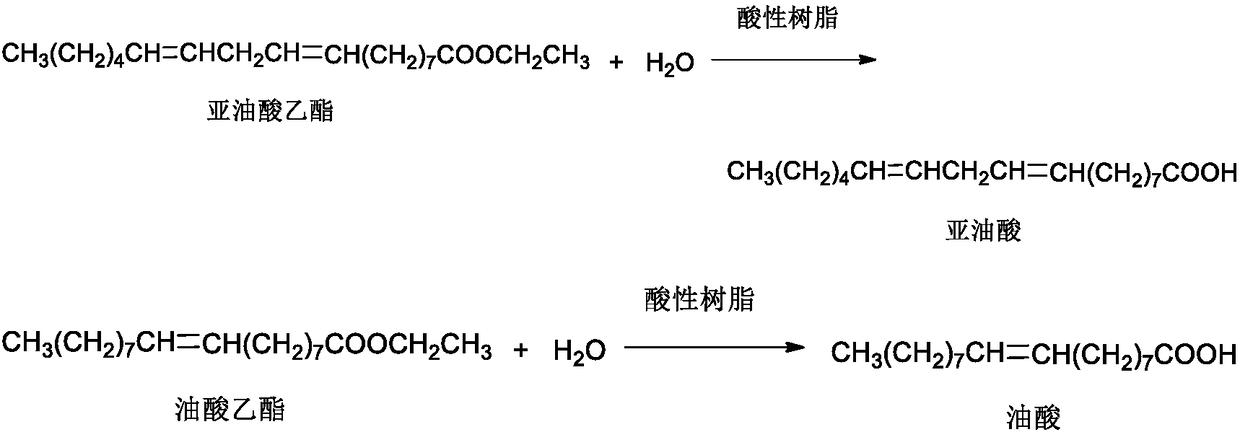

Patents

Literature

51results about How to "Improve hydrogen supply capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

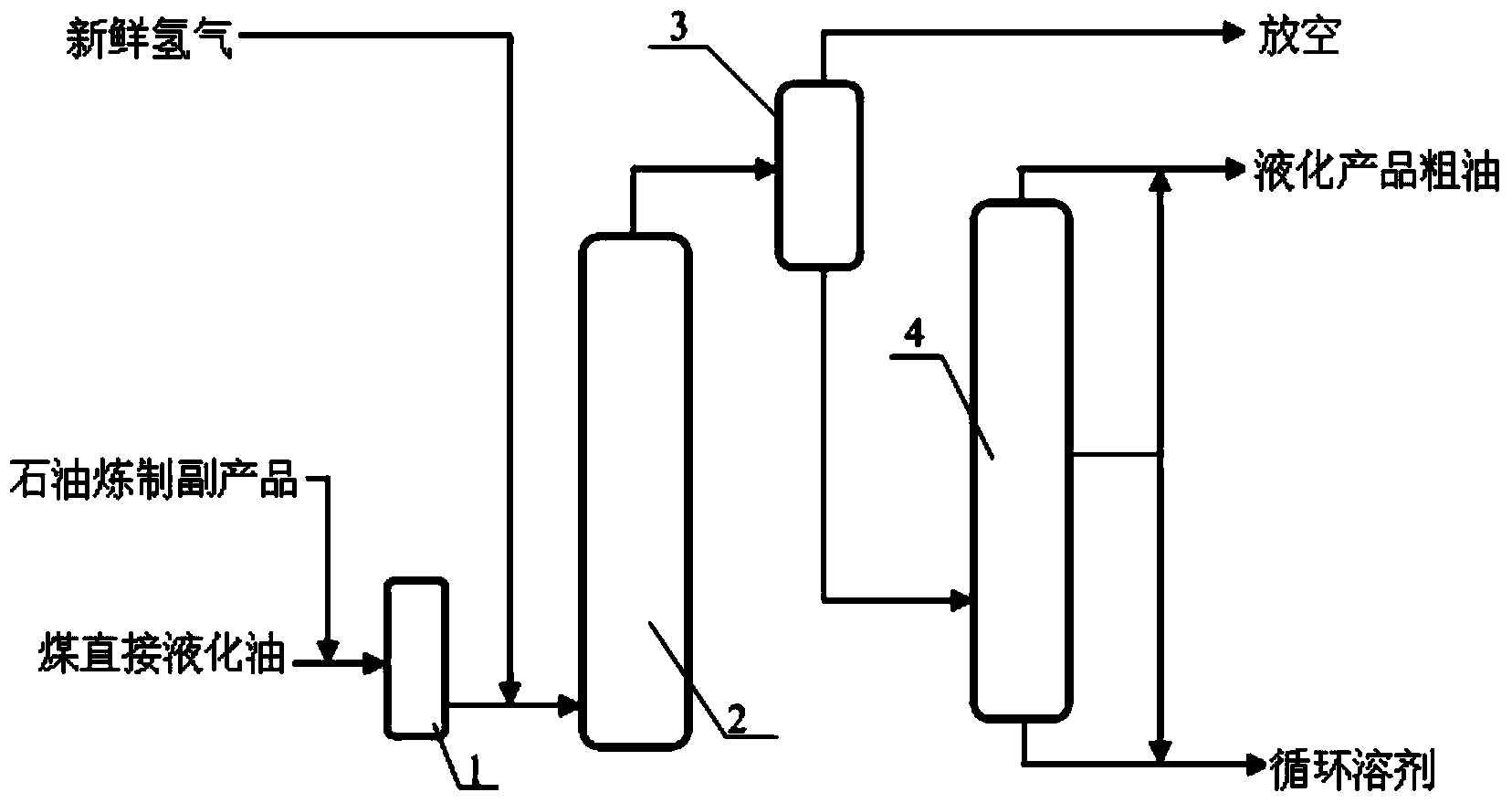

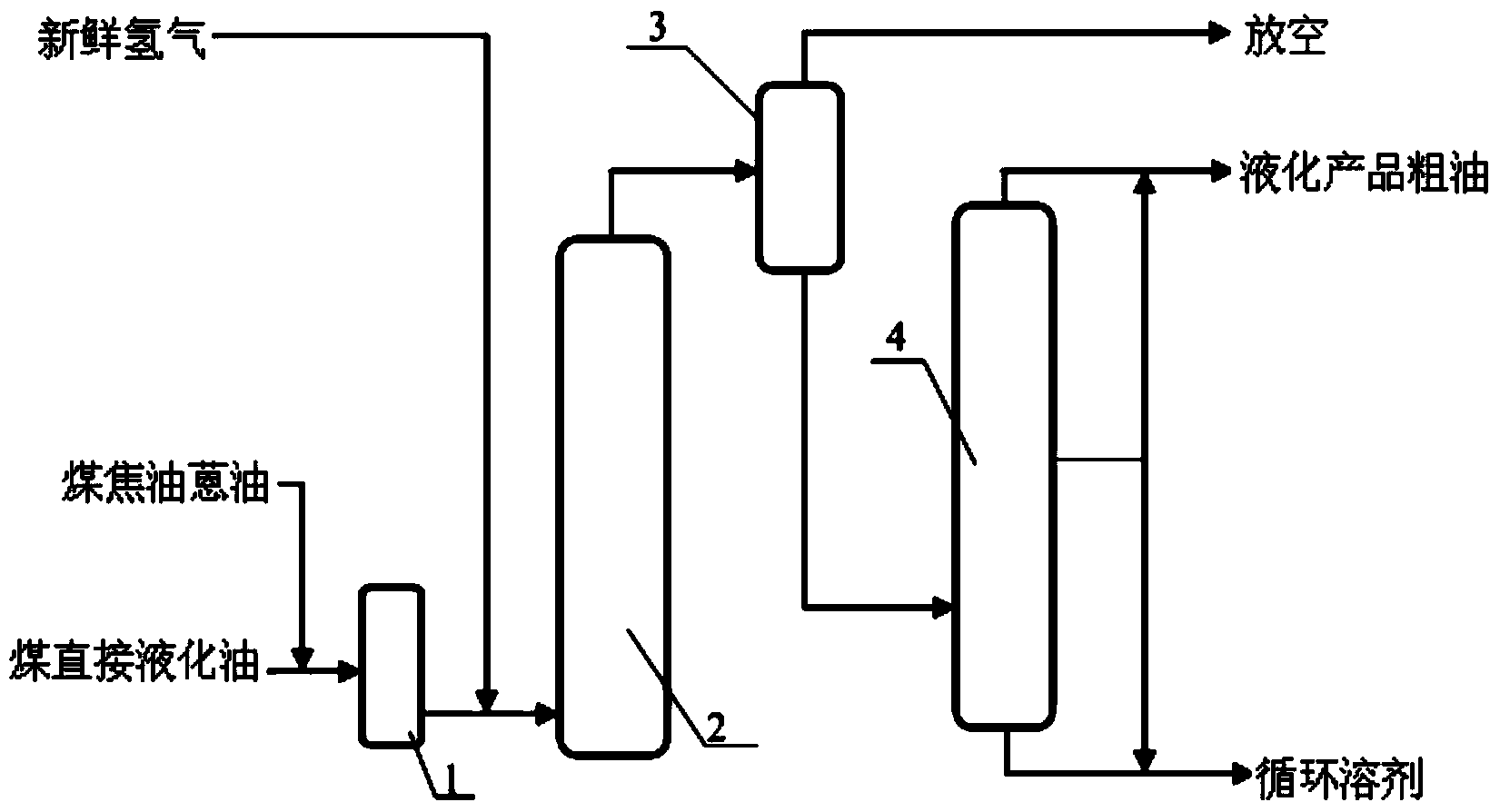

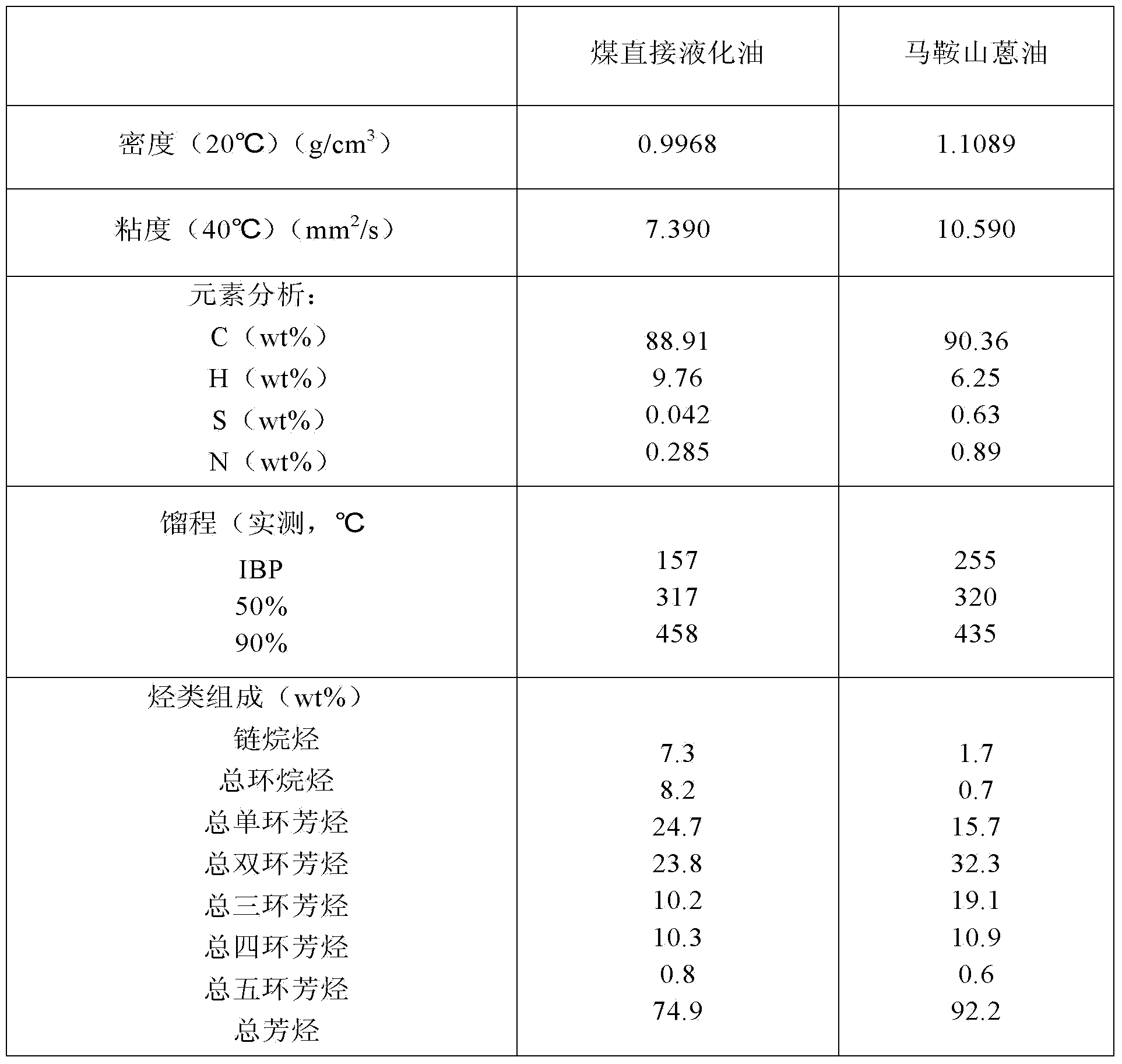

Method for mixing and processing wash oil and direct coal liquefaction oil

ActiveCN102517071AImprove hydrogen supply performanceReduce reaction temperature riseRefining to eliminate hetero atomsSolventChemistry

The invention provides a method for mixing and processing wash oil and direct coal liquefaction oil, which includes the following steps: (a) mixing the wash oil and the direct coal liquefaction oil to be mixed with hydrogen, and enabling the mixture to enter a mixed oil hydrogenation reactor; (b) enabling mixture of the wash oil, the direct coal liquefaction oil and the hydrogen in the step (a) to be contacted with hydrofining catalyst to be subjected to a reaction in the mixed oil hydrogenation reactor; and (c) separating and fractionating objects obtained from the reaction of step (b) and discharged from an outlet of the mixed oil hydrogenation reactor to obtain light distillate oil, medium distillate oil and heavy distillate oil. The heavy distillate oil is mixed with a part of the medium distillate oil to serve as hydrogen-donor solvent, and the light distillate oil is mixed with the rest medium distillate oil to obtain liquefaction product raw oil. The method can effectively convert coal tar and wash oil, obtains high-performance hydrogen-donor solvent and diesel products with high cetane number, and can avoid a phenomenon of speeding up deactivation of catalyst caused by overlarge reaction temperature rise in an independent hydrogenation process for the wash oil.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

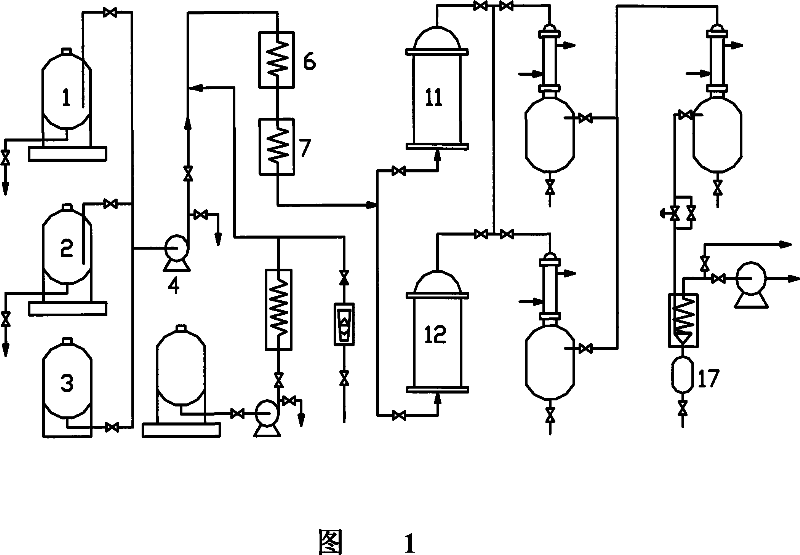

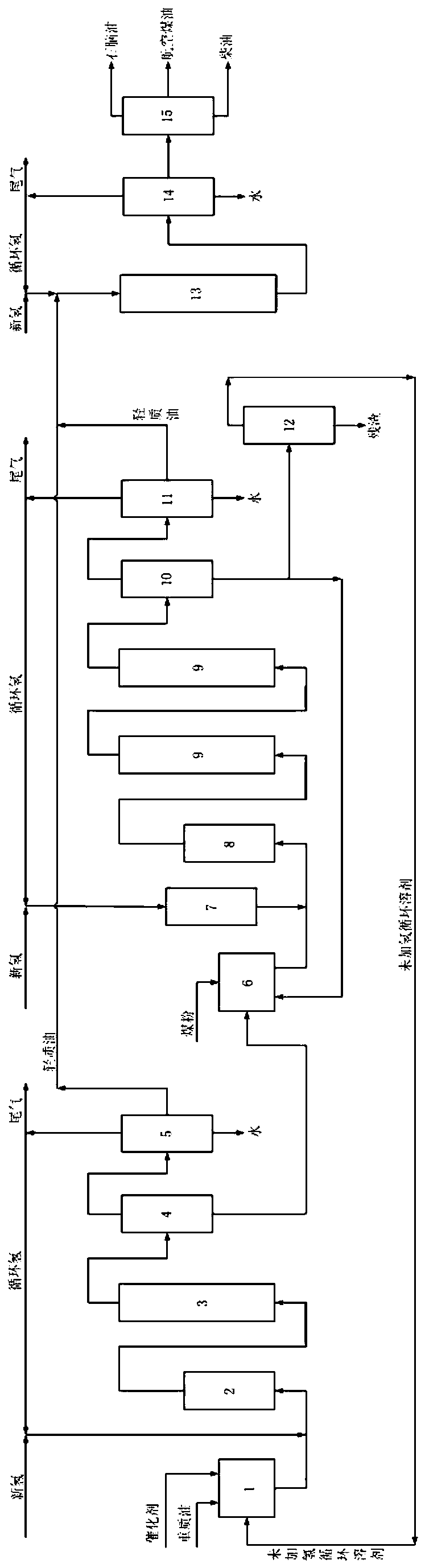

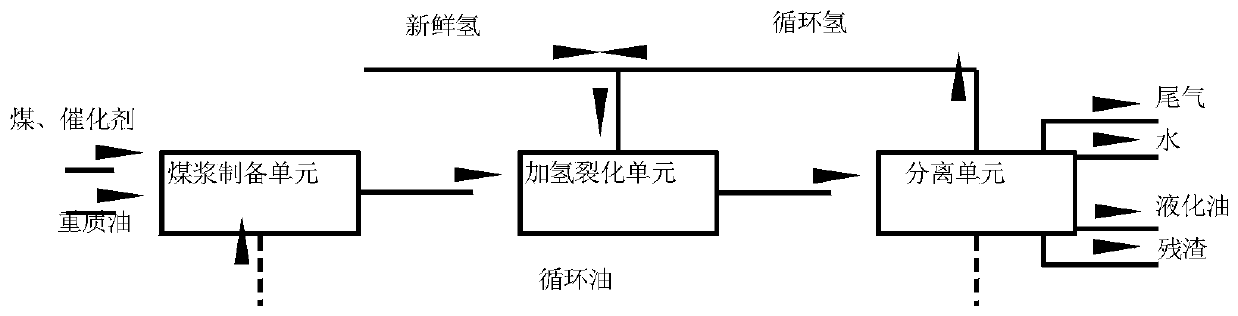

Coal and oil coprocessing method and device

ActiveCN106433775ALow viscosityImprove protectionTreatment with hydrotreatment processesSlurrySolvent

The invention relates to a coal and oil coprocessing method and device. The coprocessing method comprises steps as follows: step one, oil slurry pretreatment: heavy oil, a non-hydrogenated cycling solvent and a first catalyst are mixed, oil slurry is prepared and subjected to first hydrocracking reaction, a first product is obtained and separated, and first light distillate oil and first heavy distillate oil are obtained; step two, coal and oil coprocessing, solvent oil circulation and finished product separation. The coprocessing device comprises an oil slurry pretreatment device, a coal and oil coprocessing device body, a solvent oil circulating device and an oil product quality improving device. According to the coal and oil coprocessing method and device, selectivity for the heavy oil during coal and oil coprocessing is reduced, the percentage amount of pulverized coal in a coal and oil coprocessing process is increased, and the coal and oil coprocessing method and device are more suitable for practical application.

