Patents

Literature

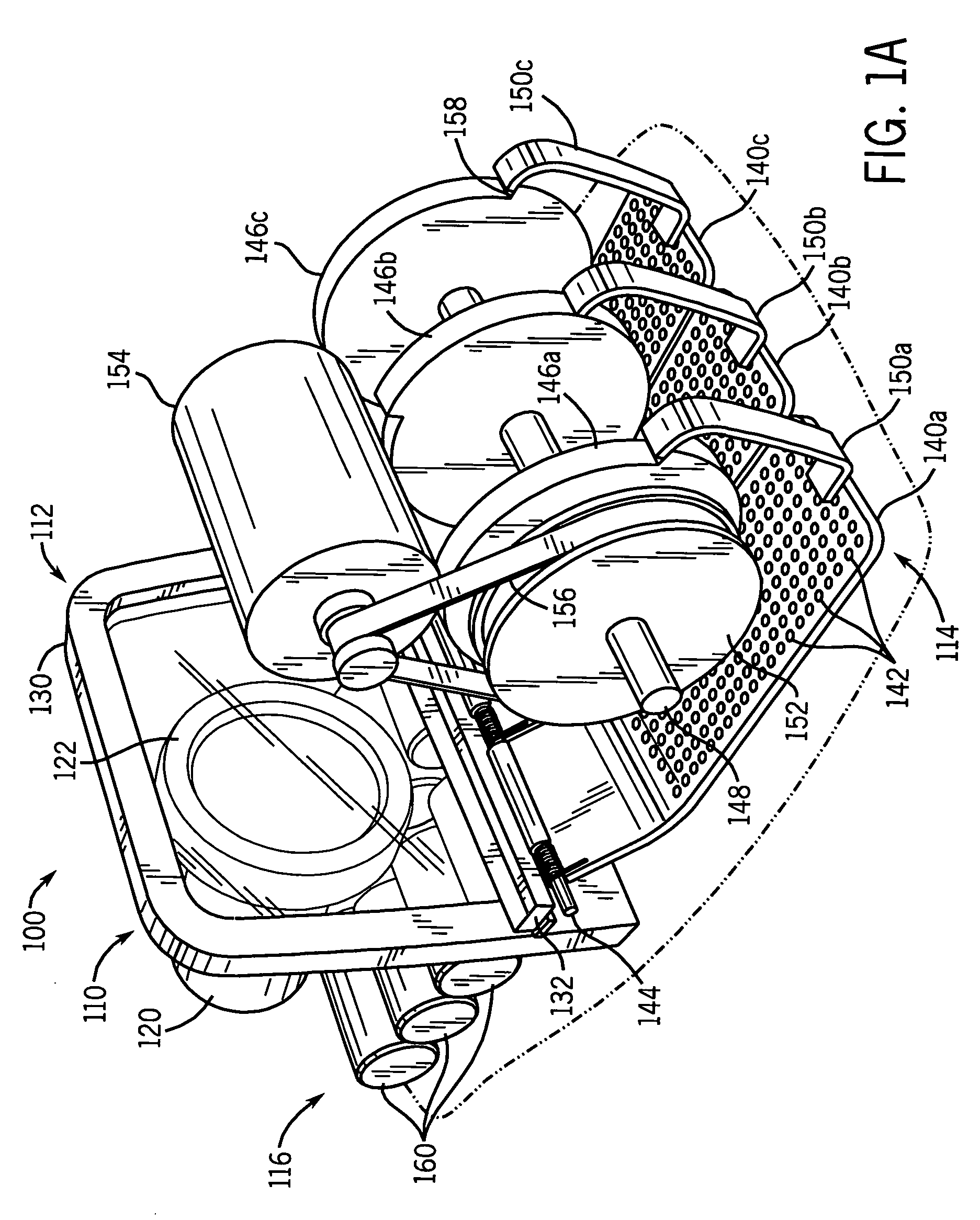

2498 results about "Mechanical devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

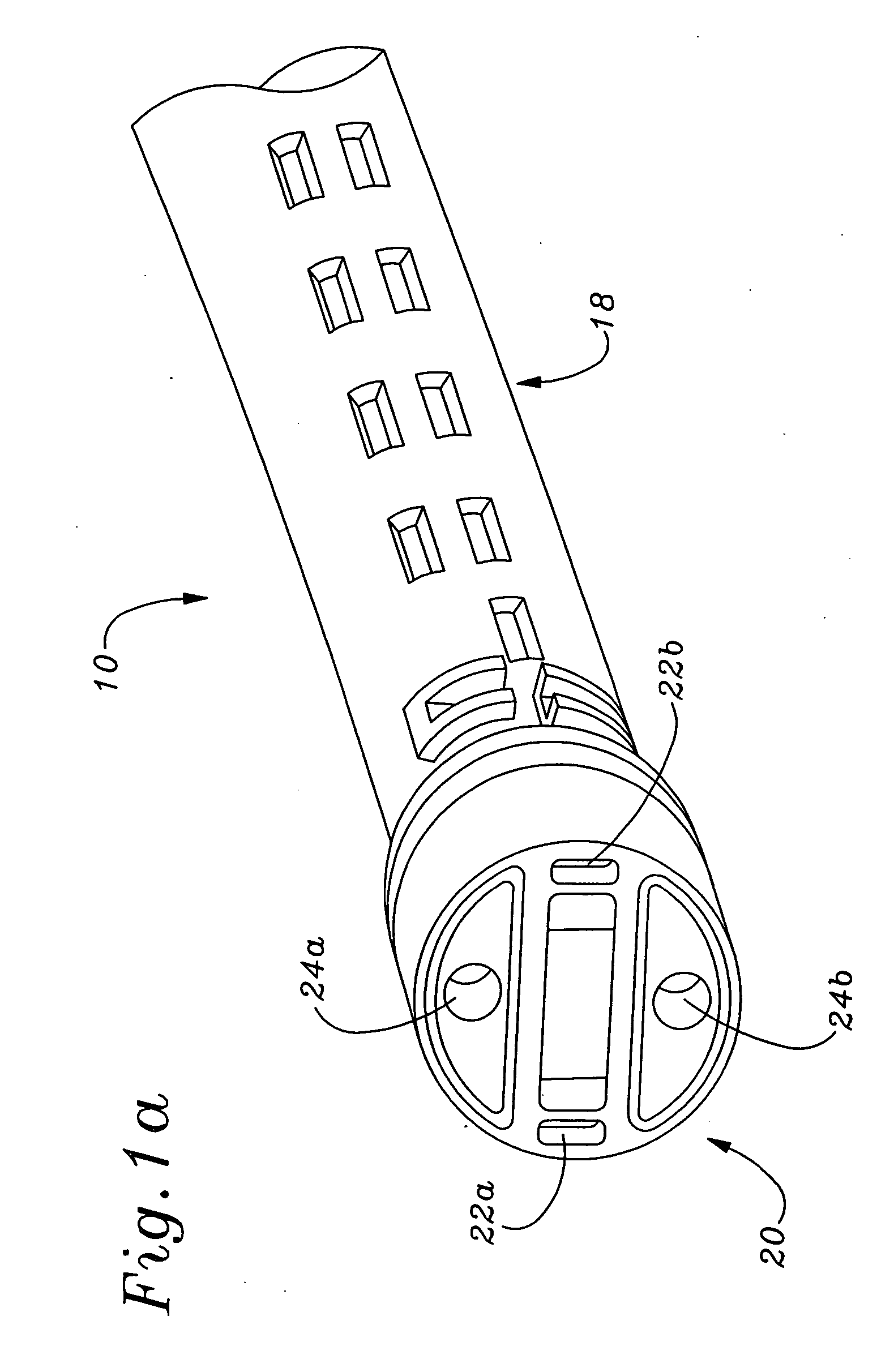

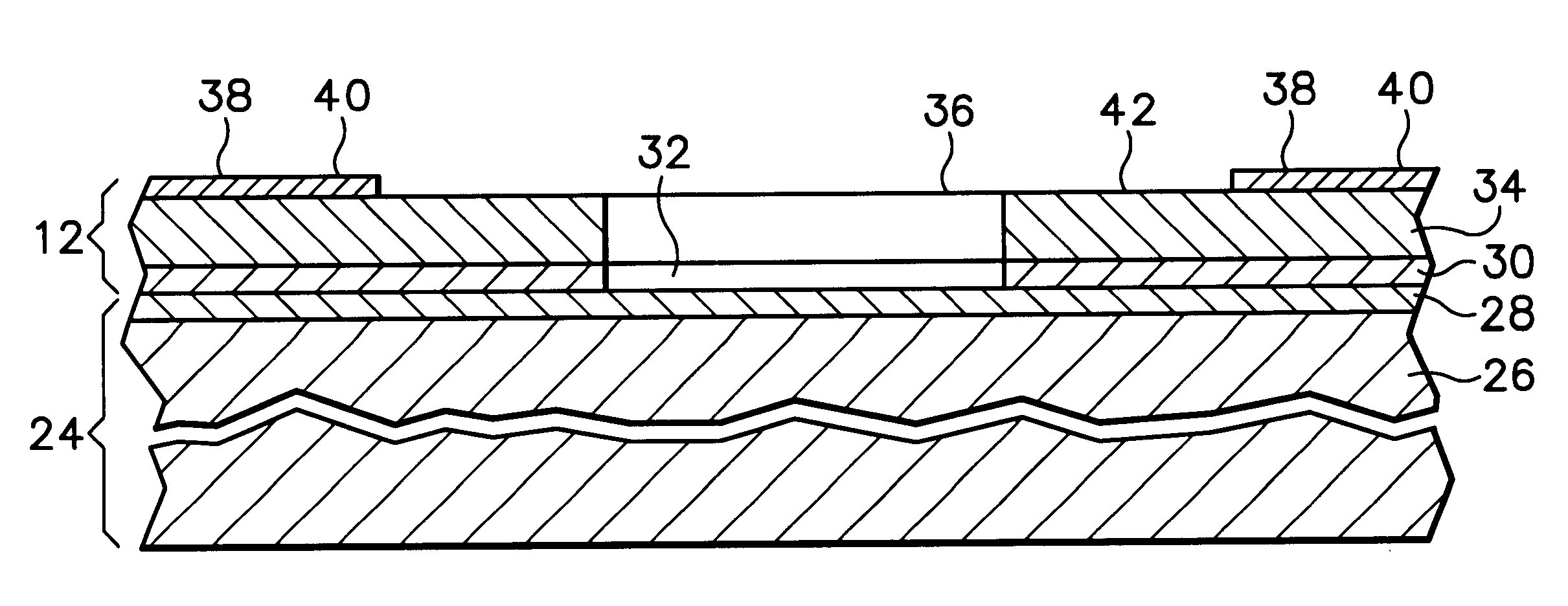

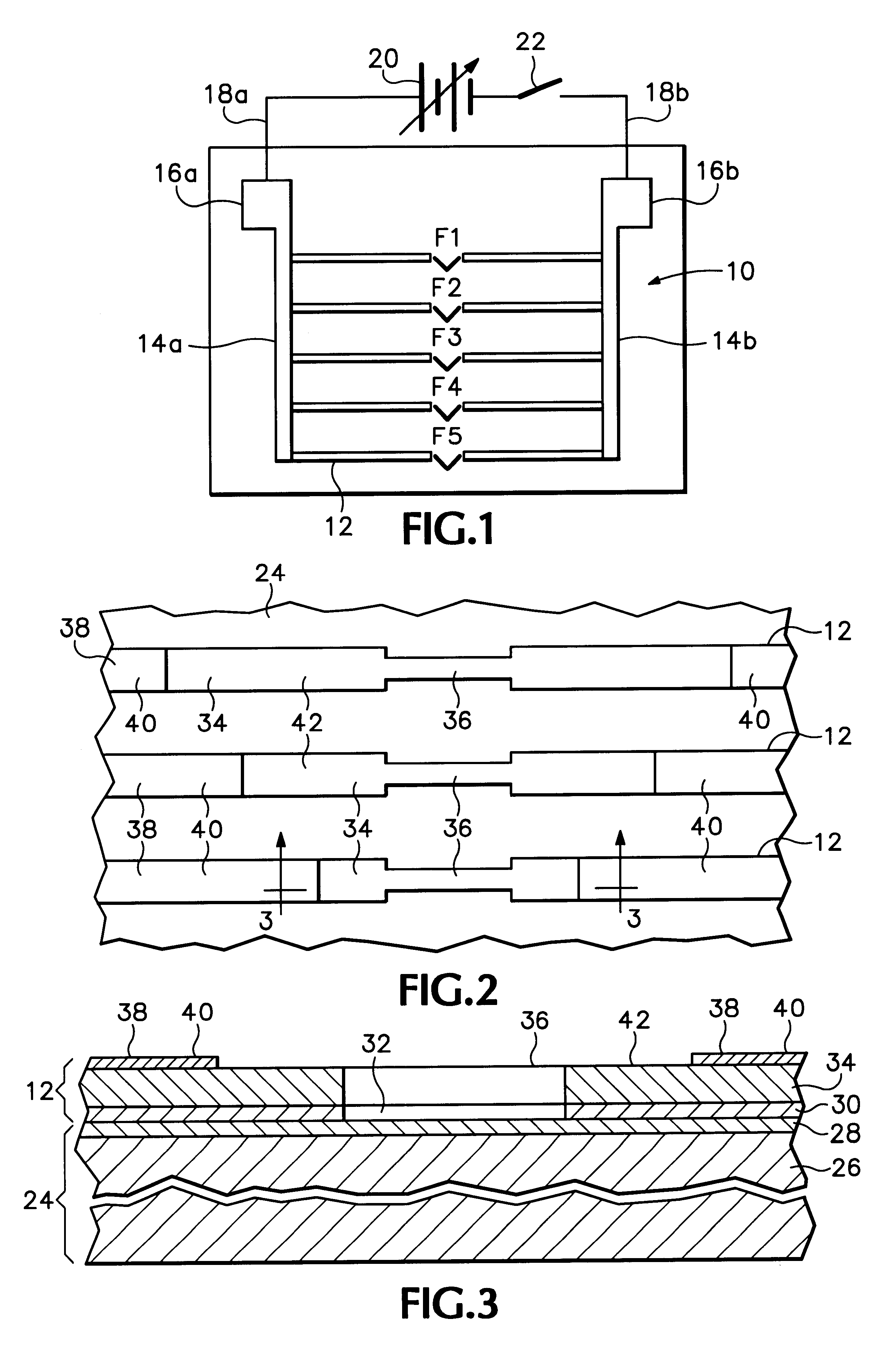

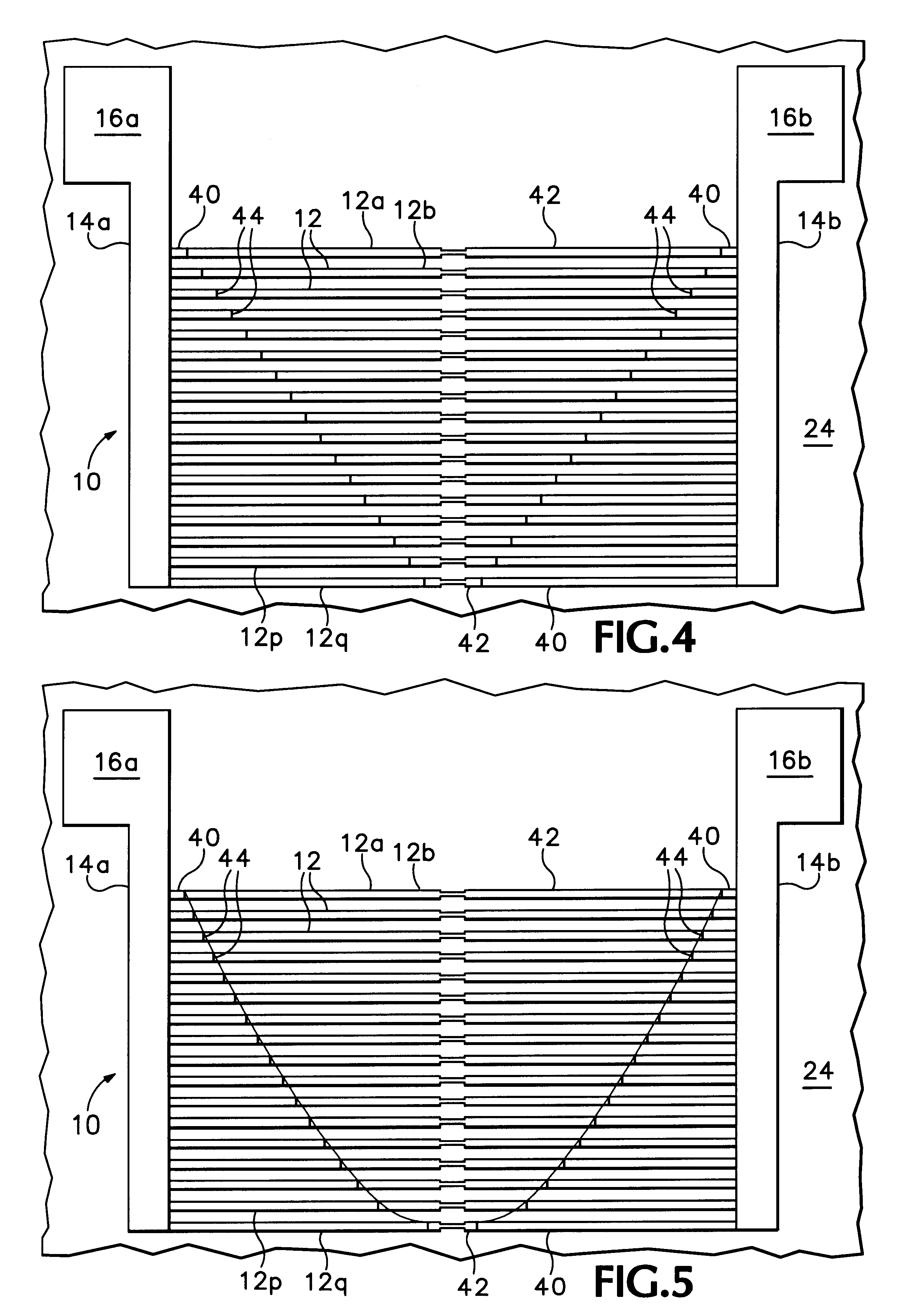

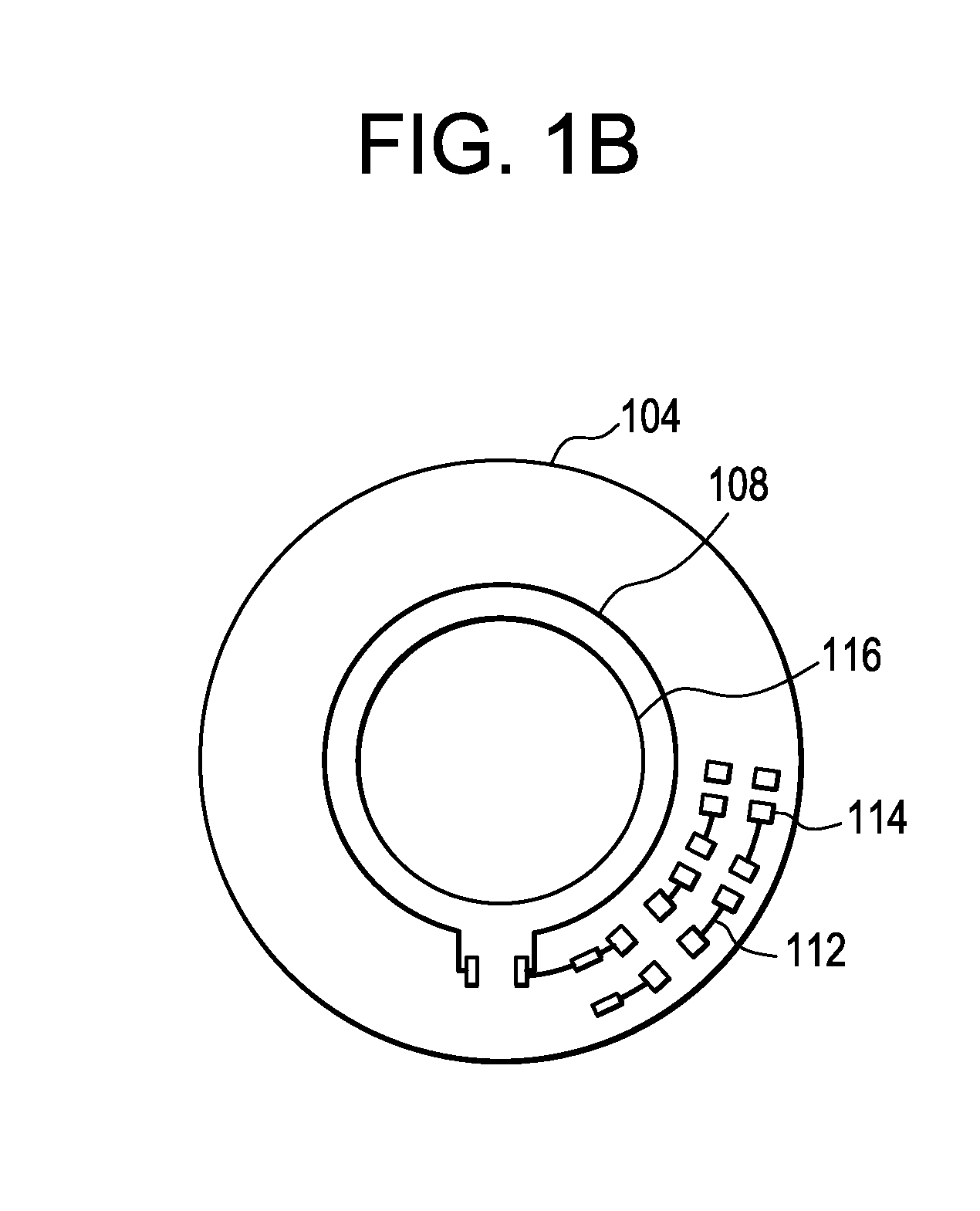

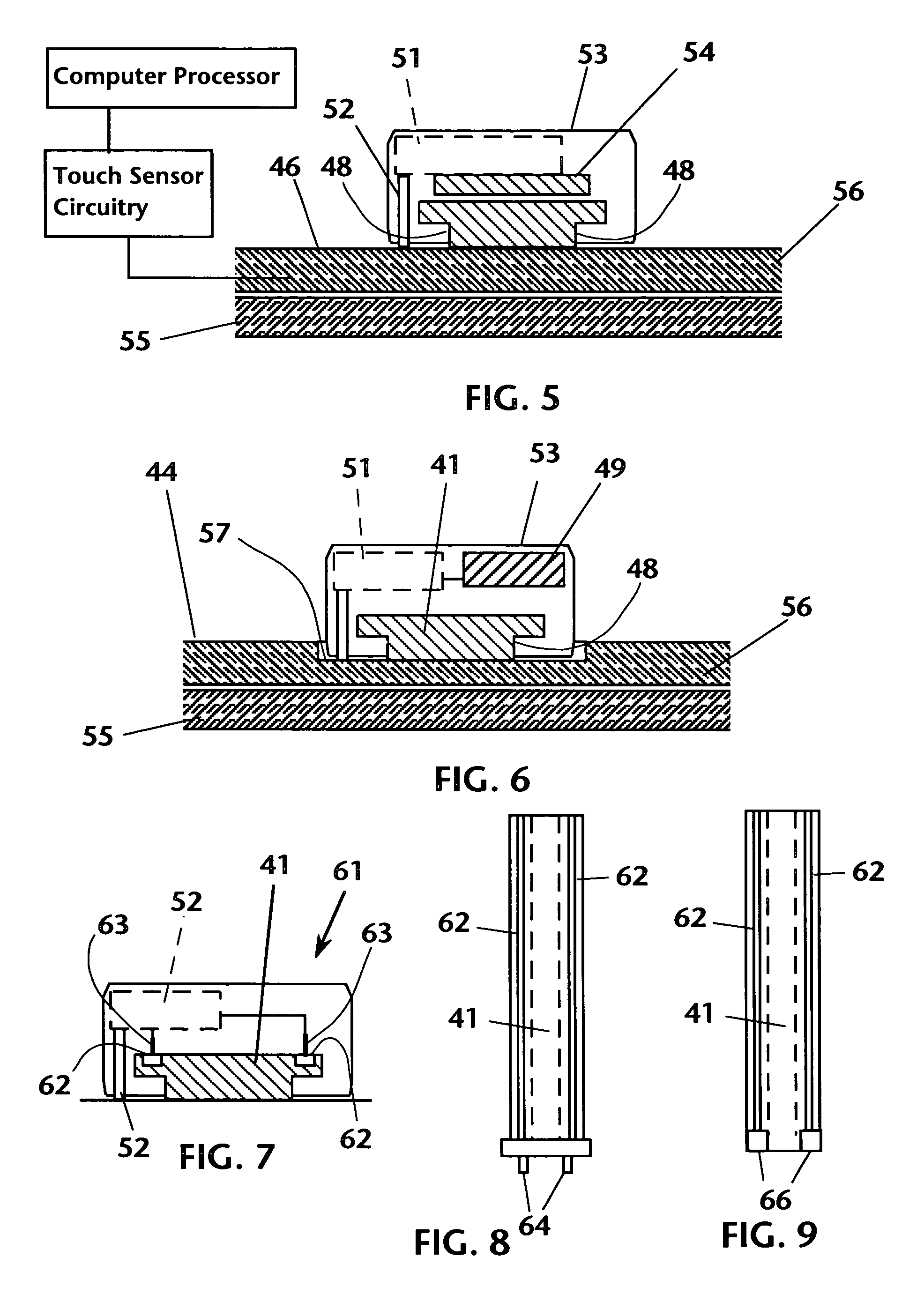

Touch sensor control devices

InactiveUS20080238879A1Not easy to connectEliminate needInput/output processes for data processingElectrical conductorJoystick

