Patents

Literature

487 results about "Fiber suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

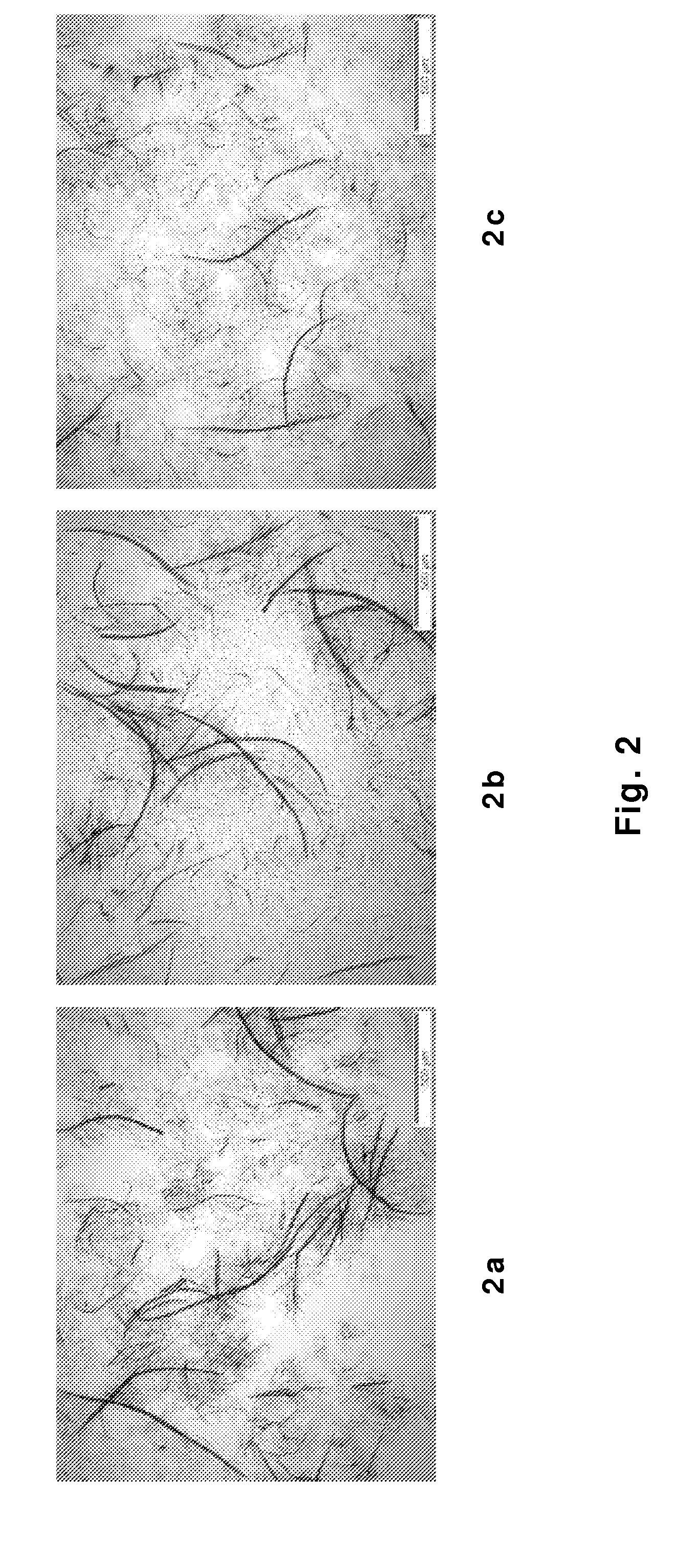

Process for producing nanofibers

ActiveUS20080057307A1Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberNanofiber

