Patents

Literature

583 results about "Hydrocarbon mixtures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocarbon mixtures are a group of various volatile, highly flammable, mixtures used chiefly as nonpolar solvents.

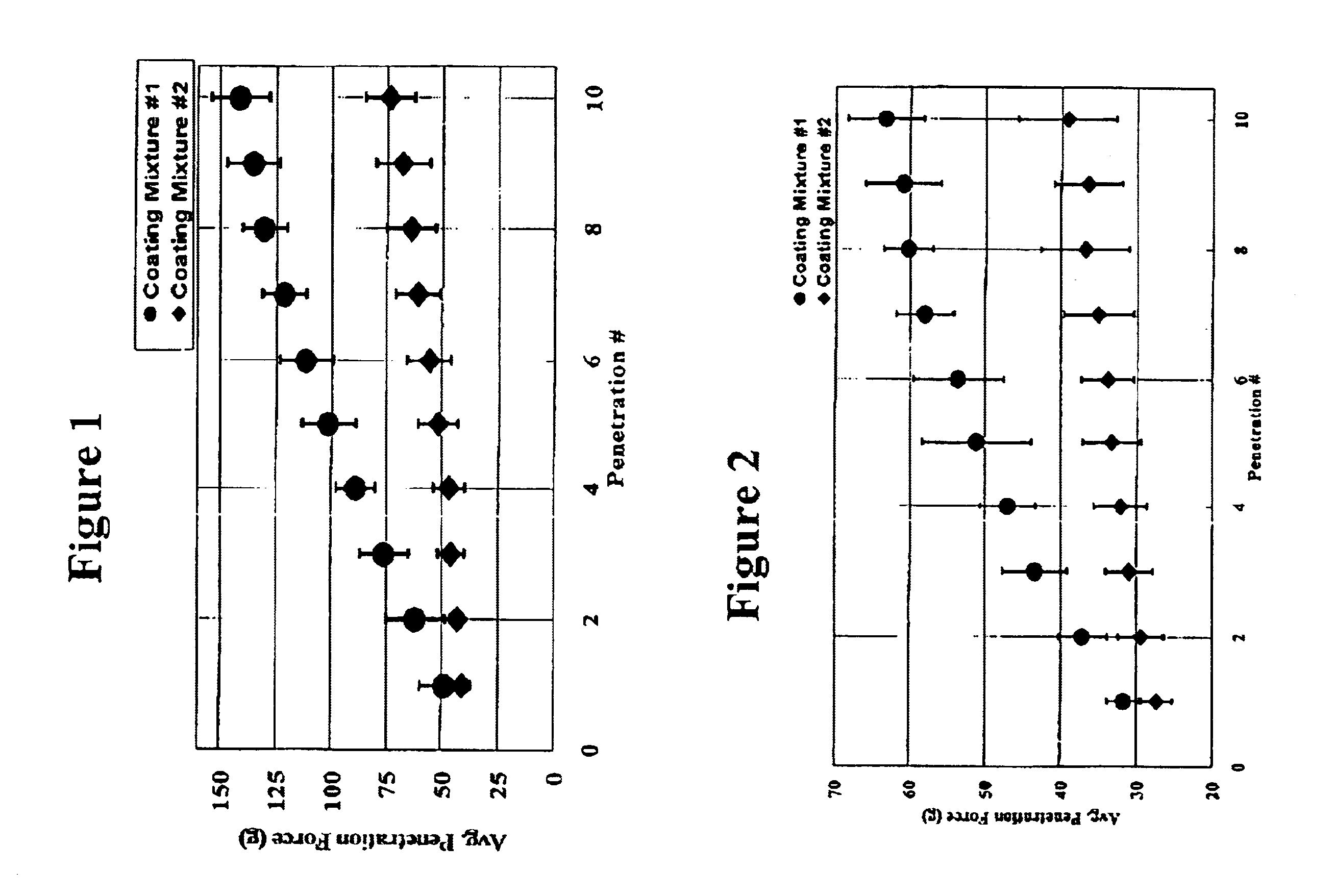

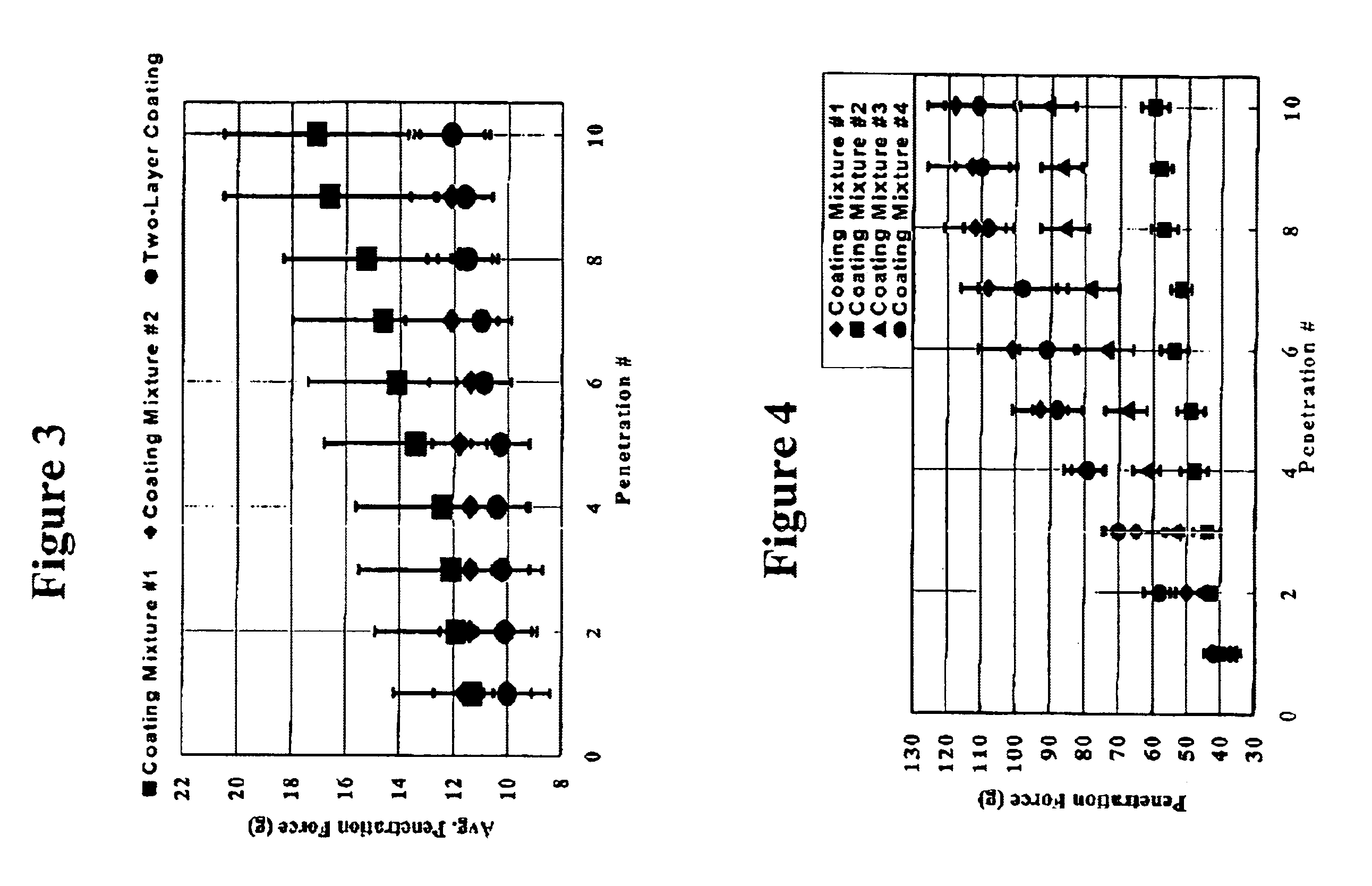

Medical devices having durable and lubricious polymeric coating

A medical device having a contact surface exposed repeatedly to bodily tissue is disclosed. The contact surface is coated with a silicone polymer and one or more non-silicone hydrophobic polymers. The preferred medical device is a surgical needle, and the preferred coating is a polydimethylsiloxane and polypropylene wax hydrocarbon mixture. The incorporation of the non-silicone hydrophobic polymer increases the durability of the coating on the device without sacrificing lubricity.

Owner:ETHICON INC

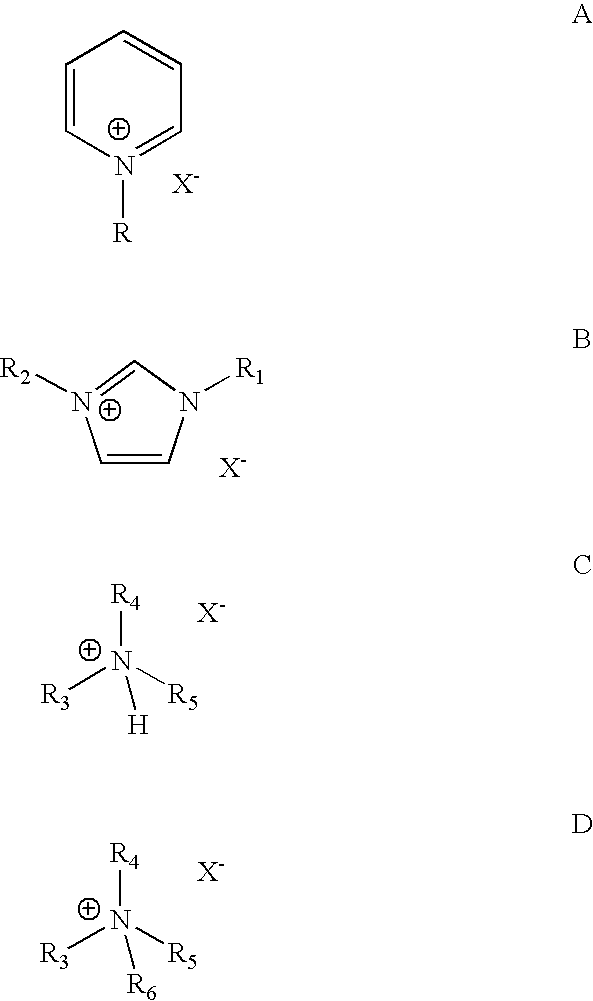

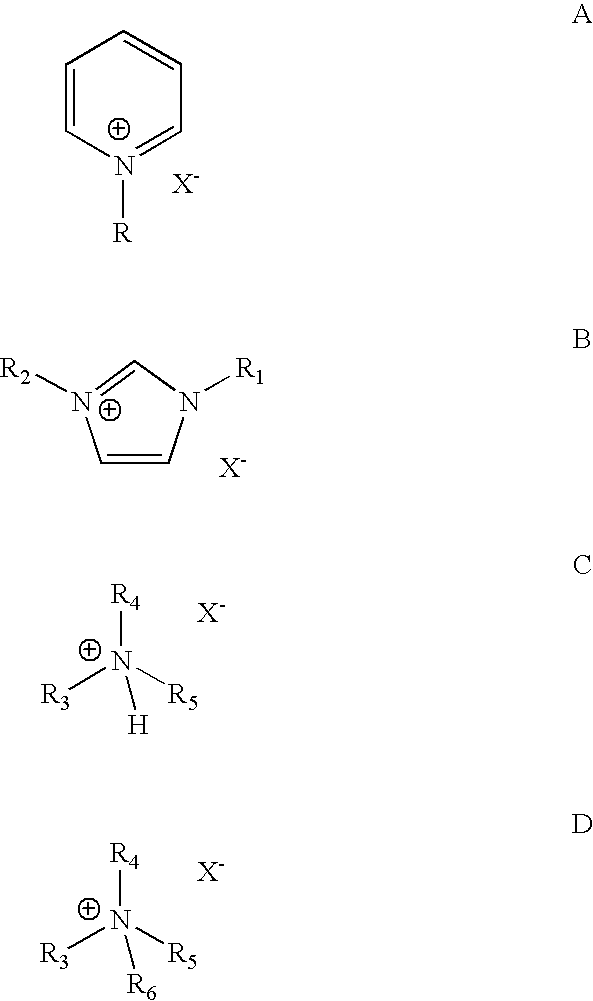

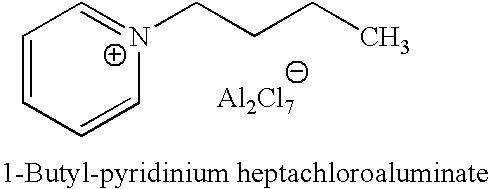

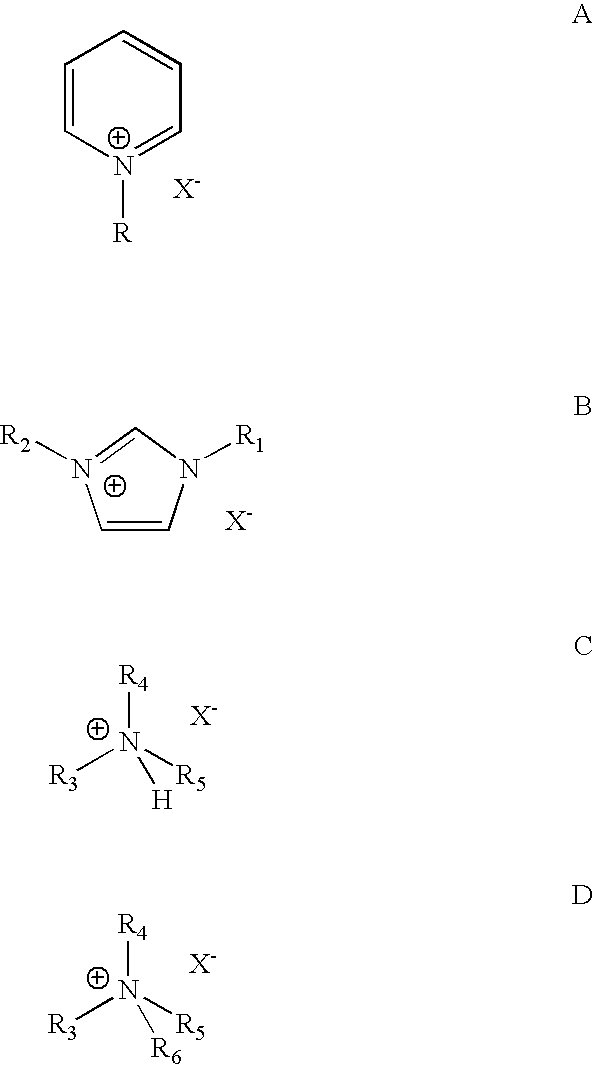

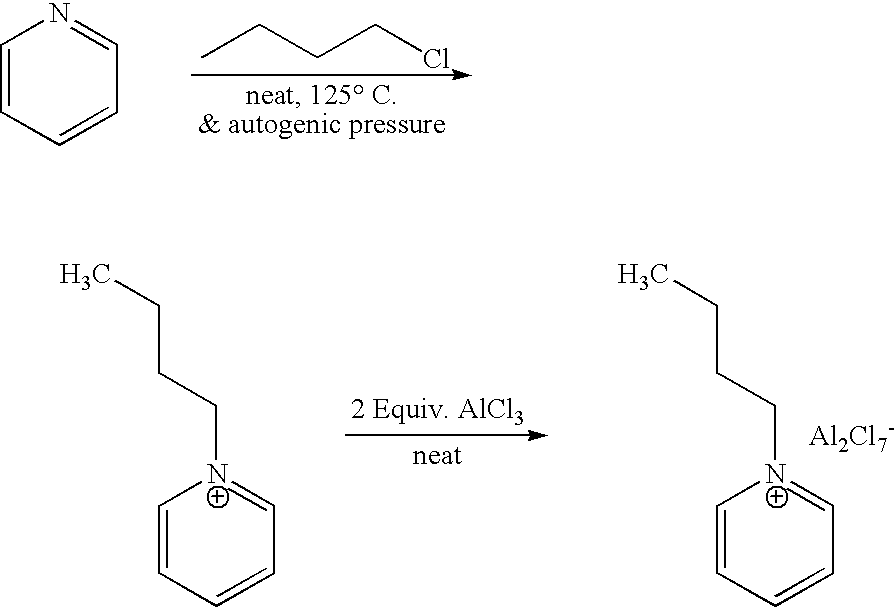

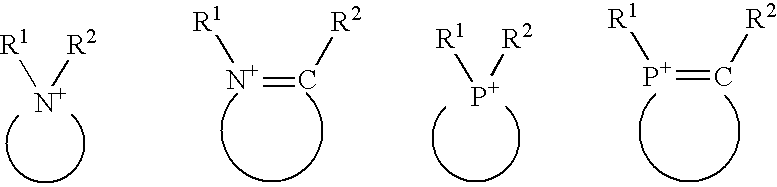

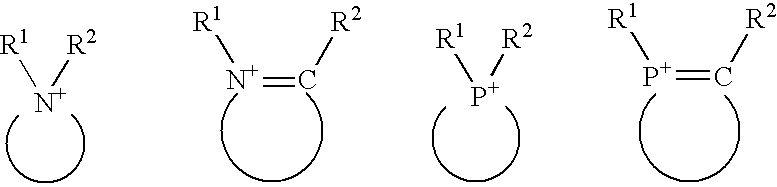

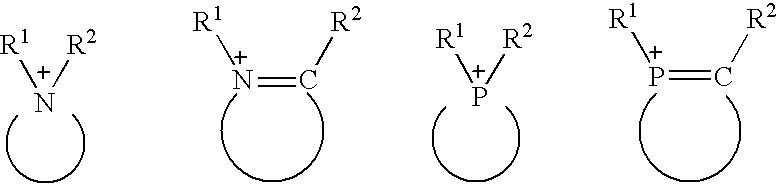

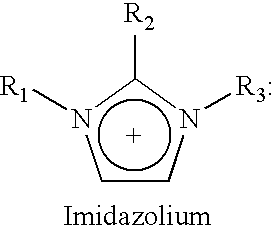

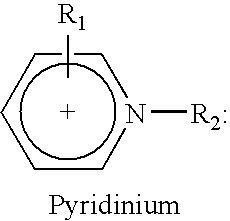

Alkylation process using an alkyl halide promoted ionic liquid catalyst

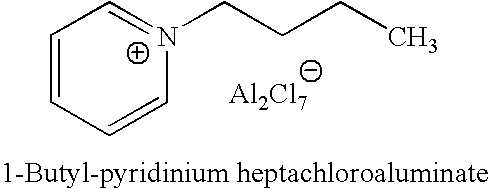

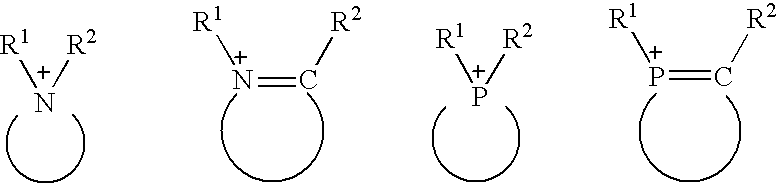

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. In one embodiment, the acidic ionic liquid is chloroaluminate ionic liquid prepared by mixing aluminum trichloride (AlCl3) and a hydrocarbyl substituted pyridinium halide, a hydrocarbyl substituted imidazolium halide, trialkylammonium hydrohalide or tetraalkylammonium halide of the general formulas A, B, C and D, respectively,where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same, and R3, R4, and R5 and R6=methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R3, R4, R5 and R6 may or may not be the same.

