Patents

Literature

344results about How to "Stable temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

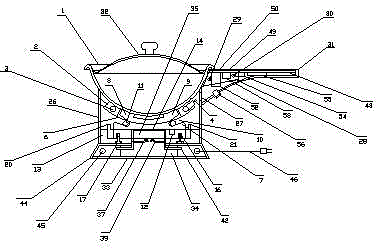

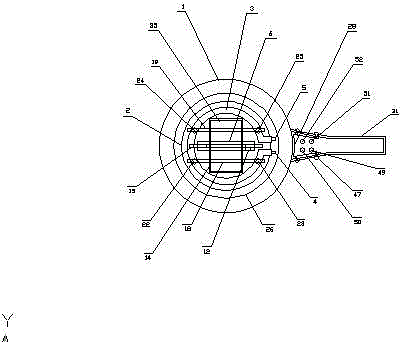

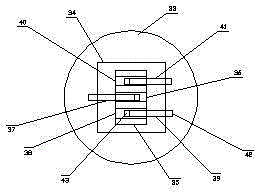

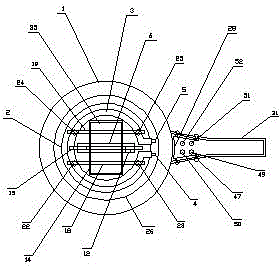

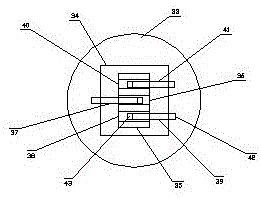

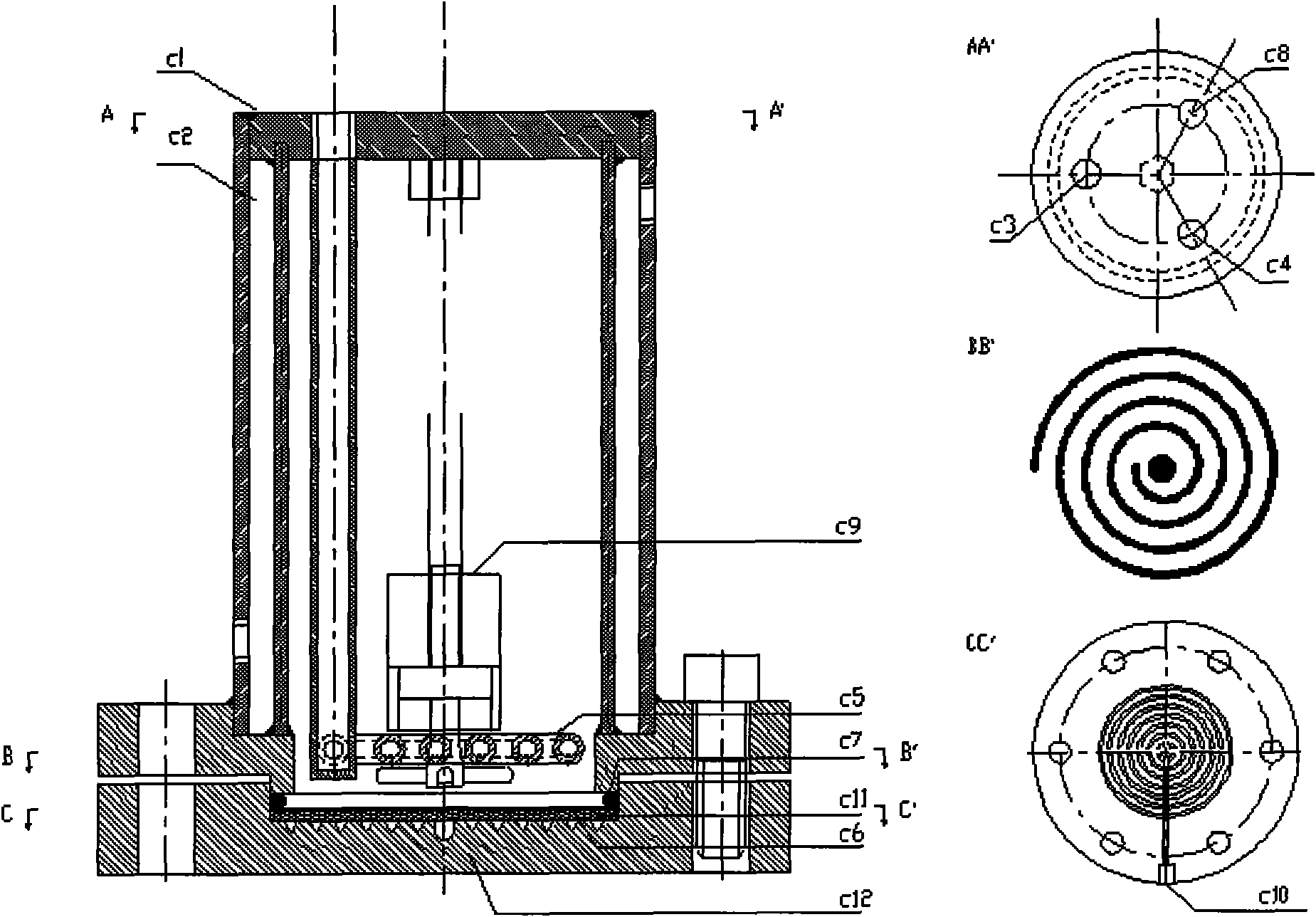

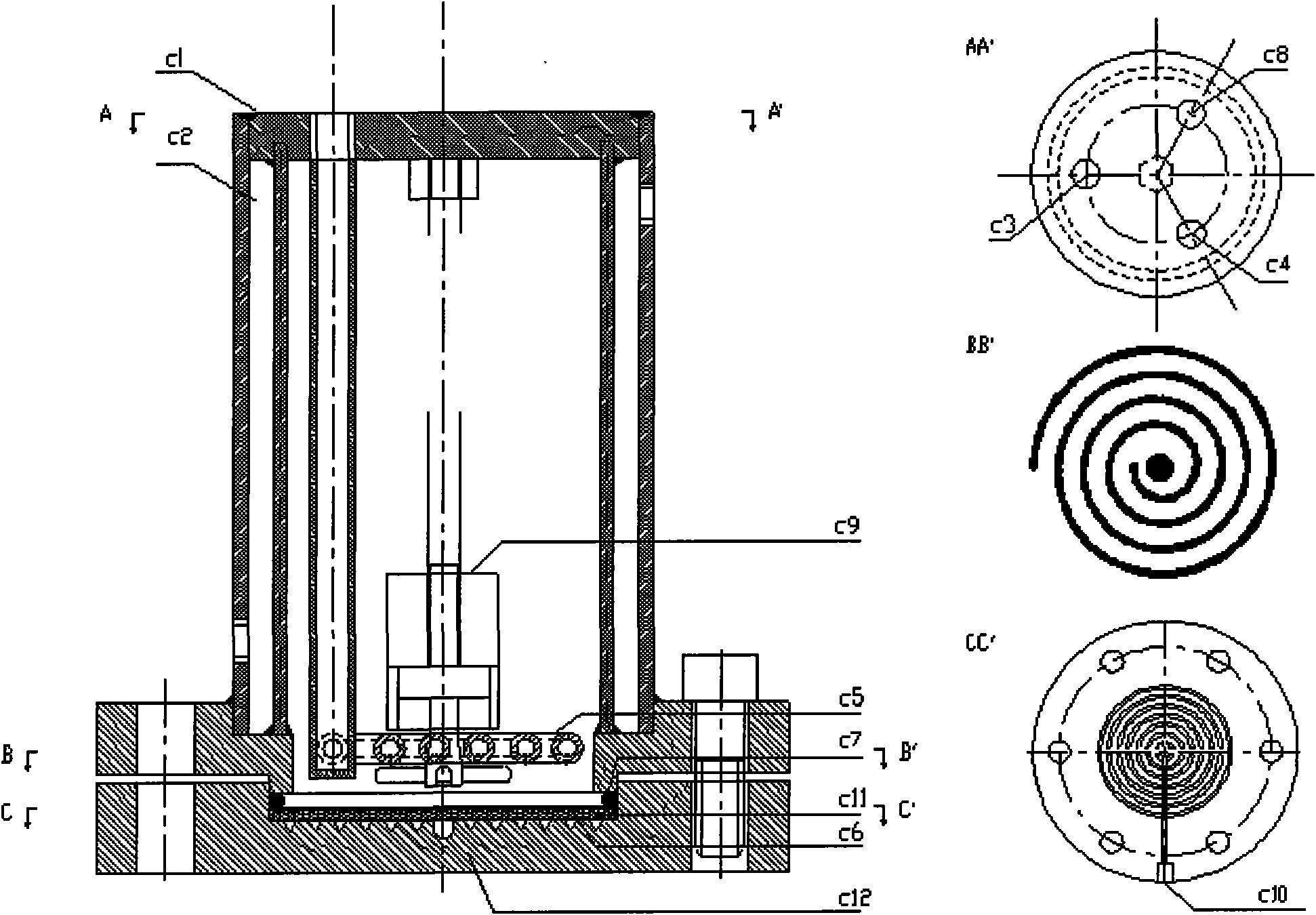

Critical water-controlled type semiautomatic electric heating cooking pot

ActiveCN104605727ASimple structureImprove heat transfer efficiencyCooking vesselsPower couplingElectricity

A critical water-controlled type semiautomatic electric heating cooking pot consists of a wireless coupling electric heating cooking pot body and a power coupling seat, wherein an electric heating plate and a heat-conduction connecting plate are arranged on a semi-spherical surface of a non-stick pot bottom; the heat-conduction connecting plate penetrates in a strip-shaped channel in the middle of the electric heating plate and is provided with a temperature sensor; a circular base is arranged on the heat-conduction connecting plate; a rectangular coupling socket is formed in the middle of the circular base; the left end and the right end of the coupling socket are provided with a connecting plate groove and a front and back blade groove; the heat-conduction connecting plate in the connecting plate groove and a front and back electric contact blade in the front and back blade groove are respectively in contact with an earthing spring plate and a front and back power spring plate on a coupling plug of the power coupling seat, so that power wires of the heat-conduction connecting plate and the front and back electric contact blade are in coupling connection with the coupling plug of the power coupling seat; a triangular machine box is arranged on the left side of a control handle; and an operating panel is arranged at the left upper end of the triangular machine box and is respectively provided with a high-temperature button, a high-temperature indicator lamp, a low-temperature button and a low-temperature indicator lamp. The temperatures of different regions of the surface in the pot are correspondingly changed along with change of the quantity of water in the electric heating cooking pot, and are measured and controlled according to change of a critical temperature, the electric heating cooking pot can be switched off automatically during cooking, the circumstance that a user forgets to switch off the cooking pot and food in the cooking pot is burned are avoided, the time is saved, the user does not need to worry about the food in the cooking pot, and troublesome problems are avoided.

Owner:广东万迪电器有限公司

Critical water-controlled semi-automatic electric cooking pot

ActiveCN104605727BSimple structureImprove heat transfer efficiencyCooking vesselsElectricityPower coupling

A critical water-controlled type semiautomatic electric heating cooking pot consists of a wireless coupling electric heating cooking pot body and a power coupling seat, wherein an electric heating plate and a heat-conduction connecting plate are arranged on a semi-spherical surface of a non-stick pot bottom; the heat-conduction connecting plate penetrates in a strip-shaped channel in the middle of the electric heating plate and is provided with a temperature sensor; a circular base is arranged on the heat-conduction connecting plate; a rectangular coupling socket is formed in the middle of the circular base; the left end and the right end of the coupling socket are provided with a connecting plate groove and a front and back blade groove; the heat-conduction connecting plate in the connecting plate groove and a front and back electric contact blade in the front and back blade groove are respectively in contact with an earthing spring plate and a front and back power spring plate on a coupling plug of the power coupling seat, so that power wires of the heat-conduction connecting plate and the front and back electric contact blade are in coupling connection with the coupling plug of the power coupling seat; a triangular machine box is arranged on the left side of a control handle; and an operating panel is arranged at the left upper end of the triangular machine box and is respectively provided with a high-temperature button, a high-temperature indicator lamp, a low-temperature button and a low-temperature indicator lamp. The temperatures of different regions of the surface in the pot are correspondingly changed along with change of the quantity of water in the electric heating cooking pot, and are measured and controlled according to change of a critical temperature, the electric heating cooking pot can be switched off automatically during cooking, the circumstance that a user forgets to switch off the cooking pot and food in the cooking pot is burned are avoided, the time is saved, the user does not need to worry about the food in the cooking pot, and troublesome problems are avoided.

Owner:广东万迪电器有限公司

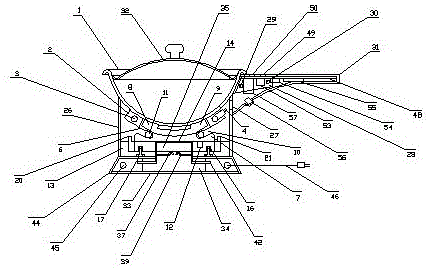

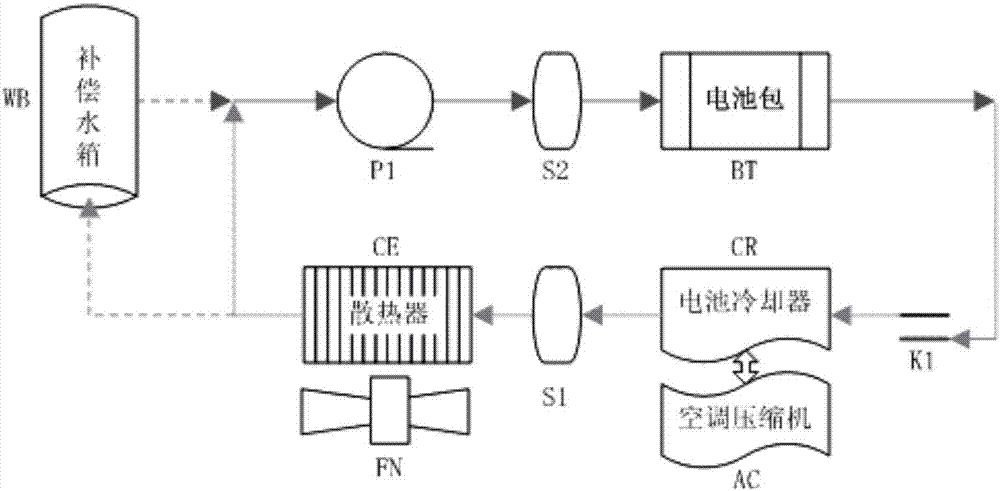

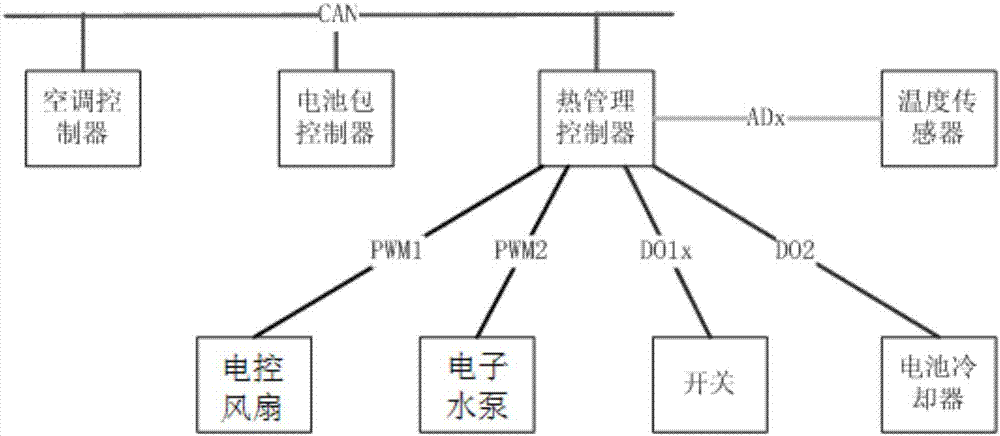

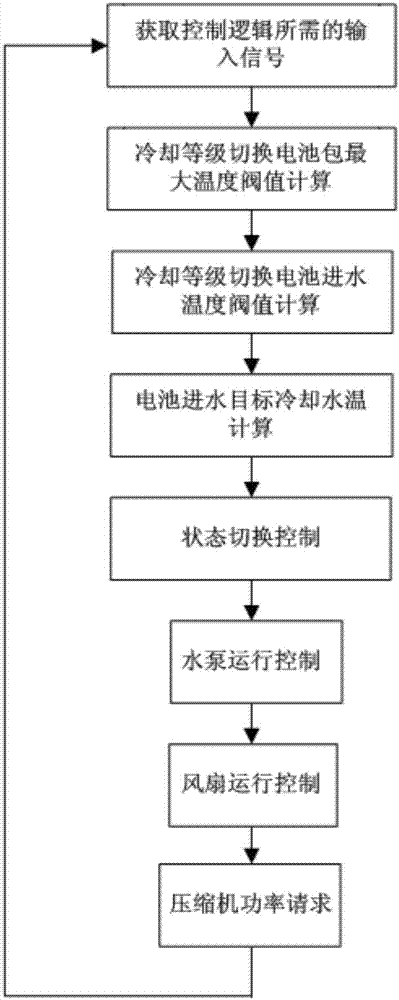

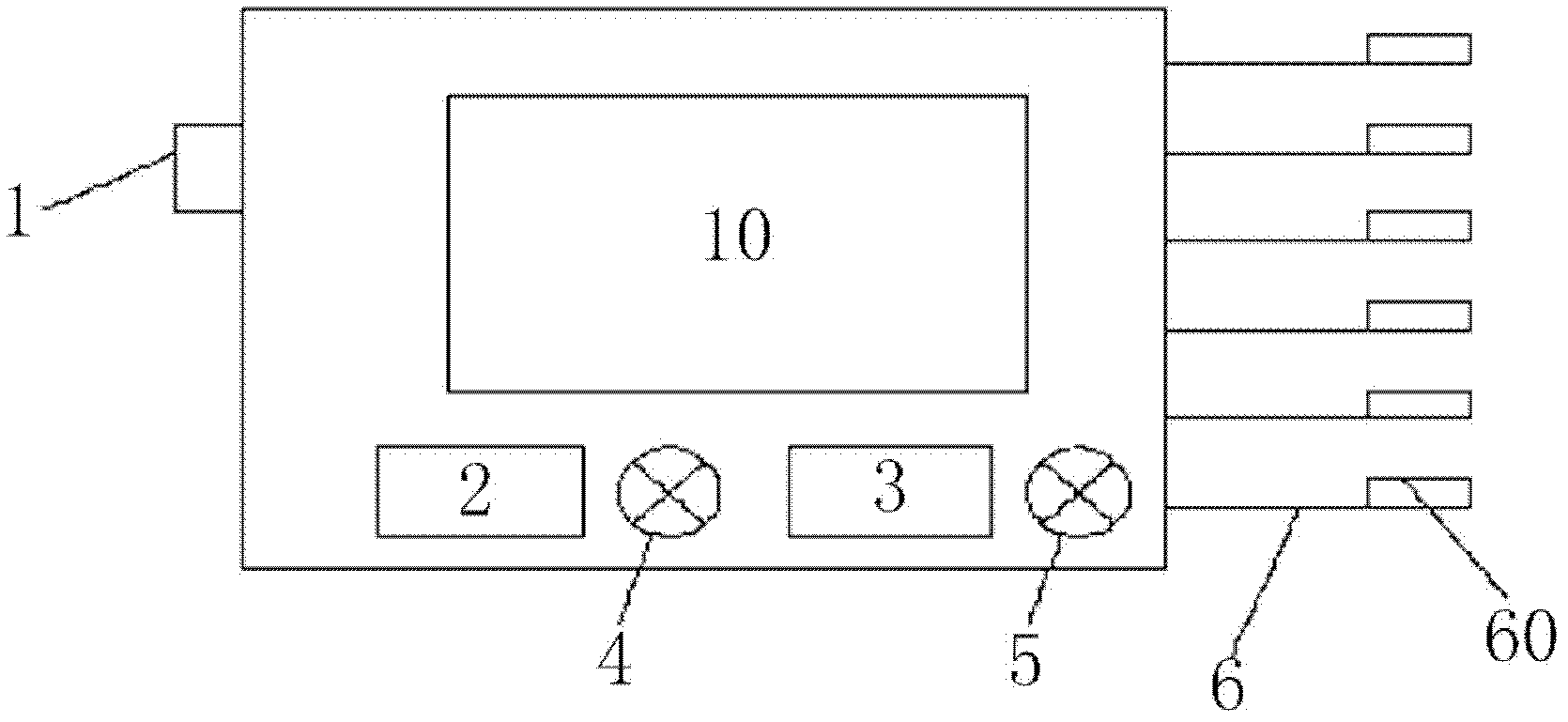

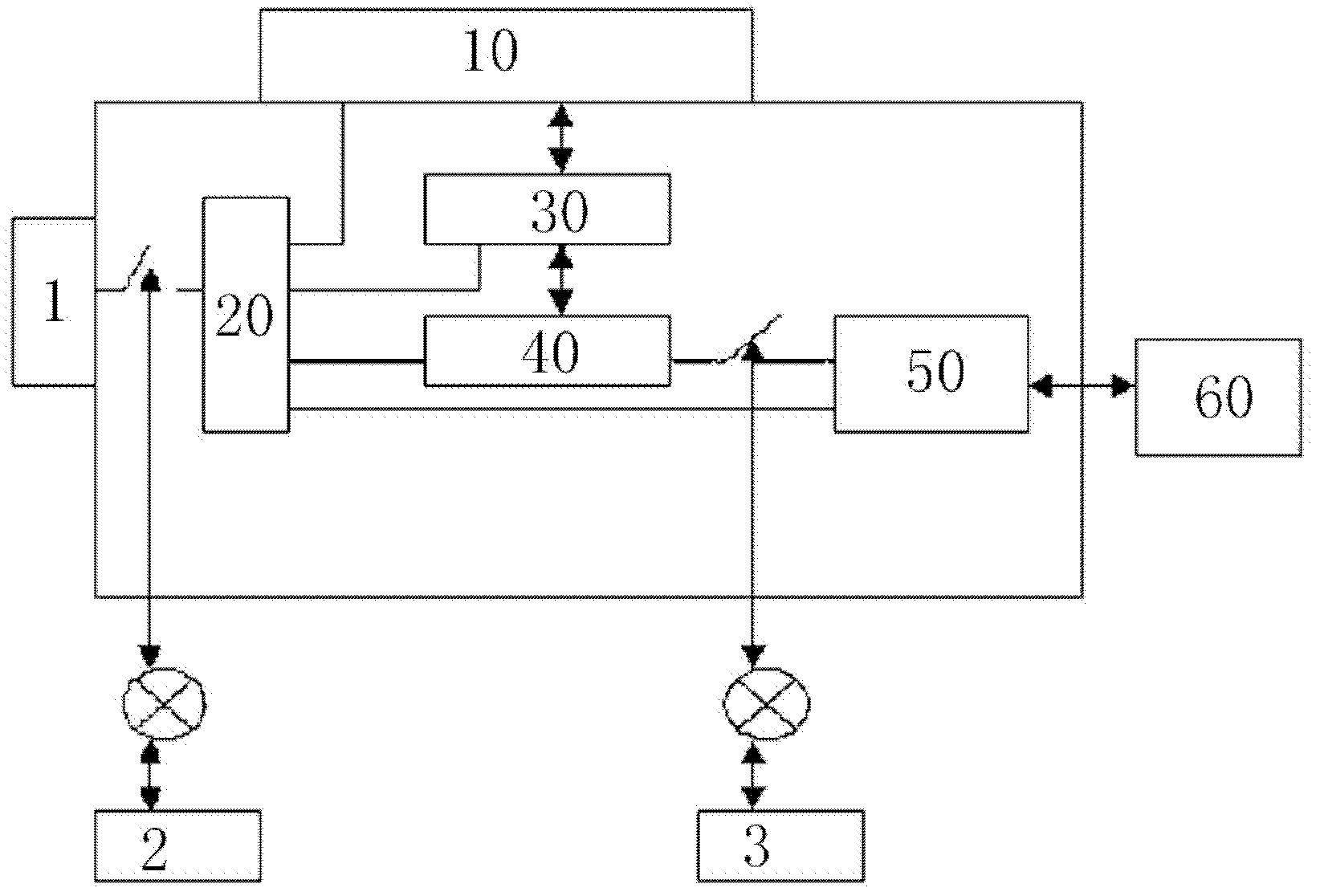

Cooling control system and method for power battery of hybrid electric vehicle

ActiveCN107230812AImprove cooling effectMeet the needs of different levels of coolingCell temperature controlVehicular energy storagePower batteryControl system

The invention relates to a cooling control system for a power battery of a hybrid electric vehicle. By adoption of the cooling control system, influence of the vehicle operation working condition to the battery pack cooling is analyzed and evaluated comprehensively; and air cooling, water cooling and compressor refrigerating are controlled to realize in-time and effective cooling by virtue of integration of the working environment temperature of the battery pack, the residual electric quantity of the battery and the battery output power according to different requirements in battery cooling, so that compatibility and part sharing with the conventional automobile thermal management system are realized, and power consumption management can be realized easily. The invention also relates to a cooling control method for the power battery of the hybrid electric vehicle; the cooling control method comprises three cooling modes, including a natural water cooling mode, a fan water cooling mode and a forced cooling mode, so that requirements of different levels in battery pack cooling can be satisfied, stable transition of different cooling modes can be realized, and energy-saving design of the system is also taken into consideration.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

