Patents

Literature

17401results about How to "Improve heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

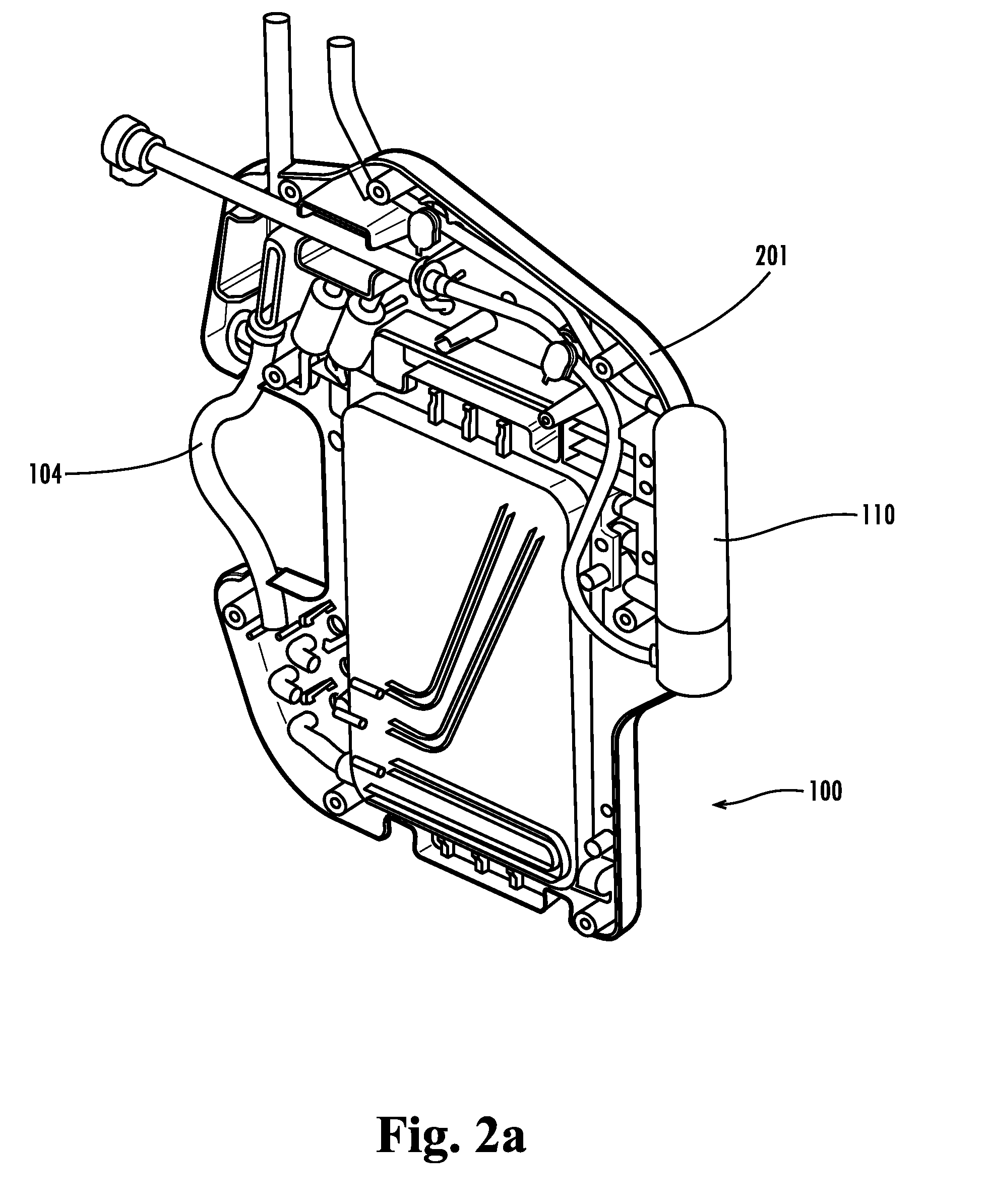

Apparatus and methods for altering temperature in a region within the body

InactiveUS20070225781A1Kinking undesirableMinimize any undesirable heat transferSurgeryTherapeutic coolingControl electronicsMedicine

Apparatus and methods for cooling and / or heating selected regions within a body are described herein. An implantable system is used to cool or heat nerve bodies down to about 15° C. to diminish nerve impulses. In one embodiment, the system can include an implantable unit containing a pumping mechanism and / or various control electronics. The system has a cooling element. The cooling element can be a Peltier junction or a catheter through which hot or cold fluid flows. The heated portion of the Peltier junction can be cooled by a liquid heat transfer medium which absorbs the heat from the junction and dissipates the heat elsewhere.

Owner:NIDUS MEDICAL

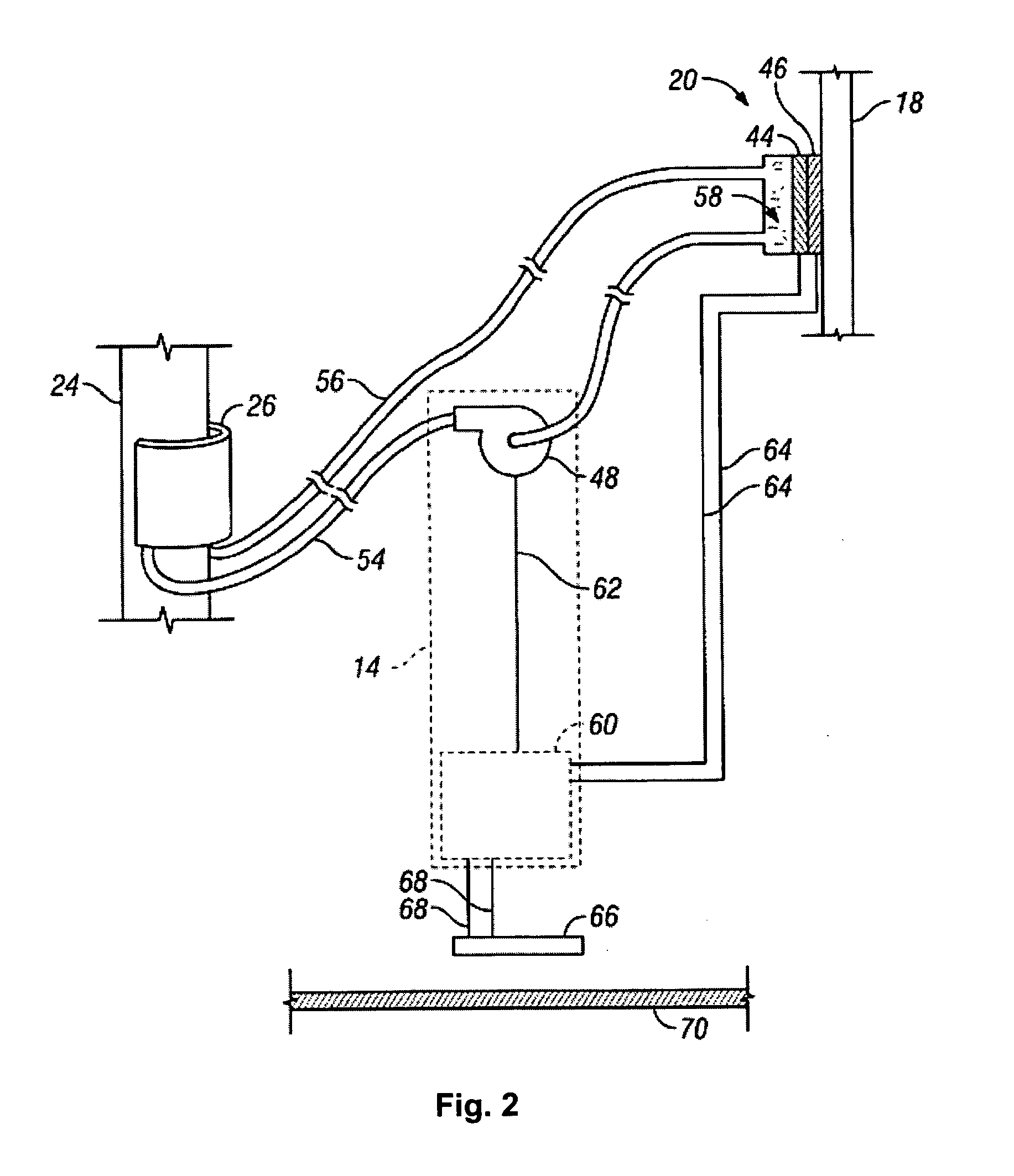

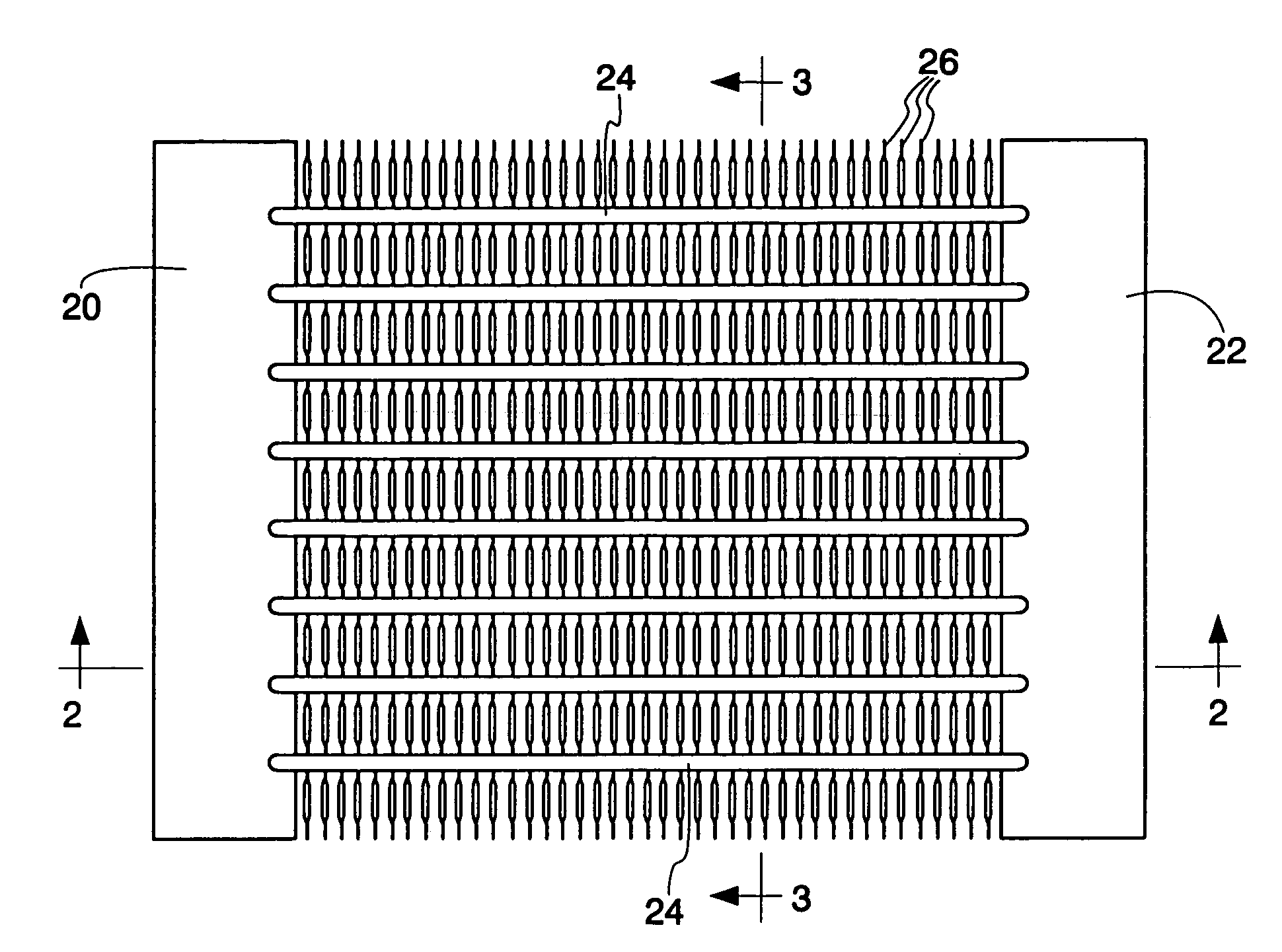

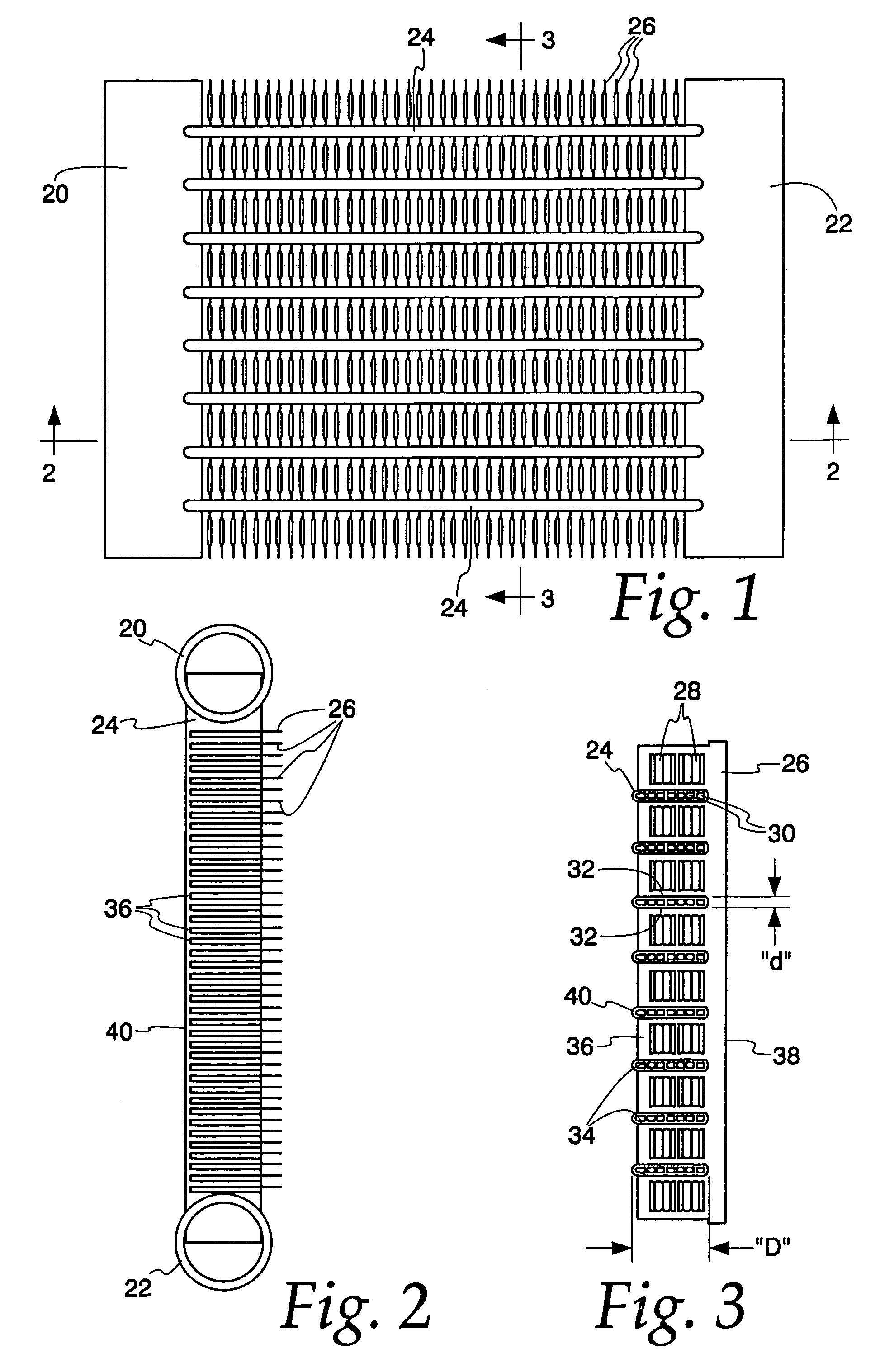

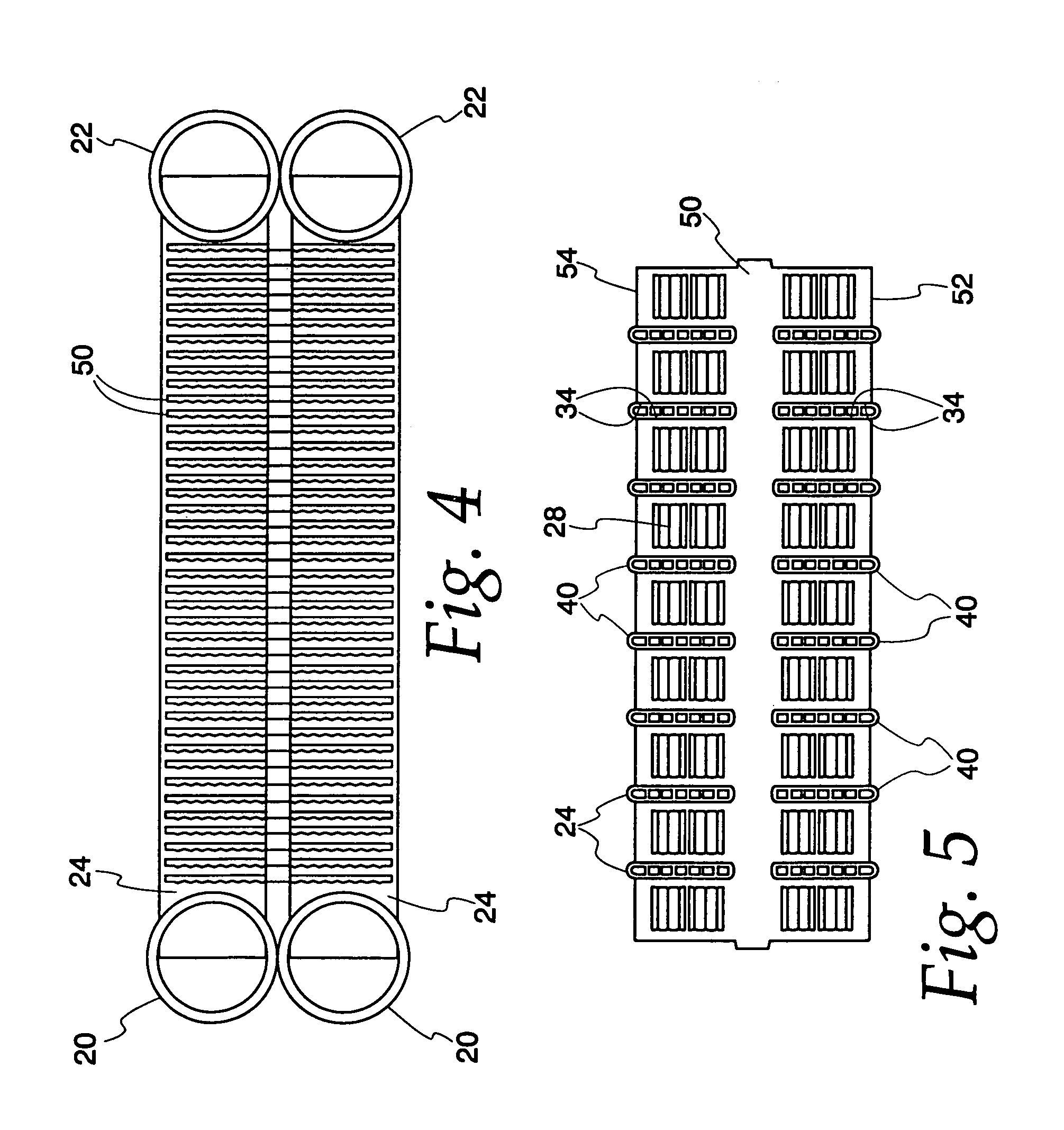

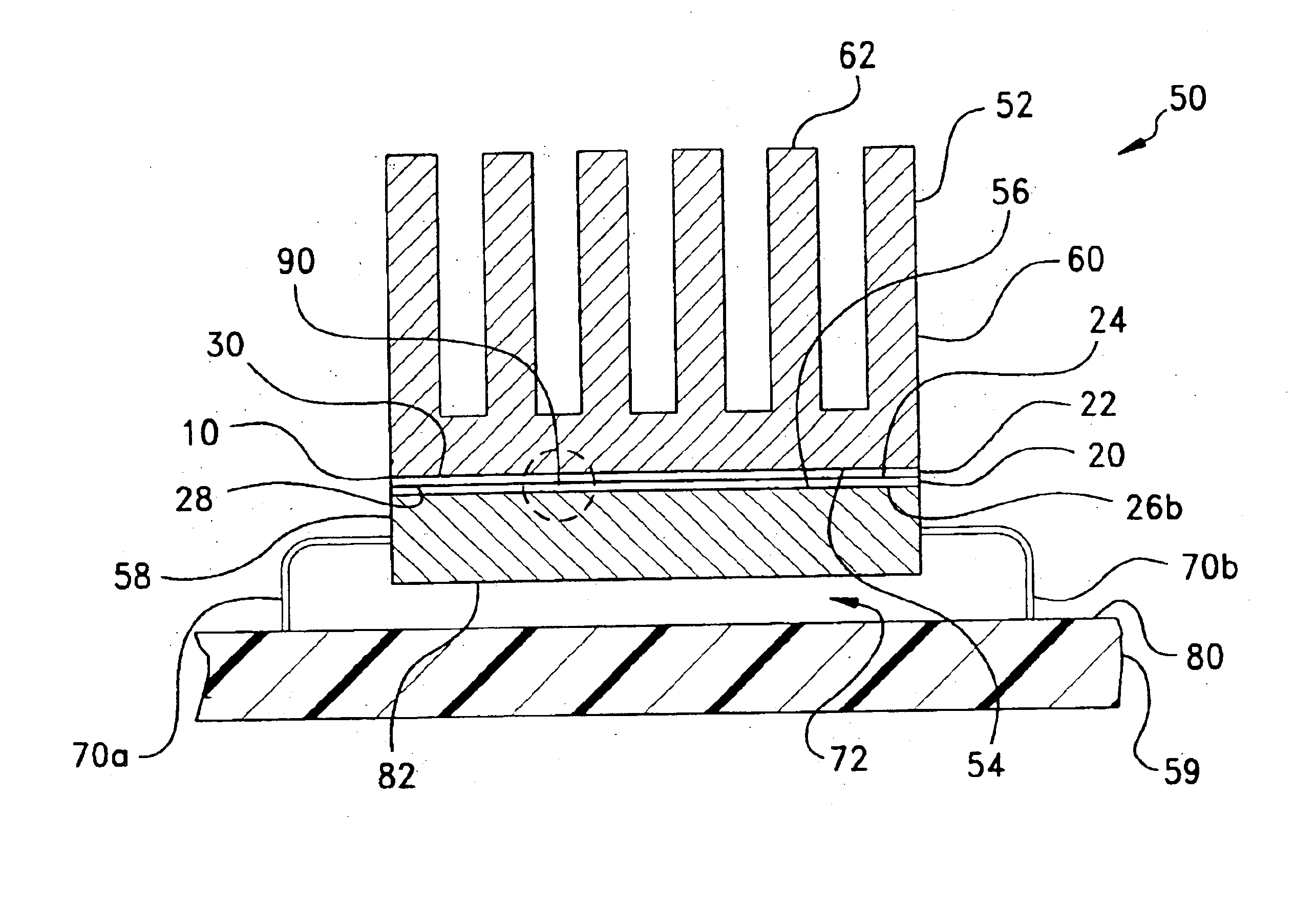

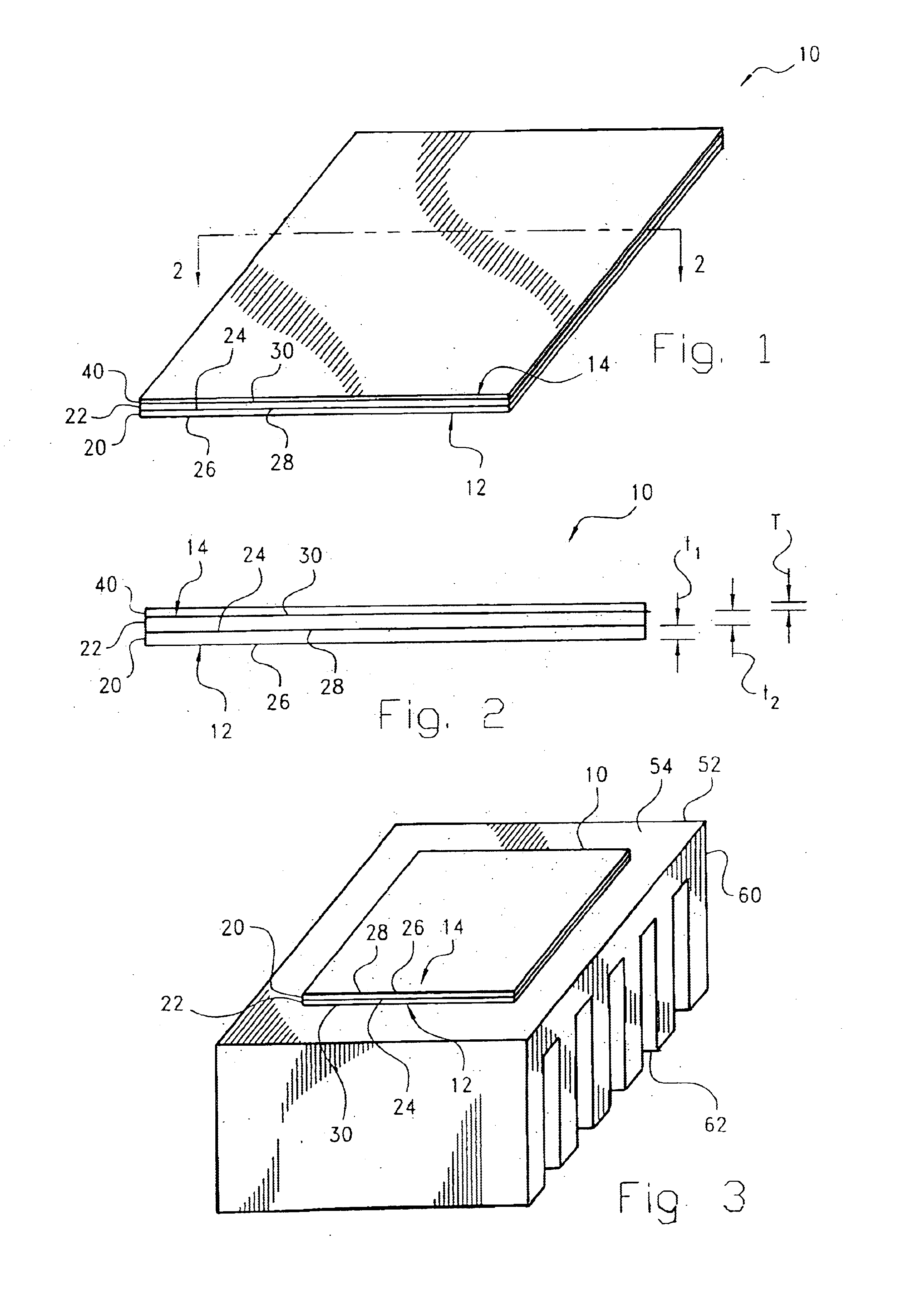

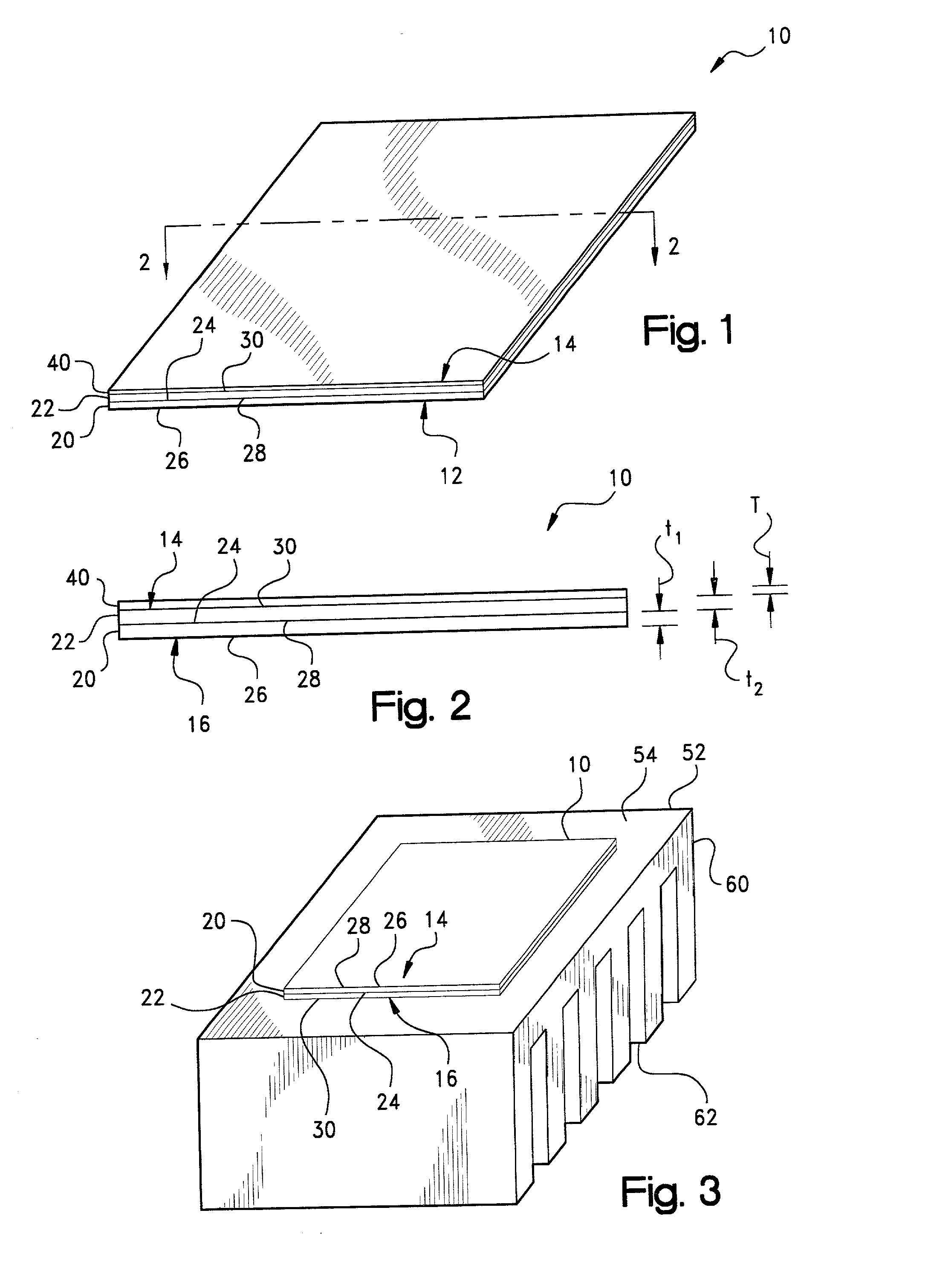

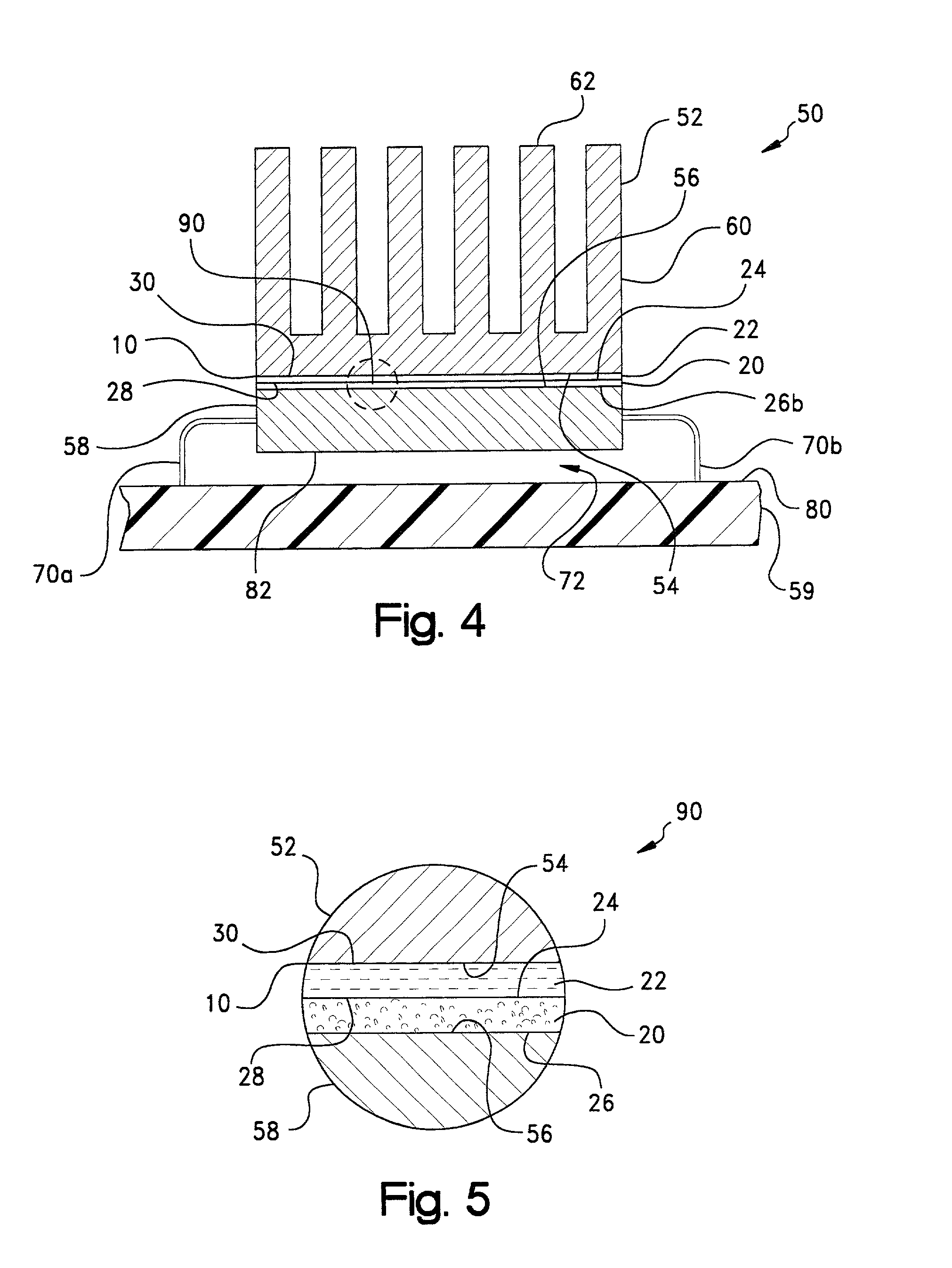

Heat exchanger

InactiveUS6964296B2Eliminate requirementsImprove relationshipSoldering apparatusHeat exhanger finsEngineeringMechanical engineering

Heat exchange inefficiencies found in round tube plate fin heat exchangers are eliminated in an aluminum heat exchanger that includes first and second headers (20), (22) and at least one flattened tube (24), (70) extending between the headers (20), (22). A plurality of generally parallel tube runs are defined and each has opposite edges. A plurality of plate fins (26), (50) are arranged in a stack and each has a plurality of open ended slots (34), one for each run of the tubes (24), (70). Each of the tube runs (24), (70) is nested within corresponding slots (26) and the fins (26), (50) with one of the edges (40) of the tube runs extending outwardly of the corresponding fin (34). The assembly is brazed together.

