Preparation method of hard carbon felt

A technology of hard carbon and short carbon fiber, which is applied in the field of hard carbon felt preparation, which can solve the problems of high cost, low preparation cost, and hazards to environmental operators, and achieve long service life, good heat preservation effect, and uniform density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

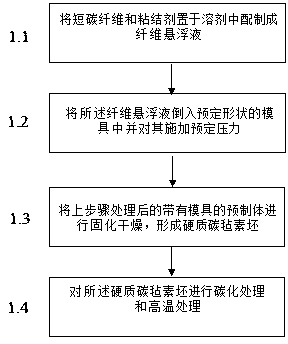

[0020] see figure 1 , the invention provides a kind of preparation method of hard carbon felt, comprises the following steps:

[0021] 1.1 Prepare short carbon fibers of predetermined length and a binder, and place the short carbon fibers and binder in a solvent to prepare a fiber suspension.

[0022] As an embodiment, the predetermined length of short carbon fibers prepared in the step 1.1 is a single length or different lengths. A dispersant is also added to the fiber suspension to uniformly disperse the short carbon fibers in the solvent. As an example, the dispersant is polyethylene glycol. The binder is a carbon-containing resin including phenolic resin, furfural resin or epoxy resin, so the solvent is water or an organic solvent.

[0023] 1.2 Pour the fiber suspension into a mold of a predetermined shape and apply a predetermined pressure to it to remove the solvent and promote uniform fiber distribution.

[0024] 1.3 Curing and drying the prefabricated body with the...

example 1

[0037] Example 1: Pour chopped fibers (containing binder, fiber length of 5mm, phenolic resin ratio of 5:1) into water solvent, the ratio of fiber to water is 1:20, and the dispersant is polyethylene glycol. Disperse the fibers completely and pour them into a mold of a certain shape. After the solution is completely poured into the mold, cover the mold cover to ensure the uniformity of each part and control the thickness to ensure that the density of the carbon felt is 0.16g / mm 3, After removing the solvent, heat it at 150°C for 5 hours, demould and carbonize it. The carbonization condition is 900°C and heat it for 2 hours. The carbonized hard felt is kept at 2000°C for 1 hour under the protection of argon. heat treatment. High temperature treated carbon felt has a density of 0.158 g / mm 3 , the thermal conductivity is 0.23W / m·K (room temperature), and the plane flexural strength is 1.7MPa.

example 2

[0038] Example 2: Pour chopped fibers (containing binder, fiber lengths of 2mm and 5mm respectively, ratio of 1:1, phenolic resin ratio of 5:1) into the water solvent, the ratio of fiber to water is 1:15 , the dispersant is polyethylene glycol, disperse the fiber completely, pour it into a mold of a certain shape, after the solution is completely poured into the mold, cover the mold cover to ensure the uniformity of each part and control the thickness to ensure that the carbon felt The density is 0.16g / mm 3, After removing the solvent, heat it at 150°C for 5 hours, demould and carbonize it. The carbonization condition is 1000°C and heat it for 2 hours. The carbonized hard felt is kept at 1600°C for 1 hour under the protection of argon. heat treatment. High temperature treated carbon felt has a density of 0.62 g / mm 3 , the thermal conductivity is 0.3W / m·K (room temperature), and the plane flexural strength is 2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com