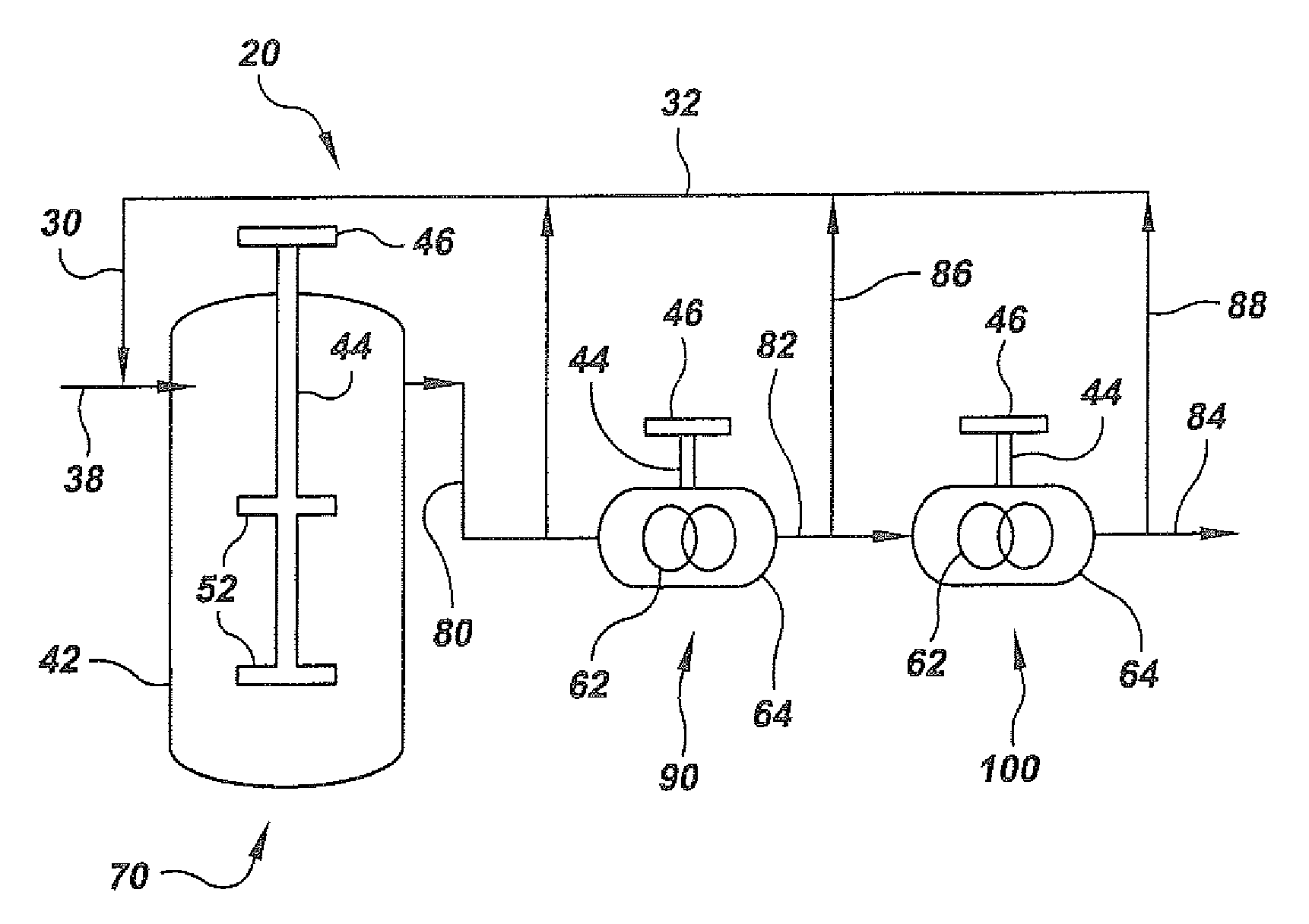

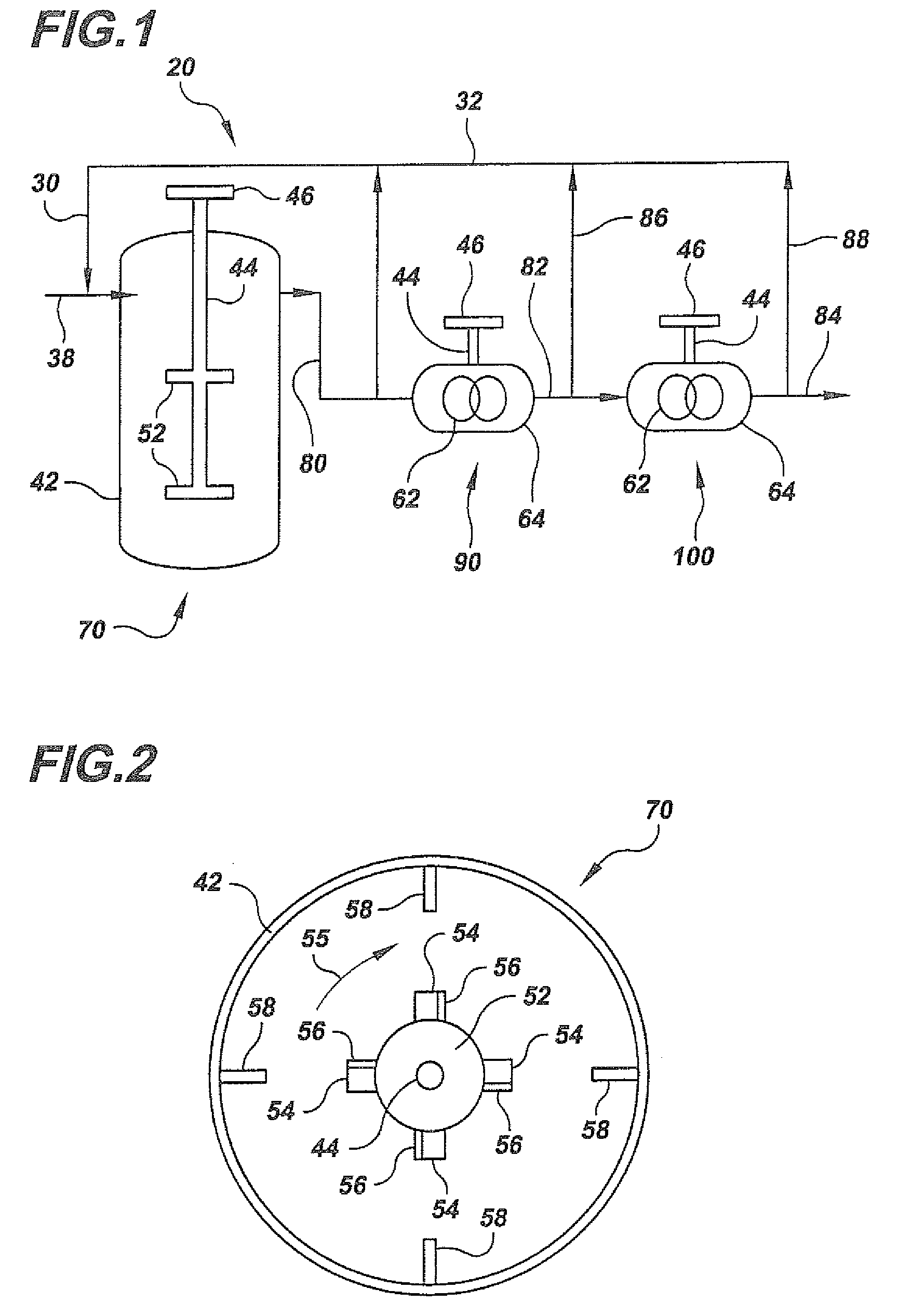

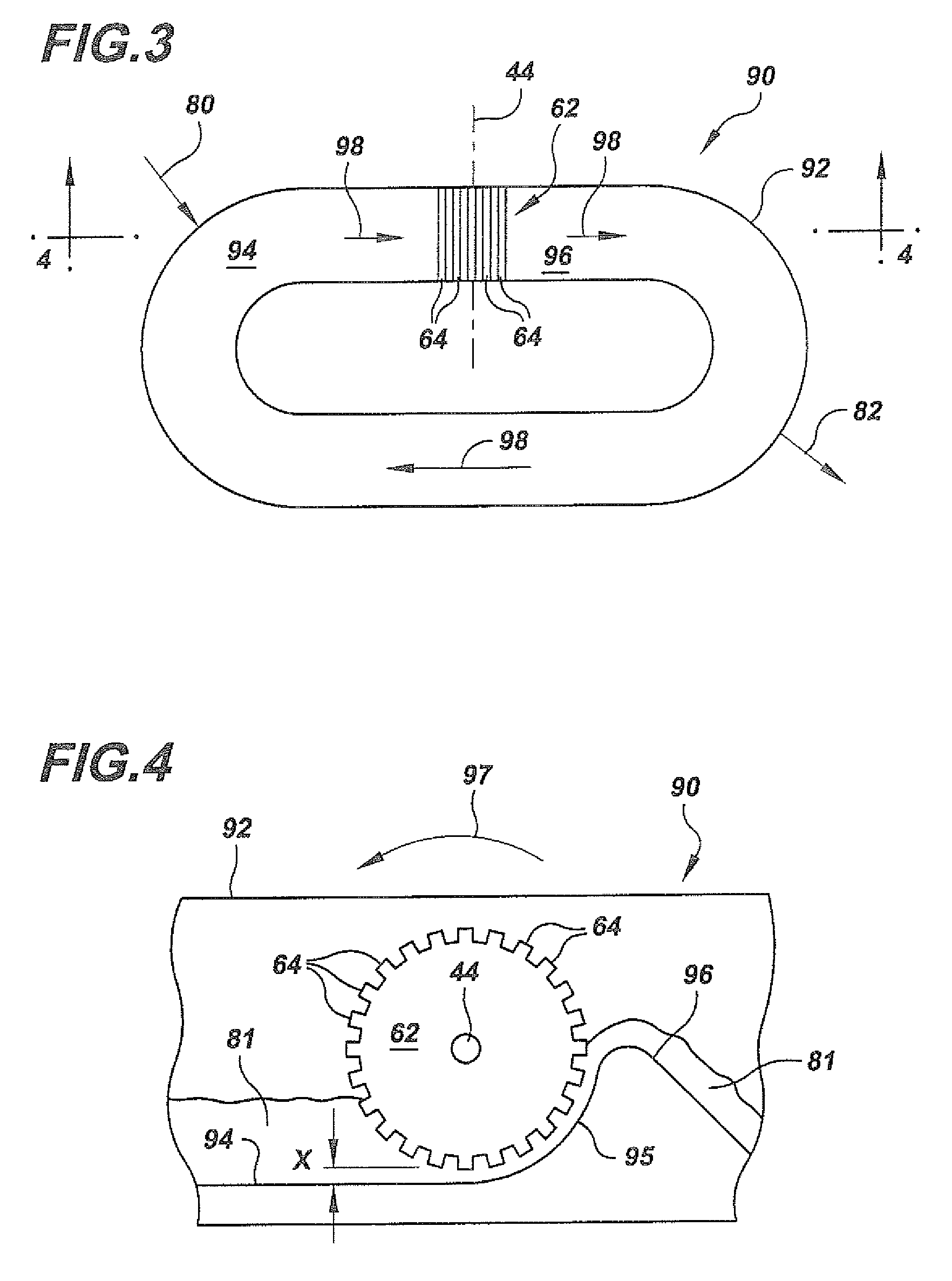

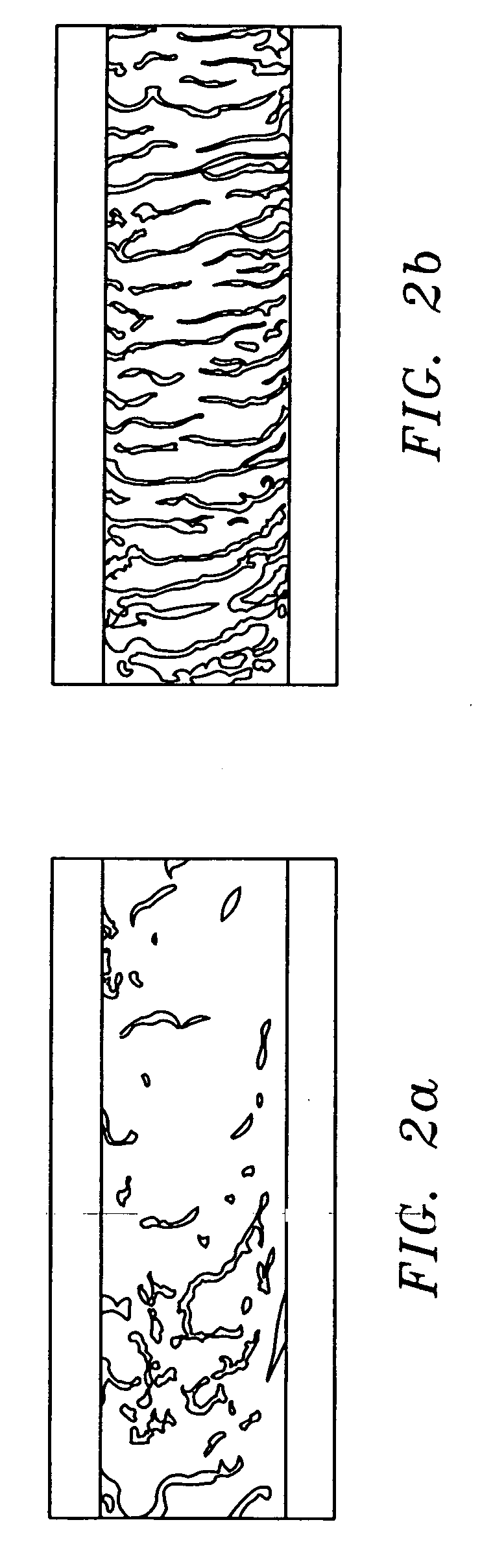

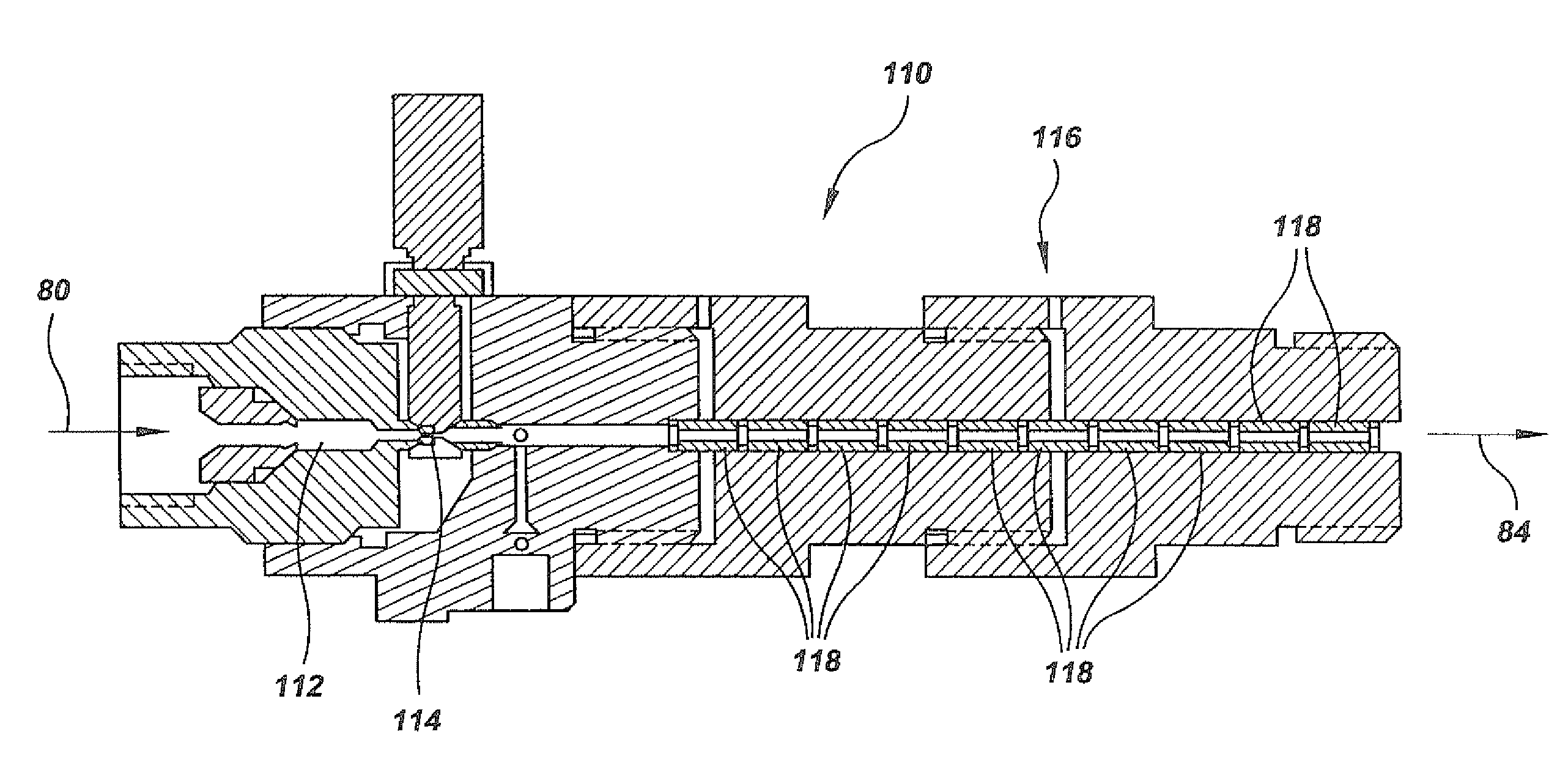

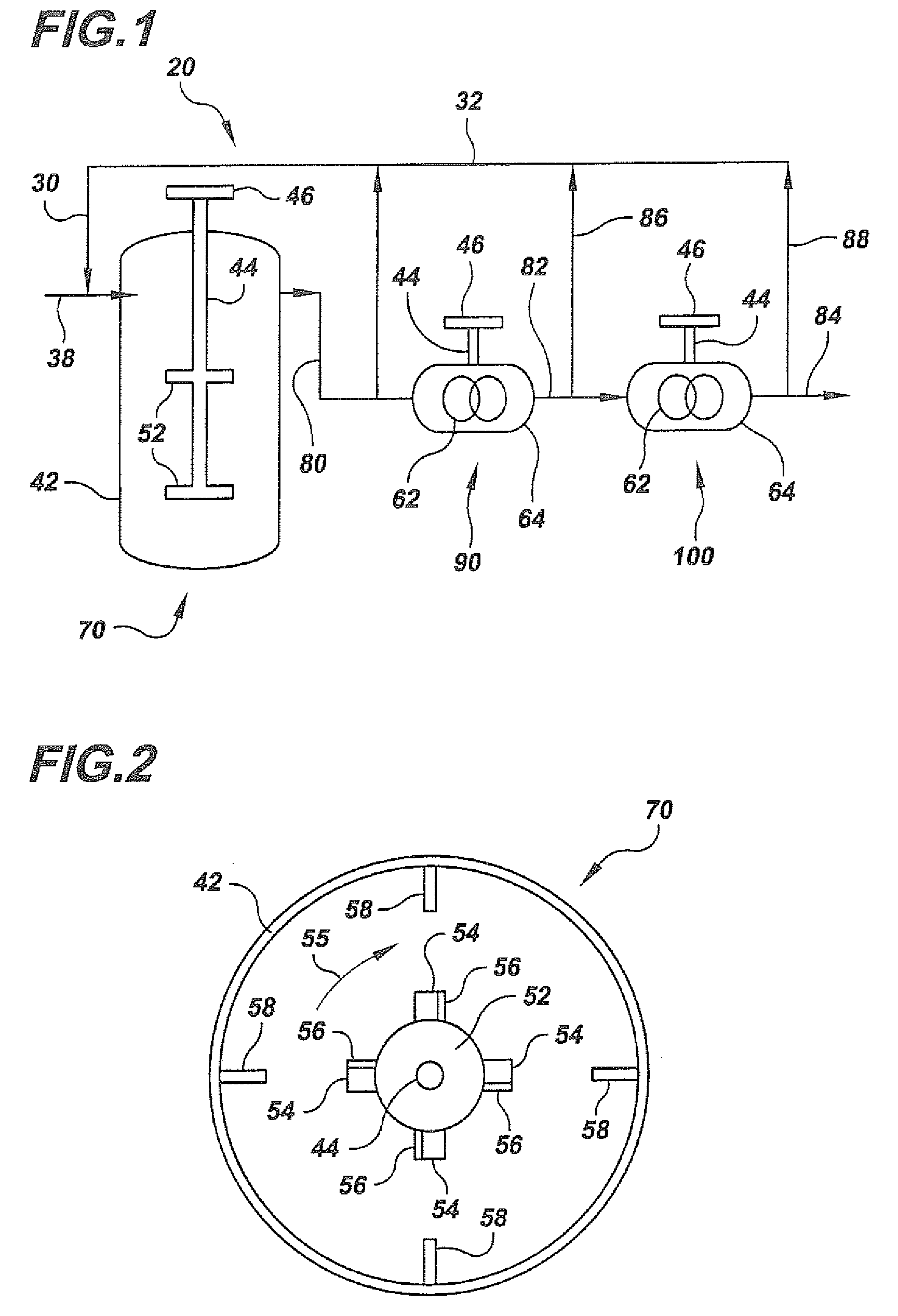

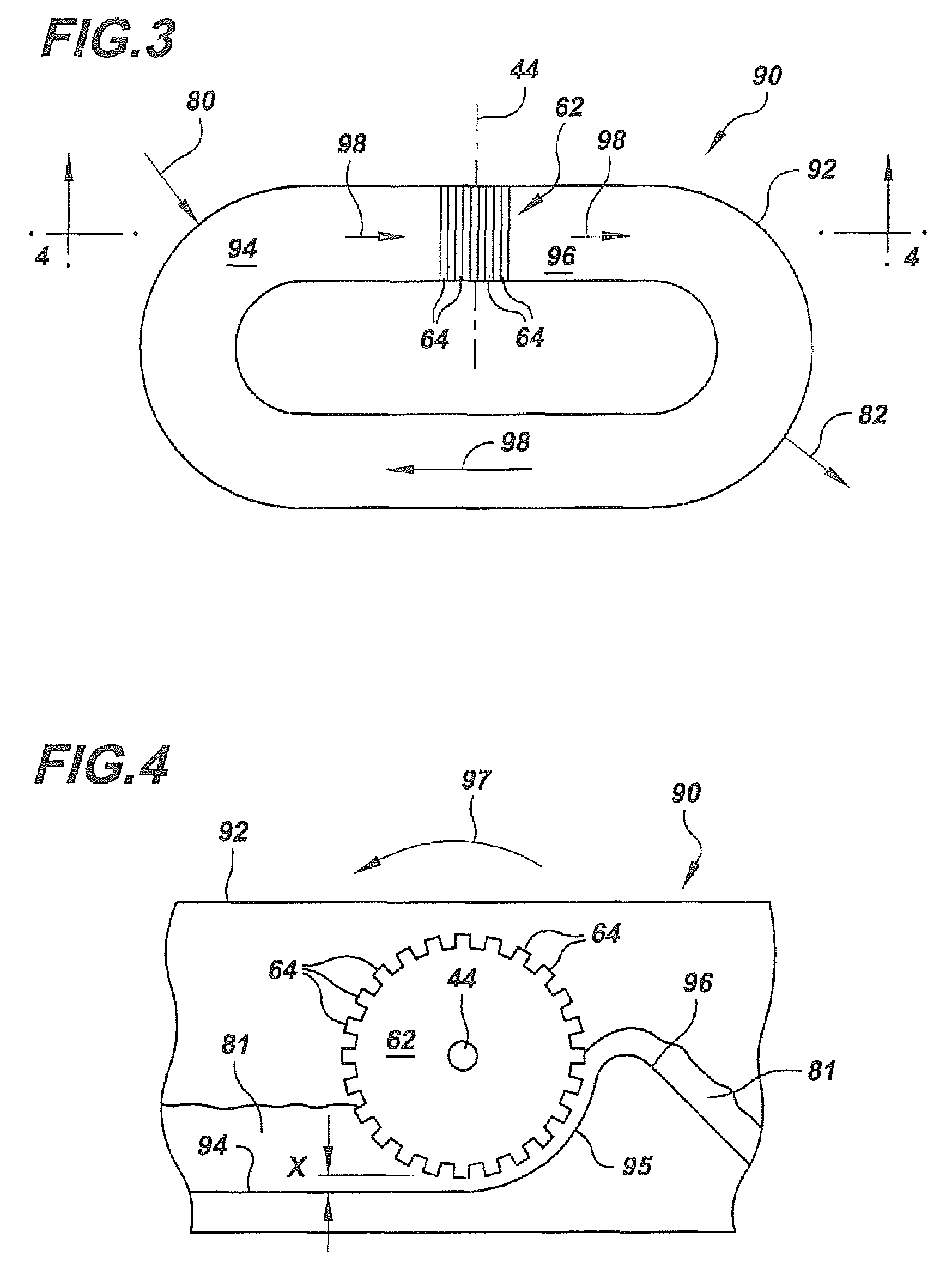

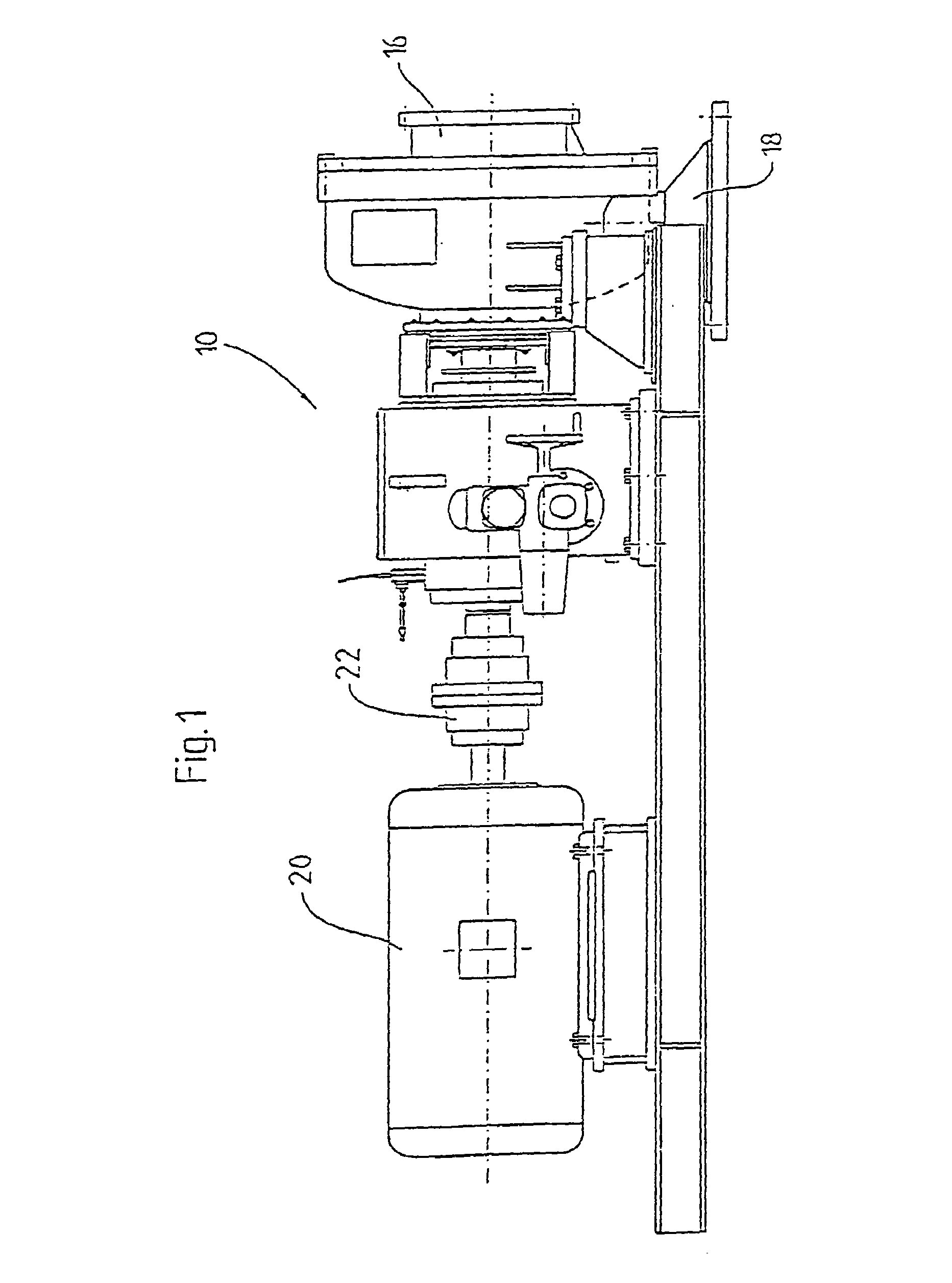

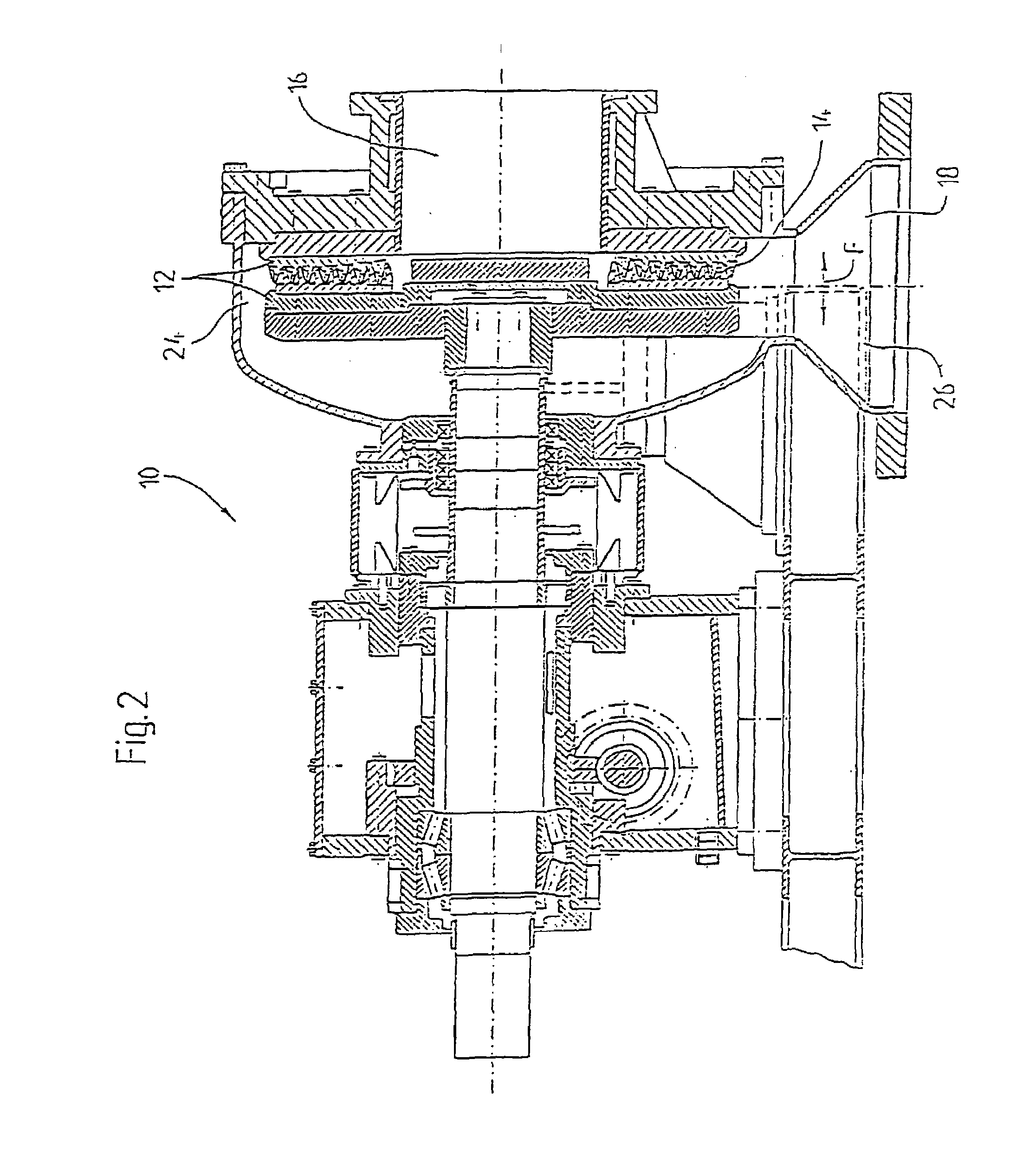

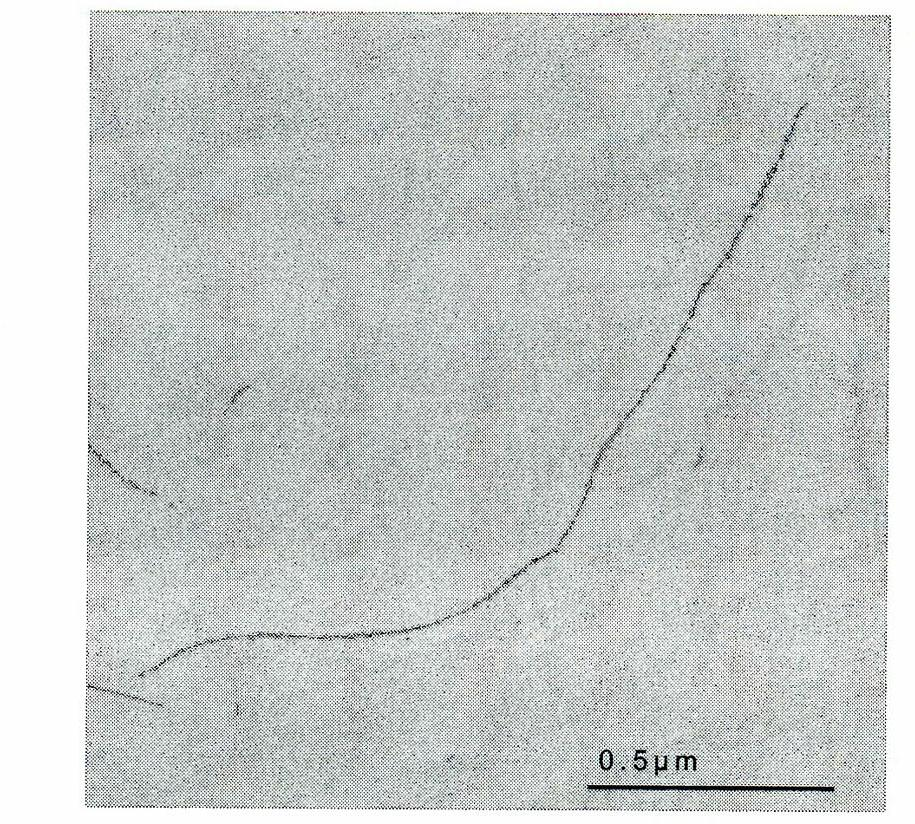

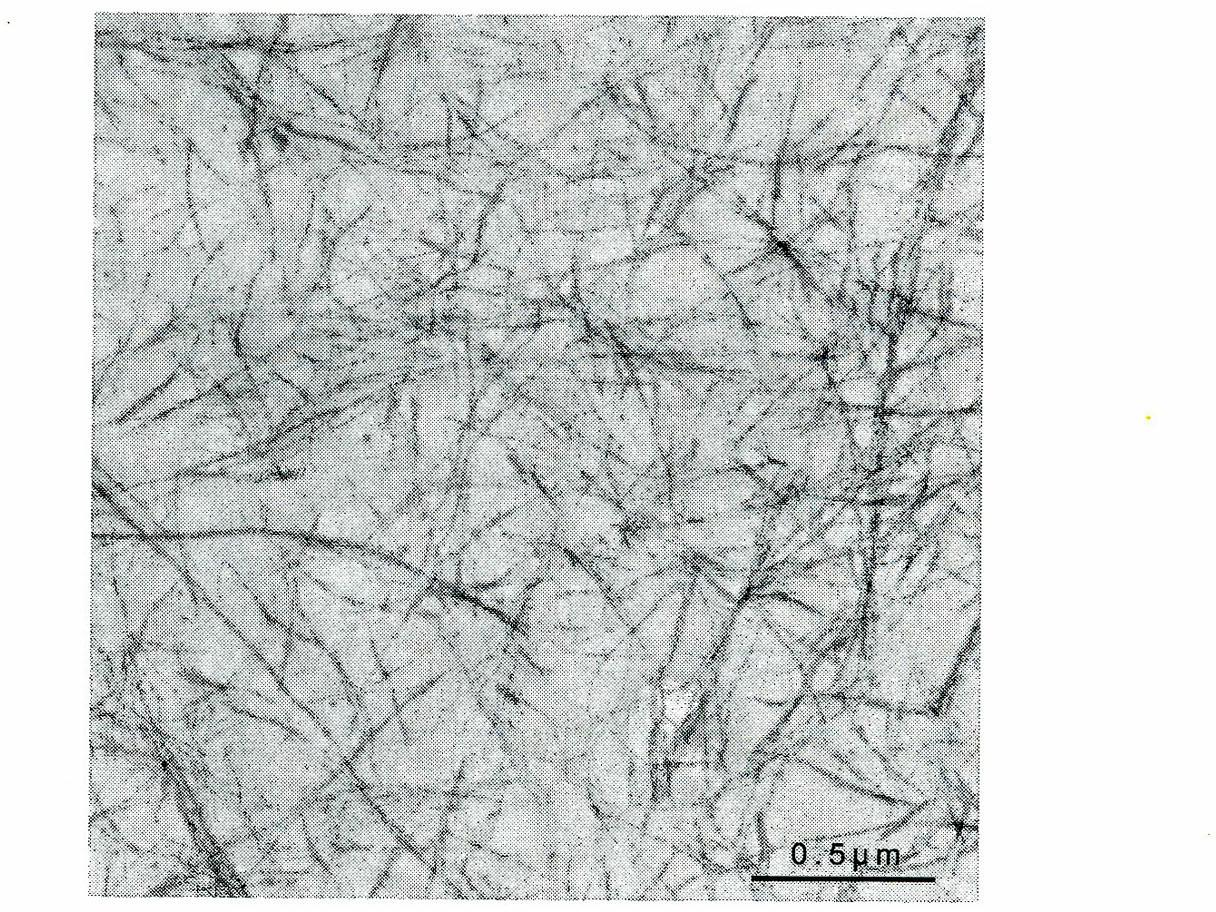

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

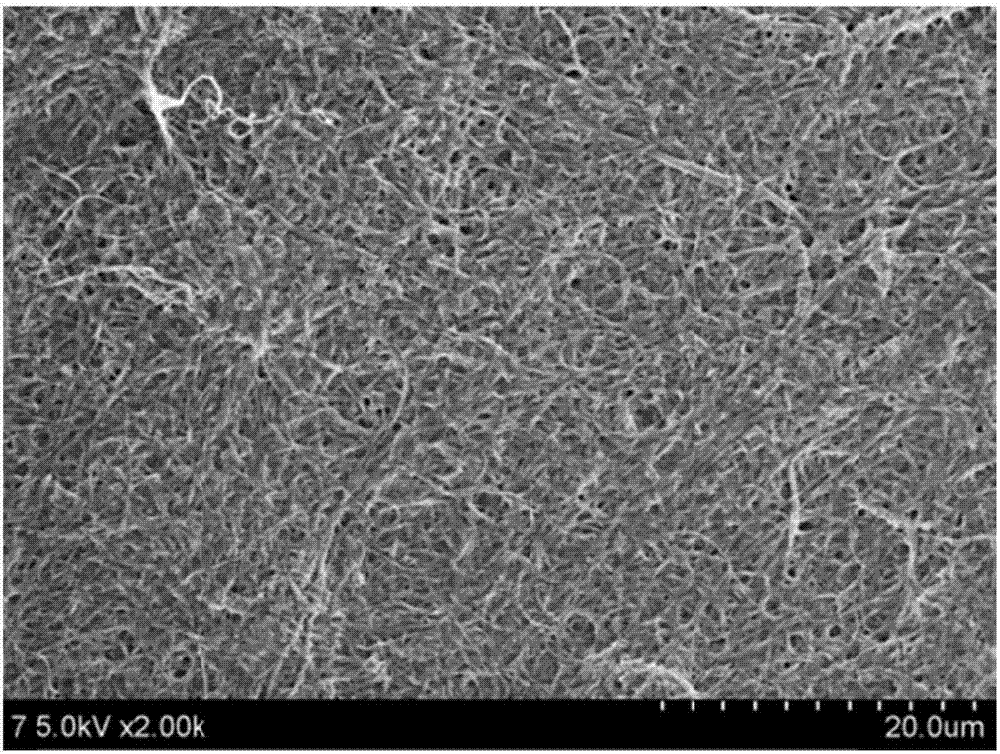

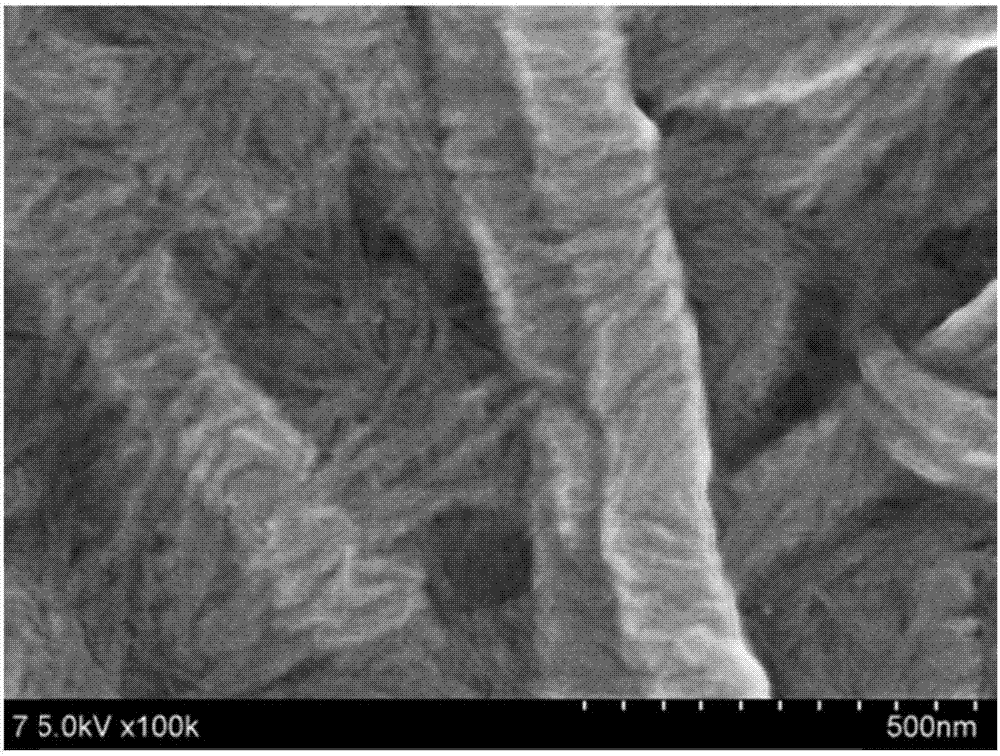

Modified three-dimensional fiber-based aerogel material and preparation method thereof

The invention relates to a preparation method of a modified three-dimensional fiber aerogel material and a modified three-dimensional fiber aerogel material product. The preparation method comprises the following steps of: preparing a fiber suspension or fiber / functional particulate matter composite suspension; processing the suspension by curing; removing a solvent cured in a curing block to obtain a non-cross-linking fiber-based aerogel; then processing by crosslinking stabilizing, or further processing by modifying to obtain the modified three-dimensional fiber-based aerogel material. The product is a three-dimensional network type material formed by the interfingering and staggering of the fibers, or the functional particles are dispersed into the three-dimensional network type material to form a composite structure; and the product has the volume density of 0.1 to 500mg / cm<3>, average pore size of 0.01 to 2,000 microns and specific surface area of 0.2 to 2,000m<2> / g. The preparation method is simple in preparation process and few in limitations to raw materials; and the modified three-dimensional aerogel material product is high in flexibility and connectivity and has a wide application prospect in a plurality of fields.

