Patents

Literature

188results about How to "Reduce the content of metal ions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

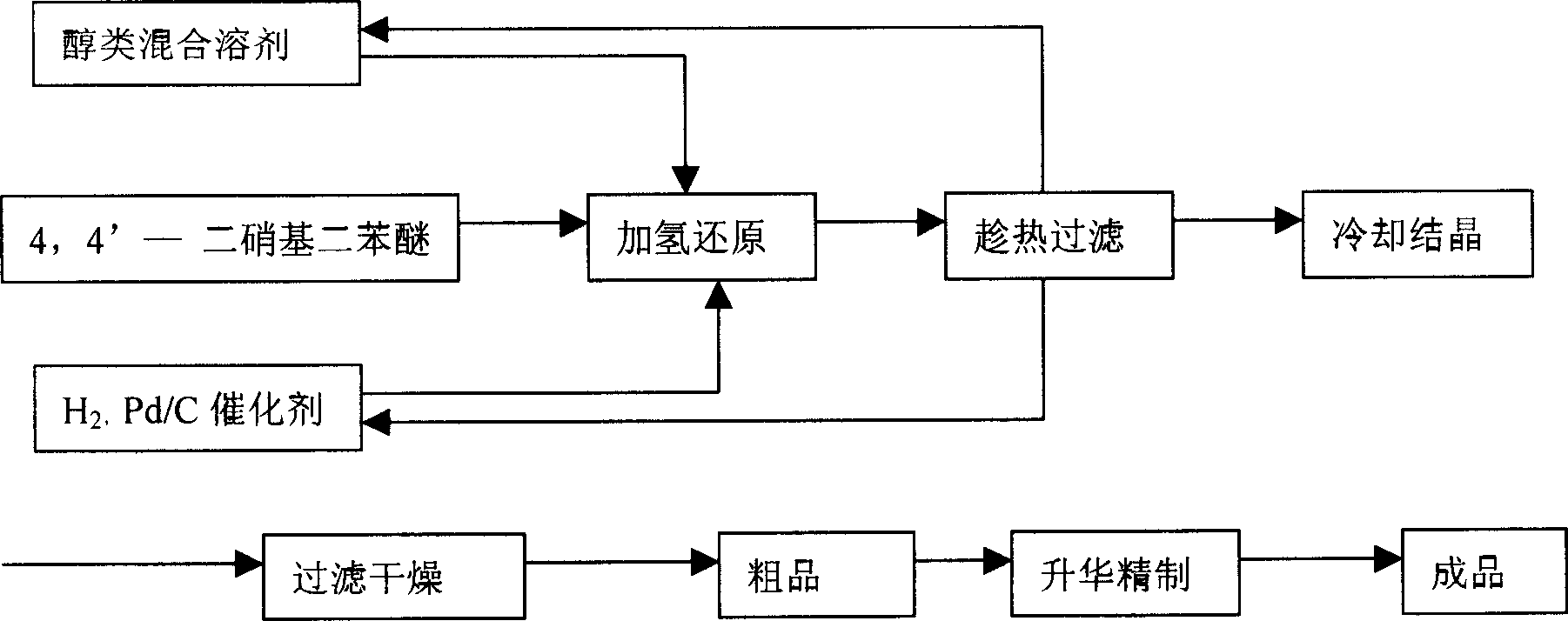

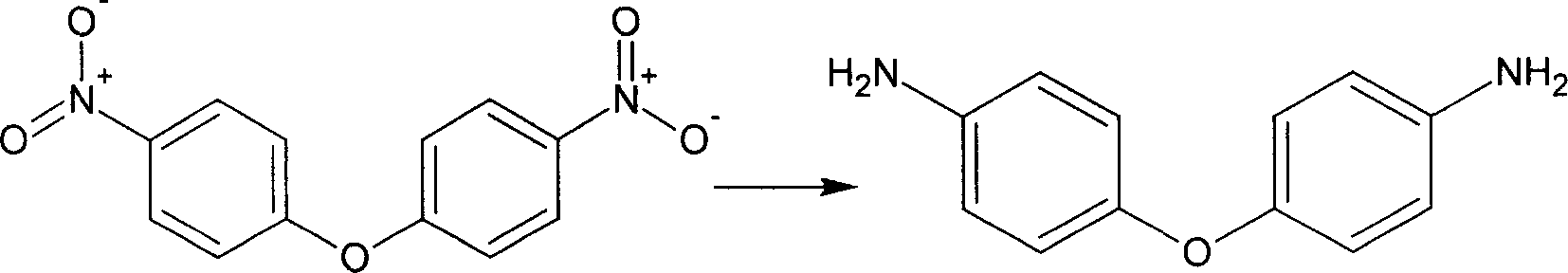

Method for preparing 4,4'-diaminodiphenyl ether

InactiveCN1807399AReduce manufacturing costReduce pollutionOrganic compound preparationAmino-hyroxy compound preparationDiphenyl etherDiaminodiphenyl ether

The invention relates to a preparation method for 4, 4'-diamino diphenyl ether, which comprises: taking catalytic hydrogenation reduction reaction to the 4, 4'-dinitro diphenyl ether in alcohol solvent; crystallizing to obtain the coarse product; reducing pressure to sublimate and refine the coarse product for final product. This invention has well product quality and no pollution with low cost, and more fit to spread than the traditional ferrous powder-chlorhydric acid reduction method.

Owner:CHANGZHOU SUNLIGHT PHARMA

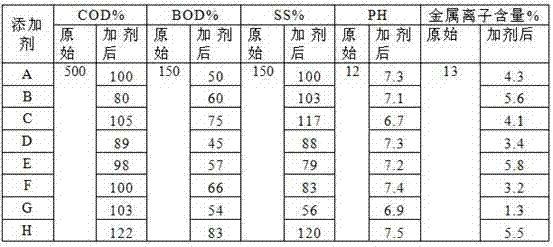

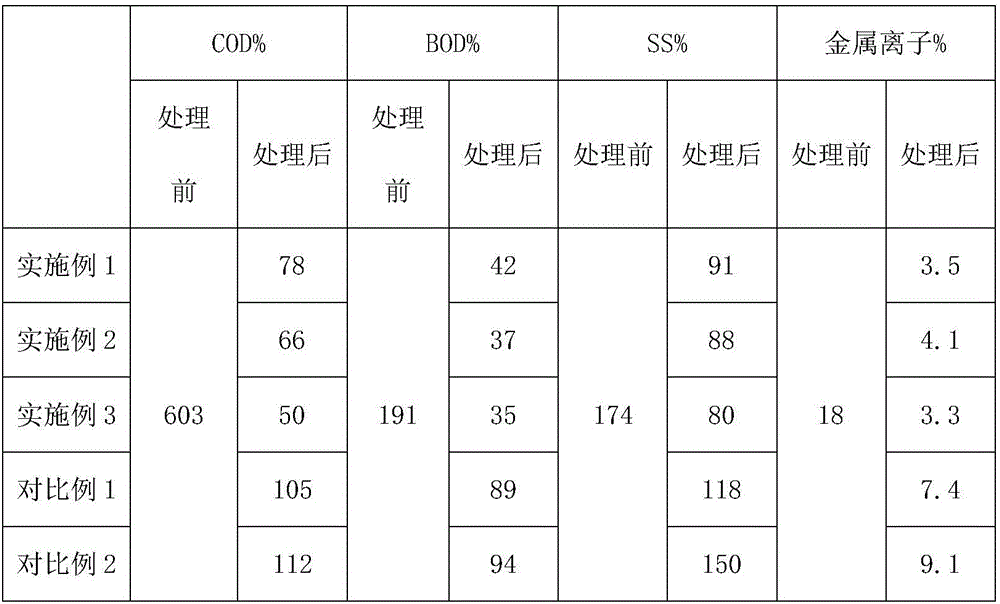

Treating agent applied to papermaking sewage

ActiveCN102951715AReduce CODReduce BODWater/sewage treatment by ion-exchangeWater/sewage treatment by neutralisationSorbentSewage

The invention belongs to the technical field of a sewage treating agent and especially relates to a treating agent applied to papermaking sewage. The treating agent applied to the papermaking sewage comprises the following components by weight part: 40-55 parts of flocculating agents, 15-25 parts of chelating agents, 10-15 parts of adsorbents and 5-35 parts of PH(Potential of Hydrogen) regulators. The treating agent can enable the physicochemical indexes of the papermaking sewage to meet the GB18918-2002 standard, the contents of COD (Chemical Oxygen Demand), BOD (Biochemical Oxygen Demand), SS (Suspended Solids) and metal ions are effectively reduced and the PH is approximately neutral and meets a emission standard.

