Wear-resistant anticorrosive paint for polar ships and preparation method thereof

A technology for anti-corrosion coatings and ships, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effects of improving adhesion and impact resistance, good low-temperature toughness and wear resistance, excellent mechanical properties and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of modified nano filler is:

[0057] 1) Add 0.5g of nano-filler powder to 100ml of deionized water, first magnetically stir for 30 minutes, and then disperse by ultrasonic waves for 20 minutes to obtain a 5g / L nano-filler dispersion;

[0058] 2) Adjust the pH of the dispersion to 4, add a coupling agent with a mass of 1% to 4% of the nanofiller powder to the dispersion and react at 80°C for 2 to 3 hours;

[0059] 3), centrifuge the mixed solution after the reaction in step 2) (separate at a speed of 10000r / min for 20min), take the separated precipitate and add it to deionized water, and then perform ultrasonic dispersion for 10min;

[0060] 4), repeat step 3) until the excess coupling agent is completely removed, dry the dispersion after removing the coupling agent at 100° C. for 24 hours, and then perform vacuum cooling for 1 hour to obtain the modified nano filler.

[0061] Preferably, the wear-resistant filler is compounded by hard filler and ...

Embodiment 1

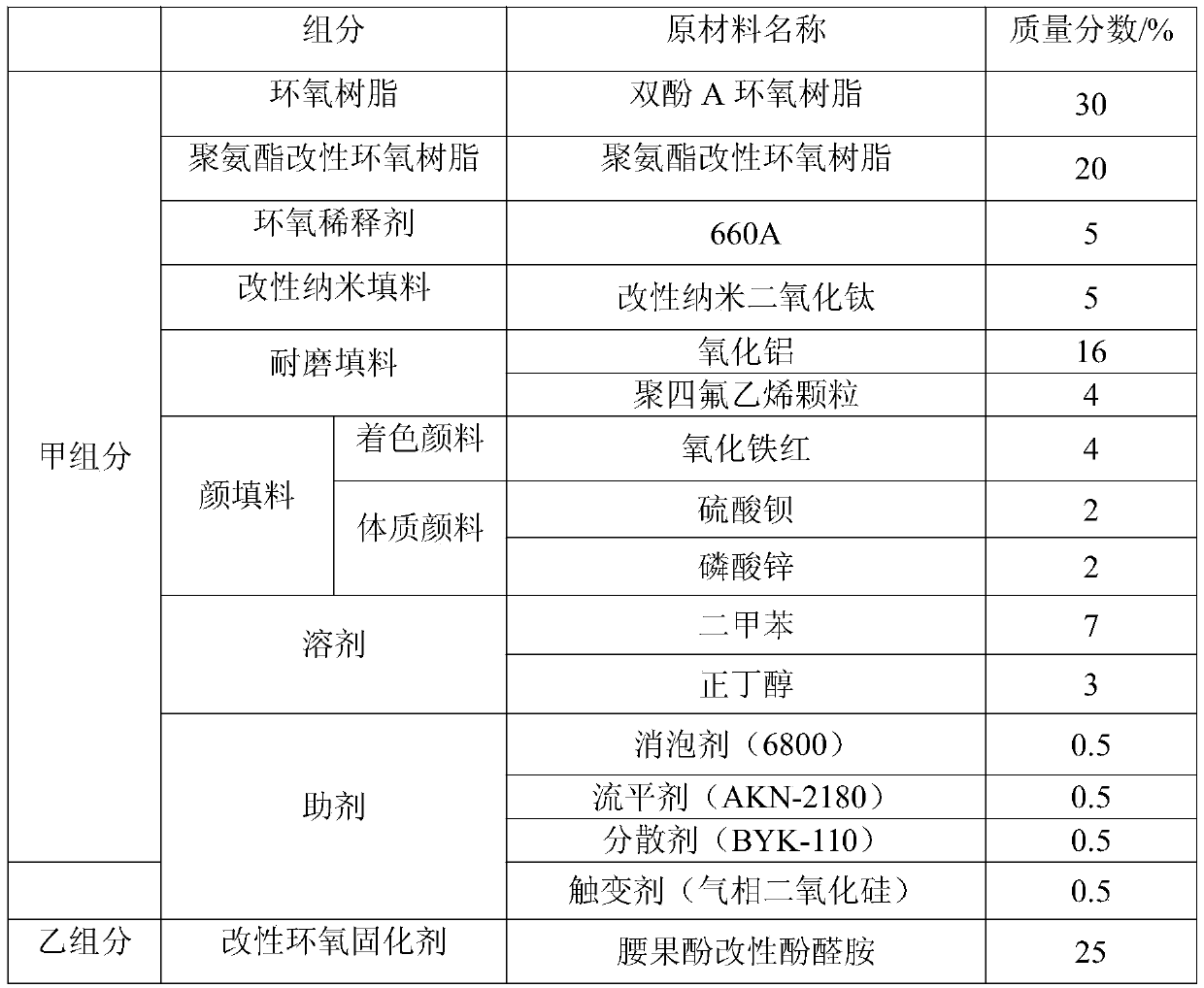

[0076] A wear-resistant and anti-corrosion coating for polar ships, its components and corresponding mass fractions are shown in Table 1.

[0077] The wear-resisting anticorrosion coating of table 1 embodiment 1 is calculated by mass fraction

[0078]

[0079] The preparation method of this coating comprises the steps:

[0080] (1) Weigh each component according to the mass percentage, place the weighed pigments and fillers in an oven, dry at a temperature of 110±5°C for 2 to 12 hours, and then cool naturally to room temperature to obtain the dried After the pigment;

[0081] (2), the epoxy resin that step (1) takes by weighing, polyurethane modified epoxy resin, epoxy thinner, dispersant, defoamer, leveling agent and the solvent that account for 70% of total amount are mixed, stir The equipment stirs at a speed of 500-800r / min for 5-45min;

[0082] (3), adding the modified nano-filler to the mixture obtained in step (2), stirring at a speed of 1200-1500r / min for 20-30mi...

Embodiment 2

[0086] The components and corresponding mass fractions of the wear-resistant and anti-corrosion coating in Example 2 are shown in Table 2.

[0087] The wear-resisting anticorrosion coating of table 2 embodiment 2 is calculated by mass fraction

[0088]

[0089] The preparation method of embodiment 2 is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com