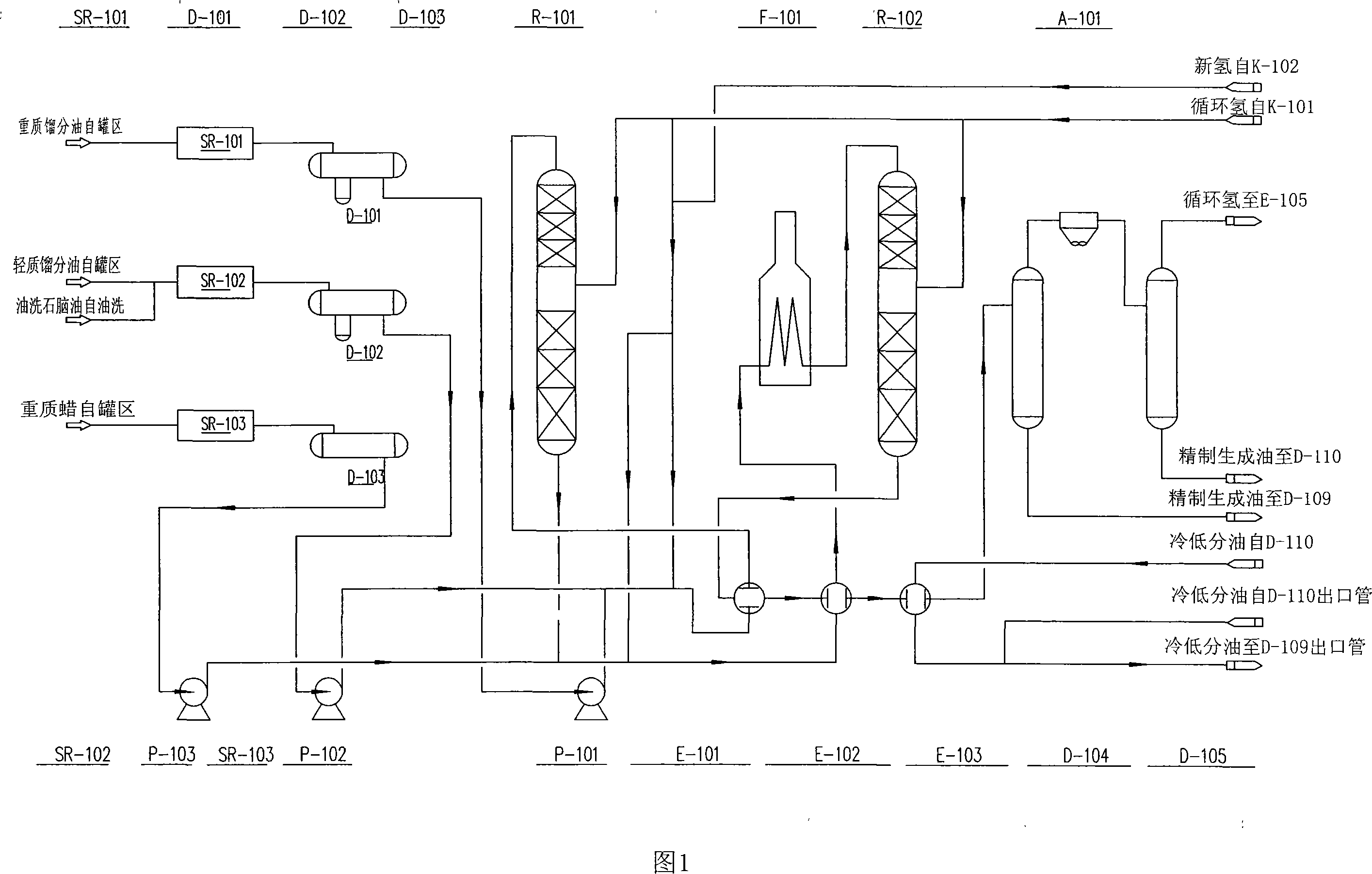

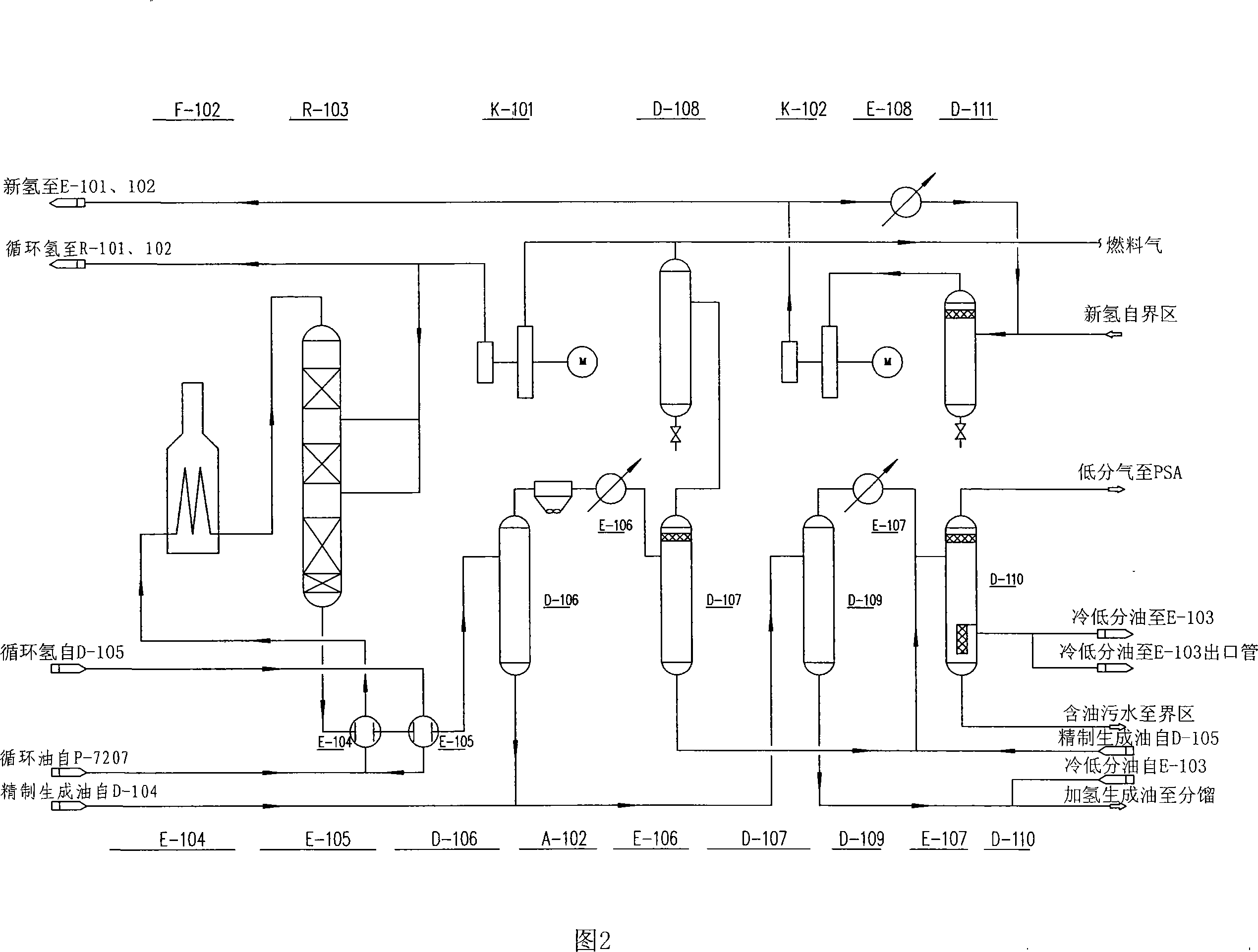

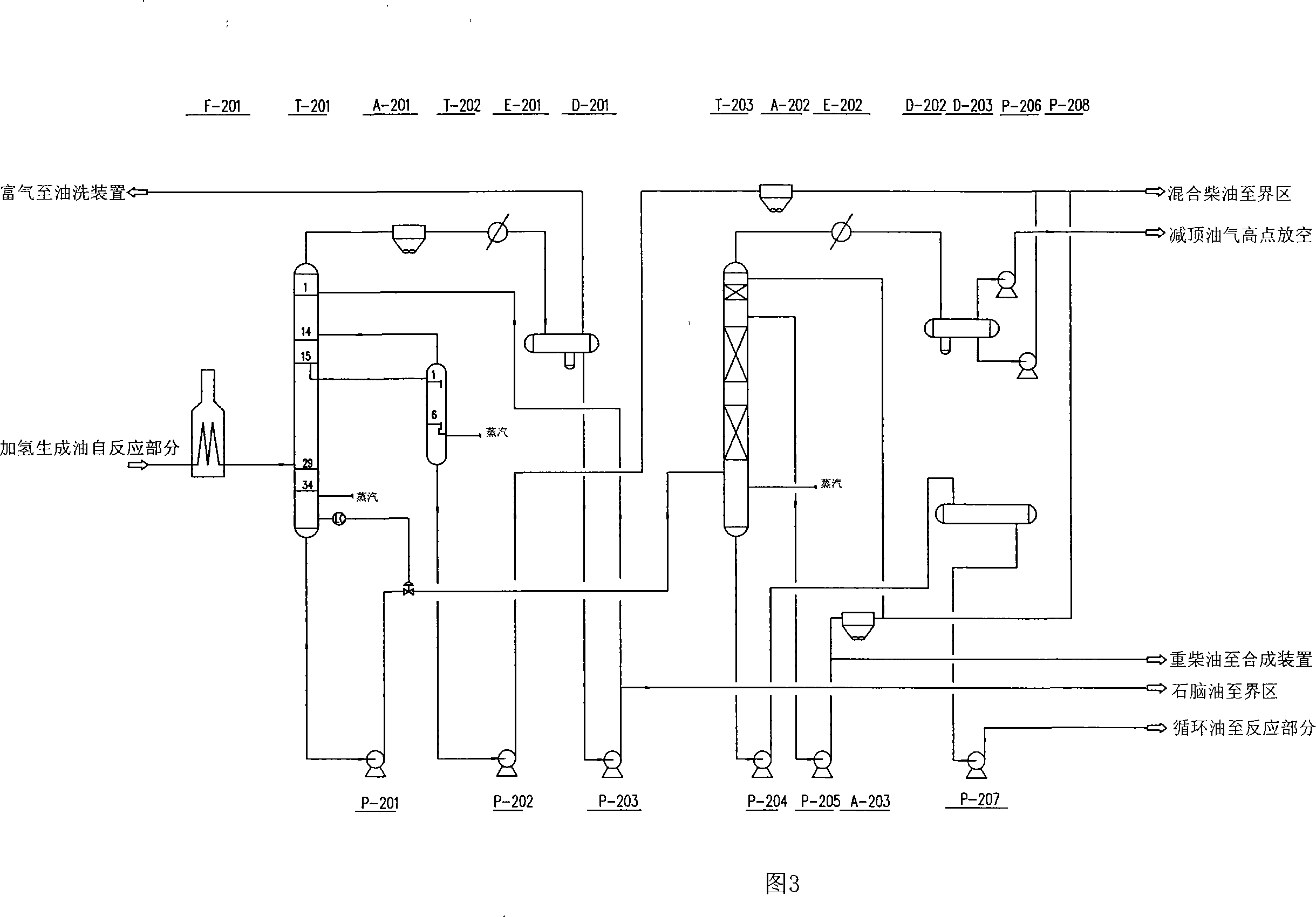

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

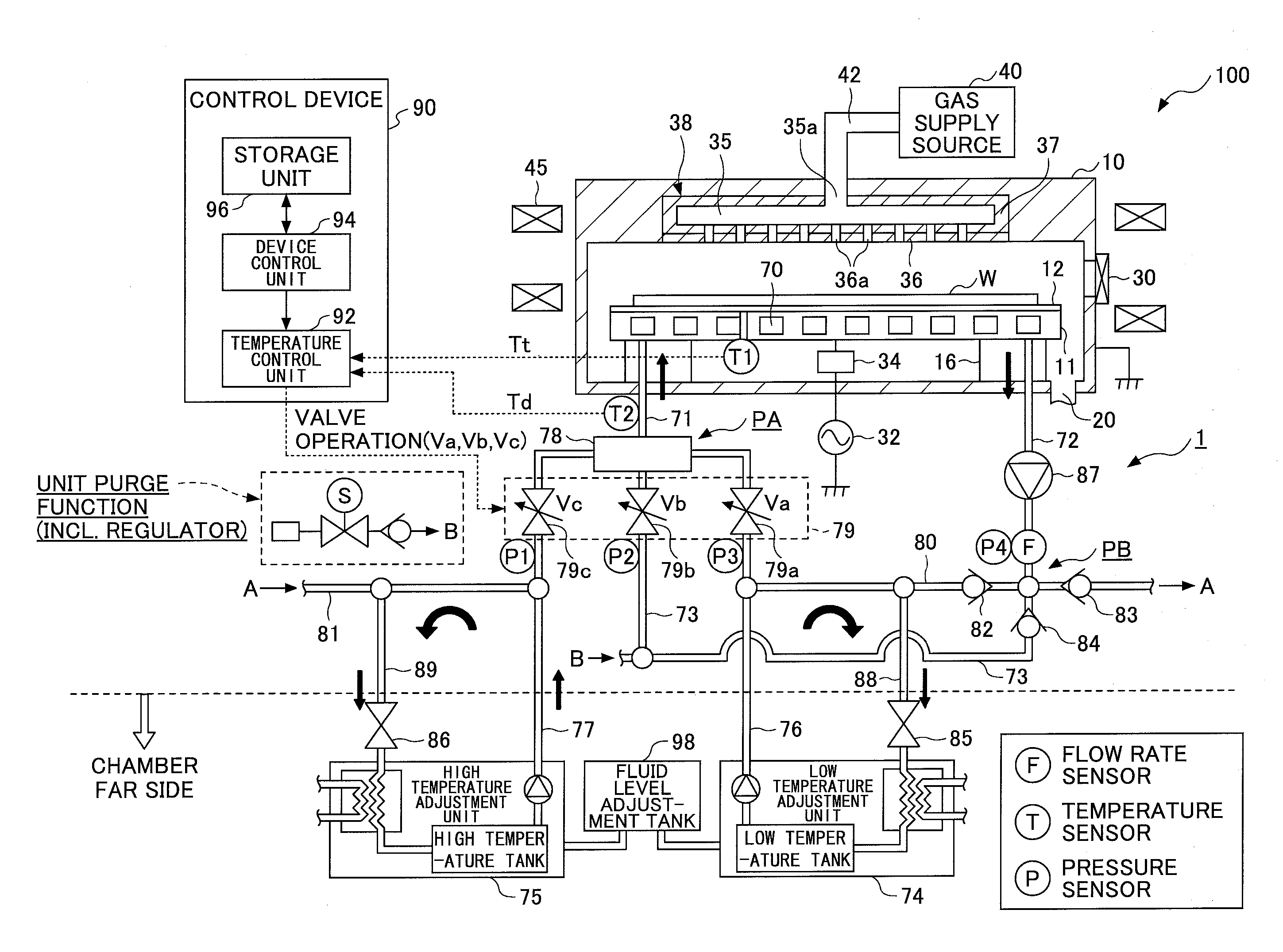

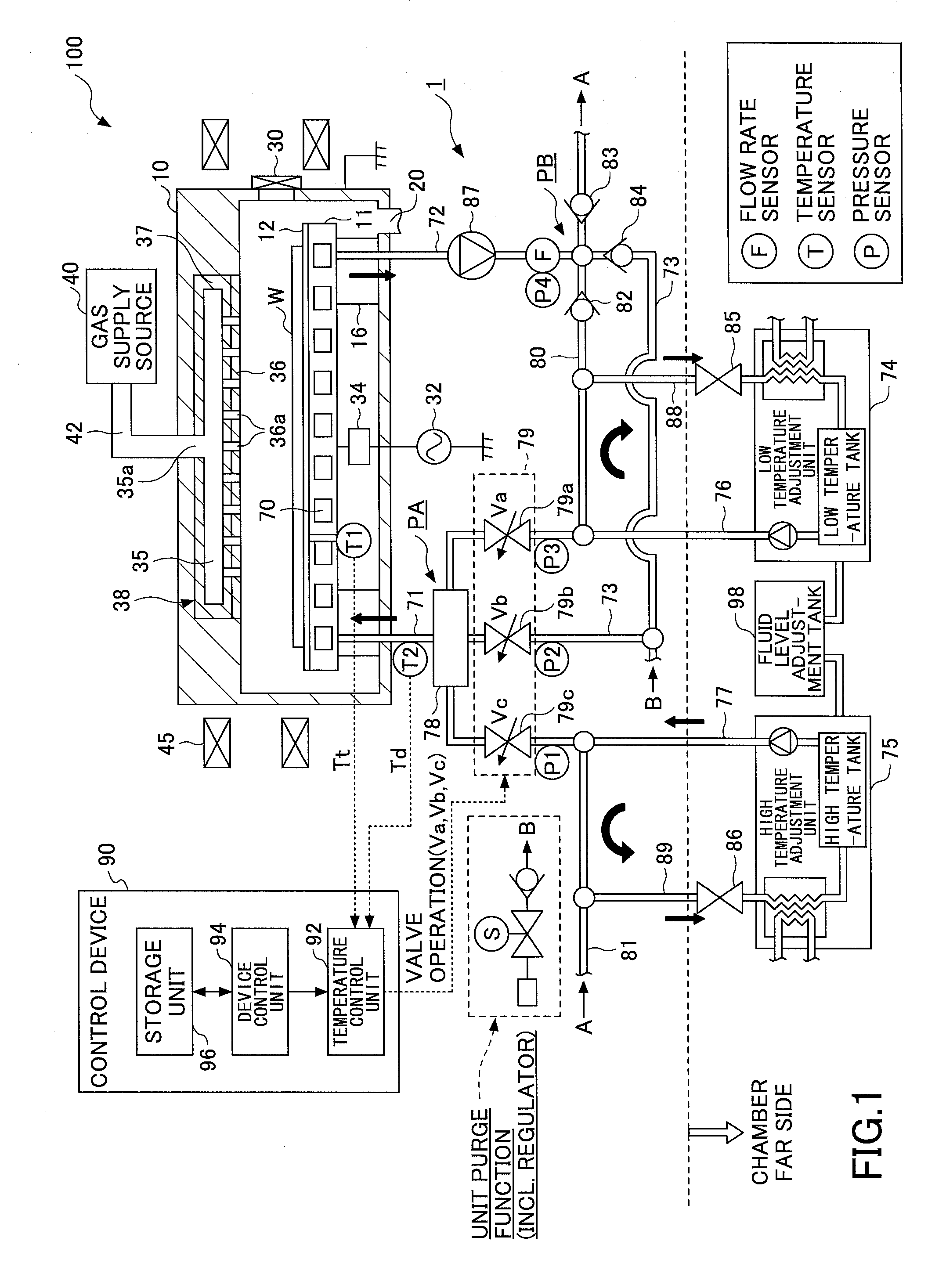

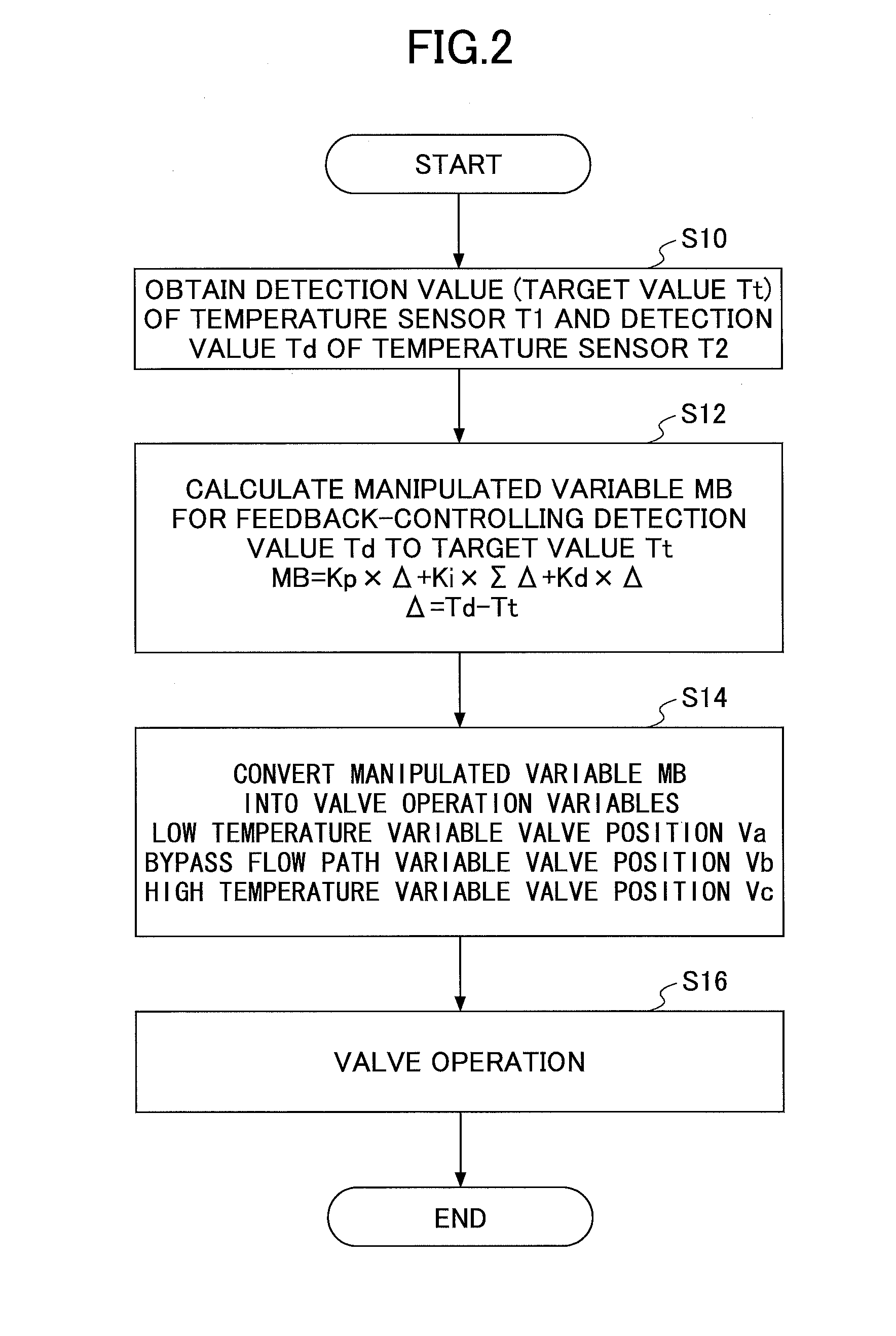

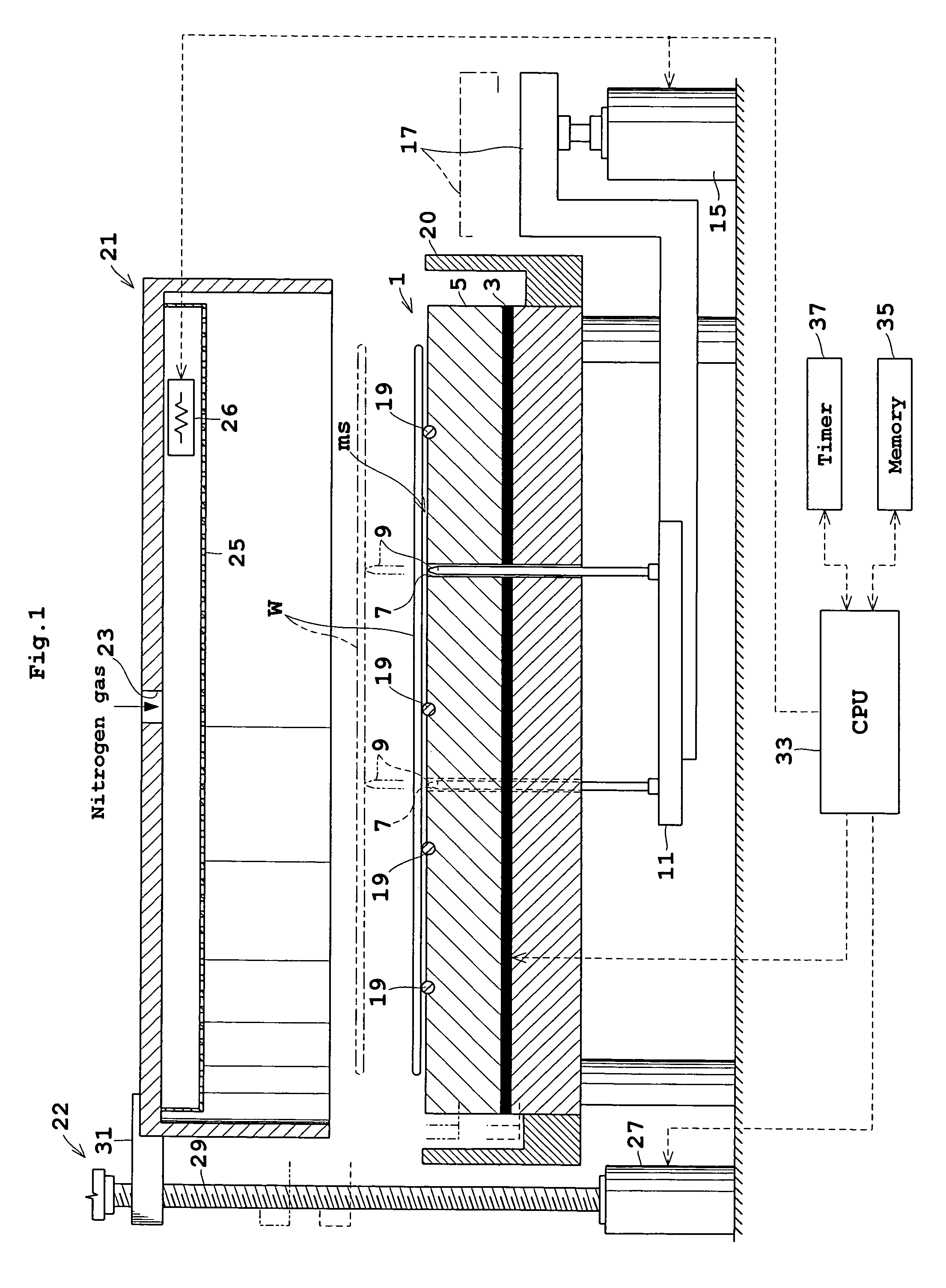

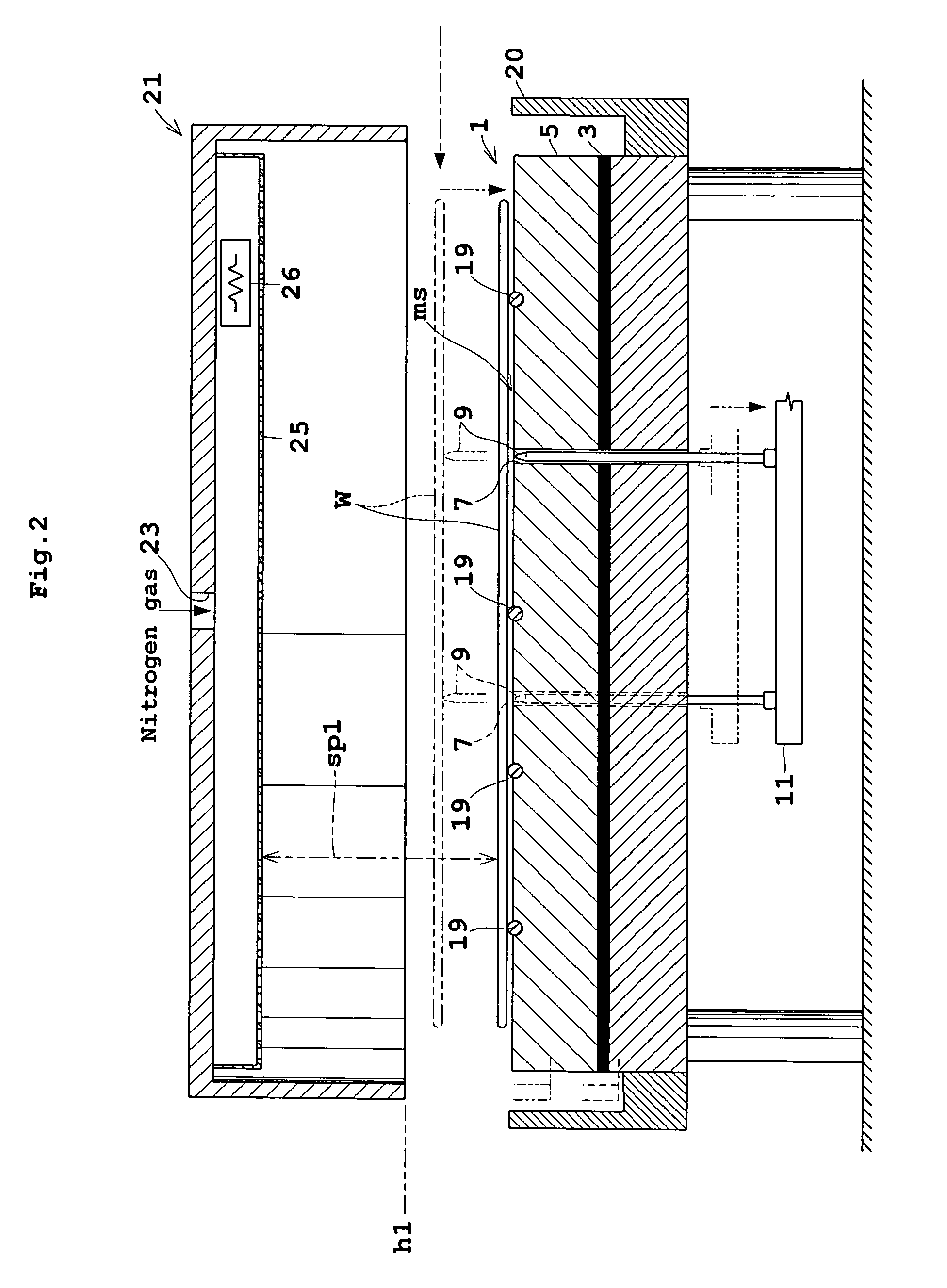

Temperature control system, semiconductor manufacturing device, and temperature control method

ActiveUS20140262199A1Stable temperature controlSufficient storage volumeTemperatue controlSemiconductor/solid-state device manufacturingTemperature controlControl system

A temperature control system includes a first temperature adjustment unit storing fluid at a first temperature; a second temperature adjustment unit storing fluid at a second temperature higher than the first temperature; a low-temperature flow path for passing fluid supplied from the first temperature adjustment unit; a high-temperature flow path for passing fluid supplied from the second temperature adjustment unit; a bypass flow path for circulating fluid; a combination flow path for passing fluid from the low-temperature flow path, the high-temperature flow path, and the bypass flow path merged at a merging part; a temperature adjustment part that passes fluid from the combination flow path and cools / heats a member of a semiconductor manufacturing device; and a control device that controls valve positions of variable valves attached to the three flow paths upstream of the merging part and adjusts the flow rate distribution ratio for the three flow paths.

Owner:TOKYO ELECTRON LTD +1

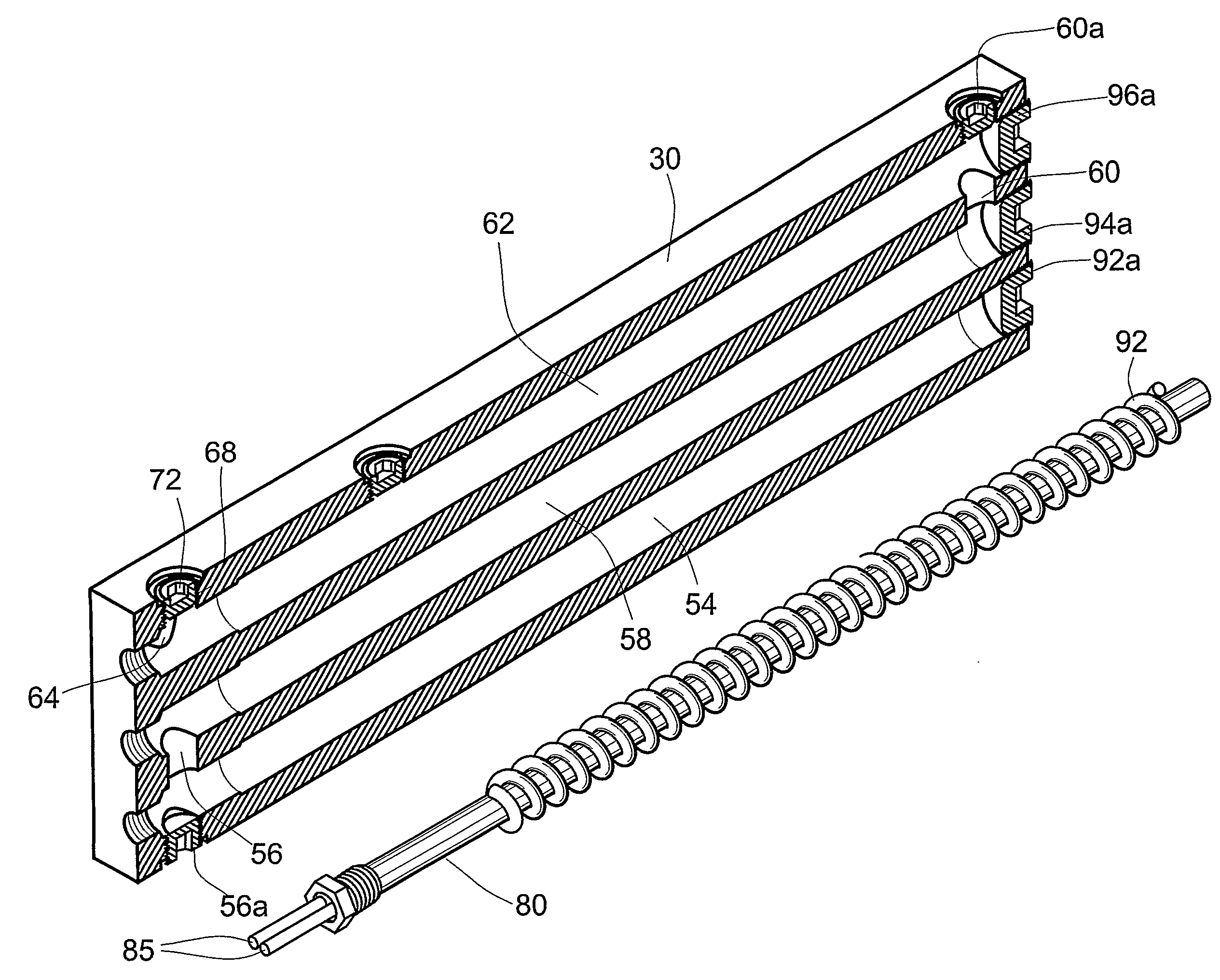

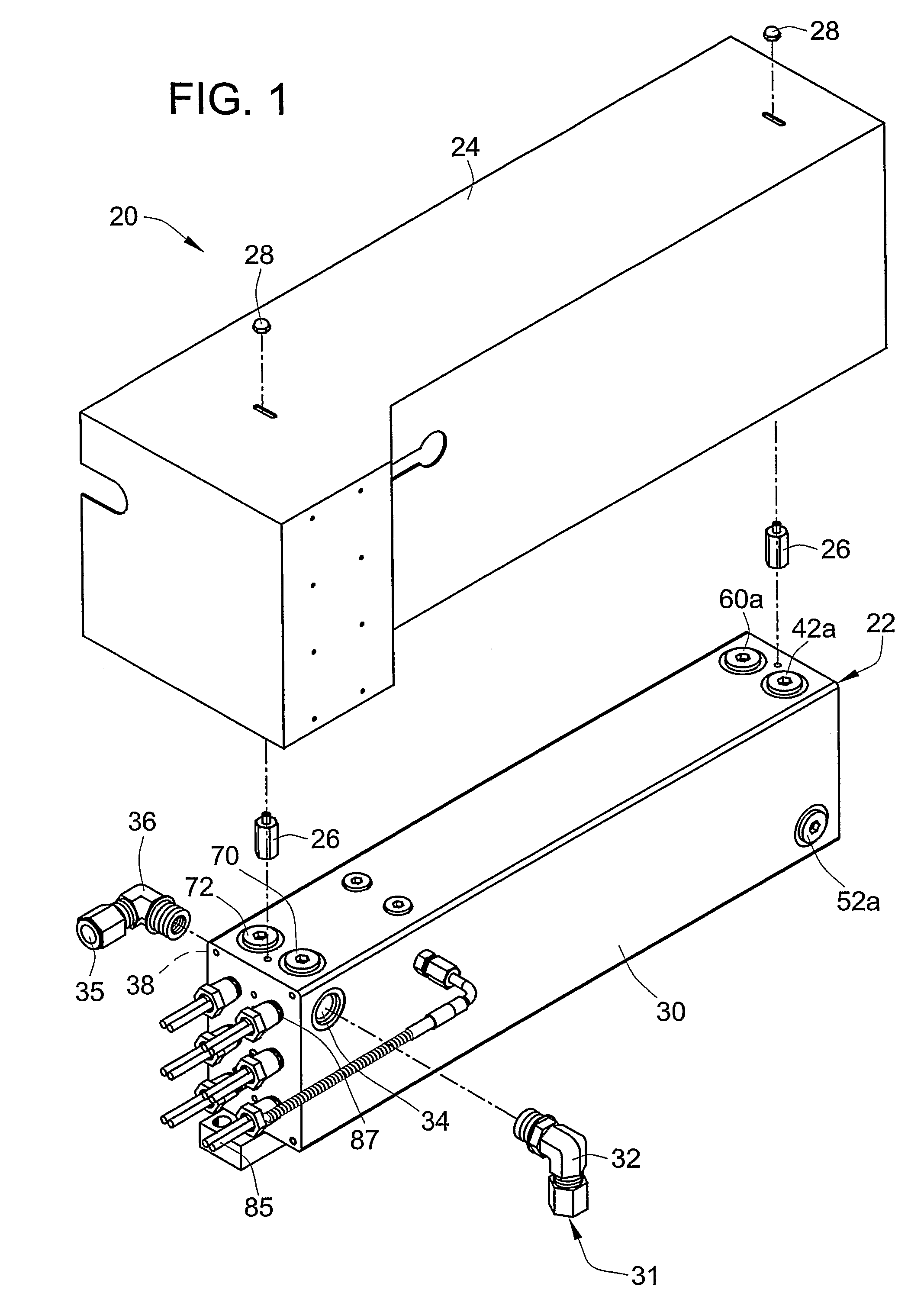

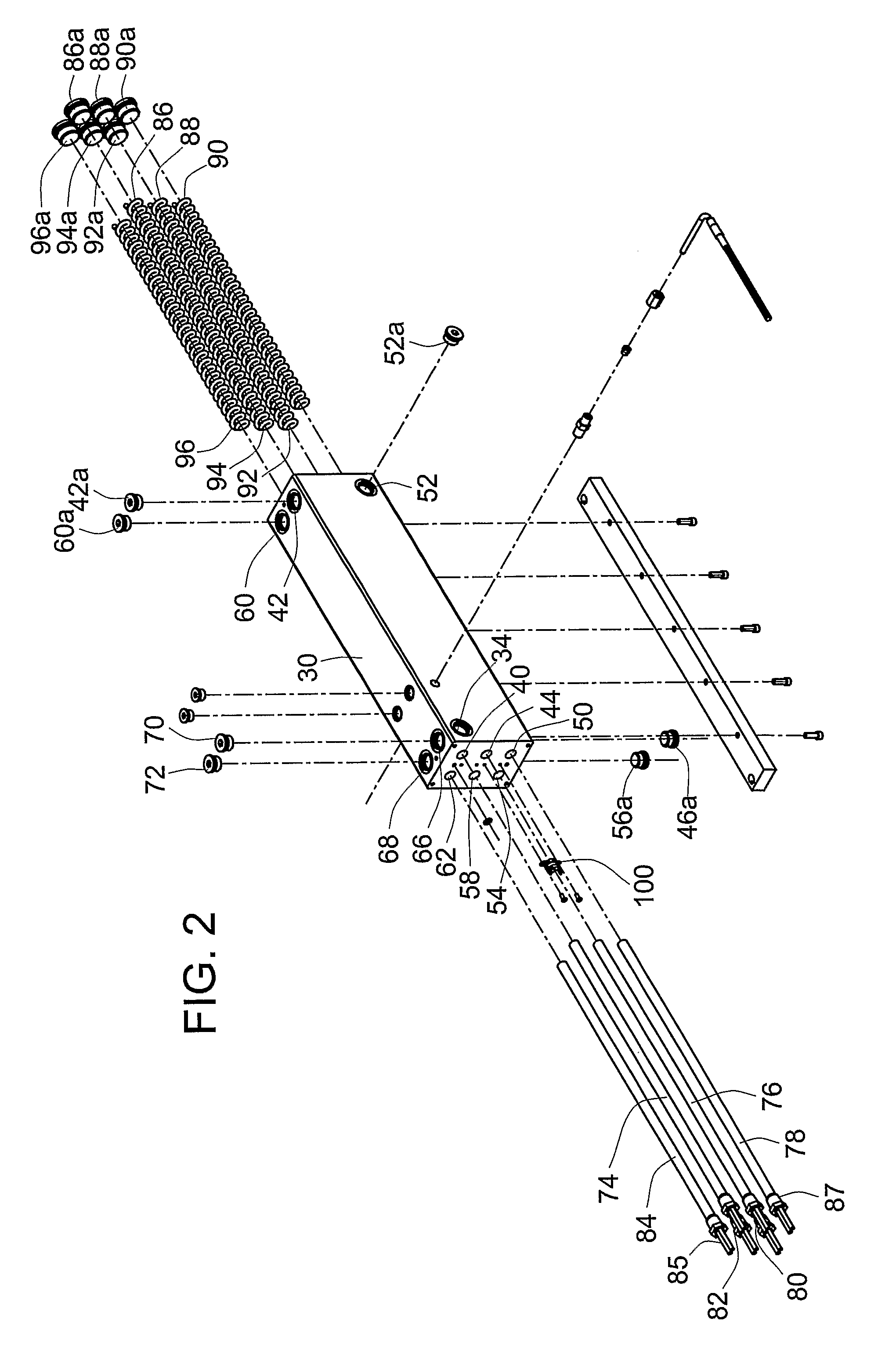

Hybrid heater

ActiveUS7822326B2Minimizing and eliminating associated disadvantageRapid warm up cycleImmersion heating arrangementsBeverage vesselsCoil springHeater Rod

A hybrid heater that includes a structural mass into which passages are provided to create a labyrinth for chemical flow through the structural mass, the passages being sized and disposed to receive a plurality of heater rods such that the chemical is traversed through the passages in direct contact with the heater rods. A coiled spring may be disposed or other spiral arrangement provided in the space between and against the walls of the passages and the heater rod to facilitate flow uniformity around the rods. A temperature sensor may be provided in direct contact with the heating element and may be fitted with a mass sleeve to draw off any excess heat on the sensor during transitions.