Owner:临沂星火知识产权服务有限公司

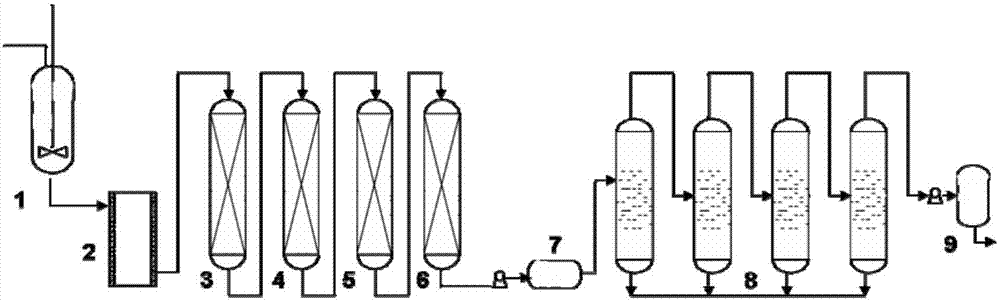

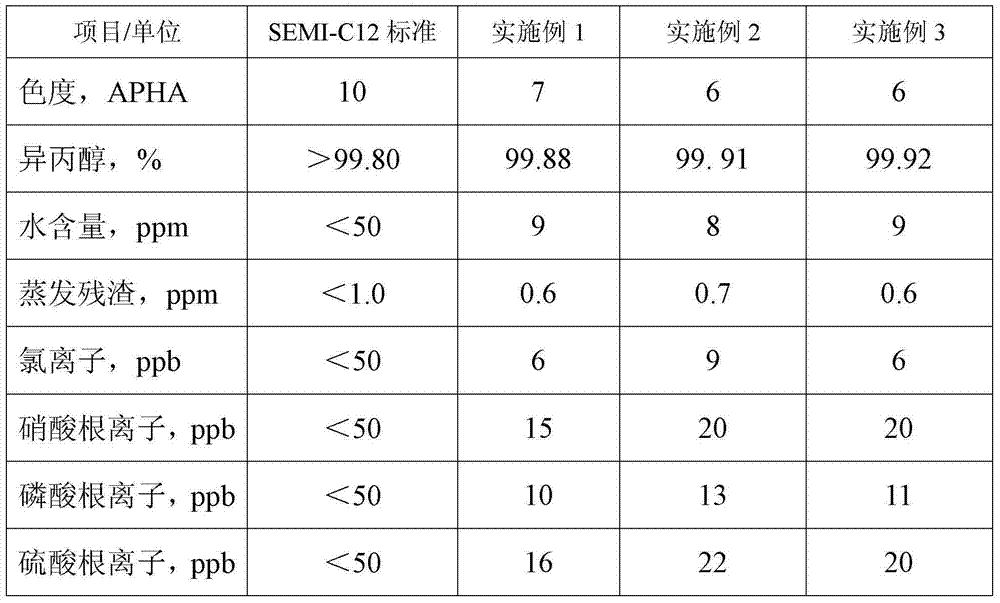

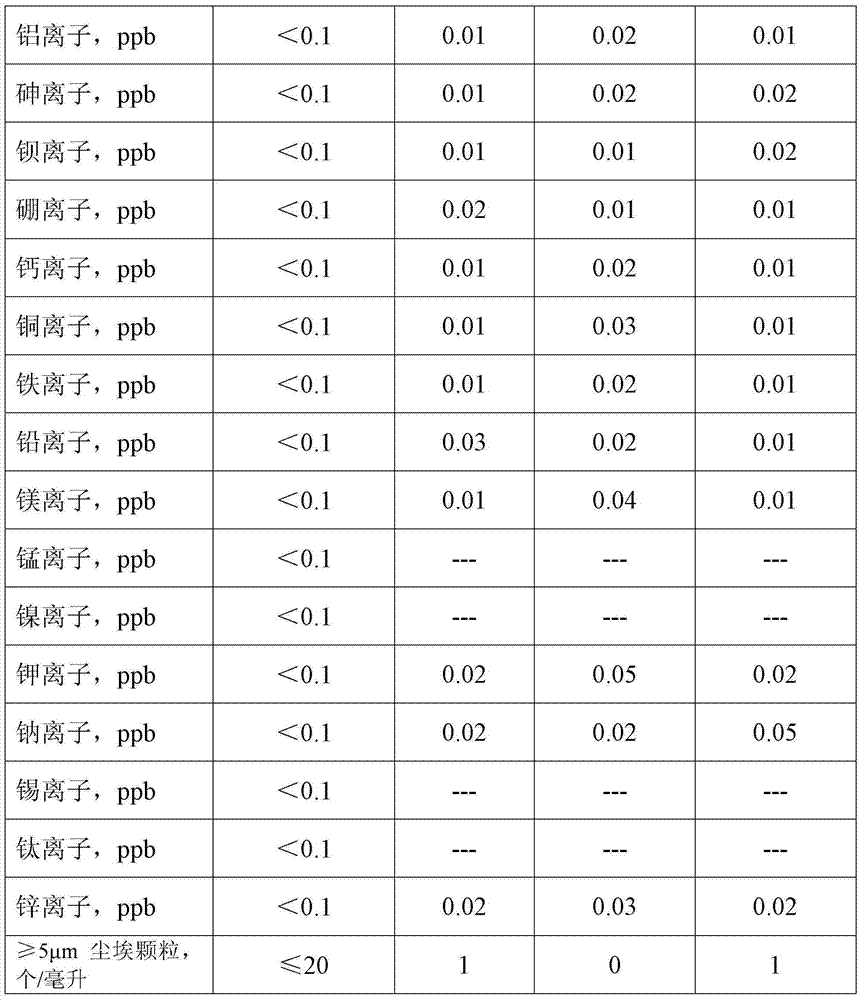

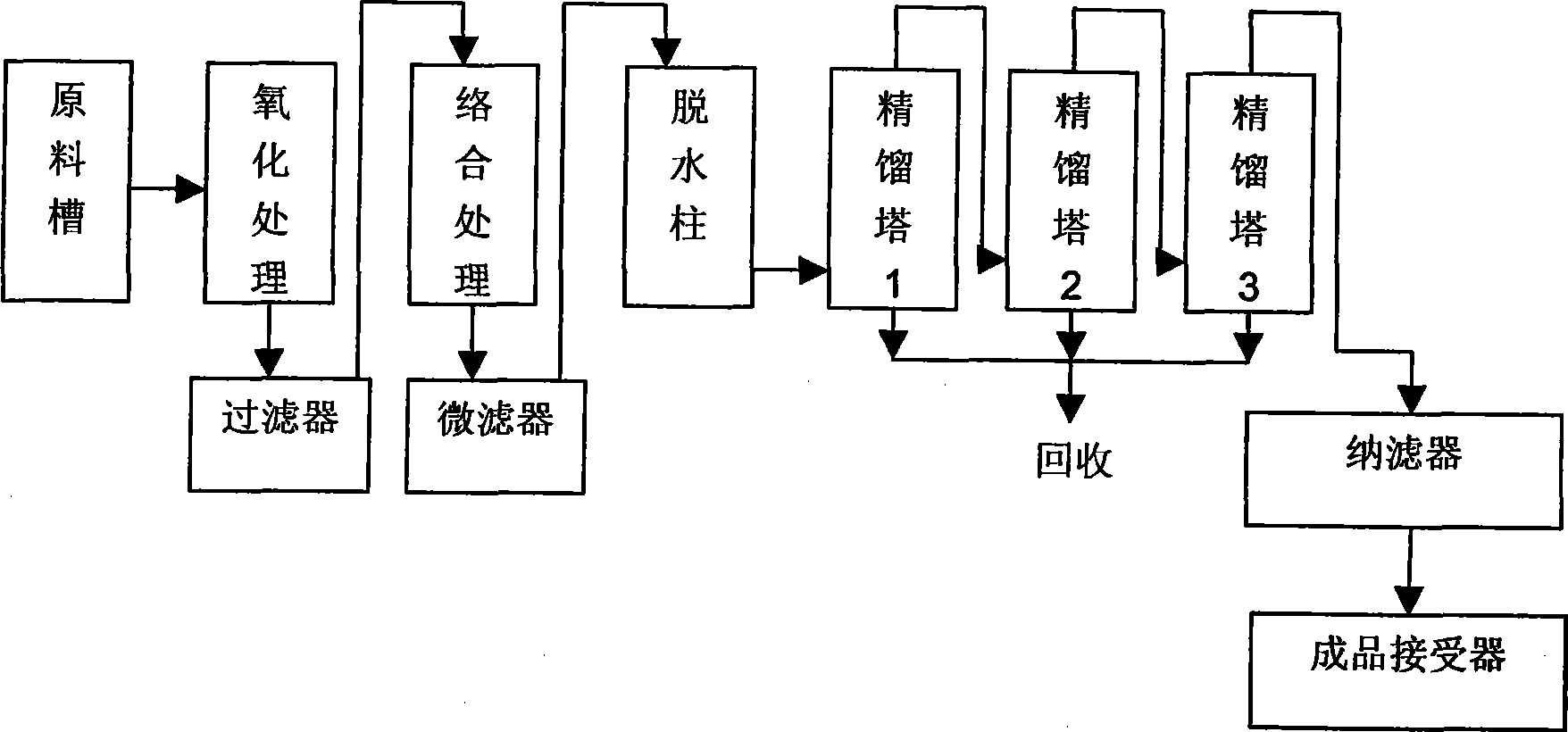

Preparation method of ultrapure isopropanol

ActiveCN103613486AImprove membrane efficiencyRelieve stressOrganic compound preparationElectrophoretic processesWater contentMolecular sieve

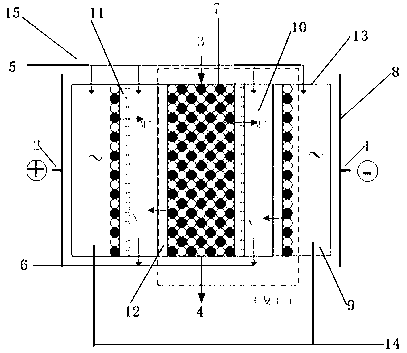

The invention discloses a preparation method of ultrapure isopropanol, which comprises the following steps: by using industrial isopropanol as a raw material, adding a metal ion complexing agent ethylene diamine tetraacetic acid disodium salt to form a charged chelate, moving charged corpuscles to positive and negative poles through an electrophoresis tank, removing impurity ions in the isopropanol respectively by anion and cation exchange resin exchange, dehydrating through a molecular sieve and a superstrong water-absorbing resin, filtering with a microfilter, carrying out multistage continuous rectification, and filtering with a nanofilter to obtain the target product ultrapure isopropanol. The main body content of the ultrapure isopropanol is higher than 99.80, the water content is lower than 10 ppm, the cation content is lower than 0.1 ppb, and the anion content is lower than 50 ppb. The product has the advantages of high purity, low content of metal impurities and stable quality; and the method has high operation continuity and is suitable for industrial production.

Owner:SHANGHAI CHEM REAGENT RES INST

Method for purifying yellow phosphorus by using methods of activated carbon adsorption together with dilute nitric acid rinsing

ActiveCN102107859AAdequate adsorption capacityImprove adsorption capacityPhosphorus compoundsHigh concentrationActivated carbon

The invention discloses a method for purifying yellow phosphorus by adopting methods of activated carbon adsorption together with dilute nitric acid rinsing. Firstly, activated carbon and molten industrial yellow phosphorus are mixed and stirred in a refining kettle, and after the adsorption is completed, the activated carbon is separated from the yellow phosphorus by a filter machine; then the processed yellow phosphorus is circularly rinsed with dilute nitric acid in an acid pickling tower; residual organic matters, arsenic and low-price metal ions in the yellow phosphorus, which are not adsorbed by the activated carbon, are oxidized by utilizing the oxidizability of the dilute nitric acid; and afterwards, the yellow phosphorus is circularly rinsed in a water washing tower by using deionized water, thereby completing yellow phosphorus purification. The invention adopts a process with treatment methods of activated carbon adsorption, dilute nitric acid rinsing and deionized water rinsing, and integrates the advantages of various methods; and the content of arsenic in the acquired yellow phosphorus is reduced to below 20 ppm, so that high-purity yellow phosphorus satisfying the requirement for producing electronic grade phosphoric acid can be acquired, and the hidden danger of explosion caused by using high concentration nitric acid is avoided.

Owner:湖北兴福电子材料股份有限公司

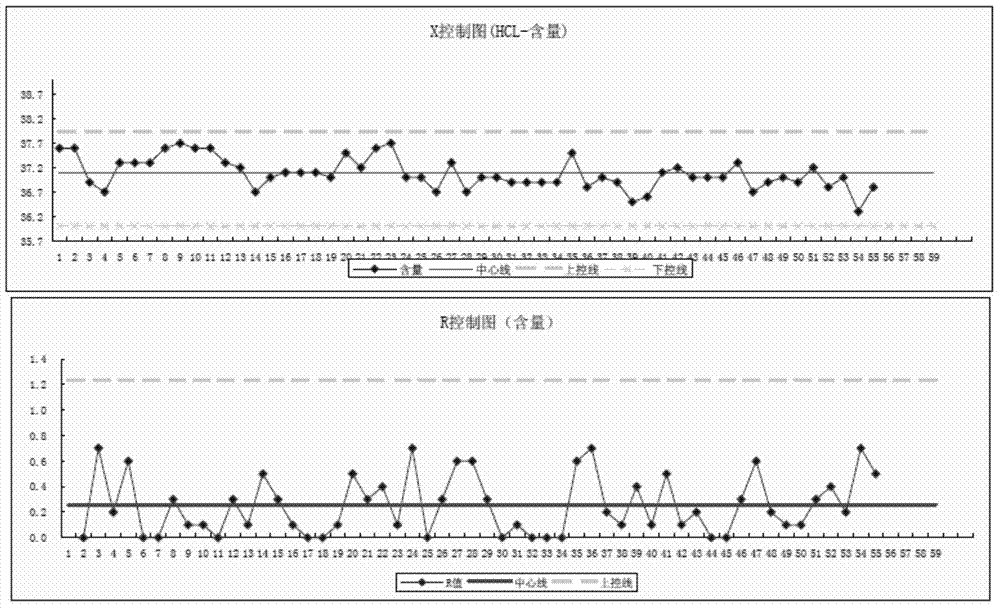

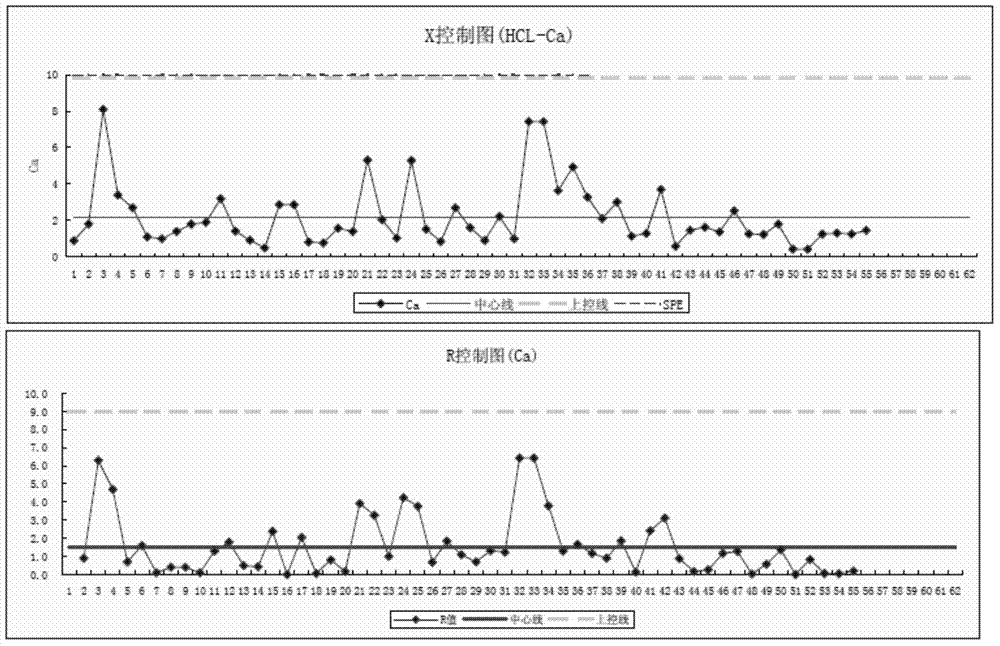

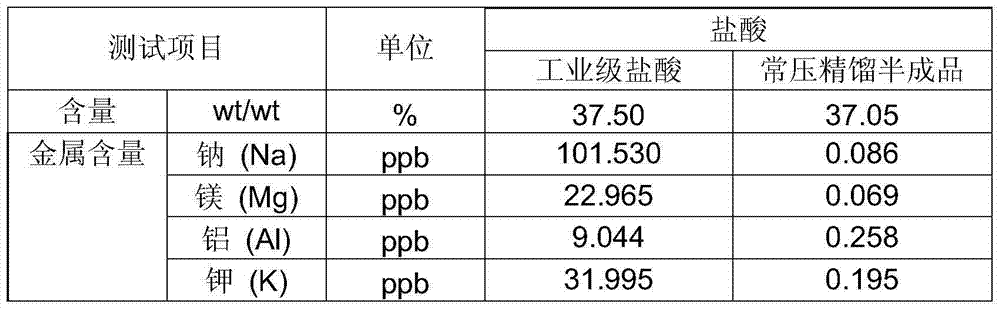

Continuous production method of high-purity hydrochloric acid

ActiveCN103879964AReliable productionQuality improvementChlorine/hydrogen-chloride purificationEnvironmental resistanceTechnical grade

The invention relates to a continuous production method of high-purity hydrochloric acid; the continuous production method is carried out by chemically dechlorinating, rectifying at normal pressure, filtering in a circulating manner, decompressing and rectifying by taking industrial hydrochloric acid as the raw material; in the event of decompressing and rectifying, the pressure in a decompressing and rectifying kettle is controlled within 25-95 KPa; the reflux ratio is 1:(1.8-2.5); and various processes in the process are carried out sequentially and continuously. According to the invention, high-purity hydrochloric acid achieving the SEMIC12 semiconductor grade requirements can be produced environmentally, efficiently and continuously through the four simple steps; in the obtained hydrochloric acid product, the content of single metal ion can be reduced to be below 50 ppt; the content of anion can be reduced to be below 50 ppb; and the content of free chlorine can be reduced to be below 300 ppb. An online control technology and a totally-enclosed purified production manner provided by the invention are further combined, therefore, hydrochloric acid products having steady quality can be produced reliably for a long time; and long-term, large-batch and steady specific requirements in the semiconductor industry are satisfied.

Owner:SUZHOU CRYSTAL CLEAR CHEMICAL CO LTD

Process for preparing 4,4'-diaminodiphenyl ether by hydrogenation reduction method

InactiveCN102850229ASolve pollutionImprove working environmentOrganic compound preparationAmino-hyroxy compound preparationMaterials preparationDiaminodiphenyl ether

The invention provides a process for preparing 4,4'-diaminodiphenyl ether by a hydrogenation reduction method, which comprises a material preparation procedure, a condensation procedure, a hydrogenation reduction procedure, and a sublimation crystallization procedure, and has the advantages of environment pollution improvement, production cost reduction, reaction rate and yield improvement, metal ion content reduction, and the like.

