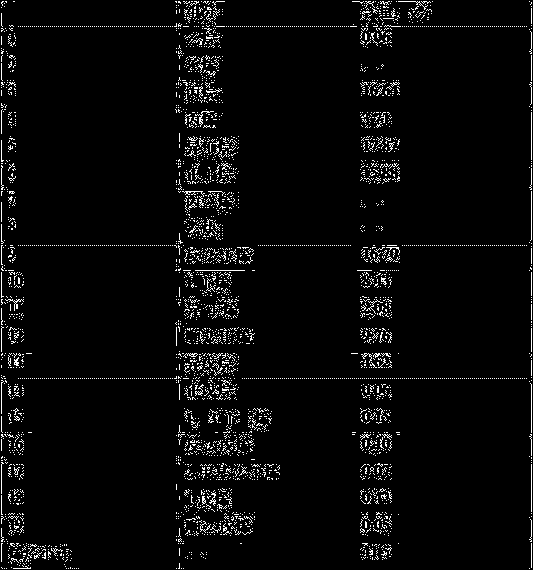

Patents

Literature

45results about How to "Reduce reaction temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

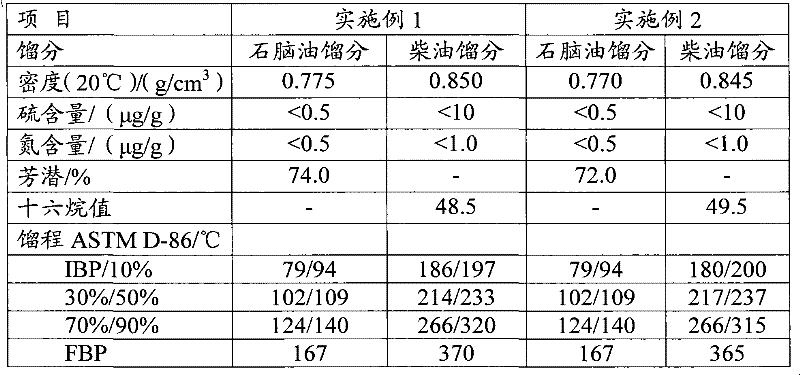

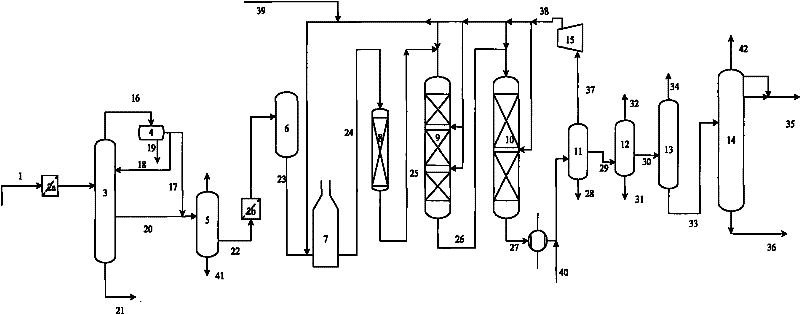

Method for producing clean diesel from coal tar

ActiveCN102443424AAvoid cokingAvoid inactivationTreatment with hydrotreatment processesChemical reactionSulfur

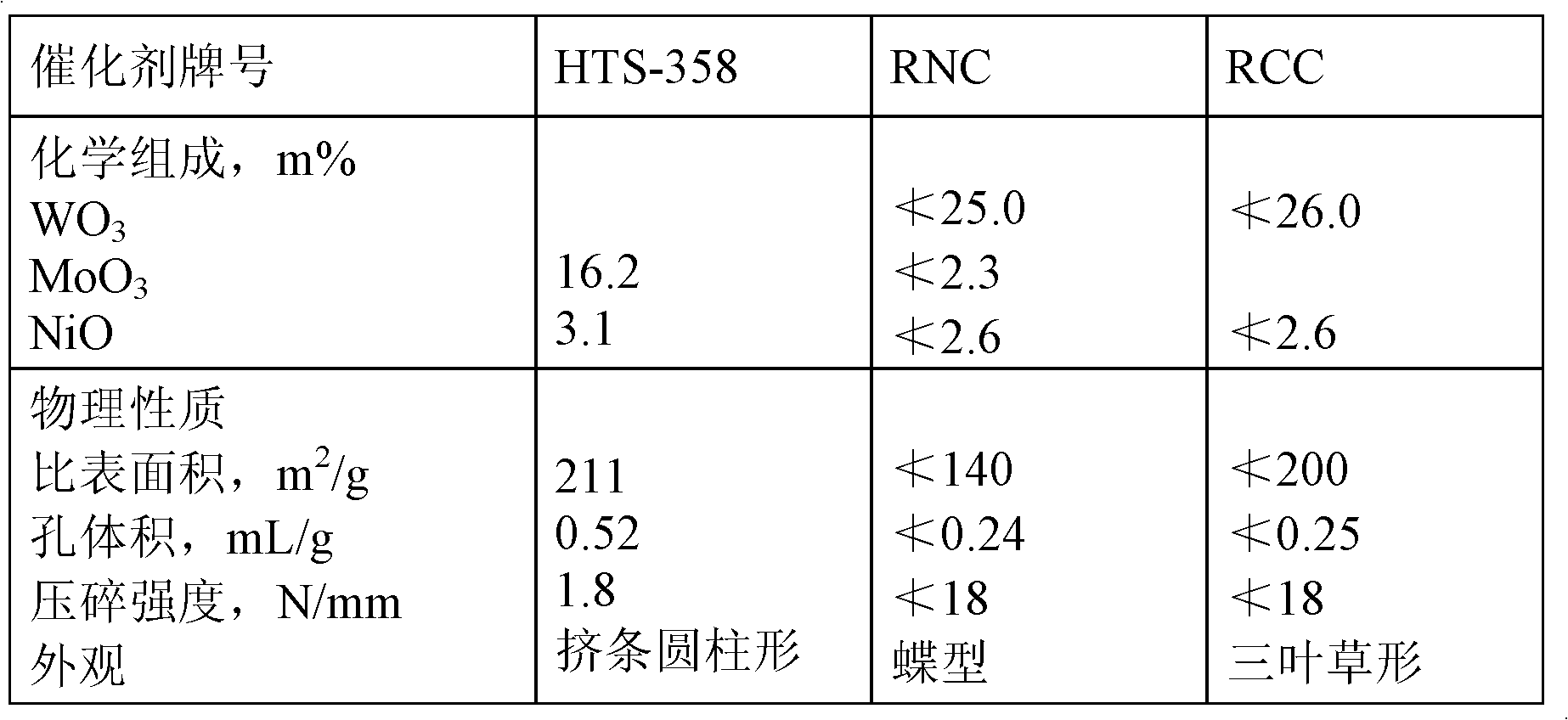

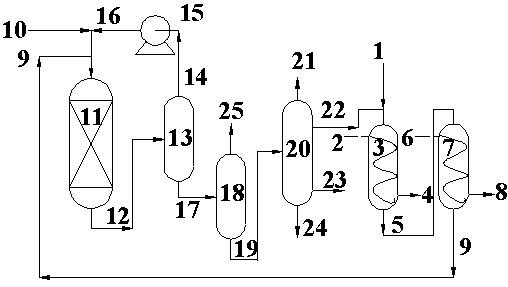

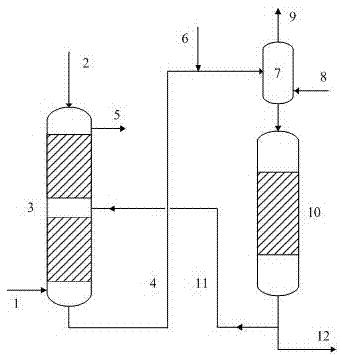

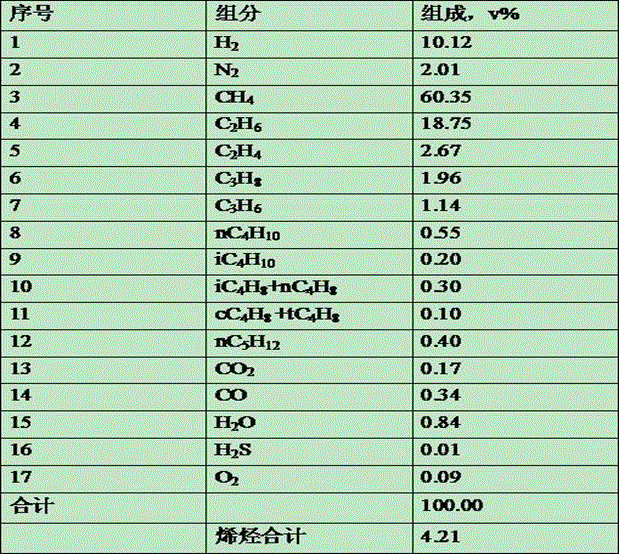

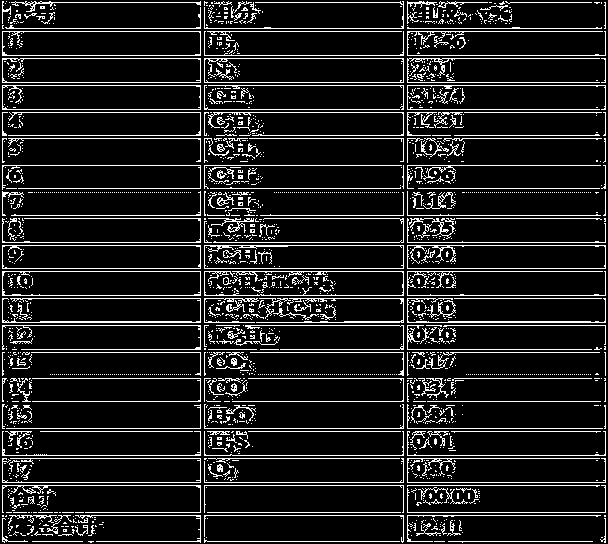

A method for producing clean diesel from coal tar comprises the following steps: introducing the coal tar raw materials and hydrogen into two tandem hydrogenation reaction zones in turn under the hydrogenation reaction to contact with a plurality of catalyst beds in the hydrogenation reaction zones; filling hydrogenation protective agent in the first hydrogenation reaction zone, and filling hydrorefining catalyst in the second hydrogenation reaction zone; controlling the temperature rise of each catalyst bed of hydrorefining reaction zone as 15-35 DEG C. After adopting the method provided by the invention, the sulphur content of the diesel product is less than 50 mug / g and the cetane number of the diesel product is more than 45. The method also can be used for transforming the gasoline fraction in the coal tar into reforming feedstock with more than 70% of potential aromatics. The invention can be also used for effectively increasing the use ratio of catalyst to improve the chemical reaction effect and prolong operating period of device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for mixing and processing wash oil and direct coal liquefaction oil

ActiveCN102517071AImprove hydrogen supply performanceReduce reaction temperature riseRefining to eliminate hetero atomsSolventChemistry

The invention provides a method for mixing and processing wash oil and direct coal liquefaction oil, which includes the following steps: (a) mixing the wash oil and the direct coal liquefaction oil to be mixed with hydrogen, and enabling the mixture to enter a mixed oil hydrogenation reactor; (b) enabling mixture of the wash oil, the direct coal liquefaction oil and the hydrogen in the step (a) to be contacted with hydrofining catalyst to be subjected to a reaction in the mixed oil hydrogenation reactor; and (c) separating and fractionating objects obtained from the reaction of step (b) and discharged from an outlet of the mixed oil hydrogenation reactor to obtain light distillate oil, medium distillate oil and heavy distillate oil. The heavy distillate oil is mixed with a part of the medium distillate oil to serve as hydrogen-donor solvent, and the light distillate oil is mixed with the rest medium distillate oil to obtain liquefaction product raw oil. The method can effectively convert coal tar and wash oil, obtains high-performance hydrogen-donor solvent and diesel products with high cetane number, and can avoid a phenomenon of speeding up deactivation of catalyst caused by overlarge reaction temperature rise in an independent hydrogenation process for the wash oil.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Cumyl hydroperoxide and propylene epoxidation method

ActiveCN104230855AReduce reaction temperature riseHigh selectivityOrganic chemistryChemical recyclingChemistryHydrogen peroxide

The invention relates to a cumyl hydroperoxide and propylene epoxidation method, which mainly solves the problems of high reaction temperature and high molar ratio of propylene and cumyl hydroperoxide to keep high reaction efficiency in the prior art. The method is as below: introducing the materials of cumyl hydroperoxide and liquid phase propylene into a reaction zone, and contacting the materials with a Ti-silica catalyst to conduct an epoxidation reaction under the conditions of epoxidation reaction temperature of 15-160 DEG C, pressure of 1.0-12.0 MPa and molar ratio of propylene and cumyl hydroperoxide of 2-30, so as to generate epoxypropane, wherein part of the epoxidation reaction products containing epoxypropane recycles to a reaction zone entrance. The technical scheme can well solve the above problems, and can be used in industrial production of epoxypropane from epoxidation of cumyl hydroperoxide and the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

