Patents

Literature

38results about How to "Achieve hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high-boron iron-based wear-resistant surfacing flux-cored wire

InactiveCN102284806ASmall sizeAchieving wear resistanceWelding/cutting media/materialsSoldering mediaBorideWear resistant

The invention relates to a high-boron iron-based wear-resistant surfacing flux-cored welding wire. The welding wire is composed of a low-carbon steel sheath and a core powder. It is characterized in that the iron element in the low-carbon steel sheath and the core powder are contained in the core powder. Elements include boron, carbon, manganese, and silicon. The weight percentage of boron, carbon, manganese, and silicon in the core powder of the welding wire is: boron 6 to 12%, carbon 0.1 to 3%, manganese 0.6 to 2%, silicon 0.3~1.5%, the balance is iron. It can also include Ti0.3~3.5%, Mn 0.6~2%, Si0.3~1.5%, molybdenum 0~1%, K / Na modifier 0~1%, and aluminum-magnesium alloy 0~1.5%. The high boron iron-based wear-resistant cladding flux-cored welding wire of the present invention mainly relies on boron, titanium, carbon and other alloying elements to form boride and a small amount of carbide to achieve the wear resistance of the cladding alloy, and by adding rare earth, nickel, Aluminum-magnesium alloys, etc. improve the overall performance of cladding alloys.

Owner:BEIJING UNIV OF TECH +1

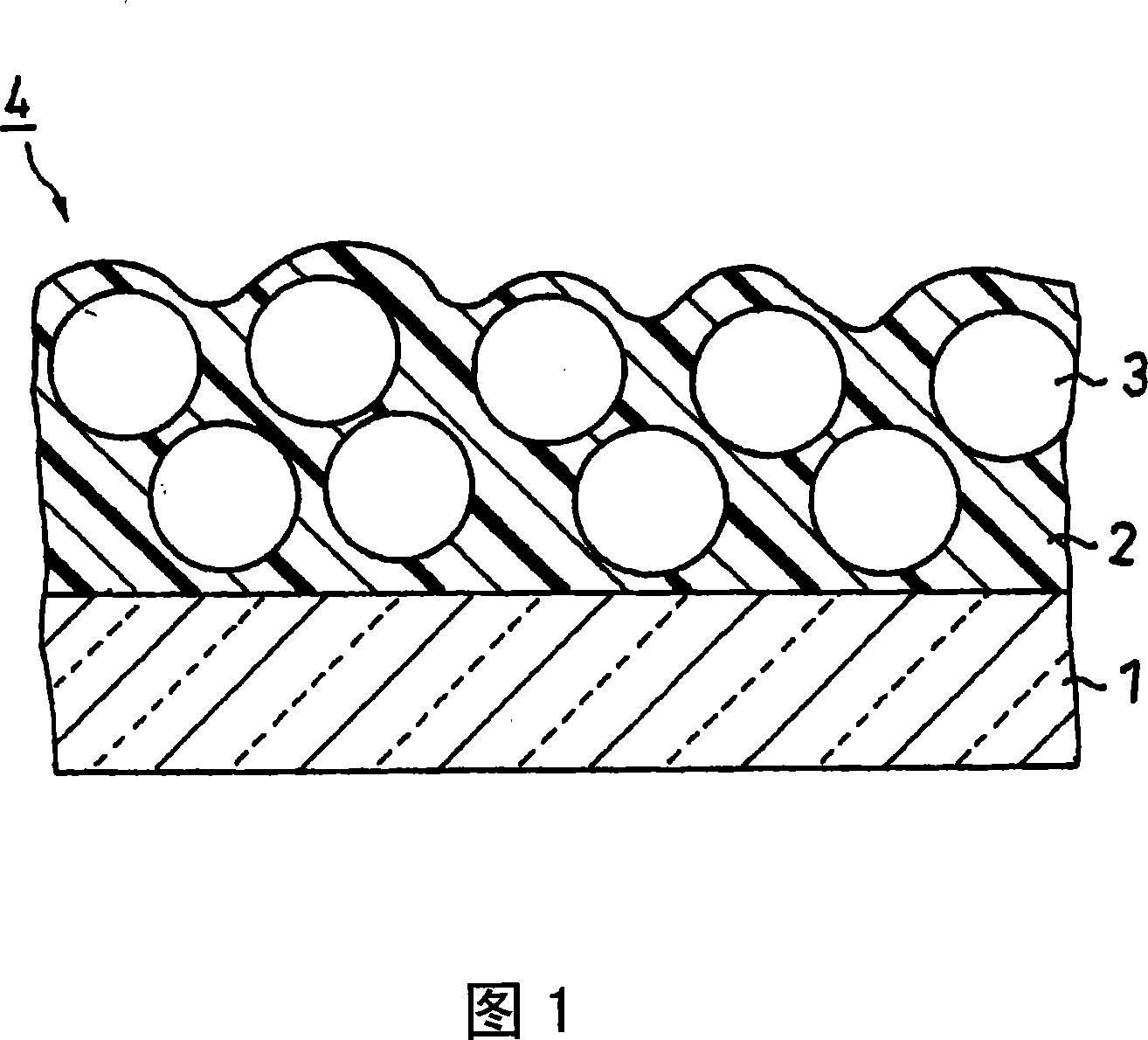

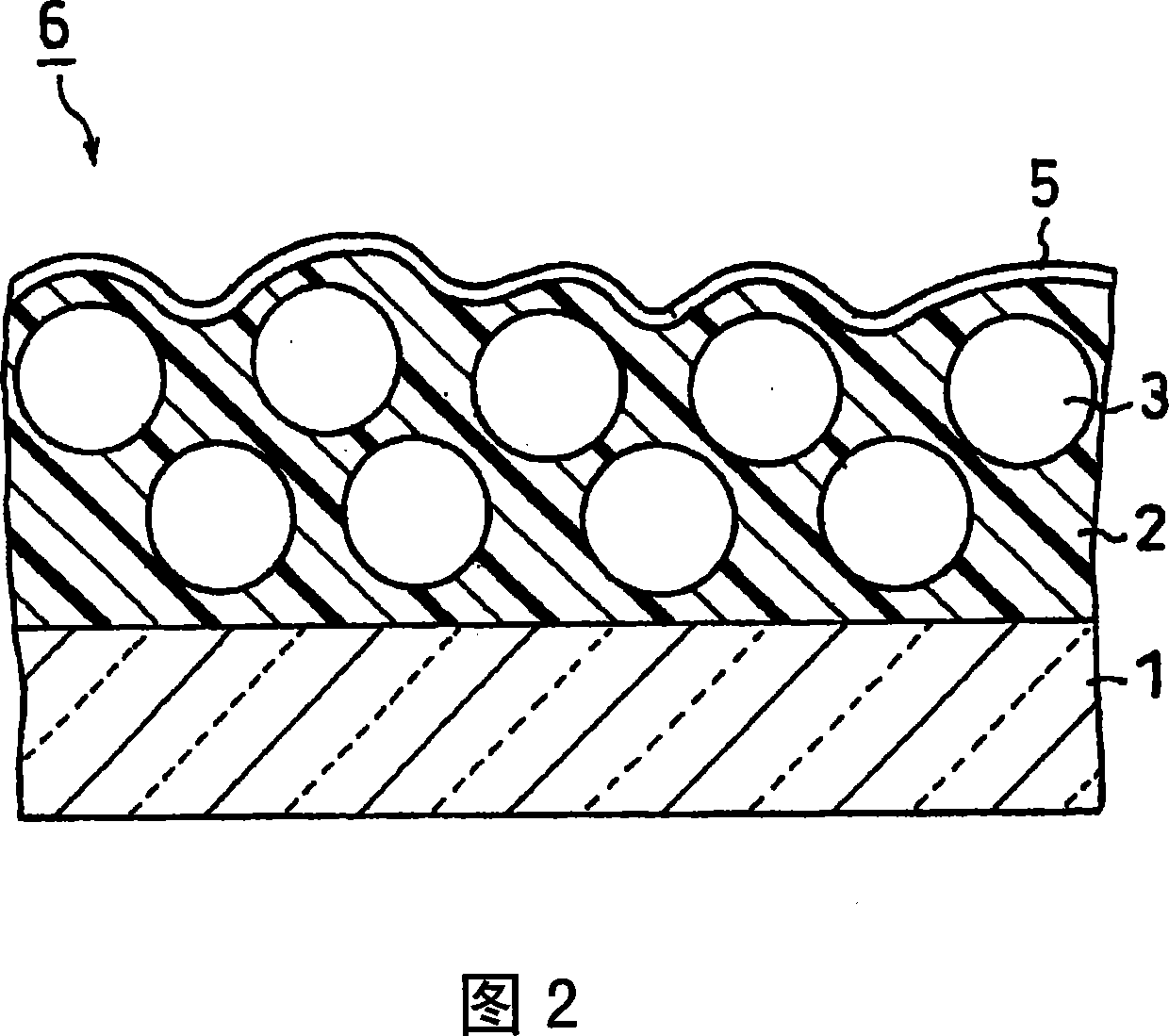

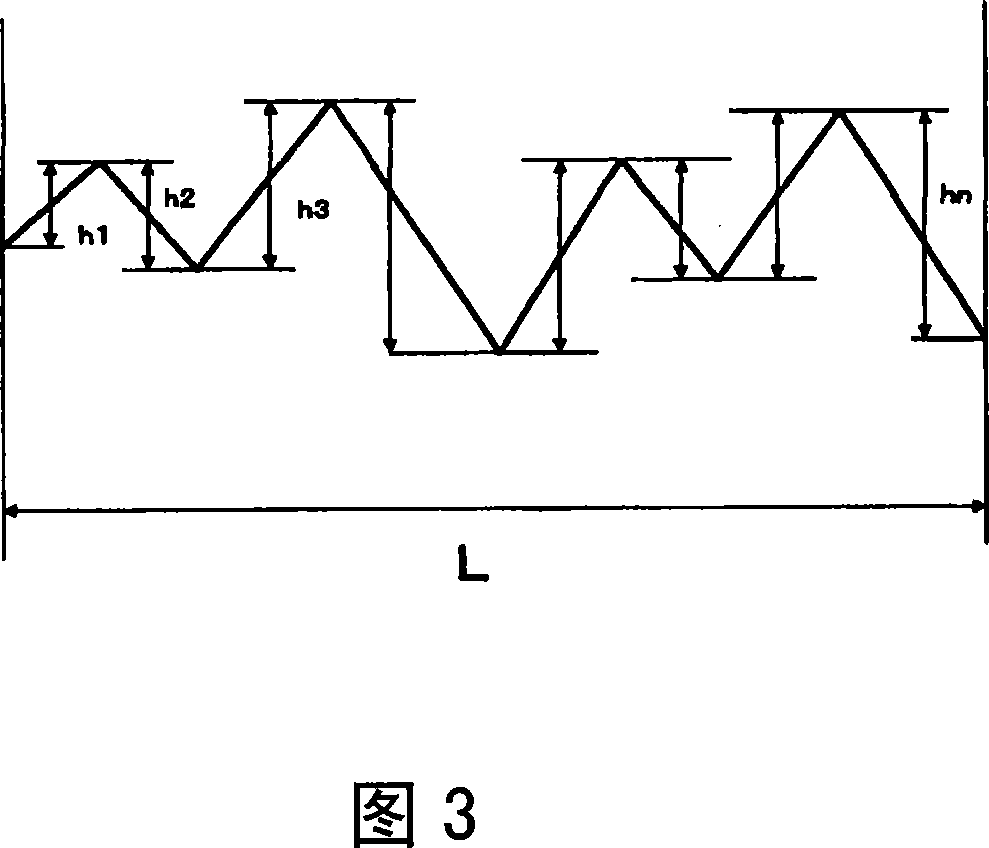

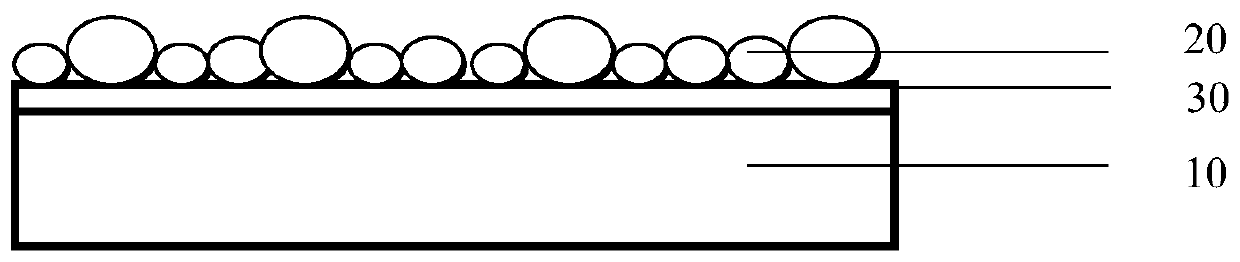

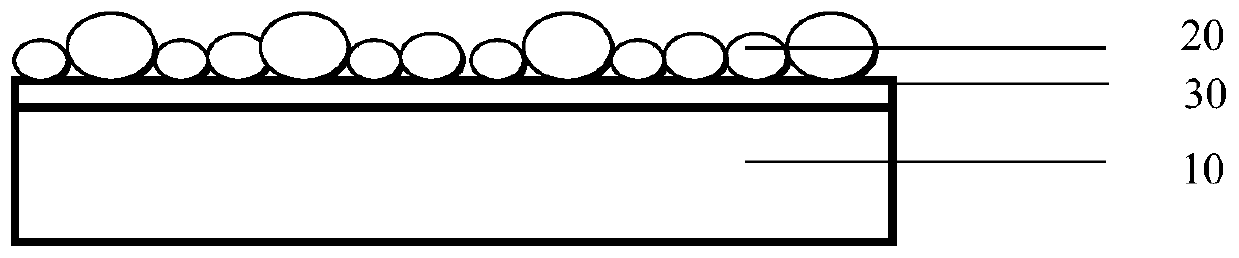

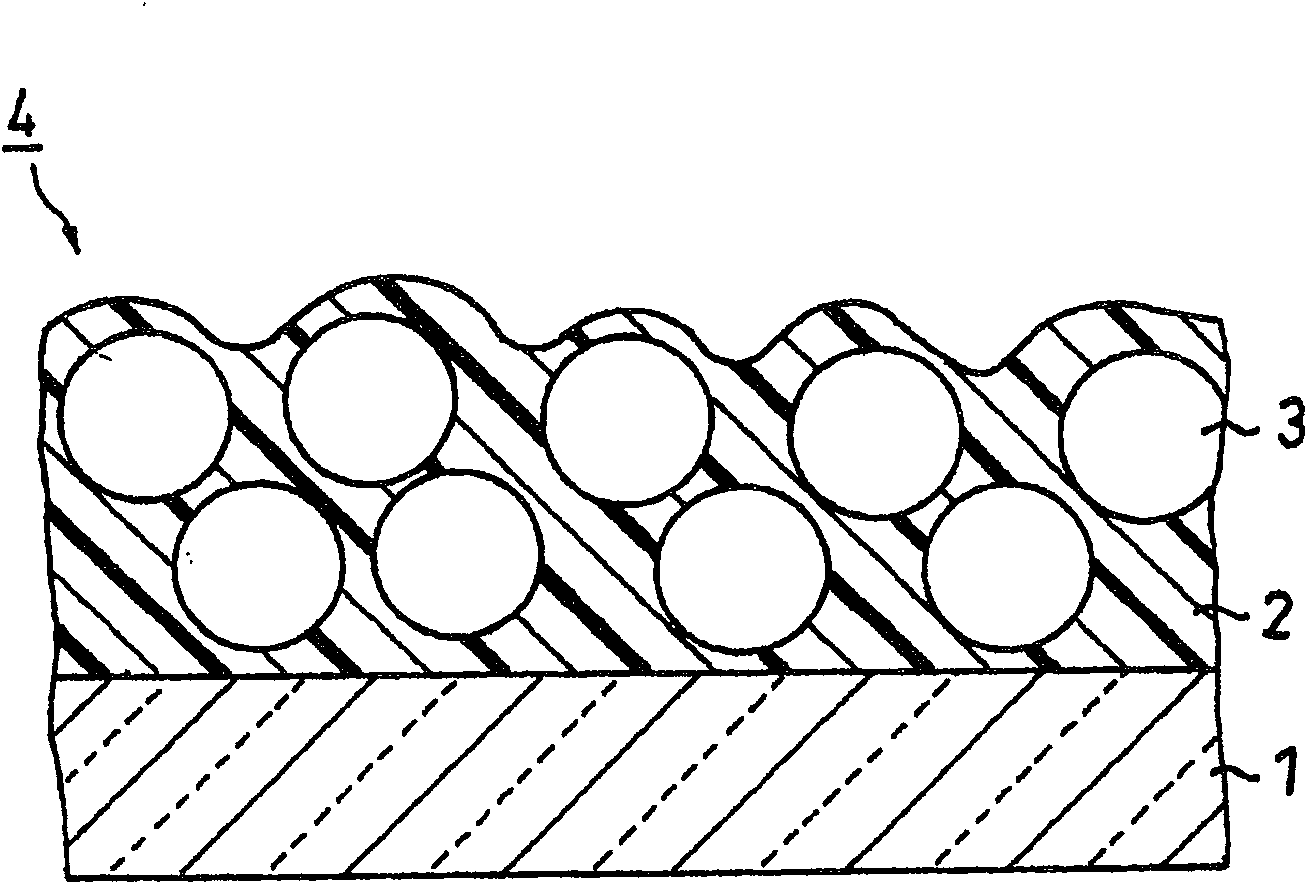

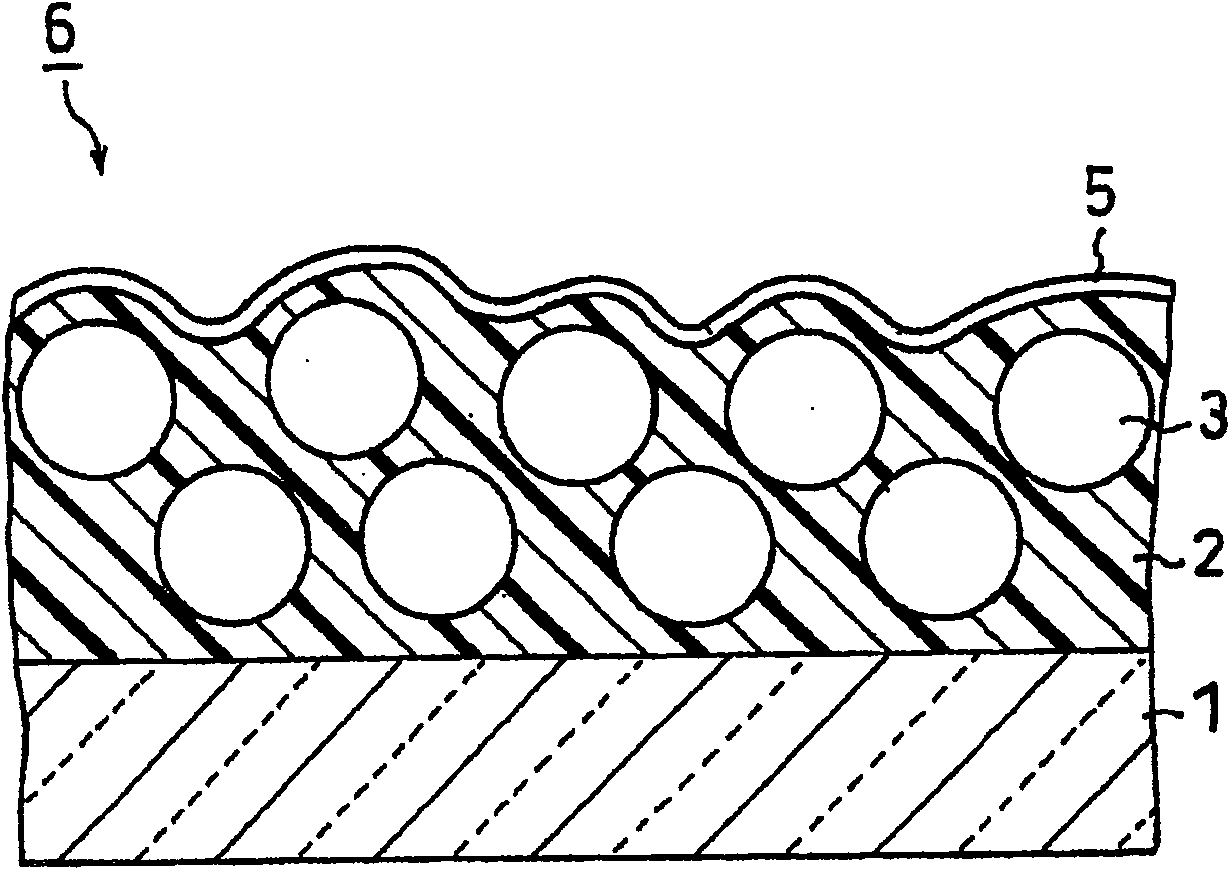

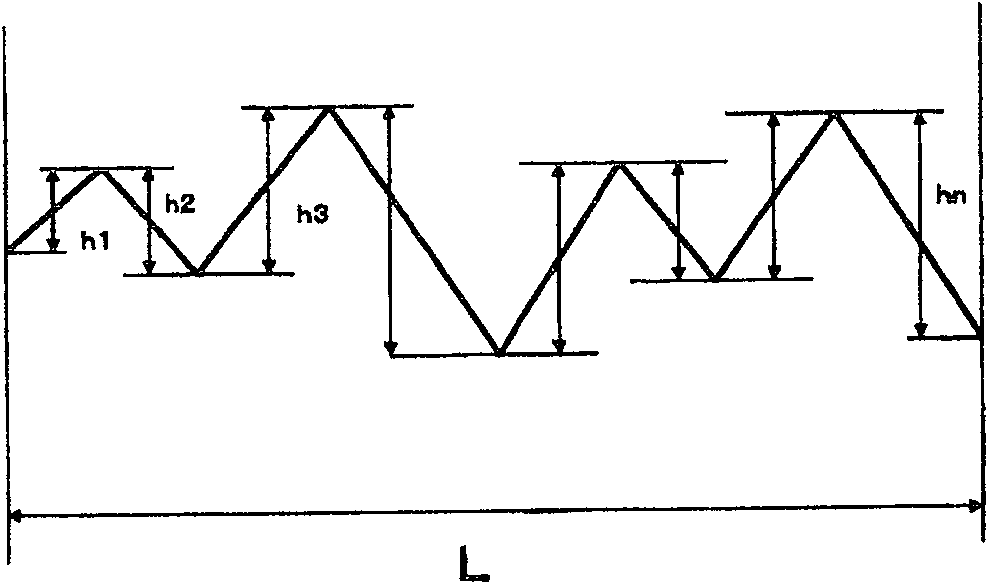

Hard-coated antiglare film, polarizing plate, image display, and method of manufacturing hard-coated antiglare film

