Patents

Literature

734 results about "Carbon felt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing C/SiC composite material through low-cost fused silicon impregnation method

The invention relates to a method for preparing a C / SiC composite material through a low-cost fused silicon impregnation method, which comprises the following steps: performing calcining pretreatment on a carbon felt or graphite felt at 400-600 temperature; immersing the pretreated carbon felt or graphite felt in a melamine and boric acid solution, thus coating a boron nitride protective layer; immersing in a carbon / silicon carbide slurry water solution, performing impregnation to ensure that pores of the carbon felt or graphite felt are fully filled with carbon / silicon carbide, placing in a sintering furnace, and performing primary fused silicon impregnation treatment at 1600-1800 DEG C; immersing in liquid phenolic resin, and performing carbonization treatment under the protection of an inert atmosphere at 800-1000 DEG C to ensure that all the resin is carbonized; and finally, performing secondary fused silicon impregnation treatment to ensure that carbon produced by carbonization of the resin totally reacts with silicon to generate silicon carbide, thus obtaining the C / SiC composite material. The obtained C / SiC composite material is high in density, low in air pore and free silicon content, and favorable in material strength, toughness and frictional wear performance, and can be used for manufacturing of brake pads.

Owner:山东宝纳新材料有限公司

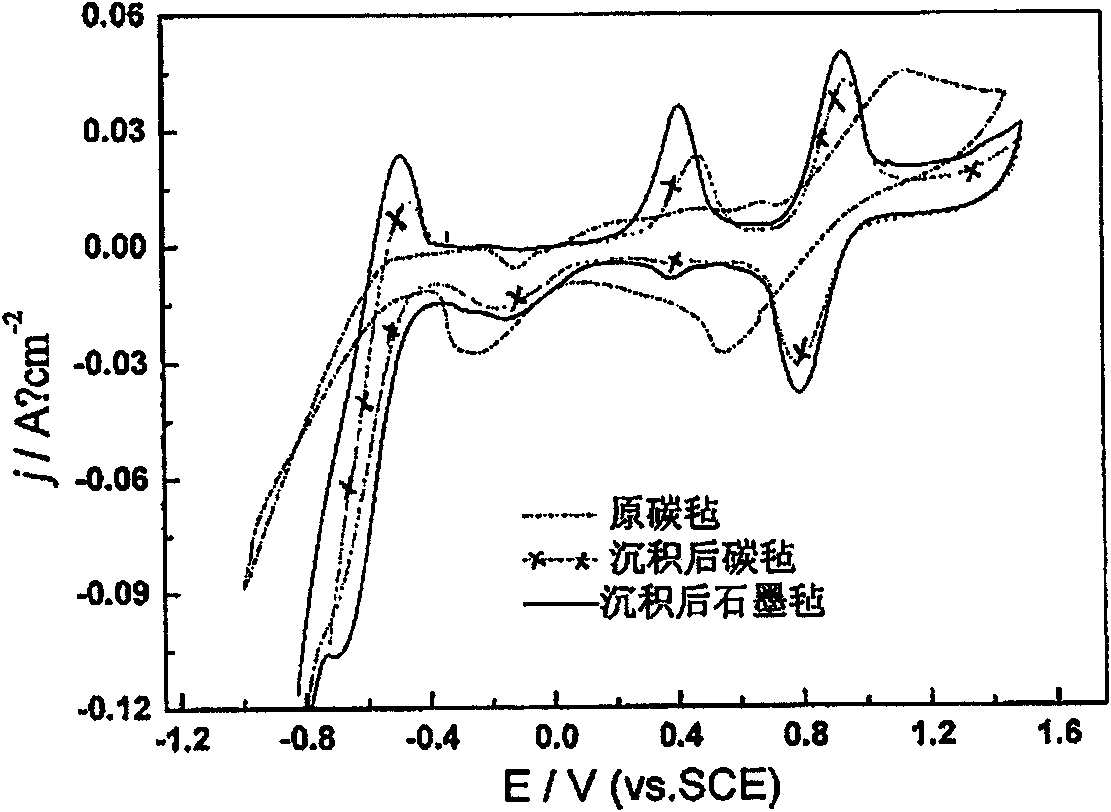

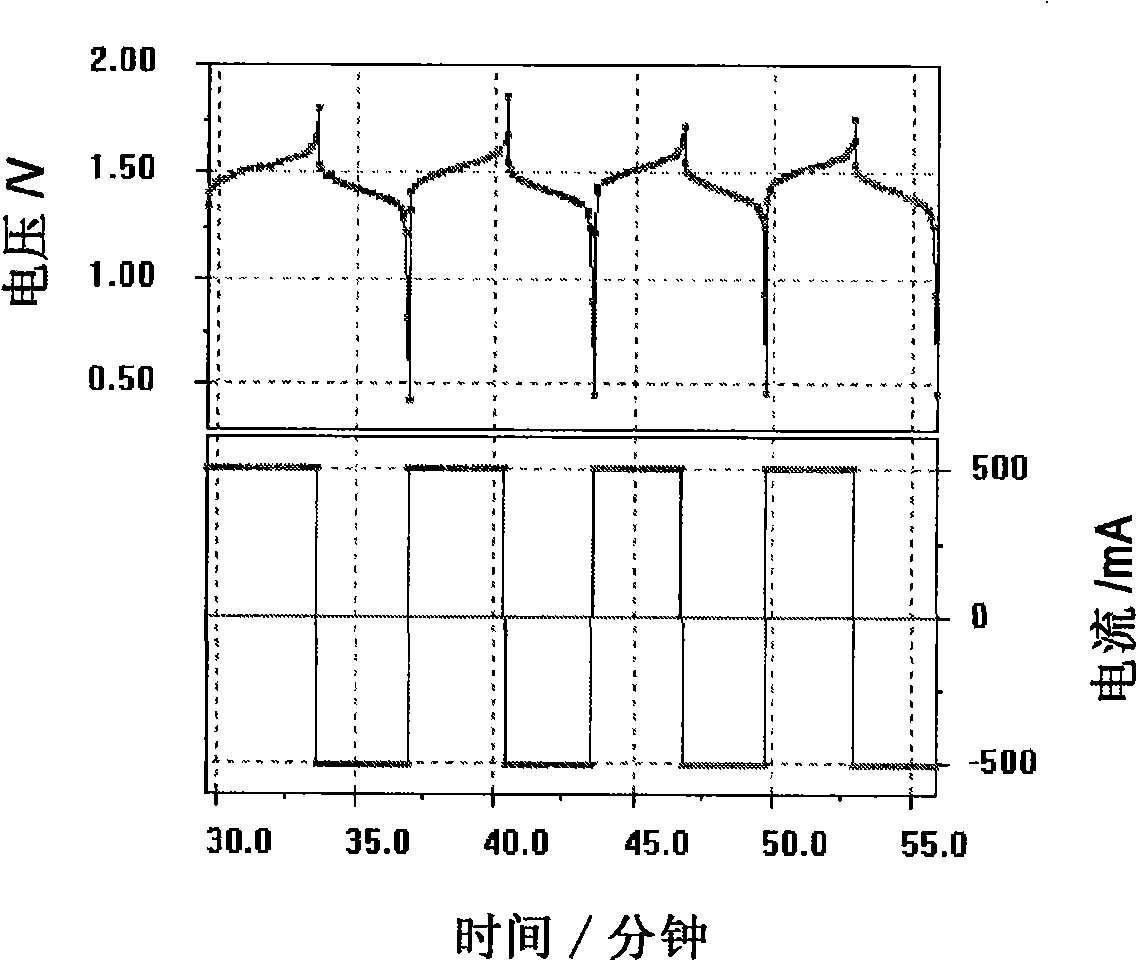

Graphite felt watch surface modified method and modified mineral carbon felt

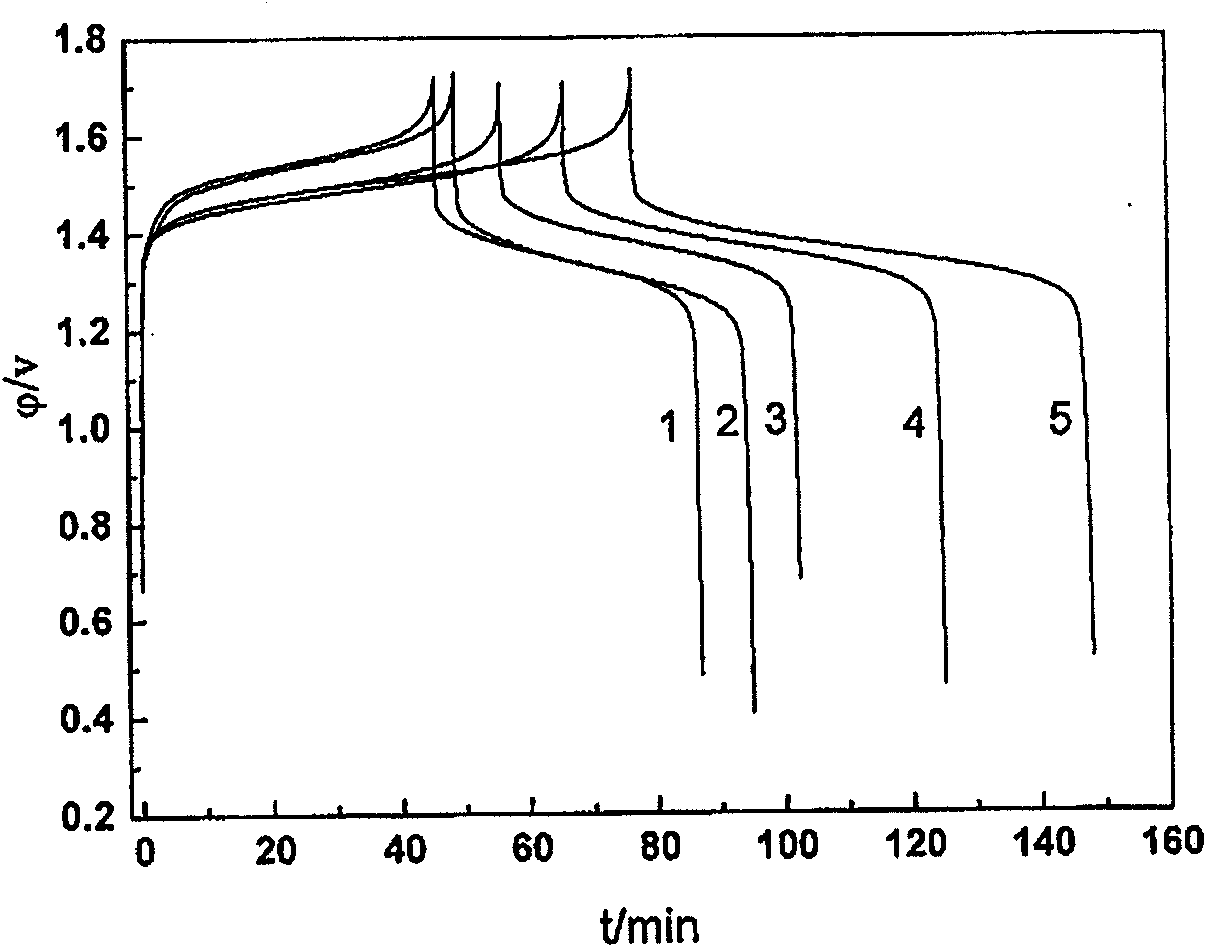

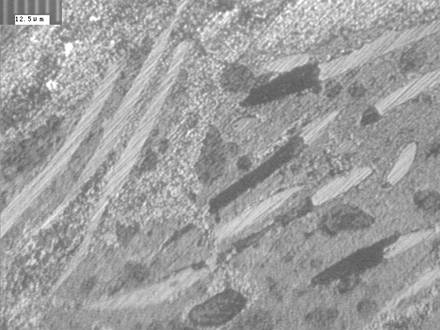

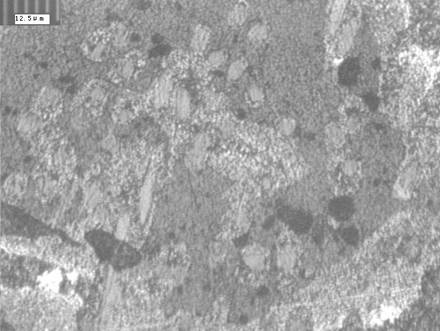

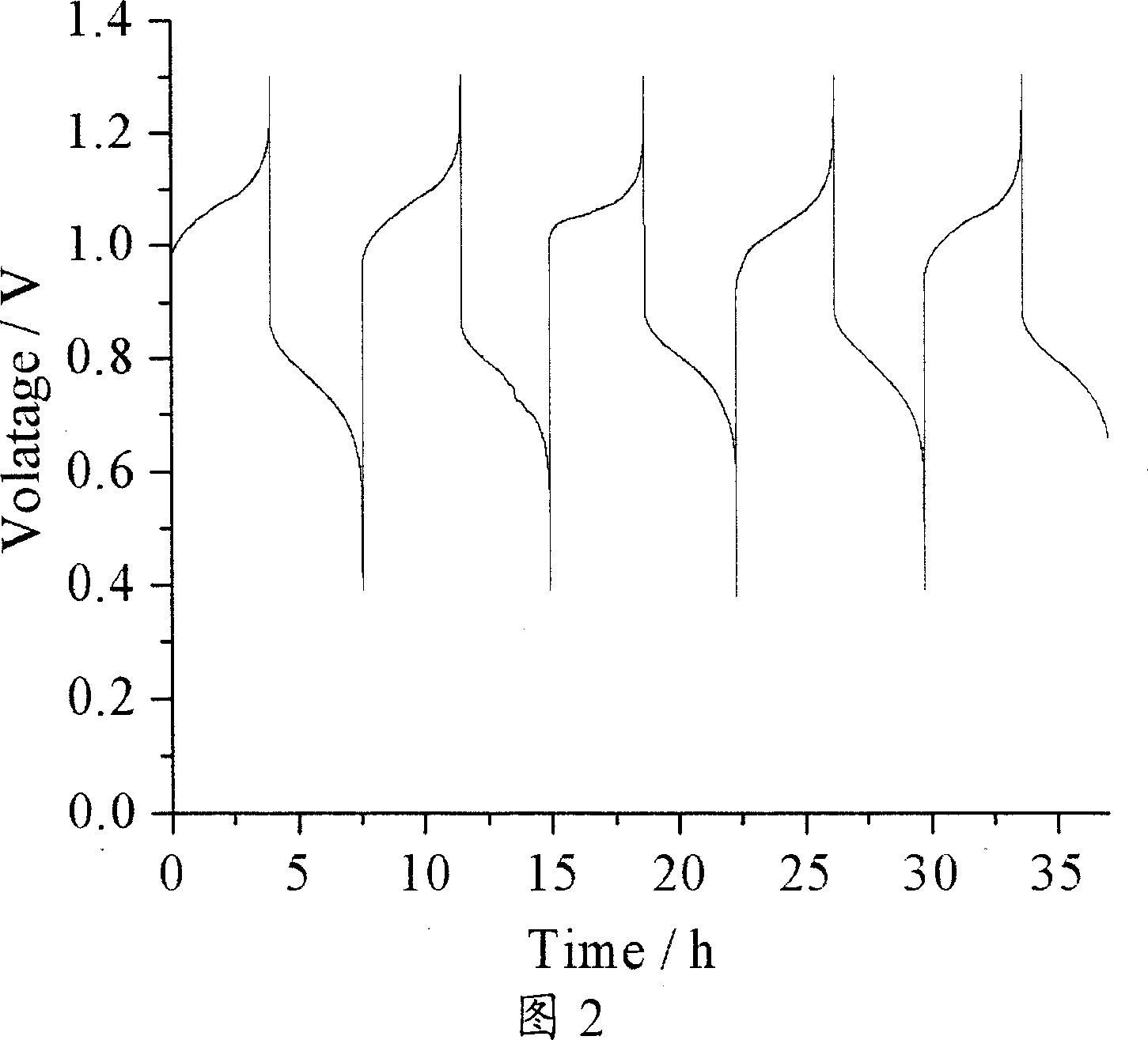

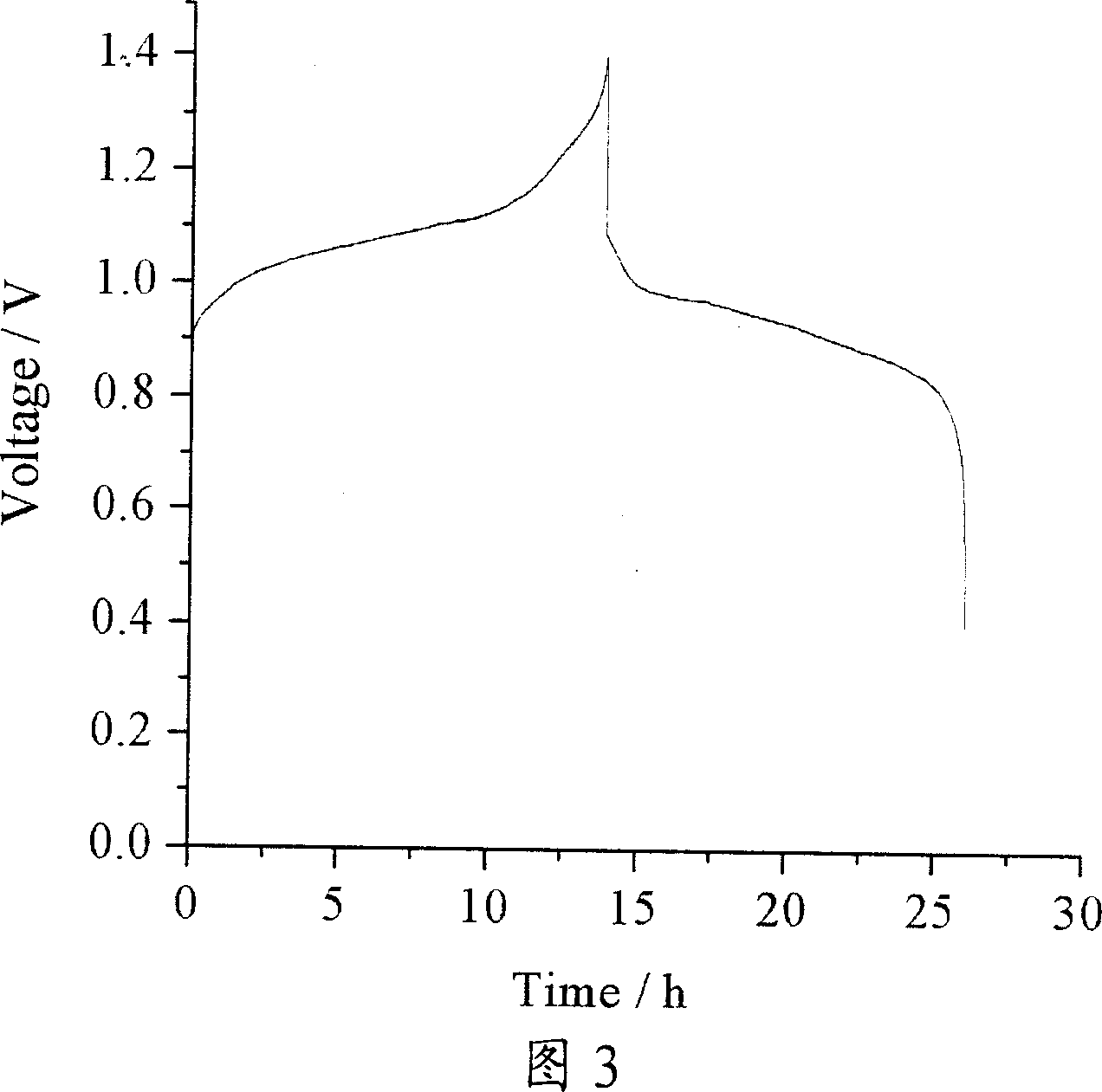

InactiveCN101182678AImprove wettabilityImprove charge and discharge performanceElectrode manufacturing processesPhysical treatmentFiberVanadium redox battery

The invention relates to a graphite fiber felt surface modification method and a modified graphite fiber felt, and belongs to the all vanadium redox flow battery electrode manufacture technical field. The method step is that the electrochemical cathode modification treatment is conducted before the anode oxidation treatment. When used as an electrode, a modified graphite fiber felt greatly improves the electrochemical activity in the preparation of an all vanadium redox flow battery, promotes the voltage efficiency and the battery energy efficiency during the battery discharging, and increases the stable discharging time, so the recharging and discharging performance of the all vanadium redox flow battery is greatly improved. Moreover, the method is easy for implantation and low in the cost. No particular devices are required. The invention provides a good-performance electrode material for the battery manufacture field.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Electrode materials and all-vanadium redox flow battery containing electrode materials

InactiveCN101651201AReduce dosageLow costElectrode manufacturing processesRegenerative fuel cellsCarbon nanotubeRedox

The invention provides an electrode for a vanadium battery, comprising a carbon basal body and a carbon nano-tube layer formed on the surface of the basal body, wherein the carbon basal body is selected from a graphite felt, a carbon felt, a carbon paper and carbon cloth. The invention also provides an all-vanadium redox flow battery containing the electrode. The electrode has improved electrochemical activity and reliable mechanical strength.

