Patents

Literature

58 results about "Olefin synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

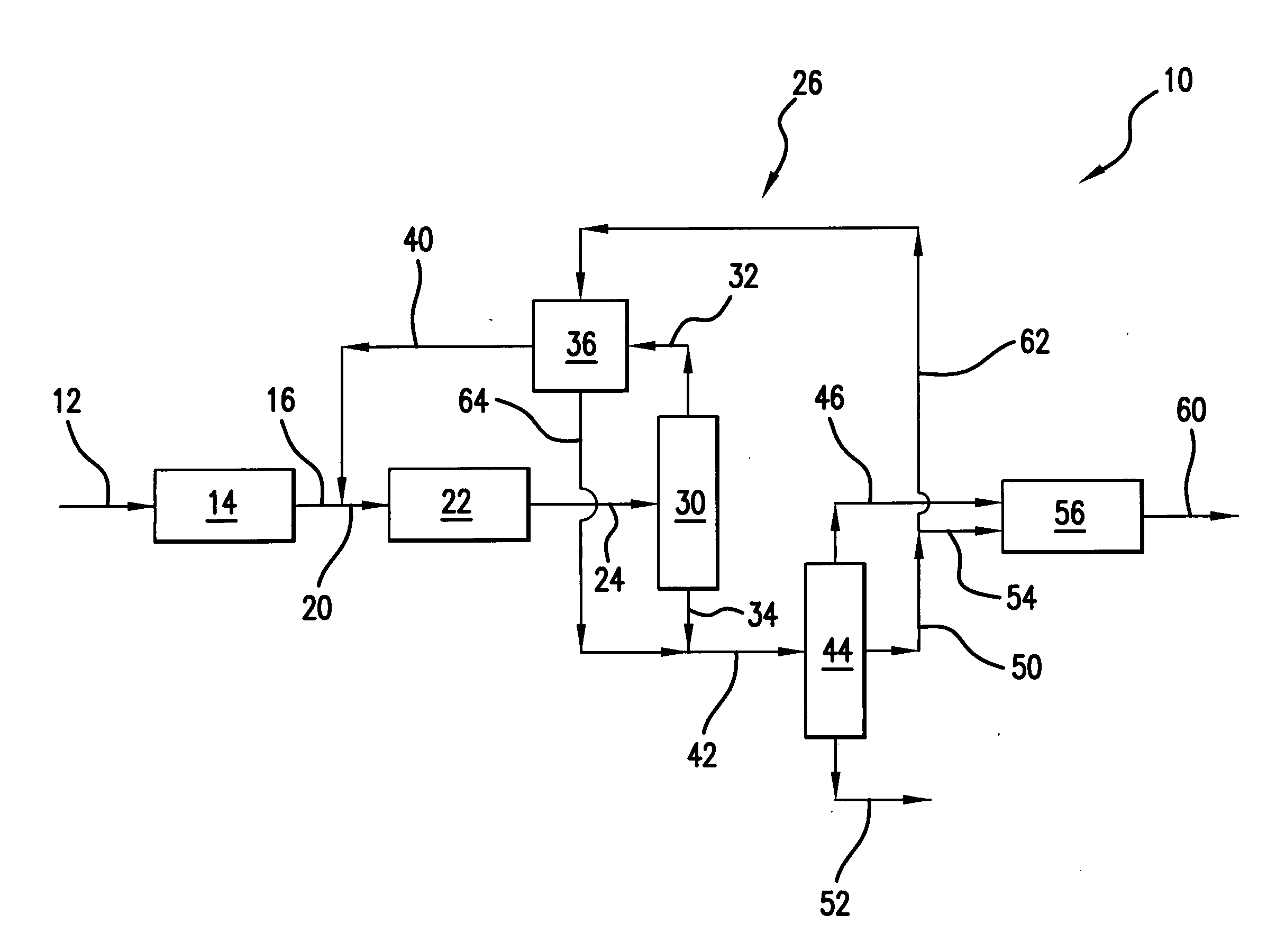

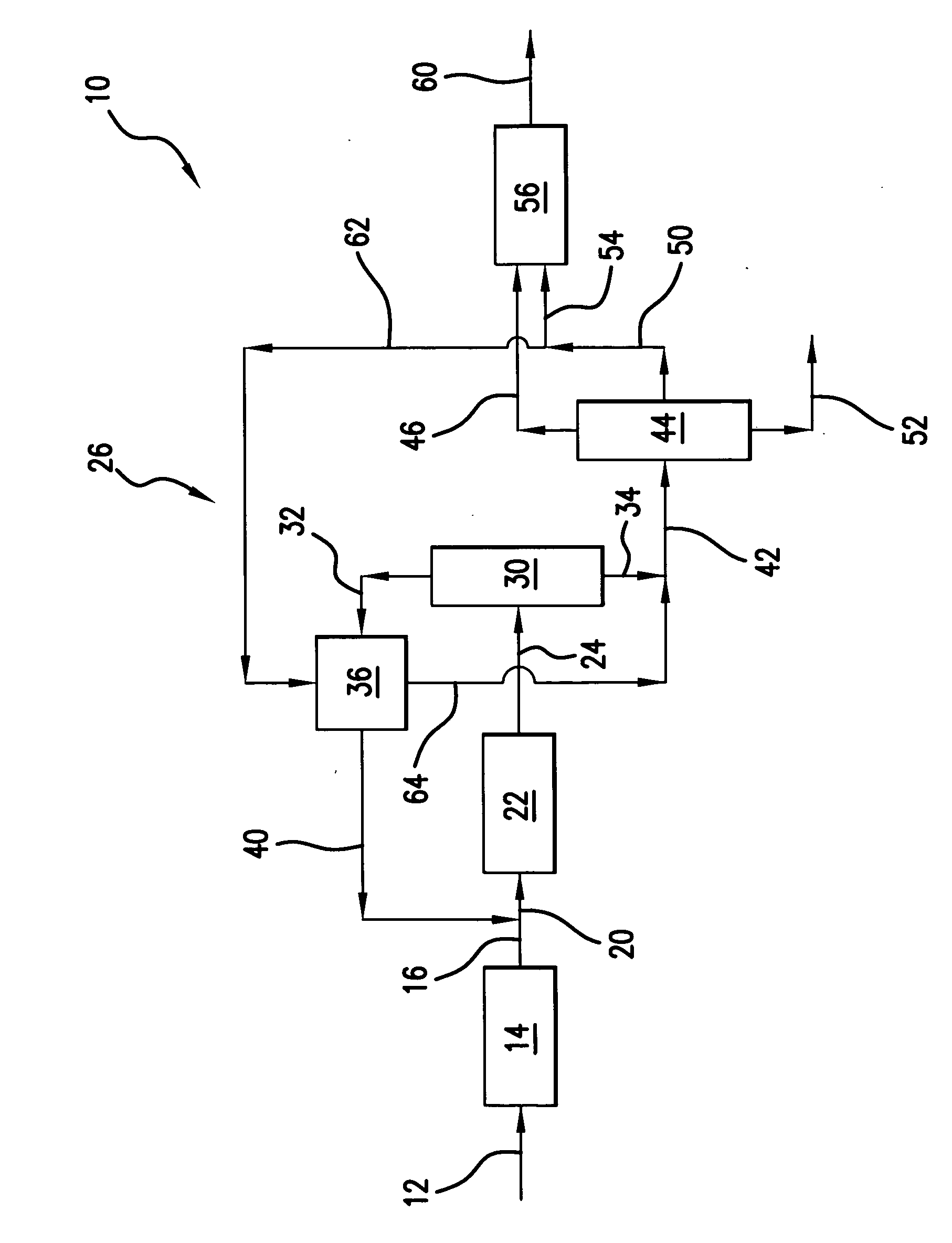

Light olefin production via dimethyl ether

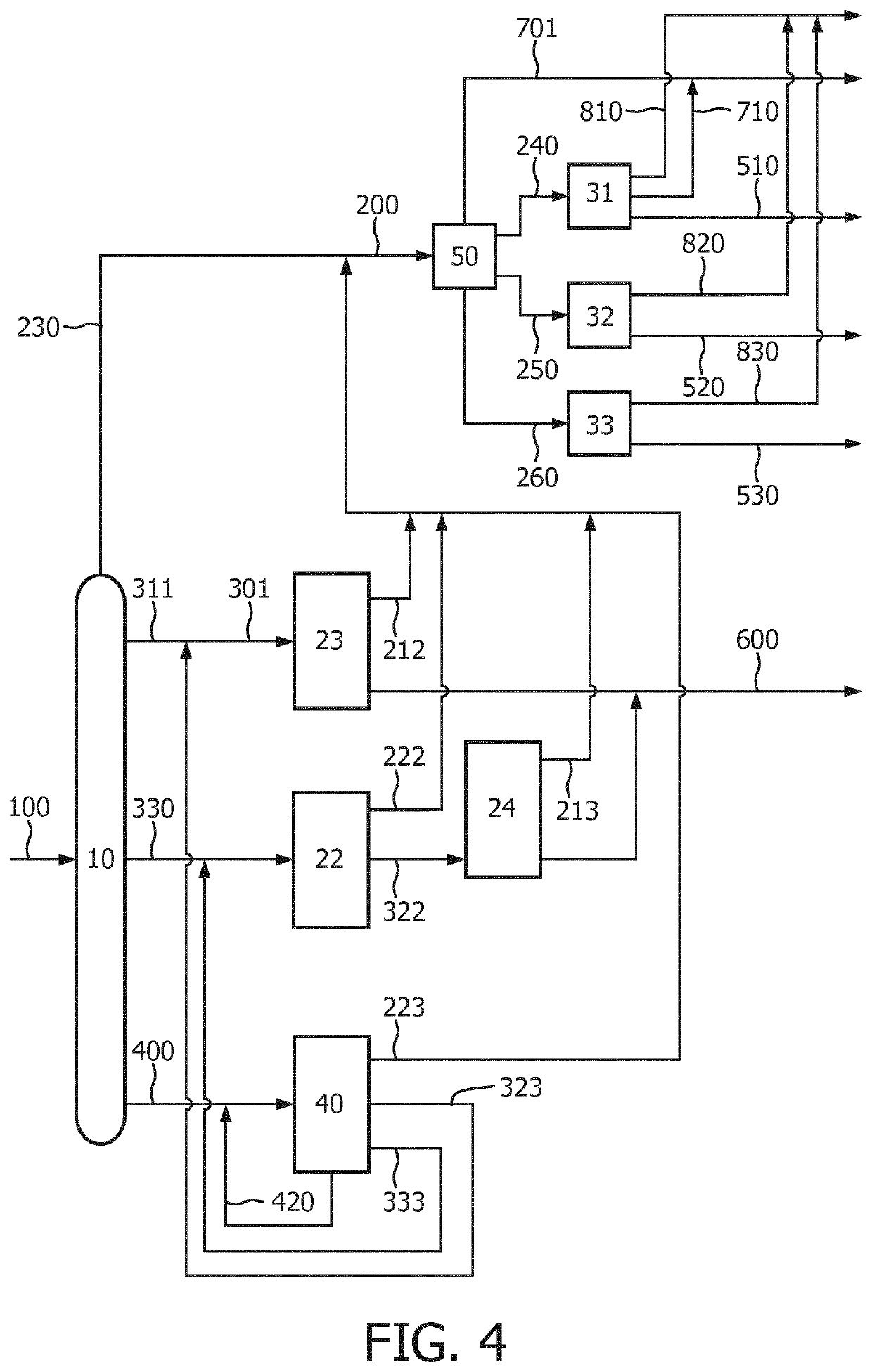

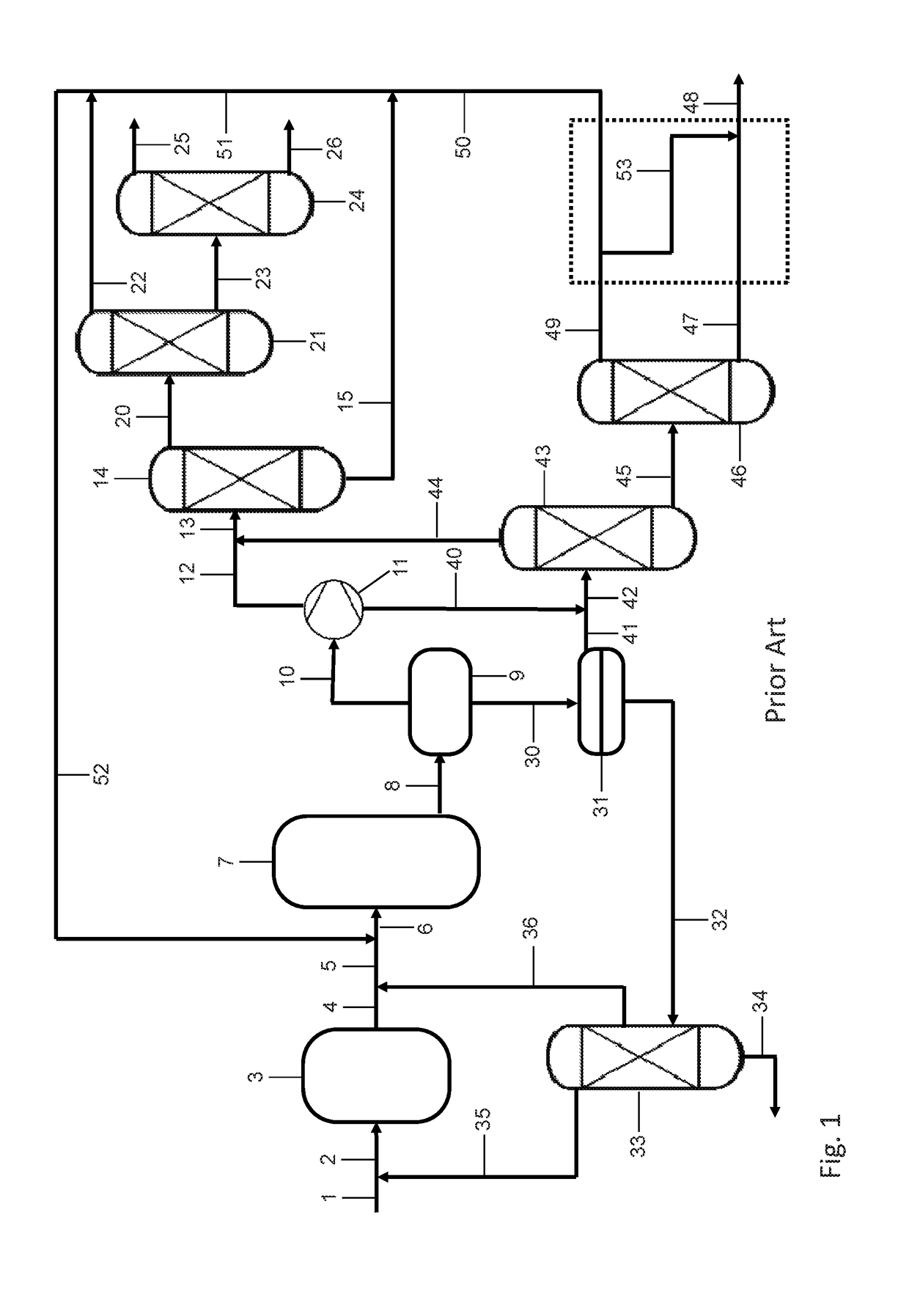

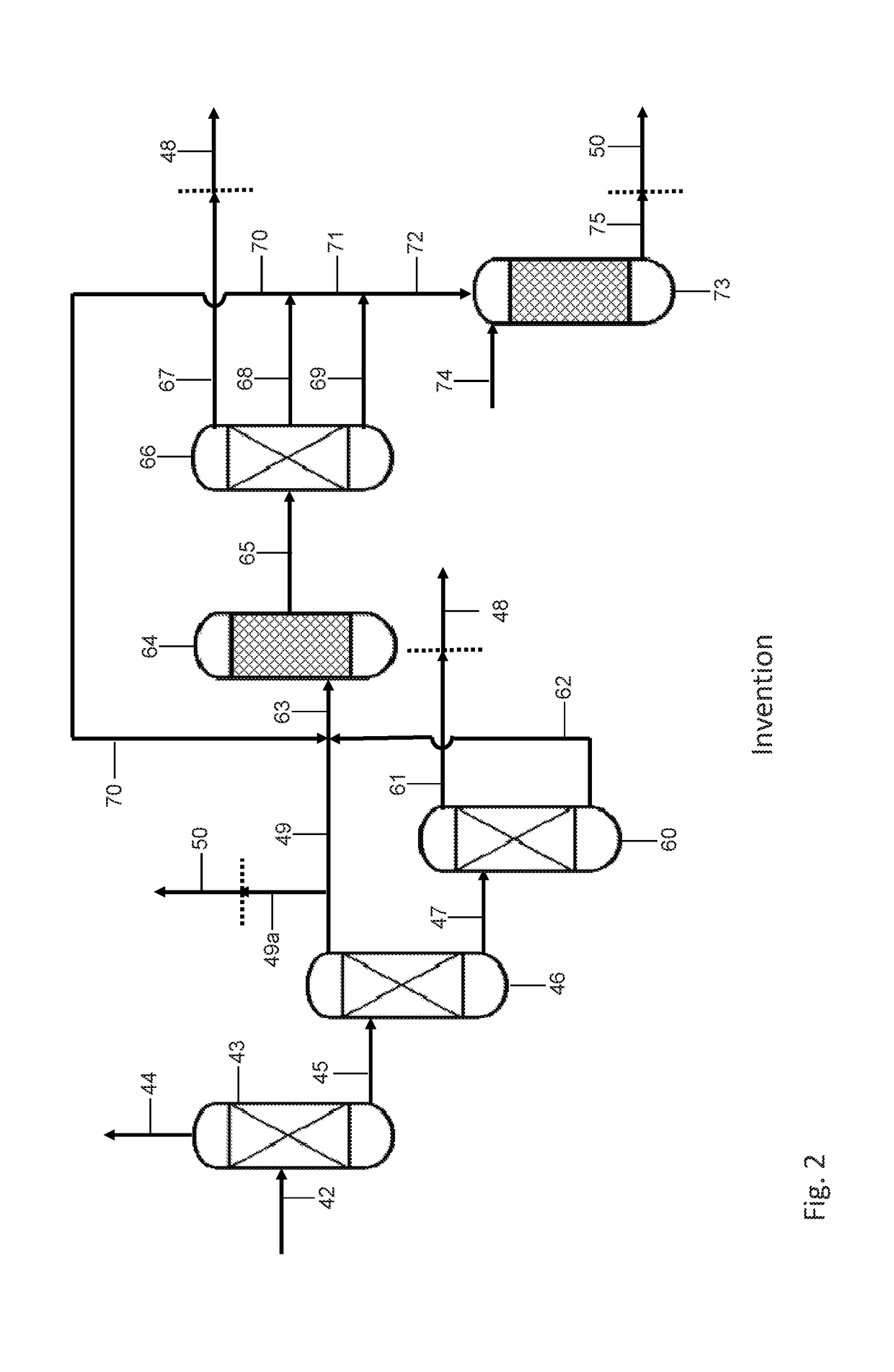

InactiveUS20070203380A1Improved arrangementImproved processing schemeOrganic compound preparationOxygen compounds preparation by reductionOlefin synthesisDimethyl ether

Improved processing for the production of light olefins is provided involving synthesis gas conversion to form an effluent including product dimethyl ether, subsequent separation of the product dimethyl ether and conversion thereof to the desired light olefins. The synthesis gas conversion effluent may also desirably include methanol and at least a portion of such methanol may be employed to effect the separation of the product dimethyl ether.

Owner:UOP LLC

Universal type synthetic gasoline-diesel lubrication oil and preparation method thereof

ActiveCN104498144AHigh viscosity indexImprove the lubrication effectBase-materialsGasolineClearing Agent

The invention belongs to the technical field of development and manufacture of petrochemical products and in particular relates to universal type synthetic gasoline-diesel lubrication oil and a preparation method thereof. The lubrication oil comprises the following raw materials in parts by weight: 0.01-30 parts of synthetic ester base oil, 0.01-90 parts of mineral oil, 0.01-90 parts of olefin synthesis oil PAO, 5.0-10.0 parts of a viscosity modifier, 3-10.0 parts of a clearing agent, 1.0-5.0 parts of a dispersing agent, 0.5-3.0 parts of an oxidation and corrosion inhibitor, 1.0-3.0 parts of a pour point depressant, 0.5-3.0 parts of FK303 and 0.0001-0.01 part of a defoaming agent. The preparation method of the lubrication oil comprises the following steps: step one, adding synthetic ester base oil, the mineral oil and the olefin synthesis oil PAO in a mixing kettle, and stirring at 80-90 DEG C for 1 hour; step two, adding the viscosity modifier into the mixing kettle in the step one, and continuing to stir at 80-90 DEG C for 3 hours; adding the clearing agent, the dispersing agent, the oxidation and corrosion inhibitor, the pour point depressant, FK303 and the defoaming agent into the mixing kettle and continuing to stir at 80-90 DEG C for 1-2 hours to obtain the lubrication oil. The universal type synthetic gasoline-diesel lubrication oil is mainly used in the application field of motor vehicle lubricating oil.