InactiveCN101063721AImprove adhesionProper protectionLayered productsPolarising elementsCoated surfacePolymer science

A hard-coated antiglare film is provided that has high hardness and excellent antiglare properties and can prevent white blur from occurring when viewed from oblique directions. The hard-coated antiglare film of the present invention includes a transparent plastic film substrate and a hard-coating antiglare layer that is formed of fine particles and a hard-coating resin on at least one surface of the transparent plastic film substrate. The hard-coating antiglare layer has a thickness of 15 to 30 mum, the fine particles have a weight average particle size of 30 to 75% of a thickness of the hard-coating antiglare layer, in the unevenness of the hard-coating antiglare layer surface that is formed by the fine particles, an average tilt angle thetaa is 1.0 DEG to 2.0 DEG , and an arithmetic average surface roughness Ra according to JIS B 0601 (1994 version) is 0.12 to 0.30 mum.

Owner:NITTO DENKO CORP

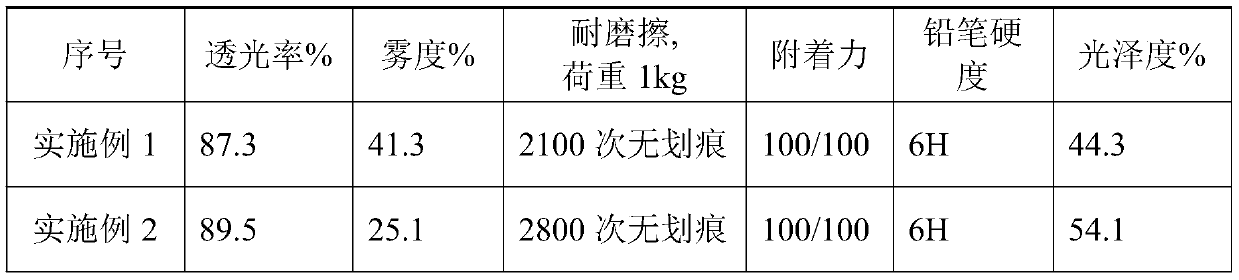

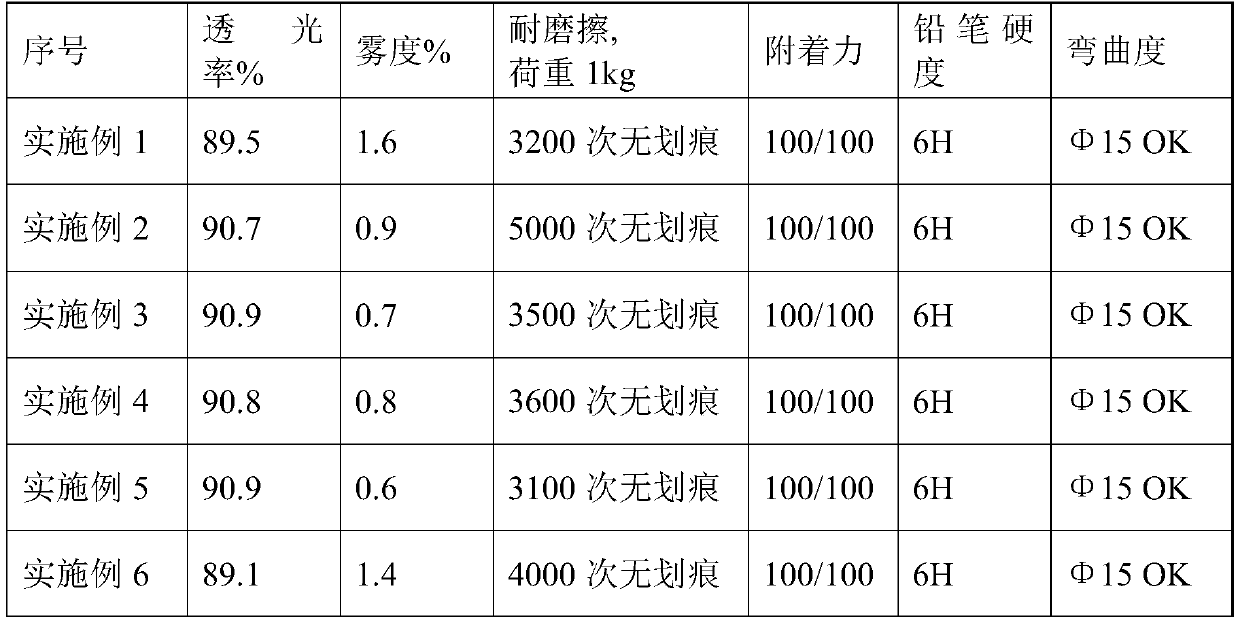

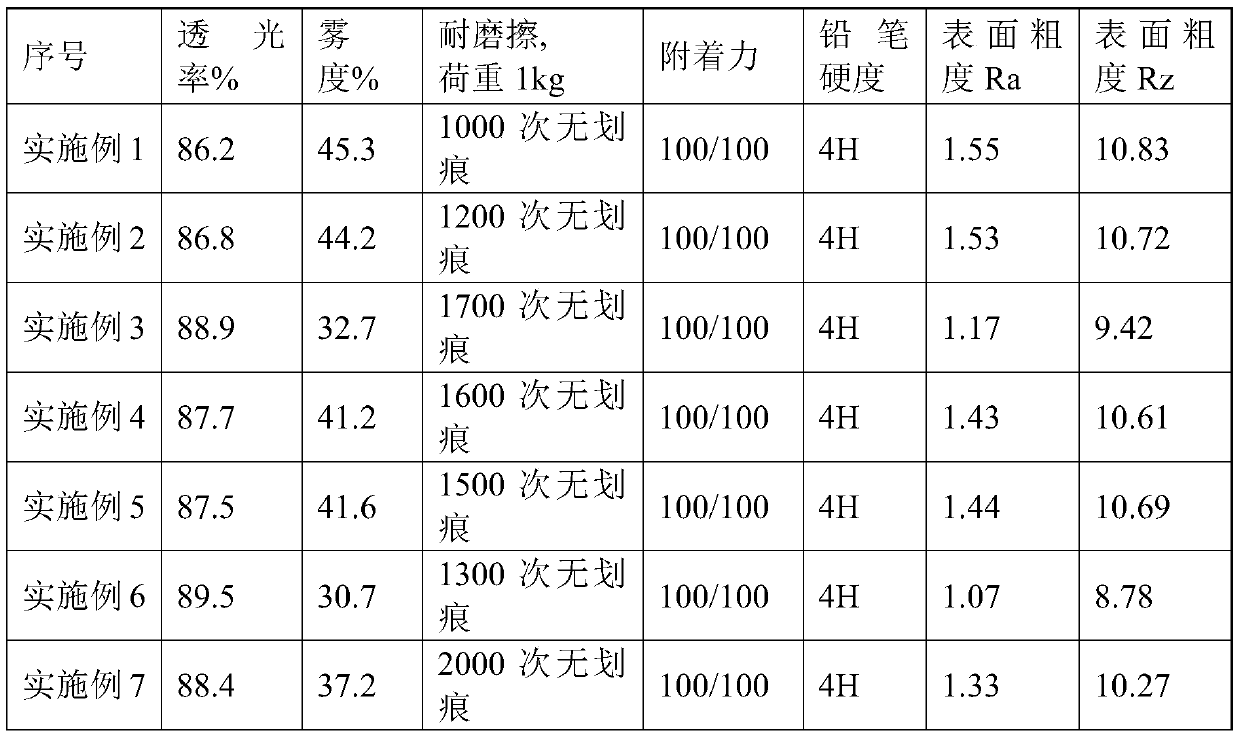

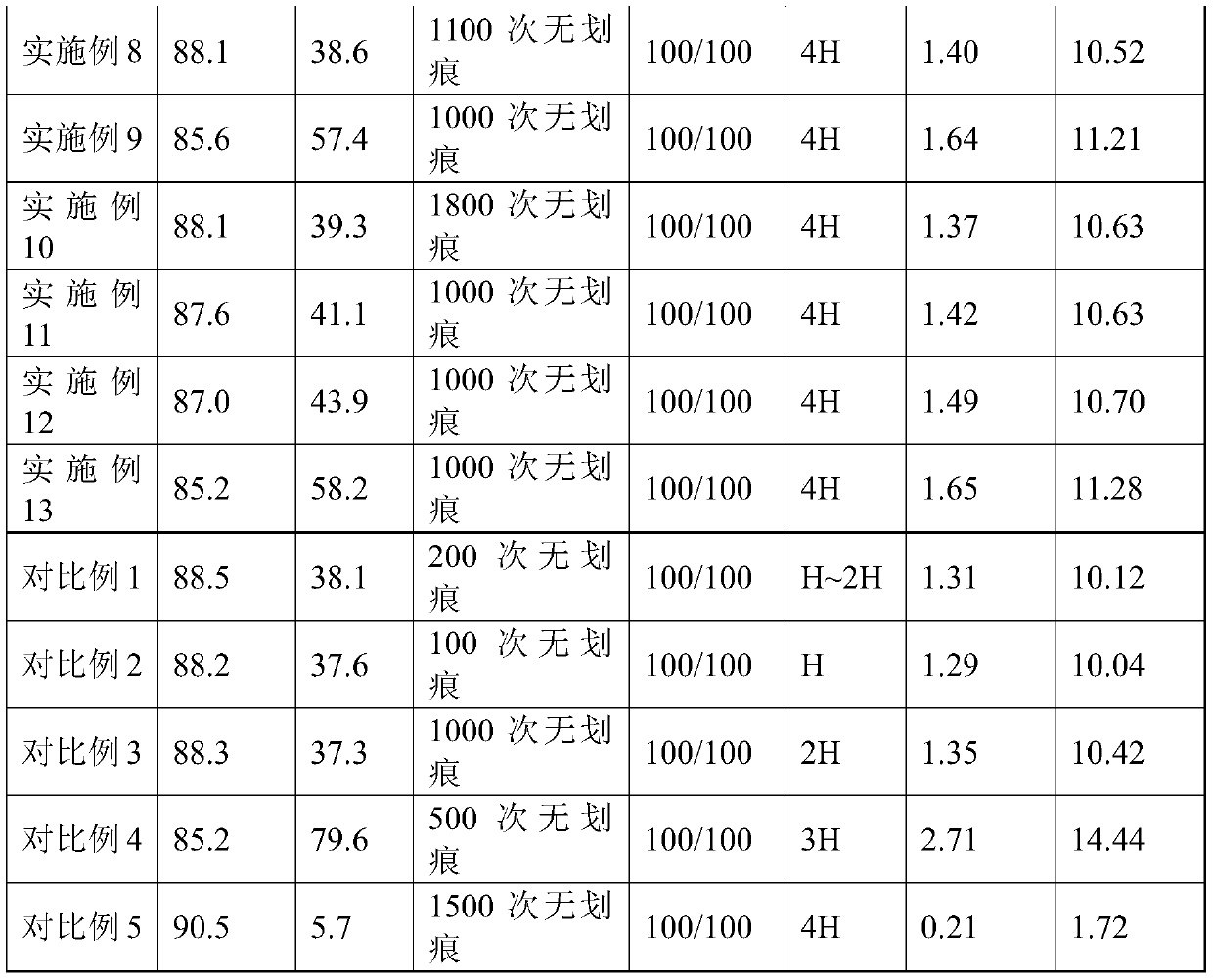

High-hardness and anti-dazzle hardening layer coating liquid and hardening film

The invention relates to the technical field of a hardening film, in particular to high-hardness and anti-dazzle hardening layer coating liquid and a hardening film. In order to solve the problems that the existing hardening film cannot realize high hardness or anti-dazzle performance at the same time, the invention provides the high-hardness and anti-dazzle hardening layer coating liquid and thehardening film. The hardening layer coating liquid contains 40 to 80 percent of acrylic ester prepolymers, 10 to 30 percent of acrylic ester monomers, 7 to 30 percent of silicon dioxide, 2 to 6 percent of photoinitiators and 0.1 to 0.5 percent of auxiliary agents in percentage by weight. The hardening layer coating liquid provided by the invention forms a hardening layer after the curing; high hardness and anti-dazzle performance are realized. The hardening film provided by the invention has high hardness and anti-dazzle protection effects.

Owner:NINGBO EXCITON TECH

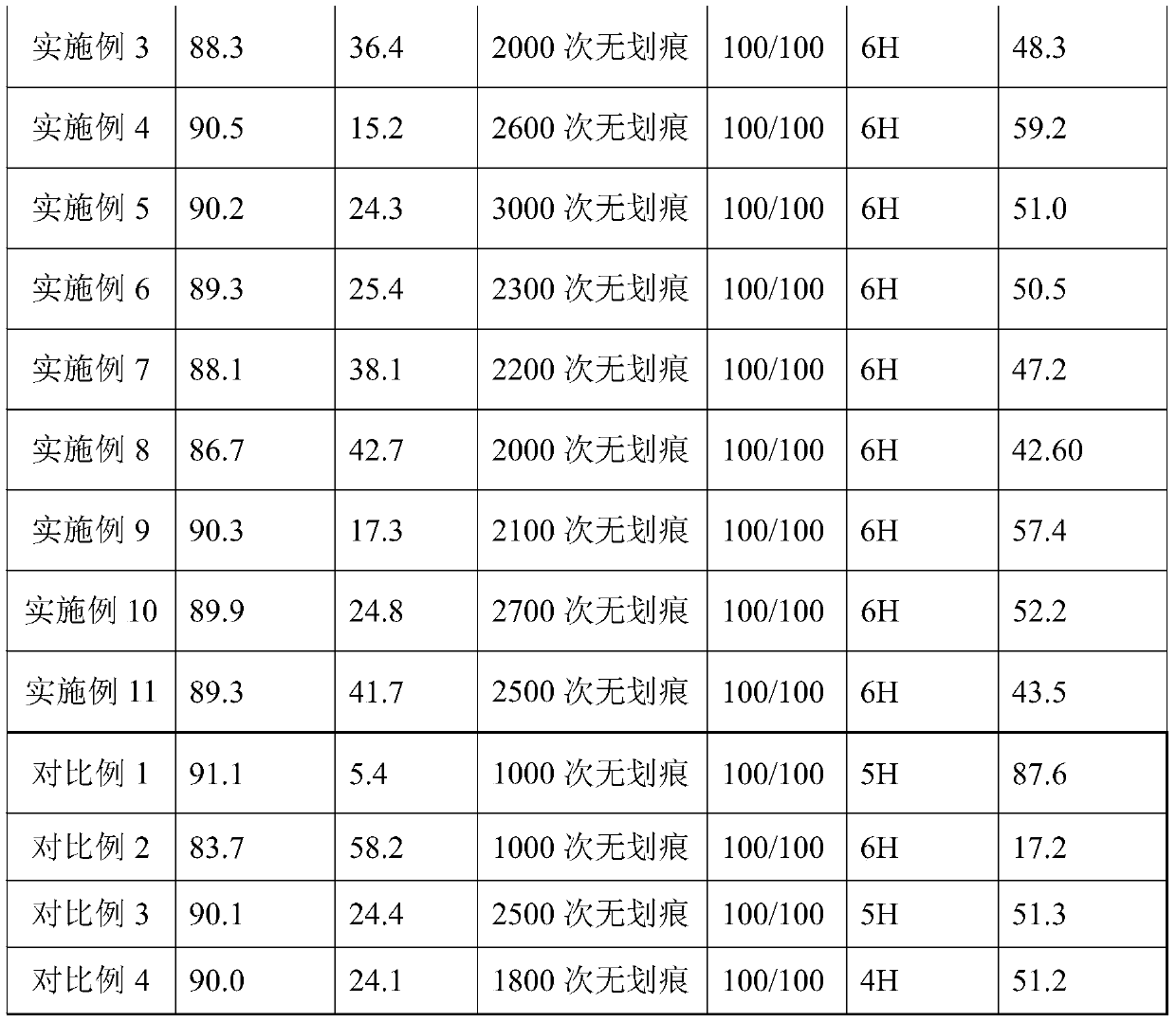

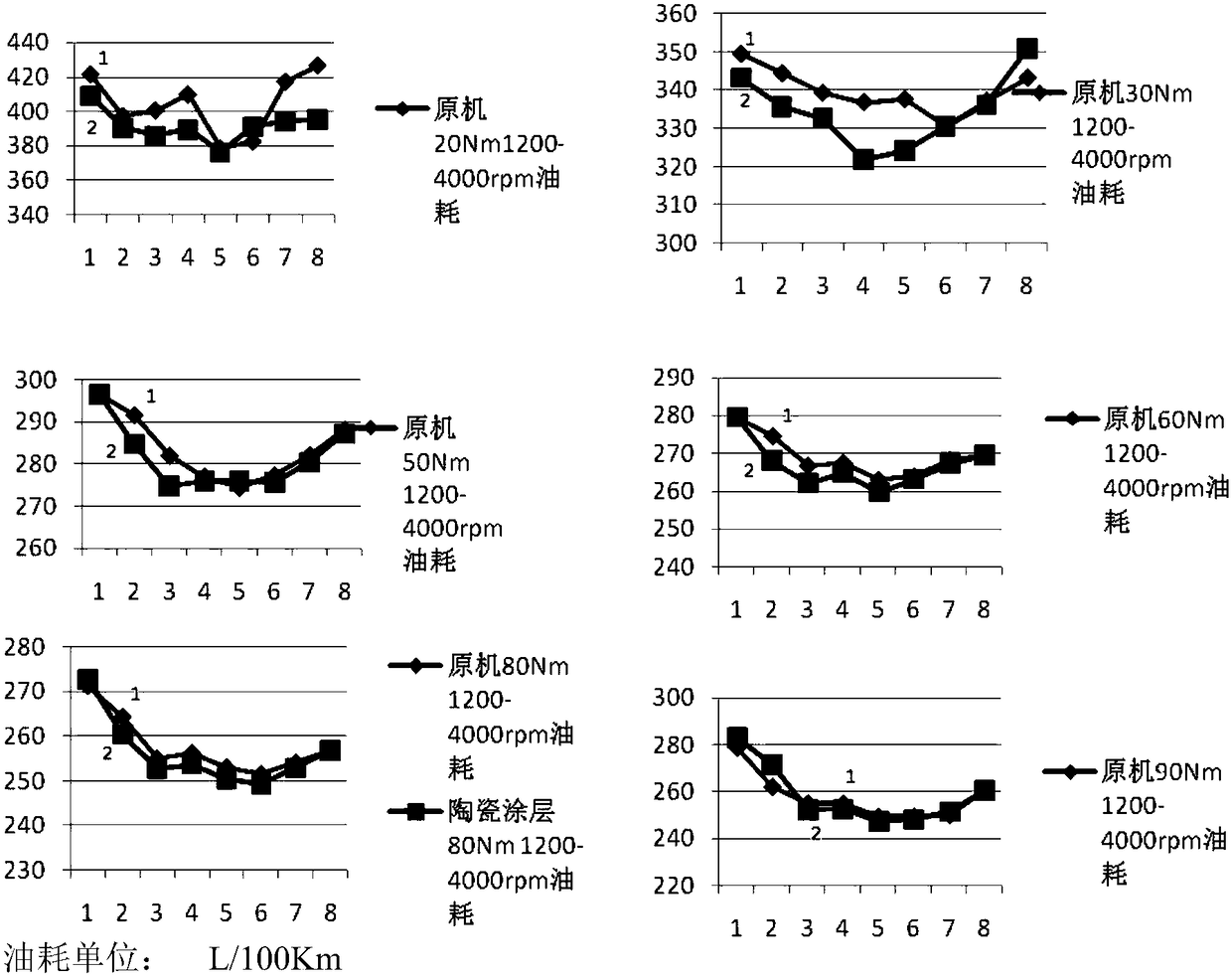

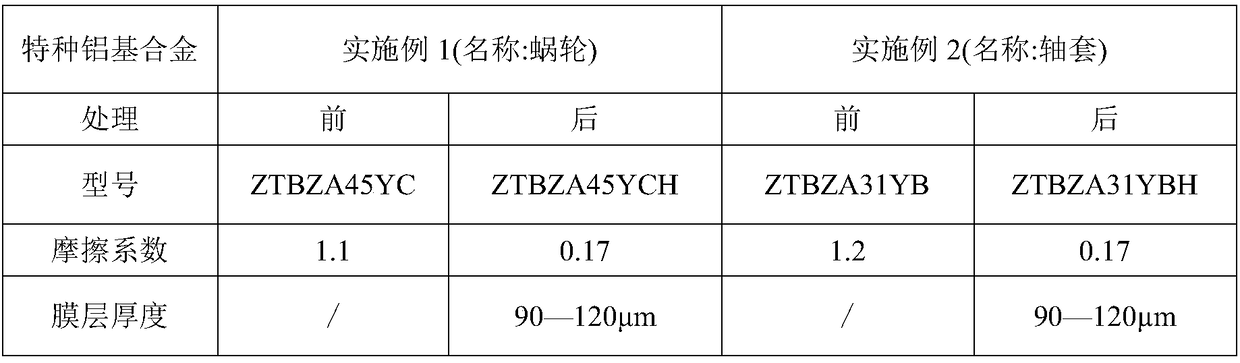

Nanometer graphene reflection thermal insulation composite multifunctional ceramic coating layer and preparation method thereof