Owner:MODINE MFG CO

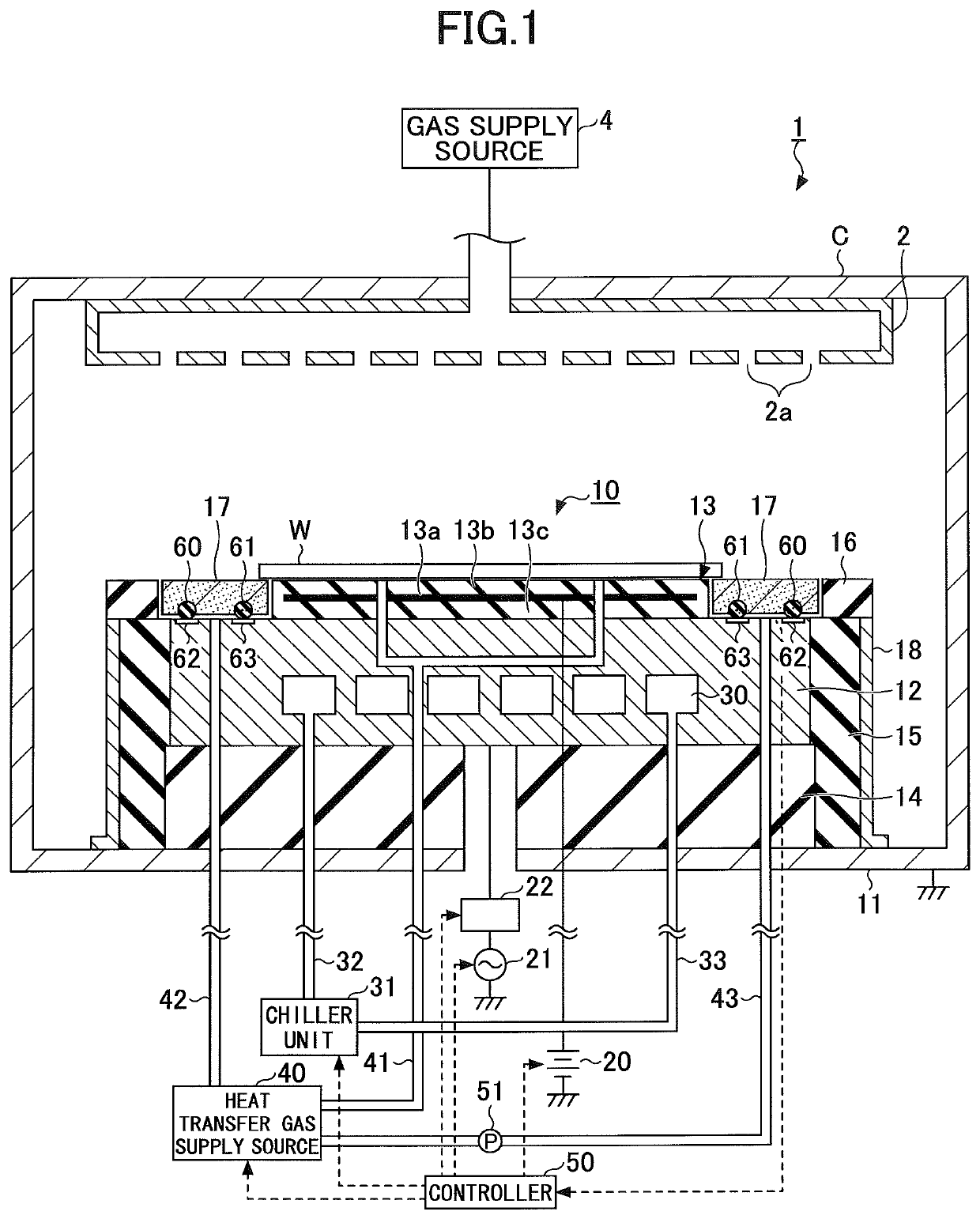

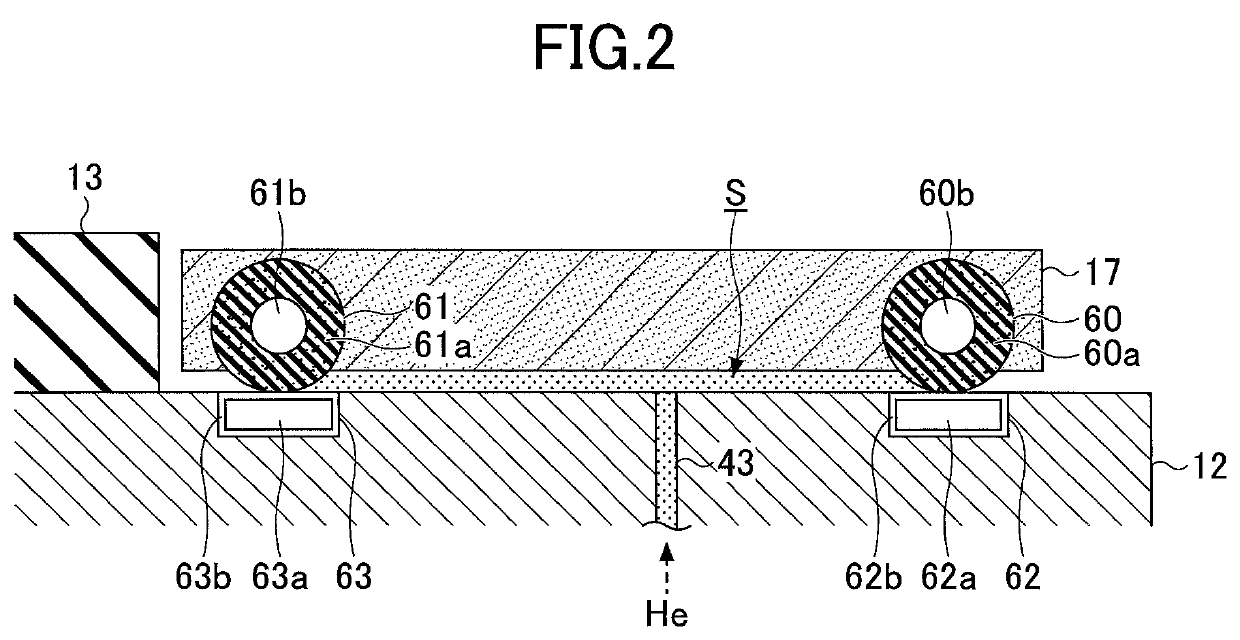

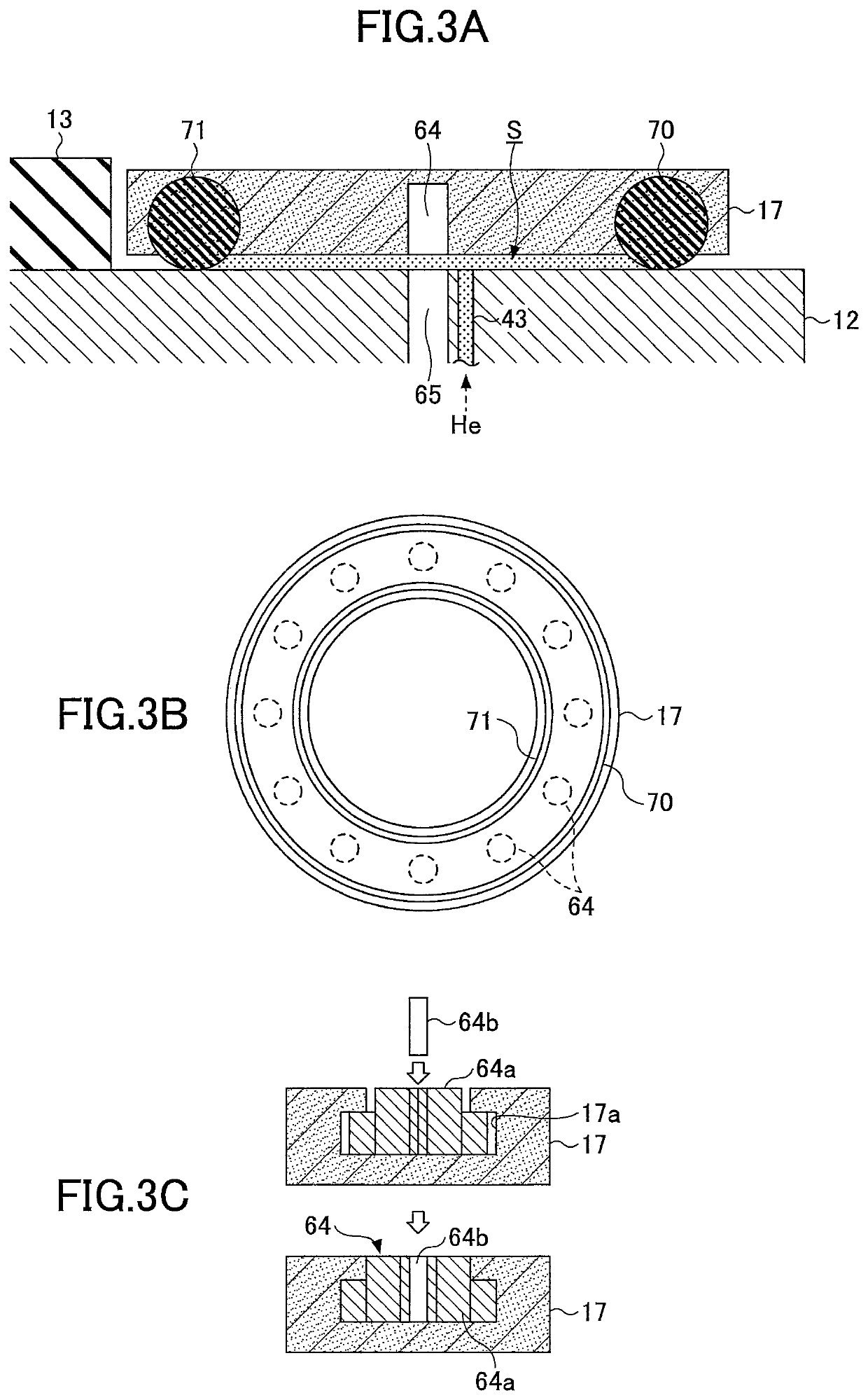

Plasma processing apparatus

ActiveUS10622196B2Efficient heat transferTemperature controlElectric discharge tubesEngineeringMechanical engineering

A plasma processing apparatus includes a mounting stage on which a substrate is mounted, a focus ring arranged around a periphery of the mounting stage, a plurality of magnetic members arranged at a surface of the focus ring and a surface of the mounting stage facing opposite each other, and a temperature adjustment unit configured to adjust a temperature of the focus ring by introducing a heat transfer gas between the surface of the focus ring and the surface of the mounting stage facing opposite each other.

Owner:TOKYO ELECTRON LTD

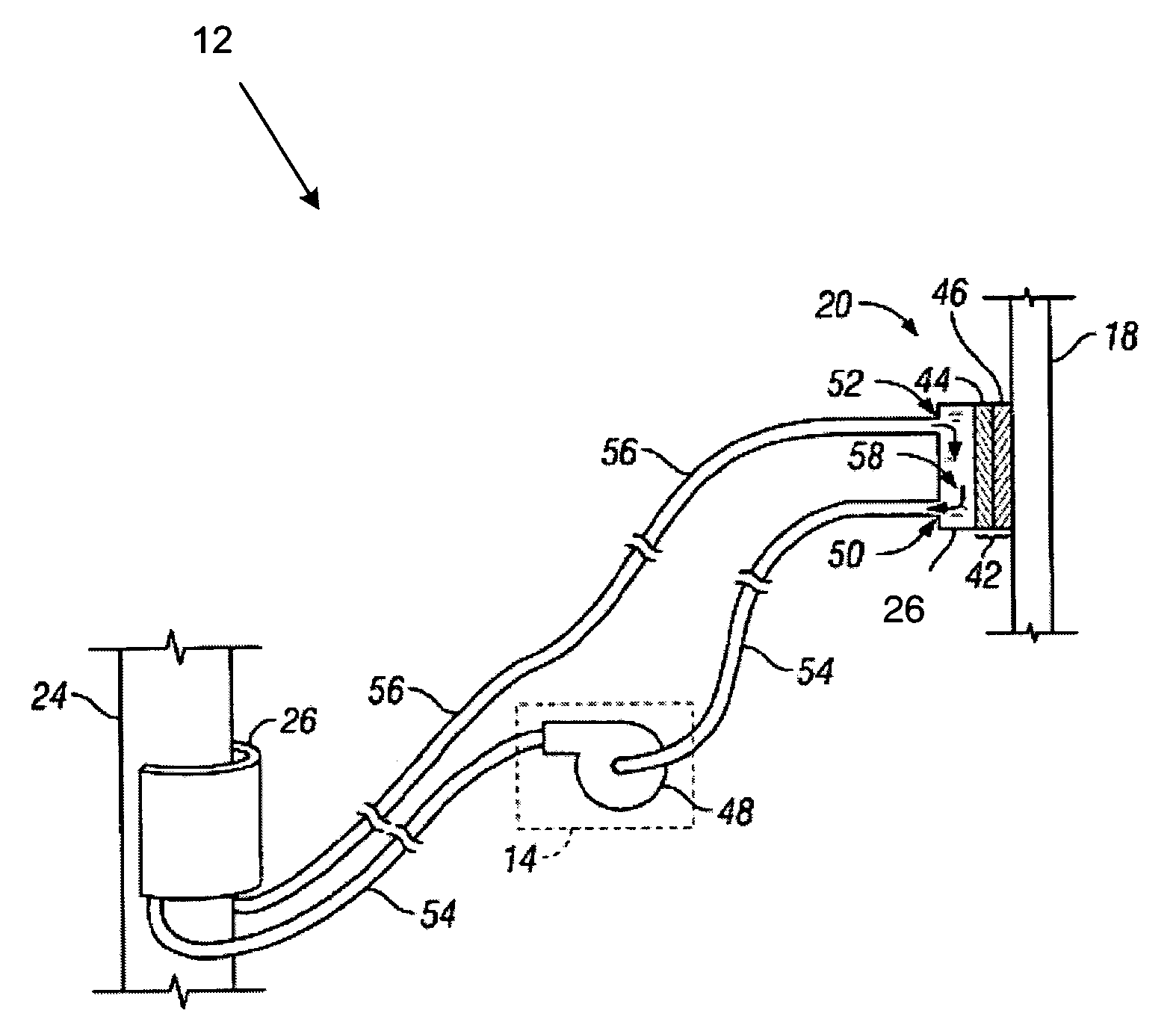

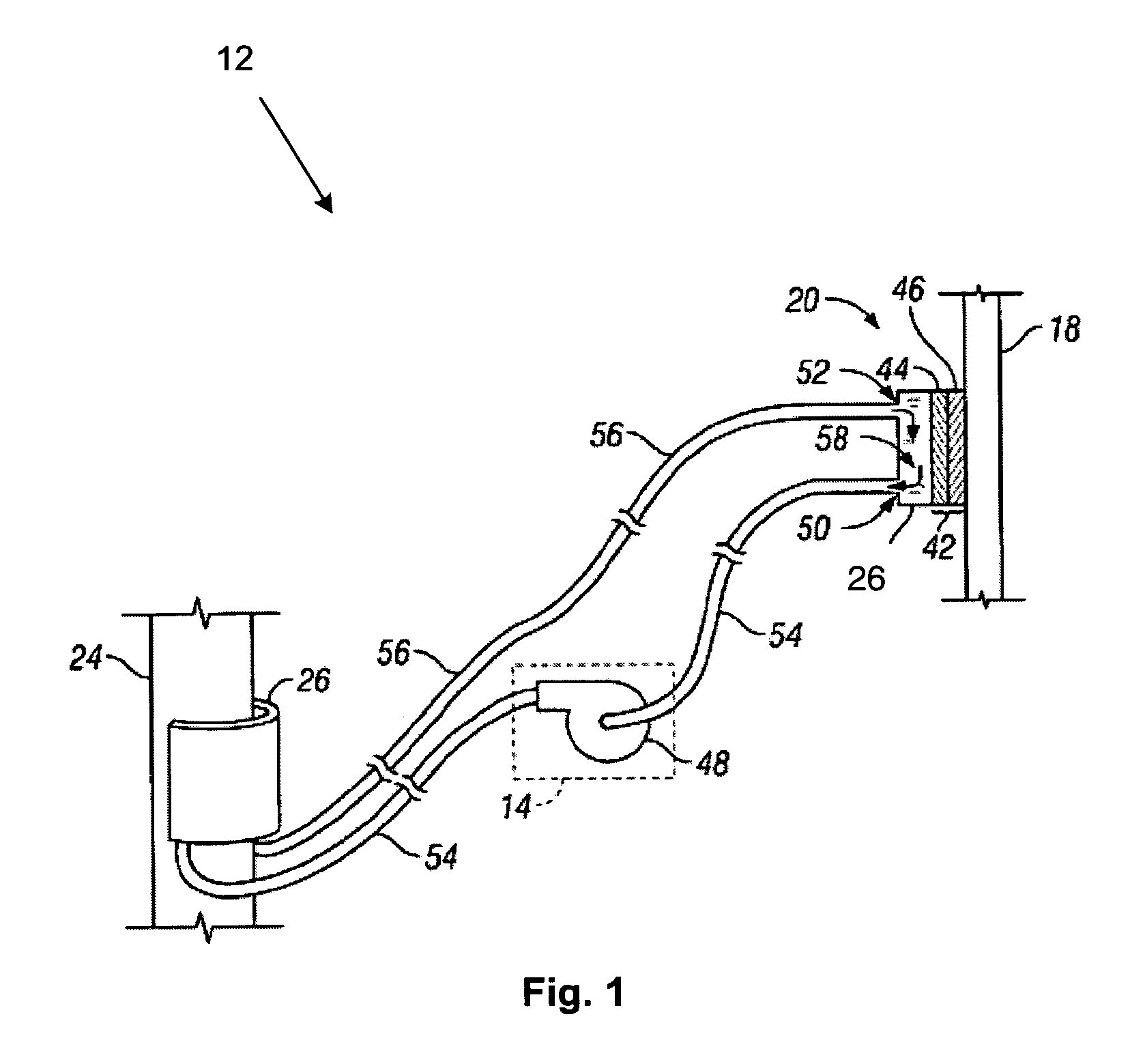

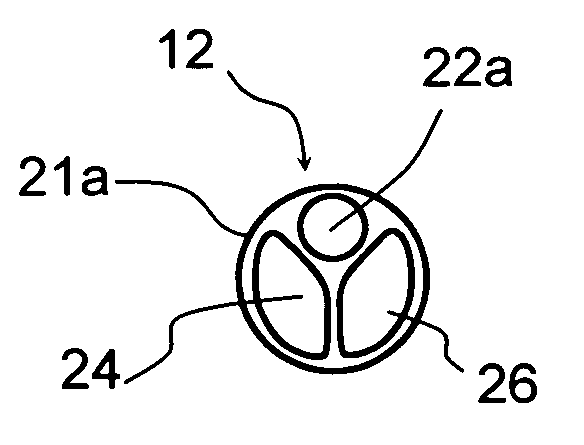

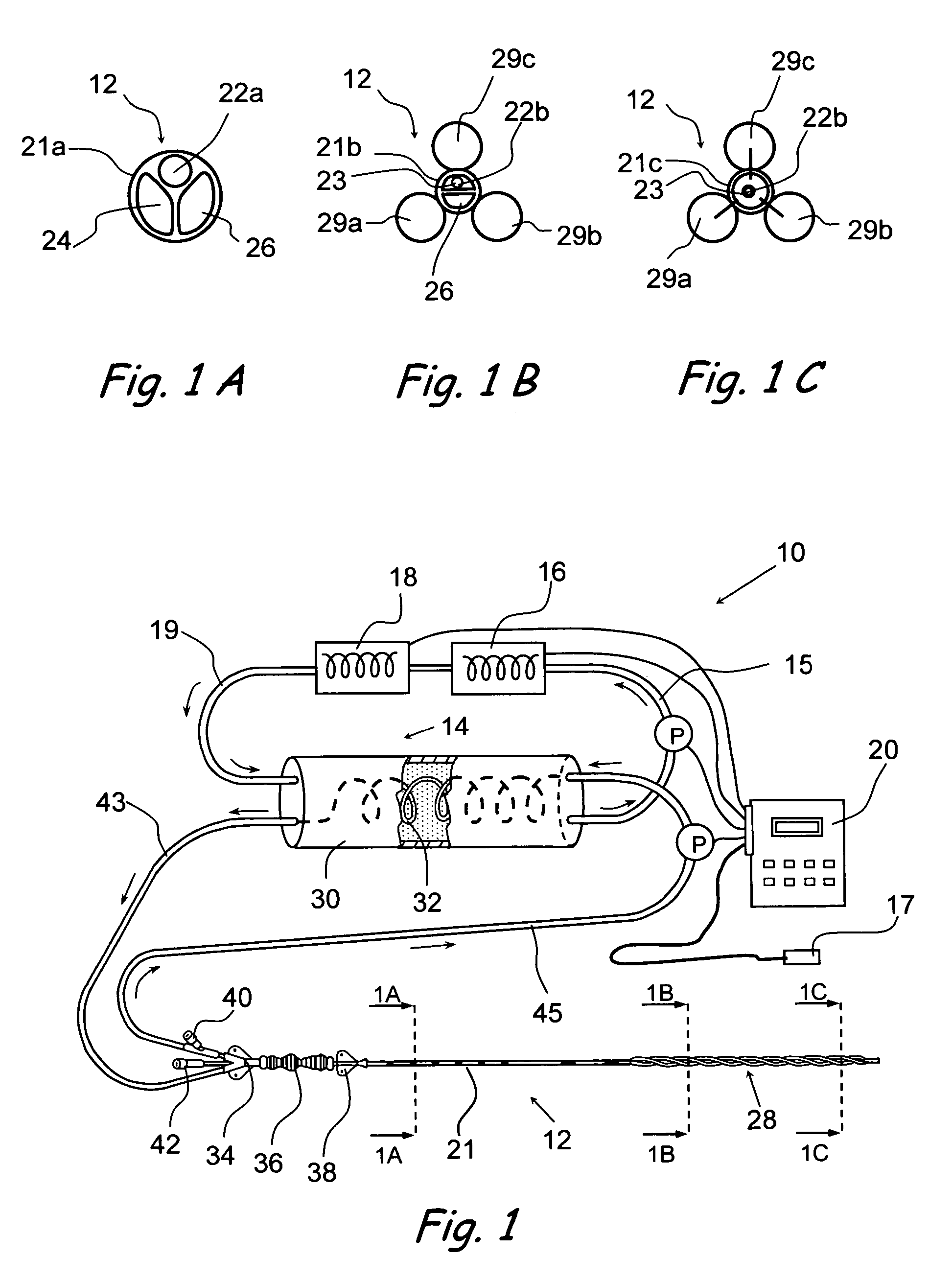

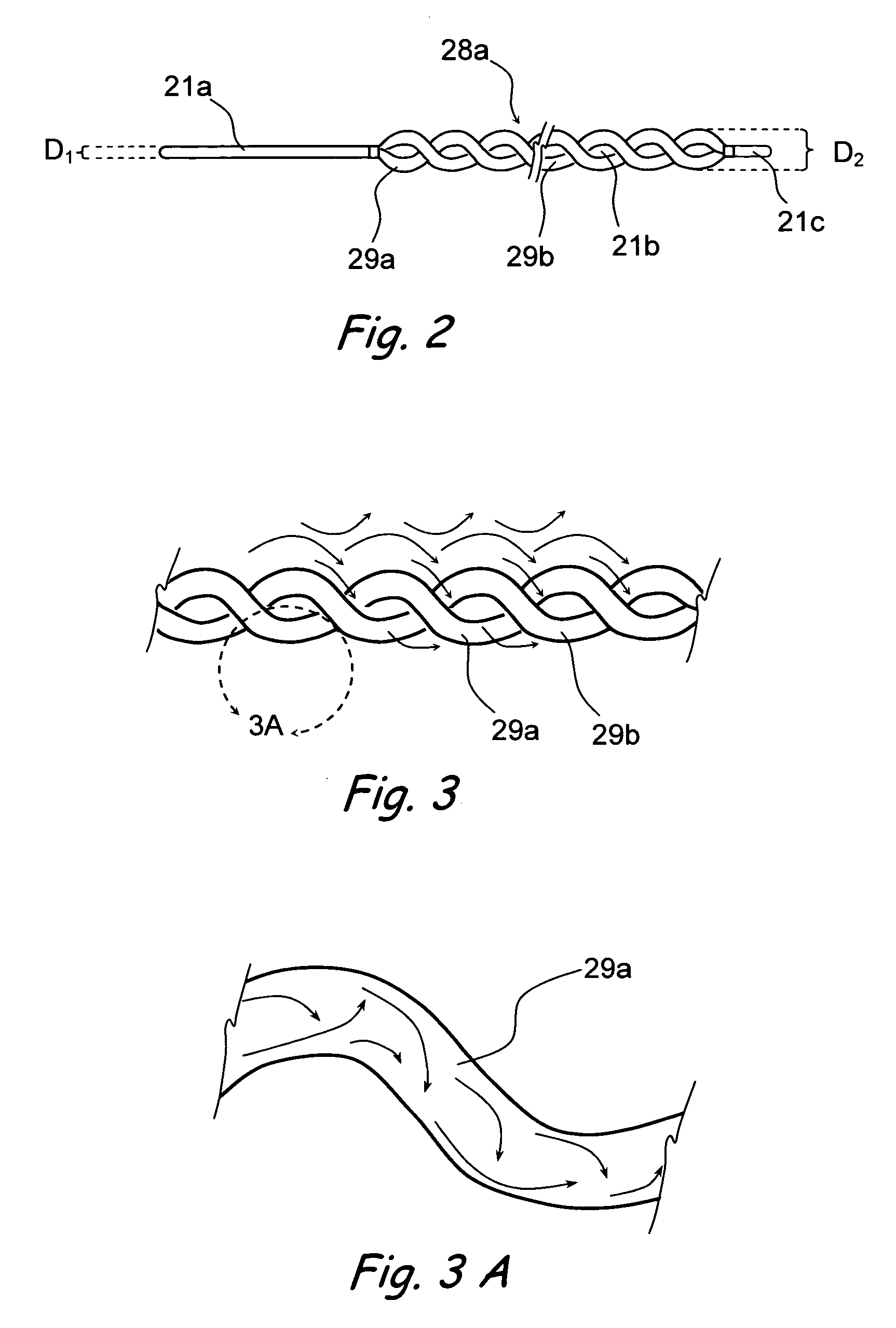

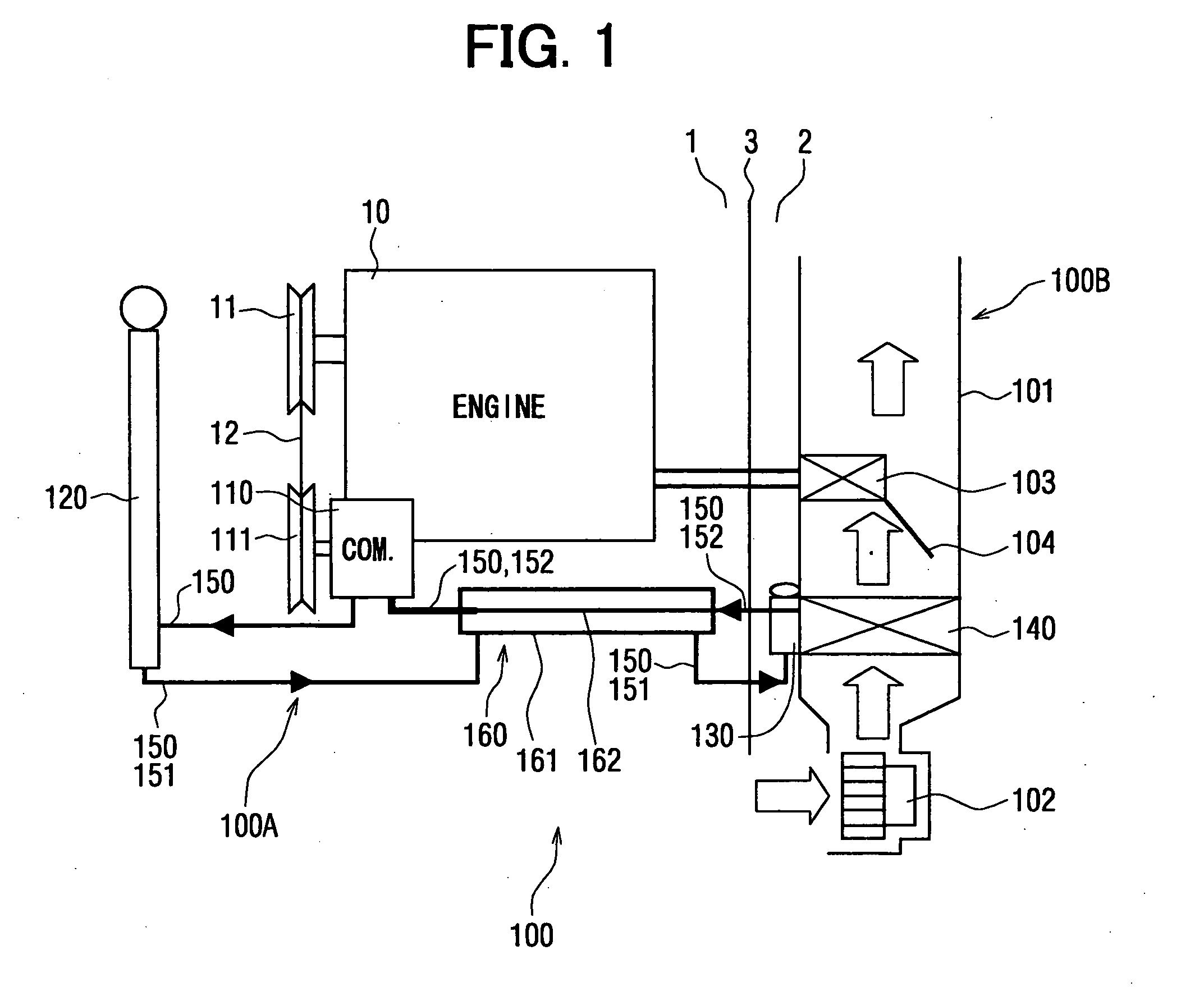

Devices, systems and methods for rapid endovascular cooling

ActiveUS20070043409A1Improve heat transfer efficiencySpeed up heat exchangeStentsBalloon catheterMedicineBlood flow

Devices and methods for warming or cooling blood flowing through the vasculature of a human or animal subject so as to alter or control the temperature of all or part of the subject's body. Heat exchangers are positioned within the subject's vasculature and heated or cooled heat exchange fluid is circulated through the heat exchanger. For certain therapeutic applications, the heat exchanger and associated elements of the system have sufficient power to lower the subject's body temperature by at least 3 degrees C. in less than 30 minutes.

Owner:ZOLL CIRCULATION

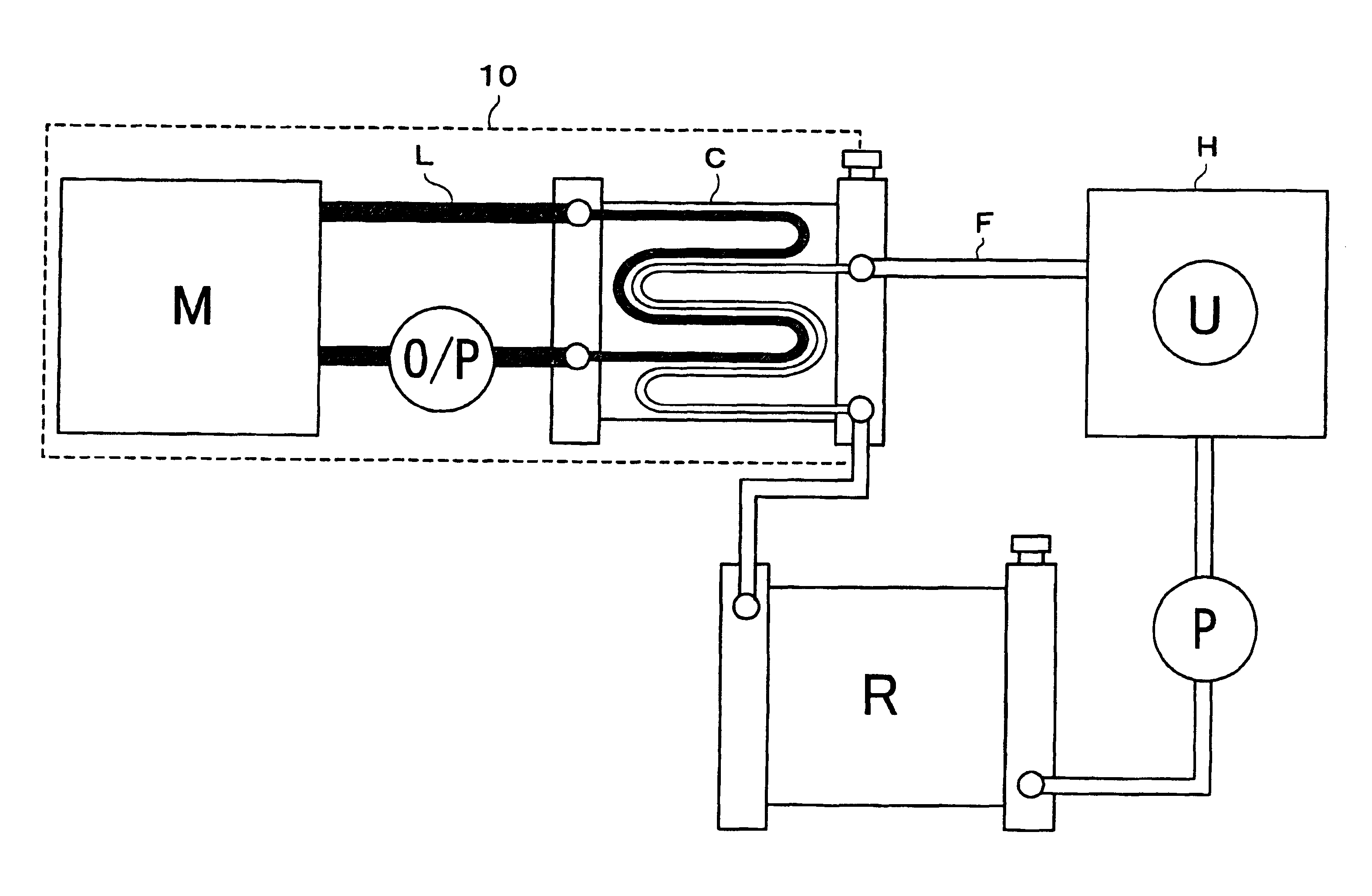

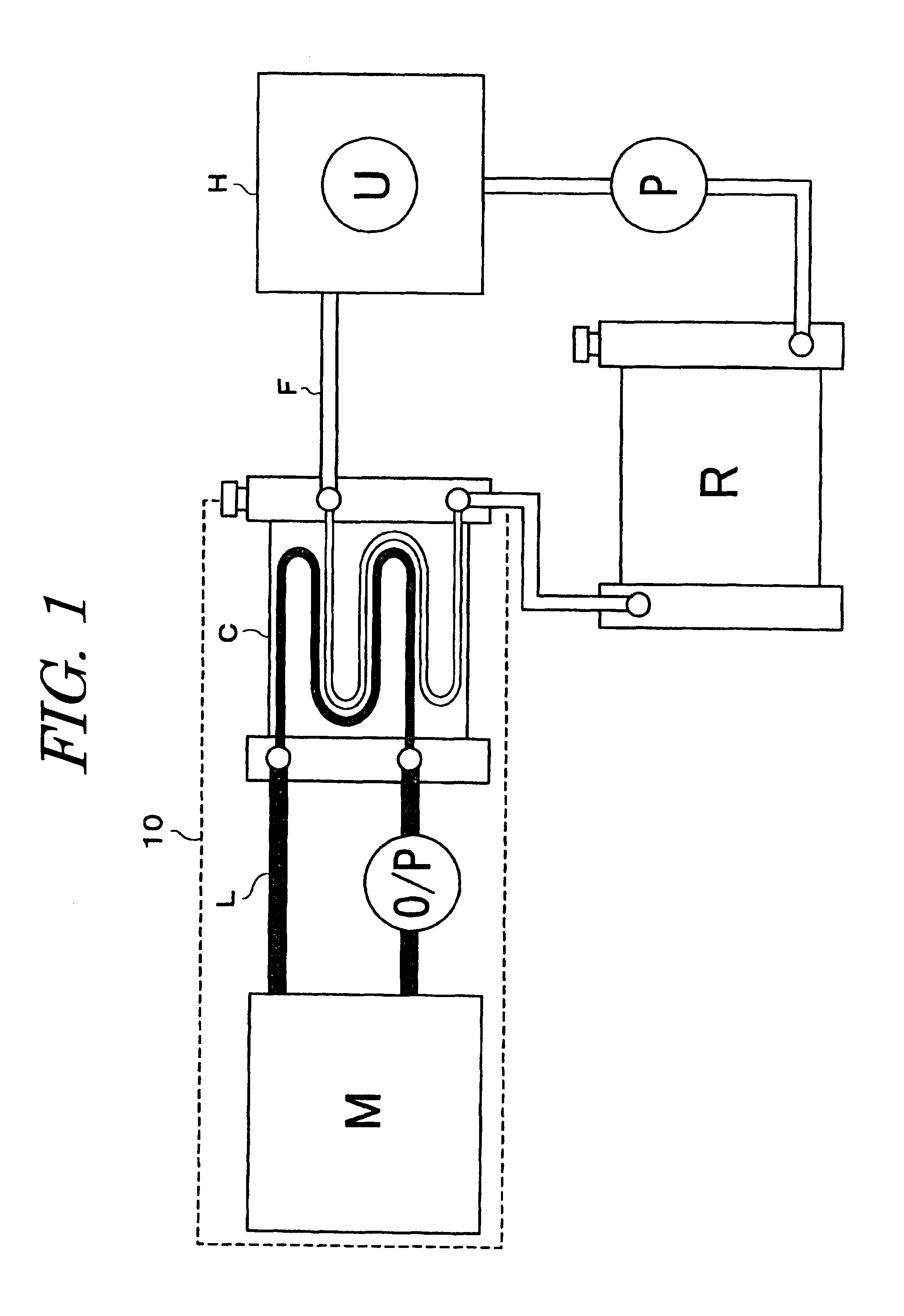

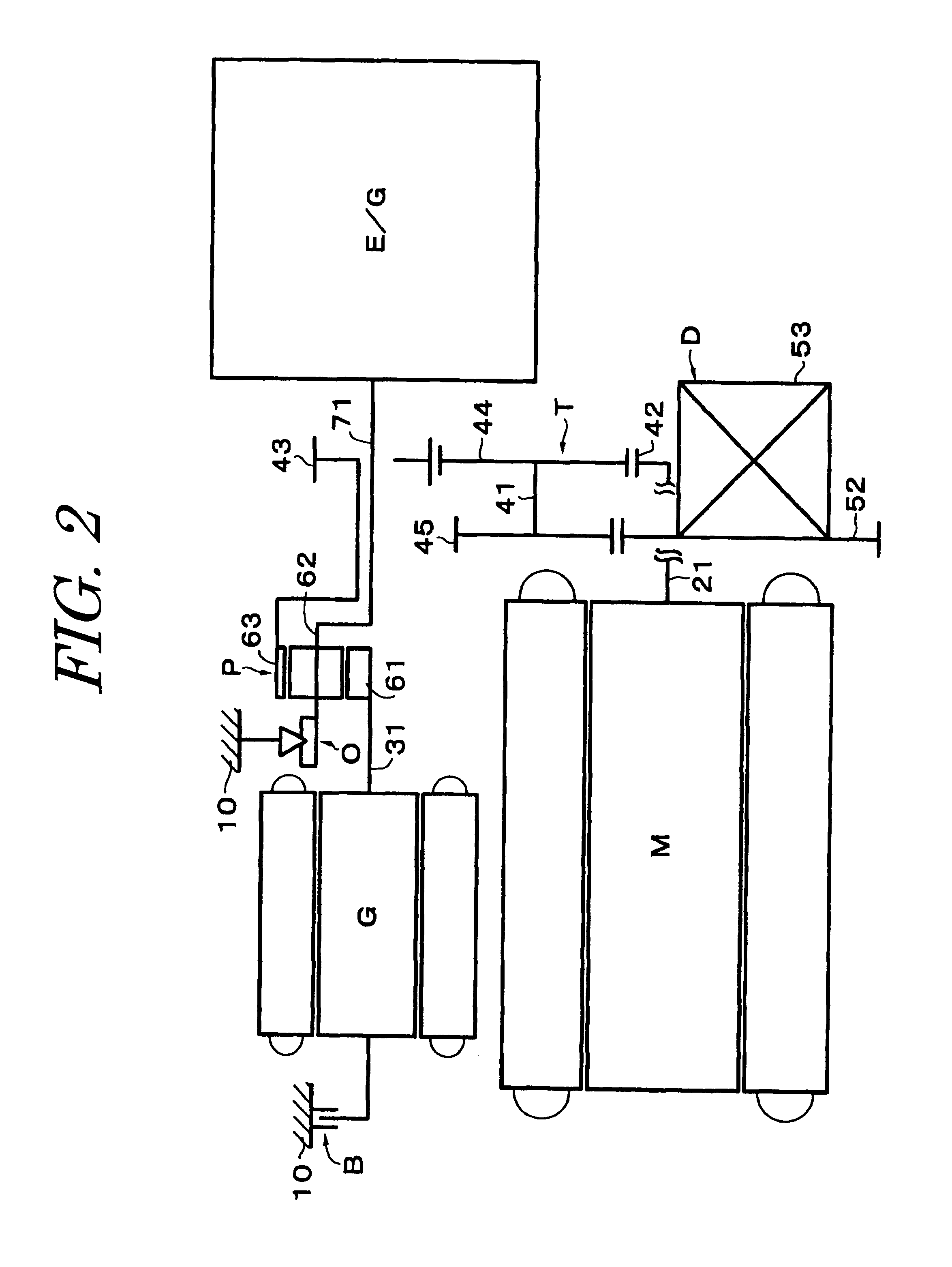

Drive unit with two coolant circuits for electric motor

InactiveUS6323613B1Improve cooling effectHeat exchangerTemperatue controlEmergency protective circuit arrangementsEngineeringCooling fluid

A drive unit includes an electric motor as a power source, and a simplified coolant circuit for cooling the electric motor. The drive unit further includes, in the drive unit case, a circulation passage L for coolant for cooling the motor M. A circulation passage F for a second coolant is provided separate from the circulation passage L for coolant. A heat exchange portion C within the circulation passage L for the first coolant is provided in the drive unit case for heat exchange with the second coolant in the circulation passage F, and the first coolant for cooling the electric motor is cooled by heat transfer to the second coolant in that heat exchange portion C. Accordingly, the coolant circuit in the drive unit case is simplified.