Owner:CCTEG CHINA COAL RES INST

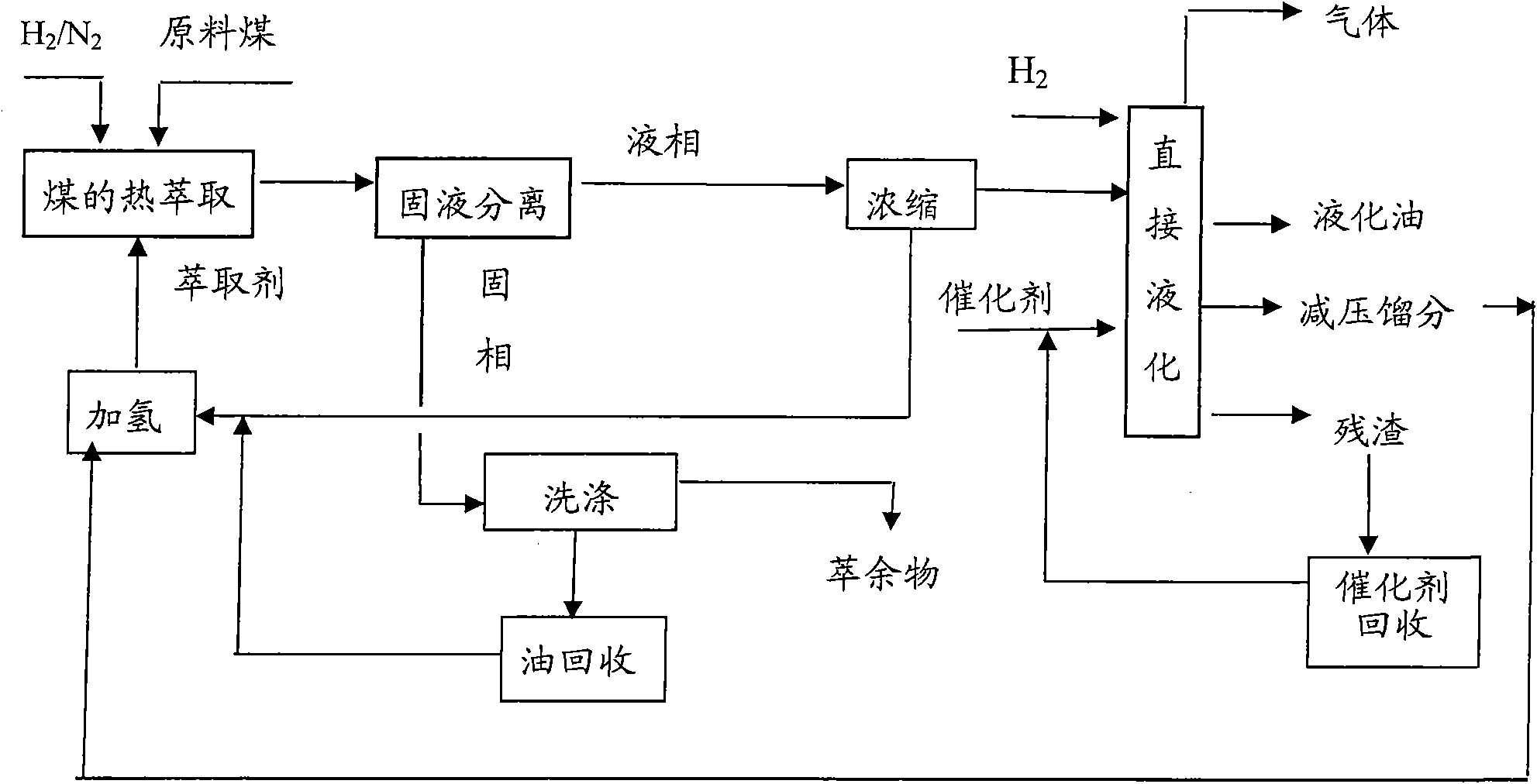

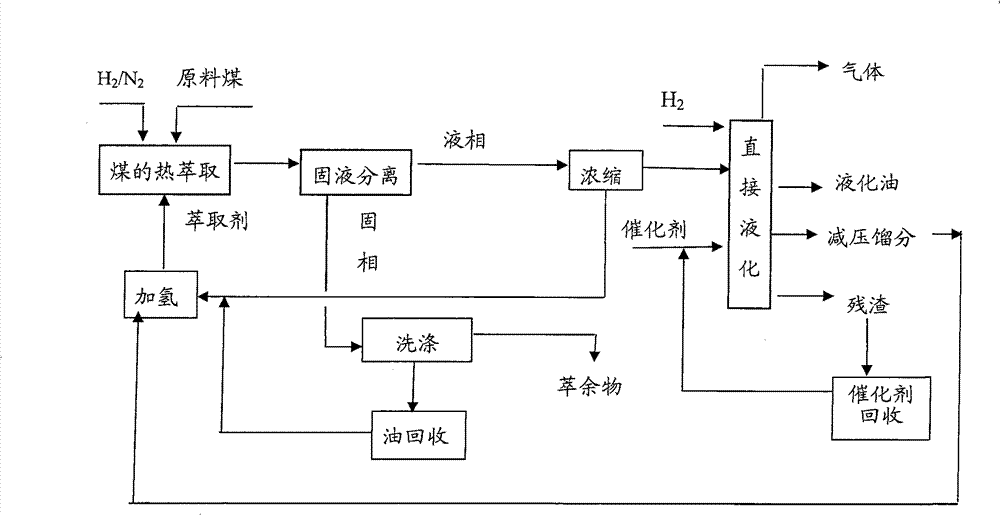

Coal liquefaction method

ActiveCN101643660AReduce oxygen contentReduce wearLiquid hydrocarbon mixture productionLiquid productThermal state

The invention provides a coal liquefaction method, and the method comprises the following steps: (1) carrying out solvent thermal extraction pre-treatment on raw materials of coal; (2) carrying out thermal state solid-liquid separation; (3) concentrating the liquid part for obtaining ultra-pure coal slurry; or carrying out back extraction on the liquid part for preparing solid ultra-pure coal, andmixing with a thermal extraction solvent for preparing ultra-pure coal slurry; and (4) carrying out liquefaction reaction on the ultra-pure coal slurry for obtaining a coal liquefied oil product, wherein, the thermal extraction solvent is a liquid product obtained by carrying out hydrogenation treatment on the coal liquefied oil, such as the liquid products obtained by carrying out the hydrogenation treatment on coal liquefied light oil, coal liquefied middle oil and / or coal liquefied heavy oil, a coal liquefaction hydrogenation circulating solvent, or the mixture thereof. The method can reduce hydrogen consumption during the liquefaction process, water yield and gas yield, reduce wear on coal liquefaction equipment and be conductive to realizing the recycling of a coal liquefaction catalyst. The method can adopt any traditional liquefaction process and be conductive to saving energy consumption.

Owner:CHINA COAL RES INST +1

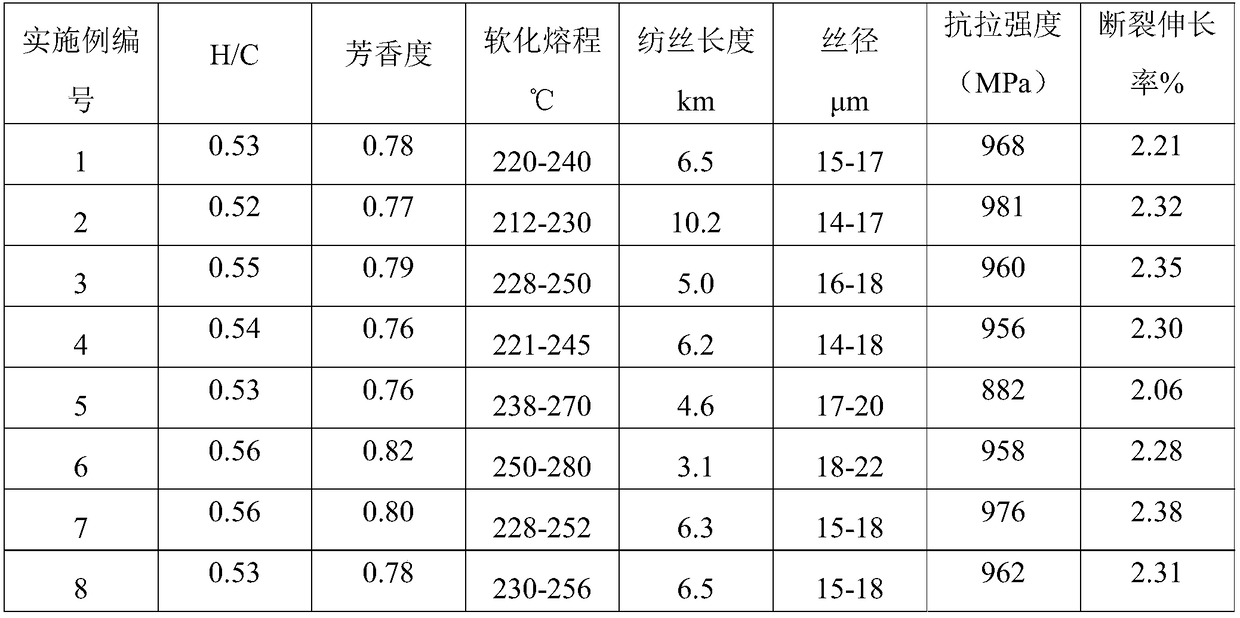

Method for preparing spinnable pitch from coal tar pitch

ActiveCN109181733AHigh yieldHigh overall yield (27-32%), softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansFiltrationNitrogen

A method for preparing spinnable pitch from coal tar pitch comprises the following steps: crushing medium-low-temperature coal tar pitch to 20 meshes or below, performing extracting by using tetrahydrofuran, performing filtration to obtain a medium-low-temperature coal tar pitch soluble component, and recovering the tetrahydrofuran solvent from the soluble component to obtain refined pitch; and mixing the refined pitch with petrolatum, adding the obtained mixture into a reactor, introducing nitrogen under normal pressure, heating the reactor to 180-220 DEG C at a heating rate of 1-10 DEG C / min, switching to air, introducing the air into the reactor at a rate of 10-60 mL / min.g, heating the reactor to 280-350 DEG C at a heating rate of 1-10 DEG C / min, and allowing the obtained mixture to stay for 1-10 h to obtain the spinnable pitch. The method has the advantages of high yield, low price and moderate thermal polycondensation temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Improved method of delay coking process

InactiveCN101302435AImproved coke kineticsReduce concentrationThermal non-catalytic crackingWaxNaphtha

The invention provides a method for improving the delayed coking technique. The method is as follows: coked raw material residual oil is heated by a heating furnace and enters into a coking tower; coke generated is accumulated in the coking tower; and gas, naphtha, light diesel oil, heavy diesel oil, light wax oil and heavy wax oil are obtained after separation of oil gas fluid products through a coking and fractionating tower. The light diesel oil, the heavy diesel oil, the light wax oil or the heavy wax oil are used as circulation materials through adjustment of the sources, the distillation range and the circulation of the circulation materials, and then the coking induction period of mixture can be prolonged and the coking dynamics of the coked raw material residual oil can be changed; and the coking reaction of the residual oil is delayed to be performed in the coking tower more completely, thereby achieving the aim of prolonging the operating period of a heating furnace tube. The operating period of the coking and heating furnace can be prolonged to be between 3 and 18 months generally according to the extended degree of the coking induction period determined by the sources, the distillation range and the circulation of the circulation materials selected.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

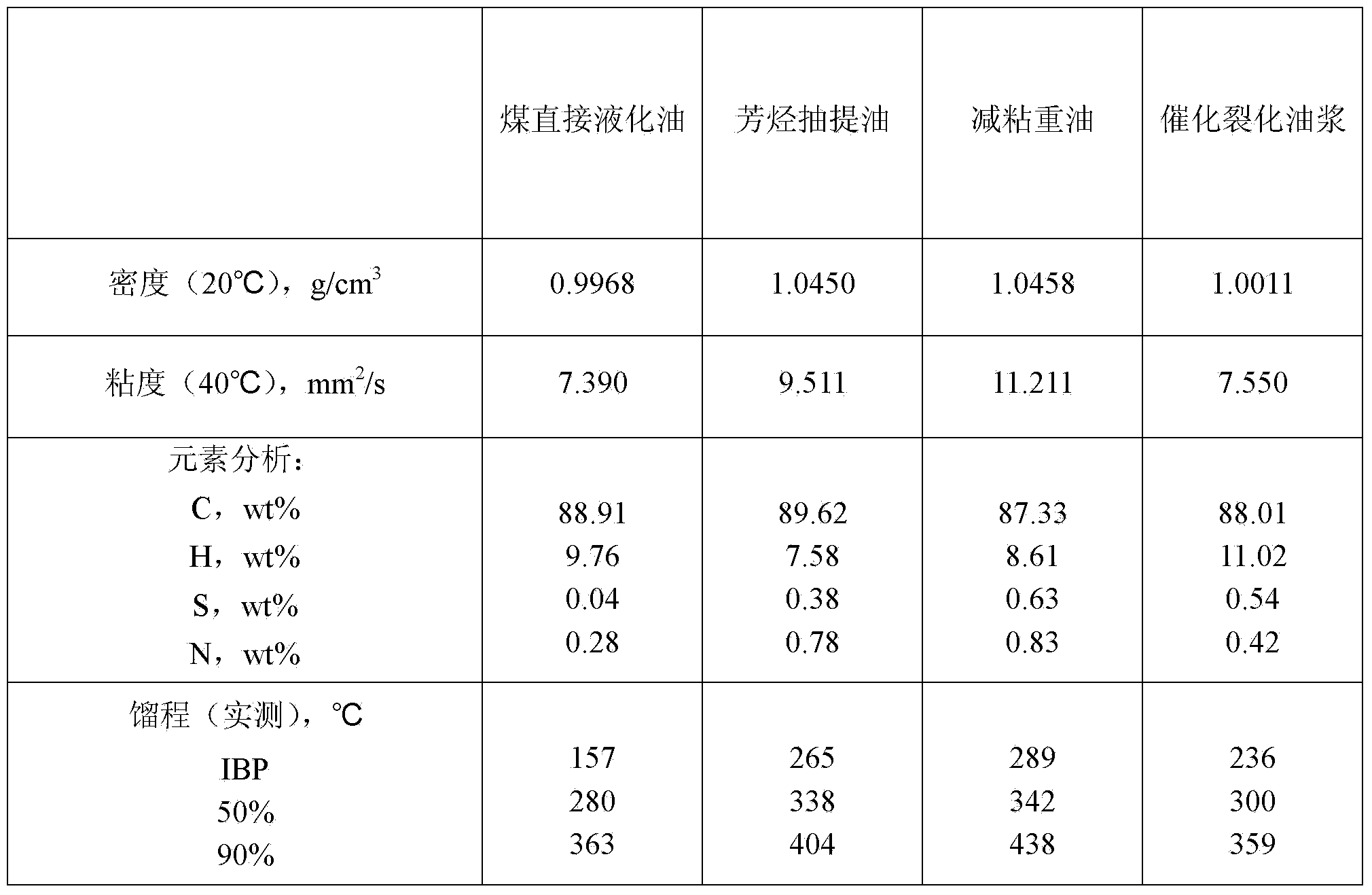

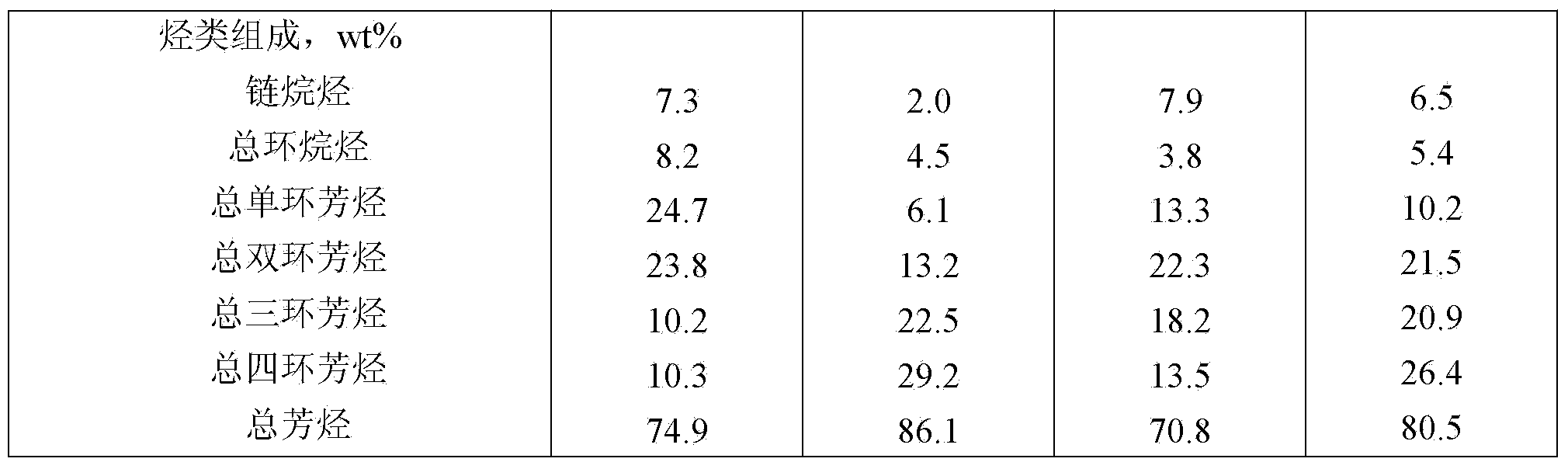

Direct coal liquefaction cycle solvent, preparation method thereof and application thereof

ActiveCN103468314ASolve the problem of low utilization valueImprove hydrogen supply capacityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesSolventHydrogen supply

The invention provides a direct coal liquefaction cycle solvent, a preparation method of the direct coal liquefaction cycle solvent and application of the direct coal liquefaction cycle solvent. The preparation method comprises the steps of S1, carrying out hydrogenation on a mixture of petroleum refining secondary products and direct coal liquefaction oil, and obtaining a hydrogenation product, S2, fractionating the hydrogenation product, and obtaining light distillate oil, medium distillate oil and heavy distillate oil, and S3, mixing the heavy distillate oil with a part of the medium distillate oil, and obtaining the direct coal liquefaction cycle solvent. In the preparation method of the direct coal liquefaction cycle solvent, on one hand, a large amount of arene is contained in the petroleum refining secondary products, the hydrogenation product is rich in components such as tetrahydronaphthalene, therefore, the hydrogen supplying capacity of the direct coal liquefaction cycle solvent can be obviously improved, and the yield of the direct coal liquefaction oil is improved; on the other hand, a part of high-added-value diesel distillate with the boiling range lower than 350 DEG C in the direct coal liquefaction cycle solvent is substituted with the petroleum refining secondary products, the diesel yield is improved, the economical efficiency of the coil liquefaction technology is remarkably improved, and the problem that an existing cycle solvent gets light can be solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Nutritional food with beautifying and whitening effects

InactiveCN102551063AImprove hydrogen supply capacityImprove antioxidant capacityFood preparationBiotechnologyGreen teas

The invention discloses a nutritional food with beautifying and whitening effects, belongs to the field of nutritional foods, and aims to provide a nutritional food which acts rapidly and has good effects. The nutritional food is made from the following raw materials: green tea, green apples, onions, Chinese wolfberry fruits, shii-take mushroom, mulberry fruits, safflowers and lily flowers. The nutritional food has the effects of enhancing immunity, nourishing the blood, promoting blood flow, removing blood stasis, reducing melanin in the skin and making the skin beautiful and white; and is advantageous in good effect and rapid onset of action.