ActiveCN105951151AOutstanding heat insulationOutstanding FeaturesAnodisationCombustion chamberPlasma electrolytic oxidation

The invention discloses a reinforced alloy material; and a surface layer of the alloy material contains such elements as aluminum oxide, silicon dioxide and nanometer graphene. The alloy material is deeply extended on the basis of anodic oxidation, microarc oxidation and multi-component composite oxidation, and is a result under a complex effect of instant high temperature, multi-component composite oxidation liquid and nanometer penetrant through applying positive and negative high voltage, high current and positive and negative pulses by using unique structures, physical and chemical characteristics as ultrahigh hardness and high-temperature resistance, small size effects and surface and interface effects of such nanometer materials as nanometer graphene and nanometer silicon dioxide. The method comprises the steps of: (1) surface cleaning; (2) oxidation; and (3) penetration. The light alloy material after surface reinforcement by the method, in particular a combustion chamber of an internal combustion engine with fuel combustion consumption and generating a pollution source is prominent in reflection thermal insulation anti-carbon self catalysis function, and is higher in high-temperature erosion resistance and wear resistance.

Owner:四川鸿森达铝业科技有限公司

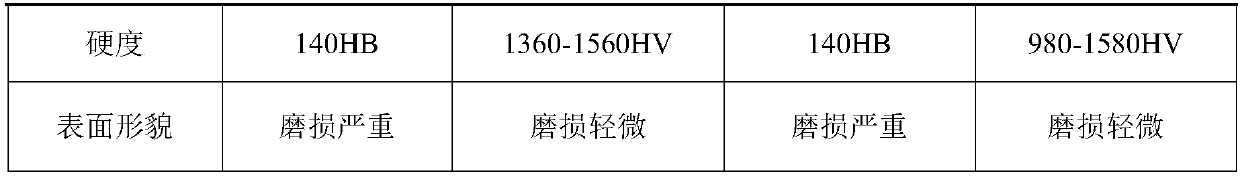

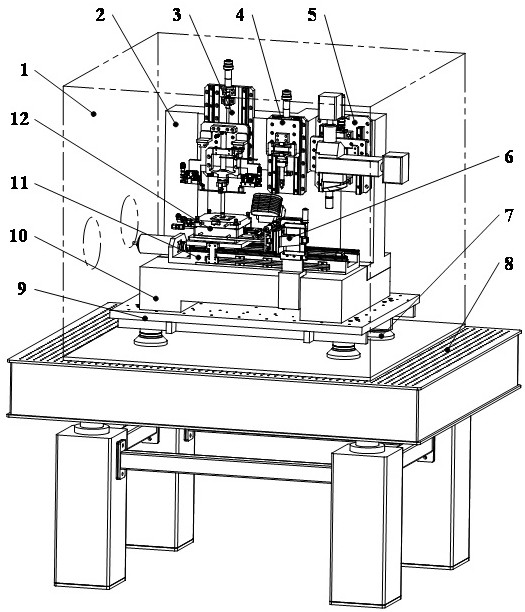

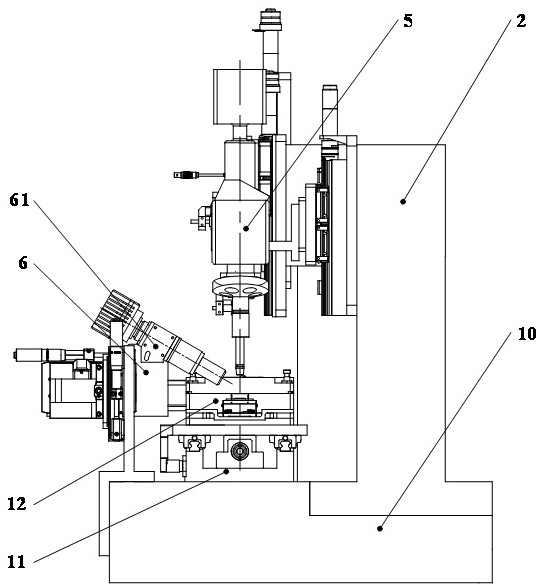

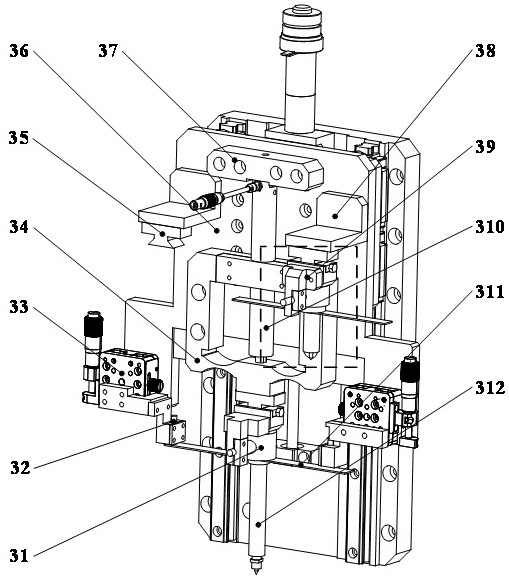

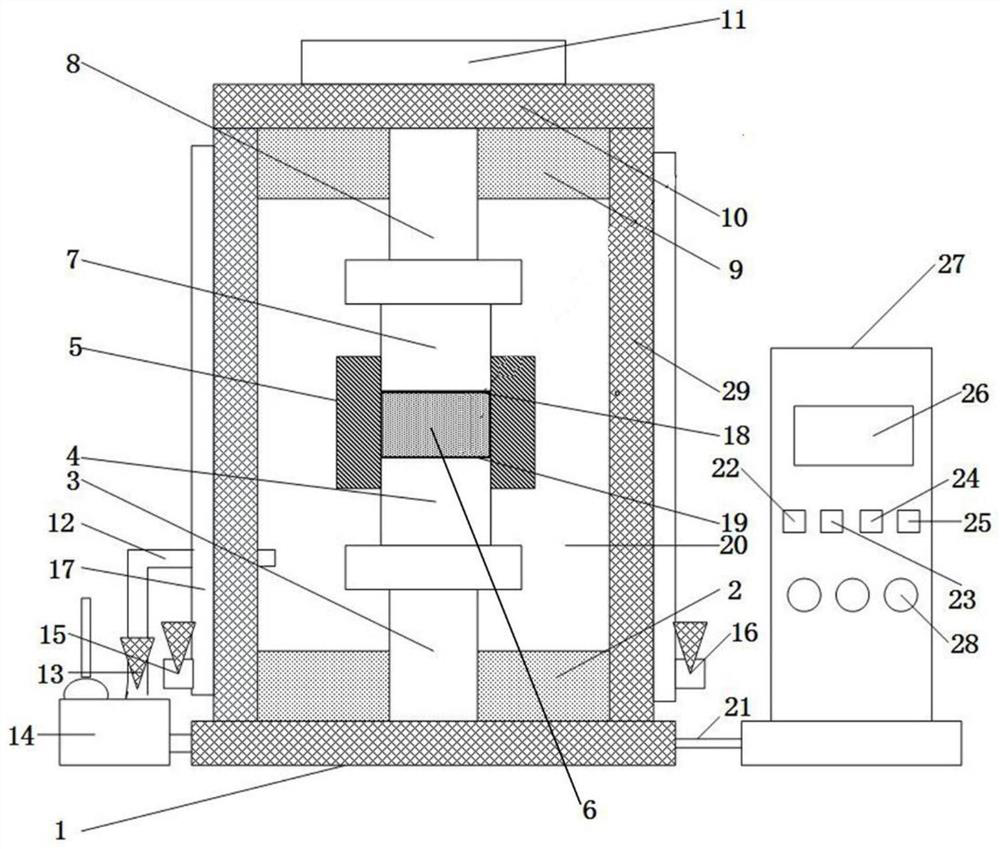

Traceable in-situ micro-nano indentation test instrument and method under variable-temperature working condition

PendingCN111855457AAchieve hardnessAchieving a modulus of elasticityMaterial strength using tensile/compressive forcesInvestigating material hardnessMicro nanoMaterials testing

The invention relates to a traceable in-situ micro-nano indentation test instrument and a traceable in-situ micro-nano indentation test method under a variable temperature working condition, and belongs to the technical field of precise instruments and material test. The macro-micro switching type mechanical loading module, the nano mechanical loading module and the press-in position optical positioning module are fixed on the gantry cross beam; the optical imaging axis of the optical microscopic in-situ observation / needle alignment module is coplanar with the loading axis of the nano mechanical loading module, the optical microscopic in-situ observation / needle alignment module and the function switching module are installed on the table top of the marble base, and the contact / atmosphere mixed temperature changing module is fixed to the function switching module. Modular design, a micro-nano indentation test instrument is used as a core; the multi-stage vacuum / atmosphere chamber, the press-in depth traceability calibration module and the multiple groups of optical microscopic imaging assemblies are combined to realize researches of press-in depth calibration under a variable temperature working condition, needle alignment of a nano mechanical loading micro-force sensor, accurate positioning of a press-in position, in-situ dynamic monitoring of micro-area mechanical properties and a damage mechanism of a test material in different dimensions and the like.

Owner:JILIN UNIV

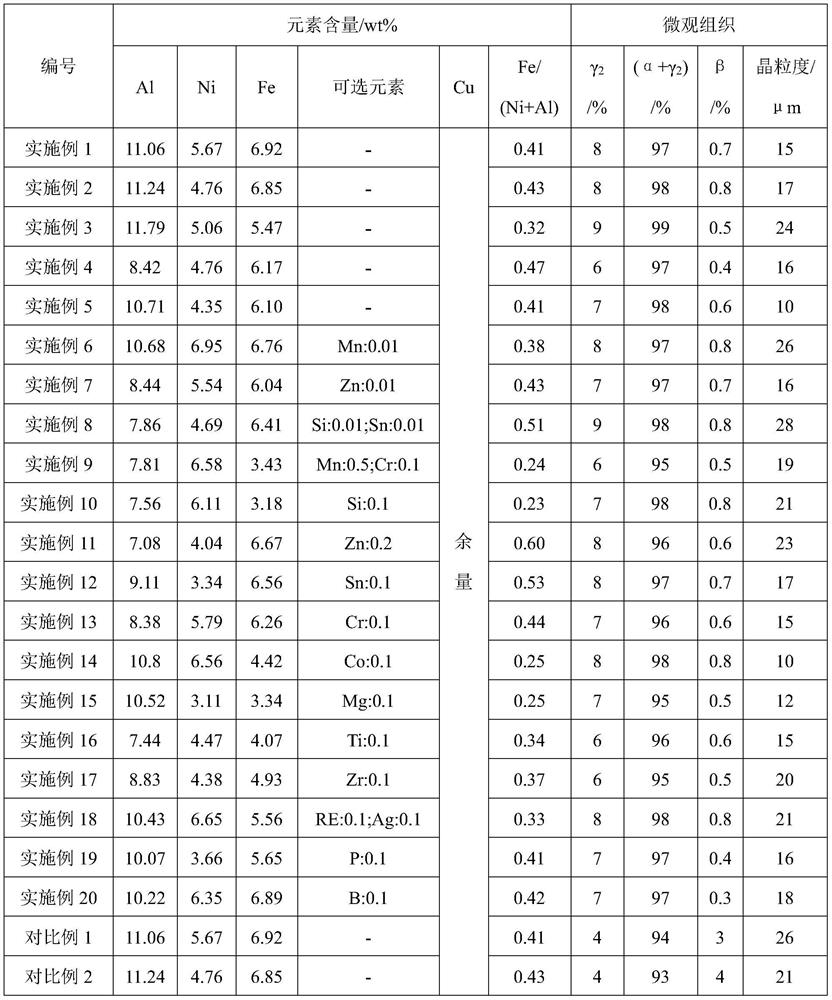

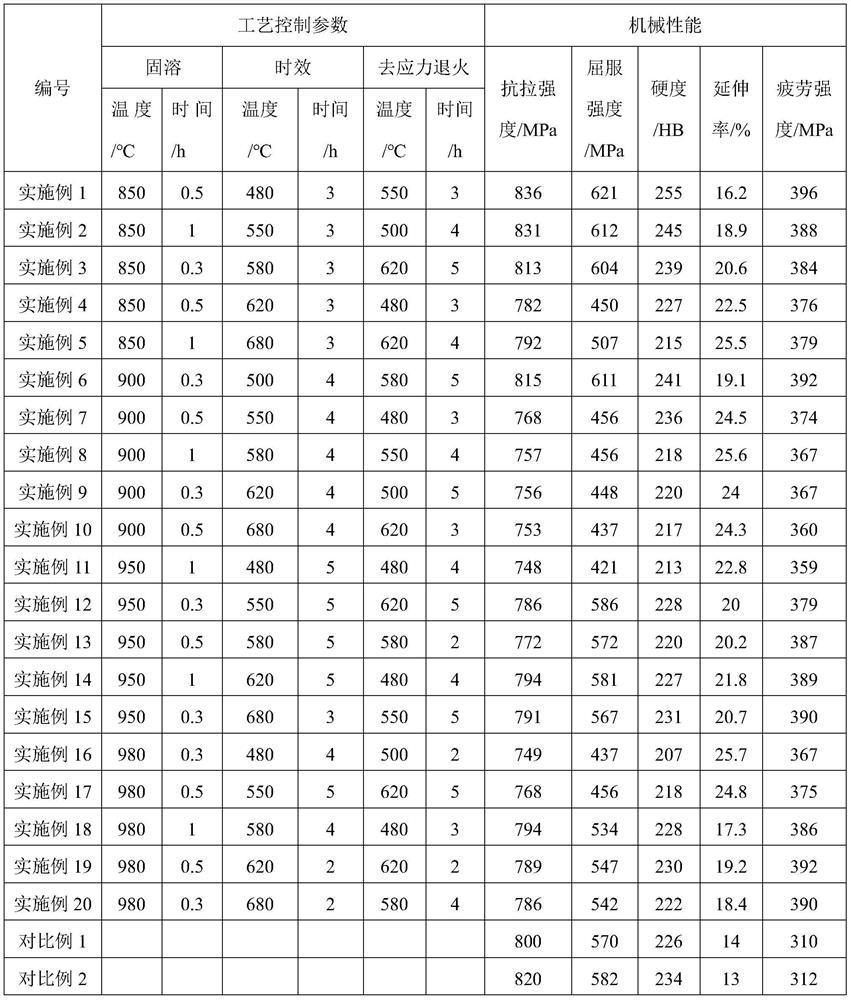

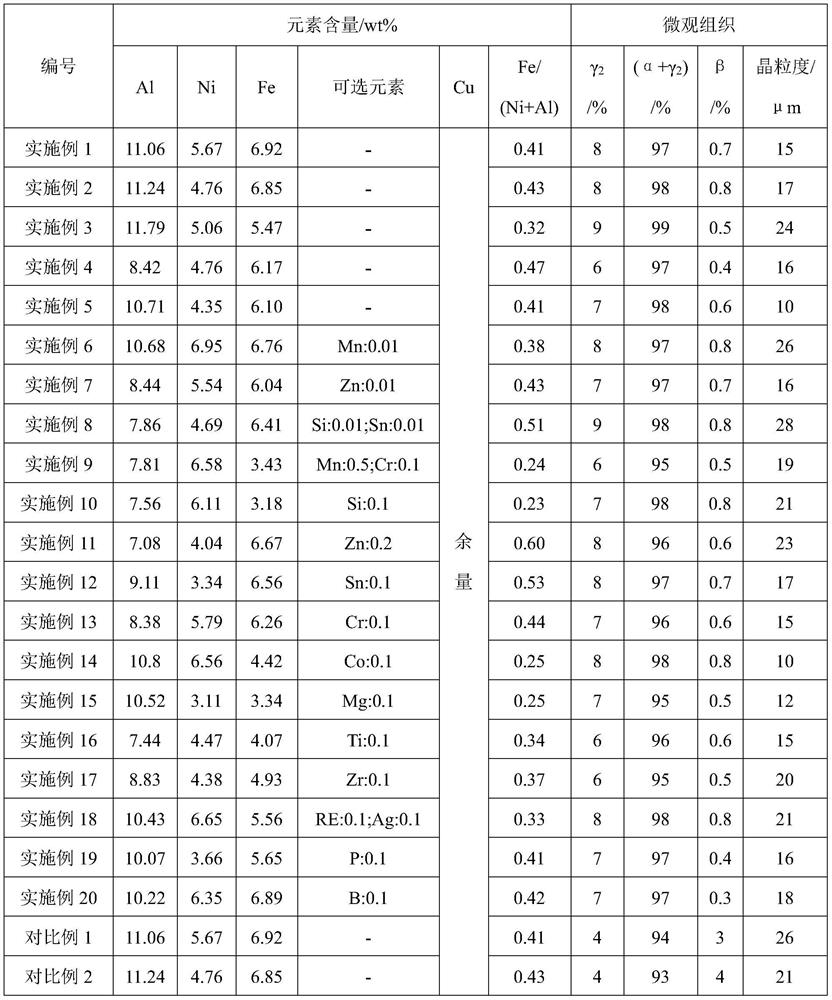

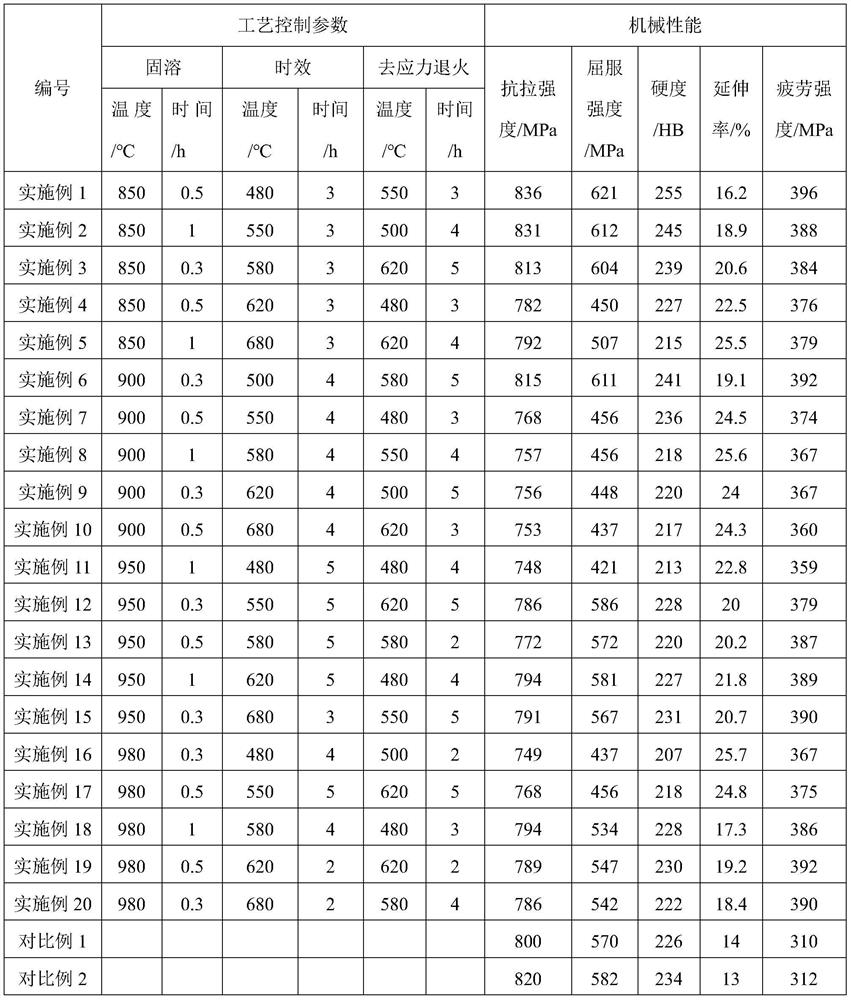

Aluminum bronze and preparation method thereof

The invention discloses aluminum bronze. The aluminum bronze is characterized by comprising the following components in percentage by mass: 7.0-12.0% of Al, 3.0-7.0% of Ni, 3.0-7.0wt% of Fe, 0-1.0wt%of Mn, 0-1.0wt% of Zn, 0-0.5wt% of Si, 0-0.5wt% of Sn, and the balance Cu and inevitable impurities; and a microstructure of the aluminum bronze contains an alpha phase and a gamma 2 phase. The aluminum bronze has the tensile strength of not less than 740MPa, the yield strength of not less than 400MPa, the ductility of not less than 15% and the hardness of not less than 200HB; when the stretchingcycle times are 107 times, the fatigue strength is 355-400MPa; and the aluminum bronze can satisfy the requirements of structural parts, wear resisting parts, corrosion resisting parts and the like working in such places as mechanical industry, ship and ocean industry, petrochemical industry and electric industry on comprehensive performances of the aluminum bronze.