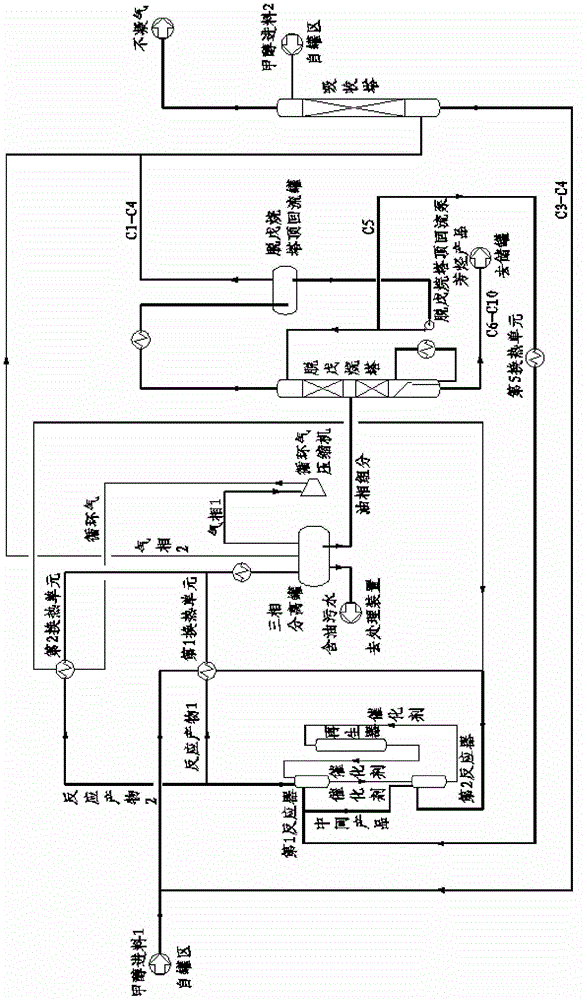

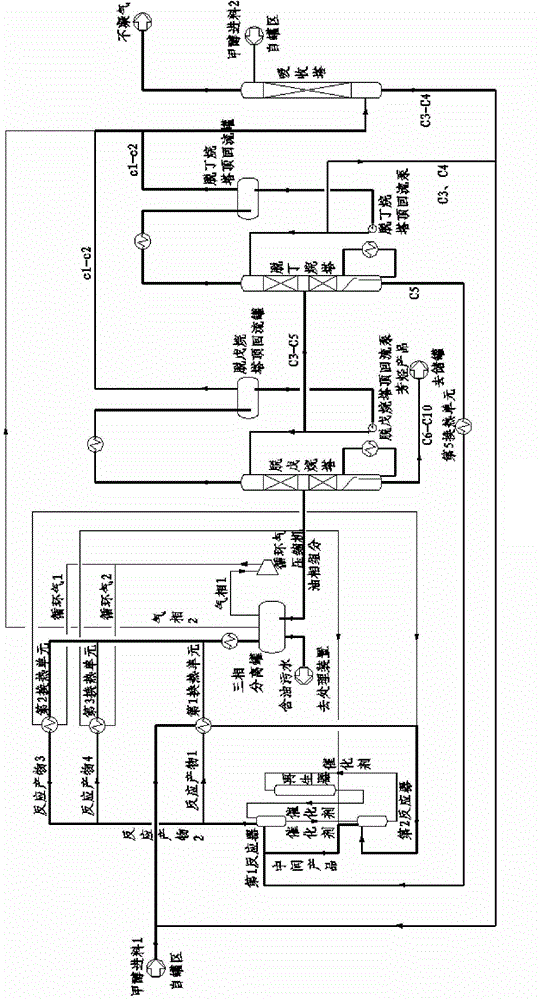

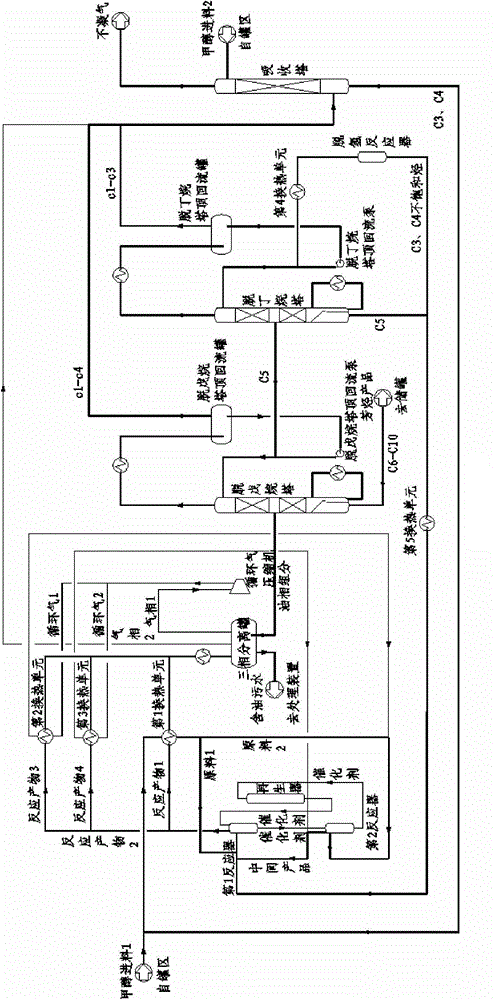

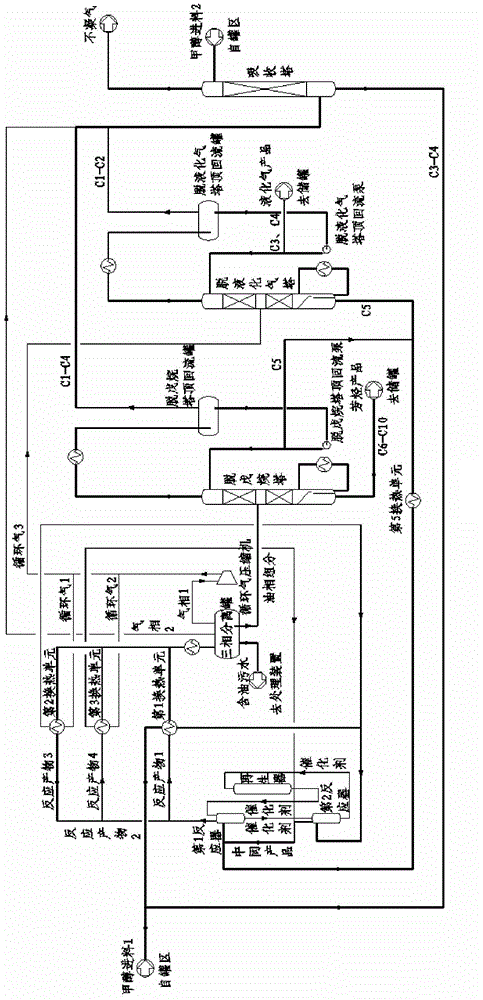

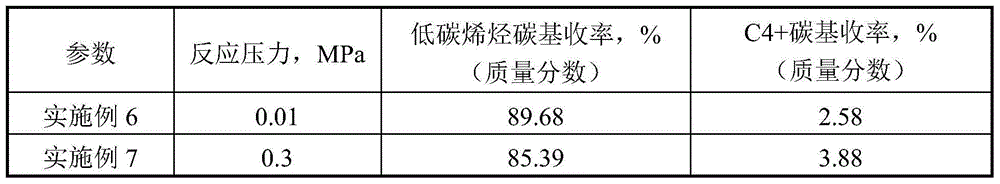

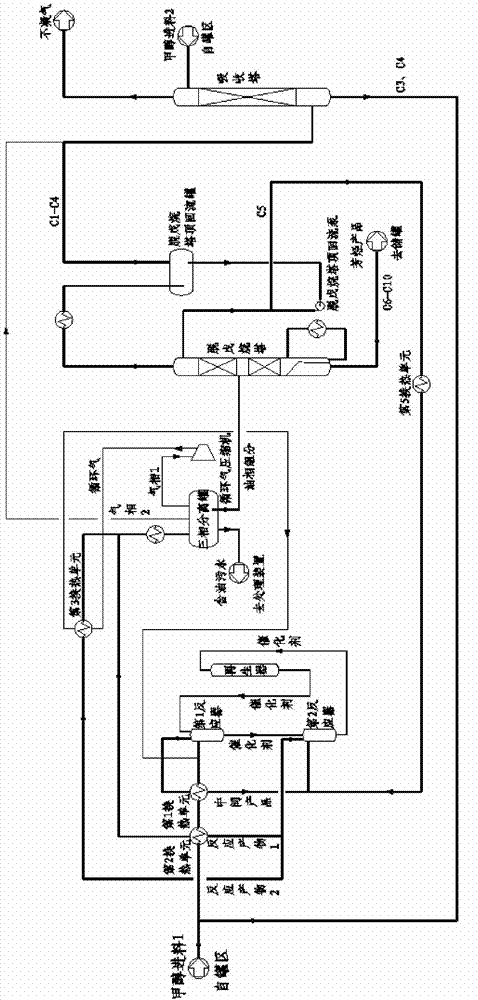

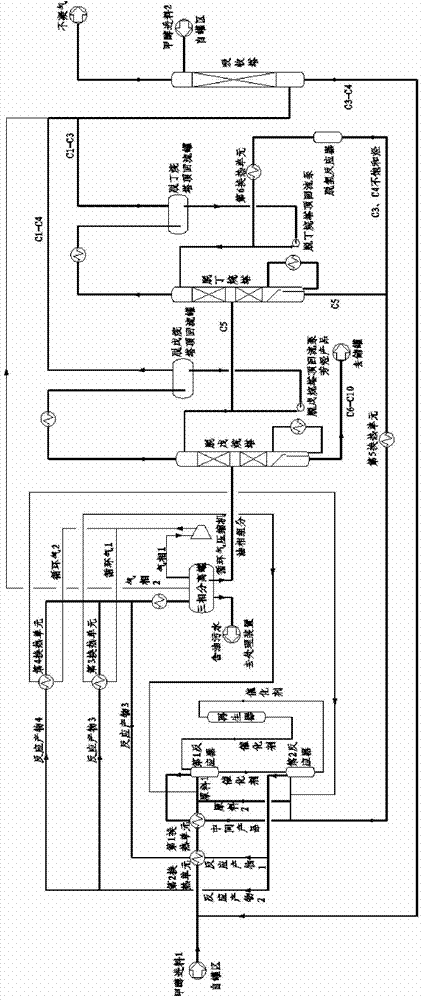

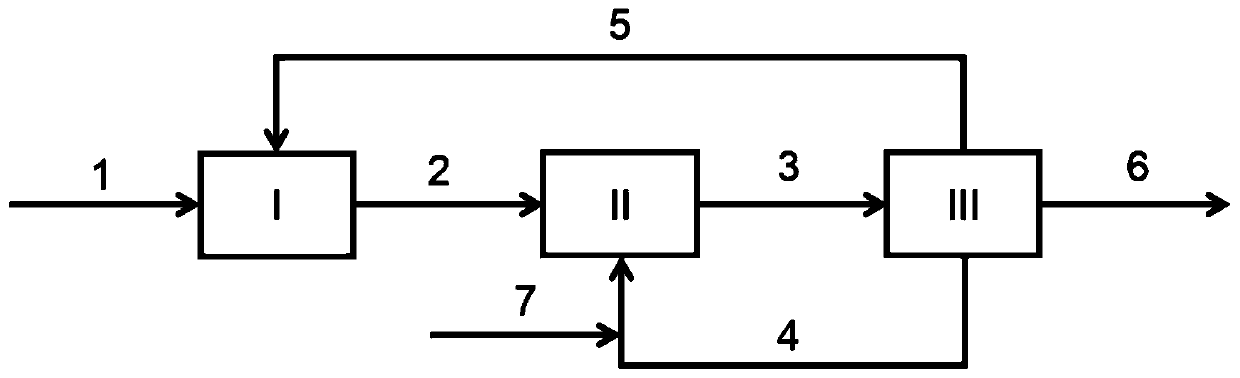

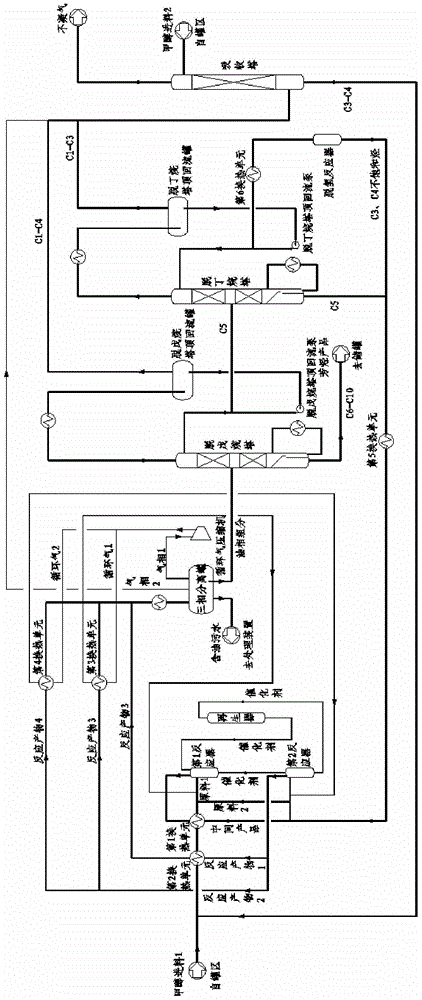

Moving bed methanol-to-hydrocarbon method

ActiveCN104818042AGuaranteed conversion rateImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAromatic hydrocarbonMoving bed

The invention relates to a moving bed methanol-to-hydrocarbon method. The method comprises the steps of hydrocarbon synthesis, separation and post-treatment, at least two serially connected reactors are adopted in the hydrocarbon synthesis step, a reaction raw material and a catalyst sequentially flow through the reactors in a countercurrent direction, low carbon olefin-containing circulation gas generated in the separation step returns to different feeding positions in the hydrogen synthesis step as quenching gas or raw material supplement gas in the hydrocarbon synthesis step, and a raw material methanol is used to wash and absorb C1-C4 light components generated in the separation step, returns, is fed and is converted in order to convert methanol into mixed aromatic hydrocarbon-containing stable light hydrocarbon with high added values. The method allows step complete utilization of the activity of the catalyst to be carried out, so the method improves the fine control of the reaction process, realizes effective material utilization and heat integration between processing processes, improves the product yield, reduces energy consumption and reduces environmental pollution.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