Owner:GRACO INC

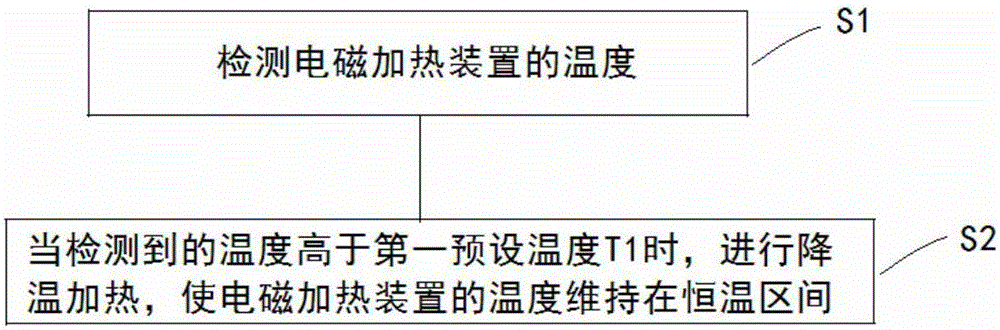

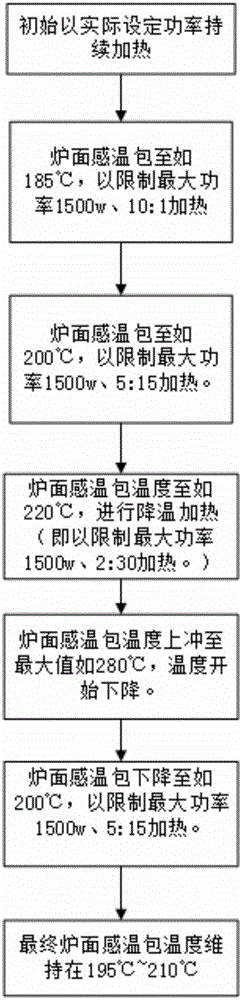

Heating control method of electromagnetic heating apparatus

ActiveCN106211395ATemperature controlStable temperature controlDomestic stoves or rangesLighting and heating apparatusHeat controlElectromagnetic heating

The invention proposes a heating control method of an electromagnetic heating apparatus. The method comprises the steps of detecting a current temperature of the electromagnetic heating apparatus; and performing output power limitation and intermittent heating adjustment on the electromagnetic heating apparatus according to the detected current temperature for enabling the electromagnetic heating apparatus to keep a predetermined temperature interval. By use of the heating control method, the electromagnetic heating apparatus can be subjected to multilevel control, so that the bottom of a pan is slowly heated or cooled during cooking and can be further kept in a specific temperature range, and various cooking demands are better met.

Owner:GREE ELECTRIC APPLIANCES INC

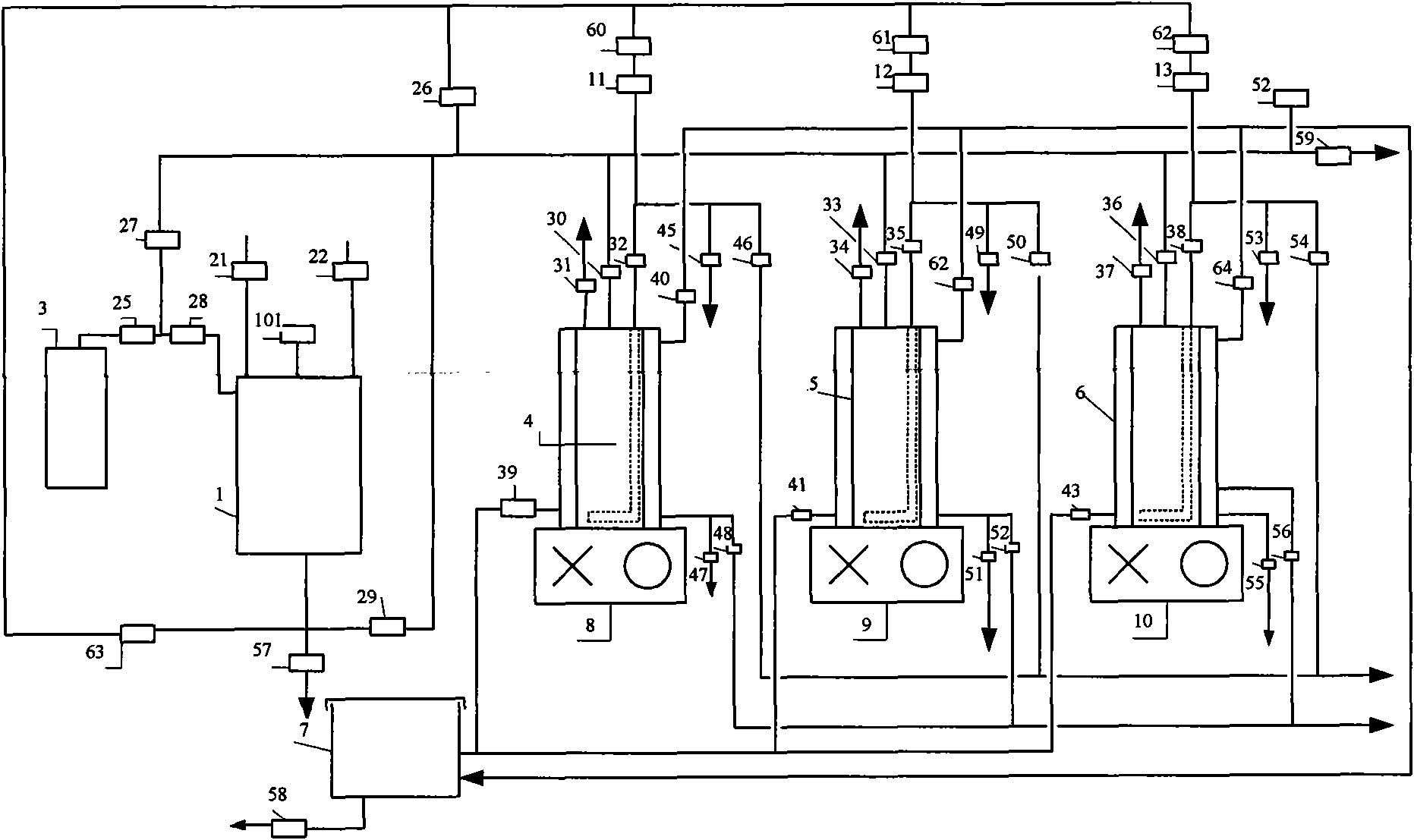

Membrane performance tester and application thereof

ActiveCN102049199AExtended stayStable temperature controlSemi-permeable membranesUltrasound attenuationWater baths

The invention provides a performance tester of a continuous flat ultrafiltration membrane and a reverse osmosis membrane and a use method thereof. The tester comprises a water supply unit, a drainage unit and a plurality of parallel infiltration ponds, wherein each infiltration pond comprises a substrate, a shell, a water inlet, a water outlet, an exhaust port, a bottom inserting tube, a stirrer and a constant-temperature water bath jacket. Produced water penetrating through a separation membrane to be measured is discharged out of the infiltration ponds via the water outlets. The tester can carry out constant-temperature and stable operation at higher temperature and can realize the functions of testing membrane separation performance and membrane flux attenuation, extracting key pollutants of the membrane, cleaning the membrane on line and testing membrane performance restore after cleaning.