Owner:NINGBO POWERWAY ALLOY MATERIAL

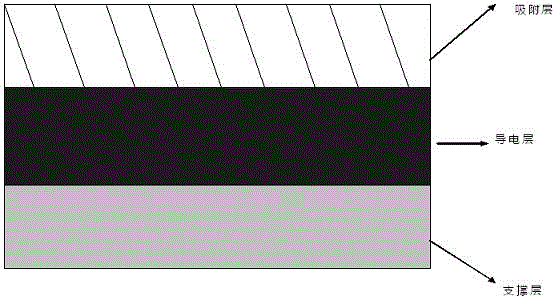

Transparent conductive glass substrate

ActiveCN103189931ASoftAchieve hardnessConductive layers on insulating-supportsCable/conductor manufactureRADIUSTransmittance

To provide a flexible transparent conductive glass substrate having flexibility similar to a plastic substrate, achieving hardness and transparency not found in plastics, and having adherence that can withstand use with a curved surface. [Solution] A transparent conductive glass substrate having a conductive polymer layer on at least one surface of a thin glass substrate, and having a surface resistance of 1.8 GO / sq or less, total light transmittance of 85% or greater, surface pencil hardness of H or greater, and no failure with bending of a radius of 25 mm is manufactured. Furthermore, a conductive polymer application forming the conductive polymer layer contains a conductive polymer and polyanions and also contains one or a plurality selected from a group that includes binders, curing agents, conductivity increasing agents, surface active agents, catalysts, and agents for improving adhesion.

Owner:SHIN-ETSU POLYMER CO LTD +1

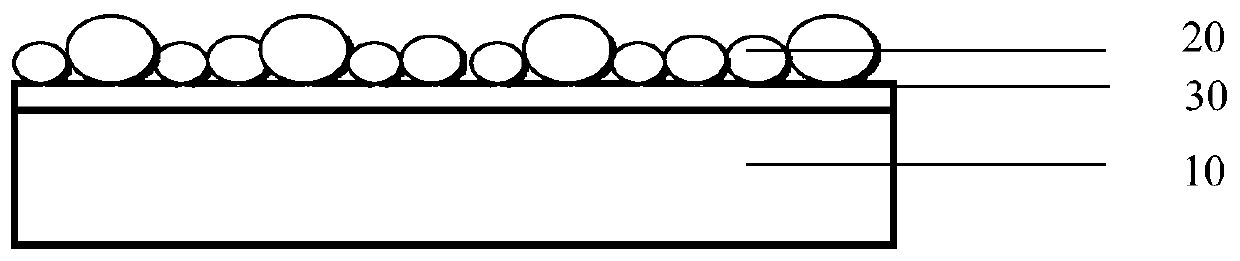

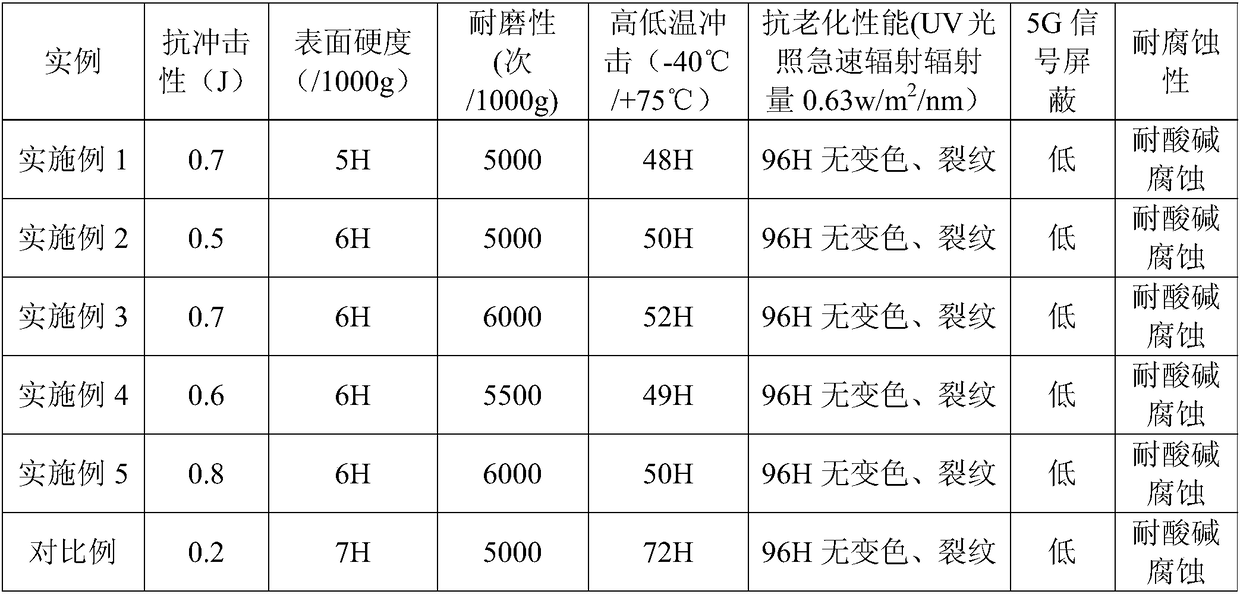

High-wear-resistance high-toughness hardened layer coating liquid and hardened film

InactiveCN109880507AImprove wear resistanceImprove toughnessPolyurea/polyurethane coatingsPliabilityTransmittance

The invention relates to the technical field of hardened films, in particular to a high-wear-resistance high-toughness hardened layer coating liquid and a hardened film. In order to solve the problemof poor wear resistance of the surface of an existing transparent film, the invention provides the high-wear-resistance high-toughness hardened layer coating liquid and the hardened film. The hardenedlayer coating liquid comprises the following components in percentage by weight: 30%-80% of an acrylate prepolymer, 5%-30% of an acrylate monomer, 10%-40% of silicon dioxide nanoparticles, 1%-6% of aphotoinitiator and 0.1%-0.5% of an auxiliary agent, wherein the particle size of the silicon dioxide nanoparticles is 10-100 nm. The hardened layer coating liquid provided by the invention has high wear resistance and good flexibility after being cured to form a hardened layer. The hardened film provided by the invention has the characteristics of high hardness, high wear resistance, high light transmittance and low haze, meets the proper toughness requirement, and is suitable for the external protection function of a display screen.

Owner:NINGBO EXCITON TECH

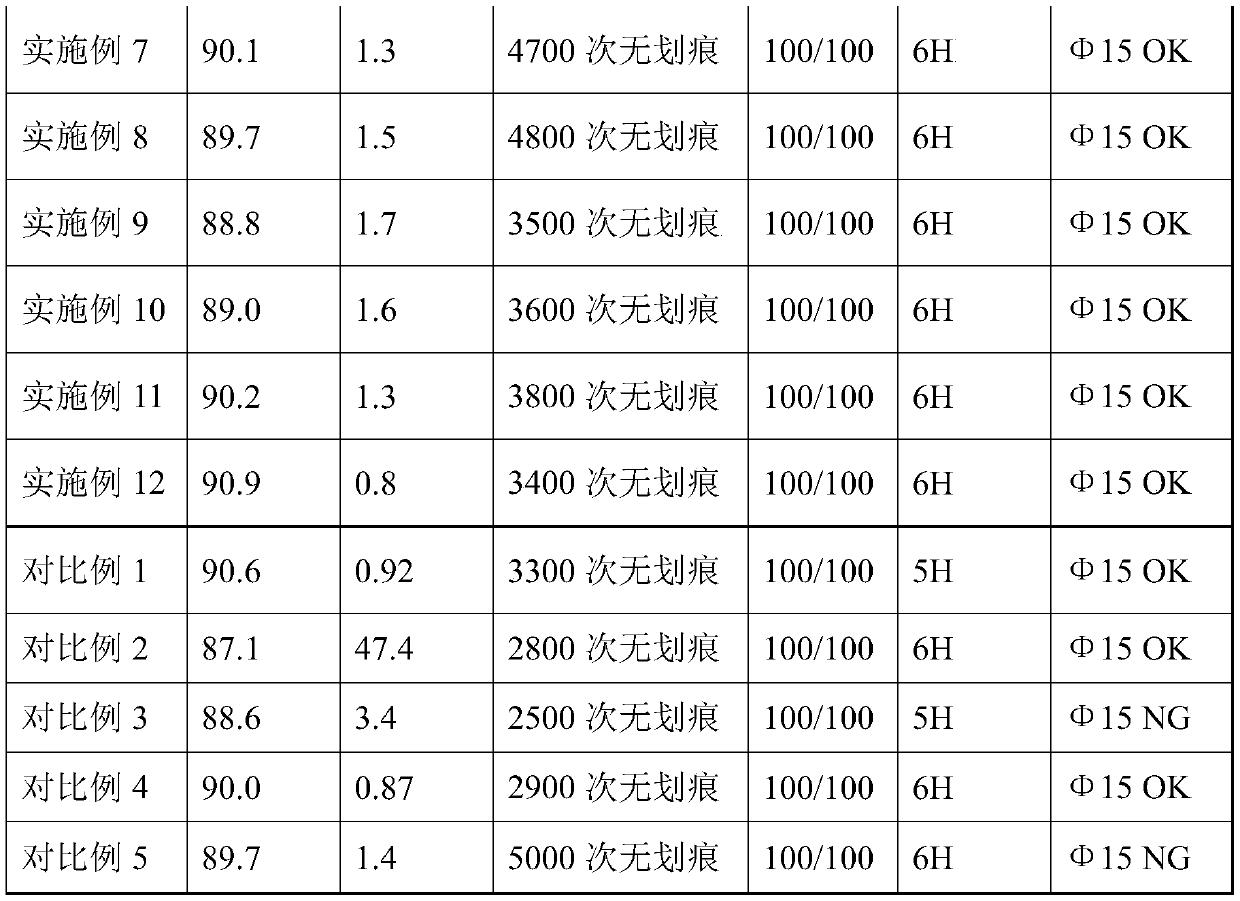

Preparation method for integral glass-imitated 3D curved surface cover plate

InactiveCN108215053AAchieve hardnessLow costVacuum evaporation coatingSputtering coatingCorrosionHardness

The invention provides a preparation method for an integral glass-imitated 3D curved surface cover plate. The preparation method includes the following steps: 1) 3D injection molding: carrying out 3Dinjection molding of an optical-graded transparent plastic; 2) hardening treatment: carrying out hardening treatment of the material after 3D injection molding of the step 1); 3) OPVD film plating: carrying out OPVD film plating of the material after hardening treatment of the step 2); and 4) spraying: carrying out spray treatment of the material after OPVD film plating of the step 3), to obtain the integral glass-imitated 3D curved surface cover plate. The integral glass-imitated 3D curved surface cover plate prepared by the preparation method has the advantages of strong plasticity, good impact resistance, low shielding of 5G signals, low electromagnetic wave loss, high hardness, and good abrasion resistance, corrosion resistance, high and low temperature impact and aging resistance, issuitable for mobile phones, wearing, intelligent household appliances, intelligent consumption electronic products and other 3C products, and can optimize and replace conventional metal and glass panels.

Owner:KUNSHAN SANJING SCI & TECH

Ion exchange resin modified polyvinylidene fluoride (PVDF) charcoal electrode and preparation method thereof

ActiveCN102718291ASalt removal achievedAchieve hardnessDispersed particle separationActivated charcoal powderActivated carbon

The invention relates to an ion exchange resin modified polyvinylidene fluoride (PVDF) charcoal electrode and a preparation method thereof. The ion exchange resin modified PVDF charcoal electrode is used for a fresh water treatment technology, and is prepared from activated charcoal powder, graphite powder, PVDF, ion exchange resin powder, organic solvent and the like. The prepared ion exchange resin modified PVDF charcoal electrode can adsorb ions in water by means of applied voltage, thereby efficiently removing salt in water; and the electrode has sufficient mechanical strength for bearingthe shearing force of water flow and favorable reversibility, thereby having a wide application range of raw water quality. The PVDF used as a binder can bind the activated charcoal powder and the graphite, the doping of the ion exchange resin powder can increase -SO3H and -OH on the electrode, and both the -SO3H and -OH are hydrophilic functional groups. The preparation process provided by the invention is simple and low in energy consumption, produces no byproduct, has no secondary pollution, and is low in treatment cost. The ion exchange resin modified PVDF charcoal electrode can perform electro-adsorption salt removal under normal temperature and normal pressure, and the salt removal rate is up to 90%. Thus, the invention can be used in the electro-adsorption water treatment field.

Owner:CHUTIAN HUATONG PHARM EQUIP CO LTD

High-hardness and erasing-resistant hardening coating liquid and hardened film

InactiveCN109776838AAchieve hardnessAchieving wear resistancePolyurea/polyurethane coatingsHardnessHigh wear resistance

The invention relates to the technical field of hardened films, in particular to a high-hardness and erasing-resistant hardening coating liquid and a hardened film. In order to solve the problem thatthe protective film for a screen of an educational machine cannot have both high hardness and erasing resistance, the invention provides the high-hardness and erasing-resistant hardening coating liquid and the hardened film. The hardening coating liquid comprises the following components by weight percentage: 30-70% of acrylate prepolymer, 10-40% of acrylate monomer, 10-30% of polymethyl methacrylate particles, 1-5% of a light initiator and 0.1-1% of an aid. The hardening coating liquid forms a hardened layer after curing, which has both high hardness and erasing resistance. The hardened filmhas the characteristics of high hardness, high wear resistance and erasability, and is suitable for external protection of display screens.

