Double-wall pipe and refrigerant cycle device using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

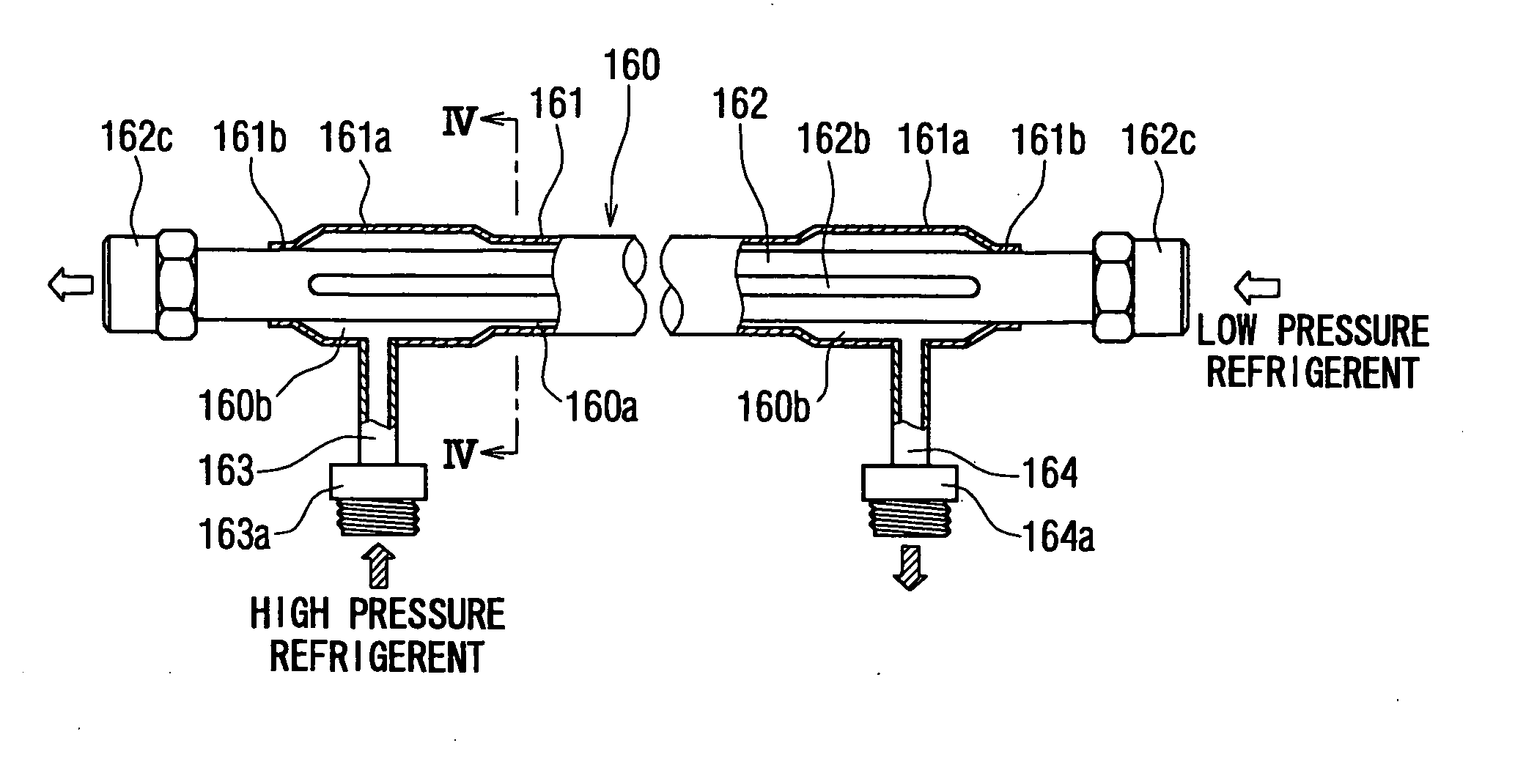

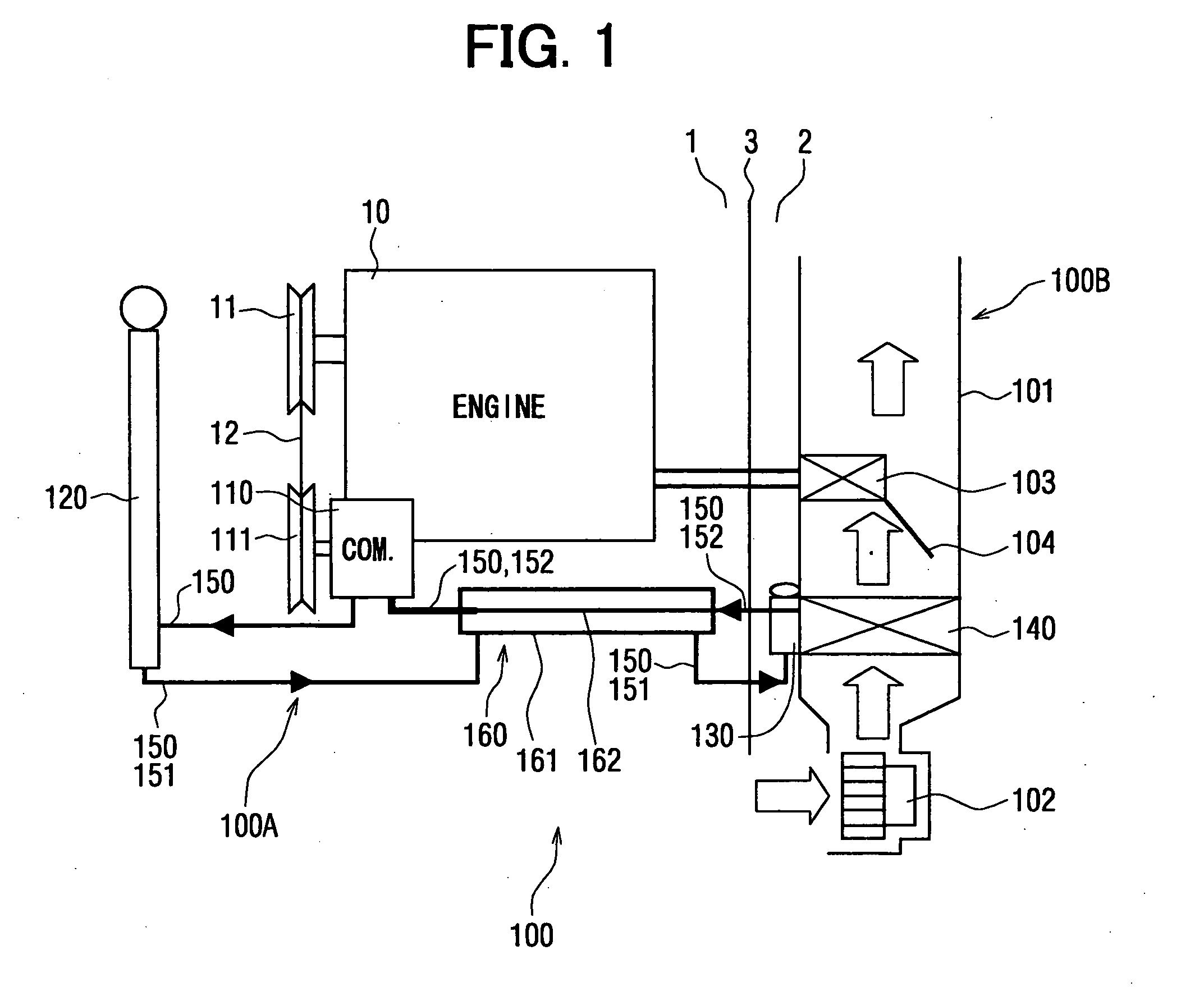

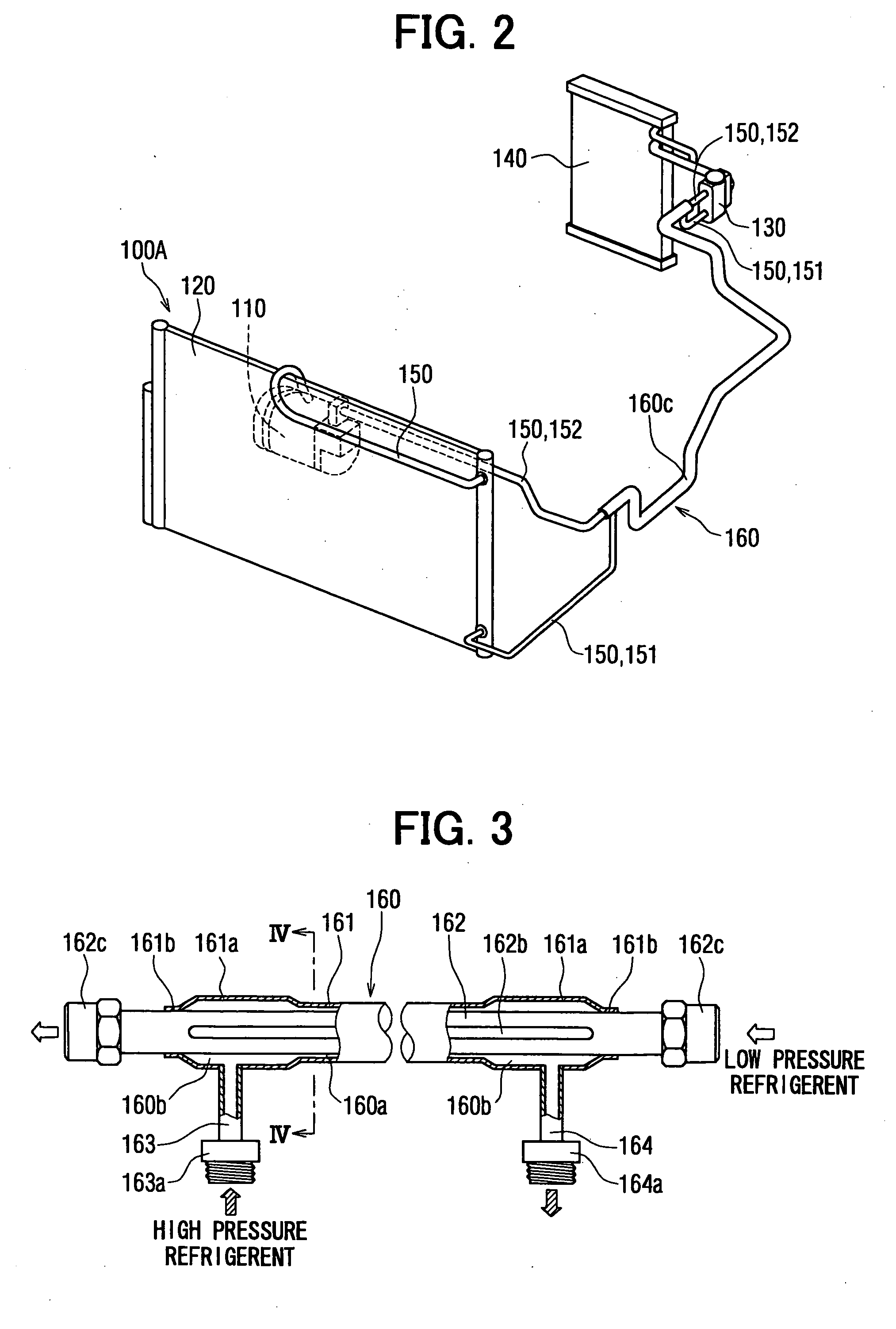

[0042] In this embodiment, a double-wall pipe 160 for carrying a refrigerant is typically used for a refrigerant cycle device 100A for a vehicle air conditioning system 100. The double-wall pipe 160 will be described with reference to FIGS. 1 to 4.

[0043] A vehicle has an engine room 1 holding an engine 10 therein and a passenger compartment 2 separated from the engine room 1 by a dash panel 3. The air conditioning system 100 has the refrigerant cycle device 100A including an expansion valve 130 and an evaporator 140, and an interior unit 100B. Components of the refrigerant cycle device 100A excluding the expansion valve 130 and the evaporator 140 are disposed in a predetermined mounting space of the engine room 1. The interior unit 100B is arranged in an instrument panel placed in the passenger compartment 2.

