Patents

Literature

84 results about "Cobalt atom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt is the first element in the ninth column of the periodic table. It is classified as a transition metal. Cobalt atoms have 27 electrons and 27 protons with 32 neutrons in the most abundant isotope.

Process for activating cobalt catalysts

InactiveUS20050227866A1Improve reducibilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsParticulatesHydrogen

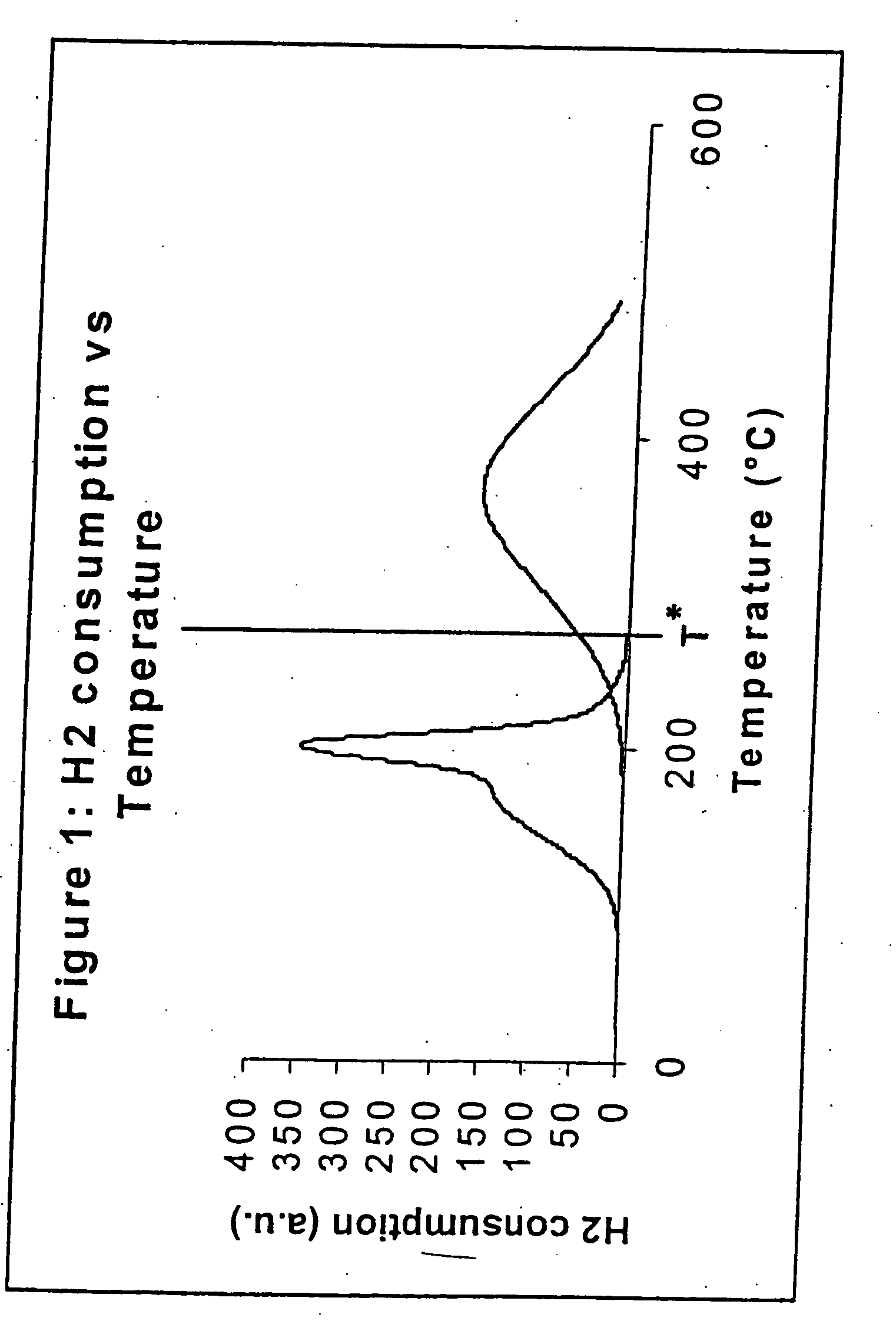

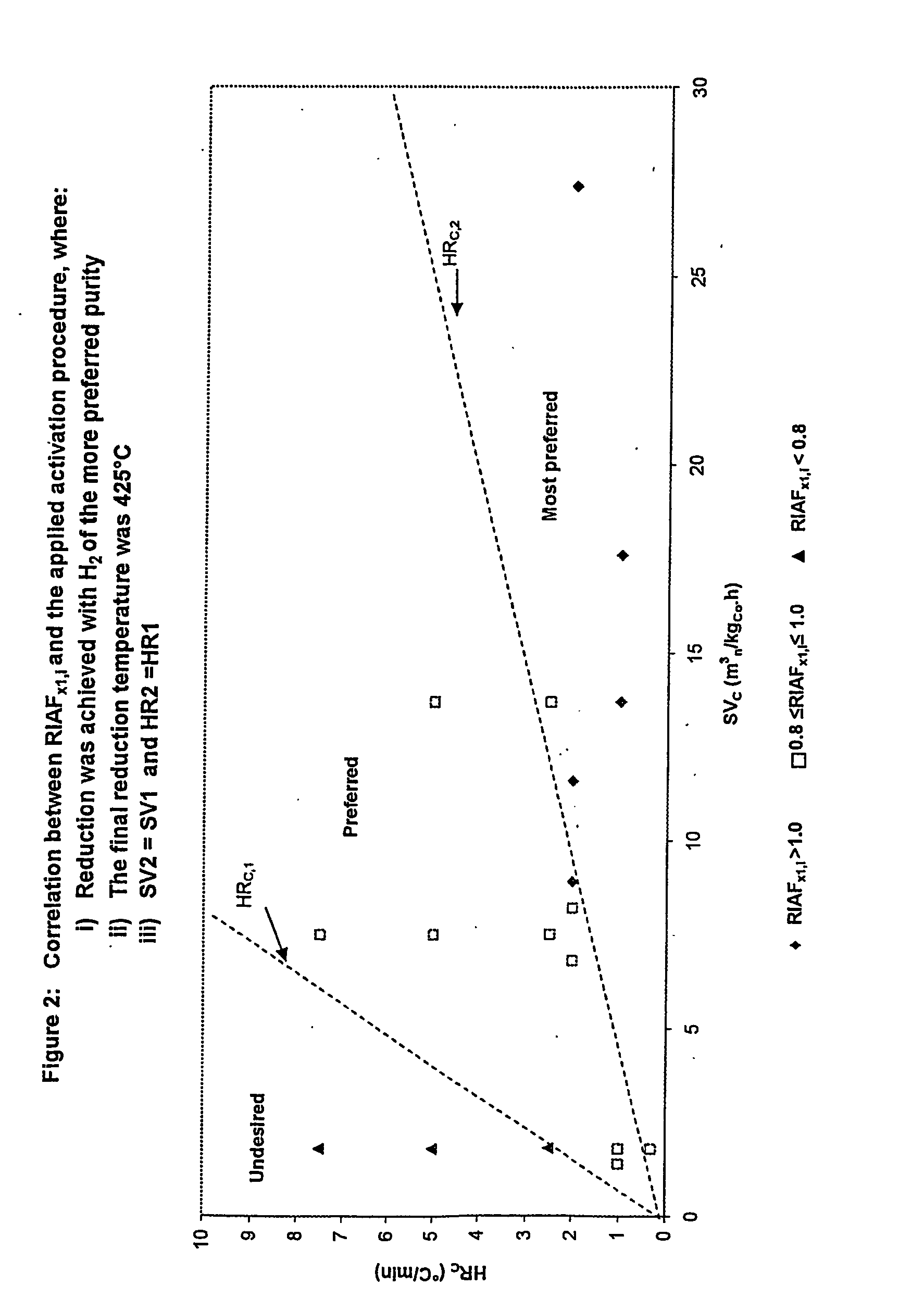

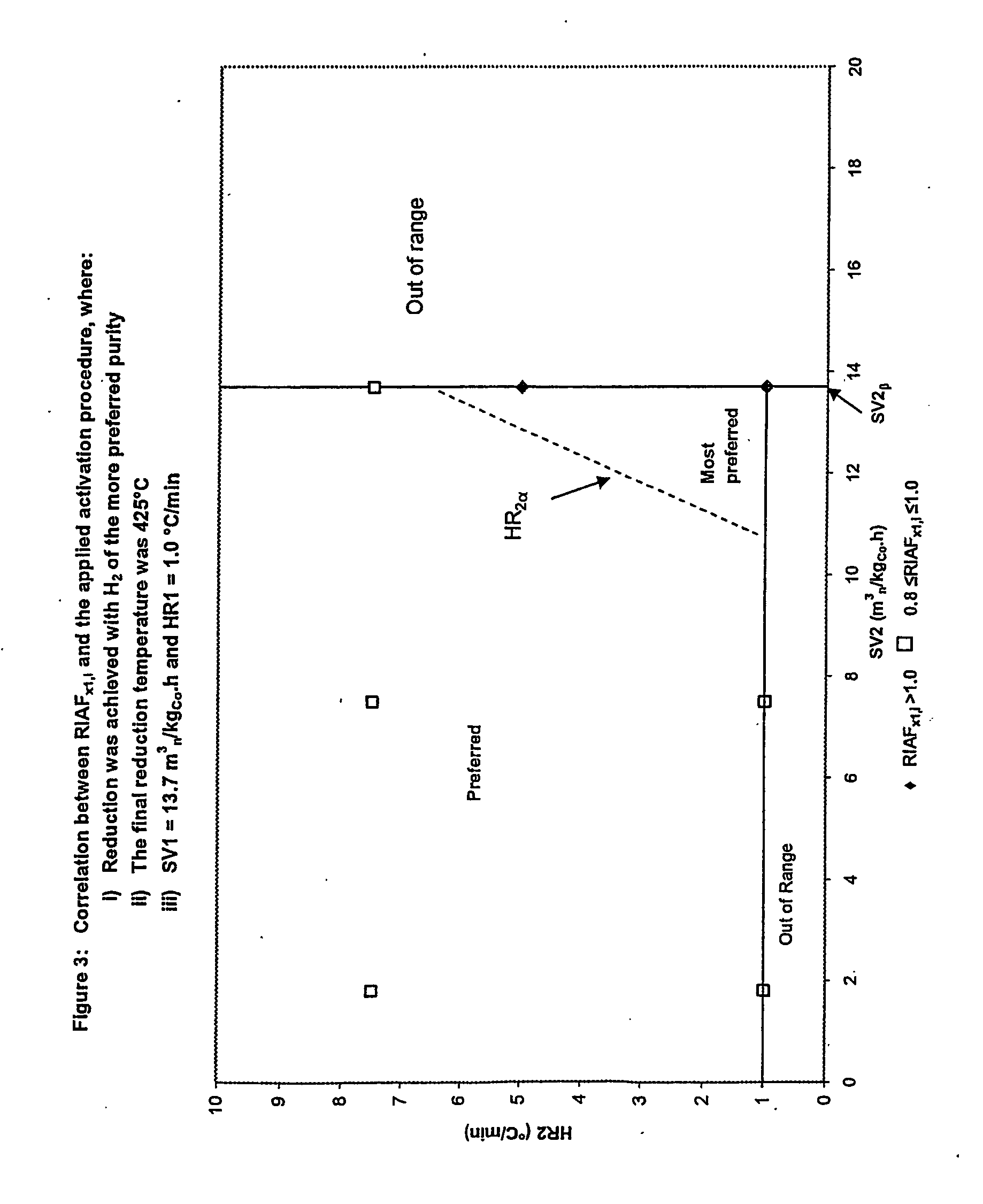

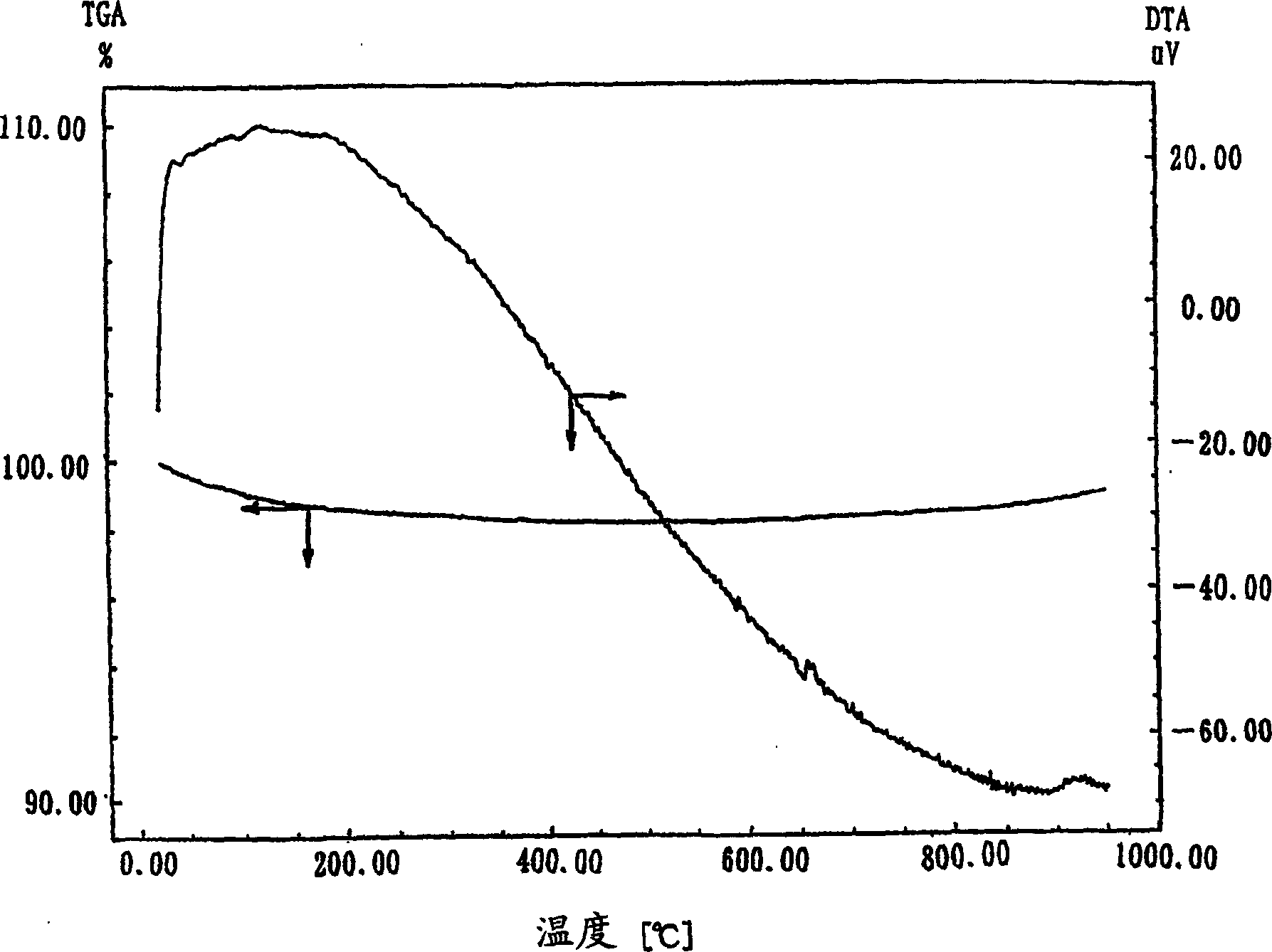

A particulate pre-reduction cobalt supported Fischer-Tropsch synthesis catalyst precursor which comprises a catalyst support impregnated with cobalt, is treated with a pure hydrogen reducing gas, at a first specific feed gas space velocity, SV1, and at a first heating rate, HR1, to obtain a partially reduced precursor. The support contains reducible cobalt oxide in a calcined state and having a formula-unit in which each mole of cobalt atoms is associated with more than 4 / 3 moles of oxygen atoms and displaying a reducible cobalt oxide specific surface area at least equal to that of Co3O4 spinel. The partially reduced precursor is then treated with a pure hydrogen reducing gas, at a second specific feed gas space velocity, SV2, and at a second heating rate, HR2, to obtain an activated supported Fischer-Tropsch catalyst, with SV2≦SV1 and / or HR2≧HR1; however, when SV2=SV1, HR2≠HR1 and when HR2=HR1, SV2≠SV1.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

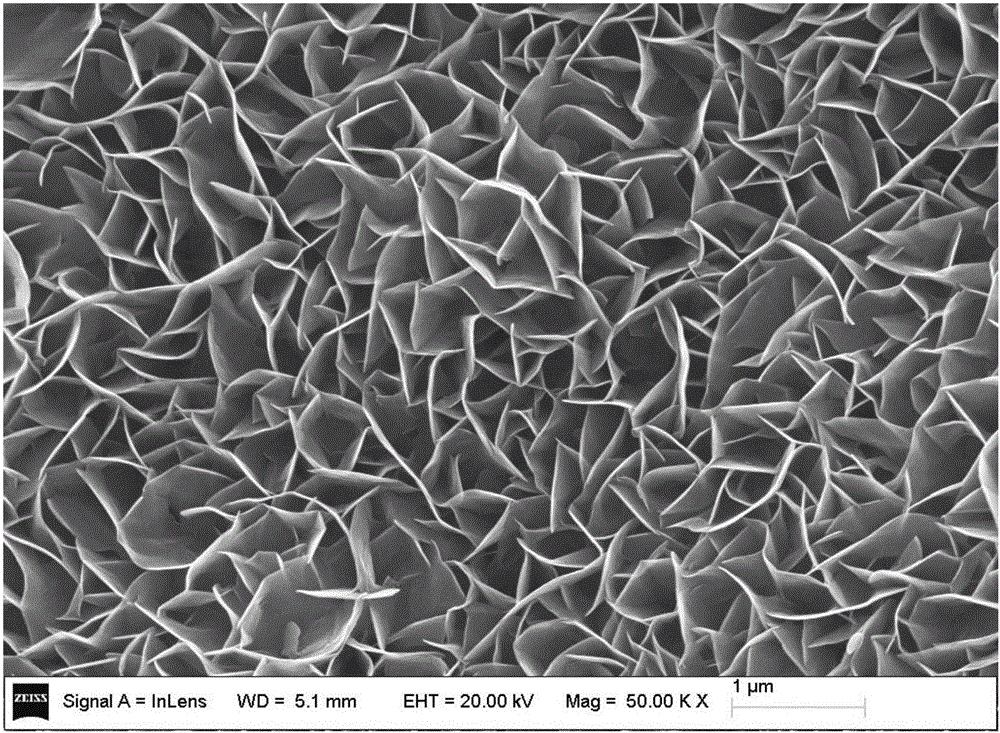

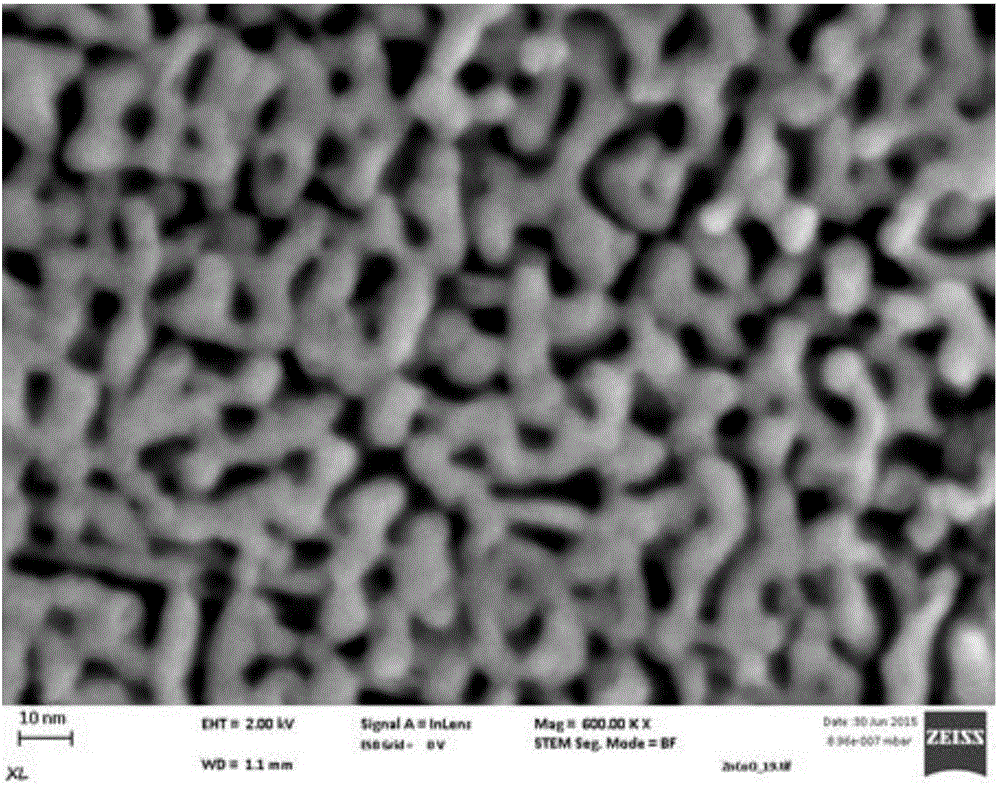

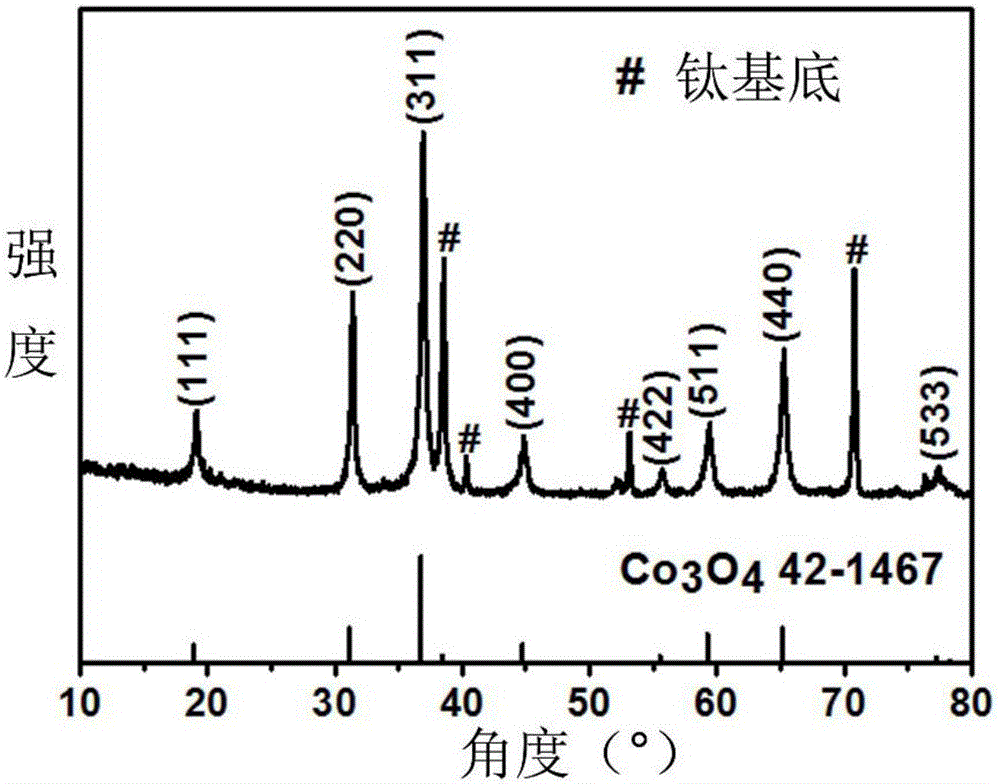

Ultrathin nanosheet array electro-catalytic material with nano-porous structure and oxygen vacancies

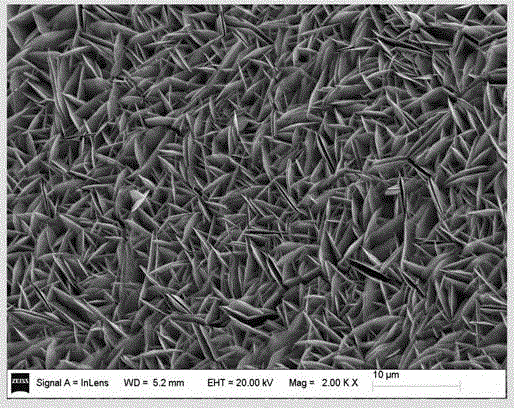

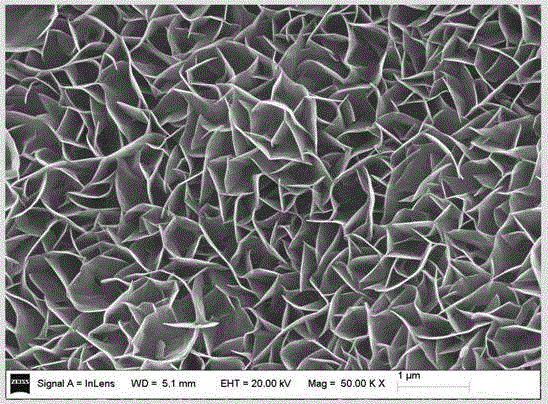

The invention relates to an ultrathin nanosheet array electro-catalytic material with a nano-porous structure and oxygen vacancies. The material is a cobaltosic oxide primary nanosheet array which grows vertically on a conductive substrate and is doped with a metal; an ultrathin nanosheet with oxygen vacancies and nanopores is obtained on each primary nanosheet; the conductive substrate is a titanium sheet or a foamed nickel sheet, and the doped metal is zinc, nickel or manganese; and the thickness of each cobaltosic oxide ultrathin nanosheet doped with the metal is 1.22 nm, nanosheets are in a three-dimensional porous structure, and the nano-pore diameter is 3-6 nm. The ultrathin nanosheet array electro-catalytic material with the nano-porous structure and oxygen vacancies has the following advantages: the material can effectively reduce the overpotential and the spike potential of an oxygen evolution reaction, increase the conversion rate of a single cobalt atom and work continuously and stably in an alkali environment; the steps of a preparation method of the material are simple, the operation is convenient, the cost is low, and the material is environmental-friendly; and new ideas and strategies are provided for the function-oriented design and the performance optimization of an oxygen evolution catalyst of a water electrolysis system.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