Owner:万达集团股份有限公司

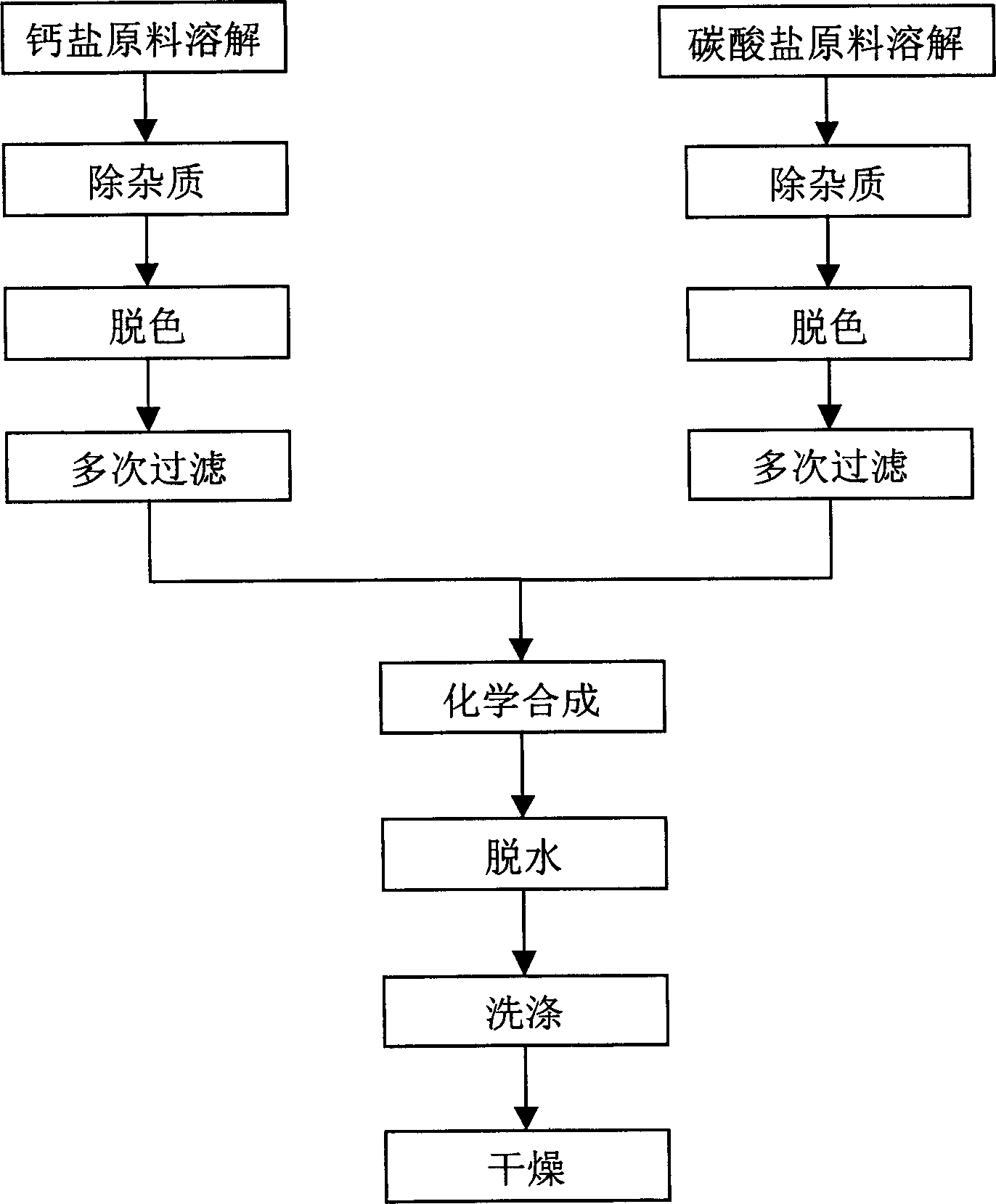

Manufacturing method of high purity calcium carbonate for electron industry

A process for preparing high-purity calcium carbonate used as insulating filler and crystal grain fining agent in electronic industry includes such steps as providing Ca-contained compound and SO4 radical contained compound, multi-step depositing for removing impurities, synthesizing reaction to generate deposit, washing and drying.

Owner:胡志彤

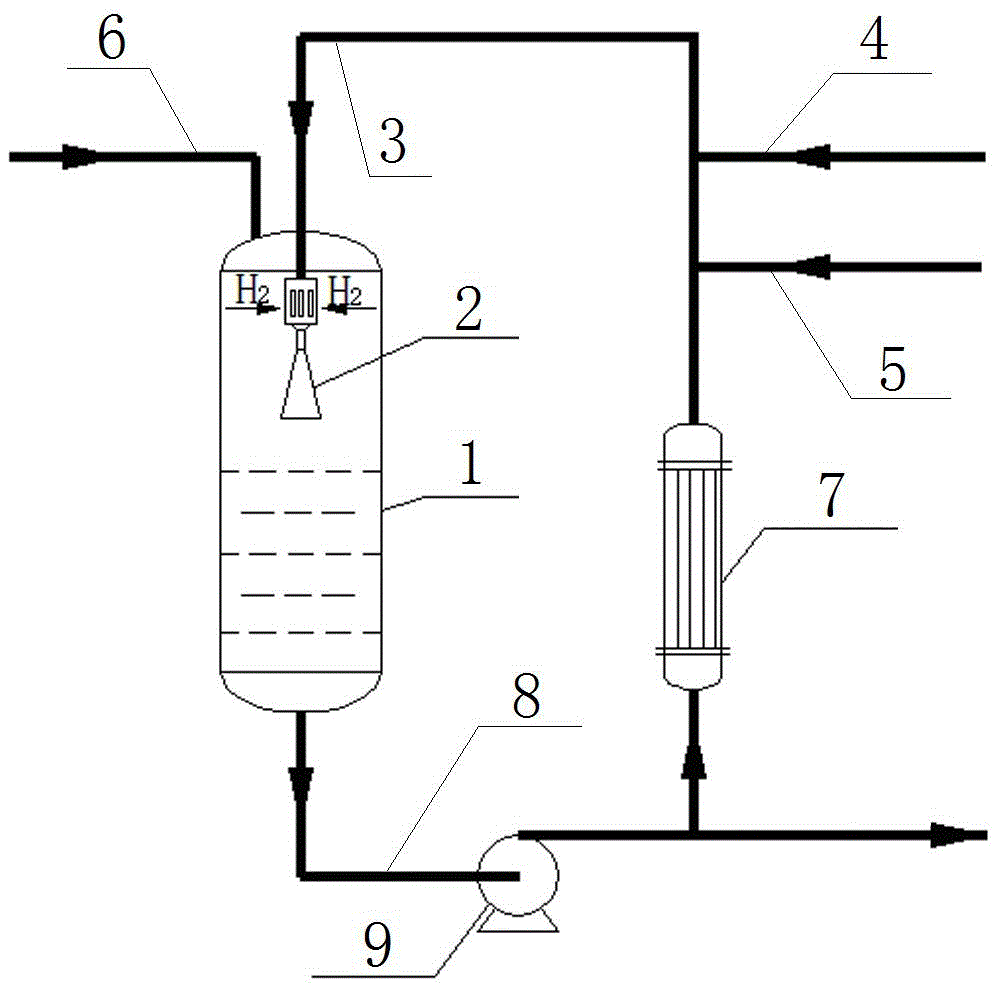

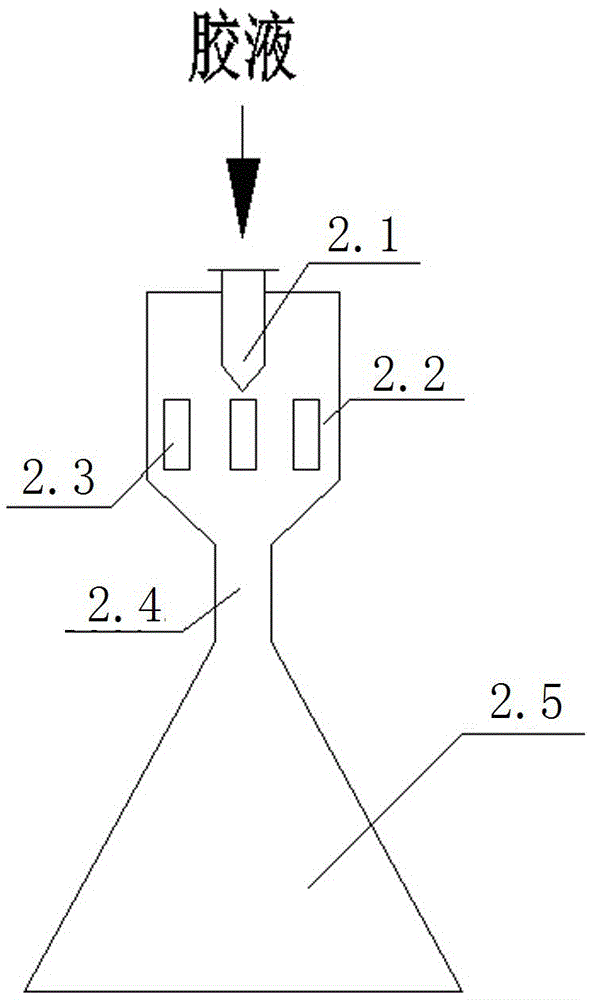

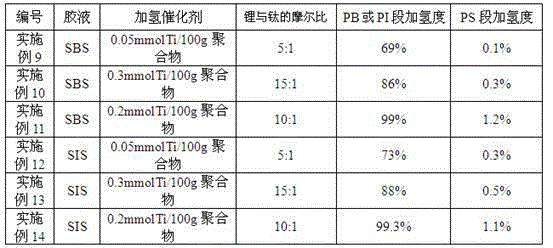

Hydrogenation device and hydrogenation method for polymer continuous hydrogenation

The invention discloses a hydrogenation device and hydrogenation method for polymer continuous hydrogenation. The method comprises the following steps: in the presence of a hydrogenation catalyst, carrying out catalytic hydrogenation on a polymer colloidal liquid containing olefin unsaturated bond and hydrogen, wherein the used hydrogenation kettle contains a high-efficiency jet reactor; and sending the colloidal liquid part after hydrogenation into the subsequent unit, and circulating the rest colloidal liquid by a circulating liquid heat exchanger. The method avoids the side reaction of hydrogenating the benzene ring in the reaction kettle by the hydrogenation polymer, and one device can adapt to hydrogenation reaction of multiple polymers, thereby lowering the catalyst consumption, enhancing the yield of the colloidal liquid with satisfactory hydrogenation degree, and reducing the waste of the polymerization colloidal liquid in the hydrogenation process. The polymer continuous hydrogenation method disclosed by the invention can obtain the hydrogenation product with satisfactory hydrogenation degree.

Owner:山东聚圣科技有限公司

Silicon wafer chemical-mechanical polishing composition with high dilution ratio and high stability

InactiveCN102618174AImprove surface qualityReduce the content of metal ionsPolishing compositions with abrasivesActive agentCompound (substance)

The invention provided a silicon wafer chemical-mechanical polishing composition with high dilution ratio and high stability, which comprises an abrasive material, salt, a potential of hydrogen (pH) conditioning agent, a chelating agent, an active agent and a buffer system. The silicon wafer chemical-mechanical polishing composition with the high dilution ratio and high stability has the technical advantages that (1) the scientific reasonable buffer system is selected, the pH of the polishing composition is not improved blindly, the variation amplitude of a pH value is small in polishing process, the quality of the silicon wafer surface is good after polishing, and surface scratch and other damages do not exist; (2) when the polishing composition is prepared, a material for stabilizing silica sol particles is added so as to enable the particles in the preparation process of the polishing composition to be balanced highly, and the specific buffer system can increase the pH buffering performance of diluent, enables the pH of the polishing composition to be maintained at a certain level and stabilizes the polishing speed; (3) the polishing composition is simple in preparation process and suitable for industrial production, and the using cost of the polishing composition can be reduced.

