Patents

Literature

16892 results about "Anti-corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-corrosion refers to the protection of metal surfaces from corroding in high-risk (corrosive) environments. When metallic materials are put into corrosive environments, they tend to have chemical reactions with the air and/or water. The effects of corrosion become evident on the surfaces of these materials. For example, after putting a piece of iron into a corrosive atmosphere for an extended period, it starts rusting due to oxygen interaction with water on the surface of the piece of iron.

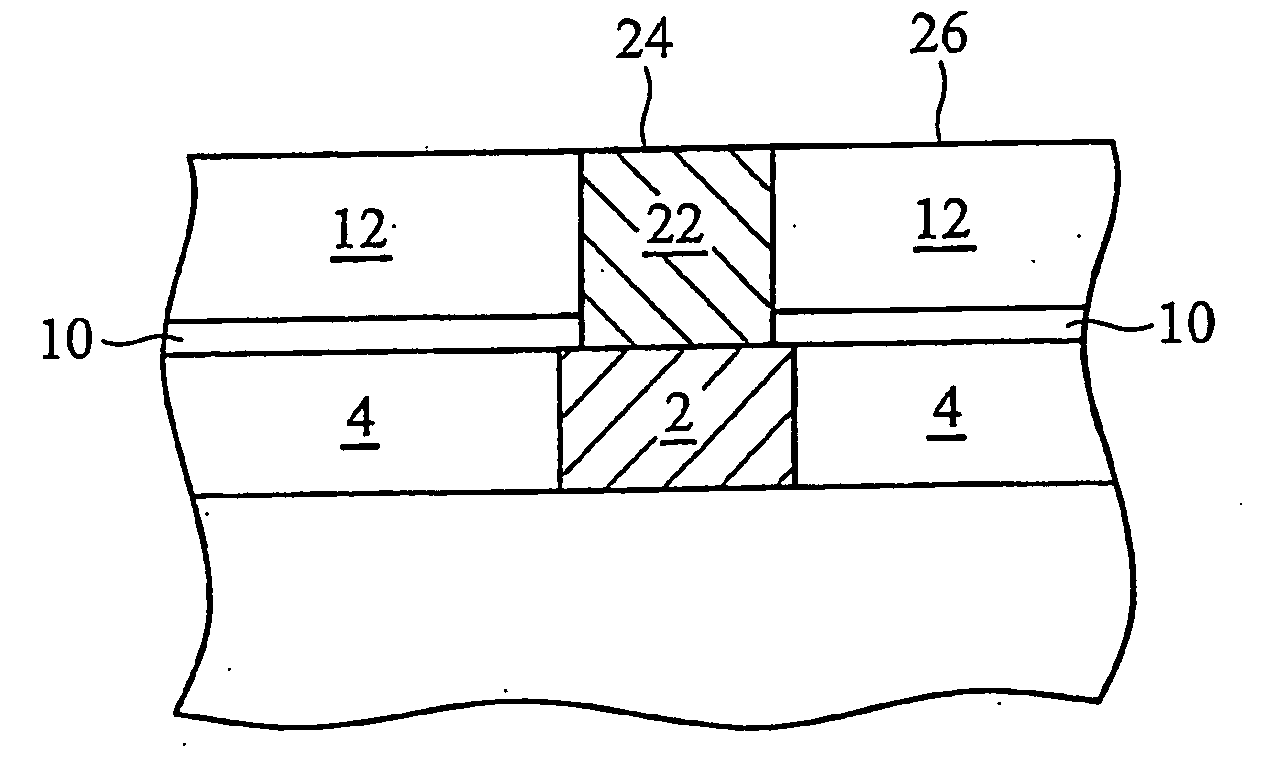

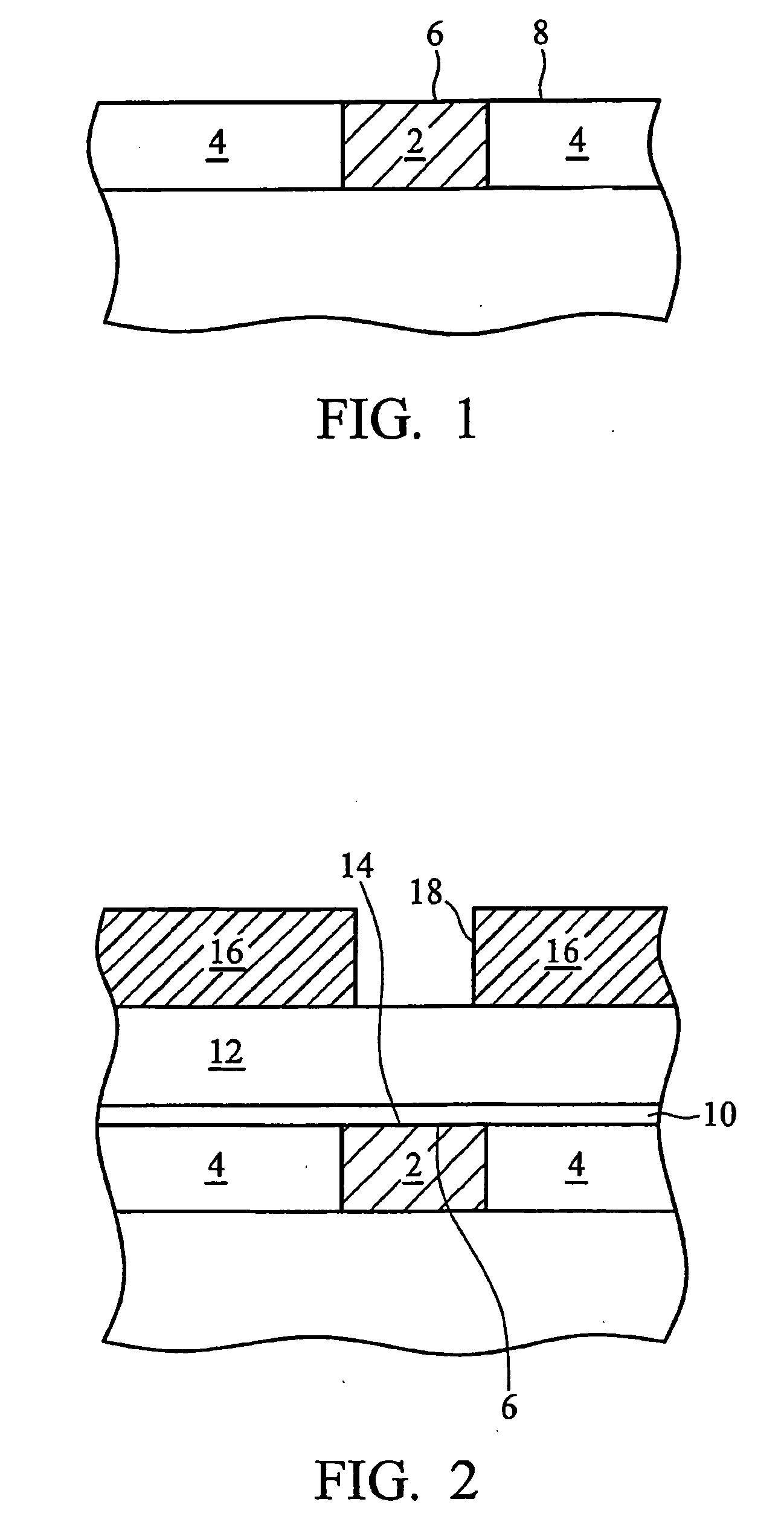

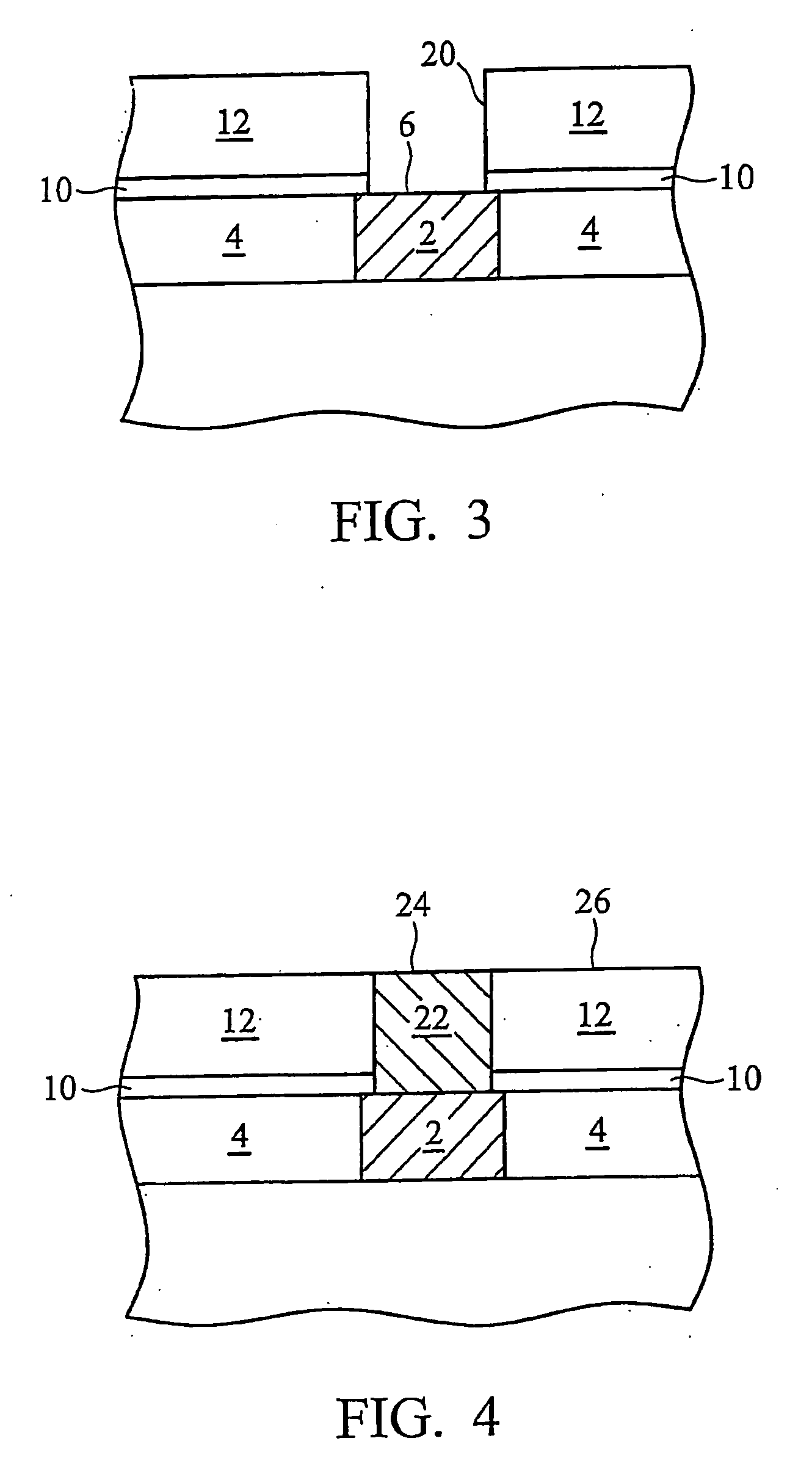

Post etch copper cleaning using dry plasma

A method for post-etch copper cleaning uses a hydrogen plasma with a trace gas additive constituting about 3-10 percent of the plasma by volume to clean a copper surface exposed by etching. The trace gas may be atomic nitrogen or other species having an atomic mass of 15 or greater. The trace gas adds a sputtering aspect to the plasma cleaning and removes polymeric etch by-products and polymeric and other residuals formed during the deposition of dielectric materials or etch stop layers over the copper surface. An anti-corrosion solvent may be used to passivate the copper surface prior to formation of the dielectric materials or etch stop layers.

Owner:TAIWAN SEMICON MFG CO LTD

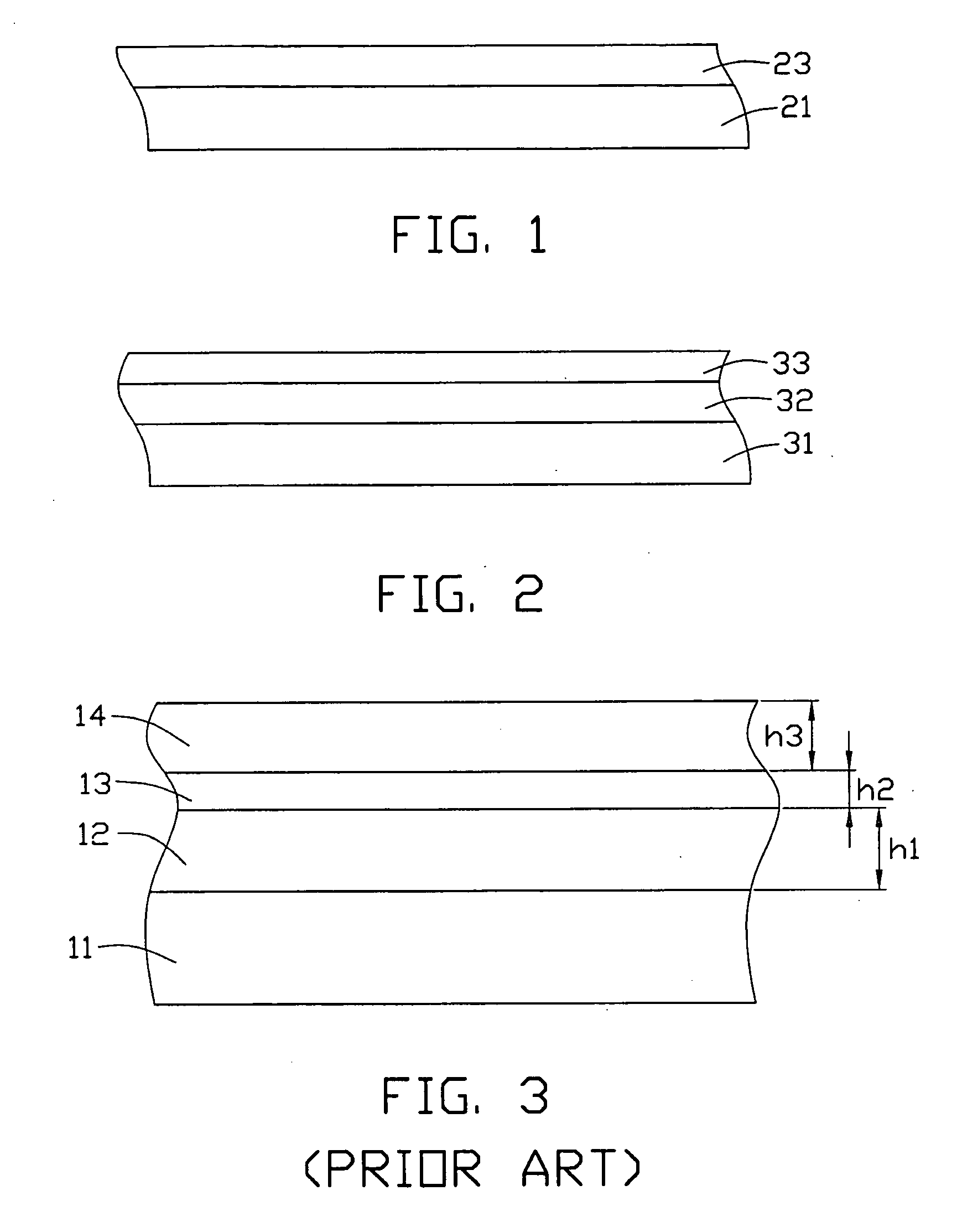

Anti-fingerprint coating construction

InactiveUS20060110537A1Easy to cleanImprove anti-corrosion performanceMaterial nanotechnologyFouling preventionNanometreAntibacterial property

An anti-fingerprint coating construction (23) for application to a surface of a substrate (21) includes a layer formed of a material selected from the group consisting of a hydrophobic nano-composite material, an oleophobic nano-composite material, and a super-amphiphobic nano-composite material. When the anti-fingerprint coating construction is employed on a metal surface or a nonmetal surface, sweat or / and grease on fingers of a user is not liable to be adhered to the surface. Therefore a fingerprint of the user is prevented from being imprinted on the surface, and the surface can remain clean and aesthetically pleasing. Because the anti-fingerprint coating construction is easy to clean, the anti-fingerprint coating construction has good anti-corrosion and antibacterial properties. The anti-fingerprint coating construction contains no chromium, and therefore does not need to be processed by an acid or alkali solution. This makes the anti-fingerprint coating construction environmentally friendly.

Owner:HON HAI PRECISION IND CO LTD

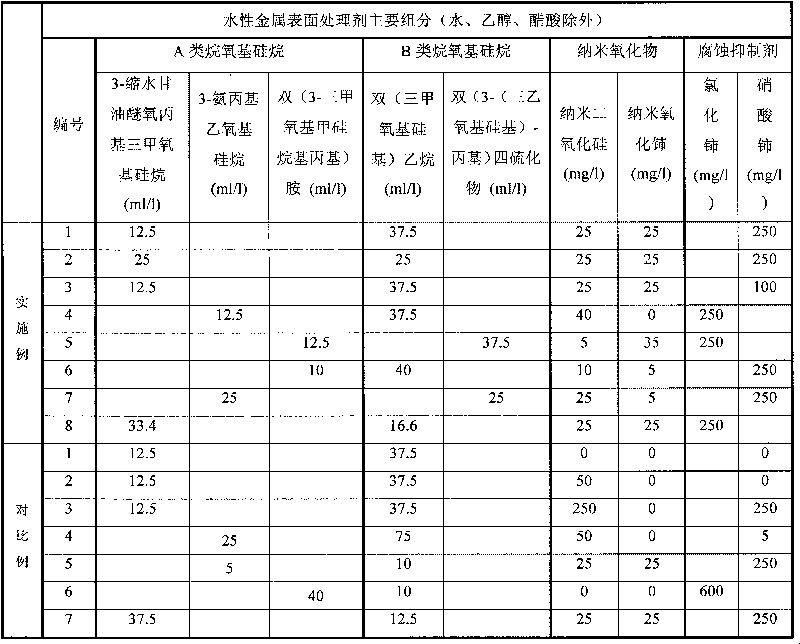

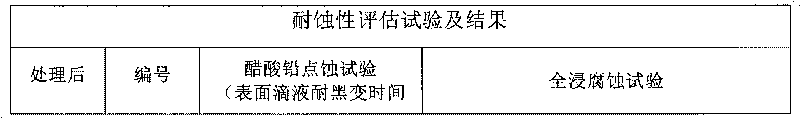

Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

ActiveCN101717930ASimple processApplicable industrial scaleMetallic material coating processesWater basedEpoxy

The invention discloses an environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface. The treatment agent is water-based silane solution which consists of at least one alkoxy silane containing epoxy or at least one alkoxy silane containing amino, at least one disilyl silane, nano-silicon dioxide, rare earth salt type corrosion inhibitor or rare earth salt type and rare earth nano oxide, water, or acetic acid and a small amount of ethanol. The metal material is coated by using the silane solution for impregnation, brushing, spraying or spin-coating, a siloxane layer is formed on the metal surface, then the long-acting corrosion resistance is formed by curing for 3 hours at the temperature of 100 DEG C, and a nano organic silane film which has close bonding force with a coating is formed. Nanoparticles can not only improve the corrosion resistance and enhance the mechanical strength of the silane film in a coating layer, but also realize the synergistic corrosion resistance with the corrosion inhibitor. The technology has the advantages of simple process, greenness, environmental protection and strong practicality.