Owner:XINJIANG FUKE OIL PROD CO LTD

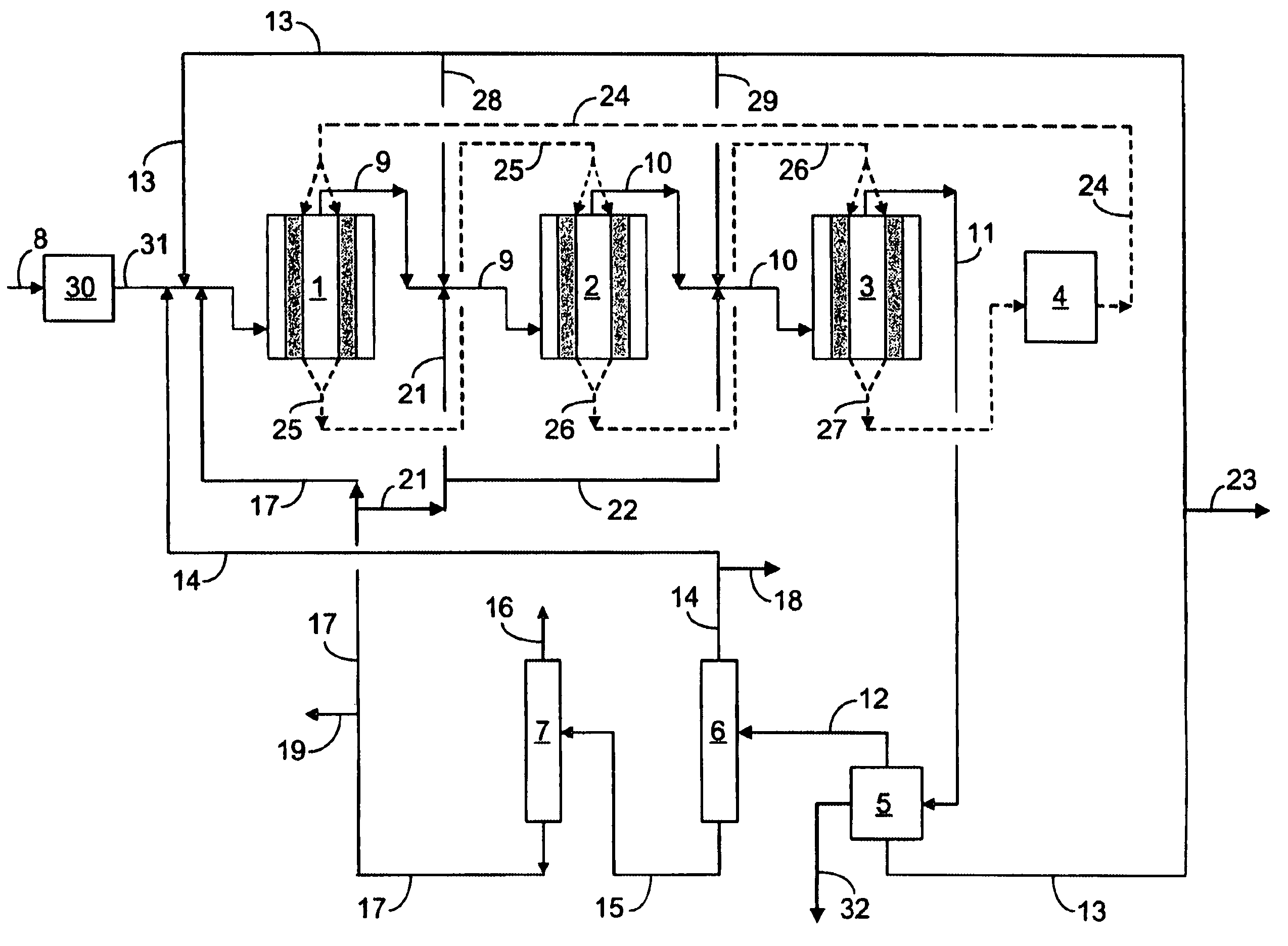

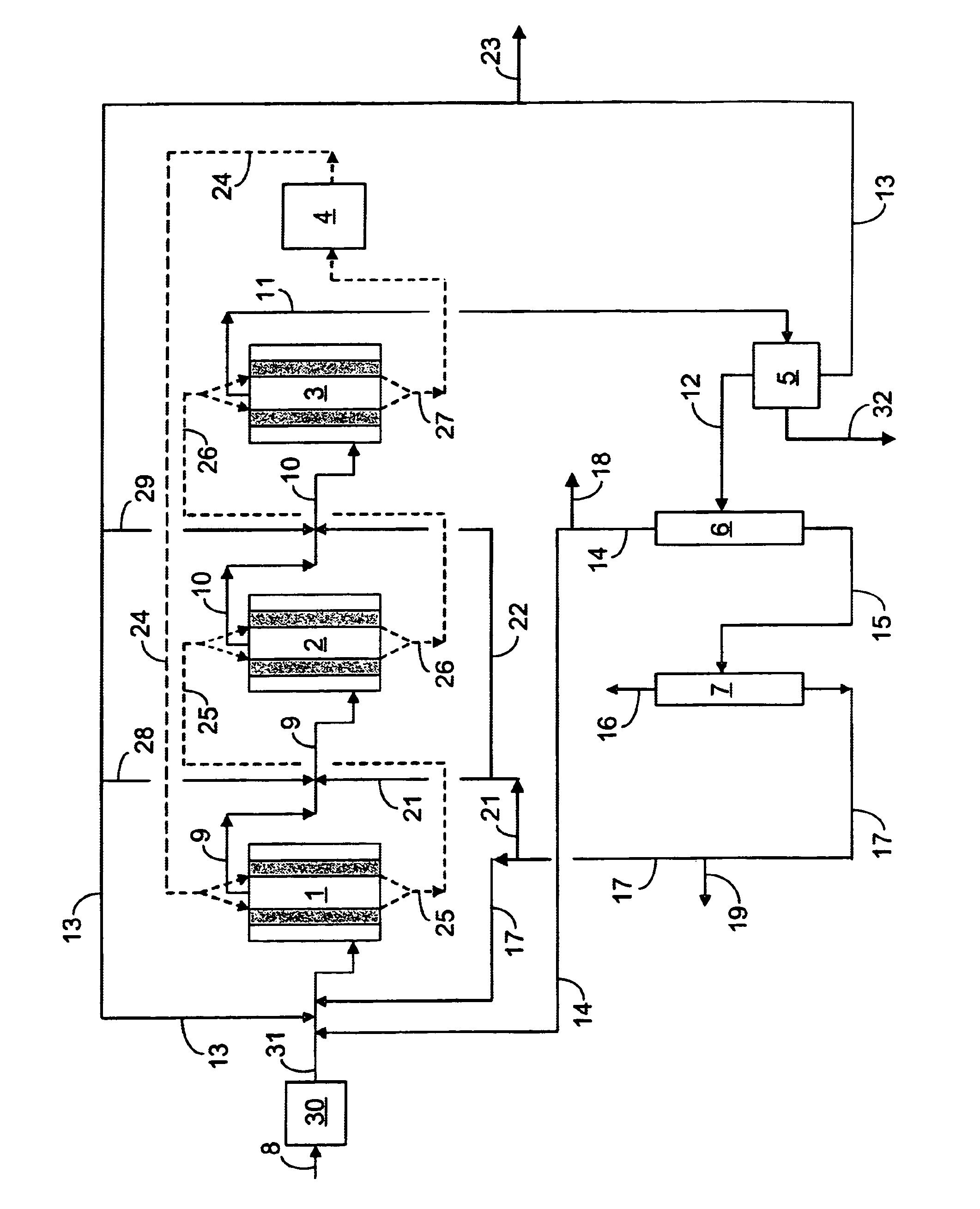

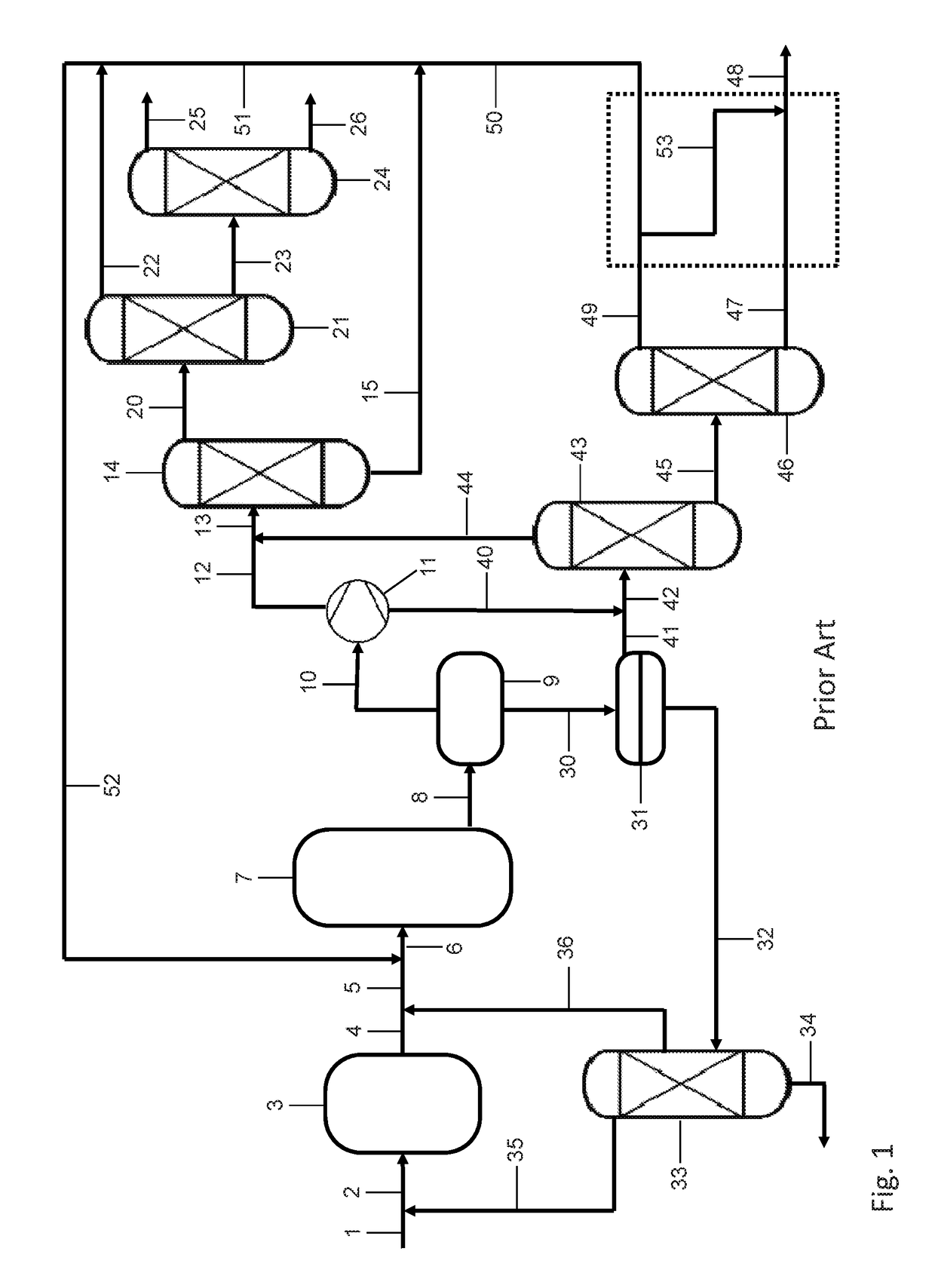

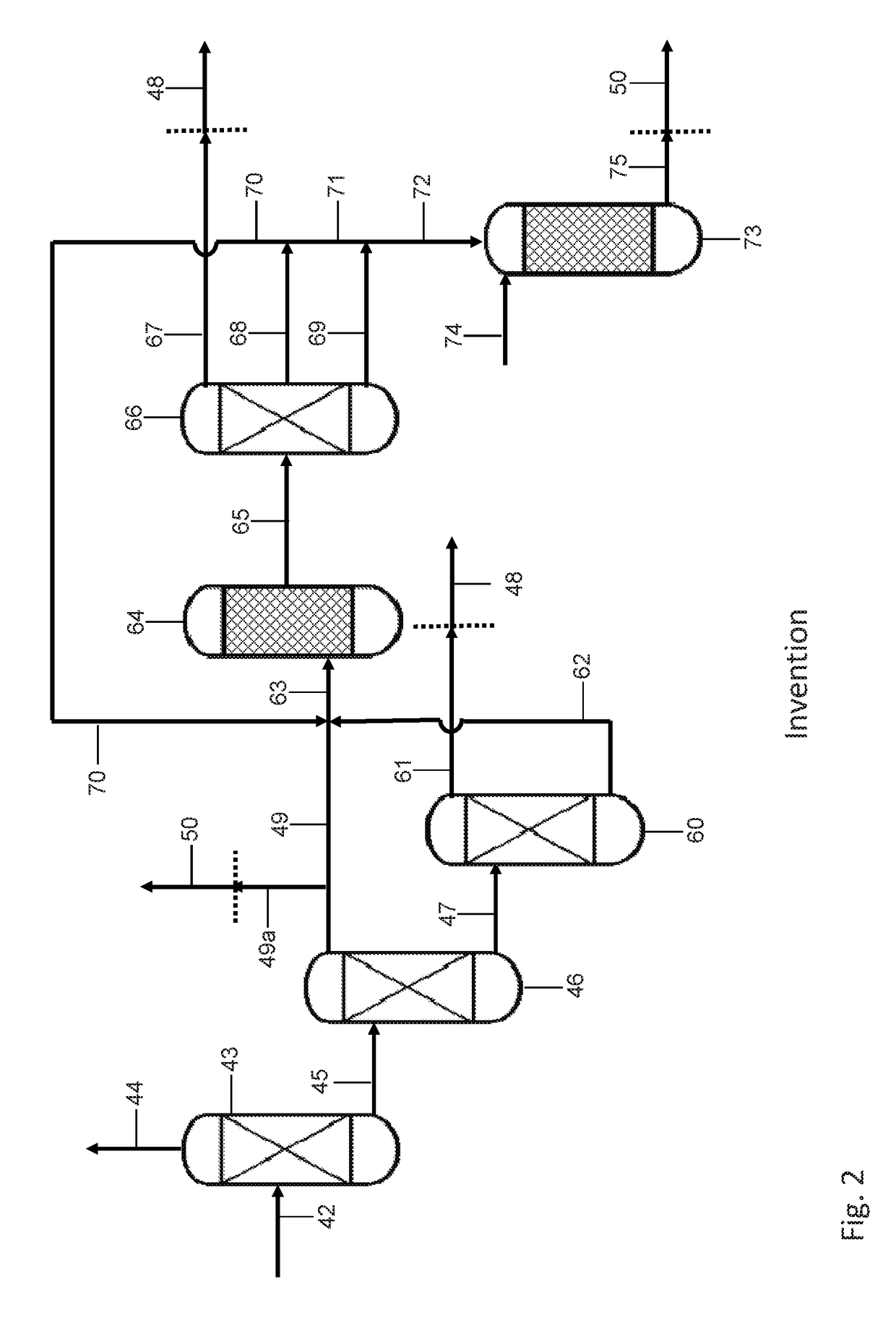

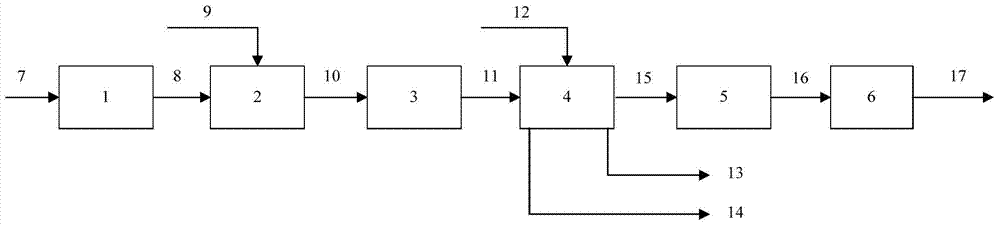

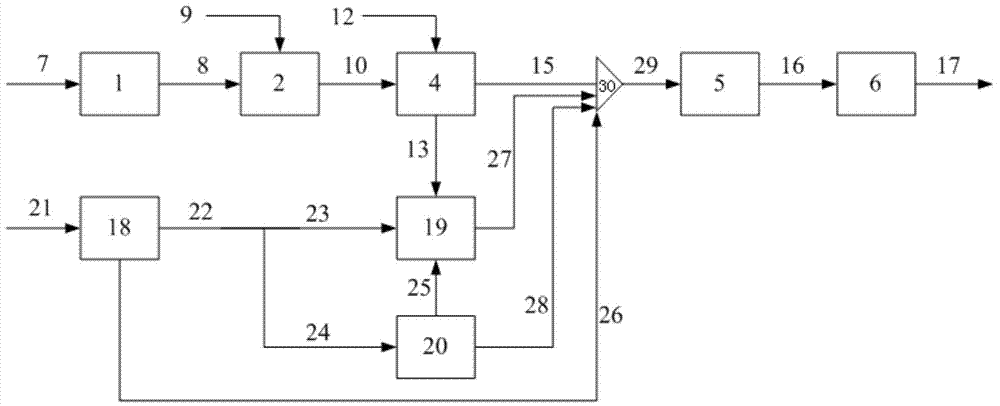

Conversion of an alcoholic oxygenate to propylene using moving bed technology and an etherification step

InactiveUS7371916B1Improve economyReduce the amount requiredHydrocarbon from carbon oxidesMolecular sieve catalystAlcoholFixed bed

The average propylene selectivity per on-stream cycle of an alcoholic oxygenate to propylene (OTP) process using one or more fixed beds of a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a feed pretreatment step involving a catalytic etherification reaction, by switching to moving bed reactor technology in the olefin synthesis portion of the OTP flow scheme in lieu of fixed bed technology and by the selection of a catalyst on-stream cycle time of 300 hours or less. These provisions hold the build-up of coke deposits on the dual-function catalyst to a level which does not substantially degrade catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of propylene average cycle yield at essentially start-of-cycle levels. The propylene average cycle yield improvement enabled by the present invention over that achieved by the fixed bed system of the prior art using the same or a similar dual-function catalyst system is of the order of about 1.5 to 5.5 wt-% or more.