Owner:DONGHUA UNIV

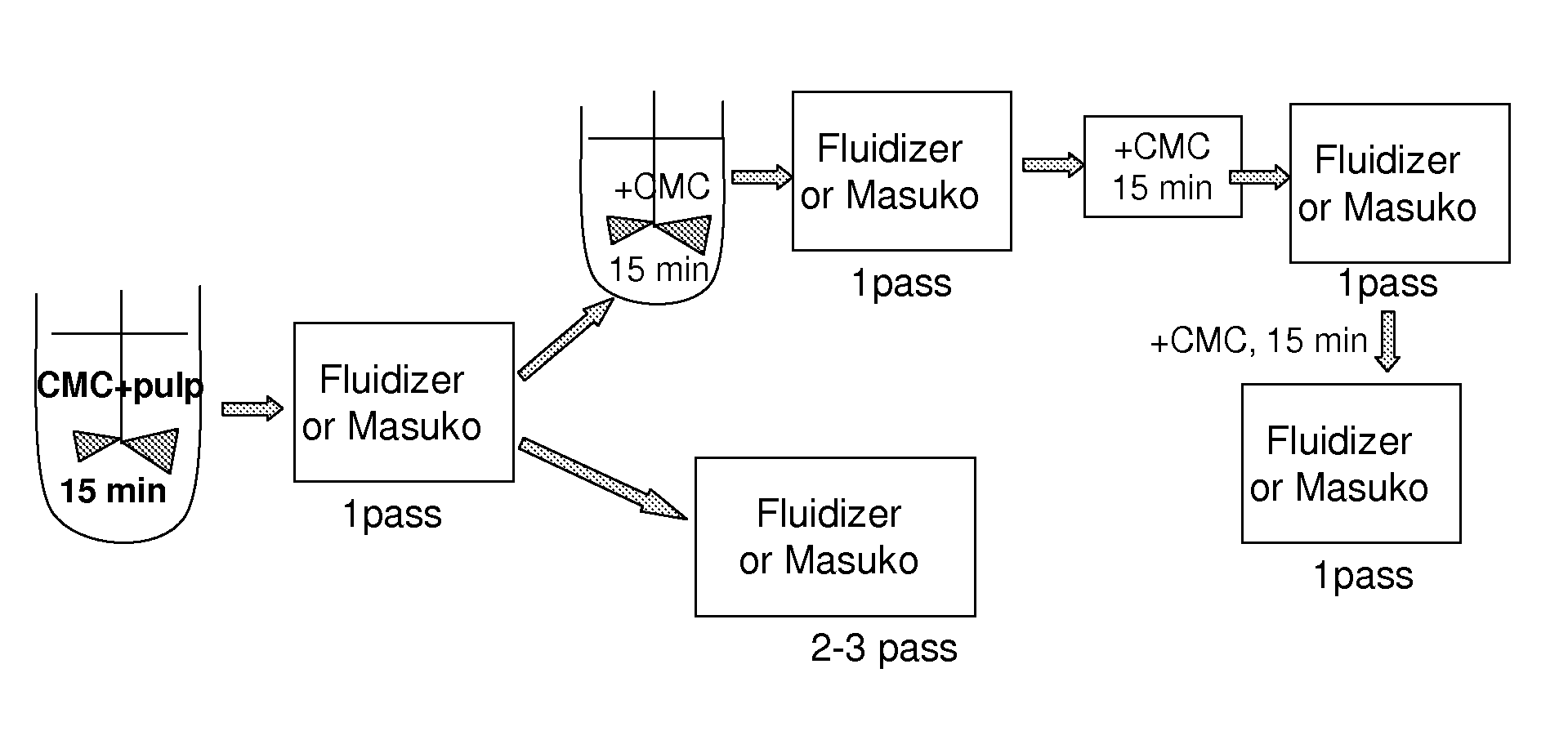

Method for producing modified cellulose

InactiveUS20120043039A1Improve propertiesEfficient productionSpecial paperPaper after-treatmentFiberFiber suspension

The present invention provides a method for producing modified nanofibrillated cellulose characterized by bringing cellulosic material into a fiber suspension, adsorbing a cellulose derivative or polysaccharide or polysaccharide derivative onto fibers in said fiber suspension under special conditions and subjecting the obtained fiber suspension derivative to mechanical disintegration. A modified nanofibrillated cellulose obtainable by a method of the present invention is provided. Furthermore, the invention relates to the use of said modified nanotibrillated cellulose.

Owner:UPM-KYMMENE OYJ

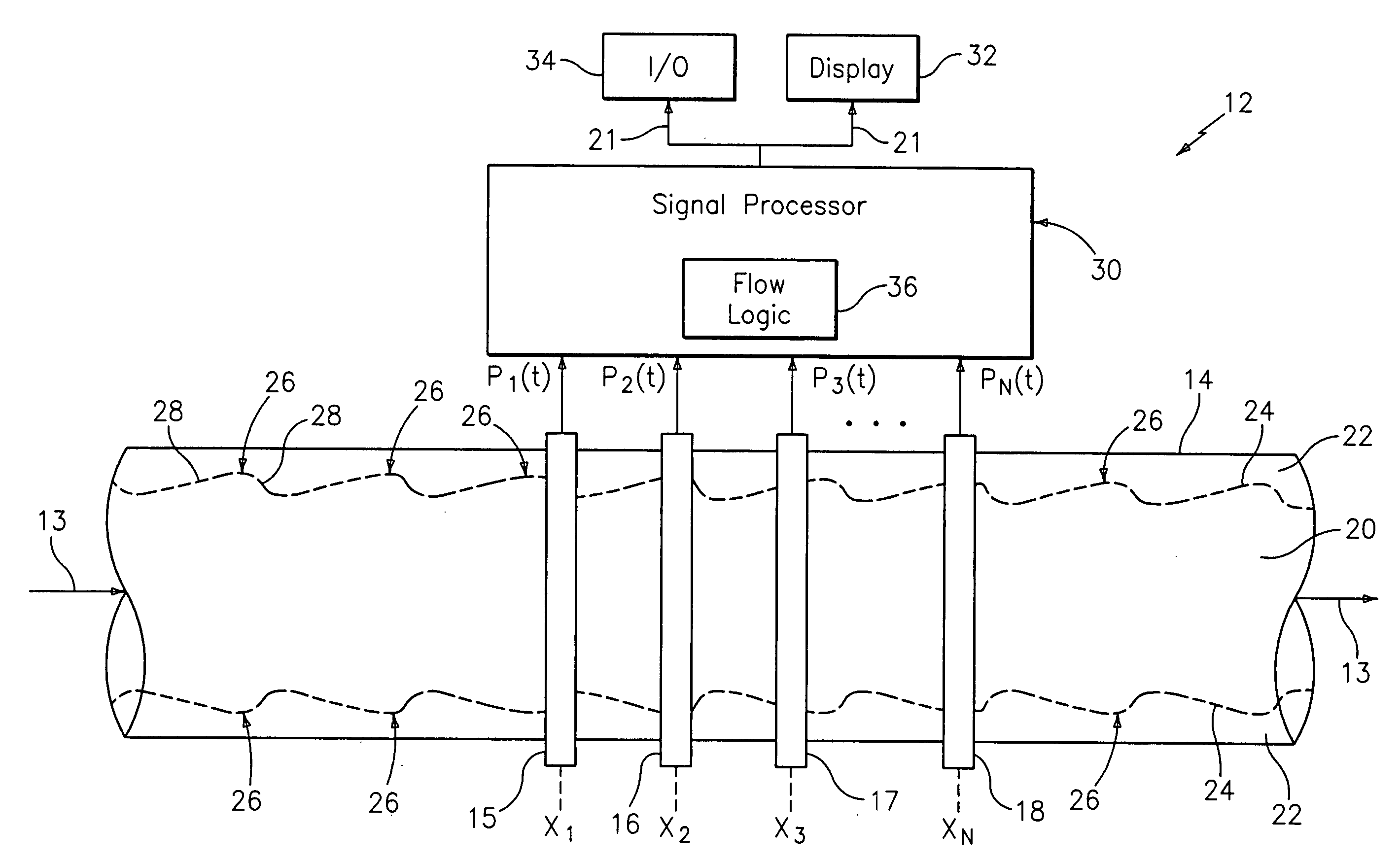

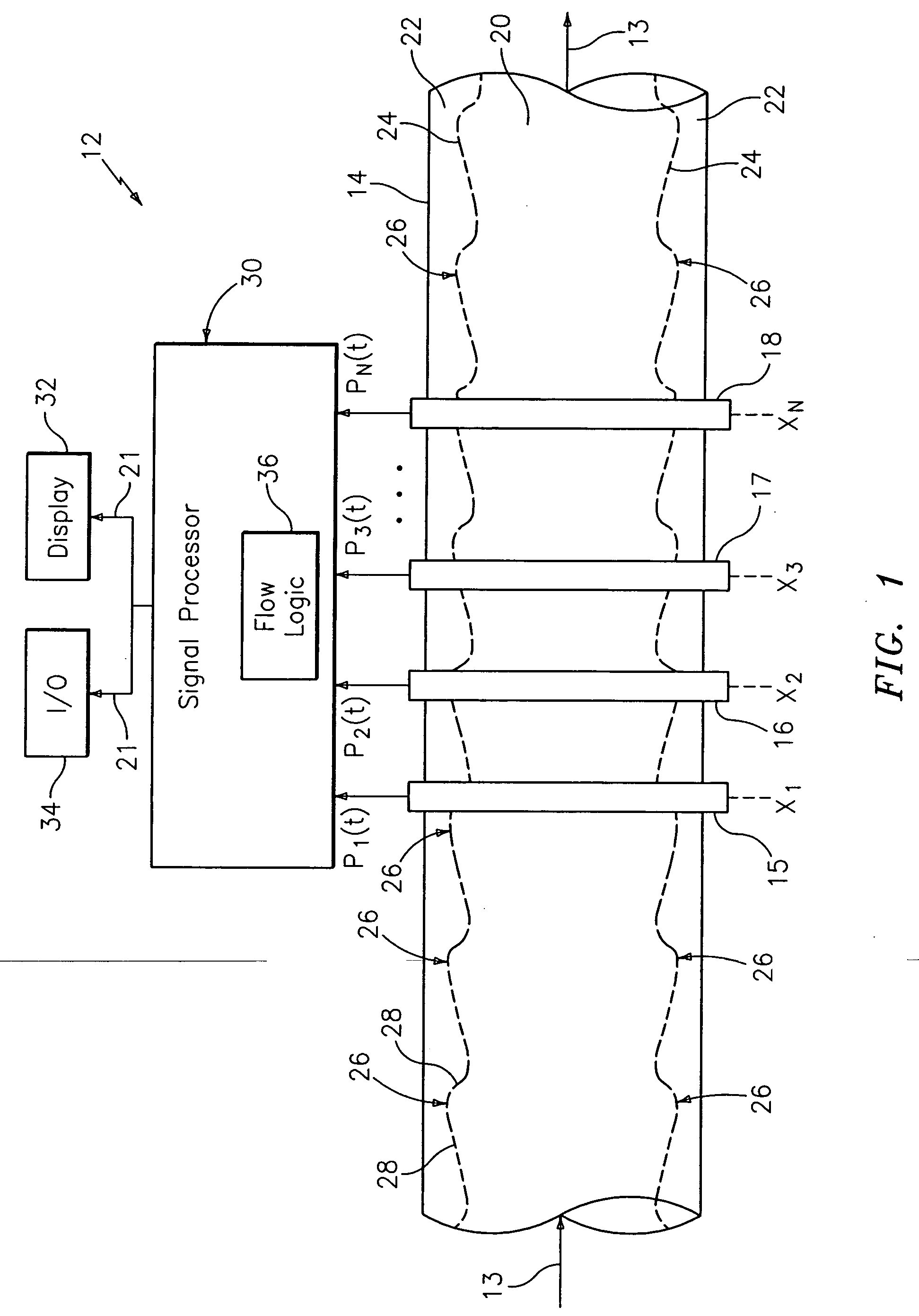

Method and apparatus for measuring characteristics of core-annular flow

ActiveUS20050033545A1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsFiberEngineering

An apparatus and method are disclosed wherein at least one parameter associated with a core-annular flow (CAF) in a pipe is measured by sensing unsteady pressures associated with undulations formed at the interface of a core region and an annular region in the CAF at different axial locations along the pipe. The at least one parameter, which may include a flow velocity of the CAF, Mach number associated with the CAF, and a volumetric flow rate of the CAF, is determined using sensed unsteady pressures. The CAF may be developed from a shear thinning fluid, such as bitumen froth or from a wood pulp fiber suspension. Alternatively, the CAF may be developed from a lubricating fluid, such as water, and a fluid to be transported, such as oil, where the fluid to be transported forms the core region and the lubricating fluid forms the annular region.

Owner:CIDRA

Process for producing nanofibers

ActiveUS8444808B2Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberShear rate

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

Process for recycling and preparing coated white board paper by using waste paper

The embodiment of the invention discloses a process for recycling and preparing coated white board paper by using waste paper. The process comprises the following steps of: taking waste paper, repulping, screening, deinking, deslagging, washing and concentrating, whitening, storing in a pulp pool and making paper, wherein the step of repulping comprises the steps of dispersing the waste paper into a fiber suspension liquid, heating the fiber suspension liquid to be at 40-55 DEG C, adding a cellulose liquid and rotating for 20-35minutes so as to conduct primary deinking; the step of deinking comprises a step of further deinking by using an ultrasonic generator; the step of whitening comprises steps of oxidation and reduction whitening; the step of making paper comprises the steps of respectively feeding the whitening pulp into a surface layer, a core layer and a base layer of a paper machine conveying system, respectively making the pulp into three layers by using a paper machine according to the ratio of 38-78wt%, 15-35wt% and 12-30wt%, and subsequently conducting composite paper making so as to manufacture a raw paper board. According to the process, no raw wood pulp is used, so that the resource is saved, the environment is protected, the production cost is lowered, and moreover the produced white board paper is good in whiteness, high in strength and applicable to requirements of high-quality package and decoration.

Owner:GUANGDONG SONGYANG RECYCLE RESOURCES

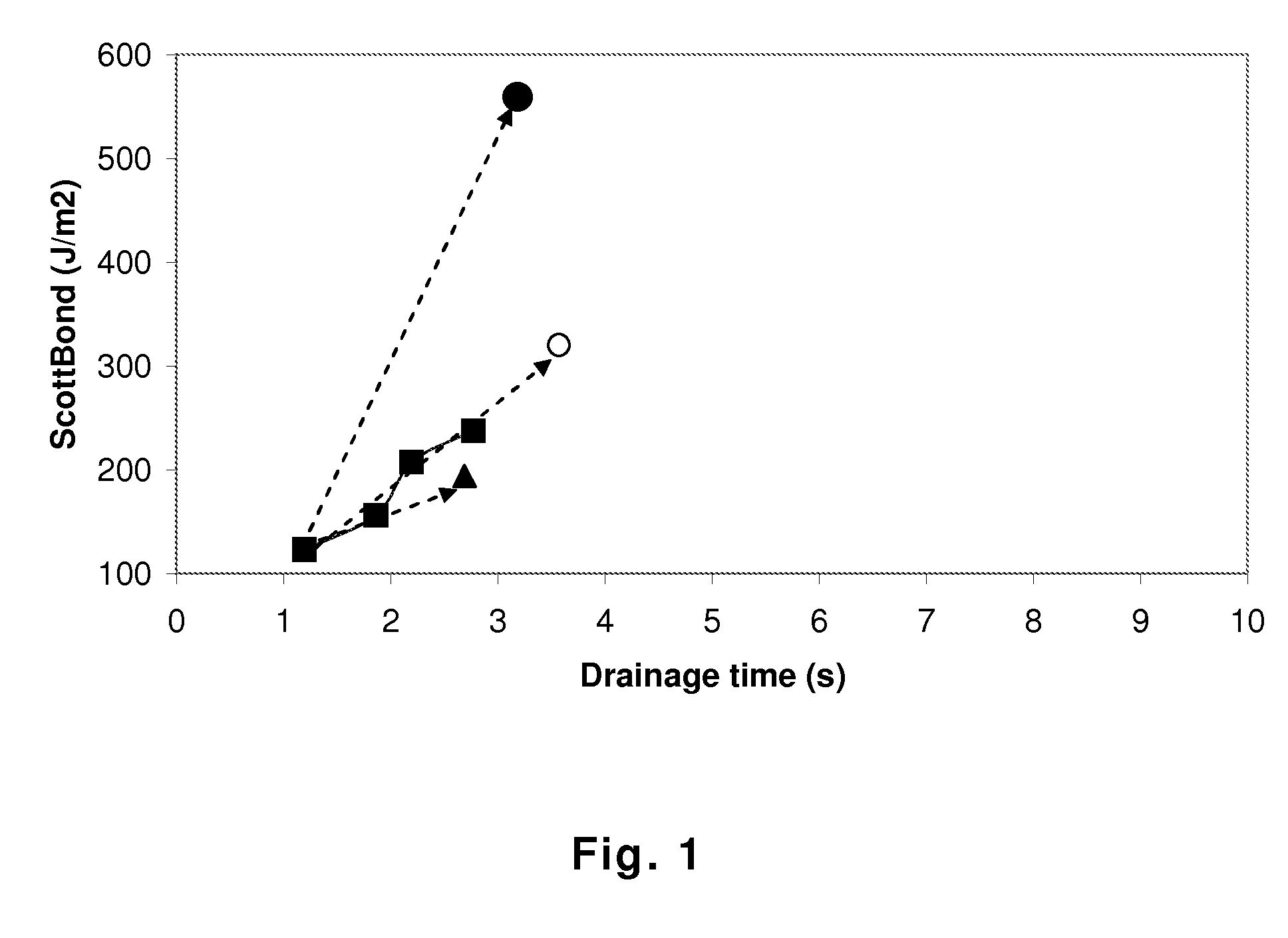

Process for improving optical properties of paper

InactiveUS20100132901A1Increase brightnessHigh whitenessNatural cellulose pulp/paperSpecial paperOptical propertyCellulose fiber

The present invention is directed to a method of efficiently maintaining or increasing brightness and whiteness of refined paper. In one aspect, the invention is directed to a method for substantially maintaining (or even increasing) brightness and / or whiteness of paper with increased pulp refining, the method including refining the pulp down to reduce the freeness at least about 100 CSF and adding a combination of an OBA and a carrier polymer to the paper surface in the size press in amounts sufficient to increase brightness and / or whiteness of the final paper. In another aspect, the invention is directed to a method of making paper from refined pulp that includes refining a cellulosic fiber suspension to reduce the freeness at least about 100 CSF and contacting the cellulosic fibers with at least one optical brightening agent (OBA) during or after the refining step prior to adding any additional wet end chemicals.

Owner:AKZO NOBEL NV

Process and a fluffer device for treatment of a fiber stock suspension

InactiveUS7169258B2Marked homogenization improvementNatural cellulose pulp/paperSpecial paperCardboardFiber

A device treats a fiber stock suspension with at least one additive, the fiber stock suspension being used for production of at least one of paper and cardboard. The fiber stock suspension includes a suspension medium and a fiber material. The fiber material has fiber surfaces, the fiber surfaces being moistened by the suspension medium. The device includes a fluffer having an inlet for receiving at least one of the fiber stock suspension and the at least one additive. The fluffer is coupled to the inlet, the fluffer being configured for separating the fiber material and enlarging a specific surface of the fiber surfaces.