Owner:CHEVROU USA INC

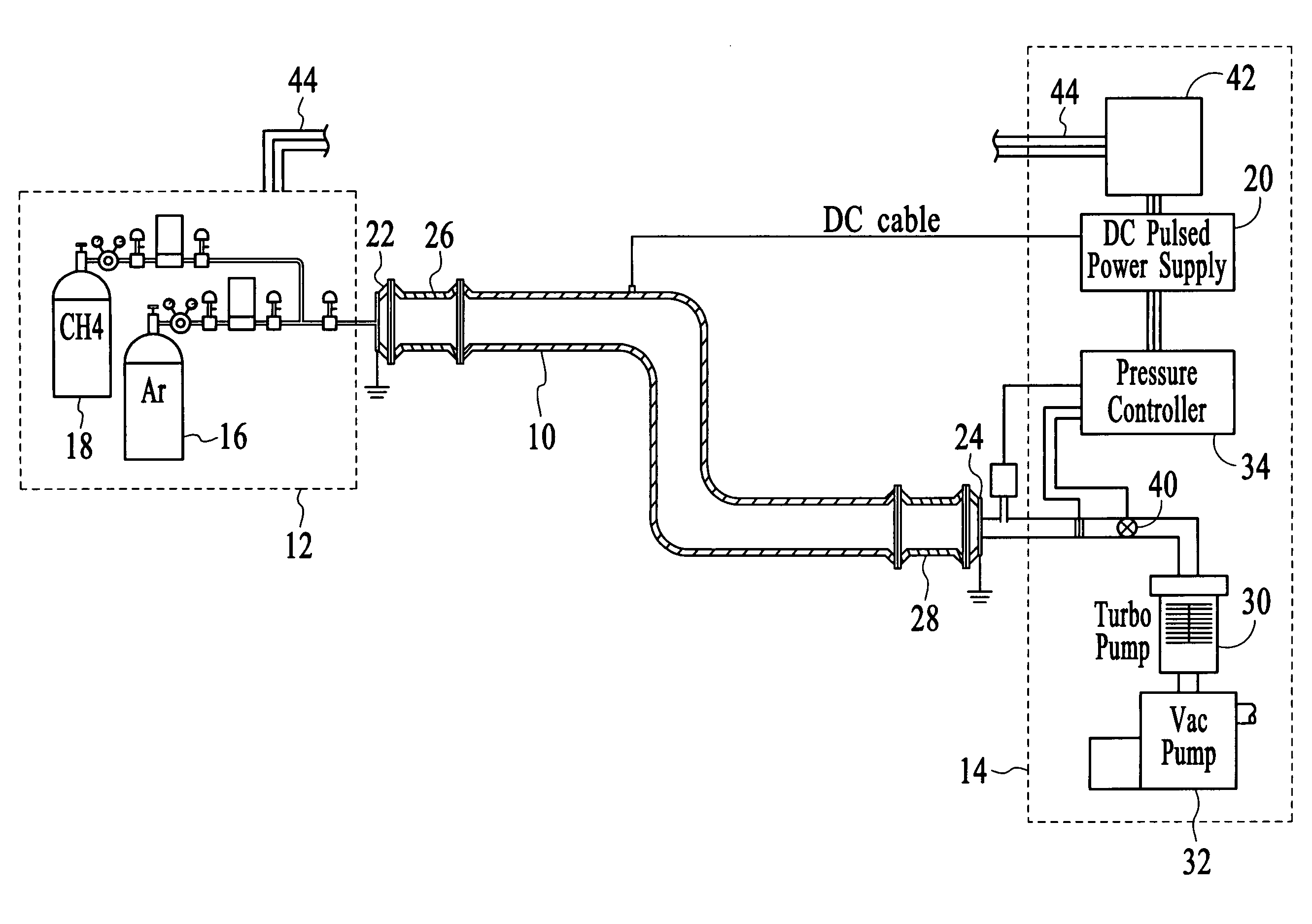

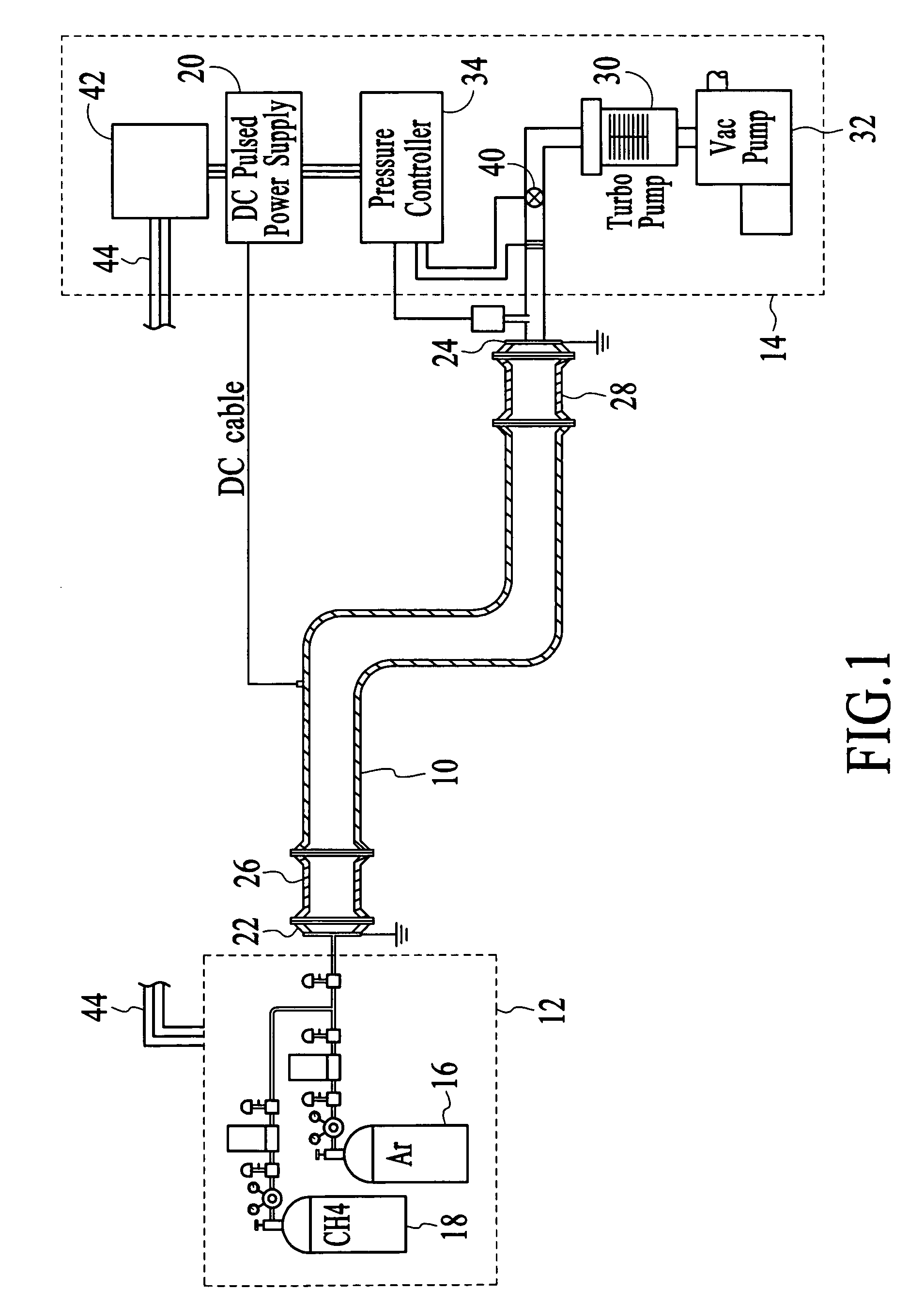

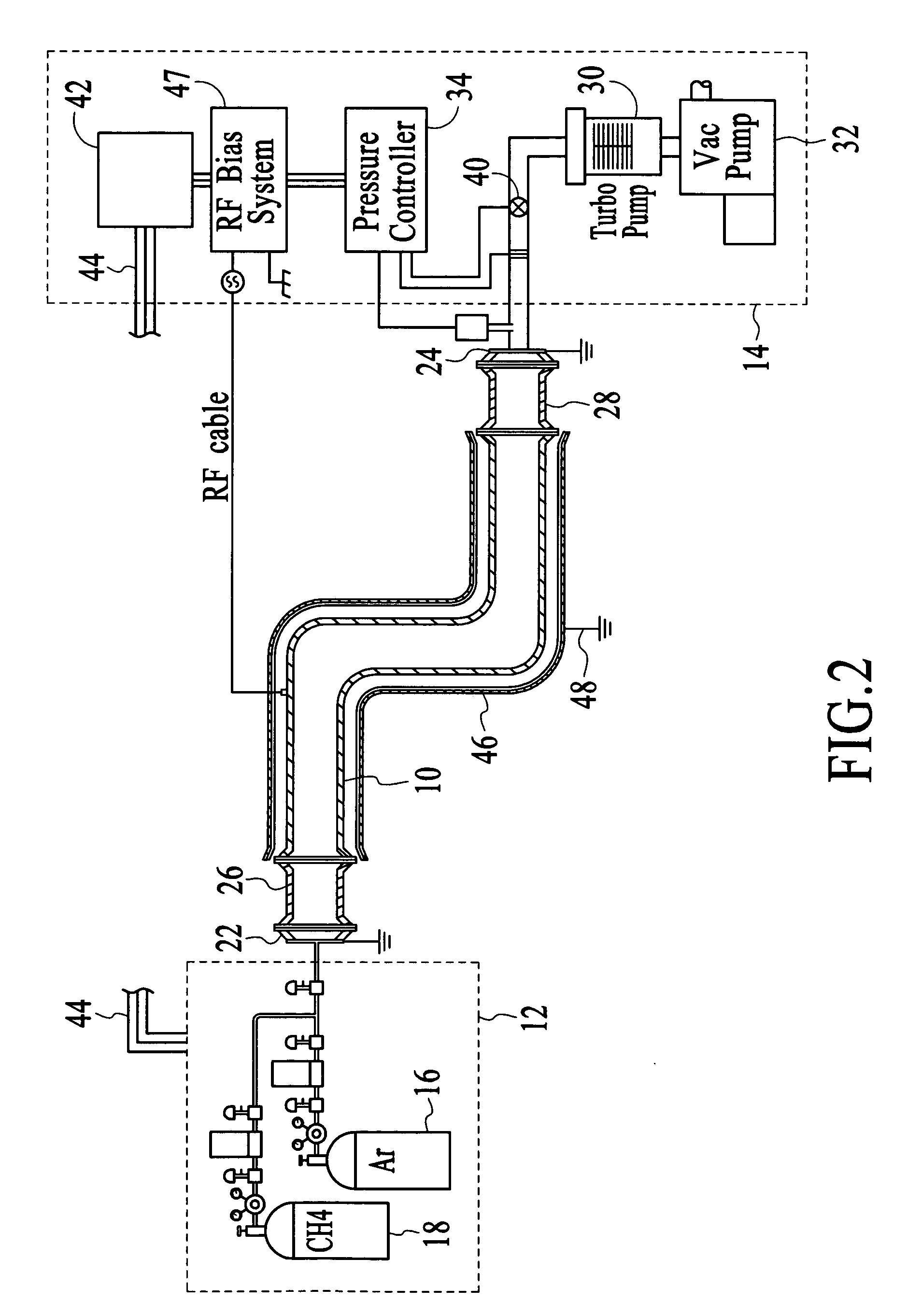

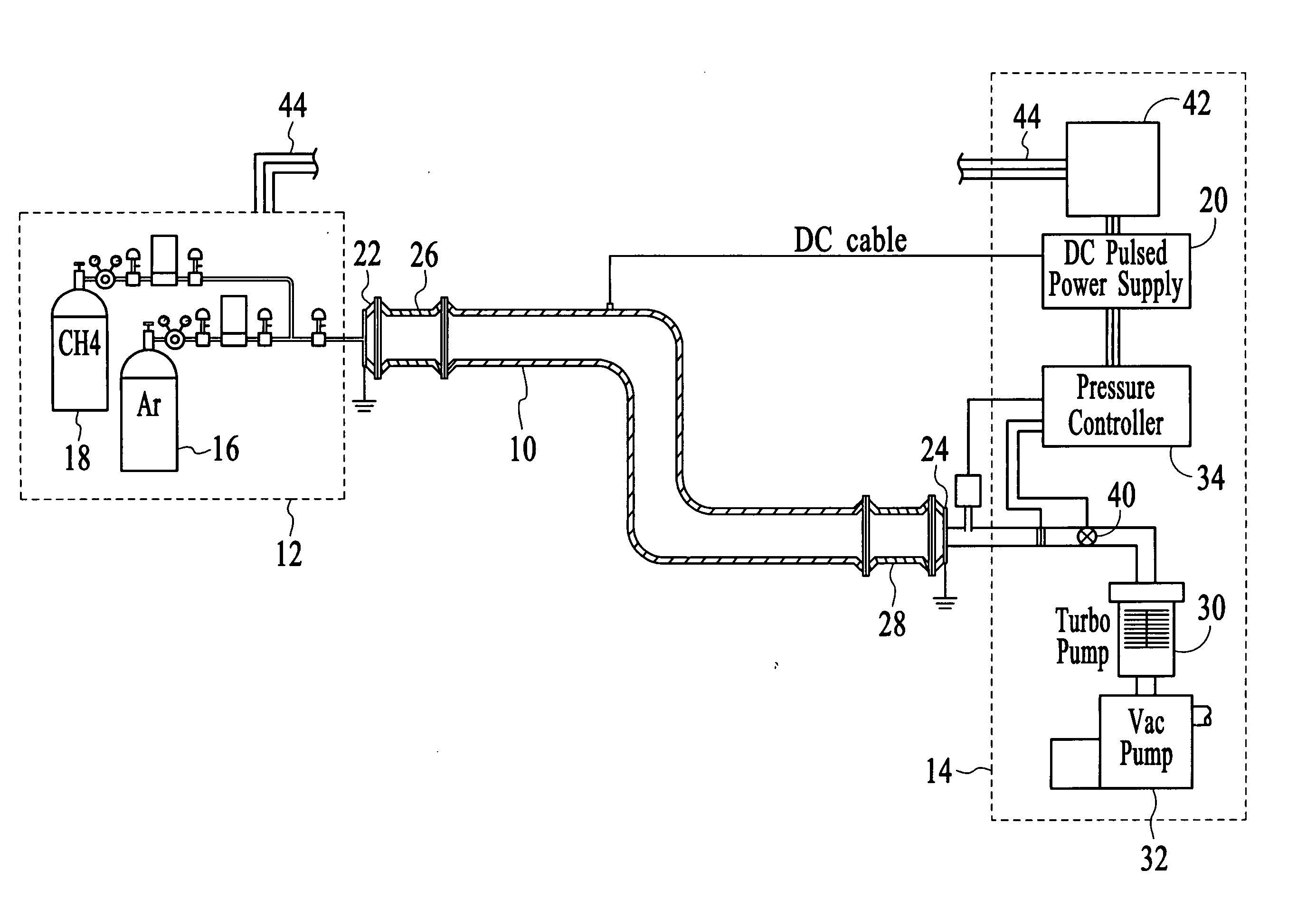

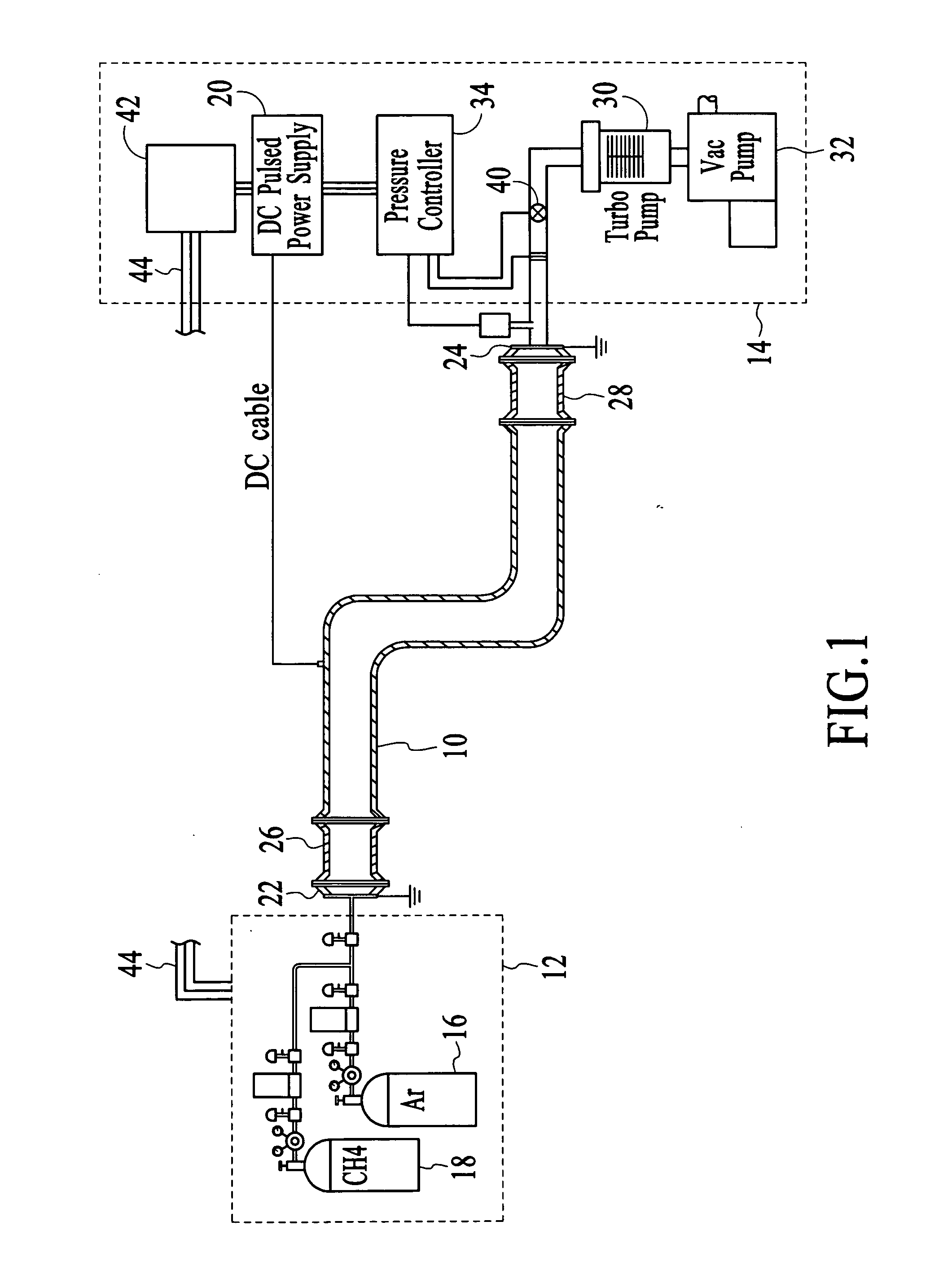

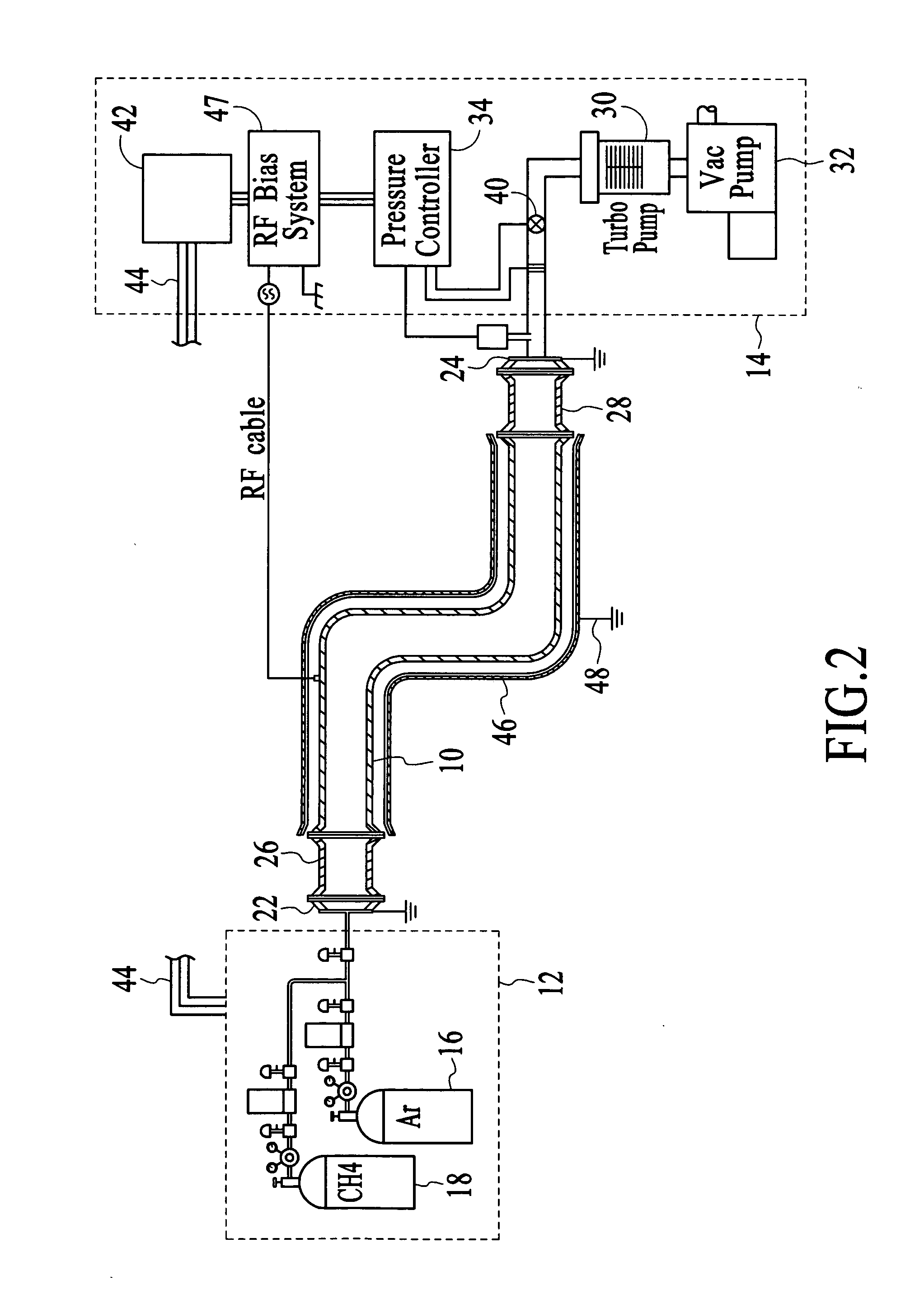

Method and system for coating internal surfaces of prefabricated process piping in the field

ActiveUS7300684B2Improve adhesionIncreases magnitudeLiquid surface applicatorsVacuum evaporation coatingHydrocarbon mixturesDiamond-like carbon

The coating of internal surfaces of a workpiece is achieved by connecting a bias voltage such that the workpiece functions as a cathode and by connecting an anode at each opening of the workpiece. A source gas is introduced at an entrance opening, while a vacuum source is connected at an exit opening. Pressure within the workpiece is monitored and the resulting pressure information is used for maintaining a condition that exhibits the hollow cathode effect. Optionally, a pre-cleaning may be provided by introducing a hydrocarbon mixture and applying a negative bias to the workpiece, so as to sputter contaminants from the workpiece using argon gas. Argon gas may also be introduced during the coating processing to re-sputter the coating, thereby improving uniformity along the length of the workpiece. The coating may be a diamond-like carbon material having properties which are determined by controlling ion bombardment energy.

Owner:AGM CONTAINER CONTROLS

Alkylation process using an alkyl halide promoted ionic liquid catalyst

ActiveUS7531707B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsHydrogen halideAlkane

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. The alkylhalide by reacting to at least a portion of the olefin with a hydrogen halide.

Owner:CHEVROU USA INC

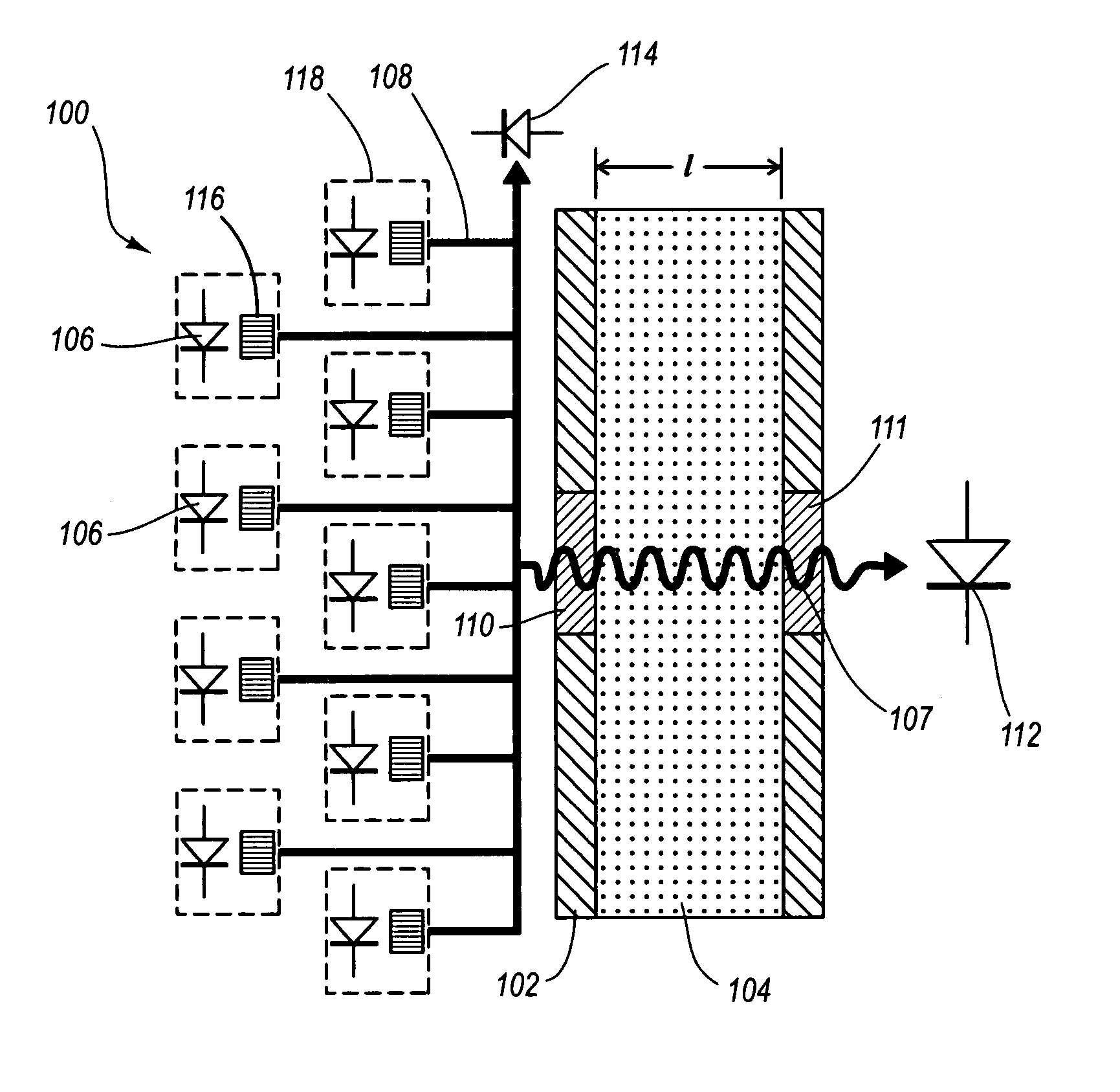

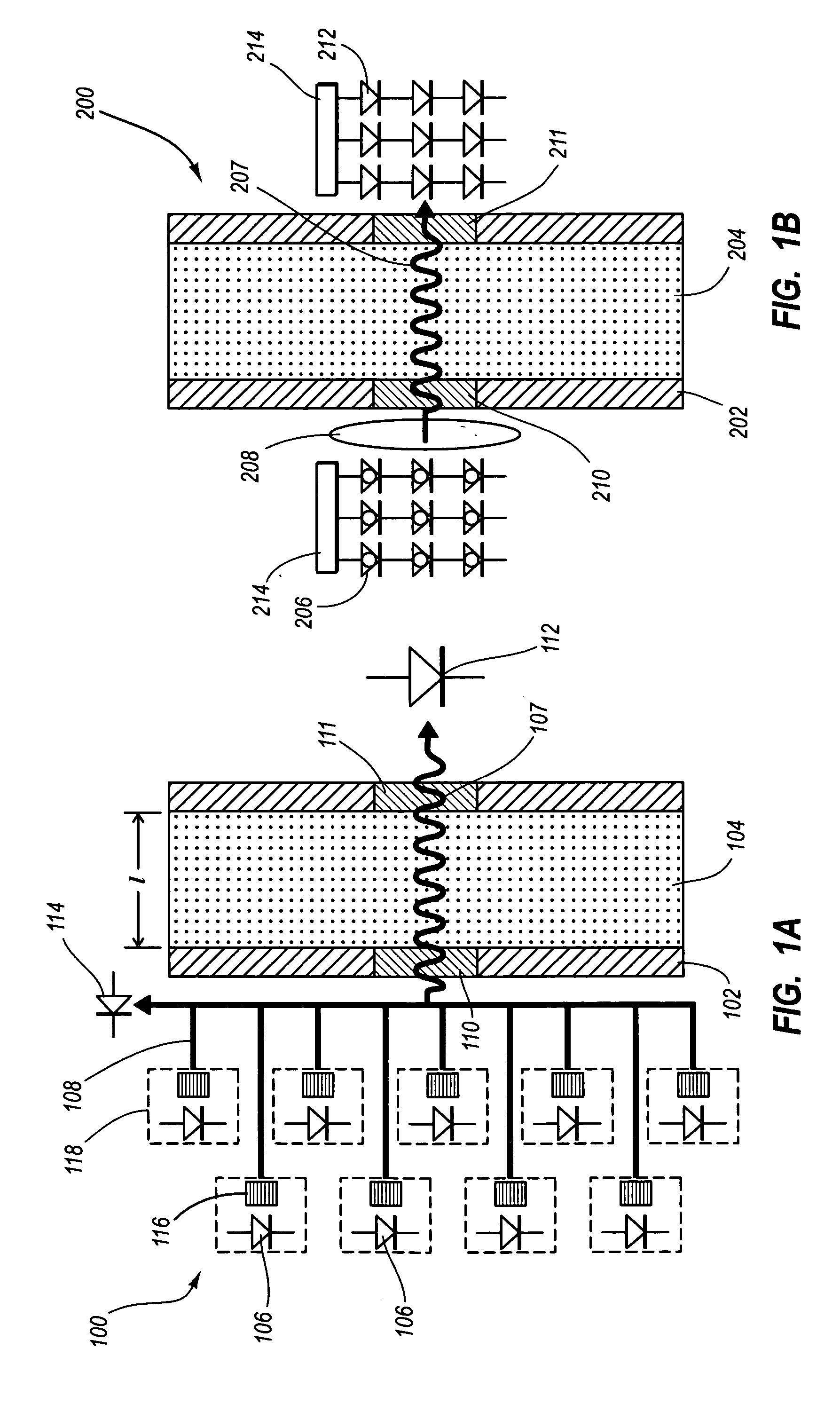

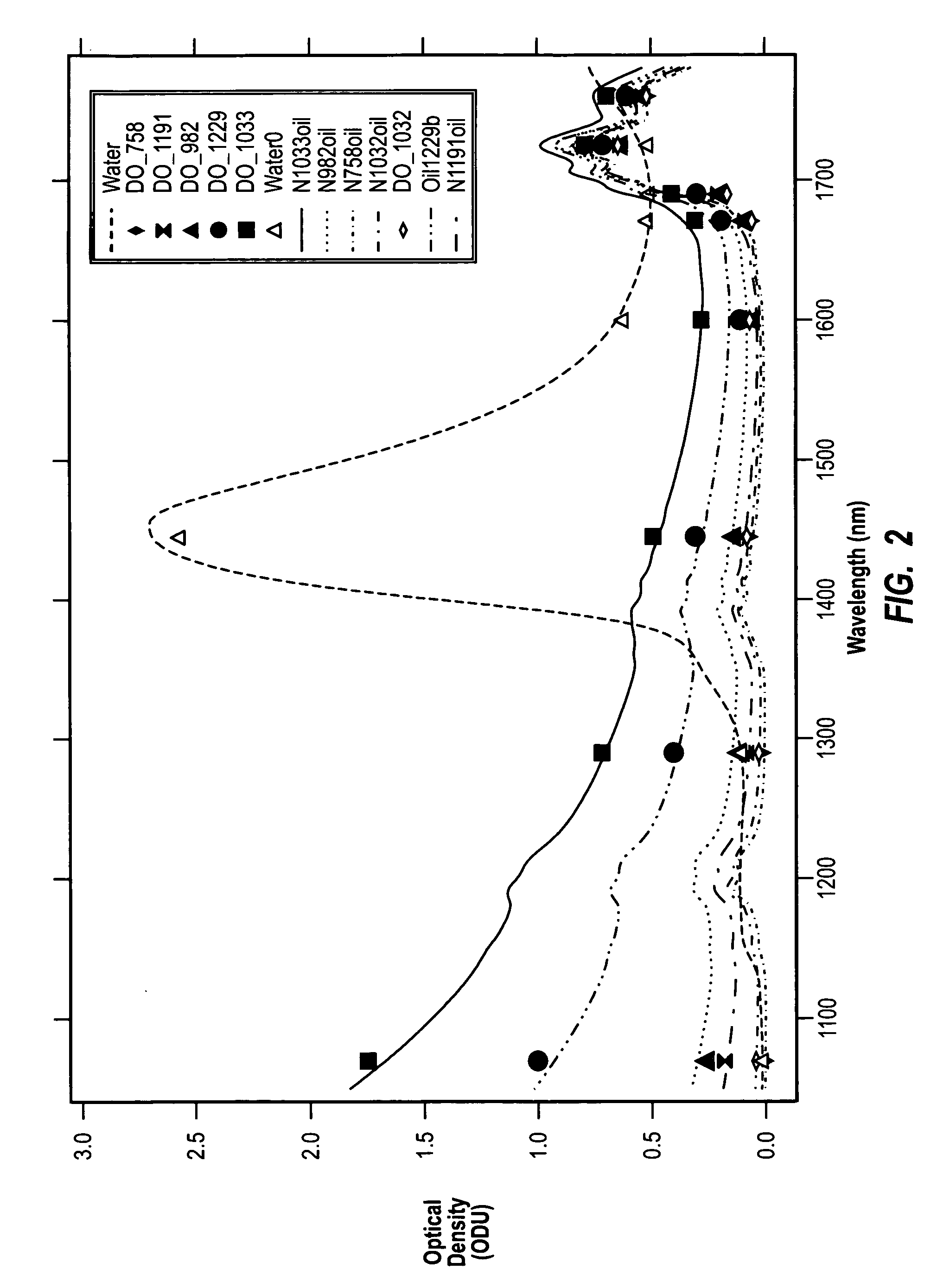

Method and apparatus for composition analysis in a production logging environment

InactiveUS20070035737A1Reduce the impactReduce impactMaterial analysis by optical meansNuclear radiation detectionHydrocarbon mixturesPhotodetector

Methods and apparatus for analyzing a hydrocarbon mixture are disclosed, comprising at least one light-emitting diode (LED) and at least one photodetector positioned to detect energy transmitted by the LED through a sample of the hydrocarbon mixture. In at least one embodiment an optical filter is coupled to the output of the LED to mitigate the adverse effects of the LED's sensitivity to temperature.