Owner:NINGBO EXCITON TECH

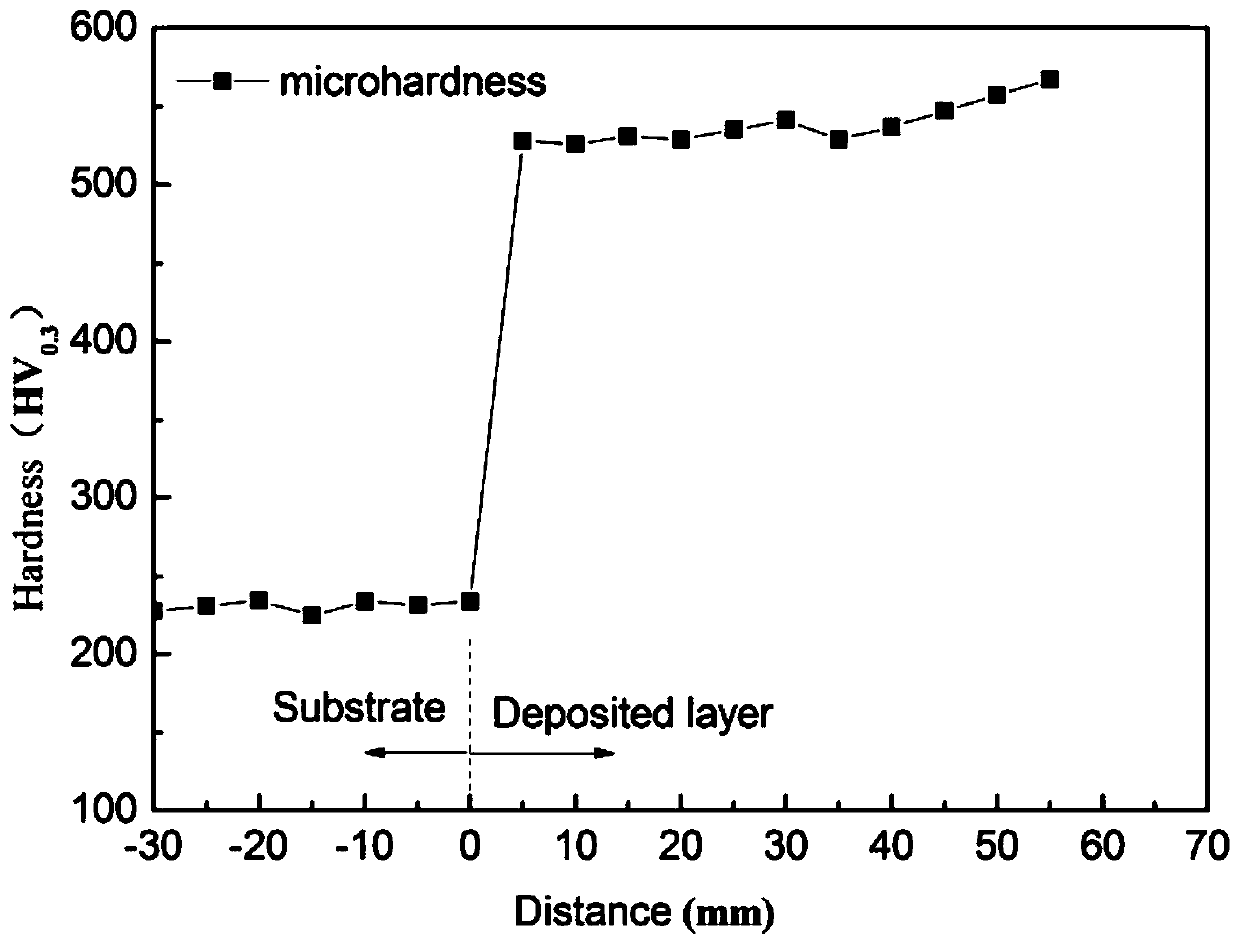

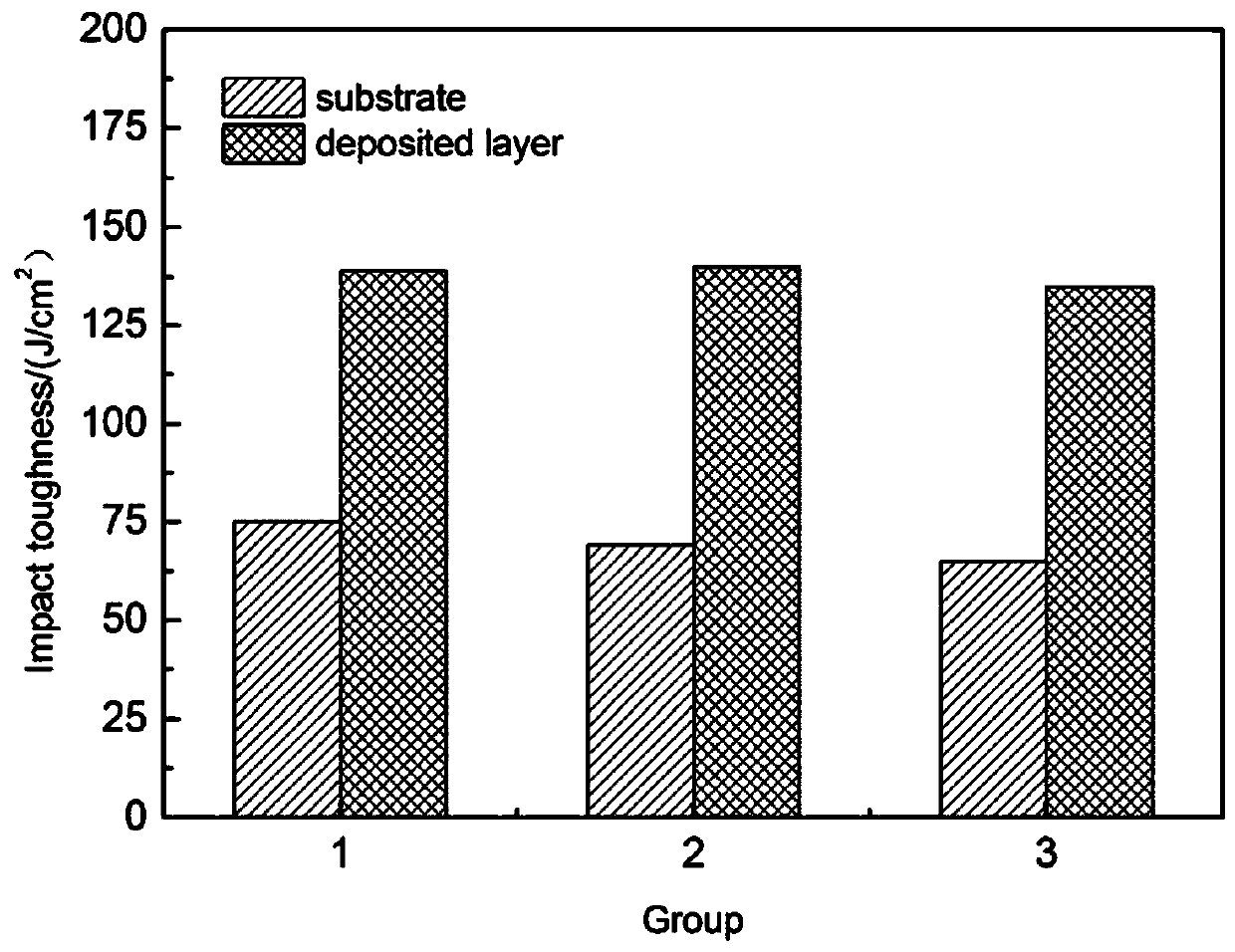

Method for improving wear resistance and impact resistance of laser additive manufacturing alloy steel component

ActiveCN110788323AGuaranteed coefficient of thermal expansionInhibitionAdditive manufacturing apparatusTransportation and packagingDeposition processLaser additive manufacturing

The invention belongs to the field of metal laser additive manufacturing, and particularly relates to a method for improving wear resistance and impact resistance of a laser additive manufacturing alloy steel component. The method is suitable for obviously improving the wear resistance and impact resistance of various alloy steel component laser additive materials. First, one, two or more powdersof Mo, TiC, B, Si, V, Cr, Ni and the like which have the same particle size as an alloy steel powder are adopted, are uniformly mixed for a certain proportion in the alloy steel powder through a ballmill, a laser deposition substrate is preheated, then laser deposition is performed in a vacuum glove box by using a synchronous powder feeding method, a laser deposition active area is covered with argon with a certain flow rate in the deposition process, and the substrate is heated and maintained by using induction, so that the compact deposited layer and timely controllable wear resistance andimpact resistance laser additive manufacturing can be realized. According to the method, an efficient and reliable novel technological method for improving the wear resistance and impact resistance ofthe laser additive manufacturing of the alloy steel component is provided, and the method has important significance for manufacturing the alloy steel component and the laser surface modification ofthe alloy steel component.

Owner:浙江翰德圣智能再制造技术有限公司

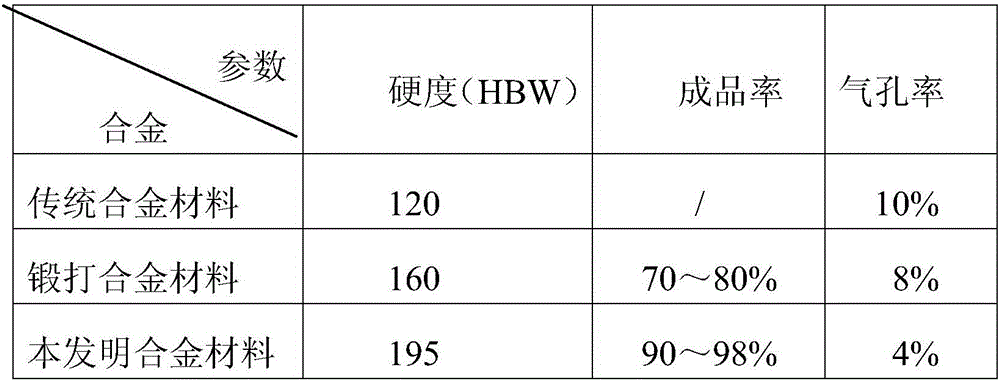

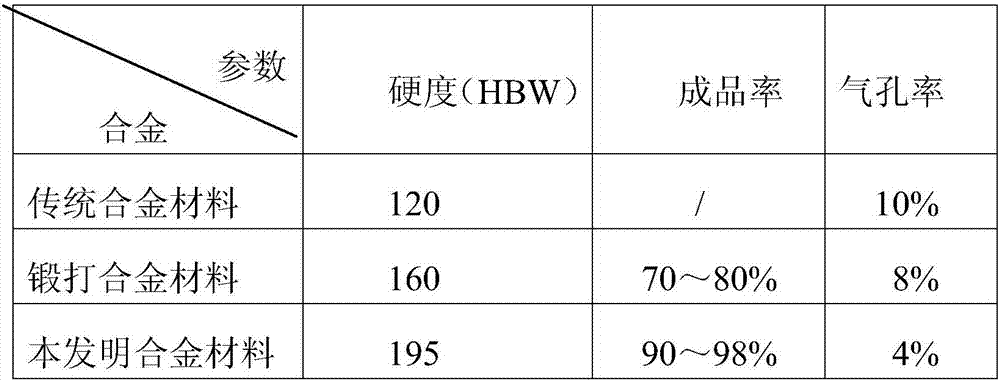

Casting material for nuclear power steam turbine abrasion-resisting pump block and manufacturing method of casting material

The invention discloses a manufacturing method of a casting material applied to a nuclear power steam turbine abrasion-resisting pump block. The manufacturing method includes the following steps that by mass percent, 2%-3.5% of aluminum, 7%-8% of iron, 1%-3% of manganese, 5%-7% of nickel and the balance copper are placed into a main frequency furnace, are heated to 1100 DEG C, are completely melted and then are subject to heat preservation. According to the casting material for the nuclear power steam turbine abrasion-resisting pump block, titanium boride ceramic particles are added into a traditional bronze material to be used for improving the hardness of a casting alloy material; and the corresponding rare earth element, namely lanthanum or cerium, is appropriately added to be used for further refining and improving the size particle organization structure of alloy internal materials, the strength and the hardness of the alloy material can be achieved without further forging or heat treatment of the material, and the requirement for the material for the nuclear power steam turbine abrasion-resisting pump block is further met.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

Anticorrosive coating for metal surfaces

PendingCN109233562APlay a synergistic roleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention provides an anticorrosive coating for metal surfaces and a preparation method thereof. The anticorrosive coating comprises epoxy resin, nano magnesium hydroxide, graphene oxide, modifiedinorganic oxide particles, a functional additive and a solvent. The anticorrosive coating achieves a good anticorrosive effect, and all the components are synergistic. The preparation method is simple and easy to implement, and can realize large-scale industrial production. The prepared anticorrosive coating can realize long-term corrosion protection to hulls in deep sea environments.

Owner:SUZHOU ZEMEI NEW MATERIAL TECH

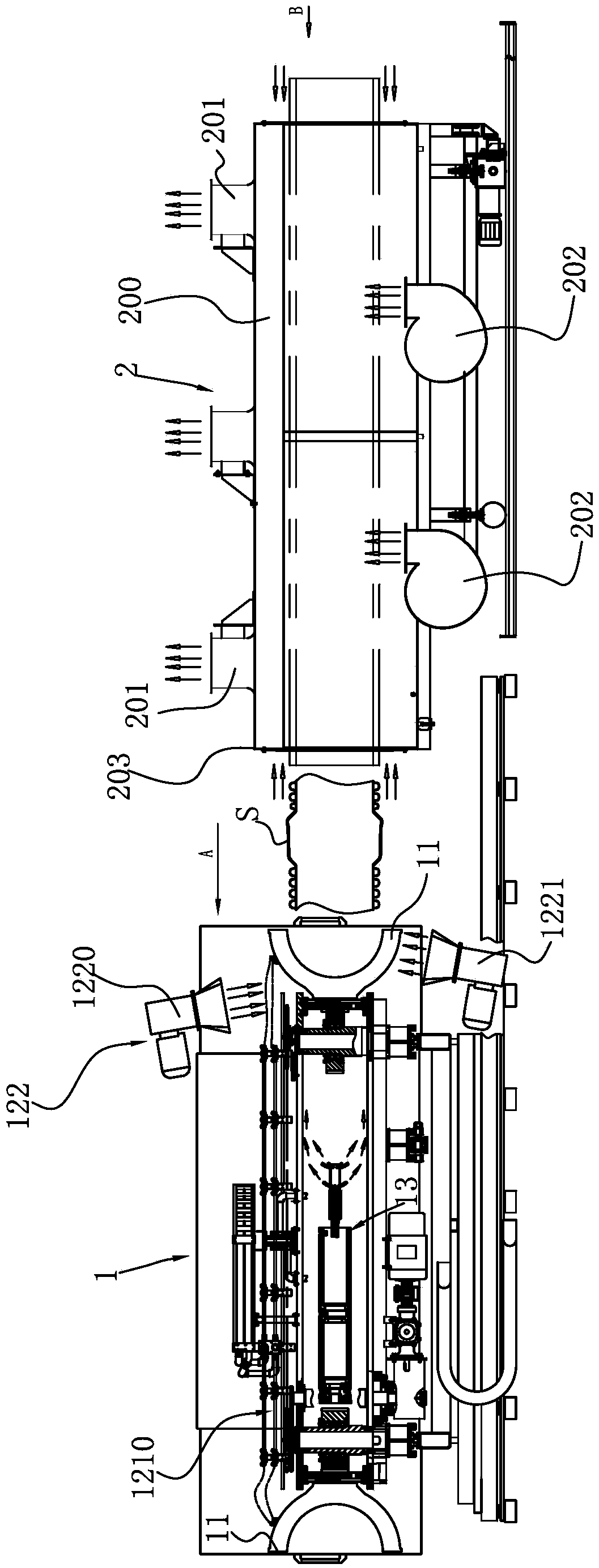

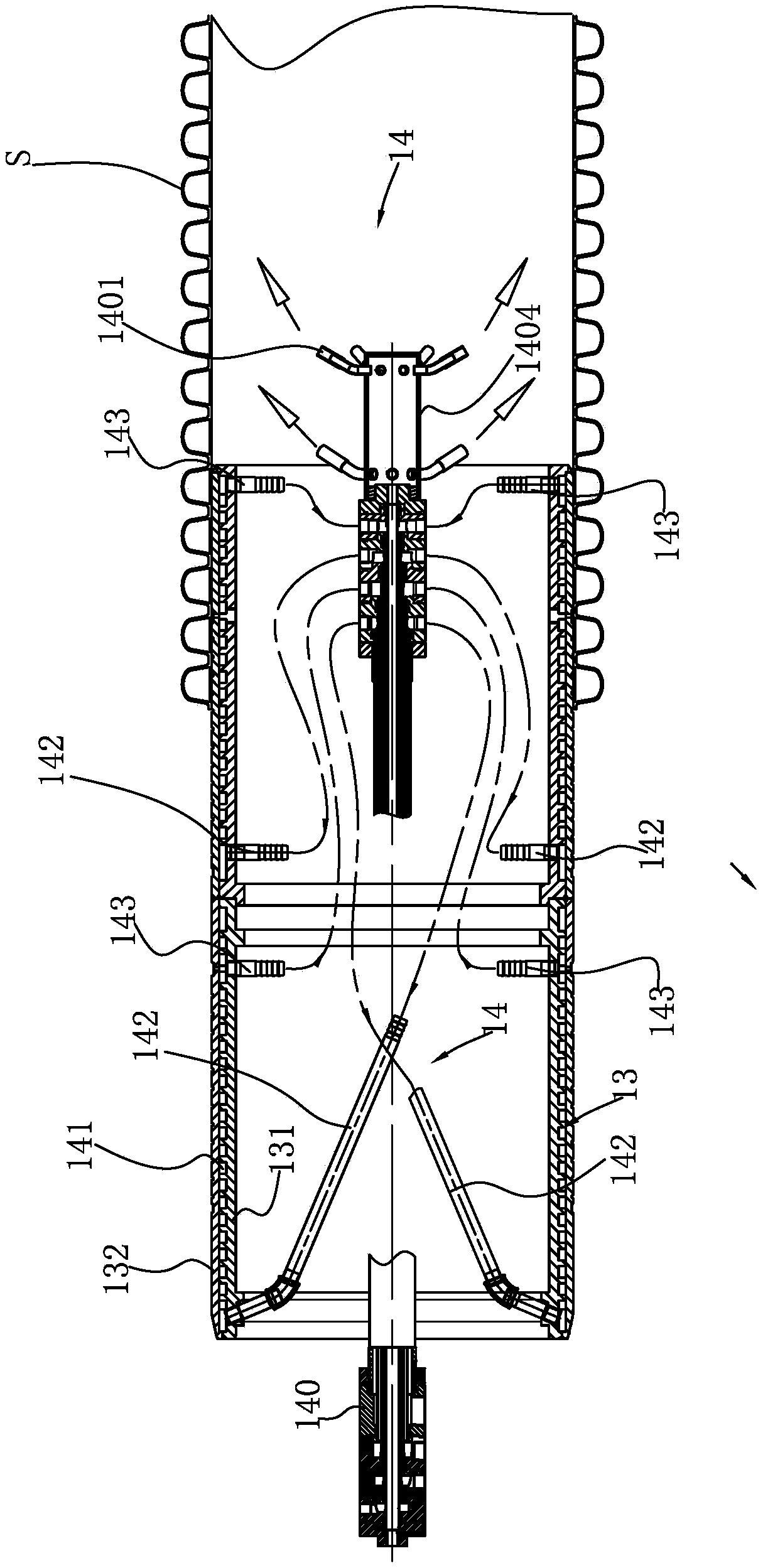

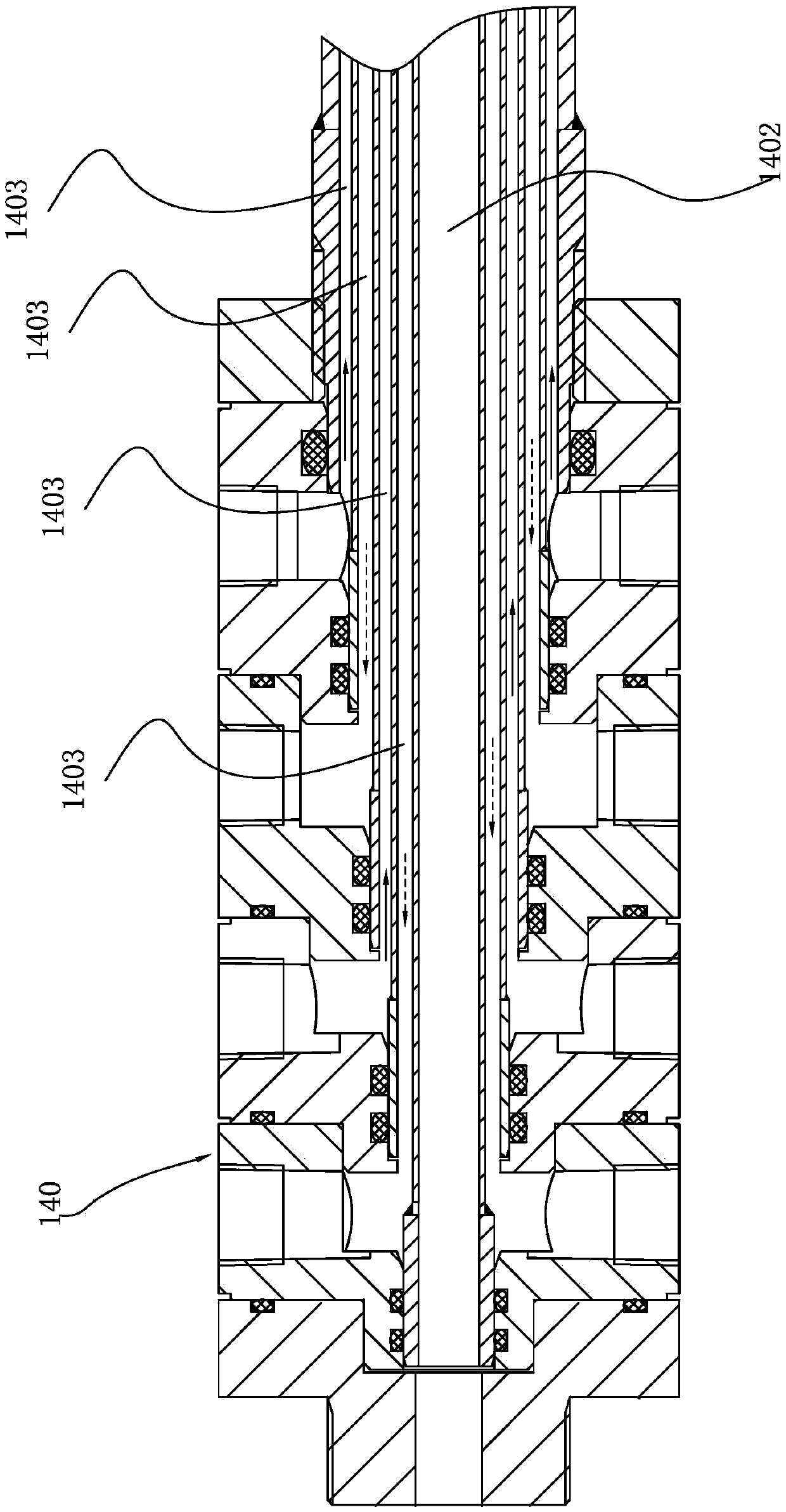

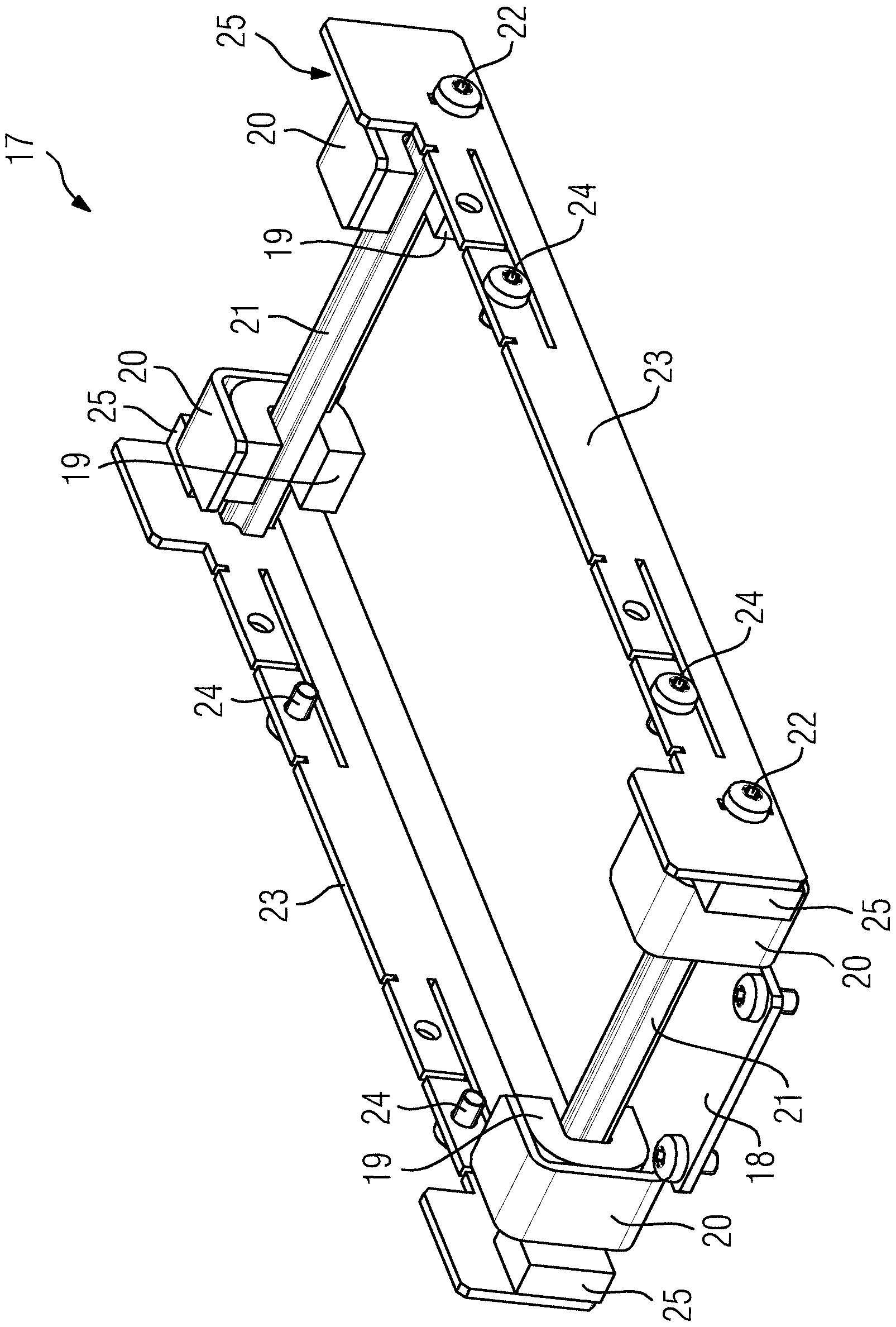

Cooling system for plastic corrugated pipe equipment

PendingCN109531956AImprove efficiencyAccelerated cooling and settingTubular articlesPipingAir channel

