Treatment method for starch wastewater

A technology for starch wastewater and treatment method, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, secondary pollution, long time consumption, etc. Low, no secondary pollution, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 starch wastewater treatment method of the present invention

[0049] Wastewater: Take starch sewage and filter and take samples for water quality analysis. The analysis results are COD: 7241mg / L, BOD5 5412mg / L, NH4 + 61.2mg / L, protein 2104mg / L, carbohydrate 5329mg / L, pH5.73.

[0050] 1. Processing method

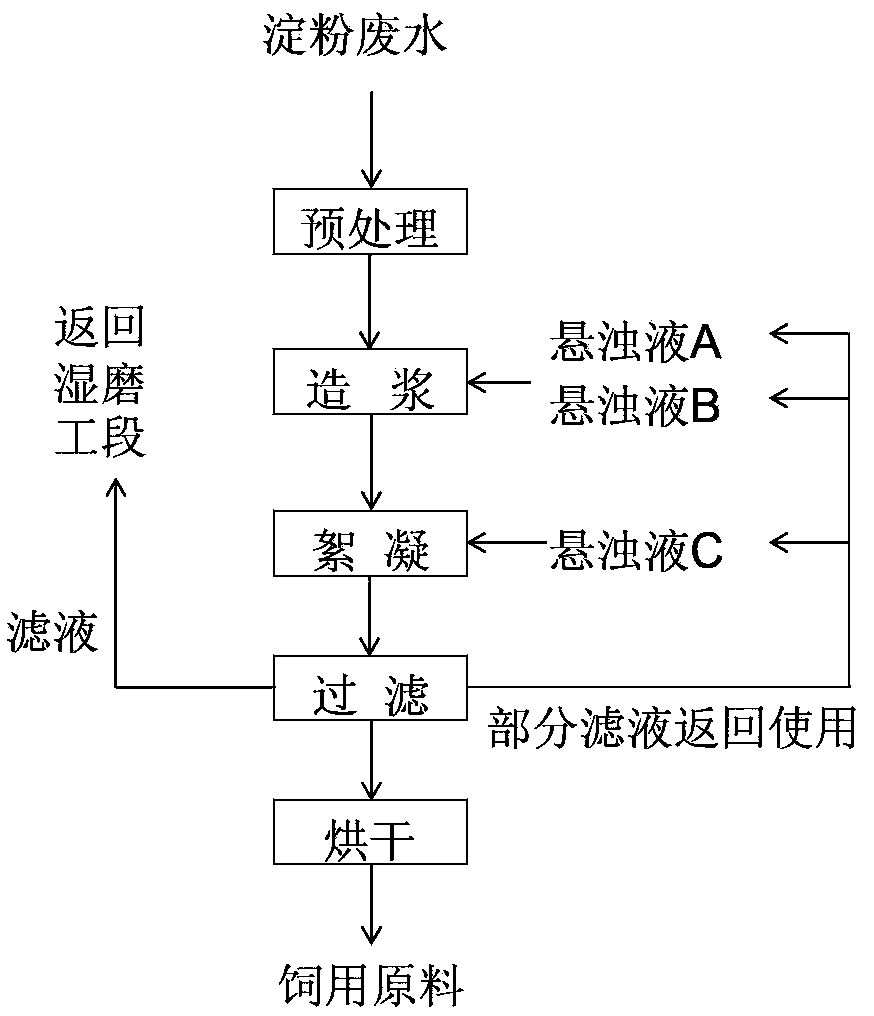

[0051] Such as figure 1 The process flow chart shown:

[0052] (1) Take starch wastewater and process it through a grid with a gap of 2mm;

[0053] (2) Take 1000ml of filtered starch wastewater and put it in a beaker for use. Quickly add the suspension A made of 0.5g of feed-grade chlorella powder and 2ml of water into the beaker filled with wastewater, stir and mix; Check the pH during the process, and the final pH is stable at 5.81. Use 3mol / L sodium hydroxide solution to adjust the pH to be stable at 6.22; quickly prepare the suspension prepared by 0.4g of feed grade dry yeast powder (brewer's yeast) and 3ml of water B is slowly added to the wast...

Embodiment 2

[0057] Embodiment 2 starch wastewater treatment method of the present invention

[0058] After the starch sewage was filtered, samples were taken for water quality analysis, and the analysis results were COD: 9462mg / L, BOD5 7128mg / L, NH4 + 75.8mg / L, protein 2953mg / L, carbohydrate 6541mg / L, pH5.59.

[0059] 1. Processing method

[0060] Such as figure 1 The process flow chart shown:

[0061] (1) Take starch wastewater and process it through a grid with a gap of 5mm;

[0062] (2) Take 1000ml of filtered starch wastewater and put it in a beaker for later use. Quickly add the suspension A prepared in advance from 0.8g of feed grade Sargassum powder and 8ml of water into the beaker filled with wastewater, stir and mix; Check the pH during the homogenization process, and the final pH is stable at 5.67. Use 3mol / L sodium hydroxide solution to adjust the pH to be stable at 6.89. Quickly prepare the suspension prepared by 1.0g of feed grade dry yeast powder (brewer's yeast) and 4m...

Embodiment 3

[0066] Embodiment 3 starch wastewater treatment method of the present invention

[0067] After filtering starchy sewage, samples were taken for water quality analysis, and the analysis results were COD: 6583mg / L, BOD5 4354mg / L, NH4 + 58.4mg / L, protein 1932mg / L, carbohydrate 5089mg / L, pH6.01.

[0068] 1. Processing method

[0069] Such as figure 1 The process flow chart shown:

[0070] (1) Take starch wastewater and process it through a grid with a gap of 8mm;

[0071] (2) Take 1000ml of filtered starch wastewater and put it in a beaker for later use. Quickly add the suspension A prepared in advance from 0.3g of spirulina powder and 1ml of water into the beaker filled with wastewater, stir and mix well; Check the pH, and the final pH is stable at 6.05. Use 3mol / L sodium hydroxide solution to adjust the pH to be stable at 7.86. Quickly mix the suspension B prepared in advance with 0.2g of feed grade dry yeast powder (brewer's yeast) and 2ml of water. Add it to the wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com