Coking inhibitor and preparation method and application thereof

A technology of coking inhibitors and catalysts, which is applied in the fields of corrosion/fouling treatment equipment, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of low hydrogen content, low coking inhibition ability, and poor hydrogen supply capacity of coking inhibitors, and achieve Improve the critical decomposition temperature, improve the anti-coking ability, and increase the effect of hydrogen supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

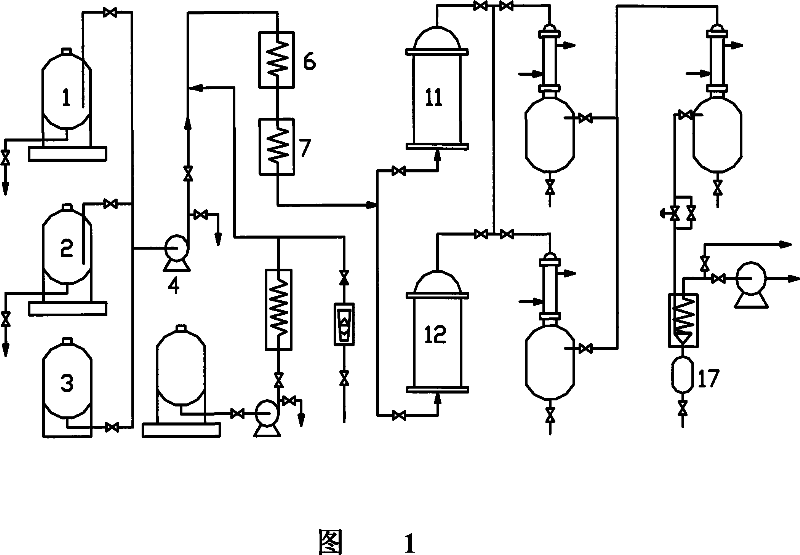

Image

Examples

Embodiment 1

[0025] Using coal tar fraction oil blended with partial ethylene tar mixed oil as raw material, adopts two-stage series connection, 30% full-fraction hydrotreating oil is recycled to the inlet process of hydro-upgrading section, and the refined catalyst is selected as Mo-Ni / Al 2 o 3 type, where MoO 3 It accounts for 15.62% of the total weight of the catalyst, and NiO accounts for 2.91% of the total weight of the catalyst; the hydrogenation modification catalyst is selected as W-Mo-Ni / Al 2 o 3 type, where WO 3 Accounting for 21.27% of the total weight of the catalyst, MoO 3 It accounts for 5.91% of the total weight of the catalyst, NiO accounts for 2.84% of the total weight of the catalyst, and accounts for 30% of the feed to the device. The full fraction hydrogenated oil is recycled to the reaction unit before the reactor. The properties of the raw oil, operating conditions and properties of the produced oil are shown in the table 1.

Embodiment 2

[0027] The distillate oil of coal tar is blended with part of the mixed oil from catalytic cracking and refined oil as the raw material, and the process of two-stage series connection and one-way operation is adopted, and the refined catalyst is W-Ni / Al 2 o 3 type, where WO 3 It accounts for 24.79% of the total weight of the catalyst, and NiO accounts for 3.05% of the total weight of the catalyst; the modified catalyst is selected as W-Mo-Ni / Al2 o 3 type, where WO 3 Accounting for 21.27% of the total weight of the catalyst, MoO 3 It accounts for 5.91% of the total weight of the catalyst, and NiO accounts for 2.84% of the total weight of the catalyst.

Embodiment 3

[0029] The whole distillate of the hydromodified oil produced in Example 1 was used as a coking inhibitor, added to the feed oil in an amount of 3% of the total weight of the feed oil, and tested on a medium-scale delayed coking test device. Tables 3 and 4 are Operating conditions and raw oil properties, when 3m% coking inhibitor is injected into the raw oil, the normal operation time of the device is increased by more than 1.5 times from 32.6 hours to 51.2 hours, and there is no adverse effect on product distribution and product properties.

[0030]

[0031] project

[0032] project name

[0033] project name

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com