The invention discloses a cooling system for plastic corrugated pipe equipment. The cooling system for the plastic corrugated pipe equipment comprises a molding module cooling device which is arrangedon a molding module and a diameter fixing sleeve cooling device which is arranged on a diameter fixing sleeve, wherein the diameter fixing sleeve cooling device comprises a main pipeline assembly which is provided with a water channel and an air channel; the main pipeline assembly passes through an inner cavity of the diameter fixing sleeve in the axial direction; the inner part of the peripheralwall of the diameter fixing sleeve is provided with a diameter fixing sleeve cooling water channel; a plurality of diameter fixing sleeve water distribution pipe groups are connected between the diameter fixing sleeve cooling water channel and the main pipeline assembly; a plurality of air outlets which communicate with the air channel are formed in the tail end of the main pipeline assembly; andthe molding module cooling device comprises a molding module water cooling device and a molding module air cooling device. The inner wall and the outer wall of a corrugated pipe are cooled through the diameter fixing sleeve cooling device and the molding module cooling device, so that the inner wall and the outer wall of the corrugated pipe are quickly cooled, and the plastic corrugated pipe is further cooled through a corrugated pipe secondary air cooling device, so that the plastic corrugated pipe is quickly cooled, subsequent cutting is convenient to carry out, and the production efficiency of the plastic corrugated pipe is improved.

Owner:潍坊中云科研有限公司

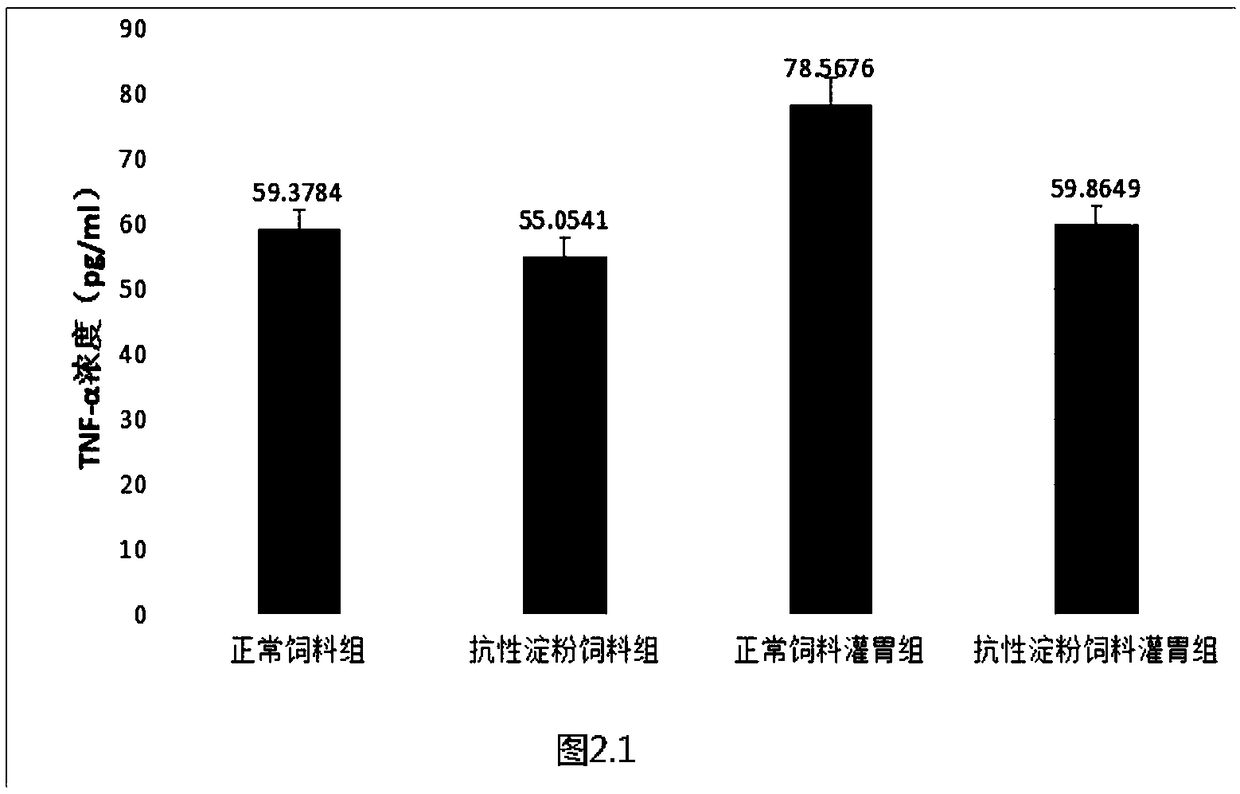

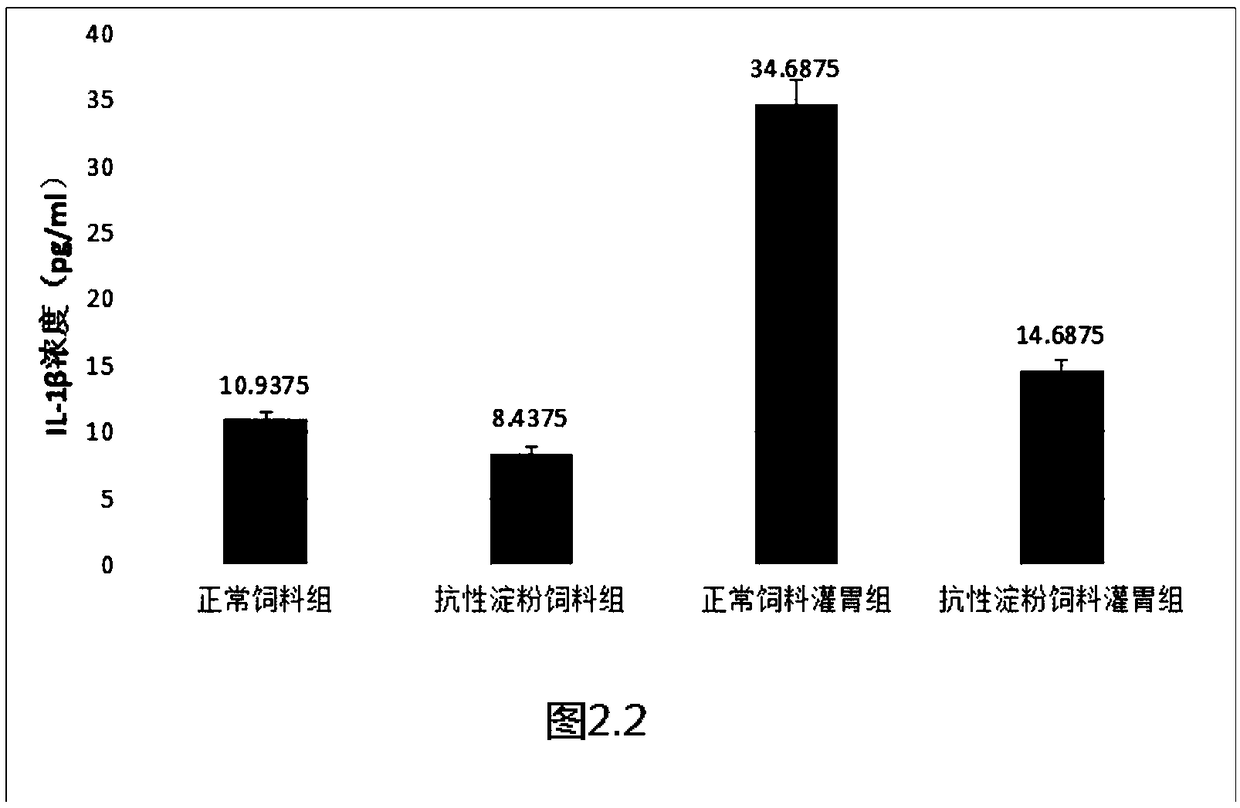

Mouse feed for preventing and controlling mouse salmonella typhi infection as well as preparation method and application thereof

InactiveCN109258961ASimple equipment requirementsGood effectAntibacterial agentsFood processingSOYBEAN SEED OILCorn starch

The invention relates to mouse feed for preventing and controlling mouse salmonella typhi infection. The mouse feed is prepared from the following raw materials according to the ratio of g / kg: 340 to390 parts of corn starch, 55 to 105 parts of resistant starch, 240 to 280 parts of fish meal, 80 to 100 parts of sucrose, 40 to 50 parts of soybean oil, 50 to 60 parts of wheat bran, 20 to 35 parts ofcompound mineral premix, 10 to 20 parts of multivitamin premix, 2 to 3 parts of DL-methionine, 2 to 3 parts of L-cystine, 1 to 2 parts of choline chloride, 1 to 2 parts of choline bitartrate and 20 to 50 parts of gelatin. The mouse feed provided by the invention has the effects of eliminating dampness and stopping diarrhea, and resisting bacteria and diminishing inflammation, and can be used forpreventing and controlling a salmonella typhi disease of a laboratory mouse; the problem that drug-resisting strains occur, caused by the fact that antibiotics are abused to prevent and control the salmonella typhi disease, is solved. The invention provides a green and safe dietetic therapy which has the advantages of simple requirements on equipment, remarkable effect, safety and no side effect,and is suitable for large-scale popularization and application.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

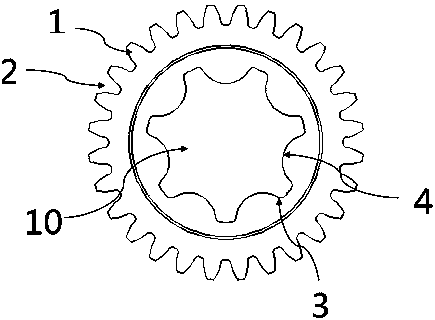

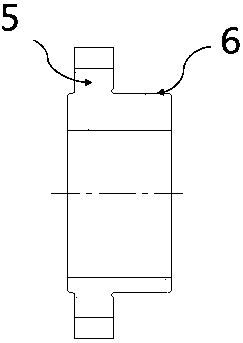

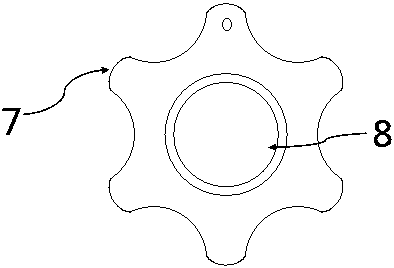

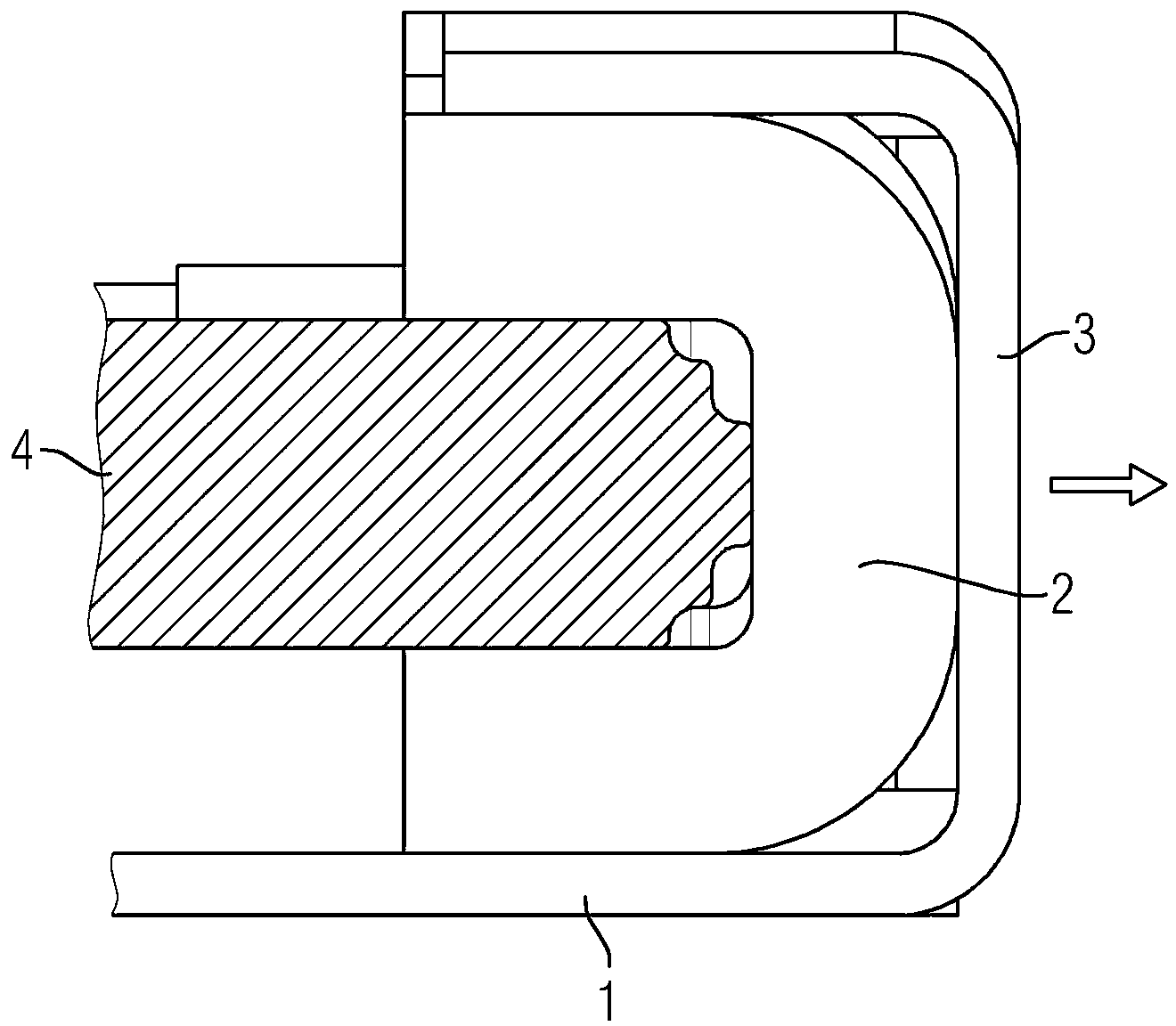

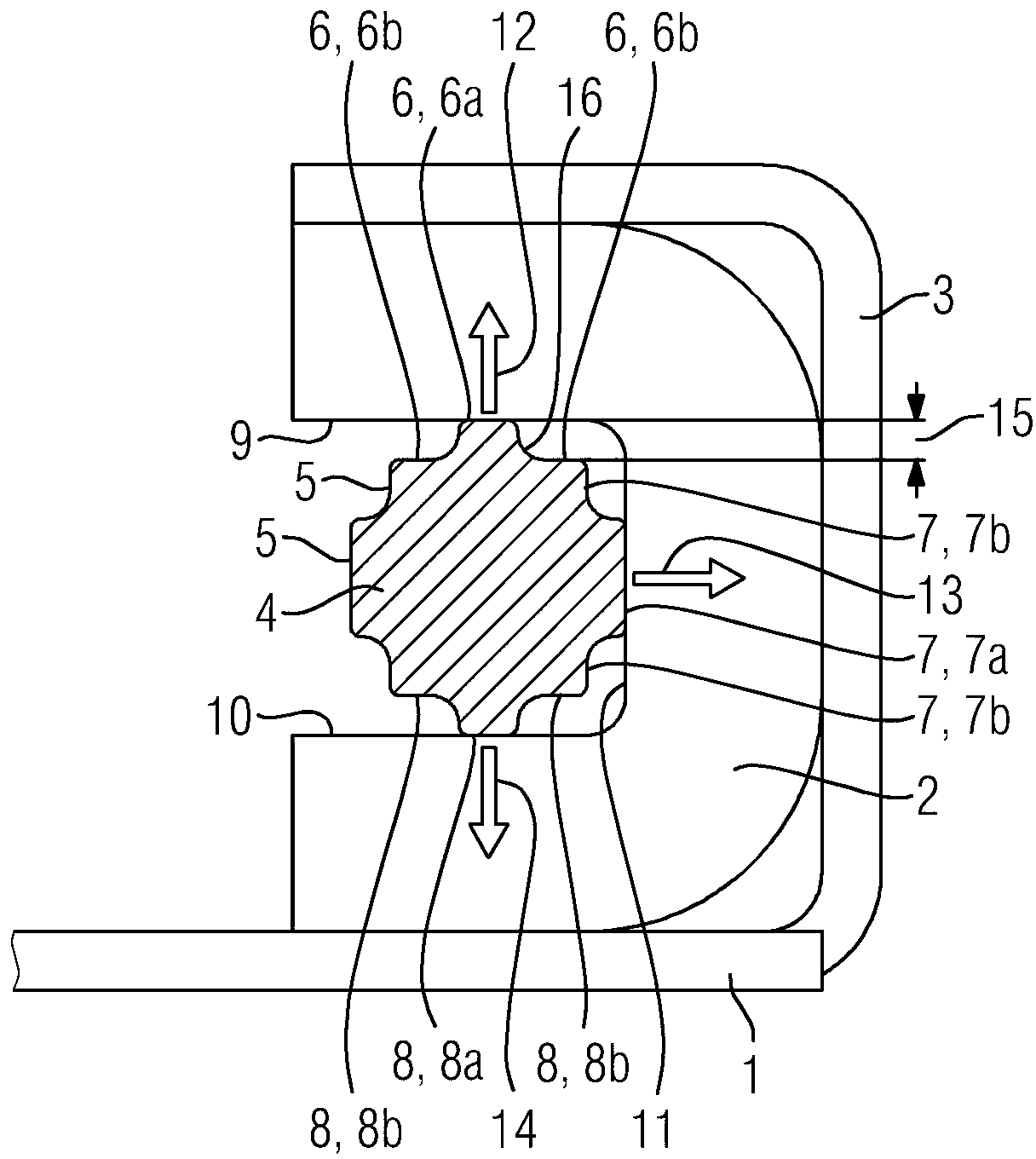

Combined cycloid rotor and preparation method thereof

PendingCN108547767AAchieve hardnessFulfillment requirementsTransportation and packagingMetal-working apparatusCycloidMechanical engineering

The invention relates to the field of machines, in particular to a combined cycloid rotor and a preparation method thereof. The combined cycloid rotor comprises an outer rotor body with an outer circle being provided with a tooth disc, and an inner cycloid rotor body matched in the molded line. The outer rotor body comprises the cylindrical outer circle. The tooth disc is arranged at the end face,close to the cylindrical outer circle, of the outer rotor body and formed by N sets of tooth crests and tooth troughs which are arranged alternately and distributed circumferentially and evenly. A groove is formed in the intersection of the tooth disc and the outer circle. An inner cavity of the outer rotor body is a cavity designed according to the pump flow requirement. The cavity is formed bycircumferentially and evenly distributing N tooth-shaped arcs and 2N transition arcs r. The inner rotor body comprises a cylindrical inner hole. The two ends of the cylindrical inner hole are providedwith chamfers facilitating assembling. An outline curve of the inner rotor body is a cycloidal curve conjugated with an inner cavity curve of the outer rotor body. The number of teeth of the cycloidal curve is one fewer than that of the outer rotor body.