Owner:AISIN AW CO LTD

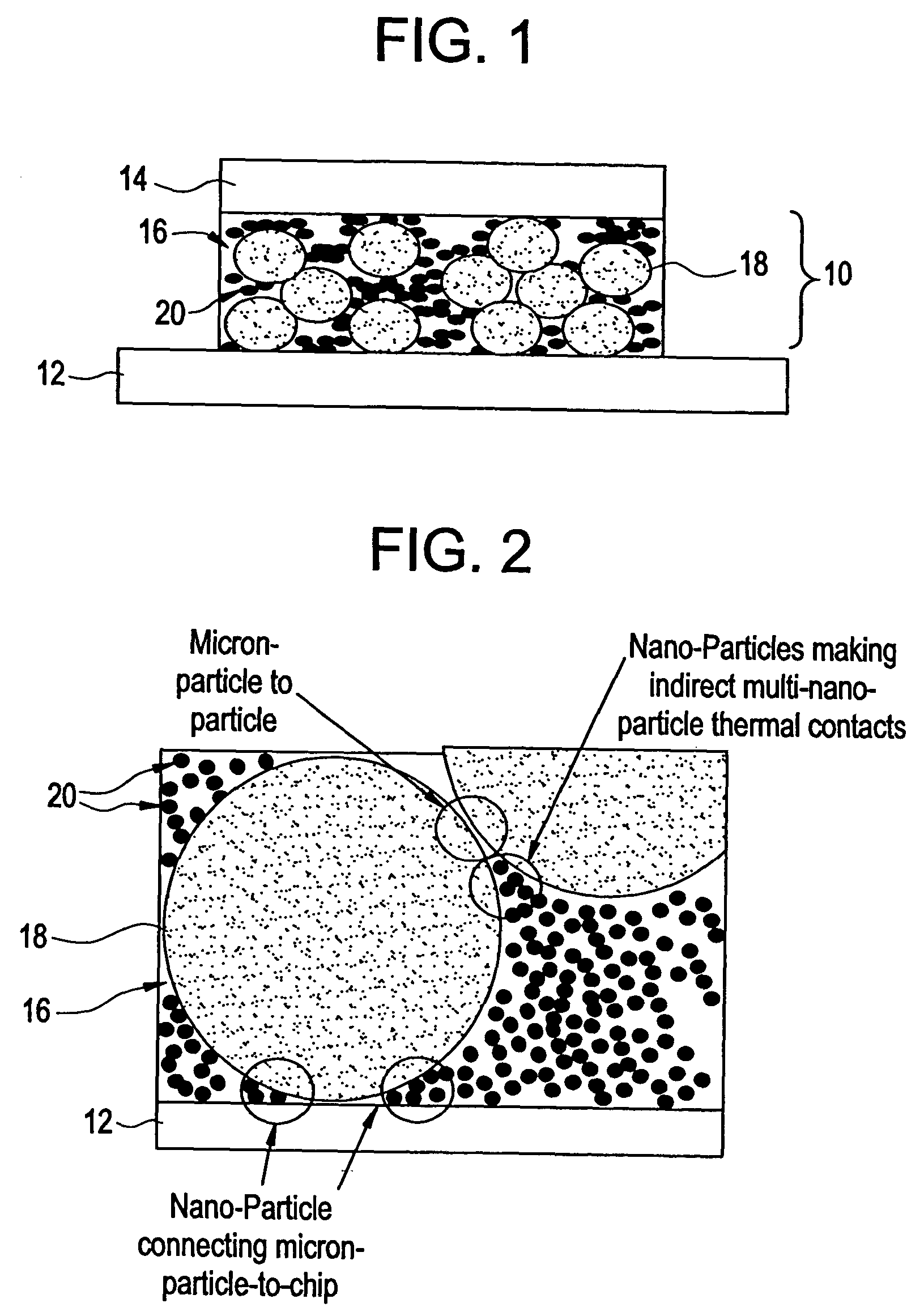

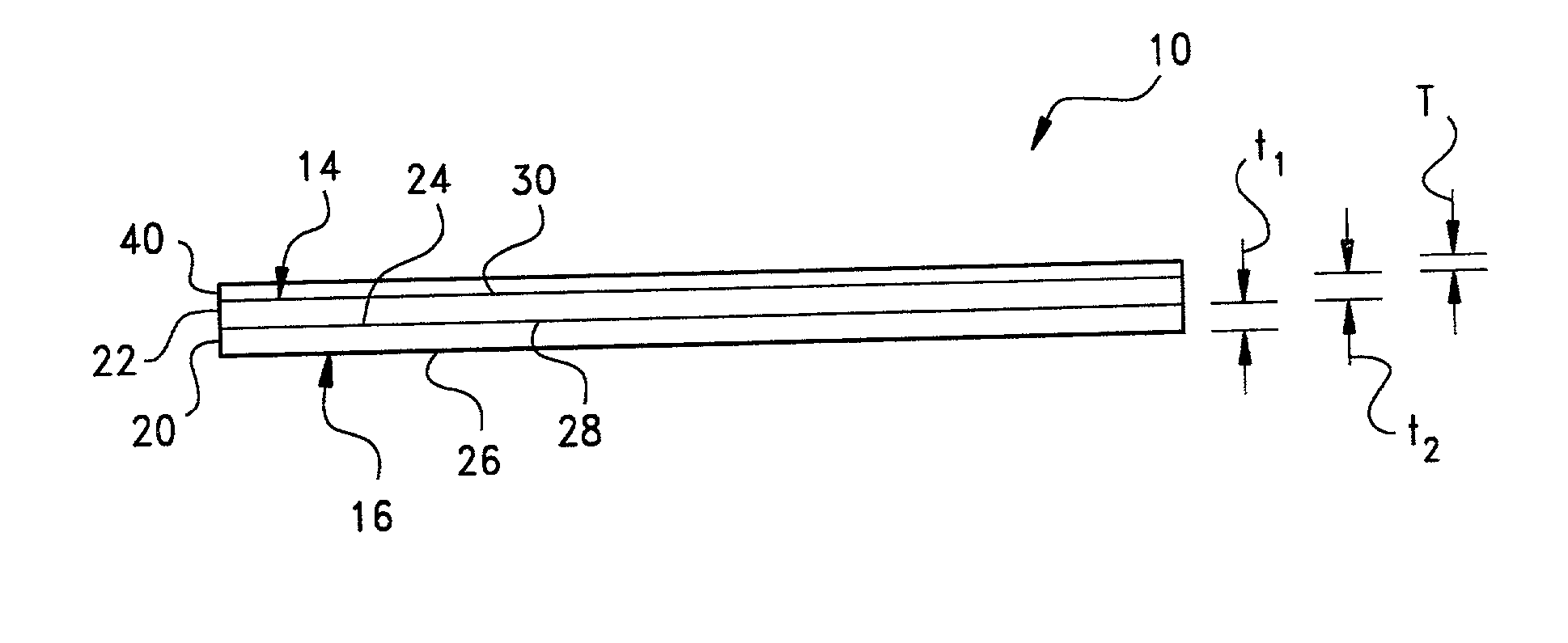

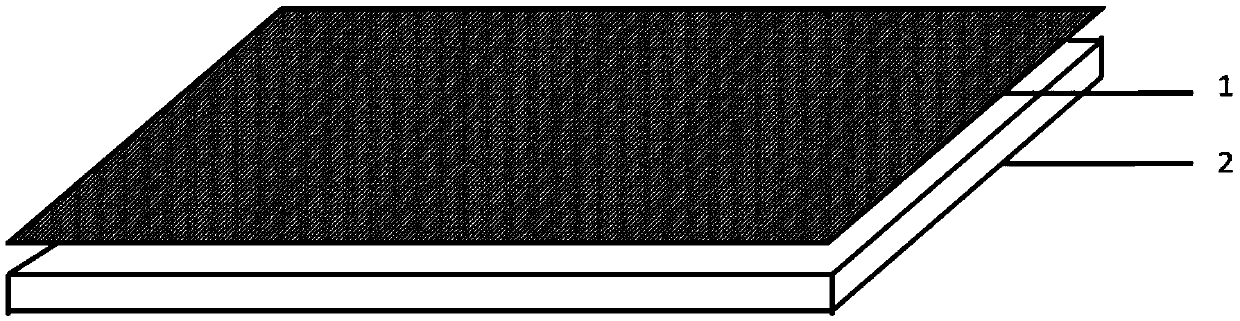

Clean release, phase change thermal interface

InactiveUS6835453B2Improve efficiencyIncrease ratingsSemiconductor/solid-state device detailsSynthetic resin layered productsGraphitePhase change

A laminar, thermally-conductive interface interposable intermediate a first heat transfer surface and an opposing second heat transfer surface to provide a thermally-conductive pathway therebetween. The interface includes a first layer formed of a flexible, lamellar graphite or tin foil material, and a second layer formed of a thermally-conductive phase-change material.

Owner:PARKER INTANGIBLES LLC

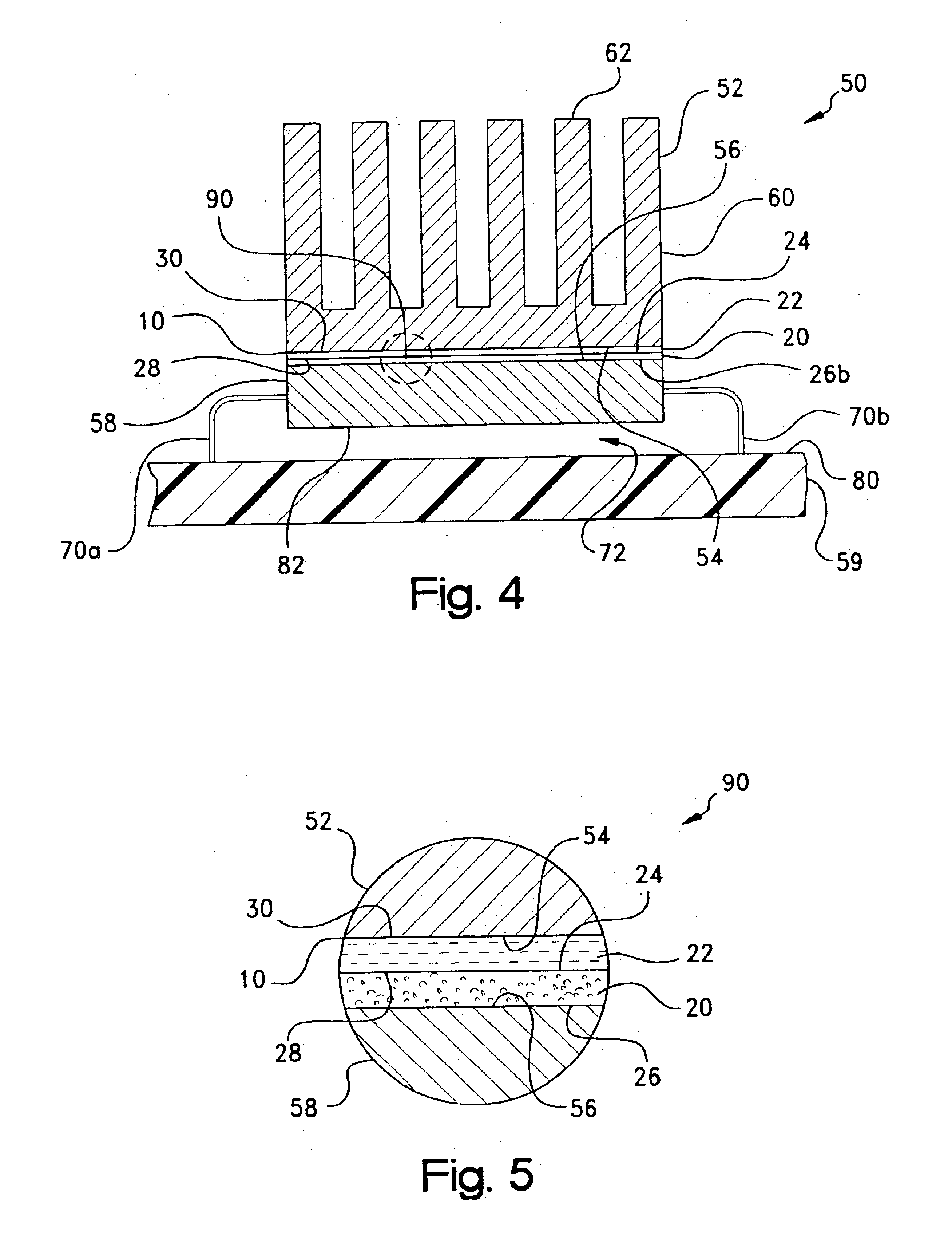

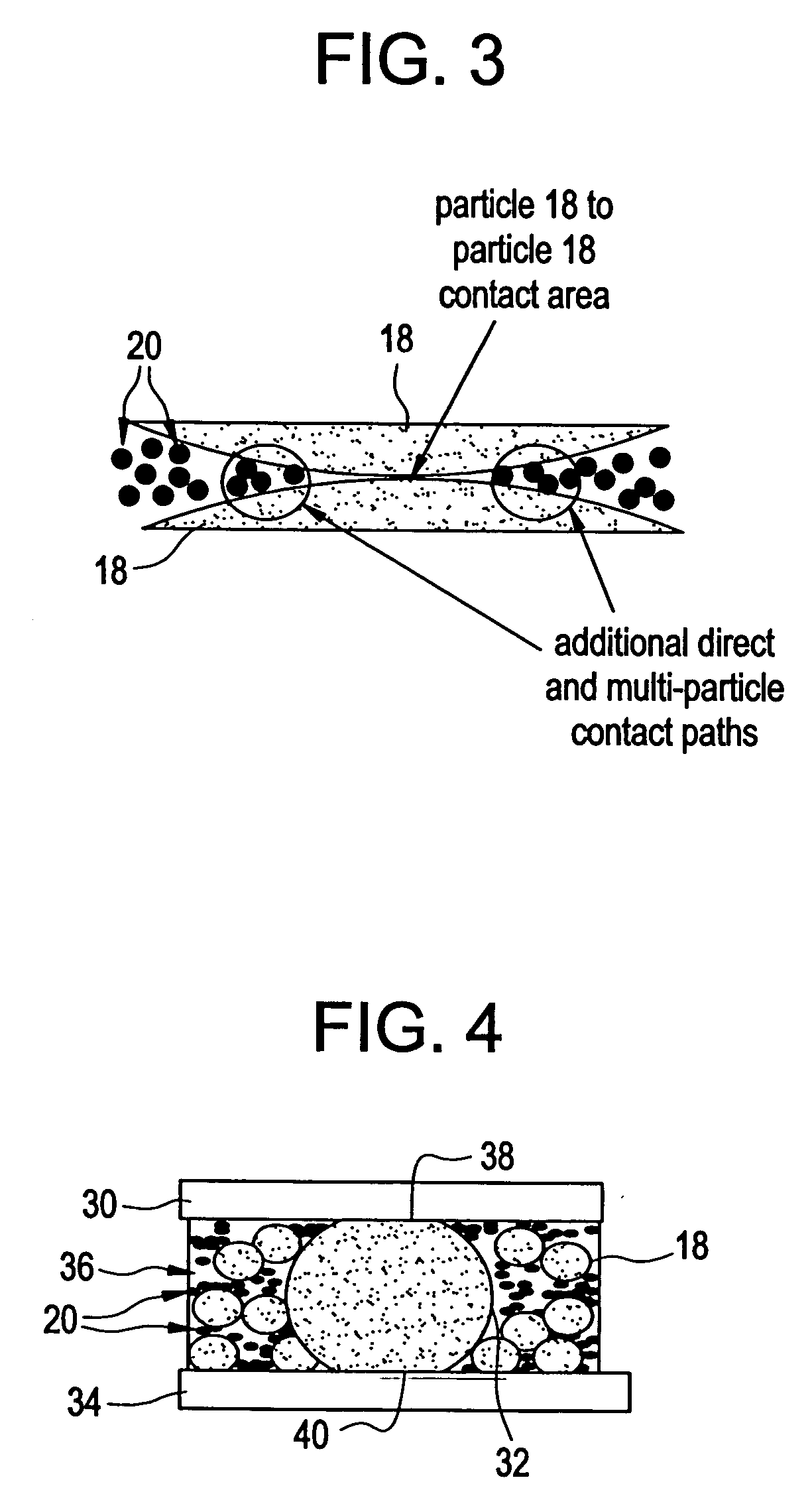

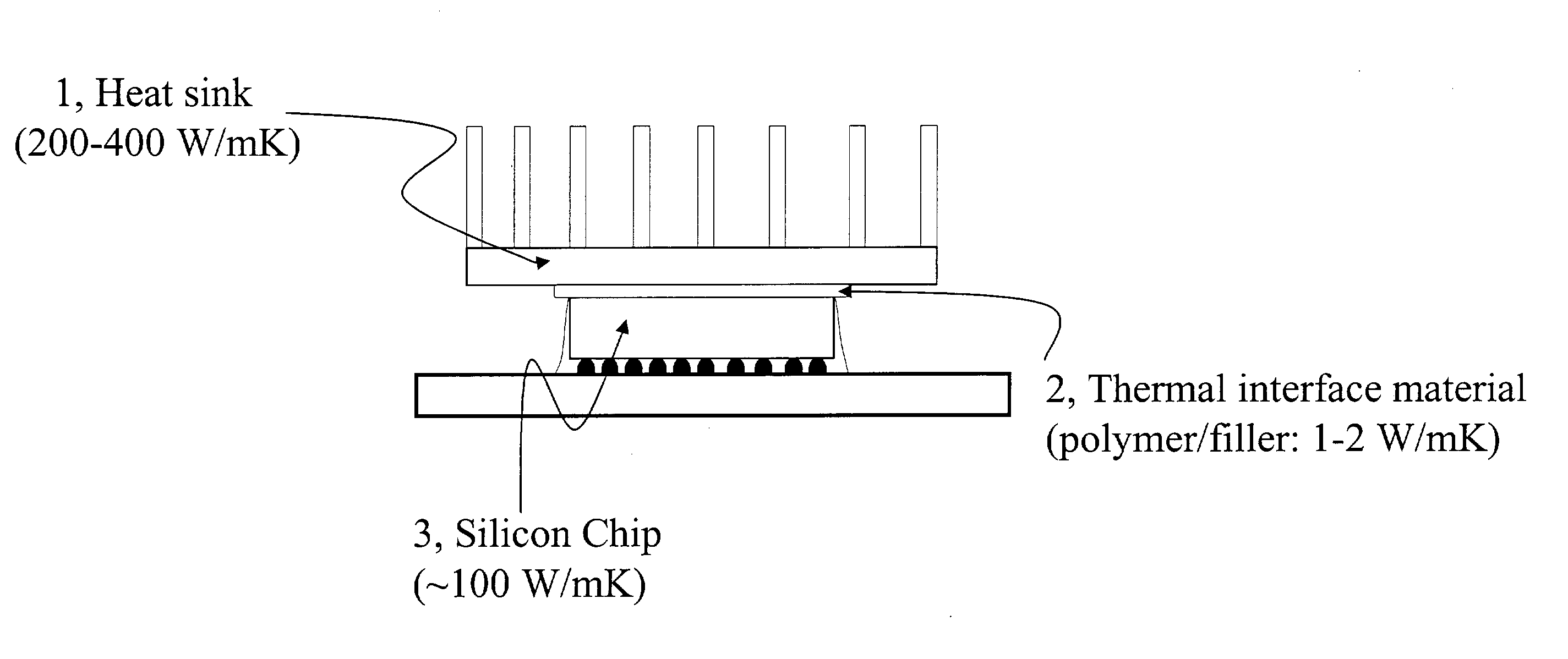

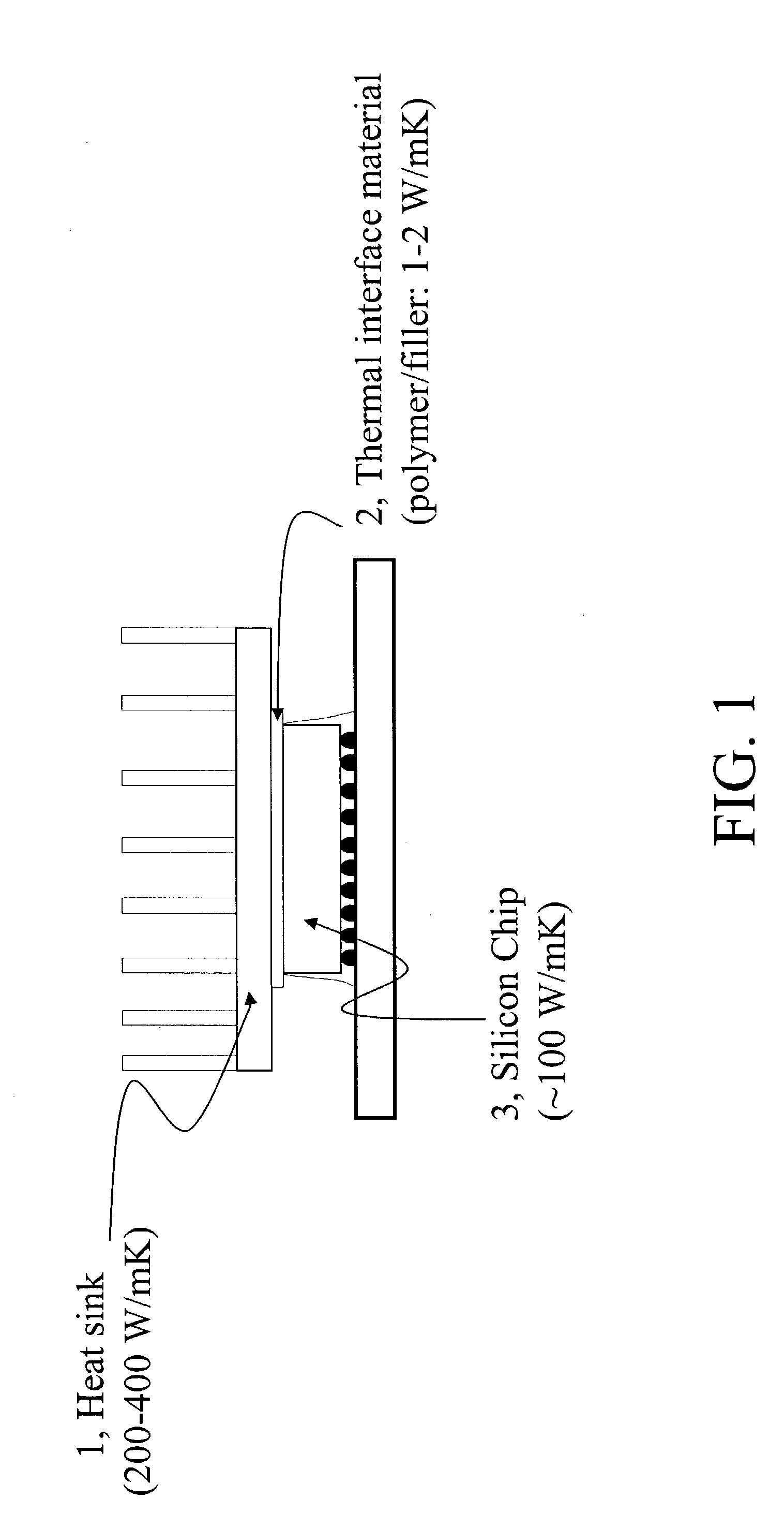

Thermal conductive material utilizing electrically conductive nanoparticles

ActiveUS20050045855A1Improve heat transfer efficiencySemiconductor/solid-state device detailsConductive materialNanoparticleInterfacial resistance

Thermal interface compositions contain both non-electrically conductive micron-sized fillers and electrically conductive nanoparticles blended with a polymer matrix. Such compositions increase the bulk thermal conductivity of the polymer composites as well as decrease thermal interfacial resistances that exist between thermal interface materials and the corresponding mating surfaces. Such compositions are electrically non-conductive. Formulations containing nanoparticles also show less phase separation of micron-sized particles than formulations without nanoparticles.

Owner:GENERAL ELECTRIC CO

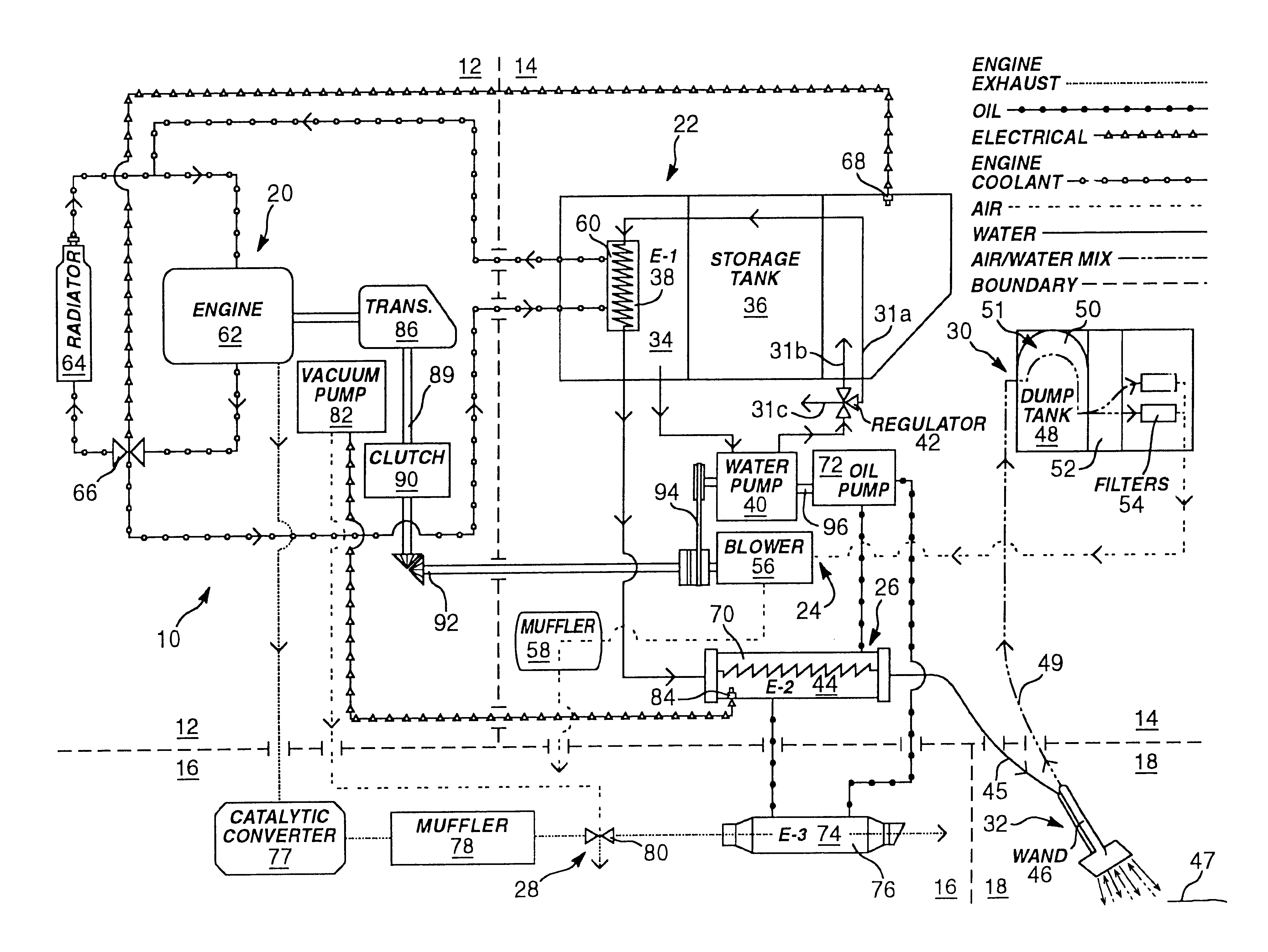

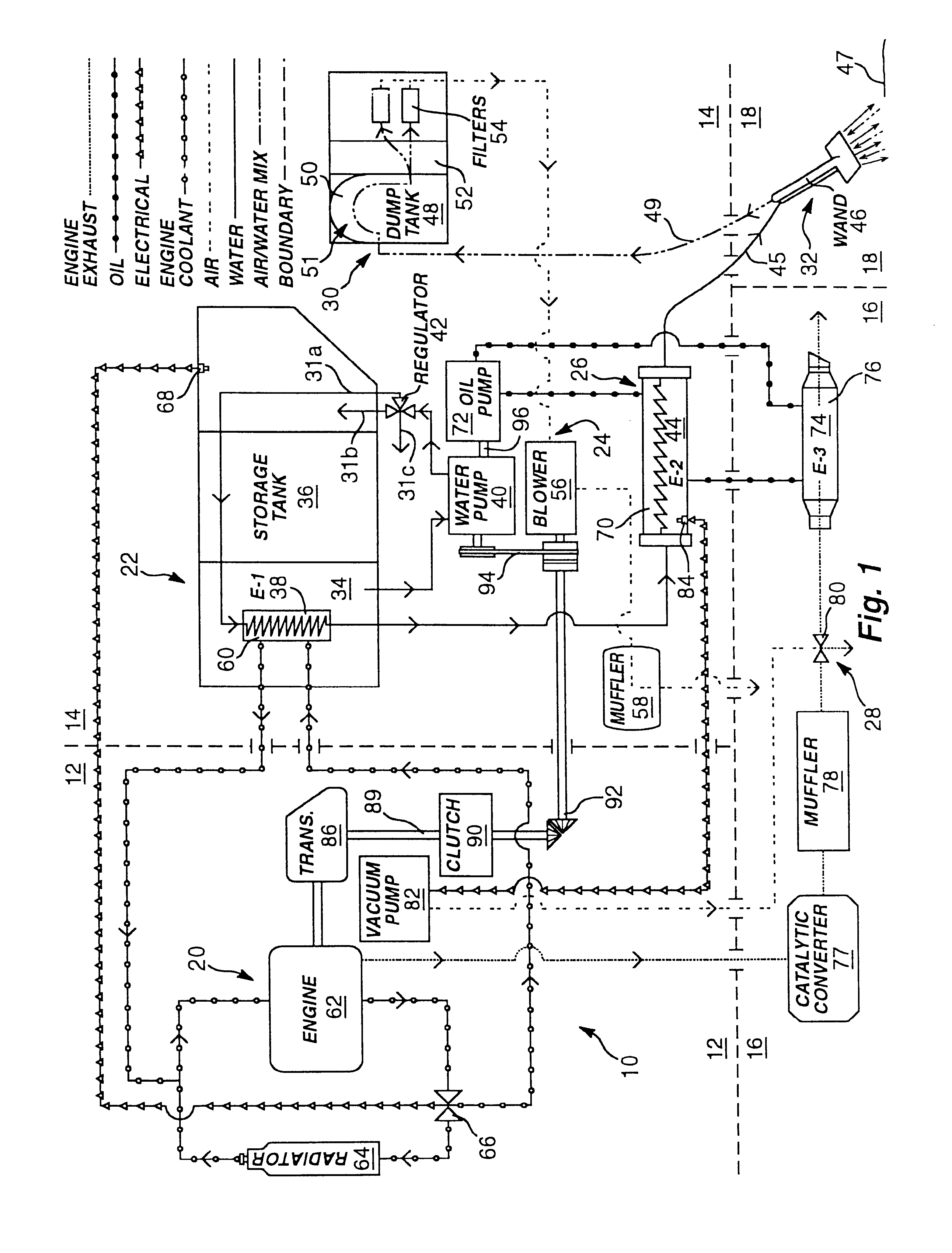

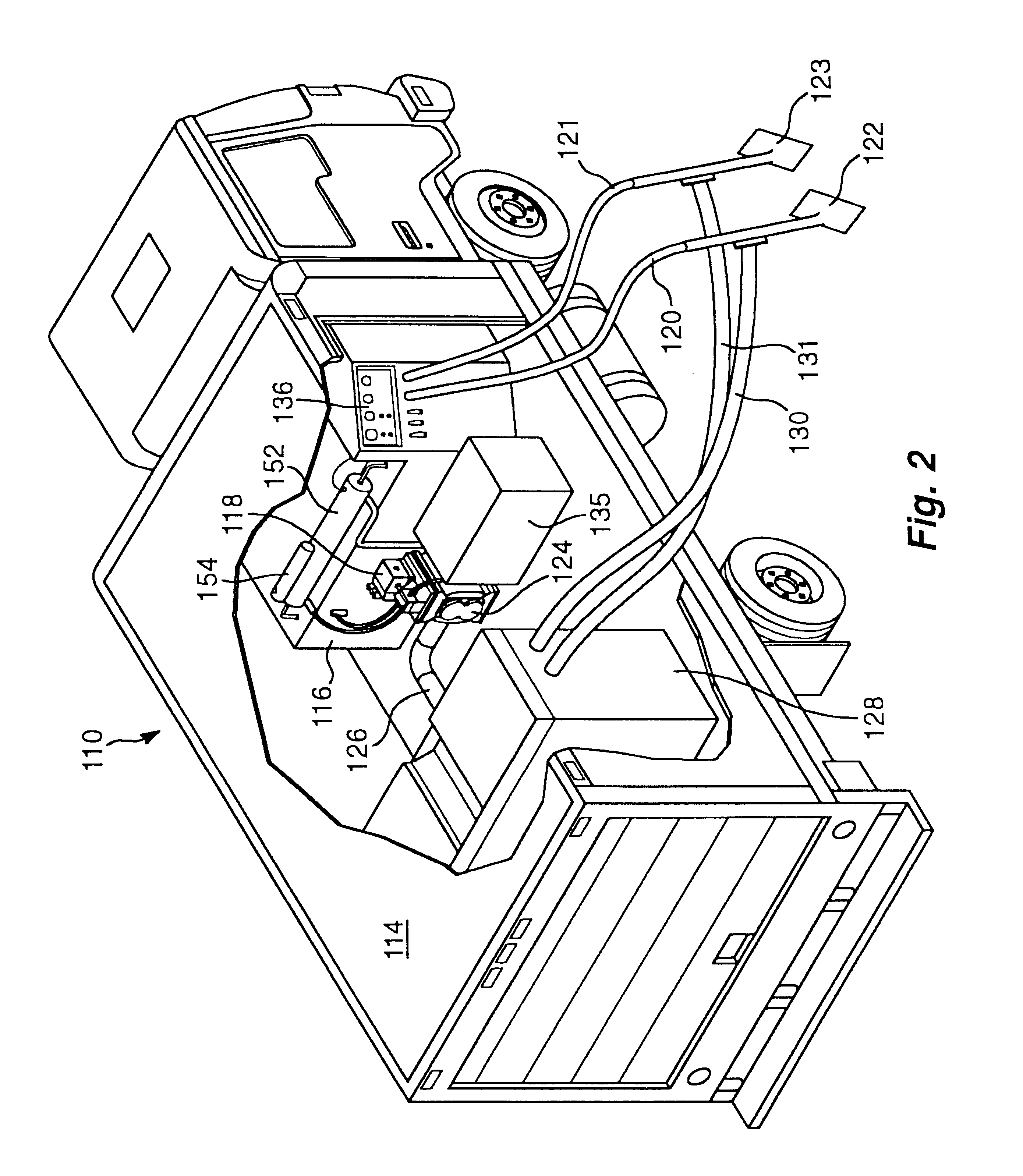

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

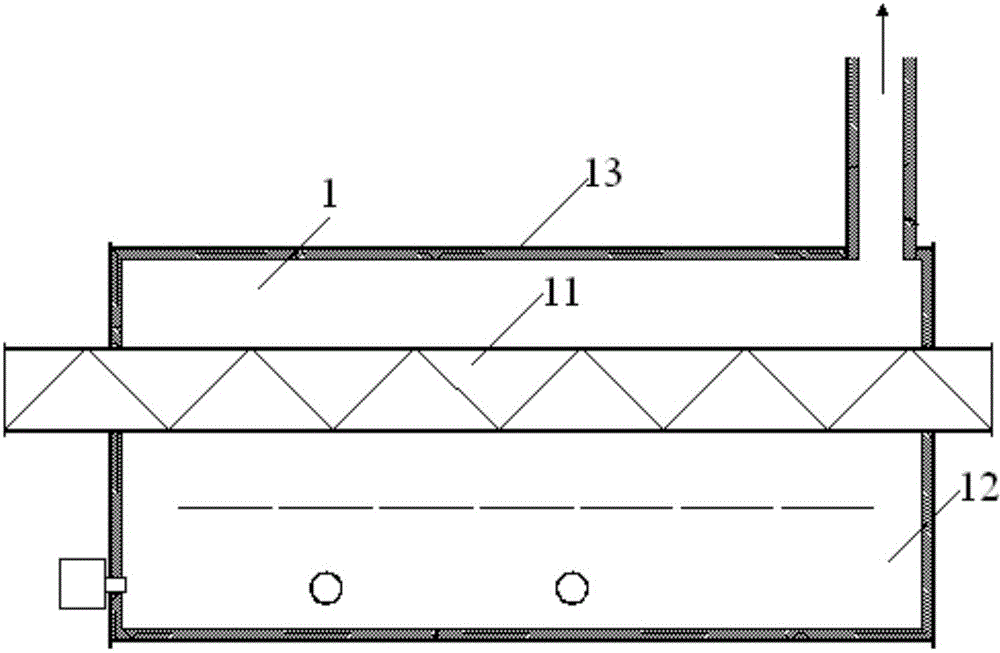

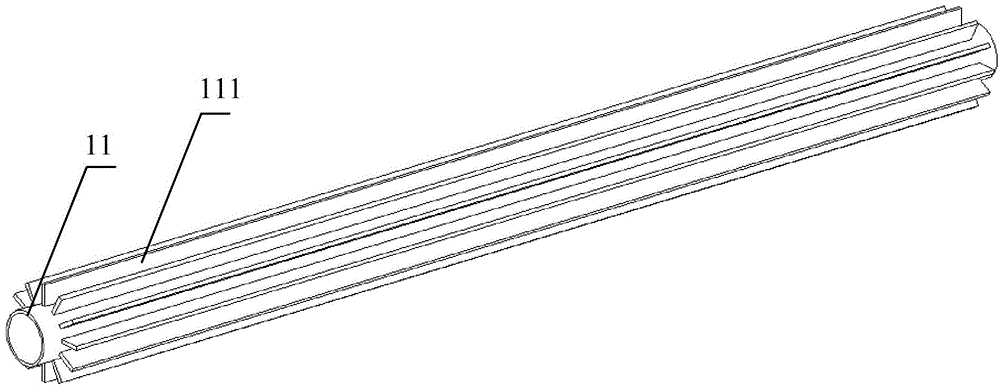

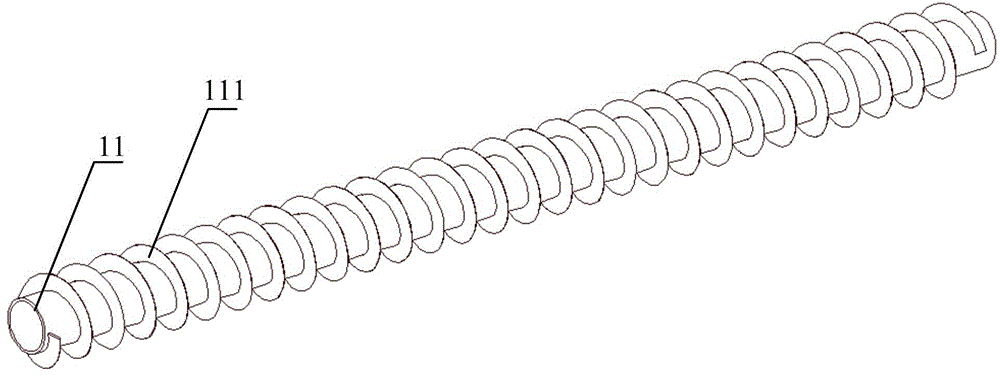

Thermal decomposition device of oil field waste

InactiveCN104402186AImprove heat transfer efficiencyIncrease the effective heat transfer areaWaste water treatment from quariesSpecific water treatment objectivesOil fieldEngineering

The invention discloses a thermal decomposition device of oil field wastes. The thermal decomposition device comprises a casing, wherein a flue and a heating cavity are formed inside the casing; the heating cavity is isolated from the flue; ribs are arranged on the casing with the heating cavity. Fume inside the flue flashes the casing with the heating cavity, so that the heat can be conducted; due to adoption of the ribs on the casing with the heating cavity, the heat exchange area is effectively increased when being compared with that of the prior art, and the heat exchange efficiency of the thermal decomposition device is improved.

