Patents

Literature

75results about How to "Avoid rewetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

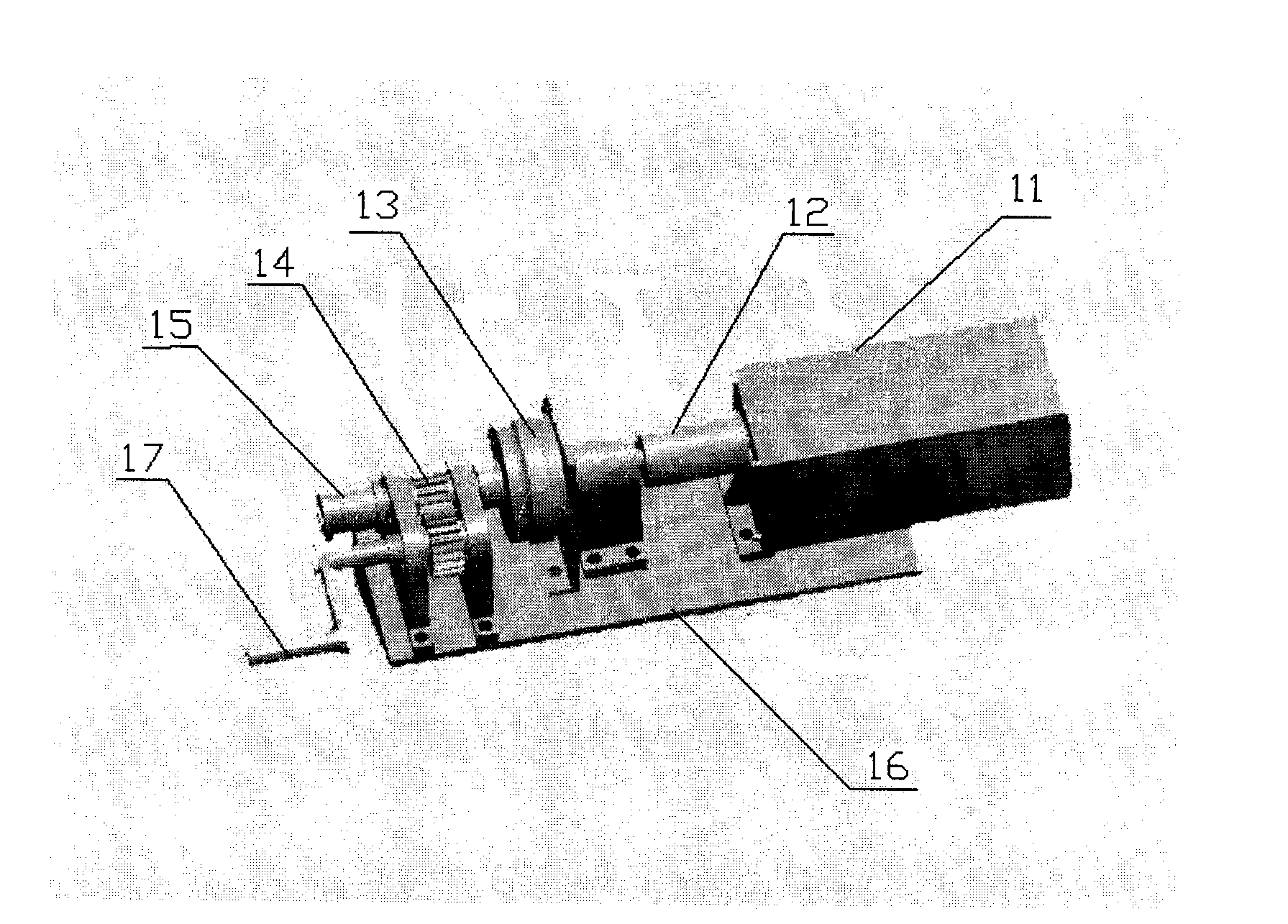

Belt type filter press

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

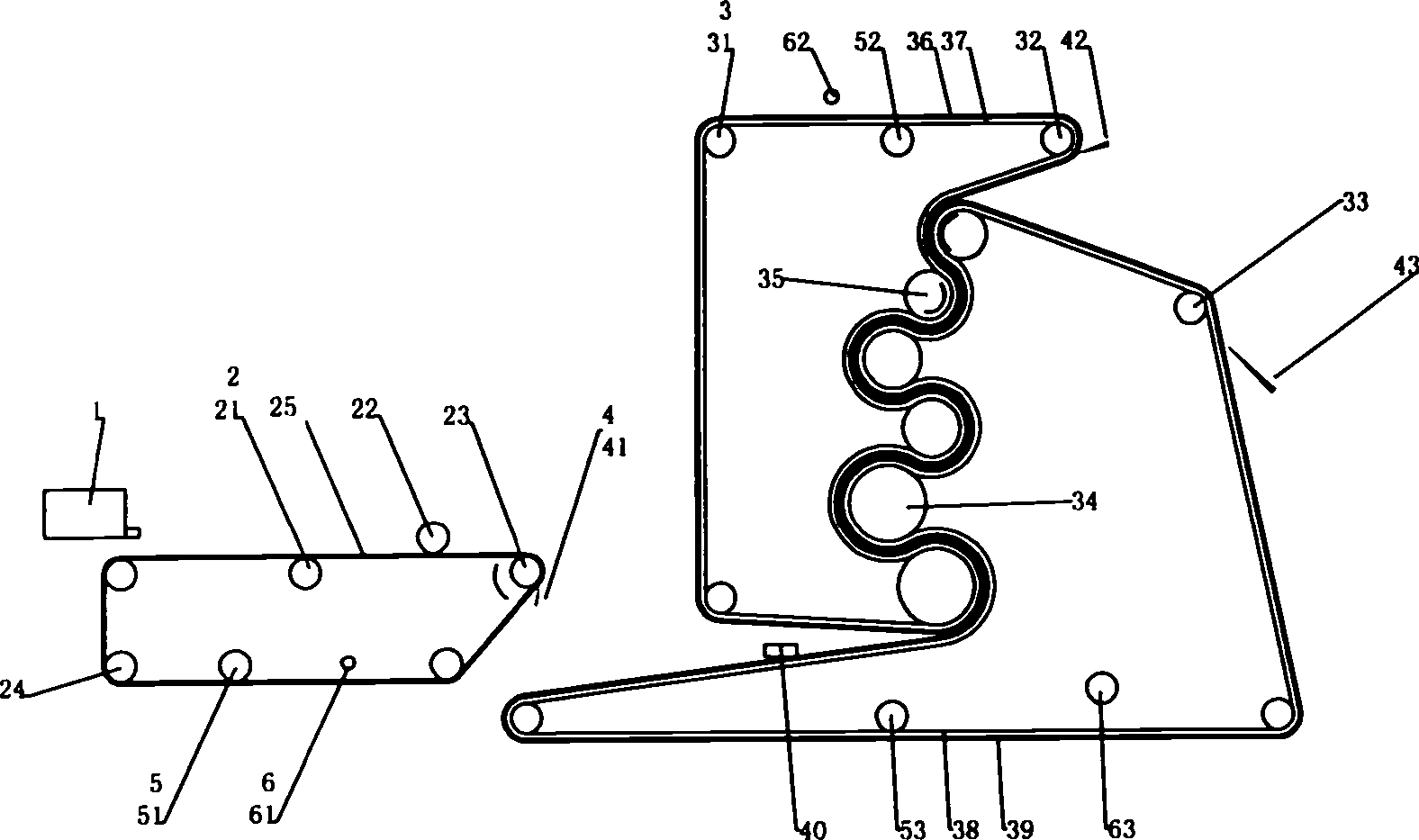

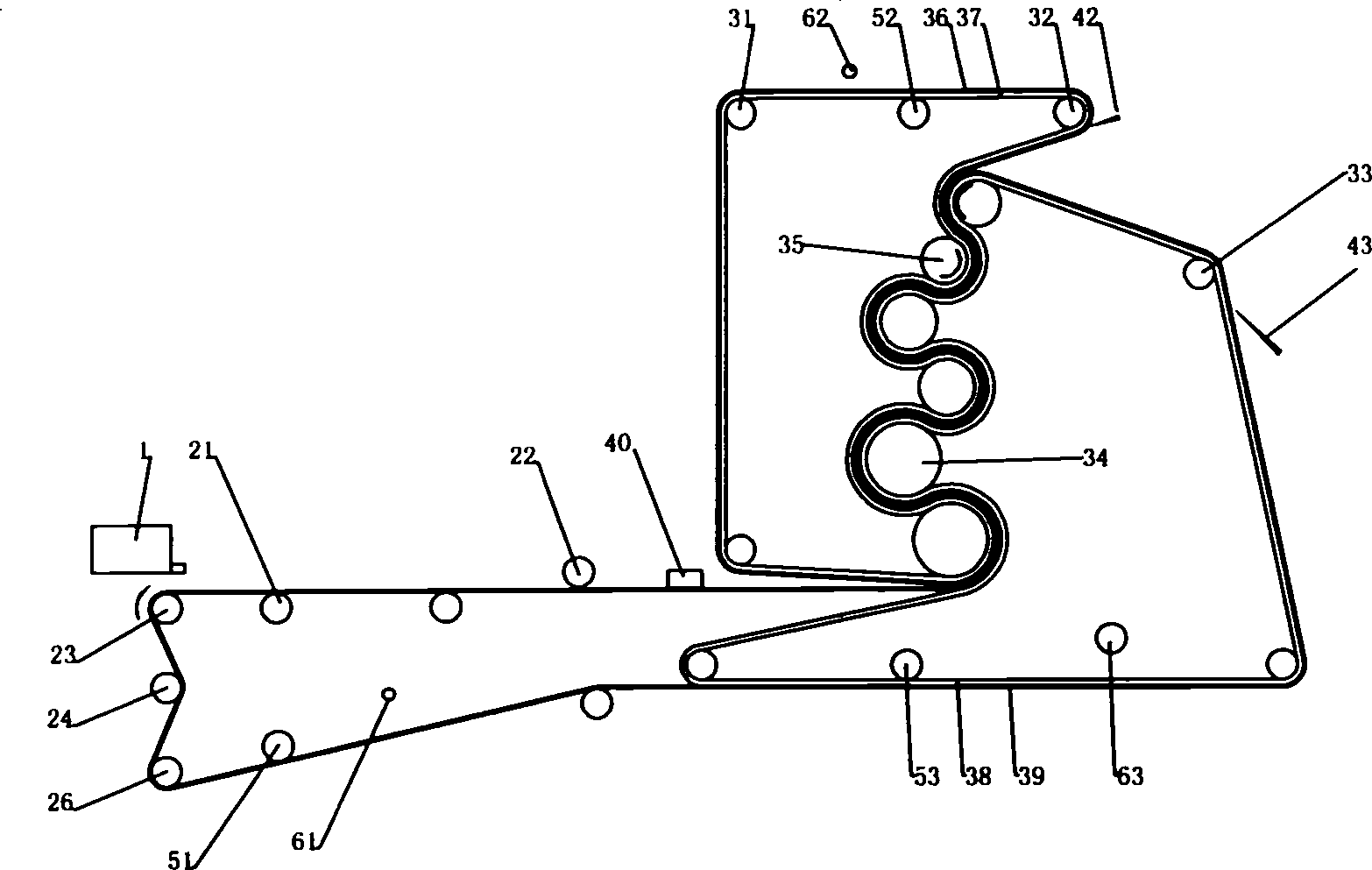

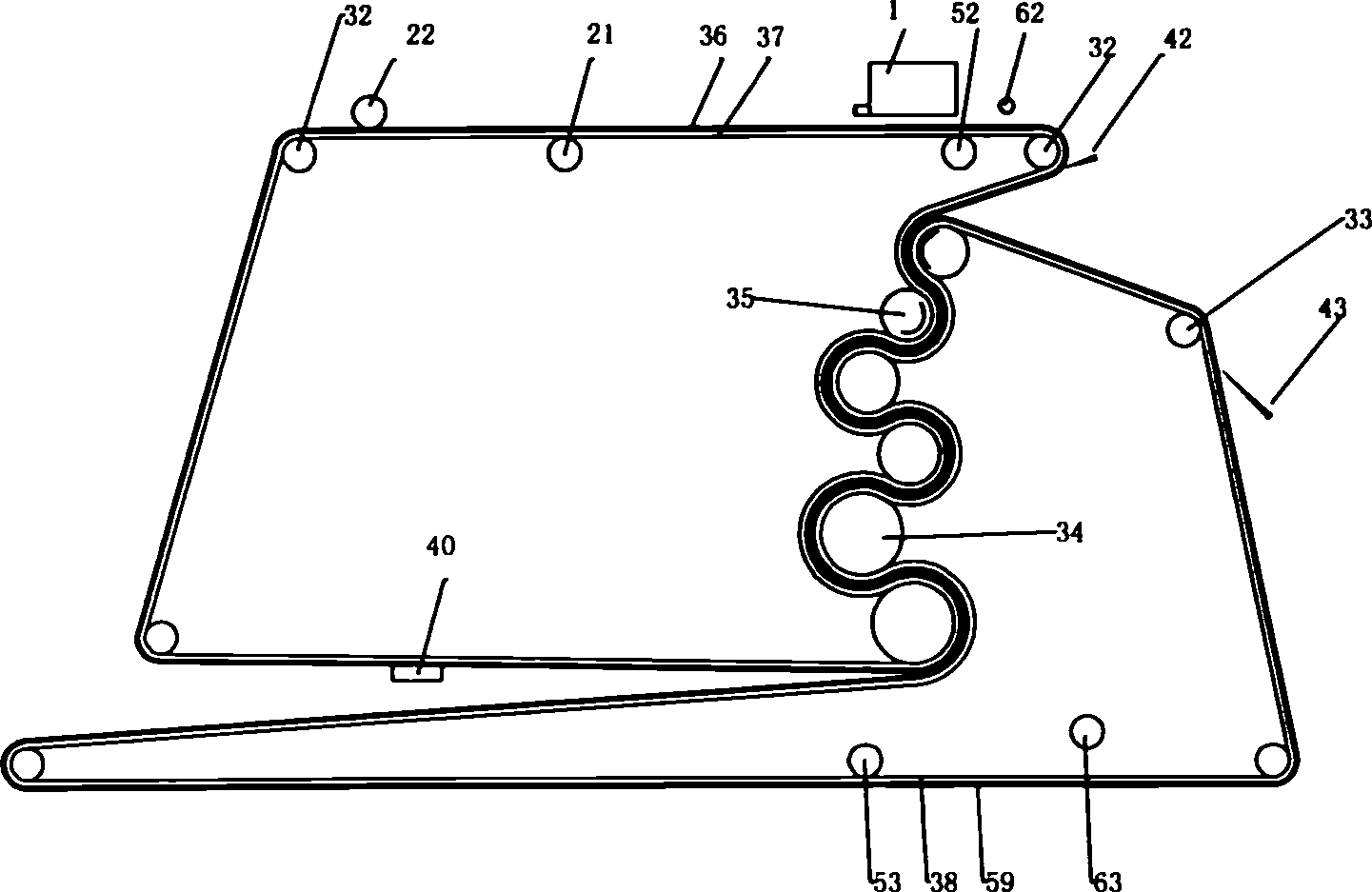

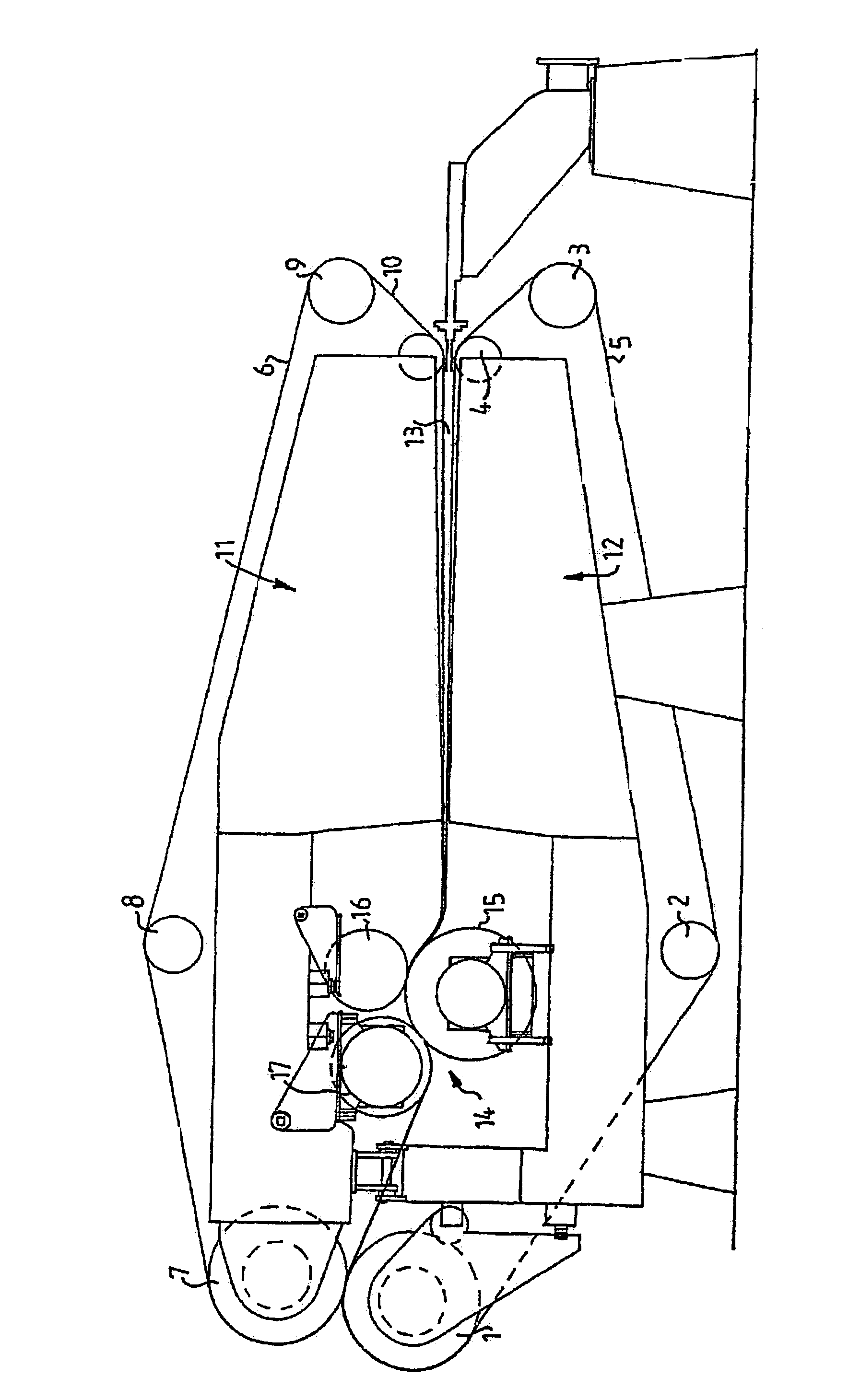

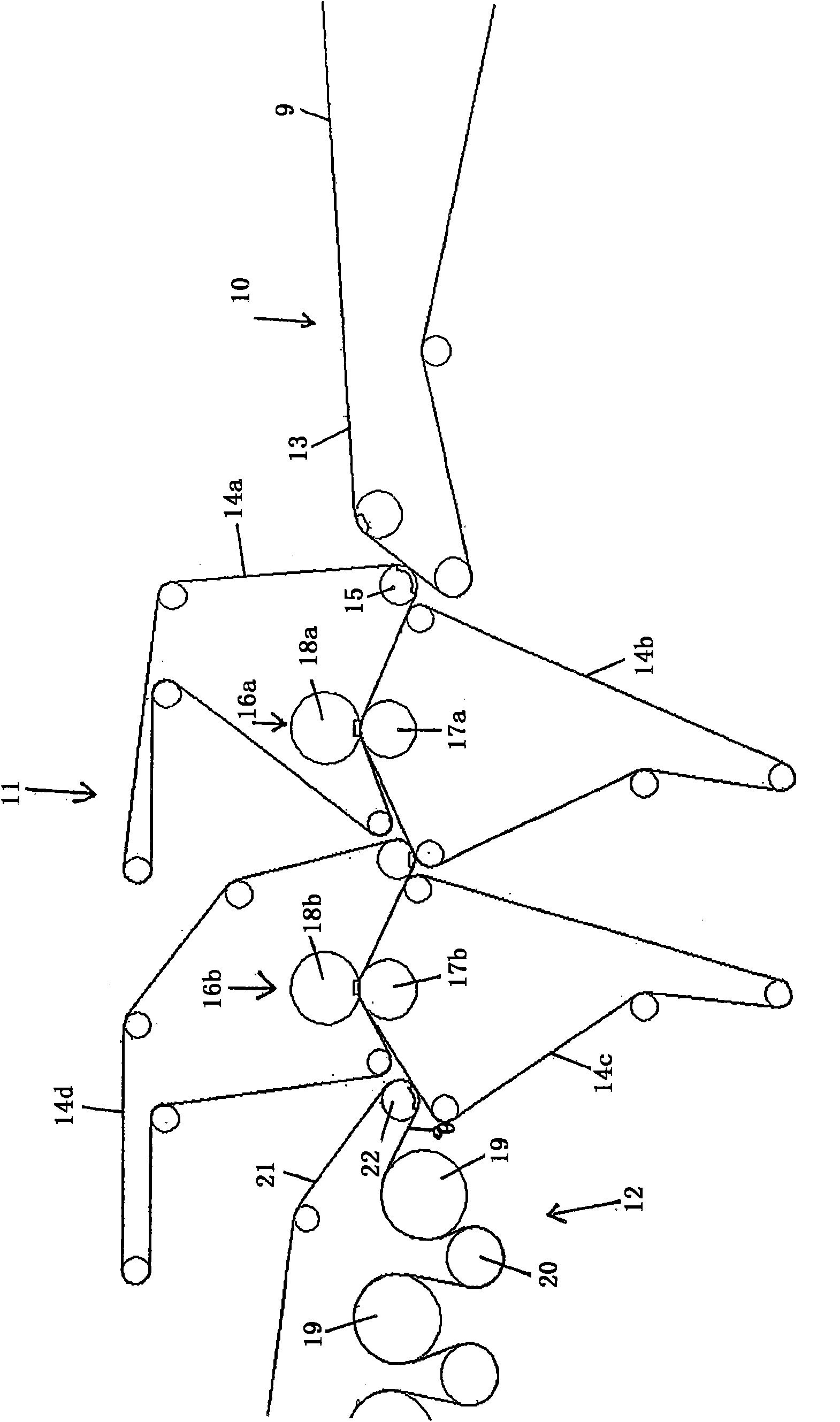

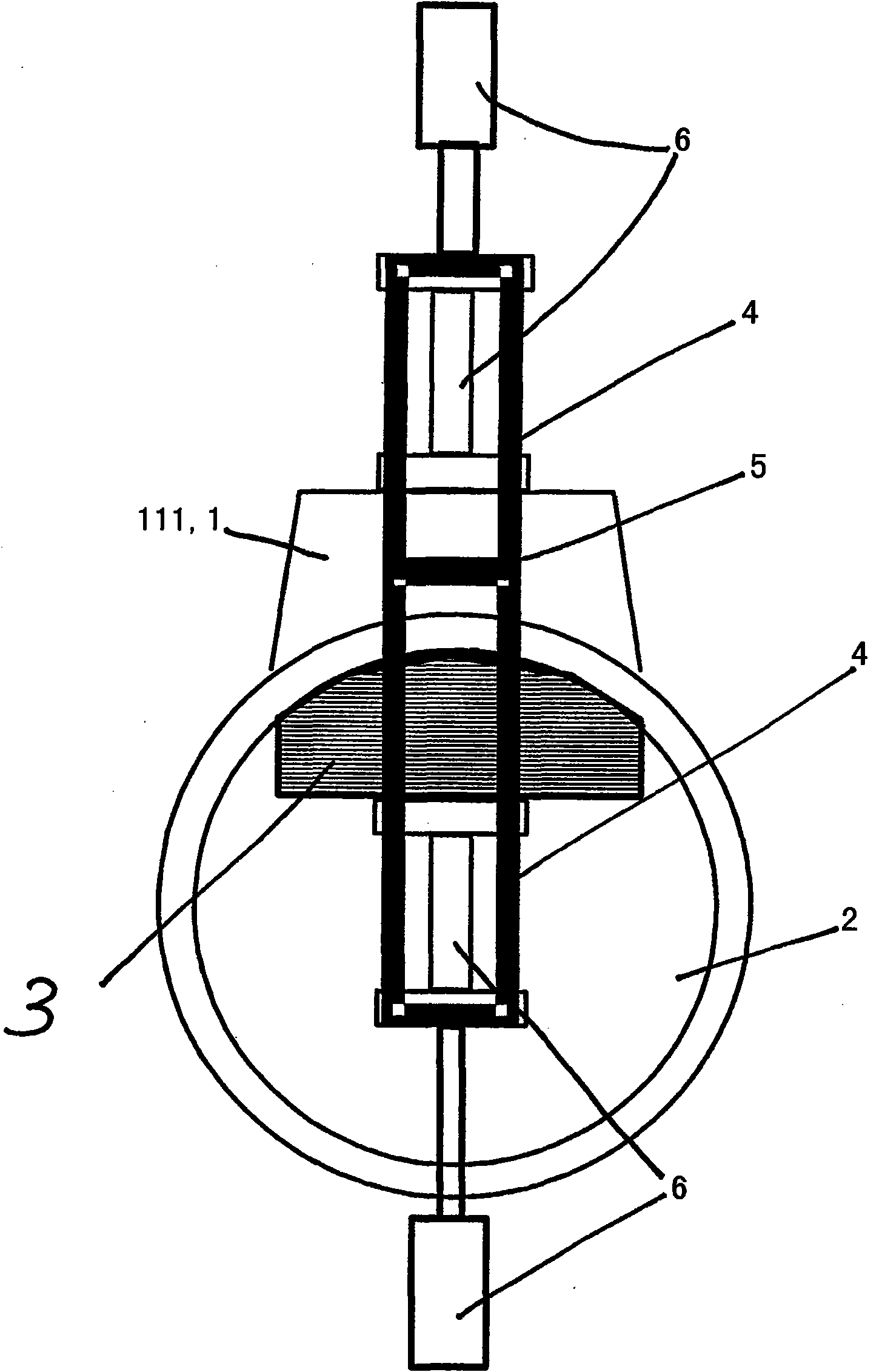

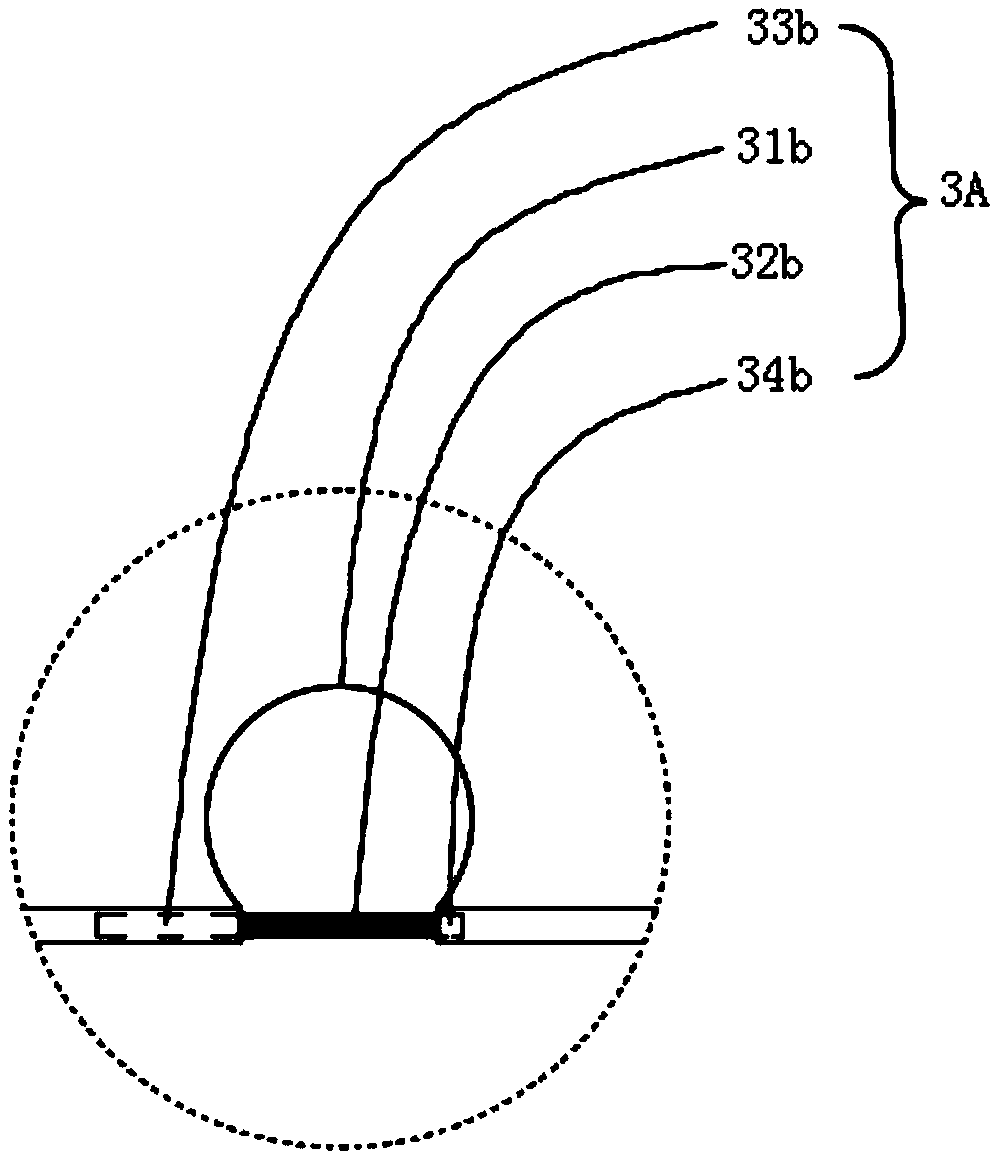

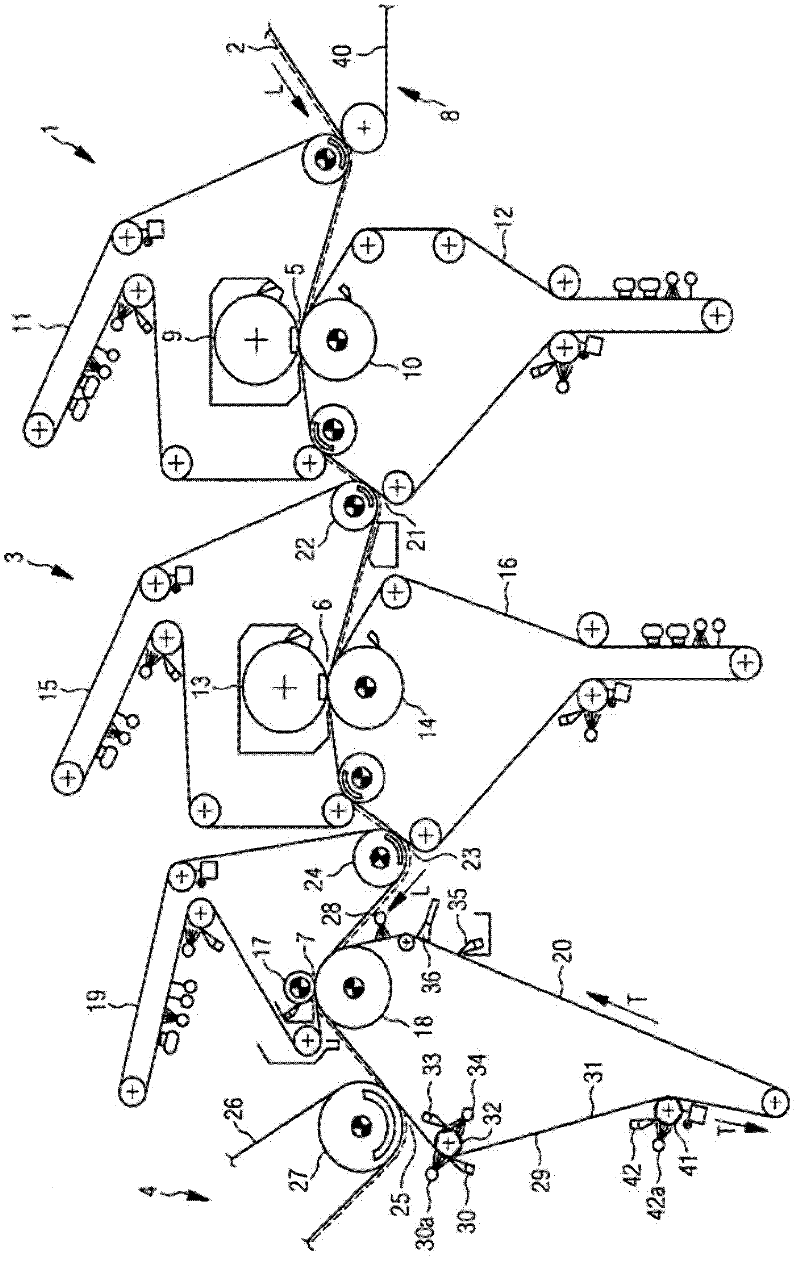

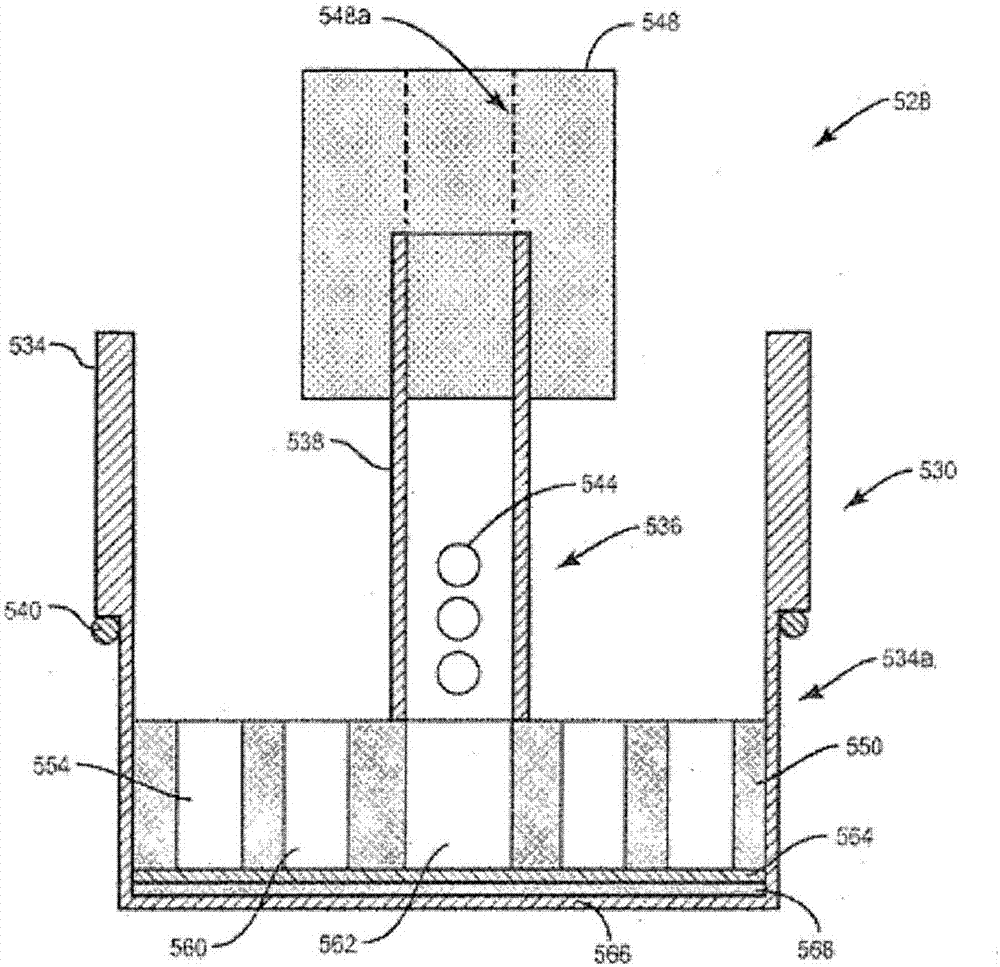

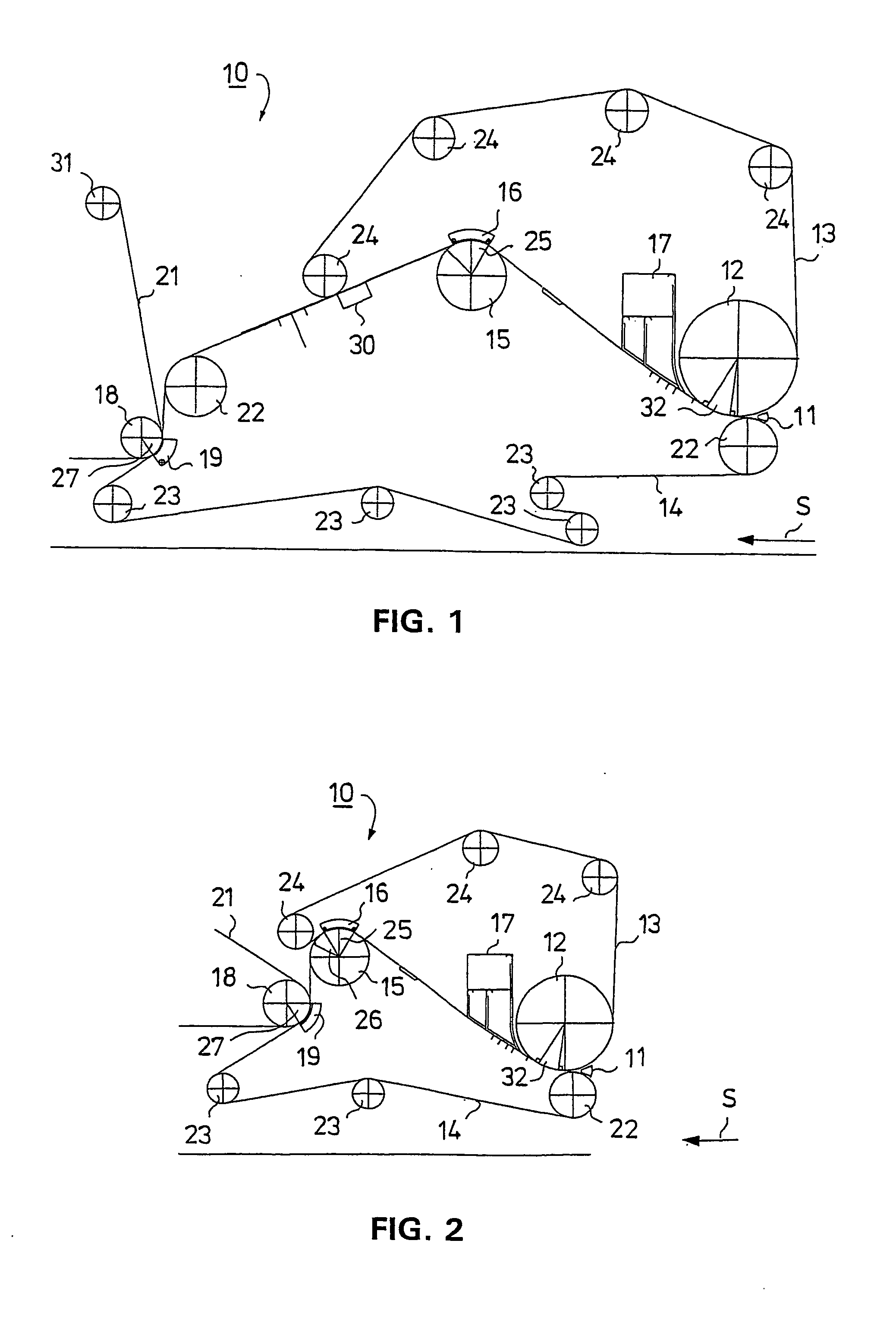

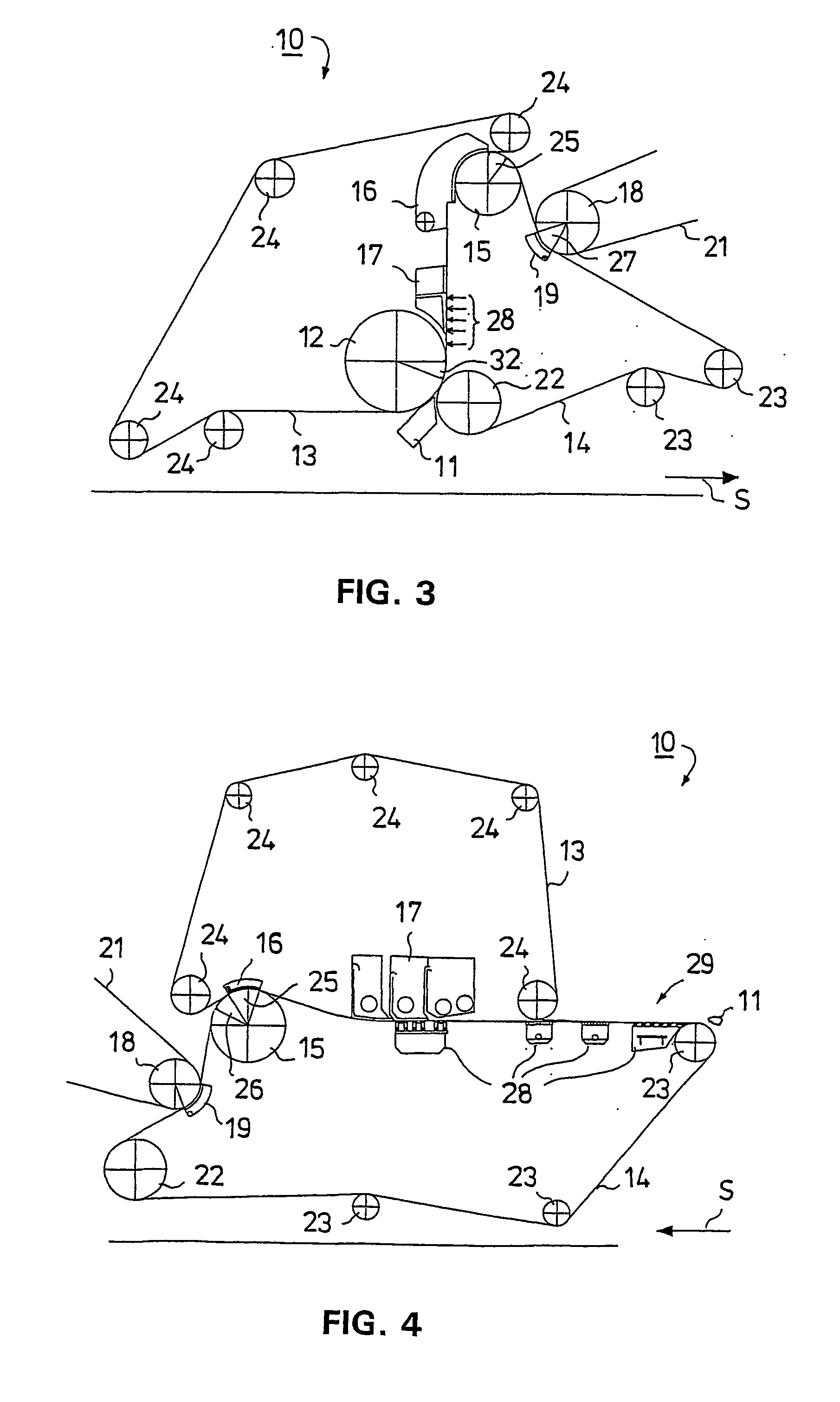

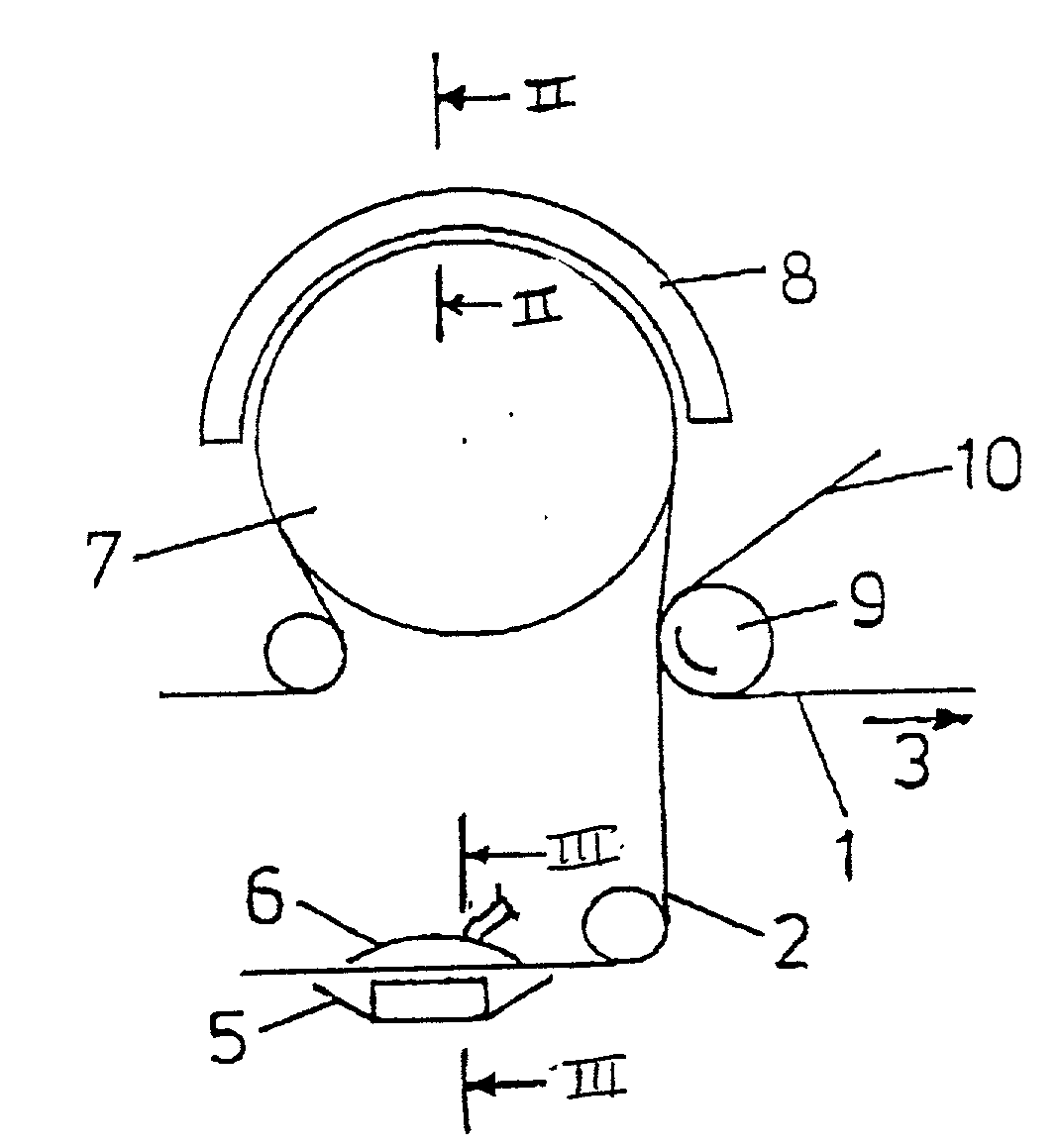

Twin-wire belt press

InactiveUS7051882B2Simpler and small and cheap and reliableAvoid rewettingMachine wet endPress sectionFiberEngineering

A twin-wire belt press is disclosed for dewatering a fiber suspension and forming a continuous web of the fiber suspension. The twin wire belt includes a plurality of upper and lower rolls, a perforated roll and endless upper and lower wire belts. Dewatering tables are used to support the endless upper and lower wire belts and form a wedge-shaped pressure space between the endless upper and lower wire belts for initially pressing and dewatering the fiber suspension and forming a web therebetween. Roll members, including at least two press rolls which form press roll nips with the perforated roll and another roll, press and dewater the web between the endless upper and lower wire belts.

Owner:VALMET TECH INC

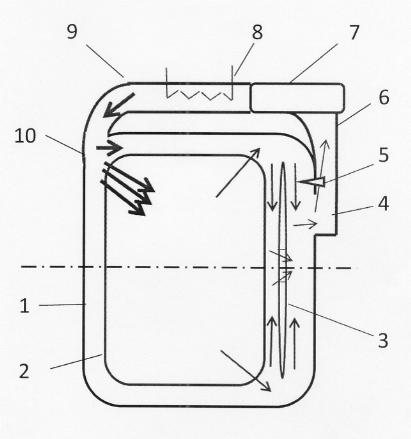

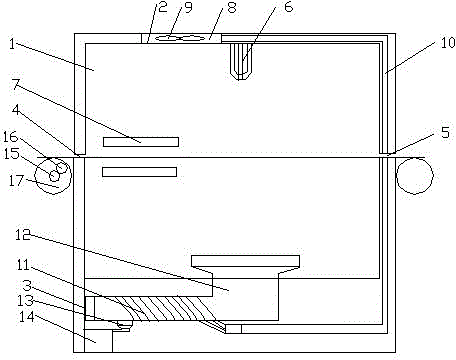

Condensing device and condensing method of washing and drying integrated machine

InactiveCN102691198AReduce consumptionImprove energy efficiencyTextiles and paperLaundry driersCold airEngineering

The invention relates to a condensing device and a condensing method of a washing and drying integrated machine. The condensing device comprises a condensing disk, a nozzle and a cold source supply tube, wherein the condensing disk is arranged on the back of an inner drum, and is rotated along with the inner drum; the nozzle is arranged between the back of the inner drum and the back of an outer drum and sprays cold water or cold air to the condensing disk to keep the condensing disk at a low temperature; the cold source supply tube is embedded at