Owner:HAISO TECH

Surface anti-corrosion sol for aeronautic aluminum alloy material and treatment method thereof

The invention discloses surface anti-corrosion sol for an aeronautic aluminum alloy material and a treatment method thereof in the technical field of aluminum alloy surface treatment. The sol comprises the following components in percentage by weight: 1-15 percent of organosiloxane, 45-93 percent of organic solvent, 0.1-10 percent of additive, 0.5-10 percent of rare earth salt, 5-50 percent of deionized water and 0.1-5 percent of catalyst. In the invention, a coating with a compact netlike crosslinking structure is formed on the surface of an aluminum alloy matrix and has high chemical stability and thermal stability, so that influence of an external acidic and alkaline environment and temperature variation on the coating can be resisted; and the coating has higher mechanical strength, rain washing resistance, friction resistance and scratch resistance. The technical method is simple, is easy and convenient to operate, does not have high requirement on equipment and is environmentally-friendly and pollution-free.

Owner:SHANGHAI JIAO TONG UNIV +1

Improved soil matrix and remediation method for green mine

InactiveCN109534737AFull of nutritionSuitable for growthGrowth substratesCulture mediaWater storageFriction angle

The invention provides an improved soil matrix and a remediation method for a green mine. According to the improved soil matrix and the remediation method for the green mine, a certain gradient of a mountain is formed by trimming a cliff of the mine, a hard material is laid in a certain mode, then a plastic-coated metal net covers the hard material, and finally, the novel improved soil matrix covers the plastic-coated metal net with a certain thickness so as to realize the effective remediation of the mine. The improved soil matrix and the remediation method for the green mine have the beneficial effects that the improved soil matrix can stably float on the surface of the mine with the gradient of less than 80 degrees, the adhesive force is greater than 20 Kpa, the inner friction angle isgreater than 18 degrees, the anti-corrosion index is greater than 99.1%, the anti-scouring index is greater than 2.0 L.min / g, the structure is high, and scouring of heavy rainfall or heavier can be effectively resisted after three days of spraying; the improved soil matrix is rich in nutrition, loose and breathable, and is suitable for growth of plants; and lots of organic matter such as agricultural and forestry leftovers are adopted, so that the water storage performance is high, and the construction cost and the maintenance cost are greatly saved.

Owner:杰瑞(莱州)矿山治理有限公司

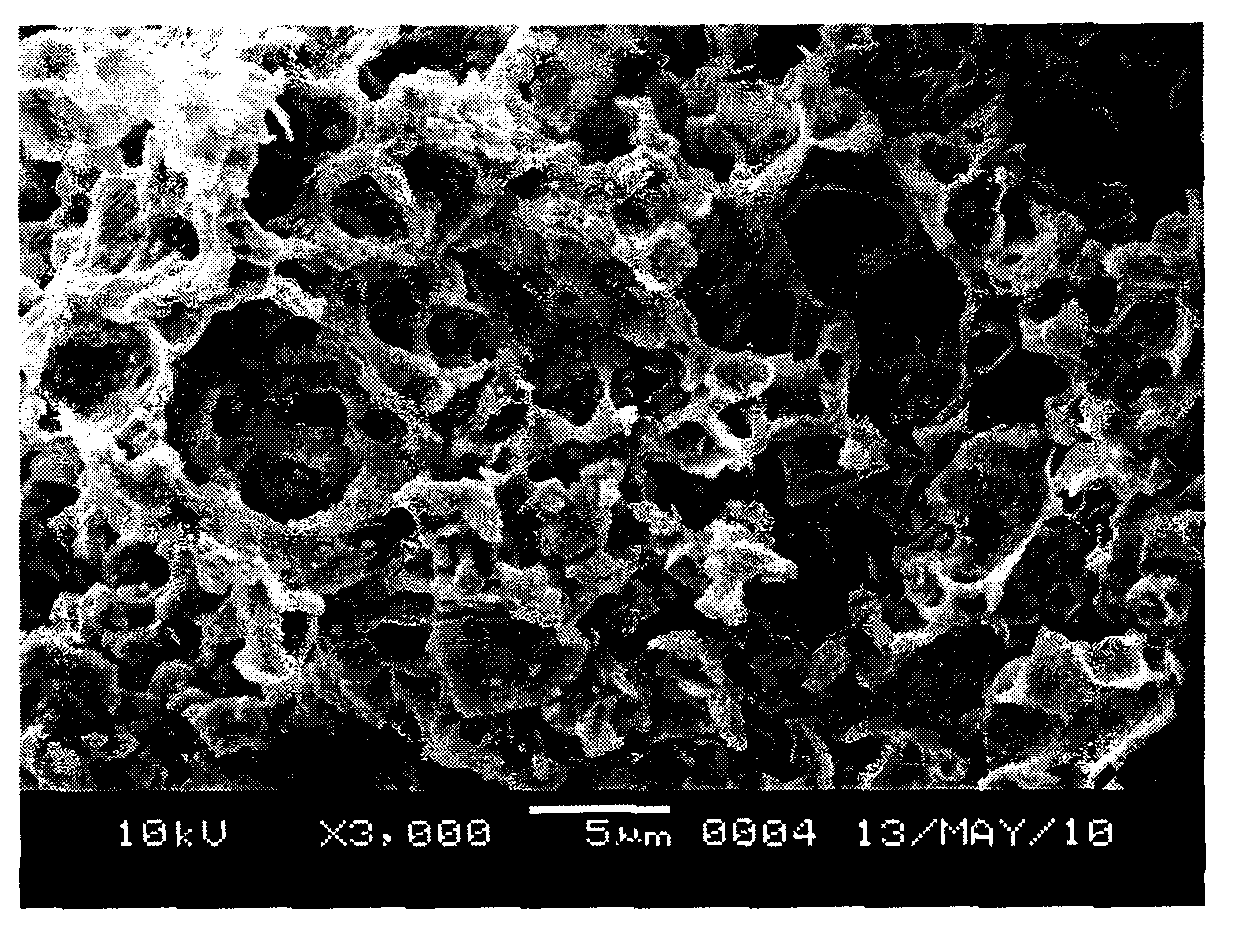

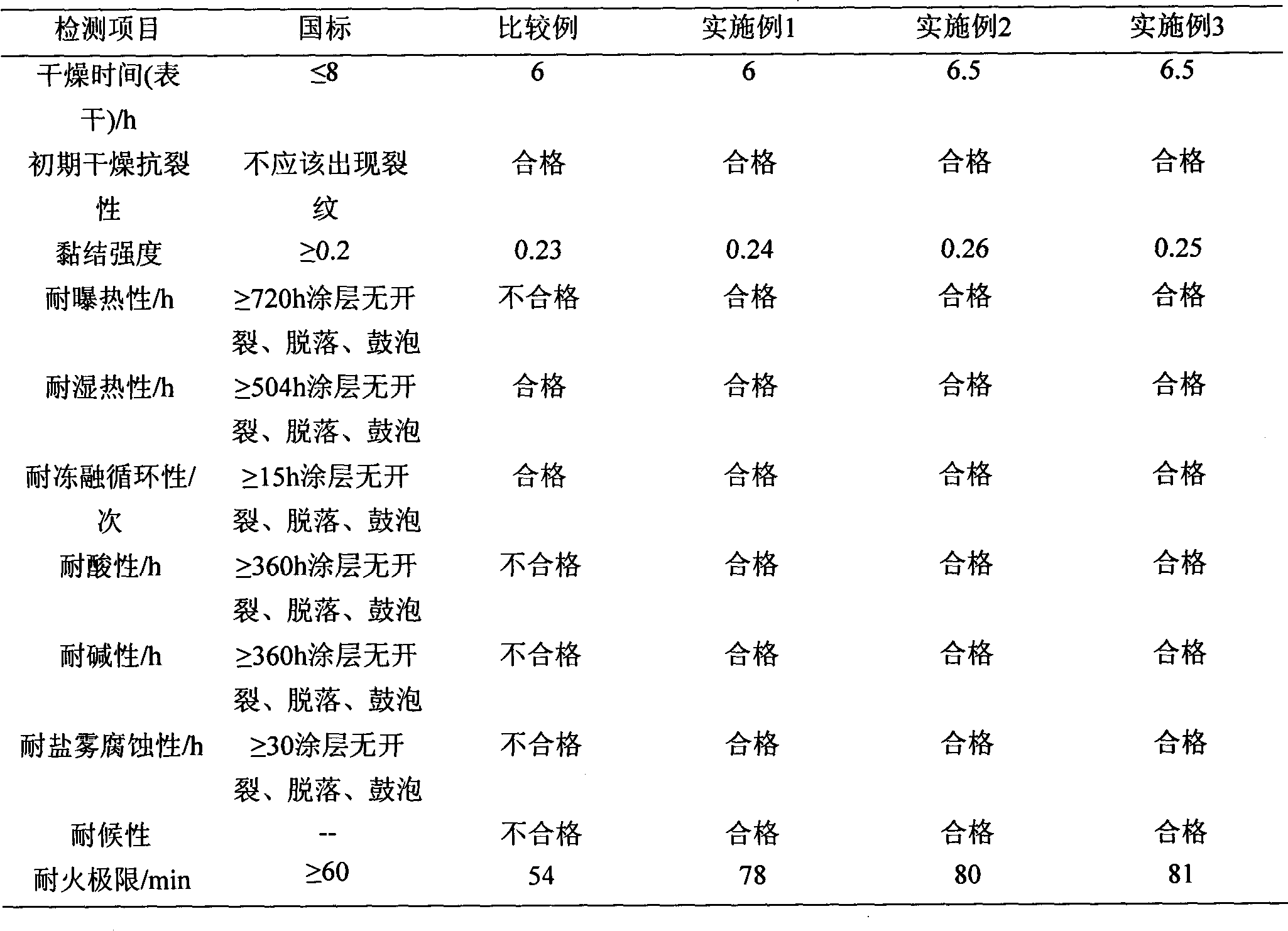

Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

InactiveCN101857760AGuaranteed expansion heightHas anti-rustFireproof paintsAnti-corrosive paintsAcrylic resinRust

The invention relates to an aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and a preparation method thereof. The fire-proof anti-corrosive paint is prepared by adding ammonium polyphosphate, pentaerythritol, melamine, titanium white, expandable graphite, a preservative, a ceramic filler, an antifoaming agent, a dispersing agent, a plasticizer and the like into organic silicon-modified acrylic resin emulsion serving as a film forming base material. The paint has the advantages of high fire-proof performance, anti-corrosion and anti-rust function, and high water resistance, acid-alkali resistance and corrosion resistance, capability of meeting the requirements of various steel structures on the fire-proof and anti-corrosion performance, environmental friendliness, low cost, and readily available raw materials, so the paint can be widely applied to fire-proof protection of various steel structures.

Owner:EAST CHINA UNIV OF SCI & TECH

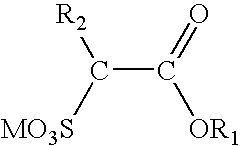

Epoxidized ester additives for reducing lead corrosion in lubricants and fuels

Fuels, especially hydrocarbon fuels, and lubricants, especially lubricating oils, contain a class of anti-corrosion, anti-fatigue, and anti-wear additives that are derived epoxidized esters of fatty acids. Epoxidized 2-ethylhexyl tallate is particularly effective.

Owner:CHEMTURA CORP

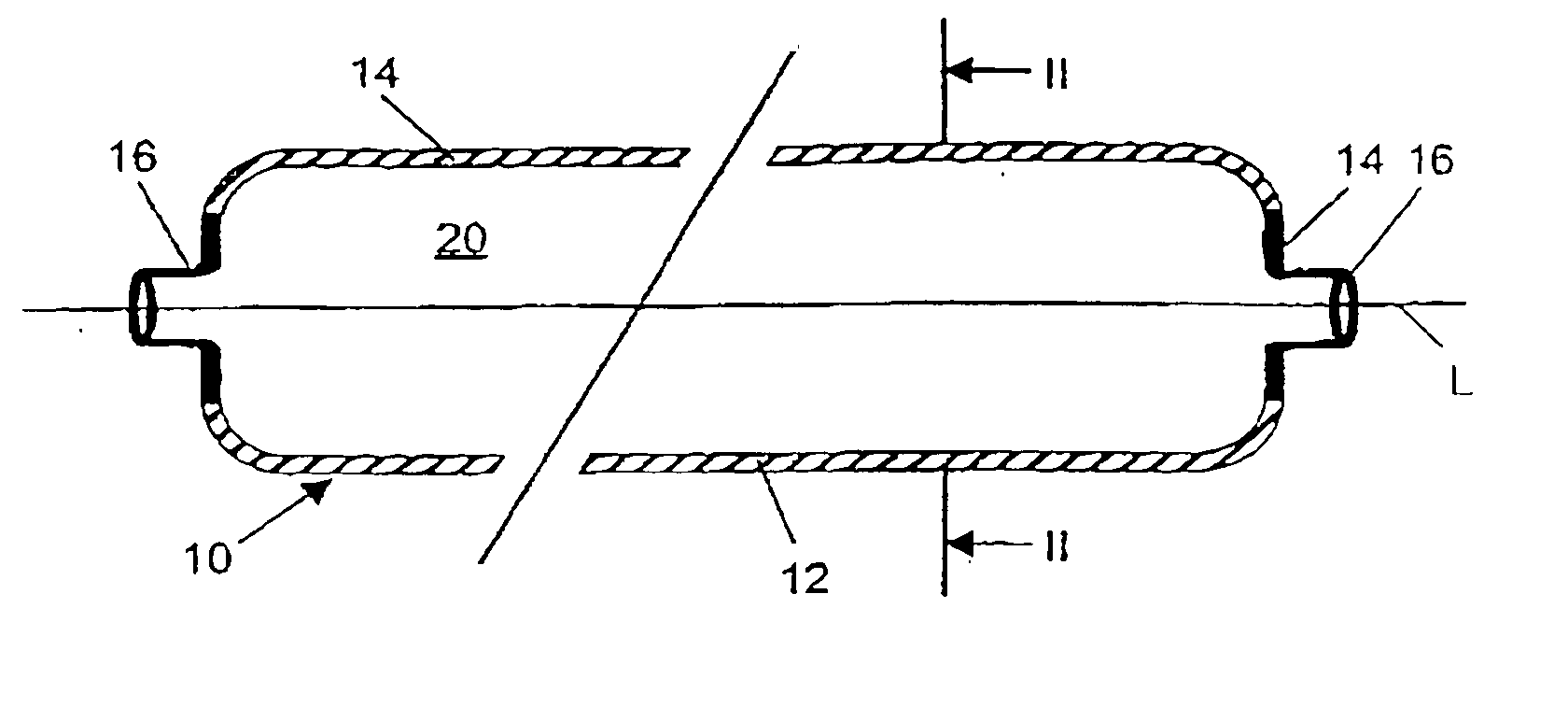

Gastight container

InactiveUS20040149759A1Reduce quality problemsNegligible in recyclingAircraft componentsVessel mounting detailsHydrogenComposite film

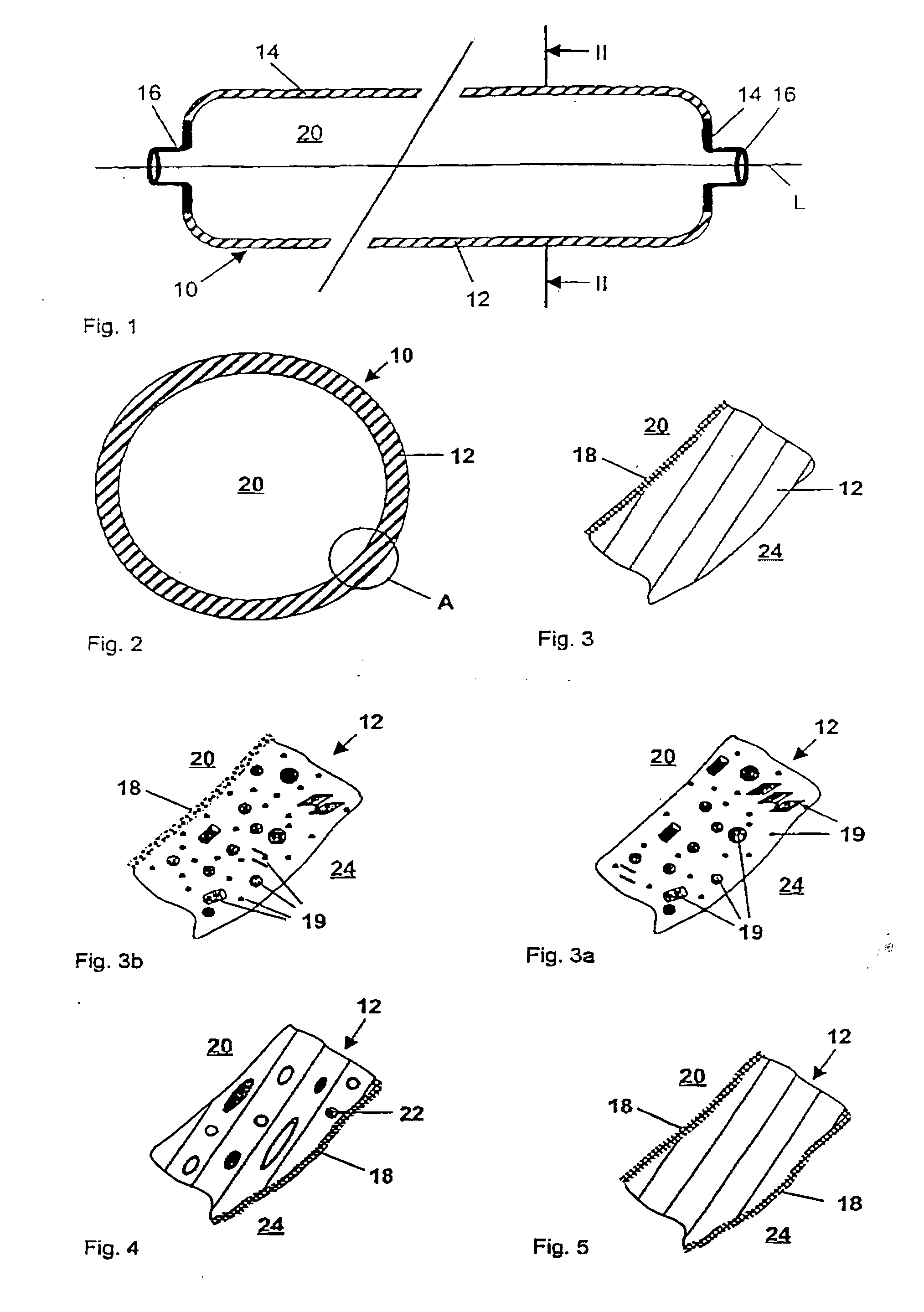

The invention relates to a gastight, pressure-resistant storage and / or transport container (10) for low-molecular, reactive filling media, especially for hydrogen, oxygen, air, methane and / or methanol. Said container has a high filling pressure and is embodied in an essentially rotationally symmetric manner, having at least one connector cap (15) with a sealing device (16). The wall (12) of the container is essentially comprised of a thermoplastic synthetic material having at least one diffusion barrier (18, 19) system and / or a diffusion barrier and anti-corrosion system (18, 19). In order to offer protection for hydrogen and oxygen containers, the diffusion barrier system can be embodied in the form of at least one compact layer and / or can contain finely dispersed, distributed reactive nanoparticles (18) in the wall (12) of the container, in at least one composite film (28) and / or in at least one diffusion barrier layer (18).