Owner:BIG PAWER ELECTRICAL TECH XIANGYANG +1

Preparation method of C/C-SIC ceramic composite material

The invention discloses a preparation method of a C / C-SIC ceramic composite material, comprising the following steps: using a cheap low-density PAN-based flat carbon felt as a precursor, and preparing a protective layer on the surface of carbon fibers through chemical vapor deposition; preparing phenolic resin, acetone, ethanol and silicon carbide powder in proportion into a slurry, immersing the carbon felt with the protective layer in the slurry and vacuumizing, then pressing for impregnating; pressing the pre-impregnated carbon felt into shape, then carrying out solidification and carbonization; then putting the carbonized precursor in a furnace, carrying out high temperature siliconizing reaction and filling to obtain a compact base substrate, and then removing residual silicon from the surface to obtain the high-performance high-density C / C-SIC ceramic composite material having a density of 2.30-2.70 g / cm<3>. According to the invention, the preparation process is simple, the raw materials are cheap, the production time and procedures are greatly reduced. The invention can be suitable for batch production and is easy to industrialization.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

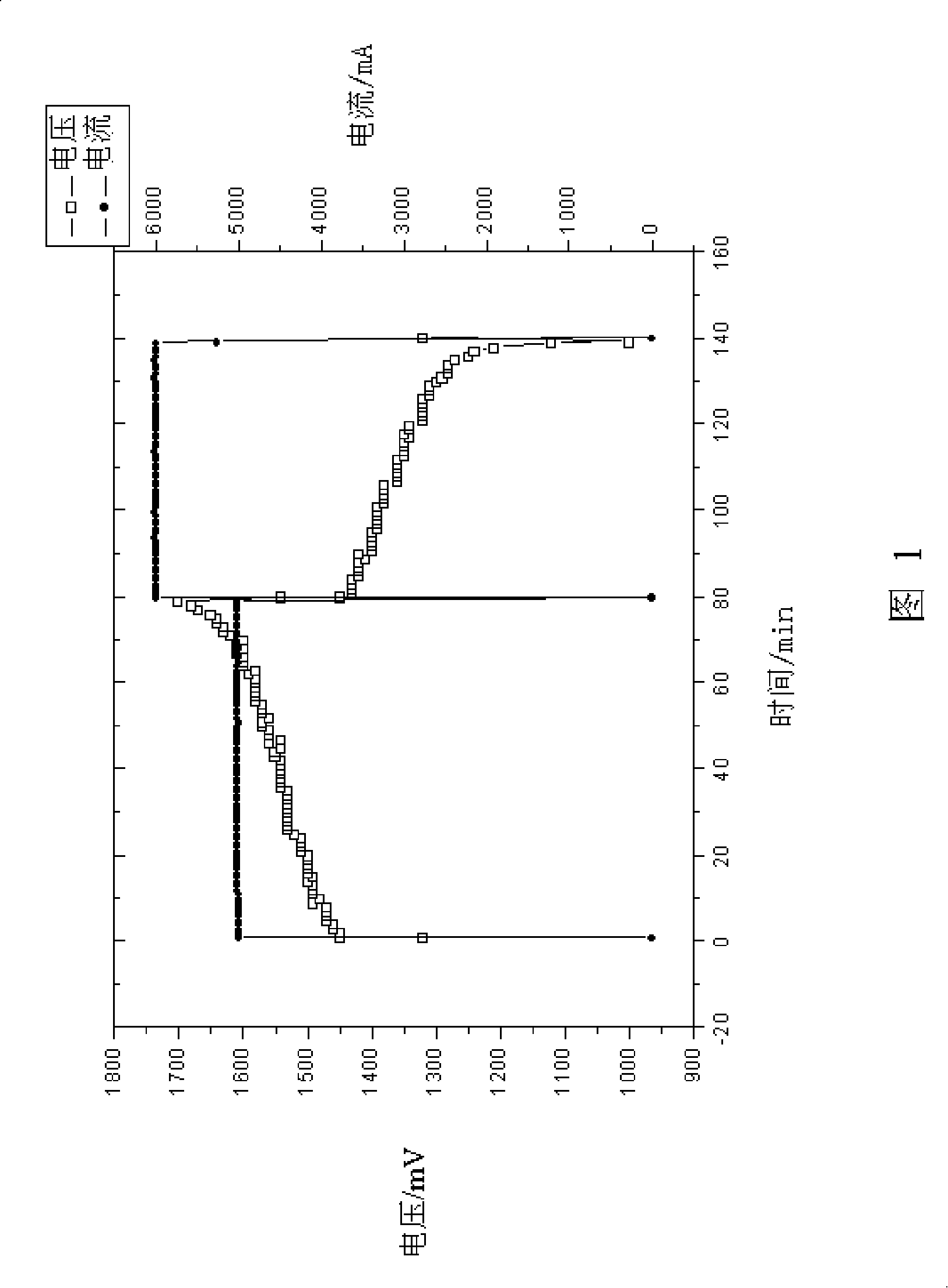

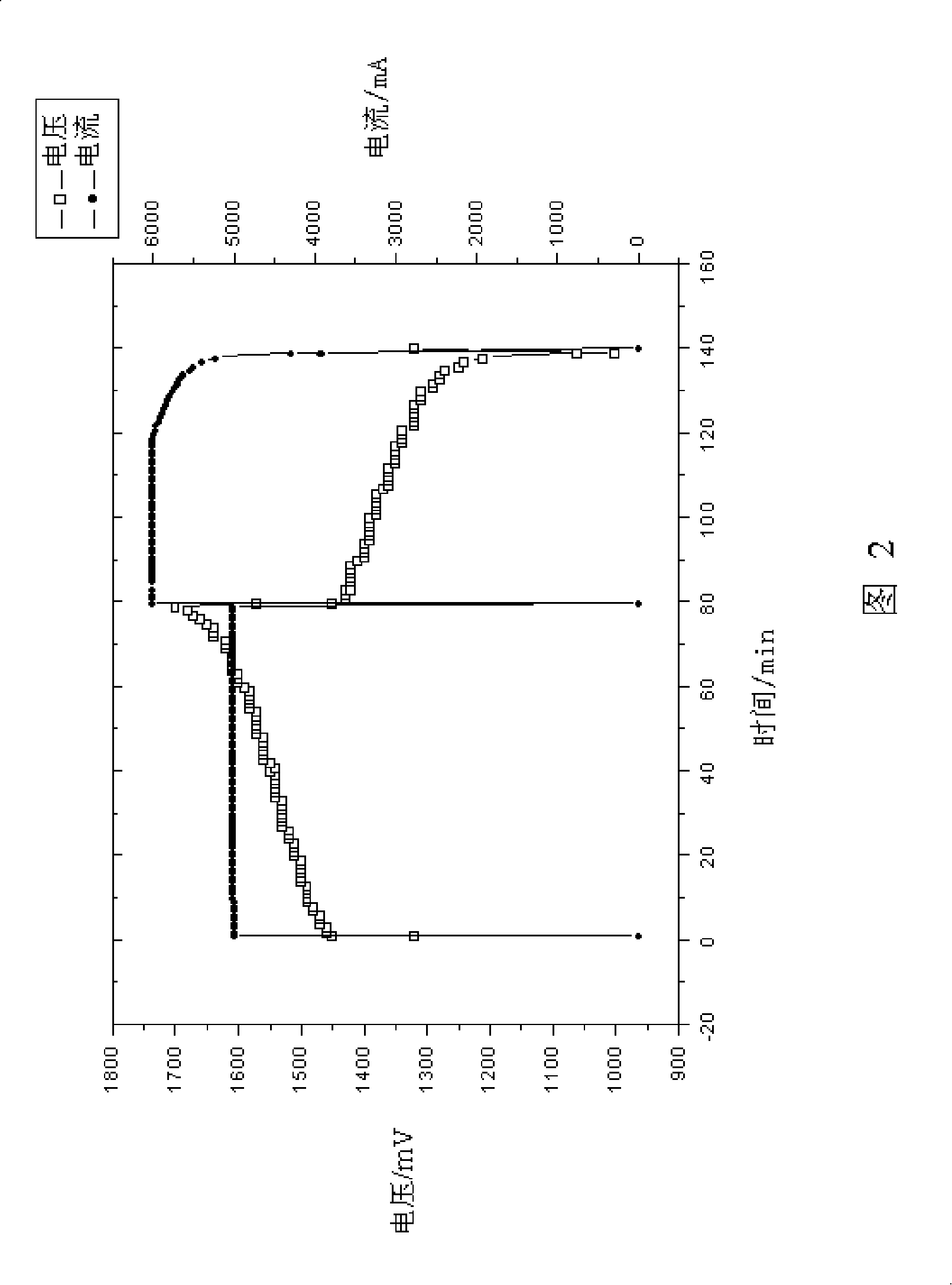

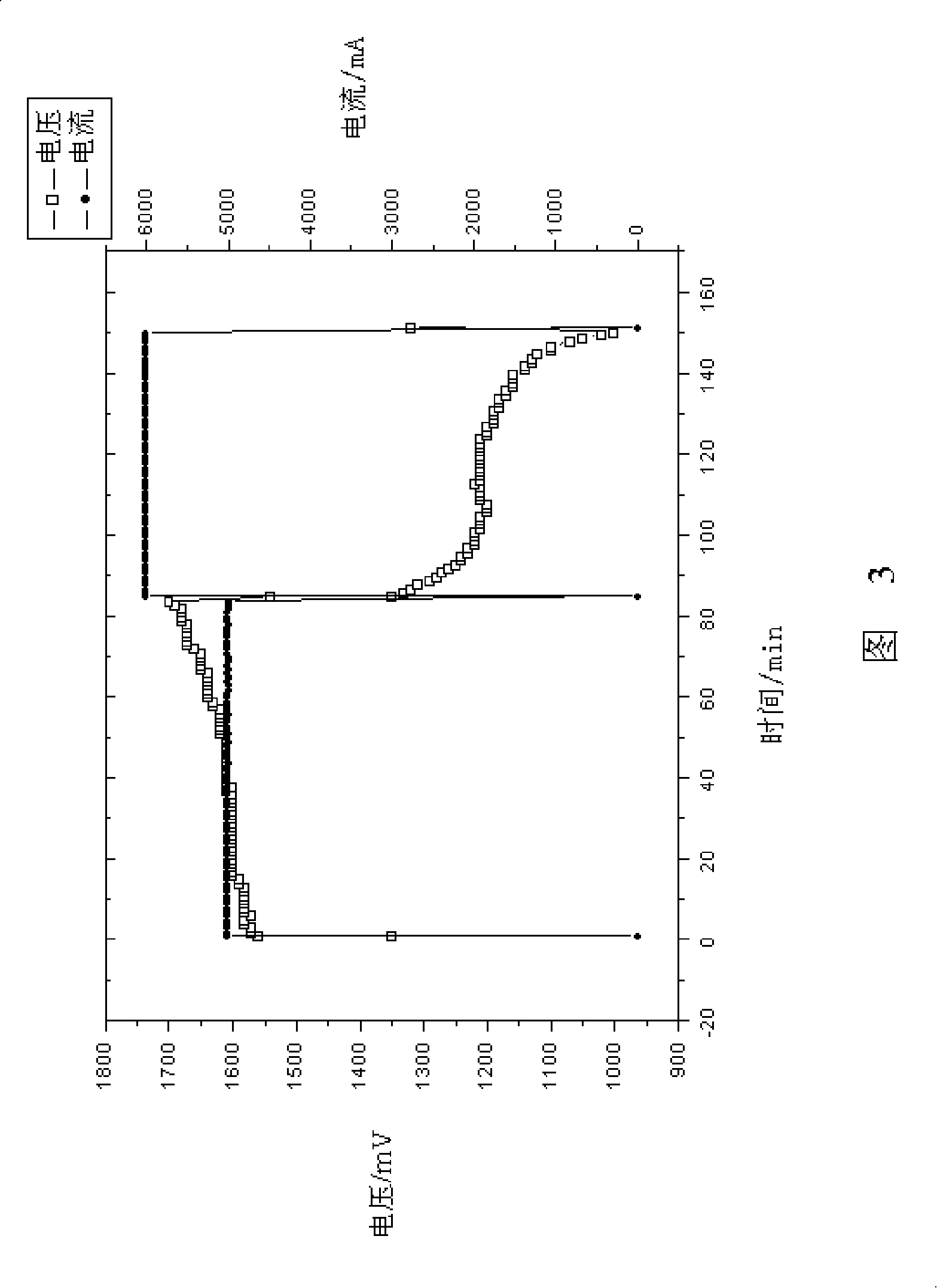

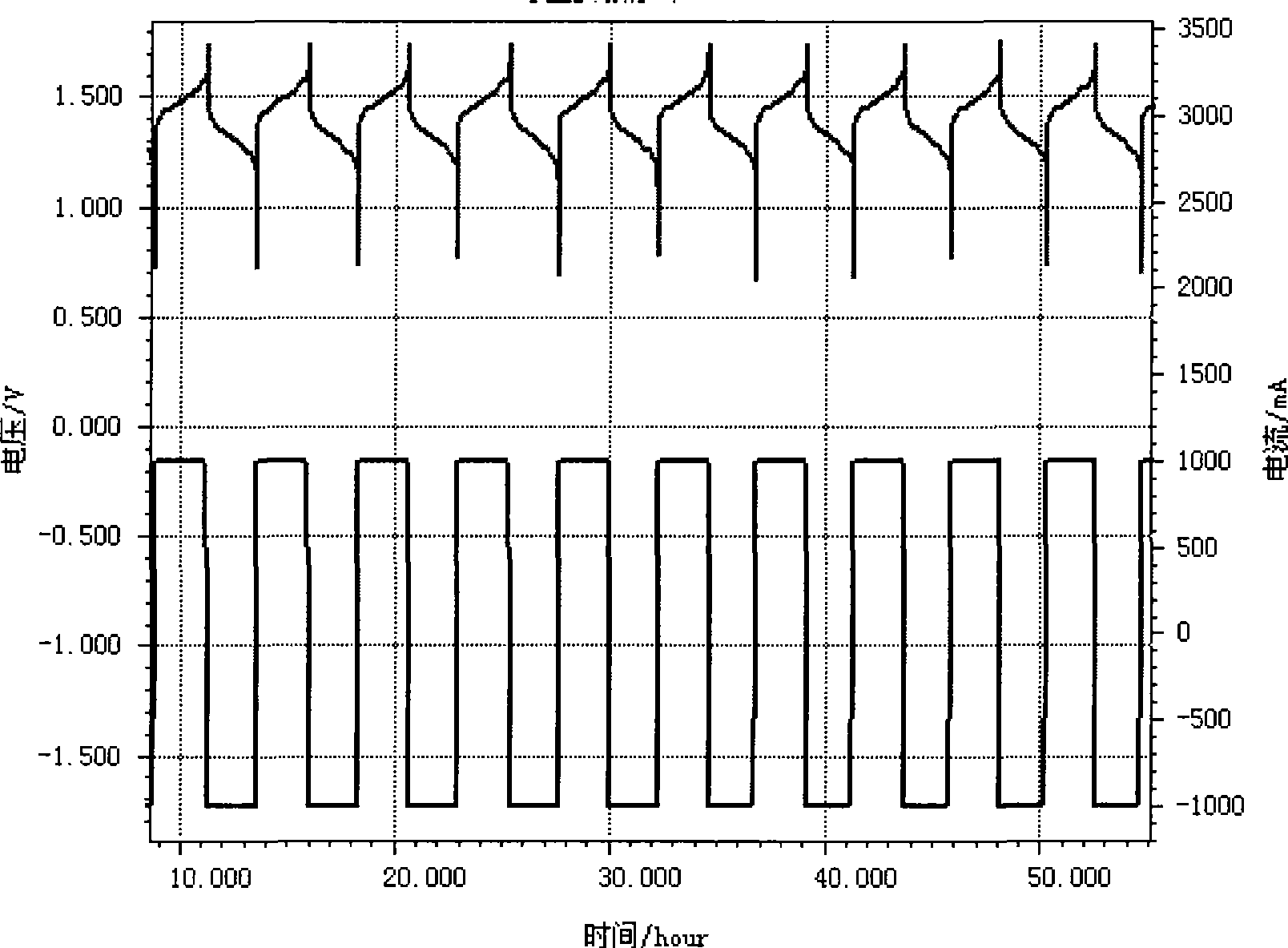

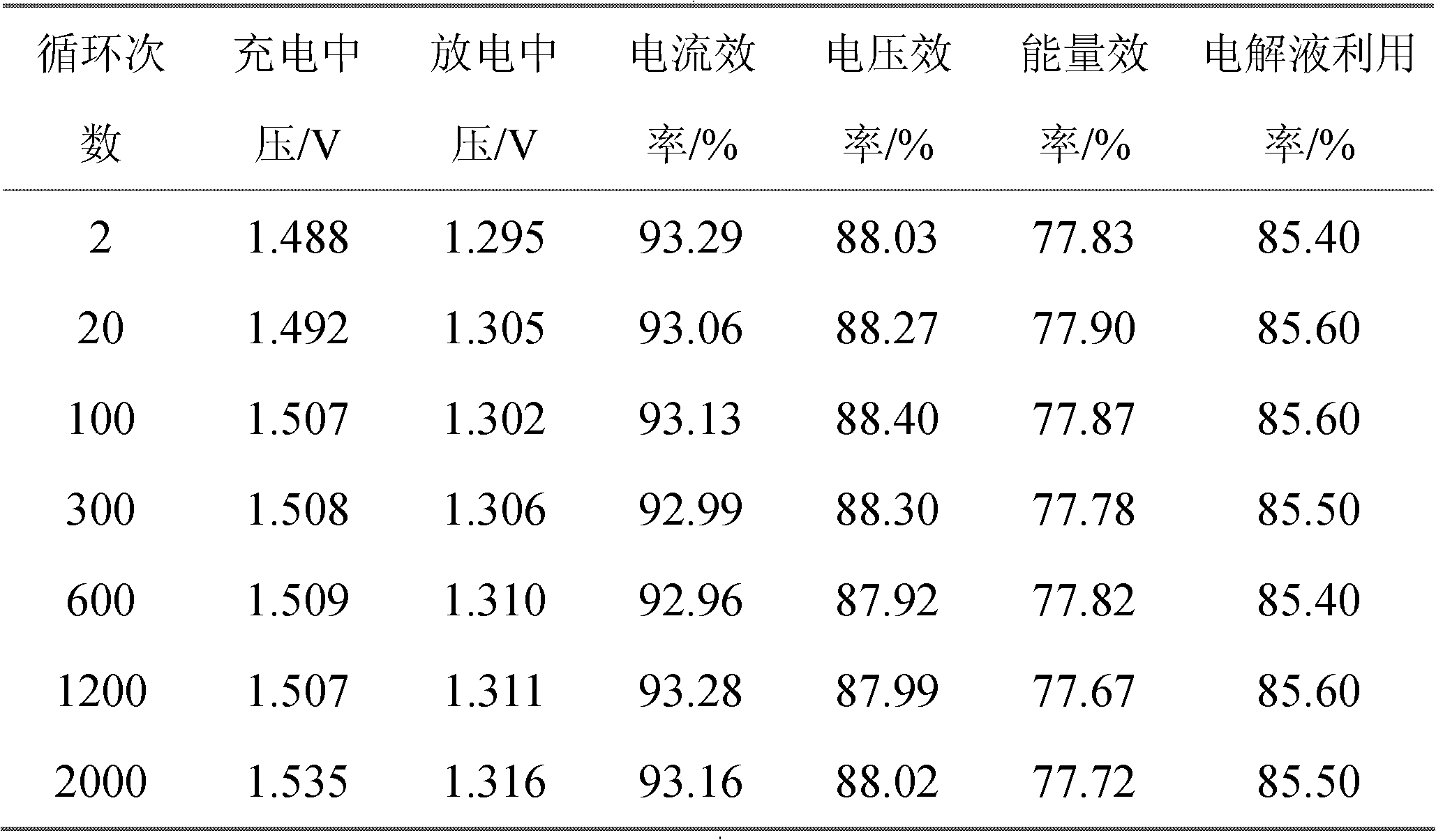

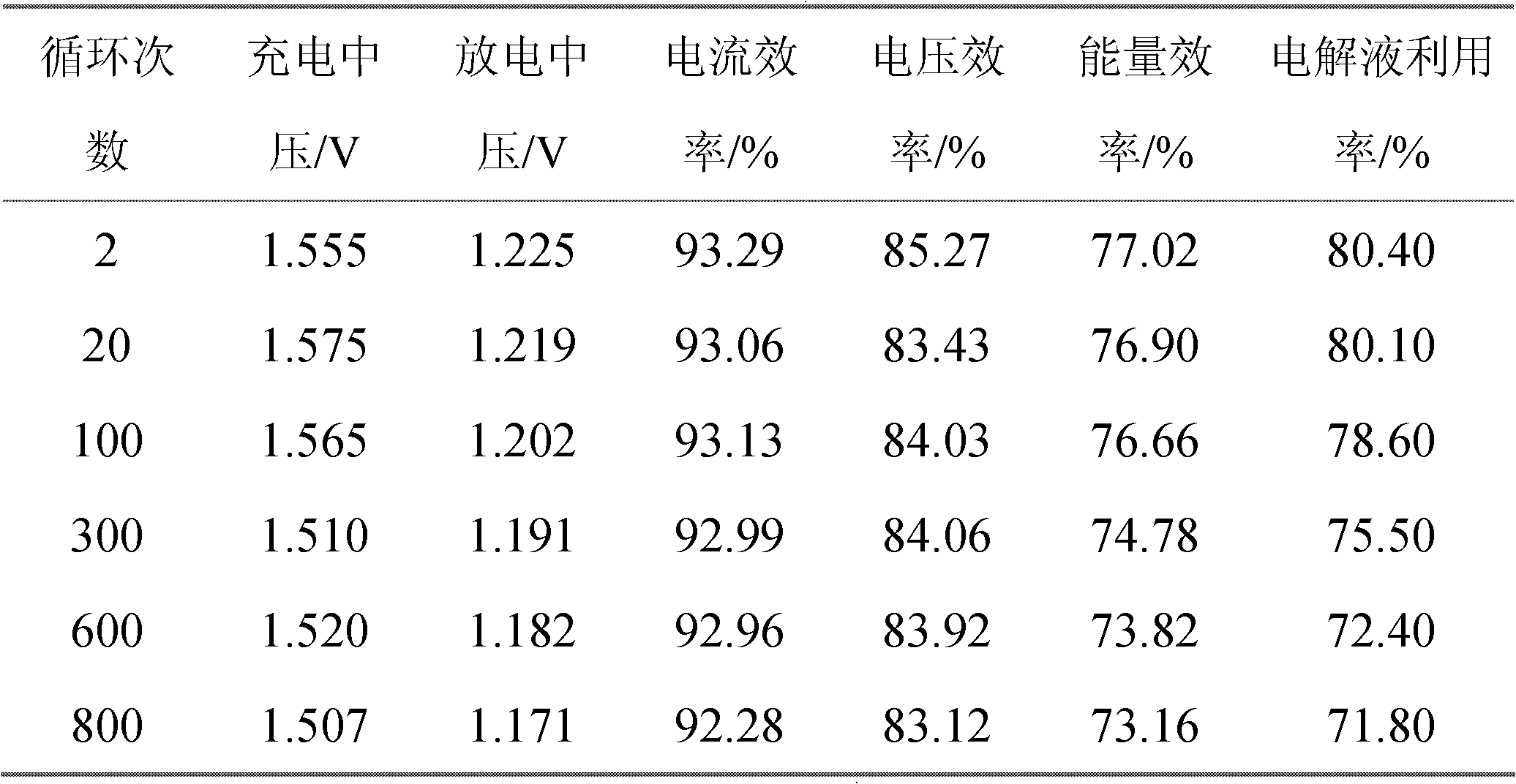

Electrochemical treatment method for improving vanadium cell electrode material activity

ActiveCN101465417AReduced stabilityShort lifeElectrode manufacturing processesRegenerative fuel cellsElectrolysisInternal resistance

The invention relates to the field of battery manufacturing and energy storage, in particular to an electrochemical treatment method for improving the activity of vanadium cell electrode materials. Graphite felt or carbon felt which is used as anode is immerged in active electrolyte and carries out electrochemical active treatment in an electrobath with a certain current density and time, then the graphite felt or carbon felt is washed and dried for obtaining activated graphite felt or carbon felt electrode material. The method carries out moderate and controllable electrochemical anode activation treatment by choosing suitable activated electrolyte and current density, and overcomes the disadvantages that the stability of the electrode material is deceased owning to overoxidation of the material caused by heat and acid treatment and the service life of the battery is reduced; the method has simple process and low cost. The graphite felt or carbon felt treated by the method is used as electrode and takes a cation-exchange membrane as a diaphragm, and the anode and cathode electrolytes are 1.5M of vanadyl sulfate and 2M of sulphuric acid; after the battery is combined, the ohm internal resistance is greatly reduced, and the current efficiency, voltage efficiency and energy efficiency of the battery are obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