Owner:VOITH PATENT GMBH

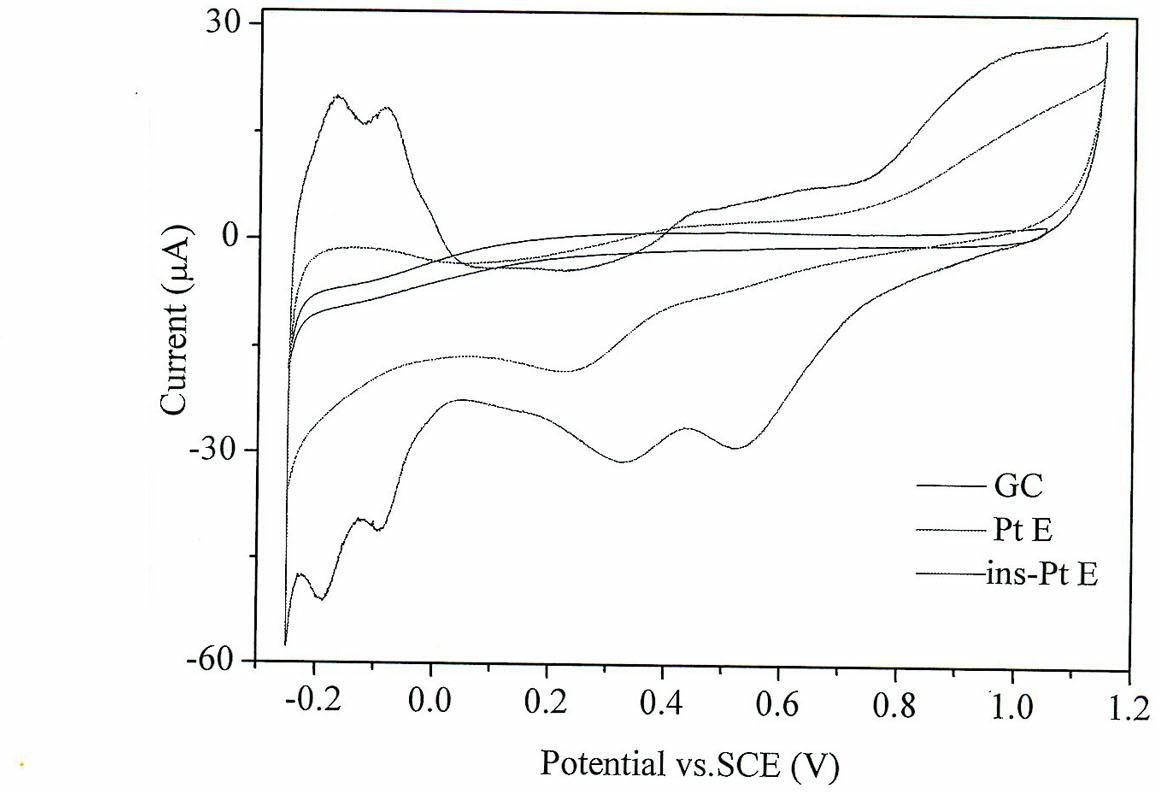

Preparation method of ultrafine platinum nano-wire

The invention relates to a preparation method of an ultrafine platinum nano-wire. The method mainly comprises that an insulin fiber suspension is obtained by dissolving bovine insulin powders into a hydrochloric acid solution with the concentration of 10-25 mM to prepare an insulin hydrochloric acid solution, blending the insulin hydrochloric acid solution with vortexes, and heating the blended insulin hydrochloric acid solution for 5-20 h in a constant-temperature metal bath at the temperature of 65-70 DEG C; and that the ultrafine platinum nano-wire is obtained by adding a chloroplatinic acid solution into the above insulin fiber suspension, fully blending the mixture, incubating the mixture for 10-20 h in a shaking table at the temperature of 4-10 DEG C and with the rotating speed of 50-100 r / min, dropwise adding a sodium borohydride reductant solution with a concentration of 5-10 mM into the mixture, and vibrating the mixture for 8-24 h in a shaking table at the temperature of 4-10 DEG C and with the rotating speed of 50-100 r / min to make the mixture fully reacted. The method of the invention has the advantages of a simple process, mild reaction conditions, and good repeatability, and is environment protective and highly efficient. With the method, appearance of the platinum nano-wire has no obvious changes while output of the nano-wire increases substantially. Thus, the nano-wire is provided with higher aspect ratio and simpler regulation and control method of output, thereby being easier to realize large-scale production.

Owner:YANSHAN UNIV

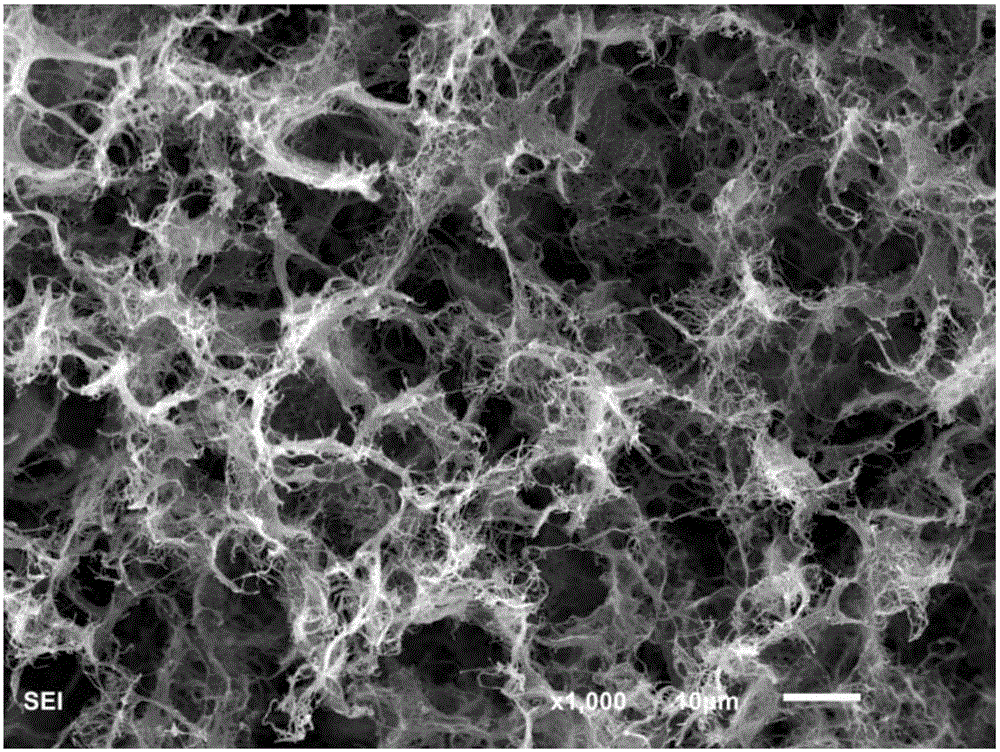

Polymeric nanofiber-based aerogel material and preparation method thereof

The invention discloses a polymeric nanofiber-based aerogel material and a preparation method thereof, and belongs to the fields of aerogel materials and preparation methods thereof. The preparation method comprises the steps that a thermoplastics polymer and cellulose acetate butyrate are subjected to melt blending, drawing, extracting and the like to prepare polymeric nanofibers, the polymeric nanofibers are added into water or a water solvent prepared from water and an organic solvent to generate polymeric nanofiber dispersion liquid, a cross-linking reaction is conducted to obtain cross-linked polymeric nanofiber suspension liquid, freeze drying is conducted on the cross-linked polymeric nanofiber suspension liquid, and then the polymeric nanofiber-based aerogel material is prepared. The polymeric nanofiber-based aerogel material prepared through the method has the advantages of being obvious in nanofiber porous structure, good in mechanical property and the like. The material prepared through the method can be applied to the fields of air filtration, thermal insulation, adsorption and the like directly or by being composited with other materials.

Owner:武汉维晨科技有限公司

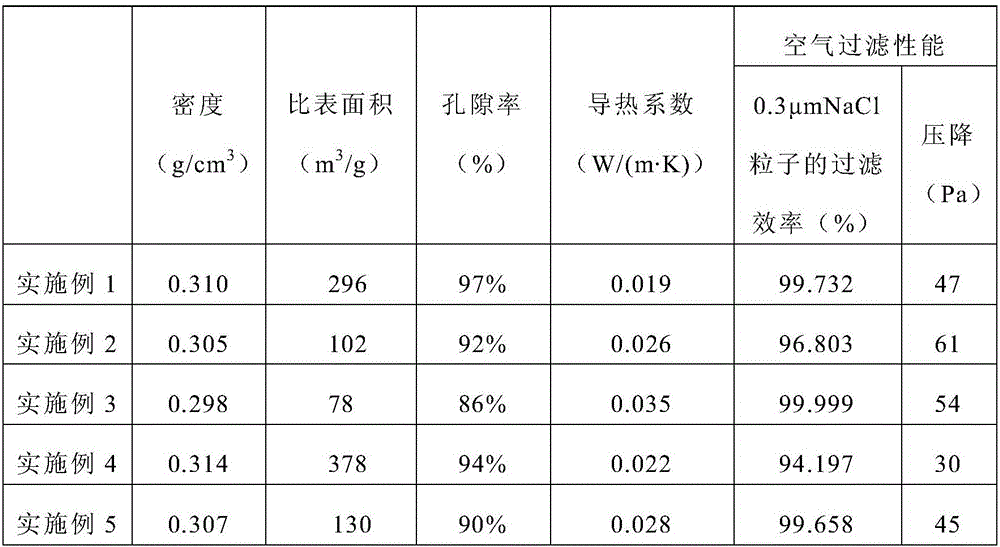

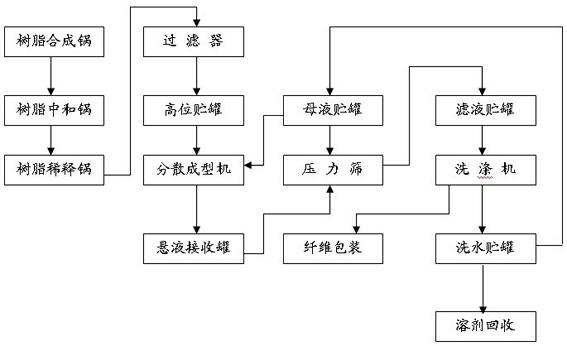

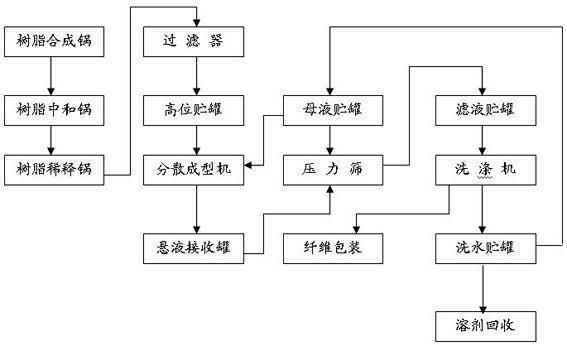

Production method of meta-position aramid paper fibrid

InactiveCN102660795AEasy to shapeGood dispersionSynthetic cellulose/non-cellulose material pulp/paperMonocomponent polyamides artificial filamentChlorideFiber suspension

The invention discloses a production method of a meta-position aramid paper fibrid. The production method comprises the following steps of: polymerizing m-phenylenediamine and isophthaloyl chloride in DMAC (M, N-dimethylacetamide) to form PMIA (polyisophthaloyl metaphenylene diamine) resin); producing hydrogen chloride gas by a neutralization reaction; diluting the resin, dispersing in a mother liquor and precipitating to obtain a fibrid suspending liquid in accordance with the manufacturing conditions of the meta-position aramid paper; pumping the fibrid suspending liquid and deionized water into a washing and filtering machine, and removing the solvent, additive and moisture containing in the fibrid to obtain the fibrid in accordance with the manufacturing conditions of the meta-position aramid paper. The method has advantages of low cost, high efficiency, stable process, simple used equipment and suitability for sustainable industrial production.

Owner:SICHUAN YUNTONG CHEM IND CO LTD

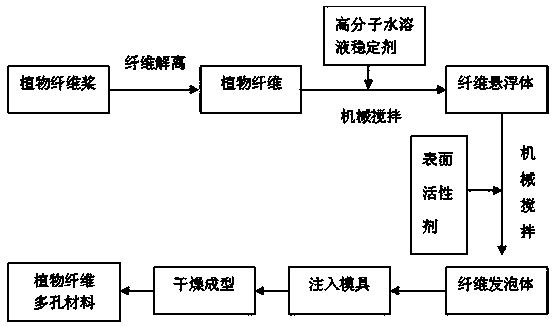

Preparation method of plant fiber porous composite material

The invention relates to a preparation method of a plant fiber foaming composite material. By taking plant fiber, an anionic surfactant and a water-soluble polymer foaming agent as raw materials, the preparation method mainly comprises the working procedures of preparation and mixing of a water-soluble polymer aqueous solution stabilizer, as well as forming, drying molding of plant fiber suspension liquid and plant fiber foams. The preparation method comprises the steps of: adding the water-soluble polymer stabilizer into a certain amount of water, stirring and dissolving at a certain temperature to form an aqueous solution with mass fraction of 1%-20%; adding a certain amount of plant fiber into the aqueous solution of the water-soluble polymer stabilizer, mechanically stirring at the room temperature so that the plant fiber is dispersed uniformly to form the plant fiber suspension liquid; adding the anionic surfactant into the plant fiber suspension liquid, mechanically stirring at a high speed and foaming to form a plant fiber foaming system; and pouring the plant fiber foaming system into a mould, drying and molding at 60-120 DEG C to prepare the plant fiber foaming composite material with a three-dimensional network structure. The main raw material plant fiber needed by the preparation method is abundant and low in price and can be recycled, the production process does not pollute the environment, and the product is stable in performance and light in weight.

Owner:HUBEI UNIV OF TECH

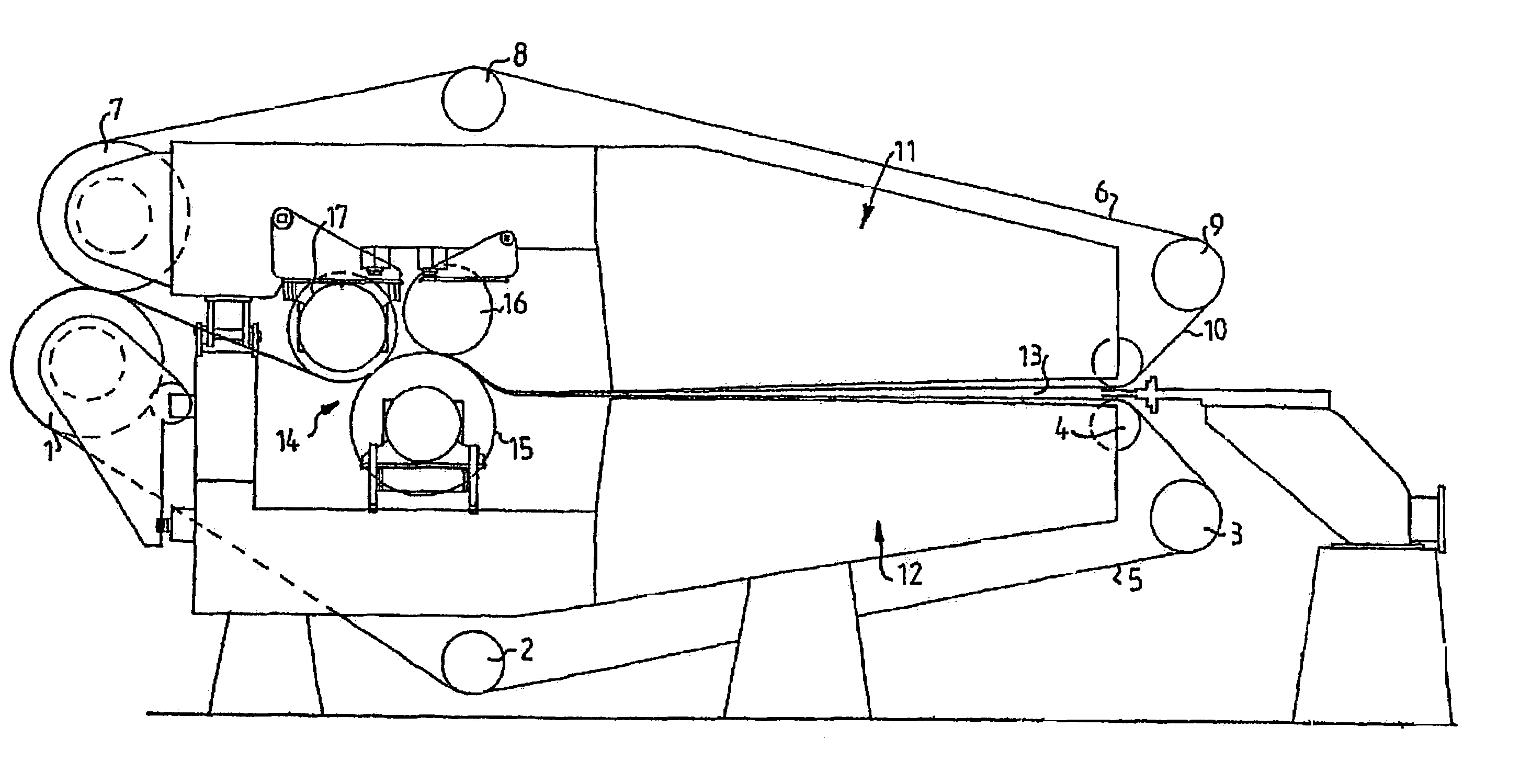

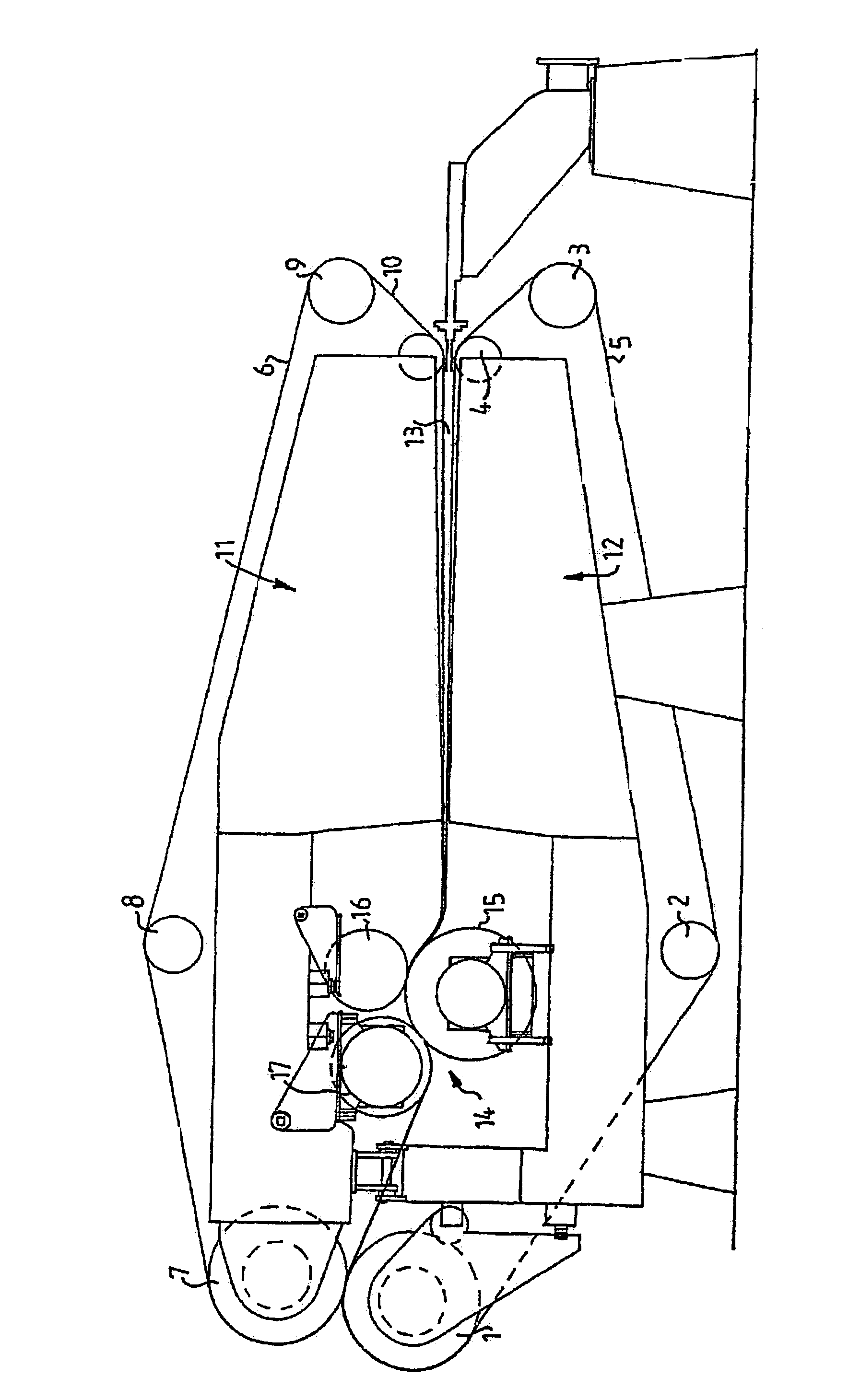

Twin-wire belt press

InactiveUS7051882B2Simpler and small and cheap and reliableAvoid rewettingMachine wet endPress sectionFiberEngineering

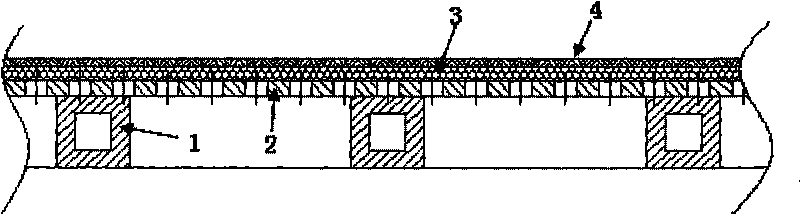

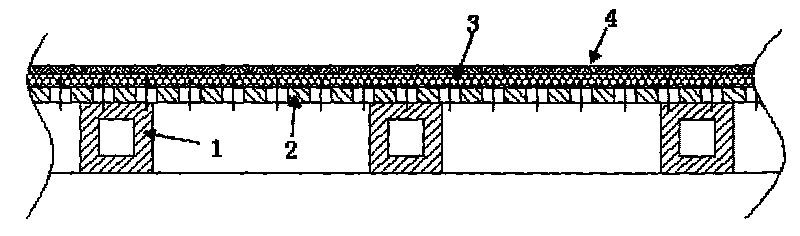

A twin-wire belt press is disclosed for dewatering a fiber suspension and forming a continuous web of the fiber suspension. The twin wire belt includes a plurality of upper and lower rolls, a perforated roll and endless upper and lower wire belts. Dewatering tables are used to support the endless upper and lower wire belts and form a wedge-shaped pressure space between the endless upper and lower wire belts for initially pressing and dewatering the fiber suspension and forming a web therebetween. Roll members, including at least two press rolls which form press roll nips with the perforated roll and another roll, press and dewater the web between the endless upper and lower wire belts.