Owner:MOSER EVA MARIA +1

Single-surface glue water tape and making method thereof

The invention discloses a single-side glue water belt and a preparation method thereof; the water belt consists of a fiber knitting layer and a polyurea elastomer coating which is used as a lining layer which has the thickness of 0.5-1.0mm; high-strength aramids are preferably selected for the warp and woof of the knitting layer; the preparation method comprises the steps as follows: tabular knitting layer is knitted on a circular loom firstly; subsequently, isocyanate composition and resin composition are mixed and heated to 60-70DEG C and pressurized to 12-15MPa; subsequently, the mixture is sprayed at the internal side of the fiber knitting layer by a spraying gun, thus forming a polyurea elastomer coating which is then dried so as to gain the product; the water belt is used for delivering water or industrial liquids in the industries such as fire control or agriculture and industry, building and the like, has the advantages of wearability, anti-corrosion, anti-impact, long service life and the like, has simple preparation method, few equipment investment, high production efficiency and meeting the requirement of environmental protection.

Owner:5ELEM HI TECH CORP

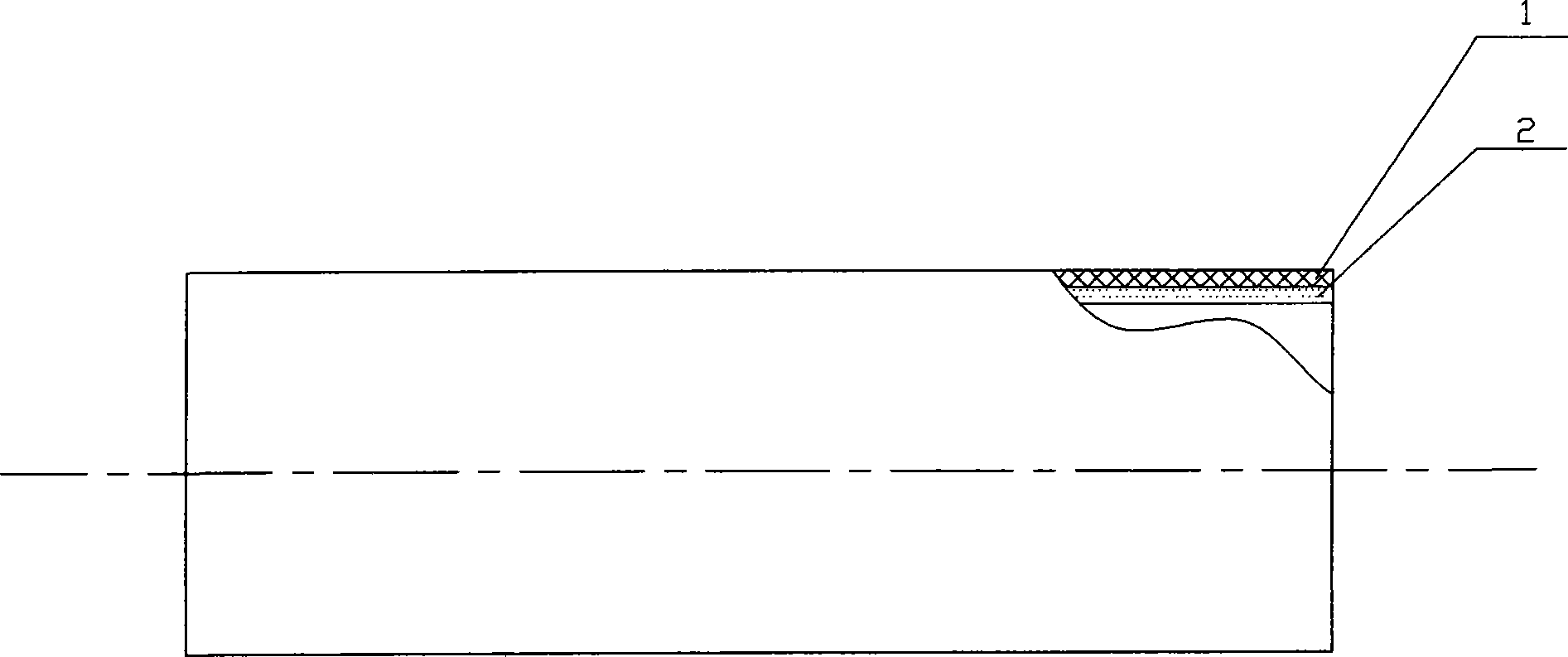

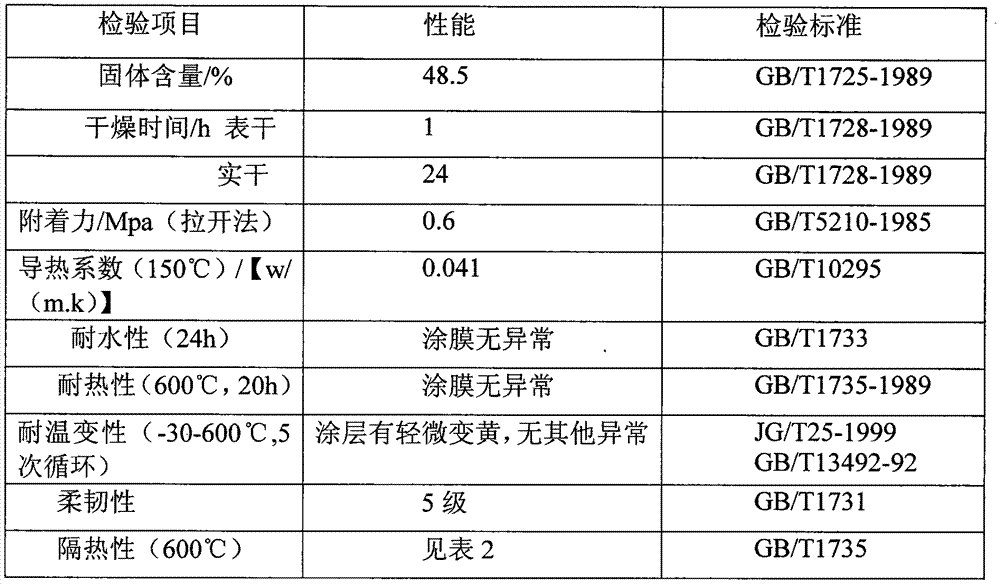

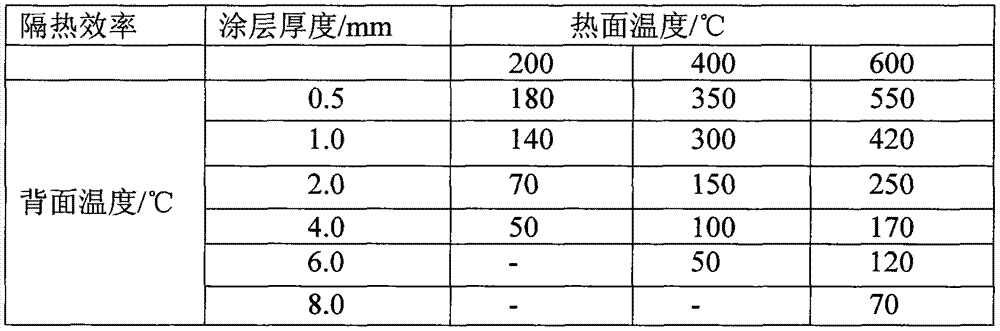

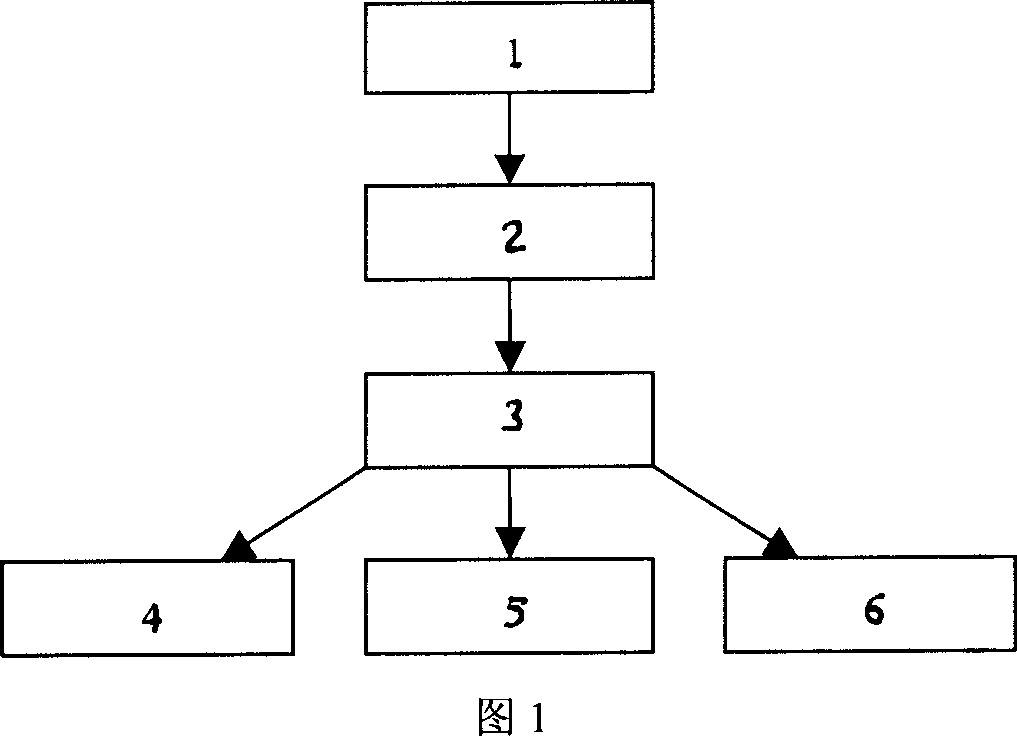

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

Silver-free tin-bismuth-copper leadless solder and preparation method

ActiveCN1927525AGood solder wettabilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaShielding gasIngot

The invention relates to a tin-base leadless solder without silver, and relative production. Wherein, it comprises Bi at 7.5-60% (without 7.5%), Cu at 0.1-3.0%, and the left is tin; and it also can contain Zn, Ni, P, Ge, Ga, In, Al, La, Ce, Sb, Cr, Fe, Mn, or Co while the total amount of micro alloy element is not higher than 1.0%. And the production comprises that in protective gas or vacuum, smelting middle alloy Sn-Cu10; then smelting into leadless solder alloy ingot which can be used as solder directly or be made into bar band, wire plate or powder. The inventive solder has low cost while its fusion point can be controlled between 140 and 230Deg. C. And it has strong anti-oxidization and anti-corrosion properties.

Owner:BEIJING COMPO ADVANCED TECH

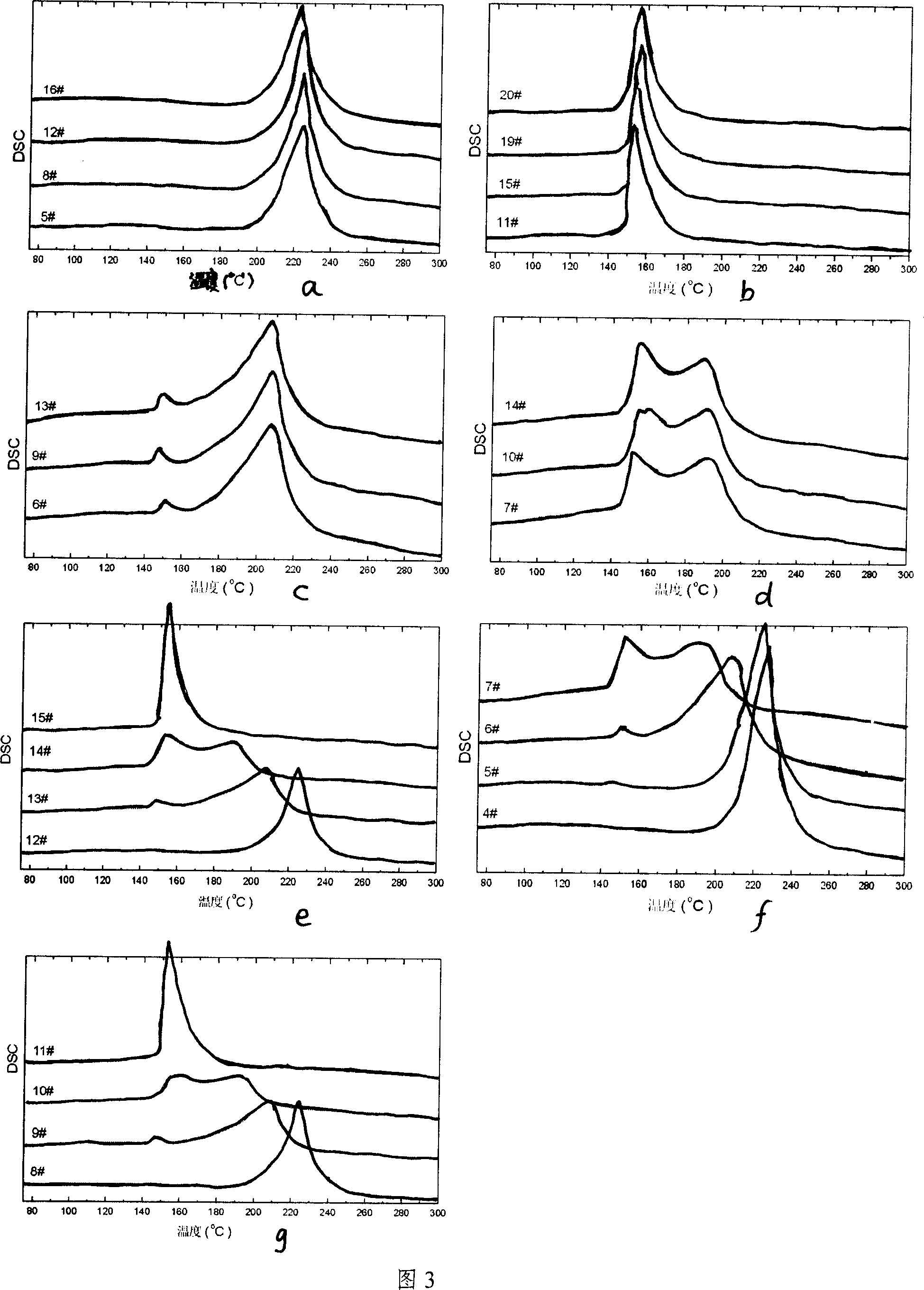

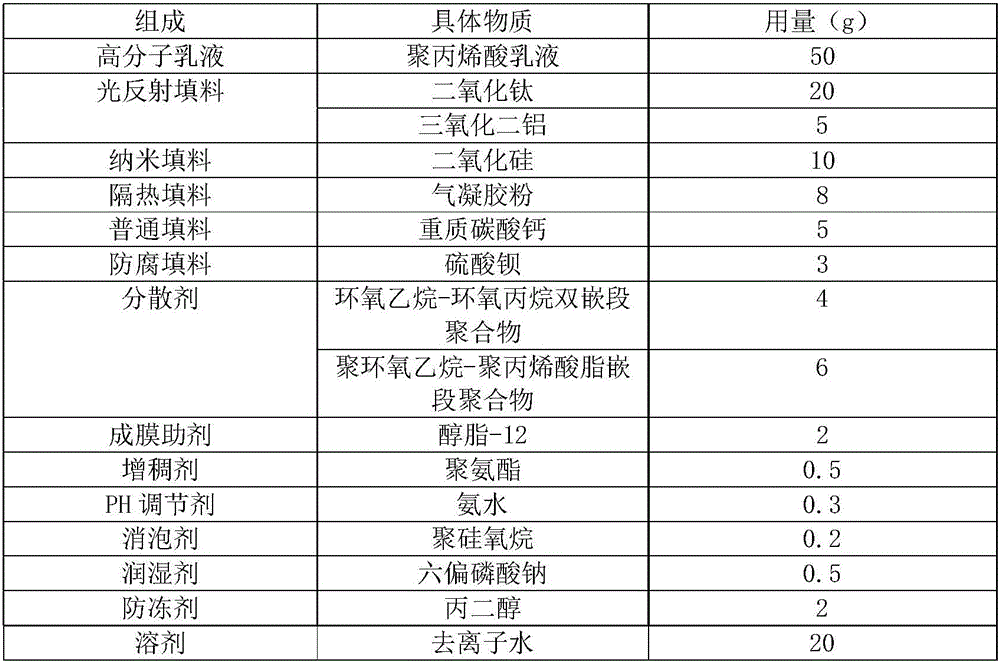

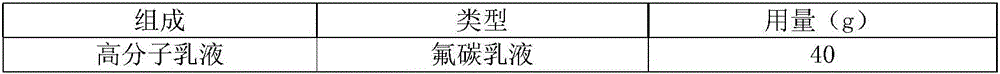

Water-based light reflex industrial insulation coating and preparation method thereof

ActiveCN106752526AGood compatibilityImprove thermal insulation performanceAnti-corrosive paintsReflecting/signal paintsWater basedDefoaming Agents

The invention relates to an industrial coating, in particular to a water-based industrial insulation coating with light reflection, heat insulation and corrosion protection effects and a preparation method thereof. The coating is prepared from the following components in percentage by weight: 25 percent to 50 percent of polymer emulsion, 5 percent to 30 percent of light reflective filler, 1 percent to 5 percent of nanofiller, 5 percent to 10 percent of heat-insulating filler, 5 percent to 10 percent of anti-corrosion filler, 5 percent to 8 percent of normal filler, 0 percent to 10 percent of curing agent, 1 percent to 5 percent of dispersing agent, 0.1 percent to 4 percent of coalescing agent, 0.1 percent to 2 percent of thickening agent, 0 percent to 1 percent of defoaming agent, 0.01 percent to 0.5 percent of PH (Potential Of Hydrogen) regulator, 0.1 percent to 2 percent of wetting agent, 0.5 percent to 1 percent of antifreezing agent, and the balance of deionized water. The coating provided by the invention has the effects on light reflection, heat insulation and corrosion protection at the same time, can be applied in the fields of storage tanks, pipelines, outdoor equipment, containers and the like, has the characteristics of safety, nontoxicity, environmental protection and pollution free, and has favorable weather fastness, stain resistance, salt fog resistance and scrubbing resistance.