the back of the outer drum, and cold water or cold air flows in the tube; the rear side of the outer drum is provided with an air outlet; the condensing device is not provided with a condensing tube; and a fan and a heating tube of the washing and drying integrated machine are arranged in a drying channel, and the drying channel is connected with the front side of the outer drum through an air inlet. According to the condensing method, saturated hot air generates a condensation effect through the nozzle and the condensing disk, so that condensed water is discharged. The invention breaks through the convention, the original condensing tube is omitted, the condensing disk is arranged on the back of the inner drum, a condensing area is directly moved into the outer drum, the condensing efficiency is greatly improved when energy consumption is reduced, the drying performance and the energy saving effect are obviously improved, and adverse effects can not be caused on indoor environment.

Owner:WHIRLPOOLCHINA INVESTEMENT

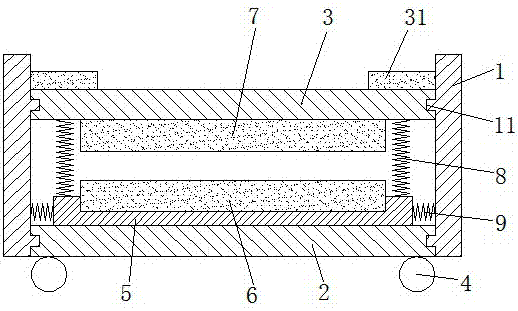

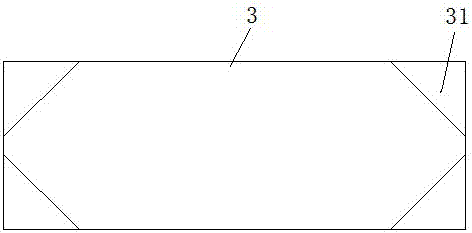

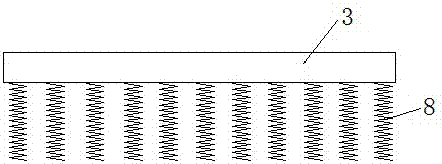

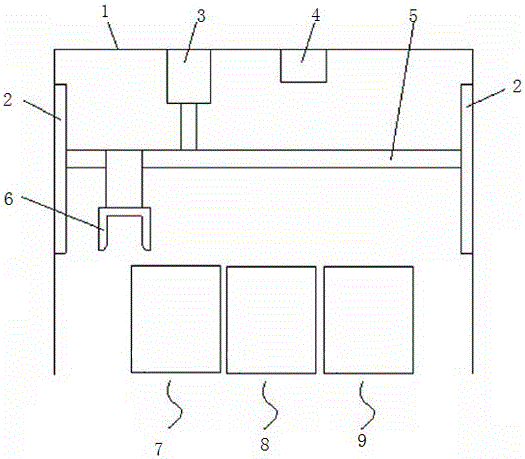

Damping base

InactiveCN107339552APrevent impactReduce vibrationPortable framesNon-rotating vibration suppressionEngineeringHorizontal and vertical

The invention provides a shock-absorbing base, which includes a bottom surface and a side wall. A lower support plate is provided on the upper end of the bottom surface, and the lower support plate and the side wall are connected by a plurality of transverse compression springs; the lower support plate A groove is arranged on the groove, and a lower magnet is arranged on the groove, and the lower support plate is connected with the upper support plate through a longitudinal compression spring, and the upper support plate is connected with the side wall; the lower part of the upper support plate An upper magnet is provided, a gap is provided between the upper magnet and the lower magnet, and the upper magnet and the lower magnet are arranged opposite to each other with the same magnetic poles. The invention can reduce the vibration from the horizontal and vertical directions, and reduce the noise when the equipment is running; it can bear heavy weight, is not easy to break, and has a simple and reasonable structure.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