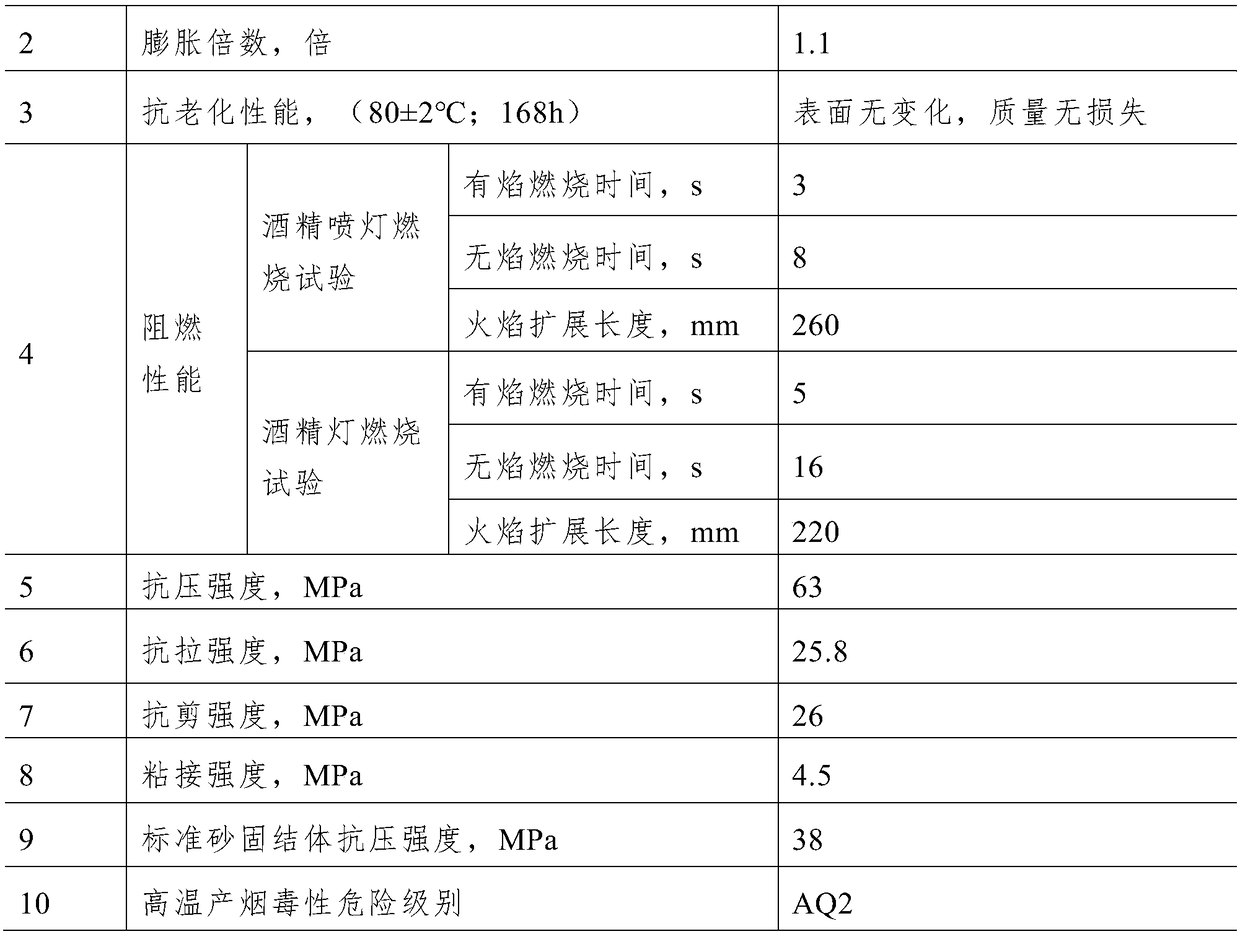

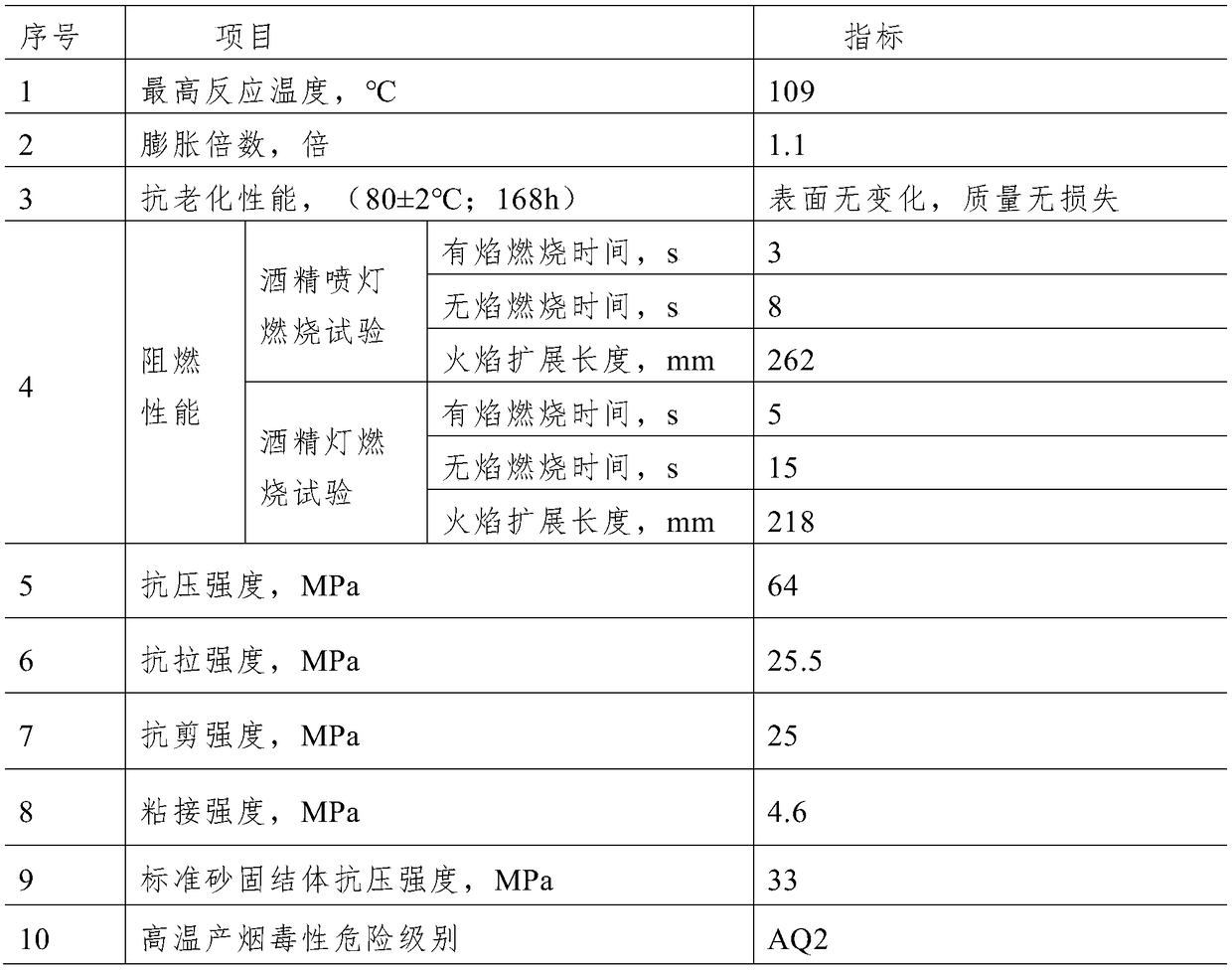

Low-heat polyurethane grouting reinforcement material

The invention relates to a low-heat polyurethane grouting reinforcement material. The reinforcement material comprises a component A and a component B, wherein the component A contains 60-90 parts byweight of polymeric MDI; the component B contains, by weight, 10-40 parts of polyether polyol, 10-20 parts of polymer polyol, 0.01-6 parts of a catalyst, 1-10 parts of a flame retardant and 10-20 parts of an assistant; and at least one of the component A and the component B further contains vegetable fat or modified vegetable fat. The above formula contains a certain amount of the vegetable fat ormodified vegetable fat, so the reinforcement material can quickly absorb heat released by a reaction of the polymeric MDI and the polyether polyol, and participates in some of chemical reactions, thereby the reaction of the whole system is mild, and the reaction heat is slowly aggregated, and the overall reaction temperature rise is significantly lower than that of existing polyurethane groutingmaterials; and the addition of the vegetable fat and modified vegetable fat has no negative influences on the application properties and the comprehensive mechanical properties of the polyurethane grouting materials.

Owner:BEIJING RUINUOANKE NEW ENERGY TECH

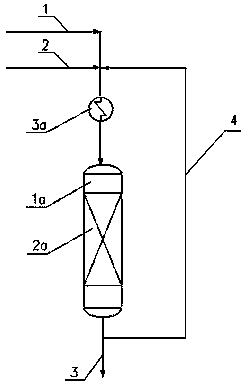

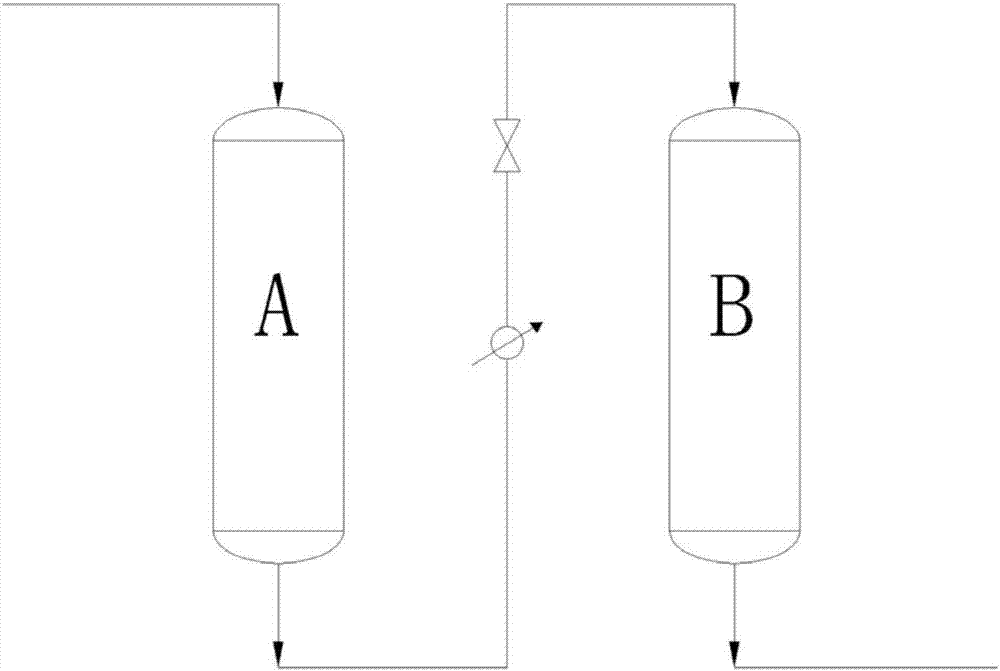

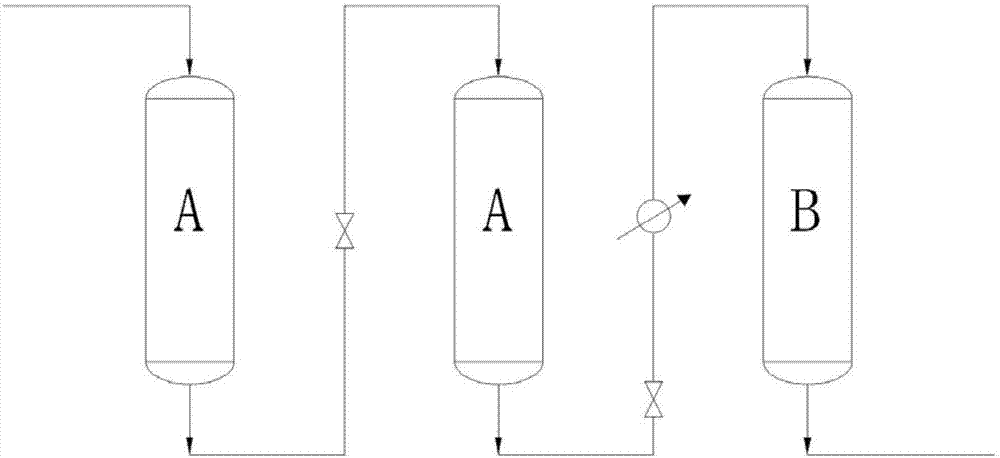

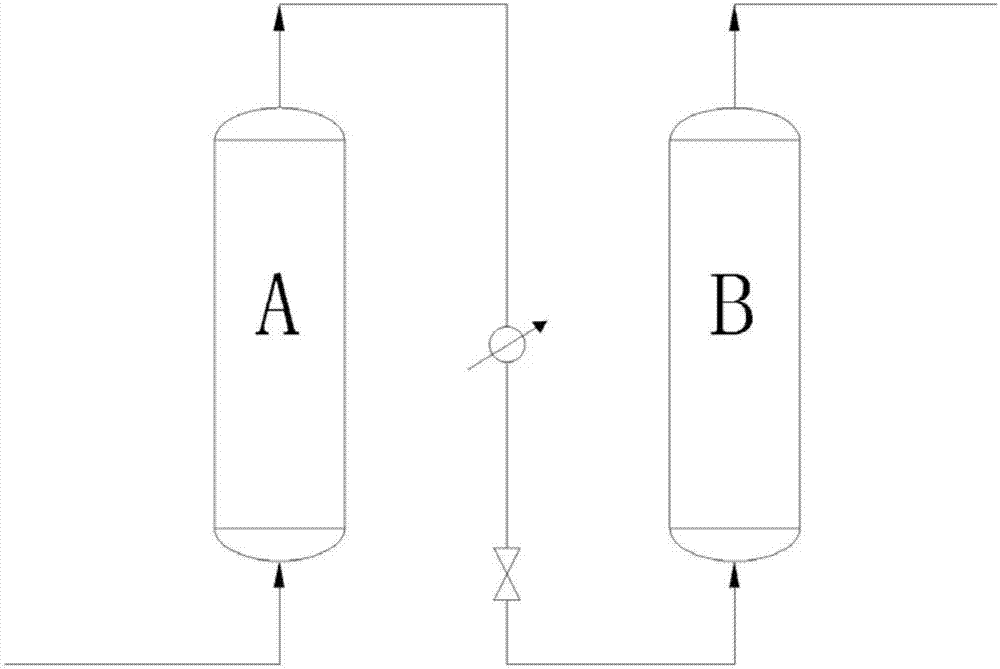

Catalyst packing structure for isobutene oligomerization

InactiveCN107973680AImprove conversion rateExtended service lifeCatalystsHydrocarbon preparation catalystsStrong acidsIon-exchange resin

The present patent application provides a catalyst packing structure for isobutene oligomerization. At least two reactors are arranged in series according to the preparation process direction, a process front-stage reactor is filled with a temperature-resistant strong acid cation exchange resin catalyst, a process rear-stage reactor is filled with normal-temperature strong acid cation exchange resin catalyst, and a condenser is connected between the front-stage reactor and the rear-stage reactor. According to the technical scheme provided by the invention, practices show that in an oligomerization reaction, the conversion ratio of isobutylene can be improved by 5-15%, the selectivity of diisobutylene can be improved by 2-5%, and the service life of the resin catalyst can be prolonged by 1time compared with those of the manner that each reactor of the preparation process is singly filled with the temperature-resistant strong acid cation resin exchange catalyst or the normal-temperaturestrong acid cation resin exchange catalyst.