Owner:UOP LLC

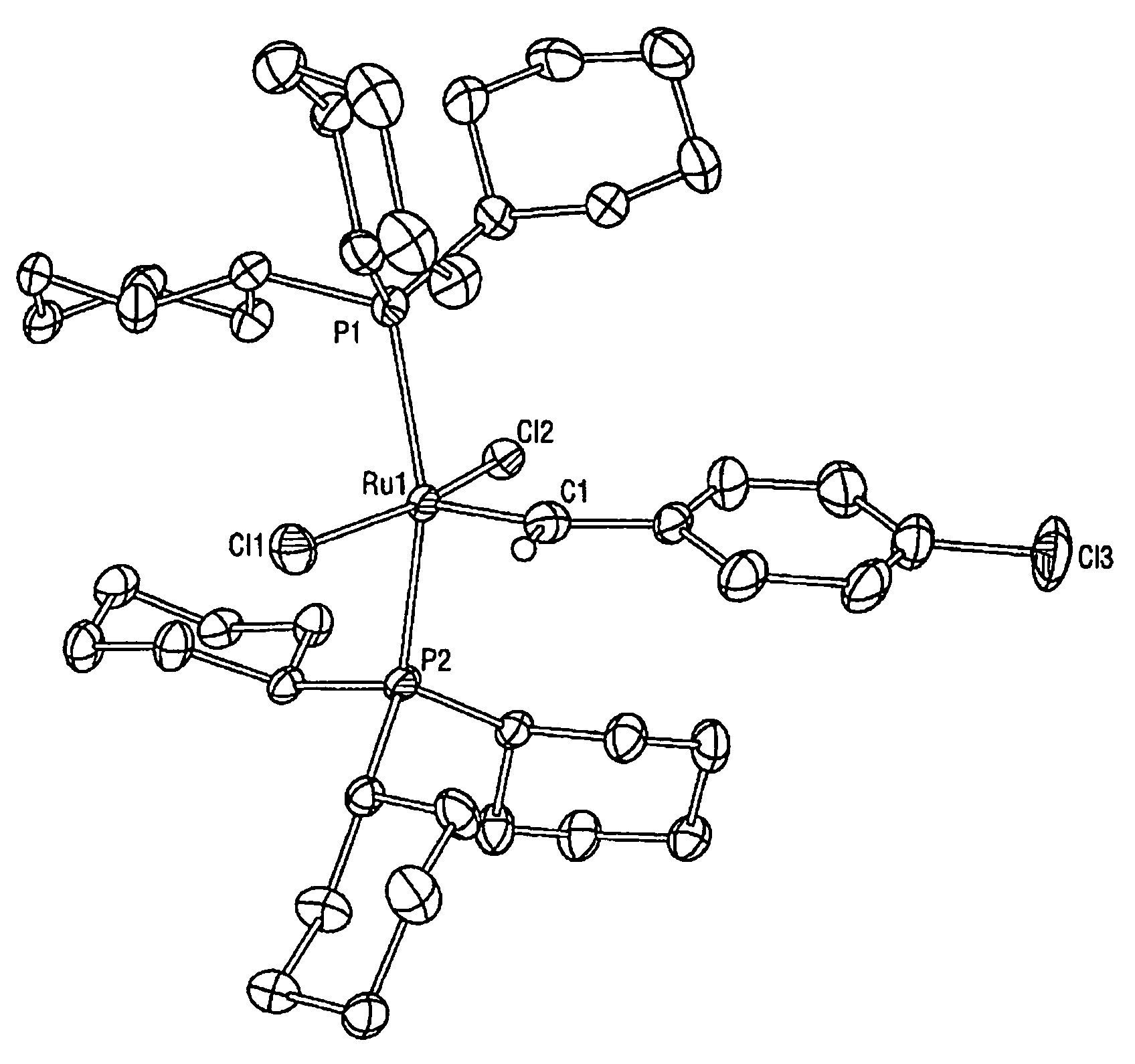

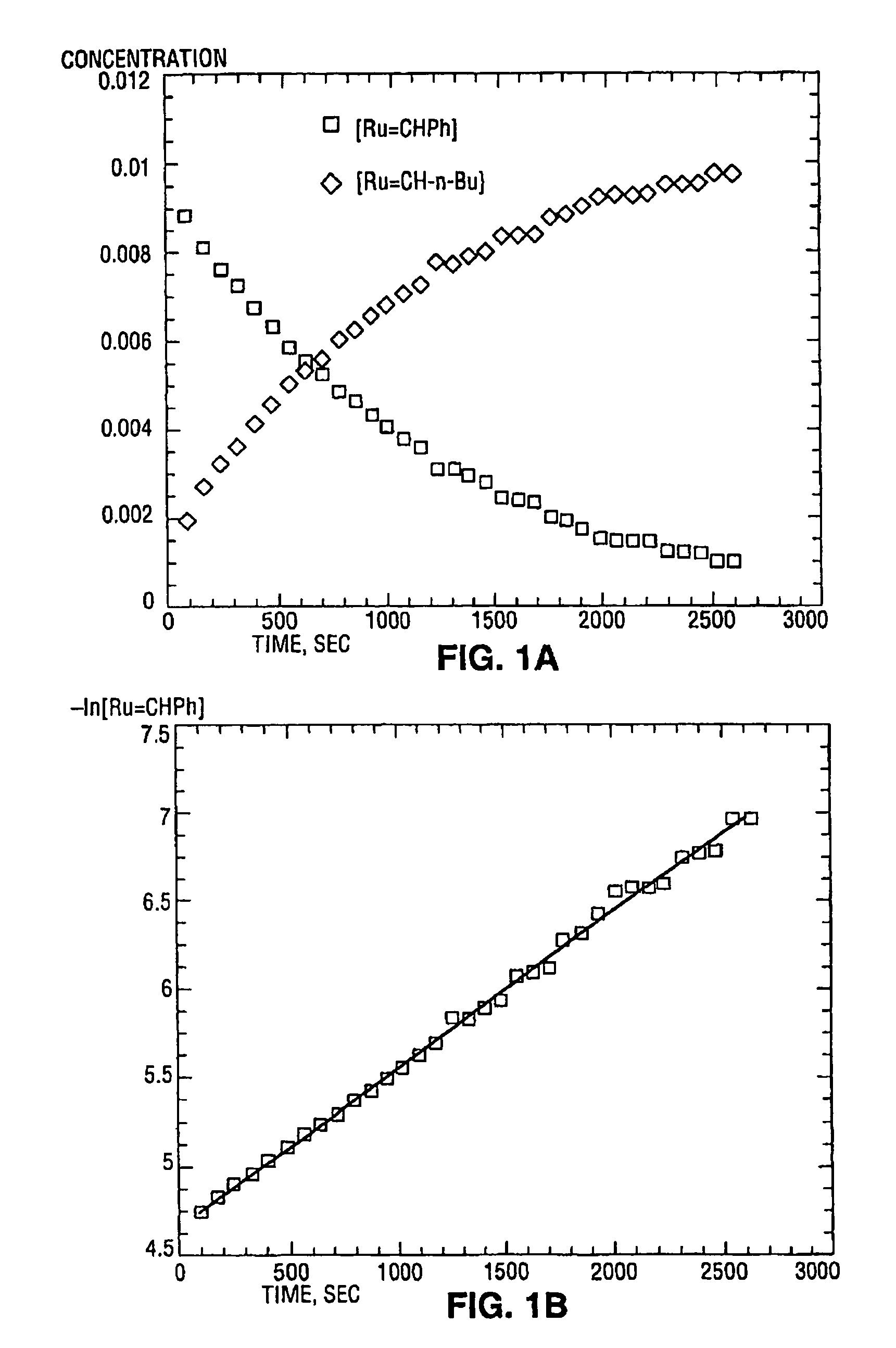

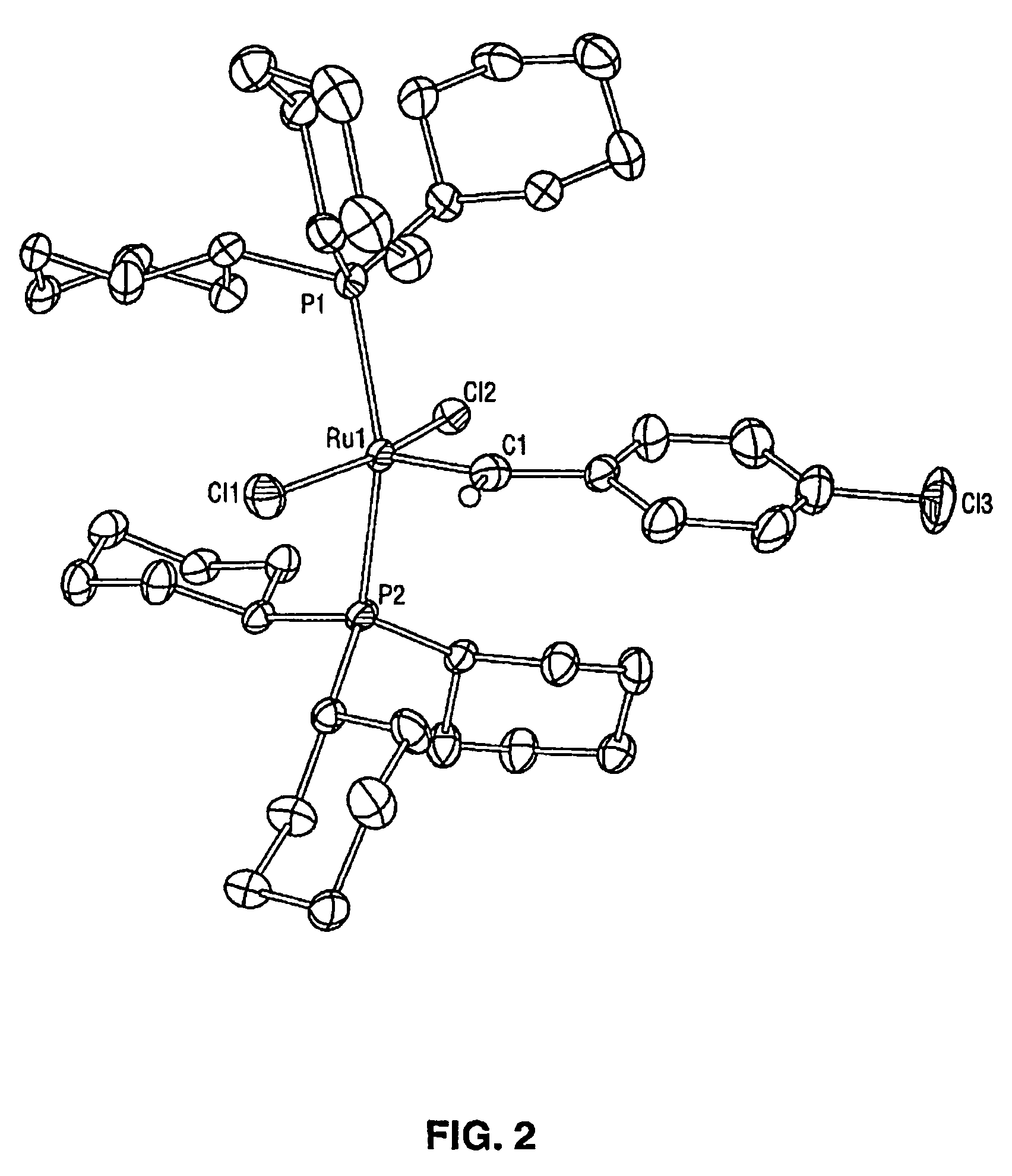

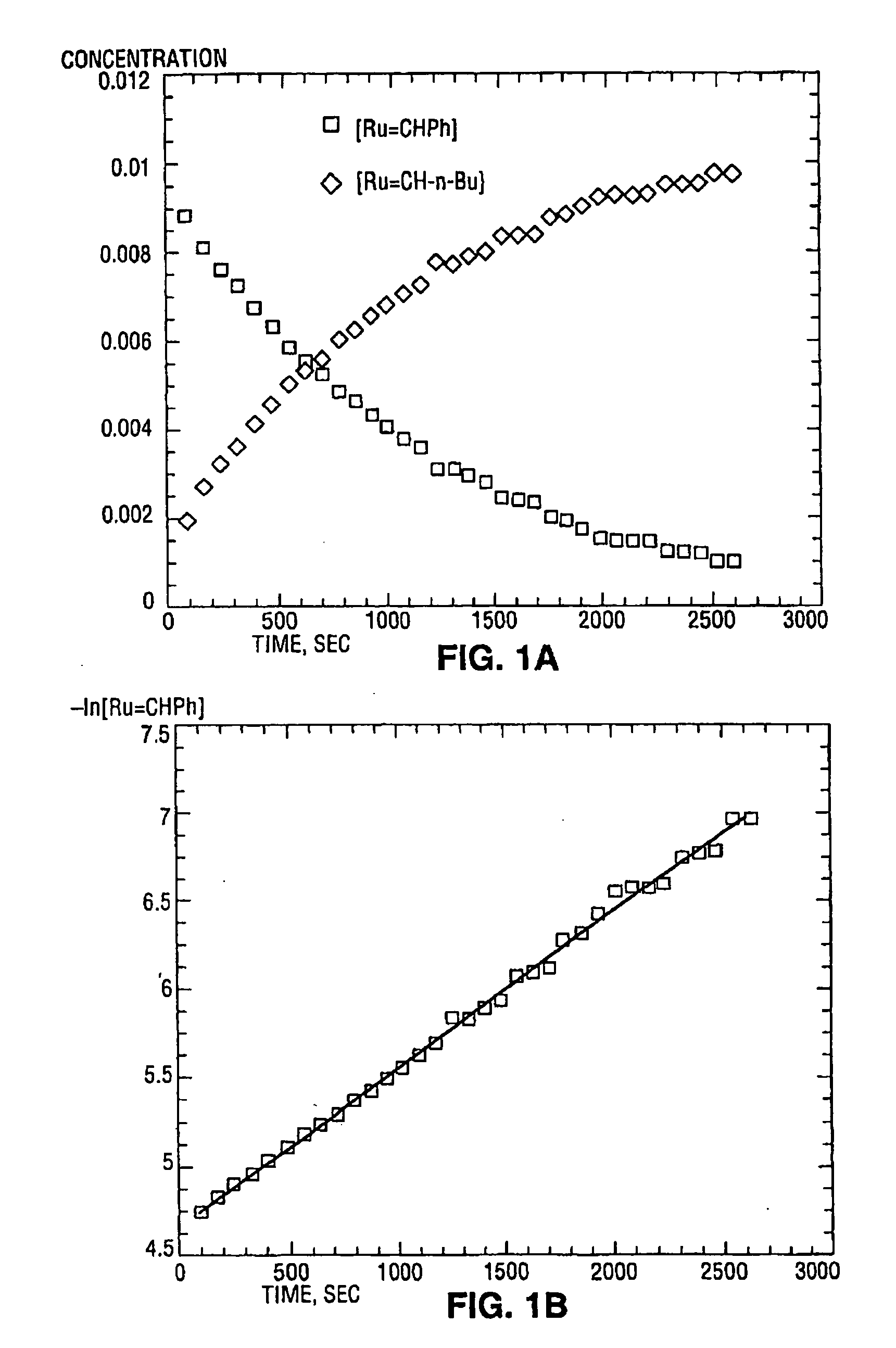

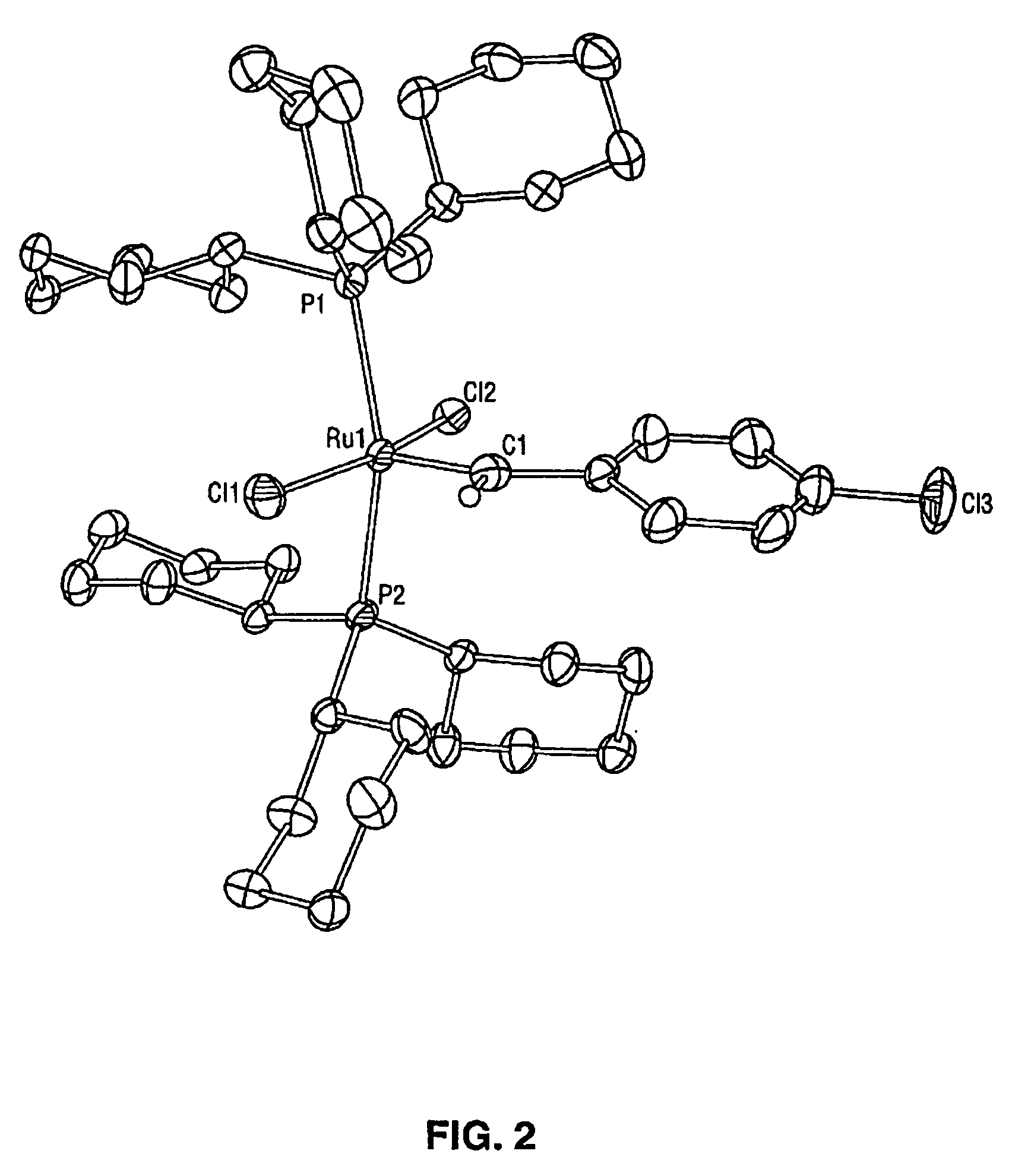

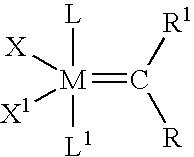

High metathesis activity ruthenium and osmium metal carbene complexes

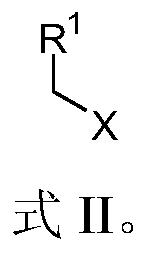

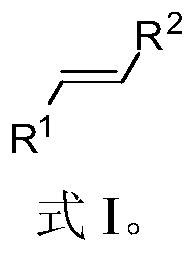

InactiveUS7288666B2Increase the probability of activationHighly active andRuthenium organic compoundsGroup 5/15 element organic compoundsDepolymerizationElectron donor

Ruthenium and osmium carbene compounds that are stable in the presence of a variety of functional groups and can be used to catalyze olefin metathesis reactions on unstrained cyclic and acyclic olefins are disclosed. Also disclosed are methods of making the carbene compounds. The carbene compounds are of the formulawhere M is Os or Ru; R<1> is hydrogen; R is selected from the group consisting of hydrogen, substituted or unsubstituted alkyl, and substituted or unsubstituted aryl; X and X<1> are independently selected from any anionic ligand; and L and L<1> are independently selected from any neutral electron donor. The ruthenium and osmium carbene compounds of the present invention may be synthesized using diazo compounds, by neutral electron donor ligand exchange, by cross metathesis, using acetylene, using cumulated olefins, and in a one-pot method using diazo compounds and neutral electron donors. The ruthenium and osmium carbene compounds of the present invention may be used to catalyze olefin metathesis reactions including, but not limited to, ROMP, RCM, depolymerization of unsaturated polymers, synthesis of telechelic polymers, and olefin synthesis.

Owner:CALIFORNIA INST OF TECH

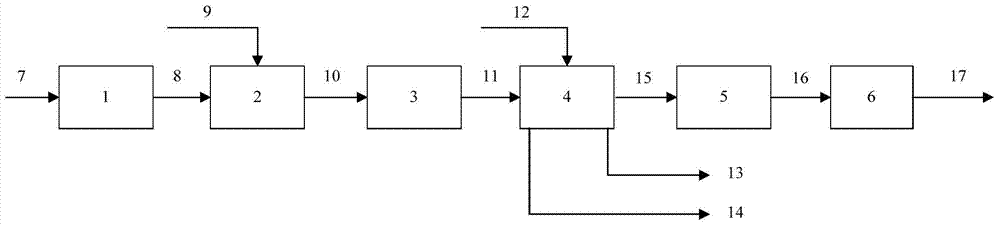

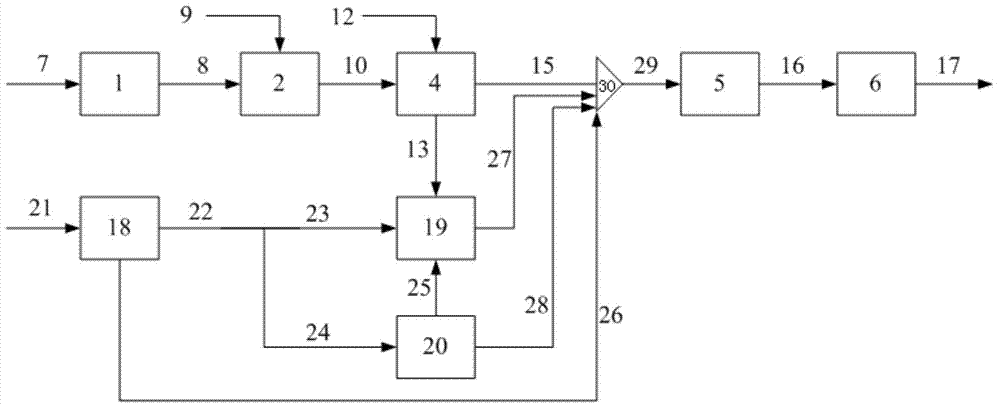

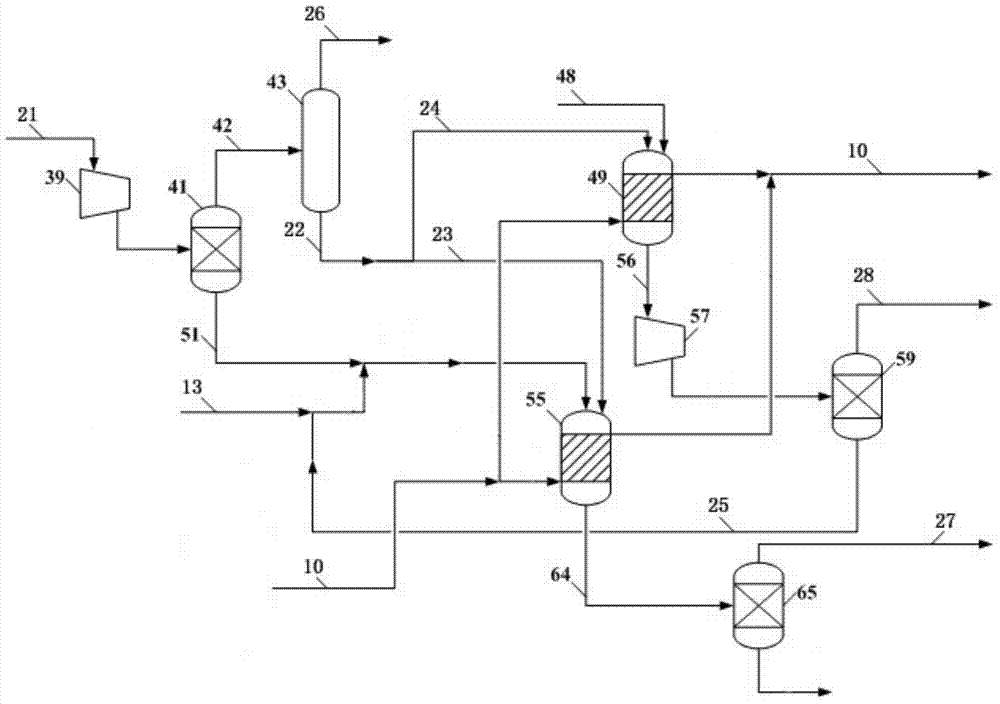

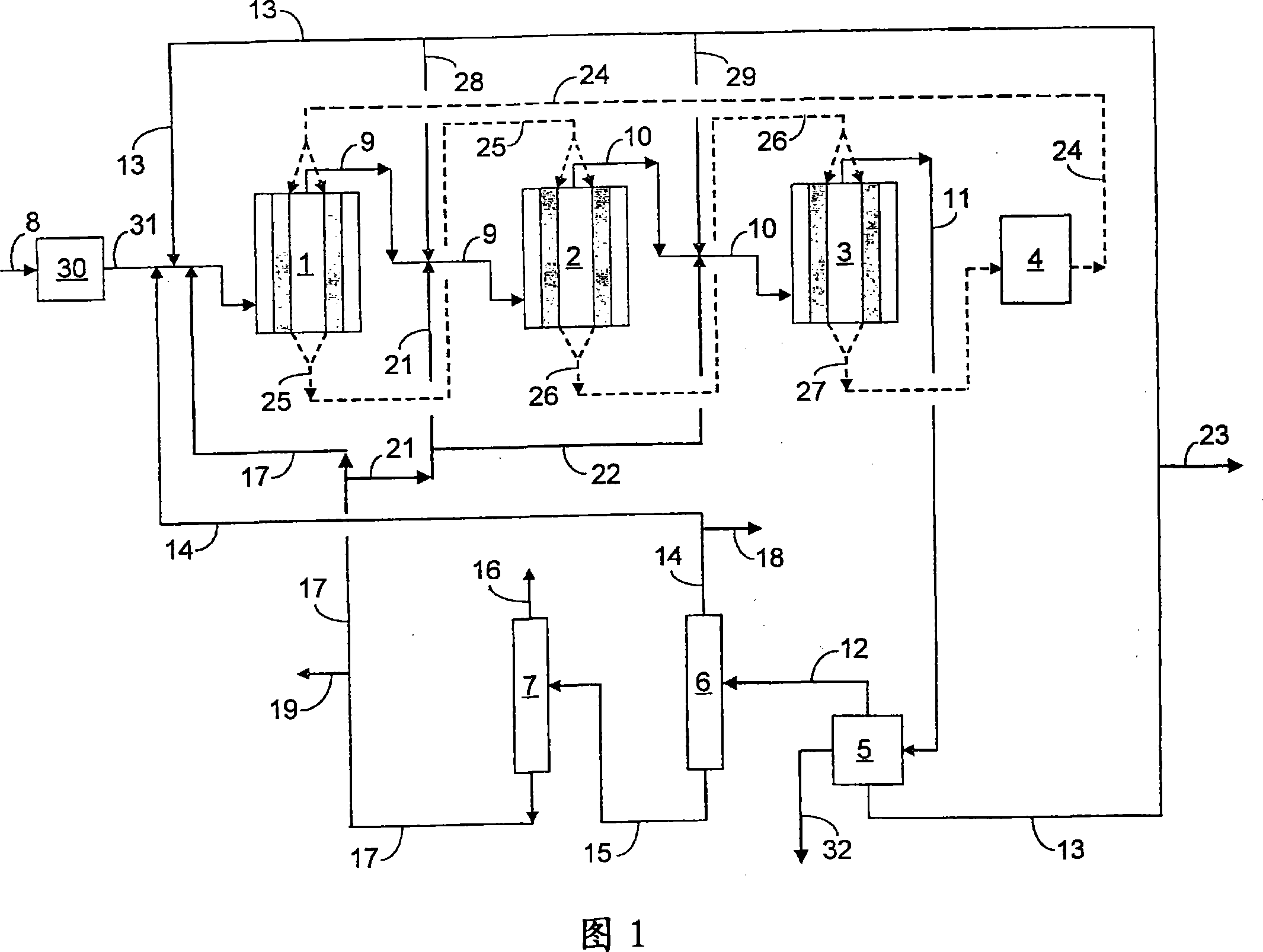

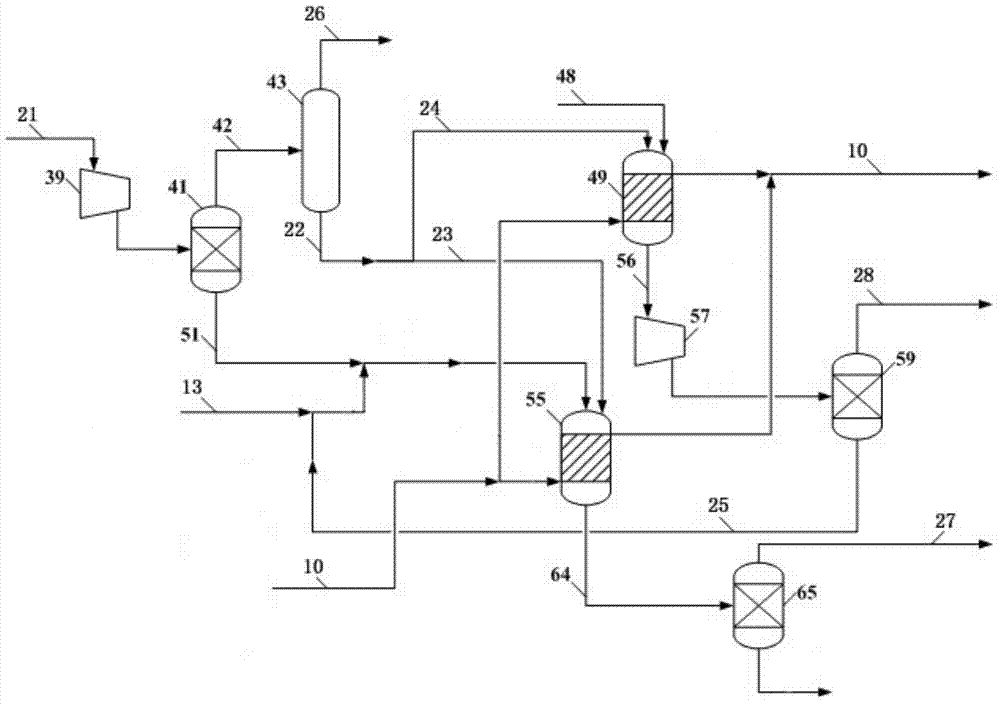

System and process for preparing olefin by taking coal and coke-oven gas as raw materials

ActiveCN103694074AEfficient use ofEmission reductionChemical industryHydrocarbon from oxygen organic compoundsChemical industryWater vapor

The invention belongs to the technical fields of energies and chemical industry, and discloses a system and a process for preparing olefin by taking coal and coke-oven gas as raw materials. The system for preparing olefin by taking coal and coke-oven gas as raw materials comprises a water-coal-slurry preparation unit, a coal gasification unit, a synthesis gas purification unit, a methanol synthesis unit, an olefin synthesis unit, a coke-oven gas separation unit, a methane dry-reforming unit, a methane vapour reforming unit and a gas mixer. By using the system for preparing olefin, hydrogen separated by the coke-oven gas separation unit, methane dry reforming synthesis gas, methane vapour reforming synthesis gas and the clean synthesis gas generated by the coal gasification unit can be mixed, the hydrogen-carbon ratio of the synthesis gas is adjusted to meet the requirements of methanol synthesis so as to synthesize methanol, and then olefin is synthesized. By adopting the device and the process disclosed by the invention, the emission amount of CO2 during the existing coal-to-olefin process can be decreased, the energy utilization ratio can be increased, and the exhaust emission of the industrial coal coking industry can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