Owner:JEREH ENERGY SERVICES

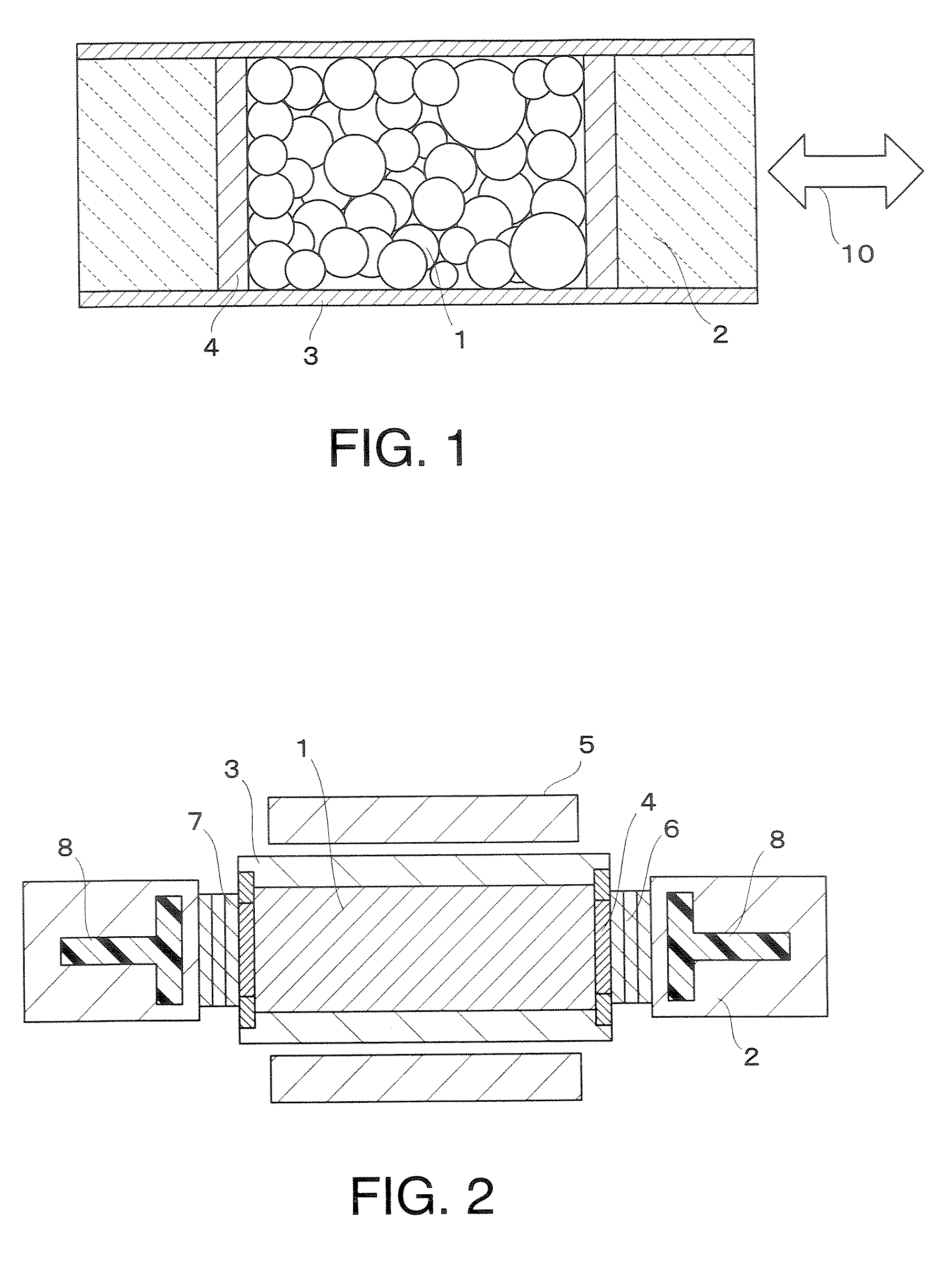

Magnetic refrigeration material and magnetic refrigeration device

InactiveUS20070220901A1Avoid Heat Exchange EfficiencyImprove heat transfer efficiencyTransportation and packagingEnergy efficient heating/coolingOxidation resistantMagnetic refrigeration

A magnetic refrigeration material has magnetic material particles with a magnetocaloric effect and an oxidation-resistant film formed on the surfaces of the magnetic material particles.

Owner:KK TOSHIBA

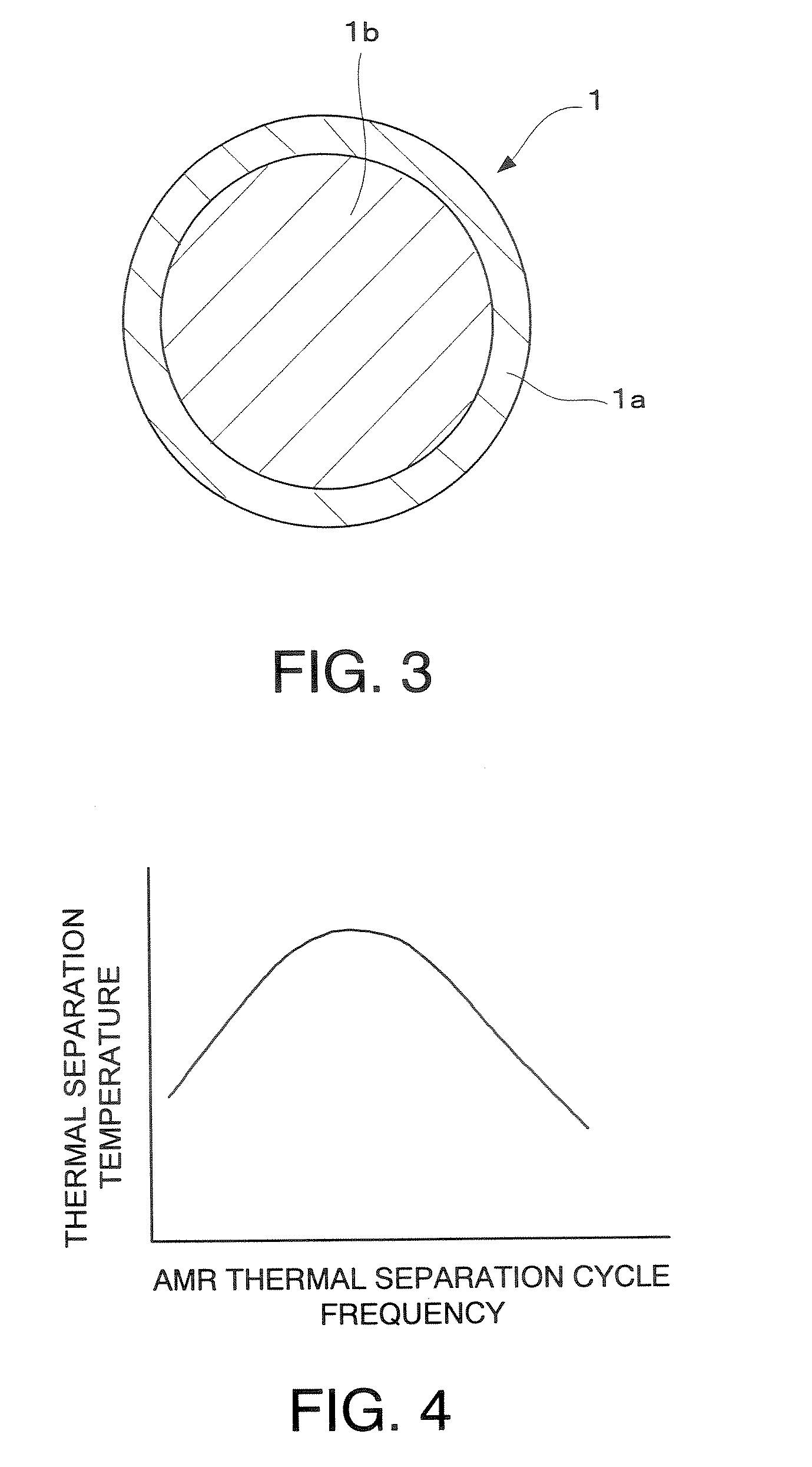

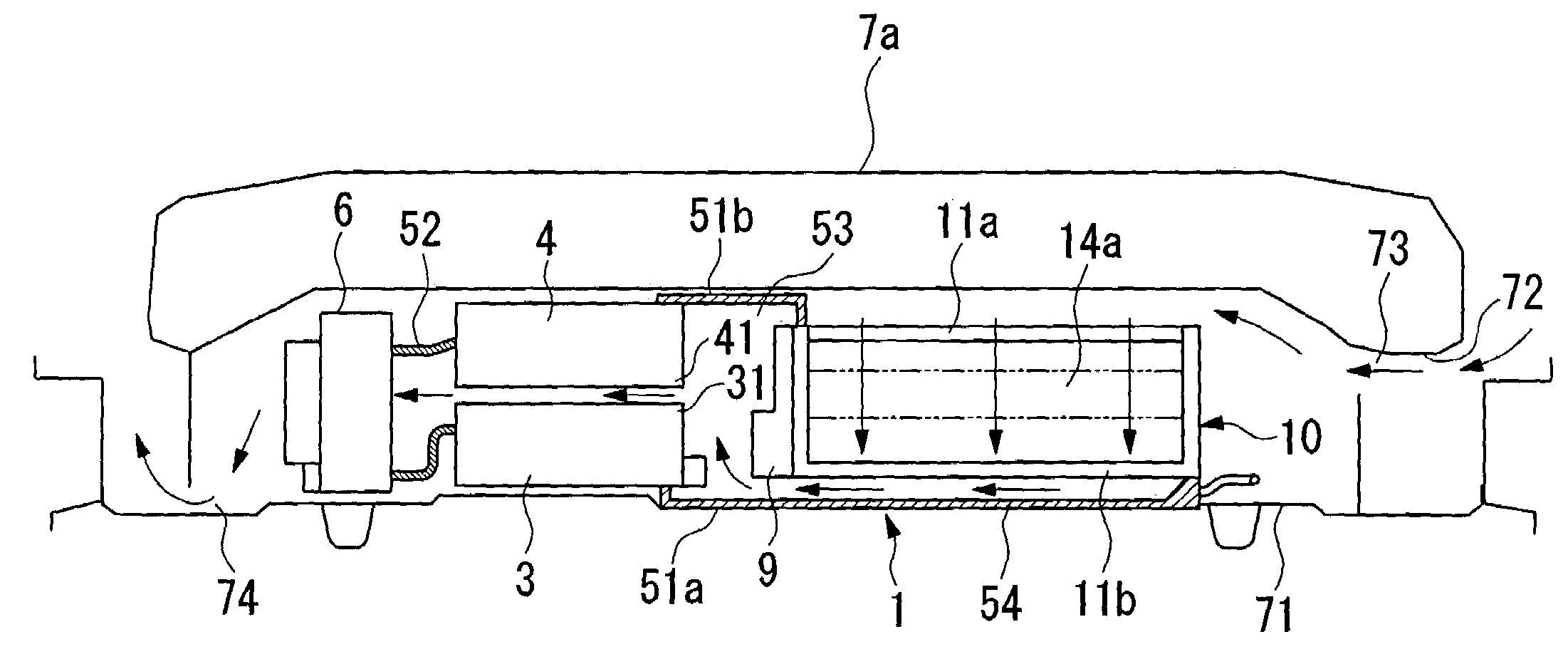

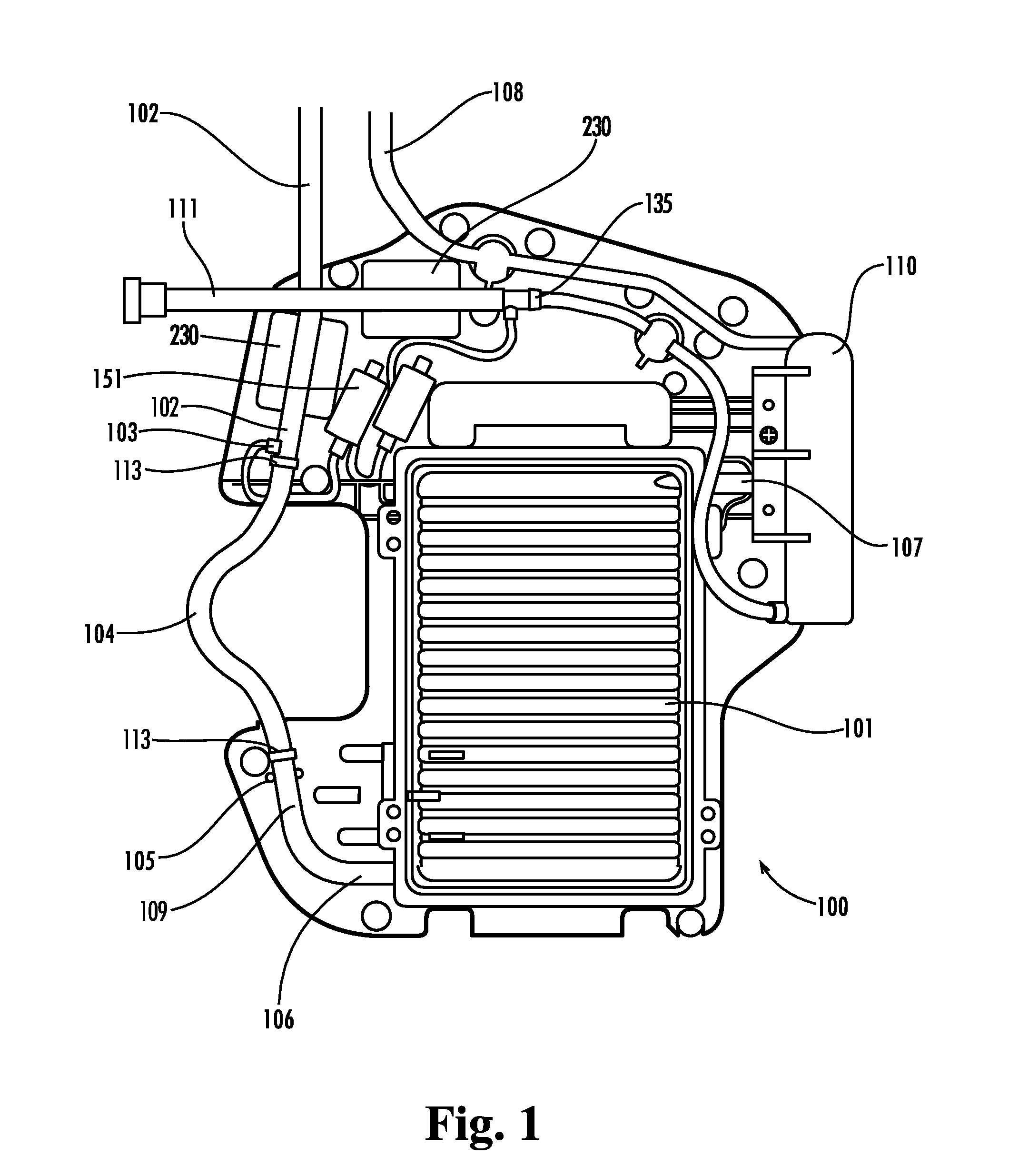

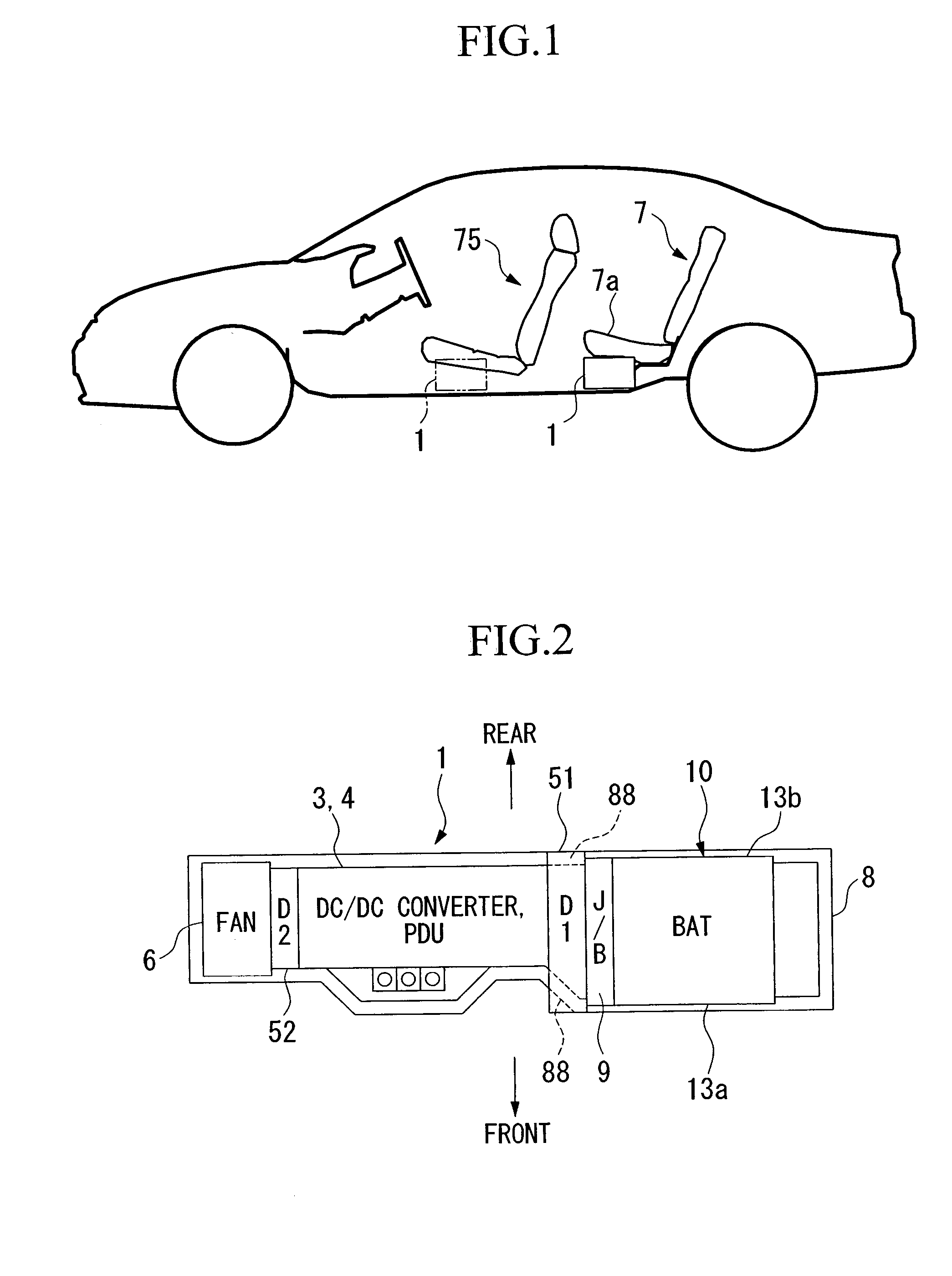

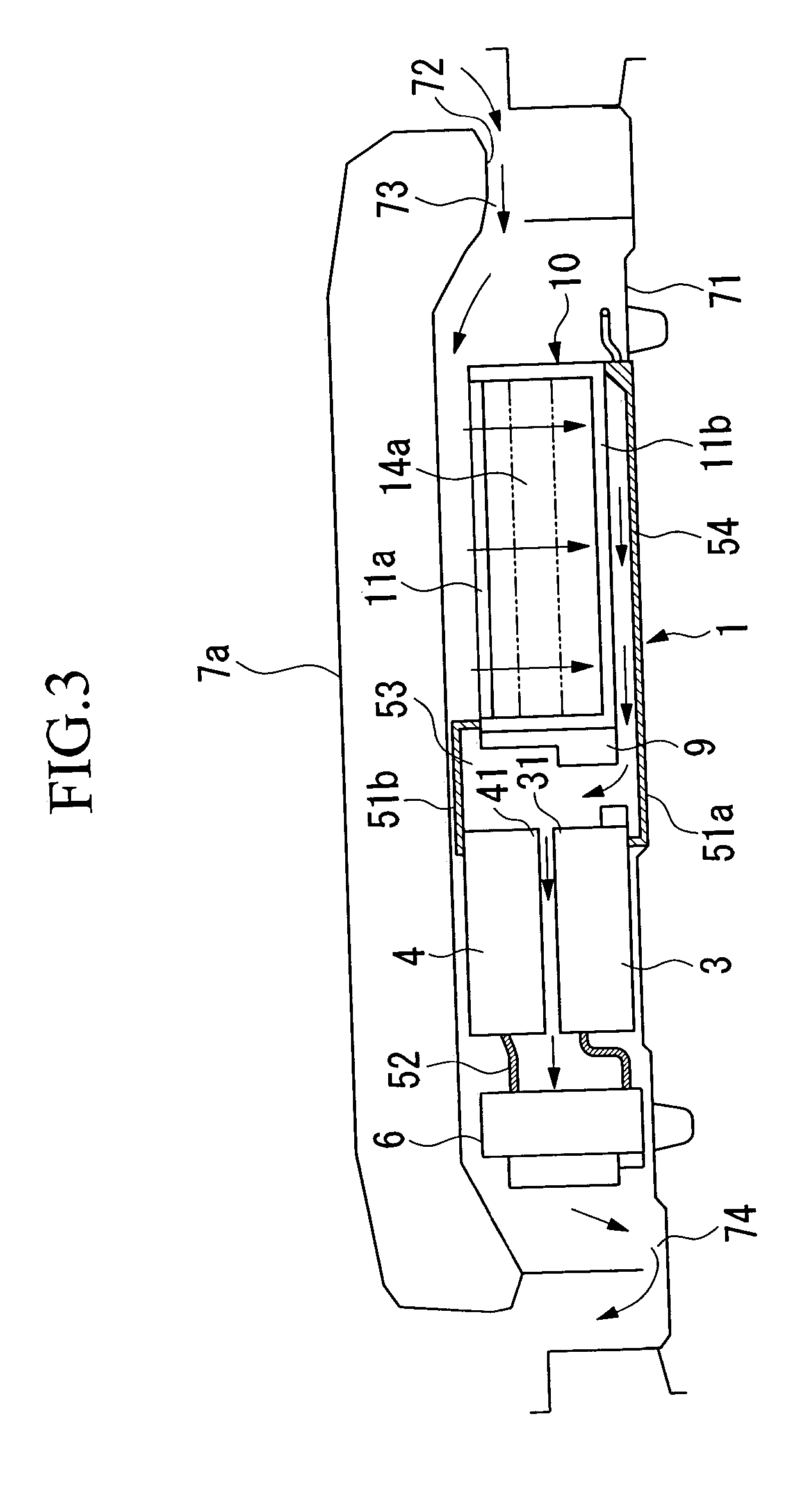

Cooling device high voltage electrical unit for motor of vehicle, and hybrid vehicle

ActiveUS7079379B2High voltageImprove heat transfer efficiencyModifications for power electronicsPlural diverse prime-mover propulsion mountingHigh pressureHybrid vehicle

A cooling device for a high voltage electrical unit for a motor of a vehicle, includes: an inverter for controlling the motor that drives the vehicle; an electrical energy storing device for supplying electrical energy to the motor via the inverter; a downverter for decreasing source voltage of the electrical energy storing device, the downverter, the inverter, and the electrical energy storing device disposed under a seat of the vehicle in a concentrated manner; a fan, disposed under the seat, for moving cooling air to the electrical energy storing device and the inverter; an air inlet disposed under the seat and at an end of the seat as viewed in a width direction of the vehicle; and an air outlet disposed under the seat and at the other end of the seat as viewed in a width direction of the vehicle.