Owner:SCHLUMBERGER TECH CORP

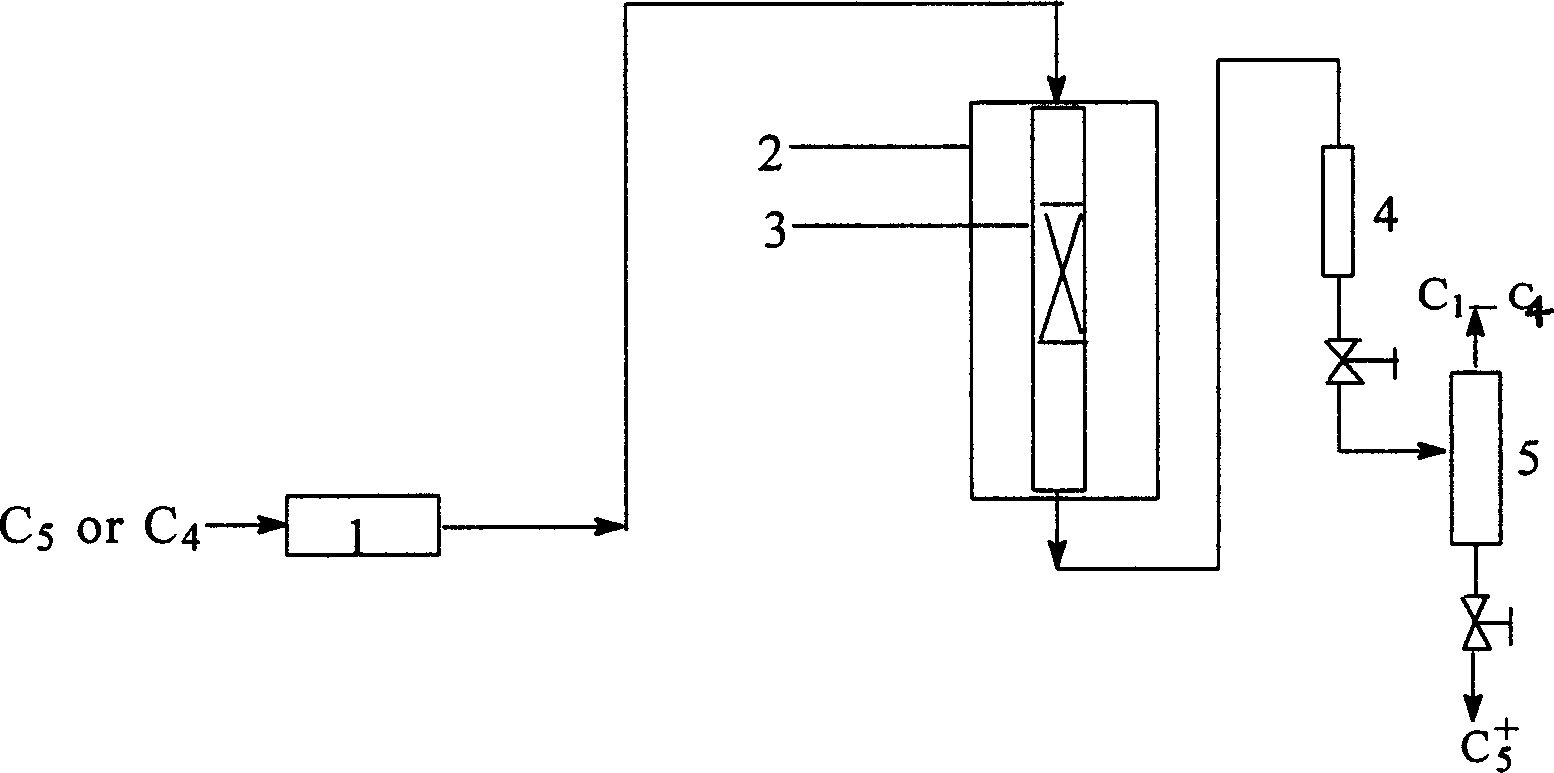

Method for preparing ethene and propylene

InactiveCN1490287AImprove anti-coking performanceSimple processHydrocarbon by hydrocarbon crackingHydrocarbon mixturesFixed bed

A process for preparing ethylene and propylene from the hydrocarbon mixture containing C4 (or C5) olefine includes such steps as contacting the zeolite contained catalyst in fixed-bed reactor, reacting at 350-500 deg.C and 1-10 / hr of space speed under 0.6-1.0 MPa to obtain the mixture of ethylene and propylene, and cooling separating. Said catalyst contains Al2O3 or SiO2, high-Si zeolite and modifier.

Owner:CHINA PETROLEUM & CHEM CORP +1

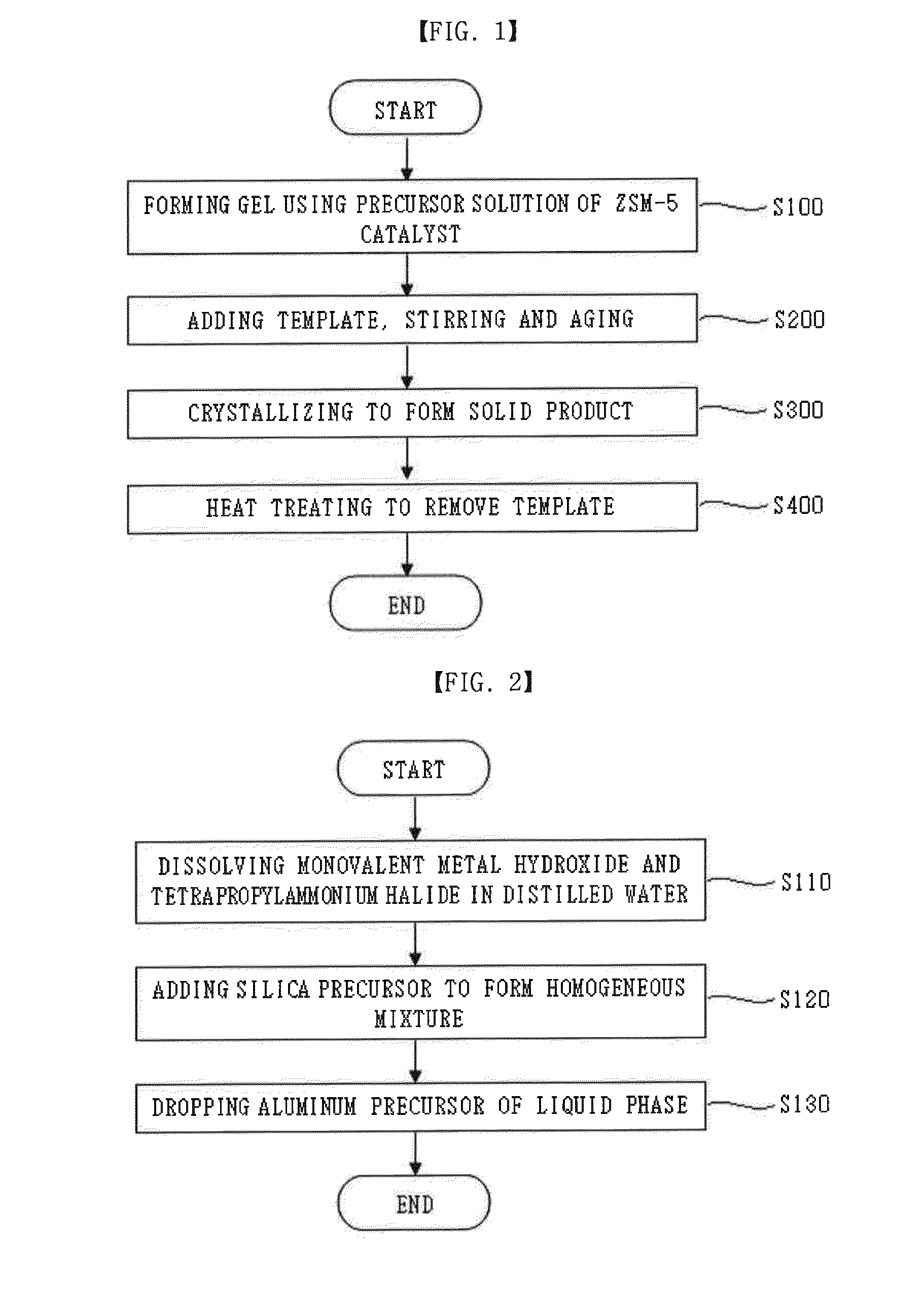

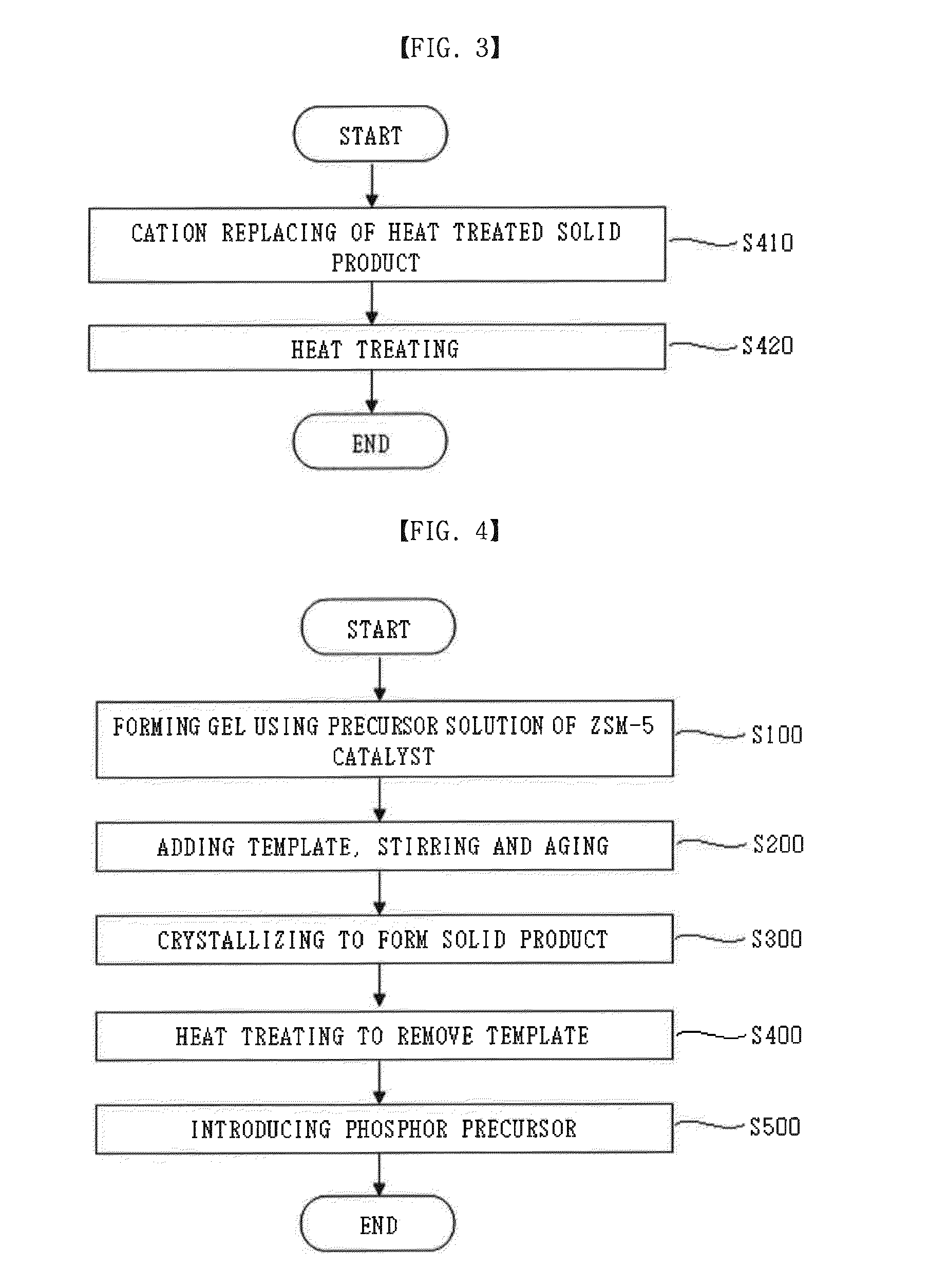

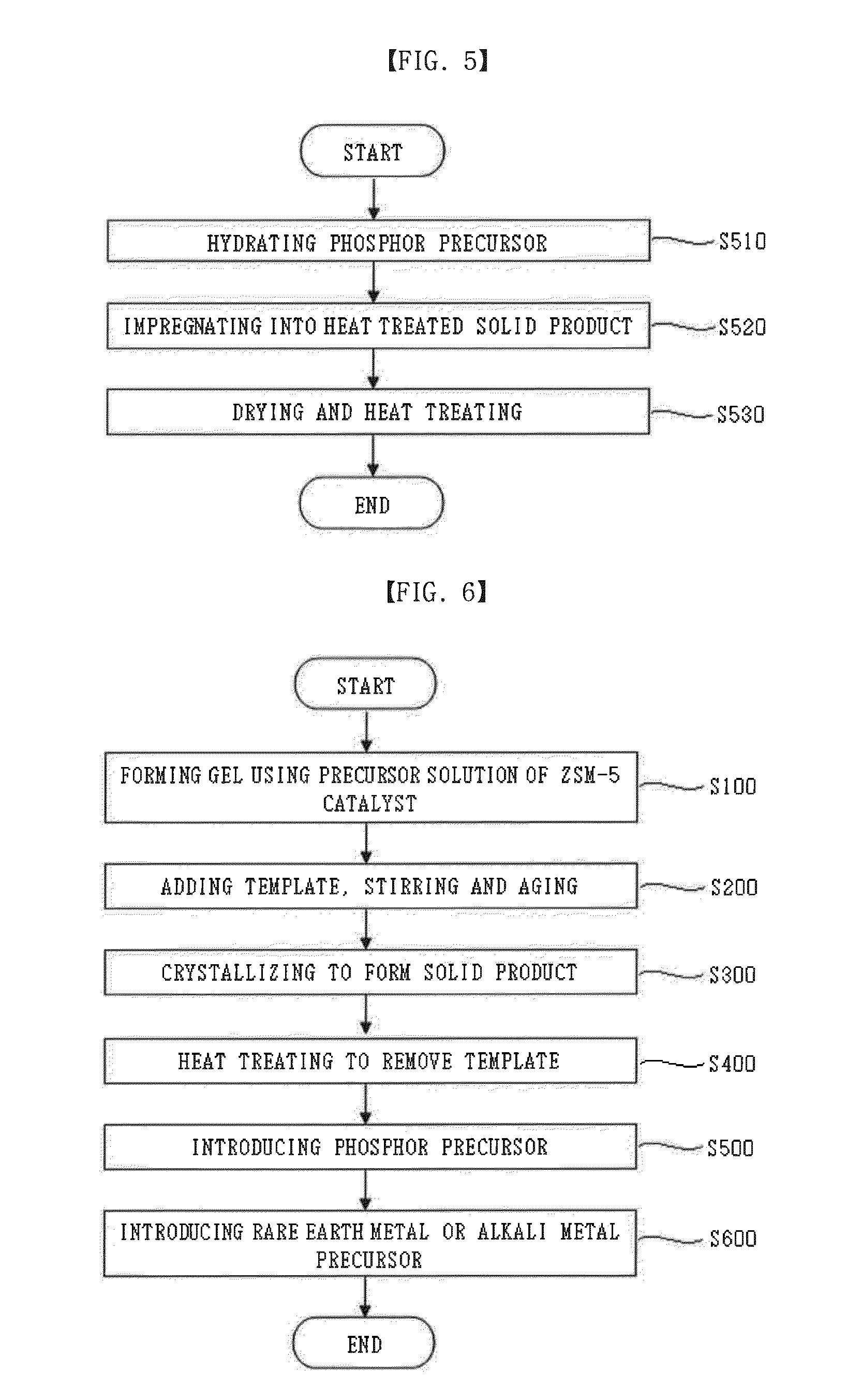

ZSM-5 catalyst with micropores and mesopores, preparation method thereof and production method of light olefins through catalytic cracking of hydrocarbons using the catalyst

InactiveUS20130085311A1Increase productionImprove featuresTreatment with plural serial cracking stages onlyCatalytic crackingHydrocarbon mixturesNaphtha

Provided is a method of preparing a ZSM-5 catalyst for preparing light olefins including ethylene and propylene through a catalytic cracking of a hydrocarbon mixture of C4 to C7 produced after a naphtha cracking. The method includes (a) forming a gel by aging a mixture solution including a silica precursor and an aluminum precursor; (b) adding a template possibly forming mesopores through a heat treatment, into the gel, stirring and then aging; (c) forming a solid product by crystallizing the aged mixture in step (b); and (d) heat treating the solid product to remove the template. The ZSM-5 catalyst may include micropores and mesopores and may have good physical and chemical properties along with a good pore property. The production yield of the light olefins may be increased.

Owner:HONAM PETROCHEM

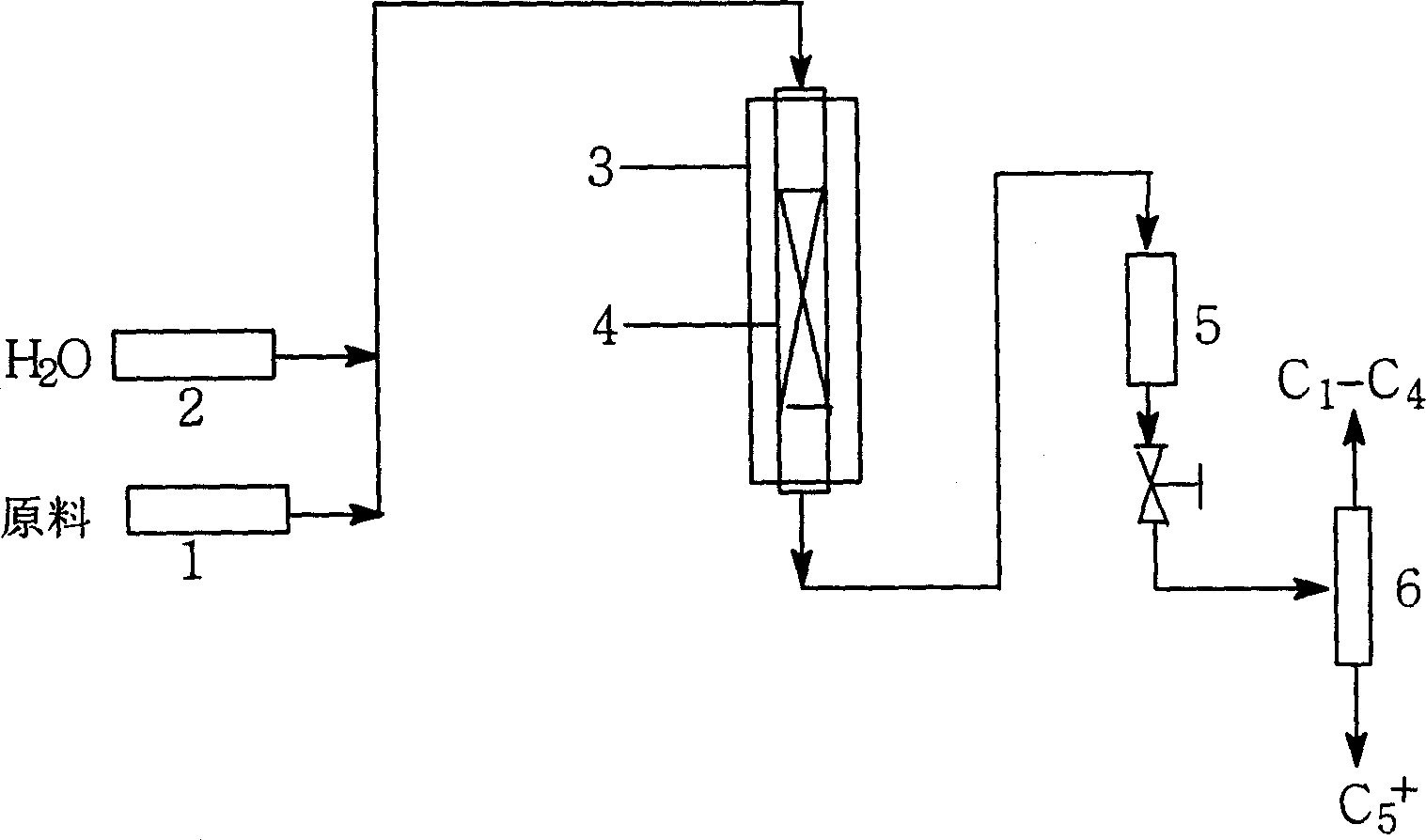

Process for preparing tert-butanol from isobutene-containing hydrocarbon mixtures

InactiveUS7002050B2Increase productionOrganic compound preparationOxygen compounds preparation by reductionHydrocarbon mixturesSolid acid

The present invention relates to a process for preparing tert-butanol (TBA) by reacting an isobutene-containing hydrocarbon mixture with water over a solid acid catalyst in a reactor cascade, wherein at least one reactor is supplied alternately with two different isobutene-containing hydrocarbon mixtures, of which one has both a higher tert-butanol content and a higher water content than the other mixture.

Owner:EVONIK DEGUSSA GMBH

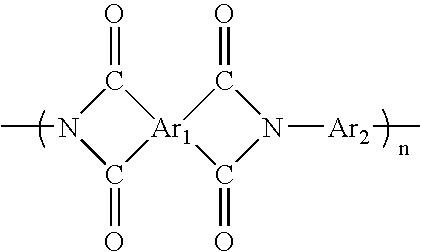

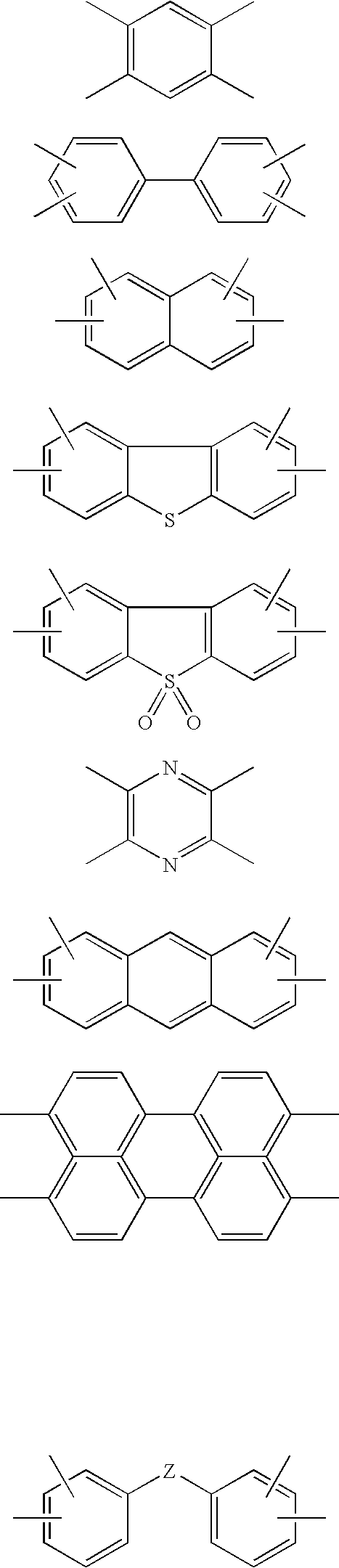

Polyimide membranes

InactiveUS20040177753A1Improve performanceStable membranes for gas/vapourMembranesIsotope separationDendrimerHydrocarbon mixtures

The present invention deals with a process for treating a polyimide comprising exposing said polyimide to a compound selected from the group consisting of dendrimers, hyperbranched polymers and mixtures thereof. The polyimide may be in the form of a membrane and the membrane, after treatment according to the process of the invention, may be suitable for use in a membrane-based separation technique, for example gas separation, filtration, microfiltration, ultrafiltration, reverse osmosis or pervaporation. The membrane may for example be suitable for separation of gas and hydrocarbon mixtures including mixtures of H2 / N2, H2 / CO2, He / N2, CO2 / CH4, and C2-C4 hydrocarbon mixtures.