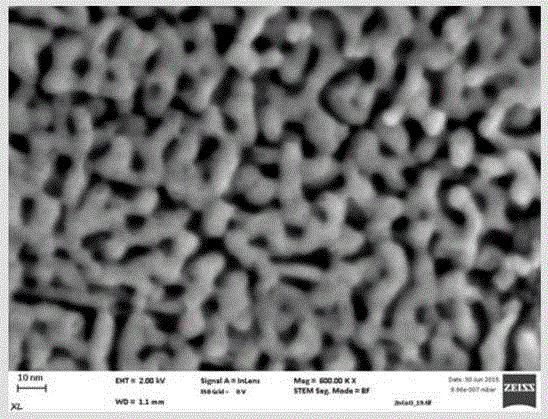

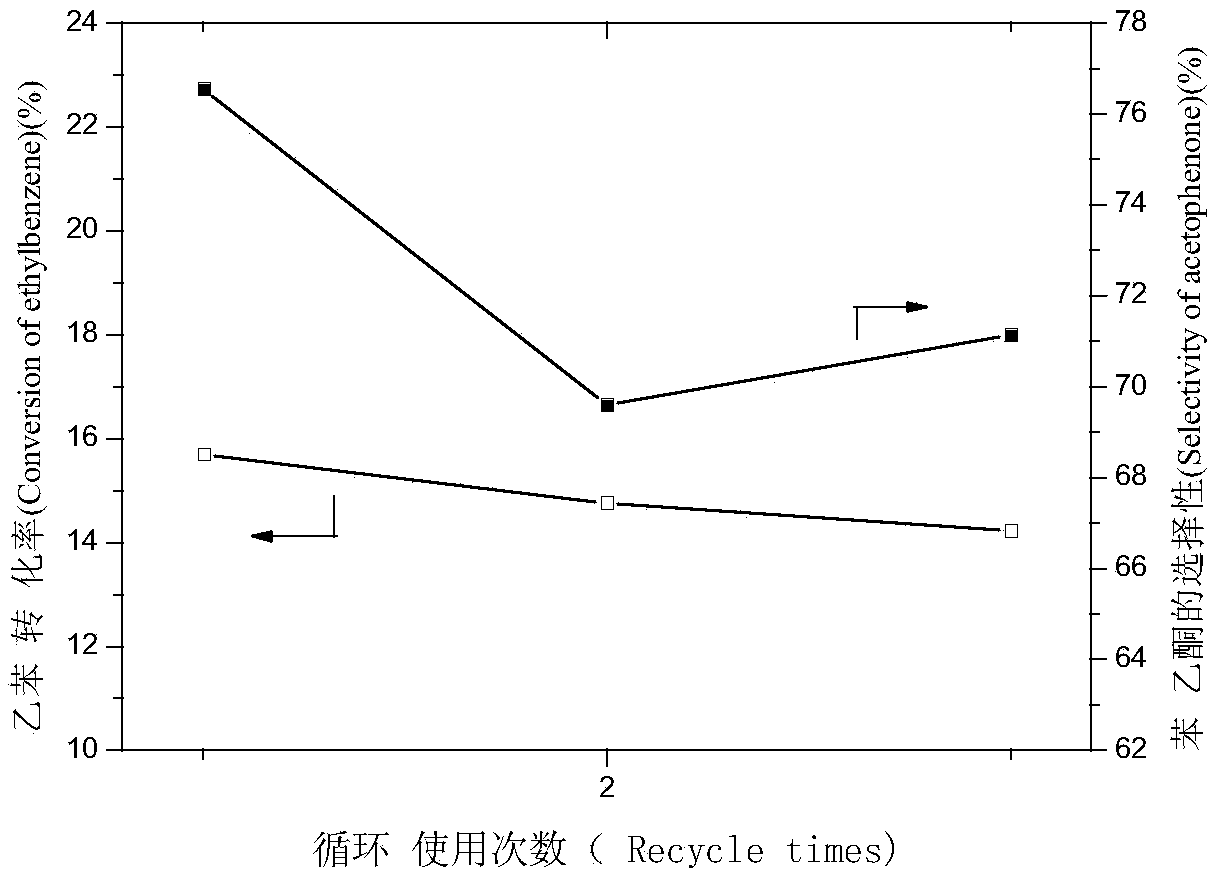

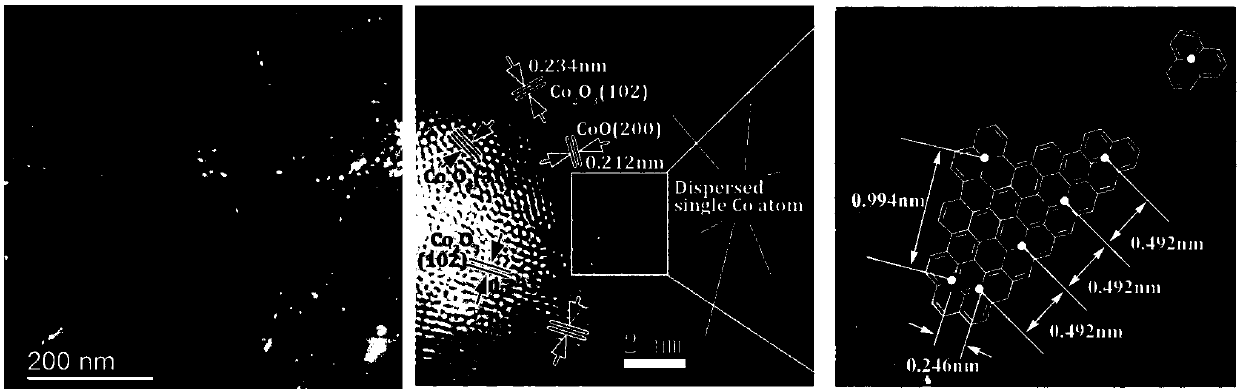

Preparation method of monatomic dispersion catalyst with high catalytic performance

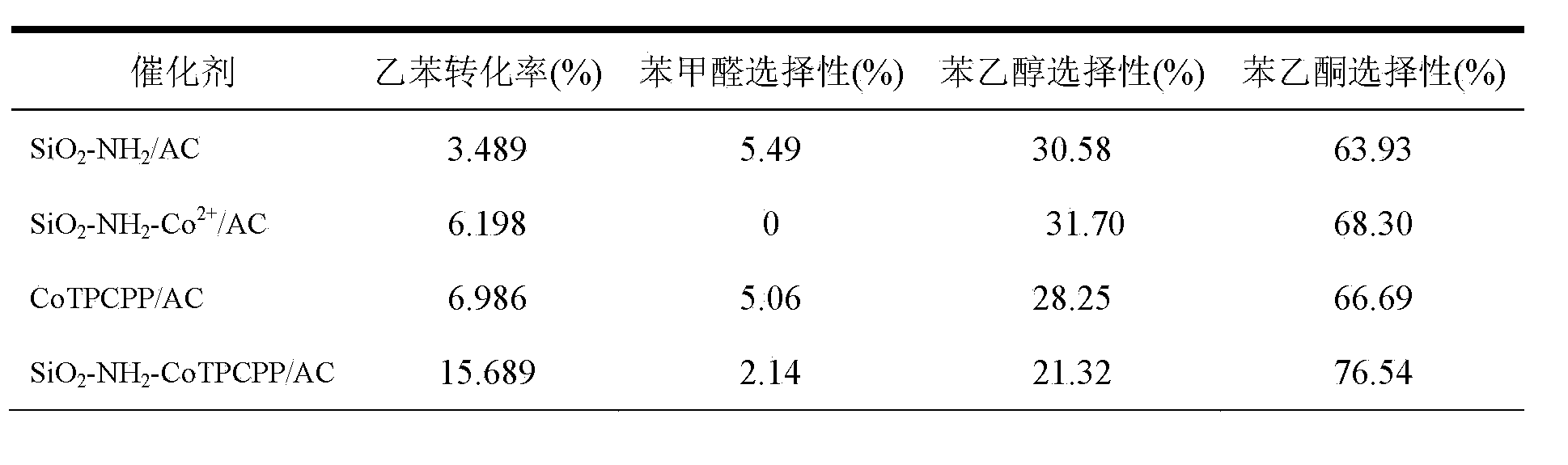

InactiveCN103566935AImprove catalytic performanceImprove stabilityPreparation by oxidation reactionsOrganic compound preparationAlkaneMicrosphere

The invention belongs to the technical field of catalysis and relates to a method for preparing a monatomic cobalt catalyst by roasting silicon dioxide pellets and immobilizing metalloporphyrin. The method is realized by adopting the following technical scheme: namely stirring and dispersing nano silicon dioxide particles, dropwise adding 3-aminopropyl triethoxy silane, so as to obtain amino modified SiO2 pellets, then linking monocarboxyl metalloporphyrin (CoTPCPP) onto an amino modified SiO2 carrier through organic complexing, carbonizing porphyrin through high-temperature calcination in an inert atmosphere, and loading highly dispersed cobalt atoms onto the amino modified SiO2 pellets, thus an amino modified silicon dioxide pellet loaded monatomic cobalt catalyst is obtained. The monatomic dispersion catalyst has high catalytic activity and stability on a molecular oxygen selective ethylbenzene catalytic oxidation reaction in absence of solvent; meanwhile, a preparation method is simple, and product quality can be easily controlled, so that the monatomic dispersion catalyst is applicable to the fields of alkane selective oxidation reactions and synthesis of medical intermediates.

Owner:HUNAN UNIV

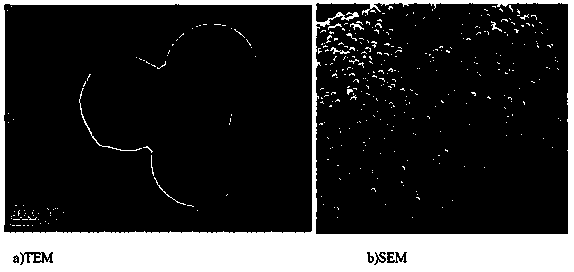

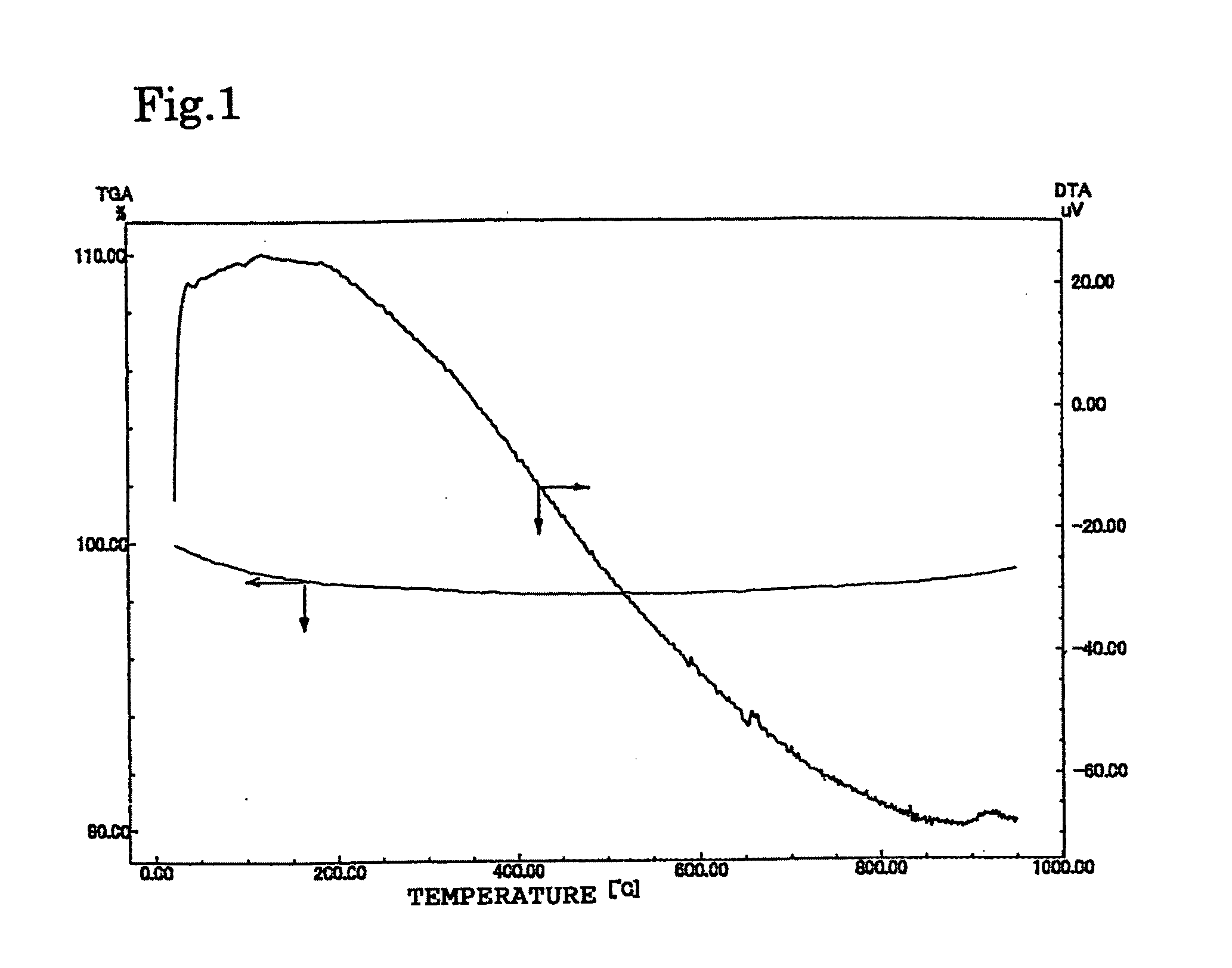

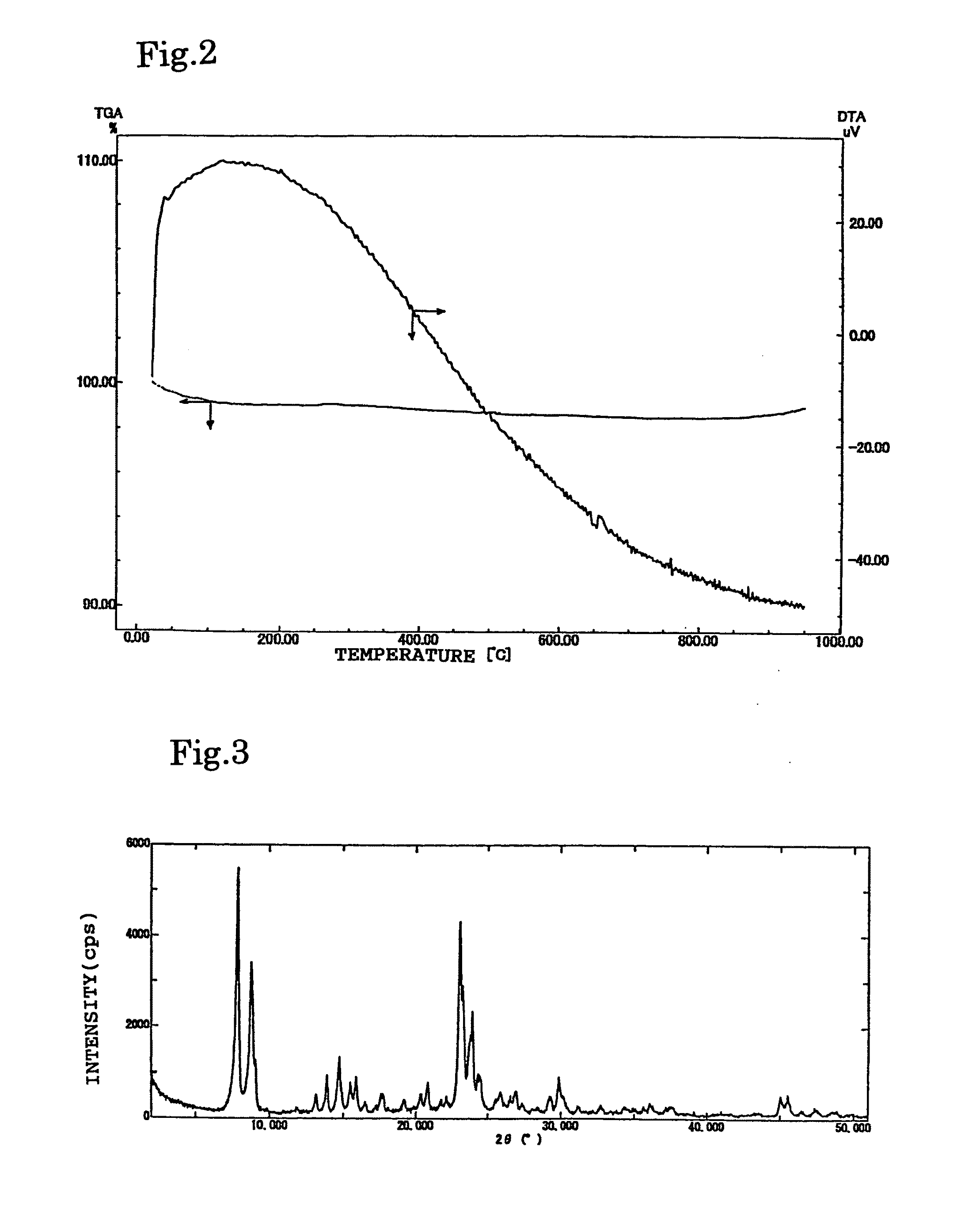

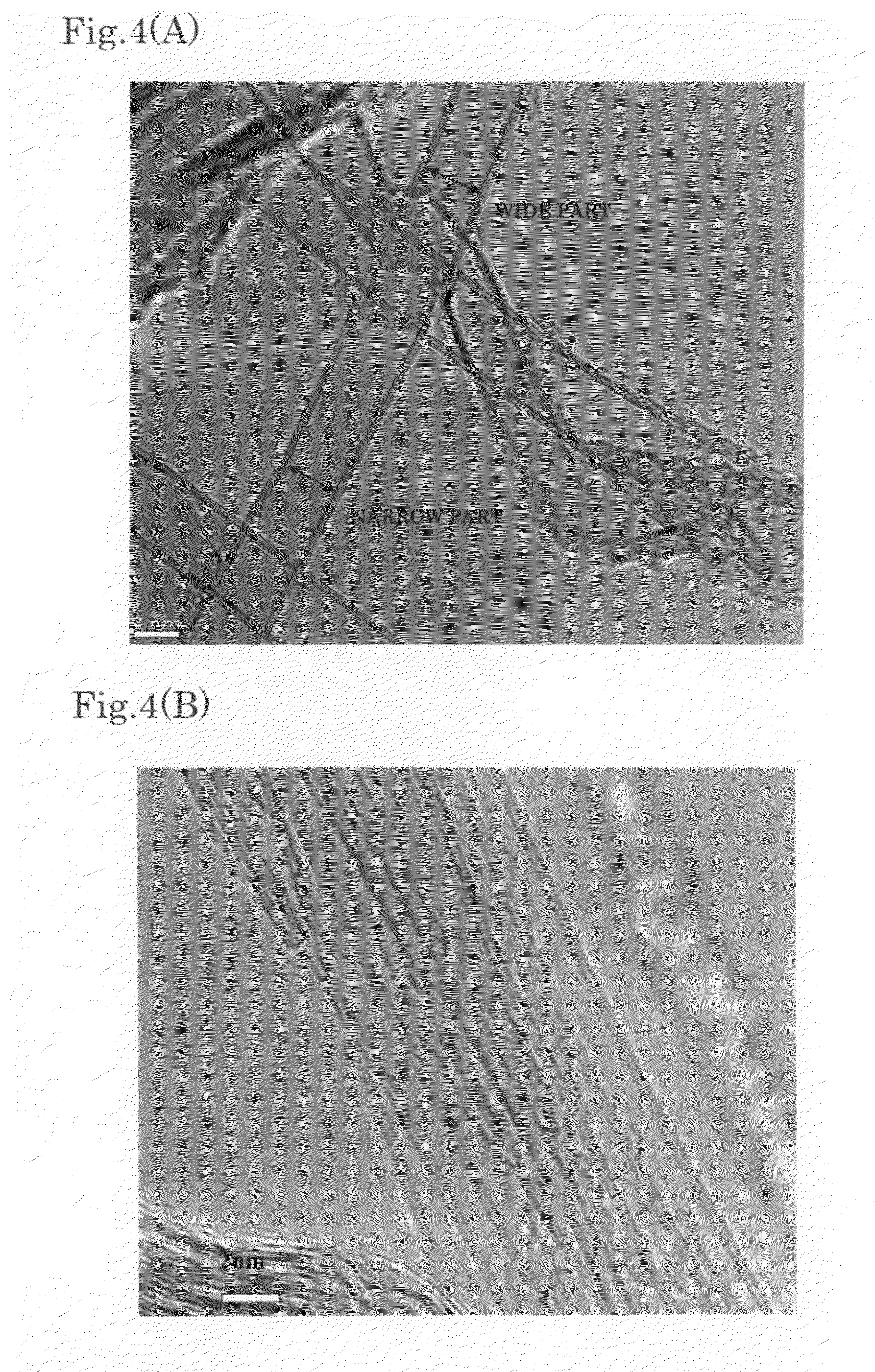

Hollow nanofibers-containing composition

InactiveUS20110027163A1Easy to separateEasy to removeMaterial nanotechnologyMolecular sieve catalystsFiberElectron

A method for preparing hollow nanofibers having carbon as a primary component by contacting a carbon-containing compound with a catalyst at 500 to 1200° C., wherein the catalyst is one of a zeolite exhibiting thermal resistance at 900° C. and, supported thereon, a metal; a metallosilicate zeolite containing a heteroatom except aluminum and silicon and a metal; a supporting material and fine cobalt particles exhibiting a binding energy of a cobalt 2P3 / 2 electron of 779.3 to 781.0 eV; a supporting material and fine cobalt particles exhibiting a cobalt atom ratio in the surface of the supporting material of 0.1 to 1.5%, as measured by the X-ray photoelectron spectroscopy at 10 kV and 18 mA; a supporting material and fine cobalt particles exhibiting a weight ratio of cobalt to a second metal component of 2.5 or more; and a zeolite having a film form and a metal.