[0044] The interior unit 100B has components including a blower 102, the evaporator 140 and a heater 103, and an air conditioner case 101 housing the components of the interio...

second embodiment

[0070]FIG. 6 shows a part of a double-wall pipe 160 of the second embodiment.

[0071] Referring to FIG. 6, the double-wall pipe 160 in the second embodiment according to the present invention has expanded passages 160b formed in longitudinal end parts thereof and different from those of the double-wall pipe 160 in the first embodiment.

[0072] Since the expanded passages 160b formed near an inlet pipe 163 and an outlet pipe 164 in the longitudinal end parts of the double-wall pipe 160, respectively, are the same in shape, only the expanded passage 160b formed near an inlet pipe 163 will be described. A depression 162a (recess portion) is formed in an inner pipe 162 by radially depressing a circumferential part of the inner pipe 162 to define the expanded passage 160b. Because the depression 162a is formed in the inner pipe 162, a narrow part is formed in the inner pipe 162 due to the depression 162a. The expanded passages 160b at the junction between the inlet pipe 163 and a passage 1...

third embodiment

[0075]FIG. 7 shows an inner pipe 160 and an outer pipe 161 of the third embodiment. Referring to FIG. 7, a double-wall pipe 160 in the third embodiment according to the present invention has an inner pipe 162 provided with three helical grooves 162d formed in the shape of a three-thread screw instead of the straight grooves 162a of the inner pipe 162 of the double-wall pipe 160 in the first embodiment. Multiple helical grooves, that is, more than one helical groove, may be formed in the shape of a multithread screw and arranged at equal or predetermined pitches or a single helical groove may be formed in the inner pipe 162 instead of the three helical grooves 162d. The three helical grooves 162d are formed by deforming the wall of the inner pipe 162. The three helical grooves 162d form helical ridges inside the inner pipe 162. The three helical grooves 162d are parallel to each other.

[0076] The three helical grooves 162d winding around the inner pipe 162 increase the bending rigidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com