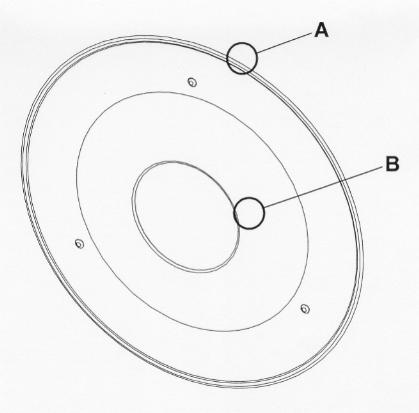

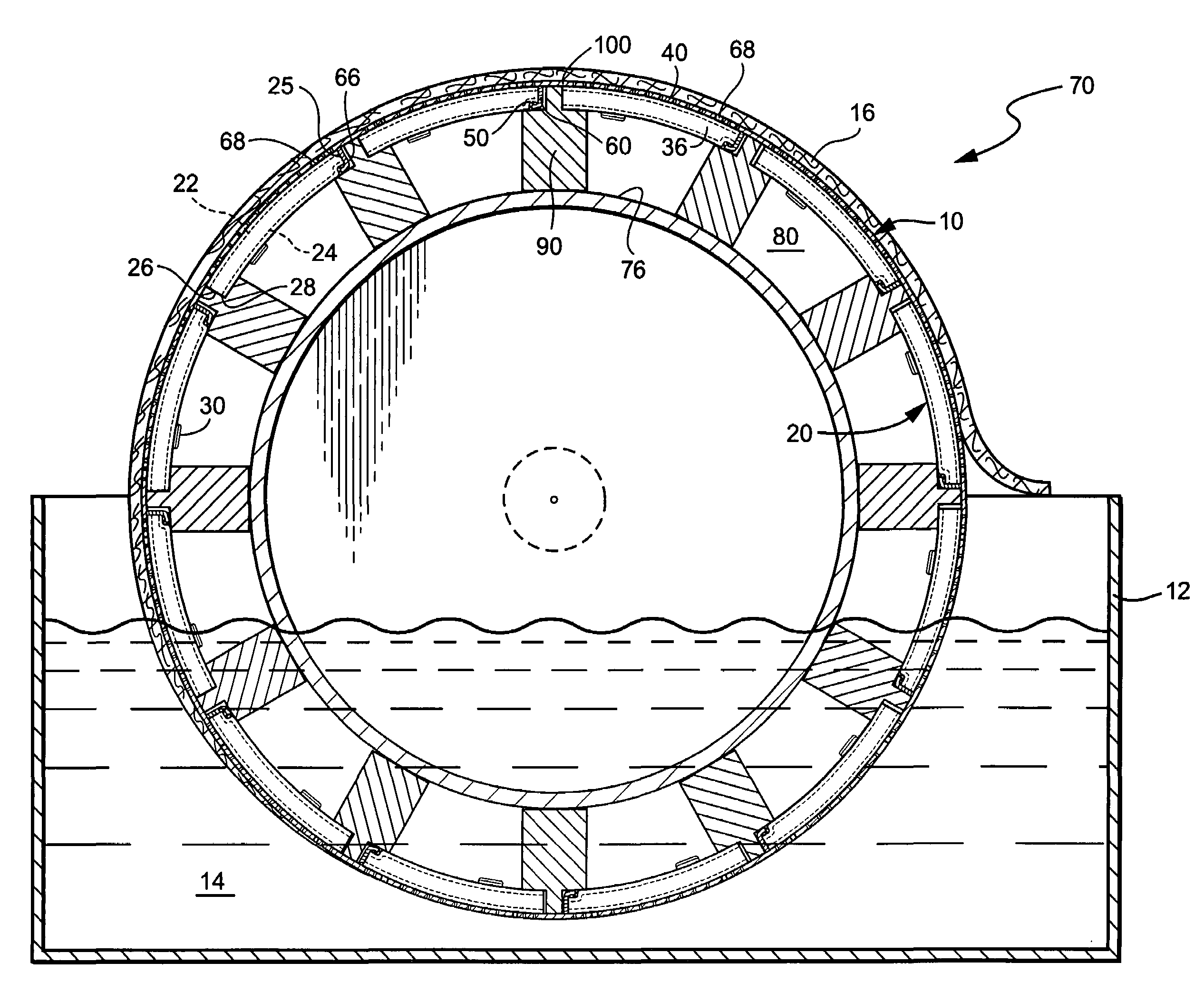

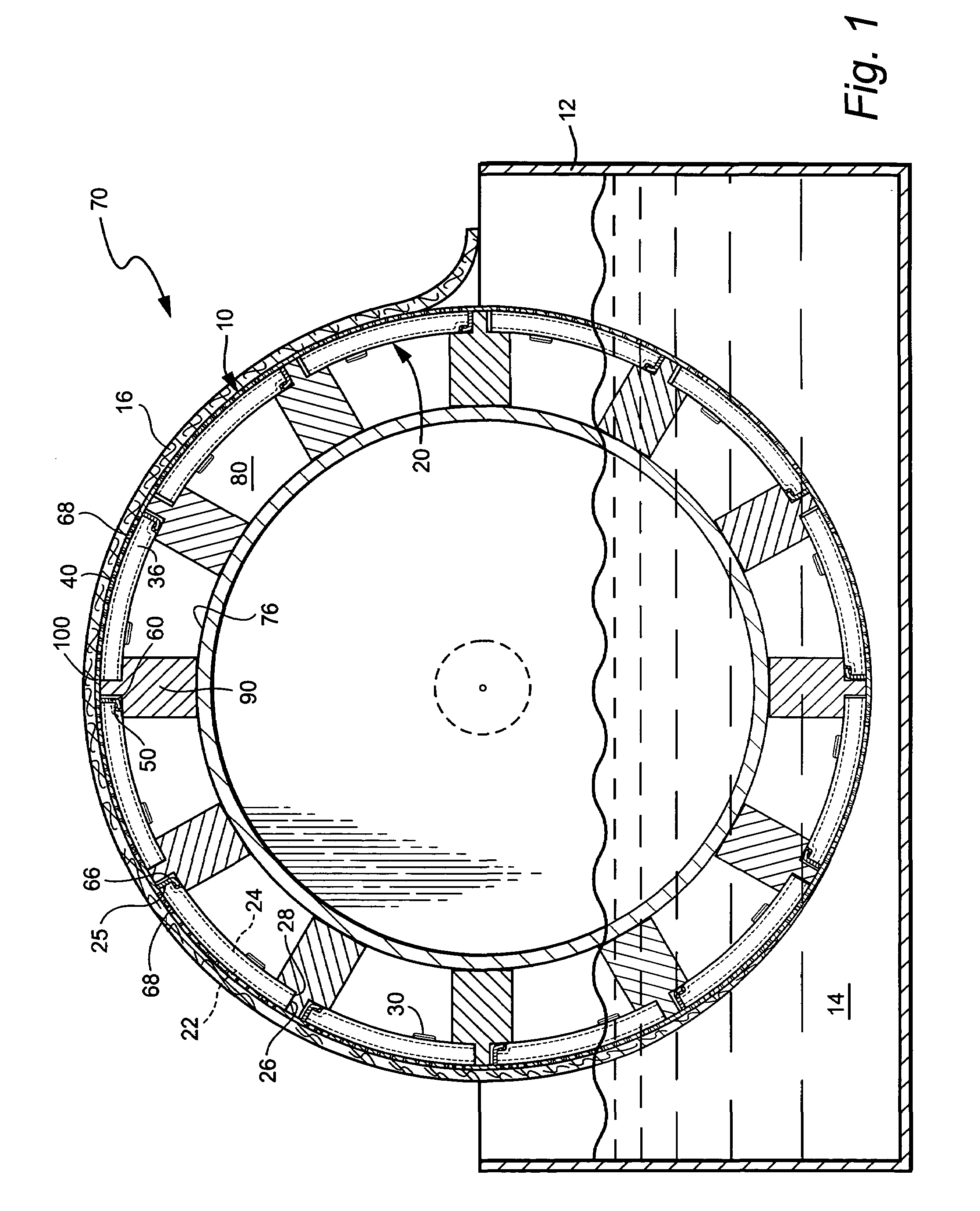

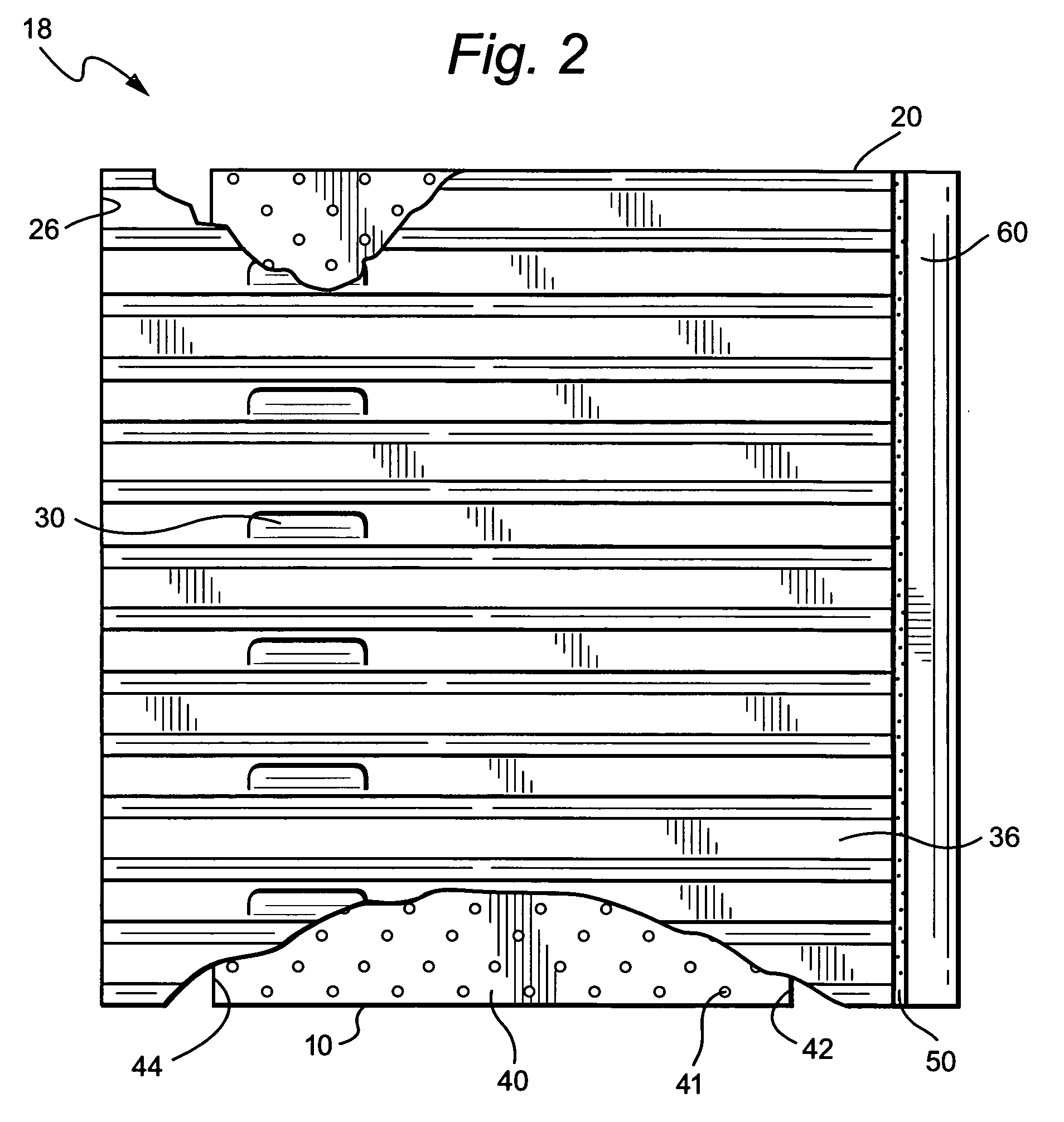

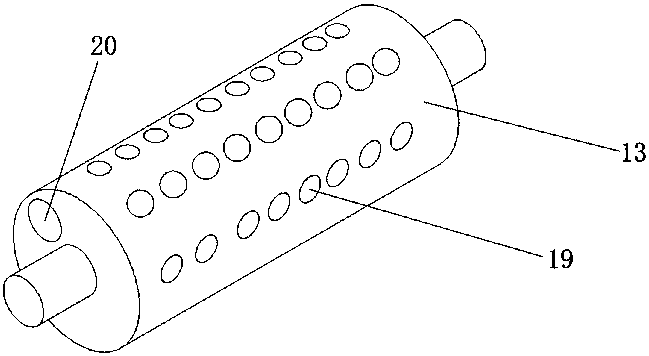

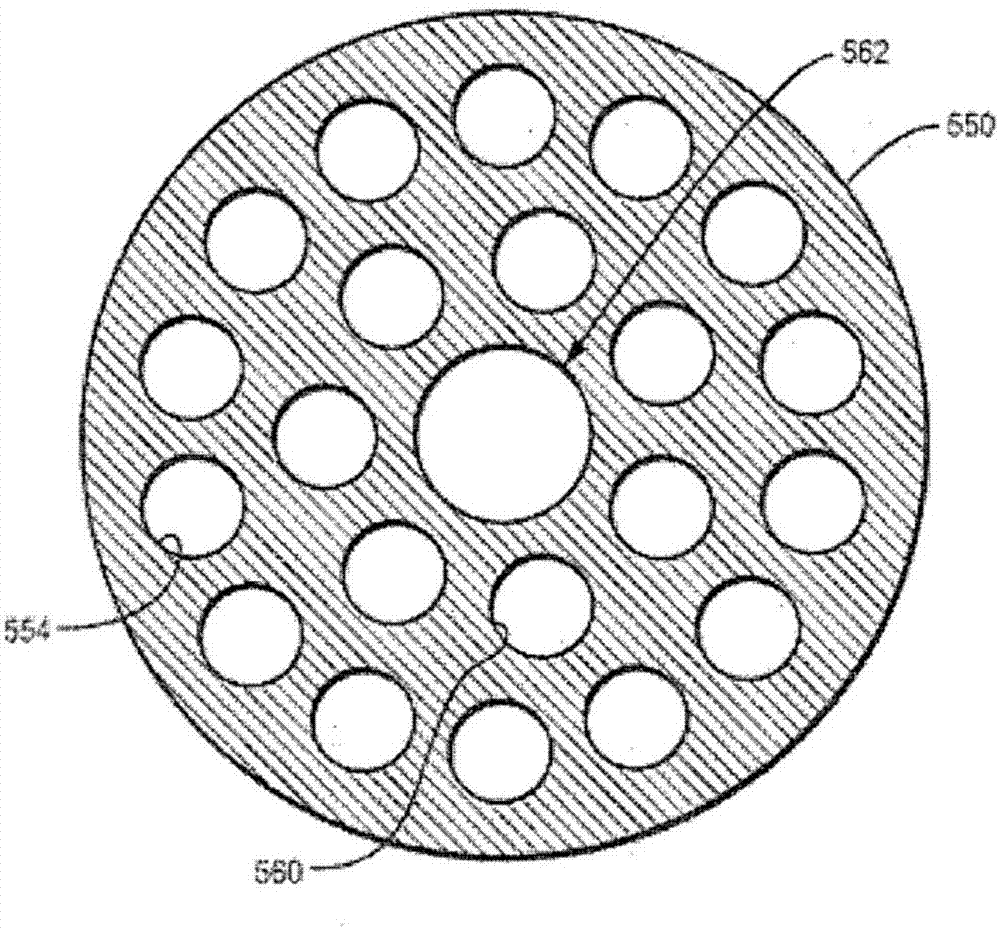

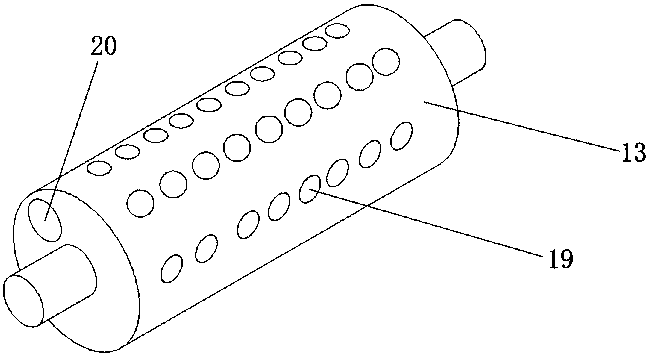

High capacity and high efficiency filter deck assembly

InactiveUS7374050B2Great drainage surfaceEfficient actionWater/sewage treatmentLoose filtering material filtersLeading edgeEngineering

A rotary drum filter has a plurality of longitudinally extending division grids mounted about the outer circumference of a drum. A plurality of corrugated sheets are provided, with the leading and trailing edges of each sheet mounted to circumferentially adjacent pairs of division grids to define filtrate compartments. An equivalent number of perforated filter plates are also provided. Each filter plate is attached to the top of a corrugated sheet and has a leading edge and a trailing edge that are set back from the leading edge and trailing edge of the corrugated sheet. A seal clip is positioned near the leading edge of each corrugated sheet. A seal member or seal members is / are held in place by the seal clip and is / are positioned at the face of the leading edge of each corrugated sheet or beneath and near the face or each corrugated sheet. A perforated cap strip can be removably attached to the top of each division grid to thereby retain for confined movement each filter plate and corrugated sheet combination (filter deck and drainage deck) during rotary drum filter operation and to allow easy replacement of the filter plate and corrugated sheet combination(s) and / or cap strip(s) when the rotary drum filter is not in operation. This rotary drum filter design and operation has increased capacity and efficiency.

Owner:ANDRITZ INC

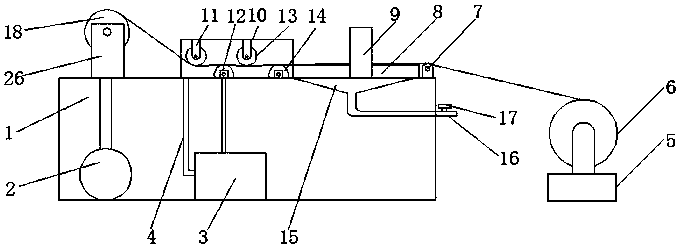

Drying equipment for textile fabric

InactiveCN105571292ASpeed up circulationAvoid rewettingDrying gas arrangementsDrying machines with progressive movementsInlet channelHeat conducting

The invention relates to a textile machine, in particular to drying equipment for textile fabric. According to the technical scheme, the drying equipment for the textile fabric comprises a drying box, an air outlet is formed in the top of the drying box, and an air inlet is formed in the bottom of the drying box; the air inlet is connected with an air inlet channel, and a textile fabric inlet and a textile fabric outlet are formed in the opposite side walls of the drying box; an electric heater is arranged in the drying box, and electric heating screens are symmetrically arranged above and below the stroke of the textile fabric to be dried in the drying box and are parallel to the textile fabric to be dried; and a collecting window is arranged at the top of the drying box, a fan is arranged in the collecting window, the collecting window is connected with a heat preservation pipe connected with a plurality of heat conducting copper pipes, and the heat conducting copper pipes are wound around the air inlet channel. The drying equipment has the beneficial effects of being reasonable in structure, good in use effect and capable of improving the drying effect and reducing energy consumption.

Owner:TAICANG QISHENG CHEM FIBER FACTORY

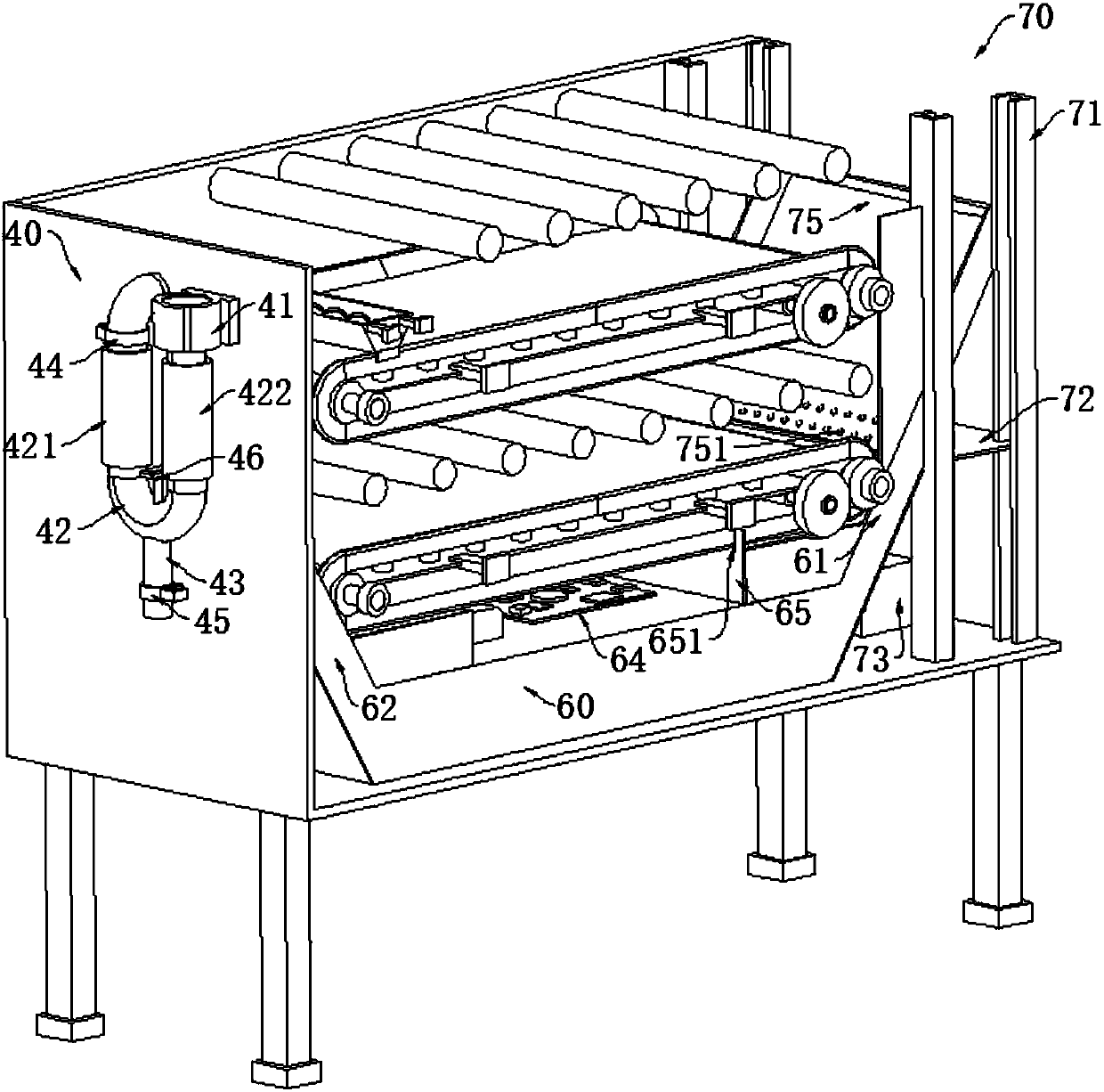

Medicinal material drying equipment

InactiveCN107702436AMaintain colorLow boiling pointDrying solid materials with heatDrying solid materials without heatVacuum pumpingBristle

The invention provides medicinal material drying equipment. The medicinal material drying equipment comprises a drying box, a feed hopper, a receiving box and a vacuum pumping device. The drying box is internally provided with a drying device, a material collection block and a lifting device. The drying device comprises a first drying unit and a second drying unit. The first drying unit and the second drying unit each comprises a material conveyor belt, ultrasonic transducers located below the material conveyor belt, a driving motor and an infrared ray lamp pole located above the material conveyor belt. A material scattering device is arranged above the first drying unit. Material retaining plates are arranged below the second drying unit. Limiting grooves and bristles are arranged above the material retaining plates. The lifting device is located on one side of the drying device. The medicinal material drying equipment conducts drying on medicinal materials through combination of ultrasound and infrared, is good in drying effect and capable of completely maintaining the original color, luster and flavor of the medicinal materials, conducts vacuum pumping on the interior of the drying box through the vacuum pumping device, can improve the drying efficiency and prevent vapor from wetting the medicinal materials again and is good in drying effect.

Owner:成都菲斯普科技有限公司

Intelligent clothes-horse

ActiveCN102851924AGood shelter from wind and rainImprove protectionOther drying apparatusTextiles and paperAutomatic controlControl system

The invention discloses an intelligent clothes-horse. The intelligent clothes-horse sends a signal to control a mechanical transmission system in response to the temperature, the humidity and the illumination of the exterior by using a humiture sensor and a photosensitive sensor which are arranged on a control system, and a motor of the mechanical transmission system drives a roller to rotate to drive connected clothes-horse bracket and rain curtain through a steel wire rope to put clothes away, in this way, the automatic control is realized; PVC (polyvinyl chloride) soft glass arranged at both sides and on the top of the clothes-horse not only can transmit light, but also can shield rain, and thus, the human-based design is realized, and the clothes-horse is excellent in the service for the life of people and brings great convenience for the life of people.