Owner:HONDA MOTOR CO LTD

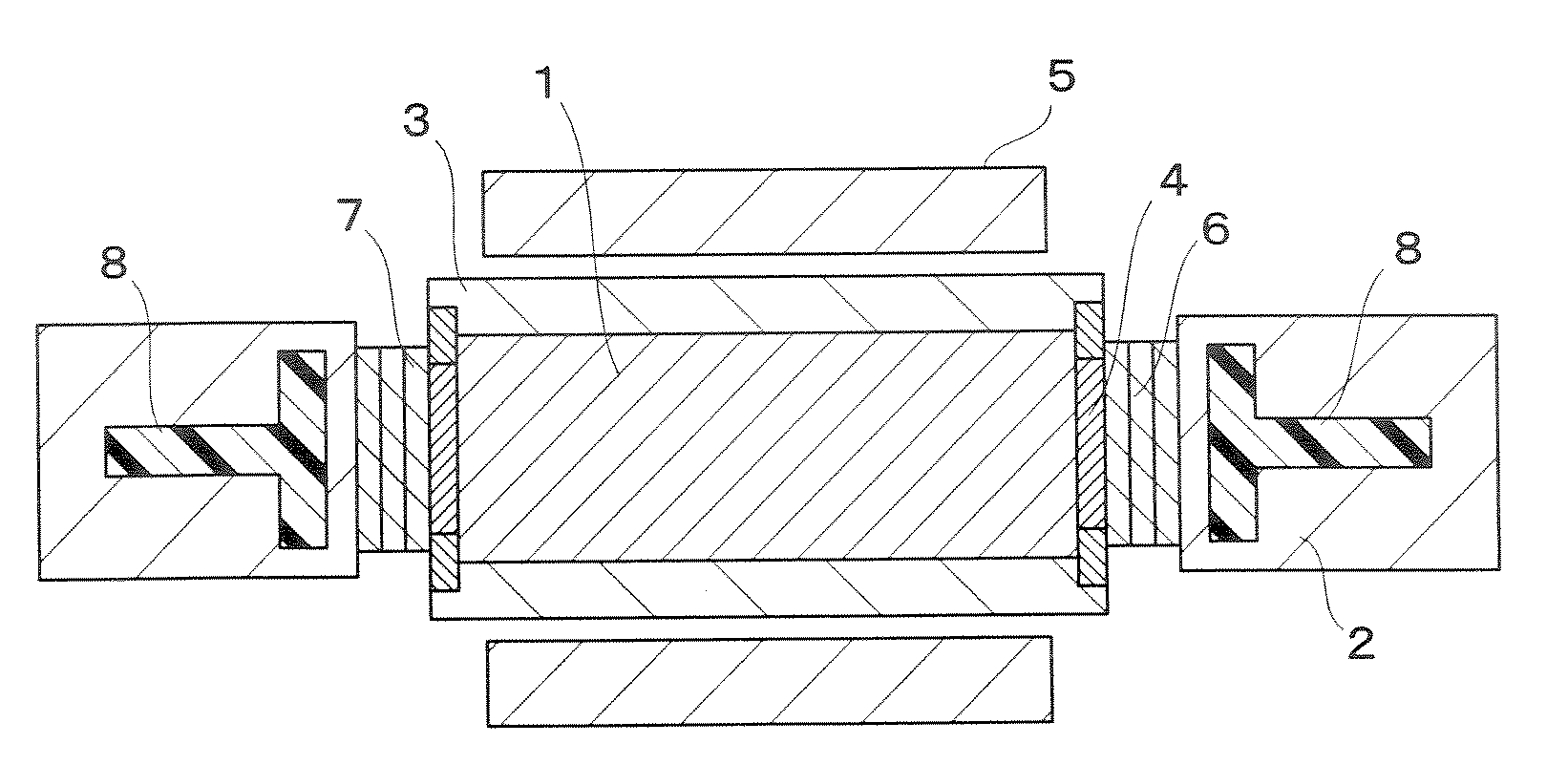

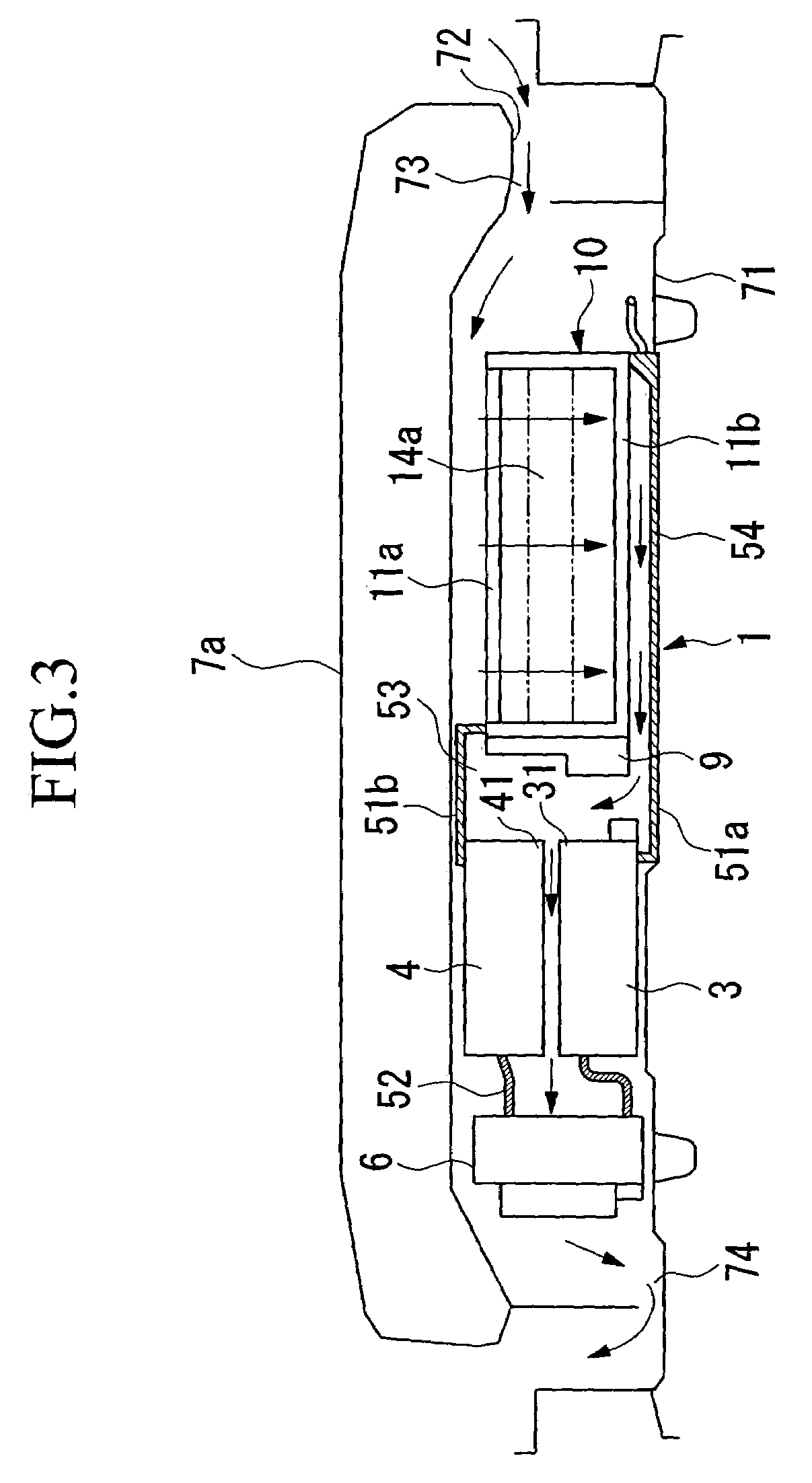

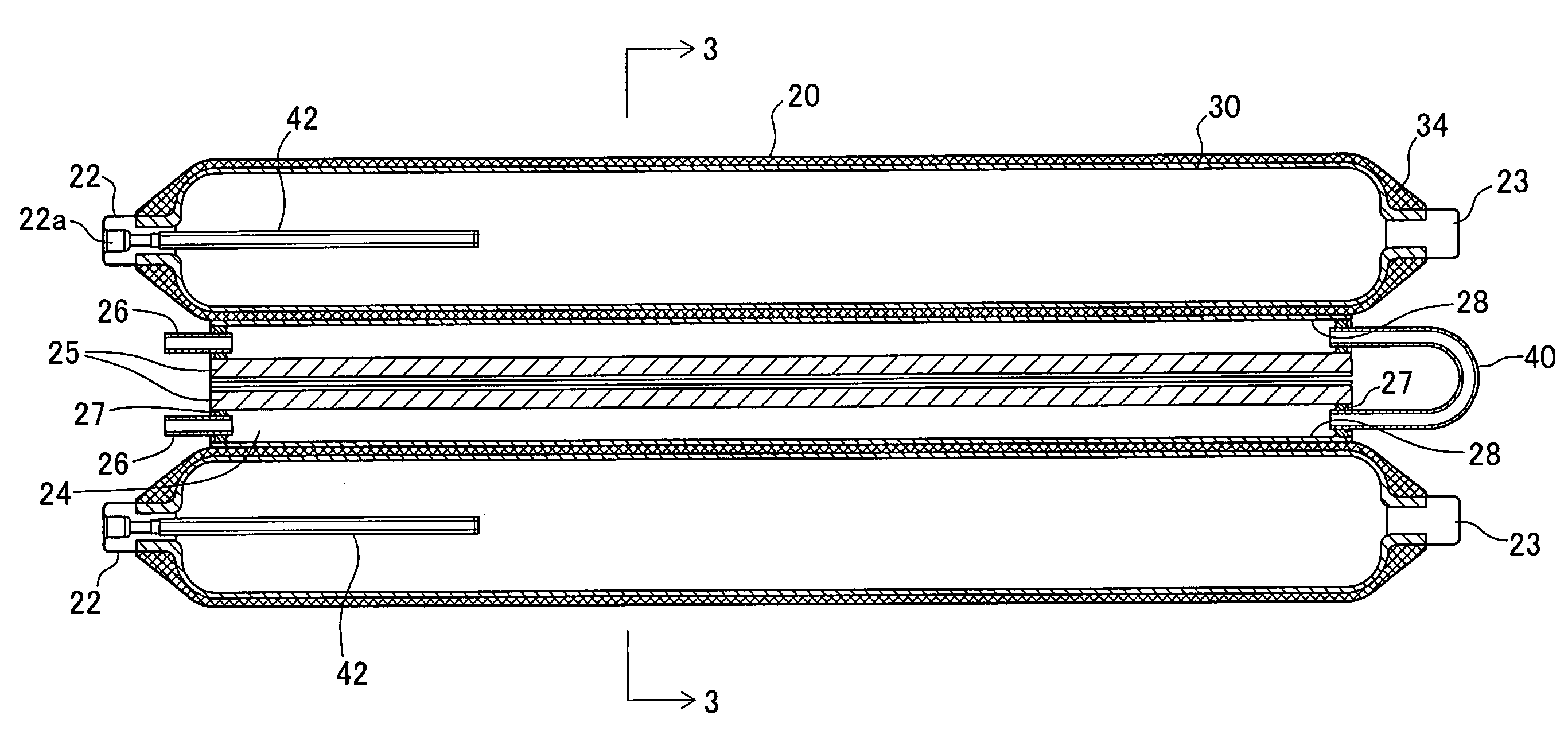

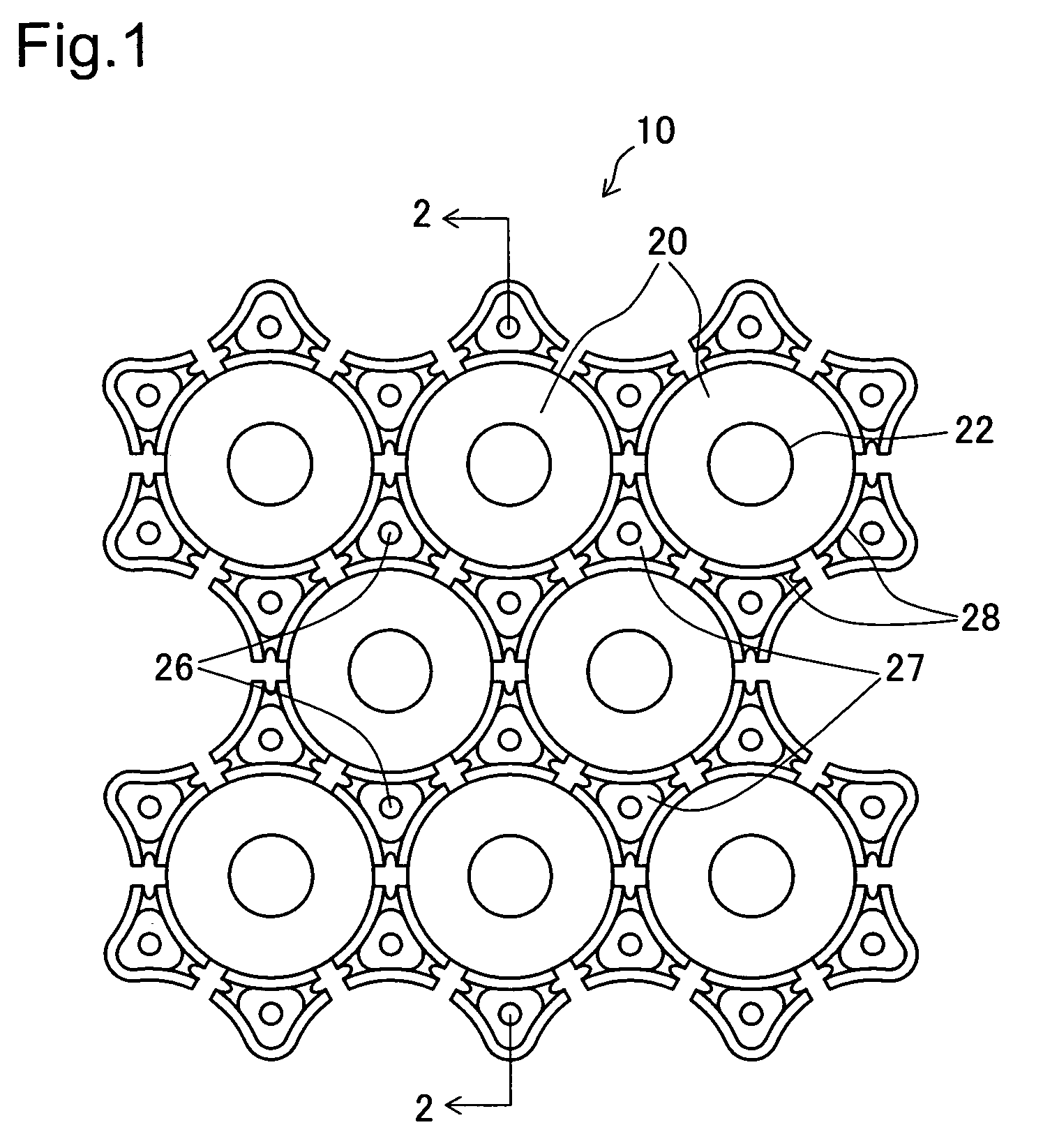

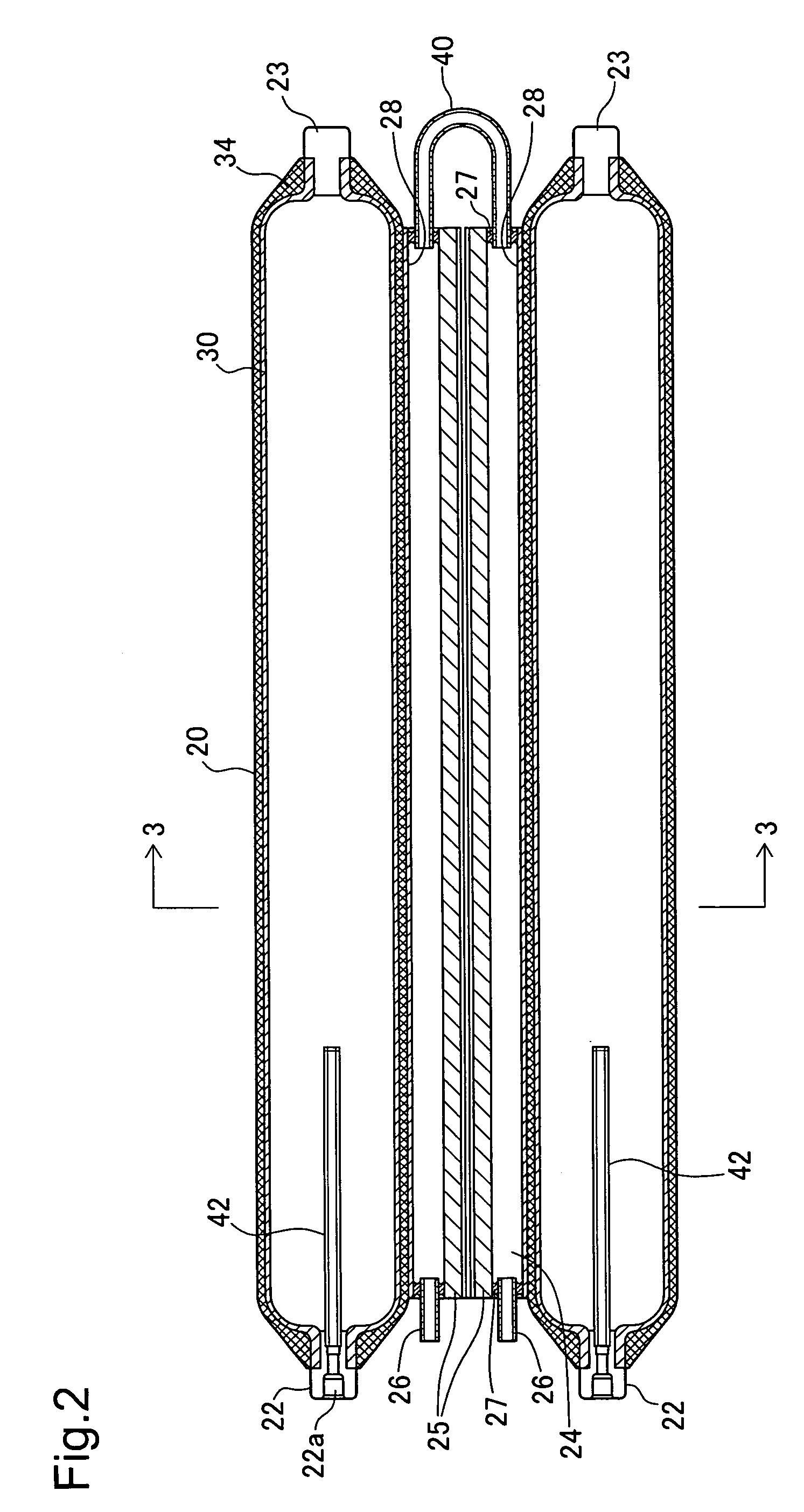

Gas storage apparatus

InactiveUS7112239B2Improve heat transfer efficiencyVessel mounting detailsReversible hydrogen uptakeCoolant flowProduct gas

A hydrogen storage apparatus that includes multiple gas storage tanks that each house a storing / adsorbing material and through the interior of which a fluid travels is provided. The gas storage apparatus 10 includes roughly cylindrical gas storage tanks 20 that house hydrogen-storing alloy. The multiple gas storage tanks 20 are disposed longitudinally parallel to each other in an ordered fashion such that roughly triangular prism-shaped empty spaces are formed between multiple adjacent hydrogen storage tanks 20. Coolant paths through which coolant flows are formed in these roughly triangular prism-shaped empty spaces. These coolant paths are thermally connected to the hydrogen-storing alloy in the gas storage tanks 20 via constituent members of the gas storage tanks 20 and via heat transfer plates 28 disposed on the gas storage tanks 20.

Owner:TOYOTA JIDOSHA KK +1

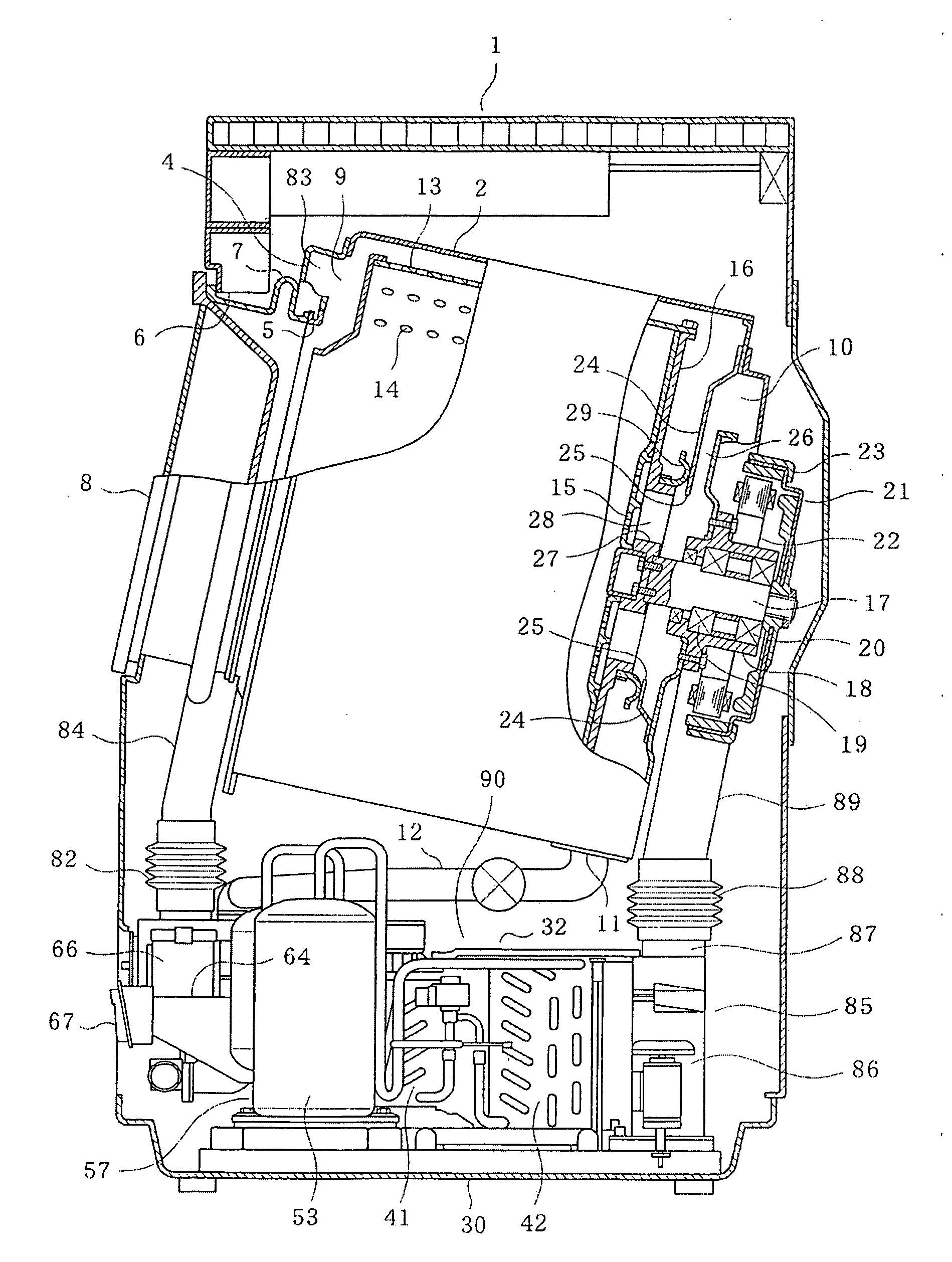

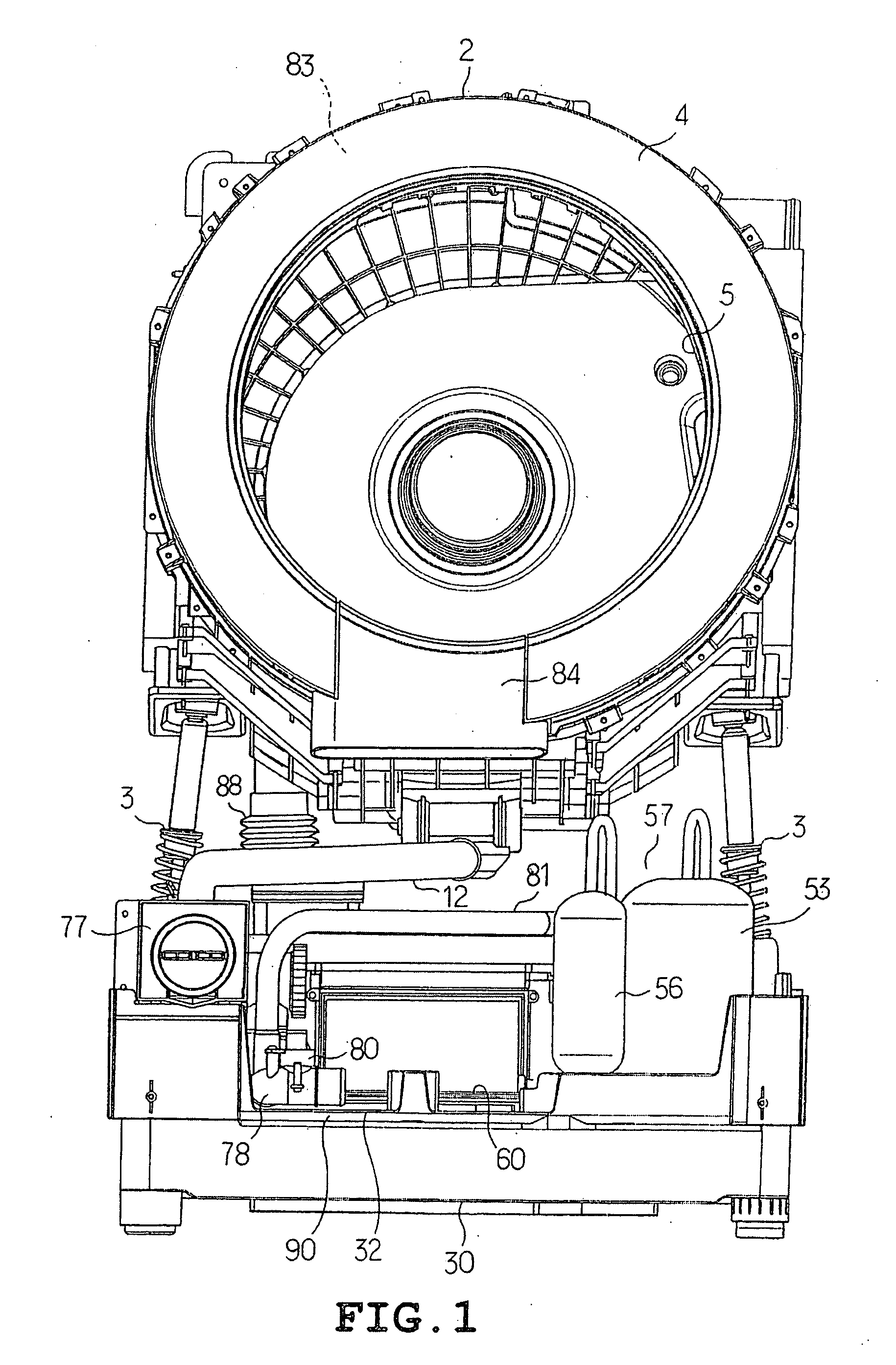

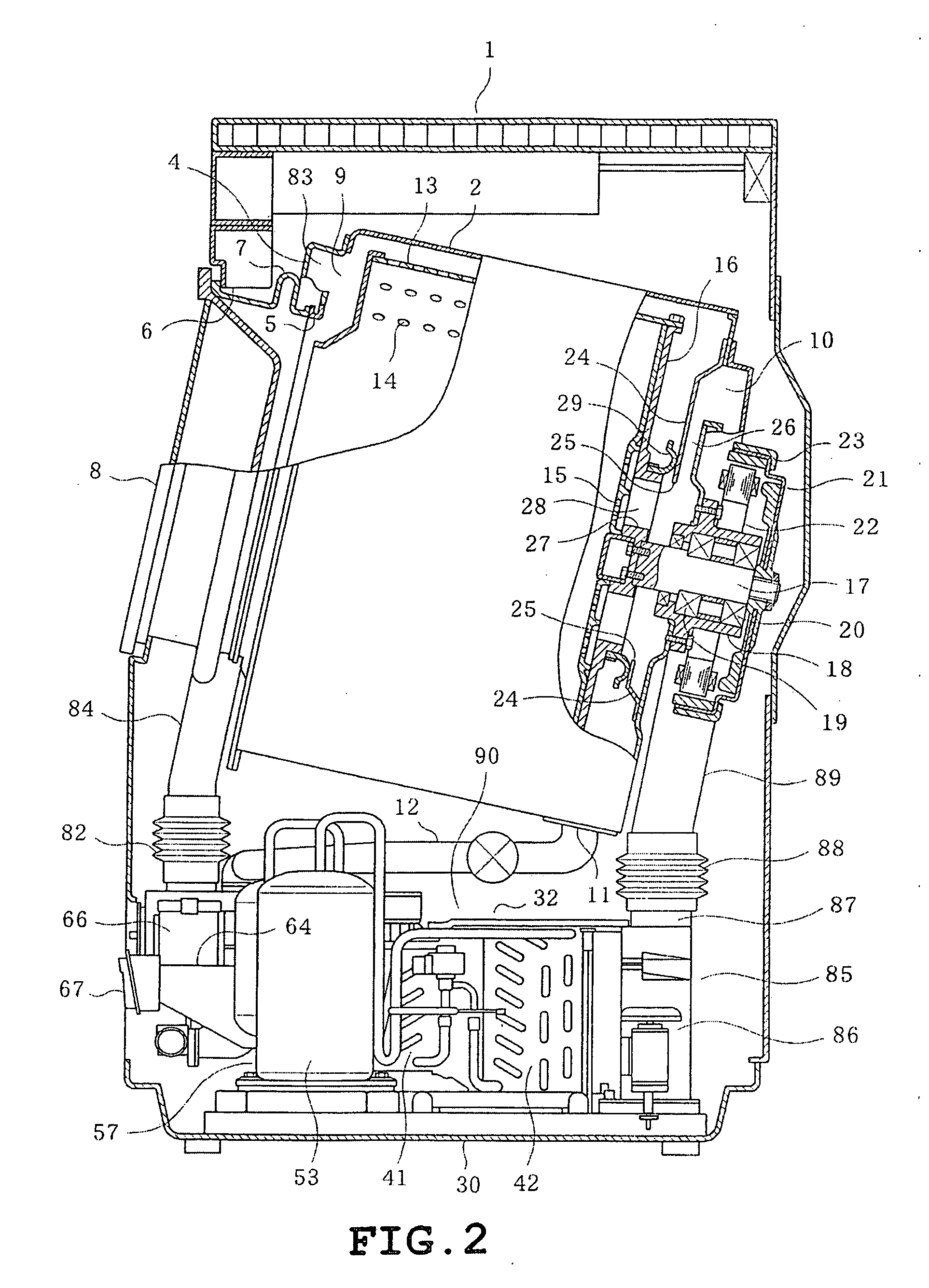

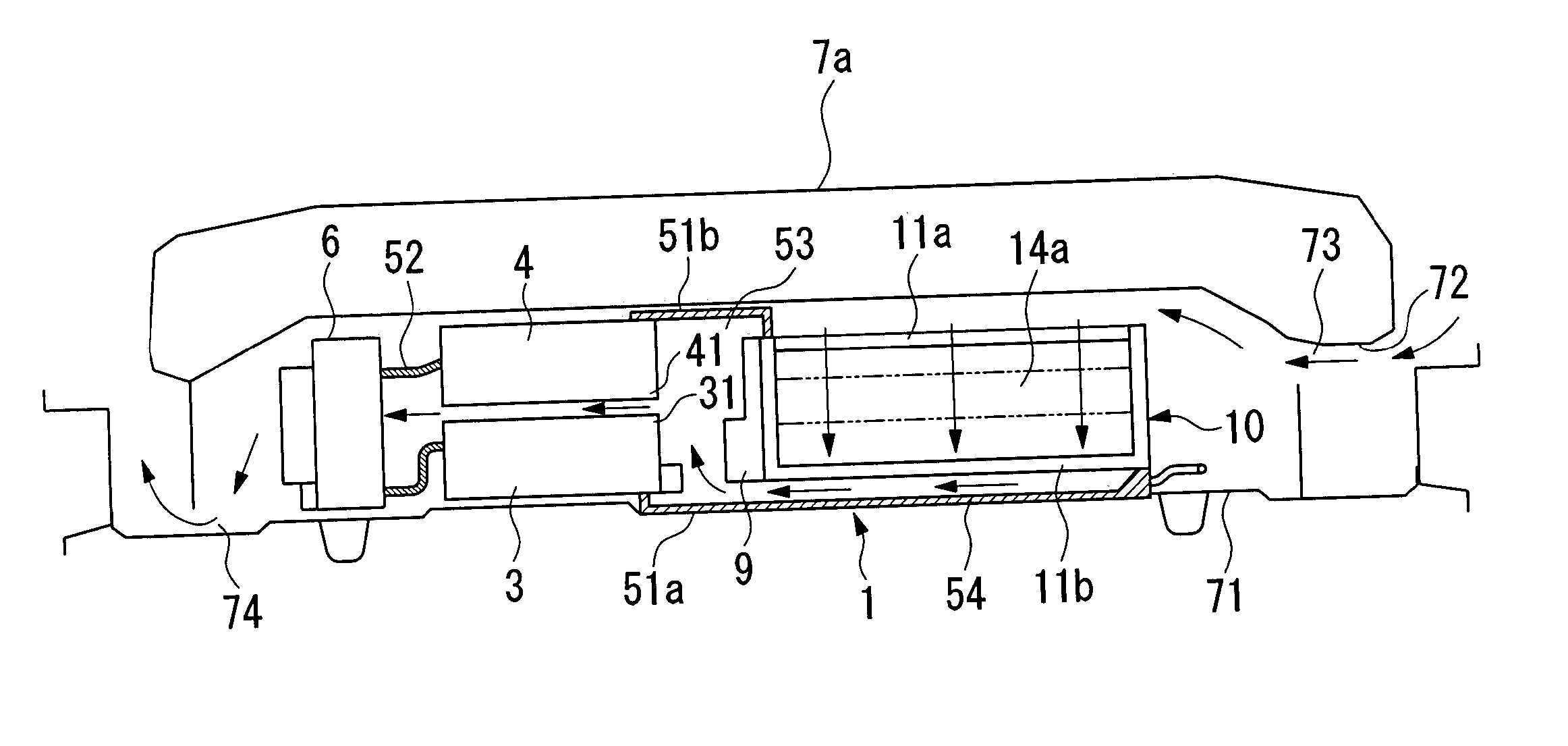

Drum-type washer/dryer

InactiveUS20100107703A1No increase in conduit resistanceIncrease volumeOther washing machinesWashing machine with receptaclesMarine engineeringHeat pump

A warm air inlet (10) and a warm air outlet (9) of a laterally provided cylindrical water tub (2) are separately arranged in the direction of the axis of the water tub (2). An airflow duct (32) connecting the warm air inlet (10) and the warm air outlet (9) is placed in the axis direction of the water tub (2), substantially directly below the water tub (2). A compressor (53) of a heat pump (57) having an evaporator (41) and a condenser (42) that are placed in the airflow duct (32) is placed at a position at a side of the airflow duct (32) so as to be orthogonal to the axis direction of the tub (2).

Owner:TOSHIBA HA PROD +2

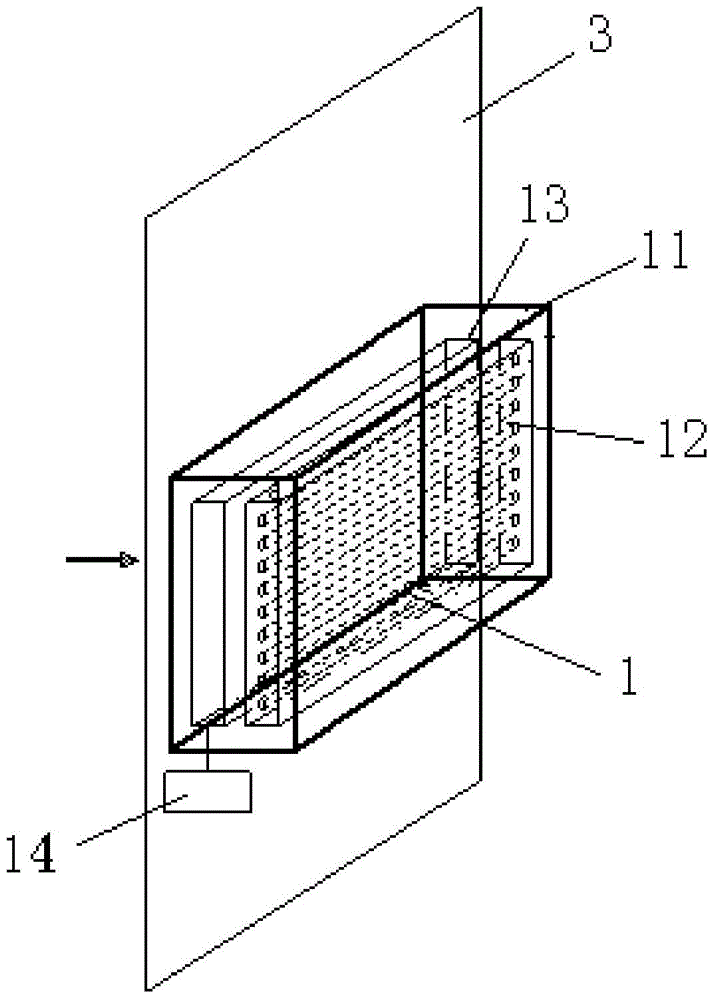

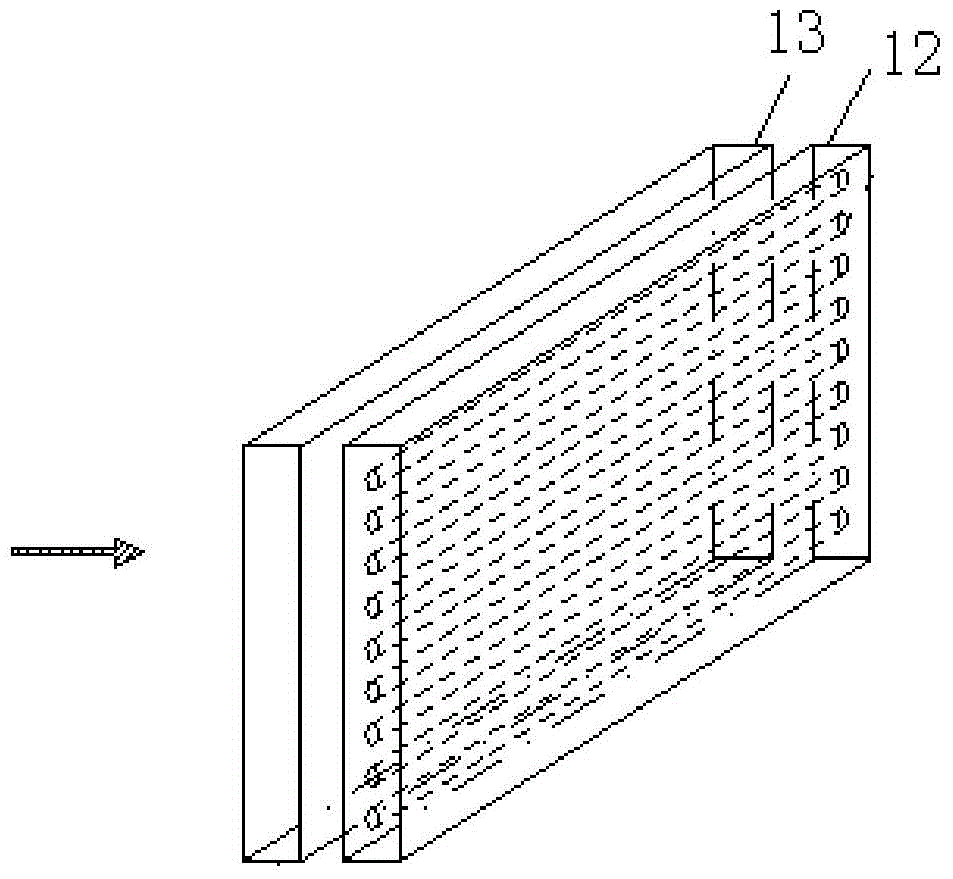

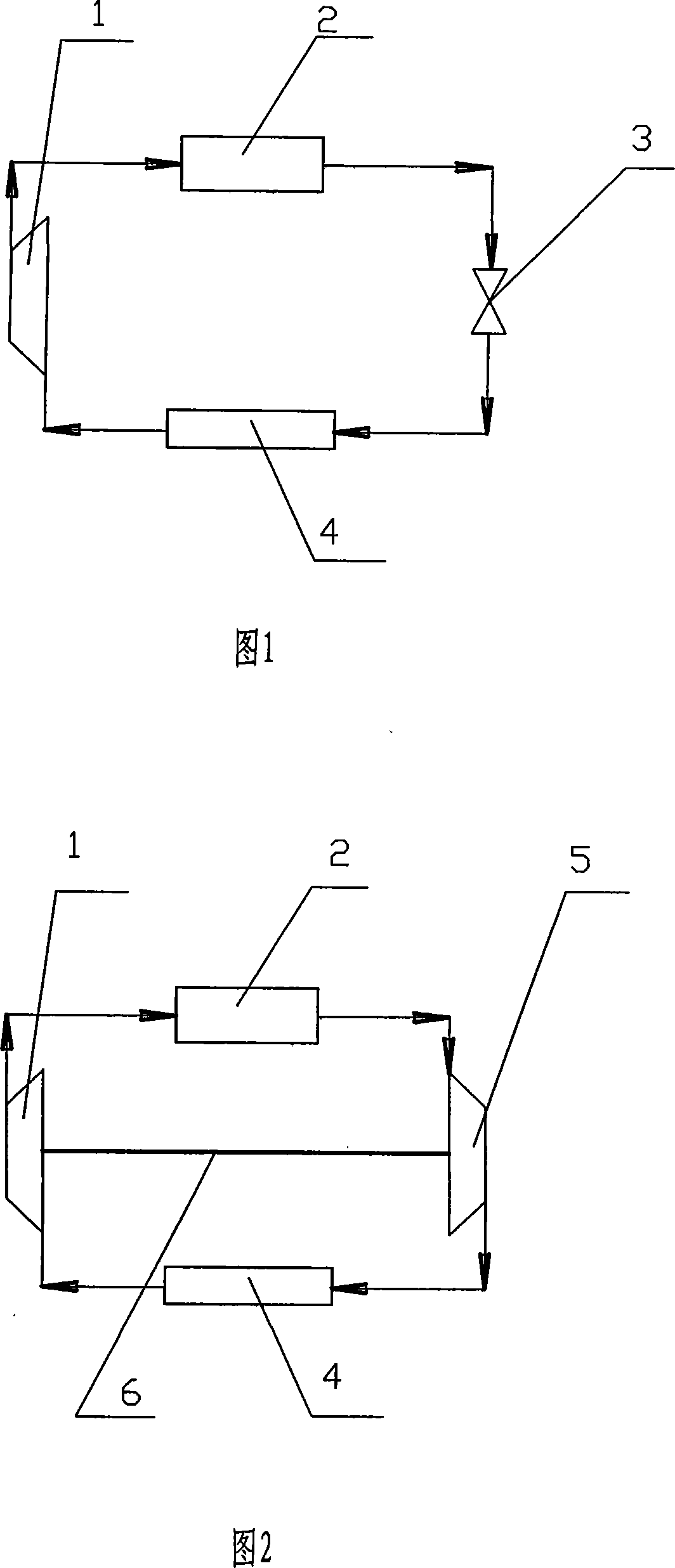

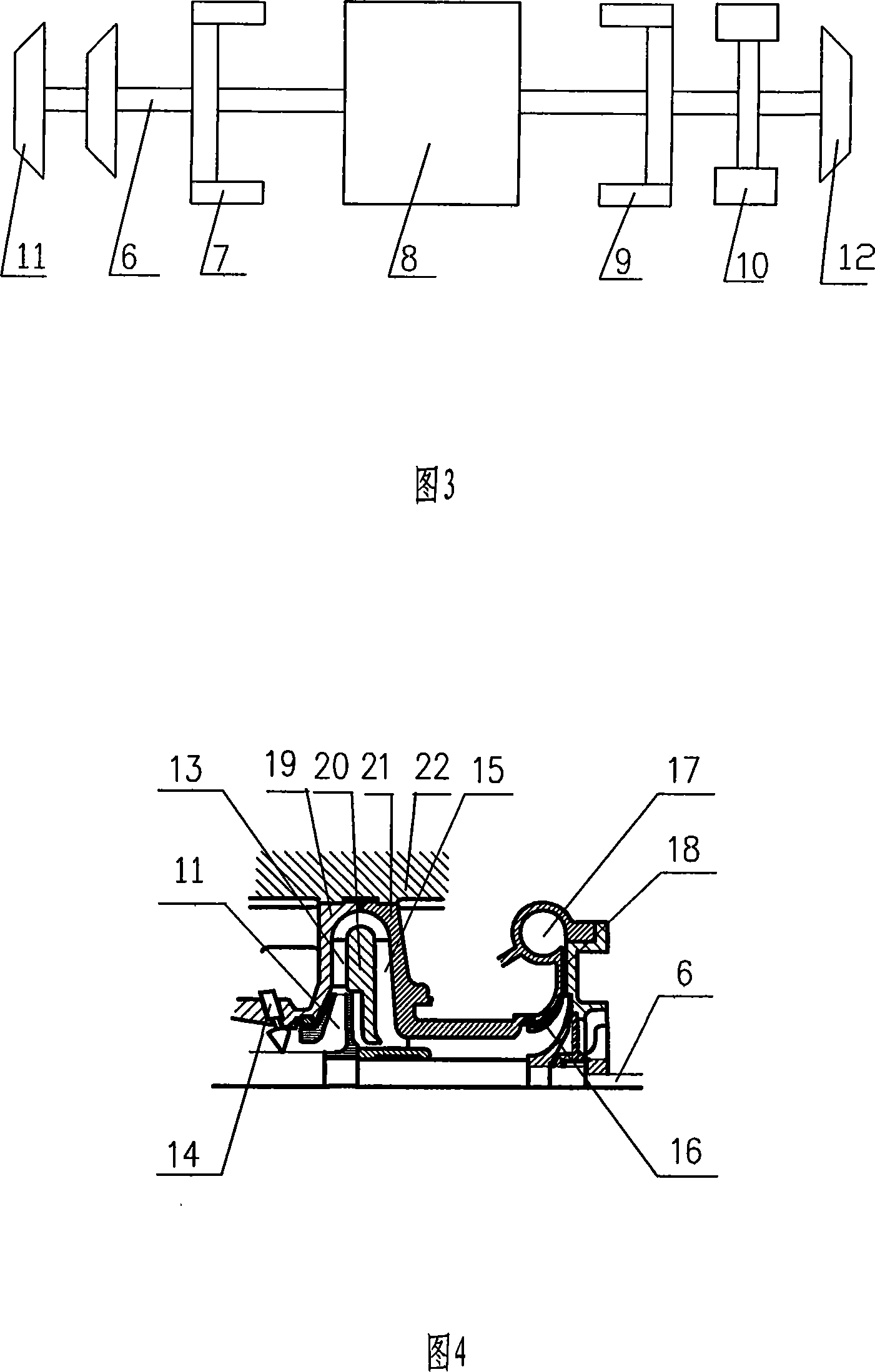

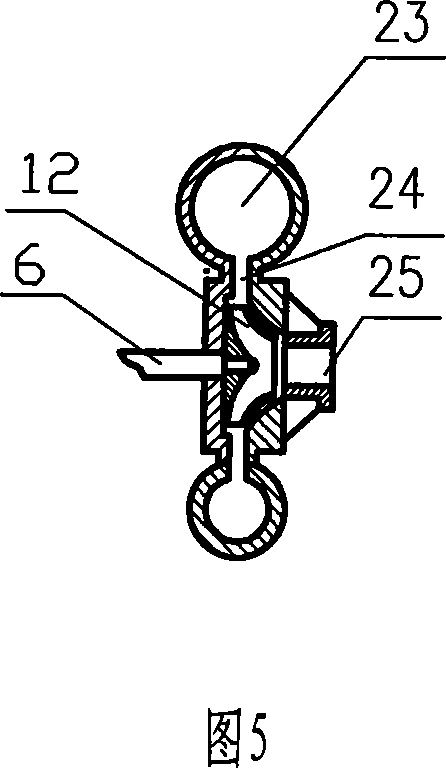

Ion wind indoor unit, ion wind air conditioner system and control method

InactiveCN105299744AReduce noiseSimple structureSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringConvection heat

The invention discloses an ion wind indoor unit, an ion wind air conditioner system and a control method, and relates to the technical field of refrigerating and heating equipment. In order to solve the problems that an existing air conditioner indoor unit is large in occupation size, large in noise and the like, the ion wind indoor unit is designed. The ion wind indoor unit comprises a shell and an indoor heat exchanger arranged in the shell; an ion wind generator is arranged on the upwind side and / or downwind side of the indoor heat exchanger, and carries out corona on air entering the interior of the generator to generate ion wind and blow out the iron wind so as to achieve convection heat exchange of indoor air; and meanwhile, the ion wind air conditioner system with the ion wind indoor unit and the control method of the air conditioner system are provided. The ion wind indoor unit can reduce the starting noise of air and eliminate electromagnetic noise of a motor and vibration noise of a structural part; use comfort is greatly improved; and meanwhile, the indoor unit structure is simplified, the occupied size of the indoor unit is reduced, the attractiveness of the indoor unit is improved, and the production cost and the assembling cost are reduced.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD

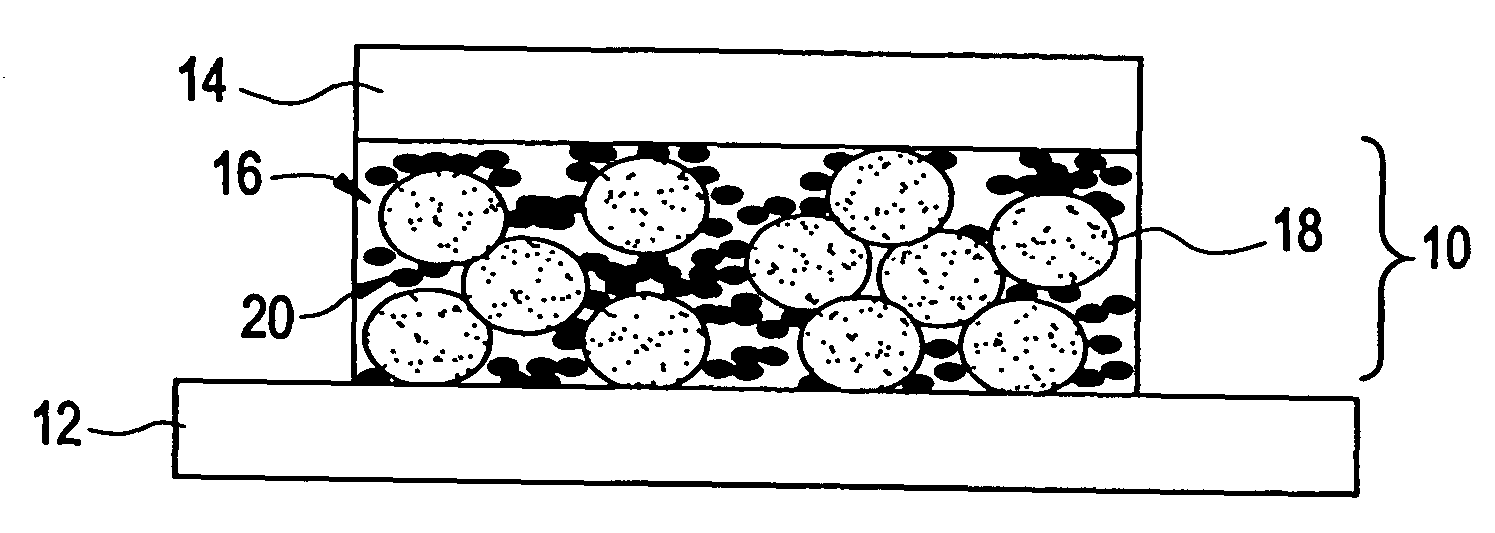

Organic matrices containing nanomaterials to enhance bulk thermal conductivity

InactiveUS20050161210A1Improve heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesNanoparticleInterfacial resistance

Thermal interface compositions contain nanoparticles blended with a polymer matrix. Such compositions increase the bulk thermal conductivity of the polymer composites as well as decrease thermal interfacial resistances that exist between thermal interface materials and the corresponding mating surfaces. Formulations containing nanoparticles also show less phase separation of micron-sized particles than formulations without nanoparticles.