Owner:JIANGSU TIANHENG NANO SCI & TECH

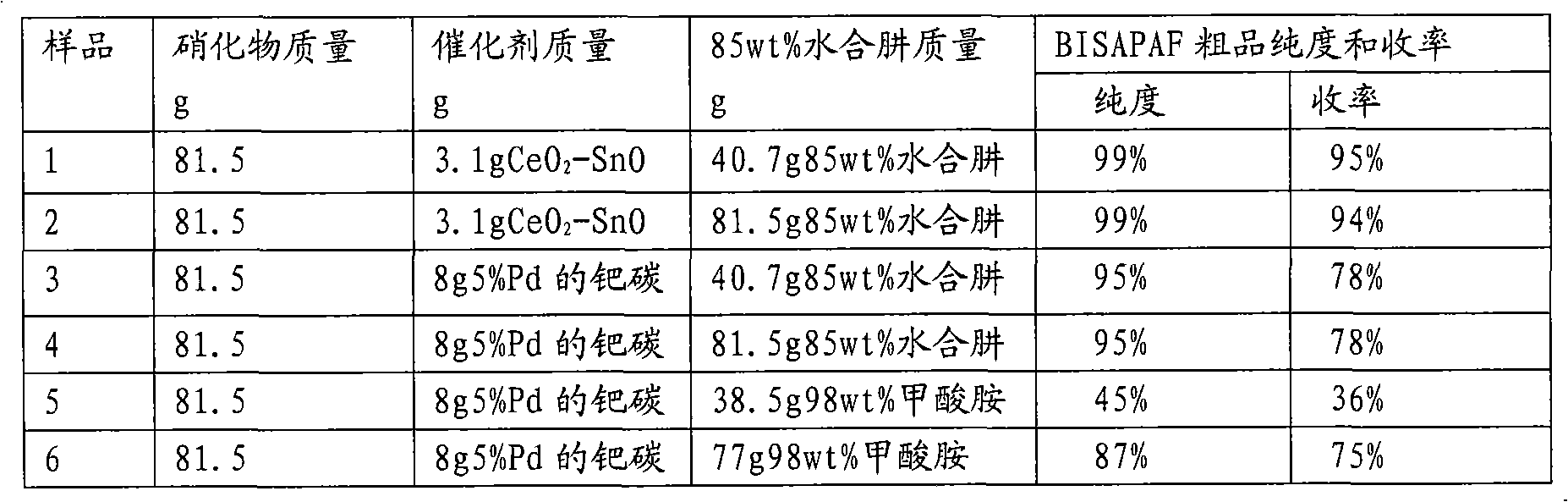

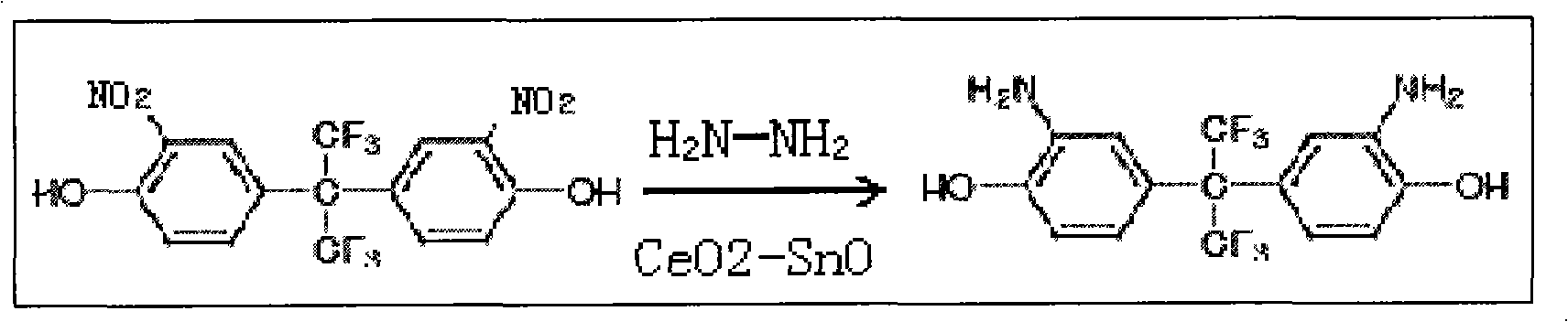

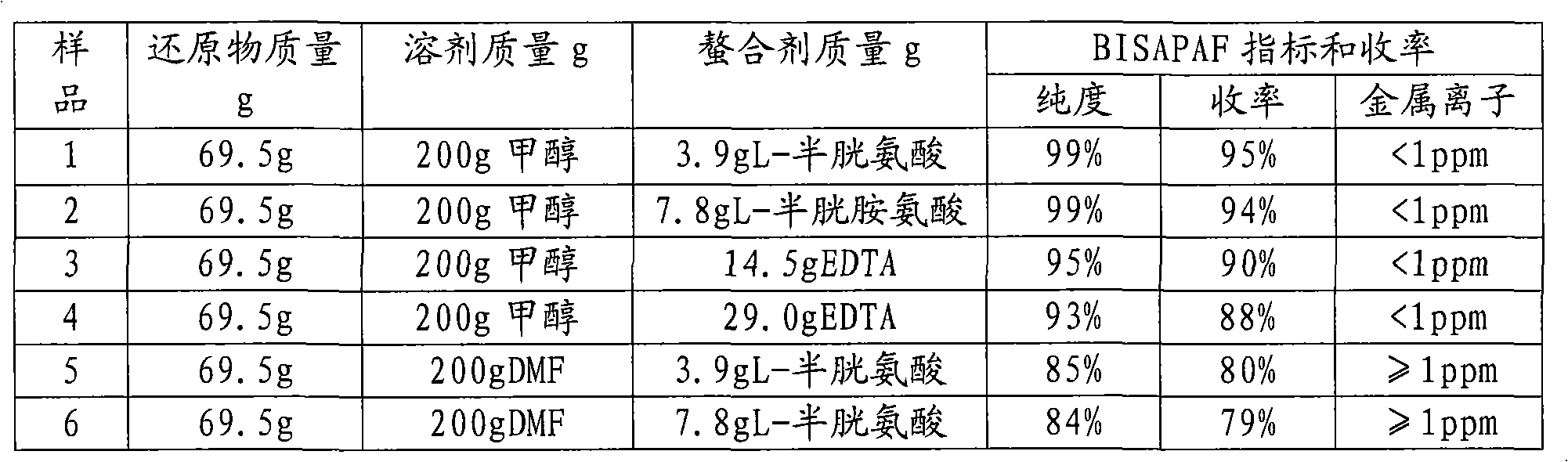

Preparation method of 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane

ActiveCN101643427APrevent oxidationNon-toxic and harmless Low boiling pointOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsHydrazine compoundVacuum sublimation

The invention discloses a preparation method of 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane, belonging to the technical field of electronic chemical materials. The preparation method comprisesthe following steps: adopting 2,2-bis(3-nitro-4-hydroxylphenyl)hexafluoropropane as raw material and hydrazine hydrate dissolved in methanol as reductant to reduce 2,2-bis(3-nitro-4-hydroxylphenyl)hexafluoropropane under the action of catalyst CeO2-SnO and obtain raw 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane, using chelating agent to remove metal ions in the raw product and performing vacuum sublimation and purification to the obtained 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane in which metal ions are removed and finally obtaining the target product. The method has low production cost, high product purity, low contents of metal ions and high yield.

Owner:自贡中天胜新材料科技有限公司

Rinse liquid and uses thereof

InactiveCN101270325AReduce the content of metal ionsNo smellSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsPhysical chemistryOxidizing agent

The invention discloses cleaning fluid, which comprises at least an oxidizer, at least a carbamidine compound and water. The invention further discloses application of the cleaning fluid in cleaning wafer after the wafer is polished chemically and mechanically. The cleaning fluid can clean polishing particles and chemical substance remaining on the surface of wafers after being polished chemically and mechanically. In addition, the cleaning fluid contains few metallic ions and is odorless, thus reducing pollution of metallic ions and environmental pollution.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

4, 4'-diamino-diphenyl ether preparing method

ActiveCN106496047AShort method stepsReduce energy consumptionOrganic compound preparationAmino-hyroxy compound preparationDiphenyl etherDiaminodiphenyl ether

The invention discloses a 4, 4'-diamino-diphenyl ether preparing method and relates to the technical field of preparation of fine chemical engineering organic materials. The method comprises the following steps of (1) adding 4, 4'-dinitro-diphenyl ether, Pd / C catalyst, mixed solvent of benzene-ring solvent and water, and antioxidant in a hydrogenation reactor, performing mixing, inletting hydrogen and increasing the temperature for catalyzed hydrogenation reaction; (2) after the catalyzed hydrogenation reaction is completed, transmitting the reacted materials into a glycol biological solvent, increasing the temperature to dissolve 4, 4'-diamino-diphenyl ether obtained through reaction, performing hot filtration, recovering the Pd / C catalyst, cooling and crystallizing filter liquor, separating solids and liquids, drying the solids to obtain the 4, 4'-diamino-diphenyl ether. The 4, 4'-diamino-diphenyl ether preparing method is short in process, low in energy consumption and simple in operation, can produce high-quality white 4, 4'-diamino-diphenyl ether crystals without sublimation and achieve a content higher than 99.8% and a recovery rate higher than 90%, thereby being applicable to industrial production.

Owner:南通汇顺化工有限公司

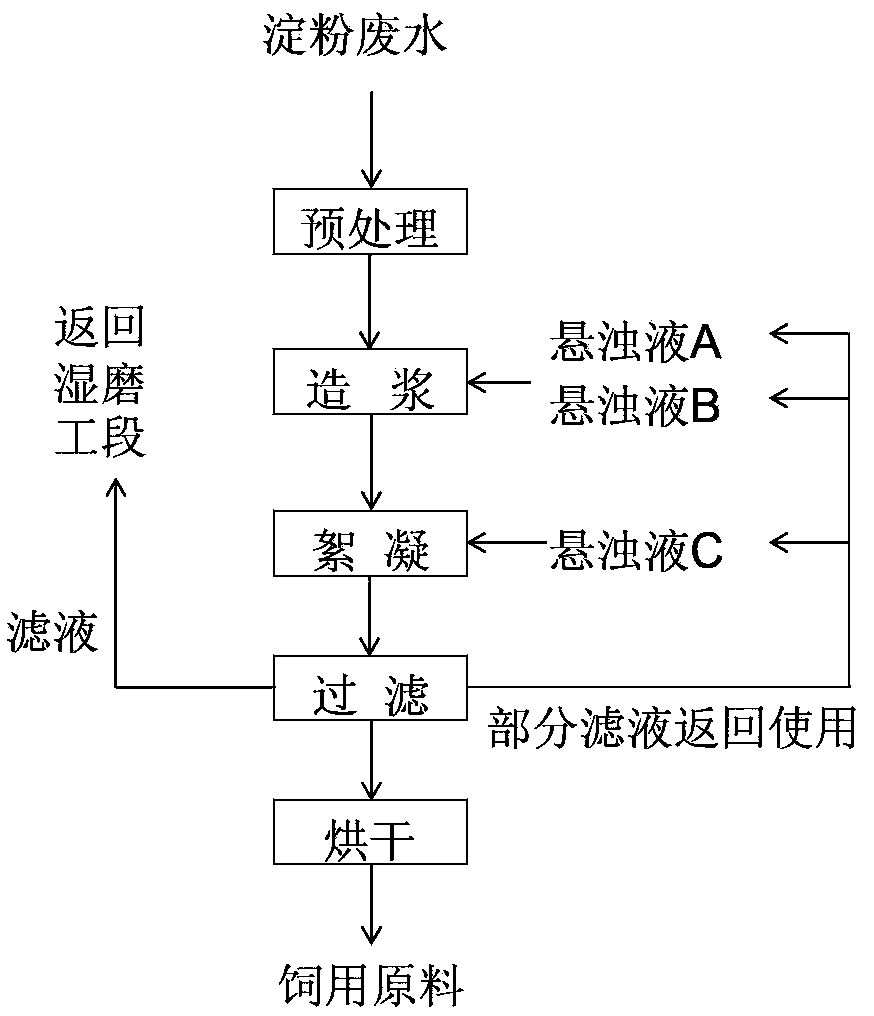

Treatment method for starch wastewater

ActiveCN104098201AHigh adsorption rate of metal ionsReduce the content of metal ionsAnimal feeding stuffMultistage water/sewage treatmentIonChemistry

The invention discloses a treatment method for starch wastewater. The method comprises the steps of: (1) pretreatment: treating starch wastewater by a grid; (2) pulping: adding a suspension liquid A having a volume 0.0005-0.01 time that of the wastewater into wastewater treated in step (1), mixing the mixture evenly, adjusting pH to 6-8, then adding a suspension liquid B having a volume 0.002-0.006 time that of the mixture, and mixing the materials evenly; (3) flocculation: adding a suspension liquid C having a volume 0.005-0.04 time that of the wastewater into the wastewater treated in step (2), stirring the mixture evenly and conducting standing for 0.5-1.0h; and (4) filtration: subjecting the wastewater treated in step (3) to sedimentation, filtering the supernatant and precipitate respectively, and combining the filtrate. With simple technological steps, the treatment method for starch wastewater provided by the invention can effectively remove organic matters from the wastewater, can achieve low metal ion residue, and is environment friendly, thus having good application prospects.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Polyphenylene sulfide resin synthesis process

ActiveCN109535426AReduce the content of metal ionsImproved performance characteristicsSynthesis methodsSodium hydrosulfide

The invention discloses a polyphenylene sulfide resin synthesis process, which aims to obtain a resin synthesis method with good particle formation, high product yield, high solvent recovery rate, andreduced corrosion degree of a polymerization reaction device. The method adopts sodium sulfhydrate containing sodium crystallization, sodium hydroxide, and p-dichlorobenzene as raw materials, and takes N-methylpyrrolidone as a solvent, and a condensation polymerization reaction is carried out in a synthesis system, after the low temperature and high temperature polycondensation is completed, acetate, NMP and an aqueous solution are added by a high-pressure pump, then the materials are insulated at a high temperature, cooled, and filtered, and a filter cake is purified by a NMP solvent, repeatedly washed with deionized water and filtered, and the filter cake is dried to obtain the polyphenylene sulfide resin. The polyphenylene sulfide resin synthesized by the invention is widely used in the fields of aerospace, electronic machinery, petrochemical, food, light industry, thermal power generation, cement industry, steel manufacturing, environmental protection, textile industry and the like.

Owner:德阳科吉高新材料有限责任公司

Coagulating sedimentation agent for treating low-temperature low-turbidity water

InactiveCN103663650AGood turbidity removal performanceSettling fastWater/sewage treatment by flocculation/precipitationChemistryInlet temperature

The invention relates to a coagulating sedimentation agent for treating low-temperature low-turbidity water and belongs to the field of applied chemistry, in particular to the field of coagulating sedimentation treatment agents of low-temperature low-turbidity water. The coagulating sedimentation agent consists of coaly activated carbon powder and oxidized polysilicate aluminium ferric according to a mass-to-volume ratio (mg / mL) of 1:1 to 10:1. The coagulating sedimentation agent is capable of breaking through the limitation that the sedimentation effects of conventional aluminum and iron salt coagulating agents are greatly influenced by factors such as water inlet temperature, suspended solids and turbidity, is taken as a high-efficiency, economic and environment-friendly coagulating agent for treating low-temperature low-turbidity water generated from power plants and water works and industrial water (living water, wastewater and the like), and has high economic benefits and obvious social benefits.

Owner:JILIN ELECTRIC POWER RES INST +1

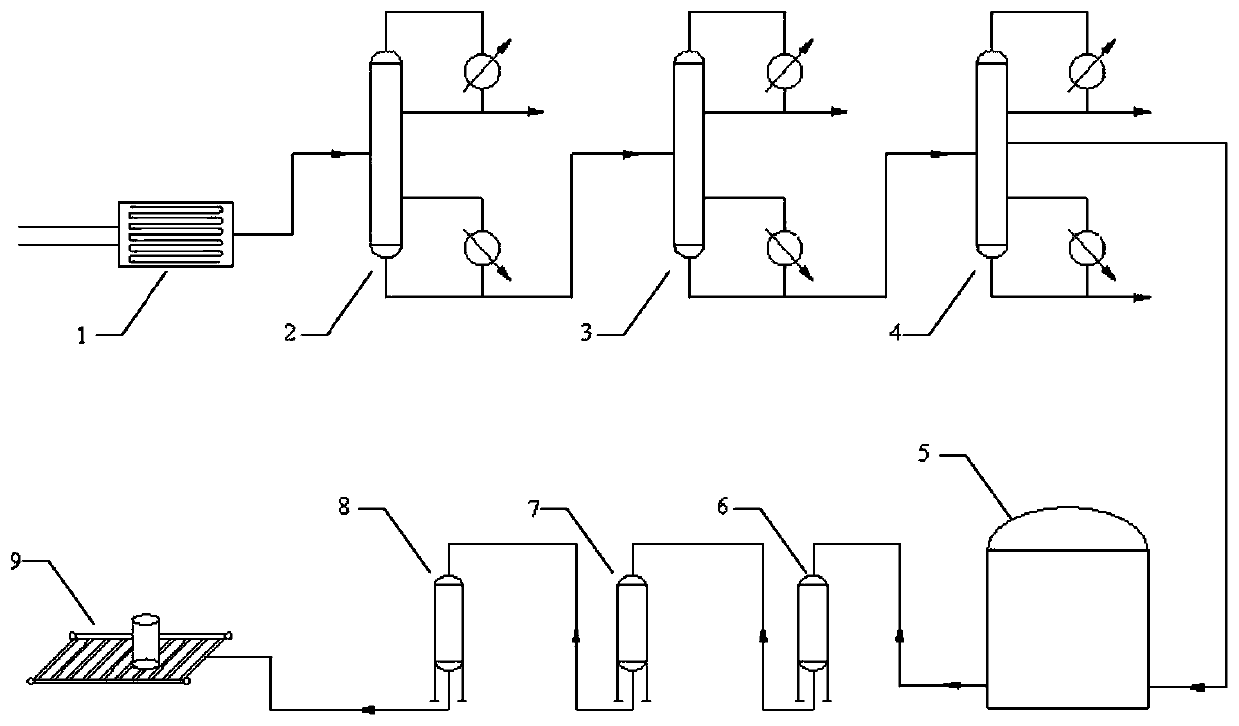

Method for preparing super-clean and high-purity acetic acid and apparatus thereof