Owner:SHENYANG RES INST OF CHEM IND

anti-corrosion coating

InactiveCN102260450AStrong adhesionEasy constructionAlkali metal silicate coatingsAnti-corrosive paintsMetal coatingSolvent

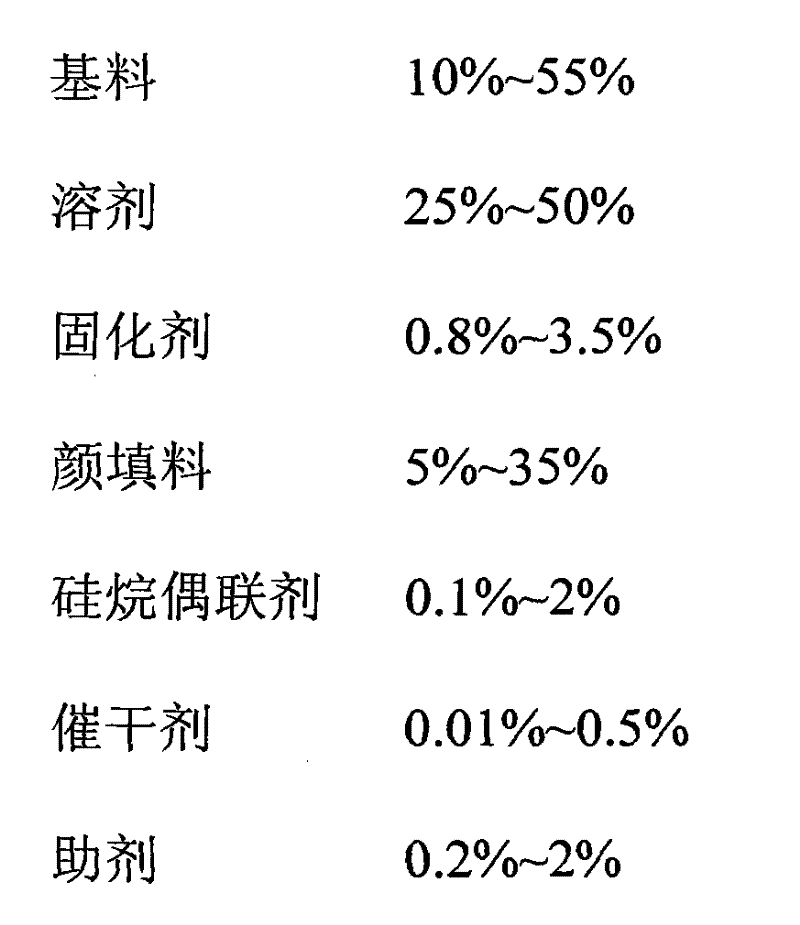

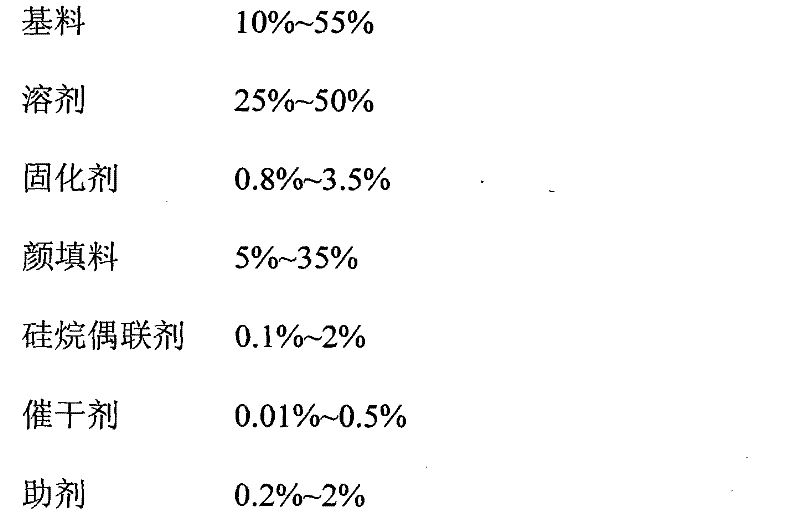

The invention belongs to the field of metal coatings, and in particular relates to a coating that can be used at high temperatures and is corrosion-resistant; the technical problem to be solved by the invention is to provide a coating that still has strong mechanical strength, strong adhesion, Corroded paint; in order to solve the above problems, the technical solution provided by the present invention is: a high-temperature anti-corrosion paint, including base material, solvent, curing agent, pigment and filler, silane coupling agent, drier, auxiliary agent; the present invention The beneficial effect is that: it has good adhesion, impact resistance and mechanical strength, the thickness of the coating film is 50 μm, the coating can withstand the temperature of 600 ° C, and has good corrosion resistance.

Owner:SNTO TECH GRP

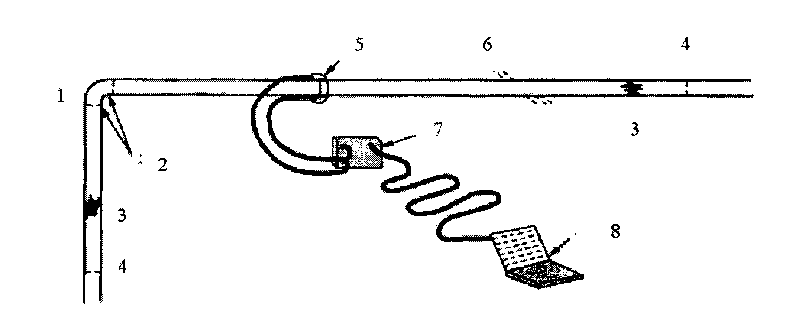

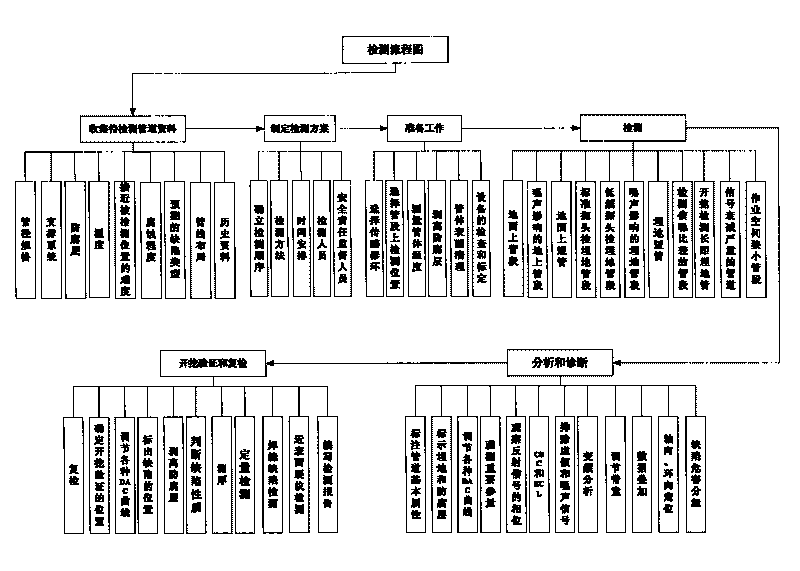

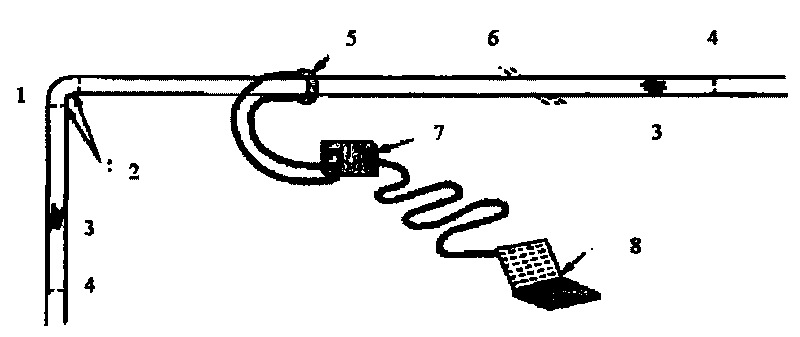

Method for rapidly detecting pipeline body defects

ActiveCN101762633ARaise the level of integrity managementReduce operational riskAnalysing solids using sonic/ultrasonic/infrasonic wavesSupporting systemLine tubing

The invention relates to a method for rapidly detecting pipeline body defects, which comprises the followings steps sequentially: 1) getting the specification, a support system, an anti-corrosion layer, the temperature, the corrosion degree, the pipeline layout and the historical information of a pipeline to be detected; 2) selecting a sensor ring, cleaning the surface of the pipeline to be detected, and inspecting and calibrating a detection system; 3) detecting each section of pipe on the ground only once, investigating with emphasis if problems are found, and determining detection times and positions of the buried pipelines according to different anti-corrosion layers and transmission media; 4) analyzing and diagnosing: labeling the basic properties of the pipeline, calibrating curves, comparing reflected signals and detection data in different positions, analyzing the variable frequency, diagnosing in a method of analyzing data in the same position in a superposition mode, observing the circumferential positions of the defects and classifying the degrees of the defects; and 5) determining a verification test pit and a detection test pit and analyzing pipe sections in the detection test pit according to diagnosis results, marking the positions of the defects, observing corrosion condition, measuring thickness, and finely scanning the defects to determine the positions, the properties and the sizes of the defects.

Owner:PIPECHINA SOUTH CHINA CO

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

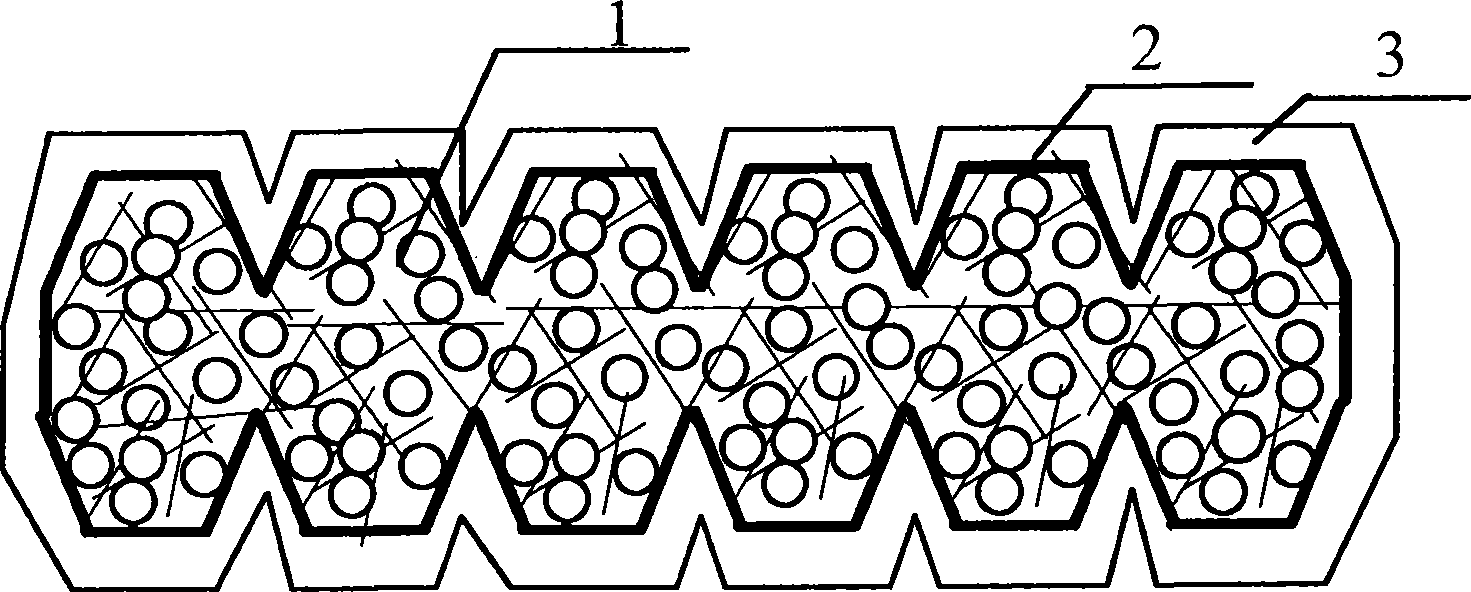

Concrete base sound absorption material for road sound screen and method of manufacturing the same

The invention relates to a cement-matrix sound-absorption material used in road noise barriers and a preparation method thereof; the sound-absorption material is a noise barrier material which can be used in airports, high-speed railways, expressways, urban viaducts, subways and light rails; the components and weight ratios are as follows: 15.4 to 62.3 percent of Portland cement, 0.1 to 15.7 percent of mineral admixture, 18.9 to 79.9 percent of lightweight porous aggregate, 0.013 to 0.078 percent of foaming agents, 0.1 to 0.7 percent of water reducing agent and 0.4 to 2.6 percent of fiber. The sound-absorption material and the preparation method thereof have the advantages of large sound absorption coefficient, high strength, good anti-impact performance, excellent durability, fire resistance, moisture resistance, anti-corrosion and self-clean function; at the same time, the sound-absorption material is wide in sources of raw materials, convenient in preparation and processing, suitable for large-scale production, low in cost, environment-friendly and good in decorativeness.

