Patents

Literature

255results about How to "Achieving wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

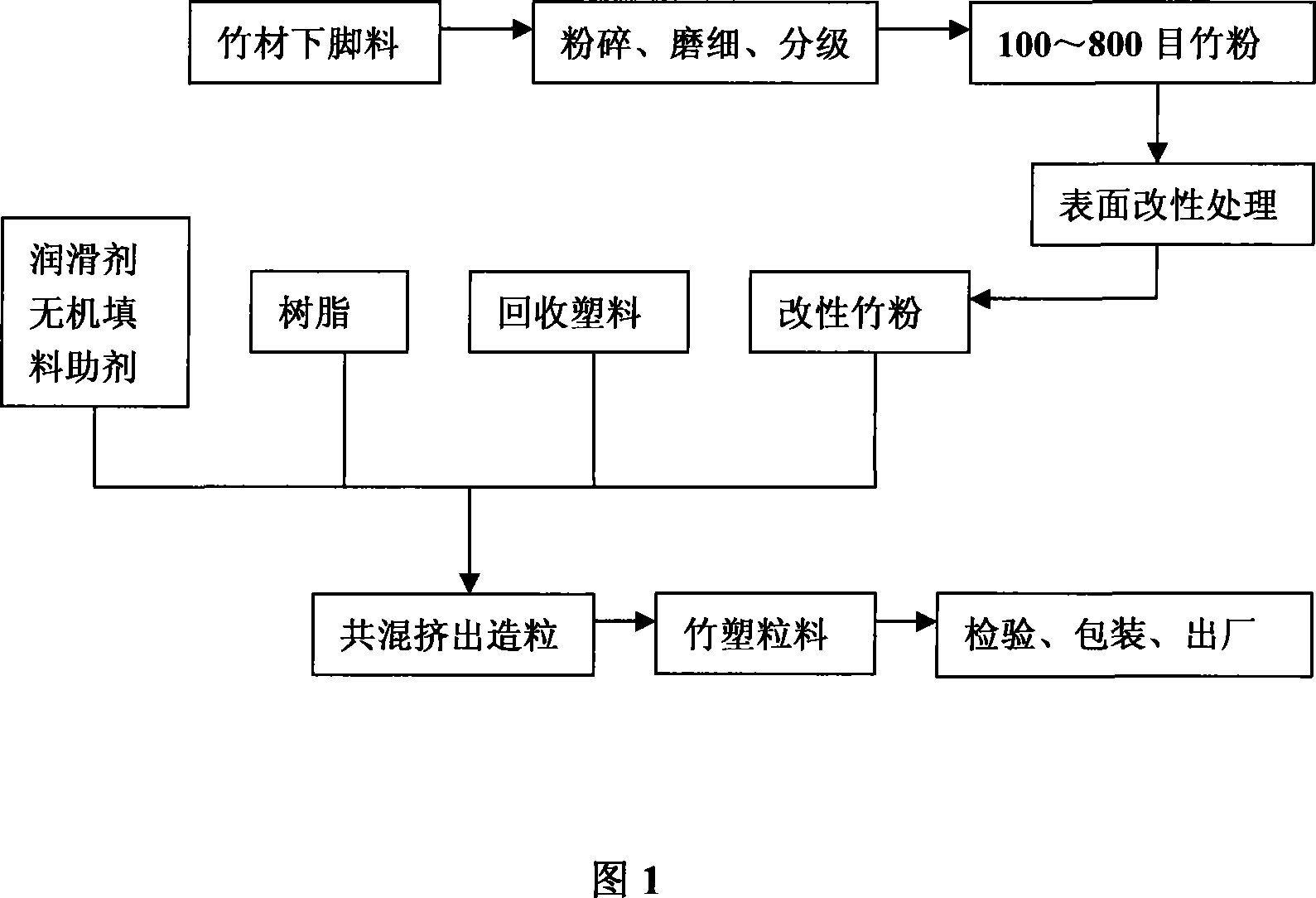

Bamboo-plastic composite material

The invention provides a bamboo-plastic composite material which is obtained by that raw materials such as plastic, recycled waste plastics, bamboo powder, modifier, chemical agent, lubricant, etc. are mixed in different proportions and extruded out to get series bamboo-plastic granule; the invention can be used for manufacturing different products such as bamboo-plastic boards, wood-plastic composite profiles and wood-plastic tubular products, etc. through extruding. The series bamboo-plastic granule can be produced in a continuous large volume and is characterized in that the production efficiency is high, the cost is low and the performance-price ratio is high, etc. The series bamboo-plastic granule can be used for replacing wood, and the cost thereof is lower than wood-plastic materials while the mechanical strength thereof is higher than wood-plastic materials, therefore the series bamboo-plastic granule can be widely popularized for use. The series bamboo-plastic granule is a novel cyclically reutilized material resource after wood-plastic material.

Owner:戴福寿 +1

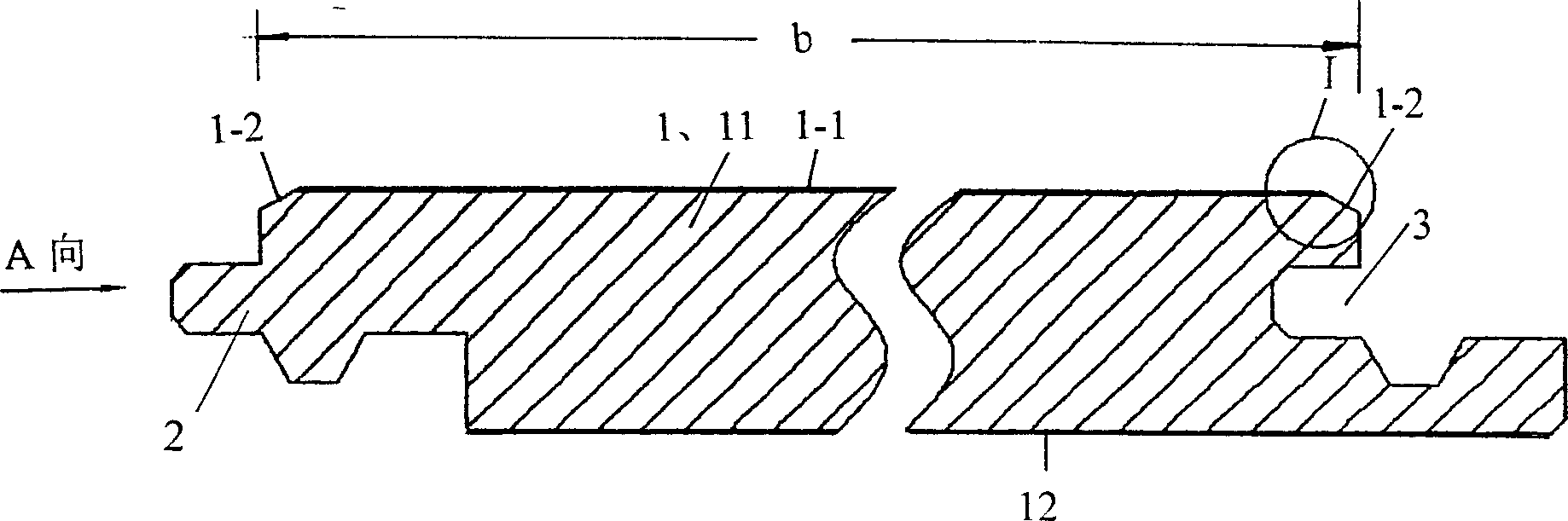

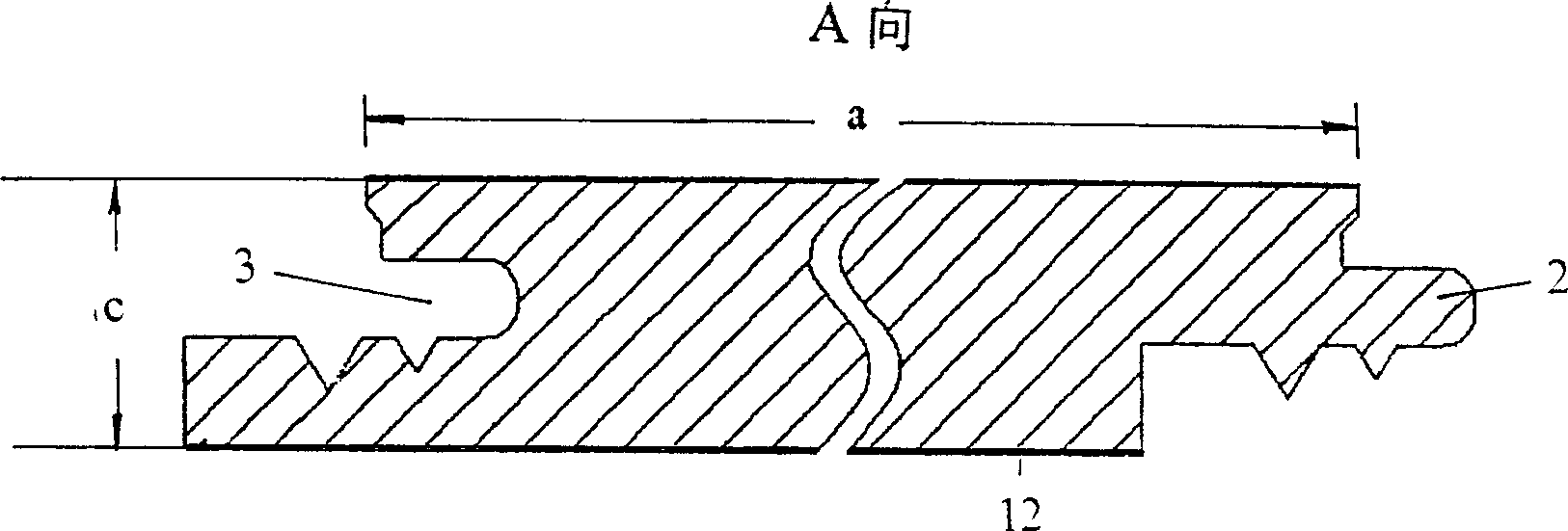

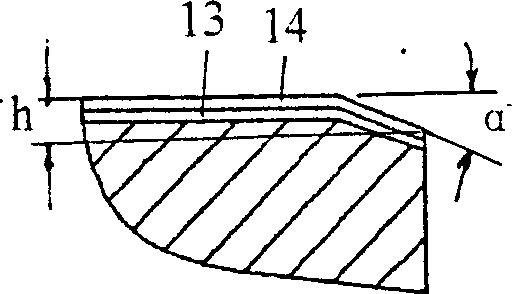

Stiffened timber floor and the manufacturing method thereof

InactiveCN1485184ALow priceExtended service lifeWood working apparatusWood layered productsSolid woodPulp and paper industry

An intensified wood floor board and its manufacturing method. One measure is, the upper surface of the floor mainbody is composed of the walking plane and inclined planes of the two sides of the walking plane; the upper surface of fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by pressing mold, balanced paper layer, fiberboard, the paper layer with wood texture and a durable paper layer are adhered with each other. The second measure is, the upper surface of the floor mainbody is composed of the walking plane parallel to the base surface and inclined planes of the two sides of the walking plane, the upper surface of the upper surface of the fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by bonding, the inclinedplanes on two sides are adhered with the paper layers with wood texture; resin varnish is coated on the paper layers with wood texture. due to inclined planes of two sides of the upper surface of floor mainbody, it is convenient to pave floor board. The floor board is durable, inexpensive and could use for a long time.

Owner:葛跃进

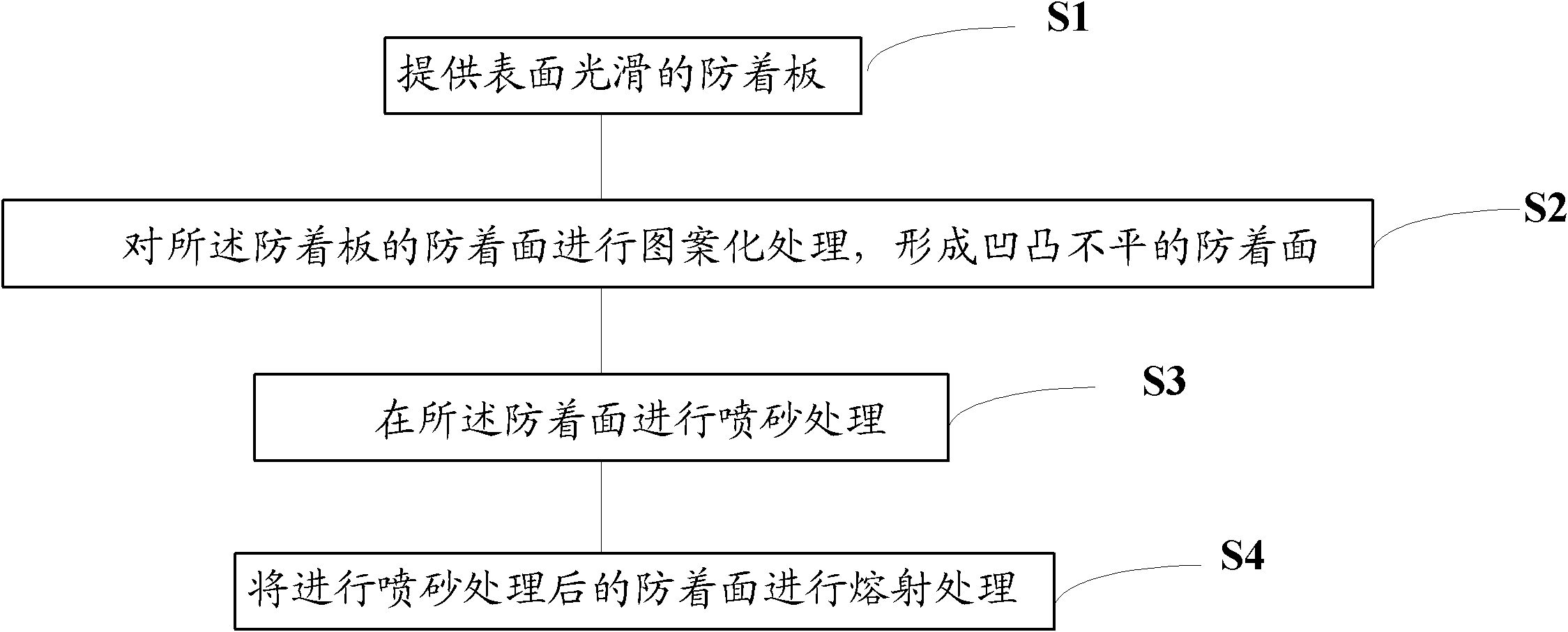

Method for processing surface of attachment-resisting plate

ActiveCN102011085AImprove corrosion resistanceImprove precipitation effectMolten spray coatingAbrasive blastingSputtering

The invention discloses a method for processing the surface of an attachment-resisting plate. The method comprises the following steps: providing an attachment-resisting plate with a smooth surface; patterning the attachment-resisting surface of the attachment-resisting plate with a smooth surface to form an uneven attachment-resisting surface; blasting the attachment-resisting surface; and meltallizing the attachment-resisting surface after blasting. The smooth surface of the attachment-resisting plate is subject to the patterning, the blasting and the meltallizing so that the surface of theattachment-resisting plate has corrosion resistance, rust prevention, abrasion resistance, lubrication, roughness, adsorption, insulation, heat insulation and other properties; the attachment-resisting surface of the attachment-resisting plate achieves even roughness; and the attachment-resisting plate can easily absorb target atoms or large-sized particles so that the target atoms or large-sizedparticles do not fall on a substrate, thereby increasing the sediment capability of the attachment-resisting plate, improving the cleanness of the inner wall of a sputtering machine, improving the filming rate of sputtering and prolonging the service life of the attachment-resisting plate.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Iron-based high-titanium wear-resistant surfacing flux-cored welding wire

InactiveCN101664862AAchieving wear resistanceImprove performanceWelding/cutting media/materialsSoldering mediaBorideCrazing

The invention relates to an iron-based high-titanium wear-resistant surfacing flux-cored welding wire. Among a plurality of types of the prior wear-resistant surfacing welding wires and alloys, some alloys have favorable wearing resistance, and some alloys have great brittleness, lower toughness and easy cracking and are not suitable for the existence of low-impact grinding wear working condition.The iron-based high-titanium wear-resistant surfacing flux-cored welding wire comprises a low-carbon steel ladle clad and core powder as well as the following alloy elements in percentage by weight:1.0-3.0 C, 1.0-12.0 Ti, 0.5-9.0 V, 0.1-1.5 Si, 0.2-2.0 Mn, 0-3.0 B, 0.00-0.10 RE, 0-13.0 Cr, 0-1.0 Mo, 0-1.0 W, 0-2.0 Ni, 0-0.5 Nb and 0-0.5 Zr. The iron-based high-titanium wear-resistant surfacing flux-cored welding wire realizes the wear-resistant performance of the alloys mainly by carbides and borides formed by the alloy elements of C, Ti, V, and the like as well as a small amount of B element and adjusts the combination of the elements of C, Ti, V, Si, Mn, B, and the like to adjust the alloy hardness, enhance the toughness and lower the crack sensitivity.