Owner:GENERAL ELECTRIC CO

Frequency conversion magnetic levitation compression expansion engine set

ActiveCN101105346AReduce frictional power consumptionHigh heat transfer efficiencyPump componentsCompression machines using turbinesLubricationEvaporator

A variable frequency magnetic suspension compressional expansion assembly comprises a compressor, an evaporator and an expansion machine that are connected. A magnetic suspension bearing centrifugal compressor is directly connected with a radial flow type expansion machine via a shaft, the shaft is suspended on a left radial magnetic suspension bearing, a right radial magnetic suspension bearing and an axial magnetic suspension bearing, a variable frequency motor is provided between the left radial magnetic suspension bearing and the right radial magnetic suspension bearing and used for driving the centrifugal compressor; and the radial flow type expansion machine comprises an air inlet chamber and an air outlet pipe, nozzles and impellers are provided between the air inlet chamber and air outlet pipe and passed through the air inlet chamber and air outlet pipe, and the impellers are fixedly connected on the shaft. The power from expansion is transmitted to the compressor, and the refrigerant after expansion is entered into the evaporator to carry out evaporative cooling; after being evaporated in the evaporator, the refrigerant is sucked by the compressor to carry out circulatory flow; and the magnetic suspension bearings assure that the shaft does not contact with the bearings when the assembly operates, so that lubrication via lubricating oil is not needed.

Owner:广东西屋康达空调有限公司

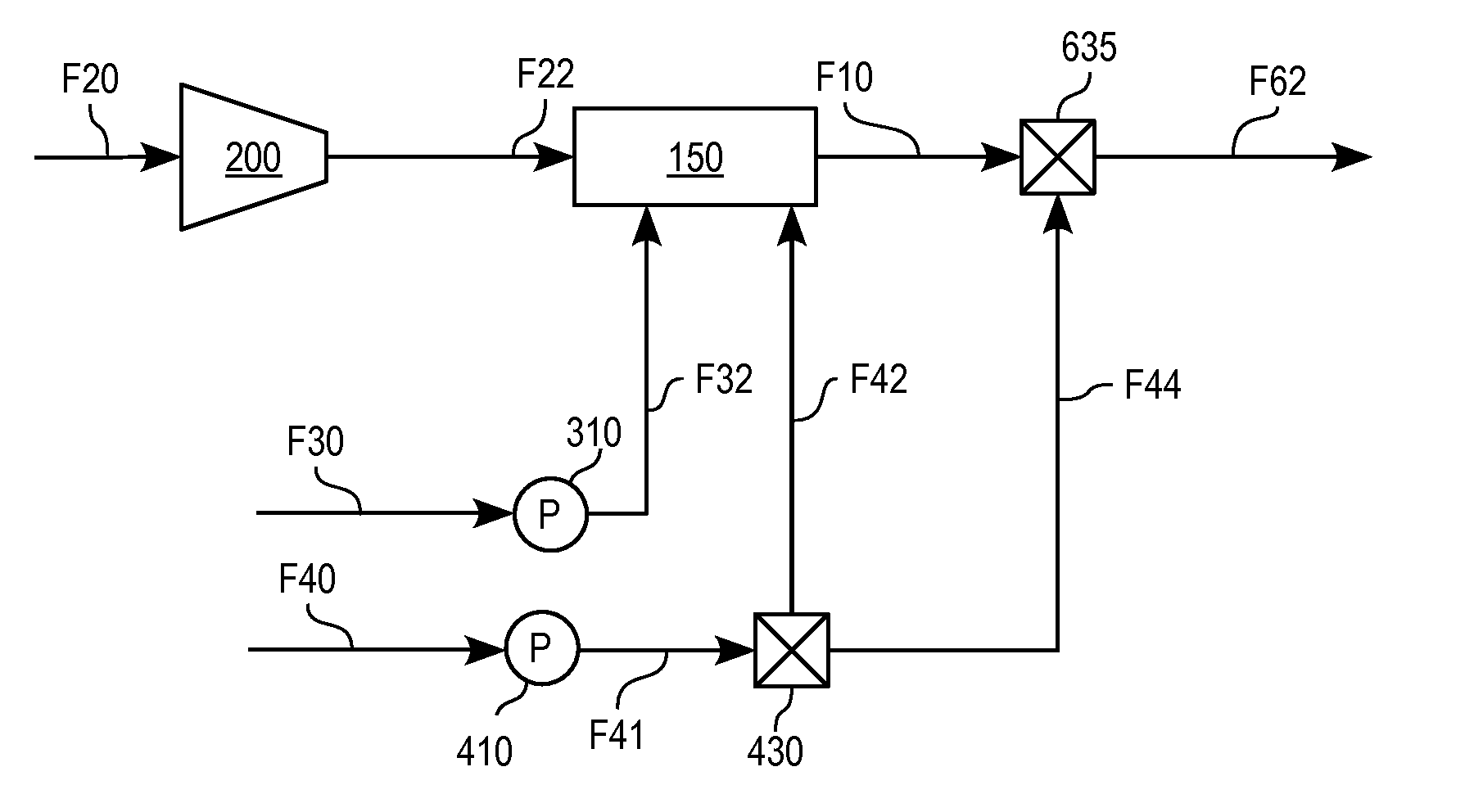

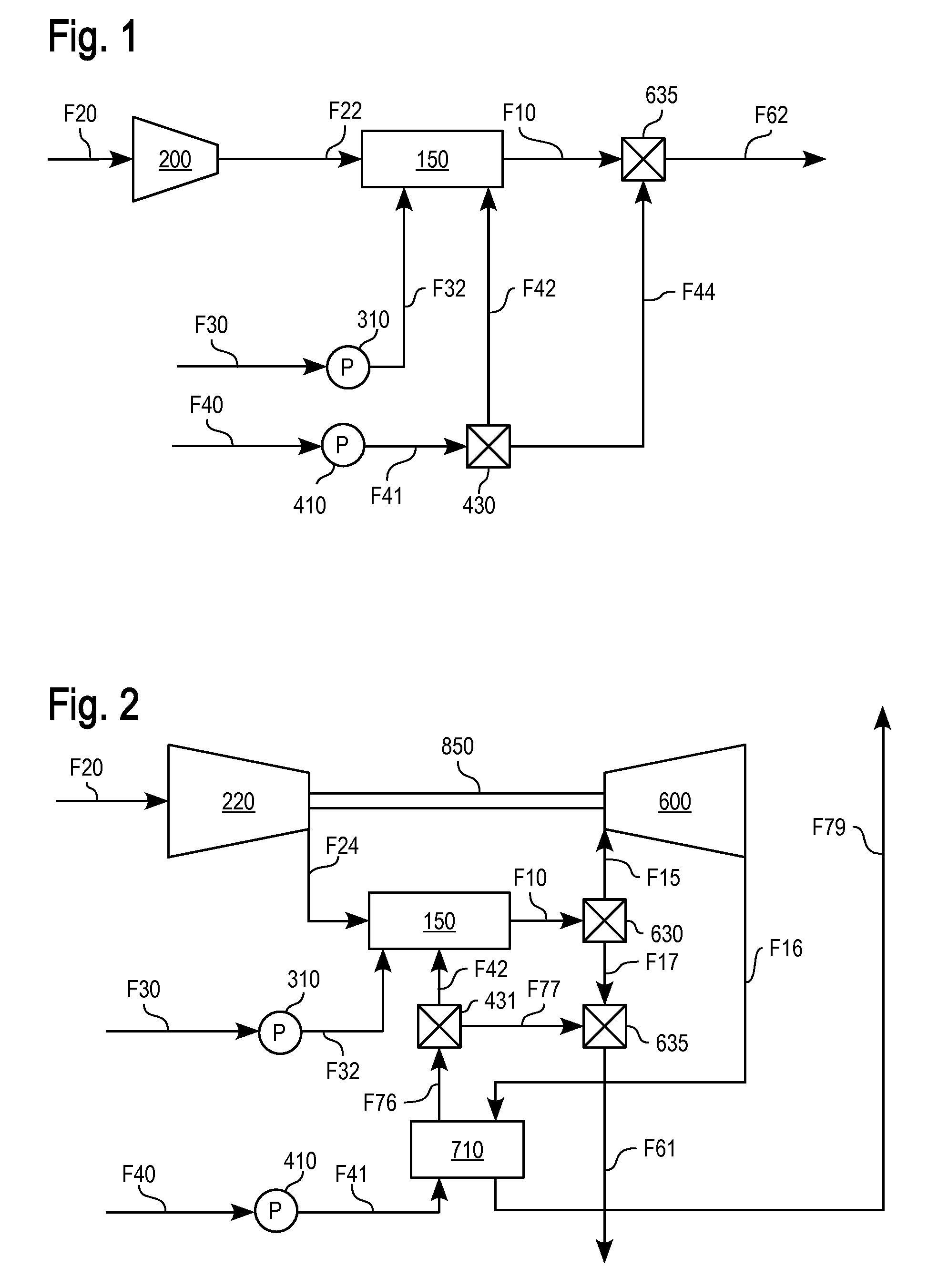

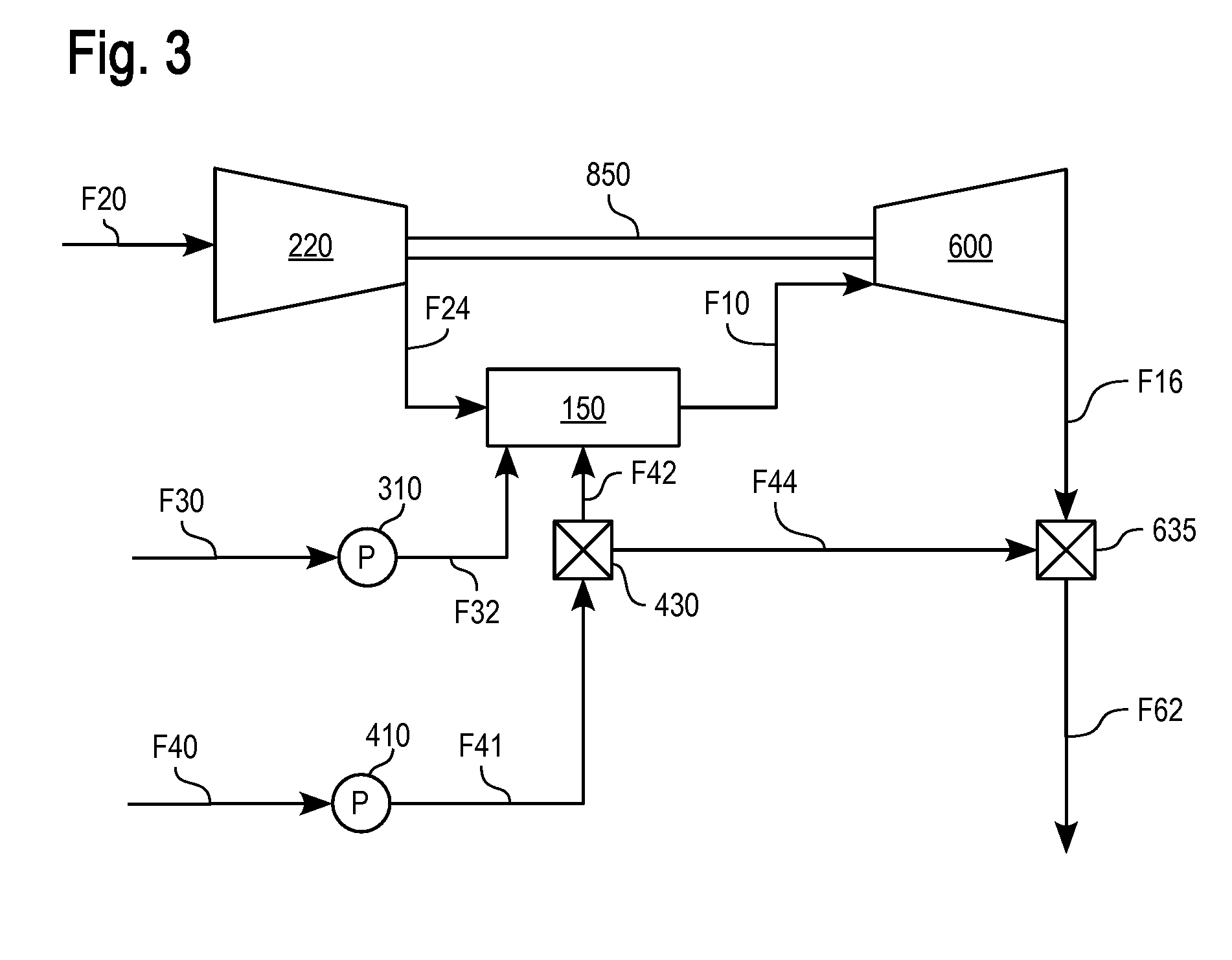

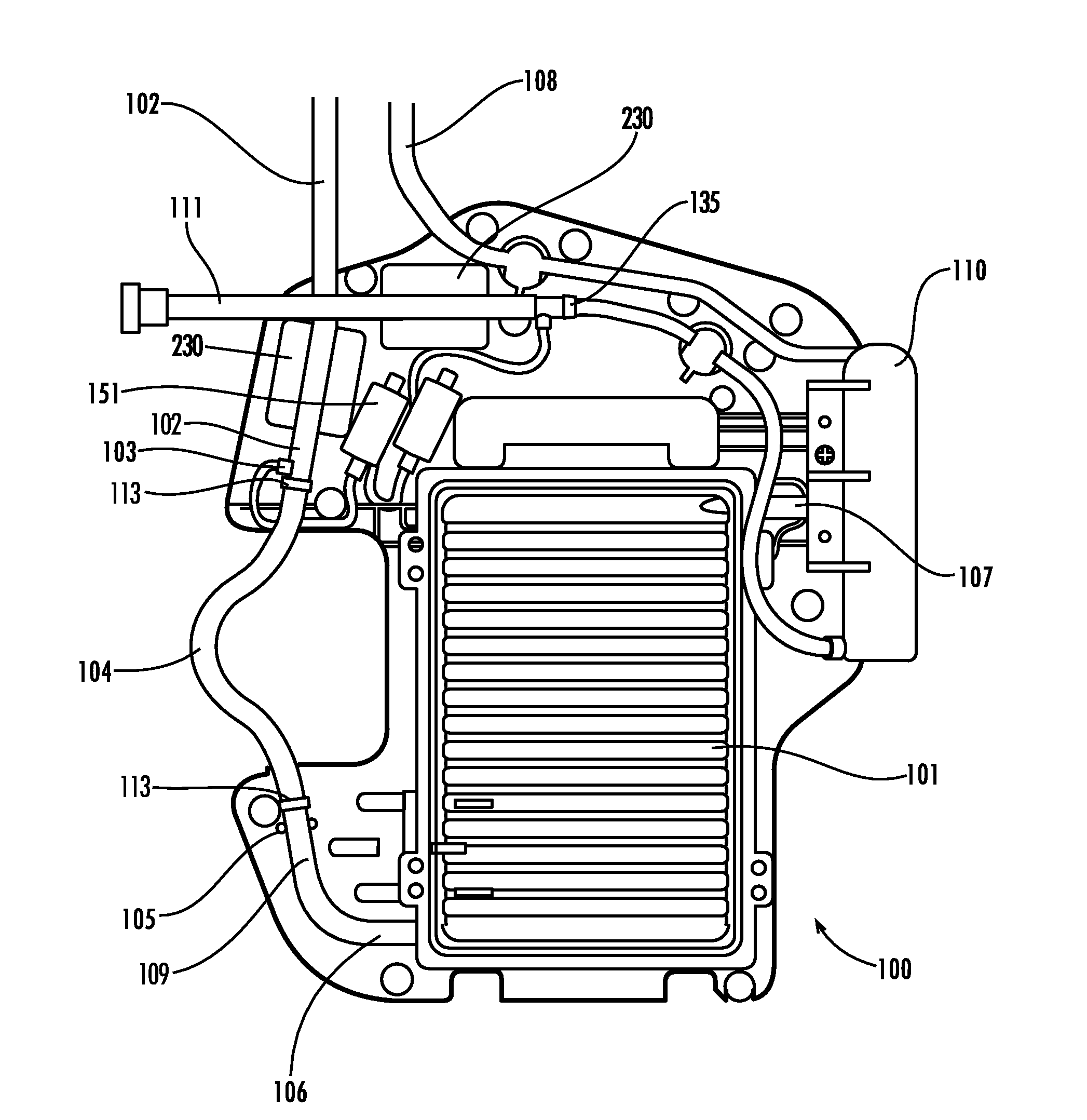

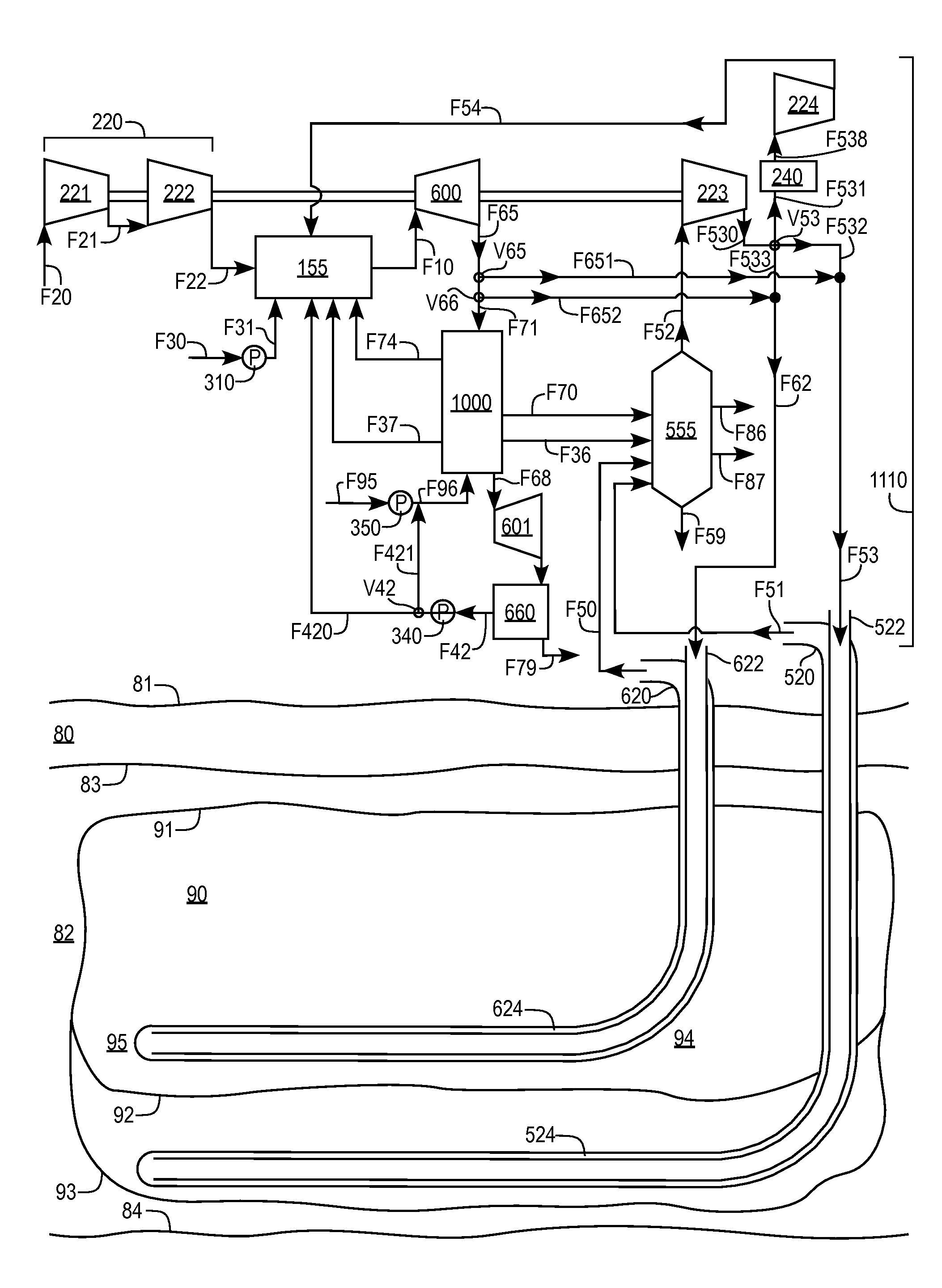

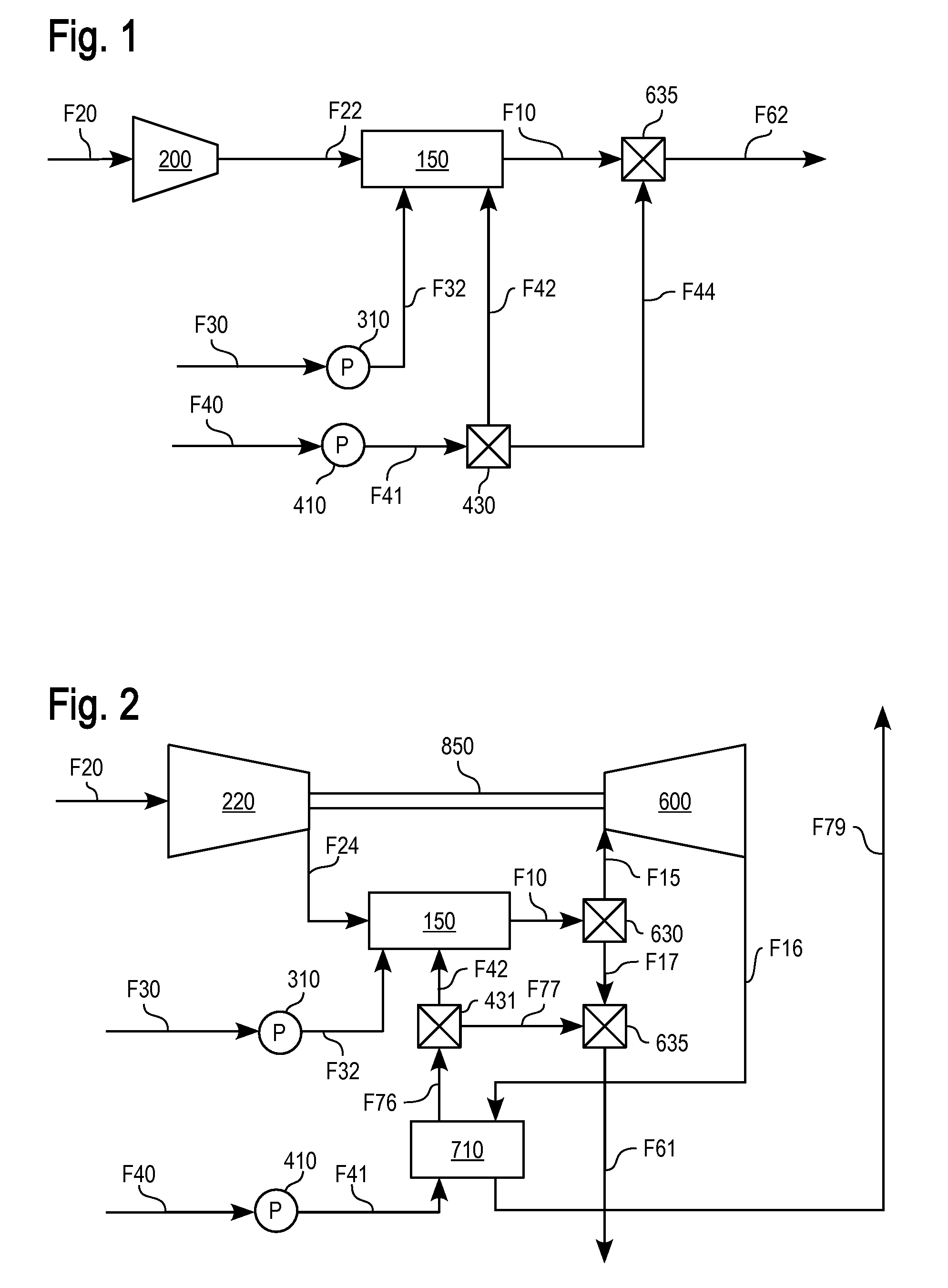

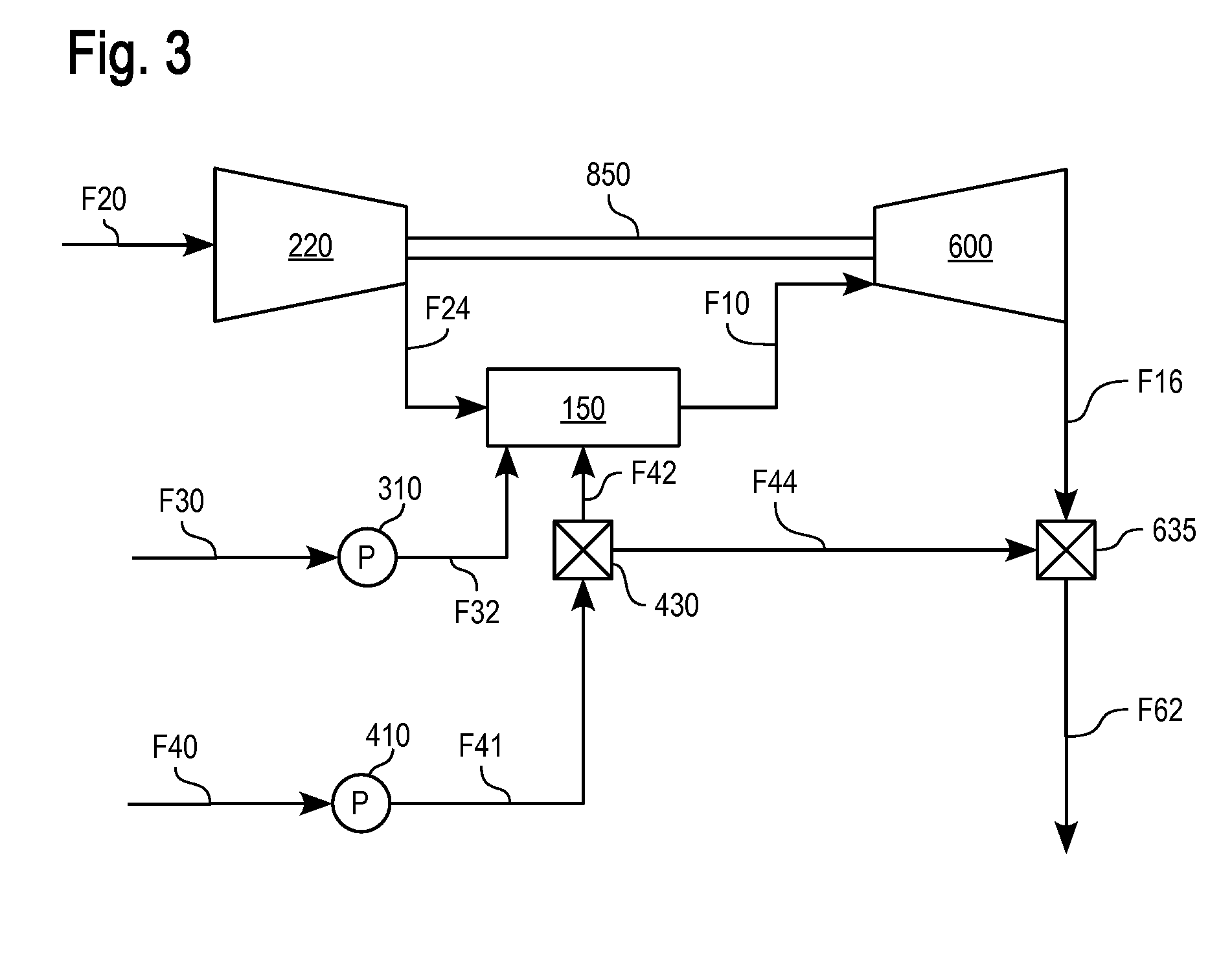

Heavy oil recovery with fluid water and carbon dioxide

ActiveUS20090071648A1Improves hydrocarbon extraction efficiencySpeed up the extraction processFluid removalFuel oilInjection well

Diluted wet combustion forms a hot process fluid or VASTgas comprising carbon dioxide (CO2) and fluid water which is delivered geologic formations and / or from surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. This may improve thermal efficiency and / or increases heat delivery for a given combustor or per capital investment. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

Dynamic Range Motor For A Pump Device

ActiveUS20080145249A1High flow accuracyReducing undesired variationFlexible member pumpsMedical devicesElectricityDigital signal processing

A pump system selectably and dynamically controls the flow rate of a fluid being delivered to a patient's body over a wide range of flow rates. The pump system includes an infusion tubing, a pumping mechanism, a motor drive assembly in mechanical communication with the pumping mechanism, a user input control, and an electronic controller in electrical communication with and at least partially controlling the motor drive assembly. The electronic controller include a digital signal processing controller in electrical communication with the motor drive assembly that is configured to receive a signal from the user input control and to cause power to be supplied to the motor drive assembly in response at least partially to the signal from the user input control. The pump system may selectably deliver fluid at rates from about 1 milliliter per hour to at least about 3000 milliliters per minute.