Owner:SOUTHEAST UNIV +1

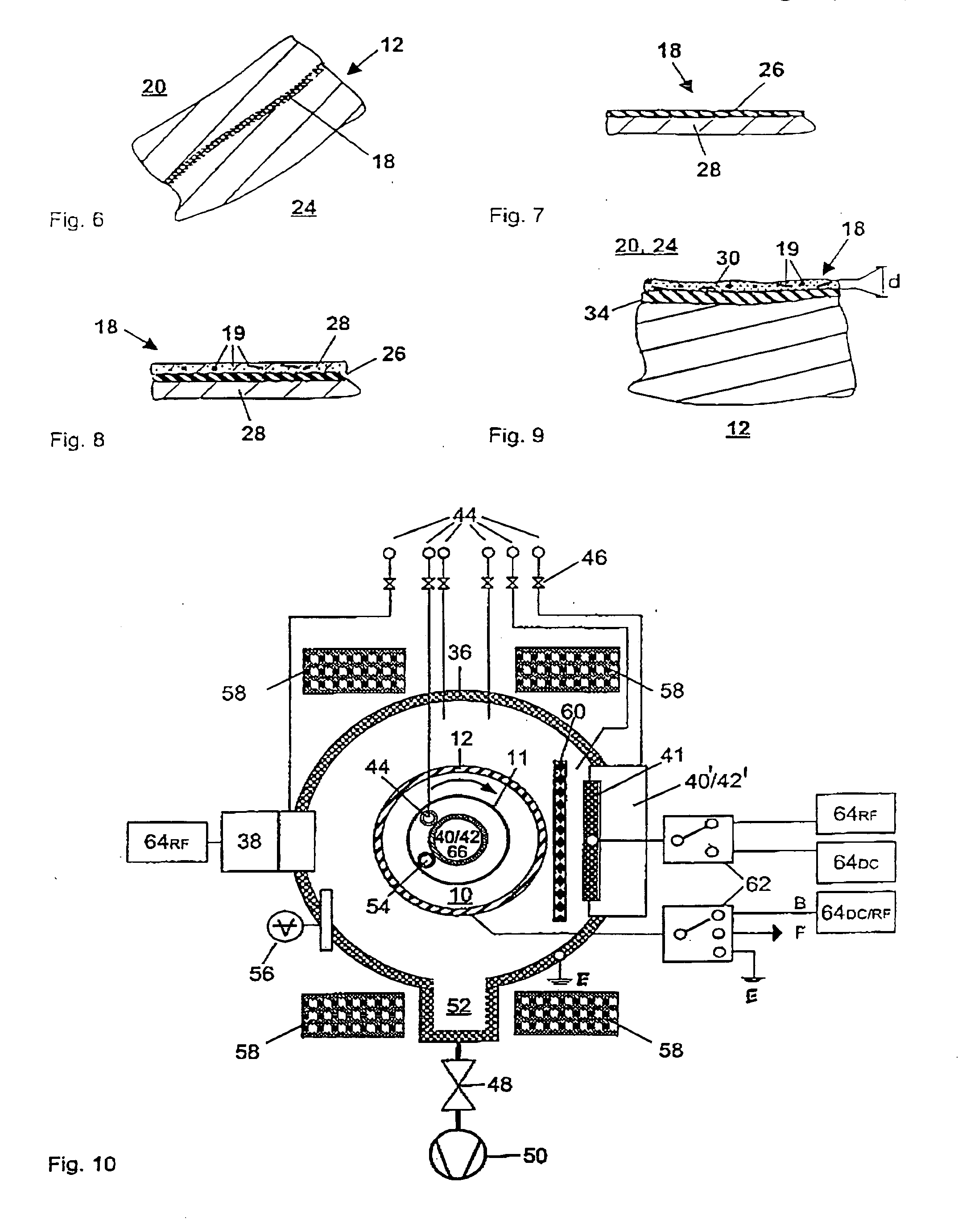

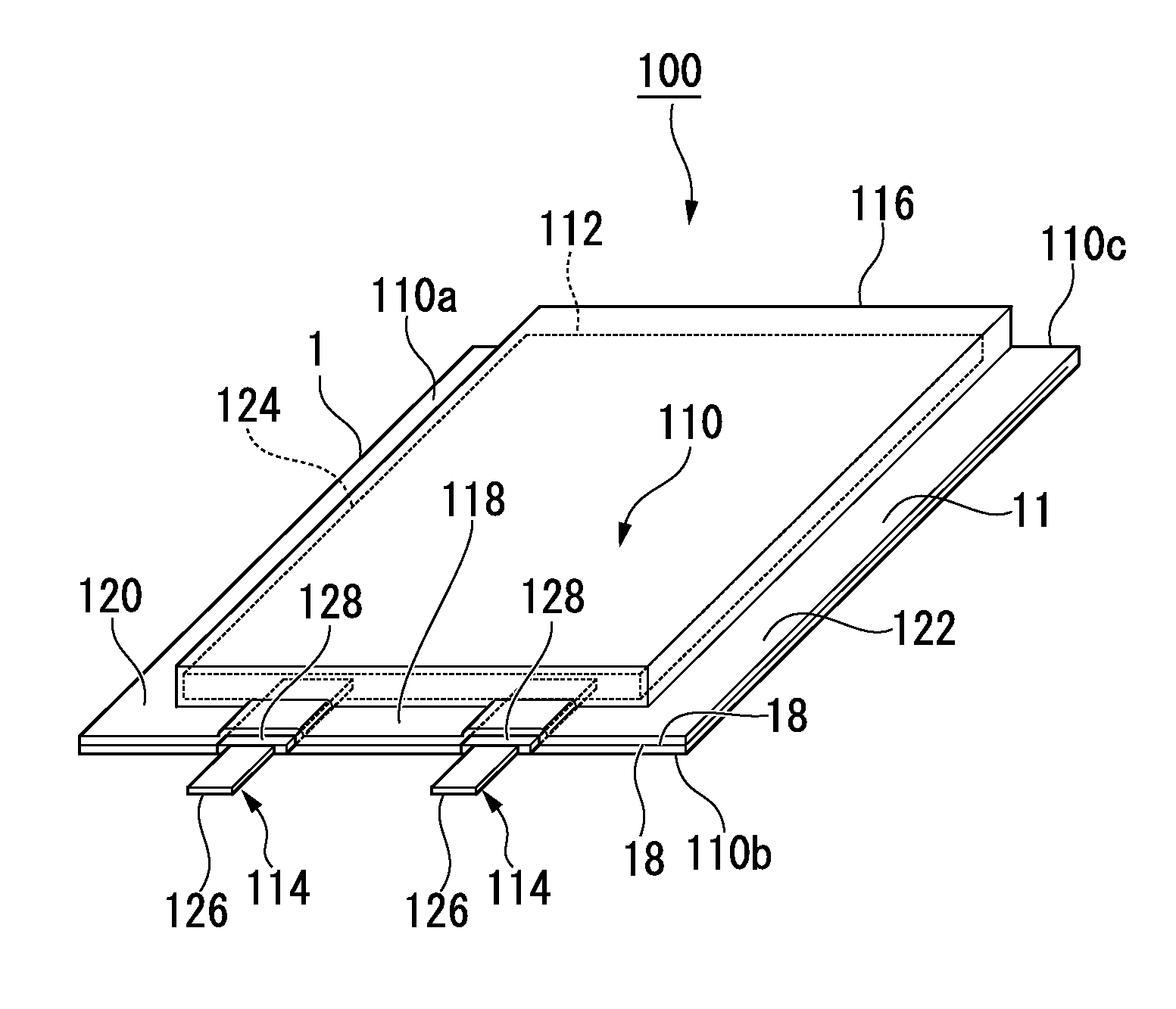

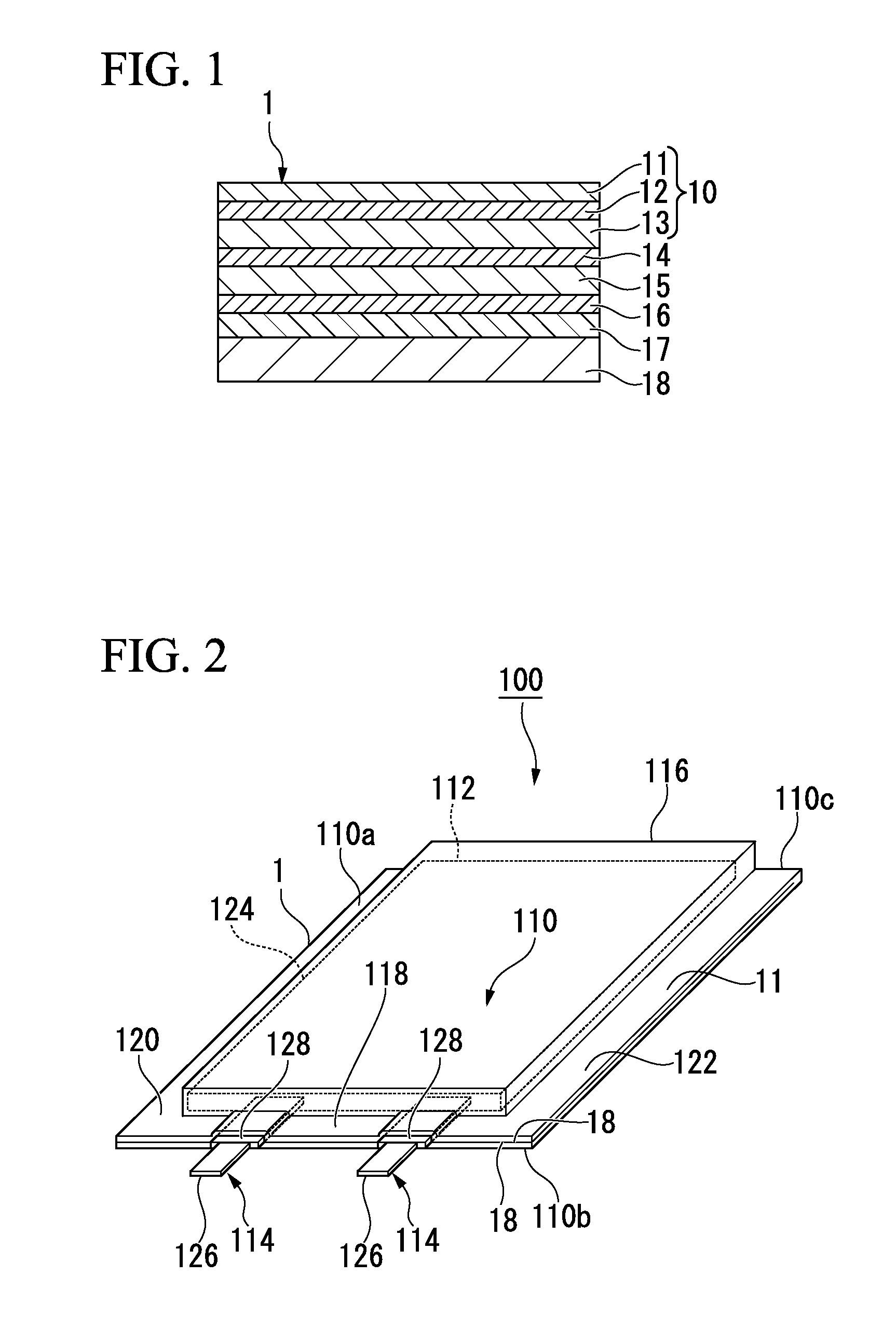

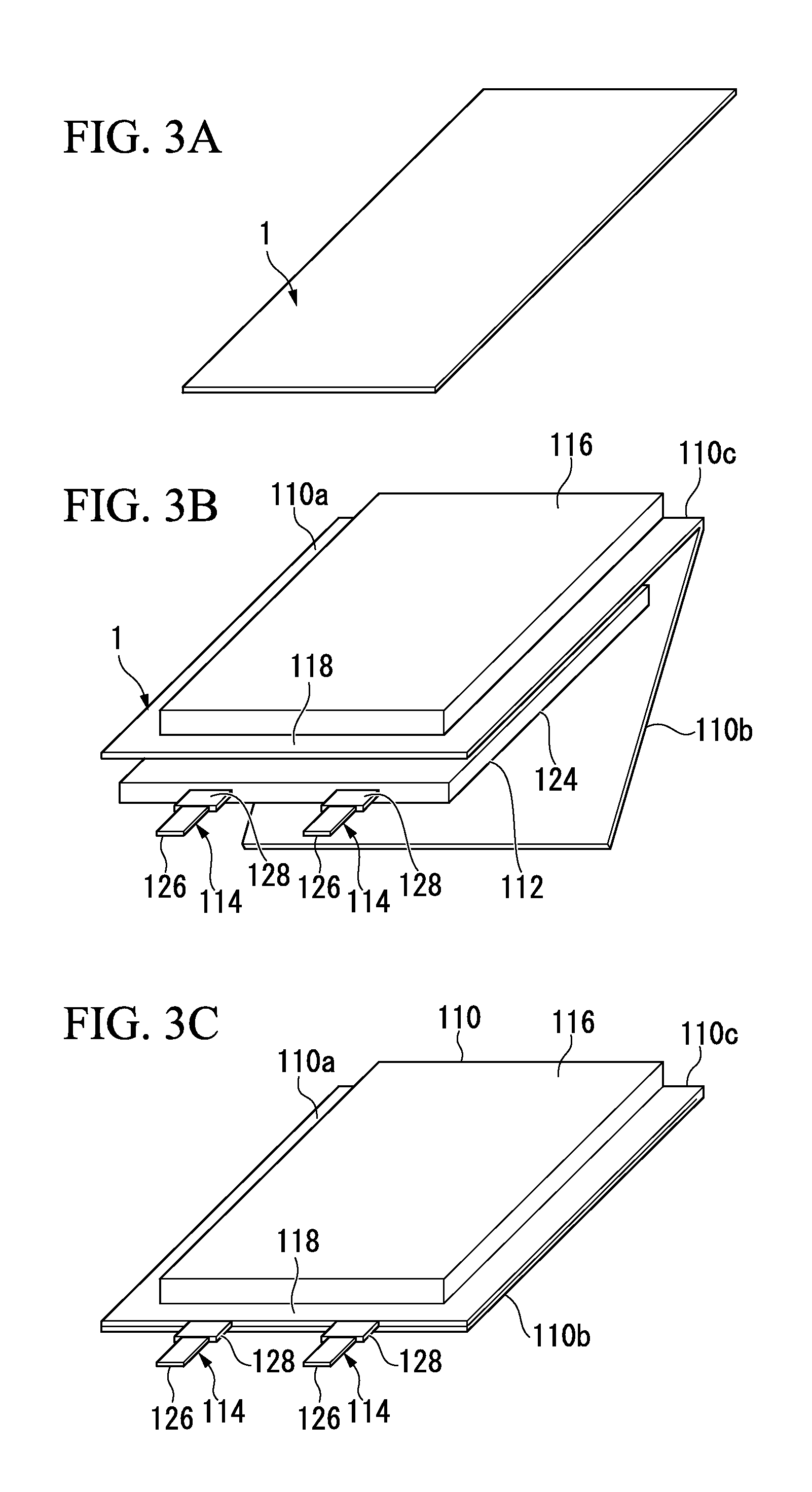

Packaging material for lithium ion battery, lithium ion battery, and method for manufacturing lithium ion battery

ActiveUS20140072864A1Good molding effectStay in shapeFinal product manufactureElectrode carriers/collectorsMetal foilPack material

A packaging material for a lithium ion battery includes: a base material layer that is formed from a film obtained by biaxially stretching a multi-layered coextruded film including a first thermoplastic resin layer having rigidity and chemical resistance and being disposed at an outer side thereof, a second thermoplastic resin layer having a capability of propagating stress and adhesiveness, and a third thermoplastic resin layer having toughness; a metal foil layer that is laminated on one surface of the base material layer; an anti-corrosion-treated layer that is laminated on the metal foil layer; an inner adhesive layer that is laminated on the anti-corrosion-treated layer; and a sealant layer that is laminated on the inner adhesive layer.