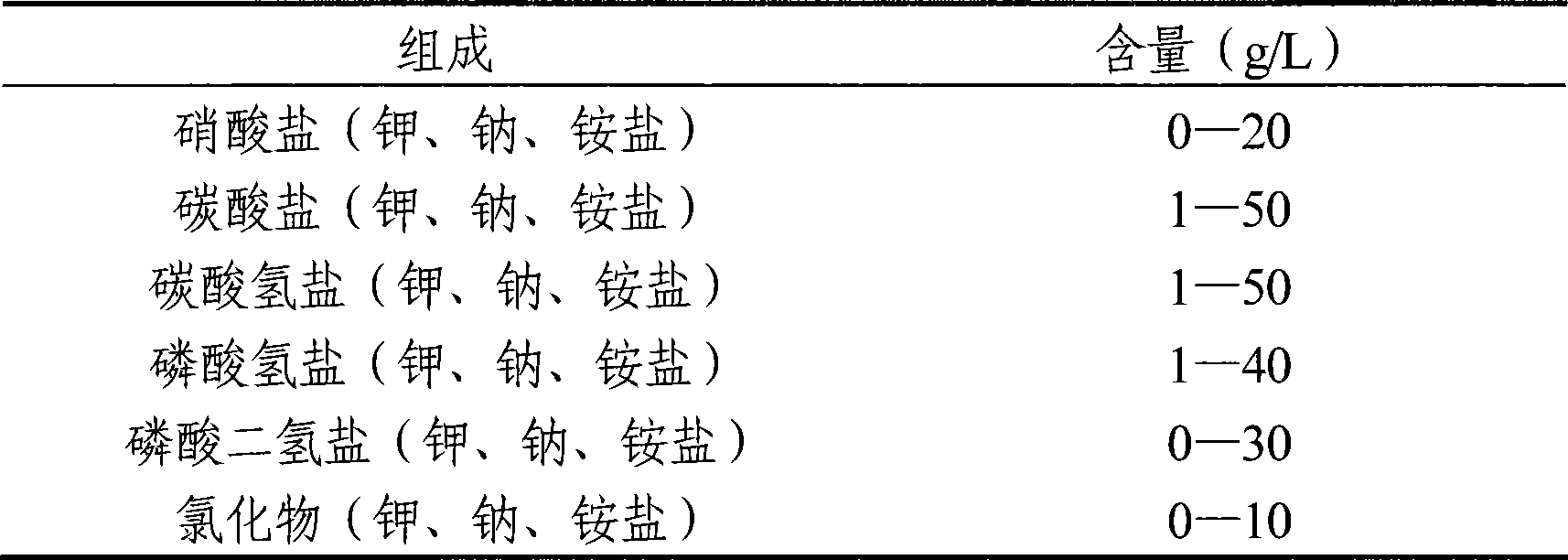

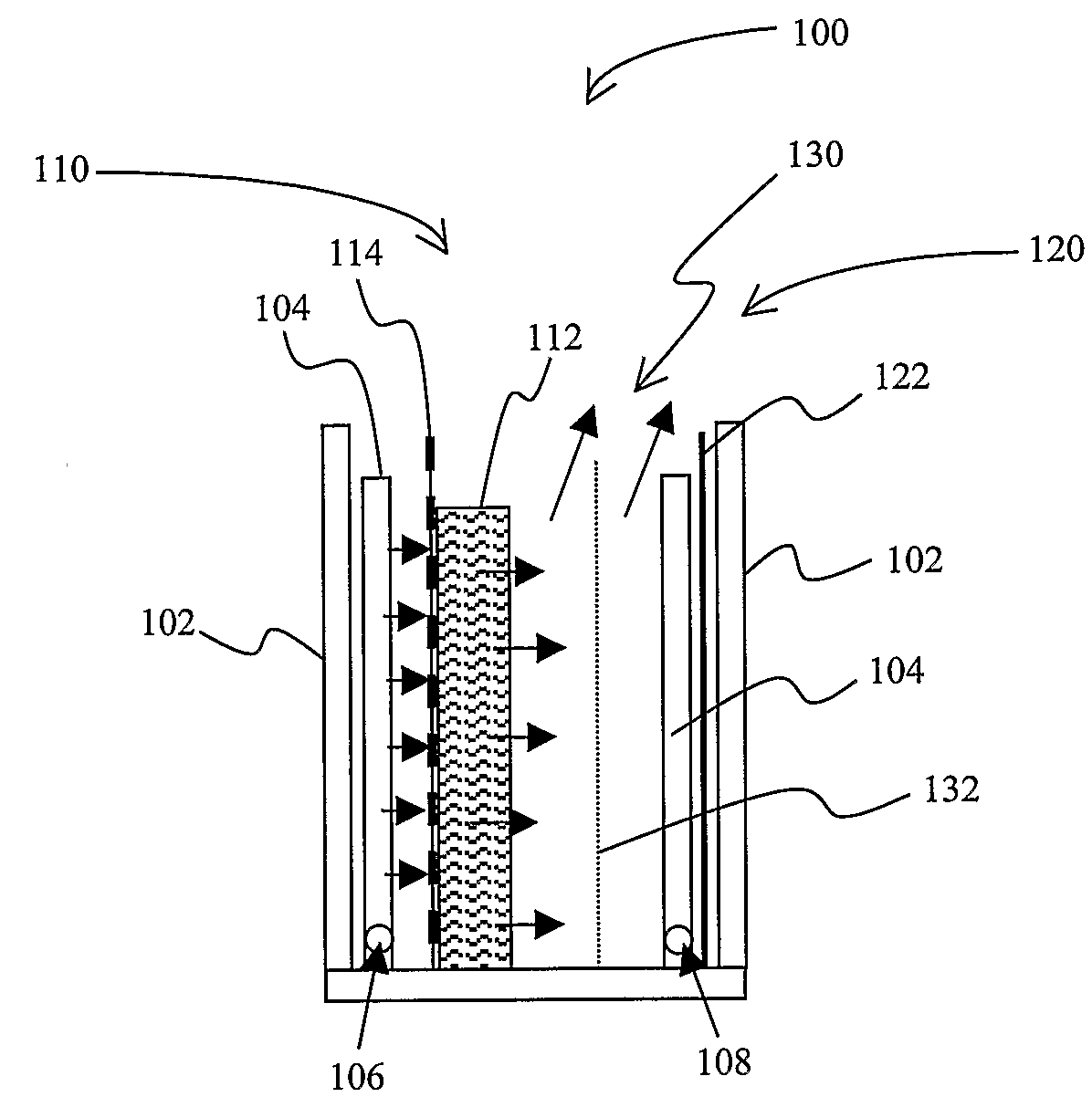

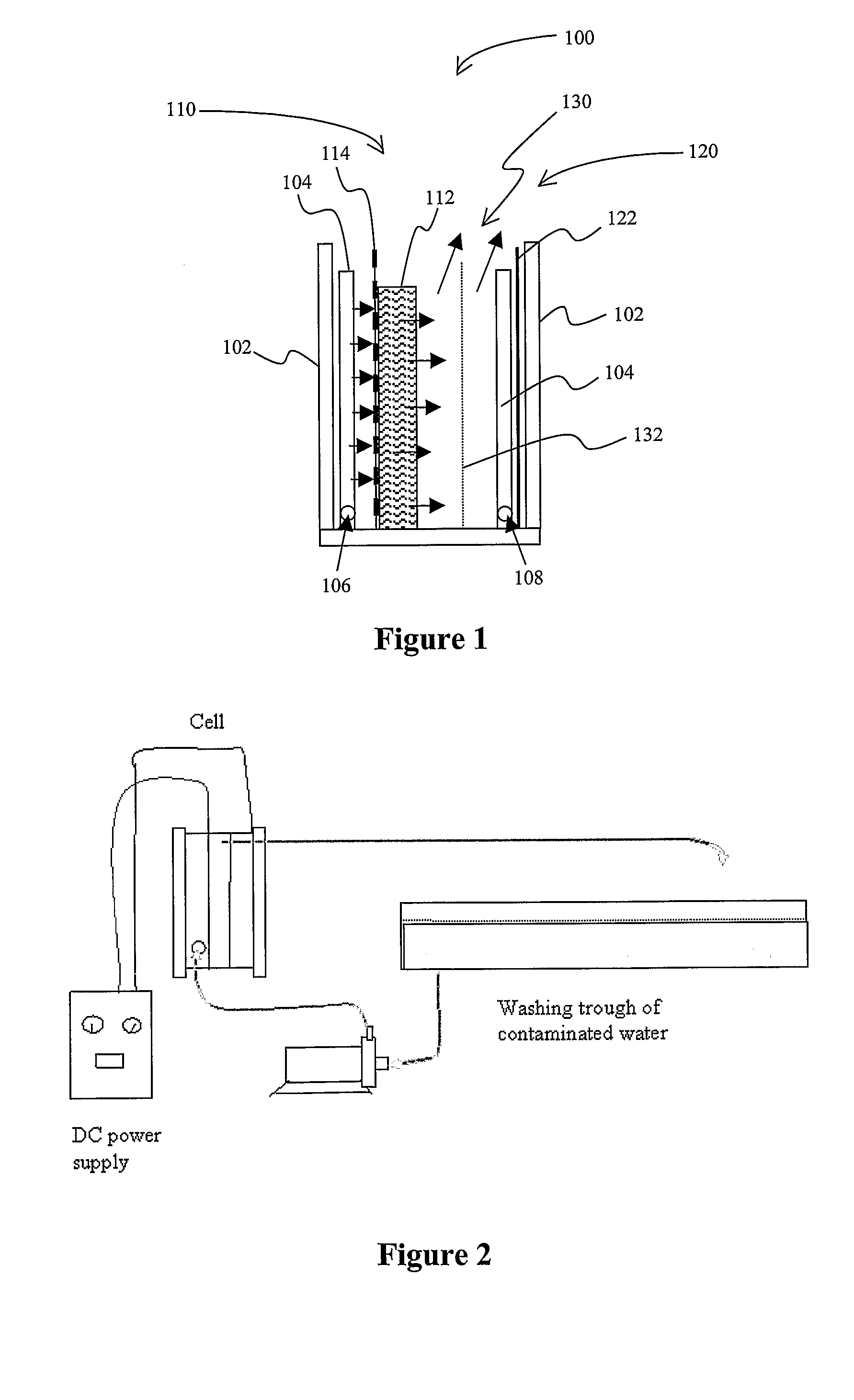

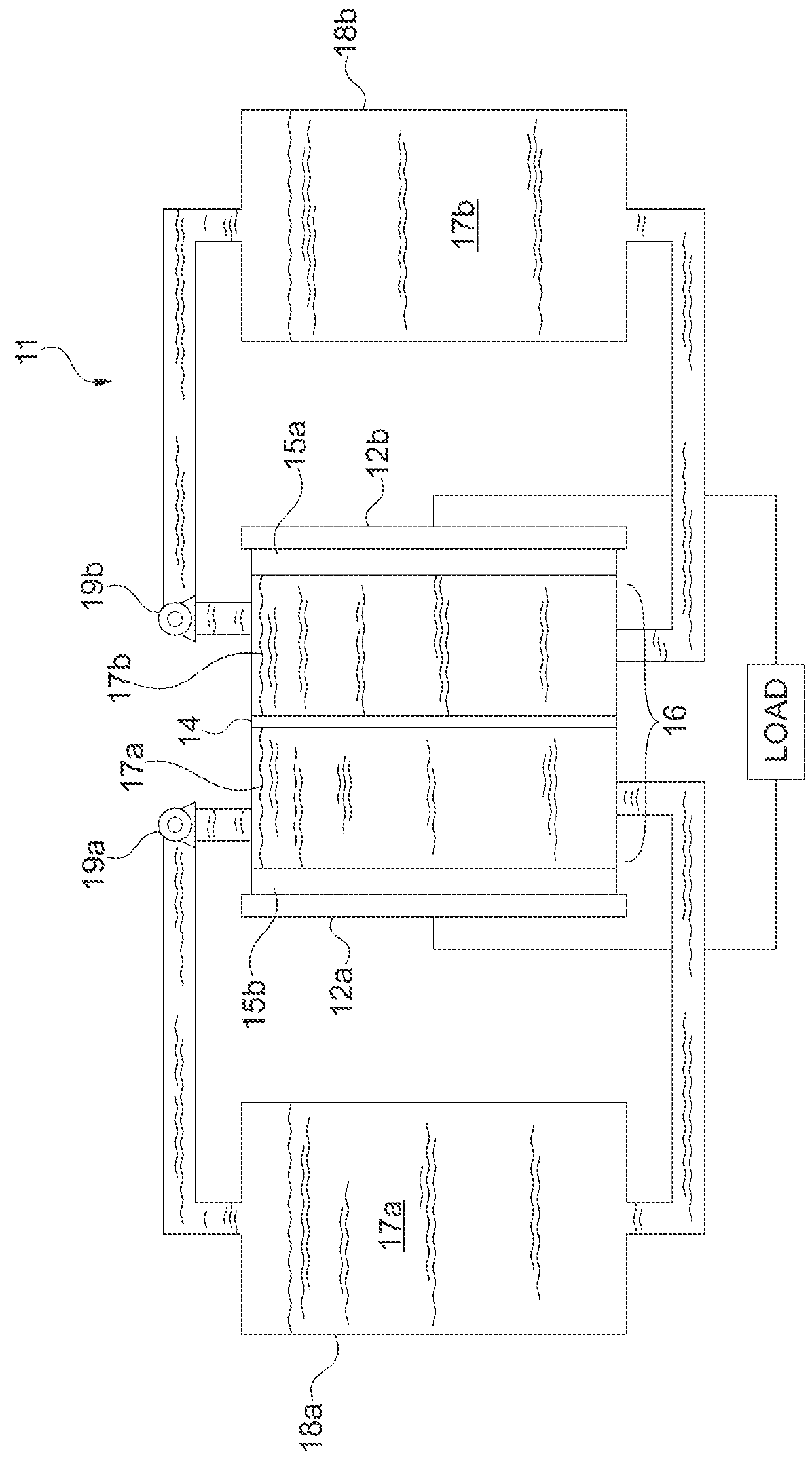

Methods and Apparatus for Generating Oxidizing Agents

InactiveUS20090152123A1Eliminate oxidative damageReduce and destroy contaminantElectrolysis componentsWater contaminantsNeutral phCarbon felt

Contemplated devices and methods include an electrolytic cell having a cathode and a carbon felt anode, wherein the carbon felt anode is configured as a flow-through anode for an aqueous solution in which a contaminant is dissolved or dispersed. The cell is operated at a current density that promotes formation of oxidizing species in neutral pH to thus destroy the contaminant and at a flow rate sufficient to prevent oxidative damage of the carbon felt.

Owner:APPLIED INTELLECTUAL CAPITAL

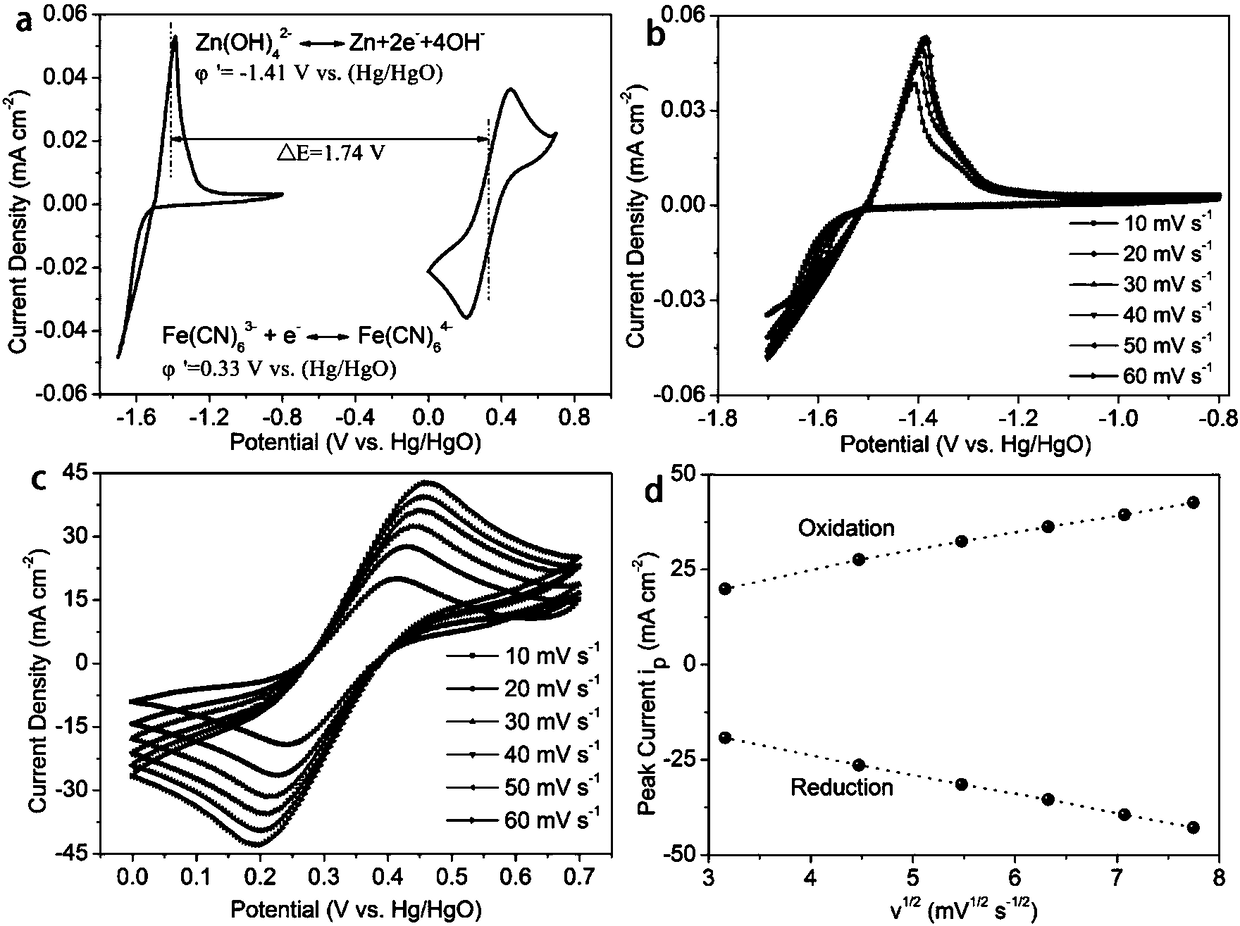

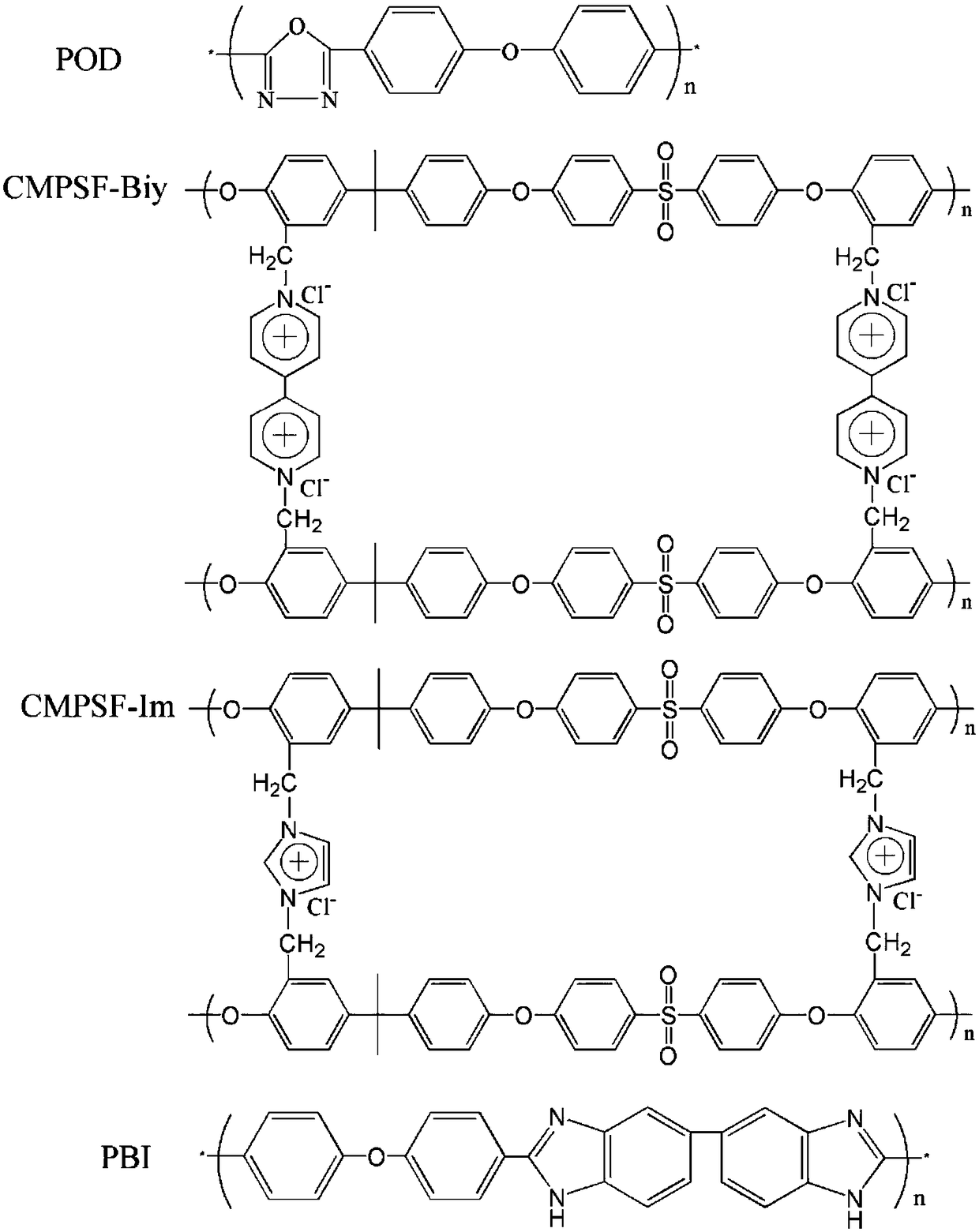

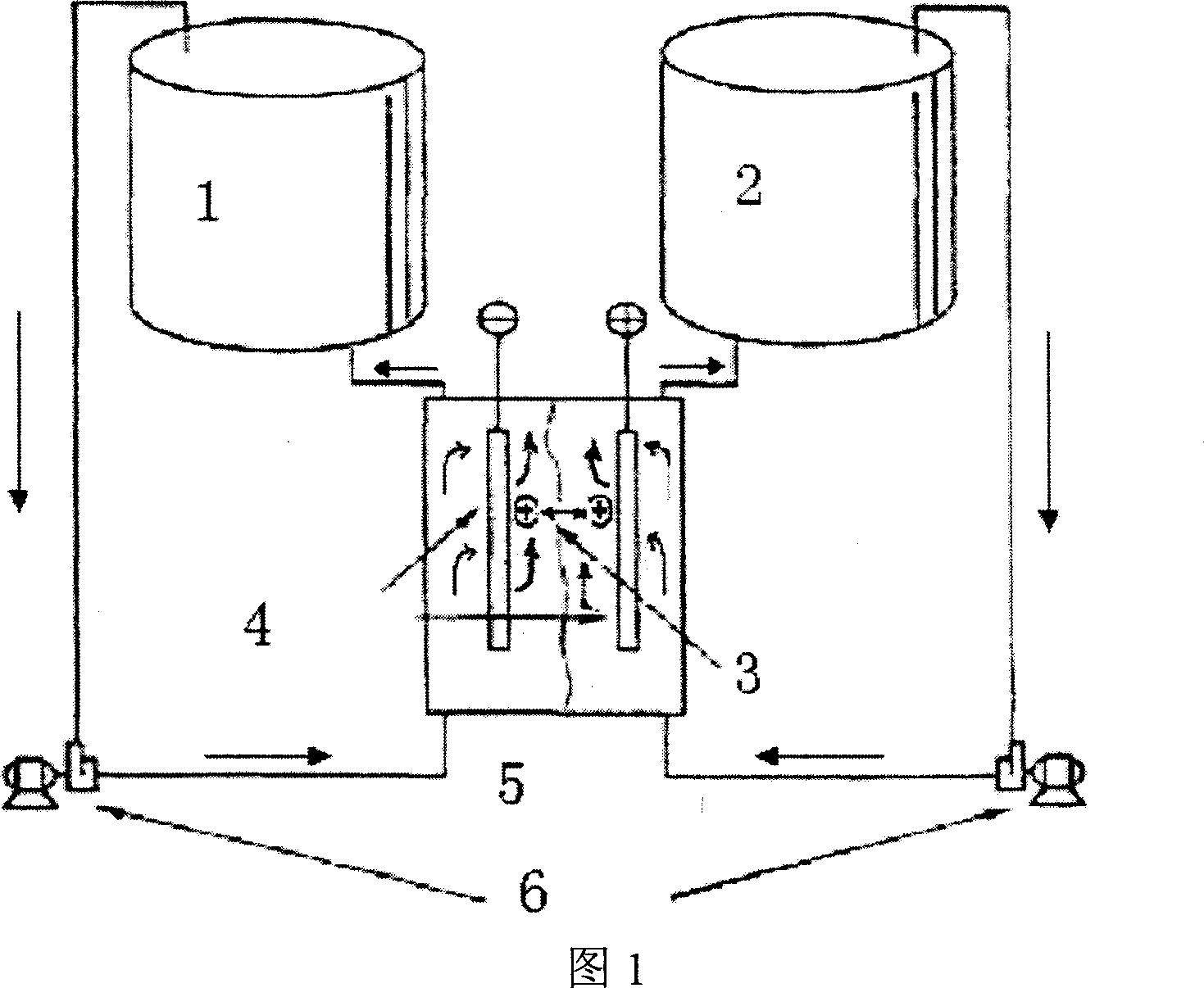

Alkaline zinc-iron flow battery

InactiveCN108461784ARich reservesLow costCell electrodesRegenerative fuel cellsHigh energyCarbon felt

The invention relates to an alkaline zinc-iron flow battery, wherein an ion conduction membrane is prepared from an aromatic polymer containing nitrogen heterocycle, electrodes are carbon felt or carbon paper, a positive electrode electrolytic solution is the mixed aqueous solution of ferrocyanide and strong alkali, a negative electrode electrolytic solution is the mixed aqueous solution of a zincsalt or / and a zinc oxide and strong alkali, the concentrations of the strong alkalis in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-10 mol / L, and the concentrations of the active substances in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-3 mol / L. According to the present invention, a class of the alkaline zinc-iron flow batteries with characteristics of high energy density, high power density and long service life are provided, wherein the performance of the batteries is comparable to or superior to the current mature all-vanadium flow batteries, and the batteries have good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High temperature furnace-grade curing carbon fiber thermal insulating material and production technology thereof

ActiveCN101550017AImprove insulation effectSimple process, energy saving and environmental protectionCarbon fibresFurnace liningsFiberCarbon fibers

The invention discloses a high temperature furnace-grade curing carbon fiber thermal insulating material having simple technology and small coefficient of heat conductivity, and a production technology thereof, characterized in that the material is made of the carbon fiber by the steps of the preparation of a preform, densification, hot-vibration purification and machine processing; the invention is free from the processes of bonding, immersion, curing and charring in the preparation of the preform and has simple technology, great energy-saving property and environmental protection ability, the carbon fibers inside the preform are distributed in a crisscross pattern, strong in cohesive force, stable in structure and free from delamination, the coefficient of heat conductivity is not larger than 0.8 W / mK and the thermal insulating property is excellent; the product consists of the high-strength carbon fiber and carbon matrix and has outstanding performances such as high specific strength, good high temperature resistance, corrosion resistance and thermal insulating property, in addition, the product integrates the fire resistance and the thermal insulating property, can bear certain loads, and is an ideal upgraded product in taking the place of related high temperature furnace-grade graphite products and soft carbon felt.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Iron composite/halogen electrochemical system for flow electric storage

InactiveCN101047261AReduce capacityImprove energy conversion efficiencyElectrolyte moving arrangementsCell electrodesElectricityHalogen

A Fe-matched matter-halogen electrochemical system used on liquid flow energy storage is prepared as separating positive / negative electrode electrolyte by positive ion exchange film and storing said electrolyte in external container, generating charge / discharge process by making oxidation / reduction reaction on inert carbon felt electrode through pump stream via battery, applying soluble Fe(III) / Fe(II) -matched matter oxidation / reduction electric pair as negative electrode and applying halogen oxidation / reduction electric pair as positive electrode.