Owner:SHINOHARA HISANORI +4

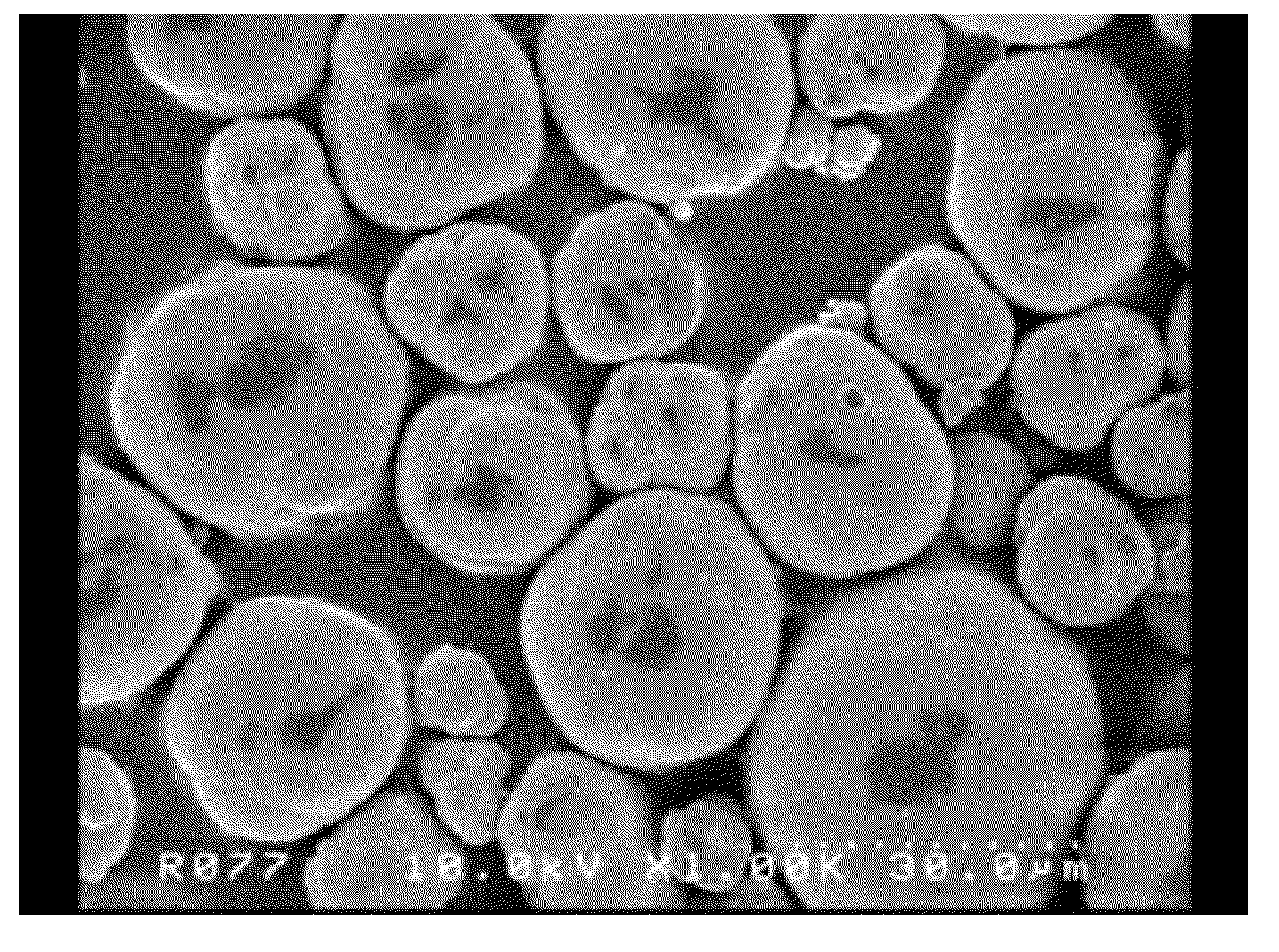

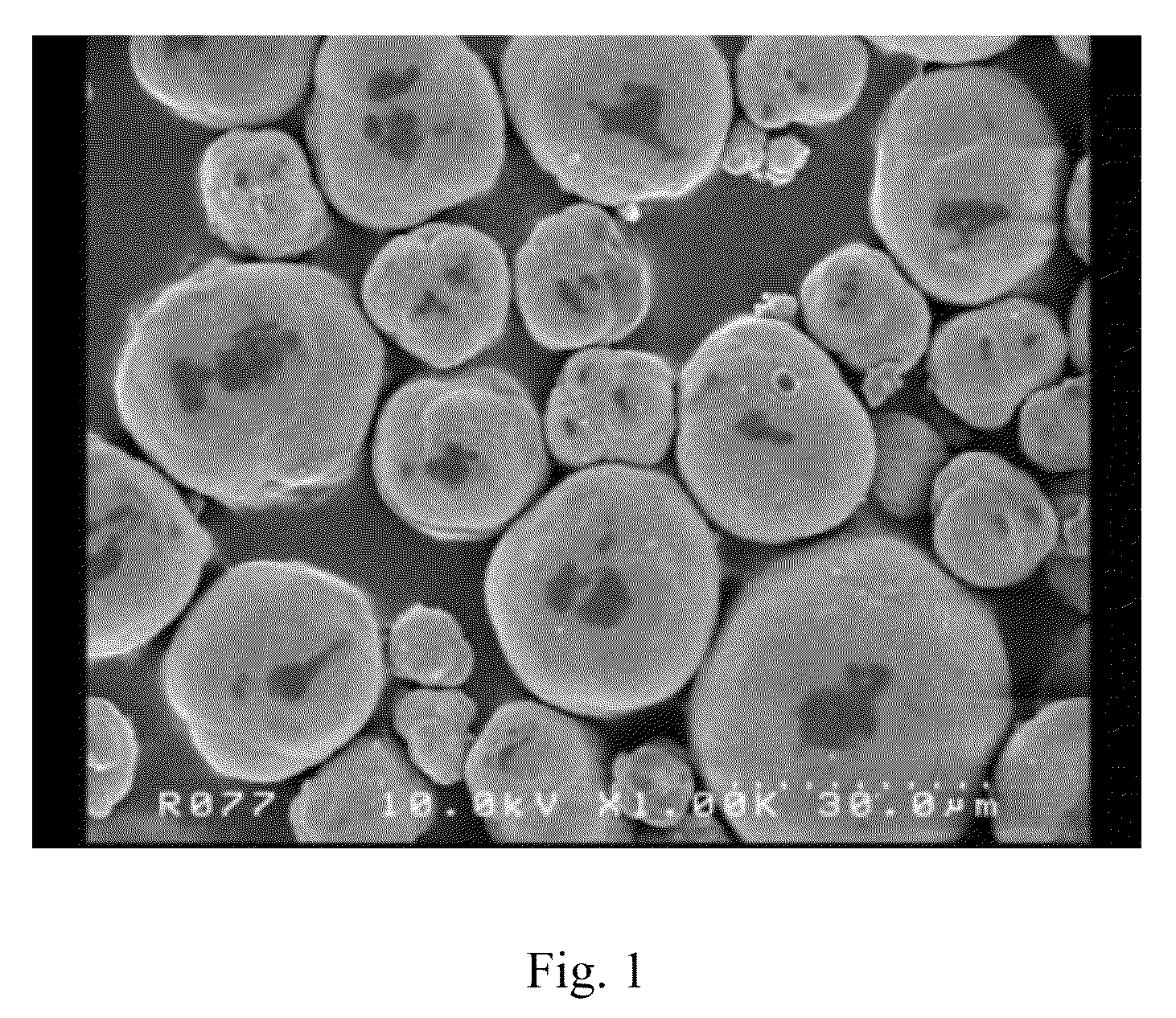

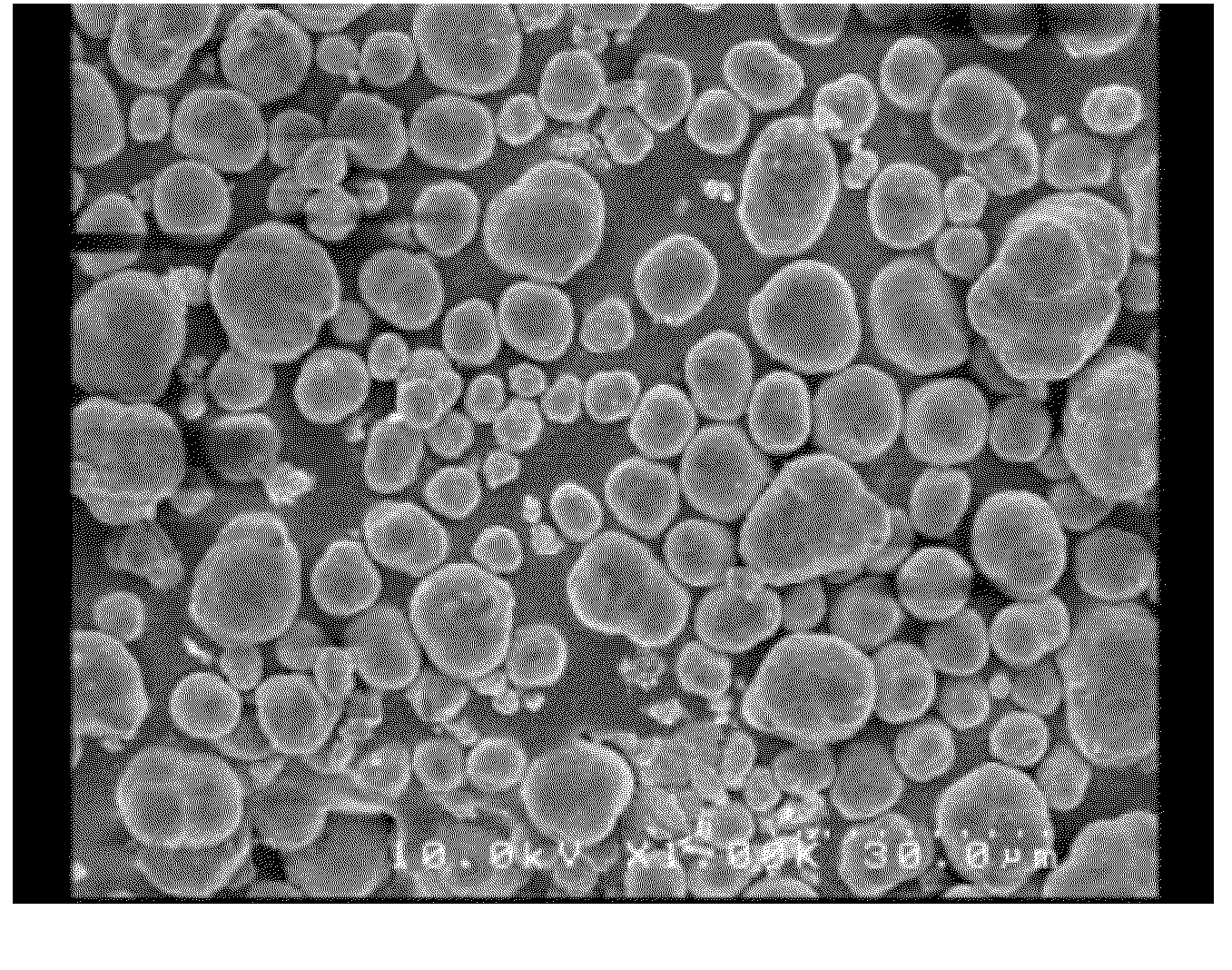

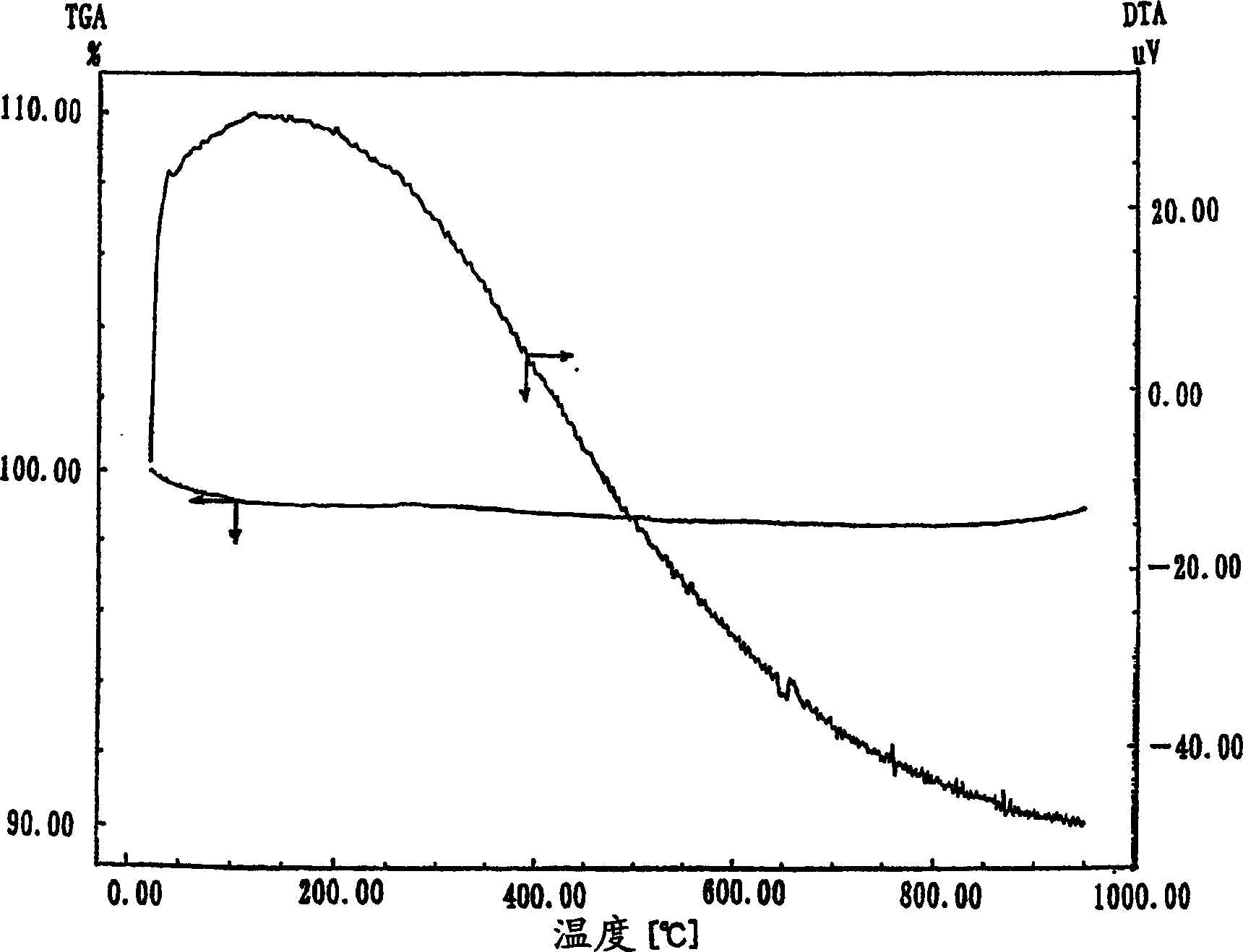

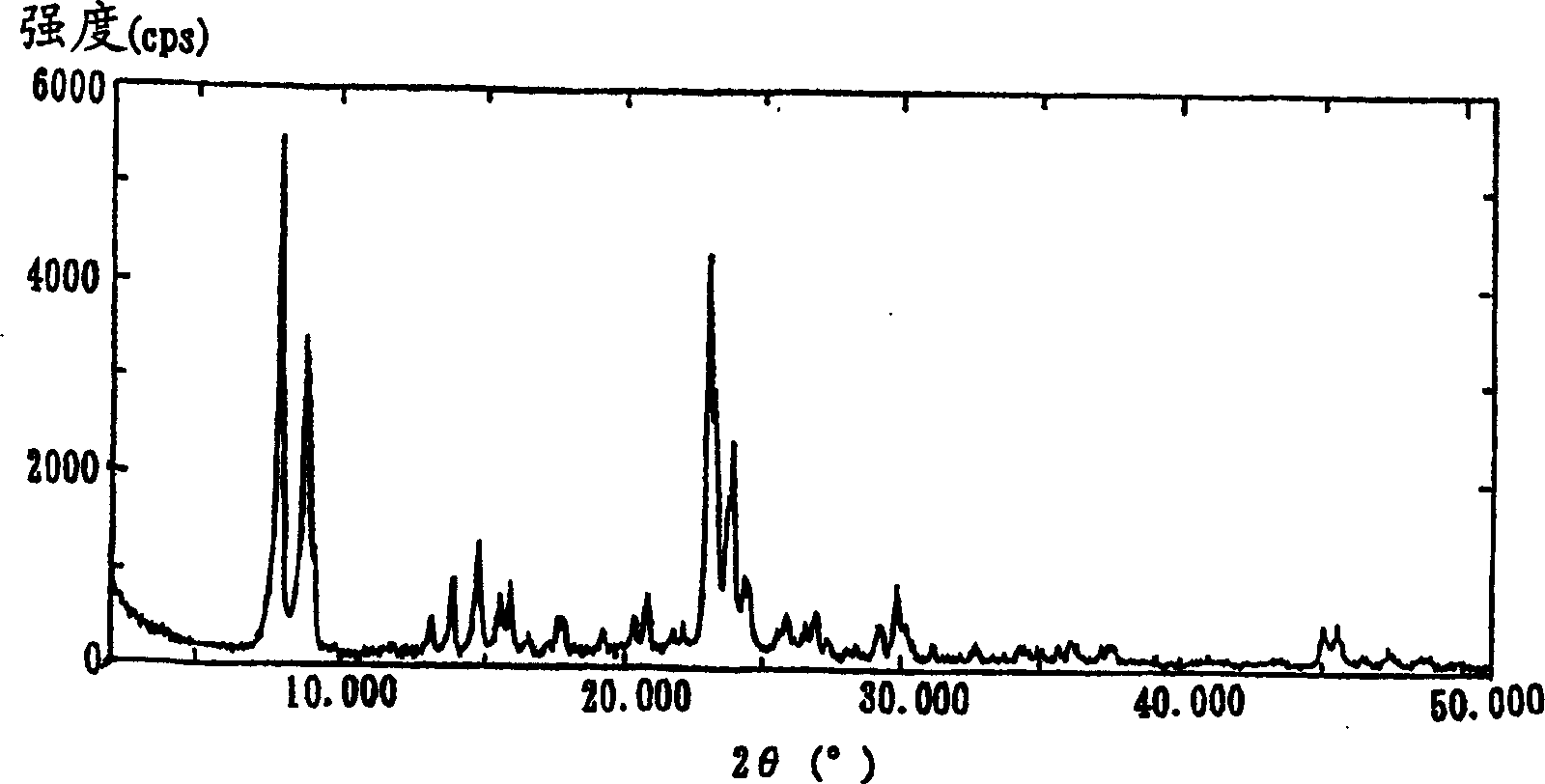

Composite carbonate and method for producing the same

InactiveUS20090194746A1Reduce the amount of wasteGood effectNon-metal conductorsConductive materialManganeseCobalt atom

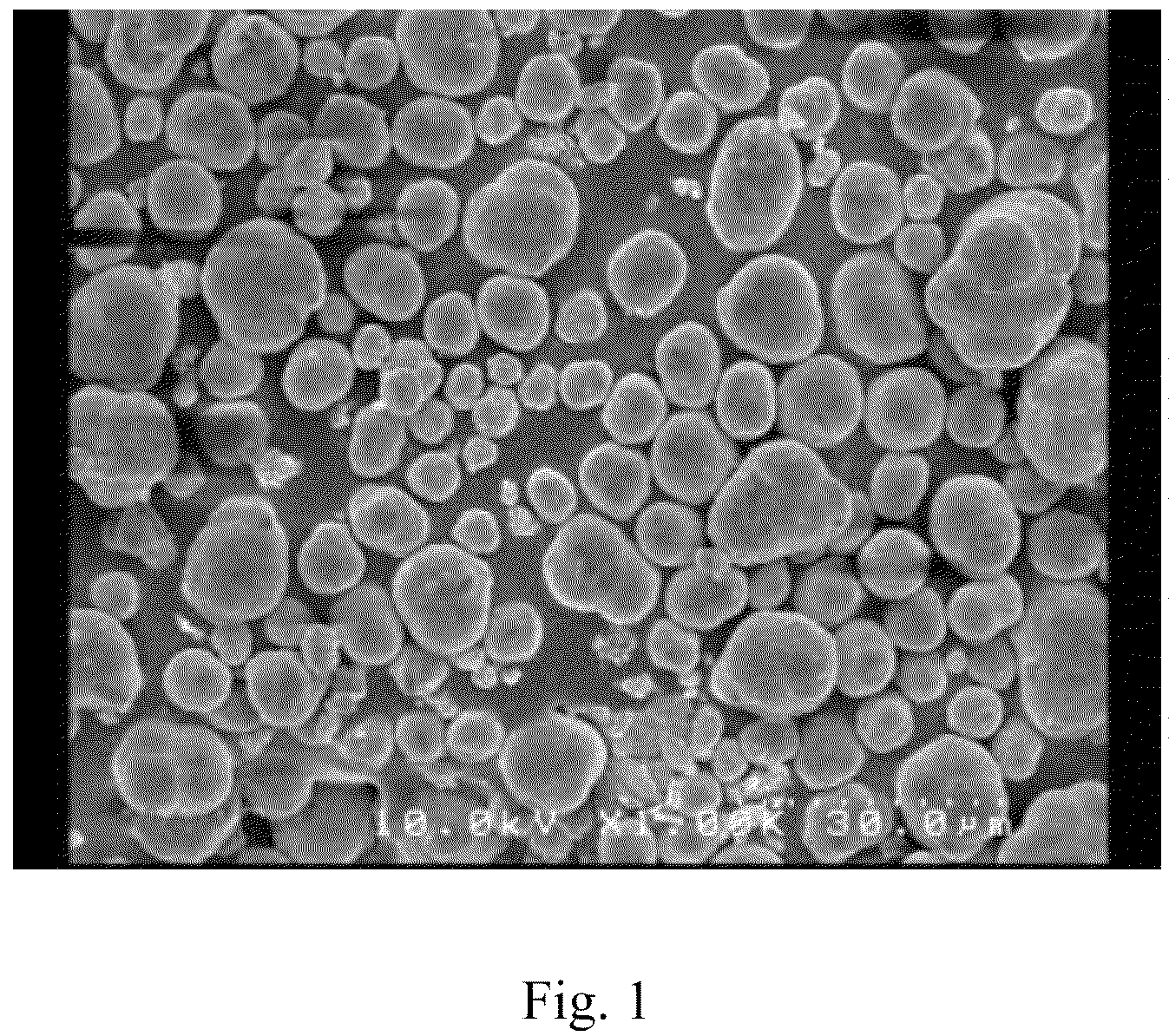

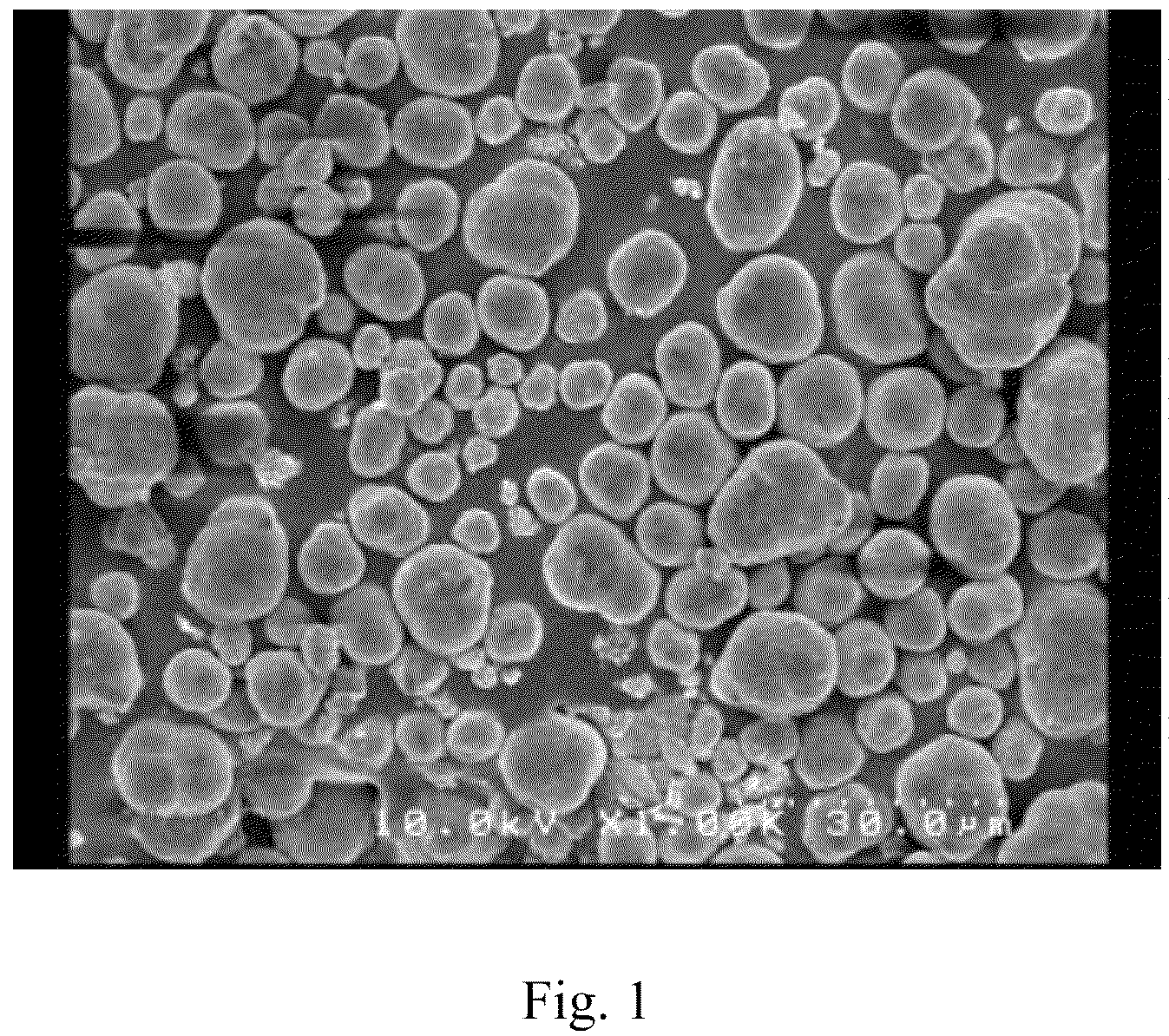

The present invention provides a nickel atom-, manganese atom- and cobalt atom-containing composite carbonate that is high in specific surface area and large in tap density, and useful as a raw material for producing a lithium nickel manganese cobalt composite oxide to be used in a positive electrode active material for use in a lithium secondary battery, and provides a method for industrially advantageously producing the composite carbonate. The composite carbonate includes nickel atoms, manganese atoms and cobalt atoms, and has an average particle size of 5 μm or more and less than 20 μm, a BET specific surface area of 40 to 80 m2 / g and a tap density of 1.7 g / ml or more.