Owner:TOPPAN PRINTING CO LTD

Composite lithium-base grease and method for making same

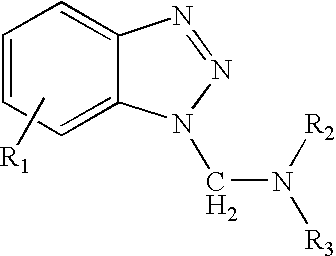

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

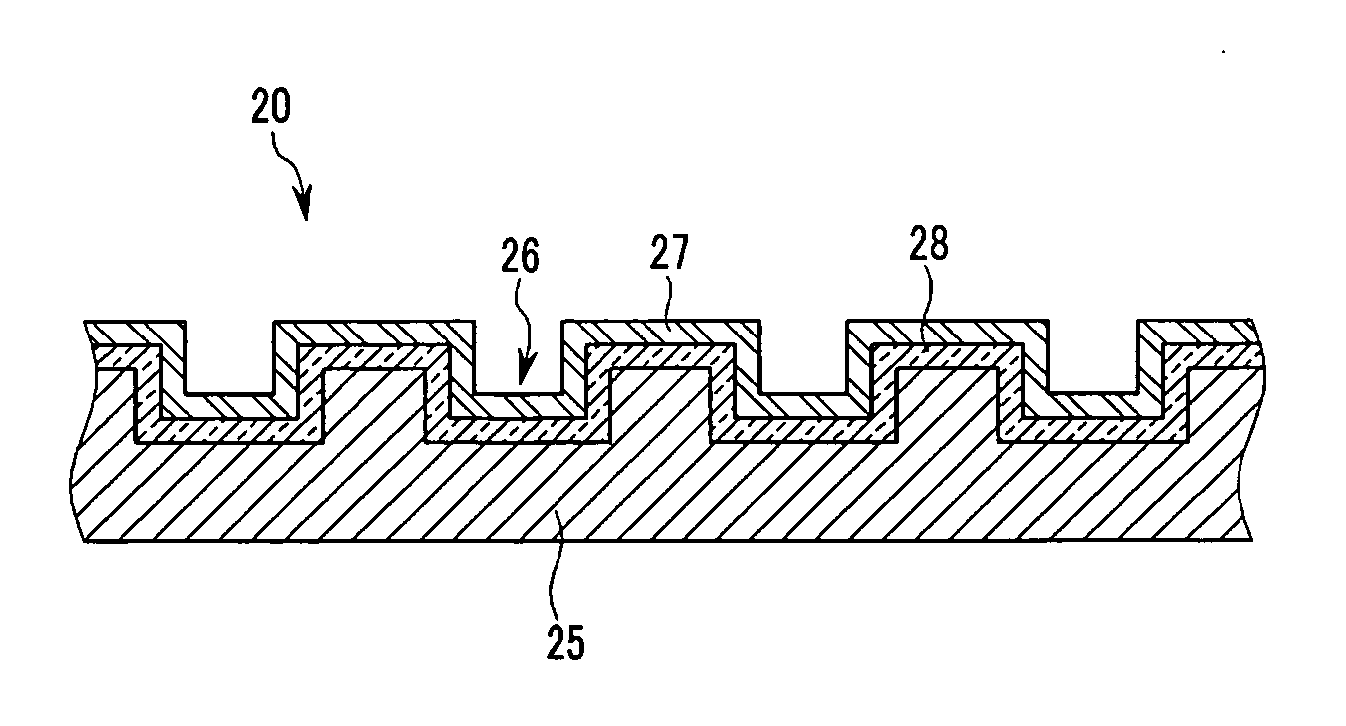

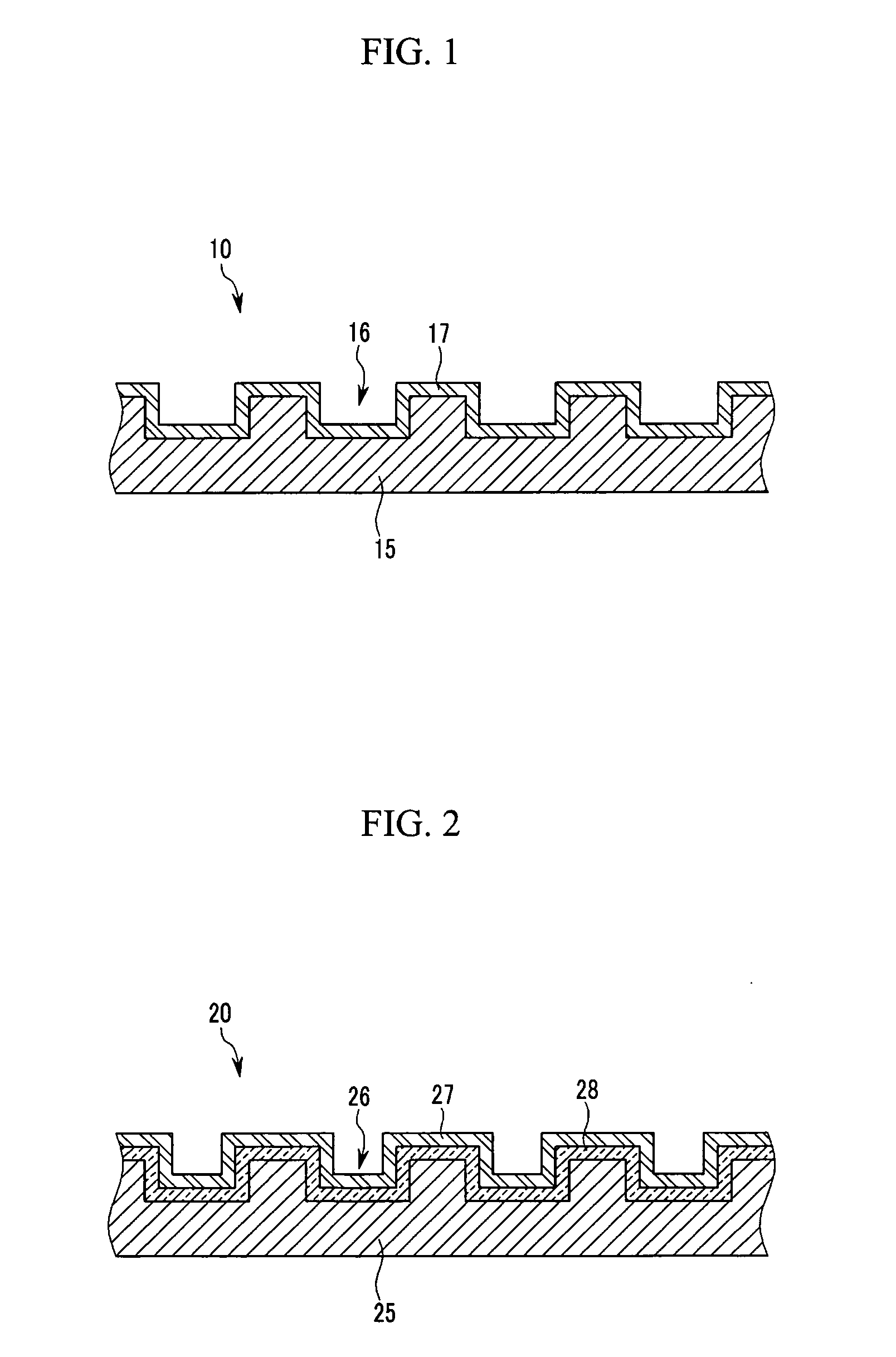

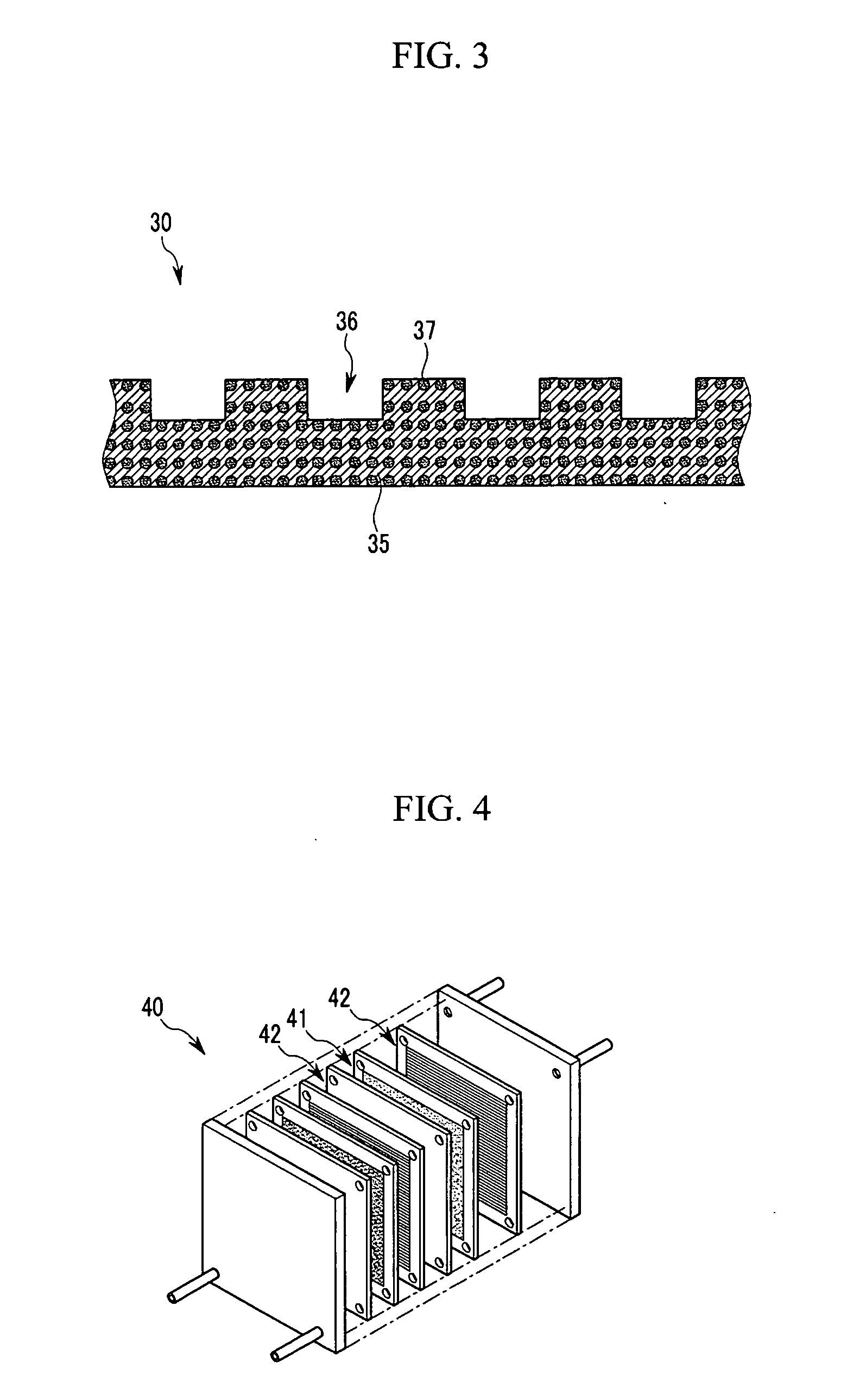

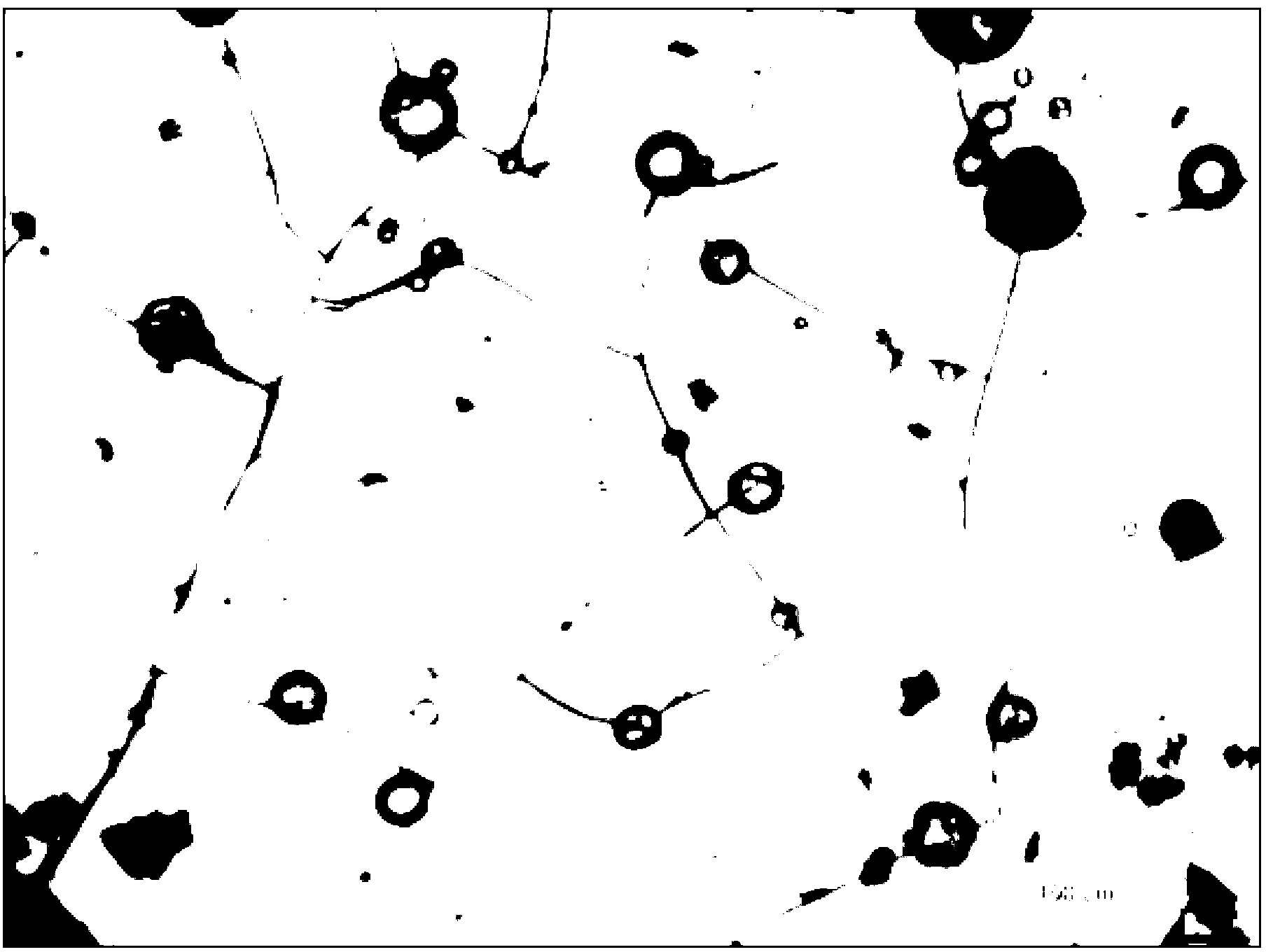

Separator for fuel cell, method for preparing the same, and fuel cell stack comprising the same

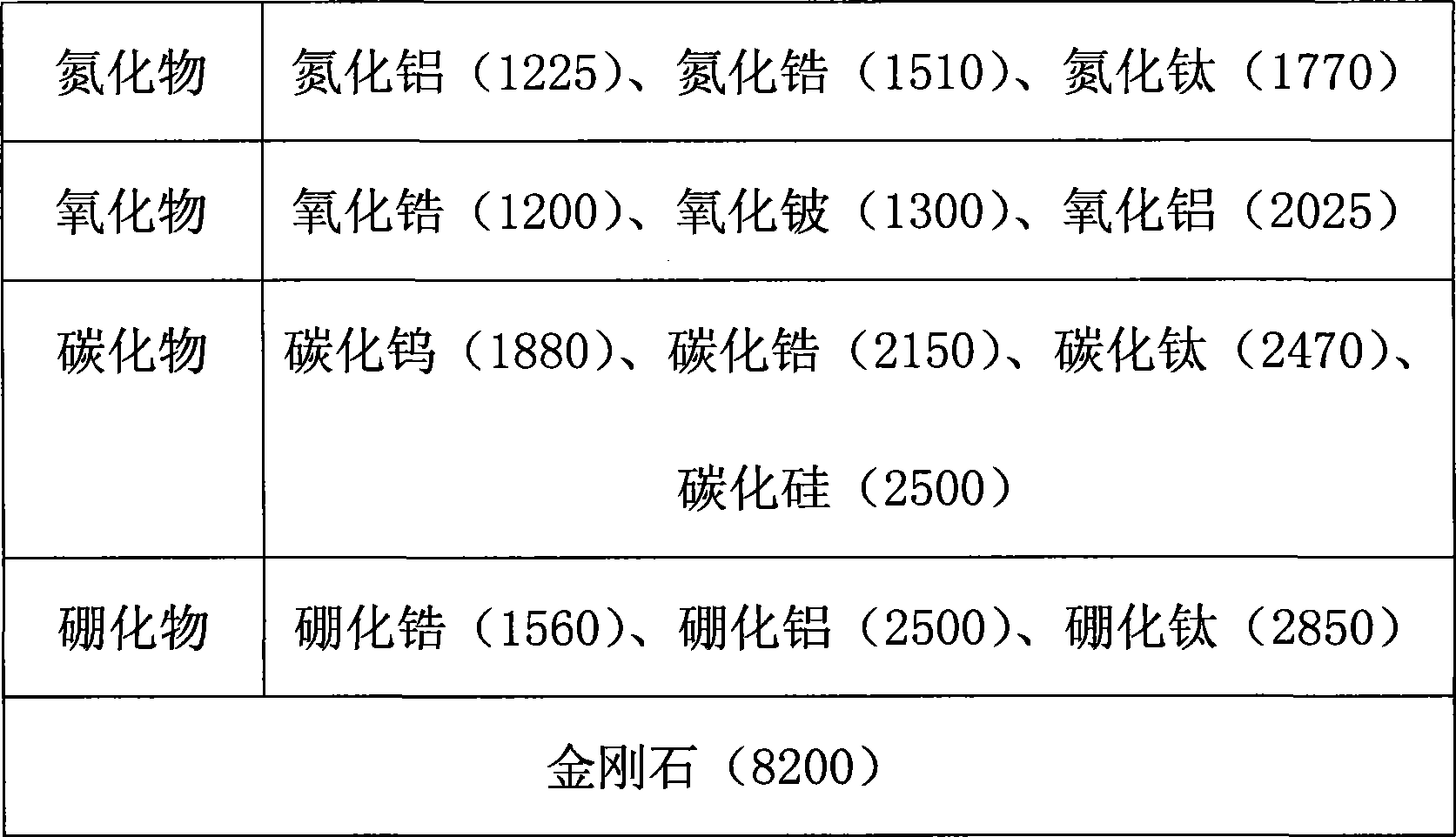

InactiveUS20060134501A1Improve anti-corrosion performanceExcellent electro-conductivity characteristicFuel cells groupingFinal product manufactureFuel cellsCarbide

The metal separator for a fuel cell of the present invention includes a metal substrate having reactant flow pathways and an electro-conductive anti-corrosion coating layer. The electro-conductive anti-corrosion coating layer covers the surface of the metal substrate on which the reactant flow pathways are formed. The coating layer may include metal carbides, metal oxides, and metal borides. A metal layer for improving adherence is formed between the surface of the metal substrate on which the reactant flow pathways are formed, and the electro-conductive anti-corrosion coating layer.

Owner:SAMSUNG SDI CO LTD

Micro-crack self-repairing microcapsule and preparation method thereof

ActiveCN102702838ARealize automatic curingFill crack voidsAnti-corrosive paintsMicroballoon preparationCyclohexanoneSolvent

The invention discloses a micro-crack self-repairing microcapsule, which comprises a capsule core and a capsule wall, wherein the capsule core comprises the following ingredients in part by weight: 10 to 60 parts of isocyanate derivative, 0.1 to 10 parts of capsule core diluent and 2 to 40 parts of cosolvent; and the capsule wall comprises ingredients with the following mol ratio: urea: formaldehyde solution, prepolymer=1: (1.0-4.0): (2.0-6.0), wherein the prepolymer is formed from the ingredients with the mol ratio: isocyanate derivative: cyclohexanone: chain extender=1: (2.0-5.0): (0.3-3.0). The invention also discloses a micro-crack self-repairing anti-corrosion coating utilizing the capsule. The micro-crack self-repairing microcapsule is free from additionally adding a repairing catalyst or an initiator, can realize completely automatic repairing function, can be widely applied to the protection field of a metal surface coating in a wet environment, and solves the problems that the contact probability between functional filling material flowing into cracks in the intelligent anticorrosion coating and the catalyst or the initiator is small.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Anti-corrosion fingerprint-resistant surface treating pigment and producing method, and use method on stainless steel plate

InactiveCN101509131AGood dispersionHigh hardnessPolyurea/polyurethane coatingsMetallic material coating processesMaterials scienceDuctility

The invention discloses a corrosion and fingerprint resistant surface treatment agent and a preparation method thereof as well as a use method on stainless steel plates. The weight percentages of the chemical ingredients are as follows: 7-45% of organic macromolecule resin, 2-15% of organic silicon resin solution, 0.5-10% of water system wax, 0.5-10% of nano-oxide, 0.1-20% of metallic compound, 0.1-15% of silane mixture and water being the rest. The preparation method comprises: a pH regulator is added into water, and then the silane mixture and nano oxide are slowly added to prepare nano oxide concentrate; the concentrate is mixed and stirred with the ingredients to form film and is mixed into a treatment agent. The use method of the treatment agent on the stainless steel plates comprises washing, coating and drying. Compared with the prior art, the coating of the invention has good adhesion and ductibility on the surface of the stainless steel and is free from flaking off, thereby enhancing the production efficiency. Coatings resisting corrosion, fingerprint and scratch and stainless steel plates can be obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Non-sticking lining with wearing resistance and anti-corrosive property and coating method thereof

The invention discloses a non-stick coating with wear resistance and corrosion resistance and a coating method thereof. The coating comprises an anti-corrosive bottom layer, a wear-resistant intermediate layer and a non-stick finish coat, wherein the bottom layer contains a fluoropolymer, 1 to 15 weight percent of at least one heat-resistant polymer adhesive, and 1 to 15 weight percent of pigment and filler; the intermediate layer is coated on the bottom layer, and contains the fluoropolymer and inorganic filler particles; and the finish coat is coated on the intermediate layer and contains the fluoropolymer with non-stick effect. A priming coat has good anti-corrosion performance due to small content and small fineness of the pigment and the filler, an intermediate coating has good wear-resistant property due to the fact that partial large particles in an organic filler are embedded into the bottom layer and are convex into the finish coat, and the finish coat has good non-stick performance.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

