic dispersion catalyst with high catalytic performance

InactiveCN103566935AImprove catalytic performanceImprove stabilityPreparation by oxidation reactionsOrganic compound preparationAlkaneMicrosphere

The invention belongs to the technical field of catalysis and relates to a method for preparing a monatomic cobalt catalyst by roasting silicon dioxide pellets and immobilizing metalloporphyrin. The method is realized by adopting the following technical scheme: namely stirring and dispersing nano silicon dioxide particles, dropwise adding 3-aminopropyl triethoxy silane, so as to obtain amino modified SiO2 pellets, then linking monocarboxyl metalloporphyrin (CoTPCPP) onto an amino modified SiO2 carrier through organic complexing, carbonizing porphyrin through high-temperature calcination in an inert atmosphere, and loading highly dispersed cobalt atoms onto the amino modified SiO2 pellets, thus an amino modified silicon dioxide pellet loaded monatomic cobalt catalyst is obtained. The monatomic dispersion catalyst has high catalytic activity and stability on a molecular oxygen selective ethylbenzene catalytic oxidation reaction in absence of solvent; meanwhile, a preparation method is simple, and product quality can be easily controlled, so that the monatomic dispersion catalyst is applicable to the fields of alkane selective oxidation reactions and synthesis of medical intermediates.