Owner:CHINA PETROLEUM & CHEM CORP +1

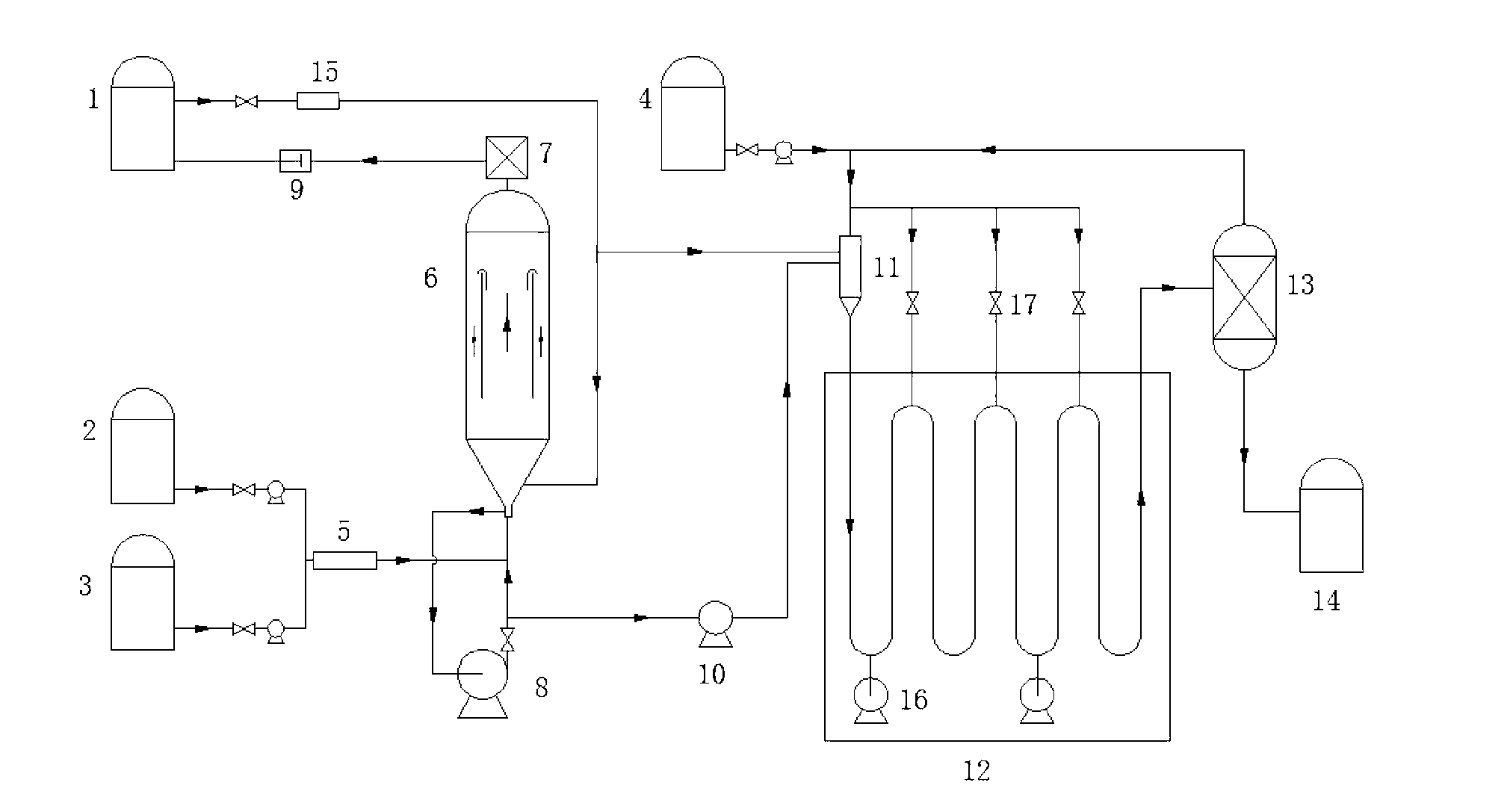

Method for preparing aliphatic polycarbonate through continuous solution polymerization method

The invention provides a method for preparing aliphatic polycarbonate through a continuous solution polymerization method. The method comprises the following steps of a, injecting an epoxy monomer, carbon dioxide and catalyst into a circulation flow reactor through a continuous way, utilizing a circulation pump to provide power for the reaction materials, circularly returning partial reaction materials to the circulation flow reactor, driving one part of the reaction materials to leave the circulation flow reactor at a speed being identical to the feeding speed to enter a tubular reactor with a built-in static mixer; b, controlling the retention time of the pulp in the tubular reactor through the ratio of the pipe length and the flowing linear speed of the reaction materials, and gradually charging a solvent step by step through a plurality of feeding ports along the length of the tubular reactor; c, feeding an end sealing agent and a stabilizer through a feeding port on the tail end of the tubular reactor to carry out the in-situ chemical or physical modification; d, ensuring the reaction endpoint pulp which continuously flows out of a discharging end to enter a middle-pressure flash evaporator, carrying out the flash evaporation by utilizing the reaction pressure, removing the solvent, and returning the pulp to the tubular reactor after the pulp is condensed; and e, devolatilizing and drying the pulp to obtain a polymerization product.

Owner:BEIJING RISUN TECH CO LTD +1

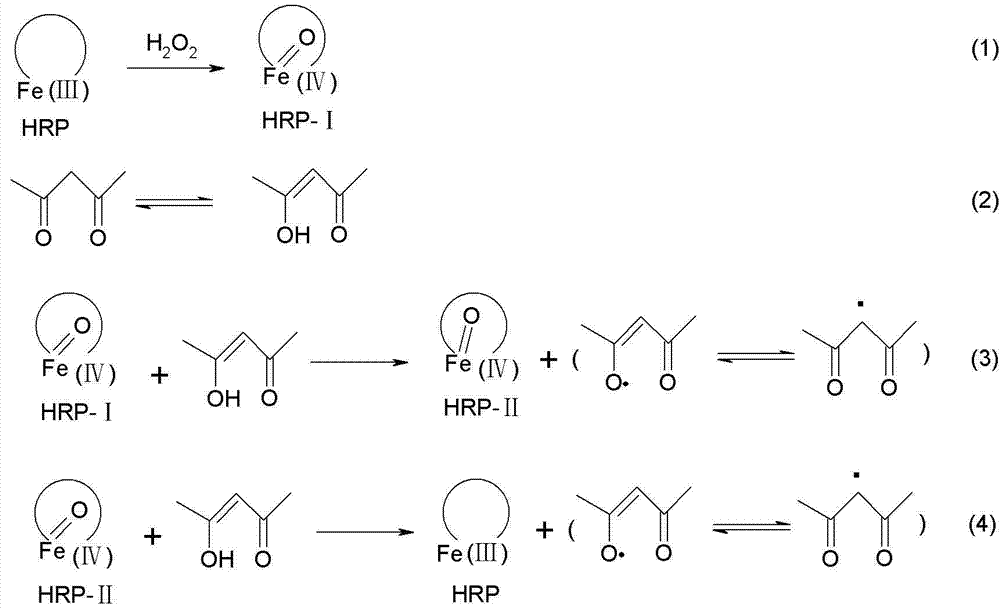

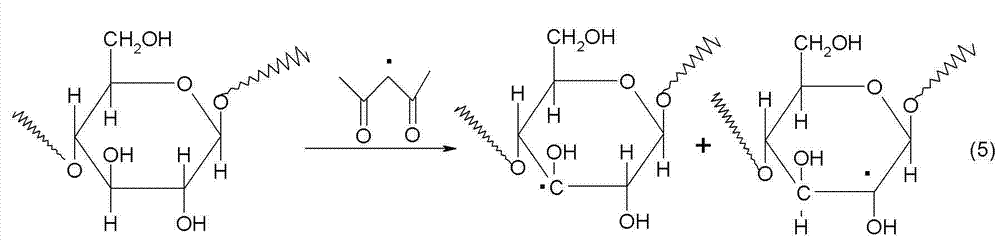

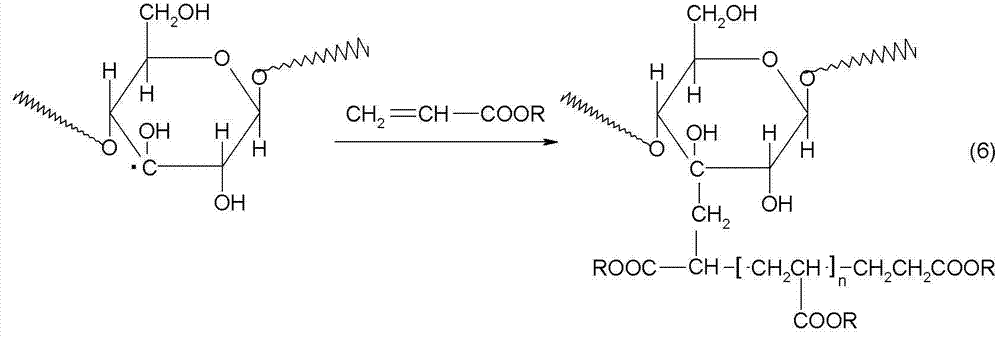

Method for producing modified starch size through bio-enzyme

ActiveCN103045702AEasy to separateStable temperature controlFibre treatmentFermentationChemistryKetone

The invention discloses a method for producing grafted starch size through bio-enzyme. The method adopts ultronic assistant debranching enzyme to pretreat original starch, the macromolecular structure and molecular weight of the starch are adjusted, and the masses of different types of enzymes are stabilized; and a mixed initiating system which consists of horse radish peroxidase, hydrogen peroxide and beta-diketone is utilized to initiate the graft copolymerization of the starch and acrylic acid monomers, and a polyacrylic acid branch is connected to a starch macromolecule. According to the method, the bio-enzyme is adopted to modify the starch, the reaction conditions are moderate, and the activity is controllable; the horse radish peroxidase initiates the polymerization reaction, so that low-temperature branching polymerization can be effectively realized, and the temperature of an initiation process is controlled stably; and the polymerization product has low viscosity and is easy to separate.

Owner:袁于斐

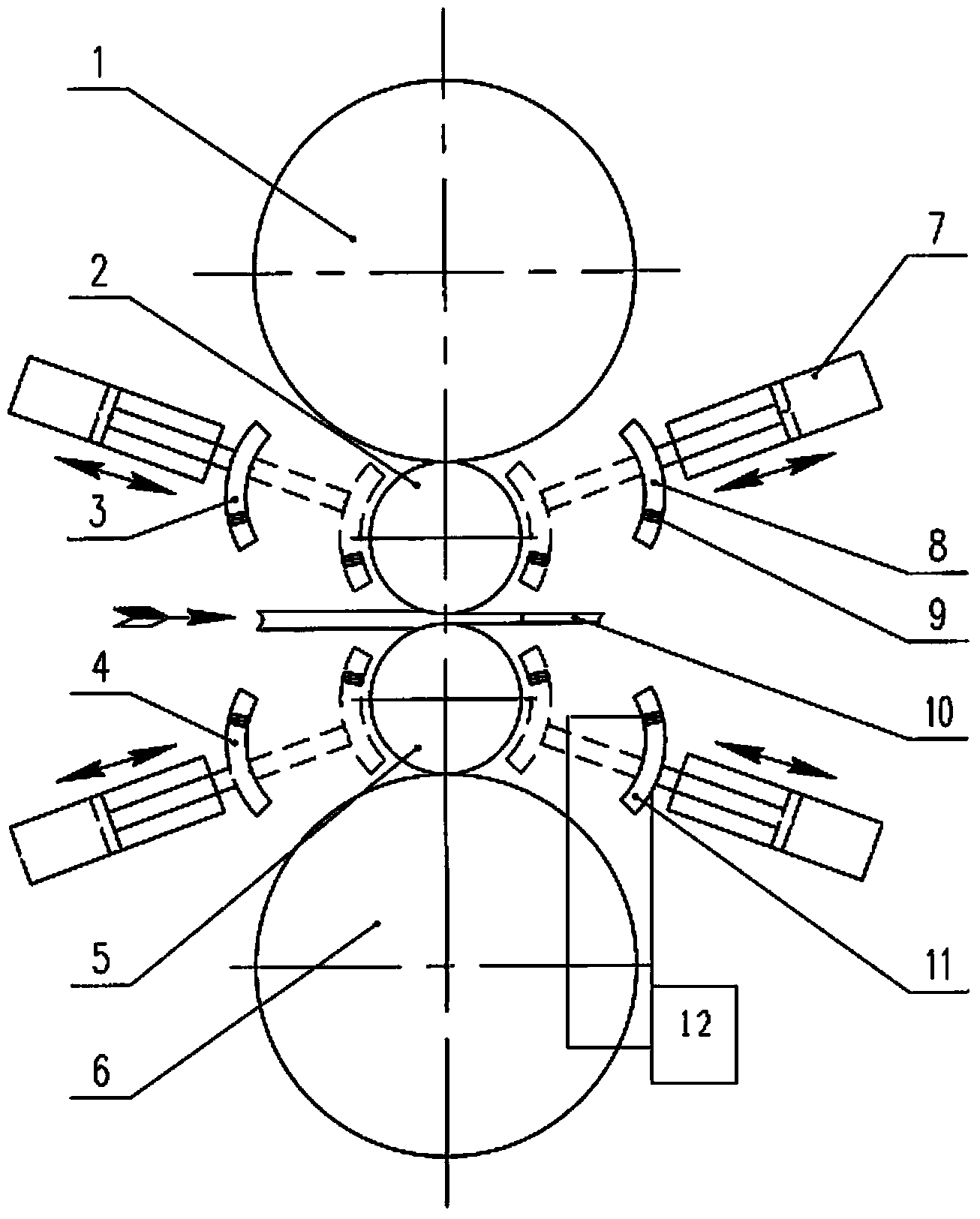

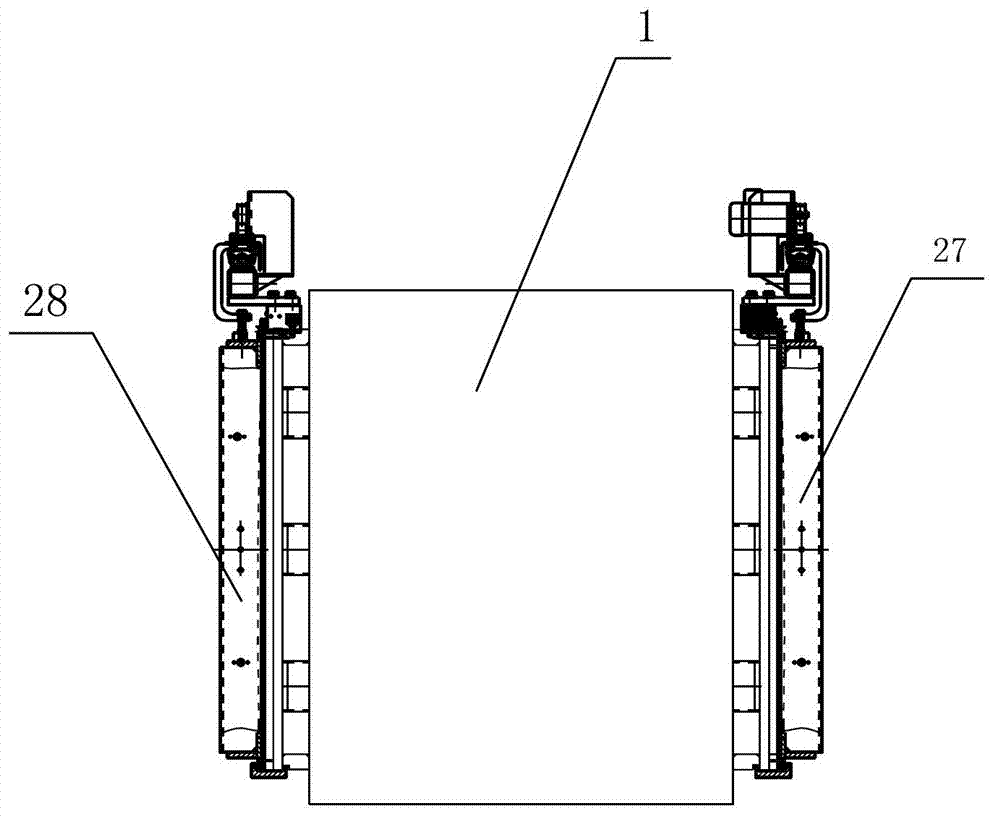

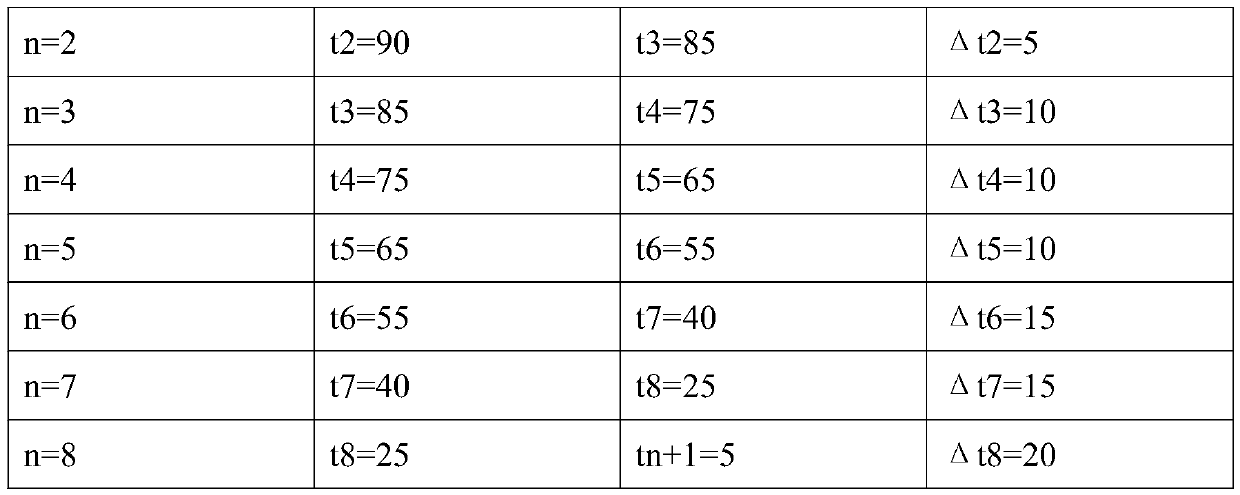

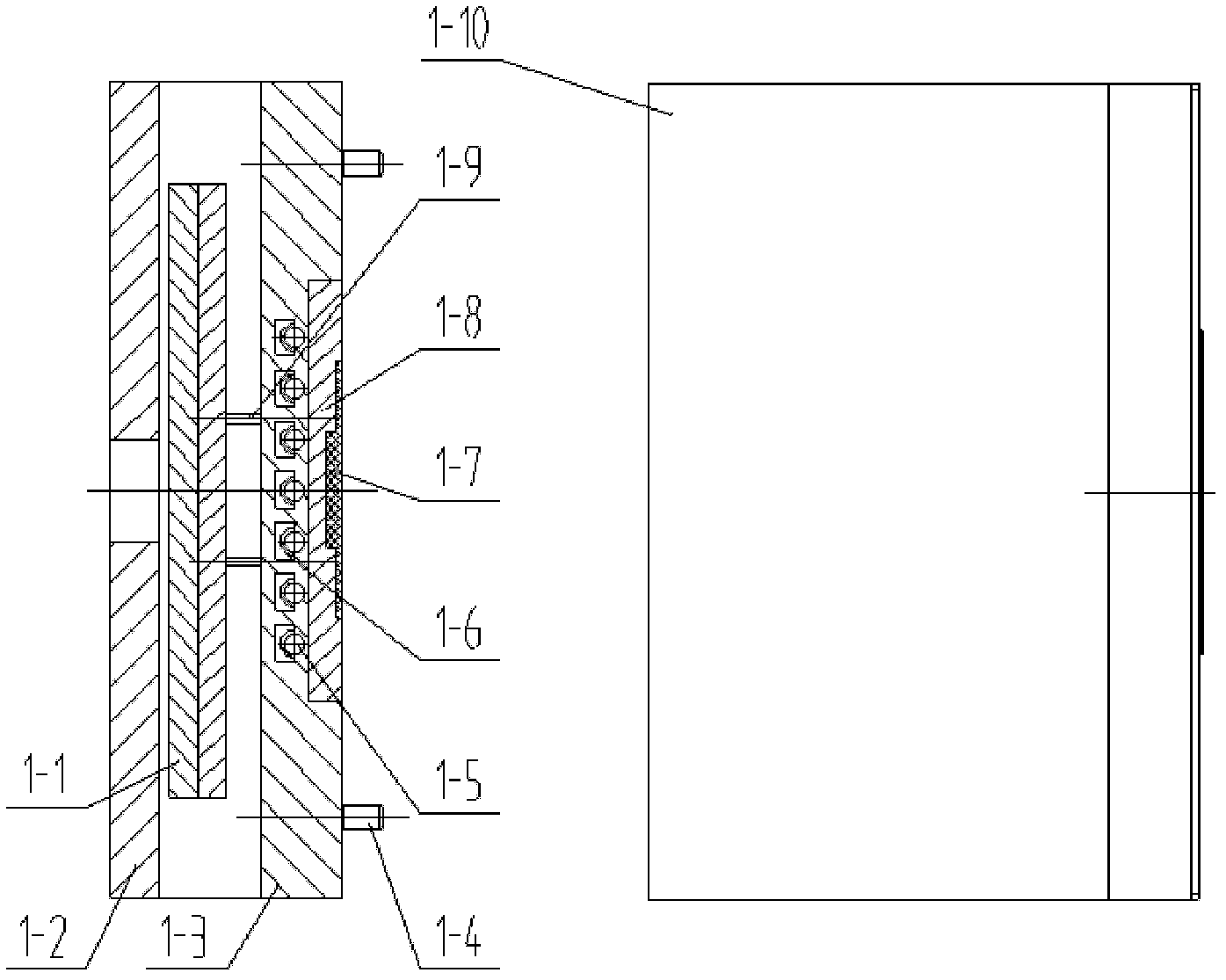

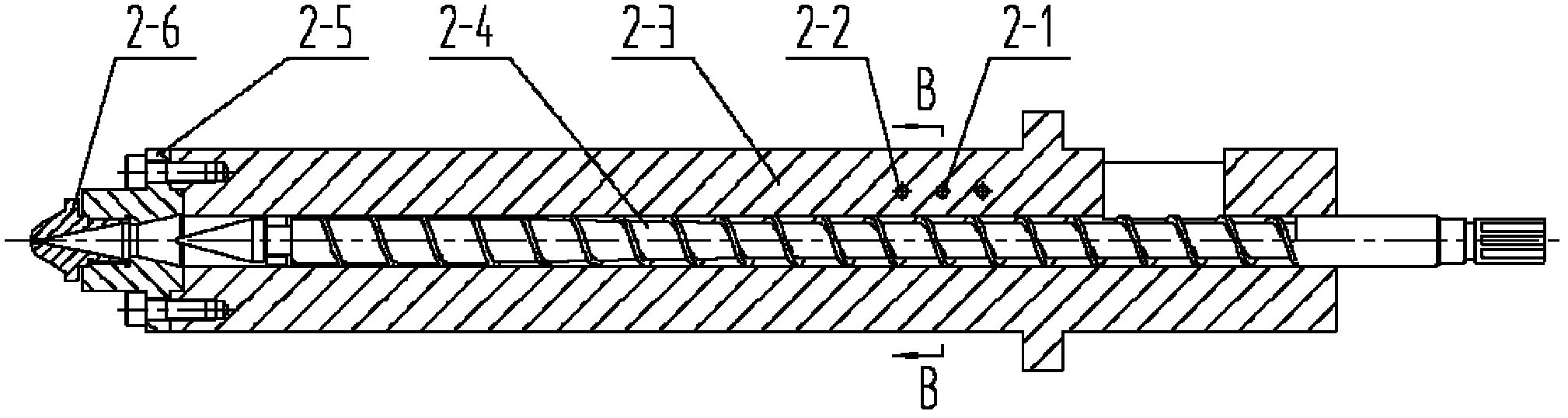

Device for on-line roller heating and temperature controlling for warm-rolling mill

InactiveCN103658189AFast online heatingStable temperature controlTemperature control deviceRollsTemperature controlProcess engineering

A device for on-line roller heating and temperature controlling for a warm-rolling mill comprises four telescopic electromagnetic induction heating arcs respectively driven by oil cylinders, an infrared thermometer arranged on each heating arc, and temperature control modules controlling starting and stopping of the heating arcs. Absolute value displacement sensors are arranged inside the oil cylinders and can accurately control the distance between the heating arcs and the surfaces of rollers, and the temperature control modules can carry out comparative analysis on the surface temperature, fed back by the infrared thermometers, of the rollers and the temperature set initially and then control starting and stopping of the electromagnetic induction heating arcs. According to the device, the on-line roller heating requirement can be met fast, the process production requirement of fast replacement of the rollers and roller abrasion can be met, and various shortcomings in the prior heating technology of the rollers of the warm-rolling mill are eliminated. The device has the advantages of being compact in structure, high in heating speed, accurate in temperature control and safe in heating.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Intelligent temperature control acupuncture therapeutic apparatus

ActiveCN103126881AAccurate temperature controlHeating fastDevices for heating/cooling reflex pointsAcupunctureEngineeringElectrical and Electronics engineering

The invention discloses an intelligent temperature control acupuncture therapeutic apparatus. The intelligent temperature control acupuncture therapeutic apparatus comprises a power module, a liquid touch screen, a touch-screen controller, an electronic temperature control component used for simulating moxibustion temperature curve and a heating head used for being inserted into the handle portion of an acupuncture pin to conduct heating, wherein the electronic temperature control component is composed of a system control module and a heating driving module, the system control module is connected with the heating driving module in a communication mode, the system control module is connected with the power module and the touch-screen controller in a communication mode, the liquid touch screen is connected with the touch-screen controller in a communication mode and used for setting the heating time and the temperature cycle period of the heating head and displaying the temperature change and the heating time of the heating head in work, the heating head is connected with the heating driving module through a guide line, and the system control module and the heating driving module control the temperature change range of the heating head from 30 DEG C to 59 DEG C. According to the intelligent temperature control acupuncture therapeutic apparatus, moxibustion technique change and moxa-cone temperature change are effectively simulated, a continuous and variational thermal stimulus state is kept, fast - slow adaptation phenomenon caused when a human body experiences the apparatus is avoided, and clinical effect is improved.