Owner:BEIJING LVYUAN QIUZHENG SCI & TECH DEV

Direct coal liquefaction circulation solvent and preparation method and application of direct coal liquefaction circulation solvent

ActiveCN103468315AHigh economic valueHigh yieldLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesAnthraceneFractionation

The invention provides a direct coal liquefaction circulation solvent and a preparation method and application of the direct coal liquefaction circulation solvent. The preparation method comprises the steps that S1, hydrogenation is carried out on a mixture of coal tar anthracene oil and direct coal liquefaction oil to obtain a hydrogenation product, S2, fractionation is carried out on the hydrogenation product to obtain light-weight distillate oil, middle-weight distillate oil and heavy-weight distillate oil, and S3, the heavy-weight distillate oil is mixed with a part of middle-weight distillate oil to obtain the direct coal liquefaction circulation solvent. According to the preparation method, on one hand, a large amount of aromatic hydrocarbon is contained in the coal tar anthracene oil, the hydrogenation product is rich in components such as tetrahydronaphthalene, therefore, the hydrogen supply capacity of the circulation solvent can be obviously improved, and the yield of direct coal liquefaction oil is improved; on the other hand, a part of high value-added gas and diesel oil distillate with the boiling range lower than 350DEG C in the direct coal liquefaction circulation solvent is substituted with the coal tar anthracene oil, the diesel oil yield is improved, in addition, the light-weight problem of an existing circulation solvent can be relieved, and deposition and coking of materials in a reactor in the direct coal liquefaction technological process are relieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Preparation method of cyclic carbonate

InactiveCN111253360AHigh activityImprove hydrogen supply capacityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCarbonate ester

The invention belongs to the technical field of green catalytic synthesis, and particularly relates to a preparation method of cyclic carbonate. Epoxide and carbon dioxide are catalyzed by using a catalyst provided by the invention to obtain the cyclic carbonate. According to the invention, the synthesis method is simple, cost is low, the catalyst has high activity and high selectivity, a reactioncondition is mild, and good reusability is realized.

Owner:NANJING UNIV OF TECH

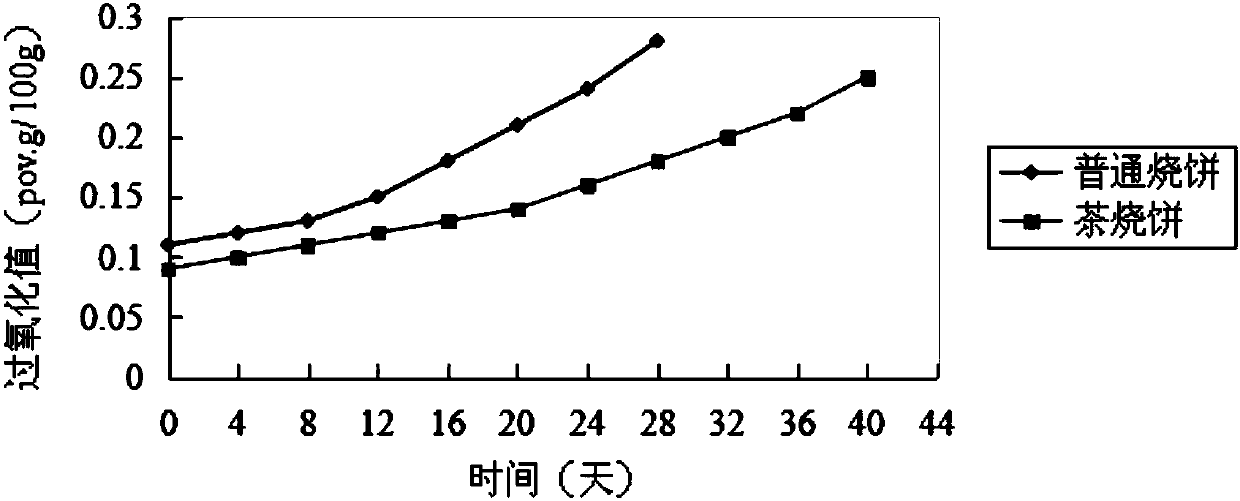

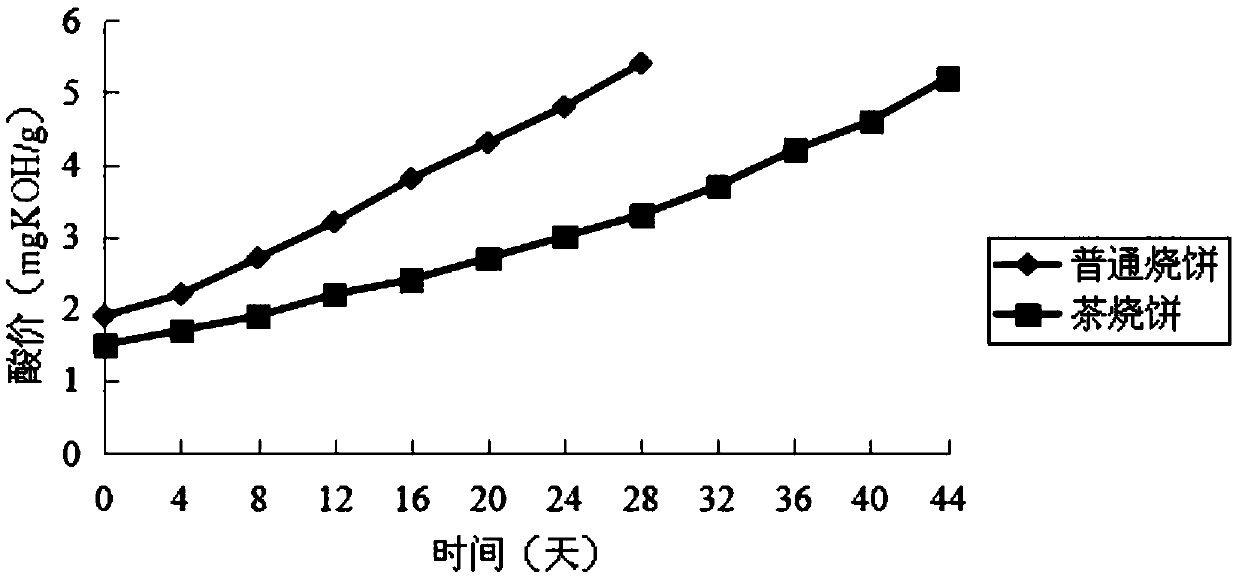

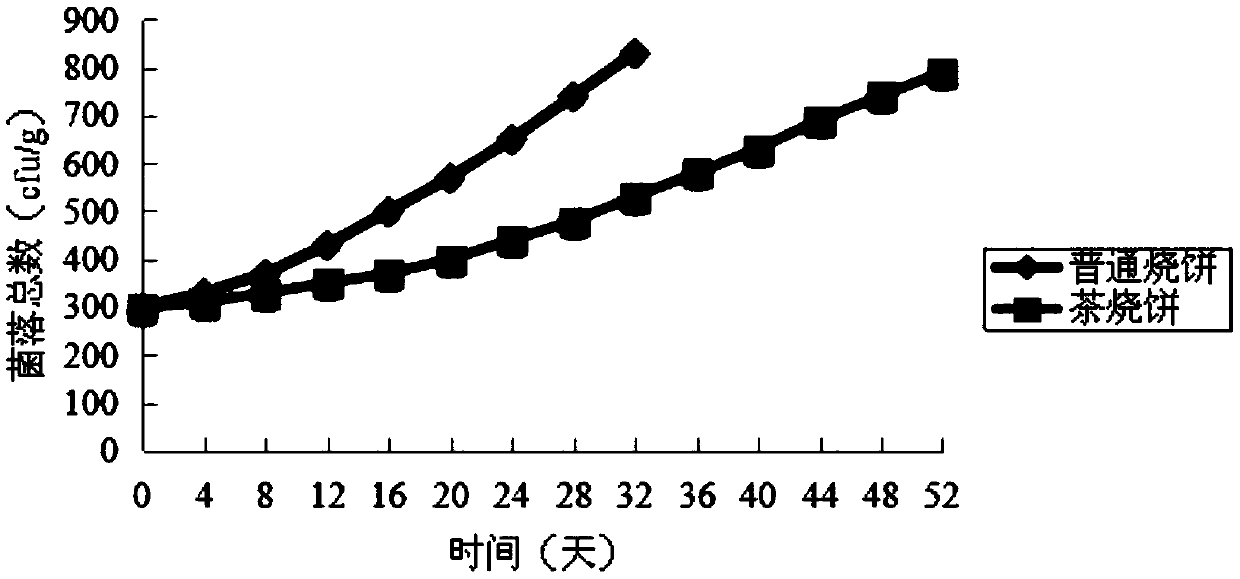

Huangshan sesame seed cake and preparation method thereof

InactiveCN107668143AExtended shelf lifeDelays the automatic oxidation process of oilBakery productsEpigallo-catechin gallateMaltose

The invention relates to the technical field of food processing, in particular to a Huangshan sesame seed cake and a preparation method thereof. The Huangshan sesame seed cake comprises, by mass, 250-350 parts of flour, 60-65 parts of ghee, 15-25 parts of green tea powder, 1-5 parts of maltose, 1-2 parts of dietary alkali, 80-90 parts of pig shop fat, 45-60 parts of preserved vegetables, 10-20 parts of white sugar, and 5-10 parts of chili powder. The Huangshan sesame seed cake is good in taste, healthy in eating and long in quality guarantee period.

Owner:TEA RES INST ANHUI ACAD OF AGRI SCI +1

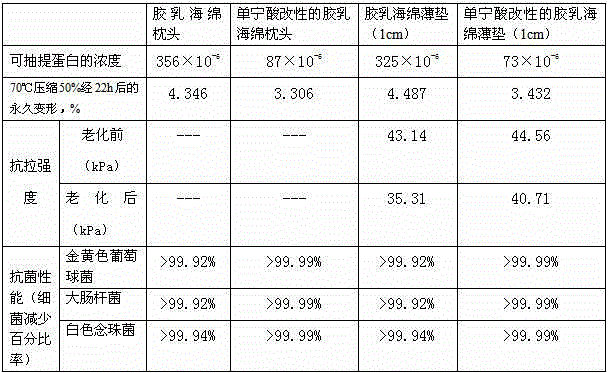

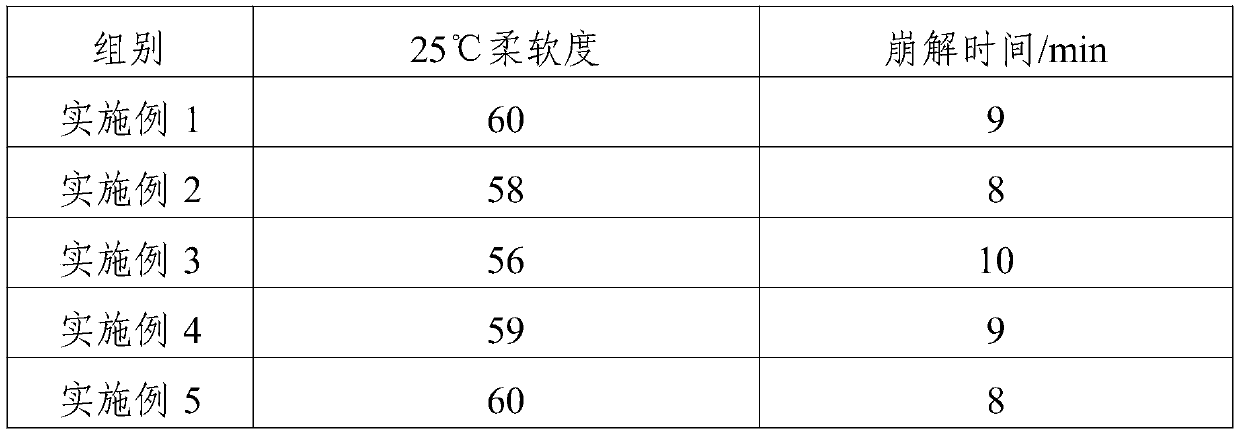

Method for preparing sponge products from tannic acid modified natural latex

ActiveCN105295127AEliminate allergic reactionsFacilitate dissociationPillowsStuffed mattressesAntibacterial propertyRaw material

The invention discloses a method for preparing sponge products from tannic acid modified natural latex. The method comprises the following steps: the first step: treating tannic acid by using soft water, strong ammonia water and a nonionic surfactant or sodium dodecyl sulfate so as to obtain a tannic acid solution, wherein the tannic acid solution is prepared from the following ingredients in mass ratio: 20 parts of tannic acid, 3-8 parts of strong ammonia water, 3-5 parts of the nonionic surfactant or sodium dodecyl sulfate and 70-75 parts of soft water; the second step: with natural latex as a raw material, uniformly adding and dispersing the tannic acid solution into natural latex according to the mass ratio that 0.5-3.0 parts of the tannic acid solution is added into each 100 parts of dry natural latex in a raw material preparation process; the third step: bubbling, carrying out injection molding, carrying out gelatinization, vulcanizing, demoulding, washing with water and drying so as to obtain the sponge products. According to the invention, since tannic acid is added into the natural latex, anaphylaxis caused by water soluble protein as well as influences of variable-valence metal ions on ageing performance of the products are eliminated, and ageing resistance and antibacterial properties of the natural latex sponge products are improved.

Owner:温州市鑫时利实业有限公司

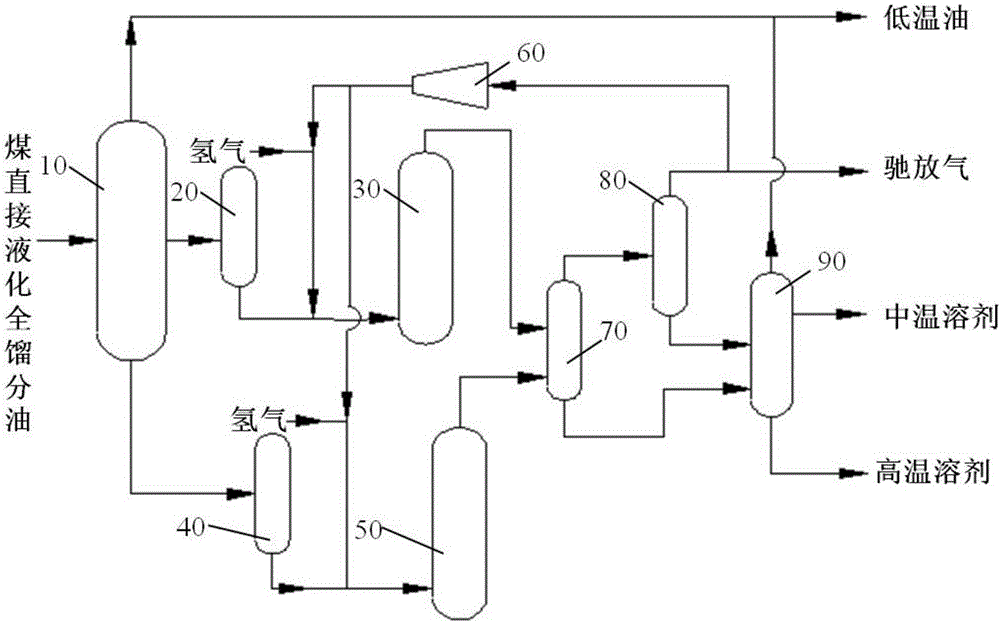

Recycling solvent and preparation method thereof

InactiveCN106479564AInhibition of hydrogen robbingImprove hydrogen supply capacityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesHydrogenation reactionFractionation

The invention provides a recycling solvent and a preparation method thereof. The preparation method comprises carrying out first fractionation on directly liquefied whole-fraction oil of coal to obtain medium temperature oil and high temperature oil, wherein the medium temperature oil is distillate oil at a temperature of 200-320DEG C and the high temperature oil is distillate oil at the temperature of greater than 320DEG C, carrying out a first hydrogenation reaction process on the medium temperature oil to obtain first hydrogenated stable oil, carrying out a second hydrogenation reaction process on the first hydrogenated stable oil to obtain second hydrogenated stable oil, carrying out second fractionation on the mixture of the first hydrogenated stable oil and the second hydrogenated stable oil to obtain a medium temperature solvent and a high temperature solvent, wherein the medium temperature solvent is distillate oil at a temperature of 200-320DEG C and the high temperature solvent is distillate oil at a temperature of 320-500DEG C, and mixing a part of the medium temperature solvent and the high temperature solvent to obtain the recycling solvent. The preparation method of the recycling solvent has the advantages of low hydrogen consumption, low gas yield and high hydrogen supplying performances.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