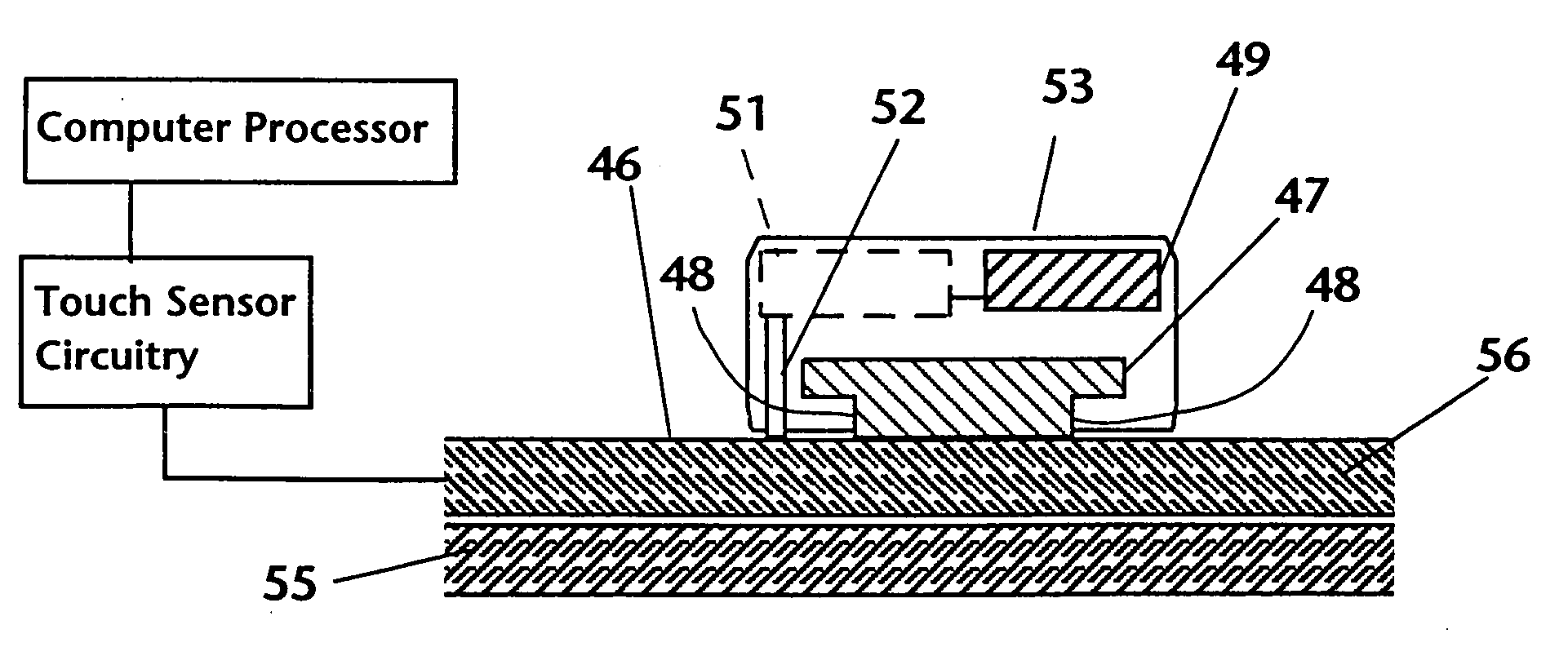

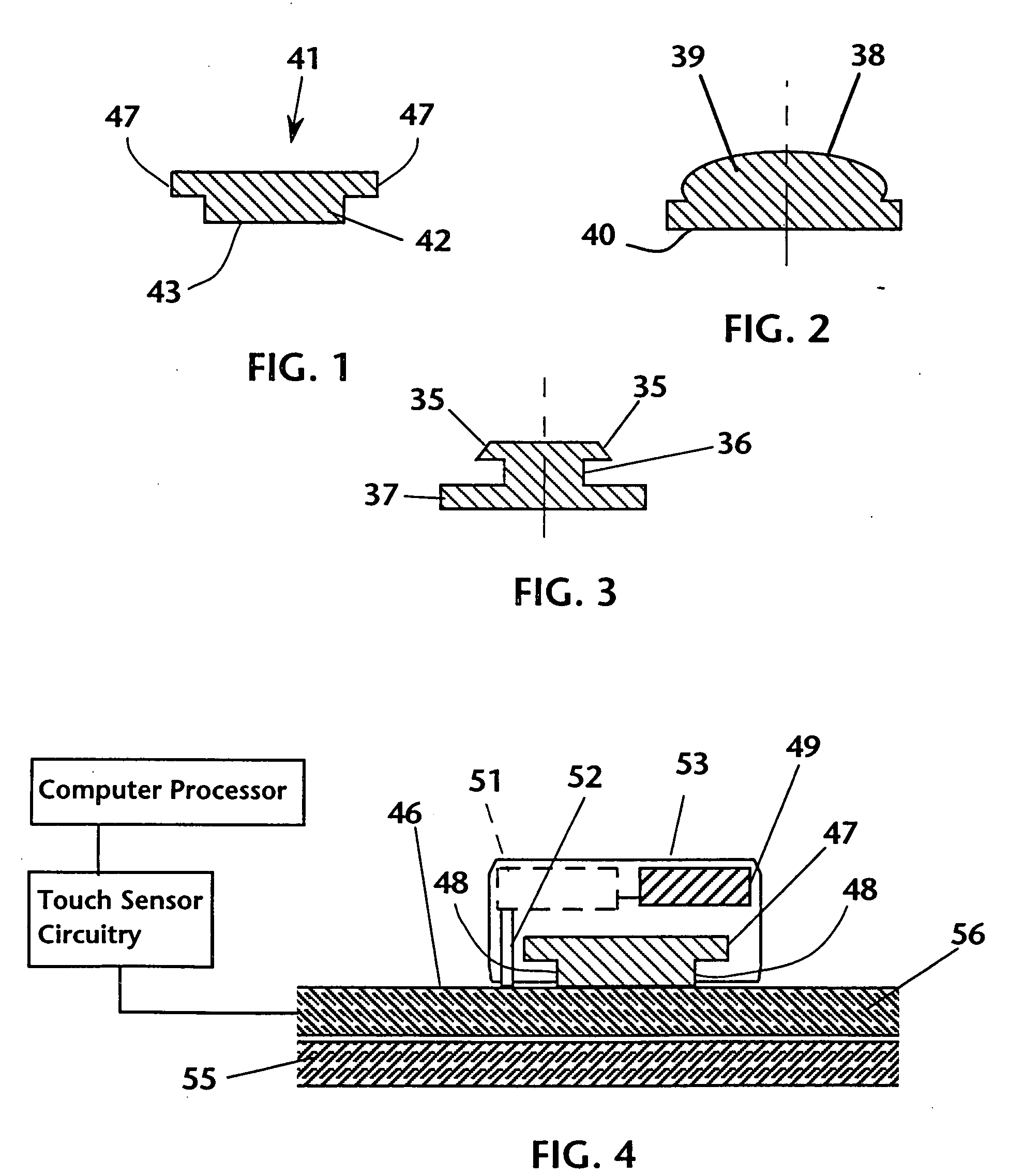

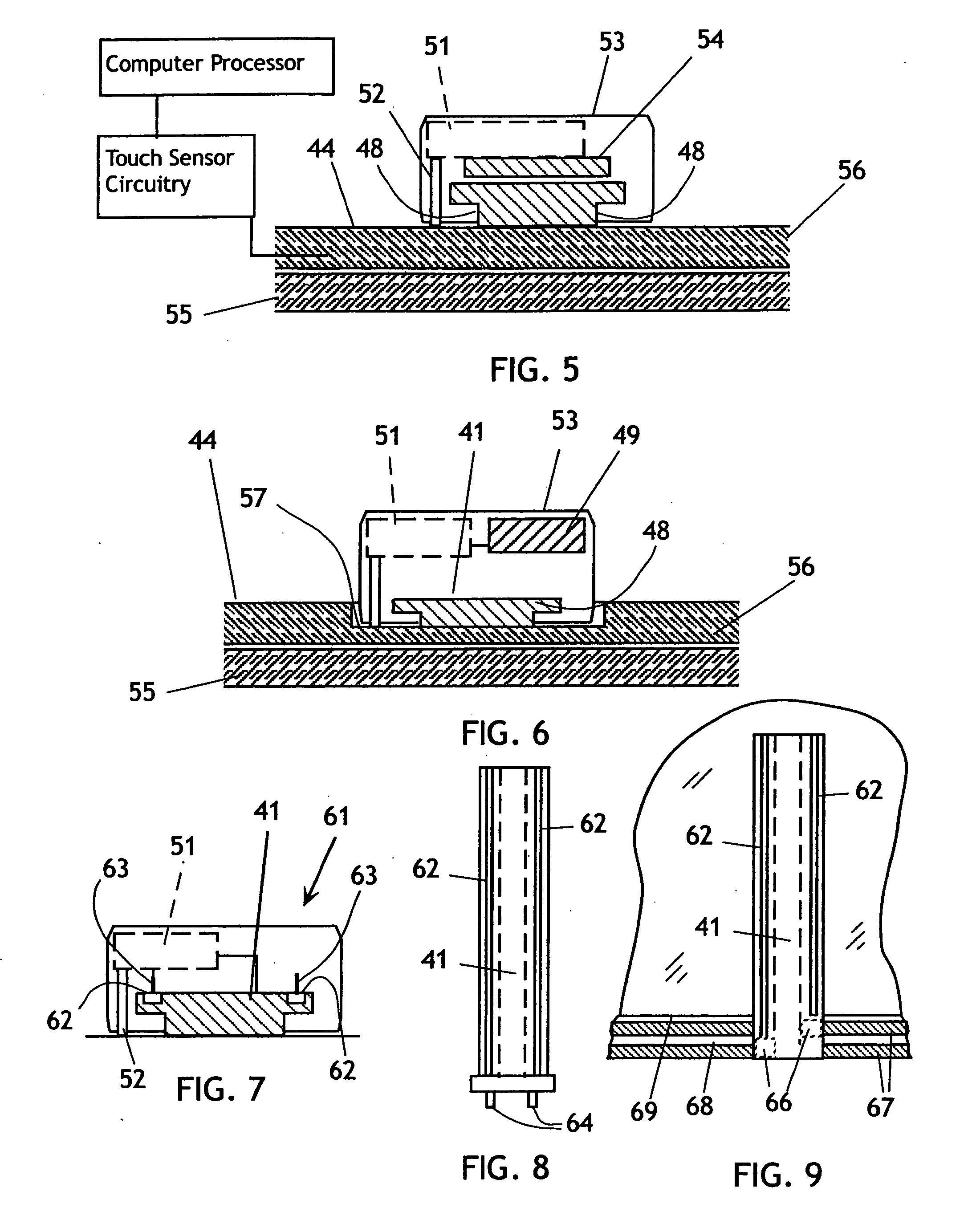

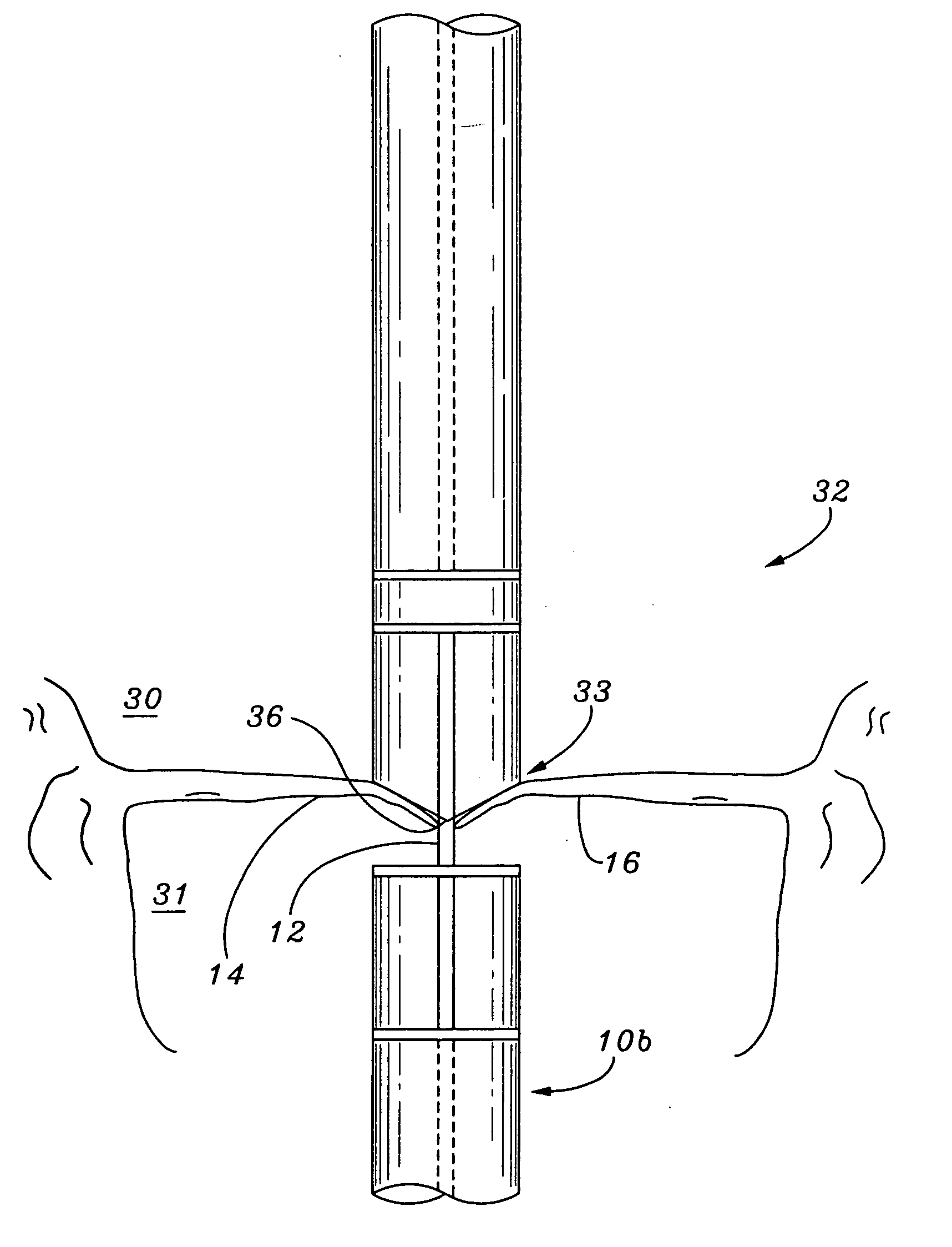

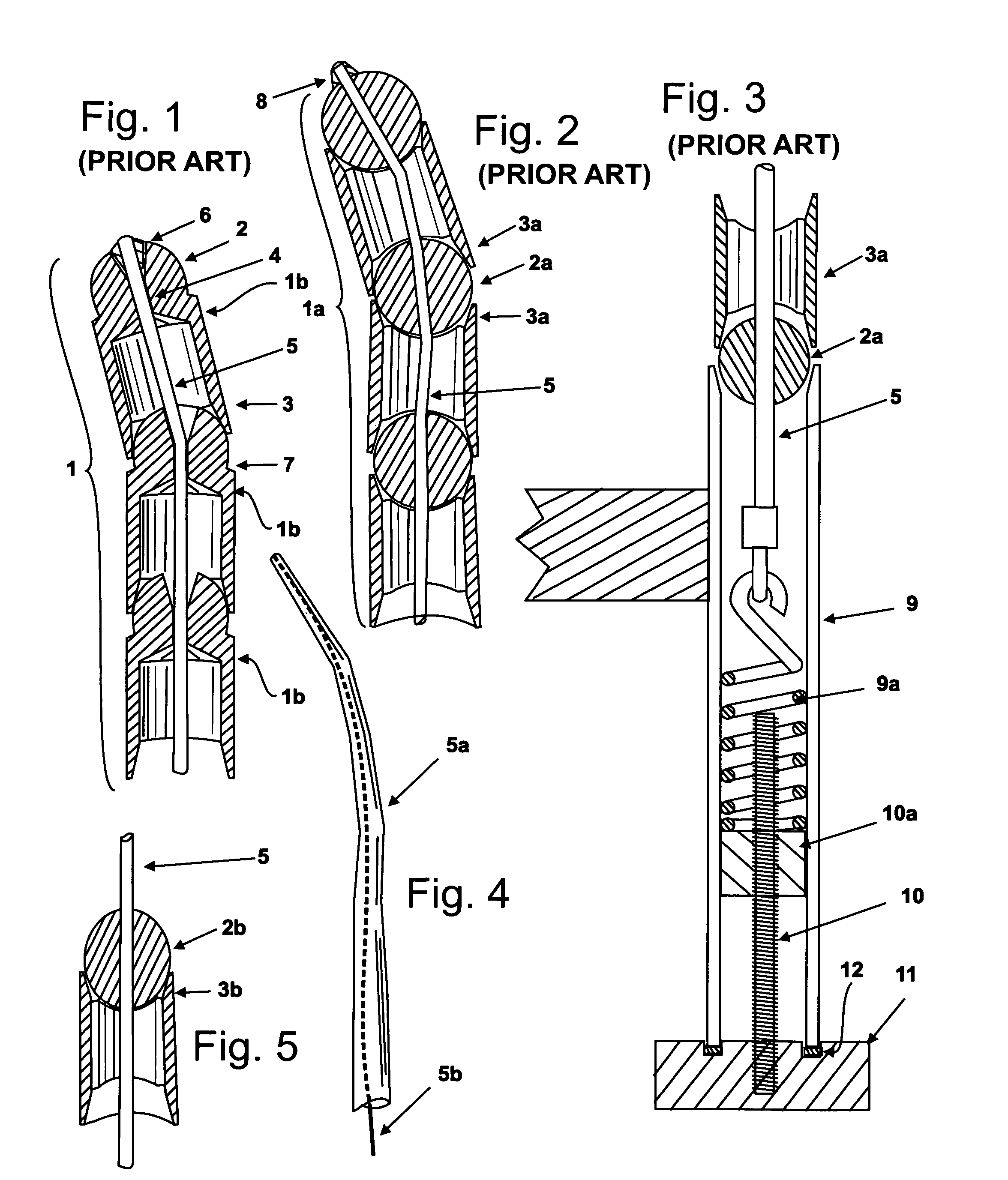

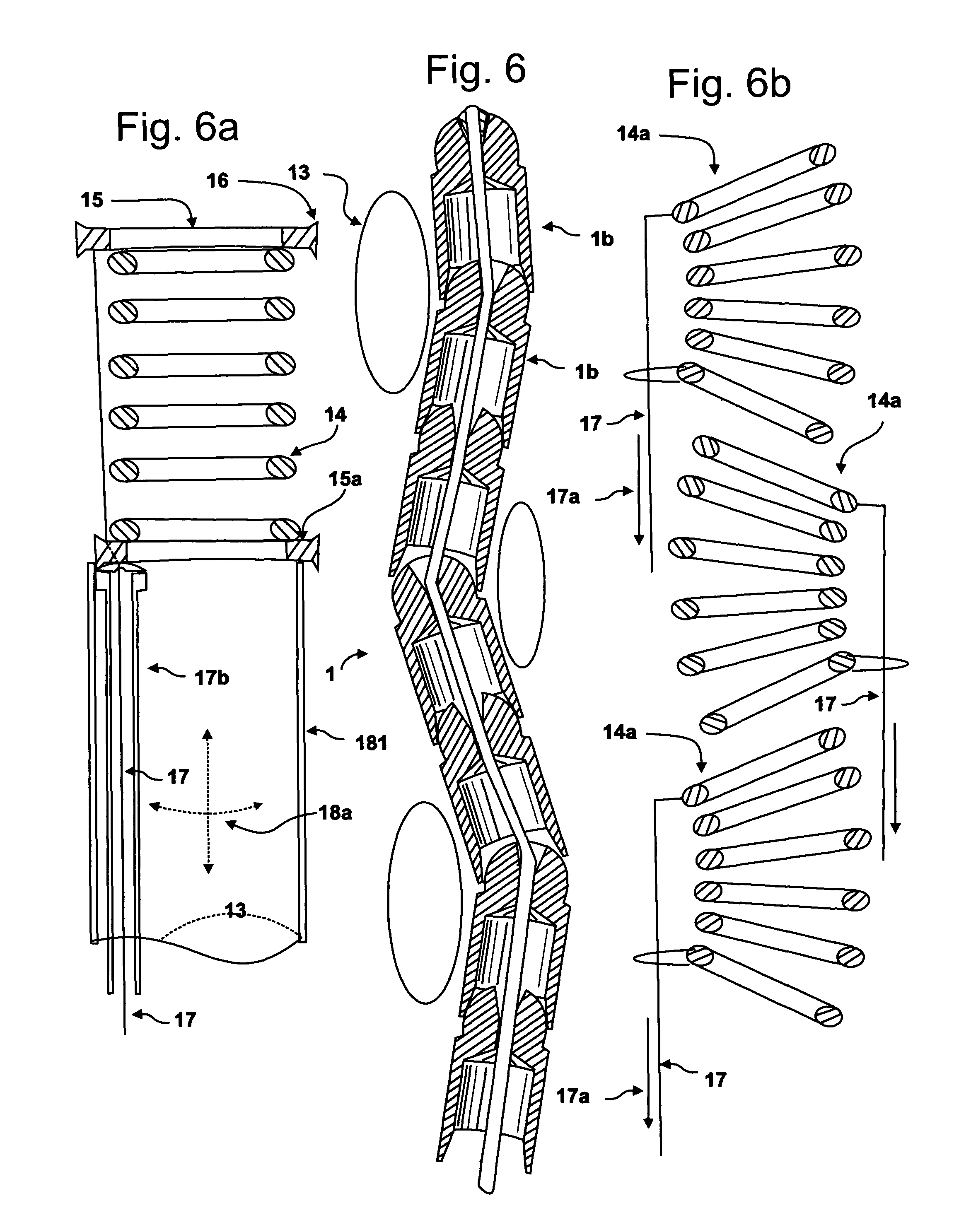

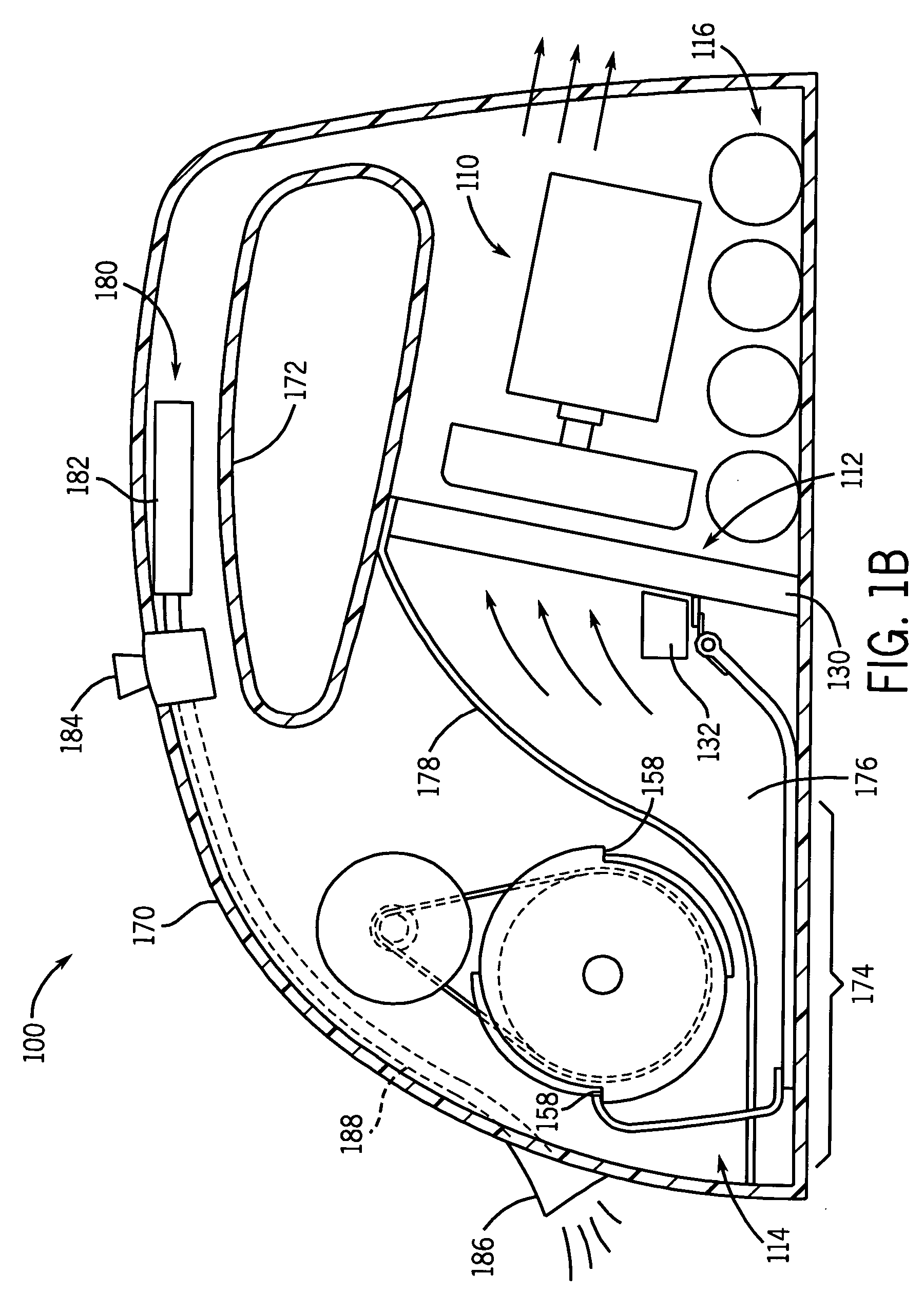

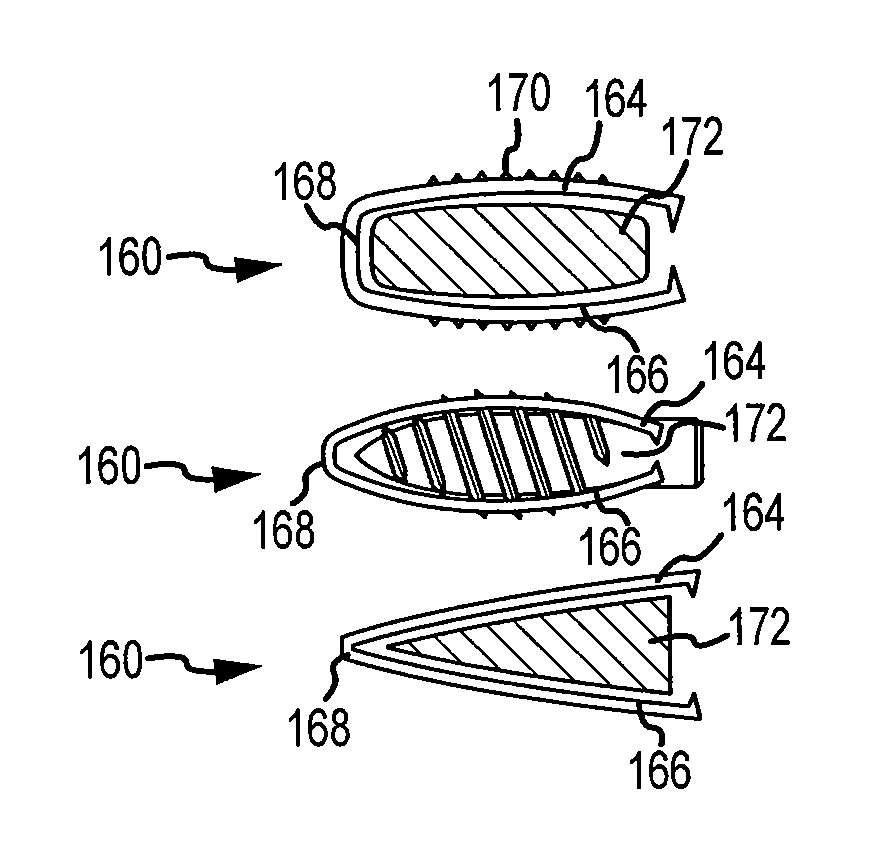

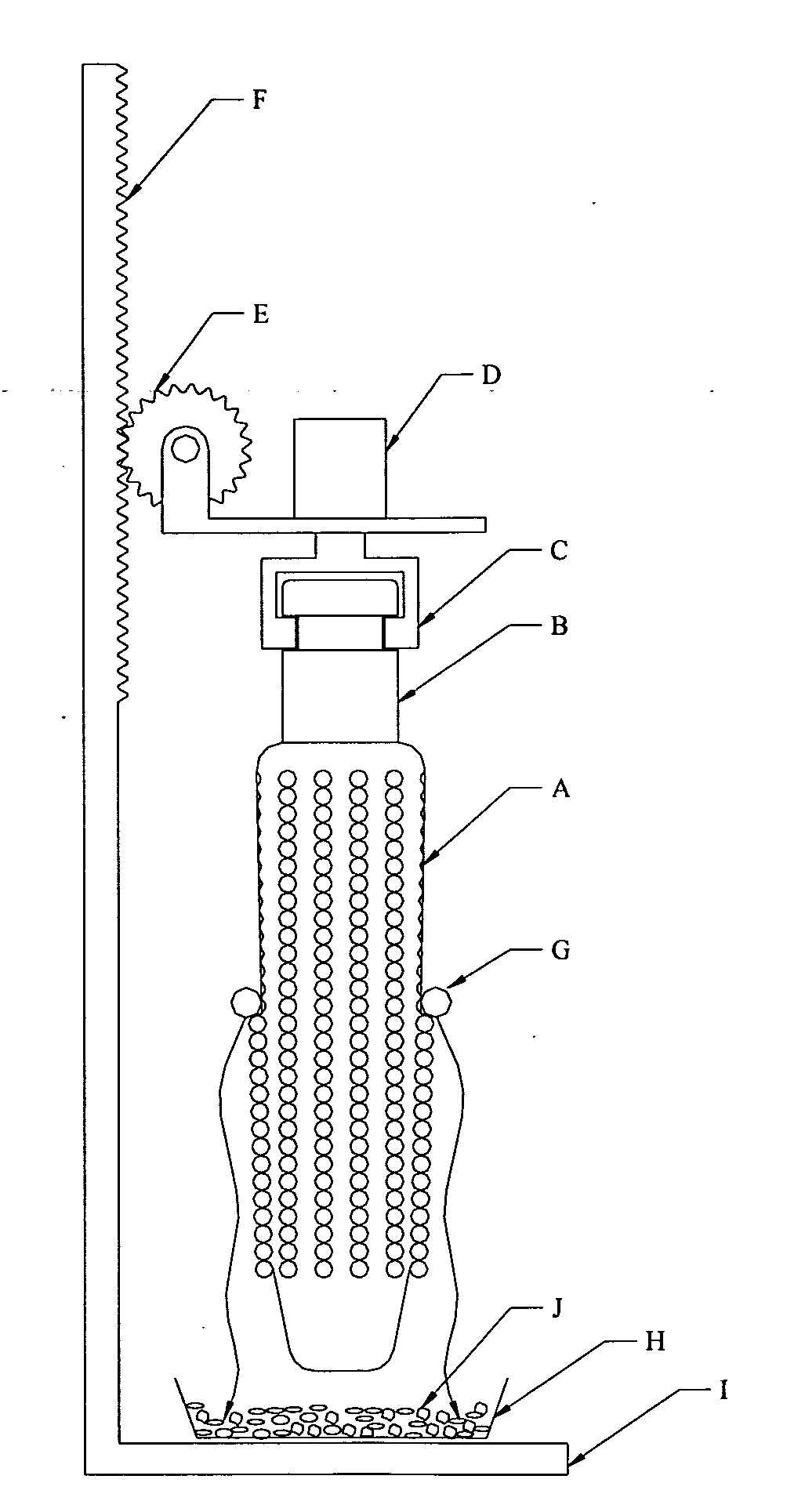

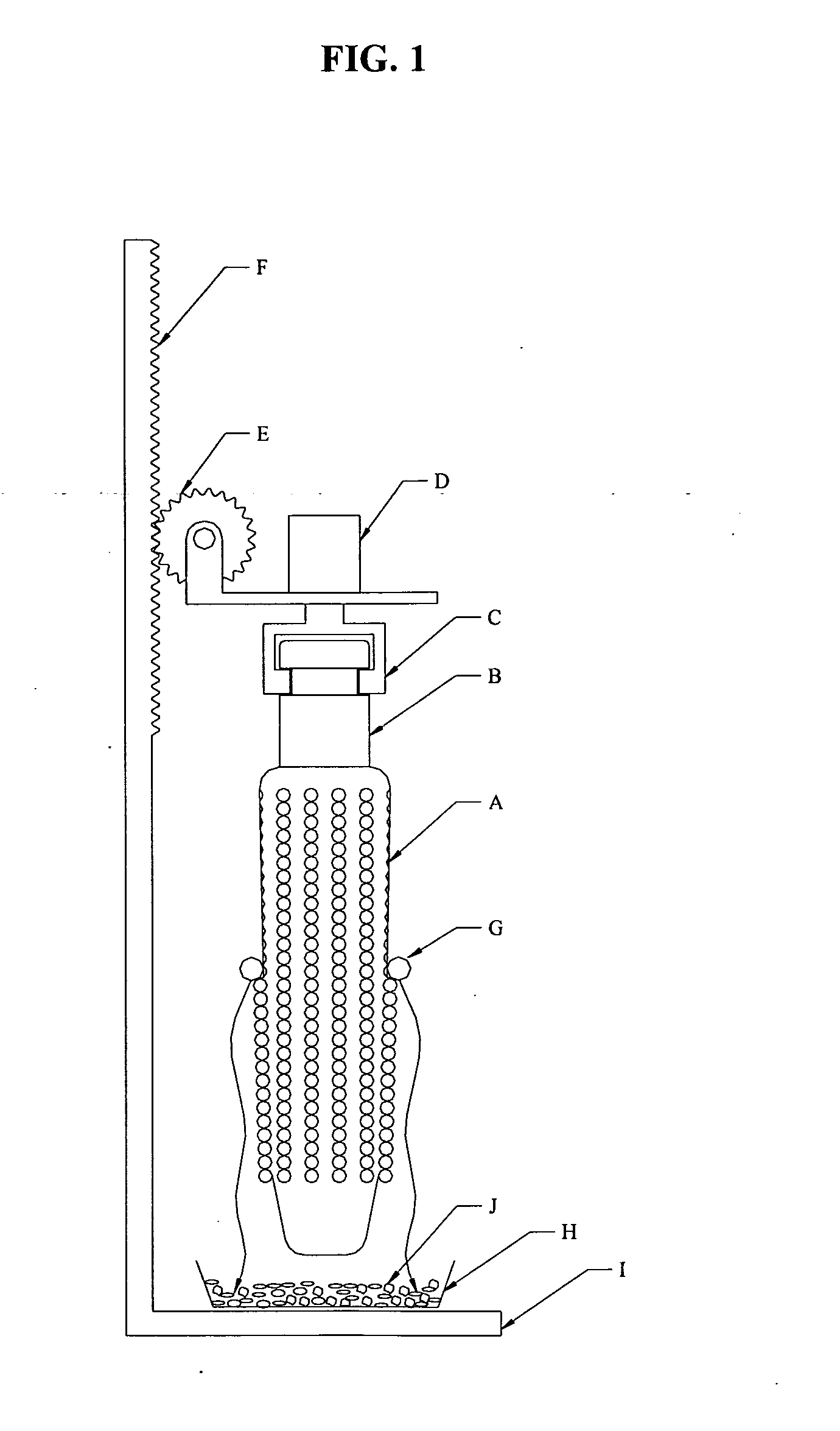

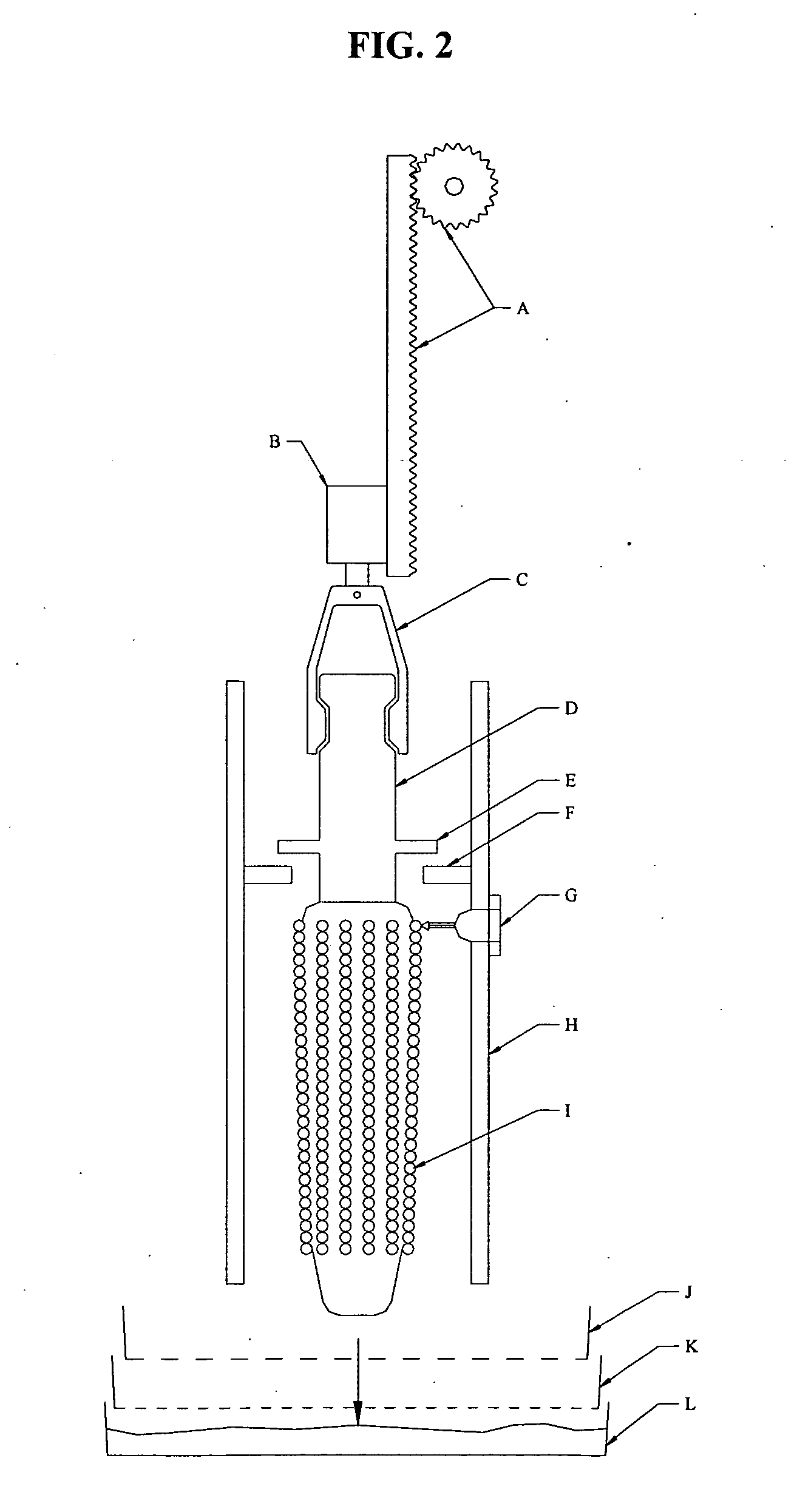

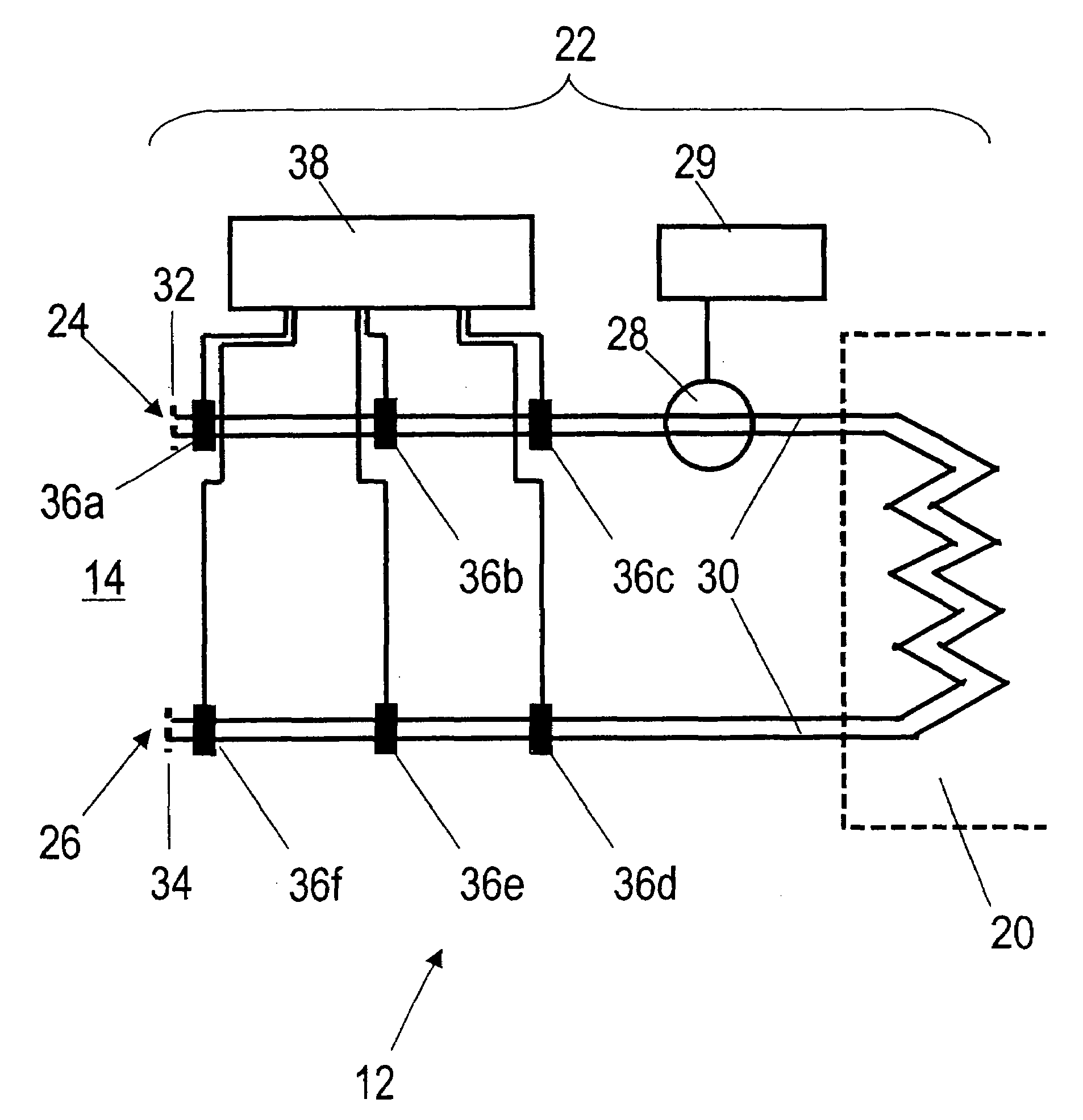

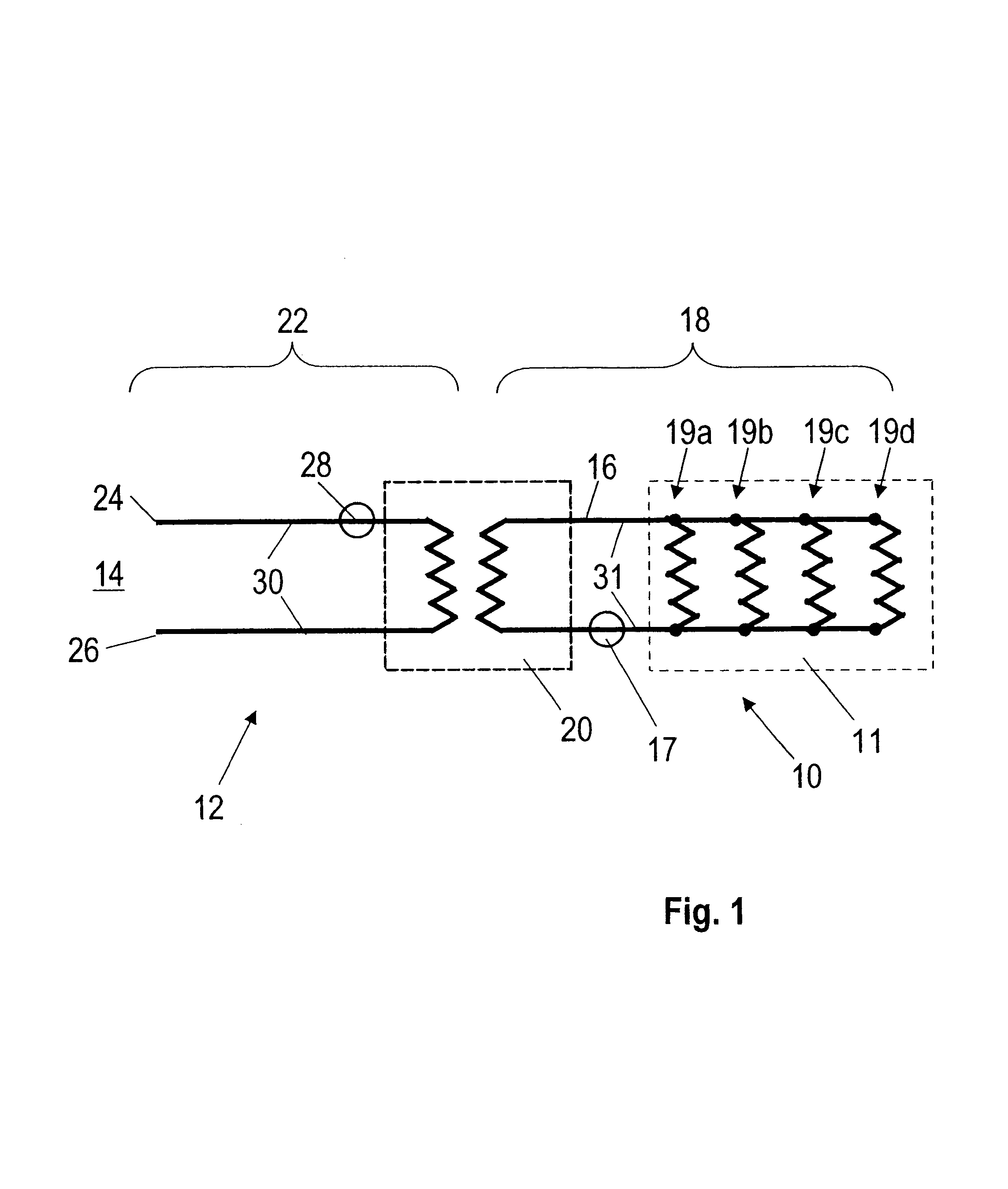

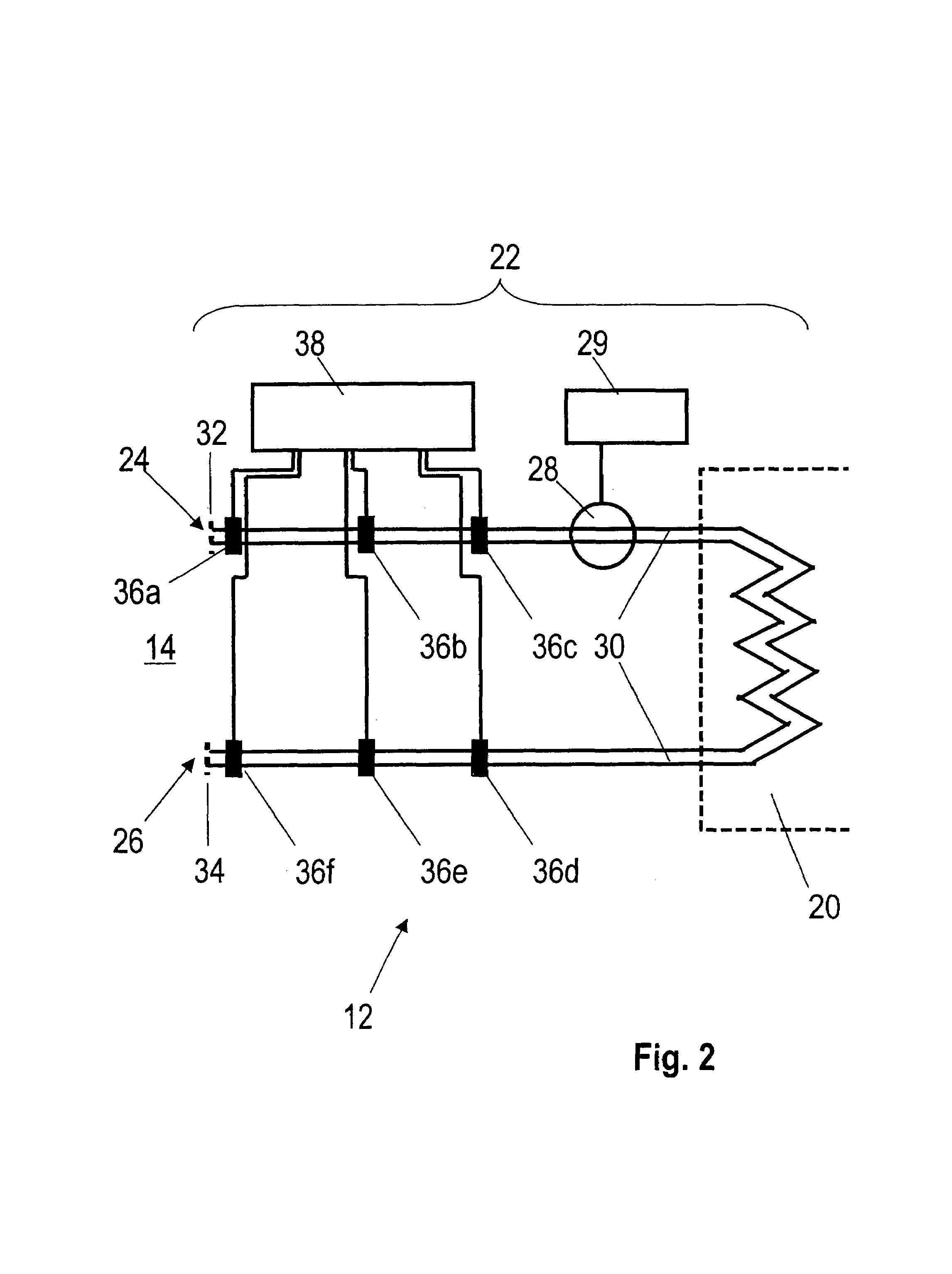

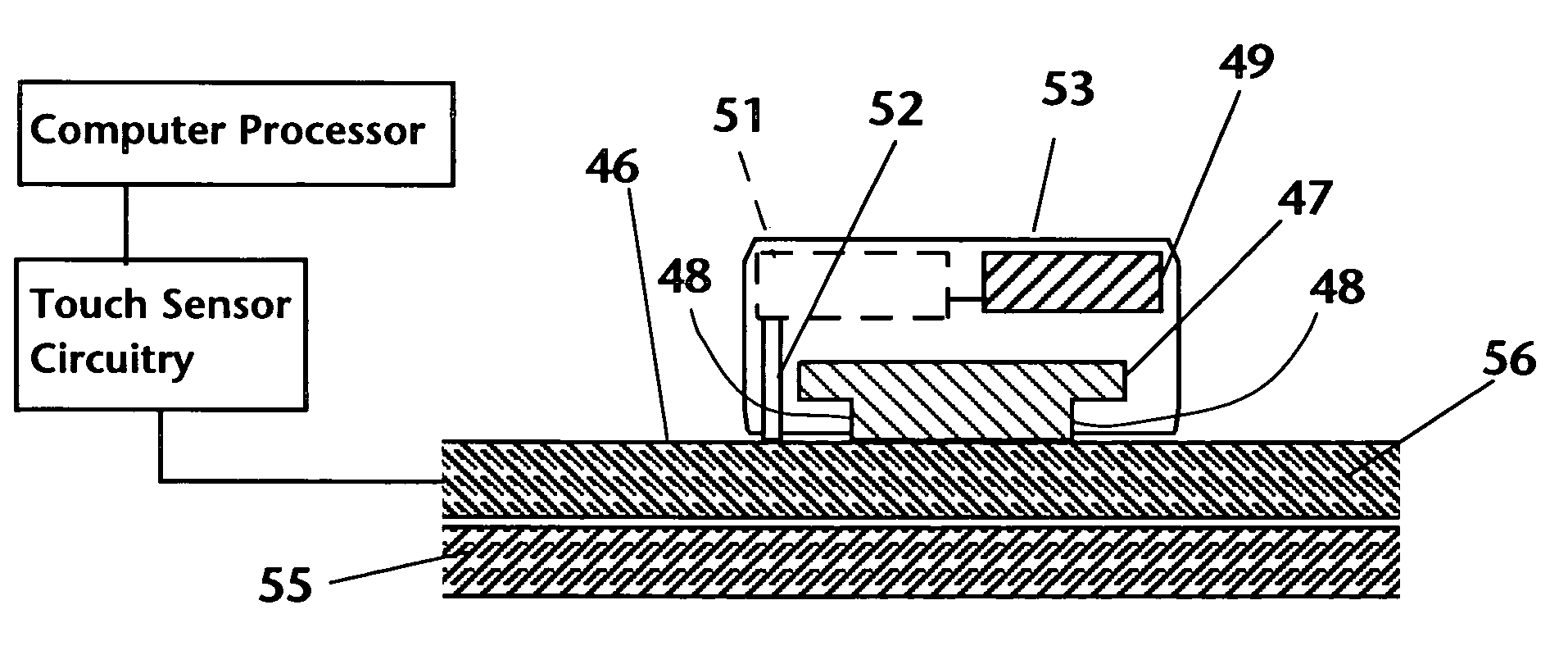

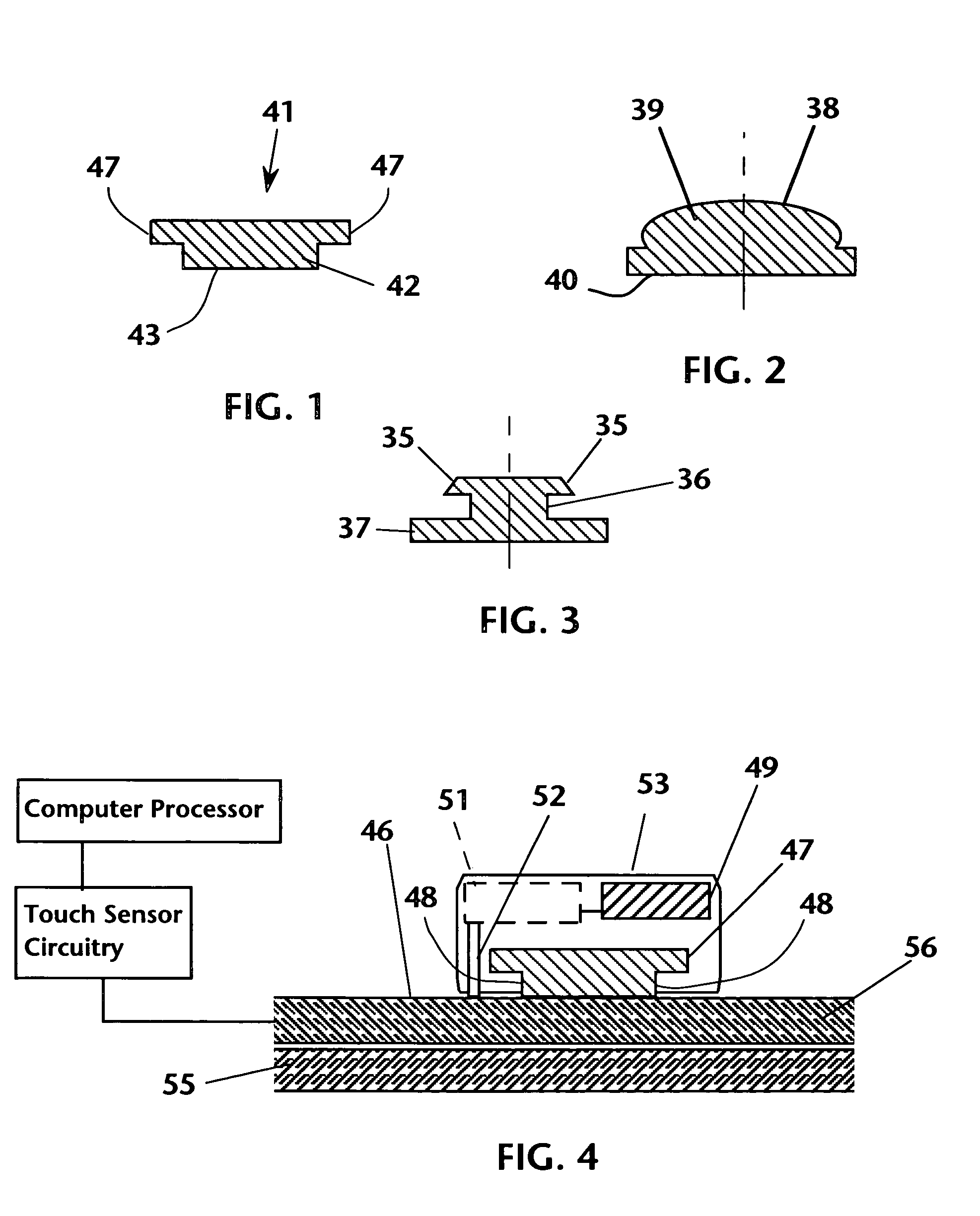

The invention provides mechanical devices to enhance the input process for touch screen devices. Fader tracks with or without fader caps, rotary and fixed knobs, and joysticks may be removably adhered to a touch screen and used to emulate their respective functions, using software interpretation of the touch detections provoked by the devices to carry out the emulations. The devices are inexpensive and simple, and the touch screen and associated software provide the function and feel of electromechanical controllers that are far more expensive and difficult to connect and maintain. The devices may be provided as components on a crack-and-peel sheet. For fixed knobs, the software application accepts initial inputs and determines the location on the touch screen, and also interprets the geometry of the input strokes as commands for selected controller emulations, such as joystick, fader, knob, or mouse. The invention also provides a touch sensor controller having a longitudinal web that incorporates touch sensor electrodes and conductors and emulates a fader controller. The invention further provides a flexible track controller mounted at the periphery of a touch screen and extendable thereover to emulate a fader controller. The flexible track may be motor driven.