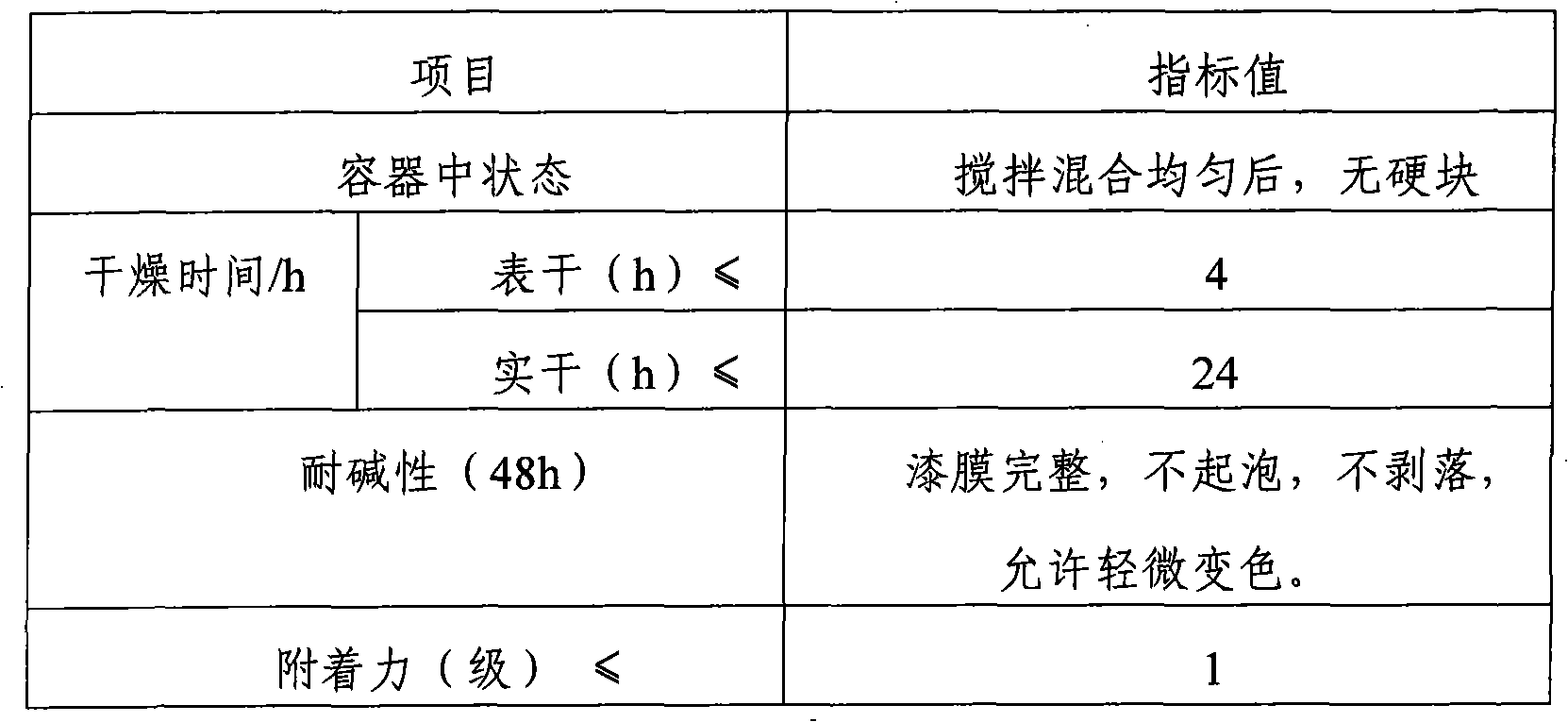

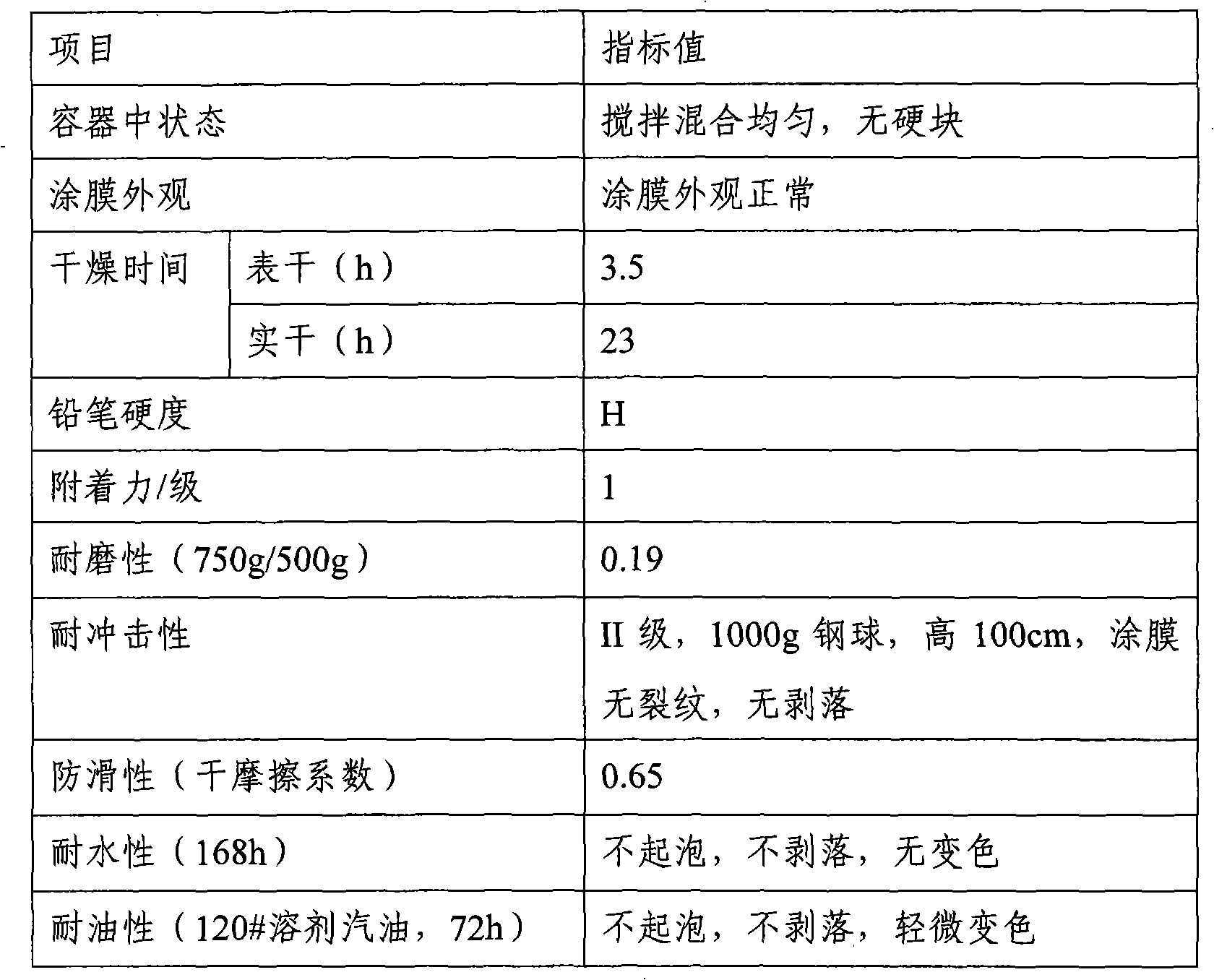

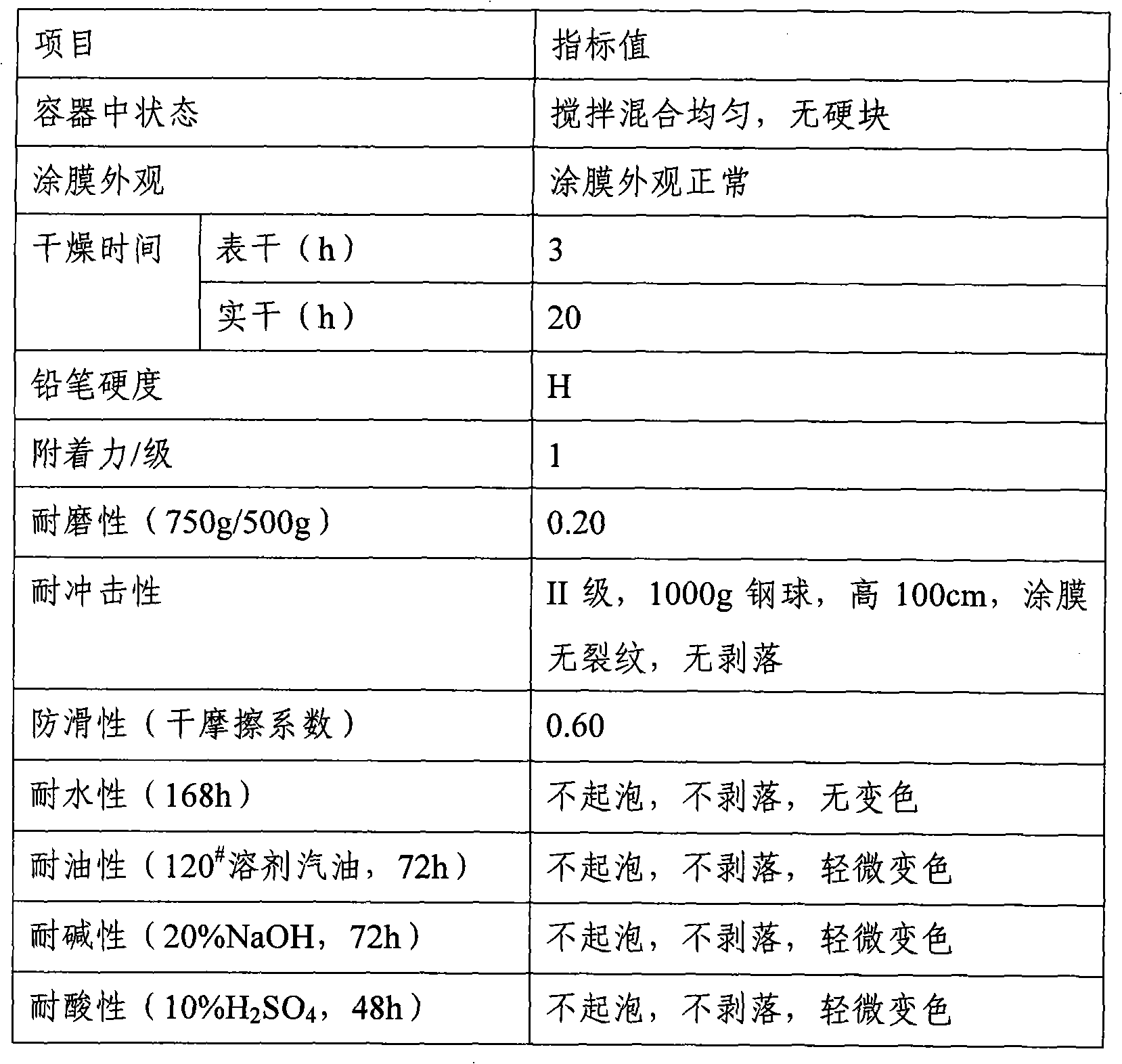

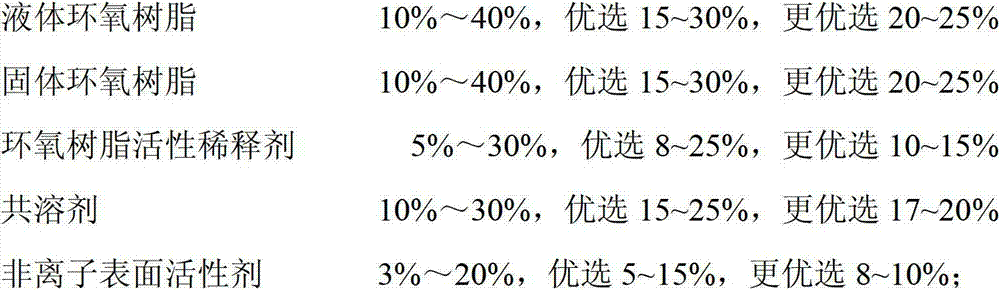

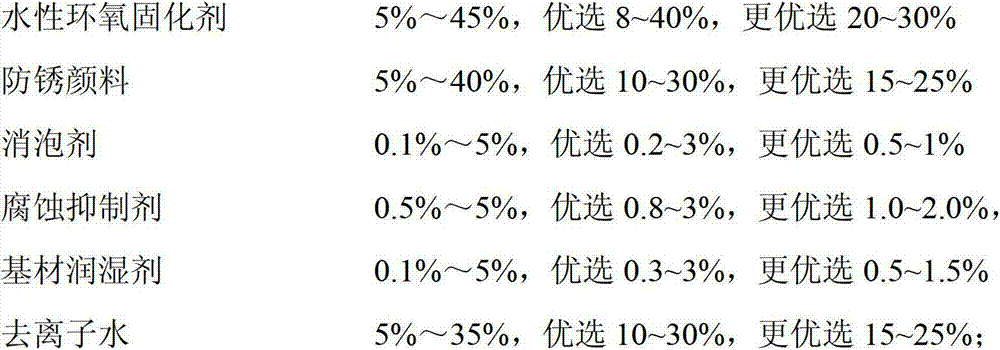

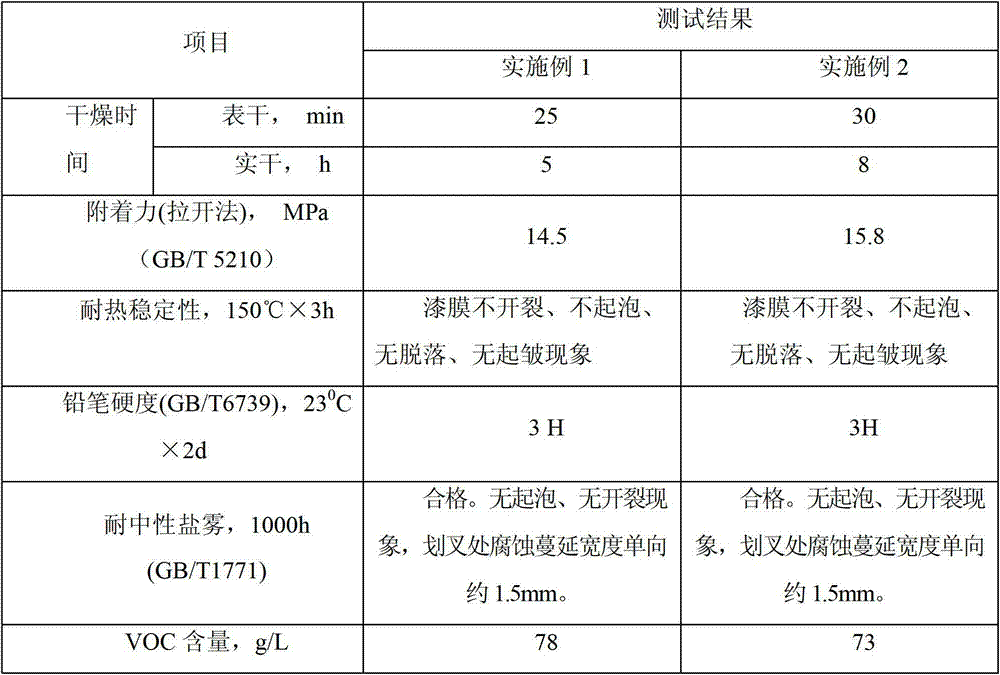

Room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and preparation method thereof

ActiveCN103087612AImprove anti-corrosion performanceFast curingAnti-corrosive paintsEpoxy resin coatingsSurface-active agentsChemistry

The invention provides a room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and a preparation method for the coating. The coating comprises A and B two components, wherein the A component consists of liquid epoxy resin, solid epoxy resin, an epoxy resin reactive diluent, a cosolvent, and a non-ionic surface active agent; the B component consists of a waterborne epoxy curing agent, an anticorrosive pigment, a foam killer, a corrosion inhibitor, a substrate wetting agent and de-ionized water, and during application, mass proportion of the A component to B component is 1:3-6. The coating is high in curing speed of coated film, the surface is dried in 30min at room temperature without being roasted; the coating has high early hardness, and the hardness can reach 3H in 48 hours; and in addition, the coating is good in thermal resistance stability, low in VOC (Volatile Organic Compound) content, excellent in anti-corrosion performance, and is capable of replacing a solvent type two-component epoxy coating to be applied to the anti-corrosion of a steel structure.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Anti-corrosion high-toughness zinc alloy implant material capable of being absorbed by human body

ActiveCN103736152AGood matching of mechanical propertiesImprove mechanical propertiesSurgeryTissue regenerationSide effectZinc alloys

The invention relates to an anti-corrosion high-toughness zinc alloy implant material capable of being absorbed by a human body. The anti-corrosion high-toughness zinc alloy implant material comprises the following elemental constituents by mass percent: 0.001-2% of Ce, 0.001-2% of Mg, 0.001-2% of Ca, 0.01-3% of Cu, and the balance of Zn. The zinc alloy material is prepared into a medical implant with absorbability by using a conventional method in the field, especially an intravascular stent, and orthopedic implants (a nail or bone lamella and the like). The zinc alloy material created by the invention has high corrosion resistance and high toughness, and the prepared medical implant can be absorbed by the human body, and is free of a side effect.

Owner:XIAN ADVANCED MEDICAL TECH

Foamed ceramics energy saving and heat preservation decorative wall brick and manufacture method thereof

InactiveCN101560111ALow thermal conductivityLow densityCeramic materials productionCeramicwareBrickSlurry

The invention discloses a foamed ceramics energy saving and heat preservation decorative wall brick and a manufacture method thereof, including the steps of conducting ball milling on 15-65 percent wt of industrial residues, 10-45 percent wt of plastic clay, 15-60 percent wt of solvent, 10-45 percent wt of pore-forming agent with the fineness being 1-100mum and proper amount of water to form slurry; spray drying or dehydration and clay preparation, and forming powder material or clay segment through staleness; and implementing pressure forming to make billet which is burned under heat preservation at temperature of 1140-1240 DEG C to finally form the foamed ceramics wall brick. The wall brick can be used not only for the heat preservation and decoration of external walls, but also for indoor heat preservation and decoration, and the external wall and the indoor space can realize the organic combination of uniform heat preservation and decoration, which agrees with the development direction of heat preservation material industry of external walls. The wall brick has the advantages of: I. high temperature resistance, acid and alkali-resistance, good chemical stability, no ageing, strong durability, long service life, no generation of heat channel and good adhesive fixity; and II. difficult water seepage and crack, strong anti-corrosion capacity, uneasy deformation and damage, simplification of mounting, laying and sticking procedures, convenience for construction, relief of labor intensity and decrease of material consumption quantity.