Owner:NAT UNIV OF SINGAPORE

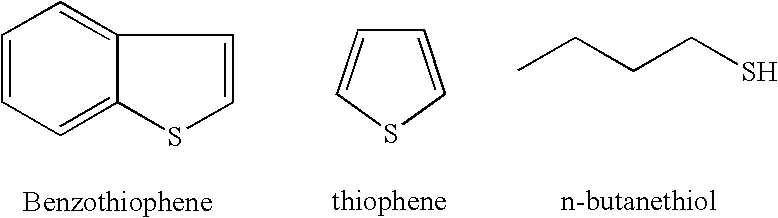

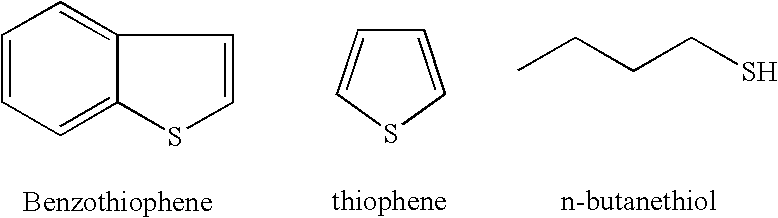

Processing for eliminating sulfur-containing compounds and nitrogen-containing compounds from hydrocarbon

InactiveUS20040045874A1Preferred solubilityPhysical/chemical process catalystsElectrolysis componentsSolubilityHydrocarbon mixtures

A process for desulfurization and, if necessary, for denitrification of hydrocarbon fractions is characterized in that: said hydrocarbon mixture is brought into contact with a non-aqueous ionic liquid of general formula Q<+>A<-> that contains at least one alkylating agent, making it possible to form ionic sulfur-containing derivatives (and, if necessary, nitrogen-containing derivatives) that have a preferred solubility in the ionic liquid; and said ionic liquid is separated from the hydrocarbon mixture that is low in sulfur and nitrogen by decanting.

Owner:INST FR DU PETROLE

Method and system for coating internal surfaces of prefabricated process piping in the field

ActiveUS20060011468A1Improve adhesionIncreases magnitudeCellsLiquid surface applicatorsDiamond-like carbonHydrocarbon mixtures

The coating of internal surfaces of a workpiece is achieved by connecting a bias voltage such that the workpiece functions as a cathode and by connecting an anode at each opening of the workpiece. A source gas is introduced at an entrance opening, while a vacuum source is connected at an exit opening. Pressure within the workpiece is monitored and the resulting pressure information is used for maintaining a condition that exhibits the hollow cathode effect. Optionally, a pre-cleaning may be provided by introducing a hydrocarbon mixture and applying a negative bias to the workpiece, so as to sputter contaminants from the workpiece using argon gas. Argon gas may also be introduced during the coating processing to re-sputter the coating, thereby improving uniformity along the length of the workpiece. The coating may be a diamond-like carbon material having properties which are determined by controlling ion bombardment energy.

Owner:AGM CONTAINER CONTROLS

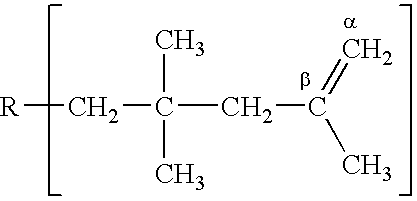

Method for producing polyisobutene

ActiveUS7217773B2Reduce molecular weightReduce the amount requiredHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsHydrocarbon mixturesBoron trifluoride

A process is described for preparing polyisobutene having a content of terminal vinylidene groups of at least 75 mol % by polymerizing isobutene or isobutenic hydrocarbon mixtures in the liquid phase in the presence of a boron trifluoride complex catalyst of the composition(BF3)a.L1b.L2c.L3dwhere L1 is water, a primary C1–C5-alkanol and / or a secondary C3–C5-alkanol, L2 is at least one aldehyde and / or one ketone, L3 is an ether having at least 5 carbon atoms, a secondary alkanol having at least 6 carbon atoms, a primary alkanol having at least 6 carbon atoms and / or a tertiary alkanol, the b:a ratio is in the range from 0.9 to 3.0, the c:a ratio is in the range from 0.01 to 0.5, and the d:a ratio is in the range from 0 to 1.0.

Owner:BASF AG

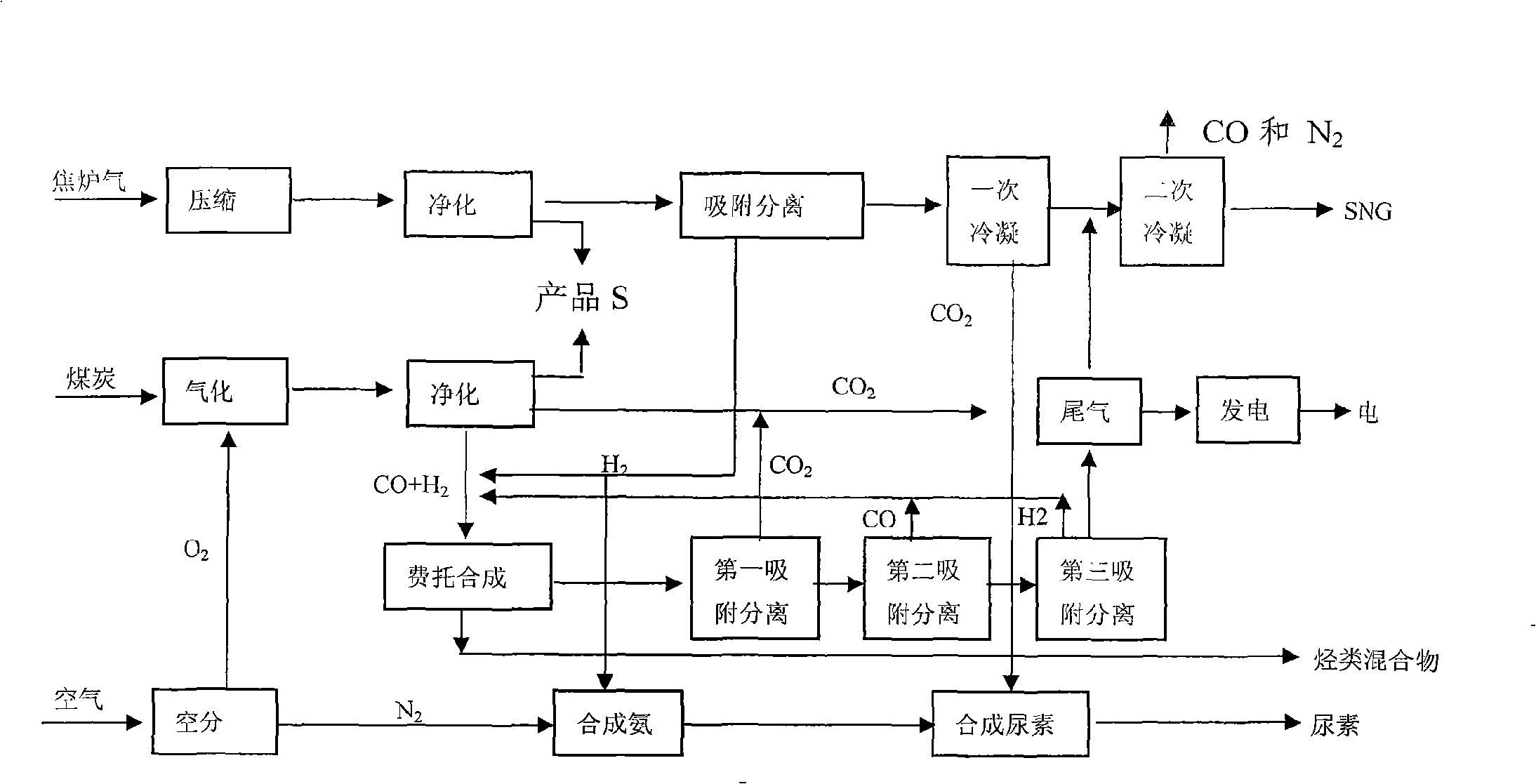

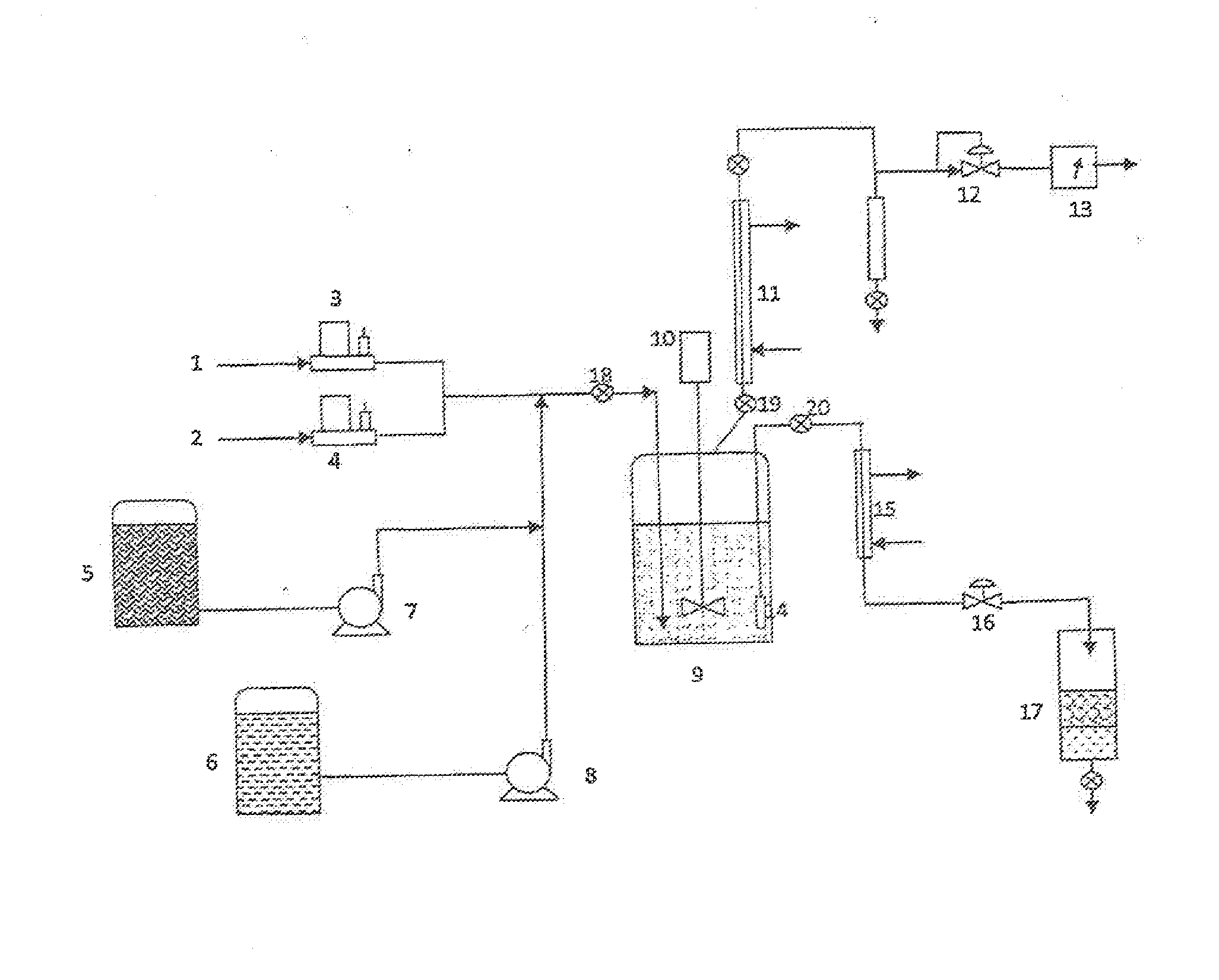

Poly-generation technique for using coal gas and coke oven gas as raw materials

ActiveCN101538483ANo conversionNo transform operationUrea derivatives preparationOrganic compound preparationHydrocarbon mixturesDesorption

The invention relates to a poly-generation technique for using coal gas and coke oven gas as raw materials. The poly-generation technique comprises the following steps of: carrying out mixing on part of H2 prepared by purified water gas and coke oven gas through pressure swing adsorption and tail gas obtained by Fischer-Tropsch synthesis, carrying out Fischer-Tropsch synthesis and obtaining hydrocarbon mixture and tail gas. The CO2 separated from tail gas separate by first pressure swing adsorption enters a urea synthesis unit for reaction, the CO and the hydrogen respectively obtained by separation of second pressure swing adsorption and third pressure swing adsorption of the residual tail gas are circulated back to a Fischer-Tropsch synthesis unit for reaction; and the residual gases can be used for generating power or obtaining SNG by secondary condensation. The coke oven gas enters pressure swing adsorption after being purified and desulphurized so as to separate H2; wherein one part of H2 is used as supplementation of H2 needed by Fischer-Tropsch synthesis and the other part of H2 is mixed with N2 for ammonia synthesis so as to obtain synthetic ammonia; and the synthetic ammonia is mixed with CO2 obtained by the first condensation and CO2 separated from the Fischer-Tropsch synthesis for urea synthesis so as to obtain urea. The CO2 separated from the first condensation of desorption gas by pressure swing adsorption of the coke oven gas is used for urea synthesis; and the residual gases is treated by the second condensation to obtain SNG and mixed gas of CO and N2. The invention has no emission of greenhouse gases, uses richness in carbon and deficiency in hydrogen of the coal gas and the richness in hydrogen and deficiency in carbon of the coke oven gas to carry out complementation, realizes modulation of product structure by Fischer-Tropsch synthesis and improves the economical efficiency of the process of Fischer-Tropsch synthesis.

Owner:中科潞安能源技术有限公司

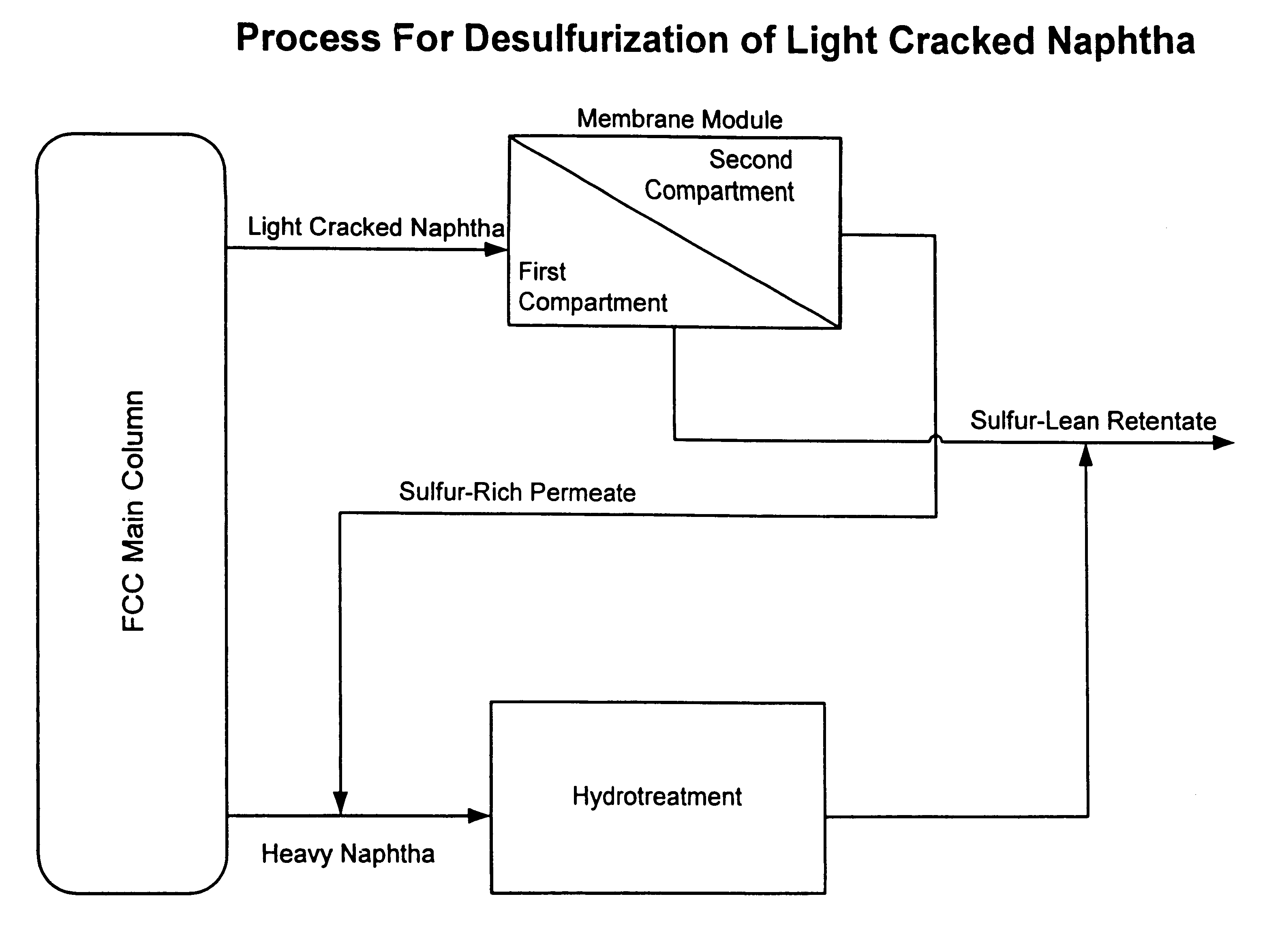

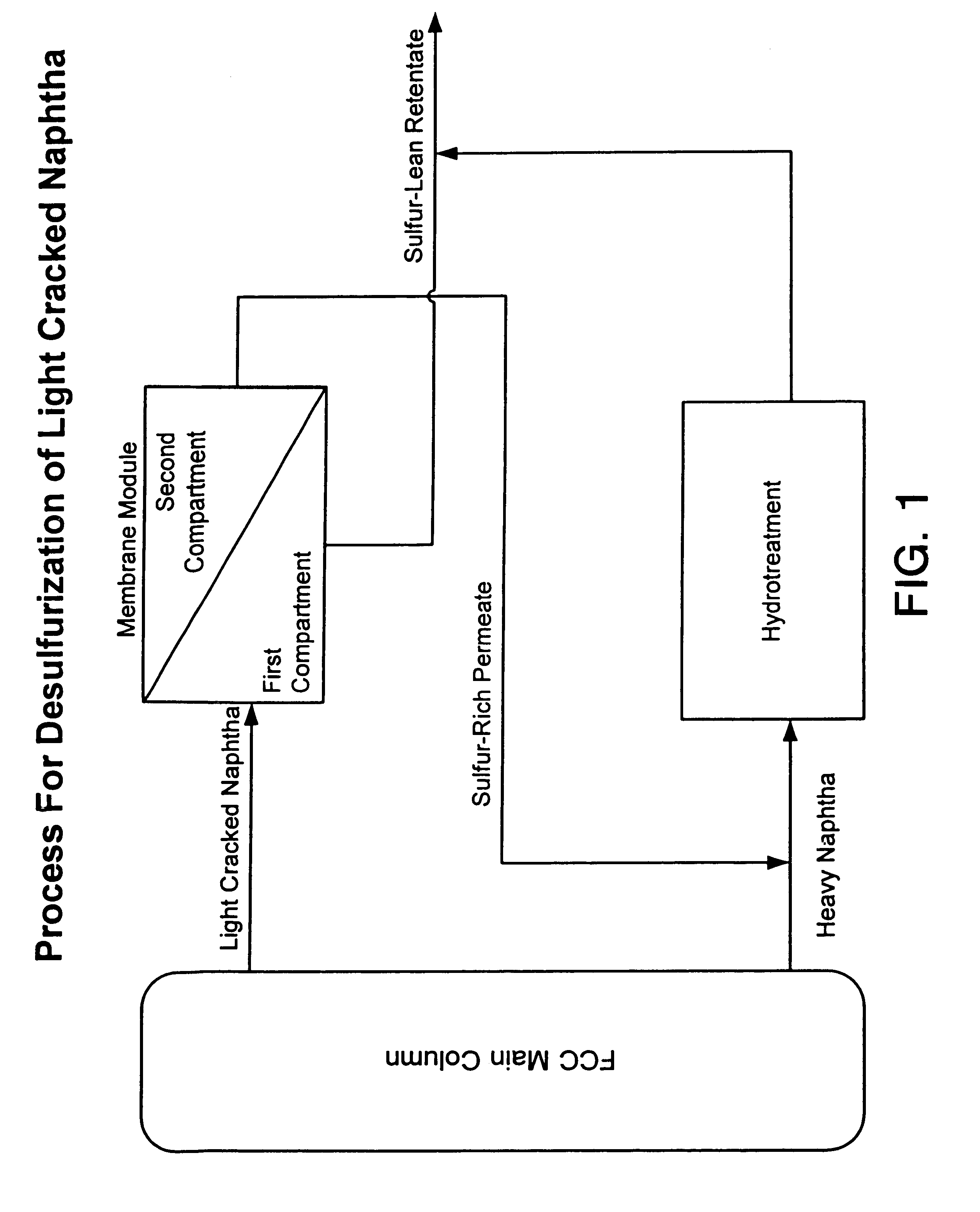

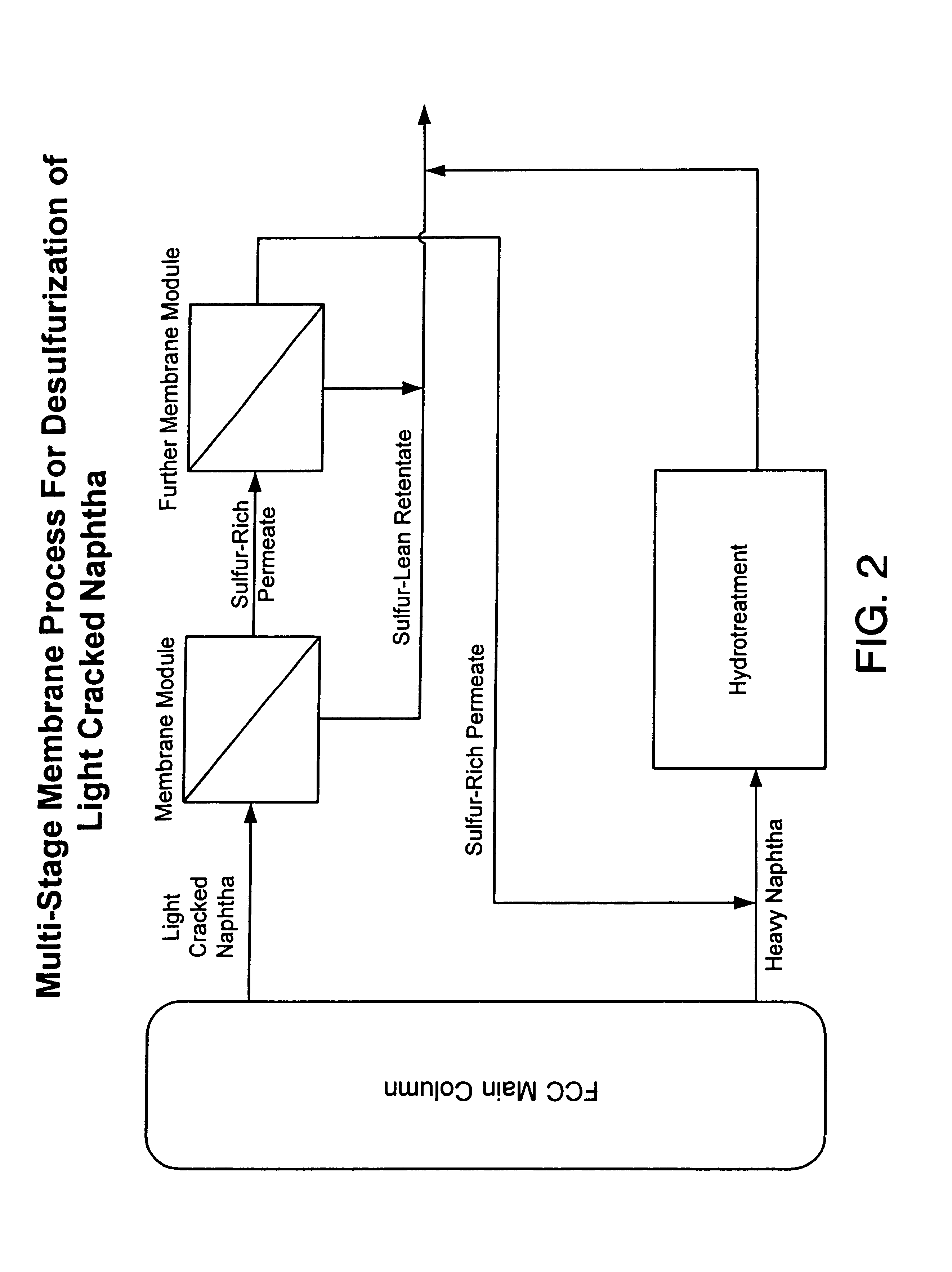

Membrane process for separating sulfur compounds from FCC light naphtha

InactiveUS6649061B2Ion-exchange process apparatusTreatment with plural serial stages onlyNaphthaHydrocarbon mixtures

A process for the separation of sulfur compounds from a hydrocarbon mixture using a membrane is provided. Preferred hydrocarbon mixtures are oil refining fractions such as light cracked naphtha. Membranes are composed of either ionic or non-ionic materials and preferentially permeate sulfur compounds over other hydrocarbons. A single or multi-stage membrane system separates the hydrocarbon mixture into a sulfur-rich fraction and a sulfur-lean fraction. The sulfur-lean fraction may be used in fuel mixtures and the sulfur-rich fraction may be further treated for sulfur reduction.