ActiveCN101362683AEfficient removalUniform porous structureCarboxylic compound separation/purificationFiltrationSmall footprint

The invention relates to a method for preparing super-clean high-purity acetic acid, and the high-purity acetic acid is mainly suitable for cleaning and corrosion in the manufacture industry of large scale integrated circuit semiconductor devices in the microelectronic industry. The method is as follows: firstly, the industrial grade acetic acid (99.0 percent) material is mixed with potassium permanganate with 0.1-0.5 percent of the weight of the acetic acid material in an oxidation processor; the mixture is filtered after 30-60 minutes under the normal temperature and pressure; the filtrate and a silicone polymer complexing agent of the bi-allyl 18-coronary-6 ether are mixed in a complexing processor for 30-120 minutes, and then the mixture is filtered by the microfiltration membrane of a microstrainer under the operation pressure of 0.1-0.2MPa; the filtrate passes through a 2,000mm dehydration column, and then enters a multi-level rectification tower with the speed of 0.05-0.20mm / s, and the semi-finished product yielded from the tower enters a product acceptor after the filtration by the nanofiltration membrane of a nanofiltration device under the operation pressure of 0.5-0.8MPa. The method has the advantages of simple process, low production cost, high product purity and low content of impurity ion. The device has the advantages of small occupied area, convenient automatic operation, stable quality and continuous production.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

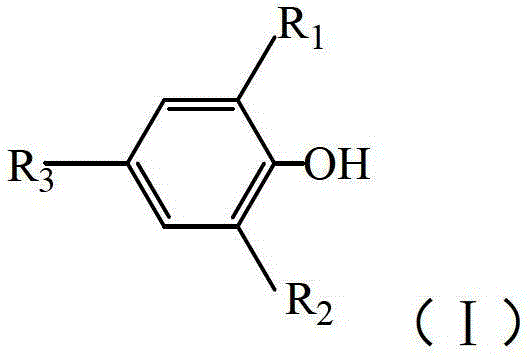

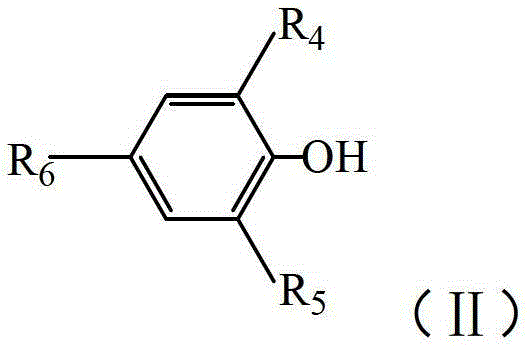

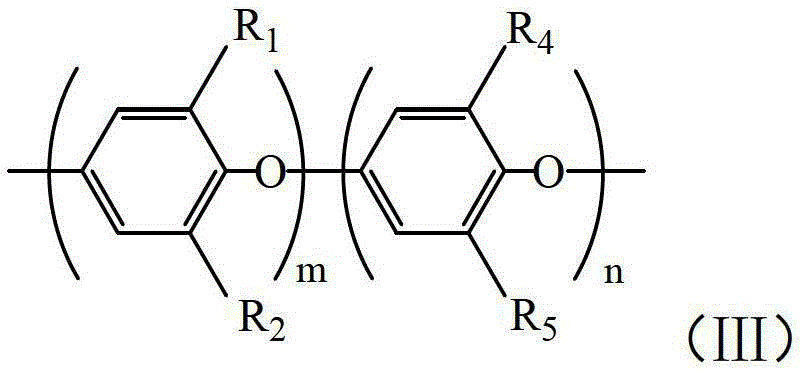

Method for preparing polyphenyl ether with side chain containing unsaturated carbon-carbon double bond in water medium

The invention discloses a method for preparing polyphenyl ether with a side chain containing an unsaturated carbon-carbon double bond in a water medium. The method comprises the following steps of: carrying out oxidative copolymerization reaction on a common phenol monomer and a phenol monomer containing the unsaturated carbon-carbon double bond in the water medium at 30-60 DEG C for 4-24 hours in the presence of a catalyst, a surfactant, an alkali compound and an oxidant; and after the oxidative copolymerization reaction is finished, carrying out demulsification, filtering and washing to obtain the polyphenyl ether with the side chain containing the unsaturated carbon-carbon double bond. The polyphenyl ether containing the unsaturated carbon-carbon double bond prepared in the water medium according to the method disclosed by the invention has the characteristics of low residual metal catalyst content, low dielectric constant, low medium loss, organic solvent resistance, high temperature resistance, good processing performance and the like; and the preparation process is green, environment-friendly, simple, convenient, and easy to implement, safe and nontoxic, has wide development space and great market application value, and is in line with the requirements of sustainable development.

Owner:ZHEJIANG UNIV

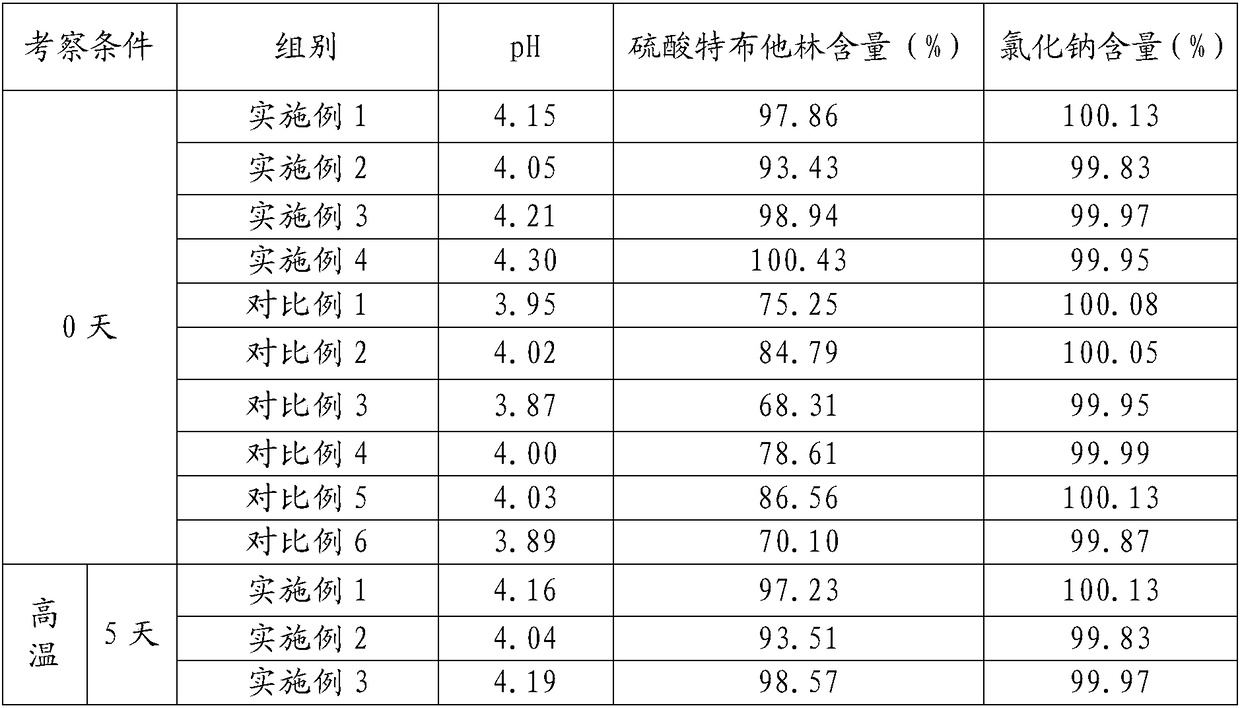

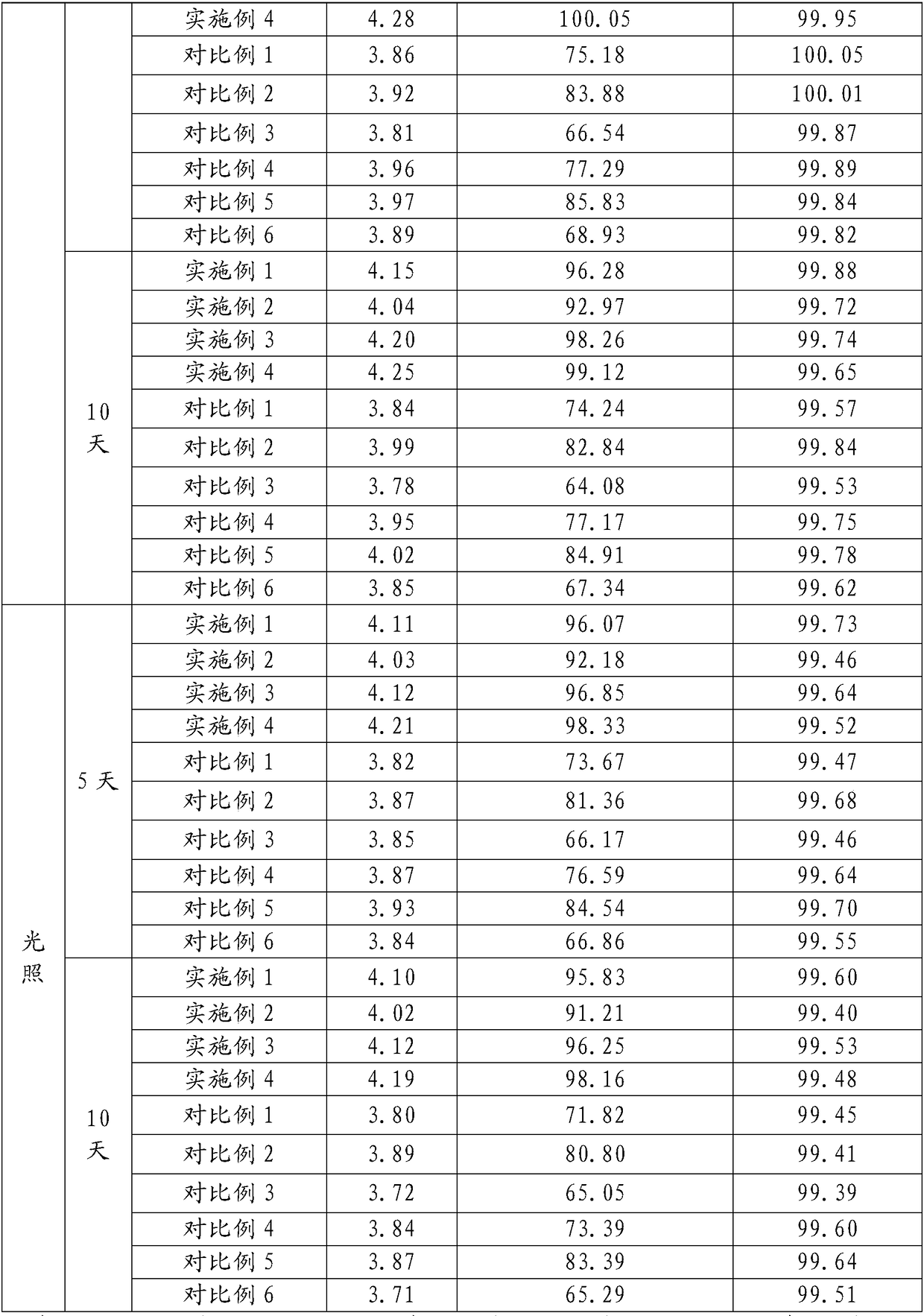

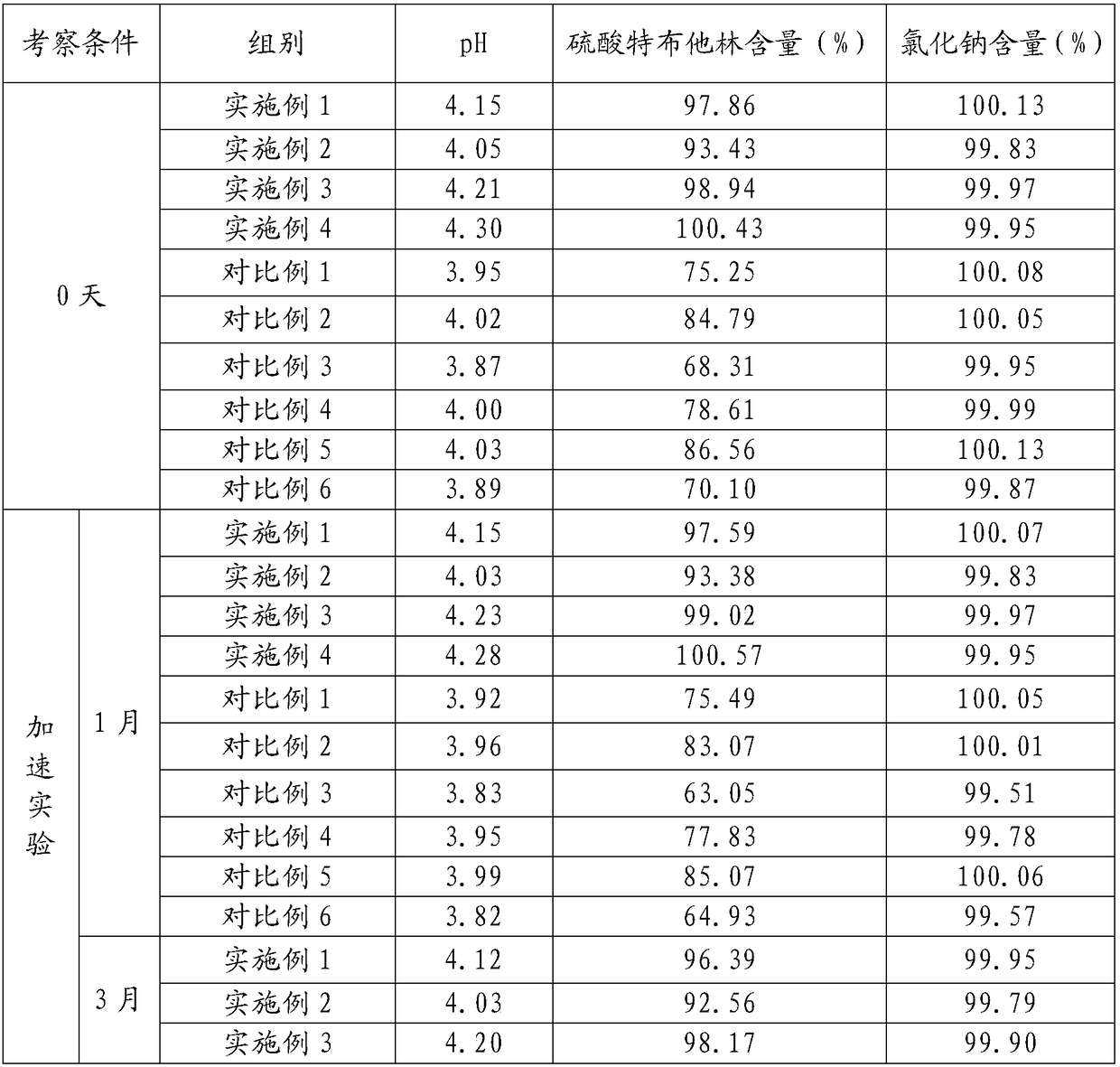

Processing method for improving stability of terbutaline sulfate injection and terbutaline sulfate injection

ActiveCN108078918AImprove stabilityStable contentOrganic active ingredientsInorganic non-active ingredientsNitrogenSilanization

The invention relates to a processing method for improving the stability of a terbutaline sulfate injection. The processing method comprises the following steps: S1, passivating a stainless steel preparation tank and a pipeline by using nitric acid of 8 wt% before preparing the terbutaline sulfate injection, wherein the passivating temperature is 49 DEG C to 52 DEG C, the passivating time is 0.5-2hours; washing with water for injection until the pH is 5.0-7.0; S2, putting the pipeline passivated by the terbutaline sulfate injection prepared through the passivated stainless steel preparation tank in a glass bottle under the protection of nitrogen, and sterilizing, wherein the inner surface of the glass bottle is modified by an active group, and the active group is one or more of amino, sulfydryl, carboxyl and anhydride. The stability of the terbutaline sulfate injection is greatly improved through passivating and silanization, so that the content of the terbutaline sulfate is kept stable before and after filling and in the long-term storage process.