Owner:DALIAN RONGKE POWER

Improved perfluorinated membranes and improved electrolytes for redox cells and batteries

InactiveCN101257121AElectrode manufacturing processesRegenerative fuel cellsSupporting electrolytePolyolefin

The invention relates to an electrode used for vanadium redox flow battery, a preparation of electrolyte and a rebalance method. The preparation comprises thermally sticking a carbon felt or agraphite felt to at least one side of a carbon-filled polyolefine substrate. A flat, low-resistance electrode having good mechanical property can be obtained by the preparation. The preparation includes dissolving at least one vanadium oxide powder to a supporting electrolyte and optional electrolysis steps. The preparation needs no toxic SO2 gas, by separating the power dissolving stage and the electrolysis stage, problems related to suspension powder electrolysis are eliminated. The rebalance method comprises partially reducing a half-cell electrolyte in the cathode chamber of an electrolytic cell.

Owner:NEWSOUTH INNOVATIONS PTY LTD

Method for manufacturing integral heater for carbon/carbon polycrystalline silicon ingot furnace

InactiveCN101905977AReduce consumptionMeet production requirementsSilicon compoundsCarbon compositesCarbonization

The invention discloses a method for manufacturing an integral heater for a carbon / carbon polycrystalline silicon ingot furnace. The method comprises the following steps of: winding carbon cloth or needled carbon felts on which resin is painted on a steel mold core layer after layer to obtain a prefabricated body; performing pressurized curing, carbonization and chemical vapor deposition densification treatment until the density of a heater product is more than or equal to 1.50 g / cm<3>; performing machining to achieve a shape and a size required by a customer; and performing high temperature purification treatment through a chemical vapor deposition (CVD) silicon carbide protective layer to obtain the integral heater for the carbon / carbon composite polycrystalline silicon ingot furnace. Compared with the conventional carbon material heater, the raw material consumption of the integral heater is lowered by over 90 percent; and a CVD surface deposition silicon carbide protective layer is formed on the surface of the product, so that corrosion of silicon steam, oxygen and the like on the product is blocked and service life is prolonged by at least more than one time.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Method for in-situ synthesis of SiC nanowires modified carbon/carbon composite preform by sol-gel method

The invention relates to a method for in-situ synthesis of a SiC nanowires modified carbon / carbon composite preform by a sol-gel method. Since a silica sol-gel system with a porous microstructure is firstly obtained by the sol-gel method, the contact area of the reaction is increased to a greater extent, and the grown nanowires have certain directionality, which is conductive to improving the mechanical properties of materials. The nanowires are immersed in a 2D carbon felt, the obtained silicon source capable of generating SiC nanowires is uniformly dispersed and has low decomposition temperature, the grown nanowires can be stably and uniformly dispersed in the carbon felt, and the efficiency of the densification can be greatly improved. The carbon sources provided by isothermal CVI process deposition natural gas and capable of generating SiC nanowires are reacted with silicon source to generate nanowires and a part of carbon sources are formed into pyrolytic carbon and coated on the surface of nanowires, and the phenomena of the falling, growing and breakage of nanowires occurring in the course of obtaining high-density C / C composite material by the subsequent densification are effectively avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and electrochemical device for low environmental impact lithium recovery from aqueous solutions

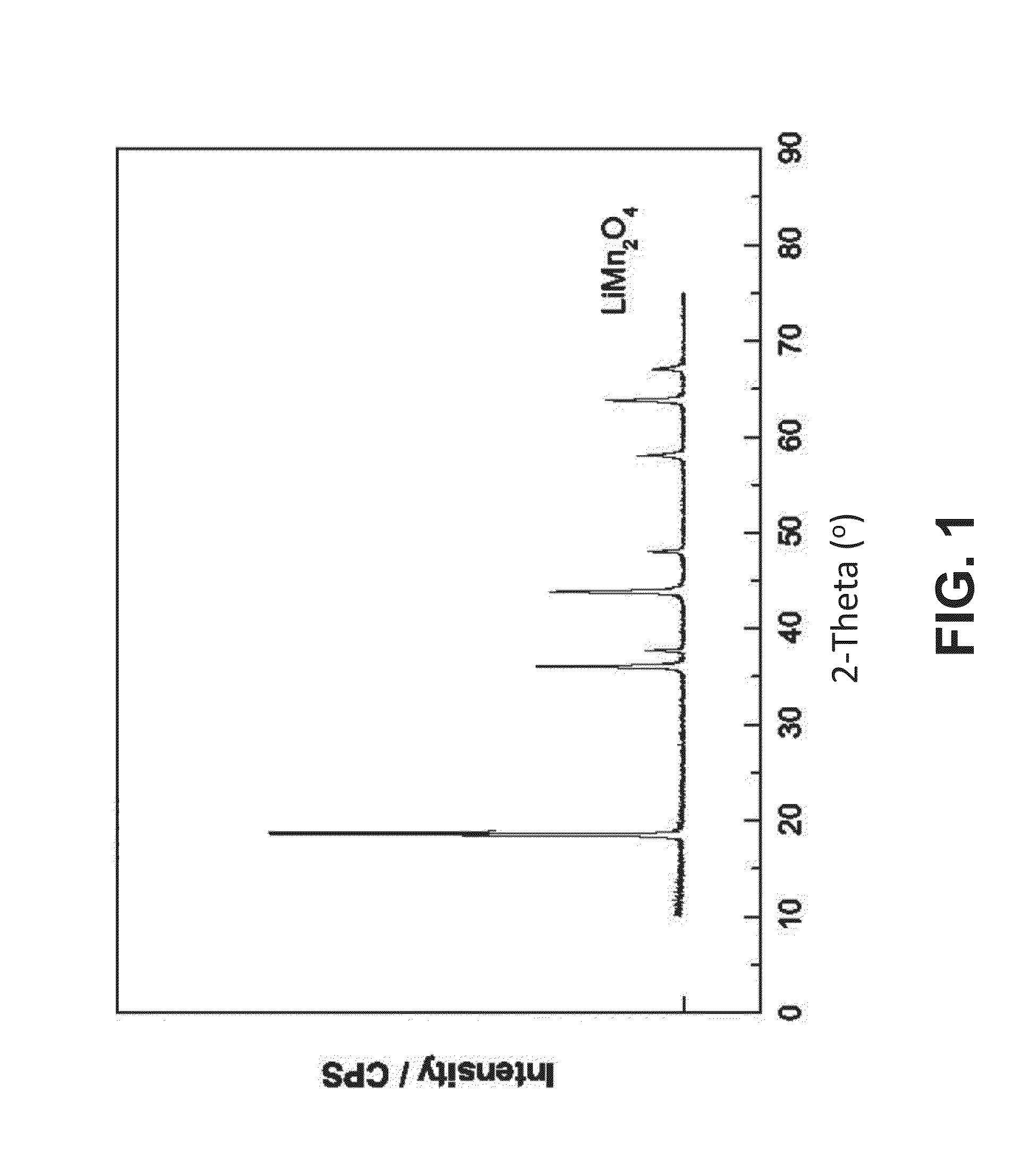

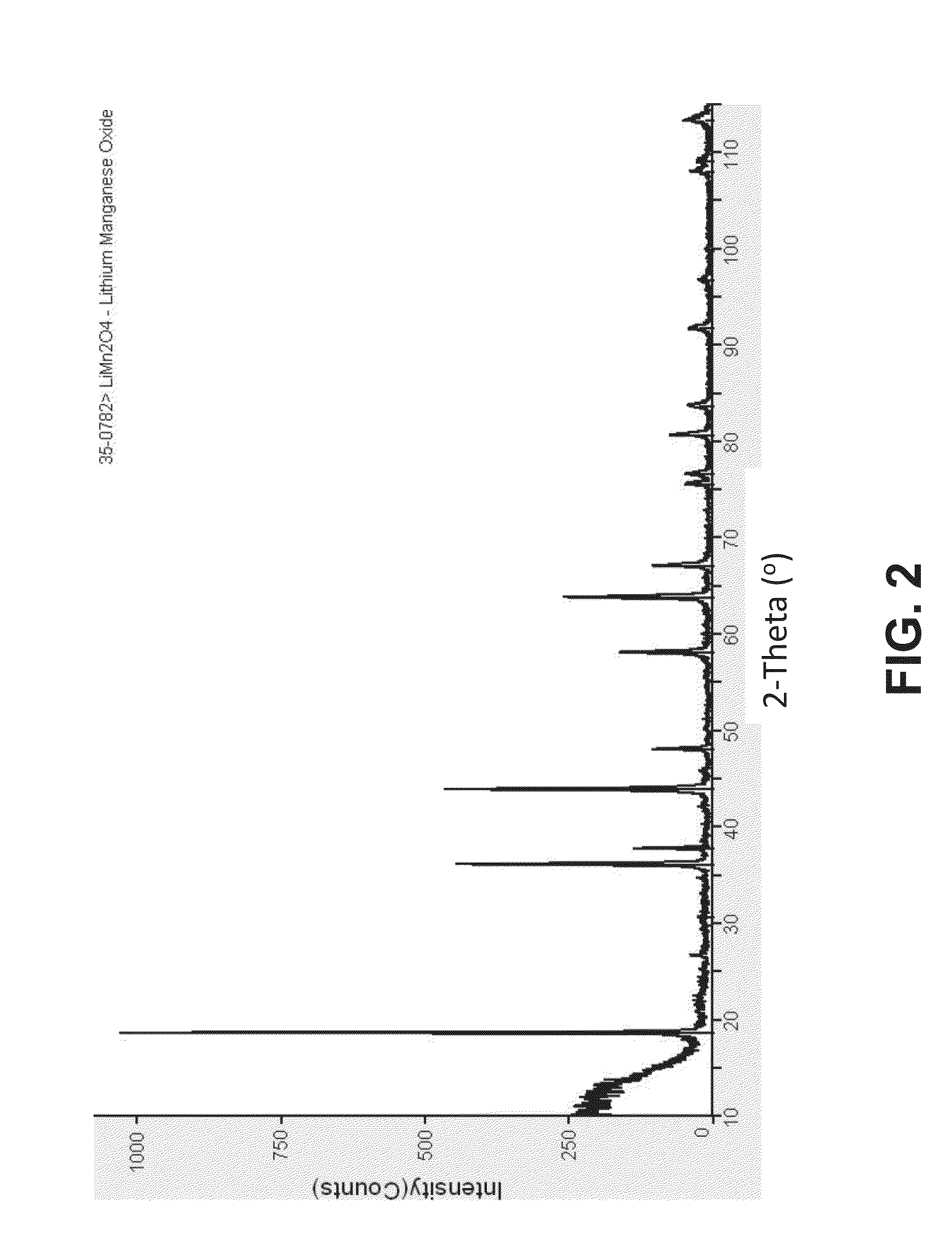

InactiveUS20140076734A1Efficient and low environmental impactHigh selectivityCellsMachining electrodesElectrochemical responseCarbon felt

An efficient and low environmental impact method is disclosed for the recovery of lithium from aqueous solution, for example, brines from high altitude salt lakes. The method comprises the use of an electrochemical reactor with electrodes which are highly selective for lithium, where lithium ions are inserted in the crystal structure of manganese oxide in the cathode, and extracted from the crystal structure of manganese oxide in the anode. Also disclosed are three-dimensional carbon electrodes embedded in manganese oxides formed by impregnating a porous support, for example a carbon felt, with a manganese oxide / carbon black slurry.

Owner:CONSEJO NAT DE INVESTIGACIONES CIENTIFICAS Y TECH CONICET

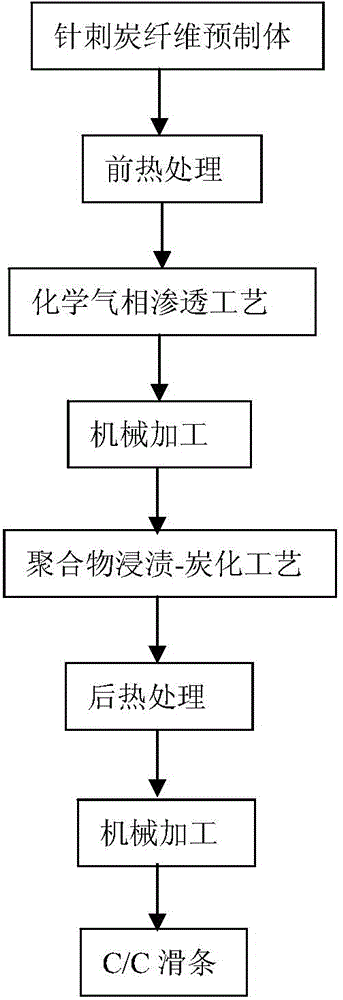

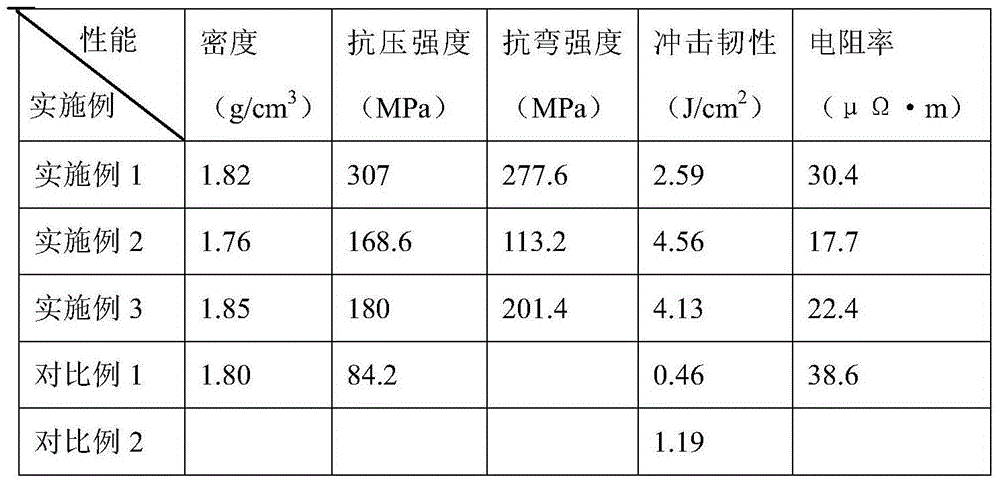

Preparation method of C/C (carbon/carbon) composite material slider for pantograph

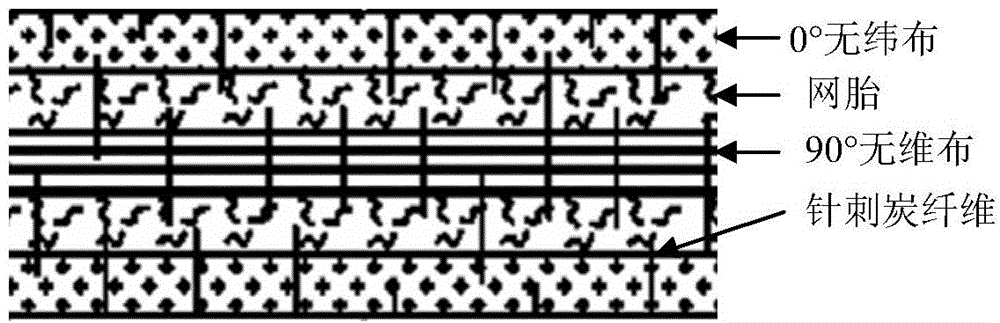

The invention relates to a preparation method of a C / C (carbon / carbon) composite material slider for a pantograph, and belongs to the technical field of preparation of materials for electric locomotives. The preparation method comprises the following steps of: according to the weight ratio of carbon cloth and carbon felt of (7.5-9): (3-1), circularly overlapping single layer 0-degree weft-free carbon cloth, carbon fiber web tire, 90-degree weft-free carbon cloth and carbon fiber web tire sequentially, and introducing carbon fiber bundles in the direction vertical to the spread by a relay type acupuncture method to form a 2.5D carbon fiber acupuncture integrated felt with density of 0.3-0.6g / cm<3>; performing high-temperature pre-treatment at 1500-2100 degrees centigrade, and performing chemical vapor deposition pyrolytic carbon treatment until obtaining the C / C composite material with the density of 1.4-1.6g / cm<3>; machining according to predetermined size, performing polymer dipping-carbonizing treatment and graphitization treatment sequentially, and then machining according to designed size, so as to obtain a product. The process is simple, a product has excellent mechanical and electrical properties, and the industrial application is prompted.

Owner:CENT SOUTH UNIV

Durable super-hydrophobic gas diffusion layer for fuel cell

InactiveCN108550876AGood effectImprove running stabilityElectrolyte holding meansFiberPorous substrate

The invention provides a durable super-hydrophobic gas diffusion layer for fuel cell. The durable super-hydrophobic gas diffusion layer comprises a conductive porous base material and a micropore layer; the conductive porous base material is one of carbon fiber paper, carbon fiber non-woven cloth, carbon felt, a foamed metal plate and a metal net through the hydrophobic treatment; and the micropore layer contains the hydrophobic microsphere. The hydrophobic treatment is the conventional treatment method, such as soaking the conductive porous base material in the fluororesin, and then performing sintering treatment; the micropore layer is formed by coating the conductive paint on the conductive porous base material surface through scrap-coating and further performing the sintering treatment; the conductive paint is composed of conductive agent, hydrophobic microsphere and the adhesive, wherein the hydrophobic microsphere is the glass microsphere or polytetrafluoroethylene microsphere with high sphere degree. By adding the hydrophobic microsphere in the conductive paint, the hydrophobicity is improved, and the sphericity enables the micropore layer to be smooth, thereby effectively preventing a catalyst from immersing, and then the durability of the gas diffusion layer of the fuel cell is improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

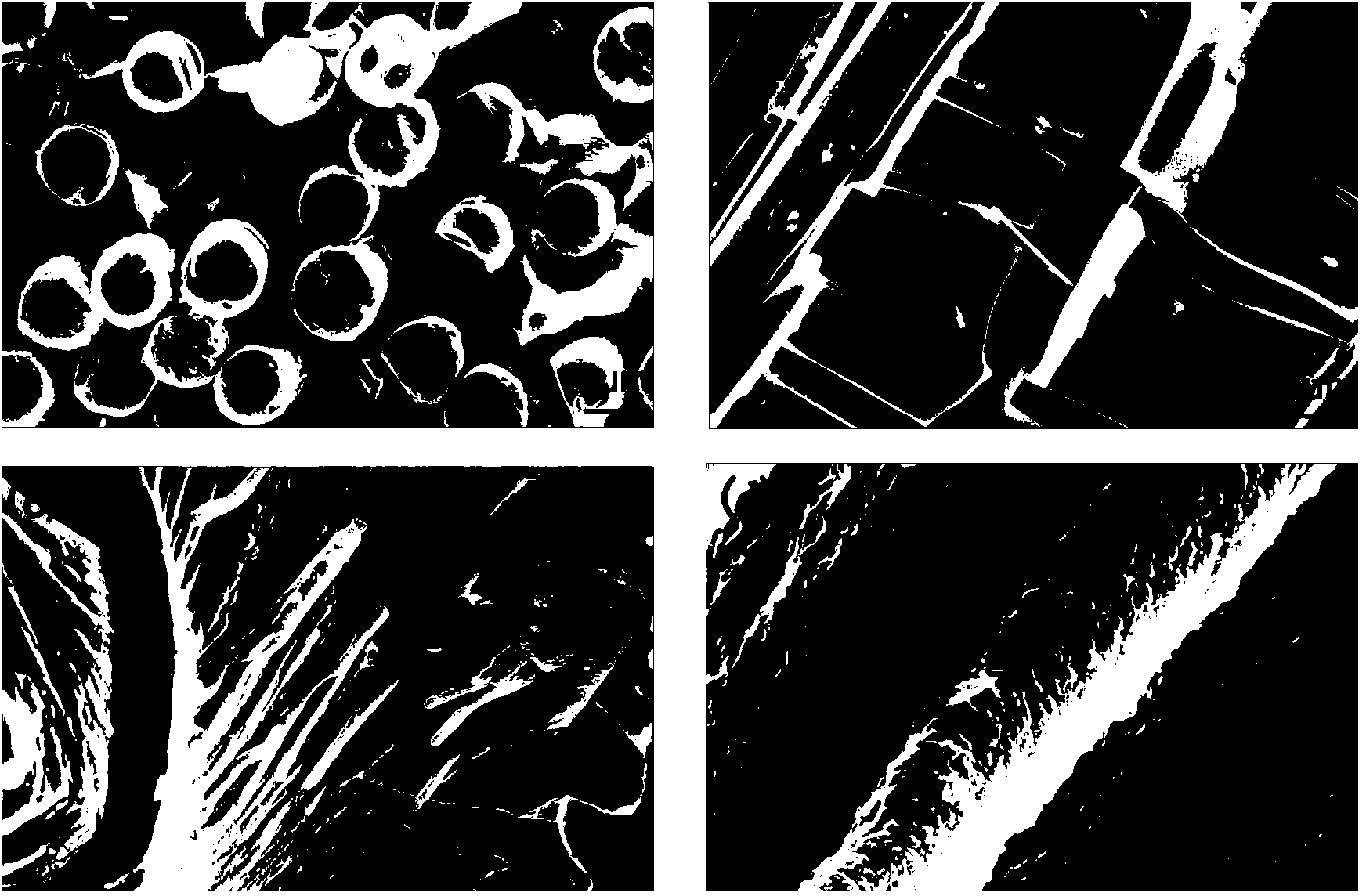

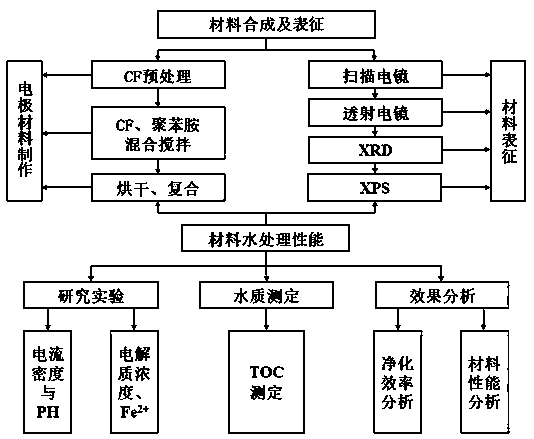

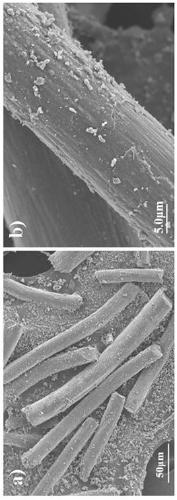

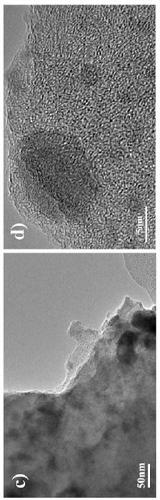

Preparation method of electro-Fenton cathode material based on carbon felt-supported iron nanoparticles and application of electro-Fenton cathode material in degradation of organic pollutants in water

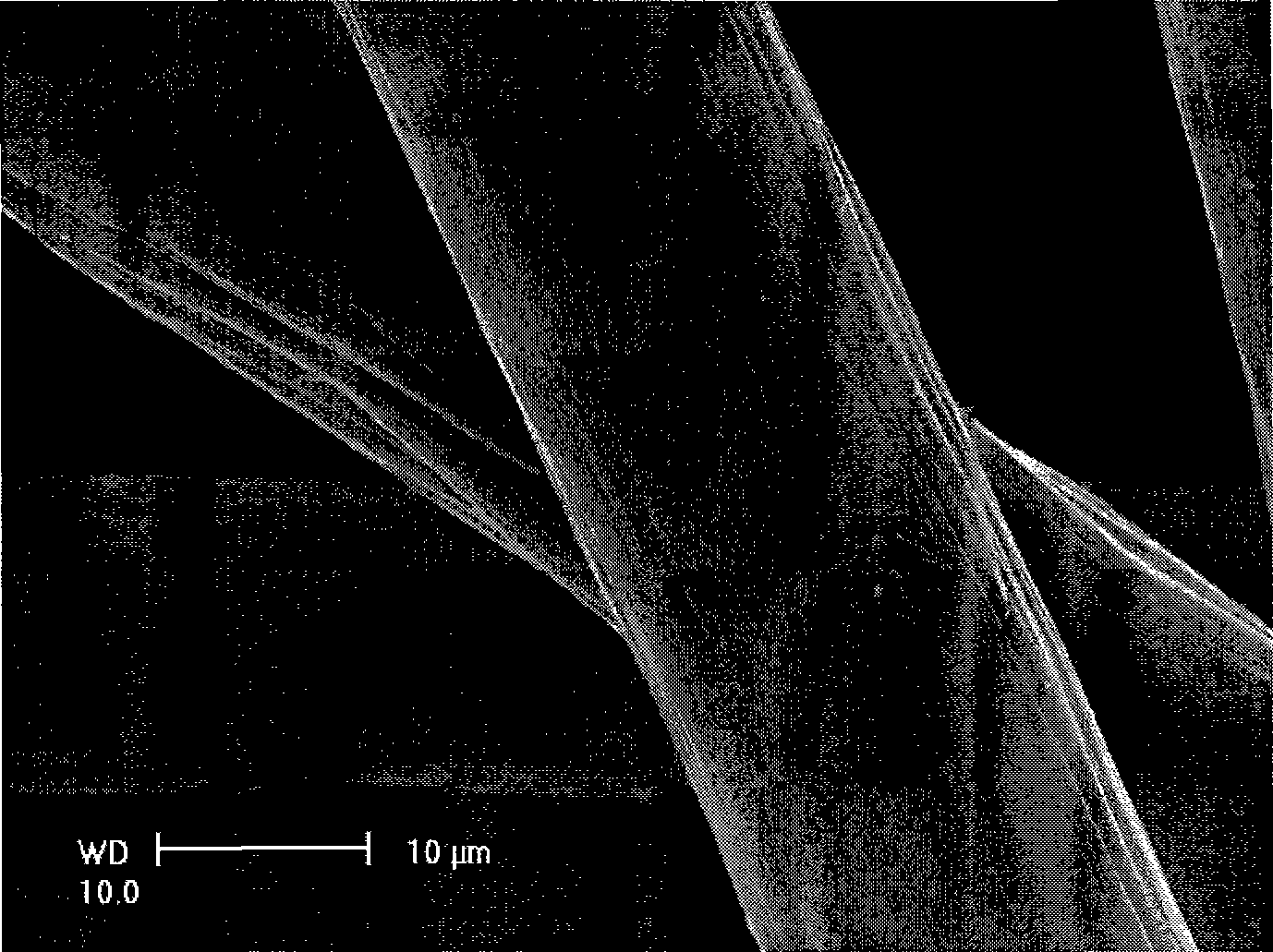

ActiveCN109896598ALarge specific surface areaImprove processing efficiencyWater contaminantsWater/sewage treatment by oxidationFiberCarbon fibers

The invention discloses a preparation method of an electro-Fenton cathode material based on carbon felt-supported iron nanoparticles and application of the electro-Fenton cathode material in the degradation of organic pollutants in water, and belongs to the technical field of preparation of electro-Fenton cathode materials and electro-Fenton water treatment. The preparation method and the electro-Fenton cathode material are characterized in that polyaniline is supported on a pure carbon felt through electrochemical deposition, iron particles are supported to obtain an iron carbon-doped porouscomposite carbon fiber material; a carbon felt acting as a cathode material can be applied to an electro-Fenton water treatment apparatus, air is charged in, and therefore, hydroxyl radicals are generated by catalysis at a cathode, and organic pollutants in water can be degraded. With the characteristic fully utilized that a carbon fiber has large specific surface area, the preparation method herein has the advantages of high treatment efficiency and greenness and the like, and has economic and social benefits for the field of treatment of industrial printing and dyeing waster and groundwater.