Owner:EXXON RES & ENG CO

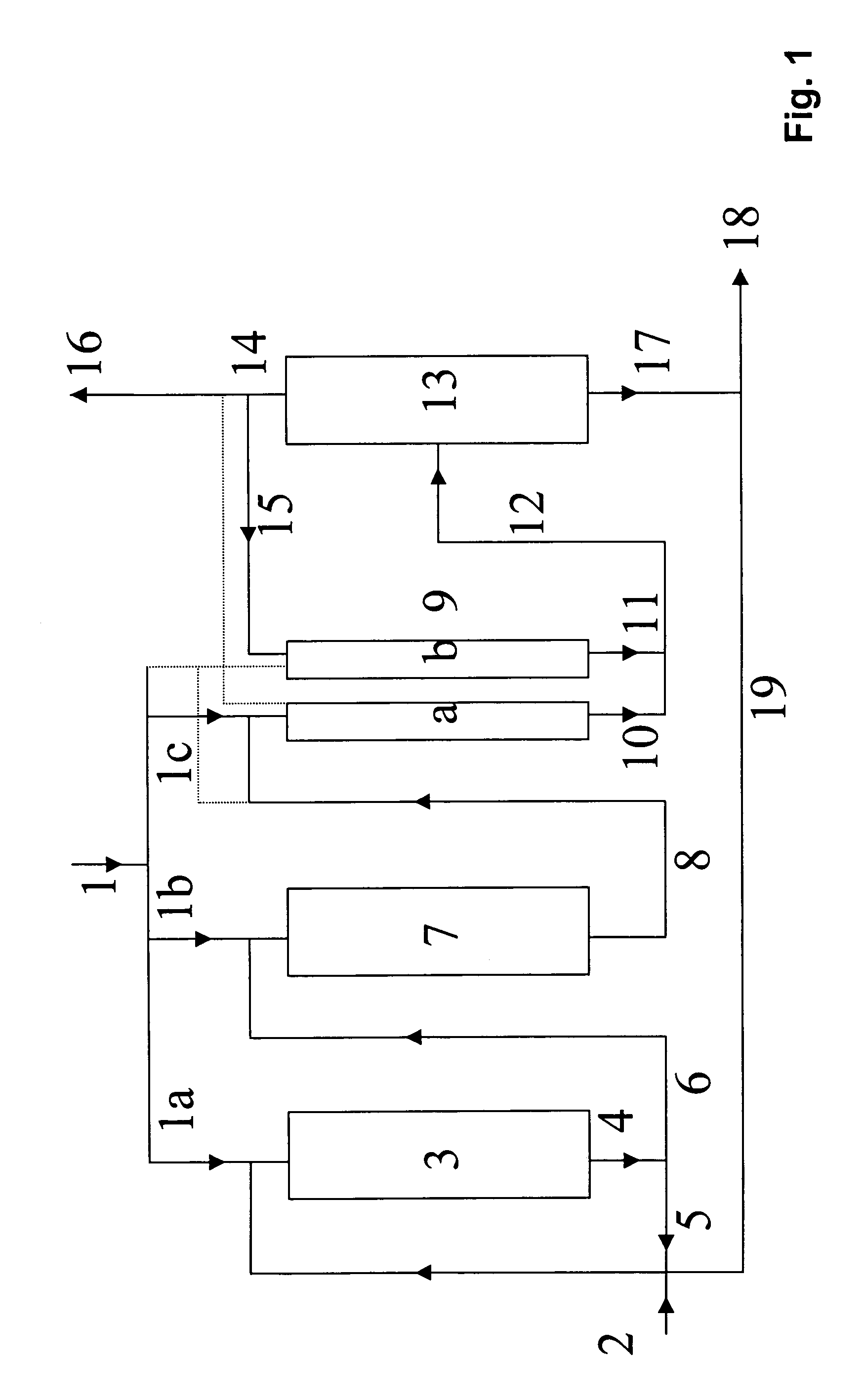

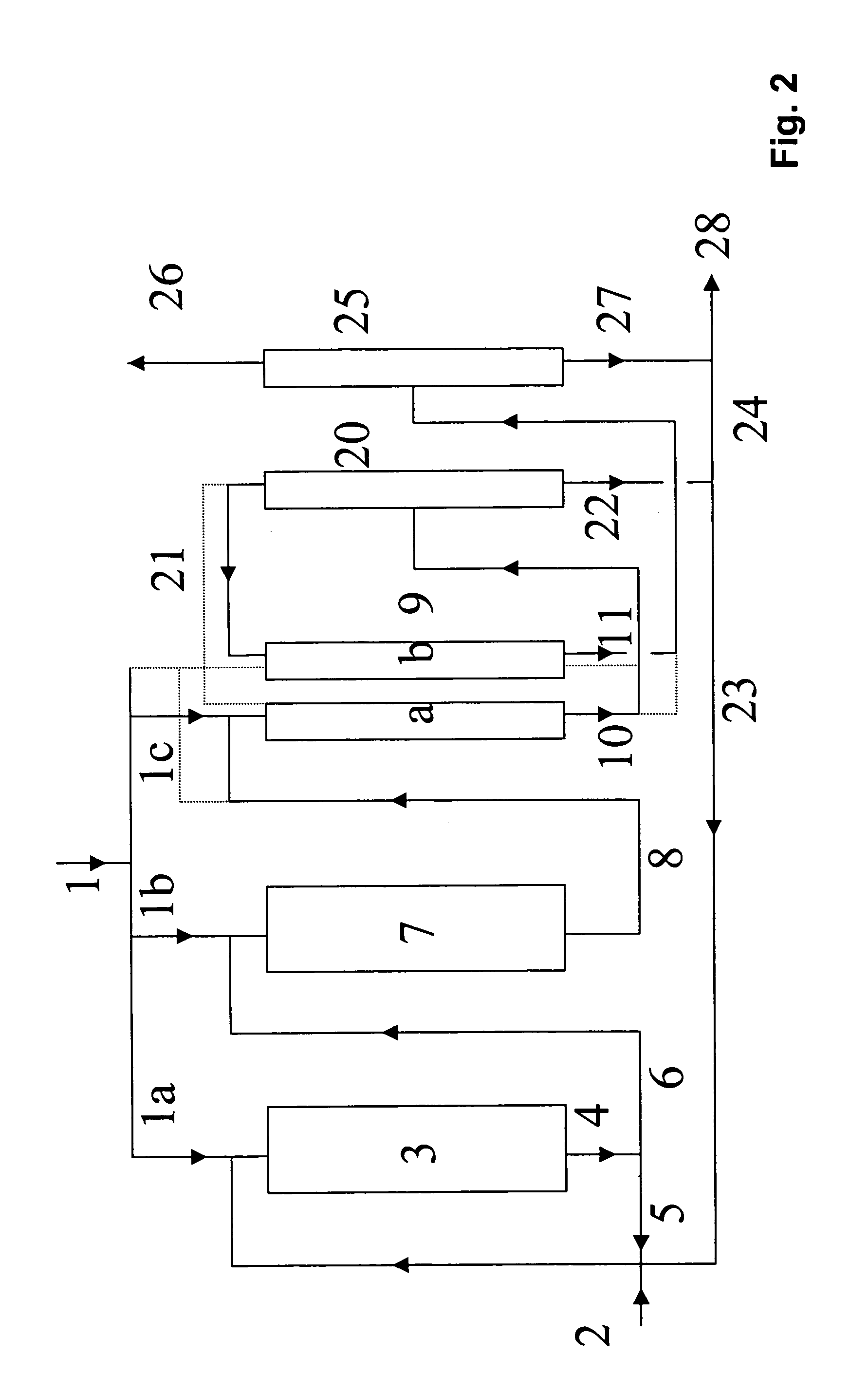

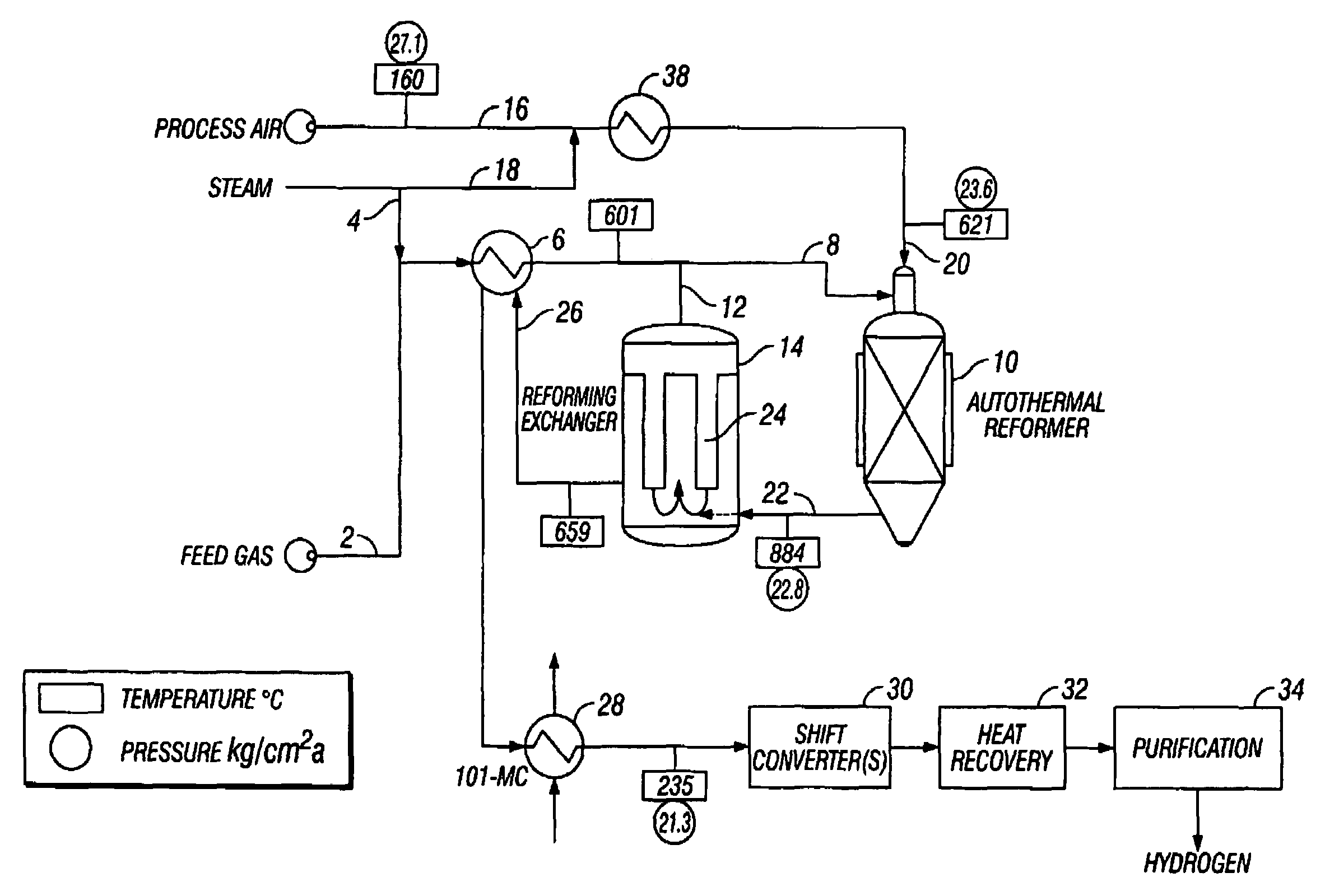

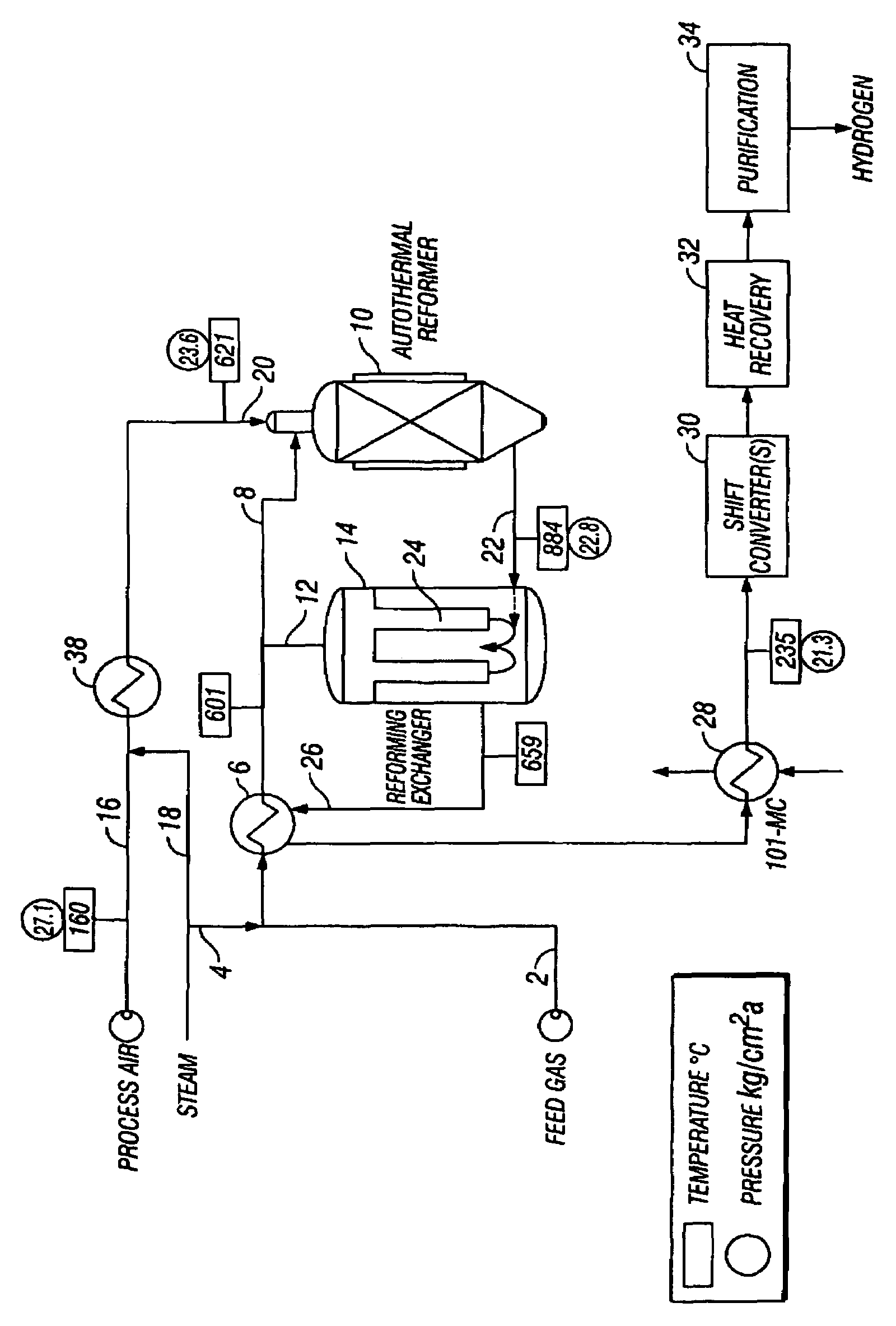

Autothermal reformer-reforming exchanger arrangement for hydrogen production

ActiveUS7220505B2Lower cost of capitalGreat ease of operationHydrogenHydrocarbon from carbon oxidesMethane reformerSyngas

Low-energy, low-capital hydrogen production is disclosed. A reforming exchanger 14 is placed in parallel with an autothermal reformer (ATR) 10 to which are supplied a preheated steam-hydrocarbon mixture. An air-steam mixture is supplied to the burner / mixer of the ATR 10 to obtain a syngas effluent at 650°-1050° C. The effluent from the ATR is used to heat the reforming exchanger, and combined reformer effluent is shift converted and separated into a mixed gas stream and a hydrogen-rich product stream. High capital cost equipment such as steam-methane reformer and air separation plant are not required.

