Preparation method of monatomic dispersion catalyst with high catalytic performance

A catalyst and atomic technology, which is applied in the field of preparation of SiO2 microsphere-supported highly dispersed metal cobalt atom catalysts, to achieve the effect of improving activity and selectivity, high stability and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Synthesis of monocarboxyporphyrins. In a 500 mL three-neck flask, add 250 mL of propionic acid, 5.565 g of benzaldehyde and 2.625 g of 4-carboxybenzaldehyde, heat to reflux, slowly drop 4.69 g of pyrrole into the flask with a constant pressure dropping funnel, control the flow rate, add 20 min use up. Under the condition of reflux, the reaction was continued for 30 min. After the reaction solution was cooled, it was placed in the refrigerator overnight, filtered with suction, and separated by a silica gel column to synthesize monocarboxyporphyrin.

[0018] Synthesis of monocarboxycobalt porphyrins. In a 250 mL three-neck flask, add 100 mL DMF, 1.0 g monocarboxyporphyrin, heat to reflux, add 2.54 g CoCl in batches within 1 h 2 ·6H 2 O. After the addition, point the plate to monitor the reaction progress, and stop the reaction when the raw material point disappears. After the reaction solution is cooled, add 2-3 times the volume of distilled water, let it stand overn...

Embodiment 2

[0020] Amino modified SiO 2 Synthesis of silica spheres.

[0021] Weigh 1 g SiO 2 Disperse in 30 mL toluene, ultrasonically disperse for 10 min, stir magnetically, raise the temperature to 60 °C, slowly add the mixed solution of (12 mL APTES + 15 mL toluene) dropwise, and react for 24 h. Wash twice with 30 mL of toluene and 30 mL of methanol, and dry under vacuum at 80 °C overnight. The resulting product is referred to as SiO 2 -NH 2 .