Owner:吴汉阳

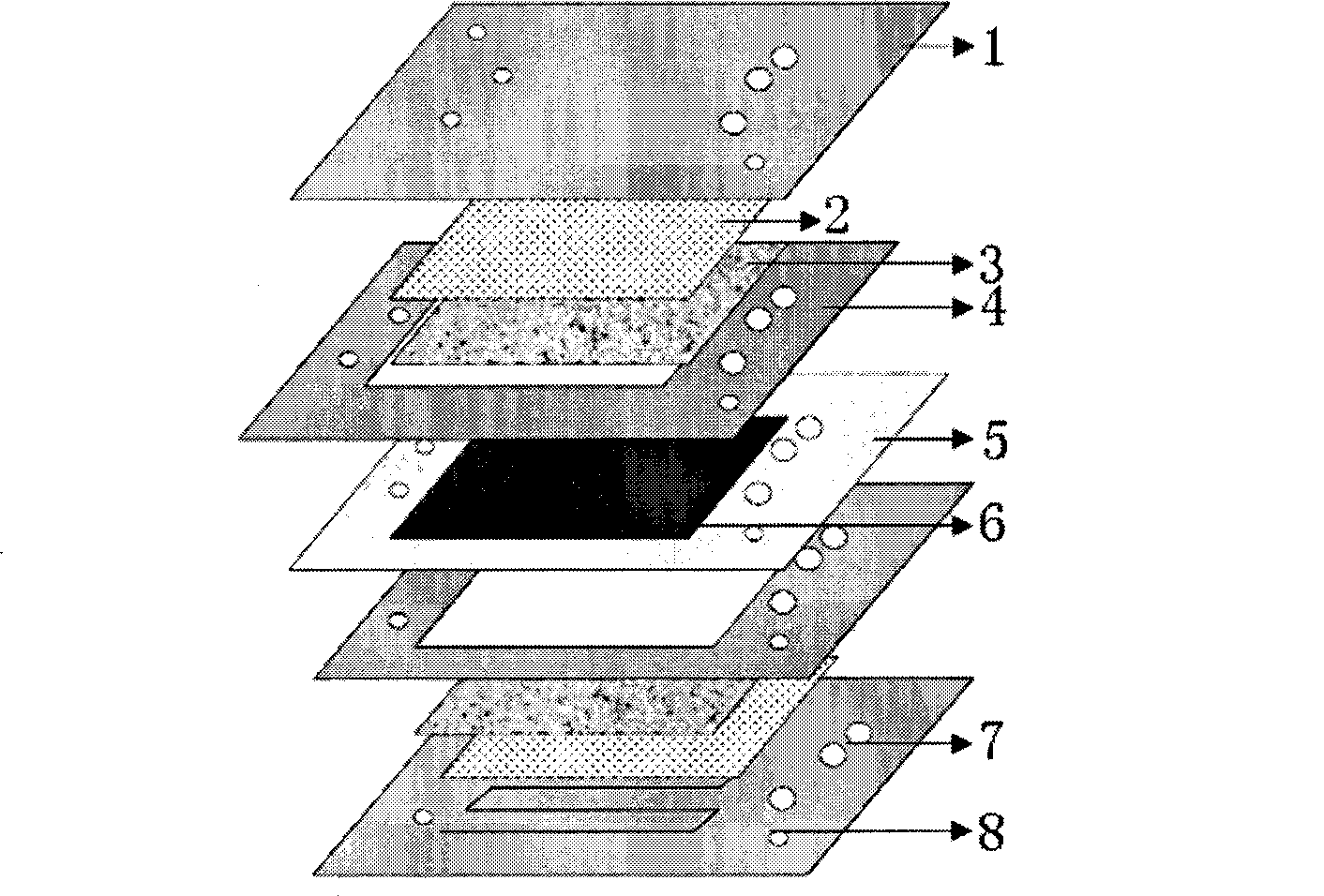

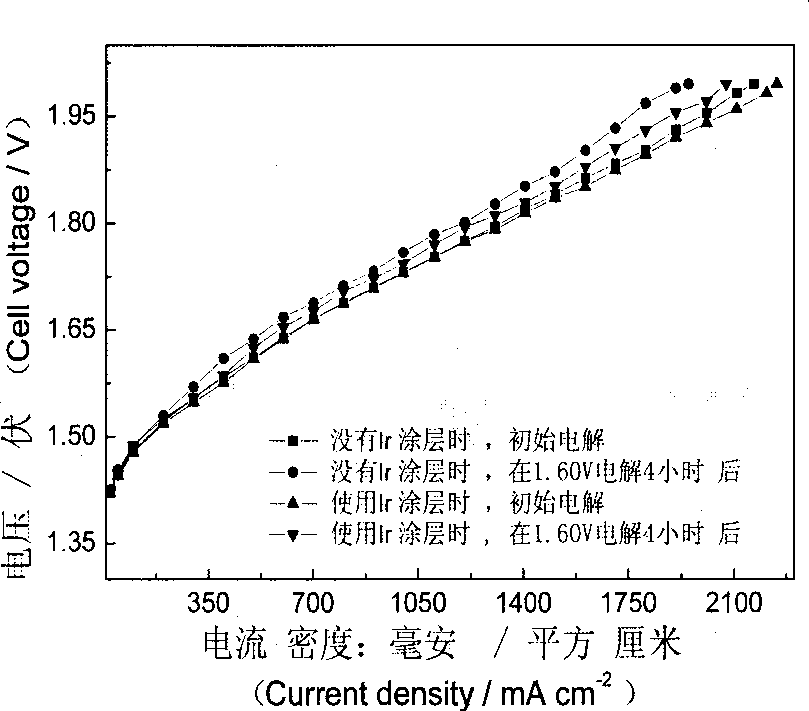

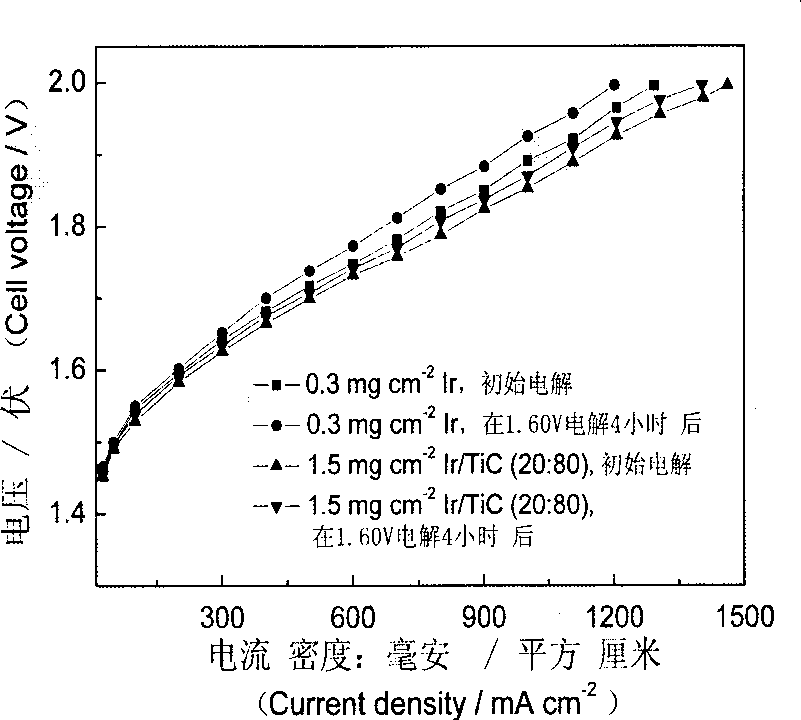

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

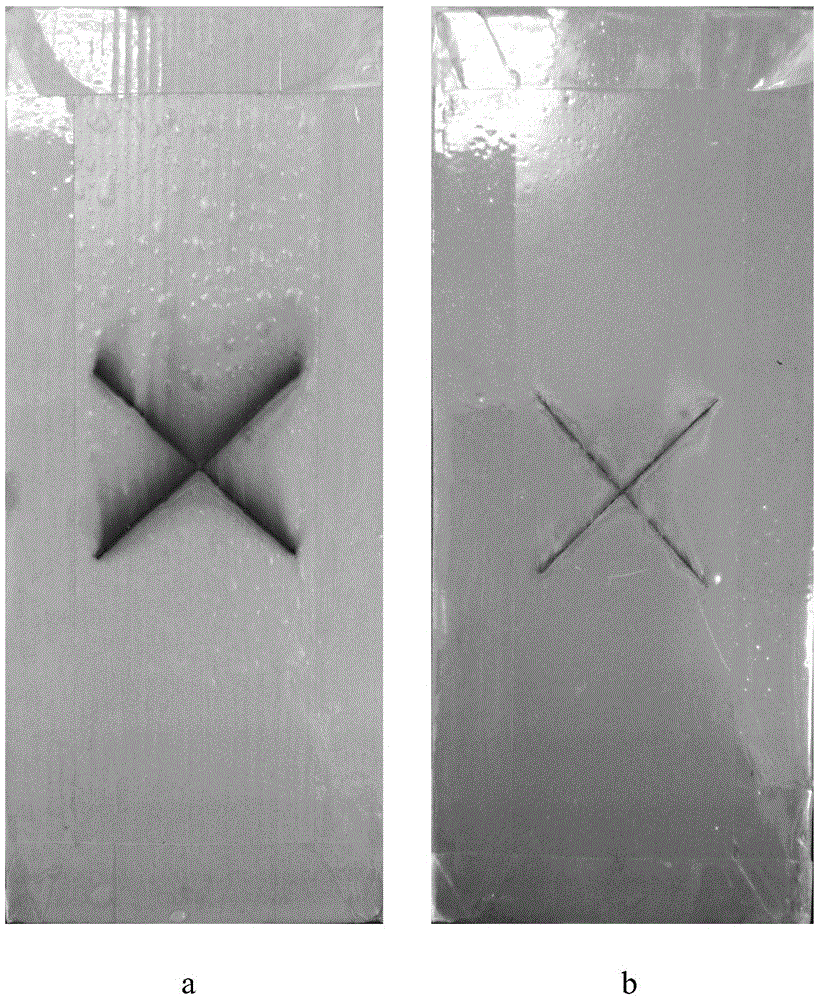

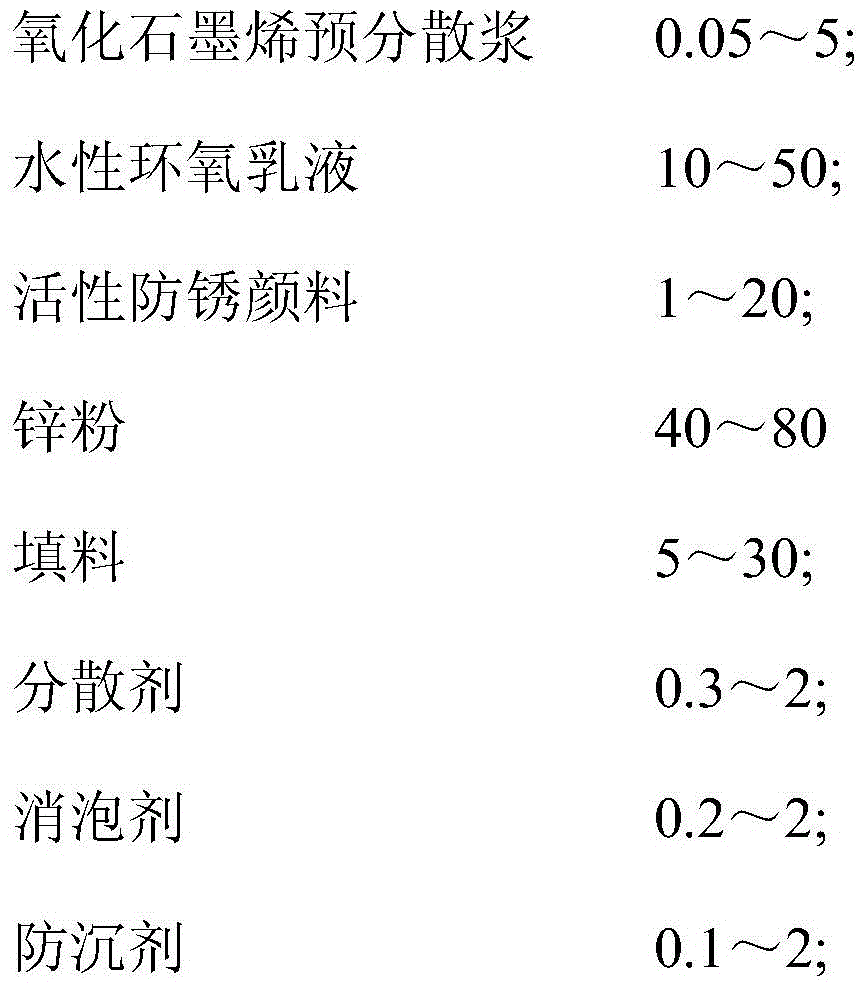

Nano graphene oxide modified double-component aqueous epoxy anti-corrosion coating and preparation method thereof

InactiveCN105419564AImprove resistance to media penetrationImprove mechanical propertiesFireproof paintsAnti-corrosive paintsEpoxyEmulsion

The invention relates to a nano graphene oxide modified double-component aqueous epoxy anti-corrosion coating and a preparation method thereof. The preparation method includes the steps of a) modifying the surface of graphene oxide with a dispersing agent and resin to prepare graphene oxide pre-dispersed slurry; b) placing the graphene oxide pre-dispersed slurry into a stirring container according to proportion and then stirring the slurry uniformly; c) adding an aqueous epoxy emulsion, an anti-rust pigment, a filling material, a dispersing agent and an anti-flash-rust agent, performing high-speed dispersion and grinding to obtain a first component A of the graphene oxide modified double-component aqueous epoxy anti-corrosion coating; d) diluting an epoxy curing agent in deionized water to obtain a second component B of the graphene oxide modified double-component aqueous epoxy anti-corrosion coating; and e) mixing the component A and the component B uniformly, curing the mixture for 10 min to 15 days at 10-120 DEG C to obtain the coating. The coating is simple in process, is low in cost, is suitable for large-scale production, maintains excellent properties of epoxy resin, is better in corrosion resistance, anti-seepage property, mechanical performance and anti-wear property, and has wide industrial application prospect.

Owner:CHANGZHOU NANOMEDIA INC LTD

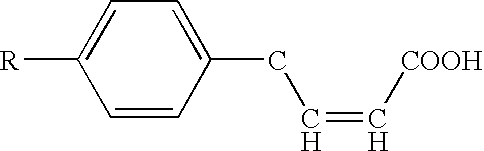

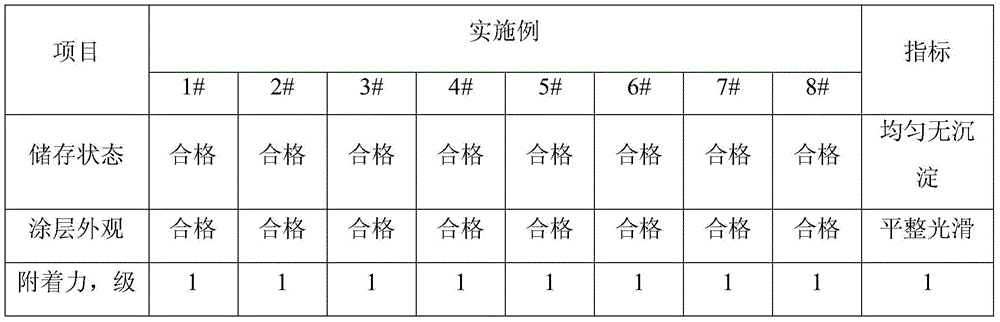

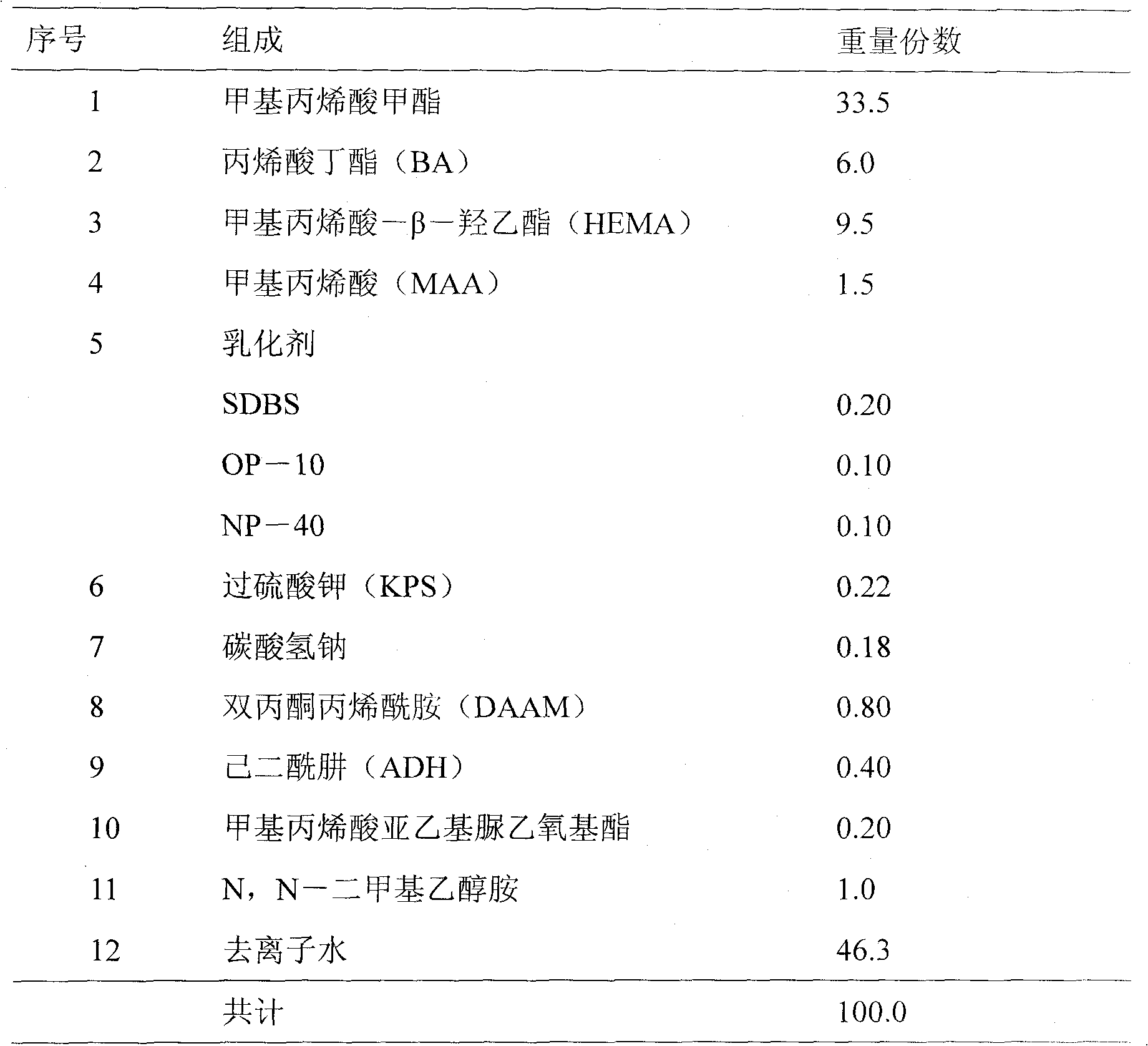

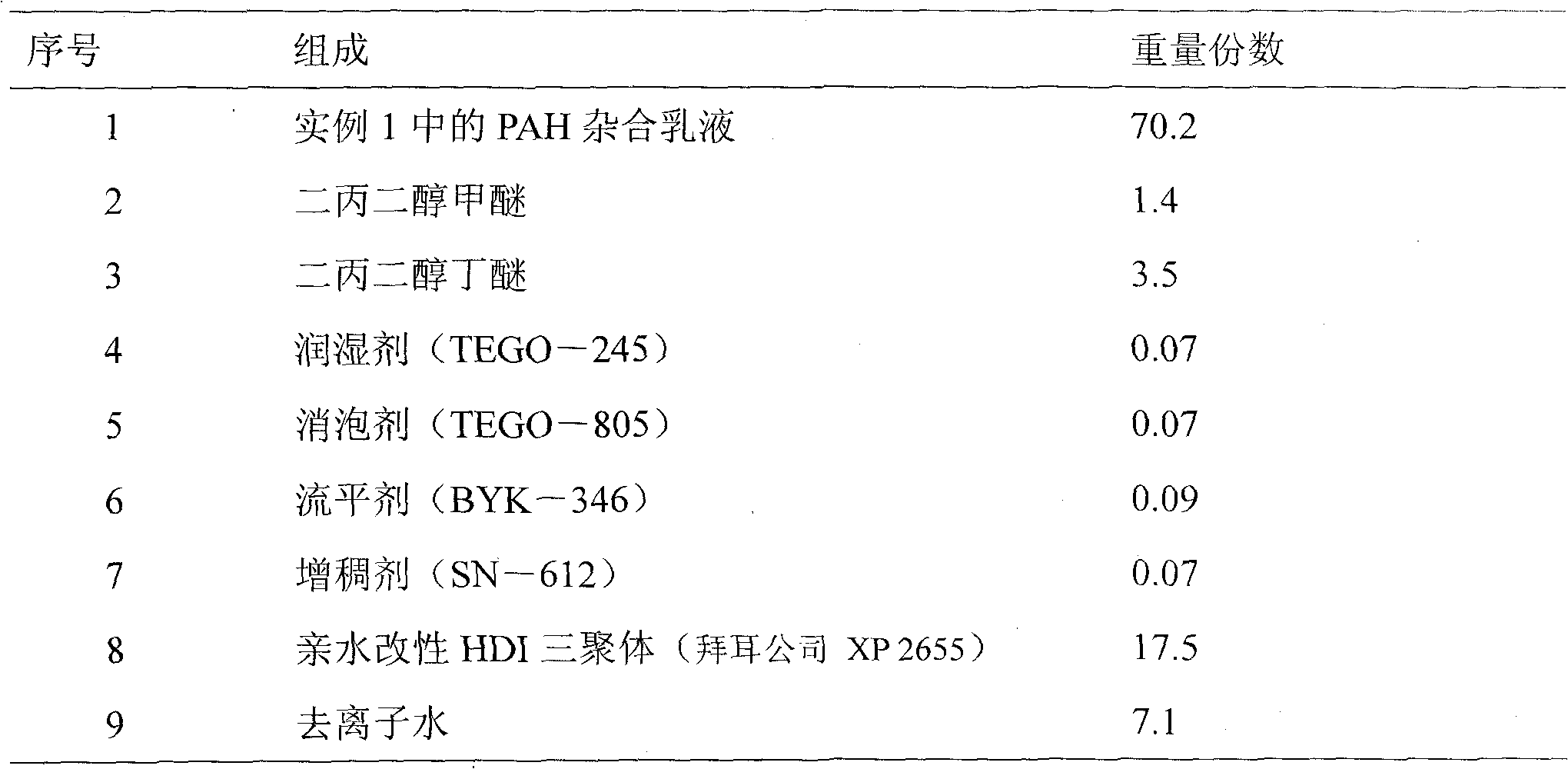

Preparation method and application of acrylate heterozygotic emulsion

ActiveCN101787098ASmall particle sizeWide particle size distributionPolyurea/polyurethane coatingsPolymer scienceLacquer

The invention discloses a preparation method and an application of an acrylate heterozygotic emulsion. In the invention, the acrylate heterozygotic emulsion is synthesized by adopting a seed emulsion polymerization process and combining a process of instantly neutralizing and segmentally adding polar monomers. The acrylate heterozygotic emulsion comprises macroparticles consisting of polymers P2 rich in hydroxyl groups on a surface layer and microparticles consisting of polymers P1 rich in carboxylate on the surface layer. Compared with a conventional hydroxy acrylate emulsion, the acrylate heterozygotic emulsion has smaller mean grain size and wider grain size distribution on emulsion particles. The acrylate heterozygotic emulsion can be adopted to prepare aqueous bi-component polyurethane wood coatings, and a coating layer of the coating has excellent property of resisting water and solvents, high crosslinking density and hardness, good mechanical property, scratching resistance and wear resistance. The acrylate heterozygotic emulsion has compact coating structure, high glossiness and better combination property, and not only can be applied to high-grade wood coatings, but also can be applied to automotive refinish paint, metallic anti-corrosion paint, other industrial protective paint, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com