Owner:石药银湖制药有限公司

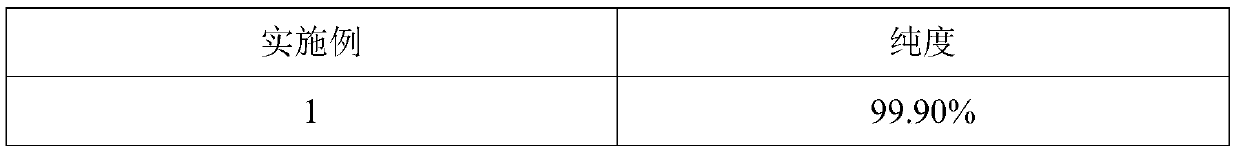

Method for reducing content and granularity of metal ions in N-methylpyrrolidone

ActiveCN110551051ASmall granularityReduce the content of metal ionsOrganic chemistryImpurityN-Methyl-2-pyrrolidone

The invention relates to the technical field of chemical engineering, more specifically to a method for reducing the content and granularity of metal ions in N-methylpyrrolidone. The method includes the following steps: methylamine and gamma-butyrolactone are added to a reactor, after reaction, the reaction system is introduced into a normal-pressure tower to remove water and methylamine, an obtained crude product enters a negative-pressure tower for removing low-boiling-point substances, then high-boiling-point substances are removed in a rectification tower, the processed crude product enters a storage tank, and then in turn passes through a primary filter, a secondary filter and a third filter after flowing out from the storage tank, and then filling is carried out by a dust-free filling line, so that ultrahigh-purity N-methylpyrrolidone is obtained. The invention provides the method for reducing the content and granularity of metal ions in N-methylpyrrolidone, and the purity of theobtained ultrahigh-purity N-methylpyrrolidone can reach 99.90% and more, and the particle content is less than or equal to 5 / mL when the particle size of impurity particles is greater than 0.5 [mu]m,and also a low-granularity product is obtained when the high purity is met.

Owner:SHANDONG QINGYUN CHANGXIN CHEM SCI TECH

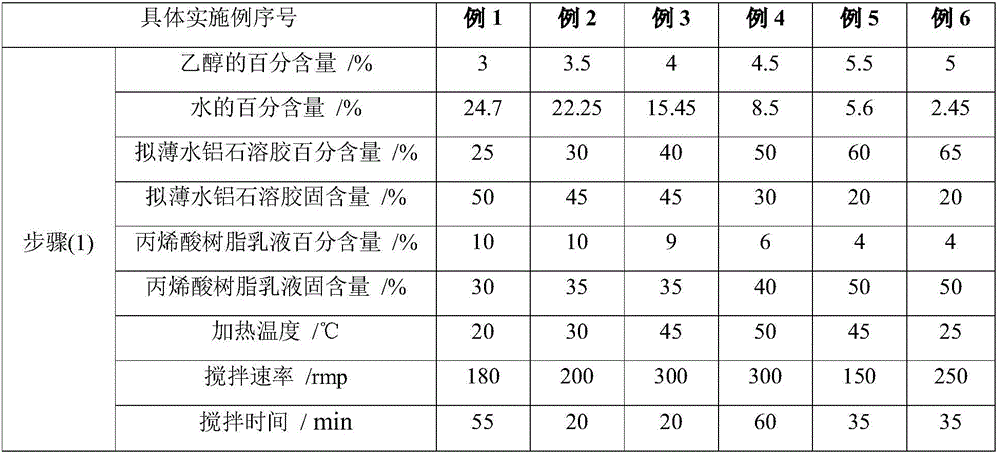

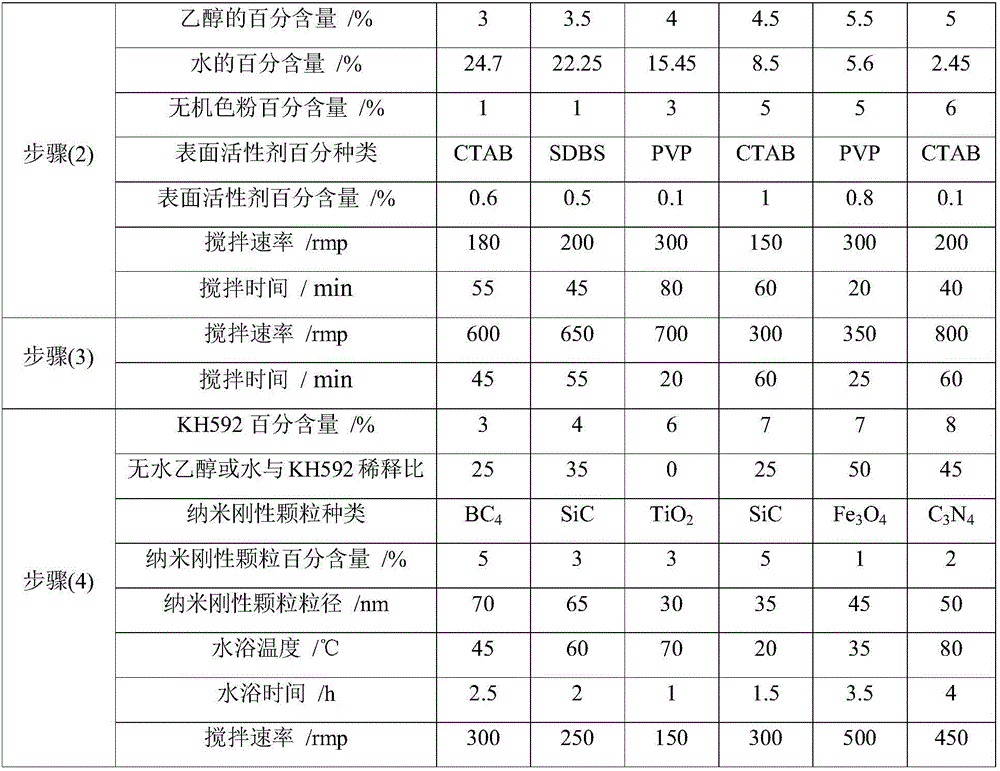

Dying seal hardener for concrete

The invention relates to the technical field of building materials and aims at providing a dying seal hardener for concrete. The dying seal hardener is prepared by mixing the raw materials in percentage by mass: 25-65% of pseudo-boehmite sol, 4-10% of an acrylic resin emulsion, 0.1-1% of a surfactant, 3-8% of a silane coupling agent, 1-5% of nano rigid particles, 1-6% of an inorganic pigment, 6-11% of ethyl alcohol and the balance of distilled water, wherein the nano rigid particles are one or a combination of SiC, BC4, C3N4, Fe3O4 or TiO2. According to the dying seal hardener, the apparent color and luster of the concrete are changed to reach visual aesthetic feeling; the problem of diverse requirements of different populations on the terrace is solved. The product is a water-based material, construction is simple and convenient, the dying seal hardener can be directly rolled on large area or sprayed on the surface of the concrete for construction; the treated concrete surface has the characteristics of high hardness, high abrasive resistance and high glossiness; the dying seal hardener is simple in preparation process and especially suitable for massive industrial production; the reaction process is easy to control; and the reaction conditions are mild.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

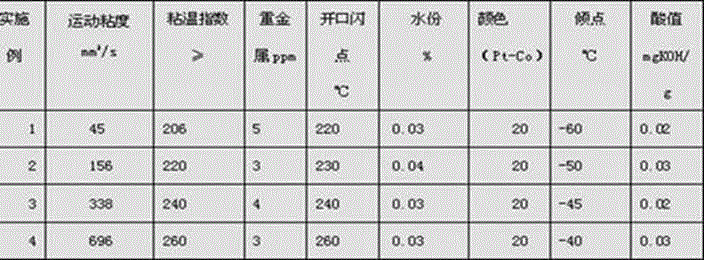

Synthetic method of water insoluble polyether synthetic base oil

InactiveCN102875798AHigh catalytic activityReduce the content of metal ionsBase-materialsChemical industryPtru catalyst

The invention provides a synthetic method of water insoluble polyether synthetic base oil and relates to a synthetic method of a chemical industry product. The synthetic method comprises the following steps of: firstly preprocessing n-butyl alcohol, throwing 10-20g of 3A molecular sieve into per kg of n-butyl alcohol, stirring to be uniform, placing for 24 hours, filtering out the molecular sieve, then throwing into the same fresh molecular sieve, and repeating the steps for three times for later use; then sequentially throwing the n-butyl alcohol and a multi-metal catalyst in a reaction kettle, carrying out an initiation reaction, slowly dropwise adding epoxypropane into the reaction kettle, after dropwise adding is finished, discharging when the temperature of the reaction kettle is reduced to 60 DEG C, thus obtaining an intermediate; and finally throwing the intermediate into the reaction kettle, slowly dropwise adding mixture of the epoxypropane and ethylene oxide into the reaction kettle, after dropwise adding is finished, discharging when the temperature of the reaction kettle is reduced to 60 DEG C, and filtering, thus obtaining a finished product. The polyether synthetic base oil prepared by the synthetic method disclosed by the invention has the advantages of high viscosity property, high viscosity index, small variation along with temperature, low flow point and freezing point, stronger lipophilicity, good intermiscibility with various penetrants, better oxidation stability and emulsion performance and certain water-retaining property.

Owner:大连广会科技有限公司

Method for developing monocrystal of potassium dihydrogen phosphate in large aperture rapidly

InactiveCN1727522AFast growth rateReduce the content of metal ionsPolycrystalline material growthFrom normal temperature solutionsPhosphatePotassium

A process for quickly growing the large-diameter monocrystal of potassium dihydrogen phosphate by solution temp lowering method features that the consumptions of potassium chloride and EDTA are respectively 1-5 M% and 0.01-0.02 Wt%, the initial over-saturation is 8 deg.C for maximum, and the temp lowering speed is 0.3-0.5 deg.C per day for initial growing stage and 2 deg.C per day for fast growing stage.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Paper mill sewage treatment agent

ActiveCN106745412ARaw materials are easy to getEasy to prepareWater/sewage treatmentWaste water treatment from plant processingSalicylic acidEmission standard

The invention discloses a paper mill sewage treatment agent. The paper mill sewage treatment agent is prepared from the following raw materials in parts by weight: 40 to 65 parts of modified bagasse powder, 11 to 16 parts of polyacrylamide, 3 to 7 parts of ethyl maltol, 3 to 8 parts of chlorella powder, 8 to 13 parts of humic acid, 13 to 18 parts of soya bean meal, 11 to 14 parts of lotus leaf ash, 7 to 10 parts of ferric chloride, 15 to 23 parts of kaolin, 98 to 125 parts of water, 2 to 5 parts of salicylic acid and 1 to 3 parts of monopotassium phosphate. By adopting the paper mill sewage treatment agent, COD (Chemical Oxygen Demand), BOD (Biochemical Oxygen Demand), SS (Stainless Steel) and metal ion content of sewage can be lowered effectively, and the emission standard can be reached; the paper mill sewage is treated with the modified bagasse, so that waste is turned into treasure, and resource waste is avoided; the paper mill sewage treatment agent has the advantages of simple preparation method, adoption of readily available raw materials, relatively low production cost and high sewage treatment efficiency.