Owner:SMISSON CARTLEDGE BIOMEDICAL

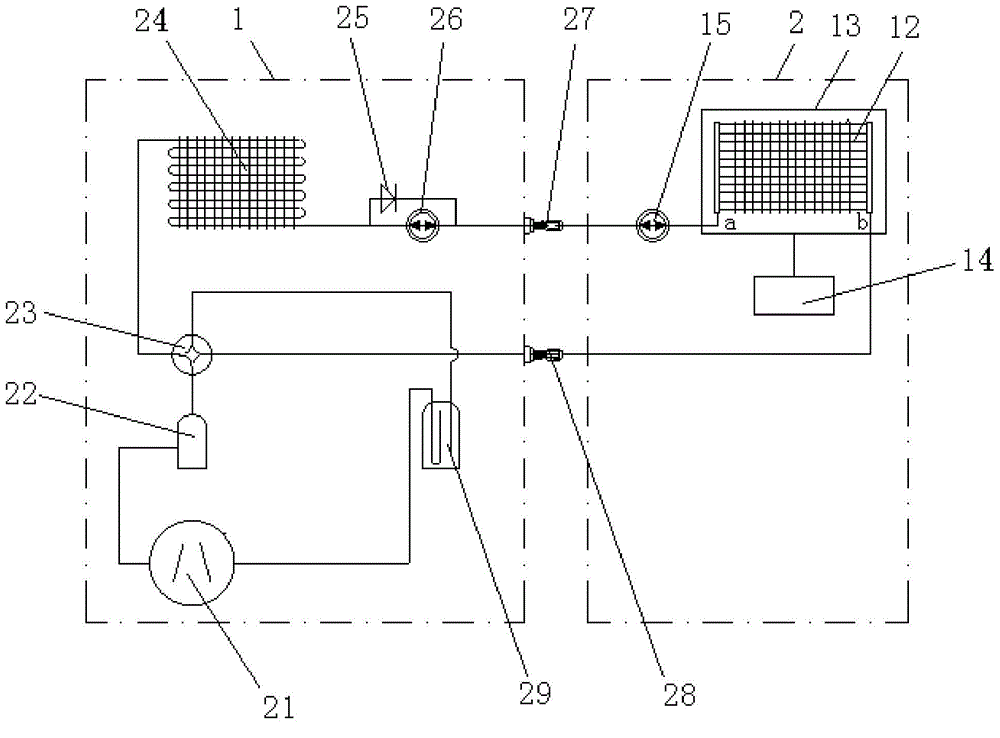

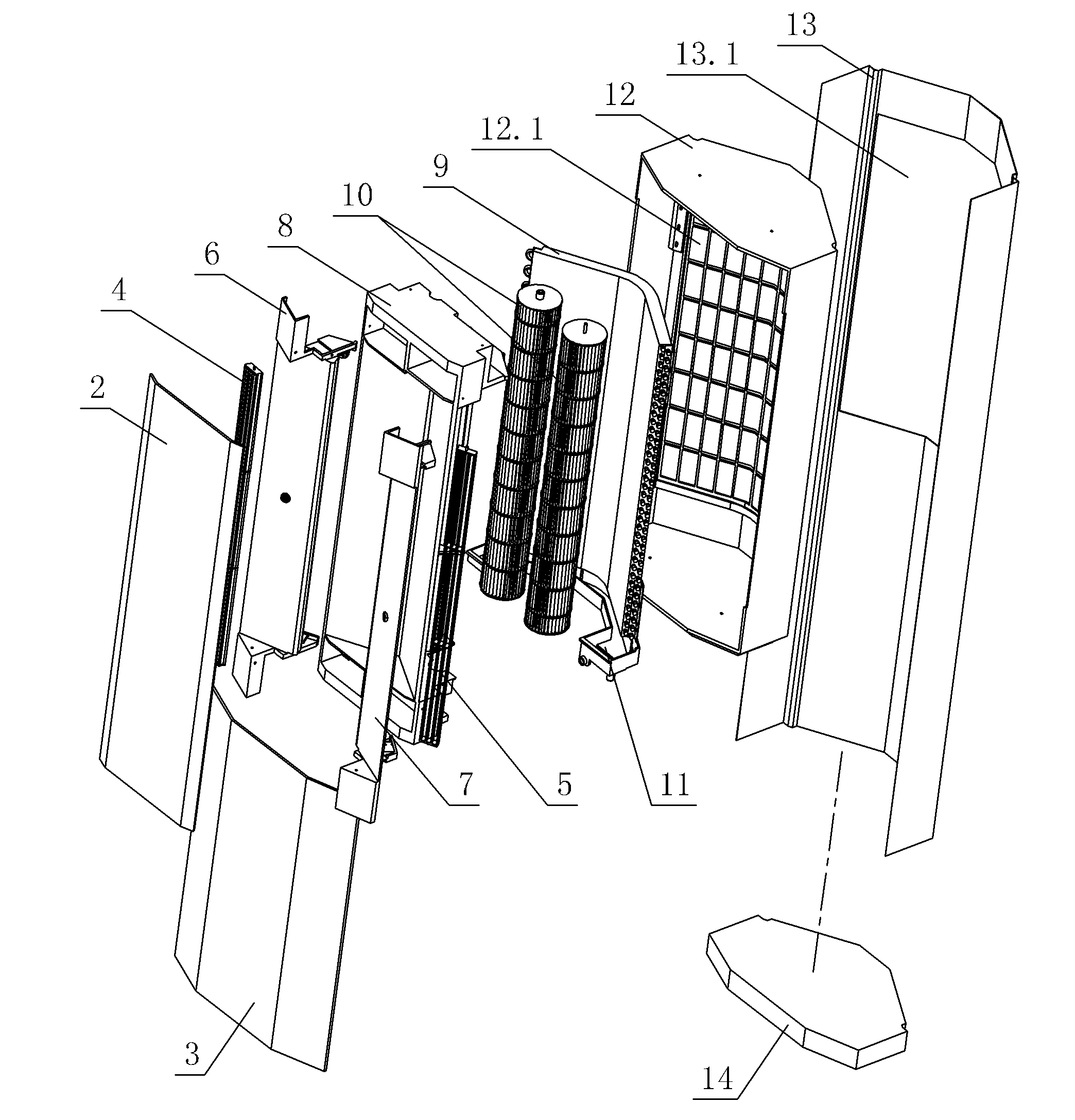

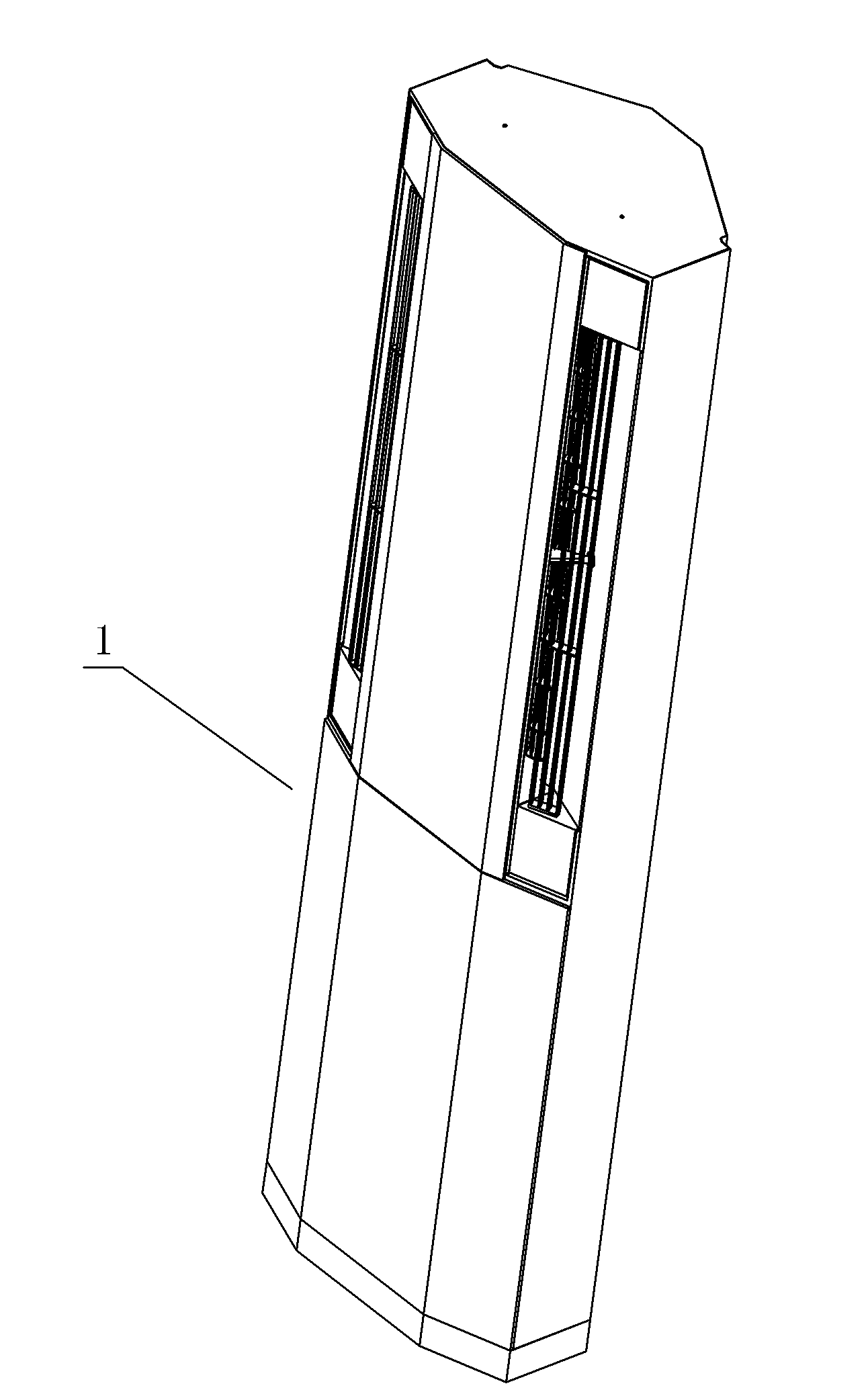

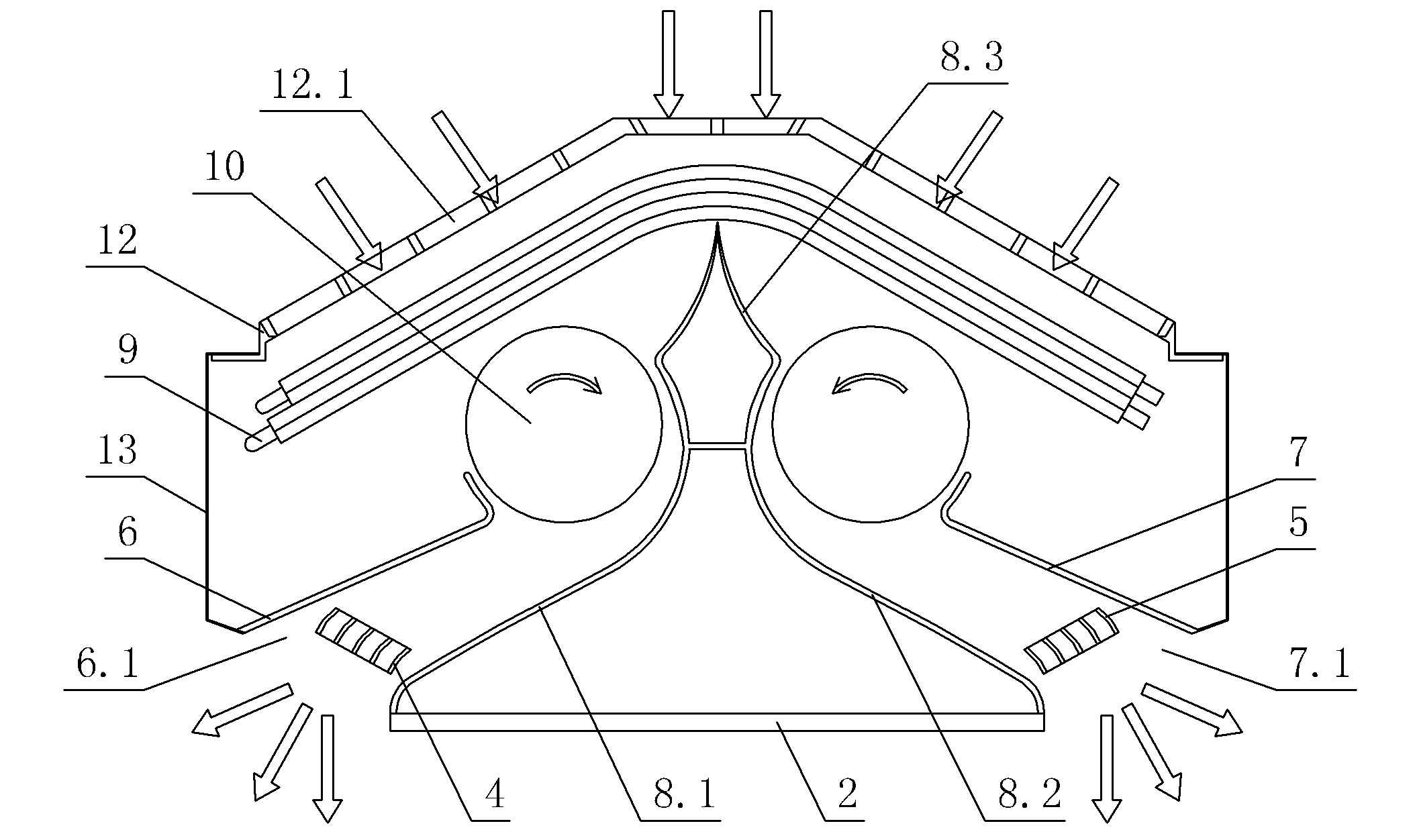

Indoor machine of two-tubular air conditioner

InactiveCN102147130AIncrease the effective heat transfer areaReduce wind resistancePump componentsLighting and heating apparatusEngineeringMicro heat exchanger

The invention discloses an indoor machine of a two-tubular air conditioner, which comprises a housing, a left and a right tubular fan wheels, a heat exchanger, an air inlet and an air outlet, wherein the housing consists of a front panel assembly and a shell; the left and the right tubular fan wheels are vertically arranged in the housing; the heat exchanger is arranged in the housing and positioned at the rear side of the tubular fan wheels; the air inlet is arranged behind the housing and the air outlet is arranged in front of the housing; the shell is connected to the rear side of the front panel assembly, the inner side of the shell is provided with a box body corresponding to the heat exchanger; back parts of the box body and the shell protrude outwards, the protruding part of the box body is provided with the air inlet, and the protruding part of the shell is provided with an air inlet window corresponding to the air inlet; the heat exchanger is bent towards the protruding direction of the back of the box body and arranged at a position close to the air inlet; and the housing is also internally provided with a volute assembly positioned between the two tubular fan wheels, the volute assembly comprises a left volute, a right volute, and a connecting bulge for connecting the left volute and the right volute together, and the connecting bulge extends to the position close to the heat exchanger. The invention has the advantages of larger air inlet area, compact assembly, low cost, small noise and high heat exchange efficiency.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Clean release, phase change thermal interface

InactiveUS20020135984A1Reduce thermal resistanceImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesGraphitePhase change

A laminar, thermally-conductive interface interposable intermediate a first heat transfer surface and an opposing second heat transfer surface to provide a thermally-conductive pathway therebetween. The interface includes a first layer formed of a flexible, lamellar graphite or tin foil material, and a second layer formed of a thermally-conductive phase-change material.

Owner:PARKER INTANGIBLES LLC

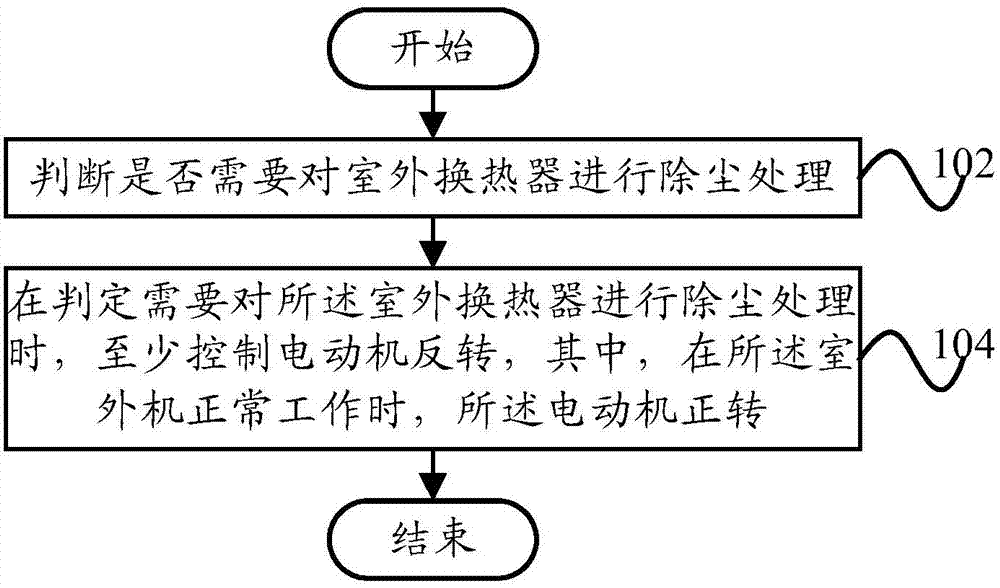

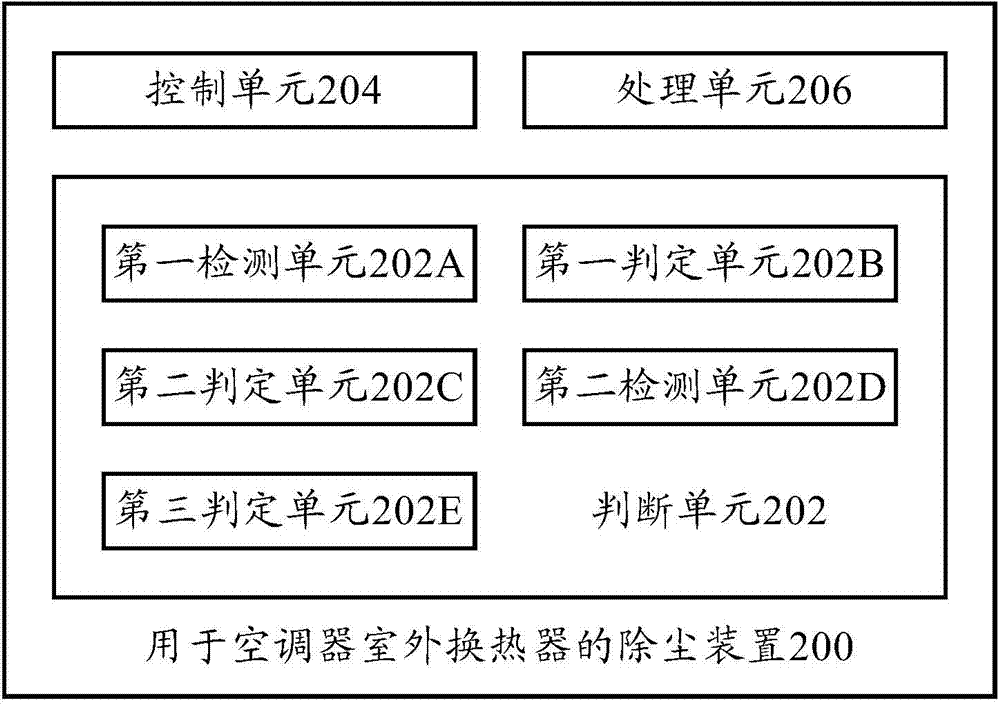

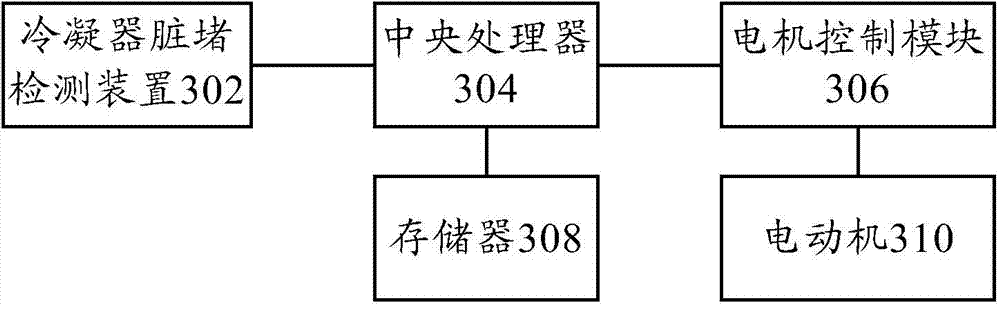

Dust removal method and device applied to air conditioner outdoor heat exchanger

InactiveCN104729016AAchieve dust removal effectEfficient removalMechanical apparatusCleaning heat-transfer devicesEngineeringHigh heat

The invention provides a dust removal method and device applied to an air conditioner outdoor heat exchanger. An outdoor unit of an air conditioner comprises the outdoor heat exchanger and an air duct system composed of a motor and vanes. The dust removal method includes the following steps that whether dust removal processing needs to be carried out on the outdoor heat exchanger is judged; when it is judged that the outdoor heat exchanger needs dust removal processing, at least the motor is controlled to rotate reversely, and when the outdoor unit works normally, the motor rotates forwards. By means of the technical scheme, the effect that the air conditioner automatically carries out dust removal on the outdoor heat exchanger is realized, a higher heat exchange efficiency of a condenser is guaranteed, and the complex operation of detaching the outdoor unit when the condenser is cleaned manually is avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

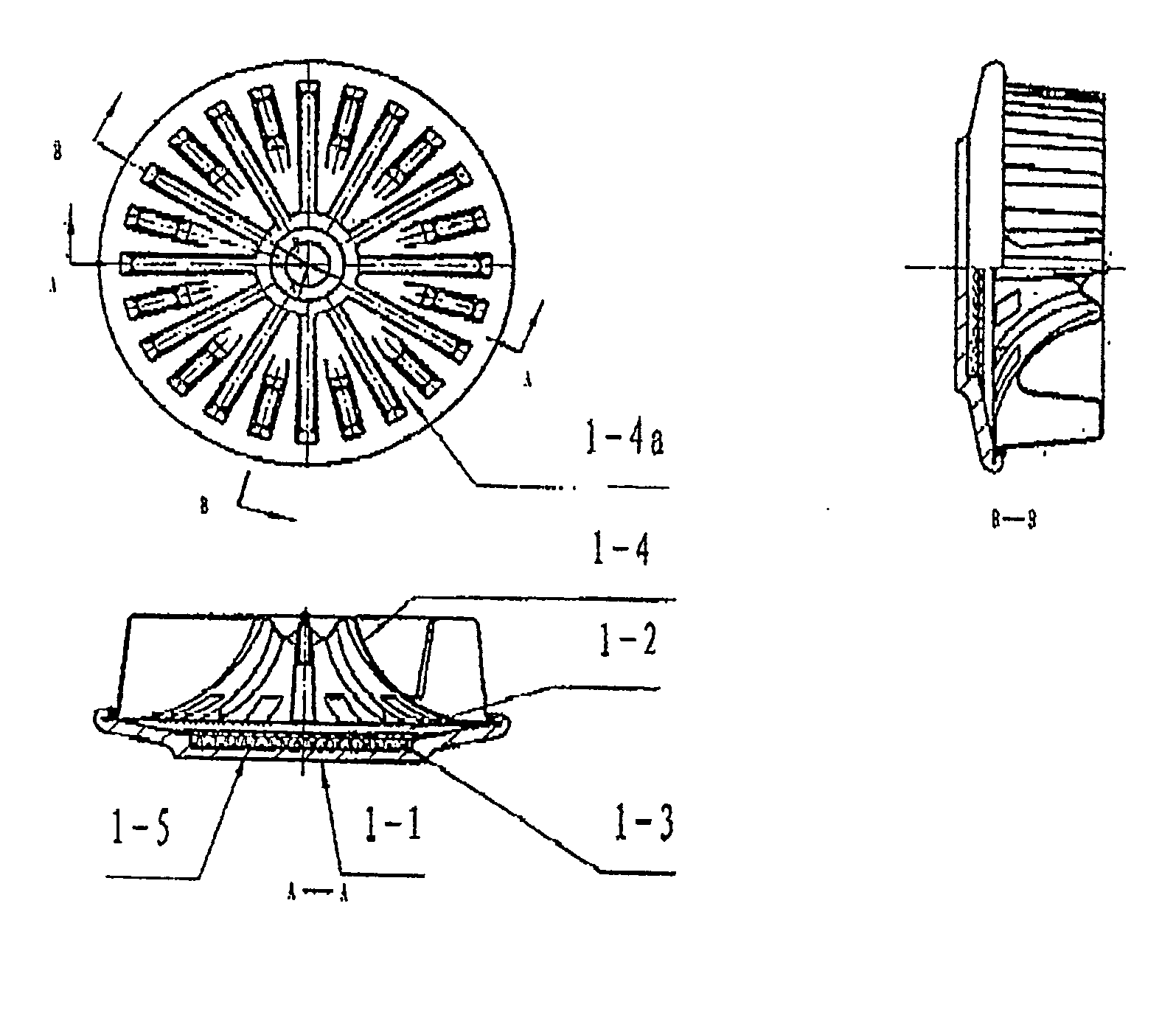

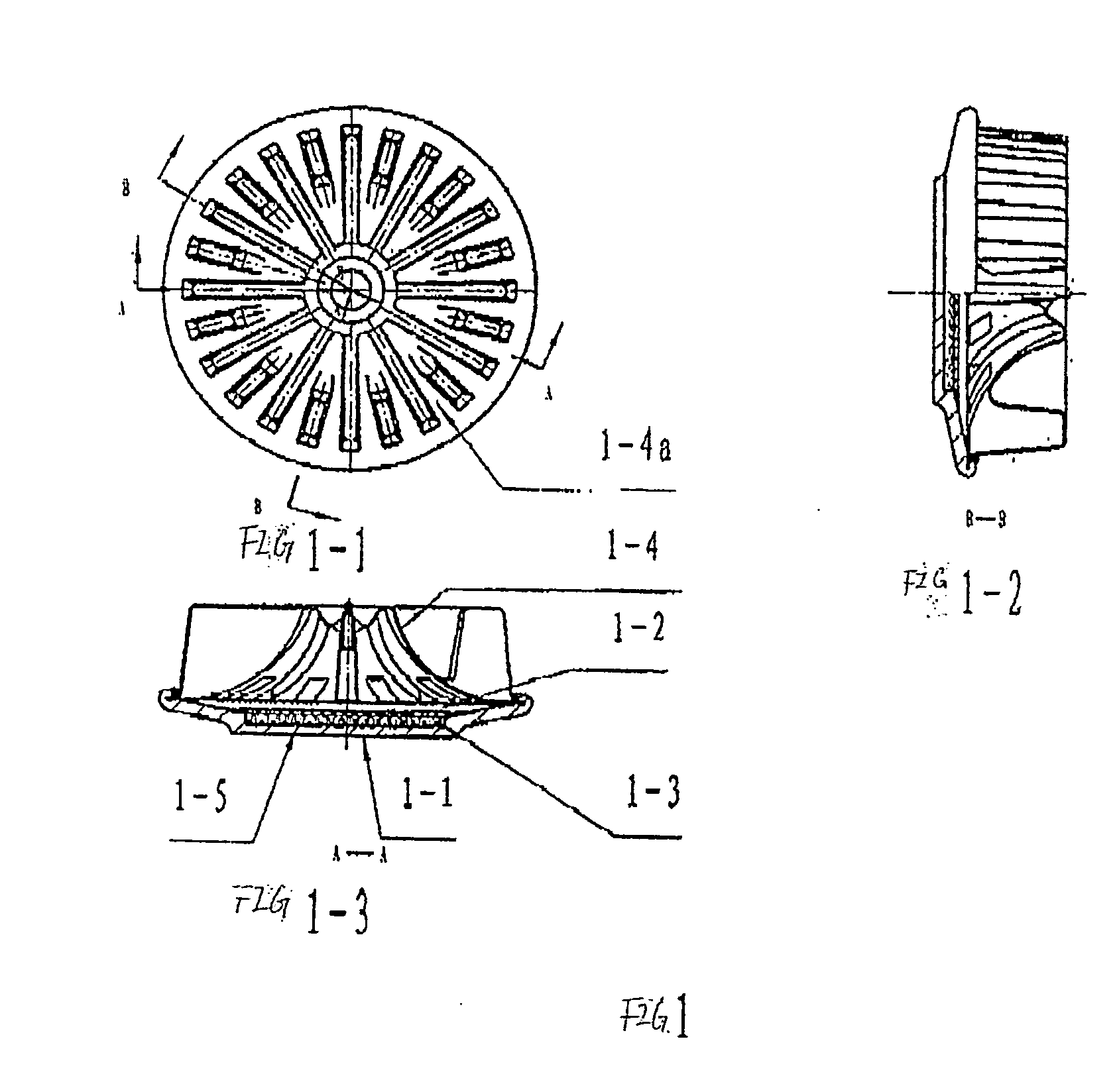

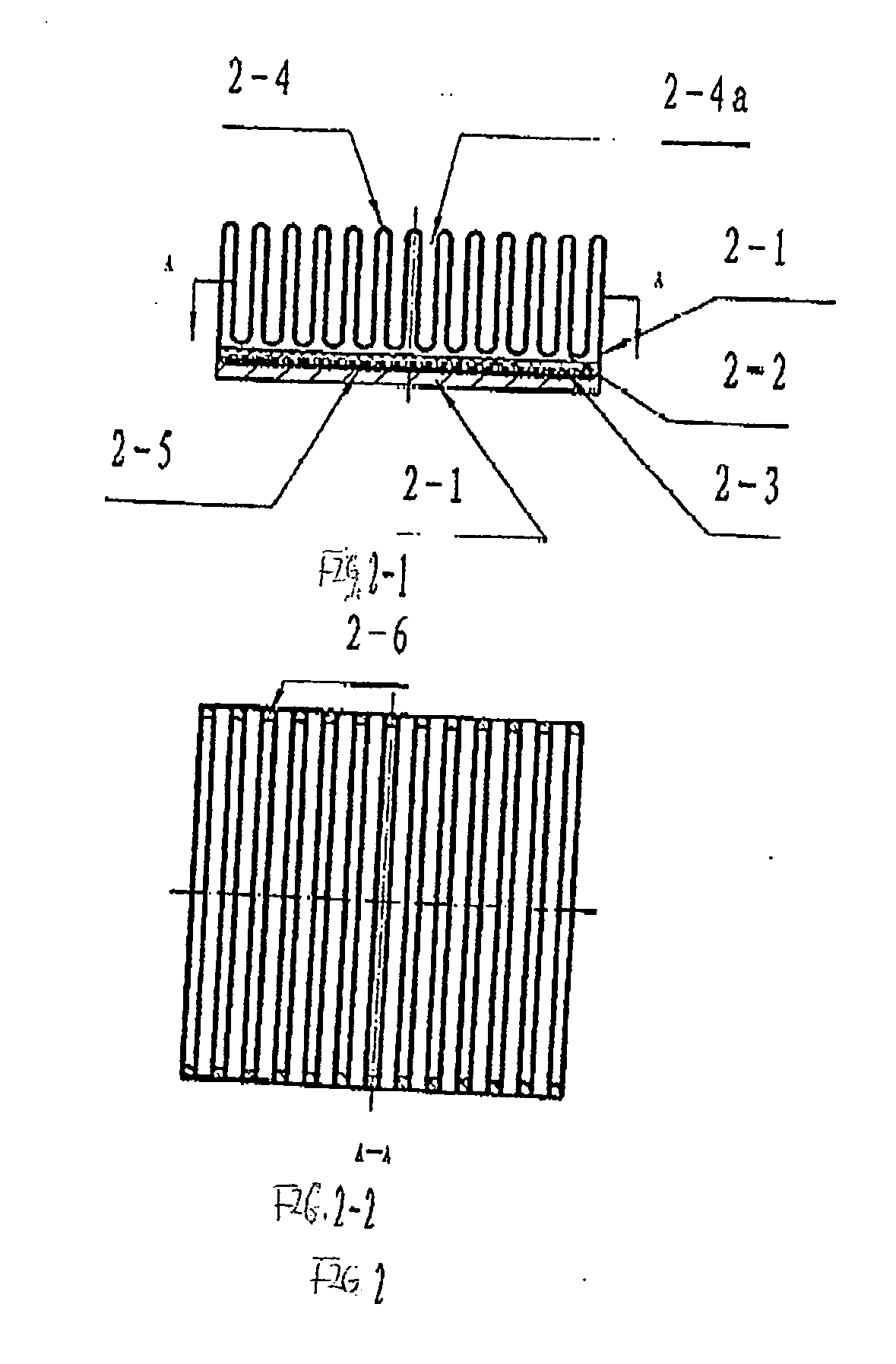

Integrated heat pipe and its method of heat exchange

InactiveUS20050061486A1Improve heat transfer efficiencyRemove heatStationary conduit assembliesHeat carrierEngineering

The present invention relates to a kind of integrated heat pipe and a method of heat exchange. The heat pipe includes a tank (1-2) as a heating potion and a lot of heat carriers (1-4) as a radiating portion. The tank (1-2) and the heat carriers (1-4) have same cavity in which a coolant (1-3) is partially filled. The tank (1-2) is held in close contact with a heat source (such as electronic elements). The heat carriers (1-4) are arranged at an interval so that the radiating channels (1-4a) are formed between them. The coolant (1-3) in the tank (1-2) is heated by the heat sources, vaporized coolant moves to the heat carriers (1-4) and condenses in there. According to the invention, the heat pipe can be increased its radiating surface significantly with the varied arrangement of the heat carriers (1-4).