Owner:HUNAN UNIV

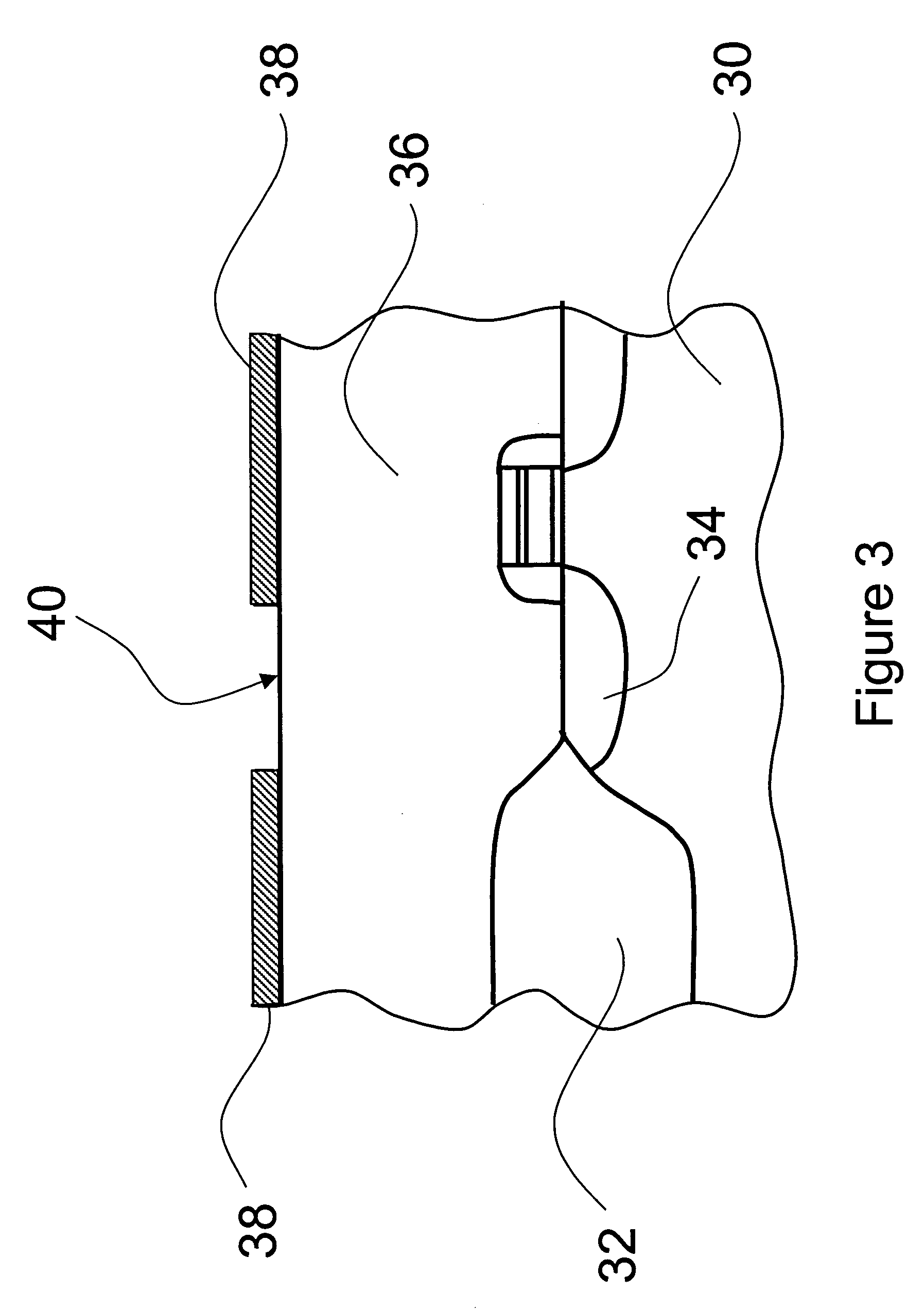

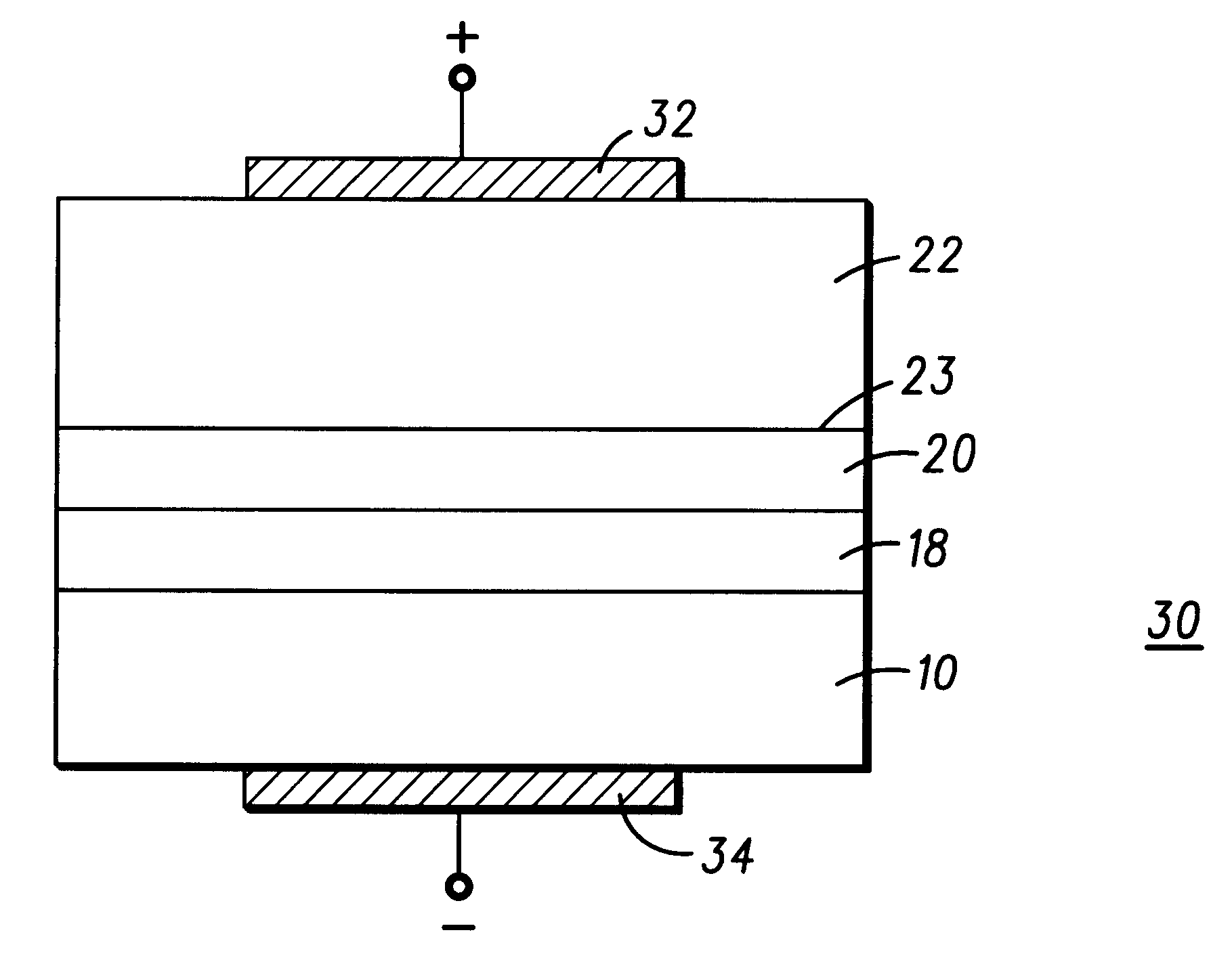

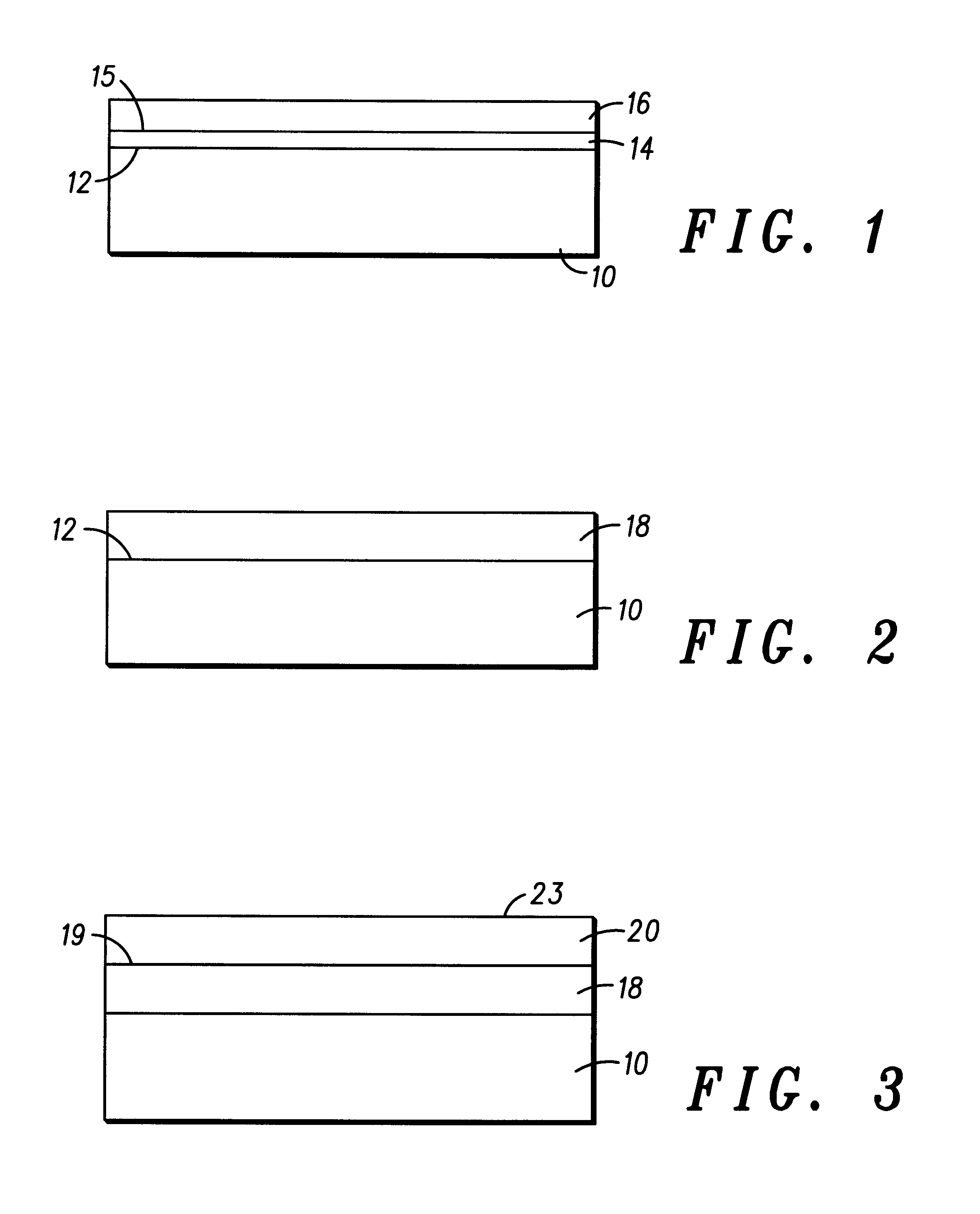

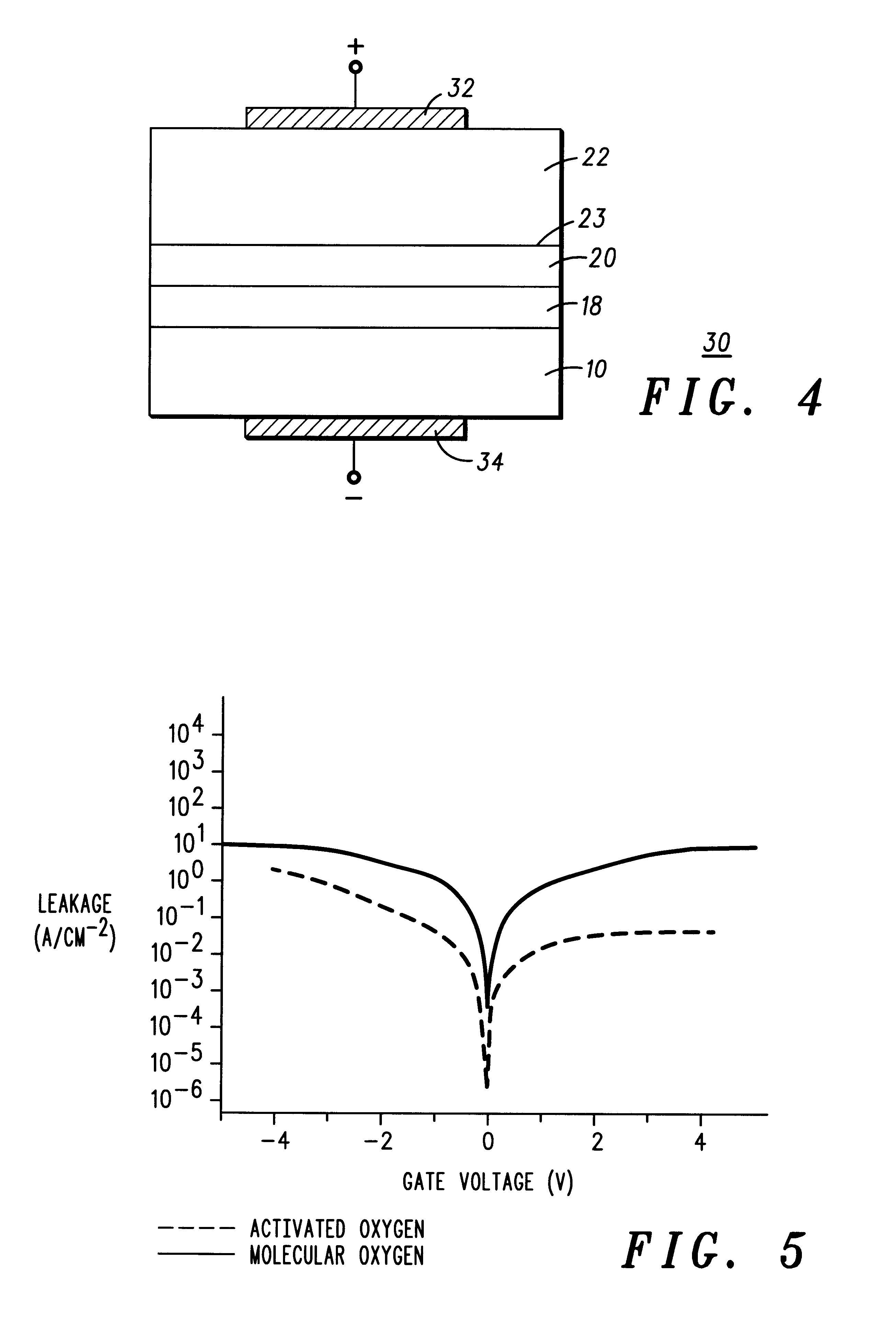

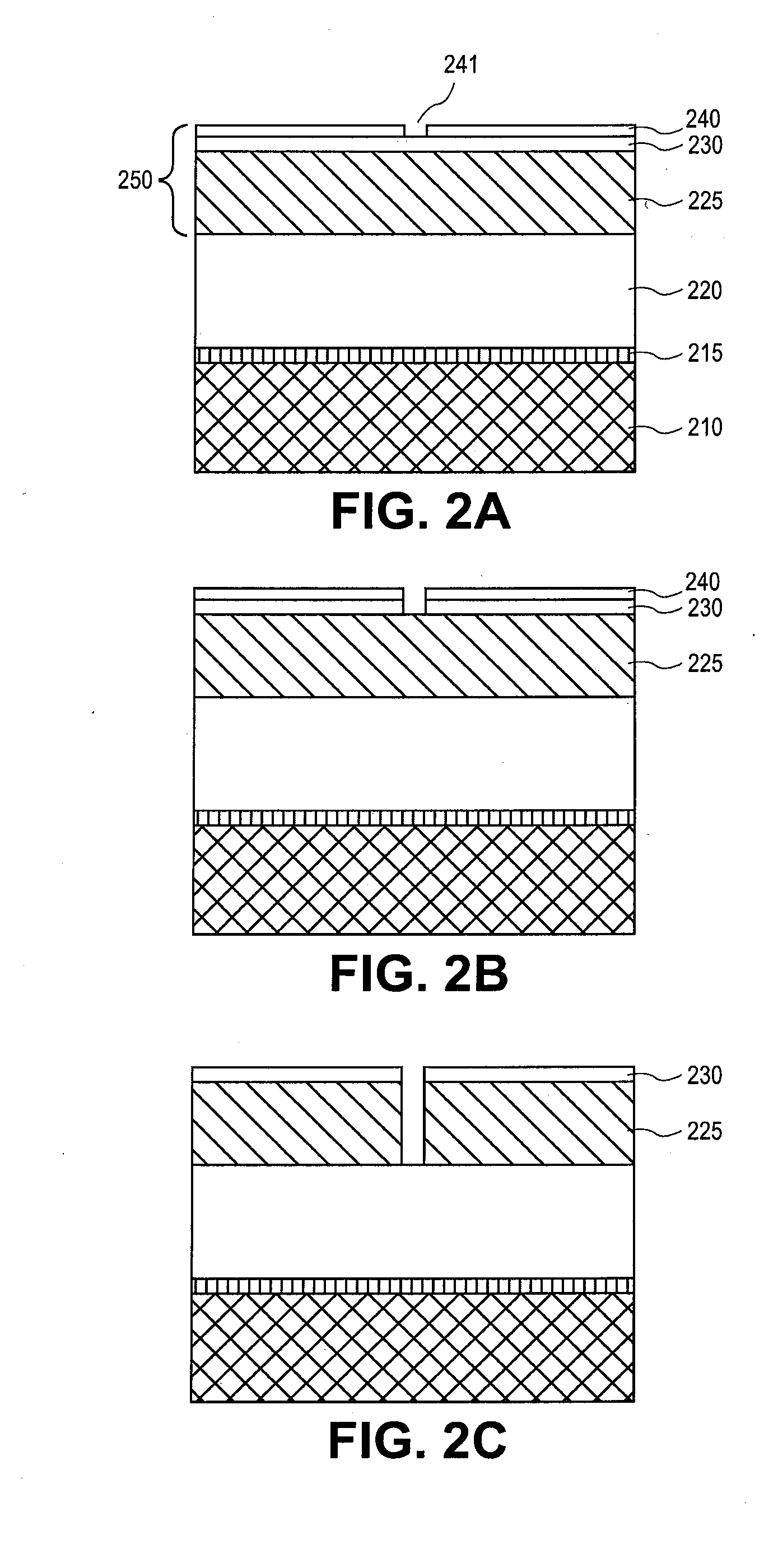

Method for fabricating a semiconductor structure with reduced leakage current density

InactiveUS6270568B1From gel statePolycrystalline material growthLeakage current densitySemiconductor structure

A method for fabricating a semiconductor structure including the steps of providing a silicon substrate (10) having a surface (12); forming an interface including a seed layer (18) adjacent to the surface (12) of the silicon substrate (10), forming a buffer layer (20) utilizing molecular oxygen; and forming one or more layers of a high dielectric constant oxide (22) on the buffer layer (20) utilizing activated oxygen.