Owner:NIPPON CHECMICAL IND CO LTD

Single-cell-thickness nano porous cobalt oxide nanosheet array electrocatalytic material

InactiveCN106025302AEnsure continuous and stable workExcellent hydrogen evolution reaction performanceMaterial nanotechnologySpecific nanostructure formationDecompositionOxygen

A single-cell-thickness nano porous cobalt oxide nanosheet array electrocatalytic material is characterized in that a metal-doped cobalt oxide primary nanosheet array is perpendicularly grown on a conductive substrate, a porous nanosheet is obtained from each primary nanosheet, and the nanosheets are of porous structure; the material is used as an electrocatalyst for oxygen evolution reaction; the material also has excellent hydrogen evolution performance and may function as a bifunctional catalyst for an alkaline full-decomposition water system. The invention has the advantages that the material can effectively reduce overpotential and peaking potential of oxygen evolution reaction, increase conversion rate of single cobalt atoms and operate stably and continuously in a strong alkali environment; the material has excellent oxygen evolution reaction performance and can be applied as an anode and cathode of a full-decomposition water system, effectively reducing trough voltage; the material is simple to prepare, convenient to operate, low in cost and environment-friendly, and new idea and strategy are provided for the guide design and performance optimization of the bifunctional catalyst for the full-decomposition water system.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Electrocatalytic hydrogen-production material and preparation method thereof

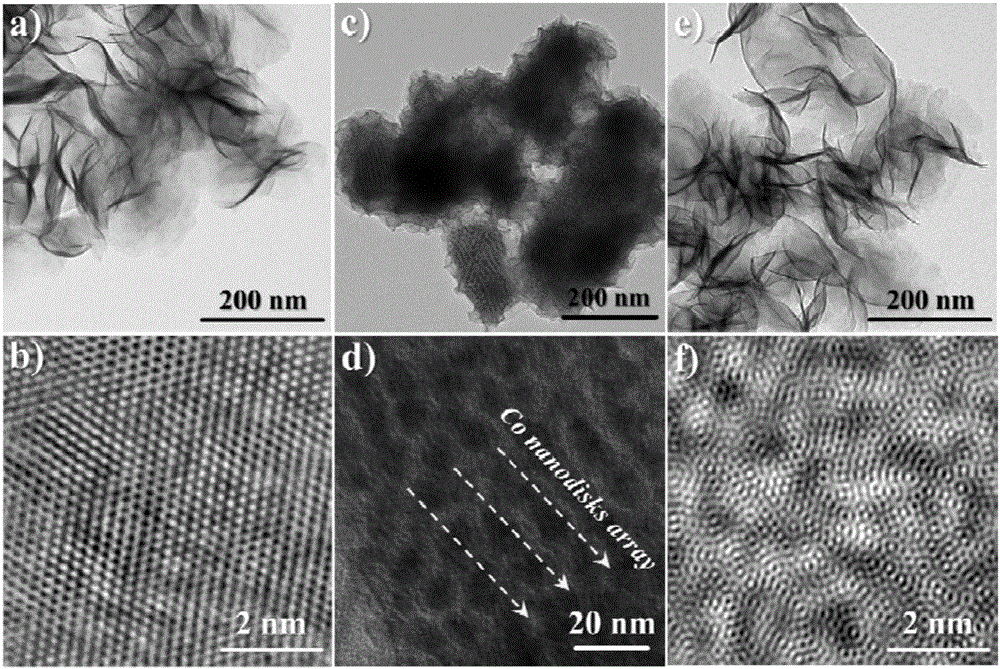

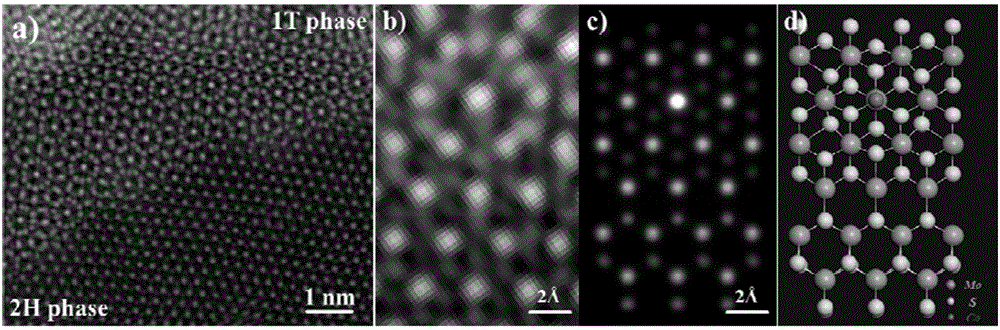

The invention discloses a high-abundance monatomic cobalt-array electrocatalytic hydrogen-production nano material based on the monatomic size effect. According to high-abundance monatomic cobalt-array electrocatalytic hydrogen-production nano material, on the basis that a hydrothermal method is used for preparing laminar molybdenum disulfide and a solvothermal method is used for preparing cobalt nanosheets, the cobalt nanosheets are modified to the surface of the molybdenum disulfide material through an ultrasonic bonding method; and then through the method that electrochemical scanning is conducted on an obtained heterostructure of the cobalt nanosheets and the molybdenum disulfide under an acid condition, redundant cobalt atoms on the surface are removed, and finally, the high-abundance monatomic cobalt-modified molybdenum disulfide lamellar nano material is obtained. The novel electrocatalytic material has good electrochemical hydrogen-production catalytic performance.

Owner:JILIN UNIV

Particulate positive electrode active material for a lithium secondary cell

InactiveUS7018741B2High dischargeImprove securityFluoride preparationPositive electrodesParticulatesHigh temperature storage

Owner:SUMITOMO CHEM CO LTD

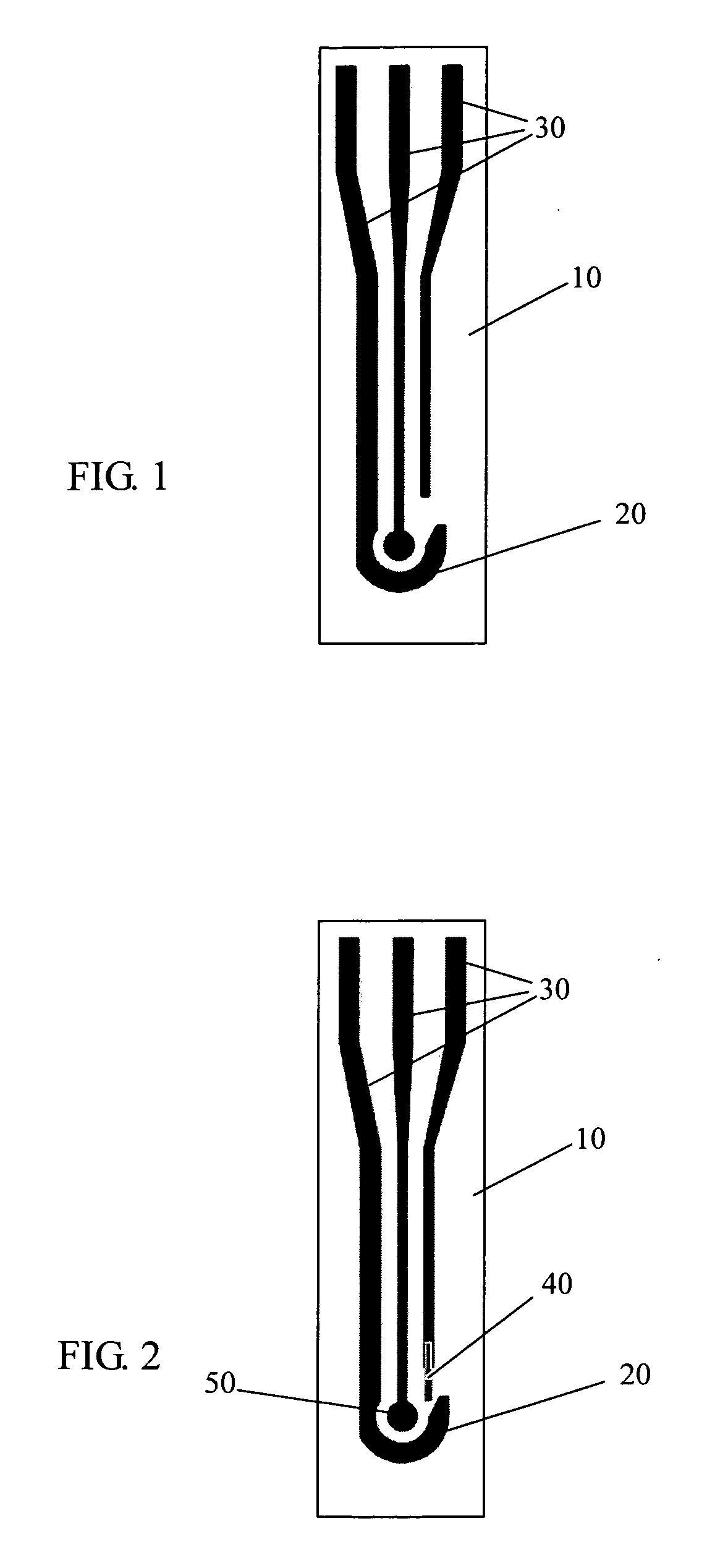

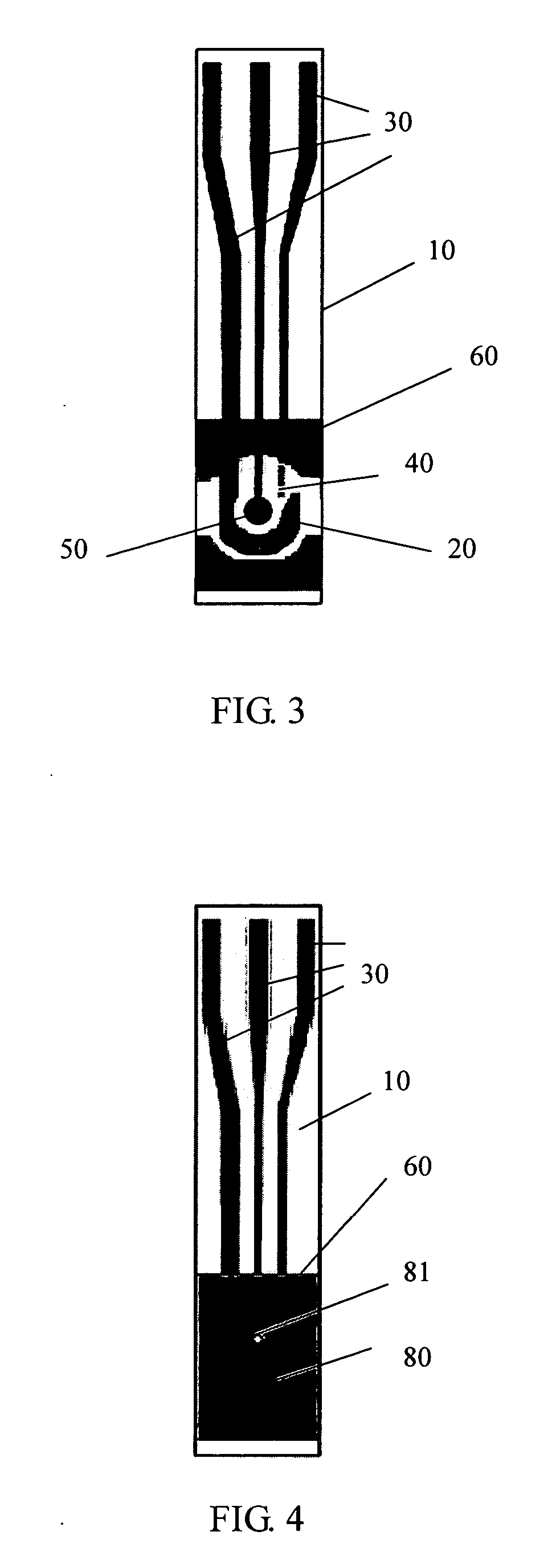

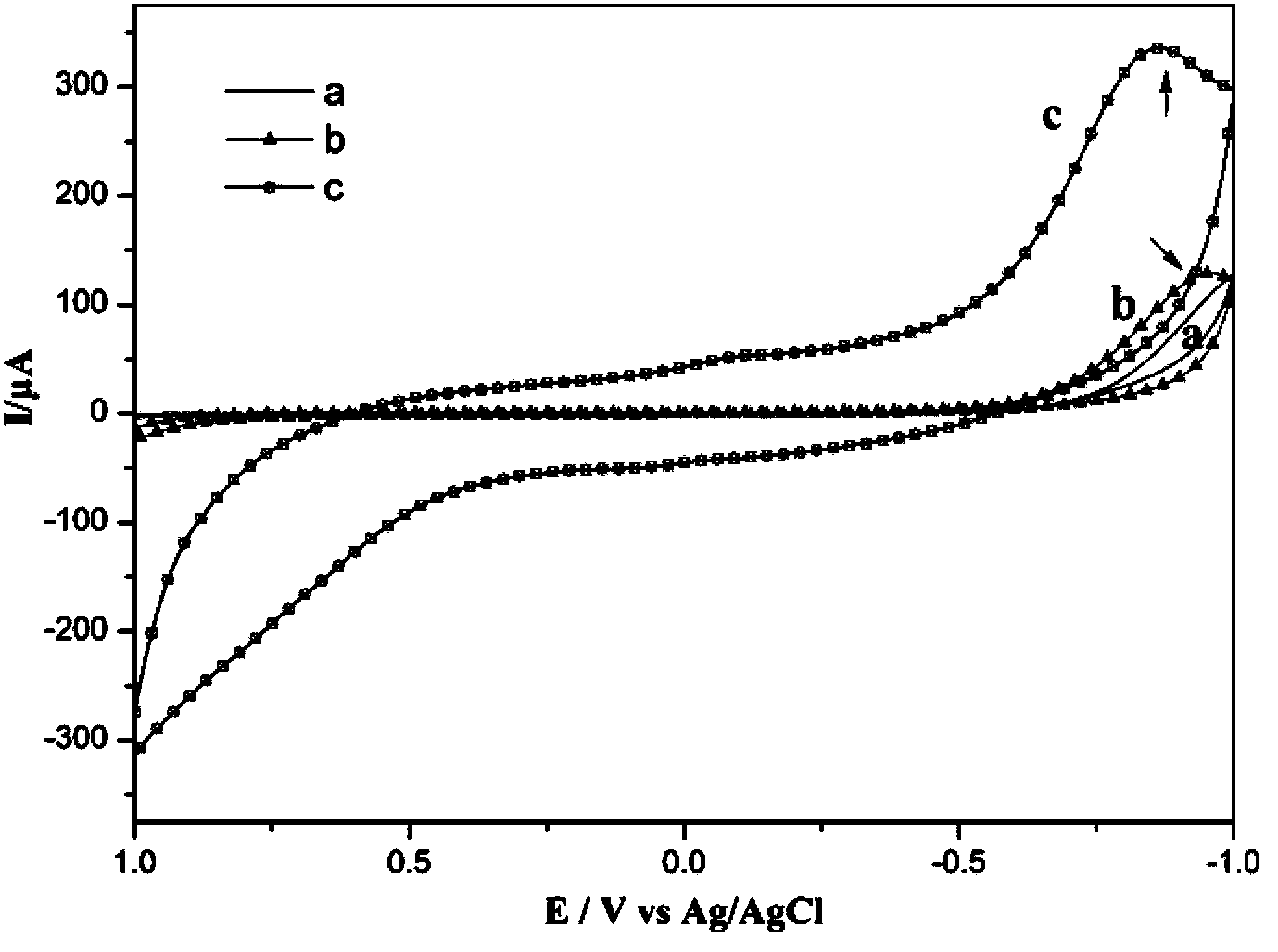

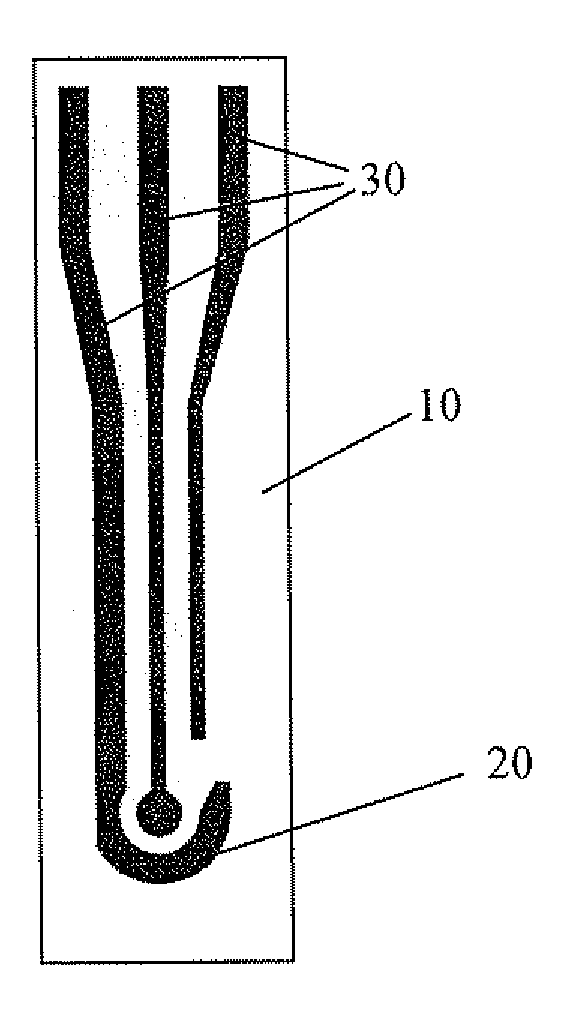

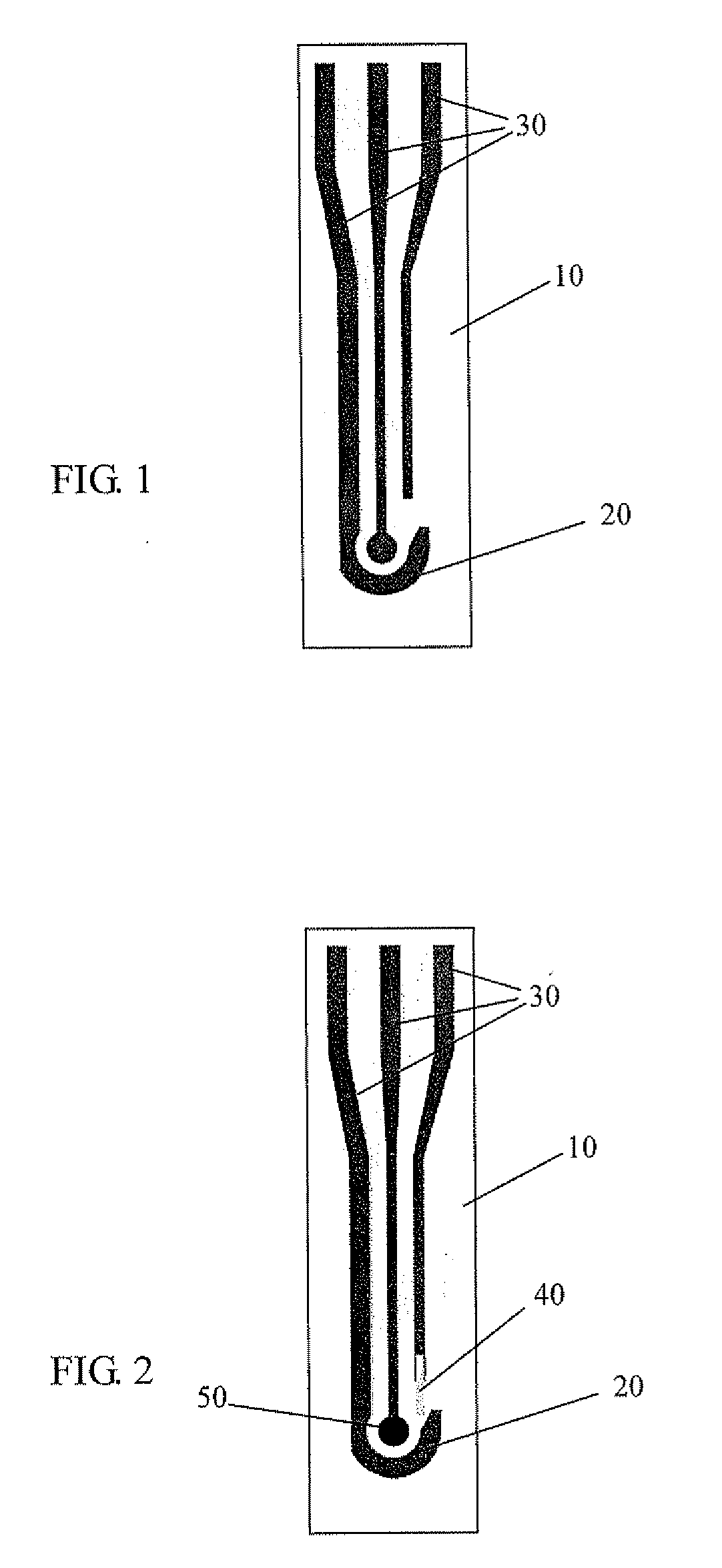

Method and electrochemical sensing strip with screen-printed three electrodes for determining concentration of dissolved oxygen in a solution

InactiveUS20070256944A1High sensitivityEasy to useWeather/light/corrosion resistanceVolume/mass flow measurementCobalt phthalocyanineElectrochemistry

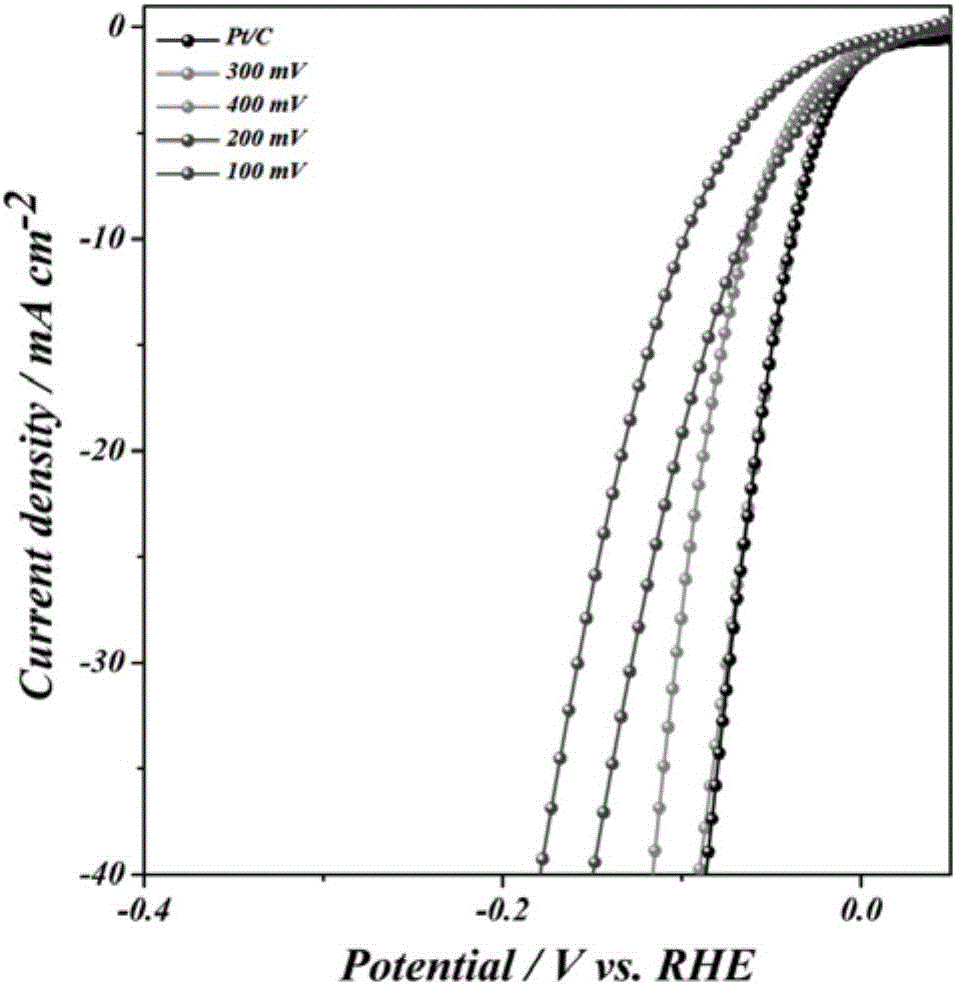

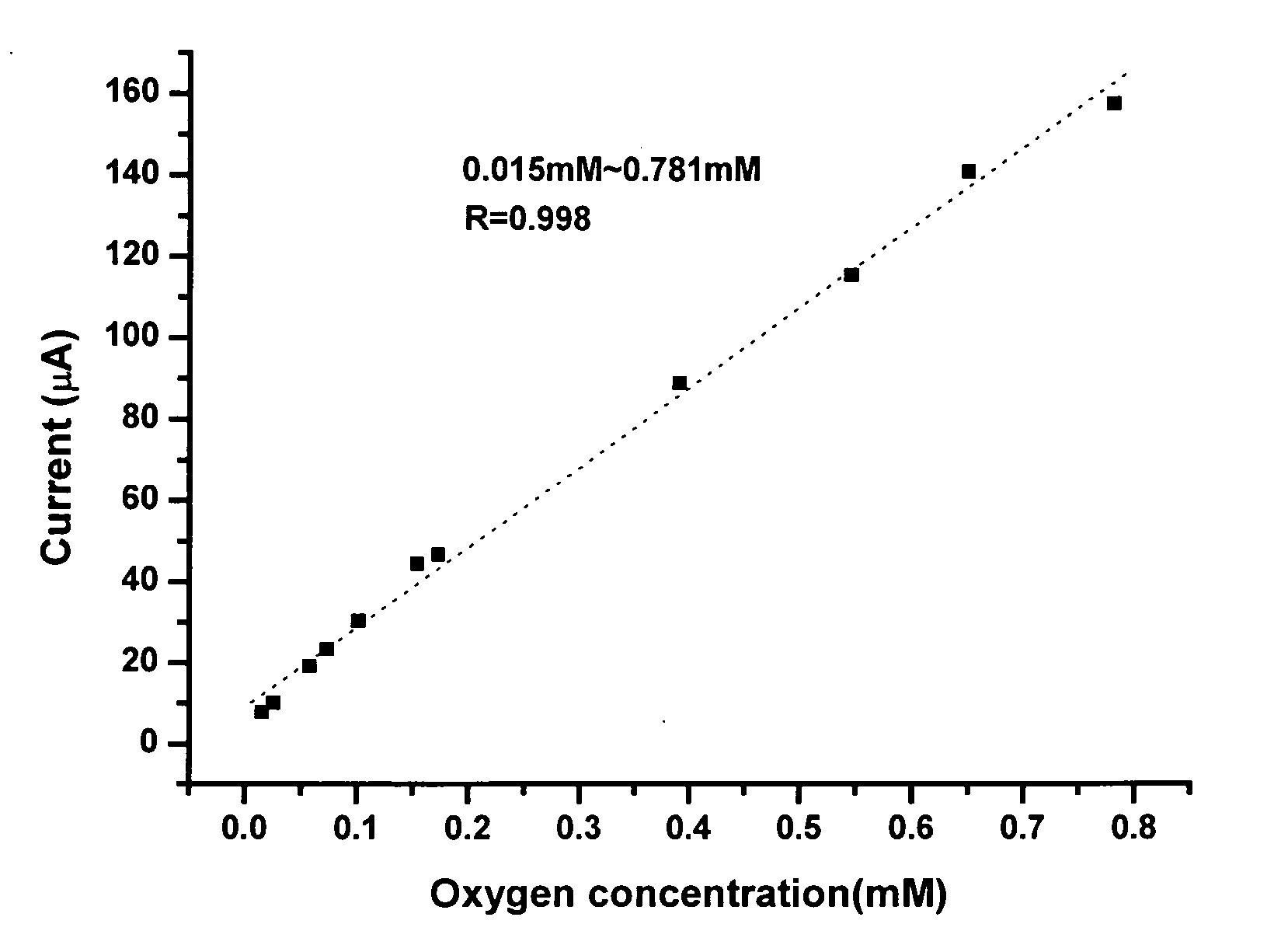

A new electrochemical method for determining dissolved oxygen concentration is developed. It employs cobalt based oxide or complex to modify a conductive electrode surface. This method can be applied to determine dissolved oxygen in regard to medical and environmental demands. The chemical formula of the cobalt based oxide or complexes can be shown as CoxOy or CoaLb. Both “x” and “a” represent the number of cobalt atom; while “y” and “b” represent the number of oxygen atom and the number of coordinating ligand, respectively. For instance, the best known example of cobalt oxide is CO3O4, and the best known examples of cobalt complexes are cobalt phthalocyanine (CoPC) and cyanocobalamin (vitamin B12), or other macrocyclic complexes with a metallic nucleus of cobalt. The present invention determines the concentration of dissolved oxygen in solution in potentiostatic mode with three electrodes. As a result, the dissolved oxygen can be determined between 0.0V and −0.3V vs. Ag / AgCl, thereby significantly reducing the interferences from the easily oxidized compounds in water solutions.