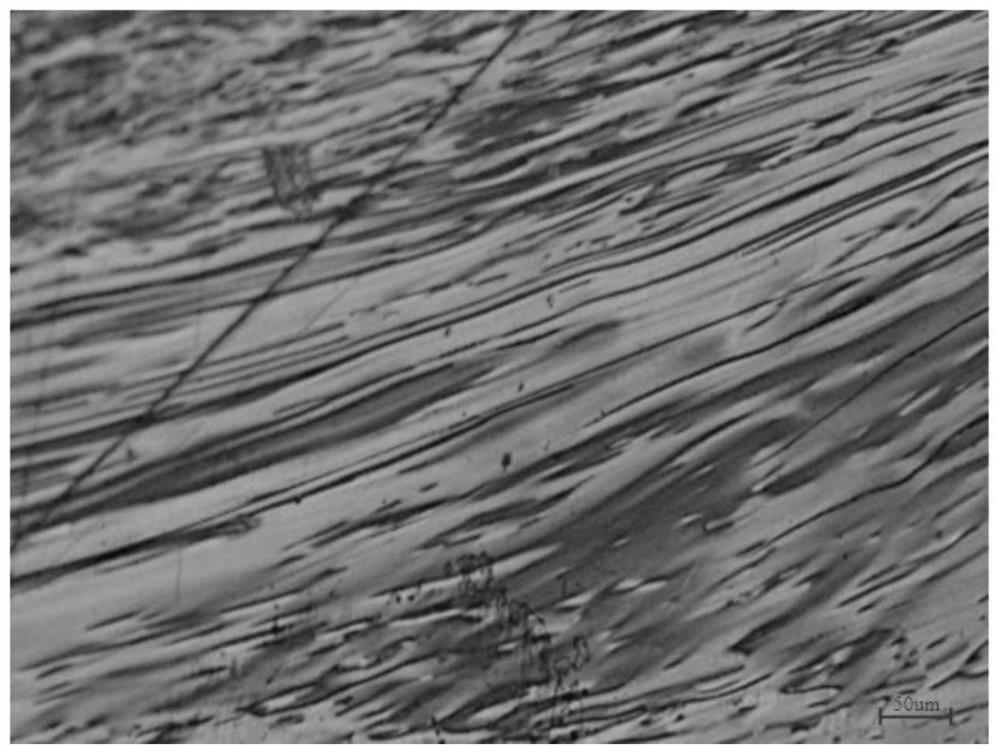

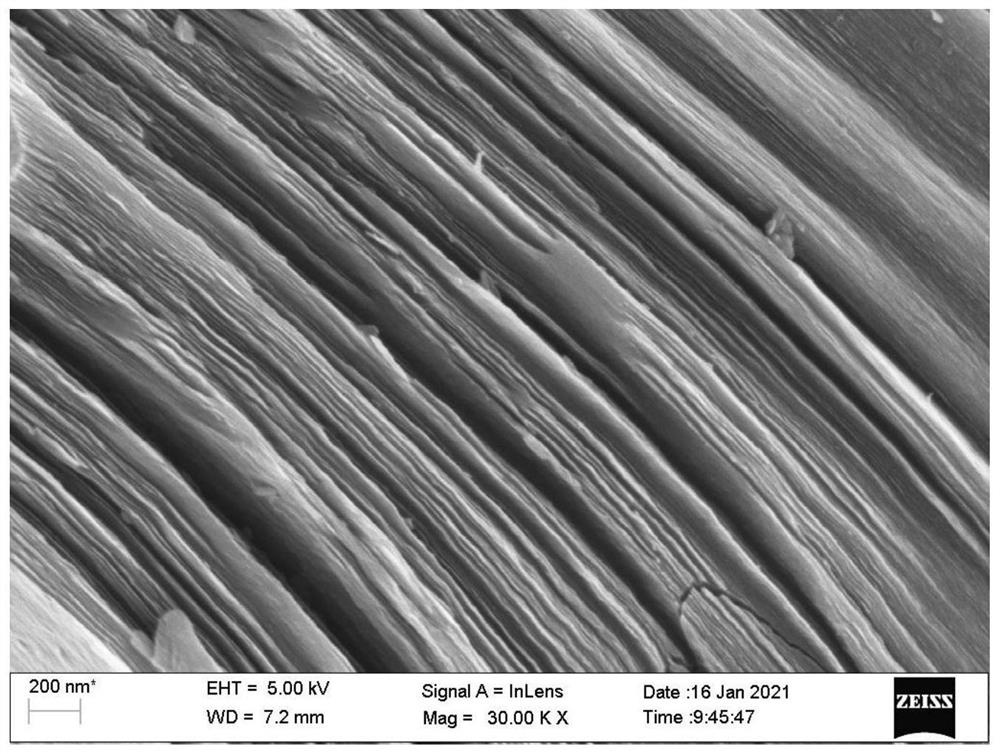

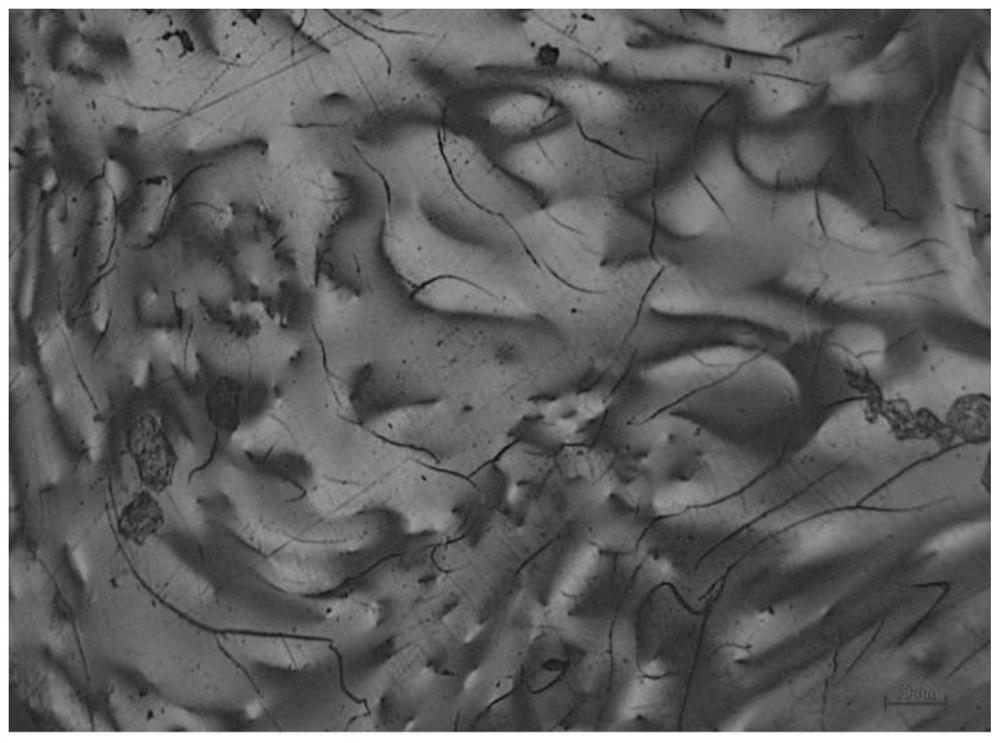

Method for preparing needle coke by medium and low temperature coal tar pitch composite extraction modification

ActiveCN113604241AHigh in fiberStable structureCoking carbonaceous materialsBulk chemical productionCarbonizationNitrogen gas

The invention belongs to the technical field of coal chemical industry, and relates to a method for preparing needle coke by medium and low temperature coal tar pitch composite extraction modification, the method comprises the following steps: 1) cutting pitch of a 360-540 DEG C fraction section from medium and low temperature coal tar full fraction; 2) sequentially adopting an organic mixed solvent extraction process, an ionic liquid extraction process and a component modification process to obtain refined asphalt from the cut asphalt; 3) carrying out thermal polymerization on the refined asphalt under a magnetic field condition to obtain semicoke; and 4) in a nitrogen atmosphere, calcining the semicoke, and cooling to obtain the needle coke. The content of N in the refined asphalt is less than 2%, the content of O is 3.5-4.2%, and the aromaticity fA is 0.7-0.9. Medium and low temperature coal tar pitch is taken as a raw material, the refined pitch is obtained by adopting a composite extraction modification process, effective directional regulation and control of the raw material are realized, the hydrogen supply capacity in the intermediate phase forming process is improved, the viscosity of the carbonization system is reduced, and the prepared product is stable in structure and high in fiber content.

Owner:NORTHWEST UNIV(CN)