Owner:上海中医药大学附属龙华医院浦东分院 +2

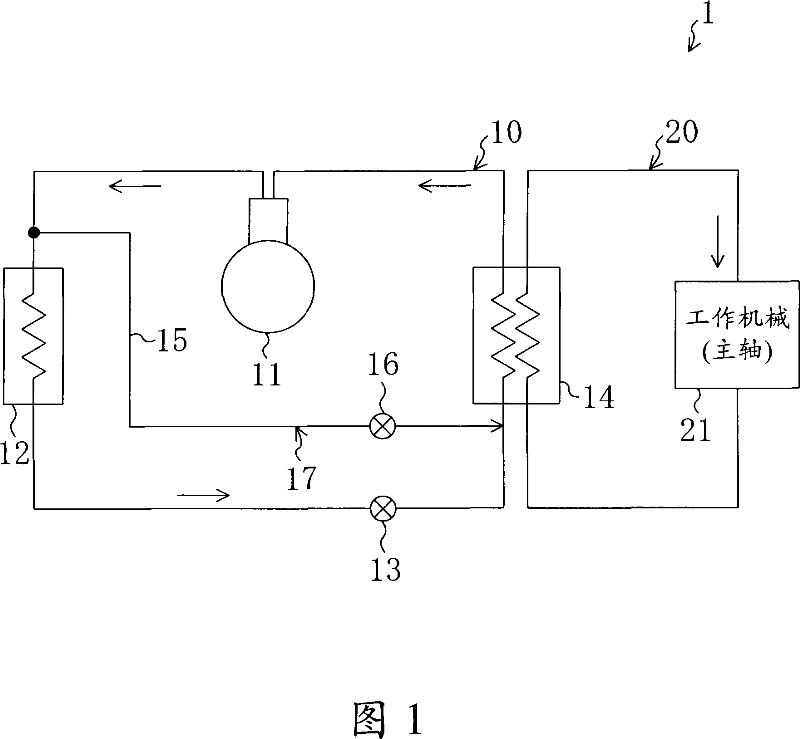

Refrigeration system

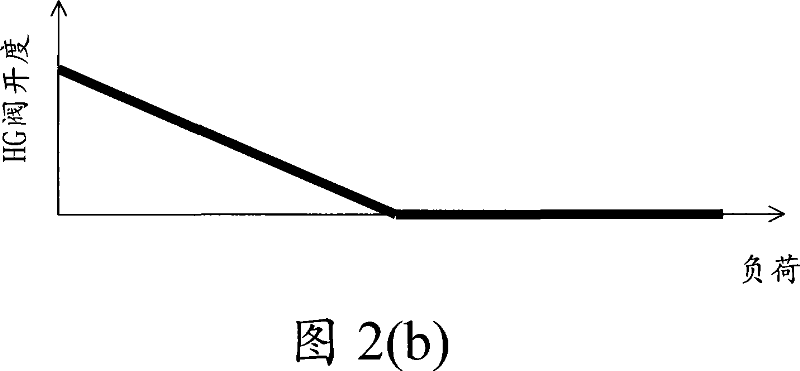

ActiveCN101044359ACooling Capacity InhibitionAdjustable cooling capacityCompression machines with non-reversible cycleEngineeringControl valves

Disclosed is a refrigeration system wherein a hot gas bypass circuit (15) is provided for allowing a refrigerant discharged from a compressor (11) to flow bypassing at least a condenser (12) and a expansion valve (13) and a flow control valve (16) is arranged in the hot gas bypass circuit (15).

Owner:DAIKIN IND LTD

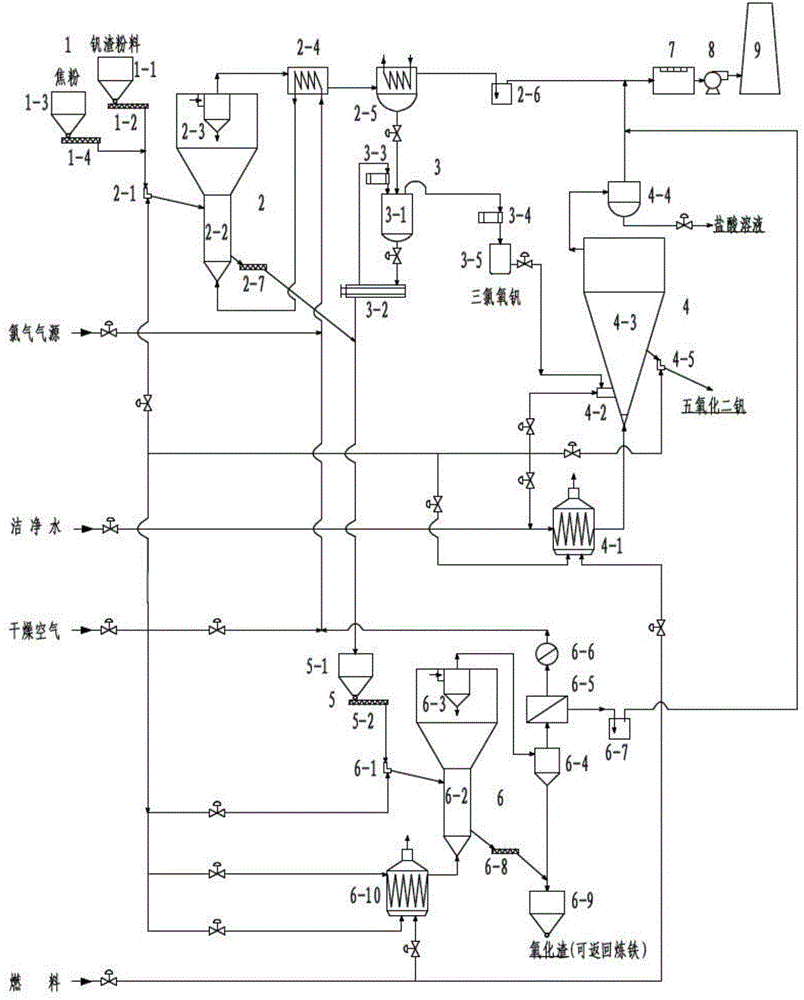

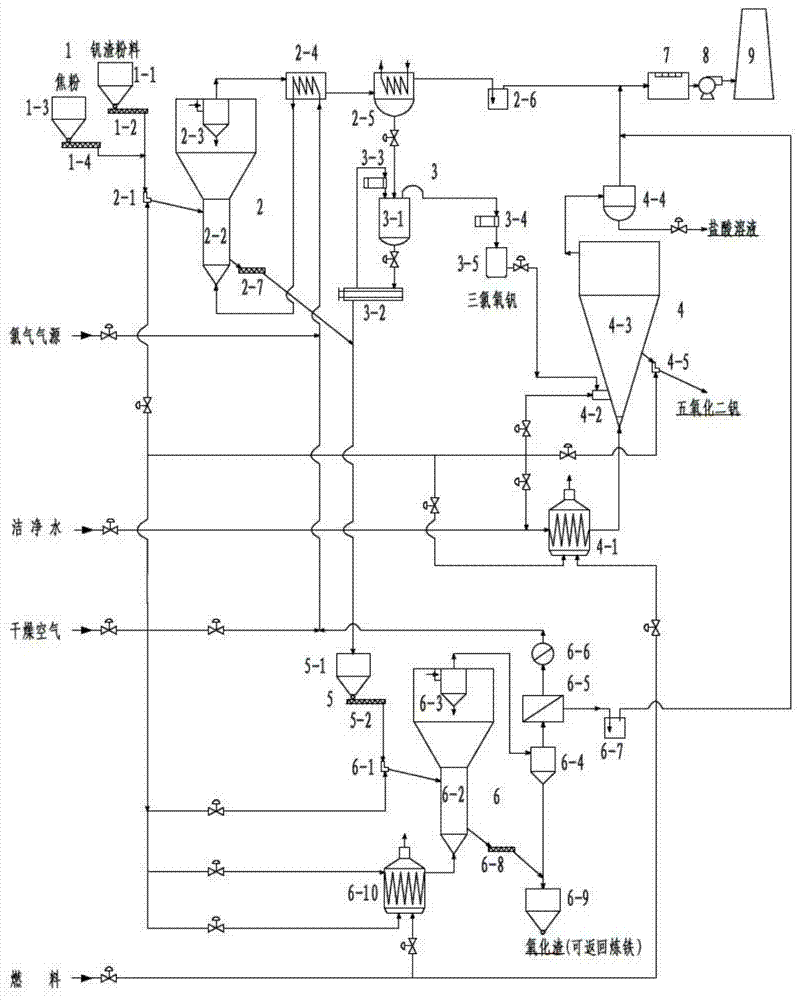

System and method for high-efficiency extraction of vanadium from vanadium slag through chlorination

ActiveCN105986126AAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementFlue gasPrecipitation

The invention specifically discloses a system and method for high-efficiency extraction of vanadium from vanadium slag through chlorination, belonging to the fields of chemical engineering and metallurgy. By means of heat exchange between chlorination gas and chlorination flue gas, the chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination; by means of high-temperature fluidization oxidation of chlorinated slag, the chlorinated slag is treated in a comprehensive manner, and the chlorine gas is recycled; furthermore, by means of vapor-phase hydrolysis of the chlorination product vanadium oxytrichloride, a powdered vanadium pentoxide product and a hydrochloric acid byproduct are obtained; so the efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of the chlorinated slag is eliminated, and the problem of ammonia-nitrogen pollution caused by conventional ammonium salt precipitation is prevented. The system and method provided by the invention are applicable to extraction of vanadium from vanadium slag containing 10 to 28 wt% of V2O5 through chlorination and have the advantages of high efficiency, low energy consumption, no pollution, good economic performance, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

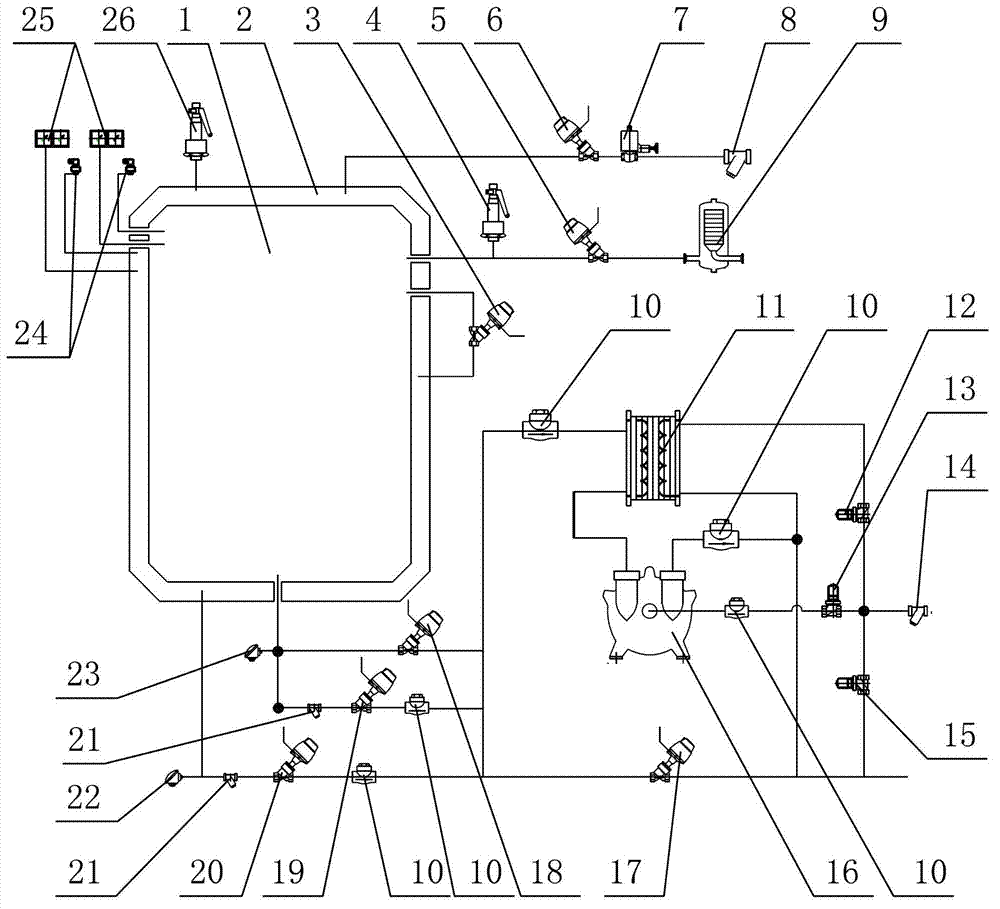

Steam sterilizer and sterilization process

The invention relates to a steam sterilizer and a sterilization process, and in particular relates to a negative-pressure and low-temperature steam sterilizer and the sterilization process. The steam sterilizer comprises a sandwich layer and an internal chamber, wherein the internal chamber consists of a space enclosed by a front door, a back door and the sandwich layer; a steam channel is formed in the sandwich layer; the sandwich layer is connected with a sandwich layer steam inlet system through a pipeline; the internal chamber is connected with an internal chamber emptying system through a pipeline; the sandwich layer is communicated with the internal chamber through a pipeline, and a first pneumatic control valve is arranged on the pipeline; the internal chamber is connected with an internal chamber vacuumizing drainage system through a pipeline; and the sandwich layer is connected with a sandwich layer vacuumizing drainage system through a pipeline. The steam sterilization process comprises: (1) vacuumizing; (2) sandwich layer steam inlet; (3) heating; (4) sterilization. The low-temperature steam sterilization of a thermolabile article is realized; by virtue of the internal chamber vacuumizing drainage system, condensed water formed in the sterilization process can be effectively drained, and the steam quality and temperature uniformity of the internal chamber are ensured.

Owner:SHINVA MEDICAL INSTR CO LTD

A system and method for efficiently chlorinating vanadium from vanadium slag

ActiveCN105986126BAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementSlagGas phase

Provided are a system and method for highly effective chlorination and vanadium extraction from vanadium slag. By means of heat exchange between a chlorination gas and a chlorination flue gas, a chlorination gas is preheated and an appropriate amount of air is added, which causes coke powder to partially combust, thus providing a balanced supply of heat during the process of chlorination; also, by means of high-temperature fluidization oxidation of the chlorinated slag, the chlorinated slag is used in a comprehensive manner, and the chlorine gas is recycled; further, by means of vapor-phase hydrolysis of the vanadium oxytrichloride product of chlorination, a powdered divanadium pentoxide product is obtained; the reaction efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of chlorinated slag is eliminated, and the pollution problem caused by conventional ammonium salt precipitation is prevented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

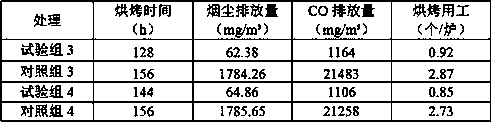

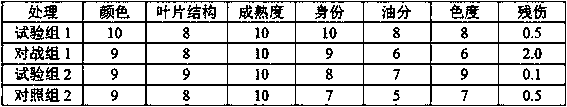

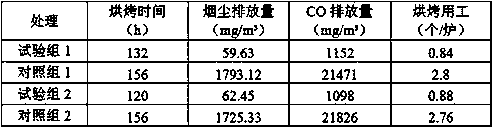

High-efficiency baking method for improving appearance quality of K326 variety of tobacco leaves

InactiveCN110638081ASolve the problem that it is easy to turn yellow and difficult to fix the colorImprove appearance qualityTobacco preparationAgricultural engineeringWet-bulb temperature

The invention discloses a high-efficiency baking method for improving appearance quality of K326 variety of tobacco leaves. The method is characterized by baking by using biomass fuel, harvesting properly mature K326 variety of tobacco leaves; arranging rods into a baking room to be baked, wherein the yellowing period control comprises initial yellowing period control, middle yellowing period control and later yellowing control, the color fixing period control comprises the initial color fixing stage and the later color fixing stage, and the initial color fixing stage control comprises temperature rise in the rate of 1 DEG C / 1-2h after the yellowing period control is finished; and the stem drying stage control comprises rising the temperature of a dry bulb to 66-67 DEG C, and adjusting thetemperature of a wet bulb to 40-42 DEG C. Through the slow temperature rise at the early color fixing stage, the problems that the grey smoke hanging and process execution are inaccurate, the bakingtime is long, the combustion efficiency is low, the pollution is large, and the feeding is frequent since the yellowing is easy and the color fixing is difficult, the tobacco leaves after baking are stiff, the fragrance is not enough, the temperature rise is slow, and the stable temperature is unstable in the traditional K326 tobacco leaf baking process are solved by combining the high temperatureand low humidity at the stage of drying the stems, and the proportion of the tobacco in middle and high quality and the quality of the baked tobacco leaves are obviously improved.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Preparation technology for large size super-high obdurability magnesium alloy thin plate

The invention relates to the preparation technology for a large size super-high obdurability magnesium alloy thin plate. The preparation technology particularly comprises the following steps that firstly, a magnesium alloy blank is heated to 250-450 DEG C and subjected to heat preservation for 1-3 h; then, the magnesium alloy blank is subjected to equal-channel angular pressing, after being extruded for one to two passes, the magnesium alloy blank is remelted and annealed, pressing is conducted for 8-12 times, and then a magnesium alloy rod material is obtained; before a rolling mill conducts rolling, a roller is preheated, the preheating temperature is 150-450 DEG C, and the roller is subjected to heat preservation treatment in the rolling process; after the obtained magnesium alloy rod material is subjected to heat preservation for 20-60 min at the temperature of 250-450 DEG C, the magnesium alloy rod material is rolled by adopting a multi-pass and small-deformation method, and the speed of the roller is 0.2-0.5 m / s; after every pass of rolling, remelting and annealing are conducted, horizontal rolling and vertical rolling are alternately conducted in the rolling process, and a magnesium alloy thin plate is obtained; and the obtained magnesium alloy thin plate is subjected to aging treatment, and then a finished magnesium alloy thin plate is obtained. According to the preparation technology of the large size super-high obdurability magnesium alloy thin plate, the prepared magnesium alloy thin plate is uniform in crystalline grain and excellent in mechanical property.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

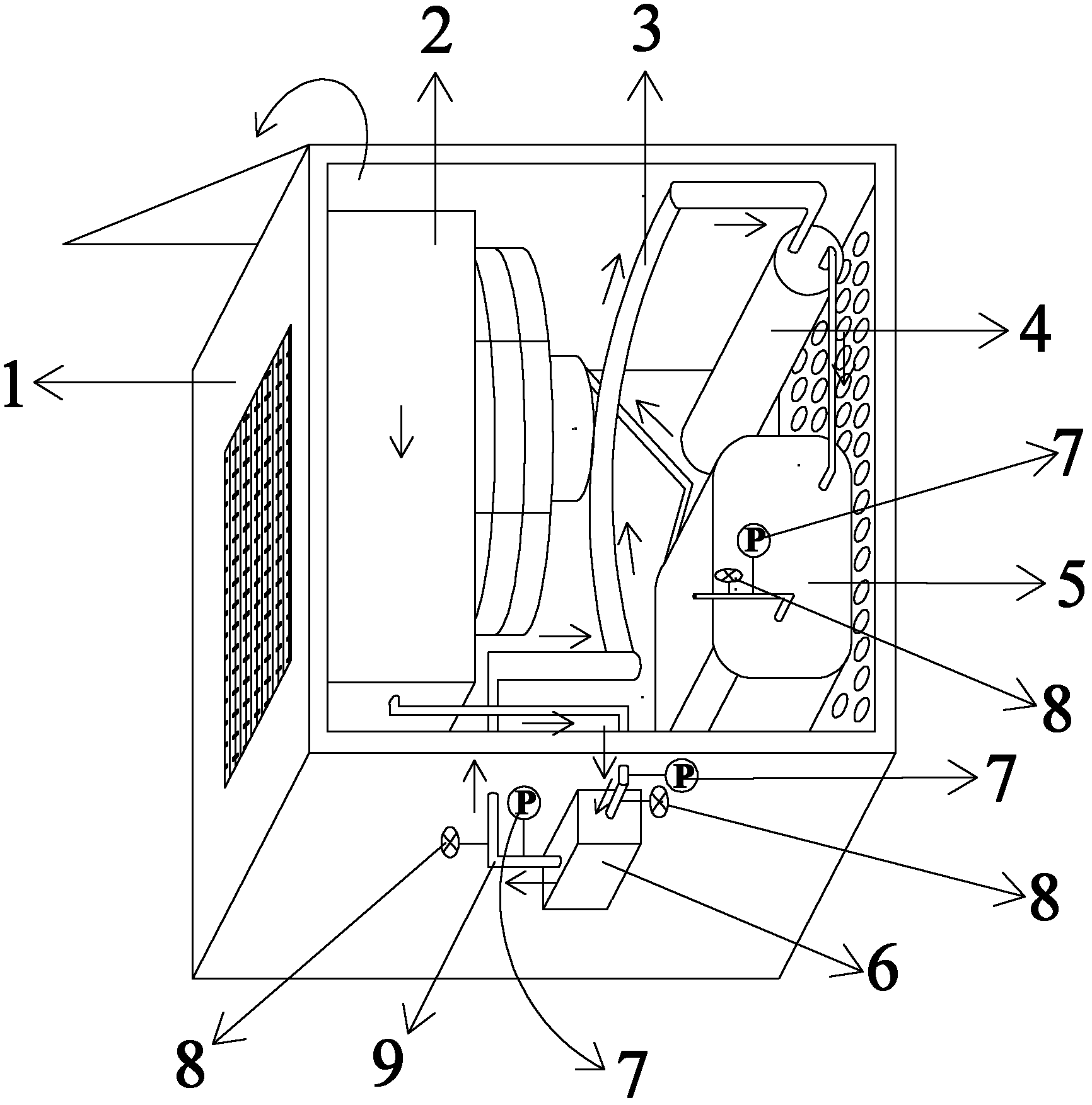

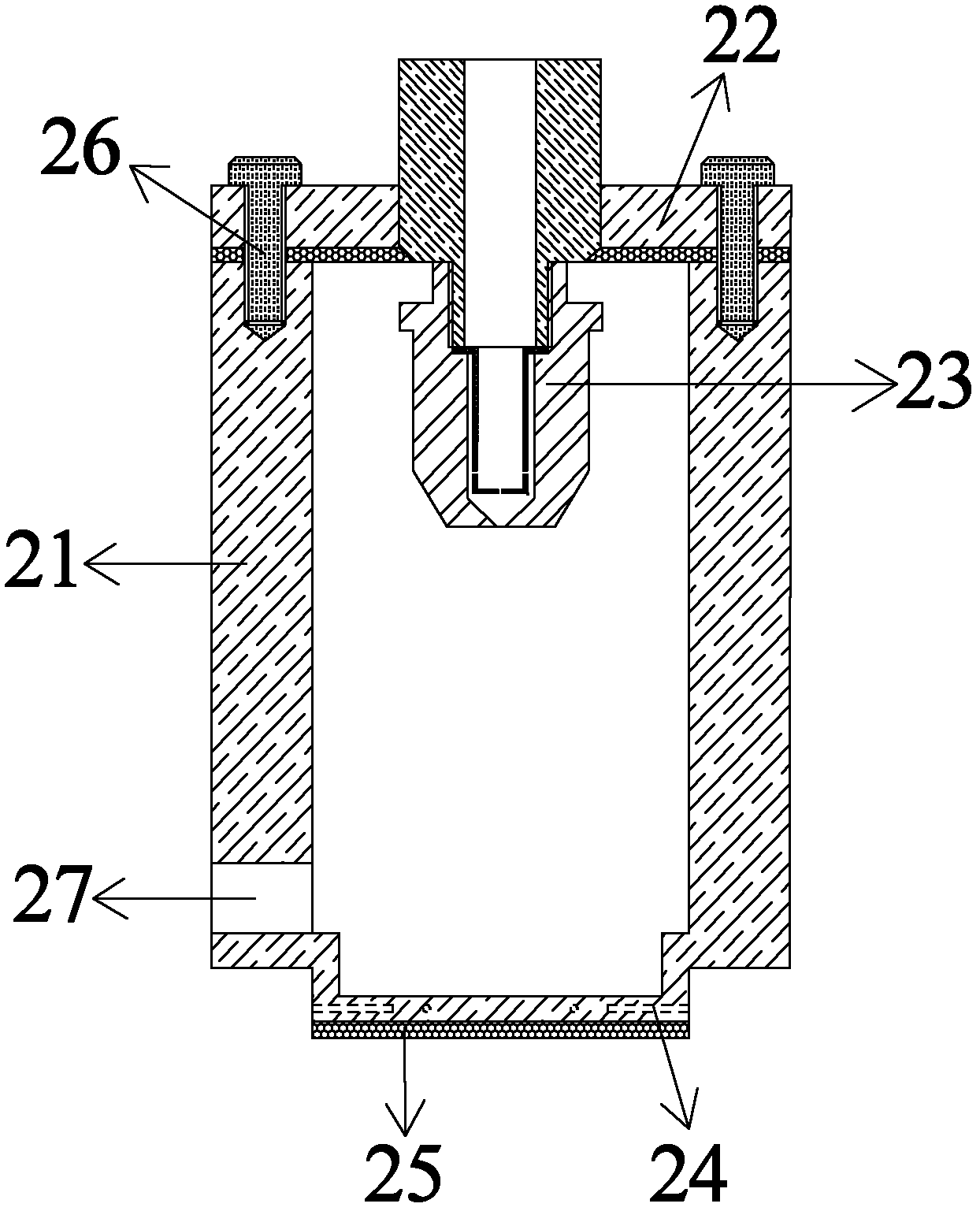

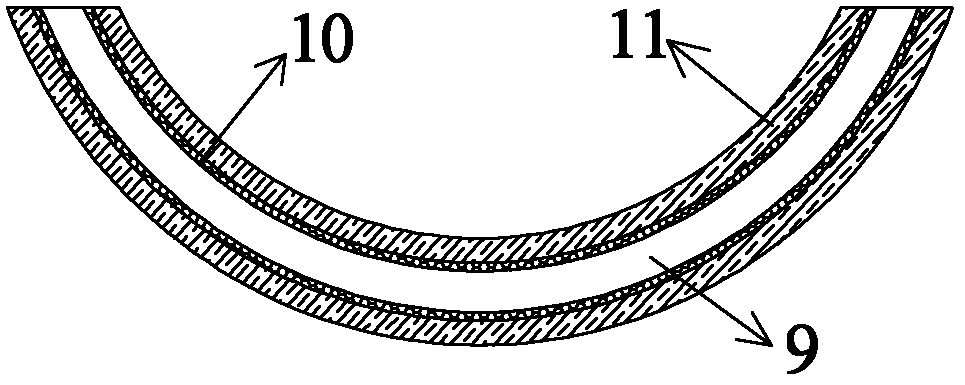

Portable temperature-equalizing type spraying cooling circulating system for high-power electronic component

InactiveCN102625642AGood application effectTroubleshooting the presence of a liquid phaseCooling/ventilation/heating modificationsVapor–liquid separatorEngineering

The invention discloses a portable temperature-equalizing type spraying cooling circulating system for a high-power electronic component. The circulating system comprises a compressor, a spraying cooler and an air condenser, wherein an outlet of the compressor is connected with an inlet of the air condenser through a connecting pipeline; the outlet of the air condenser is connected with the inlet of the spraying cooler through the connecting pipeline; the circulating system is characterized by being provided with a gas-liquid separator and an auxiliary heating device; the outlet of the spraying cooler is connected with the inlet of the gas-liquid separator through a fluid conveying pipeline; the auxiliary heating device is arranged on the fluid conveying pipeline; the outlet of the gas-liquid separator is connected with the inlet of the compressor through the connecting pipeline; and a to-be-cooled piece is fixedly arranged on the spraying cooler. The auxiliary heating device and the gas-liquid separator are utilized in the circulating system provided by the invention to solve the problems that liquid phase exists before a refrigerant enters into the compressor and residual liquid after being subjected to spraying cooling cannot directly enter into the compressor for recompressing, so that spraying cooling closed circulation is realized and energy source is saved.

