A kind of combined hydrogenation process method of animal and vegetable oil and catalytic diesel oil

A technology of animal and vegetable oils and process methods, which is applied in the field of hydrogenation process of high cetane number clean diesel oil, can solve the problems of low hydrogen dissolved amount, high hydrogen consumption of reaction, difficult to deal with catalytic cracking diesel oil, etc. The effect of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

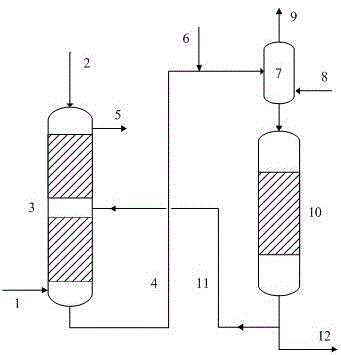

[0031] Example uses figure 1 Process flow shown. The heterogeneous pour point depressing catalysts and hydrofining catalysts used in Examples 1-3 are all commercially available catalysts, and their physical and chemical properties are listed in Table 2. The raw material properties used are shown in Table 1, and the process conditions used in Examples 1 to 3 and Comparative Examples are listed in Table 3. The evaluation results of Examples 1 to 3 and Comparative Examples are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com