Owner:沛县汉腾建设发展有限公司

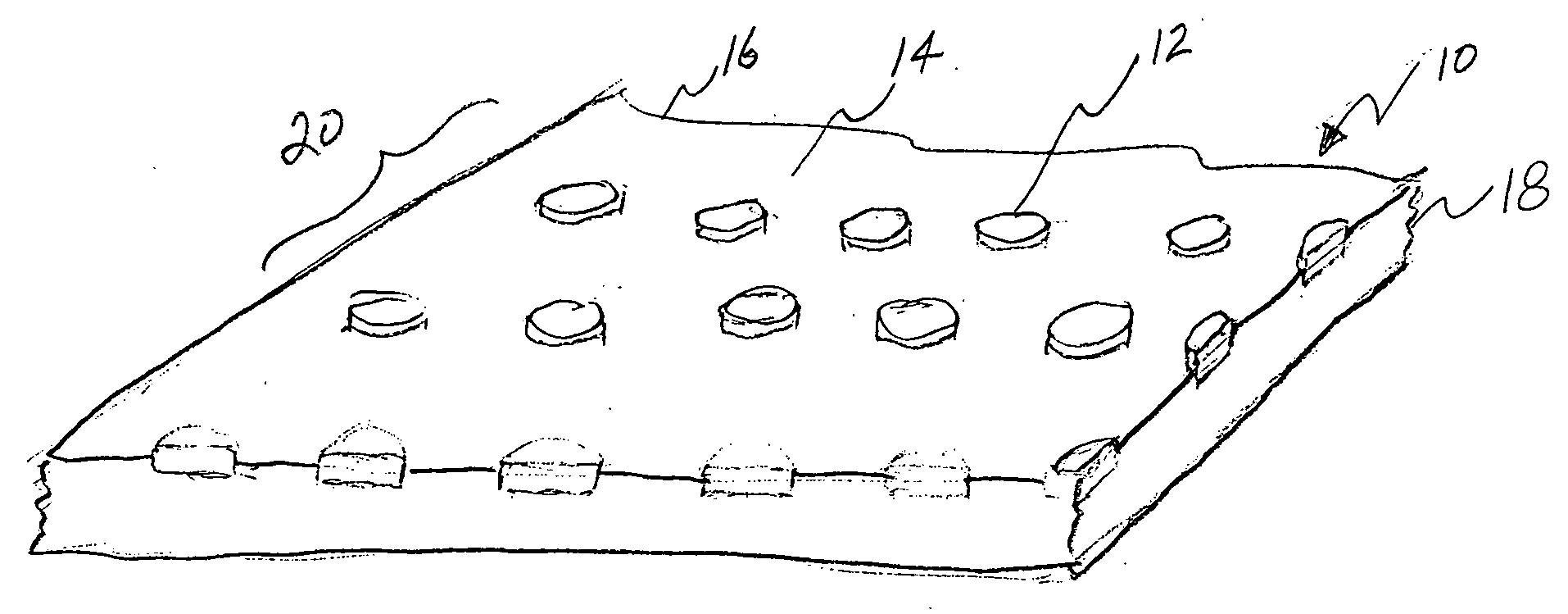

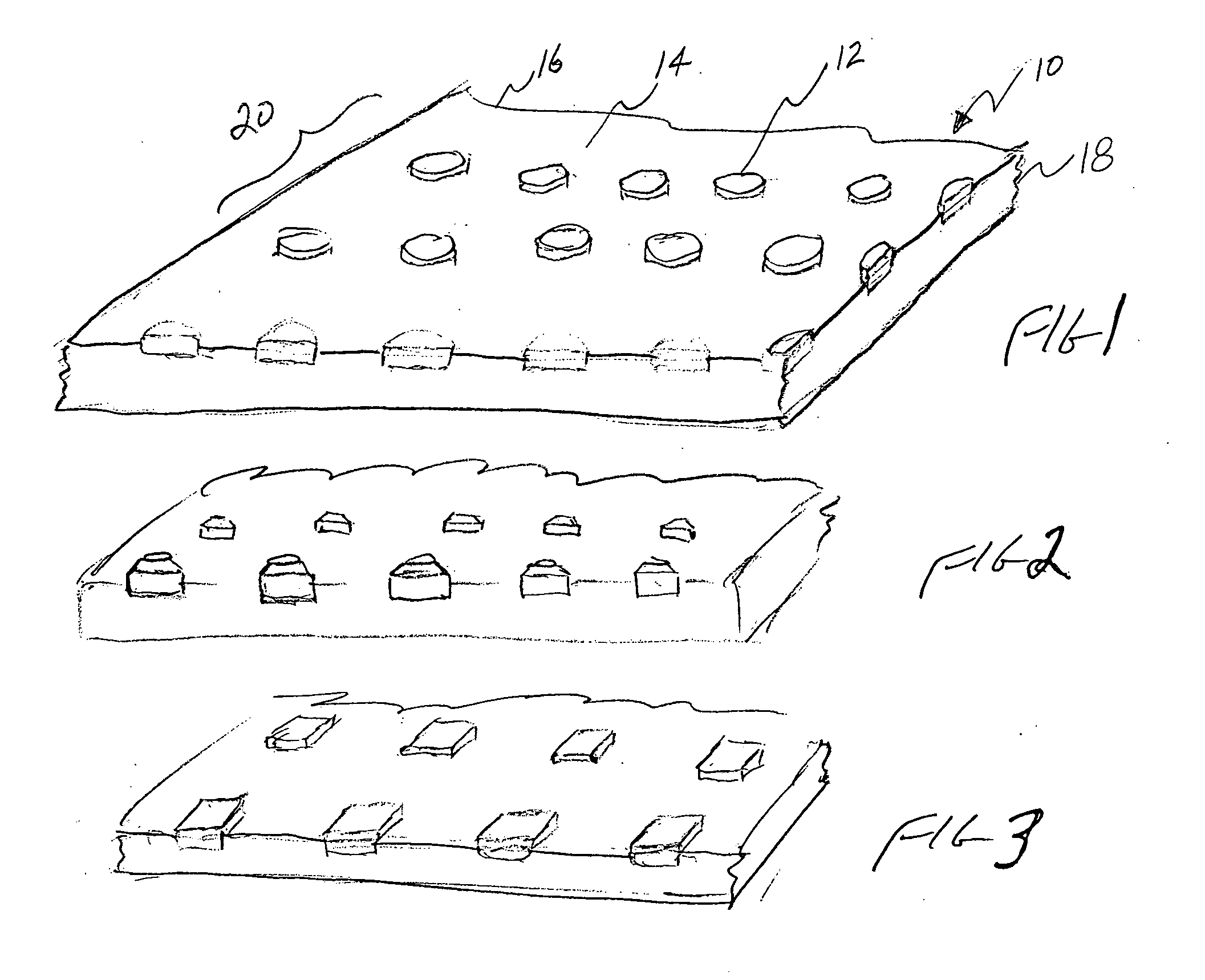

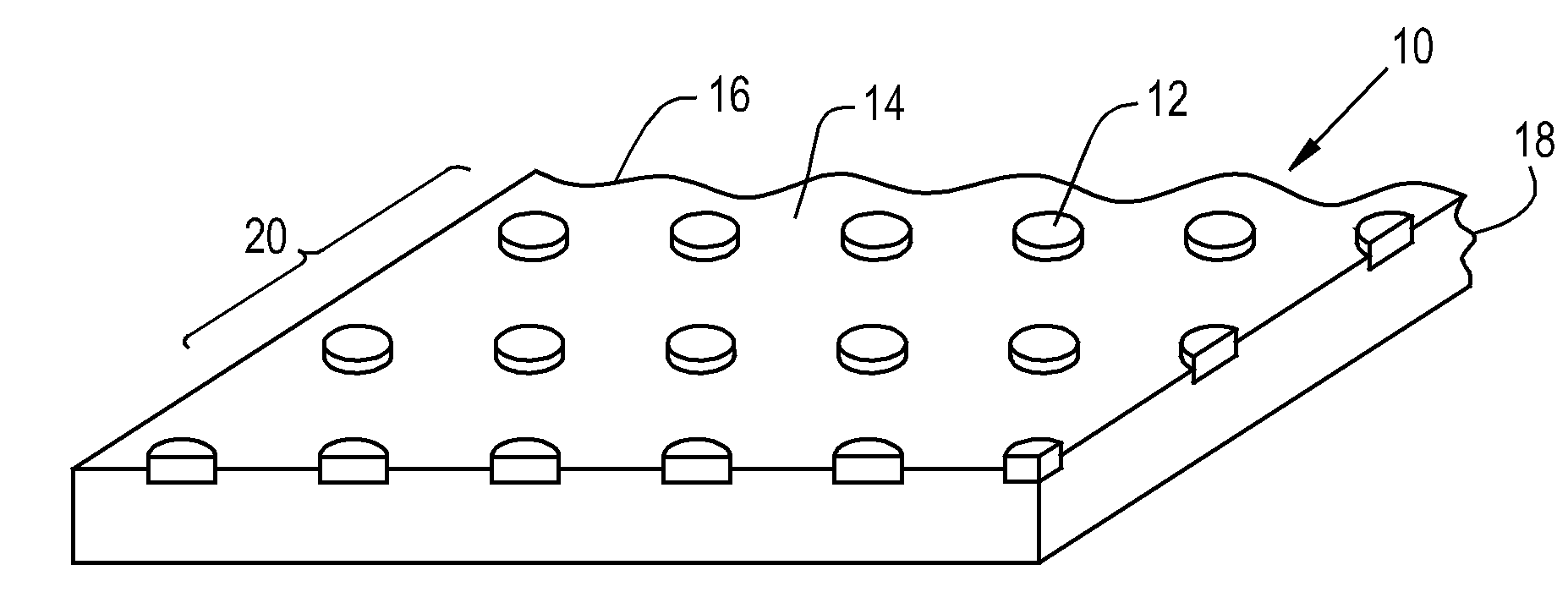

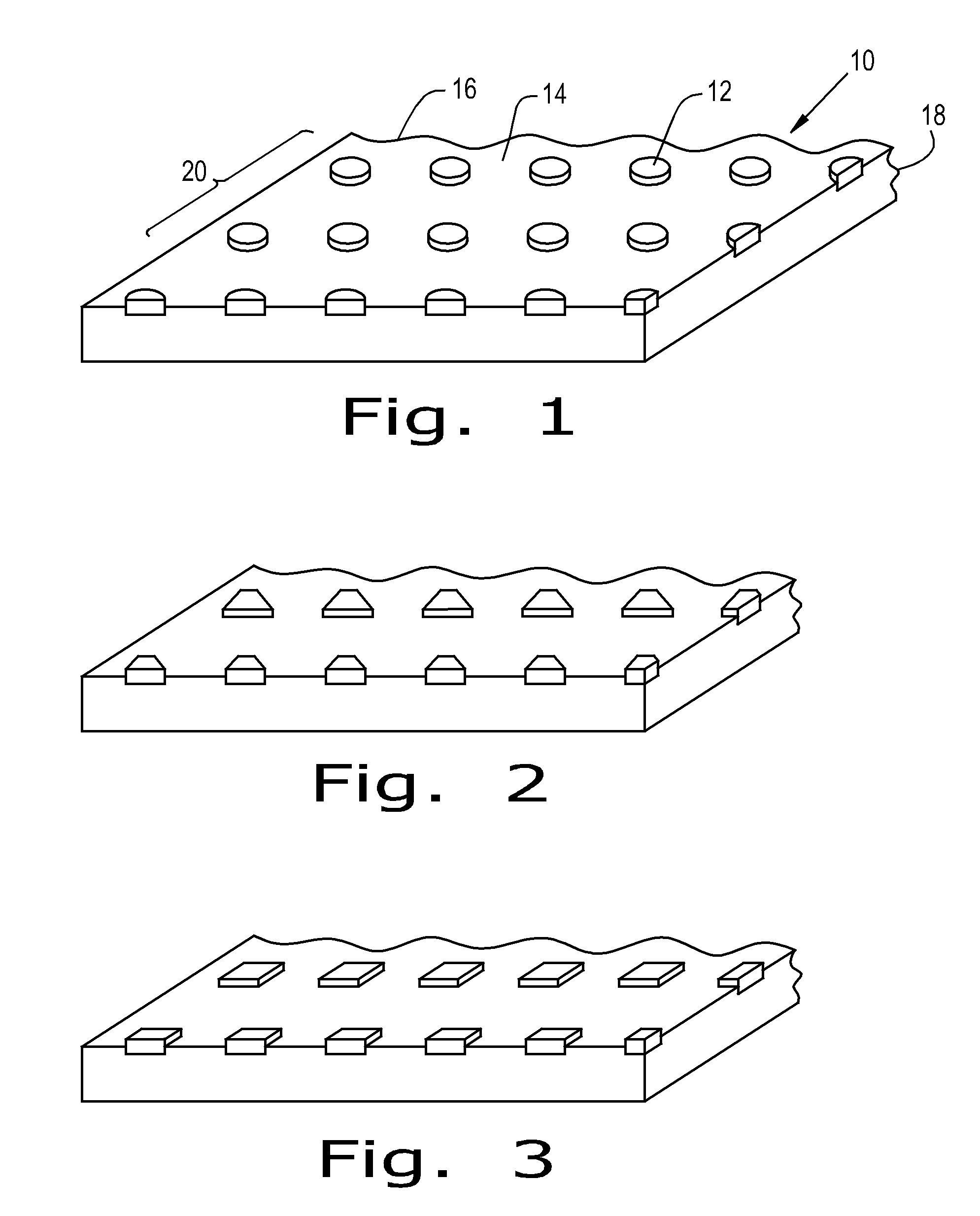

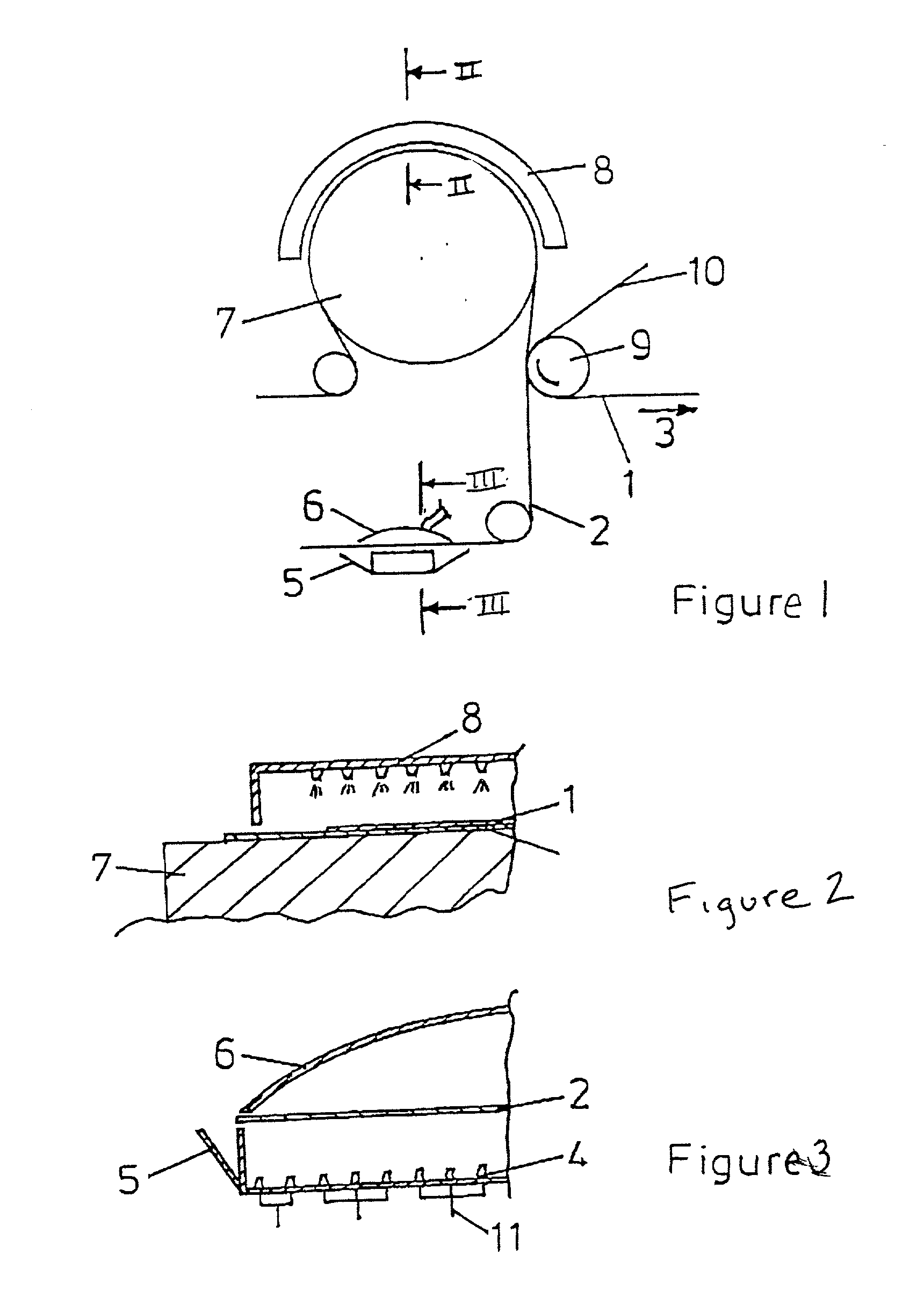

Patterned press fabric

InactiveUS20080163998A1Accelerates the dehydration processEffective markingWood working apparatusPaper/cardboardRegular gridGrid pattern

A press fabric having a plurality of surface pressing plates on a sheet side of the fabric imparts an impression onto a sheet of paper web during a pressing process. The surface pressing plates are preferably resin pressing plates, and form at least one of a random pattern of dots, a predetermined pattern of dots, a grid pattern of dots, a regular grid pattern of lines, an irregular grid pattern of lines a plurality of squiggly lines, a plurality of wavy lines, a plurality of straight lines, words and pictures.