Owner:SHANGHAI TIANLIN WATER TREATMENT EQUIP MAINTENANCE

Method for purifying organic amine electroplating additive

ActiveCN103102273AReduce the content of metal ionsImprove the purification effectAmino compound purification/separationOrganic compound preparationIon exchangeIon-exchange resin

The invention discloses a method for purifying an organic amine electroplating additive. Anion and cation impurities in the organic amine electroplating additive are eliminated by using an electric deionization device; end plates are respectively arranged on two ends of the electric deionization device; cathodes and anodes which are connected with a direct-current power supply are respectively arranged on the end plates; a plurality of purifying chambers and concentrated water chambers are sequentially and alternatively arranged in parallel between two end plates; each purifying chamber and the concentrated water chamber are respectively isolated from each other through cation exchange membranes or anion exchange membranes; the purifying chambers are filled with ion exchange resin; the concentrated water chamber and an electrode water chamber are respectively filled with 0.3-1% organic ammonium salt solutions; the flow of the purifying chamber is 1-100L / h; the flows of the concentrated water chamber and the electrode water chamber are 1-100L / h; the voltage of the direct-current power supply is 0-100V; the voltage is constant and the solution temperature is kept be at 20-70 DEG C in the purification process; and the recovery rate of the organic amine electroplating additive after being purified is greater than 80%. The method for purifying the organic amine electroplating additive, disclosed by the invention, is simple in process and easy to control, and the purification degree can achieve the fine electronic grade standard.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

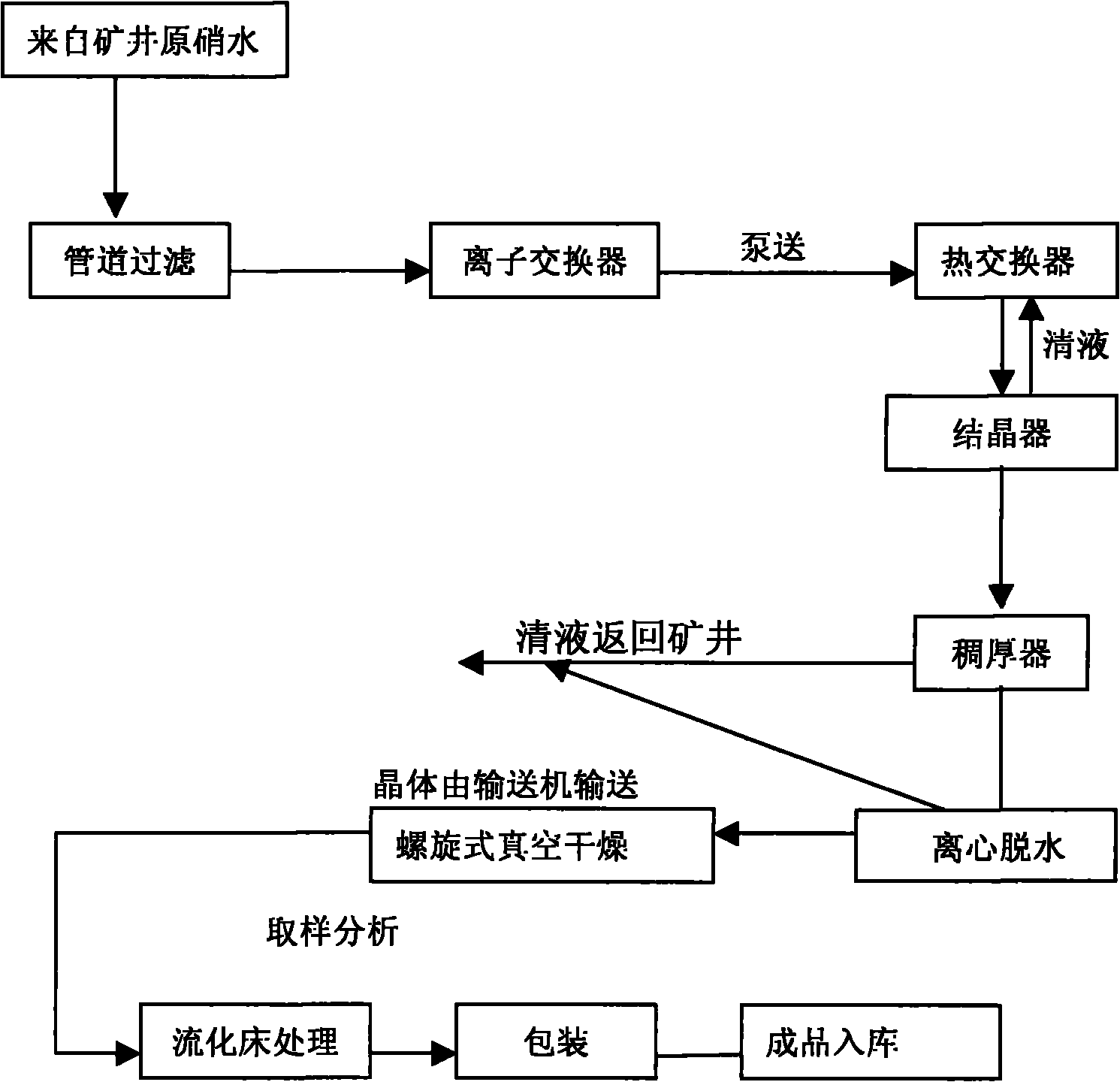

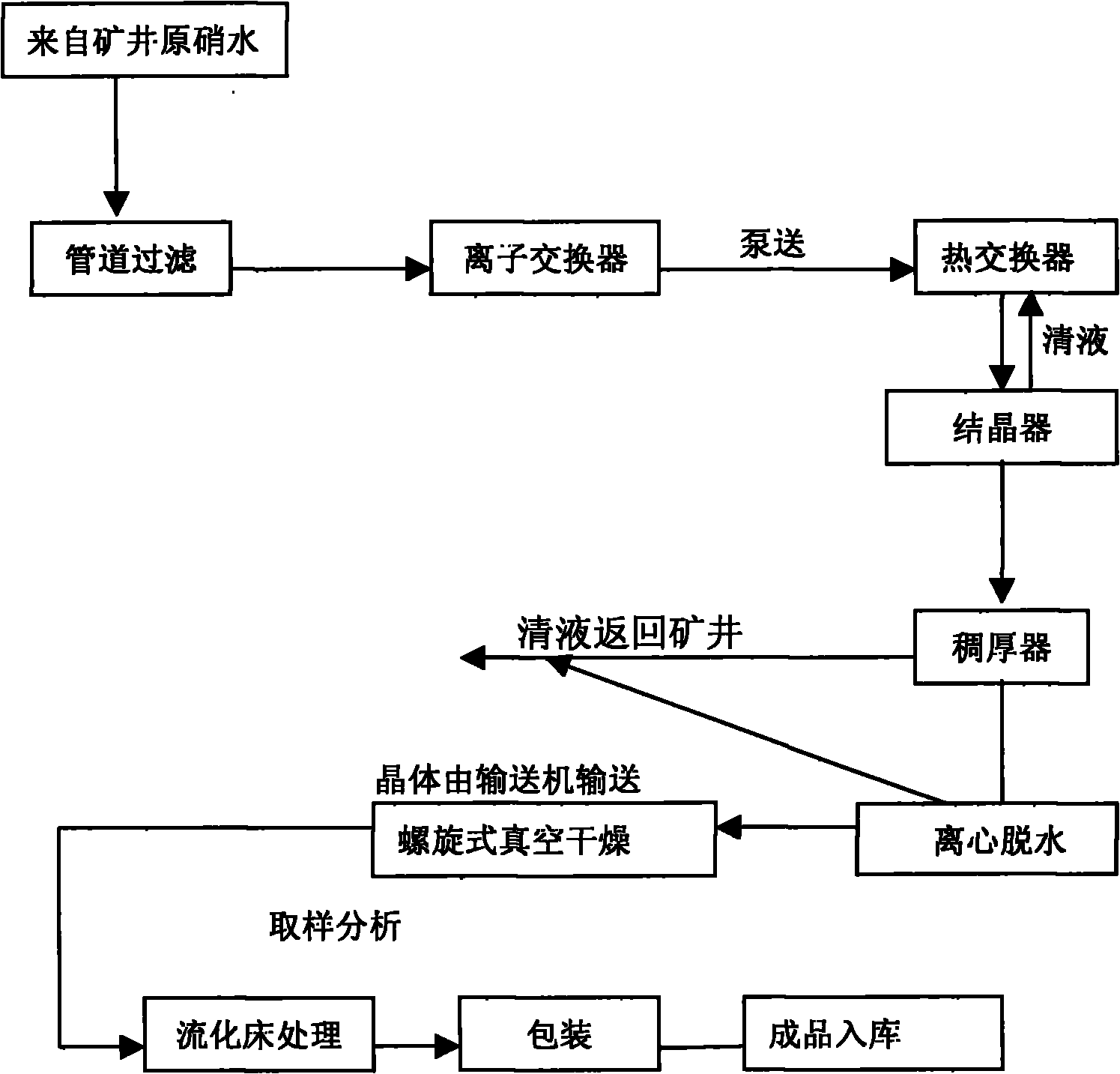

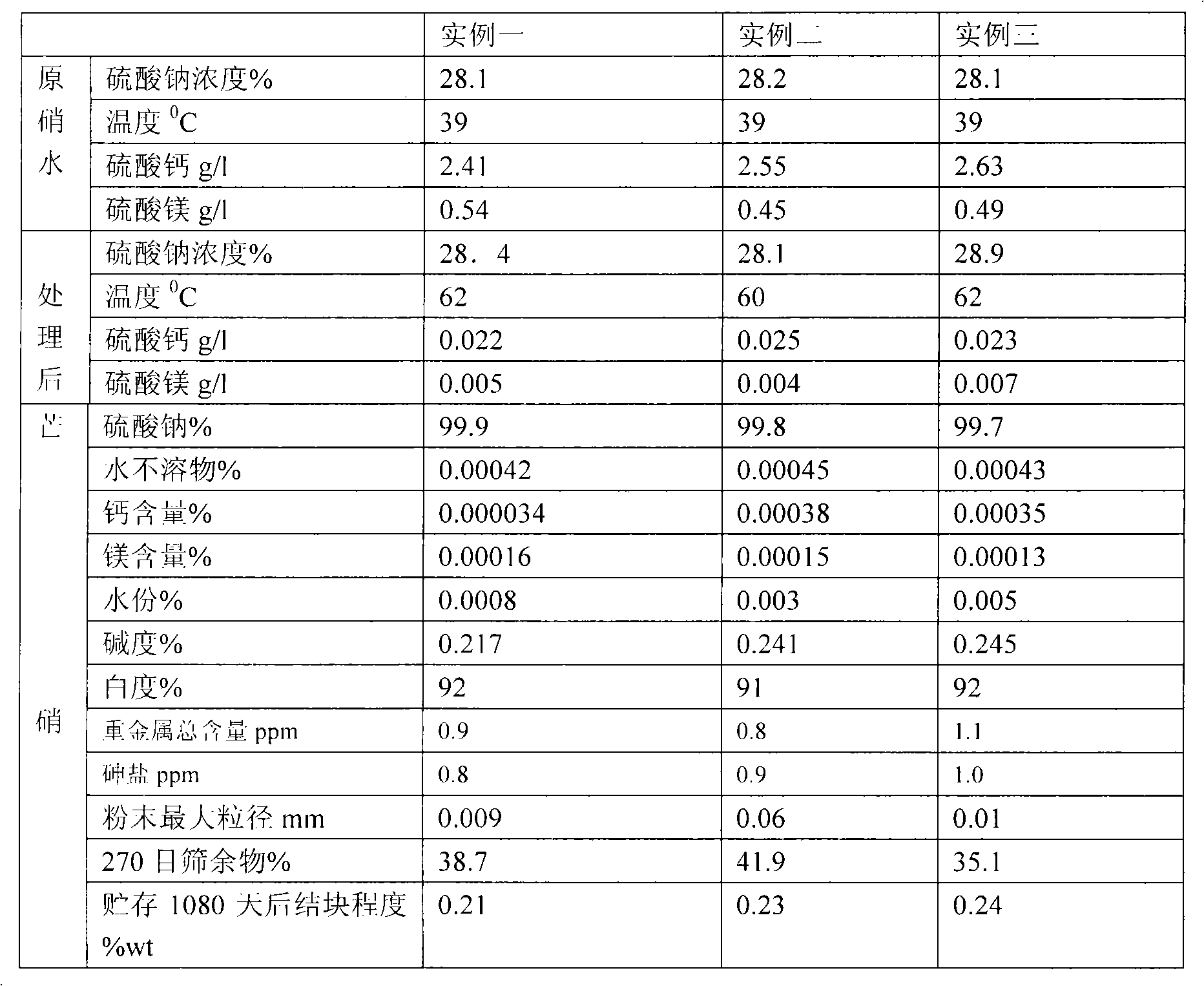

Manufacturing technique of high-purity thenardite

InactiveCN101844781ASave cleanup timeIncrease productivityAlkali metal sulfite/sulfate dehydrationChemistrySodium nitrate

The invention relates to a manufacturing technique of high-purity thenardite. The manufacturing technique comprises the steps: removing mechanical impurities in original sodium nitrate solution which has certain concentration and is conveyed under a well by a three-stage pipeline filter under the monitoring of a DCS automatic monitoring system and regulation of an AK liquid balance flow meter, using a twelve-stage ion exchanger for refining and purifying treatment to obtain refined sodium nitrate solution with extremely-low impurity content, adjusting a pH value thereof, inputting the refined sodium nitrate solution into a continuous crystallization technique system, carrying out continuous solid-liquid separation by a primary centrifugal machine, then inputting the treated sodium nitrate solution into a multi-stage spiral type vacuum dryer for drying and removing water, inputting the sodium nitrate solution into a fluidized bed for treatment, obtaining the high-purity thenardite and finally inputting the obtained high-purity thenardite into an automatic packaging machine procedure for packaging.

Owner:四川省川眉芒硝有限责任公司

Method for preparing high hydroscopicity resin by adding water-adsorbing resin for capturing polyvalent metal ion to unsaturated monomer water solution

ActiveCN1970594AReduce the total content of metal ionsReduce total contentAbsorbent padsBandagesPolymer scienceAqueous solution

The invention discloses a making method of high-hydroscopicity resin, which comprises the following steps: adding neutralizing agent and internal crosslinking agent in the insaturated monomer liquid; adding high-high-hydroscopicity resin to catch polyvalent metal ion; adding starter in the insaturated monomer solution; proceeding free-radical polymerization; cutting the gel; drying; grinding; sieving the fixed grain size; adding surface crosslinking agent; heating.