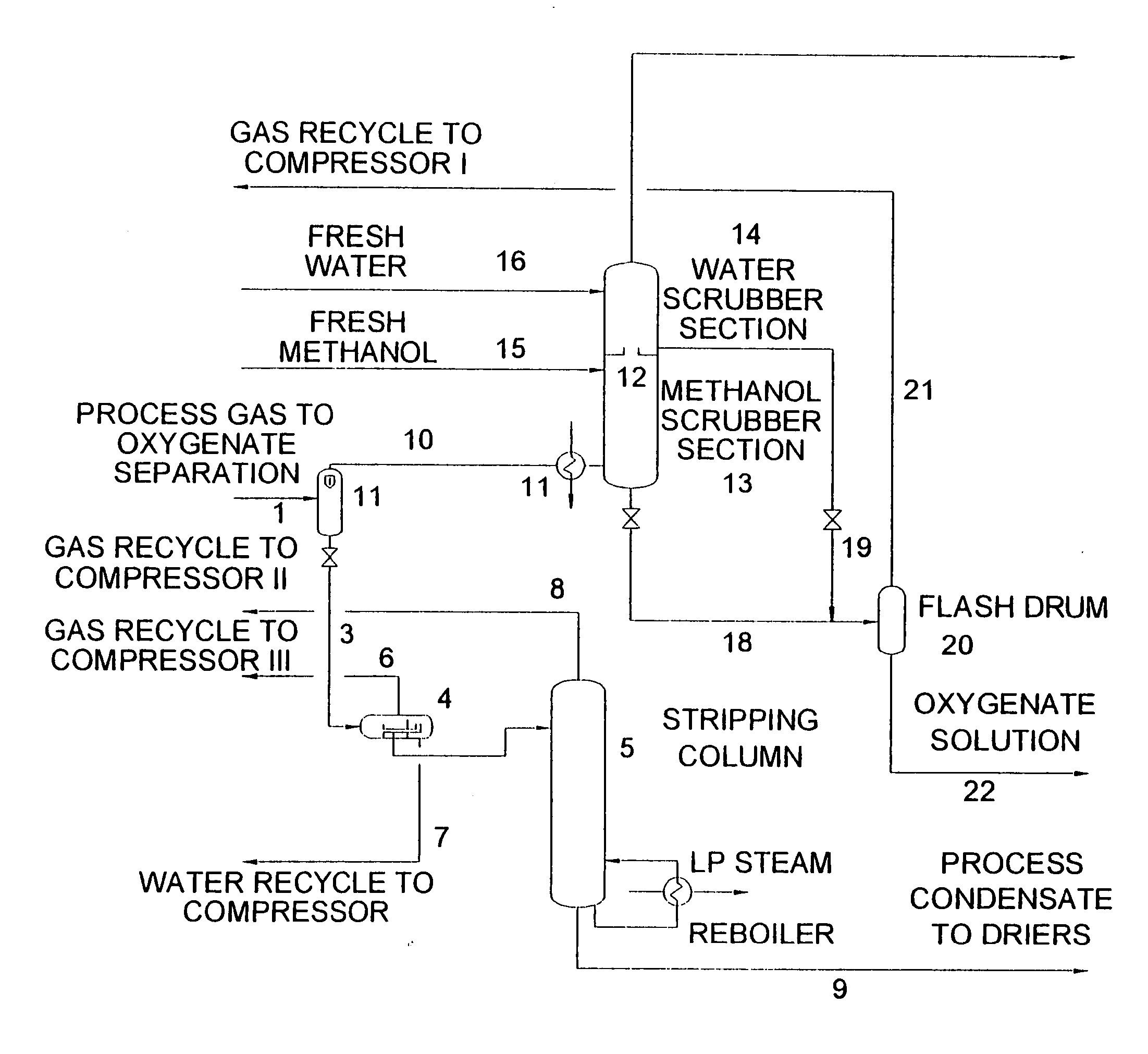

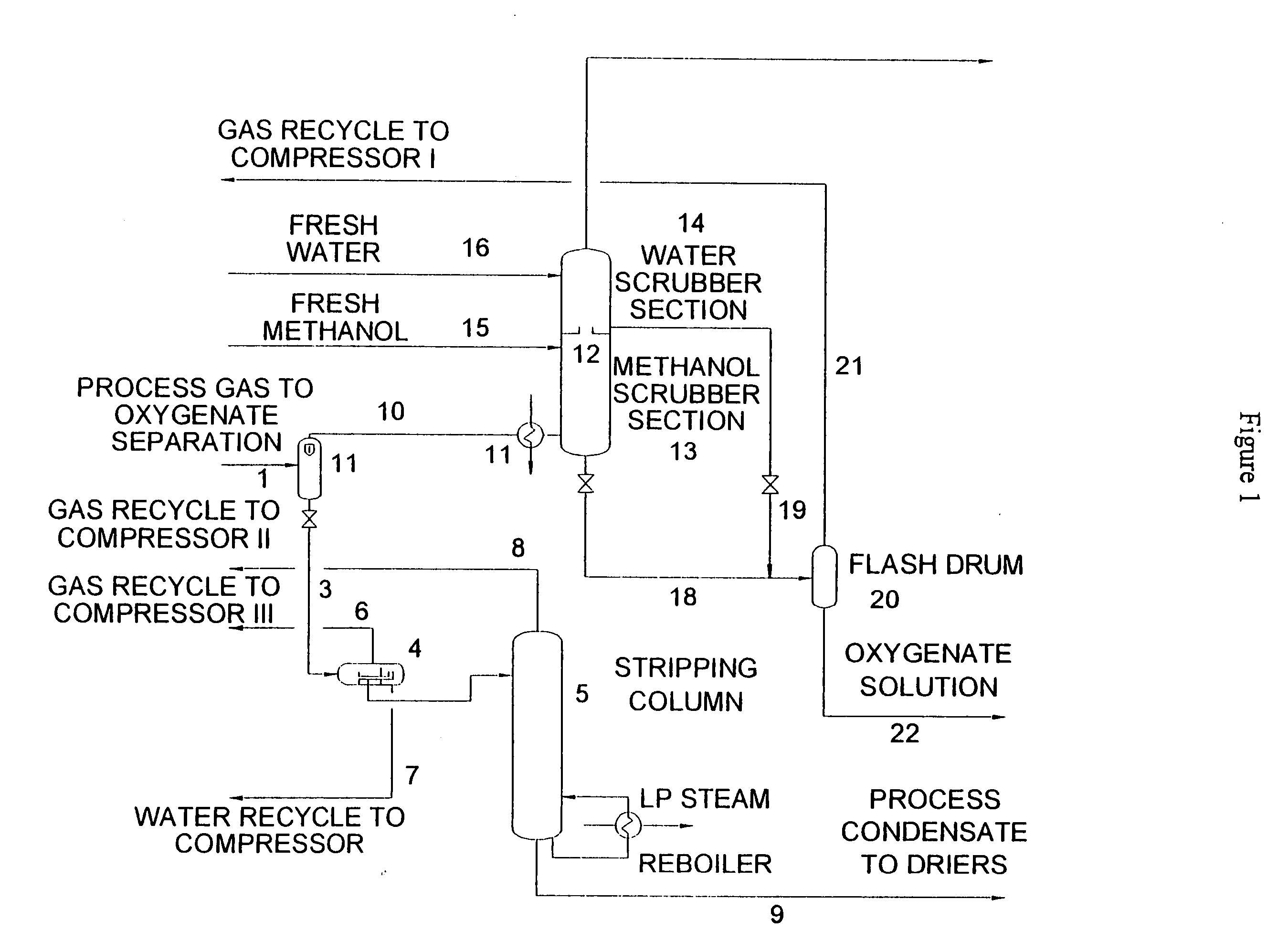

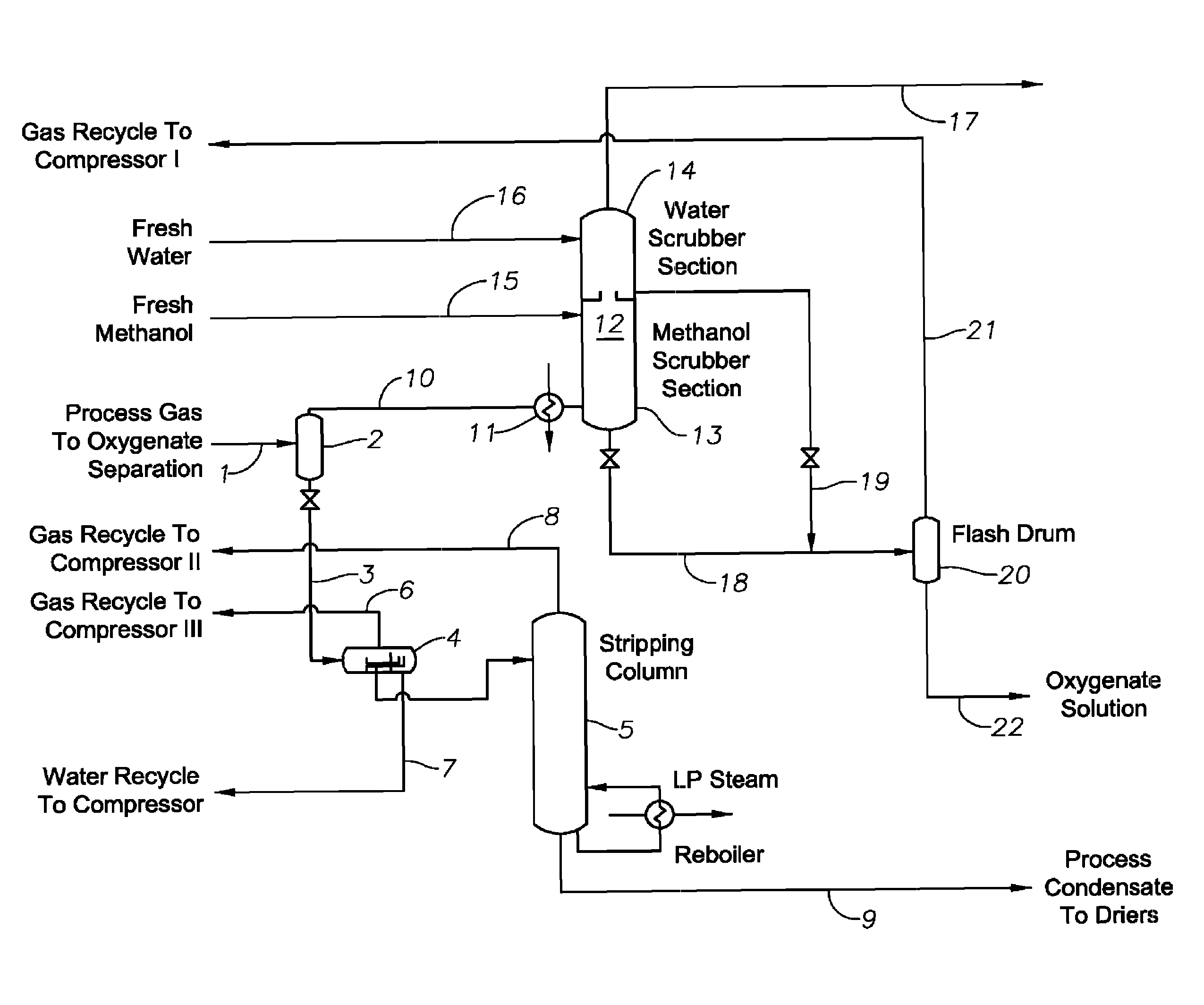

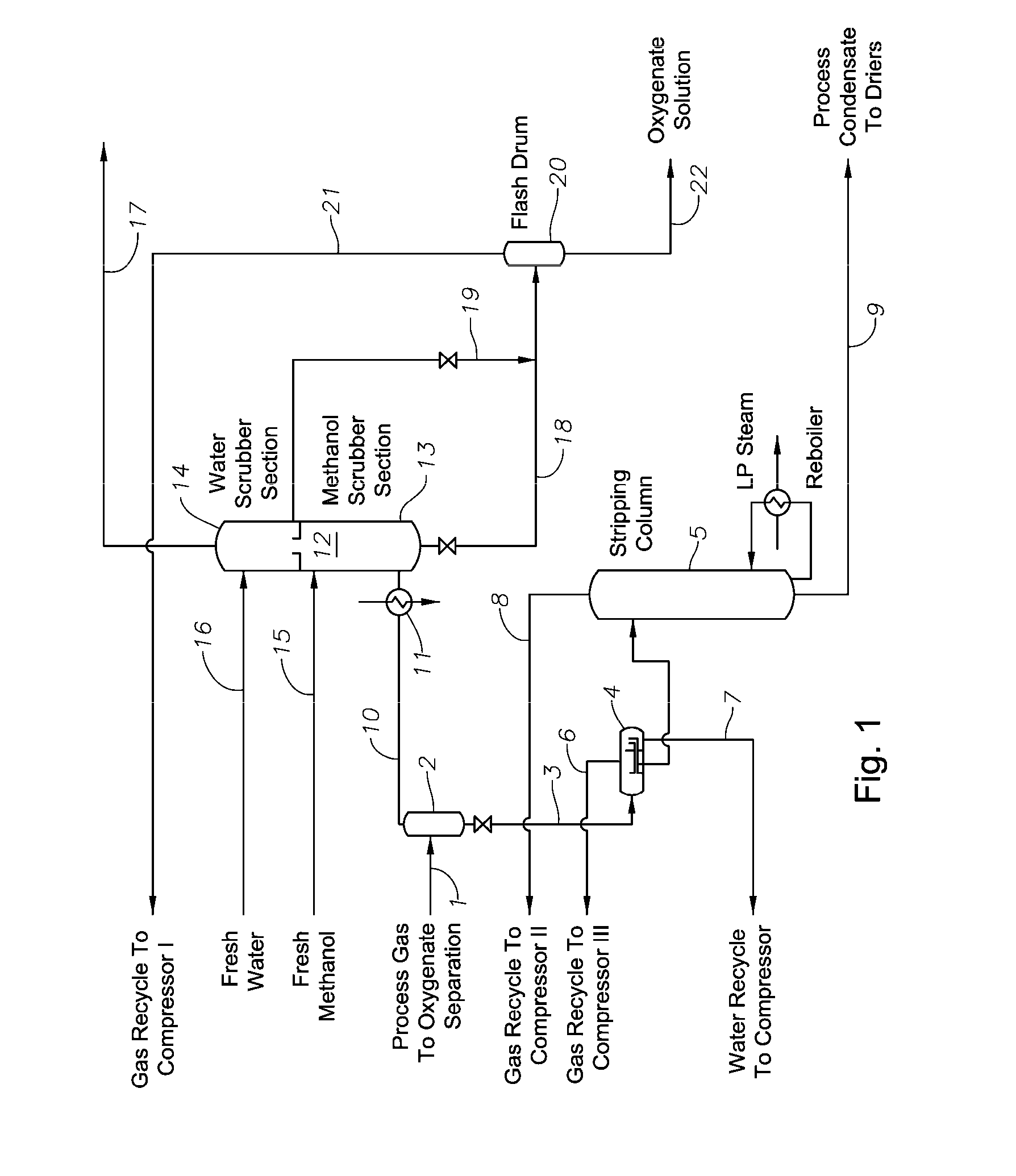

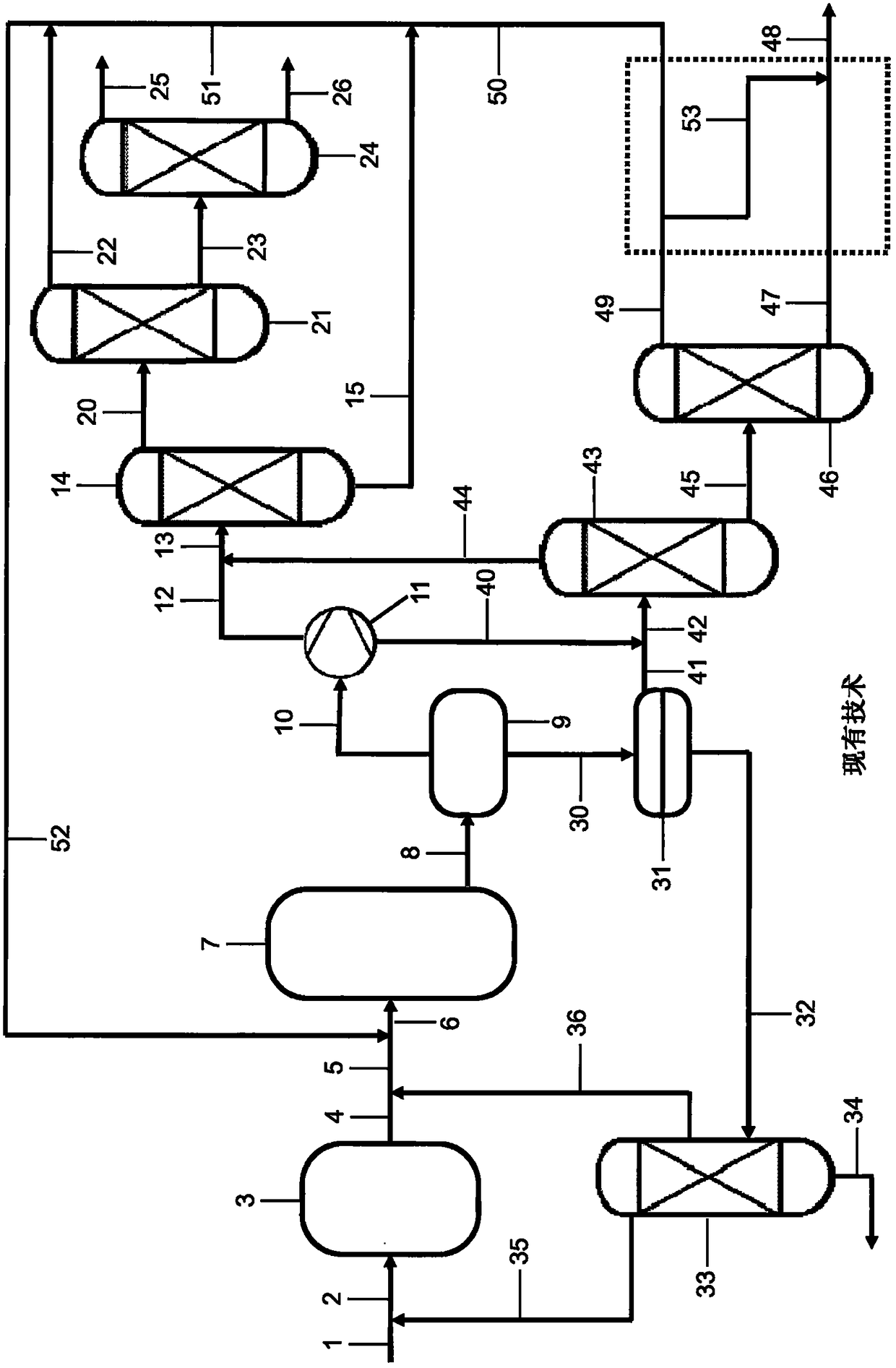

Method for processing an olefin-containing product stream

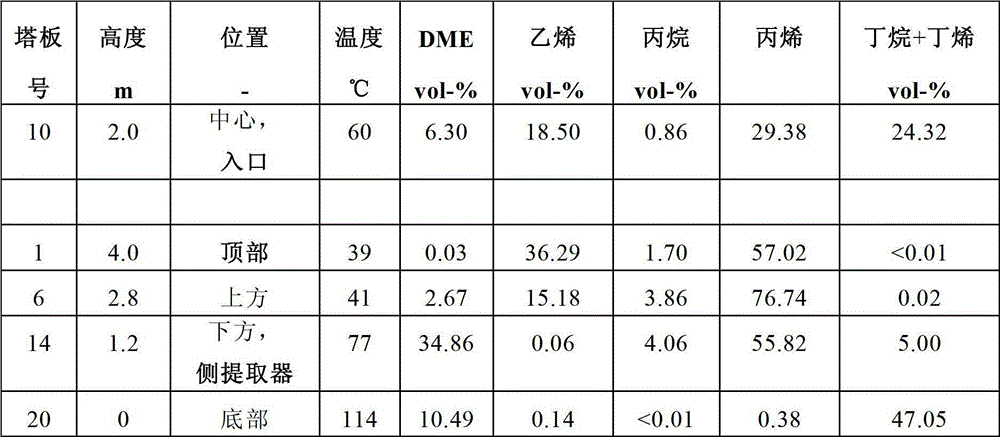

ActiveUS20050222478A1Easy to disassembleFractional condensation purification/separationEthylene productionFractionationOxygenate

A method is described for processing an olefin-containing product stream (1) that contains, besides ethylene and propylene, longer-chain olefins and compounds of hydrocarbons with oxygen (oxygenates). Such a product stream (I) can occur in particular in olefin synthesis from methanol. The product stream is dewatered in successive process steps, optionally compressed in several steps and dried. Then it is subjected to fractionation. For removal of the undesired oxygenates it is proposed that the oxygenates be washed out of the gaseous product stream after the compression steps and before the drying step in a column (12) with methanol.