Embodiment 3

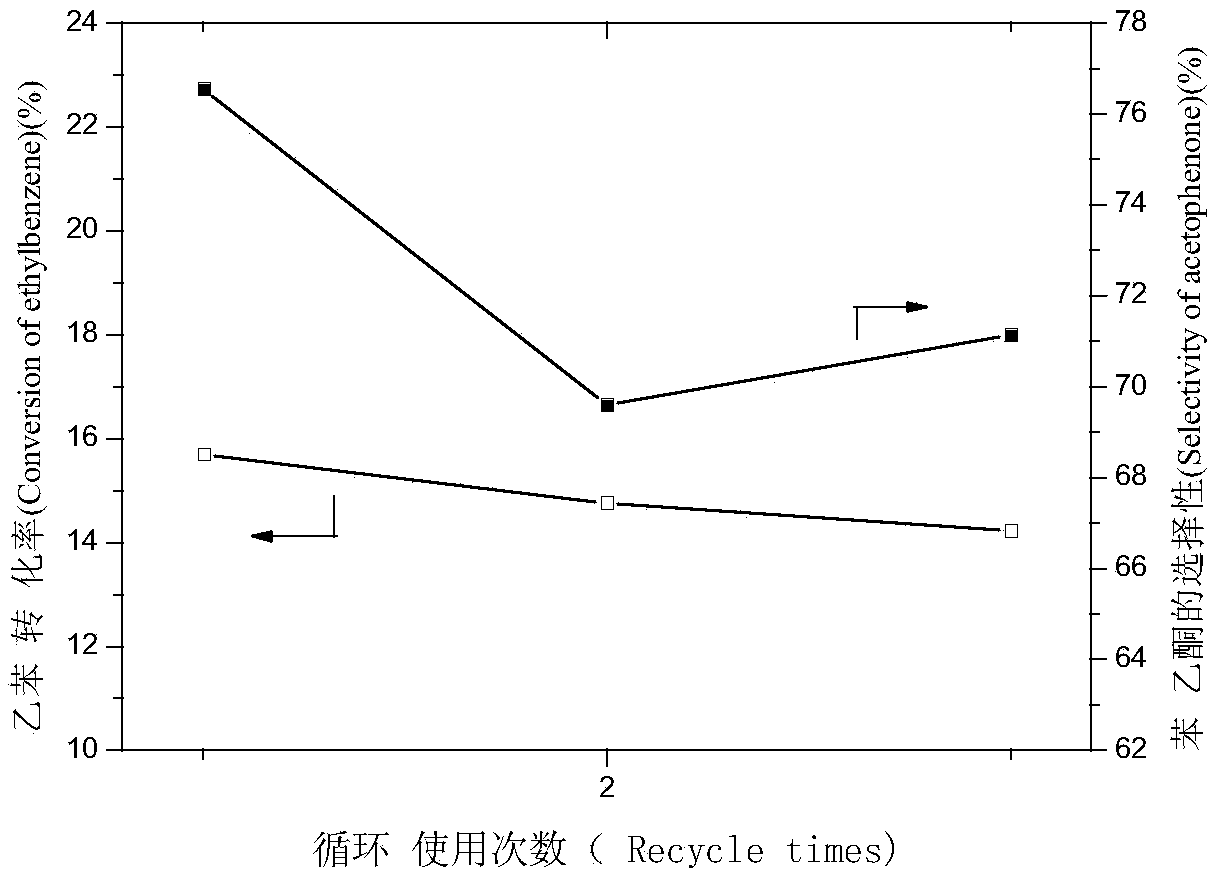

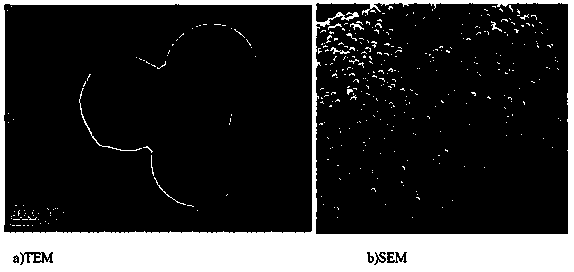

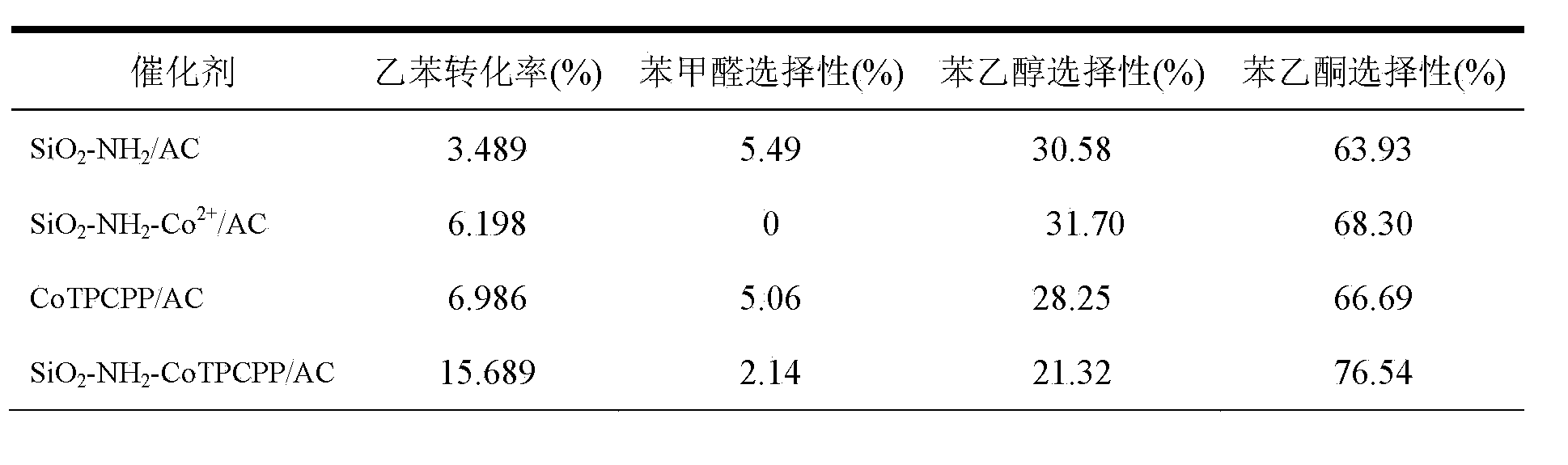

[0023] Weigh 0.010 g CoTPCPP, 0.1 g amino-modified SiO 2 Microspheres, added to a solution containing 20 mL CH 2 Cl 2 solution in a 50 mL one-necked flask, reflux for 24 h, cool, and then use 30 mL CH 2 Cl 2 and 30 mL ethanol twice, at 80 o C was dried in vacuum for 12 h, and the obtained catalyst was abbreviated as SiO 2 -NH 2 -CoTPCPP. Weigh 0.01 g SiO 2 -NH 2 -CoTPCPP is installed in the reaction tube, and the temperature is raised to 800 o C, calcined for 1 h, and N was passed through the whole process 2 protection, and then naturally cooled to room temperature, the resulting product is referred to as SiO 2 -NH 2 -CoTPCPP / AC.

[0024] Similarly, the prepared SiO 2 -NH 2 / AC, SiO 2 -NH 2 -Co 2+ / AC and CoTPCPP / AC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com