Owner:ZHEJIANG NORMAL UNIVERSITY

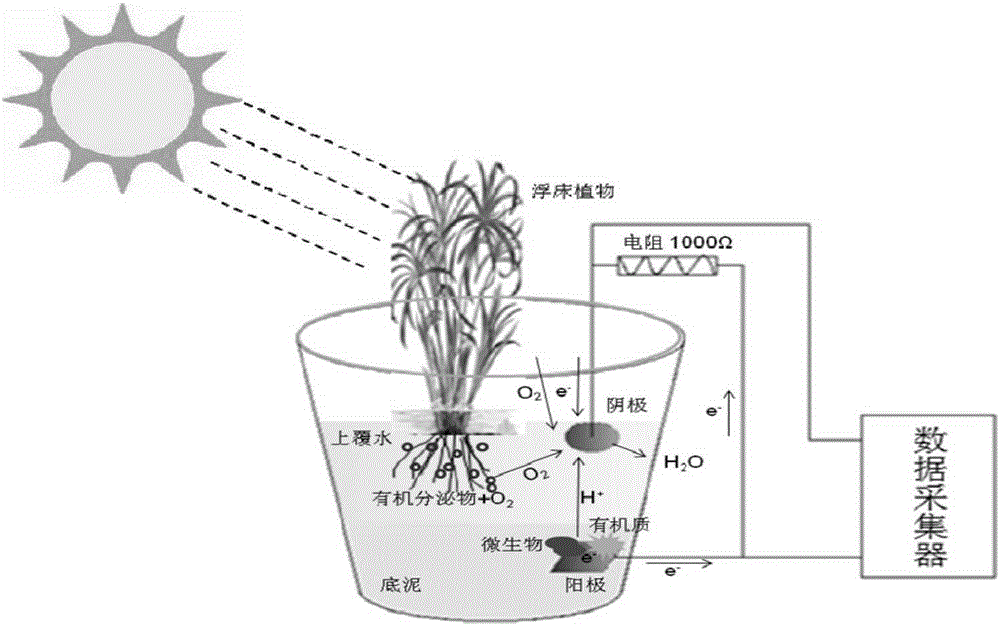

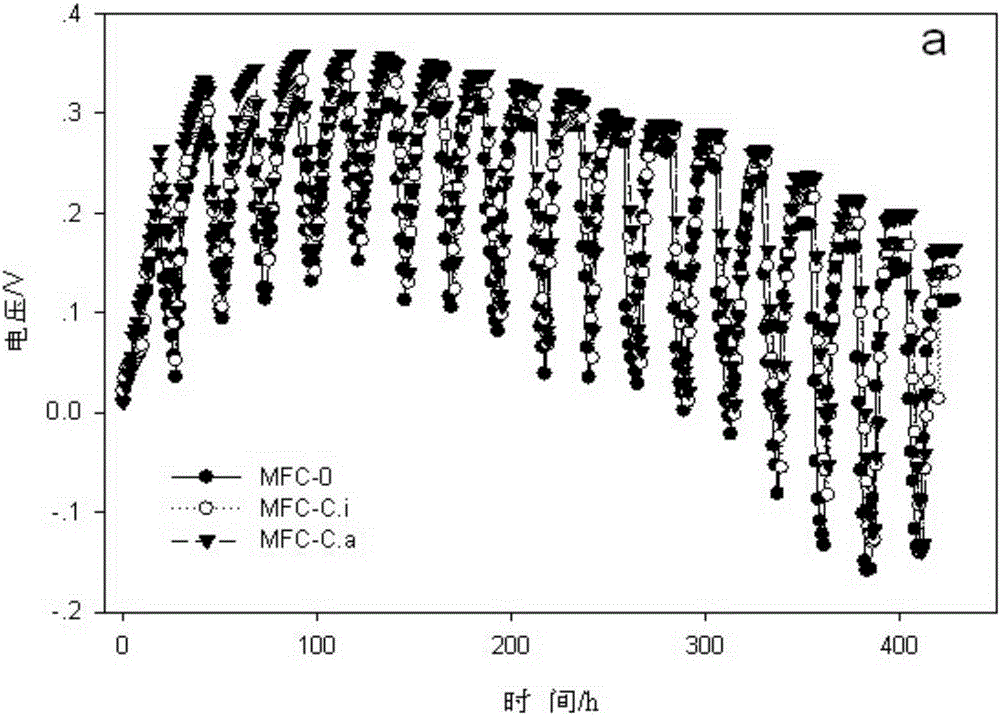

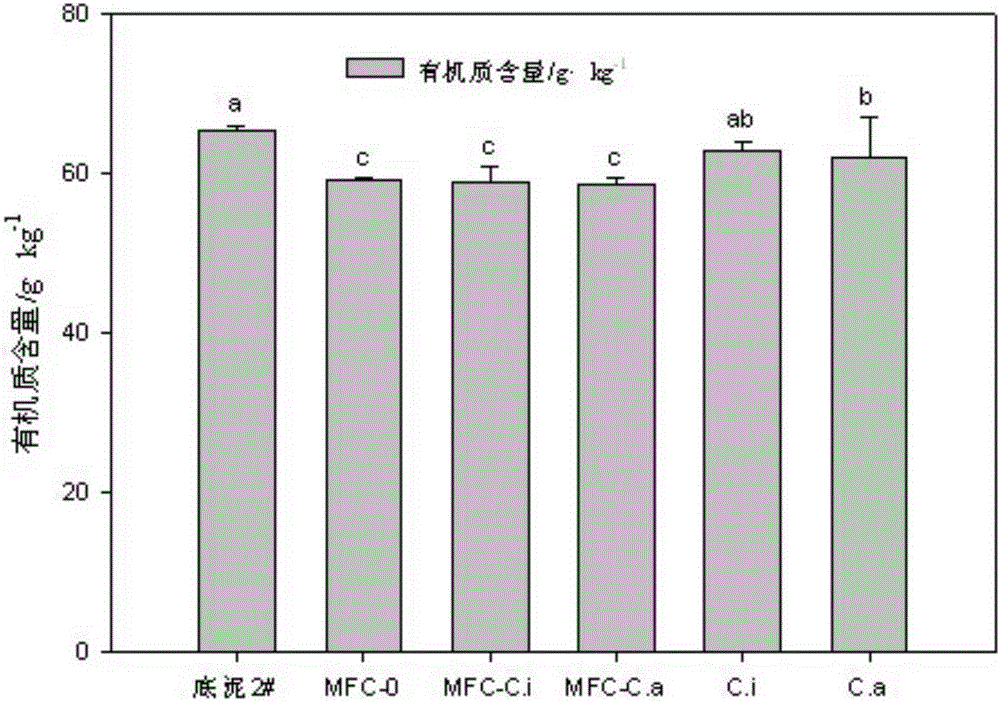

Floating-bed plant coupling sediment microbiological fuel cell water purification method

InactiveCN105236576AReduce the content of organic matterReduce pollutionWater resource protectionWater contaminantsCarbon feltCathode

The present invention relates to a microbial fuel cell water purification method, particularly to coupling of ecological floating islands and microbial fuel cells, wherein the method can be used for ecological restoration of contaminated river courses, lakes and parks, residential districts and other landscape water bodies, and belongs to the water body pollution remediation in environmental projects. According to the present invention, the black and odor river sediment or city sludge is adopted as the bottom matter, the carbon felt is adopted as the anode, and the graphite disc is adopted as the cathode to construct SMFC; floating-bed plants are introduced, and are planted on the overlying water body by using the floating body to form the floating-bed plant-sediment microbiological fuel cell (P-SMFC); with the combination of the floating-bed plant root system secretion characteristics, the root system secretions provide nutrients for the rhizospheric microorganisms; and the root system radially secretes oxygen to make the rhizospheric zone form a lot of aerobic zones, and the oxygen secreted by the plant root zone can spread to the SMFC cathode, such that the cathode region dissolved oxygen concentration is increased, and the restoration performance of the SMFC on the sediment pollution and the overlying water pollution are improved.

Owner:SOUTH CHINA UNIV OF TECH

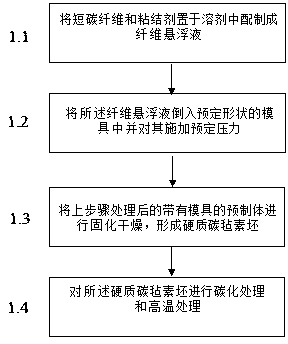

Preparation method of hard carbon felt

The invention discloses a preparation method of a hard carbon felt, and the method is mainly as follows: short carbon fiber is dispersed in a solvent by a dispersing agent, the dispersed short carbon fiber is poured into a mold of a certain size, the solvent is removed, and the hard carbon felt is obtained by curing demolding, eventual carbonization and high temperature treatment. The hard carbon felt prepared by the method has the following advantages: carbon felt density is low and controllable, heat insulation effect is good; the product is in an overall structure, size can be adjusted according to the specific requirements, and the density is uniform; the service life is long, loss under the conditions of high temperature is low, volatile components and other impurities unfavourable to products are not produced.

Owner:LIAOYUAN YIDA CARBON

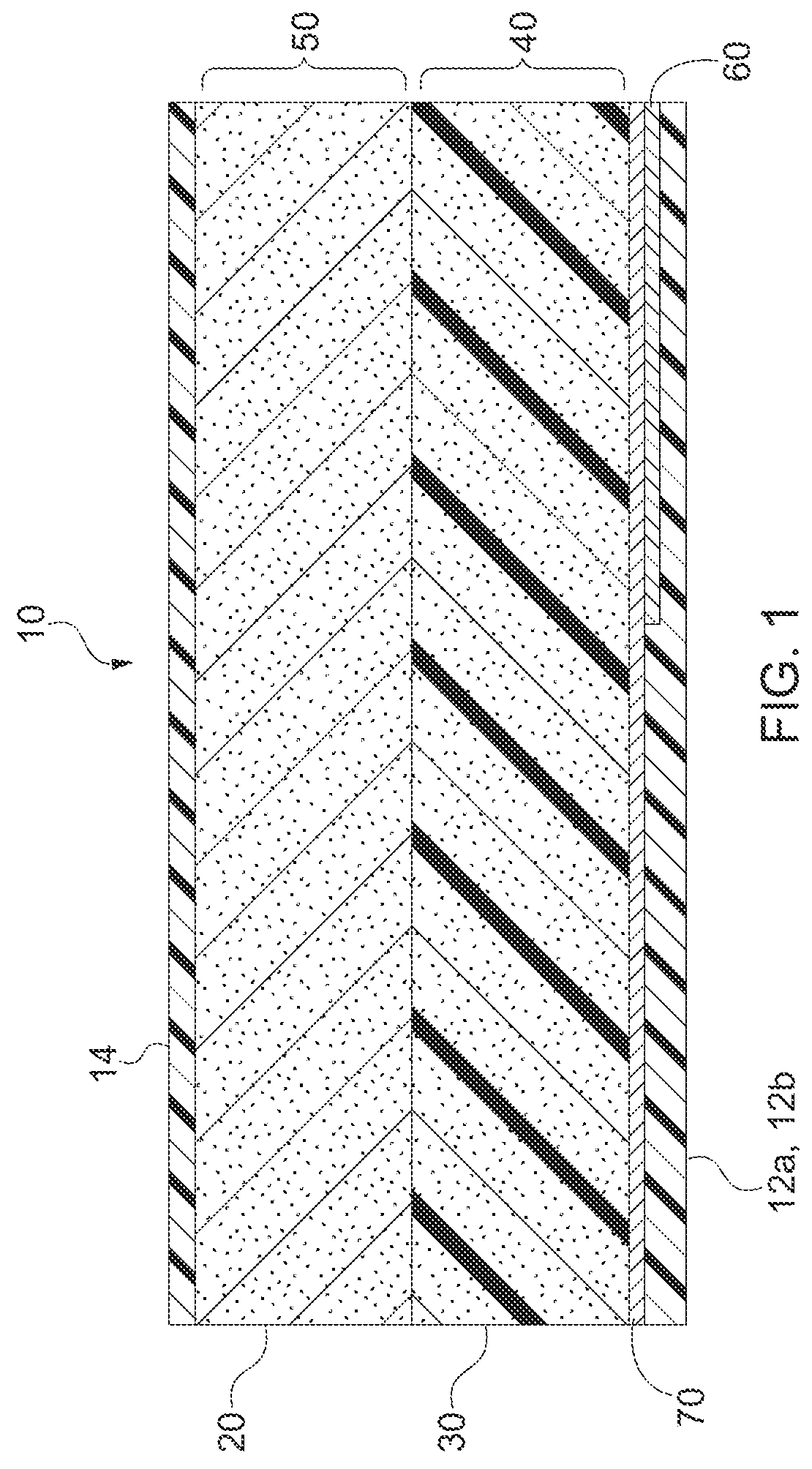

Composite electrode for flow battery

InactiveUS20160036060A1Less compressibleReduce feeding pressureCell electrodesRegenerative fuel cellsState of artComposite electrode

A composite electrode adapted for use in a flow battery stack system has a carbon felt stratum forming a semi-porous reaction zone and a carbon foam stratum forming a porous flow path zone. The composite electrode is less compressible than prior art electrodes having similar conductivity and specific surface areas. Flow battery stack systems employing the composite electrode operate with lower feed pressures, experiences a lower pressure drops across the electrodes, and realize improved electrical resistivity. Alternative embodiments provide electrical conductive elements and a current collector disposed on a surface of the composite electrode.

Owner:CONCURRENT TECH

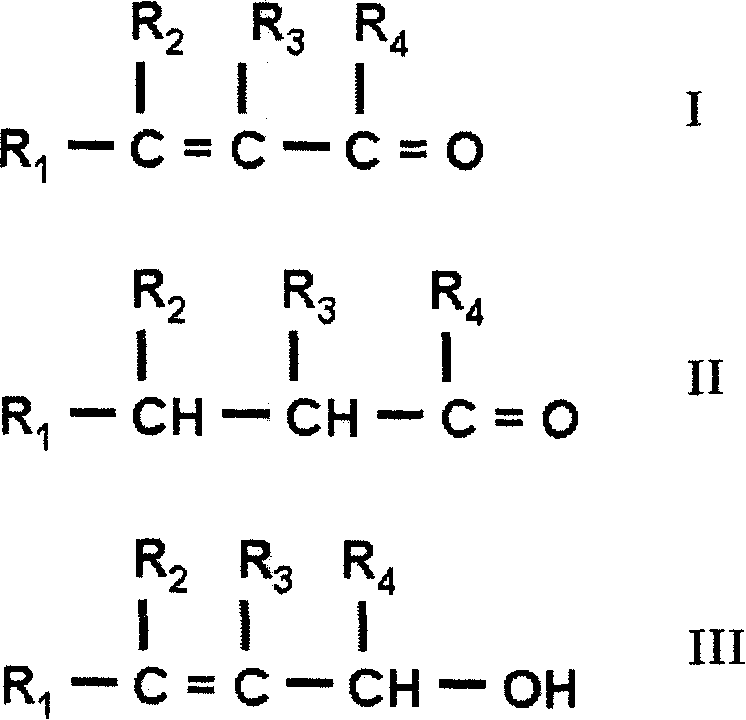

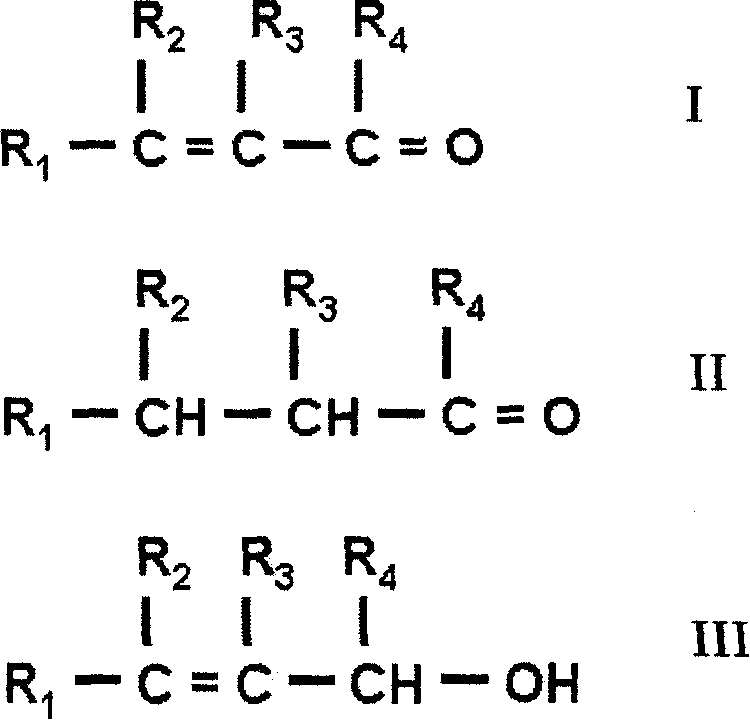

Selectivity liquid phase hydrogenation catalyst and preparation method and use thereof

InactiveCN101185904AReduce lossEasy accessOrganic compound preparationHydroxy compound preparationCarbon fibersCarbon felt

The invention relates to a catalyst, which is applicable to the selective liquid phase catalytic hydrogenation of Alpha, Beta-unsaturated carbonyl compounds to make corresponding unsaturated carbonyl compounds or unsaturated alcohol, being especially suitable for the selective hydrogenation of citral to make citronellal and / or citronellol. The catalyst of the invention is a metal component loaded on a structured composite nano carbon fiber, wherein, the metal component is selected from one of or a plurality of nickel, ruthenium, rhodium, palladium and platinum. The components of the catalyst are: 1) structured substrate, such as metal foam, honeycomb ceramic, carbon felt and ceramic fiber; 2) nano material coating, such as nano carbon fiber; 3) metal active component, such as nickel, ruthenium, rhodium, palladium and / or platinum. The invention effectively avoids deep reaction, thus enhancing the target product selectivity. The catalyst is prefabricated into a variety of shapes and installed in a reactor, so that the catalyst, the liquid phase reactants and the solution are easy to be separated, thus meanwhile reducing the loss of the catalyst.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