Owner:JAEGER DENNY +2

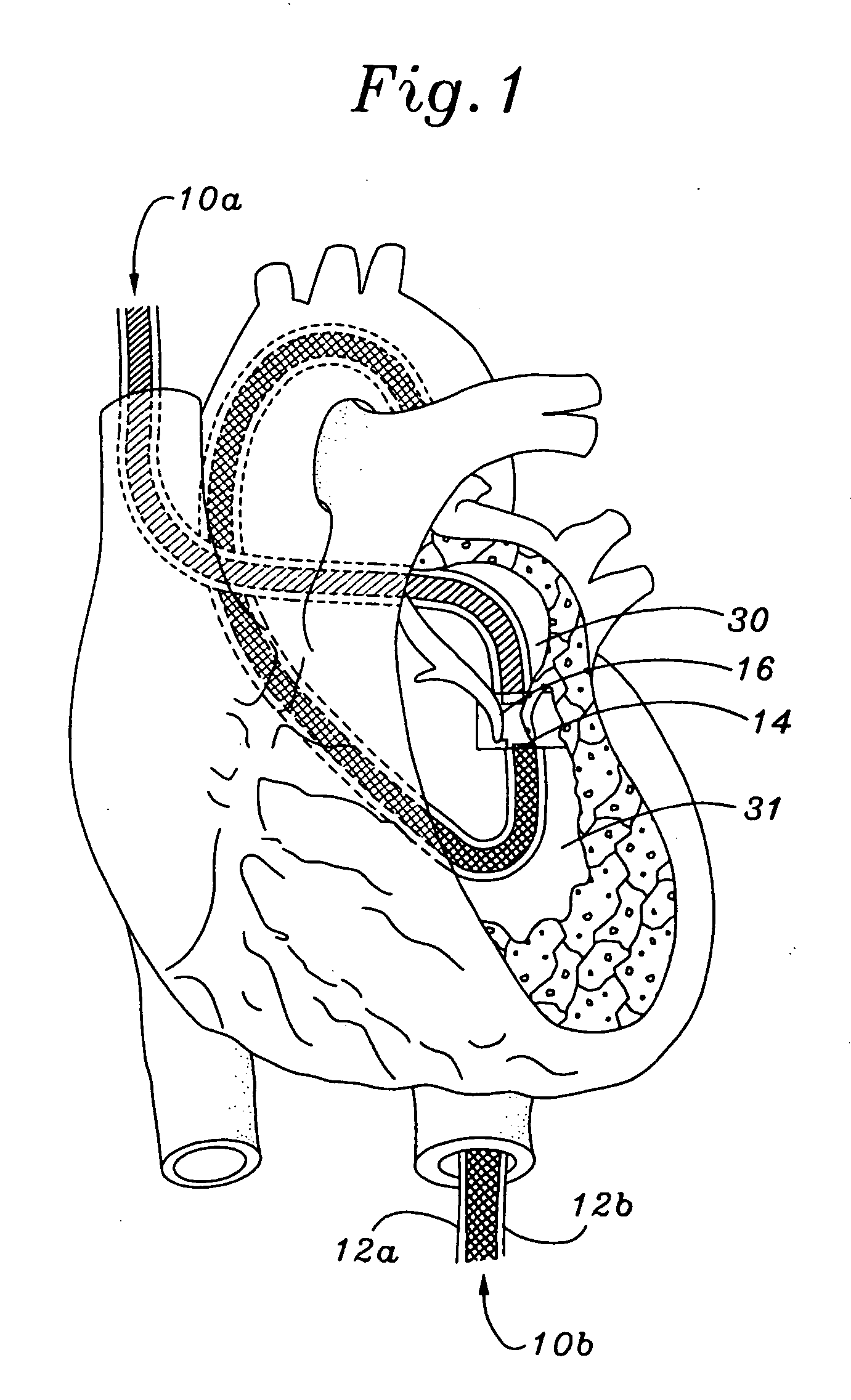

Method and system for tissue repair using dual catheters

The present system is directed to a method and system to stabilize and repair tissue. At least two opposing devices may be used to stabilize and repair the tissue, with the two devices cooperatively engaging the tissue interposed therebetween. Stabilization may be accomplished by opposing force, vacuum force, or mechanical devices disposed at the distal portion of one or both devices. After the tissue has been stabilized, fasteners may be deployed into the tissue. Fasteners include sutures, clips, and staples. Also disclosed is a minimally invasive method of accessing tissue located within a body and conducting a repair of the area using the system disclosed herein.

Owner:SCHRECK STEFAN G +7

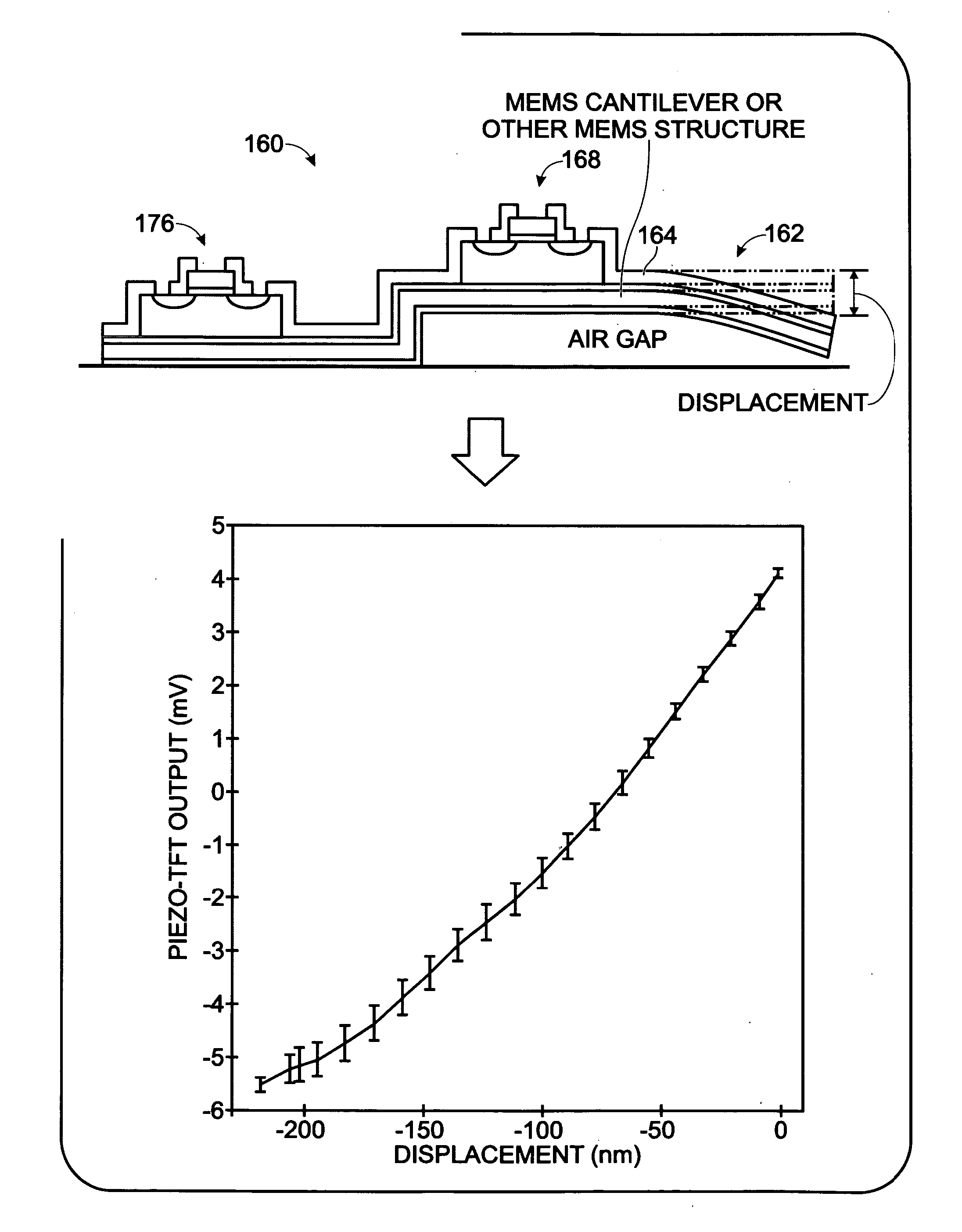

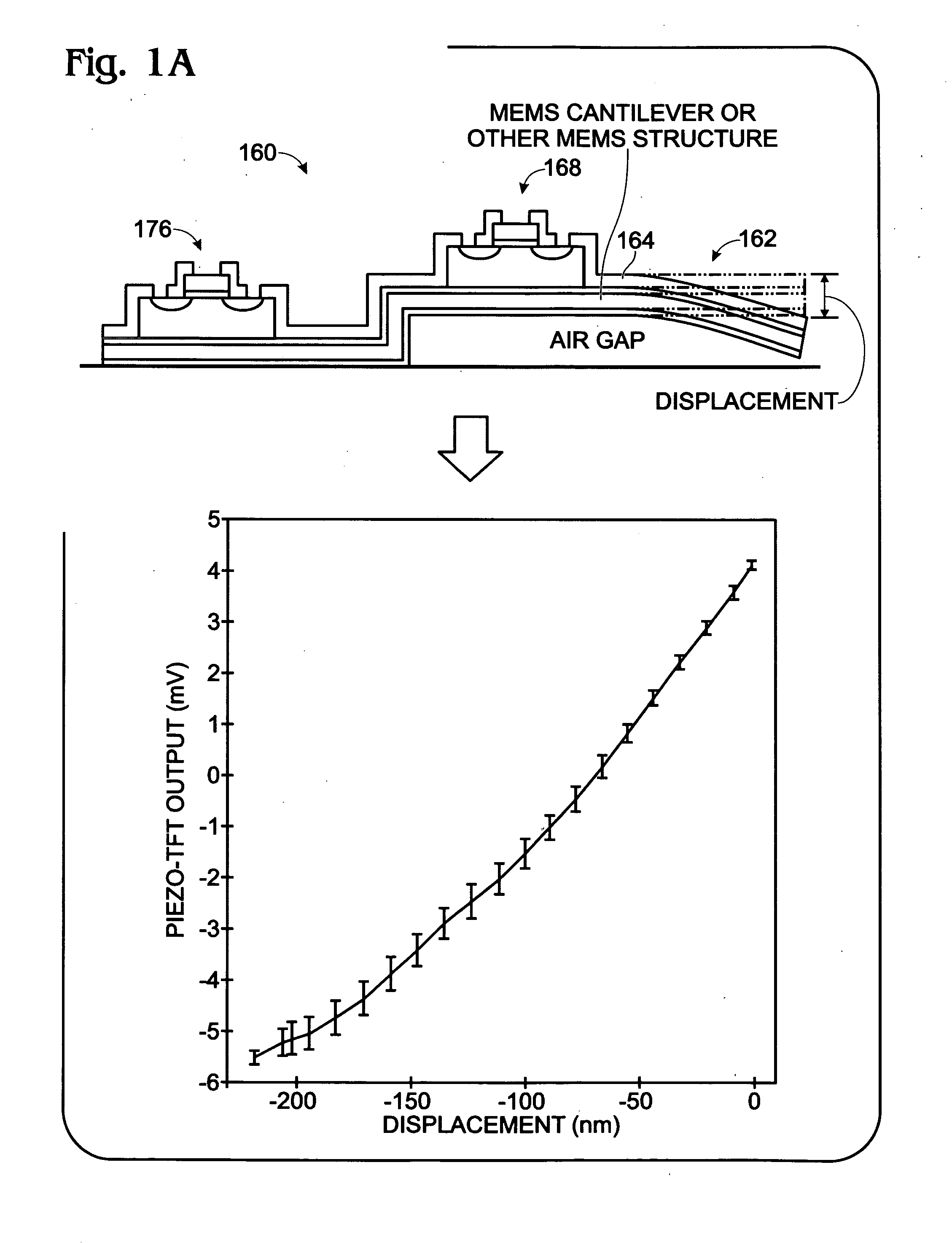

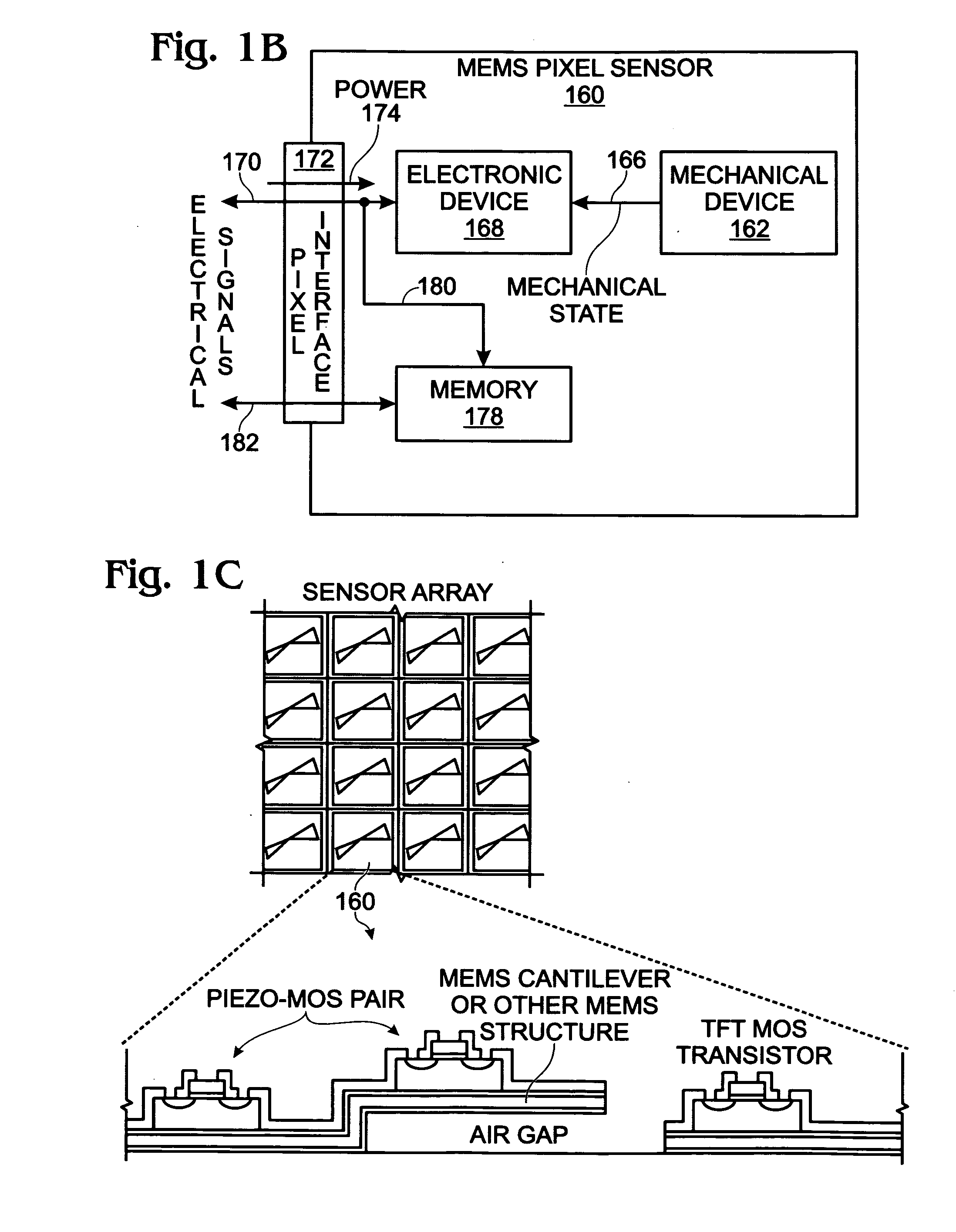

MEMS pixel sensor

InactiveUS20070023851A1Piezoelectric/electrostrictive microphonesSolid-state devicesBroadbandElectron

A MEMS pixel sensor is provided with a thin-film mechanical device having a mechanical body, with a mechanical state responsive to a proximate environment. A thin-film electronic device converts the mechanical state into electrical signals. A pixel interface supplies power to the electronic device and transceives electrical signals. The sensor is able to operate dynamically, in real-time. For example, if the mechanical device undergoes a sequence of mechanical states at a corresponding plurality of times, the electronic device is able to supply a sequence of electrical signals to the pixel interface that are responsive to the sequence of mechanical states, at the plurality of times. Each MEMS pixel sensor may include a number of mechanical devices, and corresponding electronic devices, to provide redundancy or to measure a broadband response range.