Owner:EXXONMOBIL CHEM PAT INC

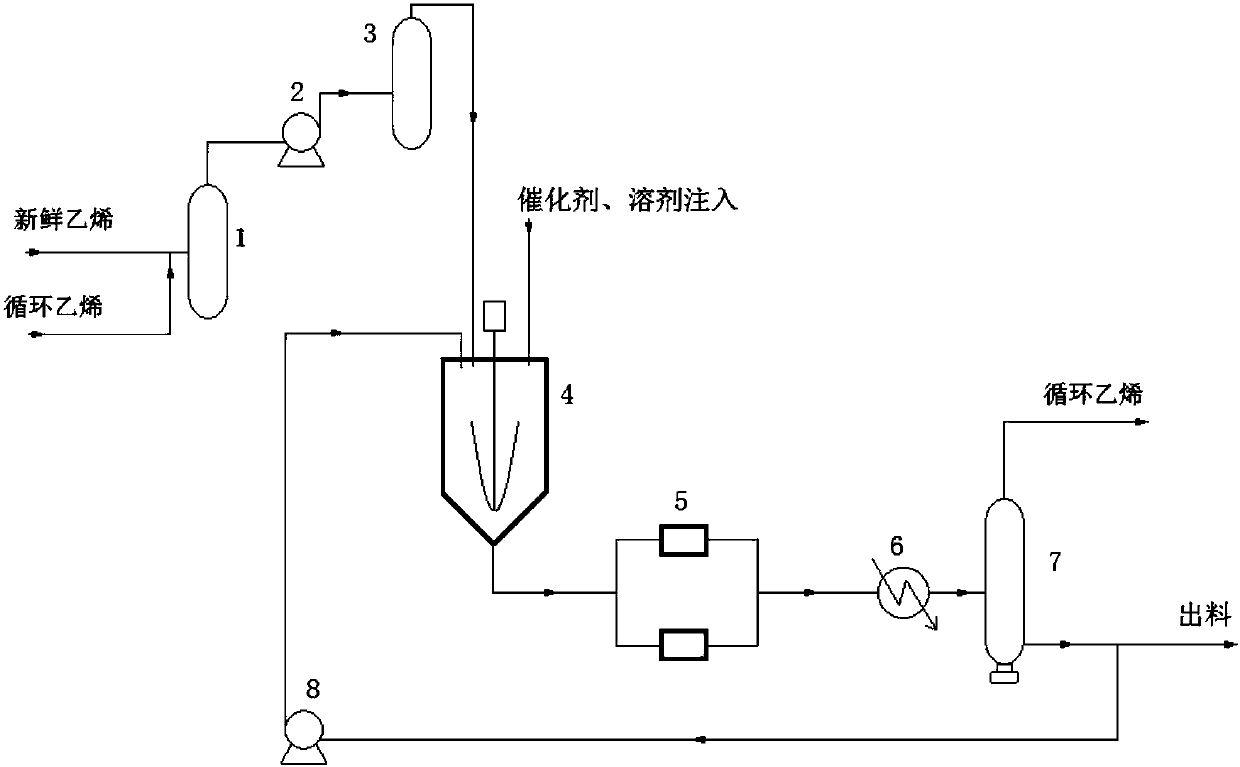

Process method and system for production of alpha-olefin by oligomerization of selective ethylene

InactiveCN107746365AHigh activityHigh selectivityCatalystsHydrocarbon preparation catalystsVapor–liquid separatorReaction temperature

The invention discloses a process method for production of alpha-olefin by oligomerization of selective ethylene; a high-pressure reaction kettle is externally connected with a material circulation pipeline; the material circulation pipeline is provided with a heat exchanger and a gas-liquid separator; in the synthesis process of alpha-olefin, ethylene is inputted to the high-pressure reaction kettle, alpha-olefin synthesized in the presence of a catalyst and a reaction solvent is dissolved in a solvent in the kettle, and a reaction liquid containing a product flows out from the bottom of thekettle, then has heat exchanged by the heat exchanger, enters the gas-liquid separator and is subjected to gas-liquid separation; gas discharged from the top of the gas-liquid separator flows back toa gas mixing tank, and a liquid is sent back to the high-pressure reaction kettle. The invention also relates to a system implementing the process. Heat generated from the reaction is removed in time,the reaction temperature is steadily controlled, and the activity and the selectivity of the catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP

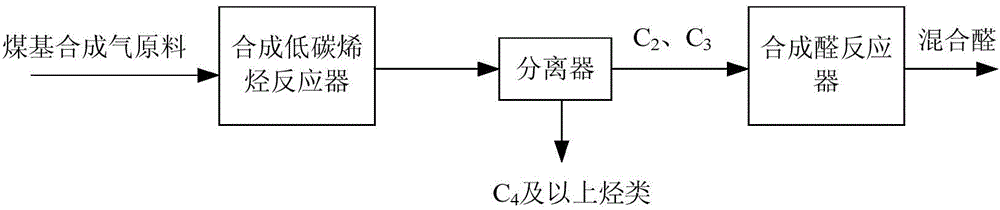

Process for preparing light olefin from coal-based synthesis gas and co-producing low-carbon mixed aldehyde

ActiveCN104478641ARealize high value utilizationReduce energy consumptionHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsSyngasOlefin synthesis

The invention provides a process for preparing light olefin from coal-based synthesis gas and co-producing low-carbon mixed aldehyde. The process comprises the following steps: carrying out contact reaction on a coal-based synthesis gas and a catalyst for light olefin synthesis, then carrying out contact reaction on a tail gas and a hydroformylation catalyst and synthesizing to obtain mixed propionaldehyde and butyraldehyde. The synthesis gas contained in the reaction product tail gas obtained in the preparation of light olefin from the coal-based synthesis gas in the process for preparing light olefin from coal-based synthesis gas and co-producing low-carbon aldehyde, which is provided by the invention, and light olefin almost just meet the raw material ratio required in preparation of aldehyde by hydroformylation, so that the resources can be fully utilized and the flow can be simplified. By the process provided by the invention, the co-production of light olefin and low-carbon mixed aldehyde can be well achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

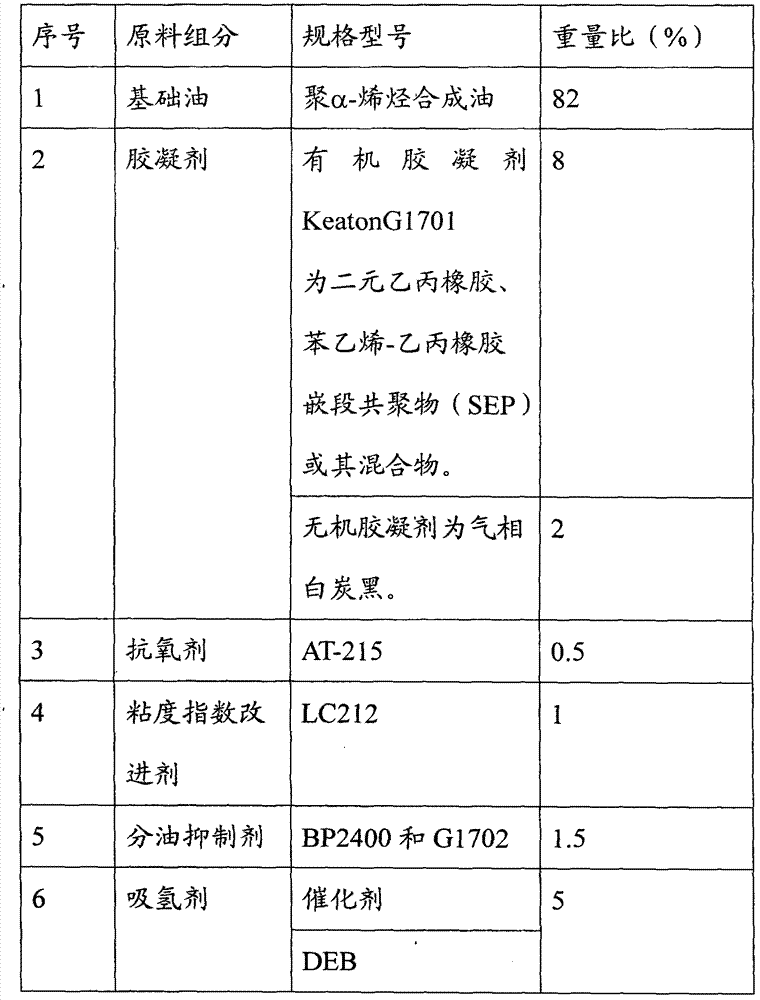

Hydrogen absorption fiber paste for optical fiber composite overhead ground wire (OPGW) optical cable and manufacture method thereof

InactiveCN102778735AGood high and low temperature performanceDrop point highFibre mechanical structuresFiberAntioxidant

The invention relates to hydrogen absorption fiber paste for an optical fiber composite overhead ground wire (OPGW) optical cable. The hydrogen absorption fiber paste comprises, by weight, 75-85% of base oil, 6-10% of gelatinizing agent, 0.3-0.6% of antioxidant, 0.8-1% of viscosity index improver, 1.5-2% of oil distribution inhibitor and 2-5% of hydrogen absorption agent. The base oil is polyalpha-olefin synthesis oil, and the gelatinizing agent is a composite of an organic gelatinizing agent and an inorganic gelatinizing agent. The hydrogen absorption fiber paste has the advantages of adopting the polyalpha-olefin synthesis oil as the base oil so as to enable the fiber paste to have good high-low-temperature performance; improving the stability of a glue body by adding an appropriate amount of silicon-containing (inorganic) glue body into a silicon-free (organic) glue body; having good hydrogen absorption performance by adding an efficient hydrogen absorption agent, removing hydrogen caused by incompatibility of the fiber paste and stainless steel and caused in welding process, reducing defects in optical fiber lattice and loss of optical fiber, and improving transmission performance of the optical fiber.

Owner:JIANGSU NANFANG COMM TECH

High metathesis activity ruthenium and osmium metal carbene complexes

InactiveUS20060241317A1Increase the probability of activationHighly active andRuthenium organic compoundsGroup 5/15 element organic compoundsDepolymerizationElectron donor

Ruthenium and osmium carbene compounds that are stable in the presence of a variety of functional groups and can be used to catalyze olefin metathesis reactions on unstrained cyclic and acyclic olefins are disclosed. Also disclosed are methods of making the carbene compounds. The carbene compounds are of the formula where M is Os or Ru; R<1> is hydrogen; R is selected from the group consisting of hydrogen, substituted or unsubstituted alkyl, and substituted or unsubstituted aryl; X and X<1> are independently selected from any anionic ligand; and L and L<1> are independently selected from any neutral electron donor. The ruthenium and osmium carbene compounds of the present invention may be synthesized using diazo compounds, by neutral electron donor ligand exchange, by cross metathesis, using acetylene, using cumulated olefins, and in a one-pot method using diazo compounds and neutral electron donors. The ruthenium and osmium carbene compounds of the present invention may be used to catalyze olefin metathesis reactions including, but not limited to, ROMP, RCM, depolymerization of unsaturated polymers, synthesis of telechelic polymers, and olefin synthesis.

Owner:CALIFORNIA INST OF TECH

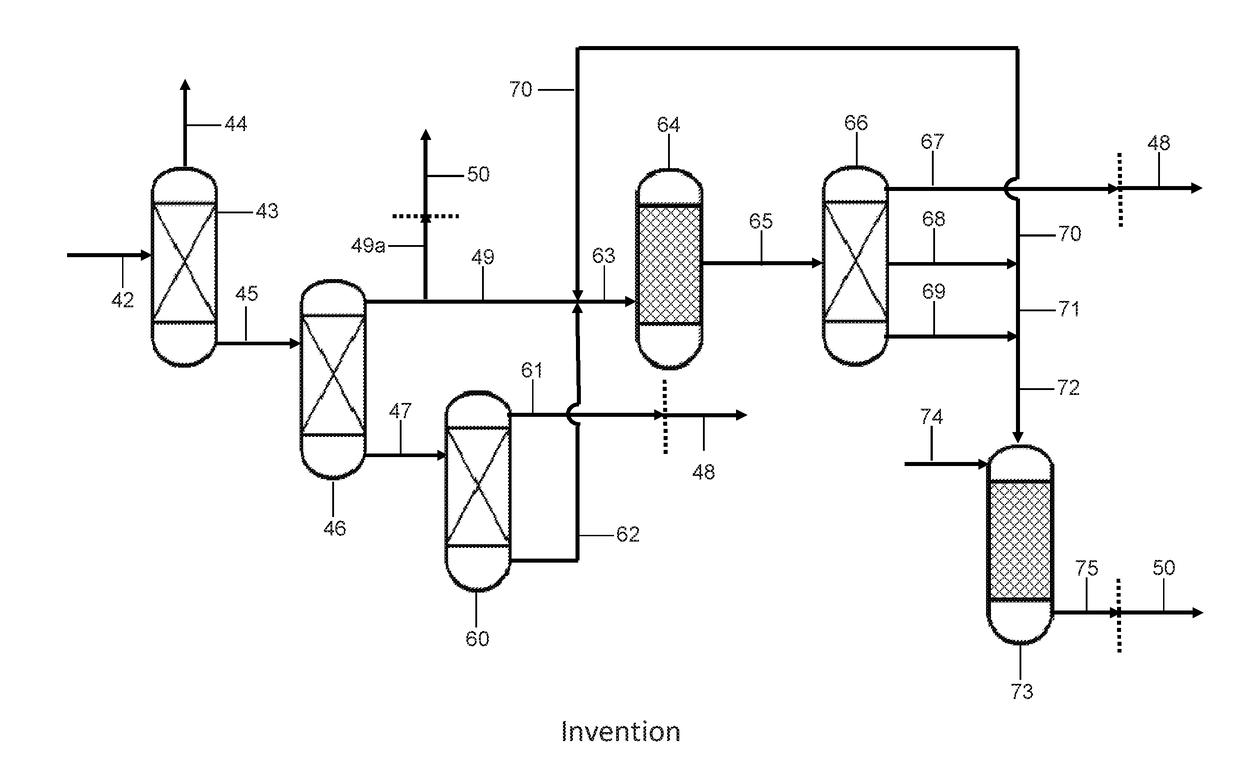

Conversion of an alcoholic oxygenate to propylene using moving bed technology and an etherification step

InactiveCN101023047AImprove economyAvoid severe inactivationHydrocarbon from carbon oxidesMolecular sieve catalystOxygenateFixed bed

The average propylene selectivity per on-stream cycle of an alcoholic oxygenate to propylene (OTP) process using one or more fixed beds of a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a feed pretreatment step involving a catalytic etherification reaction, by switching to moving bed reactor technology in the olefin synthesis portion of the OTP flow scheme in lieu of fixed bed technology and by the selection of a catalyst on-stream cycle time of 300 hours or less. These provisions hold the build-up of coke deposits to a level which does not substantially degrade catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of propylene average cycle yield at essentially start-of-cycle levels. The propylene average cycle yield improvement of the present invention over that achieved by the fixed bed system of the prior art is of the order of about 1.5 to 5.5 wt % or more.

Owner:UOP LLC

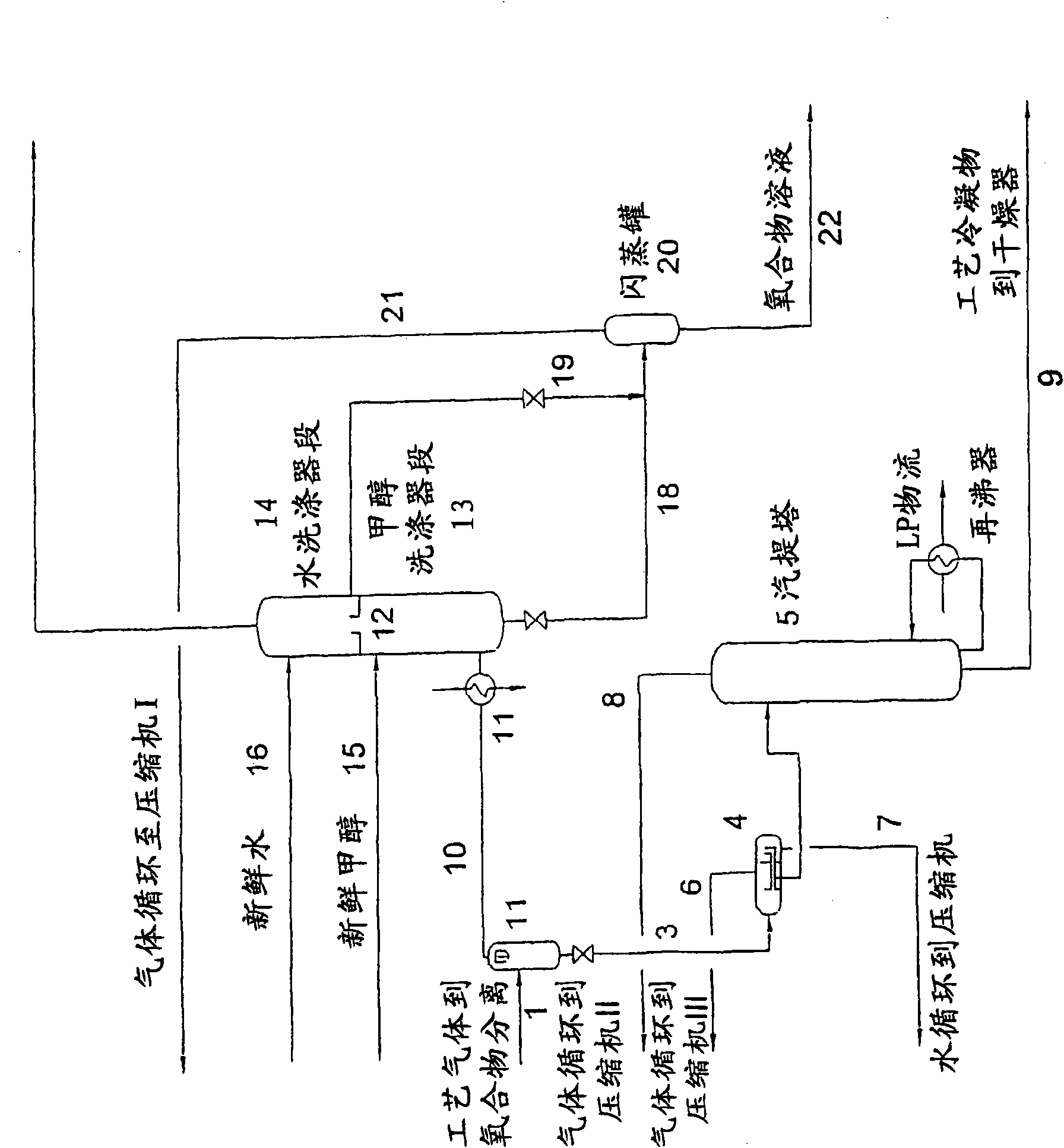

Method for processing an olefin-containing product stream

A method is described for processing an olefin-containing product stream (1) that contains, besides ethylene and propylene, longer-chain olefins and compounds of hydrocarbons with oxygen (oxygenates). Such a product stream (I) can occur in particular in olefin synthesis from methanol. The product stream is dewatered in successive process steps, optionally compressed in several steps and dried. Then it is subjected to fractionation. For removal of the undesired oxygenates it is proposed that the oxygenates be washed out of the gaseous product stream after the compression steps and before the drying step in a column (12) with methanol.