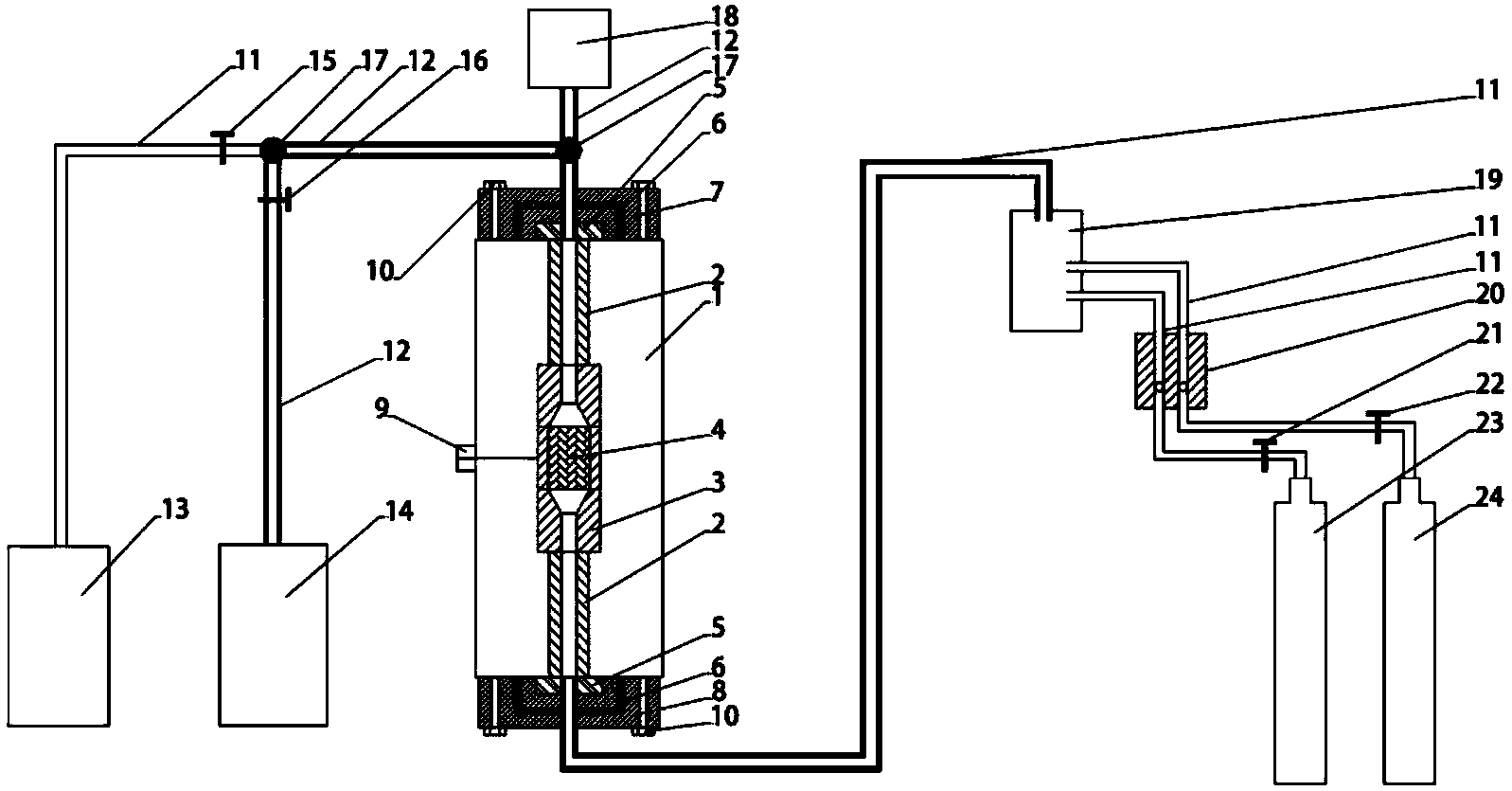

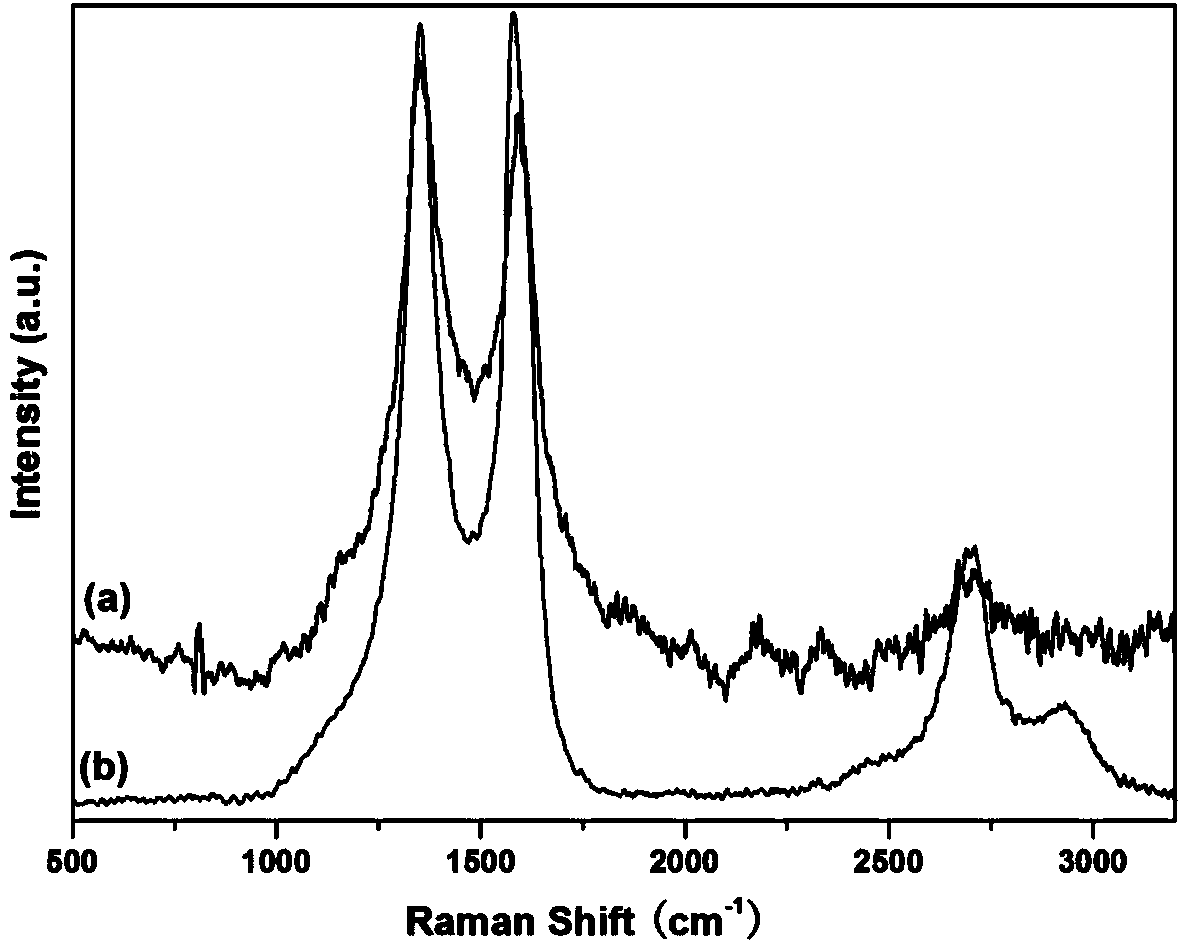

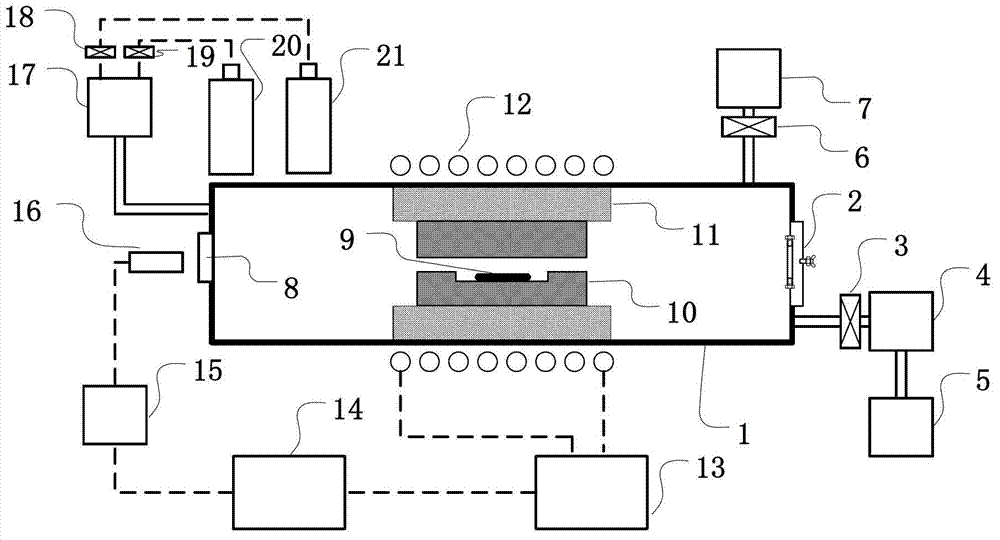

System and method for preparing graphene by means of SiC thermal cracking

The invention relates to a system and a method for preparing graphene by means of SiC thermal cracking. The system comprises a gas-refining quartz tube serving as a vacuum cavity, an SiC substrate, an induction heating graphite boat and a carbon felt heat preservation layer, wherein the SiC substrate is arranged in the middle of the vacuum cavity and in a graphite boat sample groove. The graphite boat is arranged in the middle of the carbon felt heat preservation layer. The carbon felt heat preservation layer is closely attached to the wall of the vacuum cavity to form a hollow structure. One end of the vacuum cavity is provided with a vacuum cavity door used for opening and closing the vacuum cavity. A vacuumizing gas circuit formed by sequentially connecting a baffle valve, a molecular pump and a mechanical pump is arranged below the vacuum cavity door and used for vacuumizing the vacuum cavity according to needs. The other end of the vacuum cavity is provided with an infrared detection window made of glass permeable by infrared rays. The system and the method for preparing graphene by means of SiC thermal cracking have the advantages that high-quality graphene can be prepared at the high barometric-pressure state (0.1-1 barometric pressure).

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

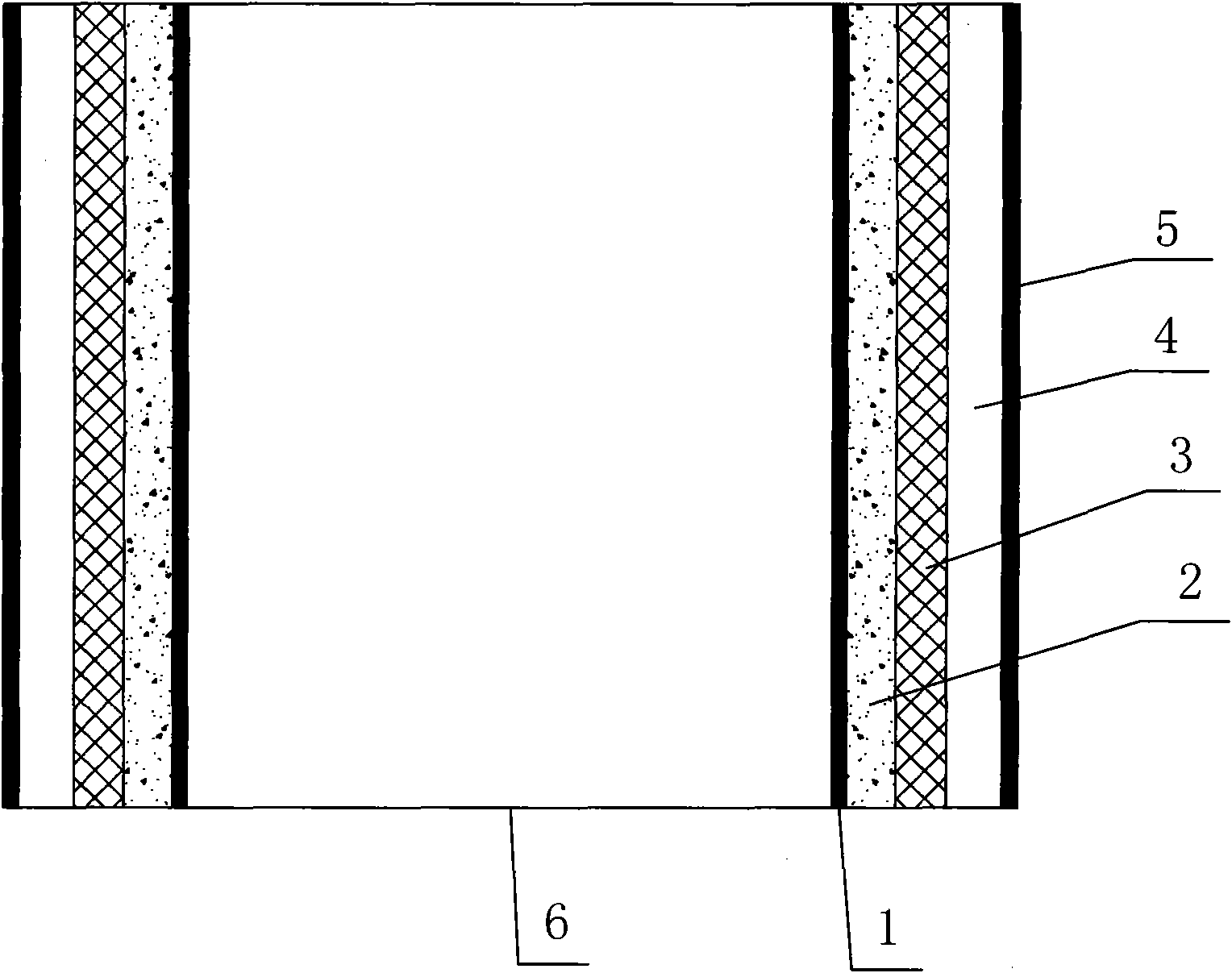

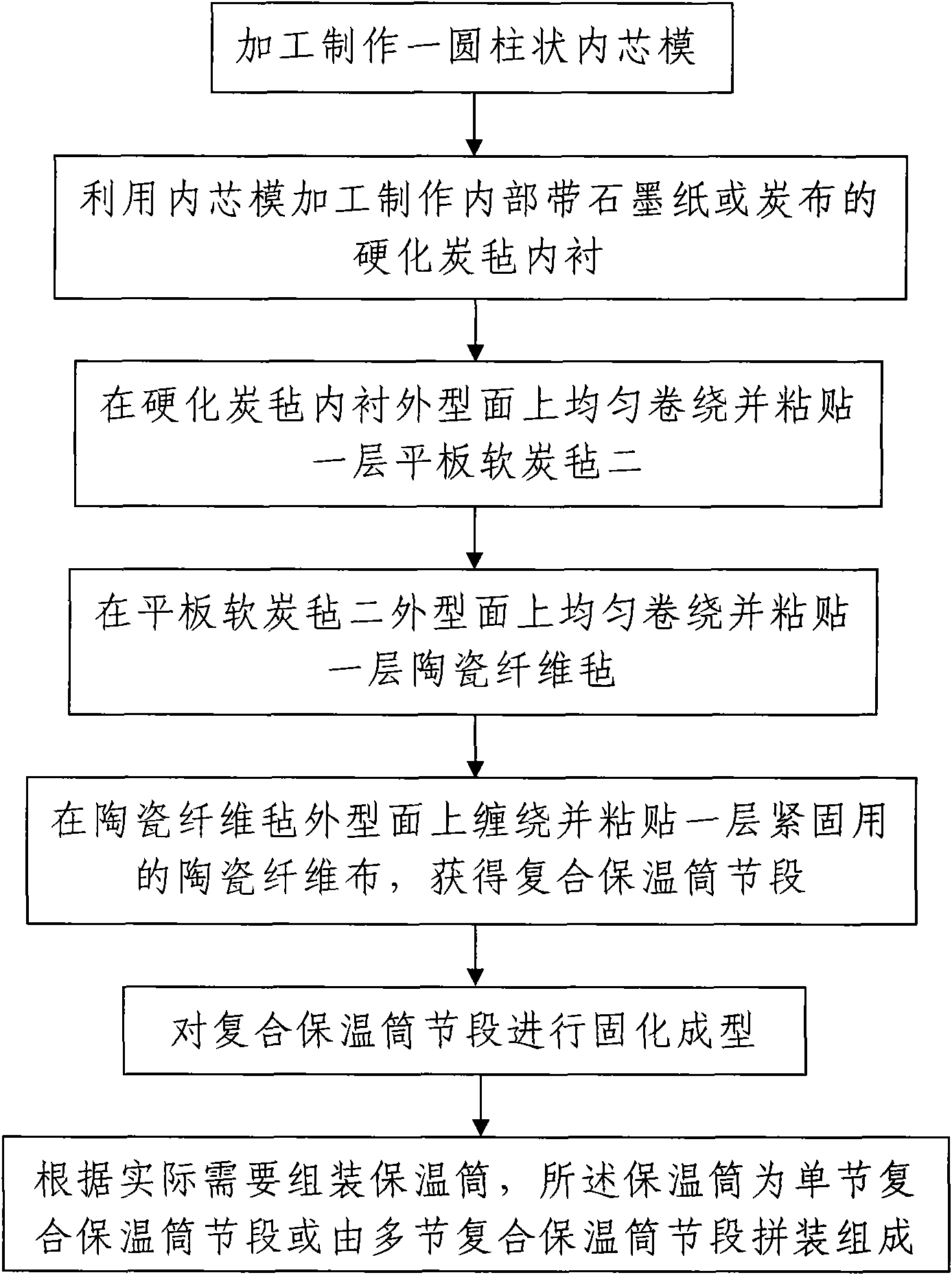

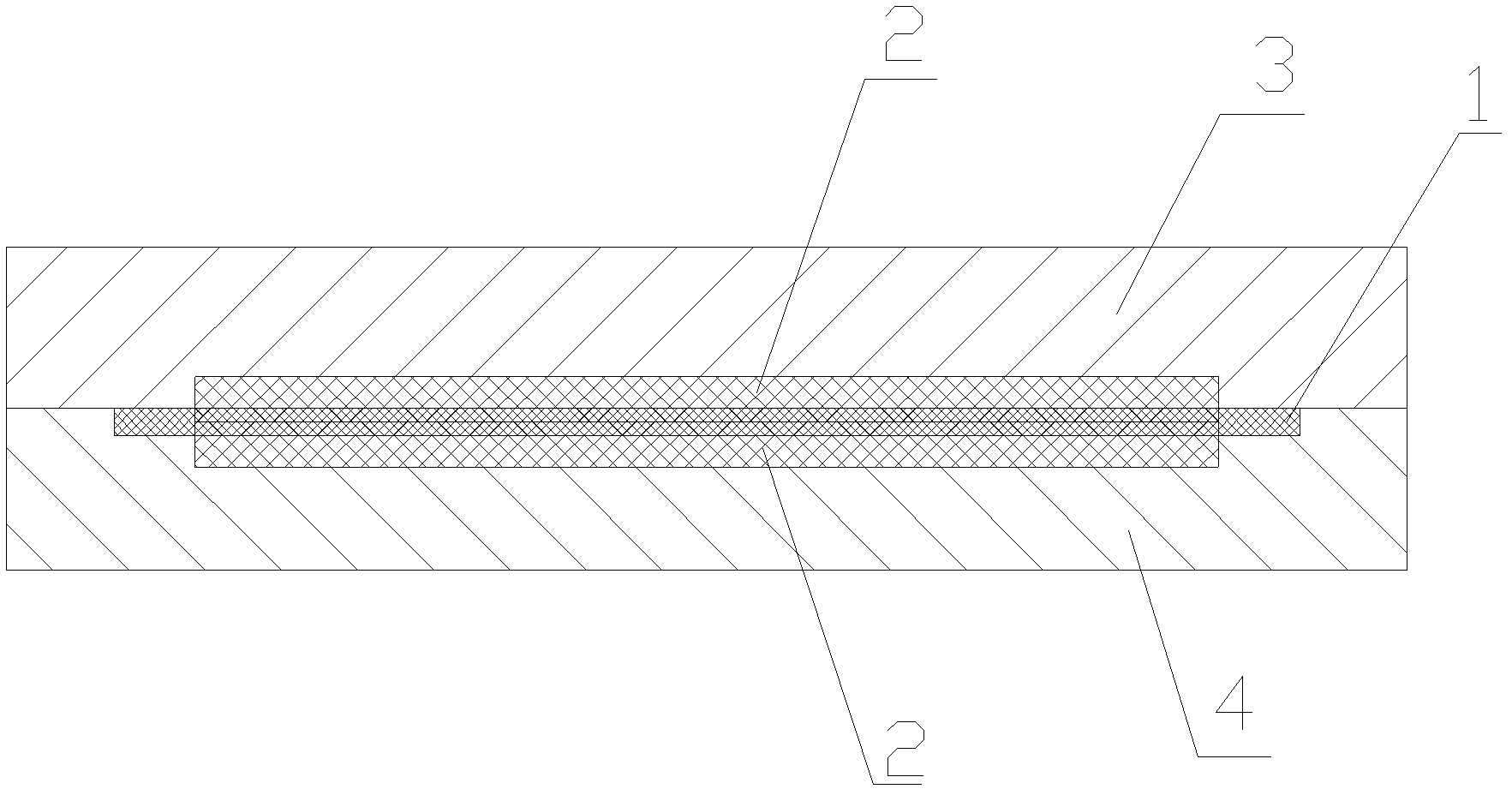

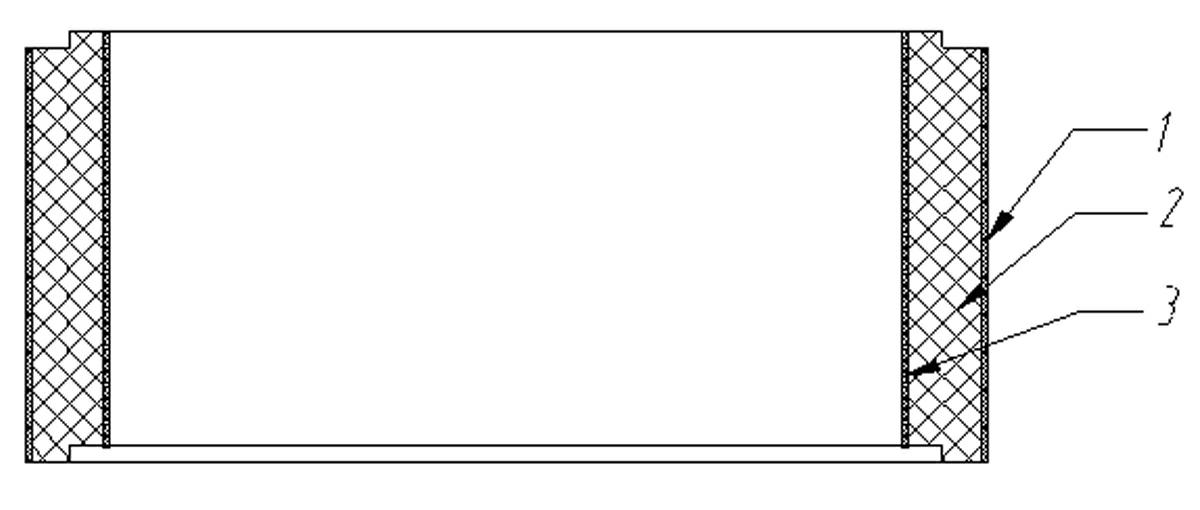

High-temperature metallurgical furnace and method for making compound insulation structure used for high-temperature metallurgical furnace

ActiveCN101639322AEasy to prepareThe preparation method is simple and easyCrucible furnacesFiberMetallurgy

The invention discloses a high-temperature metallurgical furnace and a method for making compound insulation structure used for the high-temperature metallurgical furnace. The method comprises the following steps: 1. making an insulation cylinder and 2. making an insulation cover and an insulation baseboard, which are arranged at the upper opening and the lower opening of the insulation cylinder,according to the making technology of the insulation cylinder. In the step 1, the insulation cylinder is a single insulation cylinder segment or is formed by splicing a plurality of insulation cylinder segments with the same structure. The making process of the insulation cylinder segment is as follows: making an inner core mould, using the inner core mould to process and make hardened carbon feltliners, evenly winding and pasting a layer of flat board soft carbon felt II, a layer of ceramic fibre felt and a layer of ceramic fibre cloth for fastening on the external moulded surface of the hardened carbon felt liner in sequence, thus obtaining a compound insulation cylinder segment, and carrying out curing molding on the compound insulation cylinder segment. The method of the invention issimple in steps, convenient in operation and high in production efficiency, and the made compound insulation structure is reasonable and good in insulation effect, thus effectively solving the practical problem that the existing high-temperature metallurgical furnaces and the insulation structures used for the high-temperature metallurgical furnaces have poor heat insulation effects and high making cost.