Owner:FORMOSA PLASTICS CORP

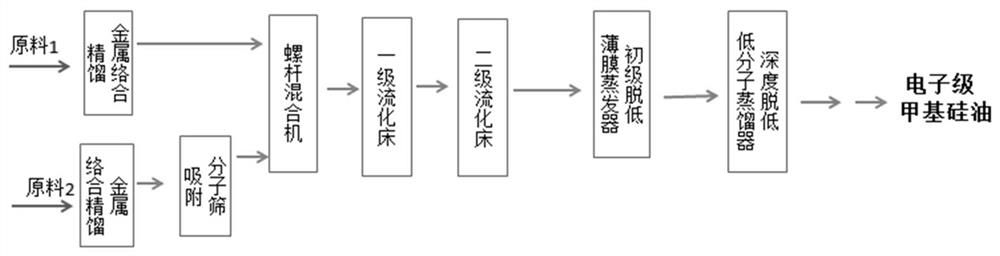

Continuous preparation method of electronic-grade methyl silicone oil

ActiveCN112142976AReduce the content of metal ionsReduce moisture contentMolecular sieveFluidized bed

The invention relates to a continuous preparation method of electronic-grade methyl silicone oil, which comprises the following steps: pretreating raw materials: carrying out metal complexing agent rectification purification or molecular sieve adsorption treatment and metal complexing agent rectification purification on the raw materials and auxiliary materials in series for use; premixing the rawmaterials: inputting the pretreated raw materials into a screw mixer according to a certain mass ratio, and performing heat preservation and mixing; polymerization: inputting the premixed material into a first-stage static fluidized bed for prepolymerization, and then inputting into a second-stage static fluidized bed for equilibrium polymerization to obtain a semi-finished product; and carryingout low-boiling-point substance removal: inputting the semi-finished product into a film evaporator, primarily removing low-boiling-point substances through first-stage purification, and then inputting the semi-finished product into a short-path low-molecular distiller for second-stage purification to obtain a finished product. The process is a continuous production process, polymerization is stable, the conversion rate is high, the finished product indexes are as follows: the molecular weight distribution coefficient is small, the low-boiling-point substance content is less than 0.20%, the silicon hydroxyl content is low, the Na, K and heavy metal ion content is less than 10ppb, and the application requirements of industries such as electronics, microelectronics and the like can be met.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD +1

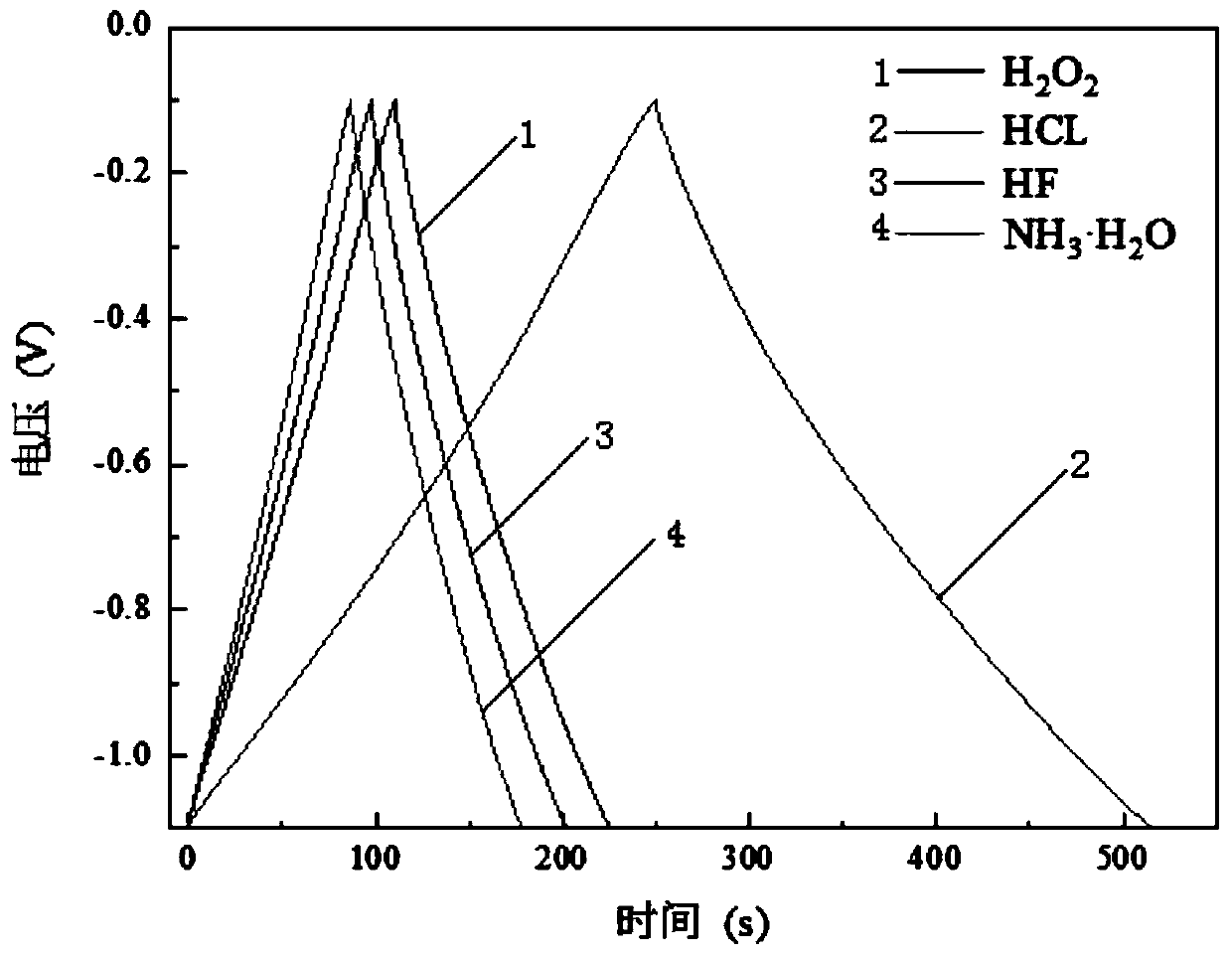

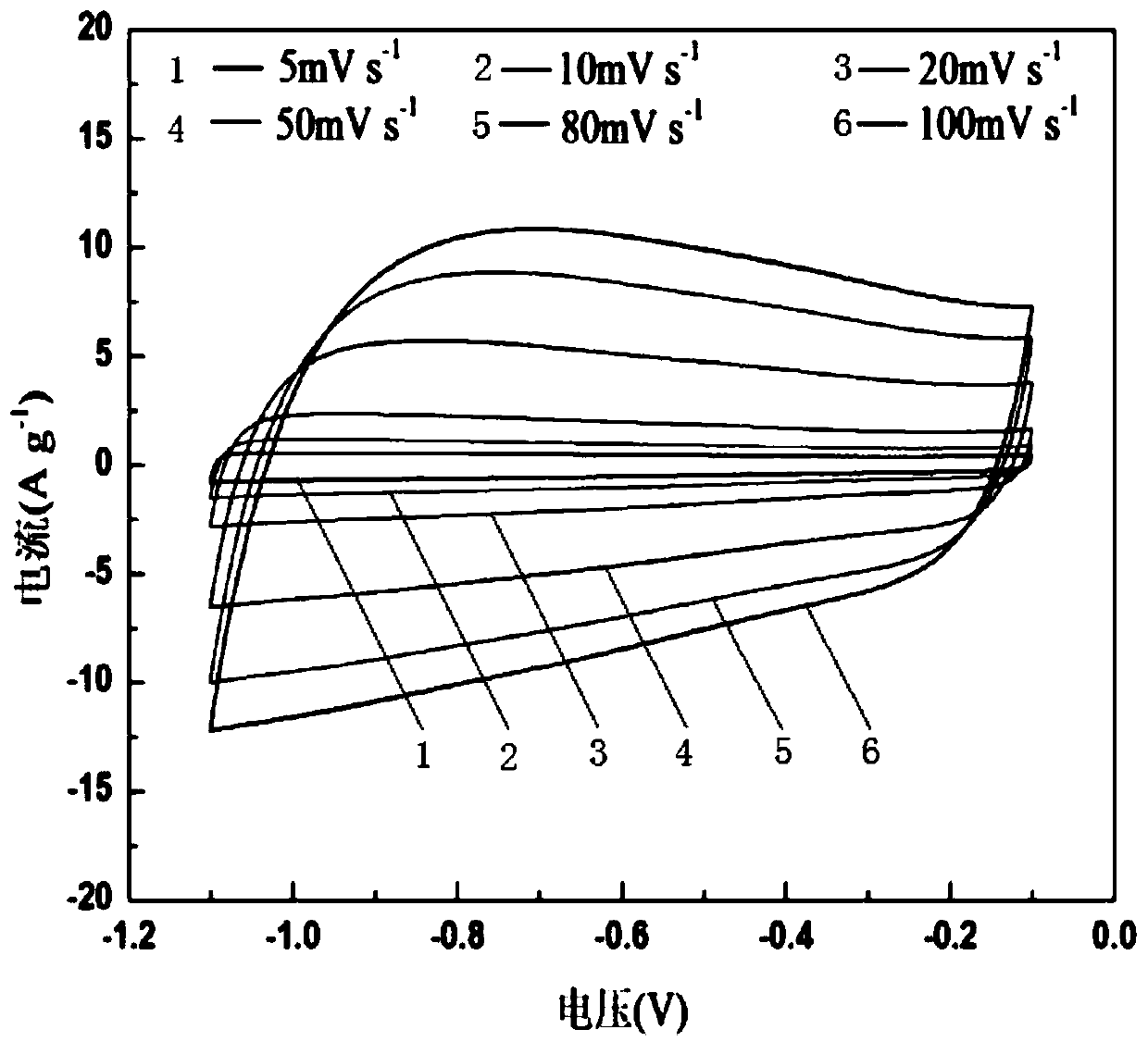

Preparation method of pig manure activated carbon electrode material

ActiveCN110176361AGood electric double layer capacitance characteristicsGood charge and discharge performanceHybrid capacitor electrodesHybrid/EDL manufactureIonCapacitance

The invention discloses a preparation method of a pig manure activated carbon electrode material, and belongs to the technical field of supercapacitor electrode materials. According to the preparationmethod, the diversified utilization of the pig manure is realized. The method comprises the following steps of 1, dipping dry pig manure with a hydrochloric acid solution, washing with deionized water until the dry pig manure is neutral, and drying; 2, carrying out high-temperature pyrolysis and cooling under a nitrogen atmosphere; 3, dipping with a KOH solution, and drying; 4, carrying out high-temperature activation under the protection of nitrogen, and cooling to room temperature; and 5, neutralizing by using a hydrochloric acid solution, then washing to neutral by using deionized water, and drying to constant weight. The pig manure activated carbon electrode material contains MgO, ZnO and Al2O3, wherein the alkali carbon ratio is 4 to 1, the activation temperature is 800 DEG C, the activation time is 1.5h, and the specific surface area of the prepared electrode material is 920 m2g-1; and the energy density of the assembled symmetrical supercapacitor can reach 6.87Wh kg-1 at 0.5A g-1, and the capacitance retention rate reaches 100% at the high current density of 5A g-1 after 10,000 cycles.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Heavy metal polluted soil restoration planting method

InactiveCN108031704AReduce the content of metal ionsRestoration of biological characteristicsContaminated soil reclamationGreenhouseSoil heavy metals

The invention relates to the technical field of soil pollution treatment and especially a heavy metal polluted soil restoration planting method. In the method, the planting mode for plants for restoration of the heavy metal polluted soil is completely changed, wherein the plants for restoration are not pre-cultured in a greenhouse and can be directly planted into the heavy metal polluted soil; themethod is free of requirement on concentration of heavy metal ions in the soil and greatly reduces planting difficulty. Heavy metal ions in the lower layer are effectively isolated by covering an asbestos fiber fabric to form an isolation layer; microorganisms are added to soil to reduce the content of metal ions in soil; the soil is watered and then is covered with a film to complex and settle the metal ions; finally, an absorption layer of attapulgite powder can absorb the metal ions for preventing secondary pollution.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

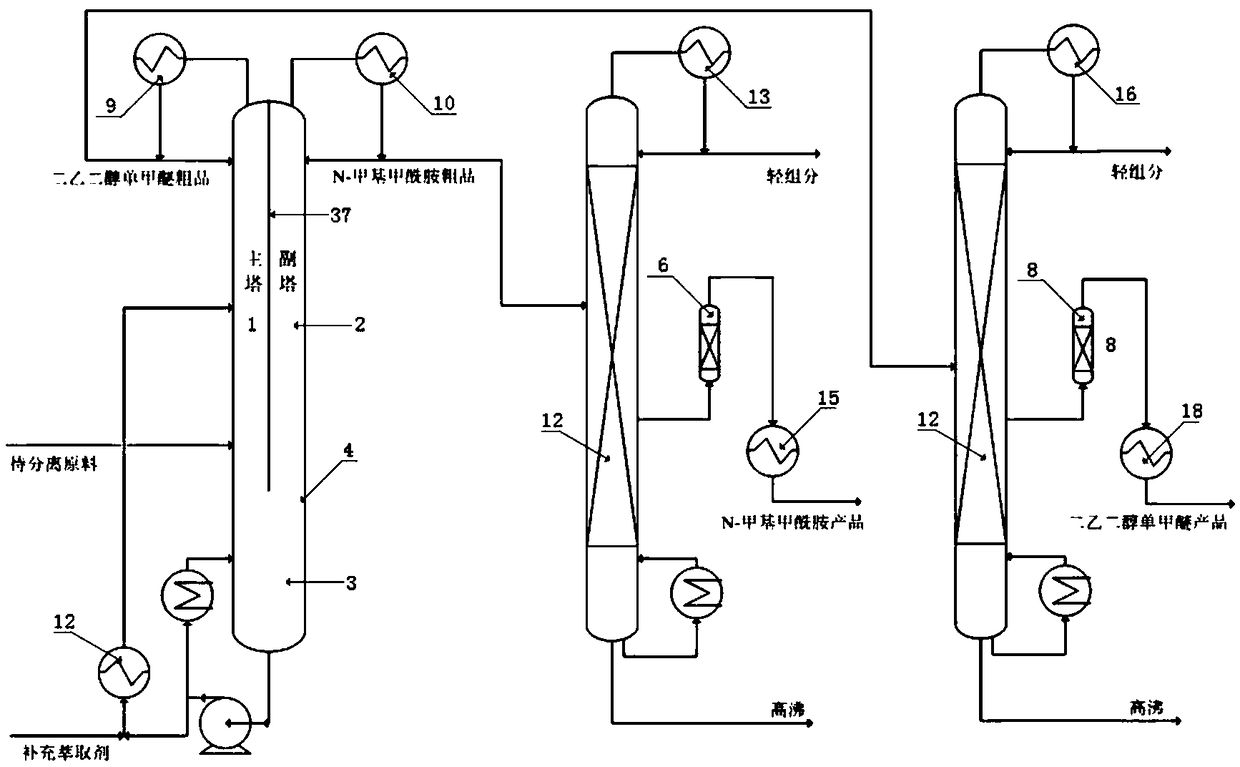

Method for recycling N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid

PendingCN109320431AAchieve separationReduce energy consumptionEther separation/purificationCarboxylic acid amide separation/purificationDiethylene glycolMetal

The invention relates to the field of solvent recycling, in particular to a method for recycling N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid. The method adopts an extraction dividing-wall rectifying method to recycle N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid; the paint remover waste liquid is rectified and separated through a main tower and an auxiliary tower of an extraction dividing-wall rectifying tower, and N-methylformamide crude product and diethylene glycol monomethyl ether crude product are obtainedrespectively; the N-methylformamide crude product passes through a N-methylformamide refining tower and a metal removing tower to obtain N-methylformamide, and the diethylene glycol monomethyl ethercrude product passes through a diethylene glycol monomethyl ether refining tower and the metal removing tower to obtain diethylene glycol monomethyl ether. The method can be adopted to conduct continuous production; the separation of the N-methylformamide and the diethylene glycol monomethyl ether is achieved; the method has the advantages that the purity of separated products is high; the technological procedure is simple; energy consumption and equipment investment in the separation process can be effectively lowered at the same time.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com