Owner:TAMKANG UNIVERSITY

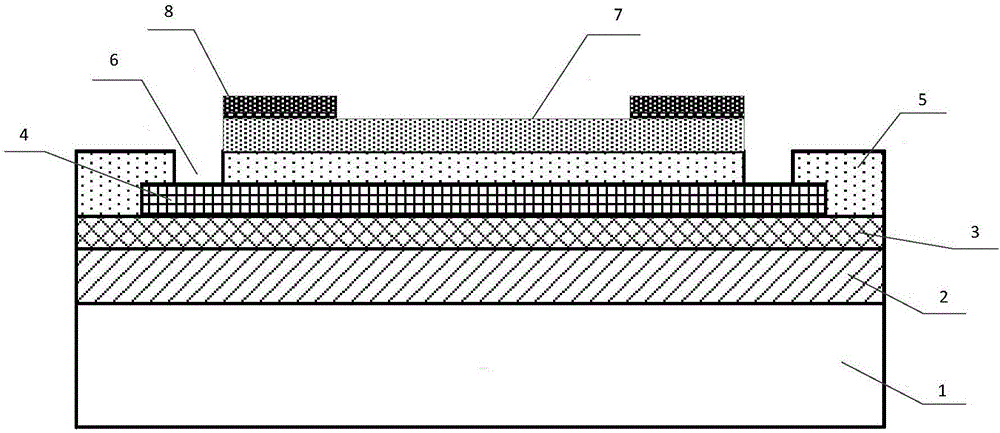

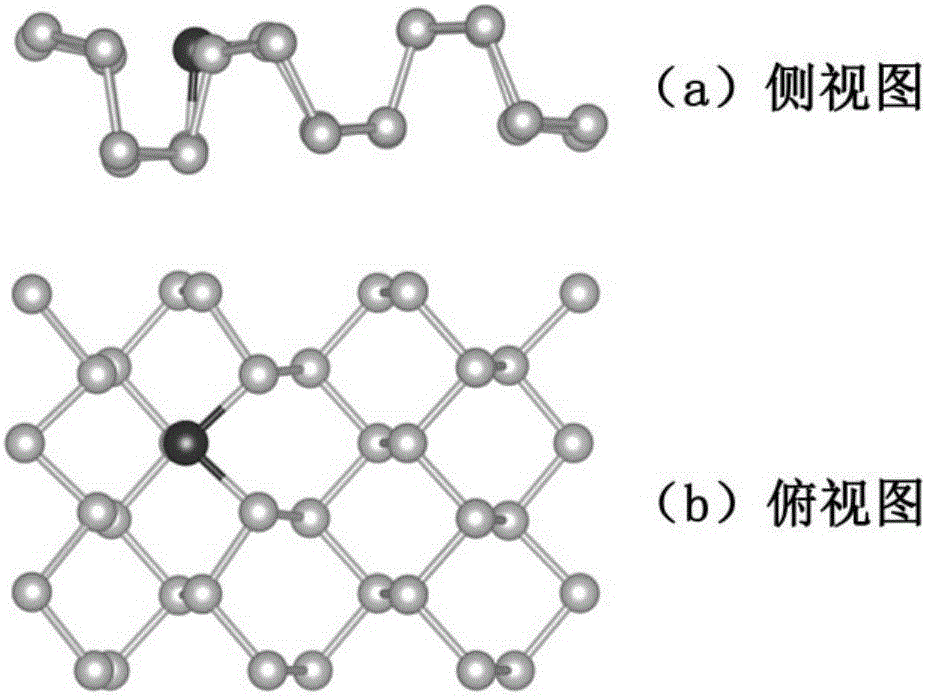

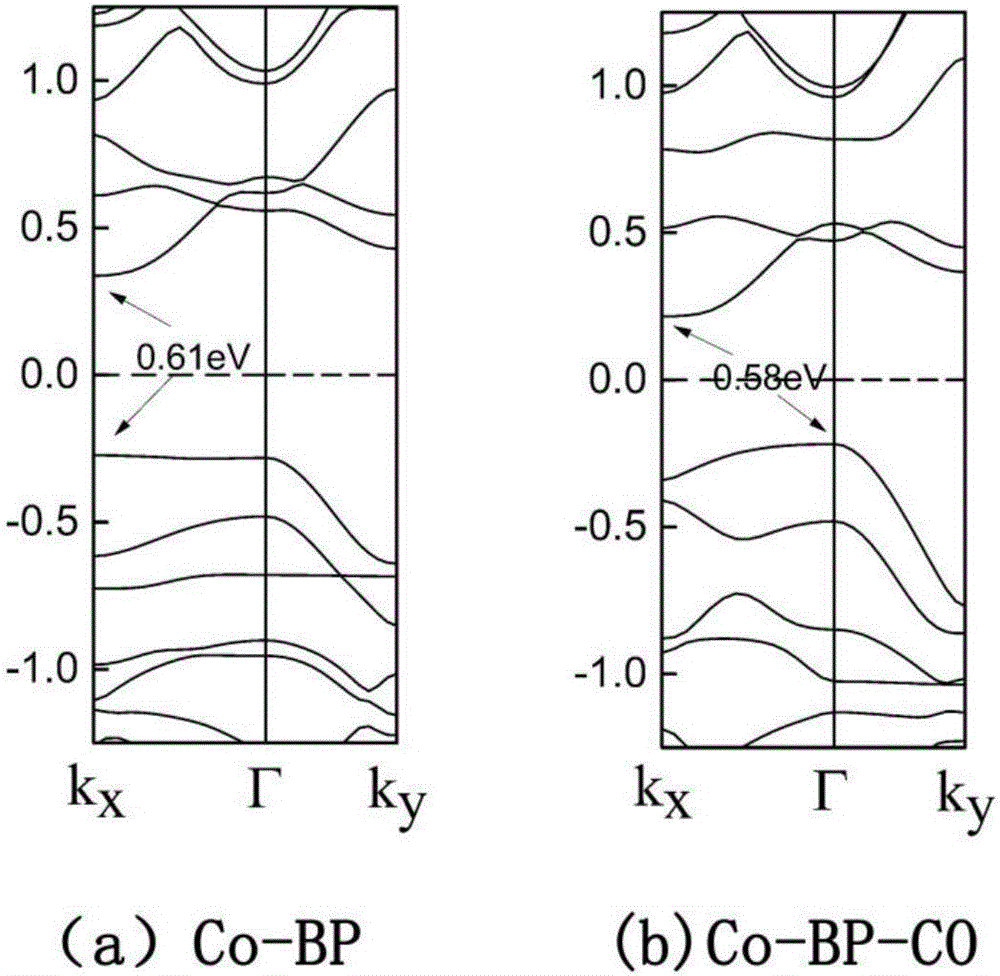

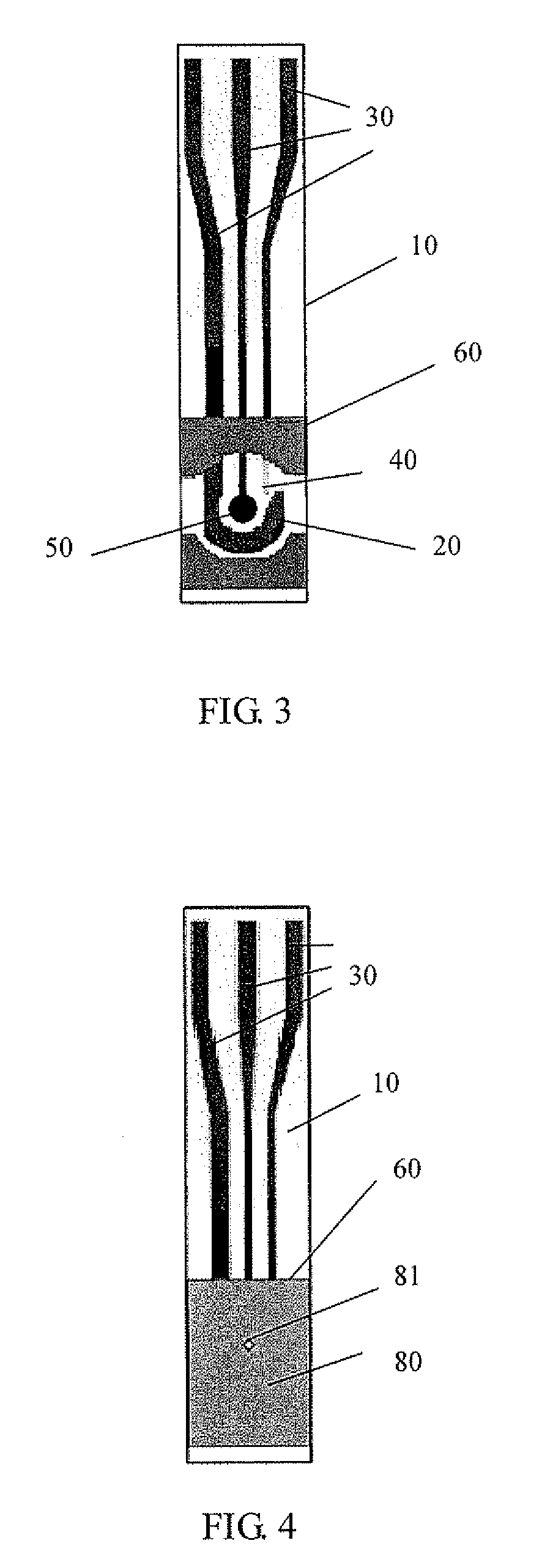

Gas sensor and preparation method thereof

ActiveCN106841338AIncrease binding energyPromote absorptionMaterial electrochemical variablesIodideBlack phosphorus

The invention discloses a gas sensor and a preparation method thereof. The gas sensor is provided with a gas sensitive layer; the gas sensitive layer comprises a gas sensitive material film and a gas sensitive electrode; the sensitive material of the gas sensitive material film is a cobalt-doped black phosphorus material and has the thickness like that of 1 to 10 atom layers; the black phosphorus material is prepared from red phosphorus and iodide of tin; the atomic number of the cobalt atoms doped in the black phosphorus accounts for 2 to 10 percent. The invention further discloses the application of the gas sensor to detection of carbon monoxide gas, and the preparation method of the sensor. According to the gas sensor provided by the invention, the combining capability of the gas sensitive material and the carbon monoxide is improved, the absorption of gas molecules is promoted and the stability of the gas sensor is guaranteed; the sensitivity of the gas sensor and the selectivity on the carbon monoxide gas are improved; the gas sensor based on the two-dimensional material black phosphorus can be made to be thin.

Owner:SOUTHEAST UNIV

A cobalt monoatomic catalyst with cobalt atoms anchored on carbon nanofibers and a preparation method and application thereof

The invention relates to a cobalt monoatomic catalyst with cobalt atoms anchored on carbon nanofibers and a preparation method and application thereof. The preparation method comprises the following steps: S1, dissolving a cobalt source, a complexing agent and a nitrogen-containing polymer in a solvent to obtain an external solution; An internal solution in which the soluble polymer is dissolved in a solvent; 2, spinning theouter solution and the inn solution into primary spinning fibers by coaxial electrostatic filament spinning; S3: after removing the soluble polymer from the silk spinning fiber, calcining at 500-1000 DEG C for 2-5h to obtain the cobalt monoatomic catalyst. The cobalt monoatomic catalyst prepared by electrostatic filament spinning technology and high-temperature calcination has the advantages of small diameter, small pore size, high porosity, good fiber homogeneity, good ORR and OER catalytic performance, excellent methanol tolerance and stability, and can be widelyapplied to fuel cells and metal-air batteries. The preparation method provided by the invention is simple in process and easy to operate.

Owner:GUANGDONG UNIV OF TECH

Composite carbonate and method for producing the same

ActiveUS20110114900A1Reduce the amount of wasteConductive materialCarbonate/bicarbonate preparationManganeseCobalt atom

The present invention provides a method for producing a nickel atom-, manganese atom- and cobalt atom-containing composite carbonate that is high in specific surface area and large in tap density, and useful as a raw material for producing a lithium nickel manganese cobalt composite oxide to be used in a positive electrode active material for use in a lithium secondary battery. The composite carbonate includes nickel atoms, manganese atoms and cobalt atoms, and has an average particle size of 5 μm or more and less than 20 μm, a BET specific surface area of 40 to 80 m2 / g and a tap density of 1.7 g / ml or more.

Owner:NIPPON CHECMICAL IND CO LTD

Composite carbonate and method for producing the same

Owner:NIPPON CHECMICAL IND CO LTD

Composite carbonate and method for producing the same

InactiveUS7897069B2Reduce the amount of wasteNon-metal conductorsConductive materialManganeseCobalt atom

The present invention provides a nickel atom-, manganese atom- and cobalt atom-containing composite carbonate that is high in specific surface area and large in tap density, and useful as a raw material for producing a lithium nickel manganese cobalt composite oxide to be used in a positive electrode active material for use in a lithium secondary battery, and provides a method for industrially advantageously producing the composite carbonate. The composite carbonate includes nickel atoms, manganese atoms and cobalt atoms, and has an average particle size of 5 μm or more and less than 20 μm, a BET specific surface area of 40 to 80 m2 / g and a tap density of 1.7 g / ml or more.

Owner:NIPPON CHECMICAL IND CO LTD

Cobalt and graphene composite nanometer material catalyst and preparation method thereof

The invention relates to a cobalt and graphene composite nanometer material catalyst and a preparation method thereof. The catalyst comprises the main components of cobalt and graphene; the preparation method includes the steps that a dipping method is adopted for loading cobalt salt onto reduction-oxidation graphene which is synthesized by itself or purchased commercially, after dipping, drying is conducted, a catalyst precursor containing cobalt salt / graphene is obtained and then calcinated in the atmosphere of nitrogen, the cobalt salt is degraded, meanwhile, a cobalt species and the graphene generate a strong interaction effect, and finally a cobalt and graphene composite nanometer material is obtained. The catalyst simultaneously contains single-atom cobalt, cobalt atom clusters and cobalt oxide nanometer particles.

Owner:DALIAN UNIV

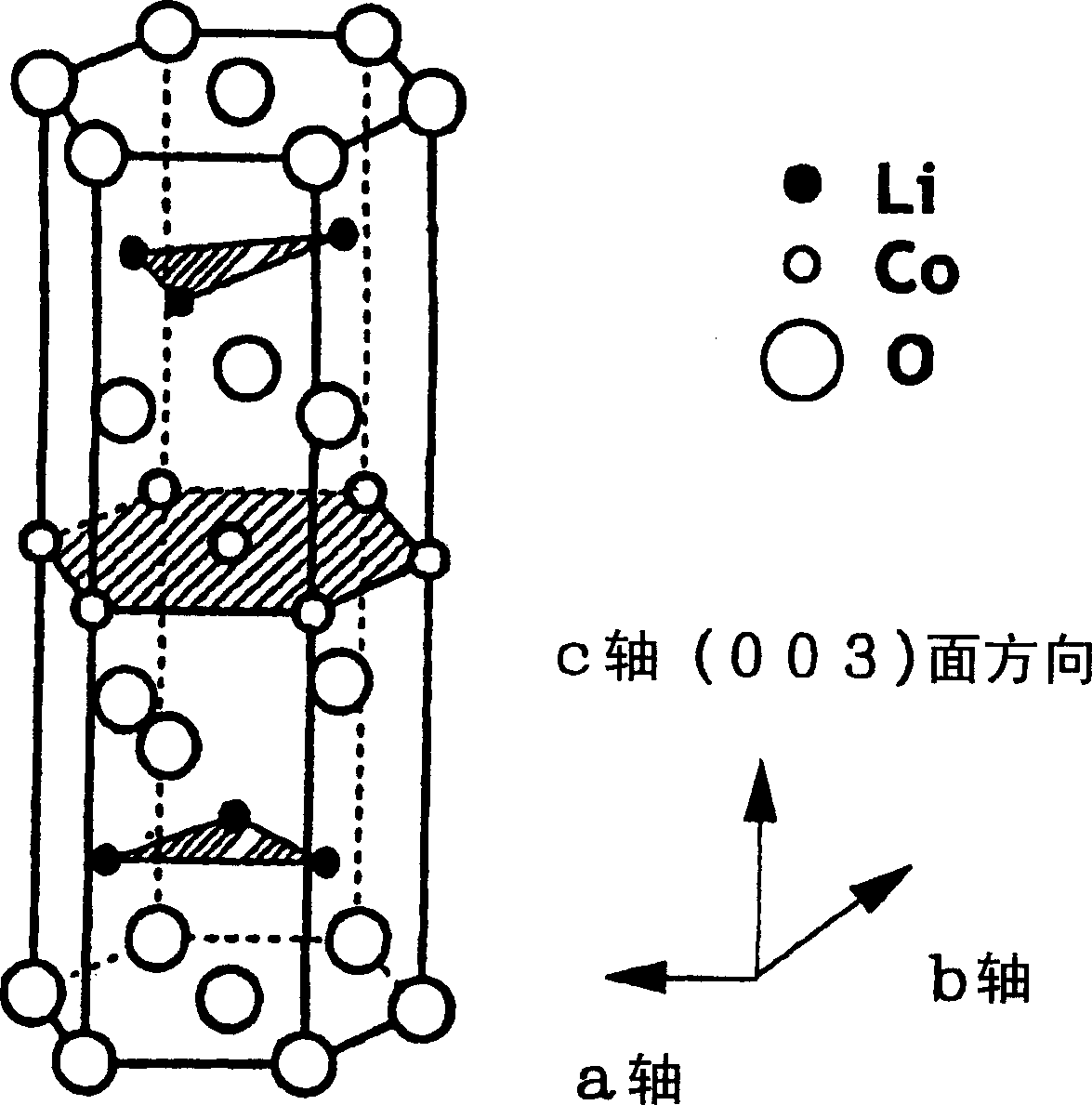

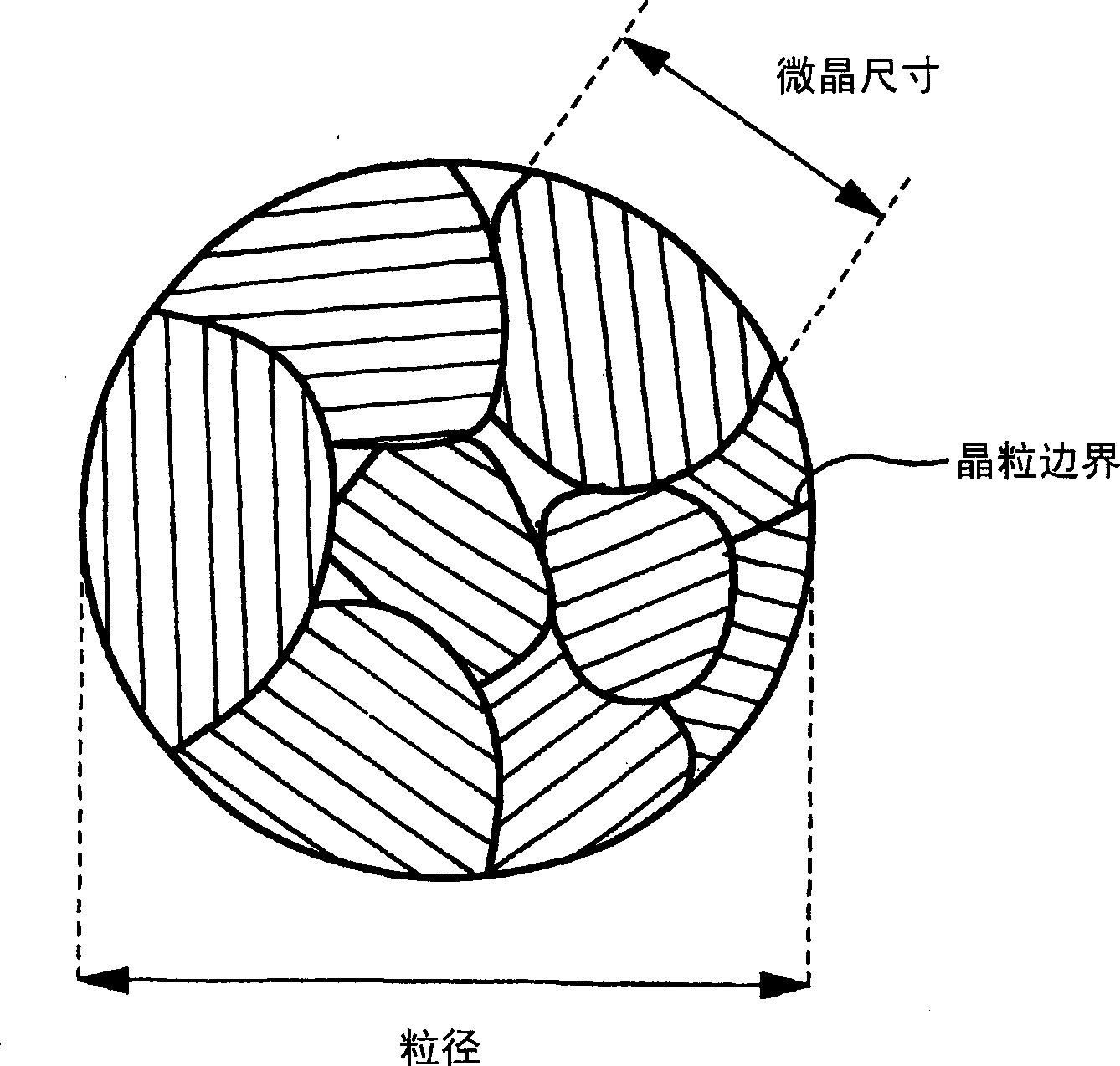

Lithium secondary cell and positive electrode active material, positive plate, and method for manufacturing them

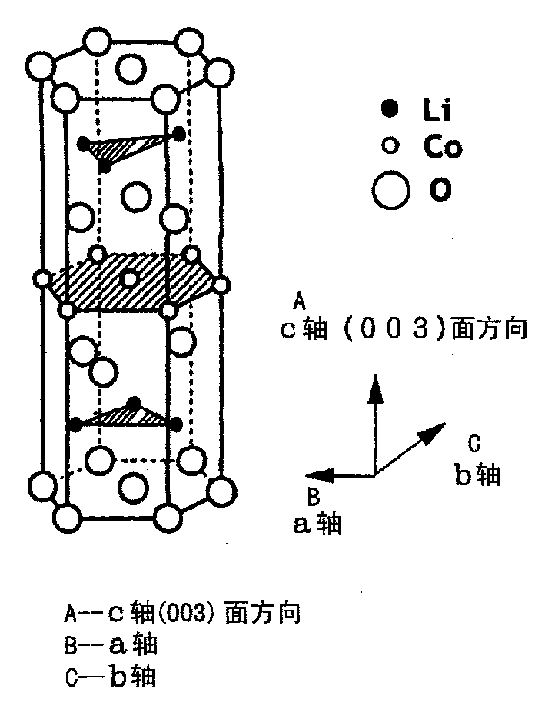

Provided is lithium secondary cell and positive electrode active material, positive plate, and method for manufacturing them. A lithium secondary cell comprises a positive electrode active material containing a crystal in which the size of crystallite in the direction parallel to the (003) plane of the crystal of lithium cobaltate is 800 ANGSTROM or more and the coordinate number of a cobalt atom with respect to another cobalt atom is 5.7 or more. The characteristics such as the rate characteristics, low-temperature characteristics, and cycle characteristics of the lithium secondary cell are improved. By adding preferable modes of the positive plate, for example, (a mode in which 50% or less of the surface of the positive electrode active material is covered with an electrically conductive material), (a mode in which the porosity of the positive electrode coating layer lies in the range from 0.08 cc / g to 0.14 cc / g by using two kinds of electrically conductive material having a particle size of 3 mu m or more and 2 mu m or less or by using one kind of electrically conductive material having a particle size of 10 mu m or less), and (a mode in which the specific area of the positive plate coating layer lies in the range from 0.5 m<2> / g to 1.0 m<2> / g by using an electrically conductive material containing at least carbon black), and further adding a mode of a combination of a preferable negative electrode active material and a preferable electrolyte, a more preferable lithium secondary cell has a sufficient cell capacity, and excellent characteristics such as the cycle characteristics, preservation characteristics, safety, and low-temperature characteristics.