Owner:VOITH PATENT GMBH

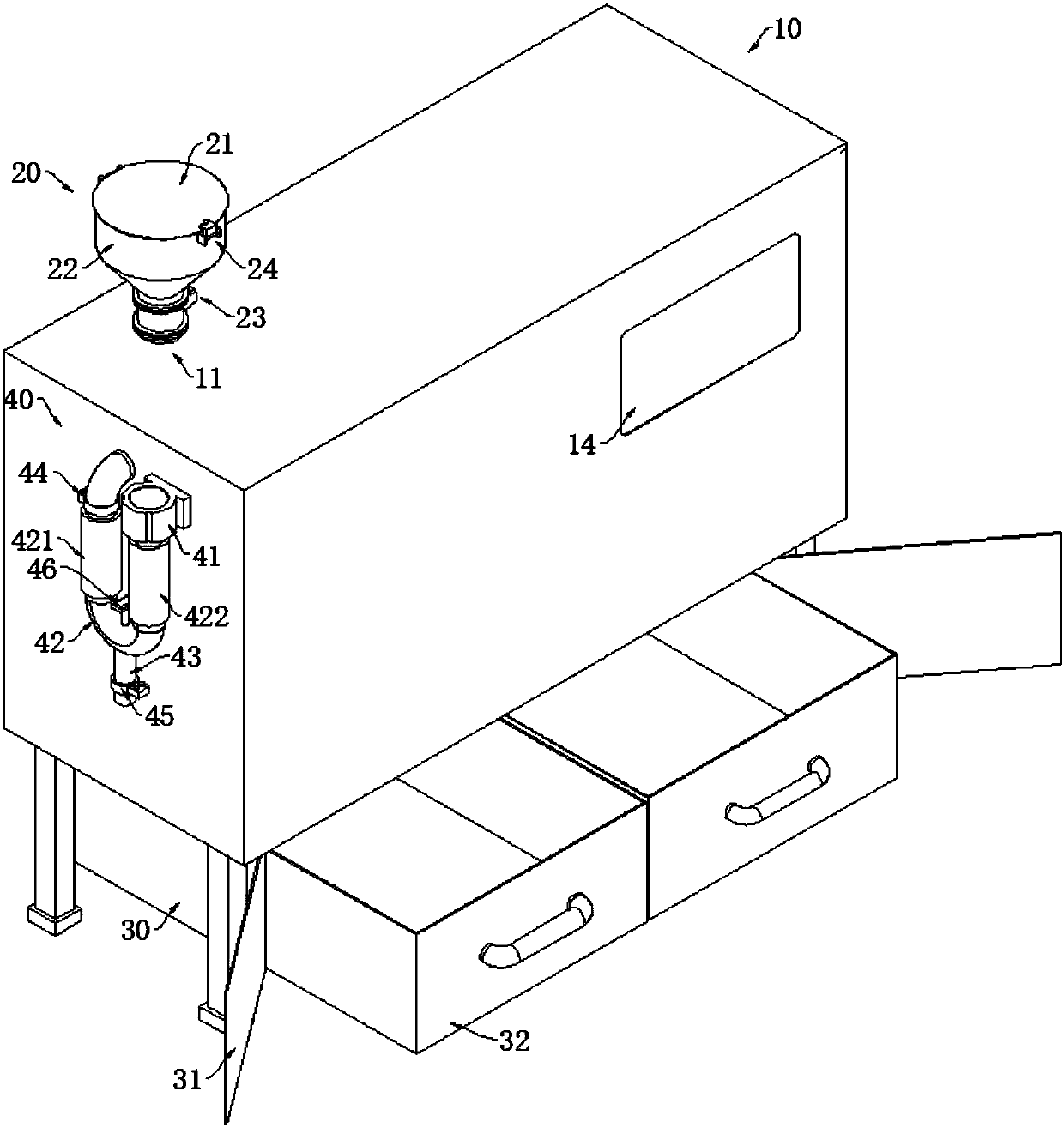

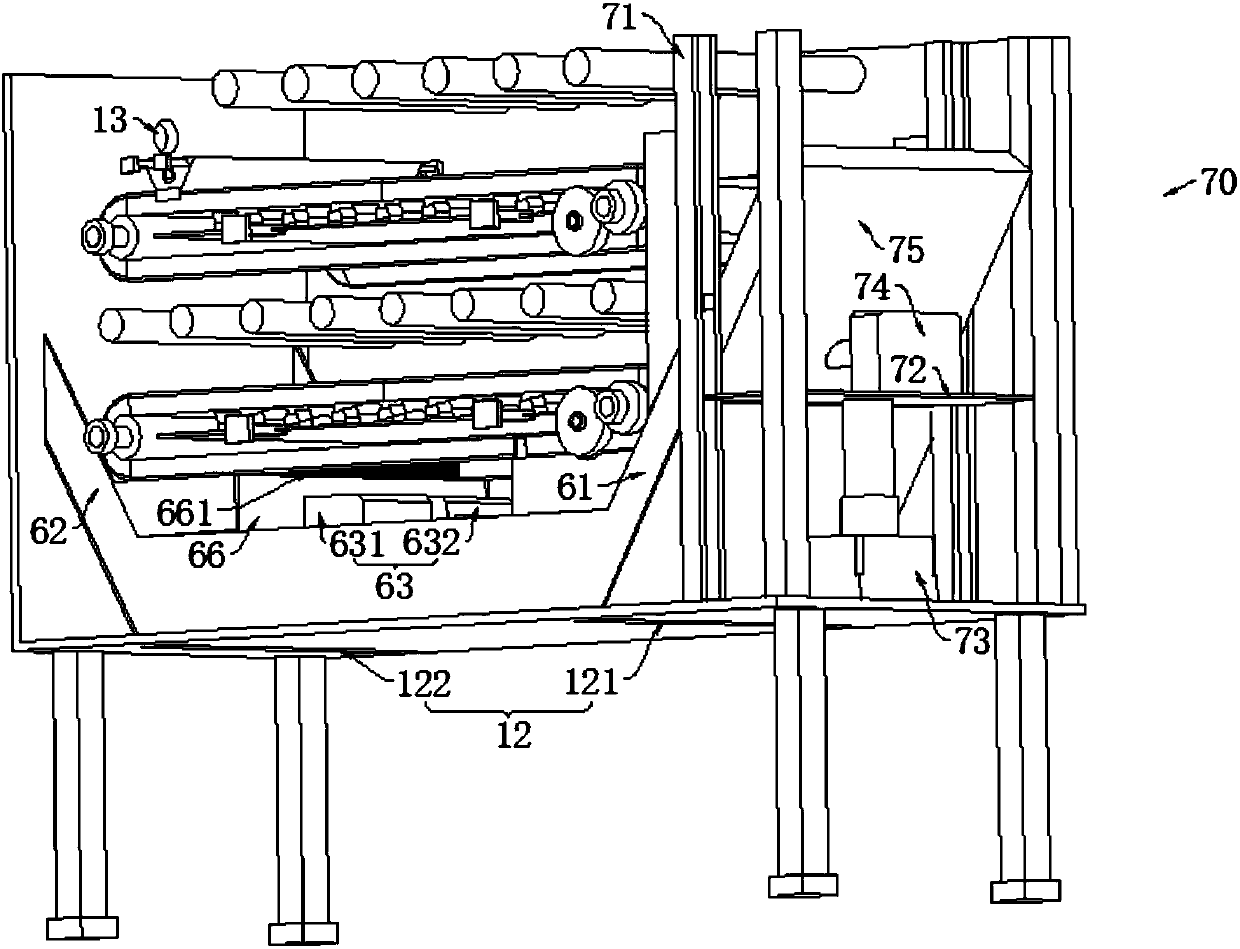

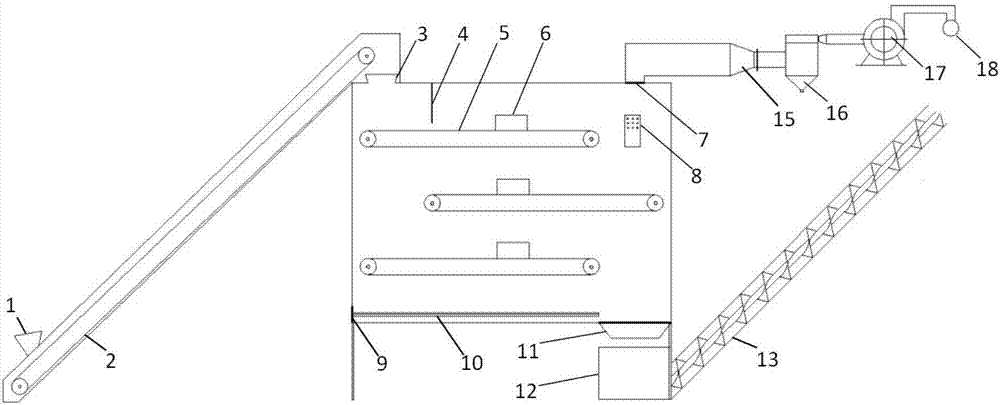

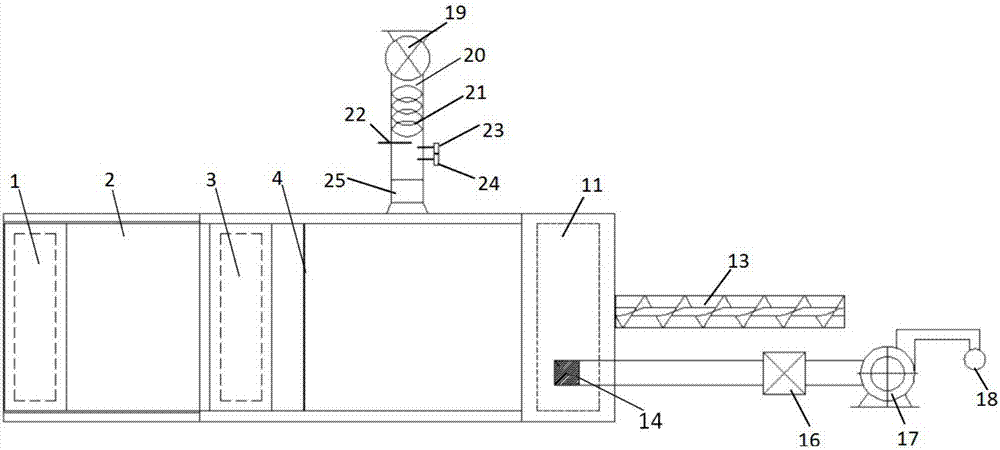

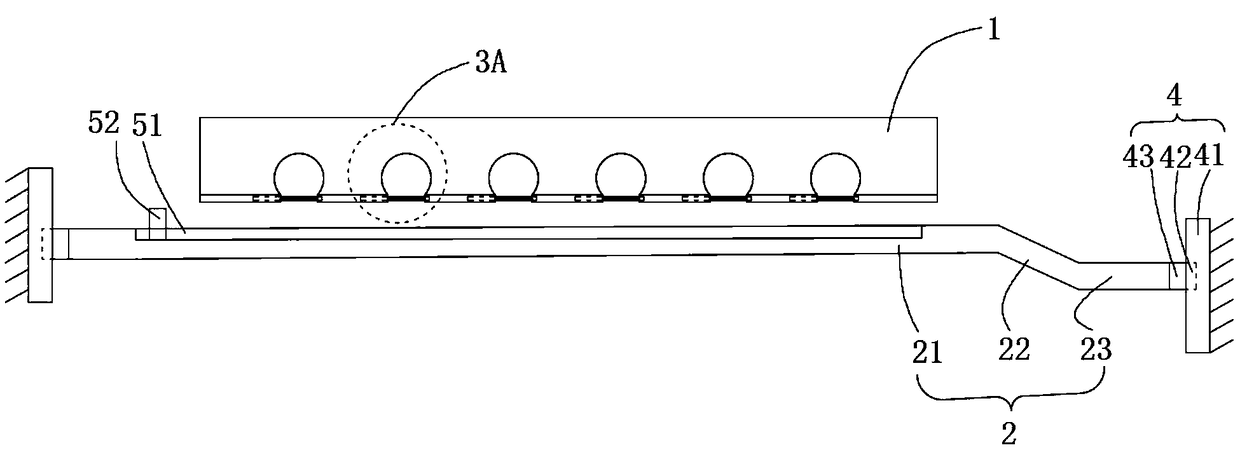

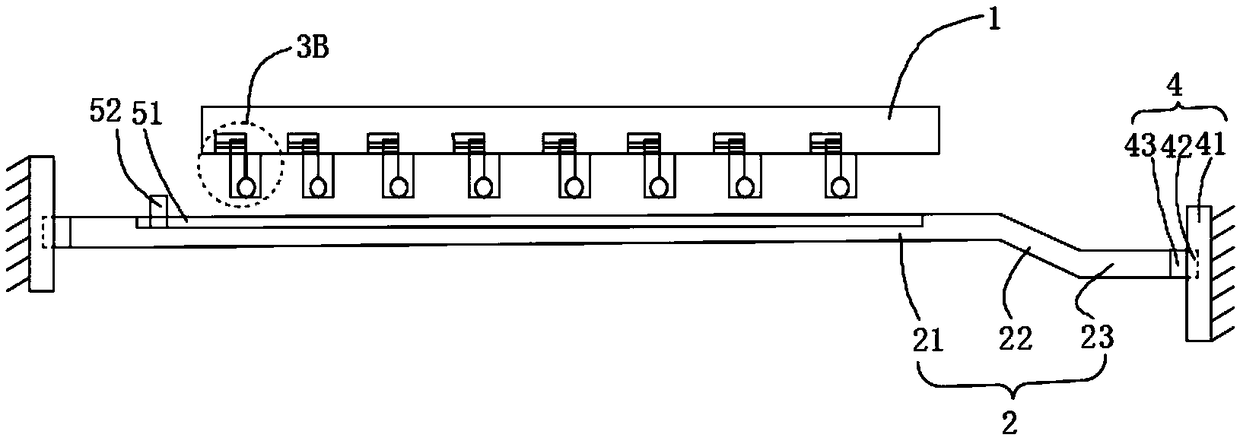

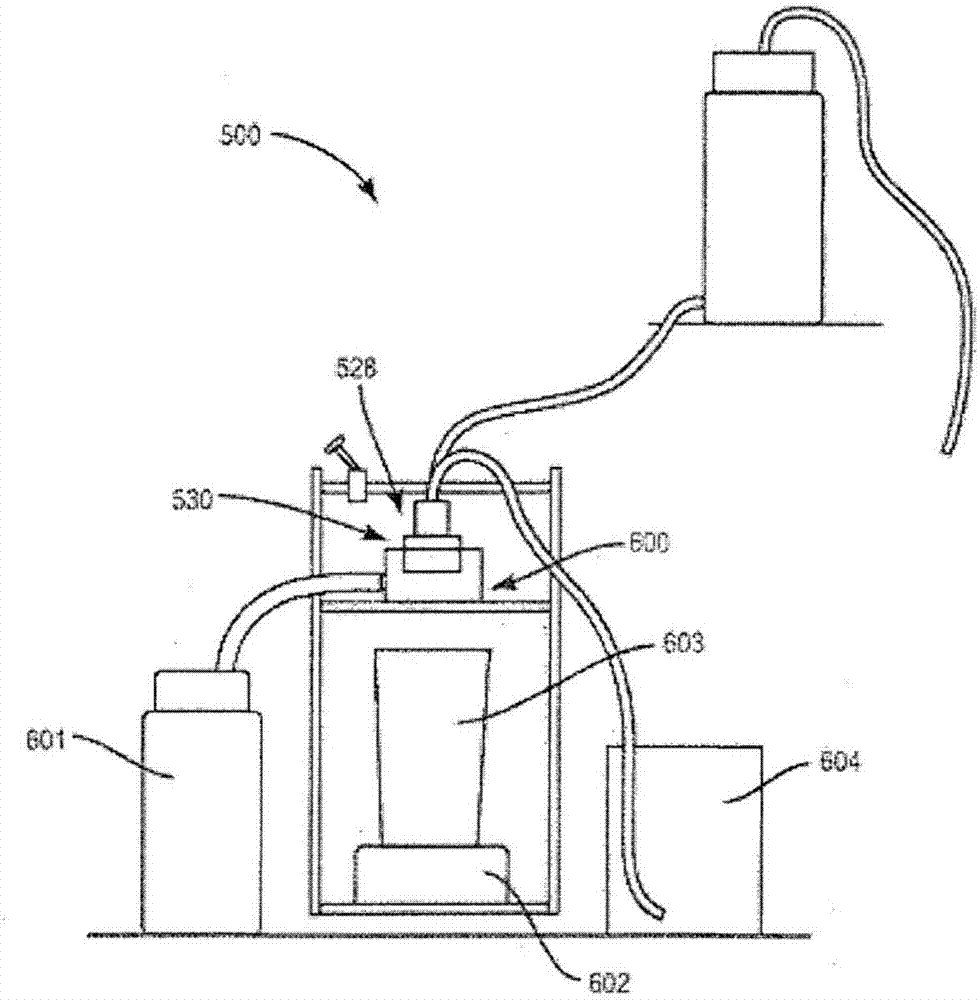

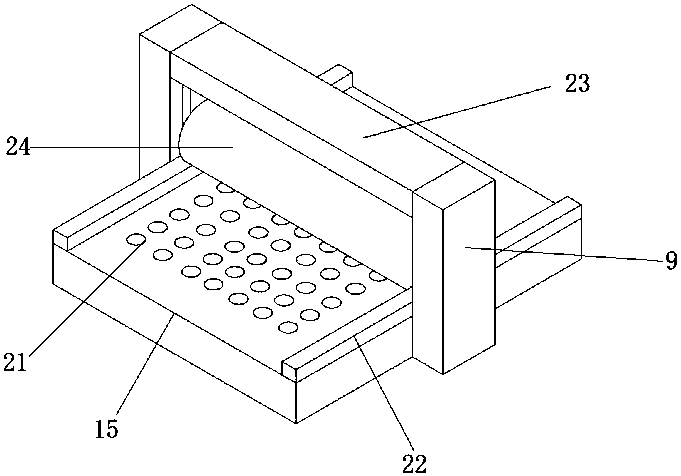

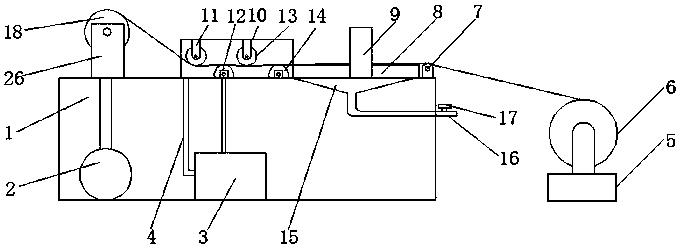

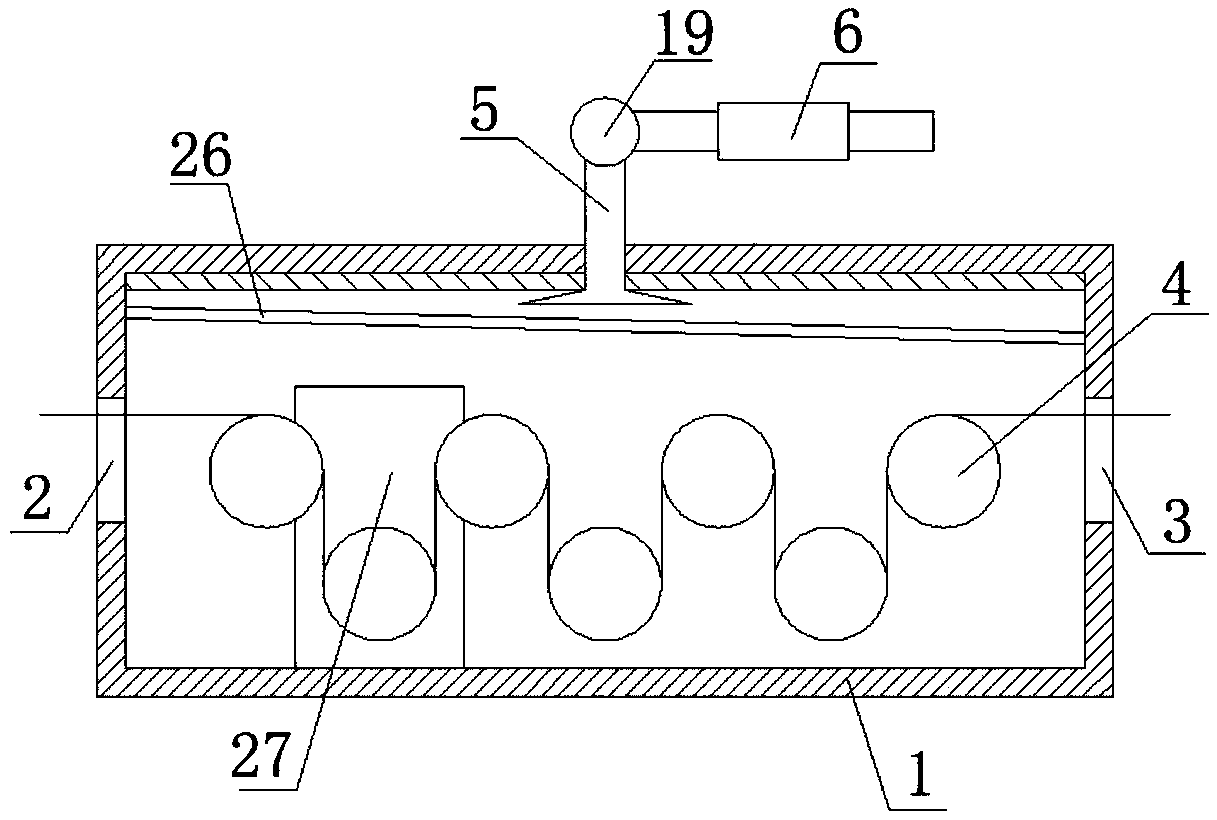

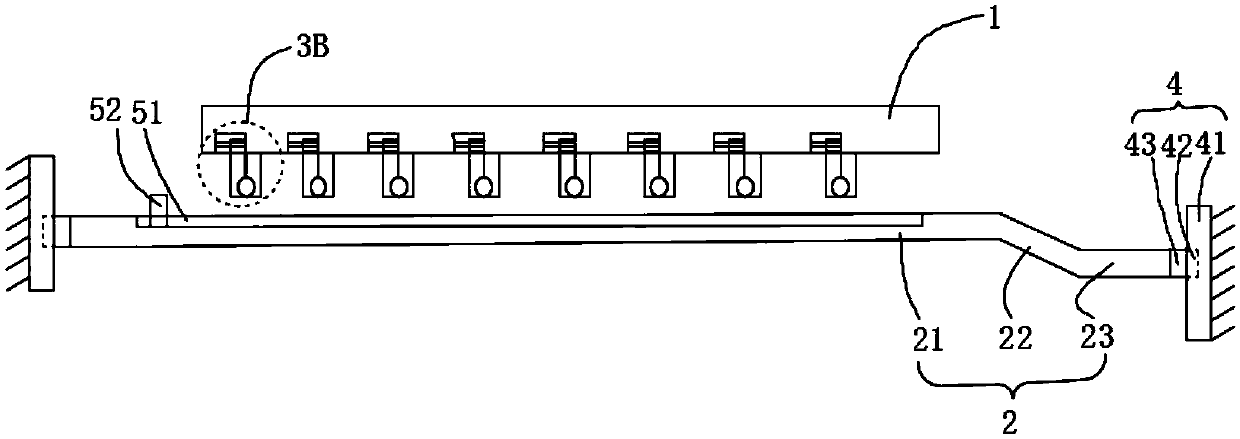

Device for making cow bed regeneration packing through solid cow dung

PendingCN107188389AAvoid rewettingAchieve dryingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMilk cow'sProcess engineering

The invention relates to the technical field of cow breeding farm excrement resourcing, in particular to a device for making cow bed regeneration packing through solid cow dung. The device comprises a box, a feeding unit, a discharging unit, a conveying unit and an air inlet heating unit; the box is provided with a feed port, a discharge port, multiple air inlets and an air outlet; the feeding unit is connected with the feed port, the discharging unit is connected with the discharge port, the conveying unit is arranged in the box, the two ends, in the conveying direction, of the conveying unit are arranged corresponding to the feed port and the discharge port respectively, the air inlets are arranged at intervals in the conveying direction of the conveying unit, the air inlet heating unit is connected with the air inlets and used for conveying hot wind to materials conveyed on the conveying unit so as to achieve drying and sterilizing effects, gas completing drying and sterilizing is discharged from the discharge port, and secondary soaking of dried materials is avoided. The device is simple in structure, the materials pass through multiple air inlets in the conveying process on the conveying unit, multiple drying and sterilizing are achieved, and the drying and sterilizing effects are improved.

Owner:CHINA AGRI UNIV

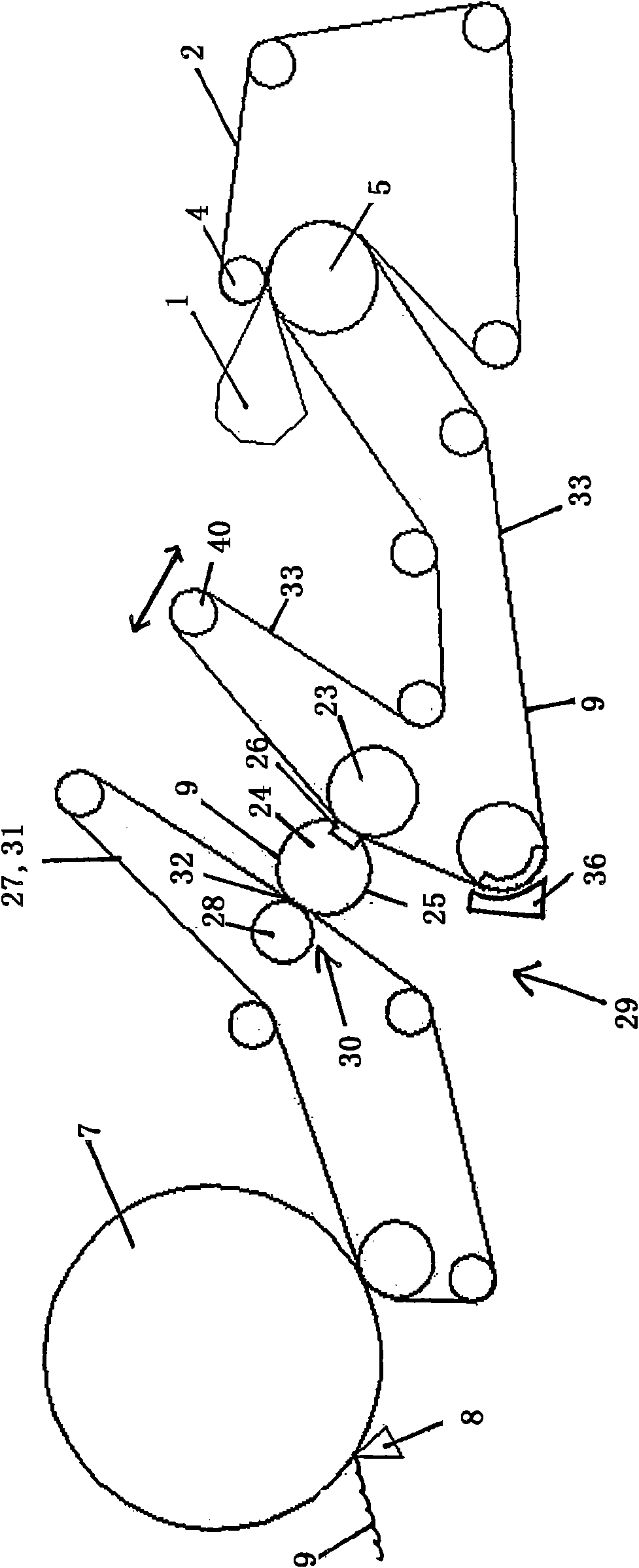

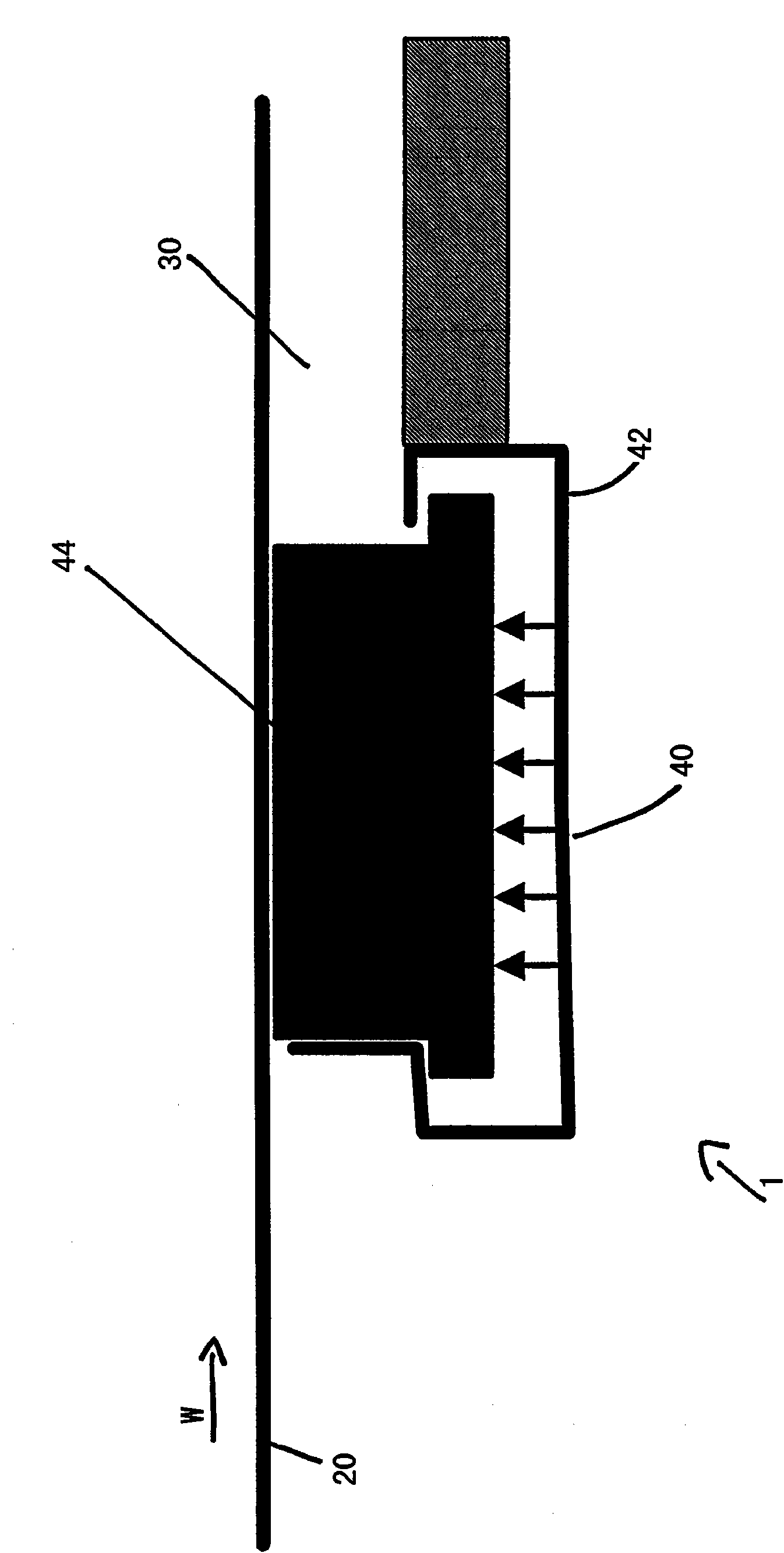

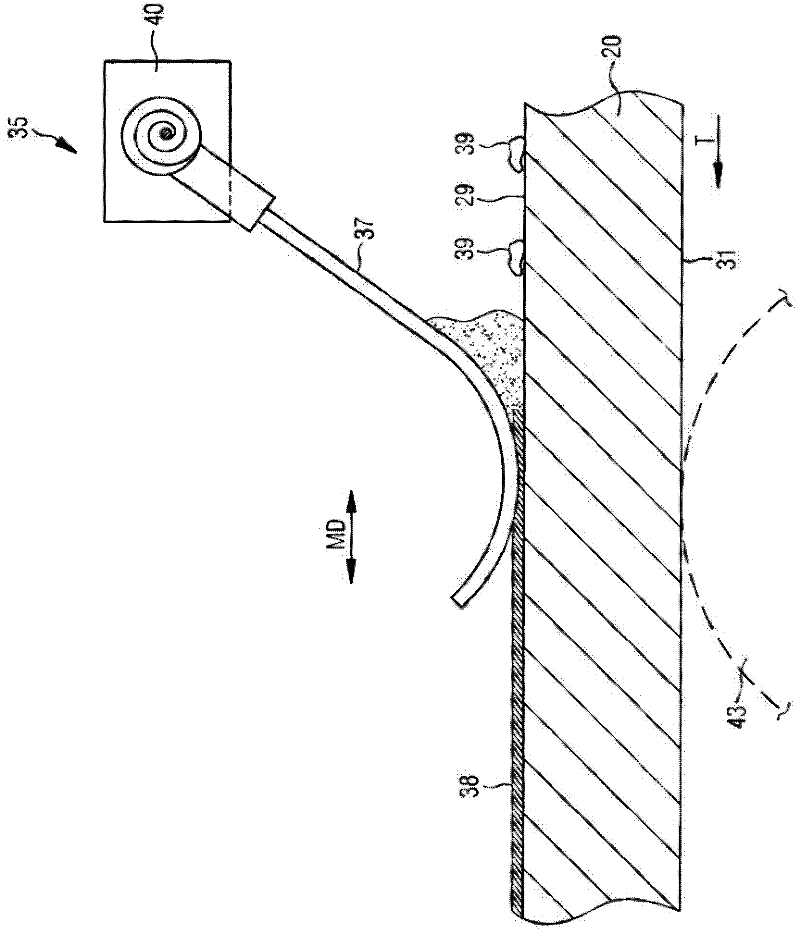

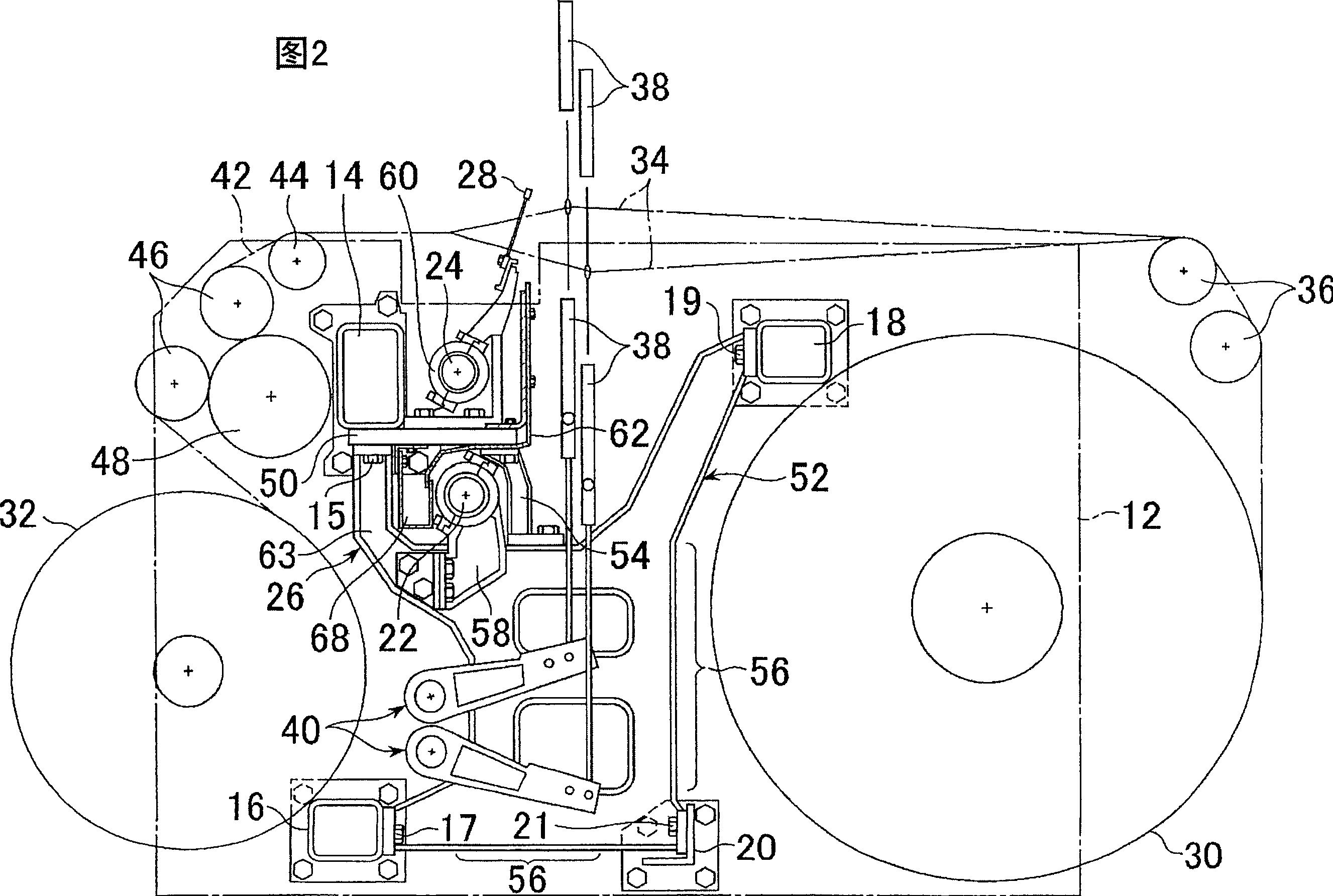

Pressing apparatus for a paper- or board-making machine for removing fluids from a web by pressing, and a method for treating a web in a paper- or board-making machine

A pressing apparatus for a paper- or board-making machine for removing fluids from a web (W) by pressing comprises at least one belt which guides the web. The belt (20) is impervious to fluids and forms an endless loop. At least one nip is formed between a press roll (2) and a pressure means (1) of the pressing apparatus. The guided web is arranged to pass through the nip. The pressure means comprises at least one pressure chamber containing a pressure medium and extending along the length of the nip in the web moving direction such that the pressure medium directly contacts the belt. The pressure chamber has a pressure-operated sealing member (40) which cooperates with the belt, and the sealing operating pressure is adjusted in accordance with the pressure acting in the pressure chamber.