Owner:XIAN CHAOMA SCI TECH

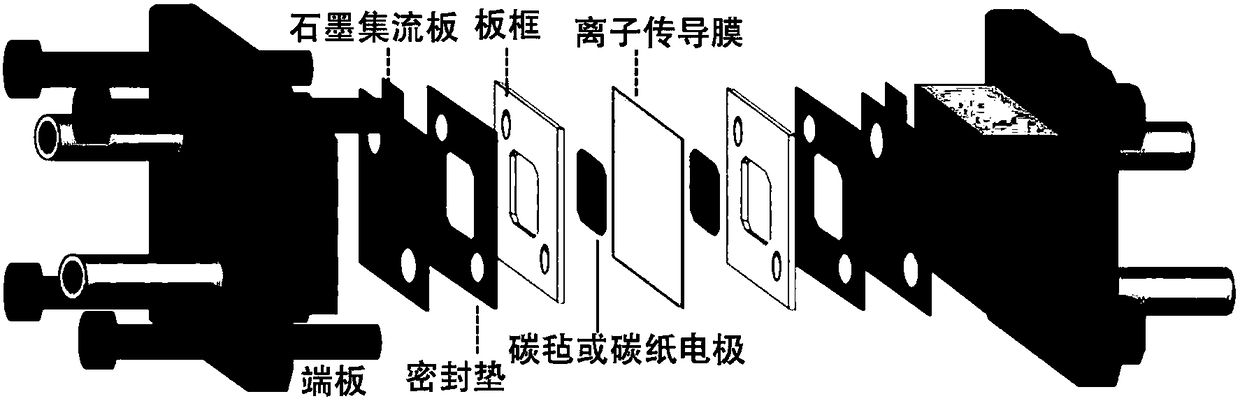

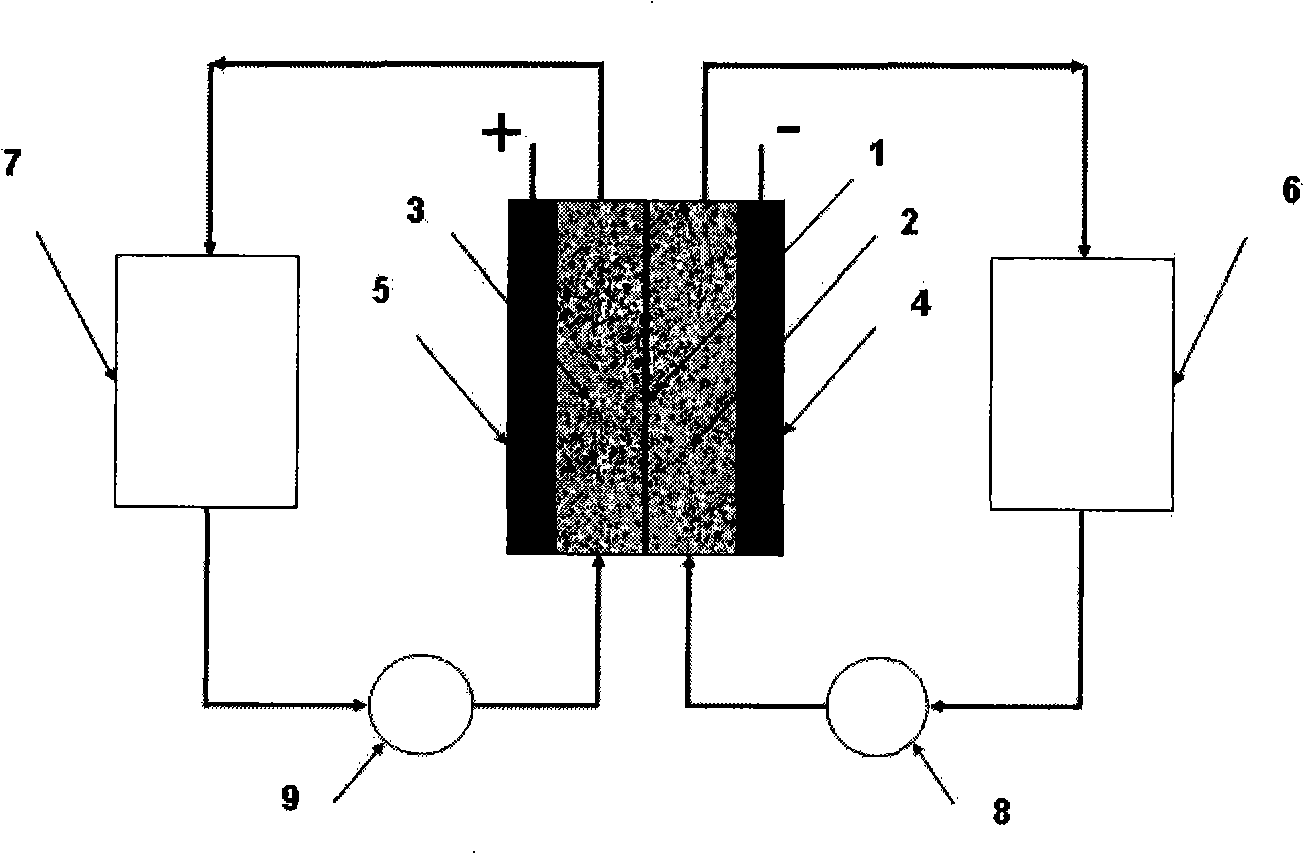

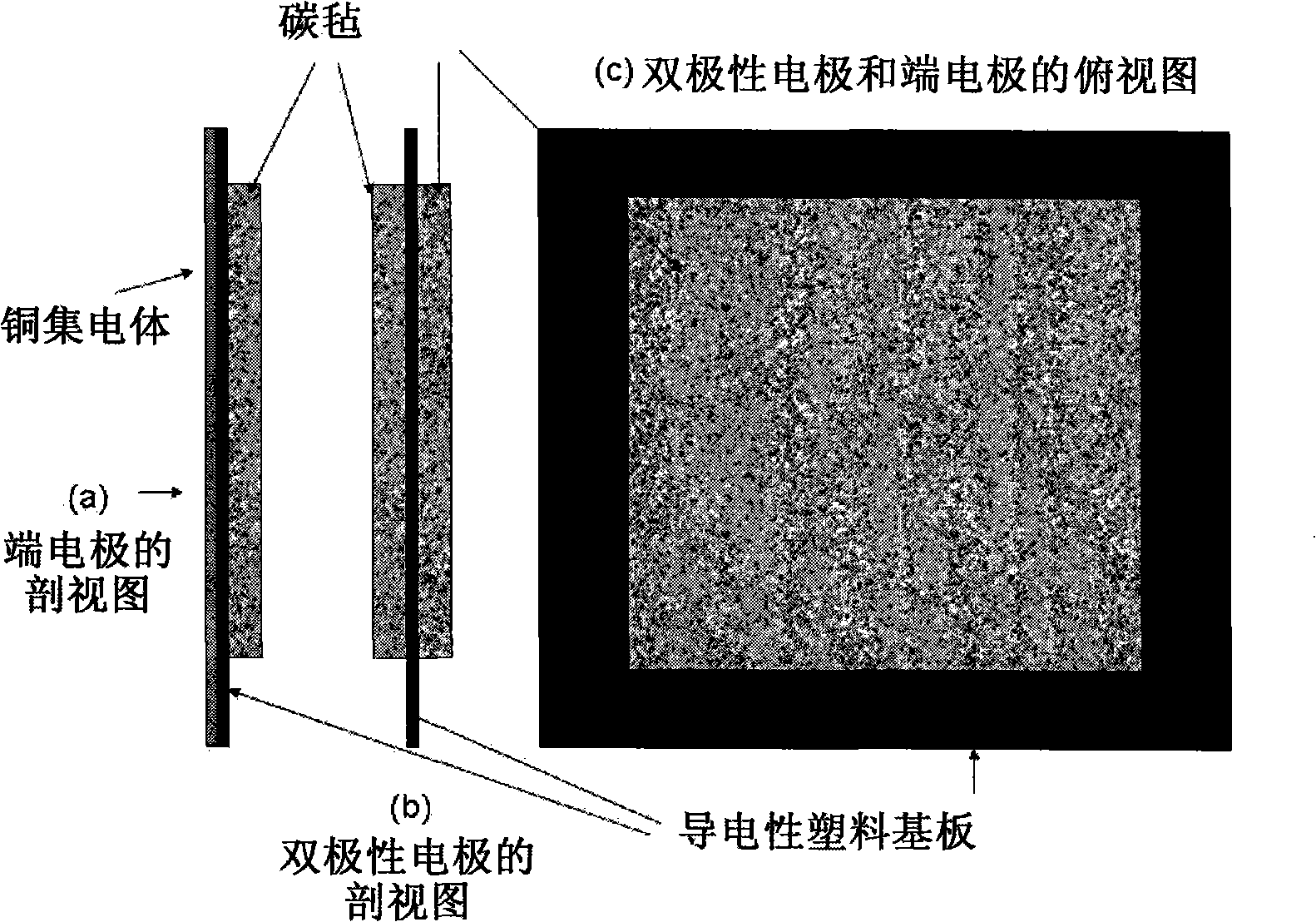

Bipolar plate of integrated composite electrode, and manufacturing method and application thereof

InactiveCN102569824ALower resistanceImprove conductivityCell electrodesRegenerative fuel cellsDecompositionLong axis

The invention discloses a bipolar plate of an integrated composite electrode, and a manufacturing method and application thereof. The bipolar plate of the integrated composite electrode consists of integrated graphite felts / carbon felts and a plastic sheet, wherein the plastic sheet is embedded between two graphite felts / carbon felts; and the long axis and the width axis of the plastic film are greater than those of the graphite felts / carbon felts. The bipolar plate of the integrated composite electrode can significantly reduce the resistance generated by tightly pressing the existing graphite felts / carbon felts and the bipolar plate; the bipolar plate of the integrated composite electrode takes the graphite felts / carbon felts conductive matrixes, so that the conductivity is significantly improved and the phenomenon that a conductive strand breaks is rarely caused; the bipolar plate of the integrated composite electrode is good in mechanical properties, easy to machine, bendable and difficult to deform and good in airtight performance; the phenomenon of fluid mixing of the battery can be avoided; the bipolar plate of the integrated composite electrode manufactured by the manufacturing method can increase the discharge medium pressure, the energy efficiency and the service life of a whole-vanadium oxide flow energy storage battery; and the structural damage of the graphite felts or carbon felts and the carbonation and decomposition of the plastic can be avoided.

Owner:黄权波

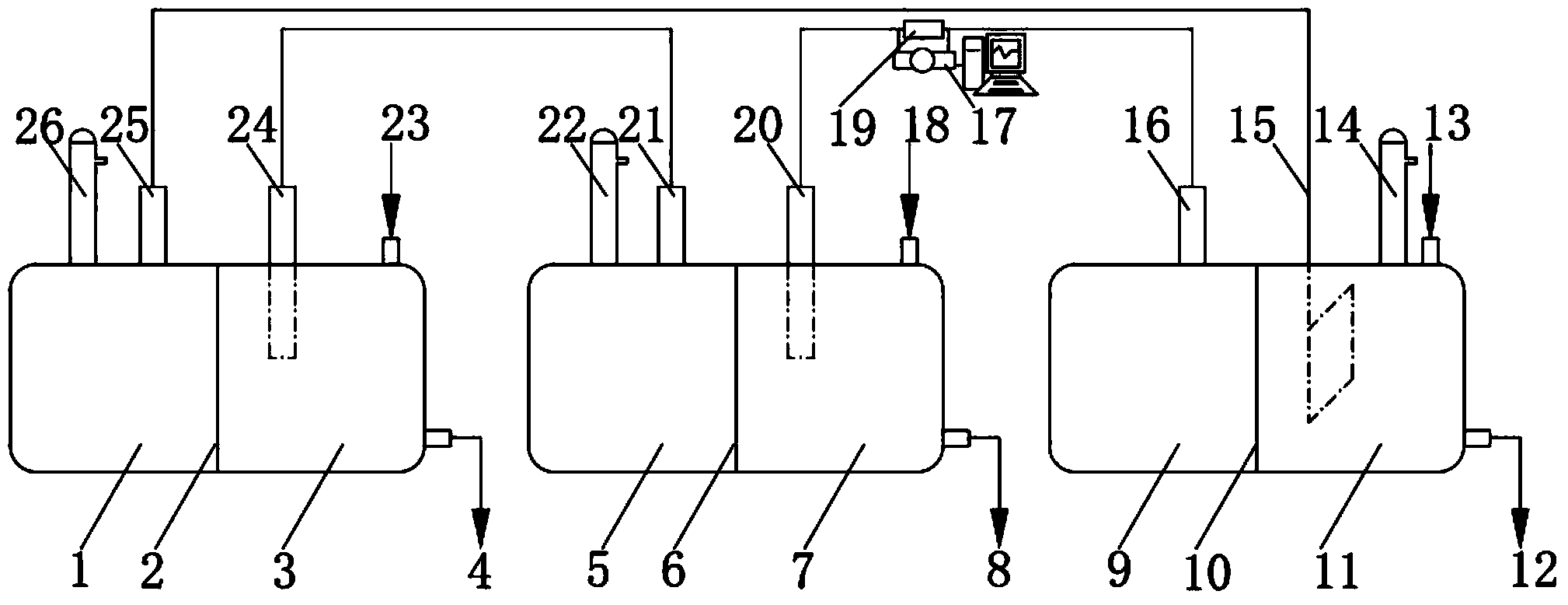

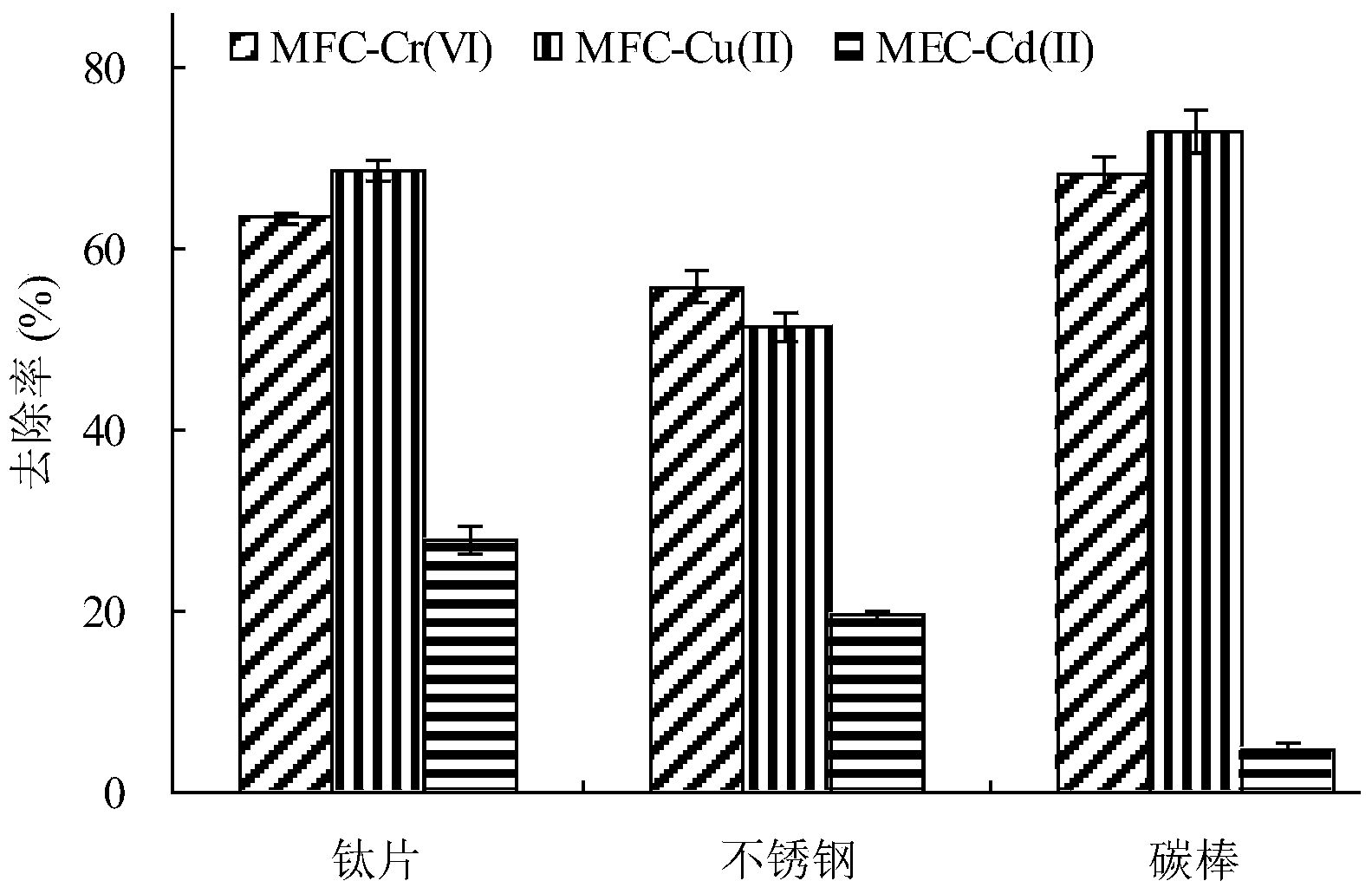

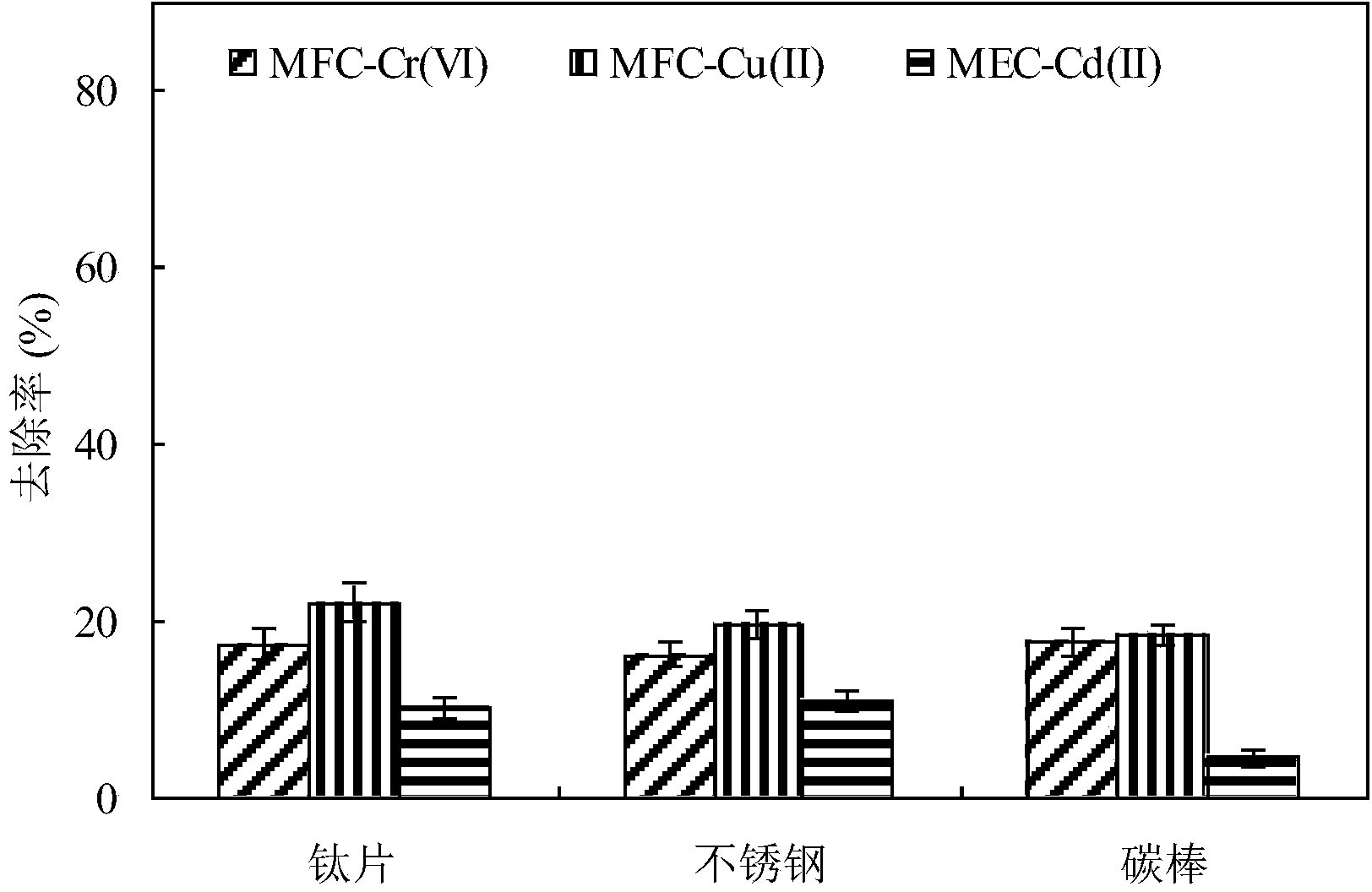

Method for recovering multiple metals through driving microbial electrolysis cells by microbial fuel cells

InactiveCN103966626AImprove pollutionResource optimizationPhotography auxillary processesProcess efficiency improvementCarbon feltPrinted circuit board

The invention relates to a method for recovering multiple metals through driving microbial electrolysis cells by microbial fuel cells, and belongs to the field of heavy metal recovery treatment. The method comprises the following steps: MFCsCr and MFCCu which adopt Cr(VI) and Cu(II) as cathode electron acceptors respectively are connected in series, the anodes of MFCsCr and MFCCu after series connection are connected with the cathode of MECsCd adopting Cd(II) as a cathode electron acceptor, the cathodes of the MFCsCr and MFCCu after series connection are connected with the anode of MECsCd through a series resistor, the cathodes of MFCsCr and MFCCu are carbon rods, the cathode of MECsCd is a stainless steel wire or a titanium sheet, and the anodes of MFCsCr, MFCCu and MECsCd are carbon felts or carbon rods. Through the adoption of the method, organic sewage such as electroplating wastewater, printed circuit board etching wastewater and municipal wastewater can be treated, and Cr metal, Cu metal and Cd metal are recovered, and broad space is provided for expanding the application field and the use range of an electrochemical system by MFCs output electric energy in situ.

Owner:DALIAN UNIV OF TECH

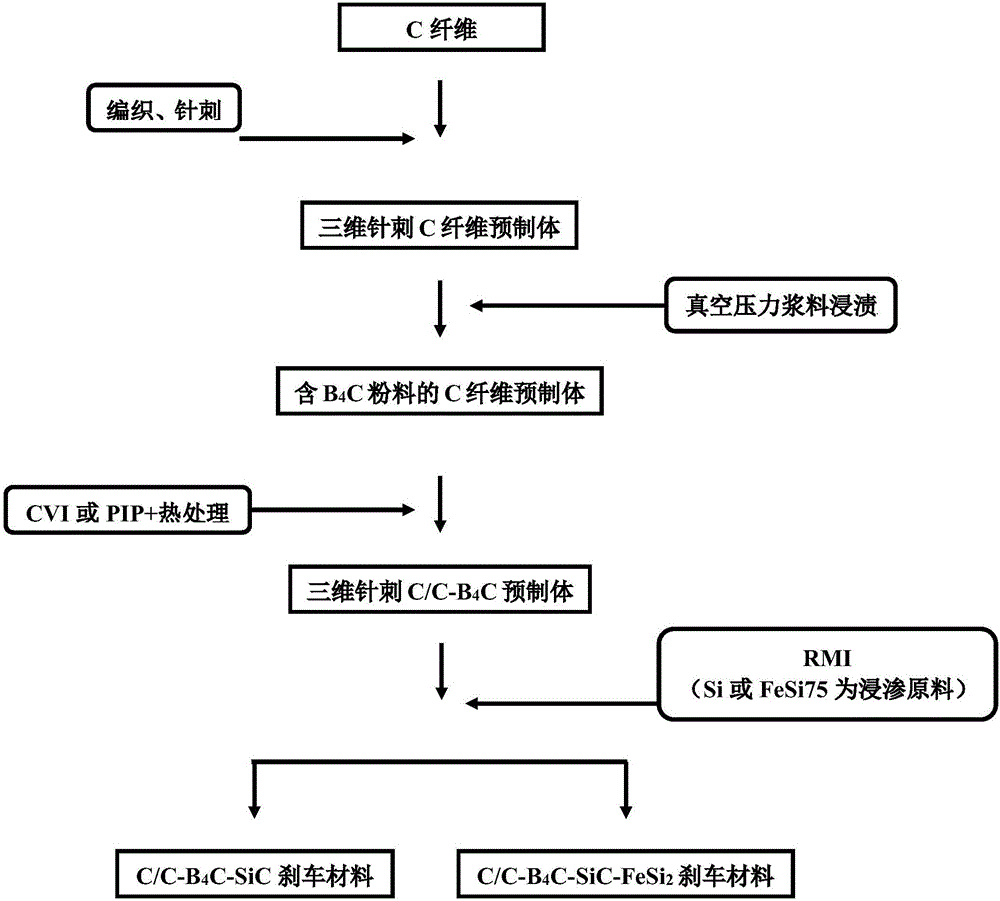

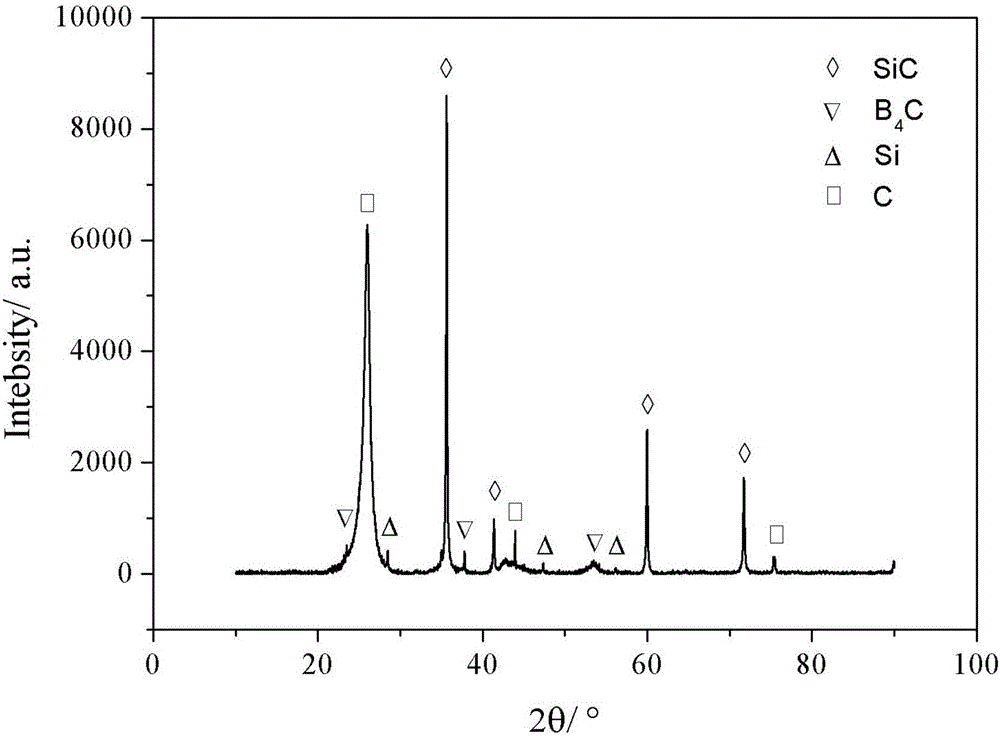

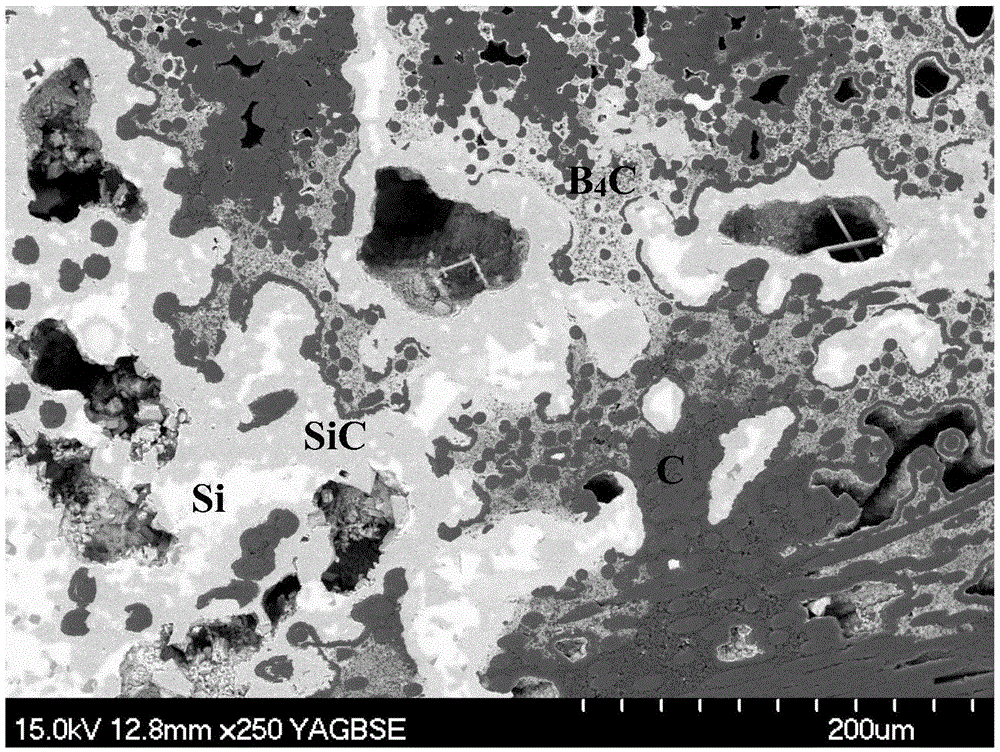

Preparation method of B4C modified C/C-SiC brake material

ActiveCN106478125AImprove friction and wear propertiesHigh specific heat capacityCarbon fibersVacuum pressure

The invention relates to a preparation method of a B4C modified C / C-SiC brake material. According to the method, a vacuum pressure dipping method is used for introducing a B4C powder material in a three-dimensional needle carbon felt with the initial density being 0.4 to 0.6g / cm<3>; CVI (chemical vapor infiltration) and RMI (reaction melt infiltration) are combined for preparing the C / C-SiC brake material. When the B4C modified C / C-SiC brake material is used, on one hand, the B4C is used as a self heeling component for achieving the protection effects on the carbon fiber and a carbon base body; the inoxidizability of the material can be obviously improved; on the other hand, the B4C has higher specific heat capacity; the integral specific heat capacity of the material can be improved; the braking temperature can be effectively reduced; the material friction performance stability is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Production method for foam carbon extraordinarily high temperature macrotype hard heat-insulating room

InactiveCN101173839AGood heat insulationSatisfy geometry requirementsLinings repairCarbon compositesAntioxidant

The invention discloses a manufacture method of an ultrahigh temperature large hard heat insulation chamber made of foam carbon, which is characterized in that: the foam carbon is used to make the prefabricated blank of a heat insulation chamber; then the prefabricated blank of the heat insulation chamber is bound to a type modulus, which is solidified and demoulded; then a permeation proof film is laid and a corrosion-proof antioxidant is coated; finally the heat insulation chamber is completed after the integral sintering. The invention has the advantages of aiming at solving the problems of the prior domestic high temperature furnaces caused by the adoption of the soft carbon felt life tenure sewing heat insulation chamber, and producing integral, hard, abnormity and large heat insulation chamber in order to meet the needs of the high-tech industries such as alloy, moncrystalline silicon and carbon or carbon composite material and replace the imported heat insulation chamber; in addition, the invention has low cost and simple and practical production method.