Owner:MITSUBISHI CABLE IND LTD

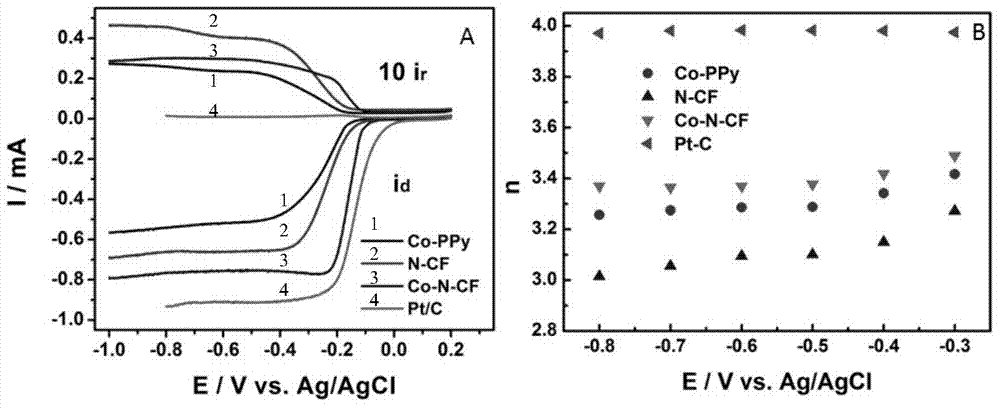

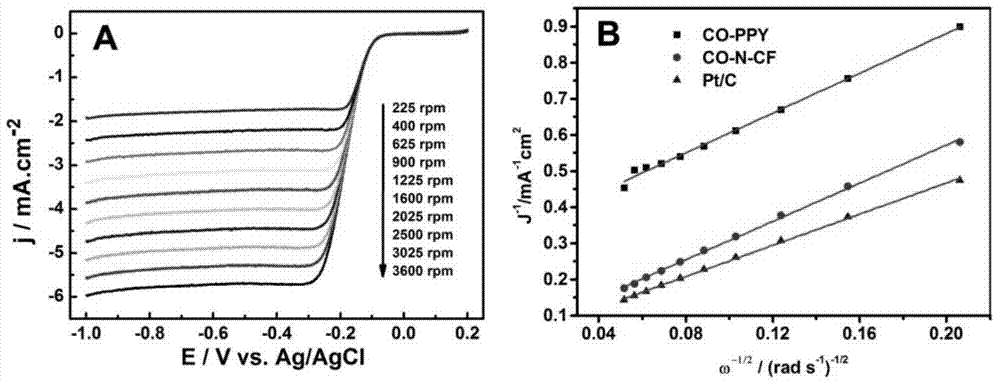

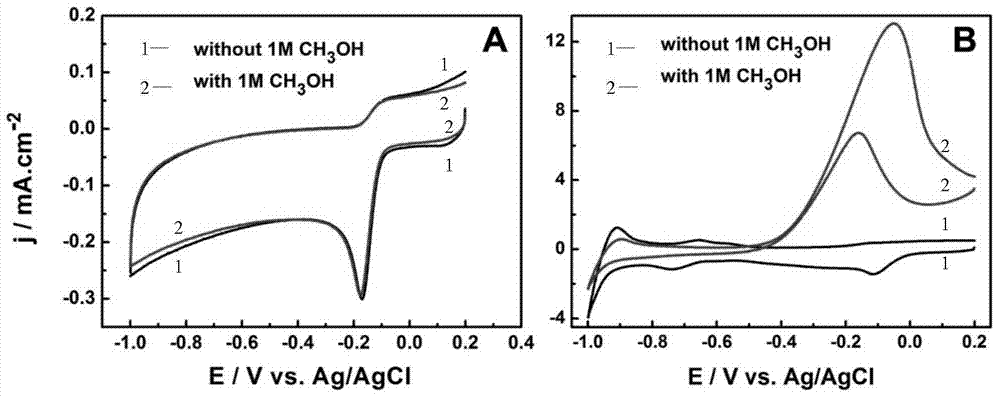

Non-noble metal doped carbon felt, and application in catalyzing oxygen reduction

InactiveCN103706387ALow costImprove developmentCatalyst carriersCell electrodesIn situ polymerizationCarbon felt

The invention relates to a non-noble metal doped carbon felt, and an application in catalyzing oxygen reduction, and belongs to the technical field of fuel cells. Specifically, the invention provides a non-noble metal doped carbon felt with a three dimensional conductive structure prepared by methods of in-situ polymerization and non-noble metal coordination pyrolysis. The carbon felt can be used for electrochemically catalyzing the oxygen reduction. The non-noble metal doped carbon felt material takes a common carbon felt material as a skeleton, forms a polymer film on the carbon felt surface by in-situ polymerization of nitrogen-containing heterocyclic ring molecules, then absorbs cobalt atoms by a coordination effect and finally form a cobalt and nitrogen doped carbonized layer on the carbon felt surface. The carbon felt material is prepared by the invention. The non-noble metal doped carbon felt has similar capacity for catalyzing the oxygen reduction with that of a commercialized platinum catalyst, and has very good stability and methanol poisoning resistance.

Owner:JILIN UNIV +1

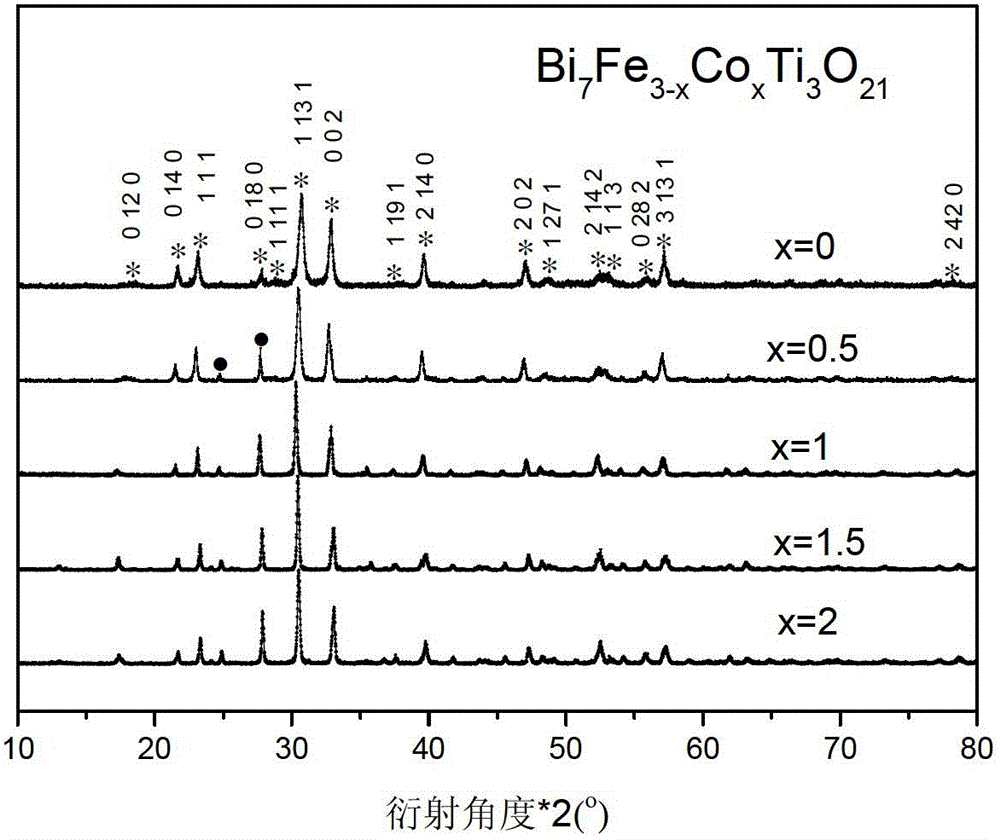

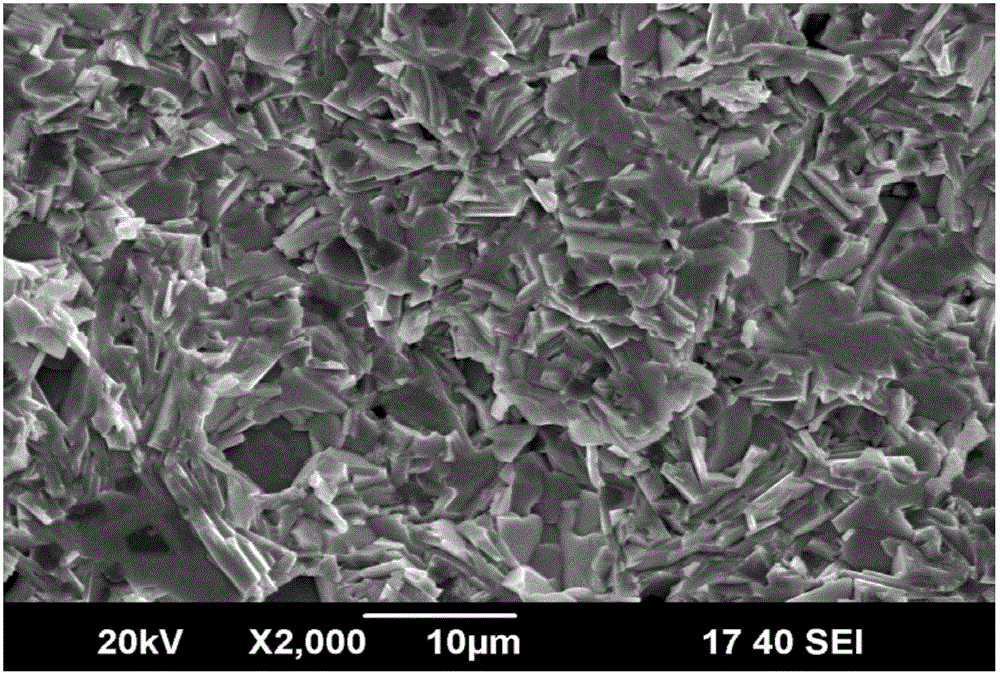

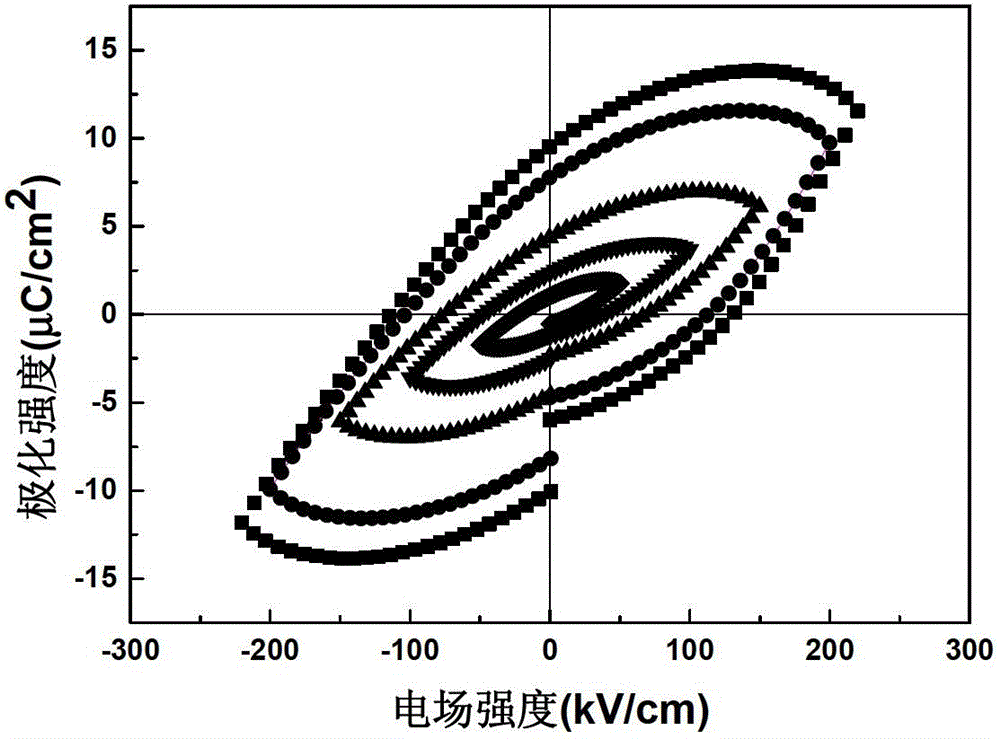

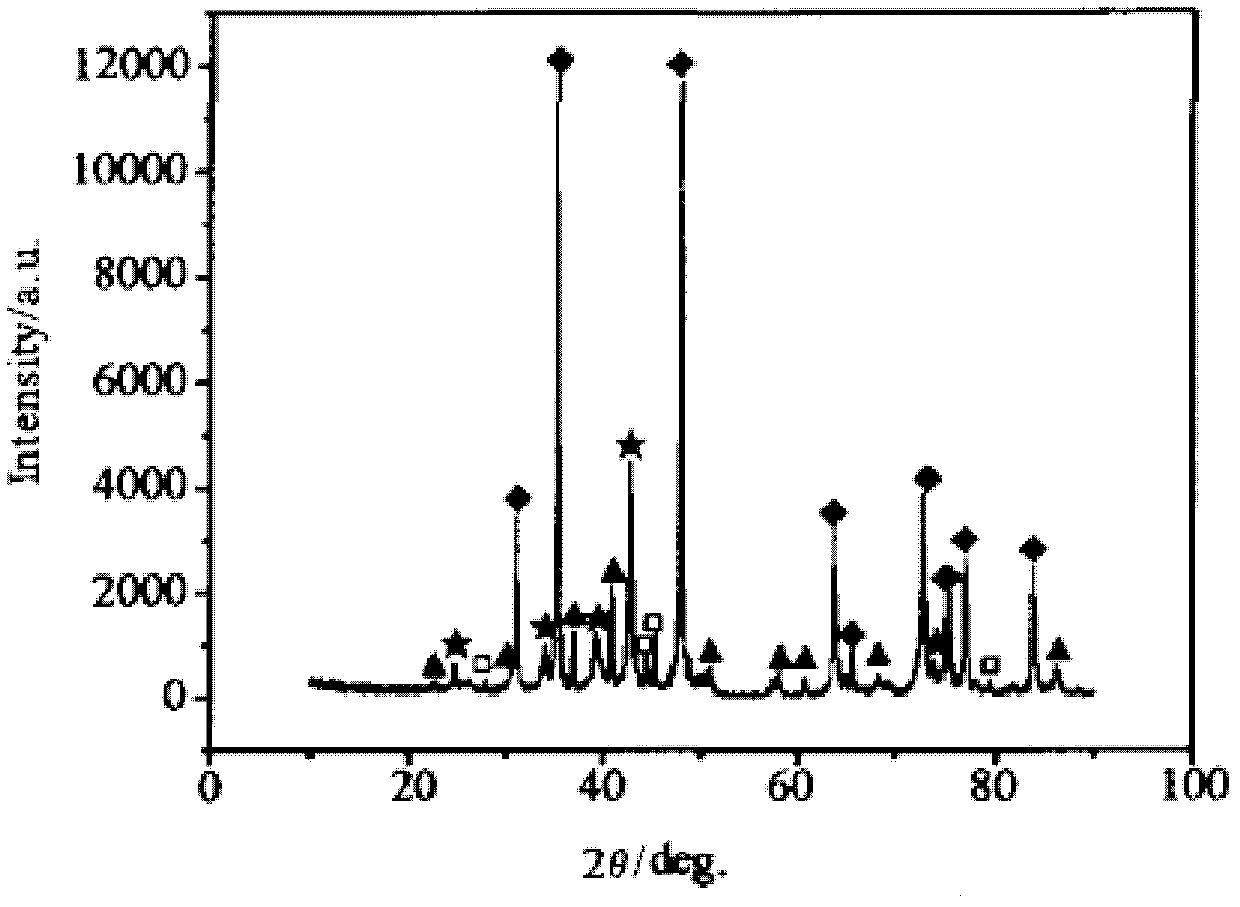

Ferrotitanium bismuth cobaltate ceramic material having layered structure and preparation method thereof

InactiveCN102942361AImprove ferroelectric propertiesImprove ferromagnetic propertiesOctahedronTitanium oxide

The present invention provides a ferrotitanium bismuth cobaltate ceramic material having a layered structure. A part of iron ions are replaced by cobalt ions to obtain Bi7Fe3-xCoxTi3O21 layered Aurivillius type multi-iron oxide ceramic, and the structure thereof includes two bismuth oxide layers ((Bi2O2)2+) and titanium oxide (Ti-O) octahedrons, iron oxide (Fe-O) octahedrons and cobalt oxide (Co-O) octahedrons sandwiched between the bismuth oxide layers, wherein because iron atoms and cobalt atoms are similar in structure, after part of the cobalt ions replace part of iron ions, the Fe-O octahedrons and Co-O octahedrons are ranked relatively in order, the Fe-O-Co coupling can be formed locally, and ferroelectric and ferromagnetic of the ceramic material are enhanced. The present invention also provides a preparation method of the ferrotitanium bismuth cobaltate ceramic material having the layered structure. The preparation temperature of the ceramic material is much lower than the preparation temperature of the prior art, the energy consumption is reduced, and the industrialization production is facilitated.

Owner:UNIV OF SCI & TECH OF CHINA

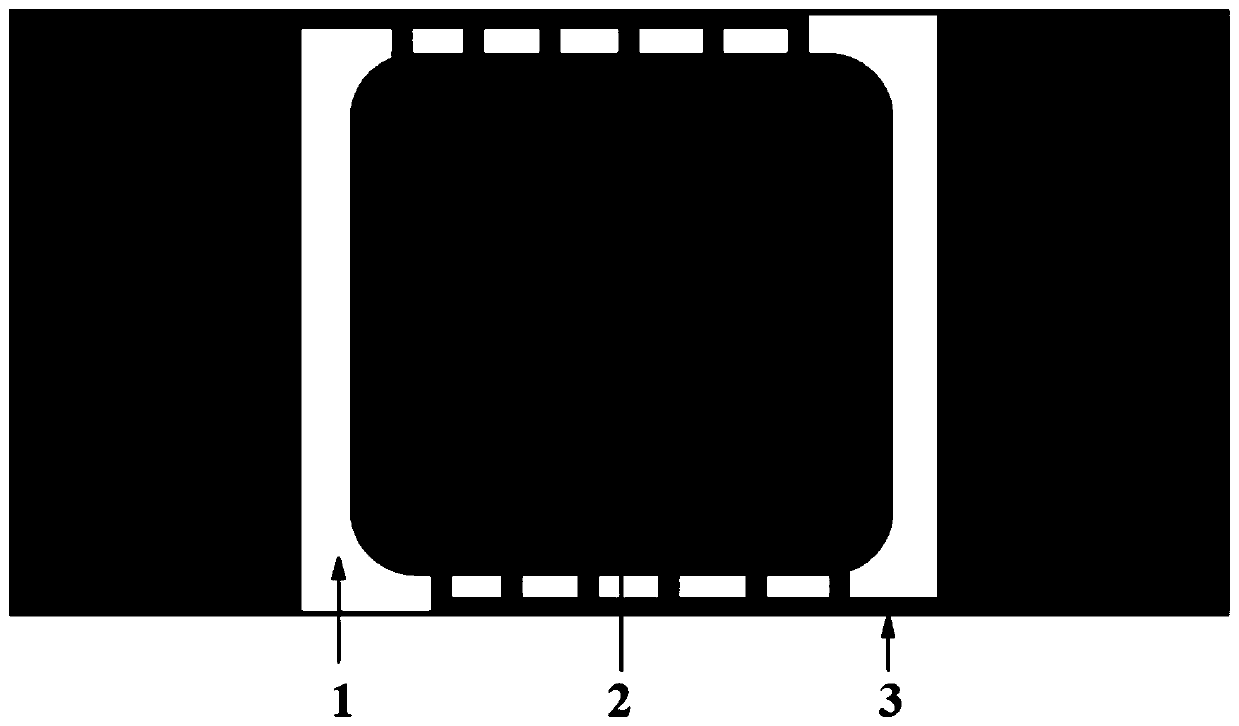

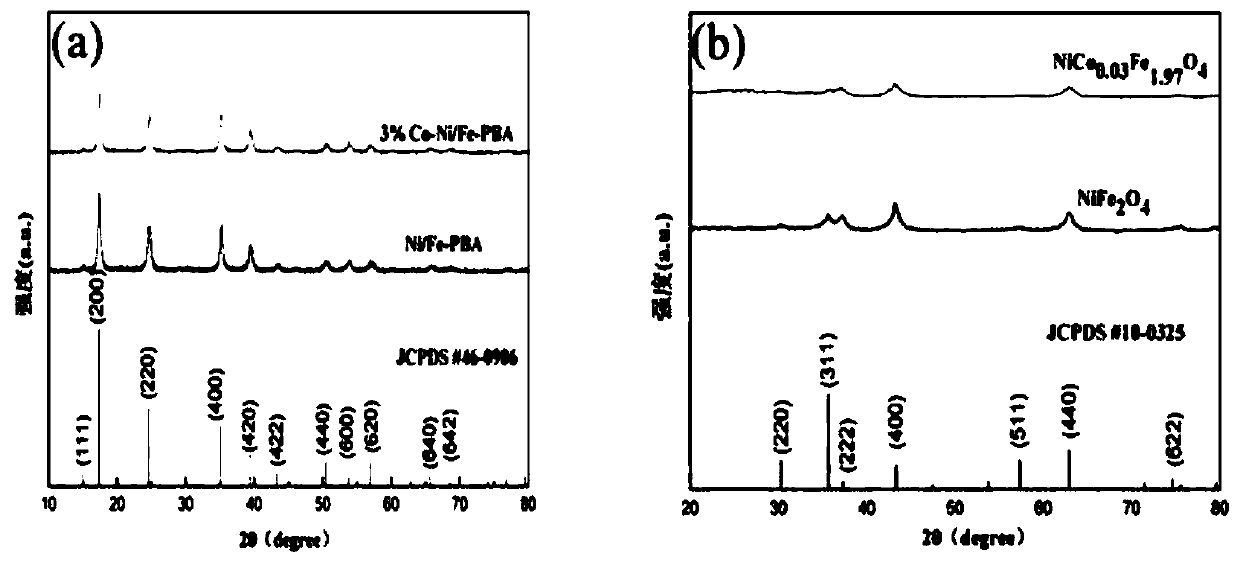

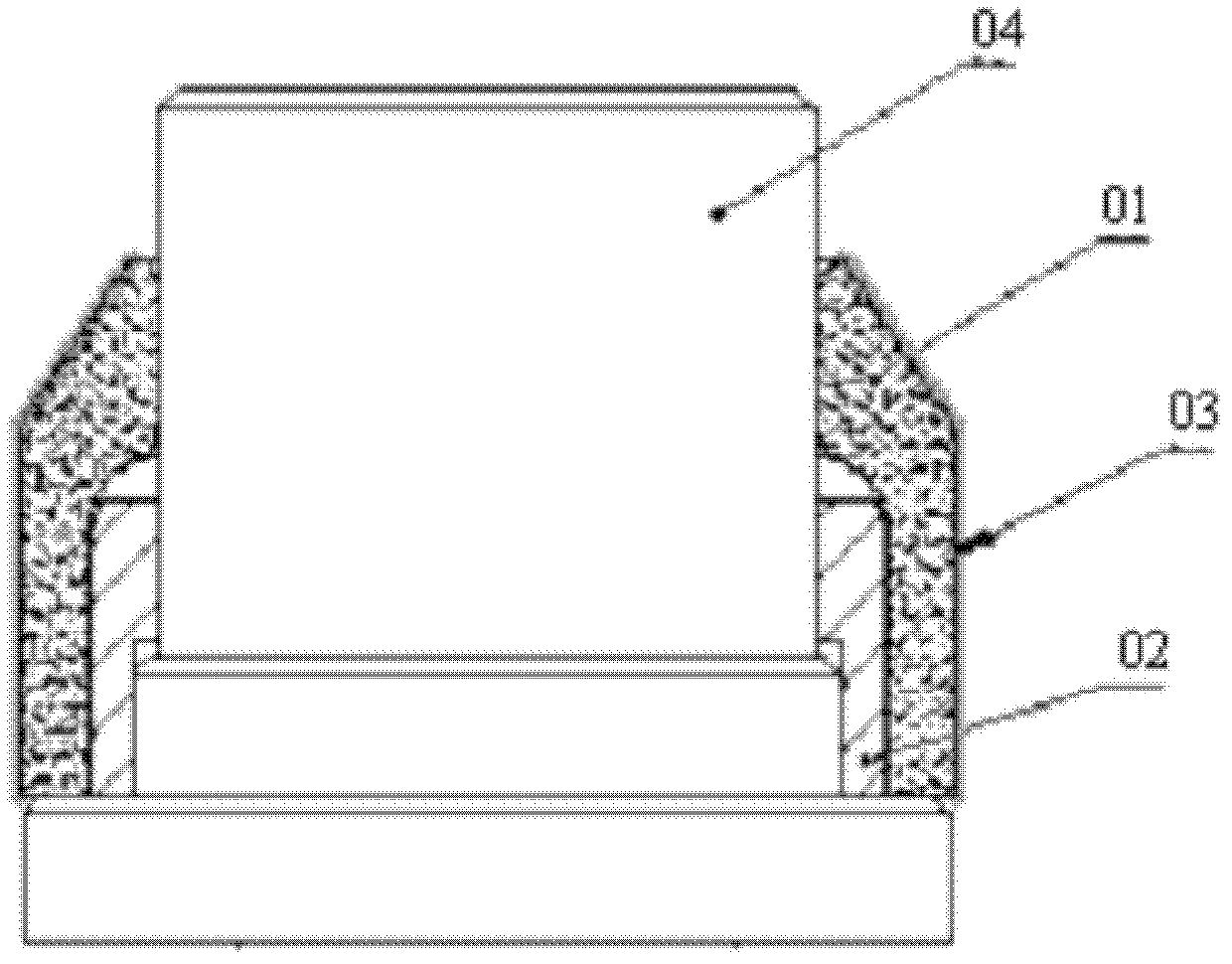

Isopropanol gas sensor based on NiCoxFe2-xO4 nano cube material and preparation method of sensor

ActiveCN110412087AReduce volumeFast response and recoveryMaterial resistanceLattice defectsHigh volume manufacturing

The invention relates to an isopropanol gas sensor based on a NiCoxFe2-xO4 (x=0.01-0.1) nano cube material prepared through a metal organic framework template and a preparation method of the sensor and belongs to the technical field of gas sensors. The sensor is composed of a Al2O3 substrate with a PD metal interdigital electrode and a NiCoxFe2-xO4 nano cube material sensitive layer prepared by adopting a coating technology on the PD metal interdigital electrode and the Al2O3 substrate from bottom to top in sequence, and the grain size of a nano cube is 50-80 nanometers. When the cube is dopedwith trace cobalt, due to the radius difference of cobalt atoms and iron atoms, the lattice defects are possibly caused, the defects are beneficial to generation of oxygen vacancies, oxygen absorption is enhanced accordingly, and the gas sensitive response is improved. The technology is simple, and the prepared sensor is small in size and suitable for large-batch production and has important application value.

