Non-noble metal doped carbon felt, and application in catalyzing oxygen reduction

A non-precious metal, carbon felt technology, applied in the field of non-precious metal doped carbon felt, to achieve the effect of solving high cost, good stability and methanol poisoning resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Material preparation:

[0022] Soak 0.0727g of the carbon felt material in an aqueous solution of pyrrole, wherein the pyrrole solution is 30mL of water + 100uL of pyrrole, and soak at room temperature for 4 hours; react the removed carbon felt in an aqueous solution of 30mM ferric chloride hexahydrate for 4h, and after taking it out 60 Dry overnight at ℃, then soak the carbon felt in an aqueous solution containing 30mM cobalt chloride, take it out after 12 hours; then dry at 60℃ overnight. The dried sample was pyrolyzed at 800°C for 2 hours under nitrogen gas, and then cooled to 380°C to obtain a non-noble metal-doped carbon felt material.

[0023] Electrochemical Characterization:

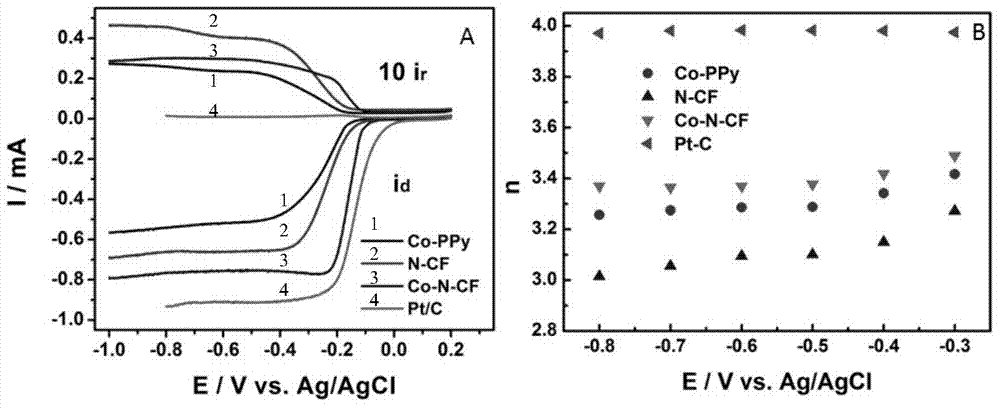

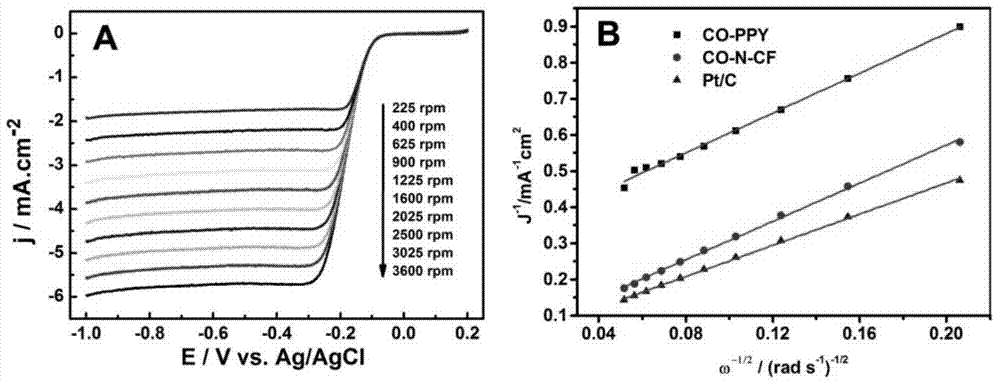

[0024] The above-mentioned non-noble metal-doped carbon felt material was ground with a mortar, and then dispersed into a mixed solution of isopropanol, water, and naphthol to obtain a 2 mg / mL solution. Then take 10uL and drop it on the surface of the platinum ring electrode on the glass...

Embodiment 2

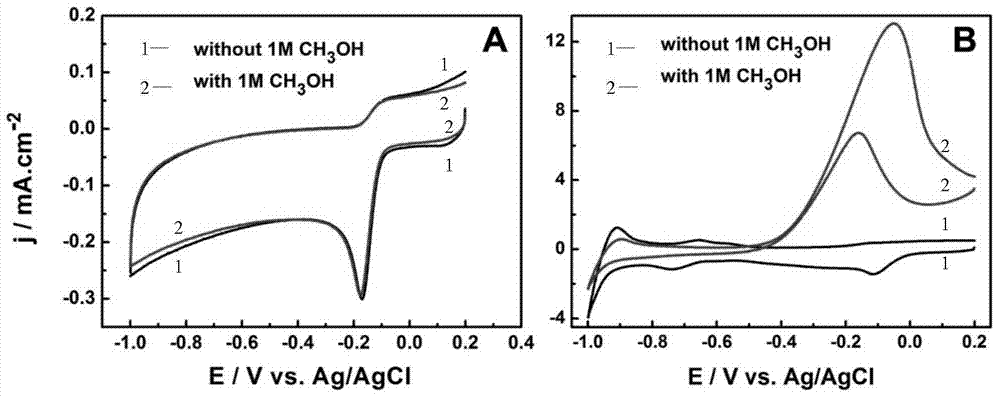

[0027] The preparation method is the same as 1, except that pyrrole is replaced with 0.08 g of 2,5-dimethylpyrrole, and the electrochemical characterization method is the same as 1. The kinetic current of cobalt and nitrogen doped carbon felt is 22.72mA cm at -0.3V -2 , Pt / C is 23.4mA cm -2 , indicating that the material has good catalytic activity. Its antitoxic effect and electron transfer number are close to the results of Example 1.

Embodiment 3

[0029] The preparation method is the same as 1, except that pyrrole is replaced with 0.06 g of 1-methylpyrrole, and the electrochemical characterization method is the same as 1. The kinetic current of cobalt and nitrogen doped carbon felt is 18.52mA cm at -0.3V -2 , has a very good anti-poisoning ability, and the electron transfer number is 3.3. slightly worse than Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com