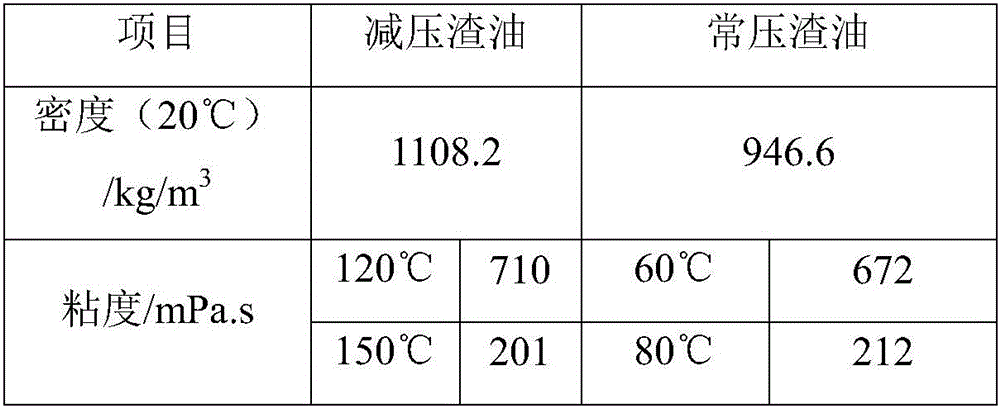

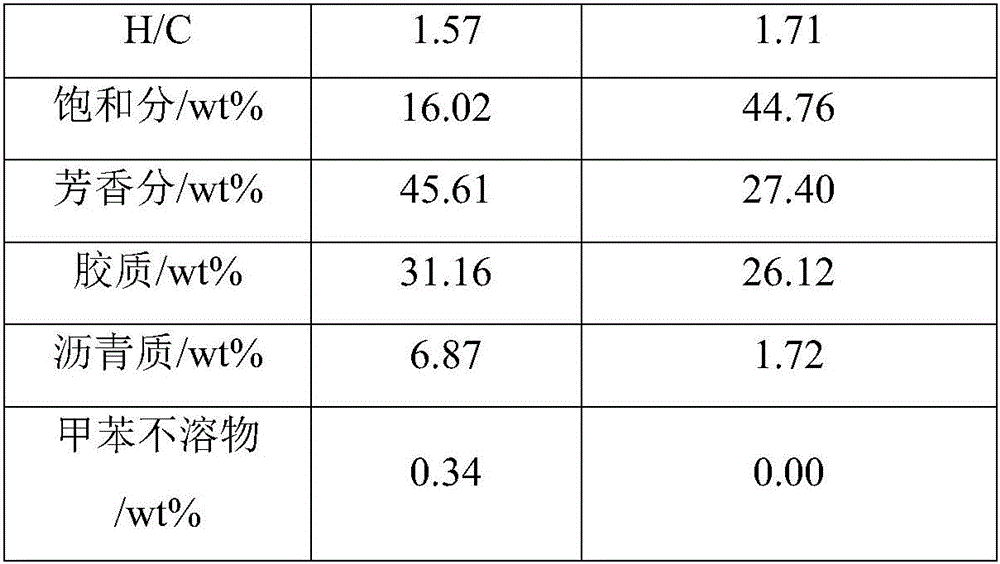

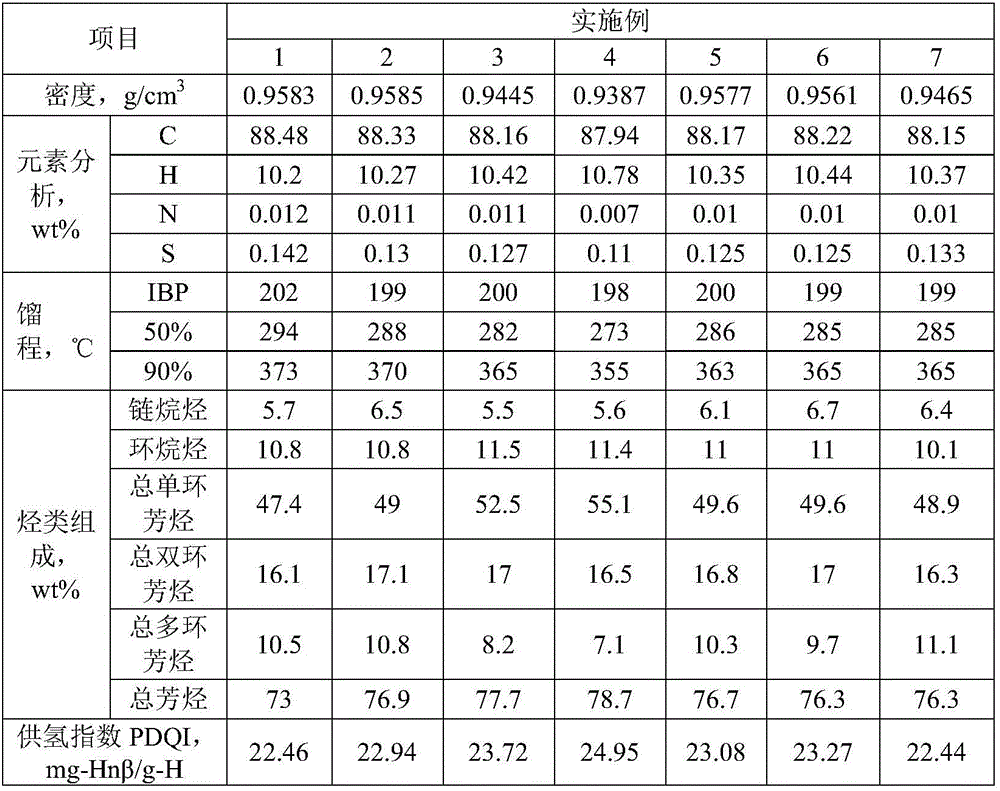

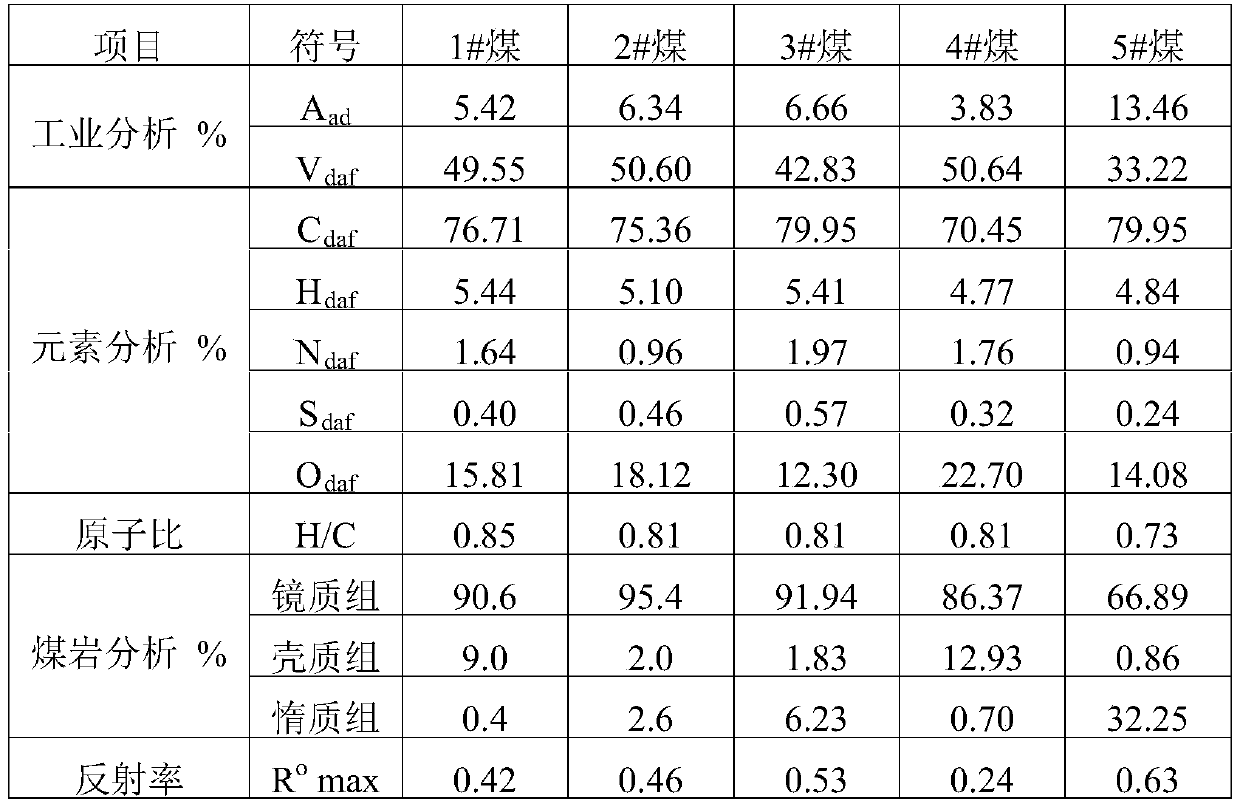

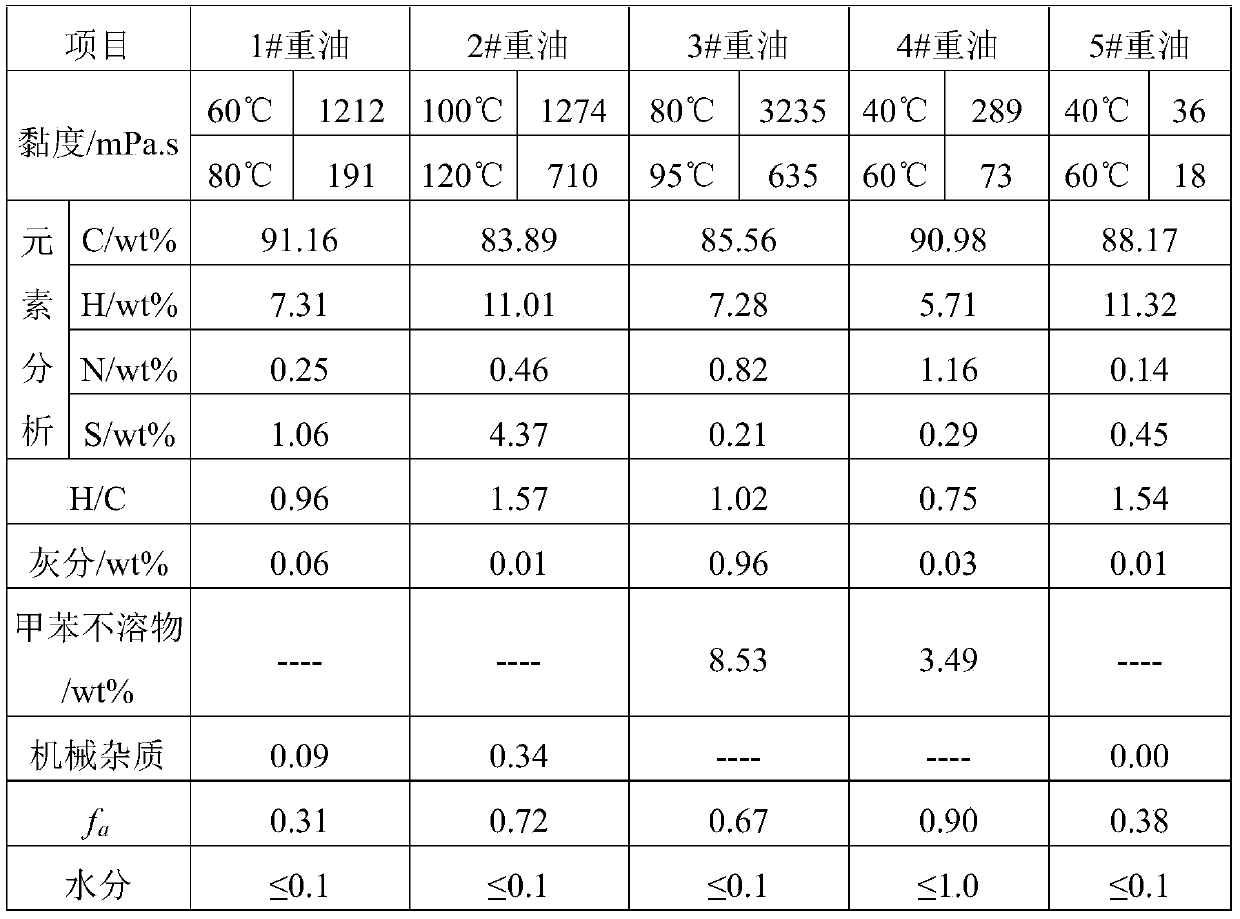

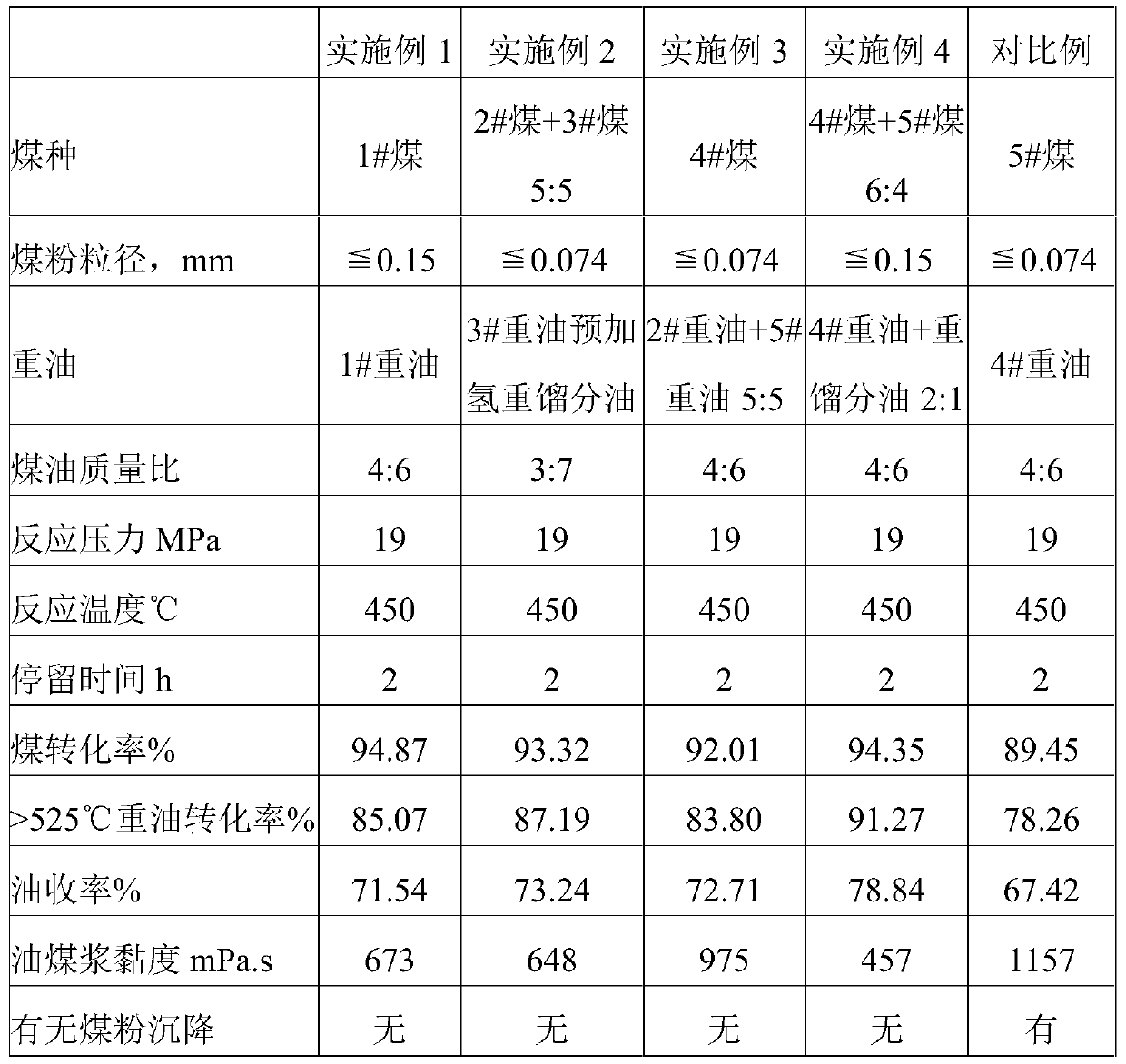

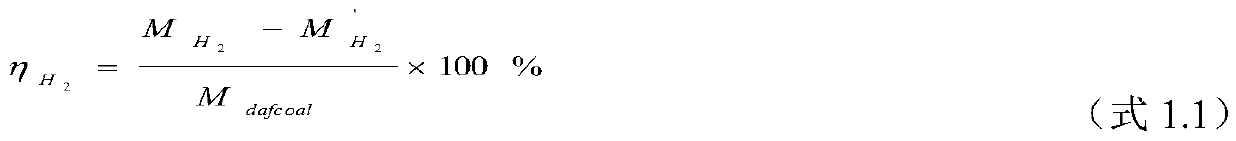

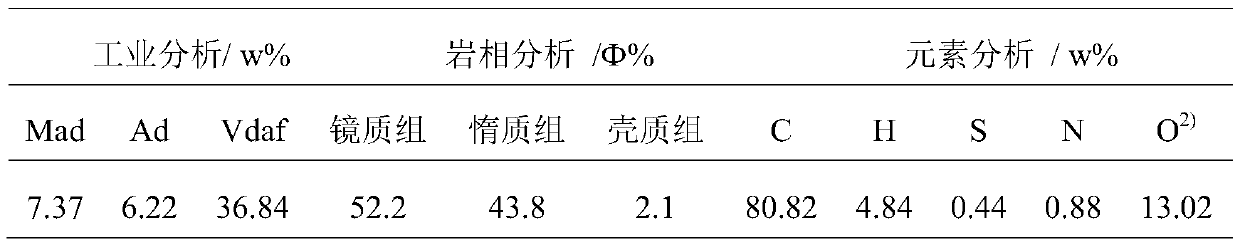

Preparation method of high-matching coal-oil slurry

The invention provides a preparation method of high-matching coal-oil slurry. The preparation method comprises the following steps: carrying out coal washing, crushing and drying, and grinding the dried coal into coal powder; mixing the coal powder with heavy oil according to a certain ratio; and adding a catalyst, and carrying out stirring to prepare the coal-oil slurry. The coal meets the following requirements that the volatile content is larger than or equal to 37%, the hydrogen-carbon atom ratio is larger than or equal to 0.75, the inertinite content is less than or equal to 20%, and vitrinite reflectance is less than or equal to 0.65. The heavy oil meets the following requirements that the ash content is less than or equal to 1.0%, dynamic viscosity of the heavy oil at 100 DEG C is less than or equal to 1500 MPa, the hydrogen-carbon atomic ratio is 0.7-1.70, and the aromatic degree is greater than 0.20. The coal-oil slurry prepared by the method has high matching performance, andthe coal and heavy oil in the coal-oil slurry can be prevented from layering, so that the problem that coking is caused due to local overheating caused by the fact that the coal-oil slurry is deposited in a preheater or a reactor can be solved. Meanwhile, the synergistic effect between the coal and heavy oil can be fully exerted, the conversion rate and the oil yield of the coal and heavy oil areimproved, and therefore the method is more practical.

Owner:CCTEG CHINA COAL RES INST

Direct coal liquefaction method

InactiveCN110041954AImprove hydrogen supply capacityImprove conversion rateLiquid hydrocarbon mixture productionSlurrySolvent

The invention provides a direct coal liquefaction method. The method comprises the following steps: S1, enabling tetrahydronaphthalene, dihydrophenanthrene, dihydroanthracene, naphthalene and decalinto be mixed to form a hydrogen-supplying solvent; S2, enabling pulverized coal and the hydrogen-supplying solvent to be filled into an autoclave to form coal-oil slurry, and enabling the coal-oil slurry to be subjected to direct coal liquefaction reaction to obtain a reaction solution; and S3, collecting n-hexane soluble matter, which is a liquefied oil product, in the reaction solution. In the direct coal liquefaction method provided by the invention, a solution formed by mixing the tetrahydronaphthalene, the dihydrophenanthrene, the dihydroanthracene, the naphthalene and the decalin is adopted as the hydrogen-supplying solvent. The hydrogen-supplying solvent has a very strong hydrogen-supplying capacity, can effectively reduce hydrogen consumption in the process of direct coal liquefaction, and can remarkably improve the coal liquefaction conversion rate and oil yield, finally, the coal liquefaction conversion rate can be as high as 88% or more, the oil yield can be up to 63-68%, andthe hydrogen consumption is 5% or less.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Peony-seed-oil soft capsule and preparation method thereof

The invention relates to the technical field of vegetable-oil soft capsules, in particular to a peony-seed-oil soft capsule and a preparation method thereof. The peony-seed-oil soft capsule is prepared by mixing and gelling of raw materials, capsule pressing and forming, hardening, sizing, scrubbing and drying. The peony-seed-oil soft capsule comprises the following raw materials in parts by weight: 80-95 parts of peony seed oil, 1-3 parts of fucosterol, 1-3 parts of squalene, 1-3 parts of propyl gallate, 0.05-0.25 part of tocopherol, 0.05-0.25 part of soya bean lecithin, 0.15-0.25 part of vitamin C, 5-10 parts of gelatin, 5-10 parts of water, 1.3-2.5 parts of sorbierite, and 2.5-5 parts of glycerol. The peony-seed-oil soft capsule is nutritious and safe, has the obvious effects of reducing blood fat, blood pressure and cholesterol, and can enhance the self immunity, prevent the diabetes, prevent and treat cancers, reduce weight, prevent cerebral stroke and myocardial infarction, clear harmful substances in blood, prevent and treat heart diseases and relieve the climacteric syndrome.

Owner:HEZE RUIPU PENOY IND TECH DEV

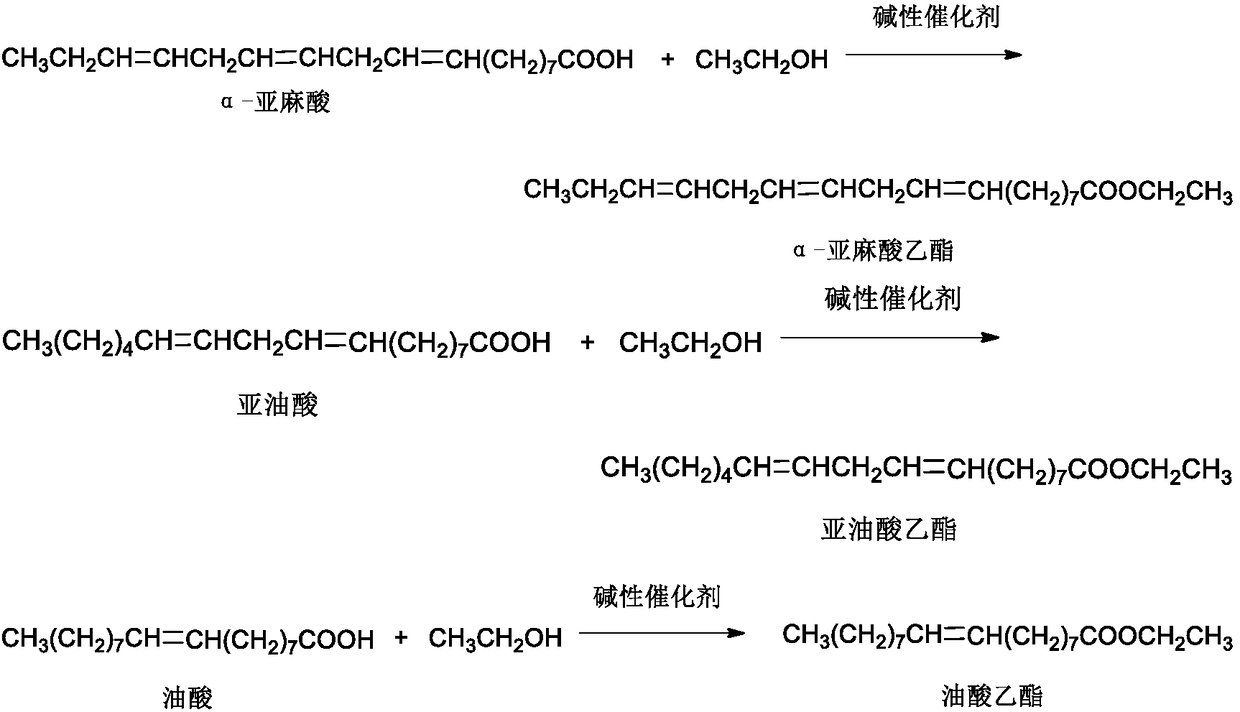

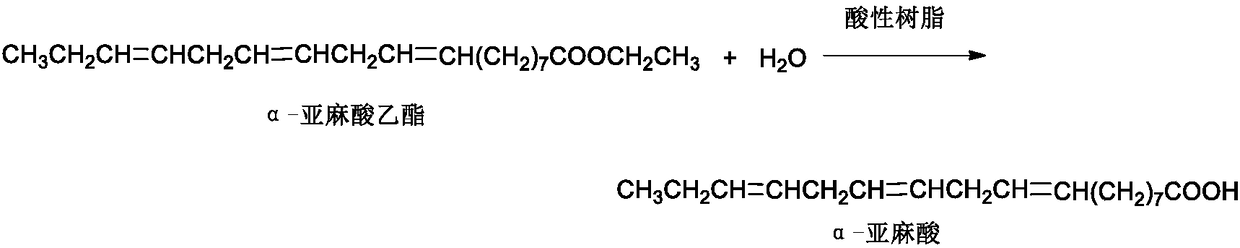

Peony seed oil and processing technology thereof

InactiveCN109007064ABacteriostaticAnti-inflammatoryFatty acid esterificationFatty acids production/refiningNutritive valuesThree level

The invention discloses peony seed oil and a processing technology thereof. The peony seed oil comprises components as follows: crude peony seed oil, a propolis liquid, a compound antioxidant and a preservative. The processing technology comprises steps as follows: pretreating peony seeds, performing enzymolysis of peony seeds and tretament after enzymolysis to obtain crude peony seed oil, conducting an esterification reaction on the crude peony seed oil and ethanol, performing three-level molecular distillation, urea complexation and hydrolysis of ester to obtain alpha-linolenic acid, linoleic acid and oleic acid, and mixing and stirring the three substances with the propolis liquid, the compound antioxidant and the preservative until the mixed solution is clear to obtain finished peony seed oil. The peony seed oil has good quality and high nutrient value, has the unsaturated fatty acid content of 97% or above, takes linolenic acid and linoleic acid as main materials, has light colorand better anti-oxidation function. The processing technology is short in extraction time and high in extraction rate.

Owner:江苏国色天香油用牡丹科技发展有限公司

Method for preparing benzaldehyde and benzyl alcohol

ActiveCN107954840AHigh selectivityImprove conversion rateOrganic compound preparationHeterogenous catalyst chemical elementsDistillationBenzaldehyde

The invention relates to the technical field of preparation of benzaldehyde and benzyl alcohol, and discloses a method for preparing benzaldehyde and benzyl alcohol. The method comprises the followingsteps: a mixed solution containing benzoate and tetrahydronaphthalene is allowed to react under the presence of a bifunctional catalyst, and a reaction product is subjected to distillation separation, wherein the bifunctional catalyst comprises manganese oxide, zinc oxide, aluminum oxide, and iron oxide and / or molybdenum oxide; and based on a standard of the total weight of the manganese oxide, the zinc oxide and the aluminum oxide, the content of the manganese oxide in terms of MnO2, the zinc oxide in terms of ZnO, and the aluminum oxide in terms of Al2O3 is 15-56% by weight, 15-55% by weight, and 5-40% by weight respectively, and the sum of the content of the iron oxide in terms of Fe2O3 and the molybdenum oxide in terms of MoO2 is 1-10% by weight. The method can improve the conversionrate of the benzoate and the selectivity of benzaldehyde and benzyl alcohol, so as to produce benzaldehyde and benzyl alcohol with a high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal liquefaction method

ActiveCN101643660BReduce oxygen contentReduce wearLiquid hydrocarbon mixture productionLiquid productThermal state

The invention provides a coal liquefaction method, and the method comprises the following steps: (1) carrying out solvent thermal extraction pre-treatment on raw materials of coal; (2) carrying out thermal state solid-liquid separation; (3) concentrating the liquid part for obtaining ultra-pure coal slurry; or carrying out back extraction on the liquid part for preparing solid ultra-pure coal, and mixing with a thermal extraction solvent for preparing ultra-pure coal slurry; and (4) carrying out liquefaction reaction on the ultra-pure coal slurry for obtaining a coal liquefied oil product, wherein, the thermal extraction solvent is a liquid product obtained by carrying out hydrogenation treatment on the coal liquefied oil, such as the liquid products obtained by carrying out the hydrogenation treatment on coal liquefied light oil, coal liquefied middle oil and / or coal liquefied heavy oil, a coal liquefaction hydrogenation circulating solvent, or the mixture thereof. The method can reduce hydrogen consumption during the liquefaction process, water yield and gas yield, reduce wear on coal liquefaction equipment and be conductive to realizing the recycling of a coal liquefaction catalyst. The method can adopt any traditional liquefaction process and be conductive to saving energy consumption.

Owner:CHINA COAL RES INST +1

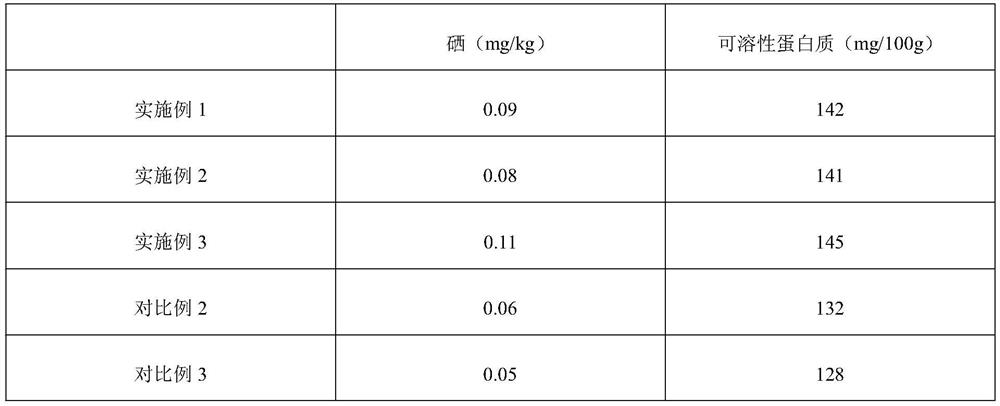

Rice machining process

InactiveCN111700213AAvoid churnPrevent spoilageSeed preservation by coatingFood coatingBiotechnologyFreeze-drying

The invention provides a rice machining process. Selenium-rice rice is used as a raw material; and firstly, the selenium-rice rice is subjected to three-machine series rice milling to prepare husked rice, then the husked rice is subjected to two-machine series rice milling to obtain refined rice and an aleurone-embryo mixture, then the aleurone-embryo mixture is subjected to superfine grinding toprepare superfine powder with a particle size smaller than or equal to 10mum, the superfine powder is dispersed into basic aqueous solution to prepare pre-treating liquid, and finally, the refined rice is soaked in the pre-treating liquid to carry out vacuum freezing drying, so that films are formed on the surfaces of the refined rice to obtain the pre-treated refined rice, then the pre-treated refined rice is flushed by utilizing the basic aqueous solution, and natural air-drying is carried out. In the machining process of the rice machining process provided by the invention, after an aleurone layer and embryos, which are rich in nutrient substances, are prepared into the superfine powder, the superfine powder is recoated to the surfaces of the refined rice, and finally, the films are formed on the surfaces by utilizing the basic aqueous solution so as to effectively avoid loss and deterioration of the nutrient substances such as selenium, proteins and the like in the machining and storing process.