Owner:EXXONMOBIL CHEM PAT INC

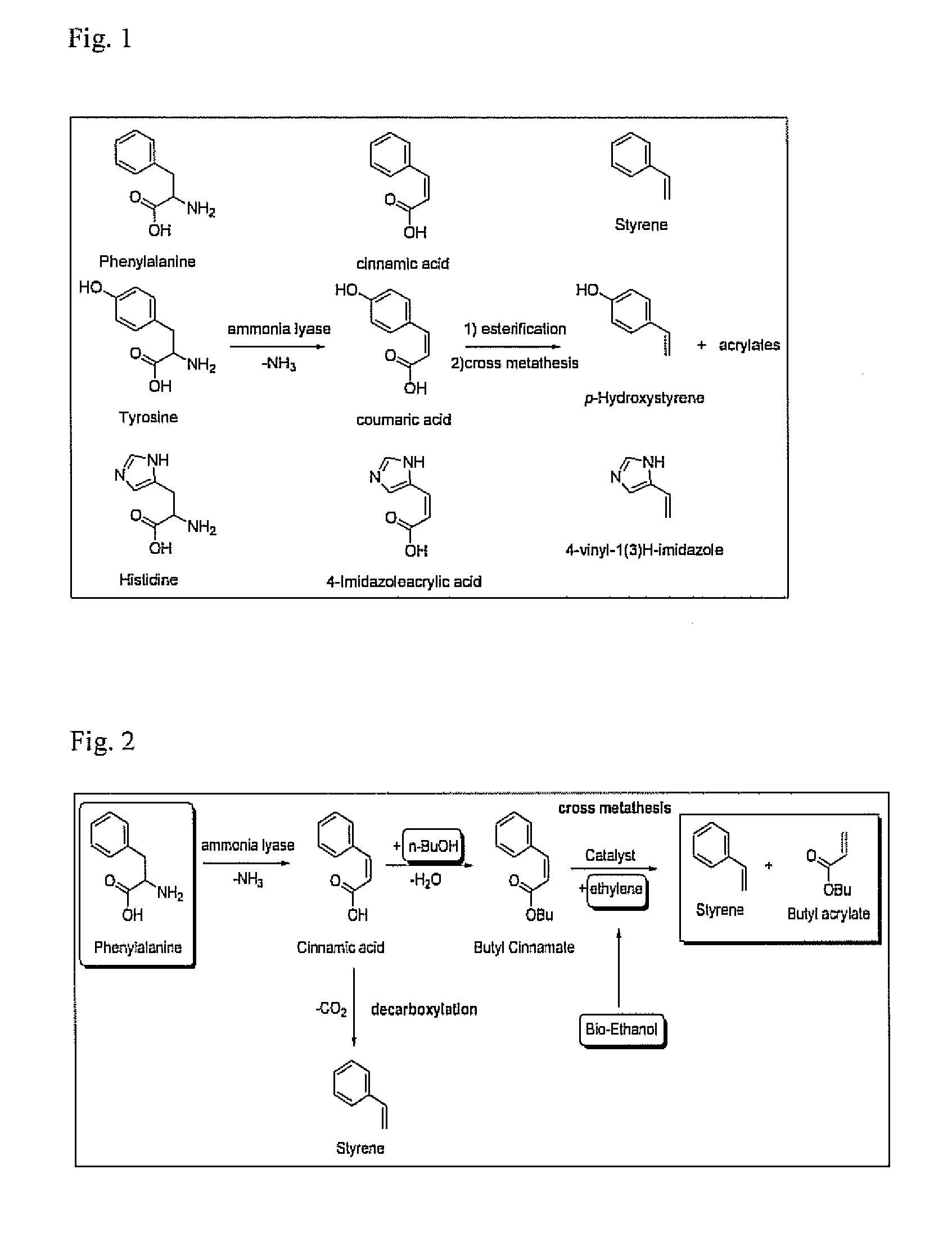

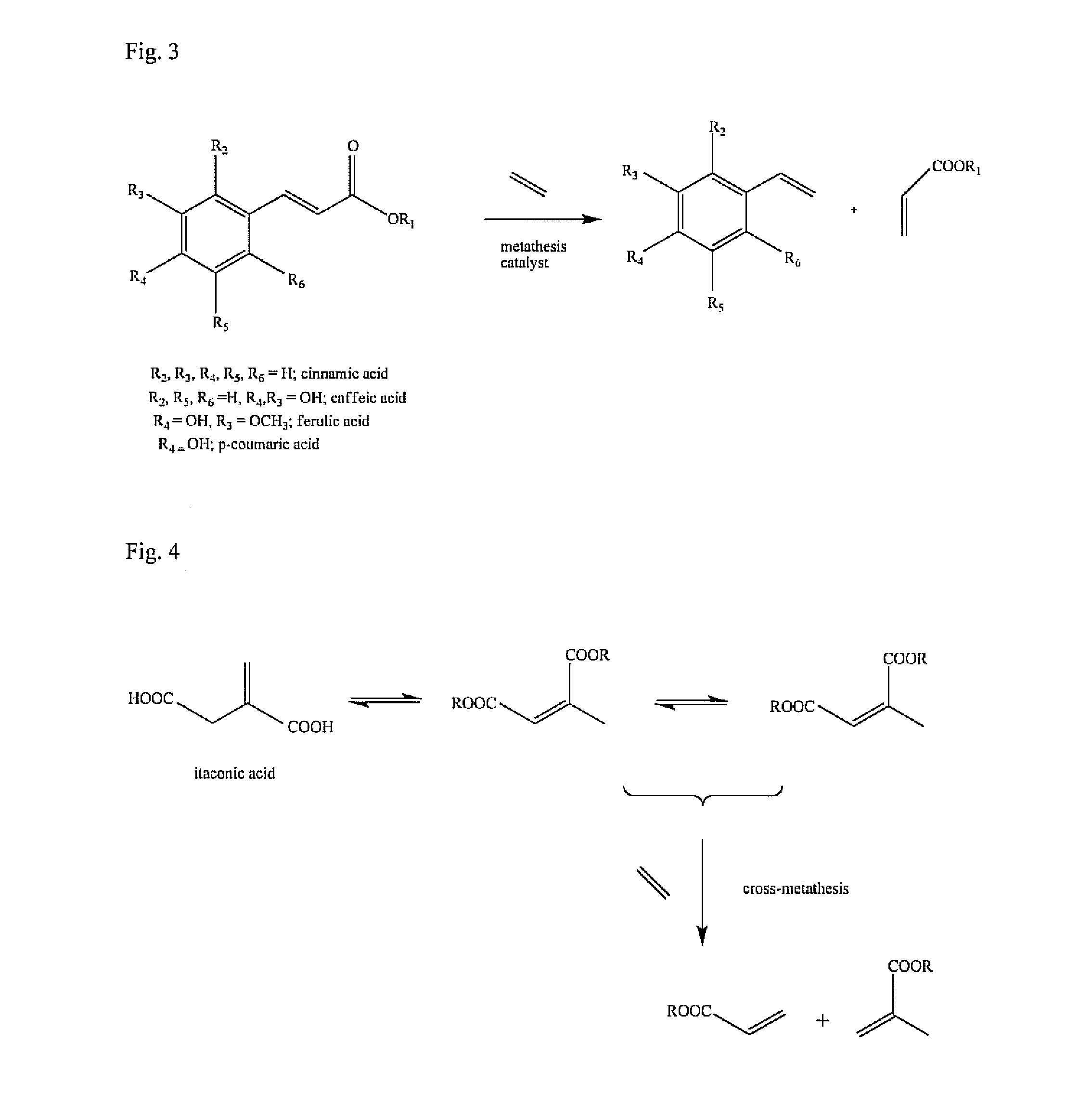

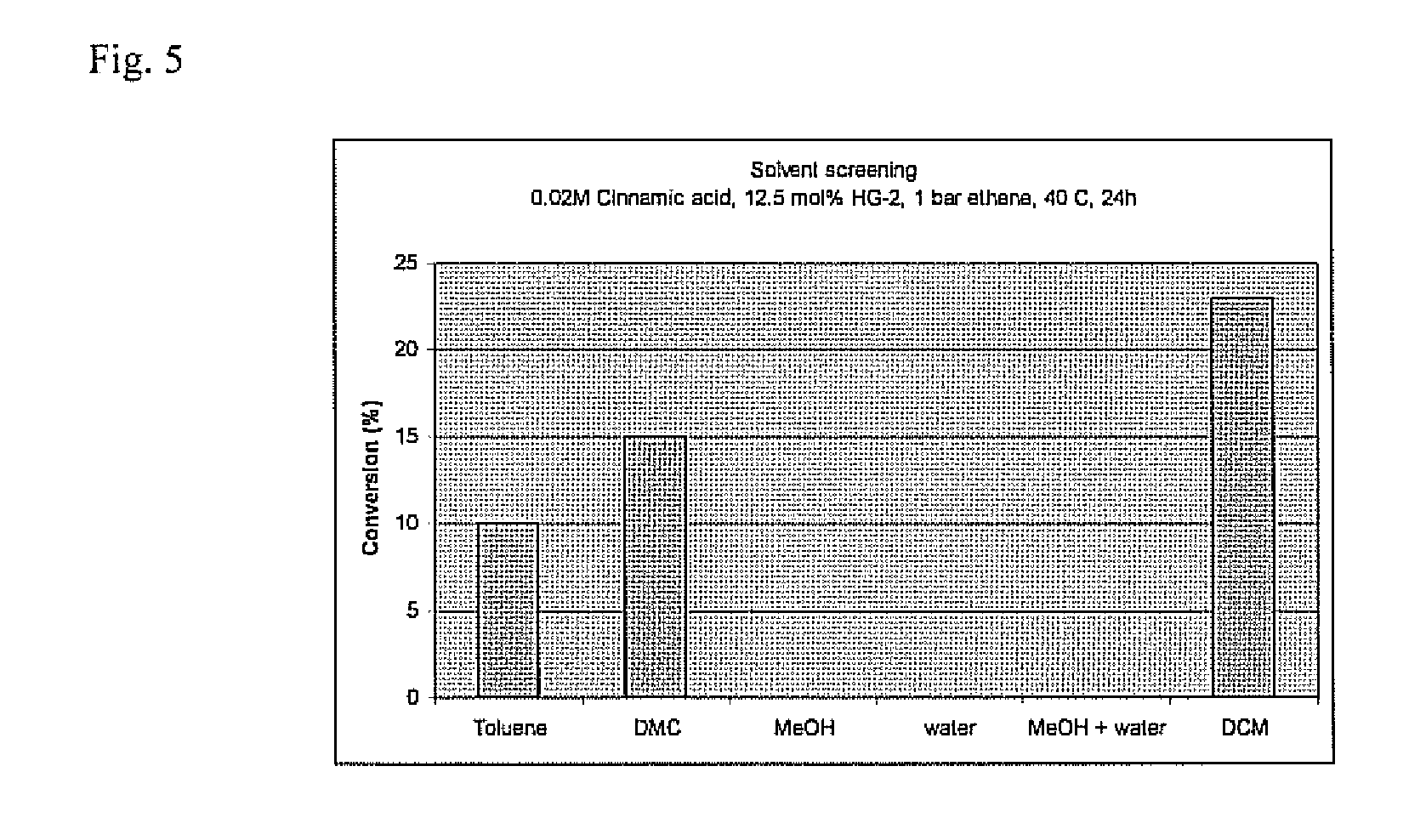

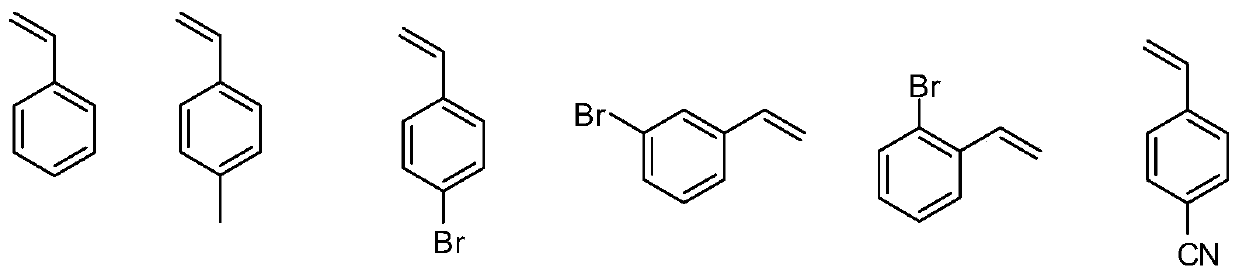

Bio-derived olefin synthesis

InactiveUS20120178961A1Better addressOrganic compound preparationCarboxylic acid esters preparationAmino acid synthesisTyrosine

Disclosed is a method for the combined synthesis of at least two vinylic monomers, at least one of which being an acrylic compound, comprising subjecting a monoconjugated alkene-1-carboxylic compound to reaction with a C2-C4 alkene under conditions of olefin cross-metathesis. The invention is particularly useful for extracting value from protein side streams. Upon protein hydrolysis, suitable amino acids (preferably phenylalanine or tyrosine) are subjected to reductive amination so as to form the corresponding alkene-1-carboxylic acid. Preferably after esterification and separation, this is used in cross-metathesis for the concomitant production of styrene resp. hydroxy styrene, and acrylates. The invention is applicable more widely, to the synthesis of olefins on the basis of carbohydrates, naturally occurring phenolic components, natural protein resources, or amino acids obtained from fermentations.

Owner:STICHTING DIENST LANBOUWKUNDIG ONDERZOEK +1

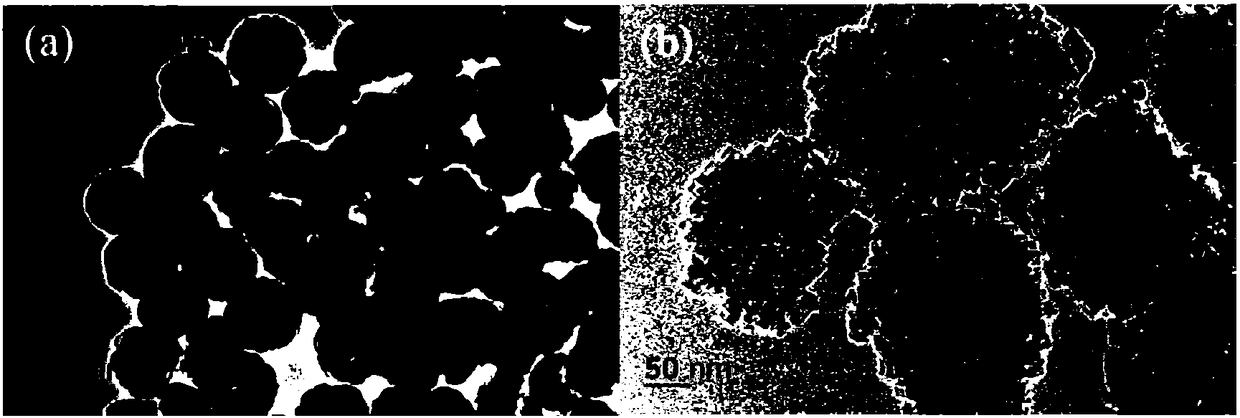

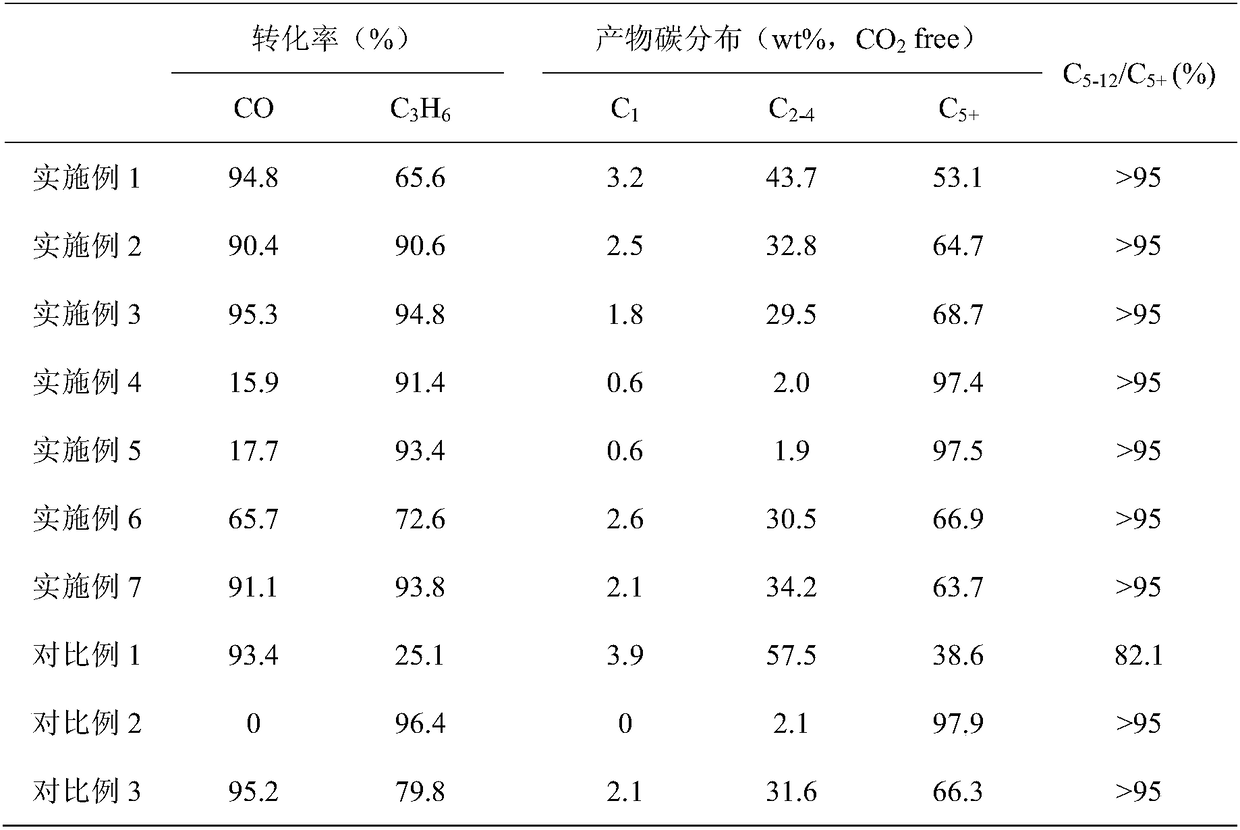

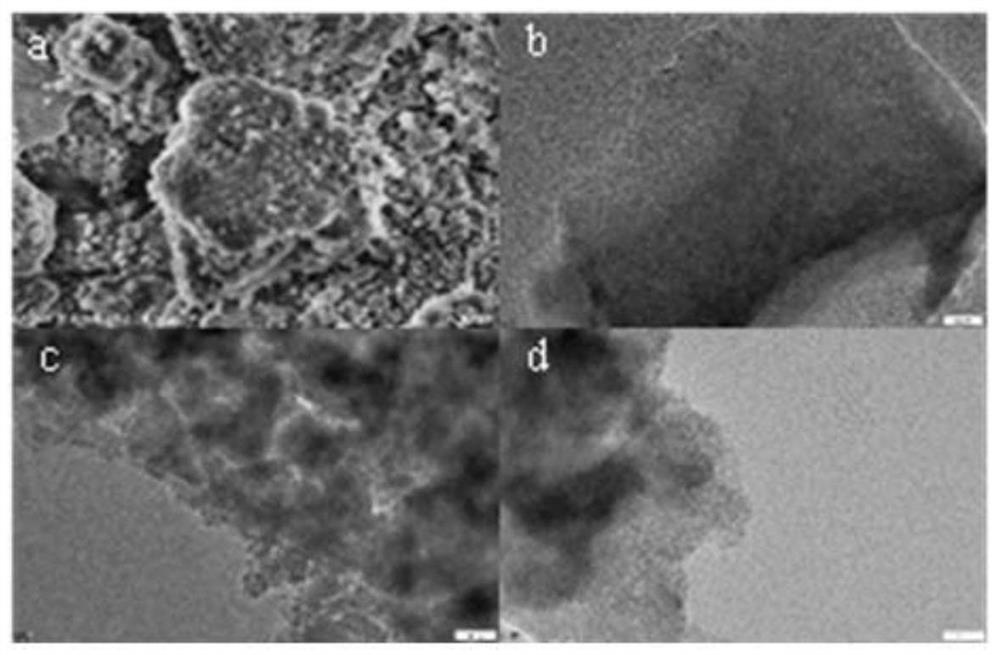

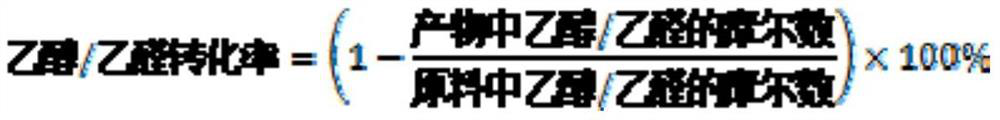

Fe base-molecular sieve catalyst used for Fischer Tropsch-oligomerization coupling reaction, and preparation method and application thereof

ActiveCN108080020AImprove stabilityHigh reactivityMolecular sieve catalystsLiquid hydrocarbon mixtures productionHigh carbonFe based

The invention provides a Fe base-molecular sieve catalyst used for Fischer Tropsch-oligomerization coupling reaction, and a preparation method and application thereof. A hydrothermal synthesis methodis adapted to respectively prepare hydrothermally stable nano Fe3O4 catalyst and nano HZSM-5 catalyst; the nano Fe3O4 catalyst and the nano HZSM-5 catalyst are coupled as an FT-Oli (Fischer Tropsch-oligomerization) catalytic system to be applied to FT-Oli coupling catalytic reaction to realize efficient catalytic conversion from olefin-rich synthesis gas to liquid hydrocarbon. The Fe base-molecular sieve catalyst has the advantages of wide raw material source, low cost and low reaction condition, the prepared catalyst system enables the Fischer Tropsch-oligomerization coupling reaction activity to be 90% or more, C5+hydrocarbon selectivity can be about 70%, and an effective carbon source in olefin synthesis gas is effectively utilized and is converted into liquid hydrocarbon. The Fe base-molecular sieve catalyst has the characteristics of simple process, environment protection, low carbon, high carbon utilization ratio, intensive product distribution and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

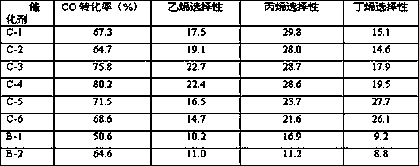

Method for Production of Lower Olefin

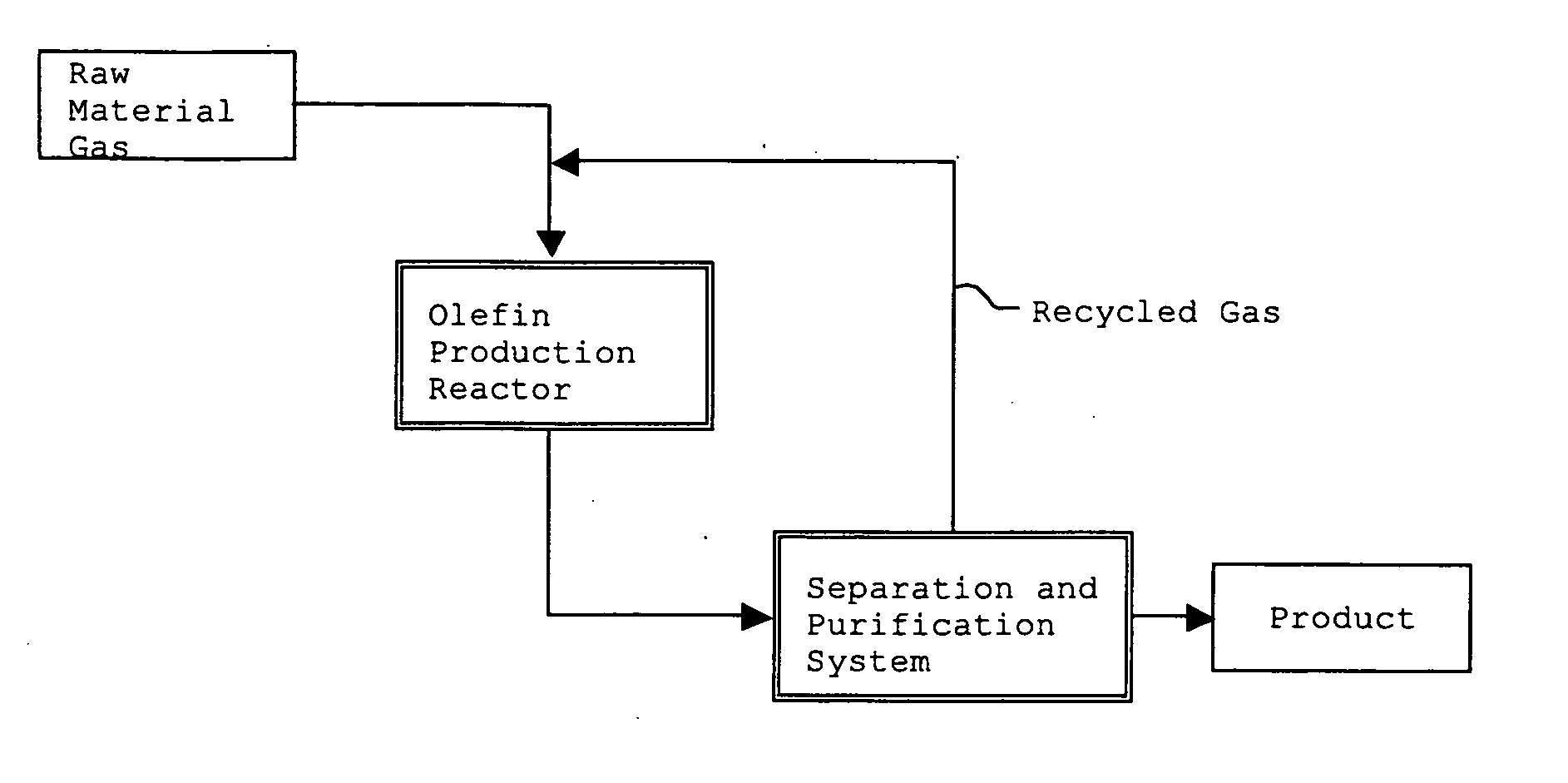

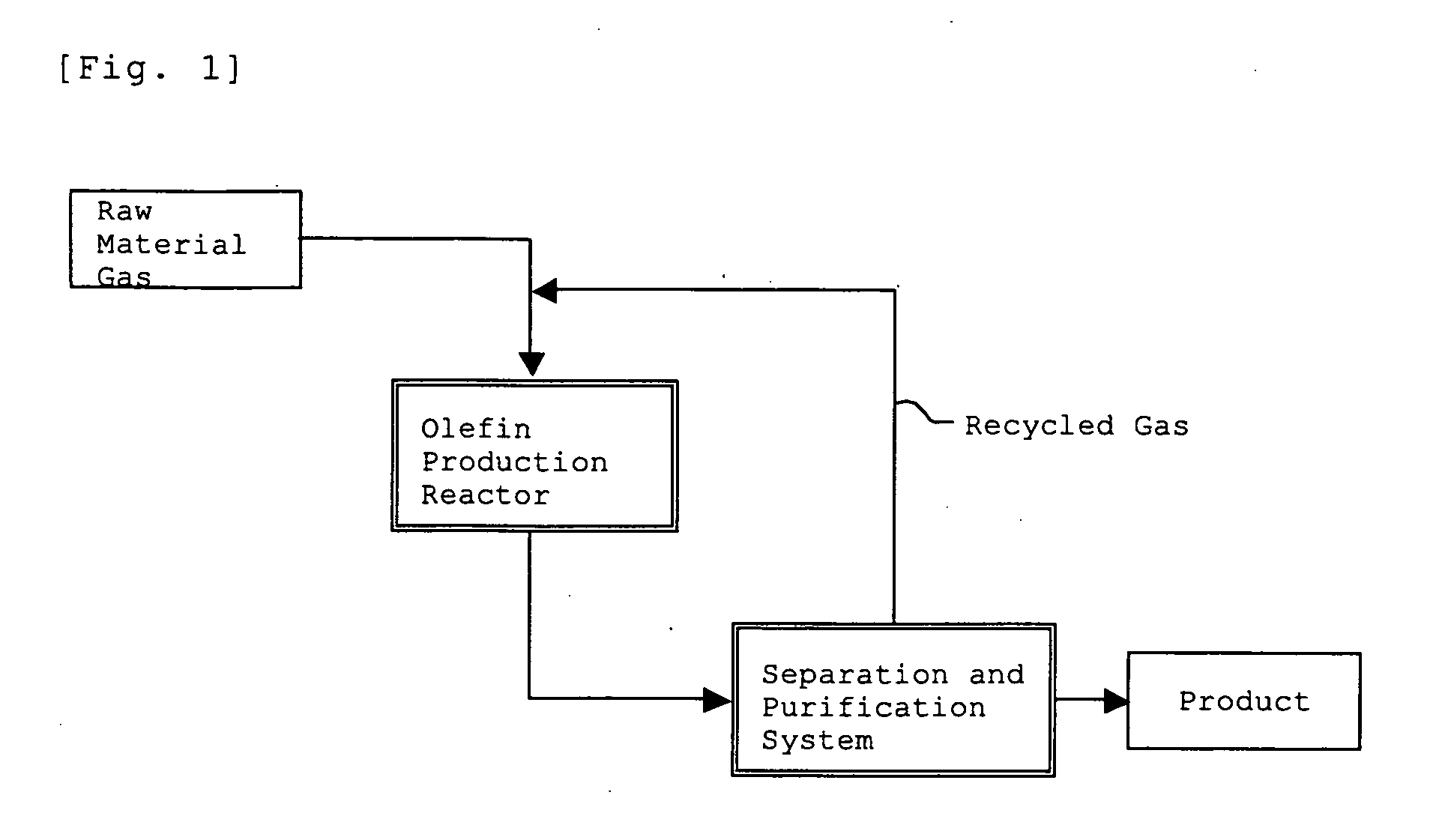

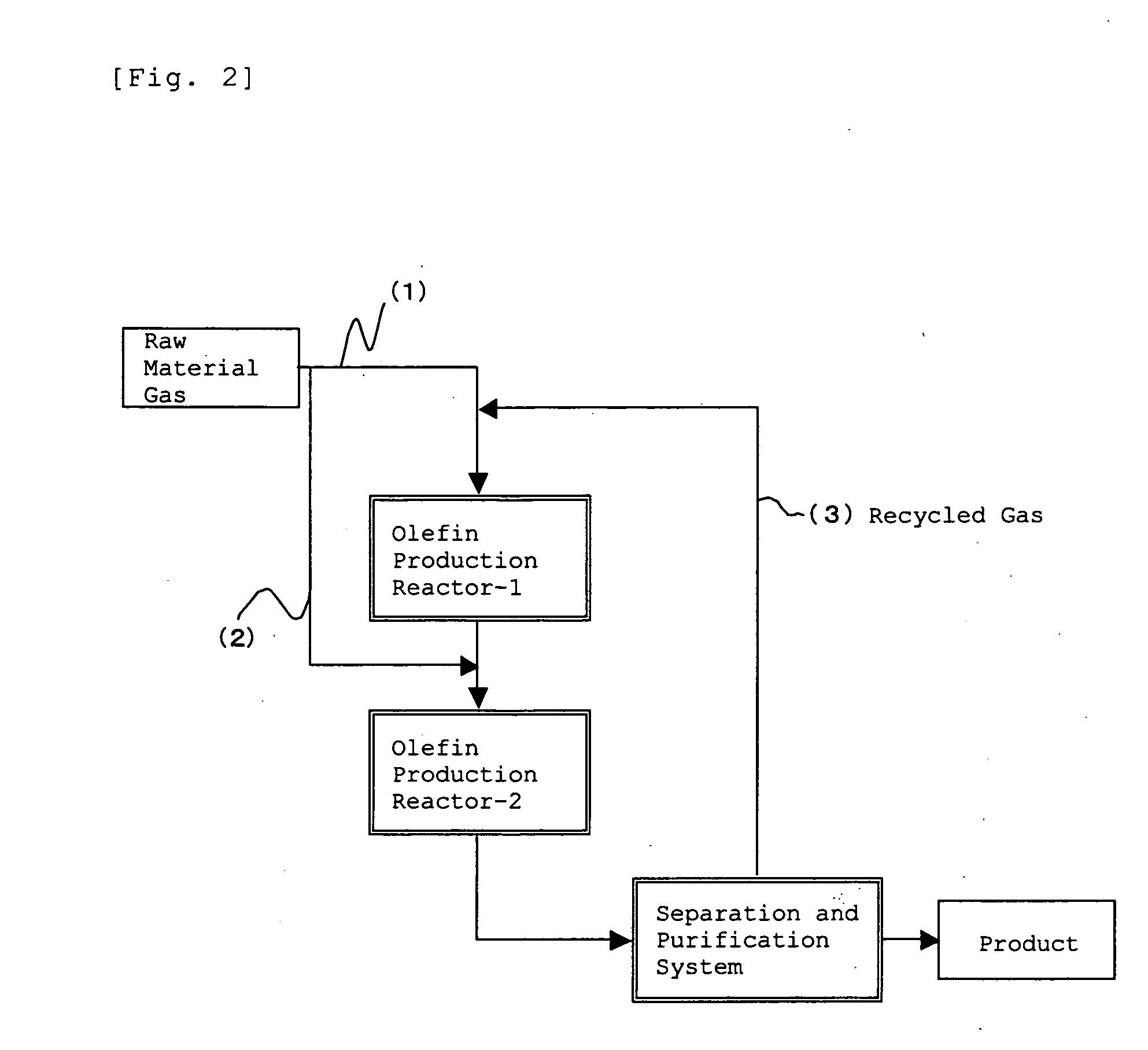

InactiveUS20100217054A1High yieldPropylene selectivity is highMolecular sieve catalystsMolecular sieve catalystOlefin synthesisThermal efficiency

Disclosed is a method for production of lower olefins from a raw material containing dimethyl ether (DME), which can produce lower olefins (e.g. propylene) with good yield and in an economically advantageous manner by prolonging the time until the reversible deactivation of a zeolite catalyst and preventing the irreversible deactivation of the catalyst, can reduce the amount of water to be recycled to increase the thermal efficiency of the process, and can simplify the facilities and operations. Also disclosed is a method for improving the yield of propylene with good efficiency under practical operating conditions. A feed gas which comprises a DME-containing feedstock gas and an additive gas and further contains steam at a specific proportion is introduced into an olefin synthesis reactor to contact the feed gas with a zeolite catalyst, thereby producing a hydrocarbon product containing C2-C5 olefins. Propylene or the like is separated / collected from the hydrocarbon product, and at least a part of the remainder is used as at least a part of the additive gas.