Owner:JILIN UNIV

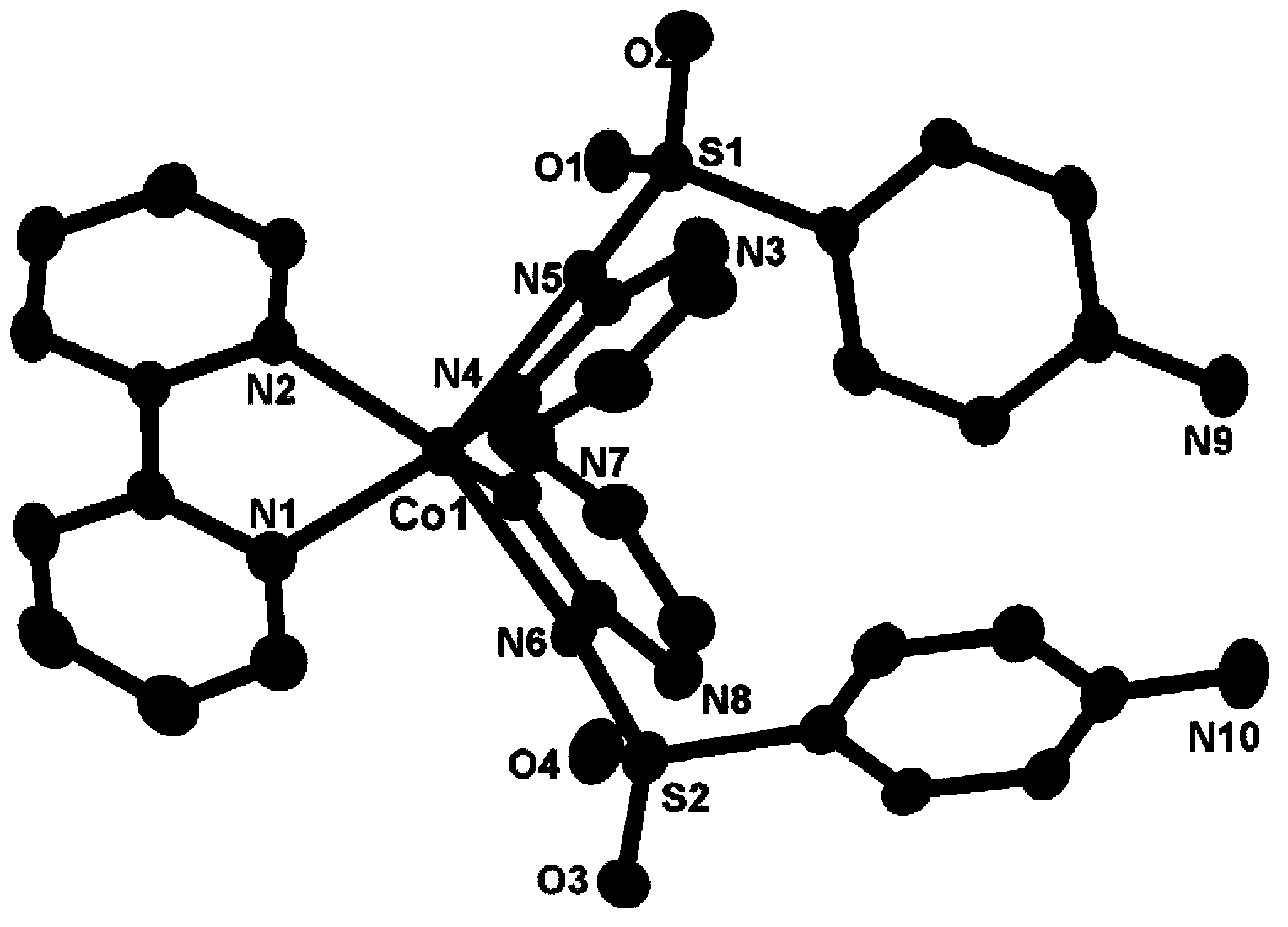

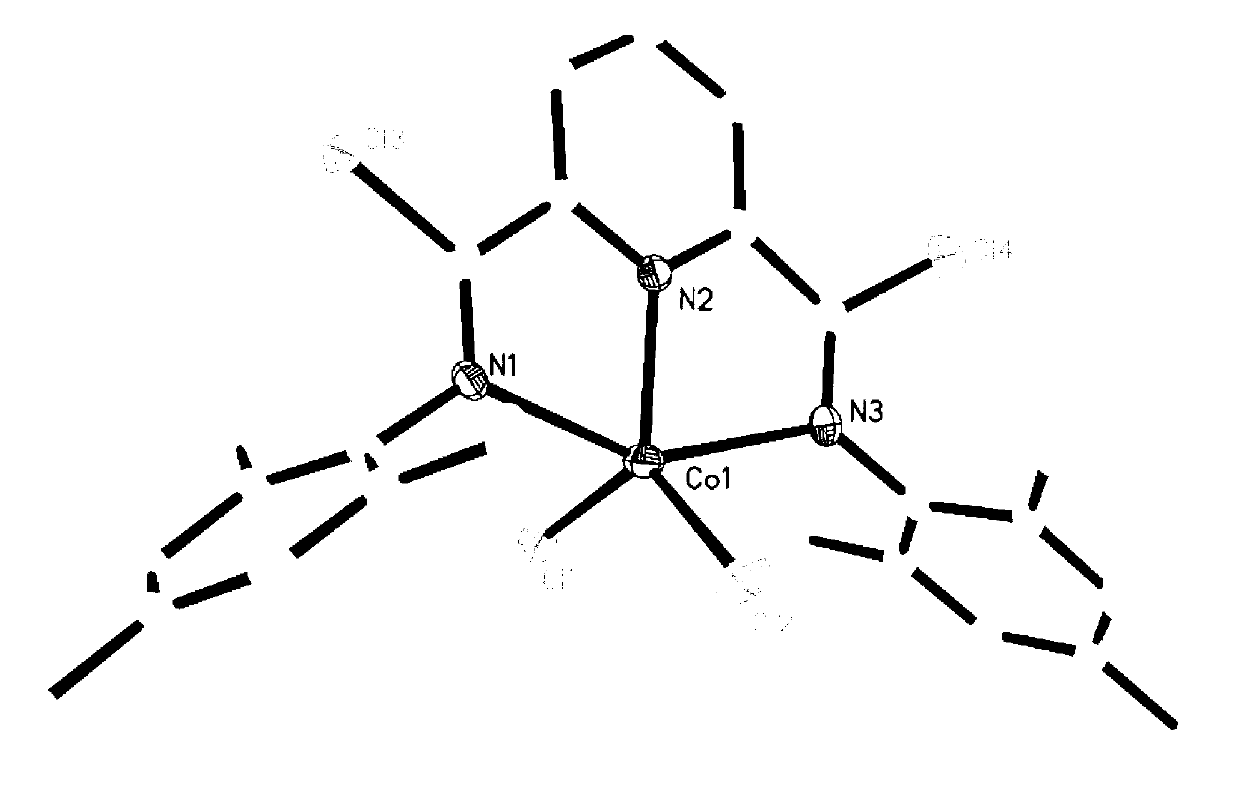

Cobalt complex with electrochemical catalytic activity

InactiveCN103435659AHigh electrochemical catalytic activityAccurate spatial structureCobalt organic compoundsElectrochemical responseChemical reaction

The invention discloses a cobalt complex with electrochemical catalytic activity and a preparation method thereof. The cobalt chemical combined electro-catalysis material is a cobalt complex with a certain spatial structure, the molecular formula of the cobalt complex is C3OH26CoN10O4S2. The preparation method of the cobalt complex chemical combined electro-catalysis material comprises the following steps: enabling sulfadiazine with conjugate big Phi bond, 2, 2'-dipyridyl and cobalt ions with electro-catalysis activity to be subjected to chemical reaction, so as to obtain the novel cobalt complex containing sulfadiazine and dipyridyl. According to the invention, the cobalt complex has electro-catalysis activity, accurate spatial structure and molecular formula; cobalt atoms can form a stable coordination bond with a ligand by using the empty d electronic orbit of the atoms, so as to facilitate electron to be transmitted, and further facilitate the proceeding of the electrochemical reaction; the prepared cobalt complex has good electro-catalysis activity, and has wide application prospects as an electro-catalysis active material.

Owner:NINGBO UNIV

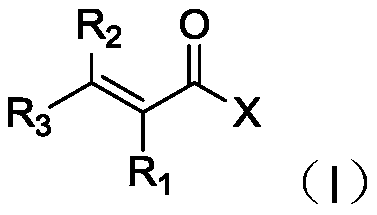

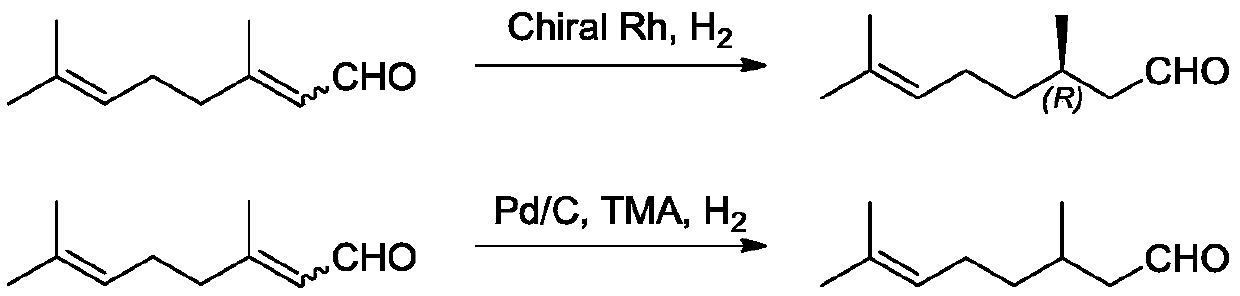

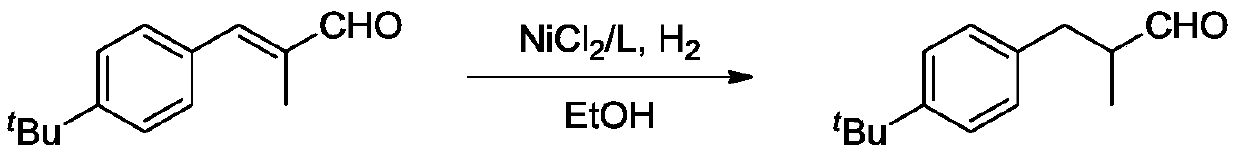

Method for selectively hydrogenating alpha, beta-unsaturated carbonyl compound by cobalt complex

ActiveCN110437054ALow costReduce dosageOrganic compound preparationCarboxylic acid esters preparationIridiumReaction rate

The invention provides a method for selectively hydrogenating an alpha, beta-unsaturated carbonyl compound. The method for selectively hydrogenating the alpha, beta-unsaturated carbonyl compound comprises the steps that first, a cobalt metal precursor and a carbene ligand are coordinated in a solution to obtain a cobalt complex, and the cobalt complex selectively enables the alpha, beta-unsaturated carbonyl compound to be reduced into a corresponding saturated carbonyl compound in a hydrogen atmosphere under the activation of an activator. The method for selectively hydrogenating the alpha, beta-unsaturated carbonyl compound has the main advantages that cobalt is used as a catalyst, and metal cobalt is cheap and easy to obtain relative to noble metal such as palladium, ruthenium, osmium, iridium and platinum, and the catalyst cost is greatly reduced; secondly, the carbene ligand used in the method has the advantages of simple structure, low price, strong coordination ability with cobalt atoms compared with a commonly used phosphine ligand; and finally, the addition of the activator can further significantly increase the activity of the cobalt catalyst. The hydrogenation reaction condition is mild, the reaction rate is high, substantially no carbonyl hydrogenation side reaction occurs, and the carbonyl compound can be obtained in a high yield.

Owner:WANHUA CHEM GRP CO LTD

Boriding method of wear-resisting composite member

InactiveCN102634752AAffects connection strengthThere will be no phenomenon of melting and welding falling offSolid state diffusion coatingTungsten atomBoriding

The invention provides a boriding method of a wear-resisting composite member. The boriding method comprises the following steps: a) preheating the wear-resisting composite member by adopting a hot spray gun so as to rise the temperature of the surface of the wear-resisting composite member to be 800 DEG C-850 DEG C; b) spraying a boriding agent to the surface of the wear-resisting composite member obtained from the step a to obtain the wear-resisting composite member with the boronized surface. When the wear-resisting composite member is subjected to boriding, the wear-resisting composite member is preheated by using the hot spray gun, so that the temperature of the surface of a workpiece is high, the internal temperature of the workpiece is lower than the surface temperature of the workpiece, the brazing connection position of the composite member can not be affected, the connection strength of the composite member can not be affected, after the wear-resisting composite member is preheated, the boriding agent is sprayed to the surface of the composite member, the boriding agent is subjected to reaction under high temperature so as to generate active boron atoms, the active boron atoms combine with cobalt atoms and tungsten atoms melt in the surface, so as to form a compound, so that a boriding layer of a boron compound is formed.

Owner:SEED TECH CORP LTD

Method and electrochemical sensing strip with screen-printed three electrodes for determining concentration of dissolved oxygen in a solution

InactiveUS20100326845A1Easy to useFast and stable and cost-effectiveWeather/light/corrosion resistanceVolume/mass flow measurementCobalt phthalocyanineOxygen

A new electrochemical method for determining dissolved oxygen concentration is developed. It employs cobalt based oxide or complex to modify a conductive electrode surface. This method can be applied to determine dissolved oxygen in regard to medical and environmental demands. The chemical formula of the cobalt based oxide or complexes can be shown as CoxOy or CoaLb. Both “x” and “a” represent the number of cobalt atom; while “y” and “b” represent the number of oxygen atom and the number of coordinating ligand, respectively. For instance, the best known example of cobalt oxide is Co3O4, and the best known examples of cobalt complexes are cobalt phthalocyanine (CoPC) and cyanocobalamin (vitamin B12), or other macrocyclic complexes with a metallic nucleus of cobalt. The present invention determines the concentration of dissolved oxygen in solution in potentiostatic mode with three electrodes. As a result, the dissolved oxygen can be determined between 0.0V and −0.3V vs. Ag / AgCl, thereby significantly reducing the interferences from the easily oxidized compounds in water solutions.

Owner:TAMKANG UNIVERSITY

Positive electrode active substance used in lithium secondary battery, and manufacturing method thereof

ActiveCN103326011AExcellent cycle characteristicsEasy to prepareCell electrodesSubstance useElectrical battery

The invention discloses a positive electrode active substance used in lithium secondary battery, and a manufacturing method thereof. The positive electrode active substance is a lithium composite oxide of a positive electrode active substance comprising Ti atoms, wherein the substance has a general formula of LixNi1-y-zCoyMnzTiaO2. x is no lower than 0.95 and no higher than 1.30; y is no lower than 0 and no higher than 0.6; z is no lower than 0 and no higher than 0.8; and y+z is smaller than 1, and a is no lower than 0 and no higher than 0.1. According to the manufacturing method, a lithium compound, a compound comprising nickel atoms, cobalt atoms and manganese atoms, and titanium oxide are mixed; and the mixture is calcined, such that the positive electrode active substance comprising the lithium composite oxide with the general formula is obtained. With the positive electrode active substance, lithium secondary battery with excellent circulation characteristics can be obtained. Also, the preparation method is simple. With the method, the positive electrode active substance can be manufactured through an industrial beneficial method.

Owner:NANTONG RESHINE NEW MATERIAL

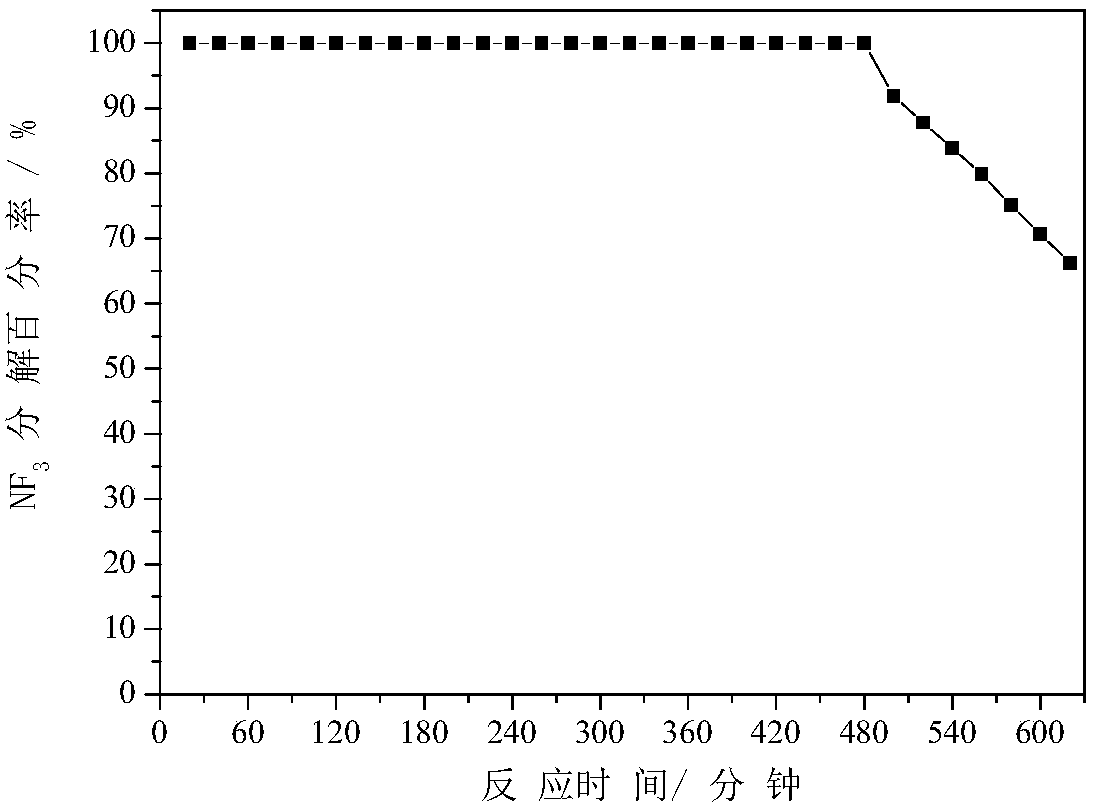

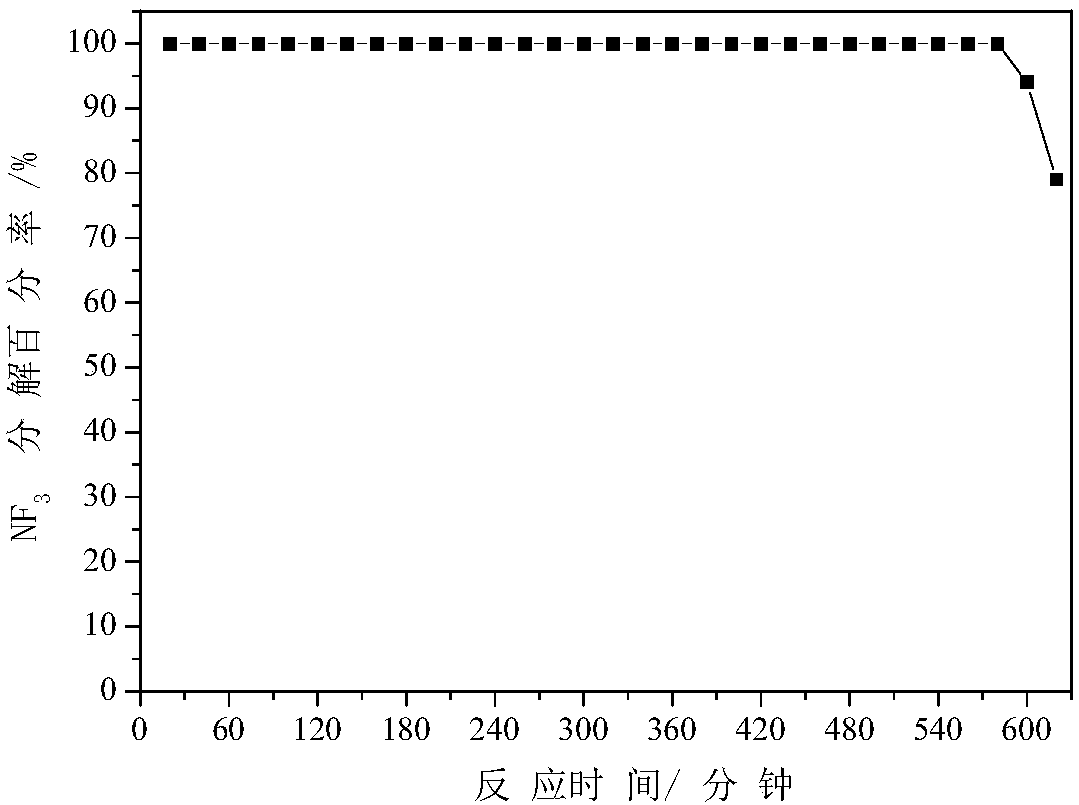

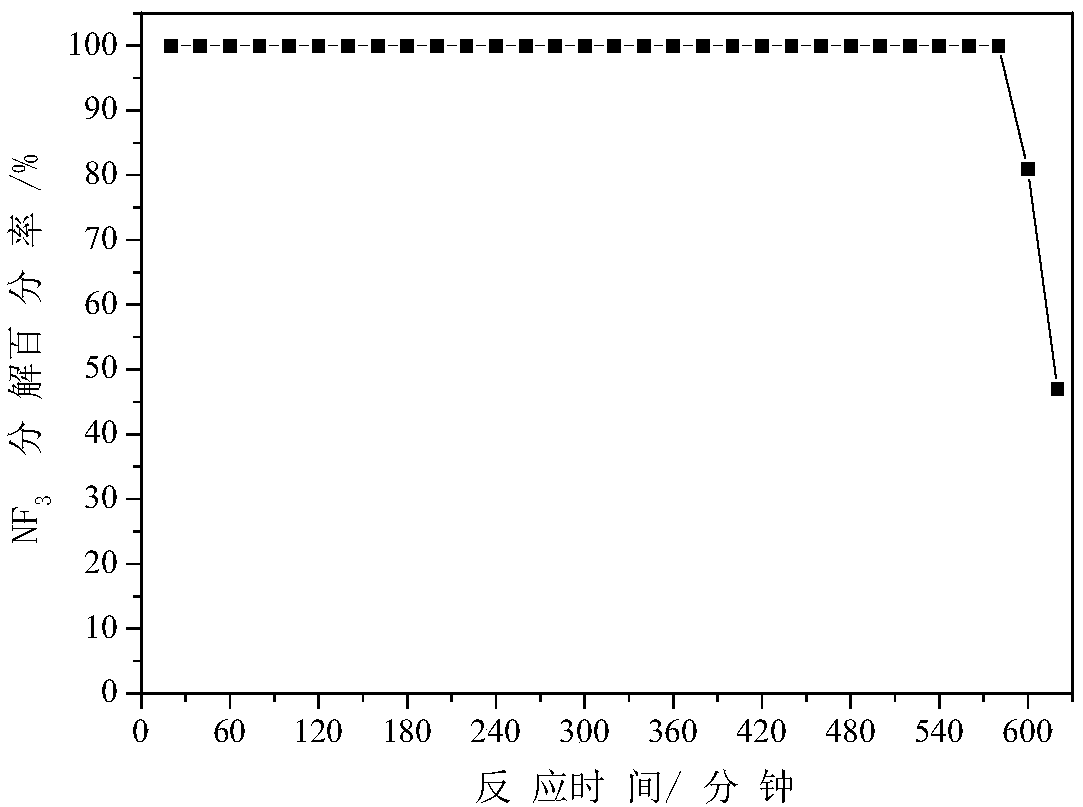

Fluorine-fixing agent with high utilization rate and preparation method thereof

ActiveCN108579397ASimple preparation processPreparation process parameters are easy to controlGas treatmentDispersed particle separationThin shellsCobalt atom

The invention relates to a fluorine-fixing agent with a high utilization rate and a preparation method thereof. The preparation method comprises synthesizing Al2O3 with thin-shell morphology, adding aurea, manganese nitrate or cobalt nitrate aqueous solution into the Al2O3, carrying out rotation crystallization in an autoclave to obtain a thin-shelled Al2O3-supported Mn2O3 or Co3O4 precursor, andcalcining the precursor in air to obtain a thin-shelled Al2O3-supported Mn2O3 or Co3O4 fluorine-fixing agent, wherein the mass ratio of the manganese or cobalt atoms to Al2O3 is 3% to 8% and the optimum mass ratio is 5%. The fluorine-fixing agent is used for decomposing the nitrogen trifluoride waste gas discharged through the electronics industry, has high fluorine-fixing agent reactivity, has ahigh use rate of 98% and realizes recovery of the fluorine resource.