Owner:王新虎

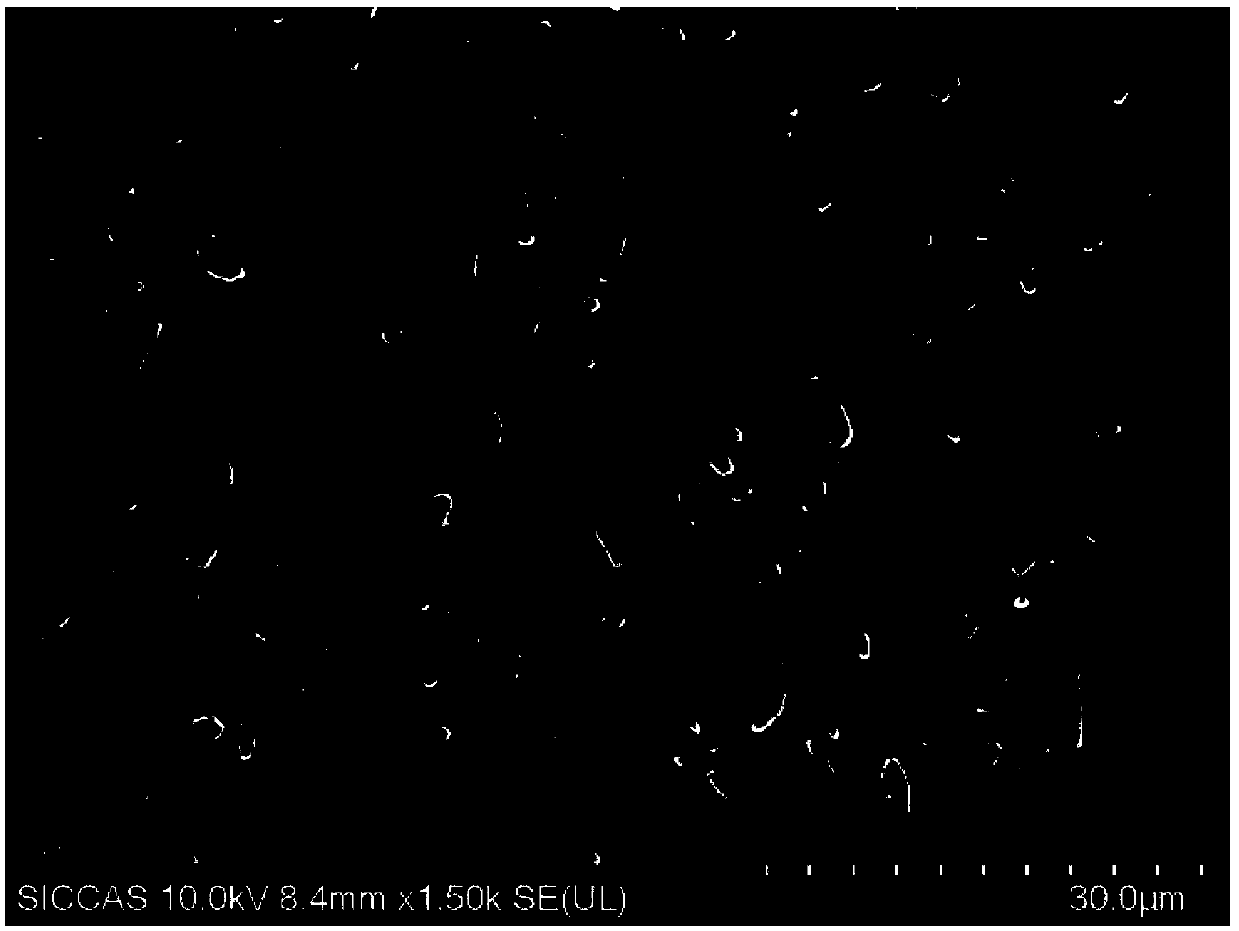

A kind of metal surface modification method

InactiveCN102268626AWide range of applicationsSave resourcesMolten spray coatingCoated surfaceState of art

The invention relates to a metal surface modification method. The invention first obtains a textured surface with a certain surface roughness value on the surface of a material by an electron beam texturing method, forms uniform tiny pits, and increases the bonding strength of the interface; then uses plasma The spraying process uses Co-based alloy or Ni-based alloy powder as the material to form a coating; finally, laser remelting technology is used to remelt the coating surface to improve the surface structure of the coating and improve the surface performance. Compared with the existing technology, this process can realize high temperature resistance, corrosion resistance, oxidation resistance, and fatigue resistance, and has high bonding strength, and the coating structure is uniform and compact, thereby greatly broadening the application range.

Owner:SHANGHAI UNIV OF ENG SCI

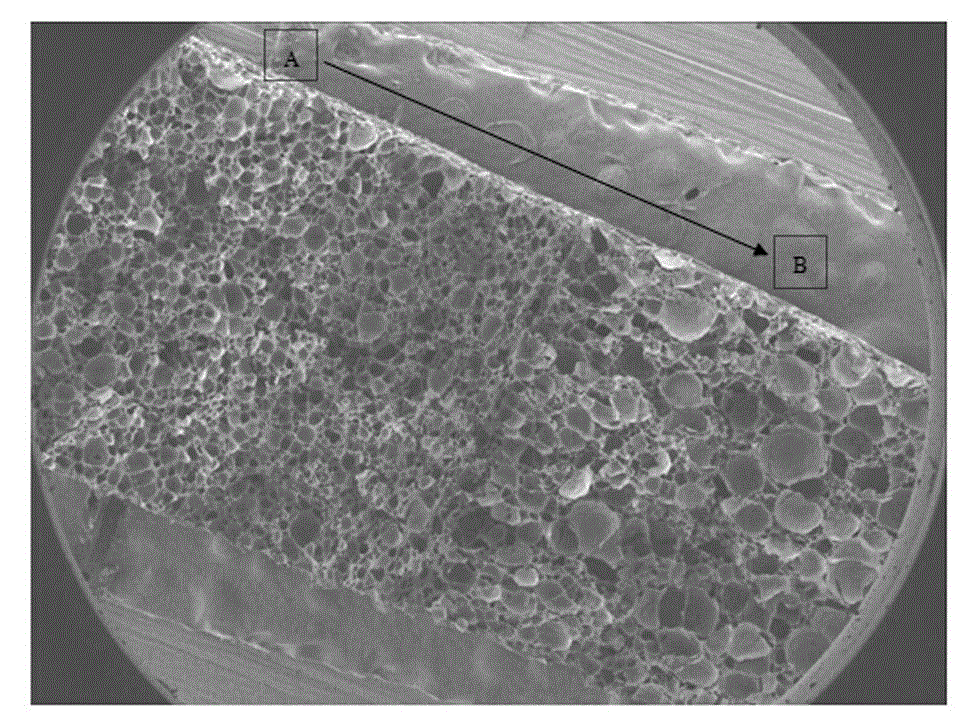

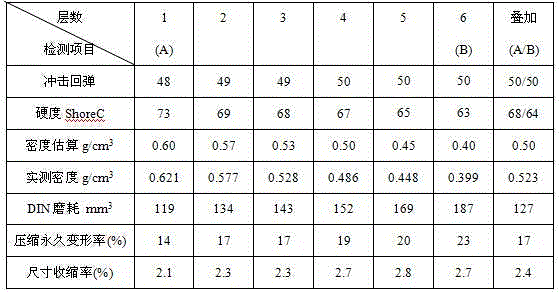

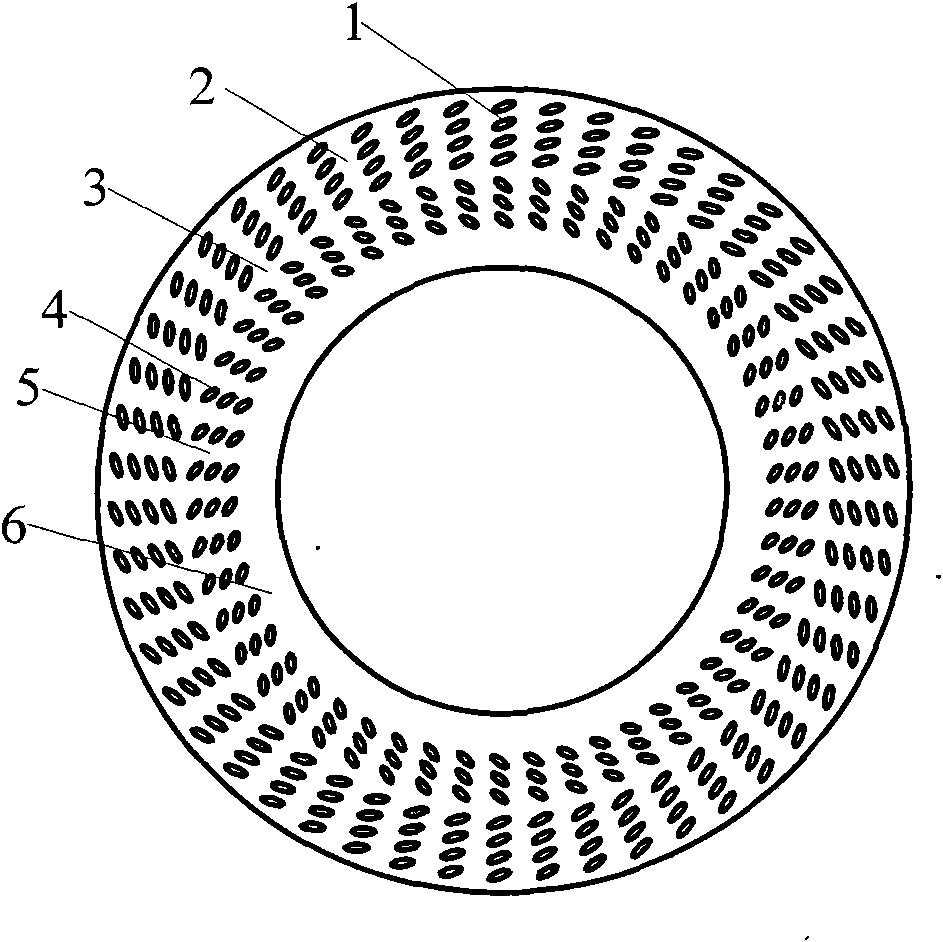

Lightweight wear-resistant density-gradient foamed sole material and preparation method thereof

The invention relates to a lightweight wear-resistant density-gradient foamed sole material and a preparation method thereof. The lightweight wear-resistant density-gradient foamed sole material is mainly composed of EPDM, ethylene-octene copolymer, low density polyethylene, a cross-linking agent, a filling material, a foaming agent and a foaming promoter. On the basis of foaming of EPDM, POE and LDPE and through control of a foaming ratio and density difference values of each layer of materials, a heterogeneous expandable rubber compound composed of a plurality of layers and having quasi-continuously changing performances in the thickness direction of the materials are subjected to one-shot mould pressing, foaming and moulding so as to prepare the foamed sole material, and function gradient differences of density, hardness and wear resistance are realized. Due to gradual change of density, stress concentration is mitigated, and the prepared foamed sole material does not warp. The foamed material has low density at one side close to the vola while the foamed material has high density at one side close to the outer sole, so the foamed sole material has good wear resistance, reduces the weight of the sole and has improved wearing comfortableness.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

A high-boron iron-based wear-resistant surfacing flux-cored wire

InactiveCN102284806ASmall sizeAchieving wear resistanceWelding/cutting media/materialsSoldering mediaBorideWear resistant

The invention relates to a high-boron iron-based wear-resistant surfacing flux-cored welding wire. The welding wire is composed of a low-carbon steel sheath and a core powder. It is characterized in that the iron element in the low-carbon steel sheath and the core powder are contained in the core powder. Elements include boron, carbon, manganese, and silicon. The weight percentage of boron, carbon, manganese, and silicon in the core powder of the welding wire is: boron 6 to 12%, carbon 0.1 to 3%, manganese 0.6 to 2%, silicon 0.3~1.5%, the balance is iron. It can also include Ti0.3~3.5%, Mn 0.6~2%, Si0.3~1.5%, molybdenum 0~1%, K / Na modifier 0~1%, and aluminum-magnesium alloy 0~1.5%. The high boron iron-based wear-resistant cladding flux-cored welding wire of the present invention mainly relies on boron, titanium, carbon and other alloying elements to form boride and a small amount of carbide to achieve the wear resistance of the cladding alloy, and by adding rare earth, nickel, Aluminum-magnesium alloys, etc. improve the overall performance of cladding alloys.