Owner:VALMET TECH INC

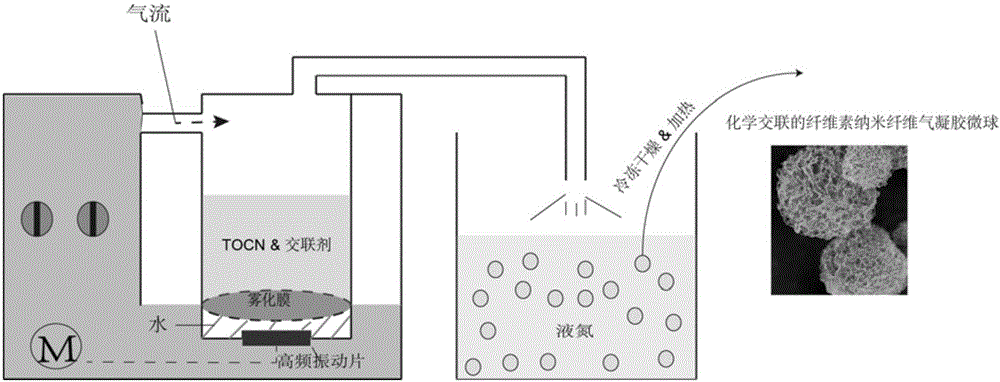

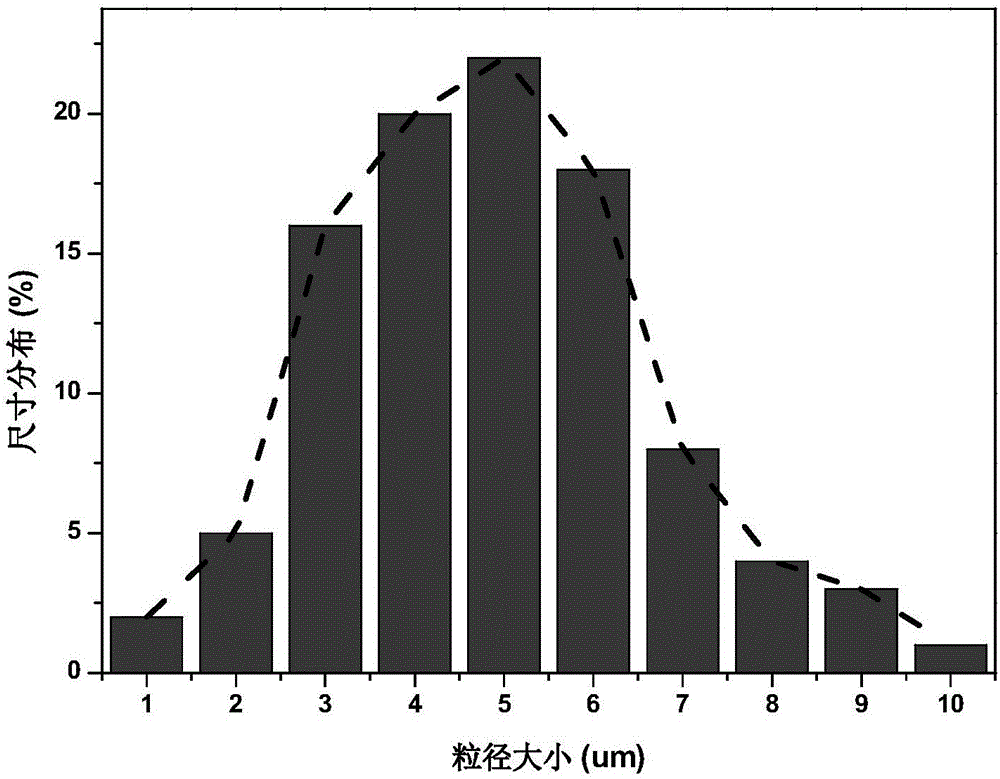

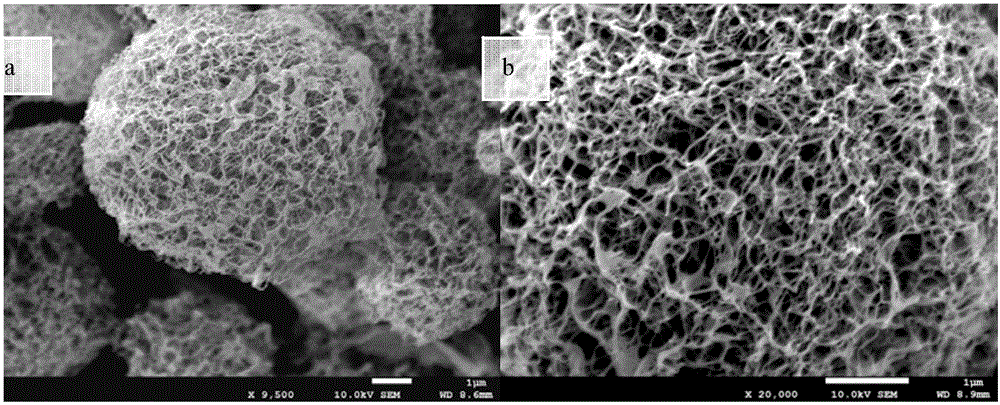

Technique for preparing cellulose nano fiber aerogel microspheres by ultrasonic atomization

The invention discloses a technique for preparing cellulose nano fiber aerogel microspheres by ultrasonic atomization. The technique comprises the following steps: defibering bleached coniferous wood sheet pulp, adding tetramethyl piperidine oxide, sodium hypochlorite and sodium bromide, and carrying out oxidation reaction for 2-4 hours under the pH value of 9.5-11; carrying out ultrasonic dissociation on the oxidated pulp to prepare a cellulose nano fiber suspension; and adding a crosslinking agent into the cellulose nano fiber suspension, pouring into an atomization cup of an ultrasonic atomizer, blowing the atomized oxidated nano cellulose fog drops containing the crosslinking agent and tetramethyl piperidine oxide into a liquid-nitrogen-filled container, carrying out freeze-drying on fast-frozen ice microspheres, and finally, carrying out crosslinking reaction on the dried aerogel microspheres at 110-130 DEG C for 2-4 hours, thereby obtaining the cellulose nano fiber aerogel microspheres.

Owner:LIANSHENG PAPER IND LONGHAI

Machine for producing a fibrous web

InactiveUS20060060321A1Suitable for productionImprove paper qualityMachine wet endFiberFiber suspension

Owner:VOITH PATENT GMBH

Method and device for preparing chopped fiber continuous orientation felt

ActiveCN106758481AIncreasing the thicknessIncrease widthPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiber suspensionControllability

The invention provides a method for preparing chopped fiber continuous orientation felt and belongs to the field of fiber fabric. The method comprises the following processes: dispersion, orientation, separation, drying and rolling, wherein in the orientation process: a chopped fiber suspension dispersed in a storage device is introduced into reducing orientation nozzles and is spread on conveying mesh belt running continuously after passing through the reducing orientation nozzles; in the separation process: moisture and a dispersant in the chopped fiber suspension on the conveying mesh belt are separated by negative pressure suction box located below the conveying mesh belt, and wet chopped fiber continuous orientation felt is obtained after washing. The device has high degree of automation, the prepared chopped fiber continuous orientation felt is high in controllability of thickness, width, length and fiber content, the orientation degree of chopped fibers in the chopped fiber continuous orientation felt is high, and the orientation structure is uniform; the device is energy-saving, environment-friendly, high-quality and efficient, the problems of low production efficiency and the failure in continuous and large-scale production are solved, and technical guarantee is provided for industrial application of the chopped fiber orientation felt.

Owner:BEIJING UNIV OF CHEM TECH

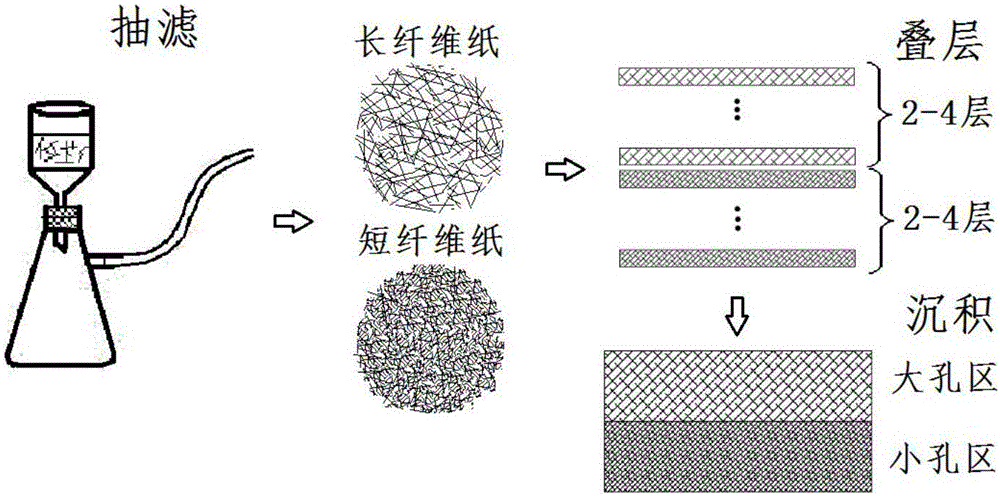

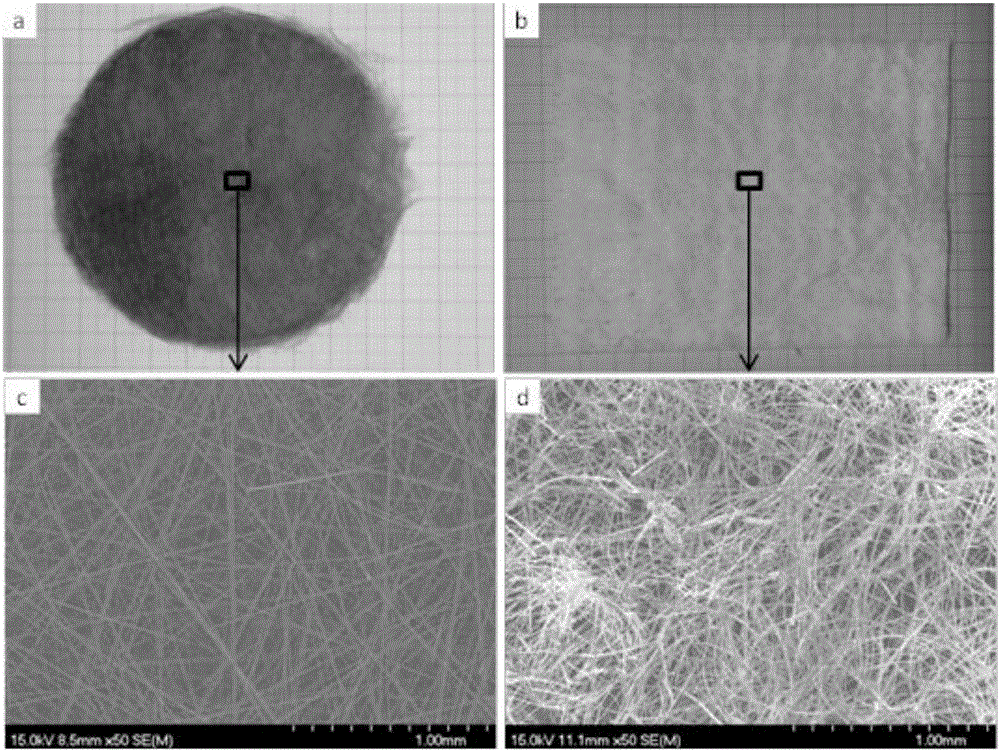

Preparation method of ceramic fiber porous combustion medium with gradient pore structure

The invention relates to a preparation method of a ceramic fiber porous combustion medium with a gradient pore structure. The preparation method comprises the following steps: respectively preparing a ceramic fiber suspension with different lengths or diameters by using ceramic fibers with different lengths or ceramic fibers with different diameters; carrying out suction filtration on the suspension to obtain ceramic fiber papers with different pore structures; laminating the ceramic fiber papers with a gradient pore structure (the fiber papers with a large pore structure are laminated at the upper portion, and the fiber papers with a small pore structure are laminated at the lower portion) according to a certain rule, and applying a certain pressure to obtain a ceramic fiber felt with a certain thickness and a gradient pore structure; and preparing a ceramic phase matrix on the ceramic fiber felt through a chemical vapor deposition (CVD) technology or a polymer infiltration pyrolysis (PIP) technology, and connecting ceramic fibers to obtain the ceramic fiber porous combustion medium with a gradient pore structure. The gradient pore structure makes a gas fuel be premixed in the upstream small pore zone and be combusted in the downstream large pore zone, so the combustion stability is improved, and the lean combustion limit is widened.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

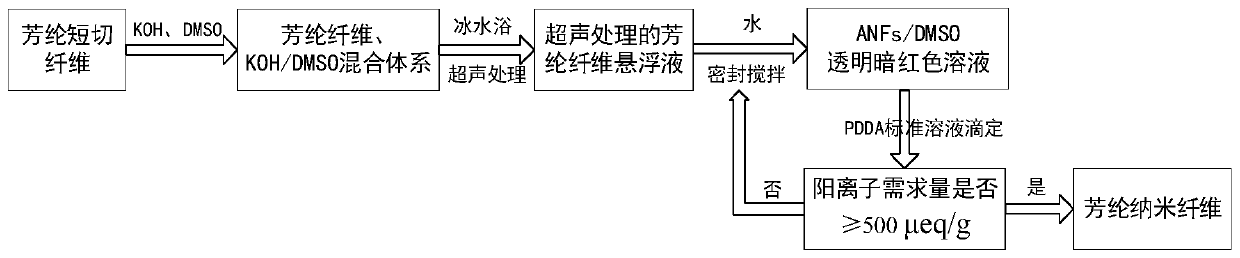

Method for preparing aramid nanofibers

ActiveCN110055797ASpeed up the deprotonation reaction rateImprove rigidityPaper material treatmentIce waterNanofiber

The invention discloses a method for preparing aramid nanofibers. Para-aramid fibers and KOH are added into DMSO (dimethylsulfoxide) solution to obtain a mixed system of para-aramid fibers, KOH and DMSO; the mixed system of para-aramid fibers, KOH and DMSO is ultrasonically treated in an ice water bath to obtain a para-aramid fiber suspension A; water is added into the para-aramid fiber suspensionA to obtain a para-aramid fiber suspension B; after being sealed, the para-aramid fiber suspension B is stirred to obtain an ANFs / DMSO (aramid nanofibers / DMSO) solution; the ANFs / DMSO solution is subjected to colloidal titration through a cation standard liquid; whether a reaction endpoint is reached is judged according to cation demand; if the reaction endpoint is reached, aramid nanofibers areprepared; if the reaction endpoint is not reached, the previous step is repeated until the reaction endpoint is reached. The method has the advantages that reaction time is shortened greatly, reactionconcentration is increased, reaction efficiency is improved evidently, and the method is easy to apply to large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Hollocellulose lithium ion battery diaphragm and preparation method thereof

ActiveCN107331823AImprove absorption rateImprove ionic conductivityCell component detailsPorosityFiber

The invention belongs to the crossing field of lithium ion battery diaphragms and biomass materials and specifically discloses a hollocellulose lithium ion battery diaphragm and a preparation method thereof. The preparation method comprises the steps: taking nano fibril cellulose, nano microcrystalline cellulose and cellulose derivative according to different mass fractions, dispersing into water and dispersing evenly by ultrasonic wave to obtain fiber suspension; preparing the fiber suspension into a wet diaphragm by a suction filtration method, hot pressing the wet diaphragm and performing vacuum drying on the wet diaphragm to obtain the hollocellulose lithium ion battery diaphragm. The prepared diaphragm is a hollocellulose completely-degradable diaphragm, the thickness of the diaphragm is 15 to 45mu m, the porosity is 45 to 80%, electrolyte absorptivity is larger than 400%, an ionic conduction rate is larger than 1.0mS cm<-1>, thermal stability is good, and a size change rate under condition of 200 DEG C for 3h is smaller than 0.1%.