Owner:崔艳兰

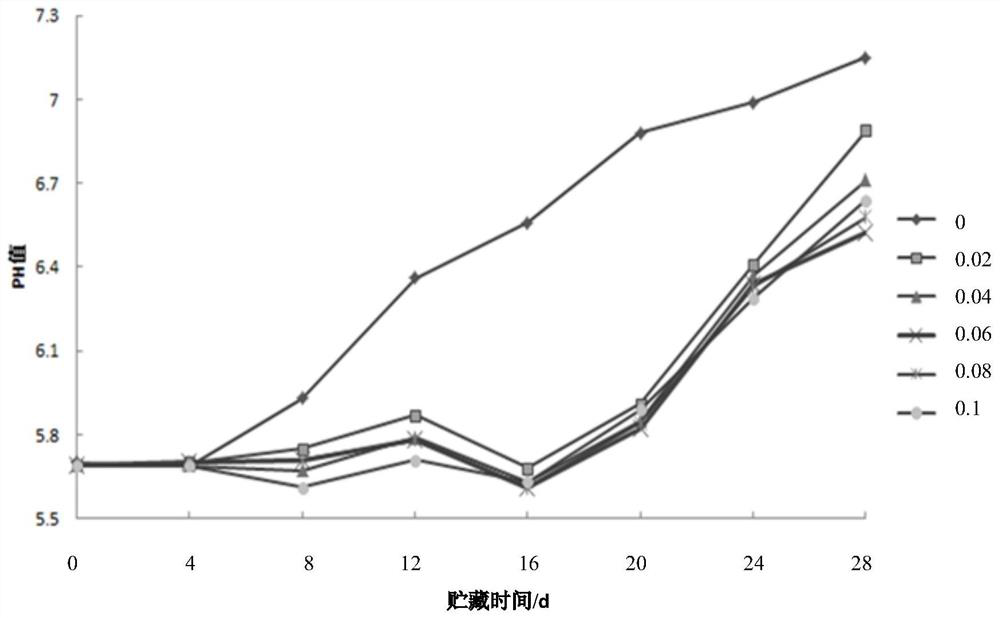

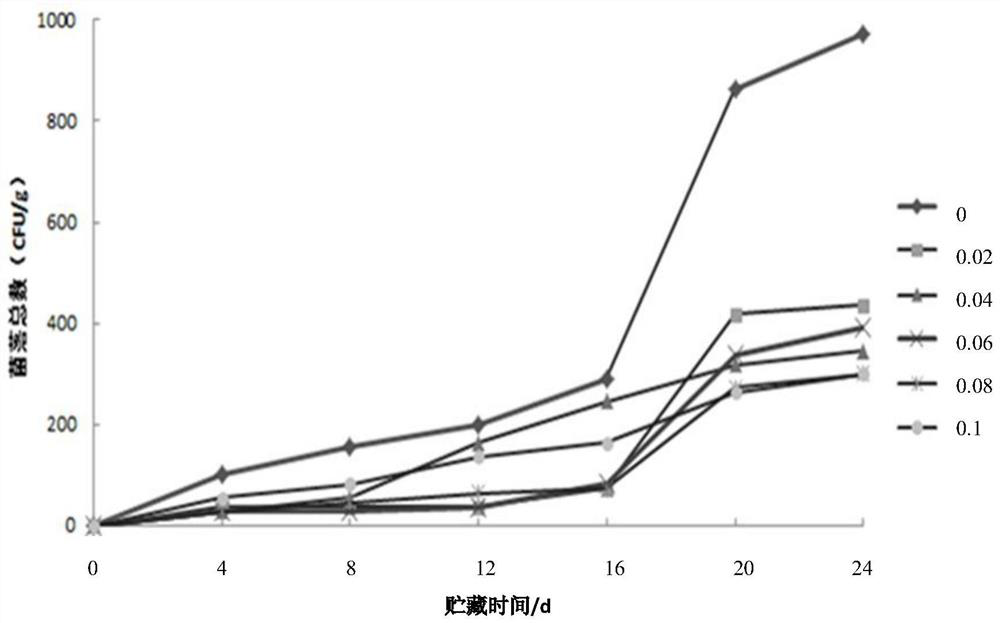

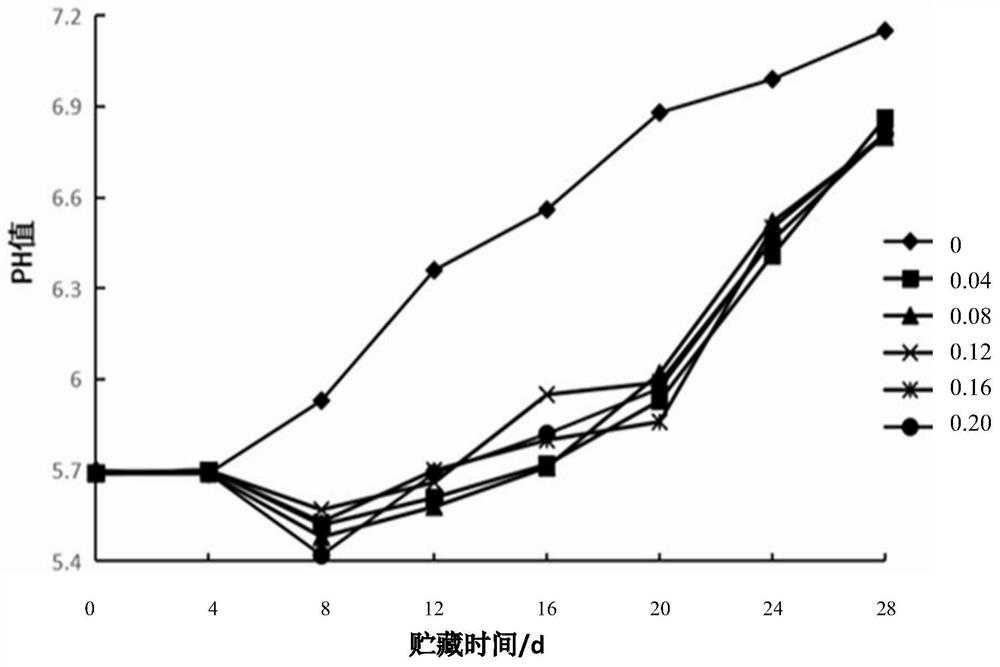

Formula, preparation method and use method of biological preservative for chilled beef

PendingCN113662035APrevent intrusionAvoid churnMeat/fish preservation using chemicalsAcidic food ingredientsBiotechnologyPhenolic content in tea

The invention discloses a formula of a biological preservative for chilled fresh beef. The formula comprises the following raw materials in parts by mass: 0.01 to 0.03 part of nisin, 0.006 to 0.03 part of epsilon-polylysine, 0.004 to 0.02 part of tea polyphenol, 0.006 to 0.03 part of natamycin and 20 parts of modified sodium alginate antibacterial liquid. A preparation method of the modified sodium alginate antibacterial liquid comprises the following steps: dissolving 0.4-1.6 parts by mass of multi-aldehyde sodium alginate in 20 parts by mass of pure water, adjusting the pH value to 6.0-6.5 by using a gluconic acid solution, then adding 0.02-0.1 part by mass of lysozyme and 0.04-0.2 part by mass of kojic acid, carrying out a stirring reaction at 32-40 DEG C for 0.5-2 h, then adding 0.01-0.05 part by mass of an artemisia apiacea extract, carrying out uniform stirring, and conducting cooling to 0-4 DEG C so as to obtain the modified sodium alginate antibacterial liquid. According to the invention, a tight biological membrane is formed on the surface of the beef by utilizing the cross-linking effect of the multi-aldehyde sodium alginate and beef protein molecules, bacteria invasion is prevented, meanwhile, juice loss of the chilled beef is prevented, and the immobilized lysozyme and the artemisia apiacea extract are utilized for slow-release sterilization, so that the shelf life of the chilled beef is effectively prolonged.

Owner:BENGBU COLLEGE

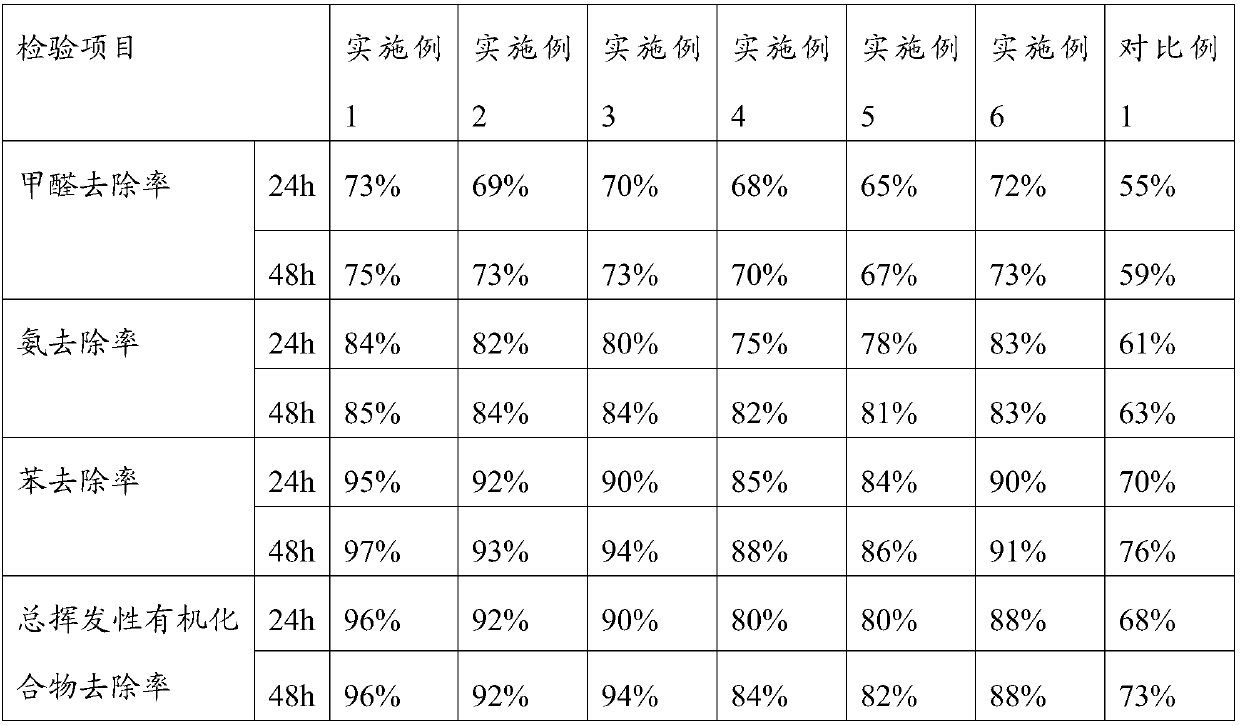

Air purification composition and preparation method and application thereof

InactiveCN109675427AImproves antioxidant activityImprove hydrogen supply capacityGas treatmentDispersed particle separationAdhesiveHazardous substance

The invention relates to an air purification composition and a preparation method and application thereof. The air purification composition is prepared from the following raw materials in parts by mass: 0.02-0.1 part of tea polyphenol type compounds, 0.008-0.03 part of an antibacterial agent and 2-4 parts of an adhesive. According to the air purification composition, through optimization of the mass ratio of the tea polyphenol type compounds, the antibacterial agent and the adhesive, the obtained air purification composition can effectively play the characteristics of the tea polyphenol type compounds, meanwhile, carry the tea polyphenol type compounds through the adhesive and make the tea polyphenol type compounds stick to each other, so as to produce the synergistic amplification effectto enhance purification activity, meanwhile, growth or reproduction of certain microorganisms (bacteria, fungi, yeast, algae, virus, and the like) is kept below the necessary level by addition of a certain amount of the antimicrobial agent, volatile organic compounds are prevented from further increasing or leavening, harmful substances such as formaldehyde, benzene, ammonia and total volatile organic compounds in air can be effectively removed, the toxic effect on a human body is reduced, and the air quality is improved.

