Process and apparatus for producing an olefin stream low in oxygenates

A compound and product flow technology, applied in chemical instruments and methods, separation methods, distillation purification/separation, etc., can solve expensive and high-priced problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (invention)

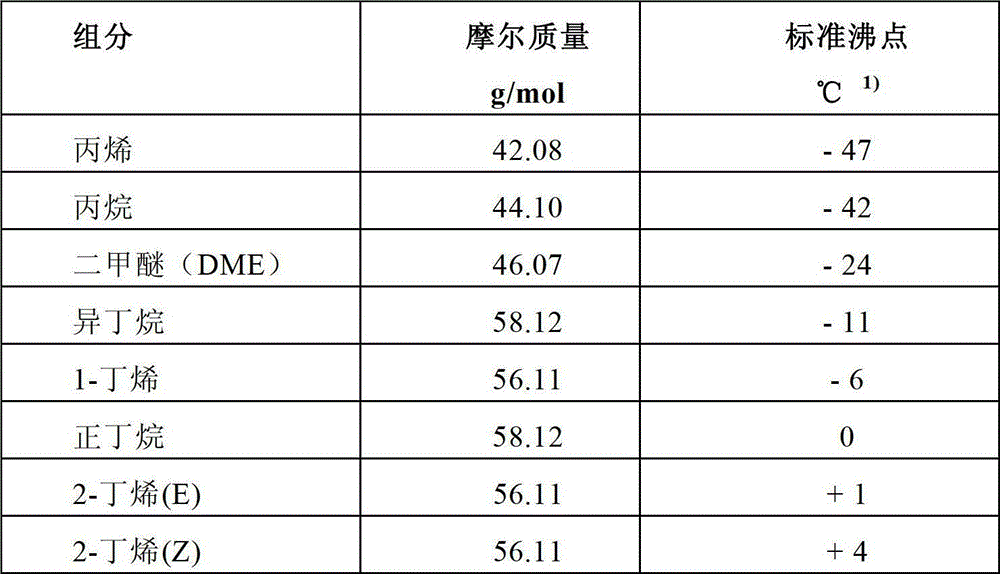

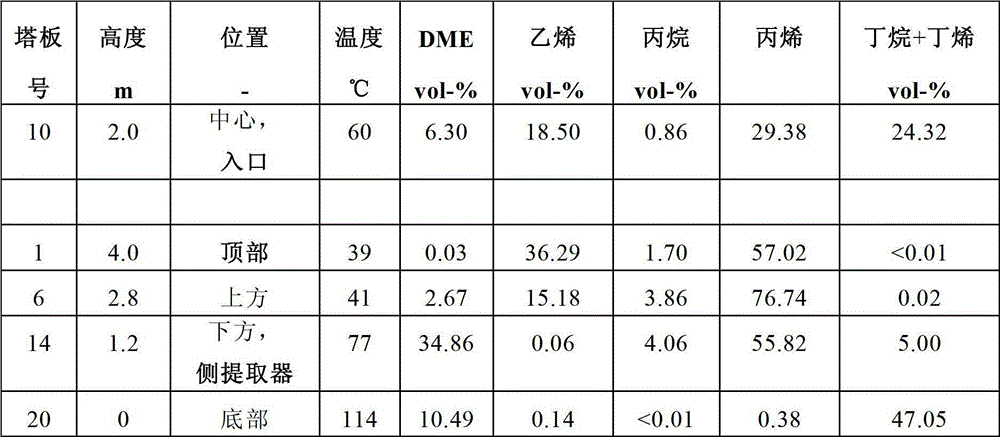

[0034] Experiments were carried out with regard to the distillative separation of a hydrocarbon mixture feed stream, wherein the hydrocarbon mixture feed stream was produced by the Method-controlled upstream olefin synthesis. The hydrocarbon stream to be separated contains ethylene, propylene, propane, butanes and butenes as well as higher hydrocarbons, as well as significant amounts of DME. The separation column used for the distillation separation has a height of 4m and is equipped with a Sulzer type of structured packing. Under the selected process conditions, the separation column has a separation efficiency of 20 theoretical plates, so the theoretical plate height (HETP value) is about 0.20m. The separation column was operated at a pressure of 1.83 MPa(a). The temperature at the bottom of the separation column is from 100 to 120°C and at the top of the column is about 40°C. The reflux ratio was 25. The feed line for the hydrocarbo...

Embodiment 2

[0040] Embodiment 2 (the present invention)

[0041] About the basis The continuous olefin synthesis of method is carried out long-term test, and also according to the separating column that embodiment 1 operates is configured in described Downstream of the synthesis reactor. Due to the continuous aging or deactivation of the catalyst used in the synthesis reactor, DME is no longer completely converted; the concentration of DME in the product stream of the synthesis reactor is therefore constantly increasing. According to the invention, the separation column was operated with a side extractor and for comparison without a side extractor during different tests. In the table below, the measured DME concentration in the overhead product is shown as a function of the operating cycle of the pilot plant and the operating conditions of the side extractor. For comparison, the DME concentration in the hydrocarbon mixture feed stream is also shown as a function of the run time corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com