Pressing apparatus for a paper- or board-making machine for removing fluids from a web by pressing, and a method for treating a web in a paper- or board-making machine

A technology of paper machine and board machine, applied in the direction of paper machine, paper making, pressing part, etc., can solve the problems of paper machine or board machine operation efficiency reduction, pressure loss, pressurized medium leakage, etc., achieve excellent operating characteristics, improve processing Pressure, improve the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

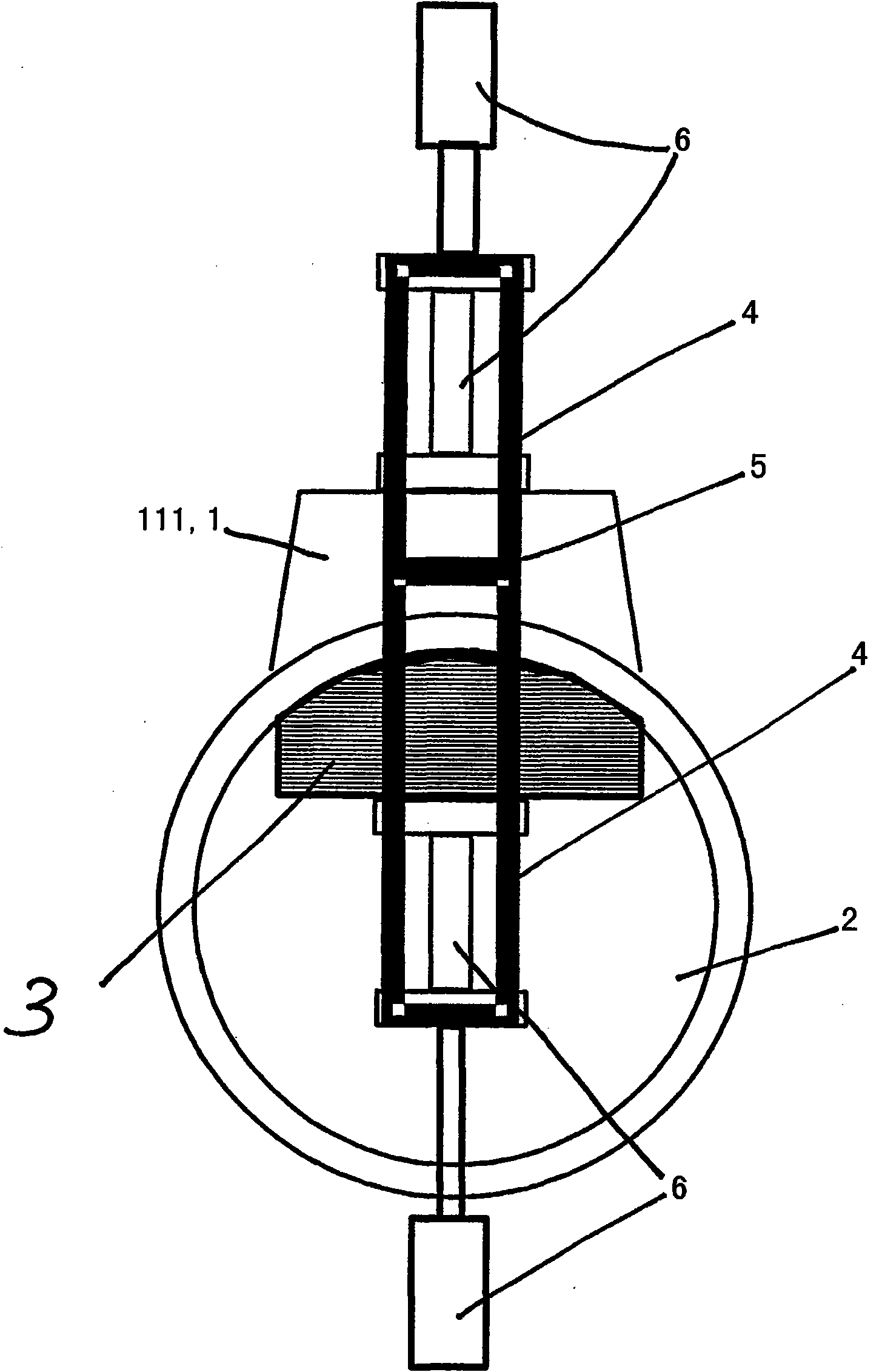

[0054] figure 1 A sectional view of a first embodiment of a pressing plant according to the invention is shown, taken in the transverse direction of the plant. The press is used in a paper or board machine to remove fluid from a web by pressing.