Owner:JGC CORP

Photochemical process for olefin synthesis of oxygen-containing compound

InactiveCN1704355AHigh selectivityWater/sewage treatment by irradiationWater/sewage treatment by oxidationUltraviolet lightsOxygen

The invention discloses a photochemical process for olefin synthesis of oxygen-containing compound which comprises, inducing olefin with ultraviolet light / visible light, oxygenizing in water or the mixed medium of organic / water. The olefin includes alkenylene, annular olefin, aromatic hydrocarbon and substituted alkenylene, substituted annular olefin, or substituted aromatic hydrocarbon.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

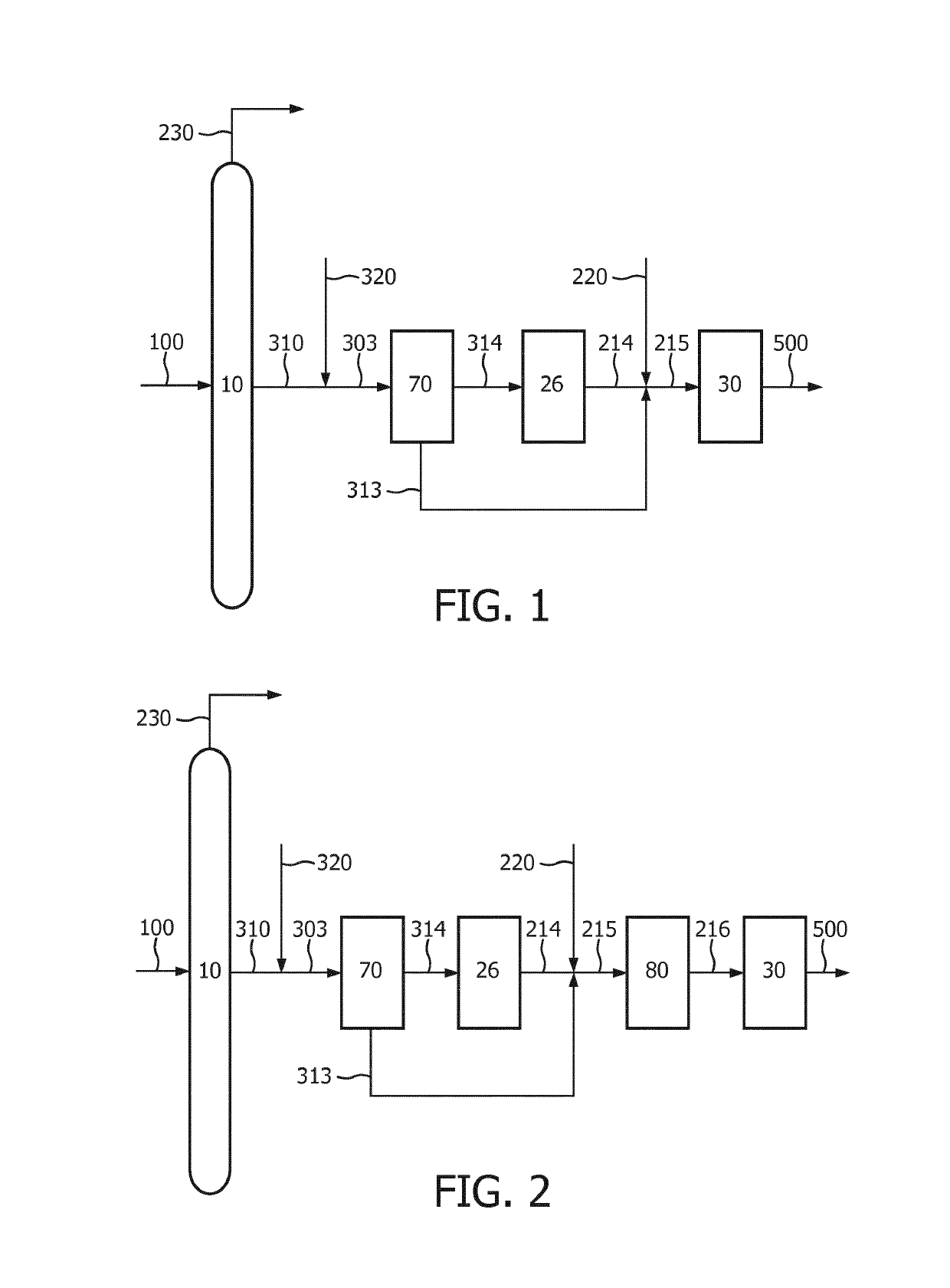

Process and installation for the conversion of crude oil to petrochemicals having an improved ethylene yield

ActiveUS10260011B2Increase productionImprove ethylene yieldThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAlkaneDistillation

The present invention relates to an integrated process to convert crude oil into petrochemical products comprising crude oil distillation, dearomatization, ring opening, and olefins synthesis, which process comprises subjecting a hydrocarbon feed to dearomatization to produce a first stream enriched in aromatic hydrocarbons and naphthenic hydrocarbons and a second stream enriched in alkanes; subjecting a stream enriched in aromatic hydrocarbons and naphthenic hydrocarbons to ring opening to produce alkanes; and subjecting refinery unit-derived alkanes produced in the process to olefins synthesis. Furthermore, the present invention relates to a process installation to convert crude oil into petrochemical products comprising a crude distillation unit comprising an inlet for crude oil and at least one outlet for one or more of naphtha, kerosene and gasoil; a dearomatization unit comprising an inlet for a hydrocarbon feed to dearomatization, an outlet for a stream enriched in aromatic hydrocarbons and naphthenic hydrocarbons and a second stream enriched in alkanes; a ring opening unit comprising an inlet for aromatics and naphthenes produced by dearomatization and an outlet for alkanes; a unit for olefins synthesis comprising an inlet for alkanes and an outlet for olefins. The hydrocarbon feed subjected to dearomatization comprises one or more of naphtha, kerosene and gasoil produced by crude oil distillation in the process; and refinery unit-derived light-distillate and / or refinery unit-derived middle-distillate produced in the process. The process and the process installation of the present invention have an increased production of petrochemicals at the expense of the production of fuels and an improved ethylene yield.

Owner:SAUDI BASIC IND CORP SA +1

Process and installation for the conversion of crude oil to petrochemicals having an improved carbon-efficiency

ActiveUS10676681B2Increase productionImprove efficiencyThermal non-catalytic crackingEnergy inputNaphthaKerosene

The present invention relates to an integrated process to convert crude oil into petrochemical products comprising crude oil distillation, hydrocracking and olefins synthesis, which process comprises subjecting a hydrocracker feed to hydrocracking to produce LPG and BTX and subjecting the LPG produced in the process to olefins synthesis. Furthermore, the present invention relates to a process installation to convert crude oil into petrochemical products comprising: a crude distillation unit comprising an inlet for crude oil and at least one outlet for one or more of naphtha, kerosene and gasoil; a hydrocracker comprising an inlet for a hydrocracker feed, an outlet for LPG and an outlet for BTX; and a unit for olefins synthesis comprising an inlet for LPG produced by the integrated petrochemical process installation and an outlet for olefins. The hydrocracker feed used in the process and the process installation of the present invention comprises one or more of naphtha, kerosene and gasoil produced by crude oil distillation in the process; and refinery unit-derived light-distillate and / or refinery unit-derived middle-distillate produced in the process. The process and process installation of the present invention have an increased production of petrochemicals at the expense of the production of fuels and an improved carbon efficiency in terms of the conversion of crude oils into petrochemicals.

Owner:SAUDI BASIC IND CORP SA +1

Method for processing an olefin-containing product stream

InactiveCN101565347ADistillation purification/separationFractional condensation purification/separationFractionationOxygenate

Owner:EXXONMOBIL CHEM PAT INC

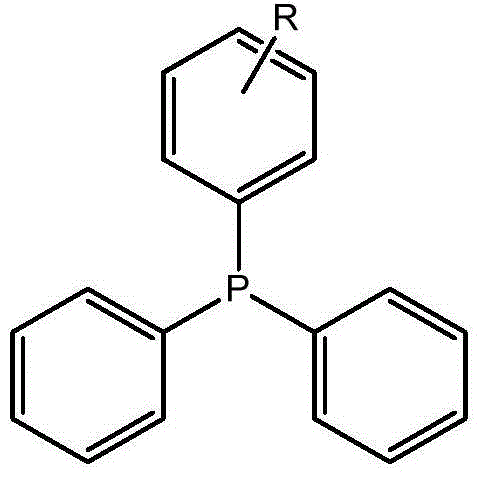

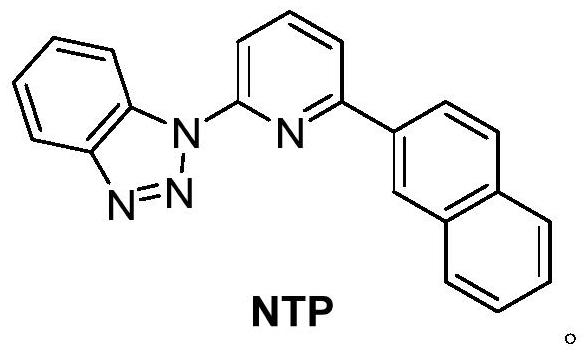

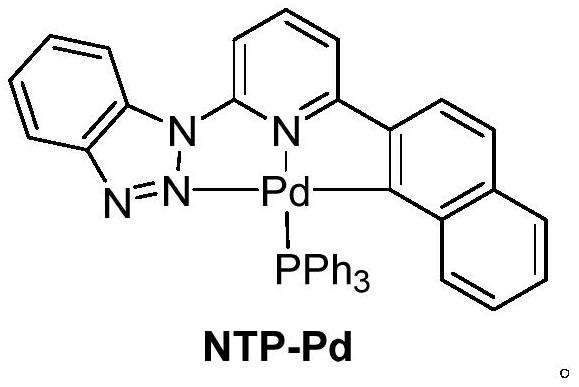

Palladium catalyst for catalyzing quinazolinone synthesis and olefination reaction

ActiveCN112958162AImprove catalytic performanceIn line with the concept of green chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsArylPtru catalyst

The invention discloses a palladium catalyst for catalyzing quinazolinone synthesis and olefination reaction, and belongs to the technical field of catalysts. A novel homogeneous palladium catalyst is prepared by combining a specific nitrogen-containing ligand with transition metal palladium, and a heterogeneous catalyst can be obtained by combining the homogeneous palladium catalyst with mesoporous silica. The obtained homogeneous or heterogeneous palladium catalyst is used for catalyzing quinazolinone cascade reaction and olefin synthesis reaction of alcohol and aryl sulfone, has excellent catalytic activity, and is more environment-friendly than a traditional catalyst.