Owner:VALMET CHINA CO LTD

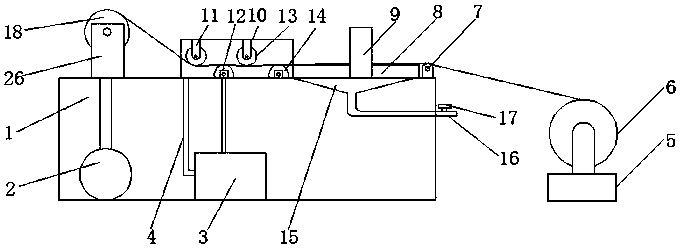

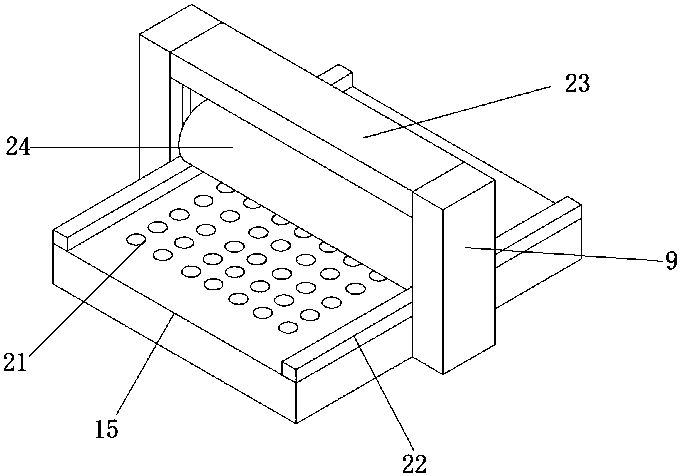

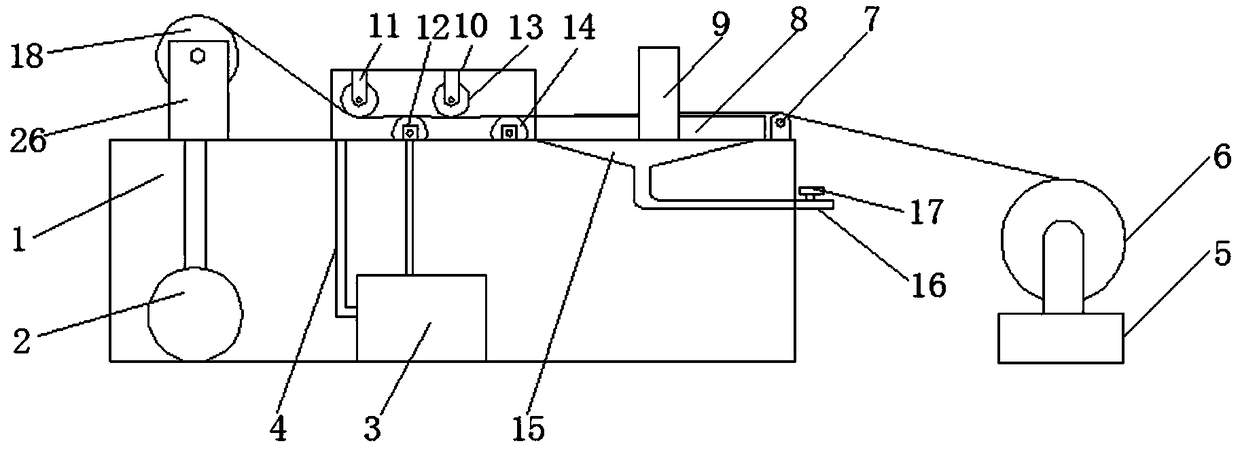

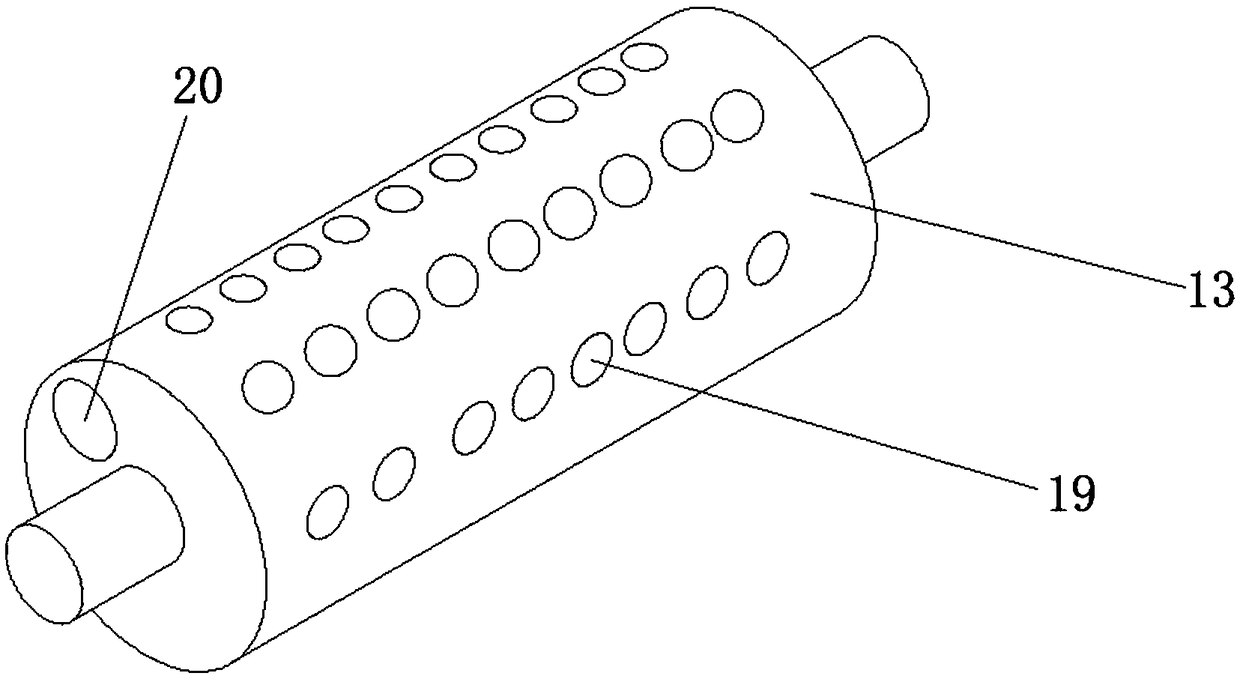

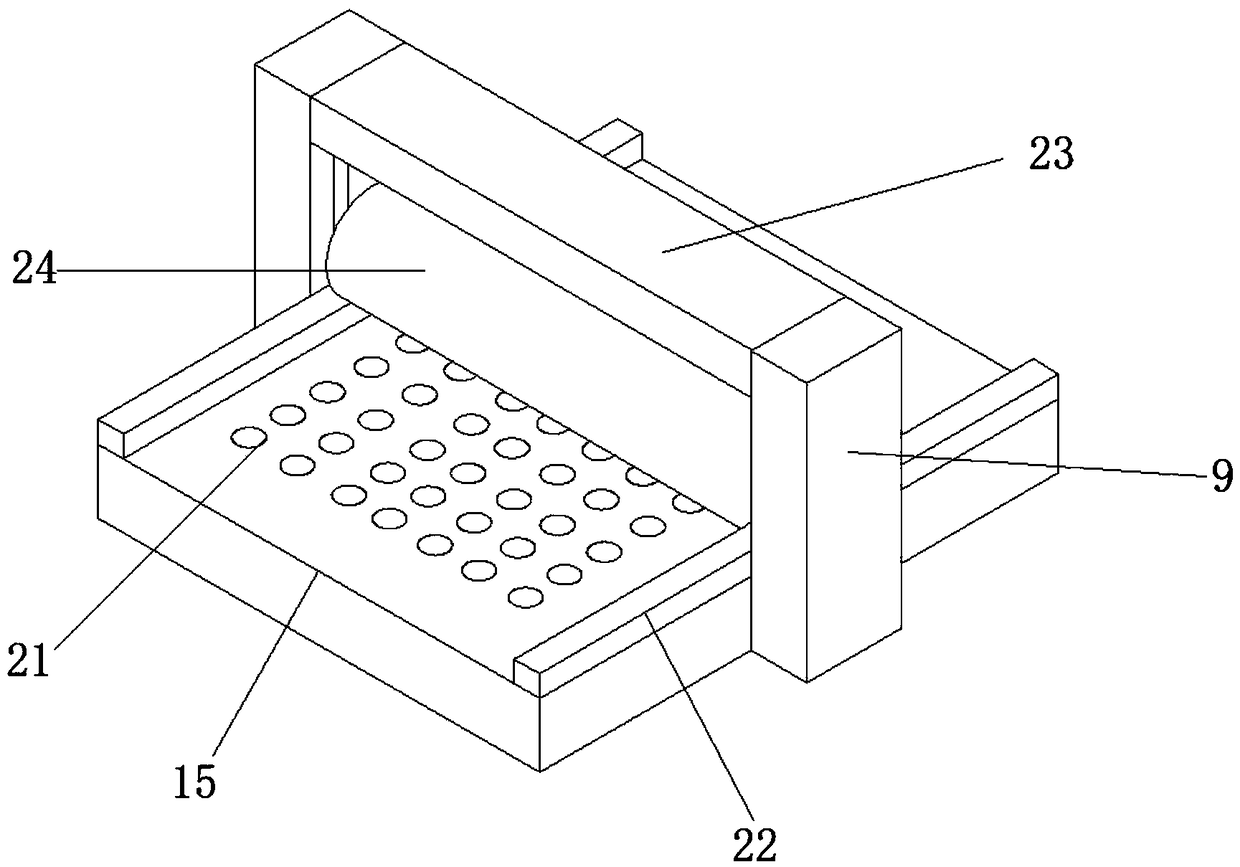

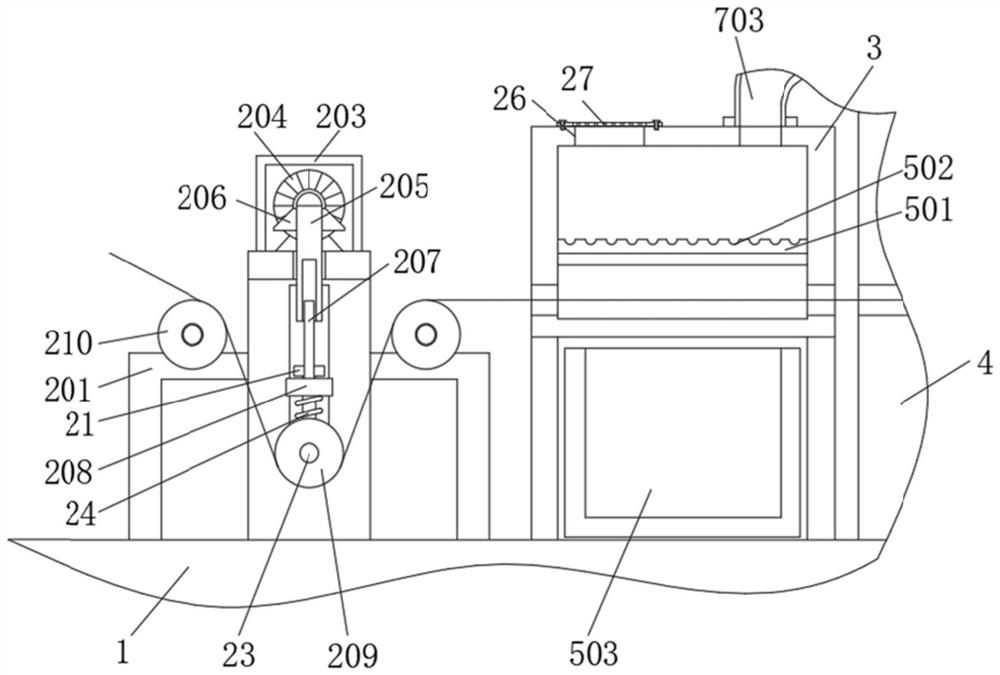

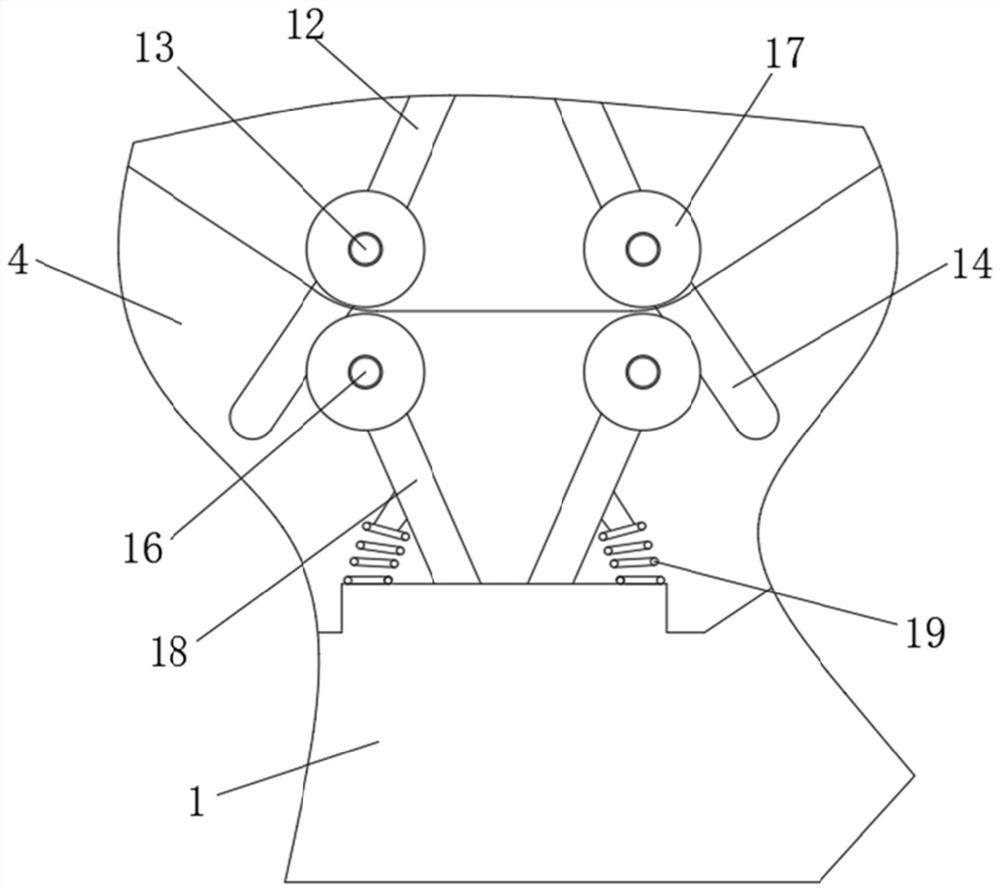

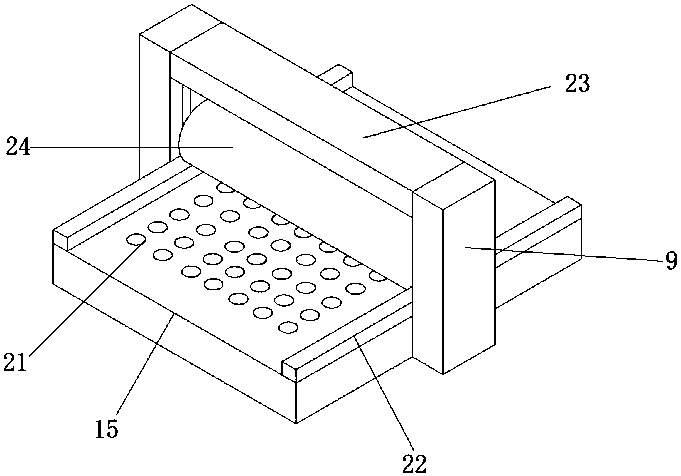

Clothing fabric drying device

InactiveCN108332532AShorten drying timeImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringFixed frame

The invention discloses a clothing fabric drying device. The clothing fabric drying device comprises a workbench, a feeding roller, a material collecting roller, a drying room and an extruding table,wherein the feeding roller is fixedly arranged on a storage frame; the feeding roller is rotatably connected with supporting rods at the two sides of the upper end surface of the storage frame; the storage frame is fixedly arranged at the right side of the workbench; a guide rotary shaft, an extruding table, a drying room and a fixed frame are arranged on the upper end surface of the workbench from right to left in sequence; the guide rotary shaft is fixedly mounted on the rightmost end of the upper end surface of the workbench; the guide rotary shaft is rotatably connected with the workbench;the extruding table is a rectangular structure; fixed rods are fixedly arranged at the two sides of the extruding table vertically; the bottom ends of the fixed rods are fixedly arranged on the workbench; the left side of the extruding table is adjacent to the drying room; and the right side of the extruding table is adjacent to the guide rotary shaft. The clothing fabric drying device can be used for simultaneously drying upper and lower sides of the fabric, can quickly and completely remove water in cloth, saves drying time, and improves drying efficiency.

Owner:石狮市恒鑫电子科技有限公司

Garment hanging device and a control method thereof

ActiveCN109306609AImprove life experienceStrong reliabilityOther drying apparatusTextiles and paperEngineering

Owner:FUZHOU MAILIAO AUTOMATION EQUIP CO LTD

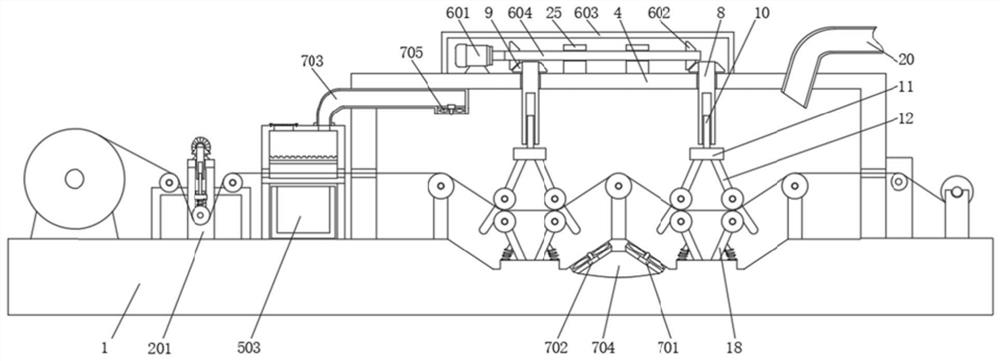

Integrated type washing and drying machine for weaving

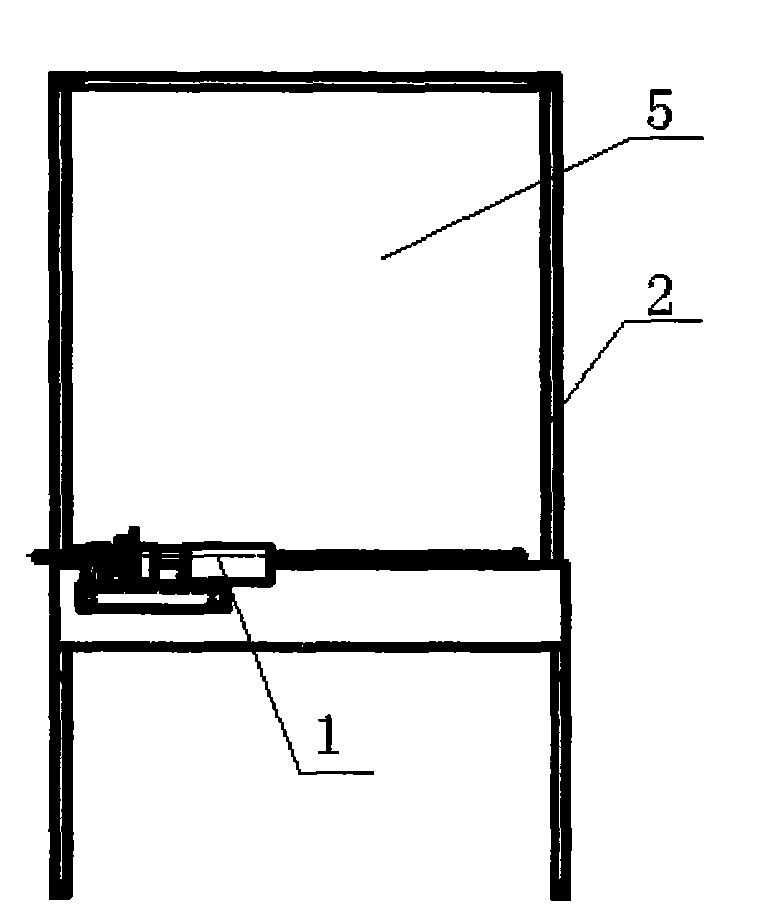

InactiveCN106048937AAvoid rewettingSimple structureLiquid/gas/vapor removalTextile treatment carriersPulp and paper industryManipulator

The invention discloses an integrated type washing and drying machine for weaving. The integrated type washing and drying machine comprises a frame, and a longitudinal guide rail, a cylinder and a controller which are arranged on the frame, and a transverse guide rail is connected to the cylinder; the transverse guide rail is vertically connected with two longitudinal guide rails so that an H-shaped structure is formed. A manipulator is connected to the transverse guide rail; the manipulator and the cylinder are connected with a controller; a fabric washing mechanism, a fabric filtering mechanism, and a fabric drying mechanism are successively arranged below the manipulator. The washing and drying device are simple in structure and convenient and quick to use. Through the washing and filtering, cleaning, filtering and drying of fabrics are ensured; the fabrics are easy to dry; air in a drying box body is kept dry; secondary soaking of the fabrics is avoided; and excellent drying effects are achieved.

Owner:SUZHOU KANGJIAN TEXTILE

Garment cloth drying device

InactiveCN108709394AEasy to useAvoid enteringDrying gas arrangementsDrying machines with progressive movementsPulp and paper industryDrying time

The invention discloses a garment cloth drying device. The garment cloth drying device comprises a workbench, a feed roller, a material collecting roller, a drying chamber and an extrusion platform, wherein the feed roller is fixed to a storage rack, the feed roller is rotatably connected with support rods on both sides of the upper end surface of the storage rack, the storage rack is fixed to theright side of the workbench, a guide rotating shaft, the extrusion platform, the drying chamber and a fixed frame are arranged on the upper end surface of the workbench in sequence from right to left, the guide rotating shaft is fixedly installed on the right end of the upper end surface of the workbench, the guide rotating shaft is rotatably connected with the workbench, the extrusion platform is of a cuboid structure, fixed rods are vertically fixed to both sides of the extrusion platform respectively, the bottom ends of the fixed rods are fixed to the workbench, the left side of the extrusion platform is close to the drying chamber, and the right side of the extrusion platform is close to the guide rotating shaft. According to the cloth drying device for garment processing, the upper and lower sides of cloth are dried at the same time, so that water in the cloth can be quickly and thoroughly removed, the drying time is saved, and the drying efficiency is improved.

Owner:柳晓燕

Machines for manufacturing and/or processing fibrous webs

A machine for the manufacture and / or treatment of a fibrous web, in particular a paper or cardboard web, with a press section and a dryer section arranged after the press section in the running direction of the web, wherein the press section has a pass through upper and the last press nip formed with the lower press roll, through which the fibrous web is guided between the upper and lower blankets of the last press nip; the penultimate press nip before the press nip through which the fiber web is guided between the upper and lower dewatering belts, especially the press felt, of the penultimate press nip, Therein, the fiber web is guided from the last press nip all the way to a take-up position on the lower blanket of the last press nip, and at this take-up position is transferred from the lower blanket to the first drying group of the dryer section. a drying screen, wherein the fibrous web has a dryness of at least 38%, preferably at least 45%, particularly preferably at least 50%, before entering the last press nip, and the lower press roll has a larger diameter than the upper press roll, and Wherein, the upper blanket of the last press nip is designed as a dewatering belt, and the lower blanket of the last press nip is designed as a substantially impermeable conveyor belt, and the upper blanket is designed along the web after leaving the last press nip The running direction partially surrounds the lower pressure roller.

Owner:VOITH PATENT GMBH

Super absorbent resin

ActiveCN107406562AIncrease absorption rateAvoid rewettingAbsorbent padsBandagesSuper absorbentAbsorption rate

The present invention relates to a super absorbent resin, and the super absorbent resin can exhibit a fast absorption rate and high gel strength even in a partially swollen state through the size optimization of partially swollen gel particles. Therefore, the use of the super absorbent resin can effectively prevent a rewetting phenomenon.

Owner:LG CHEM LTD

Fabric drying device

InactiveCN108342860AEasy to useAvoid enteringLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersEngineeringDrying time

The invention discloses a fabric drying device. The fabric drying device comprises a workbench, a feeding roller, a collecting roller, a drying chamber and a squeezing platform, the feeding roller isfixed to a storage frame and is rotatably connected with struts at the two sides of the upper end face of the storage frame, the storage frame is fixed to the right side of the workbench, a guide rotary shaft, the squeezing platform, the drying chamber and a fixed frame are arranged on the upper end face of the workbench from right to left in sequence, the guide rotary shaft is fixedly installed at the rightmost end of the upper end face of the workbench and is rotatably connected with the workbench, the squeezing platform is of a cuboid structure, fixed rods are vertically fixed to both sidesof the squeezing platform, the bottoms of the fixed rods are fixed to the workbench, the left side of the squeezing platform is close to the drying chamber, and the right side of the squeezing platform is close to the guide rotary shaft. By means of the fabric drying device for clothes processing, by drying the upper side and the lower side of fabric simultaneously, water in the fabric can be quickly and thoroughly removed, the drying time is saved, and the drying efficiency is improved.

Owner:石狮市恒鑫电子科技有限公司

Textile fabric drying and forming system with automatic adjusting function

InactiveCN113551484AIncrease the lengthExtension of timeDrying gas arrangementsHeating/cooling textile fabricsHigh humidityElectric machinery

The invention discloses a textile fabric drying and forming system with an automatic adjusting function, and relates to the technical field of textile fabric drying equipment. The textile fabric drying and forming system with the automatic adjusting function comprises a base, a tensioning mechanism is arranged on the upper surface of the base, a preheating box and a drying box are further arranged on the upper surface of the base, a water collecting mechanism is arranged in the preheating box, a power mechanism is arranged on the upper surface of the drying box, a heat circulation mechanism is arranged in the drying box, a first sleeve is movably embedded in the upper surface of the drying box, and a first bevel gear is connected to the surface of the first sleeve in a sleeving mode. By arranging a second motor, a first sleeve, a first movable rod and a preheating box, the problems that the drying speed is lower, the working efficiency is low and the practicability of the textile fabric drying equipment is lower due to the fact that the drying time of the textile fabric with higher humidity is longer and the length of the textile fabric cannot be conveniently and automatically adjusted in the drying equipment are solved.

Owner:JIANGSU LUYI TEXTILE TECH CO LTD

Cloth drying device for garment processing

InactiveCN108398001AShorten drying timeImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsMoistureDrying time

The invention discloses a cloth drying device for garment processing. The cloth drying device comprises a workbench, a feeding roller, a material collecting roller, a drying chamber and an extruding table, wherein the feeding roller is fixed on a storage frame, and is rotationally connected with supporting rods on the two sides of the upper end face of the storage frame, and the storage frame is fixed on the right side of the workbench; a guide rotating shaft, the extruding table, the drying chamber and a fixing frame are sequentially arranged on the upper end surface of the workbench from right to left, wherein the guide rotating shaft is fixedly arranged at the rightmost end of the upper end surface of the workbench, and the guide rotating shaft is connected with the workbench in a rotating mode; the extruding table is of a cuboid structure, fixing rods are vertically fixed on the two sides of the extruding table, and the bottom ends of the fixing rods are fixed on the workbench; andthe left side of the extruding table is close to the drying chamber, and the right side of the extruding table is close to the guide rotating shaft. According to the cloth drying device for the garment processing, the upper side and the lower side of cloth are dried at the same time, so that the moisture in the cloth can be rapidly and thoroughly removed, the drying time is saved, and the dryingefficiency is improved.

Owner:石狮市恒鑫电子科技有限公司

Patterned press fabric

InactiveUS7658821B2Avoid rewettingWood working apparatusPaper/cardboardStructural engineeringMechanical engineering

A press fabric having a plurality of surface pressing plates on a sheet side of the fabric imparts an impression onto a sheet of paper web during a pressing process. The surface pressing plates are preferably resin pressing plates, and form at least one of a random pattern of dots, a predetermined pattern of dots, a grid pattern of dots, a regular grid pattern of lines, an irregular grid pattern of lines a plurality of squiggly lines, a plurality of wavy lines, a plurality of straight lines, words and pictures.

Owner:VOITH PATENT GMBH

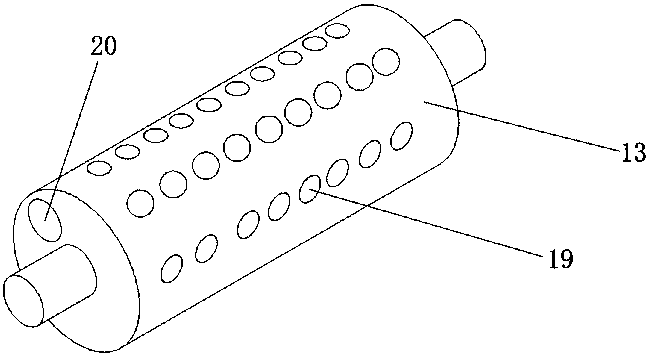

A dryer for chemical fabric

InactiveCN109099679AAvoid getting wetUniform surface temperatureDrying machines with progressive movementsDrying solid materialsOutfallEngineering

The invention discloses a chemical fabric dryer, which comprises an oven provided with two top and bottom drying cylinders which are interlaced with each other; an exhaust pipe is connected to the topof the oven and a heat exchanger is connected to it. The drying cylinder comprises a cylinder body fixedly connected with rotating shafts on both sides. A through hole is arranged in a middle portionof the rotating shaft on both sides of the cylinder body, wherein one of the through holes is provided with a steam pipe, and the other through hole is provided with an outlet pipe. A cavity with a hollow inner cylinder is in the cylinder body. The two sides of the inner cylinder are rotationally connected with the two sides of the cylinder body; the top of it is provided with an air inlet fixedly connected to the steam pipe; the bottom is provided with a outfall fixedly connected with the outlet pipe. The invention not only can improve the drying effect but has the advantages of high utilization of heat energy, uniform surface temperature and faster heating of the drying cylinder and less steam consumption as well.