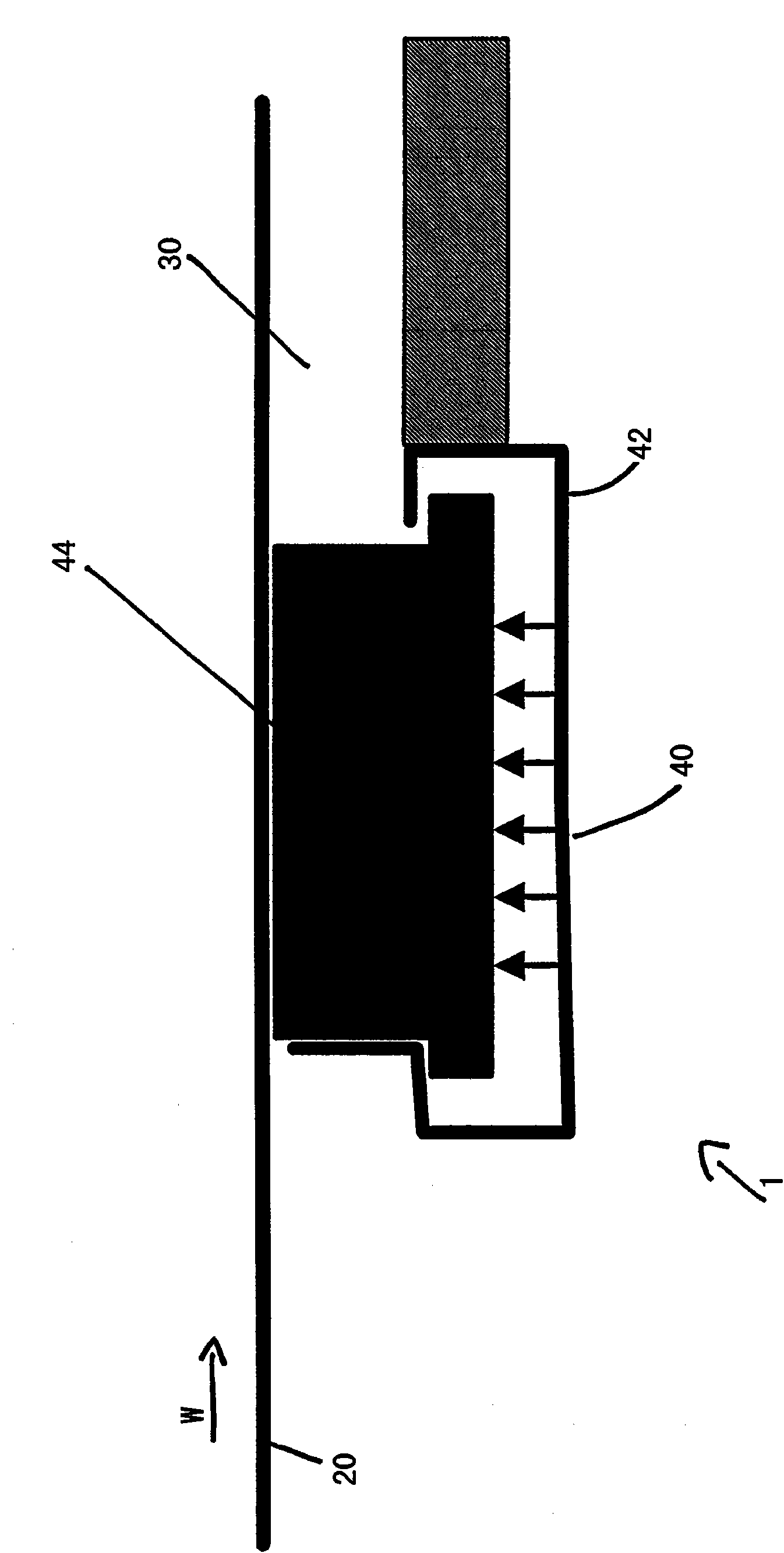

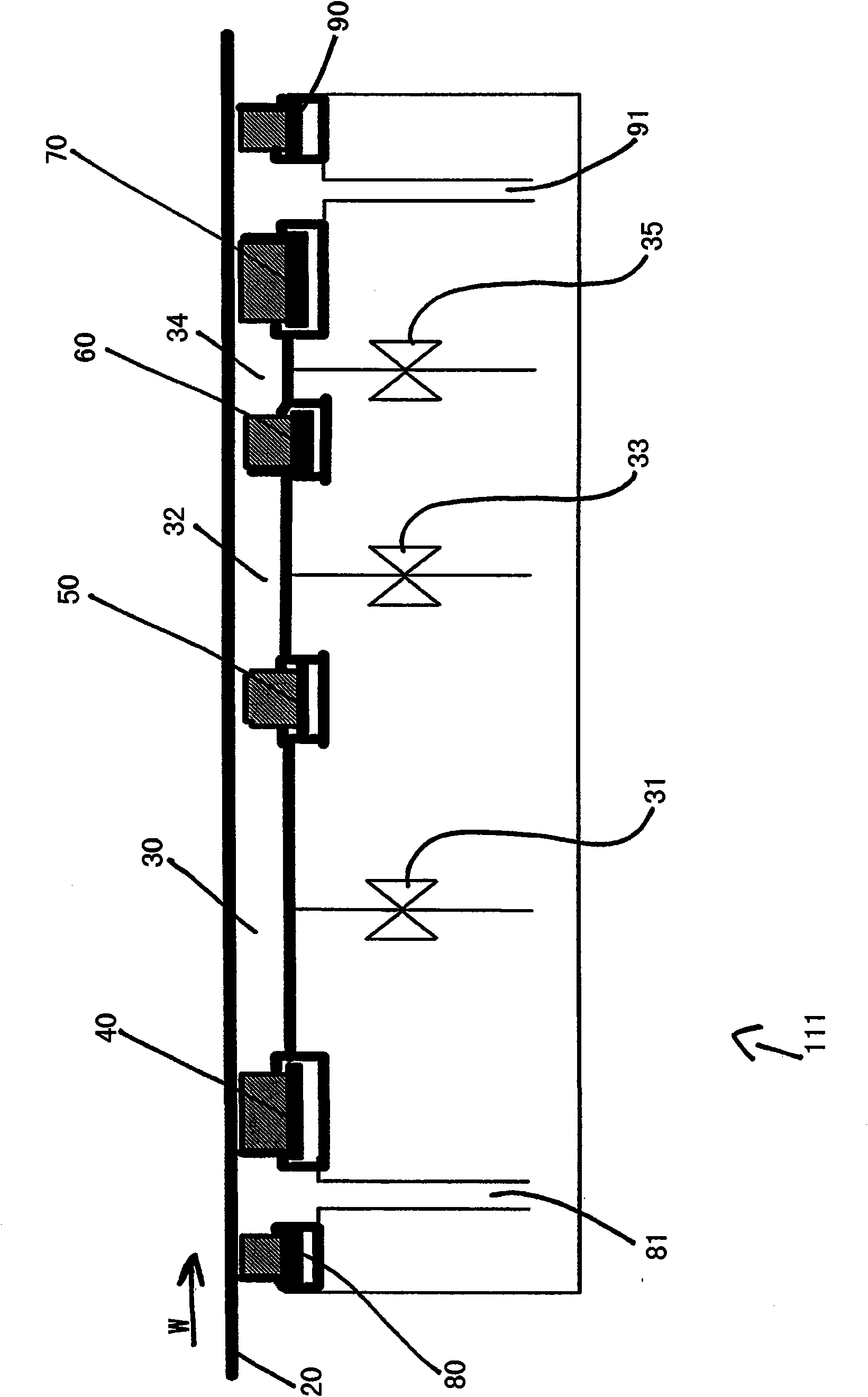

[0055] In this press apparatus, a nip is formed between a loading device (pressing device) 1 and a press roll 2 . The loading device 1 comprises at least one pressurized chamber 30 (see figure 2 ), the pressurized chamber 30 contains a pressurized fluid (medium) such as water, water with additives, oil or air, to bear against the metal band 20 which is fluid impermeable and formed as an annular ring (see figure 2 ). The loading device 1 extends along the length of the nip in the direction of web movement, i.e. from figure 1 and figure 2 The left side in extends to the right side.

[0056] Furthermore, the press roll 2 has inside it a support 3 to transmit and carry the load applied by the pressurized fluid in the loading dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com