Owner:SOUTH CHINA UNIV OF TECH

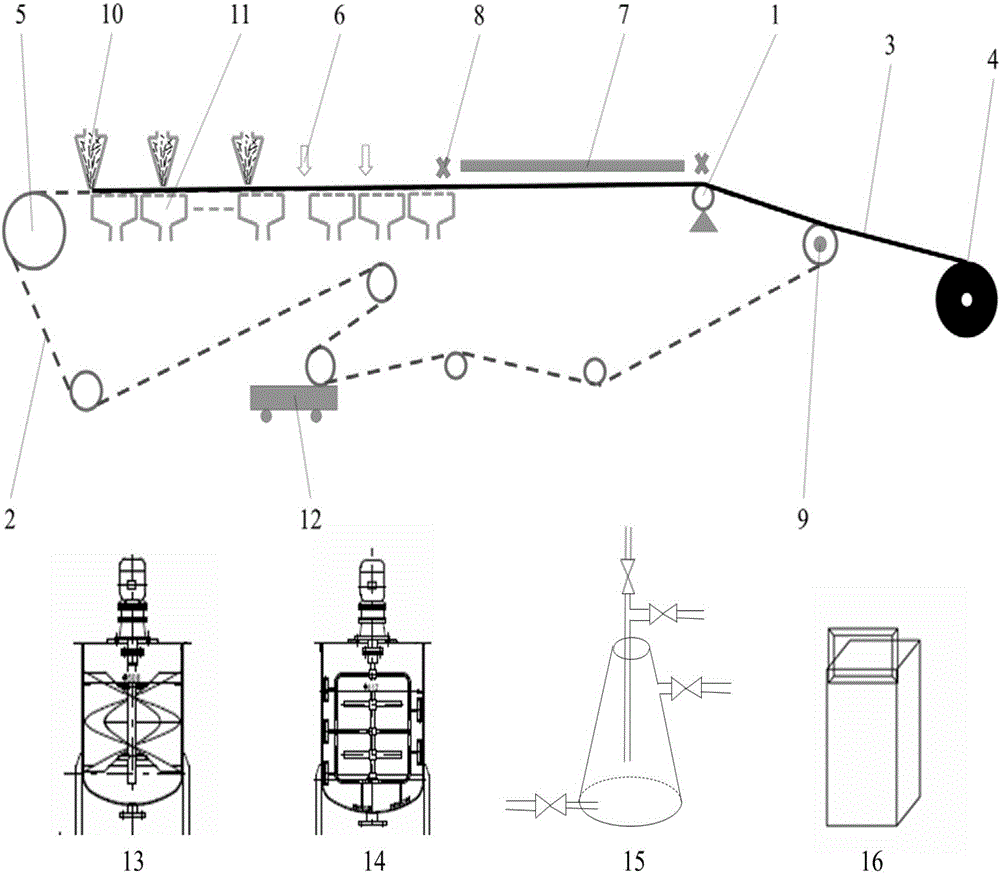

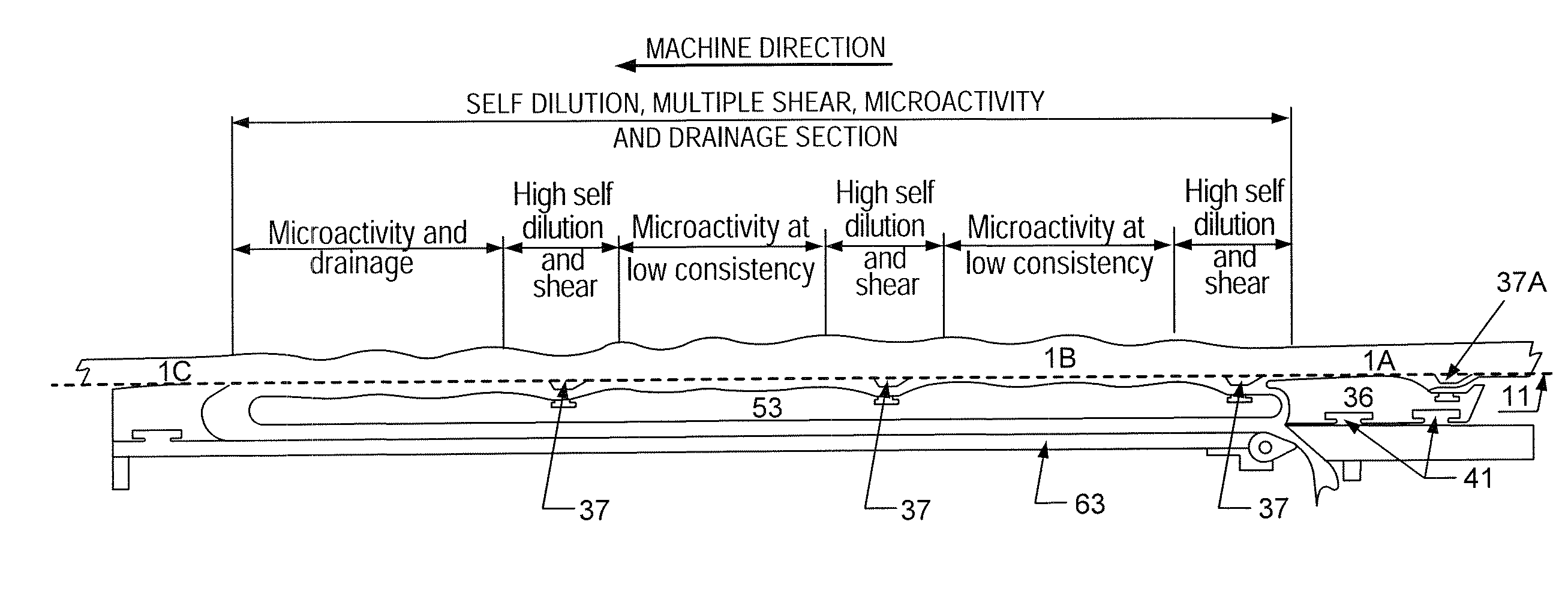

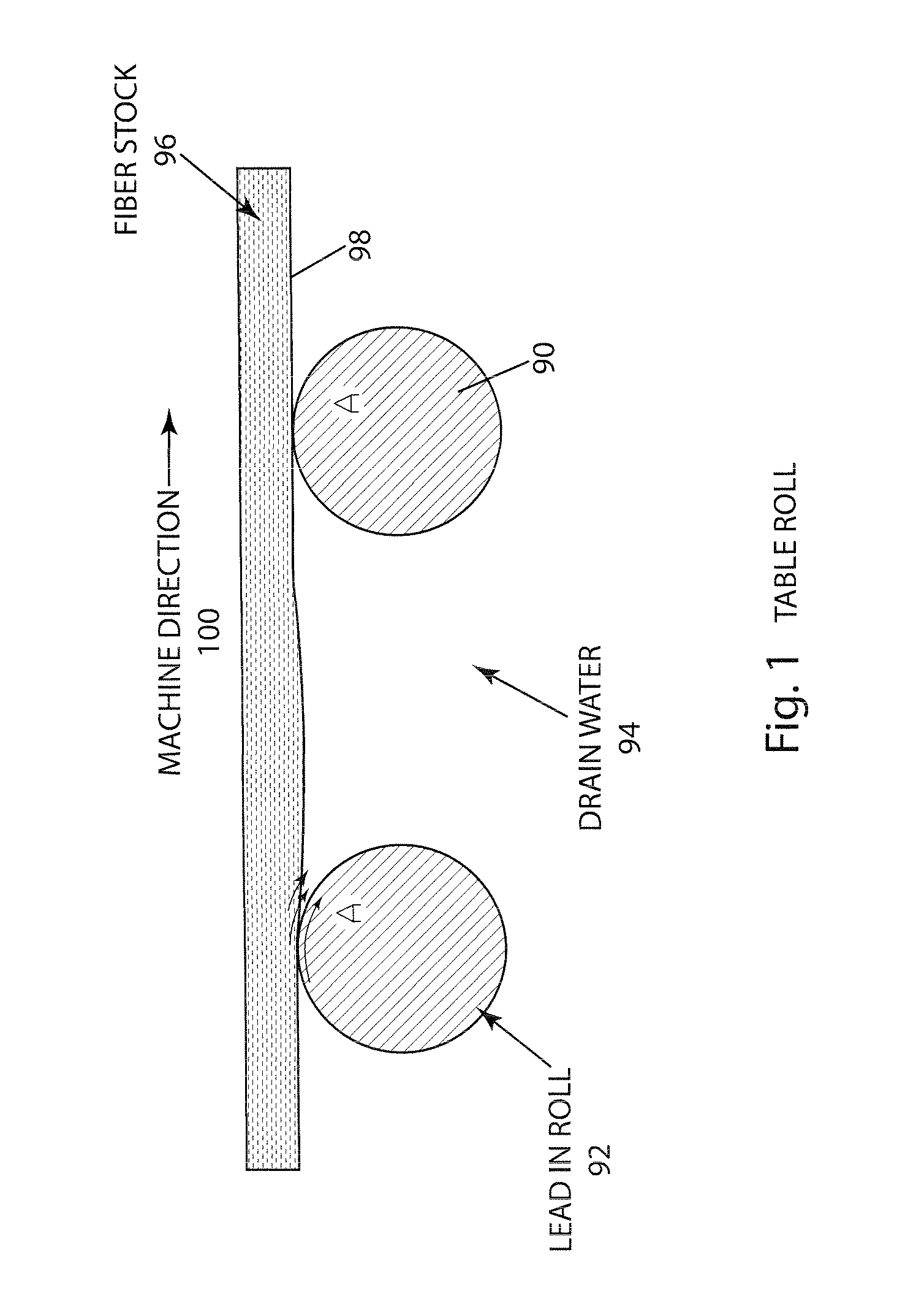

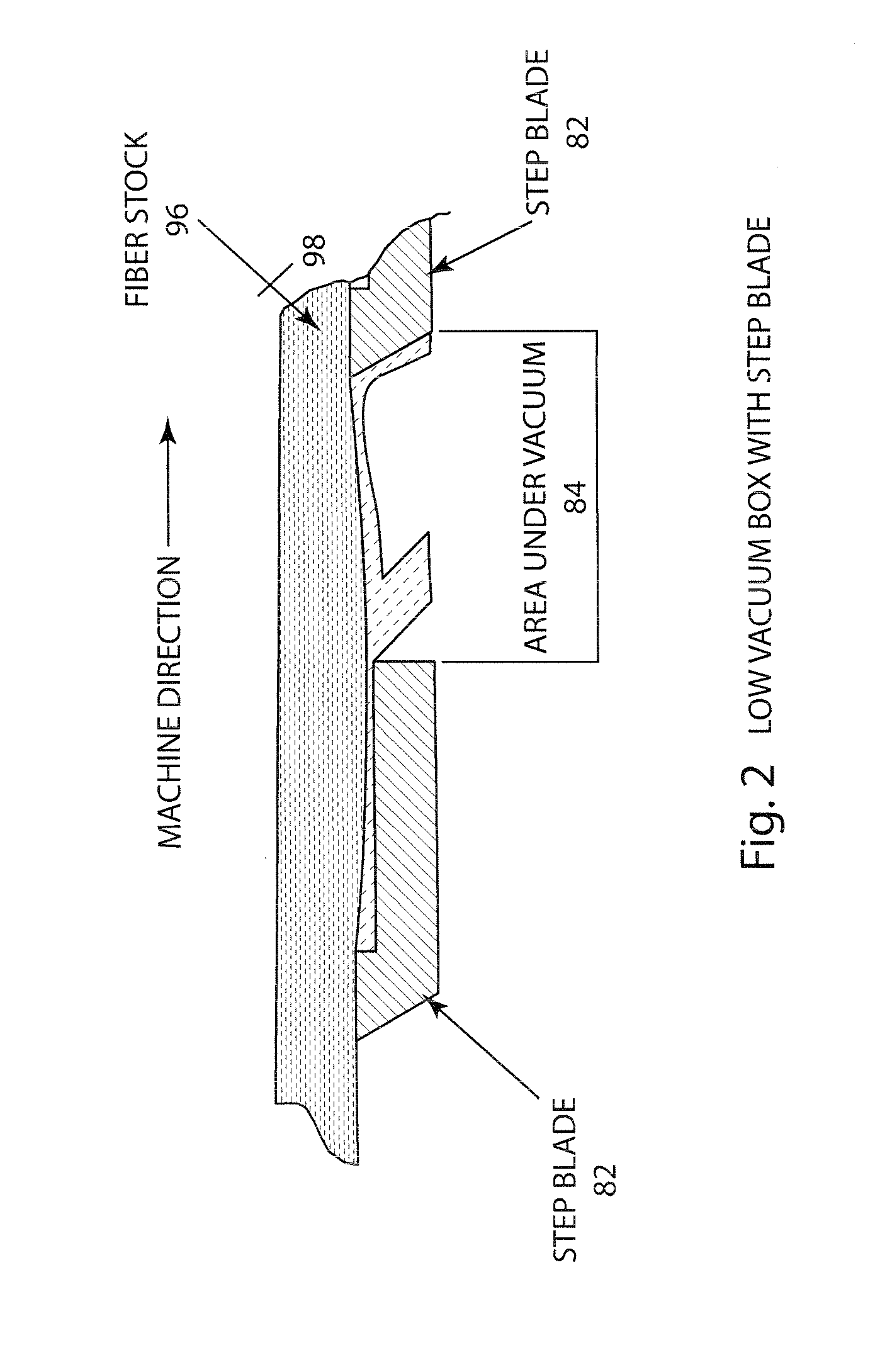

Energy saving papermaking forming apparatus system, and method for lowering consistency of fiber suspension

InactiveUS20110186254A1Increased recirculationEasy to implementFibreboardMachine wet endFiberPulp and paper industry

The present invention is directed to an apparatus used in the formation of paper. More specifically the present invention is directed to an apparatus, system, and method for lowering the consistency or degree of density of fiber suspension on the forming table, and improving the quality and physical properties of the paper formed thereon.