Owner:BEIJING UNIV OF TECH +1

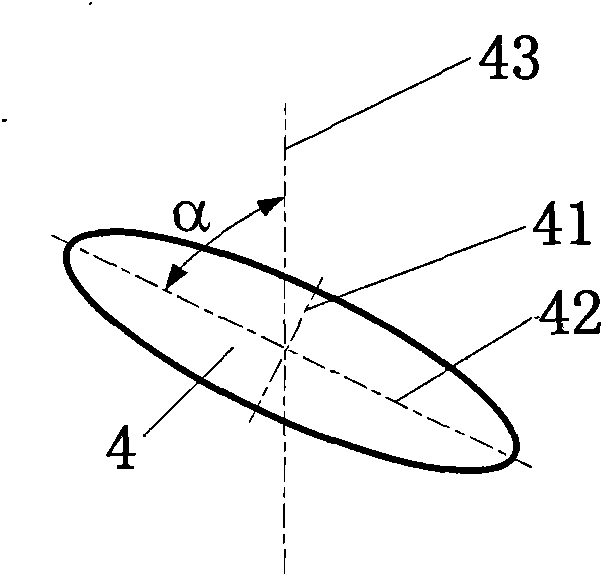

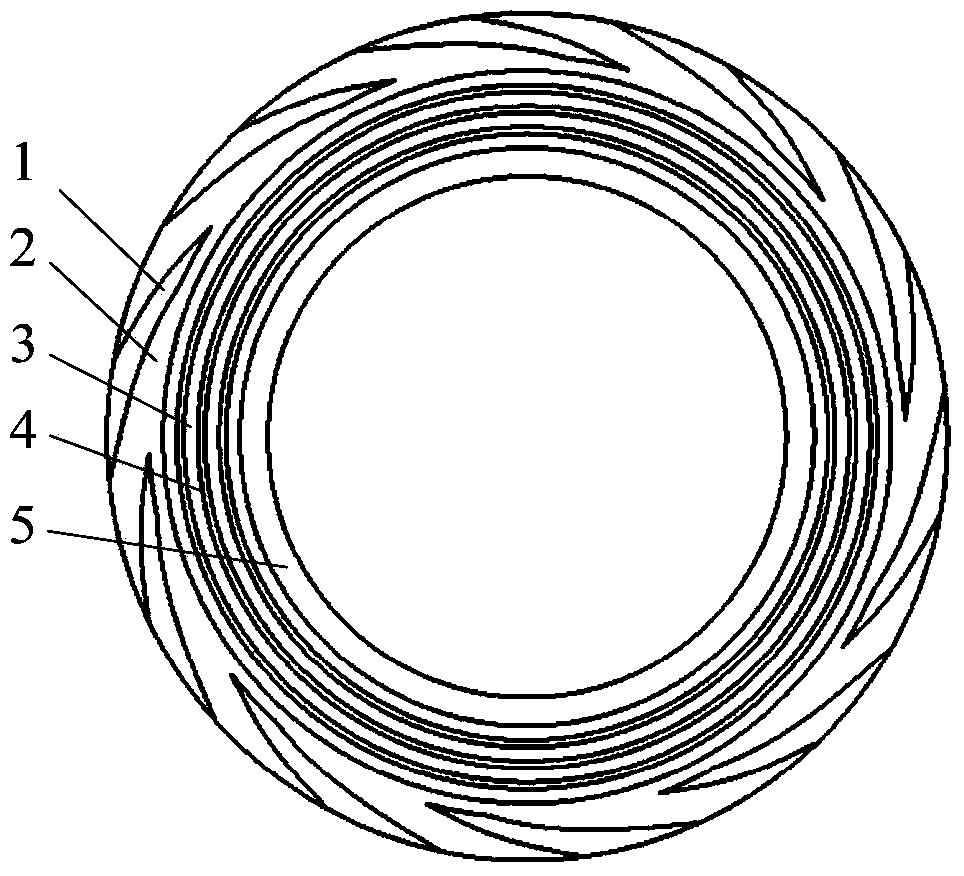

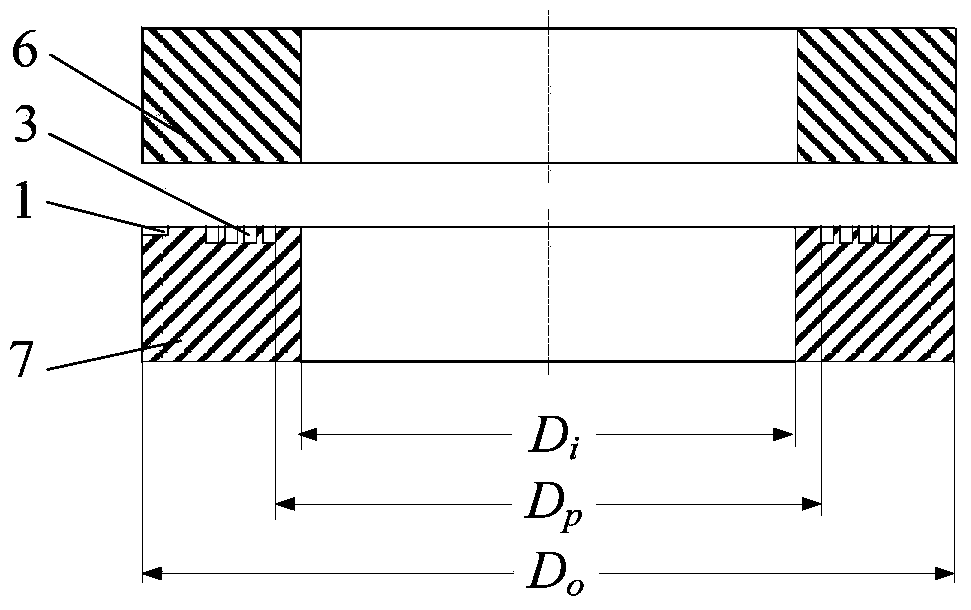

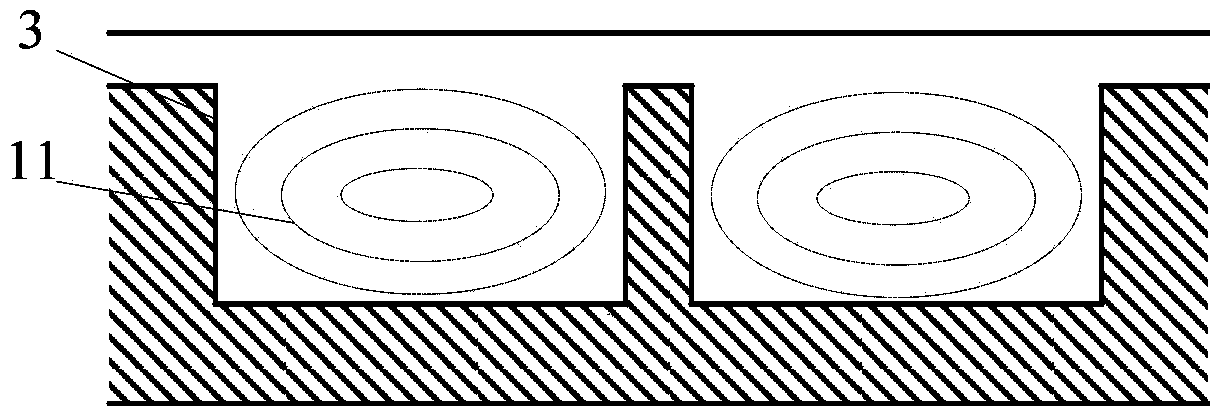

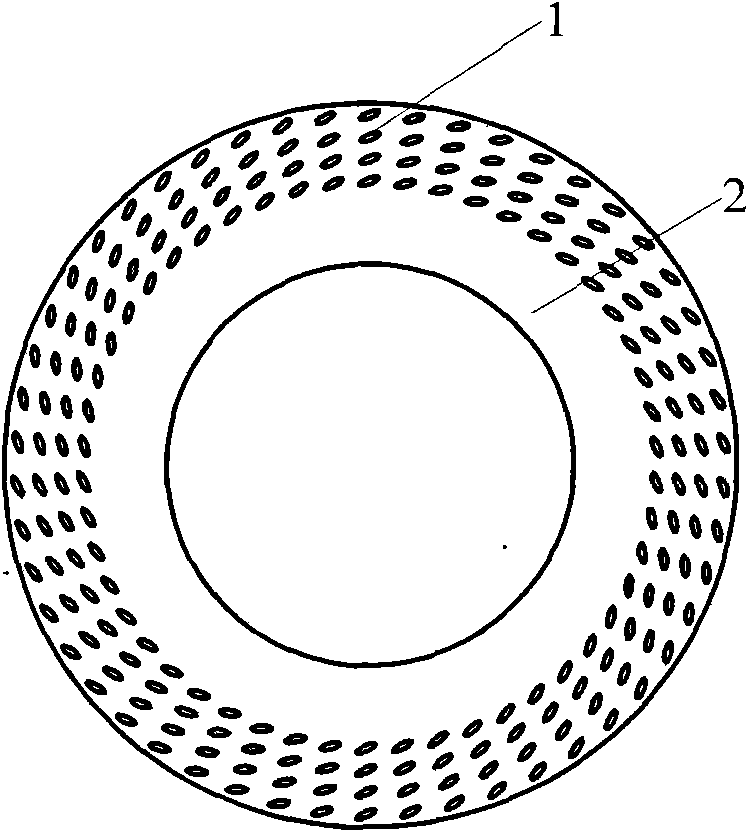

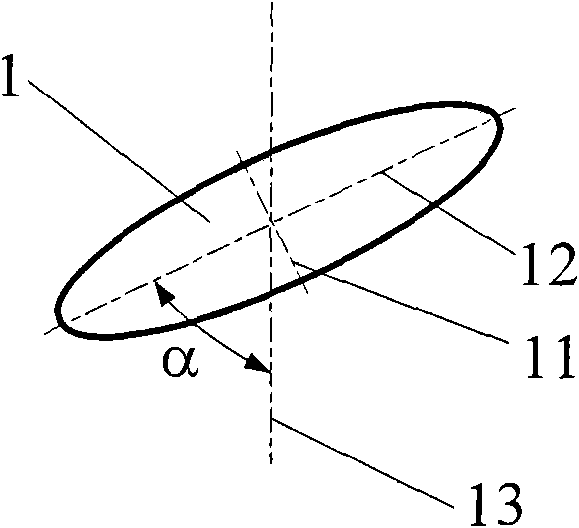

Double-row tilting directional microporous end surface no-leakage mechanical sealing structure

ActiveCN101672364AImproved hydrodynamic effect and tightnessGood start and stop effectEngine sealsDouble rowEngineering

The invention relates to a double-row tilting directional microporous end surface no-leakage mechanical sealing structure, comprising a dynamic ring and a static ring which are sealed mechanically, wherein one side of the end surface of the dynamic ring or the static ring is an high-voltage side, namely an upstream part, and the other side thereof is a low-voltage side, namely an downstream part,the end surface of the dynamic ring or the static ring is provided with an outer microporous ring belt and an inner microporous ring belt; microporous long shafts of the outer microporous ring belt and the inner microporous ring belt are opposite to the direction of a tilting angle of the diameter of the sealing end surface passing through the center of the micropore; the outer microporous ring belt and the inner microporous ring belt are respectively arranged on the upstream part and the downstream part of the end surface; and a continuous ring-shaped sealing dam are respectively arranged between the outer microporous ring belt and the inner microporous ring belt and the downstream part of the inner microporous ring belt. The mechanical sealing structure has the beneficial effects of: realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

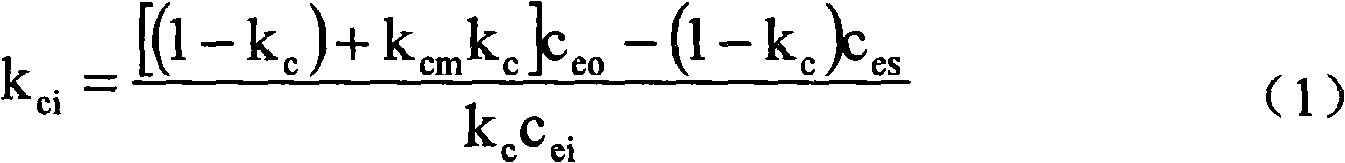

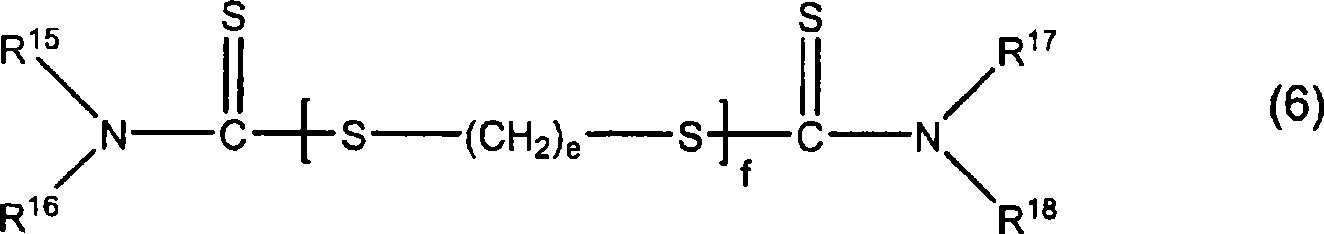

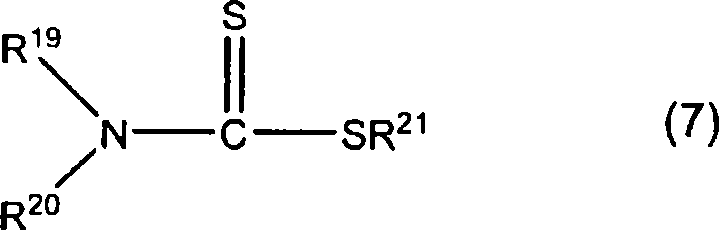

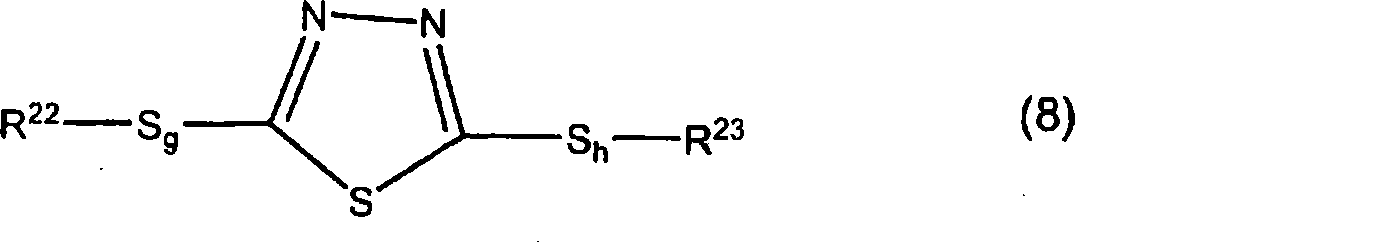

Lube base oil, lubricating oil composition for internal combustion engine, and lubricating oil composition for drive transmission device

InactiveCN101379171AExcellent viscosity-temperature characteristicsReduce energy lossBase-materialsMeth-Chemical composition

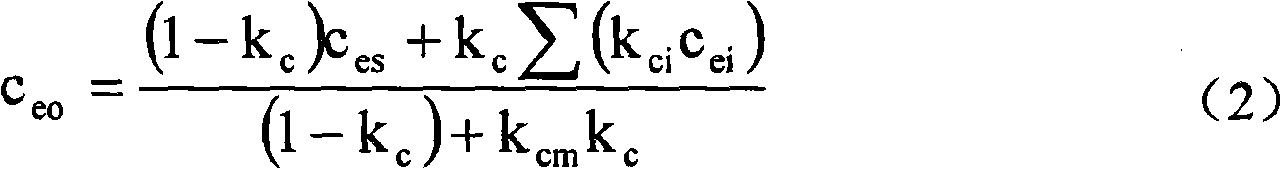

A lube base oil satisfying at least one of the following requirements (a) and (b). A lubricating oil composition for internal combustion engines is provided which comprises the lube base oil, an ash-free antioxidant containing no sulfur as a constituent element, and at least one member selected among ash-free antioxidants containing sulfur as a constituent element and organ omolybdenum compounds. Also provided is a lubricating oil composition for drive transmission devices which comprises the lube base oil, a poly(meth)acrylate-type viscosity index modifier, and a phosphorus compound. (a) The content of saturated matters is 90 mass% or higher and the proportion of cyclic saturated matters in those saturated matters is 10-40 mass%. (b) The lube base oil satisfies the relationship represented by the following expression (1). 1.440=n20-0.002OEv100=1.453 (1) [In the expression, n20 indicates the refractive index at 20 DEG C of the lube base oil and kv100 indicates the dynamic viscosity (mm2 / s) at 100 DEG C of the lube base oil].

Owner:NIPPON OIL CO LTD +1

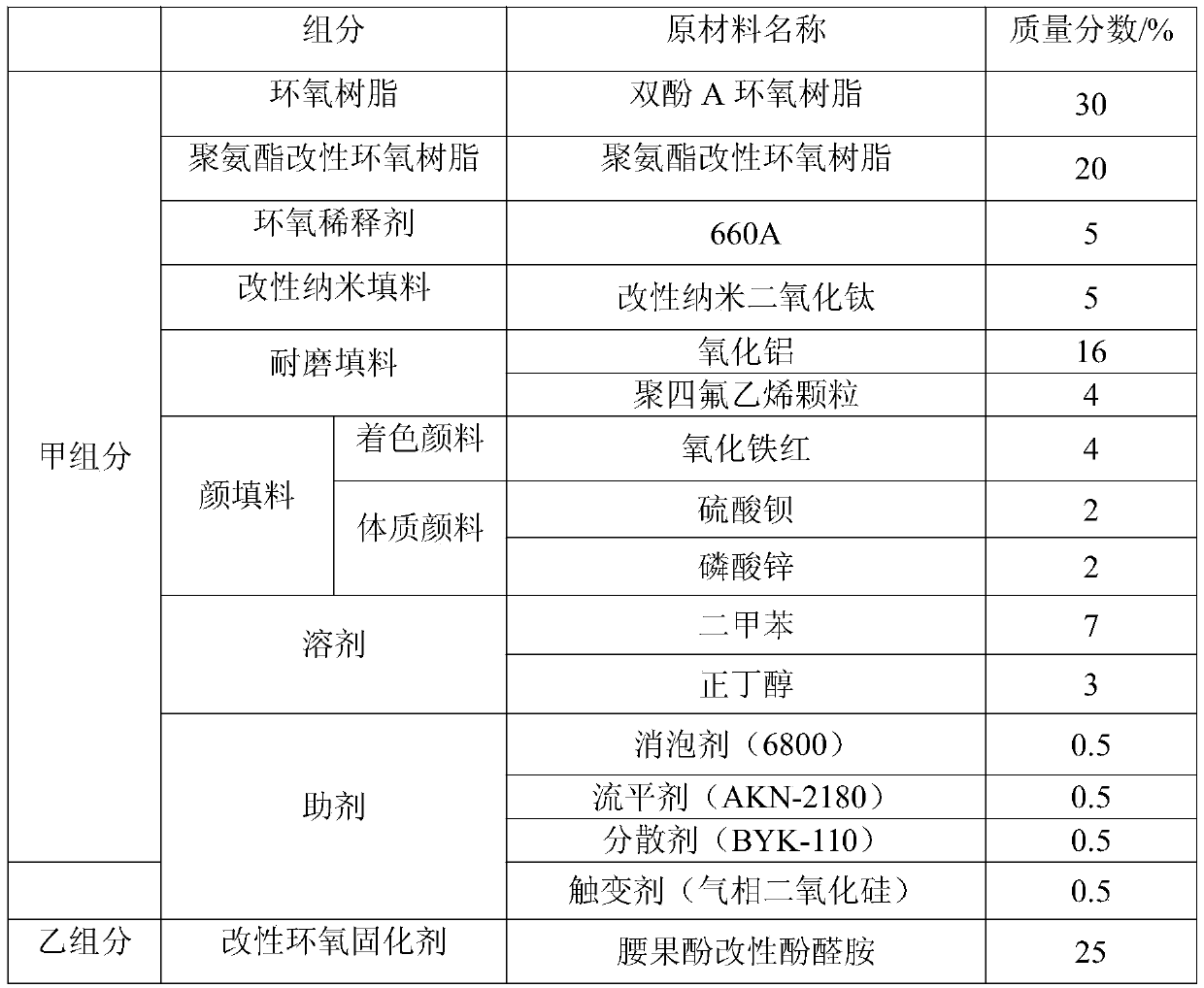

Wear-resistant anticorrosive paint for polar ships and preparation method thereof

InactiveCN110903734AImprove flexibilityImprove adhesion and impact resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentPolymer chemistry

The invention discloses a wear-resistant anticorrosive paint for polar ships and a preparation method thereof, the wear-resistant anticorrosive paint comprises a component A and a component B which are mixed according to a mass ratio of (4-5.5): 1, the component A comprises the following components by mass percentage: 30-40 wt% of bisphenol A epoxy resin; 10-20 wt% of polyurethane modified epoxy resin, 5-10 wt% of an epoxy diluent, 2-5 wt% of a modified nano-filler, 13-20 wt% of a wear-resistant filler, 8-15 wt% of a pigment filler, 8-10 wt% of a solvent, and 2-3 wt% of an auxiliary agent. Andthe component B is a modified epoxy curing agent. The wear-resistant anticorrosive paint has the advantages of favorable film-forming property, high glossiness, favorable low-temperature toughness, favorable wear resistance and excellent corrosion resistance, and can satisfy the impact and friction requirements of the polar ship hull protective paint on the ice layer under low-temperature conditions.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Heat treatment method for diesel engine cam

InactiveCN101476029AReduce distortionReach hardnessSolid state diffusion coatingFurnace typesMechanical equipmentCam

The invention discloses a diesel engine cam thermal treatment method comprising a carburizing step, a quenching step and a tempering step.After the carburizing step, a pit cooling method is adopted for reducing the deformation of the cam because of the heat treatment process, two times of alkaline bath quenching are adopted for not only reducing thermal stress and deformation, but also having functions of thinning heart crystal grains and eliminating network carbide for satisfying metallography requirement in the first quenching process of the cam, and having a function of assuring to obtain cryptocrystal martensite, residual austenite and partial of granule carbide on the surface for satisfying performance requirements of rigidity, wearing resistance property, contact fatigue degree and the like of the cam surface in the second quenching process of the cam;simultaneously, the cam heart can obtain lath martensite and fine homogeneous ferrite, and the mechanical property of the cam heart can be improved; according to the invention, design requirements of heat rigidity, wearing resistance property, fatigue strength, mechanical property of the cam heart and deflection can all be satisfied, therefore, the manufactured cams can be extensively used in large-scale heavy-duty mechanical equipment.

Owner:CHONGQING YUEJIN MACHINERY

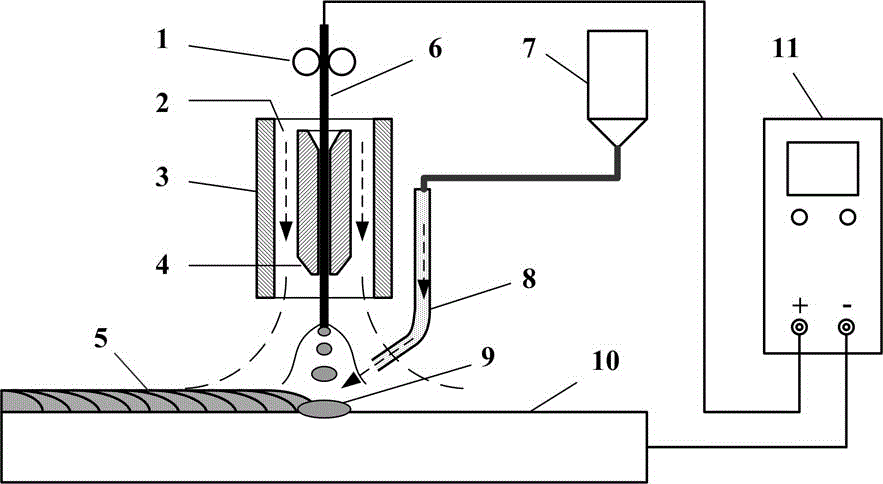

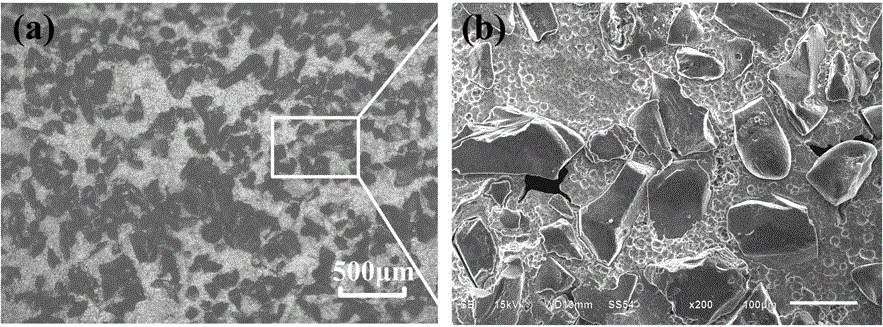

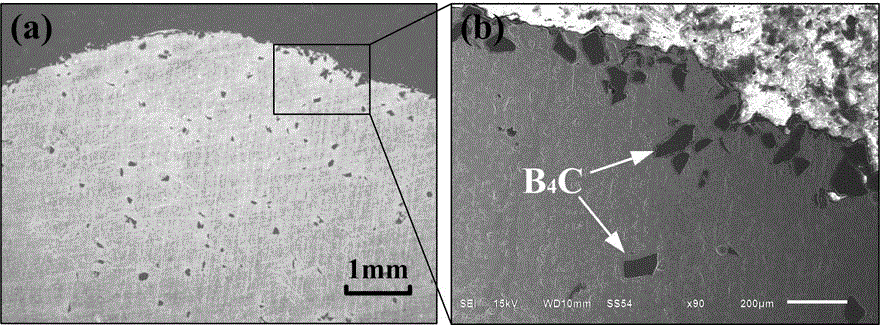

Aluminum alloy surface B4C particle reinforced Al base composite cladding layer and preparation method