Owner:湖州甬邦纺织品织造有限公司

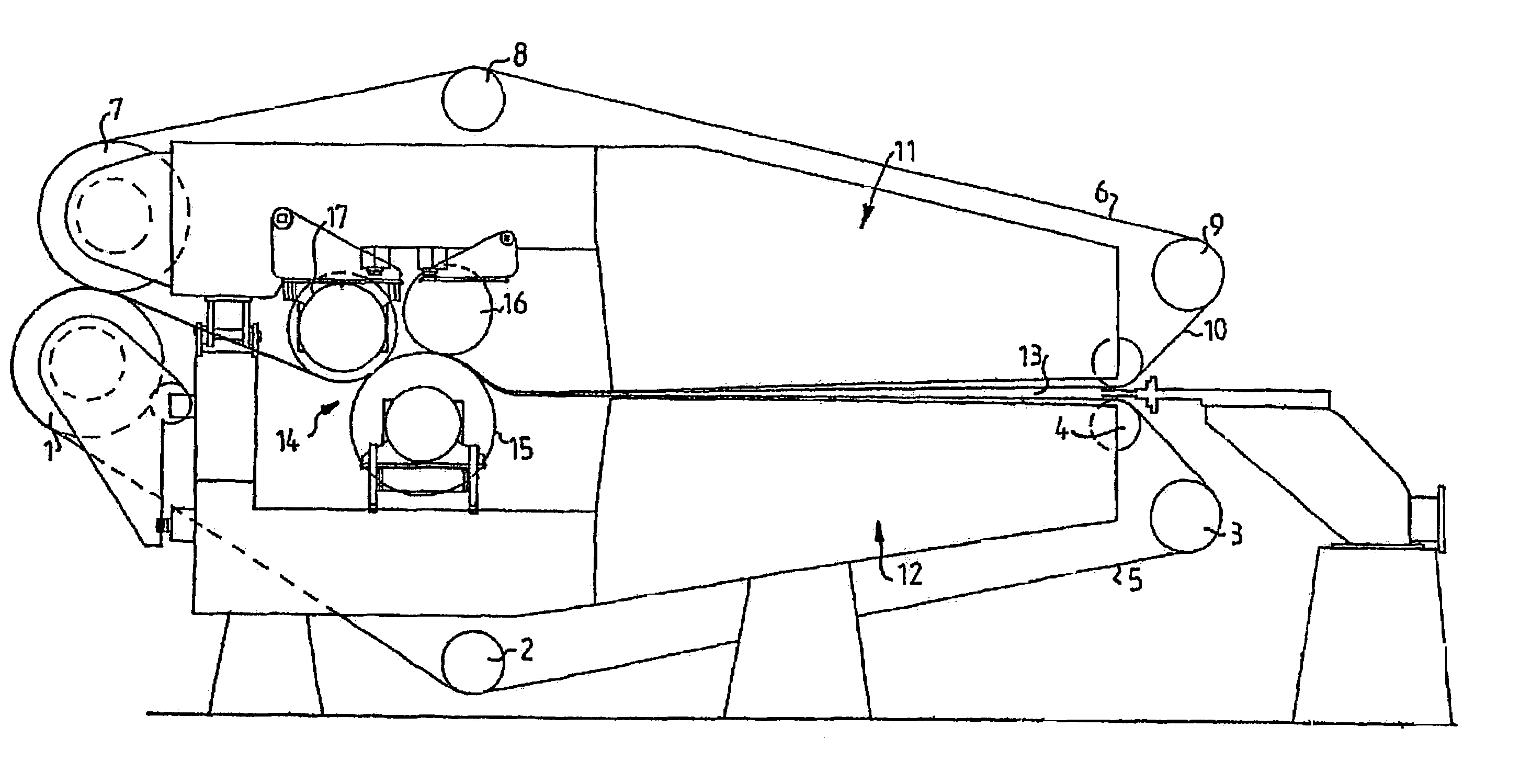

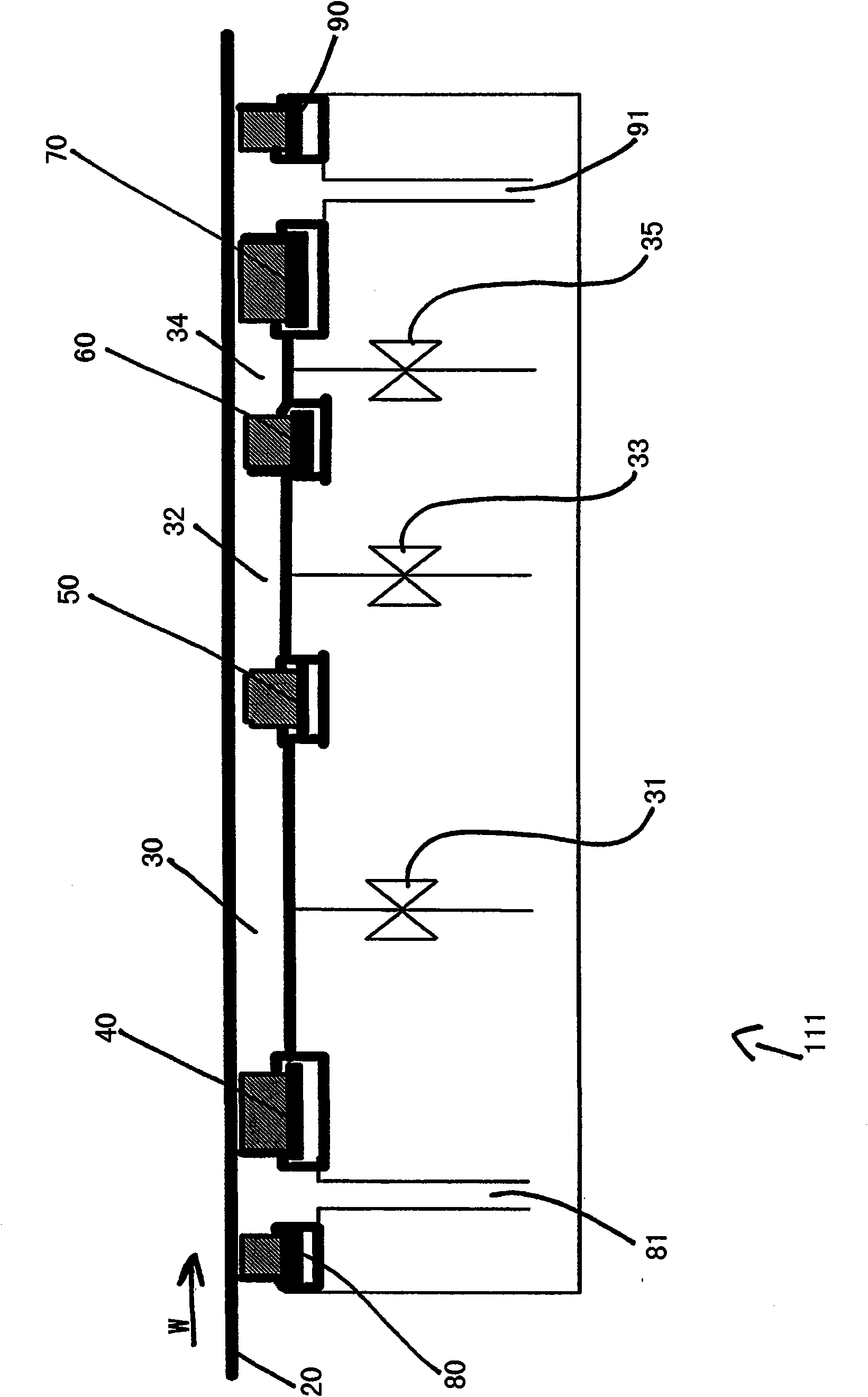

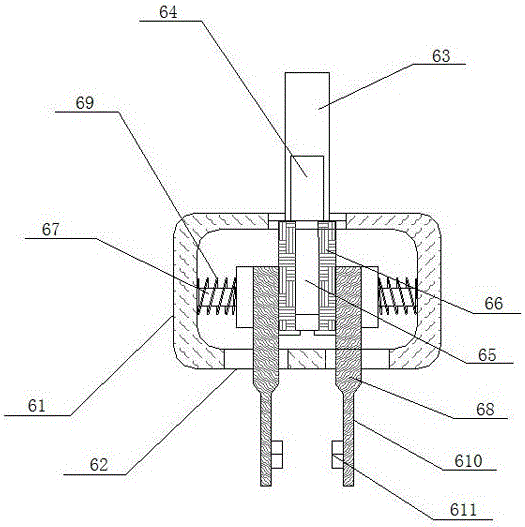

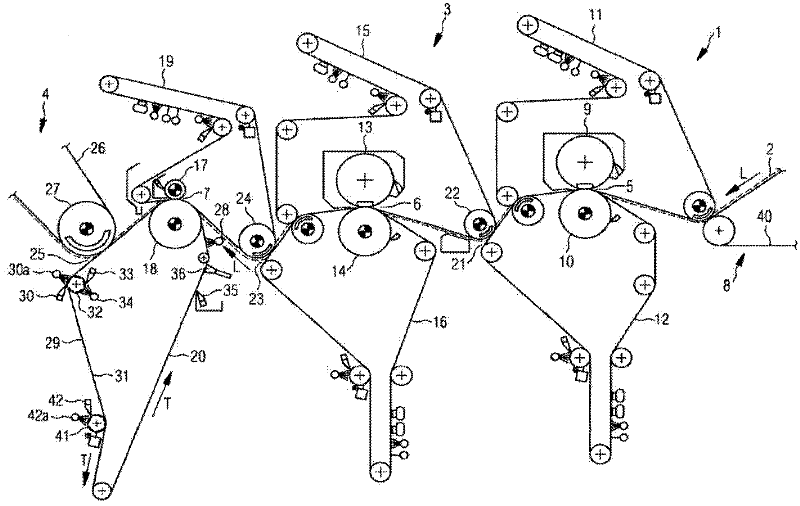

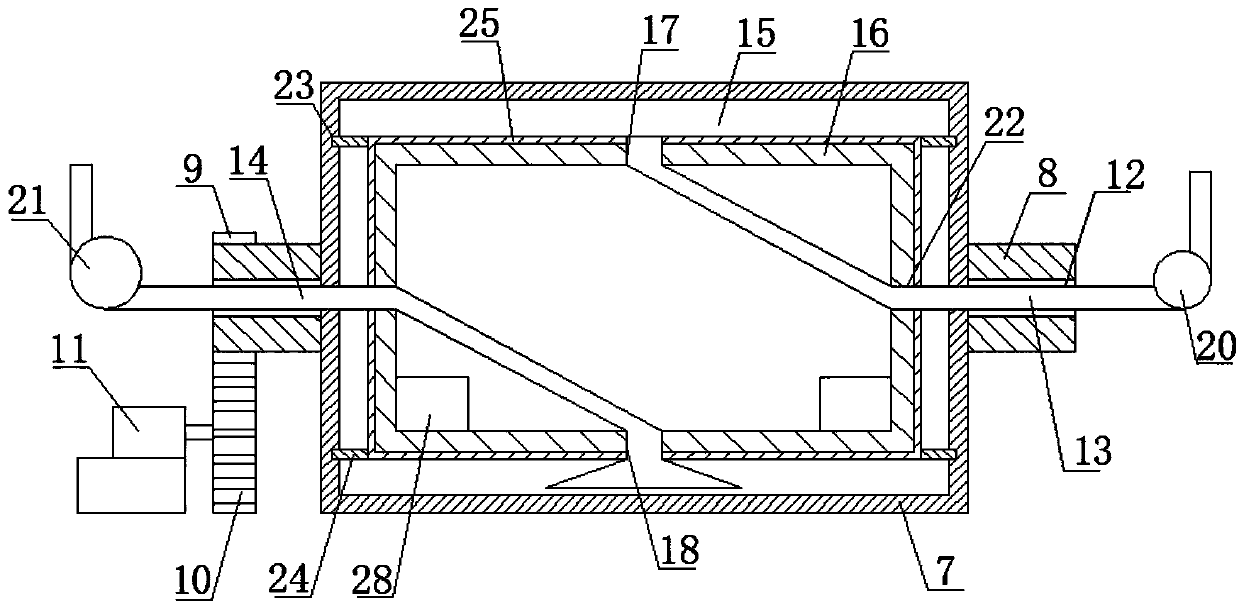

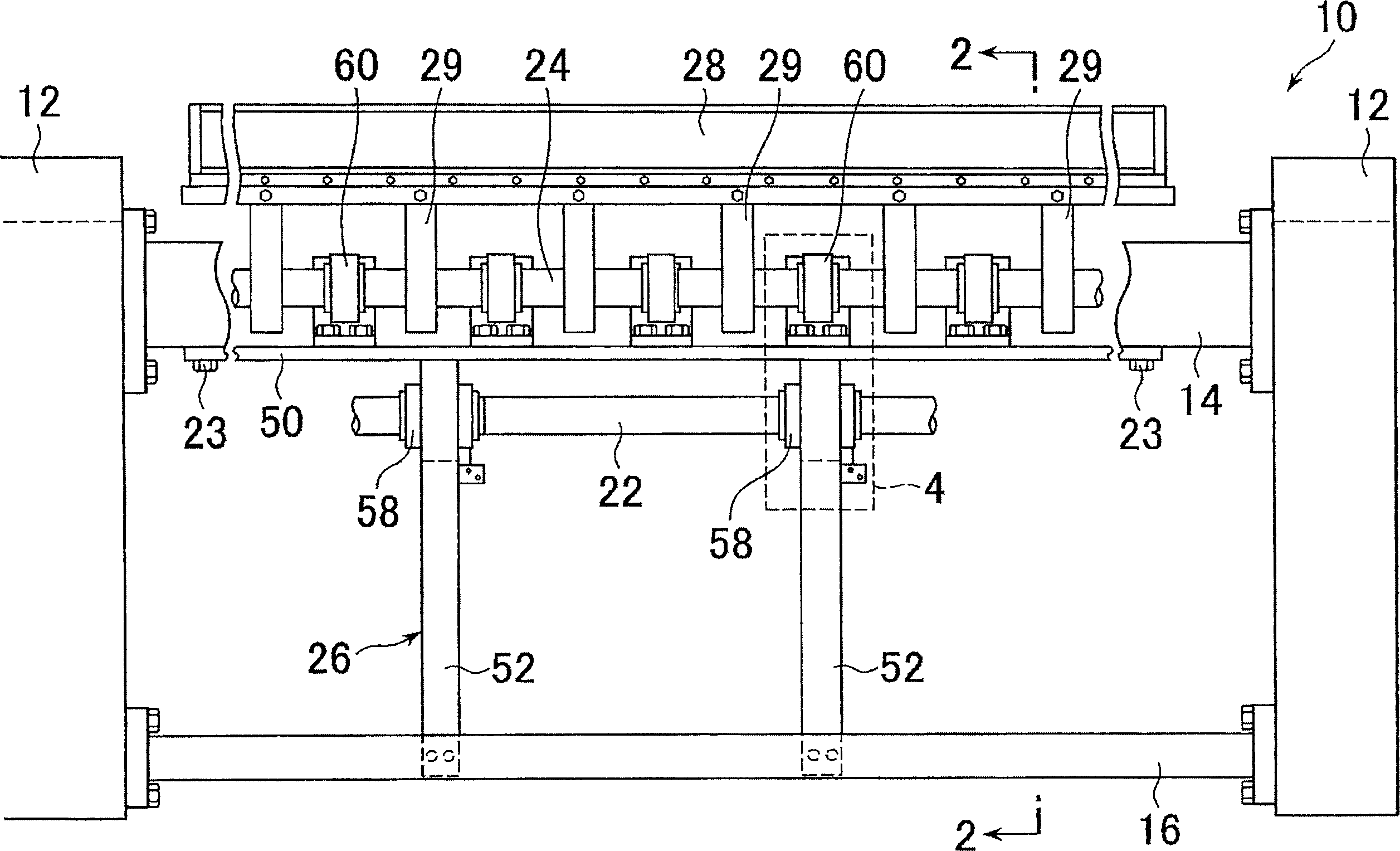

Arrangement for a wire section of a paper or board machine

Owner:PACT XPP TECH +1

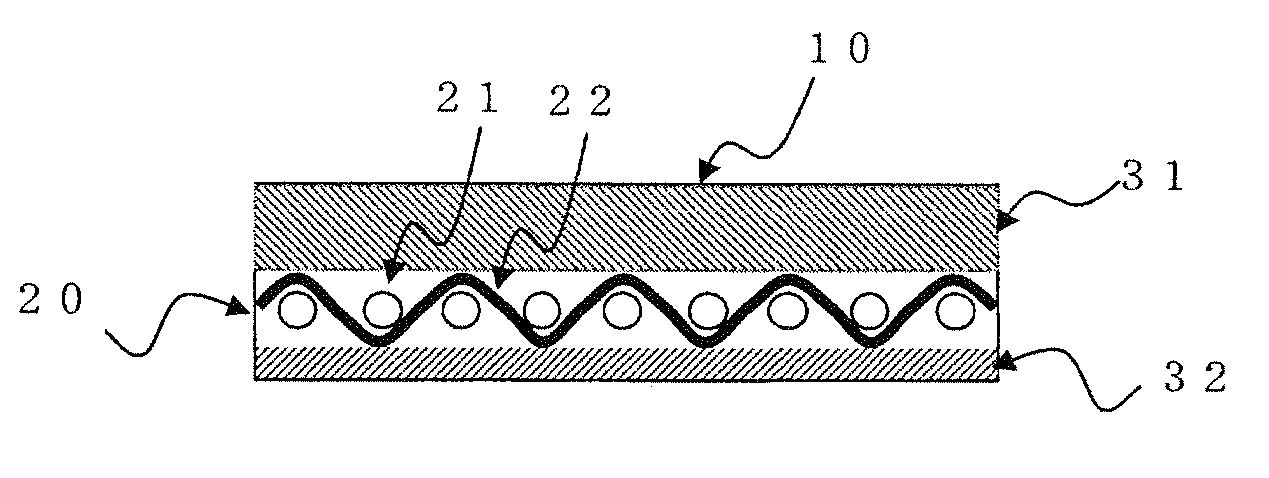

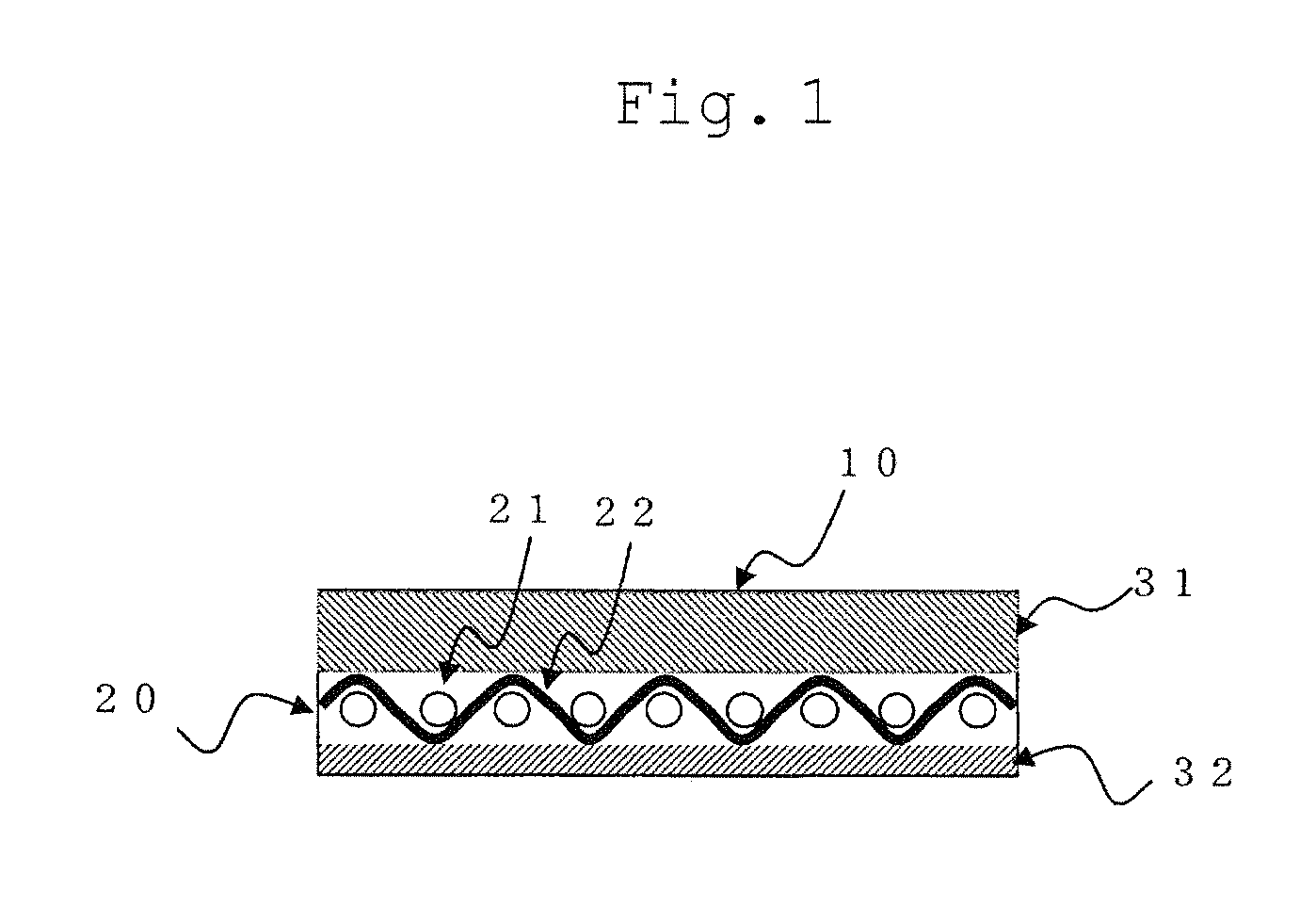

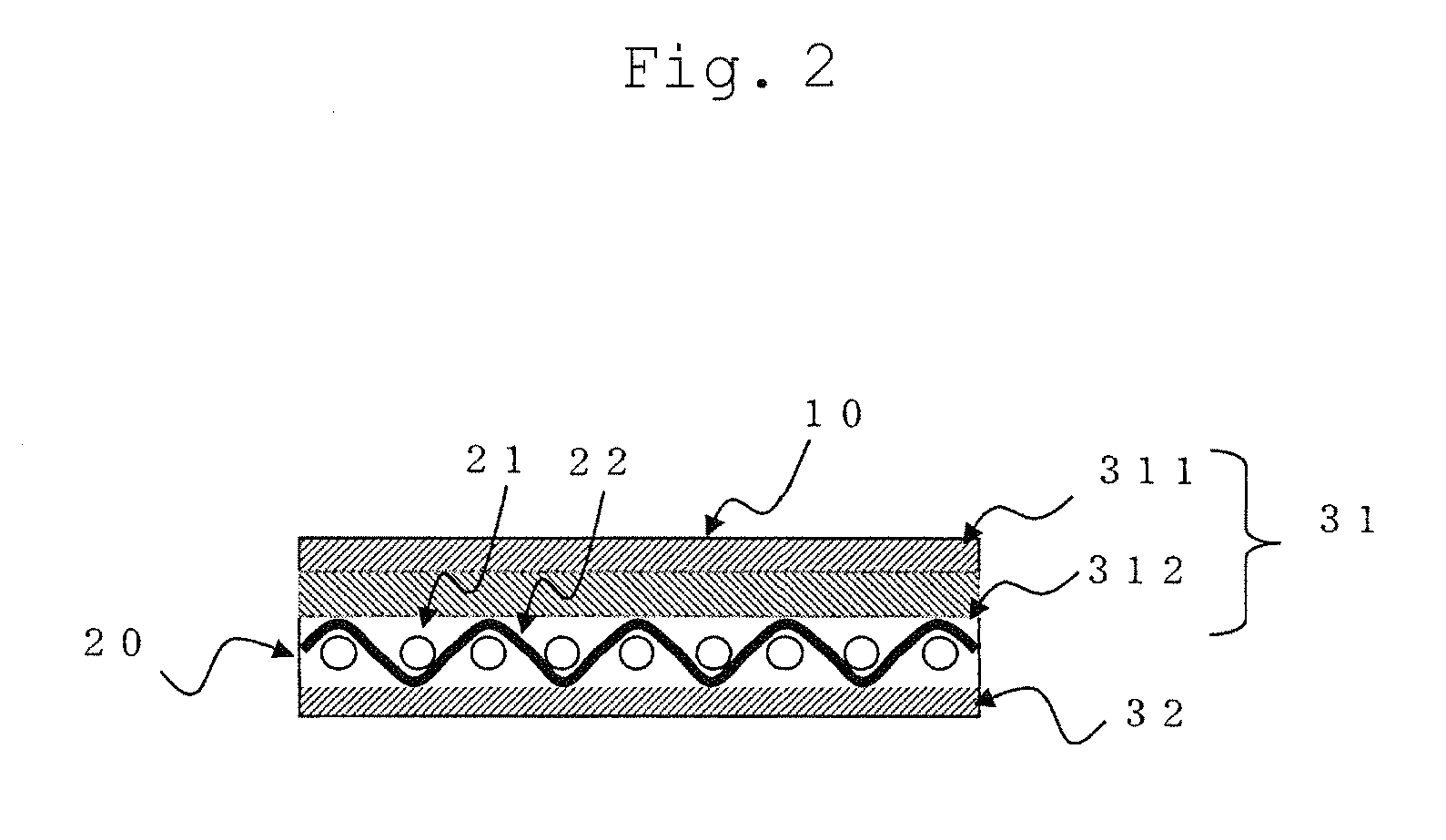

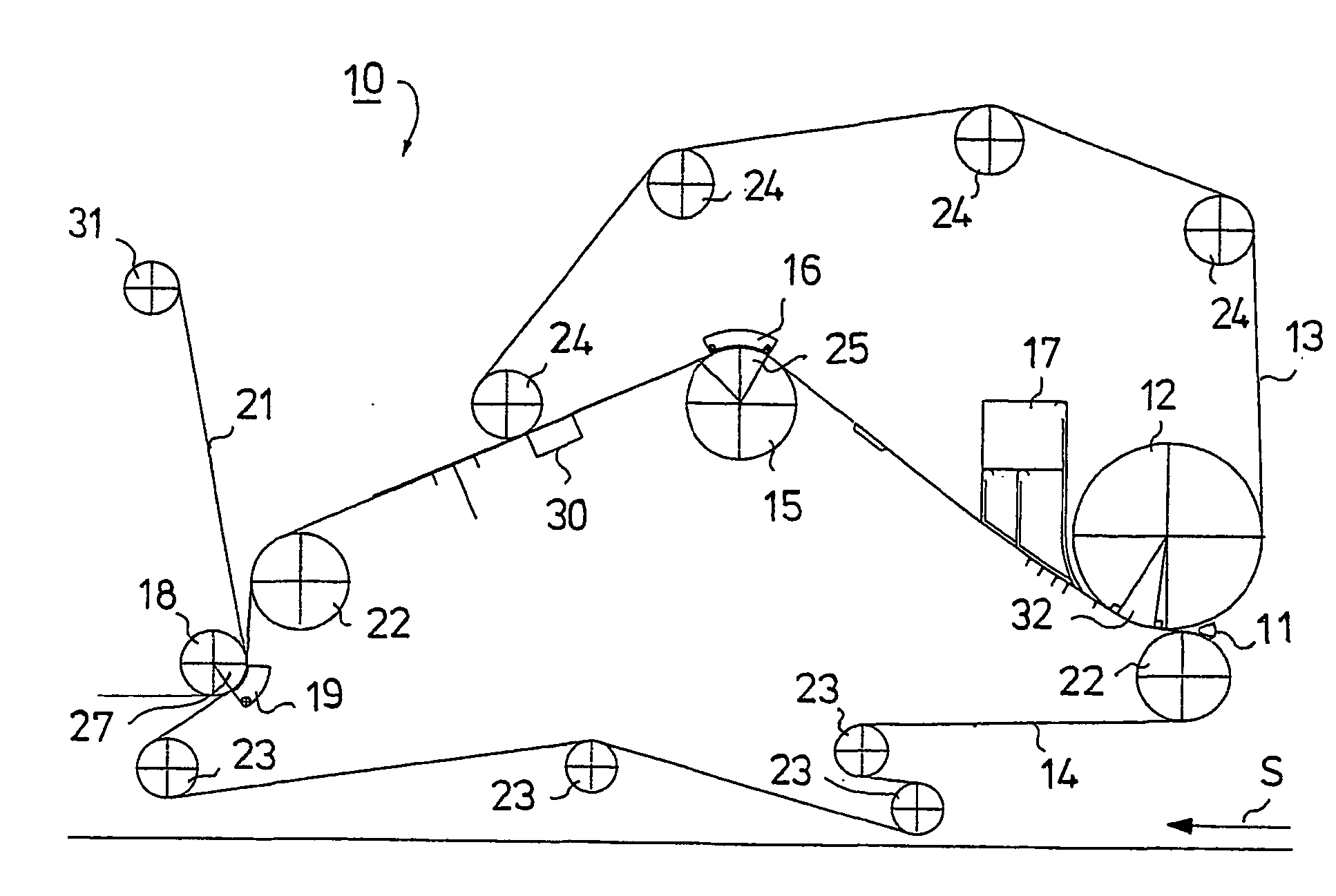

Felt for papermaking

The papermaking felt 10 of the present invention comprises a base body 20, a wet paper web side batt fiber layer 31, and a backside batt fiber layer 32, in which the wet paper web side batt fiber layer 31 is contained in high molecular weight elastic material and the backside batt fiber layer 32 includes a melting fiber.

