Hydrogenation device and hydrogenation method for polymer continuous hydrogenation

A hydrogenation device and polymer technology, which is applied in the field of continuous hydrogenation device for polymers containing olefinic unsaturated bonds, can solve the problems of complex control of continuous hydrogenation process, difficult control of intermittent hydrogenation temperature, and low hydrogenation efficiency , to achieve the effect of strong adaptability, improved product quality and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

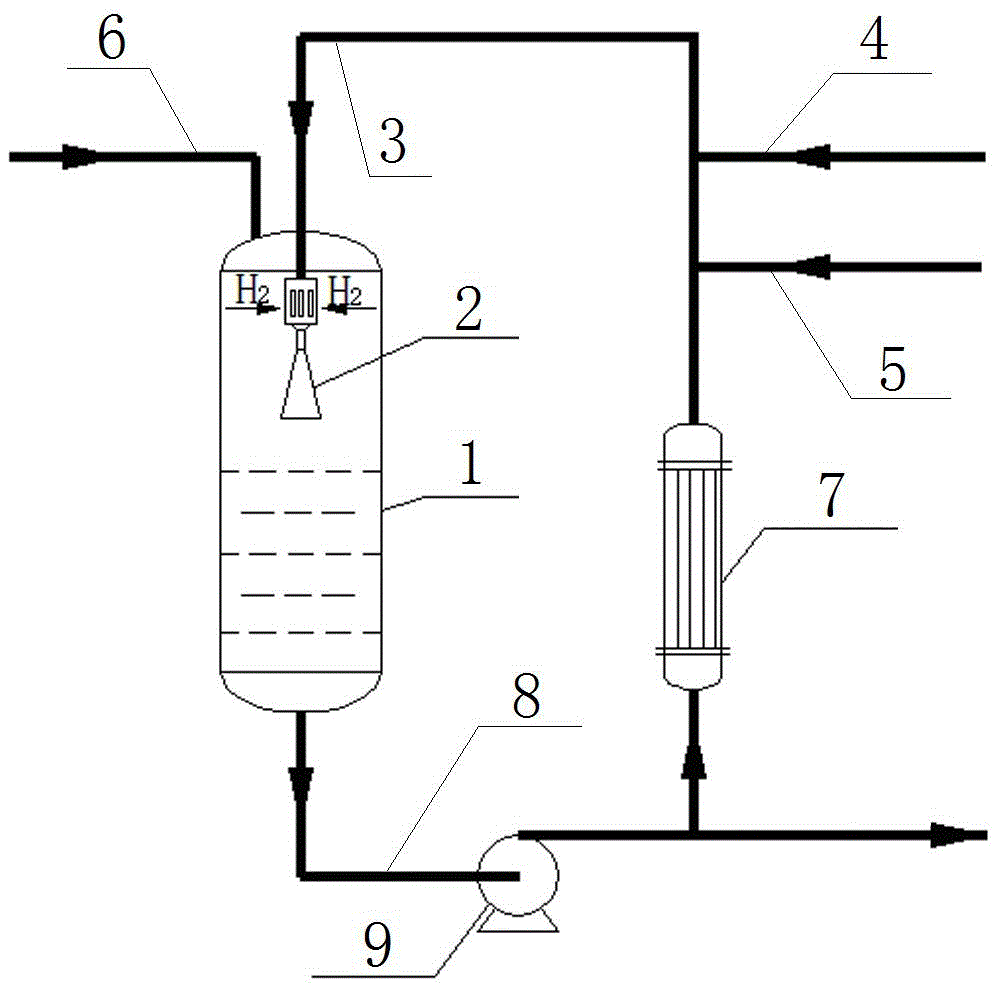

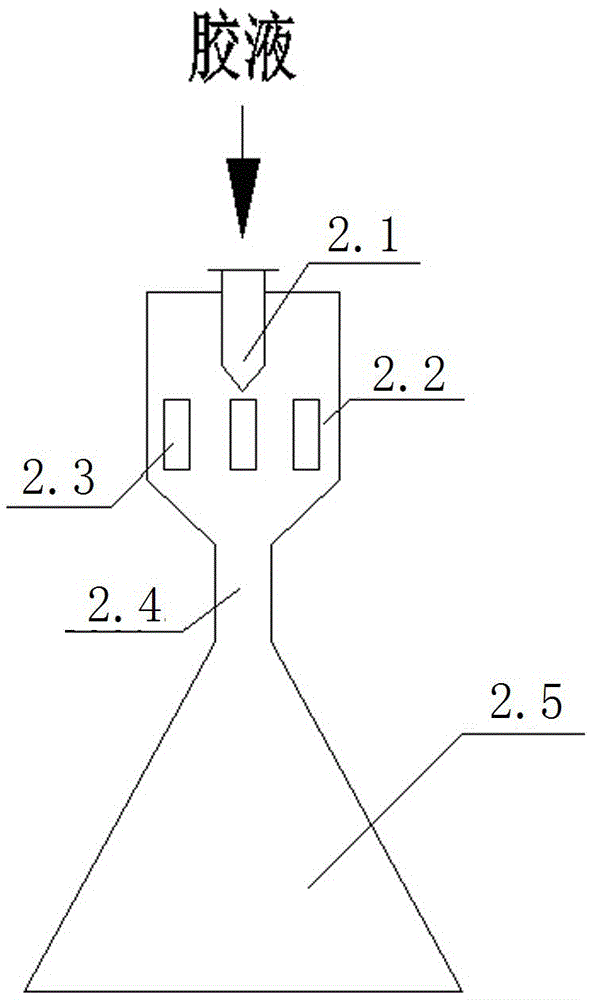

[0017] See attached figure 1 and 2 , a hydrogenation device for continuous hydrogenation of polymers, a hydrogen pipeline 6 connected to the upper part of the hydrogenation kettle 1, and a polymer glue discharge pipeline 8 connected to the lower part; a jet reactor 2 is installed on the upper part of the inner cavity of the hydrogenation kettle 1, The inlet end of the jet reactor 2 is connected to the outlet end of the circulating fluid heat exchanger 7 outside the hydrogenation kettle 1 through the return line 3, and the polymer glue discharge pipeline 8 is provided with a branch and the inlet end of the circulating fluid heat exchanger 7 Connect and install the circulating pump 9 on the polymer glue discharge pipeline 8; the polymer glue feed pipeline 4 and the hydrogenation catalyst feed pipeline 5 are connected to the return pipeline 3; The reactor consists of four parts connected in sequence from top to bottom: nozzle 2.1, suction chamber 2.2, mixing chamber 2.4 and diff...