Owner:KELLOGG BROWN & ROOT LLC

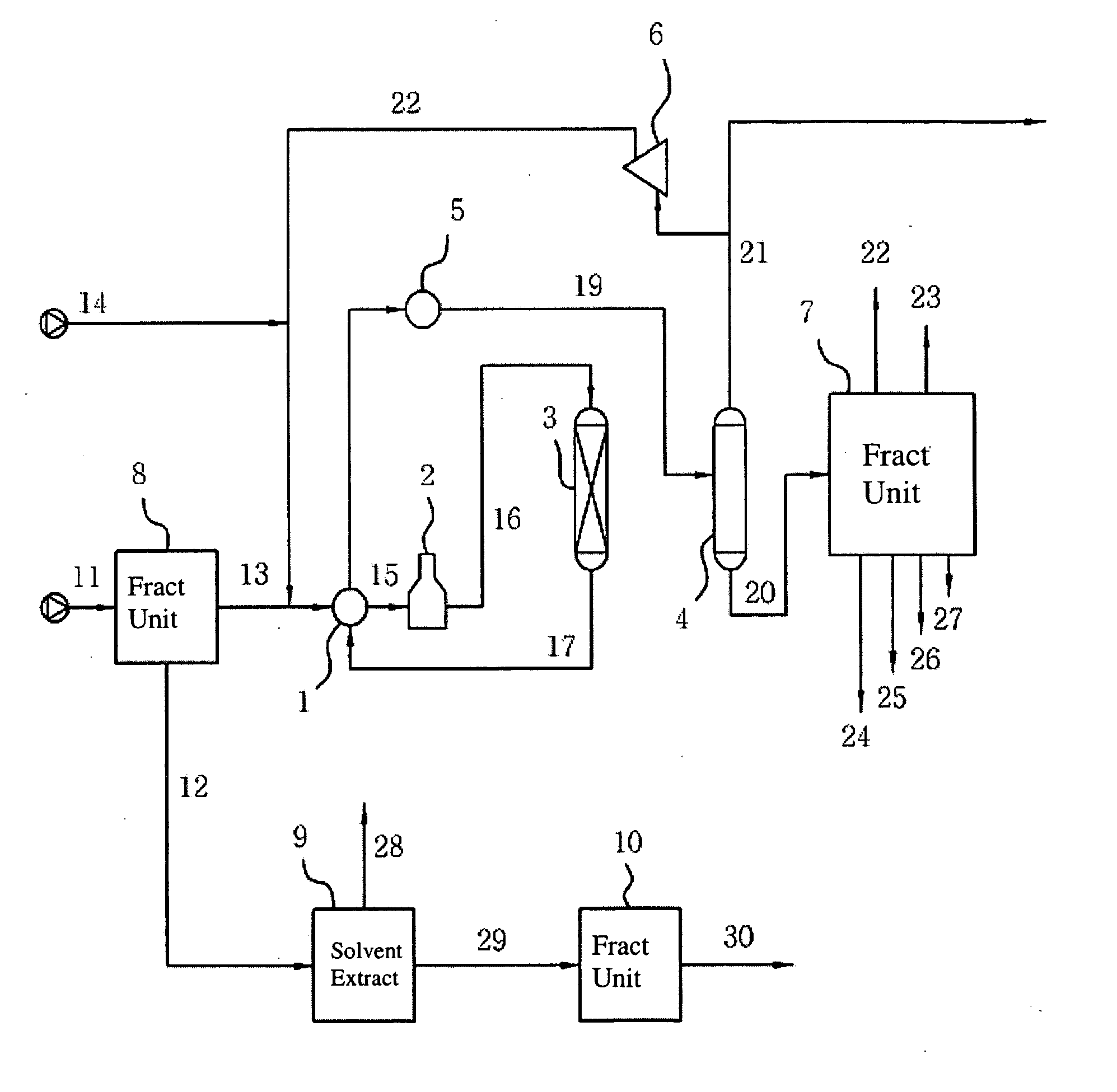

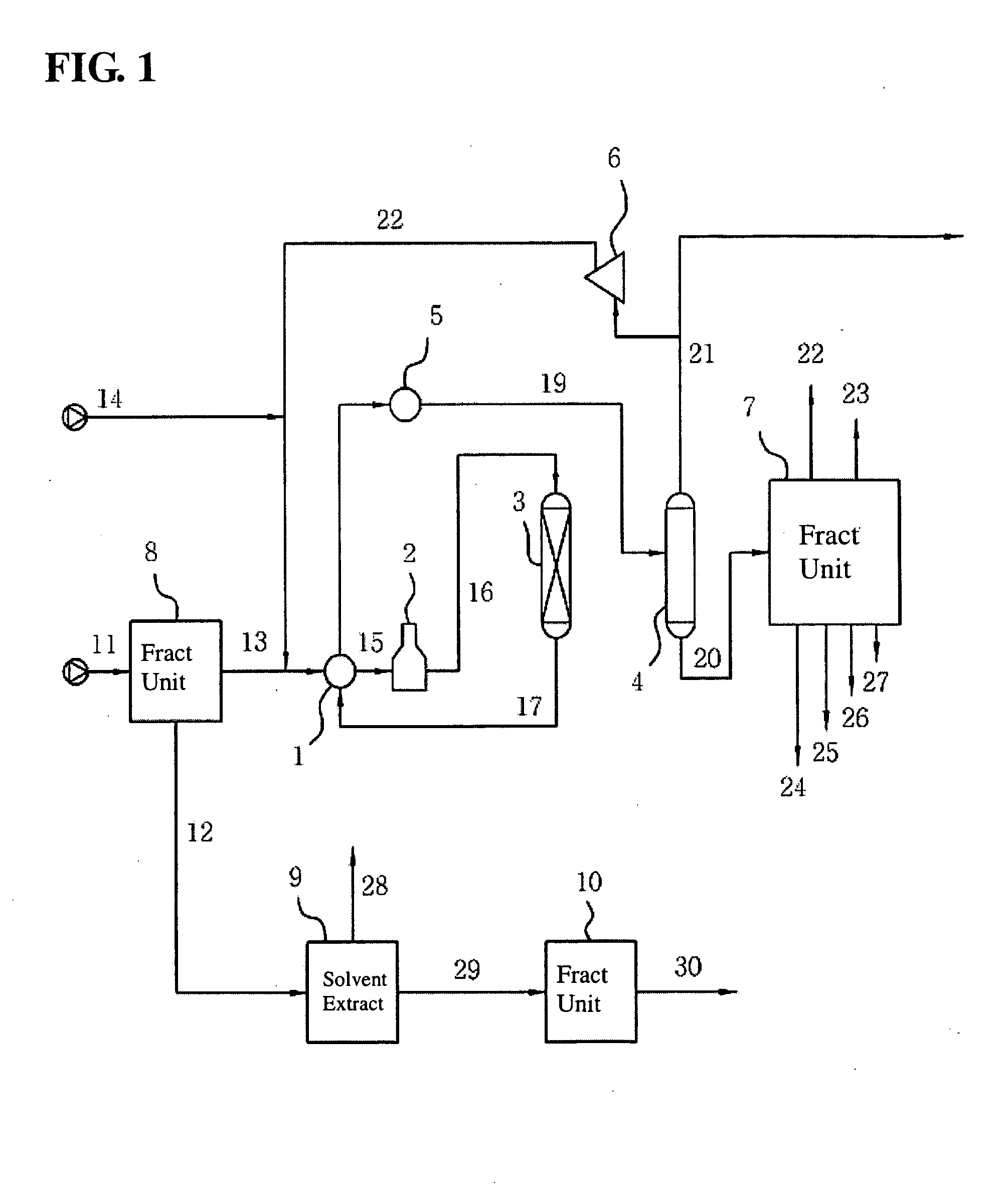

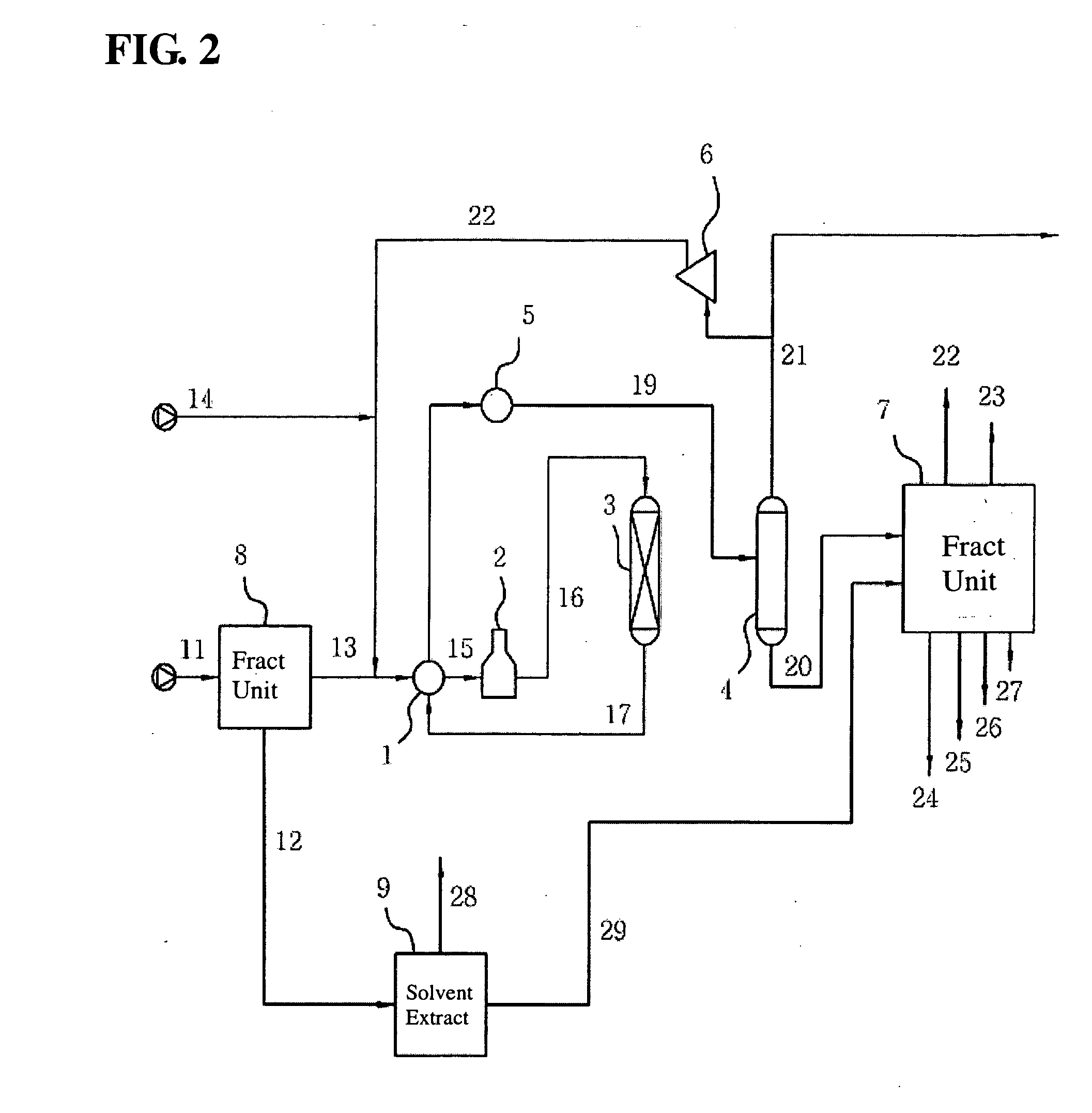

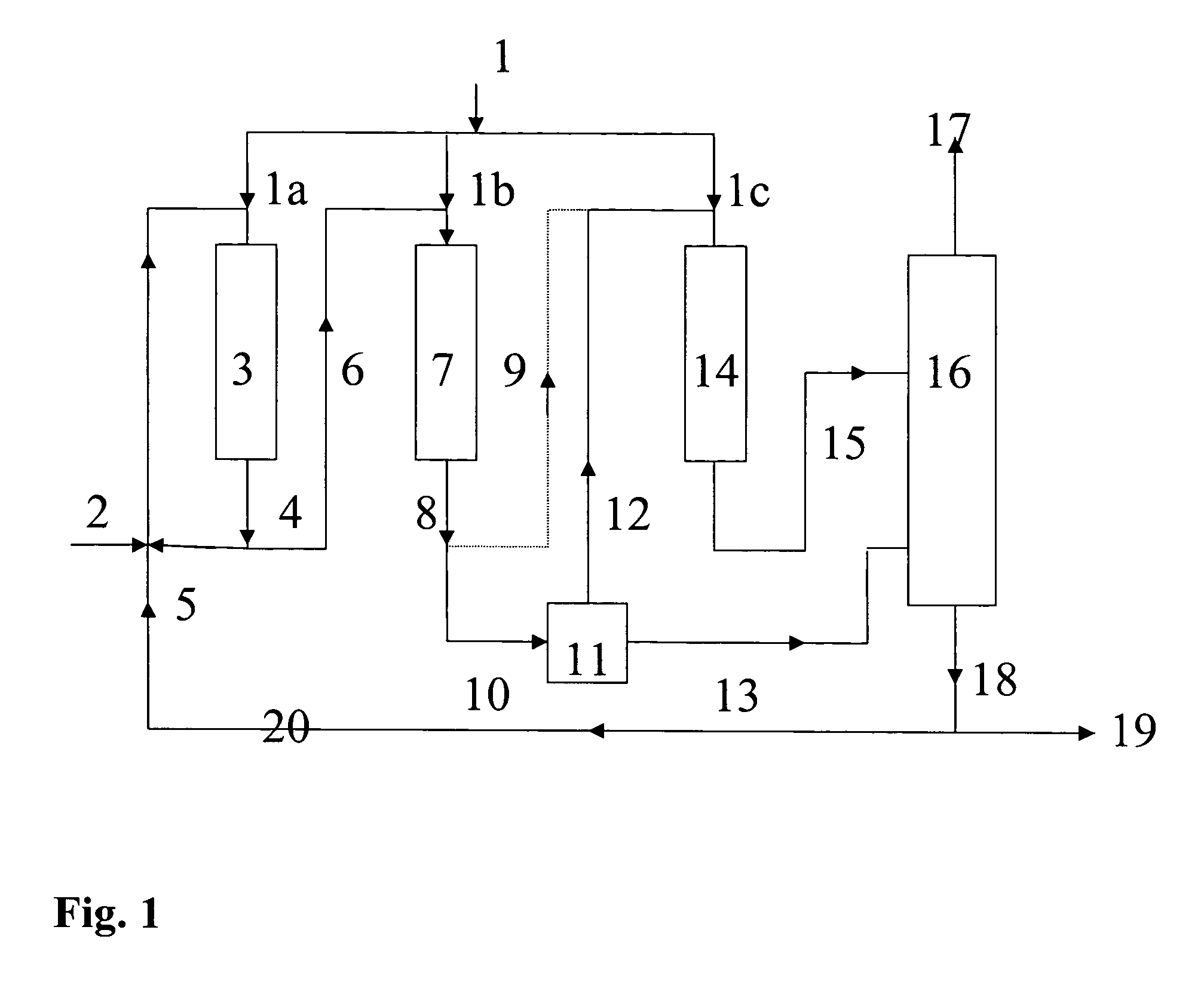

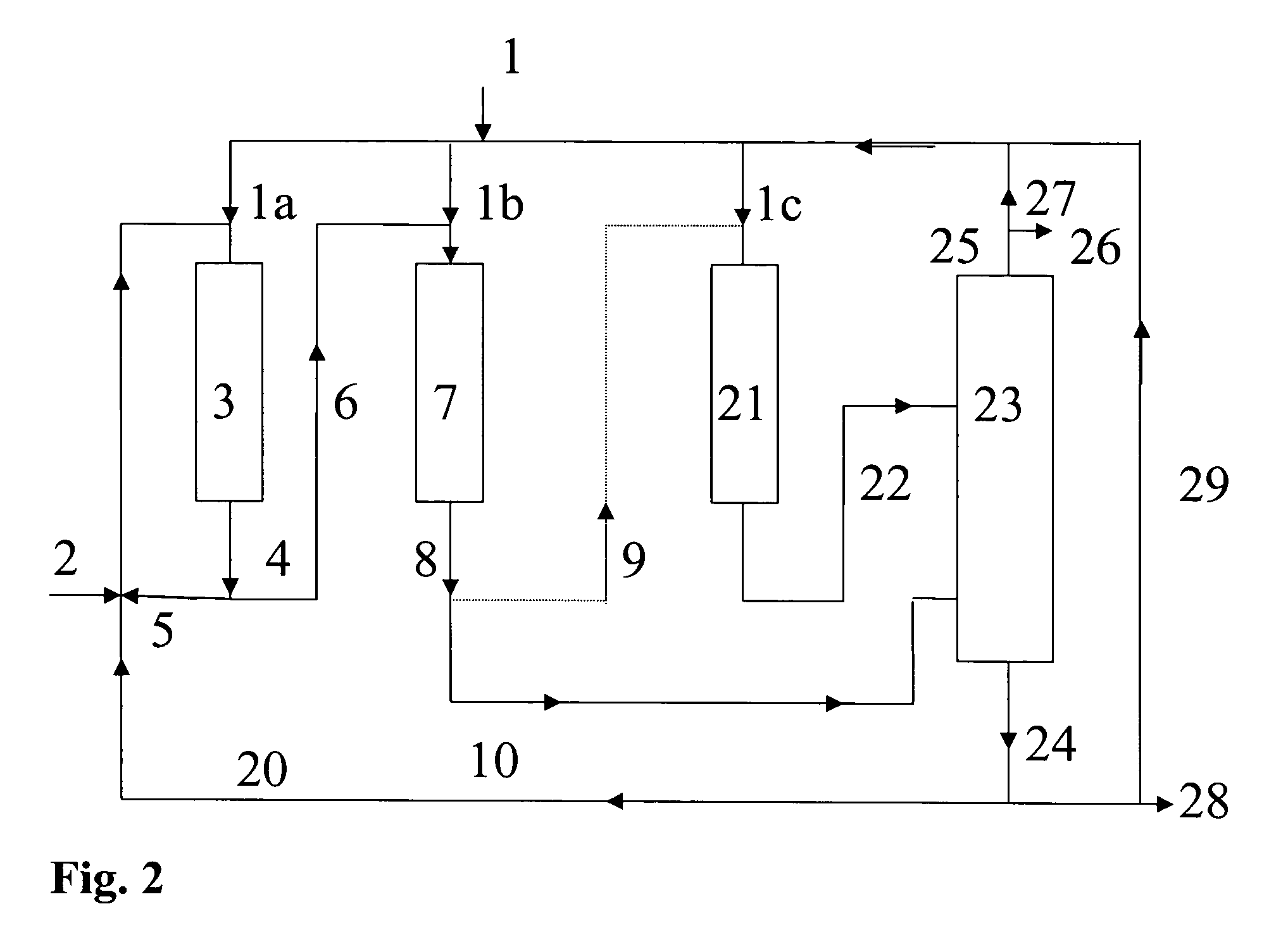

Process for increasing production of benzene from hydrocarbon mixture

ActiveUS20060287564A1Increase productivityImprove efficiencyHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonBenzeneHydrocarbon mixtures

A process for increasing the production of benzene from a hydrocarbon mixture. A process for producing an aromatic hydrocarbon mixture and liquefied petroleum gas (LPG) from a hydrocarbon mixture, and a solvent extraction process for separating and recovering polar hydrocarbons from a hydrocarbon mixture containing polar hydrocarbons (that is, aromatic hydrocarbons) and nonpolar hydrocarbons (that is, non-aromatic hydrocarbons) are integrated, thereby it is possible to increase the production of benzene.

Owner:SK INNOVATION CO LTD

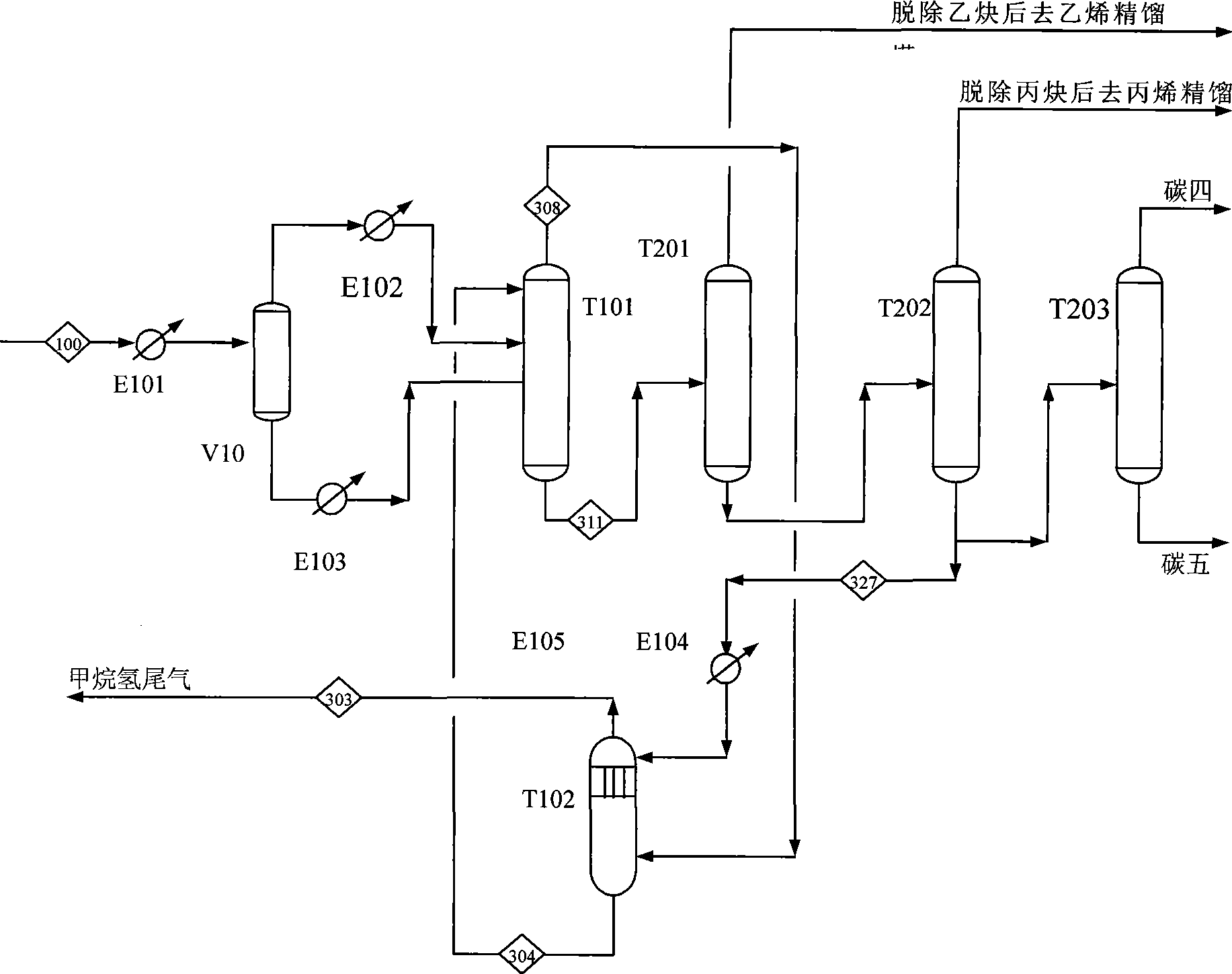

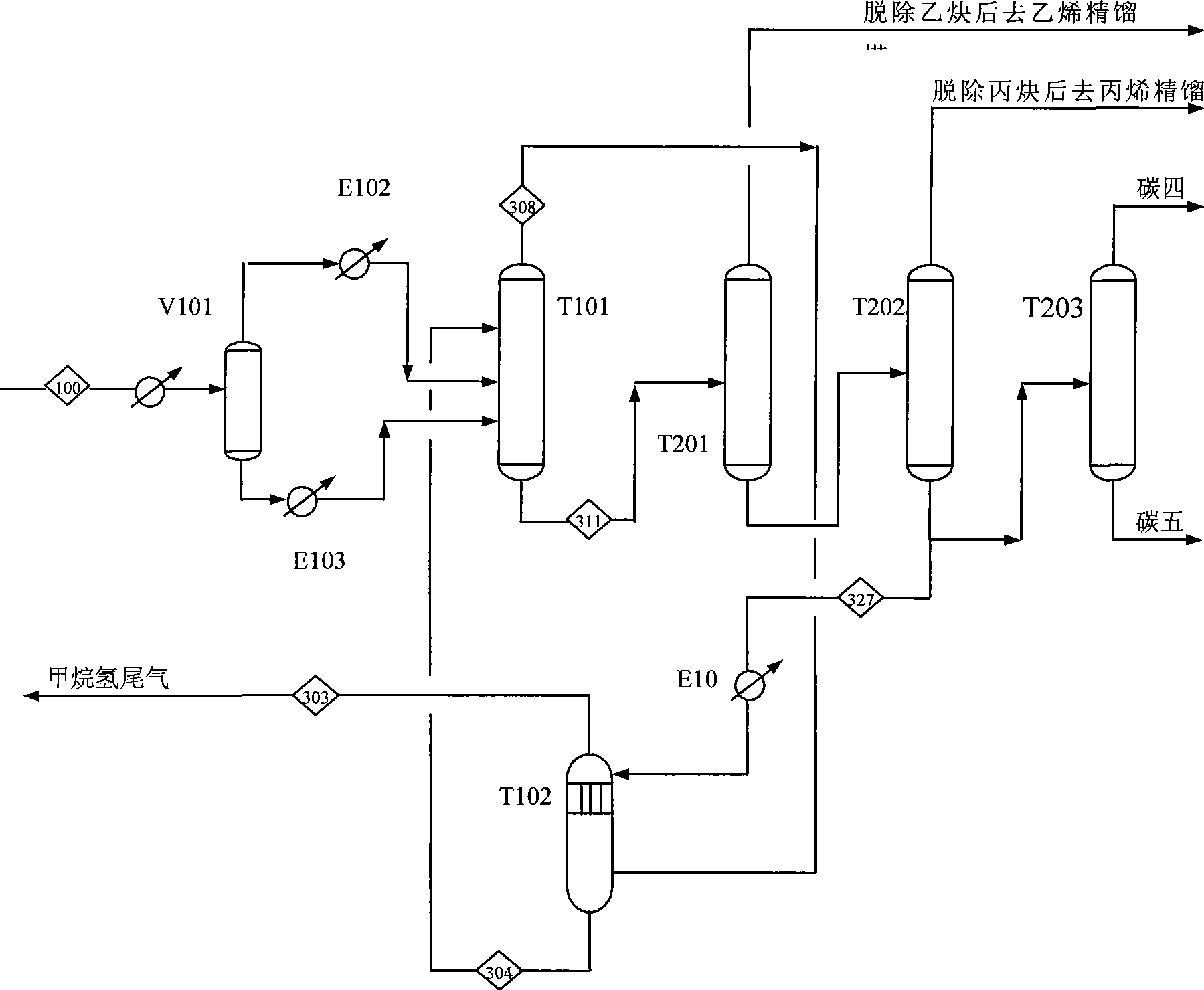

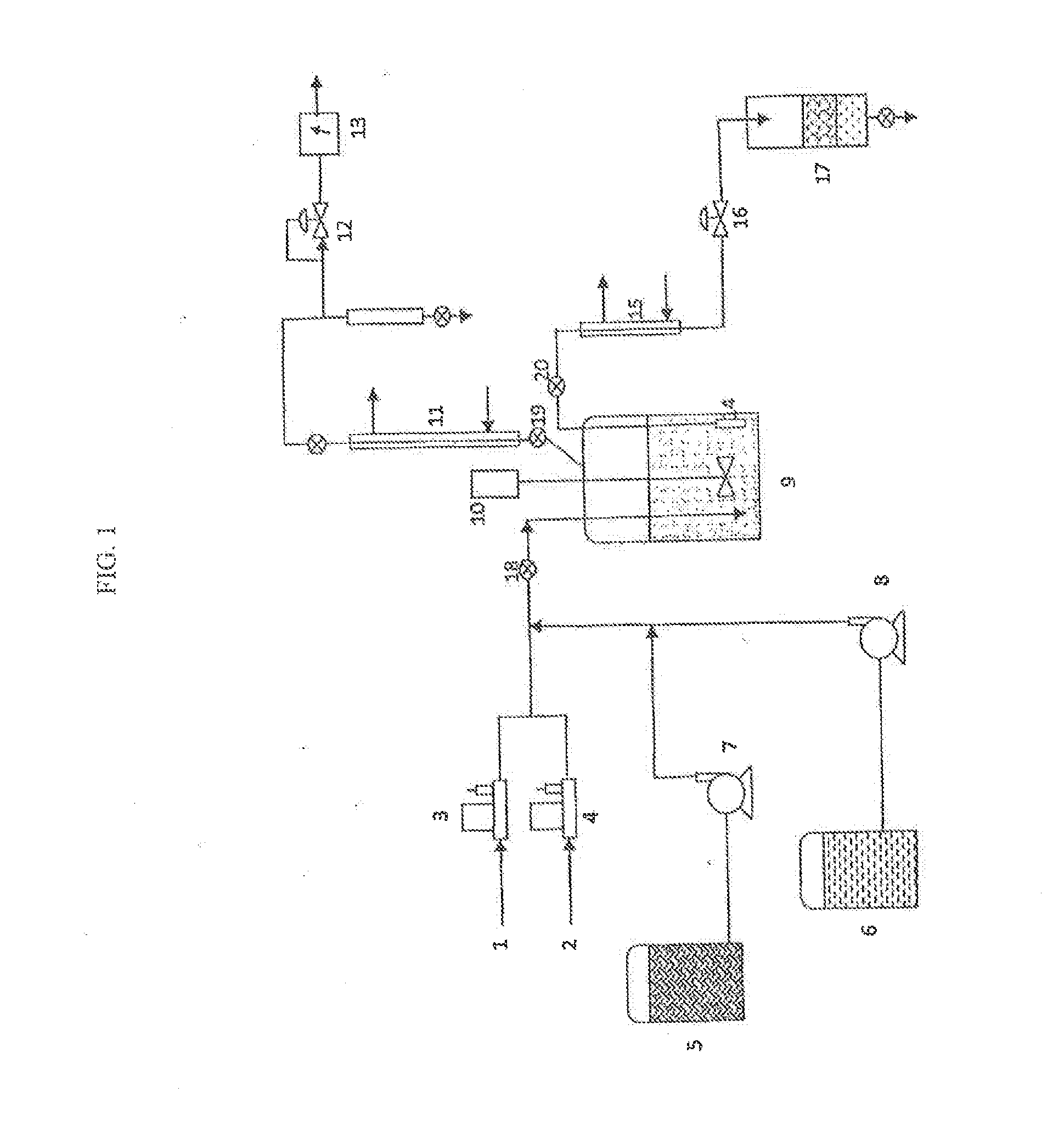

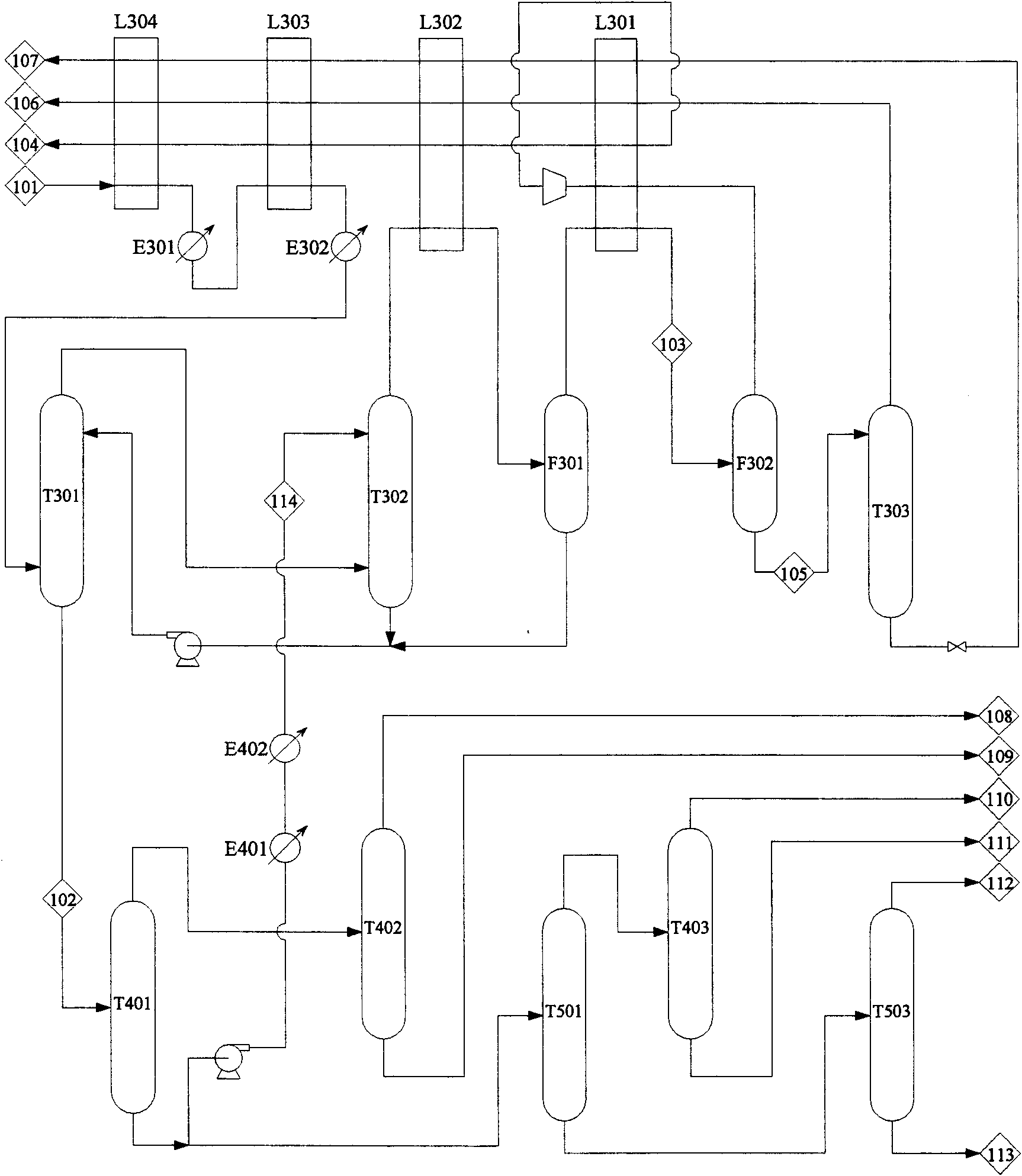

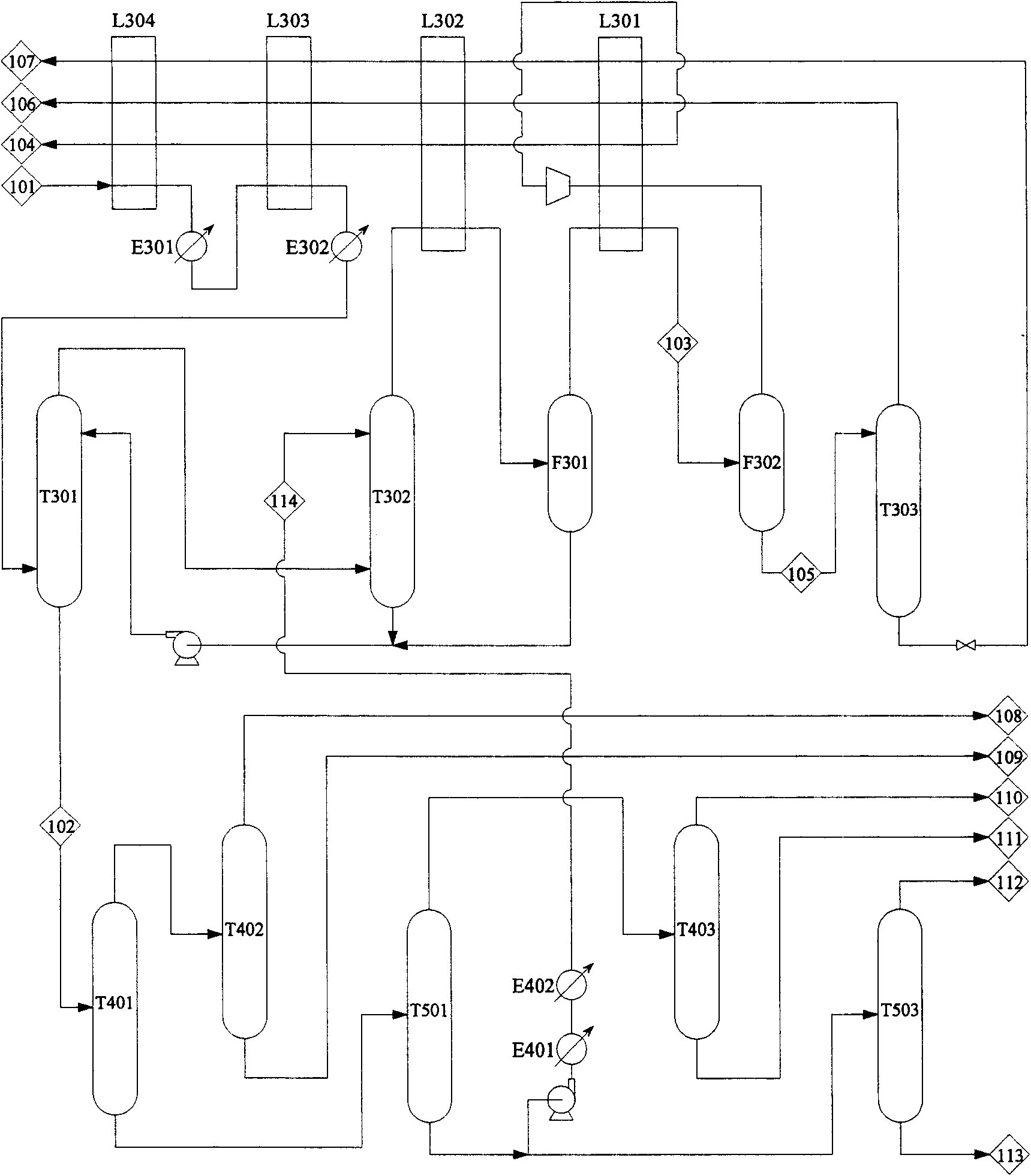

Method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption

ActiveCN101445419AHigh recovery rateLess investmentDistillation purification/separationAbsorption purification/separationHydrocarbon mixturesDistillation

The invention relates to a method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption, comprising the steps as follows: (1) pre-disposed gas at the outlet of a reactor is cooled to the temperature ranging from 10 DEG C to -37 DEG C and sent to a pre-cutting tower; (2) the gas at the outlet of the pre-cutting tower is sent to an absorption tower and C1 and C2 in the gas are separated by taking C3 or C4 or C5 or C6 or hydrocarbon mixtures as absorbent; (3) outcomes generated at the bottom of the absorption tower are sent to the pre-cutting tower; with C2 distillate further absorbed and methane and lighter components removed in the pre-cutting tower, the outcome is sent to a deethanizer so that the C2 and C3 are clearly cut. Compared with the prior art, the method has the advantages of little investment, low energy dissipation, high material recovery rate, simple operation, small maintenance quantity, reliable running, requiring no ethane refrigerant compressor, and the like.