Owner:FCPAPEL

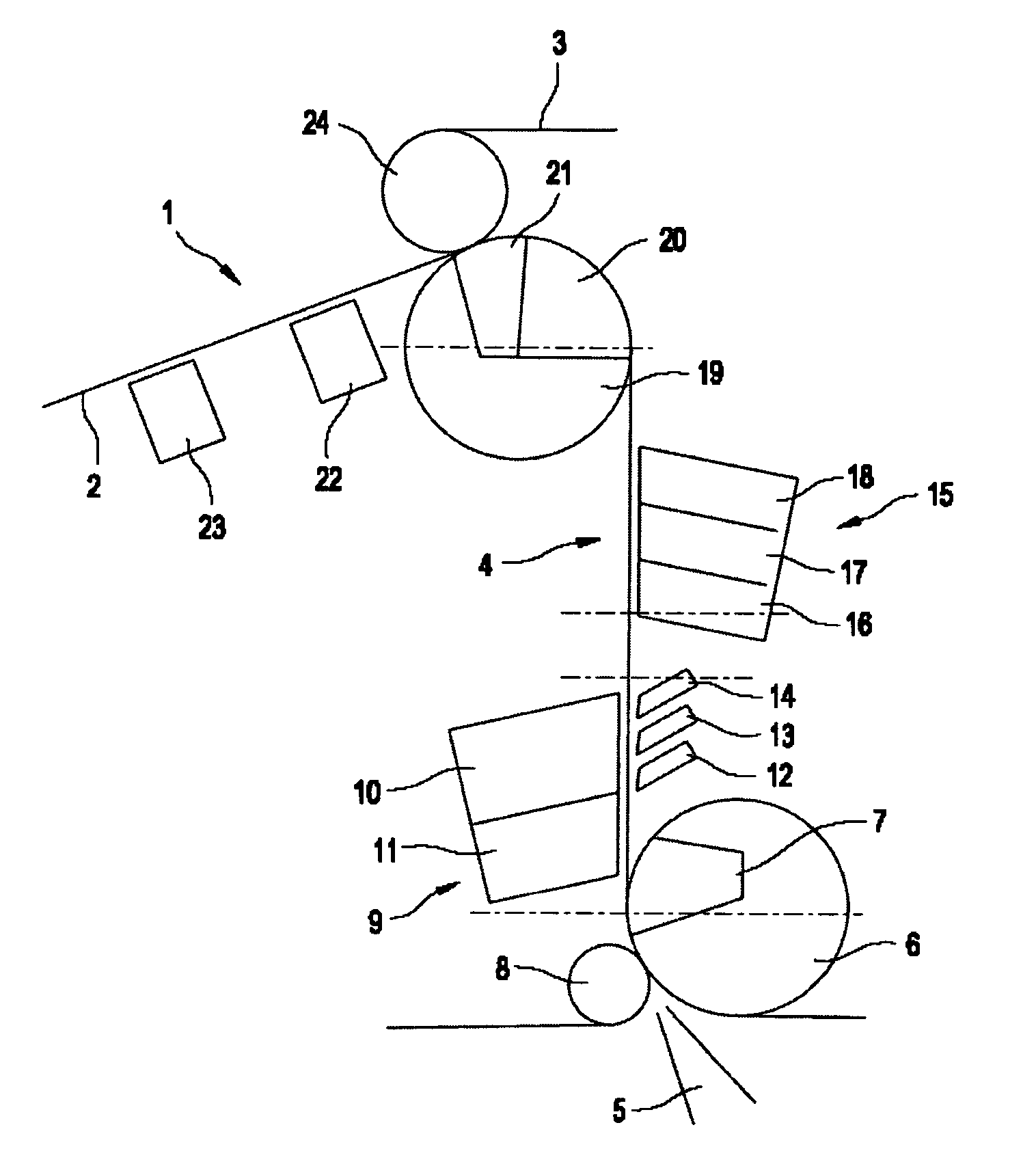

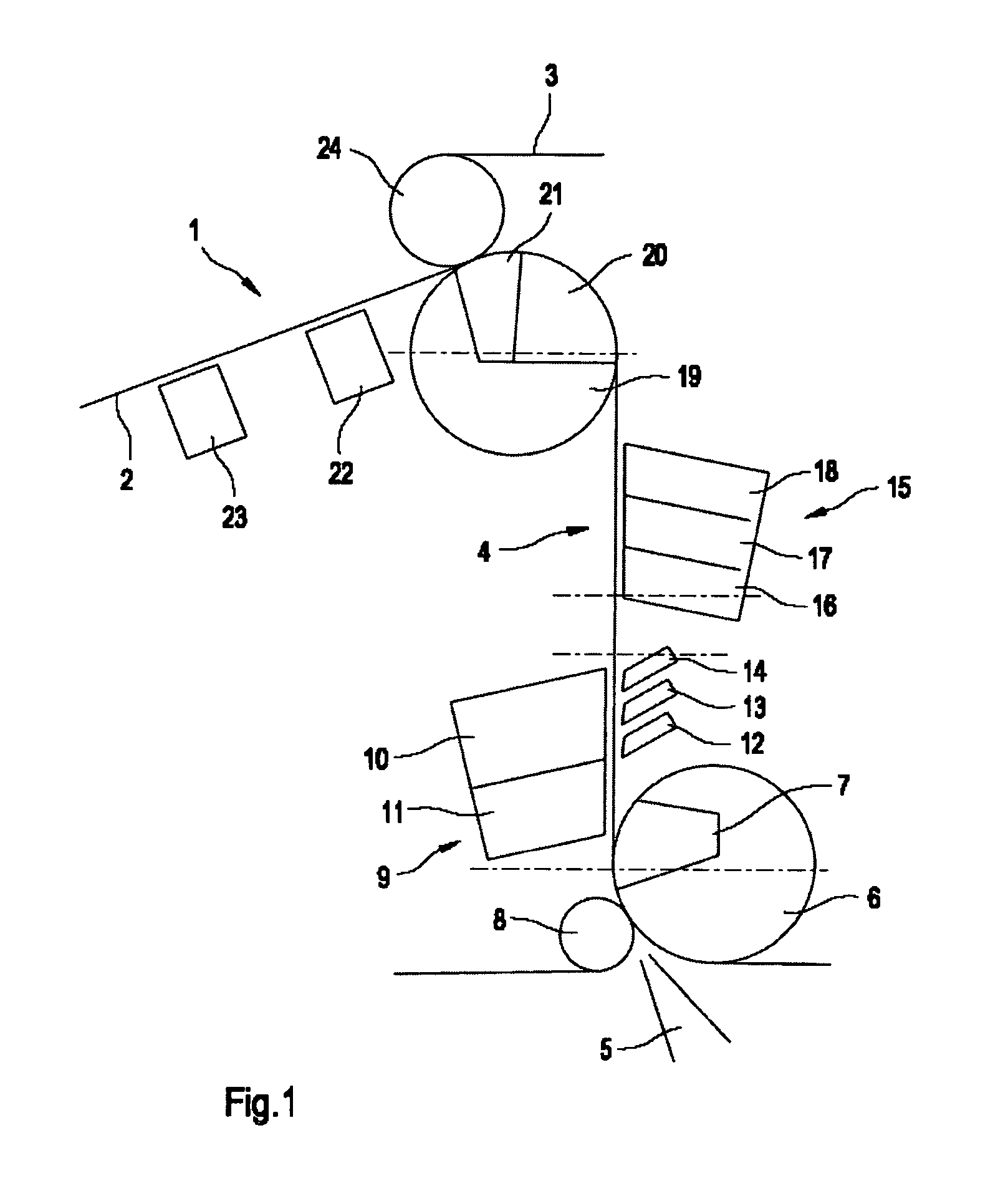

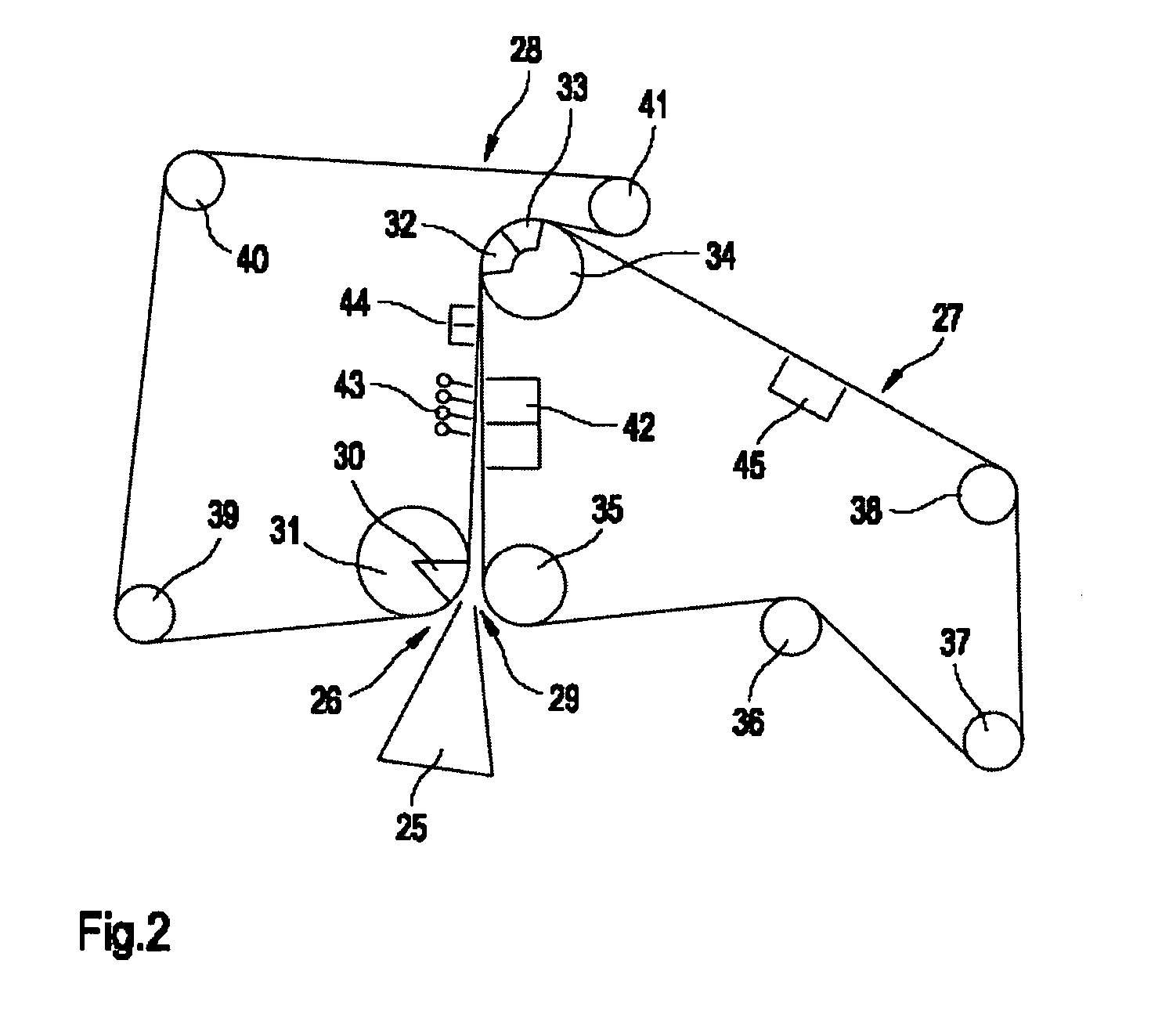

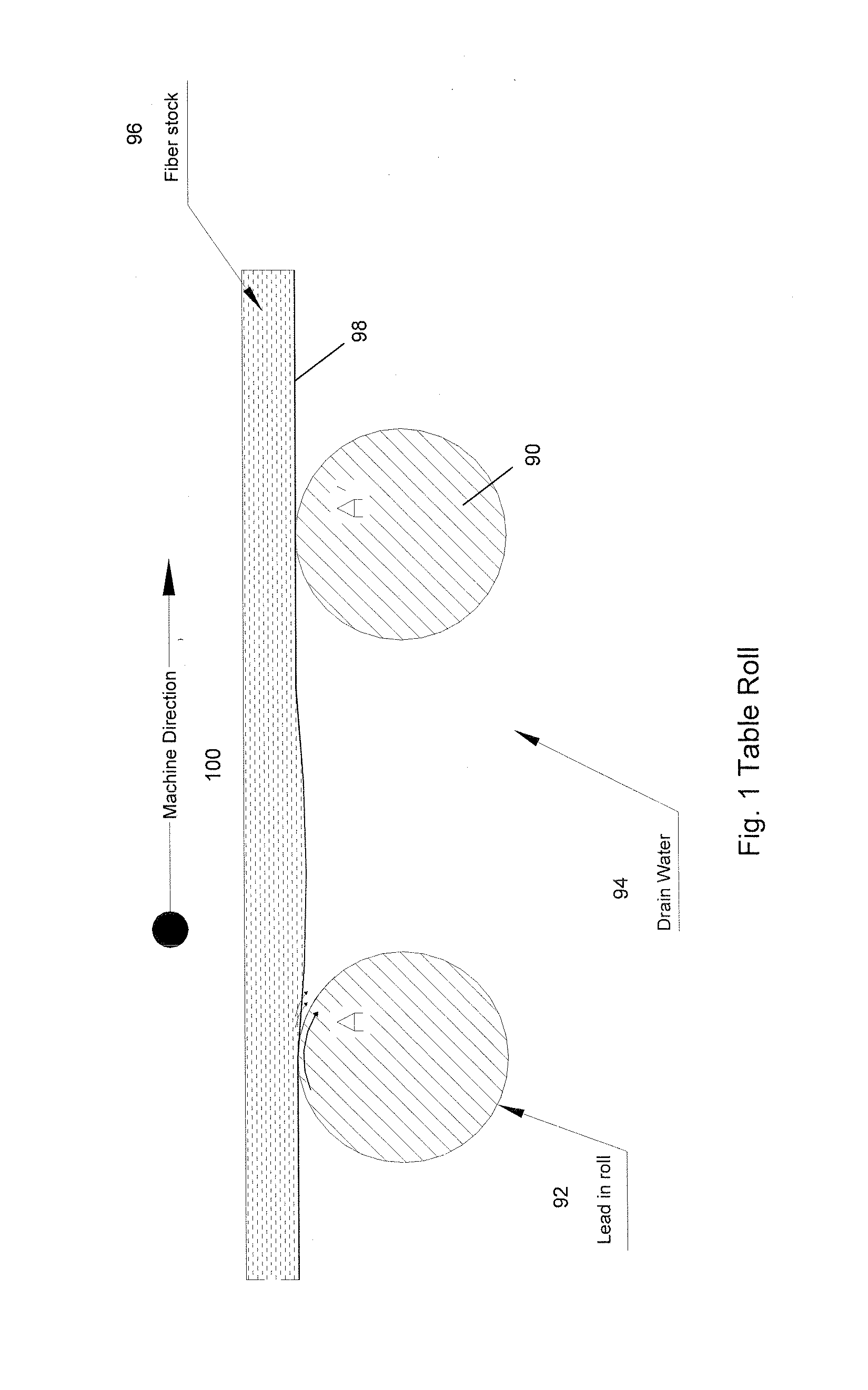

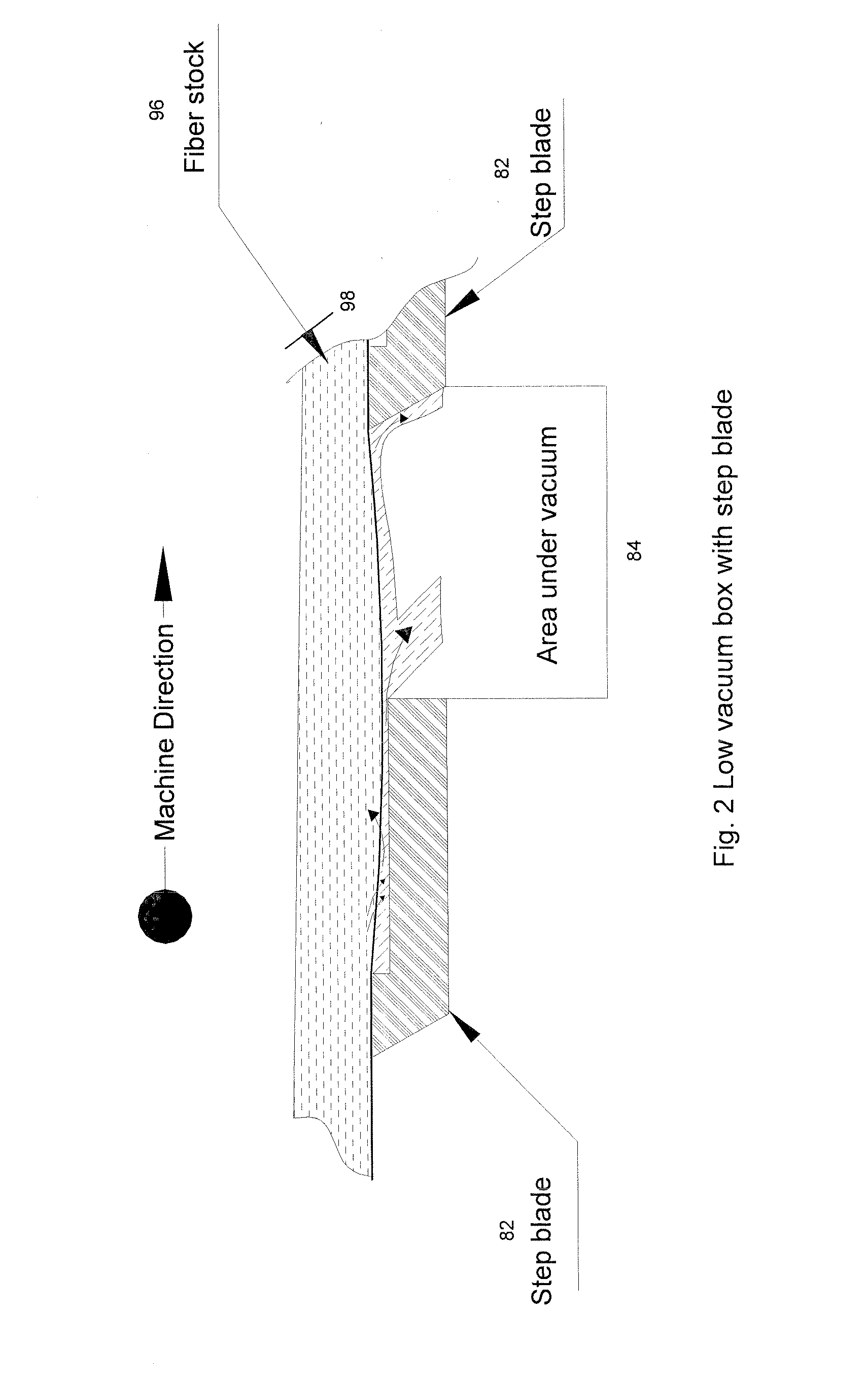

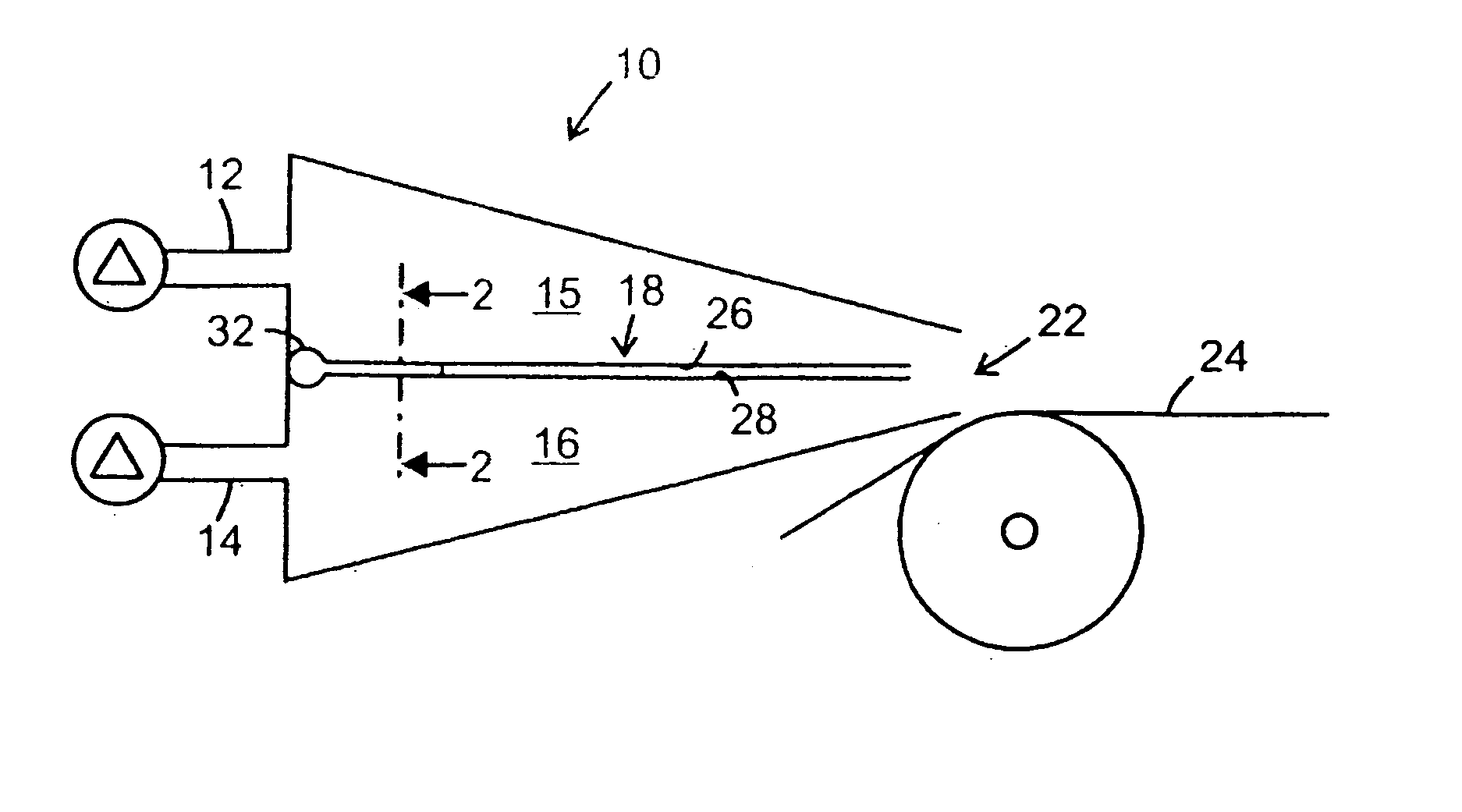

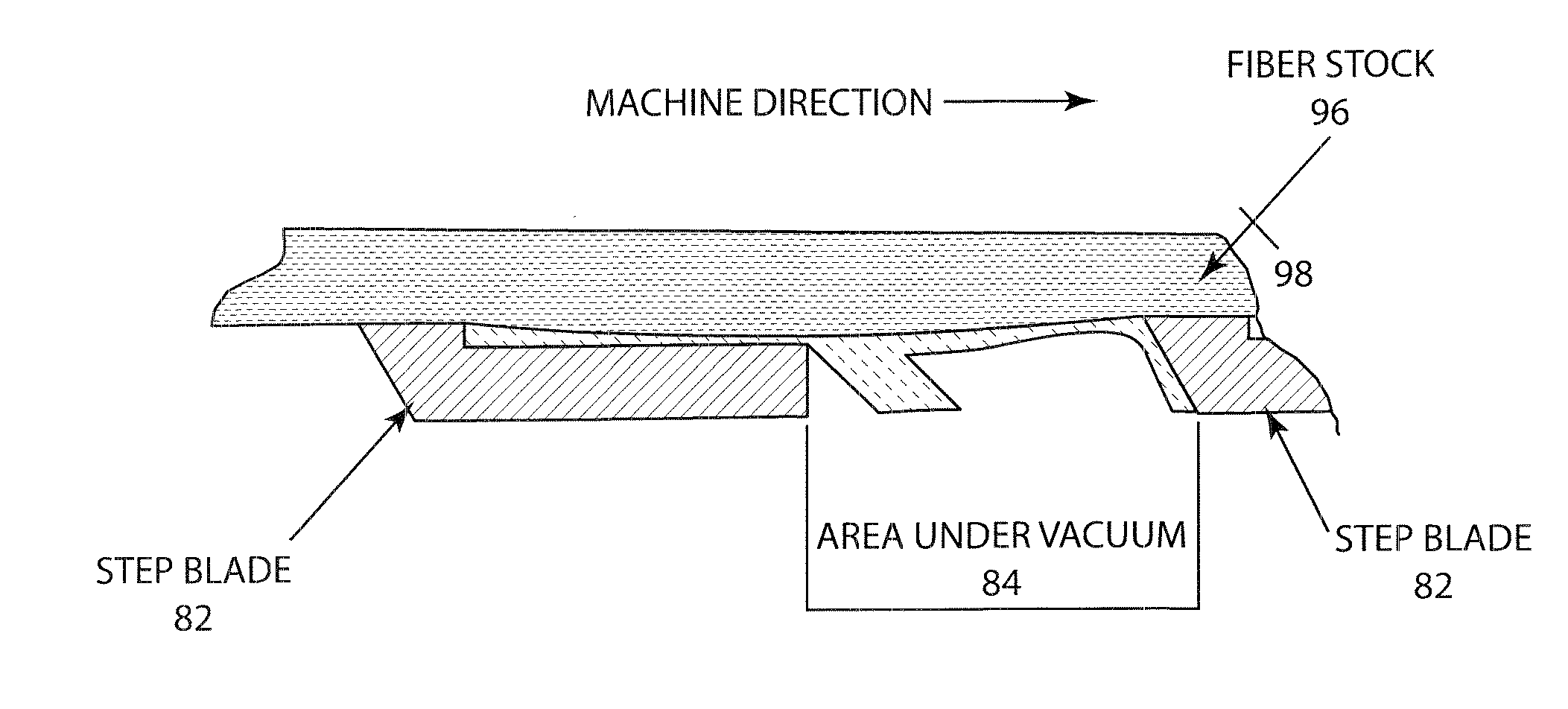

Method of forming a fibrous web and machine therefor

InactiveUS20050034827A1Avoid mixingReduce wake effectsNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

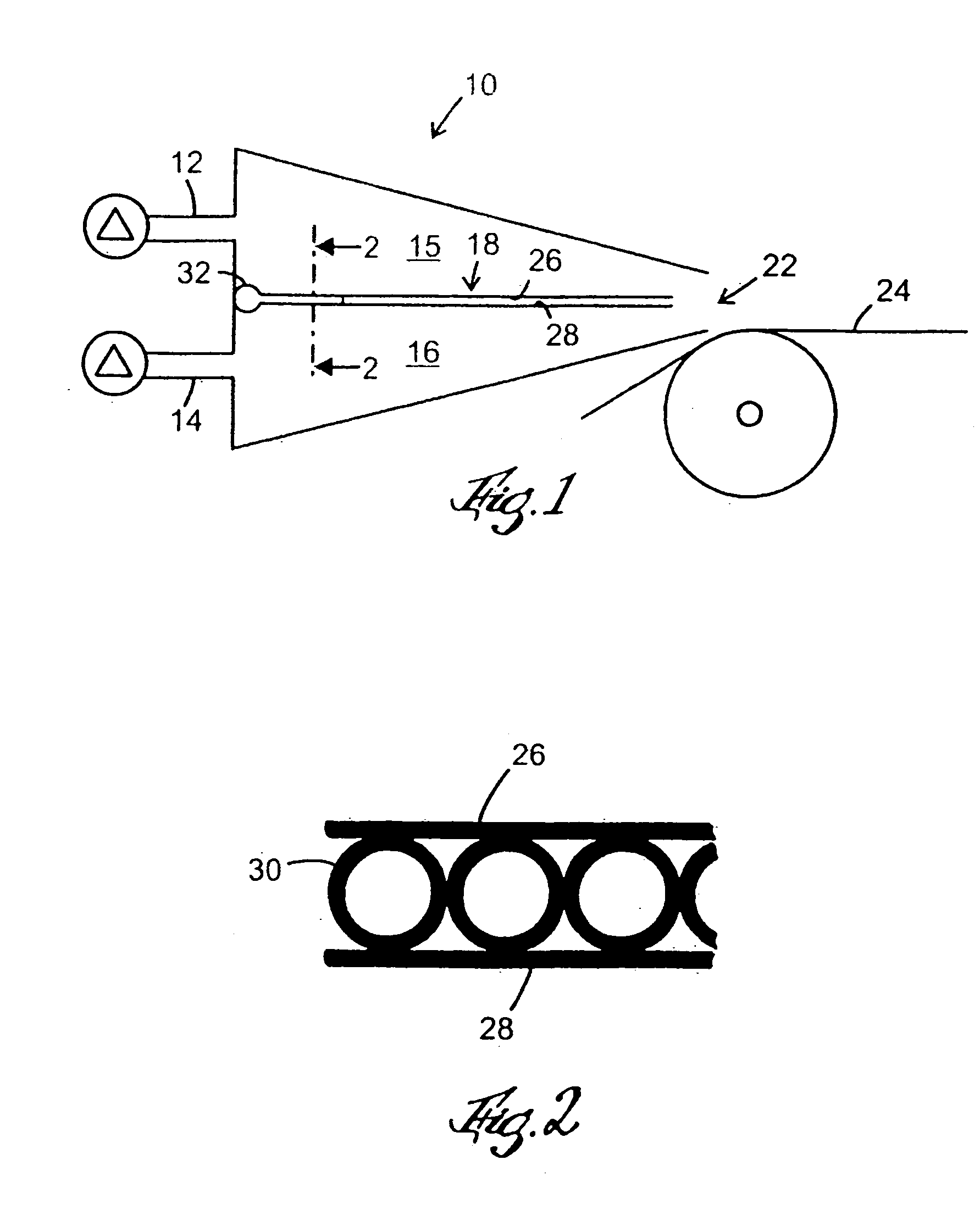

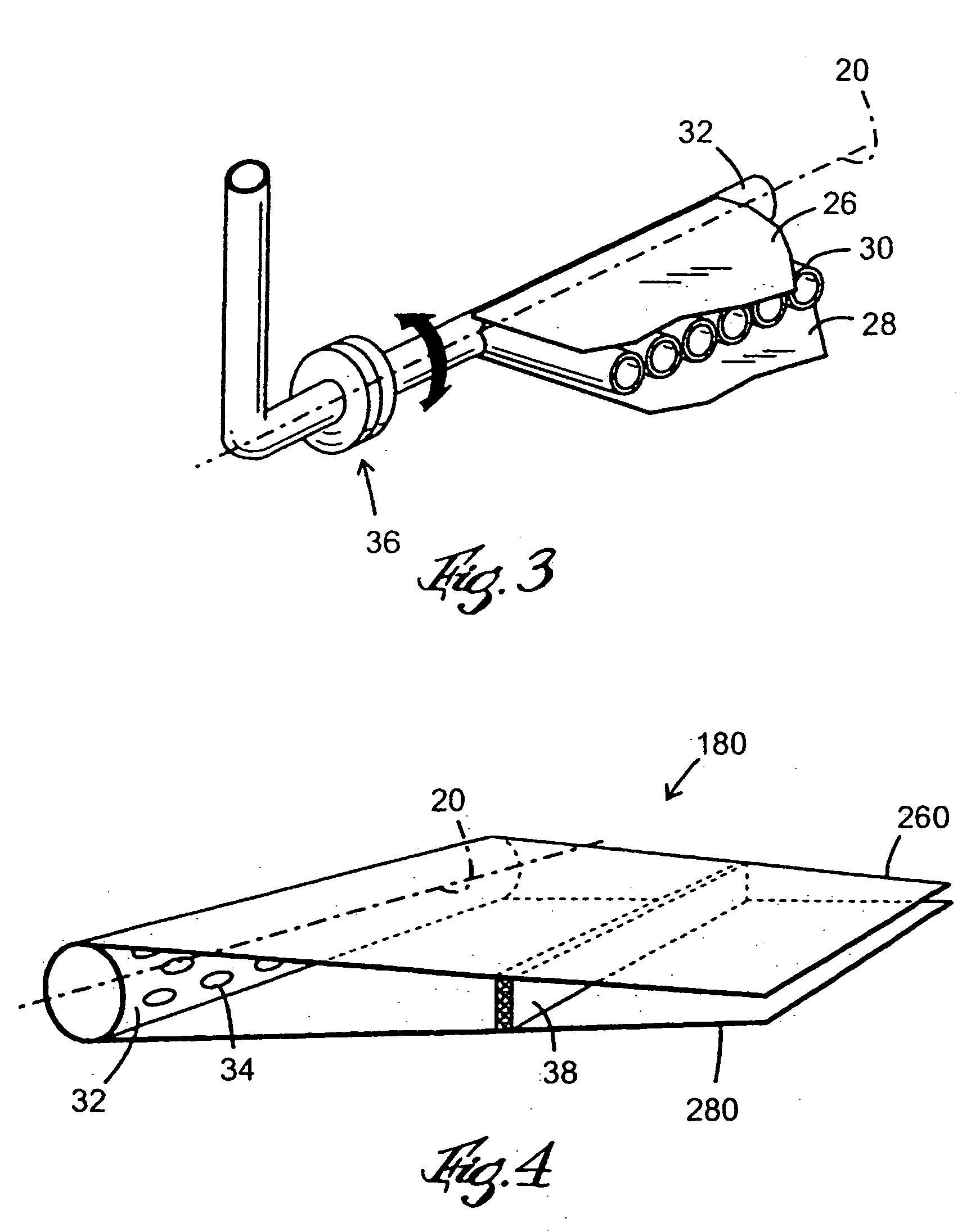

In a method of forming a layered fibrous web, the method includes the steps of leading at least two different fiber suspensions through a head box (10), separating the fiber suspensions from each other by a blade device (18, 180), supplying the fiber suspensions to a web forming device (24) and forming a water layer having a transversely uniform flow at an outlet at the end of the blade device (18, 180), such that the water layer constitutes an extension of the blade device and thereby prevents mixing of the fiber suspensions. The blade device (18, 180) can be freely movable in a substantially vertical direction in order to permit an equalization of pressure between the fiber suspension layers separated by the blade device and thereby reducing wake effects downstream the edge of the blade device. A paper machine for carrying out the method is also disclosed.

Owner:STFI

Method for manufacturing chopped carbon fiber reinforced concrete

InactiveCN101712183AGood dispersionThe total amount is largeMixing operation control apparatusCement mixing apparatusCarbon fibersEther

The invention relates to a method for manufacturing chopped carbon fiber reinforced concrete, particularly comprising the following steps: dispersing chopped carbon fiber in aqueous solution of water-soluble cellulose ether; adopting a papermaking method to filter the carbon fiber from carbon fiber suspension by a filter screen or a mop; taking down the dried carbon fiber from the filter screen or the mop; cutting the take-down carbon fiber felt into small blocks with side length being 4-8cm; dry mixing the small blocks with the concrete raw material for 1-4min, then adding water to mix for 1-4min, and finally casting and tightly molding the mixture to obtain the chopped carbon fiber reinforced concrete, wherein the dosage of carbon fiber accounts for 0.2-2.5% of the total volume of the chopped carbon fiber reinforced concrete. The invention is beneficial to blending and dispersing the carbon fiber and the concrete, improving the tightness of the concrete, lowering production cost and mixing a large amount of the chopped carbon fiber reinforced concrete with stable and uniform performance on-site.

Owner:WUHAN UNIV OF TECH

Preparation method of transparent waterproof plant nanometer fiber composite material

InactiveCN102977393AGood mechanical propertiesGood weather resistanceSynthetic resin layered productsCoatingsFiberEpoxy

The invention discloses a preparation method of a transparent waterproof plant nanometer fiber composite material. By the method, firstly water loss of a nanometer fiber suspension is used to form fiber films, hydrogen bonds of which are mutually bonded to be compact, and then single-layer films are laminated to obtain a high-strength light composite material of a target thickness by using a thermosetting epoxy resin. The laminated composite material prepared by the method disclosed by the invention is excellent in mechanical property, high in specific strength, good in weather fastness and thermal resistance, environment-friendly, and is a biomass nanometer composite material of great potential.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

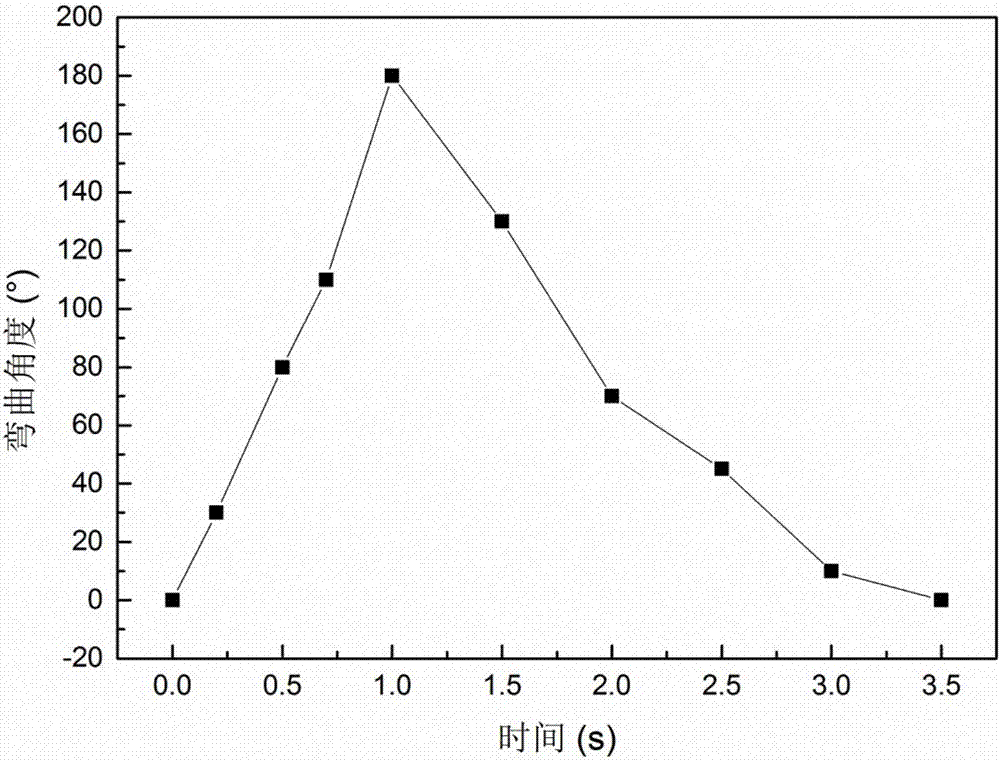

Nanocrystalline cellulose nano-fiber composite membrane sensitive to humidity and preparing method thereof

The invention relates to the field of humidity sensor materials, in particular to a nanocrystalline cellulose nano-fiber composite membrane sensitive to humidity and a preparing method thereof. The preparing method of the nanocrystalline cellulose nano-fiber composite membrane sensitive to humidity includes the following steps that cellulose is hydrolyzed by acid to prepare nanocrystalline cellulose suspension, then the nanocrystalline cellulose suspension and thermoplastic polymer nano-fiber suspension are mixed uniformly and then coated on the surface of a base material, a membrane layer is formed on the surface of the base material after drying, and the nanocrystalline cellulose nano-fiber composite membrane sensitive to humidity is obtained after the base material is removed. The nanocrystalline cellulose nano-fiber composite membrane has the advantages of being high in humidity response speed and high in recovery speed.

Owner:WUHAN TEXTILE UNIV +1

Dry-wet united web forming compound process

The invention relates to a dry-wet united web forming compound process. The dry-wet united web forming compound process includes the following steps that a, the preparation before web forming is conducted, clean pure cattle leather is ground to prepare cattle leather fibers through a splitting process; b, the fiber carding is conducted; c, the united web forming is conducted, since the dry-laid web forming and the wet-laid web forming are conducted at the same time, the carded cattle leather fibers are prepared into a mixture of fibers and water through waterpower dispersing, beating, dilution and adding of a dispersing agent, the cattle leather fibers are loosened in the water in a filament form to form fiber suspension pulp, the fiber suspension pulp is transported to a web former, the fiber suspension pulp is tiled on the surface of non-woven fabric in a wet state to form a web, and the formed web is a semi-finished product web; on the semi-finished product web, the cattle leather fibers are blown to the web forming curtain on the semi-finished product web to form a second layer fiber web by the adoption of an airflow clutter web forming method, through the paper-making wet method dewatering, a cattle leather fiber web with the moisture content of 120%+ / -5% is formed on the surface of the non-woven fabric, and then the cattle leather fibers composite with the non-woven fabric through the reinforcing of a spun-laced method.

Owner:东莞市信诺无纺科技有限公司

Method for manufacturing formaldehyde-free straw fiber board

The invention relates to a method for manufacturing formaldehyde-free straw fiber boards, comprising the following steps: adding NaAc-HAc buffer solution in wheat straw chemime chanical pulp so as to dilute the pulp into wheat straw fiber suspension liquid with mass concentration of 3-10%, stirring the wheat straw fiber suspension liquid fully and uniformly, respectively addingndustrial lignin being 10-50% of i of oven-dry wheat straw pulp and wax emulsion being 1-10% of oven-dry wheat straw pulp, then adding 10U / g to 100U / g laccase to start the reaction, scattering the treated wheat straw fiber by an electric mixer, molding in a fiber molding machine and then removing redundant moisture by pre-pressing, and then forming the fiber board by hot-pressing. According to the method, lignin is selected to replace the traditional binder used in the productions of middle-density fiber board and high-density fiber board, and the formaldehyde diffusion is inexistent due to the fact that the formaldehyde based binder is unused. The method of the invention is reasonable and simple in operation; and with the adoption of the waste materials of crops wheat stalk, straw and the like, the environment pollution can be reduced, the added value of the product can be enhanced, and the high-strength formaldehyde-free environment-friendly fiber boards are manufactured.