Owner:SHARP KK

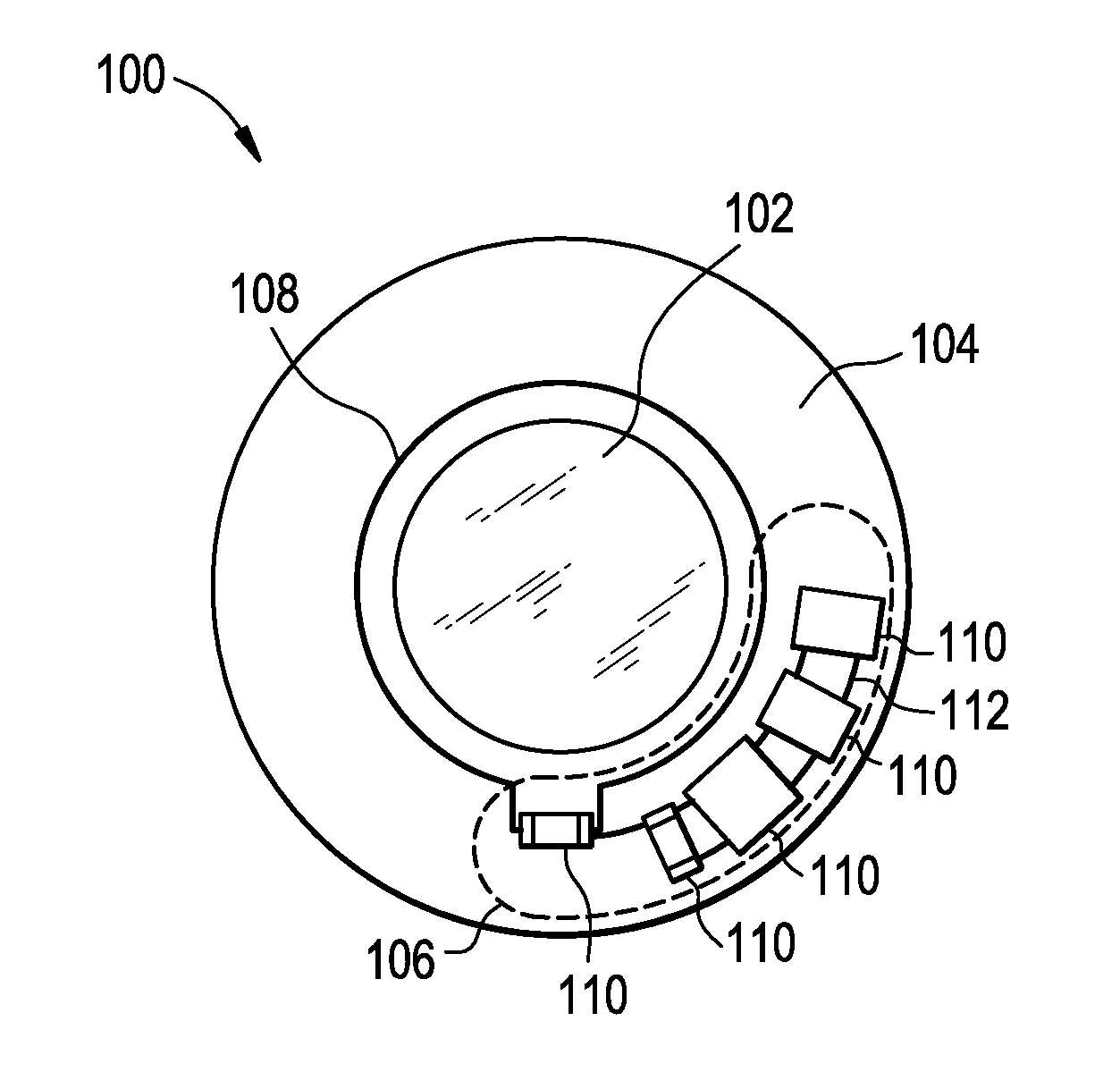

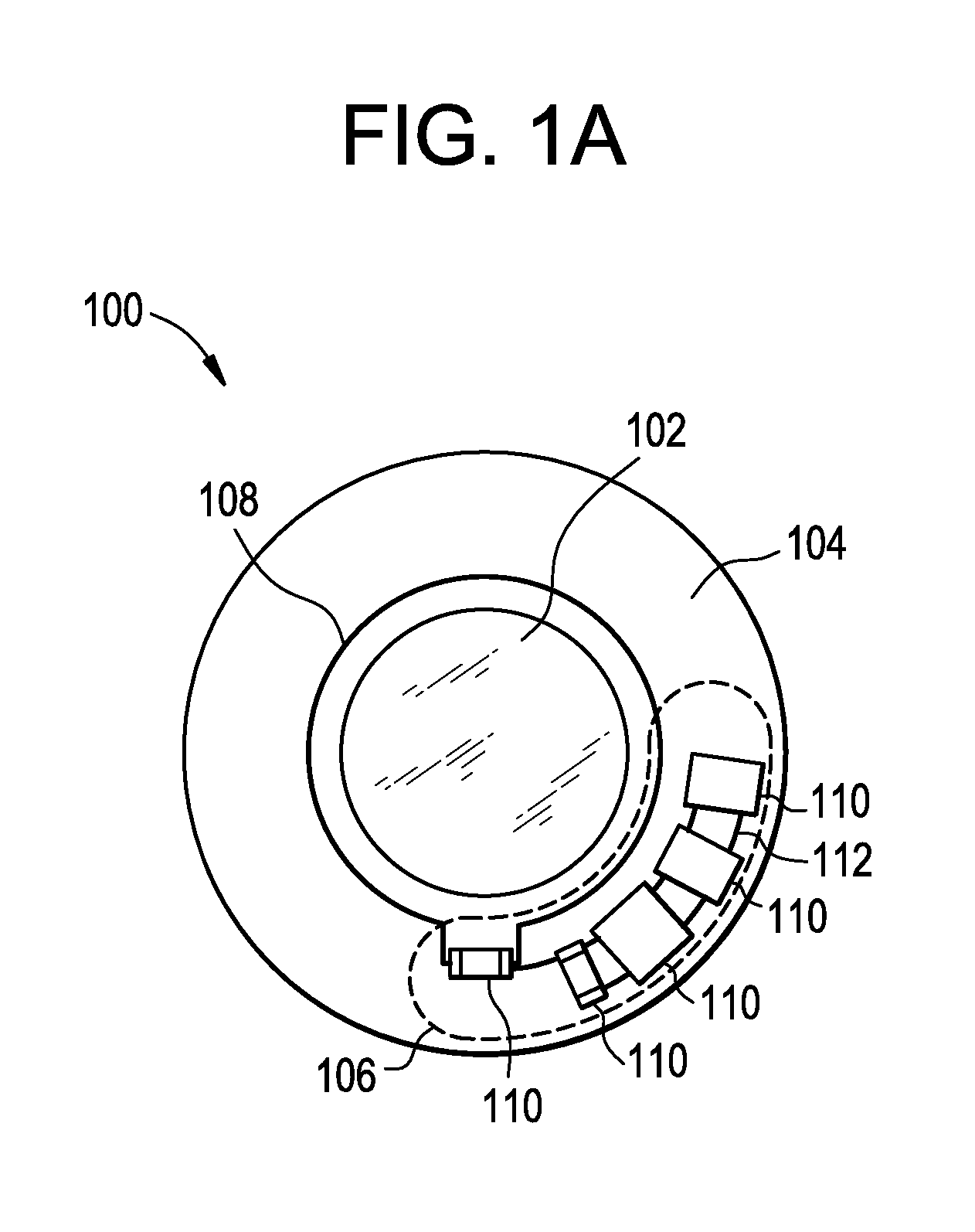

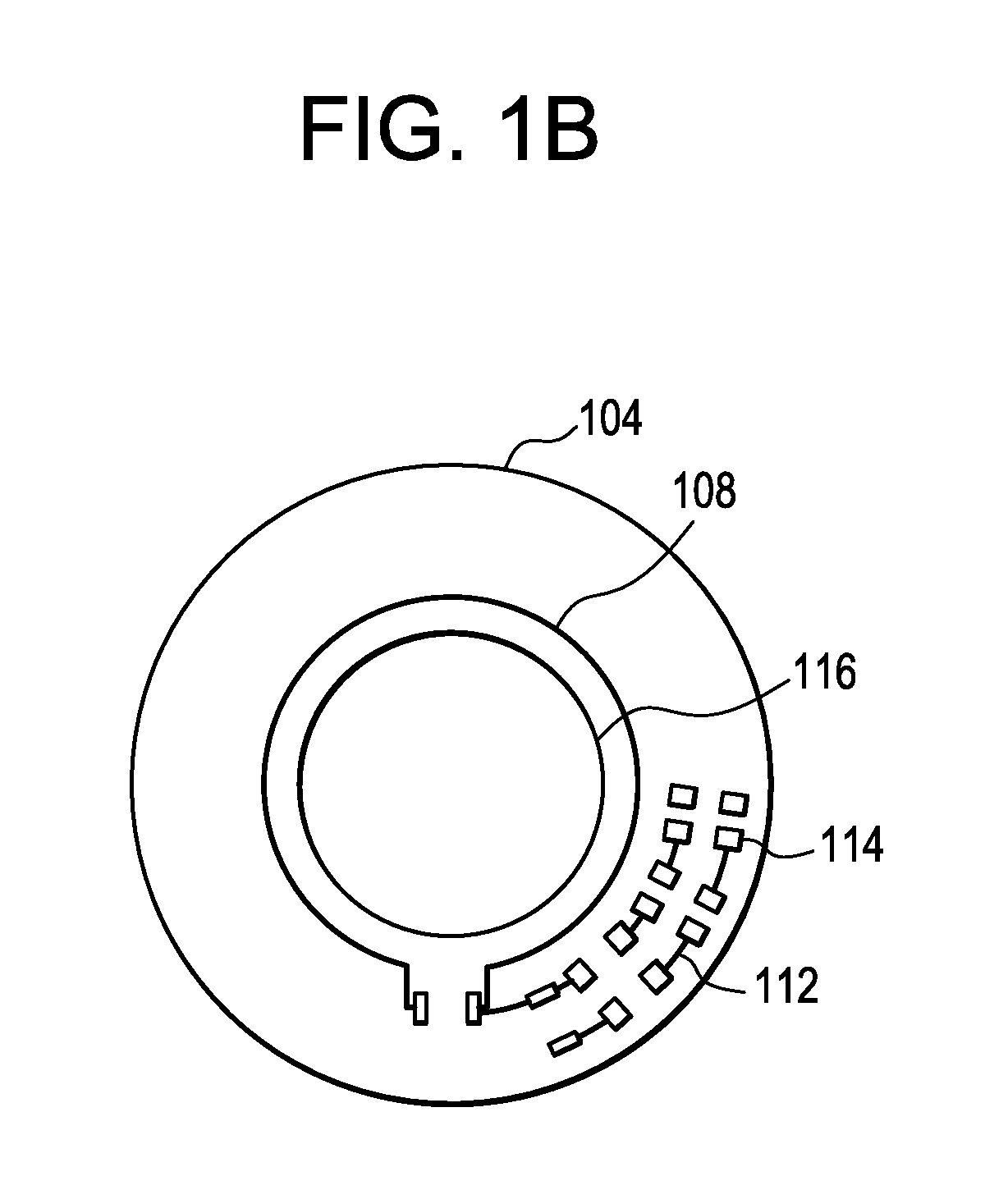

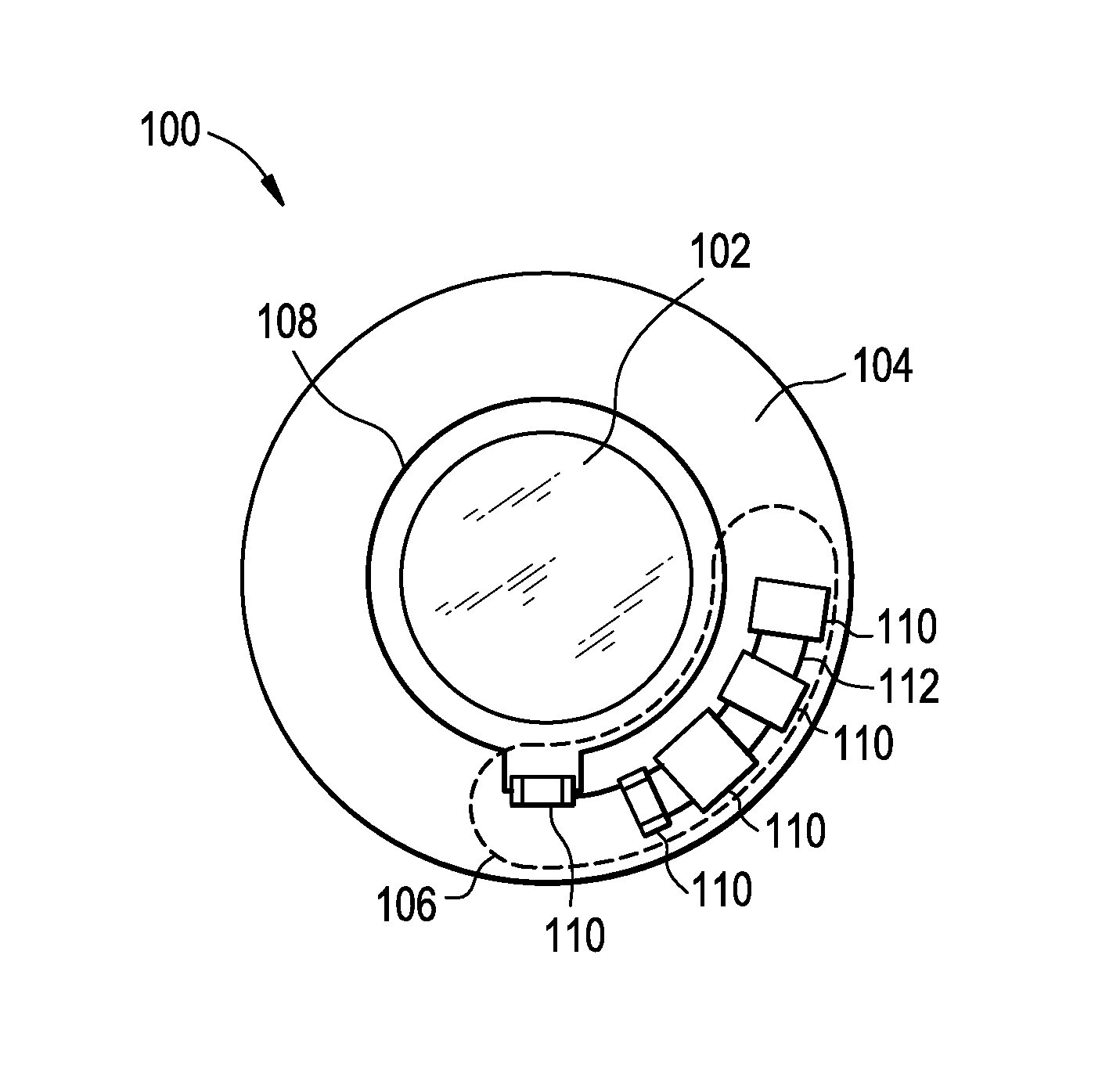

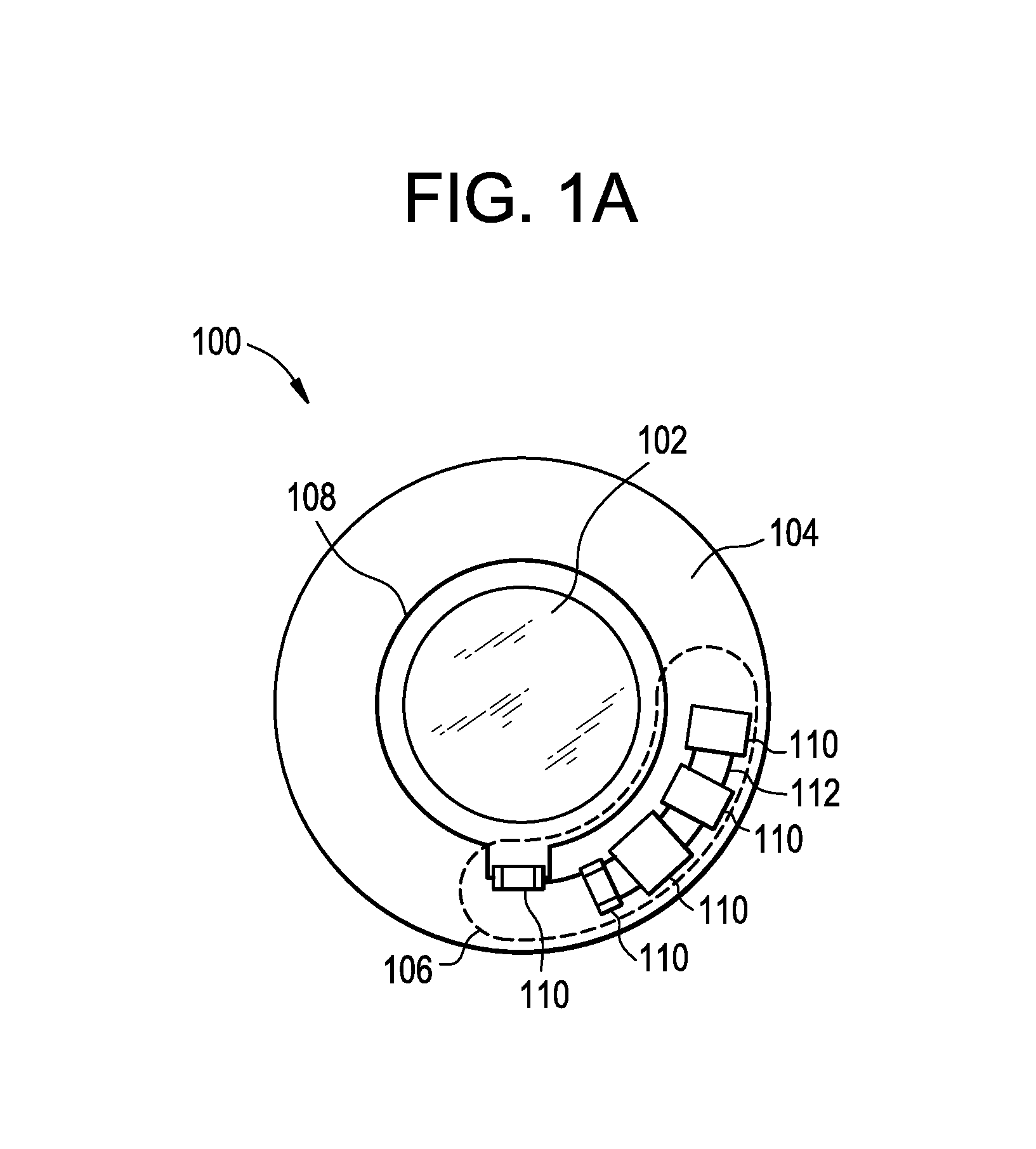

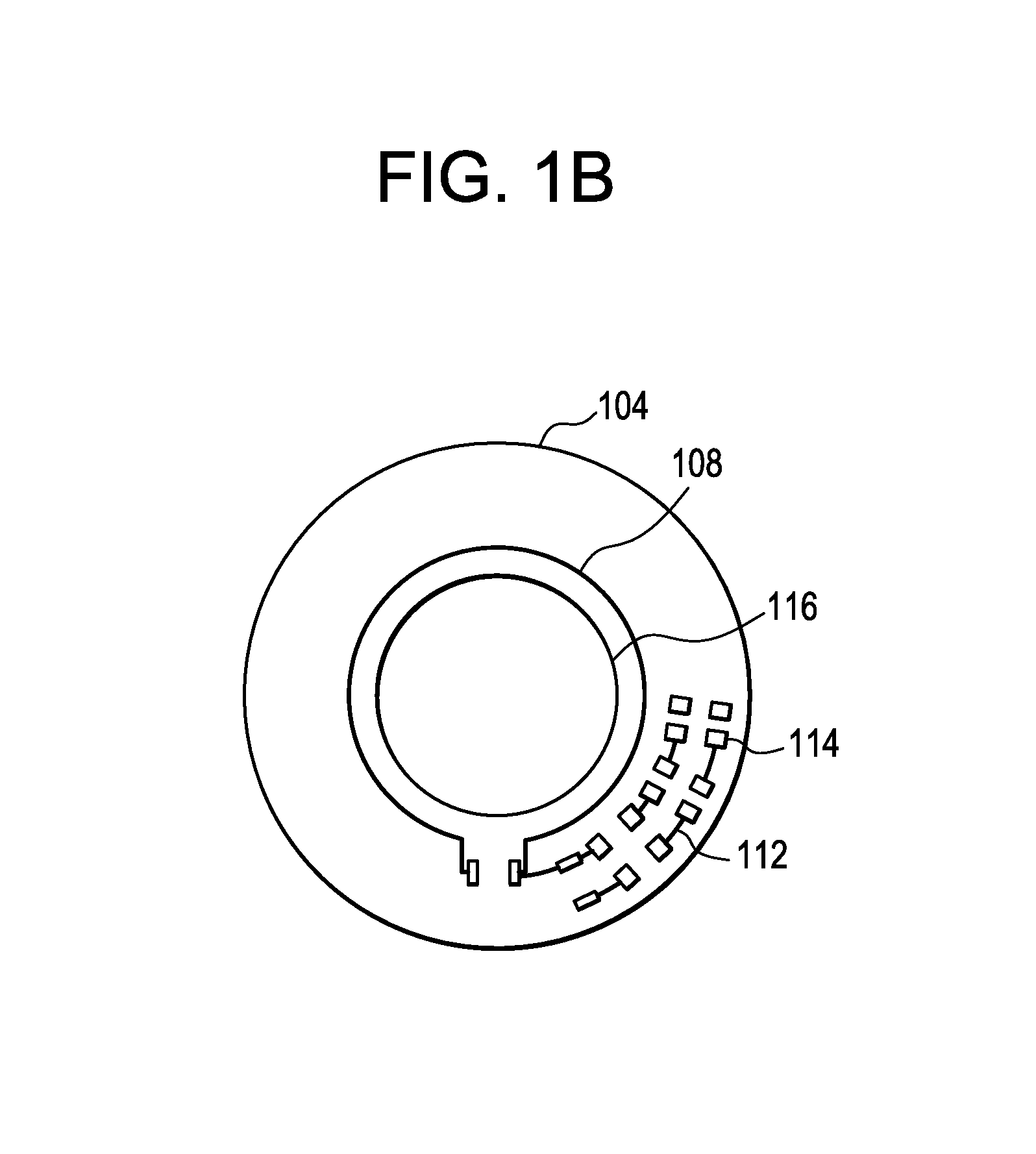

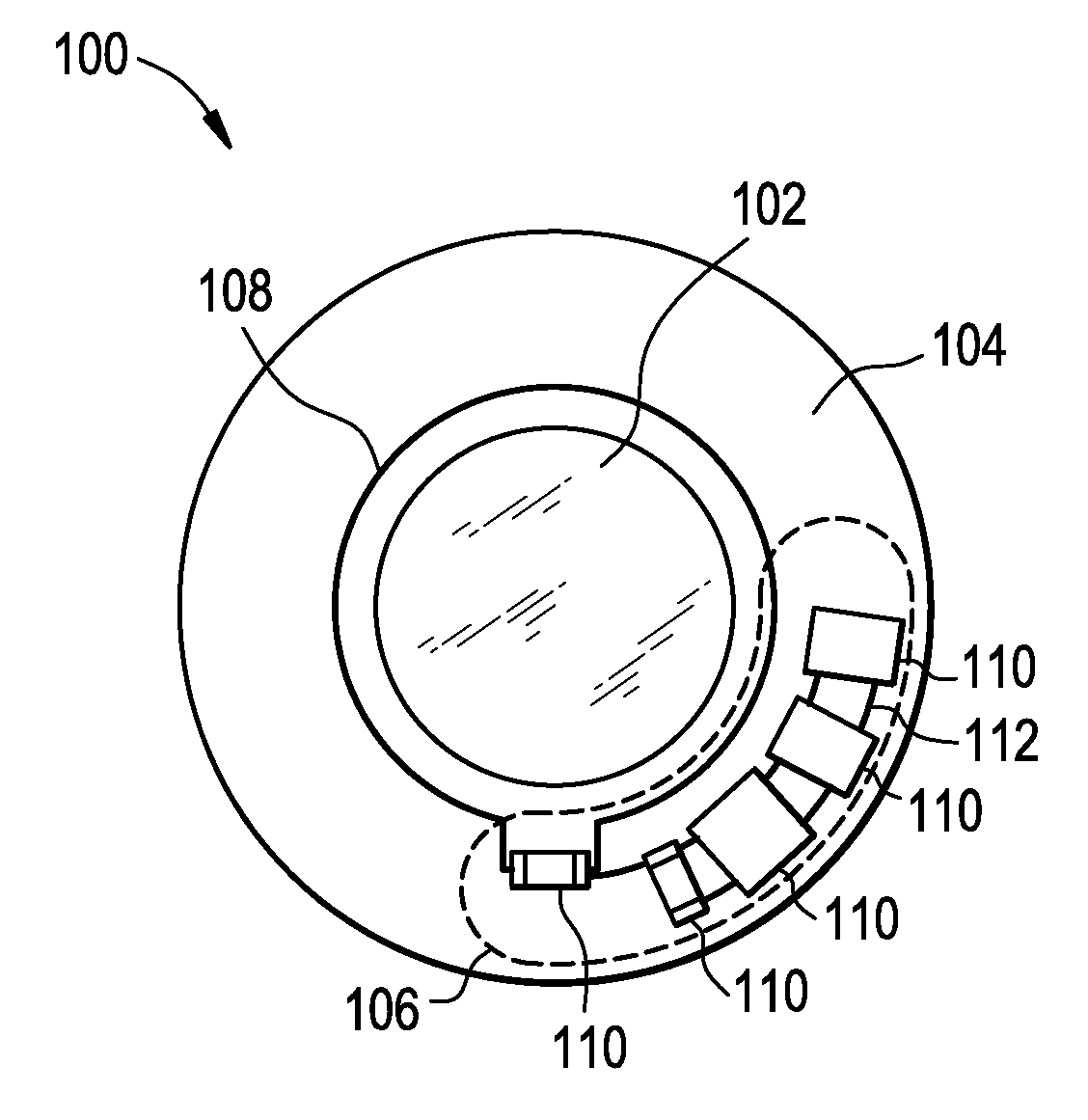

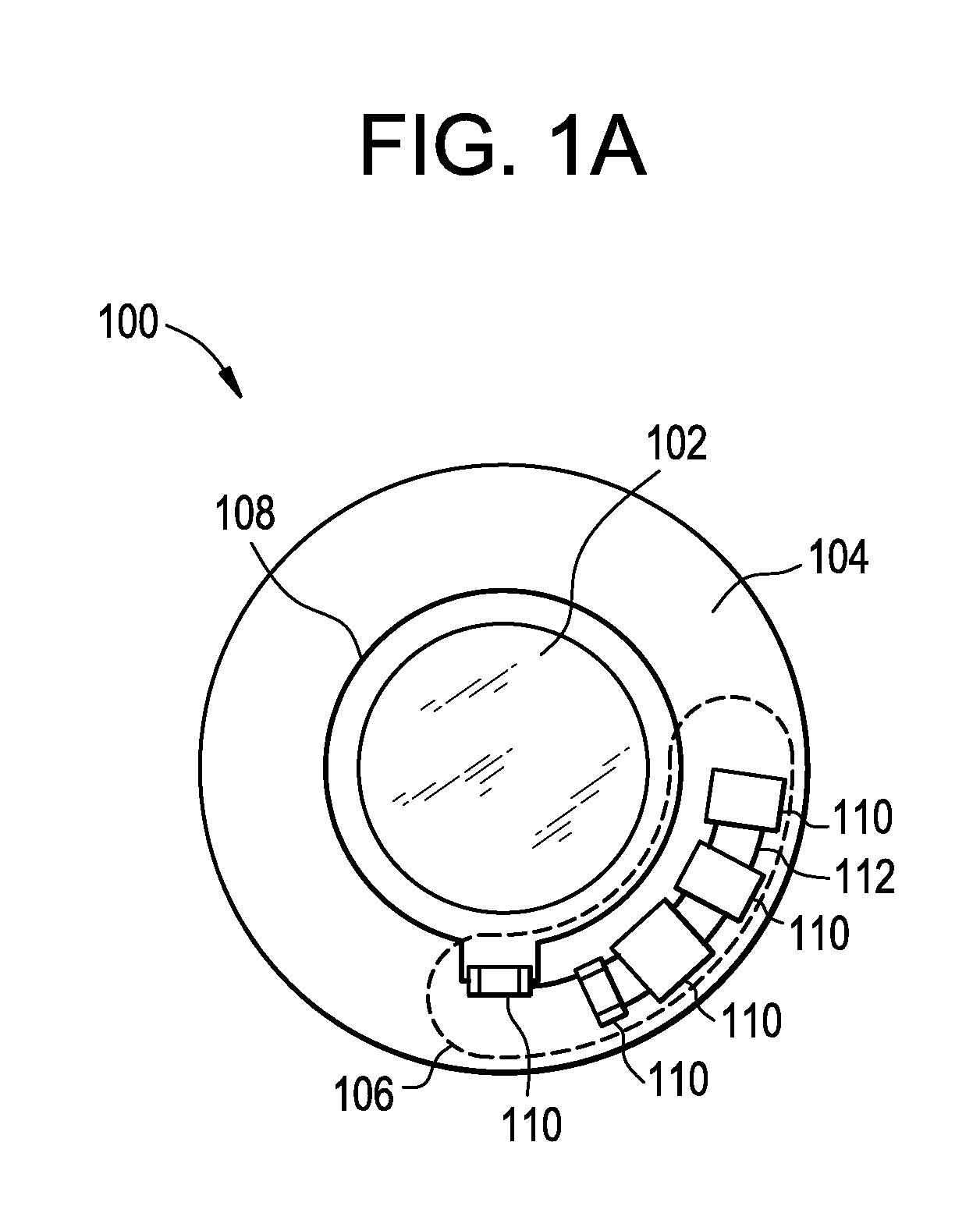

Ophthalmic lens assembly having an integrated antenna structure

ActiveUS20130194540A1Improve performanceAntenna supports/mountingsOptical articlesIntegrated antennaMedical device

Antennas and antenna systems may be designed and configured for incorporation into mechanical devices, including medical devices, such as ophthalmic devices, including contact lenses. These antennas and antenna systems may be utilized to transmit data from the mechanical device to a receiver, to receive data from a transmitter, and / or to inductively charge an electromechanical cell or the like incorporated into the mechanical device.

Owner:JOHNSON & JOHNSON VISION CARE INC

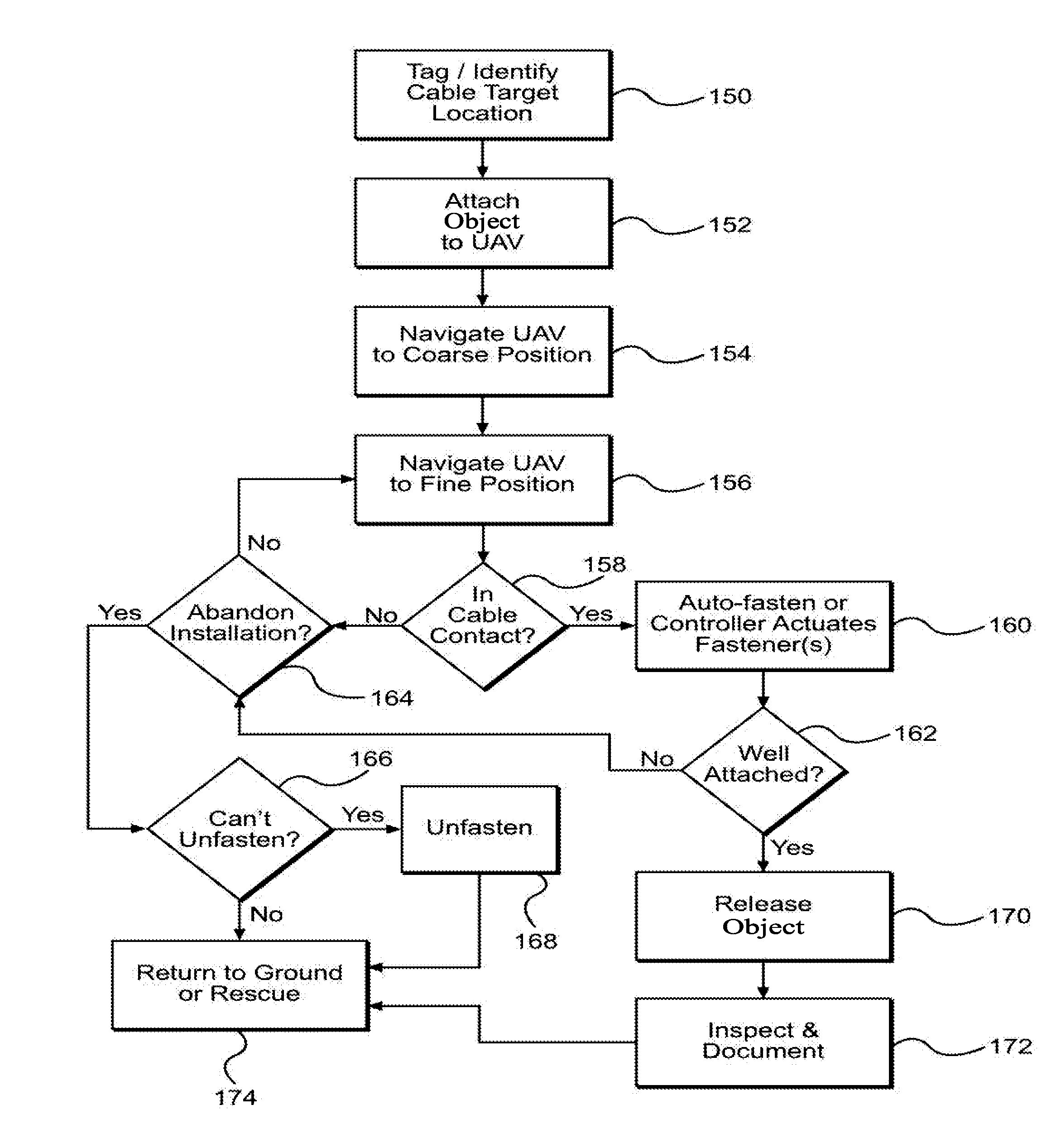

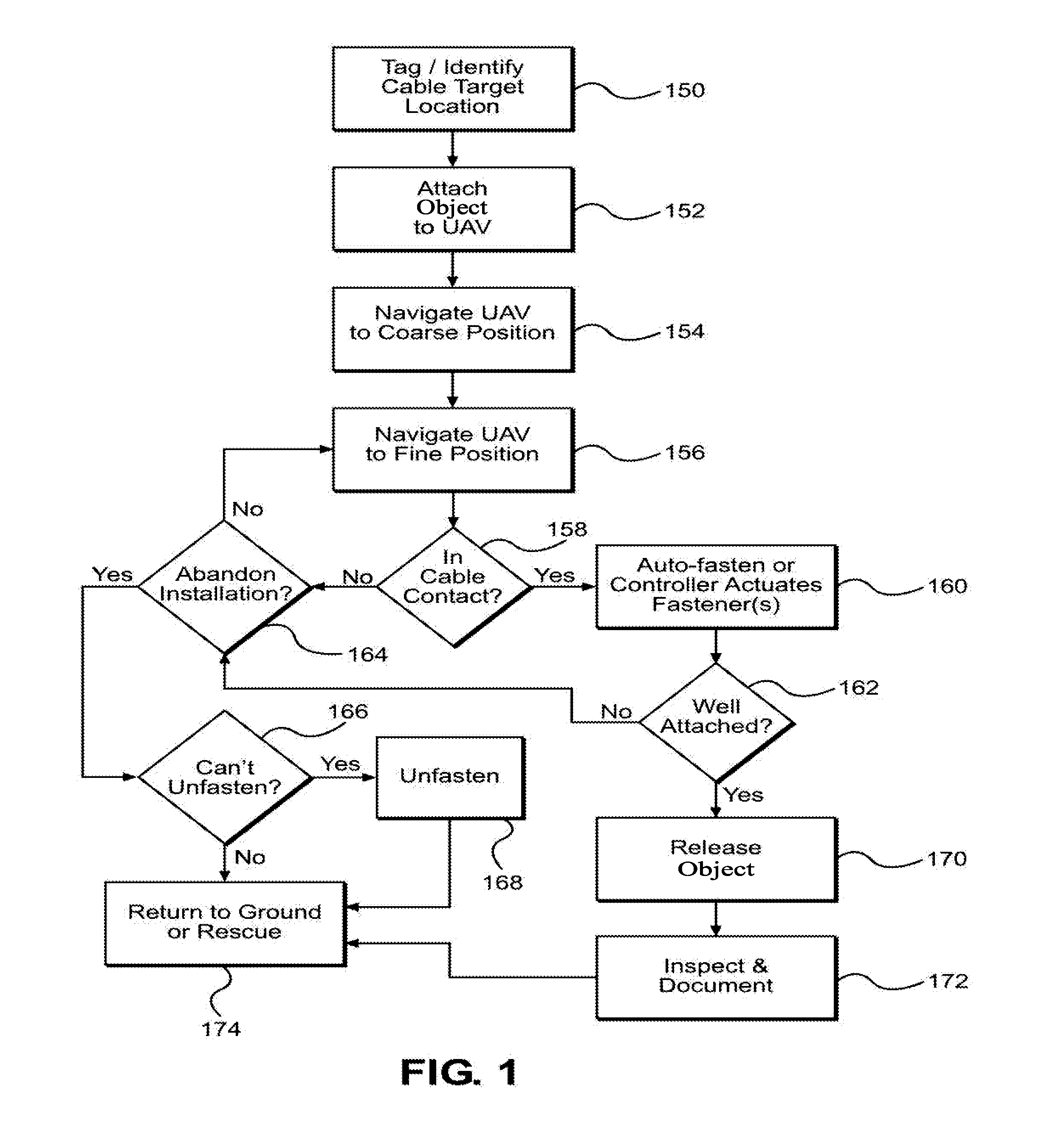

Method for installing an object using an unmanned aerial vehicle

ActiveUS20160023761A1Overhead installationUnmanned aerial vehiclesAircraft flight control systemMechanical devices

A method for using an unmanned aerial vehicle to install objects on wire and catenary structures is described. The method includes tagging the location, attaching the object to the UAV, navigating the UAV to the position, attaching the object, testing the attachment, releasing the object, inspecting the attachment, and returning the UAV to the ground. Sensors, flight control systems, means for attachment, and variations of embodiments of the methods, systems, and mechanical devices are described.

Owner:MCNALLY JONATHAN

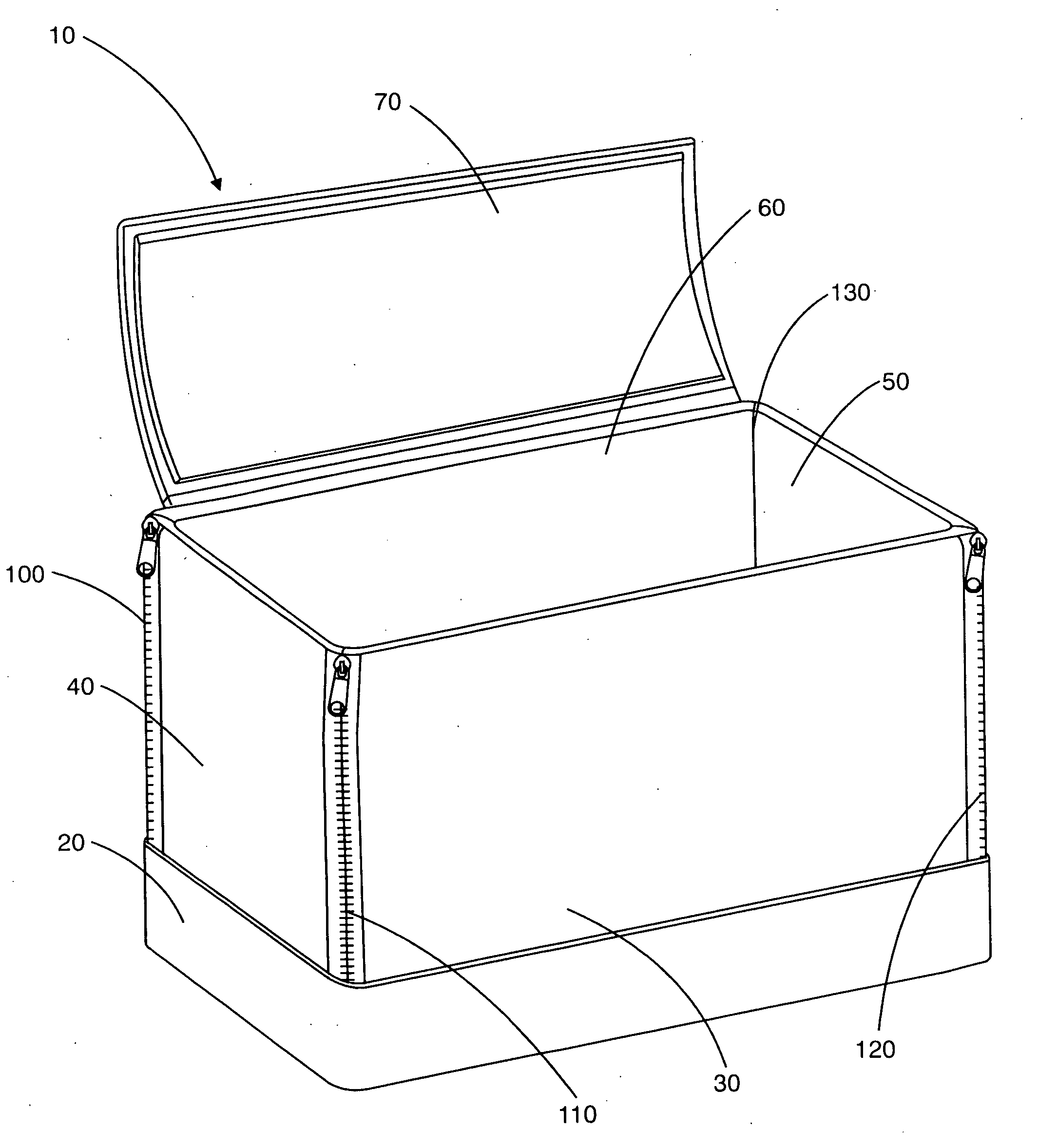

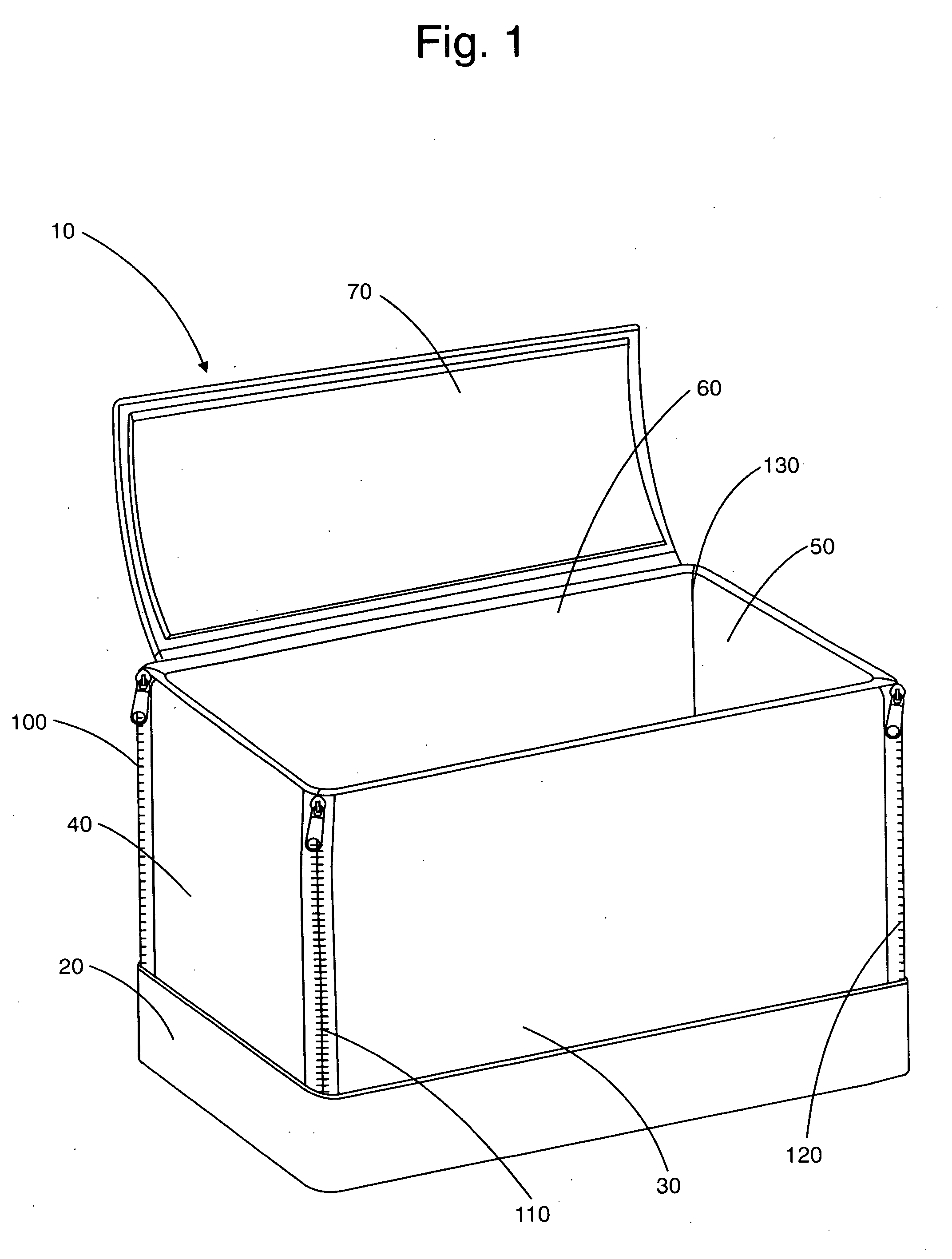

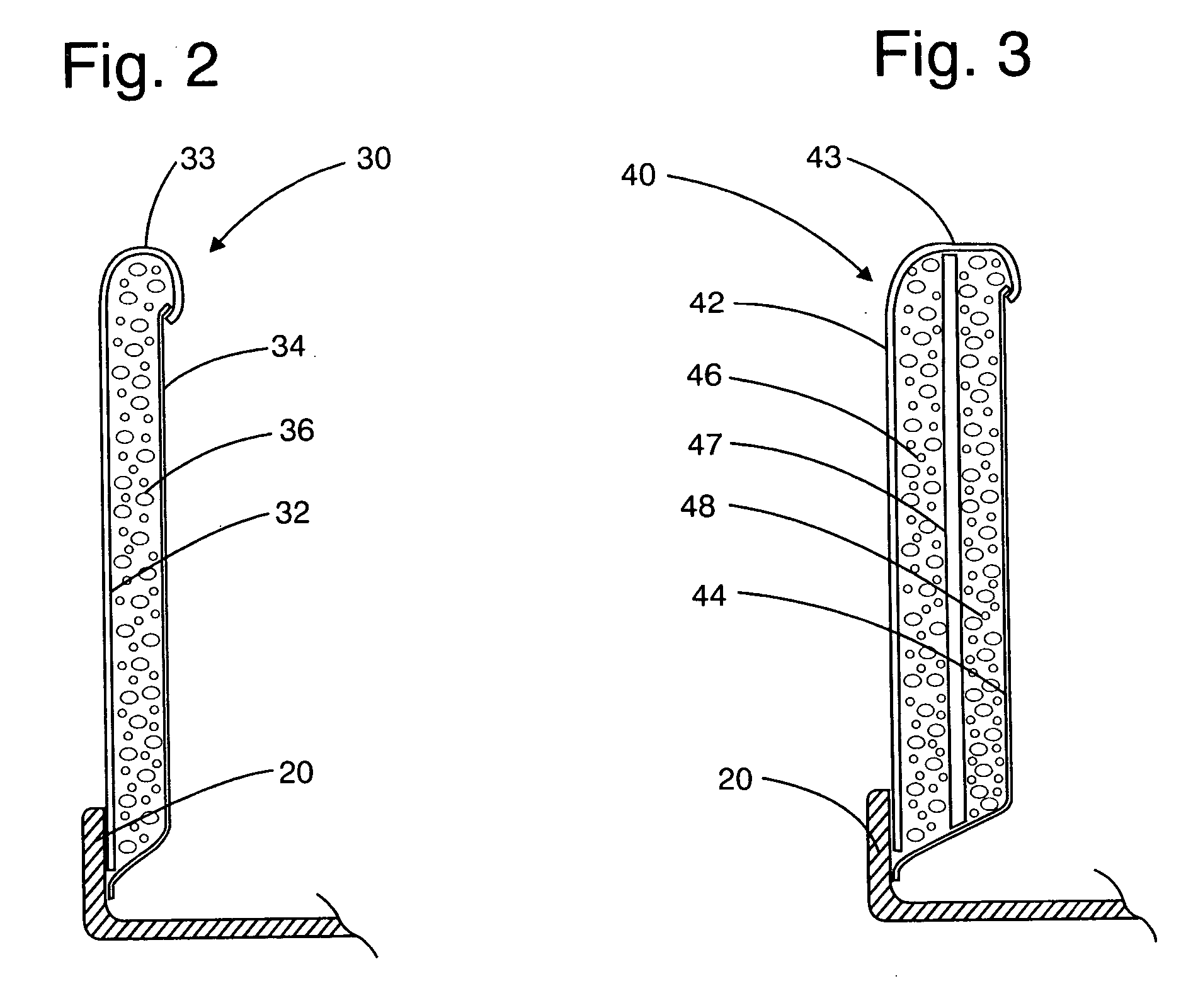

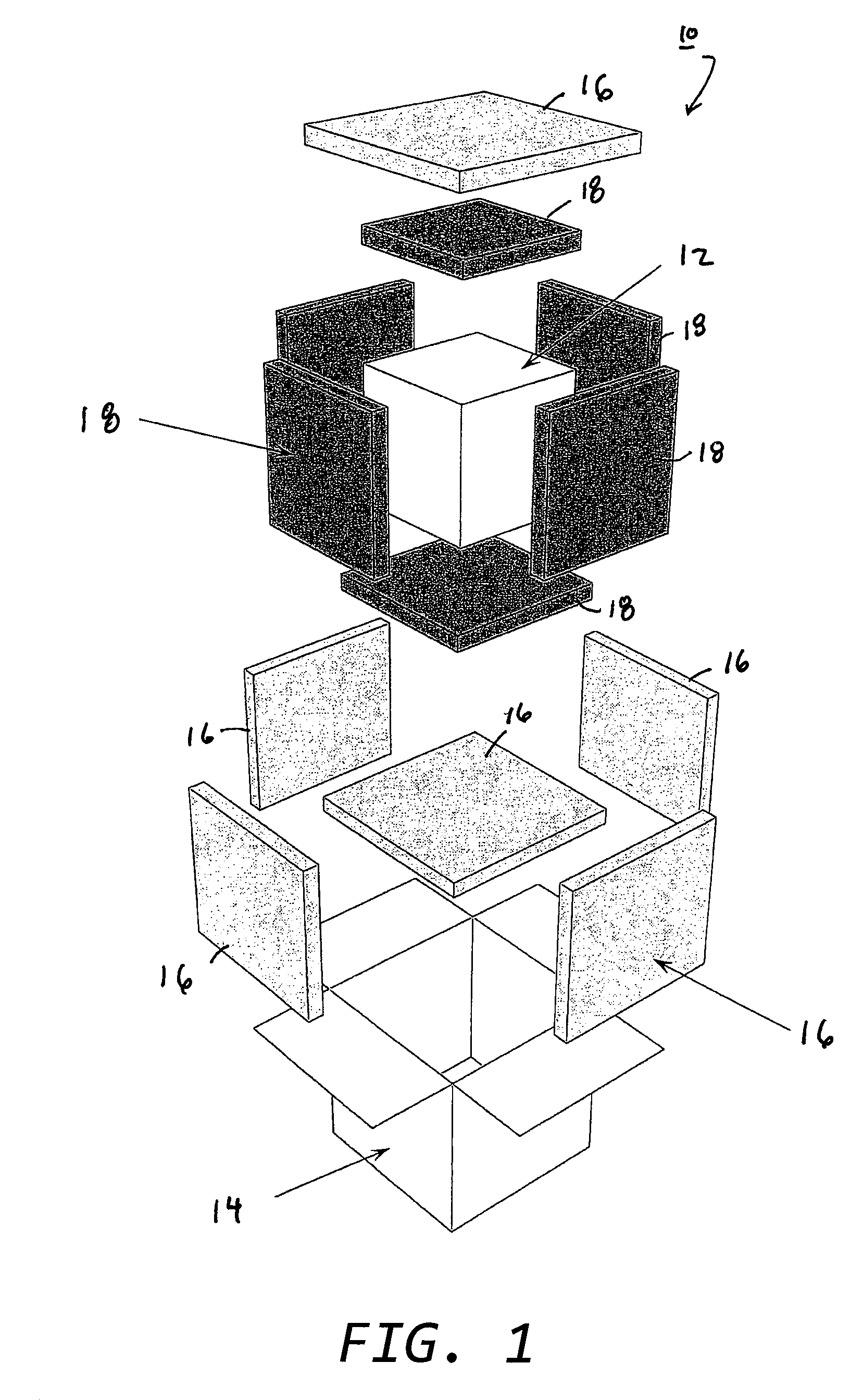

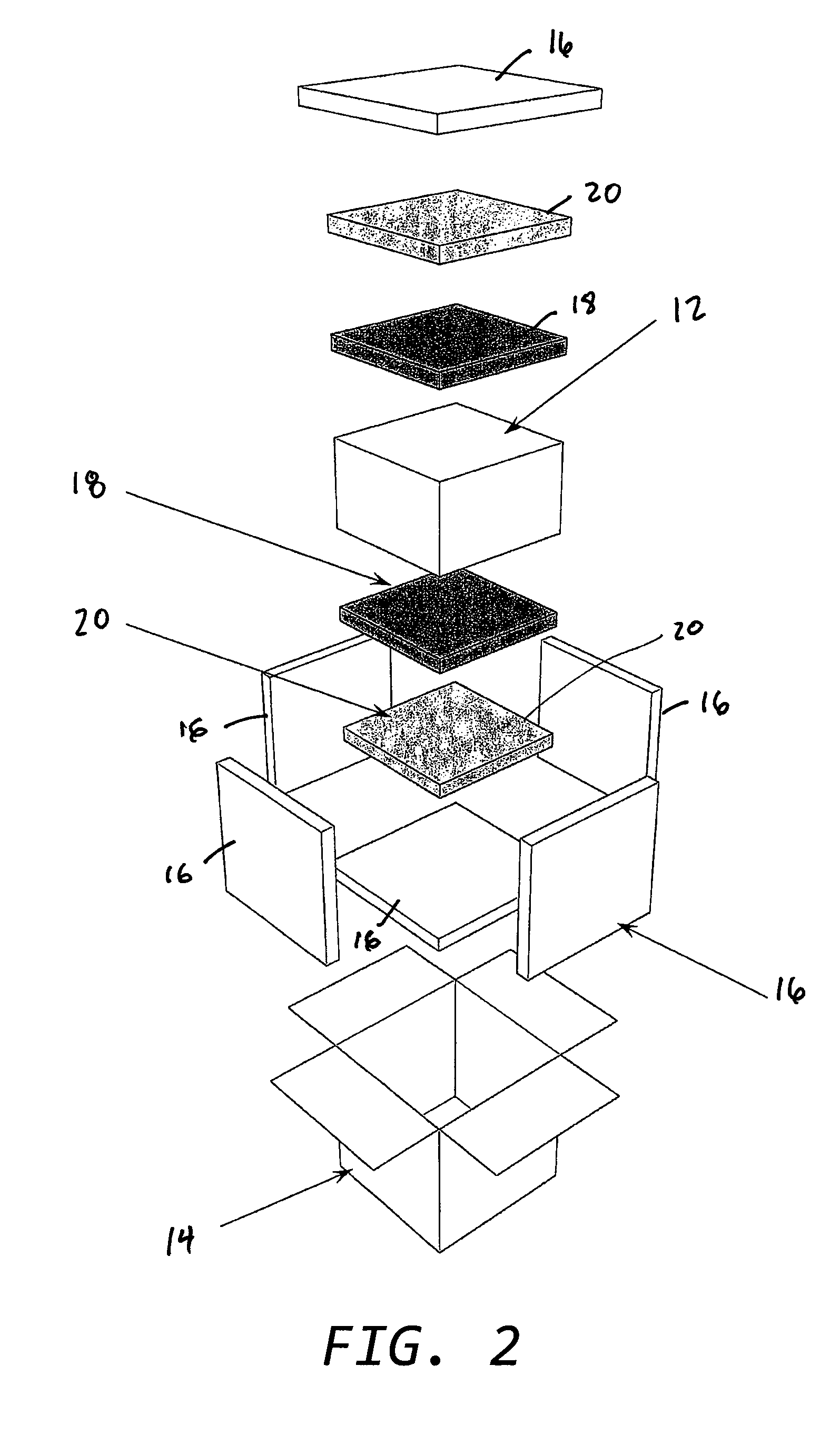

Stowable cooler

Stowable Cooler with insulated walls, resealable mechanical devices, a stowing medium, and an access lid. A preferred embodiment includes the insulated walls having a soft or semi-rigid construction. The lower edges of the insulated walls are permanently secured to the stowing medium forming a flexible bond. The side edges of the insulated walls each feature at least one half of at least one resealable mechanical device. The lower edges of each resealable mechanical device are secured to the stowing medium. The stowable cooler has a stowing mode and a usage mode. The stowing mode is true when the sealable mechanical devices are unsealed, and the usage mode is true when the sealable mechanical devices are sealed. The stowing medium is of sufficient volume to house the insulated walls while in stowing mode in a plurality of overlapping flats.