Owner:丹东明珠特种树脂有限公司

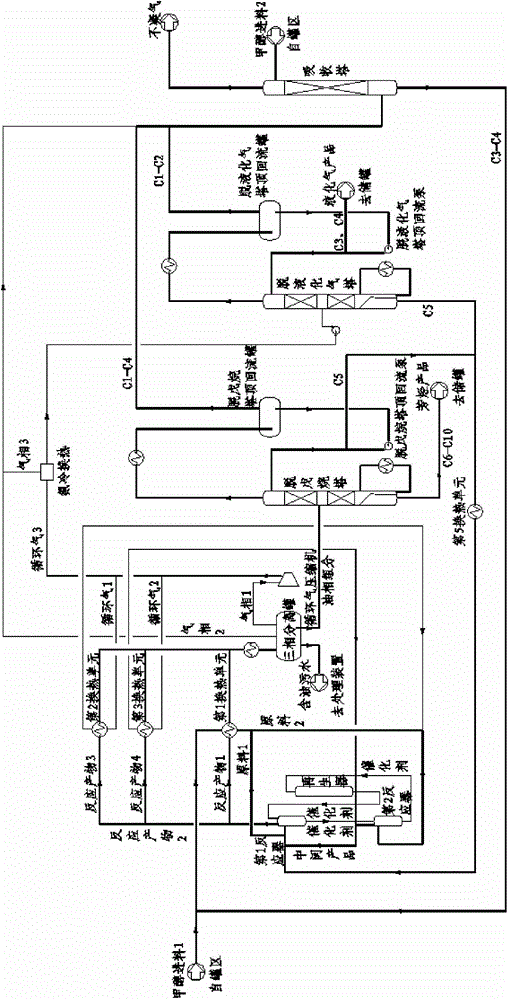

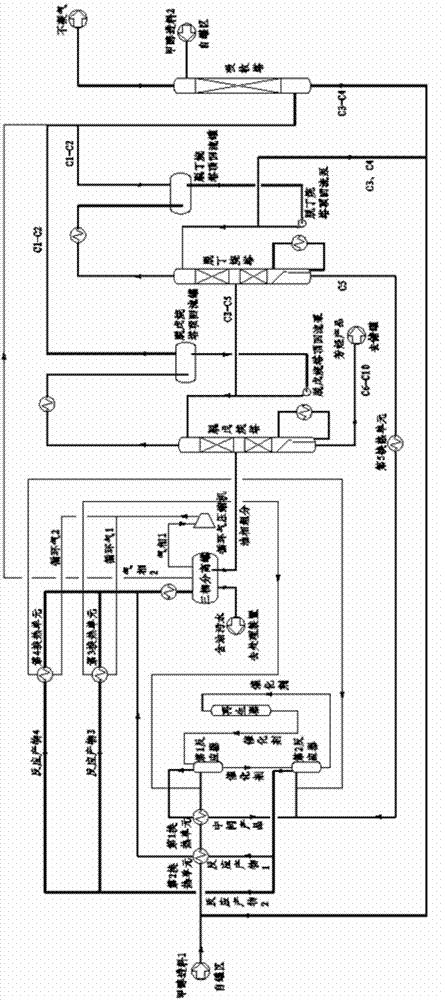

Moving bed methanol aromatization method for coproducing liquefied gas

ActiveCN104818044AGuaranteed conversion rateImprove conversion rateGaseous fuelsHydrocarbon from oxygen organic compoundsAromatizationTower

The invention relates to a moving bed methanol aromatization method for coproducing liquefied gas. The method comprises the steps of hydrocarbon synthesis and separation, at least two serially connected reactors are adopted in the hydrocarbon synthesis step, a reaction raw material and a catalyst sequentially flow through the reactors in a countercurrent direction, and most low carbon olefin-containing circulation gas generated in the separation step returns to different feeding positions in the hydrogen synthesis step as quenching gas or raw material supplement gas in the hydrocarbon synthesis step, a small part of the circulation gas is fractioned through a liquefied gas removal tower, and a raw material methanol is used to wash and absorb C1-C4 light components generated in the separation step, returns, is fed and is converted. The method allows methanol to be converted into mixed aromatic hydrocarbons with high added values and liquefied gas to be produced as a byproduct. The method allows step complete utilization of the activity of the catalyst to be carried out, so the method improves the fine control of the reaction process, realizes effective material utilization and heat integration between processing processes, improves the product yield, reduces energy consumption and reduces environmental pollution.

Owner:CHINA KUNLUN CONTRACTING & ENG

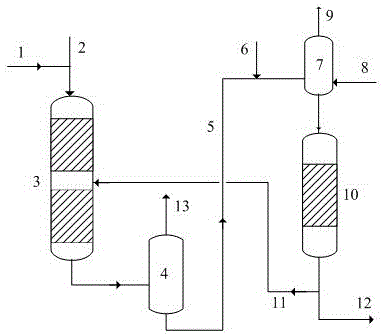

Method for producing ethylene cracking material through liquefied gas hydrogenation

ActiveCN108085061AControl reaction speedAchieve conversion rateGaseous mixture working upHydrocarbon oils treatment productsReaction speedHydrogenation reaction

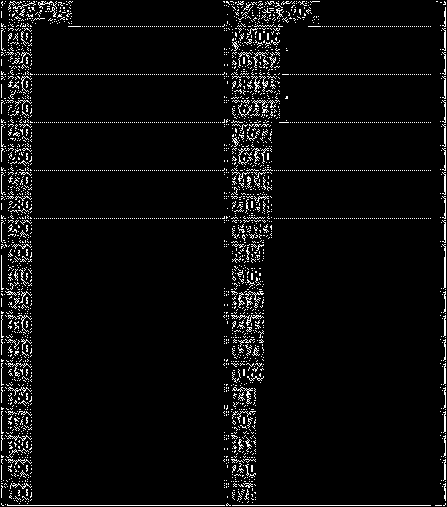

The invention discloses a method for producing an ethylene cracking material through liquefied gas hydrogenation. The method is characterized in that liquefied gas and hydrogen pass through a hydrogenation reactor through a cocurrent flowing mode, then are contacted with a hydrogenation catalyst under hydrogenation technical condition and subjected to a reaction; the hydrogenation reactor comprises more than two reaction segments, and according to a contact sequence with a reaction material, the activity of the catalyst in a downstream reaction segment is higher than the activity of the catalyst in an upstream reaction segment. The method reduces the relative average reaction speed at an entrance of a catalyst bed layer, changes problem of large relative average reaction speed at the entrance of the catalyst bed layer, a difference of the average reaction speed of each segment of the catalyst bed layer is greatly reduced, and the relative average reaction speed of each segment of the catalyst bed layer is more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

Slurry Bed Reaction Process for Aromatic Alkylation

ActiveCN104557426BTake full advantage of activityExtend your lifeMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferLiquid product

The invention relates to an aromatic hydrocarbon alkylation slurry bed reaction method, and mainly solves the technical problems of multiple side reactions, low utilization ratio of the alkylation reagent, poor catalyst stability and the like in the existing aromatic hydrocarbon alkylation production method. The method comprises the following steps: part of liquid aromatic hydrocarbons and an alkylation catalyst are premixed and arranged in a slurry bed reactor, and the gasified alkylation reagent and a carrier gas are together introduced into the slurry bed reactor through the reactor bottom to perform alkylation reaction; the liquid product is discharged via the lower part of the reactor and separated from the alkylation catalyst, and enters an aromatic hydrocarbon separation system, and meanwhile, the separated alkylation catalyst and a fresh aromatic hydrocarbon material are together introduced into the slurry bed reactor via the upper part to perform alkylation reaction; and low-carbon hydrocarbons generated after the reaction and the carrier gas are discharged via the top of the reactor and are separated, and the separated carrier gas is recycled. The technical scheme solves the problems of multiple side reactions, low utilization ratio of the alkylation reagent, catalyst deactivation and the like, and can be used in industrial production of the alkylated aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method of paraffin-based diesel oil

PendingCN111100697ALow yieldReduce the inlet temperature to ensure the yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsParaffin waxMolecular sieve

The invention discloses a hydrocracking method of paraffin-based diesel oil. The hydrocracking method comprises the following steps: (1) mixing a paraffin-based diesel oil raw material with hydrogen,and feeding the mixture into a hydrofining reactor for desulfurization, denitrification and aromatic saturation reaction; (2) enabling an effluent obtained in the step (1) to enter a hydrocracking reactor, wherein the mass content of a Y molecular sieve in a hydrocracking catalyst filled in the hydrocracking reactor is in a high-low-high tendency along the material flow direction; and (3) carryingout gas-liquid separation and liquid-phase fractionation on the effluent of the hydrocracking reactor to obtain naphtha, aviation kerosene and diesel oil. According to the method, the temperature distribution of each bed of the hydrocracking reactor is improved while the yield of heavy naphtha with high aromatic potential content is increased, and the operation stability of the device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

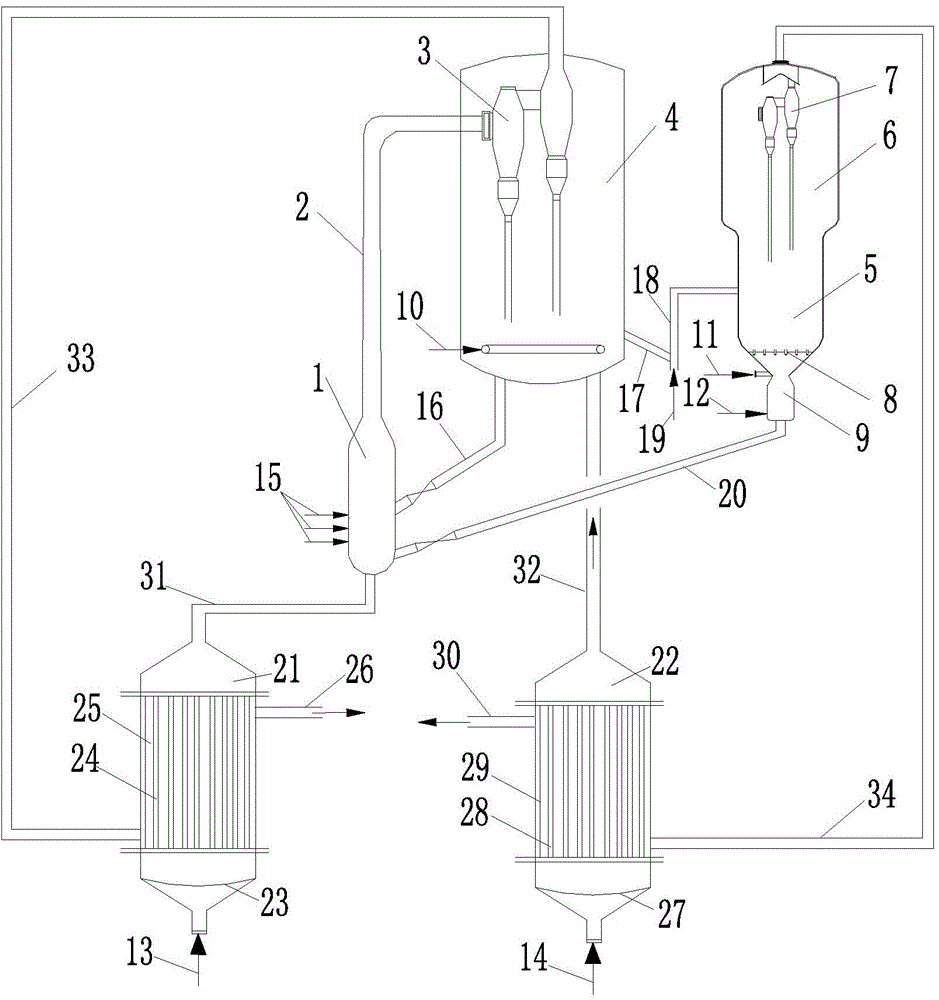

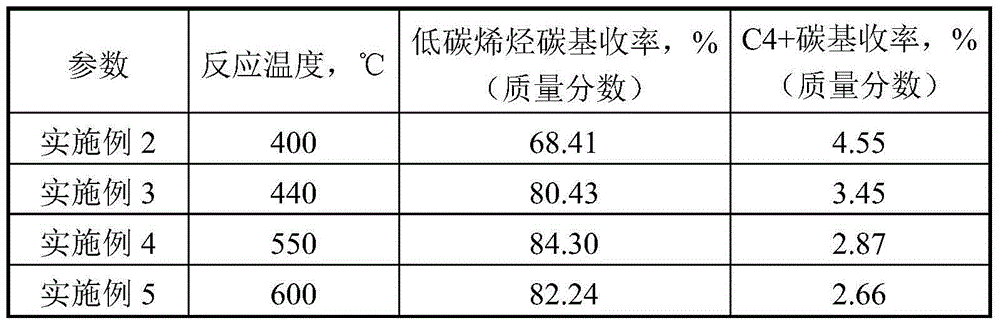

Method for preparing low carbon olefins from oxygen-containing compound by conversion

ActiveCN105085131AHigh yieldSave energy supplyHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveFluidized bed

The present invention relates to a method for preparing low carbon olefins from an oxygen-containing compound, and mainly solves the problems that low carbon olefin yield is not high, art byproducts of hydrocarbons with four or more than four C atoms are more in the prior art. According to the method for preparing the low carbon olefins from one oxygen-containing compound, a product produced by contact of the oxygen-containing compound with a catalyst I in a prereactor enters into a fluidized bed reactor, and contacts with a molecular sieve based catalyst II to produce a product stream containing the low carbon olefins, after heat transfer with the prereactor, the product stream enters into a product separation system, a to-be-regenerated catalyst in a settler is divided into two parts to enter into a fluidized bed reactor and a regenerator, the regenerated catalyst is degassed by a stripper, then enters into a fluidized bed reactor, hydrocarbons with four or more than four C atoms are contacted with a catalyst III in a fixed bed reactor, the produced product stream containing the low carbon olefins enters into the settler, and by the technical schemes, the problem are well solved, and the method can be used for industrial production of preparing of the low carbon olefins from the oxygen-containing compound by conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