ActiveCN106513929AWell combinedGood wear resistanceArc welding apparatusMetallic material coating processesAlloy substrateAlloy surface

The invention discloses an aluminum alloy surface B4C particle reinforced Al base composite cladding layer and a preparation method, overcomes the problem that a traditional technology is difficult to remove compact oxide films quickly grown on surfaces of aluminum and an alloy of the aluminum, solves the problems of difficult powder feeding due to light mass of B4C particles and weak wettability with aluminum alloy molten liquid, and effectively leads the B4C particles in the aluminum alloy surface layer to form an Al base composite cladding layer with excellent metallurgic bonding. In cooperation with the powder-wire composite cladding technical scheme, by using consumable electrode inert gas protective welding-MIG welding, aluminum alloy welding wires are transited to the aluminum alloy wire, the side injection of the B4C particles is assisted to fuse in the Al base cladding layer, that is, the B4C particle reinforced Al base composite cladding layer is prepared on the aluminum alloy surface. The B4C particle reinforced Al base composite cladding layer and an aluminum alloy substrate are excellently bonded, and the B4C particles in the cladding layer and an Al matrix are excellently bonded, and obvious defects such as air holes and cracks are avoided; and the aluminum alloy surface B4C particle reinforced Al base composite cladding layer is higher in wear resistance compared with 45 steel.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

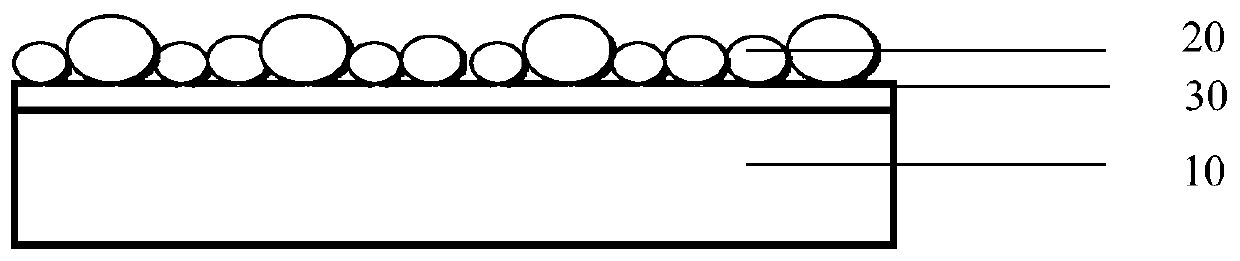

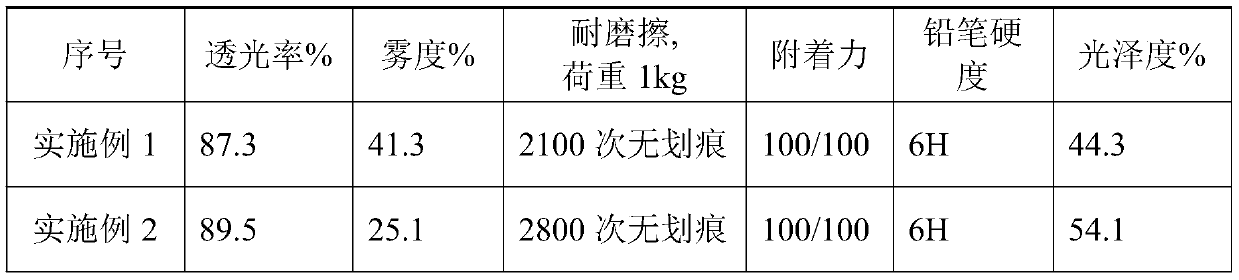

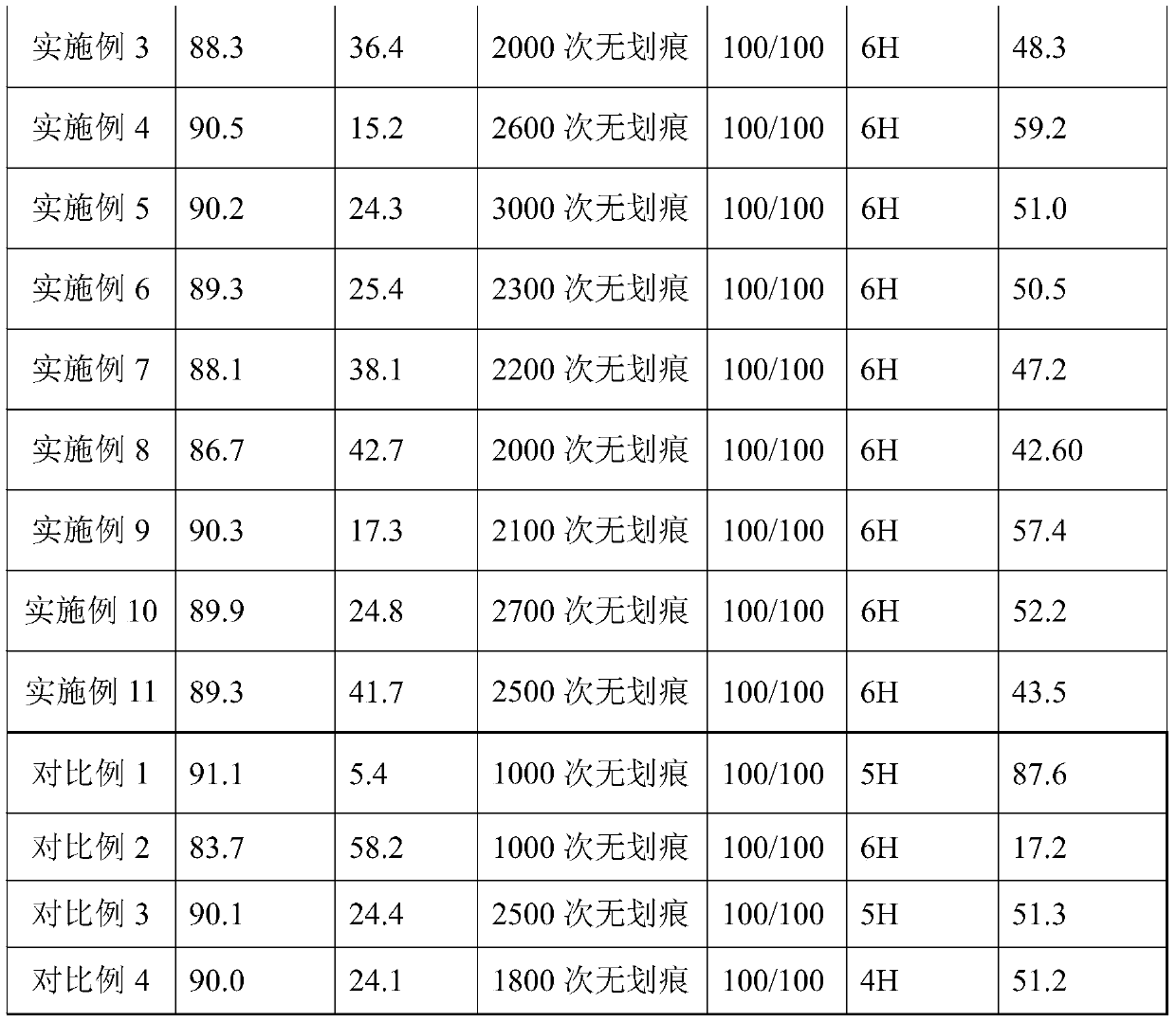

High-hardness and anti-dazzle hardening layer coating liquid and hardening film

The invention relates to the technical field of a hardening film, in particular to high-hardness and anti-dazzle hardening layer coating liquid and a hardening film. In order to solve the problems that the existing hardening film cannot realize high hardness or anti-dazzle performance at the same time, the invention provides the high-hardness and anti-dazzle hardening layer coating liquid and thehardening film. The hardening layer coating liquid contains 40 to 80 percent of acrylic ester prepolymers, 10 to 30 percent of acrylic ester monomers, 7 to 30 percent of silicon dioxide, 2 to 6 percent of photoinitiators and 0.1 to 0.5 percent of auxiliary agents in percentage by weight. The hardening layer coating liquid provided by the invention forms a hardening layer after the curing; high hardness and anti-dazzle performance are realized. The hardening film provided by the invention has high hardness and anti-dazzle protection effects.

Owner:NINGBO EXCITON TECH

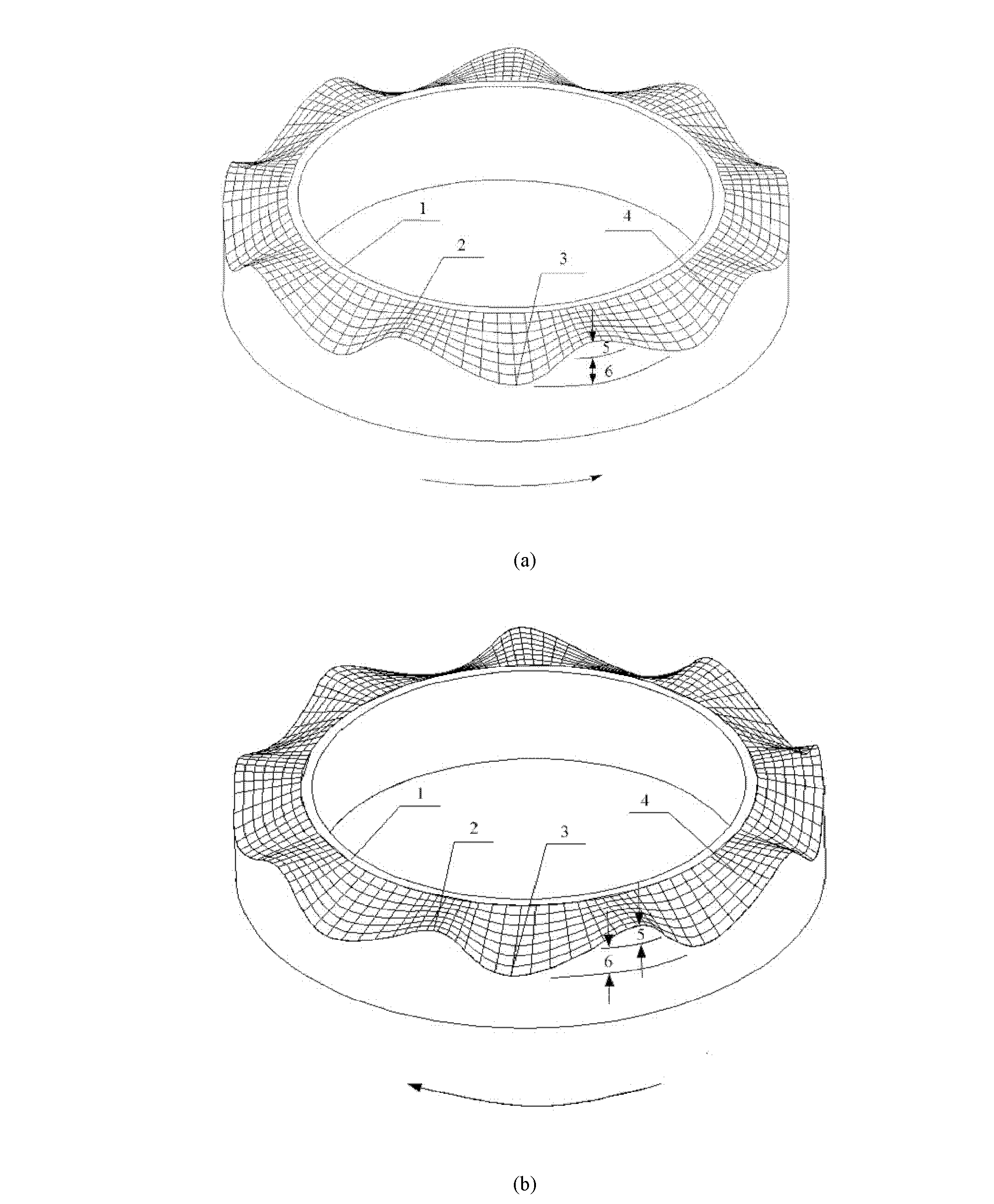

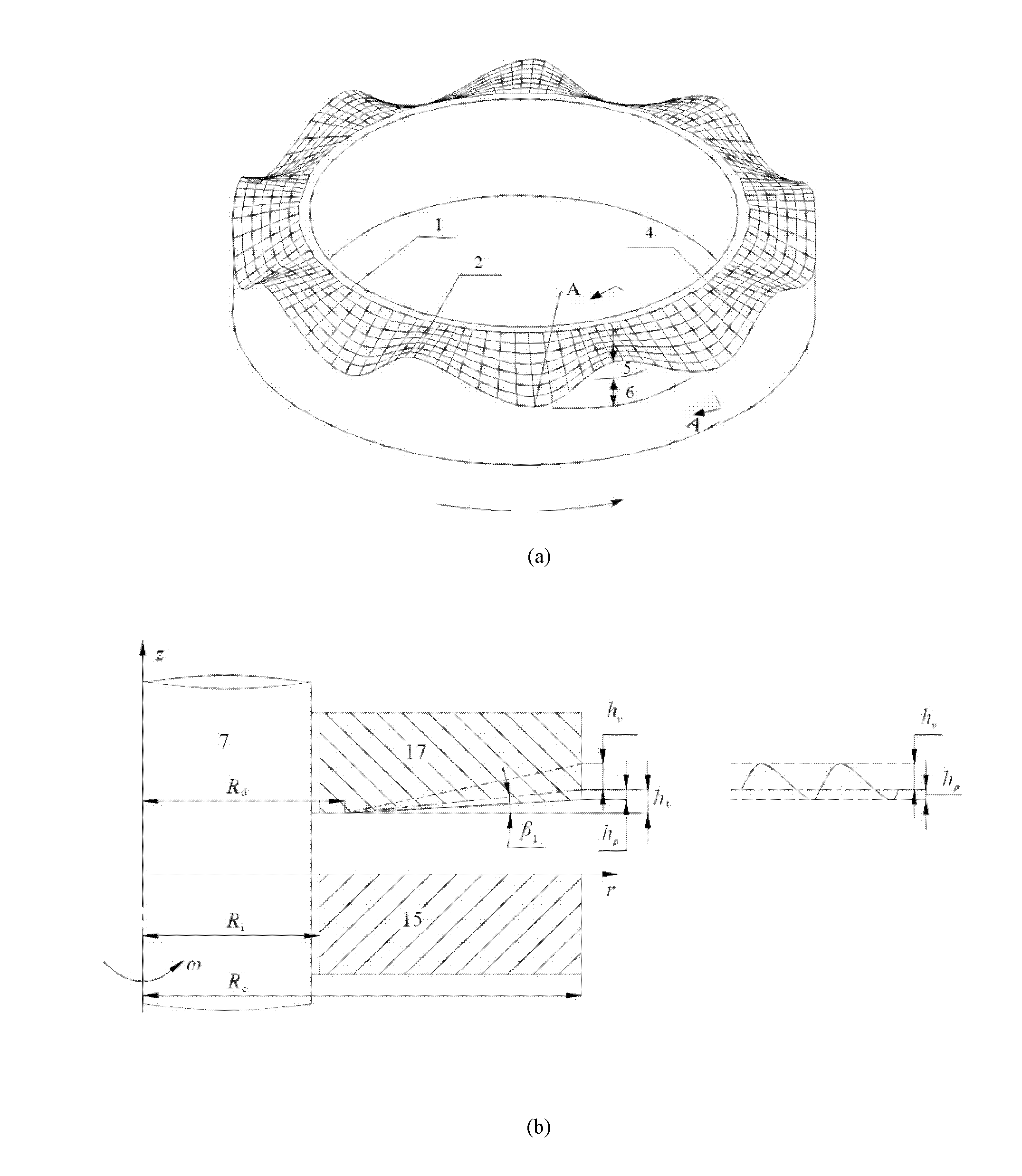

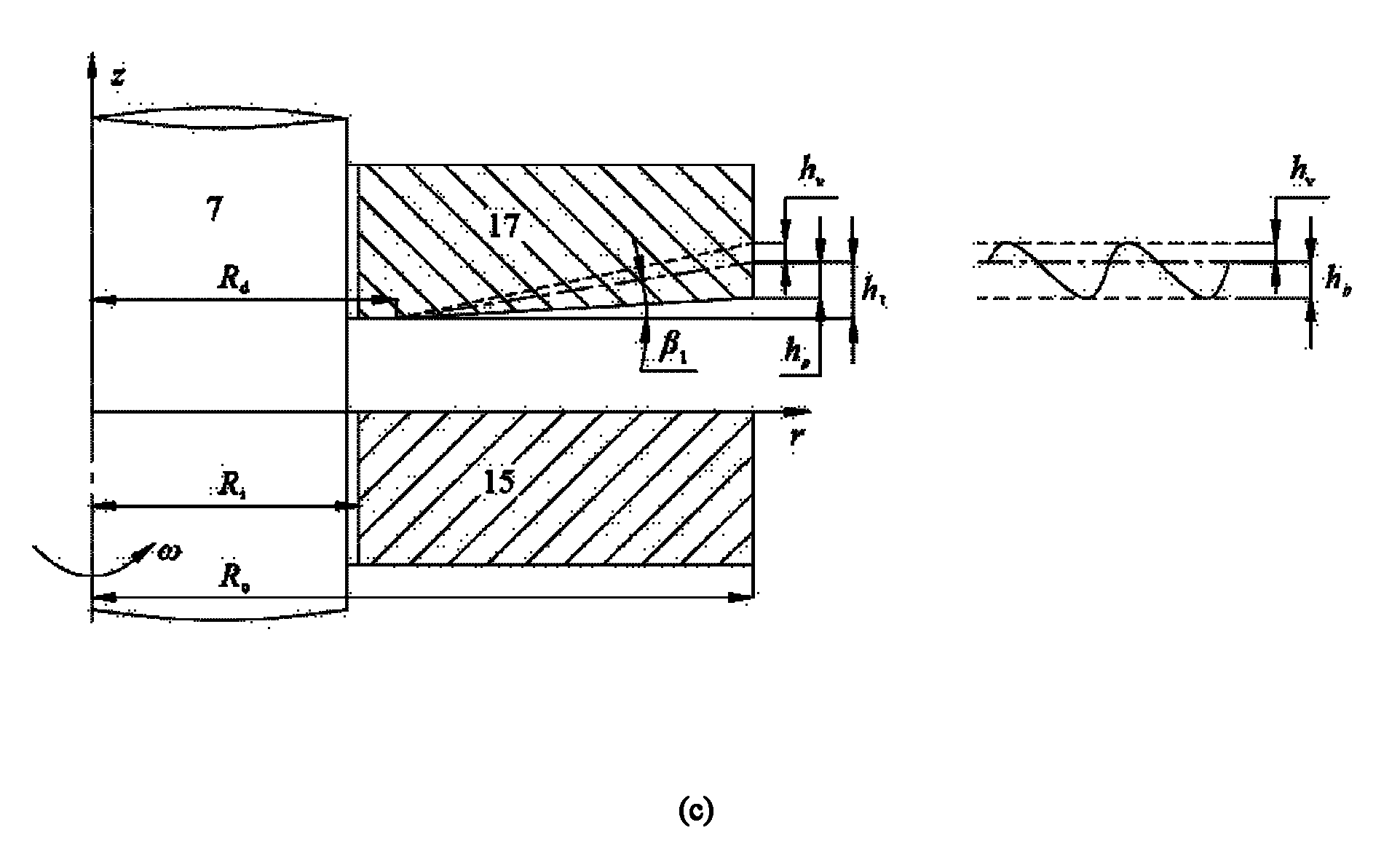

Dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure

ActiveCN102322528AEnhance the dynamic pressure effectImprove work performanceEngine sealsNon symmetricEngineering

The invention provides a dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure. At least one sealing end face on a moving ring and a stationary seal ring is provided with more than two three-dimensional asymmetrical waviness appearances, the asymmetrical waviness is in a periodical arrangement on the at least one sealing end face, the asymmetrical waviness sealing end face comprises a dam area, a conical surface and a wave crest and a wave trough of the asymmetrical waviness, the dam area is a groove-less parallel annular sealing dam arranged at the low-pressure side, the wave crest and the wave trough are connected through the conical surface, the conical surface is a linear convergence cone formed from the high-pressure side to a low-pressure side and is connected with the dam area, the conical surface can realize sealed non-contact static pressure effect; the conical degree combines with the asymmetrical waviness so that the sealing reliability can be improved, an asymmetrical waviness smooth transition curve can prevent the particles in the sealing fluid from being cumulated, and the dam area can realize static sealing when the axle is stationary. The structure provided by the invention has strong pressure resistance and antijamming capability, the leakage rate is lower at the conditions of high parameters, the fluid has good dynamic pressure effect in the process of start and stop and the fluid bearing capacity is sufficient in the normal operation.