Owner:KITCHENS MARK CHARLES +2

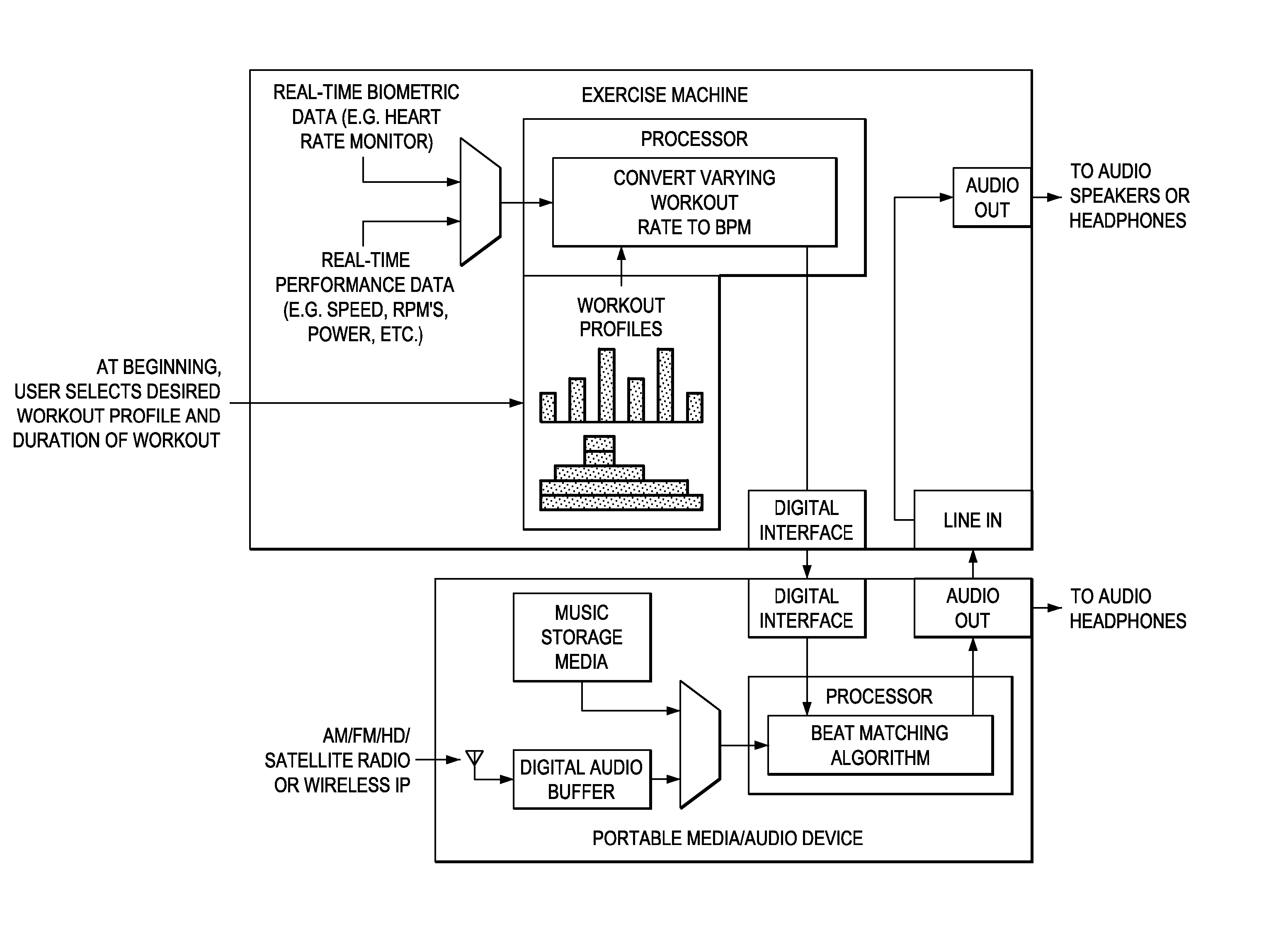

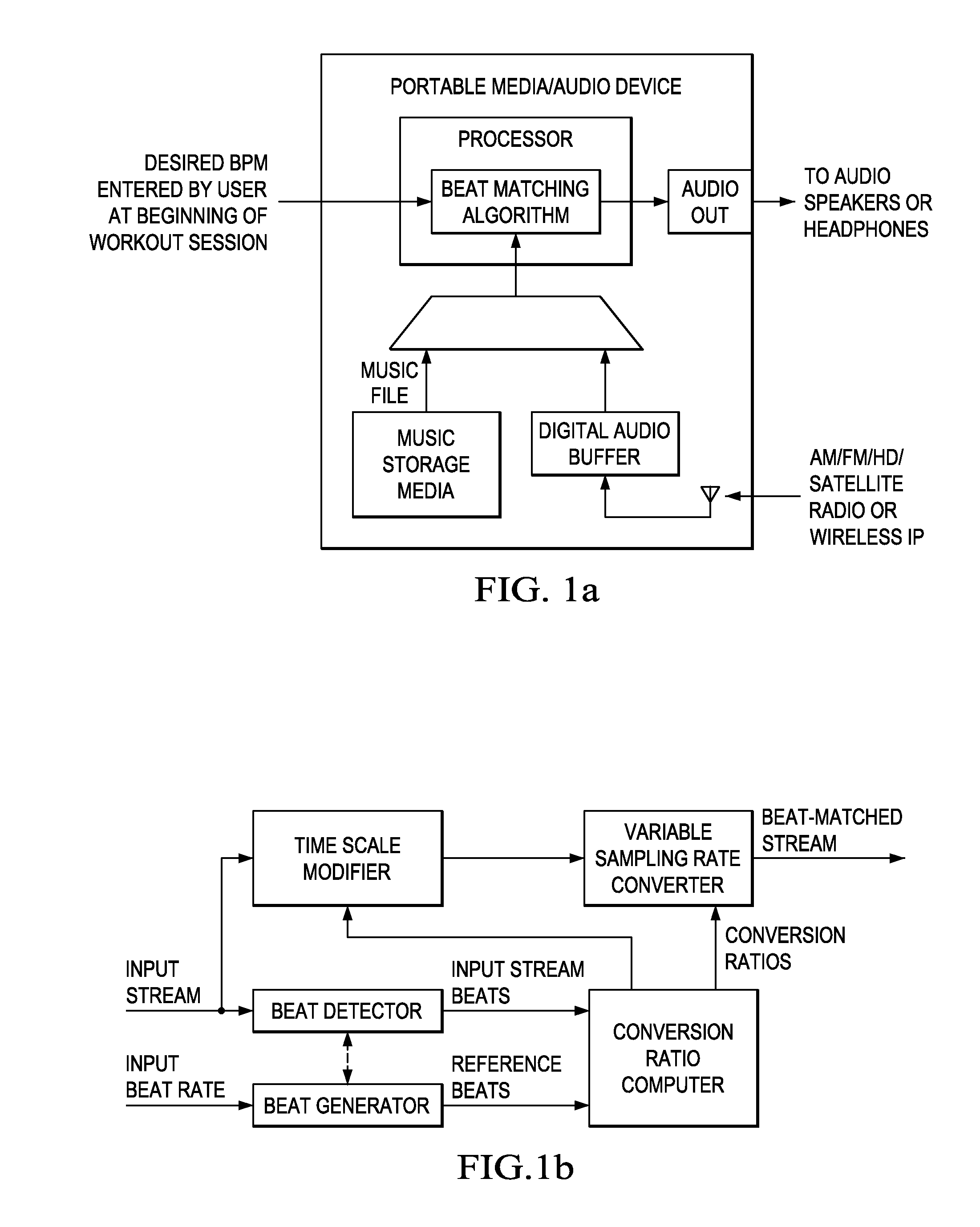

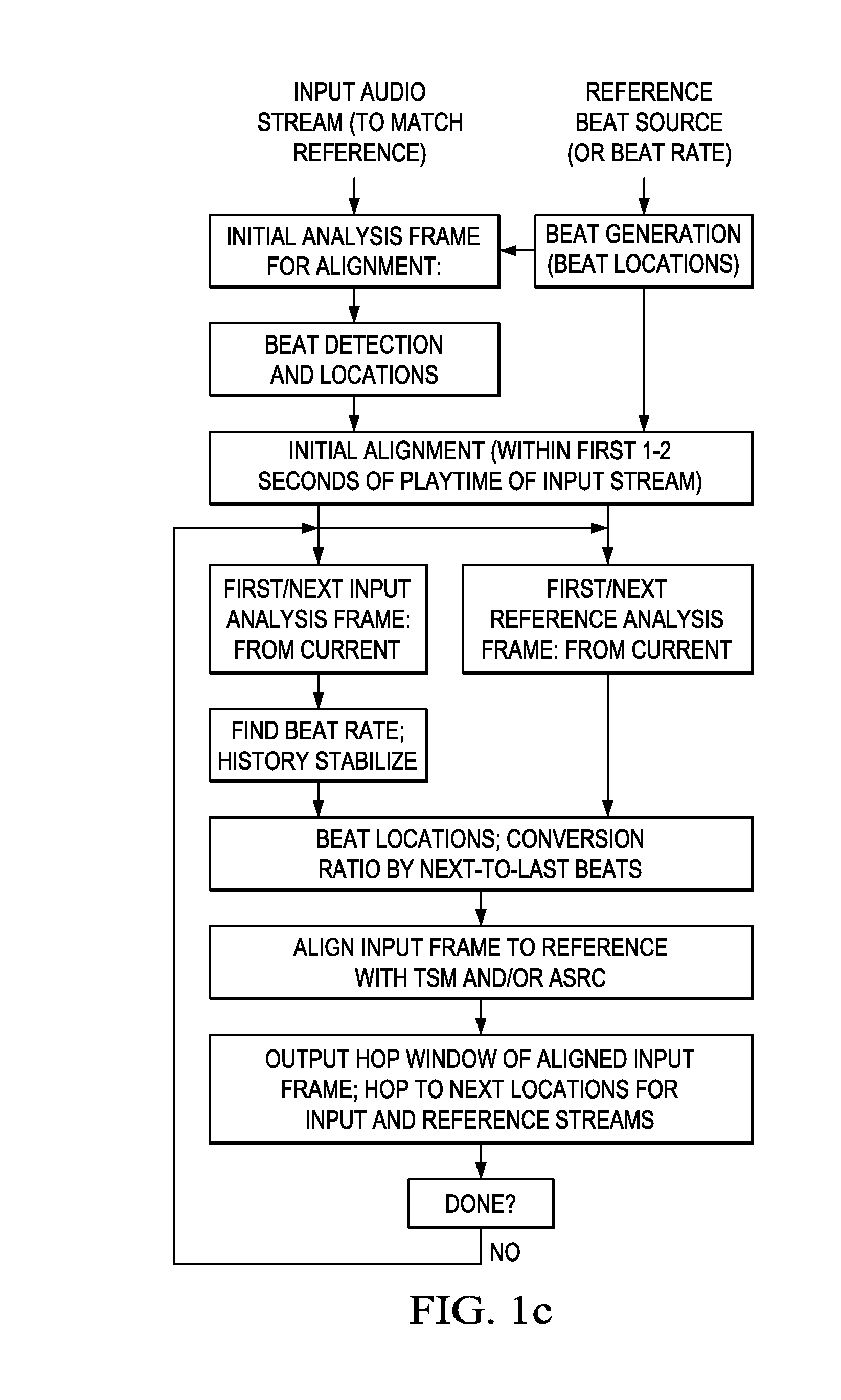

Beat matching systems

InactiveUS20080097633A1Electrophonic musical instrumentsRecording carrier detailsMotion parameterBeat rate

Beat detection in audio streams for various applications: (i) to encourage desired athletic parameters, such as target or current heart rate, during training or workout by adjusting tempo of accompanying music; (ii) to monitor operating conditions of mechanical devices which inherently include vibrations; (iii) to synchronize audio play-out beat rate to mechanical device beat rate.

Owner:TEXAS INSTR INC

Addressable fuse array for circuits and mechanical devices

InactiveUS6501107B1Semiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceElectricity

A fuse array having a plurality of fusible links that can be addressed by two electrodes is disclosed. The fuse array includes two conductive strips having the plurality of fusible links located therebetween and electrically coupled to the conductive strips. The fusible links have different electrical resistance and each fusible link includes a fuse portion. A voltage potential applied across the conductive strips induces current flow through the fusible links in accordance with Ohm's law and ohmic heating occurs at the fuse portion in proportion to the square of the current. The voltage is increased to cause sufficient ohmic heating to occur in the most conductive fusible link (the fusible link having the lowest electrical resistance) so that the fuse portion in that fusible link fuses. Because the fusible links are connected in parallel to the conductive strips, an equivalent resistance of the plurality of fusible links increases and the current flow diminishes so that no further fuse portions are fused at the selected voltage level. Thereafter, the voltage level may be increased to fuse the most conductive fusible link remaining that is not fused. The fuse array may be incorporated into a circuit as a resistor that can be tuned to circuit requirements or as a physical structure in MEMS devices wherein the fuse array may be tuned to change physical properties of the MEMS device.

Owner:MICROSOFT TECH LICENSING LLC

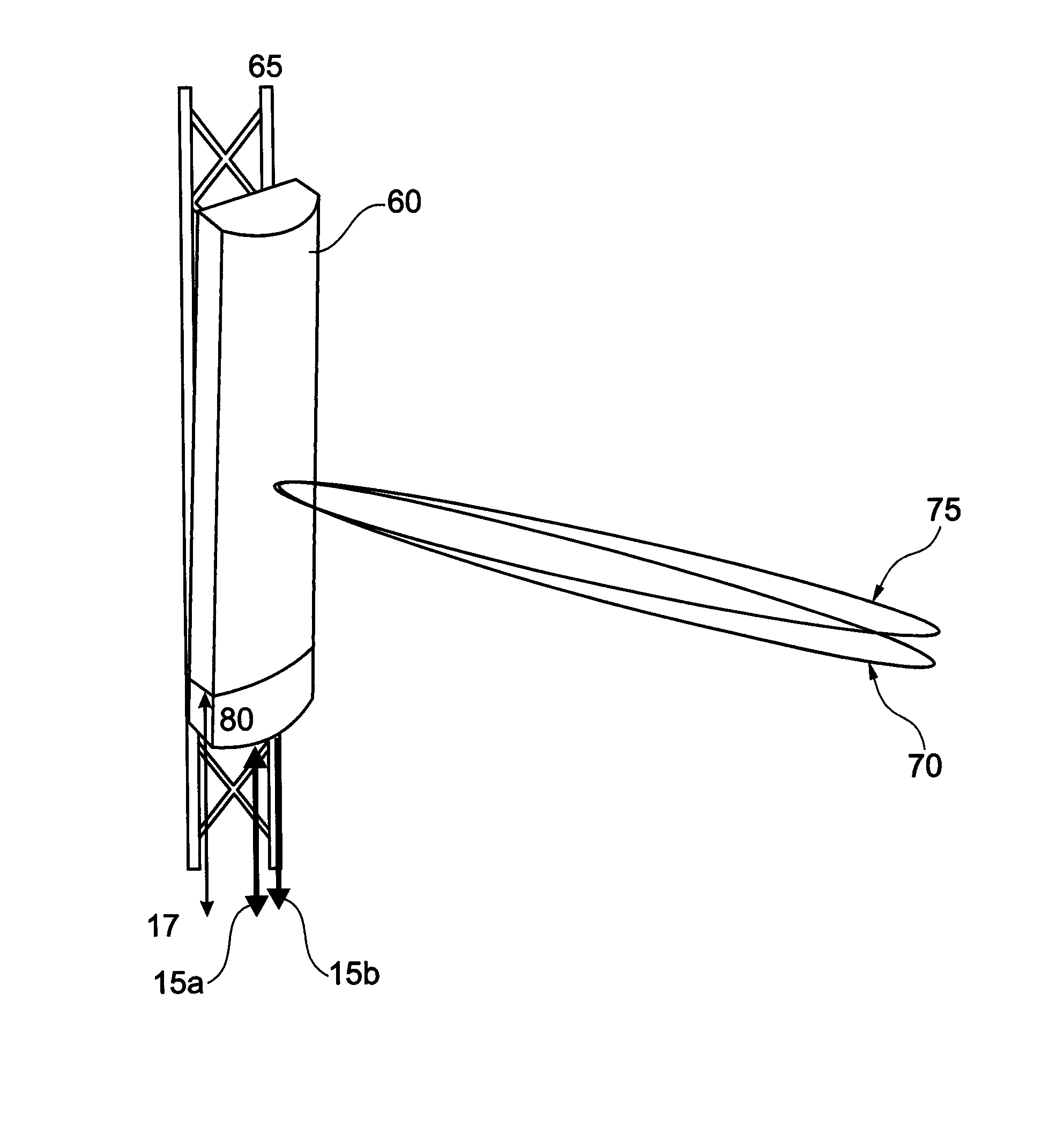

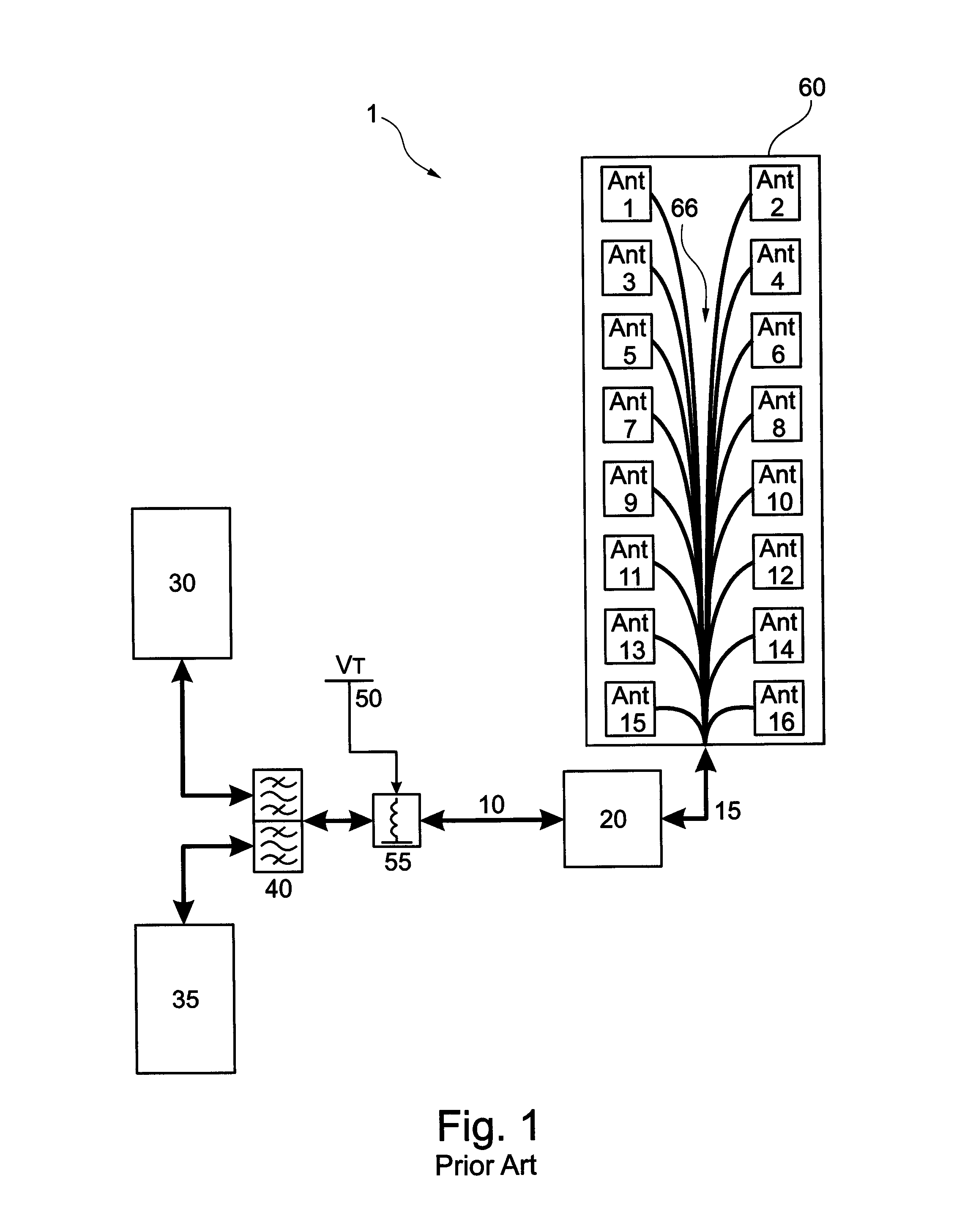

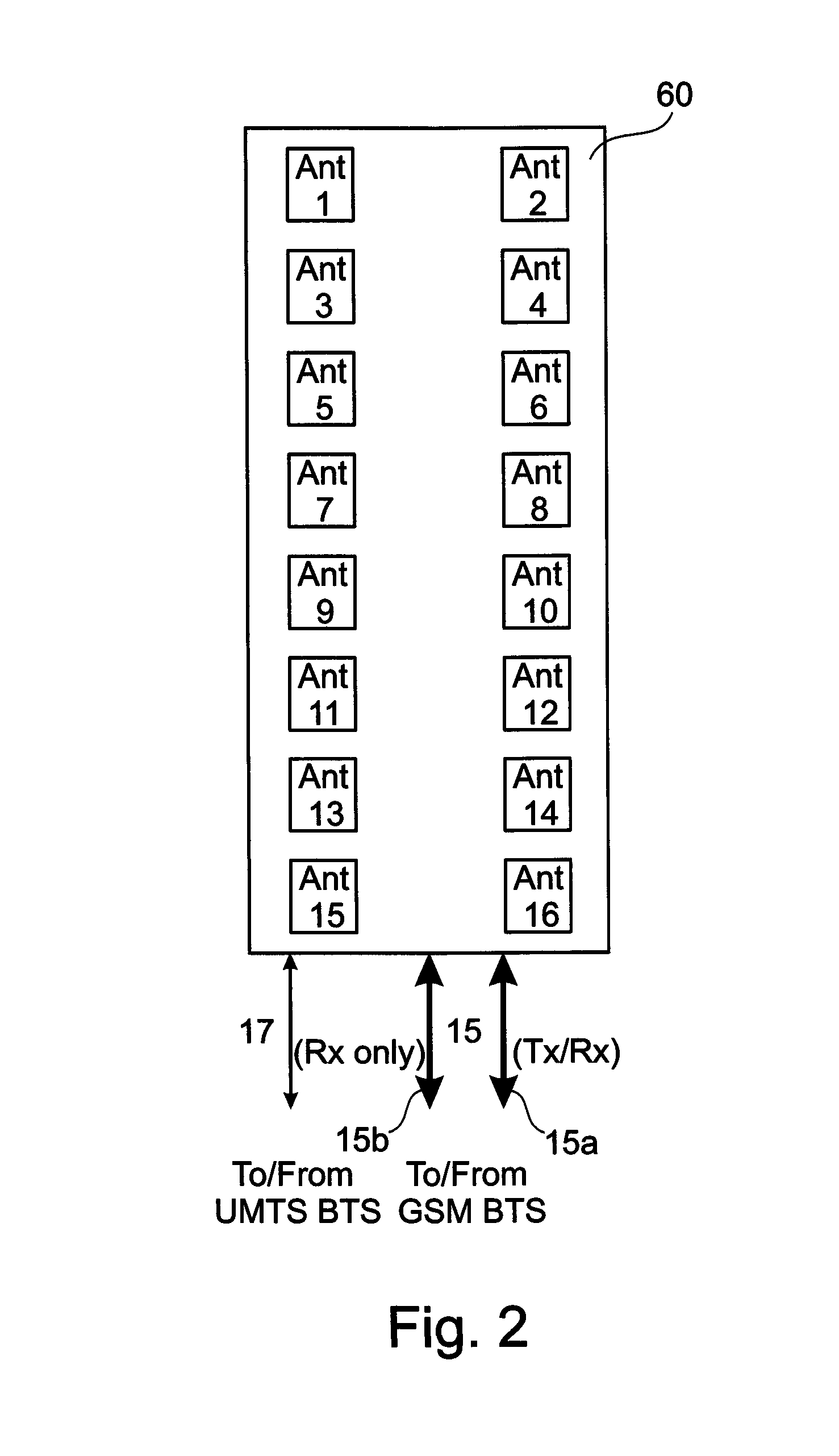

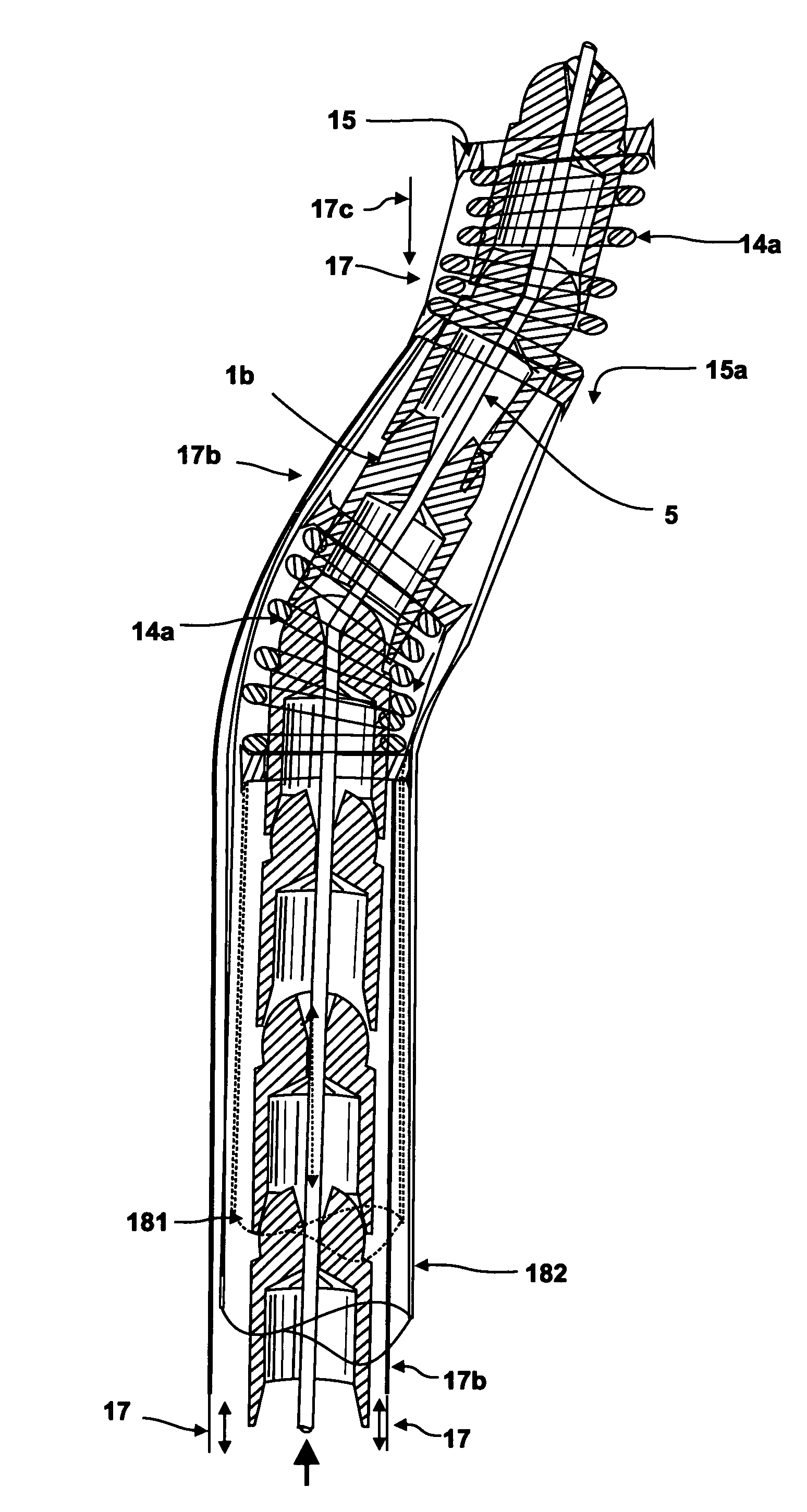

Method and apparatus for tilting beams in a mobile communications network

An antenna array for a mobile communications network is disclosed which comprise mechanical devices for altering a direction of a first beam and electronic beam forming apparatus for shaping a second beam. A method for tilting radio beams in a mobile communications network using the antenna array is also disclosed. The method comprises mechanical tilting a first protocol radio beam and electronic tilting a second protocol radio beam.

Owner:KATHREIN SE

Snaking robotic arm with movable shapers

ActiveUS8224485B2Overcome difficultiesMaking the articulable column sufficiently stiffProgramme-controlled manipulatorComputer controlRobotic armEngineering

Owner:TITAN MEDICAL INC

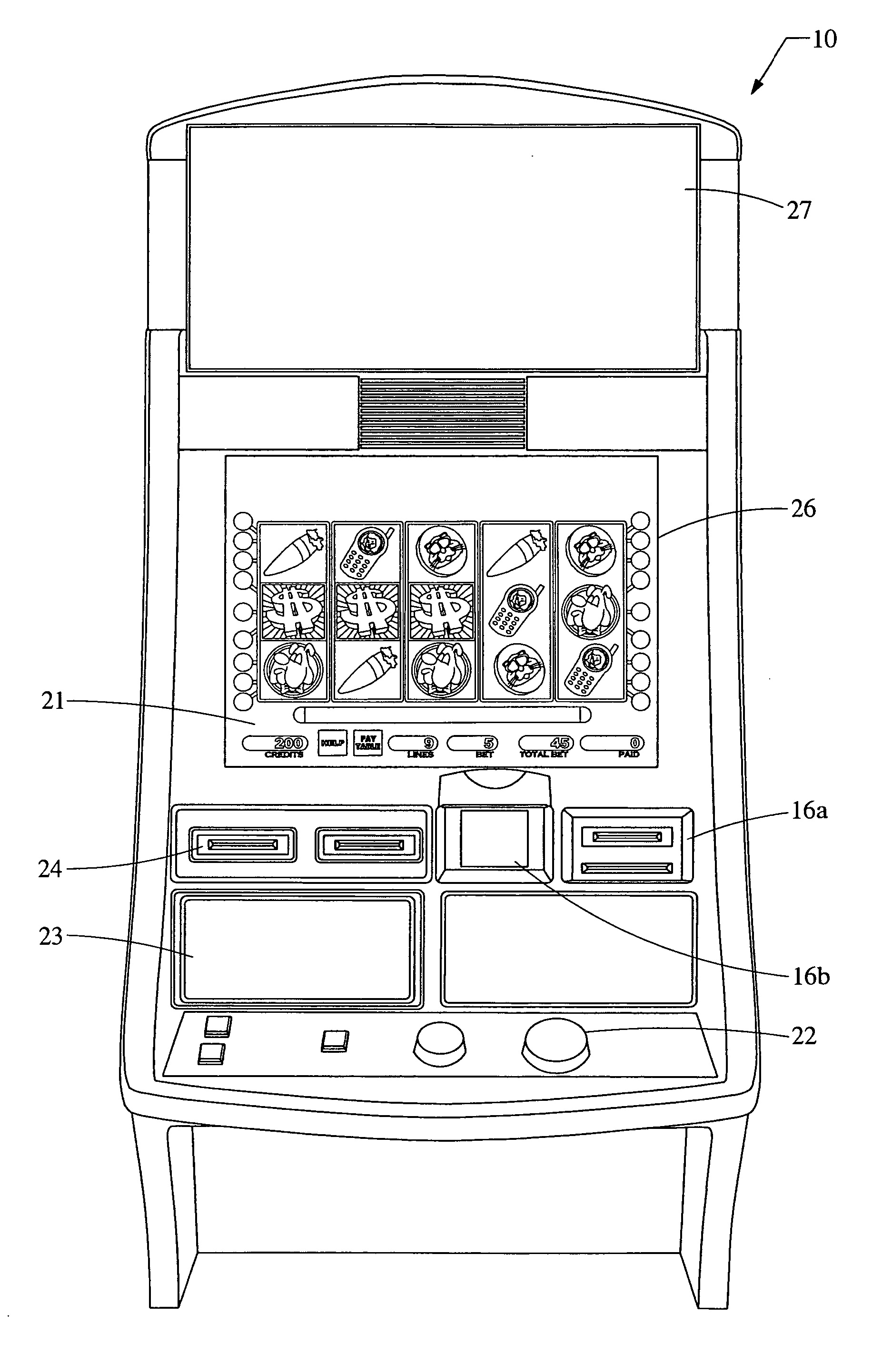

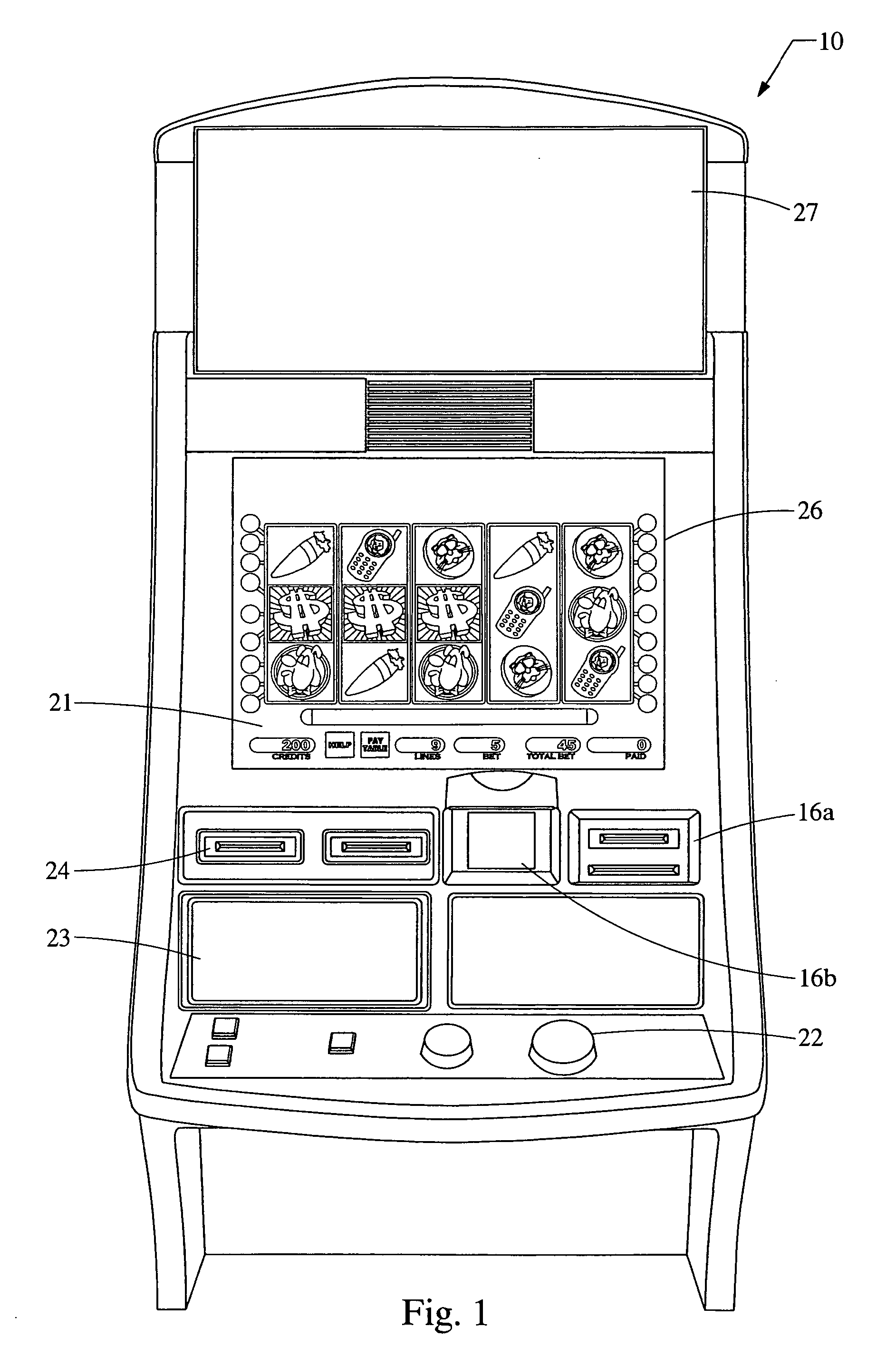

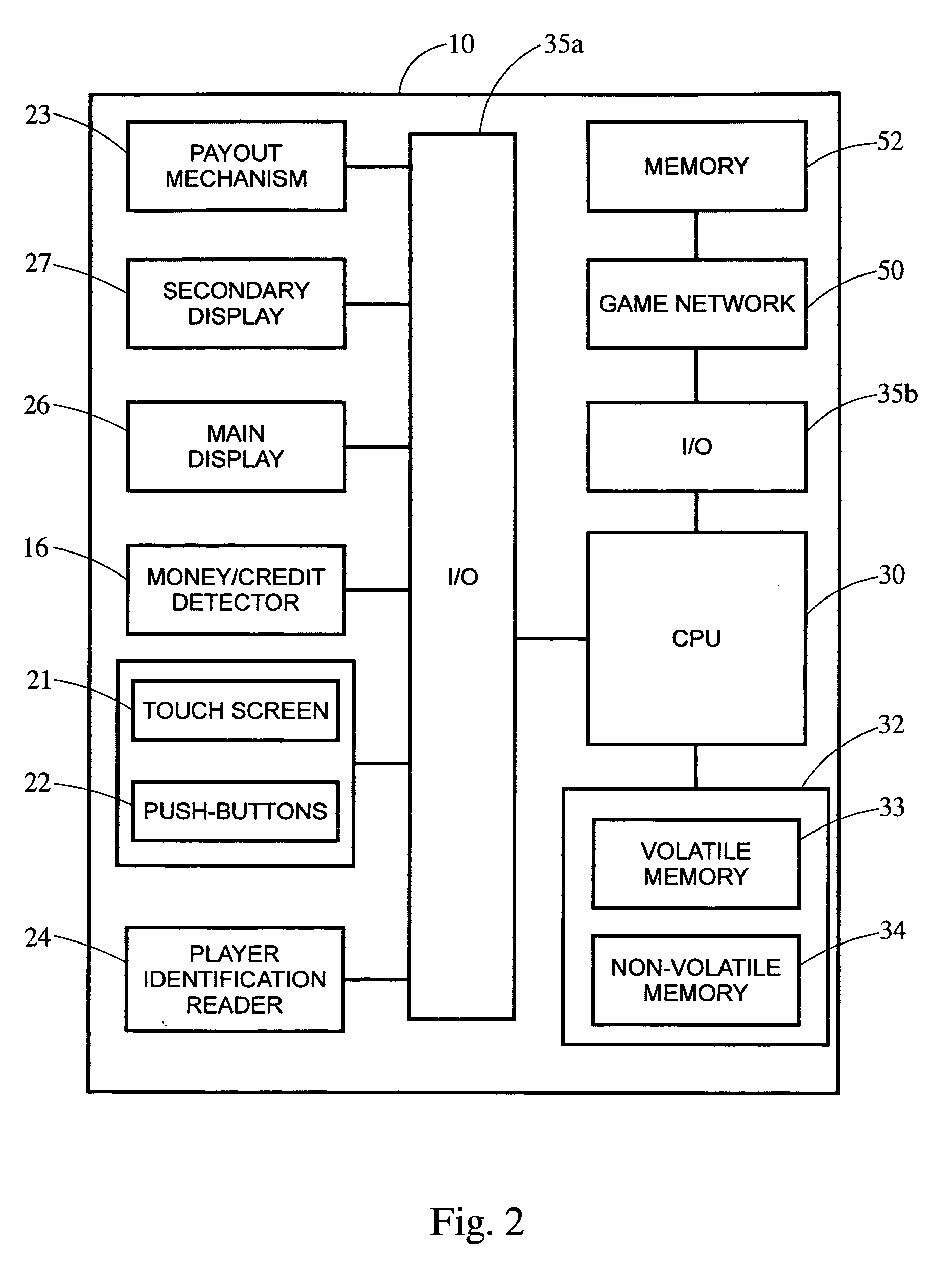

Wagering game with 3D rendering of a mechanical device

A stand-alone or server-linked gaming terminal that displays on a plasma display in the top-box area a 3D-rendered mechanical device that is pre-rendered or rendered in real time using a 3D-graphics processor or the like. The 3D-rendered mechanical device depicts the game outcome or a bonus game displayed in the top box display. The images or animation representing the 3D-rendered mechanical device may be stored on a digital video recorder (DVR) within the gaming terminal or downloaded remotely from a storage device coupled to the gaming terminal. The DVR outputs the mechanical device images as analog video, and is capable of receiving analog video input, converting the analog video to a digital format such as MPEG, and storing the converted video on a storage media. Additional structural elements such as a frame may be arranged about the top-box display to add depth or dimensionality to the 3D-rendered images displayed thereon.