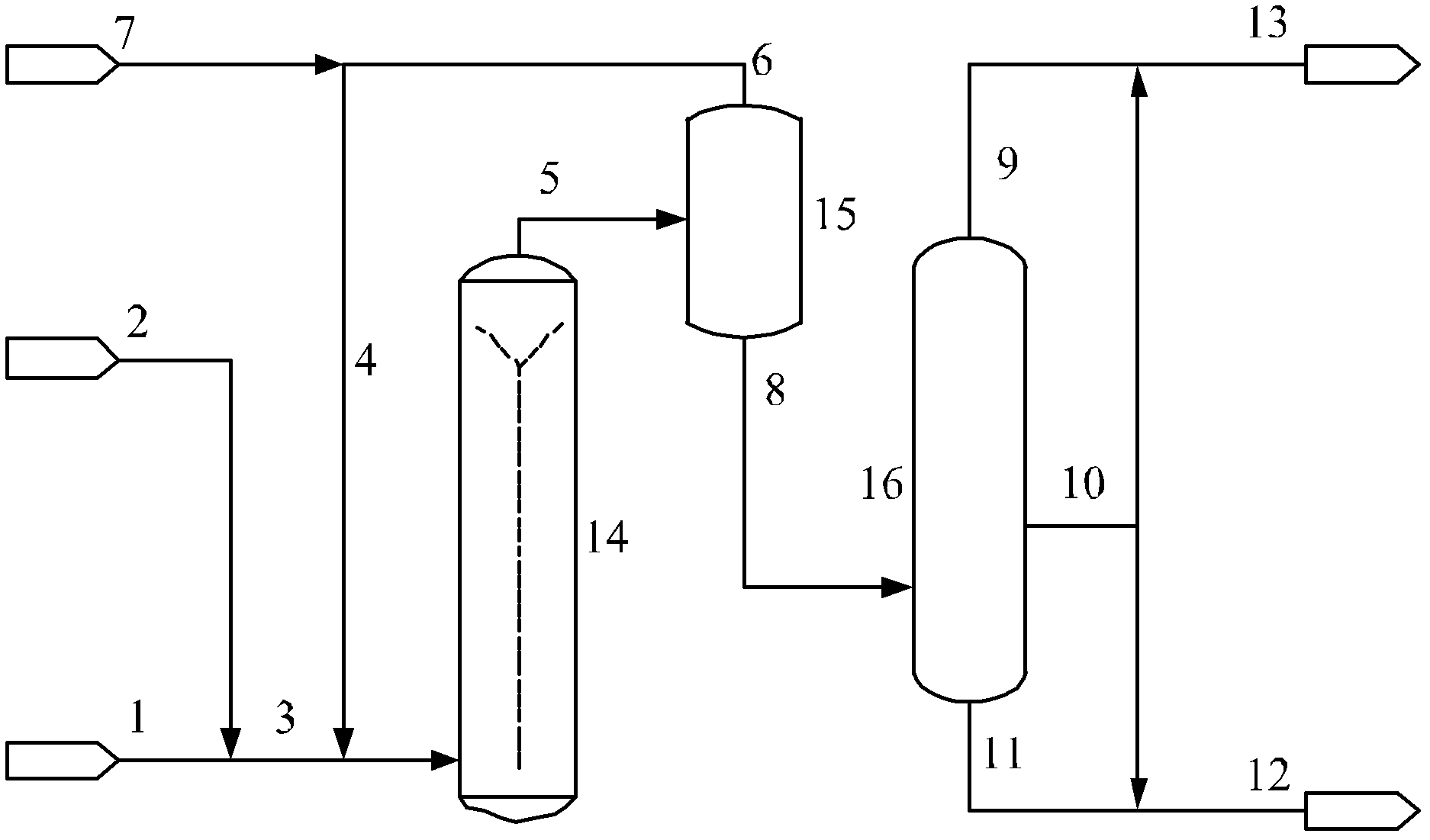

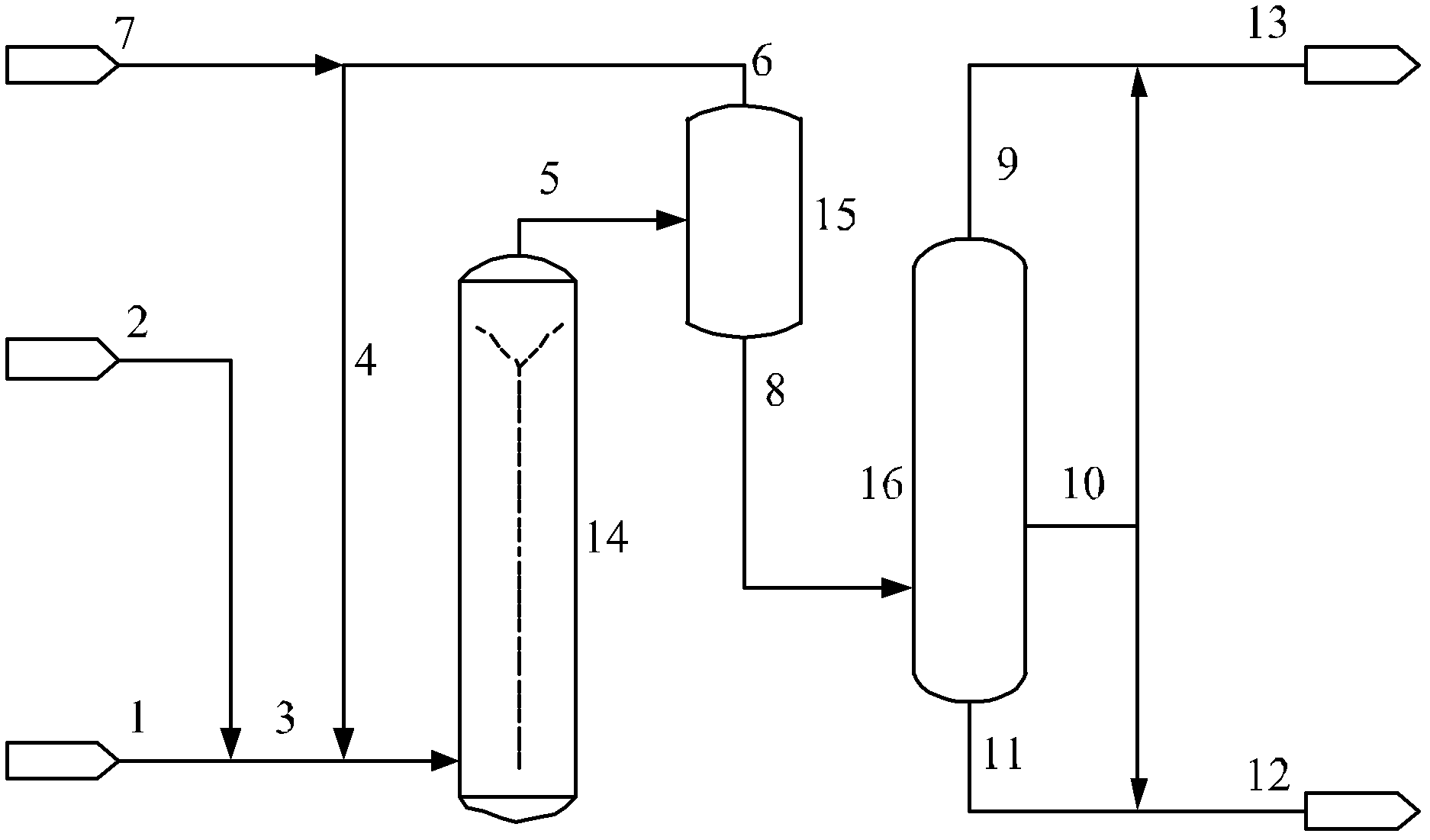

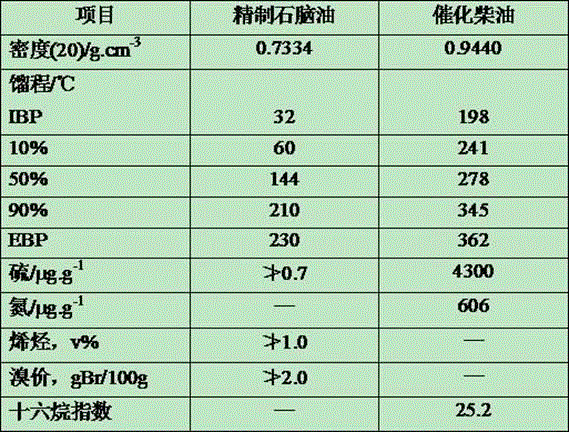

Plant and animal oil and catalytic diesel oil associated hydrogenation process

ActiveCN103773459ALowering the freezing pointSolve the problem that dissolved hydrogen cannot meet the needs of hydrogenation reactionTreatment with hydrotreatment processesIsomerizationHigh pressure

The invention discloses a plant and animal oil and catalytic diesel oil associated hydrogenation process. The method is as follows: plant and animal oil is mixed with hydrogen, and then the mixture enters into a hydrogenation isomerization reactor for hydrogenfinishing and isomerized condensation point reduction reactions; a reaction effluent enters into a hot high-pressure separator for separation, a hot high pressure liquid separation phase is mixed with catalytic cracking diesel oil, then the mixture enters into a hydrogen mixing tank for hydrogen mixing, and then the mixture enters into a liquid phase hydrogenation reactor for the hydrogenfinishing reaction, and part of the hydrogenfinished diesel oil is cycled to a lower catalyst bed layer of the hydrogenation isomerization reactor. After hydrogenation isomerization condensation point reduction of the plant and animal oil, on one hand, the hydrogen dissolving amount of the liquid phase hydrogenation reactor can be improved, the condensation point is reduced, and the plant and animal oil has a high cetane number, and can make up for the shortage of a deficient cetane number of catalytic diesel oil by catalytic associated hydrogenation. The method broadens the sources of raw materials for diesel oil production of a refinery plant, and provides a way out for processing of poor-quality catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

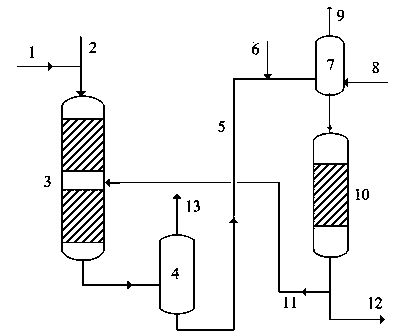

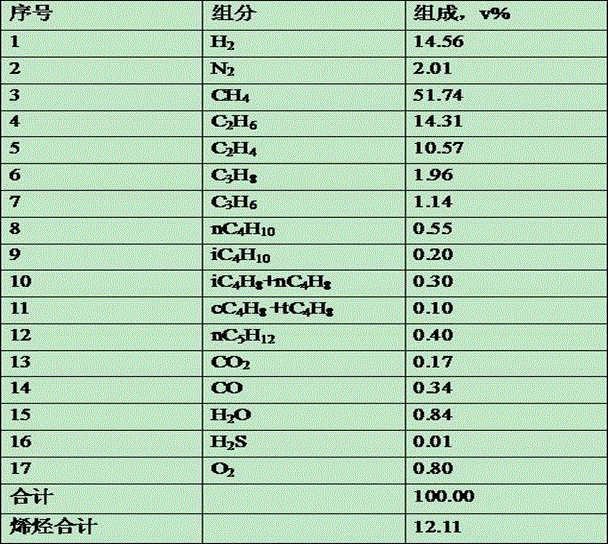

Process for preparing ethylene cracking material through hydrogenation of dry gas

ActiveCN106753560ASlow reaction speedControlled smallGaseous mixture working upHydrogenation reactionReaction temperature

The invention discloses a process for preparing an ethylene cracking material through hydrogenation of dry gas. The process comprises the following steps: introducing dry gas containing olefin, optional supplementing hydrogen and distillate oil into a fixed-bed reactor; allowing the above mentioned substances to contact with a hydrogenation catalyst under the hydrogenation process conditions for a reaction; and separating reaction products so as to obtain dry gas with saturated olefin, wherein at least a part of the distillate oil is in a liquid phase under the reaction conditions. The process provided by the invention can control the speed of an olefin hydrogenation reaction, allows the conversion rate of the olefin hydrogenation reaction to be gradually increased along a feeding direction and enables reaction heat to be gradually and smoothly released and reaction temperature rise of a catalyst bed to be decreased, so the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