Owner:CHONGQING UNIV

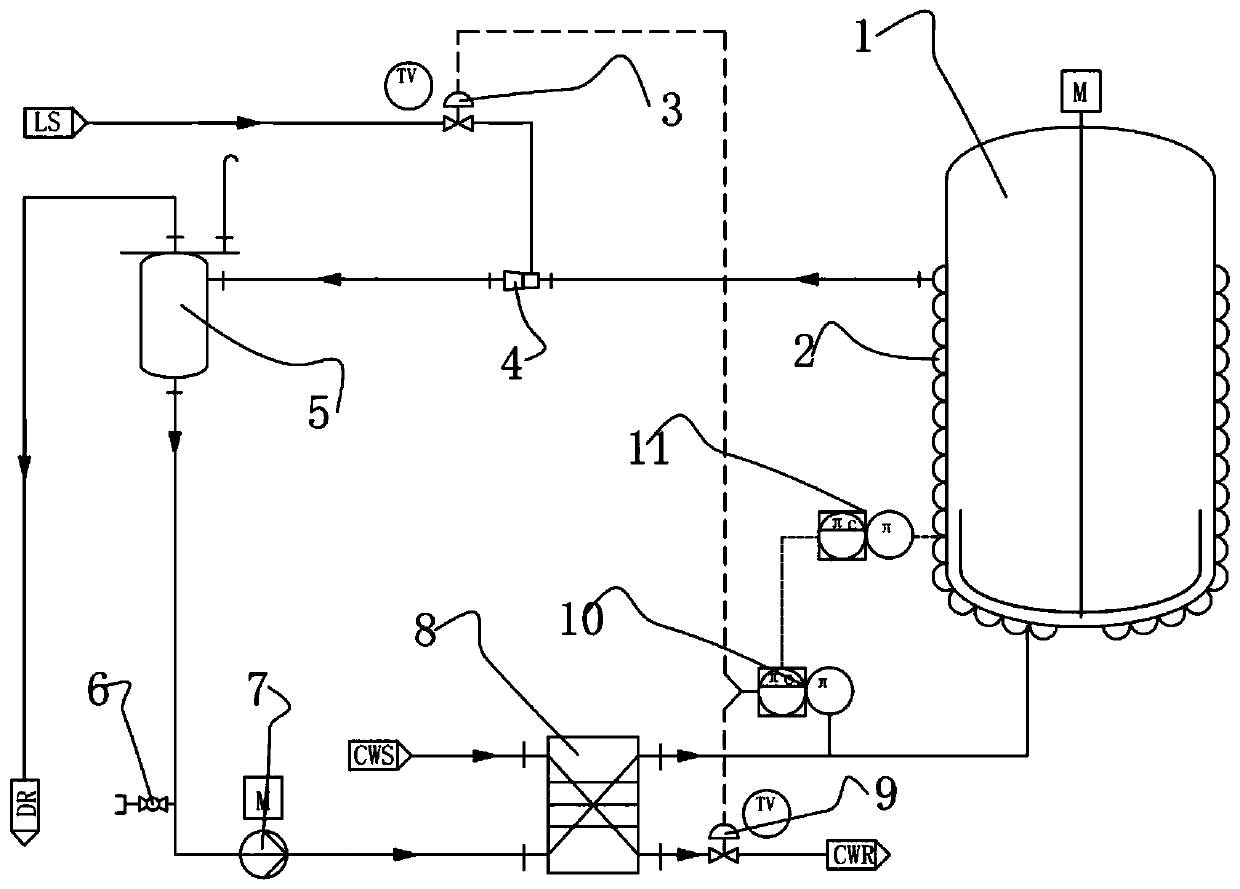

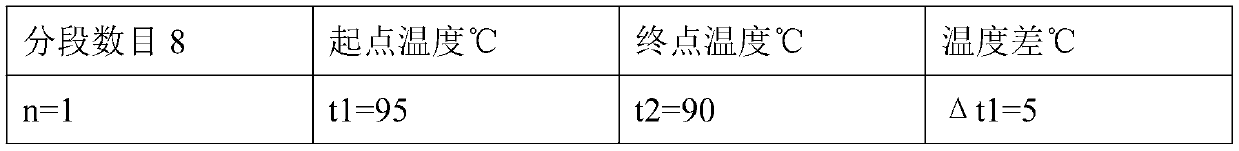

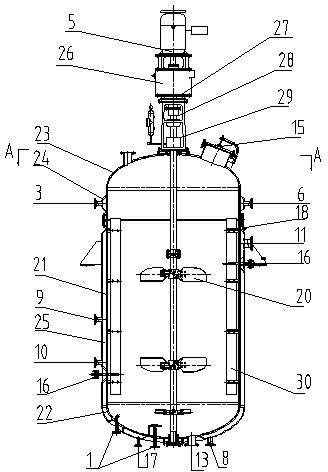

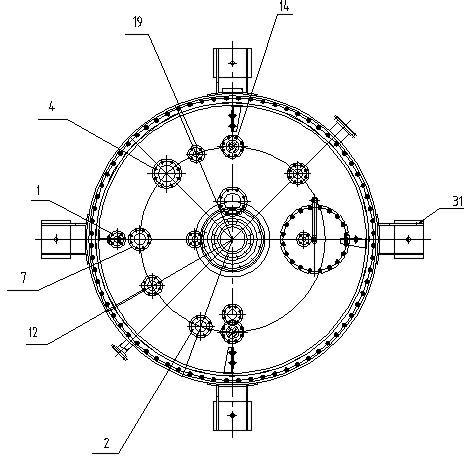

Crystallizing kettle temperature control system and control method

InactiveCN109692495AStable temperature controlWide range of temperature controlSolution crystallizationHeat exchange cooling cystallizationLower limitTemperature control

The invention discloses a crystallizing kettle temperature control system and control method, wherein the temperature control system is composed of a crystallizing kettle provided with an outer coil pipe, a water storage tank, a heat exchanger, a DCS control system and a conveying pipeline; before materials enter a crystallizing kettle, steam is introduced, and the crystallizing kettle is preheated by heating circulating water; when the crystallizing operation begins, a steam regulating valve is closed, freezing water is introduced, the temperature of the circulating water is reduced by a heatexchanger, and the crystallization kettle is cooled. The temperature control method DCS controls to set different temperature difference [delta]t according to different temperature t sections of thecrystallizing kettle to ensure the quality of crystallization products and improve the crystallization speed of the products. The crystallizing kettle temperature control system integrates heating andcooling of the crystallizing kettle, can flexibly and steadily control the temperature of the crystallizing kettle, has a wide range of temperature control, can also achieve a good cooling effect forthe crystallizing reaction with the terminal temperature of crystallization as low as 5 DEG C, can effectively and smoothly control the temperature in the crystallizing kettle, ensures the smooth progress of the crystallizing process, and also increases the lower limit of the cooling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Temperature control method based on phase-transition energy-accumulation material

The invention discloses a temperature control method based on a phase-transition energy-accumulation material. In the method, the phase-transition energy-accumulation material is selected according to a required control temperature, so that the phase-transition temperature of the phase-transition energy-accumulation material can be a set control temperature of a device; in a product processing process, the selected phase-transition energy-accumulation material in a solid-liquid mixed state is introduced into an energy-accumulation material channel, a temperature-control area is close to the phase-transition energy-accumulation material channel, and a constant-temperature temperature-control medium is provided by utilizing the energy-accumulation property of the phase-transition energy-accumulation material. By adopting the temperature control method based on the phase-transition energy-accumulation material, the temperature around a cavity is stably controlled under the phase-transition temperature of the selected material, the phase-transition material is molten from the solid state to the liquid state at a fixed temperature after absorbing heat so as to form a heat-absorption mechanism, and large heat absorption amount ensures that the temperature around the cavity is relatively balanced; after being properly cooled, the phase-transition material is solidified from the liquid state to the solid state so as to form a heat release mechanism at the fixed temperature, so that the temperature around the cavity is relatively balanced and continuously recycled.

Owner:BEIJING UNIV OF CHEM TECH

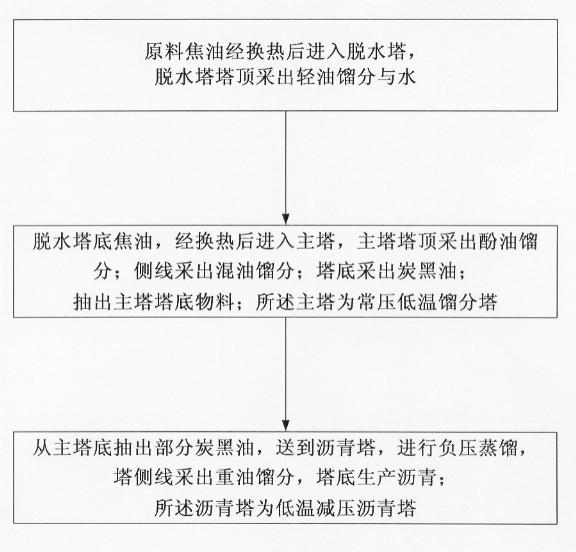

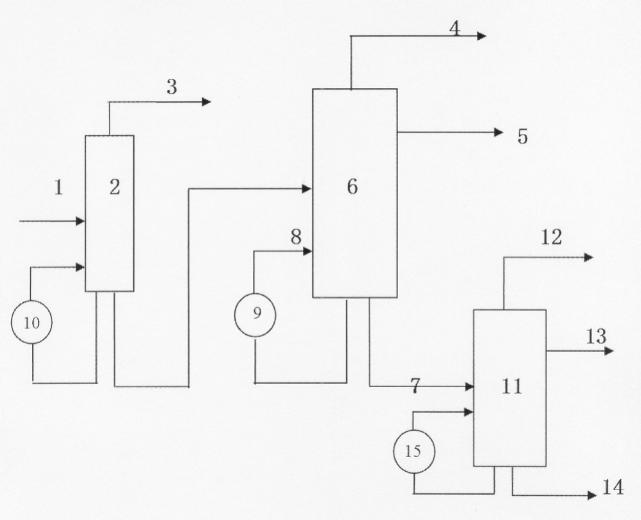

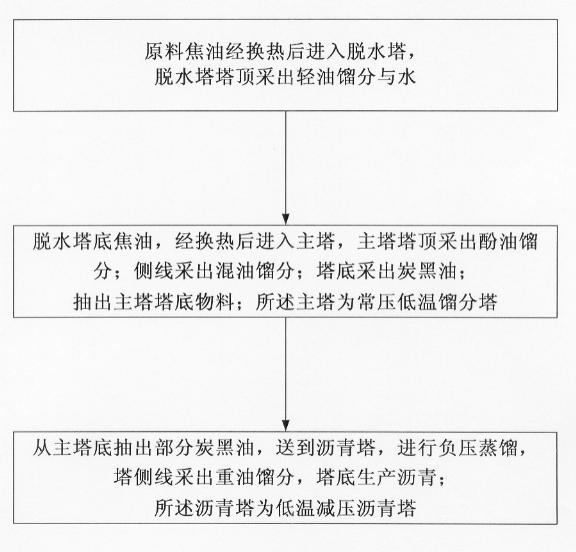

Coal tar alkali-free normal/reduced-pressure distillation process and device

ActiveCN102161901AReduce sodium ion contentAvoid corrosionTar working-up by water removalTar working-up by distillationAlkali freeDistillation

The invention relates to a coal tar alkali-free normal / reduced-pressure distillation process and a coal tar alkali-free normal / reduced-pressure distillation device. In the process, raw material coal tar is subjected to heat exchange and delivered into a dehydrating tower, and light oil distillate and water are collected from the top of the dehydrating tower; the coal tar at the bottom of the dehydrating tower is subjected to heat exchange and delivered to a main tower, and a carbolic oil distillate is collected from the top of the main tower; a mixed oil distillate is collected from a lateralline; carbon black oil or soft asphalt is collected from the bottom of the tower; bottom material of the main tower is pumped out; part of soft asphalt is pumped out from the bottom of the main towerand delivered to an asphalt tower for distillation under a negative pressure, a heavy oil distillate is collected from a lateral line of the tower, and asphalt is produced at the bottom of the tower;and the main tower is a normal-pressure low-temperature distillate tower, the asphalt tower is a low-temperature reduced-pressure asphalt tower, and all distillates are not added with alkali in the whole flow. In the device, the bottom of the dehydrating tower is connected with the middle of the main tower through a pipe, and the bottom of the main tower is connected with the middle of the asphalt tower through a pipe. The internal circulation at bottom of the main tower is realized through a heating furnace, and internal circulation at the bottom of the asphalt tower is realized through a heating furnace. The process and the device have the advantages that: all distillates are not added with alkali; distillates are cut according to market demands and temperature gradient; direct super-heated steam is not used; new process waste water is avoided; the energy consumption is low; the product quality is high; and the like.

Owner:BAOSTEEL ENG & TECH GRP

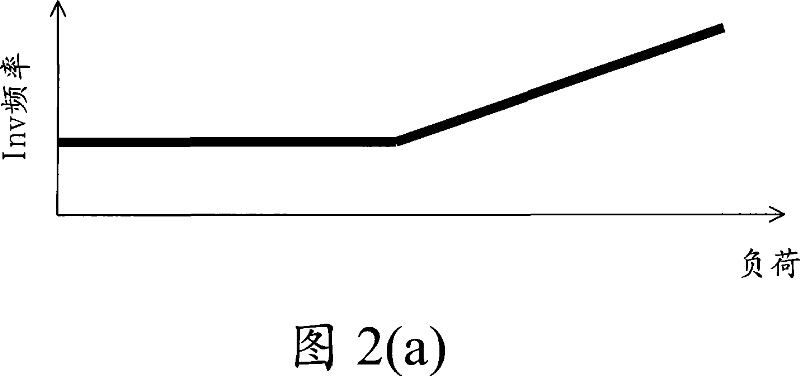

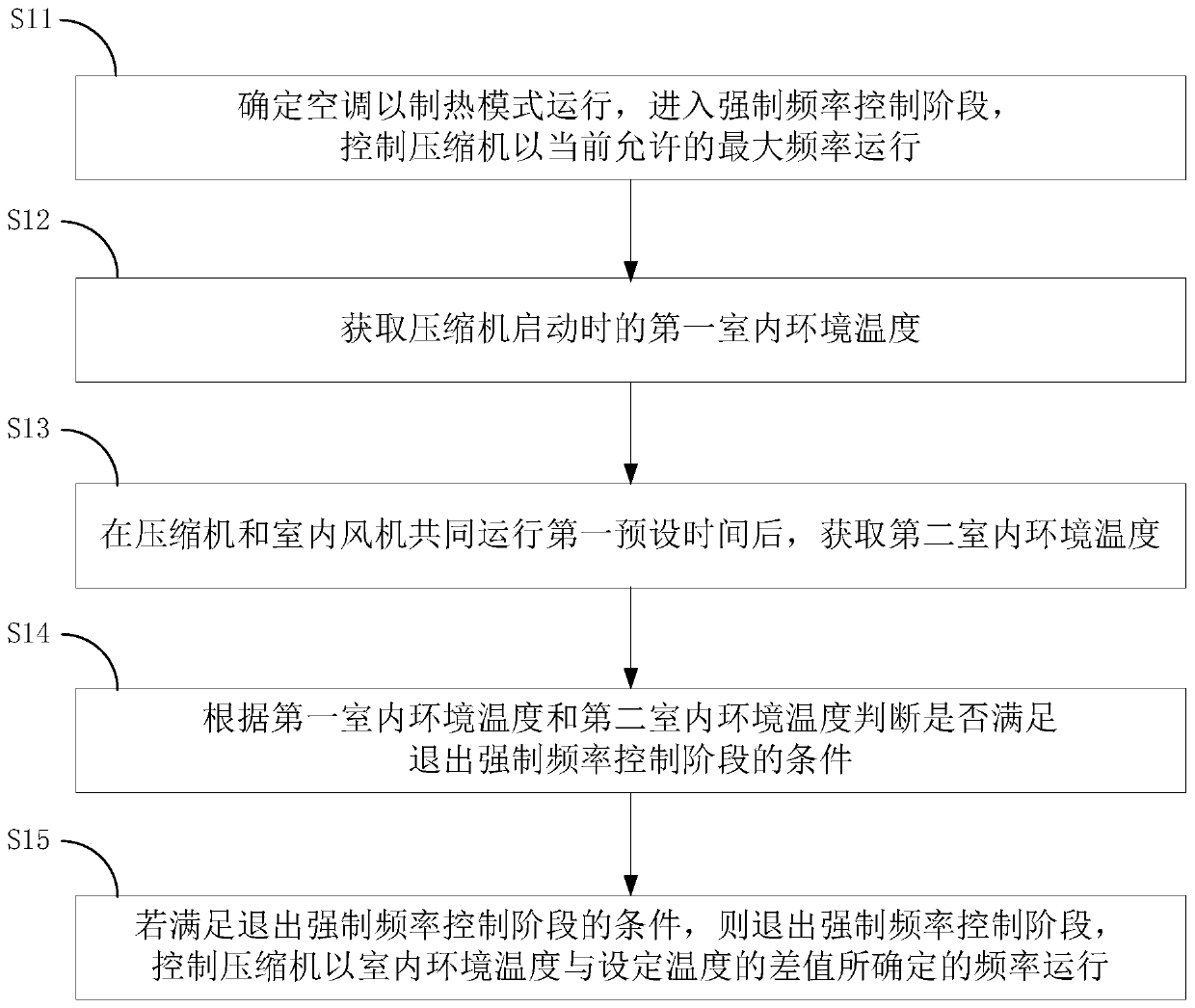

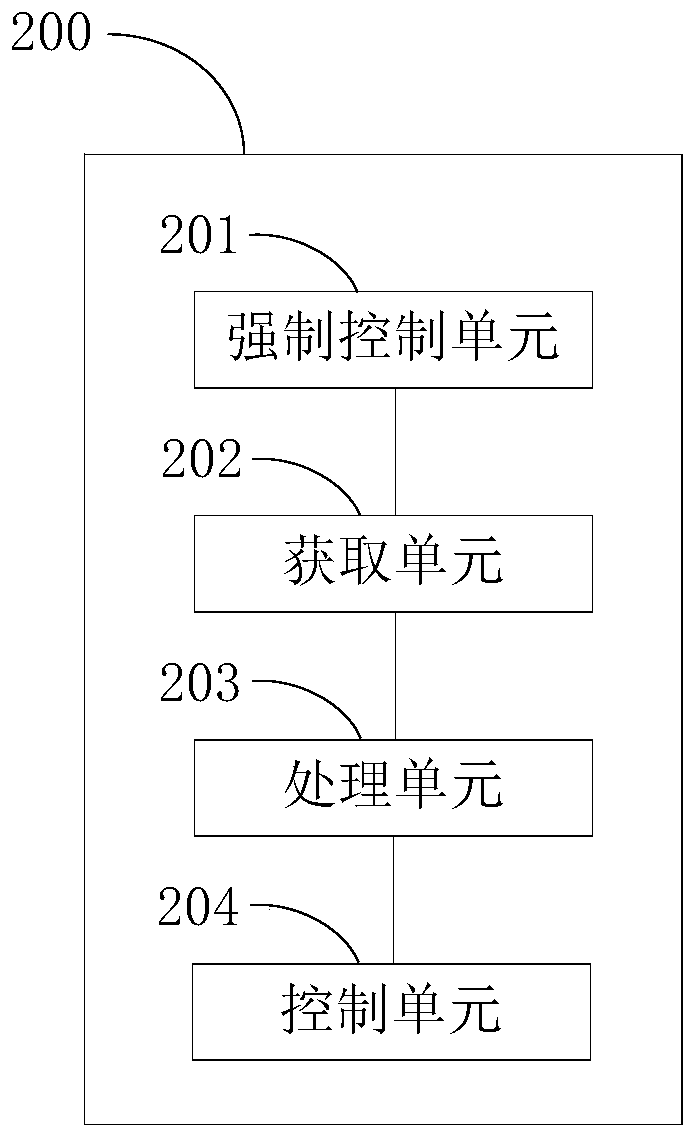

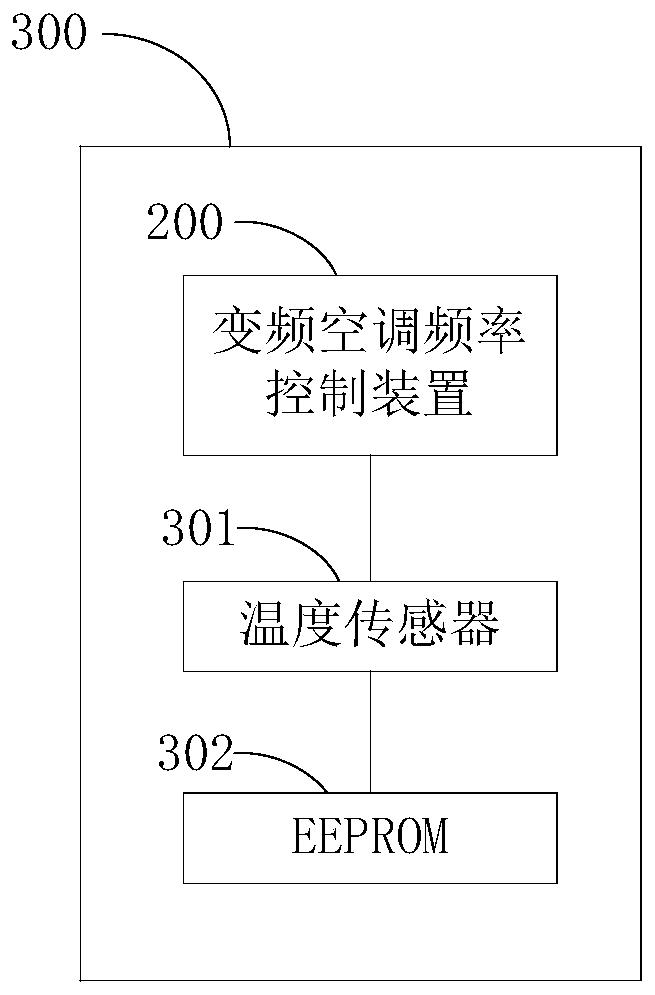

Variable frequency air conditioner frequency control method and device and air conditioner

ActiveCN110595007AAvoid errorsAvoid running abnormallyMechanical apparatusSpace heating and ventilation safety systemsForce frequencyTemperature control

The invention provides a variable frequency air conditioner frequency control method, a variable frequency air conditioner frequency control device and an air conditioner, and relates to the technicalfield of air conditioners. The variable frequency air conditioner frequency control method includes: confirming that the air conditioner runs under a heating mode, entering a forcing frequency control stage, and controlling a compressor to run at the maximum frequency allowed at present; acquiring first indoor environment temperature when starting the compressor; acquiring second indoor environment temperature after the compressor and an indoor draught fan both run for a first preset time; judging if meeting conditions of exiting from the forcing frequency control stage according to the firstindoor environment temperature and the second indoor environment temperature; and if yes, exiting from the forcing frequency control stage, and controlling the compressor to run at frequency confirmed according to difference value between the indoor environment temperature and set temperature. The variable frequency air conditioner frequency control method can solve running abnormity caused by uneven distribution of a temperature field to the air conditioner, automatically realizes accurate indoor environment temperature detection, guarantees accuracy and reliability of system temperature control, and improves user experience.