Owner:APPLE INC +1

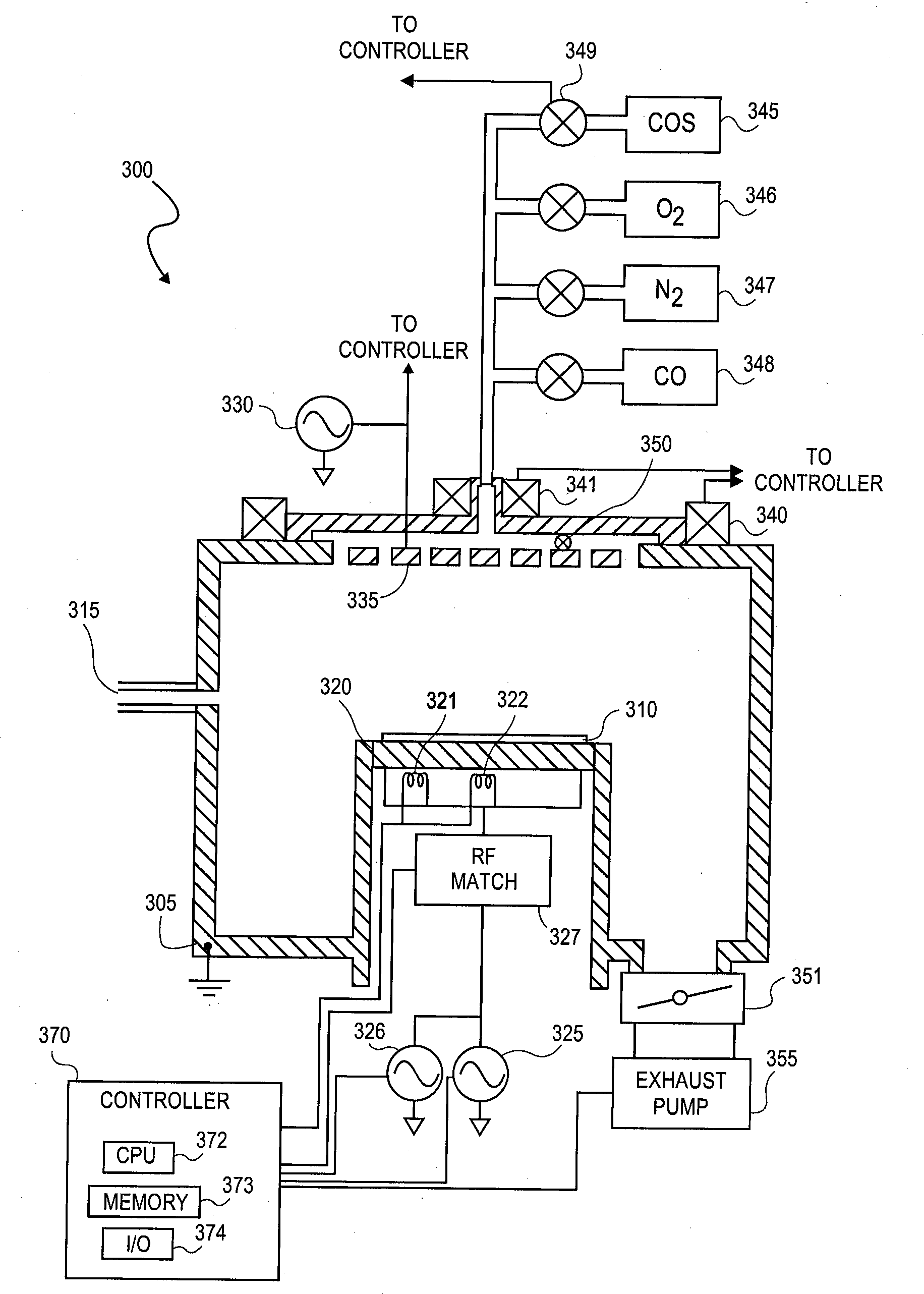

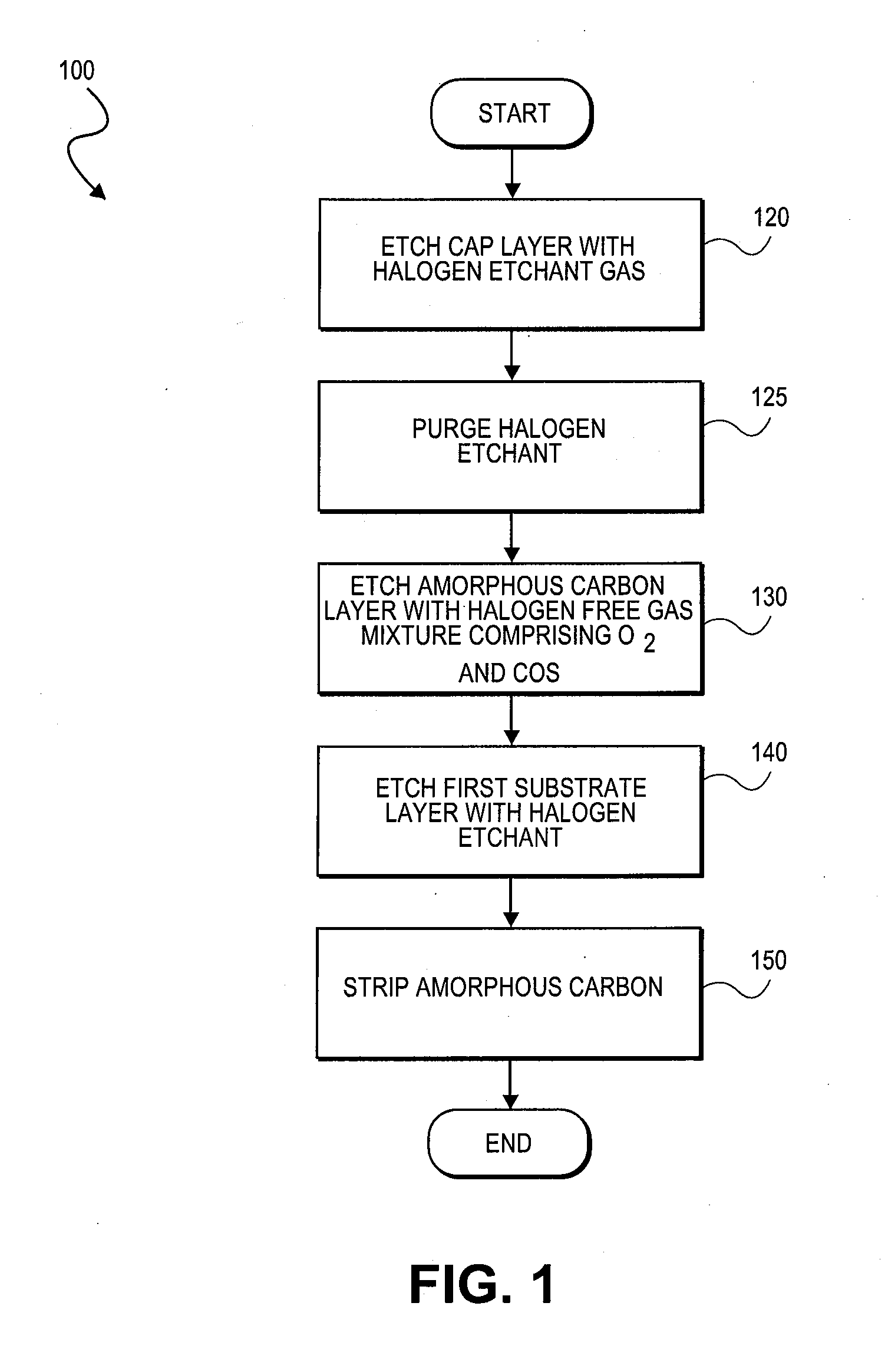

Plasma etching carbonaceous layers with sulfur-based etchants

InactiveUS20090212010A1Improve uniformityMinimal bowingDecorative surface effectsSemiconductor/solid-state device manufacturingSulfurMolecular nitrogen

Etching of carbonaceous layers with an etchant gas mixture including molecular oxygen (O2) and a gas including a carbon sulfur terminal ligand. A high RF frequency source is employed in certain embodiments to achieve a high etch rate with high selectivity to inorganic dielectric layers. In certain embodiments, the etchant gas mixture includes only the two components, COS and O2, but in other embodiments additional gases, such as at least one of molecular nitrogen (N2), carbon monoxide (CO) or carbon dioxide (CO2) may be further employed to etch to carbonaceous layers.

Owner:APPLIED MATERIALS INC

Process for producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation

Owner:ASAHI KASEI KK

Catalytic oxidation of alkanes to corresponding acids

A mixed metal oxide Mo-V-Ga-Pd-Nb-X catalytic system, where X is selected from La, Te, and Zn, provides the oxidation of C2-C8 hydrocarbons to corresponding acids with a molecular oxygen-containing gas.