Owner:TSINGHUA UNIV

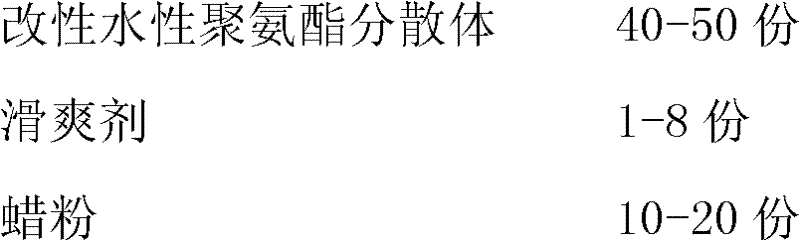

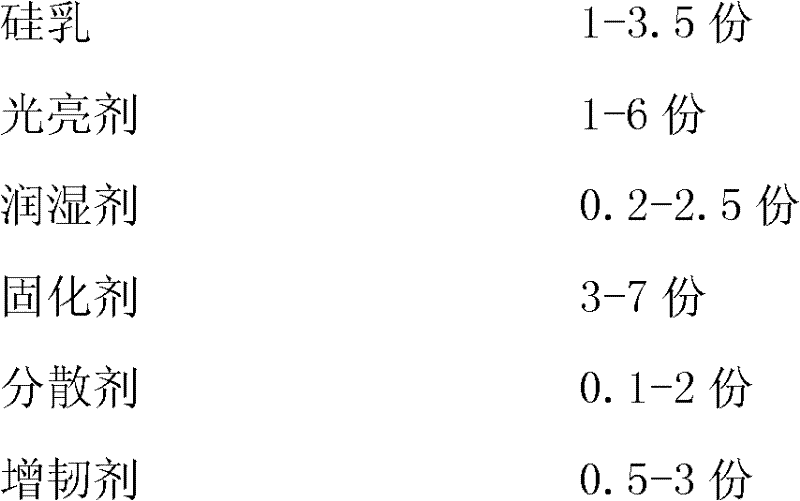

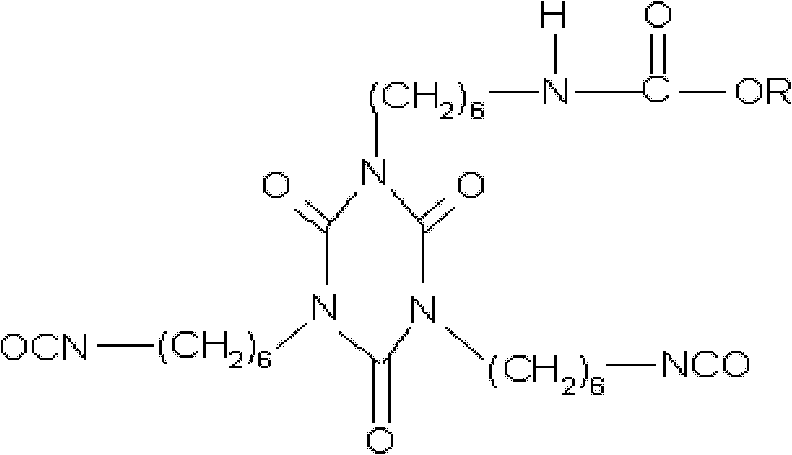

Water-borne polyurethane sponge strip coating and preparation method and application thereof

InactiveCN102585679AGood dispersionGood adhesionPolyurea/polyurethane coatingsStainingPolyvinyl chloride

The invention provides water-borne polyurethane sponge strip coating and a preparation method and application thereof. The water-borne polyurethane sponge strip coating comprises the following components in parts by weight: 40-50 parts of modified water-borne polyurethane dispersion, 1-8 parts of a slip agent, 10-20 parts of wax powder, 1-3.5 parts of silicon emulsion, 1-6 parts of a brightening agent, 0.2-2.5 parts of a wetting agent, 3-7 parts of curing agent, 0.1-2 parts of dispersant, and 0.5-3 parts of plasticizer. The coating provided by the invention can be used on the surfaces of automobile door window sealing strips with EPDM (ethylene propylene diene monomer) and PVC (polyvinyl chloride) as base materials, achieving the effects of slippage increase, esthetic appearance, wear resistance and staining resistance. The product has excellent adhesiveness to the base materials, and the coating has excellent water resistance, weather resistance, washing resistance, creasing resistance and fouling resistance.

Owner:上海集宝材料科技有限公司

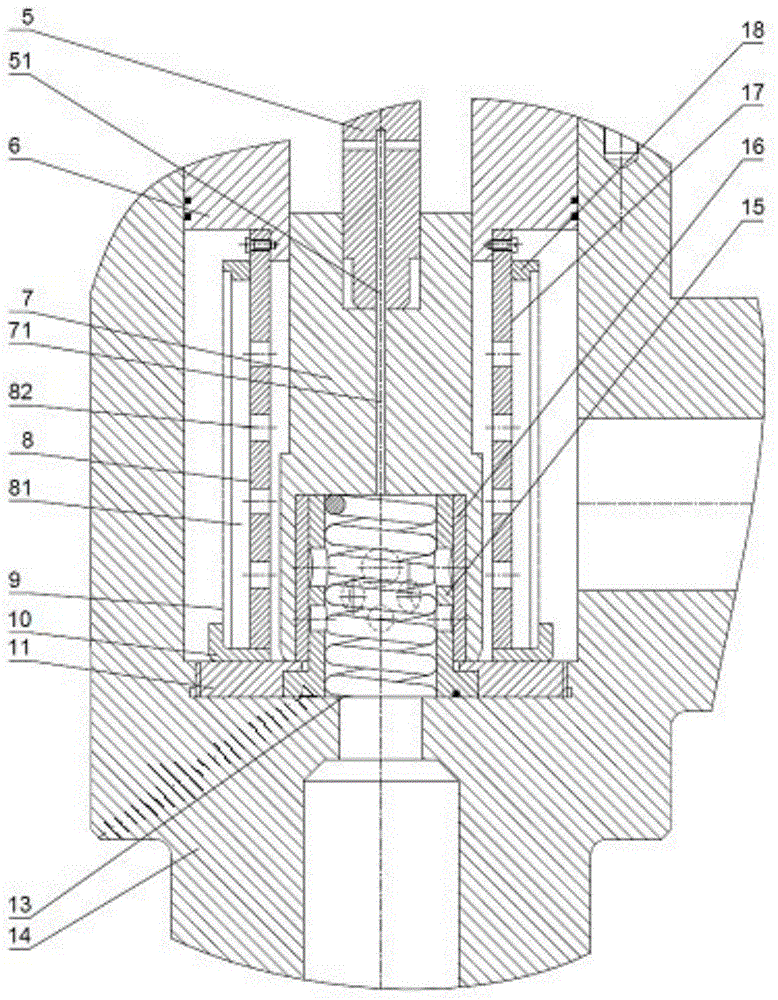

Deep groove belt dynamic pressure type end face mechanical sealing structure

ActiveCN104019237AIncrease end face dampingReduce leakageEngine sealsEnd face mechanical sealEngineering

A deep groove belt dynamic pressure type end face mechanical sealing structure comprises a dynamic ring and a static ring, wherein the dynamic ring and the static ring are sealed in a mechanical mode, one side of the end face of the dynamic ring and one side of the end face of the static ring are high-pressure sides, namely upstream portions, the other side of the end face of the dynamic ring and the other side of the end face of the static ring are low-pressure sides, namely downstream portions, one end face of the dynamic ring or the static ring is provided with a dynamic pressure groove and a groove ring throttling groove, the dynamic pressure groove and the groove ring throttling groove are symmetrically distributed according to the rotation center, the dynamic pressure groove is arranged in the upstream portion of the end face, the deep ring throttling groove is formed in the tail end of the downstream portion of the dynamic pressure groove, the deep ring throttling groove is formed due to concentrically and intensively distribution of two or more annular deep grooves in the radial direction, a first annular sealing dam with a smooth plane is arranged between the dynamic pressure groove and the deep ring throttling groove, and a second annular sealing dam with a smooth plane is arranged between the inner diameter of the deep ring throttling groove and the inner diameter of the sealing ring.

Owner:自贡市川密机械密封件有限公司

Reinforced aluminum-based composite material and preparation method thereof

The invention relates to an enhanced aluminum-based composite material and a preparation method thereof. Si3N4 whiskers are used as an enhancement phase of the composite material, pure aluminum or aluminum-based alloy are used as a matrix phase of the composite material, and beta-Si3N4 whiskers are uniformly distributed in the pure aluminum or aluminum alloy matrix.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

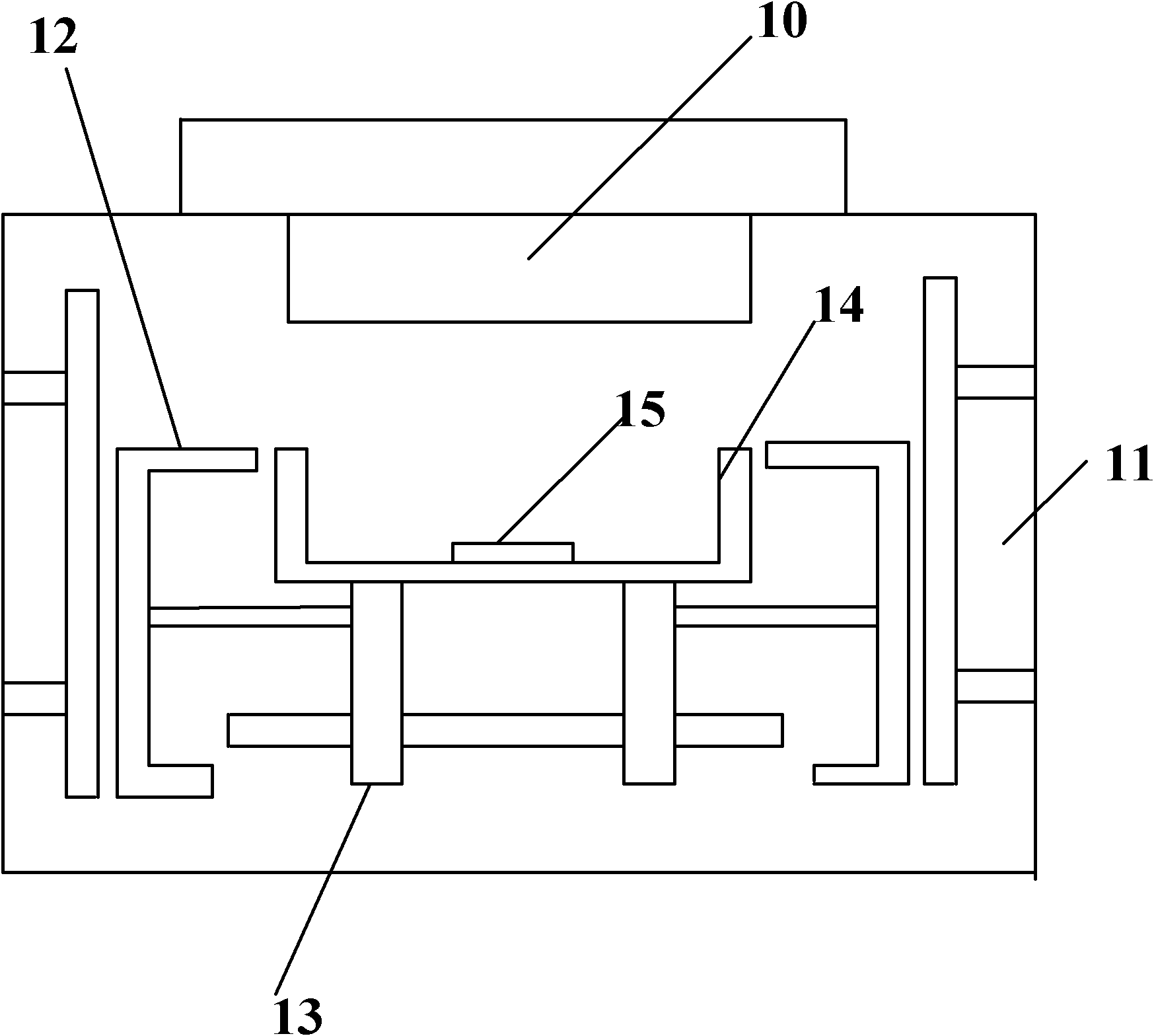

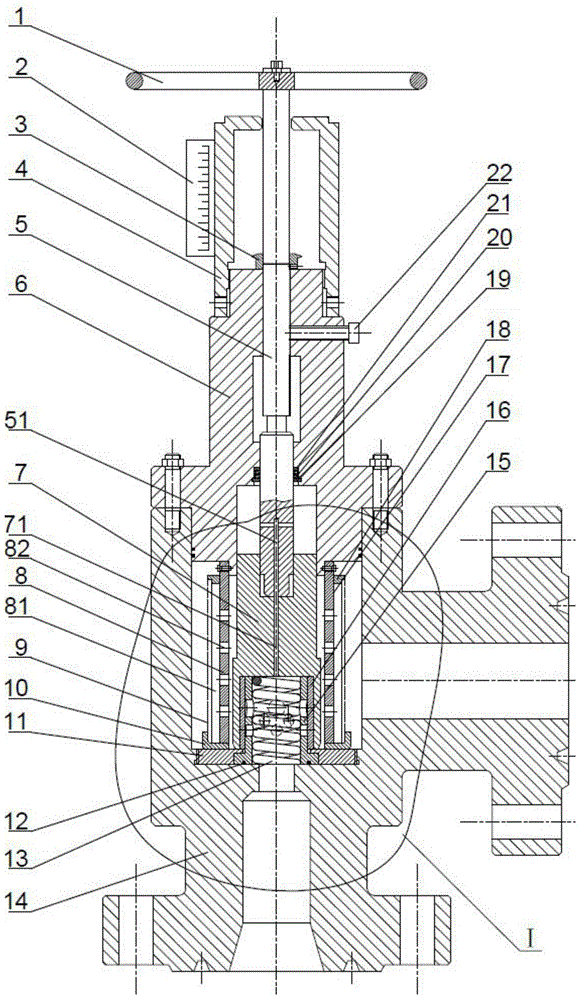

Cage sleeve type throttle valve

ActiveCN105065682AReasonable structural designGuaranteed uptimeValve members for absorbing fluid energyLift valveEngineeringScrew thread

The invention discloses a cage sleeve type throttle valve which comprises a valve body (14), a valve seat (15) installed in the valve body (14) and a spring (13) installed in a hole of the valve seat (15). A pressing ring (11) is pressed on the valve seat (15) after being connected with the valve body (14), the outer circle of the valve seat (15) is sleeved with a lower inner hole of a cage sleeve (7), and the outer circle of a valve rod (5) is sleeved with an upper inner hole of the cage sleeve (7). A valve deck (6) is installed on the valve body (14) and connected with the valve rod (5) through threads. A cylindrical filtering support (17) is connected with the lower end of the valve deck (6), the upper end of the valve rod (5) is connected with a hand wheel (1), the lower end of the valve rod (5) is connected with the cage sleeve (7), and a cage sleeve balance hole (71) in the cage sleeve (7) is communicated with a valve rod balance hole (51) in the valve rod (5). The cage sleeve type throttle valve is reasonable in structural design, low in noise, resistant to erosion and abrasion and long in service life, and flow can be precisely controlled.