Owner:BALLY GAMING INC

Ophthalmic lens assembly having an integrated antenna structure

ActiveUS8857983B2Improve performanceAntenna supports/mountingsOptical articlesIntegrated antennaEngineering

Owner:JOHNSON & JOHNSON VISION CARE INC

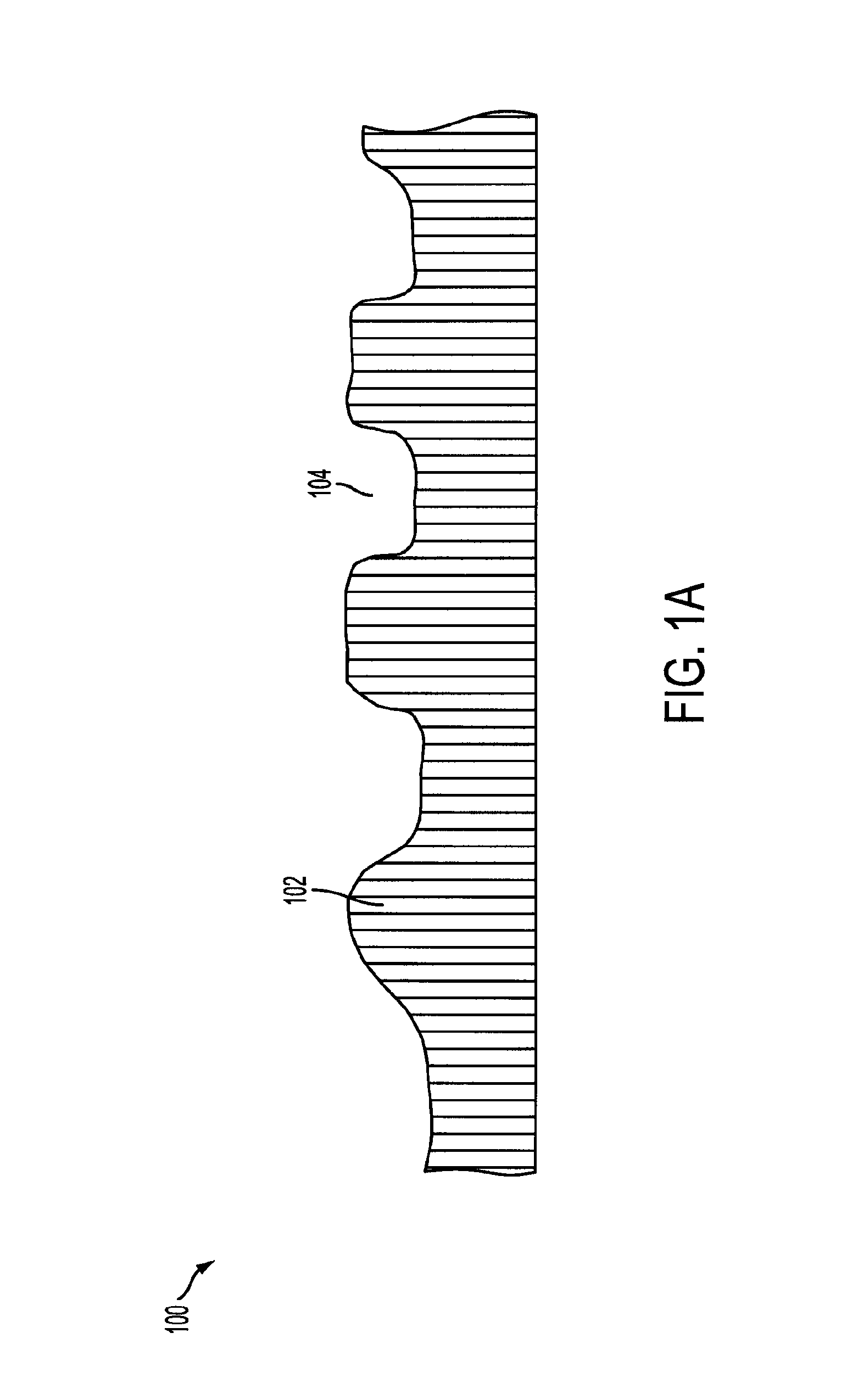

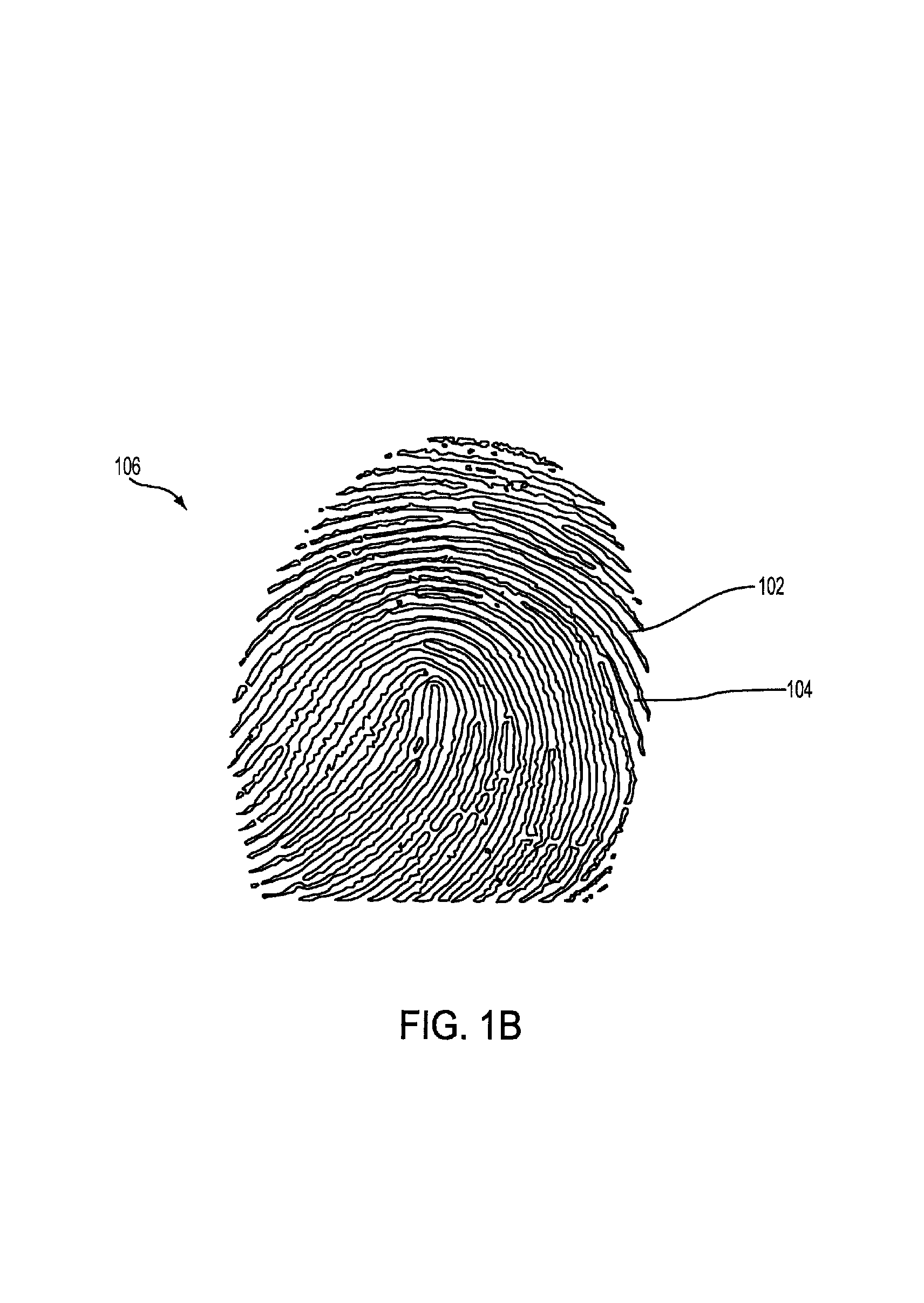

Mechanical resonator optimization using shear wave damping

ActiveUS8335356B2Material analysis using sonic/ultrasonic/infrasonic wavesPrint image acquisitionEngineeringLength wave

Provided is a fingerprint sensor including one or more mechanical devices for capturing the fingerprint. The mechanical devices include a matrix of pillars and are configured to be mechanically damped based upon an applied load. A q factor of the pillars is optimized by adjusting a distance between pillars within the matrix in accordance with a quarter shear wavelength at an operating wavelength.

Owner:SONAVATION INC

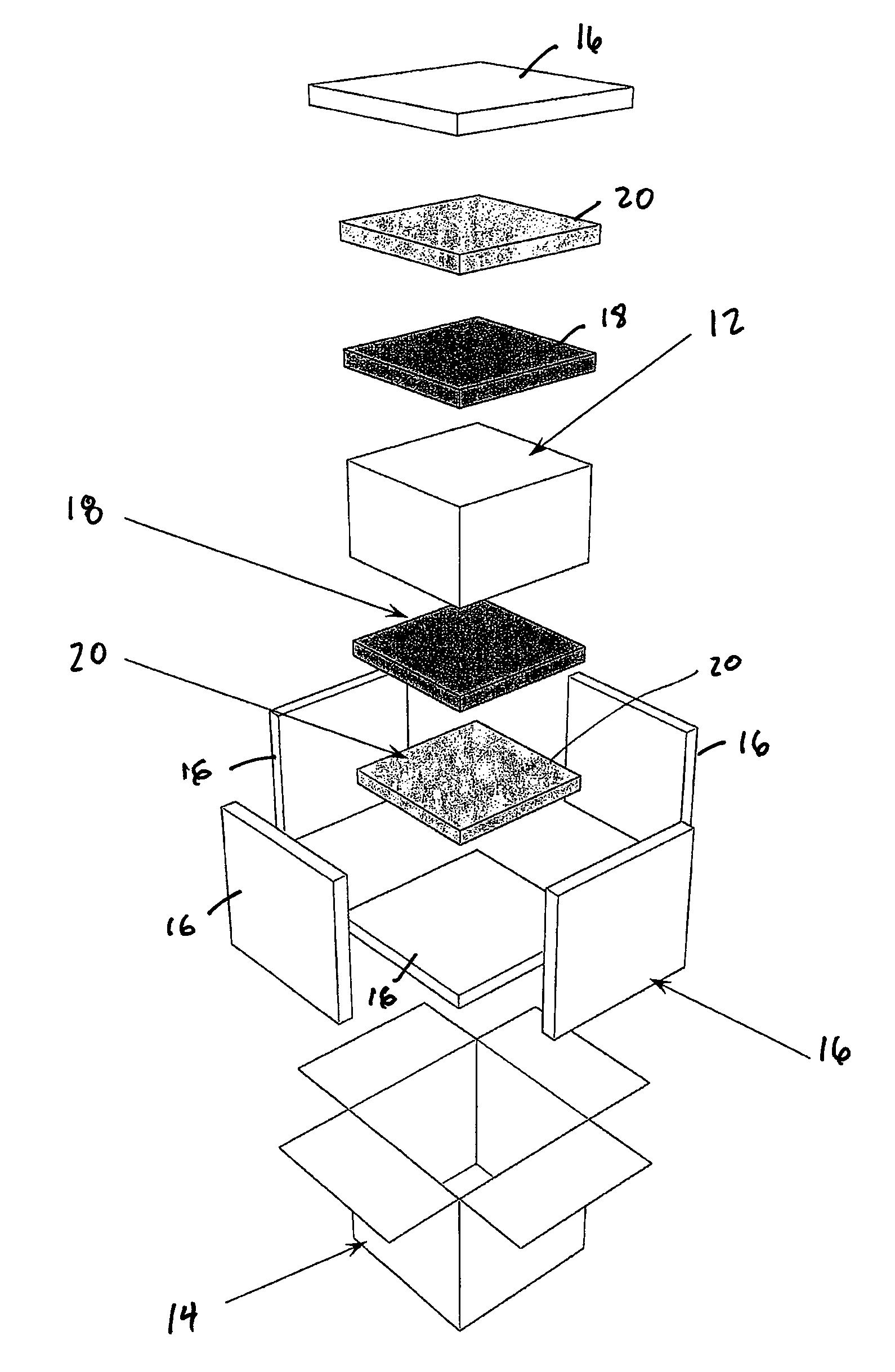

Package having phase change materials and method of use in transport of temperature sensitive payload

ActiveUS7908870B2Maintain temperatureLighting and heating apparatusContainer/bottle contructionThermal insulationEngineering

Owner:ENTROPY SOLUTIONS

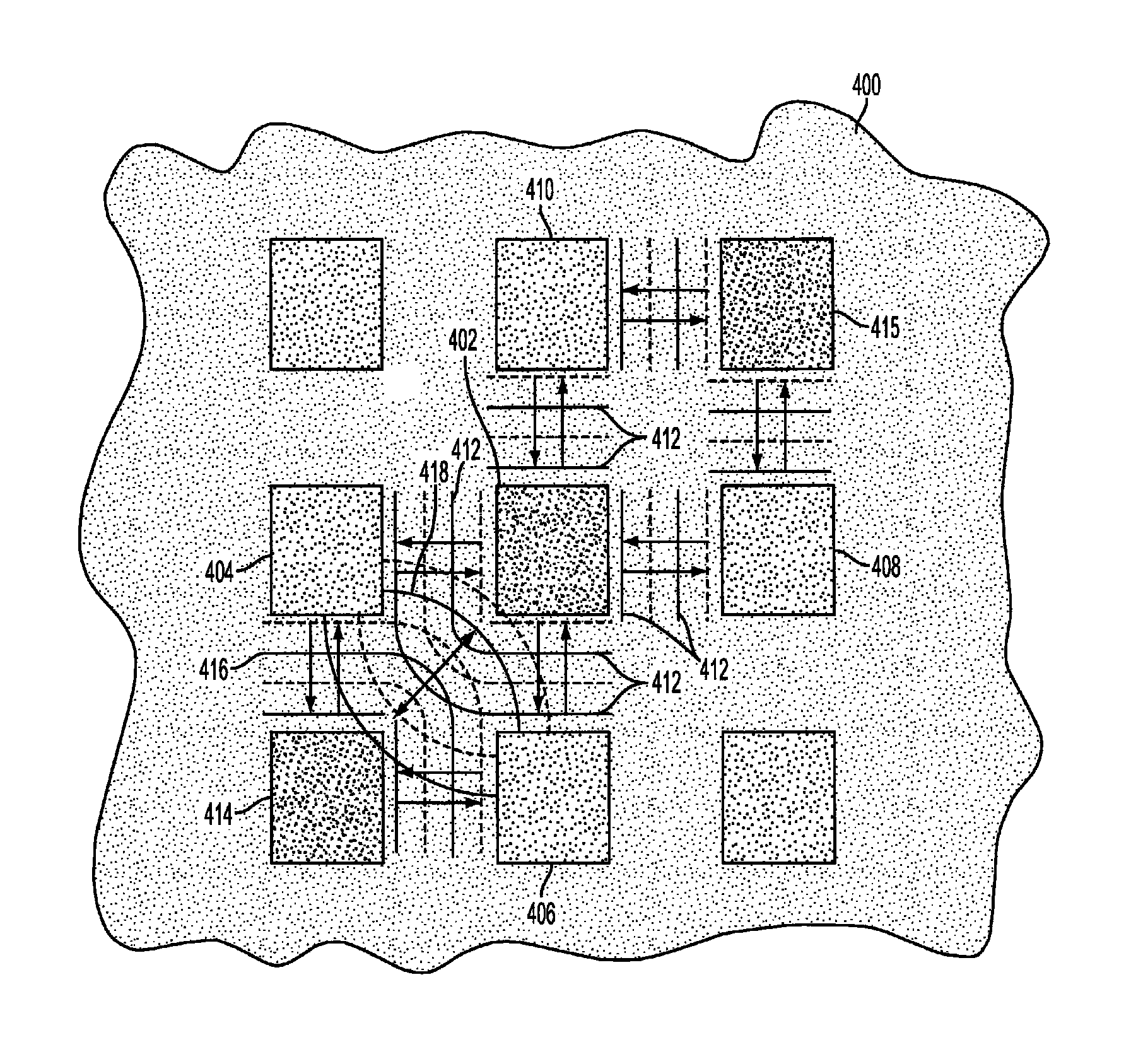

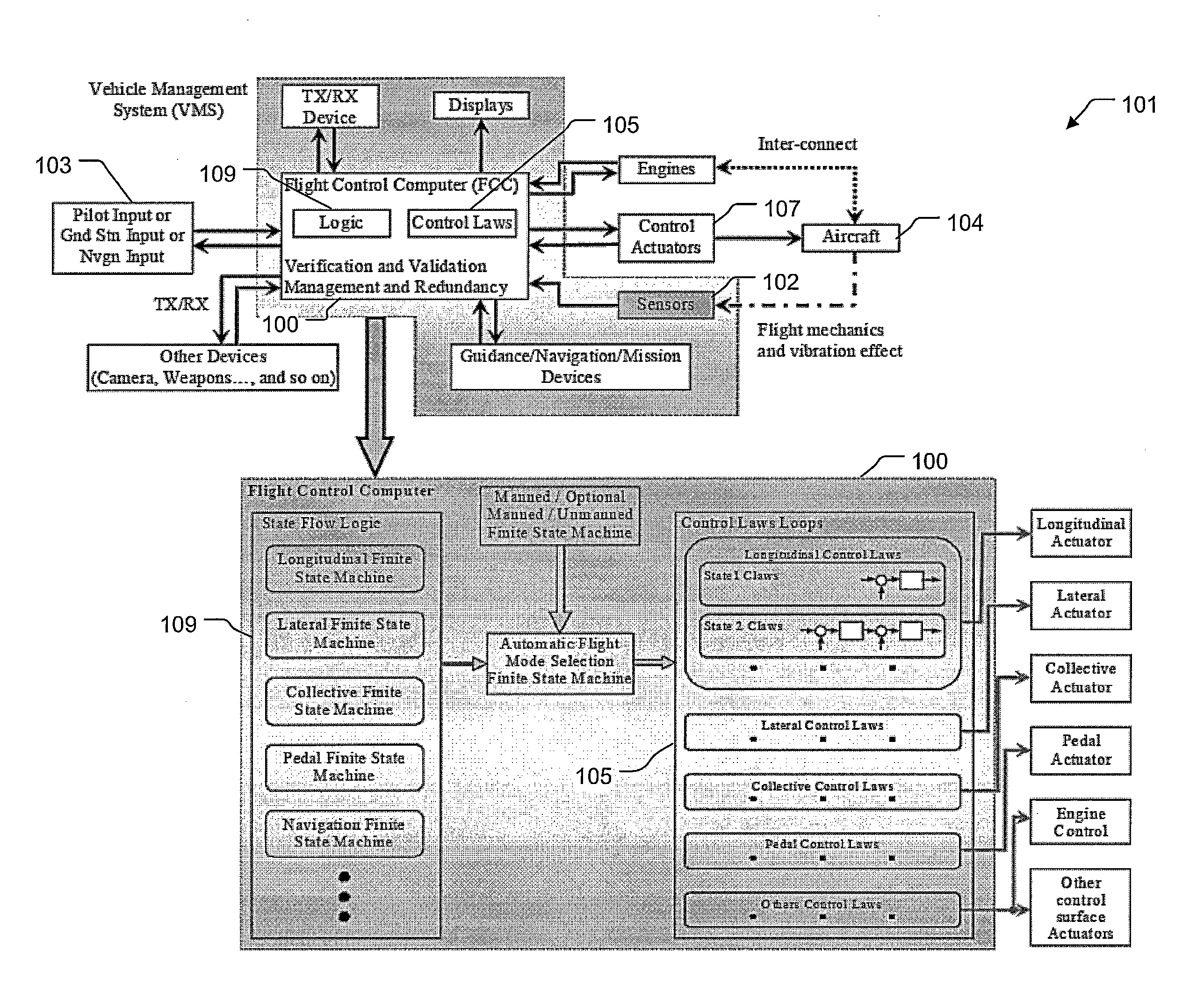

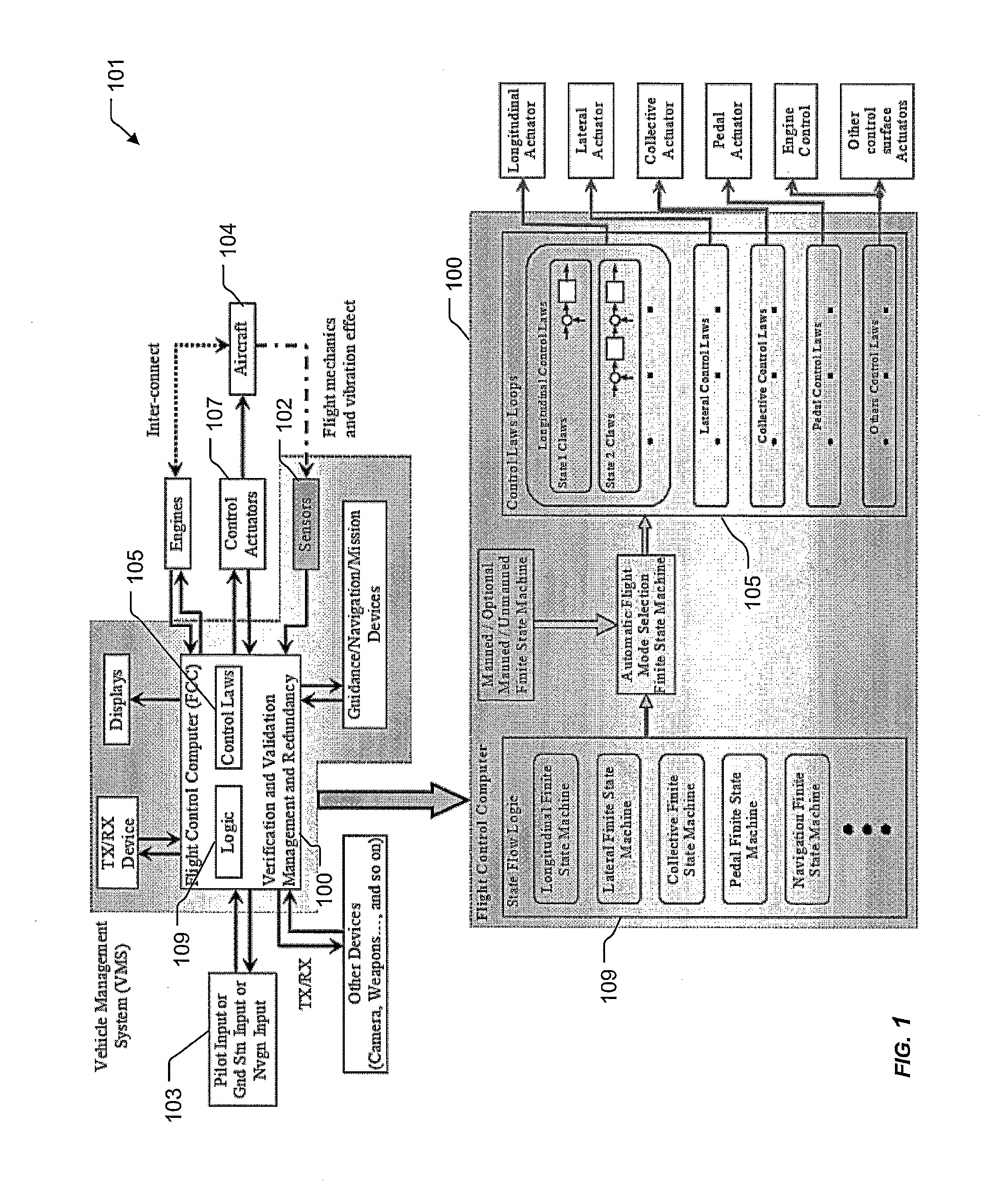

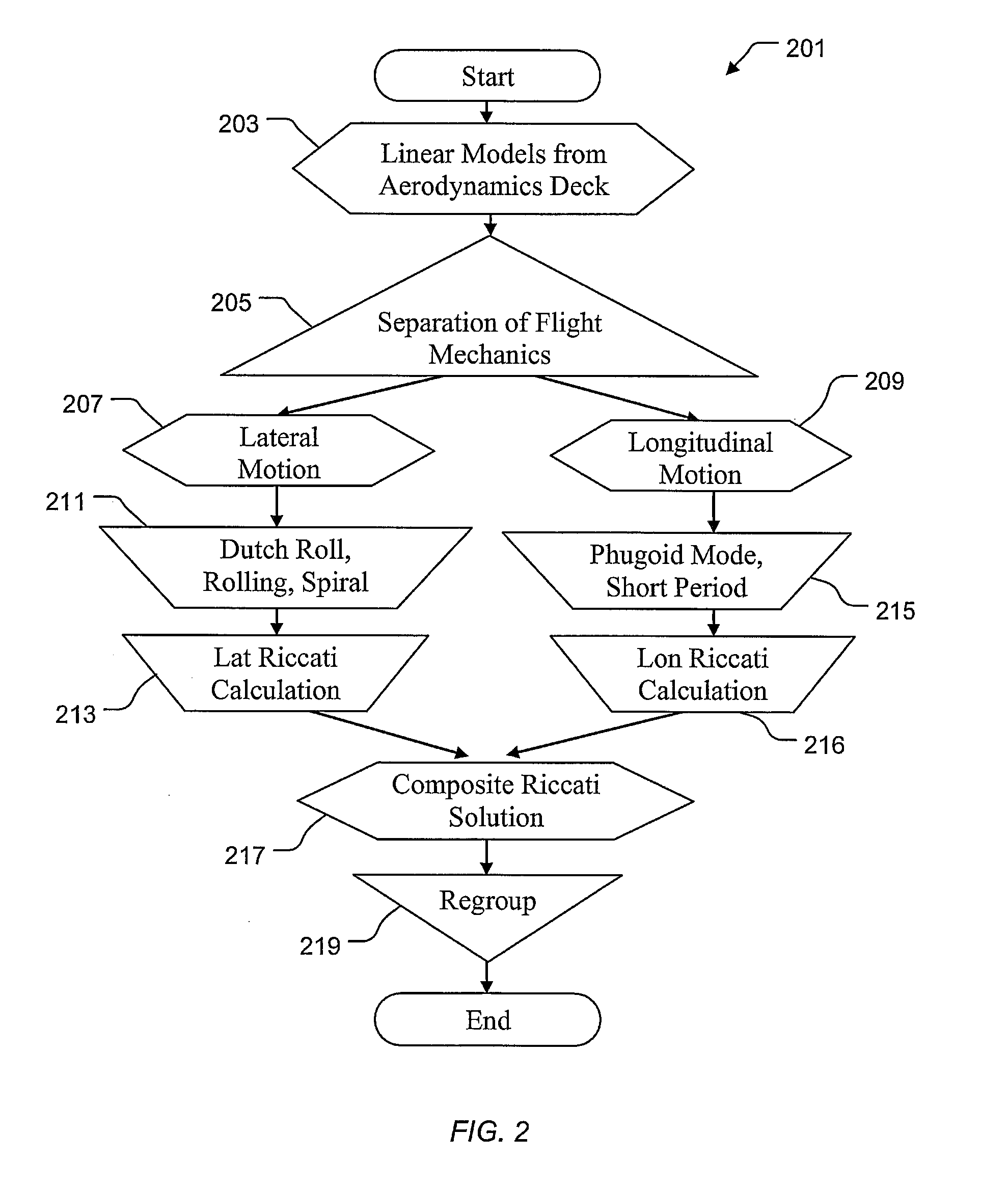

Vehicle management system using finite state machines

A system includes a plurality of actuators and a management system operably associated with the plurality electronic and mechanical devices. The management architecture includes interfaces configured to the entire electronics and mechanics to provide a parameter to a computer. The computer includes a control and management architecture using modular finite state flow designs configured to analyze the parameter. The computer with a plurality of finite state machines can conduct a plurality of control laws operably associated with one or more actuators for finite functions of mobility. The method includes matching the parameter with the finite state machine and controlling the actuator via control law operably associated with finite state machine. The method can therefore be achieved either manually, semi-autonomously and autonomously with seamless and switchless control using a central control computer with integration of electronic and mechanic sensors and devices.

