Critical water-controlled type semiautomatic electric heating cooking pot

A semi-automatic, critical water technology, used in cooking utensils, household appliances, applications, etc., can solve the problems of inhumanization, poor heat transfer efficiency, unstable temperature control, etc., to avoid forgetting scorching, high heat transfer efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

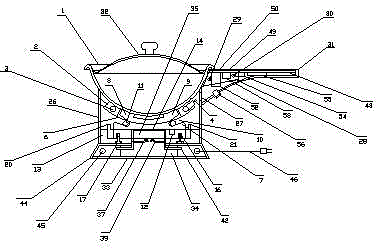

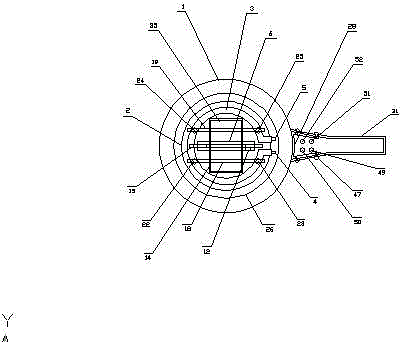

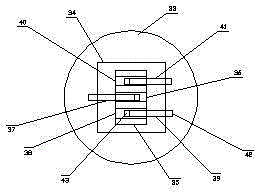

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] exist figure 1 , figure 2 , image 3Among them, the electric heating pot is a wirelessly coupled electric heating cooking pot, which is provided with a non-stick pot 1. The non-stick pot is a hemispherical stainless steel pot with a traditional shape. There is an electric heating plate 2, the hemispherical curve of the upper end of the electric heating plate is consistent with the hemispherical curve of the bottom end of the non-stick pan, and closely matches. The inner circumference of the electric heating plate is equipped with an Ω-shaped electric heating tube 3, and the Ω-shaped electric heating tube with a specification of 220V and 1000W is selected. The plate is casted with aluminum alloy. The right end of the electric heating plate is equipped with two electric heating tube terminal posts 4 and 5. The middle part of the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com