Owner:江苏天氟隆防腐设备有限公司

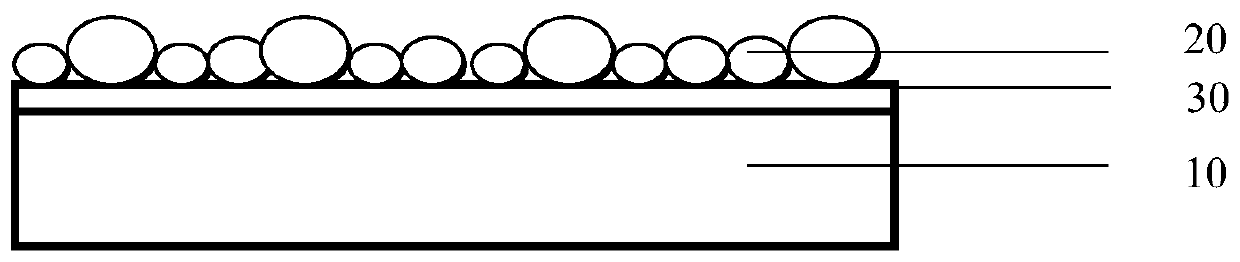

Abrasion-proof portable electronic device casing

InactiveCN101056505AAchieving wear resistanceElectrical apparatus casings/cabinets/drawersPlastic materialsBoron nitride

The invention provides a wearable portable electronic device casing. The casing is integrated produced by wearable plastic or produced by following steps: producing base by other rigid or plastic material, than coating wearable material to achieve wearable effect, adding the additive for enhancing the toughness in the wearable plastic or dope. The additive is zirconium dioxide, boron nitride, tungsten carbide, carborundum or the mixture containing more than two above materials.

Owner:郭春樱

High-toughness wear-resistant polyformaldehyde composition and preparation method thereof

ActiveCN101885896AImprove wear resistanceReduce wear ratePolytetrafluoroethylenePOLYOXYETHYLENE ETHER

The invention discloses a high-toughness wear-resistant polyformaldehyde composition and a preparation method thereof, and belongs to the field of engineering plastic plasticizing and functional modification technology and preparation. The polyformaldehyde composition comprises the following components in percentage by weight: 48.0 to 84.4 percent of polyformaldehyde, 10.0 to 30.0 percent of polyoxyethylene, 5.0 to 20.0 percent of polytetrafluoroethylene fiber, 0.25 to 0.5 percent of antioxidant 1010, 0.25 to 0.5 percent of antioxidant 168 and 0.1 to 1.0 percent of formaldehyde absorbent. The preparation method comprises the following steps of: drying the polyformaldehyde, the polytetrafluoroethylene fiber and polyethylene oxide; placing each component in a stirrer for full mixing according to the proportion; melt-blending and extruding the mixture through a twin screw extrusion pelletizer; and cooling and pelletizing the mixture. The prepared polyformaldehyde composition is applied to manufacturing of the mechanical components with high requirements on impact resistance and wear resistance.

Owner:BEIJING UNIV OF CHEM TECH

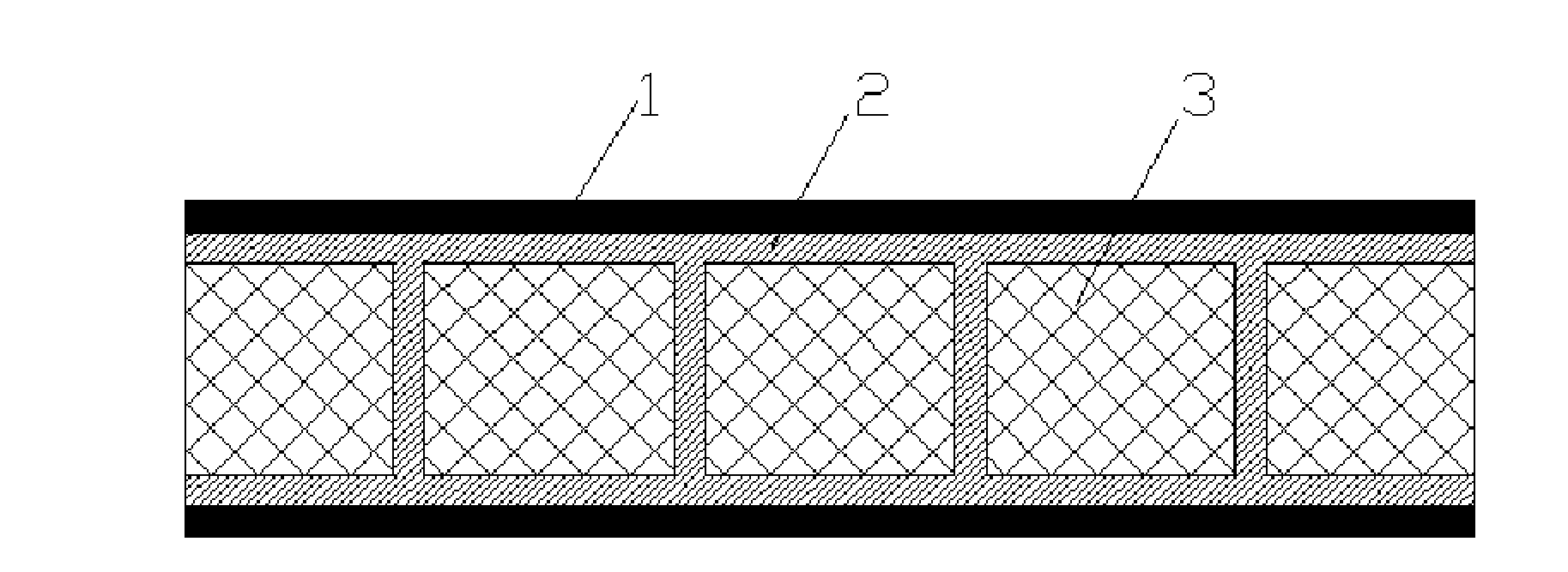

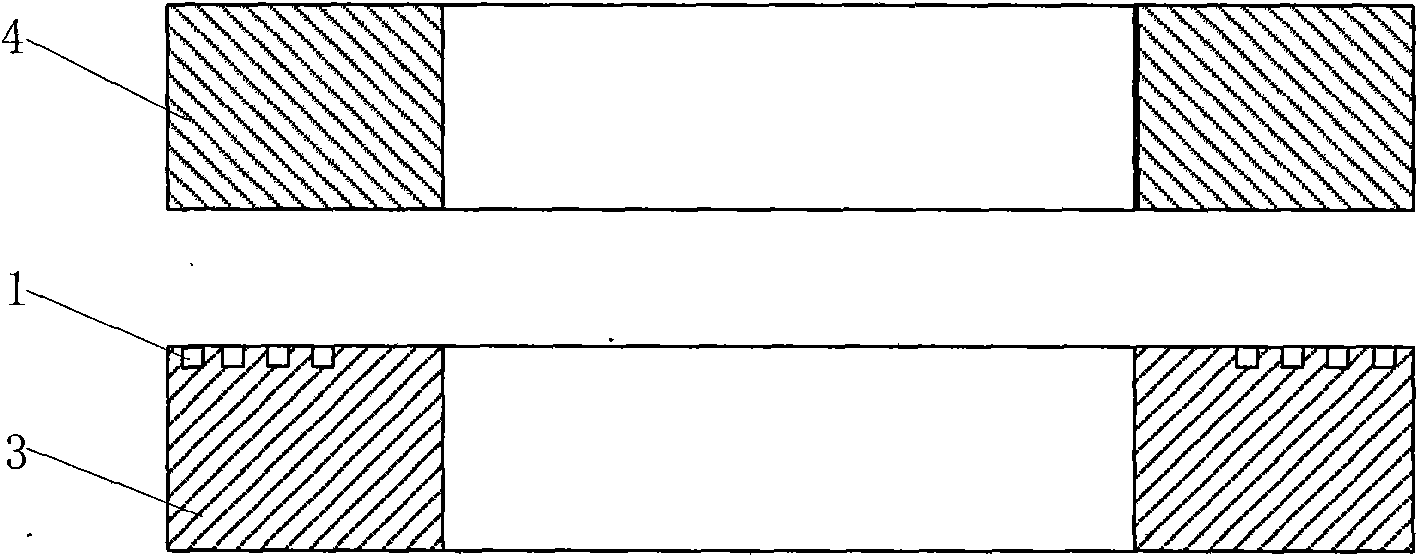

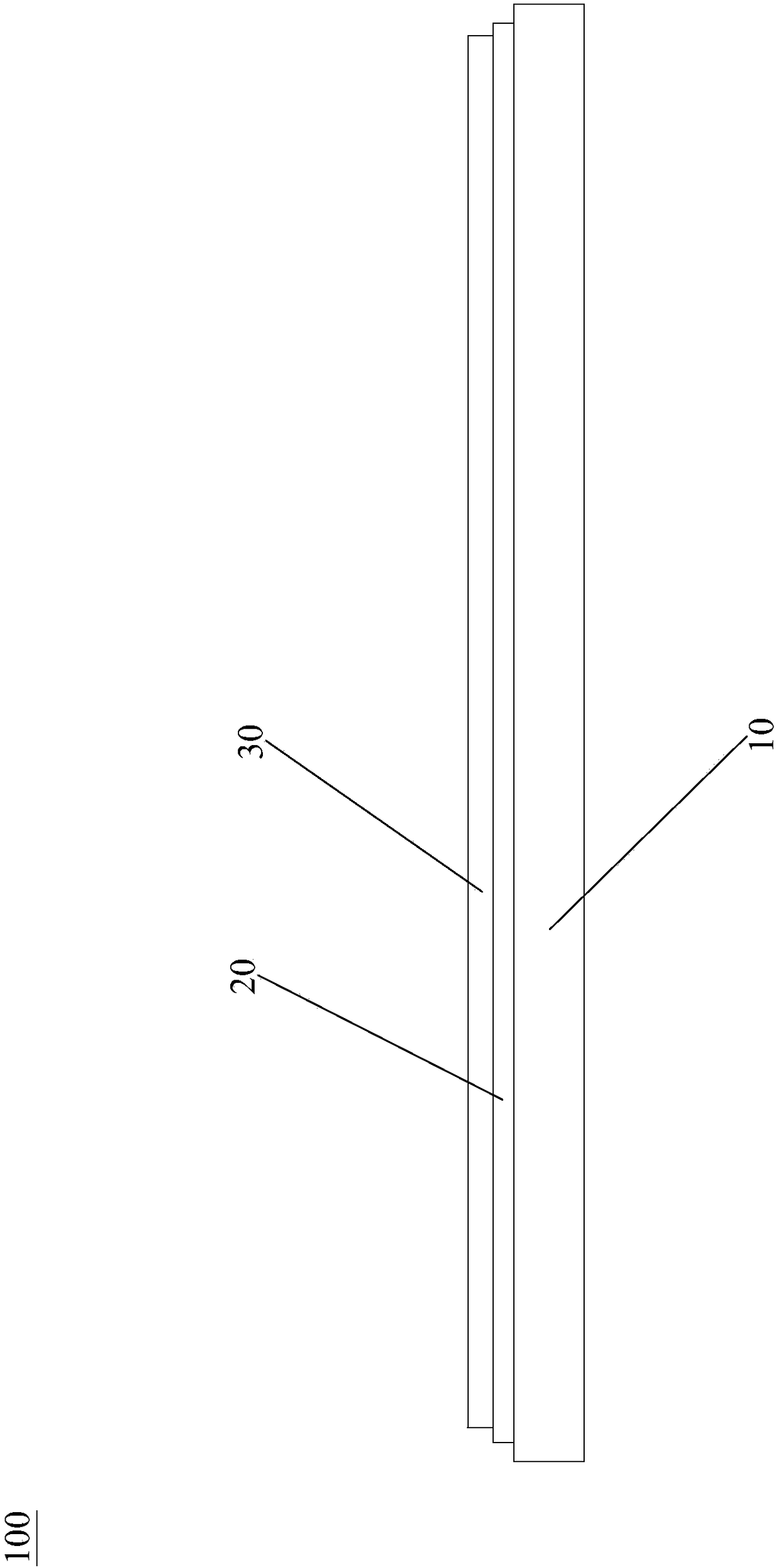

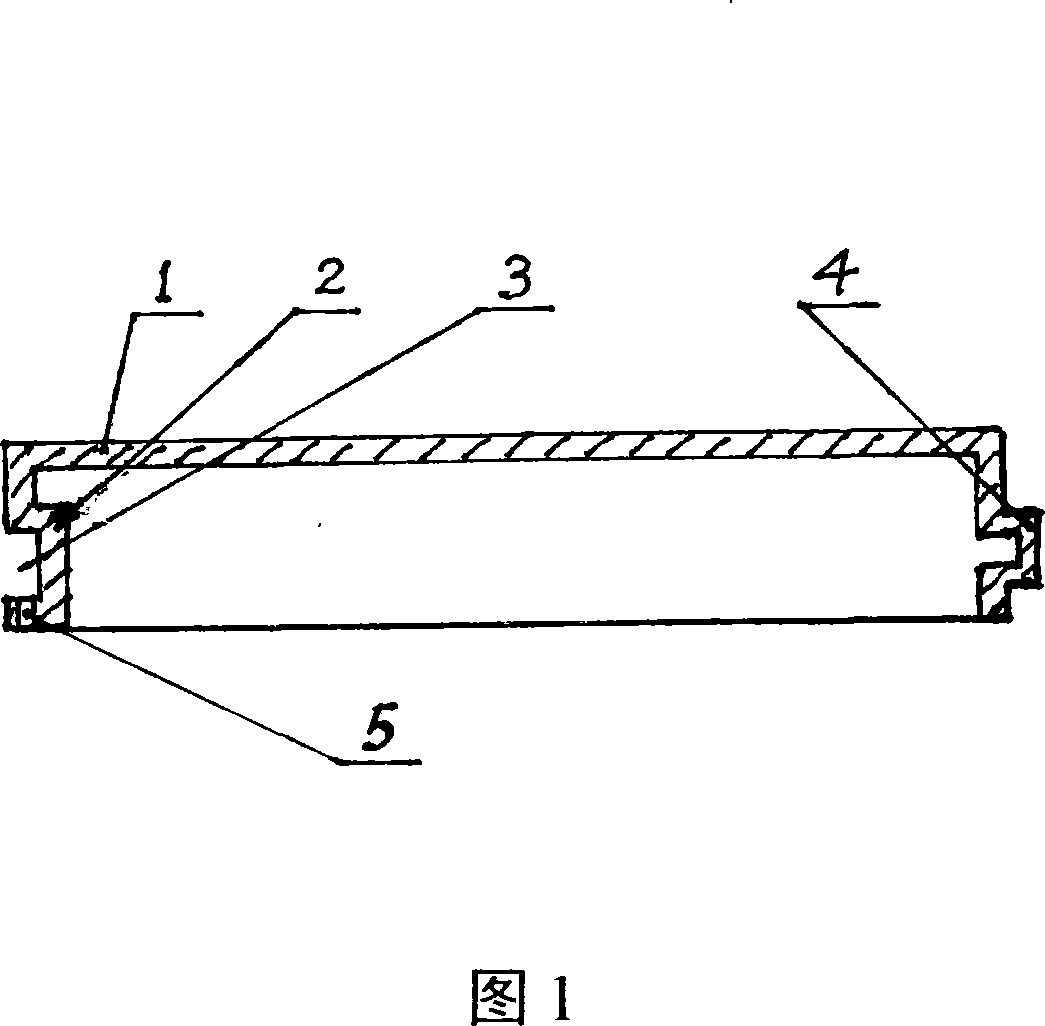

Composite material sweeping board, preparation method and application of composite material sweeping board

InactiveCN103009726AImprove wear resistanceImprove impact resistanceLamination ancillary operationsSynthetic resin layered productsFiberGlass fiber

The invention provides a composite material sweeping board, a preparation method and an application of the composite material sweeping board. The sweeping board comprises a panel (1), a core material (2) and a light sandwich material (3), wherein the panel (1) comprises an ultra-high molecular weight polyethylene fiber; the core material (2) comprises a glass fiber, a carbon fiber or a hybrid fiber; the light sandwich material (3) is arranged in the middle of the core material (2) in a clamping manner; the panel (1) is completely coated on the upper surface and the lower surface of the core material (2); and the panel (1), the core material (2) and the light sandwich material (3) are solidified to be an integral structure by the same thermosetting resin. According to the composite material sweeping board provided by the invention, the comprehensive performance, in particular the wear resistance is greatly improved, so that on the basis of keeping the bearing capability, a breakthrough of using the composite material sweeping board to replace steel in light weight and abrasion resistance is achieved, and the composite material sweeping board is especially suitable for bottom plates and side plates of truck boxes, bottom plates of containers and the like; and the composite material sweeping board is simple in preparation method, easy to operate, and suitable for industrial promotion and application.

Owner:蓝星环境工程有限公司

Mining hard alloy composite ball tooth and preparing method thereof

InactiveCN105177389AHigh strengthImprove wear resistanceDrill bitsInter layerPolycrystalline diamond

The invention discloses a mining hard alloy composite ball tooth and a preparing method thereof. The mining hard alloy composite ball tooth is composed of a polycrystalline diamond layer, an intermediate layer and a hard alloy matrix layer. A cylinder is arranged at the lower end of the hard alloy matrix layer, and a hemisphere is arranged at the upper end of the hard alloy matrix layer. The polycrystalline diamond layer adheres to the outer surface of the hemisphere of the hard alloy matrix layer through the intermediate layer. The sum of the thickness of the polycrystalline diamond layer and the thickness of the intermediate layer is 2.05 mm-2.3 mm. The intermediate layer is made of titanium carbonitride and cubic boron nitride. The hard alloy matrix layer is made of titanium carbonitride, cubic boron nitride and cobalt powder. The mining hard alloy composite ball tooth with the cobalt content being increased gradually from outside to inside is obtained through preparation of the hard alloy matrix layer, preparation of the intermediate layer and the polycrystalline diamond layer and high-pressure sintering. According to the mining hard alloy composite ball tooth and the preparing method thereof, the technique is simple, the prepared composite ball tooth has extremely high abrasion resistance and tenacity, the service life can be greatly prolonged, working efficiency is improved, and operation cost is reduced.