Owner:YANG HONGWU

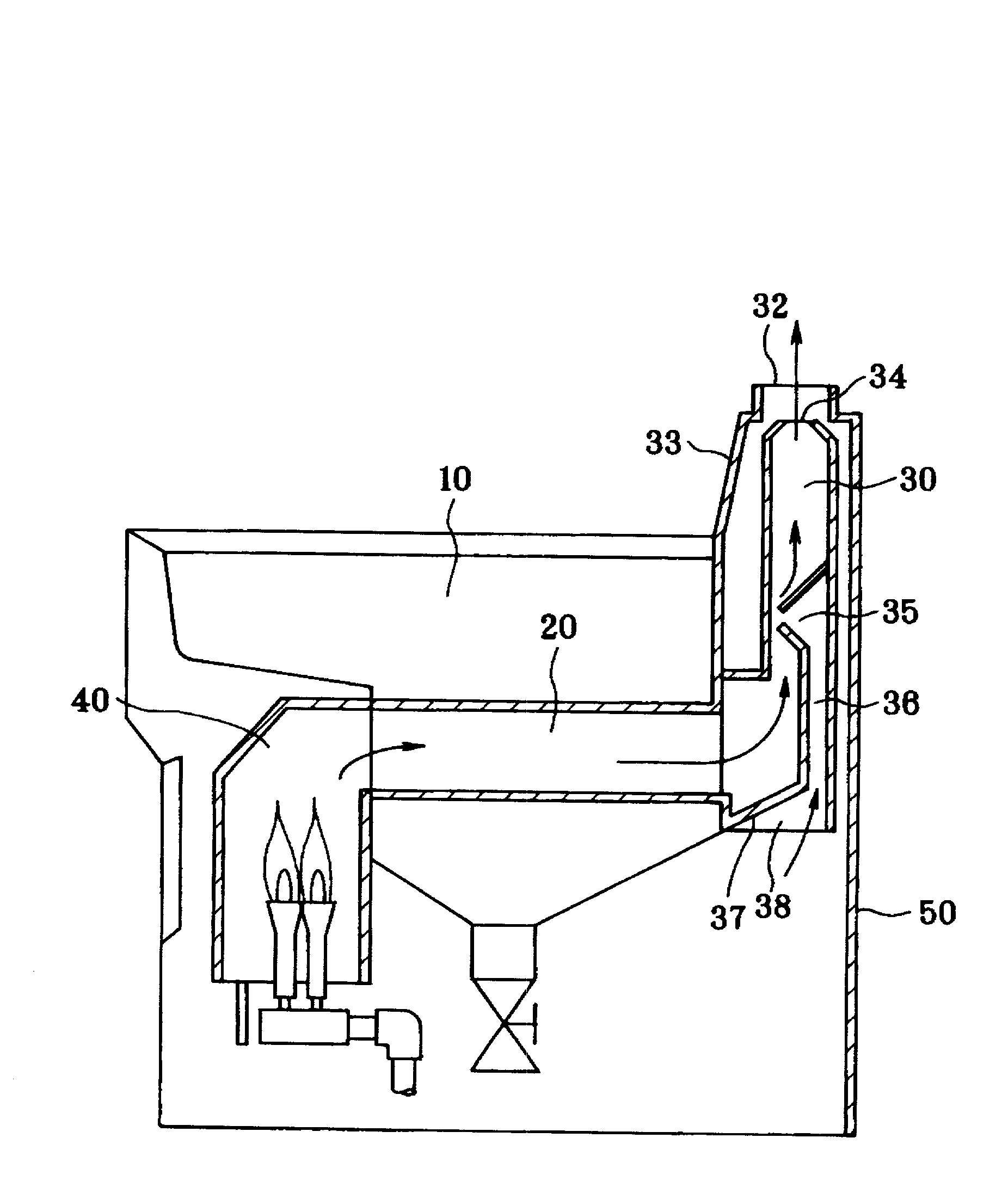

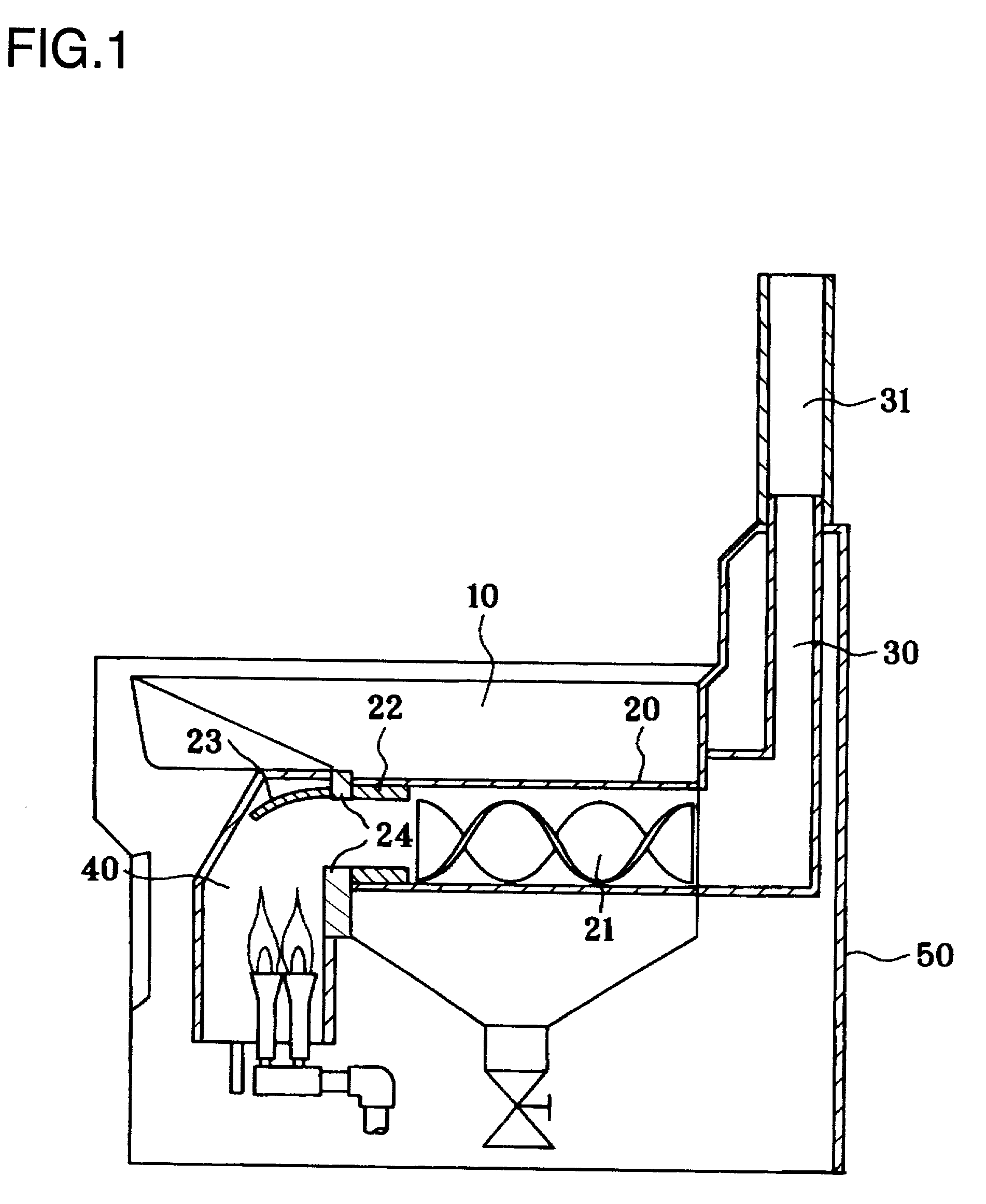

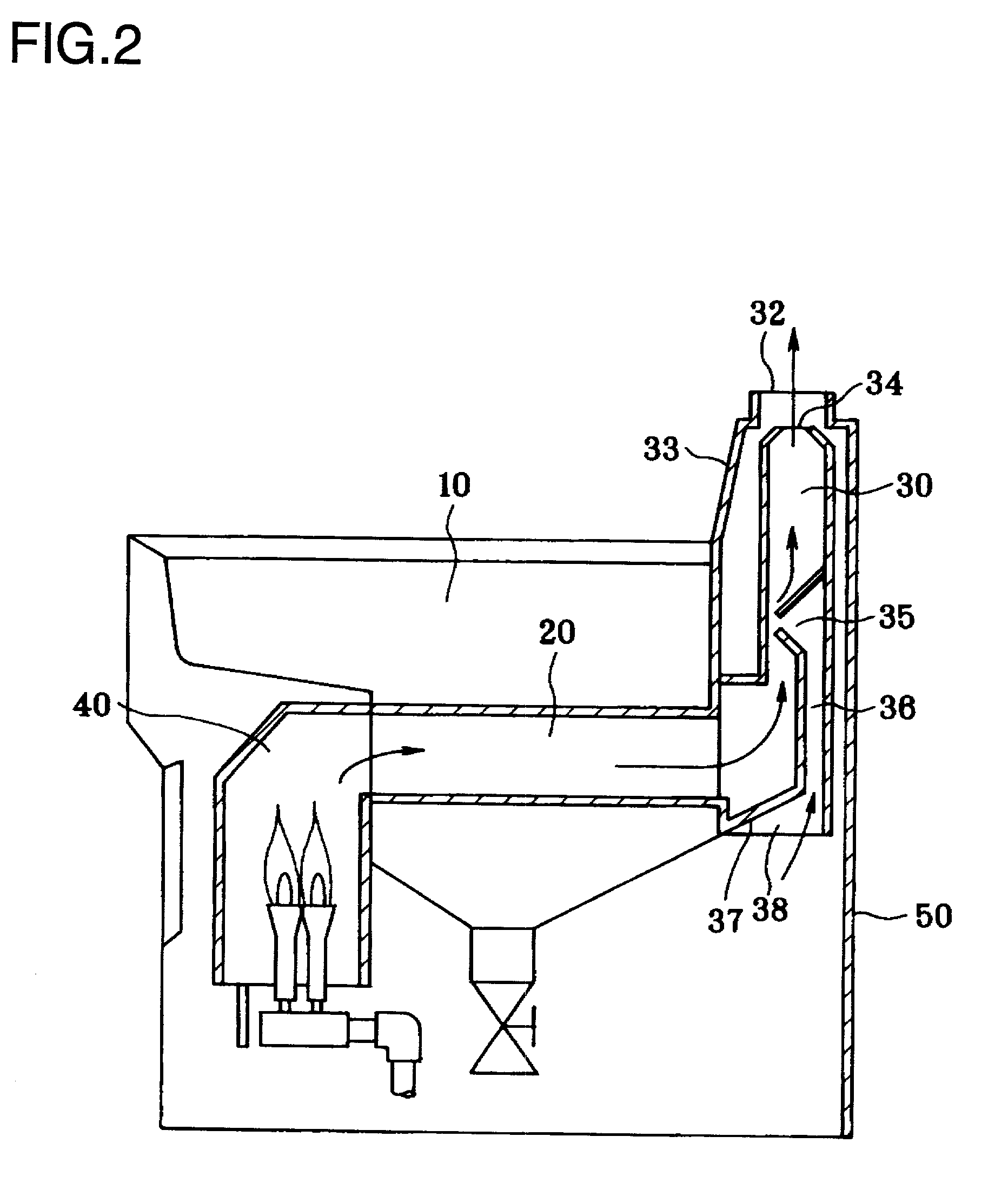

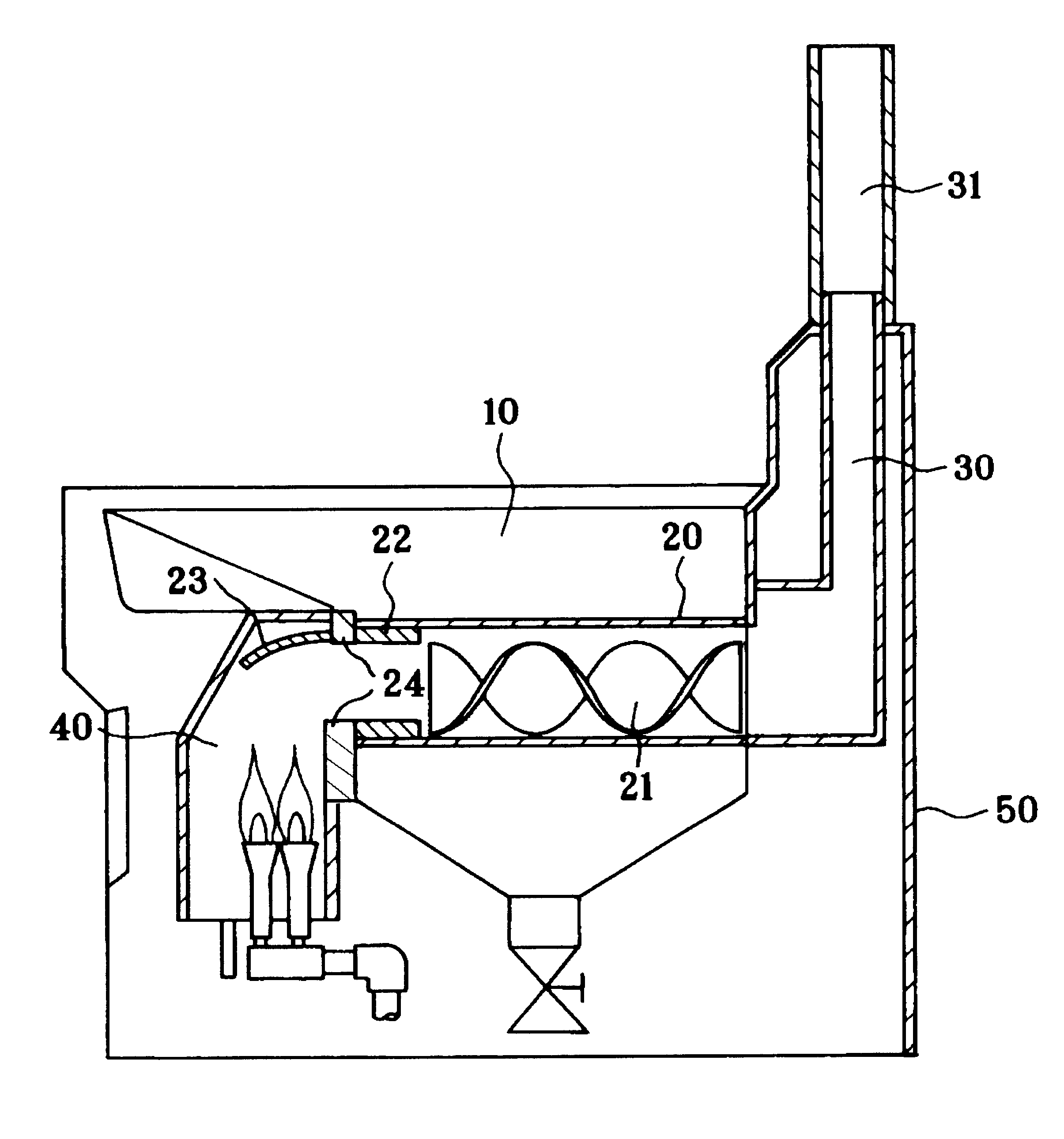

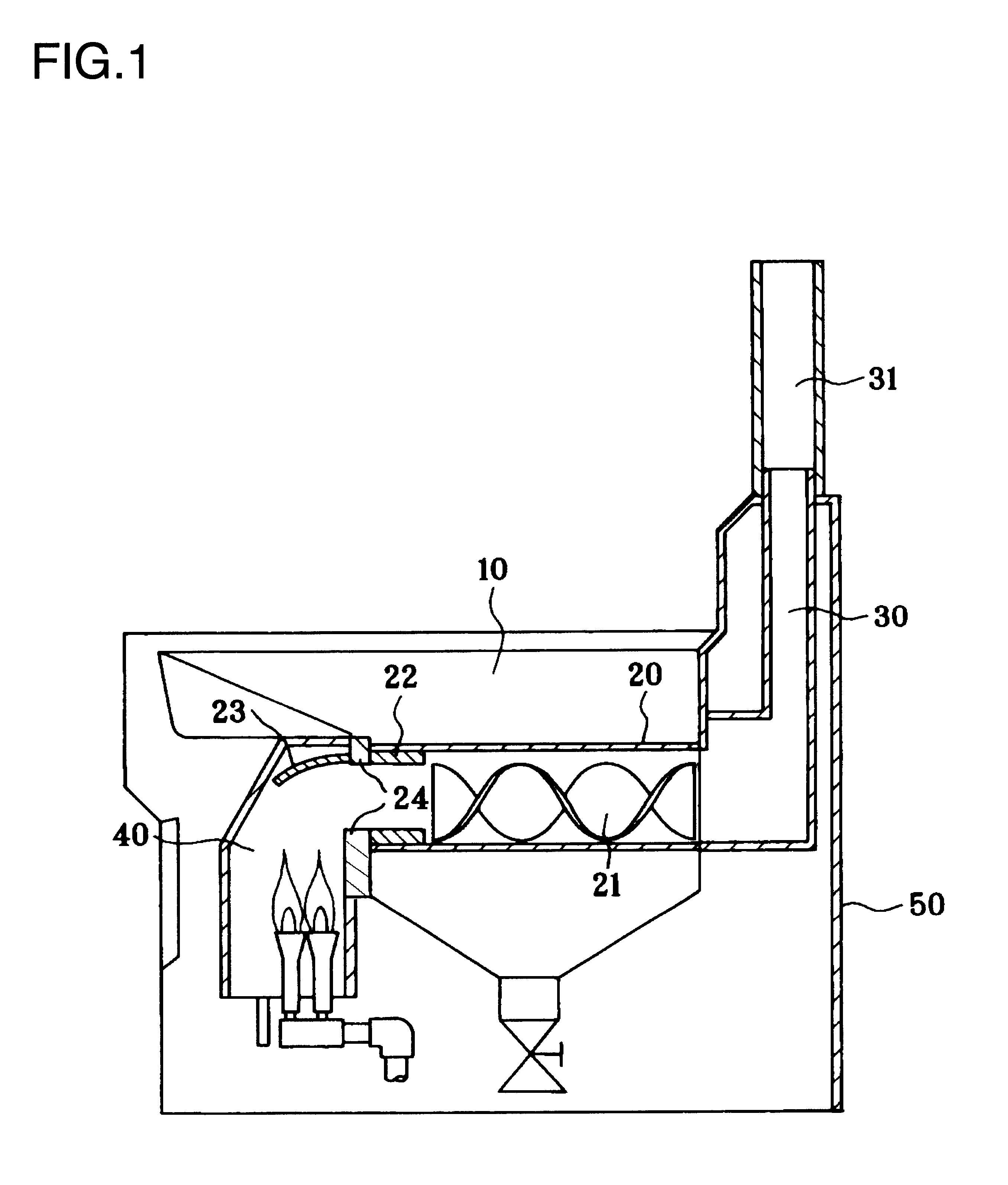

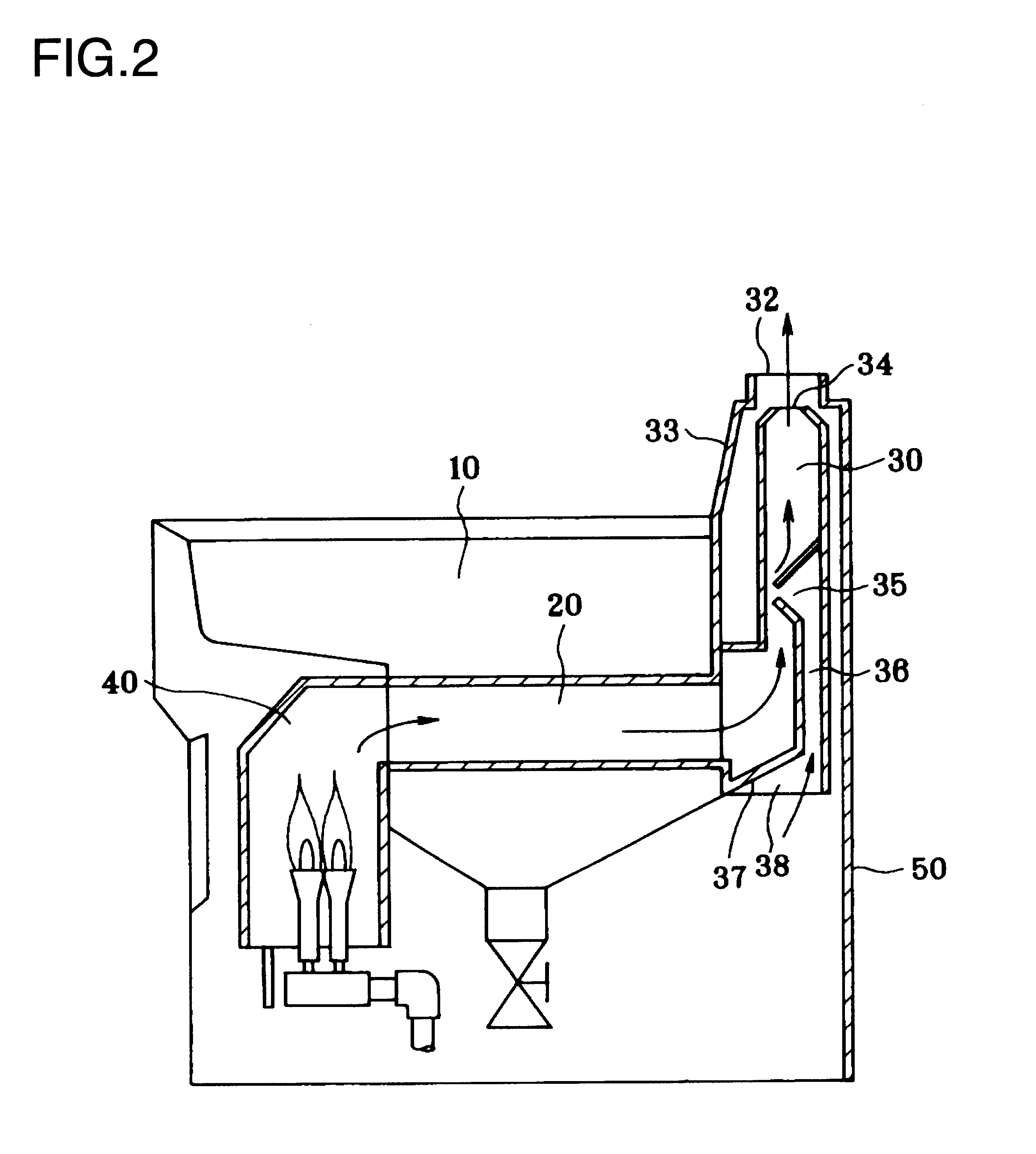

Gas fryer with improved heat-exchange properties

InactiveUS20030034027A1Prevent degradationUneven temperature of gasEnlarged heating surface vesselsWater heatersCombustion chamberFresh air

A gas fryer comprising: a tank for holding cooking oil, a heat pipe located proximate in the middle depth of said tank so that said heat pipe is soaked in said cooking oil, a combustion chamber located at the combustion gas inlet side of said heat pipe, and a flue located at a combustion gas outlet side of said heat pipe, wherein said heat pipe comprises a sleeve fitted in the inner wall of said heat pipe, and a spirally shaped mixer installed in said heat pipe, and wherein said flue comprises an introduction system of fresh air, said system comprising of a blowing nozzle of the fresh air positioned proximate to a narrowed region located proximate in the middle of said flue along a longitudinal axis, an inlet of fresh air located at a part of said flue, and a passage of fresh air provided along the inner and / or outer wall of said flue was provided.

Owner:K K FUJI ENTERPRIZE +1

Heavy oil recovery with fluid water and carbon dioxide

Diluted wet combustion forms a hot process fluid or VASTgas including carbon dioxide (CO2) and fluid water which is delivered to geologic formations and / or to surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be used to pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into a well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

Cooling device high voltage electrical unit for motor of vehicle, and hybrid vehicle

ActiveUS20050111167A1High voltageImprove heat transfer efficiencyModifications for power electronicsPlural diverse prime-mover propulsion mountingElectric machineHybrid vehicle

A cooling device for a high voltage electrical unit for a motor of a vehicle, includes: an inverter for controlling the motor that drives the vehicle; an electrical energy storing device for supplying electrical energy to the motor via the inverter; a downverter for decreasing source voltage of the electrical energy storing device, the downverter, the inverter, and the electrical energy storing device disposed under a seat of the vehicle in a concentrated manner; a fan, disposed under the seat, for moving cooling air to the electrical energy storing device and the inverter; an air inlet disposed under the seat and at an end of the seat as viewed in a width direction of the vehicle; and an air outlet disposed under the seat and at the other end of the seat as viewed in a width direction of the vehicle.

Owner:HONDA MOTOR CO LTD

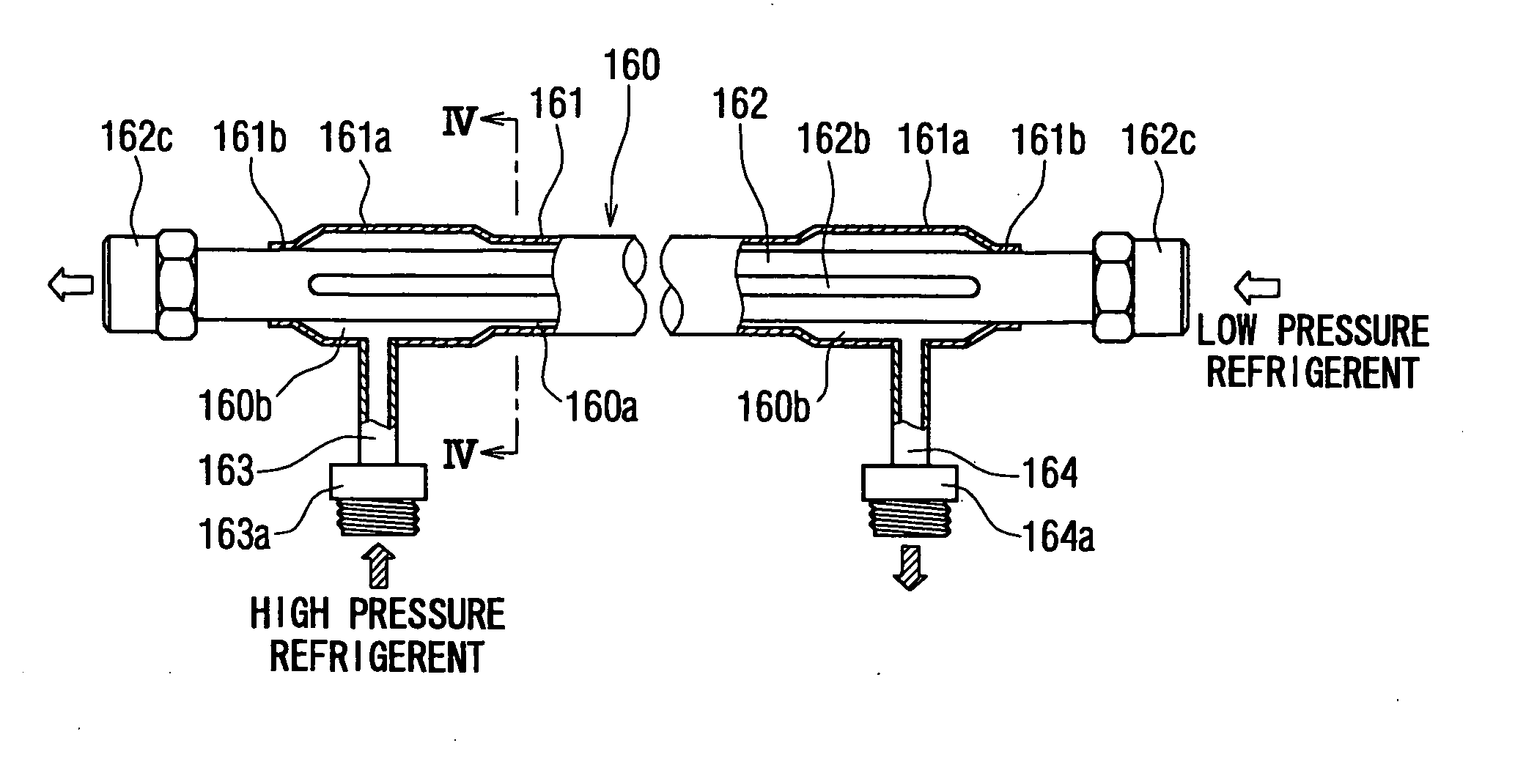

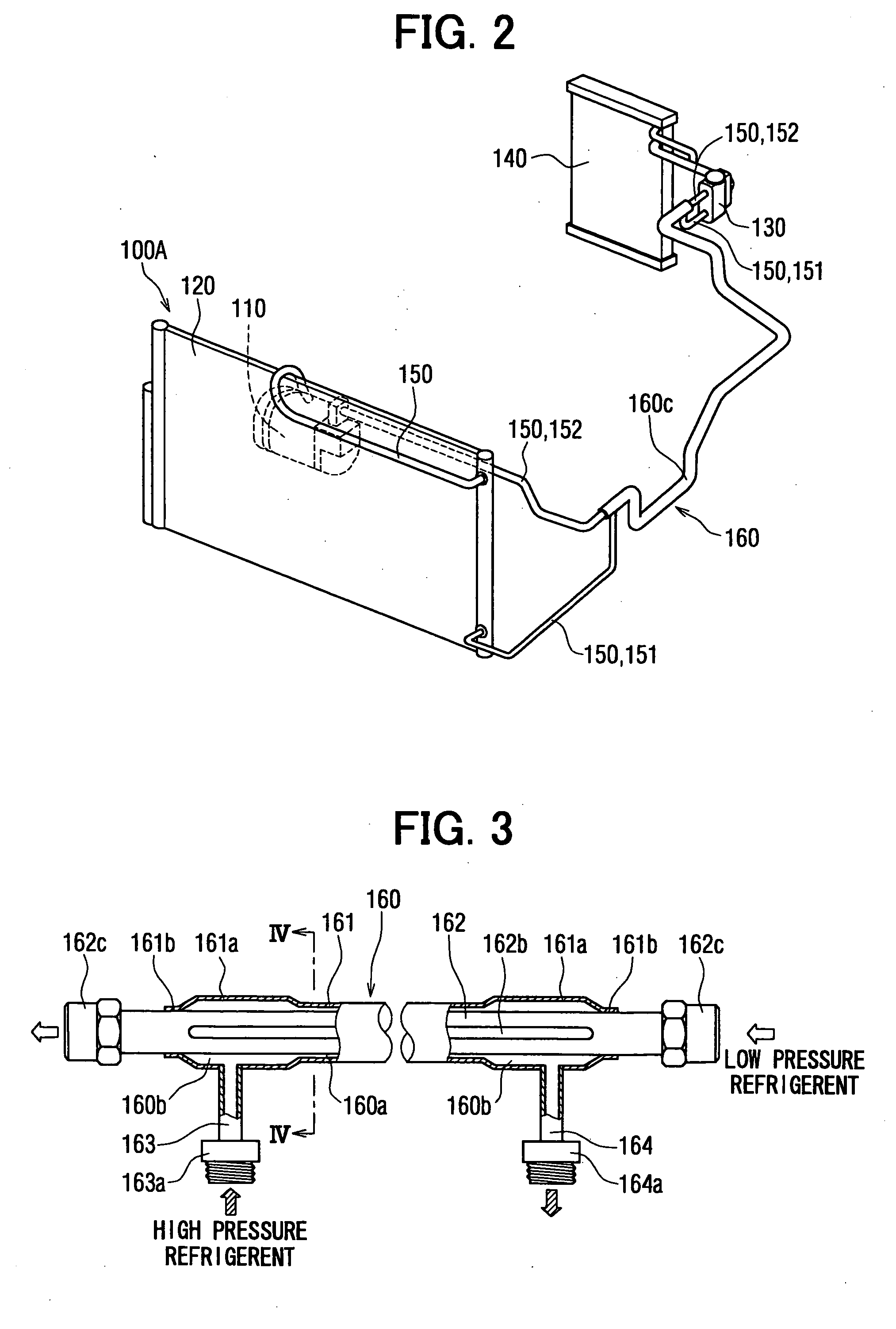

Double-wall pipe and refrigerant cycle device using the same

InactiveUS20060096314A1Improve heat transfer efficiencyEfficiently transferredPipe supportsCompression machines with non-reversible cycleRefrigerantEngineering

A double-wall pipe includes an outer pipe provided with first and second openings, respectively, at first and second end parts of the outer pipe in a pipe longitudinal direction, and an inner pipe inserted in the outer pipe to define a passage between the outer pipe and the inner pipe. An inlet portion is connected to the outer pipe to communicate with the passage through the first opening, and an outlet portion is connected to the outer pipe to communicate with the passage through the second opening. In the double-wall pipe, the outer pipe and the inner pipe can be disposed to define an expanded portion having an expanded sectional area in the first passage, and the expanded portion can be provided at least at a portion near the inlet portion and the outer portion. The inner pipe can be provided with plural grooves in the double-wall pipe.

Owner:DENSO CORP +1

Gas fryer with improved heat-exchange properties

InactiveUS6736131B2Prevent degradationUneven temperature of gasEnlarged heating surface vesselsWater heatersCombustionFresh air

A gas fryer includes a tank for holding cooking oil, a heat pipe located in the middle depth of the tank so that the heat pipe is soaked in the cooking oil, a combustion chamber located at the combustion gas inlet side of the heat pipe, and a flue located at a combustion gas outlet side of the heat pipe. The heat pipe has a sleeve fitted in the inner wall of the heat pipe, and a spirally shaped mixer installed in the heat pipe. The flue also has an introduction system for fresh air, with a blowing nozzle of the fresh air positioned proximate to a narrowed region located about in the middle of the flue along a longitudinal axis, an inlet of fresh air located at a part of the flue, and a passage of fresh air provided along the inner and / or outer wall of the flue.

Owner:K K FUJI ENTERPRIZE +1

Composite graphene infrared radiation and heat conduction film and manufacturing method thereof

ActiveCN105514066AImprove infrared radiation performanceFast heat conductionSemiconductor/solid-state device detailsConjugated diene hydrocarbon coatingsOptoelectronicsHeat sink

The invention discloses a composite graphene infrared radiation and heat conduction film and a manufacturing method of the composite graphene infrared radiation and heat conduction film, and is characterized in that a substrate is provided with a composite graphene infrared radiation coating layer. According to the manufacturing method of the composite graphene infrared radiation and heat conduction film disclosed by the invention, a thin film manufactured by utilizing good infrared radiation capacity and good heat conduction capacity of a composite graphene infrared radiation material has the good heat conduction capacity in both directions which are parallel to and vertical to the substrate, so that heat can be rapidly transferred from a heating part to a heat sink device or an environment, the heat conduction efficiency is increased, local hot points in a device are removed, and temperature gradient in a heat conduction path is reduced; the composite graphene infrared radiation and heat conduction film disclosed by the invention has the advantages that the manufacturing is simple and convenient, and a powerful support is provided for high integration of electronic devices and rapid heat conduction of heating devices.

Owner:宿州晶禾科技有限公司

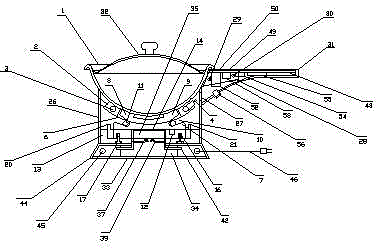

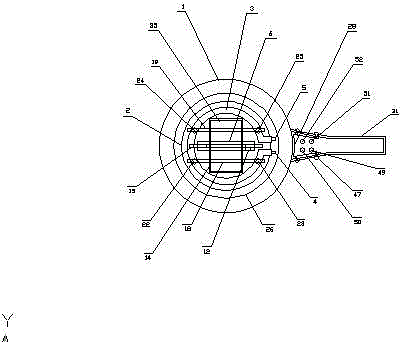

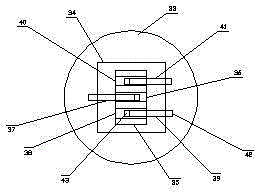

Critical water-controlled type semiautomatic electric heating cooking pot

ActiveCN104605727ASimple structureImprove heat transfer efficiencyCooking vesselsPower couplingElectricity

A critical water-controlled type semiautomatic electric heating cooking pot consists of a wireless coupling electric heating cooking pot body and a power coupling seat, wherein an electric heating plate and a heat-conduction connecting plate are arranged on a semi-spherical surface of a non-stick pot bottom; the heat-conduction connecting plate penetrates in a strip-shaped channel in the middle of the electric heating plate and is provided with a temperature sensor; a circular base is arranged on the heat-conduction connecting plate; a rectangular coupling socket is formed in the middle of the circular base; the left end and the right end of the coupling socket are provided with a connecting plate groove and a front and back blade groove; the heat-conduction connecting plate in the connecting plate groove and a front and back electric contact blade in the front and back blade groove are respectively in contact with an earthing spring plate and a front and back power spring plate on a coupling plug of the power coupling seat, so that power wires of the heat-conduction connecting plate and the front and back electric contact blade are in coupling connection with the coupling plug of the power coupling seat; a triangular machine box is arranged on the left side of a control handle; and an operating panel is arranged at the left upper end of the triangular machine box and is respectively provided with a high-temperature button, a high-temperature indicator lamp, a low-temperature button and a low-temperature indicator lamp. The temperatures of different regions of the surface in the pot are correspondingly changed along with change of the quantity of water in the electric heating cooking pot, and are measured and controlled according to change of a critical temperature, the electric heating cooking pot can be switched off automatically during cooking, the circumstance that a user forgets to switch off the cooking pot and food in the cooking pot is burned are avoided, the time is saved, the user does not need to worry about the food in the cooking pot, and troublesome problems are avoided.

Owner:广东万迪电器有限公司

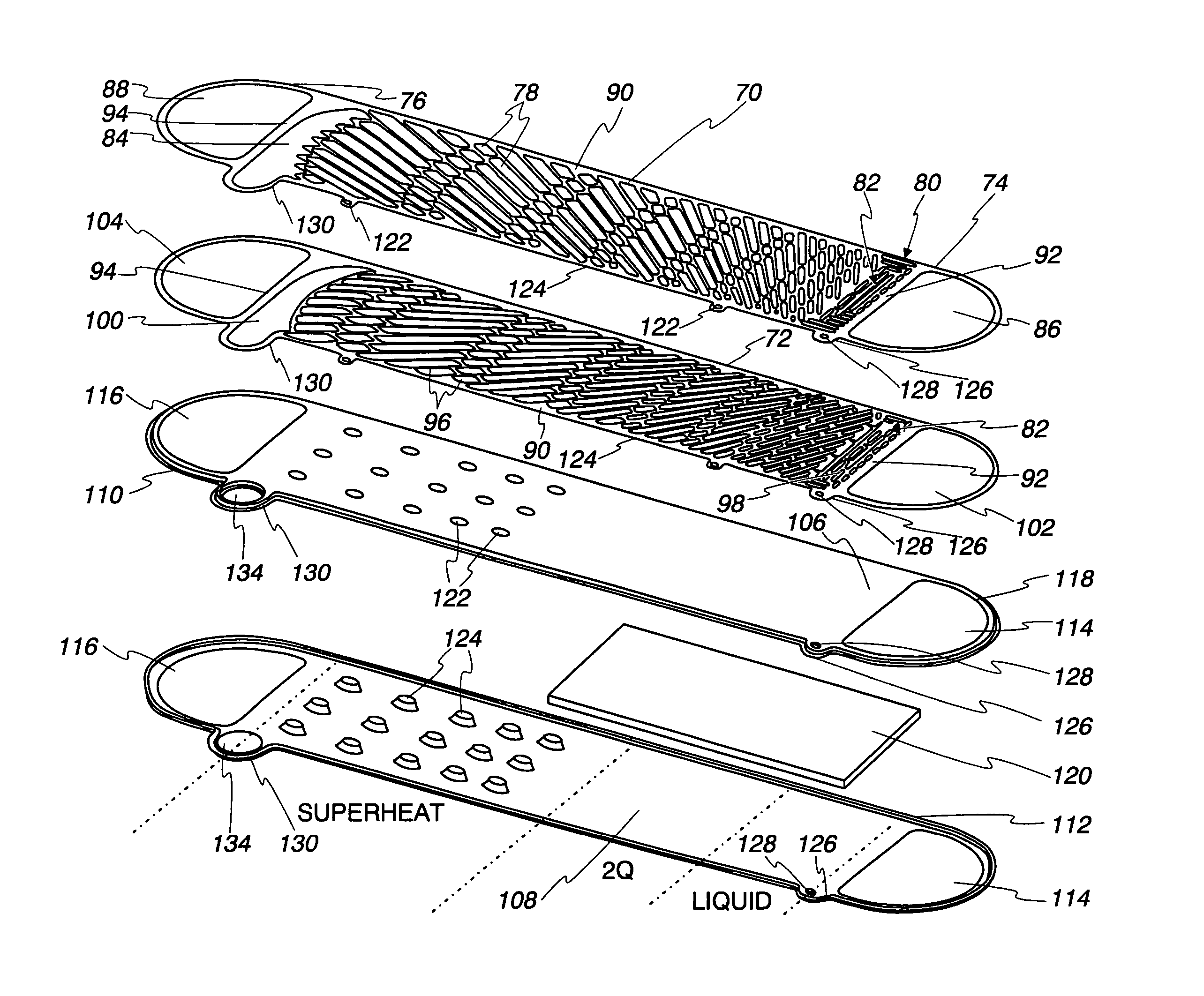

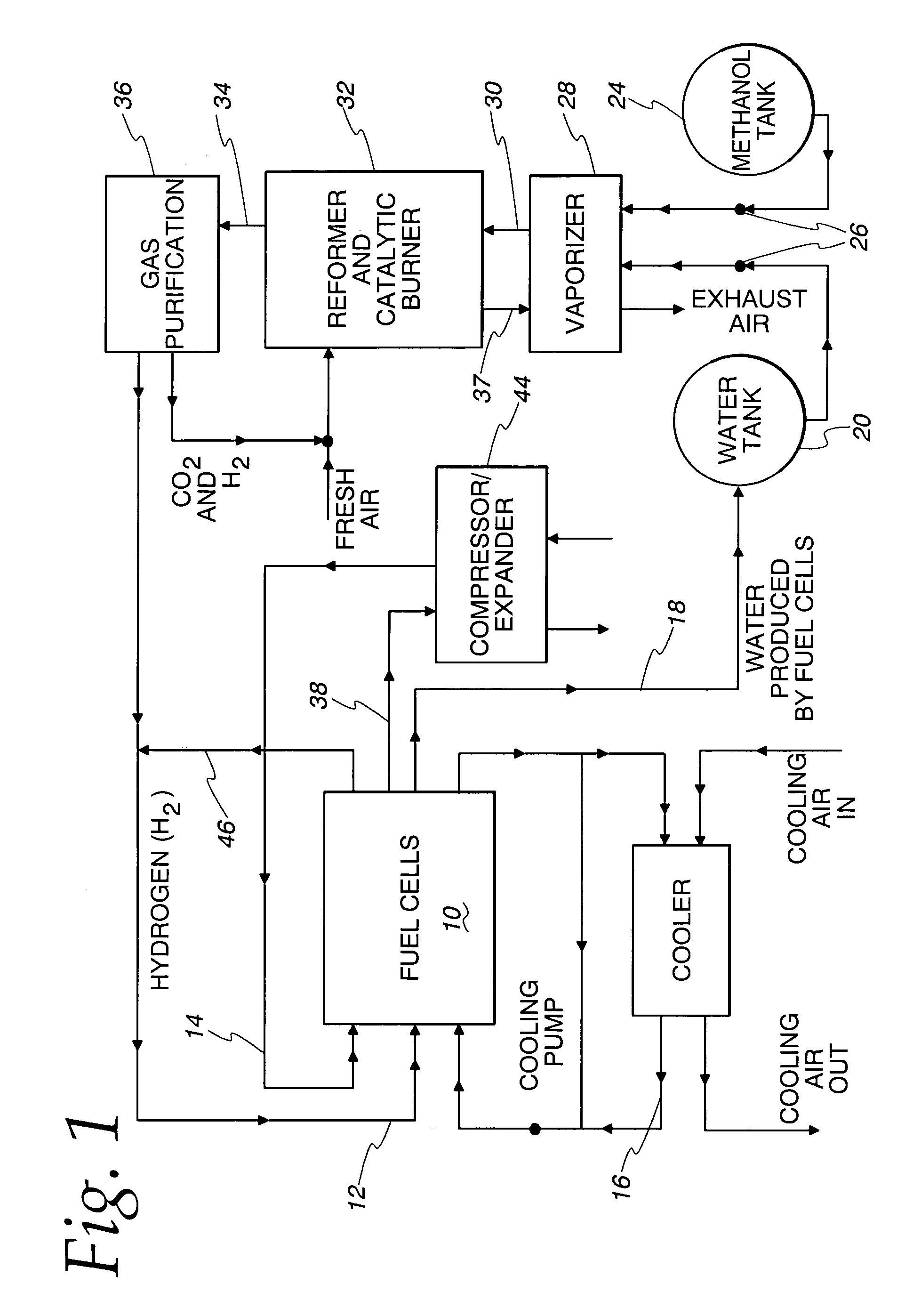

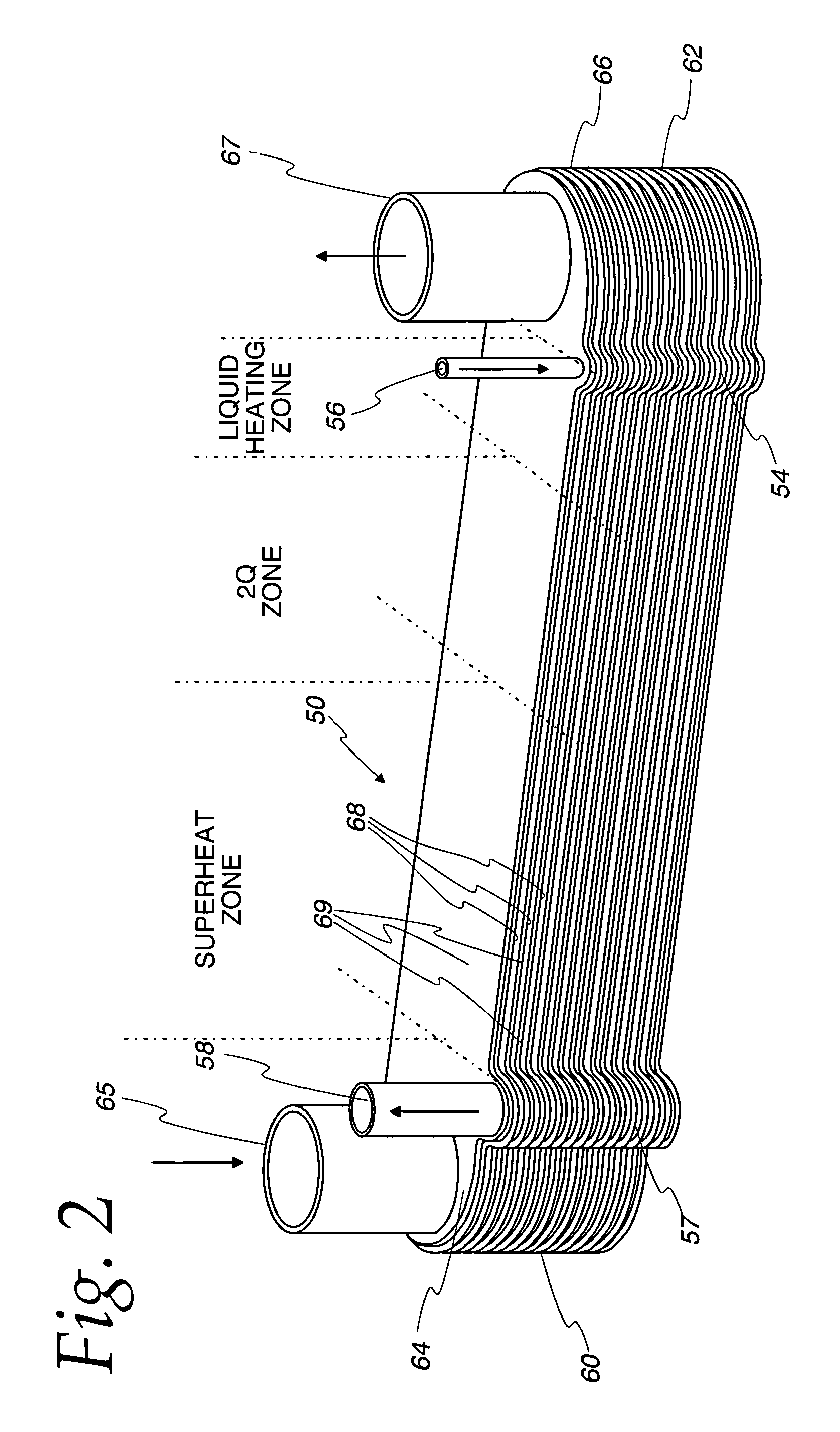

Fuel vaporizer for a reformer type fuel cell system

InactiveUS7063047B2Short response timeReduced effectivenessFuel cell heat exchangeHeat transfer modificationFuel cellsWater flow

Large thermal stresses are avoided and the fuel charge reduced in a vaporizer particularly suited for use in a reformer type fuel cell system and having a construction that includes alternating fuel / water flow path defining cells (68) and hot gas flow path cells (69) by providing heat transfer augmentation, such as a lanced and offset fin (120), only in that part of the gas flow path structure (69) adjacent the regions in the fuel / water flow path cells (68) where heating of the liquid fuel / water and vaporizing of the fuel / water where the mixture exists is a two phase material occurs and not in the area adjacent those parts of the fuel / water flow path structure (68) in which superheating of the vaporized fuel / water mixture is occurring.

Owner:MODINE MFG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com