Embodiment 2

[0021] A hydrogenation method for continuous hydrogenation of polymers, the steps comprising:

[0022] 1) Catalyst preparation: Mix nickel naphthenate and triisobutylaluminum at an aluminum-nickel molar ratio (calculated as metal) of 6:1, and age at 60°C for 30 minutes.

[0023] 3) The device of Example 1 was used for the hydrogenation reaction operation, which mainly includes a hydrogenation tank, a jet reactor and a circulating fluid heat exchanger. The whole device was pre-purged with nitrogen, and then replaced with hydrogen.

[0024] 4) Hydrogenation reaction: add SBS polymer glue (the concentration of the polymer glue is 5-20wt%) and the catalyst obtained in step 1 to the hydrogenation kettle after hydrogen replacement, and the amount of the hydrogenation catalyst for the first time is 0.06 gNi / 100g polymer, while passing hydrogen at the top of the hydrogenation tank and maintaining the hydrogen pressure at 3.0MPa (gauge pressure). The hydrogenated glue is released from...

Embodiment 3

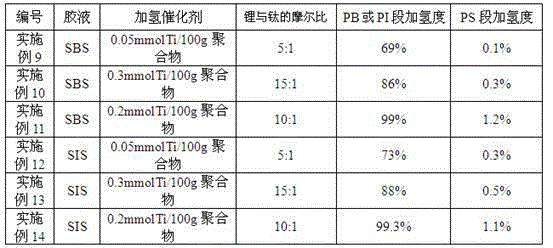

[0026] Example 2 was basically repeated, except that the hydrogenation catalyst consumption was 0.05gNi / 100g polymer, and the hydrogenation reaction product was SEBS. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com