Owner:TEXTRON INNOVATIONS

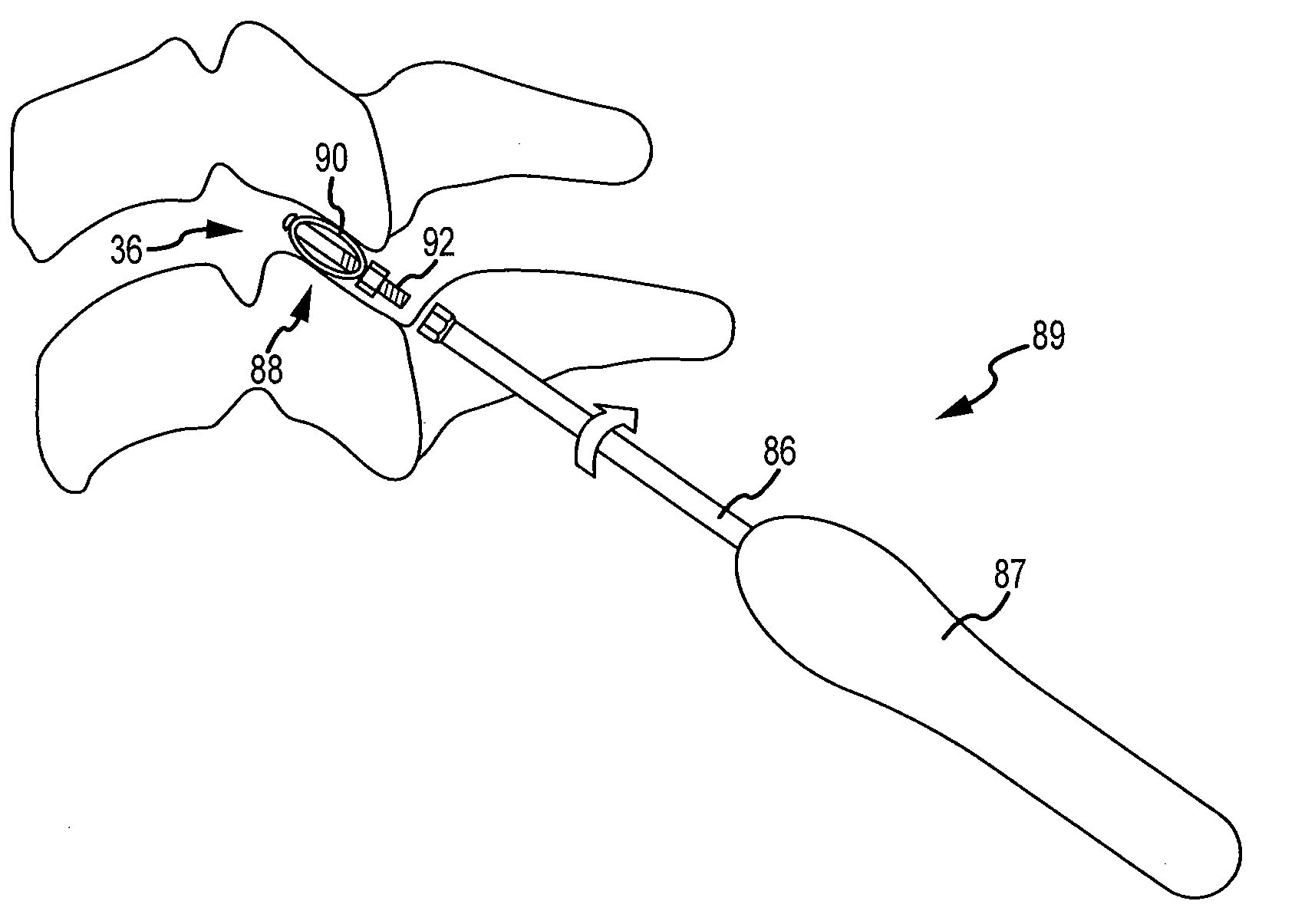

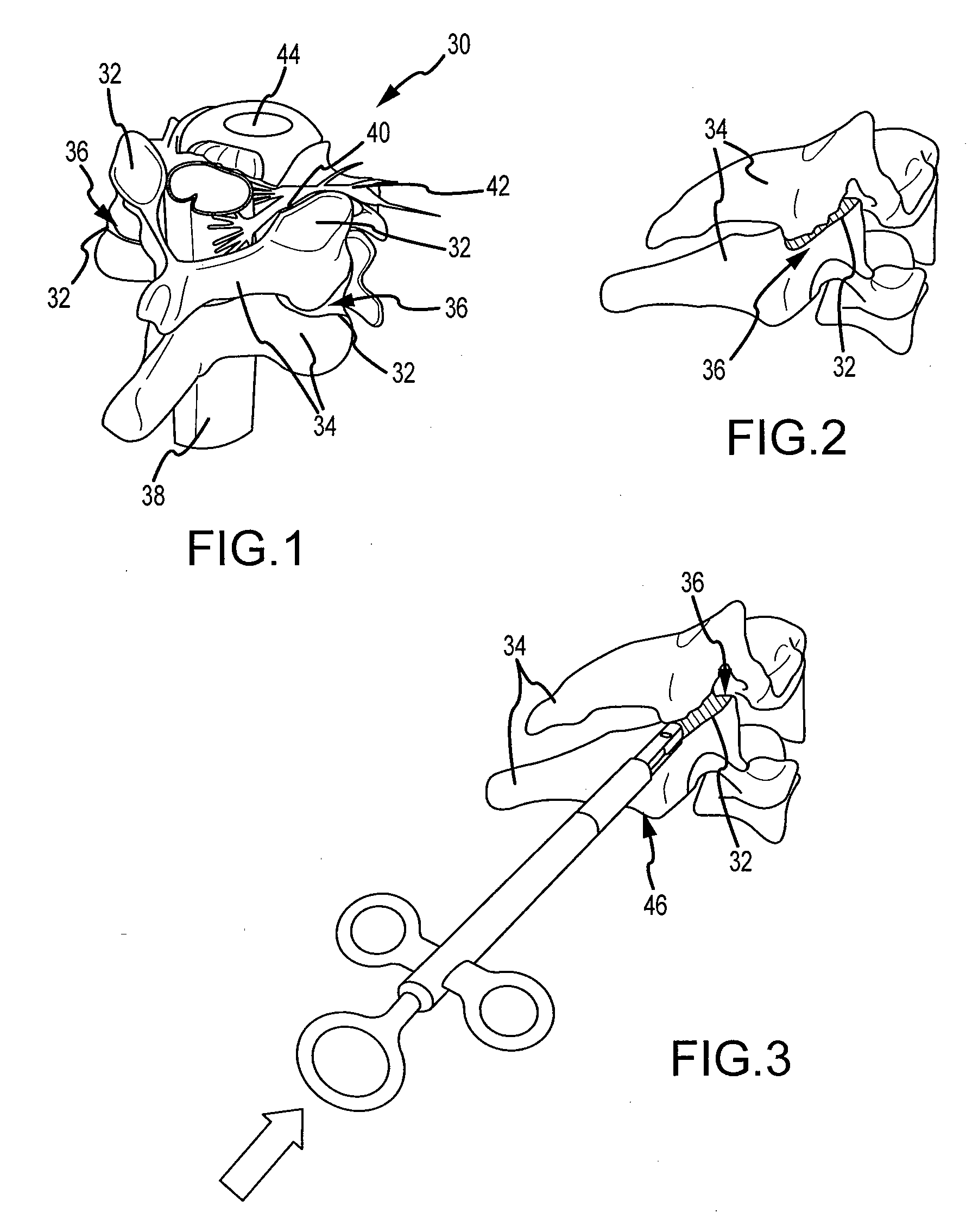

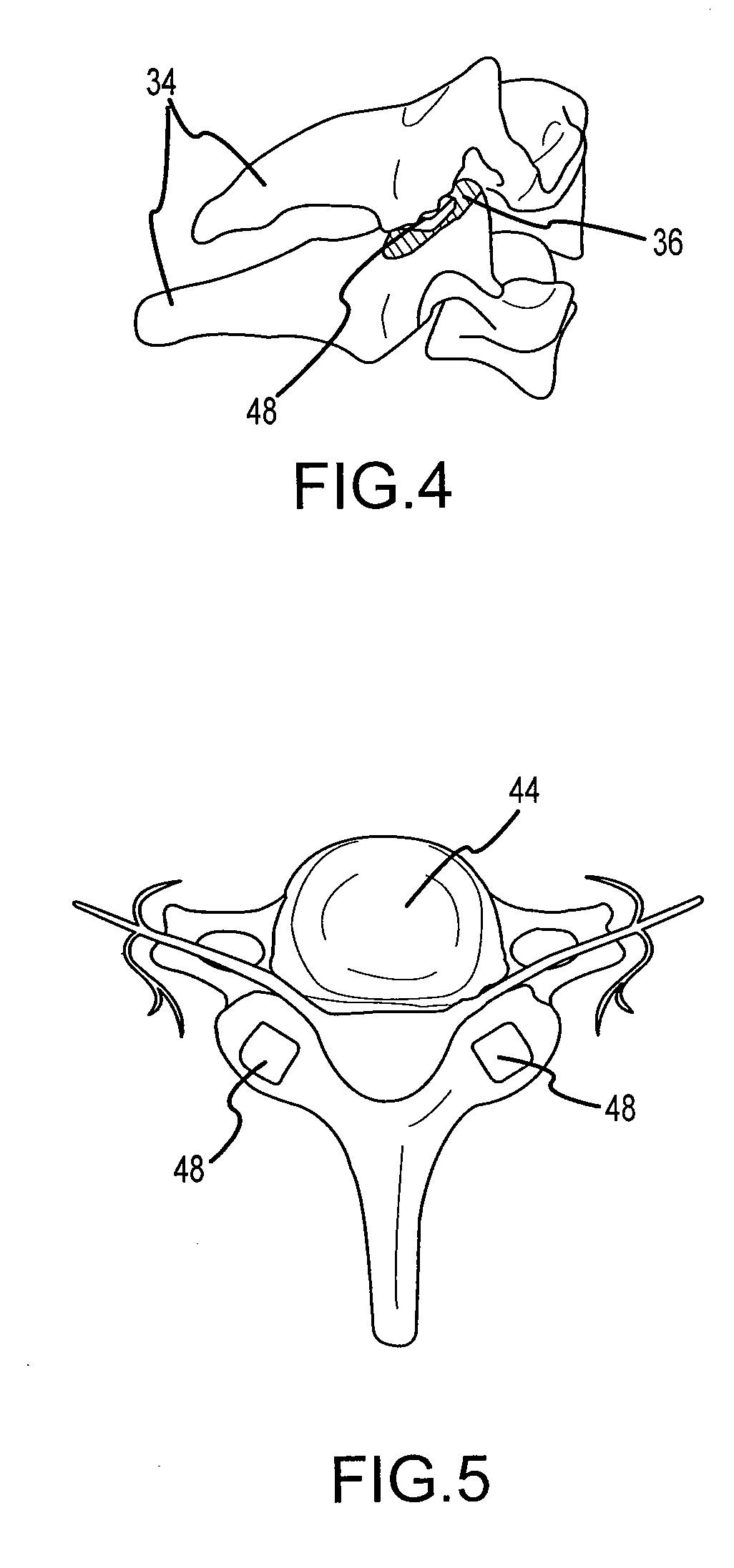

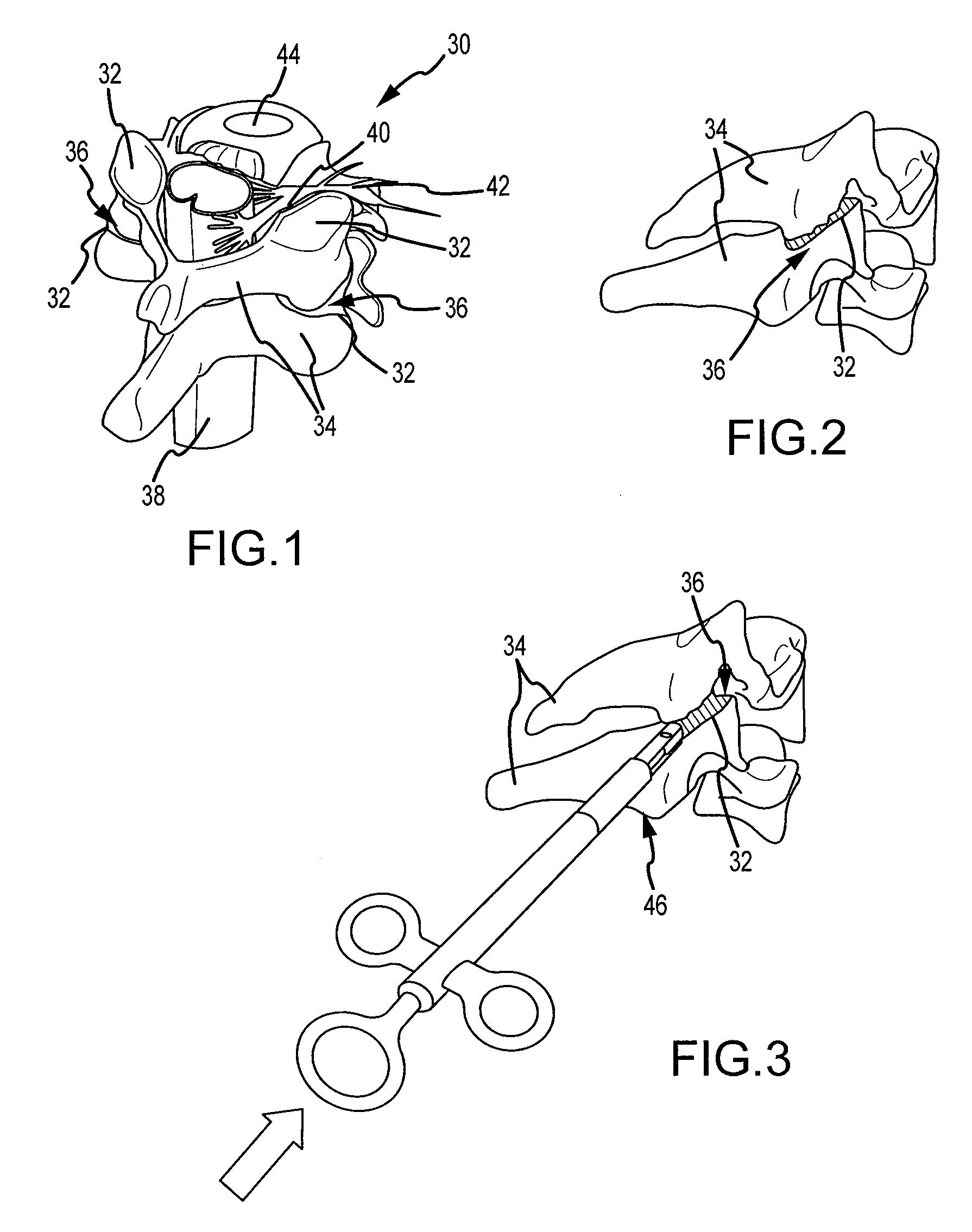

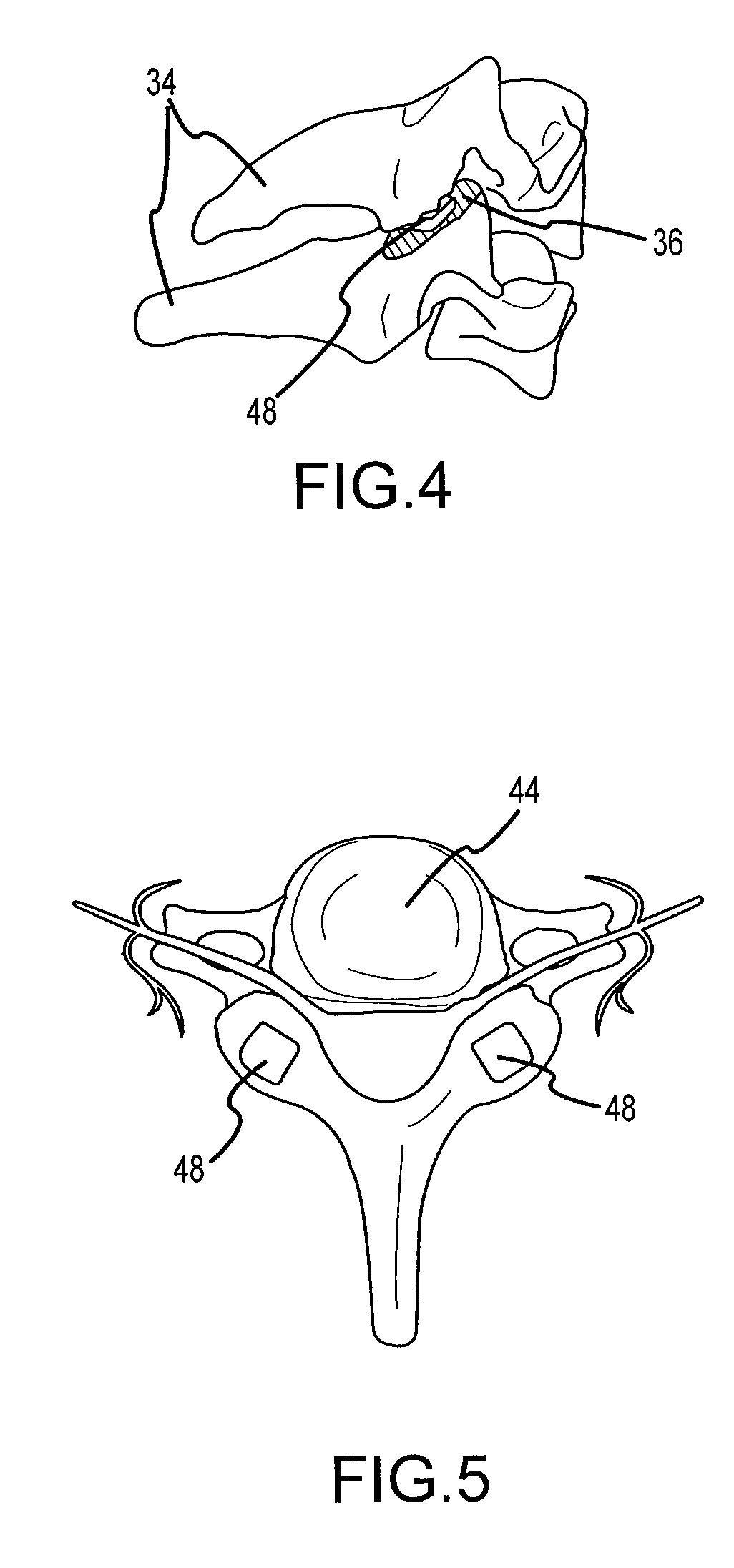

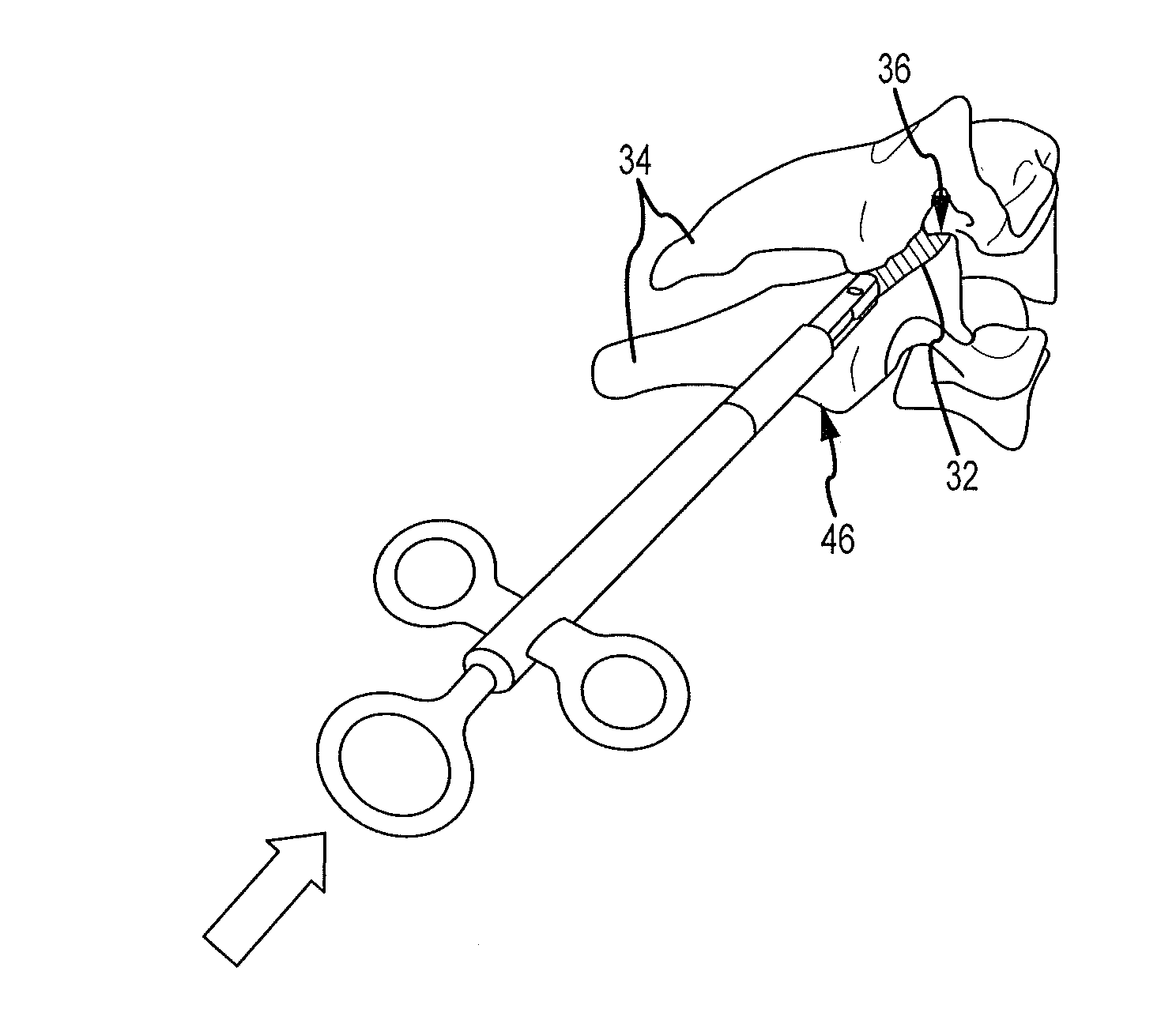

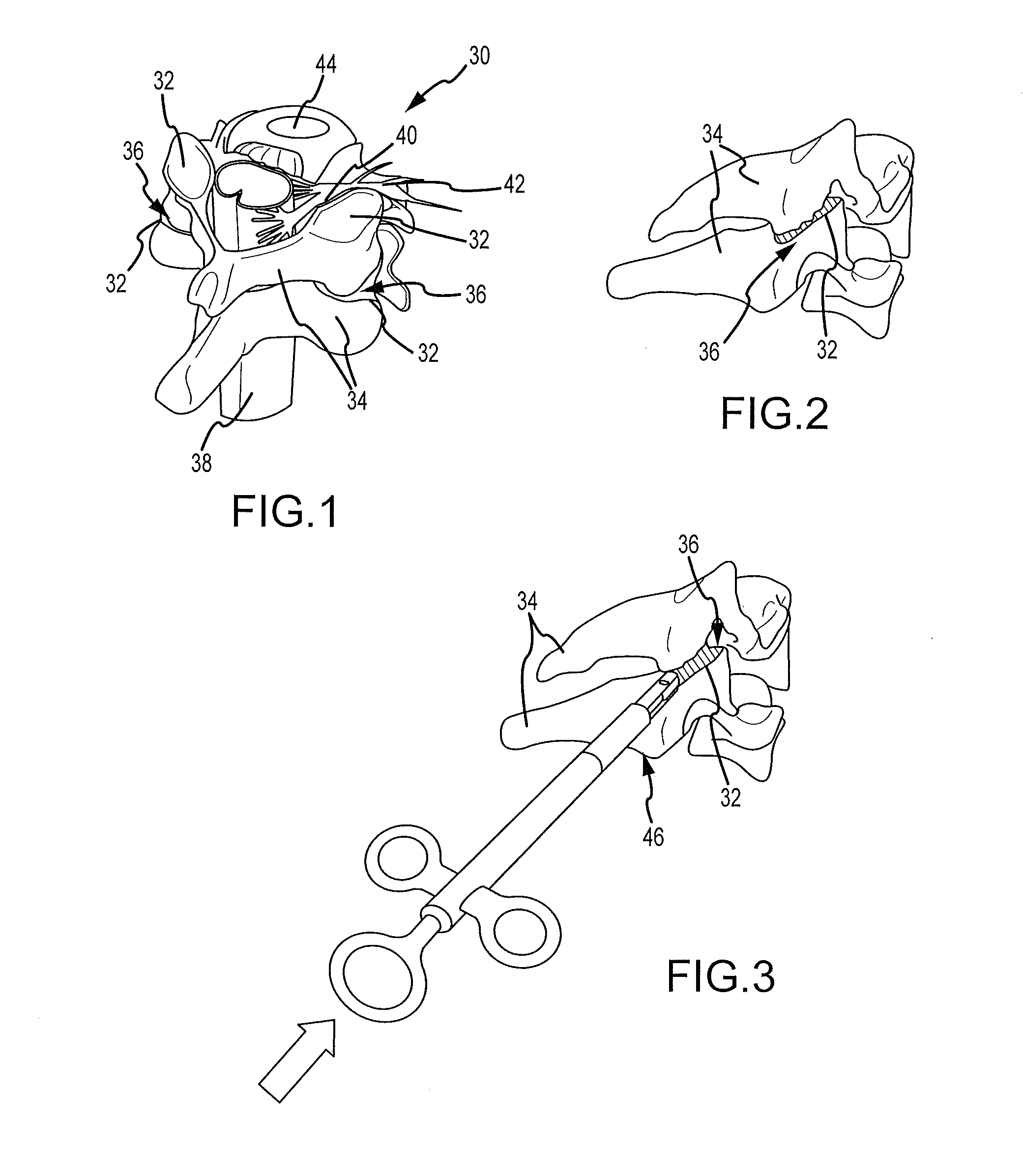

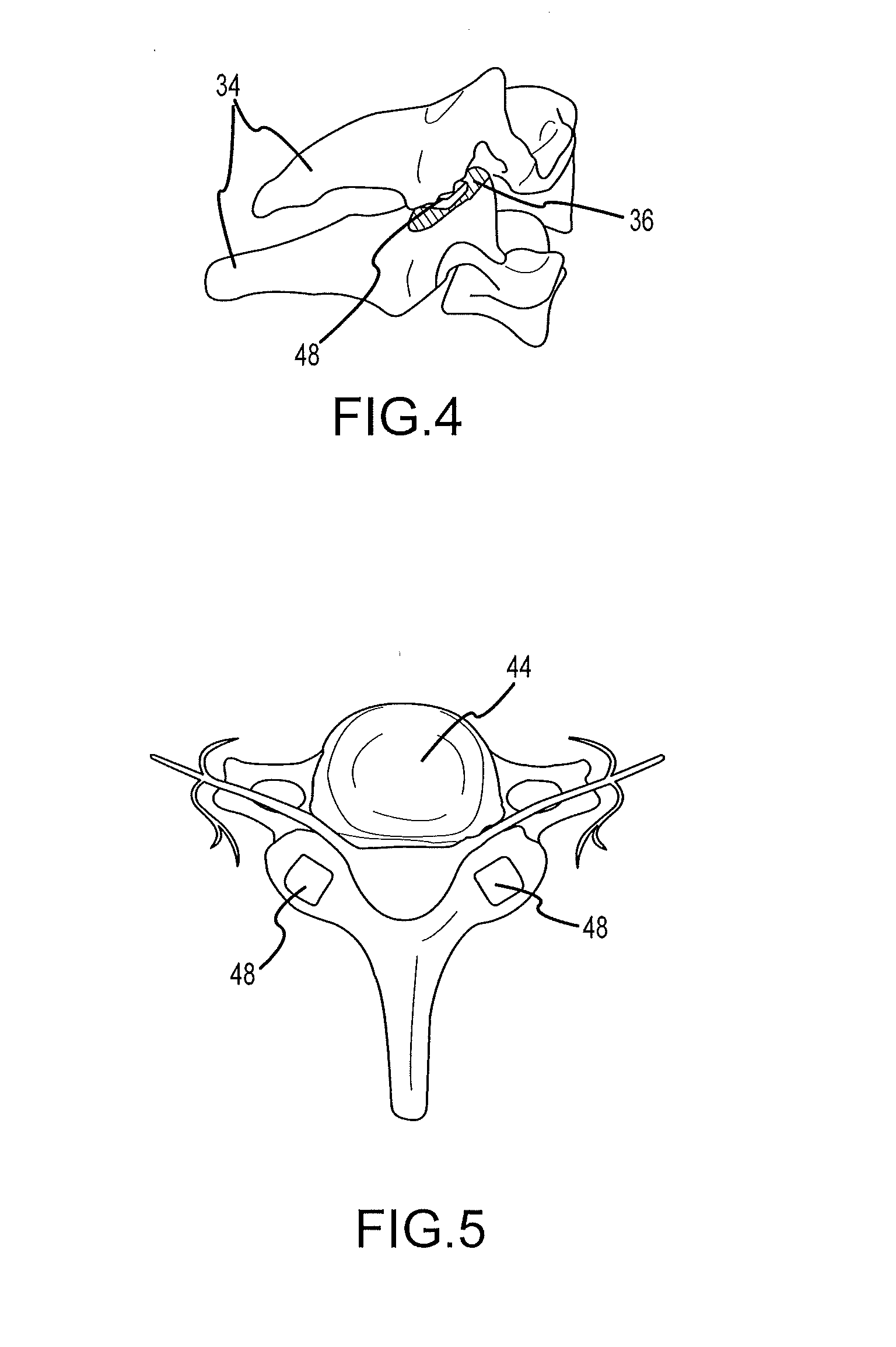

Cervical distraction/implant delivery device

ActiveUS20100069912A1Minimum distanceIncrease foraminal dimensionInternal osteosythesisDiagnosticsDistractionPermanent implant

Systems for distracting a facet joint and positioning a permanent implant in the joint are disclosed. The implants serve to retain a distracted position of the facet joint which is achieved with positioning of the leading end of a distraction tool in the facet joint and then distracting or enlarging the joint a desired amount. The permanent implant could be part of the distraction mechanism which can be separated from the delivery tool once the joint has been distracted or an auxiliary implant may be positioned before the distraction mechanism is removed from the distracted joint. The permanent implants can be solid, mechanical devices that may have fixation means thereon to hold them in place or injected fluids such as hydrogels or fluids confined within balloons.

Owner:PROVIDENCE MEDICAL TECH

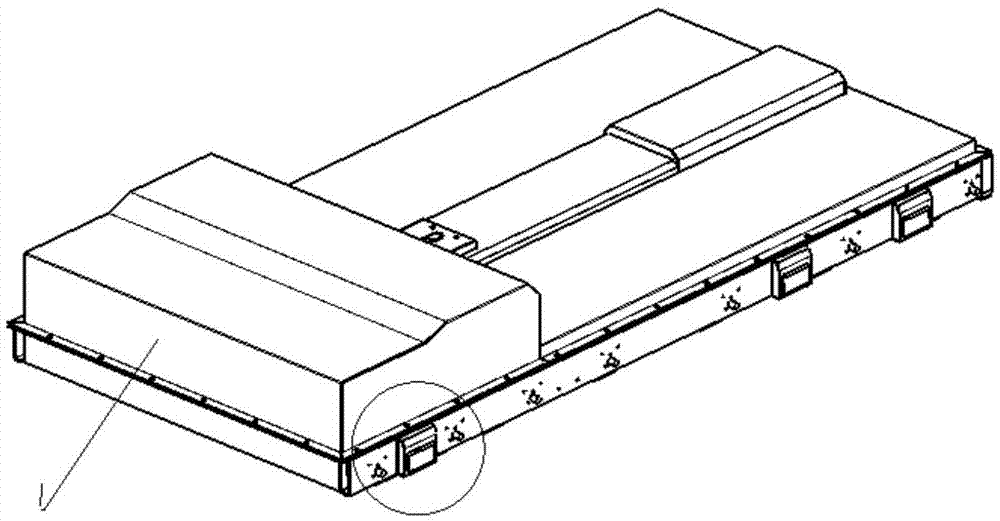

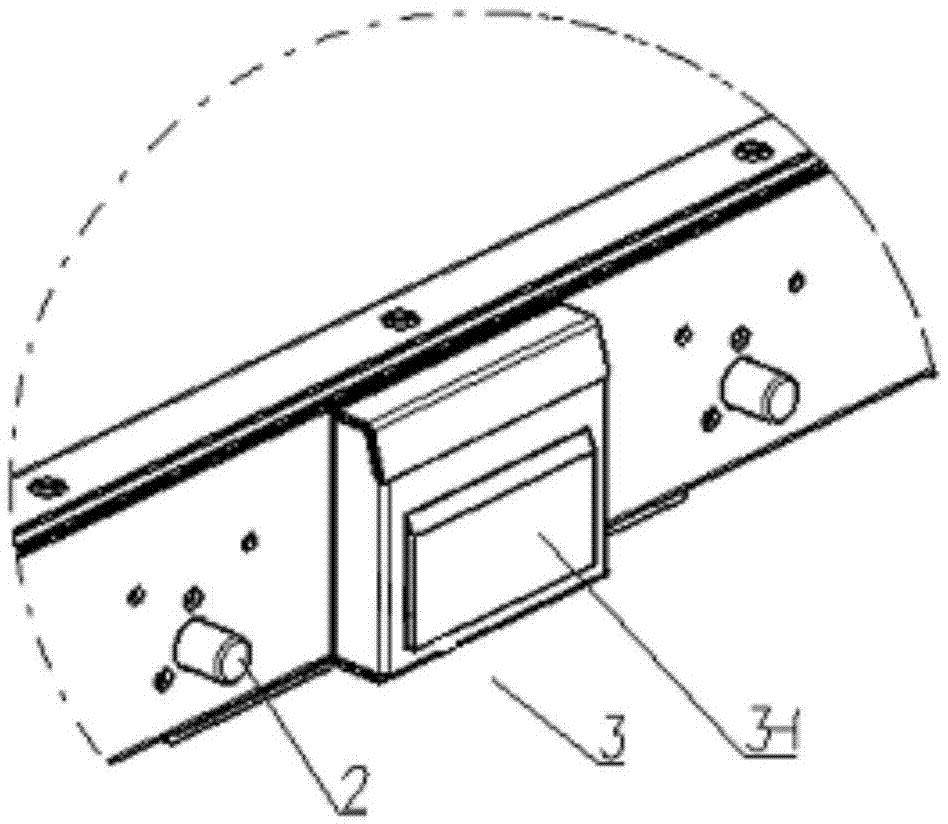

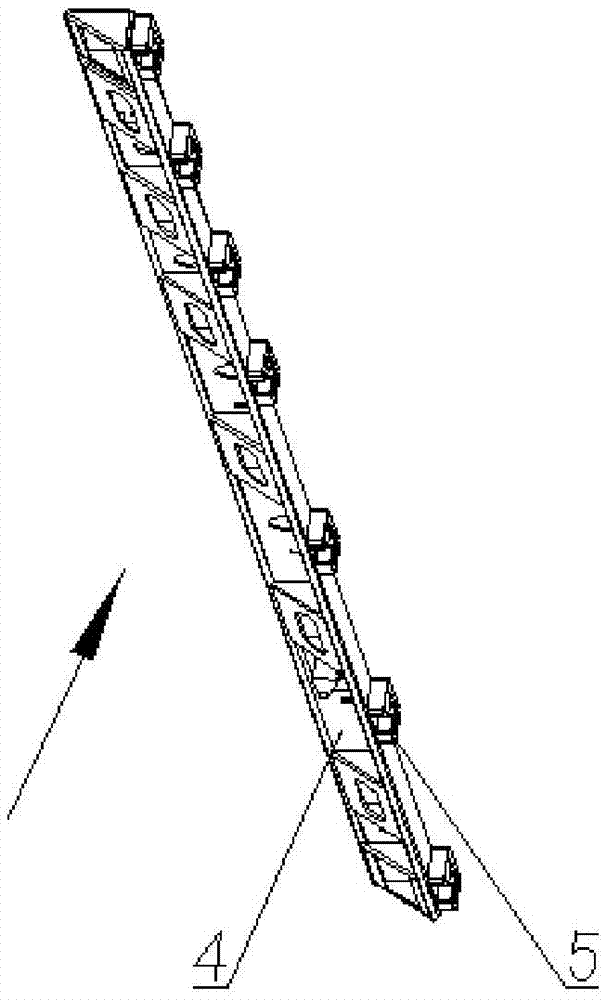

Locking mechanism of rechargeable battery box for electric passenger vehicle

InactiveCN105437945AImprove securitySimple structureElectric propulsion mountingElectricityLocking mechanism

The invention relates to the technical field of rechargeable battery boxes and in particular relates to a locking mechanism of a rechargeable battery box for an electric passenger vehicle. A locking rod is fixedly arranged on the side face of the rechargeable battery box; a lock body is arranged on a fixed support frame; an opening is formed in the upper end of the lock body; one end of a bolt penetrates through the opening of the lock body and is rotatablely connected with the lock body, and the other end of the bolt is rotatablely connected with a linkage rod; and the lower end of the lock body is also provided with an open slot and a limiting slot which is communicated with the open slot and can contain the locking rod. When the rechargeable battery box is locked, the locking rod enters the limiting slot through the open slot and blocks the opening, communicated with the limiting slot, of the open slot through rotation of the bolt. The locking mechanism of the rechargeable battery box for the electric passenger vehicle, provided by the invention, adopts pure mechanical devices and is simple in structure, simple and convenient in recharging operation and short in recharging time; and the locking is more reliable by virtue of the design of multiple locking points, so that the safety of the electric passenger vehicle is greatly improved.

Owner:JASMIN INT AUTO RES ANDDEV BEIJING CO LTD

Ophthalmic lens assembly having an integrated antenna structure

ActiveUS20140306361A1Improve performanceAntenna supports/mountingsOptical articlesIntegrated antennaMedical device

Antennas and antenna systems may be designed and configured for incorporation into mechanical devices, including medical devices, such as ophthalmic devices, including contact lenses. These antennas and antenna systems may be utilized to transmit data from the mechanical device to a receiver, to receive data from a transmitter, and / or to inductively charge an electromechanical cell or the like incorporated into the mechanical device.

Owner:JOHNSON & JOHNSON VISION CARE INC

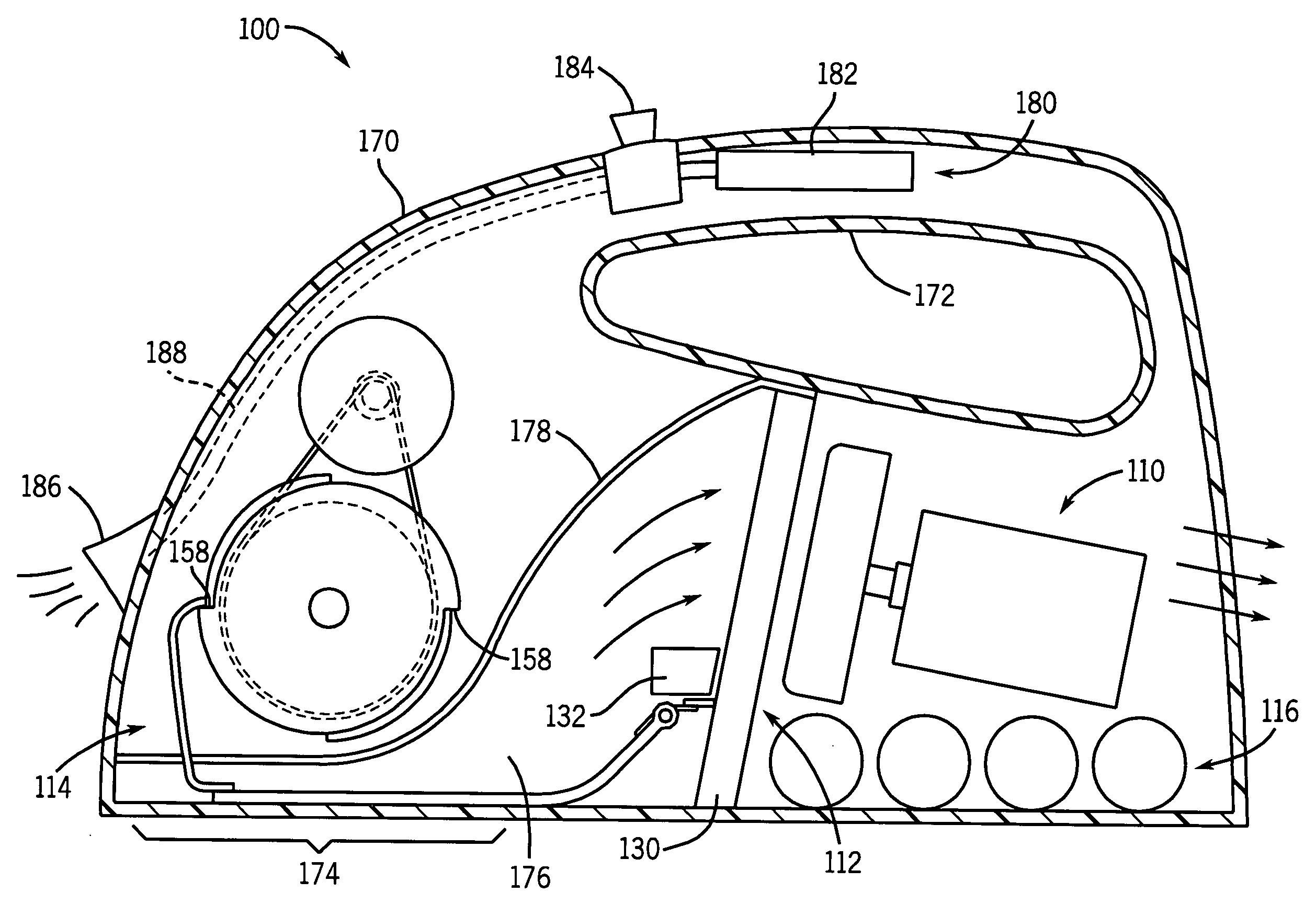

Handheld mechanical soft-surface remediation (SSR) device and method of using same

InactiveUS20060288516A1Efficient executionIncrease the areaCarpet cleanersFloor cleanersParticulatesRestoration device

A handheld mechanical soft-surface remediation (SSR) device and method of dislodging, displacing, and disposing of particulates from surfaces and performing disinfection and / or freshening is disclosed. The device is preferably lightweight, easy-to-use and includes a fan assembly, filter assembly, flapper assembly, battery assembly, and chemical delivery system. Performing soft-surface remediation with the mechanical SSR device includes the steps of retrieving the device from storage, installing the consumables into the device, activating the device, performing the cleaning operation, deactivating the device, removing the consumables from device, preparing the device for the next use, storing the device and, optionally, recharging the batteries.

Owner:SAWALSKI MICHAELM

Cervical distraction/implant delivery device

ActiveUS8512347B2Increase spacingImprove the situationInternal osteosythesisDiagnosticsDistractionPermanent implant

Systems for distracting a facet joint and positioning a permanent implant in the joint are disclosed. The implants serve to retain a distracted position of the facet joint which is achieved with positioning of the leading end of a distraction tool in the facet joint and then distracting or enlarging the joint a desired amount. The permanent implant could be part of the distraction mechanism which can be separated from the delivery tool once the joint has been distracted or an auxiliary implant may be positioned before the distraction mechanism is removed from the distracted joint. The permanent implants can be solid, mechanical devices that may have fixation means thereon to hold them in place or injected fluids such as hydrogels or fluids confined within balloons.

Owner:PROVIDENCE MEDICAL TECH

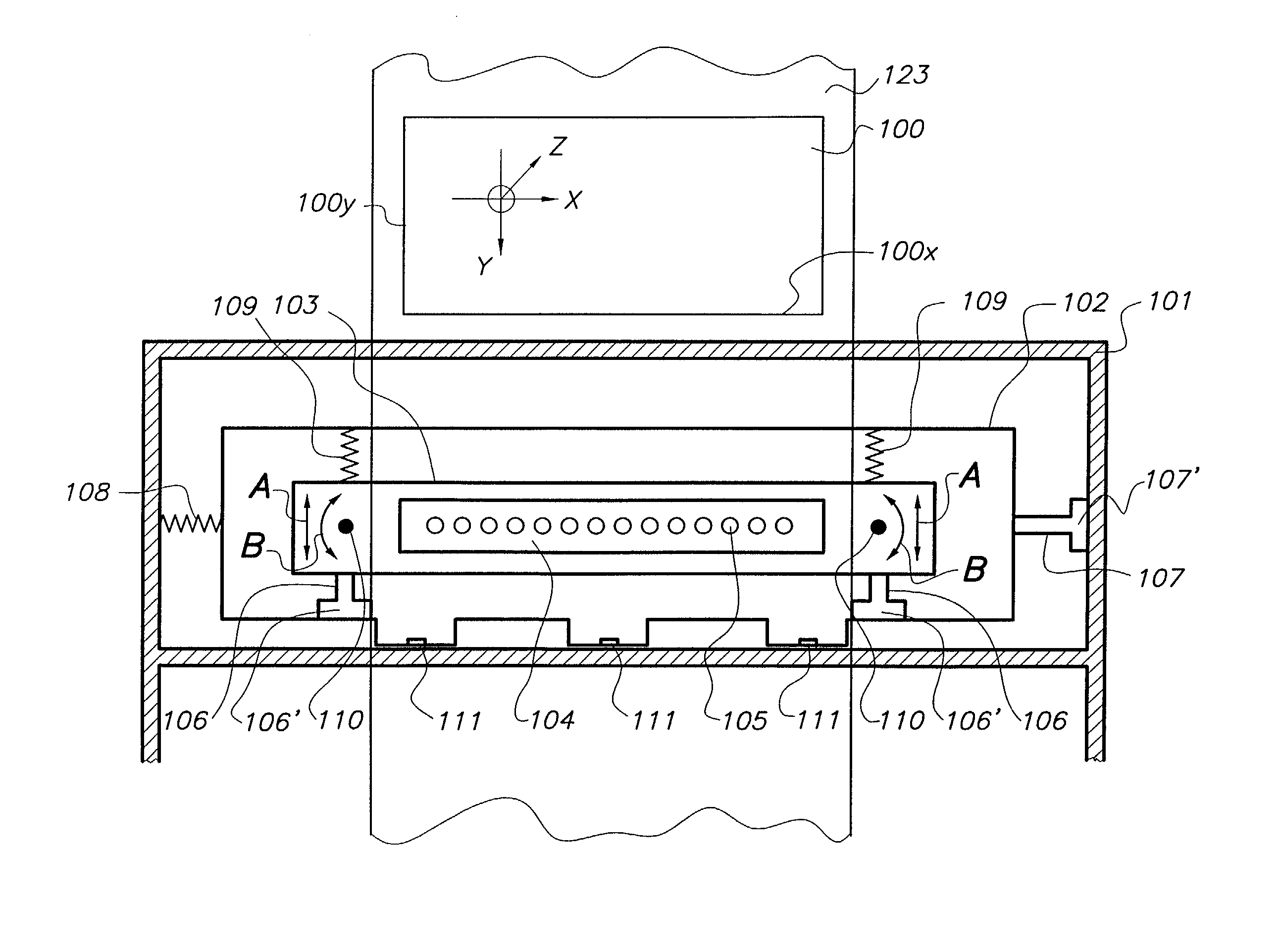

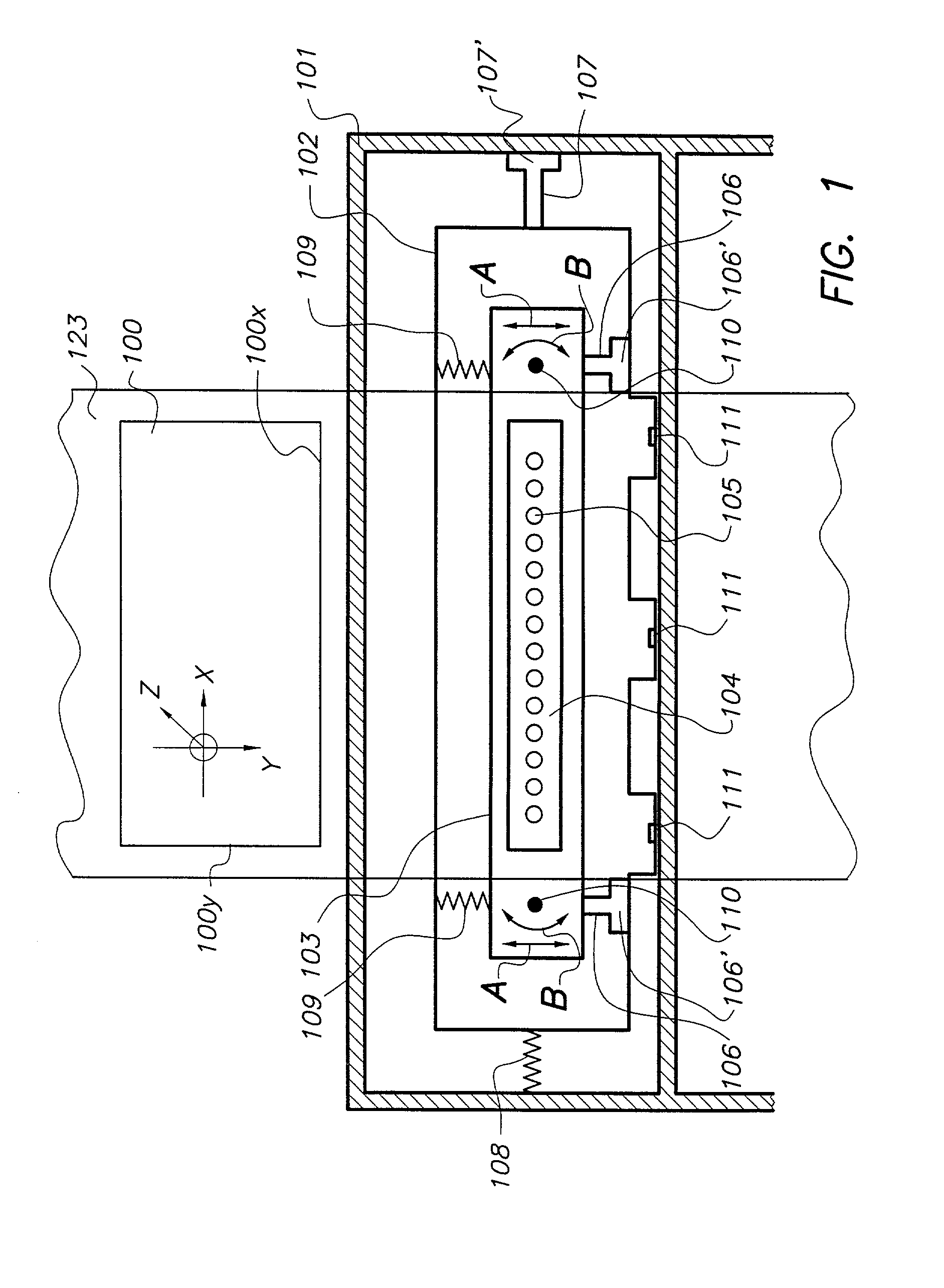

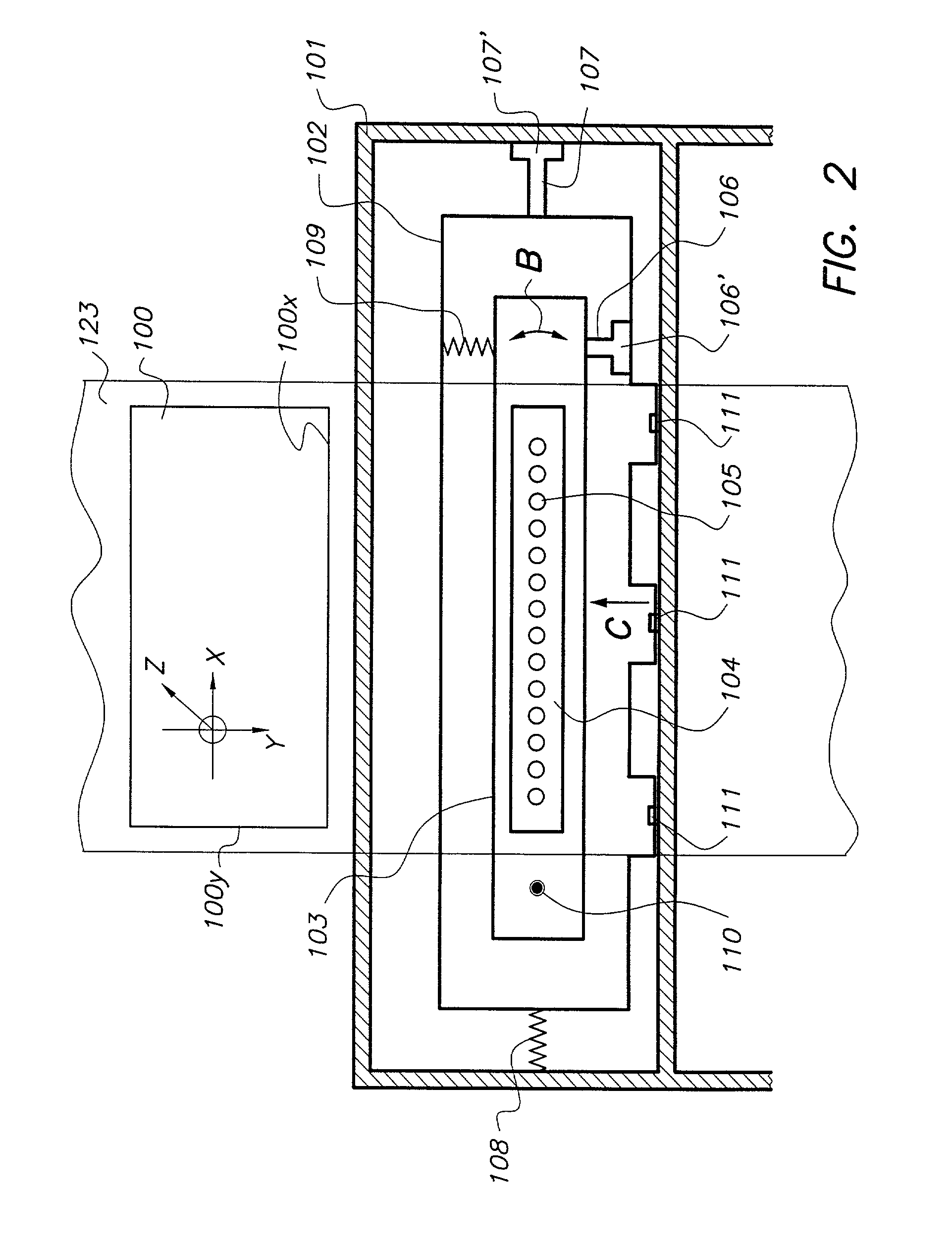

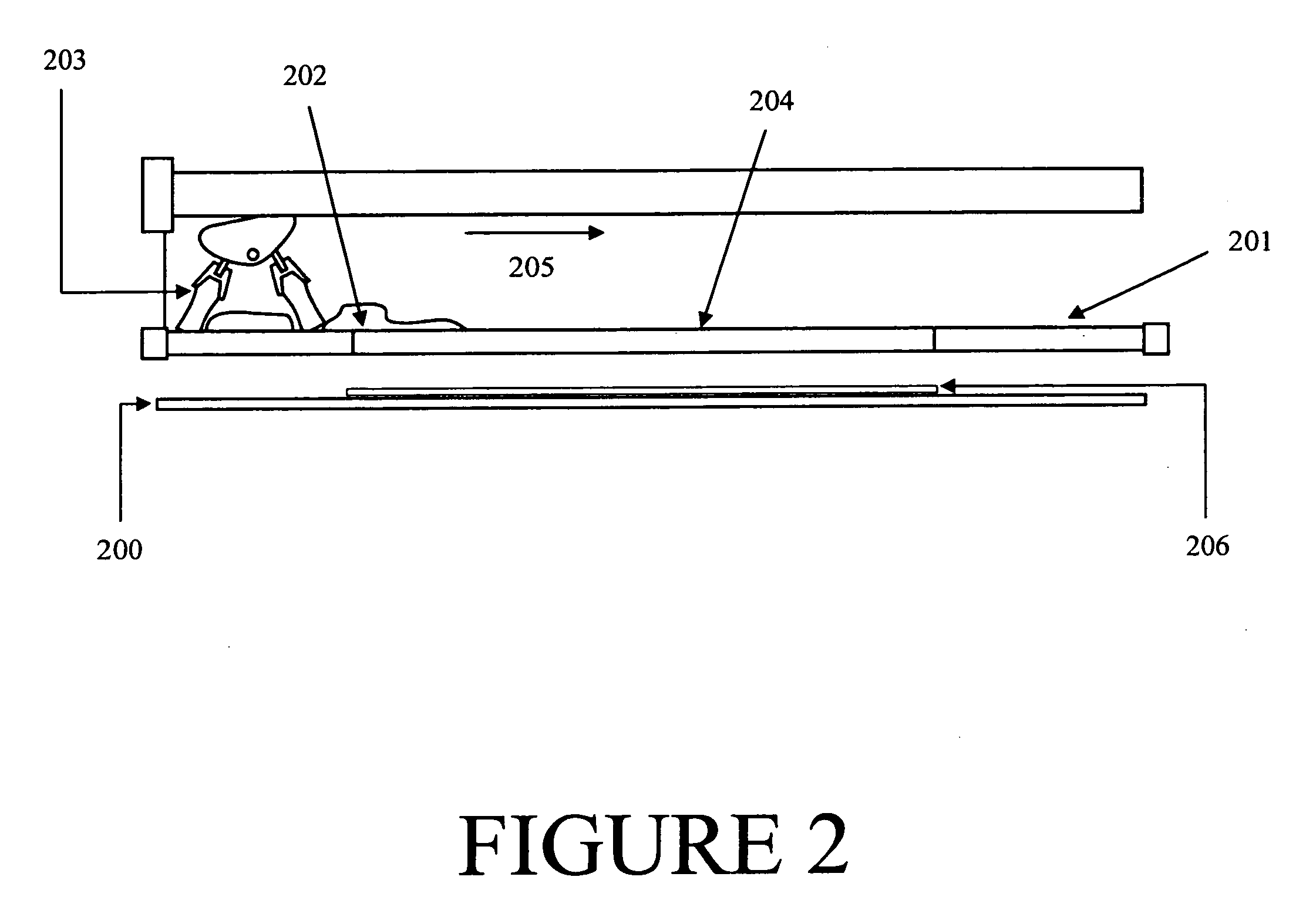

Ink-jet printer equipped for aligning the printheads

InactiveUS20020126169A1Power drive mechanismsOther printing apparatusBiomedical engineeringMechanical devices

An ink-jet printer includes pagewidth printheads mounted in a frame, wherein the printheads are coupled to mechanical devices for aligning the printheads with respect to each other, with respect to an edge of the image receiving substrate, or with respect to both. The printer may include devices for sensing the possible misalignment, coupled to a computer for automatically aligning the printheads.