Owner:山西东睦华晟粉末冶金有限公司

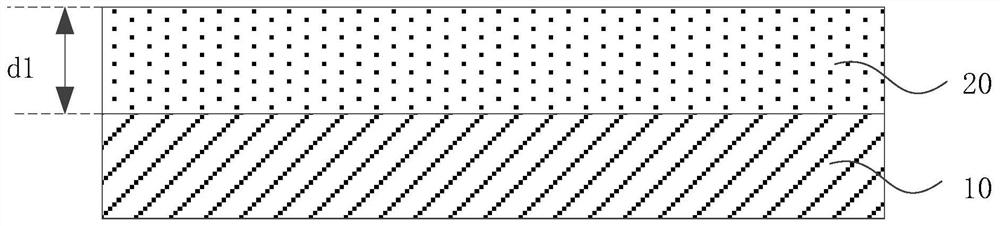

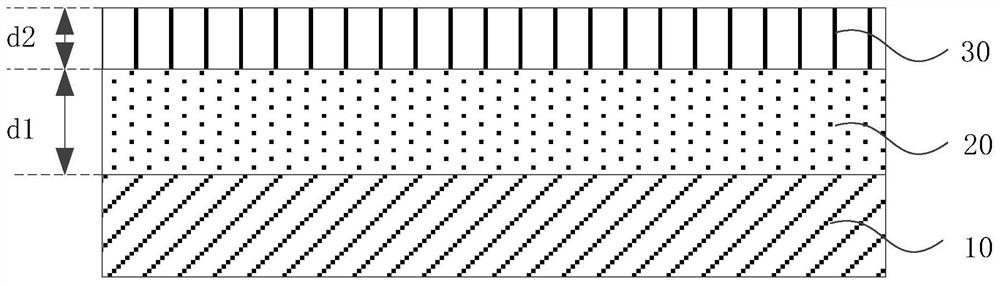

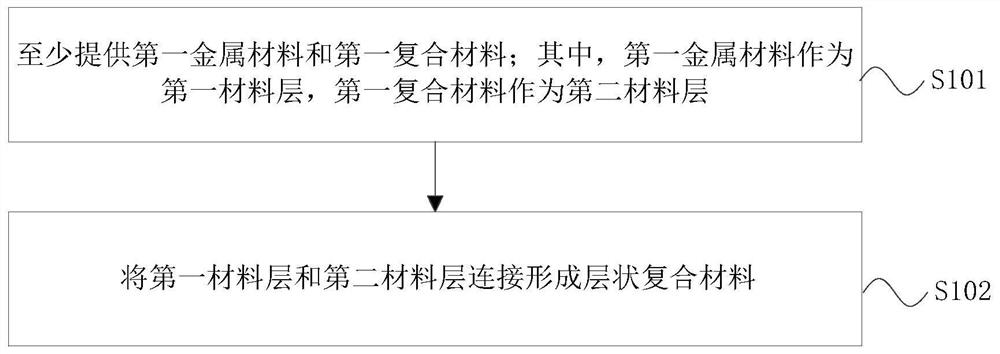

Electronic equipment, rotating shaft, layered composite material and manufacturing method of layered composite material

PendingCN114103302AImprove wear resistanceImprove thermal conductivitySemiconductor/solid-state device detailsLaminationMetallic materialsUltimate tensile strength

The embodiment of the invention provides electronic equipment, a rotating shaft, a layered composite material and a manufacturing method thereof, the layered composite material comprises at least two material layers which are stacked, the at least two material layers comprise a first material layer and a second material layer which are adjacent, the first material layer is made of a first metal material, and the second material layer is made of a second metal material. The yield strength of the first metal material is larger than 200 Mpa, and the elongation of the first metal material is larger than 6%; the second material layer is made of the first composite material, and the first composite material comprises the second metal material and the diamond particles, so that the fracture resistance and the wear resistance of the rotating shaft are ensured, the heat conduction and heat dissipation performance of the rotating shaft is improved, and the experience feeling of a user is improved.

Owner:HUAWEI TECH CO LTD

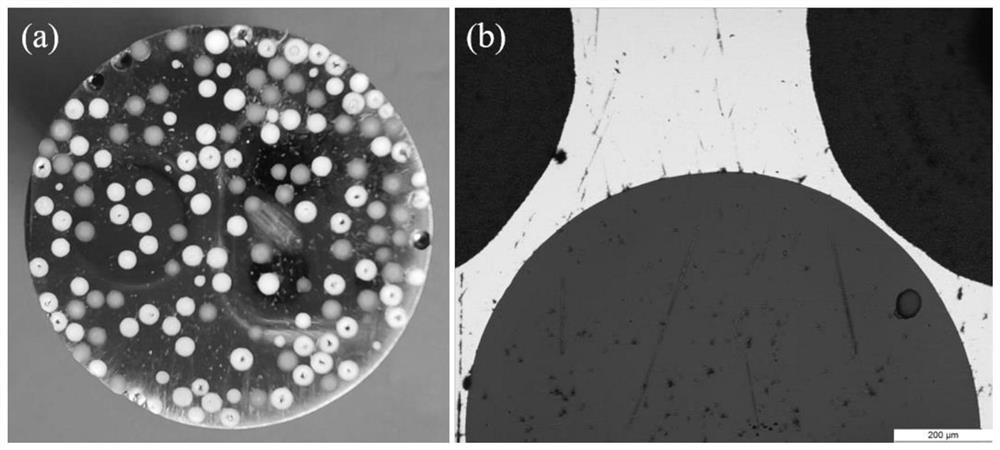

Preparation method of hybrid synergistically reinforced iron-based wear-resistant material

ActiveCN112872351ATightly boundImprove wear resistanceTransportation and packagingMetal-working apparatusWear resistanceMetal

The invention belongs to the technical field of preparation and application of wear-resistant materials, and particularly relates to a preparation method of a hybrid synergistically reinforced iron-based wear-resistant material. In order to solve the problem about how to add Al2O3 and ZrO2 ceramics into a metal matrix through an advanced preparation method, adjust the proportion of Al2O3 and ZrO2, ensure uniform dispersion of Al2O3 and ZrO2 in the material at the same time and avoid direct contact of Al2O3 and ZrO2 so as to meet the requirement of heavy industry for wear resistance of mechanical equipment parts, the preparation method of the hybrid synergistically reinforced iron-based wear-resistant material is provided. According to the method, Al2O3 and ZrO2 in a proper proportion are uniformly added into iron-based alloy through the advanced preparation technology, high-quality combination of ceramic particles in the material and the metal matrix is ensured, and the volume ratio of Al2O3 to ZrO2 is optimized and adjusted under the condition of adding a certain amount of the ceramic particles according to the actual working conditions, so that the wear resistance of the mechanical equipment parts is further improved. The method is also of great significance to economic development and social development in China.

Owner:TAIYUAN UNIV OF TECH

Quenching oil capable of enabling screw to blacken automatically after quenched and quenching method thereof

ActiveCN105925770AGuaranteed surface hardnessGuaranteed internal metallographic structureFurnace typesMetallic material coating processesAntioxidantFatty alcohol

The invention discloses quenching oil capable of enabling an screw to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 6-10 parts of cooling catalyzed composite agent, 0.4-0.6 parts of blackening composite agent, 0.3-0.7 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The cooling catalyzed composite agent is a mixture of dialkyl naphthalene and petroleum sulfonate; the blackening composite agent the mixture of short oil alkyd resin, colouring agent and wetting agent; the brightening agent is the mixture of imidazoline oleate and methyl terpene resin; the surface activating agent is span-80. The colouring agent is disperse black 9; the wetting agent is fatty alcohol-polyoxyethylene ether. The best using temperature of the quenching oil is between 75 DEG C and 80 DEG C. Between 75 DEG C and 80 DEG C, the cooling speed of the quenching oil for the screw is moderate, the surface can be blackened automatically and a protective film can be formed while the quenching, so that the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

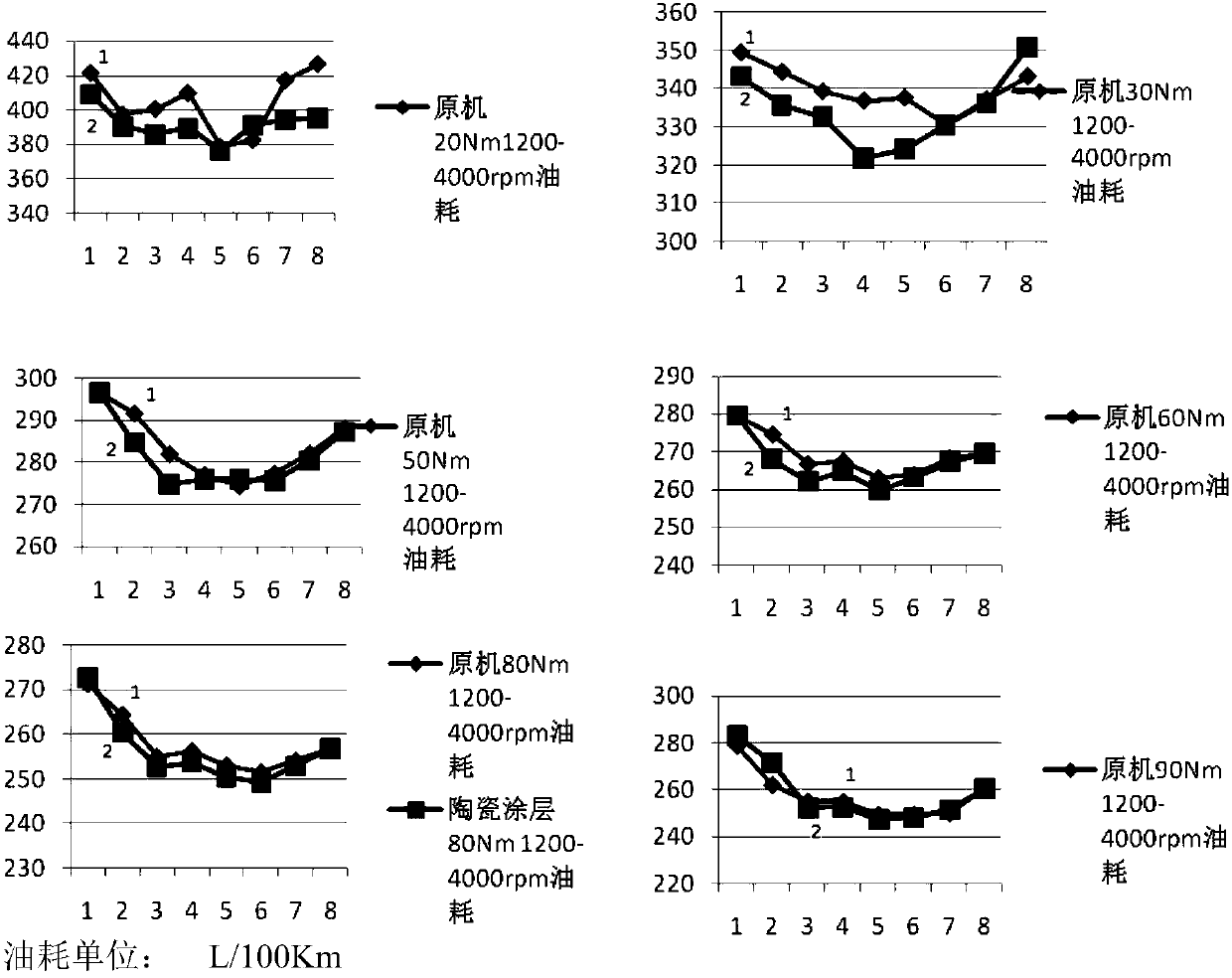

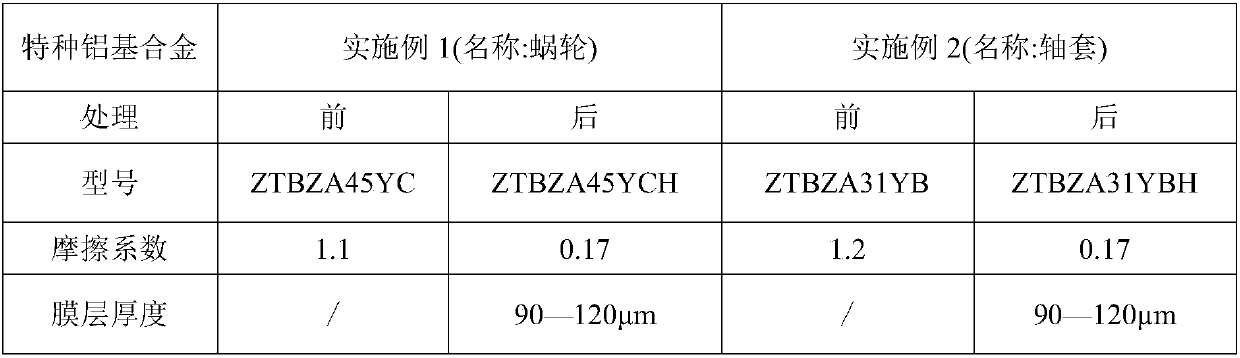

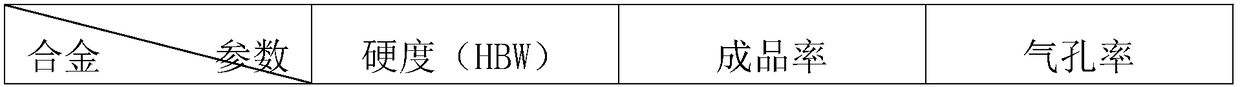

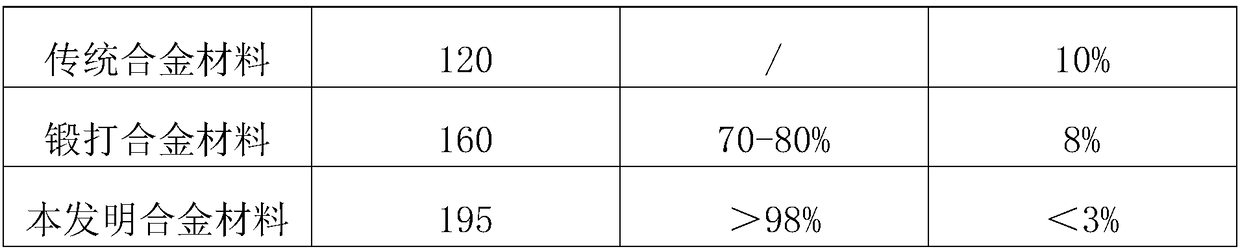

Alloy material for power mechanical parts and preparation method thereof

The invention discloses an alloy material for power mechanical parts and a preparation method thereof. The alloy material comprises the components of titanium boride, aluminum, iron, manganese, nickel, lanthanum or cerium, tin, zinc, silicon, phosphorus and copper, wherein the weight percentages of the components of the alloy material are as follows: 3-4.5% of titanium boride, 17-19% of aluminum,10-11.5% of iron, 3-4.5% of manganese, 4-5.5% of nickel, 2-3.5% of lanthanum or cerium, 1-2.5% of tin, 1-3.5% of zinc, 0.5-1.5% of silicon, 0.5-1% of phosphorus, and the balance of copper. Titanium boride ceramic particles are added in traditional bronze materials for improving the hardness of casting alloy materials; and corresponding rare earth elements of lanthanum or cerium are properly addedfor further refining and improving the particle size structures of alloy internal materials, so that the strength and the hardness off the alloy materials can further meet the requirements of materials for nuclear power steam turbine wear resisting pump blocks under the precondition of no need of further forging or heat treatment of the materials.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

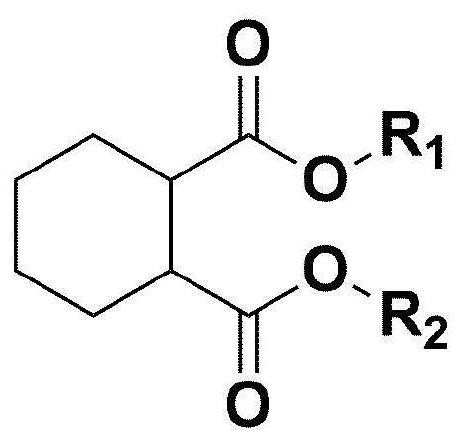

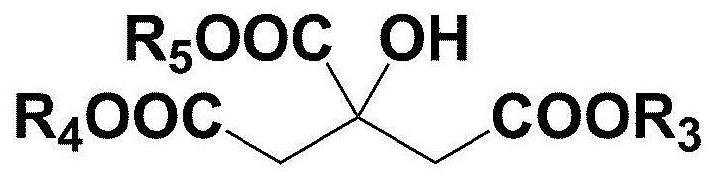

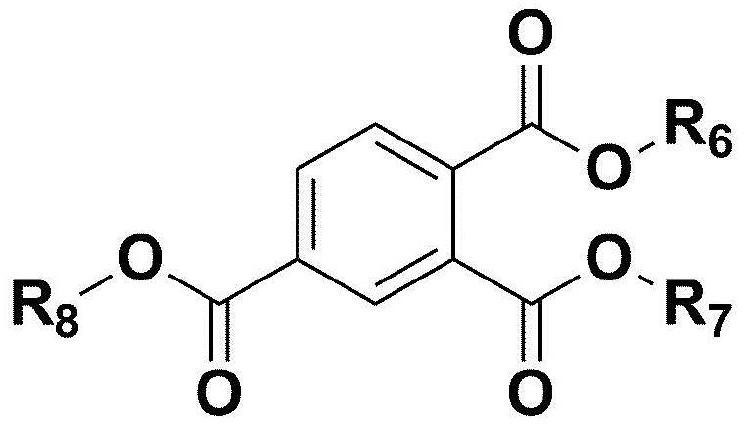

Plasticizer composition, and resin composition comprising same

PendingCN112041383AEnvironmentally friendlyImprove stabilityOrganic chemistryPolymer scienceCITRATE ESTER

The present invention relates to a plasticizer composition which comprises cyclohexane-1,2-diester material and a citrate material, the plasticizer composition being environmentally friendly whilst having excellent stability and basic physical properties.