Owner:SAUDI BASIC IND CORP SA

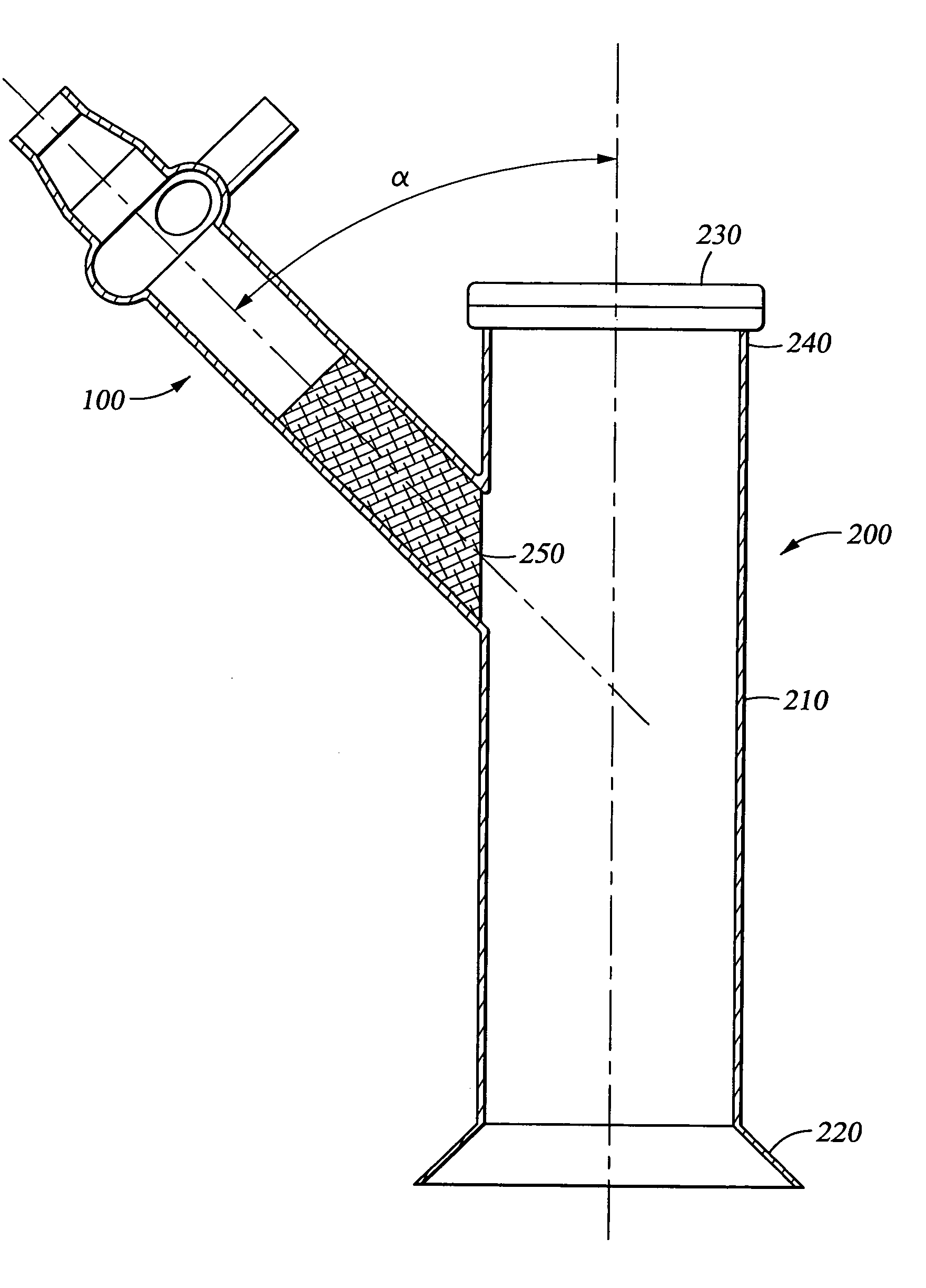

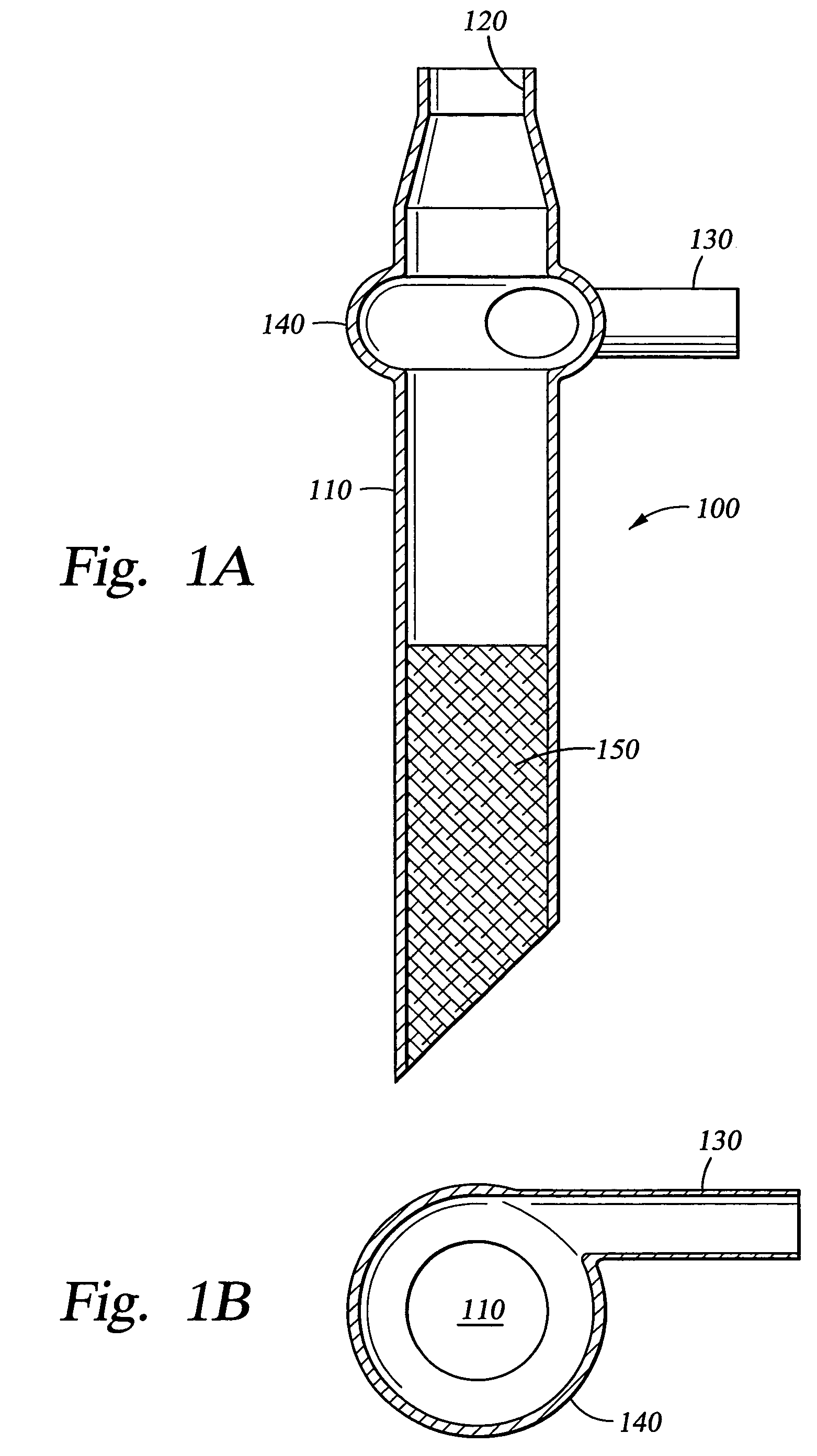

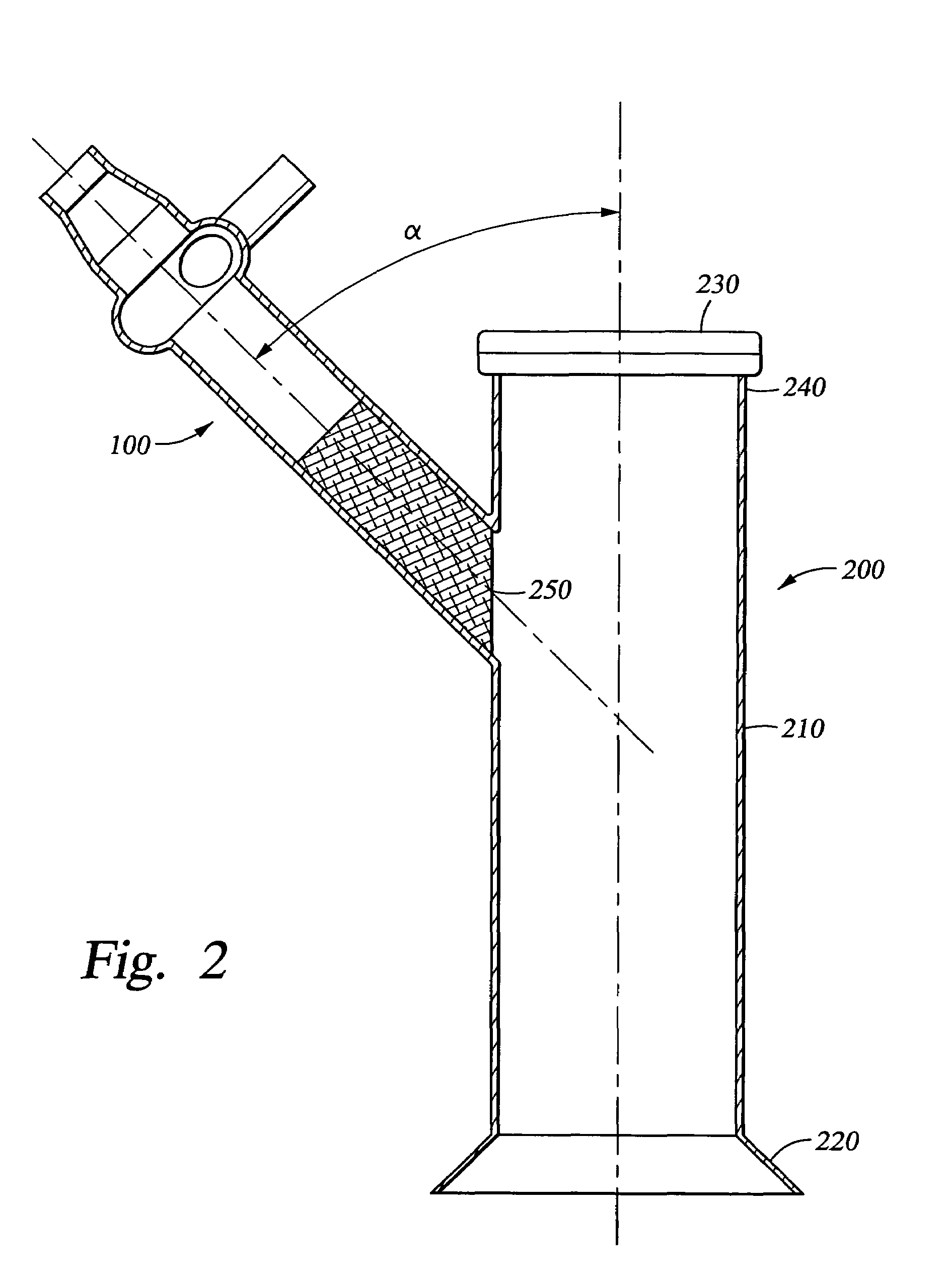

Feed mixer for a partial oxidation reactor

ActiveUS20050095186A1Suitable for useImprove efficiencyFlow mixersTransportation and packagingPartial oxidationProcess engineering

Methods and apparatus for mixing a plurality of gases, preferably a fuel and an oxidant. The preferred embodiments are characterized by methods and apparatus for mixing at least a methane-containing gas and an oxygen-containing gas, preferably natural gas and molecular oxygen. The preferred embodiments of the present invention include a mixing section having a centrifugal mixer with a tangential inlet where the mixed gases are then injected at an angle into the reactor section. The oxidant and the fuel are mixed by the tangential motion of the fuel to form a reactant gas that then flows through a permeable mixing material that is also disposed within the chamber. The reactant gas injected at an angle into a reactor inlet chamber provides a substantially unobstructed path between the reactor and a pressure relief device.