Owner:ICHIKAWA ELECTRIC CO LTD

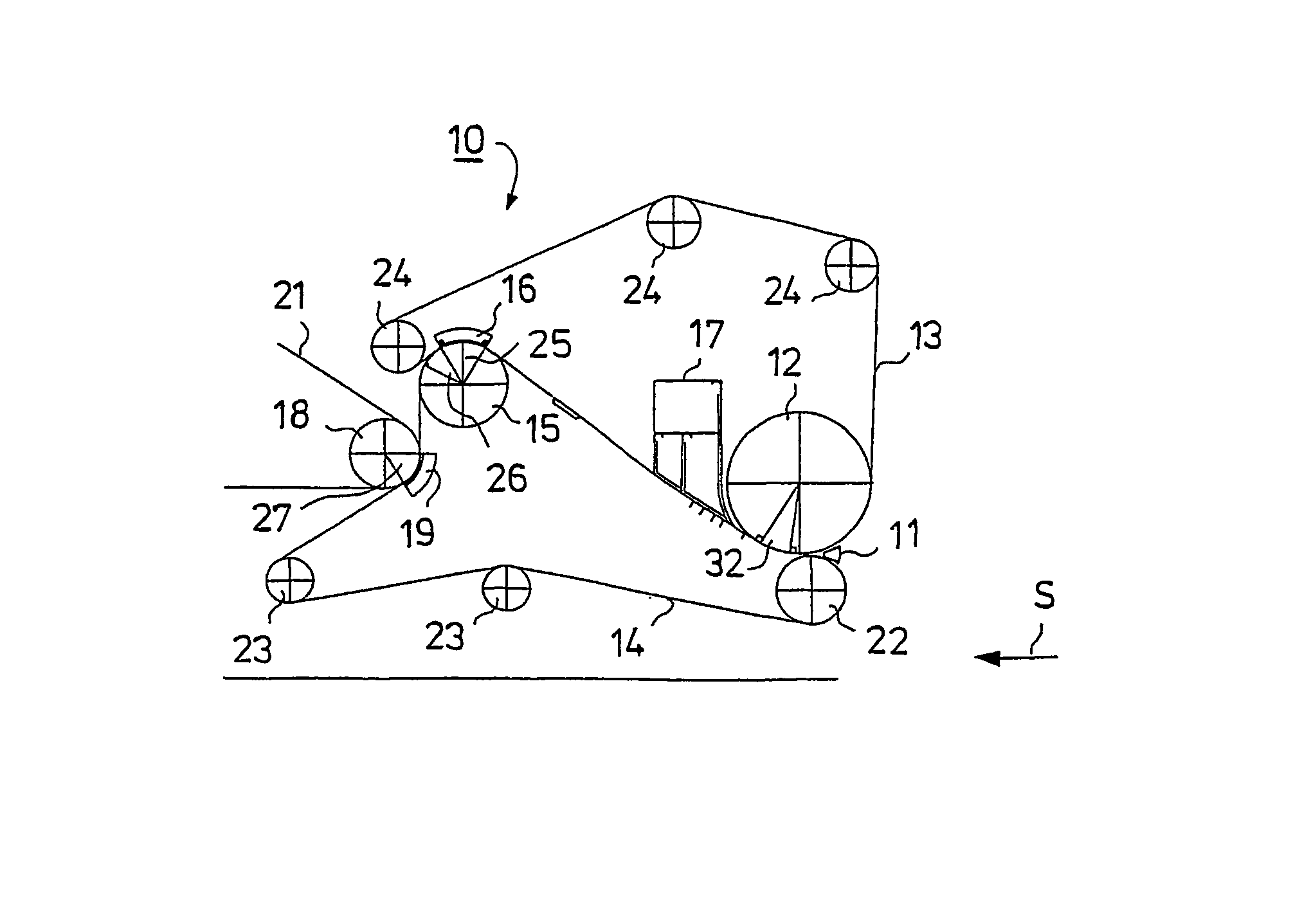

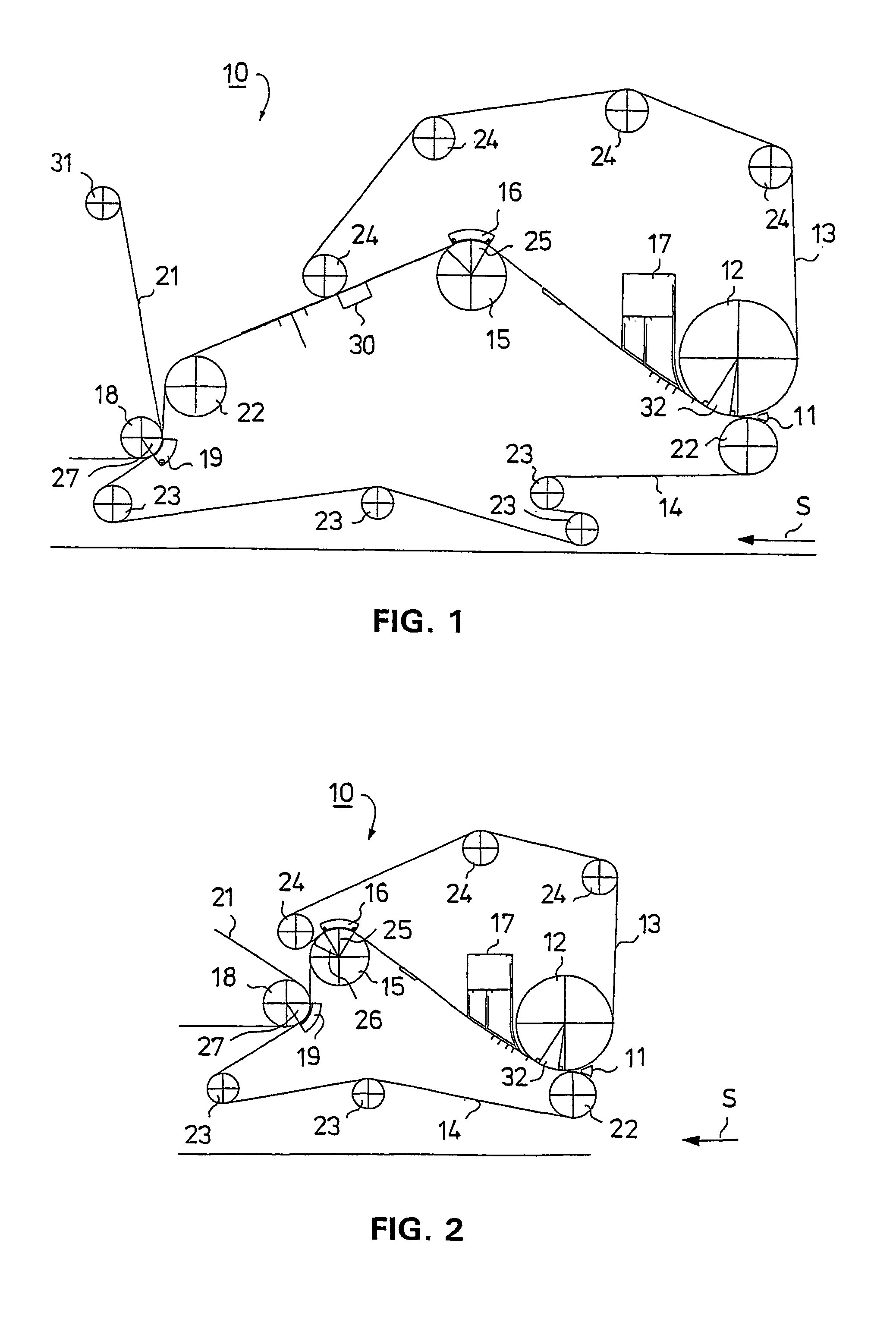

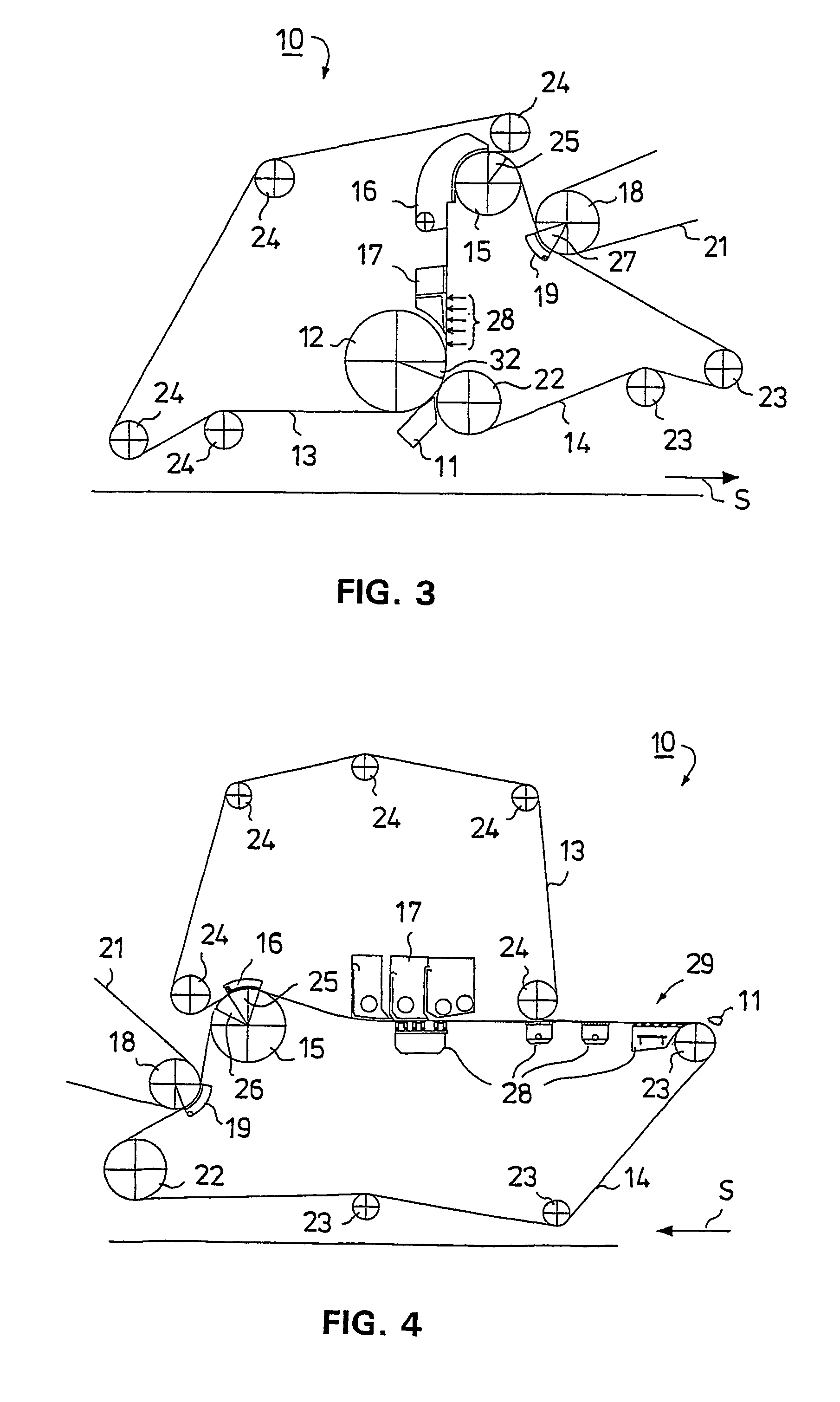

Arrangement for a wire section of a paper or board machine

InactiveUS20050241792A1Dry solid content is increasedAvoid rewettingMachine wet endPress sectionWire loopElectric wire

A web is formed between two wire loops (13, 14), in a wire section of a paper or board machine, in connection with which dewatering elements (12, 17, 15, 28) are placed and in which water is drained from a stock suspension from between the two wires (13, 14). In the region of a twin-wire zone, a suction roll (15) is placed within one wire loop and a suction box (16) having a curved surface is situated in opposed relationship with the suction roll (15) on the side of the other wire loop. After the suction box (16), the web is guided, due to the effect of a vacuum of the suction roll (15), forwards on the surface of the wire loop on the side of the suction roll (15).

Owner:PACT XPP TECH +1

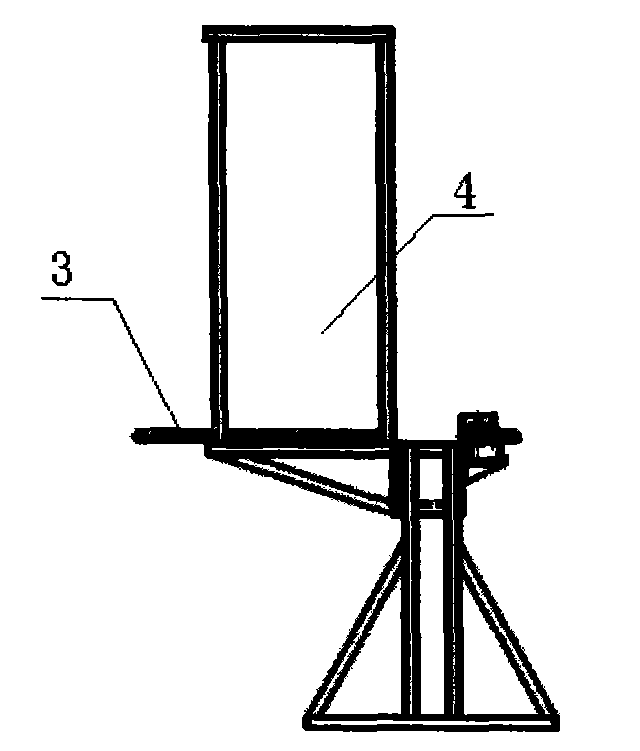

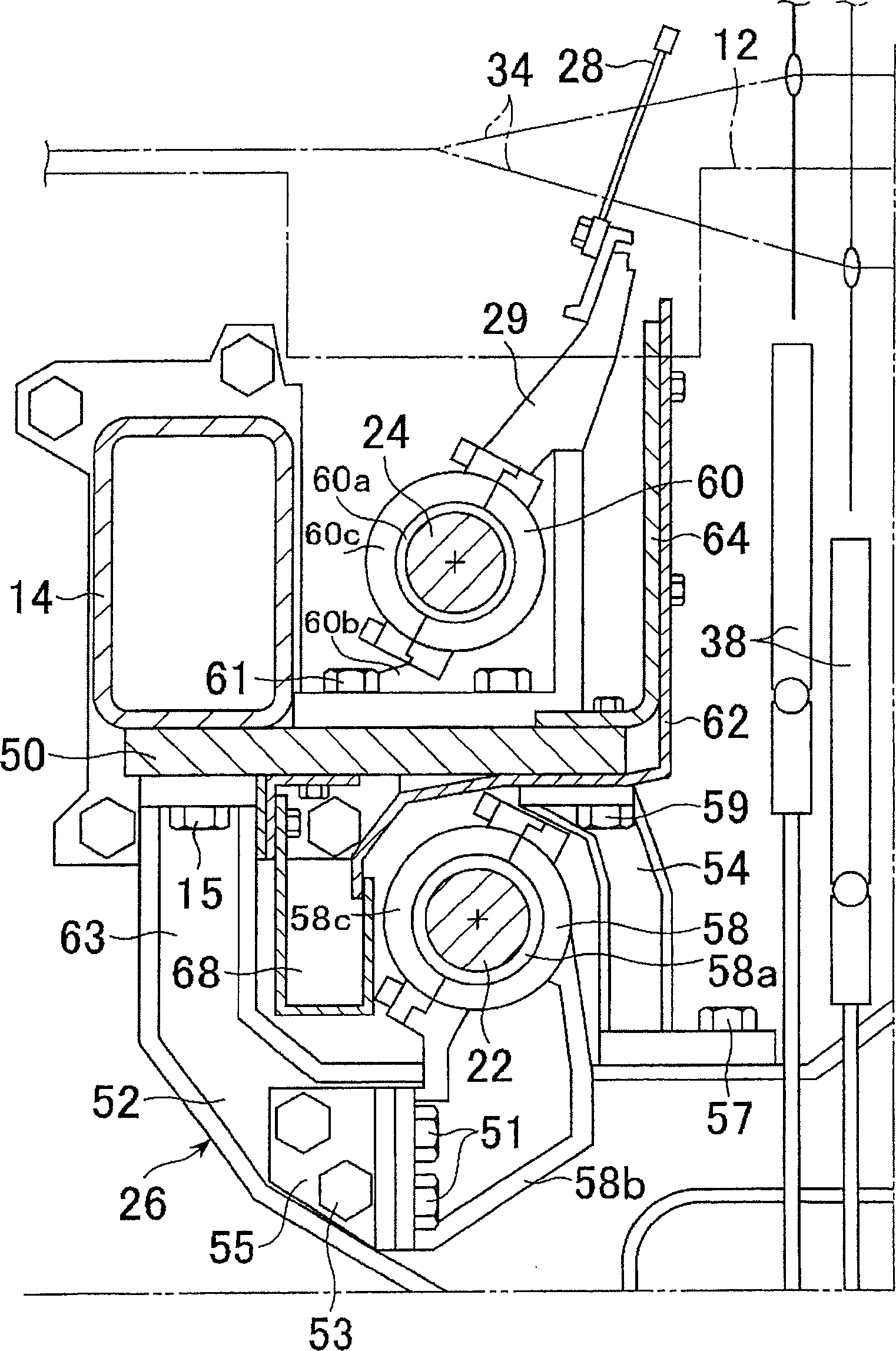

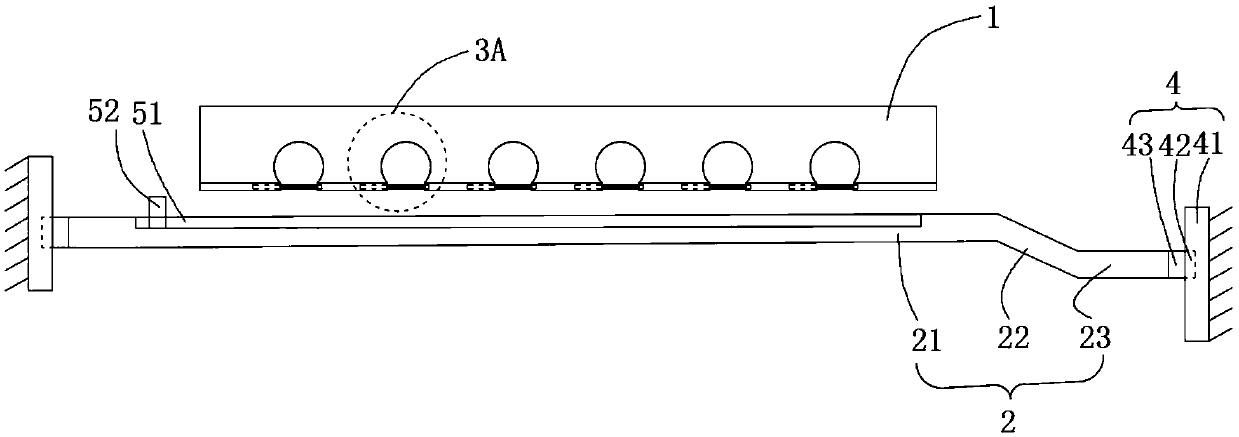

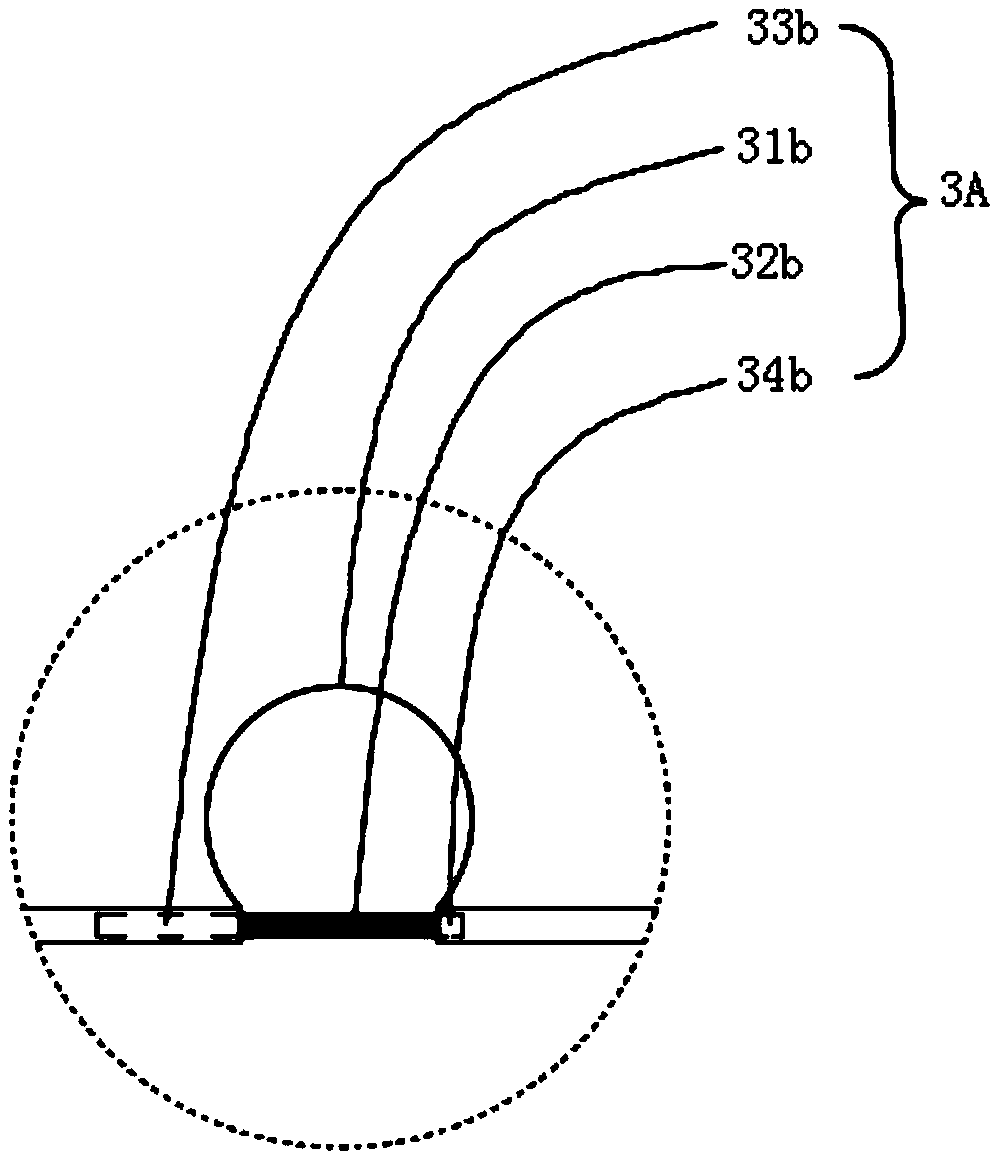

Reinforcing structure of loom battening device and water-spray type loom comprising the same

ActiveCN1844528AStable supportReduce vibrationLoomsAdverse effect compensationEngineeringOperability

The present invention relates to a reinforcement structure, comprising: a base part extending along the weaving direction between loom frames for supporting a plurality of bearing parts supporting a rocking shaft; At least one auxiliary frame is connected to at least one auxiliary frame of at least one of the first strut and the base member located at the front upper position and at least one of the other 2nd to 4th struts. Its purpose is to support the bearing member of the rocking shaft at the most appropriate position in the weaving direction without impairing the operator's operability of various devices arranged between the loom frames.

Owner:TSUDAKOMA KOGYO KK

Impinging stream dryer

InactiveUS20020116838A1Separate controlAvoid rewettingDrying solid materials with heatDryer sectionFiberEngineering

Impinging stream dryer and process for drying a fibrous material web that includes an air-permeable, endlessly circulating support belt structured and arranged to support a side of the fibrous material web, a device for impinging an opposite side of the fibrous material web with an impinging stream, and a belt cooling device arranged to cool at least an edge zone of said support belt that is directly impinged with the impinging stream.

Owner:VOITH PATENT GMBH

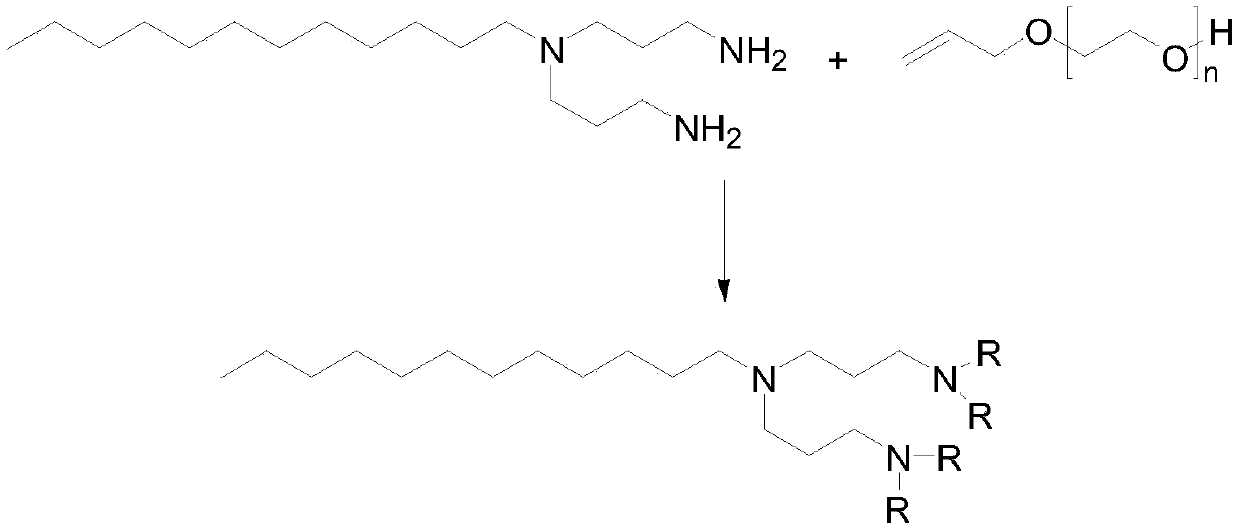

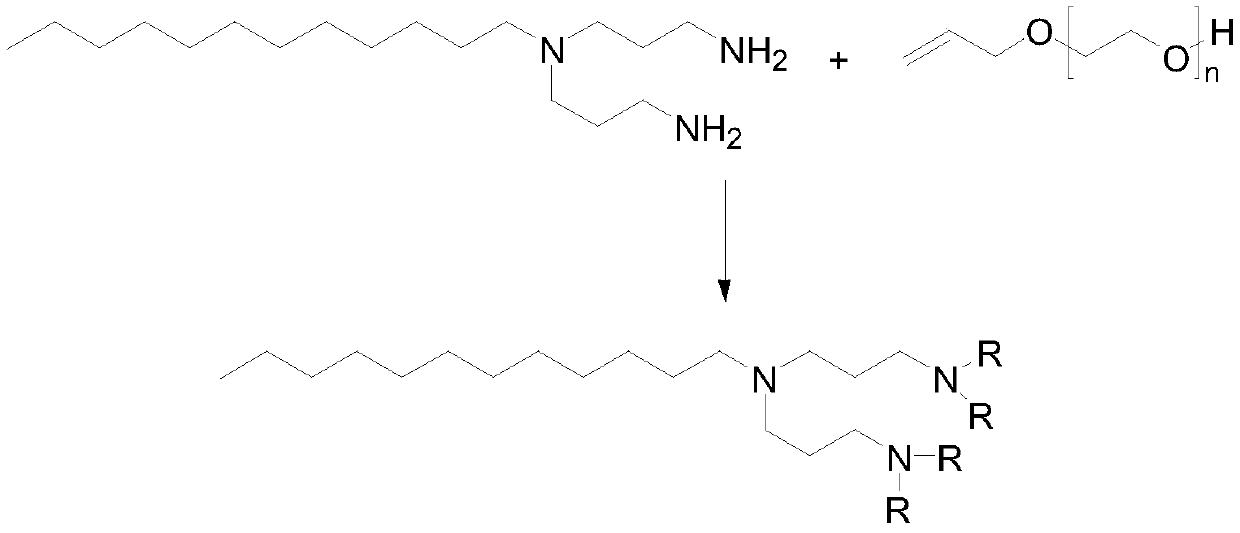

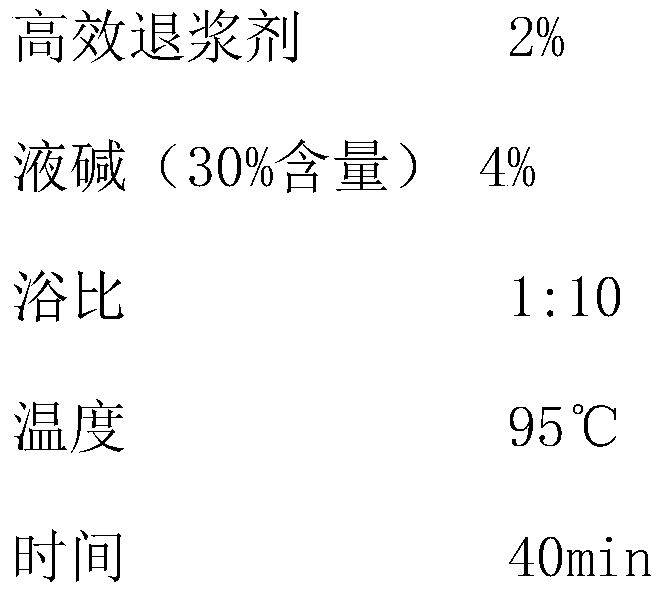

Preparation method of polyamine type efficient desizing agent

ActiveCN111535009AGood dispersionAvoid rewettingOrganic compound preparationDry-cleaning apparatus for textilesDioxyethylene EtherPolyamine

The invention relates to a preparation method of a polyamine type efficient desizing agent. The polyamine type efficient desizing agent is prepared by compounding lauryl amine dipropylenediamine polyoxyethylene ether, sodium polyaspartate and sodium gluconate. Nonionic polyoxyethylene chain segments and a plurality of amino groups capable of being protonated in the components of the desizing agentcan form ionic bond or hydrogen bond combination with polyacrylate slurry, so that the removed slurry is more stably dispersed in water, and the slurry is prevented from being re-stained. The sodiumpolyaspartate and the sodium gluconate which are easy to biodegrade are compounded, so that the desizing agent has extremely high chelating capacity on calcium, magnesium and iron ions in water, and has double effects of corrosion inhibition and scale inhibition, and the product can adapt to different working condition environments and reduce the burden of sewage treatment.

Owner:HANGZHOU MEIGAO HUAYI CHEM

Clothes airing device and control method thereof

ActiveCN109594309AImprove life experienceStrong reliabilityOther drying apparatusTextiles and paperEngineeringClothes hanger

The invention relates to the technical field of clothes airing, in particular to a clothes airing device and control method thereof. The clothes airing device comprises a clothes airing rod, a gravitysensing unit, a clothes withdrawing rod, a moving device and a controller, wherein the clothes airing rod comprises a plurality of clothes hanger hanging parts capable of releasing clothes hangers downwardly; the gravity sensing unit is used for detecting the gravity or the gravity change of the clothes hangers hung on the the clothes hanger hanging parts; the clothes withdrawing rod is positioned below the clothes hanger hanging parts; the projections of the axis of the clothes withdrawing rod and the axis of the clothes airing rod on the ground are roughly parallel; the moving device is used for moving the clothes withdrawing rod to be close to or far away from the clothes airing rod; the controller is electrically connected with the gravity sensing unit and is used for receiving the gravity or the gravity change, controlling the clothes hanger hanging parts to release the clothes hangers when the gravity or the gravity change meets a preset condition and controlling the moving device to move the clothes withdrawing rod. The clothes airing device can separate wet and dry clothes and is high in reliability.

Owner:FUZHOU MAILIAO AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com