A kind of hydrogenation method of animal and vegetable oil and catalytic diesel oil

A technology for animal and vegetable oil and catalytic diesel oil, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for hydrogenating animal and vegetable oils and catalytic diesel oil of the present invention will be described in detail below through specific examples.

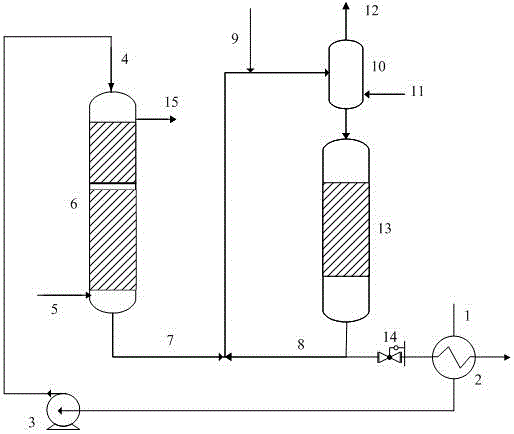

[0029] Such as figure 1 As shown, the flow process of the animal and vegetable oil and catalytic diesel hydrogenation method of the present invention is as follows: hydrogen enters the gas phase circulation hydrogenation reactor 6 from the bottom of the reactor through the pipeline 5, and the animal and vegetable raw material oil first enters the liquid phase circulation hydrogenation reaction through the pipeline 1 The low-pressure heat exchanger 2 of the device 13 exchanges heat with the liquid-phase hydrogenation effluent, and then passes through the raw oil pump 3, and after further heating, enters the gas-phase circulating hydrogenation reactor 6 through the pipeline 4 under the condition of gas-liquid countercurrent The hydrogenation refining and hydrogenation modification isomerization depreciation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com