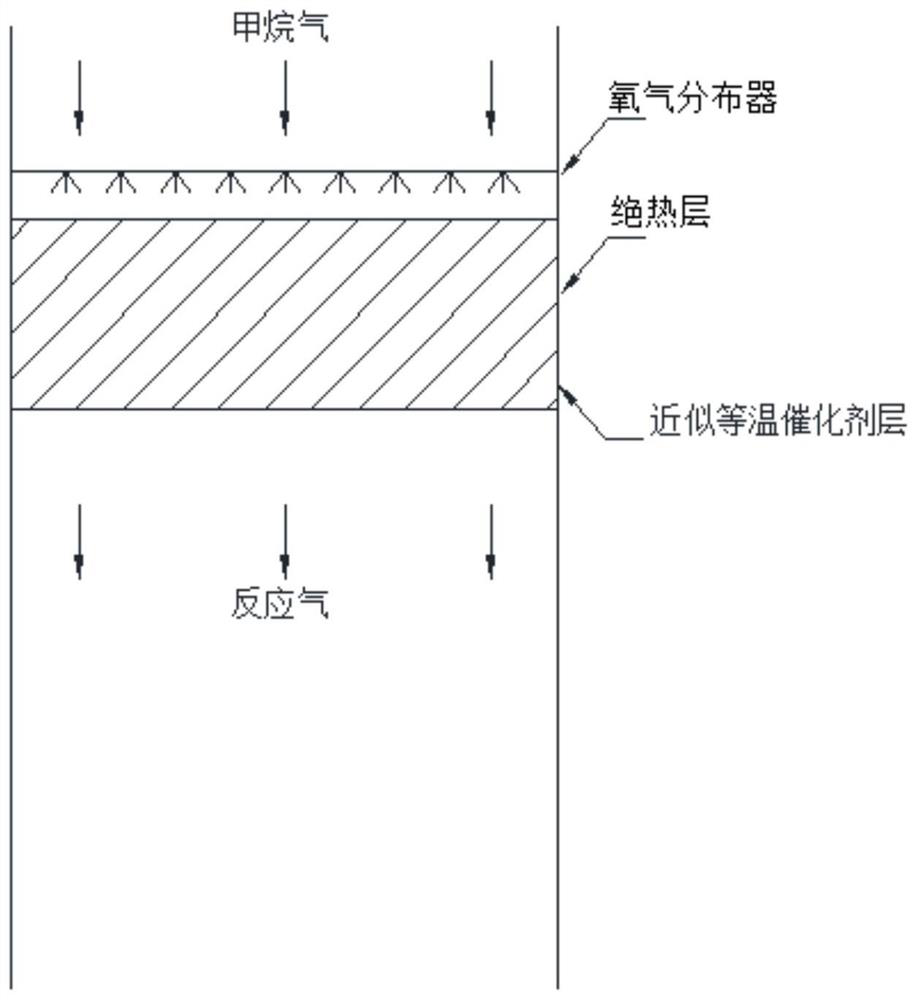

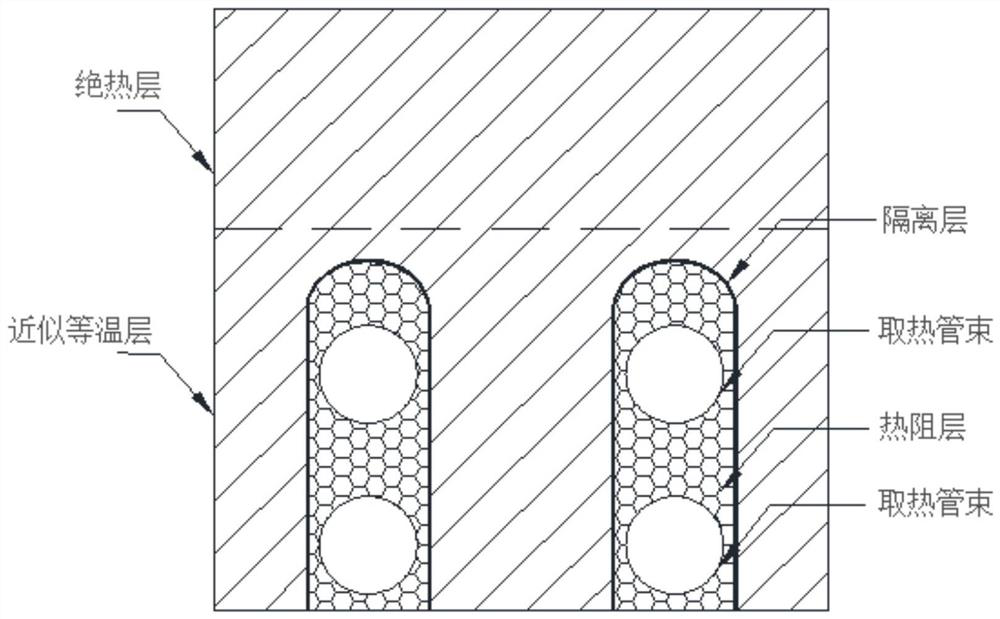

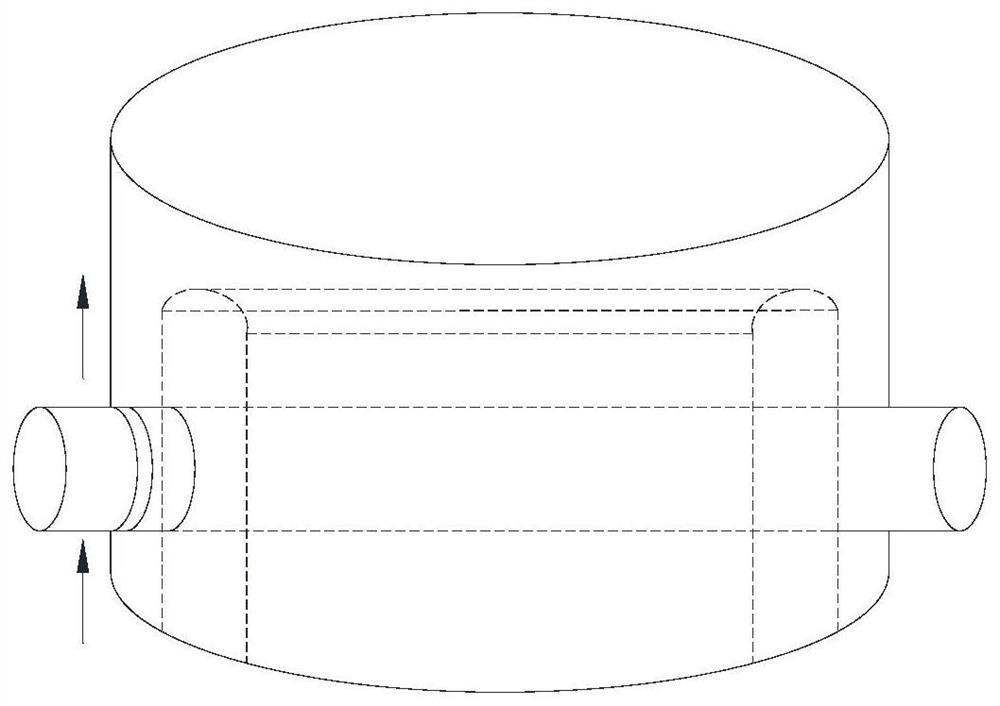

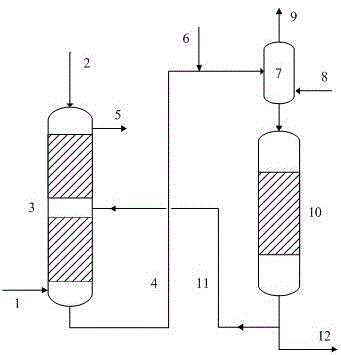

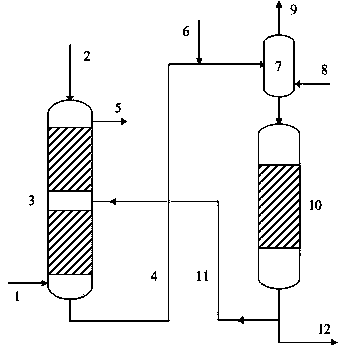

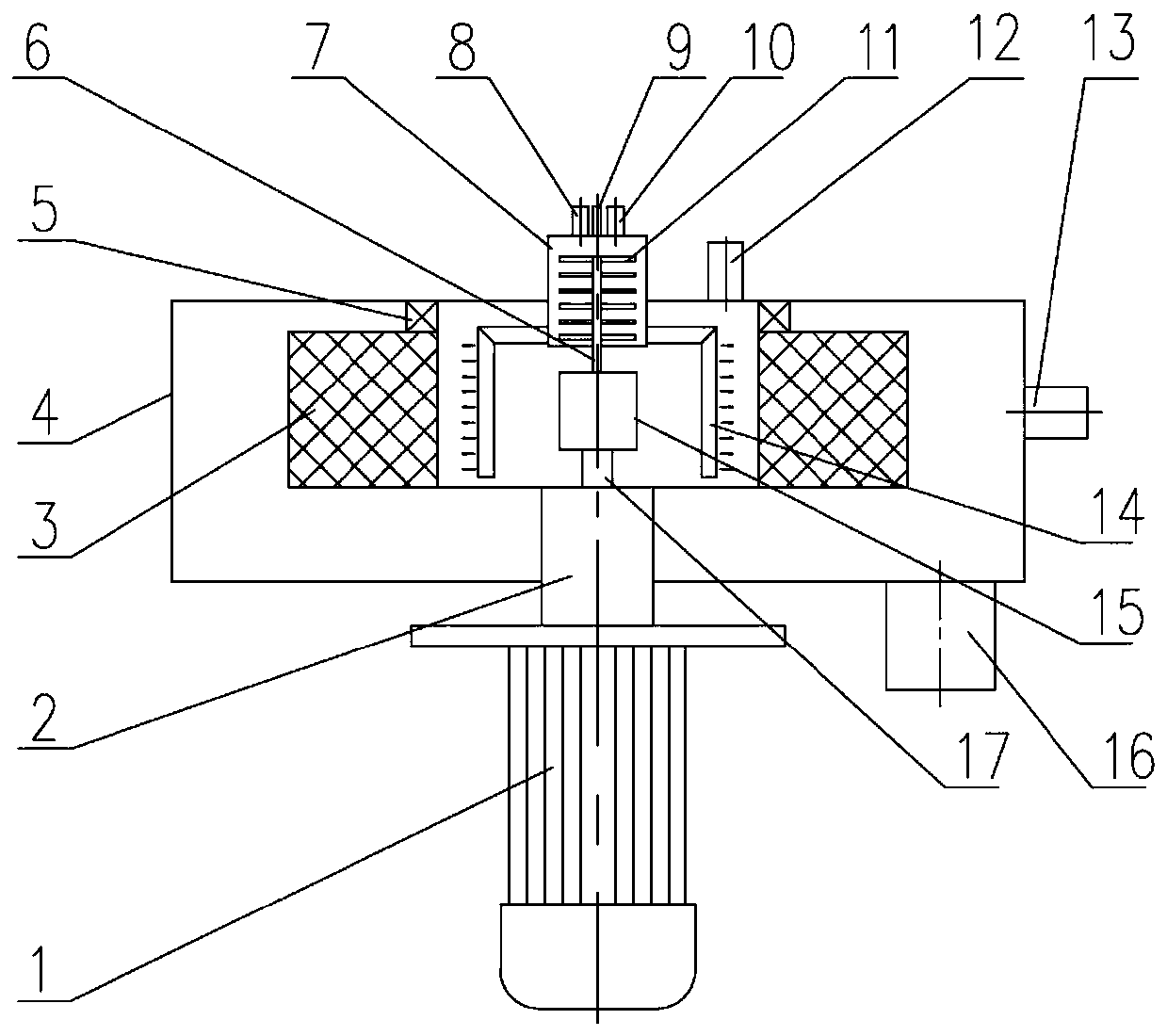

Fixed bed reactor for methane oxidative coupling reaction and method for preparing ethylene by methane oxidative coupling

ActiveCN111744434AEasy to industrializeHigh selectivityHydrocarbon by hydrocarbon condensationChemical/physical processesThermodynamicsPtru catalyst

The invention belongs to the field of preparation of ethylene by oxidative coupling of methane, and particularly relates to a fixed bed reactor for oxidative coupling reaction of methane and a methodfor preparing ethylene by oxidative coupling of methane. The reactor comprises a reactor shell, and comprises a catalyst bed layer, a plurality of U-shaped heat removal pipe bundles and a high-pressure steam overheating section which are arranged in the reactor shell, wherein the high-pressure steam overheating section is arranged at the lower part of the catalyst bed layer; the catalyst bed layeris divided into an upper layer and a lower layer, the upper layer is a heat-insulating layer, and the lower layer is an approximately isothermal layer; the multiple U-shaped heat removal pipe bundlesare arranged in the approximate isothermal layer, one part of the pipe bundles are used for generating high-pressure saturated steam, and the other part of the pipe bundles are used for overheating the high-pressure saturated steam. The invention provides an ideal reactor and a control scheme which can be implemented industrially, are small in reaction temperature rise, good in heating effect, high in ethylene selectivity and convenient and adjustable in system for the reaction for preparing ethylene through oxidative coupling of methane, and promote industrialization of preparing ethylene through oxidative coupling of methane.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of combined hydrogenation process method of animal and vegetable oil and catalytic diesel oil

ActiveCN103773455BSolve problems that cannot meet the needs of hydrogenation reactionsImprove hydrogen solubilityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesBiotechnologyVegetable oil

The invention discloses an animal and vegetable oil-catalytic diesel oil combined hydrogenation method. The animal and vegetable oil-catalytic diesel oil combined hydrogenation method comprises following steps: countercurrent contact of animal and vegetable oil with hydrogen is carried out in a hydrogenation heterogeneous reactor, and hydrofinishing and condensation point reduction reaction are carried out; an obtained liquid effluent is mixed with catalytically cracked diesel oil, an obtained mixture is delivered into a hydrogen mixing tank for hydrogen mixing, and then is delivered into a liquid phase hydrogenation reactor for hydrofinishing; a part of obtained hydrofined diesel oil is cycled to a lower catalyst bed layer of the hydrogenation heterogeneous reactor. On the one hand, hydrogenation heterogeneous condensation point reduction of the animal and vegetable oil is capable of increasing hydrogen dissolving amount of the liquid phase hydrogenation reactor, and on the other hand condensation point of the animal and vegetable oil is reduced, the animal and vegetable oil is high in cetane value, and combined hydrogenation of the animal and vegetable oil with catalytic diesel oil is capable of solving a problem that the cetane value is too low. The animal and vegetable oil-catalytic diesel oil combined hydrogenation method is capable of widening raw material sources for refinery diesel oil production, and also providing a method for processing of low-quality catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas phase-liquid phase mixed hydrogenation method

ActiveCN103773474AModerate reaction temperatureDeep deoxygenationTreatment with hydrotreatment processesHydrodesulfurizationGas phase

The invention discloses a gas phase-liquid phase circulating mixed hydrogenation method. The gas phase-liquid phase circulating mixed hydrogenation method comprises following steps: inferior diesel oil is subjected to gas phase counter current hydrogenation reaction; obtained liquid oil is mixed with straight-run diesel oil, and an obtained mixture is subjected to saturated hydrogen dissolving, and then is delivered into a liquid phase circulating hydrogenation reactor for reaction; and then a low-sulfur diesel oil product is obtained. According to the gas phase-liquid phase circulating mixed hydrogenation method, after gas phase hydrogenation reaction, aromatic hydrocarbons of the inferior diesel oil are saturated, hydrogen consumption of further reactions is relatively low, and saturated dissolved hydrogen content is increased; at the same time, a large amount of hydrogen, which is not reacted, is dissolved in the obtained liquid oil, enough dissolved hydrogen is provided for deep desulphurization reaction in the liquid phase circulating hydrogenation reactor, two-reverse charging properties are optimized, and it is beneficial for performing of deep hydrodesulfurization reaction. The invention provides the novel method used for producing ultra-low sulphur diesel oil by taking inferior diesel oil and straight-run diesel oil as raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

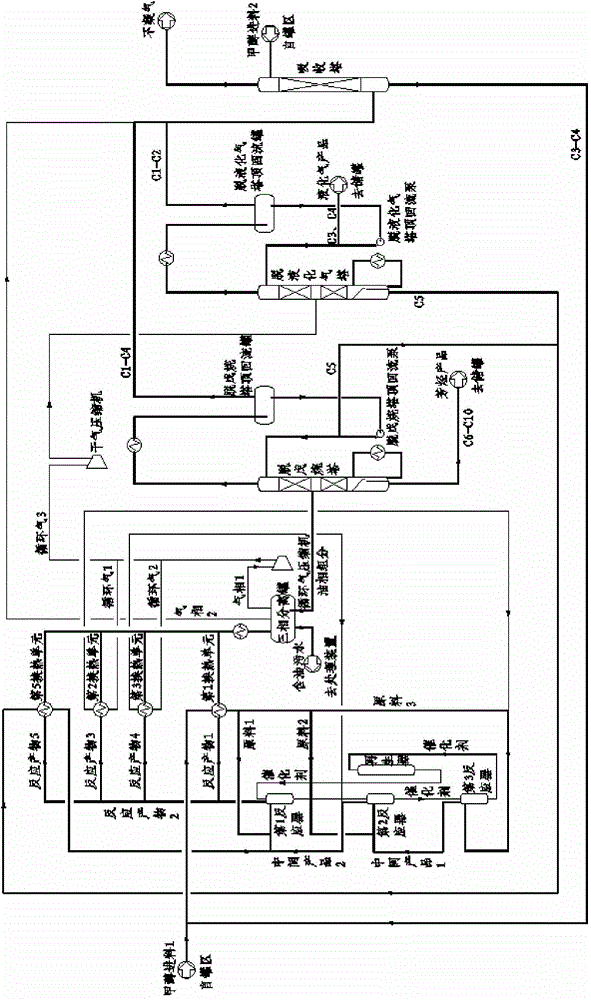

Efficient heat-integrated method for preparing hydrocarbon from methanol by adopting moving bed

ActiveCN104844402AGuaranteed conversion rateImprove conversion rateHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAfter treatmentHydrogen

The invention relates to an efficient heat-integrated method for preparing hydrocarbon from methanol by adopting a moving bed. The method comprises a hydrocarbon synthesis step, a separation step and an after-treatment step, wherein in the hydrocarbon synthesis step, two reactors which are connected with each other in series are adopted; reaction products of a plurality of reactors are utilized to perform heat-exchange heating on reaction raw materials and low-carbon-hydrogen containing recycle gas produced in the separation step, so that the recycle gas is returned to different feeding positions of the hydrocarbon synthesis step as quenching gas or raw material supplementing gas of the hydrocarbon synthesis step; the raw material methanol is utilized to perform scrubbing-absorption on C1-C4 light components generated in the separation step, and returned for being fed and converted, so that the methanol is transformed into high value-added stable light hydrocarbon comprising mixed aromatic hydrocarbons. According to the method, the refining control on a reaction process is improved through inter-stage heat exchange of reaction prdocuts, so that the materials are effectively utilized and thermally integrated among processing processes, and the environmental pollution is reduced while the product yield is increased and the energy consumption is reduced.