Owner:JIANGNAN UNIV

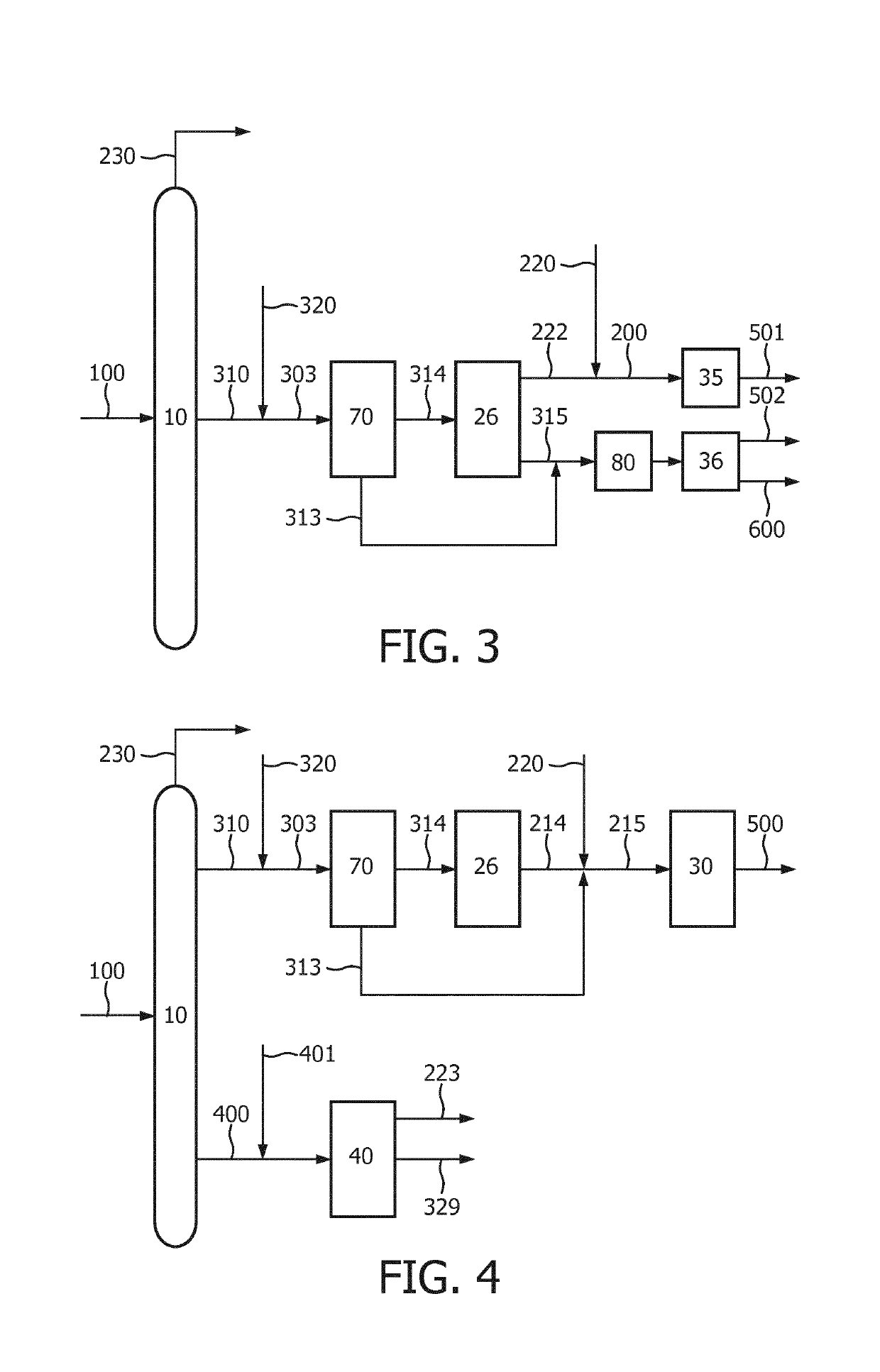

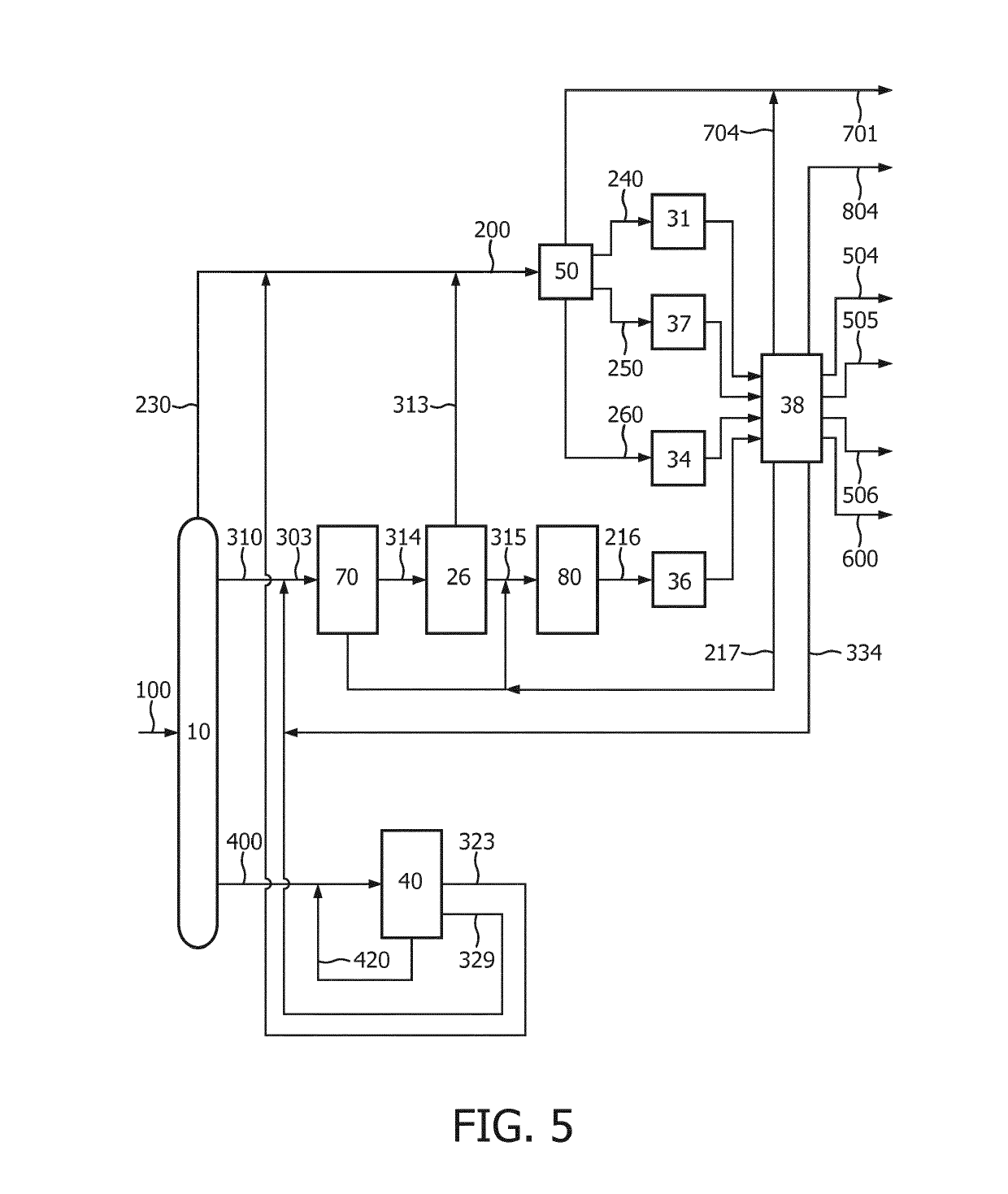

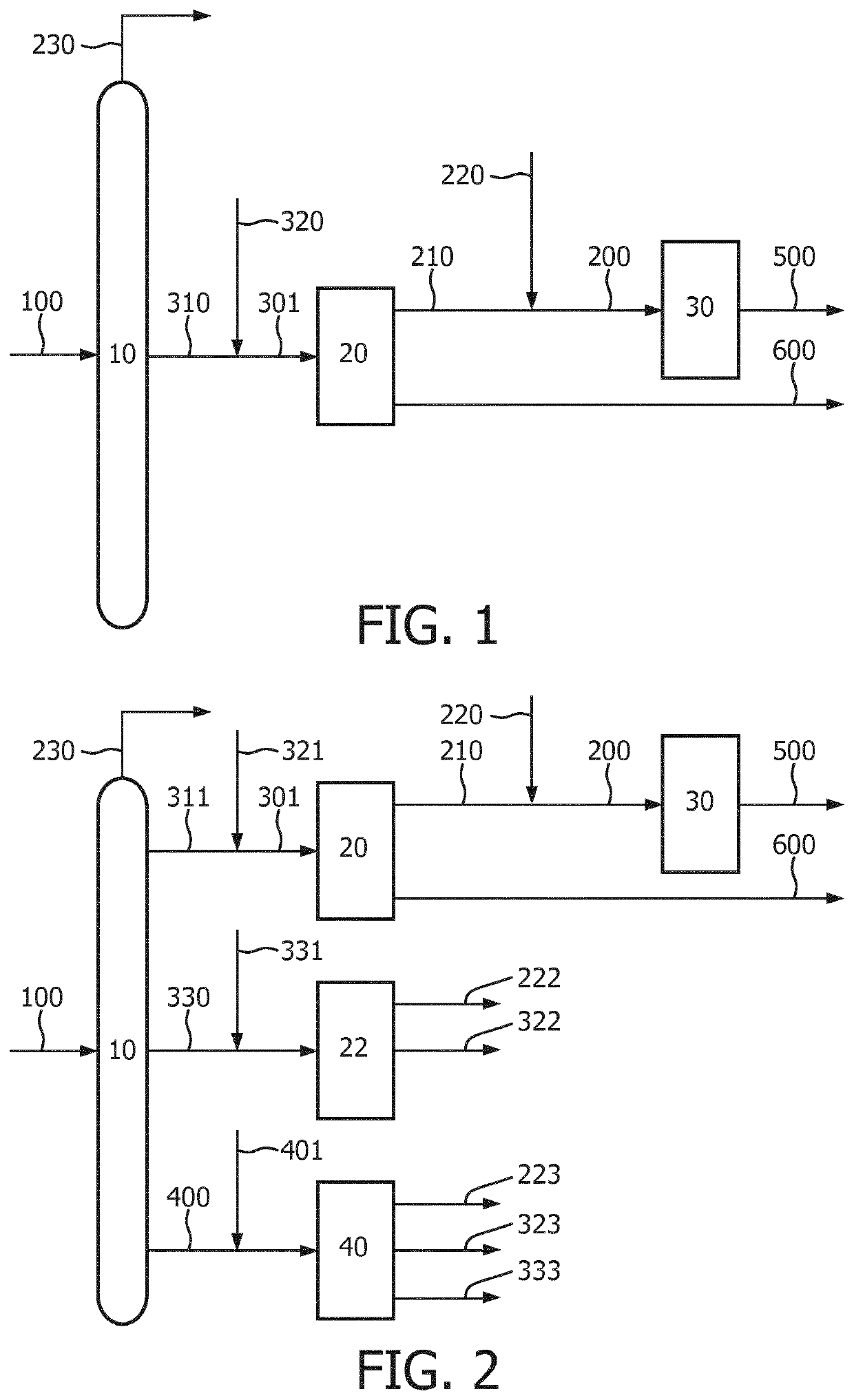

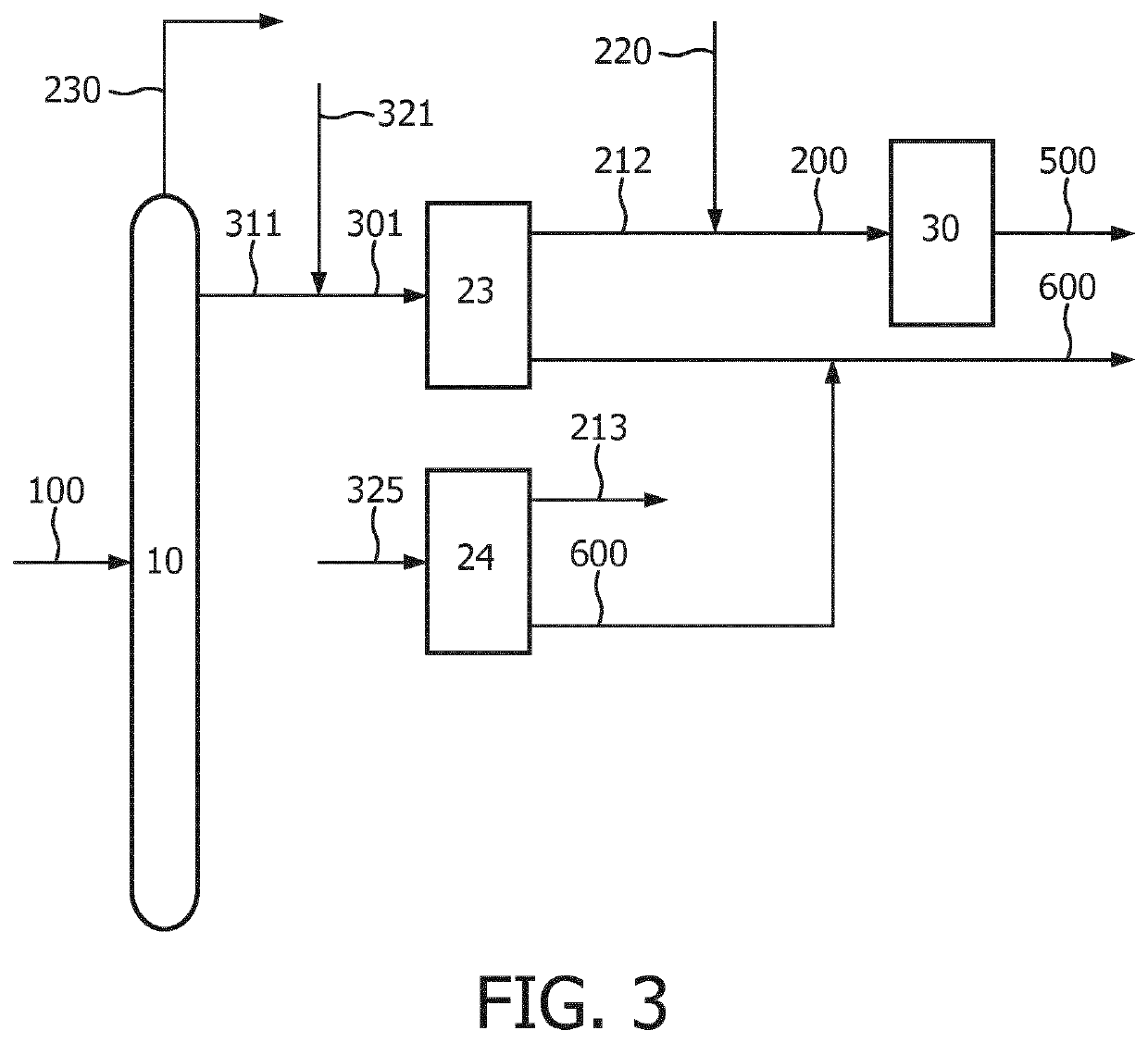

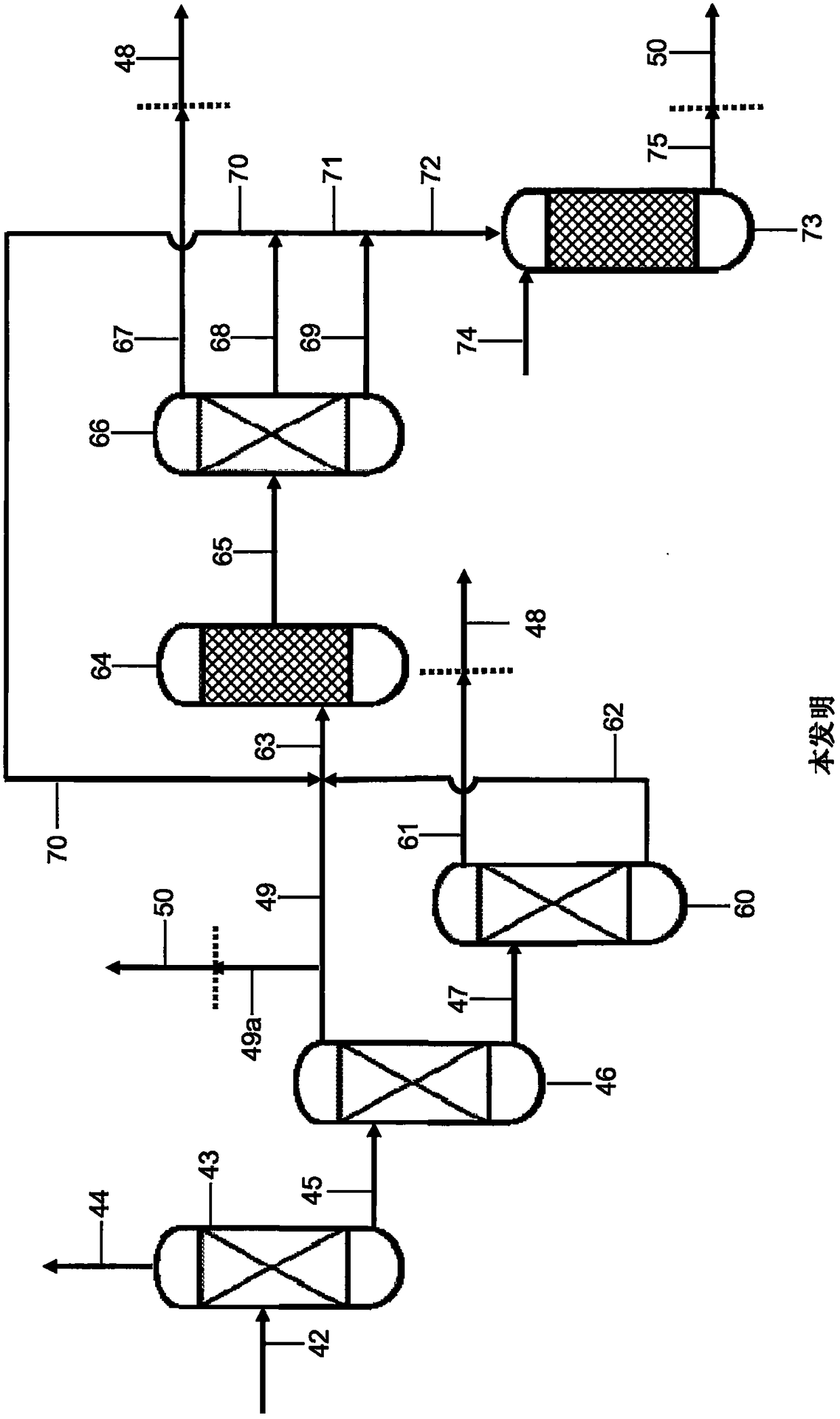

Process and plant for the recovery and utilization of higher olefins in the olefin synthesis from oxygenates

InactiveUS20180305626A1Valid choiceHydrocarbon by hydrogenationHydrocarbon distillationChain lengthOlefin synthesis

A process and a plant for producing olefins from oxygenates such as methanol and / or dimethyl ether are proposed, in which initially the oxygenates are converted to a primary product containing propylene, other olefins, paraffins and aromatics in an olefin synthesis reactor. The primary product is separated into hydrocarbon fractions of different C chain length, wherein short-chain olefins such as propylene are obtained and beside further fractions there is also obtained a C7− fraction which contains C5 / C6 olefins, as well as a C7+ fraction which contains aromatics. From the latter, the aromatics are separated and alkylated with the C5 / C6 olefins to obtain alkyl aromatics. The same are hydrogenated completely and recirculated to the olefin synthesis reactor, where they likewise are converted to short-chain olefins.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

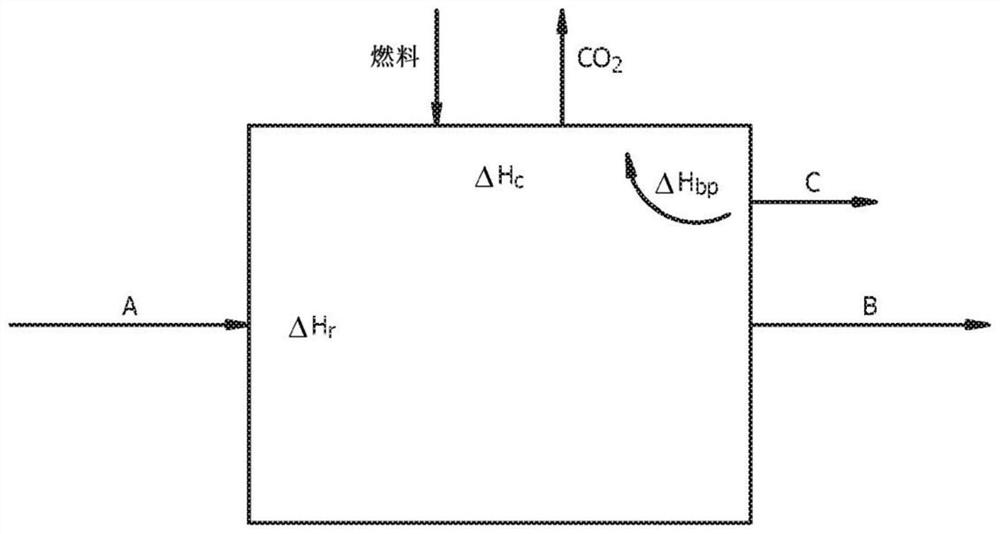

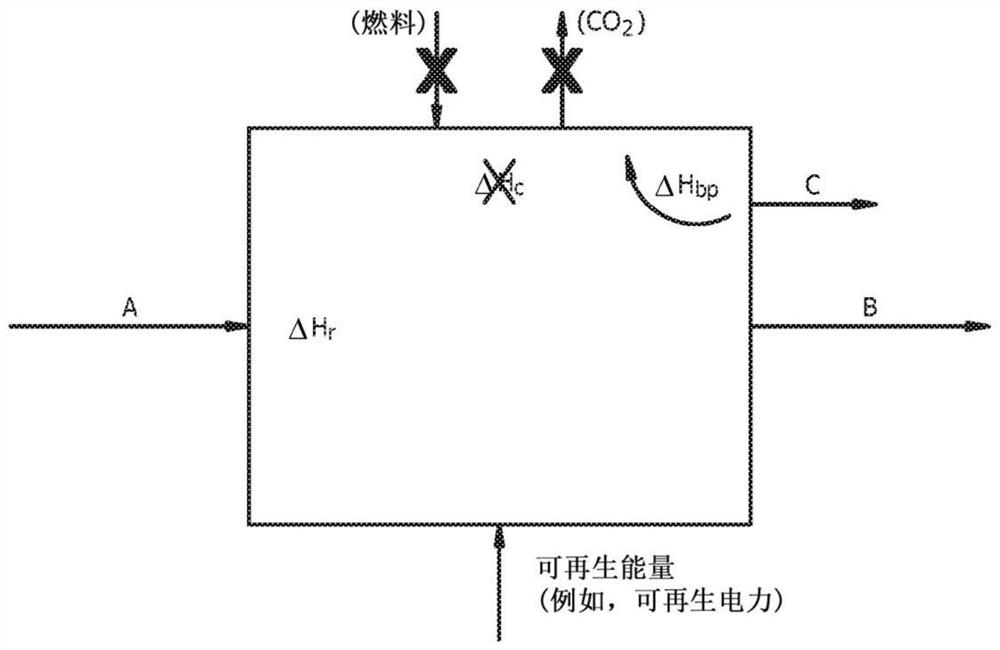

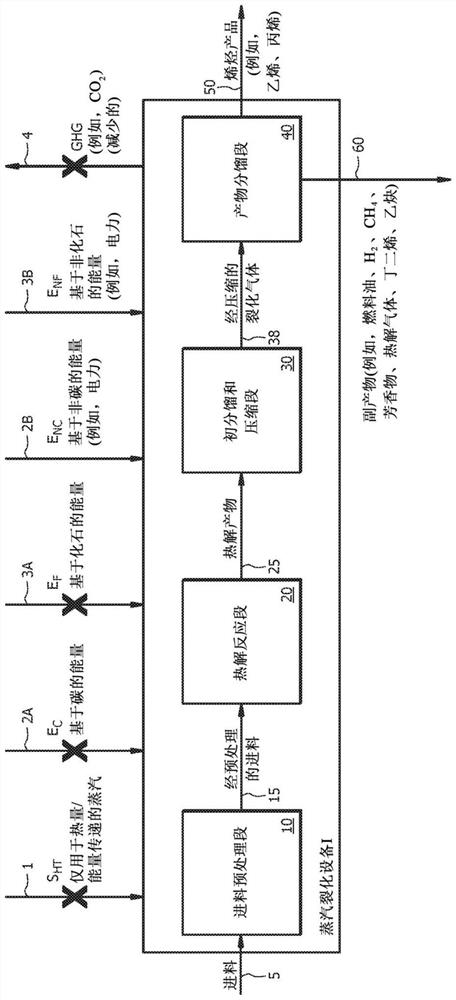

Use of renewable energy in olefin synthesis

An olefin synthesis plant comprising: a feed pretreatment section configured to pretreat a feed stream; a pyrolysis section comprising one or more pyrolysis reactors configured to crack hydrocarbons in the feed stream in the presence of a diluent to produce a cracked gas stream; a primary fractionation and compression section configured to provide heat recovery from and quenching of the cracked gas stream; remove a component from the cracked gas stream; and compress the cracked gas stream, thus providing a compressed cracked gas stream; and / or a product separation section configured to separate a product olefin stream from the compressed cracked gas stream, wherein the olefin synthesis plant is configured such that, relative to a conventional olefin synthesis plant, more of the energy and / or the net energy required by the olefin synthesis plant and / or one or more sections thereof, is provided by a non-carbon based and / or renewable energy source and / or electricity.

Owner:SABIC GLOBAL TECH BV

Process and plant for the recovery and utilization of higher olefins in the olefin synthesis from oxygenates

ActiveCN109485533AHigh yieldHydrocarbon by hydrogenationHydrocarbon distillationChain lengthOlefin synthesis

A process and a plant for producing olefins from oxygenates such as methanol and / or dimethyl ether are proposed, in which initially the oxygenates are converted to a primary product containing propylene, other olefins, paraffins and aromatics in an olefin synthesis reactor. The primary product is separated into hydrocarbon fractions of different C chain length, wherein short-chain olefins such aspropylene are obtained and beside further fractions there is also obtained a C7- fraction which contains C5 / C6 olefins, as well as a C7+ fraction which contains aromatics. From the latter, the aromatics are separated and alkylated with the C5 / C6 olefins to obtain alkyl aromatics. The same are hydrogenated completely and recirculated to the olefin synthesis reactor, where they likewise are converted to short-chain olefins.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Supported catalyst and preparation method thereof

InactiveCN112295556ASimple compositionRaw materials are cheap and easy to getHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCombinatorial chemistry

The present invention discloses a supported catalyst, the supported catalyst comprises a carrier and an active component supported on the carrier, and the carrier comprises silica; the active component comprises tantalum pentoxide and zirconium dioxide. The supported catalyst is an efficient catalyst for olefin synthesis, the composition is simple, and the raw materials are cheap and easily available. The invention also discloses a preparation method of the supported catalyst. The method at least comprises the following steps: (1) obtaining a solution containing an active component precursor;and (2) adding the carrier into the solution containing the active component precursor, reacting and roasting to obtain the supported catalyst. The preparation method of the supported catalyst is simple in process and strong in operability, and can be used for large-scale industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of supported iron-based catalyst

ActiveCN105709791BImprove conversion rateHigh selectivityPhysical/chemical process catalystsHydrocarbon from carbon oxidesAdjuvantNickel salt

The invention discloses a preparation method of a supported iron-based catalyst, which comprises the following steps: (1) The alumina carrier is equal volume saturated and impregnated with a buffer solution containing ammonium salt, and dried until the adsorption amount of the buffer solution containing ammonium salt is equal to that of the alumina carrier The amount of saturated absorption solution is 30-60%, and the modified alumina carrier is obtained after roasting; (2) The mixed aqueous solution of nickel salt and gallium salt is prepared, and the modified alumina carrier prepared in step (1) is impregnated by unsaturated impregnation method The above mixed aqueous solution is dried and then roasted; (3) impregnating the carrier after step (2) roasting with the wetting solution containing adsorbent by unsaturated impregnation method; The mixed solution of metal iron, additive manganese and additive potassium is dried and calcined to prepare a catalyst for producing low-carbon olefins from syngas. The catalyst has the characteristics of high activity and stability in long-period operation, and is beneficial to industrial application and popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of multi-component metal doped silicon phosphorus aluminum molecular sieve and its preparation method and application

ActiveCN112441595BRegulates hydrophobicityImprove water absorptionMolecular sieve catalystsOther chemical processesPtru catalystManganese

The invention relates to a multi-element transition metal-doped metal silicoaluminophosphate molecular sieve and a preparation method thereof, wherein the metal atoms are at least two of vanadium, copper, molybdenum, cobalt, manganese, magnesium, iron, nickel and zinc, etc., And at least one of copper, iron and nickel is contained. The high-purity product was prepared by one-step hydrothermal reaction, and its anhydrous composition can be expressed as: mR·nMe·(Si x Al y P z )O 2 , where R is the template agent in the molecular sieve, m is per mole (Si x Al y P z )O 2 Contains the molar amount of the template agent, m=0.15-0.45; Me is the metal in the molecular sieve framework, and n is each mole (Si x Al y P z )O 2 The total molar amount of contained metals, n=0.01‑0.2, where each transition metal is relative to each mole (Si x Al y P z )O 2 The ratio is between 0.0001‑0.2. The synthesized metal silicoaluminophosphate molecular sieve has excellent adsorption performance, and the catalyst made from it can be applied to olefin synthesis and SCR denitration reaction.

Owner:DALIAN MARITIME UNIVERSITY

Process and apparatus for producing an olefin stream low in oxygenates

ActiveCN102884029BDistillation purification/separationDistillation separationSimple Organic CompoundsHydrocarbon mixtures

A process and a plant for producing an olefin stream from a hydrocarbon mixture feed stream, wherein the olefin stream is depleted as regards its content of oxygen-containing organic compounds (oxygenates) as compared to the feed stream. The hydrocarbon mixture feed stream is charged to a separation column operated by a thermal separation process, for example to a distillation column, wherein a material stream enriched in oxygenates is withdrawn via a side outlet and removed from the process. The process according to the invention is particularly useful for processing the product streams obtained in the olefin synthesis by an OTO process.

Owner:LURGI

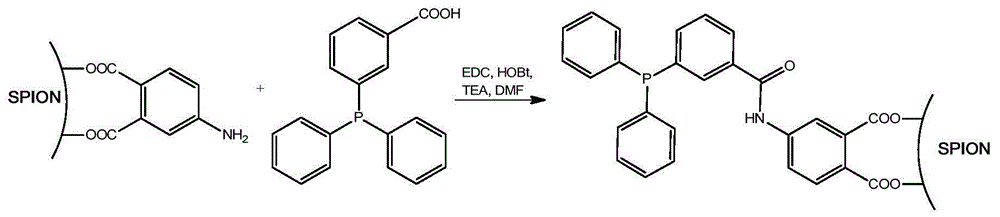

A light-induced one-pot method for synthesizing olefinic compounds

ActiveCN108658716BCarboxylic acid nitrile preparationOrganic compound preparationHalohydrocarbonPtru catalyst

The invention discloses a method for synthesizing an olefin compound by a photo-induced one-pot process. The method comprises the following step of subjecting a halohydrocarbon and an aldehyde compound to a reaction under the condition of irradiation in an inert atmosphere by taking alkali metal carbonate as a base, taking an organic phosphine compound as an adjuvant and taking a photosensitizer as a catalyst, thereby obtaining the olefin compound. According to the method disclosed by the invention, the olefin compound is produced from the halohydrocarbon and the aldehyde compound in a high-yield manner under the condition of irradiation in the inert atmosphere under normal-temperature reaction conditions by taking acetonitrile, DMF (N,N-dimethylformamide) or DMA (N,N-dimethylacetamide) asa solvent, taking an organic phosphine reagent as a reaction adjuvant, taking the alkali metal carbonate as the base and taking the photosensitizer as the catalyst. Compared with the conventional olefin synthesis methods, the method disclosed by the invention has the obvious advantages that the reaction raw materials are readily available, the tolerance to a variety of functional groups on halohydrocarbons and aldehydes is high, the yield is high, the separation and purification of a product are simple and convenient, and the like.

Owner:TSINGHUA UNIV

Process and plant for the recovery and utilization of higher olefins in the olefin synthesis from oxygenates

InactiveUS10202554B2Valid choiceHydrocarbon by hydrogenationHydrocarbon distillationChain lengthParaffin oils

A process and a plant for producing olefins from oxygenates such as methanol and / or dimethyl ether are proposed, in which initially the oxygenates are converted to a primary product containing propylene, other olefins, paraffins and aromatics in an olefin synthesis reactor. The primary product is separated into hydrocarbon fractions of different C chain length, wherein short-chain olefins such as propylene are obtained and beside further fractions there is also obtained a C7− fraction which contains C5 / C6 olefins, as well as a C7+ fraction which contains aromatics. From the latter, the aromatics are separated and alkylated with the C5 / C6 olefins to obtain alkyl aromatics. The same are hydrogenated completely and recirculated to the olefin synthesis reactor, where they likewise are converted to short-chain olefins.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

System and process for preparing olefin by taking coal and coke-oven gas as raw materials

ActiveCN103694074BEfficient use ofEmission reductionChemical industryHydrocarbon from oxygen organic compoundsChemical industryWater vapor

The invention belongs to the technical fields of energies and chemical industry, and discloses a system and a process for preparing olefin by taking coal and coke-oven gas as raw materials. The system for preparing olefin by taking coal and coke-oven gas as raw materials comprises a water-coal-slurry preparation unit, a coal gasification unit, a synthesis gas purification unit, a methanol synthesis unit, an olefin synthesis unit, a coke-oven gas separation unit, a methane dry-reforming unit, a methane vapour reforming unit and a gas mixer. By using the system for preparing olefin, hydrogen separated by the coke-oven gas separation unit, methane dry reforming synthesis gas, methane vapour reforming synthesis gas and the clean synthesis gas generated by the coal gasification unit can be mixed, the hydrogen-carbon ratio of the synthesis gas is adjusted to meet the requirements of methanol synthesis so as to synthesize methanol, and then olefin is synthesized. By adopting the device and the process disclosed by the invention, the emission amount of CO2 during the existing coal-to-olefin process can be decreased, the energy utilization ratio can be increased, and the exhaust emission of the industrial coal coking industry can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com