Owner:广州康滤净化科技有限公司

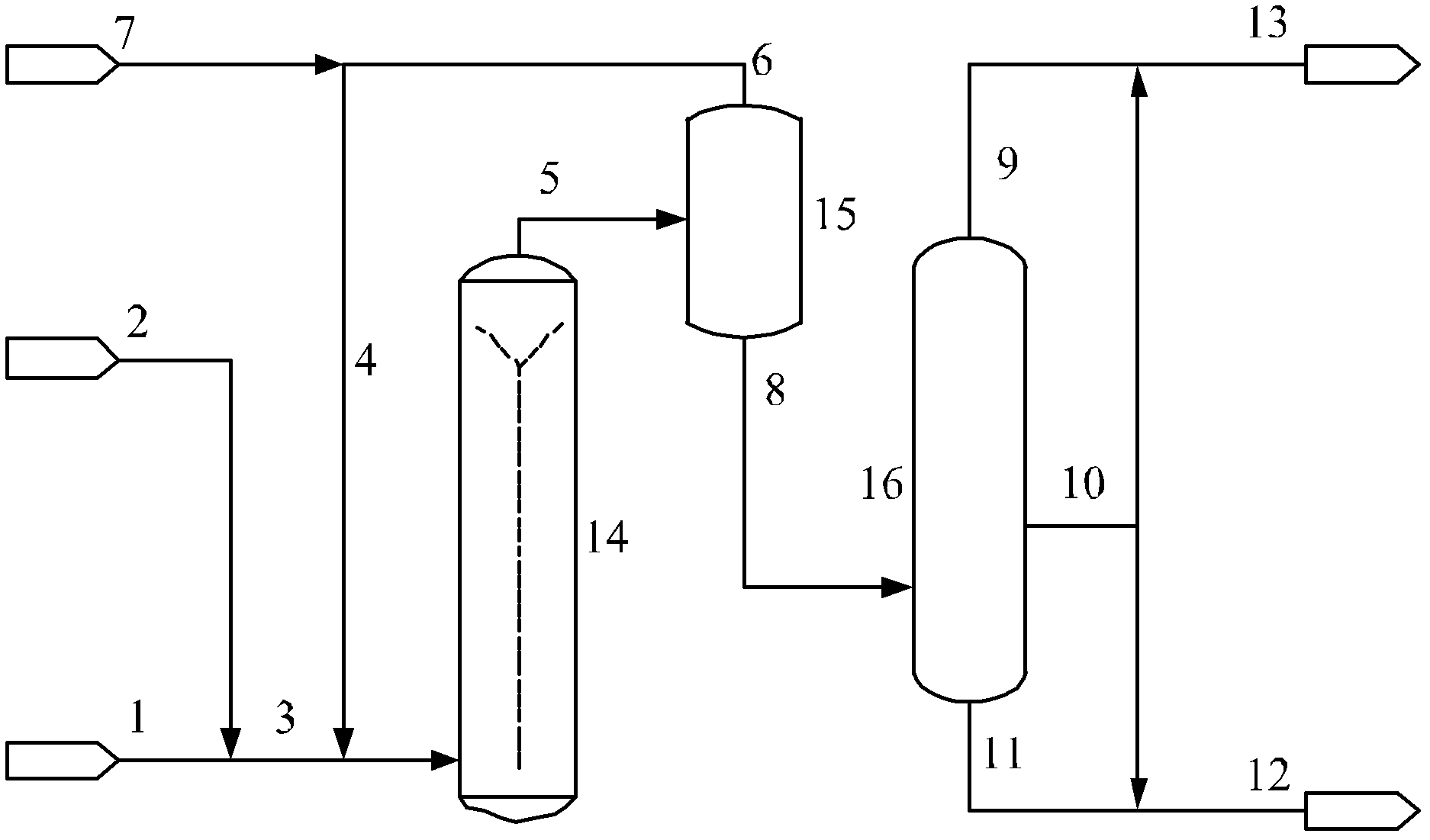

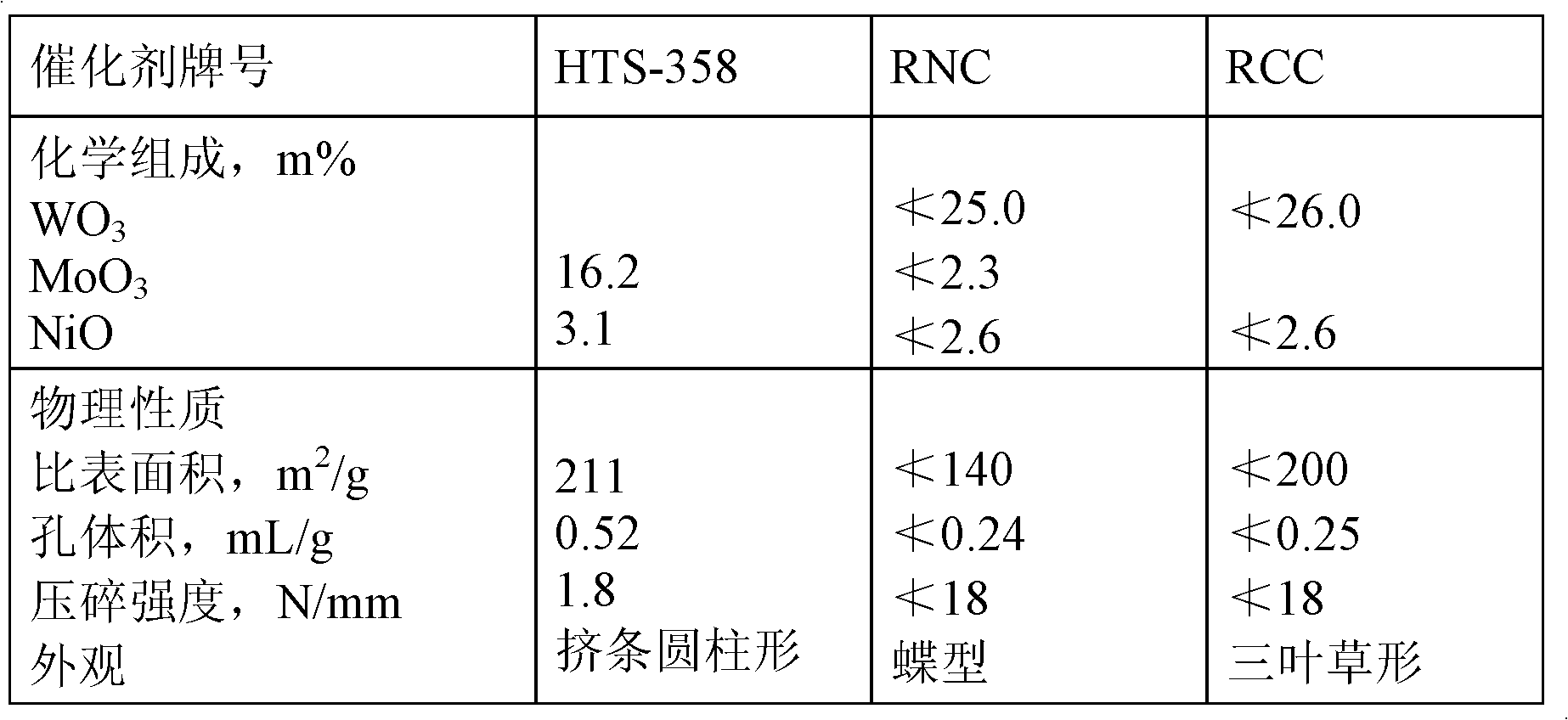

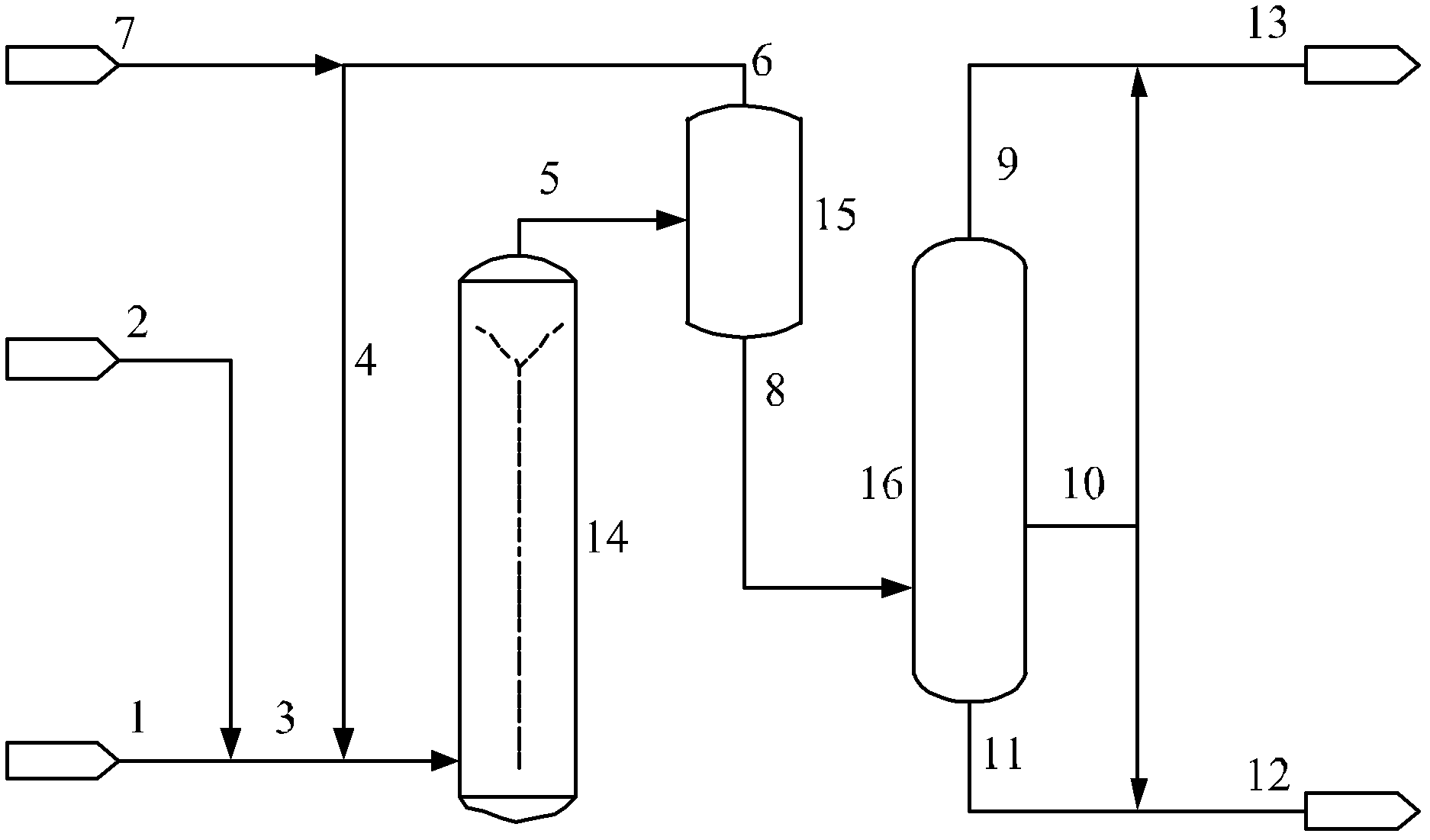

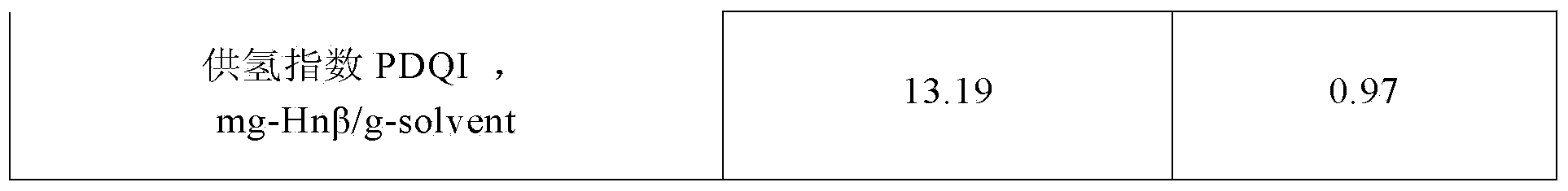

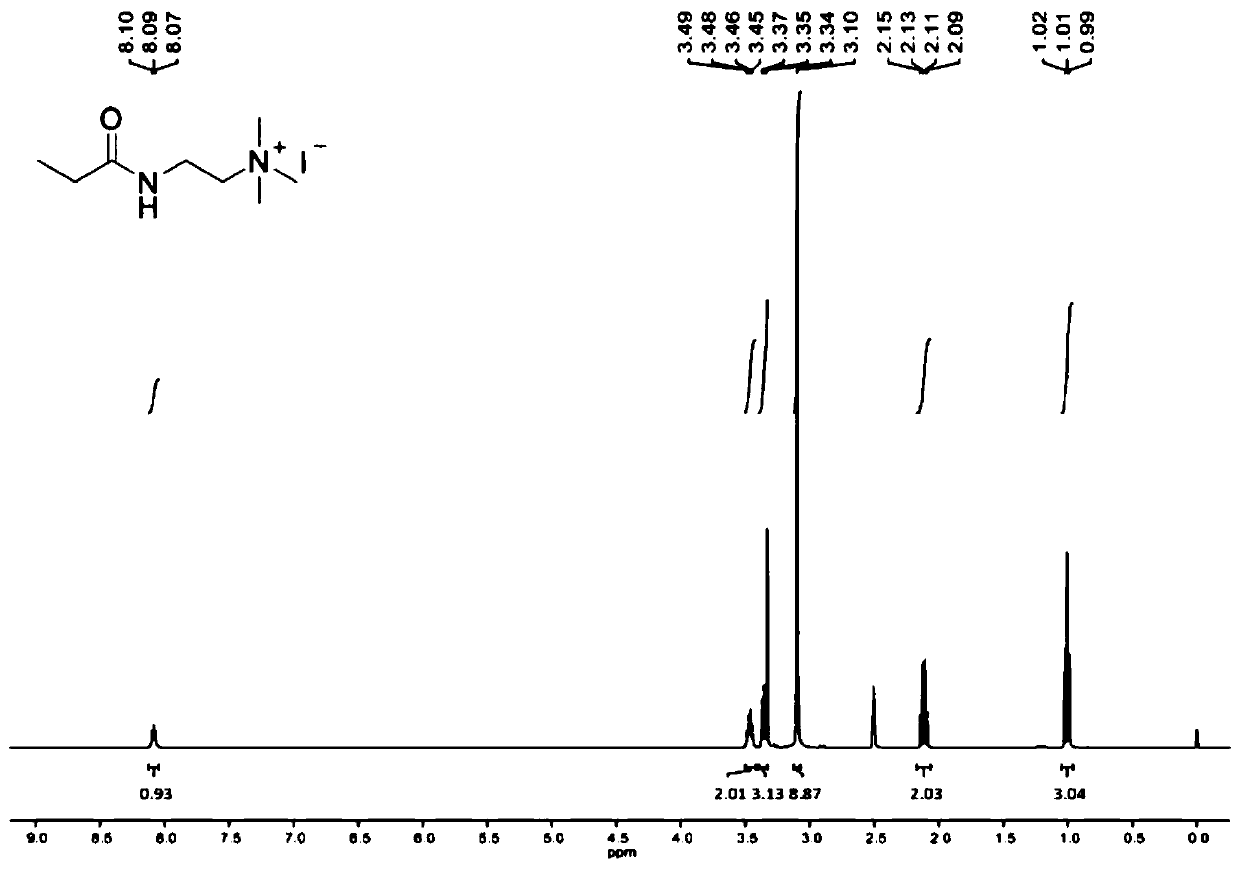

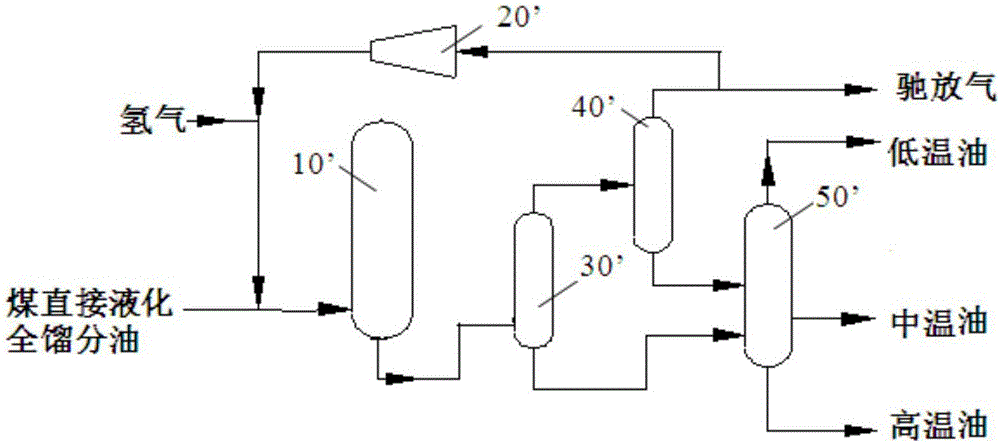

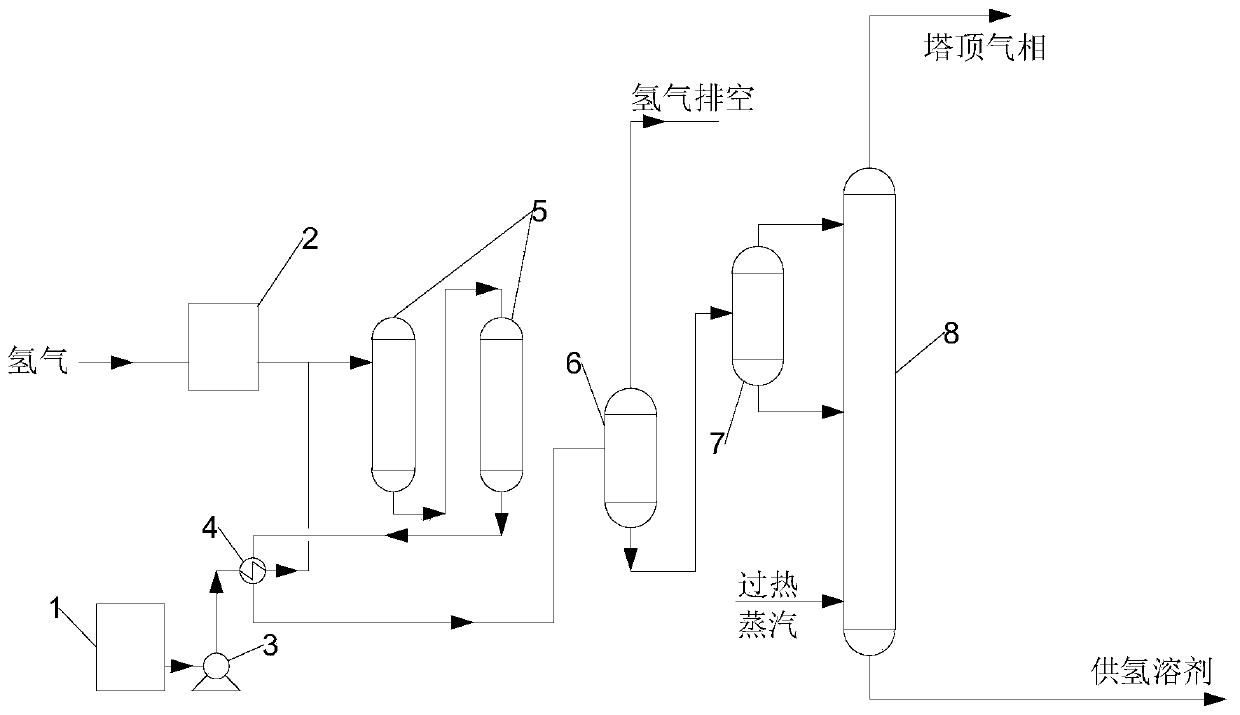

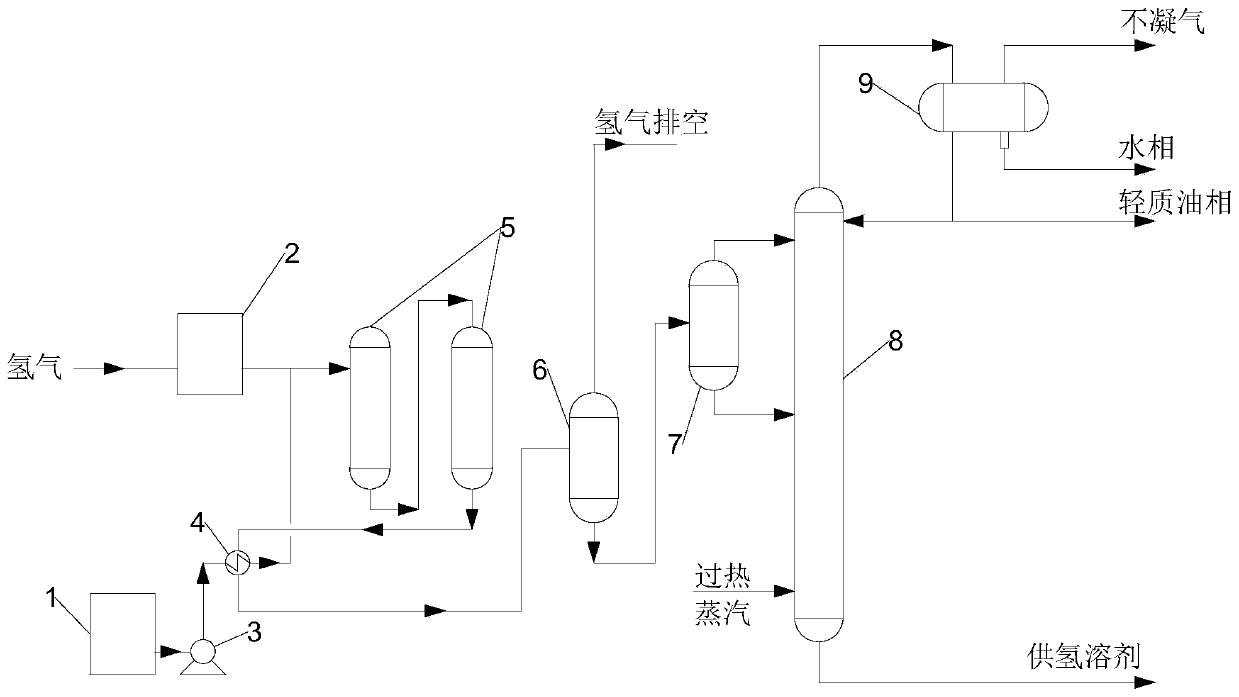

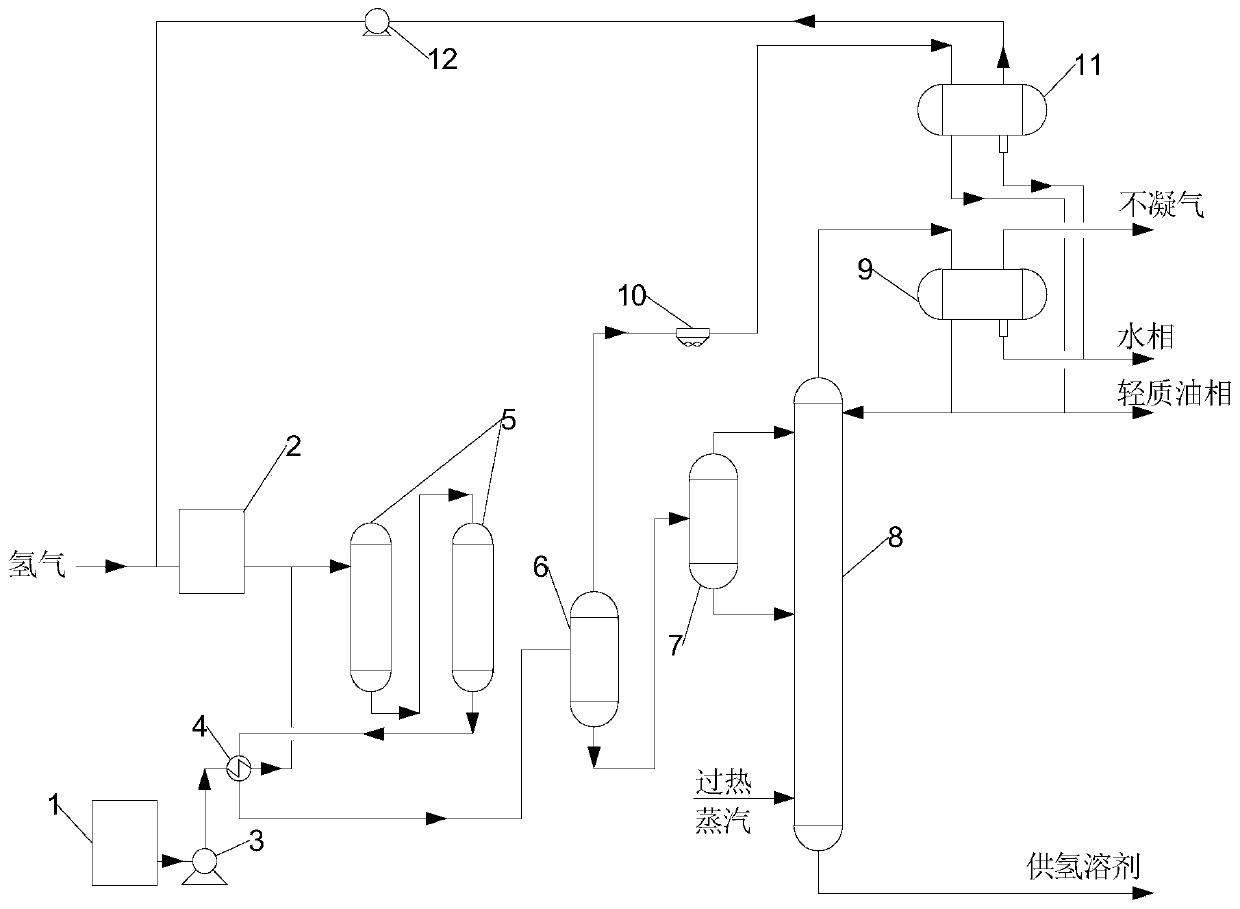

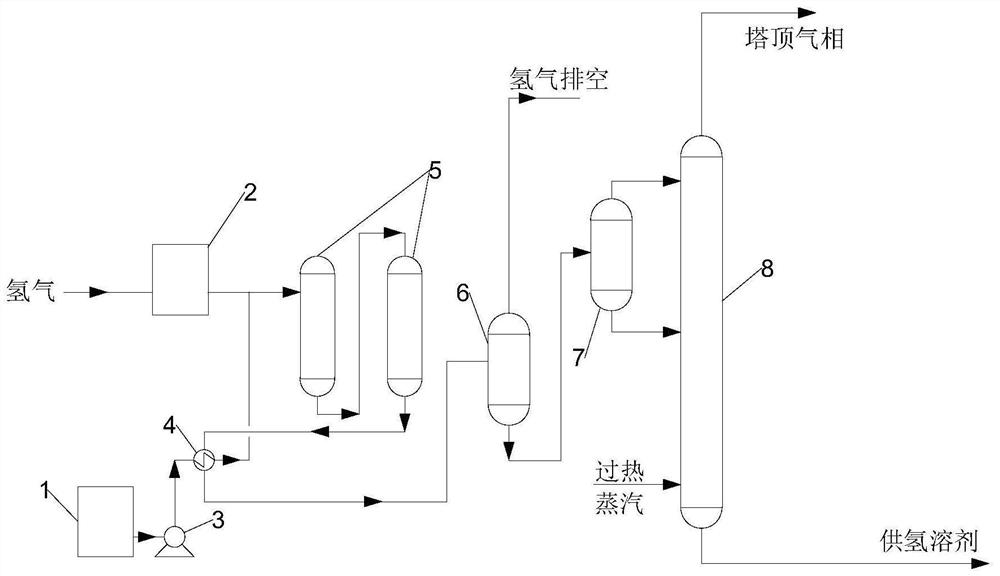

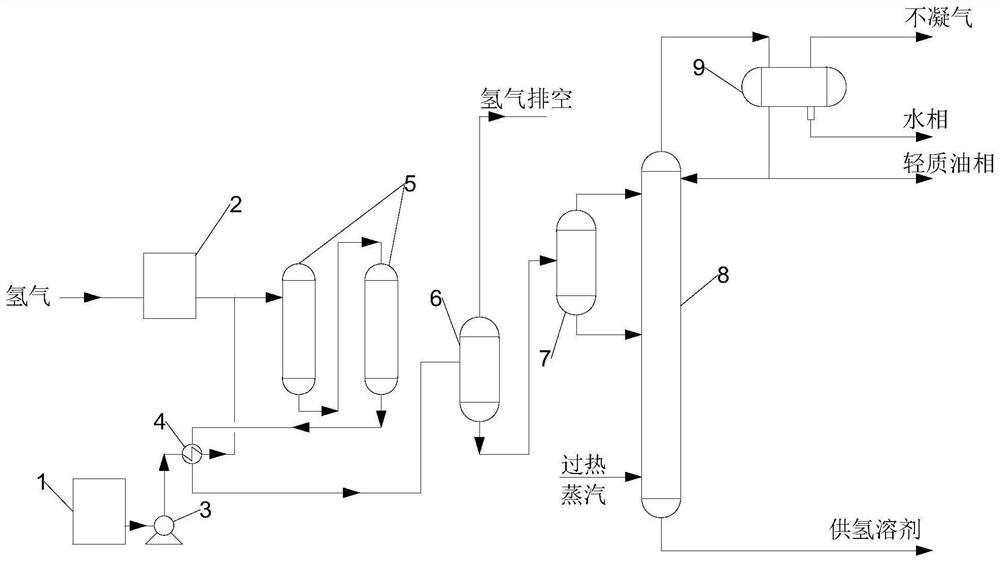

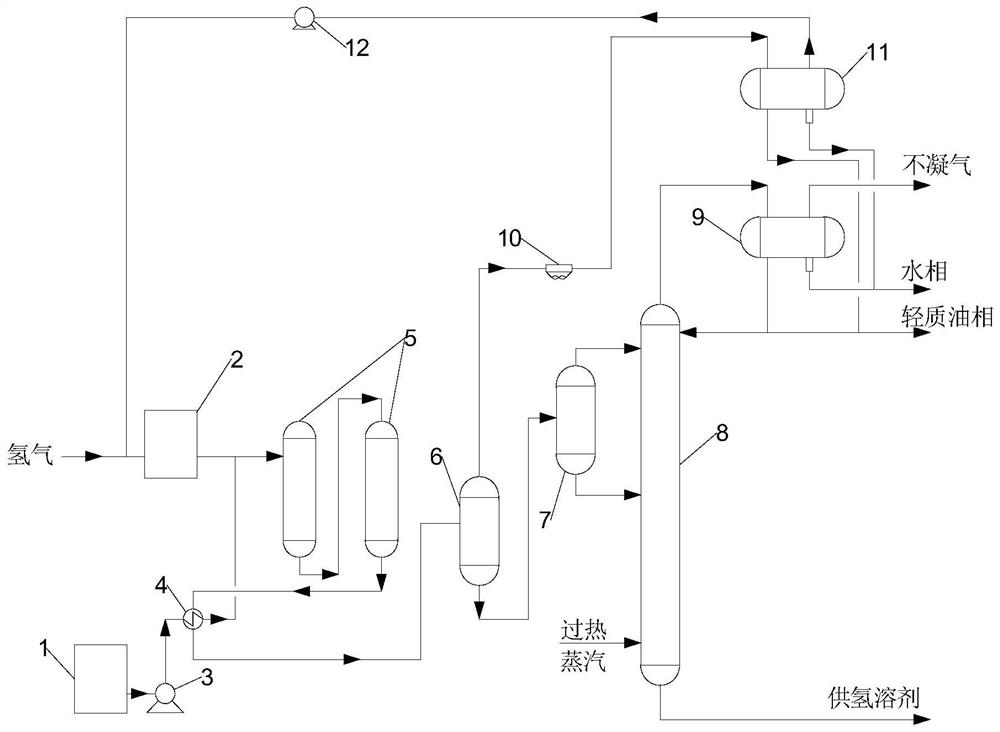

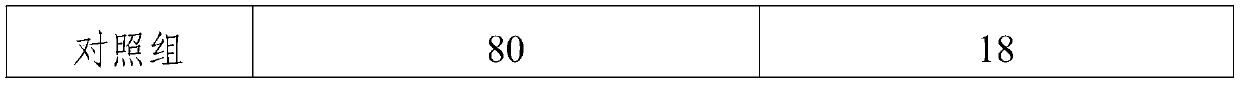

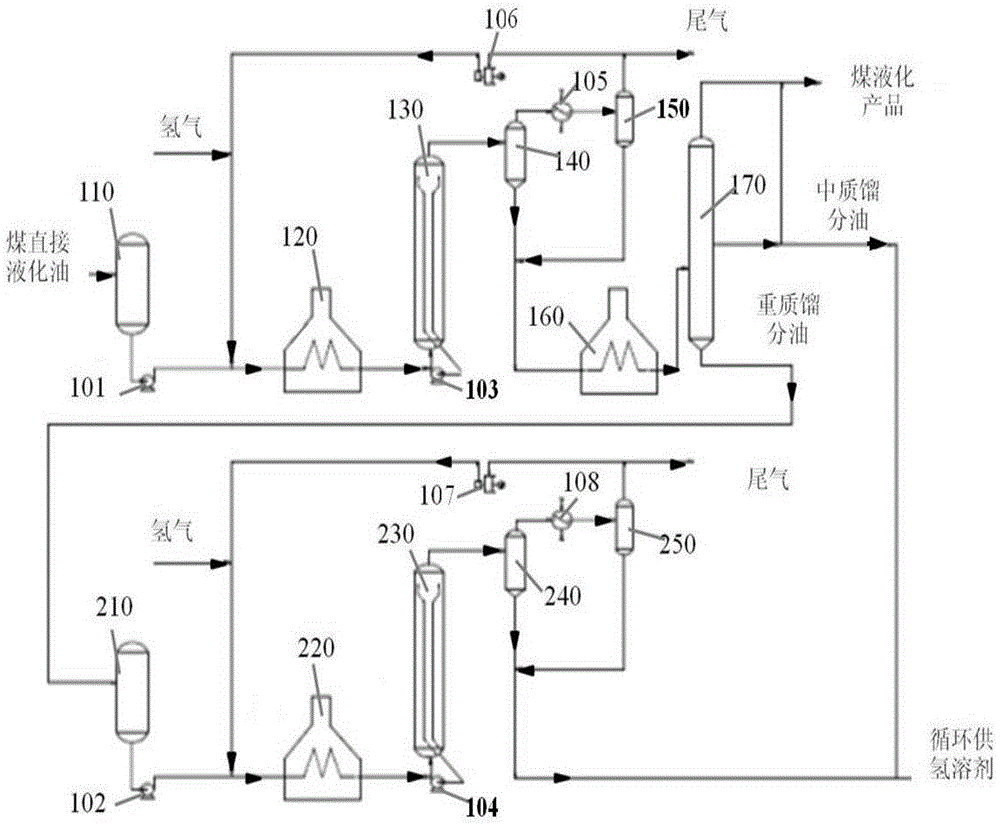

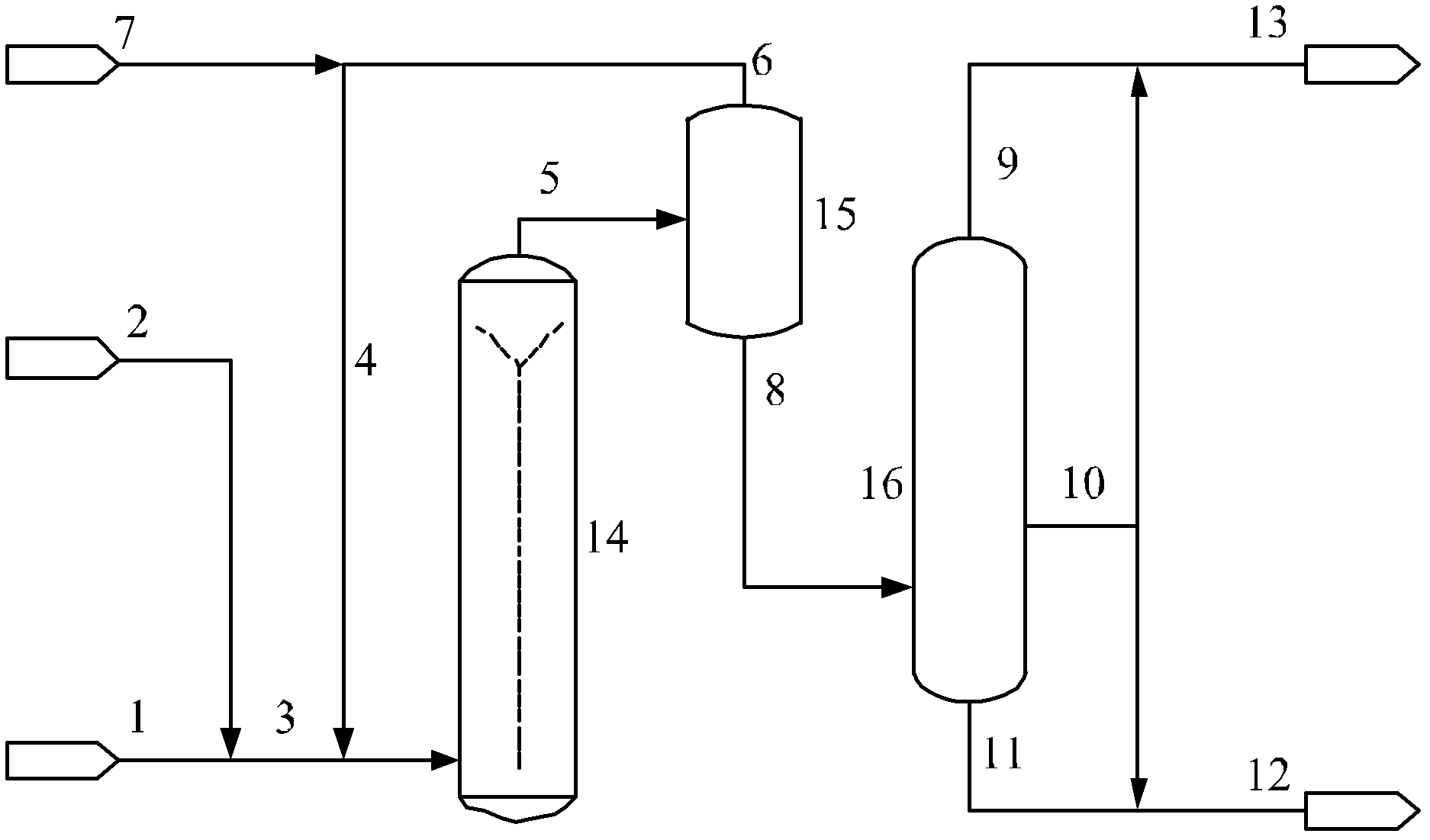

Production device and preparation method of hydrogen-donor solvent

ActiveCN110003949AImprove hydrogen supply capacitySimple structureTreatment with hydrotreatment processesHydrogenation reactionReaction temperature

The present application relates to a production device and preparation method of a hydrogen-donor solvent. The production device comprises a hydrogen supply unit, a raw material oil supply unit, a hydrogenation reaction unit, a separation unit and a stripping column; the preparation method comprises the following steps: after raw material oil is heated, mixing the heated oil and hydrogen, performing a hydrogenation reaction, and performing gas-liquid separation to obtain hydrogenated base oil; performing fractional distillation on the hydrogenated base oil, adding light components of the baseoil from the upper part of the stripping column, and adding heavy components of the base oil from the middle of the stripping column; and performing stripping on the light components of the base oil and the heavy components of the base oil to obtain the hydrogen-donor solvent at the bottom of the stripping column. The hydrogen-donor solvent provided by the invention has a hydrogen supply index of20.82, and strong hydrogen supply capacity; the preparation method of the hydrogen-donor solvent has a simple process, and prevents supersaturation of the hydrogen-donor solvent by controlling operation parameters such as a hydrogen-oil ratio, reaction temperature, reaction pressure and a space velocity; and the yield of the hydrogen-donor solvent is as high as 88.64%.

Owner:胜帮科技股份有限公司

Coal treatment method of high inertinite content coal and heavy oil

ActiveCN106906001BLow viscosityGuaranteed concentrationLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesLiquid productPtru catalyst

The invention relates to a method for co-processing coal high in inertinite content and heavy oil. The method includes the steps that heavy oil, a first hydrogenation-free recycling solvent and a catalyst are mixed to prepare oil slurry, hydrocracking is conducted to obtain a first product, and separation is conducted to obtain first light distillate oil and first heavy distillate oil; the first heavy distillate oil, a second hydrogenation-free recycling solvent and pulverized coal are mixed to prepare coal-oil slurry, hydrocracking is conducted to obtain a second product, and separation is conducted to obtain second light distillate oil and second heavy distillate oil; one part of the second heavy distillate oil is separated to obtain residue and third heavy distillate oil, wherein the third heavy distillate oil serves as the first hydrogenation-free recycling solvent for preparing the oil slurry; the other part of the second heavy distillate oil serves as the second hydrogenation-free recycling solvent for preparing the coal-oil slurry; hydrogenation upgrading is conducted on the first light distillate oil and the second light distillate oil to obtain a third product, and separation is conducted to obtain naphtha, aviation kerosene and diesel oil. The method improves the conversion rate of the coal high in inertinite content, and the yield of the liquid product is increased.

Owner:CCTEG CHINA COAL RES INST

A production device and preparation method of a hydrogen-donating solvent

ActiveCN110003949BImprove hydrogen supply capacitySimple structureTreatment with hydrotreatment processesHydrogenation reactionHydrogen index

This application relates to a production device and preparation method of a hydrogen-donating solvent. The production device includes a hydrogen supply unit, a feedstock oil supply unit, a hydrogenation reaction unit, a separation unit, and a stripping tower; the preparation method includes the following steps: After the oil is heated, it is mixed with hydrogen, and after the hydrogenation reaction, the gas-liquid is separated to obtain a hydrogenated bottom oil; the hydrogenated bottom oil is fractionated, the light component of the bottom oil is fed from the middle and upper part of the stripping tower, and the heavy component of the bottom oil is fed from the upper part of the stripping tower. Feeding in the middle of the stripping tower; stripping the light components of the bottom oil and the heavy components of the bottom oil, and obtaining hydrogen-donating solvent oil at the bottom of the stripping tower. The hydrogen-supply index of the obtained hydrogen-supply solvent is as high as 20.82, and the hydrogen-supply capacity is strong; the process flow of the hydrogen-supply solvent preparation method is simple, and the hydrogen-supply solvent is prevented from supersaturated, and the yield of hydrogen-donating solvent is as high as 88.64%.