Owner:ANHUI UNIV OF SCI & TECH

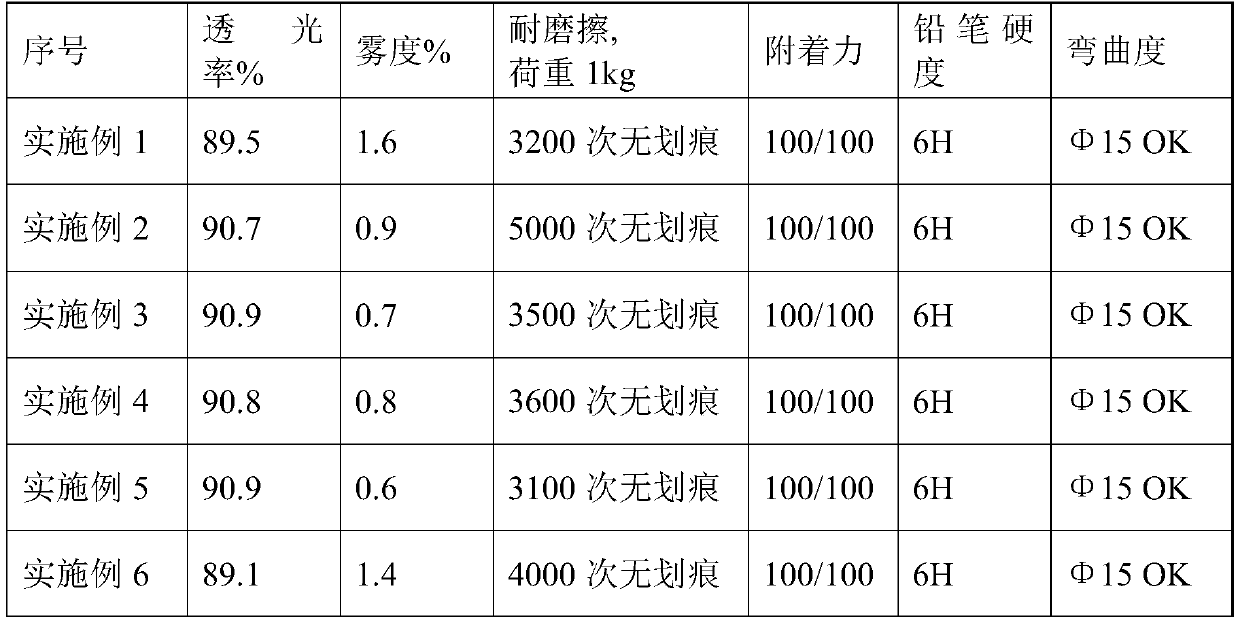

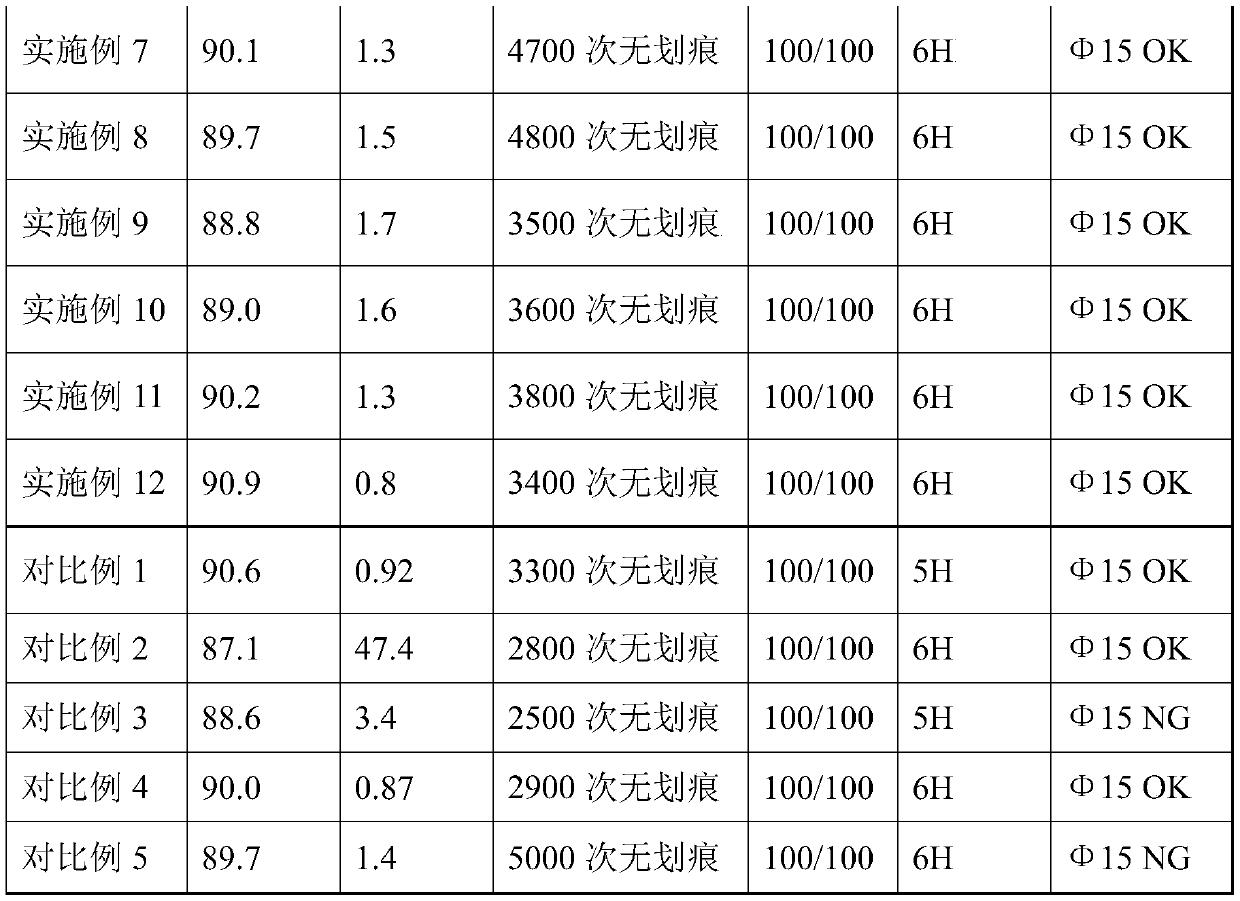

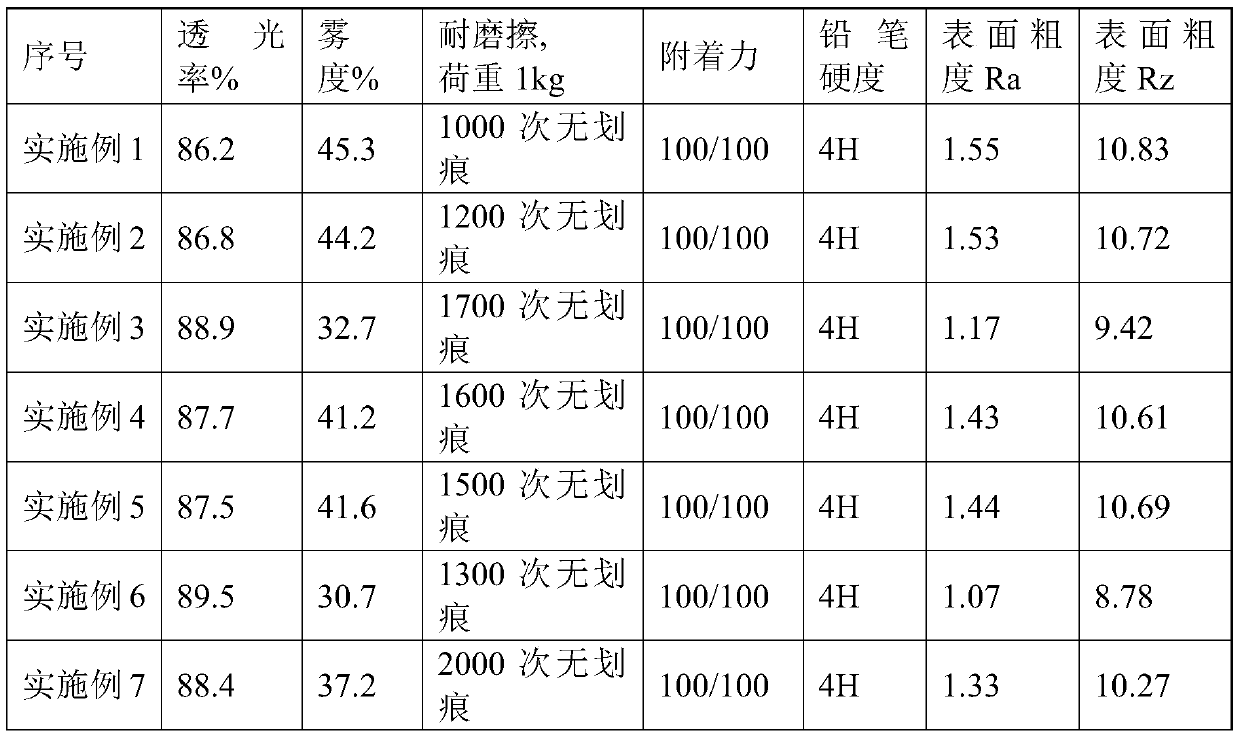

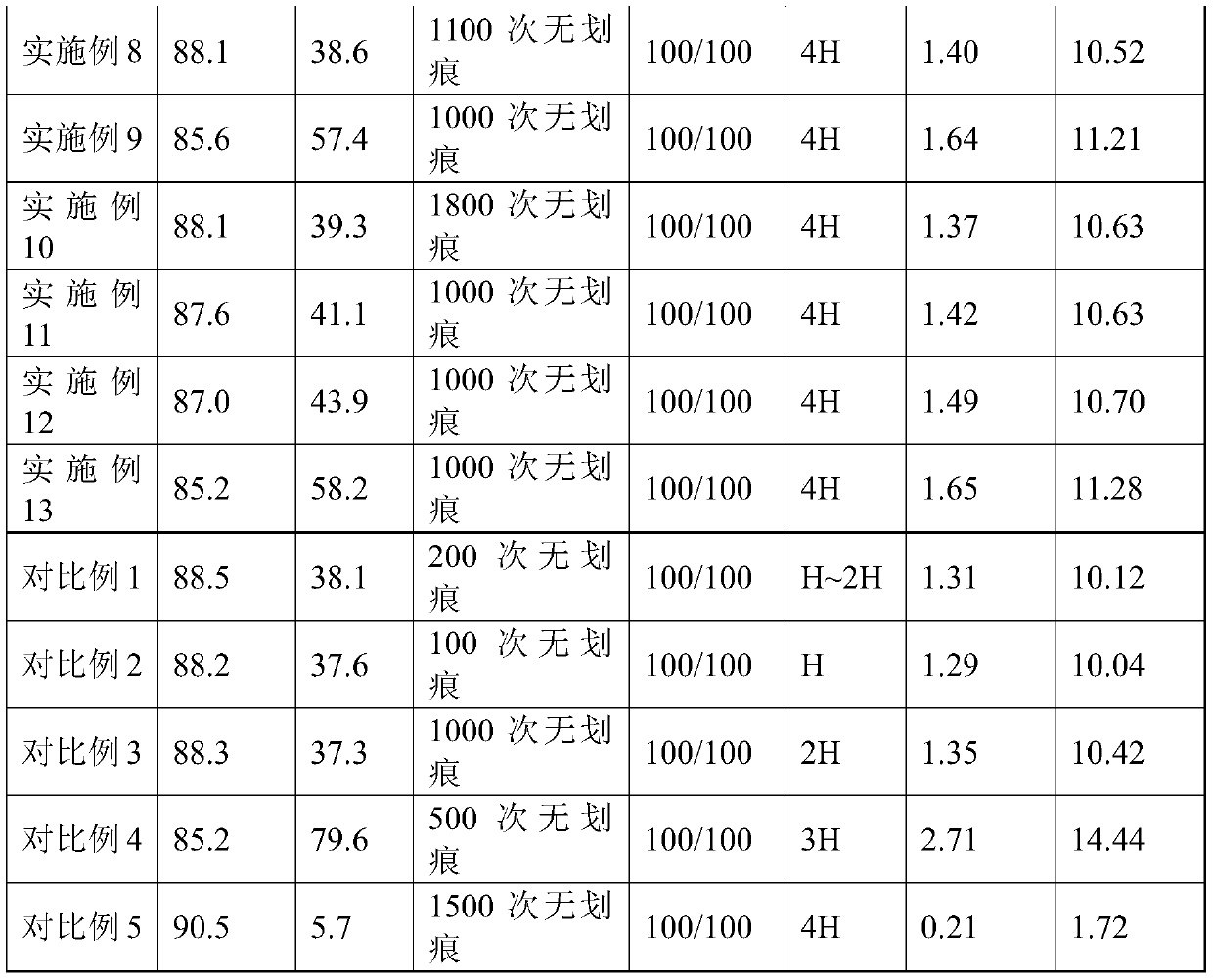

High-wear-resistance high-toughness hardened layer coating liquid and hardened film

InactiveCN109880507AImprove wear resistanceImprove toughnessPolyurea/polyurethane coatingsPliabilityTransmittance

The invention relates to the technical field of hardened films, in particular to a high-wear-resistance high-toughness hardened layer coating liquid and a hardened film. In order to solve the problemof poor wear resistance of the surface of an existing transparent film, the invention provides the high-wear-resistance high-toughness hardened layer coating liquid and the hardened film. The hardenedlayer coating liquid comprises the following components in percentage by weight: 30%-80% of an acrylate prepolymer, 5%-30% of an acrylate monomer, 10%-40% of silicon dioxide nanoparticles, 1%-6% of aphotoinitiator and 0.1%-0.5% of an auxiliary agent, wherein the particle size of the silicon dioxide nanoparticles is 10-100 nm. The hardened layer coating liquid provided by the invention has high wear resistance and good flexibility after being cured to form a hardened layer. The hardened film provided by the invention has the characteristics of high hardness, high wear resistance, high light transmittance and low haze, meets the proper toughness requirement, and is suitable for the external protection function of a display screen.

Owner:NINGBO EXCITON TECH

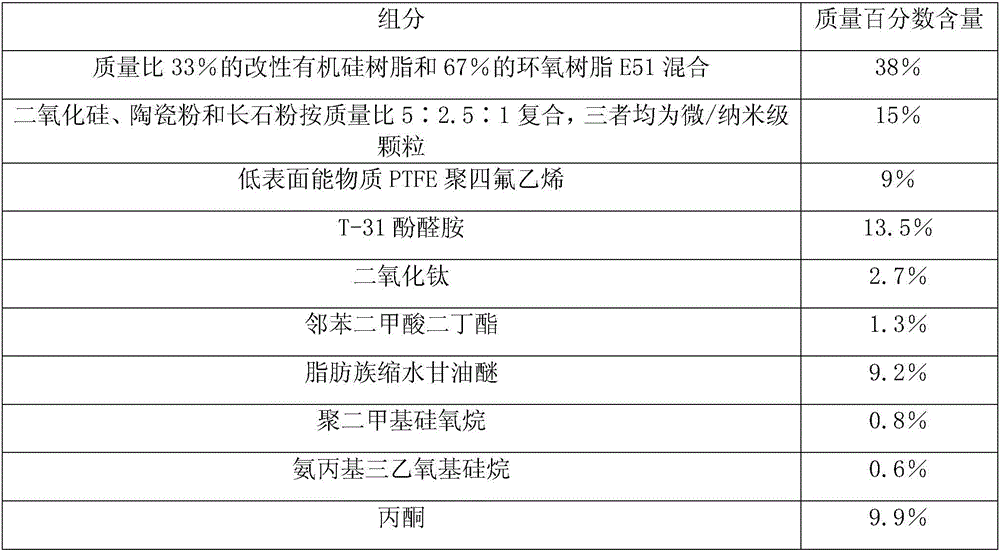

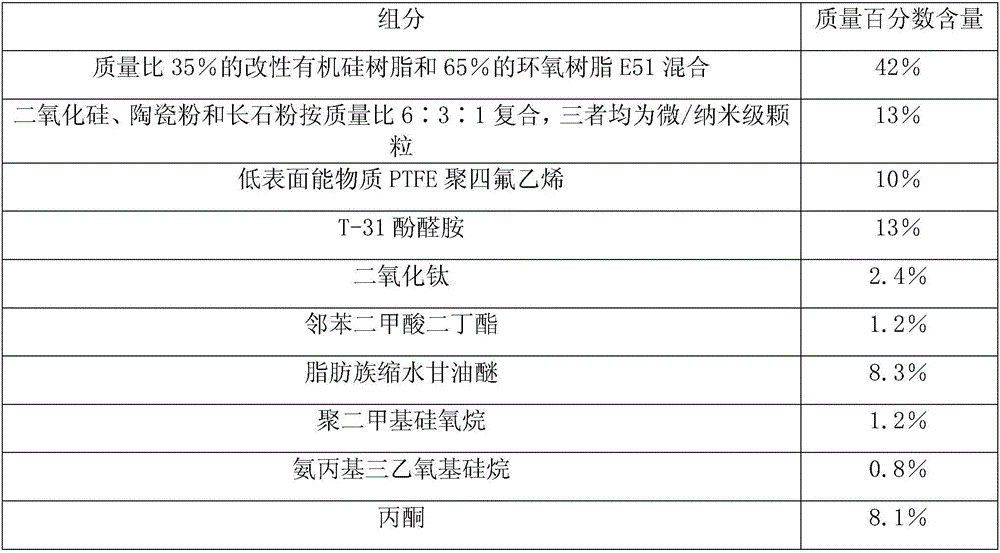

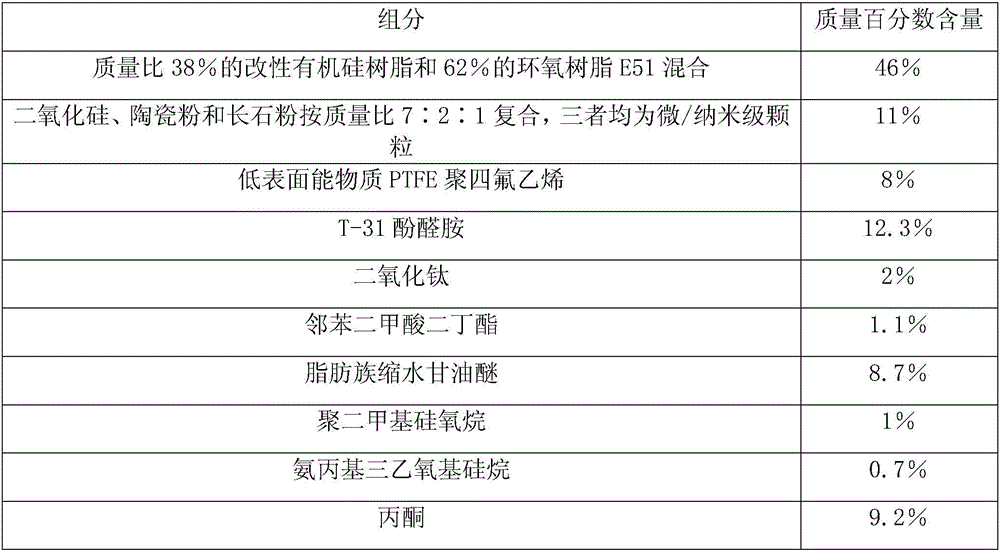

Hydrophobic corrosion-resistant ceramic paint and preparing method thereof

InactiveCN106010122AImprove performanceStrong adhesionAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceEpoxy

The invention discloses a hydrophobic anti-corrosion ceramic coating, which uses epoxy resin and modified silicone resin as a film-forming material, and adds various fillers, auxiliary agents and solvents, including body fillers, pigments and fillers, curing agents, coloring Agent, toughener, diluent, leveling agent, epoxy coupling agent and solvent. The hydrophobic anti-corrosion ceramic coating of the present invention has stable performance, strong adhesion, excellent salt water resistance, strong acid and alkali corrosion resistance, good weather resistance, high hardness, and excellent wear resistance; and it is environmentally friendly and non-toxic (low VOC), and has Good protection, decoration and functional effects, low price of raw materials, simple preparation method, suitable for the surface of metal substrates that need to be protected under harsh corrosion environments.