Owner:CHINA KUNLUN CONTRACTING & ENG

Heterogeneous rearrangement method for preparing caprolactam from cyclohexanone oxime

InactiveCN110683989AReduce reaction temperature riseEnhanced reaction process controlLactams preparationOleumSulfuric acid

The invention belongs to the technical field of chemical reaction engineering and particularly relates to a heterogeneous rearrangement method for preparing caprolactam from cyclohexanone oxime. The method comprises the steps: dissolving the cyclohexanone oxime into a recycled inert solvent to form an inert solvent solution of the cyclohexanone oxime, subjecting the inert solvent solution of the cyclohexanone oxime to a reaction with a cyclic acid phase containing caprolactam and fuming sulfuric acid in a rearrangement reactor, then, dividing the reaction solution into two phases, i.e., an inert solvent phase and an acid phase by a phase splitter, mixing the acid phase with the fuming sulfuric acid prior to cycling one part of the acid phase to the rearrangement reactor, then, enabling themixture to enter the rearrangement reactor, and discharging the other part of the acid phase at a corresponding inflow velocity of inlet raw materials; and cycling the inert solvent phase to preparethe inert solvent solution of the cyclohexanone oxime. According to the method disclosed by the invention, the reaction rate can be greatly increased, the selectivity can be greatly improved, and theenergy consumption of a process can be lowered.

Owner:TSINGHUA UNIV

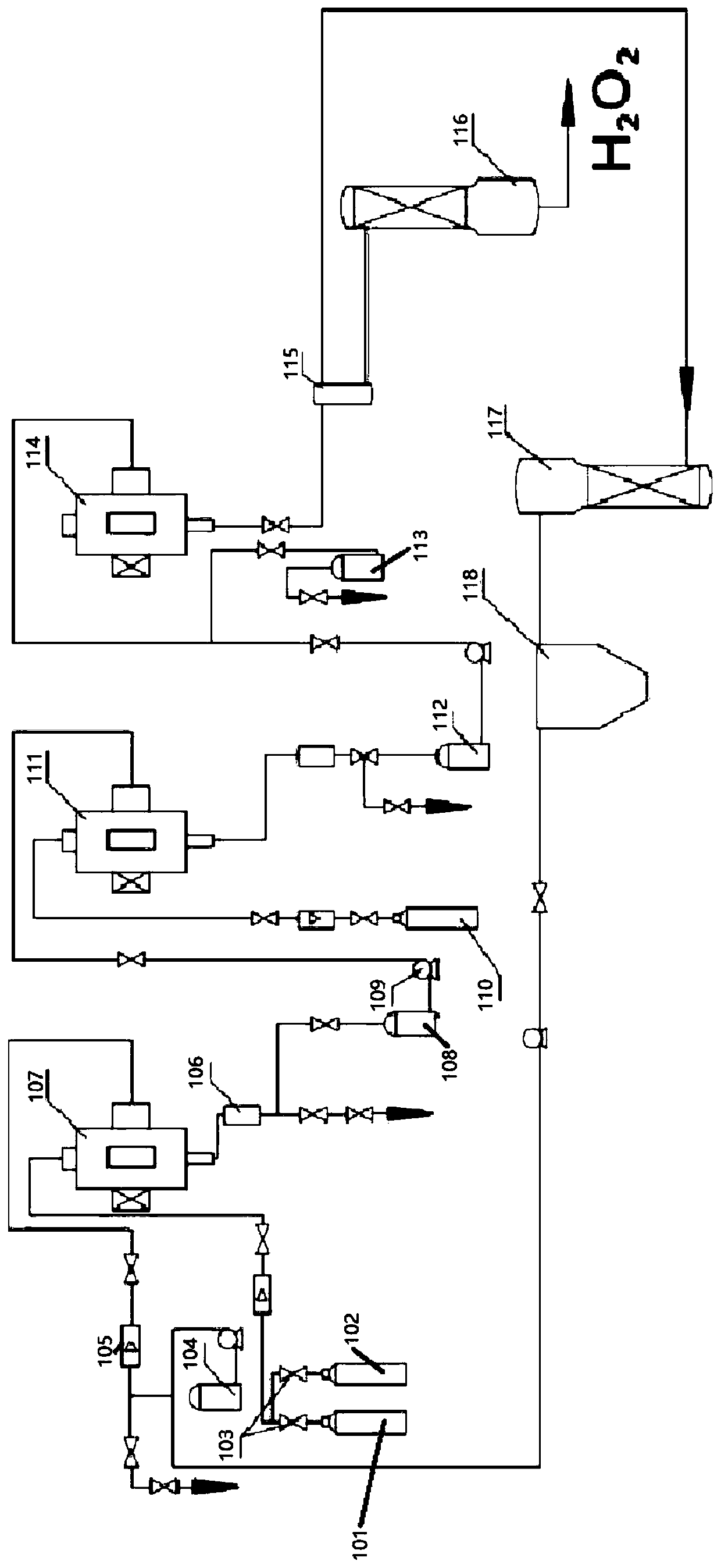

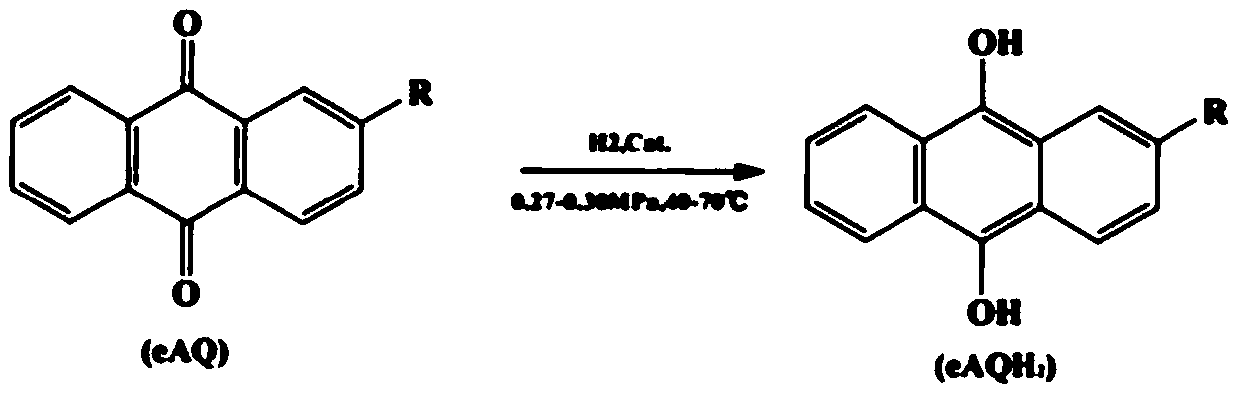

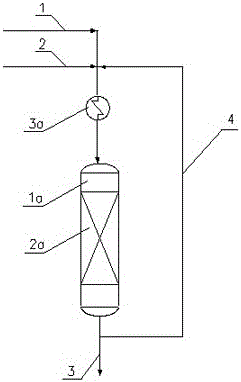

A kind of production technology that uses anthraquinone method to prepare hydrogen peroxide

ActiveCN107473188BExtension of timeImprove mass transfer efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityHydrazine compound

The invention discloses a production process for preparing hydrogen peroxide by using an anthraquinone process. The production process comprises the following steps: sequentially connecting a hydrogenation hyper-gravity reactor, an oxidation hyper-gravity reactor and an extraction hyper-gravity reactor in series; inputting hydrogen and an anthraquinone-containing solution into a feeding cavity to perform gas-liquid two-phase high-efficiency mixing, and forming a gas-liquid mixture to carry out a hydrogenation reaction so as to obtain a working solution containing oxanthranol; inputting oxygen and the working solution containing oxanthranol into the feeding cavity to perform gas-liquid two-phase high-efficiency mixing, and forming a gas-liquid mixture to carry out an oxidation reaction so as to obtain a working solution containing hydrogen peroxide and anthraquinone; enabling the working solution containing hydrogen peroxide and anthraquinone and deionized water to enter the extraction hyper-gravity reactor to extract; and separating after extraction, thereby obtaining the hydrogen peroxide. According to the production process, gas-liquid solid-phase mass transfer can be intensified by insoluble hydrogen by efficiently utilizing reducing hydrogen when the liquid solubility reaches supersaturation; and moreover, according to the method disclosed by the invention, the hydrogenation efficiency is more than or equal to 13g / L, and the oxidation reaction conversion rate is more than or equal to 95%.

Owner:BEIJING UNIV OF CHEM TECH

The method for the epoxidation of cumene hydrogen peroxide and propylene

ActiveCN104230855BIncrease the proportion of propyleneHigh selectivityOrganic chemistryChemical recyclingBenzeneReaction temperature

The invention relates to a method for epoxidation of cumene hydroperoxide and propylene, which mainly solves the problem of high reaction temperature rise in the prior art and the need for relatively high propylene and isopropyl hydroperoxide in order to maintain high reaction efficiency. The question of the molar ratio of benzene. The present invention enters the reaction zone by adopting raw materials cumene hydroperoxide and propylene liquid phase, and the total molar ratio of propylene and cumene hydroperoxide is 15-160°C at the epoxidation reaction temperature and 1.0-12.0MPa pressure. Under the condition of 2 to 30, the raw material is contacted with Ti-silicon dioxide catalyst to carry out epoxidation reaction to generate propylene oxide; wherein, the technical scheme that the epoxidation reaction product containing propylene oxide is partially recycled to the entrance of the reaction zone is better This problem has been completely solved, and it can be used in the industrial production of propylene oxide from cumene hydroperoxide and propylene epoxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

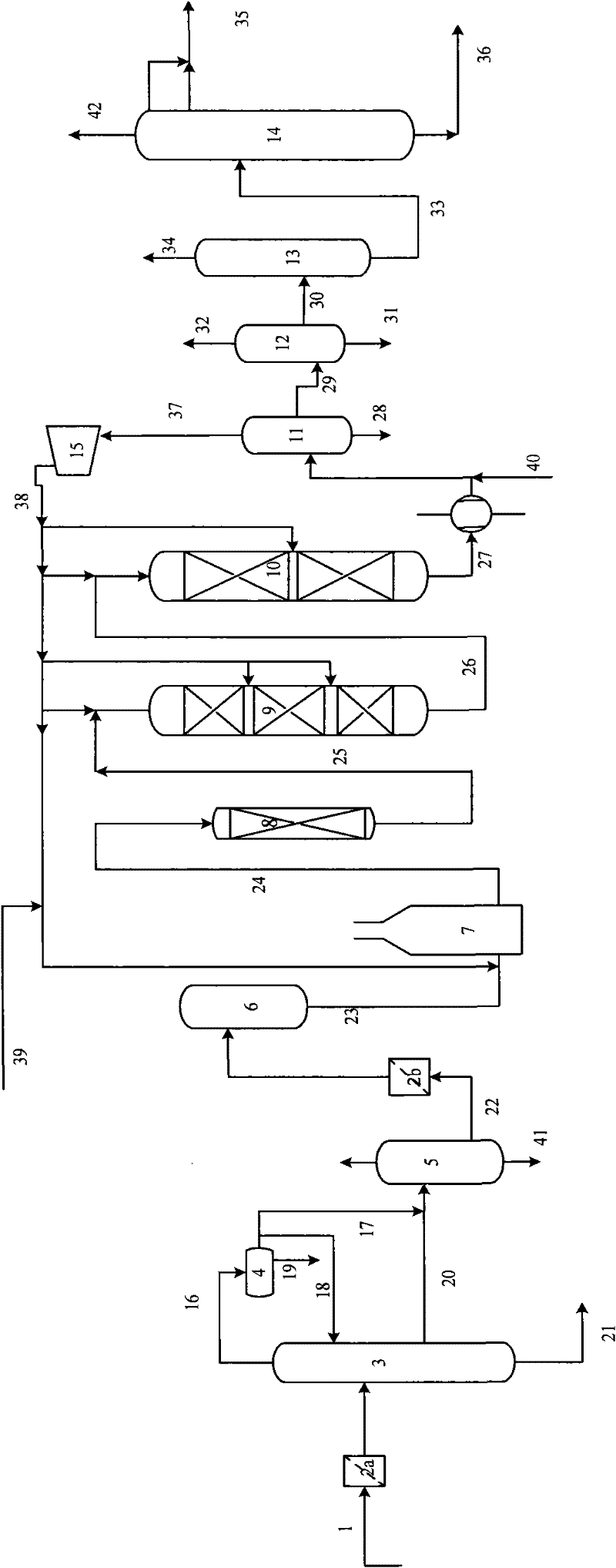

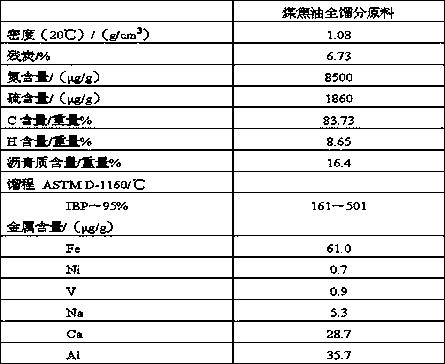

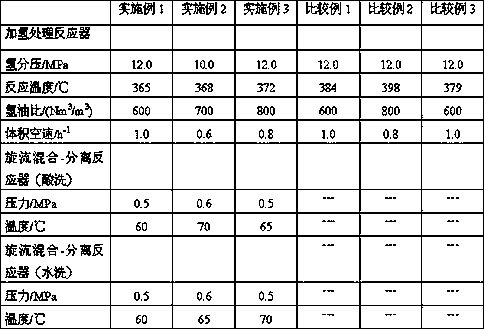

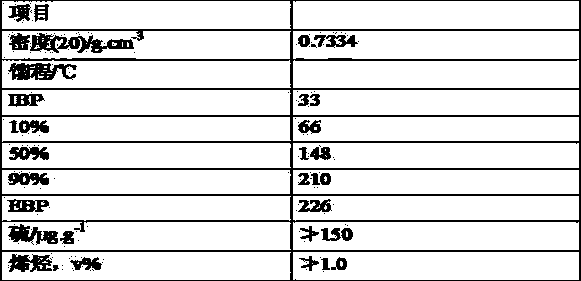

Coal tar hydrotreatment process

ActiveCN111154505ALow operating temperatureReduce nitrogen contentTar working-up by distillationTar working-up by chemical refiningProcess engineeringFuel oil