Owner:胜帮科技股份有限公司

Improved method of delay coking process

InactiveCN101302435BImproved coke kineticsReduce concentrationThermal non-catalytic crackingWaxNaphtha

The invention provides a method for improving the delayed coking technique. The method is as follows: coked raw material residual oil is heated by a heating furnace and enters into a coking tower; coke generated is accumulated in the coking tower; and gas, naphtha, light diesel oil, heavy diesel oil, light wax oil and heavy wax oil are obtained after separation of oil gas fluid products through acoking and fractionating tower. The light diesel oil, the heavy diesel oil, the light wax oil or the heavy wax oil are used as circulation materials through adjustment of the sources, the distillation range and the circulation of the circulation materials, and then the coking induction period of mixture can be prolonged and the coking dynamics of the coked raw material residual oil can be changed; and the coking reaction of the residual oil is delayed to be performed in the coking tower more completely, thereby achieving the aim of prolonging the operating period of a heating furnace tube. The operating period of the coking and heating furnace can be prolonged to be between 3 and 18 months generally according to the extended degree of the coking induction period determined by the sources,the distillation range and the circulation of the circulation materials selected.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Middle-aged and elderly health-care capsules and preparation method thereof

InactiveCN111557446AEnhances autoxidationIncreased autoxidationFood preservationFood shapingBenzoic acidVitamin C

The invention discloses a middle-aged and elderly people health care capsule and a preparation method thereof, which belongs to the technical field of health care products, the middle-aged and elderlypeople health care capsule comprises a content and a capsule shell, the content comprises the following raw materials by weight: 60-80 parts of olive oil, 15-25 parts of auxiliary oil, and 1-5 partsof vitamin; wherein the capsule shell is prepared from the following raw materials in parts by weight: 40 to 50 parts of gelatin, 30 to 40 parts of deionized water, 10 to 18 parts of glycerol, 5 to 8parts of sorbitol, 1 to 3 parts of polyethylene glycol, 1 to 2 parts of titanium dioxide, 3 to 5 parts of tea polyphenol and 0.1 to 0.5 part of preservative; by adding methyl hydroxybenzoate and ethylparaben, generation of aldehyde substances is effectively inhibited, the service life of the health-care capsule is prolonged, and release of the contents is facilitated; by adding the tea polyphenol,the tea polyphenol contains more than two ortho-hydroxyl polyhydric phenols, has strong hydrogen supply capacity and excellent oxidation resistance, inhibits self-oxidation of gelatin, and meanwhile,the tea polyphenol and vitamin C in the contents have a synergistic effect, so that the oxidation resistance of the tea polyphenol is further improved.

Owner:王素荣

Coal direct liquefaction circulating hydrogen supply solvent and its preparation method

ActiveCN104910961BImprove conversion rateHigh yieldTreatment with hydrotreatment processesGas phaseDissolution

The invention provides a direct-coal-liquefied circulating hydrogen-donor solvent and a preparation method thereof. The preparation method comprises the following steps: (S1) carrying out first-time catalytic hydrogenation on a direct-coal-liquefied effluent so as to obtain a first gas-phase product and a first liquid-phase product; (S2) carrying out fractional distillation on the first liquid-phase product so as to obtain a light oil fraction, a medium oil fraction and a heavy oil fraction; (S3) carrying out second-time catalytic hydrogenation on part or all of the heavy oil fraction so as to obtain a second liquid-phase product; (S4) mixing the second liquid-phase product with part or all of the medium oil fraction so as to form the direct-coal-liquefied circulating hydrogen-donor solvent, wherein the distillation range of the light oil fraction is lower than 200 DEG C, the distillation range of the medium oil fraction is 200-350 DEG C, and the distillation range of the heavy oil fraction is higher than 350 DEG C. According to the preparation method, the dissolution, dispersion and hydrogen supply effects of the circulating hydrogen-donor solvent during direct coal liquefaction reaction can be improved, and the conversion rate of coal and yield of oil are further increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for mixing and processing wash oil and direct coal liquefaction oil

ActiveCN102517071BImprove performanceImprove hydrogen supply capacityRefining to eliminate hetero atomsReaction temperatureHydrogenation process

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com