Owner:GUANGXI UNIV

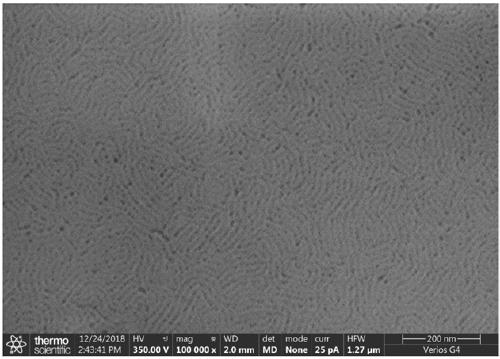

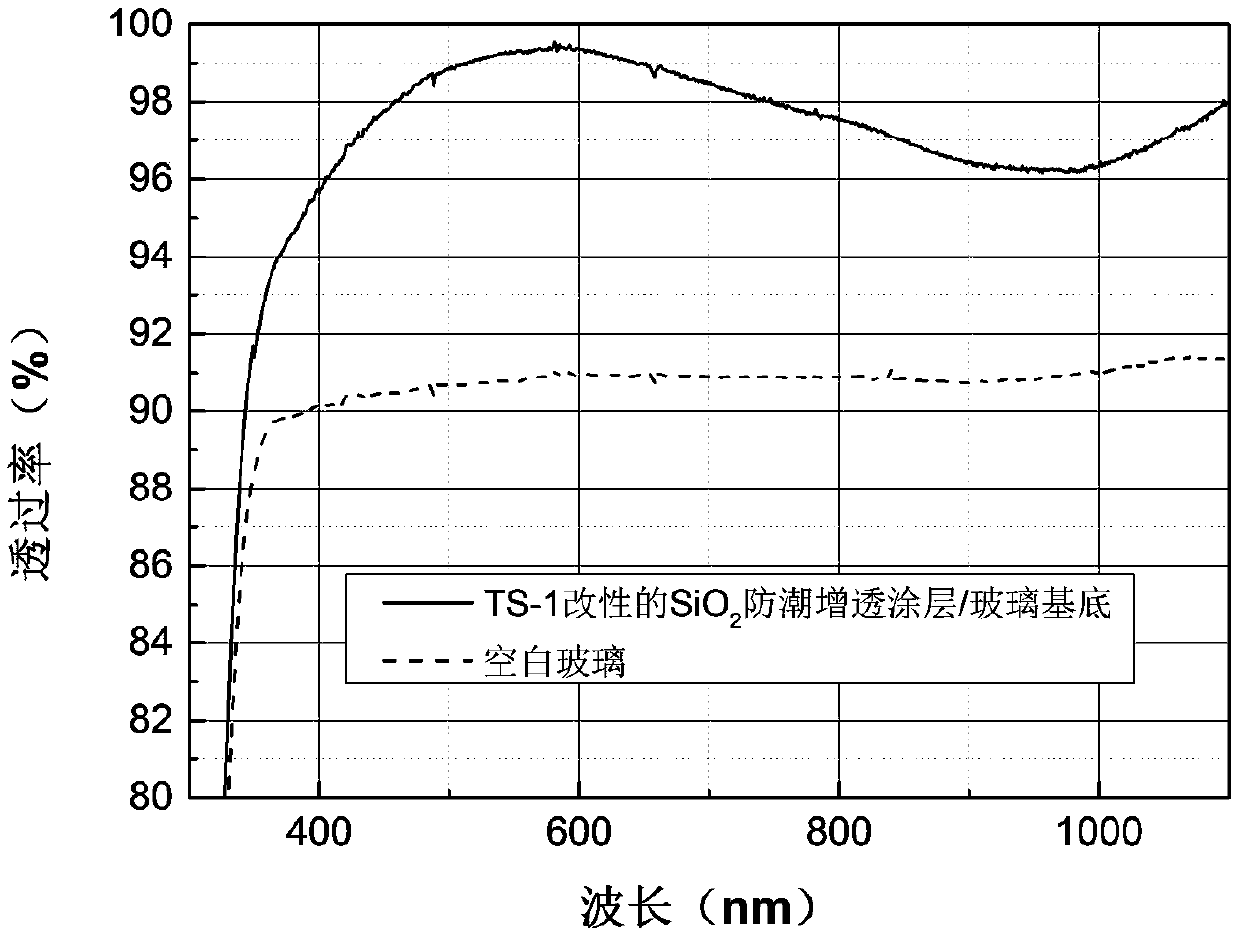

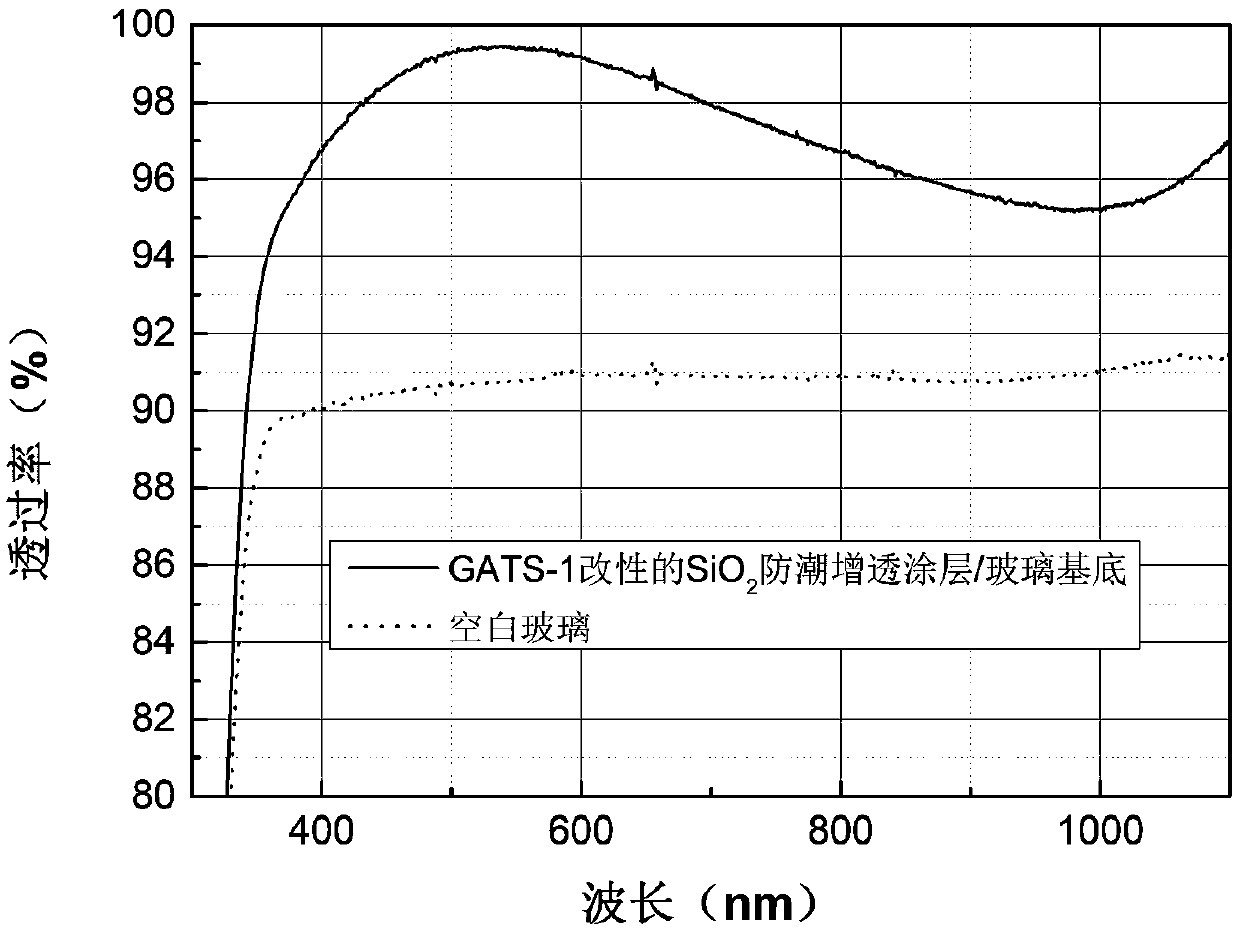

Preparation method of modified porous silicon dioxide moisture-proof anti-reflection coating

The invention discloses a preparation method of a modified porous silicon dioxide moisture-proof anti-reflection coating. The method comprises the following steps: firstly synthesizing multi-arm silane via siloxane containing epoxy group and siloxane containing primary amine or secondary amine through ring-opening addition reaction, taking multi-arm silane and silane monomers containing siloxane as common silicon source monomers, preparing a precursor solution of polysiloxane sol under an acid catalysis condition, then preparing a pore-forming agent solution, then preparing modified silicon dioxide sol, finally carrying out one-time film formation on a transparent substrate via the modified silicon dioxide sol through a dipping-pulling method to prepare the modified porous silicon dioxidemoisture-proof anti-reflection coating. The coating has a wide-spectrum reflection reduction effect, is flat and smooth in surface, excellent in abrasion resistance and weather resistance and excellent in moisture-proof function, has tightly stacked particles, has a thickness of 100-200nm, a section pore size of 5-10nm and a surface pore size of 10-40nm, and is beneficial to reversible adsorptionand desorption of water vapor.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

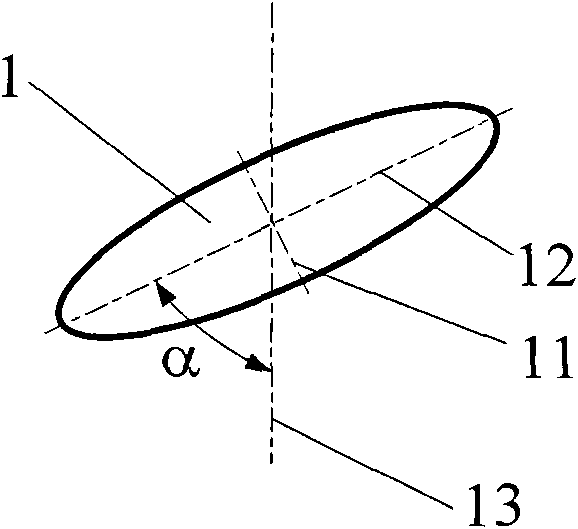

Tilting directional microporous end surface mechanical sealing structure

ActiveCN101672366AImprove reliabilityEnhanced hydrodynamic effectEngine sealsStart stopLiquid medium

The invention relates to a tilting directional microporous end surface mechanical sealing structure comprising a dynamic ring and a static ring which are sealed mechanically, one side of the end surface of the dynamic ring and the static ring is a high-voltage side, namely, an upstream part, and the other side thereof is a low-voltage side, namely, a downstream part; the end surface of the dynamicring or the static ring is provided with a microporous ring belt which is arranged on the upstream part of the end surface; the downstream part of the microporous ring belt is provided with a continuous ring-shaped sealing dam; and a long shaft of the micropore forms a tilting angle with the diameter of the sealing end surface passing through the center of the micropore. The tilting directional micropore end surface mechanical sealing structure has the beneficial effects of: greatly improving hydrodynamic effect of the microporous end surface, leading the sealing to have good starting-stopping effect under low-voltage condition, being capable of being applied in a liquid medium and a gas medium by setting the depth of the micropore, being capable of fully exerting the capabilities and advantages of microporous solid particles, realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

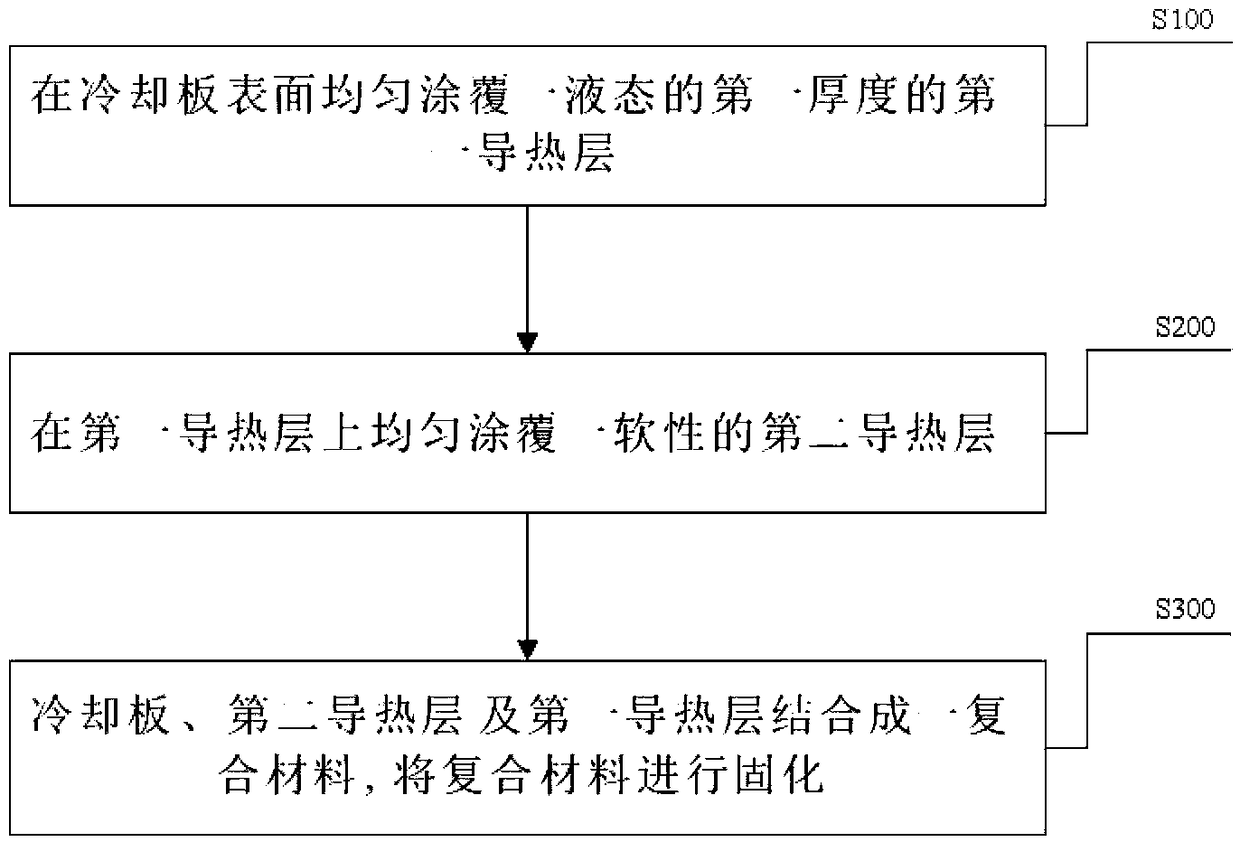

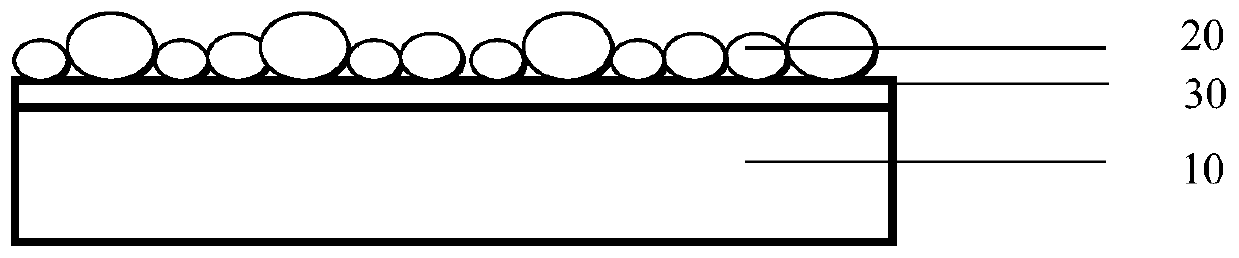

Manufacturing method of composite heat dissipation material

InactiveCN108258364AEfficient heat conductionAchieve fixationSecondary cellsWear resistantHeat conducting

The invention discloses a manufacturing method of a composite heat dissipation material. The manufacturing method specifically comprises the following steps: uniformly coating the surface of a coolingplate with a liquid first heat conducting layer of the first thickness; uniformly coating the first heat conducting layer with a soft second heat conducting layer; combining the cooling plate, the second heat conducting layer and the first second heat conducting layer into the composite heat dissipation material; curing the composite heat dissipation material. The manufacturing method disclosed by the invention has the benefits that the composite heat dissipation material is formed on the surface of the cooling plate by relying on the first high-hardness and high-mechanical strength wear-resistant first heat conducting layer and the second low-hardness flexible second heat conducting layer, the fixation, the wear resistance and the efficient heat conductivity of the composite heat dissipation material are realized, and the insulation reliability is improved.

Owner:东莞优邦材料科技股份有限公司

High-hardness and erasing-resistant hardening coating liquid and hardened film

InactiveCN109776838AAchieve hardnessAchieving wear resistancePolyurea/polyurethane coatingsHardnessHigh wear resistance

The invention relates to the technical field of hardened films, in particular to a high-hardness and erasing-resistant hardening coating liquid and a hardened film. In order to solve the problem thatthe protective film for a screen of an educational machine cannot have both high hardness and erasing resistance, the invention provides the high-hardness and erasing-resistant hardening coating liquid and the hardened film. The hardening coating liquid comprises the following components by weight percentage: 30-70% of acrylate prepolymer, 10-40% of acrylate monomer, 10-30% of polymethyl methacrylate particles, 1-5% of a light initiator and 0.1-1% of an aid. The hardening coating liquid forms a hardened layer after curing, which has both high hardness and erasing resistance. The hardened filmhas the characteristics of high hardness, high wear resistance and erasability, and is suitable for external protection of display screens.

Owner:NINGBO EXCITON TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com