Owner:WISON ENG

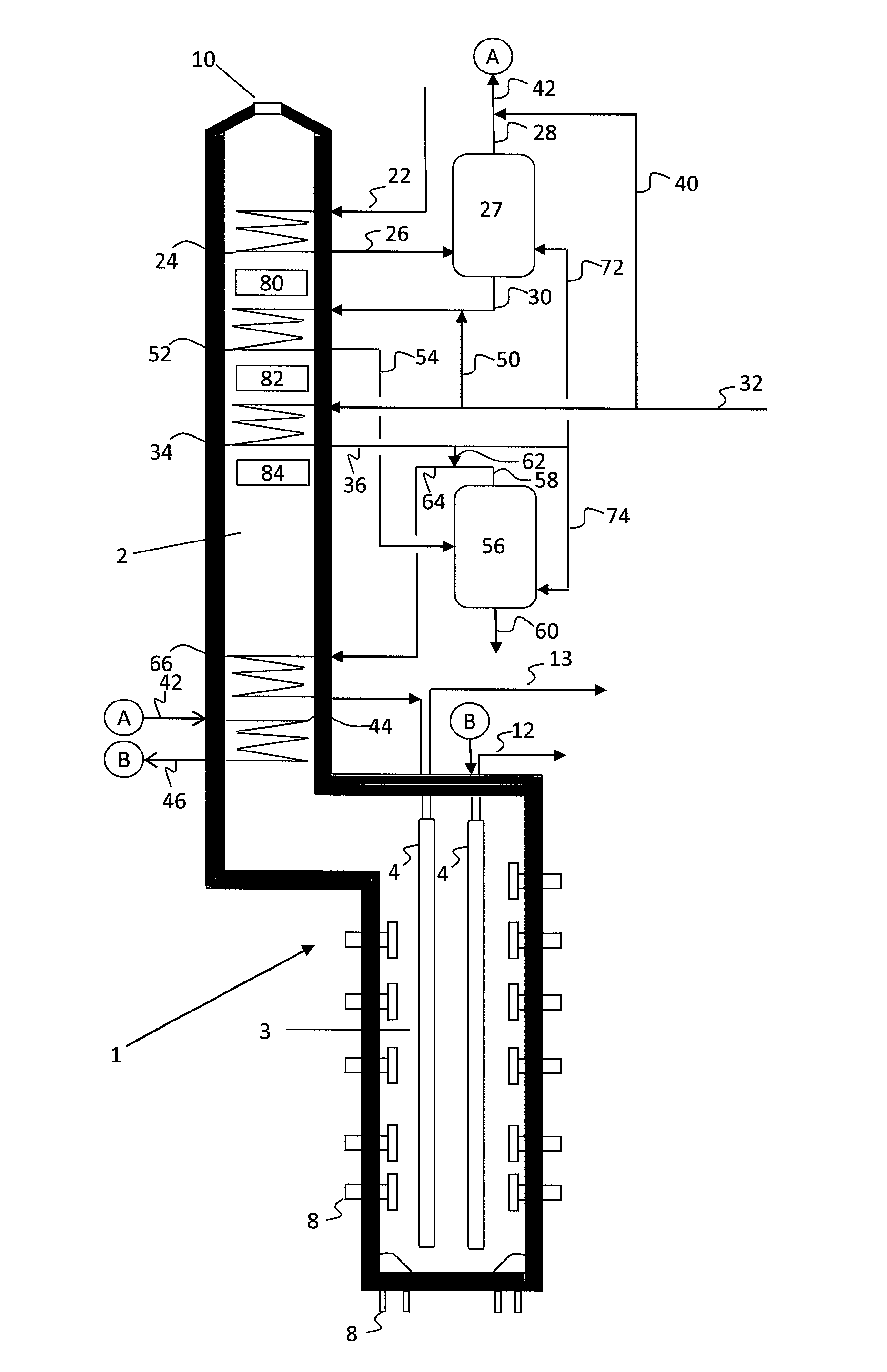

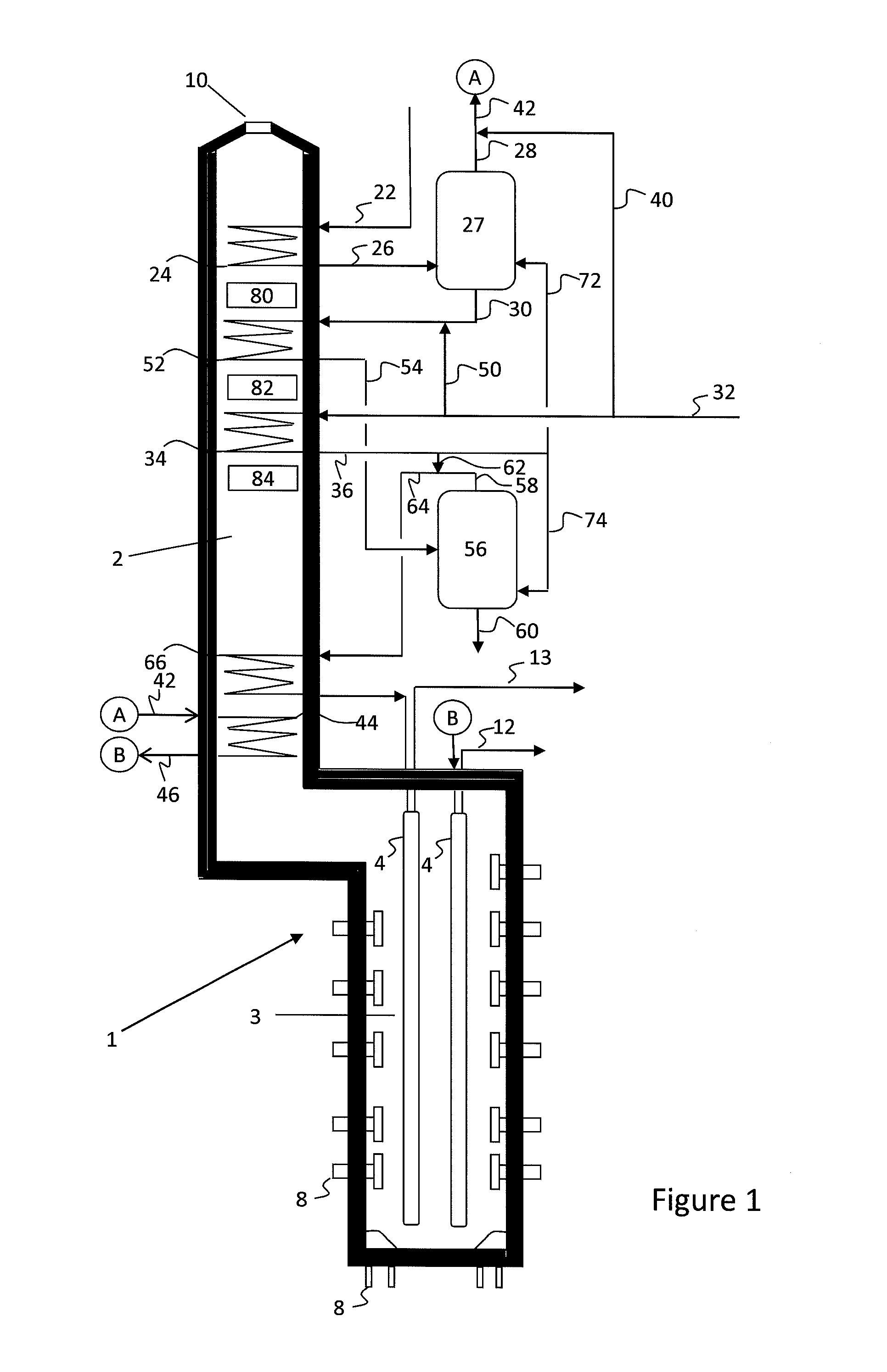

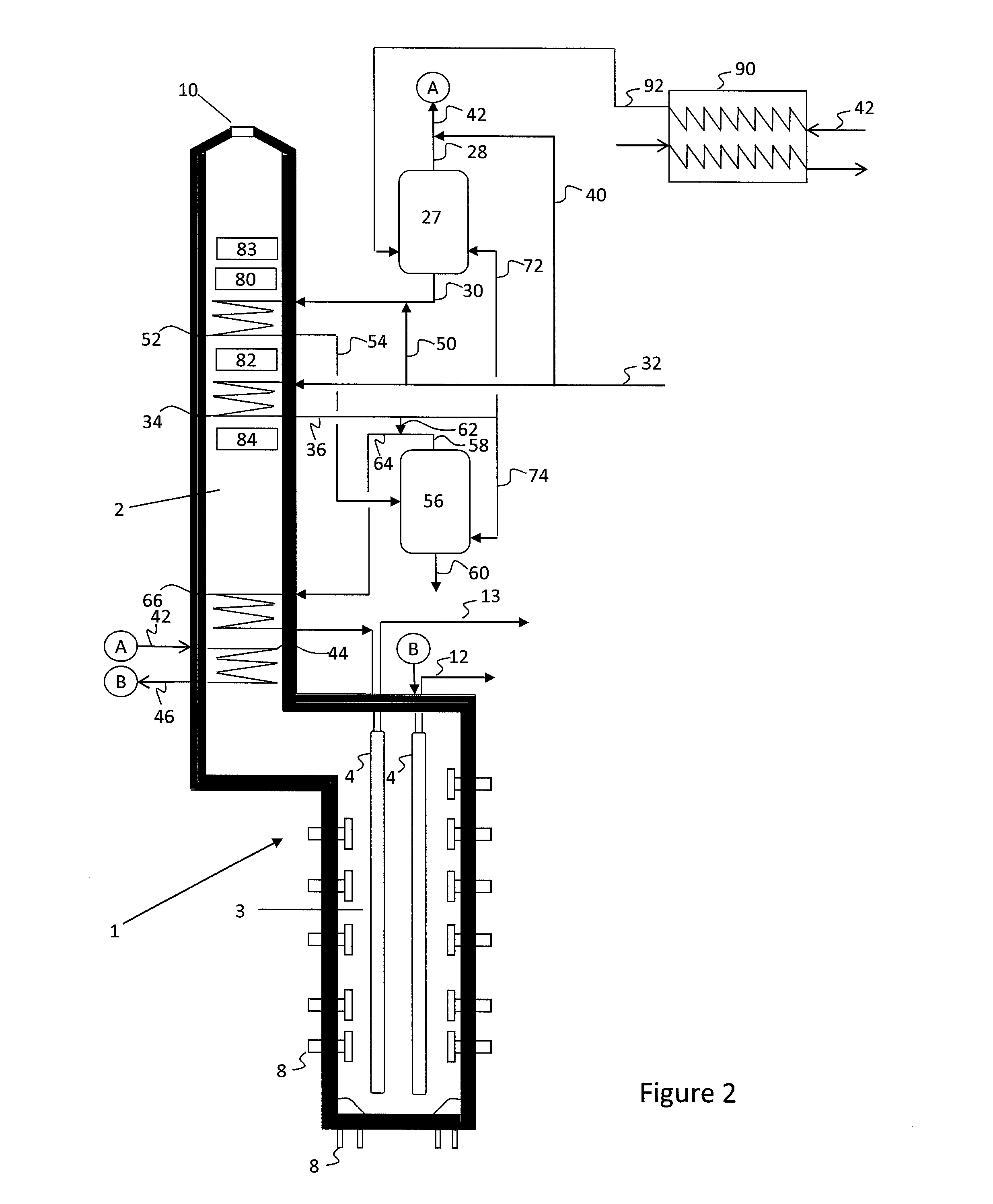

Thermal cracking of crudes and heavy feeds to produce olefins in pyrolysis reactor

ActiveUS20160097002A1Alleviate cokingReduce foulingThermal non-catalytic crackingTreatment with plural serial stages onlyHydrocarbon mixturesReactor system

Systems and processes for efficiently cracking of hydrocarbon mixtures, such as mixtures including compounds having a normal boiling temperature of greater than 450° C., 500° C., or even greater than 550° C., such as whole crudes for example, are disclosed.

Owner:LUMMUS TECH LLC

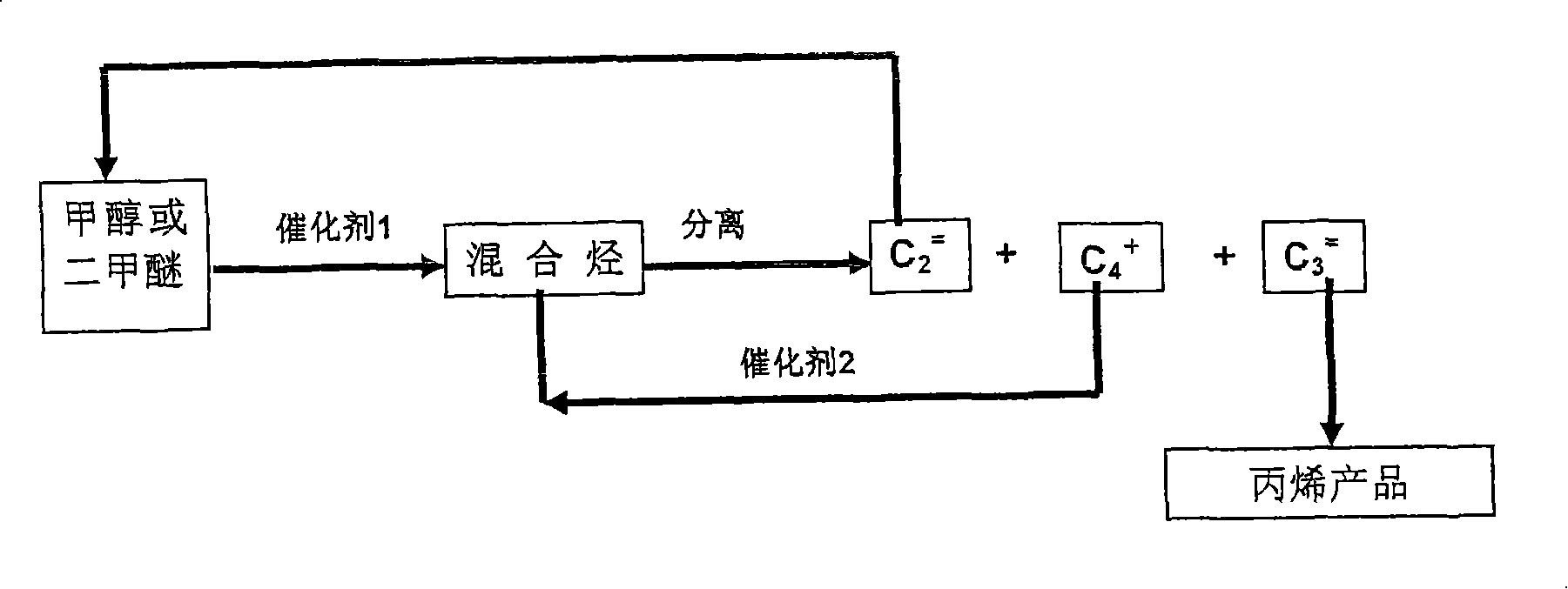

Method for producing propylene by carbinol or dimethyl ether

ActiveCN101177374AHighly selective preparationHydrocarbon from oxygen organic compoundsEthylene productionHydrocarbon mixturesMoving bed

The invention relates to a method for preparing olefin by methanol or dimethyl ether, in particular to a high selectivity preparation method of propylene, which comprises a conversion reaction of methanol or dimethyl ether, alkylation of methanol and ethylene and a catalytic cracking reaction of a plurality of heavy components above C4. A hydrocarbon mixture rich in propylene is generated by preheated material contacting with a first catalyst in a circulating fluidized bed or a moving bed reactor. After the propylene is separated from the hydrocarbon mixture, a plurality of light components of the hydrocarbon mixture comprising hydrogen and methane return to a methanol conversion reactor, the propylene is generated by the alkylation of methanol and ethylene in the light components. The invention is characterized in that the C4 and the heavy components above C4 separated from separation system are contacted with cracking catalyst in the circulating fluidized bed, generating hydrocarbonmixture contained ethylene, propylene and other light components by the catalytic cracking reaction, then the hydrocarbon mixture returns to the separation system for obtaining propylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Processing for eliminating sulfur-containing compounds and nitrogen-containing compounds from hydrocarbon

InactiveUS7198712B2Increase contentReduce sulfur contentPhysical/chemical process catalystsElectrolysis componentsSolubilityPhosphonium

For desulfurization and, if necessary, for denitrification of hydrocarbon fractions the hydrocarbon mixture is brought into contact with a non-aqueous ionic liquid of general formula Q+A−, wherein Q+ is a ammonium, phosphonium or sulfonium cation, that contains at least one alkylating agent of the formula RX−, making it possible to form ionic sulfur-containing derivatives (and, if necessary, nitrogen-containing derivatives) that have a preferred solubility in the ionic liquid; and the ionic liquid is separated from the hydrocarbon mixture that is low in sulfur and nitrogen by decanting.

Owner:INST FR DU PETROLE

Methods of upgrading biooil to transportation grade hydrocarbon fuels

InactiveUS20140288338A1Lower cost of capitalReduce operating costsHydrocarbon by hydrogenationHydrocarbon from oxygen organic compoundsHydrocarbon mixturesHydrogen

The present invention relates to the field of biomass derived fuels. It further relates to thermochemical production of liquids (biooils) from biomass. Specifically the present invention relates to methods of upgrading biooil. More specifically it relates to a method for upgrading biooil comprising contacting a dispersed mixture of hydrocarbon liquids, biooil, and partially upgraded biooil, with a transition metal containing catalyst and hydrogen gas at a temperature of around 330° C. and a pressure of about 1700 psi (11.7 MPa) for a period of time sufficient to reduce the oxygen content of the biooil such that it separates on cooling into an aqueous phase and an organic phase, and optionally, to further subject the organic phase to hydrotreating, hydrocracking or catalytic cracking to produce a mixture of hydrocarbons boiling in the range of gasoline, diesel and jet fuel.

Owner:INST FR DU PETROLE +2

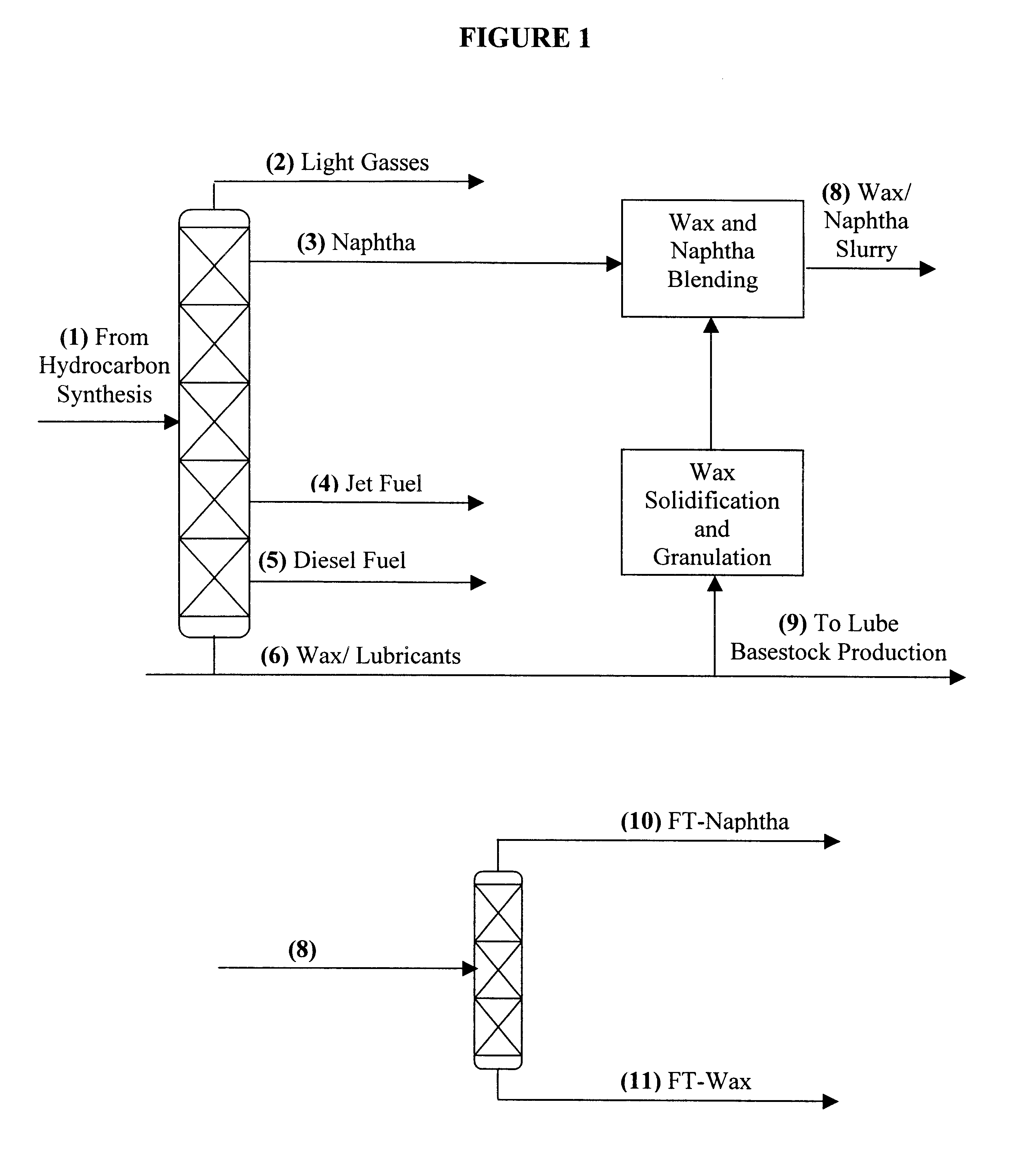

Fischer-Tropsch wax and hydrocarbon mixtures for transport (law938)

The invention is a process for producing a mixture of Fischer-Tropsch product that is solid at ambient conditions (between 32° F. and 95° F.), such as wax, and hydrocarbon liquid, such as naphtha, that can be pumped at ambient temperature (between 32° F. and 95° F.). The temperature of the mixture is controlled below the melting point of the Fischer-Tropsch product. The present invention provides for the transport of Fischer-Tropsch product from a remote location in a readily available medium, such as naphtha, via pipeline, tanker or railcar. At the completion of the transport, the hydrocarbon liquid and Fischer-Tropsch product are separated by conventional methods such as flashing, distillation, or filtration with minimal contamination from the hydrocarbon liquid.