The invention discloses a coal tar hydrotreatment process. The process comprises the following steps: (1) mixing a coal tar raw material with a diesel fraction obtained by a hydrotreating unit to obtain a mixture flow A, and then sequentially carrying out acid pickling treatment and water washing treatment to obtain a hydrotreating unit feed; and (2) feeding the hydrotreating unit feed obtained instep (1) and hydrogen into the hydrotreating unit, contacting the hydrotreating unit feed with a hydrotreating catalyst, carrying out a hydrogenation reaction, and fractionating the obtained hydrogenation reaction product to obtain naphtha, diesel oil, fuel oil, tail oil and other fractions. High-quality fuel oil can be produced, the problem that the operation period of a hydrogenation device isinfluenced due to the fact that the content of metal, mechanical impurities and the like in the coal tar raw material is high is solved, the reaction temperature in the hydrotreatment process is reduced, energy consumption is reduced, and safety is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A process for preparing ethylene cracking material by hydrogenation of dry gas

ActiveCN106753560BSlow reaction speedControlled smallGaseous mixture working upHydrogenation reactionReaction temperature

The invention discloses a process for preparing an ethylene cracking material through hydrogenation of dry gas. The process comprises the following steps: introducing dry gas containing olefin, optional supplementing hydrogen and distillate oil into a fixed-bed reactor; allowing the above mentioned substances to contact with a hydrogenation catalyst under the hydrogenation process conditions for a reaction; and separating reaction products so as to obtain dry gas with saturated olefin, wherein at least a part of the distillate oil is in a liquid phase under the reaction conditions. The process provided by the invention can control the speed of an olefin hydrogenation reaction, allows the conversion rate of the olefin hydrogenation reaction to be gradually increased along a feeding direction and enables reaction heat to be gradually and smoothly released and reaction temperature rise of a catalyst bed to be decreased, so the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A gas phase, liquid phase mixed hydrogenation process method

ActiveCN103773474BReduce hydrogen consumptionEasy to useTreatment with hydrotreatment processesGas phaseHydrodesulfurization

The invention discloses a gas phase-liquid phase circulating mixed hydrogenation method. The gas phase-liquid phase circulating mixed hydrogenation method comprises following steps: inferior diesel oil is subjected to gas phase counter current hydrogenation reaction; obtained liquid oil is mixed with straight-run diesel oil, and an obtained mixture is subjected to saturated hydrogen dissolving, and then is delivered into a liquid phase circulating hydrogenation reactor for reaction; and then a low-sulfur diesel oil product is obtained. According to the gas phase-liquid phase circulating mixed hydrogenation method, after gas phase hydrogenation reaction, aromatic hydrocarbons of the inferior diesel oil are saturated, hydrogen consumption of further reactions is relatively low, and saturated dissolved hydrogen content is increased; at the same time, a large amount of hydrogen, which is not reacted, is dissolved in the obtained liquid oil, enough dissolved hydrogen is provided for deep desulphurization reaction in the liquid phase circulating hydrogenation reactor, two-reverse charging properties are optimized, and it is beneficial for performing of deep hydrodesulfurization reaction. The invention provides the novel method used for producing ultra-low sulphur diesel oil by taking inferior diesel oil and straight-run diesel oil as raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene cracking material by hydrogenation of liquefied gas

ActiveCN108085061BImprove hydrogenation activityAverage reaction speedGaseous mixture working upHydrocarbon oils treatment productsHydrogenReaction speed

The invention discloses a method for producing an ethylene cracking material through liquefied gas hydrogenation. The method is characterized in that liquefied gas and hydrogen pass through a hydrogenation reactor through a cocurrent flowing mode, then are contacted with a hydrogenation catalyst under hydrogenation technical condition and subjected to a reaction; the hydrogenation reactor comprises more than two reaction segments, and according to a contact sequence with a reaction material, the activity of the catalyst in a downstream reaction segment is higher than the activity of the catalyst in an upstream reaction segment. The method reduces the relative average reaction speed at an entrance of a catalyst bed layer, changes problem of large relative average reaction speed at the entrance of the catalyst bed layer, a difference of the average reaction speed of each segment of the catalyst bed layer is greatly reduced, and the relative average reaction speed of each segment of the catalyst bed layer is more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-efficiency heat-integrated moving-bed methanol-to-hydrocarbon process

ActiveCN104844402BGuaranteed conversion rateImprove conversion rateHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon and non-hydrocarbon condensationHydrogenAfter treatment

The invention relates to an efficient heat-integrated method for preparing hydrocarbon from methanol by adopting a moving bed. The method comprises a hydrocarbon synthesis step, a separation step and an after-treatment step, wherein in the hydrocarbon synthesis step, two reactors which are connected with each other in series are adopted; reaction products of a plurality of reactors are utilized to perform heat-exchange heating on reaction raw materials and low-carbon-hydrogen containing recycle gas produced in the separation step, so that the recycle gas is returned to different feeding positions of the hydrocarbon synthesis step as quenching gas or raw material supplementing gas of the hydrocarbon synthesis step; the raw material methanol is utilized to perform scrubbing-absorption on C1-C4 light components generated in the separation step, and returned for being fed and converted, so that the methanol is transformed into high value-added stable light hydrocarbon comprising mixed aromatic hydrocarbons. According to the method, the refining control on a reaction process is improved through inter-stage heat exchange of reaction prdocuts, so that the materials are effectively utilized and thermally integrated among processing processes, and the environmental pollution is reduced while the product yield is increased and the energy consumption is reduced.

Owner:CHINA KUNLUN CONTRACTING & ENG

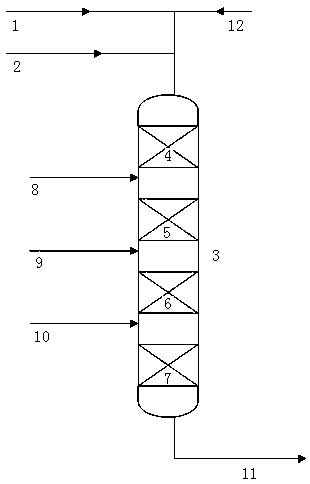

Method for producing ethylene cracking material through dry gas hydrogenation

ActiveCN106753558AReduced Relative Average Reaction SpeedSlow reaction speedGaseous mixture working upDry gasFixed bed

The present invention discloses a method for producing an ethylene cracking material through dry gas hydrogenation. According to the method, olefin-containing dry gas and optional supplemented hydrogen enter a fixed bed hydrogenation reactor in a co-current flow manner, and contact a hydrogenation catalyst under a hydrogenation process condition, a reaction is performed, and the obtained reaction products are separated to obtain the dry gas having the saturated olefin; and the hydrogenation reactor comprises four reaction sections, and according to the sequence of the contact between the material and the catalyst, the law of the hydrogenation activity metal contents in the catalysts in each reaction section is the low content, the high content, the low content and the high content. According to the present invention, with the method, the relatively average reaction rate of the inlet section of the catalyst bed layer is reduced, the problem that the relatively average reaction rate of the inlet section of the catalyst bed layer is high is solved, the difference among the average reaction rates of each section of the bed layer is substantially reduced, and the relatively average reaction rates of each section are uniform; and with the method, the deep oxygen removal can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

A joint hydrogenation process of animal and vegetable oil and catalytic diesel oil

ActiveCN103773459BSolve problems that cannot meet the needs of hydrogenation reactionsImprove hydrogen solubilityTreatment with hydrotreatment processesIsomerizationOil production

The invention discloses a plant and animal oil and catalytic diesel oil associated hydrogenation process. The method is as follows: plant and animal oil is mixed with hydrogen, and then the mixture enters into a hydrogenation isomerization reactor for hydrogenfinishing and isomerized condensation point reduction reactions; a reaction effluent enters into a hot high-pressure separator for separation, a hot high pressure liquid separation phase is mixed with catalytic cracking diesel oil, then the mixture enters into a hydrogen mixing tank for hydrogen mixing, and then the mixture enters into a liquid phase hydrogenation reactor for the hydrogenfinishing reaction, and part of the hydrogenfinished diesel oil is cycled to a lower catalyst bed layer of the hydrogenation isomerization reactor. After hydrogenation isomerization condensation point reduction of the plant and animal oil, on one hand, the hydrogen dissolving amount of the liquid phase hydrogenation reactor can be improved, the condensation point is reduced, and the plant and animal oil has a high cetane number, and can make up for the shortage of a deficient cetane number of catalytic diesel oil by catalytic associated hydrogenation. The method broadens the sources of raw materials for diesel oil production of a refinery plant, and provides a way out for processing of poor-quality catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene cracking feed by hydrogenation of dry gas

ActiveCN106753559AImprove hydrogenation activityAverage reaction speedGaseous mixture working upPtru catalystHydrogenation reaction

The invention discloses a method for producing an ethylene cracking feed by hydrogenation of dry gas. The dry gas containing olefins and optional supplemented hydrogen enter a fixed bed hydrogenation reactor in a parallel flow manner and are in contact with hydrogenation catalysts under a process condition of hydrogenation for reacting; an obtained reaction product is separated to obtain olefin-saturated dry gas; two or more reaction sections are arranged in the hydrogenation reactor; according to the contact sequence of the catalysts and materials, the activity of the hydrogenation catalyst in a downstream reaction section is higher than that of the hydrogenation catalyst in an upstream reaction section. According to the method disclosed by the invention, the speed of the hydrogenation reaction of the olefins can be controlled, and the conversion rate of the hydrogenation reaction of the olefins is enabled to be steadily and gradually improved along a catalyst bed layer; reaction heat is gradually and gently released rather than be centrally released, so that reaction temperature rise of the catalyst bed layer is reduced, a temperature bulb of the catalyst bed layer is greatly gentle, and further the service life of the catalysts is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene cracking material by hydrogenation of dry gas

ActiveCN106753558BReduced Relative Average Reaction SpeedSlow reaction speedGaseous mixture working upReaction rateFixed bed

The present invention discloses a method for producing an ethylene cracking material through dry gas hydrogenation. According to the method, olefin-containing dry gas and optional supplemented hydrogen enter a fixed bed hydrogenation reactor in a co-current flow manner, and contact a hydrogenation catalyst under a hydrogenation process condition, a reaction is performed, and the obtained reaction products are separated to obtain the dry gas having the saturated olefin; and the hydrogenation reactor comprises four reaction sections, and according to the sequence of the contact between the material and the catalyst, the law of the hydrogenation activity metal contents in the catalysts in each reaction section is the low content, the high content, the low content and the high content. According to the present invention, with the method, the relatively average reaction rate of the inlet section of the catalyst bed layer is reduced, the problem that the relatively average reaction rate of the inlet section of the catalyst bed layer is high is solved, the difference among the average reaction rates of each section of the bed layer is substantially reduced, and the relatively average reaction rates of each section are uniform; and with the method, the deep oxygen removal can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for preparing ethylene cracking material by hydrogenation of liquefied gas

ActiveCN106753561BReduce reaction temperature rise"warm bag" gentleGaseous mixture working upHydrocarbon oils treatment productsHydrogenation reactionReaction temperature

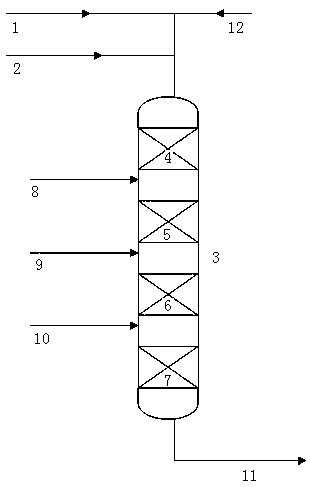

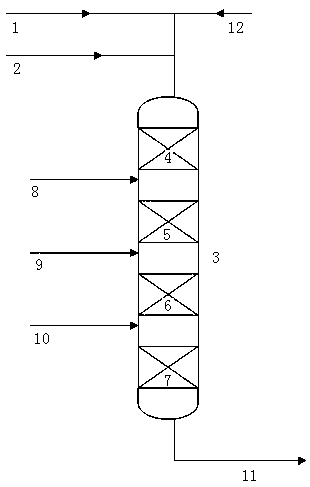

The invention discloses a method for preparing ethylene cracking feed by hydrogenation of liquefied gas. Liquefied gas and hydrogen pass through a hydrogenation reactor in a parallel flow manner and is in contact with hydrogenation catalysts for reaction; two or more hydrogenation catalyst bed layers are arranged in the hydrogenation reactor; the hydrogen enters the two or more hydrogenation catalyst bed layers from different feeding openings respectively; the amounts of the hydrogen entering all the hydrogenation catalyst bed layers are 5 to 95 volume percent of chemical hydrogen consumption required by reaction separately; except the last hydrogenation catalyst bed layer, the sum of total amounts of the hydrogen entering other hydrogenation catalyst bed layers is smaller than the required chemical hydrogen consumption. According to the method disclosed by the invention, by controlling partial pressures of the hydrogen entering different catalyst bed layers, the reaction speed is effectively controlled, and accurate control over the conversion rate is realized, so that reaction temperature rise of all sections of catalyst bed layers in the reactor is reduced, further the carbon deposit speed of the catalyst is retarded, and the single-pass service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com