Owner:HUBEI UNIV OF TECH

Composite super-hydrophobic particle, preparation method thereof and super-hydrophobic coating preparation method

ActiveCN105237811AImprove the shortcoming that it is difficult to be ball-milled into required particlesImprove brittlenessCoatingsFiberAnhydrous ethanol

The invention relates to a preparation method of a nanocellulose fiber / SiO2 composite super-hydrophobic particle. The preparation method comprises 1, preparing a nanocellulose fiber suspension liquid with content of 1-5wt%, carrying out refrigeration molding, and carrying out freeze-drying to obtain nanocellulose fiber aerogel, 2, respectively dipping the nanocellulose fiber aerogel in a solution A and a solution B for 5-30min, 3, dipping the nanocellulose fiber aerogel treated by the step 2 in anhydrous ethanol and dipping the nanocellulose fiber aerogel in n-hexane, and 4, dipping the nanocellulose fiber aerogel treated by the step 3 in a solution C at a room temperature, carrying out drying to obtain nanocellulose fiber / SiO2 composite aerogel in a white solid form and carrying out granulation to obtain the composite super-hydrophobic particle. The invention also relates to the composite super-hydrophobic particle obtained by the preparation method. The invention further relates to a method for preparing a coating from the composite super-hydrophobic particles.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Energy saving papermaking forming apparatus, system, and method for lowering consistency of fiber suspension

InactiveUS20130042987A1Increased recirculationEasy to implementFibreboardDryer sectionFiberPulp and paper industry

The present invention is directed to an apparatus used in the formation of paper. More specifically the present invention is directed to an apparatus, system, and method for lowering the consistency or degree of density of fiber suspension on the forming table, and improving the quality and physical properties of the paper formed thereon.

Owner:FCPAPEL

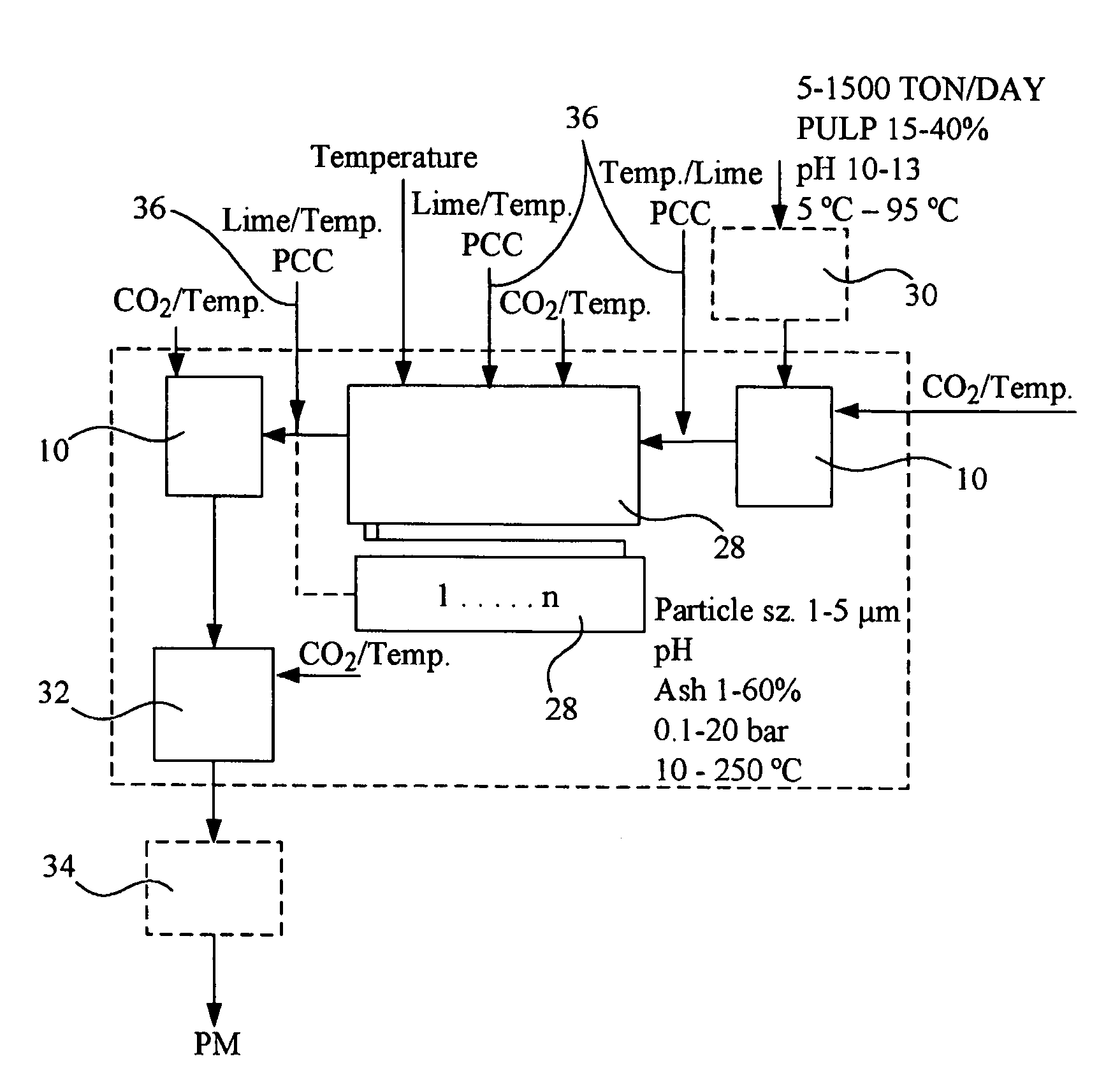

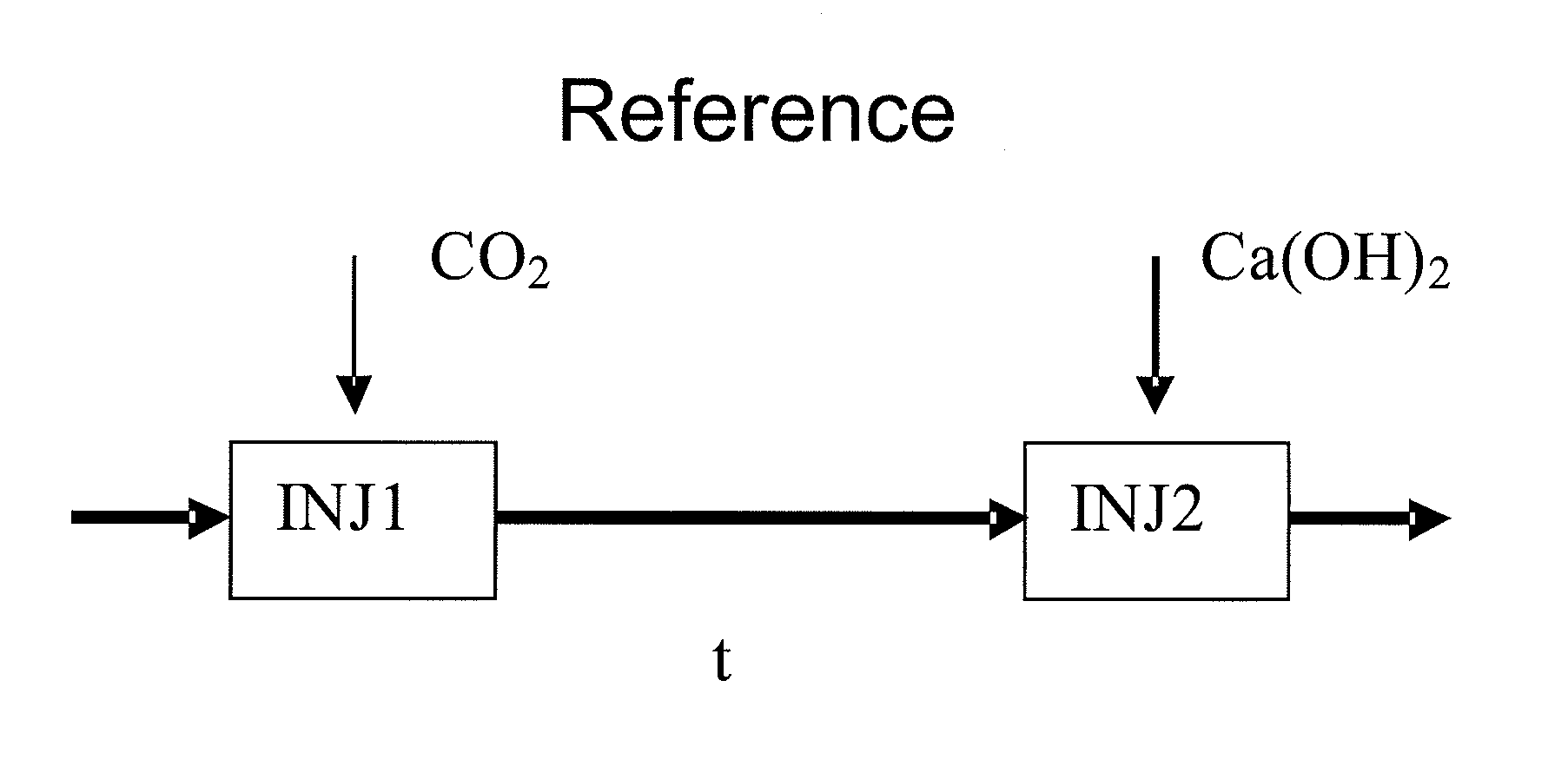

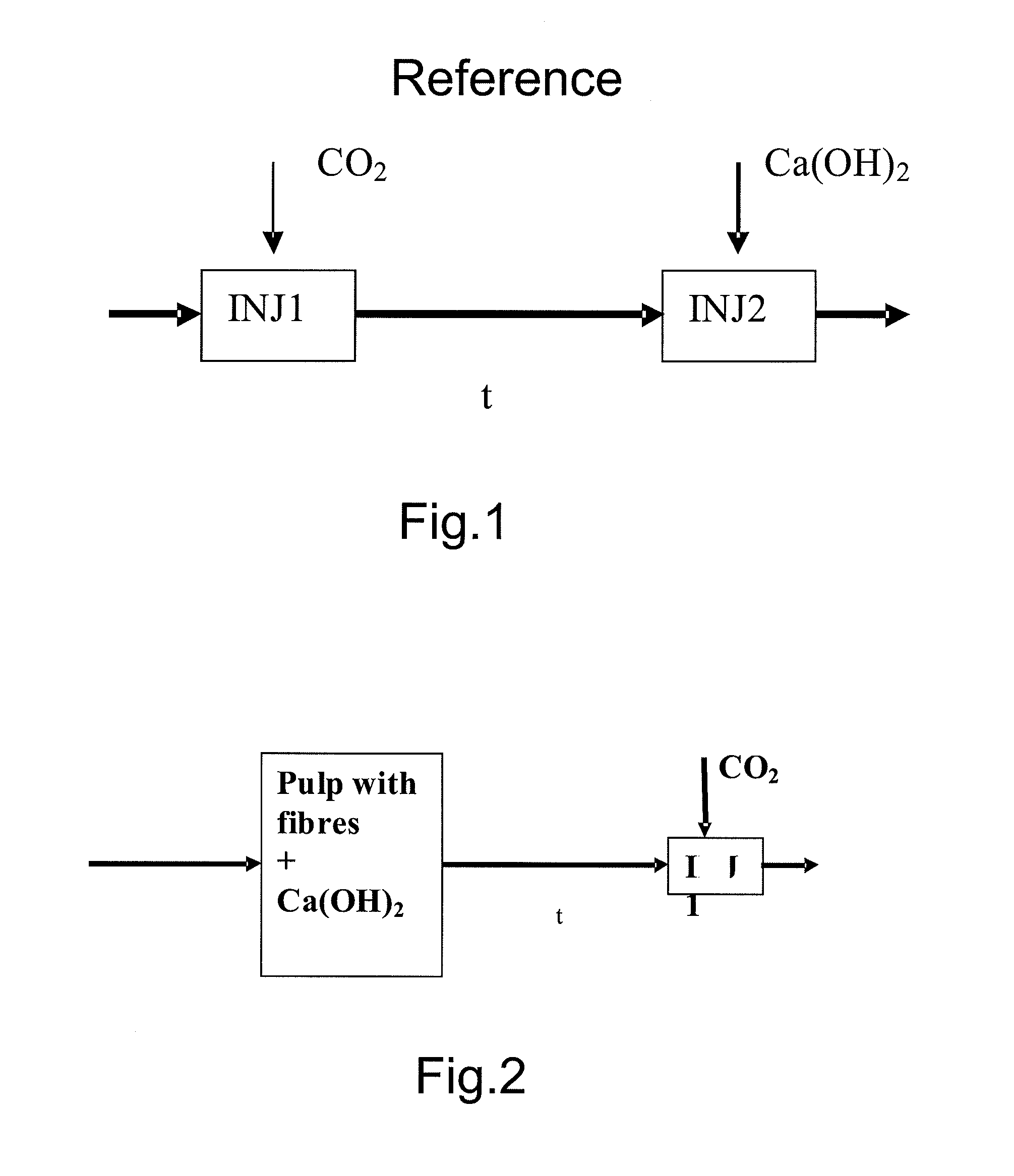

Method and a system for precipitation of calcium carbonate and a product comprising calcium carbonate

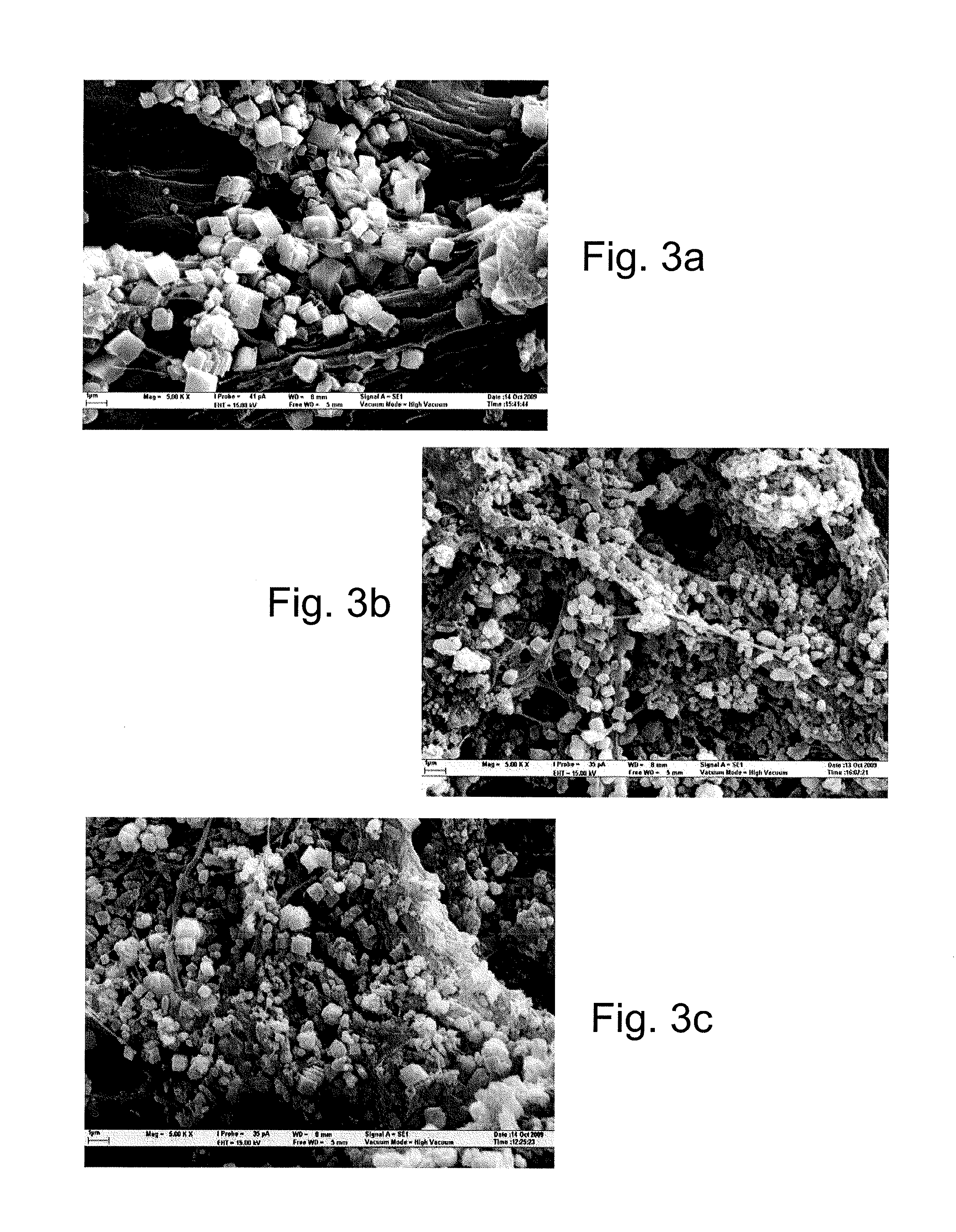

ActiveUS20130126116A1Good light scatteringInhibition formationCalcium/strontium/barium carbonatesNatural cellulose pulp/paperCalcium hydroxidePrecipitated calcium carbonate

The invention relates to a method for precipitating calcium carbonate, in which method calcium hydroxide is introduced to a fibre suspension containing cellulose-containing fibres, the calcium hydroxide is allowed to attach onto the surfaces of fibres for a pre-determined time, and the aqueous suspension of calcium hydroxide and fibres is brought into contact with carbon dioxide for precipitating the calcium carbonate. The invention also relates to a corresponding system for precipitating calcium carbonate in connection with cellulose-containing fibres. In addition, the invention relates to a fibrous product, which comprises pulp material produced by said method and comprising calcium carbonate.

Owner:WETEND TECH

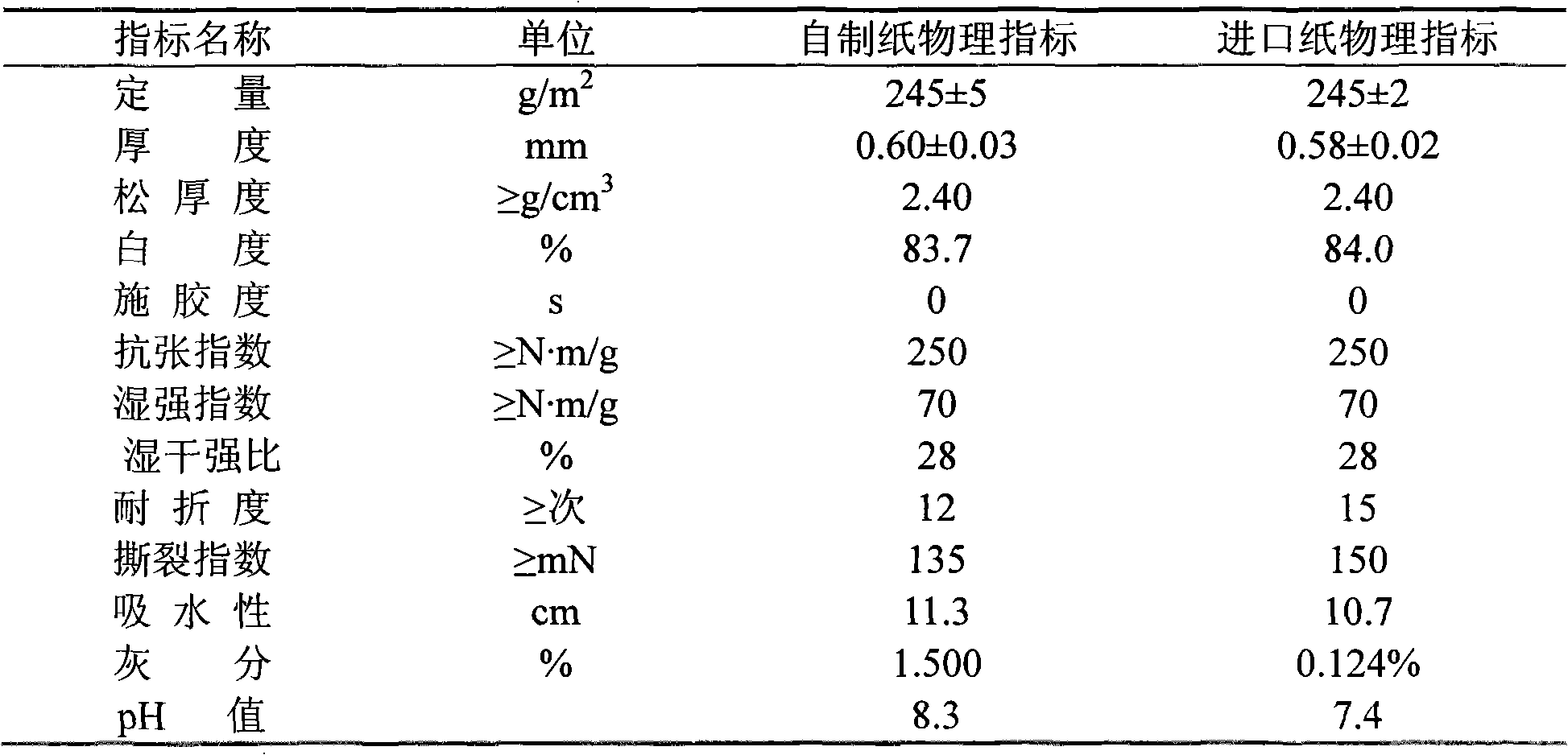

Special acid-free paper for protection of historical relics and manufacturing method thereof

InactiveCN101328699APromote absorptionWith adsorption regeneration functionFlexible coversNatural cellulose pulp/paperCalcium biphosphateFiber

The invention provides acid free paper special for the historic preservation, consisting of plant pulp fiber, an aggressive gas adsorbing agent, a humidity adjusting agent, a pH buffering agent and a wet strengthening agent, which are mixed according to a certain mass percentage. The preparation method comprises the following steps that: firstly, the plant pulp fiber is added with de-ionized water to be scattered into a fiber suspending liquid; secondly, the aggressive gas adsorbing agent, the humidity adjusting agent, the pH buffering agent and the wet strengthening agent are added into the defibered paper pulp suspending liquid and are stirred evenly; finally, the mixture is formed on a paper sheet-making machine and is filtered and dewatered so that a wet paper disc is obtained; and the acid free paper special for the historic preservation is obtained by drying the wet paper disc. The special acid free paper have no acid substance, adopts the chlorine bleaching free paper pulp, adds calcium phosphate taken as the buffering agent, is alkalescence, has good adsorbing effect of acid gas, has the function of adjusting the humidity of the microspace environment of the protective article, and has the advantage of recycling.

Owner:NANJING FORESTRY UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com