Owner:AGFA NV

Cervical distraction/implant delivery device

InactiveUS20130310943A1Increase spacingIncrease distanceInternal osteosythesisDiagnosticsPermanent implantCervical traction

Systems for distracting a facet joint and positioning a permanent implant in the joint are disclosed. The implants serve to retain a distracted position of the facet joint which is achieved with positioning of the leading end of a distraction tool in the facet joint and then distracting or enlarging the joint a desired amount. The permanent implant could be part of the distraction mechanism which can be separated from the delivery tool once the joint has been distracted or an auxiliary implant may be positioned before the distraction mechanism is removed from the distracted joint. The permanent implants can be solid, mechanical devices that may have fixation means thereon to hold them in place or injected fluids such as hydrogels or fluids confined within balloons.

Owner:PROVIDENCE MEDICAL TECH

Vegetable oil lubricant comprising all-hydroprocessed synthetic oils

InactiveUS20050059562A1Improve propertiesEnhanced microbial biodegradabilityLiquid carbonaceous fuelsAdditivesVegetable oilLubricant

The present invention discloses vegetable oil based compositions having an effective combination of properties including lubricity, rheology, electrical insulating value and microbial biodegradability making them particularly useful for the proper functioning of mechanical devices.

Owner:RENEWABLE LUBRICANTS INC

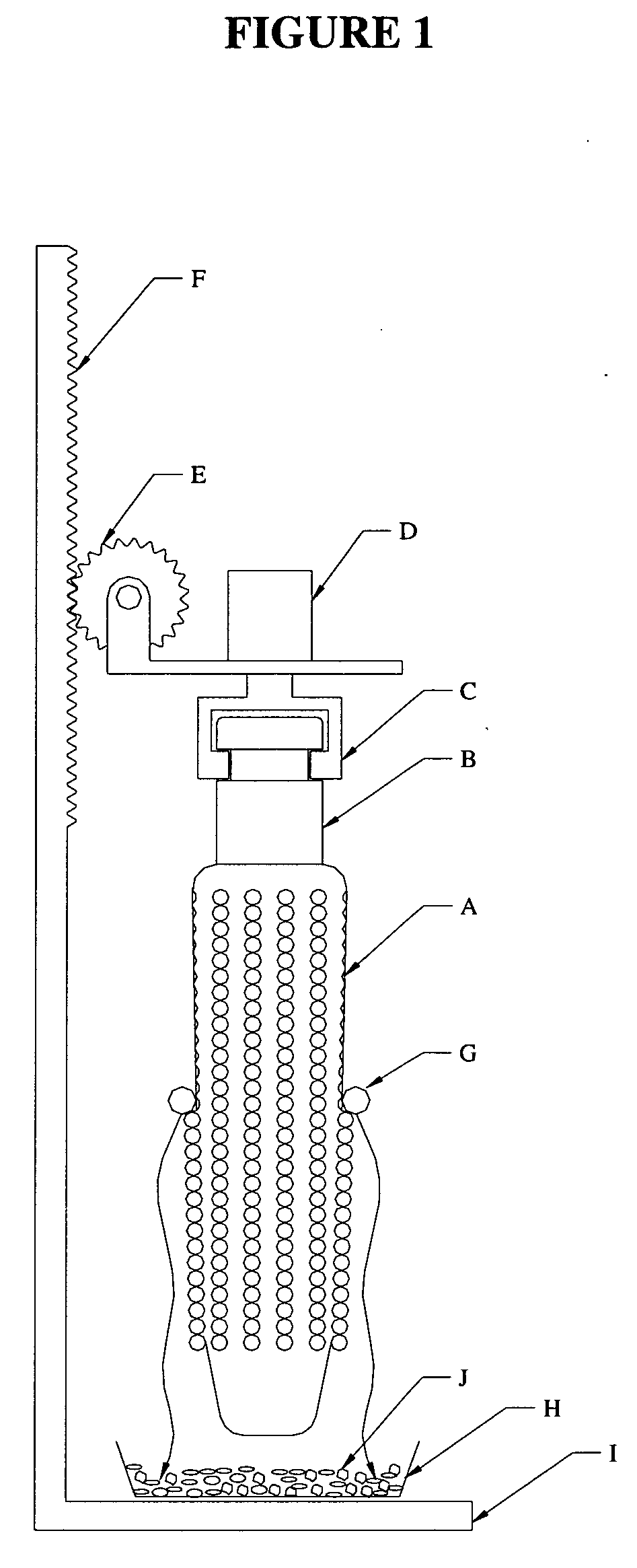

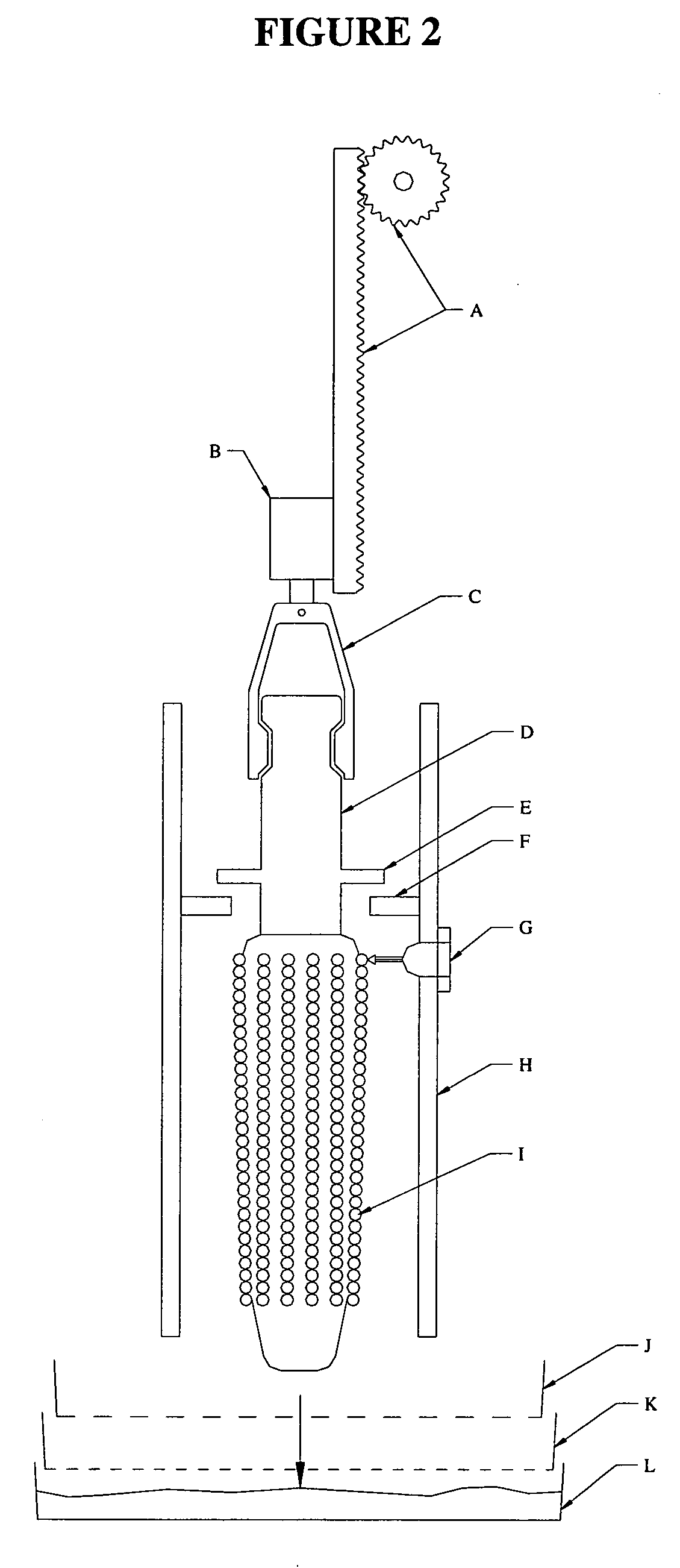

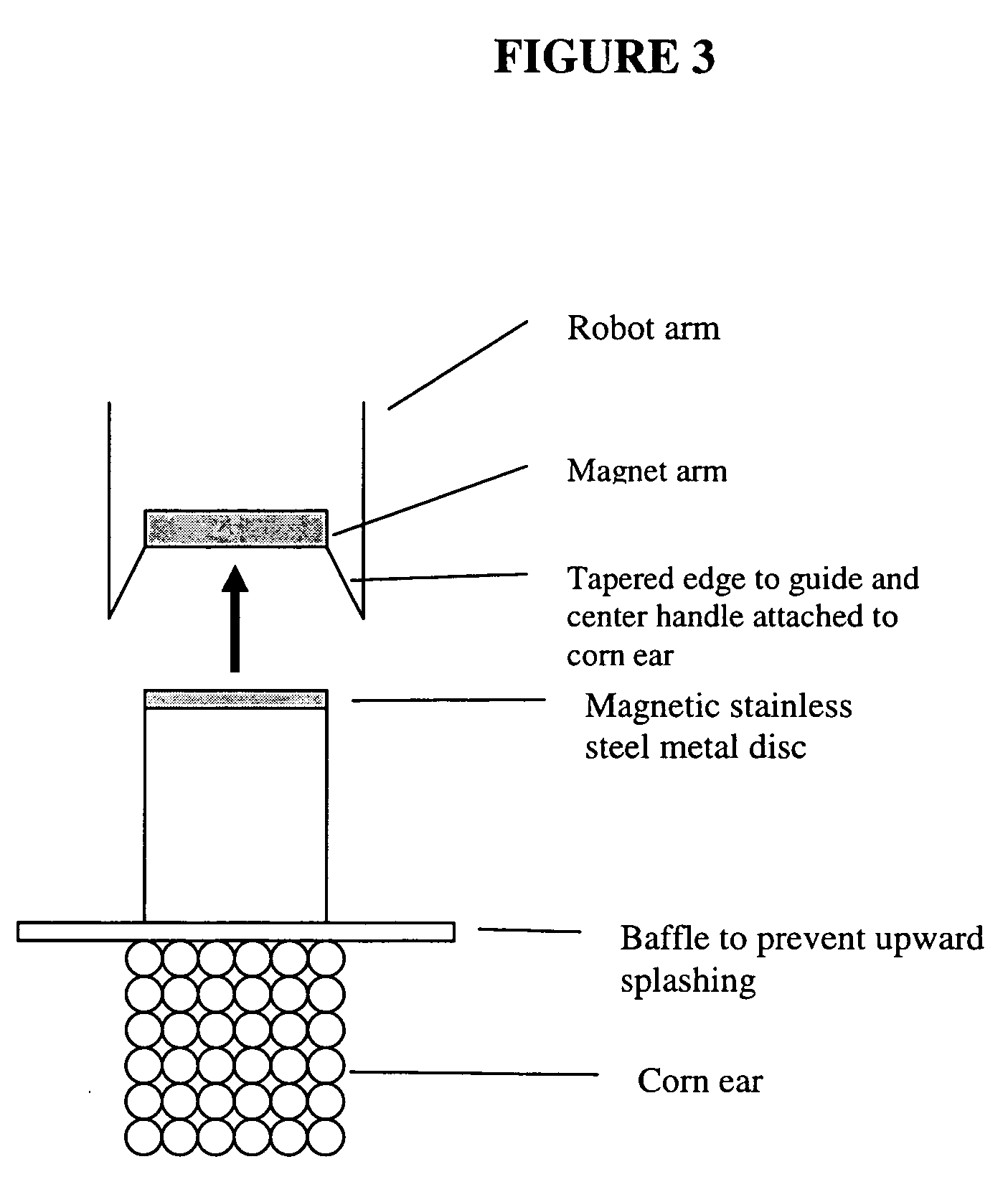

Method and apparatus for substantially isolating plant tissues

ActiveUS20050246786A1Improve reliabilityReduce harmOther foreign material introduction processesFermentationPlant tissueGMO Plants

The present invention discloses and claims methods and devices for the rapid mechanical isolation of monocot plant tissues suitable for transformation or tissue culture. The invention includes mechanical devices for substantially isolating target plant tissues for use as transformable explants, and propagation of transgenic plants and plant tissues.

Owner:MONSANTO TECH LLC

Method and apparatus for substantially isolating plant tissues

ActiveUS20090142837A1Bioreactor/fermenter combinationsBiological substance pretreatmentsPlant tissueEmbryo

The present invention provides methods and devices for the rapid isolation of monocot plant embryos suitable for transformation or tissue culture. The invention includes mechanical devices for substantially isolating plant embryos for use as transformable explants. Media suitable for isolating plant embryos and methods for their preparation are also provided.

Owner:MONSANTO TECH LLC

Cooling arrangement for an offshore wind energy installation

InactiveUS7111668B2Reduce stepsEffective preventionDomestic cooling apparatusEngine fuctionsAmbient waterMechanics

A cooling arrangement for an offshore wind energy installation, having a heat-absorbing device for absorbing heat generated by the electronic devices and / or the mechanical devices of the offshore energy installation, which is to be removed, and a coupled heat-dissipating device for dissipating heat to the surrounding water. The heat-absorbing device has a first cooling circuit operated by a fluid coolant which, in a heat exchanger device, transfers the absorbed heat to the heat-dissipating device having an open second cooling circuit operated with the ambient water as the coolant. A plurality of electrodes are arranged on the inner walls of the conduits of the second cooling circuit, which are spaced apart from each other in its extension direction, each of which is connected with a voltage supply device for generating an alternating high voltage between at least two of the electrodes.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Touch sensor control devices

InactiveUS8199114B1Minimal electronicsLow costTransmission systemsCathode-ray tube indicatorsMotor driveElectrical conductor

Owner:NBOR CORP

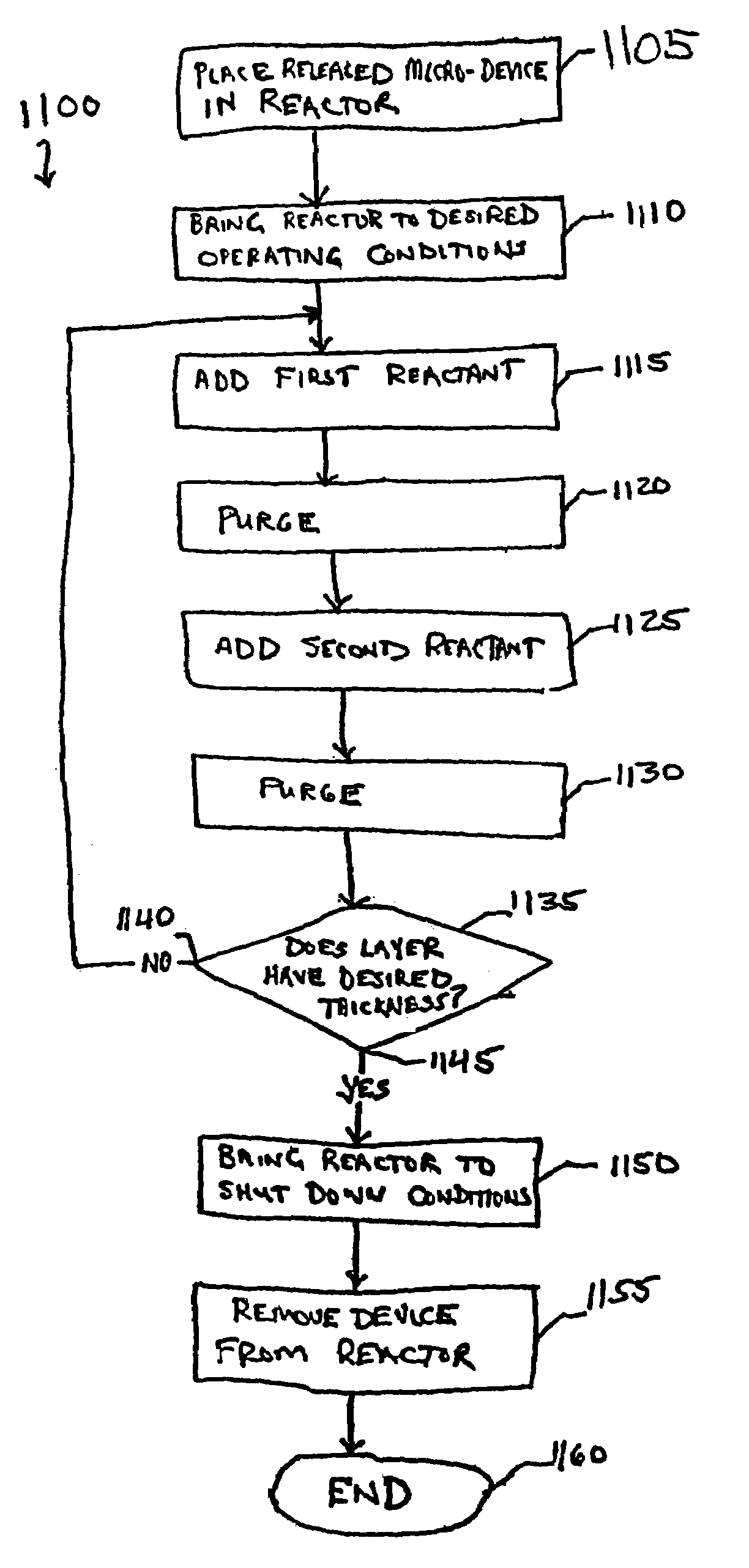

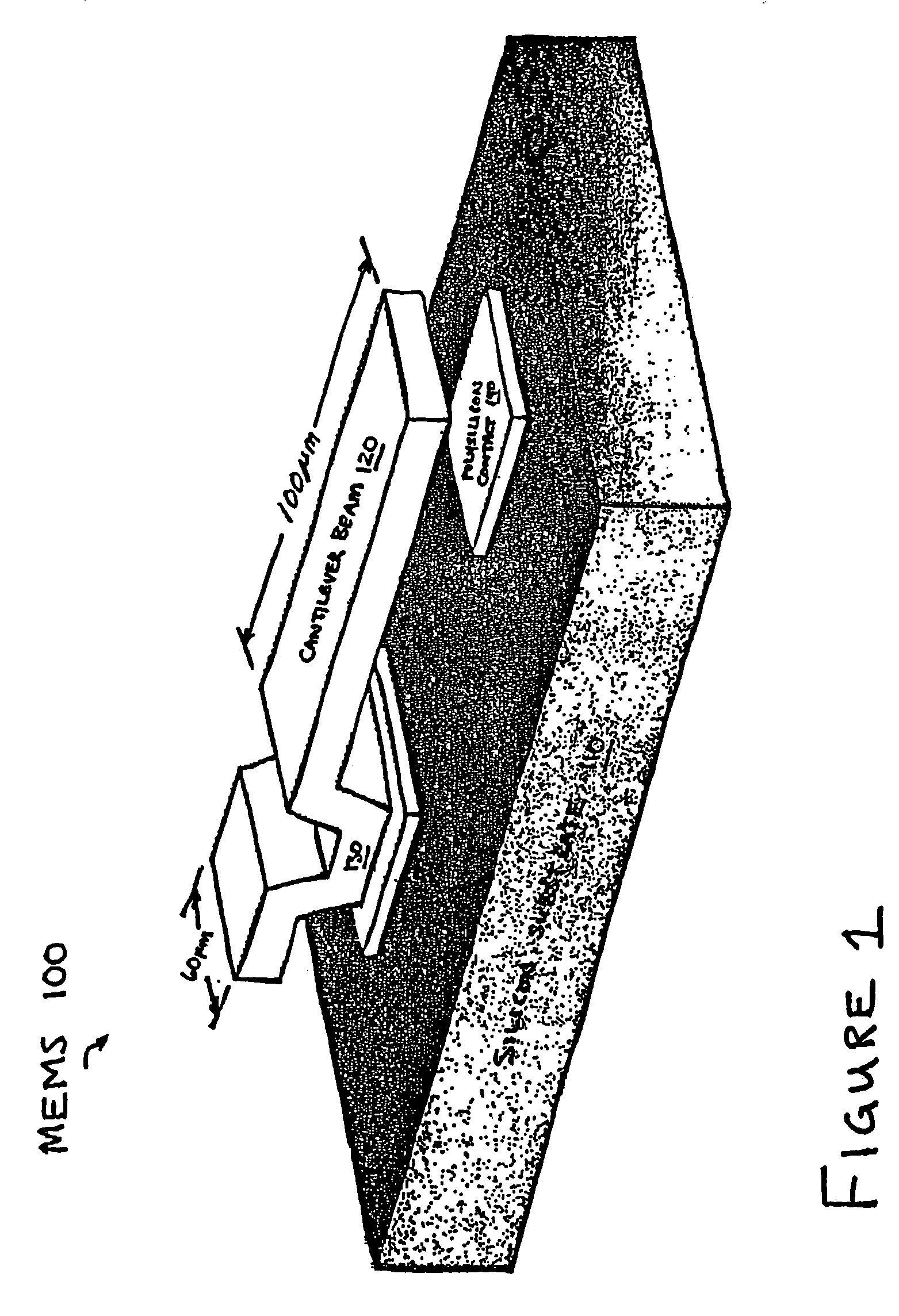

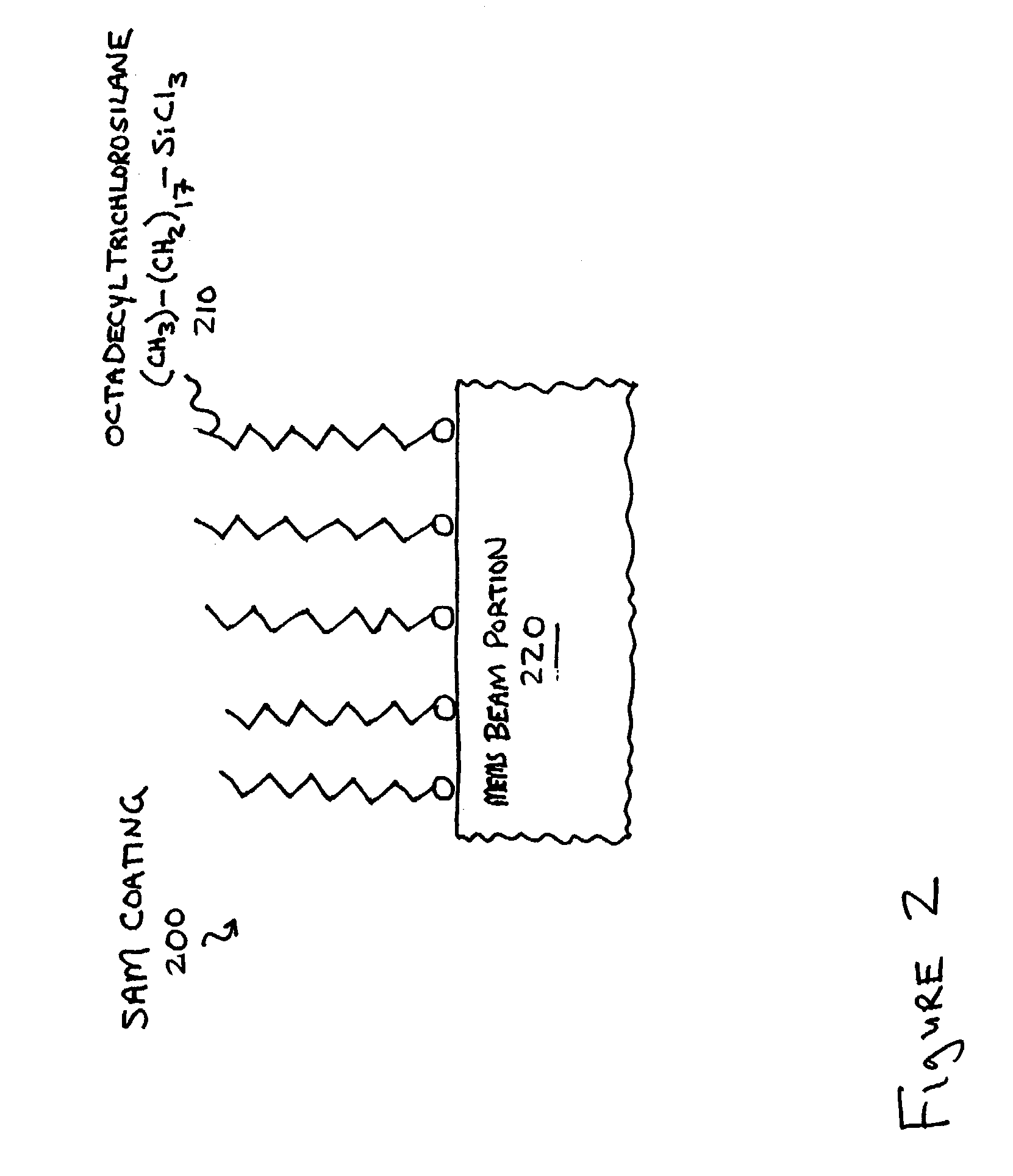

Atomic layer deposition on micro-mechanical devices

InactiveUS7426067B1Flexible microstructural devicesMicrostructural device manufactureElectricityMulti material

A micro-electromechanical device or MEMS having a conformal layer of material deposited by atomic layer deposition is discussed. The layer may provide physical protection to moving components of the device, may insulate electrical components of the device, may present a biocompatible surface interface to a biological system, and may otherwise improve such devices. The layer may also comprise a combination of multiple materials each deposited with great control to allow creating layers of customizable properties and to allow creating layers having multiple independent functions, such as providing physical protection from wear and providing electrical insulation.

Owner:UNIV OF COLORADO THE REGENTS OF

Sullage solidifying method

InactiveCN101220590AHigh strengthThe surrounding environment is beautified and tidyRoadwaysSolid waste managementSludgePrice ratio

A sludge solidification method is a method for carrying out solidification treatment to the sludge produced in water conservancy projects and civil engineering. The method is that: a. the liquid water content, the clay content and organic content of dredging sludge are tested. b. curing agent is prepared: the curing agent mainly contains cement and calcium oxide which play the function of solidification; wherein, the weight proportion is between 1 : 1 to 4 : 1; waste gypsum is used as water reducing agent which occupies 1 to 8 percent of the sum of cement and calcium oxide in proportion; mealy sand or pulverized fuel ash are used as concrete aggregate which occupies 3 to 5 percent of the sum of the cement and calcium oxide in proportion; c. the curing agent-mixing ratio which is usually controlled from 5 to 20 percent is determined; sampling respectively is carried out, setting time is tested and the unconfined compressive strength which maintains 7, 14 and 28 days is tested by sampling, and the curing agent-mixing ratio finally is determined according to optimal performance price ratio; d. the sludge is carried out curing and constructing in site; mechanical devices are used for stirring the curing agent and the sludge rapidly and evenly, thereby leading the solidification to be rapid and full.

Owner:SOUTHEAST UNIV

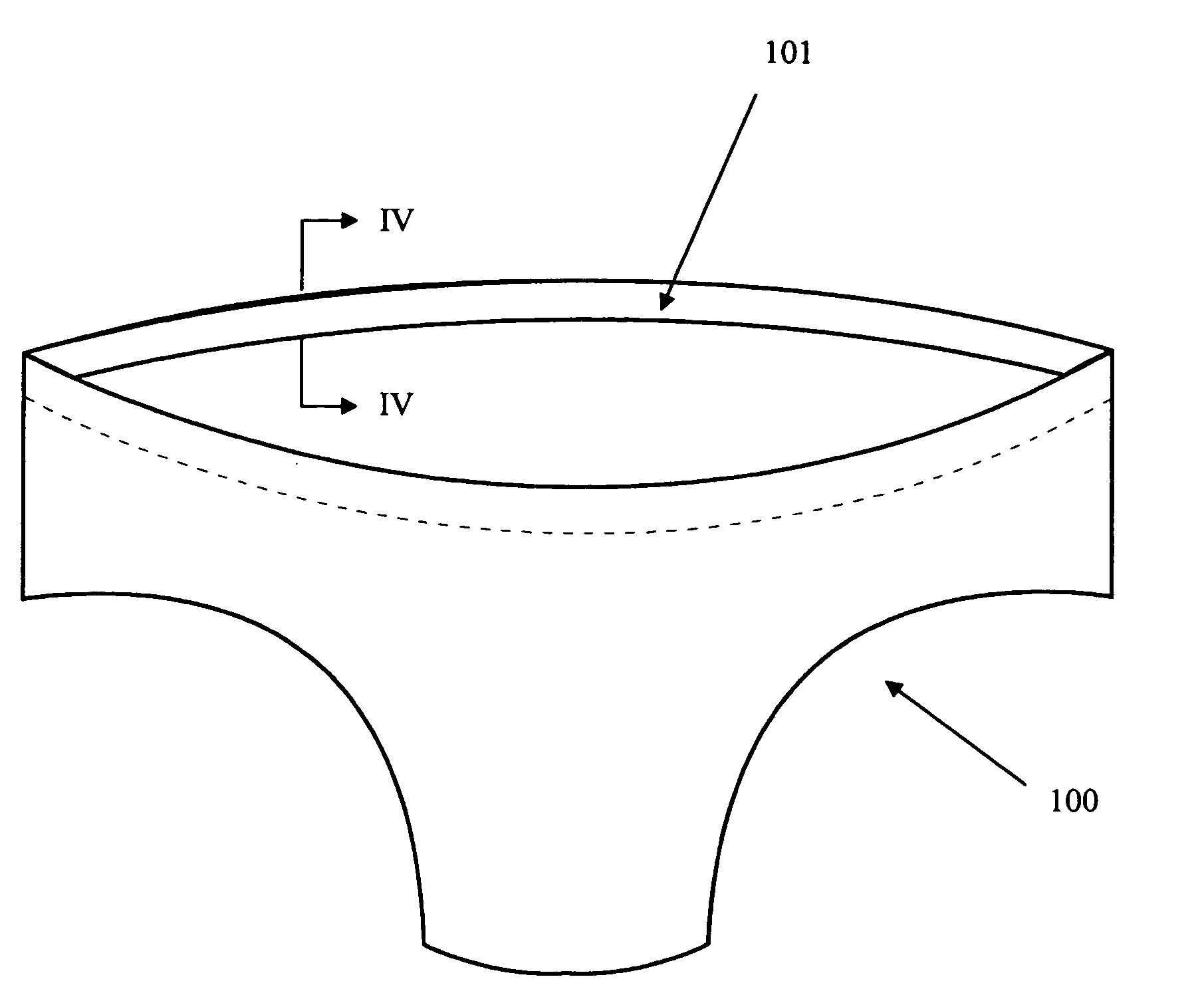

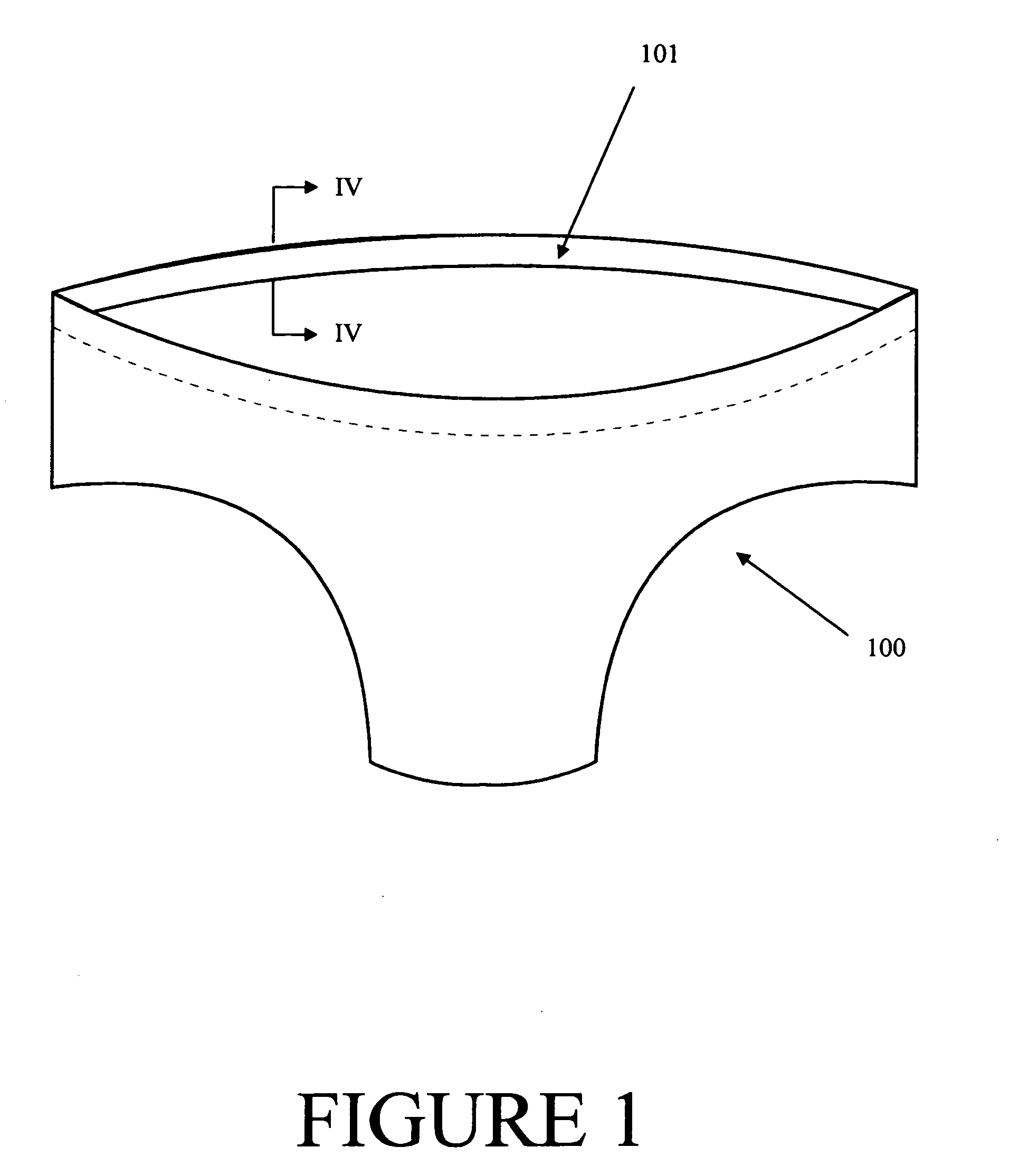

Flocked elastomeric coated garments

A new and improved garment includes support bands fabricated from an elastomeric adhesive and flocking with one end of the flocking fibers embedded within the elastomeric adhesive. In addition, a process for producing garments with flocking fibers manufactured using electrostatic or mechanical devices.

Owner:NTT NEW TEXTILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com