Owner:LG CHEM LTD

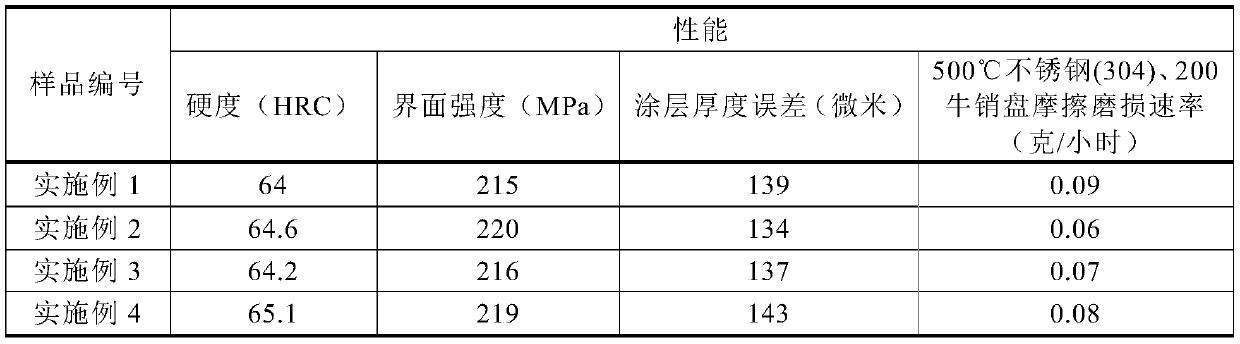

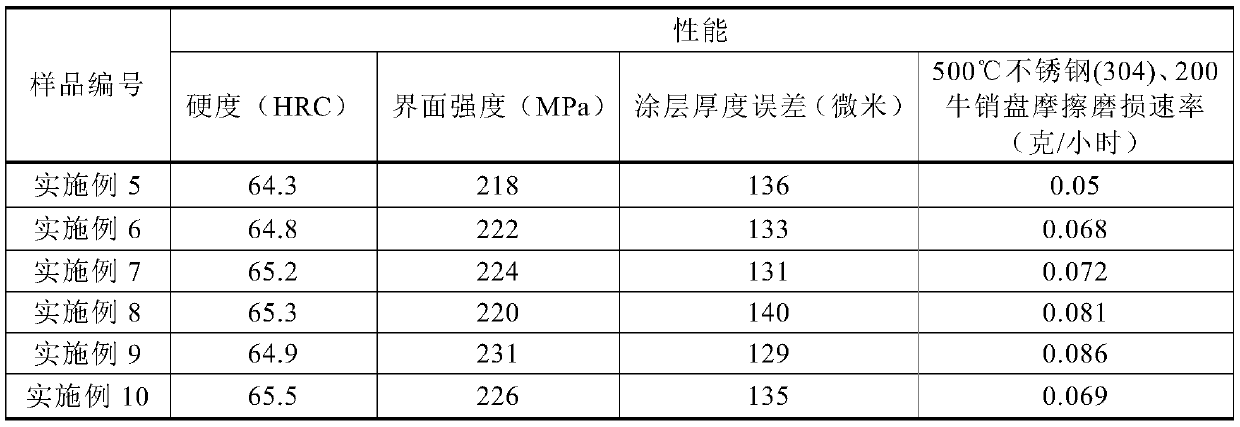

Method for preparing shell structure imitated steel-based coating on aluminium substrate

ActiveCN110643919APreventing the Kirkendall EffectImprove wear resistanceMolten spray coatingCarbide siliconAluminium matrix

The invention discloses a method for preparing a shell structure imitated steel-based coating on an aluminium substrate. The method comprises the following steps of first, laminating iron-aluminum alloy foil and stainless steel foil in sequence and spreading on the surface of the aluminium substrate, and placing in a high vacuum heating furnace for foil-substrate adhesive suction treatment to obtain a coating perform; and then preparing a steel bonded silicon carbidemetal ceramic layer on the surface of the coating perform from atomized stainless steel powder and granulated silicon carbide powder as raw materials by adopting a supersonic plasma dual-spraying technology, and bonding the stainless steel foil on the surface of the steel bonded silicon carbide metal ceramic layer, and obtaining a metal ceramic layer by adopting the dual-spraying technology, in such a way, and finally completing the preparation of the shell structure imitated steel-based coating on the aluminium substrate.The method has the advantages that the coating thickness control precision is high, the process stability and repeatability are higher, and the strong interface and the high performance of the shell structure imitated steel-based coating can be realized.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

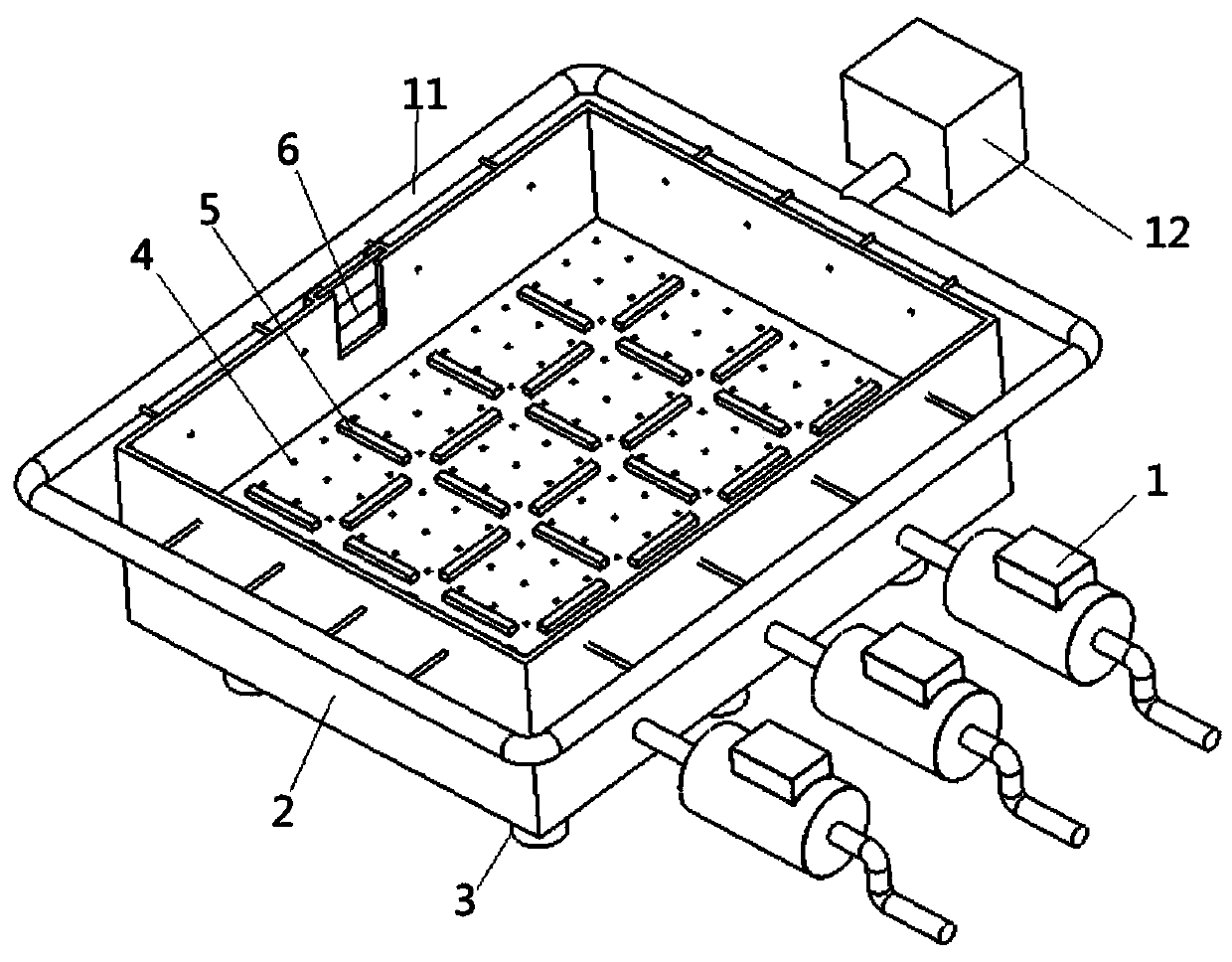

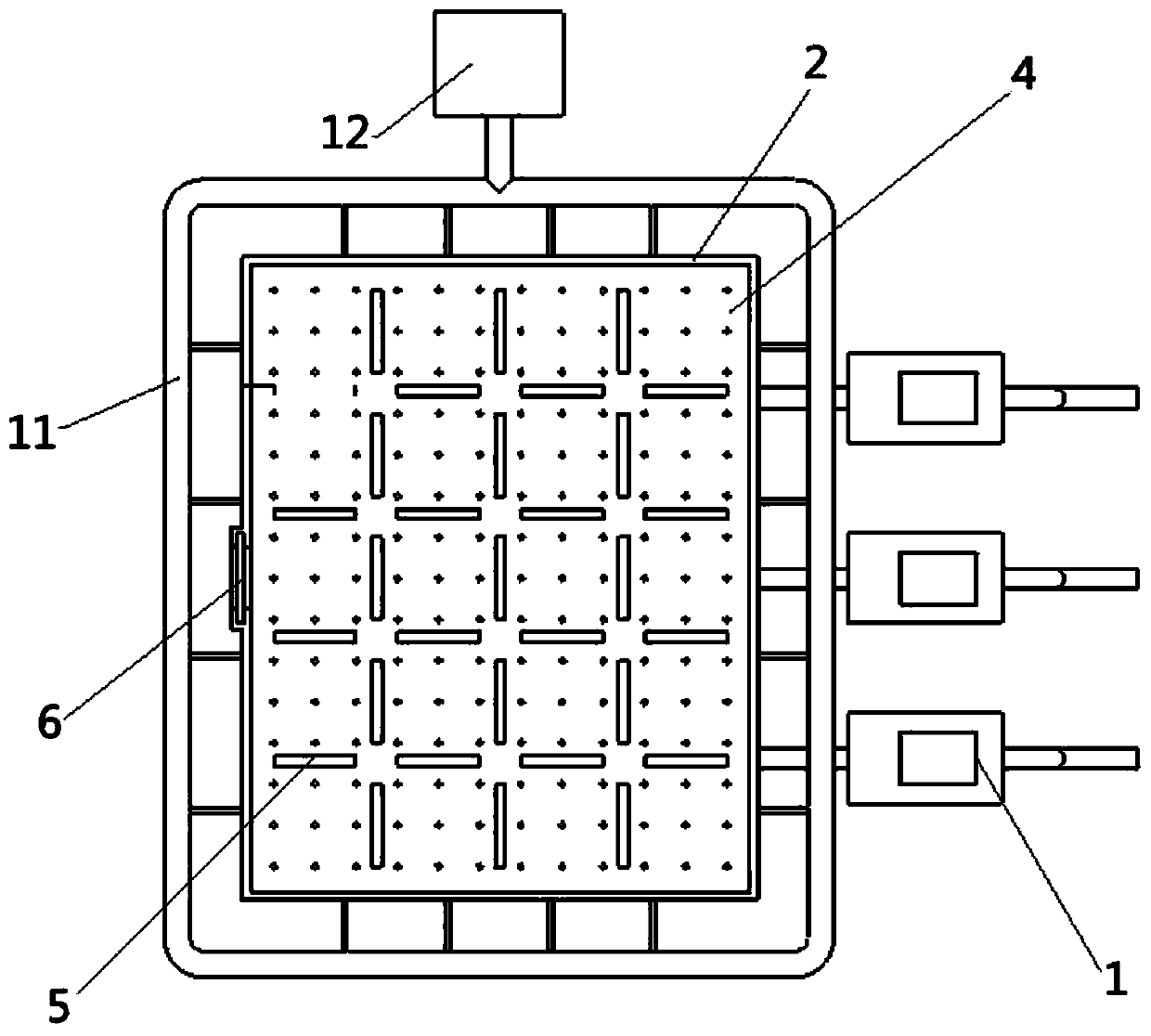

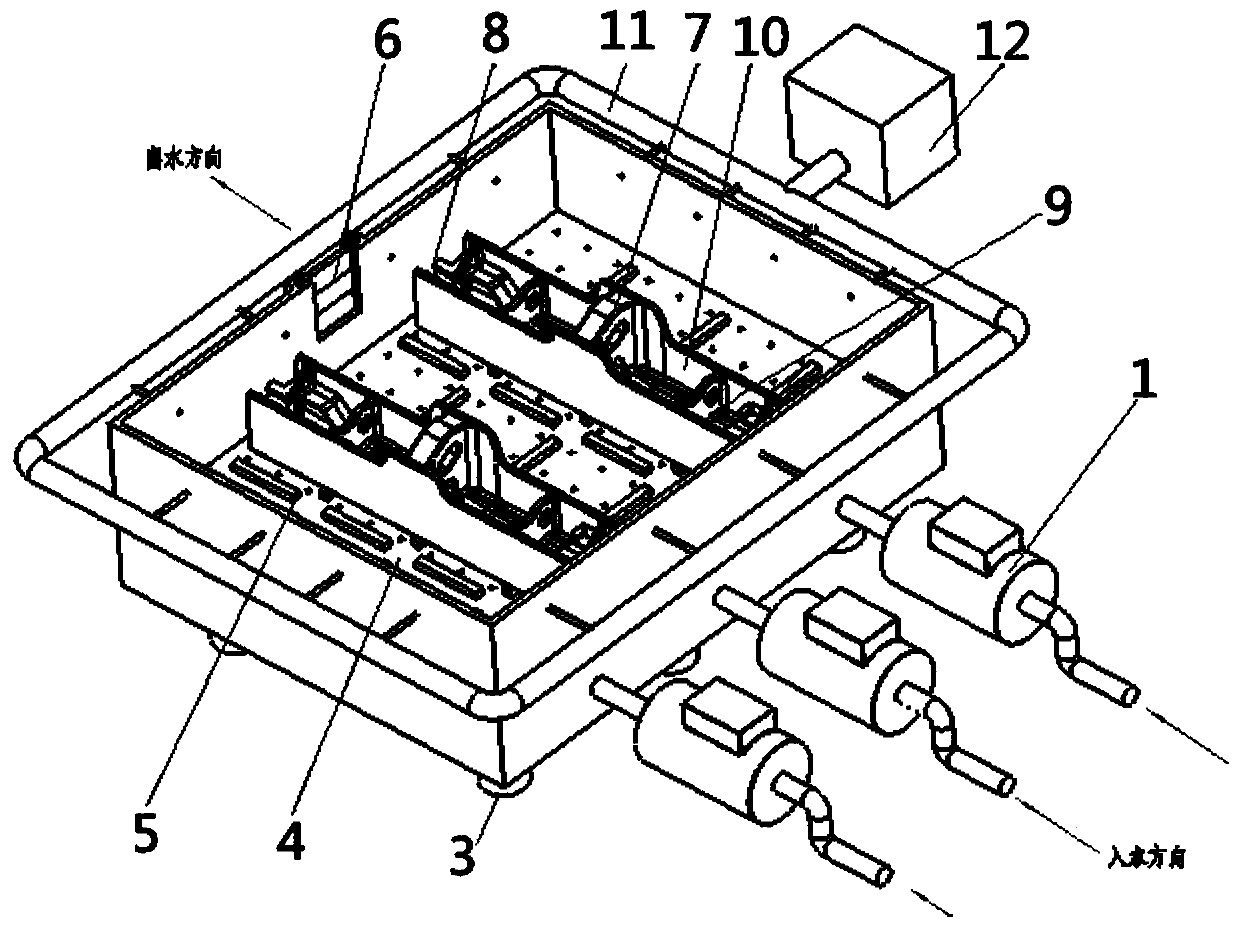

A kind of differential speed quenching device and process method of casting groove for mining scraper machine

ActiveCN106868271BHigh impact energyHigh hardnessProcess efficiency improvementQuenching devicesWater levelQuenching

The invention belongs to the technical field of ledge casting and particularly relates to a sectionalized differential quenching device and process method for a mine scraper blade machine casting ledge. The sectionalized differential quenching device for the mine scraper blade machine casting ledge comprises water pumps and a water trough. A waterpower hole plate is arranged in the water trough, water outlet holes are evenly distributed in the waterpower hole plate, and a plurality of supporting strips are arranged on the waterpower hole plate. The waterpower hole plate divides the water trough into an upper layer and a lower layer. The lower layer of one side wall of the water trough is provided with at least one water inlet, and each water inlet is correspondingly connected with one water pump. The upper layer of the side wall of the water trough is provided with a water outlet, and a water level adjusting device is arranged at the position of the water outlet. The sectionalized differential quenching device for the mine scraper blade machine casting ledge is convenient to operate, the process is advanced and reasonable, the ledge performance is improved, meanwhile, the quenching temperature is improved, the temperature keeping time is shortened, grains are refined, the production efficiency is improved, and the electric energy is saved.

Owner:山西煤矿机械制造股份有限公司

A kind of aluminum bronze and preparation method thereof

The invention discloses an aluminum bronze, which is characterized in that the mass percentage composition of the aluminum bronze is: 7.0-12.0% Al, 3.0-7.0% Ni, 3.0-7.0wt% Fe, 0-1.0wt% Mn , the Zn of 0~1.0wt%, the Si of 0~0.5wt%, the Sn of 0~0.5wt%, the balance is Cu and unavoidable impurity; The microstructure of described aluminum bronze contains α phase, γ 2 Mutually. The tensile strength of the aluminum bronze of the present invention is ≥740MPa, the yield strength is ≥400MPa, the elongation is ≥15%, and the hardness is ≥200HB; when the number of stretching cycles is 10 7 The second time, the fatigue strength is 355-400MPa; it can meet the comprehensive performance requirements of aluminum bronze for structural parts, wear-resistant parts and corrosion-resistant parts working in machinery industry, shipbuilding and marine industry, petrochemical industry and electrical industry.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Nano graphene reflective heat insulation composite multifunctional ceramic coating and preparation method thereof

ActiveCN105951151BAchieve thicknessAchieve hardnessAnodisationCombustion chamberPlasma electrolytic oxidation

The invention discloses a reinforced alloy material; and a surface layer of the alloy material contains such elements as aluminum oxide, silicon dioxide and nanometer graphene. The alloy material is deeply extended on the basis of anodic oxidation, microarc oxidation and multi-component composite oxidation, and is a result under a complex effect of instant high temperature, multi-component composite oxidation liquid and nanometer penetrant through applying positive and negative high voltage, high current and positive and negative pulses by using unique structures, physical and chemical characteristics as ultrahigh hardness and high-temperature resistance, small size effects and surface and interface effects of such nanometer materials as nanometer graphene and nanometer silicon dioxide. The method comprises the steps of: (1) surface cleaning; (2) oxidation; and (3) penetration. The light alloy material after surface reinforcement by the method, in particular a combustion chamber of an internal combustion engine with fuel combustion consumption and generating a pollution source is prominent in reflection thermal insulation anti-carbon self catalysis function, and is higher in high-temperature erosion resistance and wear resistance.

Owner:四川鸿森达铝业科技有限公司

Holder for storing and holding an oscillation and/or shock-sensitive component

ActiveCN102840268AEasy to manufactureAchieve hardnessMachine supportsNon-rotating vibration suppressionEngineeringSupport surface

Owner:SIEMENS AG

Casting material for wear-resistant pump block of nuclear power steam turbine and manufacturing method thereof

A method for preparing a casting material for an abrasion-resistant pump block of a nuclear-powered steam turbine, comprising the following steps: placing, in percentage by mass, 2-3.5% of aluminium, 7-8% of iron, 1-3% of manganese, 5-7% of nickel and the balance of copper in a mains frequency induction furnace, heating same to 1100°C, and maintaining the temperature after same has completely melted. In the provided casting alloy material for an abrasion-resistant pump block of a nuclear-powered steam turbine, titanium boride ceramic particles are added to a traditional bronze material to increase the hardness of the casting alloy material; and a corresponding rare earth element of lanthanum or cerium is appropriately added to further refine and improve the particle structure of the internal material of the alloy, so that the strength and hardness of the alloy material can be achieved without further forging or heat treatment of the material, so as to further satisfy the requirements of the materials for the abrasion-resistant pump block of a nuclear-powered steam turbine.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

Transparent Conductive Glass Substrate

InactiveCN103189931BSoftAchieve hardnessConductive layers on insulating-supportsCable/conductor manufacturePolymer sciencePtru catalyst

[Problem] To provide a flexible transparent conductive glass substrate having flexibility similar to a plastic substrate, achieving hardness and transparency not found in plastics, and having adherence that can withstand use with a curved surface. [Solution] A transparent conductive glass substrate having a conductive polymer layer on at least one surface of a thin glass substrate, and having a surface resistance of 1.8 GO / sq or less, total light transmittance of 85% or greater, surface pencil hardness of H or greater, and no failure with bending of a radius of 25 mm is manufactured. Furthermore, a conductive polymer application forming the conductive polymer layer contains a conductive polymer and polyanions and also contains one or a plurality selected from a group that includes binders, curing agents, conductivity increasing agents, surface active agents, catalysts, and agents for improving adhesion.

Owner:SHIN-ETSU POLYMER CO LTD +1

Hard-coated antiglare film, polarizing plate, image display, and method of manufacturing hard-coated antiglare film

InactiveCN100582818CImprove adhesionProper protectionLayered productsPolarising elementsCoated surfacePolymer science

A hard-coated antiglare film is provided that has high hardness and excellent antiglare properties and can prevent white blur from occurring when viewed from oblique directions. The hard-coated antiglare film of the present invention includes a transparent plastic film substrate and a hard-coating antiglare layer that is formed of fine particles and a hard-coating resin on at least one surface of the transparent plastic film substrate. The hard-coating antiglare layer has a thickness of 15 to 30 mum, the fine particles have a weight average particle size of 30 to 75% of a thickness of the hard-coating antiglare layer, in the unevenness of the hard-coating antiglare layer surface that is formed by the fine particles, an average tilt angle thetaa is 1.0 DEG to 2.0 DEG , and an arithmetic average surface roughness Ra according to JIS B 0601 (1994 version) is 0.12 to 0.30 mum.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com