Owner:EXXON RES & ENG CO

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

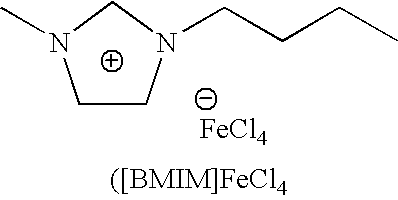

Desulfurization of hydrocarbons by ionic liquids and preparation of ionic liquids

ActiveUS20090288992A1Improve efficiencyShort timeOrganic chemistryOther chemical processesHydrocarbon mixturesPyridinium

The present invention relates to an ionic liquid compound of general formula C+A−, where C+ represents an organic cation such as alkyl-pyridinium, di-alkyl imidazolium and tri-alkyl imidazolium; and A− is an anion of halides of iron (III), such as, for example, FeCl4− and to a method of producing the ionic liquid compound by heating the reactants using microwave energy. The ionic liquids can be used to desulfurize hydrocarbon mixtures by a liquid-liquid extraction.

Owner:INST MEXICANO DEL GASOLINEEO

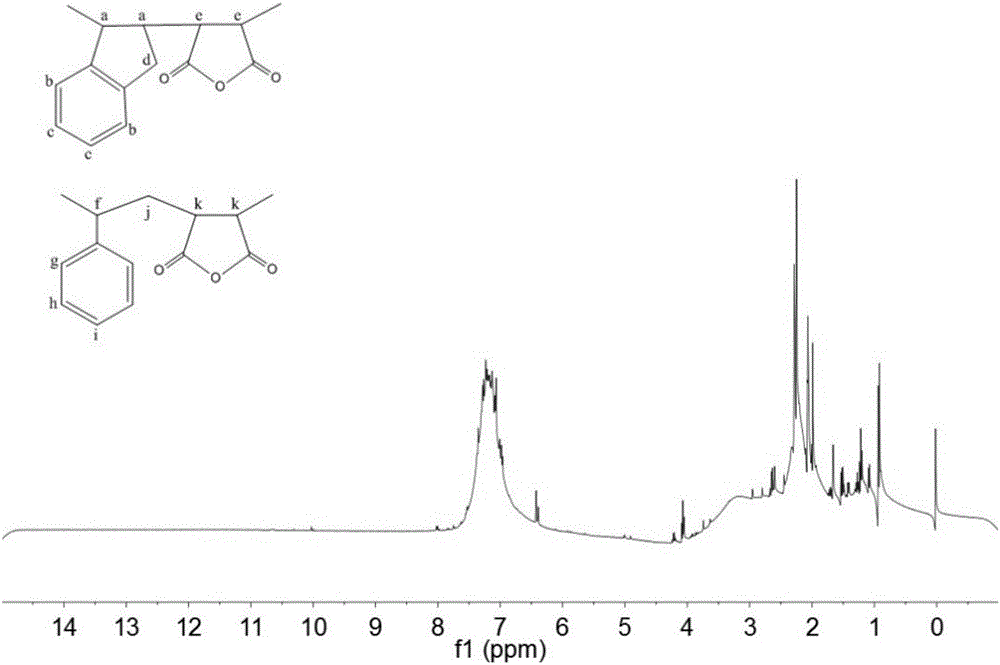

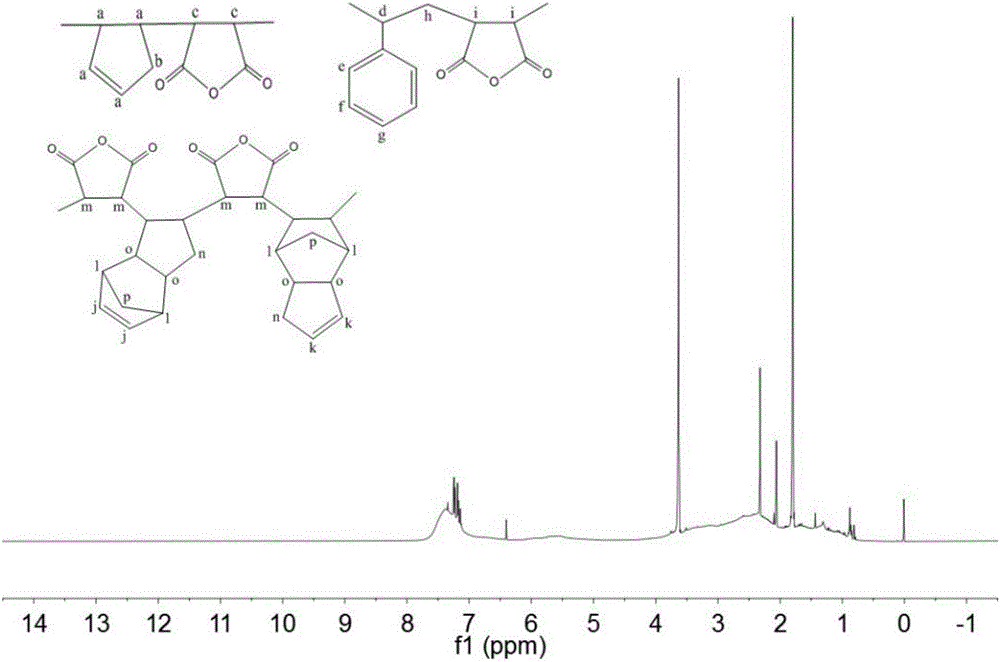

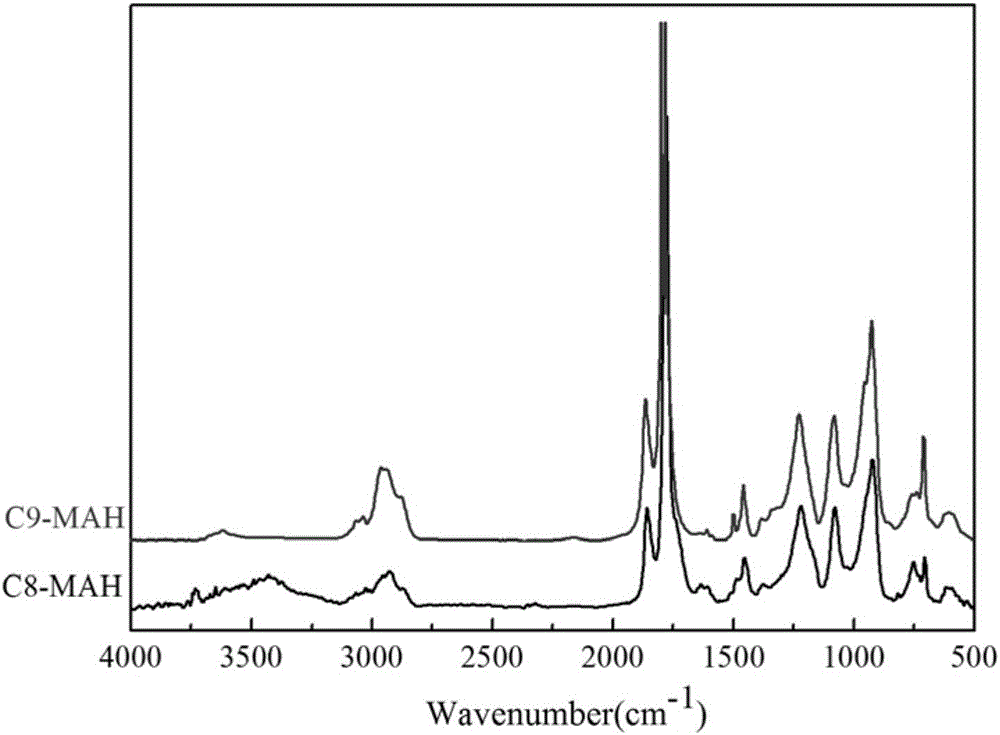

Functional copolymer directly prepared from higher olefin mixture and preparation method

ActiveCN105949388AOvercome difficultyOvercoming issues that limit its applicationHydrocarbon mixturesNitrogen

The invention relates to a functional copolymer directly prepared from higher olefin mixture and a preparation method, and belongs to the field of application of petroleum resources. The preparation method includes: under the condition of nitrogen protection, adding one or more of MAH (maleic anhydride), maleimide and derivatives thereof and itaconic anhydride as well as oil soluble free radical initiator into selected solvent to be fully dissolved, then adding one or more of C8 and C9 fraction and light fraction of coal tar into the system to be mixed evenly, performing reaction at the temperature of 60-120 DEG C, and after reaction is finished, performing separating and drying to obtain the functional copolymer formed by copolymerization of olefin components and maleic anhydride in the mixture. C8 and C9 fraction and light fraction of coal tar are taken raw materials directly to be subjected to one-step reaction for preparing the copolymer comprising functional radicals, the process is simple, reaction conditions are mild, preparation efficiency is high, the prepared copolymer and non-polymerization components are easy to separate, the copolymer is high in functional radical content, and resources of C8 and C9 fraction and light fraction of coal tar can be utilized reasonably and effectively.

Owner:BEIJING UNIV OF CHEM TECH

Obtaining tert-butanol

InactiveUS7026519B2Speed up the conversion processImprove viabilityOrganic compound preparationOrganic chemistry methodsHydrocarbon mixturesChemistry

The invention relates to a process for preparing tert-butanol (TBA) by reacting isobutene-containing hydrocarbon mixtures with water over acidic solid catalysts in a plurality of reactors, wherein the conversion is increased upstream of the last reactor by removing a portion of the TBA present in the reaction mixture.

Owner:EVONIK DEGUSSA GMBH

Olefin production from low sulfur hydrocarbon fractions

InactiveUS20030135077A1Thermal non-catalytic crackingLiquid hydrocarbon mixture productionSyngasHydrocarbon mixtures

Provided is a process for converting methane at a remote natural gas site into ethylene and other products. Methane is converted into syngas which is converted into a low-sulfur liquid hydrocarbon mixture containing less than 1 ppm sulfur via Fischer-Tropsch (FT) syntheses. The low-sulfur Fischer-Tropsch liquids are transferred from the remote site to an existing facility where a sulfur-containing compound or a sulfur-containing hydrocarbon mixture is added to avoid coking problems. The resultant blend of hydrocarbons which has a sulfur content of at least 1 ppm, is fed to a naphtha cracking unit and ethylene recovered.

Owner:CHEVROU USA INC

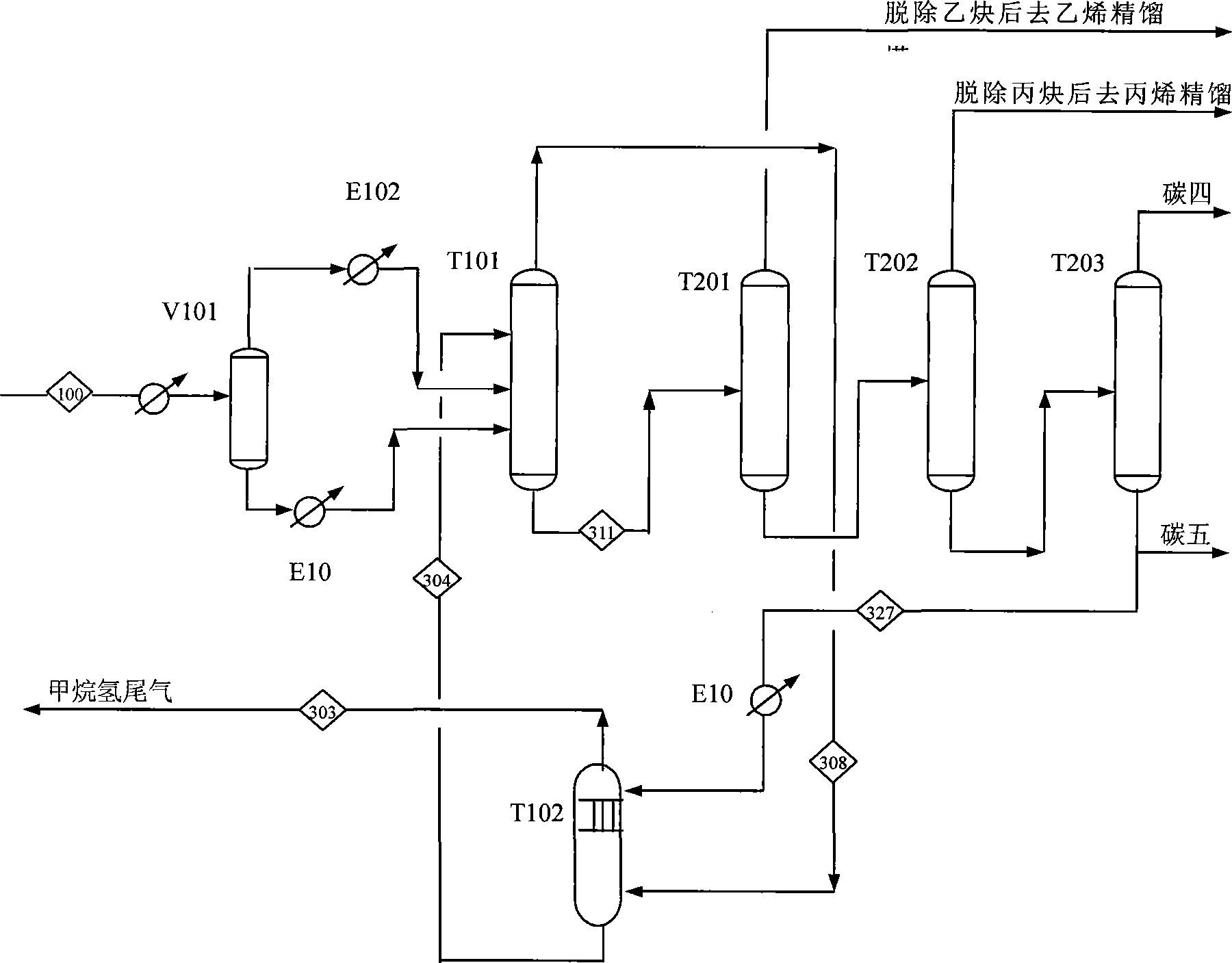

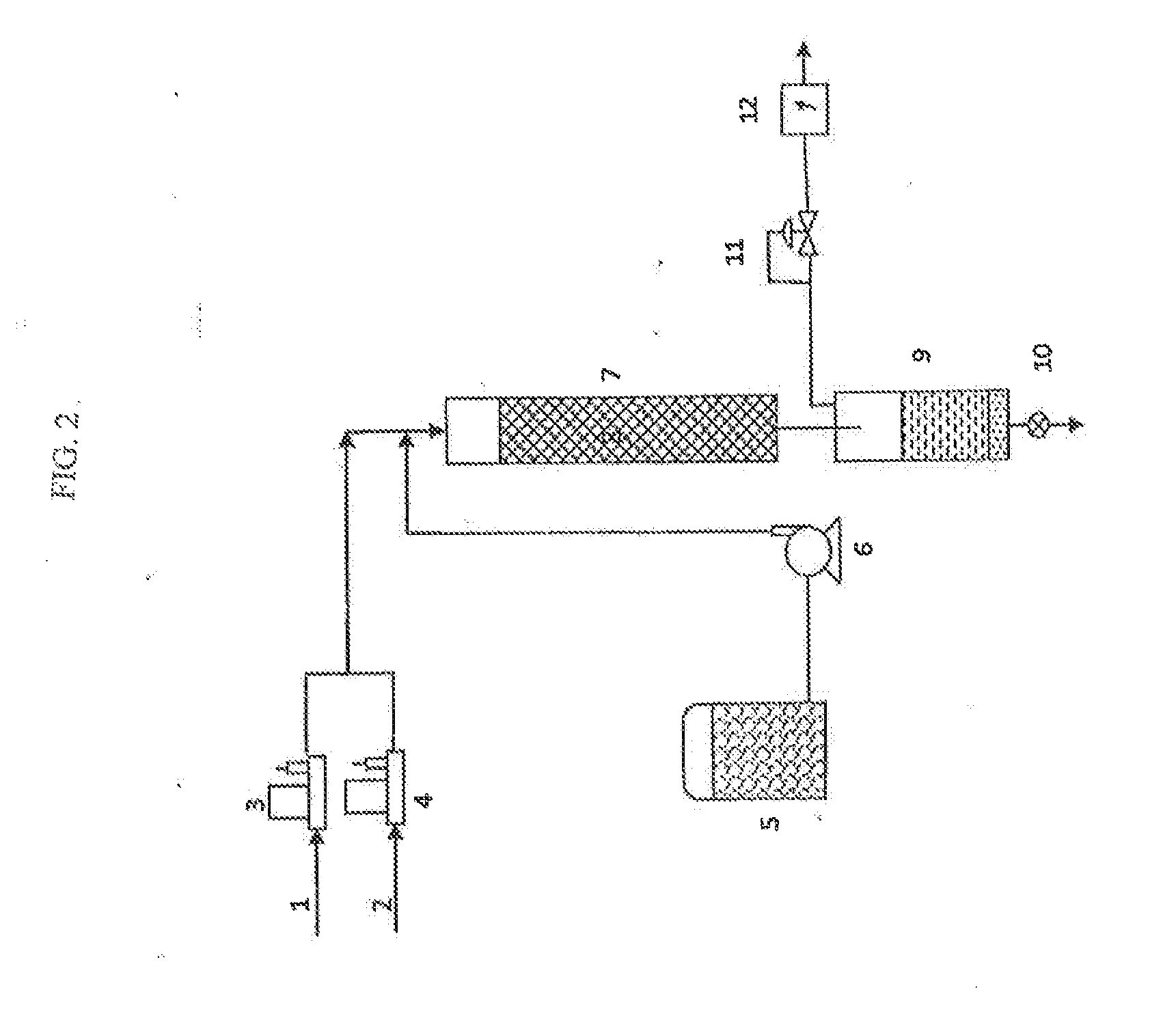

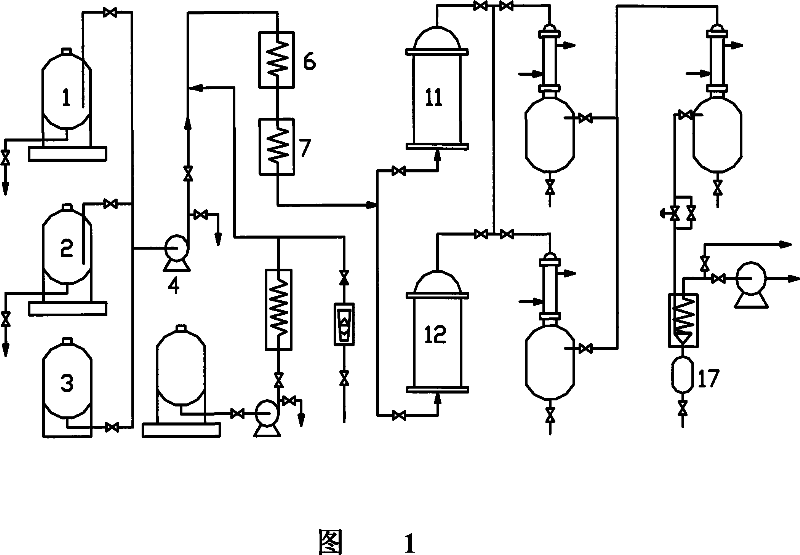

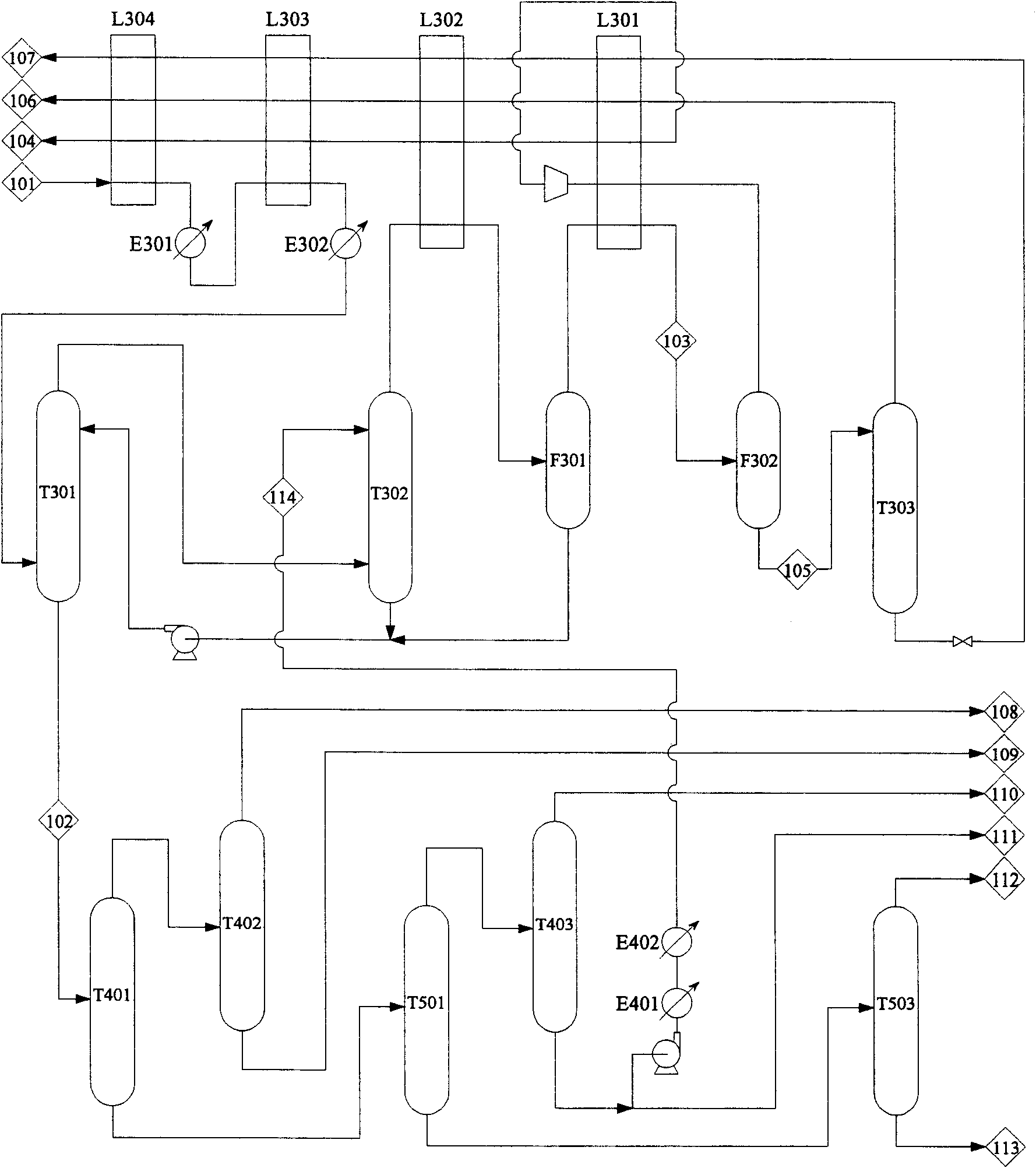

Separation method of Fischer-Tropsch synthesis gas by combining rectification and solvent absorption

ActiveCN101559320AIncrease concentrationEasy to separateSolidificationLiquefactionHydrogenHydrocarbon mixtures

The invention relates to a separation method of Fischer-Tropsch synthesis gas by combining rectification and solvent absorption. The separation method comprises the following steps: Fischer-Tropsch synthesis gas pretreated is conveyed to a demethanizer after being cooled; the top of the demethanizer separates hydrogen and other light gas, methane, part of C2 fraction and little amount of C3; the mixed gas enters an absorption tower and uses C3, C4 or C5 or hydrocarbon mixture as an absorbing agent to absorb C2 and heavier components; the products of the top of the absorption tower comprise hydrogen and other light gas, methane, the little balanced amount of C2 and the absorbing agent; the products of the bottom of the tower are components above C2 and little amount of hydrogen and methane; the materials are conveyed to the demethanizer for further absorbing C2 and heavier fraction and removing the methane and lighter components therein. The light hydrocarbon mixture of the bottom of the demethanizer can adopt conventional light hydrocarbon separation method to separate out various light hydrocarbon products with needed purity and recycling rate. Compared with the prior art, the invention has the advantages of simple process, low energy consumption and high recycling rate of various components and the like.

Owner:WISON ENG

Oligomerization of isobutene in N-butenic hydrocarbon streams

InactiveUS7161053B2Efficient preparationOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon mixturesProton

Isobutene in isobutenic hydrocarbon mixtures is oligomerized over a solid acidic ion exchange resin, said acidic ion exchange resin containing, for example, sulfonic acid groups, some of whose protons have been exchanged for metal ions.

Owner:EVONIK DEGUSSA GMBH

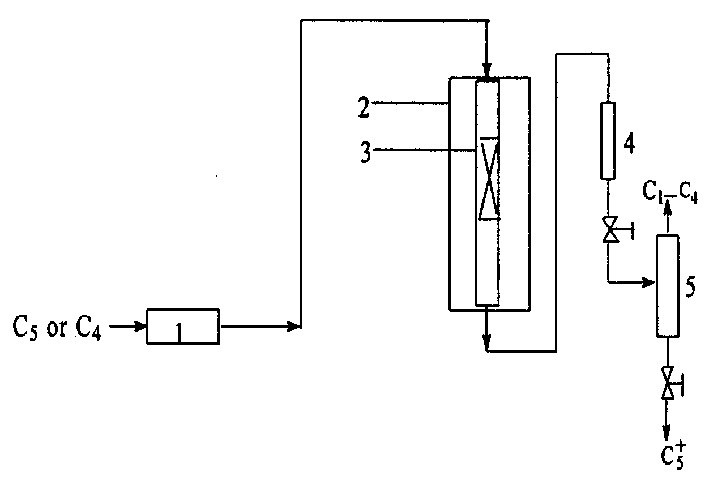

Method for preparing low carbon number olefin by catalytic pyrolysis

ActiveCN1676499AHigh yieldHigh selectivityHydrocarbon by hydrocarbon crackingCarbon numberCatalytic pyrolysis

This invention discloses a method that makes low-carbon olefin hydrocarbon by catalyzing decomposition. This method uses mixture of C4 or C5 without double olefin hydrocarbon as raw materials, mixes the raw materials and water with their volume ratio 0.3-1.5, in the solid bed reactor to react contacting with the zeolite catalyst with high silicon aluminum ratio, and produces the reacting mixture containing propene and ethane. The zeolite catalyst is composed of high silicon zeolite20-65%, the silicon-aluminum ratio 50-300, monox 20-65%, inorganic oxidant 0-20%. This invention can get high yields of ethane and propene, therefore, this invention explores the important way of compound utilization of C4 and C5 cut fractions in the ethane mills and refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com