Owner:YANTAI UNIV

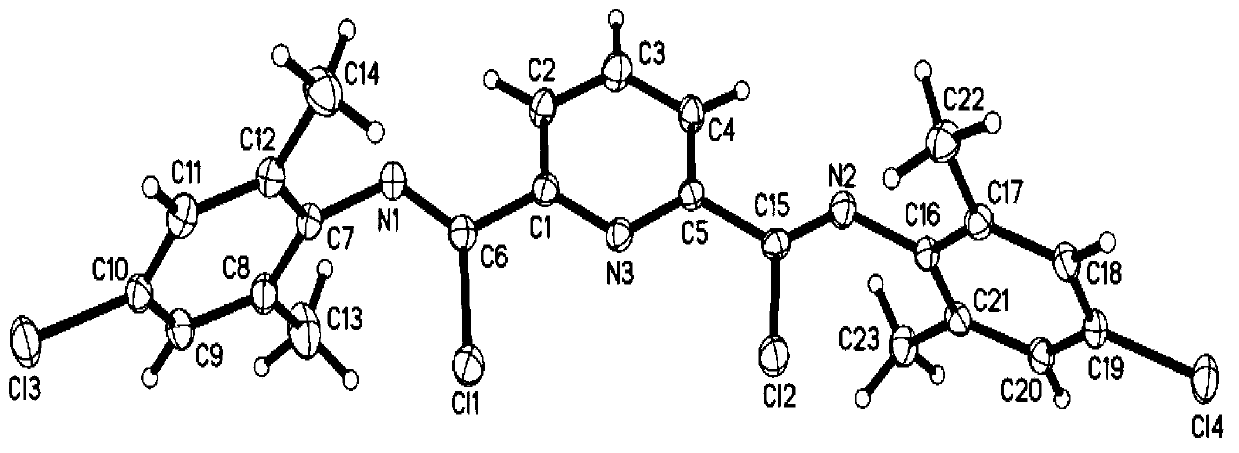

Method of using a cobalt-amine based metal complex as an antiviral compound and a method for the preparation of functionalized analogs thereof

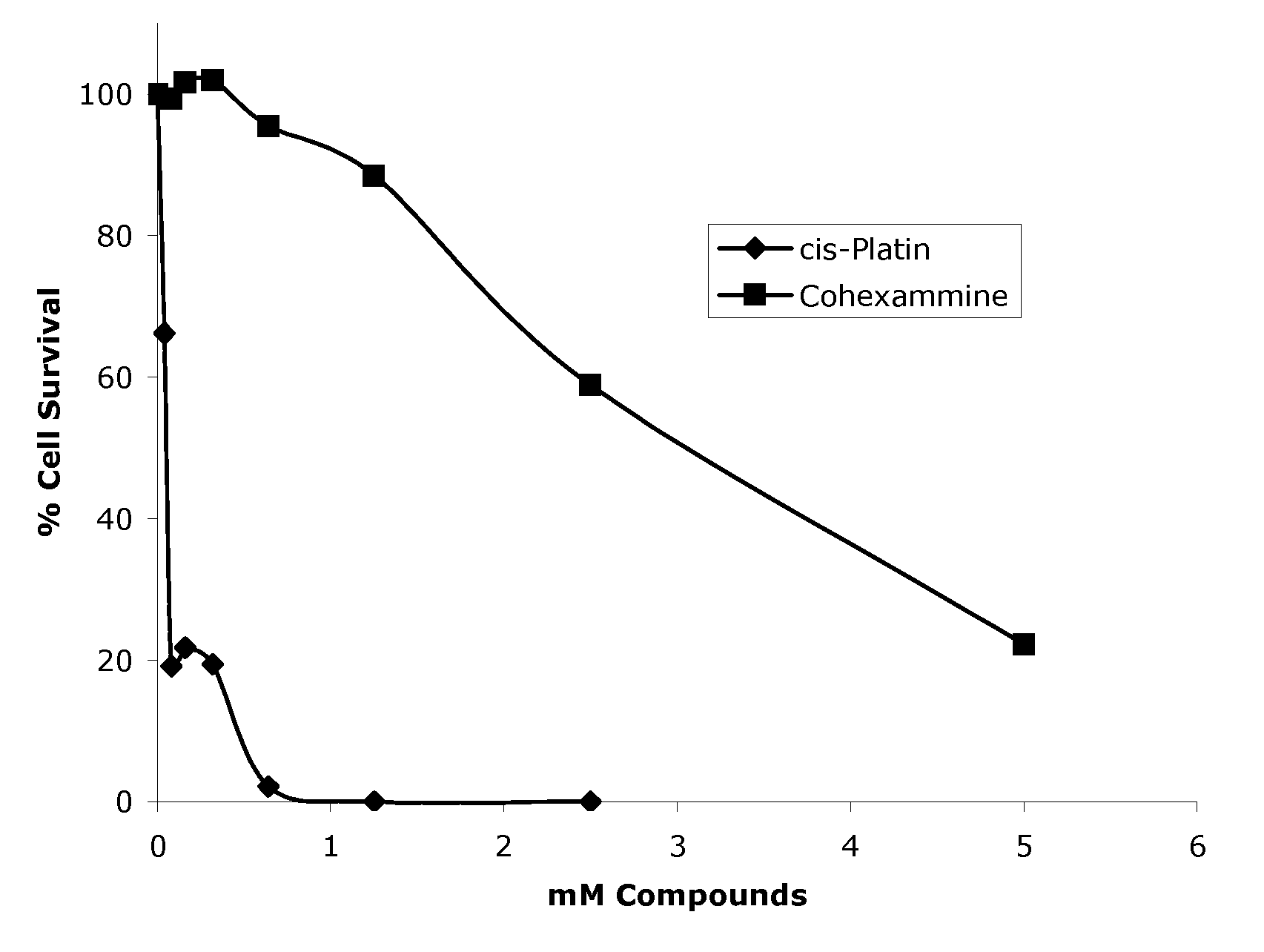

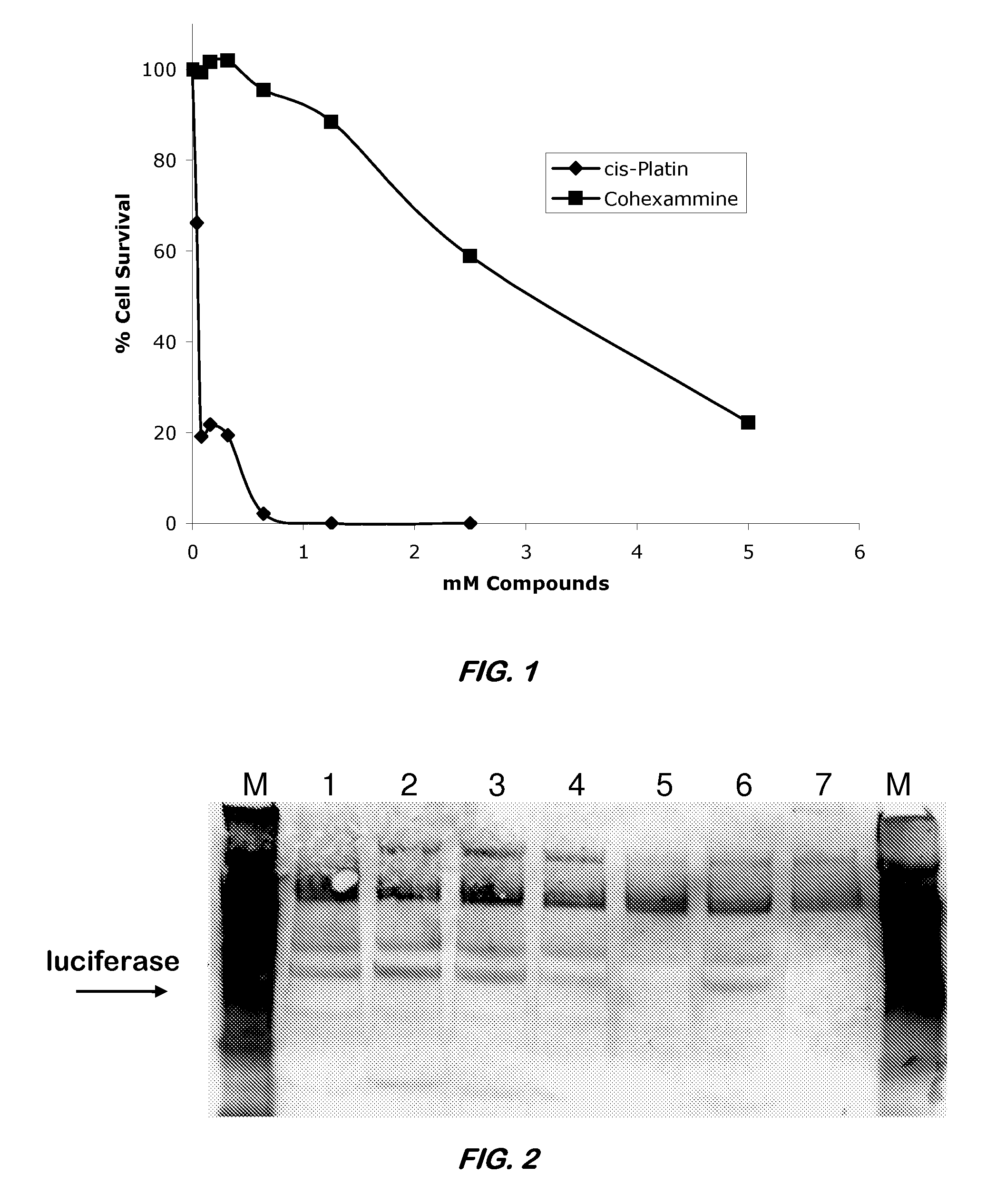

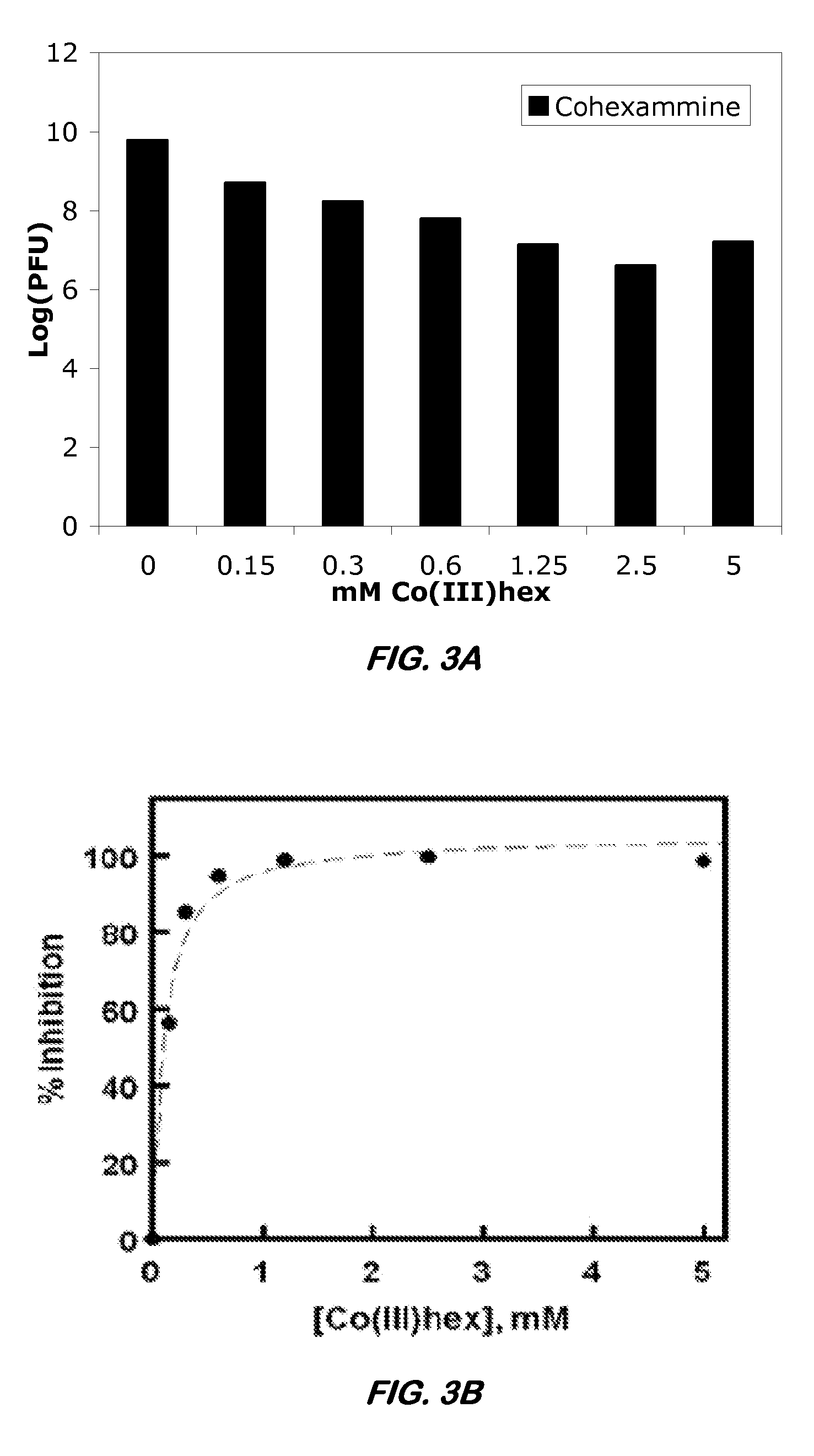

InactiveUS20080182835A1Potent inhibitionBiocideOrganic active ingredientsCoordination siteCobalt atom

The present invention is generally directed to a method of prophylaxis against viral infection of a cell or subject or a method of treating a subject infected with a virus including administering an antiviral composition having the general Structure III,wherein each of R1, R2, R3, R4, R5 and R6 is the same or different and includes an N-based ligand donor atom selected from the group consisting of ammonia, primary amine or secondary amine, or salt thereof. The present invention is also generally directed to a method of preparing an antiviral agent including providing a cobalt pentammine salt having a non-amine coordination site and mono-substituting the non-amine coordination site with a functional group incorporating a strong coordinator atom to cobalt to form a CoHex structure of Structure III, in which R1 incorporates the functional group having the strong coordinator atom coordinated with the cobalt atom, or a salt thereof.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for preparing hollow nanofiber, hollow nanofiber and catalyst composition for preparing hollow nanofiber

Owner:TORAY IND INC

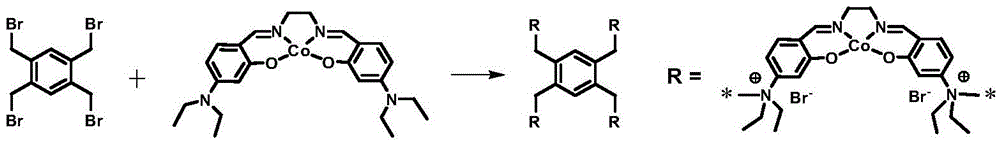

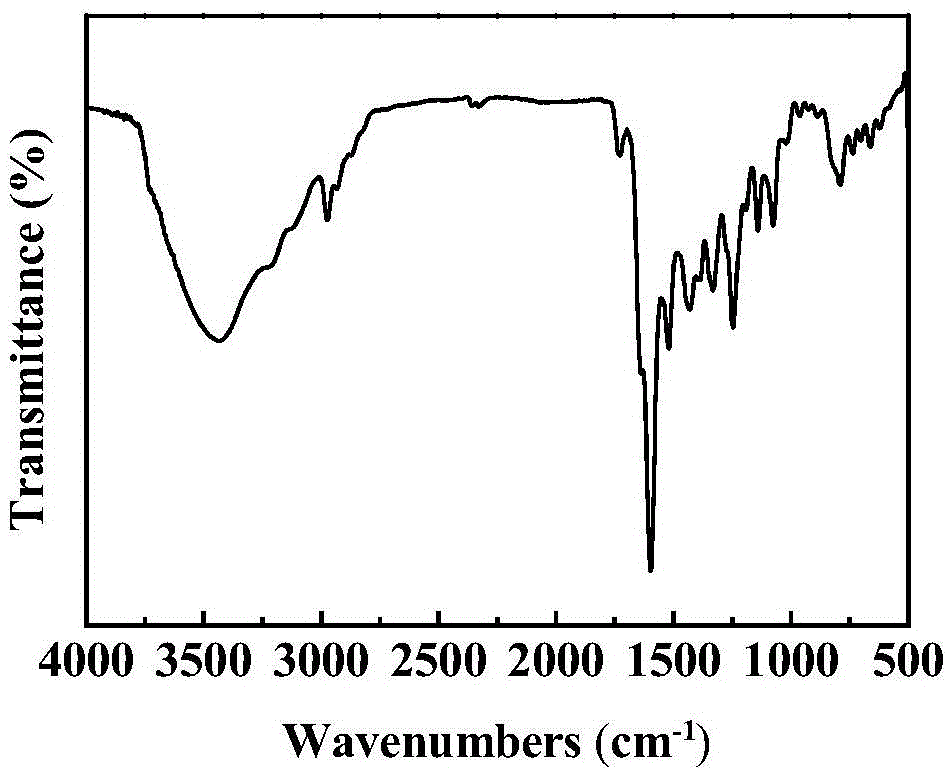

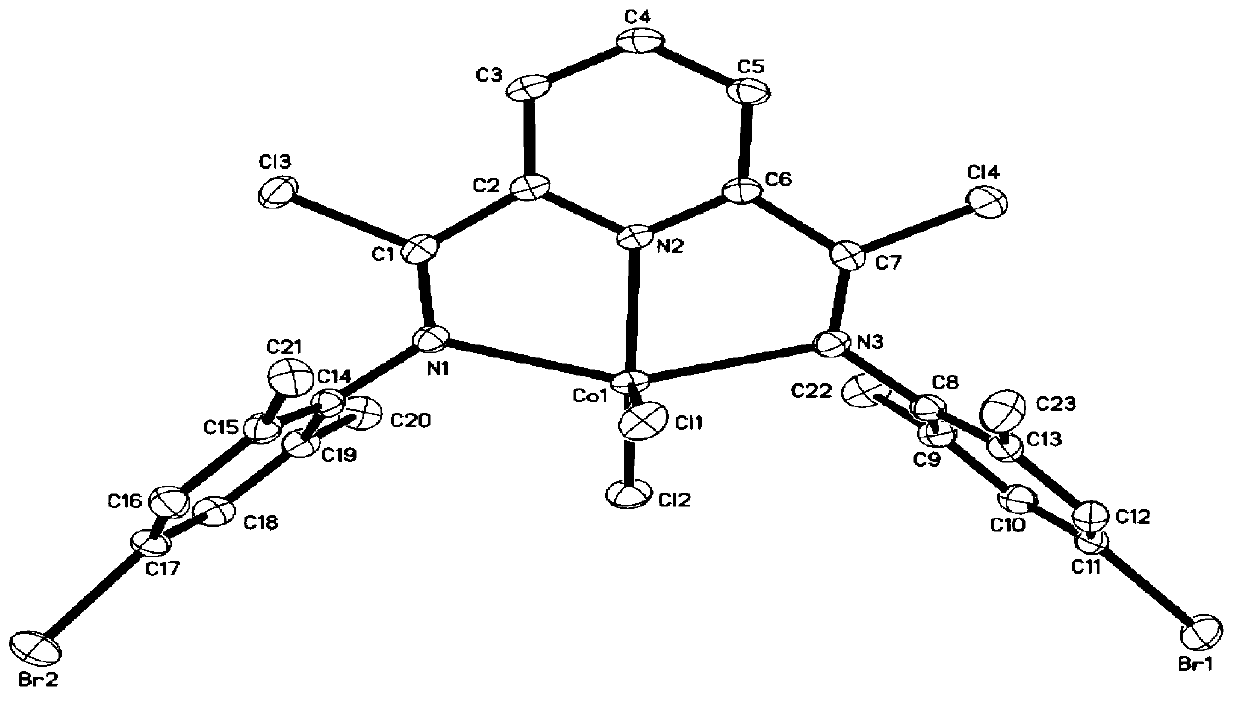

Dual-function catalyst for preparing cyclic carbonates through cycloaddition of CO2 and epoxy compound and preparation method thereof

ActiveCN105665022AEasy to makeHigh catalytic activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCycloadditionCobalt atom

The invention discloses a dual-function catalyst for preparing cyclic carbonates through cycloaddition of CO2 and an epoxy compound and a preparation method thereof. Tetrakisbenzene and Salen-Co complexes are adopted as a precursor to be subjected to a reaction to obtain the dual-function catalyst containing bromine negative ions and metal cobalt atoms. The dual-function catalyst has the advantages that the preparation method of the catalyst is simple and easy to implement, the production cost is low, the catalytic activity and selectivity are high, no solvent or auxiliaries need to be added into a reaction system, reaction conditions are mild, and the preparation method is expected to become a clean CO2 cycloaddition technological path with the huge competitiveness.

Owner:湖州优研知识产权服务有限公司

Preparation method of polybutadiene

ActiveCN102775539AHigh yieldHigh catalytic activityCobalt organic compoundsOrganic solventCobalt atom

The invention provides a preparation method of a polybutadiene, which comprises the following steps: under the actions of a cocatalyst and a cobalt complex disclosed as Formula (I), carrying out polymerization reaction on butadiene in an organic solvent to obtain polybutadiene. In the polybutadiene preparation process, the cobalt complex disclosed as Formula (I) and the cocatalyst are used as the catalyst, the electrophilic chlorine atoms introduced into the ligand structure of the cobalt complex increase the electropositivity of the active center cobalt atom, thereby endowing the butadiene monomer with larger coordination space; and thus, the cobalt complex has higher catalytic activity, so the polybutadiene has higher yield. The experiment proves that the yield of polybutadiene is 72-97% in the butadiene catalytic polymerization process of the cobalt complex.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for prolonging endurance life of diamond compact and diamond compact

The invention relates to the technical field of super-hard composite materials, in particular to a method for prolonging the endurance life of a diamond compact and the diamond compact. The method forprolonging the endurance life of the diamond compact includes the steps: irradiating an interface between a substrate and a diamond layer and the surface of the diamond layer by ultra-fast pulse laser beams; polishing the surface of the diamond layer. The diamond compact is manufactured by the ultra-fast pulse laser beams, a gradient transition layer is generated between layers, so that the substrate and the diamond layer are firmly combined, and sudden change of a thermal quantity and a mechanical quantity on the interlayer interface is avoided. The surface (cold annealing) of the diamond layer is irradiated by the ultra-fast pulse laser beams, thermal stress concentration and lattice defects of the diamond layer can be eliminated, D-D bonds on the surface of the diamond layer can be firmly bonded, cobalt atoms are 'extruded' to the surface of the diamond layer, a rich cobalt layer is removed by polishing, ultra-high surface smoothness is realized, the high-temperature resistance ofthe diamond compact is improved, and the service life of the diamond compact is prolonged.

Owner:上海梁为科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com