Owner:PHILLIPS 66 CO

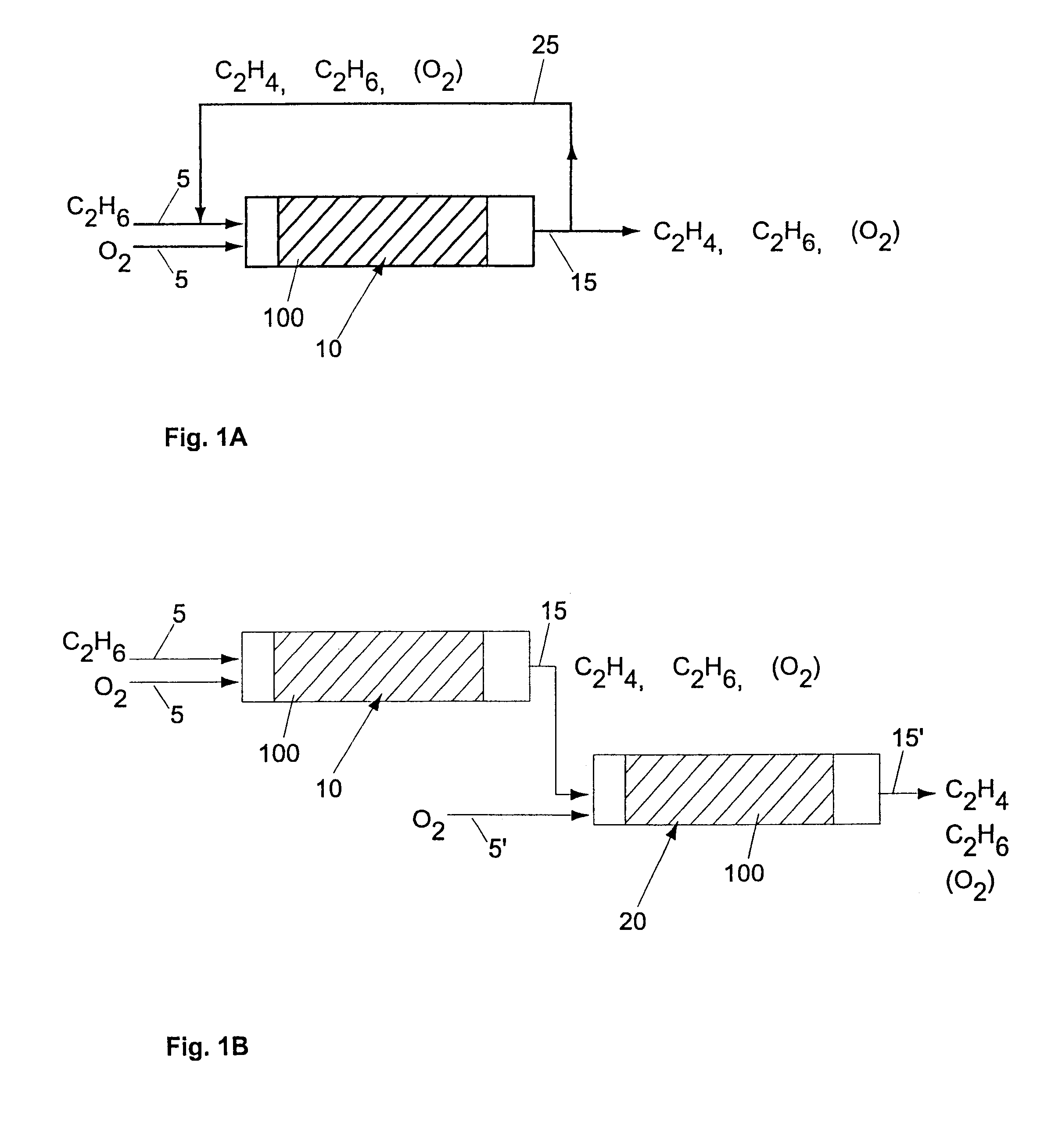

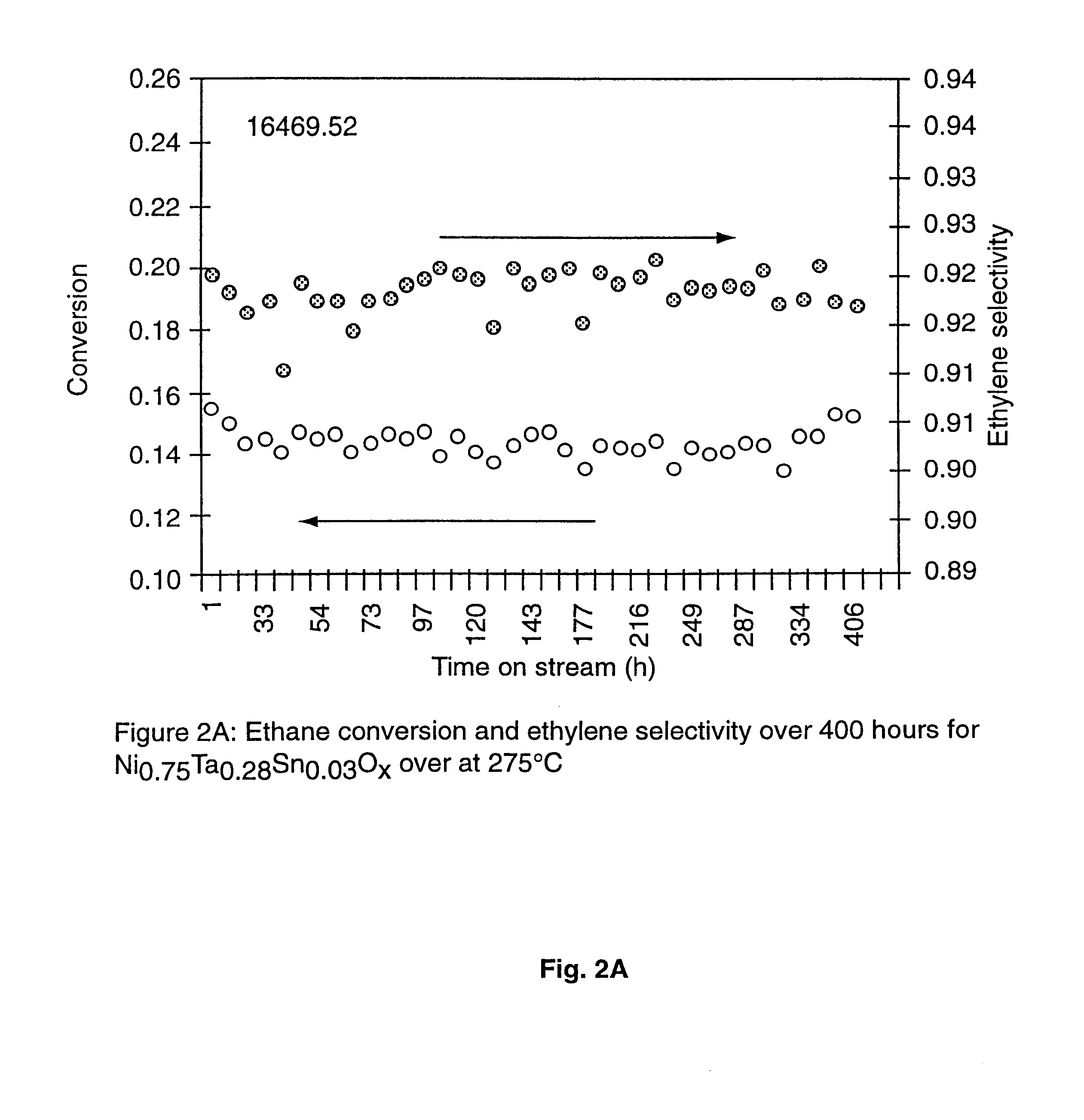

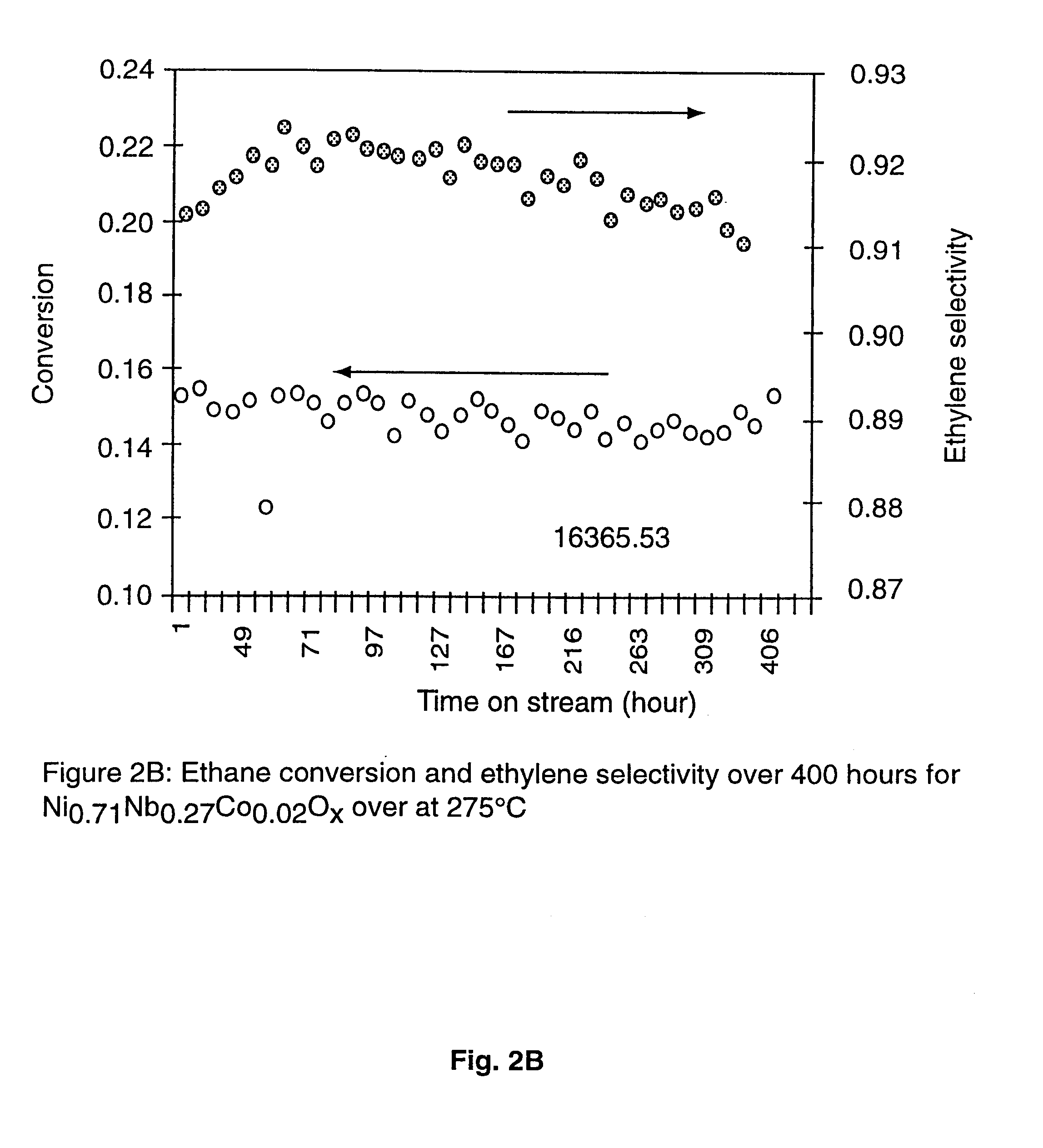

Ni catalysts and methods for alkane dehydrogenation

Owner:CELANESE INT CORP

Feed mixer for a partial oxidation reactor

ActiveUS7108838B2Improve efficiencyReadily apparentFlow mixersTransportation and packagingPartial oxidationProcess engineering

Owner:PHILLIPS 66 CO

Liquid phase oxidation of P-xylene to terephthalic acid in the presence of a catalyst system containing nickel, manganese, and bromine atoms

ActiveUS20050240055A1Production controlOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsManganeseSolvent

A method for liquid phase oxidation of p-xylene with molecular oxygen to terephthalic acid that minimizes solvent loss through solvent burn and minimizes the formation of incomplete oxidation products such as 4-carboxybenzaldehyde (4-CBA). P-xylene is oxidized at a temperature in the range of 120° C. to 250° C. and in the presence of a source of molecular oxygen and a catalyst composition substantially free of zirconium atoms comprising a source of nickel (Ni) atoms, a source of manganese (Mn) atoms, and a source of bromine (Br) atoms, to form a crude reaction mixture comprising terephthalic acid and incompletely oxidized reaction products comprising 4-CBA, wherein the stoichiometric molar ratio of bromine atoms to manganese atoms is 1.5 or less, and the amount of nickel atoms is at least 500 ppm.

Owner:ALPEK POLYESTER SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com