Owner:NINGBO AUX ELECTRIC +1

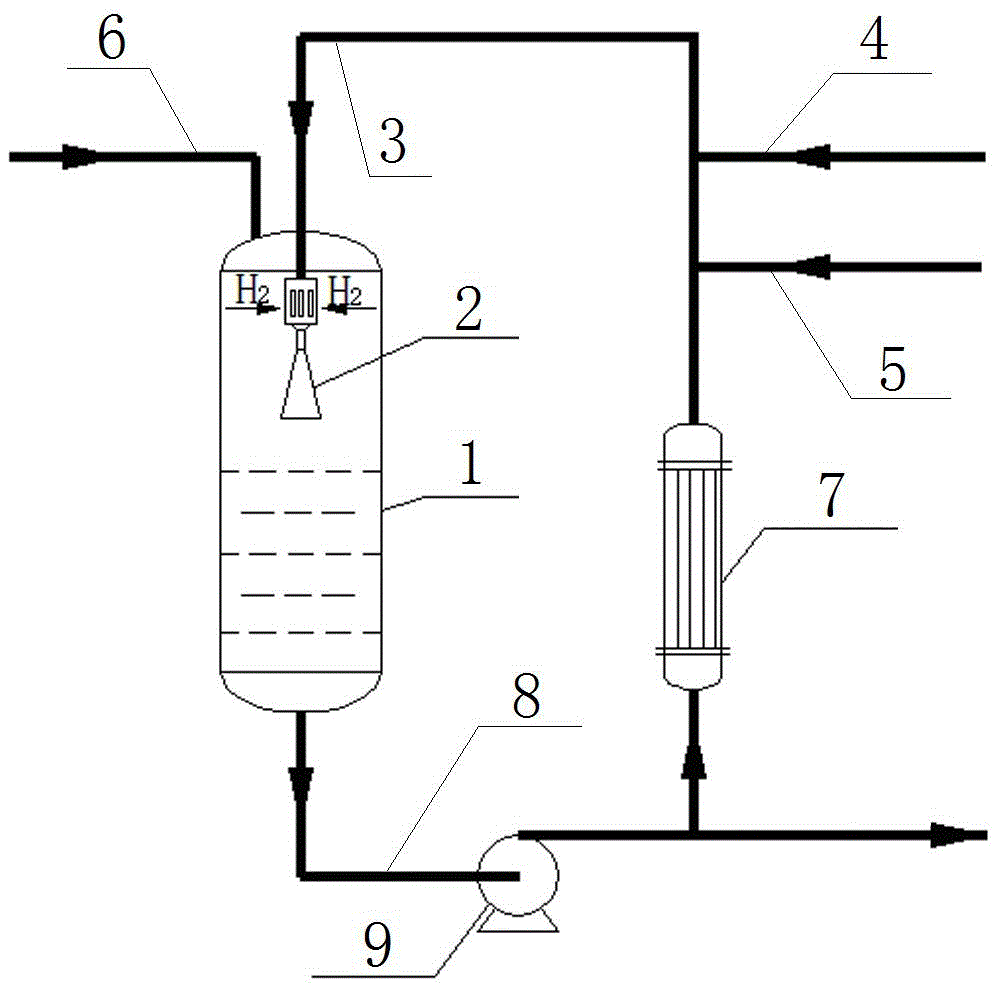

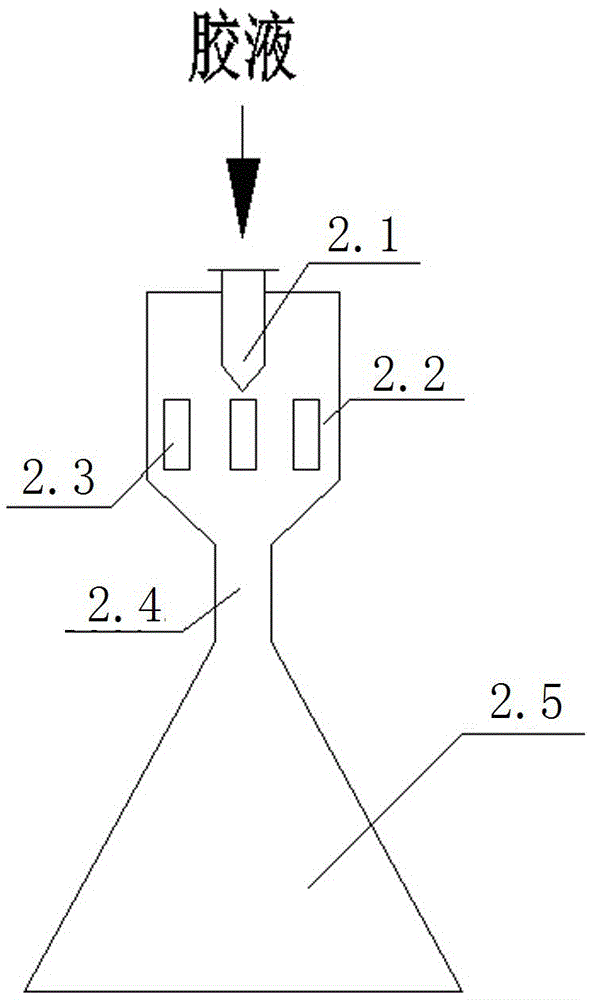

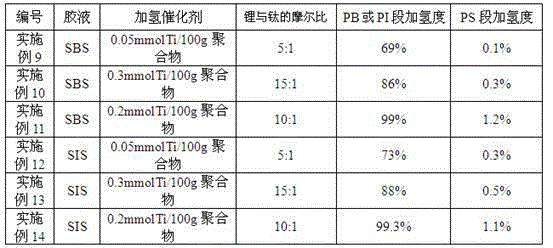

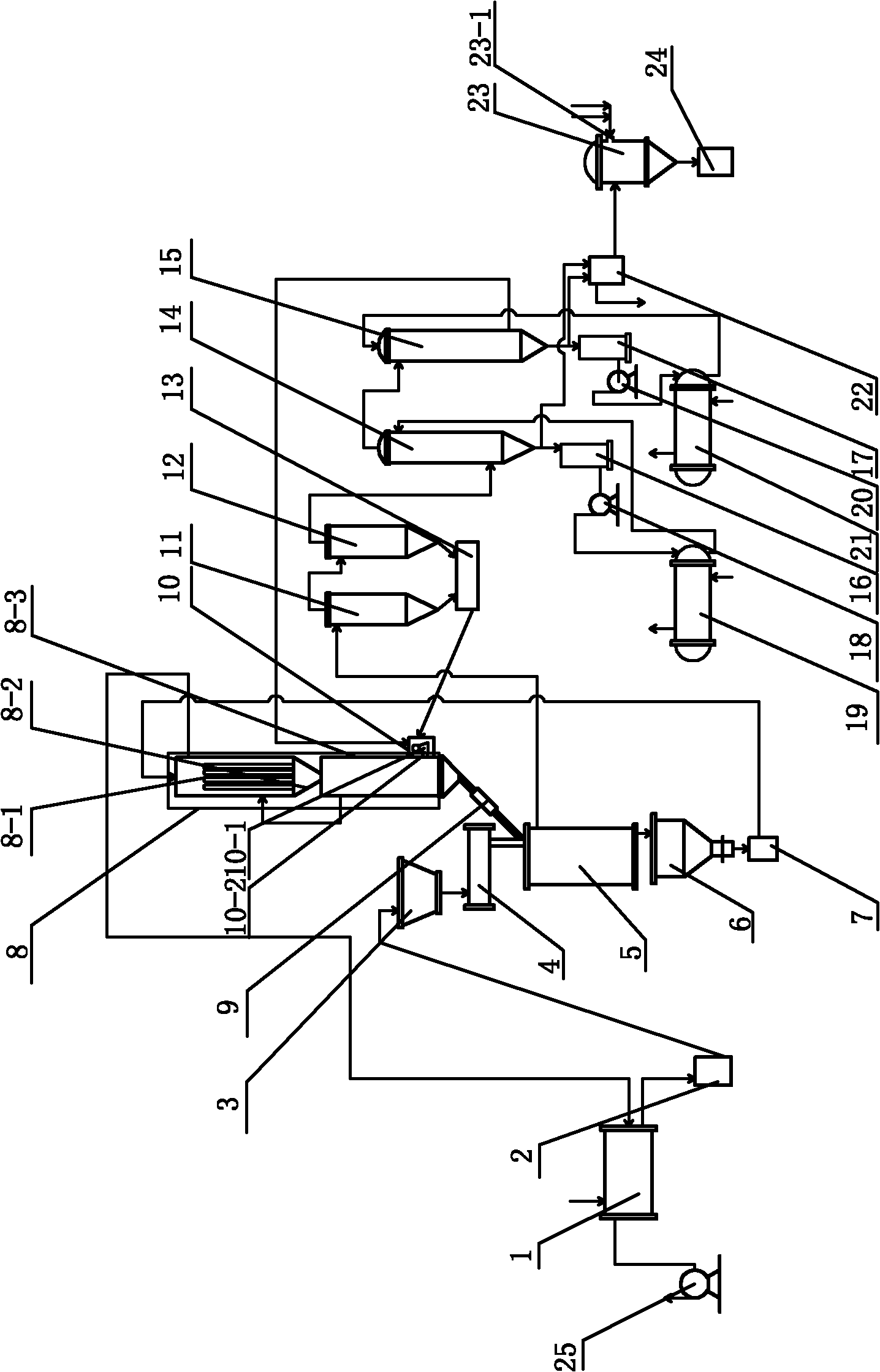

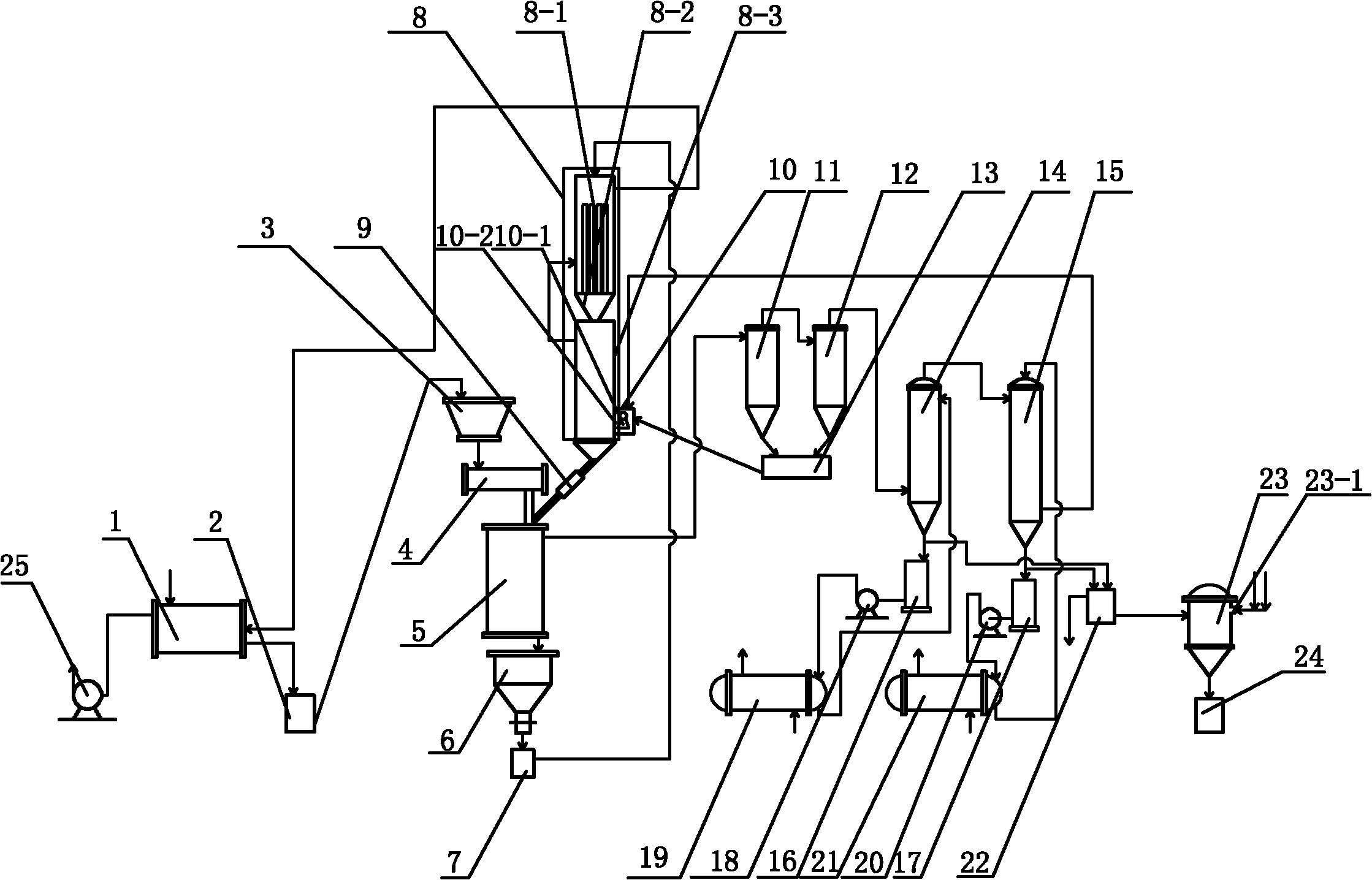

Hydrogenation device and hydrogenation method for polymer continuous hydrogenation

The invention discloses a hydrogenation device and hydrogenation method for polymer continuous hydrogenation. The method comprises the following steps: in the presence of a hydrogenation catalyst, carrying out catalytic hydrogenation on a polymer colloidal liquid containing olefin unsaturated bond and hydrogen, wherein the used hydrogenation kettle contains a high-efficiency jet reactor; and sending the colloidal liquid part after hydrogenation into the subsequent unit, and circulating the rest colloidal liquid by a circulating liquid heat exchanger. The method avoids the side reaction of hydrogenating the benzene ring in the reaction kettle by the hydrogenation polymer, and one device can adapt to hydrogenation reaction of multiple polymers, thereby lowering the catalyst consumption, enhancing the yield of the colloidal liquid with satisfactory hydrogenation degree, and reducing the waste of the polymerization colloidal liquid in the hydrogenation process. The polymer continuous hydrogenation method disclosed by the invention can obtain the hydrogenation product with satisfactory hydrogenation degree.

Owner:山东聚圣科技有限公司

Device and method for producing biological fuel oil by quickly cracking biomass

InactiveCN102031133AStable temperature controlFully condensedDirect heating destructive distillationBiofuelsThermal energyTemperature control

The invention discloses a device and a method for producing biological fuel oil by quickly cracking biomass, relates to a device and a method for producing biological fuel oil and aims to solve the problems of low energy utilization ratio, high operating cost and poor practical production continuity existing in the conventional biomass thermal cracking process and the problem of the absence of accurate heat carrier heating temperature regulating function in the conventional biomass thermal cracking process device. In the scheme of the device, the bottom of a heat carrier heating device is communicated with a heat carrier inlet end of a cracking reactor through an accurate heat carrier temperature control device; the cracking reactor is communicated with a separator; the separator is communicated with a condenser; the condenser is communicated with a heat energy supply device; and the heat energy supply device is communicated with the heat carrier heating device. In the scheme of the method, products produced by the thermal cracking reaction of biomass powder comprise thermal cracking gas and carbon; a heat carrier enters a heat carrier collecting box; and uncondensed thermal cracking gas enters a non-condensable gas burner to burn, and then smoke gas is produced and enters the heat carrier heating device. The device and the method are used for producing biological fuel oil.

Owner:NORTHEAST FORESTRY UNIVERSITY

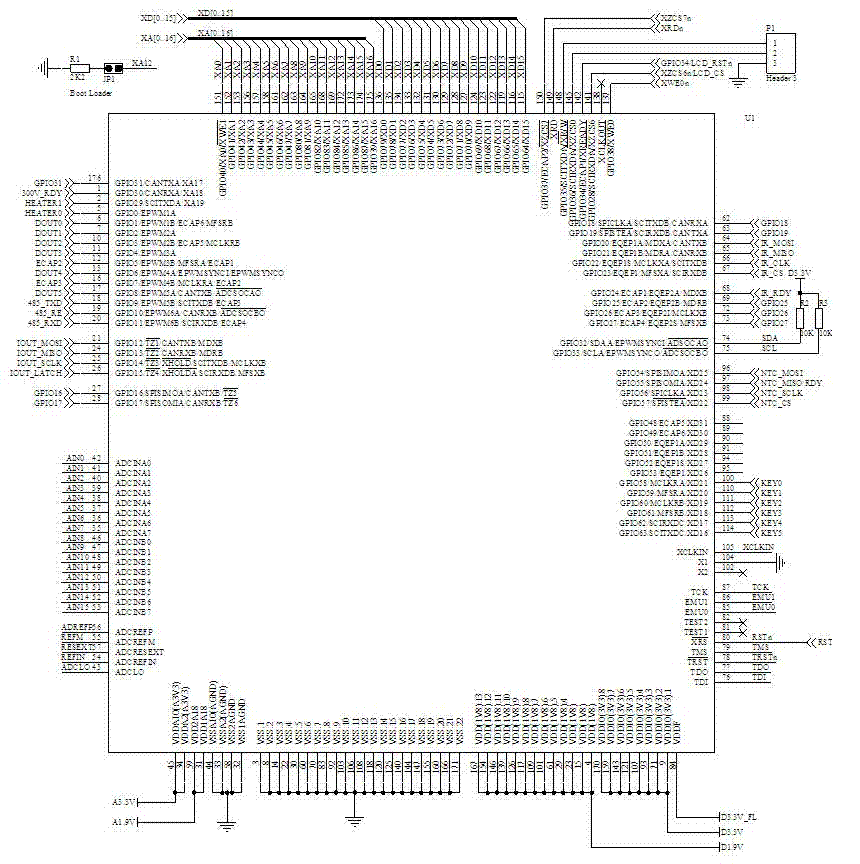

Digital signal processing and controlling system of nondispersive infrared gas analyzer

ActiveCN102879354ASimple structureGuaranteed accuracyColor/spectral properties measurementsControl systemInfrared gas analyzer

The invention relates to the field of component detection, in particular to a digital signal processing and controlling system of a non-dispersive infrared gas analyzer. A digital signal processor (DSP) is used as a core of the digital signal processing and controlling system. The digital signal processing and controlling system comprises a DSP chip, an infrared signal conditioning circuit, a 24-bit analog-to-digital converter (ADC) circuit, a temperature acquiring circuit, a gas pressure acquiring circuit, a 16-bit ADC circuit, an external expansion static random access memory (SRAM) circuit, a ferroelectric memory circuit, a real-time clock circuit, a reset circuit with a watchdog and a power monitor, a thermal resistance driving circuit, a key circuit, a digital output circuit, an RS-232 / 485 interface, a liquid crystal display circuit, a 4-20mA / 0-20mA output circuit and software. The amplitude of signals is solved by a spectral analysis method based on fast Fourier transform (FFT), the center of gravity is corrected, the amplitude of the signals is measured accurately, and signal processing accuracy is guaranteed; a mathematical model which meets requirements on engineering application is set up, and the relation between input and output is non-linearly corrected; and temperatures are controlled by using a proportion-integration (PI) control algorithm based on pulse-width modulation (PWM).

Owner:HEFEI UNIV OF TECH +1

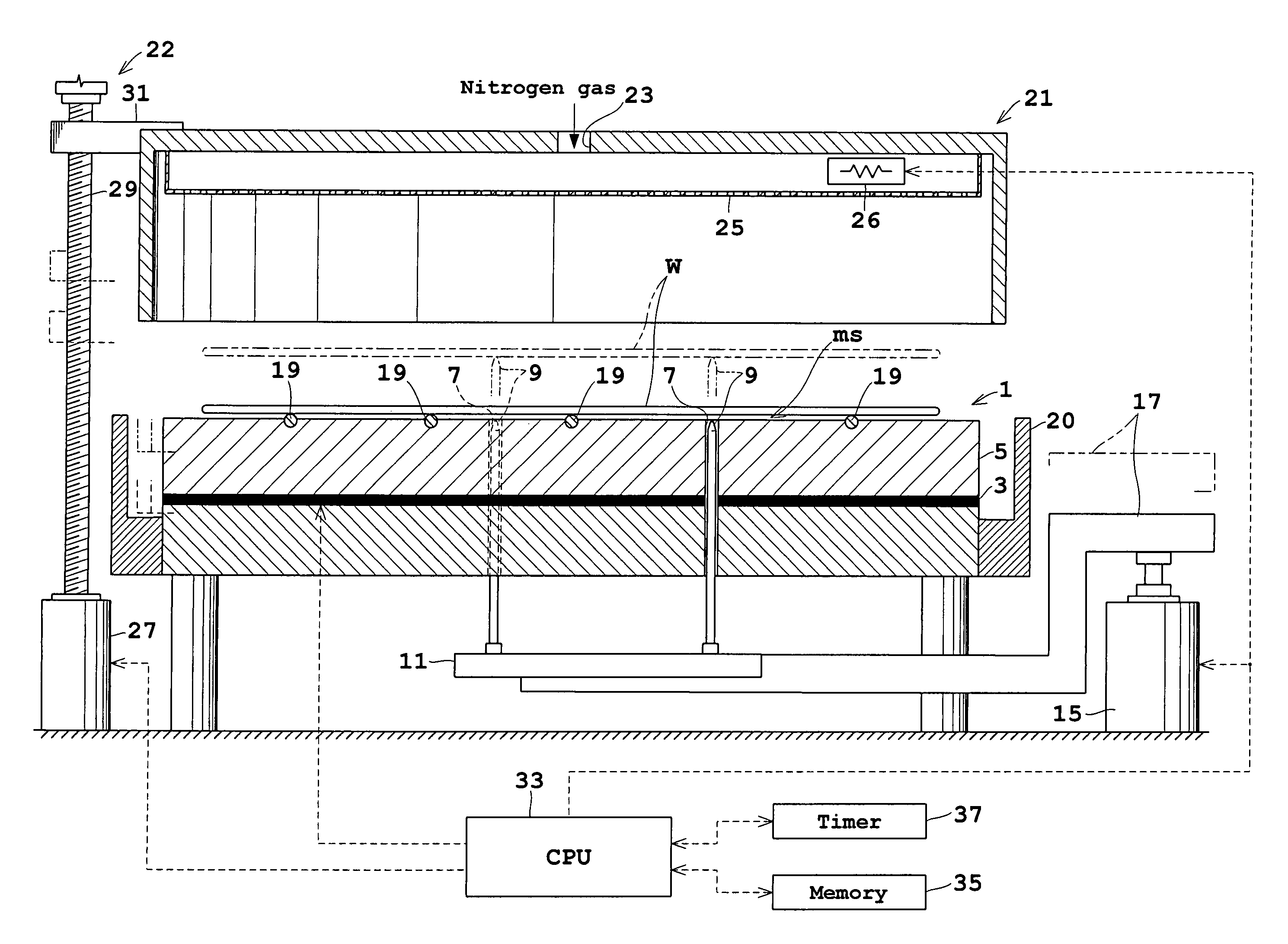

Substrate heat treatment apparatus

InactiveUS7467901B2Stable temperature controlShorten the timeLiquid processingPhotomechanical apparatusTemperature controlTransitional Use

A substrate heat treatment apparatus for heat-treating a substrate includes a bake plate for supporting the substrate, and a cover disposed above the bake plate and temperature-controlled for securing a heat-treating atmosphere of the bake plate. An adjusting device adjusts a space between the cover and the bake plate. A control device adjusts the space, through the adjusting device, successively to a transport space for allowing transport of the substrate, a transitional space smaller than the transport space and close to the bake plate, and a steady space smaller than the transport space and larger than the transitional space.

Owner:DAINIPPON SCREEN MTG CO LTD

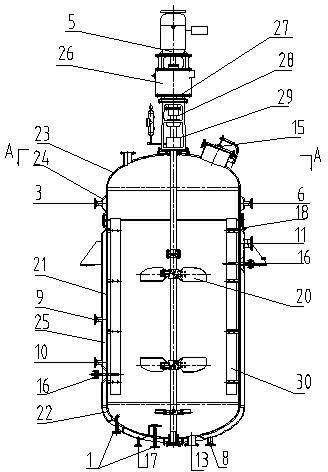

Alloy chlorination reaction kettle for production of chlorinated polyethylene

InactiveCN102633916AIncrease volumeIncrease productivityChemical/physical/physico-chemical stationary reactorsReaction temperatureWater chlorination

The invention provides an alloy chlorination reaction kettle for production of chlorinated polyethylene, which is capable of effectively eliminating reaction temperature delay during synthesis of the chlorinated polyethylene, and is short in production cycle, high in efficiency, low in labor intensity and energy consumption and easy in implementation of automated operation.