Owner:烟台鲁航炭材料科技有限公司

Preparation method of C/C-SiC composite material

The invention discloses a preparation method of a C / C-SiC composite material, and belongs to the technical field of preparation of C / C composite materials. The method comprises the following steps: putting a carbon felt of which the density is 0.4-0.55g / cm<3> into an impregnant to steep under a protective atmosphere; carrying out curing treatment and carbonization treatment; repeating vacuum impregnation, pressure impregnation, curing treatment and carbonization treatment and putting the obtained preform into a polyaniline methyl silane solution to steep after a C / C porous preform of which the density is 1.2-1.3g / cm<3> is obtained; carrying out curing treatment; repeating the steeping and curing technologies for 2-3 times, and then cracking under the protective atmosphere; and repeating the steeping, curing and cracking technologies until the C / C-SiC composite material of which the density is 1.9-2.1g / cm<3> is obtained according to the system of cracking once after steeping and curing for 2-3 times. The preparation method is short in preparation cycle, and low in cost, and the obtained C / C-SiC composite material is excellent in performance, and convenient to achieve industrial production.

Owner:湖南中坚科技有限公司

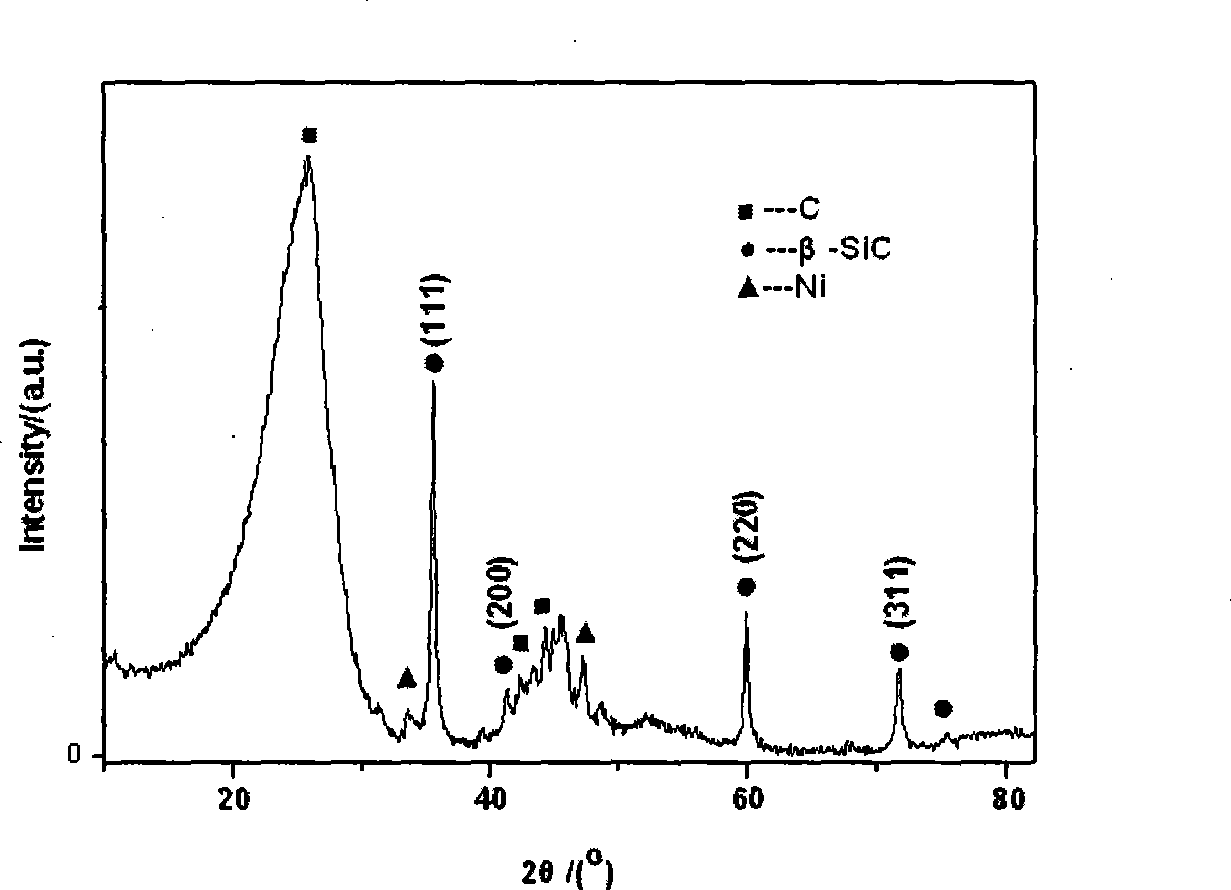

Method for manufacturing silicon carbide nanometer fibre/carbon fibre composite felt body

The invention discloses a method for preparing silicon carbide nano-fiber or carbon fiber composite felt, which comprises following steps: eliminating adhesion of needle integrated carbon felt or not eliminating the adhesion, then, absorbing one of transition group cobalt or nickel on the surface of carbon felt fiber in a mode of fine grained shapes through adopting a method of electroplating or electroless plating, drying, then, depositing silicon carbide in a chemical vapor deposition furnace, controlling the flow capacity of deposition gas source trichloromethylsilanes, carrier gas hydrogen and diluted argon, keeping the furnace pressure to be 20-500Pa when the deposition temperature is 1073-1373K, keeping the depositing time to be 1 to 15 hours, cooling along the furnace, then, taking out of the furnace, and obtaining the composite felt whose carbon felt fiber surface is grown with nanometer silicon carbide fiber. The composite felt which is weaved through adopting the method sufficiently exerts the mechanical and physical properties of each direction in situ growing nano-sic fiber and takes the mechanical and physical properties as an enhanced body of traditional C / C or C / SiC composite materials, the anisotropy of the composite materials is increased, and the using performance is increased.

Owner:CENT SOUTH UNIV +1

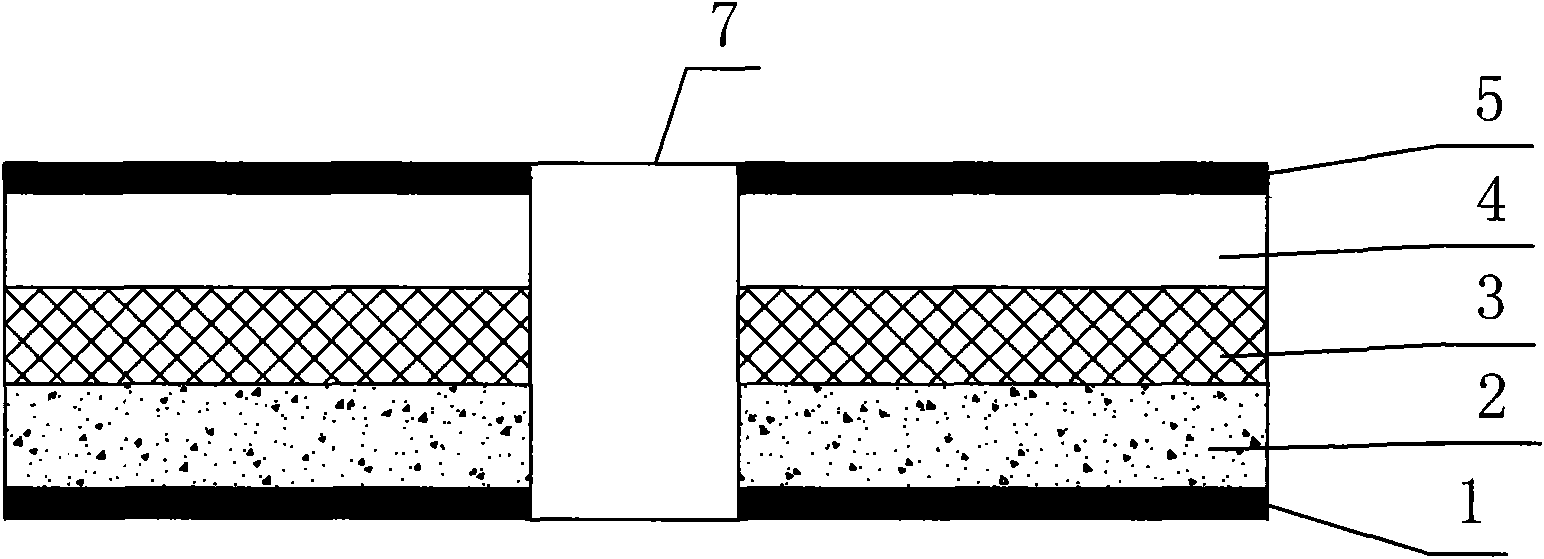

Carbon/carbon heat screen of polysilicon hydrogenation furnace and manufacture method thereof

The invention discloses a carbon / carbon heat screen of a polysilicon hydrogenation furnace and a manufacture method thereof. A carbon / carbon heat screen body of the polysilicon hydrogenation furnace is of a sandwich structure, an outer surface layer and an inner surface layer of the heat screen body are formed by densifying three-dimensional integral needled carbon felts or carbon fabrics with density of more than or equal to 1.2g / cm<3>, a middle layer of the heat screen body is formed by densifying carbon felts with density of less than or equal to 0.25g / cm<3>, and a silicon carbide protective layer is coated on the surface of the heat screen body. The manufacture method comprises the following steps of: 1, manufacturing a heat screen steel loose tooling according to the design requirement; 2, preparing a heat screen body blank; 3, curing; 4, carbonizing; 5, demoulding the steel loose tooling; 6, carrying out CVD (Chemical Vapor Deposition) densifying treatment; 7, machining two ends of the heat screen; 8, coating the silicon carbide protective layer; and 9, carrying out high-temperature purification treatment. The carbon / carbon heat screen of the polysilicon hydrogenation furnace has better heat-insulation performance, corrosion resistance and scouring resistance, high mechanical strength, long service life, and low production cost because of being manufactured by using a pure-molding and less-cutting process.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

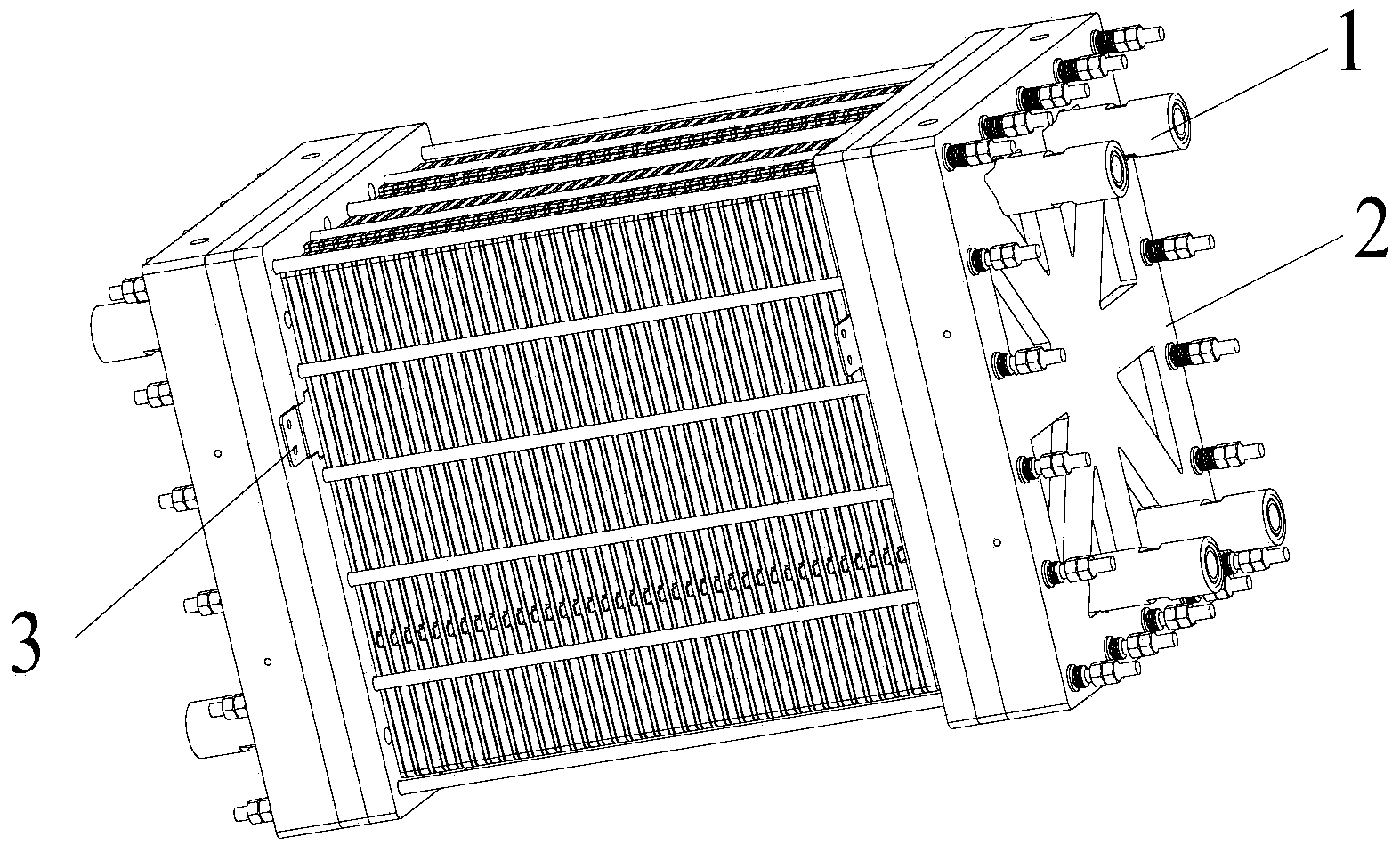

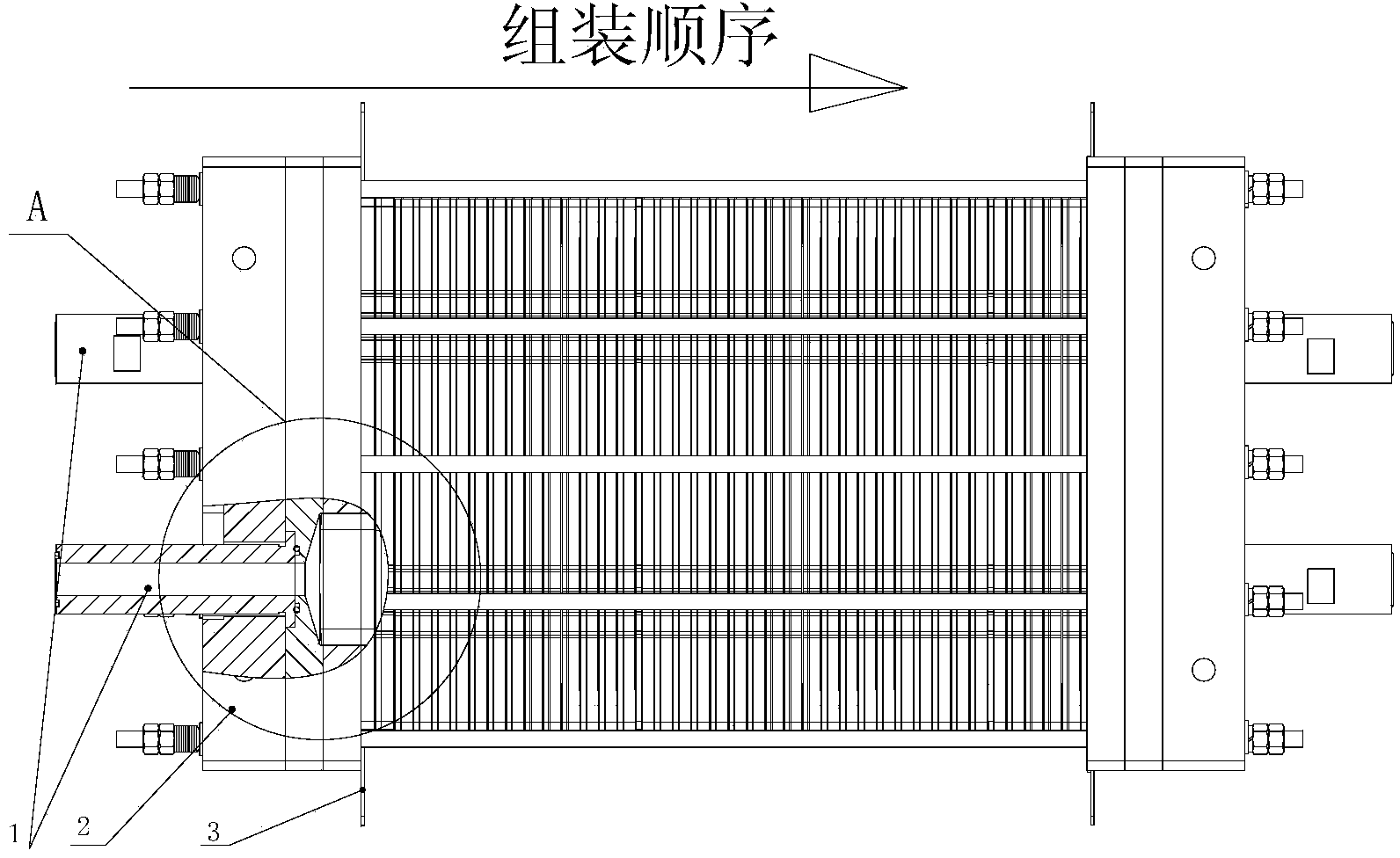

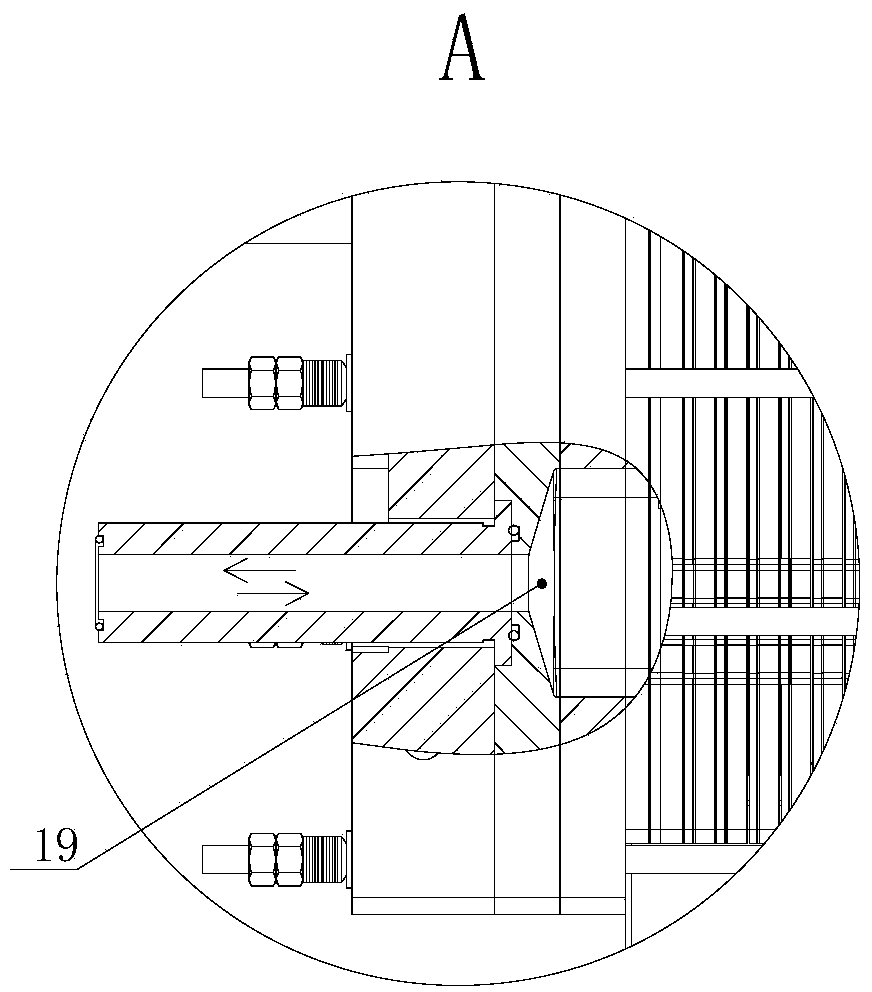

Liquid phase flow battery pile of Fe/Cr system

InactiveCN104183858AEasy to moveAvoid the danger of not being able to workFuel cell detailsCarbon feltLiquid phase

The invention provides a liquid flow frame of a Fe / Cr flow battery and an electric pile consisting of the liquid flow frame. A runner for flowing of an electrolyte is formed in the liquid flow frame and comprises a sharing channel, two snakelike runners, uniform-distributing tanks, horn mouths and uniform-flowing tanks, wherein the electrolyte flows into single batteries through the sharing channel and flows into the snakelike runners through runners in a pole plate, multiple horn mouths are formed in the tail end of each snakelike runner, and all the horn mouths are communicated to the uniform-flowing tanks. A battery pile is formed by multiple single batteries through series connection, wherein each single battery comprises a positive electrode, a negative electrode, a diaphragm, a positive electrode electrolyte and a negative electrode electrolyte, the positive electrode consists of a bipolar plate and a carbon felt and is arranged in the liquid flow frame, and four sides, opposite to the liquid flow frame, of the bipolar plate are surrounded by a package type sealing structure.

Owner:SUZHOU JIURUN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com