Owner:威海金泓高分子有限公司

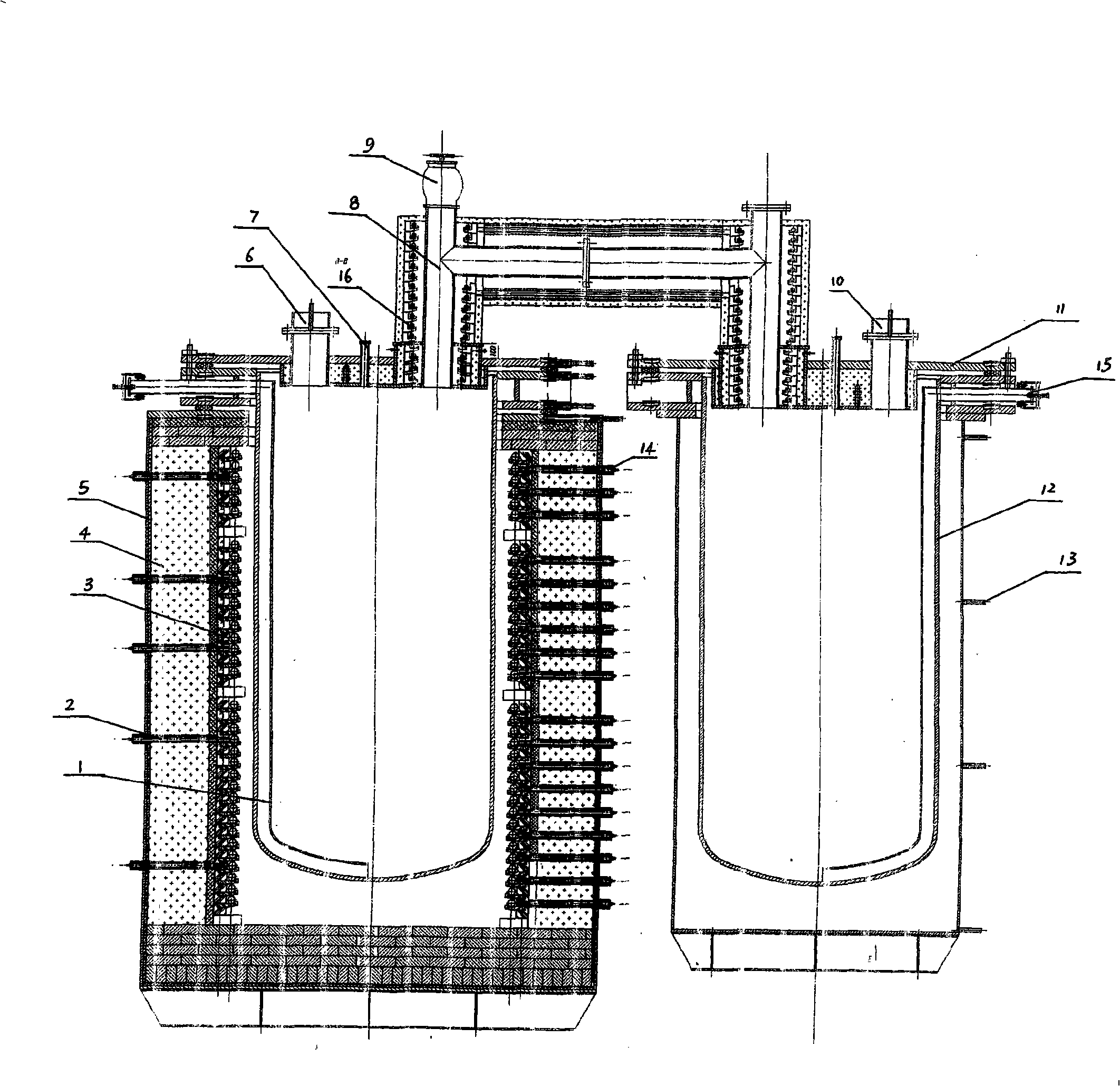

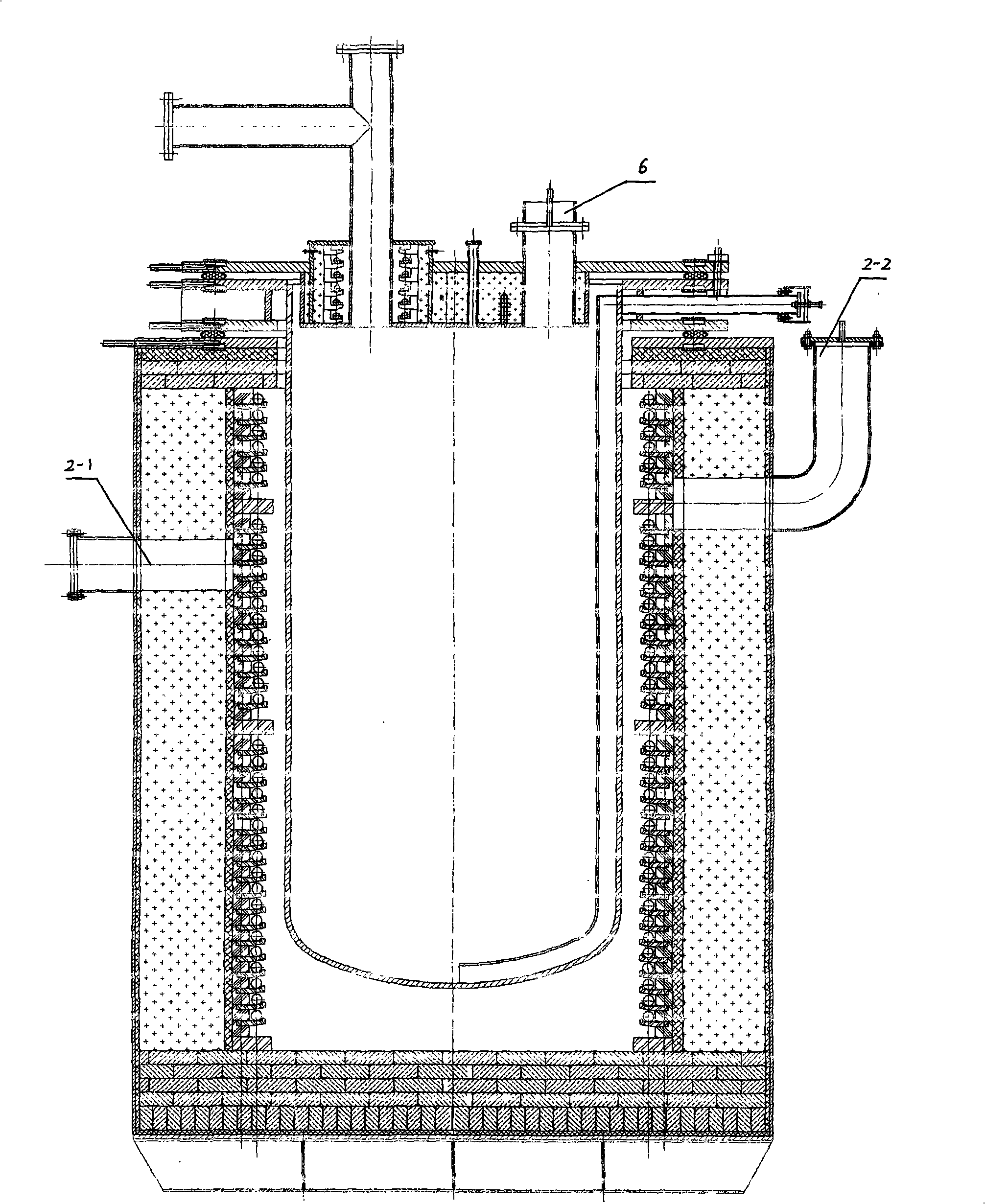

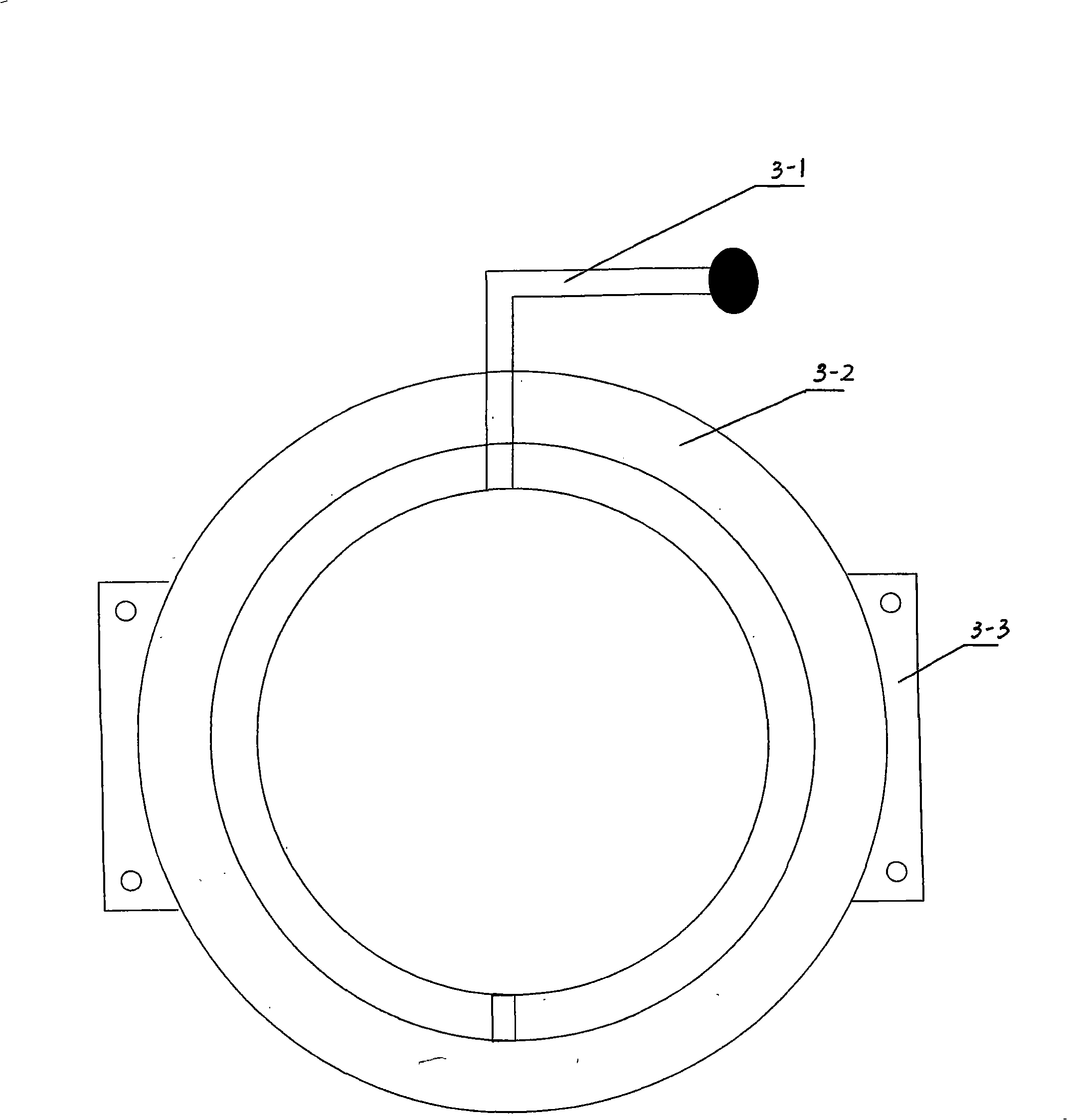

Titanium sponge preparation technique and titanium sponge reaction furnace

The invention discloses a preparation technology of sponge titanium and a reaction furnace of sponge titanium, and belongs to the field of nonferrous metallurgy technology. The reaction furnace of the invention comprises a reacting pot and a cooling pot. The outside of the inner wall of the reacting pot is fixedly equipped with an electrically heated wire which is connected with a conductive rod. The reacting pot is wrapped with an insulation layer and the furnace wall and the upper part of the reacting pot is communicated with an evacuation tube. The cooling pot is equipped with a cooling water jacket, the upper part of which is communicated with an evacuation tube of the cooling pot. The reacting pot and the cooling pot are fixed respectively by the top heads at two sides and in parallel arrangement, and communicated with a central tube. The central tube is wrapped with an inner heating jacket. The upper part of the cooling pot is communicated with a discharge tube. Simultaneously the invention also provides a preparation technology of sponge titanium by using reaction furnace, the technology has the advantages of changing the problem of serial furnace including the unstable production quality, the large energy consumption, the serious environmental pollution, the large operation intensity of worker and the large workload. Changing the furnace to parallel type and the middle connection of using an inner heating tube has the advantages of the energy conservation, safety and the short reaction time.

Owner:杜德忠

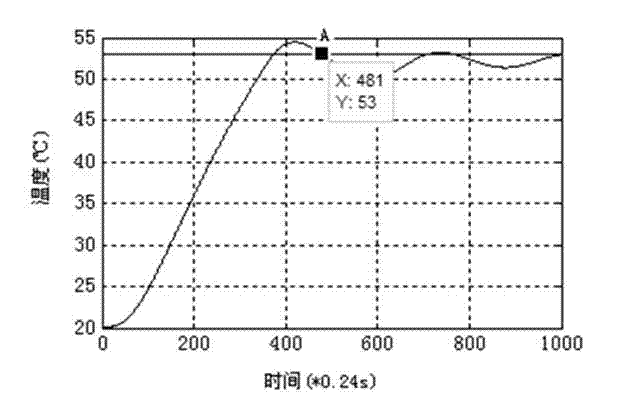

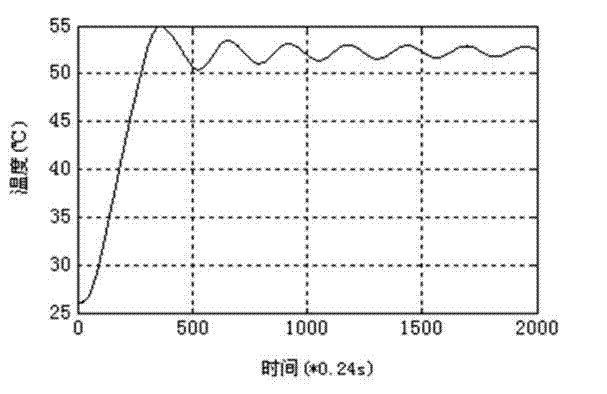

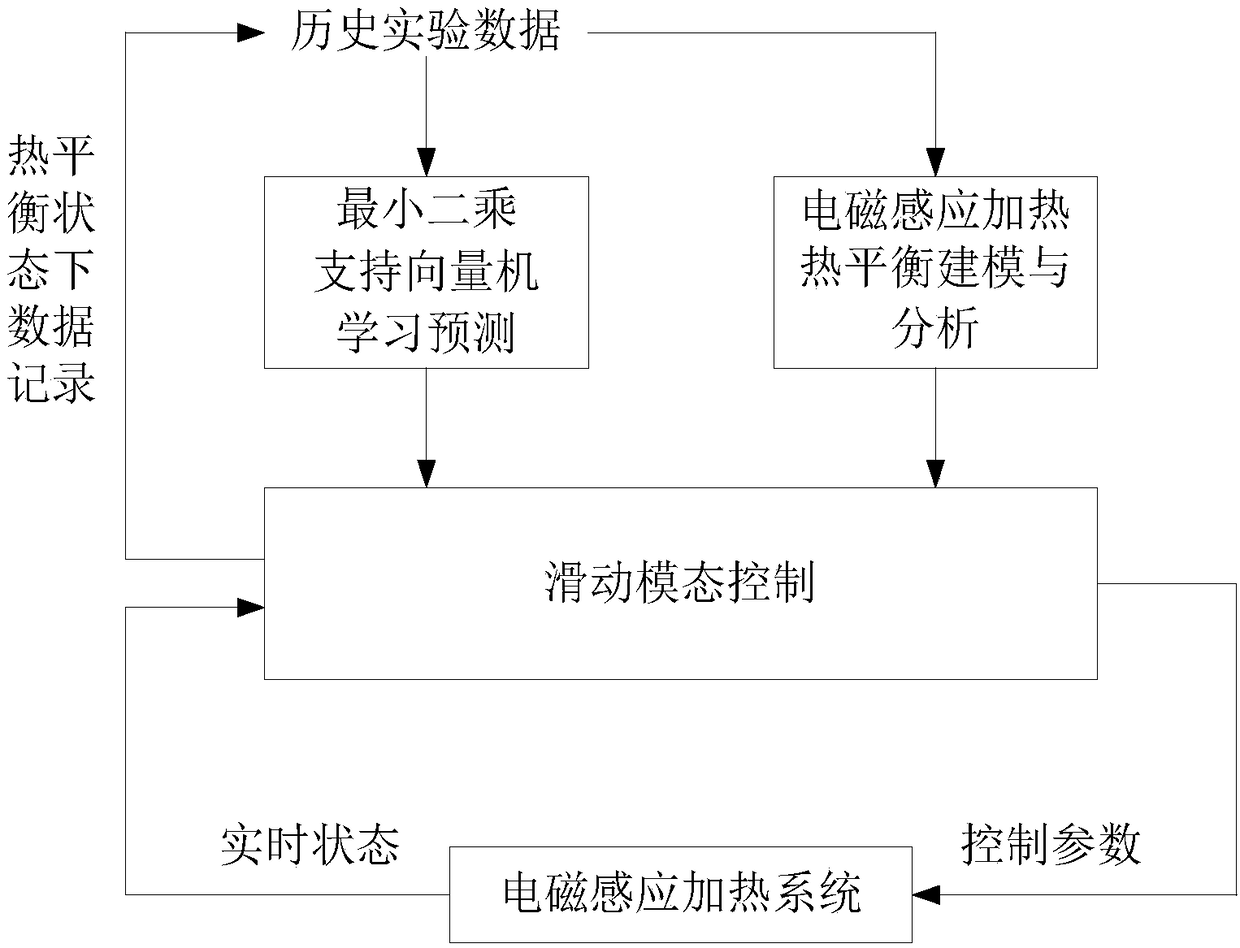

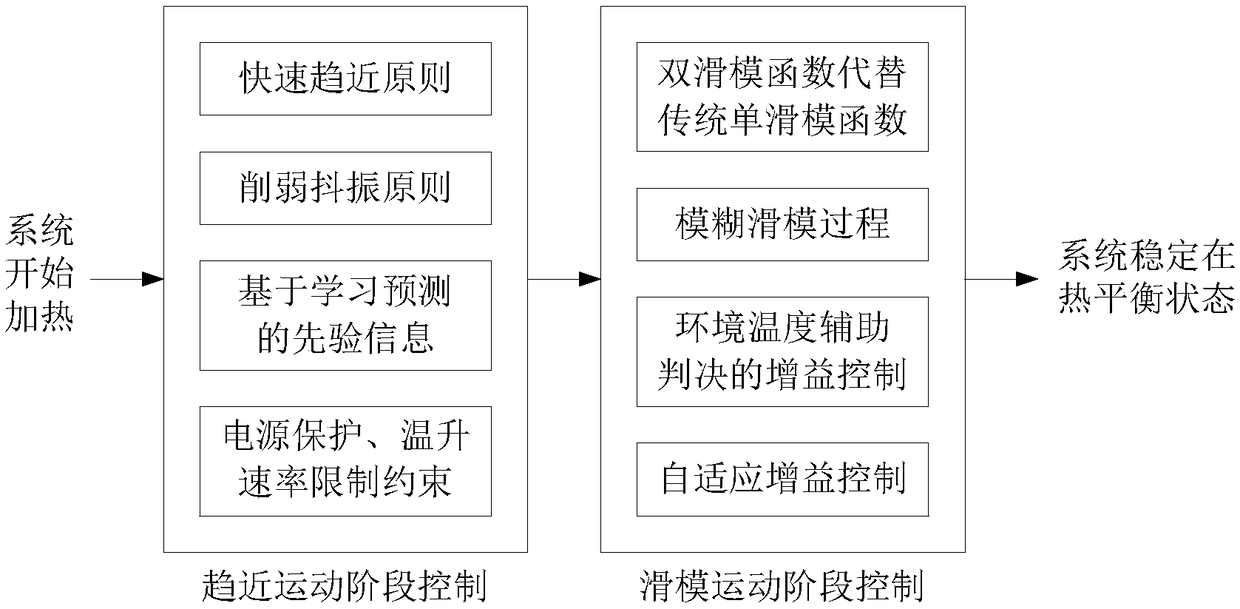

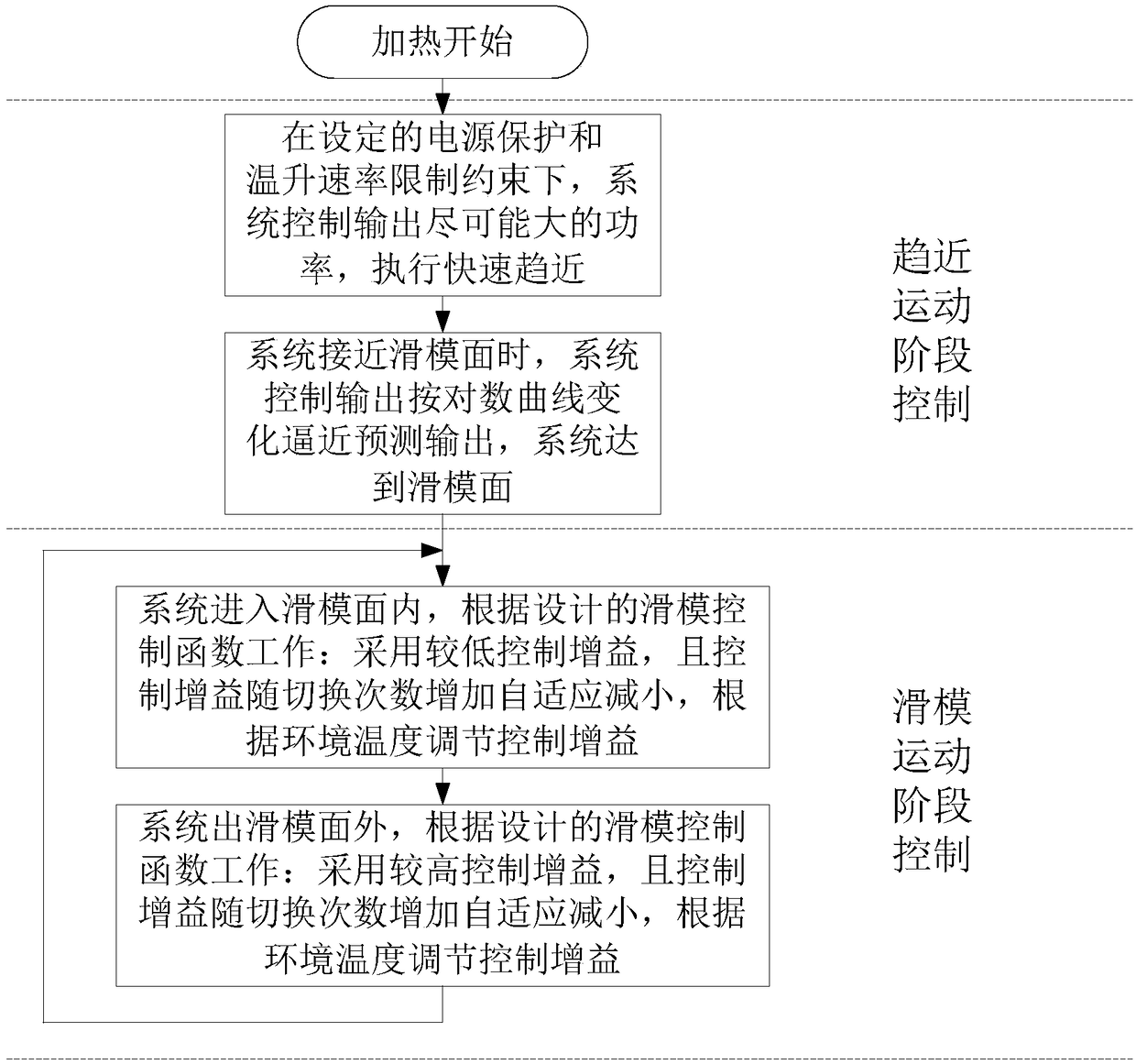

Temperature control method of electromagnetic induction heating system with uncertain stochastic delay

ActiveCN108196607ADetermine temperature controlAccurate control of the temperature of the heating object under deterministic conditionsTemperatue controlTemperature controlPrior information

The invention discloses a temperature control method of an electromagnetic induction heating system with uncertain stochastic delay, comprising: employing fuzzy sliding mode control, including an approach motion phase and a sliding mode motion phase; in early stage of approach motion, executing maximum power quick approach under power protection constraint and temperature rise speed limiting constraint; in later stage of approach motion, approaching a sliding mode surface in logarithmic curve manner so that the system has small vibration when approaching the sliding mode surface; in the sidingmode motion phase, using fuzzy control of dual sliding mode switching function and an adaptive adjusting mechanism of switching gain, so that vibration is effectively weakened and stable control is achieved. In the sliding mode control process, learning and prediction of a least squares support vector machine and electromagnetic induction heating thermal balance modeling and analysis are employedto provide prior information for sliding mode control, and speed and stability in electromagnetic induction heating temperature control are improved.

Owner:四川飙风科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com